Page 1

BiPAP® Focus™ Ventilator

SERVICE MANUAL

REF 1029568 Rev A

Page 2

Copyright © 2006. Respironics, Inc.

ALL RIGHTS RESERVED.

This work is protected under Title 17 of the United States copyright code and is the sole property of Respironics.

No part of this document may be copied or otherwise reproduced, or stored in any electronic information

retrieval system, except as specifically permitted under United States copyright law, without the prior written

consent of Respironics.

In the U.S. and Canada

Respironics California, Inc.

2271 Cosmos Court

Carlsbad, CA 92011

USA

1-800-345-6443

For Technical support, contact:

Respironics, Inc. Customer Service

Within the U.S.A. 1-800-345-6443

Outside the U.S.A. 724-387-4000

Facsimile 724-387-5012

service@respironics.com

II BiPAP® Focus™ Ventilator Service Manual © Respironics, Inc. REF 1029568 Rev A

Page 3

Table of Contents

1. Introduction and Intended Use. . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Recommended Tools and Test Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Where to Go for Help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

2. Warnings and Cautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Cautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

3. Theory of Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Back Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Default Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Settings: CPAP Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Settings: S/T Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Measured Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Alarm Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Nurse Call Station/Serial Communications Connector Pinout . . . . . . . . . . . . 3-10

Physical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Triggers and Cycles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Environmental . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Bacteria Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Date of Manufacture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Pneumatics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

4. Periodic Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Storing the BiPAP Focus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Cleaning the Reusable Air Inlet Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Replacing the Air Inlet Filter(s) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Replacing the Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

5. Diagnostic Mode and Troubleshooting . . . . . . . . . . . . . . . . . . . . . . 5-1

Entering Diagnostic Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Product Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

System Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Preferences. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Significant Event Log. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Setting Up the Serial Interface for DRPT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

REF 1029568 Rev A BiPAP® Focus™ Ventilator Service Manual © Respironics, Inc. III

Page 4

Table of Contents

6. Ventilator Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

7. Performance Verification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Generating a Diagnostic Report (DRPT) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

Sensor Readings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

System Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

Significant Event Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

Download Service Software to the Service PC . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Installing Communications Software on the Service PC . . . . . . . . . . . . . . . . . . . . 6-2

Starting the BiPAP Focus Wizard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Downloading Controller Board Software to the Ventilator . . . . . . . . . . . . . . . . . . . 6-4

Downloading UI Software to the Ventilator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

Reprogramming the BiPAP Focus Serial Number . . . . . . . . . . . . . . . . . . . . . . . 6-13

Required Test Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Preliminary Cleaning, Inspection, and Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Electrical Safety Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Alarm/LED Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

BiPAP Focus System Run-in. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

Equipment Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

Real-time Clock Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

Equipment Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

If Real-Time Clock Calibration Fails . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

MFTS Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

Multi Function Test Station Set-up (MFTS) . . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

MFTS software setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-9

Unit Under Test setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-10

Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-11

Field Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-17

Equipment Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-17

Recording Serial Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-17

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-18

Performance Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-28

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-28

Performance Verification Data Form . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-29

8. Component Removal/Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Disconnecting Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

