Page 1

Rotonda

SC.

|

上

|

uantum

.

Pressure

IAE

Support

Ventilator

Service

Manual

RESPIRONICS“

Page 2

Page 3

RESPIRONICS"

TABLE

OF

CONTENTS

Respironics,

1501

Ardmore

Pittsburgh, PA

Phone:

Respironics

1255

1-800-345-6443

Fax:

1-800-886-0245

Kennestone

Marietta,

Phone:

1-800-421-8754

Fax:

1-770-499-0117

Respironics®

Gewerbesterasse

D-82211

Herrsching

Inc.®

Bivd.

15221

Georgia,

GA

Inc.®

Circle

30066

Deutschland

17

Germany

Respironics®

Quantum

PSV

7700

Service

Manual,

1002917

1

Page 4

TABLE

OF

CONTENTS

№)

RESPIRONICS"

Section

About

Servicing

Service

Service

Recommended

Engineering

Equipment

Authorized

Servicing

Section

Warnings

Cautions

ESDS

Seciion

Front

Performance

Physical

Power

Output

Alerts

Front

Rear

Rear

Power

Patient

System

1.0

IntroducCtiON

this

Manual

and

Warranty

Location

and

Inspection

Service,

Change

Inspection

Service

Guidelines

2.0

Warnings

Warnings

3.0

Specifications

Panel

and

Controls

Specification

Specifications

Requirements

Signals

Panel

Visual

Panel

Visual

Panel

Alert

Alert

Alert

.....ocoooonocinnonensononaranan

Forms

Repair,

and

Test

conc

Equipment

Orders

Centers

and

CautionS

recerca

Cautions

and

AlarTS

Indicators

Indicators

cnc r nor

nora

noe

ena

Rd

ARRE R RADAR

RAR

RONALD

AR

rana

rra

rro

6

ros

rieioenenenio

14

18

Section

2

4.0

Troubleshooting

Chart

Respironics®

Quantum

PSV

7700

Service

Manual,

1002917

Page 5

ej

RESPIRONICS”

TABLE

OF

CONTENTS

Section

.

5.0

Operaitional

Operational

Using

an

RT-200

Visual

Inspection

AC

Line

Indicator

Diagnostic

Panel

Lock

CPAP/EPAP

IPAP

Control

Low

Pressure

High

Pressure

Risetime

BPM

%l

Bar

Mode

Pressure

CPAP

IPAP

Spontaneous

Spontaneous/Timed

Approximate

Power

Patient

System

Estimated

Communication

Analog

Analog

Control

Control

Time

Control

Graph

Selection

Verification

Pressure

Pressure

Alert

Alert

Alert

Pressure

Flow

Checks

Check

Check

Control

CPAP

Performance

CPAP

Performance

Display

Check

Parameters

Check

Check

Check

Mode

Timing

Check

Check

Port

Output

Output

Check

Check

Mode

Check

Check

Check

CheckS

Check

Check

Check

AAA

Check

Check

29

Section

Respironics?

6.0

Preventive

Mandatory

Quality

Preventive

Service

Engineering

Assurance

Quantum

Service

Procedures

Change

Checkout

PSV

7700

Orders

Procedures

Service

Manual,

(ECOs)

1002917

PEER

LEE

EEE

ERE

ELLE

EDER

LENS

ENE R ERE

40

3

Page 6

TABLE

OF

CONTENTS

RESPIRONICS®

Section

Disassembly,

Case

Intake

Blower

Fan

Removal

Hour

AC

Inlet

Alarm

Controller

Encoder

Power

Front

Front

Alarm

Display

Valve

Sensor

Pressure

Solenoid

Old

Style

Noise

Final

7.0

Disassembly,

Inspection,

Removal

Baffle

Removal

Assembiy

Meter

Removal

Removal

Battery

Board

Board

Board

Removal

Panel

Removal

Pane!

Bracket

Assembly

Board

Removal

Board

Switch

Removal

Auxiliary

Unit

Reassembly

and

and

Inspection

Removal

Replacement

Removal

Removal

Removal

Removal

Removal

Removal

Removal

Valves

Inspection,

Reassembly

and

Reassembly

sonores

44

Section

Mandatory

ECO

ECO

ECO

ECO

ECO

ECO

ECO

Section

Run-In

Guidelines

8.0

ECO

ChandeS

Engineering

#:

67266670

#:

6065

Fuse

#:

5850

Valve

#:5769

#:

#:

#:

9.0

CPU

5557/5505

5465

Valve

5147

Controller

RUN-İN

Requirements

Change

U31

Relay

Drawer

Replacement

Board

Hour

Replacement

Change

Upgrade

Meter

Board

---

Orders

Replacement

Out

installation

Upgrade

μυ..."

for

New

Style

Back

Panels

ERE

κκ κκλοώκοσακα

σεντ

κκ

καν ν οσο κ 22 κκ

κακκκκκὠκκλα

κος

58

62

4

Respironics®

Quantum

PSV

7700

Service

Manual,

1002917

Page 7

RESPIRONICS*

TABLE

OF

CONTENTS

Section

Section

10.0

Calibration

Calibration

Blower/Valve/Sensor

AC

Line

indicator

Diagnostic

Mode

Pressure

CPAP

IPAP

Spontaneous

Spontaneous/Timed

Approximate

Power

Patient

.

System

Estimated

Communication

Analog

Analog

Service

Paris

Check

Selection

Verification

Pressure

Pressure

Alert

Check

Alert

Alert

Parameters

Pressure

Flow

11.0

Parts

Kits

List

Check

Check

Check

Mode

Timing

Check

Check

Port

Output

Output

List

and

Board

Check

Mode

Check

Check

Check

Check

Check

...

Testing

Calibration

Check

Section

System

Main

Physical

Power

Power

Alarm

Encoder

Display

CPU

Control

Section

12.0

Theory

Components

Unit

Internal

Board

Arrangement

Distribution

On/Off

Circuit

Board

13.0

Control

Subsystem

Board

Board

Board

SchematieS

of

Operation

Components

Subsystem

asmenennnnrenenonennnnnenenennnnnnenennnense

iii

er

80

106

Respironics®

Quantum

PSV

7700

Service

Manual,

1002917

5

Page 8

SECTION

1.0

e,

RESPIRONICS"

Introduction

About

this

Manual

Servicing

Service

Service

Recommended

Engineering

Equipment

Authorized

Servicing

and

Location

and Inspection

Change

Inspection

Service

Guidelines

Warranty

Service,

Orders

Centers

Forms

Repair,

and

Test

Equipment

Section

1.0

6

Respironics®

Quantum

PSV

7700

Service

Manual,

1002917

Page 9

RESPIRONICS“

About

this

Manual

W

This

manual

PSV

7700.

Sections

are

included.

familiar

functions.

change

with

The

without

is

intended

covering

Personne!

the

Quantum

information

notice.

for

use

when

servicing

troubleshooting,

servicing

PSV

contained

the

7700

Quantum

Operating

within

circuit

PSV

Manual

this

document

SECTION

Introduction

the

Respironics®

descriptions,

7700

must

and

the

is

and

be

thoroughly

ventilators

subject

1.0

Quantum

testing

to

ーー

Servicing

and

Warranty

.

W

tis

authorized

recorded

check

parts

Respironics

rial

and

unit

replacements,

to

be

the

customer

This

repaired

stability

abuse,

during

carrier

recommended

Respironics

on

the

the

performance

as

necessary.

warrants

workmanship

is

properly

defective.

warranty

or

altered

or

reliability,

or

accident.

shipping.

or

individual

that

the

Customer

hour

meter.

of

the

the

Quantum

for a period

operated, under

repairs,

The

has

does

or

defective

received

not

apply

in a way

or

which

This

warranty

If

there

is

who

delivered

issues

approval

that,

any

Quantum

Satisfaction

This

allows

unit,

check

PSV

of

one

normal

credit

unit

may

from

to

any

unit

in

Respironics'

has

been subjected

does

damage

the

PSV

7700

Center

Respironics

the

electrical

7700

to

be

year

after

conditions.

for

equipment

be

returned

Respironics

or

individual

not

cover

during

unit.

shipping,

be

serviced

every

Service

integrity,

free

from

delivery,

Respironics

prepaid

judgement,

to

damage

provided

or

parts

to

to

return

parts

which

misuse,

which

please

by

an

800

hours

Personnel

and

replace

defects

affects

in

that

makes

which

are

Respironics

the

unit.

have

the

negligence,

may

occur

contact

to

mate-

the

found

after

been

the

Respironics®

Quantum

PSV

7700

Service

Respironics

PSV

7700.

ventilators.

it

is

necessary

Respironics

unit

in-line

month-to-month

Manual,

offers a month-to-month

The

Ifa

distributor

with

1002917

maintenance

unit

is

out

of

for

the

owner

for

Respironics

maintenance

contract

warranty,

to

submit

servicing,

standards.

contract.

maintenance

covers

and a maintenance

the

unit

on a time

The

contract

all

parts, labor,

to

Respironics

and

material

unit

may

then

on

the

and

loaner

contract

or

a

basis,

be

placed

Quantum

is

desired,

to

bring

under

the

a

7

Page 10

SECTION

Introduction

1.0

RESPIRONICS"

Respironics®,

product

notice.

