Philips SD4.00SA Service Manual

DVD-Video Player DVD Module SD-4.00SA_CH

Contents Page

1 Technical Specifications 2

2 Safety Instructions, Warnings, and Notes 6

3 Directions for Use (not available) 7

4 Mechanical Instructions 8

5 Test Instructions Mono Board DVD-SD4.00SA_CH11

Diagnostic Software Description 23

6 Block Diagram and Testpoint Overview

Block Diagram 35

Testpoint Overview Mono Board 36

7 Electrical Diagrams & Pwb’s Diagr. PWB

Front-End Proc. and Laser Supply(Diagram M1) 37 47-49

Front-End Processor Iguana (Diagram M2) 38 47-49

Front-End Loader Interface (Diagram M3) 39 47-49

Back-End Memory (Diagram M4) 40 47-49

Memory and Service Interface (Diagram M5) 41 47-49

Back-End Host Processor (Diagram M6) 42 47-49

Power Supply & A/V Interface (Diagram M7) 43 47-49

SACD Decoder (Diagram M8) 44 47-49

System Clocks (Diagram M9) 45 47-49

DAC Interface (Diagram M10)46 47-49

8 Alignments (not available) 51

9 Circuit Description 51

List of Abbreviations 56

IC Data 57

10 Spare Part List 63

©

Copyright 2002 Philips Consumer Electronics B.V. Eindhoven, The Netherlands.

All rights reserved. No part of this publication may be reproduced, stored in a

retrieval system or transmitted, in any form or by any means, electronic,

mechanical, photocopying, or otherwise without the prior permission of Philips.

Published by PF0265 Service Singapore Printed in the Netherlands Subject to modification EN 3122 785 12480

EN 2 SD-4.00SA_CH1.

Technical Specifications

1. Technical Specifications

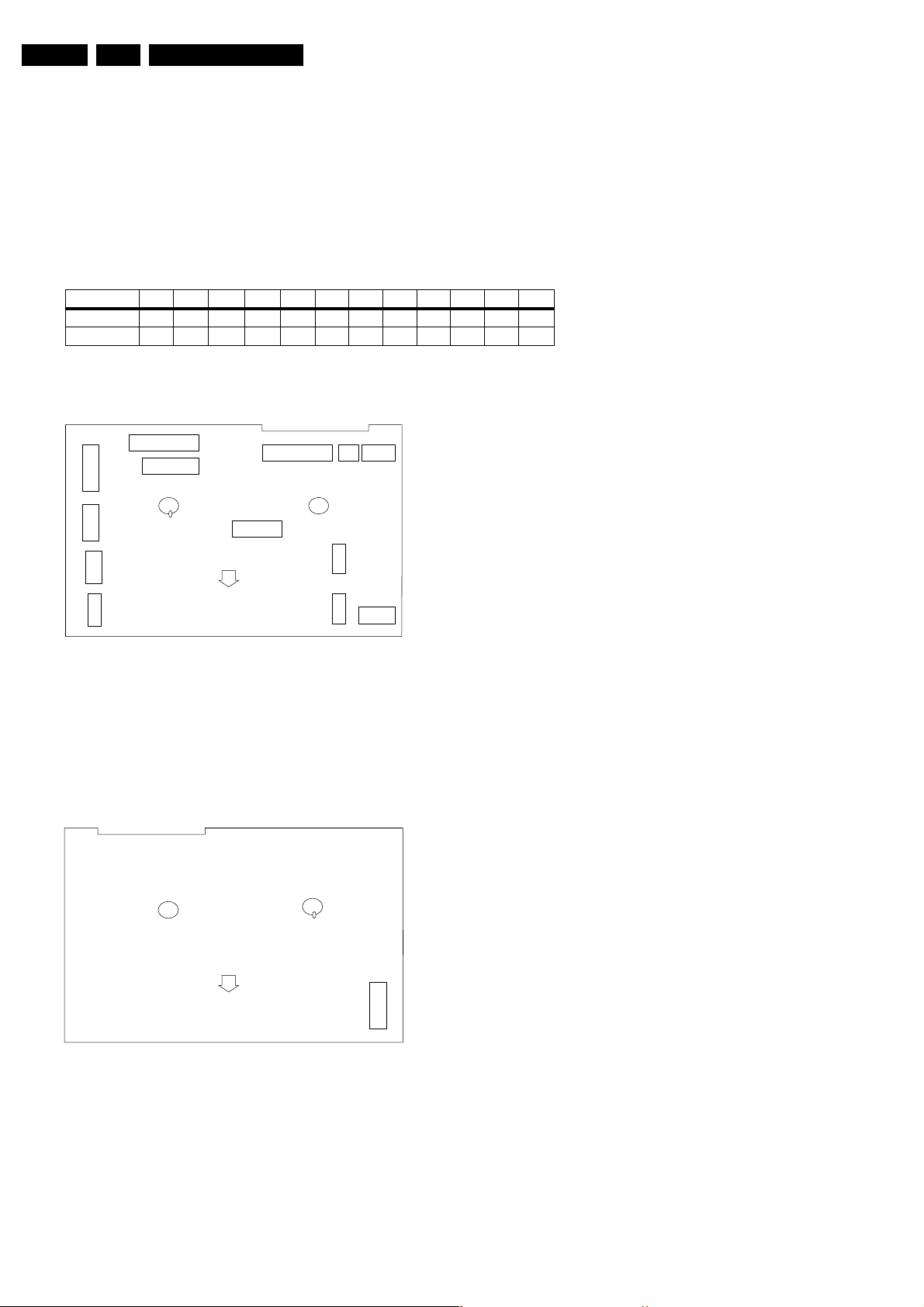

1.1 Interfaces and Pin Assignments

SD4 00_SA CH supports both configurations of single-disc and

5-disc changer SACD player.

In table 1-1, interfaces or connectors stuffing options are given

for applications of single-disc and 5-disc changer.

Table 1-1 Interfaces or connectors stuffing options

Disc Type 1100 1300 1301 1302 1500 1701 1702 1703 1704 1900 1012 1013

Single-disc √√ √ √ √ √√√ √

5-disc √√ √ √√√√√√ √

The interfaces or connectors are placed on both PCB layers of

top and bottom as shown in figure 1-1 and figure 1-2

respectively.

130

AV_SACHI

111

Motor Driver Bd

119

1014

17

SERVICE

18

Karaoke

1900

1500

1702

1013

AV_1000

1012

124

MONOBOARD

FRONT

TOP VIEW

OPU Connector

1100

220

AV_4.0

1703

124

Figure 1-1 Interfaces placement on PCB top layer

Connector 1705 is an option for the usage of SACD1000 set

only for connecting monoboard to front panel board. Connector

1701 is also an option for the monoboard power supply 12V/

5V/3V3 in case of the requirements needed for further

improvement on audio performance of SACD.

Connector 1014 is for either DCU (Diagnostic Controller Unit)

or BST (Boundary Scan Test) used by industrial only.

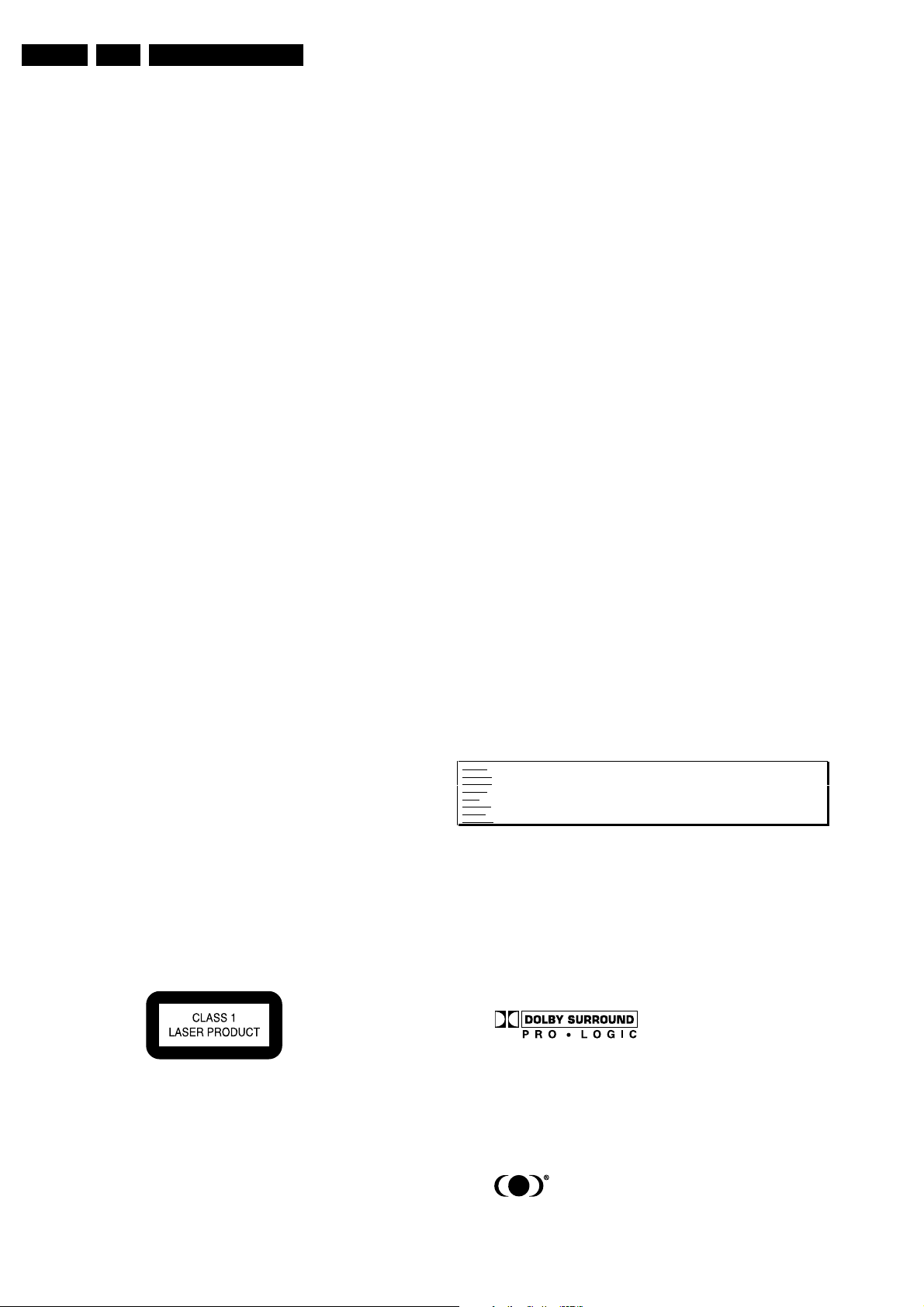

MONOBOARD

BOTTOM VIEW

FRONT

Figure 1-2 Interfaces placement on PCB bottom layer

1.2 Connections

1.2.1 Interface AV_4.0 at Location 1703:

2

1. I

C_SCL/SIODATA I2C SCL

2

2. I

C_SDA/SIOCLK I2C SDA

3. SCART1 low blanking 1 (0/6/12V)

4. SCART0 low blanking 0 (0/6/12V)

1705

130

Sledge PCS

1301

Spindle Motor

1300

CL 26532053_041.eps

CL 26532053_042.eps

1701

1517

18111

Tray Motor

1302

14

Digital YUV

1704

130502

130502

124

5. B_REF GND

6. B_U B_output

7. G_REF GND

8. G_Y G_output

9. R_REF GND

10. R_V R_output

11. Y_REF GND

12. Y Y_output

13. C_REF GND

14. C C_output

15. CVBS-REF GND

16. CVBS CVBS output

17. +3V3 Power supply +3V3

18. +3V3 Power supply +3V3

19. +5V Power supply +5V

20. +12V Power supply +12V

21. +12V Power supply +12V

22. MUTE Analogue output Mute

23. GND GND

24. PCMSCLK PCM Bit clock

25. PCMDATA0 PCM data 0

26. GND GND

27. PCMCLK PCM Clock

28. PCMLRCLK PCM Word clock

29. GND GND

30. SPDIF SPDIF outpu

1.2.2 Optional Interface AV_1000 at Location 1012:

1. GND GND

2. 384FS DAC mastering clock

16.9344MHz

3. GND GND

4. SEL_PCM/

DSD_LFE LFE channel (Ch-3)

5. GND GND

6. DATA_CeLf/

DSD_CENTRE Front Centre channel (Ch-2)

7. GND GND

8. SEL_PCM/DSD_Rs Right surround (Ch-5)

9. GND GND

10. DATA_LsRs/DSD_Ls Left surround (Ch-4)

11. GND GND

12. SEL_PCM/DSD_RIGHT Front Right Channel (Ch-1)

13. GND GND

14. DATA_LeRi/DSD_LEFT Front Left Channel (Ch-0)

15. GND GND

16. WORK_CLK/SEL_DSD DSD stereo

17. GND GND

18. BIT_CLK/DSD_CLK DSD clock

19. GND GND

20. 256FS Audio Clock

FS=32KHz, 44.1KHz,

48KHz and 96KHz

21. GND GND

22. SCL-DAC I

23. SDA-DAC I

2

C SCL for DAC

2

C SDA for DAC

Technical Specifications

EN 3SD-4.00SA_CH 1.