Top Enclosure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

VGA Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-6

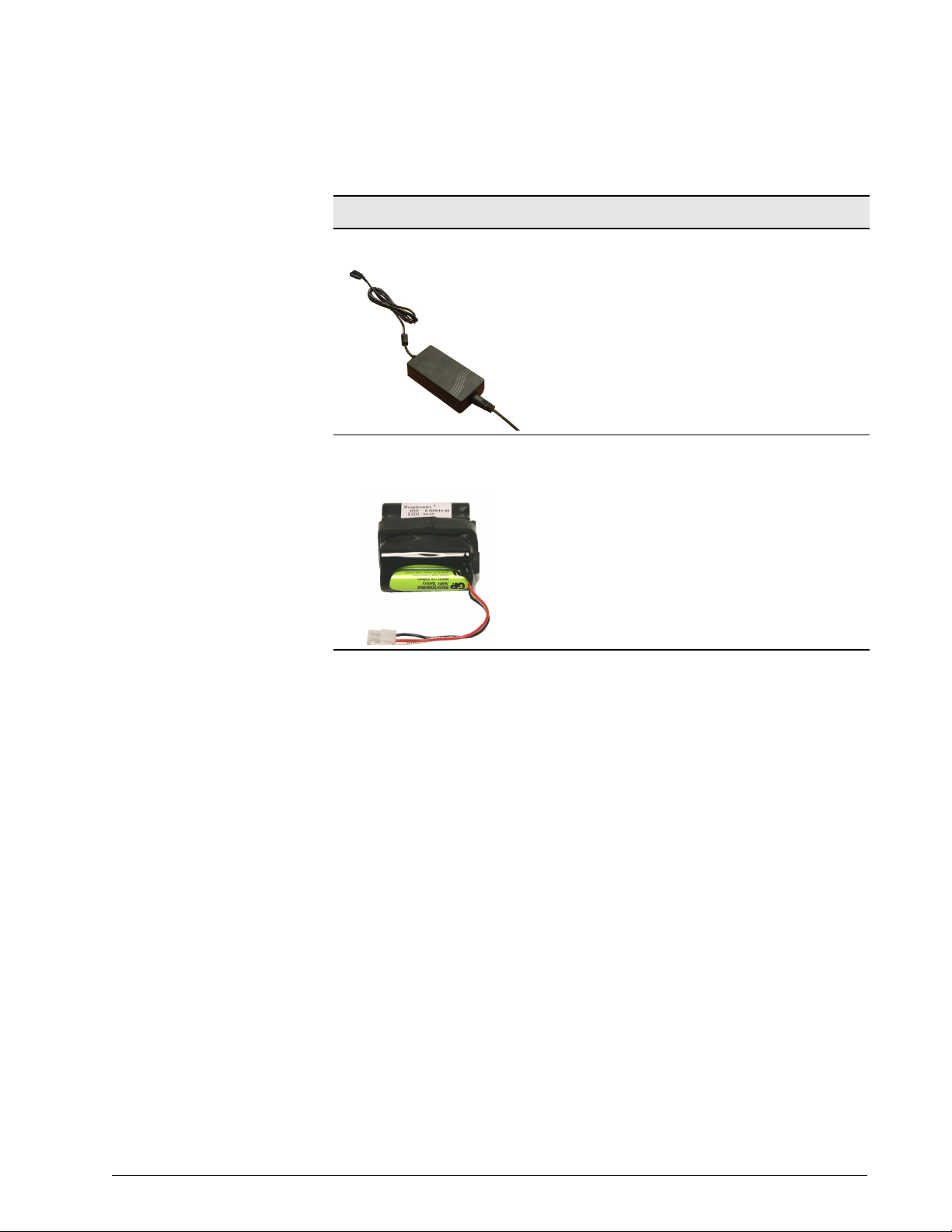

User Interface Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-10

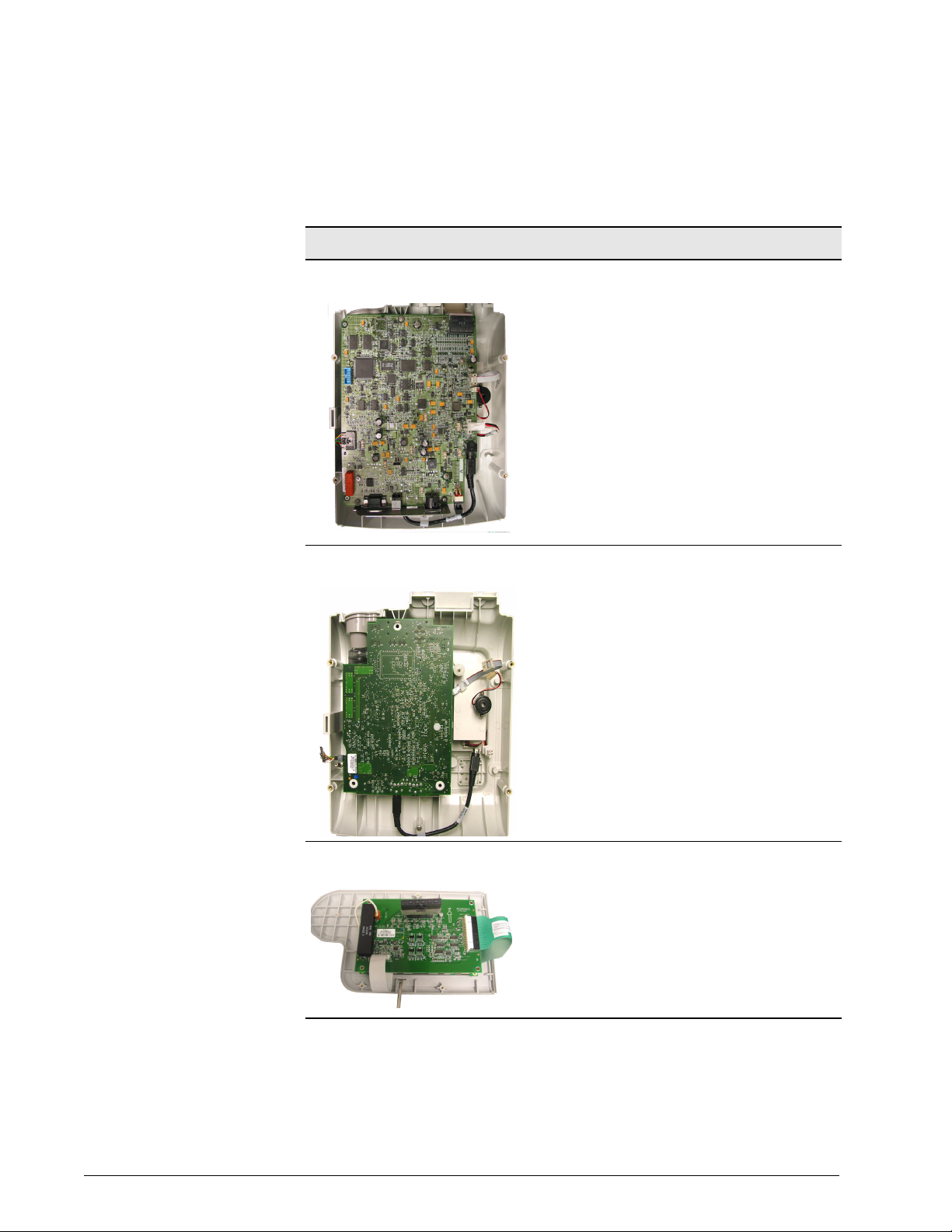

Controller PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-11

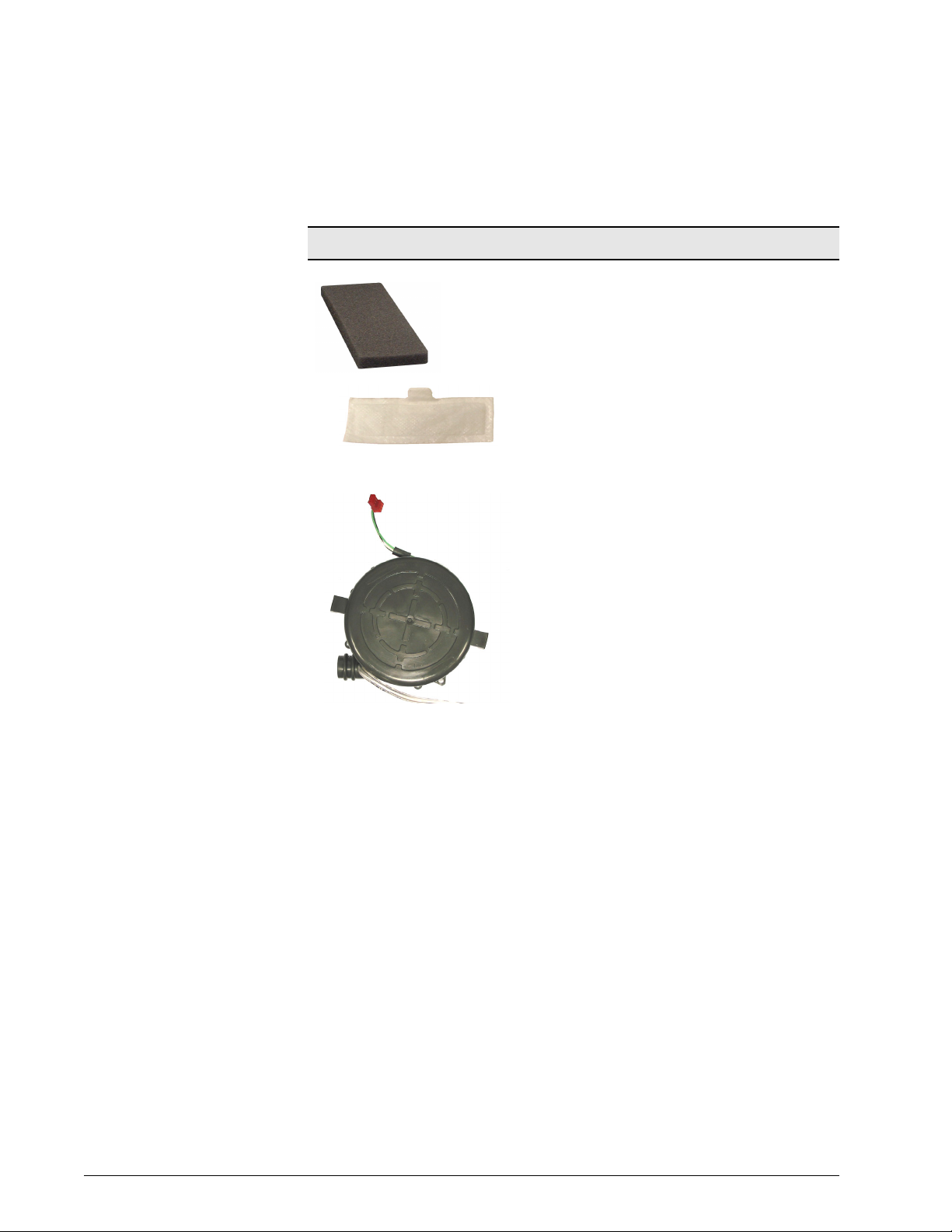

Valve Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-13

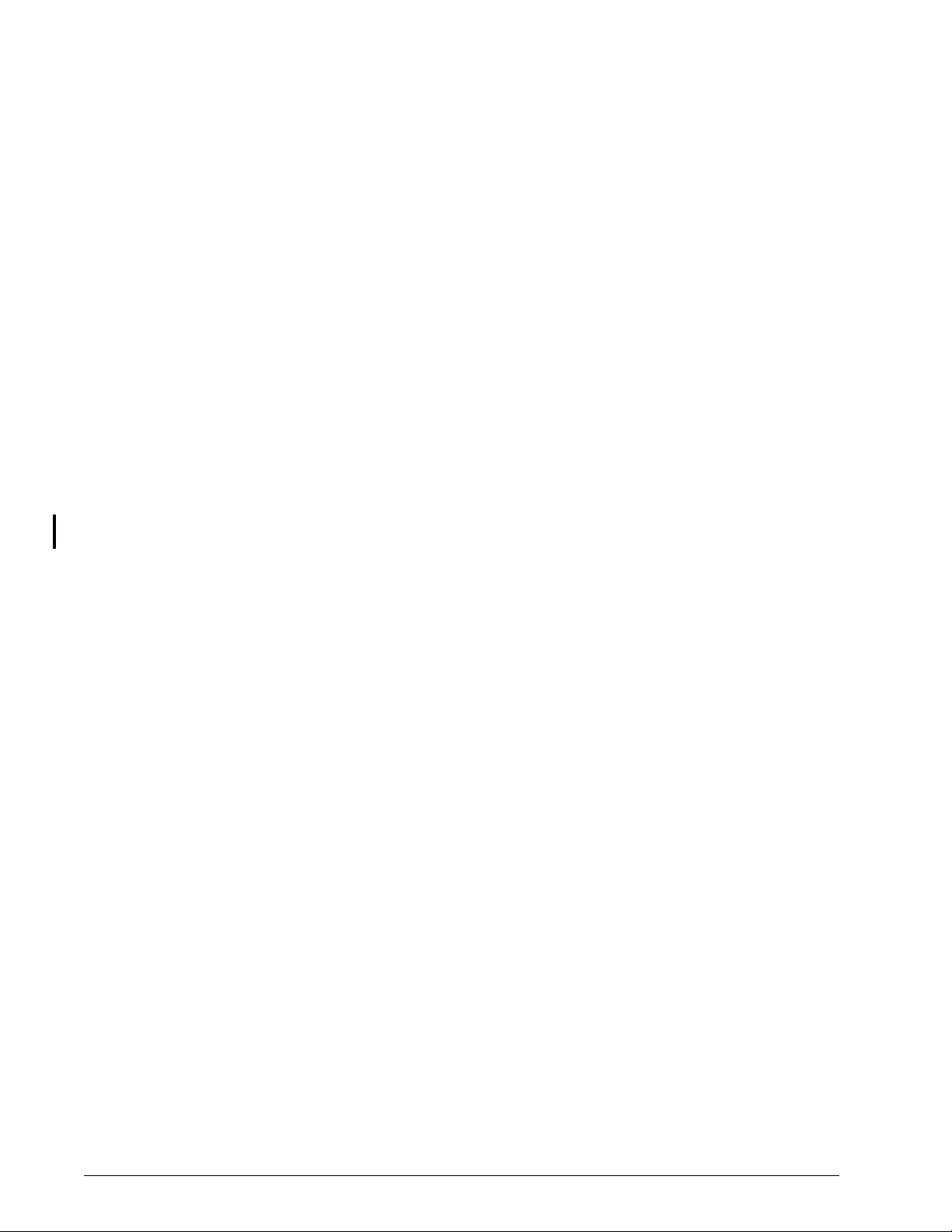

Blower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-14

IV BiPAP® Focus™ Ventilator Service Manual © Respironics, Inc. REF 1029568 Rev A

Page 5

Table of Contents

Secondary Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-15

Primary Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-16

Main Body Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-16

Interconnect Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-17

9. BiPAP Focus Replacement Parts List . . . . . . . . . . . . . . . . . . . . . . . 9-1

Complete Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

Exterior. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-3

Exterior

(continued) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-4

Front Panel/User Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-4

Ventilator Interior . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-5

Communications Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-6

Electronic Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-7

REF 1029568 Rev A BiPAP® Focus™ Ventilator Service Manual © Respironics, Inc. V

Page 6

Table of Contents

VI BiPAP® Focus™ Ventilator Service Manual © Respironics, Inc. REF 1029568 Rev A

Page 7

Chapter 1. Introduction and Intended Use

The BiPAP Focus Non-invasive Ventilator is a microprocessor-controlled,

electrically powered mechanical ventilator. The BiPAP® Focus™ Ventilator

System provides noninvasive ventilation for adult (over 30 kg or 66 lbs.)

patients for the treatment of respiratory insufficiency and distress, and

obstructive sleep apnea. The BiPAP Focus is appropriate for acute, sub-acute,

and intra-hospital transport settings.

The BiPAP Focus System is intended for use with nasal and full face masks.

The BiPAP Focus is not intended to be a life-support device.

The BiPAP Focus Ventilator meets or exceeds all applicable safety

requirements, consensus guidelines, US regulatory statutes, and international

regulatory standards for life support/mechanical ventilation devices.

Read this manual thoroughly prior to performing service or maintenance on the

BiPAP Focus Ventilator. This manual contains advanced troubleshooting,

calibration, and maintenance instructions for the BiPAP Focus. All

maintenance and repair work should be performed by qualified biomedical

technicians who have received appropriate training and authorization to

provide maintenance, repair, and service for the BiPAP Focus.

Review the operating instructions for the BiPAP Focus Ventilator before

running tests, checking operational readiness, or initiating patient use. These

instructions include important information about ventilator safety and

operation.

For additional information about accessories or related equipment, such as

humidifiers and remote alarm systems, refer to the appropriate instruction

manual prior to operating with the BiPAP Focus Ventilator.

The BiPAP Focus Operator’s Manual for the BiPAP Focus Ventilator lists all

applicable warnings and cautions. Review these notices thoroughly before

operating the ventilator.

REF 1029568 Rev A BiPAP® Focus™ Ventilator Service Manual © Respironics, Inc. 1-1

Page 8

Chapter 1

Introduction and Intended Use

Recommended Tools

and Test Equipment

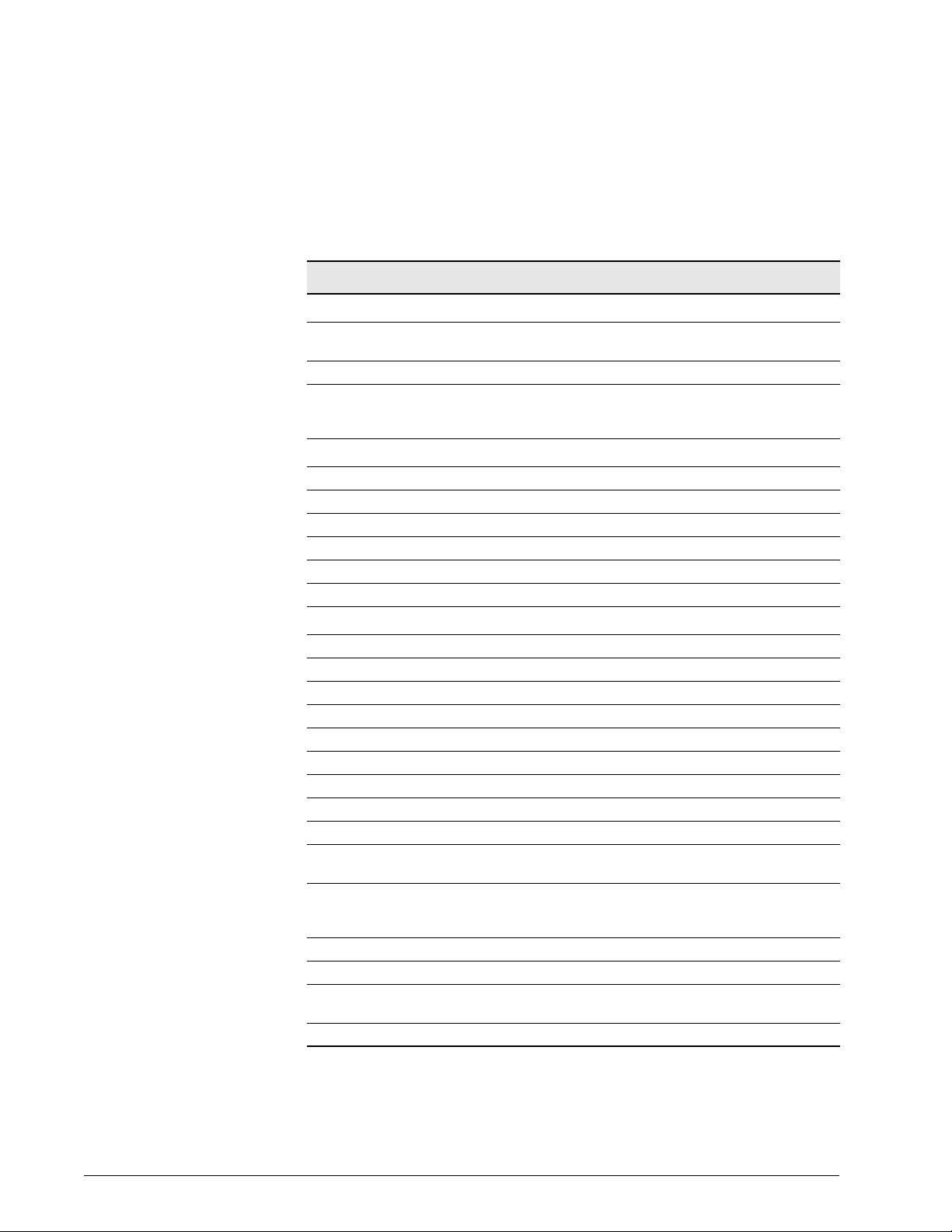

Table 1-1 lists the recommended tools, test equipment, and materials required

to service and maintain the BiPAP Focus Ventilator.

Description Manufacturer and Model

Test Equipment

Digital multimeter (DMM) accurate to three decimal

places

Electrical safety analyzer Dale LT 5440 or equivalent

Pneumatic calibration analyzer capable of measuring

low pressure (cmH

(liters)

O), flow rate (LPM), and volume

2

Ventilator Accessories

Connector, plastic, 22mm OD Respironics P/N 1006242 or equivalent

Connector, 22-mm (quantity 2) Respironics P/N or equivalent

Flow Control Valve Respironics P/N 1006120

Pressure test adapter Respironics P/N 312710

Tee, plastic with silicone rubber coupling Respironics P/N C06260 or equivalent

Tee silicone (quantity 2) Respironics P/N 1006243 or equivalent

Hand Tools and Materials

Pliers Local supplier

#1 Phillips head screwdriver Local supplier

#2 flat head screwdriver Local supplier

#2 Phillips head screwdriver Local supplier

Cleaning Cloth Local supplier

Isopropyl Alcohol Local supplier

Metric hex key set (rounded ends), 1.5 to 4 mm Local supplier

Mild detergent or antiseptic wipes Local supplier

Needle nose pliers Local supplier

BiPAP Focus Communications Cable Kit

(USB & DB9)

PC or laptop (required for downloading software) Required: Windows XP operating

Pen size flat head screwdriver Local supplier

Pen size Phillips head screwdriver Local supplier

Test lung, hard sided Respironics P/N 1021671 or local

Torque driver capable of 1 to 25 in.-lbs (N-m) Local supplier

Local Supplier

Respironics P/N 1012598 or equivalent

Respironics P/N 1030010

systems, serial comm port, and USB

port

supplier

Table 1-1: Recommended Test Equipment, Tools, and Materials

1-2 BiPAP® Focus™ Ventilator Service Manual © Respironics, Inc. REF 1029568 Rev A

Page 9

Introduction and Intended Use

Where to Go for Help For Customer Service and Product Support contact:

Respironics, Inc.

USA telephone: 1-800-345-6443

USA: 1-800-886-0245

International telephone: 724-387-4000

International fax: 724-387-5012

service@respironics.com.

clinical@respironics.com.

www.respironics.com.

Chapter 1

REF 1029568 Rev A BiPAP® Focus™ Ventilator Service Manual © Respironics, Inc. 1-3

Page 10

Chapter 1

Introduction and Intended Use

(This page is intentionally blank.)

1-4 BiPAP® Focus™ Ventilator Service Manual © Respironics, Inc. REF 1029568 Rev A

Page 11

Chapter 2. Warnings and Cautions

Warnings, Cautions, and Notes are used throughout this manual to

identify possible safety hazards, conditions that may result in

equipment or property damage, and important information that must be

considered when performing service and testing procedures on the

BiPAP Focus.

WARNING: A condition that could cause injury to a patient, operator or technician if

the operating instructions in this manual are not followed correctly.

CAUTION: A condition that could cause damage to, or shorten the service life of,

the device.

NOTE: Important information concerning the construction or operation of the

device.

Warnings • To assure the safety of the service technician and the specified

performance of the device, Respironics recommends that only

technicians having prior training or experience servicing

ventilatory devices perform any repairs or adjustment to the BiPAP

Focus.

• Use only Respironics repair/service parts. Use of non-Respironics

parts may alter ventilator reliability resulting in damage. Use of

non-Respironics repair parts will affect the ventilator warranty.

Contact Customer Service at 1-800-345-6443 or 724-387-4000

for more information.

• High voltages are present in the AC/DC Power Supply, Power Cord

and VGA PCB. To avoid electrical shock, disconnect the power

cord before attempting any repairs on the device or cleaning.

• DO NOT immerse this device into any fluids or allow any liquid to

enter the cabinet or the filter intake.

• To avoid personal injury, always disconnect external AC and DC

power sources from the ventilator before servicing or cleaning.

• To avoid personal injury or the possibility of damage to the

ventilator, regularly inspect the power cord to ensure it is free from

defects and any obvious wear and is properly grounded.

