Philips SA5778 Datasheet

INTEGRATED CIRCUITS

SA5778

Serial triple gauge driver (STGD)

Product specification

Supersedes data of 1997 May 27

IC18 Data Handbook

1998 Apr 03

Philips Semiconductors Product specification

SA5778Serial triple gauge driver (STGD)

DESCRIPTION

The Serial Triple Gauge Driver (STGD), is a single chip air core

driver providing drive to one major gauge, and two minor gauges, for

automotive applications such as Speedometer, Fuel, Temperature,

Tachometer, Volts, and Oil pressure information display. The STGD

operates in conjunction with a microcontroller receiving serial data

inputs, and can provide status back to the microcontroller either

serially or via a status line. The protocol is compatible with the

Philips Single Gauge Driver (SGD) and Dual Gauge Driver (DGD).

The STGD also includes a protected battery supply for external

single Serial Gauge Drivers or Dual Gauge Drivers.

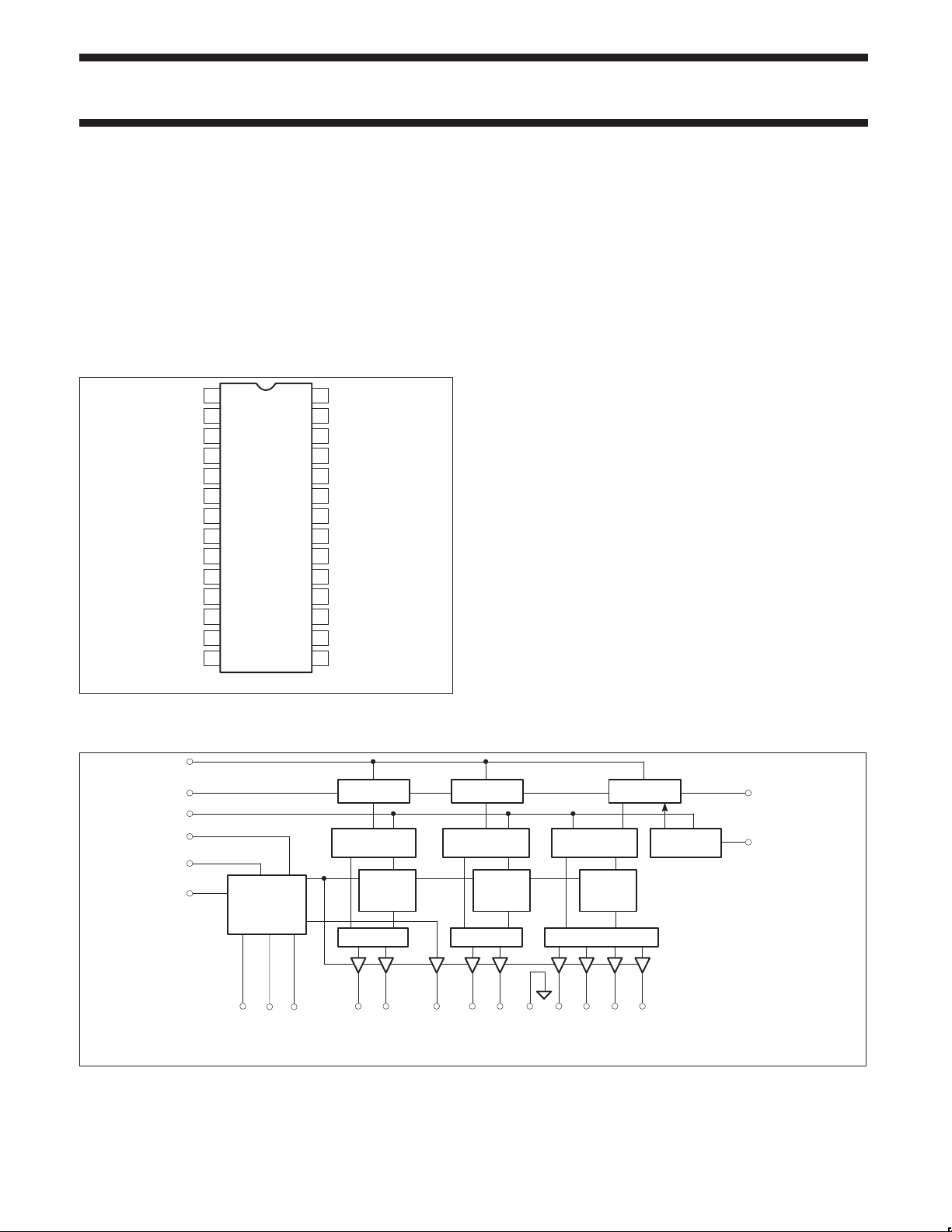

PIN CONFIGURATION

SIN+

1

RUN

2

GOE

3

SwCONTROL

SwBATT1

SwBATT2

DATA

4

5

GND GND

6

GND

7

GND GND

821

GND GND

9

V

10

BATT

11

12

OUT

COM

13

C2–

14

SIN–

28

COS+

27

26

COS–

ST

25

24

S

CLK

23

GND

22

20

CS

19

DATA

18

IN

C1–

17

C1+

16

C2+

15

FEATURES

•Major Gauge 10-bit resolution Drive provides 0.35° resolution

– Sine/Cosine outputs for 360° operation

– 0.2° accuracy typical throughout entire range

•Minor gauge drivers provide 0.35° resolution

– 112° operation

