Page 1

1. Description

2. Features

SA5211

Transimpedance amplifier (180 MHz)

Rev. 03 — 07 October 1998 Product specification

The SA5211 is a 28 kΩ transimpedance, wide-band, low noise amplifier with

differential outputs, particularly suitable for signal recovery in fiber optic receivers.

The part is ideally suited for many other RF applications as a general purpose gain

block.

■ Extremely low noise: 1.8 pA / √Hz

■ Single 5 V supply

■ Large bandwidth: 180 MHz

■ Differential outputs

■ Low input/output impedances

■ High power supply rejection ratio

■ 28 kΩ differential transresistance

3. Applications

c

c

■ Fiber optic receivers, analog and digital

■ Current-to-voltage converters

■ Wide-band gain block

■ Medical and scientific Instrumentation

■ Sensor preamplifiers

■ Single-ended to differential conversion

■ Low noise RF amplifiers

■ RF signal processing

Page 2

Philips Semiconductors

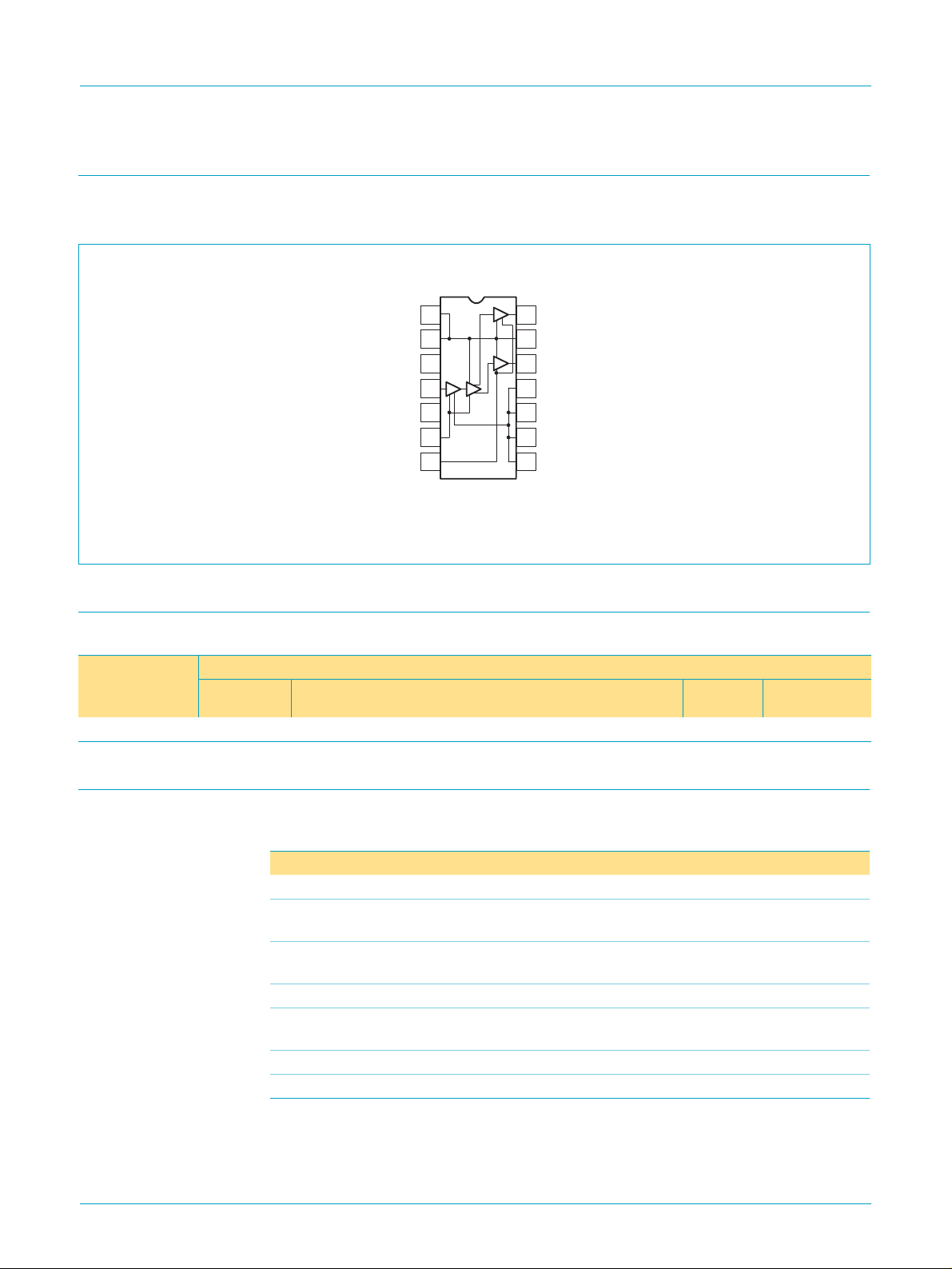

4. Pinning information

4.1 Pinning

SA5211

Transimpedance amplifier (180 MHz)

D Package

1

GND

2

2

GND

2

3

NC

4

I

IN

5

NC

6

V

CC1

78

V

CC2

TOP VIEW

14

OUT (–)

13

GND

12

OUT (+)

11

GND

10

GND

9

GND

GND

SD00318

2

1

1

1

1

Fig 1. Pin configuration.

5. Ordering information

Table 1: Ordering information

Type number Package

Name Description Version Temperature

range (°C)

SA5211D SO14 plastic small outline package; 14 leads; body width 3.9 mm SOT108-1 −40 to +85

6. Limiting values

Table 2: Limiting values

In accordance with the Absolute Maximum Rating System (IEC 60134).

Symbol Parameter Conditions Min Max Unit

V

CC

T

amb

power supply − 6V

operating ambient

-40 +85 °C

temperature range

T

J

operating junction

-55 +150 °C

temperature range

T

STG

P

D MAX

I

IN MAX

θ

JA

[1] Maximum dissipation is determined by the operating ambient temperature and the thermal resistance:

[2] The use of a pull-up resistor to V

9397 750 07427

Product specification Rev. 03 — 07 October 1998 2 of 28

storage temperature range -65 +150 °C

power dissipation, TA=25°C

(still-air)

maximum input current

[1]

[2]

− 1.0 W

− 5mA

thermal resistance − 125 °C/W

θJA= 125 °C/W

, for the PIN diode is recommended.

CC

© Philips Electronics N.V. 2001. All rights reserved.

Page 3

Philips Semiconductors

SA5211

Transimpedance amplifier (180 MHz)

Table 3: Recommended operating conditions

Symbol Parameter Conditions Min Max Unit

V

CC

T

amb

T

J

supply voltage 4.5 5.5 V

ambient temperature range -40 +85 °C

junction temperature range -40 +105 °C

7. Static characteristics

Table 4: DC electrical characteristics

Min and Max limits apply over operating temperature range at VCC= 5 V, unless otherwise specified. Typical data apply at

= 5 V and T

V

CC

Symbol Parameter Test conditions Min Typ Max Unit

V

IN

V

O±

V

OS

I

CC

I

OMAX

I

IN

I

IN MAX

=25°C.

amb

input bias voltage 0.55 0.8 1.00 V

output bias voltage 2.7 3.4 3.7 V

output offset voltage − 0 130 mV

supply current 20 26 31 mA

output sink/source current

input current

(2% linearity)

maximum input current

overload threshold

[1]

Test Circuit 8,

Procedure 2

Test Circuit 8,

Procedure 4

34− mA

±20 ±40 −µA

±30 ±60 −µA

[1] Test condition: output quiescent voltage variation is less than 100 mV for 3 mA load current.

8. Dynamic characteristics

Table 5: AC electrical characteristics

Typical data and Min and Max limits apply at VCC= 5 V and T

Symbol Parameter Test conditions Min Typ Max Unit

R

R

R

R

f

R

C

T

O

T

O

3dB

IN

IN

transresistance (differential output) DC tested RL = ∞

output resistance (differential output) DC tested − 30 −Ω

transresistance (single-ended output) DC tested

output resistance (single-ended output) DC tested − 15 −Ω

bandwidth (-3dB) TA = 25°C

input resistance − 200 −Ω

input capacitance − 4 − pF

∆R/∆V transresistance power supply sensitivity V

∆R/∆T transresistance ambient temperature sensitivity ∆T

I

N

RMS noise current spectral density (referred to

input)

I

T

integrated RMS noise current over the

bandwidth (referred to input)

=25°C

amb

21 28 36 kΩ

Test Circuit 8, Procedure 1

10.5 14 18.0 kΩ

RL = ∞

− 180 − MHz

Test circuit 1

= 5±0.5 V − 3.7 − %/V

CC

= T

amb

amb MAX-Tamb MIN

Test Circuit 2

− 0.025 − %/°C

− 1.8 − pA/√Hz

f = 10 MHz

TA = 25 °C

TA = 25 °C

−−−−

Test Circuit 2

9397 750 07427

Product specification Rev. 03 — 07 October 1998 3 of 28

© Philips Electronics N.V. 2001. All rights reserved.