Y

Satisfaction

9234

you.

Y

the

577-7701-00

1002917

Field

improvement

The

Quantum

for

the

BNING:

Use

the

Quantum

Comm

Center

location

Sician.

following

PSV

98-07

Inc.,

and

Respironics?

and

PSV

7700

located

of

the

Federalláw

forms

7700:

reserve

may

be

throughout

Respironics

restrict

:

and

procedures

Quantum

Quantum

Quantum

Georgia,

the

right

repaired

most

Customer

PSV

Clinical

PSV

Service

PSV

Screening

Inc.

to

alter

at

any

of

the

during

Manual

Manual

have a policy

specifications

Respironics

world.

Satisfaction

servicing

Procedure

Customer

Please

Center

or

inspection

without

of

continued

call

800/669-

nearest

of

Servicing

Service

Inspection

and

Warranty

(Continued)

Location

Service

and

Forms

Current

Respironics

revisions

of

these

Customer

Phone:

forms

and

procedures

Satisfaction

Attention:

1001

Murrysville,

1-888-276-0715 « Fax:

Center

Respironics,

Technical

Murry

Ridge

PA

or

Inc.

15668

may

be

obtained

by

contacting:

Services

Lane

1-800-422-5816

from

any

8

Respironics®

Quantum

PSV

7700

Service

Manual,

1002917

Page 11

RESPIRONICS*

SECTION

Introduction

1.0

Recommended

Service,

Test

Repair,

Equipment

and

W A complete

Respironics

Part

98260

90902

90037

98559

98560

98251

98577

98144

98128

98129

98906

98537

98265

98561

98565

7700-18

TS-7700-031

TS-7700-032

06658

7703

EQUIPMENT

list

of

service

Number

kits

may

be

Description

Tie

Wrap Gun

Gate

Valve

Pressure

Allen

DriverSet

Nut

Driver

Soldering

Fluke

Meter/Ohmmeter

45or

equivalent

Solder

Wrist

Wrist

Cord,

Mat,

Shunt, 1 Meg

Pliers,

Heat

Test

Y-Tube

Restricted,

Unrestricted,

Test

Quantum

1/8” x 18”

Timeter

Wick,

Strap,

Cord,

Wrist

Table,

Snap

Gun

Kit

Lung, 1 liter

Training/Test

Mini-Phono

Torque

12”

Long

Pneumotach

found

in

Section

Assembly

Restricter,

Set

Station

110"

Antistatic

Antistatic

Strap,

Antistatic,

Ohm

Ring

Simulator

Connector,

Coupler,

Remote

long

Allen

RT-200,

OR

Lung

Model

26001)

Plug

Control

Screwdriver

#1

Phillips

Flow

11.0.

PLV

(Multimeter)

Copper

Grounding

2' x 4'

(included

Aptr

22

mm

Unit

Driver

EQUIVALENT

(Michigan

Screwdriver

Meter

Model

in

Test

Kit)

22

mm

(Test

I.D.

(Test

TEST

Instruments

Kit)

Kit)

Respironics®

Quantum

PSV

7700

Service

Miscellaneous

98573

98574

302227

Manual,

1002917

Equipment:

Wire

Cutters

Needle

Reguiar

Straight

Jewelers

Phillips

Wire

Hemostat,

Solder,

*

Magnehelic

+

Magnehelic

*

Digital

orequivalent)

+

Respironics

Flow

Nose

Pliers

Blade

Screwdriver

Head

Strippers

6"

Pure,

Pressure

Source

Pliers

Screwdriver

Set

Screwdriver

Soldering

60/40

Gauge,

Gauge,

0-20

0-150

Manometer

Digital

Manometer

(p/n

7300

or

cm

H,0

cm

HO

(Merical

equivalent)

DP2001

Page 12

SECTION

Introduction

EQUIVALENT

V

Any

Quantum

are

found

ECO

PSV

in

TEST

not

7700

Section

1.0

*

May

be

EQUIPMENT

installed

unless

8.0

of

in a unit,

it

used

is

listed as

this

in

place

must

manual.

of

the

Timeter

be

installed

optional

in

during

this

RT-200,

service

service

OR

of

manual.

the

ECOS

RESPIRONICS"

Engineering

Change

Orders

w

Respironics

equipment.

Center

Certification

personneliraining

The

Service

representative

quality

Only

sold

center

Y

7715)

repairs.

those

replacement

contact

Before

and

English

German

French

Italian

Spanish

recognizes

To

ensure

and

Center

has

facilities

parts.

Technical

returning a unit

the

appropriate

577-7700-10

577-7700-34

577-7700-31

577-7700-36

577-7700-37

the

need

quality

Program

service,

consisting

certification.

Certification

at

their

disposal

which

are

authorized

For

information

Services

to

the

instruction

for

outside

Respironics

of

is

designed

the

proper

Respironics

on

at

800/669-9234,

customer,

sheet

Swedish

Dutch

Greek

Danish

Finnish

centers

has

developed a Service

two

parts;

facility

to

ensure

facilities

that a certified

Service

becoming

an

include a new

in

the

shipping

to

maintain

inspections

necessary

Centers

authorized

bacterial

box.

577-7700-40

577-7700-41

577-7700-42

577-7700-43

577-7700-44

their

own

and

service

to

complete

are

service

filter

(p/n

Authorized

Shipping

Bacteria

Service

Centers

New

Filter

10

Respironics®

Quantum

PSV

7700

Service

Manual,

1002917

Page 13

RESPIRONICS*

SECTION

Introduction

1.0

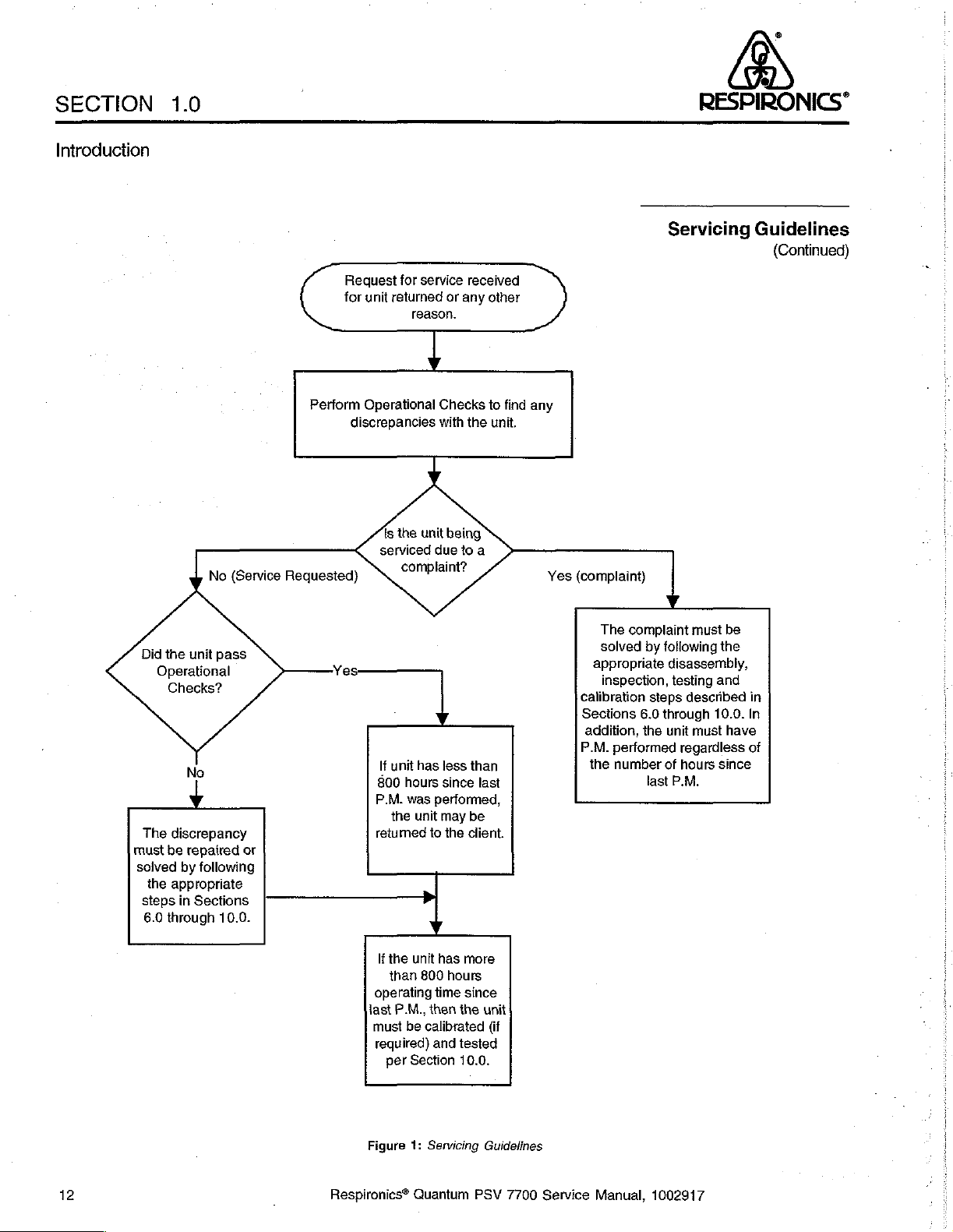

Servicing

Guidelines

W

A unit

passes

operation

adjustments

cover.