• This device is not for life support.

REF 1029568 Rev A BiPAP® Focus™ Ventilator Service Manual © Respironics, Inc. 2-1

Page 12

Chapter 2

Warnings and Cautions

• Never troubleshoot while a patient is connected to the ventilator,

since normal operation is suspended.

• If the ventilator has been operating, the internal parts may be hot.

Use caution when accessing.

• To prevent disease transmission, use protective equipment when

handling contaminated bacteria filters or other patient

accessories. Follow manufacturers' labeling and institutional

guidelines for disposal of contaminated accessories.

• To avoid cross-contamination between the test equipment and

ventilator, always install a bacteria filter between the main outlet

and test device.

• Explosion hazard. Do not operate the ventilator in the presence of

flammable anesthetic agents.

• To avoid the risk of fire, use only Respironics-approved batteries.

All battery connections are keyed to ensure proper connection. Do

not attempt to connect a battery incorrectly. Only qualified

technicians should install the battery.

• Use only Respironics-supplied cables with the nurse call station/

serial communications connector.

• To avoid personal injury or the possibility of damage to the

ventilator, DO NOT operate this device if it has failed any of its

diagnostic tests, either self or service initiated.

Cautions • Federal law (US) restricts this device to sale by, or on the order of,

a physician.

• Failure to replace a dirty filter may cause the device to operate at

higher than normal temperatures and damage the device.

• Use only Respironics-approved filters.

• Use only Respironics-approved batteries.

• The gray reusable air inlet filter must be completely dry before

use. Never place a wet filter into the device.

• Do not place more than one gray reusable air inlet filters that

come with the ventilator into the device at the same time. One

gray reusable air inlet filter and one white disposable ultra-fine

filter may be used.

• Replace any filter that is damaged.

• Do not attempt to clean or reuse disposable air inlet filters.

• Electronic components used in this device are subject to damage

from static electricity. Repairs made to this device must be

performed only in an antistatic, Electro-static Discharge (ESD)protected environment.

2-2 BiPAP® Focus™ Ventilator Service Manual © Respironics, Inc. REF 1029568 Rev A

Page 13

Chapter 2

Warnings and Cautions

• Care should be taken to avoid exposure of the BiPAP Focus to

temperatures at or near the extremes of those specified in Chapter

3. If exposure to such temperatures has occurred, the device

should be allowed to return to room temperature before being

turned on.

• Never place liquids on or near the BiPAP Focus.

• The information in this manual is provided for service personnel

reference.

• Always ensure that you are following proper electrostatic discharge

(ESD) grounding procedures before handling static-sensitive

devices.

• Be careful not to pull or crimp any cables, tubes or wires.

• Troubleshooting and repair should be performed only by a

qualified service technician.

Notes • Refer to the BiPAP Focus Operator’s Manual for product use,

additional Warnings, Cautions and Notes.

REF 1029568 Rev A BiPAP® Focus™ Ventilator Service Manual © Respironics, Inc. 2-3

Page 14

Chapter 2

Warnings and Cautions

(This page is intentionally blank.)

2-4 BiPAP® Focus™ Ventilator Service Manual © Respironics, Inc. REF 1029568 Rev A

Page 15

Chapter 3. Theory of Operation

The BiPAP® Focus™ Ventilator System provides noninvasive breathing

support for adult patients weighing 30 kg (66 lbs.) or greater.

The BiPAP Focus System offers two ventilation modes:

• Continuous positive airway pressure (CPAP), which provides a single

level of positive pressure to the patient.

• Spontaneous/Timed (S/T), which provides two levels of positive

pressure (one during inspiration and one during exhalation), and

delivers timed breaths if the patient does not initiate a breath.

The BiPAP Focus System alarms annunciate when high or low pressure

regulation, apnea, patient disconnect, low power, or loss of mains power

conditions occur. The system displays a real-time estimated delivered pressure

bar graph.

An Apnea Rate (#Apnea) Alarm is provided to alert the caregiver to repeated

periods of short apneas of 10 seconds or more. The caregiver can set the value

for how many apnea periods (10 seconds or more) can occur within an hour

before alarming. The total number of Apnea periods (10 seconds or more) for

the previous hour is displayed as part of the patient data. Because the previous

hours data is displayed, the number of apnea periods for the first hour is an

estimate only.

The BiPAP Focus System includes alarm silence and alarm pre-silence

features. Battery backup provides a minimum of 45 minutes of backup power

at default settings in case AC power is not available (for example, during

transport within the hospital).

The BiPAP Focus System features Digital Auto-Trak™, which allows it to

recognize and compensate for unintentional leaks and promote synchrony by

adjusting its trigger and cycle algorithms to maintain optimum performance.

REF 1029568 Rev A BiPAP® Focus™ Ventilator Service Manual © Respironics, Inc. 3-1

Page 16

Chapter 3

Theory of Operation

Air Delivery System Components

Air Inlet Filter(s) The air inlet filter removes coarse particulate from

Blower The blower draws room air though the air inlet filter and

ambient air as it is entrained into the blower assembly.

See Section 4 for periodic maintenance information.

The BiPAP Focus has a reusable dust filter that is gray in

color. An optional pollen filter, white in color is also

available.

muffler, and outputs air for delivery to the patient. The

DC impeller-type blower recirculates air through the flow

valve when not delivering gas to the patient. Compressor

speed is determined by patient settings. The controller

PCB controls compressor speed.

Table 3-1: Air Delivery System Components

3-2 BiPAP® Focus™ Ventilator Service Manual © Respironics, Inc. REF 1029568 Rev A

Page 17

Chapter 3

Theory of Operation

Air Delivery System Components (Continued)

Flow valve (FV) The flow valve (valve assembly) is a mechanical sliding

assembly driven by an electromagnetic coil. Valve

commands from the PCB control current (-125mA to

675mA) to the coil. Movement of the flow valve is

proportional to the current through the coil. The flow

valve operates as a closed-loop system, using feedback

from the flow sensor and pressure transducers.

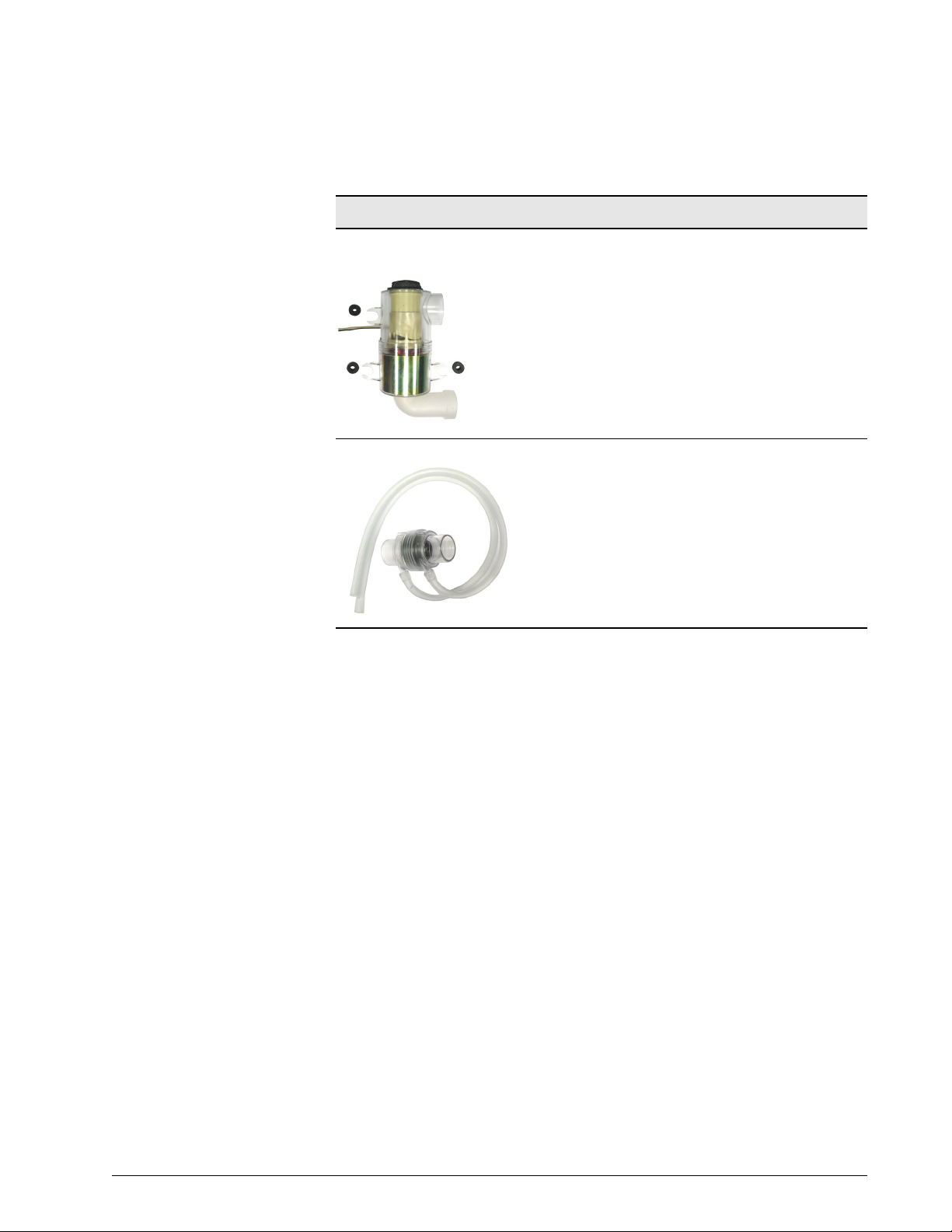

Air Flow Sensor The air flow sensor measures flow from the flow valve.

The ventilator uses this measurement to provide closed

loop control of the flow valve and to compute the flow

and volume delivered to the patient.

Table 3-1: Air Delivery System Components

REF 1029568 Rev A BiPAP® Focus™ Ventilator Service Manual © Respironics, Inc. 3-3

Page 18

Chapter 3

Theory of Operation

Electronic System Components

User Interface PCB • Motorola 68332 microcontroller

• Inter-processor communication with controller PCB

• VGA Display, Keyboard and front panel LED Interface

• Primary alarm driver

• Remote alarm relay

• USB and RS-232 serial communication

• Internal Battery charging and monitoring

• Temperature monitor

• Microcontroller watchdog and reset logic

• Voltage monitoring

Controller PCB • Blower On / Off / Closed-Loop Speed Control

• Air Flow Valve Controller

• Pressure Measurement

• RS-232 Communication

• Inter-processor communication with interface PCB

• Backup alarm driver

VGA PCB • STN Blue Mode Transmissive Viewing

• One-Quarter VGA (320 x 240)

• Dot Pitch 0.36mm x 0.36mm

Table 3-2: Electronic System Components

3-4 BiPAP® Focus™ Ventilator Service Manual © Respironics, Inc. REF 1029568 Rev A

Page 19

Theory of Operation

Electronic System Components (Continued)

