INTEGRATED CIRCUITS

DATA SH EET

SAA3500H

Digital audio broadcast channel

decoder

Preliminary specification

File under Integrated Circuits, IC01

2000 Jun 14

Philips Semiconductors Preliminary specification

Digital audio broadcast channel decoder SAA3500H

CONTENTS

1 FEATURES

2 APPLICATIONS

3 GENERAL DESCRIPTION

4 QUICK REFERENCE DATA

5 ORDERING INFORMATION

6 BLOCK DIAGRAM

7 PINNING

8 FUNCTIONAL DESCRIPTION

9 INTERFACE DESCRIPTION

9.1 Input interface

9.2 Memory interface

9.3 Parallel output interface

9.4 Serial output interface

9.5 Simple full capacity output

9.6 RDI output

9.7 Microcontroller interface

9.7.1 I2C-bus mode

9.7.2 L3-bus mode

9.7.3 Microcontroller interface registers

10 LIMITING VALUES

11 THERMAL CHARACTERISTICS

12 DC CHARACTERISTICS

13 AC CHARACTERISTICS

14 APPLICATION INFORMATION

14.1 Clock oscillator

14.2 Reset input

14.3 Boundary scan test interface

15 PACKAGE OUTLINE

16 SOLDERING

16.1 Introduction to soldering surface mount

packages

16.2 Reflow soldering

16.3 Wave soldering

16.4 Manual soldering

16.5 Suitability of surface mount IC packages for

wave and reflow soldering methods

17 DATA SHEET STATUS

18 DEFINITIONS

19 DISCLAIMERS

20 PURCHASE OF PHILIPS I2C COMPONENTS

2000 Jun 14 2

Philips Semiconductors Preliminary specification

Digital audio broadcast channel decoder SAA3500H

1 FEATURES

• DigitalAudioBroadcast(DAB)full-capacitydemodulator

and decoder

• Supports DAB transmission modes I, II, III and IV

• Integrated Analog-to-Digital Converter (ADC) for

IF input

• Digital mixer with on-chip digital Automatic Frequency

Control (AFC) and Automatic Gain Control (AGC)

• Detectors for null symbol, DAB mode and transmitter

identification

• On-chip or external synchronization algorithms and

control loops

• On-chip timing PLL and DCXO

• Dynamic DAB multiplex reconfiguration supported

• Equal and unequal error protection for up to

64 sub-channels

• Fast information channel buffering

• Simple full capacity output

• Receiver data interface

• Serial output for three sub-channels

• I2C-bus or L3-bus control interface.

2 APPLICATIONS

• Mobile receivers (FM/DAB car radios)

• Personal Computer add-ons

• Test and measurement equipment

• Portable radios.

3 GENERAL DESCRIPTION

The Philips SAA3500H is a Digital Audio Broadcast (DAB)

channel decoder according to the ETSI specification

ETS 300 401.The SAA3500H is a successor tothePhilips

FADIC and SIVIC chip set and provides an IF ADC, digital

mixer, full DAB ensemble demodulation and decoding as

well as time and frequency synchronization functions.

Because of the full-speed Viterbi decoding capacity and a

high-speed receiver data output interface, DAB data

reception is not limited by the SAA3500H channel

decoder.

4 QUICK REFERENCE DATA

SYMBOL PARAMETER MIN. TYP. MAX. UNIT

V

V

I

DD

f

clk

T

T

DD

i(max)

amb

stg

supply voltage 3.0 3.3 3.6 V

maximum input voltage −0.5 − VDD+ 0.5 V

DC supply current −− 180 mA

clock frequency − 24576 − kHz

ambient temperature −40 +25 +85 °C

storage temperature −65 − +150 °C

5 ORDERING INFORMATION

PACKAGE

TYPE NUMBER

NAME DESCRIPTION VERSION

SAA3500H QFP100 plastic quad flat package; 100 leads (lead length 1.95 mm);

body 14 × 20 × 2.7 mm; high stand-off height

SOT317-1

2000 Jun 14 3

Philips Semiconductors Preliminary specification

Digital audio broadcast channel decoder SAA3500H

6 BLOCK DIAGRAM

ADE

ADC

OUT[7:0]

OCLK

OIQ

OCIR

OEN

AIF

99

1

39 to 32

27

29

30

31

AD CONVERTER

(8 BIT)

CHANNEL IMPULSE

RESPONSE

PROCESSOR

AUTOMATIC FREQUENCY

CONTROL PROCESSOR

SYMBOL

SELECT

CAPACITY UNIT

BYP

AGC

INP[9:0] IQS

217

sync

SELECT

21 20 25 24 19 41 4 5

to

8

DIGITAL MIXER

AND FILTERS

FAST FOURIER

TRANSFORMATION

DIFFERENTIAL

DEMODULATOR

FREQUENCY & TIME

DE-INTERLEAVER

SLI

metrics

ADCLK

NULL DETECTOR,

OSCI

MCLK

TIMEBASE,

BOUNDARY

SCAN TEST

OSCO

DCXO

SAA3500H

62 to 68, 81 to 91

23

22

97

95

96

93

98

70

71 to 78

69

61

FSO

FSI

TMS

TCK

TDI

TDO

TRST

A17

A[17:0]

D[7:0]

RD

WR

UNEQUAL/EQUAL

ERROR PROTECTION

CONTROL

MCI

MICROCONTROLLER

INTERFACE

55

CFIC

RESET RDE

52 54 53

51

CMODE

CCLK

CDATA SOD[1:3] REF

inhibit

FIC

VITERBI

DECODER

BUFFER

49

to

50

47

Fig.1 Block diagram.

2000 Jun 14 4

SERIAL OUTPUT

46

to

44

43

SFCOSOV[1:3]SOC

56

58 57

RDC

ERROR FLAG

DETECT/COUNT

59

RDO

Philips Semiconductors Preliminary specification

Digital audio broadcast channel decoder SAA3500H

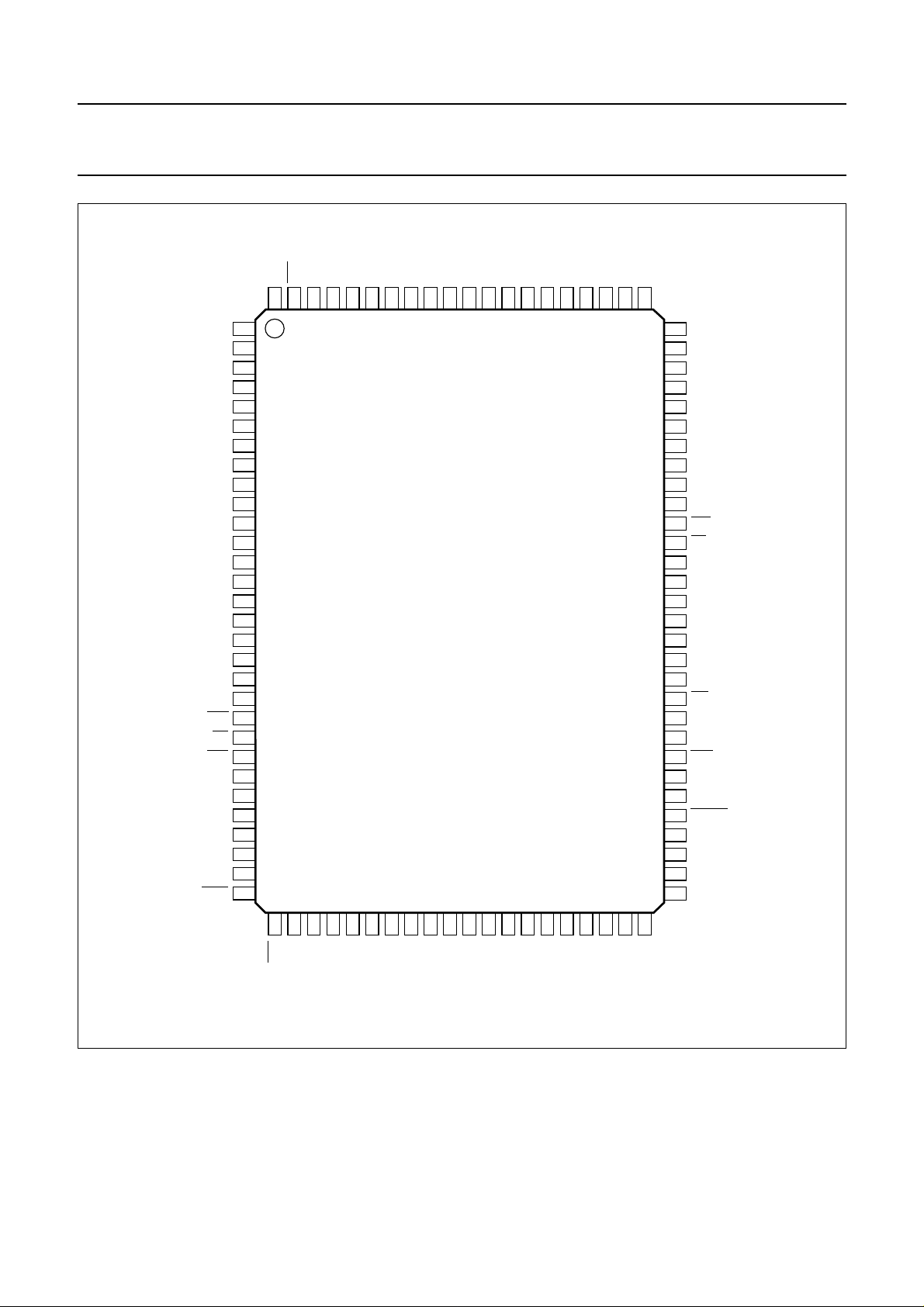

7 PINNING

SYMBOL PIN TYPE DESCRIPTION

ADC 1 input analog-to-digital converter DC input

AIF 2 input analog-to-digital converter IF input

V

SSA

ADE 99 input analog-to-digital converter enable (active LOW)

