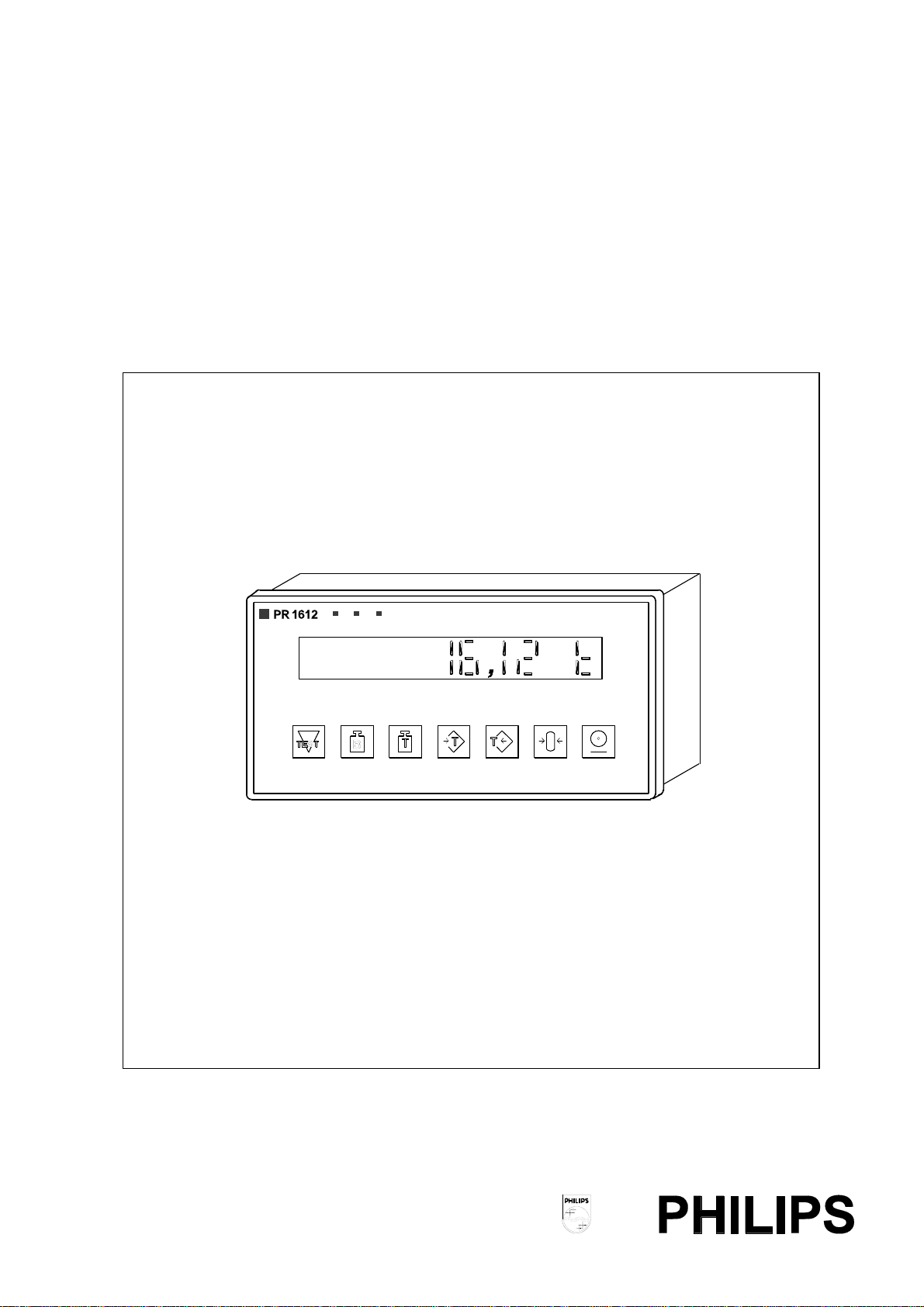

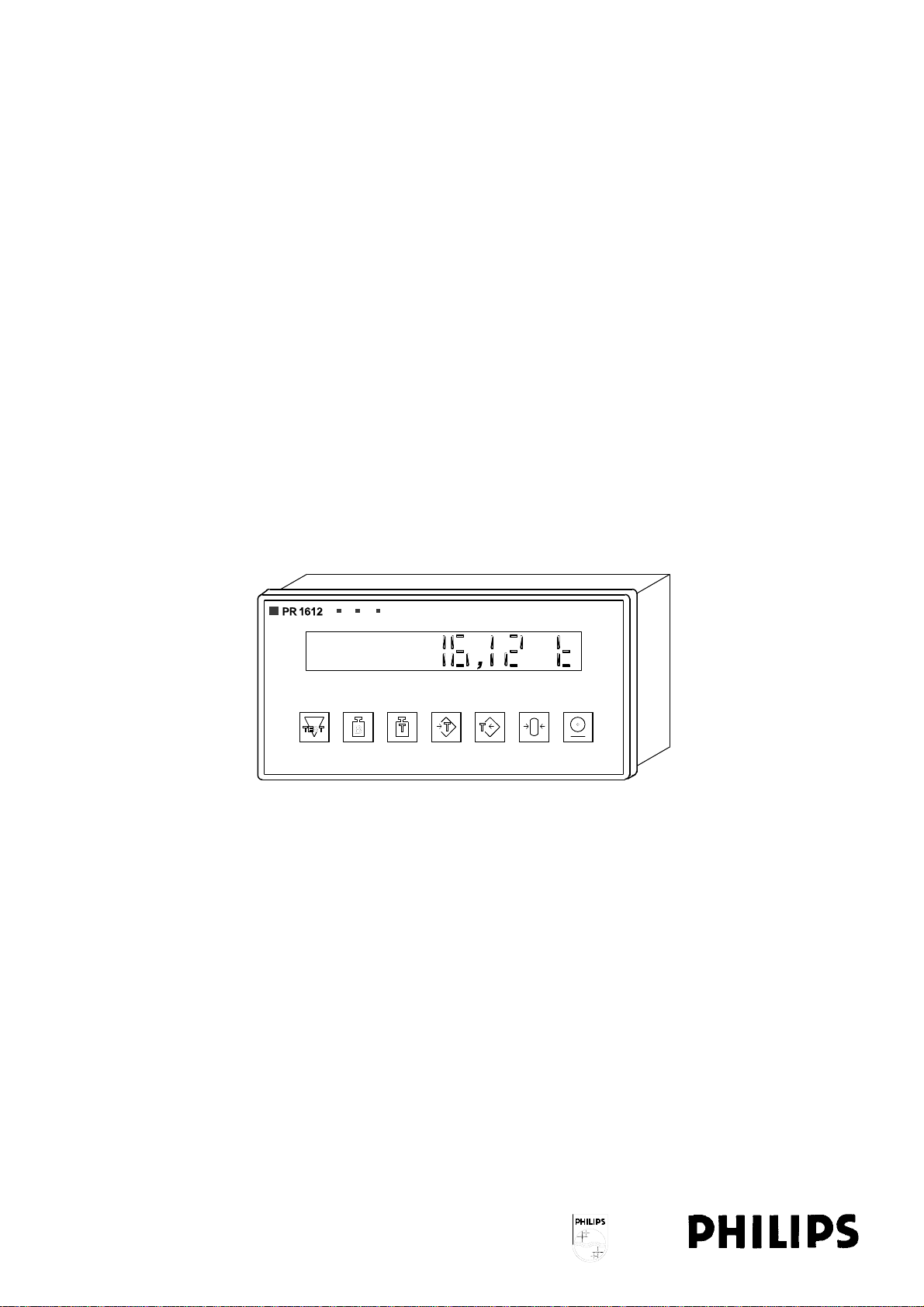

Weight indicator PR 1612/02

Operating manual

Philips

Weighing

Weight indicator 1612/02

Operating manual

First edition

9499 050 37910

970106

Please note

In correspondence concerning this instrument, please quote the type number and serial number as

given on the type plate.

If available, also note the software release number, printed on the label at the EPOM's on the main

print.

Bitte beachten

Bei Schriftwechsel über dieses Gerät wird gebeten, die Typennummer und die Gerätenummer

anzugeben. Diese befinden sich auf dem Typenschild an der Rückseite des Gerätes.

Falls vorhanden, geben Sie auch die Software-Version an, die Sie auf dem Etikett der EPROMs auf

der Leiterplatte im Gerät finden.

Noter s.v.p.

Dans votre correspondance et dans vos réclamations se rapportant à cet appareil, veuillez toujours

indiquer le numéro de type et le numéro de série qui sont marqués sur la plaquette de

caractéristiques.

Si disponible, veuille également indiquer le software rel. no que vous trouvez sur l'ètiquette des

EPROMs qui se trouvent sur la platine principale.

Important

As the instrument is an electrical apparatus, it may be operated only by trained personnel.

Maintenance and repairs may also be carried out only by qualified personnel.

Wichtig

Da das Gerät ein elektrisches Betriebsmittel ist, darf die Bedienung nur durch eingewiesenes

Personal erfolgen. Wartung und Reparatur dürfen nur von geschultem, fach- und sachkundigem

Personal durchgeführt werden.