– 0.5° accuracy typical throughout entire range

•Serial Data Input

– Supports interface from microcontrollers

– Compatible with Philips SGD SA5775A and DGD SA5777A

•Serial Data Output

– Permits the STGD to be wired in series using a common chip

select to additional STGDs, SGDs, and DGDs

– Permits fault status information to be returned to the

microcontroller

•Over Voltage Protection, Over Temperature Protection and Low

Standby Current Operation

– Gauge drivers disabled when supply voltage exceeds specified

operating voltage, protection to 40V .

– Gauge drivers disabled when die temperature exceeds

operating range

– External switch may supply overvoltage protected battery

supply to other devices operating off battery

•Thermally Enhanced SO-28 surface mount package

Figure 1. Pin Configuration

BLOCK DIAGRAM

S

CLK

DATA

IN

CS

GOE

RUN

V

BATT

BIAS, TSD

SwBATT,

COMMON

REFERENCE

SwBATT1

SwControl

SR01116

MINOR GAUGE 2

10-BIT SR 10-BIT SR 10-BIT SR

9-BIT DATA

ENABLE

SwBATT2

MINOR GAUGE 1 MAJOR GAUGE

LATCH

7-BIT

MUX

C2–

Tan

DAC

C2+

9-BIT DATA

LATCH

7-BIT

Tan

DAC

MUX MUX

C1–

COM

C1+

GND

10-BIT DATA

LATCH

COS–

Figure 2. STGD Internal Block Diagram

7–BIT, SINE

/COSINE

DAC

SIN–

COS+

4-BIT STATUS

LATCH

SIN+

DATA

ST

OUT

SR01117

1998 Apr 03 853–2055 19199

2

Philips Semiconductors Product specification

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

SA5778Serial triple gauge driver (STGD)