If

the

Section

Sections

performed,

A

unit

installed.

Refer

guidelines.

otherthan;

unit

is

5.0

to

6.0

regardless

automatically

to

the

Operational

that

do

being

find

through

flow

chart

internal

not

require

serviced

any

other

10.0,

including

of

the

fails

operational

on

the

Checks

battery

due

to a complaint,

discrepancies

number

next

if

no

replacement,

disassembly

Preventive

of

hours

checks

page

for a further

discrepancy

or

other

of

the

unit

perform

with

unit

operation.

Service

remaining.

if

any

mandatory

description

is

discovered

minor

repairs

other

than

the top

Operational

The

MUST

aiso

be

ECO

of

servicing

in

unit

Checks

steps

is

not

or

in

in

Respironics®

Quantum

PSV

7700

Service

Manual,

1002917

11

Page 14

SECTION

Introduction

1.0

RESPIRONICS"

Did

Operational

The

must

solved

the

steps

6.0

No (Service

the

unit

pass

Checks?

No

y

discrepancy

be

repaired

by

following

appropriate

in

Sections

through

10.0.

or

Reguested)

Reguest

for

Perform

discrepancies

Yes:

for

service

unit

returned

reason.

Operational

ls

the

unit

serviced

complaint?

If

unit

has

800

hours

P.M.

was

the

unit

retumed

If

the

unit

than

800

operating

last

P.M.,

must

be

required)

per

Section

received

or

any

other

Checks

with

due

the

being

to

a

to

less

than

since

last

performed,

may

be

to

the

client.

has

more

hours

time

since

then

the

unit

calibrated

and

(if

tested

10.0.

find

any

unit.

Yes

(complaint)

The

complaint

solved

appropriate

inspection,

calibration steps

Sections

addition,

P.M.

the

6.0

performed

number

Servicing

must

by

following

disassembly,

testing

described

through

the

unit

must

regardless

of

hours

last

P.M.

Guidelines

be

the

and

in

10.0.

In

have

of

since

(Continued)

12

Figure

1:

Servicing

.

Respironics®

Quantum

Guidelines

PSV

7700

Service

Manual,

1002917

Page 15

RESPIRONICS®

SECTION

Introduction

1.0

(This

page

intentionally

left

blank)

Respironics®

Quantum

PSV

7700

Service

Manual,

1002917

13

Page 16

SECTION

2.0

RESPIRONICS’

Wamings

and

Cautions

Warnings

Warnings

Cautions

ESDS

Warnings

and

Cautions

and

Cautions

Section

2.0

14

Respironics®

Quantum

PSV

7700

Service

Manual,

1002917

Page 17

RESPIRONICS*

SECTION

2.0

Warnings

This

is a non-continuous

breathing.

it

is

Airflow

selection

may

The

moisture

The

contamination.

DO

Never

Do

notuse

or

Respironics

not

intended

generated

result

use

of a water

from

use

of

NOT

use

operate

It

must

of

certain

in a situation

entering

bacteria

the

this

this

device

immediately.

not

be

used

to

provide

by

this

combinations

where

trap

and/or

the

ventilator.

filters

are

QUANTUM

device

if

ithas

if

ventilator

as a ventilator

the

device

and

total

ventilatory

is

limited

of

settings

pressure

hydrophobic

recommended

PSV

in

the

presence

the

power

cord

been

dropped

Warnings

is

intended

that

supports

requirements

to

(i.e.,

support

filter

to

ensure

is

damaged.

or

damaged.

to

150

liters

high

rate

levels

cannot

is

recommended

client

of

flammable

Contact

and

augment

or

sustains

of

the

per

minute.

and

short

be

safety

anesthetics.

Cautions

patient

life,

and

patient.

The

risetime)

obtained.

to

prevent

from

cross

your

dealer

Cautions

Use

only

an

identically

Oxygen

oropen

before

the

Do

Do

Always

Performance

The

properoperation.

Connect

Quantum

above

vigorously

flame

turning

device

nat

block

not

kink

unplug

Quantum

the

PSV

40°C.

when

on

off.

Do

any

or

crimp

the

verification

PSV

Quantum

performance

rated

accelerates

using

supplemental

the

supplemental

not

smoke

air

intake

air

outlet

Quantum

of

must

be

PSV

to a grounded

and

sized

fuse

combustion.

oxygen.

oxygen.

within 6 feet

vents.

hoses.

PSV

before

the

Quantum

periodically

is

affected

checked

at

for

replacement.

Keep

this

This

Turn

off

the

(2

meters)

cleaning

PSV

must

the

be

and

+

hospital

temperatures

grade

device

away

device

must

oxygen

of

this

before

unit.

enclosure.

performed

maintained

outlet

only.

below

5°C

from heat

be

running

turning

before

use.

to

ensure

and

Respironics®

Quantum

PSV

7700

Service

Manual,

1002917

15

Page 18

SECTION

2.0

RESPIRÔNICS*

Warnings

+

Replace

blow

fuse,

*

Positioning

on

the

¢

Verity

that

*

Connect

Recording

not

insert

*

All

ESDS

shipping

ㆍ

All

persons

resistive

‧

Coverall

work

surfaces

and

Cautions

the

back

5mm x 20mm.

the

rear

panel.

the

alarms

only

Model

Devices

any

devices

items

must

bags,

foam,

handling

grounded

ESDS

and

panei

Quantum

are

7703

into

into

be

or

. 。

ESDS

wrist

bench

tops

equipment

shipping

PSV

fuse,

must

operational.

Remote

the

signal

output

the

signal

stored

tote

bins.

items

strap.

with

in

approved

must

grounded

to

earth

as

required,

not

block

Control

part

input

be

grounded

conductive

ground.

the

cables

(SOP)

part

(SIP)

with a 3-amp

air

intake

or

other

ofthe

Quantum

of

the

250V

ports

certified

Quantum

conductive packaging,

.

via a 1

mats

Meg

and

ohm

connect

fast

located

Sleep

PSV.

Do

PSV.

tubes,

ail

[170770

ESDS

and

Cautions

(Continued)

σσ

Warnings

Cautions

σ

.

.

s

Transport

container.

ο:

DONOT

tubes

* © DONOT

electronic

e

Never

unattended

*

‘Avoid

styrofoam

+

Use

only

grounded

+

Use

only

“antistatic”

procedures.

all

assemblies

use

cellophane

together.

handle

parts.

place

ESDS

in

an

cellophane

coffee

ESD

safe

DIP

installation

properly

quick-chill

ESDS

items

items

open

area.

wrappers,

cups,

solder

designed

sprays

containing

adhesive

by

their

on

ungrounded

synthetic

etc.

when

suckers,

tools.

heat

during

ESDS

items

tape

to

wrap

DIP

pins

or

mix

surfaces

carpeting,

working

grounded

lamps,

with

soldering

heat

chambers,

troubleshooting

in a conductive

(dual

in-line

them

with

other

or

leave

them

warm

or

cool

ESDS

items.

irons,

and/or

or

stress

bag

package)

routine

air

blasts,

and

testing

or

16

Respironics®

Quantum

PSV

7700

Service

Manual,

1002917

Page 19

RESPIRONICS"

SECTION

2.0

ESDS

and

(Continued)

Warnings

Cautions

*

The

and

Controller

CPU

Display

Power

Sensor

Encoder

following

require

special

PCB

PCB

PCB

Supply

PCB

PCB

assemblies

handling:

PCB

in

the

Quantum

Warnings

PSY

are

easily

and

Cautions

damaged

by

ESD

Respironics®

Quantum

PSV

7700

Service

Manual,

1002917

17

Page 20

SECTION

3.0

RESPIRONICS“

Specifications

and

Alerts

Specification

Front

Panel

Controls

Performance

Physical

Power

Output

Aleris

Front

Panel

Rear

Panel

Rear

Panel

Power

Patient

System

Specification

Specifications

Requirements

Signals

Visual

Visual

Alert

Alert

Alert

and

Alarms

Indicators

Indicators

Section

3.0

18

Respironics®

Quantum

PSV

7700

Service

Manual,

1002917

Page 21

RESPIRONICS"

SECTION

3.0

Front

Panel

Controls

Performance

Specifications

Power

On,

Off

Alert

Status

Power

Pressure

Failure,

cmH,0

Mode

Selection

CPAP,

Spontaneous,

Estimated

Peak

Flow,

Patient

Settings

CPAP/EPAP,

CPAP/EPAP

2-25

cmHL.O

IPAP

Range

2 — 80

cm

2-35

cm

2—

37

em

Patient

Spontaneous/Timed

Parameters

Minute

Volume,

IPAP,

Risetime,

Pressure

H,0,

(Domestic)

HO,

(35

ст

H,O,

(International

Leak,

Range

H,O

System

Tidal

Rate, % 1

.