Important

Comme l'instrument est un équipement électrique, le service doit être assuré par du personnel

qualifié. De même, l'entretien et les réparations sont à confier aux personnes suffisamment

qualifiées.

© Philips Wägetechnik GmbH

Meiendorfer Str. 205, 22145 Hamburg

1997

All rights are strictly reserved.

Reproduction or divulgation in any form whatsoever is not permitted without written authority from

the copyright owner.

Printed in Germany

1st. edition 1. Ausgabe 1er tirage

OPERATING MANUAL PR 1612/02, Rel. $$ 2.30 Page: 0 - 1

CONTENTS

PART 1 PREFACE, DESCRIPTION

PART 2 SAFETY INSTRUCTIONS

PART 3 TECHNICAL DATA

PART 4 MOUNTING, INSTALLATION AND LOADCELL CONNECTION

PART 5 OPERATION

PART 6 SETTING AND CALIBRATION

PART 7 HW-OPTIONS, APPLICATION, and INTERFACING

PART 8 COMMUNICATING WITH SUPERORDINATE OR SUBORDINATE

INSTRUMENTS / SYSTEMS

PART 9 SHORT FORM DESCRIPTION FOR SETTING AND CALIBRATION

PART 10 INDEX

APPENDIX 1 CORNER POINT ADJUSTMENT

APPENDIX 2 INCREMENTAL CALIBRATION WITH MAKE-UP WEIGHT

OPERATING MANUAL PR 1612/02, Rel. $$ 2.30 Page: 1 - 0

CONTENTS OF PART 1 Page

1. PREFACE, DESCRIPTION 1-1

1.1 INFORMATION ON THIS MANUAL 1-1

1.2 SUPPLEMENTARY DOCUMENTATION 1-3

1.3 INSTRUMENT DESCRIPTION 1-3

1.3.1 General 1-3

1.3.2 Special features and functions 1-4

1.4 OPTIONS 1-4

1.4.1 SW-options 1-4

1.4.2 HW-options 1-4

OPERATING MANUAL PR 1612/02, Rel. $$ 2.30 Page: 1 - 1

1. PREFACE, DESCRIPTION

Ladies and gentleman,

PHILIPS WEIGHING thanks you for the confidence shown by the acquisition of this instrument.

