Page 1

Respironics V200/Esprit Ventilator

Service Manual

580-1000-02 H

Page 2

This work is protected under Title 17 of the United States copyright code and is the sole property of Respironics.

No part of this document may be copied or otherwise reproduced, or stored in any electronic information

retrieval system, except as specifically permitted under United States copyright law, without the prior written

consent of Respironics.

Copyright © 2004-2009. Respironics, Inc.

All rights reserved.

For Technical support, contact:

Respironics, Inc. Customer Service

Within the U.S.A. 1-800-345-6443

Outside the U.S.A. 724-387-4000

Facsimile 724-387-5012

service@respironics.com

United States of America

Respironics California, Inc.

2271 Cosmos Court

Carlsbad, CA 92011

USA

1-800-345-6443

or 724-387-4000

Authorized Representative

Respironics Deutschland, Inc.

Gewerbestrasse 17

D-82211 Herrsching Deutschland

+49-8-15-29-30-60

ii Respirionics V200/Esprit Ventilator Service Manual © Respironics, Inc. REF 580-1000-02 H

Page 3

Table of Contents

1 Introduction and Intended Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.1 Recommended Tools and Test Equipment . . . . . . . . . . . . . . . . . . . . . . . 1-2

2 Warnings, Cautions, and Notes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.1 General Warnings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.2 General Cautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.3 General Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

3 Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.1 Pneumatic System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.1.1 Blower Inlet Filter (F1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3.1.2 Muffler (Silencer). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3.1.3 Blower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3.1.4 Cooling Fan Filter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3.1.5 Cooling Coil. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3.1.6 Cooling Coil Fan. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3.1.7 Air Valve Assembly (AV) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3.1.8 Air Flow Sensor (FS1). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3.1.9 Oxygen Water Trap/Inlet Filter Assembly (F2) . . . . . . . . . . . . . . . 3-4

3.1.10 Oxygen Inlet Connector (O

3.1.11 Oxygen Supply Pressure Switch (PS1) . . . . . . . . . . . . . . . . . . . . 3-4

3.1.12 Oxygen Regulator (REG 1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3.1.13 Oxygen Valve (OV) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

3.1.14 Oxygen Flow Sensor (FS2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

3.1.15 Crossover Solenoid (SOL1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

3.1.16 Cross-Contamination Check Valve (CV5) . . . . . . . . . . . . . . . . . . . 3-5

3.1.17 Safety Valve Pilot Solenoid (SOL2) . . . . . . . . . . . . . . . . . . . . . . 3-5

3.1.18 Safety Valve (SV) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

3.1.19 Air System Check Valve (CV2) . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

3.1.20 Inspiratory Non-Rebreathing Check Valve (CV3) . . . . . . . . . . . . . 3-6

3.1.21 Pressure Relief Valve (PRV). . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

3.1.22 Oxygen Sensor (OS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

3.1.23 Inspiratory Pressure Transducer (PT3) . . . . . . . . . . . . . . . . . . . . 3-6

3.1.24 Inspiratory Pressure Transducer Solenoid (SOL4) . . . . . . . . . . . . 3-7

3.1.25 Heated Exhalation Filter (F3) . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

3.1.26 Exhalation Pressure Transducer (PT2) . . . . . . . . . . . . . . . . . . . . 3-7

) . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

2

REF 580-1000-02 H Respironics V200/Esprit Ventilator Service Manual © Respironics, Inc. iii

Page 4

Table of Contents

3.1.27 Exhalation Pressure Transducer Solenoid (SOL3) . . . . . . . . . . . . 3-7

3.1.28 Exhalation Non-Rebreathing Check Valve (CV4) . . . . . . . . . . . . . 3-8

3.1.29 Exhalation Valve (EV) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

3.1.30 Exhalation Flow Sensor (FS3) . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

3.2 Ventilator System Electronics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

3.2.1 Main PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

3.2.2 CPU PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

3.2.3 Analog PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

3.2.4 Digital PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

3.2.5 VGA Controller PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

3.2.6 Blower Controller PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

3.2.7 Motor Controller PCBs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

3.2.8 Sensor PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

3.2.9 Man-Machine Interface (MMI) PCB . . . . . . . . . . . . . . . . . . . . . 3-15

3.2.10 Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

3.2.11 Backlight Inverter PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

3.2.12 Real-Time Clock Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

3.2.13 Backup Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

3.2.14 External Battery. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

3.2.15 DC/DC Converter PCB. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

3.2.16 Optical Rotary Encoder. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

3.2.17 Graphic User Interface (GUI) . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

3.2.18 Remote Alarm (Nurse Call) . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

4 Periodic Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.1 Cleaning the Ventilator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.2 Annual PM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

4.3 12,500-Hour PM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

5 Diagnostic Mode and

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.1 Entering Diagnostic Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5.2 User Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5.2.1 Setting the Date and Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

5.2.2 Setting Altitude . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

5.2.3 Enabling Circuit Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

5.2.4 Selecting 12 or 12 Hour Clock . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

5.2.5 Confirm Backup Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

5.3 Short Self Test (SST) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

5.4 Extended Self Test (EST) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

iv Respironics V200/Esprit Ventilator Service Manual © Respironics, Inc. REF 580-1000-02 H

Page 5

Table of Contents

5.5 Software Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

5.6 Diagnostic Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

5.7 Hardware Diagnostics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

5.8 Pneumatic Component Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . 5-13

5.8.1 Oxygen Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-14

5.8.2 Oxygen Flow Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

5.8.3 Oxygen Regulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

5.8.4 Air Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-17

5.8.5 Air Flow Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-17

5.8.6 Inhalation and Exhalation Solenoids . . . . . . . . . . . . . . . . . . . . 5-18

5.8.7 Safety Valve and Safety Solenoid . . . . . . . . . . . . . . . . . . . . . . . 5-18

5.8.8 Pressure Relief Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-19

5.8.9 Crossover Solenoid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-20

5.8.10 Exhalation Flow Sensor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-21

5.8.11 Check Valve 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-22

5.8.12 Check Valve 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-22

5.8.13 Check Valve 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-23

5.8.14 Filter Heater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-23

5.8.15 Blower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-24

5.8.16 Inhalation/ Exhalation Pressure Transducers and Exhalation

Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-25

5.8.17 Oxygen Pressure Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-26

5.8.18 External Oxygen Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-26

5.8.19 High Internal Oxygen Alarm Test . . . . . . . . . . . . . . . . . . . . . . . 5-26

5.8.20 Sensor PCB Voltage Indicators . . . . . . . . . . . . . . . . . . . . . . . . 5-27

5.9 Bacteria Filter Back Pressure Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-28

6 Diagnostic Codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.1 Diagnostic Code 1012 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . 6-24

6.2 Diagnostic Code 5000 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . 6-26

7 Ventilator Communications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

7.1 Downloading Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

7.2 Programming the Ventilator Serial Number . . . . . . . . . . . . . . . . . . . . . . . 7-4

7.3 Enabling Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

7.4 Setting Up the Serial Interface for DRPT . . . . . . . . . . . . . . . . . . . . . . . . 7-6

7.5 Generating a Diagnostic Report (DRPT) . . . . . . . . . . . . . . . . . . . . . . . . . 7-9

7.6 Analog Output Port (Chart Recorder) Pinout . . . . . . . . . . . . . . . . . . . . . 7-11

REF 580-1000-02 H Respironics V200/Esprit Ventilator Service Manual © Respironics, Inc. v

Page 6

Table of Contents

8 Performance Verification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

8.1 Required Test Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

8.2 Preliminary Cleaning, Inspection and Setup . . . . . . . . . . . . . . . . . . . . . . 8-5

8.3 Preliminary Pneumatic Calibration Analyzer Setup . . . . . . . . . . . . . . . . . 8-6

8.4 Certifier FA Plus Setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-7

8.4.1 Measurement Selection Screen . . . . . . . . . . . . . . . . . . . . . . . . . 8-7

8.4.2 Averaging Setup Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-9

8.4.3 Trigger Options Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-10

8.4.4 Configuration Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-10

8.4.5 Saving Configurations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-11

8.5 Performance Verification Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . 8-13

8.5.1 Test 1: Electrical Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-14

8.5.2 Test 2: Extended Self Test (EST). . . . . . . . . . . . . . . . . . . . . . . 8-15

8.5.3 Test 3: Air Flow Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-16

8.5.4 Test 4: Oxygen Flow Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . 8-19

8.5.5 Test 5: Pressure Accuracy. . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-21

8.5.6 Test 6: PEEP System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-23

8.5.7 Test 7: Breath Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-26

8.5.8 Test 8: Alarm/Analog Output Signals, Alarm Volume,

and Remote Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-27

8.5.9 Test 9: Gas Volume Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . 8-30

8.5.10 Test 10: Oxygen Accuracy. . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-32

8.5.11 Test 11: Heated Exhalation Bacteria Filter, Power Fail Alarm,

and Display Intensity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-34

8.5.12 Test 12: Neonatal Option Testing . . . . . . . . . . . . . . . . . . . . . . 8-36

8.5.13 Test 13: Backup Battery and External Battery (If Installed) . . . . 8-38

8.6 Returning Ventilator to Normal Operation . . . . . . . . . . . . . . . . . . . . . . . 8-40

8.7 Performance Verification Troubleshooting/Repair . . . . . . . . . . . . . . . . . 8-42

8.7.1 Test 1: Electrical Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-42

8.7.2 Test 2: Extended Self Test . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-42

8.7.3 Test 3: Air Flow Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-43

8.7.4 Test 4: Oxygen Flow Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . 8-43

8.7.5 Test 5: Pressure Accuracy. . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-44

8.7.6 Test 6: PEEP System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-44

8.7.7 Test 7: Breath Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-44

8.7.8 Test 8: Alarm Output Signal, Volume, and Remote Alarm . . . . . 8-45

8.7.9 Test 9: Gas Volume Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . 8-45

8.7.10 Test 10: Oxygen Accuracy. . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-45

8.7.11 Test 11: Heated Exhalation Bacteria Filter, Power Failure Alarm,

and Display Intensity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-46

vi Respironics V200/Esprit Ventilator Service Manual © Respironics, Inc. REF 580-1000-02 H

Page 7

Table of Contents

8.7.12 Test 12: Neonatal Option Test. . . . . . . . . . . . . . . . . . . . . . . . . 8-47

8.7.13 Test 13: Backup Battery and External Battery Test . . . . . . . . . . 8-48

8.8 Neonatal Option Data Form. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-49

8.9 Electrical Safety/Extended Self Test (EST) Data Form . . . . . . . . . . . . . . 8-51

8.10 Performance Verification Data Form. . . . . . . . . . . . . . . . . . . . . . . . . . . 8-52

9 Esprit Ventilator Component

Removal/Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

9.1 Filter Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-3

9.2 Top Enclosure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-5

9.3 Sensor PCB. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-6

9.4 Power Supply Fan/Shroud . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-8

9.5 Backlight Inverter PCB (9.5-in. GUI) . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-9

9.6 Backlight Inverter PCB (Original 10.4-in. GUI only) . . . . . . . . . . . . . . . 9-10

9.7 DC/DC Converter PCB (Original 10.4-in. GUI only) . . . . . . . . . . . . . . . . 9-11

9.8 Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-12

9.9 Power Supply Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-15

9.10 MMI PCB (9.5-in. GUI) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-17

9.11 MMI PCB (10.4-in. GUI) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-20

9.12 GUI Assembly (9.5-in. GUI) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-22

9.13 GUI Assembly (Original 10.4-in. GUI) . . . . . . . . . . . . . . . . . . . . . . . . . 9-24

9.14 GUI Assembly (2nd Generation 10.4-in. GUI). . . . . . . . . . . . . . . . . . . . 9-25

9.15 Intensity and Volume Potentiometers (9.5-in. GUI) . . . . . . . . . . . . . . . . 9-28

9.16 Intensity and Volume Potentiometers (10.4-in. GUI’s). . . . . . . . . . . . . . 9-29

9.17 Rotary Encoder (9.5-in. GUI) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-30

9.18 Rotary Encoder (10.4-in. GUI’s) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-31

9.19 GUI Front Panel Overlay (10.4-in. GUI’s) . . . . . . . . . . . . . . . . . . . . . . . 9-32

9.20 VGA Display Assembly (9.5-in. GUI) . . . . . . . . . . . . . . . . . . . . . . . . . . 9-33

9.21 Touch Screen/LED Indicator Assembly and Front Panel Overlay

(9.5-in. GUI) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-34

9.22 Backlight Inverter PCB, VGA Display, and Touch Frame

(Original 10.4-in. GUI). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-35

9.23 Transition PCB, LCD, IR Touch Frame, and Backlight Inverter PCB

(2nd Generation 10.4-in. GUI) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-36

9.24 GUI Cleaning and Dust Gasket Installation

(2nd Generation 10.4-in. GUI) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-38

9.25 Increased Minimum Alarm Volume Harness . . . . . . . . . . . . . . . . . . . . . 9-41

9.26 Backup Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-42

9.27 AC Distribution Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-43

9.28 AC Cord Bracket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-45

REF 580-1000-02 H Respironics V200/Esprit Ventilator Service Manual © Respironics, Inc. vii