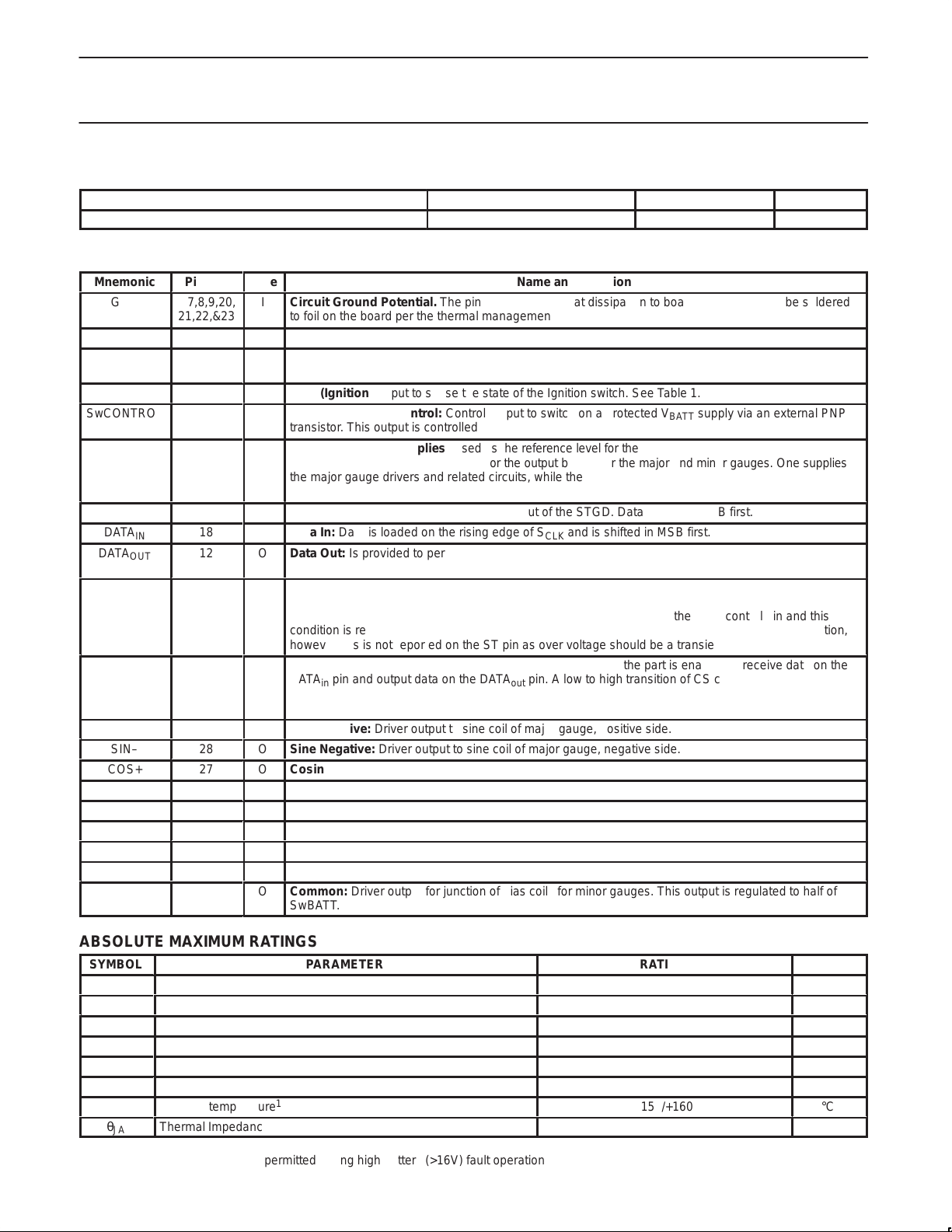

ORDERING INFORMATION

DESCRIPTION TEMPERATURE RANGE ORDER CODE DWG #

28-Pin Small Outline (SO) thermally enhanced Package –40 to +105°C SA5778D SOT136-1

PIN DESCRIPTION

Mnemonic

GND

V

BATT

GOE

ÁÁÁ

RUN

SwCONTROL

ÁÁÁ

SwBATT1

SwBATT2

ÁÁÁ

ÁÁÁ

S

CLK

DATA

IN

DATA

OUT

ÁÁÁ

ST

ÁÁÁ

ÁÁÁ

CS

ÁÁÁ

ÁÁÁ

SIN+

SIN–

COS+

COS–

C1+

C1–

C2+

C2–

COM

ÁÁÁ

Pin No.

