Page 1

查询SC16C2550供应商

1. Description

SC16C2550

Dual UART with 16 bytes of transmit and receive FIFOs

and infrared (IrDA) encoder/decoder

Rev. 03 — 19 June 2003 Product data

The SC16C2550 is a 2 channel Universal Asynchronous Receiver and Transmitter

(UART) used for serial data communications. Its principal function is to convert

parallel data into serial data and vice versa. The UART can handle serial data rates

up to 5 Mbits/s.

The SC16C2550 is pin compatible with the ST16C2550. It will power-up to be

functionally equivalent to the 16C2450. The SC16C2550 provides enhanced UART

functions with 16-byte FIFOs, modemcontrol interface, DMA mode data transfer. The

DMA mode data transfer is controlled by the FIFO trigger levels and the TXRDY and

RXRDY signals. On-board status registers provide the user with error indications and

operational status. System interrupts and modem control features may be tailored by

software to meet specific user requirements. An internal loop-back capability allows

on-board diagnostics. Independent programmable baud rate generators are provided

to select transmit and receive baud rates.

2. Features

The SC16C2550 operates at 5 V, 3.3 V and 2.5 V and the Industrial temperature

range, and is available in plastic PLCC44, LQFP48 and DIP40 packages.

■ 2 channel UART

■ 5 V, 3.3 V and 2.5 V operation

■ Industrial temperature range

■ Pin and functionally compatible to 16C2450 and software compatible with

INS8250, SC16C550

■ Up to 5 Mbits/s data rate at 5 V and 3.3 V, and 3 Mbits/s at 2.5 V

■ 16 byte transmit FIFO to reduce the bandwidth requirement of the external CPU

■ 16 byte receive FIFO with error flags to reduce the bandwidth requirement of the

external CPU

■ Independent transmit and receive UART control

■ Four selectable Receive FIFO interrupt trigger levels

■ Automatic software/hardware flow control

■ Programmable Xon/Xoff characters

■ Software selectable Baud Rate Generator

■ Sleep mode

■ Standard asynchronous error and framing bits (Start, Stop, and Parity Overrun

Break)

■ Transmit, Receive, Line Status, and Data Set interrupts independently controlled

Page 2

Philips Semiconductors

SC16C2550

Dual UART with 16 bytes of transmit and receive FIFOs and IrDA

encoder/decoder

■ Fully programmable character formatting:

◆ 5-, 6-, 7-, or 8-bit characters

◆ Even-, Odd-, or No-Parity formats

◆ 1-, 11⁄2-, or 2-stop bit

◆ Baud generation (DC to 1.5 Mbit/s)

■ False start-bit detection

■ Complete status reporting capabilities

■ 3-State output TTL drive capabilities for bi-directional data bus and control bus

■ Line Break generation and detection

■ Internal diagnostic capabilities:

◆ Loop-back controls for communications link fault isolation

■ Prioritized interrupt system controls

■ Modem control functions (CTS, RTS, DSR, DTR, RI, DCD).

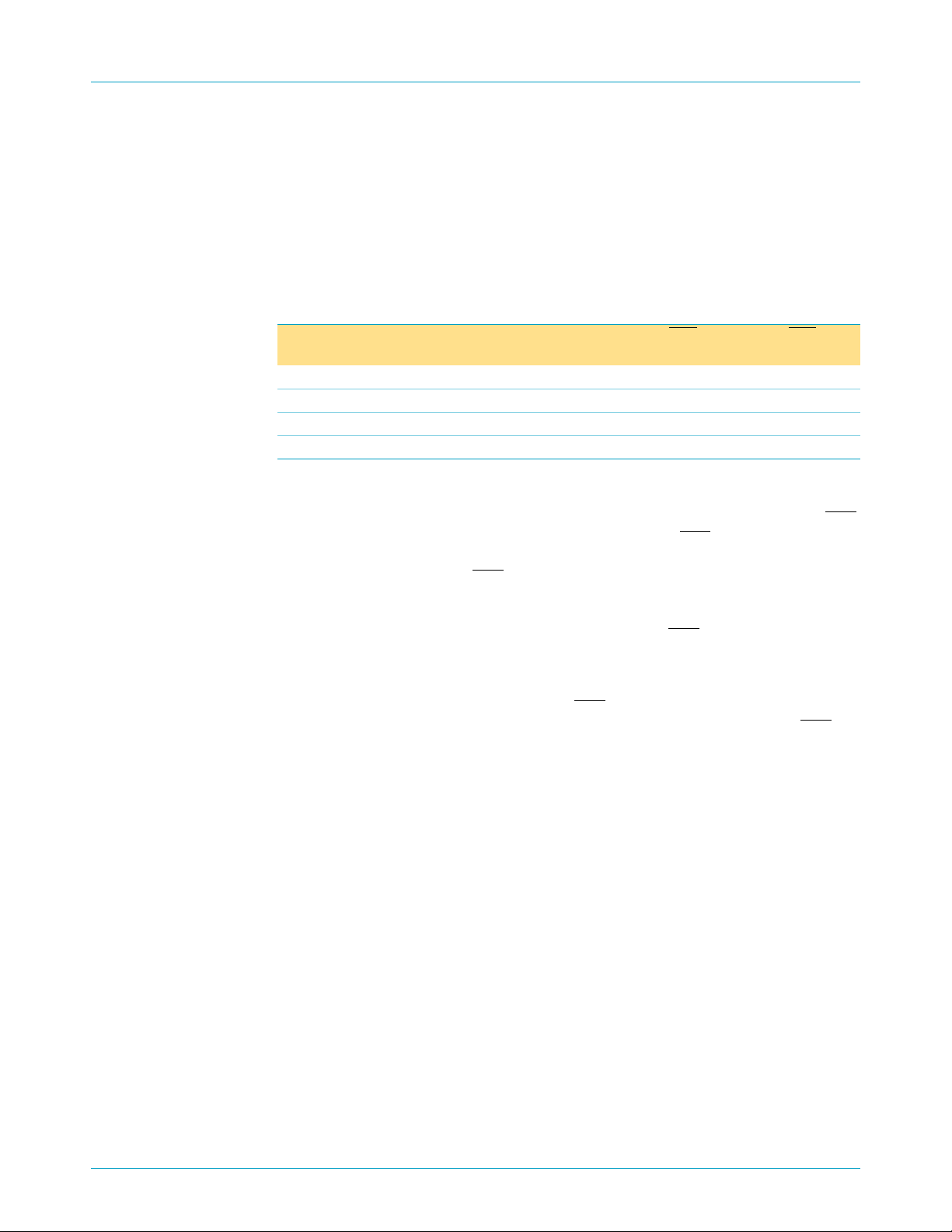

3. Ordering information

Table 1: Ordering information

Type number Package

Name Description Version

SC16C2550IN40 DIP40 plastic dual in-line package; 40 leads (600 mil) SOT129-1

SC16C2550IA44 PLCC44 plastic leaded chip carrier; 44 leads SOT187-2

SC16C2550IB48 LQFP48 plastic low profile quad flat package; 48 leads; body 7 × 7 × 1.4 mm SOT313-2

9397 75011621

Product data Rev. 03 — 19 June 2003 2 of 46

© Koninklijke Philips Electronics N.V. 2003. All rights reserved.

Page 3

Philips Semiconductors

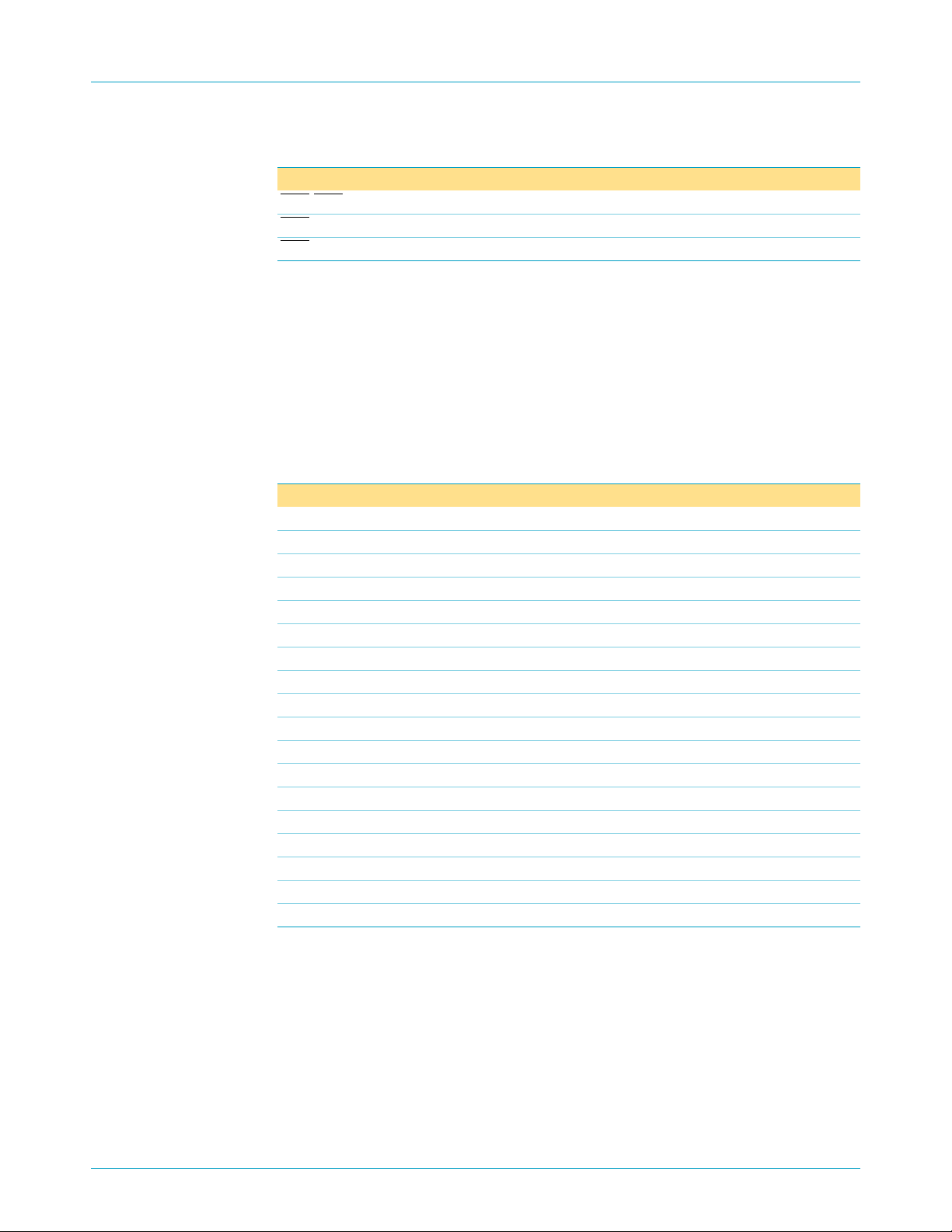

4. Block diagram

SC16C2550

SC16C2550

Dual UART with 16 bytes of transmit and receive FIFOs and IrDA

encoder/decoder

D0–D7

IOR

IOW

RESET

A0–A2

CSA

CSB

INTA, INTB

, TXRDYB

TXRDYA

RXRDYA, RXRDYB

DATA BUS

AND

CONTROL LOGIC

REGISTER

SELECT

LOGIC

INTERRUPT

CONTROL

LOGIC

AND

CONTROL SIGNALS

INTERCONNECT BUS LINES

TRANSMIT

FIFO

REGISTER

RECEIVE

FIFO

REGISTER

CLOCK AND

BAUD RATE

GENERATOR

TRANSMIT

SHIFT

REGISTER

RECEIVE

SHIFT

REGISTER

MODEM

CONTROL

LOGIC

TXA, TXB

RXA, RXB

DTRA, DTRB

RTSA, RTSB

OP2A, OP2B

, CTSB

CTSA

RIA, RIB

CDA, CDB

DSRA, DSRB

002aaa119

XTAL2XTAL1

Fig 1. SC16C2550 block diagram.