As each of our instruments is submitted to severe quality checks before leaving the factory,

you may be sure that you have bought a high-quality state-of-the-art product.

Moreover,this product is the result of extensive market research and meets the requirements

of more than 40 countries in which Philips Weighing is present.

Our quality system fulfils the requirements of DIN ISO 9001 for quality assurance in

design/development, production, installation and servicing.

For the PR 1612/02, certificate of type approval no. D93-09- 120 by Physikalische-Technische

Bundesanstalt (PTB) in Braunschweig i s available, i. e. the indicator meets the prerequisites

for approval by the local authorities in all countries of the European community.

In order to facilitate weights & measures approval by the local authorities, labels and seals,

which can be fitted on the indicators shown in the example in part 7.12 are enclosed in a

plastic bag in the cover of this manual.

We recommend using a fibre-tipped pen with water and ultraviolet light resistant ink,

e. g. type Staedtler PANCOLOR EAM 4007817-32116. for the inscription on the labels.

If nec essary, this pen is available under service code no. 5312 310 18045 from your local

Philips Weighing sales or service organization.

1.1 INFORMATION ON THIS MANUAL

This operating manual for the indicator PR 1612/02 contains information for persons with and

without previous knowledge entrusted with commissioning, use, project planning, installation

and service of this instrument.

For commissioning without previous knowledge, we recommend following the

instructions given in this manual step by step.

In case of problems or questions, you are invited to contact your local Philips Weighing sales

and service organization, or agent respectively.

This manual is structured as follows:

OPERATING MANUAL PR 1612/02, Rel. $$ 2.30 Page: 1 - 2

Part 1: PREFACE, DESCRIPTION

For previous information of all readers.

Part 2: SAFETY INSTRUCTIONS

Important for all users.

Part 3: TECHNICAL DATA

Important for all users.

Part 4: MOUNTING, INSTALLATION, AND LOAD CELL CONNECTION

For persons responsible for installation, commissioning and project planning.

Part 5: OPERATION

For operators.

Part 6: SETTING AND CALIBRATION

For commissioning without previous knowledge.

Part 7: APPLICATION, INTERFACING

For project planning and commissioning with previous knowledge.

Part 8: COMMUNICATING WITH SUPERORDINATE OR SUBORDINATE

INSTRUMENTS / SYSTEMS

For project planning and commissioning with previous knowledge.

Part 9: SHORT-FORM INSTRUCTIONS FOR SETTING AND CALIBRATION

For commissioning with previous knowledge.

Part 10: INDEX

Appendix 1 CORNER POINT ADJUSTMENT

For commissioning with previous knowledge.

Appendix 2 INCREMENTAL CALIBRATION WITH MAKE-UP WEIGHTS

For commissioning with previous knowledge.

OPERATING MANUAL PR 1612/02, Rel. $$ 2.30 Page: 1 - 3

1.2 SUPPLEMENTARY DOCUMENTATION

The indicator PR 1612/02 provides the functions mentioned in section 1.3.2.

Upon delivery the PR 1612/02 communicates with superordinate or subordinate instruments

or systems by means of the Philips EW protocol.

For instruments or systems which do not 'understand' this EW protocol, the software option

PR 1613/05 is available.

The special functions of this option require separate descriptions and are not described in

this Operating Manual.

The operating instructions are delivered with the corresponding SW option.

This manual is also available from the local Philips Weighing organization or agents as

follows:

- Operating manual PR 1612/02 English = 9499 050 37910

(This operating manual) German = 9499 050 37918

French = 9499 050 37932

- Application Information No. 6

(Communication possibilities with superordinate or English = 9499 059 36710

subordinate equipment when using Philips

Weighing Processors)

- Application Information No. 13

(Philips Indicators/Batchers in connection with PLC's) English = 9499 059 37610

1.3 INSTRUMENT DESCRIPTION

1.3.1 General

The PR 1612/02 is a microcomputer-controlled weight indicator, which is designed

especially for industrial Weights & Measures applications.

The instrument is particularly suitable for:

- platforms,

- weighbridges,

- tanks and vessels, and

- as weight indicator in intelligent control systems.

The PR 1612/02 can also be used as multi-range weight indicator by setting parameters C52

and C59 accordingly.

OPERATING MANUAL PR 1612/02, Rel. $$ 2.30 Page: 1 - 4

1.3.2 Special features and functions

- EC type approval,

- EC certificate of conformity acc. to directives 90/384/EEC and EN 45501,

- EC certificate of conformity acc. to directive 89/336/EEC (EMC),

- Various interface modules for serial and parallel connections

- Multi-range weighing applications can be realized easily

- Built-in self-test and analogue test functions,

- 2 adjustable limit values,

- Loadcell supply voltage 12 V or 20 V,

- Built-in software clock for printing time and date on reports,

- High long-term stability and reliability,

- Input signal filter can be switched on and off via software,

- Bright vacuum fluorescent displays,

- Sequences for easy calibration and configuration,

- Calibration without calibration weights possible,

- Subsequent deadload suppression without re- calibration,

- Calibration data can be stored in non-volatile EEPROMs, and protected against

overwriting by switch,

- Configuration data are protected against power failure by back-up battery and can be protected against overwriting by code number.