V

DDA

INP[0:9] 8 to 17 input 2048 kHz IF or baseband digital parallel input data (8 or 10 bits)

ADCLK 19 output analog-to-digital clock output 8192 kHz if

IQS 20 input clock signal indicating I or Q baseband data if

BYP 21 input IF input stage bypass (active LOW)

FSI 22 input frame sync input (LOW indicates DAB null symbol detection)

FSO 23 output null detector/frame sync output (LOW indicates DAB null symbol position)

SLI 24 output AGC synchronization lock indicator (HIGH if synchronized)

AGC 25 output AGC level comparator output (HIGH if input sample > reference level, else LOW)

OSCI 4 input oscillator or system clock input, 24576 kHz

OSCO 5 output oscillator output

MCLK 41 output master clock output, 24576 kHz

V

SS

V

DD

TEST 92 input connect to ground for proper operation

OUT[0:7] 32 to 39 output baseband or channel impulse response output

OCLK 27 output output data clock (negative edge indicates new data)

OIQ 29 output output I or Q select signal if

OCIR 30 input output select: baseband if OCIR = HIGH, CIR if OCIR = LOW

OEN 31 input output enable (active LOW)

CFIC 51 output microcontroller interface signal indicating Fast Information Channel (FIC) processing

CMODE 52 input microcontroller interface mode input (only L3-bus)

CDATA 53 I/O microcontroller interface serial data I

CCLK 54 input microcontroller interface clock input I

RESET 55 input chip reset input (active LOW)

A[17:11] 62 to 68 output address outputs external RAM

A[10:0] 81 to 91 output address outputs external RAM

WR 61 output write data to RAM (active LOW)

RD 69 output read data from RAM (active LOW)

A17 70 output address bit 17 inverted for second RAM (128k × 8)

D[0:7] 71 to 78 I/O data input/output external RAM

3 ground analog supply ground

100 supply analog voltage supply (+3.3 V)

signal for swapping I and Q data bytes if BYP = HIGH

7, 18,

supply digital supply ground

26, 40,

60, 80

and 94

6, 28,

supply digital voltage supply (+3.3 V)

42 and

79

BYP = HIGH, 4096 kHz if BYP = LOW

BYP = LOW;

OCIR = HIGH, or frame trigger if OCIR = LOW

2

C-bus or L3-bus (5 V tolerant)

2

C-bus or L3-bus

2000 Jun 14 5

Philips Semiconductors Preliminary specification

Digital audio broadcast channel decoder SAA3500H

SYMBOL PIN TYPE DESCRIPTION

SOV3 44 output serial output valid data 3

SOV2 45 output serial output valid data 2

SOV1 46 output serial output valid data 1

SOD3 47 output serial output data 3

SOD2 48 output serial output data 2

SOD1 49 output serial output data 1 (from channel decoder)

SOC 50 output serial output clock (384 kHz continuous)

REF 43 output receiver error flag [from Viterbi decoder, for Simple Full Capacity Output (SFCO)]

SFCO 56 output simple full capacity output (direct from Viterbi decoder)

RDC 57 output receiver data clock (6144 kHz continuous) or SFCO clock (burst)

RDE 58 input RDI output enable (active LOW)

RDO 59 output receiver data interface bi-phase output

TDO 93 output boundary scan test serial output

TCK 95 input boundary scan test clock input

TDI 96 input boundary scan test serial input

TMS 97 input boundary scan test mode select input

TRST 98 input boundary scan test reset input

2000 Jun 14 6

Philips Semiconductors Preliminary specification

Digital audio broadcast channel decoder SAA3500H

DDA

V

TRST

TMS

TDI

TCK

VSSTDO

ADC

AIF

V

SSA

OSCI

OSCO

V

DD

V

SS

INP0

INP1

INP2

INP3

INP4

INP5

INP6

INP7

INP8

INP9

V

SS

ADCLK

IQS

BYP

FSI

FSO

SLI

AGC

V

SS

OCLK

V

DD

OIQ

OCIR

ADE

99989796959493929190898887868584838281

100

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

TESTA0A1A2A3A4A5A6A7A8A9

SAA3500H

A10

80

79

78

77

76

75

74

73

72

71

70

69

68

67

66

65

64

63

62

61

60

59

58

57

56

55

54

53

52

5130

V

SS

V

DD

D0

D1

D2

D3

D4

D5

D6

D7

A17

RD

A11

A12

A13

A14

A15

A16

A17

WR

V

SS

RDO

RDE

RDC

SFCO

RESET

CCLK

CDATA

CMODE

CFIC

31323334353637383940414243444546474849

OEN

OUT0

OUT1

OUT2

OUT3

OUT4

OUT5

OUT6

OUT7

Fig.2 Pin configuration.

2000 Jun 14 7

50

MXXxxx

SS

DD

MCLK

REF

V

SOV3

SOV2

SOV1

SOD3

SOD2

SOD1

SOC

V

Philips Semiconductors Preliminary specification

Digital audio broadcast channel decoder SAA3500H

8 FUNCTIONAL DESCRIPTION

The 2.048 MHz IF signal is digitized by an 8-bit flash

Analog-to-Digital Converter (ADC), which samples at

8.192 MHz. The required input level is limited to a

peak-to-peak voltage of 2 V. Due to a fast

sample-and-hold circuit sub-sampling is possible, so that

all IF frequencies of N × 8.192 ±2.048 MHz can be used.

If a higher resolution ADC is wanted, anexternal ADCcan

be connected.

The digital mixer accepts a 2.048 MHzIF signal atits input

and converts it to baseband with In-phase (I) and

Quadrature-phase (Q) components. The mixer frequency

is adjusted on a DAB frame basis with 1 Hz resolution to

prevent performance degradation. The mixer output

signals are digitally filtered and subjected to internal

Automatic Gain Control (AGC) before entering the

subsequent Fast Fourier Transform (FFT) stage.

The output of the digital AGC detectors indicates for each

input sample whether the level is below or above the

reference input level. By means of external filtering and

gain control, the signal can be used to adjust the input

signal level of the analog-to-digital converter (external

AGC).

The on-chip null detector operates on the digital baseband

signal and indicates the coarse position of the DAB null

symbol (FSO = LOW), which is used for time base

initialization. The spacing of detected null symbols is used

to detect the DAB transmission mode.

The time base counts samples on a symbol and a frame

basis in order to generate the internal control windows for

the FFT and to generate a frame sync signal (FSO) during

thenullsymbol.Initializationofthe time base is determined

by the null detector signal (FSI) and the selected DAB

mode. After time base initialization the SAA3500H will be

in symbol processing mode and the null detector will be

deactivated.

The OFDM symbol demodulator applies a real-time FFT

and differential demodulation to the baseband signal. The

output is quantized to 4-bit metrics for the Viterbi decoder.

The position of the FFT window is adjusted on a DAB

frame basis in order to avoid Inter-Symbol Interference

(ISI).

TheFFTresultof the reference symbol is processed bythe

synchronization core, which performs two functions:

estimation of the frequency error of the baseband signal,

which is needed to adjust the digital mixer (AFC), and

calculation of the Channel Impulse Response (CIR) to be

used for positioning of the FFT window and the system

clock.All timing and frequency controlloopsare realized in

the synchronization core and can be influenced from the

control interface.

The Viterbi decoder is preceded by frequency and time

de-interleavingof the incoming metricsinexternal RAM, to

distribute burst errors caused by channel fading. Variable

rate decoding is done with 3.072 Mb/s decision speed.

Output bits are re-encoded and compared to

corresponding input bits in order to generate an error flag

signal.

Sub-channel selection is done on a Capacity Unit (CU)

basis. All standardized Unequal Error Protection (UEP)

puncturing schemes for audio and Equal Error Protection

(EEP) schemes for data are provided. Up to

64 sub-channelscanbeselectedseparately,whichmeans

virtually unlimited DAB decoding capabilities.

The output interface provides a full-speed standardized

Receiver Data Interface (RDI) for all sub-channel data.

This allows to extend every DAB receiver with external

decoders for all kind of services. A dedicated interface is

provided for the Philips SAA2502H audio source decoder,

which completes the DAB receiver.

The system clock of 24.576 MHz, can be generated by an

integrated DCXO, which is internally locked to the DAB

signal. The clockis available on the MCLKpin to provide a

synchronous clock to the MPEG decoder and

microcontroller.

The I2C-bus or L3-bus configurable control interface

provides access to Automatic Frequency Control (AFC),

Channel Impulse Response (CIR), Fast Information

Channel (FIC) and sub-channel selection controls.

2000 Jun 14 8

Philips Semiconductors Preliminary specification

Digital audio broadcast channel decoder SAA3500H

9 INTERFACE DESCRIPTION

9.1 Input interface

The input interface can be used in 3 different modes, depending on the bypass (BYP) and IQ Select (IQS) pins. Digital

input data should be in two’s complement format (optionally: offset binary) and synchronized with the ADCLK output

signal. Input data are read on the rising edge of ADCLK.