6,7,8,9,20,

21,22,&23

10

3

ÁÁ

2

4

ÁÁ

5,

11

ÁÁ

ÁÁ

24

18

12

ÁÁ

25

ÁÁ

ÁÁ

19

ÁÁ

ÁÁ

1

28

27

26

16

17

15

14

13

ÁÁ

Type

I

Circuit Ground Potential. The pins are used for heat dissipation to board. All pins should be soldered

Name and Function

to foil on the board per the thermal management description.

I

Battery supply voltage

I

Gauge Output Enable: A high on this input enables normal operation of the gauge coil drivers.

See Table 1.

ББББББББББББББББББББББББ

I

RUN (Ignition): Input to sense the state of the Ignition switch. See Table 1.

O

Switched Battery Control: Control output to switch on a protected V

ББББББББББББББББББББББББ

transistor. This output is controlled by the RUN input, GOE input and the on chip protection circuits.

I

Switched Battery Supplies: Used as the reference level for the DACs, bias voltage for the second coils

I

of the minor gauges, and the supply for the output buffers for the major and minor gauges. One supplies

ББББББББББББББББББББББББ

the major gauge drivers and related circuits, while the other supplies the minor gauge circuits. Both

SwBATT inputs must be connected to the control transistor as the two inputs are not connected internally.

ББББББББББББББББББББББББ

I

Serial Clock: Used to clock data into and out of the STGD. Data is shifted MSB first.

I

Data In: Data is loaded on the rising edge of S

O

Data Out: Is provided to permit the STGD to pass status information back to the controlling

microcontroller, and to allow multiple devices to be connected in series.

ББББББББББББББББББББББББ

O

Status Output: This is an open drain output. Status outputs from several devices may be wire OR’ed

and is shifted in MSB first.

CLK

supply via an external PNP

BATT

together. This output is low when the outputs are disabled due to a fault condition. The outputs may be

disabled due to shorted outputs, over temperature, power up reset, or the GOE control pin and this

ББББББББББББББББББББББББ

condition is reflected on the ST pin. The outputs will also be disabled due to an over voltage condition,

ББББББББББББББББББББББББ

however this is not reported on the ST pin as over voltage should be a transient condition.

I

Chip Select: Active high chip select input. When CS is high, the part is enabled to receive data on the

pin and output data on the DATA

DATA

in

ББББББББББББББББББББББББ

the shift register for output. A high to low transition of CS loads gauge data from the shift register into

the data latches.

ББББББББББББББББББББББББ

O

Sine Positive: Driver output to sine coil of major gauge, positive side.

O

Sine Negative: Driver output to sine coil of major gauge, negative side.

O

Cosine Positive: Driver output to cosine coil of major gauge, positive side.

O

Cosine Negative: Driver output to cosine coil of major gauge, negative side.

O

Coil 1 Positive: Driver output to driven coil of minor gauge 1, positive side.

O

Coil 1 Negative: Driver output to driven coil of minor gauge 1, negative side.

O

Coil 2 Positive: Driver output to driven coil of minor gauge 2, positive side.

O

Coil 2 Negative: Driver output to driven coil of minor gauge 2, negative side.

O

Common: Driver output for junction of bias coils for minor gauges. This output is regulated to half of

ББББББББББББББББББББББББ

SwBATT.

pin. A low to high transition of CS captures device status in

out

ABSOLUTE MAXIMUM RATINGS

SYMBOL

V

VIN1

VIN2

VIN3

T

BATT

P

amb

T

θ

Battery supply voltage, with recommended 1K series resistor

Input voltage; Data In, CS, SCLK, GOE

Input voltage; Sw

BATT

Input voltage; RUN, with recommended RC Circuit

Power Dissipation (T

D

Ambient operating temperature

Junction temperature

J

Thermal Impedance

JA

NOTE:

1. 160°C junction temperature is permitted during high battery (>16V) fault operation