24. GND GND

1.2.3 Optional Power Supply Connector at Location 1701:

1. +3V3 Power supply +3V3

2. +3V3 Power supply +3V3

3. +5V Power supply +5V

4. GND Ground

5. GND Ground

6. MGND Power ground

7. +12V Power supply +12

1.2.4 Optional Connector of Sacd1000 Set (From Monoboard to

Front Panel) at Location 1705:

1. SCL I

2. GND Ground

3. SDA I

4. STB_CONT Standby Control

5. P50 Project P5

1.2.5 Interface AV_SACHI at Location 1013:

1. GND GND

2. 384FS DAC mastering clock

3. GND GND

4. SEL_PCM/DSD_LFE LFE channel (Ch-3)

5. GND GND

6. DATA_CeLf/DSD_CENTRE Front Centre channel (Ch-2)

7. GND GND

8. SEL_PCM/DSD_Rs Right surround (Ch-5)

9. GND GND

10. DATA_LsRs/DSD_Ls Left surround (Ch-4)

11. GND GND

12. SEL_PCM/DSD_RIGHT Front Right Channel (Ch-1)

13. GND GND

14. DATA_LeRi/DSD_LEFT Front Left Channel (Ch-0)

15. GND GND

16. WORK_CLK/SEL_DSD DSD stereo

17. GND GND

18. BIT_CLK/DSD_CLK DSD clock

19. GND GND

20. 256FS Audio Clock

21. GND GND

22. SCL-DAC I2C SCL for DAC

23. SDA-DAC I2C SDA for DAC

24. GND GND

25. PCMDATA3/DSD_PCM8 Option 1:PCMDATA3

26. GND GND

27. P50 P50 (I2C Slave Data Available

28. GPIO2 General I/O port 2

29. GPIO3 General I/O port 3

30. GPIO1 General I/O port

2

C SCL

2

C SDA

16.9344MHz

FS=32KHz, 44.1KHz,

48KHz and 96KHz

Option 2: DSD_Ch7

Interrupt)

Option 1 : Supporting 3

control line type DAC,

DAC_CLK

Option 1: Supporting 3 control

line type DAC, DAC_DATA

Option 1: Supporting 3 control

line type DAC, DAC_C

4. GND Ground

5. KOKDATA Karaoke PCM data (I2S

format)

6. GND Ground

7. KOKPCMCLK Karaoke PCM system clock

(I2S format)

8. KOKVOCDET Karaoke vocal detect signal

1.2.7 Digital YUV Interface at Location 1704:

1. GND Ground

2. SDA I2C SDA

3. SCL I2C SCL

4. Odd/Even

5. HSYNC Horizontal Sync

6. GND Ground

7. 27MHz Clock 27MHz Clock

8. GND Ground

9. YC0 Digital video bit 0

10. GND Ground

11. YC1 Digital video bit 1

12. GND Ground

13. YC2 Digital video bit 2

14. GND Ground

15. YC3 Digital video bit 3

16. +5V Power Supply +5V

17. YC4 Digital video bit 4

18. +3V3 Power Supply +3V3

19. YC5 Digital video bit 5

20. +3V3 Power Supply +3V3

21. YC6 Digital video bit 6

22. GND Ground

23. YC7 Digital video bit 7

24. GND Ground

1.2.8 Service connector at Location 1500:

1. TXD_SER TXD service UART

2. SERVICE Service or normal mode select

3. RXD_SER RXD service UART

4. RTS_SER Not used (RTS service UART)

5. GND Ground

6. CTS_SER Not used (CTS service UART)

7. +5V_SER Positive 5V (isolated from

internal +5V by ferrite bead

1.2.9 To Motor Driver Board Interface at Location 1900:

1. TBL-POS Carousel Rotation Position

Detection

2. I2CSCL I2C Clock

3. I2CSDA I2C Data

4. GND Ground

5. Clockwise_CM Carousel Clockwise Rotation

Control

6. Counterclockwise_CM Carousel Counterclockwise

Rotation Control

7. +5V +5V Power Supply

8. GND Ground

9. +12V +12V Power Supply

10. +12V +12V Power Supply

11. GND Ground

1.3 Signal Specifications

1.2.6 Karaoke Interface at Location 1702:

1. KOKSCLK Karaoke PCM bit clock (I2S

format)

2. +12V Power Supply +12V

3. KOKLRCLK Karaoke PCM left-right / word

clock (I2S format)

This the specification of all signals as described under

“Connections”

H = +5V ±0.5V

h = 3V3 ±0.3V

L = 0V ±0.5V

l = 0V ±0.3V

EN 4 SD-4.00SA_CH1.

Technical Specifications

Stby : There is no standby

mode at module level.

The module operate

in power-off and

Standby control line : Not available on

P50 : Connection between

Slow blanking scart : This signal has three

Audio mute : Can be used for audio

I2S data0 out : I2S front data output.

I2S wordselect / I2S bitclock : I2S timing signals

I2S systemclock : 256xFS audio

Clockwise/Counterclockwise_CM : Carousel output for 5-

TBL_POS : Position sensor for

LFE_SEL : Low frequency effect

Center_on : Switches the center

Karaoke : I2S input - h / l

SPDIF out : Digital audio output

Hor. Sync : Video Horizontal

DSD/PCM output : Digital output for High

2

C clock / I2C data : I2C databus

I

TXD / RXD / RTS / CTS : Service UART to be

power-on only.

module level.

front and A/V board,

and can be used as

P50 signal line.

: The signal is not

connected to the

module electronics.

levels which depend

on the level of the

output ports SCART0

and SCART1. It will

be converted by the

external board to 0/6/

12 voltage level use

for scart function

switching.

mute transistors

during stop or power

On/Off.

: Mute on : 3V3 ±0V3

: Mute off: 0V ±0V3

: Level - h / l

: Level - h / l

systemclock.

: Level - h / l

Disc changer

: Level - h / l

carousel rotation of 5-

disc changer

: Level - h / l

selection for the A/V

board.

: LFE_SEL_low - l

: LFE_SEL_high - h

audio to the scart

output.

: Center to scart - h

: L/R to scart - l

: PCMCLK output - h / l

level - H / L

synchronisation

: Level - h / l

End DAC

: Level - h / l

: Level - H / L at

modules connectors

connected direct to

PC serial input.

: Output levels - H / L

: Input levels RS232

compliant

Service activation : To activate service

mode, this line is tied

to GND

1.4 Performance:

1.4.1 Digital Output

CDDA/LPCM : according IEC60958

MPEG1 is converted to LPCM :

MPEG2, AC3 audio.MP3 : according IEC1937

DTS. : according IEC61937

amendment 1.

: Digital output level is

0V / 5V with GND as

reference. To meet

the standards a

decouple circuit is

necessary.

1.4.2 I2S Output

Resolution : Up to 24bit.

Sample rate : 32kHz / 44.1kHz /

48kHz / 64kHz /

88.2kHz / 96kHz /

128kHz / 176.4kHz /

192kHz.

Standard : Philips I2S output

Number of I2S outputs : Basic 6 channels:

Front / Surround /

Center-LFE.

: Additional 2 channels:

downmix stereo

Deemphasis : Internally processed

by the module.

Audio source streams : PCM / LPCM /MPEG1

/ MPEG2 / AC3 / MP3

/ DTS / MLP.

Audio processing : Dolby ProLogic

decoder / Dolby

surround downmix /

SRS TruSurround /

Circle Surround /

TruBass.

1.4.3 Analog Audio

The module has no analog audio

ouput. : The analog audio

specification will be

determined by the

external DAC circuit.

1.4.4 Video.

Standards : The video output

standard will follow

the source material.

: The OSD standard is

switchable between

PAL or NTSC.

Outputs : The module has 6

analog outputs in 4

formats:

Y/C;

CVBS;

RGB / YUV.

RGB / YUV

component video

signals share the

same lines.

Therefore, the module

Technical Specifications

is unable to output

both RGB and YUV

simultanious.

Specification. : The output comply

fully with [PQR-IMS]

Class III.

: DC level - sync

bottom at 0.43V ±10%

(100% white) and

0.9V ±10% (black).

: Output impedance -

75Ohm.

: The following

specification points

are significantly better

then [PQR_IMS]

: SNR on all video

outputs is better then

65dB.

: Video bandwidth -

8MHz (±3dB) / 16MHz

(±3dB) for STi5588

progressive scan.

EN 5SD-4.00SA_CH 1.

EN 6 SD-4.00SA_CH2.

Safety Instructions, Warnings, and Notes

2. Safety Instructions, Warnings, and Notes

2.1 Safety Instructions

2.1.1 General Safety

Safety regulations require that during a repair:

• Connect the unit to the mains via an isolation transformer.

• Replace safety components, indicated by the symbol ,

only by components identical to the original ones. Any

other component substitution (other than original type) may

increase risk of fire or electrical shock hazard.

Safety regulations require that after a repair, you must return

the unit in its original condition. Pay, in particular, attention to

the following points:

• Route the wires/cables correctly, and fix them with the

mounted cable clamps.

• Check the insulation of the mains lead for external

damage.

• Check the electrical DC resistance between the mains plug

and the secondary side:

1. Unplug the mains cord, and connect a wire between

the two pins of the mains plug.

2. Set the mains switch to the 'on' position (keep the

mains cord unplugged!).

3. Measure the resistance value between the mains plug

and the front panel, controls, and chassis bottom.

4. Repair or correct unit when the resistance

measurement is less than 1 MΩ.

5. Verify this, before you return the unit to the customer/

user (ref. UL-standard no. 1492).

6. Switch the unit ‘off’, and remove the wire between the

two pins of the mains plug.

2.1.2 Laser Safety

This unit employs a laser. Only qualified service personnel may

remove the cover, or attempt to service this device (due to

possible eye injury).

2.2 Warnings

2.2.1 General

• All ICs and many other semiconductors are susceptible to

electrostatic discharges (ESD, "). Careless handling

during repair can reduce life drastically. Make sure that,

during repair, you are at the same potential as the mass of

the set by a wristband with resistance. Keep components

and tools at this same potential. Available ESD protection

equipment:

– Complete kit ESD3 (small tablemat, wristband,

connection box, extension cable and earth cable) 4822

310 10671.

– Wristband tester 4822 344 13999.

• Be careful during measurements in the live voltage section.

The primary side of the power supply (pos. 1005), including

the heatsink, carries live mains voltage when you connect

the player to the mains (even when the player is 'off'!). It is

possible to touch copper tracks and/or components in this

unshielded primary area, when you service the player.

Service personnel must take precautions to prevent

touching this area or components in this area. A 'lightning

stroke' and a stripe-marked printing on the printed wiring

board, indicate the primary side of the power supply.

• Never replace modules, or components, while the unit is

‘on’.

2.2.2 Laser

• The use of optical instruments with this product, will

increase eye hazard.

• Only qualified service personnel may remove the cover or

attempt to service this device, due to possible eye injury.