Page 8

Table of Contents

9.29 Humidifier Receptacle Rotation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-46

9.30 Printed Circuit Boards (Daughter PCBs) (Except Main PCB) . . . . . . . . . . 9-48

9.31 CPU PCB with 4.10 or Greater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-49

9.32 Main PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-50

9.33 Remote Alarm Jack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-53

9.34 Power Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-54

9.35 FIO

9.36 Exhalation Flow Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-56

9.37 Exhalation Valve Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-58

9.38 Primary Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-61

9.39 Filter Heater Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-62

9.40 Oxygen Flow Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-63

9.41 Inspiratory Manifold Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-65

9.42 Installing the Cable Extension Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-69

9.43 Three-Station Solenoid Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-71

9.44 Air Flow Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-72

9.45 Air Valve Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-73

9.46 Oxygen Valve Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-74

9.47 Oxygen Regulator Assembly (with Oxygen Pressure Switch) . . . . . . . . . . 9-76

9.48 Elapsed Time Meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-78

9.49 Oxygen Water Trap Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-79

9.50 Blower Motor Controller PCB (Original) . . . . . . . . . . . . . . . . . . . . . . . . 9-80

9.51 Blower Motor Controller PCB (Updated) . . . . . . . . . . . . . . . . . . . . . . . . 9-81

9.52 Blower Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-82

9.53 Blower Muffler Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-85

9.54 Cooling Fan/Cooling Coil Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-86

9.55 GUI Upgrades . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-88

9.56 Replacing the GUI (9.5-in. to original 10.4-in.) . . . . . . . . . . . . . . . . . . 9-90

9.57 Replacing the GUI (9.5-in. to 2nd Generation 10.4-in.) . . . . . . . . . . . . 9-95

Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-55

2

9.56.1 Installing the CPU and DC/DC Converter PCBs . . . . . . . . . . . . . 9-93

9.56.2 Downloading Ventilator Software . . . . . . . . . . . . . . . . . . . . . . . 9-93

9.56.3 Calibrating the Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-94

9.56.4 Enabling Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-94

9.56.5 Final Checkout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-94

9.57.1 Installing the CPU PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-96

9.57.2 Downloading Ventilator Software . . . . . . . . . . . . . . . . . . . . . . . 9-97

9.57.3 Calibrating the Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-97

9.57.4 Enabling Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-97

9.57.5 Final Checkout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-97

viii Respironics V200/Esprit Ventilator Service Manual © Respironics, Inc. REF 580-1000-02 H

Page 9

Table of Contents

9.58 Replacing the GUI (Original 10.4-in. to 2nd Generation 10.4-in) . . . . . . 9-98

9.58.1 Installing the CPU PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-102

9.58.2 Downloading Ventilator Software . . . . . . . . . . . . . . . . . . . . . . 9-102

9.58.3 Calibrating the Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-103

9.58.4 Enabling Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-103

9.58.5 Final Checkout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-103

10 Respironics V200 Ventilator Component Removal/Installation . . . . . . . 10-1

10.1 Inlet Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-3

10.1.1 Air Inlet Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-3

10.1.2 Blower Inlet Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-4

10.1.3 Oxygen Inlet Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-5

10.2 GUI Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-6

10.2.1 GUI Assembly Removal/Installation . . . . . . . . . . . . . . . . . . . . . 10-6

10.2.2 Backlight Inverter PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-8

10.2.3 Transition PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-9

10.2.4 LCD Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-9

10.2.5 Touch Frame and Alarm LED PCB . . . . . . . . . . . . . . . . . . . . . . 10-9

10.2.6 GUI Front Panel Overlays . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-10

10.2.7 GUI Cleaning and Dust Gasket Installation . . . . . . . . . . . . . . . 10-11

10.3 Separating the Top and Bottom Enclosures . . . . . . . . . . . . . . . . . . . . 10-14

10.4 Enclosure Brace . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-16

10.5 Sensor PCB. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-17

10.6 Intensity and Volume Potentiometers . . . . . . . . . . . . . . . . . . . . . . . . . 10-19

10.7 Rotary Encoder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-20

10.8 Power Supply Shroud . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-21

10.9 Power Supply Fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-21

10.10 Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-22

10.10.1Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-22

10.10.2Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-24

10.11 Power Supply Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-25

10.12 MMI PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-26

10.13 Backup Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-28

10.14 AC Distribution Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-29

10.15 AC Power Cord Bracket and Power Cord . . . . . . . . . . . . . . . . . . . . . . . 10-31

10.16 Elapsed Time Meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-32

10.17 Printed Circuit Boards (Daughter PCBs) (Except Main PCB) . . . . . . . . . 10-33

10.18 Main PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-34

10.19 Remote Alarm Jack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-37

10.20 Power Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-38

REF 580-1000-02 H Respironics V200/Esprit Ventilator Service Manual © Respironics, Inc. ix

Page 10

Table of Contents

10.21 FIO2 Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-39

10.22 Exhalation Flow Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-40

10.22.1Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-40

10.22.2Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-40

10.23 Exhalation Valve Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-42

10.23.1Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-42

10.23.2Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-43

10.24 Primary Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-43

10.25 Filter Heater Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-44

10.26 Oxygen Flow Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-45

10.26.1Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-45

10.26.2Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-46

10.27 Air Flow Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-47

10.28 Inspiratory Manifold Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-48

10.28.1Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-48

10.28.2Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-50

10.29 Three-Station Solenoid Valve Assembly . . . . . . . . . . . . . . . . . . . . . . . 10-51

10.30 Air Valve Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-52

10.31 Oxygen Valve Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-53

10.32 Oxygen Water Trap/Inlet Filter Assembly . . . . . . . . . . . . . . . . . . . . . . 10-54

10.32.1Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-54

10.32.2Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-55

10.33 Oxygen Regulator Assembly (with Oxygen Pressure Switch) . . . . . . . . . 10-56

10.33.1Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-56

10.33.2Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-56

10.34 Blower Motor Controller PCB. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-58

10.35 Blower Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-59

10.35.1Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-59

10.35.2Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-60

10.36 Blower Muffler Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-62

10.36.1Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-62

10.36.2Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-62

10.37 Cooling Fan/Cooling Coil Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . 10-63

10.37.1Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-63

10.37.2Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-64

10.38 Installing the CPU PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-66

10.38.1Downloading Ventilator Software . . . . . . . . . . . . . . . . . . . . . . 10-66

10.38.2Calibrating the Display Screen . . . . . . . . . . . . . . . . . . . . . . . 10-66

10.38.3Enabling Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-66

10.38.4Final Checkout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-66

x Respironics V200/Esprit Ventilator Service Manual © Respironics, Inc. REF 580-1000-02 H

Page 11

Table of Contents

11 Where to Go for Help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-1

12 Respironics V200/Esprit Ventilator Replacement Parts List . . . . . . . . . 12-1

12.1 Major Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-1

12.1.1 Electronics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-2

12.1.2 GUI Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-3

12.1.3 Oxygen Pneumatics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-7

12.1.4 Air Pneumatics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-8

12.1.5 Exhalation Pneumatics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-10

12.1.6 Inspiration Pneumatics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-11

12.1.7 Back Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-12

12.1.8 Cart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-13

12.2 Service Part Inventory List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-15

12.3 Complete Repair Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-17

A Pneumatic Schematics for EST. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

A.1 Block Patient Wye (Test 1, Step 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

A.2 Block Patient Wye (Test 1, Step 3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

A.3 Block Patient Wye (Test 1, Step 4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

A.4 Block Patient Wye (Test 1, Step 5) . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-4

A.5 Safety Valve (Test 2, Step 1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-5

A.6 Safety Valve (Test 2, Step 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-6

A.7 Blower (Test 3, Step 1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-7

A.8 Blower (Test 3, Step 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-8

A.9 Oxygen Supply (Test 4, Step 1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-9

A.10 Oxygen Supply (Test 4, Step 2). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-10

A.11 Crossover Circuit (Test 5, Step 1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-11

A.12 Crossover Circuit (Test 5, Step 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-12

A.13 Crossover Circuit (Test 5, Step 3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-13

A.14 Oxygen Delivery (Test 6, Step 1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-14

A.15 Oxygen Sensor (Test 7, Step 1). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-15

A.16 Air Delivery (Test 8, Step 1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-16

A.17 Pressure Relief Valve (Test 9, Step 1) . . . . . . . . . . . . . . . . . . . . . . . . . A-17

A.18 Exhalation Valve (Test 10, Step 1) . . . . . . . . . . . . . . . . . . . . . . . . . . . A-18

A.19 Exhalation Valve (Test 10, Step 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . A-19

A.20 Patient Circuit (Test 11, Step 1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-20

A.21 Patient Circuit (Test 11, Step 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-21

A.22 Heated Filter (Test 12, Step 1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-22

A.23 Heated Filter (Test 12, Step 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-23

REF 580-1000-02 H Respironics V200/Esprit Ventilator Service Manual © Respironics, Inc. xi

Page 12

Table of Contents

B Field Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

C Respi-Link . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Index-1

xii Respironics V200/Esprit Ventilator Service Manual © Respironics, Inc. REF 580-1000-02 H

Page 13

Chapter 1. Introduction and Intended Use

The Esprit and Respironics V200 ventilators are microprocessor-controlled,

electrically powered mechanical ventilators. They are intended for use by

qualified medical personnel to provide continuous or intermittent ventilatory

support for adult, pediatric, and neonatal patients as prescribed by a

physician. They are intended for use in either invasive or non-invasive

applications in institutional environments.

The Esprit and Respironics V200 ventilators meet or exceed all applicable

safety requirements, consensus guidelines, U.S. regulatory statutes, and

international regulatory standards for life support/mechanical ventilation

devices.

Read this manual thoroughly prior to performing service or maintenance on the

ventilators. This manual contains advanced troubleshooting, calibration, and

maintenance instructions. All maintenance and repair work should be

performed by qualified biomedical technicians who have received appropriate

training and authorization to provide maintenance, repair, and service for the

Esprit and Respironics V200 ventilators.

Review the Esprit or Respironics V200 Operator’ s Manual and become familiar

with the operation before running tests, checking operational readiness, or

initiating patient use. The operator’s manual includes important information

about ventilator safety and operation.

Schematic diagrams of the Esprit and Respironics V200 ventilators are

available upon request.

For additional information about accessories or related equipment, such as

humidifiers and remote alarm systems, refer to the appropriate instruction

manual prior to operating the ventilator.

WARNING: Patients on life-support equipment should be visually monitored by competent

medical personnel, since life-threatening circumstances may arise that may

not activate alarms. Heed all appropriate alarms and follow the instructions

and warnings in this service manual and the operator’s manual. Always check

life-support equipment for proper operation before use.

NOTE: The Esprit or Respironics V200 Operator’s Manual lists all applicable

warnings and cautions. Review these notices thoroughly before operating

the ventilator.

REF 580-1000-02 H Respironics V200/Esprit Ventilator Service Manual © Respironics, Inc. 1-1

Page 14

Chapter 1

Introduction and Intended Use

1.1 Recommended

Tools and Test

Equipment

The following table lists the recommended tools, test equipment, and

materials required for ventilator service and maintenance (Table 1-1). Test

equipment must meet the requirements in Table 1-2.