Page 4

Philips Semiconductors

SA5211

Transimpedance amplifier (180 MHz)

Table 5: AC electrical characteristics

Typical data and Min and Max limits apply at VCC= 5 V and T

…continued

amb

=25°C

Symbol Parameter Test conditions Min Typ Max Unit

I

n

I

n

PSRR power supply rejection ratio

[1]

CS=0

∆f = 50 MHz

∆f = 100 MHz

∆f = 200 MHz

CS= 1pF ∆f = 50 MHz

∆f = 100 MHz

∆f = 200 MHz

(V

CC1

= V

CC2

[2]

)

DC tested, ∆V

Equivalent AC

= 0.1V

CC

−

13

−

nA

−

20

−

−

35

−

−

13

−

nA

−

21

−

−

41

−

23 32 − dB

Test Circuit 3

PSRR power supply rejection ratio

) DC tested, ∆VCC = 0.1V

CC1

23 32 − dB

[2]

(V

Equivalent AC

Test Circuit 4

PSRR power supply rejection ratio

[2]

(V

) DC tested, ∆VCC = 0.1V

CC2

45 65 − dB

Equivalent AC

Test Circuit 5

PSRR power supply rejection ratio (ECL

[2]

V

OMAX

configuration)

maximum differential output voltage swing RL = ∞

f = 0.1 MHz

Test Circuit 6

− 23 − dB

1.7 3.2 − V

Test Circuit 8, Procedure 3

V

IN MAX

t

R

maximum input amplitude for output duty cycle

of 50±5%

rise time for 50mV output signal

[3]

[4]

Test Circuit 7 160 −−mV

Test Circuit 7 − 0.8 1.8 ns

P-P

P-P

[1] Package parasitic capacitance amounts to about 0.2pF

[2] PSRR is output referenced and is circuit board layout dependent at higher frequencies. For best performance use RF filter in VCC lines.

[3] Guaranteed by linearity and overload tests.

[4] tR defined as 20 to 80% rise time. It is guaranteed by -3dB bandwidth test.

9397 750 07427

Product specification Rev. 03 — 07 October 1998 4 of 28

© Philips Electronics N.V. 2001. All rights reserved.

Page 5

Philips Semiconductors

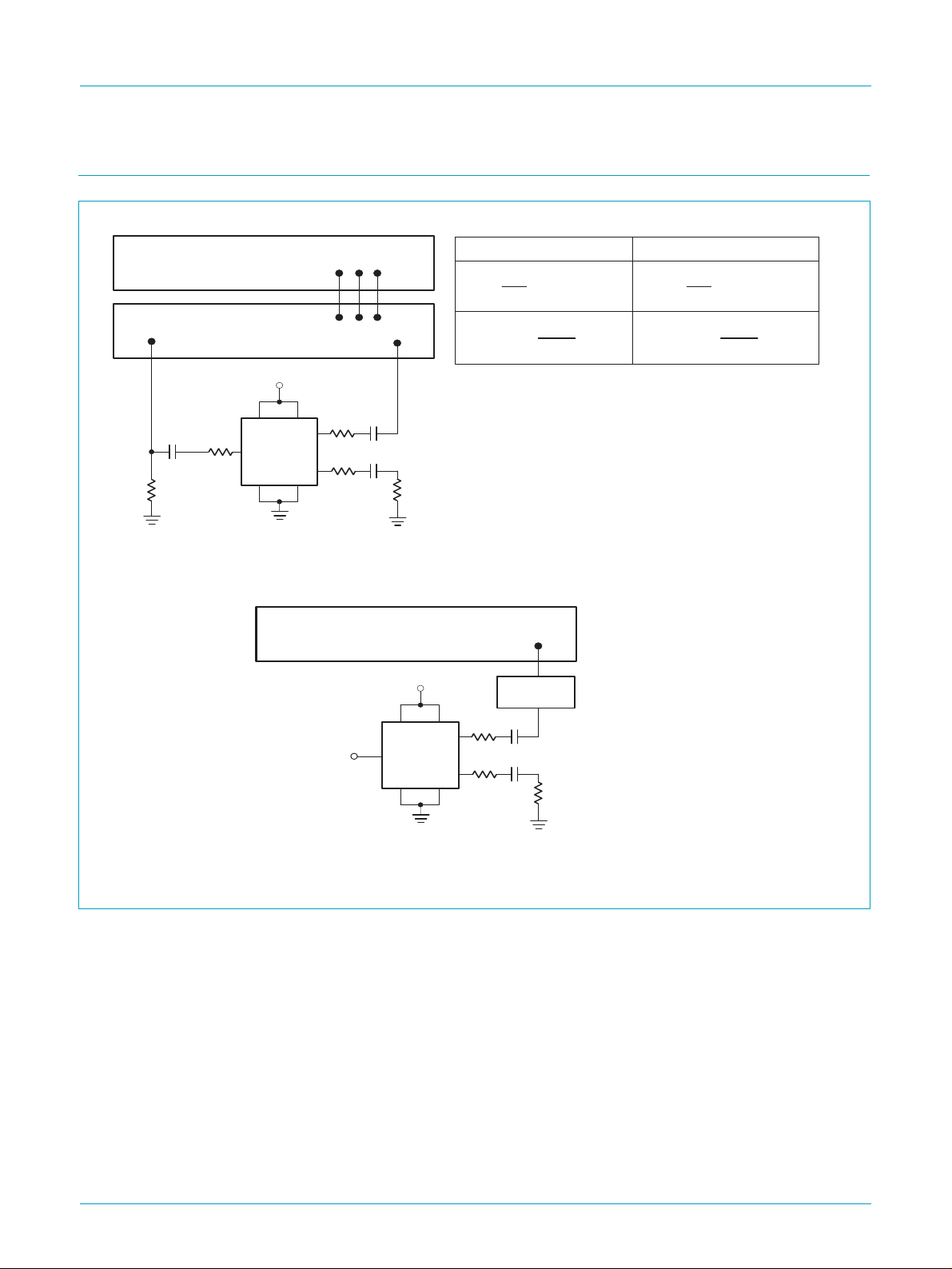

9. Test circuits

SA5211

Transimpedance amplifier (180 MHz)

ZO = 50

PORT 1

0.1µF

50

NETWORK ANALYZER

S-PARAMETER TEST SET

5V

V

R = 1k

GND

CC1

IN DUT

1

V

CC2

OUT

OUT

GND

PORT 2

0.1µF

33

0.1µF

33

2

Test Circuit 1

SPECTRUM ANALYZER

V

CC1

NC

IN DUT

GND

SINGLE-ENDED DIFFERENTIAL

V

OUT

RT

RO ≈ Z

Z

= 50

O

= 50

R

L

5V

V

CC2

33

OUT

GND

33

2

OUT

1

R = 2 × S21 × RR

≈

V

IN

1 + S22

O

1 – S22

AV = 60DB

0.1µF

0.1µF

– 33 RO = 2Z

= 50

Z

O

= 50

R

L

V

OUT

=

T

V

IN

R = 4 × S21 × R

1 + S22

O

1 – S22

– 66

Test Circuit 2

SD00319

Fig 2. Test circuits 1 and 2.

9397 750 07427

Product specification Rev. 03 — 07 October 1998 5 of 28

© Philips Electronics N.V. 2001. All rights reserved.

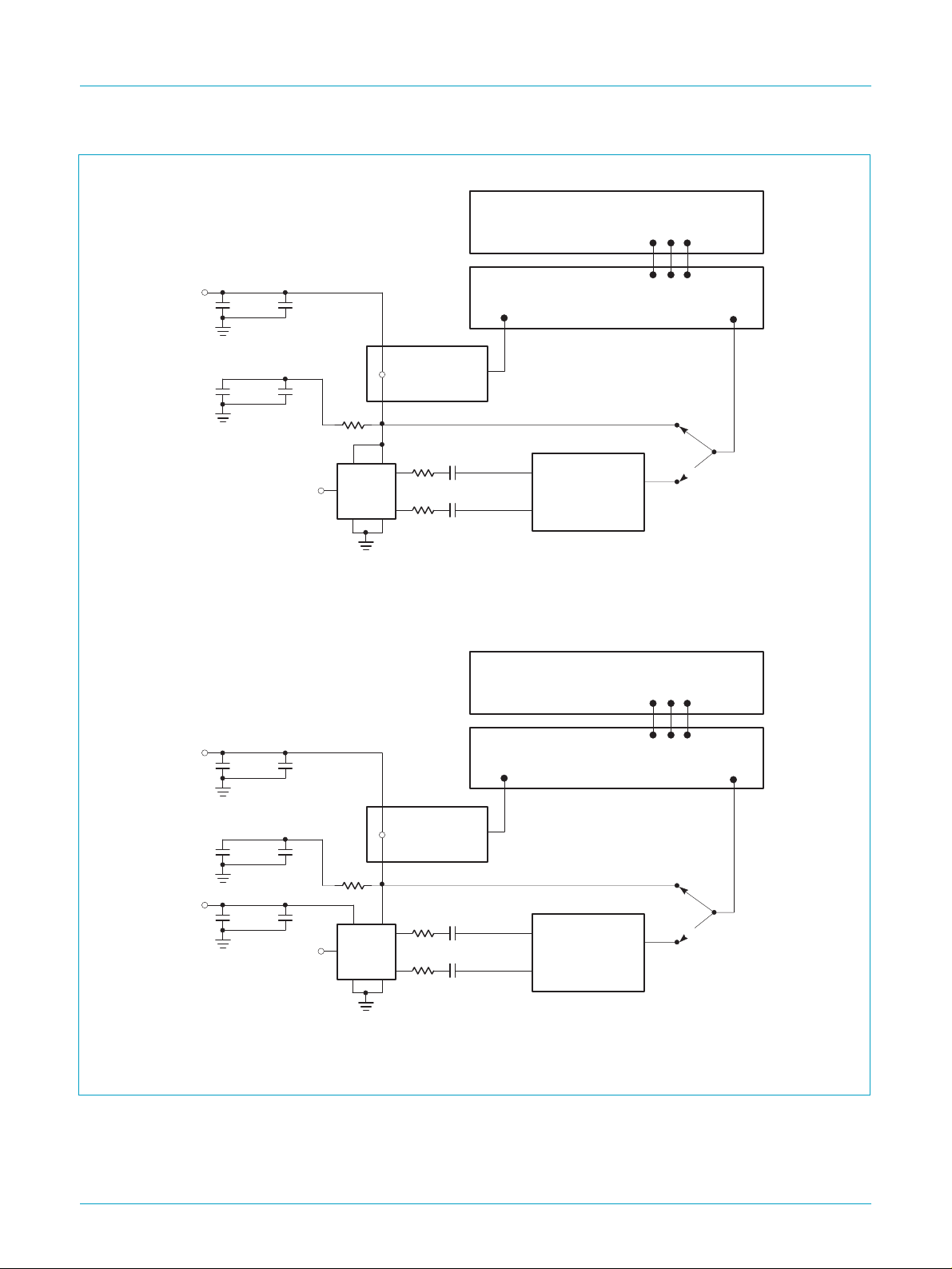

Page 6

Philips Semiconductors

SA5211

Transimpedance amplifier (180 MHz)

NETWORK ANALYZER

5V

10µF

10µF

0.1µF

0.1µF

IN

V

GND

CC1

16

1

CURRENT PROBE

1mV/mA

V

CC2

GND

33

33

2

OUT

OUT

0.1µF

0.1µF

PORT 1 PORT 2

100

BAL.