Table 1 Input modes

BYP IQS DESCRIPTION

0 clk digital baseband input sampled at 2048 kHz and with I and Q data multiplexed

1 0 digital IF input sampled at 8192 kHz, internal I/Q demodulator

1 1 digital IF input sampled at 8192 kHz, internal I/Q demodulator with I and Q swapped

In case of baseband input the IQ select signal shall indicate whether the current sample is either I or Q data (INP[9:0]).

ADCLK

INP[9:0]

IQS

Q

I

0

1

Q

I

1

Q

2

2

4096 kHz

10 bits

2048 kHz

Fig.3 Baseband input signals (BYP = LOW).

Digital IF input is, typically, at a frequency of 2048 kHz. It is possible to apply sub-sampling on a N × 8.192 ±2.048 MHz

(N = 1, 2, 3,...,19) IF signal, but care should be taken with the jitter of the crystal clock, which is proportional to N.

ADCLK

INP[9:0]

8192 kHz

10 bits

Fig.4 IF input signals [BYP = HIGH, IQS = LOW (no swap) or HIGH (swap)].

To use the on-chip null detector, pins

FSI and FSO shall simply be connected to each other.

When using an external null detector, the FSI input shall indicate the position of the null symbol in the baseband signal

(FSI = LOW). The negative edge may have a maximum delay of 512 samples with respect to an ideal null detector. The

delay compensation can be set via the I2C/L3 interface (register ATCWinControl). The FSI input provides edge jitter

suppression of up to 40 samples starting from the first negative edge. Once the SAA3500H is in symbol processing

mode, the FSI signal is ignored. During the null detection state, the Sync Lock Indicator (SLI) will be continuously LOW.

9.2 Memory interface

An external SRAM memory of either 128 or 256 kbytes is required to store the metrics from the data de-interleaver for

half (432 CUs) or full (864 CUs) decoding capacity, respectively. The upper address line A17 is available both true and

inverted (A17) to allow memory extension without an address decoder. 3.3 V RAMs should be used with either an 8 or

(2 ×) 4-bit data bus and an access time of ≤80 ns. Input data are read on the rising edge of RD, output data shall be

latched on the rising edge of WR.

2000 Jun 14 9

Philips Semiconductors Preliminary specification

Digital audio broadcast channel decoder SAA3500H

A[17:0]

D[7:0]

RD

WR

Fig.5 RAM access.

9.3 Parallel output interface

The digital parallel output interface can be used in 3 different modes depending on the OCIR and OEN select pins.

Output data shall be latched on the falling edge of OCLK.

Table 2 Parallel output modes

X = don’t care.

OCIR OEN DESCRIPTION

0 0 channel impulse response sampled at 64 kHz, OIQ = frame trigger

1 0 baseband sampled at 2048 kHz and with I and Q data multiplexed

X 1 OUT[7:0], OIQ and OCLK disabled

By means of an external digital-to-analog converter, either the CIR or I/Q data can be displayed on an oscilloscope.

Digitaloutput data isclockedout on thefallingedge of theOCLKoutput signal. Incaseof baseband outputtheOIQ signal

indicates, if the current sample is either I or Q data.

OCLK

OUT[7:0]

OIQ

QIQIQ

4096 kHz

signed

2048 kHz

Fig.6 Baseband output signals (OCIR = HIGH, OEN = LOW).

OCLK

OUT[7:0]

OIQ

64 kHz

unsigned

trigger

Fig.7 CIR output signals (OCIR = LOW, OEN = LOW).

2000 Jun 14 10

Philips Semiconductors Preliminary specification

Digital audio broadcast channel decoder SAA3500H

In the CIR output mode the channel impulse response is clocked out in a burst of N (unsigned) samples at 64 kHz each

frame after CIR processing (bit SyncBusy = logic 0). The edges of the frame trigger signal (OIQ) allow to trigger a CIR

display either at the start of the symbol or at the start of the symbol guard. In the latter case the CIR peak for a Gaussian

channel will be at the left of the display.

9.4 Serial output interface

The serial output interface is intended for transferring up to three sub-channels to the source decoder(s) with a total

maximum bit rate of 384 kbit/s. The sub-channels for these outputs should be selected with the appropriate I2C or L3

commands. The output clock is 384 kHz. Each sub-channel has its own serial data and data valid line, but the clock is

common. Serial output data shall be latched on the rising edge of SOC.

SOC

SOD

SOV

Fig.8 DAB3 serial output.

9.5 Simple full capacity output

This interface provides serial access to all the Viterbi decoder output bits without any formatting. Transmission framing

is indicated by the CFIC window, which can also be used to separate the FIC data (CFIC = HIGH) from the Main Service

Channel (MSC) data (CFIC = LOW). The bit CFICMode can be used to signal on CFIC the beginning of the selected

sub-channels (CFICMode = logic 0). The clock is a 3072 kHz burst clock, activated for each new output bit.

Accompanied with the data is the error flag, obtained by re-encoding the Viterbi output bits and comparison with the

corresponding Viterbi decoder input bits (REF = HIGH for error bit).

CFIC

RDC

SFCO

REF

CFICMode = 0

Fig.9 Simple full capacity output (CFICMode = logic 1).

9.6 RDI output

For external use a bi-phase modulated output (RDO) is provided, which carries all the FIC and MSC data, formatted

according to the DAB receiver data interface specification

“EN 50255”

, which is based on the IEC 60958 digital audio

interface. Optionally, a clock (6144 kHz) and word select signal (48 kHz) can be provided (instead of SFCO signals).

Transmitter Identification Information (TII) is not signalled on this RDI. The FIC however is always signalled, with the

Cyclic Redundancy Check (CRC) performed and the Error Check Field containing the resulting CRC (normally 0).

Selected sub-channels will be directed to the RDI interface in the extended capacity mode (22 bits for MSC), but the

number of RDI frames and the reliability are not signalled (i.e., set to all logic 0s and all logic 1s, respectively).

2000 Jun 14 11

Philips Semiconductors Preliminary specification

Digital audio broadcast channel decoder SAA3500H

RDO

Fig.10 RDI output (normal mode, RDE = LOW).

In case SFCO data output is not desired, a particular ‘RDI plus’ mode can be selected, which provides a continuous

6144 kHz clock on RDC, synchronous to the bi-phase RDI data and accompanied by a fixed word select signal, to allow

RDI source reception without an extra clock recovery circuit. Output data shall be latched on the rising edge of RDC.

RDC

RDO

SFCO

Channel 1 (32 bits)

Channel 2 (32 bits)

Fig.11 RDI output (RDI plus mode, RDE = LOW).

9.7 Microcontroller interface

The microcontroller interface of the SAA3500H operates in one of two distinct modes of operation: I2C-bus or L3-bus.

Mode setting is determined at initialization, as described in Fig.12. On either control bus data are transferred in 8-bit

packets, or bytes.

The interface uses three signals and the function in the L3-bus mode or I2C-bus mode is indicated in Table 3.

Table 3 Control bus modes

SIGNAL L3-BUS MODE I2C-BUS MODE DIRECTION DESCRIPTION

CDATA L3DATA SDA input/output microcontroller interface serial data

CCLK L3CLK SCL input microcontroller interface bit clock

CMODE L3MODE none input microcontroller interface mode select

During a hard reset of the device, the microcontroller interface mode is determined. As a consequence, the interface

cannot be used while the reset signal is asserted. Mandatory action must be taken for correct microcontroller interface

start-up at a hard reset, as explained in Fig.12.