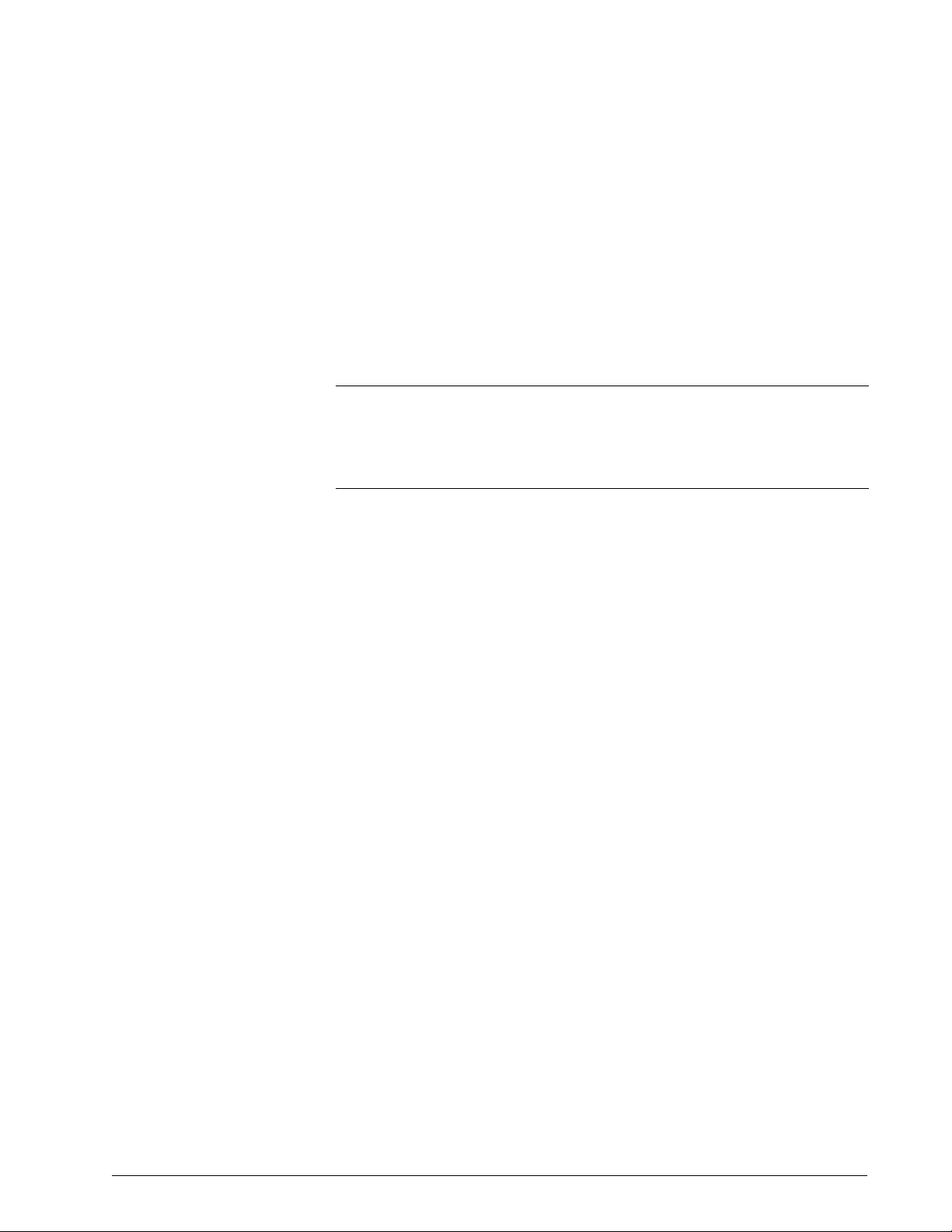

External AC/DC Power Supply • 90-240 VAC, 40-60Hz Input

• 120 Watt 18 Volt DC Output

Chapter 3

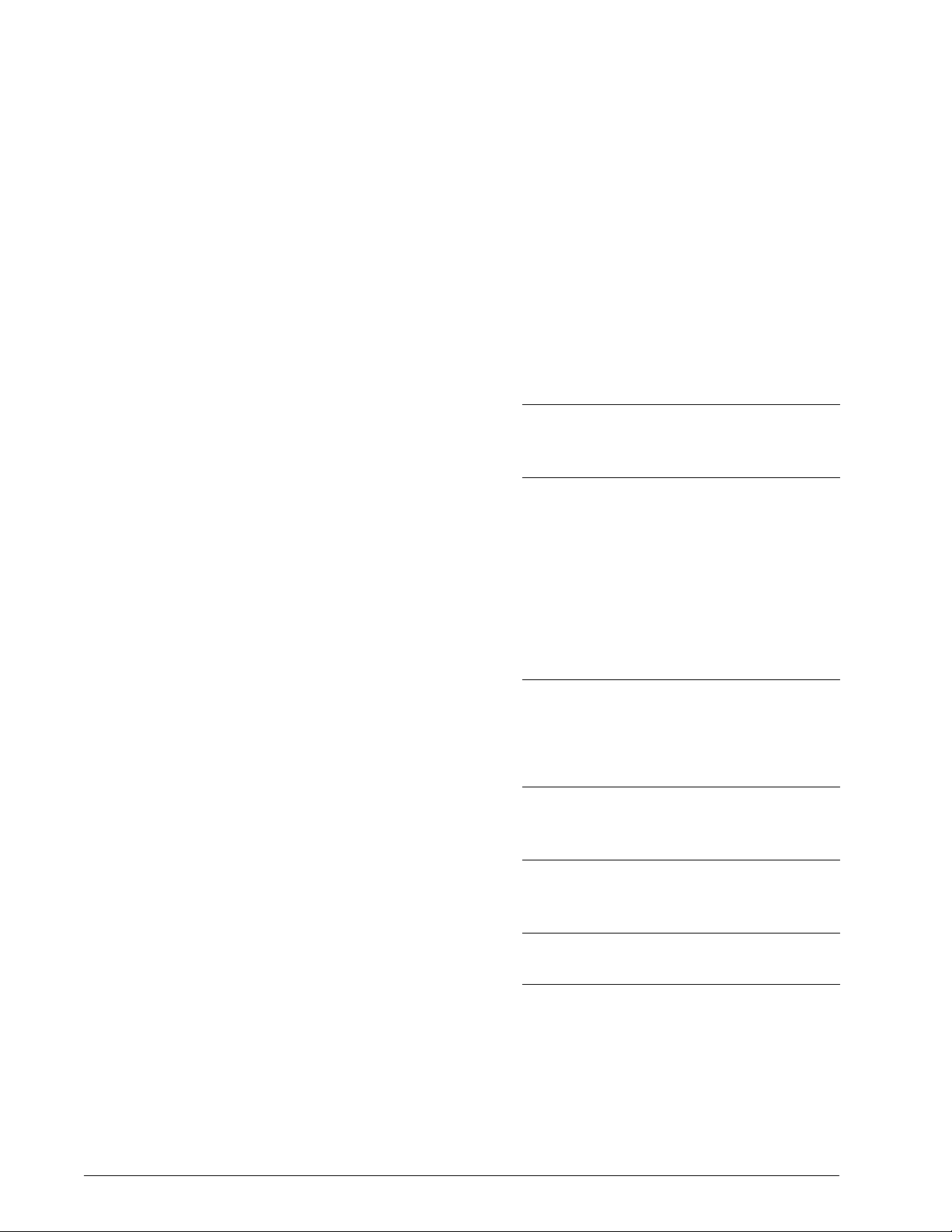

Internal NiMH (Nickel Metal Hydride)

Battery

Table 3-2: Electronic System Components

• 8 cell 3.8 Amp Hour provides 9.6 Volt output

nominal

• In-line thermal fuse

• Built-in thermistor for temperature monitoring

• Nominal charge time under 5 hours

• Nominal run time 45 minutes

REF 1029568 Rev A BiPAP® Focus™ Ventilator Service Manual © Respironics, Inc. 3-5

Page 20

Chapter 3

Theory of Operation

Back Panel The back panel has three connection points and the On/Off switch.

• Nurse call station / serial communications port

•USB port

• AC/DC Power supply input & power cord relief clip

•ON/OFF switch

USB

port

AC/DC power

supply input

ON/OFF switch

Shown in the

OFF position

Nurse call station/serial

communications port

Specifications Default Settings

S/T mode RR = 4/min

IPAP = 12 cmH

EPAP = 4 cmH

Rise-Time = 2 Ramp Start = 4 cmH

Settings: CPAP Mode

CPAP

Continuous Positive Airway

Pressure

Power cord relief clip

Figure 3-1: Back Panel

O I-Time = 1 sec

2

O Ramp Time = 0 min

2

Range: 4-20 cmH

Resolution: 1 cmH

Dynamic accuracy: ±5 cmH

O (4-20 hPa)

2

O (1 hPa)

2

O

2

O (5 hPa)

2

Ramp Time

Period over which the ventilator

increases inspiratory pressure

from Ramp Start setting to

CPAP setting.

Range: 0-45 min.

Resolution: 5 min.

Accuracy: ±10% of setting

3-6 BiPAP® Focus™ Ventilator Service Manual © Respironics, Inc. REF 1029568 Rev A

Page 21

Chapter 3

Theory of Operation

Ramp Start

Initial inspiratory pressure

Settings: S/T Mode

IPAP

Inspiratory positive airway

pressure, the inspiration

pressure setting

EPAP

Expiratory positive airway

pressure, the exhalation

pressure setting

Rise-Time

How quickly the ventilator

increases inspiratory pressure

from EPAP pressure to 67% of

pressure support level

Range: 4 cmH2O to CPAP setting (4 hPa to

CPAP setting)

Resolution: 1 cmH2O (1 hPa)

Range: 4-30 cmH

Resolution: 1 cmH

O (4-30 hPa)

2

O (1 hPa)

2

Dynamic accuracy: ±5 cmH2O (5 hPa)

IPAP cannot be set below EPAP.

Range: 4-25 cmH

O (4-25 hPa)

2

Resolution: 1 cmH2O (1 hPa)

Dynamic accuracy: ±5 cmH

O (5 hPa)

2

Range: 1-6 (where 1 = 0.1 sec and 6 = 0.6 sec)

Resolution: 1

Accuracy: ± (0.15 + 10% of setting) sec

Rate

Respiratory rate, used to

determine if a timed breath is

delivered

Range: 1-30/min

Resolution: 1/min

Accuracy: ±1/min or ±10% of setting, whichever

is greater over a 4-minute period.

I-Time and Rate settings cannot allow I-Time to

exceed expiratory time.

I-Time

Inspiratory time

Range: 0.5-3 sec

Resolution: 0.1 sec

Accuracy: ± (0.1 + 10% of setting) sec

I-Time and Rate settings cannot allow I-Time to

exceed expiratory time.

Ramp Time Range: 0-45 min

Resolution: 5 min

Accuracy: ±10% of setting

Ramp Start

Initial inspiratory pressure

Range: 4 cmH

2

Resolution: 1 cmH

O to EPAP (4 hPa to EPAP)

O (1 hPa)

2

REF 1029568 Rev A BiPAP® Focus™ Ventilator Service Manual © Respironics, Inc. 3-7

Page 22

Chapter 3

Theory of Operation

Measured Data

Patient circuit pressure bar

graph (continuous display)

Rate

Measured respiratory rate

Est. Vt

Estimated delivered tidal

volume

Est. MV

Estimated exhaled minute

volume

Range: 0-35 cmH2O (0-35 hPa)

Resolution: 1 cmH

Accuracy: ±10% of scale

In the event of total loss of power, the inspiratory

and expiratory pressure measured at the patient

exhalation port at 60 L/min is less than 1 cmH2O

by virtue of mask and ventilator design.

Range: 0-60/min

Resolution: 1/min

Accuracy: ± (1 + 10% reading)

Range: 0-4000 mL

Resolution: 1 mL

Accuracy (S/T Mode): ± (50 mL + 10% reading)

(when leak <60 L/min, using the Vision circuit)

Accuracy (CPAP Mode): ± (100 mL + 10%

reading) (when leak <60 L/min, using the Vision

circuit)

Vt display flashes when peak inspiratory flow for

successive breaths varies by more than 15 L/

min.

Range: 0-99 L/min

Resolution: 0.1 L/min

Accuracy: ± 1 L or ± 10% actual, whichever is

greater (when leak is <60 L/min using the Vision

circuit).

O (1hPa)

2

Leak

Estimated Patient leak

#Apnea

Brief apnea periods

Trigger

Breath trigger

NOTE: Est. Vt and Est. MV estimates are at ambient temperature and pressure, dry

(ATPD). Pressure signals are filtered using a 50-Hz low pass Butterworth filter.

Range: 0-150 L/min

Resolution: 1 L/min

Accuracy: ± (15 L/min +10%)

Range: 0-99/hour

Resolution: 1/hour

Accuracy: ± 1/hour (after 1 hour)

Range: Patient or Timed (ventilator)

3-8 BiPAP® Focus™ Ventilator Service Manual © Respironics, Inc. REF 1029568 Rev A

Page 23

Alarm Settings

Chapter 3

Theory of Operation

Apnea

The length of time without a

spontaneous breath that triggers the

Apnea alarm

#Apnea

The number of periods (10-seconds or

more) in the previous hour where the

patient has not initiated a

spontaneous breath.

NOTE: For the first hour, this value is

an estimate only.

Options

Display Units

Unit of pressure: centimeters of water

(cmH

O), hectoPascals (hPa), or

2

millibars (mbar).

Alarm Volume

Audible alarm volume

Range: 20, 40, 60 sec or OFF

Default setting: 20 sec

Range: 5, 10, 20, or OFF

Default setting: OFF

Range: cmH

Range: OFF, or minimum volume, to

maximum volume, in 5 discrete

settings.

O, hPa, or mbar

2

Contrast

Screen contrast

Brightness

Screen brightness

Reverse Video

Toggles reverse video

Screen Lock Timer Range: ON or OFF

Range: 20% to 100%

Range: 10% to 100%

Range: ON or OFF

REF 1029568 Rev A BiPAP® Focus™ Ventilator Service Manual © Respironics, Inc. 3-9

Page 24

Chapter 3

Theory of Operation

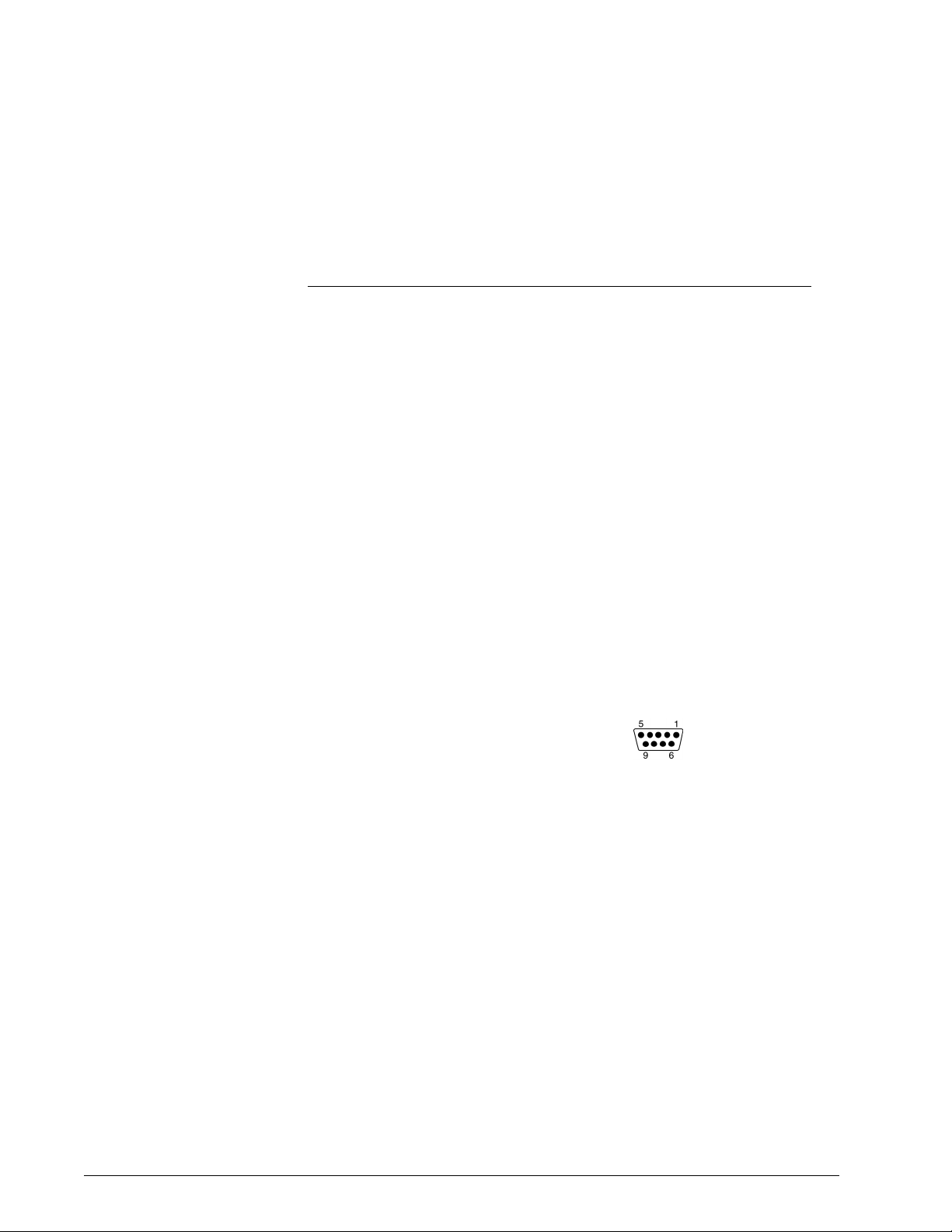

Nurse Call Station/Serial Communications Connector Pinout

Pin Signal

Nurse Call Station

1 Nurse call station common

6 Normally open (NO) during normal (non-alarm) operation

9 Normally closed (NC) during normal (non-alarm) operation

Serial Communications

2 Respironics advanced serial protocol (RASP) RS-232 Transmit (Tx)

3 RASP RS-232 Receive (Rx)

4 Not used

5 RS-232 signal ground

7 RS-232 Tx (reserved for future use)

8 RS-232 Rx (reserved for future use)

NOTE:

• When pins 1 and 6 are used, the relay is open during normal operation,

and closed during an alarm condition including loss of power.