S-PARAMETER TEST SET

TRANSFORMER

NH0300HB

50

UNBAL.

CAL

TEST

Test Circuit 3

NETWORK ANALYZER

5V

10µF

0.1µF

PORT 1 PORT 2

S-PARAMETER TEST SET

CURRENT PROBE

OUT

OUT

V

GND

CC1

1mV/mA

33

33

2

Test Circuit 4

0.1µF

0.1µF

100

BAL.

TRANSFORMER

NH0300HB

50

UNBAL.

CAL

TEST

SD00320

10µF

0.1µF

5V

10µF

0.1µF

16

V

CC2

IN

GND

1

Fig 3. Test circuits 3 and 4.

9397 750 07427

Product specification Rev. 03 — 07 October 1998 6 of 28

© Philips Electronics N.V. 2001. All rights reserved.

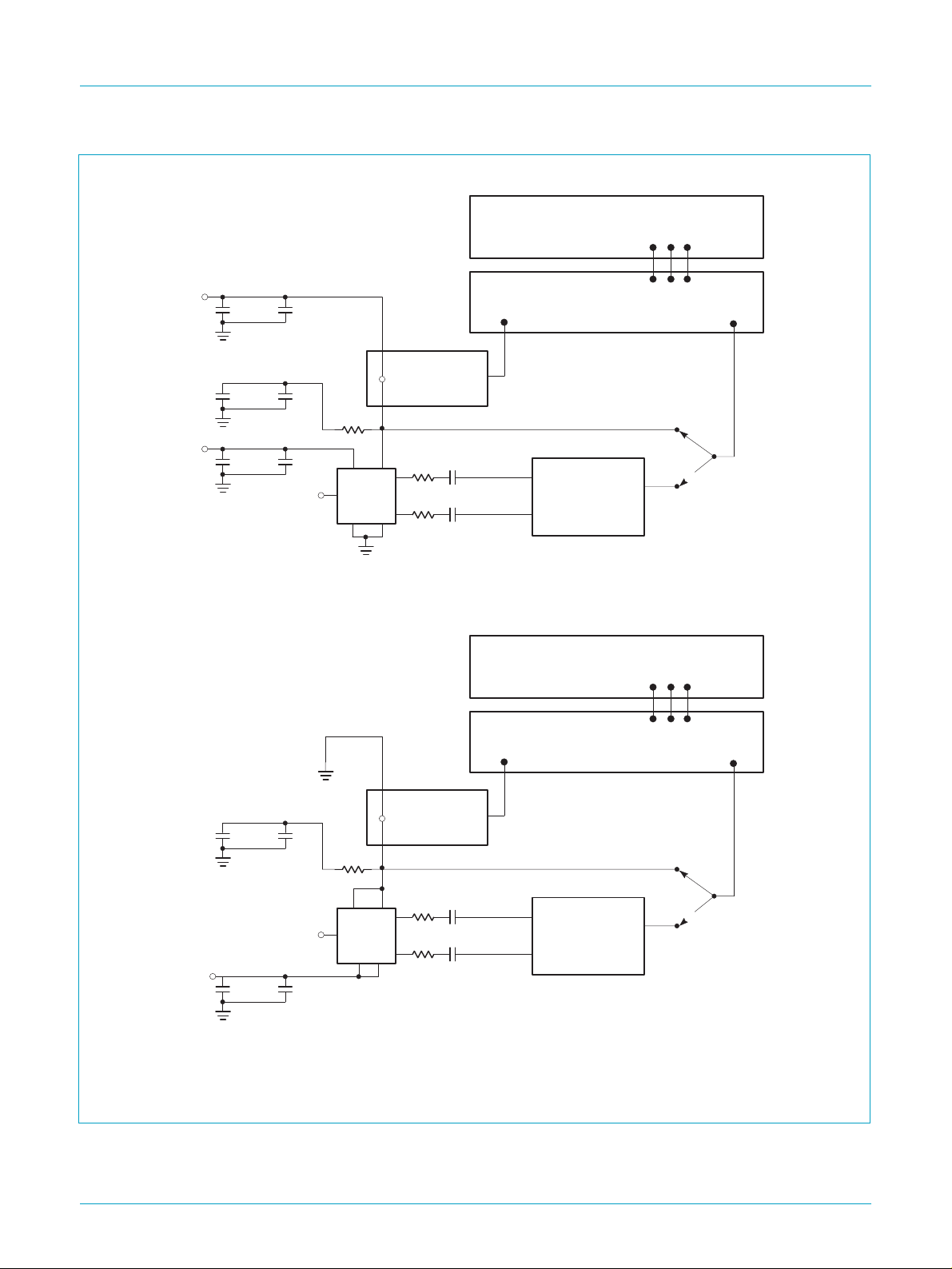

Page 7

Philips Semiconductors

SA5211

Transimpedance amplifier (180 MHz)

NETWORK ANALYZER

5V

5V

10µF

10µF

10µF

0.1µF

0.1µF

0.1µF

IN

V

GND

CC1

PORT 1 PORT 2

CURRENT PROBE

1mV/mA

16

V

CC2

OUT

OUT

1

GND

0.1µF

33

100

33

0.1µF

2

BAL.

S-PARAMETER TEST SET

TRANSFORMER

NH0300HB

50

UNBAL.

CAL

TEST

Test Circuit 5

NETWORK ANALYZER

S-PARAMETER TEST SET

GND

PORT 1 PORT 2

CURRENT PROBE

OUT

OUT

V

GND

CC2

1mV/mA

2

0.1µF

33

33

Test Circuit 6

0.1µF

100

BAL.

TRANSFORMER

NH0300HB

50

UNBAL.

CAL

TEST

SD00321

5.2V

10µF

10µF

0.1µF

0.1µF

16

GND

1

IN

V

CC1

Fig 4. Test circuits 5 and 6.

9397 750 07427

Product specification Rev. 03 — 07 October 1998 7 of 28

© Philips Electronics N.V. 2001. All rights reserved.