9397 750 11621

Product data Rev. 03 — 19 June 2003 3 of 46

© Koninklijke Philips Electronics N.V. 2003. All rights reserved.

Page 4

Philips Semiconductors

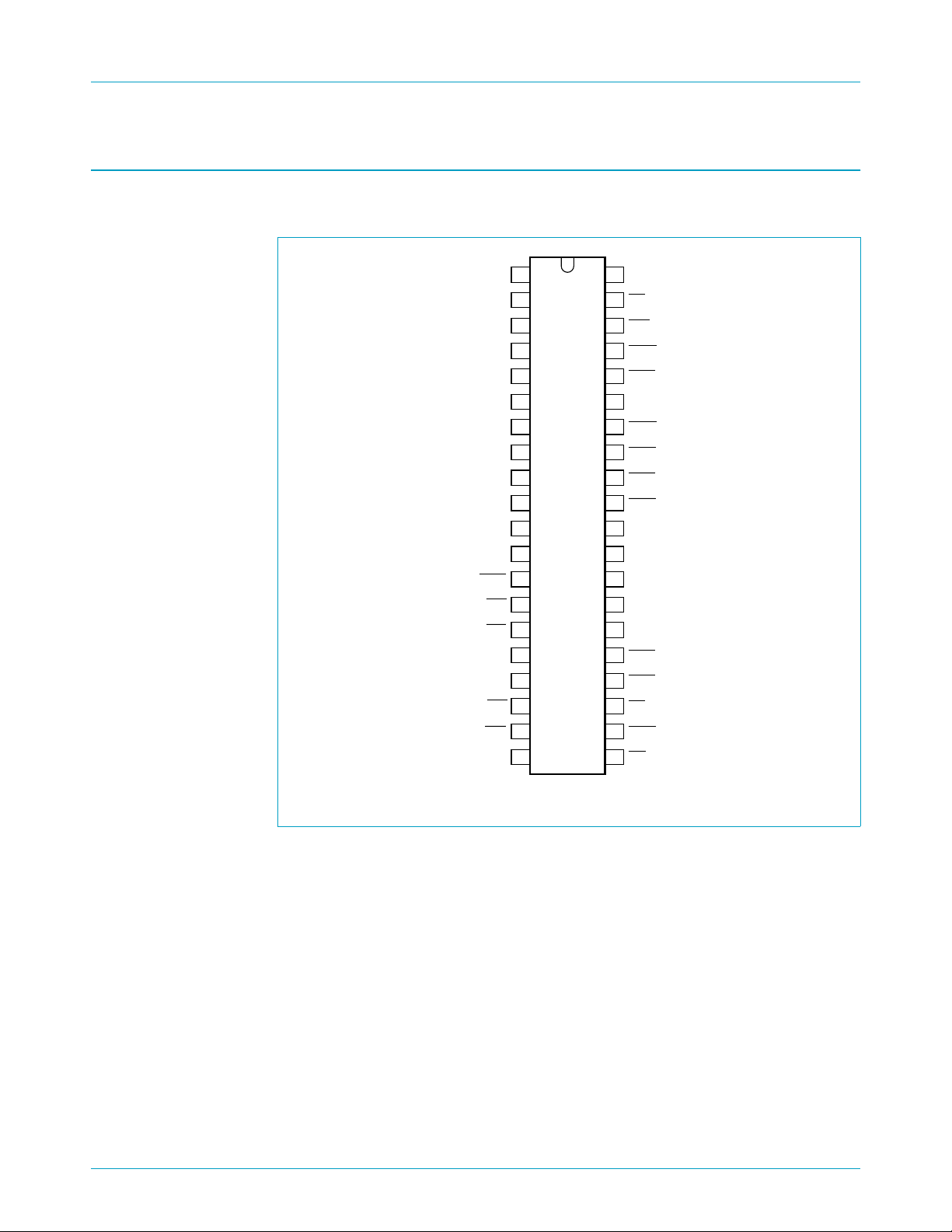

5. Pinning information

5.1 Pinning

SC16C2550

Dual UART with 16 bytes of transmit and receive FIFOs and IrDA

encoder/decoder

D0

D1

D2

D3

D4

D5

D6

D7

RXB

RXA

TXA

TXB

OP2B

CSA

CSB

XTAL1

XTAL2

IOW

CDB

GND

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

SC16C2550IN40

002aaa105

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

V

CC

RIA

CDA

DSRA

CTSA

RESET

DTRB

DTRA

RTSA

OP2A

INTA

INTB

A0

A1

A2

CTSB

RTSB

RIB

DSRB

IOR

Fig 2. DIP40 pin configuration.

9397 750 11621

Product data Rev. 03 — 19 June 2003 4 of 46

© Koninklijke Philips Electronics N.V. 2003. All rights reserved.

Page 5

Philips Semiconductors

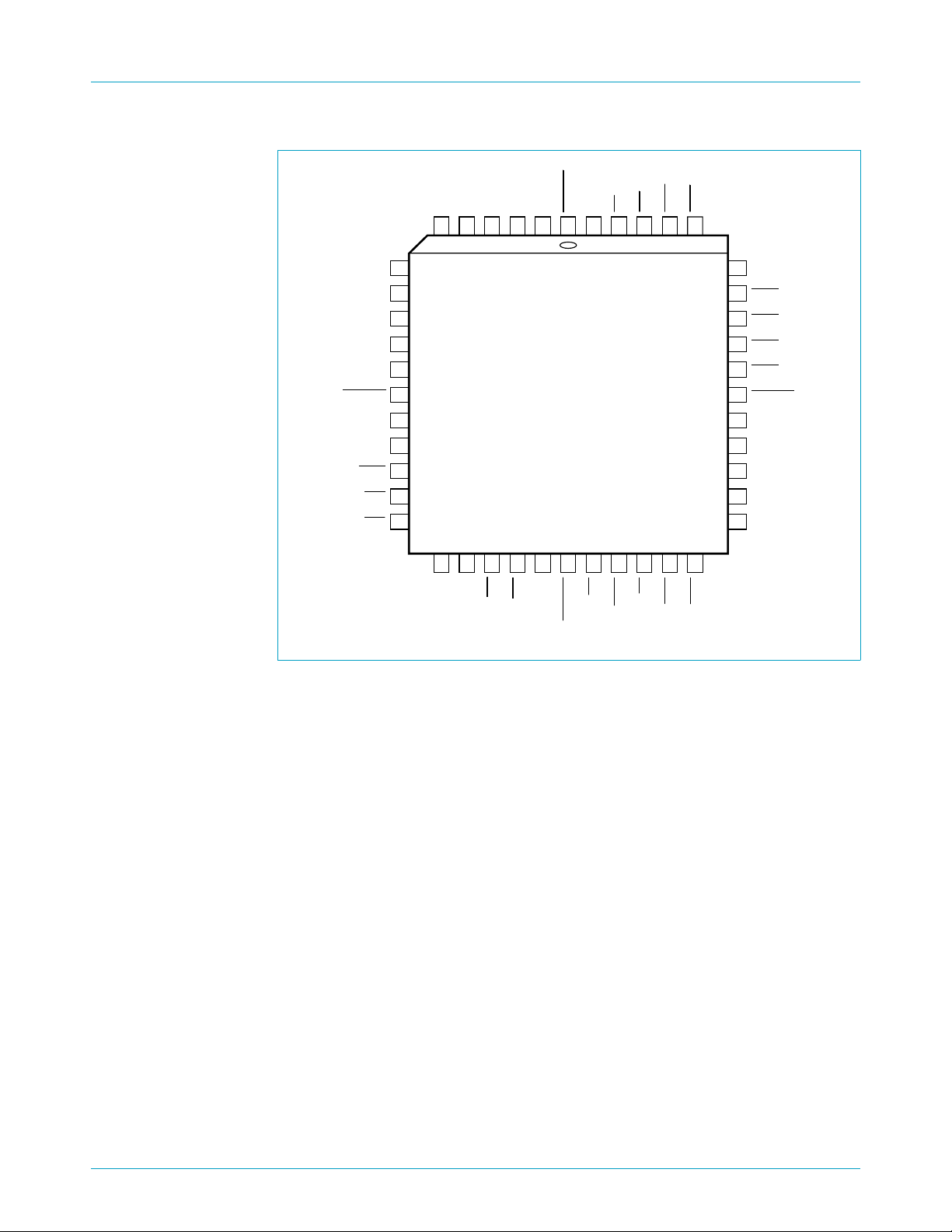

SC16C2550

Dual UART with 16 bytes of transmit and receive FIFOs and IrDA

encoder/decoder

D4

D3

D2

6

5

4

7

D5

8

D6

9

D7

10

RXB

11

RXA

TXA

TXB

OP2B

CSA

CSB

12

13

14

15

16

17

18

19

20

XTAL2

IOW

XTAL1

TXRDYB

Fig 3. PLCC44 pin configuration.

D1

3

D0

2

CC

TXRDYA

V

1

44

SC16C2550IA44

21

22

23

24

CDB

GND

IOR

RXRDYB

RIA

43

25

DSRB

CDA

42

26

RIB

DSRA

41

27

RTSB

CTSA

40

28

002aaa103

CTSB

39

38

37

36

35

34

33

32

31

30

29

RESET

DTRB

DTRA

RTSA

OP2A

RXRDYA

INTA

INTB

A0

A1

A2

9397 750 11621

© Koninklijke Philips Electronics N.V. 2003. All rights reserved.

Product data Rev. 03 — 19 June 2003 5 of 46

Page 6

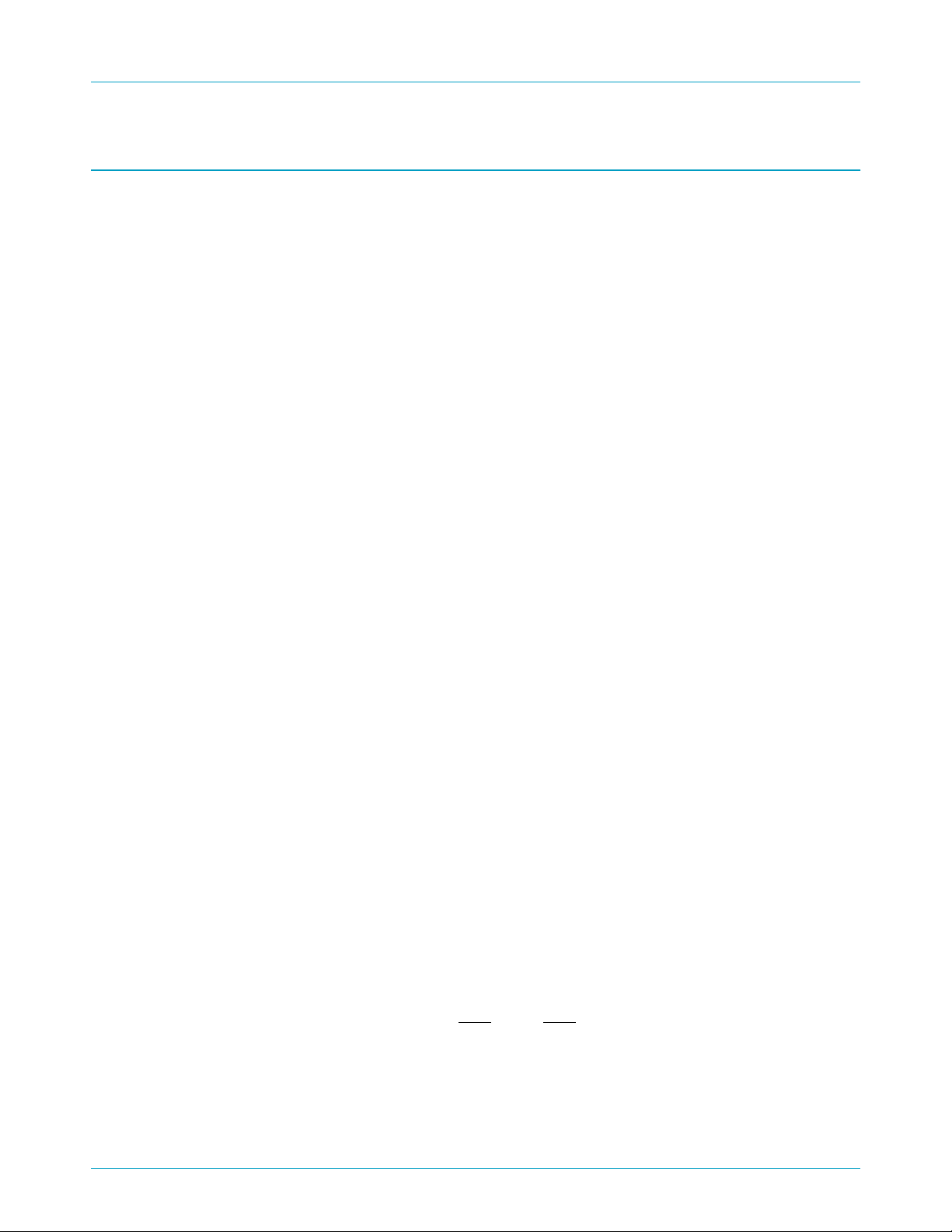

Philips Semiconductors

SC16C2550

Dual UART with 16 bytes of transmit and receive FIFOs and IrDA

encoder/decoder

D5

D6

D7

RXB

RXA

TXRDYB

TXA

TXB

OP2B

CSA

CSB

N.C.