- High RF interference suppression,

- Protection type IP 65,

- Various communication programs for connection to a PLC and to a superordinate or

subordinate system,

The PR 1612/02 system weight indicator is mounted in a compact aluminium housing, which

is suitable for panel mounting, but also for use of the instrument as table top version.

Operation is via 7 front-panel keys to which other functions are allocated during instrument

adjustment.

Moreover, the instrument is suitable for complete remote control via a separate terminal or a

supervisory system.

1.4 OPTIONS

1.4.1 SW-options

Upon delivery the PR 1612/02 communicates with superordinate or subordinate instruments

or systems by means of the Philips EW protocol.

For instruments or systems which do not 'understand' this EW protocol, the software option

PR 1613/05 is available.

It enables also the communication via SIEMENS DUST 3964R, 3964R-RK512, 3964R

forTeleperm M, and J-BUS, or MOD-BUS

The options can be activated by means of a licence number which will be supplied together

with the SW-option when buying.

OPERATING MANUAL PR 1612/02, Rel. $$ 2.30 Page: 1 - 5

1.4.2 HW-options

For easy matching of the PR 1612/02 indicator to various requirements, several interface

modules are available a s options can be plugged in.

- PR 1601 20 mA TX/RX current loop,

- PR 1602 RS 232 (V24),

- PR 1604 RS 422/485,

- PR 1606 0/2..10 V or 0/4..20 mA analogue output module,

- PR 1608/00 BCD/PLC output module with common supply,

- PR 1608/10 BCD/PLC output module with common ground,

Note !

None of the above listed modules are factory- fitted on the PR 1612/02 indicators.

OPERATING MANUAL PR 1612/02, Rel. $$ 2.30 Page: 2 - 0

CONTENTS OF PART 2 Page

2. SAFETY INSTRUCTIONS 2-1

2.1 INITIAL INSPECTION 2-1

2.2 BEFORE COMMISSIONING 2-1

2.2.1 General 2-1

2.2.2 Mounting 2-1

2.2.3 Dismantling the instrument 2-1

2.2.4 Typ of protection 2-1

2.2.5 Connection of supply voltages 2-2

2.2.6 Earthing 2-2

2.3 MAINTENANCE AND REPAIR 2-2

2.3.1 Failure and excessive stress 2-2

2.3.2 Repairs 2-2

2.3.3 Replacing fuses 2-2

2.3.4 For special attention 2-3

2.3.5 Electrostatically sensitive components 2-3

2.3.6 Battery replacement 2-3

OPERATING MANUAL PR 1612/02, Rel. $$ 2.30 Page: 2 - 1

2. SAFETY INSTRUCTIONS

This apparatus has been designed and tested in accordance with Safety Class I requirements

of IEC Publication 348, Safety Requirements for Electronic Measuring Apparatus, and has

been supplied in a safe condition. This manual contains some information and warnings which

mus t be followed by the user to ensure safe operation and to retain the apparatus in a safe

condition.

2.1 INITIAL INSPECTION

Check the contents of the consignment for completeness and note whether any damage has

occ urred during transport. If the contents are incomplete, or if there is a damage, a claim

should be filed with the carrier immediately.

Als o t he loc al Organization o f Philips Weighing has to be informed in order to facilitate the

repair or replacement of the instrument.

2.2 BEFORE COMMISSIONING

2.2.1 General

Bef ore putting the instrument into operation after storage or transport, visually check it for

physical damage.

2.2.2 Mounting

The i ns trument is suitable for panel mounting. Heat influence, such as direct solar radiation

etc., should be avoided. Please observe the required environmental conditions as given in the

technical data.

2.2.3 Dismantling the instrument

When removing the housing, covers or other protecting parts, live parts or terminals will be

exposed.

! CAUTION - DANGER TO LIFE !

The refore setting the switched-on instrument must be performed only by trained personnel

aware of the risks.

2.2.4 Type of protection

The instrument is protected according to class I (protective earth) of the IEC 348 or the

German VDE 0411 regulations.

The connection cable must contain a protective earth conductor which must not be interrupted

ins ide or outside the instrument (e.g. by using an extension cable without protective earth

conductor).

OPERATING MANUAL PR 1612/02, Rel. $$ 2.30 Page: 2 - 2

2.2.5 Connection of supply voltages

The PR 1612/02 can be connected to nominal 110, 128, 220 or 238 V AC.

Upon delivery it is set to 220 V AC . Check whether it is adapted to the local nominal mains

voltage.

For connecting the supply voltage cable (including protective earth or earth conductor) to the

instrument, strictly observe the relevant Operating Manual. As the instrument has no switch,

it will be in operation as soon as the supply voltage is applied.

2.2.6 Earthing

The instrument must be connected to earth by means of a special protective earth conductor

(of the mains cord). The separate conductor must be connected to one of the clamps at the

rear of the instrument.

2.3 REPAIR AND MAINTENANCE

2.3.1 Failure and excessive stress

If the instrument is suspected of being unsafe, take it out of operation and make sure it

cannot be operated inadvertently. This is the case when the instrument

- shows physical damage

- does not function any more

- is stressed beyond the tolerable limits (e.g. during storage and transportation).

2.3.2 Repairs

Caution !

The instruments sold by Philips Weighing are subject to a repair procedure.

In case of defect or malfunction, please contact your local Philips Weighing organization for

the required measures.