• When pins 1 and 9 are used, the relay is closed during normal operation,

and open during an alarm condition including loss of power.

• Female DB9 connector pin configuration:

WARNING: Use only Respironics-supplied cables with the nurse call station/serial

communications connector.

Physical

BiPAP Focus

System Dimensions

355-mm H x 290-mm W x 140-mm D (14.0-in. H x 11.4-in.

W x 5.5-in. D)

Excluding accessories, gas inlets, patient connections.

Weight 4.5 kg (10 lbs.)

3-10 BiPAP® Focus™ Ventilator Service Manual © Respironics, Inc. REF 1029568 Rev A

Page 25

Chapter 3

Theory of Operation

Power

Input range 90-264 V~, 47-63 Hz, 90 VA

Battery backup 3.8 amp-hour (Ah) nickel metal hydride (NiMH) battery

provides 45 minutes of operation at default settings.

System automatically activates the battery charge cycle

when connected to AC power and the ON/OFF switch is

ON ( | ) (during normal operation or Standby mode).

Recharge time is typically under 5 hours, but may extend

further depending on machine settings if operating on

battery prior to recharge, or if operating in elevated

ambient temperature (above 28°C). Charge is complete

when the green CHARGING LED extinguishes.

Nurse call station relay Rated current: 0.280 A

Rated voltage: 250V

Fuse type No replaceable fuses.

Power cord Refer to the“Complete Parts List” on page 9-1

Triggers and Cycles

Volume-based trigger

Flow reversal cycle

Shape signal

Timed trigger

IPAP maximum of 3.0 seconds

Peak flow cycle

Supplemental Oxygen

Flow and pressure into

oxygen valve

Maximum flow: 15 L/min at ambient pressure

Environmental

Temperature Operating: +5 to +35°C at 10 to 95% relative

humidity

Storage: -20 to 60°C at 95% relative humidity

Atmospheric pressure Operating: 83 to 102 kPa (830 to 1020 mBar)

REF 1029568 Rev A BiPAP® Focus™ Ventilator Service Manual © Respironics, Inc. 3-11

Page 26

Chapter 3

Theory of Operation

Storage When the BiPAP Focus is not in use for periods

of 2 weeks or longer, it is recommended that the

unit be stored in a clean, sanitized plastic bag.

Bacteria Filter

Dead space 68 mL

Bacteria/viral filter

efficiency

Resistance 0.7 cmH

Connectors Male connector 15-mm I.D./22-mm O.D.

>99.99%

P/N 342077

O/L/s at 0.5 L/s

2

Female connector 22-mm I.D.

Date of Manufacture

The 12-digit serial number located on the base of the unit indicates the date of

manufacture. From left to right, the fifth and sixth digits indicate the year; the

seventh and eighth, the month; the ninth and tenth, the day. For example, the

serial number 0001050903-20 indicates that the device was manufactured 3

September, 2005.

3-12 BiPAP® Focus™ Ventilator Service Manual © Respironics, Inc. REF 1029568 Rev A

Page 27

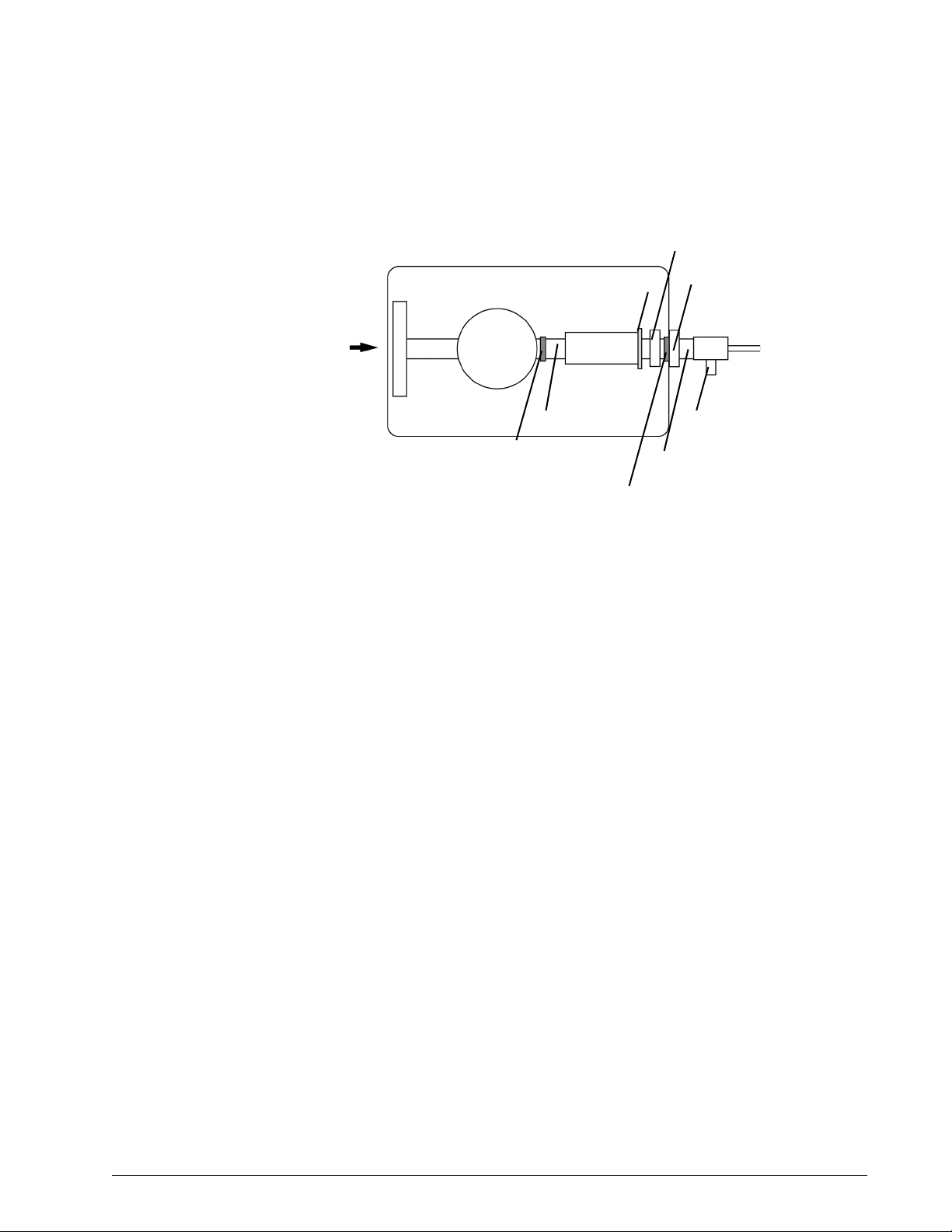

Pneumatics BiPAP Focus System pneumatic diagram:

Chapter 3

Theory of Operation

Air inlet

port

BiPAP Focus System

Air inlet

filter

Muffler

Blower

(motor)

Pressure sensor

Flow sensor

Control

valve

Tubing (elbow)

Diffuser

Bacteria filter

(mandatory)

Patient circuit

(to mask outlet)

Oxygen adapter

(if using oxygen)

Oxygen valve

(if using oxygen)

Outlet port and

pressure sensor

REF 1029568 Rev A BiPAP® Focus™ Ventilator Service Manual © Respironics, Inc. 3-13

Page 28

Chapter 3

Theory of Operation

(This page is intentionally blank.)

3-14 BiPAP® Focus™ Ventilator Service Manual © Respironics, Inc. REF 1029568 Rev A

Page 29

Chapter 4. Periodic Maintenance

This chapter provides guidelines and illustrates the cleaning and maintenance

procedures for the BiPAP Focus system.

Table summarizes maintenance procedures for the BiPAP Focus System.

To ensure correct operation, perform all maintenance at the recommended

intervals.

BiPAP Focus System Maintenance

Part Interval Procedure

Battery Replace the battery if a

Batt. Charge Failure alarm

occurs, or as indicated in

See “Replacing the

Battery” on page 4-3.

Air inlet filter(s) Reusable: clean monthly

or as needed.

Reusable: every year or as

needed.

Disposable: replace as

needed.

The air path cannot be

cleaned.

System exterior As needed. Clean the exterior of the ventilator with

Qualified service technician only.

NOTE: If the unit has been in

storage or has not been used for 3

months, the battery will require a

full charge.

Follow the “Cleaning the Reusable Air

Inlet Filter” on page 4-2.

Replace.

Do not attempt to clean or reuse

disposable filters.

a soft damp cloth moistened with any

of the following solutions:

• Mild detergent or soapy water

• 10% bleach solution (90% water)

• Isopropyl alcohol (91%)

• Quaternary ammonium germicides

(sprays or disposable cloths)

Do not spray or immerse in liquid. Do

not allow liquid to penetrate the

system.

Flow Valve

Assembly

10,000 hours

(Total operating hours

Refer to Figure 5-3 on

page 5-3.)

Replace Flow Valve Assembly

Table 4-1: BiPAP Focus System Maintenance

REF 1029568 Rev A BiPAP® Focus™ Ventilator Service Manual © Respironics, Inc. 4-1

Page 30

Chapter 4

Periodic Maintenance

Storing the BiPAP

Focus

Cleaning the

Reusable Air Inlet

Filter

When the BiPAP Focus is not in use for periods of 2 weeks or longer, it is

recommended that the unit be stored in a clean, sanitized plastic bag.

While the unit is being stored, ensure that the power switch on the back of the

unit is in the OFF (O) position. If the switch is not turned OFF, the internal

battery will be depleted within two weeks. If the unit is stored with the power

switch in the OFF (O) position, the internal battery will deplete within 3

months.