D4

D3

D2

D1

D0

48

47

46

45

44

1

2

3

4

5

6

7

8

9

10

11

12

13

14

XTAL1

XTAL2

SC16C2550IB48

15

16

IOW

CDB

17

GND

CC

TXRDYA

V

43

42

18

19

IOR

RXRDYB

RIA

41

20

DSRB

CDA

40

21

RIB

DSRA

39

22

RTSB

CTSA

38

23

CTSB

N.C.

37

24

N.C.

36

35

34

33

32

31

30

29

28

27

26

25

002aaa104

RESET

DTRB

DTRA

RTSA

OP2A

RXRDYA

INTA

INTB

A0

A1

A2

N.C.

Fig 4. LQFP48 pin configuration.

5.2 Pin description

Table 2: Pin description

Symbol Pin Type Description

DIP40 PLCC44 LQFP48

A0 28 31 28 I Address 0 select bit. Internal register address selection.

A1 27 30 27 I Address 1 select bit. Internal register address selection.

A2 26 29 26 I Address 2 select bit. Internal register address selection.

CSA, CSB 14, 15 16, 17 10, 11 I Chip Select A, B (Active-LOW).This function is associated with individual

channels, A through B. These pins enable data transfers between the user

CPU and the SC16C2550 for the channel(s) addressed. Individual UART

sections (A, B) are addressed by providing a logic 0 on the respective

CSB pin.

D0-D7 1-8 2-9 44-48,

1-3

I/O Data bus (bi-directional). These pins are the 8-bit, 3-State data bus for

transferring information to or from the controlling CPU. D0 is the least

significant bit and the first data bit in a transmit or receive serial data

stream.

GND 20 22 17 I Signal and power ground.

CSA,

9397 750 11621

© Koninklijke Philips Electronics N.V. 2003. All rights reserved.

Product data Rev. 03 — 19 June 2003 6 of 46

Page 7

Philips Semiconductors

SC16C2550

Dual UART with 16 bytes of transmit and receive FIFOs and IrDA

encoder/decoder

Table 2: Pin description

Symbol Pin Type Description

DIP40 PLCC44 LQFP48

INTA,

INTB

IOR 21 24 19 I Read strobe (Active-LOW strobe). A logic 0 transition on this pin will load

IOW182015IWrite strobe (Active-LOW strobe). A logic 0 transition on this pin will

OP2A,

OP2B

RESET 35 39 36 I Reset (Active-HIGH). A logic 1 on this pin will reset the internal registers

RXRDYA,

RXRDYB

TXRDYA,

TXRDYB

V

CC

XTAL1 16 18 13 I Crystal or external clock input. Functions as a crystal input or as an

30, 29 33, 32 30, 29 O Interrupt A, B (3-State). This function is associated with individual channel

31, 13 35, 15 32, 9 O Output 2 (user-defined). This function is associated with individual

- 34, 23 31, 18 O Receive Ready A, B (Active-LOW). This function is associated with

- 1, 12 43, 6 O Transmit Ready A, B (Active-LOW). This function is associated with

40 44 42 I Power supply input.

…continued

interrupts, INTA, INTB. INTA, INTB are enabled when MCR bit 3 is set to a

logic 1, interrupts are enabled in the interrupt enable register (IER), and is

active when an interrupt condition exists. Interrupt conditions include:

receiver errors, available receiver buffer data, transmit buffer empty, or

when a modem status flag is detected.

the contents of an internal register defined by address bits A0-A2 onto the

SC16C2550 data bus (D0-D7) for access by external CPU.

transfer the contents of the data bus (D0-D7) from the external CPU to an

internal register that is defined by address bits A0-A2.

channels, A through B. The state at these pin(s) are defined by the user

and through MCR register bit 3. INTA, INTB are set to the active mode and

OP2 to logic 0 when MCR[3] is set to a logic 1. INTA, INTB are set to the

3-State mode and

bit 3, Modem Control Register (MCR[3]). Since these bits control both the

INTA, INTB operation and

at one time, INT or

and all the outputs. The UART transmitter output and the receiver input will

be disabled during reset time. (See Section 7.11 “SC16C2550 external

reset condition” for initialization details.)

PLCC44 and LQFP48 packages only. This function provides the

RX FIFO/RHR status for individual receive channels (A-B).

primarily intended for monitoring DMA mode 1 transfersforthe receivedata

FIFOs. A logic 0 indicates there is a receive data to read/upload, i.e.,

receive ready status with one or more RX characters available in the

FIFO/RHR. This pin is a logic 1 when the FIFO/RHR is empty or when the

programmed trigger level has not been reached. This signal can also be

used for single mode transfers (DMA mode 0).

PLCC44 and LQFP48 packages only. These outputs provide the

TX FIFO/THR status for individual transmit channels (A-B).

primarily intended for monitoring DMA mode 1 transfers for the transmit

data FIFOs. An individual channel’s

is indicated by logic 0, i.e., at lease one location is empty and available in

the FIFO or THR. This pin goes to a logic 1 (DMA mode 1) when there are

no more empty locations in the FIFO or THR. This signal can also be used

for single mode transfers (DMA mode0).

external clock input. A crystal can be connected between this pin and

XTAL2 to form an internal oscillator circuit. This configuration requires an

external 1 MΩ resistor between the XTAL1 and XTAL2 pins. Alternatively,

an external clock can be connected to this pin to provide custom data rates.

(See Section 6.8 “Programmable baud rate generator”.) See Figure 5.

OP2 to a logic 1 when MCR[3] is set to a logic 0. See

OP2 outputs, only one function should be used

OP2.

RXRDYn is

TXRDYn is

TXRDYA, TXRDYB buffer ready status

9397 750 11621

Product data Rev. 03 — 19 June 2003 7 of 46

© Koninklijke Philips Electronics N.V. 2003. All rights reserved.

Page 8

Philips Semiconductors

SC16C2550

Dual UART with 16 bytes of transmit and receive FIFOs and IrDA

encoder/decoder

Table 2: Pin description

Symbol Pin Type Description

DIP40 PLCC44 LQFP48

XTAL2 17 19 14 O Output of the crystal oscillator or buffered clock. (See also XTAL1.)

CDA,

CDB

CTSA,

CTSB

DSRA,

DSRB

DTRA,

DTRB

RIA, RIB 39, 23 43, 26 41, 21 I Ring Indicator (Active-LOW). These inputs are associated with individual

RTSA,

RTSB

RXA, RXB 10, 9 11, 10 5, 4 I Receive data A, B. These inputs are associated with individual serial

TXA, TXB 11, 12 13, 14 7, 8 O Transmit data A, B. These outputs are associated with individual serial

38, 19 42, 21 40, 16 I Carrier Detect (Active-LOW). These inputs are associated with individual

36, 25 40, 28 38, 23 I Clear to Send (Active-LOW). These inputs are associated with individual

37, 22 41, 25 39, 20 I Data Set Ready (Active-LOW). These inputs are associated with

33, 34 37, 38 34, 35 O Data Terminal REady (Active-LOW). These outputs are associated with

32, 24 36, 27 33, 22 O Request to Send (Active-LOW). These outputs are associated with

…continued

Crystal oscillator output or buffered clock output. Should be left open if an

external clock is connected to XTAL1. For extended frequency operation,

this pin should be tied to V

UART channels A through B. A logic 0 on this pin indicates that a carrier

has been detected by the modem for that channel.

UART channels, A through B. A logic 0 on the CTS pin indicates the

modem or data set is ready to accept transmit data from the SC16C2550.

Status can be tested by reading MSR[4]. This pin has no effect on the

UART’s transmit or receive operation.

individual UART channels, A through B. A logic 0 on this pin indicates the

modem or data set is powered-on and is ready for data exchange with the

UART. This pin has no effect on the UART’s transmit or receive operation.

individual UART channels, A through B. A logic 0 on this pin indicates that

the SC16C2550 is powered-on and ready. This pin can be controlled via

the modem control register. Writing a logic 1 to MCR[0] will set the

output to logic 0, enablingthe modem. This pin will be a logic 1 after writing

a logic 0 to MCR[0], or after a reset. This pin has no effect on the UART’s

transmit or receive operation.

UARTchannels, A through B. A logic 0 on this pin indicates the modem has

received a ringing signal from the telephone line. A logic 1 transition on this

input pin will generate an interrupt.

individual UART channels, A through B. A logic 0 on the RTS pin indicates

the transmitter has data ready and waiting to send. Writing a logic 1 in the

modem control register MCR[1] will set this pin to a logic 0, indicating data

is available. After a reset this pin will be set to a logic 1. This pin has no

effect on the UART’s transmit or receive operation.

channel data to the SC16C2550 receive input circuits, A-B. The RX signal

will be a logic 1 during reset, idle (no data), or when the transmitter is

disabled. During the local loop-back mode, the RX input pin is disabled and

TX data is connected to the UART RX input, internally.

transmit channel data from the SC16C2550. The TX signal will be a logic 1

during reset, idle (no data), or when the transmitter is disabled. During the

local loop-back mode, the TX output pin is disabled and TX data is

internally connected to the UART RX input.

via a 2 kΩ resistor.

CC

DTR

9397 750 11621

Product data Rev. 03 — 19 June 2003 8 of 46

© Koninklijke Philips Electronics N.V. 2003. All rights reserved.

Page 9

Philips Semiconductors

6. Functional description

The SC16C2550 provides serial asynchronous receive data synchronization,

parallel-to-serial and serial-to-parallel data conversions for both the transmitter and

receiver sections. These functions are necessary for converting the serial data

stream into parallel data that is required with digital data systems. Synchronization for

the serial data stream is accomplished by adding start and stop bits to the transmit

data to form a data character (character orientated protocol). Data integrity is insured

by attaching a parity bit to the data character.The parity bit is checked by the receiver

for any transmission bit errors. The electronic circuitry to provide all these functions is

fairly complex, especially when manufactured on a single integrated silicon chip. The

SC16C2550 represents such an integration with greatly enhanced features. The

SC16C2550 is fabricated with an advanced CMOS process.