Important !

Maintenance or repairs must be performed only by trained personnel aware of the risks (see

chapter 2.2.). Make sure that the construction of the instrument is not altered to the

detriment of safety. Above all, leakage paths, air gaps, and insulation layers must not be

reduced.

2.3.3 Replacing fuses

Replacing fuses is described in part 4.8.

Make sure that only fuses of the required current rating, and of the specified type to IEC 127

are used for renewal. The use of repaired fuses, and/or short-circuiting of fuse holders is

prohibited. Fuses shall only be renewed by a qualified person who is aware of the hazard

involved.

OPERATING MANUAL PR 1612/02, Rel. $$ 2.30 Page: 2 - 3

Warning:

The instrument must be disconnected from all voltage sources when a fuse is to be

renewed, or when the instrument is to be adapted to a different mains voltage.

2.3.4 For special attention

When soldering on the circuit boards it is essential

a. to switch off the power, and

b. to use a low-voltage soldering iron, galvanically separated from the mains side.

Suitable soldering irons should have temperature control and different types of nozzles (pin

point tips), e.g. Weller Magnastat WTCP or WECP, Ersa TC 70/24 V.

If a higher wattage-rating soldering iron is used, excessive heat can cause the printed circuit

tracks to separate from the board base material, thus irreparably damaging the printed circuit

board.

In general, use short time heating with high tip temperature at a small point, avoid long time

heating.

2.3.5 Electrostatically sensitive components

The instrument contains electrical components which are susceptible to damage from

electrostatic discharge. Servicing statically sensitive assemblies or components should be

performed only at an antistatic work station by qualified service personnel.

2.3.6 Battery replacement

This instrument is equipped with lithium back-up batteries. When the battery voltage is below

the specified value, or the batteries are defective, they must be replaced by a trained person,

or by the Customer Support of the local Organization of Philips Weighing. For disposal, the

local regulations must be followed.

OPERATING MANUAL PR 1612/02, Rel. $$ 2.30 Page: 3 - 0

CONTENTS OF PART 3 Page

3. TECHNICAL DATA 3-1

3.1 CHARACTERISTICS, SPECIFICATIONS 3-1

3.2 GENERAL DATA 3-1

3.3 ACCURACY AND STABILITY 3-1

3.4 VOLTAGE SUPPLY 3-1

3.5 ANALOGUE PART 3-2

3.5.1 Loadcell connection 3-2

3.5.2 Supply voltage sensing 3-2

3.5.3 Measuring signal input 3-2

3.6 DIGITAL PART 3-3

3.7 DISPLAY 3-3

3.8 SERIAL INPUTS/OUTPUTS 3-4

3.8.1 Type of interface module(s) 3-4

3.8.1.1 PR 1601 3-4

3.8.1.2 PR 1602 3-4

3.8.1.3 PR 1604 3-5

3.9 CONTROL OUTPUTS 3-5

3.10 ANALOGUE OUTPUT MODULE (PR1606) 3-6

3.11 BCD/PLC OUTPUT MODULE 3-6

WITH COMMON SUPPLY (PR1608/00)

3.11.1 BCD-mode 3-6

3.12 BCD/PLC OUTPUT MODULE 3-7

WITH COMMON GROUND (PR1608/10)

3.12.1 BCD-mode 3-8

3.13 ENVIRONMENTAL CONDITIONS 3-9

3.14 ELECTROMAGNETIC COMPATIBILITY 3-9

3.15 DIMENSIONS AND WEIGHTS 3-10

3.16 APPROVALS 3-10

3.17 ACCESSORIES 3-10

OPERATING MANUAL PR 1612/02, Rel. $$ 2.30 Page: 3 - 1

3. T E C H N I C A L D A T A

3.1 CHARACTERISTICS, SPECIFICATIONS

Values given with limits are guaranteed by the manufacturer, values without limits are average

values and are used for information only. These characteristics are valid after a warm - up

period of the instrument of at least 60 min (reference temperature = 23 C) . If nothing else is

said, the relative and absolute tolerances refer to the adjusted measuring output value.

3.2 GENERAL DATA

Type PR 1612/02

Order number 9405 116 12001

Measuring principle integrating ADC, operating radiometrically to the loadcell supply

voltage.

Housing made of aluminium,

MTBF 35000 h

3.3 ACCURACY AND STABILITY

Resolution 3000 d OIML class lll

Linearity < 0.007 %, related to straight line through zero and final

Zero-point stability < 0.1µV/K, RTI < 8,5 ppm at 1 mV/V and 12V loadcell

SPAN stability < 6 ppm/K

Noise < 0.4 µV p-p, RTI

3.4 VOLTAGE SUPPLY

Nominal values adjustable for 110, 128, 220, or 238 V AC

designed for panel mounting, or table top use

value

supply

Permissible deviation + 10 % / - 15 %

Frequency range 50/60 Hz

Power consumption 25 VA, 19 W at 220 V and at max. Ioad (all options inserted)

Fuses 200mA time delayed with 110/128 V AC, and

100mA time delayed with 220/238 V AC, inserted in the

EURO type mains socket at instruments rear.

OPERATING MANUAL PR 1612/02, Rel. $$ 2.30 Page: 3 - 2

Mains voltage filter fitted with built-in EMI type filter.

Safety class I (protective earth) acc. to VDE 0411 and IEC 348.

Connections by means of 3-pole EURO connector acc. to CEE-

3.5 ANALOGUE PART

A/D conversion integrating, ratiometrically to the loadcell voltage supply.