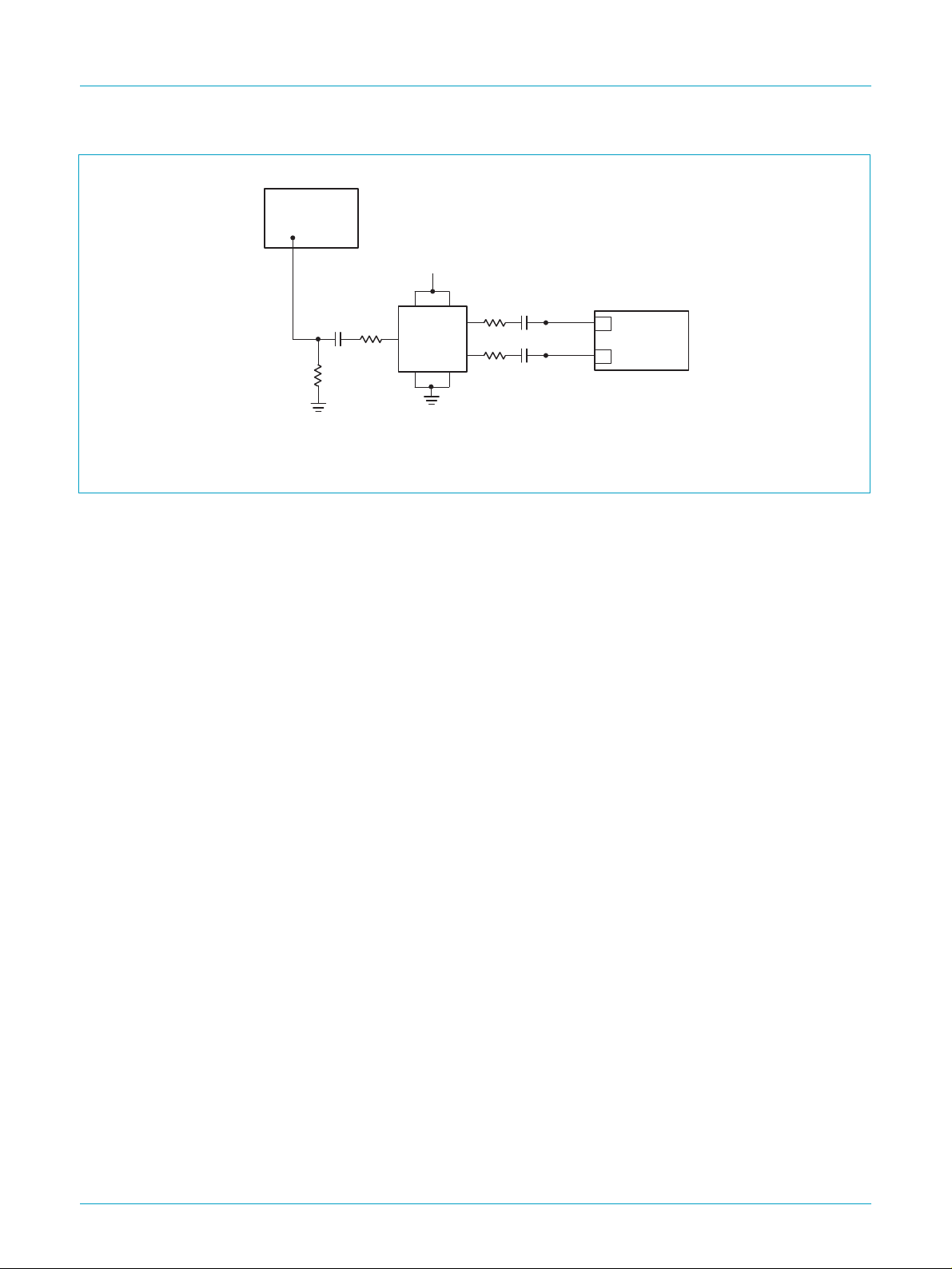

Page 8

Philips Semiconductors

PULSE GEN.

50

0.1µF

1k

V

CC1VCC2

IN

DUT

GND

1

OUT

OUT

GND

SA5211

Transimpedance amplifier (180 MHz)

0.1µF

33

33

0.1µF

2

A

Z

= 50Ω

O

OSCILLOSCOPE

B

Z

= 50Ω

O

Measurement done using

differential wave forms

Fig 5. Test circuit 7.

Test Circuit 7

SD00322

9397 750 07427

© Philips Electronics N.V. 2001. All rights reserved.

Product specification Rev. 03 — 07 October 1998 8 of 28

Page 9

Philips Semiconductors

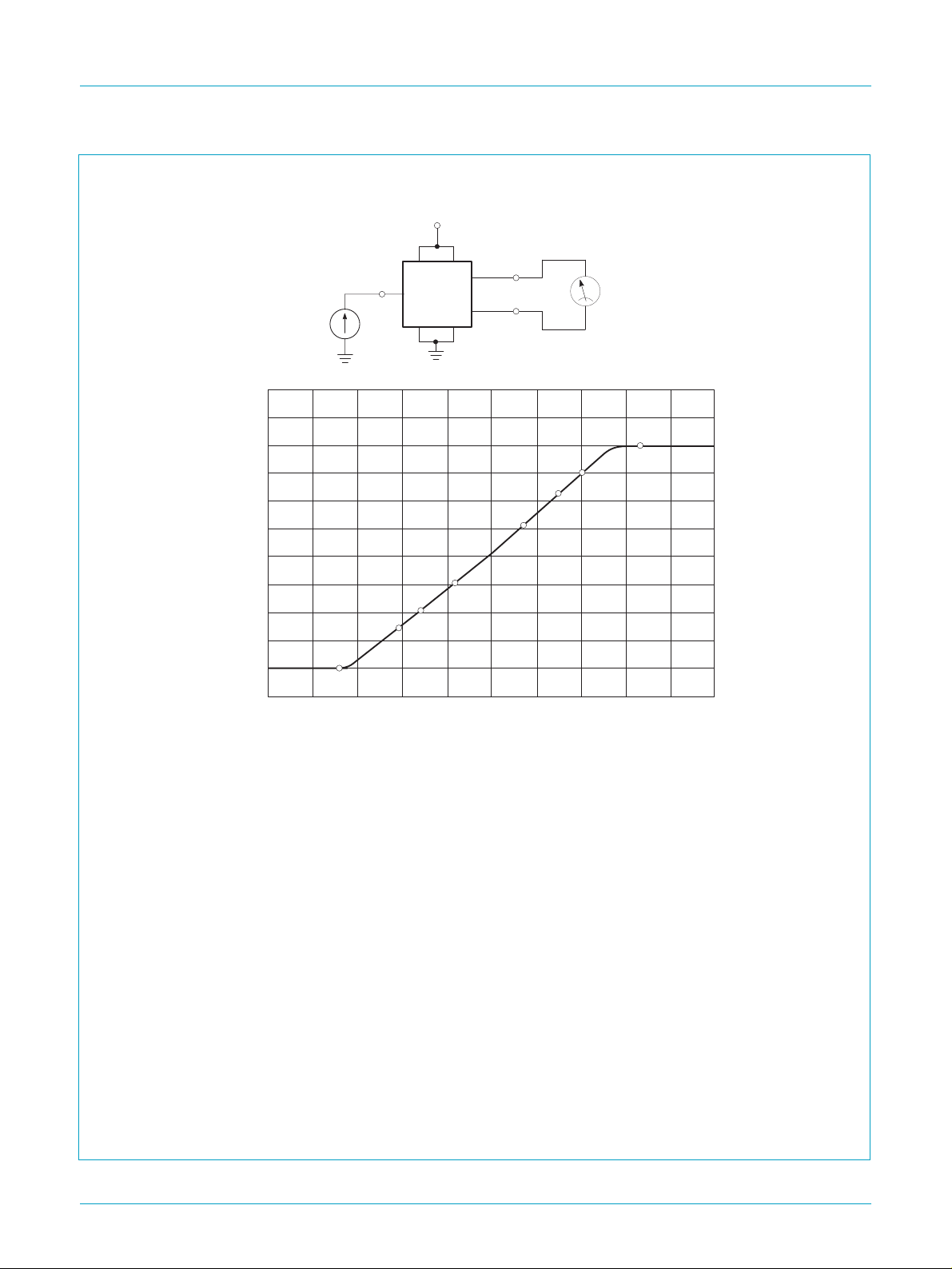

Typical Differential Output Voltage

vs Current Input

5V

SA5211

Transimpedance amplifier (180 MHz)

OUT +

IN

DUT

GND

1

OUT –

GND

2

CURRENT INPUT (µA)

IIN (µA)

2.00

1.60

1.20

0.80

0.40

0.00

–0.40

–0.80

DIFFERENTIAL OUTPUT VOLTAGE (V)

–1.20

–1.60

–2.00

–100 –80 –60 –40 –20 0 20 40 60 80 100

+

V

(V)

OUT

–

NE5211 TEST CONDITIONS

Procedure 1 R

Procedure 2 Linearity = 1 – ABS((V

Procedure 3 V

Procedure 4 I

Test Circuit 8

measured at 15µA

T

R

= (VO1 – VO2)/(+15µA – (–15µA))

T

Where: V

Where: V

Where: VO7 Measured at IIN = +65µA

IN

V

Where: V

Measured at IIN = +15µA

O1

Measured at IIN = –15µA

V

O2

– VOB) / (VO3 – VO4))

OA

Measured at IIN = +30µA

O3

Measured at IIN = –30µA

V

O4

VOA = RT × (+ 30 µA) + V

VOB = RT × (– 30 µA) + V

= VO7 – V

OMAX

Test Pass Conditions:

– VO5 > 20mV and V06 – VO5 > 50mV

O7

O8

Measured at IIN = –65µA

V

O8

Measured at IIN = +40µA

O5

Measured at IIN = –400µA

V

O6

V

Measured at IIN = +65µA

O7

Measured at IIN = –65µA

V

O8

OB

OB

SD00331

Fig 6. Test circuit 8.

9397 750 07427

Product specification Rev. 03 — 07 October 1998 9 of 28

© Philips Electronics N.V. 2001. All rights reserved.

Page 10

Philips Semiconductors

10. Typical performance characteristics

SA5211

Transimpedance amplifier (180 MHz)

NE5211 Supply Current

vs Temperature

30

28

26

CC2

24

CC1

(I + I )

22

TOTALSUPPLY CURRENT (mA)

20

18

60 20 0 20 40 60 80 100 120

5.5V

5.0V

4.5V

40

AMBIENT TEMPERATURE (°C)

NE5211 Input Bias Voltage

vs Temperature

950

900

850

800

750

700

INPUT BIAS VOLTAGE (mV)

650

5.5V

4.5V

60 20 0 20 40 60 80 100 12040 140

AMBIENT TEMPERATURE (°C)

140

NE5211 Output Bias Voltage

vs Temperature

3.50

VCC= 5.0V

3.45

PIN 14

3.40

3.35

PIN 12

3.30

OUTPUT BIAS VOLTAGE (V)

3.25

60 20 0 20 40 60 80 100 12040 140

AMBIENT TEMPERATURE (°C)

NE5211 Output Bias Voltage

4.1

3.9

3.7

3.5

3.3

3.1

2.9

OUTPUT BIAS VOLTAGE (V)

2.7

60 20 0 20 40 60 80 100 12040 140

vs Temperature

PIN 14

5.5V

5.0V

4.5V

AMBIENT TEMPERATURE (°C)

NE5211 Output Voltage

vs Input Current

2.0

0

55°C

DIFFERENTIAL OUTPUT VOLTAGE (V)

+125°C

2.0

100.0 0 +100.0

+85°C

INPUT CURRENT (mA)

+85°C

+25°C

+125°C

55°C

NE5211 Differential Output Voltage

vs Input Current

2.0

0

4.5V

5.5V

DIFFERENTIAL OUTPUT VOLTAGE (V)

2.0

100.0 0 +100.0

5.0V

INPUT CURRENT (mA)

5.5V5.0V

4.5V

+25°C

NE5211 Output Offset Voltage

vs Temperature

40

VOS=V

20

0

20

40

60

80

100

120

OUTPUT OFFSET VOLTAGE (mV)

140

60 20 0 20 40 60 80 100 12040 140

OUT12VOUT14

4.5V

5.0V

5.5V

AMBIENT TEMPERATURE (°C)

NE5211 Differential Output Swing

vs Temperature

4.0

3.8

DC TESTED

=

¥

R

L

3.6

5.5V

3.4

3.2

5.0V

3.0

2.8

4.5V

2.6

2.4

DIFFERENTIAL OUTPUT SWING (V)

2.2

60 20 0 20 40 60 80 100 12040 140

AMBIENT TEMPERATURE (°C)

NE5211 Output Voltage

vs Input Current

+125°C

4.5

OUTPUT VOLTAGE (V)

2.5

100.0 0 +100.0

INPUT CURRENT (mA)

+85°C

+25°C

+125°C

+25°C

55°C

+85°C

55°C55°C

+85°C

+25°C

SD00332

+125°C

Fig 7. Typical performance characteristics.