The SC16C2550 is an upward solution that provides a dual UART capability with

16 bytes of transmit and receive FIFO memory, instead of none in the 16C2450. The

SC16C2550 is designed to work with high speed modems and shared network

environments that require fast data processing time. Increased performance is

realized in the SC16C2550 by the transmit and receive FIFOs. This allows the

external processor to handle more networking tasks within a given time. For example,

the ST16C2450 without a receive FIFO, will require unloading of the RHR in

93 microseconds (this example uses a character length of 11 bits, including start/stop

bits at 115.2 kbits/s). This means the external CPU will have to service the receive

FIFO less than every 100 microseconds. However, with the 16 byte FIFO in the

SC16C2550, the data buffer will not require unloading/loading for 1.53 ms. This

increases the service interval, giving the external CPU additional time for other

applications and reducing the overall UART interrupt servicing time. In addition, the

four selectable receive FIFO trigger interrupt levelsis uniquely provided for maximum

data throughput performance especially when operating in a multi-channel

environment. The FIFO memory greatly reduces the bandwidth requirement of the

external controlling CPU, increases performance, and reduces power consumption.

SC16C2550

Dual UART with 16 bytes of transmit and receive FIFOs and IrDA

encoder/decoder

The SC16C2550 is capable of operation up to 5 Mbits/s with a 80 MHz clock. With a

crystal or external clock input of 7.3728 MHz, the user can select data rates up to

460.8 kbits/s.

The rich feature set of the SC16C2550 is available through internal registers.

Selectable receive FIFO trigger levels,selectable TX and RX baud rates, and modem

interface controls are all standard features. Followinga power-on reset or an external

reset, the SC16C2550 is software compatible with the previous generation,

ST16C2450.

6.1 UART A-B functions

The UART provides the user with the capability to bi-directionally transfer information

between an external CPU, the SC16C2550 package,and an external serial device. A

logic 0 on chip select pins CSA and/or CSB allows the user to configure, send data,

and/or receive data via UART channels A-B. Individual channel select functions are

shown in Table 3.

9397 750 11621

Product data Rev. 03 — 19 June 2003 9 of 46

© Koninklijke Philips Electronics N.V. 2003. All rights reserved.

Page 10

Philips Semiconductors

Table 3: Serial port selection

Chip Select Function

CSA-CSB = 1 none

CSA = 0 UART channel A

CSB = 0 UART channel B

6.2 Internal registers

The SC16C2550 provides two sets of internal registers (A and B) consisting of

12 registers each for monitoring and controlling the functions of each channel of the

UART. These registers are shown in Table 4. The UART registers function as data

holding registers (THR/RHR), interrupt status and control registers (IER/ISR), a FIFO

control register (FCR), line status and control registers (LCR/LSR), modem status

and control registers (MCR/MSR), programmable data rate (clock) control registers

(DLL/DLM), and a user accessible scratchpad register (SPR).

Table 4: Internal registers decoding

A2 A1 A0 READ mode WRITE mode

General register set (THR/RHR, IER/ISR, MCR/MSR, FCR, LSR, SPR)

0 0 0 Receive Holding Register Transmit Holding Register

0 0 1 Interrupt Enable Register

0 1 0 Interrupt Status Register FIFO Control Register

0 1 1 Line Control Register

1 0 0 Modem Control Register

1 0 1 Line Status Register n/a

1 1 0 Modem Status Register n/a

1 1 1 Scratchpad Register Scratchpad Register

Baud rate register set (DLL/DLM)

0 0 0 LSB of Divisor Latch LSB of Divisor Latch

0 0 1 MSB of Divisor Latch MSB of Divisor Latch

Enhanced register set (EFR, Xon/off 1-2)

0 1 0 Enhanced Feature Register Enhanced Feature Register

1 0 0 Xon1 word Xon1 word

1 0 1 Xon2 word Xon2 word

1 1 0 Xoff1 word Xoff1 word

1 1 1 Xoff2 word Xoff2 word

SC16C2550

Dual UART with 16 bytes of transmit and receive FIFOs and IrDA

encoder/decoder

[1]

[2]

[3]

[1] These registers are accessible only when LCR[7] is a logic 0.

[2] These registers are accessible only when LCR[7] is a logic 1.

[3] Enhanced Feature Register, Xon1, 2 and Xoff1, 2 are accessible only when the LCR is set to

‘BF(HEX)’.

9397 750 11621

Product data Rev. 03 — 19 June 2003 10 of 46

© Koninklijke Philips Electronics N.V. 2003. All rights reserved.

Page 11

Philips Semiconductors

6.3 FIFO operation

The 16 byte transmit and receive data FIFOs are enabled by the FIFO Control

Register (FCR) bit 0. The user can set the receive trigger level via FCR bits 6-7, but

not the transmit trigger level. The receiver FIFO section includes a time-out function

to ensure data is delivered to the external CPU. An interrupt is generated whenever

the Receive Holding Register (RHR) has not been read following the loading of a

character or the receive trigger level has not been reached.

Table 5: Flow control mechanism

Selected trigger level

(characters)

1141

4484

8 8 12 8

14 14 14 10

6.4 Hardware flow control

SC16C2550

Dual UART with 16 bytes of transmit and receive FIFOs and IrDA

encoder/decoder

INT pin activation Negate RTS or

send Xoff

Assert RTS or

send Xon

When automatic hardware flow control is enabled, the SC16C2550 monitors the CTS

pin for a remote buffer overflow indication and controls the RTS pin for local buffer

overflows. Automatic hardware flow control is selected by setting EFR[6] (RTS) and

EFR[7] (CTS) to a logic 1. If CTS transitions from a logic 0 to a logic 1 indicating a

flow control request, ISR[5] will be set to a logic 1 (if enabled via IER[6,7]), and the

SC16C2550 will suspend TX transmissions as soon as the stop bit of the character in

process is shifted out. Transmission is resumed after the CTS input returns to a

logic 0, indicating more data may be sent.

With the Auto RTS function enabled, an interrupt is generated when the receive FIFO

reaches the programmed trigger level. The RTS pin will not be forced to a logic 1

(RTS off), until the receive FIFO reaches the next trigger level. However, the RTS pin

will return to a logic 0 after the data buffer (FIFO) is unloaded to the next trigger level

below the programmed trigger. However, under the above described conditions, the

SC16C2550 will continue to accept data until the receive FIFO is full.

6.5 Software flow control

When software flow control is enabled, the SC16C2550 compares one or two

sequential receive data characters with the programmed Xon/Xoff or Xoff1,2

character value(s). If received character(s) match the programmed values, the

SC16C2550 will halt transmission (TX) as soon as the current character(s) has

completed transmission. When a match occurs, the receive ready (if enabled via Xoff

IER[5]) flags will be set and the interrupt output pin (if receive interrupt is enabled) will

be activated. Following a suspension due to a match of the Xoff characters’ values,

the SC16C2550 will monitor the receive data stream for a match to the Xon1,2

character value(s). If a match is found, the SC16C2550 will resume operation and

clear the flags (ISR[4]).

Reset initially sets the contents of the Xon/Xoff 8-bit flow control registers to a logic 0.

Following reset, the user can write any Xon/Xoff value desired for software flow

control. Different conditions can be set to detect Xon/Xoff characters and

suspend/resume transmissions. When double 8-bit Xon/Xoff characters are selected,

9397 750 11621

Product data Rev. 03 — 19 June 2003 11 of 46

© Koninklijke Philips Electronics N.V. 2003. All rights reserved.

Page 12

Philips Semiconductors

the SC16C2550 compares two consecutive receive characters with two software flow

control 8-bit values (Xon1, Xon2, Xoff1, Xoff2) and controls TX transmissions

accordingly. Under the above described flow control mechanisms, flow control

characters are not placed (stacked) in the user accessible RX data buffer or FIFO.

In the eventthat the receive buffer is overfillingand flow control needs to be executed,

the SC16C2550 automatically sends an Xoff message (when enabled) via the serial

TX output to the remote modem. The SC16C2550 sends the Xoff1,2 characters as

soon as received data passes the programmed trigger level. To clear this condition,

the SC16C2550 will transmit the programmed Xon1,2 characters as soon as receive

data drops below the programmed trigger level.

6.6 Special feature software flow control

A special feature is provided to detect an 8-bit character when EFR[5] is set. When

8-bit character is detected, it will be placed on the user-accessible data stack along

with normal incoming RX data. This condition is selected in conjunction with

EFR[0-3]. Note that software flow control should be turned off when using this special

mode by setting EFR[0-3] to a logic 0.

SC16C2550

Dual UART with 16 bytes of transmit and receive FIFOs and IrDA

encoder/decoder

The SC16C2550 compares each incoming receive character with Xoff2 data. If a

match exists, the received data will be transferred to the FIFO, and ISR[4] will be set

to indicate detection of a special character. Although the Internal Register Table

(Table 7) shows each X-Register with eight bits of character information, the actual

number of bits is dependent on the programmed word length. Line Control Register

bits LCR[0-1] define the number of character bits, i.e., either 5 bits, 6 bits, 7 bits or

8 bits. The word length selected by LCR[0-1] also determine the number of bits that

will be used for the special character comparison. Bit 0 in the X-registers corresponds

with the LSB bit for the receive character.

6.7 Hardware/software and time-out interrupts

The interrupts are enabled by IER[0-3]. Care must be taken when handling these

interrupts. Following a reset, if Interrupt Enable Register (IER) bit 1 = 1, the

SC16C2550 will issue a Transmit Holding Register interrupt. This interrupt must be

serviced prior to continuing operations. The LSR register provides the current

singular highest priority interrupt only. It could be noted that CTS and RTS interrupts

have lowest interrupt priority. A condition can exist where a higher priority interrupt

may mask the lower priority CTS/RTS interrupt(s). Only after servicing the higher

pending interrupt will the lower priority CTS/RTS interrupt(s) be reflected in the status

register. Servicing the interrupt without investigating further interrupt conditions can

result in data errors.

When two interrupt conditions have the same priority, it is important to service these

interrupts correctly. Receive Data Ready and Receive Time Out have the same

interrupt priority (when enabled by IER[3]). The receiver issues an interrupt after the

number of characters have reached the programmed trigger level. In this case, the

SC16C2550 FIFO may hold more characters than the programmed trigger level.

Following the removal of a data byte, the user should re-check LSR[0] for additional

characters. A Receive Time Out will not occur if the receive FIFO is empty. The

time-out counter is reset at the center of each stop bit received or each time the

9397 750 11621

Product data Rev. 03 — 19 June 2003 12 of 46

© Koninklijke Philips Electronics N.V. 2003. All rights reserved.

Page 13

Philips Semiconductors

receive holding register (RHR) is read. The actual time-out value is 4 character time,

including data information length, start bit, parity bit, and the size of stop bit, i.e., 1×,

1.5×, or 2× bit times.

6.8 Programmable baud rate generator

The SC16C2550 supports high speed modem technologies that have increased input

data rates by employing data compression schemes. For example, a 33.6 kbit/s

modem that employs data compression may require a 115.2 kbit/s input data rate.

A 128.0 kbit/s ISDN modem that supports data compression may need an input

data rate of 460.8 kbit/s. The SC16C2550 can support a standard data rate of

921.6 kbit/s.

A single baud rate generator is provided for the transmitter and receiver, allowing

independent TX/RX channel control. The programmable Baud Rate Generator is

capable of operating with a frequency of up to 80 MHz. Toobtain maximum data rate,

it is necessary to use full rail swing on the clock input. The SC16C2550 can be

configured for internal or external clock operation. For internal clock oscillator

operation, an industry standard microprocessor crystal is connected externally

between the XTAL1 and XTAL2 pins. Alternatively, an external clock can be

connected to the XTAL1 pin to clock the internal baud rate generator for standard or

custom rates (see Table 6).

SC16C2550

Dual UART with 16 bytes of transmit and receive FIFOs and IrDA

encoder/decoder

The generator divides the input 16× clock by any divisor from 1 to 216− 1. The

SC16C2550 divides the basic external clock by 16. The basic 16× clock provides

table rates to support standard and custom applications using the same system

design. The rate table is configured via the DLL and DLM internal register functions.