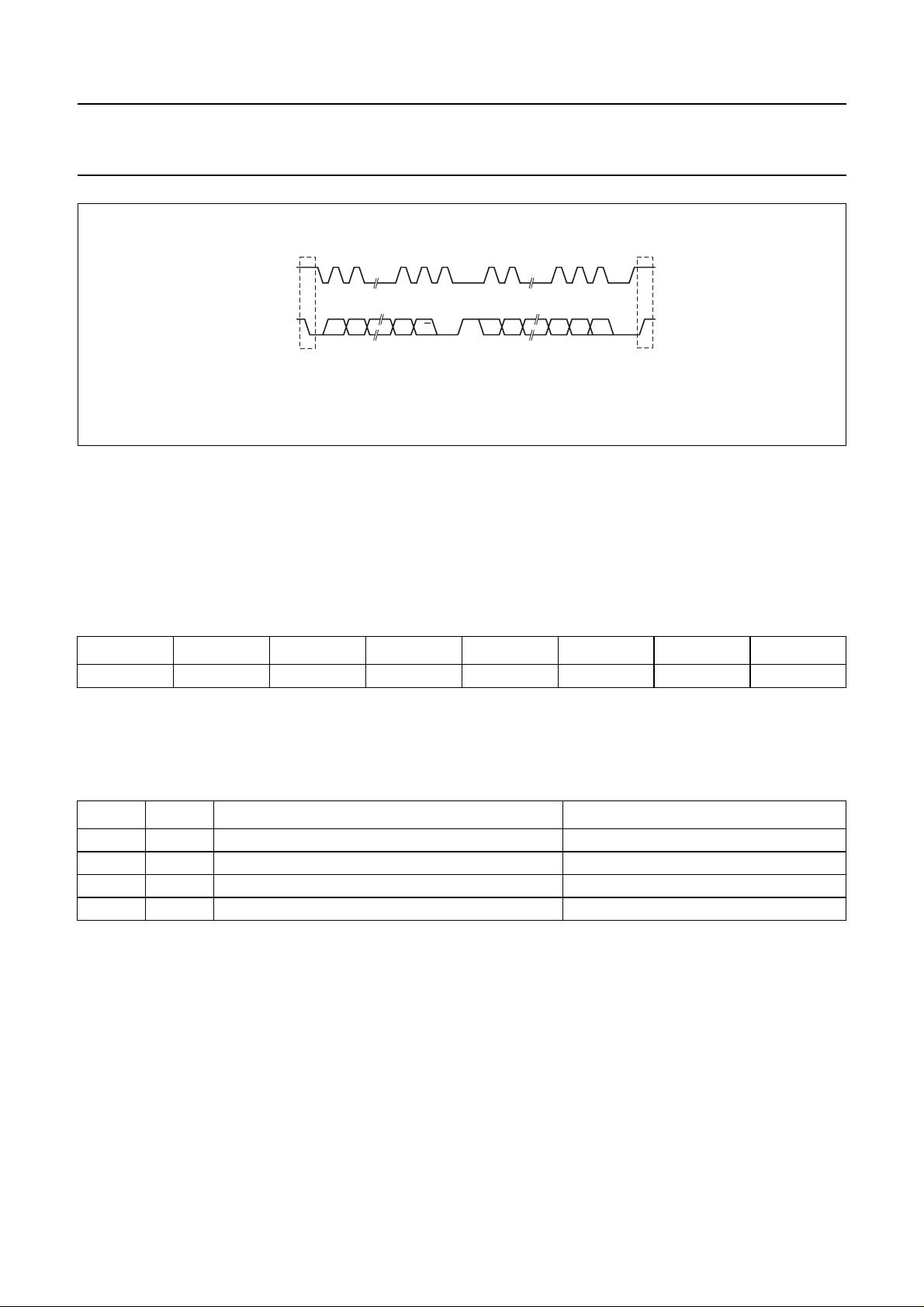

RESET

CMODE

CCLK

phase 1 phase 2 phase 3

I2C-bus mode

L3-bus mode

Fig.12 Microcontroller interface initialization procedure.

2000 Jun 14 12

Philips Semiconductors Preliminary specification

Digital audio broadcast channel decoder SAA3500H

In phase 1, the level of the CMODE signal determines the microcontroller interface mode, while reset is asserted.

CMODE = HIGHdefines I2C-busmode, CMODE = LOW definesL3-bus mode. No transferscan be performed, asCCLK

must be HIGH.

Inphase 2, which isfor L3-bus modeof operation only, it is mandatory totake CMODE HIGH,then LOW againafter reset

hasbeen de-asserted, tocorrectly initialize the interface unit. This mustoccur before anyL3-bus transfer (even toor from

other devices) is performed. CCLK shall remain HIGH during this phase.

In phase 3, the first transfer can be performed on the microcontroller interface.

Any deviation from these steps may result in undefined behaviour of the microcontroller interface, even with the

possibility of disturbing transfers to other devices connected to the control bus.

At a hardware reset, all writeable data items are forced to their default values.

The microcontroller interface provides access to all blocks, which generate or need control information. Selections on

the SAA3500H are at the sub-channel level, the required sub-channel parameters should be obtained via the Multiplex

Configuration Information (MCI), which is part of the FIC.

The CFIC window from the SAA3500H indicates FIC decoding. FIC data from the I2C/L3 interface will be invalid, if

CFIC = HIGH. It is therefore recommended to connect CFIC to a microcontroller interrupt input pin. With regard to the

real-time processing requirements, it is highly recommended to use a 16-bit microcontroller.

2

9.7.1 I

C-BUS MODE

The implemented I2C-bus interface isof the 400 kbit/s, 7-bit address type. TheCDATA output driver is of the ‘opendrain’

type in order to be compliant with the I2C-bus specification. The device address is as follows:

Table 4 I

2

C-bus device address

BIT 7 BIT 6 BIT 5 BIT 4 BIT 3 BIT 2 BIT 1 BIT 0

1101011R/

Bit 7to bit 1 comprise the7-bit I

2

C-busslave address, while bit 0indicates the transfer directionof data and acknowledge

W

bits as follows:

2

Table 5 Read and write operation to the microcontroller in I

W FUNCTION REMARK

R/

C-bus mode

0 data from microcontroller to SAA3500H all acknowledge generated by SAA3500H

1 data from SAA3500H to microcontroller acknowledge for data generated by microcontroller

Fundamentals of the I2C-bus interface protocol are shown in Fig.13.

2000 Jun 14 13

Philips Semiconductors Preliminary specification

Digital audio broadcast channel decoder SAA3500H

CCLK

CDATA

S

START

condition

2

1

address transfer data transfer

MSB

78

R/W

ACK

9

27

MSB LSB

9

81

ACK

P

STOP

condition

Fig.13 I2C-bus data transfer example.

For full details of the I2C-bus interface specification, please, refer to the I2C-bus specification

(http://www.semiconductors.com/handbook/various_38.html), which is also available on request.

9.7.2 L3-BUS MODE

The L3-bus device address is composed as follows:

Table 6 L3-bus device address

BIT 7 BIT 6 BIT 5 BIT 4 BIT 3 BIT 2 BIT 1 BIT 0

011011DOM1

(1)

DOM0

(1)

Note

1. The ‘Data Operation Mode’ bits DOM1 and DOM0 define the current sub-mode of the microcontroller interface until

the next time a device address is received (see Table 7).

Table 7 Read and write operation to the microcontroller in L3-bus mode

DOM1 DOM0 FUNCTION REMARK

0 0 data from microcontroller to SAA3500H general purpose data transfer

0 1 data from SAA3500H to microcontroller general purpose data transfer

1 0 control from microcontroller to SAA3500H register selection for data transfer

1 1 status from SAA3500H to microcontroller short device status message

Fundamentals of the L3-bus interface protocol are shown in Fig.14.

2000 Jun 14 14

Philips Semiconductors Preliminary specification

Digital audio broadcast channel decoder SAA3500H

CCLK

CMODE

CDATA

1

addressing mode

2

78

MSBLSB

27

1

data mode

8

MSBLSB

Fig.14 L3-bus command transfer example.

For full details of the L3-bus interface specification, please, refer to the SAA2502H data sheet (order number

9397 750 03068 or at http://www.semiconductors.com/products).

9.7.3 MICROCONTROLLER INTERFACE REGISTERS

Communication between the microcontroller and the SAA3500H is by addressing registers and writing or reading data.

All addresses and register contents are in hexadecimal notation.

The following registers are available for the writing of data:

Table 8 Writeable registers

ADDRESS

(HEX)

NAME DESCRIPTION

SETTING AFTER RESET

(HEX)

00 Control control 1F

01 Configuration configuration FF

10 CIFCount CIF count and occurrence change flag 00 00 00

20 CurSubChSel current sub-channel selection 00 00 00 00

21 NextSubChSel next sub-channel selection 00 00 00 00

30 SOD1 select sub-channel for serial output SOD1 40

31 SOD2 select sub-channel for serial output SOD2 40

32 SOD3 select sub-channel for serial output SOD3 40

40 AGCExternal setting of thresholds for external AGC 61 0C

41 AGCInternal settings of the internal AGC D0 49

42 AGCFixed internal AGC switch off and fixed gain setting 00

50 NullDetMargin null detector margin 40

51 TIIControl TII main/sub identifier 00 00

60 MixerFreqInput digital mixer frequency control input 80 00 00

62 CarrierShift carrier shift by n carrier positions 00

63 AFCGain AFC loop gain 10

70 ATCWinControl ATC window control input or FFT window position and null

96

detector delay compensation

71 CIRThreshold CIR detector thresholds, edge and range 02 02

73 ATCGains ATC loops gains; clock I and P gains and window gain 02 04 20

2000 Jun 14 15

Philips Semiconductors Preliminary specification

Digital audio broadcast channel decoder SAA3500H

The following registers are available for the reading of data:

Table 9 Readable registers

ADDRESS

(HEX)

NAME DESCRIPTION BYTES TO READ

00 Status internal processing status 1

10 FICErrCount FIC error count per frame 2

20 to 2B FICData FIC data inclusive CRC result 32

51 TIIOutput TII complex phase values 6

60 AFCLoopOutput AFC loop output for digital mixer frequency control 3

61 CarrierDev AFC carrier deviation detector 2

70 ATCWinOutput ATC window loop output for FFT window position 1

71 ATCDetector ATC CIR detector output 3

72 ATCClockOutput ATC clock loop output for external VCXO 1

76 CIRPower power of CIR response 2

A description of how to use the individual registers is given in a separate application note.

10 LIMITING VALUES

In accordance with the Absolute Maximum Rating System (IEC 60134).