9397 750 07427

Product specification Rev. 03 — 07 October 1998 10 of 28

© Philips Electronics N.V. 2001. All rights reserved.

Page 11

Philips Semiconductors

()

SA5211

Transimpedance amplifier (180 MHz)

NE5211 Gain vs Frequency NE5211 Gain vs Frequency

17

16

15

14

13

PIN 12

12

=25°C

T

A

GAIN (dB)

=50

W

R

11

L

10

9

8

0.1 1 10 100

FREQUENCY (MHz)

5.5V

5.0V

4.5V

NE5211 Gain vs Frequency

17

16

15

14

13

PIN 12

12

V

=5V

CC

GAIN (dB)

11

10

9

8

0.1 1 10 100

FREQUENCY (MHz)

55°C

125°C

85°C

25°C

17

16

15

14

13

PIN 14

12

T

=25°C

A

GAIN (dB)

11

R

=50

W

L

10

9

8

0.1 1 10 100

FREQUENCY (MHz)

NE5211 Gain vs Frequency

17

16

15

14

13

PIN 14

12

V

=5V

CC

GAIN (dB)

11

10

9

8

0.1 1 10 100

FREQUENCY (MHz)

5.5V

5.0V

55°C

4.5V

125°C

85°C

25°C

NE5211 Differential Transresistance

vs Temperature

33

W

DC TESTED

32

R

=

¥

L

31

30

5.5V

29

5.0V

28

4.5V

DIFFERENTIAL TRANSRESISTANCE (k )

27

60 40 20 0 20 40 10060 12080

AMBIENT TEMPERATURE (°C)

NE5211 Typical

Bandwidth Distribution

(70 Parts from 3 Wafer Lots)

60

PIN 12

SINGLE-ENDED

50

=50

W

R

L

40

30

20

POPULATION (%)

10

0

143 155 167 179 191 203

FREQUENCY (MHz)

V

T

CC

A

=25°C

140

= 5.0V

NE5211 Bandwidth

vs Temperature

220

5.5V

200

5.0V

180

4.5V

160

140

BANDWIDTH (MHz)

120

100

60 40 20 0 20 40 10060 12080

AMBIENT TEMPERATURE (°C)

PIN 12

SINGLE-ENDED

R

=50

W

L

140

NE5211 Gain and Phase

Shift vs Frequency

17

16

15

14

13

12

GAIN (dB)

PIN 12

11

10

9

8

=5V

V

CC

=25°C

T

A

0.1 1 10 100

FREQUENCY (MHz)

120

60

0

60

120

o

PHASE ( )

NE5211 Gain and Phase

Shift vs Frequency

17

16

15

14

13

12

GAIN (dB)

PIN 14

11

V

=5V

CC

10

T

=25°C

A

9

8

0.1 1 10 100

FREQUENCY (MHz)

120

270

SD00333

o

Fig 8. Typical performance characteristics. (cont.)

9397 750 07427

Product specification Rev. 03 — 07 October 1998 11 of 28

© Philips Electronics N.V. 2001. All rights reserved.

PHASE

Page 12

Philips Semiconductors

SA5211

Transimpedance amplifier (180 MHz)

NE5211 Output Resistance

vs Temperature

18

= 5.0V

V

CC

DC TESTED

17

W

16

15

14

OUTPUT RESISTANCE ( )

13

60 40 20 0 20 40 10060 12080

PIN 14

PIN 12

AMBIENT TEMPERATURE (°C)

NE5211 Output Resistance

vs Frequency

40

W

35

PIN 12

30

T

=25°C

A

25

20

15

10

5

OUTPUT RESISTANCE ( )

0

0.1 1 10 100

4.5V 5.0V

5.5V

FREQUENCY (MHz)

140

NE5211 Output Resistance

vs Temperature

18

PIN 12

DC TESTED

17

W

16

15

14

OUTPUT RESISTANCE ( )

13

60 40 20 0 20 40 10060 12080

4.5V

5.0V

5.5V

AMBIENT TEMPERATURE (°C)

NE5211 Output Resistance

80

W

70

60

50

40

30

20

10

OUTPUT RESISTANCE ( )

0

0.1 1 10 100

vs Frequency

VCC= 5.0V

FREQUENCY (MHz)

+125°C

+85°C

+25°C

55°C

140

NE5211 Output Resistance

vs Temperature

19

PIN 14

DC TESTED

18

W

17

16

15

OUTPUT RESISTANCE ( )

14

60 40 20 0 20 40 10060 12080

4.5V

5.0V

5.5V

AMBIENT TEMPERATURE (°C)

NE5211 Output Resistance

80

W

70

60

50

40

30

20

10

OUTPUT RESISTANCE ( )

0

0.1 1 10 100

vs Frequency

VCC= 5.0V

PIN 14

FREQUENCY (MHz)

140

PIN 12

NE5211 Power Supply Rejection Ratio

vs Temperature

40

V

CC1=VCC2

38

D

V

CC

DC TESTED

OUTPUT REFERRED

36

34

32

30

POWER SUPPLY REJECTION RATIO (dB)

28

60 40 20 0 20 40 10060 12080

AMBIENT TEMPERATURE (°C)

= 5.0V

=±0.1V

140

10

DELAY (ns)

NE5211 Group Delay

vs Frequency

8

6

4

2

0

20 40 60 80 100 120 140 160 180 200

0.1

FREQUENCY (MHz)

SD00335

Fig 9. Typical performance characteristics. (cont.)

9397 750 07427

Product specification Rev. 03 — 07 October 1998 12 of 28

© Philips Electronics N.V. 2001. All rights reserved.

Page 13

Philips Semiconductors

Output Step Response

SA5211

Transimpedance amplifier (180 MHz)

VCC=5V

TA=25°C

20mV/Div

0 2 4 6 8 10 12 14 16 18 20

Fig 10. Typical performance characteristics. (cont.)

11. Theory of operation

Transimpedance amplifiers have been widely used as the preamplifier in fiber-optic

receivers. The SA5211 is a wide bandwidth (typically 180 MHz) transimpedance

amplifier designed primarily for input currents requiring a large dynamic range, such

as those produced by a laser diode. The maximum input current before output stage

clipping occurs at typically 50µA. The SA5211 is a bipolar transimpedance amplifier

which is current driven at the input and generates a differential voltage signal at the

outputs. The forward transfer function is therefore a ratio of the differential output

voltage to a given input current with the dimensions of ohms. The main feature of this

amplifier is a wideband, low-noise input stage which is desensitized to photodiode

capacitance variations. When connected to a photodiode of a few picoFarads, the

frequency response will not be degraded significantly. Except for the input stage, the

entire signal path is differential to provide improved power-supply rejection and ease

of interface to ECL type circuitry. A block diagram of the circuit is shown in Figure 11.

The input stage (A1) employs shunt-series feedback to stabilize the current gain of

the amplifier. The transresistance of the amplifier from the current source to the

emitter of Q3 is approximately the value of the feedback resistor, RF= 14.4 kΩ. The

gain from the second stage (A2) and emitter followers (A3 and A4) is about two.

Therefore, the differential transresistance of the entire amplifier, RT is

(ns)

V

diff()

R

OUT

----------------------------- 2 RF2 14.4 K()28.8 kΩ====

T

I

IN

(1)

The single-ended transresistance of the amplifier is typically 14.4 kΩ.

The simplified schematic in Figure 12 shows how an input current is converted to a

differential output voltage. The amplifier has a single input for current which is

referenced to Ground 1. An input current from a laser diode, for example, will be

converted into a voltage by the feedback resistor RF. The transistor Q1 provides most

of the open loop gain of the circuit, A

≈70. The emitter follower Q2 minimizes

VOL

loading on Q1. The transistor Q4, resistor R7, and VB1 provide level shifting and

interface with the Q15 – Q16 differential pair of the second stage which is biased with

an internal reference, VB2. The differential outputs are derived from emitter followers

9397 750 07427

Product specification Rev. 03 — 07 October 1998 13 of 28

© Philips Electronics N.V. 2001. All rights reserved.

Page 14

Philips Semiconductors

SA5211

Transimpedance amplifier (180 MHz)

Q11 – Q12 which are biased by constant current sources. The collectors of Q11 – Q

are bonded to an external pin, V

stage. The output impedance is about 17Ω single-ended. For ease of performance

evaluation, a 33Ω resistor is used in series with each output to match to a 50Ω test

system.

12. Bandwidth calculations

The input stage, shown in Figure 13, employs shunt-series feedback to stabilize the

current gain of the amplifier. A simplified analysis can determine the performance of

the amplifier. The equivalent input capacitance, CIN, in parallel with the source, IS, is

approximately 4 pF (typical), assuming that CS= 0 where CSis the external source

capacitance.