Customized Baud Rates can be achieved by selecting the proper divisor values for

the MSB and LSB sections of baud rate generator.

Programming the Baud Rate Generator Registers DLM (MSB) and DLL (LSB)

provides a user capability for selecting the desired final baud rate. The example in

Table 6 shows the selectable baud rate table available when using a 1.8432 MHz

external clock input.

XTAL1

X1

1.8432 MHz

C1

47 pF

XTAL2

C2

100 pF

XTAL1

X1

1.8432 MHz

C1

22 pF

XTAL2

1.5 kΩ

C2

47 pF

002aaa169

Fig 5. Crystal oscillator connection.

9397 750 11621

Product data Rev. 03 — 19 June 2003 13 of 46

© Koninklijke Philips Electronics N.V. 2003. All rights reserved.

Page 14

Philips Semiconductors

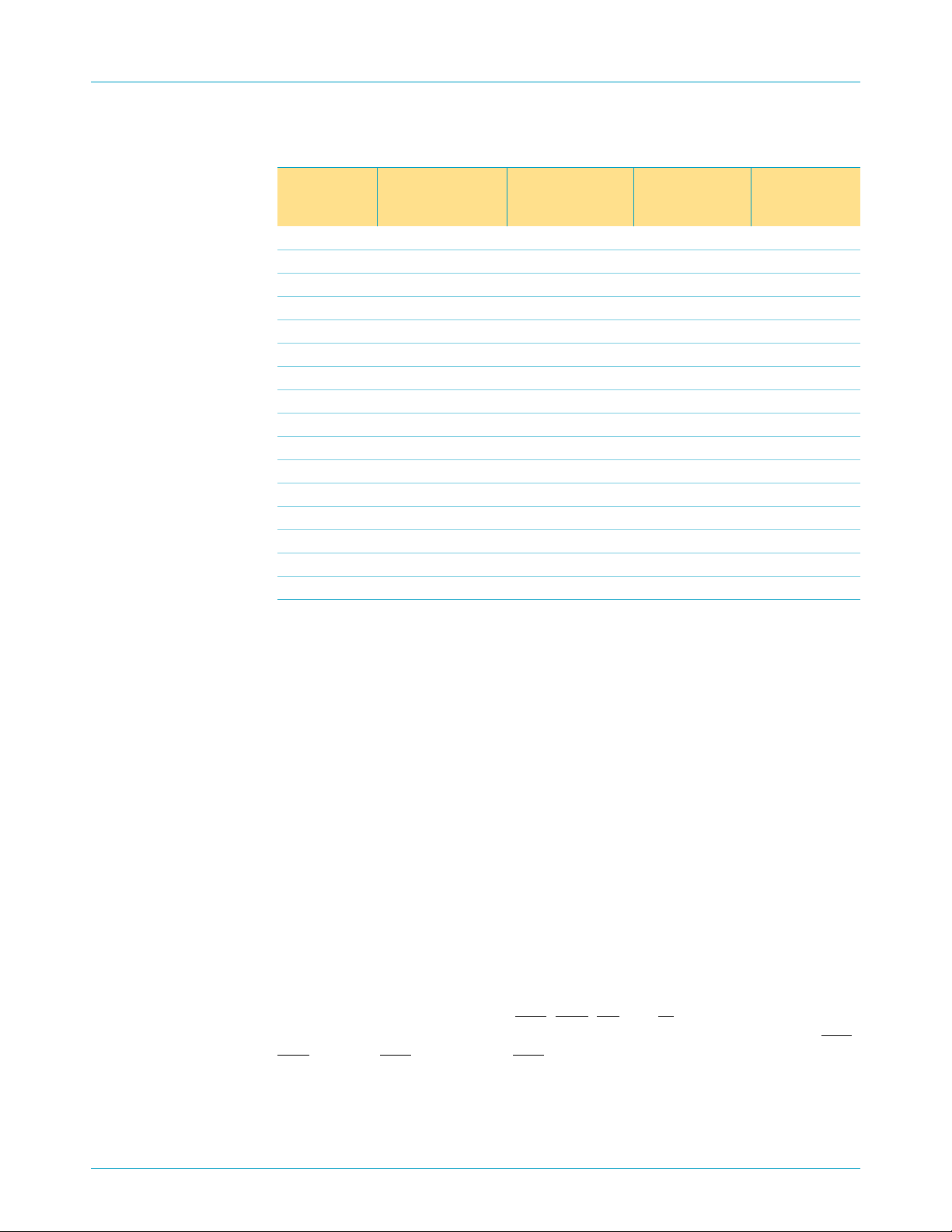

Table 6: Baud rate generator programming table using a 1.8432 MHz clock

Output

baud rate

50 2304 900 09 00

75 1536 600 06 00

110 1047 417 04 17

150 768 300 03 00

300 384 180 01 80

600 192 C0 00 C0

1200 96 60 00 60

2400 48 30 00 30

3600 32 20 00 20

4800 24 18 00 18

7200 16 10 00 10

9600 12 0C 00 0C

19.2 k 6 06 00 06

38.4 k 3 03 00 03

57.6 k 2 02 00 02

115.2 k 1 01 00 01

SC16C2550

Dual UART with 16 bytes of transmit and receive FIFOs and IrDA

encoder/decoder

Output

16 × clock divisor

(decimal)

Output

16 × clockdivisor

(HEX)

DLM

program value

(HEX)

DLL

program value

(HEX)

6.9 DMA operation

The SC16C2550 FIFO trigger level provides additional flexibility to the user for block

mode operation. LSR[5,6] provide an indication when the transmitter is empty or has

an empty location(s). The user can optionally operate the transmit and receive FIFOs

in the DMA mode (FCR[3]). When the transmit and receive FIFOs are enabled and

the DMA mode is de-activated (DMA Mode 0), the SC16C2550 activates the interrupt

output pin for each data transmit or receive operation. When DMA mode is activated

(DMA Mode 1), the user takes the advantage of block mode operation by loading or

unloading the FIFO in a block sequence determined by the receive trigger level and

the transmit FIFO. In this mode, the SC16C2550 sets the TXRDY (or RXRDY) output

pin when characters in the transmit FIFO is below 16, or the characters in the receive

FIFOs are above the receive trigger level.

6.10 Loop-back mode

The internal loop-back capability allows on-board diagnostics. In the loop-back mode,

the normal modem interface pins are disconnected and reconfigured for loop-back

internally (see Figure 6). MCR[0-3] register bits are used for controlling loop-back

diagnostic testing. In the loop-back mode, the transmitter output (TX) and the receiver

input (RX) are disconnected from their associated interface pins, and instead are

connected together internally. The CTS, DSR, CD, and RI are disconnected from

their normal modem control inputs pins, and instead are connected internally to RTS,

DTR, MCR[3] (OP2) and MCR[2] (OP1). Loop-back test data is entered into the

transmit holding register via the user data bus interface, D0-D7. The transmit UART

serializes the data and passes the serial data to the receive UART via the internal

loop-back connection. The receive UART converts the serial data back into parallel

9397 750 11621

Product data Rev. 03 — 19 June 2003 14 of 46

© Koninklijke Philips Electronics N.V. 2003. All rights reserved.

Page 15

Philips Semiconductors

data that is then made available at the user data interface D0-D7. The user optionally

compares the received data to the initial transmitted data for verifying error-free

operation of the UART TX/RX circuits.

In this mode, the receiver and transmitter interrupts are fully operational. The Modem

Control Interrupts are also operational.

SC16C2550

SC16C2550

Dual UART with 16 bytes of transmit and receive FIFOs and IrDA

encoder/decoder

D0–D7

RESET

CSA

IOR

IOW

A0–A2

, CSB

DATA BUS

AND

CONTROL LOGIC

REGISTER

SELECT

LOGIC

AND

CONTROL SIGNALS

INTERCONNECT BUS LINES

TRANSMIT

FIFO

REGISTER

RECEIVE

FIFO

REGISTER

TRANSMIT

SHIFT

REGISTER

RECEIVE

SHIFT

REGISTER

MODEM

CONTROL

LOGIC

TXA, TXB

MCR[4] = 1

RXA, RXB

RTSA, RTSB

CTSA, CTSB

DTRA, DTRB

DSRA, DSRB

(OP1A, OP1B)

INTA, INTB

, TXRDYB

TXRDYA

RXRDYA, RXRDYB

INTERRUPT

CONTROL

LOGIC

CLOCK AND

BAUD RATE

GENERATOR

XTAL2XTAL1

002aaa120

RIA, RIB

(OP2A, OP2B)

CDA, CDB

Fig 6. Internal loop-back mode diagram.

9397 750 11621

Product data Rev. 03 — 19 June 2003 15 of 46

© Koninklijke Philips Electronics N.V. 2003. All rights reserved.

Page 16

Philips Semiconductors

SC16C2550

Dual UART with 16 bytes of transmit and receive FIFOs and IrDA

encoder/decoder

7. Register descriptions

Table 7 details the assigned bit functions for the SC16C2550 internal registers. The

assigned bit functions are more fully defined in Section 7.1 through Section 7.11.

Table 7: SC16C2550 internal registers

Shaded bits are only accessible when EFR[4] is set.

A2 A1 A0 Register Default

General Register Set

[2]

0 0 0 RHR XX bit 7 bit 6 bit 5 bit 4 bit 3 bit 2 bit 1 bit 0

0 0 0 THR XX bit 7 bit 6 bit 5 bit 4 bit 3 bit 2 bit 1 bit 0

0 0 1 IER 00

0 1 0 FCR 00 RCVR

0 1 0 ISR 01 FIFOs

0 1 1 LCR 00 divisor

1 0 0 MCR 00 0

1 0 1 LSR 60 FIFO

1 1 0 MSR X0 CD RI DSR CTS ∆

1 1 1 SPR FF bit 7 bit 6 bit 5 bit 4 bit 3 bit 2 bit 1 bit 0

Special Register Set

[3]

0 0 0 DLL XX bit 7 bit 6 bit 5 bit 4 bit 3 bit 2 bit 1 bit 0

0 0 1 DLM XX bit 15 bit 14 bit 13 bit 12 bit 11 bit 10 bit 9 bit 8

Enhanced Register Set

[4]

0 1 0 EFR 00 Auto

1 0 0 Xon-1 00 bit 7 bit 6 bit 5 bit 4 bit 3 bit 2 bit 1 bit 0

1 0 1 Xon-2 00 bit 15 bit 14 bit 13 bit 12 bit 11 bit 10 bit 9 bit 8

1 1 0 Xoff-1 00 bit 7 bit 6 bit 5 bit 4 bit 3 bit 2 bit 1 bit 0

1 1 1 Xoff-2 00 bit 15 bit 14 bit 13 bit 12 bit 11 bit 10 bit 9 bit 8

[1]

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

CTS

interrupt

trigger

(MSB)

enabled

latch

enable

data

error

RTS

interrupt

RCVR

Xoff

interrupt

Sleep

mode

reserved0reserved0DMA

trigger

(LSB)

FIFOs

enabled

INT

priority

bit 4

INT

priority

bit 3

set break set parity even

parity

IR

0 loop back OP2/INT

enable

THR and

TSR

THR

empty

break

interrupt

empty

modem

status

interrupt

mode

select

INT

priority

bit 2

parity

enable

enable

framing

error

receive

line

status

interrupt

XMIT

FIFO

reset

INT

priority

bit 1

transmit

holding

register

interrupt

RCVR

FIFO

reset

INT

priority

bit 0

stop bits word

length

bit 1

(OP1) RTS DTR

parity

error

overrun

error

CD ∆RI ∆DSR ∆CTS

CTS

Auto

RTS

Special

char.

select

Enable

IER[4-7],

ISR[4,5],

Cont-3

Tx, Rx

Control

Cont-2

Tx, Rx

Control

Cont-1

Tx, Rx

Control

FCR[4,5],

MCR[5-7]

receive

holding

register

FIFOs

enable

INT

status

word

length

bit 0

receive

data

ready

Cont-0

Tx, Rx

Control

[1] The value shown in represents the register’s initialized HEX value; X = n/a.