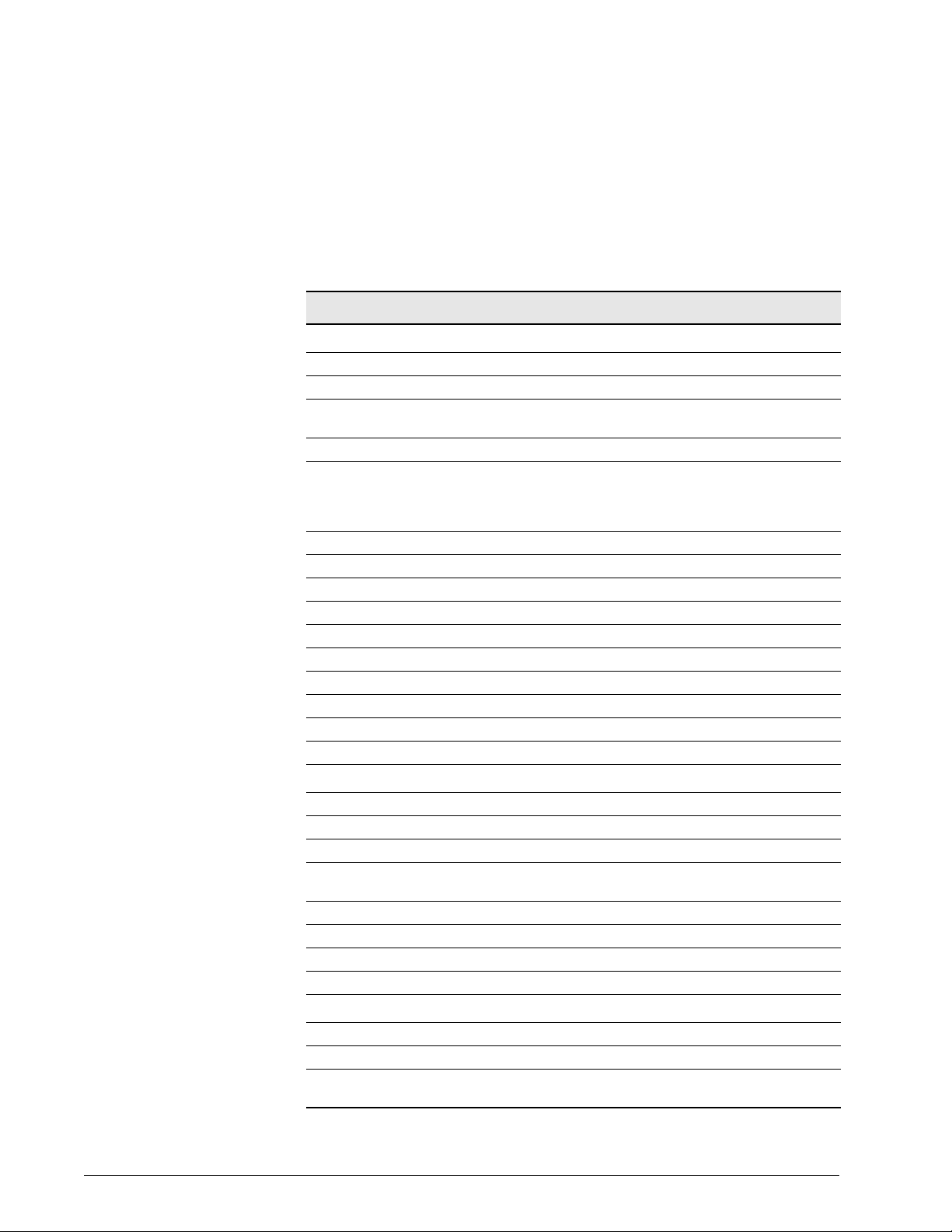

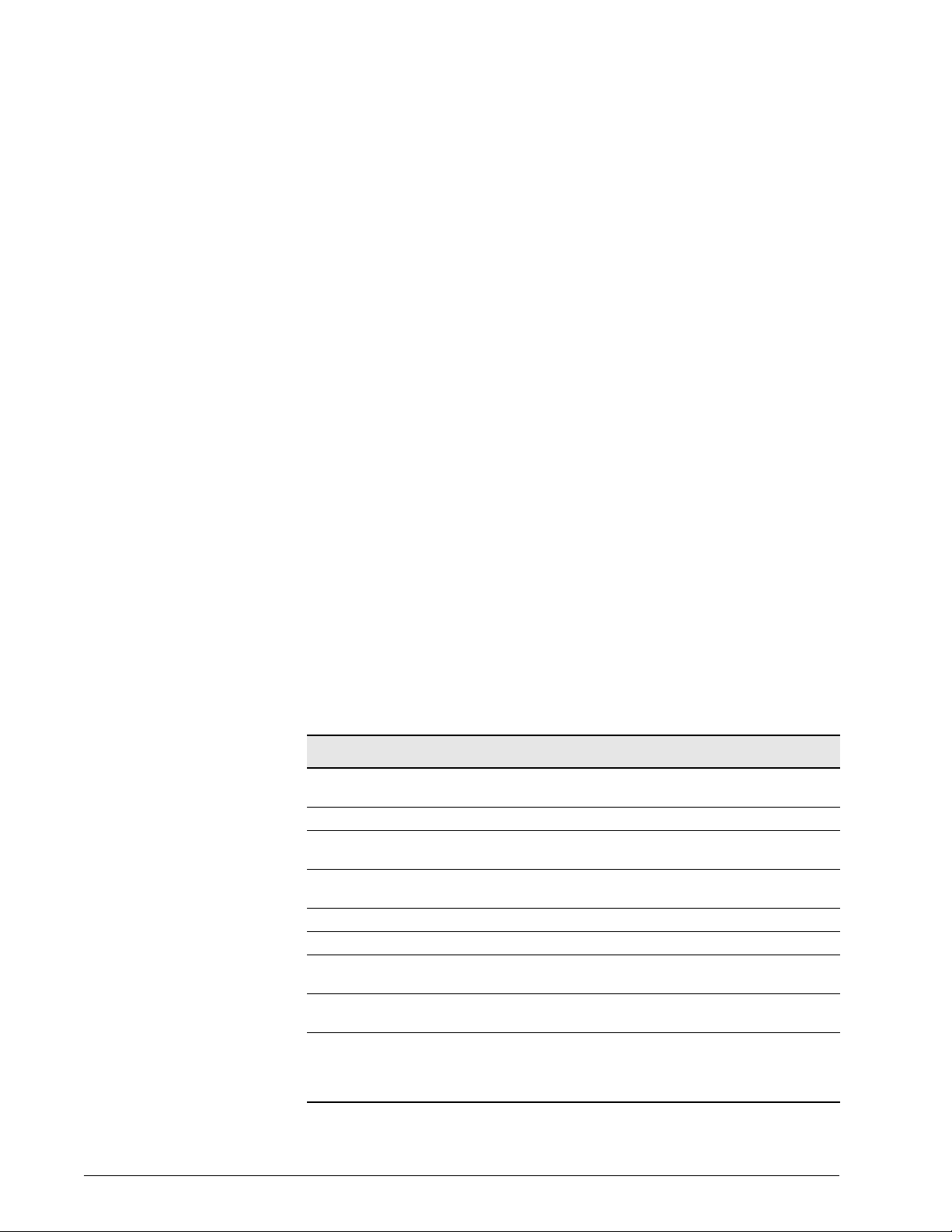

Table 1-1: Recommended Test Equipment, Tools, and Materials

Description Manufacturer and Model

Test Equipment

Adapter, USB to serial Respironics P/N 1022895

Analog output port signal selector Respironics P/N 1010891

Digital multimeter (DMM) and frequency counter

accurate to three decimal places

Electrical safety analyzer Dale LT 544D or equivalent

Pneumatic calibration analyzer capable of

measuring low pressure (cmH

(PSI), flow rate (LPM), volume (liters), and

oxygen concentration (accuracy ± 2%)

Syringe, 10-mL calibrated (neonatal testing) Hans Rudolph 5220 or equivalent

Service kit (*included in the kit) Respironics P/N 1021670

Adapter, oxygen regulator test * Respironics P/N 1001376

Adapter, parallel port * Respironics P/N 1004644

Cable, remote alarm test * Respironics P/N 1027818

Cable adapter, remote alarm test Respironics P/N 1027817

Cable assembly, null modem * Respironics P/N 1022815 or equivalent

Cork, silicone * Respironics P/N 1001735 or equivalent

Test lung, 1 L * Respironics P/N 1021671 or equivalent

O), high pressure

2

Local supplier

Certifier FA Plus Ventilator Gas Analyzer with

oxygen sensor kit (Respironics P/N 1040311

or 1040312) or equivalent

Ventilator Accessories

Adapter, oxygen sensor Respironics P/N 1001736 or equivalent

Connector, plastic, 22mm OD Respironics P/N C06335 or equivalent

Coupling, silicone rubber Respironics P/N C06348 or equivalent

Patient circuit tubes, adult, 42-in. smooth bore

(2 each)

Tee, plastic with silicone rubber coupling Respironics P/N C06260 or equivalent

Tubing, silicone, 3/16 in. ID x 6.5 ft., PAP Respironics P/N C06686 or equivalent

Wye, reusable, 22mm OD/15mm ID Respironics P/N 1003070 or equivalent

Respironics P/N 1003643 or equivalent

Hand Tools and Materials

ESD-safe field service vacuum cleaner 3M model 497-AJM or equivalent

Hex key set, metric (rounded ends), 1.5 to 4 mm Local supplier

Hex key set, standard (rounded ends), 0.050 to

5/32 in.

Local supplier

1-2 Respironics V200/Esprit Ventilator Service Manual © Respironics, Inc. REF 580-1000-02 H