• Repair handling should take place as much as possible

with a disc loaded inside the player.

• Text below is placed inside the unit, on the laser cover

shield:

Laser Device Unit

Type : Semiconductor laser

GaAlAs

Wavelength : 650 nm (DVD)

: 780 nm (VCD/CD)

Output Power : 20 mW (DVD+RW

writing)

: 0.8 mW (DVD

reading)

: 0.3 mW (VCD/CD

reading)

Beam divergence : 60 degree

Figure 2-1

Note: Use of controls or adjustments or performance of

procedure other than those specified herein, may result in

hazardous radiation exposure. Avoid direct exposure to beam.

CAUTION VISIBLE AND INVISIBLE LASER RADIATION WHEN OPEN AVOID EXPOSURE TO BEAM

ADVARSEL SYNLIG OG USYNLIG LASERSTRÅLING VED ÅBNING UNDGÅ UDSÆTTELSE FOR STRÅLING

ADVARSEL SYNLIG OG USYNLIG LASERSTRÅLING NÅR DEKSEL ÅPNES UNNGÅ EKSPONERING FOR STRÅLEN

VARNING SYNLIG OCH OSYNLIG LASERSTRÅLNING NÄR DENNA DEL ÄR ÖPPNAD BETRAKTA EJ STRÅLEN

VARO! AVATTAESSA OLET ALTTIINA NÄKYVÄLLE JA NÄKYMÄTTÖMÄLLE LASER SÄTEILYLLE. ÄLÄ KATSO SÄTEESEEN

VORSICHT SICHTBARE UND UNSICHTBARE LASERSTRAHLUNG WENN ABDECKUNG GEÖFFNET NICHT DEM STRAHL AUSSETSEN

DANGER VISIBLE AND INVISIBLE LASER RADIATION WHEN OPEN AVOID DIRECT EXPOSURE TO BEAM

ATTENTION RAYONNE MENT LASER VISIBLE ET INVISIBLE EN CAS D'OUVERTURE EXPOSITION DANGEREUSE AU FAISCEAU

!

Figure 2-2

2.2.3 Notes

Dolby

Manufactered under licence from Dolby Laboratories. “Dolby”,

“Pro Logic” and the double-D symbol are trademarks of Dolby

Laboratories. Confidential Unpublished Works. ©1992-1997

Dolby Laboratories, Inc. All rights reserved.

Figure 2-3

Trusurround

TRUSURROUND, SRS and symbol (fig 2-4) are trademarks of

SRS Labs, Inc. TRUSURROUND technology is manufactured

under licence frm SRS labs, Inc.

Figure 2-4

3. Directions for Use

There is no DFU available

Directions for Use

EN 7SD-4.00SA_CH 3.

EN 8 SD-4.00SA_CH4.

Mechanical Instructions

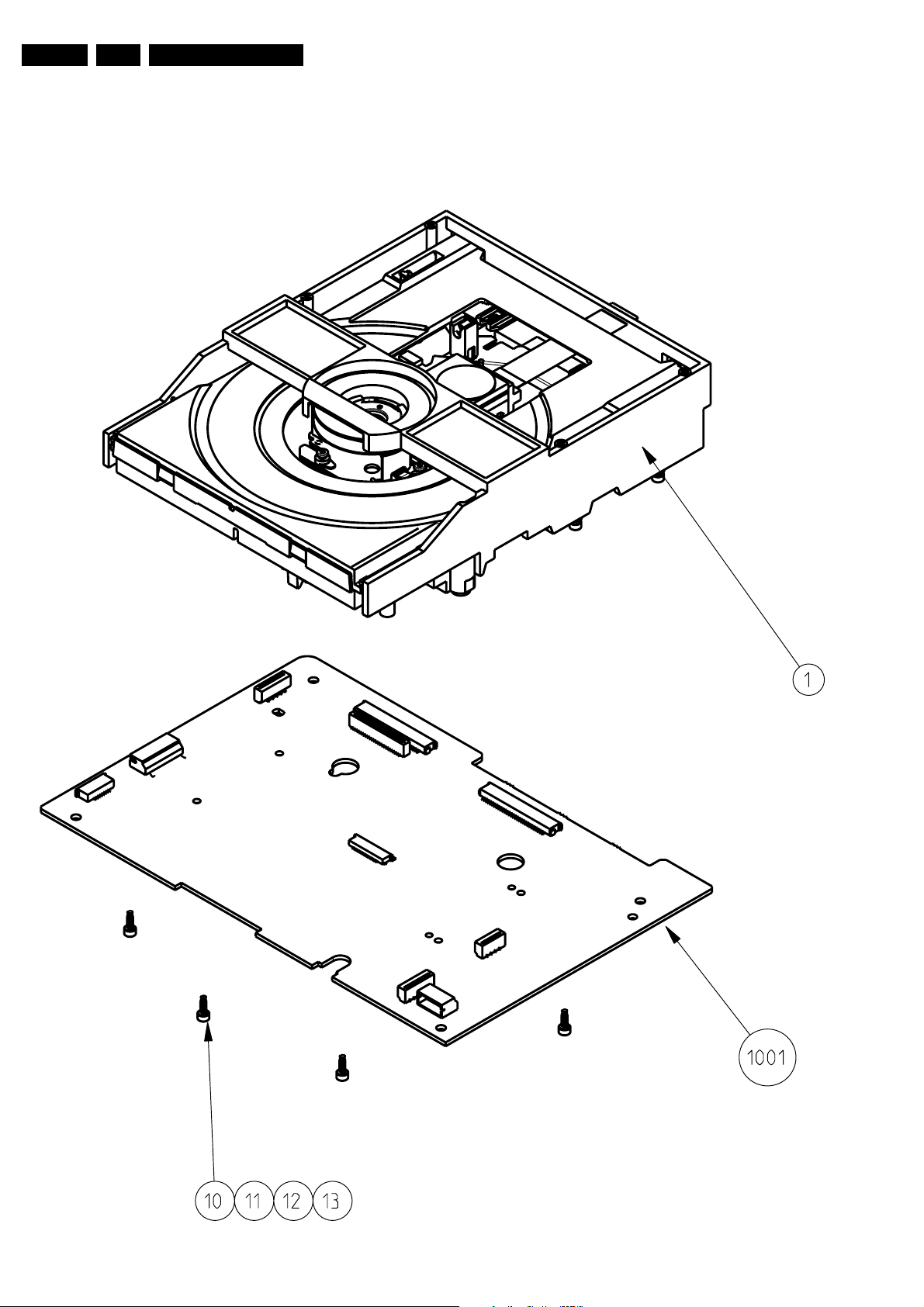

4. Mechanical Instructions

4.1 Dismantling Instruction

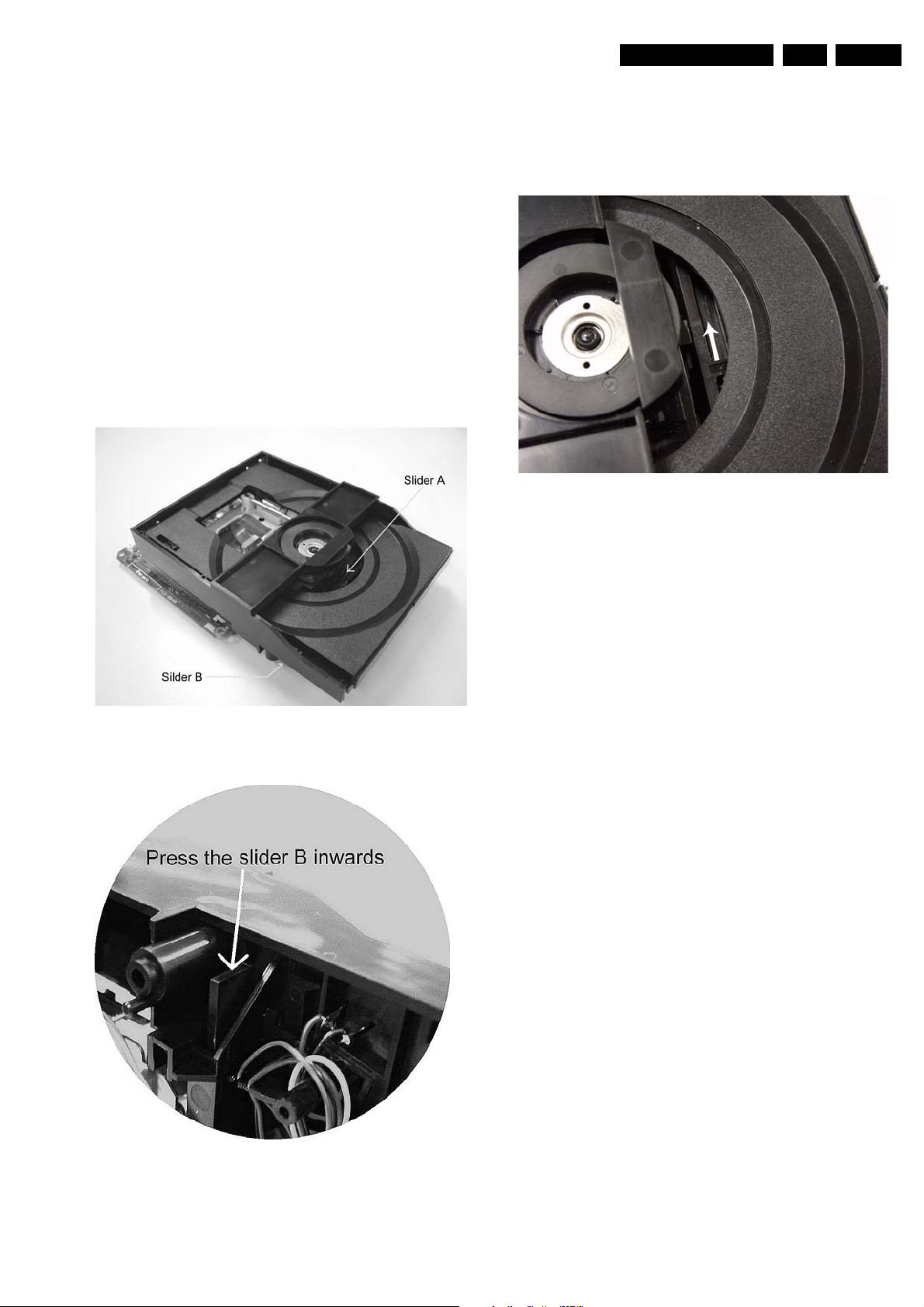

Figure 4-1

CL 26532053_072.eps

220502

Mechanical Instructions

EN 9SD-4.00SA_CH 4.

4.1.1 Dismantling of DVD Mono Board

1. See Figure 4-1 for dismantling of DVD module.

2. Unlock the OPU conn 1100, Sledge motor conn 1301

and disc motor conn 1300 and remove the Flex

connections.

3. Remove the wire connection to Tray motor conn 1302.

4. Remove 4 screws 10 to 13.

5. Remove the Mono Board

Note: Flex cables are very fragile,care should be taken during

dismounting and when mounting,ensure that Flex cables are

inserted properly into the Flex socket and locked.

4.1.2 Opening of Tray Manually

Figure 4-3.The Tray is now disengaged and can be pulled

outwards.

When no disc is loaded, unlocking the Tray can also be done

by moving the Slider A in the direction as shown in Figure 4-4

and pull the Tray outwards.

CL 06532147_043.eps

231100

Figure 4-4

Figure 4-2

CL 06532147_002.eps

CL 06532147_003.eps

151100

151100

Figure 4-3

It is possible to open the tray manually by moving the Slider in

the position as shown in Figure 4-2 and Figure 4-3

When the slider A is not accessible when a disc is loaded,

unlock the tray by pressing the slider B inward as shown in

EN 10 SD-4.00SA_CH4.

4.2 Service Hints

4.2.1 DVD Module

This module can be repaired as follows:

1. The VAL6011/14 is a combination of loading mechanism

and DVD-mechanism. Both the mechanism is not a

repairable unit and in case of failure it has to be replaced

with a new loader VAL6011/14.