Since the input is driven by a current source the input must have a low input

resistance. The input resistance, RIN, is the ratio of the incremental input voltage,VIN,

to the corresponding input current, IIN and can be calculated as:

V

R

IN

Thus CIN and RIN will form the dominant pole of the entire amplifier;

f

3db–

IN

--------I

IN

=

------------------------- -

2πRINC

R

----------------------1A

+

1

IN

F

VOL

CC2

14.4 kΩ

------------------- -

71

, in order to reduce the feedback to the input

203Ω== = =

12

(2)

(3)

13. Noise

Assuming typical values for RF = 14.4 kΩ, RIN = 200 Ω, CIN = 4 pF

f

-------------------------------------- -

3db–

2π 4 pF 200 Ω

1

200 MHz==

(4)

The operating point of Q1, Figure 12, has been optimized for the lowest current noise

without introducing a second dominant pole in the pass-band. All poles associated

with subsequent stages have been kept at sufficiently high enough frequencies to

yield an overallsingle pole response. Although wider bandwidths havebeen achieved

by using a cascade input stage configuration, the present solution has the advantage

of a very uniform, highly desensitized frequency response because the Miller effect

dominates over the external photodiode and stray capacitances. For example,

assuming a source capacitance of 1 pF, input stage voltage gain of 70, RIN = 60 Ω

then the total input capacitance, CIN = (1 + 4) pF which will lead to only a 20%

bandwidth reduction.

Most of the currently installed fiber-optic systems use non-coherent transmission and

detect incident optical power. Therefore, receiver noise performance becomes very

important. The input stage achieves a low input referred noise current (spectral

density) of 1.8 pA/√Hz (typical). The transresistance configuration assures that the

external high value bias resistors often required for photodiode biasing will not

contribute to the total noise system noise. The equivalent input

noise current is

RMS

9397 750 07427

Product specification Rev. 03 — 07 October 1998 14 of 28

© Philips Electronics N.V. 2001. All rights reserved.

Page 15

Philips Semiconductors

strongly determined by the quiescent current of Q1, the feedback resistor RF, and the

bandwidth; however, it is not dependent upon the internal Miller-capacitance. The

measured wideband noise was 41 nA RMS in a 200 MHz bandwidth.

14. Dynamic range calculations

The electrical dynamic range can be defined as the ratio of maximum input current to

the peak noise current:

SA5211

Transimpedance amplifier (180 MHz)

Electrical dynamic range, DE, in a 200 MHz bandwidth assuming I

a wideband noise of IEQ=41nA

(Max. input current)

D

=

------------------------------------------------

E

(Peak noise current)

DE(dB) 20 log

=

DEdB() 20 log

60 106–×()

---------------------------- -

2 41 10

()

60 µA()

-------------------- 60db==

58 nA()

9–

for an external source capacitance of CS= 1 pF.

RMS

= 60 µA and

INMAX

In order to calculate the optical dynamic range the incident optical power must be

considered.

For a given wavelength λ;

Energy of one Photon = watt sec (Joule)

Where h = Planck’s Constant = 6.6 × 10

hc

----- -

λ

-34

Joule sec.

c = speed of light = 3 × 108 m/sec

(5)

(6)

(7)

c / λ = optical frequency

P

----- -

No. of incident photons/sec = where P = optical incident power

No. of generated electrons/sec =

hc

----- -

λ

P

----- hc

η

×

----- -

λ

where η = quantum efficiency

no. of generated electron hole pairs

------------------------------------------------------------------------------------

=

9397 750 07427

Product specification Rev. 03 — 07 October 1998 15 of 28

no. of incident photons

© Philips Electronics N.V. 2001. All rights reserved.

Page 16

Philips Semiconductors

I∴η

SA5211

Transimpedance amplifier (180 MHz)

P

-----

hc

× e Amps (Coulombs/sec.)×=

-----

λ

where e = electron charge = 1.6 × 10

η e×

------------ -

Responsivity R = Amp/watt

hc

-------------

λ

-19

Coulombs

I PR×=

Assuming a data rate of 400 Mbaud (Bandwidth, B = 200 MHz), the noise parameter

41 109–×

1

19–

noise output to the peak response to a single hole-electron

RMS

1281== =

(8)

Zn may be calculated as:

I

EQ

Z

------- -

------------------------------------------------------------

qB

1.6 10

×()200 106×()

where Z is the ratio of

pair. Assuming 100% photodetector quantum efficiency, half mark/half space digital

transmission, 850nm lightwave and using Gaussian approximation, the minimum

required optical power to achieve 10-9 BER is:

P

avMIN

hc

12

BZ 12 2.3× 10

-----

λ

200 106× 1281()719 nW 31.5 dBm– 1139 nW 29.4 dBm–== = =

19–

×==

(9)

1. S.D. Personick,

where h is Planck’s Constant, c is the speed of light, λ is the wavelength. The

minimum input current to the SA5211, at this input power is:

λ

I

avMIN

qP

avMIN

----hc

Choosing the maximum peak overload current of I

optical power is:

hcl

P

avMAX

avMAX

--------------------- -

λq

Thus the optical dynamic range, DO is:

D

P

O

D

P

O

Optical Fiber Transmission Systems,

– 4.6– 29.4–()24.8 dB=–==

avMAXPavMIN

– 31.5– 10.6–()–==

avMAXPavMIN

1

------------

Joule

Plenum Press, NY, 1981, Chapter 3.

------------

sec

2.3 10

×

--------------------------

1.6 10

×

19–

60 10 µA× 86 µW or 10.6 dBm (optical)–===

19–

Joule

× q× = l =

707 109–× 1.6× 10

---------------------------------------------------------- -

2.3 10

×

avMAX

19–

×

19–

500 nA==

(10)

=60µA, the maximum mean

(11)

(12)

9397 750 07427

Product specification Rev. 03 — 07 October 1998 16 of 28

© Philips Electronics N.V. 2001. All rights reserved.

Page 17

Philips Semiconductors

SA5211

Transimpedance amplifier (180 MHz)

OUTPUT +

A3

Fig 11. SA5211 – Block diagram.

This represents the maximum limit attainable with the SA5211 operating at 200 MHz

bandwidth, with a half mark/half space digital transmission at 850nm wavelength.

PHOTODIODE

INPUT

INPUT

A1 A2

R

F

R

1

Q

2

Q

3

R

2

5

GND

R

Q

1

1

R

A4

OUTPUT –

SD00327

V

CC1

3

R

R

12

Q

4

+

Q

15

R

14

R

7

4

GND

R

13

Q

Q

16

R

15

+

VB2

2

V

CC2

11

Q

12

OUT–

OUT+

SD00328

Fig 12. Transimpedance amplifier.

V

CC

I

C1

R1

INPUT

I

IN

V

IN

I

B

Q1

I

F

R

F

R3

Q2

Q3

R2

V

EQ3

R4

SD00329

Fig 13. Shunt-series input stage.

9397 750 07427

Product specification Rev. 03 — 07 October 1998 17 of 28

© Philips Electronics N.V. 2001. All rights reserved.

Page 18

Philips Semiconductors

15. Application information

Package parasitics, particularly ground lead inductances and parasitic capacitances,

can significantly degrade the frequency response. Since the SA5211 has differential

outputs which can feed back signals to the input by parasitic package or board layout

capacitances, both peaking and attenuating type frequency response shaping is

possible. Constructing the board layout so that Ground 1 and Ground 2 have very low

impedance paths has produced the best results. This was accomplished by adding a

ground-plane stripe underneath the device connecting Ground 1, Pins 8-11, and

Ground 2, Pins 1 and 2 on opposite ends of the SO14 package. This ground-plane

stripe also provides isolation between the output return currents flowing to either

V

or Ground 2 and the input photodiode currents to flowing to Ground 1. Without

CC2

this ground-plane stripe and with large lead inductances on the board, the part may

be unstable and oscillate near 800 MHz. The easiest way to realize that the part is

not functioning normally is to measure the DC voltages at the outputs. If they are not

close to their quiescent values of 3.3 V (for a 5 V supply), then the circuit may be

oscillating. Input pin layout necessitates that the photodiode be physically very close

to the input and Ground 1. Connecting Pins 3 and 5 to Ground 1 will tend to shield the

input but it will also tend to increase the capacitance on the input and slightly reduce

the bandwidth.

SA5211

Transimpedance amplifier (180 MHz)

As with any high-frequency device, some precautions must be observed in order to

enjoy reliable performance. The first of these is the use of a well-regulated power

supply. The supply must be capable of providing varying amounts of current without

significantly changing the voltage level.Proper supply bypassing requires that a good

quality 0.1 µF high-frequency capacitor be inserted between V

CC1

and V

CC2

,

preferably a chip capacitor, as close to the package pins as possible. Also, the

parallel combination of 0.1 µF capacitors with 10 µF tantalum capacitors from each

supply, V

CC1

and V

, to the ground plane should provide adequate decoupling.

CC2

Some applications may require an RF choke in series with the power supply line.

Separate analog and digital ground leads must be maintained and printed circuit

board ground plane should be employed whenever possible.

Figure 14 depicts a 50 Mb/s TTL fiber-optic receiver using the BPF31, 850 nm LED,

the SA5211 and the SA5214 post amplifier.

9397 750 07427

Product specification Rev. 03 — 07 October 1998 18 of 28

© Philips Electronics N.V. 2001. All rights reserved.