Page 15

Introduction and Intended Use

Chapter 1

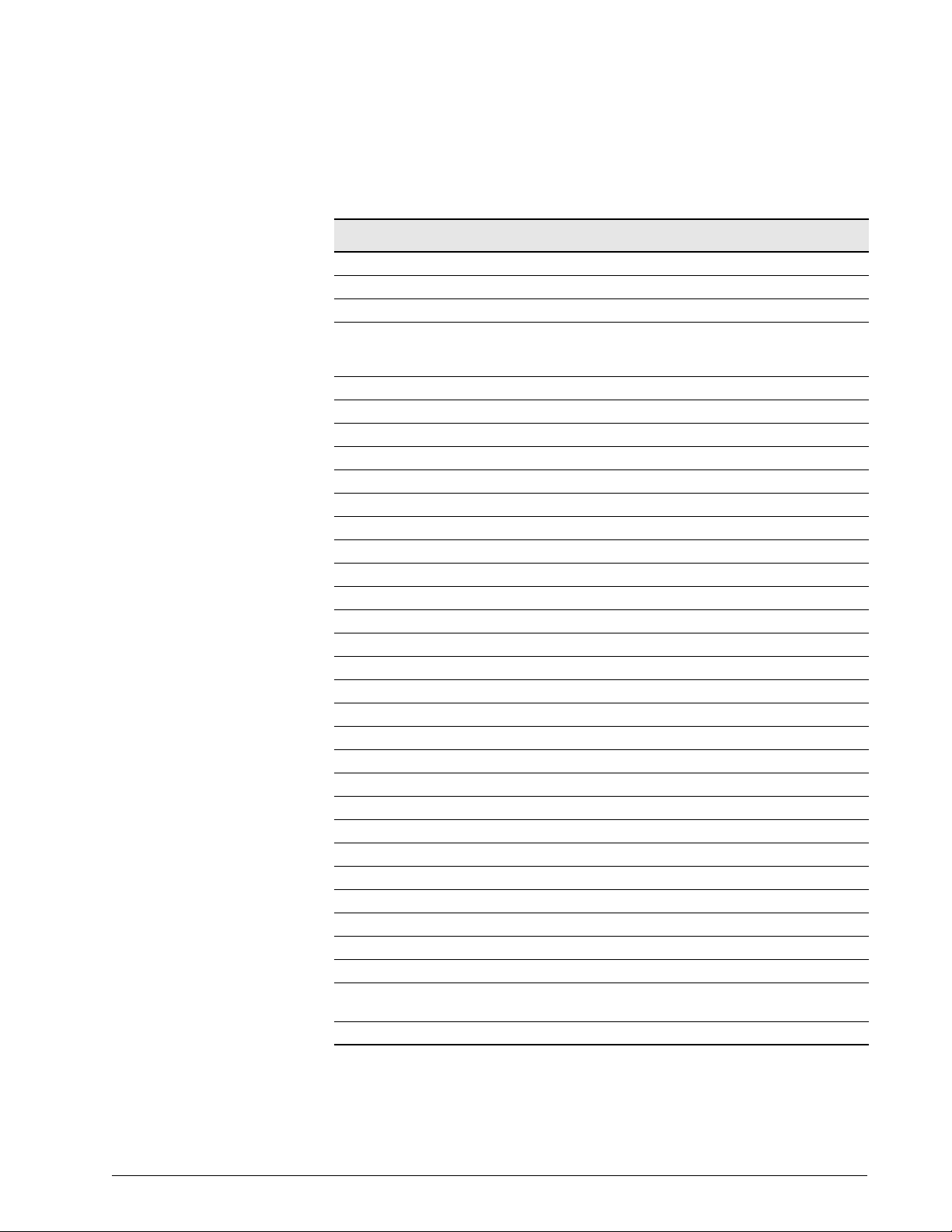

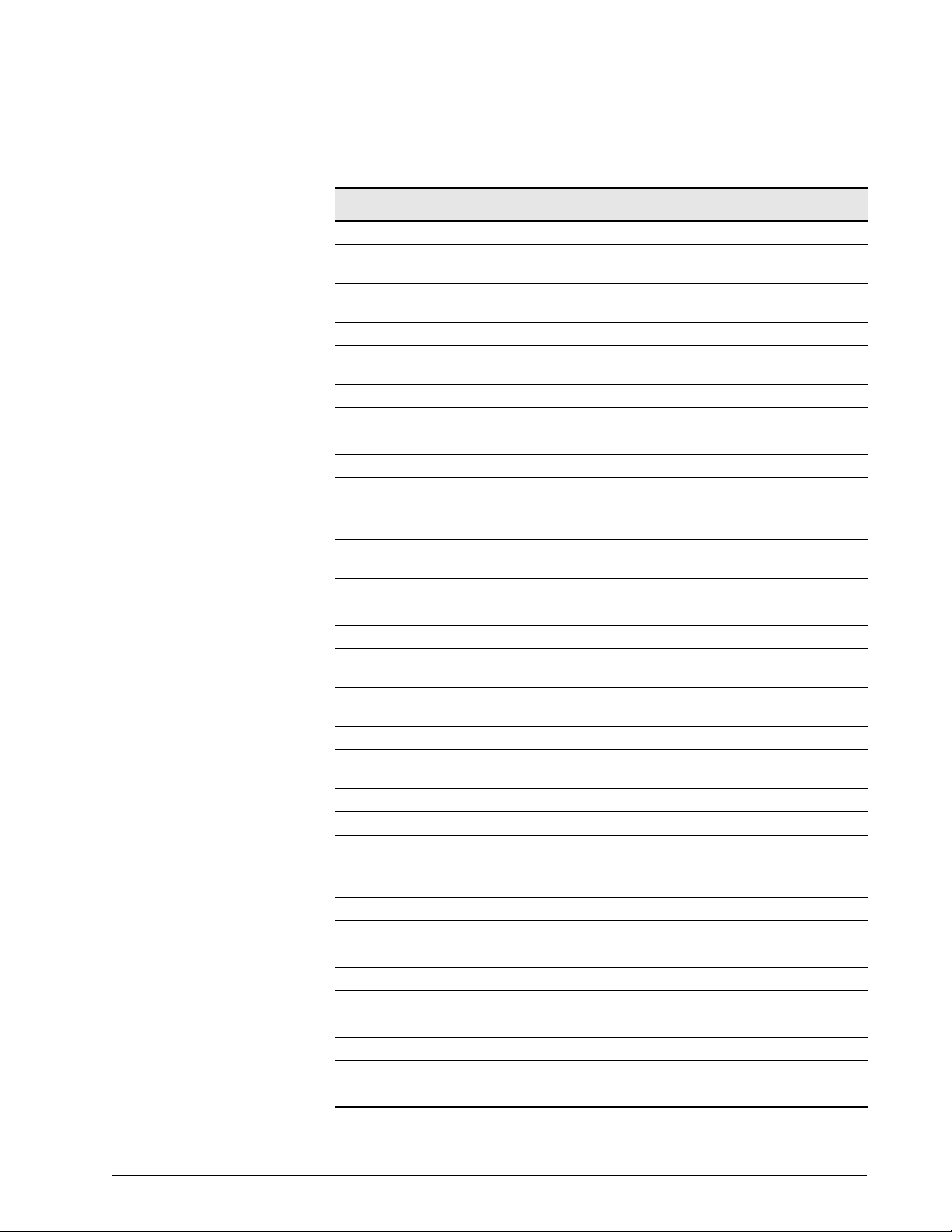

Table 1-1: Recommended Test Equipment, Tools, and Materials (Continued)

Description Manufacturer and Model

Loctite 222 Respironics P/N 200-1000-00

Lubricant, Dupont Krytox GPL226 Res pironics P/N 100-1012-00

Mild detergent or antiseptic wipes Local supplier

PC or laptop (for downloading software) with

Windows 95 or later, serial port and CD ROM

drive

Pliers Local supplier

Pliers, needle nose Local supplier

Ratchet, box, 8 mm Local supplier

Screwdriver, flat head, #2 Local supplier

Screwdriver, flat head, #3 Local supplier

Screwdriver, Phillips head, #2 Local supplier

Screwdriver, pen size flat head Local supplier

Screwdriver, pen size Phillips head Local supplier

Static dissipative field service kit Local supplier

Thread tape Local supplier

Tie wraps, 3 in. length Respironics P/N 500-1000-66 or equivalent

Tie wraps, 8 in. length Respironics P/N 500-1000-62 or equivalent

Tie wrap gun Local supplier

Torque driver capable of 5 to 25 in.-lbs. Local supplier

Tweezers, angled Local supplier

Wire cutters Local supplier

Wrench, open end, 7/32 in. Local supplier

Wrench, open end, 1/4 in. Local supplier

Wrench, open end, 5/16 in. Local supplier

Wrench, open end, 7/16 in. Local supplier

Wrench, open end, 1/2 in. Local supplier

Wrench, open end, 11/16 in. Local supplier

Wrench, open end, 5.5 mm Local supplier

Wrench, open end, 7 mm Local supplier

Wrench, open end or box, #10 Local supplier

Wrench, open end or socket, 3/16 in. Local supplier

Wrench, socket, 9/32 in. with removable 6-in.

extension bar

Wrench, socket, #10 Local supplier

Local supplier

Local supplier

REF 580-1000-02 H Respironics V200/Esprit Ventilator Service Manual © Respironics, Inc. 1-3

Page 16

Chapter 1

Introduction and Intended Use

Table 1-2: Test Equipment Specifications

Unit of

Measurement

Pressure -25 to 150 cmH2O 0 to

Flow (standard) 0 to 300 SLPM ± 2% of reading ± 0.20 SLPM (whichever is

Torque 5 to 25 in-lb. ± 1 in-lb. of reading

Volume (STP) 0 to 10 L STP ± 2% of reading ± 0.20 L STP

Voltage DC: ± 5 to 50 V

Range Accuracy

100 psi

AC: 2 to 300 V

± 1% of reading or ± 0.20 cmH2O (whichever

is greater). ± 2% of reading @ -1 to 38ºC (30

to 100ºF)

greater)

± 2% of reading

1-4 Respironics V200/Esprit Ventilator Service Manual © Respironics, Inc. REF 580-1000-02 H

Page 17

Chapter 2. Warnings, Cautions, and Notes

Throughout this manual the following definitions apply:

WARNING: A condition that could cause injury to a patient or operator if the operating

instructions in this manual are not followed correctly.

CAUTION: A condition that could cause damage to, or shorten the service life of,

the Esprit/Respironics V200 Ventilator.

2.1 General Warnings WARNING: Do not obstruct the emergency air intake near the oxygen water trap/inlet

filter assembly.

WARNING: Never troubleshoot while a patient is connected to the ventilator, since normal

operation is suspended.

WARNING: If the ventilator has been operating, the exhalation filter heater conductor may

be hot. Use caution when removing the filter.

WARNING: To prevent disease transmission, use protective equipment when handling

contaminated bacterial filters or other patient accessories.

WARNING: To avoid personal injury, always disconnect external AC and DC power

sources and high-pressure oxygen sources from the ventilator before

servicing.

WARNING: Explosion hazard. Do no operate the ventilator in the presence of flammable

anesthetic agents.

2.2 General Cautions CAUTION: Troubleshooting and repair should be performed only by a qualified

service technician. Respironics Factory Service Training is highly

recommended prior to performing service procedures on the Respironics

Ventilator. Contact Customer Service at 1-800-345-6443 or 724-3874000 for more information.

CAUTION: Use only Respironics ventilator repair/service parts. Only Respironics

parts are designed for use in this ventilator. Use of non-Respironics repair

parts may alter ventilator reliability resulting in damage. Use of nonRespironics repair parts will affect your warranty. Contact Customer

Service at 1-800-345-6443 or 724-387-4000 for more information.

CAUTION: Do not modify oxygen diameter index safety systems (DISS) connector on

rear panel. Use only medical grade oxygen.

REF 580-1000-02 H Respironics V200/Esprit Ventilator Service Manual © Respironics, Inc. 2-1

Page 18

Chapter 2

Warnings, Cautions, and Notes

CAUTION: Always ensure that you are following proper electrostatic discharge (ESD)

grounding procedures before handling static-sensitive devices.

CAUTION: Be careful not to pull or crimp any cables, tubes, or wires.

2.3 General Notes NOTE: This manual covers multiple versions of the Esprit and Respironics V200

Ventilators. The information given may not exactly match your own

ventilator.

2-2 Respironics V200/Esprit Ventilator Service Manual © Respironics, Inc. REF 580-1000-02 H

Page 19

Chapter 3. Theory of Operation

The Esprit and Respironics V200 ventilators are microprocessor-controlled

devices that can deliver air, oxygen, or a mixture of air and oxygen to the

patient’s lungs in a predetermined manner to augment or replace the work

normally performed by the patient’s respiratory system. It uses

electromechanical control circuits, flow and pressure monitors, and software

programs to deliver breaths as a flow or pressure controller.

The ventilators include a graphic user interface (GUI), internal blower, and

inspiratory module that mixes air and oxygen. The ventilators can operate from

a 40 to 90 psig (276 to 620 kPa) medical grade oxygen source for enriched

oxygen operation. It also includes multiple communications interfaces and an

internal power supply that can run from a 100 to 240 V AC 50/60 Hz or 24 V

DC power sources.

Schematic diagrams of the Esprit and Respironics V200 ventilators are

available upon request.

3.1 Pneumatic System

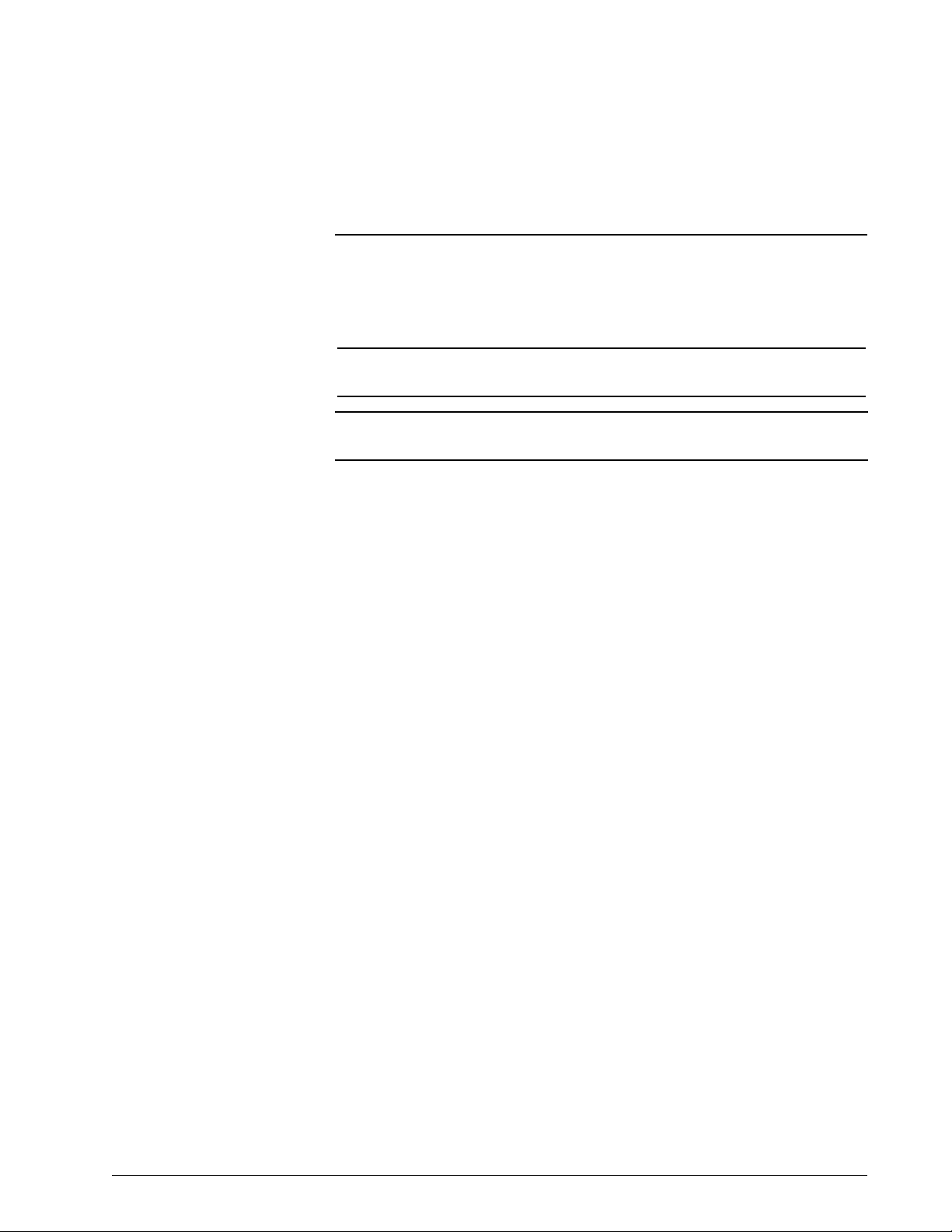

The pneumatic system consists of these subsystems (see Figure 3-1):

• Internal blower (air source)

• Oxygen regulator (oxygen source)

• Inspiratory module

• Heated exhalation filter assembly

• Exhalation valve assembly

• Expiratory flow sensor

The internal blower generates the air pressure necessary for breath delivery,

eliminating the need for an external source of medical-grade compressed air.

An internal oxygen regulator controls wall oxygen pressure. The ventilator

mixes air and oxygen in the inspiratory module before delivery to the patient.

Based on operator settings, the central processing unit (CPU) controls the air

valve, oxygen valve, and exhalation valve through stepper motor controller

printed circuit boards (PCBs). As flow is delivered to the patient, the air and

oxygen flow sensors and two pressure sensors provide feedback to the CPU.