Note: When replacing with a new VAL6011/14 two solder

joints have to be removed after connecting the OPU flex foil

to the board.

The solder joints which shortcircuits the laser diodes to

ground are for protection against ESD. Refer to Figure 4-5

and Figure 4-6 for location of solder points.

Mechanical Instructions

Figure 4-5

Figure 4-6

2. The mono board has to be repaired down to component

level. Repair handling of the monoboard requires a

workshop with sophisticated desoldering tools.

Test Instructions Mono Board DVD-SD4.00SA_CH

5. Test Instructions Mono Board DVD-SD4.00SA_CH

EN 11SD-4.00SA_CH 5.

5.1 General

• Impedance of measuring-equipment should be > 1MΩ.

• Most tests have to be done by software commands.

Together with the software command you will find a Ref.#

nbr. This is the number of the diagnostic nulceus used for

this test. More detailed information can be find in the

chapter “Diagnostic Nuclei”.

• Levels: Most measurements are digital measurements.

The signal levels specification in this document are defined

as follows:

low:< 0.3V

high:> 3.0V

LOW:< 0.4V

HIGH:> 4.5V

• All the waveforms measurement carried out in these test

instruction will be base on the testpoint indicated in the

Monoboard schematic diagram in the service manual.

5.2 General Start-up Measurements

5.2.1 Supply Check:

Table 5-1 Supply check

Testpoint Supply Used by

F781 +3V3 Main supply voltage

F782 +5V Main supply voltage

F783 +12V Main supply voltage

F710 +3V3SA Analog 3V3 front-end circuitry

F711 +3V3SD Digital 3V3 front-end circuitry

F785 FUR-3V3 Digital 3V3 Furore2 interface

F784 +3V3ST Digital 3V3 back-end circuitry

F724 3V3D Digital 3V3 cicuitry

F787 FUR-1V8 Digital 1V8 Furore2 core circuitry

F786 VDDA-FUR Analog 1V8 Furore2 circuitry

F717 +5VSA Analog 5V front-end circuitry

F715 +5VSD Digital 5V front-end circuitry

F721 +5VAV Analog 5V back-end circuitry

F718 +5VD Digital 5V back-end circuitry

F727 VDDSTA Analog STi 55xx circuitry

F729 VDDSTC Core STi 55xx circuitry

F725 VDDSTD Digital STi 55xx circuitry

STi 55xx uses various power supply voltages that depend on

which processor is being used

Table 5-2 Back-end processor

Back-end

Processor

VDDSTA

( Analog )

STi 5580 +2V5 +2V5 +2V5

STi 5588 +1V8 +1V8 +3V3

STi 5519 +2V5 +2V5 +2V5

circuitry

VDDSTC

( Core )

VDDSTD

( Digital )

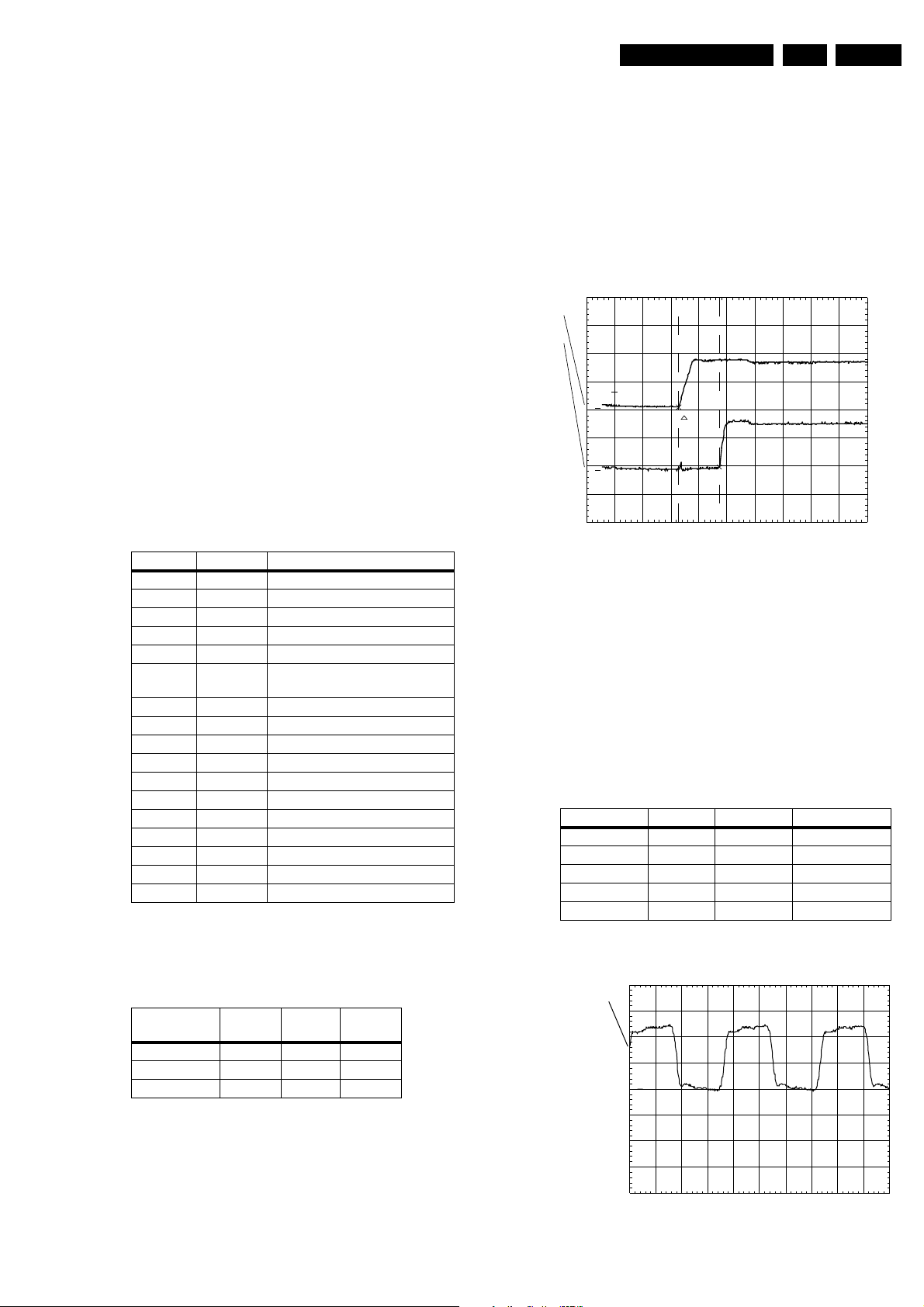

5.2.2 Reset Check:

To ensure a proper start-up of the monoboard, the back-end

reset signal RESETn is required at the STi55xx input (testpoint

F906) after power-on.

To check the reset timing, measure the RESETn (testpoint

F906) and the +3V3ST supply (testpoint F784), reset circuit

trigger signal.