SYMBOL PARAMETER CONDITIONS MIN. MAX. UNIT

V

DD

V

i

I

DD

I

i

I

o

P

tot

T

stg

T

amb

V

es

DC supply voltage note 1 −0.5 +6 V

input voltage −0.5 VDD+ 0.5 V

supply current − 200 mA

input current −10 +10 mA

output current −10 +10 mA

total power dissipation − 650 mW

storage temperature −65 +150 °C

operating ambient temperature −40 +85 °C

electrostatic handling voltage note 2 −300 +300 V

note 3 −3000 +3000 V

Notes

1. All supply connections must be made to the same external power supply unit.

2. Machine model: equivalent to discharging a 200 pF capacitor through a 0 Ω series resistor (‘0 Ω’ is actually

0.75 µH+10Ω).

3. Human body model: equivalent to discharging a 100 pF capacitor through a 1500 Ω series resistor.

11 THERMAL CHARACTERISTICS

SYMBOL PARAMETER CONDITIONS VALUE UNIT

R

th(j-a)

thermal resistance from junction to ambient in free air 60 K/W

2000 Jun 14 16

Philips Semiconductors Preliminary specification

Digital audio broadcast channel decoder SAA3500H

12 DC CHARACTERISTICS

VDD= 3.0 to 3.6 V; T

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

Supplies

V

DD(tot)

I

DD(tot)

total DC supply voltage note 1 3.0 3.3 3.6 V

total DC supply current −−180 mA

Dissipation

P

tot

total power dissipation −−650 mW

Inputs

= −40 to +85 °C; all voltages referenced to ground (VSS); unless otherwise specified.

amb

CMOS

V

V

|I

C

LEVEL INPUT (INP[9:0], FSI, CCLK AND TCK)

IH

IL

| input leakage current VI= 0 or VI=VDD−−1µA

LI

i

HIGH-level input voltage 2.0 −−V

LOW-level input voltage −−0.8 V

input capacitance − 5 − pF

CMOS LEVEL INPUT, PULL-UP (BYP, CMODE, IQS, OCIR, OEN, RDE, TDI, TMS AND TRST)

V

IH

V

IL

R

pu(VDD)(int)

C

i

HIGH-level input voltage 2.0 −−V

LOW-level input voltage −−0.8 V

internal pull-up resistor to V

DD

16 33 78 kΩ

input capacitance − 5 − pF

CMOS LEVEL INPUT, HYSTERESIS, PULL-UP (RESET)

V

IH(hys)

V

IL(hys)

V

hys

R

pu(VDD)(int)

C

i

HIGH-level hysteresis input, rising edge 1.4 − 1.9 V

LOW-level hysteresis input, falling edge 0.9 − 1.45 V

hysteresis voltage 0.4 − 0.7 V

internal pull-up resistor to V

DD

16 33 78 kΩ

input capacitance − 5 − pF

Inputs/outputs

CMOS LEVEL INPUT, HYSTERESIS, OPEN DRAIN OUTPUT (CDATA)

V

IH(hys)

V

IL(hys)

V

hys

V

OL

CMOS LEVEL INPUT, OUTPUT STAGE (D[7:0])

V

IH

V

IL

| input leakage current VI= 0 or VI=VDD−−1µA

|I

LI

V

OH

V

OL

HIGH-level hysteresis input, rising edge 1.4 − 1.9 V

LOW-level hysteresis input, falling edge 0.9 − 1.45 V

hysteresis voltage 0.4 − 0.7 V

LOW-level output voltage I

=3mA −−0.4 V

LOAD

1.5 mA

HIGH-level input voltage 2.0 −−V

LOW-level input voltage −−0.8 V

HIGH-level output voltage I

LOW-level output voltage I

= −1.5 mA 2.4 −−V

LOAD

= 1.5 mA −−0.4 V

LOAD

2000 Jun 14 17

Philips Semiconductors Preliminary specification

Digital audio broadcast channel decoder SAA3500H

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

Outputs

CMOS LEVEL, OUTPUT STAGE (A[17:0], A17, ADCLK, AGC, FSO, OCLK, OIQ, RD, SLI, SOD[1:3], SOV[1:3]

AND WR)

V

OH

V

OL

C

LOAD

CMOS LEVEL,3-STATE OUTPUT STAGE, (OUT[7:0])

V

OH

V

OL

|I

| output leakage current inactive mode;

LO

1.5 mA

HIGH-level output voltage I

LOW-level output voltage I

= −1.5 mA 2.4 −−V

LOAD

= 1.5 mA −−0.4 V

LOAD

output load capacitance −−30 pF

1.5 mA

HIGH-level output voltage I

LOW-level output voltage I

= −1.5 mA 2.4 −−V

LOAD

= 1.5 mA −−0.4 V

LOAD

−−1µA

VO= 0 or

VO=V

DD

C

LOAD

CMOS LEVEL, OUTPUT STAGE (CFIC, MCLK, RDC, RDO, REF, SFCO, SOC AND TDO)

V

OH

V

OL

C

LOAD

output load capacitance −−30 pF

3 mA

HIGH-level output voltage I

LOW-level output voltage I

= −3 mA 2.4 −−V

LOAD

=3mA −−0.4 V

LOAD

output load capacitance −−50 pF

Note

1. All supply connections must be made to the same external power supply unit.

13 AC CHARACTERISTICS

VDD= 3.0 to 3.6 V; T

=25°C; all voltages referenced to ground (VSS); unless otherwise specified.

amb

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

Oscillator input (OSC)

f

i(OSC)

δ

OSC

input frequency note 1 − 24576 − kHz

input clock duty factor 40 − 60 %

Reset input (RESET)

t

CL,RESET

reset LOW duration note 2 60 × T −−ns

Input interface (ADCLK, BYP, INP[9:0] and IQS)

BASEBAND INPUT (BYP = LOW); see Fig.15

T

cy,ADCLK

t

CL,ADCLK

t

CH,ADCLK

t

h,INP

t

h,IQS

ADCLK cycle time − 244 − ns

ADCLK LOW time − 122 − ns

ADCLK HIGH time − 122 − ns

INP[9:0] hold time 5 −−ns

IQS hold time −−80 ns

2000 Jun 14 18

Philips Semiconductors Preliminary specification

Digital audio broadcast channel decoder SAA3500H

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

IF INPUT (BYP = HIGH); see Fig.16

T

cy,ADCLK

t

CL,ADCLK

t

CH,ADCLK

t

h,INP

t

d,INP

Memory interface (A17, A[17:0], D[7:0], RD and WR); see Figs 17 and 18

T

cy,A

t

CL,RD

t

d,RD

t

h,RD

t

CL,WR

t

d,WR

t

d,D

t

h,D

Parallel output interface (OCIR, OCLK, OEN, OIQ and OUT[9:0])

ADCLK cycle time − 122 − ns

ADCLK LOW time − 80 − ns

ADCLK HIGH time − 42 − ns

INP[9:0] hold time 5 −−ns

INP[9:0] delay time −−25 ns

address cycle time − 326 − ns

RD LOW time − 163 − ns

RD delay time − 40 − ns

RD hold time − 0 − ns

WR LOW time − 163 − ns

WR delay time 0 40 − ns

data delay time − 0 − ns

data hold time −−5ns

BASEBAND OUTPUT (OCIR = HIGH); see Fig.19

T

cy,OCLK

t

CL,OCLK

t

CH,OCLK

t

su,OUT

t

su,OIQ

OCLK cycle time − 244 − ns

OCLK LOW time − 122 − ns

OCLK HIGH time − 122 − ns

OUT[7:0] set-up time − 15 − ns

OIQ set-up time − 17 − ns

CIR OUTPUT (OCIR = LOW); see Fig.20

T

cy,OCLK

t

CL,OCLK

t

CH,OCLK

t

su,OUT

t

su,OIQ

OCLK cycle time − 15.6 −µs

OCLK LOW time − 8.3 −µs

OCLK HIGH time − 7.3 −µs

OUT[7:0] set-up time − 0 − ns

OIQ set-up time − 0 − ns

Serial output interface (SOC, SOD[3:1] and SOV[3:1]); see Fig.21

T

cy,SOC

t

CL,SOC

t

CH,SOC

t

h,SOD

t

su,SOV

t

h,SOV

SOC cycle time − 2.6 −µs

SOC LOW time − 1.3 −µs

SOC HIGH time − 1.3 −µs

SOD hold time − 0 − ns

SOV set-up time − 4 − ns

SOV hold time − 2 − ns

2000 Jun 14 19

Philips Semiconductors Preliminary specification

Digital audio broadcast channel decoder SAA3500H

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

Simple full capacity output interface (CFIC, RDC, REF and SFCO); see Fig.22

t

CH,CFIC

t

SH,CFIC

t

su,CFIC

t

h,CFIC

T

cy,RDC

t

CH,RDC

t

CL,RDC

t

su,SFCO

t

su,REF

t

h,REF

RDI output interface (RDC, RDE, RDO and SFCO)