The pressure relief and safety valves in the inspiratory module provide for

patient safety in the event of an over-pressure condition or any component or

system failure that could interfere with the patient’s ability to breathe when

connected to the ventilator.

REF 580-1000-02 H Esprit® / V200 Ventilator Service Manual © Respironics, Inc. 3-1

Page 20

Chapter 3

Blower

Oxygen

Regulator

Inspiratory Module

• Gas Mixing

• Pressure Relief Valve

• Safety Valve

To P at ien t

From Patient

Heated

Exhalation

Filter

Assembly

Exhalation

Valve

Expiratory

Flow

Sensor

Room

Air

Oxygen

Supply

Air

O

2

Theory of Operation

The exhalation filter reduces the risk of contamination or component damage

due to bacteria or moisture in expired gases. The exhalation filter is housed in

a heated sleeve, which reduces the relative moisture condensation in the

exhalation filter, exhalation valve, and expiratory flow sensor. Exhaled gas is

then vented to atmosphere.

Figure 3-1: Pneumatic System Block Diagram

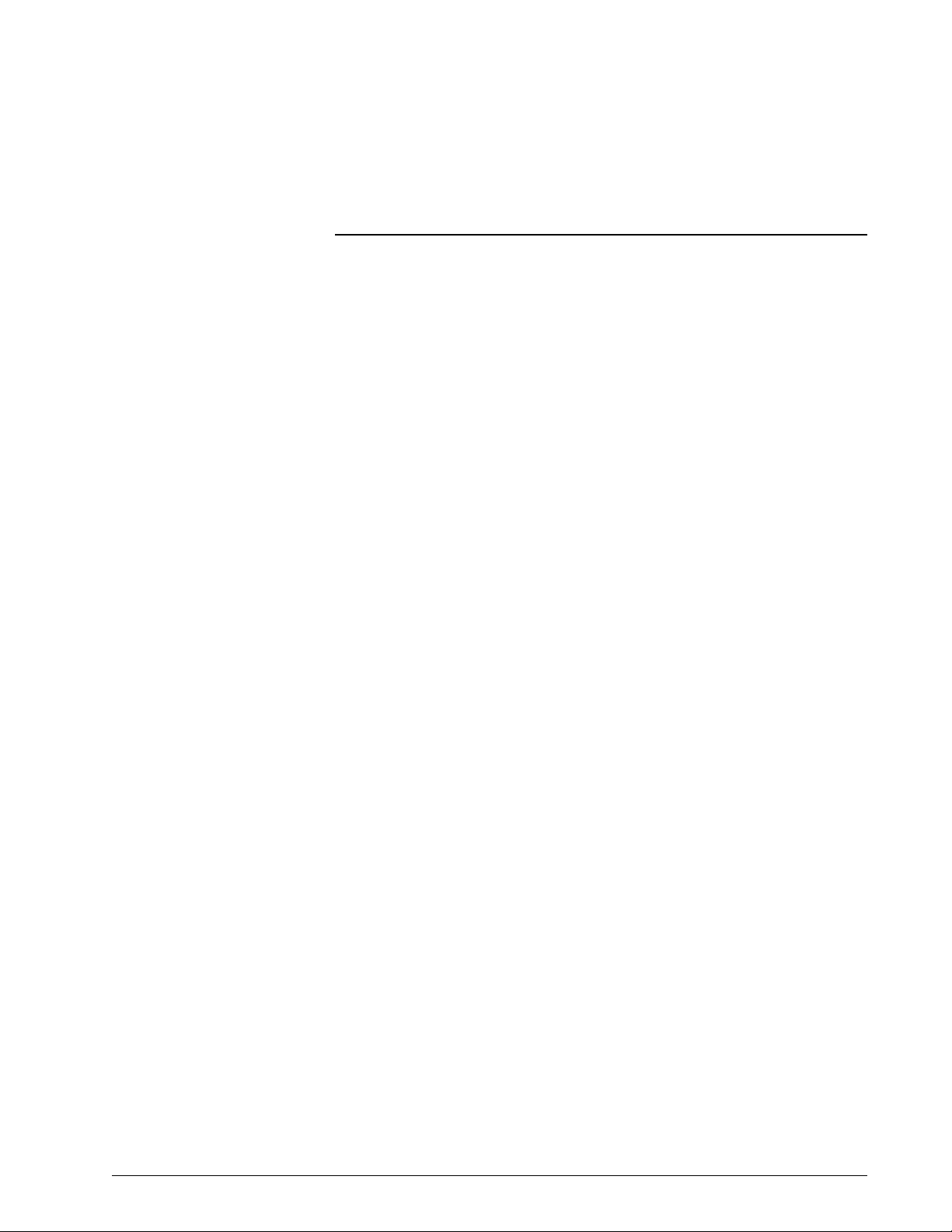

Figure 3-2 shows the pneumatic system and its components.

3-2 Respironics V200/Esprit Ventilator Service Manual © Respironics, Inc. REF 580-1000-02 H

Figure 3-2: Pneumatic Schematic

Page 21

Chapter 3

Theory of Operation

3.1.1 Blower Inlet Filter (F1)

The blower draws room air through the blower inlet filter (F1) and the muffler

(silencer) and outputs flow to the air valve assembly (AV). The blower inlet

filter removes coarse particulate from ambient air as it is entrained into the

blower assembly. See Chapter 4 for periodic maintenance information.

3.1.2 Muffler (Silencer)

The muffler reduces the noise of air flow into the blower by channeling the air

through a baffled system lined with sound absorbing material.

3.1.3 Blower

The blower draws room air though the air inlet filter and outputs the air that is

delivered to the patient, and provides the pilot pressure that can actuate the

safety valve. The blower contains a DC motor and a series of stator and

impeller assemblies. It can provide at least 200 LPM of flow.

Blower speed is automatically adjusted to account for differences in gas

density due to altitude. The altitude can be adjusted from the hardware screen

in Diagnostics mode. The high pressure alarm limit setting also affects blower

speed.

3.1.4 Cooling Fan Filter

The cooling fan filter removes coarse particulate from ambient air entrained by

the cooling fan. See Chapter 4 for periodic maintenance information.

3.1.5 Cooling Coil

The cooling coil is a copper tube connected to the outlet of the blower

dissipate heat from gas leaving the blower before it reaches the air valve.

3.1.6 Cooling Coil Fan

The 24 V DC cooling coil fan removes the heat dissipated by the cooling coil

and blower.

REF 580-1000-02 H Respironics V200/Esprit Ventilator Service Manual © Respironics, Inc. 3-3

Page 22

Chapter 3

Oxygen

inlet

connector

Theory of Operation

3.1.7 Air Valve Assembly (AV)

The air valve assembly includes a stepper motor that meters air flow from the

blower to achieve the target flow under CPU control, based on operator

selected parameters. It can deliver up to 200 LPM of flow.

3.1.8 Air Flow Sensor (FS1)

The air flow sensor measures flow from the air valve. The ventilator uses this

measurement to provide closed loop control of the air valve and to compute the

flow and volume delivered to the patient. A thermistor in the flow sensor

measures the temperature of the air and provides the microprocessor with

information to compensate the delivered flow.

3.1.9 Oxygen Water Trap/Inlet Filter Assembly (F2)

The oxygen water trap/inlet filter assembly consists of a 5-micron (µ) filter to

remove particulate (both dry and liquid) from the oxygen gas supply, a bowl

with drain for accumulated water, and an oxygen inlet connector.

3.1.10 Oxygen Inlet Connector (O2)

The oxygen inlet connector provides a country-specific connection point for an

external oxygen gas supply of 40 to 90 psig (276 to 620 kPa).

3.1.11 Oxygen Supply Pressure Switch (PS1)

The oxygen supply pressure switch is part of the oxygen regulator. PS1 is a

normally open (NO) switch that monitors oxygen supply pressure by closing

when measured pressure is over 40 psig (276 kPa), and sends a signal to the

sensor PCB to indicate if supply pressure is adequate at the oxygen inlet.

PS1 opens if measured pressure is less than 35 psig (241.3 kPa). If the

oxygen supply pressure switch opens during normal ventilation (at O

> 21%),

2

a low oxygen supply alarm results.

3.1.12 Oxygen Regulator (REG 1)

The oxygen regulator reduces the oxygen supply pressure to the proper inlet

pressure for the oxygen valve (22-24 psig, or 152-165 kPa @ 180 LPM) and

supplies the regulated pressure to the crossover solenoid, which pilots the

safety valve.

3-4 Respironics V200/Esprit Ventilator Service Manual © Respironics, Inc. REF 580-1000-02 H

Page 23

Chapter 3

SOL2

Theory of Operation

3.1.13 Oxygen Valve (OV)

The oxygen valve assembly contains a stepper motor that meters flow from the

oxygen regulator to achieve the target flow under CPU control, based on

operator-selected parameters. It can deliver up to 200 LPM of flow.

3.1.14 Oxygen Flow Sensor (FS2)

The oxygen flow sensor measures the flow from the oxygen valve. The ventilator

uses this measurement to provide closed loop control of the oxygen valve and

to compute the flow and volume delivered to the patient. A thermistor

contained in the flow sensor measures the temperature of the oxygen and

provides temperature compensation information to the microprocessor for

delivered flow.

3.1.15 Crossover Solenoid (SOL1)

The crossover solenoid is a three-way valve that supplies either air or oxygen

pressure to pilot (hold) the safety valve closed during normal ventilation. In its

normal state, SOL1 is normally de-energized to pilot the safety valve with

oxygen. If oxygen pressure is lost, SOL1 is energized and air (rather than

oxygen) controls the safety valve.

3.1.16 Cross-Contamination Check Valve (CV5)

The cross-contamination check valve prevents the oxygen supply from entering

the air delivery system (blower) in the event of a crossover solenoid leak.

3.1.17 Safety Valve Pilot Solenoid (SOL2)

SOL2 directs the output of the crossover solenoid to the safety valve or vents

the pilot pressure line to atmosphere.

During normal operation, SOL2 is energized and directs pressure from the

crossover solenoid to close the safety valve. During a high priority alarm

condition such as an occlusion or ventilator failure (VENT INOP) mode, SOL2

is deenergized, the safety valve opens, and the patient can breathe room air.

REF 580-1000-02 H Respironics V200/Esprit Ventilator Service Manual © Respironics, Inc. 3-5

Page 24

Chapter 3

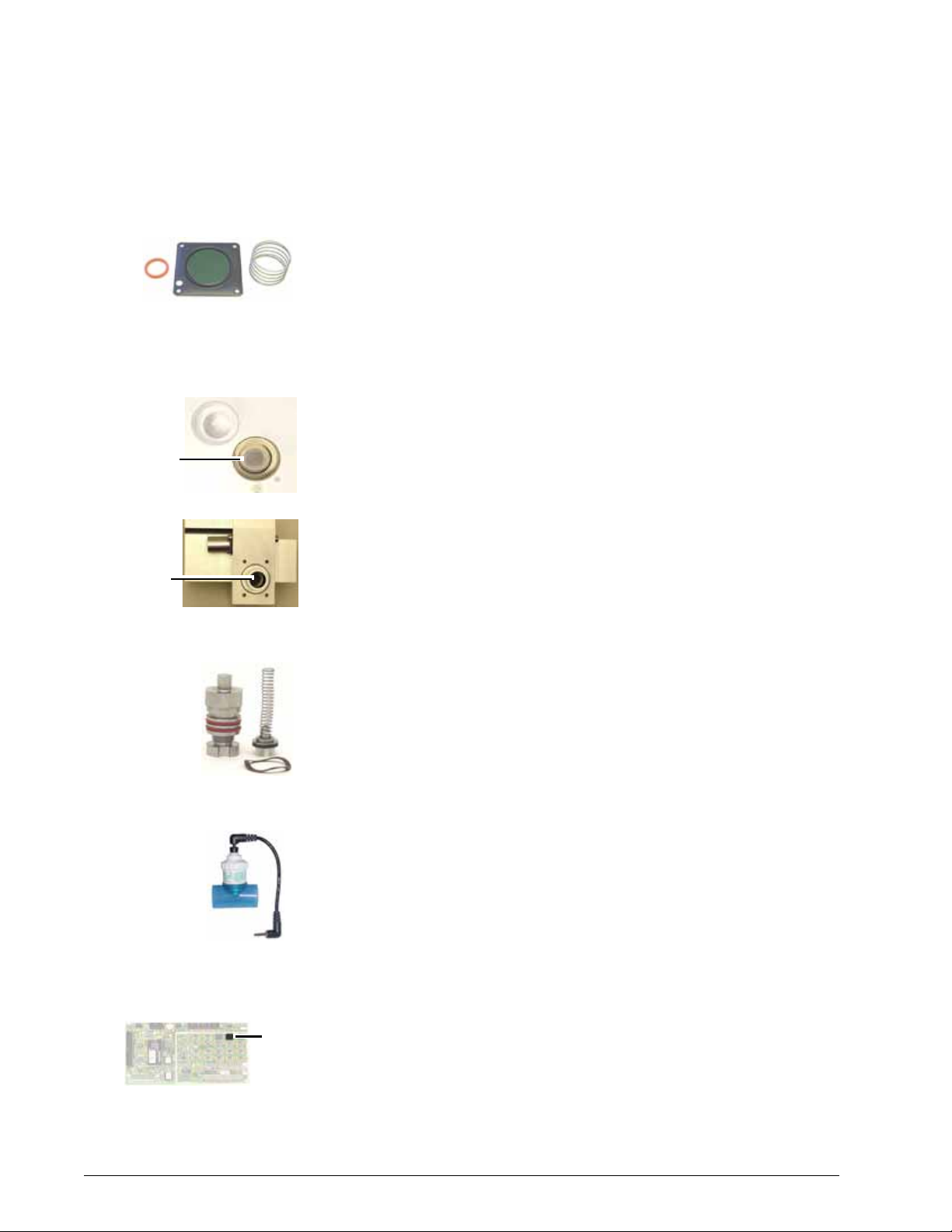

O ring

Diaphragm

Spring

CV2

CV3

PT3

Sensor PCB

Theory of Operation

3.1.18 Safety Valve (SV)

The safety valve contains a spring-loaded diaphragm that is controlled by

safety valve pilot solenoid (SOL2). Under normal conditions the safety valve is

closed, allowing delivered flow to reach the patient. In the event of a safety

valve open (SVO) condition, pilot pressure is vented to atmosphere, which

opens the safety valve and allows the patient to breathe room air through the

safety port at the back of the ventilator.