Unit)

Unit)

Failure/Firmware

Volume,

Breath Rate

Time

Specifications

Check

and

Failure

Alerts

Respironics®

Quantum

PSV

7700

Service

Pressure

1

cmH,0

Pressure

+

0.7

+

0.0/ - 0,7

Pressure

0.1

seconds

(10 - 90%

Risetime

0.1

to

(10-90%

Rate

4-40

Breath

+ 1 BPM

%|

Time

10 — 90 % of

Manual,

Control

Accuracy

at

zero

Response

of

Control

0.9

seconds

of

Control

BPM

Rate

Control

1002917

Resolution

flow

from

zero

pressure)

Range

pressure)

Range

Accuracy

Range

total

flow

Time

(Min)

in

increments

breath

time

measured

of

at

0.1

150

LPM

seconds

19

Page 22

SECTION

3.0

RESPIRONICS“

Specifications

*

FlowTiigger

Inspiration

and

Expiration

e

%l

Time

Accuracy

+1%

e

+

+

Minimum

Minimum

Maximum

Flow

Limit

150

LPM

Height

8

Width

12.75"

Expiration

Inspiration

Inspiration

20.5

31.9

Alerts

0.25

Peak

Time

Time

cm

cm

liters

Flow

Time

second

per

x.75

500

200

3

sec

msec

msec

Physical

Performance

Specifications

(Continued)

μα

Specifications

*

Length

13"

+

Weight

15.73

lbs.

16.7lbs.

‧

Voltages

120

100—

200 — 240

‧

Currentconsumption

300VA

‧

Operating

40°C

5°-

+

Storage

and

Temperature

Humidity

Barometric

32.6

cm

7.15

kg

7.6kg

50/60

at

VAC

VAC

at

50/60

Temperature

Transport

Pressure

Hz

Hz

Conditions

-20°-

10%

oo

790—525

60°C

Non-condensing

95%

—

mmHg

>

Power

Reguirements

=

Operating/Storage

Requirements

20

Respironics®

Quantum

PSV

7700

Service

Manual,

1002917

Page 23

RESPIRONICS*

SECTION

3.0

Output

Alerts

Signals

‧

Pressure

Range

Voltage

*

Flow

Fange

Voltage

*

Power

Visual/Continuous

+

Patient

Visual/Continuous

*

System

Device

Firmware Check

Failure — Visual/Continuous

0-4

vois

0.1

V= 1 cmH2O

0—4volis

1.0 V =

60

LPM

Audible

Audible

Audible

Failure — Intermittent

Specifications

Visual/tntermittent

Audible

and

Alerts

.

Front

Panel

Indicators

Visual

*

Power

Green

Indicator

*

PressurecmH,0

Green

+

Power

Bed

+

Patient

Yellow

+

System

Red

+

CPAP

Red

*

Spontaneous

Green

*

Spontaneous/Timed

Green

*

Green

Indicator

Indicator

Indicator

Peak

Digital

Bar

Alert

Light

Alert

Indicator

Alert

Light

Mode

Light

indicator

Indicator

Flow

Estimation

Indicator

Light

Graph

Light

Mode

Light

Mode

Light

Light/Digitat

Display

Respironics®

Quantum

PSV

7700

Service

ーー

+

Minute

Green

Manual,

Volume

Indicator

1002917

~

Estimation

Light/Digital

一

Display

21

Page 24

SECTION

3.0

RESPIRONICS”

Specifications

e

Tidal

Volume

Green

Indicator

*

Breath

Green

*

CPAP/EPAP

Digita!

*

IPAP

Digital

*

Risetime

Digital

*

Rate

Green

+

%1Time

Digital

Rate

Indicator

Display

Display

Display

Indicator

Display

and

Estimation

Light/Digital

Estimation

Light/Digital

Setting

Light/Digital

Alerts

」

Display

Display

Display

Front

TTT

Panel

Visual

Indicators

(Continued)

+

Hour

Meter

Digital

«

ACOn

Green

*

OutputPressure

Phone

+

Estimated

Phone

*

Serial

RS-232

*

Power

Three

*

Fuse

3A,

*

Fan

24

Display

Indicator

Type

Type

Port

Port

Receptacle

Wire

250V

VDC

Jack

Flow

Jack

AC

Light

Receptacle

Rear

Panel

Visual

Indicators

Rear

Panel

22

Respironics®

Quantum

PSV

7700

Service

Manual,

1002917

Page 25

RESPIRONICS"

SECTION

3.0

Power

Patient

System

Alert

Alert

Alert

Y

The

power

alert

to

the

device

also

sounds

restoring

w

The

that

the

thirty

seconds.

given

pressure.

level

follows

level

for

disconnections.

normal.

W

The

to

sound

from

the

device

does

not

the

blower

is

lost

when

power

fo

patient

PSV

flow

the

thirty

alert

The

As

bias flow

seconds

This

system

alert

indicating a device

set

pressure

flow

exceeds

occur.

When

to

stop.

sounds

when

the

the

yellow

rate

exceeds

flow

the

alert

causes

the

This

an

audible and

the

power

device's

device

fuse

of

turning

light

illuminates

the

rate

prediction

pressure

the

level.

Since

alert

indicates

is

reset

rises

the red

failure. A device

by

plus

or

minus 5 cmH,O

flow

limit

the

controls

alert

is

reset

visual

switch

fails.

predicted

the

is

so

the

is

This

power

and

based

does

flow

only

in

alert

the

flow

the

must

large

automatically

light

to

illuminate

failure

(150

Iprn)

the

system

are

locked

by

turning

out the

the

Specifications

alert

indicating

the

on

position.

is

silenced

switch

off.

alert

sounds

rate

by a preset

on

the

bias

bias

flow.

exceed

mask

leaks

once

the

flow

when

This

by

indicating

amount

flow

rate

The

alert

the

alert

or

rate

and

either

and a continuous

results

for

device

0.5

seconds.

alert

system

in

pressure

When

for

low

alarm

off.

Alerts

power

alert

for

for

any

trigger

trigger

circuit

returns

to

alarm

varying

the

pressures

causes

The

system

sound

device

consider

indicating

is

being

the

alert

cause

an

reset.

device

the

internal

When

to

be

non-function

red

light

to

firmware

this

alarm

illuminate

check

failure

continues

and

requiring

and

which

for

more

service.

an

intermittent

occurs

than

when

five

alarm

the

minutes,

to

Respironics®

Quantum

PSV

7700

Service

Manual,

1002917

23

Page 26

SECTION

4.0

RESPIRONICS“

Troubleshooting

Chart

Section

4.0

24

Respironics®

Quantum

PSV

7700

Service

Manual,

1002917

Page 27

RESPIRONICS”

SECTION

4.0

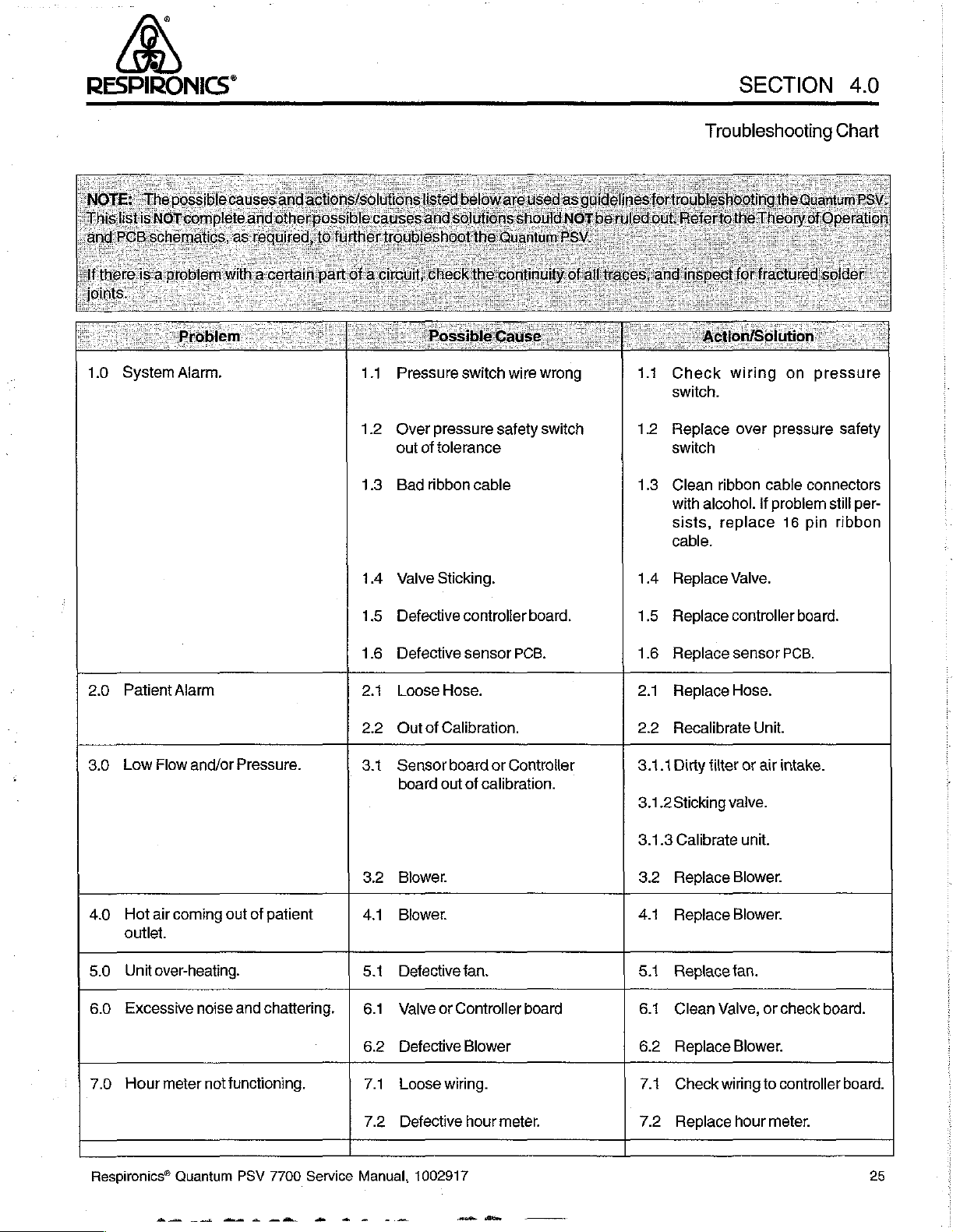

1.0

System

Alarm.