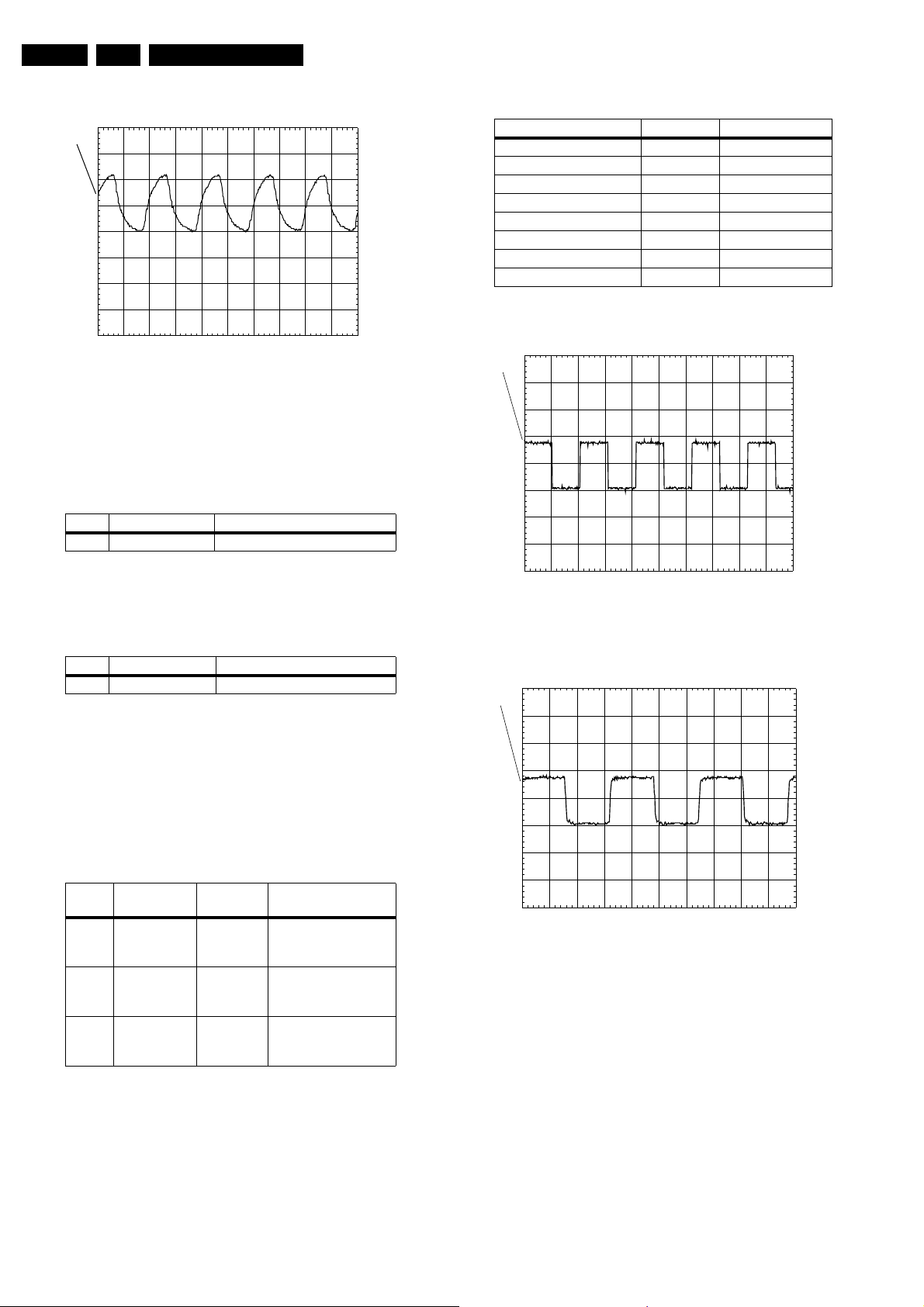

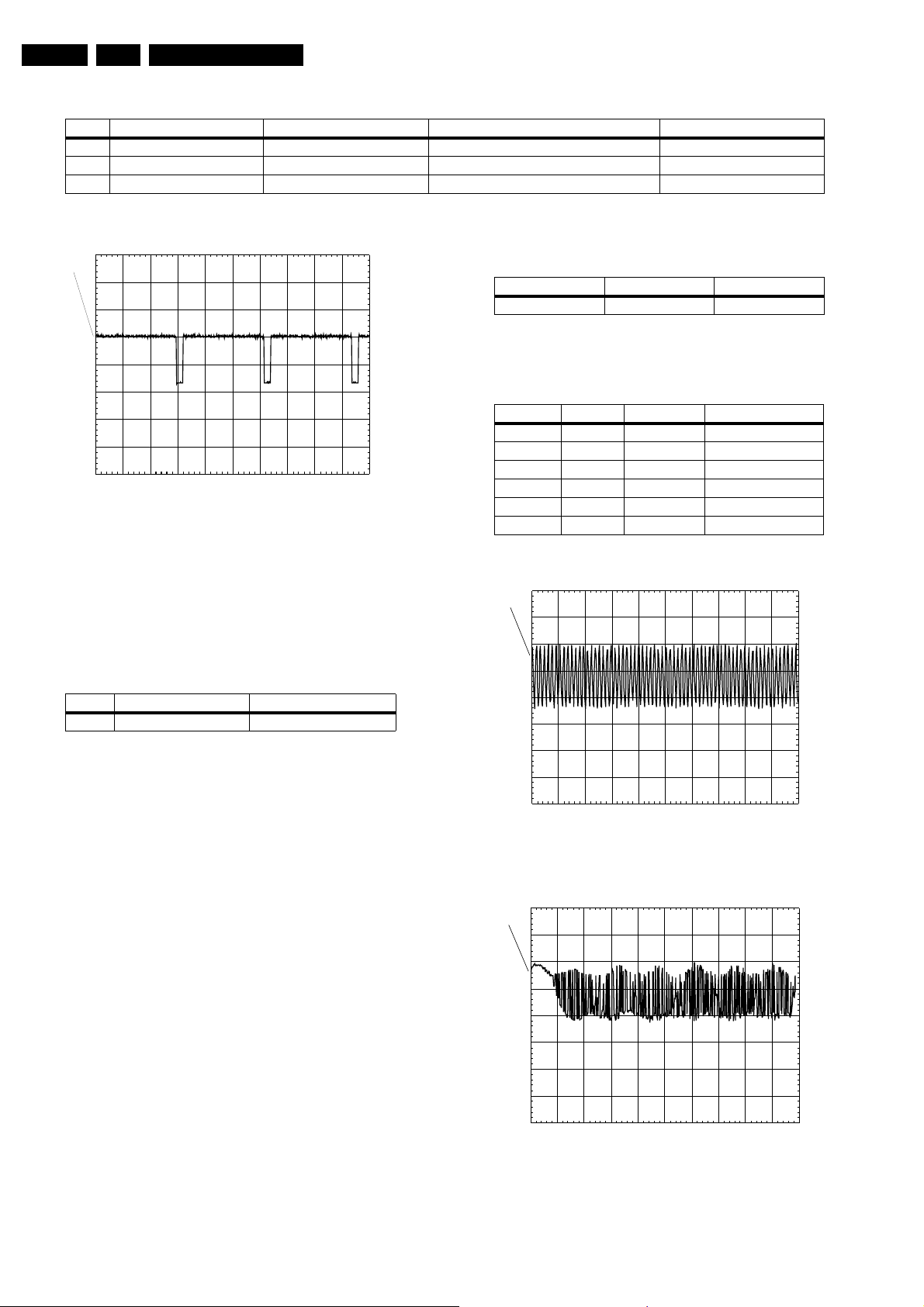

PM3380B

ch1: dT=73.0ms V1= 65.0mV

ch1

ch2

T

1

2

CH1 2.00 V=

CH2 2.00 V= MTB50.0ms- 2.92dv ch1+

Figure 5-1 Reset

Nb: The RESETn rising edge should be at least 100msec after

the +3V3ST (refer to Figure 5-1).

If the reset input does not go high then check the reset circuit

around transistor 7409.

5.2.3 Clock Check

To check the correct functioning of the STI55xx, we first have

to check the presence of all clocks.

All clocks to be measured with 0.02% tolerance.

Table 5-3 Clock check

Name Testpoint Frequency Waveform

384FS F042 16.9344MHz Refer to Fig 5-3

27M_CLK_ST F932 27MHz Refer to Fig 5-2

PCM_CLK_ST F885 11.2896MHz Refer to Fig 5-5

Audio_CLK F935 11.2896MHz Refer to Fig 5-5

Iguana_CLK F207 8.4672MHz Refer to Fig 5-4

PM3380

B

ch1

CL 16532163_019.eps

290102

The module operates in power-off and power-on only. There is

no standby mode at module level. In power-off, the module

does not response to any communication or signals.

Before starting the measurement, ensure that all power supply

are connected to the monoboard via connector 1703 or 1701

and that the PC interface cable is connected to the Service

interface connector 1500 of the monoboard.

CH1 2.00 V= MTB10.0ns ch1+

CL 26532053_062.eps

Figure 5-2 27M_CLK

210502

EN 12 SD-4.00SA_CH5.

ch1

ch1

Test Instructions Mono Board DVD-SD4.00SA_CH

PM3380

B

CH1 2.00 V= MTB20.0ns ch1+

Figure 5-3 384FS

PM3380B

CL 26532053_063.eps

210502

Table 5-4 PC connection

Connector pin Signal

1500-1 TXT_SER (STi55xx out)

1500-2 SERVICE-mode select

1500-3 RXD_SER (STi55xx in)

1500-4 RTS_SER (Not in use)

1500-5 GND

1500-6 CTS_SER (Not in use)

1500-7 +5V_SER

Now start the terminal program. Make sure that the service-pin

(pin 1500-2) of the µP is pulled low.

The terminal program of your PC should now display: “DVDv4

Diagnostic software version ...”. This message already means

that the µP is running. The first 5 commands from the

diagnostic software will be carried out automatically during

diagnostic start-up. The other commands can be carried out by

selecting the “command input” and simply type the reference

nbr. to do the test or select the “Menu - driven” test.

To be sure that the µP is able to run the diagnostic software,

serial port will be checked during start-up.

Table 5-5 Serial port check

CH1 1.00 V= MTB50.0ns ch1+

Figure 5-4 Iguana_CLK

PM3380B

ch1

CH1 2.00 V= MTB20.0ns ch1+

CL 26532053_064.eps

CL 26532053_065.eps

210502

210502

Ref. # Reference Name Remark

(1) BasicSpAcc Serial port Access test/

initialisation

(2b) BasicInterconSdram Check SDRAM

interconnection with CPU

(4) BasicSdramWrR Check Basic SDRAM

memory

With this test, the serial communication is checked in both

directions.

Figure 5-5 PCM_ST_CLK / Audio_CLK

5.3 µP Environment:

5.3.1 General:

All the tests are carried out by software tests. To start the

software tests, connect a PC to the serial bus of the STI55xx.

Use connector 1500 for this connection:

Test Instructions Mono Board DVD-SD4.00SA_CH

EN 13SD-4.00SA_CH 5.

5.3.2 Memory Check:

The µP has a data bus that is connected to a Flash and also

internal link to the MPEG SDRAM inteface.

At start-up,the SDRAM bus is checked

Table 5-6 Memory check

Ref. # Command Name Remark

(2b) BasicInterconSDRAM Data and address bus

Interconnection

6 PapChksFl Checksum FLASH

16 CompSdramWrR SDRAM Write Read

CompSdramWrR checks the complete SDRAM for failures

inside the IC.The BasicInterconSDRAM check is done by

writing & reading some well chosen patterns to all address and

data interconnections of the SDRAM.

The PapChksFI calculate and verify checksum of the FLASH.

This includes the binary file checksum and the four modules.

5.4 General I/O Port & Peripherals Check

5.4.1 I2C Bus / EEprom Check

To access the EEprom, the I2C bus is used. So by writing and

reading to the EEprom the chip and the bus is checked. With

next commands a certain byte is written to the EEprom. The

original information will always be written back into the

EEprom.

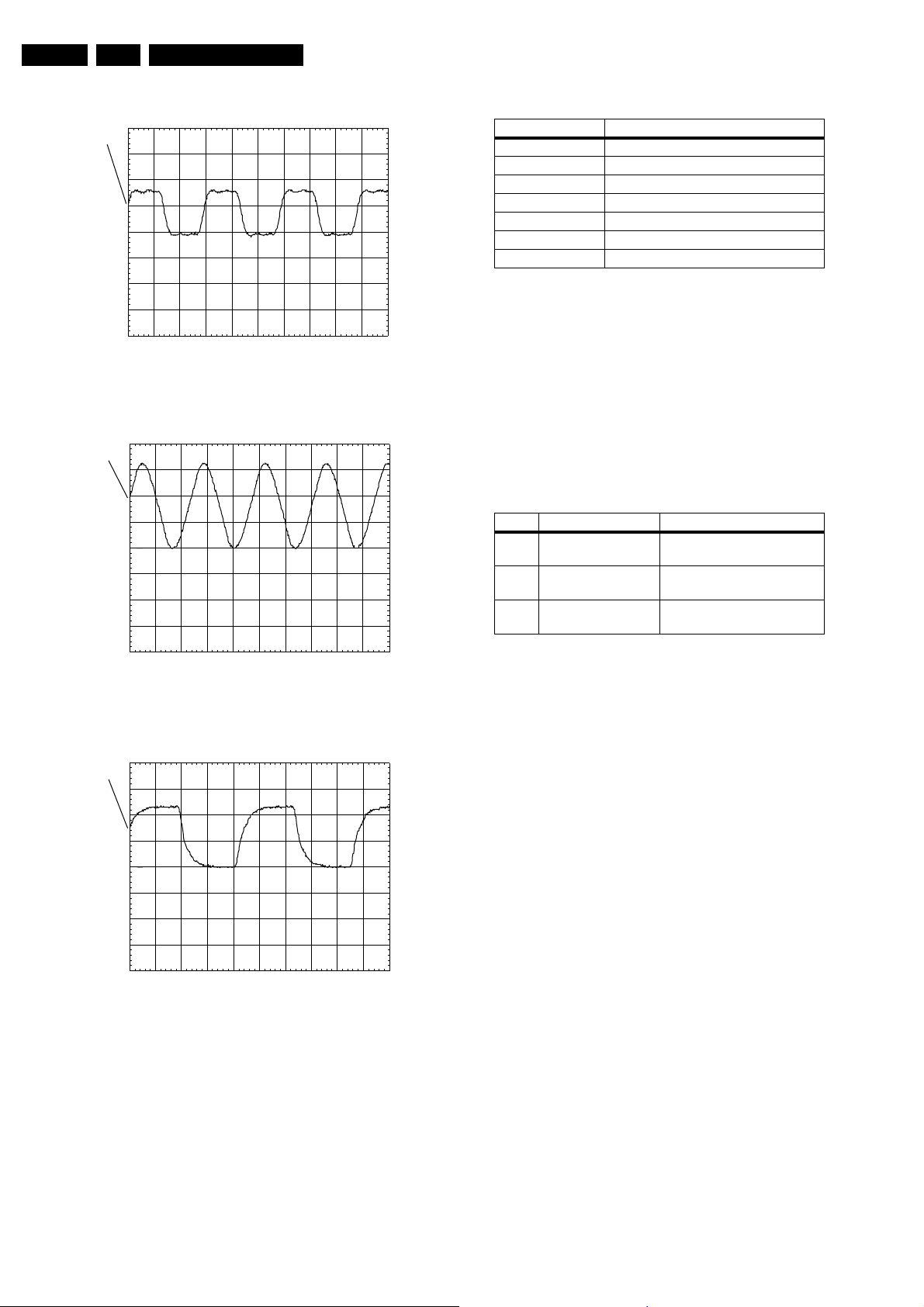

5.4.2 Audio Clock Switch Check

The internally generated Audio clock can be set to either 44.1

kHz (CD_DA), 48 kHz (DVD) or 96 kHZ (DVD). To check the

different mode, use the following commands and measure the

waveform as correct operation cannot be detected by the

Diagnostic Software.