3.1.19 Air System Check Valve (CV2)

CV2 prevents oxygen from entering the air delivery system in the event of a

blower failure.

3.1.20 Inspiratory Non-Rebreathing Check Valve (CV3)

CV3 prevents the patient from exhaling through the inspiratory limb during a

safety valve open condition, which prevents the patient from rebreathing

exhaled gas.

3.1.21 Pressure Relief Valve (PRV)

The pressure relief valve provides a backup to the operator adjustable highpressure alarm and prevents excessive pressures in the patient circuit. The

pressure relief valve is spring-loaded to limit the maximum circuit pressure to

130 to 140 cmH

O.

2

3.1.22 Oxygen Sensor (OS)

The optional oxygen sensor is installed between the 22-mm inspiratory port

and the inspiratory bacteria filter. The galvanic oxygen sensor measures the

oxygen concentration of the blended gas as it leaves the inspiratory manifold.

The output signal from the sensor is used to determine whether measured

oxygen concentration is within 6% of the %O

setting. If not, a high or low

2

oxygen concentration alarm occurs.

3.1.23 Inspiratory Pressure Transducer (PT3)

PT3 on the sensor PCB monitors system pressure from the inspiratory side of

the patient circuit during exhalation pressure transducer autozeroing, ensuring

uninterrupted pressure monitoring. PT3 is also used with the exhalation

pressure transducer (PT2) to detect patient circuit occlusions.

3-6 Respironics V200/Esprit Ventilator Service Manual © Respironics, Inc. REF 580-1000-02 H

Page 25

Chapter 3

SOL4

PT2

Sensor PCB

SOL3

Theory of Operation

3.1.24 Inspiratory Pressure Transducer Solenoid (SOL4)

SOL4 periodically vents the inspiratory pressure transducer to atmosphere and

makes a measurement at zero (atmospheric) pressure. Periodically autozeroing

the transducer allows it to correct the slight zero voltage drift that can occur

over time, and improves the overall accuracy of the pressure measurement.

During normal operation, SOL4 is de-energized and applies patient circuit

pressure to the inspiratory pressure transducer. During an autozero, SOL4 is

energized, venting the transducer to atmosphere. This occurs during power on

self test (POST), at the beginning of a breath one minute after POST, six

minutes after POST, eleven minutes after POST, and hourly thereafter.

3.1.25 Heated Exhalation Filter (F3)

The heated exhalation filter includes a heated filter sleeve and a bacteria filter.

The heater protects the exhalation flow sensor and exhalation system

components from condensation by heating exhaled gas (which has cooled in

the exhalation limb) above its dew point.

The exhalation bacteria filter protects the exhalation flow sensor and

exhalation system component from contaminants and filters exhaled gas

before it is vented to atmosphere.

3.1.26 Exhalation Pressure Transducer (PT2)

The exhalation pressure transducer on the sensor PCB measures patient circuit

pressure from the exhalation side of the patient circuit. During normal

operation PT2 is the primary transducer for measuring patient pressures,

including peak inspiratory pressure (PIP), mean airway pressure (MAP), end

inspiratory pressure, and auto-PEEP. The exhalation pressure transducer

provides monitoring data for closed loop control.

3.1.27 Exhalation Pressure Transducer Solenoid (SOL3)

The exhalation pressure transducer solenoid periodically vents the exhalation

pressure transducer to atmosphere and measures zero (atmospheric) pressure.

Periodically autozeroing the transducer allows it to correct the slight zero

voltage drift that can occur over time, and improves overall pressure

measurement accuracy.

During normal operation, SOL3 is de-energized and applies patient circuit

pressure to the exhalation pressure transducer. During an autozero, SOL3 is

energized, venting the transducer to atmosphere. This occurs during POST, at

the beginning of a breath one minute after POST, six minutes after POST,

eleven minutes after POST, and hourly thereafter.

REF 580-1000-02 H Respironics V200/Esprit Ventilator Service Manual © Respironics, Inc. 3-7

Page 26

Chapter 3

CV4

Theory of Operation

3.1.28 Exhalation Non-Rebreathing Check Valve (CV4)

CV4 prevents the patient from inspiring room air through the exhalation limb of

the patient circuit. During normal operation, it blocks the exhalation system

from atmosphere, allowing the patient to trigger a breath.

3.1.29 Exhalation Valve (EV)

The exhalation valve is controlled by a stepper motor. At the beginning of an

inspiration, the exhalation valve shuts to create a closed circuit and allow the

patient system to pressurize. The exhalation valve opens at the beginning of

exhalation, allowing system pressure to vent to atmosphere.

The exhalation valve also regulates positive end expiratory pressure (PEEP) and

expiratory positive airway pressure (EPAP) levels during exhalation.

3.1.30 Exhalation Flow Sensor (FS3)

The exhalation flow sensor measures the flow leaving the ventilator, which

includes gas exhaled by the patient, tubing compliance volume, and bias flow

(if flow triggering or Auto-Trak triggering is selected). The ventilator uses the

exhaled flow measurement to compute flow and volume coming from the

patient and the circuit.

A thermistor in the flow sensor measures the temperature of the gas and

provides the microprocessor with information to compensate the measured

flow.

3-8 Respironics V200/Esprit Ventilator Service Manual © Respironics, Inc. REF 580-1000-02 H