[2] Accessible only when LCR[7] is logic 0.

[3] Baud rate registers accessible only when LCR[7] is logic 1.

[4] Enhanced Feature Register, Xon-1,2 and Xoff-1,2 are accessible only when LCR is set to ‘BF

9397 750 11621

Product data Rev. 03 — 19 June 2003 16 of 46

’.

Hex

© Koninklijke Philips Electronics N.V. 2003. All rights reserved.

Page 17

Philips Semiconductors

7.1 Transmit (THR) and Receive (RHR) Holding Registers

The serial transmitter section consists of an 8-bit Transmit Hold Register (THR) and

Transmit Shift Register (TSR). The status of the THR is provided in the Line Status

Register (LSR). Writing to the THR transfers the contents of the data bus (D7-D0) to

the TSR and UART via the THR, providing that the THR is empty. The THR empty

flag in the LSR register will be set to a logic 1 when the transmitter is empty or when

data is transferred to the TSR. Note that a write operation can be performed when the

THR empty flag is set (logic 0 = at least one byte in FIFO/THR, logic 1 = FIFO/THR

empty).

The serial receive section also contains an 8-bit ReceiveHolding Register (RHR) and

a Receive Serial Shift Register (RSR). Receivedata is removed from the SC16C2550

and receive FIFO by reading the RHR register. The receive section provides a

mechanism to prevent false starts. On the falling edge of a start or false start bit, an

internal receiver counter starts counting clocks at the 16× clock rate. After 7-1⁄

clocks, the start bit time should be shifted to the center of the start bit. At this time the

start bit is sampled, and if it is still a logic 0 it is validated. Evaluating the start bit in

this manner prevents the receiver from assembling a false character. Receiver status

codes will be posted in the LSR.

SC16C2550

Dual UART with 16 bytes of transmit and receive FIFOs and IrDA

encoder/decoder

2

7.2 Interrupt Enable Register (IER)

The Interrupt Enable Register (IER) masks the interrupts from receiver ready,

transmitter empty, line status and modem status registers. These interrupts would

normally be seen on the INTA, INTB output pins.

Table 8: Interrupt Enable Register bits description

Bit Symbol Description

7 IER[7] CTS interrupt.

Logic 0 = Disable the CTS interrupt (normal default condition).

Logic 1 = Enable the CTS interrupt. The SC16C2550 issues an

interrupt when the CTS pin transitions from a logic 0 to a logic 1.

6 IER[6] RTS interrupt.

Logic 0 = Disable the RTS interrupt (normal default condition).

Logic 1 = Enable the RTS interrupt. The SC16C2550 issues an

interrupt when the RTS pin transitions from a logic 0 to a logic 1.

5 IER[5] Xoff interrupt.

Logic 0 = Disable the software flow control, receiveXoff interrupt

(normal default condition).

Logic 1 = Enable the software flow control, receive Xoff interrupt.

4 IER[4] Sleep mode.

Logic 0 = Disable sleep mode (normal default condition).

Logic 1 = Enable sleep mode.

3 IER[3] Modem Status Interrupt. This interrupt will be issued whenever

there is a modem status change as reflected in MSR[0-3].

Logic 0 = Disable the modem status register interrupt (normal

default condition).

Logic 1 = Enable the modem status register interrupt.

9397 750 11621

Product data Rev. 03 — 19 June 2003 17 of 46

© Koninklijke Philips Electronics N.V. 2003. All rights reserved.

Page 18

Philips Semiconductors

SC16C2550

Dual UART with 16 bytes of transmit and receive FIFOs and IrDA

encoder/decoder

Table 8: Interrupt Enable Register bits description

Bit Symbol Description

2 IER[2] Receive Line Status interrupt. This interrupt will be issued

whenever a receive data error condition exists as reflected in

LSR[1-4].

Logic 0 = Disable the receiver line status interrupt (normal

default condition).

Logic 1 = Enable the receiver line status interrupt.

1 IER[1] Transmit Holding Register interrupt. In the 16C450 mode, this

interrupt will be issued whenever the THR is empty, and is

associated with LSR[5]. In the FIFO modes, this interrupt will be

issued whenever the FIFO is empty.

Logic 0 = Disable the Transmit Holding Register Empty (TXRDY)

interrupt (normal default condition).

Logic 1 = Enable the TXRDY (ISR level 3) interrupt.

0 IER[0] Receive Holding Register. In the 16C450 mode, this interrupt will

be issued when the RHR has data, or is cleared when the RHR is

empty. In the FIFO mode, this interrupt will be issued when the

FIFO has reached the programmed trigger levelor is cleared when

the FIFO drops below the trigger level.

Logic 0 = Disable the receiver ready (ISR level 2, RXRDY)

interrupt (normal default condition).

Logic 1 = Enable the RXRDY (ISR level 2) interrupt.

…continued

7.2.1 IER versus Transmit/Receive FIFO interrupt mode operation

When the receive FIFO (FCR[0] = logic 1), and receive interrupts (IER[0] = logic 1)

are enabled, the receive interrupts and register status will reflect the following:

• The receive RXRDY interrupt (Level 2 ISR interrupt) is issued to the external CPU

when the receive FIFO has reached the programmed trigger level. It will be cleared

when the receive FIFO drops below the programmed trigger level.

• Receive FIFO status will also be reflected in the user accessible ISR register when

the receive FIFO trigger level is reached. Both the ISR register receive status bit

and the interrupt will be cleared when the FIFO drops below the trigger level.

• The receive data ready bit (LSR[0]) is set as soon as a character is transferred

from the shift register (RSR) to the receive FIFO. It is reset when the FIFO is

empty.

• When the Transmit FIFO and interrupts are enabled, an interrupt is generated

when the transmit FIFO is empty due to the unloading of the data by the TSR and

UART for transmission via the transmission media. The interrupt is cleared either

by reading the ISR register, or by loading the THR with new data characters.

9397 750 11621

Product data Rev. 03 — 19 June 2003 18 of 46

© Koninklijke Philips Electronics N.V. 2003. All rights reserved.

Page 19

Philips Semiconductors

7.2.2 IER versus Receive/Transmit FIFO polled mode operation

When FCR[0] = logic 1, resetting IER[0-3] enables the SC16C2550 in the FIFO

polled mode of operation. In this mode, interrupts are not generated and the user

must poll the LSR register for TX and/or RX data status. Since the receiver and

transmitter have separate bits in the LSR either or both can be used in the polled

mode by selecting respective transmit or receive control bit(s).

• LSR[0] will be a logic 1 as long as there is one byte in the receive FIFO.

• LSR[1-4] will provide the type of receive errors, or a receive break, if encountered.

• LSR[5] will indicate when the transmit FIFO is empty.

• LSR[6] will indicate when both the transmit FIFO and transmit shift register are

• LSR[7] will show if any FIFO data errors occurred.

7.3 FIFO Control Register (FCR)

This register is used to enable the FIFOs, clear the FIFOs, set the receive FIFO

trigger levels, and select the DMA mode.

SC16C2550

Dual UART with 16 bytes of transmit and receive FIFOs and IrDA

encoder/decoder

empty.

7.3.1 DMA mode

Mode 0 (FCR bit 3 = 0): Set and enable the interrupt for each single transmit or

receive operation, and is similar to the 16C450 mode. Transmit Ready (TXRDY) on

PLCC44 and LQFP48 packages will go to a logic 0 wheneverthe FIFO (THR, if FIFO

is not enabled) is empty. Receive Ready (RXRDY) on PLCC44 and LQFP48

packages will go to a logic 0 wheneverthe ReceiveHolding Register (RHR) is loaded

with a character.

Mode 1 (FCR bit 3 = 1): Set and enable the interrupt in a blockmode operation. The

transmit interrupt is set when the transmit FIFO is empty. TXRDY on PLCC and

LQFP48 packages remains a logic 0 as long as one empty FIFO location is available.

The receive interrupt is set when the receive FIFO fills to the programmed trigger

level.However, the FIFO continues to fill regardless of the programmed level until the

FIFO is full. RXRDY on PLCC44 and LQFP48 packages transitions LOW when the

FIFO reaches the trigger level, and transitions HIGH when the FIFO empties.

9397 750 11621

Product data Rev. 03 — 19 June 2003 19 of 46

© Koninklijke Philips Electronics N.V. 2003. All rights reserved.

Page 20

Philips Semiconductors

7.3.2 FIFO mode

Table 9: FIFO Control Register bits description

Bit Symbol Description

7-6 FCR[7]

5-4 FCR[5-4] Not used; initialized to logic 0.

3 FCR[3] DMA mode select.

2 FCR[2] XMIT FIFO reset.

SC16C2550

Dual UART with 16 bytes of transmit and receive FIFOs and IrDA

encoder/decoder

RCVR trigger. These bits are used to set the trigger level for the

(MSB),

FCR[6]

(LSB)

receive FIFO interrupt.

Logic 0 (or cleared) = normal default condition.

Logic 1 = RX trigger level.

An interrupt is generated when the number of characters in the

FIFO equals the programmed trigger level. However, the FIFO will

continue to be loaded until it is full. Refer to Table 10.

Logic 0 = Set DMA mode ‘0’

Logic 1 = Set DMA mode ‘1’

Transmit operation in mode ‘0’: When the SC16C2550 is in the

16C450 mode (FIFOs disabled; FCR[0] = logic 0) or in the FIFO

mode (FIFOs enabled; FCR[0] = logic 1; FCR[3] = logic 0), and

when there are no characters in the transmit FIFO or transmit

holding register, the

will be a logic 0. Once active, the

after the first character is loaded into the transmit holding register.

Receive operation in mode ‘0’: When the SC16C2550 is in

mode ‘0’ (FCR[0] = logic 0), or in the FIFO mode (FCR[3] = logic 0)

and there is at lease one character in the receive FIFO, the

RXRDY pin will be a logic 0. Once active, the RXRDY pin on

PLCC44 and LQFP48 packages will go to a logic 1 when there are

no more characters in the receiver.

Transmit operation in mode ‘1’: When the SC16C2550 is in

FIFO mode (FCR[0] = logic 1; FCR[3] = logic 1), the

PLCC44 and LQFP48 packageswill be a logic 1 when the transmit

FIFO is completely full. It will be a logic 0 if one or more FIFO

locations are empty.

Receive operation in mode ‘1’: When the SC16C2550 is in FIFO

mode (FCR[0] = logic 1; FCR[3] = logic 1) and the trigger level has

been reached, or a Receive Time-Out has occurred, the

pin on PLCC44 and LQFP48 packages will go to a logic 0. Once

activated,it will go to a logic 1 after there are no more charactersin

the FIFO.

Logic 0 = Transmit FIFO not reset (normal default condition).

Logic 1 = Clears the contents of the transmit FIFO and resets

the FIFO counter logic (the transmit shift register is not cleared

or altered). This bit will return to a logic 0 after clearing the FIFO.

TXRDY pin in PLCC44 or LQFP48 packages

TXRDY pin will go to a logic 1

TXRDY pin on

RXRDY

9397 750 11621

Product data Rev. 03 — 19 June 2003 20 of 46

© Koninklijke Philips Electronics N.V. 2003. All rights reserved.

Page 21

Philips Semiconductors

SC16C2550

Dual UART with 16 bytes of transmit and receive FIFOs and IrDA

encoder/decoder

Table 9: FIFO Control Register bits description

Bit Symbol Description

1 FCR[1] RCVR FIFO reset.

Logic 0 = Receive FIFO not reset (normal default condition).