Table 5-9 Audio clock switch check

Command

Ref #

Name Remark

7a PapUclkAclk

Cdda

µClock A_CLK

in 44.1kHz

Test

point Frequency

T885 11.2896MHz

mode( Fig 5-4 )

7b PapUclkAclk

Dvd

µClockA_CLK

in 48kHz mode

T885 12.288MHz

( Fig 5-5 )

7c PapUclkAclk

Dvd96

µClock A_CLK

in 96kHz mode

T885 24.576MHz

( Fig 5-6 )

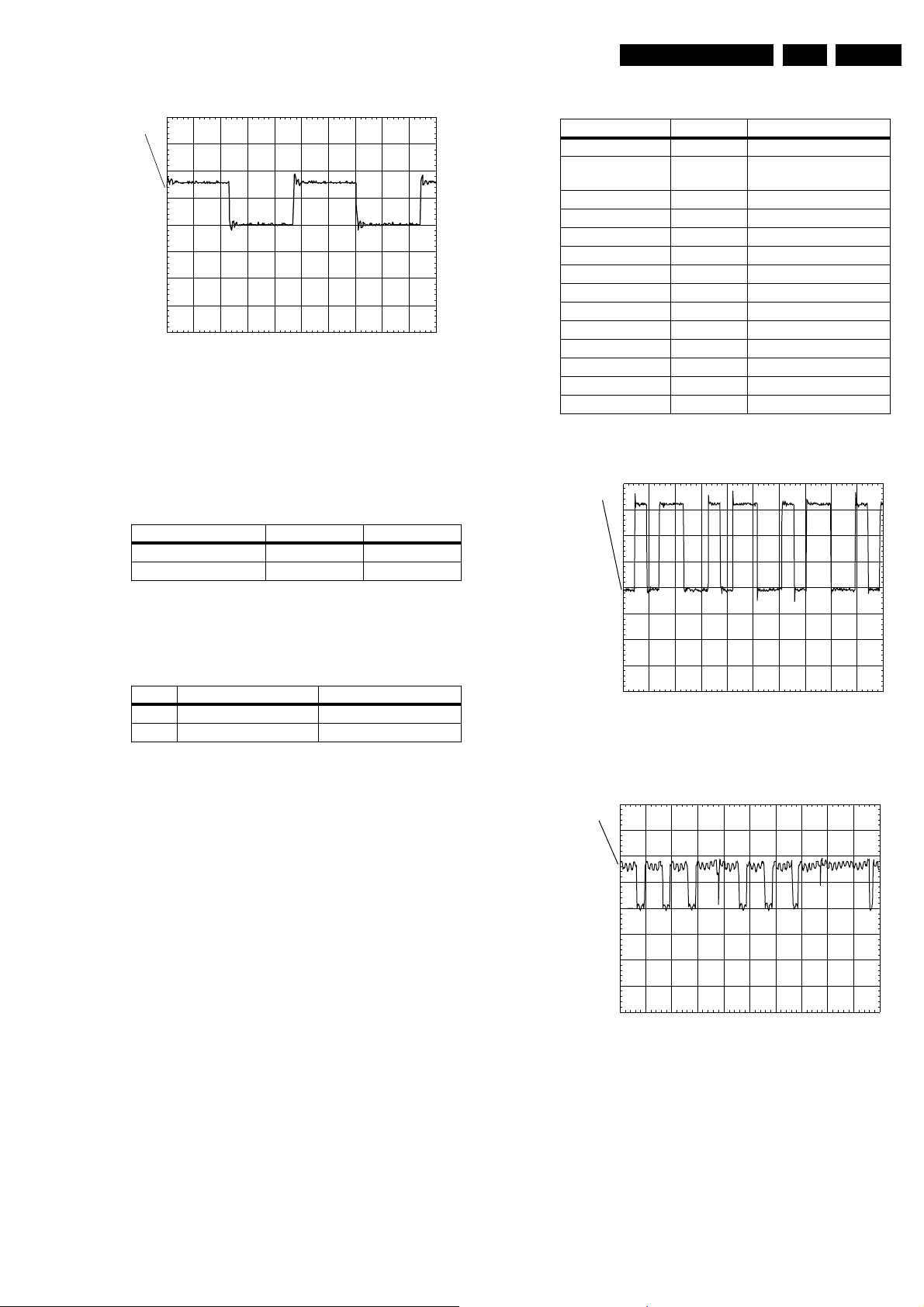

PM3380B

ch1

0.02%

0.02%

0.02%

Table 5-7 EEprom check

Ref. # Command Name Remark

11 PapI2cNvram I2C NVRAM access

The complete Eeprom can also be checked on failures by

writing to all addresses and reading back. This test takes a long

time (110 sec).

Table 5-8

Ref. # Command Name Remark

15 PapNvramWrR NVRAM Write Read

CH1 2.00 V= MTB20.0ns ch1+

CL 26532053_066.eps

Figure 5-6 µClock A_CLK in 44.1kHz mode

PM3380B

ch1

1

CH1 2.00 V= MTB20.0ns ch1+

CL 26532053_067.eps

210502

210502

Figure 5-7 µClockA_CLK in 48kHz mode

EN 14 SD-4.00SA_CH5.

Test Instructions Mono Board DVD-SD4.00SA_CH

PM3380B

ch1

1

CH1 2.00 V= MTB20.0ns ch1+

CL 26532053_068.eps

Figure 5-8 µClock A_CLK in 96kHz mode

5.4.3 Audio Mute Check

Switch on the Mute circuit by sending next command:

Table 5-10 Audio mute check

Ref. # Command Name Remark

19a AudioMuteOn AudioMuteOn

Check the Mute output again at testpoint T798: 3V3 ±10%

Switch off the Mute circuit by sending next command

Table 5-11 Audio mute check

210502

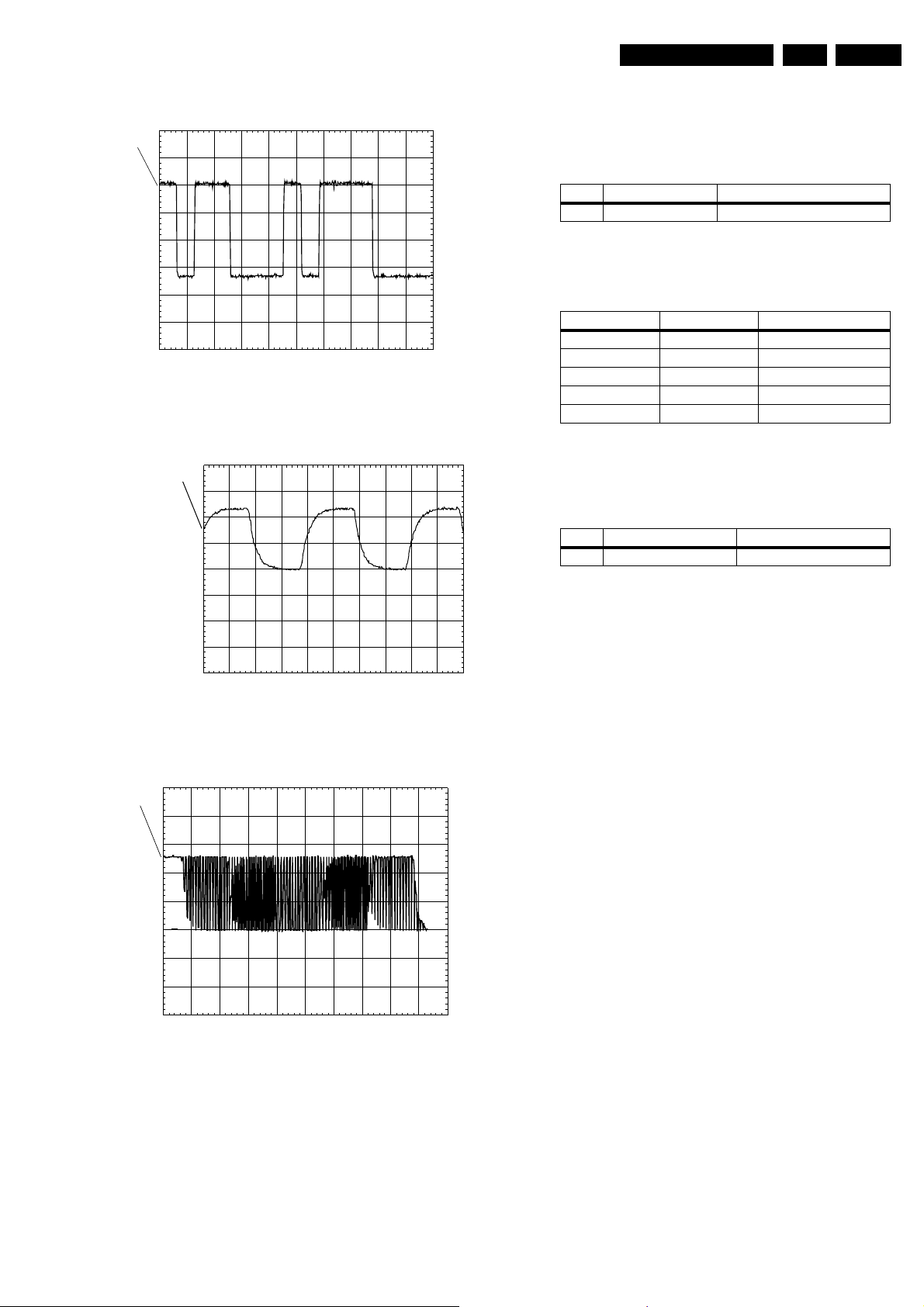

Table 5-13 NameTestpointWaveform

Name Testpoint Waveform

PCMLRCLK F886 / F021 Refer to Figure 5-9

PCMSCLK F883 / F019 Refer to Figure 5-10

PCMDATA0 F884 Refer to Figure 5-11

DATA_LR/DSD_LEFT F025 Refer to Figure 5-11

DATA_LsRs/DSD_Ls F029 Refer to Figure 5-11

DATA_CL/DSD_CENTRE F034 Refer to Figure 5-11

PCMCLK F885 / F016 Refer to Figure 5-12

SPDIF F719 Refer to Figure 5-13

PM3394B

ch1

1

CH1 2.00 V~ MTB10.0us ch1+

CL06532065_008.eps

161100

Figure 5-9 PCMLRCLK

Ref. # Command Name Remark

19a AudioMuteOff AudioMuteOff

Check the Mute output at testpoint T798: 0V ±0.3V

5.4.4 Audio I2S Check

To check the audio output, connect a audio DAC (on the A/V

board) to the I2S output and start-up the audio test. Look at the

audio outputs from the A/V board for both sine and pink noise.

Table 5-12 Audio I2S check

Command

Ref. #

21a AudioSineOn Audio Sine

Name Remark Audio outputs

Audio Sine signal On

signal Off

Sine, 1kHz on stereo

Press stop button

20a AudioPinkNoi

seOn

Audio

Pinknoise

Pink Noise on 6

channels

On

20b AudioPinkNoi

seOff

Audio

Pinknoise

Off

The audio signal (sine or pink noise) will also be present on the

digital ouput (SPDif). This can be checked by connecting an

amplifier with digital input.

Check the I2S output.

PM3394B

ch1

1

CH1 2.00 V~ MTB 100ns ch1+

Figure 5-10 PCMSCLK

CL06532065_009.eps

161100

ch1

PM3394B

Test Instructions Mono Board DVD-SD4.00SA_CH

Alternatively, there is a check that can be done without A/V

board.

First, let the decoder generate pink noise on the audio outputs.

Table 5-14

Ref. # Command Name Remark

20a AudioPinkNoiseOn Audio Pinknoise On

EN 15SD-4.00SA_CH 5.

1

CH1 1.00 V~ MTB 500ns ch1+

Figure 5-11 PCMDATA

PM3380B

ch1

1

CH1 2.00 V= MTB20.0ns ch1+

CL06532065_010.eps

161100

CL 26532053_067.eps

Measure then these signals on level and frequency.

Table 5-15

Signal Level between Frequency

PCMLRCLK low/high 48kHz 0.02%

PCMSCLK low/high 3.072MHz 0.02%

PCMCLK low/high 12.288MHz 0.02%

PCMDATA low/high N/A

SPDIF LOW/HIGH N/A

Put the pink noise off:

Table 5-16

Ref. # Command Name Remark

20b AudioPinkNoiseOff Audio Pinknoise Off

210502

Figure 5-12 PCMCLK

PM3380B

ch1

1

CH1 2.00 V= BWL MTB100ns ch1+

CL 16532163_024.eps

230102

Figure 5-13 SPDIF

To switch the audio signal OFF, press the STOP button on the

front.

Without A/V board, the switching levels are as follows:

– DATA_LsRs and DATA_CL switch between low and high

for pink noise. For sine, this is low.

– PCMDATA0, PCMLRCLK, PCMCLK and PCMSCLK

switches between low and high for both pink noise and

sine.

– SPDIF switches between LOW and HIGH

EN 16 SD-4.00SA_CH5.