Troubleshooting

Chart

1.1

1.2

1.3.

1.4

Pressure

Over

out

Bad

Valve

switch

pressure

of

tolerance

ribbon

Sticking.

safety

cable

wire

wrong

switch

1.1

1.2

1.3

1.4

Check

switch.

Replace

switch

Clean

with

alcohol.

sists,

cable.

Replace

wiring

over

ribbon

if

replace

Valve.

on

pressure

cable

connectors

problem

16

pin

pressure

safety

still

per-

ribbon

2.0

3.0

4.0

5.0

6.0

7.0

Patient

Low

Hot

outlet.

Unit

Excessive

Hour

Alarm

Flow

air

coming

over-heating.

meter

and/or

Pressure.

out

noise

and

not

functioning.

of

patient

chattering.

1.5

1.6

2.1

22

3.1

32

41

5.1

6.1

6.2

7.1

Defective

Defective

Loose

Hose.

Outof

Calibration.

Sensor

board

Blower.

Blower.

Detective

Valve

Defective

Loose

board

out

or

Controller

wiring.

controlier

sensor

of

calibration.

fan.

Blower

board.

PCB.

or

Controller

board

1.5

Replace

1.6

Replace

2.1

Replace

22

Recalibrate

3.1.1

Dirty

3.1.2Sticking

3.1.3

Calibrate

8.2

Replace

4.1

Replace

5.1

Replace

6.1

Clean

6.2

Replace

7.1

Check

controller

sensor

Hose.

filter

valve.

Blower.

Blower.

fan.

Valve,

Blower.

wiring

Unit.

or

air

unit.

or

check

to

controller

board.

PCB.

intake.

board.

board.

Respironics®

Quantum

m

mk

m

PSV

7700

Service

7.2

Defective

hour

Manual,

ω--

1002917

meter.

7.2

Replace

hour

meter.

25

Page 28

SECTION

4.0

RESPIRONICS“

Troubleshooting

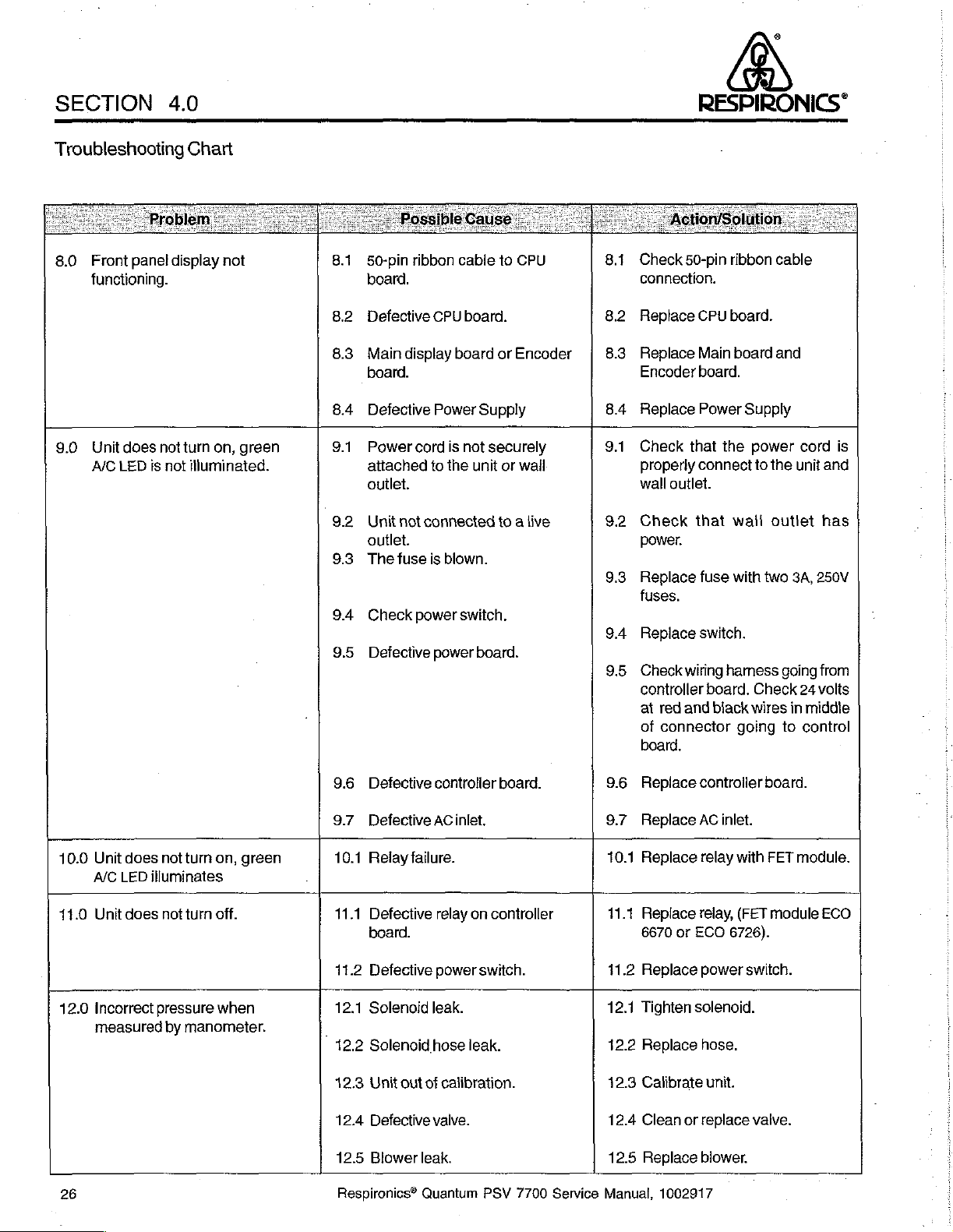

8.0

Front panel

functioning.

9.0

Unit

does

not

A/C

LED

is

not

Chart

display

not

turn

on,

illuminated.

green

8.1

50-pin ribbon

board.

8.2

Defective

8.3

Main

board.

8.4

Defective

9.1

Power

attached

outlet.

92

Unit

outlet.

9.3.

The

9.4

Check

9.5

Defective

CPU

display

Power

cord

to

not

connected

fuse

is

power

power

cable

board.

board

Supply

is

not

the

unit

blown.

switch.

board.

to

CPU

or

Encoder

securely

or

wall

to a live

8.1

Check

connection.

8.2

Replace

8.3

Replace

Encoder

8.4

Replace

9.1

Check

properly

wall outlet.

9.2

Check

power.

9.3

Replace

fuses.

9.4

Replace

9.5

Check

controller

at

of

board.

50-pin

CPU

Main

board.

Power

that

the

connect

that

fuse

switch.

wiring

board.

red

and

biack

connector

ribbon

cable

board.

board

and

Supply

power

to

the

wali

outlet

with

two

harness

Check

wires

going

cord

unit

3A,

going

24

in

middle

to

control

is

and

has

250V

from

volts

10.0

Unit

does

not

turn

on,

green

A/C

LED

11.0

Unit

12.0

Incorrect

measured

26

illuminates

does

not

pressure

by

turn

off.

when

manometer.

9.6

Defective

9.7

Defective AC

10.1

Relay

11.1

Defective

board.

11.2

Defective

12.1

Solenoid

12.2

Solenoid

12.3

Unit

12.4

Defective

12.5

Blower

Respironics®

controller

failure.

relay

power

leak.

hose

out

of

calibration.

valve.

leak.

Quantum

inlet.

on

controller

switch.

leak.

PSV

board.

7700

9.6

Replace

9.7

Replace

10.1

Replace

11.1

Replace

6670

41.2

Replace

Tighten

12.1

12.2

Replace

12.3

Calibrate

12.4

Clean

12.5

Service

Replace

Manual,

controller

AC

relay

relay,

or

ECO

power

solenoid.

hose.

or

replace

blower.