1998 Apr 03

PARAMETER

= 105°C) SO-28 Package

amb

1

3

RATING

40

–1 to +7

–1 to +24

–1 to +40

1400

–40 to +105

+150/+160

See Thermal Management Section

UNIT

V

V

V

V

mw

°C

°C

°C/W

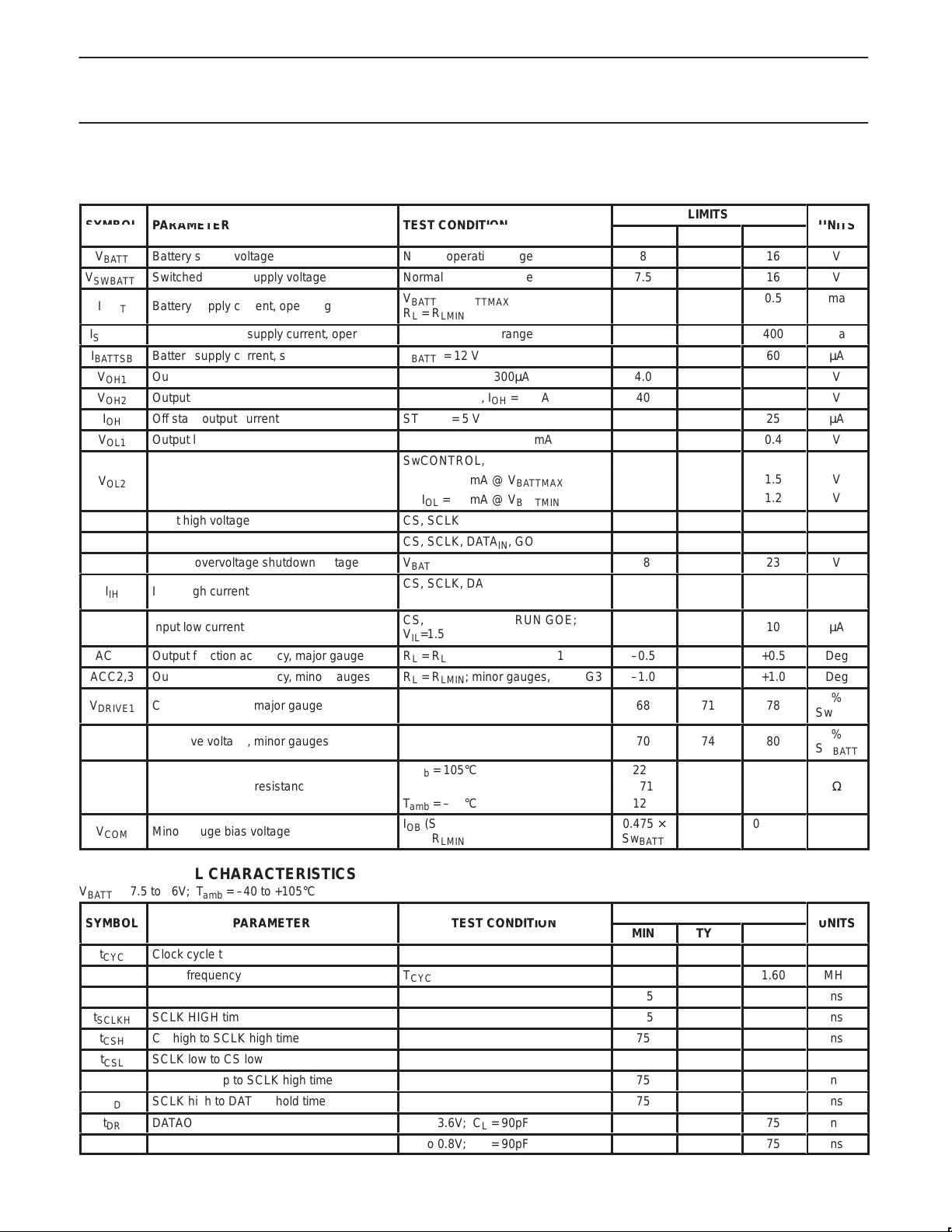

Philips Semiconductors Product specification

SYMBOL

PARAMETER

TEST CONDITION

UNITS

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

SYMBOL

PARAMETER

TEST CONDITION

UNITS

SA5778Serial triple gauge driver (STGD)