CFIC HIGH time DAB mode I − 3.738 − ms

DAB mode II − 0.935 − ms

DAB mode III − 1.246 − ms

DAB mode IV − 1.869 − ms

CFIC strobe HIGH time bit CFICMode = 0 − 75 − ns

bit CFICMode = 1 − 0 − ns

CFIC set-up time − 165 − ns

CFIC hold time − 80 − ns

RDC cycle time 325 −−ns

RDC HIGH time 250 −−ns

RDC LOW time − 75 − ns

SFCO set-up time − 5 − ns

REF set-up time − 165 − ns

REF hold time −−160 − ns

NORMAL MODE; see Fig.23

t

ONE

t

ZERO

ONE time − 163 − ns

ZERO time − 326 − ns

RDI PLUS MODE; see Fig.24

T

cy,RDC

t

CH,RDC

t

CL,RDC

T

cy,SFCO

t

CH,SFCO

t

CL,SFCO

t

su,SFCO

t

h,SFCO

RDC cycle time − 163 − ns

RDC HIGH time − 86 − ns

RDC LOW time − 77 − ns

SFCO cycle time − 20.8 −µs

SFCO HIGH time − 10.4 −µs

SFCO LOW time − 10.4 −µs

SFCO set-up time − 4 − ns

SFCO hold time − 0 − ns

Microcontroller interface

INITIALIZATION PROCEDURE; see Fig.25

t

CL,RESET

t

d,RES-MOD

t

CH,CMODE

t

d,MOD-CLK

RESET LOW time note 2 60 × T −−ns

delay time from RESET to CMODE note 2 10 × T −−ns

CMODE HIGH time note 2 10 × T −−ns

delay time from CMODE to first CCLK note 2 10× T −−ns

2000 Jun 14 20

Philips Semiconductors Preliminary specification

Digital audio broadcast channel decoder SAA3500H

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

L3-BUS MICROCONTROLLER TO SLAVE DEVICE; see Figs 26 and 28

t

cL

t

cH

t

d1

t

h1

t

h2

t

su

t

L

L3-BUS SLAVE DEVICE TO MICROCONTROLLER; see Fig.27

t

d2

t

d3

t

d4

t

d5

t

h3

I2C-BUS INPUTS/OUTPUT (CDATA AND CCLK)

t

f,I2C

f

CCLK

Notes

1. In a real application, the clock frequency may vary in a range of ±50 ppm due to timing synchronization.

2. T=4×OSC cycle time, i.e., T = 163 ns at f

L3CLK LOW time note 2 T + 10 −−ns

L3CLK HIGH time note 2 T + 10 −−ns

L3MODE set-up time before first L3CLK

10 −−ns

LOW

L3DATA hold time after L3CLK HIGH 10 −−ns

L3MODE hold time after last L3CLK HIGH 15 −−ns

L3DATA set-up time before L3CLK HIGH note 2 T + 10 −−ns

L3MODE LOW time note 2 T + 10 −−ns

L3MODE HIGH to L3DATA enabled time 0 − 20 ns

L3MODE HIGH to L3DATA stable time −−20 ns

L3CLK HIGH to L3DATA stable time note 2 −−2T + 30 ns

L3MODE LOW to L3DATA disabled time 0 − 20 ns

L3DATA hold time after L3CLK HIGH note 2 T −−ns

output fall time −−250 ns

CCLK clock frequency −−400 kHz

= 24.576 MHz.

osc

T

cy,ADCLK

ADCLK

INP[9:0]

t

h,INP

IQS

Fig.15 Baseband input timing (BYP = LOW).

T

cy,ADCLK

ADCLK

INP[9:0]

t

h,INP

Fig.16 IF input timing [BYP = HIGH, IQS = LOW (no swap) or HIGH (swap)].

2000 Jun 14 21

t

CL,ADCLK

t

CL,ADCLK

t

CH,ADCLK

t

h,IQS

t

CH,ADCLK

t

d,INP

Philips Semiconductors Preliminary specification

Digital audio broadcast channel decoder SAA3500H

T

cy,A

t

h,D

t

CL,WR

A[17:0]

D[7:0]

RD

T

cy,A

A[17:0]

D[7:0]

t

t

CL,RD

t

t

d,RD

h,D

WR

d,D

t

d,WR

Fig.17 RAM access read timing.

T

cy,OCLK

t

CH,OCLK

t

OCLK

CL,OCLK

OUT[7:0]

t

t

su,OUT

su,OIQ

OIQ

Fig.19 Baseband output timing (OCIR = HIGH,

OEN = LOW).

Fig.18 RAM access write timing.

T

cy,OCLK

t

CH,OCLK

t

OCLK

CL,OCLK

OUT[7:0]

t

su,OIQ

t

su,OUT

OIQ

Fig.20 CIR output timing (OCIR = LOW,

OEN = LOW).

T

SOC

t

cy,SOC

CL,SOC

t

CH,SOC

t

h,SOD

SOD

SOV

t

su,SOV

t

h,SOV

Fig.21 DAB3 serial output timing.

2000 Jun 14 22

Philips Semiconductors Preliminary specification

Digital audio broadcast channel decoder SAA3500H

t

t

su,CFIC

CFIC

RDC

SFCO

t

su,SFCO

REF

Fig.22 Simple full capacity output timing.

CH,CFIC

T

cy,RDC

t

CH,RDC

t

su,REF

t

h,CFIC

t

CL,RDC

t

h,REF

t

SH,CFIC

t

ONE

t

ZERO

RDO

Fig.23 RDI output timing (normal mode, RDE = LOW).

T

cy,RDC

t

CL,RDC

t

CH,RDC

RDC

RDO

t

h,SFCO

t

CL,SFCO

t

su,SFCO

SFCO

t

T

cy,SFCO

CH,SFCO

Fig.24 RDI output timing (RDI plus mode, RDE = LOW).

2000 Jun 14 23

Philips Semiconductors Preliminary specification

Digital audio broadcast channel decoder SAA3500H

t

CL,RESET

t

CH,CMODE

handbook, full pagewidth

L3MODE

L3CLK

L3DATA

RESET

CMODE

CCLK

t

d,RES-MOD

t

d,MOD-CLK

Fig.25 Microcontroller interface initialization timing.

t

d1 h2

t

cL

t

cH

t

h1

t

su

Fig.26 Timing of L3-bus addressing mode.

t

MGB507

t

handbook, full pagewidth

d1 h2

L3MODE

t

cL

t

cH

L3CLK

t

su

t

L3DATA

microcontroller

to IC

L3DATA

IC to

microcontroller

t

d2

t

d3

h1

t

h3

t

d4

Fig.27 Timing of L3-bus data transfer mode.

2000 Jun 14 24

t

t

d5

MGB508

Philips Semiconductors Preliminary specification

Digital audio broadcast channel decoder SAA3500H

t

handbook, full pagewidth

L3MODE

t

h2

L3CLK

t

L3DATA

IC to

microcontroller

d5

Fig.28 Timing of L3-bus halt mode.

14 APPLICATION INFORMATION

A suggestion for an application block diagram is shown in Fig.29.

L

t

d1

t

d2

MGB509

TUNER

BAND III/L

SAW

FILTER

AGC

MICROCONTROLLER

Fig.29 Typical application diagram.

14.1 Clock oscillator

To perform automatic fine tuning of the clock signal, the

microcontroller reads data from the SAA3500H and

controls an external (VCXO) crystal oscillator. The

following requirements should be met by that oscillator:

Table 10 VCXO specification

PARAMETER VALUE UNIT

Frequency 24576 kHz

Pull range ±50 ppm

Operating temperature −40 to +85 °C

Frequency drift with temperature ≤±20 ppm

Tolerance and ageing ≤±10 ppm

RAM

(256k × 8)

A

SAA3500H

24.576 MHz

D

DAB3

I2C or L3-BUS

SAA2502H

RDI

I2S

L/R

SPDIF

14.2 Reset input

The reset signal is active LOW and should have a

minimum duration of 60 clock cycles.

14.3 Boundary scan test interface

For normal operation set TRST LOW, TCK LOW or HIGH,

TDI and TMS not connected or HIGH. The boundary scan

chain has a length of 84 and a 5-bit instruction code.