Test Instructions Mono Board DVD-SD4.00SA_CH

5.5 VIDEO

5.5.1 Video Output Check

Measure the DC voltages at all video-outputs at conn 1703

while the video signal is turned off: 1V ± 10%

Generate a color-bar via next software commands:

Ref. # Command Name Remark

23a VideoColDencOn Colourbar DENC ON

61a VideoColOutRGB RGB Colourbar

61b VideoColOutYUV YUV Colourbar

23b VideoColDencOff Colourbar DENC OFF

Check video output at the next testpoints:

Name Testpoint Waveform

R_VID (V) F795 Refer to Figure 5-14 5-20

G_VID (Y) F796 Refer to Figure 5-15

B_VID (U) F799 Refer to Figure 5-16 5-21

CVBS_VID F788 Refer to Figure 5-17

C_VID F791 Refer to Figure 5-18

Y_VID F792/F796 Refer to Figure 5-19

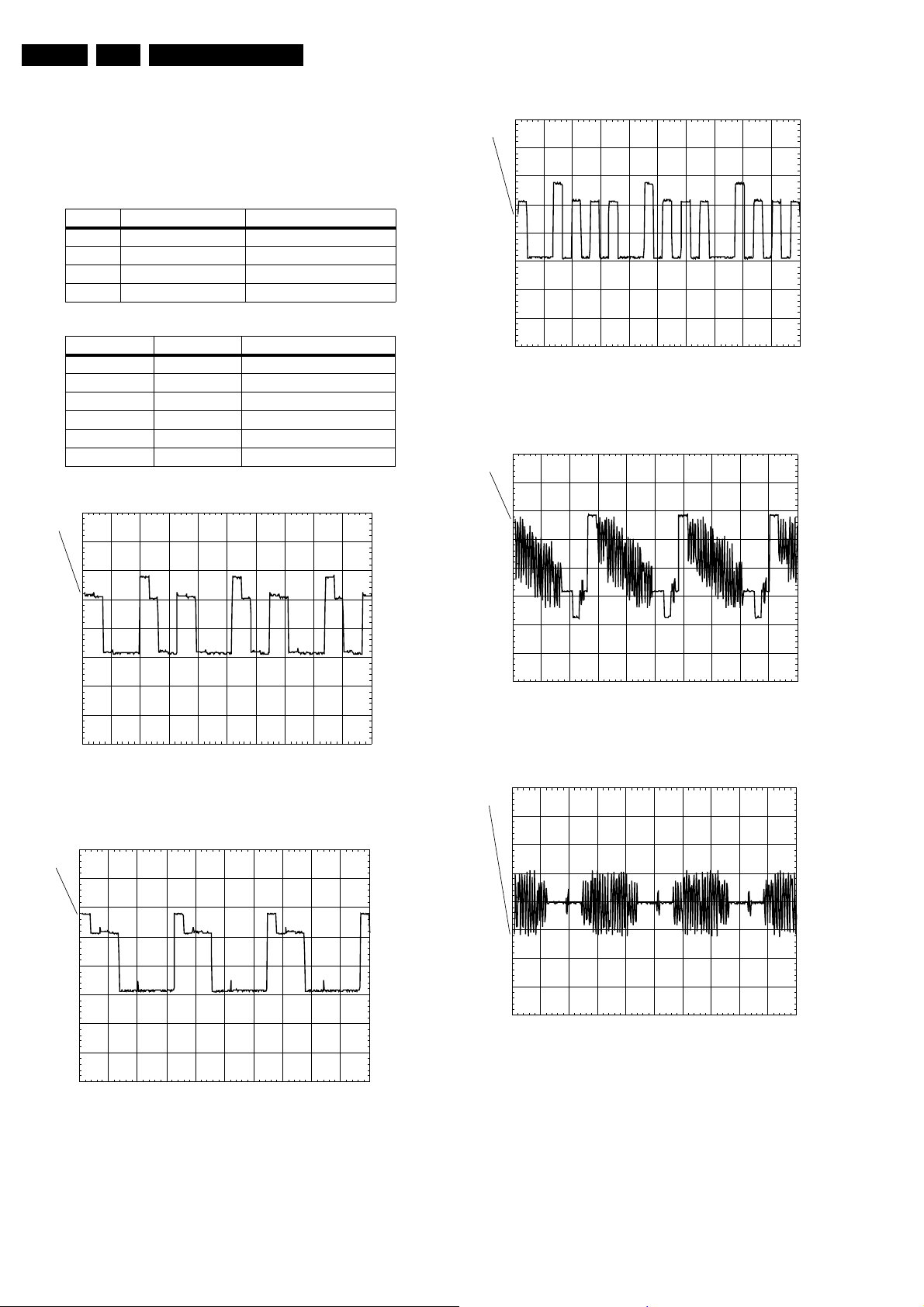

PM3380B

ch1

PM3380B

ch1

1

RUN

CH1 5 00mV~ BWL MTB20.0us ch1+

Figure 5-16 B_VID (U) with video out at RGB

PM3380B

ch1

CL 16532163_058.eps

290102

1

CH1 500mV~ BWLMTB20.0us ch1+

Figure 5-14 R_VID (V) with video out at RGB

PM3380B

ch1

1

CL 16532163_056.eps

290102

1

RUN

CH1 500mV~ BWL MTB20.0us ch1+

Figure 5-17 CVBS_VID

PM3380B

ch1

1

CH1 500mV~ BWL MTB20.0us L=1 ch1p

CL 16532163_059.eps

290102

CL 16532163_060.eps

290102

CH1 500mV~ BWLMTB20.0us ch1+

CL 16532163_057.eps

Figure 5-15 G_VID (Y) with video out at RGB

Figure 5-18 C_VID

290102

Test Instructions Mono Board DVD-SD4.00SA_CH

EN 17SD-4.00SA_CH 5.

PM3380B

ch1

1

CH1 500mV~ BWLMTB20.0us L=1 ch1p

Figure 5-19 Y_VID

PM3380B

ch1

1

CL 16532163_061.eps

290102

PM3380B

ch1

1

CH1 500mV~ BWLMTB20.0us L=1 extp

Figure 5-21 B_VID (U) with video out at YUV

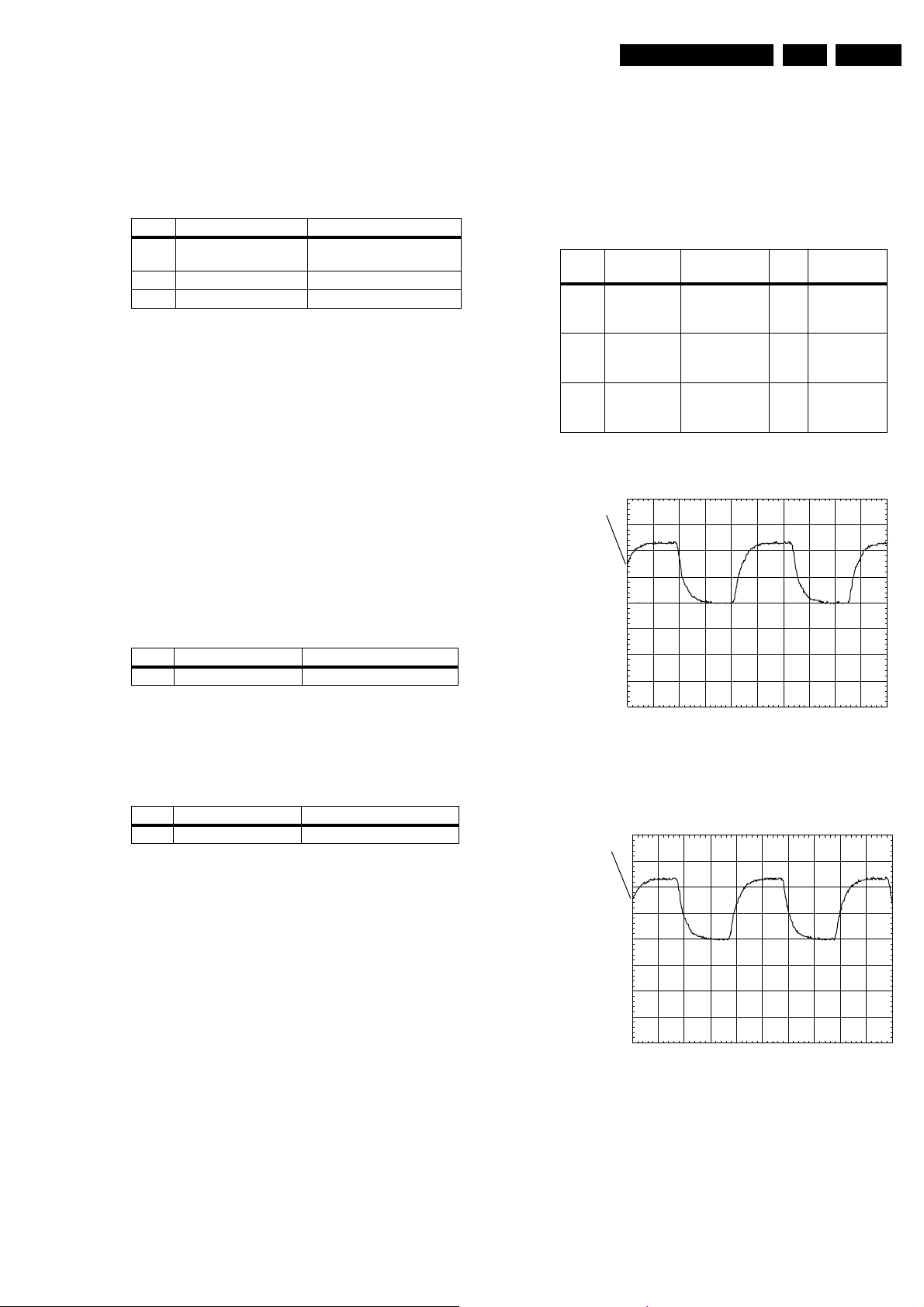

5.5.2 Slow Blanking Scart

An aditional part of the video-path is the scart functionswitching test. The scart function-switching pin has three levels

which depend on the level of the output ports SCART0 and

SCART1. These latter two signals are driven by the output pins

PIO3.6 and PIO3.7 of the STi55xx.

Check the level of SCART0 and SCART1 with the following

commands:

Table 5-17 Slow blanking scart

CL 16532163_026.eps

230102

CH1 500mV~ BWLMTB20.0us L=1 ext p

Figure 5-20 R_VID (V) with video out at YUV

5.5.3 Video Hsync Check.

To measure the Video Hsync, the connector 1704 must be

connected to the external video processing device such as high

quality progressive scan codex and high quality Video DAC,

else there will not be any waveform. To check for the Hsync,

the following commands can be used:

CL 16532163_025.eps

230102

Ref. #

Command

Name

Scart0

(PIO3.6)

Scart1

(PIO3.7)

Level on Pin 8

of scart

25a VideoScartLo 1 1 0-2V

25b VideoScartMi 0 1 4.5-7V

25c VideoScartHi 0 0 9.5-12V

EN 18 SD-4.00SA_CH5.

Test Instructions Mono Board DVD-SD4.00SA_CH

Table 5-18 Video Hsync check

Ref. # Command Name Remark Value Waveform

23a VideoColDencOn ColourbarDENC ON 15.625 kHz 0.02% Vpeak-peak > 3V Refer to Fig 5-22

61a VideoColOutRGB RGB Colourbar ON 15.625 kHz 0.02% Vpeak-peak > 3V Refer to Fig 5-22

23b VideoColDencOff Colourbar DENC OFF No measurements needed

Check Vref

PM3394B

ch1

1

CH1 2.00 V~ MTB20.0us ch1+

HSYNC

Figure 5-22 Video H Sync

5.6 Servo

5.6.1 General Start-up Measurements:

Reset the Basic Engine part

Table 5-19 Reset basic engine part

Ref. # Command Name Remark

44 BeReset Reset the Basic Engine

CL06532065_019.eps

161100

Table 5-20 Vref check

Name Testpoint Value

Vref F111 2.5V 0.3V

Play DVD test Disc and check I2S interface

Table 5-21 I2S interface check

Name Testpoint Value Value

BE_BCLK F200 6.0 MHz ± 0.1 Refer to Figure 5-23

BE_WCLK F201 high Refer to Figure 5-25

BE_DATA F202 low Refer to Figure 5-24

BE_FLAG F203 low No waveform

BE_V4 F255 low No waveform

BE_SYNC F256 low No waveform

PM3380B

ch1

1

Check if the Servo Reset (RSTN) at testpoint F258 goes from

low to high after executing BeReset commands.