1002917

inlet.

with

(FET

6726).

switch.

unit.

board.

FET

module

valve.

module.

ECO

Page 29

RESPIRONICS”

SECTION

4.0

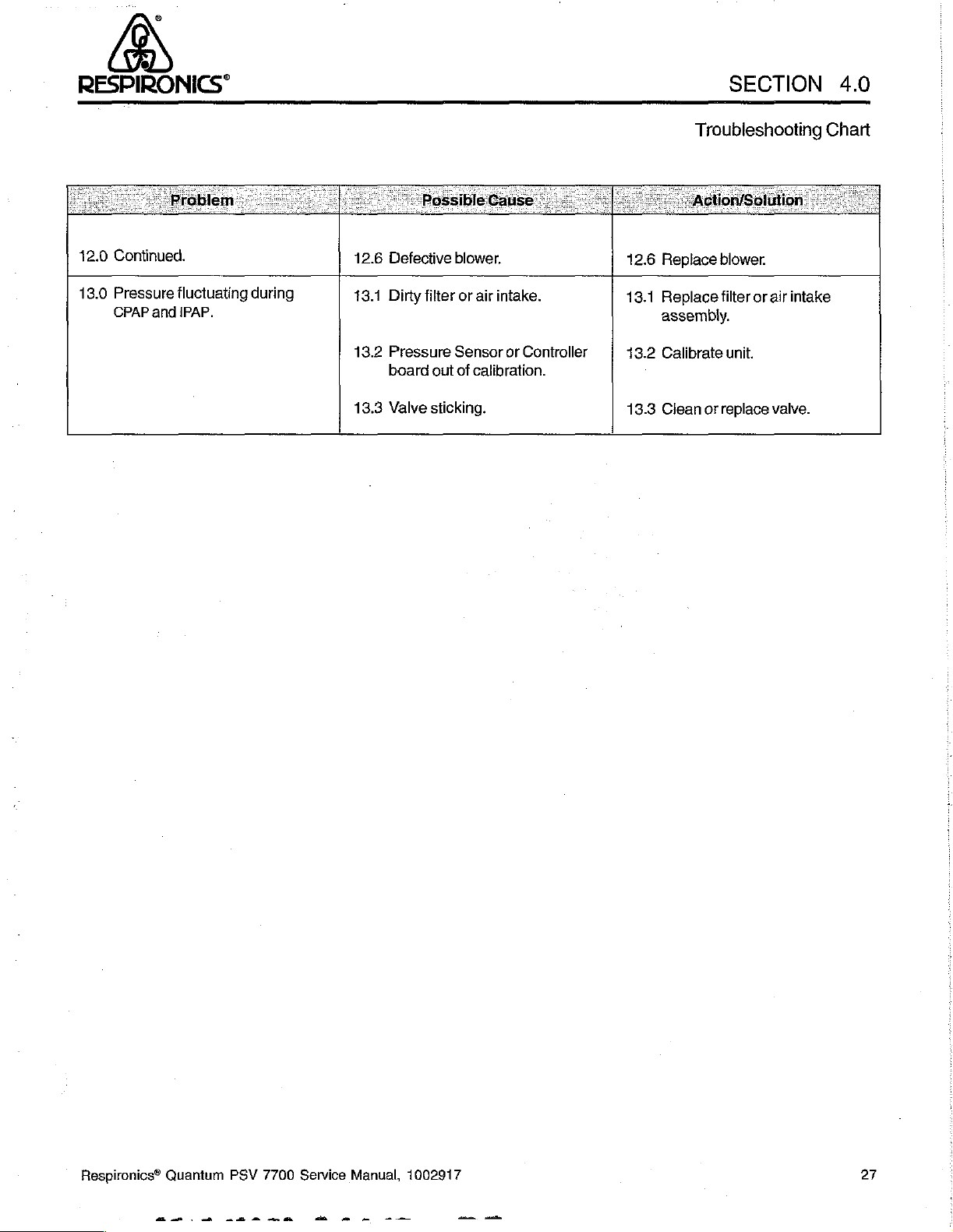

12.0

Continued.

13.0

Pressure

CPAP

fluctuating

and

IPAP.

during

12.6

Defective

13.1

Dirty

13.2

Pressure

board

13.3

Valve

blower.

filter

or

air

Sensor

out

of

calibration.

sticking.

intake.

or

Controller

12.6

Replace

13.1

Replace

assembly.

13.2

Calibrate

13.3

Ciean

Troubleshooting

blower.

filter

or

air

unit.

or

replace

valve.

Chart

intake

Respironics®

Quantum

PSV

7700

Service

Manual,

1002917

27

Page 30

SECTION

5.0

RESPIRONICS”

Operational

Checks

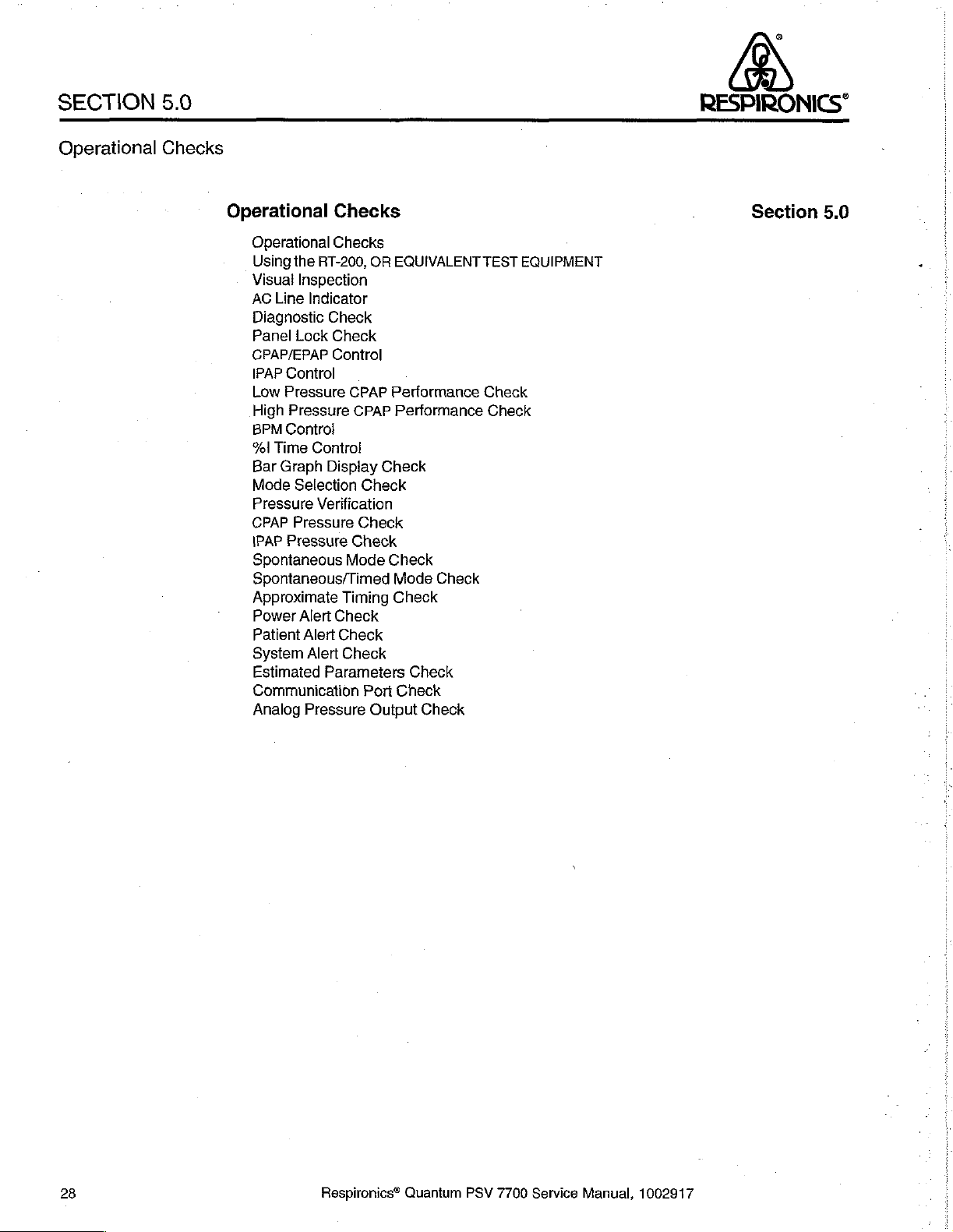

Operational

Operational

Using

the

RT-200,

Visual

Inspection

AC

Line

Indicator

Diagnostic

Panel

Lock

CPAP/EPAP

IPAP

Control

Low

Pressure

High

Pressure

BPM

Control

Yel

Time

Control

Bar

Graph

Mode

Selection

Pressure

CPAP

IPAP

Spontaneous

Spontaneous/Timed

Approximate

Power

Patient

System

Estimated

Communication

Analog

Verification

Pressure

Pressure

Alert

Alert

Alert

Parameters

Pressure

Checks

Checks

OR

EQUIVALENT

Check

Check

Control

CPAP

Performance

CPAP Performance

Display

Check

Check

Check

Gheck

Mode

Timing

Check

Check

Port

Output

Check

Check

Mode

Check

Check

Check

Check

Check

TEST

Check

Check

EQUIPMENT

.