2000 Jun 14 25

Philips Semiconductors Preliminary specification

Digital audio broadcast channel decoder SAA3500H

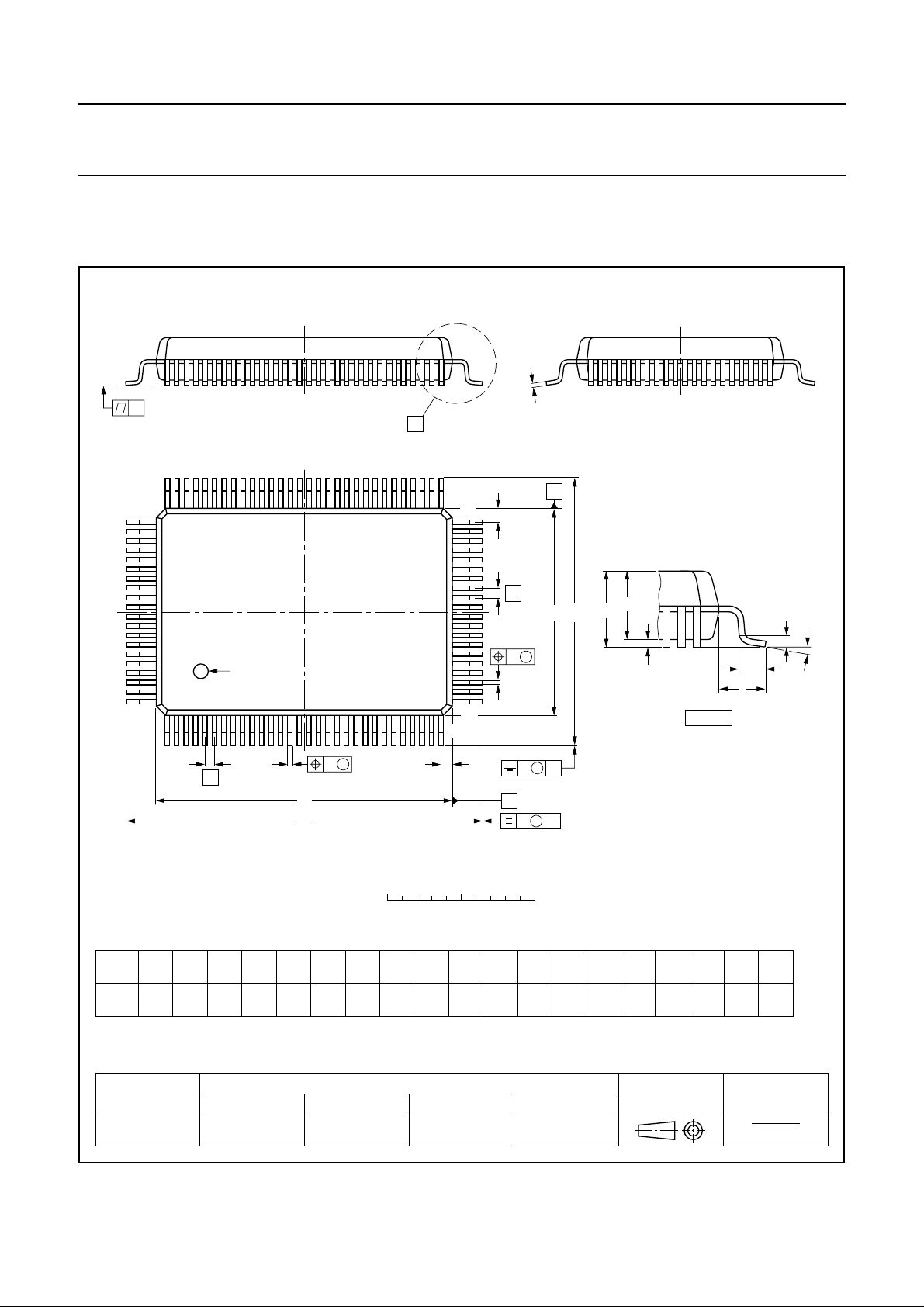

15 PACKAGE OUTLINE

QFP100: plastic quad flat package;

100 leads (lead length 1.95 mm); body 14 x 20 x 2.7 mm; high stand-off height

c

y

X

SOT317-1

80 51

81

pin 1 index

100

1

b

0.25

p

D

H

D

cE

p

0.40

0.25

0.25

0.13

e

DIMENSIONS (mm are the original dimensions)

mm

A

max.

3.3

0.36

0.10

2.87

2.57

UNIT A1A2A3b

A

50

Z

E

e

H

E

w M

b

p

31

30

w M

D

20.1

19.9

Z

D

0 5 10 mm

scale

(1)

(1) (1)(1)

eH

H

D

14.1

13.9

0.65

24.2

23.6

B

E

18.2

17.6

v M

A

v M

B

LL

1.0

0.6

p

A

2

A

E

0.151.95 0.10.2

(A )

A

1

L

detail X

Zywv θ

Z

E

D

0.8

1.0

0.4

0.6

3

θ

L

p

o

7

o

0

Note

1. Plastic or metal protrusions of 0.25 mm maximum per side are not included.

OUTLINE

VERSION

SOT317-1 MO-112

IEC JEDEC EIAJ

REFERENCES

2000 Jun 14 26

EUROPEAN

PROJECTION

ISSUE DATE

97-08-01

99-12-27

Philips Semiconductors Preliminary specification

Digital audio broadcast channel decoder SAA3500H

16 SOLDERING

16.1 Introduction to soldering surface mount

packages

Thistextgives a very brief insighttoacomplex technology.

A more in-depth account of soldering ICs can be found in

our

“Data Handbook IC26; Integrated Circuit Packages”

(document order number 9398 652 90011).

There is no soldering method that is ideal for all surface

mount IC packages. Wave soldering is not always suitable

for surface mount ICs, or for printed-circuit boards with

high population densities. In these situations reflow

soldering is often used.

16.2 Reflow soldering

Reflow soldering requires solder paste (a suspension of

fine solder particles, flux and binding agent) to be applied

tothe printed-circuit board byscreenprinting, stencilling or

pressure-syringe dispensing before package placement.

Several methods exist for reflowing; for example,

infrared/convection heating in a conveyor type oven.

Throughput times (preheating,soldering and cooling) vary

between 100 and 200 seconds depending on heating

method.

Typical reflow peak temperatures range from

215 to 250 °C. The top-surface temperature of the

packages should preferable be kept below 230 °C.

16.3 Wave soldering

Conventional single wave soldering is not recommended

forsurfacemount devices (SMDs) or printed-circuit boards

with a high component density, as solder bridging and

non-wetting can present major problems.

To overcome these problems the double-wave soldering

method was specifically developed.

• Use a double-wave soldering method comprising a

turbulent wave with high upward pressure followed by a

smooth laminar wave.

• For packages with leads on two sides and a pitch (e):

– larger than or equal to 1.27 mm, the footprint

longitudinal axis is preferred to be parallel to the

transport direction of the printed-circuit board;

– smaller than 1.27 mm, the footprint longitudinal axis

must be parallel to the transport direction of the

printed-circuit board.

The footprint must incorporate solder thieves at the

downstream end.

• Forpackageswith leads on four sides, thefootprint must

be placed at a 45° angle to the transport direction of the

printed-circuit board. The footprint must incorporate

solder thieves downstream and at the side corners.

During placement andbefore soldering, the package must

be fixed with a droplet of adhesive. The adhesive can be

applied by screen printing, pin transfer or syringe

dispensing. The package can be soldered after the

adhesive is cured.

Typical dwell time is 4 seconds at 250 °C.

A mildly-activated flux will eliminate the need for removal

of corrosive residues in most applications.

16.4 Manual soldering

Fix the component by first soldering two

diagonally-opposite end leads. Use a low voltage (24 V or

less) soldering iron applied to the flat part of the lead.

Contact time must be limited to 10 seconds at up to

300 °C.

When using a dedicated tool, all other leads can be

soldered in one operation within 2 to 5 seconds between

270 and 320 °C.

If wave soldering is used the following conditions must be

observed for optimal results:

2000 Jun 14 27

Philips Semiconductors Preliminary specification

Digital audio broadcast channel decoder SAA3500H

16.5 Suitability of surface mount IC packages for wave and reflow soldering methods

PACKAGE

WAVE REFLOW

(1)

BGA, SQFP not suitable suitable

SOLDERING METHOD

HLQFP, HSQFP, HSOP, HTSSOP, SMS not suitable

(3)

PLCC

, SO, SOJ suitable suitable

LQFP, QFP, TQFP not recommended

SSOP, TSSOP, VSO not recommended

(2)

(3)(4)

(5)

suitable

suitable

suitable

Notes

1. All surface mount (SMD) packages are moisture sensitive. Depending upon the moisture content, the maximum

temperature (with respect to time) and body size of the package, there is a risk that internal or external package

cracks may occur due to vaporization of the moisture in them (the so called popcorn effect). For details, refer to the

Drypack information in the

“Data Handbook IC26; Integrated Circuit Packages; Section: Packing Methods”

.

2. These packages are not suitable for wave soldering as a solder joint between the printed-circuit board and heatsink

(at bottom version) can not be achieved, and as solder may stick to the heatsink (on top version).

3. If wave soldering is considered, then the package must be placed at a 45° angle to the solder wave direction.

The package footprint must incorporate solder thieves downstream and at the side corners.

4. Wave soldering is only suitable for LQFP, TQFP and QFP packages with a pitch (e) equal to or larger than 0.8 mm;

it is definitely not suitable for packages with a pitch (e) equal to or smaller than 0.65 mm.

5. Wave soldering is only suitable for SSOP and TSSOP packages with a pitch (e) equal to or larger than 0.65 mm; it is

definitely not suitable for packages with a pitch (e) equal to or smaller than 0.5 mm.

2000 Jun 14 28

Philips Semiconductors Preliminary specification

Digital audio broadcast channel decoder SAA3500H

17 DATA SHEET STATUS

DATA SHEET STATUS

PRODUCT

STATUS

DEFINITIONS

(1)

Objective specification Development This data sheet contains the design target or goal specifications for

product development. Specification may change in any manner without

notice.

Preliminary specification Qualification This data sheet contains preliminary data, and supplementary data will be

published at a later date. Philips Semiconductors reserves the right to

make changes at any time without notice in order to improve design and

supply the best possible product.

Product specification Production This data sheet contains final specifications. Philips Semiconductors

reserves the right to make changes at any time without notice in order to

improve design and supply the best possible product.

Note

1. Please consult the most recently issued data sheet before initiating or completing a design.

18 DEFINITIONS

Short-form specification The data in a short-form

specification is extracted from a full data sheet with the

same type number and title. For detailed information see

the relevant data sheet or data handbook.

Limiting values definition Limiting values given are in

accordance with the Absolute Maximum Rating System

(IEC 60134). Stress above one or more of the limiting

values may cause permanent damage to the device.

These are stress ratings only and operation of the device

atthese or at any otherconditionsabovethose given in the

Characteristics sections of the specification is not implied.

Exposure to limiting values for extended periods may

affect device reliability.

Application information Applications that are

described herein for any of these products are for

illustrative purposes only. Philips Semiconductors make

norepresentationorwarranty that such applications will be

suitable for the specified use without further testing or

modification.