Page 27

Chapter 3

Theory of Operation

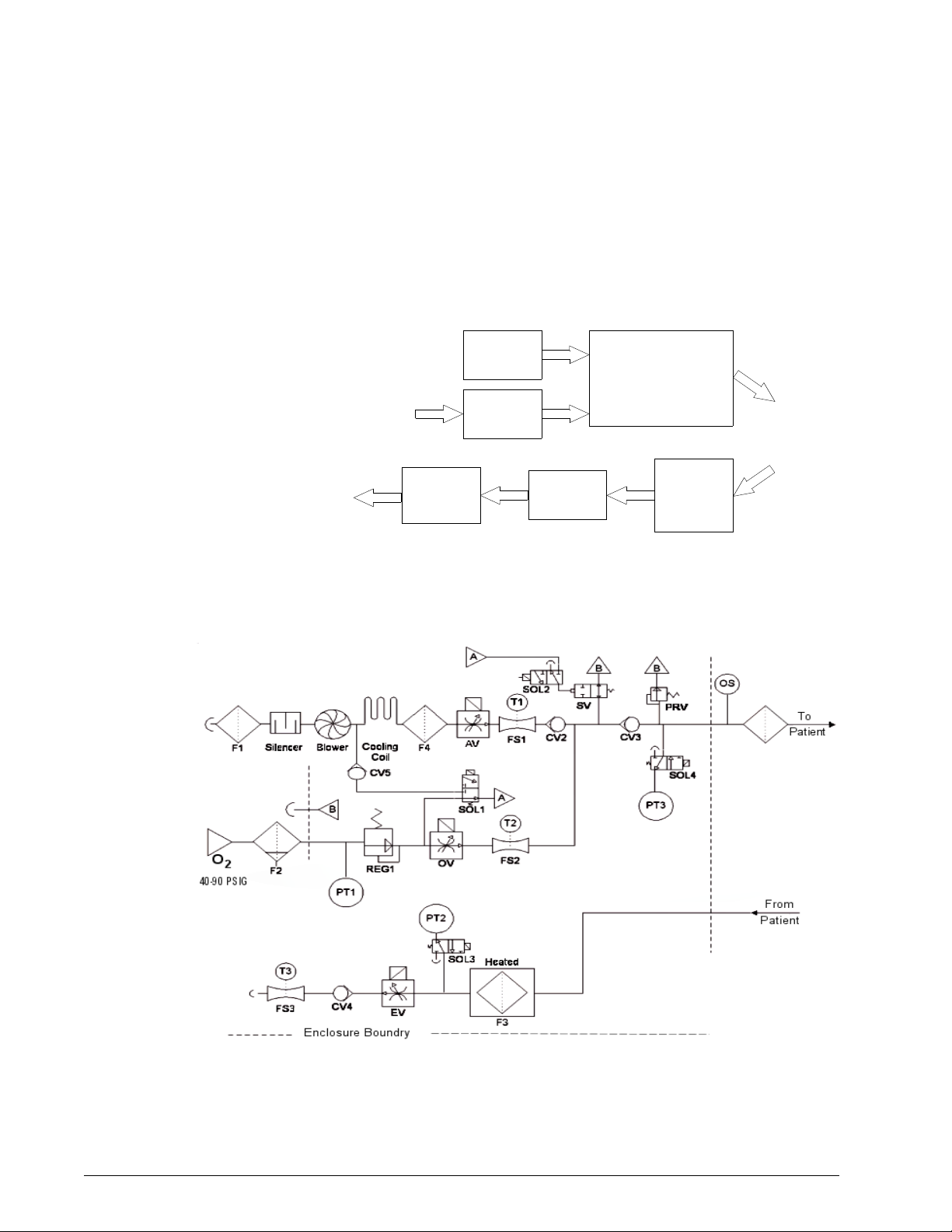

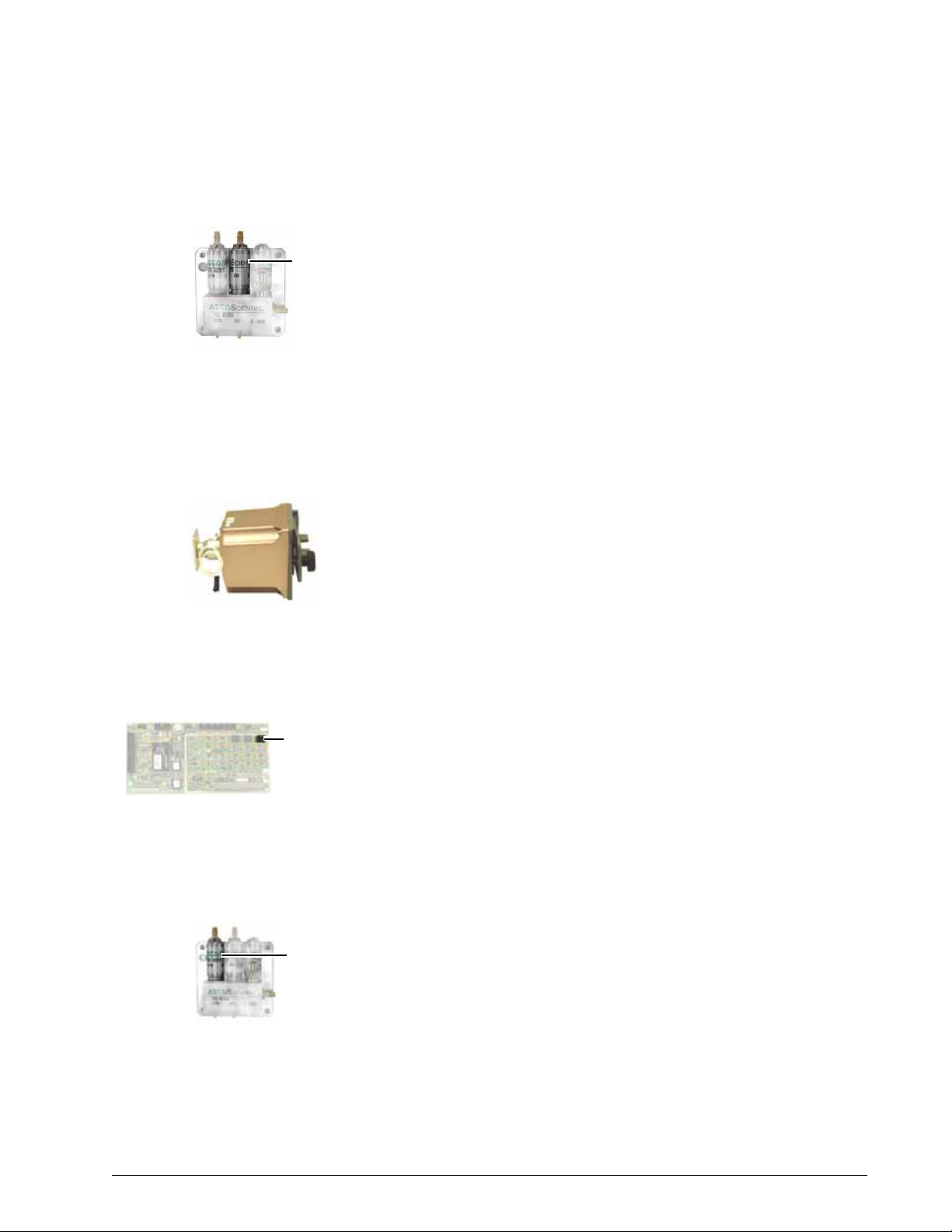

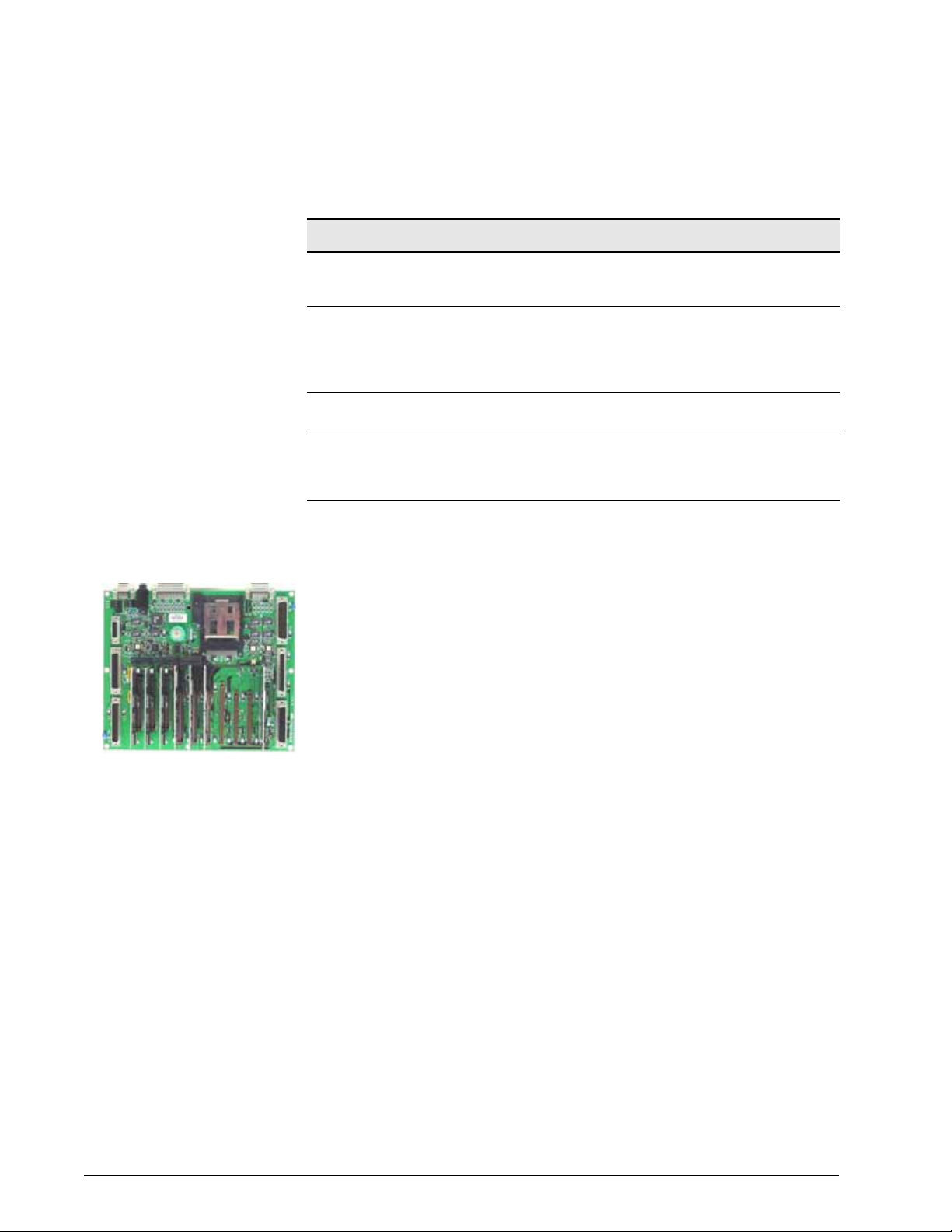

3.2 Ventilator System Electronics

Figure 3-3 shows the electronic system. Schematics are available upon

request.

Figure 3-3: Electronic System Diagram

REF 580-1000-02 H Respironics V200/Esprit Ventilator Service Manual © Respironics, Inc. 3-9

Page 28

Chapter 3

Theory of Operation

The ventilator can be powered by a 100 to 240 VAC 50/60 Hz or external 24 V

DC power source (backup battery or external battery). The power supply

conditions the input voltage and distributes + 5 V, +12 V, -12 V, a n d + 2 9 V t o

the main PCB and blower motor controller to power digital electronics,

electropneumatic components, and displays. AC power to the humidifier port

can be used on 100-120 V units only.

The microprocessor on the CPU PCB and programs stored in memory control

the interaction of the pneumatic and electronic subsystems. Using inputs from

electropneumatic sensors and the operator, the CPU controls the flow,

pressure, and volume of air and oxygen to be delivered to the patient. The CPU

also monitors alarms and independently monitors software execution.

The the CPU PCB, digital PCB, analog PCB, VGA controller PCB, and three

stepper motor controller PCBs are vertically mounted on the main PCB.

Digital control signals from the CPU are sent to the analog PCB, where they are

converted into analog signals that control blower speed and chart recorder

outputs (pressure, flow, and volume). The sensor PCB conditions and converts

analog data from the flow, pressure, and oxygen sensors, then sends the data

to the analog PCB, where it is read by the CPU.

Ventilator data from the CPU is conditioned by the VGA and man-machine

interface (MMI) PCBs, then displayed on an LCD.

Table 3-1 summarizes the electronic signal path sequences for the ventilator

components.

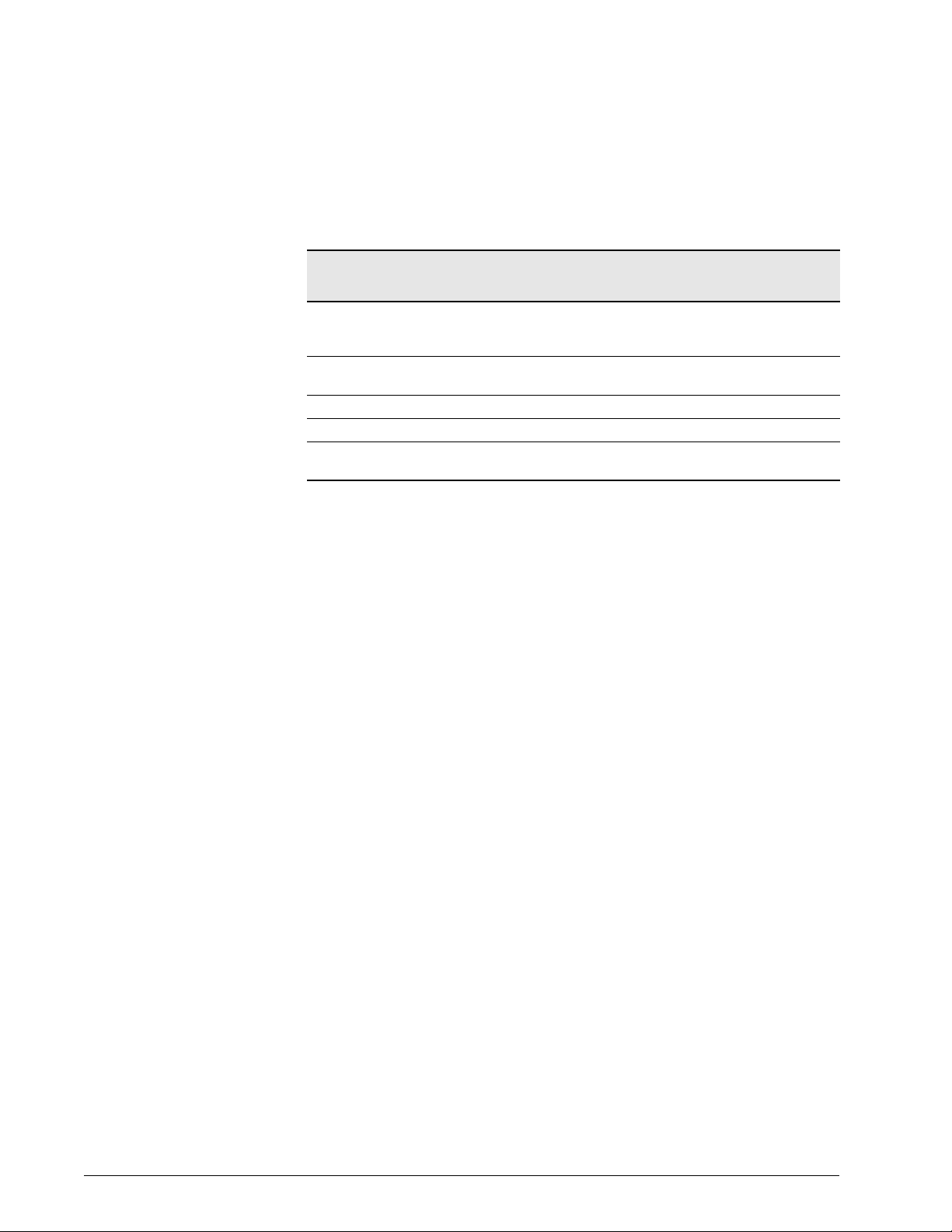

Table 3-1: Signal Path Sequences

Component Signal Path Sequence

100% O

29 V enable Main PCB, CPU PCB, power supply

Air (AV), oxygen (OV), exhalation

(EV) valves

Air (FS1), oxygen (FS2), exhalation

(FS3) flow sensors

Alarm High indicator Front panel overlay, MMI PCB, main PCB, CPU PCB

Alarm Med/Low indicator Front panel overlay, MMI PCB, main PCB, CPU PCB

Alarm Silence indicator Front panel overlay, MMI PCB, main PCB, digital PCB, CPU

Backlight (9.5 in display, standard

on Esprit ventilator)

Backlight (10.4-in display,

optional on Esprit ventilator,

standard on Respironics V200

ventilator)

indicator Front panel overlay, MMI PCB, main PCB, digital PCB, CPU

2

PCB

Main PCB, motor controller PCB, CPU PCB

Sensor PCB, main PCB, analog PCB, CPU PCB

PCB

Backlight inverter PCB, DC/DC converter PCB, main PCB,

backlight control potentiometer

Backlight inverter PCB, DC/DC converter PCB, main PCB,

backlight control potentiometer

3-10 Respironics V200/Esprit Ventilator Service Manual © Respironics, Inc. REF 580-1000-02 H

Page 29

Chapter 3

Theory of Operation

Table 3-1: Signal Path Sequences (Continued)

Component Signal Path Sequence

Backup alarm MMI PCB, main PCB, digital PCB, CPU PCB

Battery/Charging indicator Front panel overlay, MMI PCB, power supply, main PCB,

CPU PCB

Battery/In Use indicator Front panel overlay, MMI PCB, main PCB, digital PCB, CPU

PCB

Battery/Low indicator Front panel overlay, MMI PCB, digital PCB, CPU PCB

Blower DAC Blower controller PCB, sensor PCB, main PCB, analog PCB,

Blower on/off Blower controller PCB, sensor PCB, main PCB, CPU PCB

Blower temperature switch Sensor PCB, main PCB, digital PCB, CPU PCB

Console: all keys Front panel overlay, MMI PCB, main PCB, CPU PCB

Crossover solenoid (SOL1) Main PCB, CPU PCB

Enclosure temperature sensor Sensor PCB, main PCB, analog PCB, CPU PCB

Exhalation pressure transducer

(PT2)

Exhalation pressure transducer

solenoid (SOL3)

External backup battery Power supply

External Battery indicator Front panel overlay, MMI PCB, power supply

Heater Main PCB, CPU PCB

Inspiratory pressure transducer

(PT3)

Inspiratory pressure transducer

solenoid (SOL4)