Conversion time 50 ms

3.5.1 Loadcell connection

Method via 6-pole screw terminals of max. 4mm² at the rear.

standards, with integrated mains fuse, positioned at the rear of

the instrument.

Connection preferably by 6-wire technique.

Types of loadcell all types of strain gauge loadcells with linear output.

Loadcell voltage supply ± 6 V (12 V DC), 150 mA, or

Tolerance 6%

Maximum load approx. 85

3.5.2 Supply voltage sensing

Method by 6-wire technique, i.e. by measuring the loadcell supply

Sense voltage ± 6 V DC (12 V DC diff.), or ± 10V DC (20 V DC diff.)

Sense input impedance 10 M

± 10V (20 V DC), 230 mA,

with reference to ground, short circuit proof.

External load cell supply possible.

S = 6 loadcells 600 S each, connected in

parallel (= 100

4 loadcells 350

voltage at the connecting point of the loadcell junction

box. Differential input.

S), or

S each, connected in parallel (= 87.5 S).

S

3.5.3 Measuring signal input

Range of input voltage

(deadload + meas. signal) 0...36 mV = 3mV/V at 12V loadcell supply.

Range for meas. signal 2.4mV .. 36mV, or

0.12mV/V (20V) .. 3mV/V (12V) respectively

OPERATING MANUAL PR 1612/02, Rel. $$ 2.30 Page: 3 - 3

Measuring voltage input

impedance > 10M

Maximum permissible

voltage of the

measuring input 15 V

Filtering of the measuring by an active Butterworth filter, cut-off frequency fc = 2 Hz,

voltage the filter can be switched off.

Common mode rejection

ratio (CMRR) >110 dB

Dead load range 0 mV .. 33.6 mV

Span and dead load

adjustment by firmware during CALIBRATION.

3.6 DIGITAL PART

S

Measuring time 0.1s to approx. 2s, adjustable at intervals of 0.1s.

Step widths adjustable for 1, 2, 5, 10, 20 or 50.

Maximum scale value 99990, observe max. resolution (part 6.5.2).

Data protection typical 16000 hours, by lithium batteries.

3.7 DISPLAY

Type vacuum-fluorescent display module.

Elements 7 digit, 7 segment plus dimension signs and status

Height digits and dimension signs 12.5 mm.

Colour bright green.

Active digits 5 plus negative sign (-99990 at max.).

Active status indicators Gross (B), Net (NET),

indicators.

Tare and tare active (T),

standstill ( ), within ±1/4 d ( ), minus (-).

Dimension sign settable for g, kg, t, or lb.

Decimal point settable either as point or as comma during CALIBRATION

for:

00000 00000

0000.0 0000,0

000.00 000,00

00.000 00.000

OPERATING MANUAL PR 1612/02, Rel. $$ 2.30 Page: 3 - 4

3.8 SERIAL INPUTS / OUTPUTS (available as options)

Number of serial lines One.

The corresponding interface module must be inserted

- either into the 14-pole. socket of line 1(A),

- or into the 14-pole socket of line 2(B).

and by observing the following technical instructions.

3.8.1 Type of interface module(s)

3.8.1.1 Module PR 1601

Order number 9405 316 01001

Application 20 mA bidirectional, serial, opto-coupler isolated current

loop interface for balanced transmission line.

Galvanically separated from external devices.

Optionally the interface can be equipped with a relay which

prev en ts an interruption o f the TX-current loop via more than

one unit in case of a defect.

Supply of the loops by non-regulated, internal 9..10 V DC from PR 1612/02

measured at 66

Voltage drop via TX/RX 4V at minimum with 200

Signal level logic high (mark) = 18 .. 22 mA,

Baud rate settable to 300, 600,1200, 2400, or 4800 baud.

Cable length 1000 meters at maximum, using a pairwisely twisted and

Connecting external via 9-pole female plug of e.g. type Philips F 161, or

devices Cannon DB 9.