Logic 1 = Clears the contents of the receive FIFO and resets the

FIFO counter logic (the receive shift register is not cleared or

altered). This bit will return to a logic 0 after clearing the FIFO.

0 FCR[0] FIFOs enabled.

Logic 0 = Disable the transmit and receive FIFO (normal default

condition).

Logic 1 = Enable the transmit and receive FIFO. This bit must

be a ‘1’ when other FCR bits are written to, or they will not

be programmed.

Table 10: RCVR trigger levels

FCR[7] FCR[6] RX FIFO trigger level

0001

0104

1008

1114

…continued

7.4 Interrupt Status Register (ISR)

The SC16C2550 provides four levels of prioritized interrupts to minimize external

software interaction. The Interrupt Status Register (ISR) provides the user with four

interrupt status bits. Performing a read cycle on the ISR will provide the user with the

highest pending interrupt level to be serviced. No other interrupts are acknowledged

until the pending interrupt is serviced. A lower level interrupt may be seen after

servicing the higher level interrupt and re-reading the interrupt status bits. Table 11

“Interrupt source” shows the data values (bits 0-3) for the four prioritized interrupt

levels and the interrupt sources associated with each of these interrupt levels.

Table 11: Interrupt source

Priority

level

1 000110LSR(ReceiverLineStatus

2 000100RXRDY (Received Data

2 001100RXRDY (Receive Data

3 000010TXRDY (Transmitter

4 000000MSR (Modem Status

5 010000RXRDY (Received Xoff

6 100000CTS, RTS change of state

ISR[5] ISR[4] ISR[3] ISR[2] ISR[1] ISR[0] Source of the interrupt

Register)

Ready)

time-out)

Holding Register Empty)

Register)

signal) / Special character

9397 750 11621

Product data Rev. 03 — 19 June 2003 21 of 46

© Koninklijke Philips Electronics N.V. 2003. All rights reserved.

Page 22

Philips Semiconductors

Table 12: Interrupt Status Register bits description

Bit Symbol Description

7-6 ISR[7-6] FIFOs enabled. These bits are set to a logic 0 when the FIFOs are

5-4 ISR[5-4] INT priority bits 4-3. These bits are enabled when EFR[4] is set to

3-1 ISR[3-1] INT priority bits 2-0. These bits indicate the source for a pending

0 ISR[0] INT status.

SC16C2550

Dual UART with 16 bytes of transmit and receive FIFOs and IrDA

encoder/decoder

not being used in the 16C450 mode. They are set to a logic 1

when the FIFOs are enabled in the SC16C2550 mode.

Logic 0 or cleared = default condition.

a logic 1. ISR[4] indicates that matching Xoff character(s) have

been detected. ISR[5] indicates that CTS, RTS have been

generated. Note that once set to a logic 1, the ISR[4] bit will stay a

logic 1 until Xon character(s) are received.

Logic 0 or cleared = default condition.

interrupt at interrupt priority levels 1, 2, and 3 (see Table 11).

Logic 0 or cleared = default condition.

Logic 0 = An interrupt is pending and the ISR contents may be

used as a pointer to the appropriate interrupt service routine.

Logic 1 = No interrupt pending (normal default condition).

7.5 Line Control Register (LCR)

The Line Control Register is used to specify the asynchronous data communication

format. The word length, the number of stop bits, and the parity are selected by

writing the appropriate bits in this register.

Table 13: Line Control Register bits description

Bit Symbol Description

7 LCR[7] Divisor latch enable. The internal baud rate counter latch and

Enhance Feature mode enable.

Logic 0 = Divisor latch disabled (normal default condition).

Logic 1 = Divisor latch enabled.

6 LCR[6] Set break. When enabled, the Break control bit causes a break

condition to be transmitted (the TX output is forced to a logic 0

state). This condition exists until disabled by setting LCR[6] to a

logic 0.

Logic 0 = no TX break condition (normal default condition)

Logic 1 = forces the transmitter output (TX) to a logic 0 for

alerting the remote receiver to a line break condition.

5-3 LCR[5-3] Programs the parity conditions (see Table 14).

2 LCR[2] Stop bits. The length of stop bit is specified by this bit in

conjunction with the programmed word length (see Table 15).

Logic 0 or cleared = default condition.

1-0 LCR[1-0] Word length bits 1, 0. These two bits specify the word length to be

transmitted or received (see Table 16).

Logic 0 or cleared = default condition.

9397 750 11621

Product data Rev. 03 — 19 June 2003 22 of 46

© Koninklijke Philips Electronics N.V. 2003. All rights reserved.

Page 23

Philips Semiconductors

Table 14: LCR[5-3] parity selection

LCR[5] LCR[4] LCR[3] Parity selection

X X 0 no parity

X 0 1 ODD parity

0 1 1 EVEN parity

001forced parity ‘1’

111forced parity ‘0’

Table 15: LCR[2] stop bit length

LCR[2] Word length Stop bit length (bit times)

0 5, 6, 7, 8 1

15 11 6, 7, 8 2

Table 16: LCR[1-0] word length

LCR[1] LCR[0] Word length

005

016

107

118

SC16C2550

Dual UART with 16 bytes of transmit and receive FIFOs and IrDA

encoder/decoder

1

⁄

2

9397 750 11621

Product data Rev. 03 — 19 June 2003 23 of 46

© Koninklijke Philips Electronics N.V. 2003. All rights reserved.

Page 24

Philips Semiconductors

7.6 Modem Control Register (MCR)

This register controls the interface with the modem or a peripheral device.

Table 17: Modem Control Register bits description

Bit Symbol Description

7 MCR[7] Reserved; set to ‘0’.

6 MCR[6] IR enable.

5 MCR[5] Reserved; set to ‘0’.

4 MCR[4] Loop-back. Enable the local loop-back mode (diagnostics). In this

3 MCR[3]

2 MCR[2] (

1 MCR[1]

0 MCR[0]

SC16C2550

Dual UART with 16 bytes of transmit and receive FIFOs and IrDA

encoder/decoder

Logic 0 = Enable the standard modem receive and transmit

input/output interface (normal default condition).

Logic 1 = Enable infrared IrDA receive and transmit inputs/outputs.

While in this mode, the TX/RX output/inputs are routed to the

infrared encoder/decoder. The data input and output levels will

conform to the IrDA infrared interface requirement. As such, while

in this mode, the infrared TX output will be a logic 0 during idle data

conditions.

mode the transmitter output (

DSR, CD, and RI are disconnected from the SC16C2550 I/O pins.

Internally the modem data and control pins are connected into a

loop-back data configuration (see Figure 6). In this mode, the receiver

and transmitter interrupts remain fully operational. The Modem

Control Interrupts are also operational, but the interrupts’ sources are

switched to the lower four bits of the Modem Control. Interrupts

continue to be controlled by the IER register.

Logic 0 = Disable loop-back mode (normal default condition).

Logic 1 = Enable local loop-back mode (diagnostics).

OP2/INT enable

Logic 0 = Forces INT (A-B) outputs to the 3-State mode and sets

OP2 to a logic 1 (normal default condition).

Logic 1 = Forces the INT (A-B outputs to the active mode and sets

OP2 to a logic 0.

OP1). OP1A/OP1B are not available as an external signal in the

SC16C2550. This bit is instead used in the Loop-back mode only. In

the loop-back mode, this bit is used to write the state of the modem

interface signal.

RTS

Logic 0 = Force

Logic1=Force

DTR

Logic 0 = Force

Logic 1 = Force

RTS output to a logic 1 (normal default condition).

RTS output to a logic 0.

DTR output to a logic 1 (normal default condition).

DTR output to a logic 0.

TX) and the receiver input (RX), CTS,

RI

9397 750 11621

Product data Rev. 03 — 19 June 2003 24 of 46

© Koninklijke Philips Electronics N.V. 2003. All rights reserved.

Page 25

Philips Semiconductors

7.7 Line Status Register (LSR)

This register provides the status of data transfers between the SC16C2550 and

the CPU.

Table 18: Line Status Register bits description

Bit Symbol Description

7 LSR[7] FIFO data error.

6 LSR[6] THR and TSR empty. This bit is the Transmit Empty indicator. This

5 LSR[5] THR empty. This bit is the Transmit Holding Register Empty

4 LSR[4] Break interrupt.

3 LSR[3] Framing error.

2 LSR[2] Parity error.

SC16C2550

Dual UART with 16 bytes of transmit and receive FIFOs and IrDA

encoder/decoder

Logic 0 = No error (normal default condition).

Logic 1 = At least one parity error, framing error or break

indication is in the current FIFO data. This bit is cleared when

there are no remaining error flags associated with the remaining

data in the FIFO.

bit is set to a logic 1 whenever the transmit holding register and the

transmit shift register are both empty. It is reset to logic 0 whenever

either the THR or TSR contains a data character. In the FIFO

mode, this bit is set to ‘1’ whenever the transmit FIFO and transmit

shift register are both empty.

indicator.This bit indicates that the UART is ready to accept a new

character for transmission. In addition, this bit causes the UARTto

issue an interrupt to CPU when the THR interrupt enable is set.

The THR bit is set to a logic 1 when a character is transferred from

the transmit holding register into the transmitter shift register. The

bit is reset to a logic 0 concurrently with the loading of the

transmitter holding register by the CPU. In the FIFO mode, this bit

is set when the transmit FIFO is empty; it is cleared when at least

1 byte is written to the transmit FIFO.

Logic 0 = No break condition (normal default condition).

Logic 1 = The receiver received a break signal (RX was a logic 0

for one character frame time). In the FIFO mode, only one break

character is loaded into the FIFO.

Logic 0 = No framing error (normal default condition).

Logic 1 = Framing error. The receive character did not have a

valid stop bit(s). In the FIFO mode, this error is associated with

the character at the top of the FIFO.

Logic 0 = No parity error (normal default condition.

Logic 1 = Parity error. The receive character does not have

correct parity information and is suspect. In the FIFO mode, this

error is associated with the character at the top of the FIFO.

9397 750 11621

Product data Rev. 03 — 19 June 2003 25 of 46

© Koninklijke Philips Electronics N.V. 2003. All rights reserved.

Page 26

Philips Semiconductors

SC16C2550

Dual UART with 16 bytes of transmit and receive FIFOs and IrDA

encoder/decoder

Table 18: Line Status Register bits description

Bit Symbol Description

1 LSR[1] Overrun error.

Logic 0 = No overrun error (normal default condition).

Logic1=Overrun error. A data overrun error occurred in the

receive shift register.This happens when additional data arrives

while the FIFO is full. In this case, the previous data in the shift

register is overwritten. Note that under this condition, the data

byte in the receive shift register is not transferred into the FIFO,

therefore the data in the FIFO is not corrupted by the error.

0 LSR[0] Receive data ready.

Logic 0 = No data in receive holding register or FIFO (normal

default condition).

Logic 1 = Data has been received and is saved in the receive

holding register or FIFO.

…continued

7.8 Modem Status Register (MSR)

This register provides the current state of the control interface signals from the

modem, or other peripheral device to which the SC16C2550 is connected. Four bits

of this register are used to indicate the changed information. These bits are set to a

logic 1 whenever a control input from the modem changes state. These bits are set to

a logic 0 whenever the CPU reads this register.

Table 19: Modem Status Register bits description

Bit Symbol Description

7 MSR[7] CD. During normal operation, this bit is the complement of the

input. Reading this bit in the loop-back mode produces the state of

MCR[3] (

6 MSR[6] RI. During normal operation, this bit is the complement of the

input. Reading this bit in the loop-back mode produces the state of

MCR[2] (

5 MSR[5] DSR. During normal operation, this bit is the complement of the

DSR input. During the loop-back mode, this bit is equivalent to

MCR[0] (

4 MSR[4] CTS. During normal operation, this bit is the complement of the

CTS input. During the loop-back mode, this bit is equivalent to

MCR[1] (

3 MSR[3] ∆

2 MSR[2] ∆

CD

RI

OP2).