19 DISCLAIMERS Life support applications These products are not

designed for use in life support appliances, devices, or

systems where malfunction of these products can

reasonably be expected to result in personal injury. Philips

Semiconductorscustomersusingorselling these products

for use in such applications do so at their own risk and

agree to fully indemnify Philips Semiconductors for any

damages resulting from such application.

Right to make changes Philips Semiconductors

reserves the right to make changes, without notice, in the

products, including circuits, standard cells, and/or

software, described or contained herein in order to

improve design and/or performance. Philips

Semiconductors assumes no responsibility or liability for

theuseof any of these products, conveysnolicenceortitle

under any patent, copyright, or mask work right to these

products,and makes no representations orwarrantiesthat

these products are free from patent, copyright, or mask

work right infringement, unless otherwise specified.

2

20 PURCHASE OF PHILIPS I

Purchase of Philips I

C COMPONENTS

2

C components conveys a license under the Philips’ I2C patent to use the

components in the I2C system provided the system conforms to the I2C specification defined by

Philips. This specification can be ordered using the code 9398 393 40011.

2000 Jun 14 29

Philips Semiconductors Preliminary specification

Digital audio broadcast channel decoder SAA3500H

NOTES

2000 Jun 14 30

Philips Semiconductors Preliminary specification

Digital audio broadcast channel decoder SAA3500H

NOTES

2000 Jun 14 31

Philips Semiconductors – a w orldwide compan y

Argentina: see South America

Australia: 3 Figtree Drive, HOMEBUSH, NSW 2140,

Tel. +61 2 9704 8141, Fax. +61 2 9704 8139

Austria: Computerstr. 6, A-1101 WIEN, P.O. Box 213,

Tel. +43 1 60 101 1248, Fax. +43 1 60 101 1210

Belarus: Hotel Minsk Business Center, Bld. 3, r. 1211, Volodarski Str. 6,

220050 MINSK, Tel. +375 172 20 0733, Fax. +375 172 20 0773

Belgium: see The Netherlands

Brazil: see South America

Bulgaria: Philips Bulgaria Ltd., Energoproject, 15th floor,

51 James Bourchier Blvd., 1407 SOFIA,

Tel. +359 2 68 9211, Fax. +359 2 68 9102

Canada: PHILIPS SEMICONDUCTORS/COMPONENTS,

Tel. +1 800 234 7381, Fax. +1 800 943 0087

China/Hong Kong: 501 Hong Kong Industrial Technology Centre,

72 Tat Chee Avenue, Kowloon Tong, HONG KONG,

Tel. +852 2319 7888, Fax. +852 2319 7700

Colombia: see South America

Czech Republic: see Austria

Denmark: Sydhavnsgade 23, 1780 COPENHAGEN V,

Tel. +45 33 29 3333, Fax. +45 33 29 3905

Finland: Sinikalliontie 3, FIN-02630 ESPOO,

Tel. +358 9 615 800, Fax. +358 9 6158 0920

France: 51 Rue Carnot, BP317, 92156 SURESNES Cedex,

Tel. +33 1 4099 6161, Fax. +33 1 4099 6427

Germany: Hammerbrookstraße 69, D-20097 HAMBURG,

Tel. +49 40 2353 60, Fax. +49 40 2353 6300

Hungary: see Austria

India: Philips INDIA Ltd, Band Box Building, 2nd floor,

254-D, Dr. Annie Besant Road, Worli, MUMBAI 400 025,

Tel. +91 22 493 8541, Fax. +91 22 493 0966

Indonesia: PT Philips DevelopmentCorporation, Semiconductors Division,

Gedung Philips, Jl. Buncit Raya Kav.99-100, JAKARTA 12510,

Tel. +62 21 794 0040 ext. 2501, Fax. +62 21 794 0080

Ireland: Newstead, Clonskeagh, DUBLIN 14,

Tel. +353 1 7640 000, Fax. +353 1 7640 200

Israel: RAPAC Electronics, 7 Kehilat Saloniki St, PO Box 18053,

TEL AVIV 61180, Tel. +972 3 645 0444, Fax. +972 3 649 1007

Italy: PHILIPS SEMICONDUCTORS, Via Casati, 23 - 20052 MONZA (MI),

Tel. +39 039 203 6838, Fax +39 039 203 6800

Japan: Philips Bldg 13-37, Kohnan 2-chome, Minato-ku,

TOKYO 108-8507, Tel. +81 3 3740 5130, Fax. +81 3 3740 5057

Korea: Philips House, 260-199 Itaewon-dong, Yongsan-ku, SEOUL,

Tel. +82 2 709 1412, Fax. +82 2 709 1415

Malaysia: No. 76 Jalan Universiti, 46200 PETALING JAYA, SELANGOR,

Tel. +60 3 750 5214, Fax. +60 3 757 4880

Mexico: 5900 Gateway East, Suite 200, EL PASO, TEXAS 79905,

Tel. +9-5 800 234 7381, Fax +9-5 800 943 0087

Middle East: see Italy

Netherlands: Postbus 90050, 5600 PB EINDHOVEN, Bldg. VB,

Tel. +31 40 27 82785, Fax. +31 40 27 88399

New Zealand: 2 Wagener Place, C.P.O. Box 1041, AUCKLAND,

Tel. +64 9 849 4160, Fax. +64 9 849 7811

Norway: Box 1, Manglerud 0612, OSLO,

Tel. +47 22 74 8000, Fax. +47 22 74 8341

Pakistan: see Singapore

Philippines: Philips Semiconductors Philippines Inc.,

106 Valero St. Salcedo Village, P.O. Box 2108 MCC, MAKATI,

Metro MANILA, Tel. +63 2 816 6380, Fax. +63 2 817 3474

Poland: Al.Jerozolimskie 195 B, 02-222 WARSAW,

Tel. +48 22 5710 000, Fax. +48 22 5710 001

Portugal: see Spain

Romania: see Italy

Russia: Philips Russia, Ul. Usatcheva 35A, 119048 MOSCOW,

Tel. +7 095 755 6918, Fax. +7 095 755 6919

Singapore: Lorong 1, Toa Payoh, SINGAPORE 319762,

Tel. +65 350 2538, Fax. +65 251 6500

Slovakia: see Austria

Slovenia: see Italy

South Africa: S.A. PHILIPS Pty Ltd., 195-215 Main Road Martindale,

2092 JOHANNESBURG, P.O. Box 58088 Newville 2114,

Tel. +27 11 471 5401, Fax. +27 11 471 5398

South America: Al. Vicente Pinzon, 173, 6th floor,

04547-130 SÃO PAULO, SP, Brazil,

Tel. +55 11 821 2333, Fax. +55 11 821 2382

Spain: Balmes 22, 08007 BARCELONA,

Tel. +34 93 301 6312, Fax. +34 93 301 4107

Sweden: Kottbygatan 7, Akalla, S-16485 STOCKHOLM,

Tel. +46 8 5985 2000, Fax. +46 8 5985 2745

Switzerland: Allmendstrasse 140, CH-8027 ZÜRICH,

Tel. +41 1 488 2741 Fax. +41 1 488 3263

Taiwan: Philips Semiconductors, 6F, No. 96, Chien Kuo N. Rd., Sec. 1,

TAIPEI, Taiwan Tel. +886 2 2134 2886, Fax. +886 2 2134 2874

Thailand: PHILIPS ELECTRONICS (THAILAND) Ltd.,

209/2 Sanpavuth-Bangna Road Prakanong, BANGKOK 10260,

Tel. +66 2 745 4090, Fax. +66 2 398 0793

Turkey: Yukari Dudullu, Org. San. Blg., 2.Cad. Nr. 28 81260 Umraniye,

ISTANBUL, Tel. +90 216 522 1500, Fax. +90 216 522 1813

Ukraine: PHILIPS UKRAINE, 4 Patrice Lumumba str., Building B, Floor 7,

252042 KIEV, Tel. +380 44 264 2776, Fax. +380 44 268 0461

United Kingdom: Philips Semiconductors Ltd., 276 Bath Road, Hayes,

MIDDLESEX UB3 5BX, Tel. +44 208 730 5000, Fax. +44 208 754 8421

United States: 811 East Arques Avenue, SUNNYVALE, CA 94088-3409,

Tel. +1 800 234 7381, Fax. +1 800 943 0087

Uruguay: see South America

Vietnam: see Singapore

Yugoslavia: PHILIPS, Trg N. Pasica 5/v, 11000 BEOGRAD,

Tel. +381 11 3341 299, Fax.+381 11 3342 553

For all other countries apply to: Philips Semiconductors,

International Marketing & Sales Communications, Building BE-p, P.O. Box 218,

5600 MD EINDHOVEN, The Netherlands, Fax. +31 40 27 24825

© Philips Electronics N.V. SCA

All rights are reserved. Reproduction in whole or in part is prohibited without the prior written consent of the copyright owner.

The information presented in this document does not form part of any quotation or contract, is believed to be accurate and reliable and may be changed

without notice. No liability will be accepted by the publisher for any consequence of its use. Publication thereof does not convey nor imply any license

under patent- or other industrial or intellectual property rights.

2000

Internet: http://www.semiconductors.philips.com

69

Printed in The Netherlands 753503/01/pp32 Date of release: 2000 Jun 14 Document order number: 9397 750 07187

Loading...

Loading...