Page 19

Philips Semiconductors

SA5211

Transimpedance amplifier (180 MHz)

+V

CC

47µF

C1

C2

.01µF

GND

L1

C4

.01µF

10µH

10µH

L3

10µH

L2

C10

10

µF

C12

10µF

R2

220

C9

R3

47k

C11

.01µF

.01µF

LED

100pF

C13

V

D1

LED

1

C

2

PKDET

THRESH

3

GND

A

4

FLAG

5

JAM

6

V

CCD

7

V

CCA

8

GND

D

9

TTL

10 11

OUT

(TTL)

OUT

IN

IN

C

C

OUT

IN

NE5214

OUT

IN

R

HYST

R

PKDET

1B

1A

AZP

AZN

1B

8B

1A

8A

C7

20

100pF

19

C8

18

17

0.1µF

16

15

14

13

12

GND

GND

9

GND

10

GND

11

OUT

12

13

GND

OUT

14

R4

4k

V

V

NE5210

GND

GND

I

CC

CC

NC

NC

78

6

5

IN

4

3

2

1

The NE5210/NE5217 combination can operate at data rates in excess of 100 Mb/s NRZ

The capacitor C7 decreases the NE5210 bandwidth to improve overallS/N ratio in the DC-50 MHz band, but does create extra

high frequency noise on the NE5210 VCC pin(s).

Fig 14. A 50Mb/s fiber optic receiver.

R1

100

C3

10µF

BPF31

OPTICAL

INPUT

SD00330

C5

1.0µF

.01µF

C6

9397 750 07427

© Philips Electronics N.V. 2001. All rights reserved.

Product specification Rev. 03 — 07 October 1998 19 of 28

Page 20

Philips Semiconductors

SA5211

Transimpedance amplifier (180 MHz)

GND 2

INPUT

NC

NC

1

GND 2

2

3

4

5

14

OUT ()

13

GND 2

12

OUT (+)

GND 1

11

10

GND 1

GND 1

9

SD00488

ECN No.: 06027

1992 Mar 13

VCC1

VCC 2

6

78

GND 1

Fig 15. SA5211 Bonding diagram.

15.1 Die sales disclaimer

Due to the limitations in testing high frequency and other parameters at the die level,

and the fact that die electrical characteristics may shift after packaging, die electrical

parameters are not specified and die are not guaranteed to meet electrical

characteristics (including temperature range) as noted in this data sheet which is

intended only to specify electrical characteristics for a packaged device.

All die are 100% functional with various parametrics tested at the wafer level,at room

temperature only (25°C), and are guaranteed to be 100% functional as a result of

electrical testing to the point of wafer sawing only. Although the most modern

9397 750 07427

Product specification Rev. 03 — 07 October 1998 20 of 28

© Philips Electronics N.V. 2001. All rights reserved.

Page 21

Philips Semiconductors

processes are utilized for wafer sawing and die pick and place into waffle pack

carriers, it is impossible to guarantee 100% functionality through this process. There

is no post waffle pack testing performed on individual die.

Since Philips Semiconductors has no control of third party procedures in the handling

or packaging of die, Philips Semiconductors assumes no liability for device

functionality or performance of the die or systems on any die sales.

Although Philips Semiconductors typically realizes a yield of 85% after assembling

die into their respective packages, with care customers should achievea similar yield.

However, for the reasons stated above, Philips Semiconductors cannot guarantee

this or any other yield on any die sales.

SA5211

Transimpedance amplifier (180 MHz)

9397 750 07427

Product specification Rev. 03 — 07 October 1998 21 of 28

© Philips Electronics N.V. 2001. All rights reserved.

Page 22

Philips Semiconductors

16. Package outline

SA5211

Transimpedance amplifier (180 MHz)

SO14: plastic small outline package; 14 leads; body width 3.9 mm

D

c

y

Z

14

pin 1 index

1

e

8

A

2

7

w M

b

p

SOT108-1

E

H

E

A

1

L

detail X

A

X

v M

A

Q

(A )

L

p

A

3

θ

0 2.5 5 mm

scale

DIMENSIONS (inch dimensions are derived from the original mm dimensions)

mm

OUTLINE

VERSION

SOT108-1

A

max.

1.75

0.069

A

0.25

0.10

0.010

0.004

1

A2A3b

1.45

0.25

1.25

0.057

0.01

0.049

IEC JEDEC EIAJ

076E06 MS-012

0.49

0.36

0.019

0.014

p

0.25

0.19

0.0100

0.0075

UNIT

inches

Note

1. Plastic or metal protrusions of 0.15 mm maximum per side are not included.

(1)E(1)

cD

8.75

8.55

0.35

0.34

REFERENCES

eHELLpQZywv θ

4.0

1.27

3.8

0.16

0.050

0.15

6.2

5.8

0.244

0.228

1.05

0.041

1.0

0.4

0.039

0.016

0.7

0.25

0.6

0.028

0.01 0.004

0.024

EUROPEAN

PROJECTION

0.25 0.1

0.01

(1)

0.7

0.3

0.028

0.012

ISSUE DATE

97-05-22

99-12-27

o

8

o

0

Fig 16. SOT108-1.

9397 750 07427

Product specification Rev. 03 — 07 October 1998 22 of 28

© Philips Electronics N.V. 2001. All rights reserved.

Page 23

Philips Semiconductors

17. Soldering

17.1 Introduction to soldering surface mount packages

This text gives a very brief insight to a complex technology. A more in-depth account

of soldering ICs can be found in our

Packages

There is no soldering method that is ideal for all surface mount IC packages. Wave

soldering can still be used for certain surface mount ICs, but it is not suitable for fine

pitch SMDs. In these situations reflow soldering is recommended.

17.2 Reflow soldering

Reflow soldering requires solder paste (a suspension of fine solder particles, flux and

binding agent) to be applied to the printed-circuit board by screen printing, stencilling

or pressure-syringe dispensing before package placement.

Several methods exist for reflowing; for example, convection or convection/infrared

heating in a conveyor type oven. Throughput times (preheating, soldering and

cooling) vary between 100 and 200 seconds depending on heating method.

SA5211

Transimpedance amplifier (180 MHz)

Data Handbook IC26; Integrated Circuit

(document order number 9398 652 90011).

Typical reflow peak temperatures range from 215 to 250 °C. The top-surface

temperature of the packages should preferable be kept below 220 °C for thick/large

packages, and below 235 °C small/thin packages.

17.3 Wave soldering

Conventional single wave soldering is not recommended for surface mount devices

(SMDs) or printed-circuit boards with a high component density, as solder bridging

and non-wetting can present major problems.

To overcome these problems the double-wave soldering method was specifically

developed.

If wave soldering is used the following conditions must be observed for optimal

results:

Use a double-wave soldering method comprising a turbulent wave with high

•

upward pressure followed by a smooth laminar wave.

For packages with leads on two sides and a pitch (e):

•

– larger than or equal to 1.27 mm, the footprint longitudinal axis is preferred to be

parallel to the transport direction of the printed-circuit board;

– smaller than 1.27 mm, the footprint longitudinal axis must be parallel to the

transport direction of the printed-circuit board.

The footprint must incorporate solder thieves at the downstream end.

For packages with leads on four sides, the footprint must be placed at a 45° angle

•

to the transport direction of the printed-circuit board. The footprint must

incorporate solder thieves downstream and at the side corners.

9397 750 07427

Product specification Rev. 03 — 07 October 1998 23 of 28

© Philips Electronics N.V. 2001. All rights reserved.

Page 24

Philips Semiconductors

During placement and before soldering, the package must be fixed with a droplet of

adhesive. The adhesive can be applied by screen printing, pin transfer or syringe

dispensing. The package can be soldered after the adhesive is cured.

Typical dwell time is 4 seconds at 250 °C. A mildly-activated flux will eliminate the

need for removal of corrosive residues in most applications.

17.4 Manual soldering

Fix the component by first soldering two diagonally-opposite end leads. Use a low

voltage (24 V or less) soldering iron applied to the flat part of the lead. Contact time

must be limited to 10 seconds at up to 300 °C.

When using a dedicated tool, all other leads can be soldered in one operation within

2 to 5 seconds between 270 and 320 °C.

17.5 Package related soldering information

Table 6: Suitability of surface mount IC packages for wave and reflow soldering

Package Soldering method

BGA, HBGA, LFBGA, SQFP, TFBGA not suitable suitable

HBCC, HLQFP, HSQFP, HSOP, HTQFP,

HTSSOP, HVQFN, SMS

PLCC

LQFP, QFP, TQFP not recommended

SSOP, TSSOP, VSO not recommended

SA5211

Transimpedance amplifier (180 MHz)

methods

Wave Reflow

not suitable

[3]

, SO, SOJ suitable suitable

[2]

[3][4]

[5]

suitable

suitable

suitable

[1]

[1] All surface mount (SMD) packages are moisture sensitive.Depending upon the moisture content, the

maximum temperature (with respect to time) and body size of the package, there is a risk that internal

or external package cracks may occur due to vaporization of the moisture in them (the so called

popcorn effect). For details, refer to the Drypack information in the

Circuit Packages; Section: Packing Methods

[2] These packages are not suitable forwave soldering as a solder joint between the printed-circuit board

and heatsink (at bottom version) can not be achieved, and as solder may stick to the heatsink (on top

version).

[3] If wave soldering is considered, then the package must be placed at a 45° angle to the solder wave

direction. The package footprint must incorporate solder thieves downstream and at the side corners.

[4] Wave soldering is only suitable for LQFP, QFP and TQFP packages with a pitch (e) equal to or larger

than 0.8 mm; it is definitely not suitable for packages with a pitch (e) equal to or smaller than 0.65 mm.

[5] Wave soldering is only suitable forSSOP and TSSOP packages with a pitch (e) equal to or larger than

0.65 mm; it is definitely not suitable for packages with a pitch (e) equal to or smaller than 0.5 mm.