CH1 2.00 V= MTB 200ns ch1+

Figure 5-23 BE_BCLK

PM3380B

ch1

1

CH1 2.00 V = MTB20.0ns c h1+

Figure 5-24 BE_DATA

CL 16532163_027.eps

230102

CL 16532163_028.eps

230102

Test Instructions Mono Board DVD-SD4.00SA_CH

EN 19SD-4.00SA_CH 5.

PM3380B

ch1

1

CH 1 2.00 V= MTB 200ns ch1 +

Figure 5-25 BE_WCLK

5.6.2 Spindle Motor:

Before switching on the discmotor, check the following

testpoints:

Table 5-22 Spindle motor check

Name Testpoint Value

STDBY_MOTOR F308 low

MOTO1 F350 1V5 0.3

CL 16532163_029.eps

230102

Table 5-24 Disc motor switching

Name Testpoint Frequency

STDBY_MOTOR F308 high

MOTO1 I241 4Vpp ± 0.5V Refer to

Figure 5-26

A3 F301 Refer to Figure 5-27

A2 F302 Refer to Figure 5-27

A1 F303 Refer to Figure 5-27

T1 F210 Refer to Figure 5-28

T2 F211 Refer to Figure 5-28

T3 F212 Refer to Figure 5-28

H1+ F306 Refer to Figure 5-29

H1- F304 Refer to Figure 5-29

H2+ F309 Refer to Figure 5-29

H2- F305 Refer to Figure 5-29

H3+ F311 Refer to Figure 5-29

H3- F313 Refer to Figure 5-29

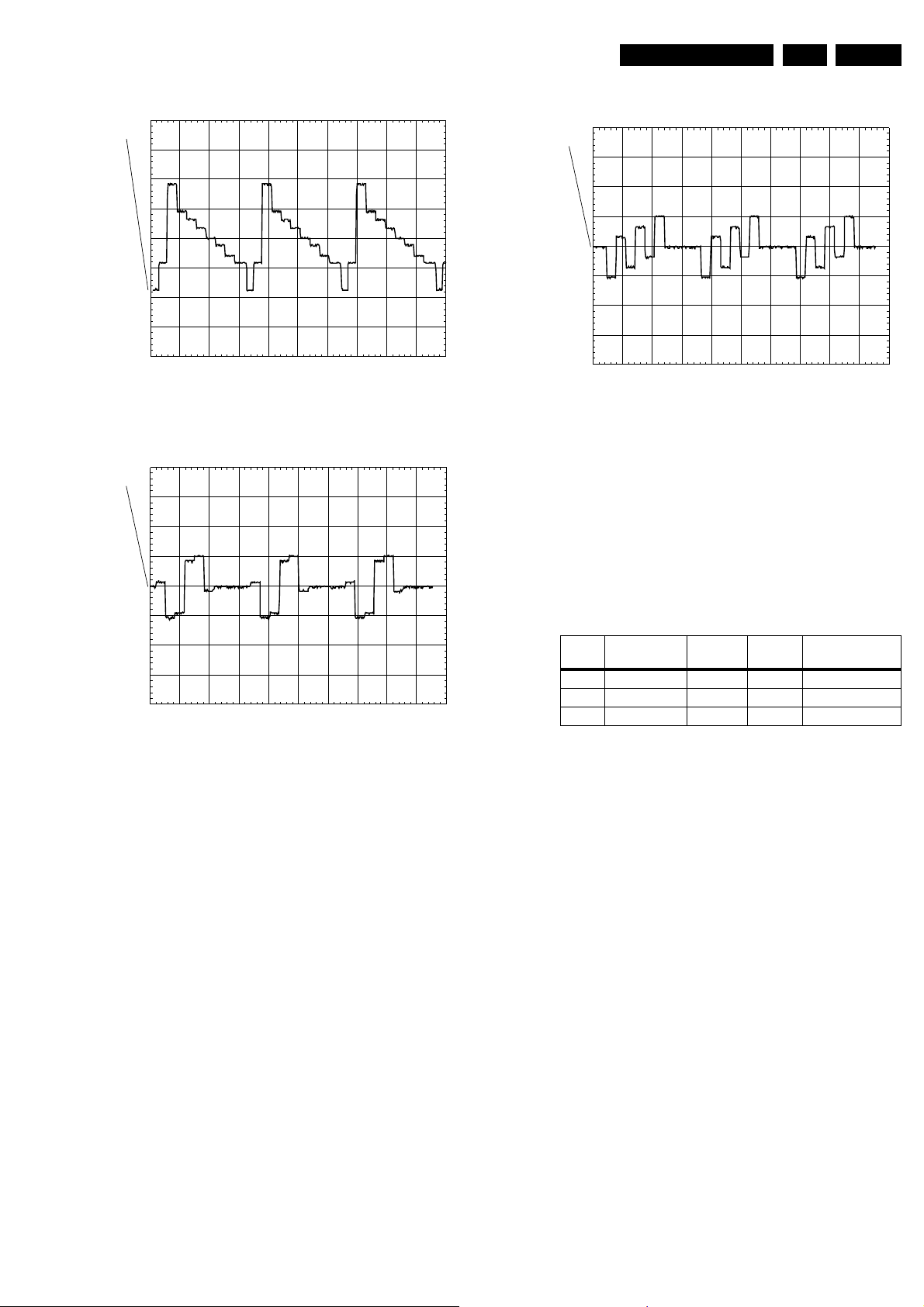

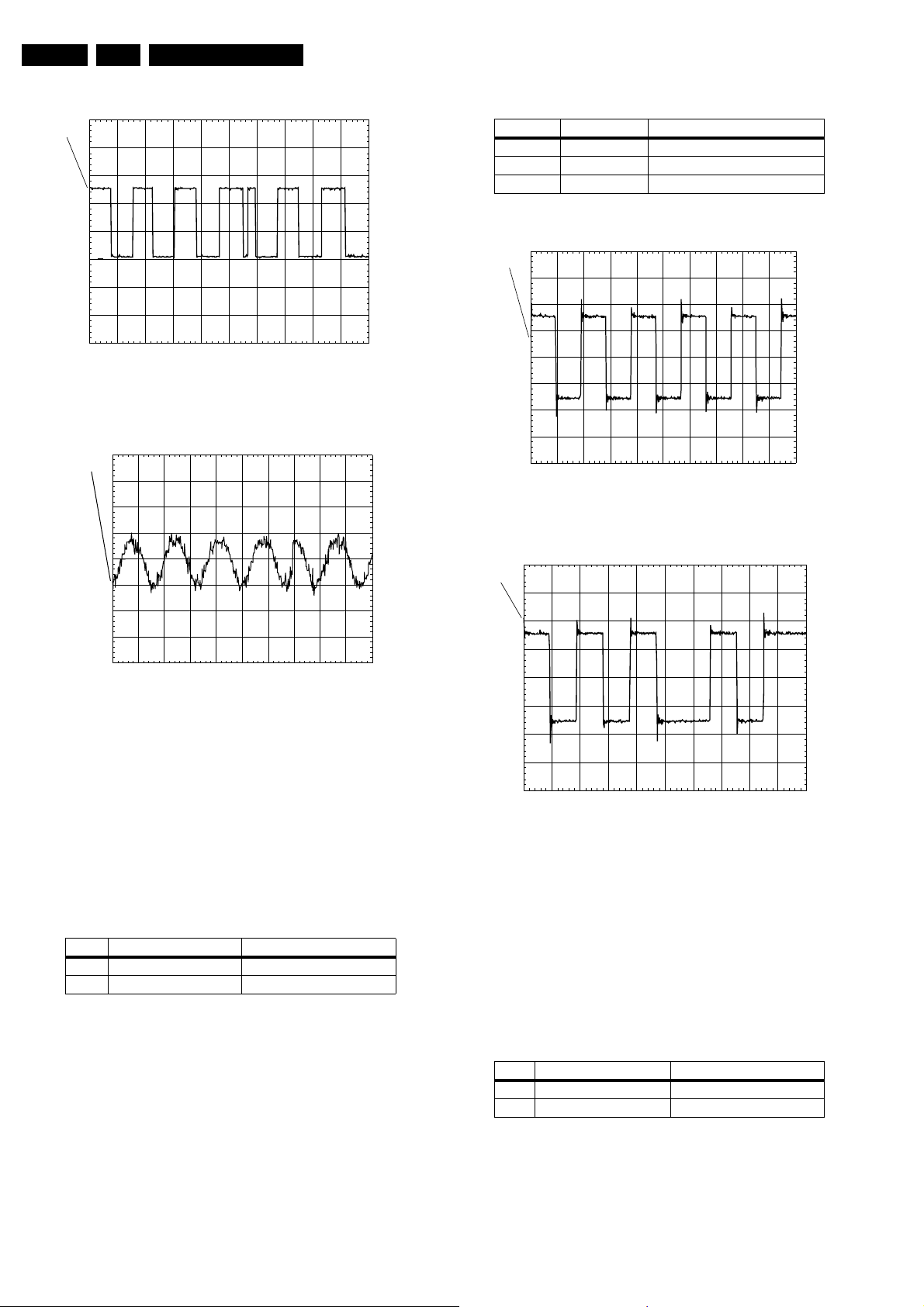

PM3380B

ch1

Switch the Discmotor ON/OFF with the following commands:

Table 5-23 Disc motor switching

Ref. # Command Name Remark

39a BeDiscmotorOn Discmotor on

39b BeDiscmotorOff Discmotor off

Check the following signals with the discmotor switched ON

and without DVD Disc inserted.

CH1 1.00 V= MTB 250ns ch1

Figure 5-26 Motor 1

PM3380B

ch1

CH1 5.00 V= MTB50.0ms ch1

Figure 5-27 A1-A2-A3

CL 26532053_069.eps

CL 26532053_070.eps

210502

210502

EN 20 SD-4.00SA_CH5.

PM3380B

ch1

Test Instructions Mono Board DVD-SD4.00SA_CH

Table 5-26 Radial

Name Testpoint Value (Radial ON)

Rad - F132 4.3V 0.5V

Rad + F133 4.3V 0.5V

RA F218 Refer to Figure 5-30 and 5-31

1

CH1 2.00 V= M TB5.00ms ch1+

Figure 5-28 T1-T2-T3

PM3380B

ch1

CH1 200mV~ MTB5.00ms ch1

CL 16532163_032.eps

230102

CL 26532053_071.eps

210502

PM3380B

ch1

1

CH1 1.00 V~ MTB 250ns ch1+

Figure 5-30 RA (BeRadialOff)

PM3380B

ch1

1

CL 16532163_035.eps

230102

Figure 5-29 H1+ ; H1- ; H2+ ; H2- ; H3+ ; H3-

When measurement is completed, switch the discmotor OFF

before executing next command

5.6.3 Radial

Radial ON will only work when the PCB is connected to a CDM

and DVD Disc is inserted.

Switch the Radial control ON/OFF with the following

commands:

Table 5-25 Radial

Ref. # Command Name Remark

40a BeRadialOn Radial control on

40b BeRadialOff Radial control off

Check the following signals before Radial control ON/OFF

CH1 1.00 V~ MT B 250ns ch1+

STOP

Figure 5-31 RA (BeRadialOn)

Visual check on the laser,when Radial control ON, if the

laserlight is visible.

Once the check is completed,switch the Radial control OFF

before executing next command

5.6.4 Sledge

Test need a DVD disc in the DVD player to operate properly.

Use the following commands to move the sledge:

Table 5-27 Sledge

Ref. # Command Name Remark

41a BeSledgeIn Sledge inwards

41b BeSledgeOut Sledge outwards

Check for the waveform ( Figure 5-32 ) of SL at testpoint F219

CL 16532163_036.eps

230102

Loading...

Loading...