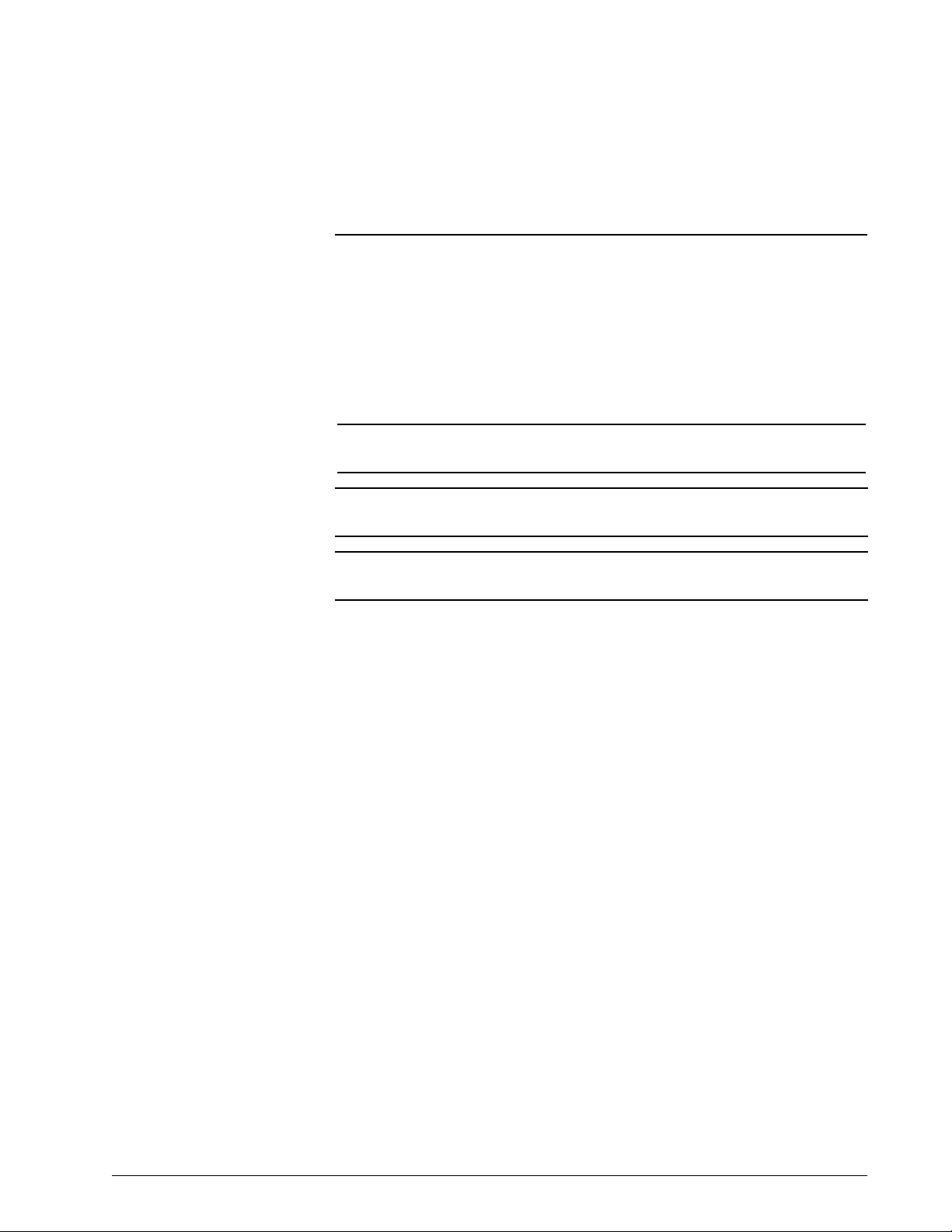

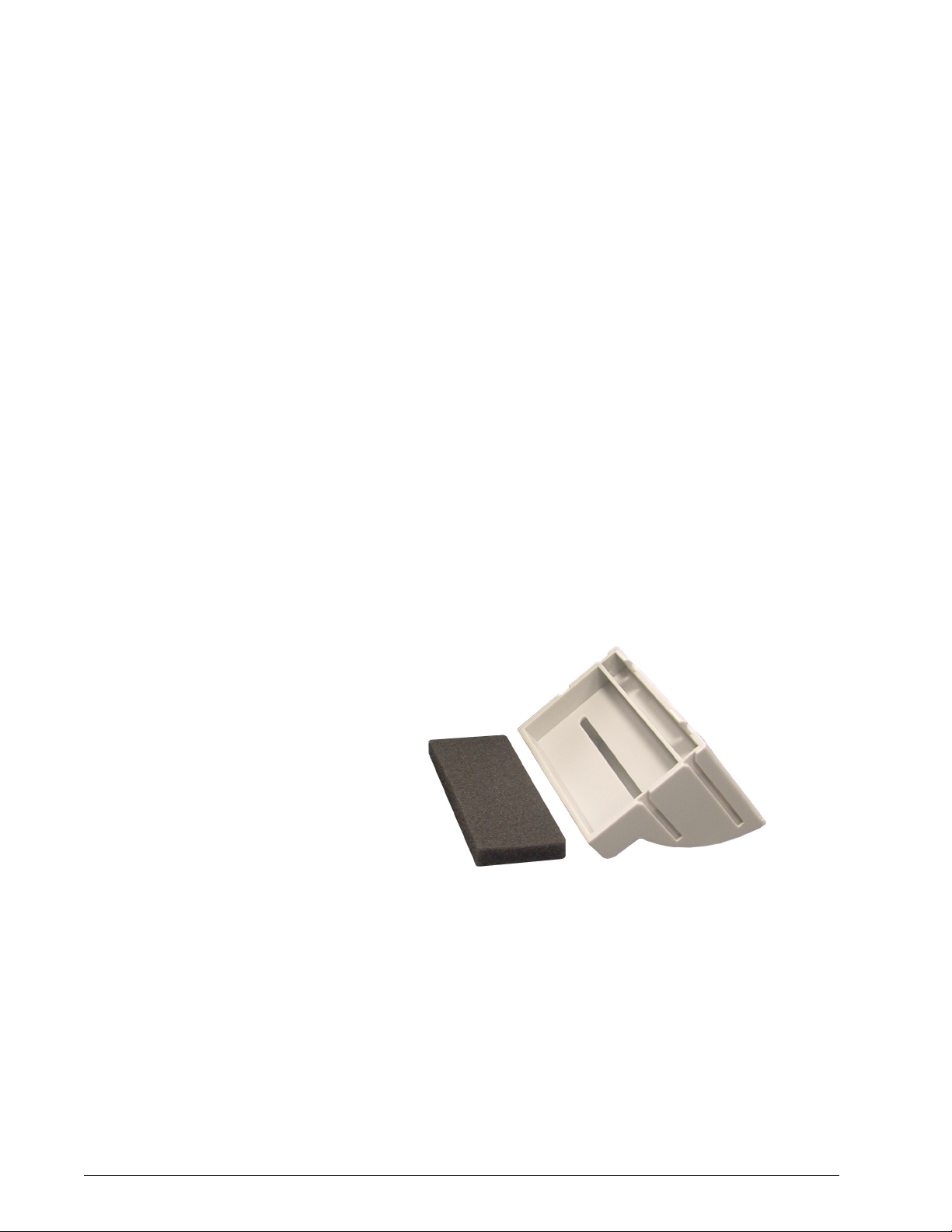

Follow these steps to clean the reusable air inlet filter (Figure 1):

1. Remove the filter via the main rear access door (filter door) and

examine for damage or debris on the filter.

2. Wash using one of the following solutions, then rinse thoroughly:

• Liquid dishwashing detergent

• White distilled vinegar (5% acidicy)

• Isopropyl alcohol (99.9%)

• Hydrogen peroxide (3%)

• Bleach

• Sodium hypochloride (6%)

3. Allow the filter to dry completely before reinstalling.

Figure 1: Reusable Air Filter

Reusable

air inlet filter

(gray)

CAUTION: Failure to replace a dirty filter may cause the device to operate at higher

than normal temperatures and damage the device.

CAUTION: Use only Respironics-approved filters.

CAUTION: The gray reusable air inlet filter must be completely dry before use. Never

place a wet filter into the device.

Filter door

4-2 BiPAP® Focus™ Ventilator Service Manual © Respironics, Inc. REF 1029568 Rev A

Page 31

Chapter 4

Periodic Maintenance

Replacing the Air

Inlet Filter(s)

The reusable air inlet filter (gray) must be installed and replaced every year.

An additional ultra-fine disposable filter (white) is also recommended for

enhanced particulate filtering.

CAUTION: Replace any filter that is damaged.

CAUTION: Do not attempt to clean or reuse disposable air inlet filters.

CAUTION: Do not place more than one gray reusable air inlet filters that come with

the ventilator into the device at the same time. One gray reusable air inlet

filter and one white disposable ultra-fine filter may be used.

Replacing the Battery WARNING: To avoid the risk of fire, use only Respironics-approved batteries. All battery

connections are keyed to ensure proper connection. Do not attempt to connect

a battery incorrectly. Only qualified technicians should install the battery.

NOTE: NOTE: If a Low Battery or Battery Depleted alarm occurs during Pre-

Operational Check, then the battery requires charging. If a Batt. Charge

Failure alarm occurs, the battery may be fully depleted. A re-charge is

recommended before proceeding. If the battery does not begin to charge

after one hour and the Batt. Charge Failure persists, contact customer

service for a replacement battery.

NOTE: Battery alarms will sound towards the end of the battery test. Gas delivery

will continue during this time, until the battery is depleted.

If the number of battery powered operations is greater than 220 per year, the

battery should be replaced every six months. If the number of battery

powered operations is less than 220 per year, the battery should be replaced

every year. It is recommended that the battery be tested once per month. A

fully charged battery is designed to operate for 45 minutes at default settings

(See “Power” on page 3-11). If the battery does not continue to deliver gas for

45 minutes at these settings, it should be replaced.

REF 1029568 Rev A BiPAP® Focus™ Ventilator Service Manual © Respironics, Inc. 4-3

Page 32

Chapter 4

Periodic Maintenance

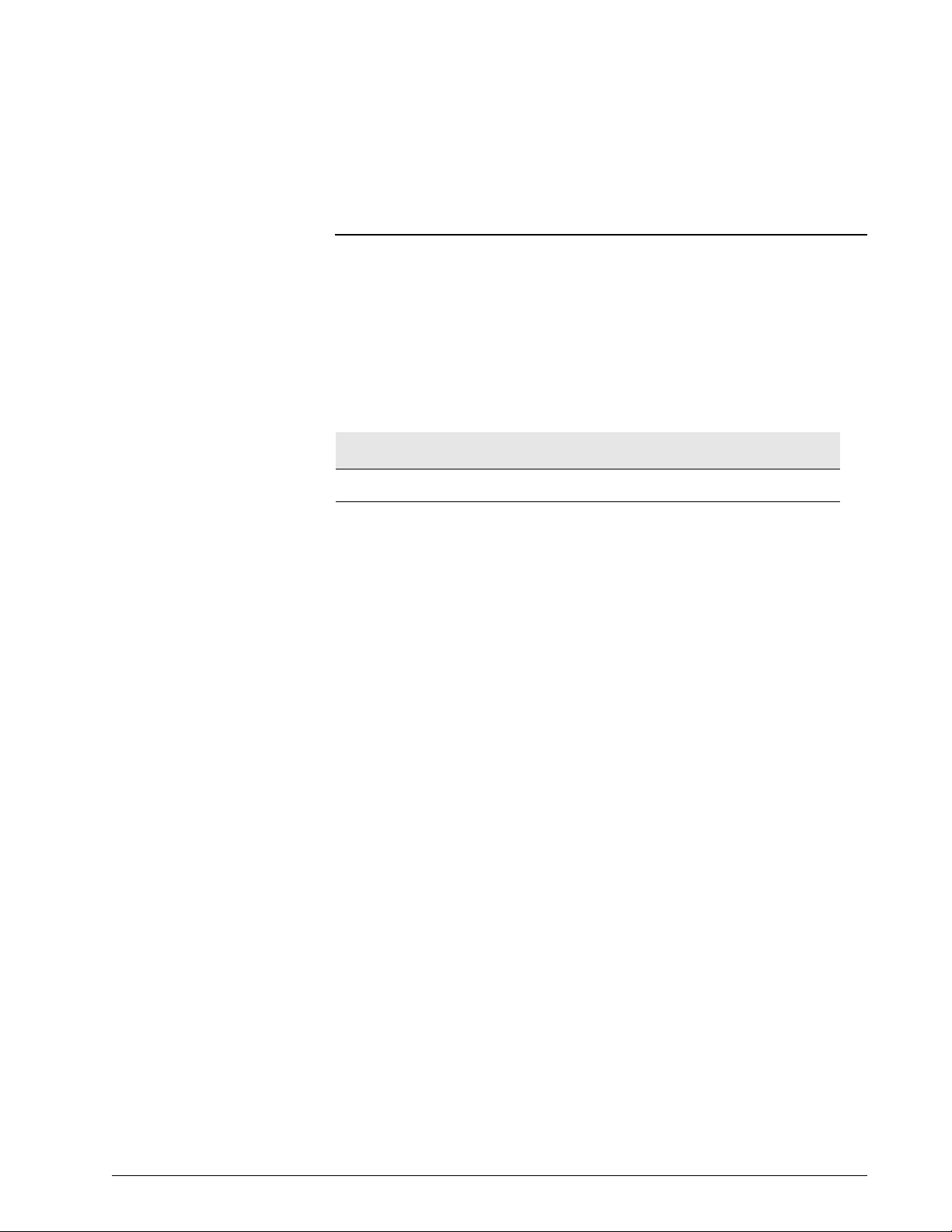

Battery compartment

Battery cable

connector

Figure 4-1: Replacing the Battery

Follow these steps:

1. Turn the system OFF and disconnect the DC power supply.

2. Remove the two screws that secure the battery compartment door.

3. Unplug the battery cable and remove the old battery from its

compartment.

4. Insert a new Respironics-approved battery (see “BiPAP Focus

Replacement Parts List” on page 9-1) into the compartment and plug

the battery cable into its connector.

5. Replace the battery compartment door and screws.

6. Reconnect the DC power supply.

CAUTION: Use only Respironics-approved batteries.

4-4 BiPAP® Focus™ Ventilator Service Manual © Respironics, Inc. REF 1029568 Rev A

Page 33

Chapter 5. Diagnostic Mode and

Troubleshooting

This section describes the BiPAP Focus diagnostic mode and other

troubleshooting procedures.

Diagnostic mode allows:

• View product information, including serial numbers and versions of

software and hardware.

• View and adjust system settings, including Language, time since last

service, date and time.

• View and adjust operator preferences, including units of pressure,

alarm volume, contrast, brightness, reverse video and screen lock.

• View the significant event log.

• View the UI board controls and sensor readings for troubleshooting.

• Test alarm indicators and view internal voltages for troubleshooting.

• Test blower and controller board backup alarm.

Entering Diagnostic

Mode

WARNING: Diagnostic mode suspends normal ventilation: disconnect the patient from

the ventilator before entering diagnostic mode.

CAUTION: Troubleshooting and repair should be performed only by a qualified

service technician.

To enter diagnostic mode, simultaneously press the Alarm/Reset and Alarm/

Silence keys on the ventilator front panel at power up for 15 seconds or until

diagnostic mode appears on the screen. At the warning prompt, press Enter to

start diagnostic mode. The diagnostic main menu (Figure 5-1) appears.

REF 1029568 Rev A BiPAP® Focus™ Ventilator Service Manual © Respironics, Inc. 5-1

Page 34

Chapter 5

Diagnostic Mode and Troubleshooting

Figure 5-1: Diagnostic Mode Main Menu

Press the arrow keys to highlight the menu selection, then press Enter.

To exit diagnostic mode at any time, turn the ventilator off.

Product Information The product information screen (Figure 5-2) displays serial number and

version number information for hardware and software components of the

ventilator.

To view the product information screen, use the arrow keys to highlight

PRODUCT INFORMATION on the diagnostic mode main menu, then

press Enter. Press Menu to return to the main menu.

Figure 5-2: Diagnostic Mode: Product Information Screen

5-2 BiPAP® Focus™ Ventilator Service Manual © Respironics, Inc. REF 1029568 Rev A

Page 35

Diagnostic Mode and Troubleshooting

System Settings The systems settings screen (Figure 5-3) allows:

• Set the date and time: select the month, day, year, hour, minute, and

12- or 24-hour format.

• Language, Time Since Service: choose the Language and reset the

time since the last service

1. Use the arrow keys to highlight the field or button whose value to

change, then press Enter.

2. Use the arrow keys to adjust a value or select a setting from a drop-

down menu, then press Enter (or press Cancel to exit without making a

change).

3. Press the Menu key to return to the main menu.

Chapter 5

Figure 5-3: Diagnostic Mode: System Settings Screen

Preferences The preferences screen (Figure 5-13) allows:

• Adjust display units.

• Adjust alarm volume.

• Adjust display contrast.

• Adjust display brightness.

• Select reverse or normal video.

• Adjust screen lock timer.