9397 750 07427

Product specification Rev. 03 — 07 October 1998 24 of 28

.

Data Handbook IC26; Integrated

© Philips Electronics N.V. 2001. All rights reserved.

Page 25

Philips Semiconductors

SA5211

Transimpedance amplifier (180 MHz)

18. Revision history

Table 7: Revision history

Rev Date CPCN Description

03 19981007 853-1799 20142 Productspecification;thirdversion;supersedes second version SA5211_2 of

1998 Oct 07 (9397 750 04624). Modifications:

The format of this specification has been redesigned to comply with Philips

Semiconductors’ new presentation and information standard.

02 19981007 853-1799 20142 Product specification; second version; supersedes first version SA5211_1 of

1995 Apr 26. Modifications:

Changed prefix from NE to SA.

01 19950426 853-1799 15170 Product specification; initial version.

9397 750 07427

Product specification Rev. 03 — 07 October 1998 25 of 28

© Philips Electronics N.V. 2001. All rights reserved.

Page 26

Philips Semiconductors

19. Data sheet status

SA5211

Transimpedance amplifier (180 MHz)

Data sheet status

Objective data Development This data sheetcontains data from theobjective specification forproduct development.Philips Semiconductors

Preliminary data Qualification This data sheet contains data from the preliminary specification. Supplementary data will be published at a

Product data Production This data sheet contains data from the product specification. Philips Semiconductors reserves the right to

[1] Please consult the most recently issued data sheet before initiating or completing a design.

[2] The product status of the device(s) described in this data sheet may have changed since this data sheet was published. The latest information is available on the Internet at

URL http://www.semiconductors.philips.com.

[1]

Product status

20. Definitions

Short-form specification — The data in a short-form specification is

extracted from a full data sheet with the same type number and title. For

detailed information see the relevant data sheet or data handbook.

Limiting values definition — Limiting values given are in accordance with

the Absolute Maximum Rating System (IEC 60134). Stress above one or

more of the limiting values may cause permanent damage to the device.

These are stress ratings only and operation of the device at these or at any

other conditions above those given in the Characteristics sections of the

specification is not implied. Exposure to limiting values for extended periods

may affect device reliability.

Application information — Applications that are described herein for any

of these products are for illustrative purposes only. Philips Semiconductors

make no representation or warranty that such applications will be suitable for

the specified use without further testing or modification.

[2]

Definition

reserves the right to change the specification in any manner without notice.

later date. Philips Semiconductors reserves the right to change the specification without notice, in order to

improve the design and supply the best possible product.

make changes at any time in order to improve the design, manufacturing and supply. Changes will be

communicated according to the Customer Product/Process Change Notification (CPCN) procedure

SNW-SQ-650A.

21. Disclaimers

Life support — These products are not designed for use in life support

appliances, devices, or systems where malfunction of these products can

reasonably be expected to result in personal injury. Philips Semiconductors

customers using or selling these products for use in such applications do so

at their own risk and agree to fully indemnify Philips Semiconductors for any

damages resulting from such application.

Right to make changes — Philips Semiconductors reserves the right to

make changes, without notice, in the products, including circuits, standard

cells, and/or software, described or contained herein in order to improve

design and/or performance. Philips Semiconductors assumes no

responsibility or liability for the use of any of these products, conveys no

licence or title under any patent, copyright, or mask work right to these

products, and makes no representations or warranties that these products

are free from patent, copyright, or mask work right infringement, unless

otherwise specified.

9397 750 07427

© Philips Electronics N.V. 2001 All rights reserved.

Product specification Rev. 03 — 07 October 1998 26 of 28

Page 27

Philips Semiconductors

Transimpedance amplifier (180 MHz)

Philips Semiconductors - a worldwide company

SA5211

Argentina: see South America

Australia: Tel. +61 2 9704 8141, Fax. +61 2 9704 8139

Austria: Tel. +43 160 101, Fax. +43 160 101 1210

Belarus: Tel. +375 17 220 0733, Fax. +375 17 220 0773

Belgium: see The Netherlands

Brazil: see South America

Bulgaria: Tel. +359 268 9211, Fax. +359 268 9102

Canada: Tel. +1 800 234 7381

China/Hong Kong: Tel. +852 2 319 7888, Fax. +852 2 319 7700

Colombia: see South America

Czech Republic: see Austria

Denmark: Tel. +45 3 288 2636, Fax. +45 3 157 0044

Finland: Tel. +358 961 5800, Fax. +358 96 158 0920

France: Tel. +33 1 4728 6600, Fax. +33 1 4728 6638

Germany: Tel. +49 40 23 5360, Fax. +49 402 353 6300

Hungary: Tel. +36 1 382 1700, Fax. +36 1 382 1800

India: Tel. +91 22 493 8541, Fax. +91 22 493 8722

Indonesia: see Singapore

Ireland: Tel. +353 17 64 0000, Fax. +353 17 64 0200

Israel: Tel. +972 36 45 0444, Fax. +972 36 49 1007

Italy: Tel. +39 039 203 6838, Fax +39 039 203 6800

Japan: Tel. +81 33 740 5130, Fax. +81 3 3740 5057

Korea: Tel. +82 27 09 1412, Fax. +82 27 09 1415

Malaysia: Tel. +60 37 50 5214, Fax. +60 37 57 4880

Mexico: Tel. +9-5 800 234 7381

Middle East: see Italy

Netherlands: Tel. +31 40 278 2785, Fax. +31 40 278 8399

New Zealand: Tel. +64 98 49 4160, Fax. +64 98 49 7811

Norway: Tel. +47 22 74 8000, Fax. +47 22 74 8341

Philippines: Tel. +63 28 16 6380, Fax. +63 28 17 3474

Poland: Tel. +48 22 5710 000, Fax. +48 22 5710 001

Portugal: see Spain

Romania: see Italy

Russia: Tel. +7 095 755 6918, Fax. +7 095 755 6919

Singapore: Tel. +65 350 2538, Fax. +65 251 6500

Slovakia: see Austria

Slovenia: see Italy

South Africa: Tel. +27 11 471 5401, Fax. +27 11 471 5398

South America: Tel. +55 11 821 2333, Fax. +55 11 829 1849

Spain: Tel. +34 33 01 6312, Fax. +34 33 01 4107

Sweden: Tel. +46 86 32 2000, Fax. +46 86 32 2745

Switzerland: Tel. +41 14 88 2686, Fax. +41 14 81 7730

Taiwan: Tel. +886 22 134 2451, Fax. +886 22 134 2874

Thailand: Tel. +66 23 61 7910, Fax. +66 23 98 3447

Turkey: Tel. +90 216 522 1500, Fax. +90 216 522 1813

Ukraine: Tel. +380 44 264 2776, Fax. +380 44 268 0461

United Kingdom: Tel. +44 208 730 5000, Fax. +44 208 754 8421

United States: Tel. +1 800 234 7381

Uruguay: see South America

Vietnam: see Singapore

Yugoslavia: Tel. +381 11 3341 299, Fax. +381 11 3342 553

For all other countries apply to: Philips Semiconductors,

Marketing Communications,

Building BE, P.O. Box 218, 5600 MD EINDHOVEN,

The Netherlands, Fax. +31 40 272 4825

Internet: http://www.semiconductors.philips.com

(SCA72)

9397 750 07427

Product specification Rev. 03 — 07 October 1998 27 of 28

© Philips Electronics N.V. 2001. All rights reserved.

Page 28

Philips Semiconductors

Contents

1 Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

3 Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

4 Pinning information. . . . . . . . . . . . . . . . . . . . . . 2

4.1 Pinning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

5 Ordering information. . . . . . . . . . . . . . . . . . . . . 2

6 Limiting values. . . . . . . . . . . . . . . . . . . . . . . . . . 2

7 Static characteristics. . . . . . . . . . . . . . . . . . . . . 3

8 Dynamic characteristics . . . . . . . . . . . . . . . . . . 3

9 Test circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

10 Typical performance characteristics . . . . . . . 10

11 Theory of operation . . . . . . . . . . . . . . . . . . . . 13

12 Bandwidth calculations . . . . . . . . . . . . . . . . . 14

13 Noise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

14 Dynamic range calculations . . . . . . . . . . . . . 15

15 Application information. . . . . . . . . . . . . . . . . . 18

15.1 Die sales disclaimer . . . . . . . . . . . . . . . . . . . . 20

16 Package outline . . . . . . . . . . . . . . . . . . . . . . . . 22

17 Soldering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

17.1 Introduction to soldering surface mount

packages . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

17.2 Reflow soldering. . . . . . . . . . . . . . . . . . . . . . . 23

17.3 Wave soldering. . . . . . . . . . . . . . . . . . . . . . . . 23

17.4 Manual soldering . . . . . . . . . . . . . . . . . . . . . . 24

17.5 Package related soldering information . . . . . . 24

18 Revision history. . . . . . . . . . . . . . . . . . . . . . . . 25

19 Data sheet status . . . . . . . . . . . . . . . . . . . . . . . 26

20 Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

21 Disclaimers. . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

SA5211

Transimpedance amplifier (180 MHz)

© Philips Electronics N.V. 2001. Printed in the U.S.A

All rights are reserved. Reproduction in whole or in part is prohibited without the prior

written consent of the copyright owner.

The information presented in this document does not form part of any quotation or

contract, is believed to be accurate and reliable and may be changed without notice. No

liability will be accepted by the publisher for any consequence of its use. Publication

thereof does not convey nor imply any license under patent- or other industrial or

intellectual property rights.

Date of release: 07 October 1998 Document order number: 9397 750 07427

Loading...

Loading...