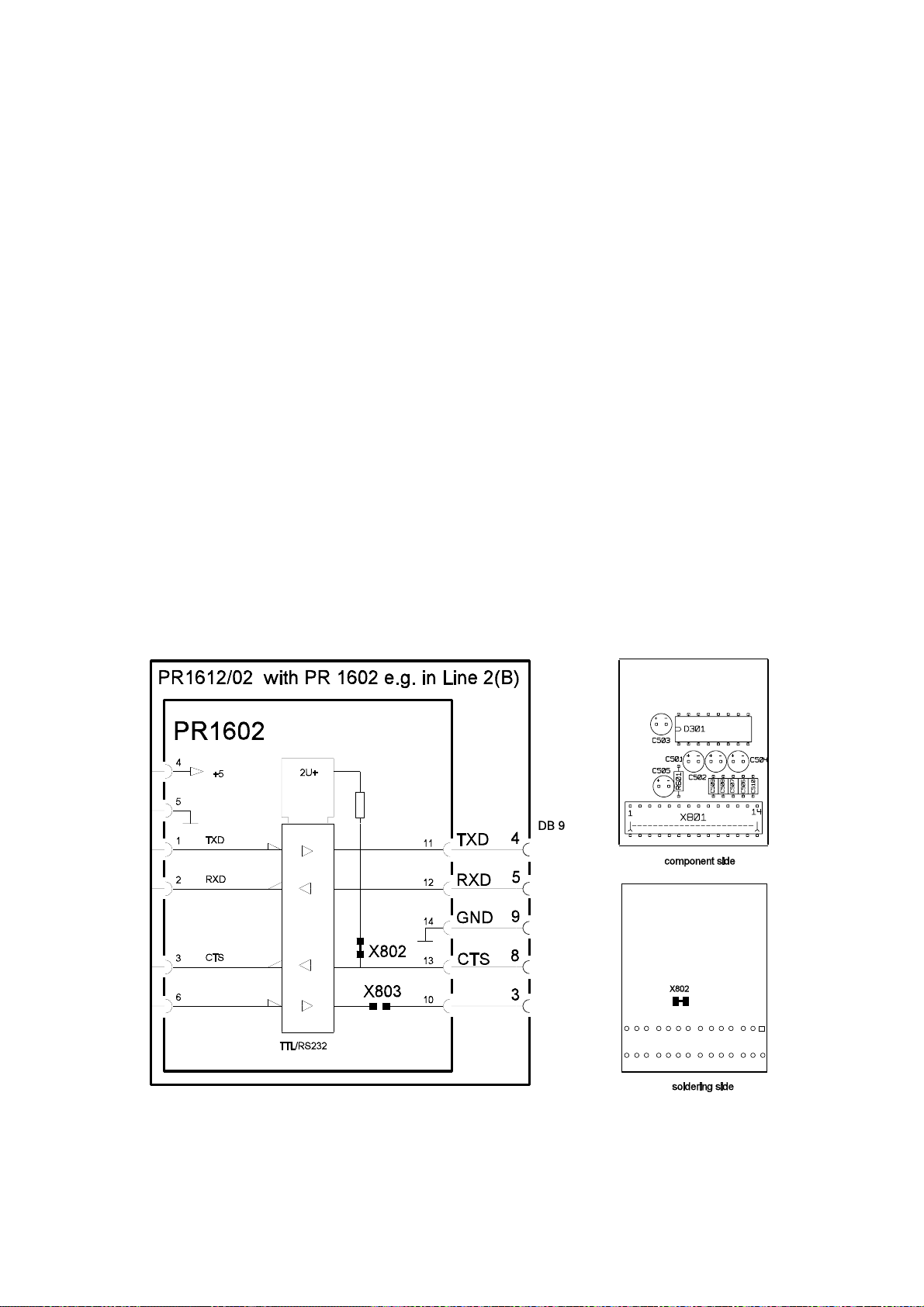

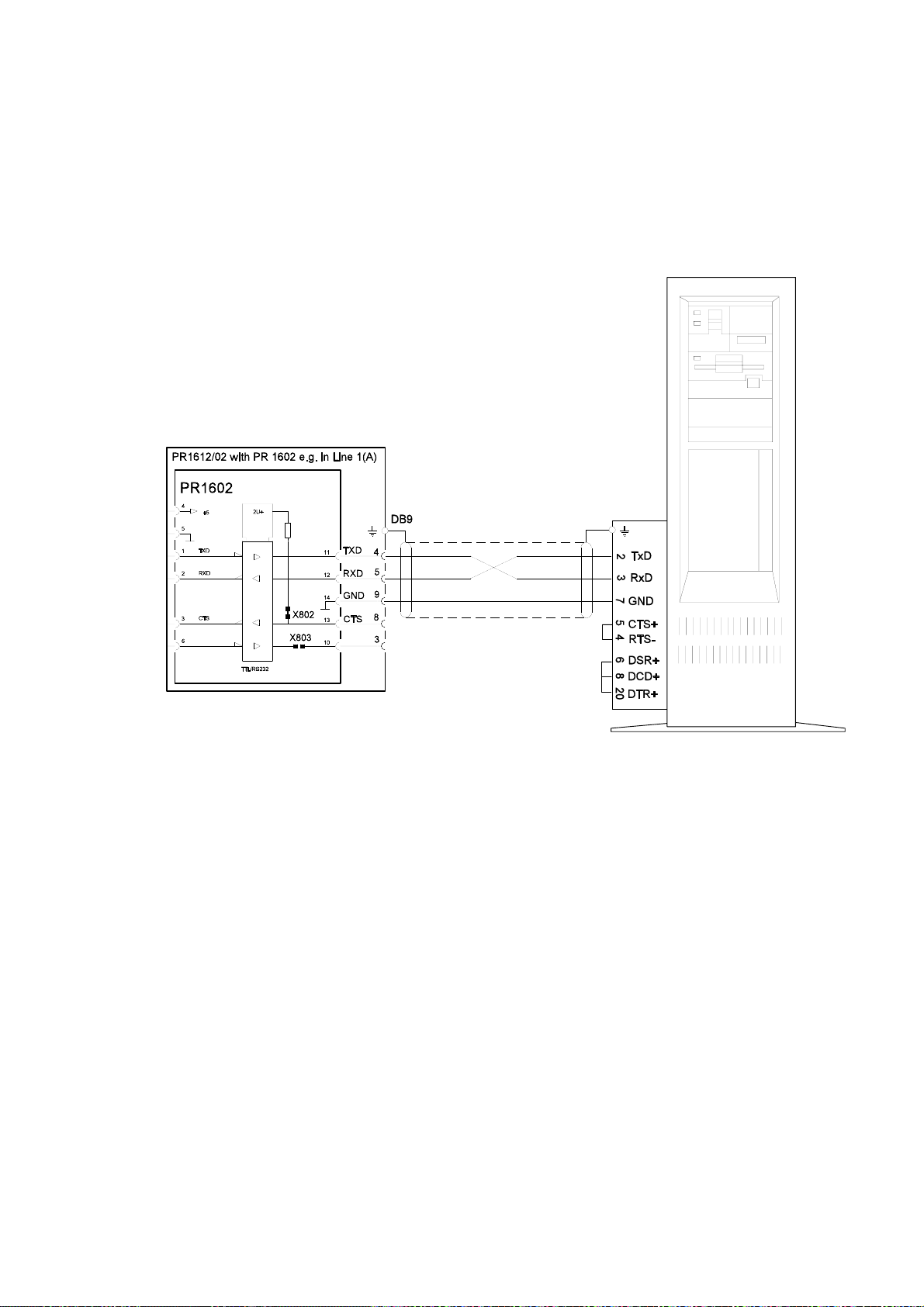

3.8.1.2 Module PR 1602

Order number 9405 316 02001

Application bidirectional, serial RS232-communication interface

S in active mode;