Section

5.0

28

Respironics®

Quantum

PSV

7700

Service

Manual,

1002917

Page 31

RESPIRONICS“

SECTION

5.0

Operational

Using

an

RT-200,

EQUIVALENT

EQUIPMENT

Checks

OR

TEST

Y

Operational

of

the

unit.

If a unit

requiring

performed.

A

unit

minor

passes

operation.

Y

Aproperly

Calibration

reassembly

Quantum

Service

TestName

CPAP

Pressure

IPAP

Pressure

Pressure

Flow

Verification

Measuremenis

Checks

fails

repairs

Operational

calibrated

Analyzer

tests,

unit

Manual.

Check

Check

are

used

any

the

steps

RT-200,

may

be

testing,

to

of

these

in

Checks

OR

used

to

or

calibration

RT-200,

find

any

discrepancies

checks,

Sections

if

no

discrepancy

EQUIVALENT

perform

procedures

Test

No.

12

12

21

36

Operational

other

than a discrepancy

6.0

through

is

TEST

EQUIPMENT

Operational

as

Checks

with

the

operation

10.0

MUST

be

discovered

Checks,

described

Readings / Scale

250cm

250

cm

20

psi

180

pm

H,O

H,O

in

in

the

unit

Visual

AC

Line

Inspection

Indicator

Y

inspect

the

case

panel

not

scratched

Y

Connect

into

an

that

the

is

knobs

AC

unit

the

unit

securely

are

secure

or

damaged

the

AC

outlet.

The

is in

standby.

case

for

fastened.

and

power

cord

green

scratches,

Check

in

good

condition.

in

any

way.

to

the

AC

LED

on

dents,

that

the

back

the

or

fan,

of

the

rear

other

hour

Check

unit.

panel

damage.

meter,

that

Plug

the

the

Check

and

displays

power

illuminates

that

front

are

cord

indicating

Respironics®

Quantum

PSV

7700

Service

Manual,

1002917

29

Page 32

SECTION

5.0

RESPIRONICS”

Operational

W Press

displays

LED

unit

15

W

simultaneously

settings

of

the

display.

vw

Verify

25

Change

the

cmH,O.

the

illuminate

displays.

is

operating.

seconds.

Lock

the

is

Estimated

With

the

the

CPAP/EPAP

omH,O.

the

CPAP/EPAP

On/Off

The

Check

panel

not

unit

unit

Checks

button

briefly,

green

Adj

is

that

by

pressing

until

Loc

possible

Parameters

in

CPAP

control

mode

control

to

start

followed

LED

next

displayed

the

unis

both

appears

in

the

locked

buttons

mode,

verify

range

to

Spont,

range

by

the

unit.

The

immediately

to

the

On/Off

on

the

Estimated

cooling

in

of

the

the

state.

fan

Estimated

display.

Unlock

simultaneously

that

the

by

setting

and

set

the

setting the

alert

sounds

by

iHlumination

button

Parameters

is

operating.

Parameters

Adjusting

the

until

CPAP mode

the

display

IPAP

control

display

from 2 cmH,0

and

all

of

all

illuminates

window

buttons

any

of

the

panel

by

pressing

Adj

appears

LED

is

from 2 cmH,O

to

30

cmH,O.

alert

other

when

the

for

system

both

in

the

illuminated.

to

Verify

to

25

Diagnostic

Panel

CPAP/EPAP

Lock

Check

Check

Control

У

With

the

IPAP

control

cmH,O

Set

for

CPAP/EPAP

CPAP/EPAP

Continue

decrease.

unit

range

35

value.

to

slowly

cm

in

Spont

H,O

to

10

Verify

lower

by

setting

units,

cmH,O.

mode,

and

Slowly

that

the

the

IPAP

set

the

37

CPAP

the

CPAP/EPAP

display

cm

H,O

lower

mode

value.

The

control

to 2 cmH,O,

for

International

the

IPAP

range

indicator

CPAP/EPAP

to 2 cmH,O.

and

to

Units).

until

is

flashing.

value

30

cmH,O

it

equals

must

Verify

the

also

(35

IPAP

Control

30

Respironics®

Quantum

PSV

7700

Service

Manual,

1002917

Page 33

RESPIRONICS*

SECTION

5.0

BPM

%I

Time

Bar

Graph

Check

Mode

Control

Control

Display

Selection

¥V

Set

the

value

of

40

BPM.

Y

Set

Timed.

control

Y

The

display

V

Press

Occlude

the

outlet

each

mode:

mode

10.

Verify

the

mode

The % i

range

by

bar

graph

in

each

the

Up

the

outlet

for

SPONT/TIMED

of

the

the

of

the

Time

displays

setting

display

of

the

and

for

unit

to

BPM

control

unit

to

the

display

must

control

Down

arrow

CPAP

and

mode.

Spont/Timed.

range

by

CPAP.

the

default

be

within

Set

from

the

value

10%

+1

modes.

keys

under

SPONT

The

following

modes,

The

BPM

setting

mode

of

to

90%.

cm

H,O

the

Mode

and

LED’s

Operational

displays

the

of

the

33%.

to

the

only

the

display

unit

to

Verify

the % |

digital

Select

partially

are

illuminated

Checks

default

from 4 BPM

Spont/

Time

CPAP/EPAP

section.

occlude

during

to

CPAP

SPONT

SPONT/TIMED

Set

CPAP/EPAP

the

following

Rate

Select

are

Spontaneous/Timed

displayed:

Risetime

CPAP

CPAP

SPONT

to

system

CPAP/EPAP

IPAP

Risetime

“el

Time

CPAPEPAP

IPAP

Rate

%

Time

LED

_LED

SPONT/TIMED

(CPAP

settings

2cm

H,O,

settings

2cmH,O

2cmHO

0.5

Blank

Blank

2cmHO

2cmHO

illuminated

flashes

LED

illuminated

LED

are

then

are

displayed:

sec

mode.

0.5

sec

10

33

LED

flashes

identical)

select

the

Verify

that

illuminated

when

CPAP/EPAP

Spontaneous

the

following

mode.

system

and

IPAP

Verify

settings

that

Respironics®

Quantum

PSV

7700

Service

Manual,

1002917

31

Page 34

SECTION

5.0

RESPIRONICS”

Operational

Set

the

system

IPAP

CPAP/EPAP

Risetime

Rate

%l

Time

Turn

off

the

unit

tum

on

the

unit.

Change

settings

Set

displayed:

the

are

CPAP/EPAP

IPAP

Risetime

Rate

%I

the

unit

unit

displayed:

Time

mode

Checks

settings

and

Verify

mode

to

to

verify

that

to

CPAP

the

following:

20

cm

H,0

10

em

H,0

0.3

sec

15

40

that

all

LEDs

the

previous

Spontaneous

10

cm

H,0

20

cm

HO

0.3

sec

Blank

Blank

and

verify

are

system

and

that

blank.

verify

the

following

Wait

thirty

settings

that

the

system

seconds

are

displayed.

following

settings

and

system

are

Mode

Selection

(Continued)

CPAP/EPAP

IPAP

Risetime

Rate

Yel

Set the

settings

Vv

hose.

figure

unit

are

CPAP/EPAP

IPAP

Risetime

Rate

%l

Connect

Connect

2).

CPAP/EPAP

IPAP

Risetime

Rate

ol

Time

Time

mode

displayed:

Time

the

restricted

the

Set

the

unit

10

cm

HO

Blank

Biank

Blank

Blank

to

Spontaneous/Timed

10

cm

HO

10

cm

HO

0.5

sec

10

33

adapter

/s"

tubing

to

on

the

following

the

2cmHO

30

cm

HO

0.1

seconds

15

BPM

50

and

verify

(TS-7700-31)

flow

restrictor

system

settings:

that

the

to

the

end

of

to a pressure

following

the

Quantum's

gauge,

system

(see

Pressure

Verification

32

Respiranics®

Quantum

PSV

7700

Service

Manual,

1002917

Page 35

RESPIRONICS”

SECTION

5.0

Pressure

(Continued)

CPAP

Pressure

Verification

Check

Verify

high

pressure

W

Connect

1/8”

tubing

that

the

the

on

low

is

flow

the

pressure

30

cm

restrictor

flow

restrictor

is 2 em

H,0 + 0.70

Flow

TS-7700-034

Figure

2:

Set-up

to

the

to a volume

H,0 + 0.70

cm

H,0.

Restricter

to

Measure

end

of

the

measuring

Operational

cm

H,O,

Pressure

Quantum’s

device,

and

verify

hose.

(see

Checks

that

they

Connect

figure

the

2).

IPAP

Pressure

Check

Select

display

the

CPAP mode

reads

25

cm

display a pressure

Set

the

CPAP

pressure

em

HO.

2

Set

the

CPAP

pressure

Y

Connect

the

1/8”

Select

to

the

the

flow

tubing

the

on

Spont/Timed

following:

CPAP/EPAP

IPAP

Domestic

international

35cm

H20

Risetime

Rate

%l

Time

on

the

H,O.