OP1).

DTR).

RTS).

[1]

Logic 0 = No CD change (normal default condition).

Logic 1 = The

since the last time it was read. A modem Status Interrupt will be

generated.

[1]

Logic 0 = No RI change (normal default condition).

Logic 1 = The

logic 0 to a logic 1. A modem Status Interrupt will be generated.

CD input to the SC16C2550 has changed state

RI input to the SC16C2550 has changed from a

CD

RI

9397 750 11621

Product data Rev. 03 — 19 June 2003 26 of 46

© Koninklijke Philips Electronics N.V. 2003. All rights reserved.

Page 27

Philips Semiconductors

SC16C2550

Dual UART with 16 bytes of transmit and receive FIFOs and IrDA

encoder/decoder

Table 19: Modem Status Register bits description

Bit Symbol Description

1 MSR[1] ∆DSR

0 MSR[0] ∆

[1] Whenever any MSR bit 0-3 is set to logic 1, a Modem Status Interrupt will be generated.

[1]

Logic 0 = No DSR change (normal default condition).

Logic1=The

since the last time it was read. A modem Status Interrupt will be

generated.

[1]

CTS

Logic 0 = No CTS change (normal default condition).

Logic 1 = The

since the last time it was read. A modem Status Interrupt will be

generated.

DSR input to the SC16C2550 has changed state

CTS input to the SC16C2550 has changed state

7.9 Scratchpad Register (SPR)

The SC16C2550 provides a temporary data register to store 8 bits of user

information.

7.10 Enhanced Feature Register (EFR)

Enhanced features are enabled or disabled using this register.

…continued

Bits 0 through 4 provide single or dual character software flow control selection.

When the Xon1 and Xon2 and/or Xoff1 and Xoff2 modes are selected, the double

8-bit words are concatenated into two sequential numbers.

Table 20: Enhanced Feature Register bits description

Bit Symbol Description

7 EFR[7] Automatic CTS flow control.

Logic0=Automatic CTS flow control is disabled (normal default

condition).

Logic 1 = Enable Automatic CTS flow control. Transmission will stop

CTS goes to a logical 1. Transmission will resume when the CTS

when

pin returns to a logical 0.

6 EFR[6] Automatic RTS flow control. Automatic RTS may be used for hardware flow

control by enabling EFR[6]. When Auto-RTS is selected, an interrupt will

be generated when the receive FIFO is filled to the programmed trigger

leveland

a logic 0 when data is unloaded below the next lower trigger level

(programmed trigger level 1). The state of this register bit changes with the

status of the hardware flow control.

hardware flow control is disabled.

RTS will go to a logic 1 at the next trigger level. RTS will return to

RTS functions normally when

0 = Automatic RTS flow control is disabled (normal default condition).

1 = Enable Automatic RTS flow control.

9397 750 11621

Product data Rev. 03 — 19 June 2003 27 of 46

© Koninklijke Philips Electronics N.V. 2003. All rights reserved.

Page 28

Philips Semiconductors

SC16C2550

Dual UART with 16 bytes of transmit and receive FIFOs and IrDA

encoder/decoder

Table 20: Enhanced Feature Register bits description

Bit Symbol Description

5 EFR[5] Special Character Detect.

Logic 0 = Special character detect disabled (normal default condition).

Logic 1 = Special character detect enabled. The SC16C2550 compares

each incoming receive character with Xoff2 data. If a match exists, the

received data will be transferred to FIFO and ISR[4] will be set to

indicate detection of special character. Bit-0 in the X-registers

corresponds with the LSB bit for the receivecharacter.Whenthis feature

is enabled, the normal software flow control must be disabled (EFR[3-0]

must be set to a logic 0).

4 EFR[4] Enhanced function control bit. The content of IER[7-4], ISR[5-4], FCR[5-4],

and MCR[7-5] can be modified and latched. After modifying any bits in the

enhanced registers, EFR[4] can be set to a logic 0 to latch the new values.

This feature prevents existing software from altering or overwriting the

SC16C2550 enhanced functions.

Logic 0 = disable/latch enhanced features. IER[7-4], ISR[5-4], FCR[5-4],

and MCR[7-5] are saved to retain the user settings, then IER[7-4]

ISR[5-4], FCR[5-4], and MCR[7-5] are set to a logic 0 to be compatible

with SC16C554 mode. (Normal default condition.)

Logic 1 = Enables the enhanced functions. When this bit is set to a

logic 1, all enhanced features of the SC16C2550 are enabled and user

settings stored during a reset will be restored.

3-0 EFR[3-0] Cont-3-0 Tx, Rx control. Logic 0 or cleared is the default condition.

Combinations of software flow control can be selected by programming

these bits. See Table 21.

…continued

Table 21: Software flow control functions

Cont-3 Cont-2 Cont-1 Cont-0 TX, RX software flow controls

0 0 X X No transmit flow control

1 0 X X Transmit Xon1/Xoff1

0 1 X X Transmit Xon2/Xoff2

1 1 X X Transmit Xon1 and Xon2/Xoff1 and Xoff2

X X 0 0 No receive flow control

X X 1 0 Receiver compares Xon1/Xoff1

X X 0 1 Receiver compares Xon2/Xoff2

1 0 1 1 Transmit Xon1/Xoff1

0 1 1 1 Transmit Xon2/Xoff2

1 1 1 1 Transmit Xon1 and Xon2/Xoff1 and Xoff2

[1] When using a software flow control the Xon/Xoff characters cannot be used for data transfer.

[1]

Receiver compares Xon1 and Xon2, Xoff1 and Xoff2

Receiver compares Xon1 and Xon2/Xoff1 and Xoff2

Receiver compares Xon1 and Xon2/Xoff1 and Xoff2

9397 750 11621

Product data Rev. 03 — 19 June 2003 28 of 46

© Koninklijke Philips Electronics N.V. 2003. All rights reserved.

Page 29

Philips Semiconductors

7.11 SC16C2550 external reset condition

Table 22: Reset state for registers

Register Reset state

IER IER[7-0] = 0

FCR FCR[7-0] = 0

ISR ISR[7-1] = 0; ISR[0] = 1

LCR LCR[7-0] = 0

MCR MCR[7-0] = 0

LSR LSR[7] = 0; LSR[6-5] = 1; LSR[4-0] = 0

MSR MSR[7-4] = input signals; MSR[3-0] = 0

SPR SFR[7-0] = 1

DLL DLL[7-0] = X

DLM DLM[7-0] = X

Table 23: Reset state for outputs

Output Reset state

TXA, TXB Logic 1

OP2A, OP2B Logic 1

RTSA, RTSB Logic 1

DTRA, DTRB Logic 1

INTA, INTB 3-State condition

SC16C2550

Dual UART with 16 bytes of transmit and receive FIFOs and IrDA

encoder/decoder

8. Limiting values

Table 24: Limiting values

In accordance with the Absolute Maximum Rating System (IEC 60134).

Symbol Parameter Conditions Min Max Unit

V

CC

V

n

T

amb

T

stg

P

tot(pack)

supply voltage - 7 V

voltage at any pin GND − 0.3 VCC+ 0.3 V

operating temperature −40 +85 °C

storage temperature −65 +150 °C

total power dissipation

per package

- 500 mW

9397 750 11621

Product data Rev. 03 — 19 June 2003 29 of 46

© Koninklijke Philips Electronics N.V. 2003. All rights reserved.

Page 30

Philips Semiconductors

SC16C2550

Dual UART with 16 bytes of transmit and receive FIFOs and IrDA

encoder/decoder

9. Static characteristics

Table 25: DC electrical characteristics

T

=−40°C to +85°C; VCC= 2.5 V, 3.3 V or 5.0 V±10%, unless otherwise specified.

amb

Symbol Parameter Conditions 2.5 V 3.3 V 5.0 V Unit

Min Max Min Max Min Max

V

IL(CK)

V

IH(CK)

V

IL

V

IH

V

OL

V

OH

I

LIL

I

CL

I

CC

C

i

LOW-level clock input voltage −0.3 0.45 −0.3 0.6 −0.5 0.6 V

HIGH-level clock input voltage 1.8 V

LOW-level input voltage

−0.3 0.65 −0.3 0.8 −0.5 0.8 V

CC

2.4 V

CC

3.0 V

CC

V

(except X1 clock)

HIGH-level input voltage

1.6 - 2.0 - 2.2 - V

(except X1 clock)

LOW-level output voltage

on all outputs

[1]

IOL=5mA

(databus)

I

=4mA

OL

-----0.4V

---0.4--V

(other outputs)

I

=2mA

OL

-0.4----V

(databus)

I

= 1.6 mA

OL

-0.4----V

(other outputs)

HIGH-level output voltage IOH= −5mA

----2.4-V

(databus)

I

= −1mA

OH

--2.0---V

(other outputs)

I

= −800 µA

OH

1.85 -----V

(data bus)

I

= −400 µA

OH

1.85 -----V

(other outputs)

LOW-level input leakage

- ±10 - ±10 - ±10 µA

current

clock leakage - ±30 - ±30 - ±30 µA

supply current f = 5 MHz - 3.5 - 4.5 - 4.5 mA

input capacitance - 5 - 5 - 5 pF

[1] Except x2, VOL= 1 V typical.

9397 750 11621

Product data Rev. 03 — 19 June 2003 30 of 46

© Koninklijke Philips Electronics N.V. 2003. All rights reserved.

Page 31

Philips Semiconductors

SC16C2550

Dual UART with 16 bytes of transmit and receive FIFOs and IrDA

encoder/decoder

10. Dynamic characteristics

Table 26: AC electrical characteristics

T

=−40°C to +85°C; VCC= 2.5 V, 3.3 V or 5.0 V±10%, unless otherwise specified.

amb

Symbol Parameter Conditions 2.5 V 3.3 V 5.0 V Unit

Min Max Min Max Min Max

, t

t

1w

t

3w

t

6s

t

6h

t

7d

t

7w

t

7h

t

9d

t

12d

t

12h

t

13d

t

13w

t

13h

t

15d

t

16s

t

16h

t

17d

t

18d

t

19d

t

20d

t

21d

t

22d

t

23d

t

24d

t

25d

t

26d

t

27d

t

28d

t

RESET

N baud rate divisor 1 2

clock pulse duration 10 - 6 - 6 - ns

2w

oscillator/clock frequency

[1]

- 48 - 80 80 MHz

address set-up time 0 - 0 - 0 - ns

address hold time 0 - 0 - 0 - ns

IOR delay from chip select 10 - 10 - 10 - ns

IOR strobe width 25 pF load 77 - 26 - 23 - ns

chip select hold time from IOR 0 - 0 - 0 - ns

read cycle delay 25 pF load 20 - 20 - 20 - ns

delay from IOR to data 25 pF load - 77 - 26 - 23 ns

data disable time 25 pF load - 15 - 15 - 15 ns

IOW delay from chip select 10 - 10 - 10 - ns

IOW strobe width 20 -

[2]

20 -

[2]

15 -

[2]

chip select hold time from IOW 0-0-0-ns

write cycle delay

[3]

25 - 25 - 20 - ns

data set-up time 20 - 20 - 15 - ns

data hold time 15 - 5 - 5 - ns

delay from IOW to output 25 pF load - 100 - 33 - 29 ns

delay to set interrupt from Modem

25 pF load - 100 - 24 - 23 ns

input

delay to reset interrupt from IOR 25 pF load - 100 - 24 - 23 ns

delay from stop to set interrupt - 1 - 1 - 1 R

delay from IOR to reset interrupt 25 pF load - 100 - 29 - 28 ns

delay from start to set interrupt - 100 - 45 - 40 ns

delay from IOW to transmit start 8 24 8 24 8 24 R

delay from IOW to reset interrupt - 100 - 45 - 40 ns

delay from stop to set RXRDY -1-1-1R

delay from IOR to reset RXRDY - 100 - 45 - 40 ns