REF 1029568 Rev A BiPAP® Focus™ Ventilator Service Manual © Respironics, Inc. 5-3

Page 36

Chapter 5

Diagnostic Mode and Troubleshooting

Figure 5-4: Diagnostic Mode: Preferences Screen

To view the preferences screen, use the arrow keys to highlight PREFERENCES

on the diagnostic mode main menu, then press Enter.

1. Use the arrow keys to highlight the button whose value to change, then

press Enter:

2. If selected:

Display Units, the screen shows the current ventilator units settings.

Use the arrow keys to highlight cmH

O, hPa, or mbar then press Enter.

2

Alarm Volume, a popup screen displays the current alarm volume

setting. Use the arrow keys to adjust the volume from 1 to 5 (in

increments of 1), then press Enter (or press Cancel to exit without

making a change). The alarm volume cannot be turned completely off.

Contrast, a popup screen displays the current display contrast setting.

Use the arrow keys to adjust the contrast from 20% to 100% (in

increments of 20%), then press Enter (or press Cancel to exit without

making a change).

Brightness, a popup screen displays the current display brightness

setting. Use the arrow keys to adjust the contrast from 10% to 100%

(in increments of 10%), then press Enter (or press Cancel to exit

without making a change).

Reverse Video, pressing Enter toggles between reverse and normal

video.

Screen Lock Timer, the screen displays on/off lock setting. Use the

arrow keys to select, the press Enter.

3. Press the Menu key to return to the main menu.

5-4 BiPAP® Focus™ Ventilator Service Manual © Respironics, Inc. REF 1029568 Rev A

Page 37

Chapter 5

Diagnostic Mode and Troubleshooting

Significant Event Log The significant event log (Figure 5-5) allows viewing a log of system events,

including settings changes, alarms, and codes that can be used for

troubleshooting. See “Significant Event Log” on page 5.which describes

significant event codes in detail. The log includes the 200 most recent events.

Setting Up the Serial

Interface for DRPT

Figure 5-5: Diagnostic Mode: Significant Event Log

To view the significant event log, use the arrow keys to highlight SIGNIFICANT

EVENT LOG on the diagnostic mode main menu, use the arrow keys to scroll

up and down. Press Menu to return to the main menu.

Follow these steps to connect the ventilator and a PC to create a diagnostic

report (DRPT):

1. Connect BiPAP Focus Communications Cable (P/N 1030010)

between the PC and BiPAP Focus ventilator. Connect the male end

labeled Diagnostics to the back of the ventilator and the female end to

the service PC.

2. Power up the ventilator in diagnostic mode: simultaneously press the

Alarm/Reset and Alarm Silence keys for approximately 15 seconds

while turning ventilator power on.

3. Launch the HyperTerminal program on the PC by clicking Start >

Programs > Accessories > Communications > HyperTerminal, then

double-clicking on the HyperTerminal icon.

4. Enter a name for the connection (BiPAP Focus Communications is

entered in Figure 5-6) and choose an icon, then click OK).

REF 1029568 Rev A BiPAP® Focus™ Ventilator Service Manual © Respironics, Inc. 5-5

Page 38

Chapter 5

Diagnostic Mode and Troubleshooting

Figure 5-6: Entering a Name for the Connection to the BiPAP Focus Ventilator

5. Select the appropriate serial port (Figure 5-7 shows Com1 selected),

then click OK.

Figure 5-7: Selecting the Serial Port

6. Enter these settings for the serial port (Figure 5-8):

Figure 5-8: Serial Port Settings

5-6 BiPAP® Focus™ Ventilator Service Manual © Respironics, Inc. REF 1029568 Rev A

Page 39

Chapter 5

Diagnostic Mode and Troubleshooting

7. Click OK.

8. The blank HyperTerminal window remains. Continue configuring the

properties. Click File > Properties from the menu bar.

9. Click on the Settings tab (Figure 5-9).

10. Select ANSIW from the Emulation drop-down list box.

Figure 5-9: HyperTerminal Settings Tab

11. Click the Terminal Setup button.

12. Select underline and blink for cursor settings then click OK.

Figure 5-10: Terminal Settings

13. Click the ASCII Setup button (Figure 5-9).

REF 1029568 Rev A BiPAP® Focus™ Ventilator Service Manual © Respironics, Inc. 5-7

Page 40

Chapter 5

Diagnostic Mode and Troubleshooting

14. Match the ASCII Setup screen (Figure 5-11), then click OK.

Figure 5-11: ASCII Setup Screen

15. Save this configuration. Select File > Save As and save to the desktop

if you want to create an icon for BiPAP Focus Communications on the

Windows desktop.

5-8 BiPAP® Focus™ Ventilator Service Manual © Respironics, Inc. REF 1029568 Rev A

Page 41

Chapter 5

Diagnostic Mode and Troubleshooting

Generating a

Diagnostic Report

(DRPT)

1. With the BiPAP Focus ventilator in diagnostic mode and the serial

communcations cable, the end labeled Diagnostics connected to the

ventilator, start HyperTerminal, open the BiPAP Focus

Communications file, or click on the BiPAP Focus Communications

icon on the PC (if created).

2. Type DRPT (all caps) in the dialog box, and press the Enter key. This

pulls information found in the significant event log.

3. If the ventilator is connected and communication occurs, a response

similar to the following appears:

Respironics Inc. BiPAP Focus Ventilator

Serial Number: 8772060206-04

Date & Time : 6/19/06 20:49

Event ID Date Time

905 Pwr O n r e set 6/1 9 / 0 6 20:43

300 POS T S u c ce ssful 6/1 9 / 0 6 20:43

102 Pow e r O f f 6/1 9 / 0 6 20:42

4 3 7 B a t t e r y V o l t a g e F a i l e d 6 / 1 9 / 0 6 2 0 : 4 2 V 6 1 5 , 6 1 5

639 Dis c o n n e ct 6/1 9 / 0 6 20:42

6 3 5 B a t t e r y D e p l e t e d 6 / 1 9 / 0 6 2 0 : 4 2 6 3 7 , 6 3 3

644 Apne a 6/19/06 20 : 4 2

639 Disconnect 6/19/06 20:

6 3 5 B a t t e r y D e p l e t e d 6 / 1 9 / 0 6 2 0 : 4 1 6 8 7 , 6 4 9

6 4 3 L o w B a t t e r y 6 / 1 9 / 0 6 2 0 : 4 1 7 1 4 , 7 2 3

905 Pwr O n r e set 6/1 9 / 0 6 20:41

300 POS T S u c ce ssful 6/1 9 / 0 6 20:41

102 Pow e r O f f 6/1 9 / 0 6 20:41

905 Pwr O n r e set 6/1 9 / 0 6 20:26

300 POS T S u c ce ssful 6/1 9 / 0 6 20:26

102 Pow e r O f f 6/1 4 / 0 6 16:52

905 Pwr O n r e set 6/1 3 / 0 6 16:32

300 POS T S u c ce ssful 6/1 3 / 0 6 16:32

102 Pow e r O f f 6/1 3 / 0 6 16:32

639 Dis c o n n e ct 6/1 3 / 0 6 16:31

905 Pwr O n r e set 6/1 3 / 0 6 16:27

300 POST Successful 6/13/06 16:27

REF 1029568 Rev A BiPAP® Focus™ Ventilator Service Manual © Respironics, Inc. 5-9

Page 42

Chapter 5

Diagnostic Mode and Troubleshooting

Figure 5-12 shows how to interpret each line of the DRPT report.

437 Battery Voltage Failed 6/19/06 20:42 V 615,615

615, 615 - Actual

measurement value

(A/D counts)

V or T - System errors

V= voltage, T= temperature

20:42 - Time stamp of most recent

diagnostic mode occurrence

6/19/06 - Date stamp of most recent

diagnostic code occurrence

Battery Voltage Failed - description

437 - Diagnostic Code

Figure 5-12: Interpreting the DRPT Report

5-10 BiPAP® Focus™ Ventilator Service Manual © Respironics, Inc. REF 1029568 Rev A

Page 43

Diagnostic Mode and Troubleshooting

Sensor Readings The sensor readings screen (Figure 5-13) allows:

View sensor readings: view these readings to see the real-time effect of

changes to voltages, temperature and control signals.

Chapter 5

Figure 5-13: Diagnostic Mode: Sensors Screen

Table 5-1 defines sensor readings for the BiPAP Focus.

NOTE: Hi = 1 and Lo = 0

Sensor Readings Defined

Diagnostics Label Actual Measured Value Description

+3.3V +3.3V_MEAS Measurement of +3.3V

Supply count limits: 883 to 976

Voltage (V) = counts * 0.003662

+5V +5V_MEAS Measurement of +5V

Supply count limits: 884 to 977

Voltage (V) = counts * 0.005371

+12V +12V_MEAS Measurement of +12V supply

Count limits: 889 to 983

Voltage(V) = counts * 0.012817

Table 5-1: Sensor Readings Defined (Sheet 1 of 4)

REF 1029568 Rev A BiPAP® Focus™ Ventilator Service Manual © Respironics, Inc. 5-11

Page 44

Chapter 5

Diagnostic Mode and Troubleshooting

Diagnostics Label Actual Measured Value Description

+18Vin 18VIN_MEAS Measurement of +18V (mains input)

+18V Boost 18V_BOOST_MEAS Measurement of +18V_Boost supply

VBATT/VTEMP VBATT_VTEMP_MEAS Battery Temperature measurement when

Sensor Readings Defined

Count limits: 882 to 1008

Voltage(V) = counts * 0.019043

Count limits: 923 to 1020

Voltage(V) = counts * 0.019043

unit operating from Mains or Battery

Voltage measurement when operating on

battery.

Counts limit (volt.): 624 to 936

Voltage(V) = counts * 0.012817

Counts limit (temp.): 79 to 421

Within limits - battery temp ok.

VOptoCap OPTO_CAP_MEAS Measurement of backup capacitor voltage

on User Interface Board.

Count limits: 616 to 782

Voltage(V) = counts * 0.005371

Board Temp BOARD_TEMP_MEAS Measurement of temperature on the User

Interface PCB

Count limits: 233 to 540

Temp. (degC) = ((counts * .00244) - 0.6) *

100

Ambient Temp TEMP_DATA Measurement of Ambient Temperature

within the unit

Limits : 0 to 60degC.

+18VINCMP VIN_COMP_BUF Signal for detection if the incoming mains

voltage is above a certain threshold

(15.64V typically).

Hi: Above threshold

Lo: Below threshold

Table 5-1: Sensor Readings Defined (Sheet 2 of 4)

5-12 BiPAP® Focus™ Ventilator Service Manual © Respironics, Inc. REF 1029568 Rev A

Page 45

Chapter 5

Diagnostic Mode and Troubleshooting

Sensor Readings Defined

Diagnostics Label Actual Measured Value Description

+18VBSTCMP 18V_BOOST_COMP Signal for detection if the 18V_Boost mains

voltage is above a certain threshold

(15.64V typically)

Hi: Above threshold

Lo: Below threshold

BattChrgFault BATT_CHRG_FAULT_BUF Signal for detection if there is a fault in the

battery charging

Hi: Fault

Lo: No Fault

BattOnChrg BATT_ON_CHG_BUF Signal for detection if the battery is being

charged

Hi: Battery charging

Lo: Battery not charging

BattChrgToc BATT_CHR_TOC Signal for detection if a top-off charge is

being applied to battery

Hi: Battery NOT in TOC state

Lo: Battery in TOC state

BattChrgRdy BATT_CHG_READY_BUF Signal for detection if the battery is ready

PORLATCH EXT_WDOG_LATCHED Signal for detection if the processor was

for charging

Hi: Ready for charging

Lo: Not ready for charging

reset due to a drop in the +3.3V rail. This

signal must be primed by software, with the

EXT_WDOG_LATCH_CLR signal. This can

be done using the PORLATCLK diagnostics

label in the System Test screen.

Hi: Loss of +3.3V supply caused last reset

Lo: Last reset not caused by loss of +3.3V

supply. Probably caused by watchdog

(software reset)

Table 5-1: Sensor Readings Defined (Sheet 3 of 4)

REF 1029568 Rev A BiPAP® Focus™ Ventilator Service Manual © Respironics, Inc. 5-13

Page 46

Chapter 5

Diagnostic Mode and Troubleshooting

Diagnostics Label Actual Measured Value Description

PWRSWMON PWR_SW_MON_PROC User interface Standby Key monitor

PWRSWLATCH PWR_SW_LATCHED Latched User interface Standby Key

Sensor Readings Defined

Hi: Standby key is in-active (released).

Lo: Standby key is active (pressed).

monitor. This signal must be primed by

software with the PWR_SW_CLK signal.

This can be done using the PWRSWCLK

diagnostics label in the System Test screen.

Hi: Standby key has NOT been pressed.

Lo: Standby key has been pressed.

Table 5-1: Sensor Readings Defined (Sheet 4 of 4)

5-14 BiPAP® Focus™ Ventilator Service Manual © Respironics, Inc. REF 1029568 Rev A

Page 47

Diagnostic Mode and Troubleshooting

System Test The alarm, indicator, and voltage screen (Figure 5-14) allows:

• Test alarms: toggle the primary alarm speaker, backup alarm speaker,

or remote alarm ON or OFF.

• Indicators: toggle the Alarm LED, Silence LED, and the On Battery

LED, ON or OFF.

• Miscellaneous Tests: toggle the following settings ON or OFF:

Blower, VBattMeasEn, V Out Enable, POWERSWCLK, PWRTUIOFF,

PORLATCLK, WDSTROBE.

NOTE: When the V BattMeasEn signal is asserted is enables the measurement

of the Battery Thermistor temperature on the sensor readings screen.