Mains indicator Front panel overlay, MMI PCB, power supply

Nonmaskable interrupt (NMI)

signal

Normal indicator Front panel overlay, MMI PCB, main PCB, CPU PCB

Oxygen Sensor (OS) Sensor PCB, main PCB, analog PCB, CPU PCB

Oxygen supply pressure switch

(PS1)

Primary alarm MMI PCB, main PCB, digital PCB, CPU PCB

Primary alarm potentiometer MMI PCB

Printer Main PCB, CPU PCB

Remote alarm (nurse call) Main PCB, CPU PCB

Rotary encoder MMI PCB, main PCB, digital PCB, CPU PCB

Safety Valve indicator Front panel overlay, MMI PCB, main PCB, CPU PCB

Safety valve pilot solenoid (SOL2) Main PCB, CPU PCB

Screen Lock indicator Front panel overlay, MMI PCB, main PCB, CPU PCB

Touch screen MMI PCB, main PCB, digital PCB, CPU PCB

Vent Inop indicator Front panel overlay, MMI PCB, main PCB, CPU PCB

CPU PCB

Sensor PCB, main PCB, analog PCB, CPU PCB

Main PCB, CPU PCB

Sensor PCB, main PCB, analog PCB, CPU PCB

Main PCB, CPU PCB

Sensor PCB, main PCB, CPU PCB

Sensor PCB, main PCB, digital PCB, CPU PCB

REF 580-1000-02 H Respironics V200/Esprit Ventilator Service Manual © Respironics, Inc. 3-11

Page 30

Chapter 3

Theory of Operation

Table 3-1: Signal Path Sequences (Continued)

Component Signal Path Sequence

VGA backlight intensity

potentiometer (9.5 in display,

standard on Esprit ventilator)

VGA backlight intensity

potentiometer (10.4-in display,

optional on Esprit ventilator,

standard on Respironics V200

ventilator)

VGA display (9.5 in display,

standard on Esprit ventilator)

VGA display (10.4-in display,

optional on Esprit ventilator,

standard on Respironics V200

ventilator)

MMI PCB, backlight inverter PCB

Backlight inverter PCB

MMI PCB, main PCB, VGA controller PCB, CPU PCB

Main PCB, VGA controller PCB, CPU PCB

3.2.1 Main PCB

The CPU and other ventilator logic interact through the system data, address,

and control buses on the main PCB. The main PCB receives input signals from

various keys on the console or touch screen display and sends them to the

CPU. The main PCB also contains signal inputs for non-maskable interrupt,

running on AC, and running on external battery.

The main PCB receives control signals from the CPU and outputs them to

various pneumatic components and console indicators. The main PCB receives

signals from the digital PCB to turn on the indicators for alarm silence, 100%

oxygen, AC power, external battery power, and backup battery status. The main

PCB receives signal from the CPU PCB to turn on the backup alarm, enable

24V, and the Screen Lock, Battery/Chargi ng, and Vent Inop indicators. The

CPU PCB reads the Accept key from the main PCB.

The main PCB includes a normal open and normal closed relay that can trigger

the remote nurse call alarm. The main PCB also includes the RS-232, parallel

printer, analog output, and remote alarm connectors.

The main PCB also routes these signals: reset, MMI PCB reset, sensor PCB

reset, primary alarm, primary alarm failure detection logic, backup alarm,

remote alarm, printer, POST timer, clocked serial interface (CSI) signals, and

the battery backed +3.6 V.

3-12 Respironics V200/Esprit Ventilator Service Manual © Respironics, Inc. REF 580-1000-02 H

Page 31

Chapter 3

Theory of Operation

3.2.2 CPU PCB

The CPU PCB contains the microprocessor, memory, I/O ports, and associated

control circuitry that controls the ventilator:

• V851 microprocessor with a 25-MHz clock

• Static RAM that stores ventilator data

• EEPROM that stores patient settings

• Flash memory that contains ventilator operating software

• One time programmable (OTP) memory that stores the POST routine

• Internal RS-232 port that receives ventilator data from the touch

screen

• Nonmaskable interrupt that tells the CPU a power source has been

lost or interrupted

• 5-msec bus timer that monitors hardware operation

• 169-msec watchdog timer that monitors software operation

• Data address and control bus to the main PCB

• 2-MB memory capacity

3.2.3 Analog PCB

The analog PCB converts digital signals to analog signals to the blower

controller PCB and analog output port. The analog PCB connects directly to

the system bus on the main PCB, and includes these functional circuits:

• An eight-bit digital to analog converter (DAC) that converts digital

signals from the CPU to analog for the blower and external devices

such as chart recorders and bedside monitors

• Clocked serial interface (CSI), a high-speed communication link

between the air, oxygen, and exhalation motor controllers and flow

sensor lookup tables contained on the CPU and the voltage monitor

register

• A circuit that retrieves converted data from the sensor PCB

3.2.4 Digital PCB

The digital PCB conditions serial port signals coming from and going to the

CPU PCB. It also contains control circuitry for the power fail alarm, primary

alarm, backup alarm, RS-232 port, and rotary encoder.

Digital inputs include analog-to-digital converter (ADC) out of range,

compressor temperature switch, and oxygen present. Digital outputs include

the alarm silence indicator, 100% oxygen indicator, running on AC indicator,

running on external battery indicator, backup battery status indicators, printer

ready signal, and printer direction.

REF 580-1000-02 H Respironics V200/Esprit Ventilator Service Manual © Respironics, Inc. 3-13

Page 32

Chapter 3

Theory of Operation

3.2.5 VGA Controller PCB

The VGA controller PCB contains the date and real time clock and LCD VGA

display controller drivers.

3.2.6 Blower Controller PCB

The blower motor controller PCB controls the speed of the blower motor based

on analog input conditioned by the sensor PCB. It includes a lockup sensing

circuit, which monitors sensors in the blower motor to detect a locked rotor

condition. If the blower motor stops running, the lockup sensing circuit shuts

off power to the blower.

3.2.7 Motor Controller PCBs

There are three motor controller PCBs for the air valve, oxygen valve, and

exhalation valve. The three boards are physically the same and are

differentiated by the slot they occupy on the main PCB:

• Exhalation valve motor controller PCB: slot CN11

• Oxygen valve motor controller PCB: slot CN12

• Air valve motor controller PCB: slot CN13

Each motor controller PCB includes a microprocessor dedicated to controlling

the corresponding motor and driving the step positions of the motor based on

input from the CPU.

3.2.8 Sensor PCB

The sensor PCB contains an analog to digital converter (ADC) that converts

analog signals from various pneumatic components and the power supply into

digital signals for the CPU. Signals include: air flow and temperature, oxygen

flow and temperature, exhalation flow and temperature, inspiratory and

exhalation pressure, battery voltage, FIO

enclosure oxygen concentration.

The sensor PCB conditions blower speed analog input and the on/off control to

the blower controller PCB. It also routes signals for the oxygen pressure and

blower temperature switches.

, enclosure temperature, and

2

The sensor PCB also includes voltage LEDs that light to indicate under- and

over-voltage conditions.

3-14 Respironics V200/Esprit Ventilator Service Manual © Respironics, Inc. REF 580-1000-02 H

Page 33

Chapter 3

3.6-V lithium

battery (original

Esprit ventilator)

3.2-V button battery

(current Esprit/

Respironics V200

ventilator)

Theory of Operation

3.2.9 Man-Machine Interface (MMI) PCB

The MMI PCB interfaces the front panel overlay, VGA display, rotary encoder,

and touch screen to the CPU via the main PCB. The MMI PCB contains control

circuitry for the primary and back-up alarms, and includes the hard keys and

LEDs on the front panel membrane keypad.

3.2.10 Power Supply

The power supply converts AC voltage to DC voltage to be used by the system

electronics. The switching power supply can accept voltage from 100 to 240 V

AC (50/60 Hz), and converts it to +5 V, + 12 V, and +29 V DC voltages. In the

absence of AC voltage, the power supply converts the +24V DC input voltage

from an external DC power source (Backup Battery or External Battery). The

power supply also includes power fail logic and charging circuitry for the

backup battery.

The power supply is cooled by a 24 VDC fan housed in a shroud covering the

power supply PCB.

3.2.11 Backlight Inverter PCB

The backlight inverter PCB converts 12 V to approximately 500 V to drive the

backlight on the VGA display assembly.

WARNING: The backlight inverter PCB generates high voltage. To avoid personal injury,

verify that the AC and external DC power sources (backup battery or external

battery) are disconnected from the ventilator.

3.2.12 Real-Time Clock Battery

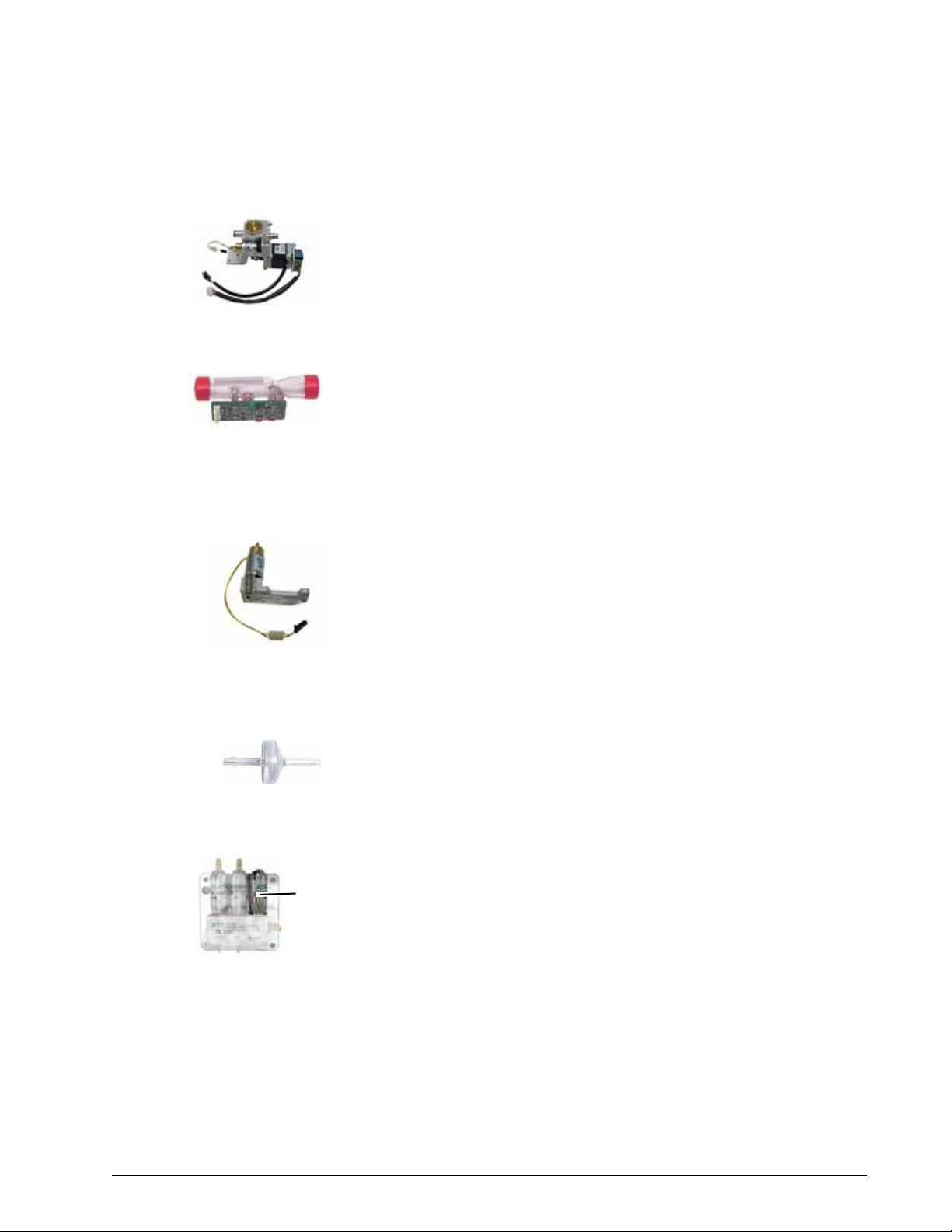

The Esprit ventilator originally included a 3.6-V lithium real-time clock/backup

alarm battery. The Esprit/Respironics V200 ventilators currently use a 3.2-V

button battery installed on the main PCB.

REF 580-1000-02 H Respironics V200/Esprit Ventilator Service Manual © Respironics, Inc. 3-15

Page 34

Chapter 3

Esprit

ventilator

backup

battery

Respironics

V200

ventilator

backup

battery

Respironics

V200

ventilator

GUI

Esprit

ventilator GUI

Theory of Operation

3.2.13 Backup Battery

The 24-V backup battery can power the ventilator for approximately 30

minutes at nominal settings in case of AC power loss.

3.2.14 External Battery

The optional external battery supplements the backup battery, and can provide

an additional two hours of ventilator operation (depending on ventilator

settings). The ventilator runs on AC power when available, then external

battery power if installed, and then backup battery power.