The

of

25

cm

to

10

to 2 cm

restrictor

the

flow

mode

2cm

H,0

Units

Units

Units

0.1

10

50

Quantum.

RT-200,

OR

H,O + 0.7

cm

H,O.

H,O.

Verify a pressure

to

the

end

restrictor

to a pressure

on

the

Quantum.

30cm

87cm

35cm

seconds

BPM

Set

the

CPAP/EPAP

EQUIVALENT

cm

Н.О.

TEST

Verify a pressure

of

the

Quantum’s

measuring

Set

the

H,O

H,0

H,0

EQUIPMENT

of

10

of 2 cm

outlet.

Quantum

knob

untii

cm

H,O + 0.7

H,O + 0.7

Connect

device.

parameters

the

must

HO.

Respironics®

Quantum

PSV

7700

Service

Manual,

1002917

33

Page 36

SECTION

5.0

RESPIRONICS“

Operational

Verify

that

the

Verify

that

the

illuminates

Reset

Proximal

Lung

Lung

Verify

Verify

illuminates

Y

Connect a flow

the

following

CPAP/EPAP

IPAP

Risetime

Rate

“el

during

the

Michigan

Resistance

Compliance

that

the

that

the

during

Time

Resistance

parameters:

Checks

five

breathing

forced

five

forced

breath

each

Lung

breathing

breath

each

restricterto

cycles

LED,

breath.

to

the

cycles

LED,

breath.

the

5

cm

H,O

15

cm

0.1

seconds

10

BPM

50

take

located

following

Rp5

Rp20

0.05

take

located

Quantum's

HO

30

seconds = 1

to

the

left

parameters:

30

seconds + 1

to

the

left

patient

second

of

the

second

of

the

outlet.

Rate

Rate

Set

to

complete.

display,

to

complete.

display,

the

unit

to

U

Do

Spontaneous/Timed

Mode

Approximate

Performance

_

Verification

Check

(Continued)

i

Timing

The

unit

defaults

H,O.

After 3 seconds + 0.5

to

for 3 seconds + 0.5

Set

the

Quantum

CPAP/EPAP

ΙΡΑΡ

to

Risetime

Rate

%l

Time

The

unit

defaults

H,0.

After 9 seconds + 0.5

to

for 3 seconds + 0.5

Set

the

Quantum

to

CPAP/EPAP

IPAP

Risetime

Rate

Sel

Time

The

unit

defaults

H,0.

After 1 second + 0.5

for 2 seconds + 0.5

to

the

EPAP

seconds,

seconds.

the

following

5cmH,0

15

0.1

5

BPM

25

the

EPAP

seconds,

seconds.

the

following

5cmH,O

15

0.1

20

66

the

EPAP

seconds,

seconds.

pressure,

parameters:

cm

H,O

seconds

pressure,

parameters:

cm

HO

seconds

BPM

pressure,

the

and

the

barograph

and

the

barograph

and

barograph

the

barograph

the

barograph

the

barograph

displays 5 cm

increases

displays 5 cm

increases

displays 5 cm

increases

to

to

to

15

15

15

cm

cm

cm

H,O

H,O

H,0

36

Respironics®

Quantum

PSV

7700

Service

Manual,

1002917

Page 37

RESPIRONICS“

SECTION

5.0

Power

Patient

Alert

Alert

Check

Check

w

With

the

alarm

must

illuminate

alarm

Y

Connect a flow

immediately.

must

parameters

CPAP/EPAP

IPAP

Risetime

Rate

%l

Time

Remove

seconds

flow

the

of

restricteron

unit

running,

sound

for

at

Plug

least

unplug

five

the

cease.

restricter(TS-7700-031)

to

the

following:

5

cm

H,O

30

cm

0.3

seconds

4

BPM

50

flow

restricterfrom

removing

the

the

flow

outlet

restrictor.

port.

the

AC

seconds,

AC

power

H,O

the

outlet

power

-

The

and

cord

to

the

port.

alert

Operational

cord

from

the

red

back

into

outlet

port.

The

alert

is

silenced

its

supply.

Power

its

supply.

Set

sounds

by

Checks

The

LED

must

The

the

within

30

replacing

the

System

Estimated

Check

Alert

Check

Parameters

Y

Set

the

Quantum

Connect a 10

outiet

port

of

The

alert

sounds,

seconds.

Y

Michigan

settings:

Set

Set

the

Proximal

Lung

Lung

the

system

To

unit

Lung

Resistance

Compliance

CPAP/EPAP

IPAP

Risetime

Rate

Yel

Time

Let

the

unit

stabilize

unit

displays

to

CPAP

mode.

cm

H,0

positive

the

unit.

Block

when

reset

the

alert,

mode

to

using a 22mm

Resistance Rps

pressure

the

exhalation

the

pressure

turn

off

Spontaneous/Timed.

hose.

Rp20

0.05

settings

the

following

for

to

one

the

following:

2

cm

H,O

25

cm

Н.О

0.1

seconds

10

BPM

25

minute

estimated

Set

the

CPAP

source

exerted

the

unit.

Set

the

(7300

port

on

exceeds 5 cmH,0

Connect

Michigan

before reading

parameters:

pressure

or

equivalent)

the

rear

panel

the

Quantum

Lung

to

displays.

to

20

cm

of

for 0.5

the

following

Verify

Η,Ο.

to

the

the

to

the

that

unit.

the

Respironics®

Quantum

PSV

7700

Service

Minute

Tidal

Rate

Manual,

Vol

Vol

1002917

17.80 + 5.34

1.780 + 0.534

10

37

Page 38

SECTION

5.0

RESPIRONICS”

Operational

Y

Connect a 7703

Verify

that

adjusting

on

the

Main

Unit.

displayed

Main

w

Using a mini-phono

tip

of

Select

Connect

7700-031)

+

0.7

Refer

measured

Unit

the

the

em

to

on

the

transmit

phono

CPAP

the

unit

and

3he”

H,O

on

the

following

at

the

Checks

Remote

the

controls

Verify

that

Remote

alert

plug,

mode

to a pressure

tubing,

the

above

Pressure

Unit.

signals

plug,

and

on

pressure

formula

pressure:

Unit

to

on

the

readings

Perform

to

connect

the

negative

the

unit.

measuring

(see

figure

gauge.

to

determine

Measured

10

the

the

the

Set

rear

panel

of

the

Remote

the

Remote

the

lead

the

2).

Verify

(cm

Unit

changes

on

the

Main

Unit

Alert

checks

Unit.

positive

device

H,0) _ voltage + 0.05

to

the

CPAP

that

the

voltage

lead

of a volt-meter

sleeve

pressure

using a flow

the

Quantum

match

to

verify

of

the

to

15

unit

pressure

measure

Main

Unit.

the

displays

those

that

the

to

the

phono

cm

plug.

Η,Ο.

restricter(TS-

is

15.0

range

volts

Communication

Analog

Output

Port

Check

Pressure

Check

38

Respironics®

Quantum

PSV

7700

Service

Manual,

1002917

Page 39

RESPIRONICS“

SECTION

5.0

Operational

Checks

(This

page

intentionally

left

blank)

Respironics®

Quantum

PSV

7700

Service

Manual,

1002917

39

Page 40

SECTION

6.0

RESPIRONICS"

Preventive

Service

Preventive

Preventive

Mandatory

Quality Control

Service

Engineering

Service

Procedures

Change

Check-Out

Orders

Procedures

(ECOs)

Section

6.0

40

Respironics®

Quantum

PSV

7700

Service

Manual,

1002917

Page 41

RESPIRONICS”

SECTION

6.0

_ .

Preventive

Service

Procedures

У

The

following

Quantum

Refer

these

Perform

*

Perform

Section

*

Check

*

Dual

PSV

to

Sections

procedures.

the

external

impeller

Inspect

Install a filter

If

inlet

Baffle

Air Inlet

Preventive

is

serviced.

4.0,

following

operational

5.0)

Filter

screenis

(p/n

Baffle

procedures:

verification

inlet

(new

siyle)

Air

intake

screen

dirty

600-07700-17)

according

Service

7.0,

and

10.0

check

filter

for

cleanliness.

blower,

Screen.

if

one

is

not

ornon-existent,

for

cleanliness.

to

the

procedures

for

detailed

and

note

Replace

(see

Section

lf

dirty,

replace

present.

check

procedures

Preventive

MUST

be

followed

information

any

7.0):

witha

blower

ifthe

in

Section

on

nonconformance

if

dirty.

new

iniet

screen

screen

7.0).

Service

each

performing

screen

is

on

dirty,

(p/n

the

replace

time

(see

7719).

Air

Inlet

a

the

Check

cleaniiness

and

valve

If

screen

impellers

Single

Impeller

Inspect

shells

and

Inspect

Inspect

hoses

as

+

Clean

valve

*

Incorporated

«

Replace

*Recalibrate

(see

battery,

Section

of

blowerhoses,

outlet

hose.

Replace

was

dirty,

remove

and

inside

of

both

(old

style)

blower,

foam

seals

to

ensure

no

air

external

blower

hose, valve

leaks.

inlet

Replace

filter

required.

per