Chapter 5

Figure 5-14: Diagnostic Mode: System Test Screen

System Test Defined

Diagnostics

Label Schematic Label Description

BLOWER TCB_SWITCH_ON

and

TCB_SWITCH_OFF

V BattMeasEn VBATT_MEAS_EN Selects ADC measurement of battery voltage or battery

Table 5-2: System Test Defined (Sheet 1 of 2)

REF 1029568 Rev A BiPAP® Focus™ Ventilator Service Manual © Respironics, Inc. 5-15

Used to turn blower on/off TCB_SWITCH_ON Hi and

TCB_SWITCH_OFF Lo: Blower ON TCB_SWITCH_ON Lo

and TCB_SWITCH_OFF Hi: Blower OFF

These signals are mutually exclusive in software

temperature

Hi: Battery voltage measured by ADC

Lo: Battery temperature measured by ADC

Page 48

Chapter 5

Diagnostic Mode and Troubleshooting

Diagnostics

Label Schematic Label Description

V Out Enable VOUT_EN Option to turn on/off the power out to the TCB.

PWRSWCLK PWR_SW_CLK Clocks the Standby Switch latch.

PWRTUIOFF PWR_TUI_OFF PWR_TUI_OFF: Control line to switch off the power.

PORLATCLK EXT_WDOG_LATC

H_CLR

System Test Defined

Reserved for future use. Therefore, the option to control

the power to the UI cannot be changed in software.

If used, the following applies:

HI: Turns on the 18V_Boost out to the Controller Board.

LO: Turns off the 18V_Boost out to the Controller Board.

Lo to Hi: Clocks a '1' to the latch output.

Hi to Lo: No change of state.

Hi: Clears the latch which removes the 18V_Boost rail

from the system, thereby shutting down power by placing

the unit in Standby mode.

Lo: No change in state

Clocks the Power On Reset latch. This can be used to

determine if an external power on reset has occurred due

to the +3.3V rail dropping.

Significant Event

Codes

Lo to Hi: No change of state.

Hi to Lo: Clocks a '1' to the latch output.

WDSTROBE WDSTROBE WDSTROBE: External watchdog strobe. Software is

required to apply a high pulse of 50ns minimum duration

at a maximum of every 1.2seconds to avoid the watchdog

resetting the processor.

Table 5-2: System Test Defined (Sheet 2 of 2)

The BiPAP Focus Ventilator generates a log of system events, including

settings changes, alarms, and codes that can be used for troubleshooting. If a

ventilator inoperative condition or unexpected reset occurs, the significant

event log includes the ventilator settings, patient data, and alarm conditions

that were in effect.

The significant event log can include at least 200 of the most recent events,

with the most recent events listed first. The ventilator maintains the significant

event log regardless of whether there is power to the ventilator.

The significant event log includes the following information:

1. Event ID: This includes a code and brief text description of the event.

5-16 BiPAP® Focus™ Ventilator Service Manual © Respironics, Inc. REF 1029568 Rev A

Page 49

Chapter 5

Diagnostic Mode and Troubleshooting

2. Date: Each event is date-stamped in a month/day/year format (for

example, 10/20/02).

3. Time : Each event is time-stamped in hour/minute/second format (for

example, 09:15:23).

4. Old value: For settings changes, the previously selected value is

displayed.

5. New value: For settings changes, the most recently selected value is

displayed.

Use the arrow keys to scroll through the log.

NOTE: Table 5-3 lists event IDs, and recommends corrective actions if

appropriate. When performing corrective actions:

• Perform the corrective actions in the order listed (if applicable)

until the problem is resolved.

• Before replacing a part, slave in a replacement part to verify that

it corrects the problem. If so, verify that the problem recurs with

the original part installed, then replace the part and confirm that

the problem is corrected.

Significant Event Log: Event IDs

Code Short text for code Comment / Corrective Action

1 ERR SOFTWARE Controller processor detected a software error.

If this persists and leads to multiple resets and the

system declaring a system error because too many

errors occurred in 24 hours, replace the controller PCB.

2 ERR PROGRAM CRC FAILURE Controller processor detected a program memory

checksum error.

If this persists replace the controller PCB.

3 ERR EXTERNAL RAM

FAI LUR E

4 ERR FIQ STACK OVERFLOW Controller processor detected a stack overflow.

Table 5-3: Significant Event Log: Event IDs (Sheet 1 of 22)

Controller processor detected an external RAM memory

error.

If this persists replace the controller PCB.

If this persists and leads to multiple resets and the

system declaring a system error because too many

errors occurred in 24 hours, replace the controller PCB.

REF 1029568 Rev A BiPAP® Focus™ Ventilator Service Manual © Respironics, Inc. 5-17

Page 50

Chapter 5

Diagnostic Mode and Troubleshooting

Code Short text for code Comment / Corrective Action

5 ERR FIQ STACK UNDERFLOW Controller processor detected a stack underflow.

6 ERR NEST STACK OVERFLOW Controller processor detected a stack overflow.

7 ERR NEST STACK

UNDERFLOW

8 ERR IRQ STACK OVERFLOW Controller processor detected a stack overflow.

9 ERR IRQ STACK UNDERFLOW Controller processor detected a stack underflow.

Significant Event Log: Event IDs (Continued)

If this persists and leads to multiple resets and the

system declaring a system error because too many

errors occurred in 24 hours, replace the controller PCB.

If this persists and leads to multiple resets and the

system declaring a system error because too many

errors occurred in 24 hours, replace the controller PCB.

Controller processor detected a stack underflow.

If this persists and leads to multiple resets and the

system declaring a system error because too many

errors occurred in 24 hours, replace the controller PCB.

If this persists and leads to multiple resets and the

system declaring a system error because too many

errors occurred in 24 hours, replace the controller PCB.

10 ERR TMR STACK OVERFLOW Controller processor detected a stack overflow.

If this persists and leads to multiple resets and the

system declaring a system error because too many

errors occurred in 24 hours, replace the controller PCB.

11 ERR TMR STACK

UNDERFLOW

12 ERR SVC STACK OVERFLOW, Controller processor detected a stack overflow.

13 ERR SVC STACK UNDERFLOW Controller processor detected a stack underflow.

14 ERR THREAD STACK

OVERFLOW

15 ERR ARM UNDEFINED

INSTRUCTION EXCEPTION

Controller processor detected a stack underflow.

If this persists and leads to multiple resets and the

system declaring a system error because too many

errors occurred in 24 hours, replace the controller PCB.

If this persists and leads to multiple resets and the

system declaring a system error because too many

errors occurred in 24 hours, replace the controller PCB.

Controller processor detected a stack overflow.

If this persists and leads to multiple resets and the

system declaring a system error because too many

errors occurred in 24 hours, replace the controller PCB.

Controller processor detected an unexpected exception.

If this persists and to multiple resets and the system

declaring a system error because too many errors

occurred in 24 hours, replace the controller PCB.

Table 5-3: Significant Event Log: Event IDs (Sheet 2 of 22)

5-18 BiPAP® Focus™ Ventilator Service Manual © Respironics, Inc. REF 1029568 Rev A

Page 51

Chapter 5

Diagnostic Mode and Troubleshooting

Significant Event Log: Event IDs (Continued)

Code Short text for code Comment / Corrective Action

16 ERR ARM SWI EXCEPTION Controller processor detected an unexpected exception.

If this persists and leads to multiple resets and the

system declaring a system error because too many

errors occurred in 24 hours, replace the controller PCB.

17 ERR ARM PREFETCH

EXCEPTION

18 ERR ARM ABORT EXCEPTION Controller processor detected an unexpected exception.

20 ERR AIC DEFAULT HANDLER Controller processor detected an unexpected interrupt.

Controller processor detected an unexpected exception.

If this persists and leads to multiple resets and the

system declaring a system error because too many

errors occurred in 24 hours, replace the controller PCB.

If this persists and leads to multiple resets and the

system declaring a system error because too many

errors occurred in 24 hours, replace the controller PCB.

If this persists and leads to multiple resets and the

system declaring a system error because too many

errors occurred in 24 hours, replace the controller PCB.

21 ERR AIC SPURIOUS

HANDLER

22 ERR CAL DATA CRC FAILURE Controller processor detected a calibration data

23 ERR INVALID DRIFT INDEX AT

CAL

24 ERR UNRECOGNIZED CAL

VERSION BY SW

Controller processor detected an unexpected interrupt.

If this persists and leads to multiple resets and the

system declaring a system error because too many

errors occurred in 24 hours, replace the controller PCB.

checksum error.

1. Attempt to re-calibrate the system.

2. If this fails, replace the controller PCB.

Controller processor detected that the flow sensor drift

check has failed. Flow sensor drift and calibration

information can be monitored using the "D) Drift

Screen" from the debug screen using the RASP utility,

capture screen output to a file.

1. Attempt to re-calibrate the system.

2. If this fails, replace the controller PCB.

Controller processor detected that the calibration table

version check has failed.

1. Attempt to re-calibrate the system.

2. If this fails, replace the controller PCB.

Table 5-3: Significant Event Log: Event IDs (Sheet 3 of 22)

REF 1029568 Rev A BiPAP® Focus™ Ventilator Service Manual © Respironics, Inc. 5-19

Page 52

Chapter 5

Diagnostic Mode and Troubleshooting

Code Short text for code Comment / Corrective Action

25 ERR DRIFT FLOW TOO HIGH Controller processor detected that the flow sensor drift

27 ERR DRIFT PRESSURE TOO

HIGH

28 ERR CAL DATA BLANK Controller processor detected that the calibration table

29 ERR DRIFT SECONDARY

PRESSURE TOO HIGH

30 ERR INVALID NVDATA

SCHEMA

31 ERR INVALID NVDATA LOCK Controller processor detected an error accessing the

32 ERR INVALID NVDATA

CHECKSUM

33 ERR NVDATA STORAGE

ERROR

Significant Event Log: Event IDs (Continued)

check has failed.

Flow sensor drift and calibration information can be

monitored using the "D) Drift Screen" from the debug

screen using the RASP utility, capture screen output to

a file.

1. Attempt to re-calibrate the system.

2. If this fails, replace the controller PCB.

Controller processor detected that the drift check on

the primary pressure has failed. Pressure sensor drift

and calibration information can be monitored using

using the "D) Drift Screen" from the debug screen using

the RASP utility, capture screen output to a file.

1. Attempt to re-calibrate the system.

2. If this fails,replace the controller PCB.

is blank.

1. Attempt to re-calibrate the system.

2. If this fails, replace the controller PCB.

Controller processor detected that the drift check on

the secondary pressure has failed.

1. Attempt to re-calibrate the system.

2. If this fails, replace the controller PCB.

Controller processor detected an error in format of the

calibration data in EEPROM.

1. Attempt to re-calibrate the system.

2. If this fails,replace the controller PCB.

calibration data in EEPROM.

1. Attempt to re-calibrate the system.

2. If this fails,replace the controller PCB.

Controller processor detected a checksum error on the

calibration in EEPROM.

1. Attempt to re-calibrate the system.

2. If this fails,replace the controller PCB.

Controller processor detected that the data structure is

bigger than the EEPROM device.

1. Attempt to re-calibrate the system.

2. If this fails,replace the controller PCB.

Table 5-3: Significant Event Log: Event IDs (Sheet 4 of 22)

5-20 BiPAP® Focus™ Ventilator Service Manual © Respironics, Inc. REF 1029568 Rev A

Page 53

Chapter 5

Diagnostic Mode and Troubleshooting

Significant Event Log: Event IDs (Continued)

Code Short text for code Comment / Corrective Action

34 ERR NVDATA QUEUE FULL Controller processor detected that the queue to the

EEPROM manager thread is full.

If this persists and leads to multiple resets and the

system declaring a system error because too many

errors occurred in 24 hours, replace the controller PCB.

35 ERR NVDATA READBACK

FAI LUR E

36 ERR NVDATA RANGE

FAI LUR E

37 ERR CORRUPT RTC VALUE Controller processor detected that the Real Time Clock

Controller processor detected that a write operation to

EEPROM failed the readback check.

If this persists and leads to multiple resets and the

system declaring a system error because too many

errors occurred in 24 hours, replace the controller PCB.

Controller processor detected that a write operation to

EEPROM failed the range check for that data item.

If this persists and leads to multiple resets and the

system declaring a system error because too many

errors occurred in 24 hours, replace the controller PCB.

time and the RTOS tick timer has drifted since it was

last tested. When changing the time, this could happen

and an RTC Failure Alarm maybe annuciated, this

alarm can be reset by pressing Alarm Reset.

No action necessary.

38 ERR RTC NOT TICKING Controller processor detected that the Real Time Clock

39 ERR UI QUEUE FULL Controller processor detected a RTOS queue full

40 ERR INVALID BIST TEST

CALL

time and the RTOS tick timer has drifted significantly

(>4 seconds) since it was last tested. When changing

the time, this could happen and an RTC Failure Alarm

maybe annuciated, this alarm can be reset by pressing

Alarm Reset.

No action necessary.

condition.

If this persists and leads to multiple resets and the

system declaring a system error because too many

errors occurred in 24 hours, replace the controller PCB.

Controller processor detected an invalid BIST test was

attempted to be run.

If this persists and leads to multiple resets and the

system declaring a system error because too many

errors occurred in 24 hours, replace the controller PCB.

Table 5-3: Significant Event Log: Event IDs (Sheet 5 of 22)

REF 1029568 Rev A BiPAP® Focus™ Ventilator Service Manual © Respironics, Inc. 5-21

Page 54

Chapter 5

Diagnostic Mode and Troubleshooting

Code Short text for code Comment / Corrective Action

41 ERR PRESSURE REG OVER Controller processor detected that a high pressure

42 ERR BIST THREAD LOCKED Controller processor detected that the built in selftest

43 ERR ALARM VOLTAGE

FAI LUR E

44 ERR 12VREF FAILURE Controller processor detected that the limits test on the

Significant Event Log: Event IDs (Continued)

condition (i.e. 5 cmH20 above the IPAP or CPAP

setting) lasted for greater than ten seconds.

1. Check for kicked tubes on the Primary pressure

sensor.

2. Check for blockages near the Primary pressure

sensor in the gas outlet port.

3. Replace the controller PCB.

4. If this persists replace the pneumatics subassembly

(blower and valve).

thread is locked, i.e. it's not alive as expected.

If this persists and leads to multiple resets and the

system declaring a system error because too many

errors occurred in 24 hours, replace the controller PCB.

Controller processor detected that the backup alarm