DC ELECTRICAL CHARACTERISTICS

V

= 8.0 to 16V; T

BATT

V

BATT

V

SWBATT

I

BATT

I

SWBATT

I

BATTSB

V

OH1

V

OH2

I

OH

V

OL1

V

OL2

V

IH

V

IL

V

OVSD

I

ÁÁ

IH

I

IL

ÁÁ

ACC1

ACC2,3

V

DRIVE1

ÁÁ

V

DRIVE2,3

R

LMIN

V

COM

Battery supply voltage

Switched battery supply voltage

Battery supply current, operating

Switched battery supply current, operating

Battery supply current, standby

Output high voltage

Output high voltage

Off state output current

Output low voltage

Output low voltage

Input high voltage

Input low voltage

Battery overvoltage shutdown voltage

Input high current

БББББББББ

Input low current

БББББББББ

Output function accuracy, major gauge

Output function accuracy, minor gauges

Coil drive voltage, major gauge

БББББББББ

Coil drive voltage, minor gauges

Minimum coil load resistance

Minor gauge bias voltage

= –40 to +105°C

amb

MIN

Normal operating range

Normal operating range

V

= V

BATT

RL = R

BATTMAX

LMIN

8

7.5

Normal operating range

V

= 12 V

BATT

DATA

SwCONTROL, IOH = 10µA

, IOH = 300µA

OUT

4.0

40

ST, VOH = 5 V

ST, DATA

, IOL = 1.5 mA

OUT

SwCONTROL,

IOL = 50 mA @ V

IOL = 20 mA @ V

CS, SCLK, DATAIN, GOE, RUN

BATTMAX

BATTMIN

3.5

CS, SCLK, DATAIN, GOE, RUN

V

BATT

CS, SCLK, DATAIN, RUN GOE;

ББББББББ

V

= 3.5

IH

18

ÁÁÁÁÁÁÁ

CS, SCLK, DATAIN, RUN GOE;

=1.5

V

IL

ББББББББ

RL = R

RL = R

ББББББББÁÁÁ

; major gauge, G1

LMIN

; minor gauges, G2 & G3

LMIN

ÁÁÁÁÁÁÁ

–0.5

–1.0

68

70

T

= 105°C

amb

T

= 25°C

amb

T

= –40°C

amb

IOB (Source or Sink)

R

= R

L

LMIN

226

171

127

0.475 ×

Sw

BATT

LIMITS

TYP

71

ÁÁ

74

MAX

16

16

0.5

400

60

25

0.4

1.5

1.2

1.5

23

10

10

+0.5

+1.0

78

Á

80

0.525 ×

Sw

BATT

V

V

ma

ma

µA

V

V

µA

V

V

V

V

V

V

µA

ÁÁ

µA

ÁÁ

Deg

Deg

%

ÁÁ

Sw

BATT

%

Sw

BATT

Ω

Ω

Ω

V

AC ELECTRICAL CHARACTERISTICS

V

BATT

F

t

SCLKL

t

SCLKH

1998 Apr 03

= 7.5 to 16V; T

t

CYC

SCLK

Clock cycle time

Clock frequency

SCLK LOW time

SCLK HIGH time

t

CSH

t

CSL

t

t

t

t

CS high to SCLK high time

SCLK low to CS low time

DATAIN setup to SCLK high time

SU

SCLK high to DATAIN hold time

HD

DATAOUT rise time

DR

DATAOUT fall time

DF

= –40 to +105°C

amb

T

CYC

0.8 to 3.6V; CL = 90pF

3.6 to 0.8V; CL = 90pF

4

MIN

625

175

175

75

75

75

75

LIMITS

TYP

MAX

1.60

75

75

ns

MHz

ns

ns

ns

ns

ns

ns

ns

ns

Philips Semiconductors Product specification

SA5778Serial triple gauge driver (STGD)

J1850

PROTOCOL

CONTROLLER

AU5780

J1850 VPW

TRANSCEIVER

J1850 BUS

80C51

MICRO–

CONTROLLER

ADDITIONAL GAUGE

DRIVERS; SA5775A

OR SA5777A

PROTECTED BY

SA5778

Figure 3. System Connections for the STGD

FUNCTIONAL DESCRIPTION

Figure 1 shows the pin-out of the STGD, which is packaged in an

SO-28 pin package, enhanced for improved thermal management.

Four pins on each side of the package serve as a heat spreader to

remove heat from the die, and also function as the ground

connection. The recommended mounting includes an area of copper

on the PC board to aid in thermal management.

Figure 2 is a block diagram of the STGD. A serial interface connects

the STGD to the microcontroller. A data output pin is provided to

permit the STGD to be wired in series with other Philips air core

gauge drivers such as the Serial Gauge Driver, SA5775, and the

Dual Gauge Driver, SA5777 or additional STGDs. Status information

may be passed back to the microcontroller via a status output, or via

the serial interface.

Figure 3 shows the connection of the STGD in a typical application.

GOE

SERIAL

SA5778

SERIAL

TRIPLE

GAUGE

DRIVER

MICROCONTROLLER

DATA

PORT N

DATA

5V

S

OUT

CLK

INT

4

2

2

V

IN

RUN

IGNITION

BATT

360° MAJOR

GAUGE

112° MINOR

GAUGE

SR01118

DATA

IN

S

CLK

CS

DATA

OUT

ST

DATA

IN

S

CLK

CS

DATA

OUT

ST

SA5778 SERIAL

TRIPLE

GAUGE DRIVER

ADDITIONAL

GAUGE DRIVER(S),

SA5775A,

SA5777A OR

SA5778

APPLICATION INFORMATION

Figure 4 demonstrates the connections between the STGD, the

microcontroller, and optionally additional gauge drivers such as the

SGD and DGD. With an active high on the chip select input (CS),

data is shifted into the STGD through DATA

. Several gauge drivers may be wired in series using a

S

CLK

common chip select and clock line, when more than three gauges

are needed. The DATA

pins are cascaded to the DATAIN pins of

OUT

the following gauge drivers. Status information can be returned to

the microcontroller via the ST pins of each gauge driver. These are

open-drain, active low outputs, which may be wire OR’ed together to

signal that a fault, such as a thermal shut down, has occurred within

one of the gauge drivers. This pin may be connected to a

microcontroller port pin for polling in software, or may be connected

to an external interrupt input to cause entry into an interrupt service

routine. The STGD, may also pass status information back to the

microcontroller serially. The rising edge of chip select loads status

information into the shift register for the first four bits that will be

shifted out of the STGD by the shift clock. Figure 11 shows the data

bits within the shift register. A low on the ST pin signals that one or

more status bits have been set in the status register. A high

indicates all status bits are reset. The status output bits include

minor gauge over current, major gauge over current, thermal

shutdown and RUN. Gauge data is captured in latches by the falling

edge of the chip select.

on the rising edge of

IN

SR01119

Figure 4. Serial Communications Between STGD,

Microcontroller and Other Gauge Drivers

Figure 5 shows the gauge connections to the STGD. The major

gauge, G1, supports full 360° operation with two coils driven. The

seven least significant bits of the gauge information are converted to

an analog level by digital-to-analog converter. The display range is

divided into eight sections, two sections per quadrant. The coils are

driven with a Sine/Cosine approximation. The three most significant

bits of gauge display information control the multiplexer to select

which coil is fed by the DAC and which coil receives a fixed bias.

The multiplexer also determines the polarity of the voltages supplied

to the coils.

The minor gauges, G2 and G3, each have one coil driven by a DAC.

The other coils of each gauge are wired in series with the switched

battery supply to supply the bias. The switched battery supply is

turned off during over voltage conditions. Only 9-bits of information

are required for the minor gauges, however, 10-bits are shifted

through the part to maintain compatibility with the SGD and DGD.

Hence, all gauges, both major and minor, are supplied with 10-bit

data for consistency.

1998 Apr 03

5

Loading...

Loading...