by external 12 .. 31 V DC in active mode.

S burden and per loop.

logic low (space) = 0 .. 1 mA.

screened cable.

module for unbalanced transmission line via signals

TX and RX. With control signals CTS and RTS.

No galvanic isolation from external devices !.

Supply By internal PR 1612/02 voltage.

Level of output

signals TX and RTS ± 5 V DC min. at R

loadTX

$ 3kOhm

OPERATING MANUAL PR 1612/02, Rel. $$ 2.30 Page: 3 - 5

Level of input

signals RX and CTS # ± 30V DC

Baud rate settable to 300, 600,1200, 2400, 4800, or 9600 b/s.

Cable length 30 meters at maximum, using a pairwisely twisted and

Connecting external via 9-pole female plug of e.g. type Philips F 161, or

devices Cannon DB 9.

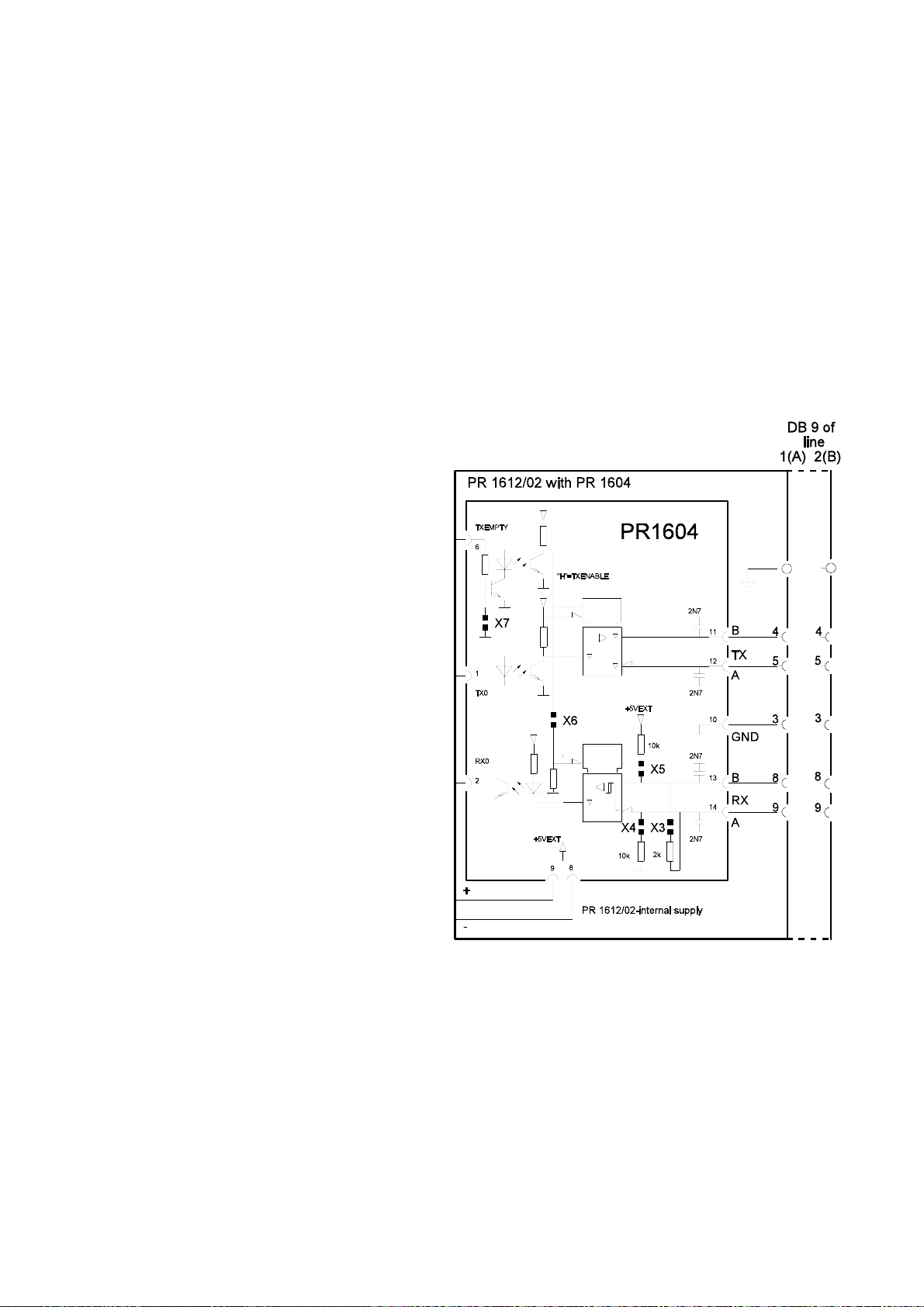

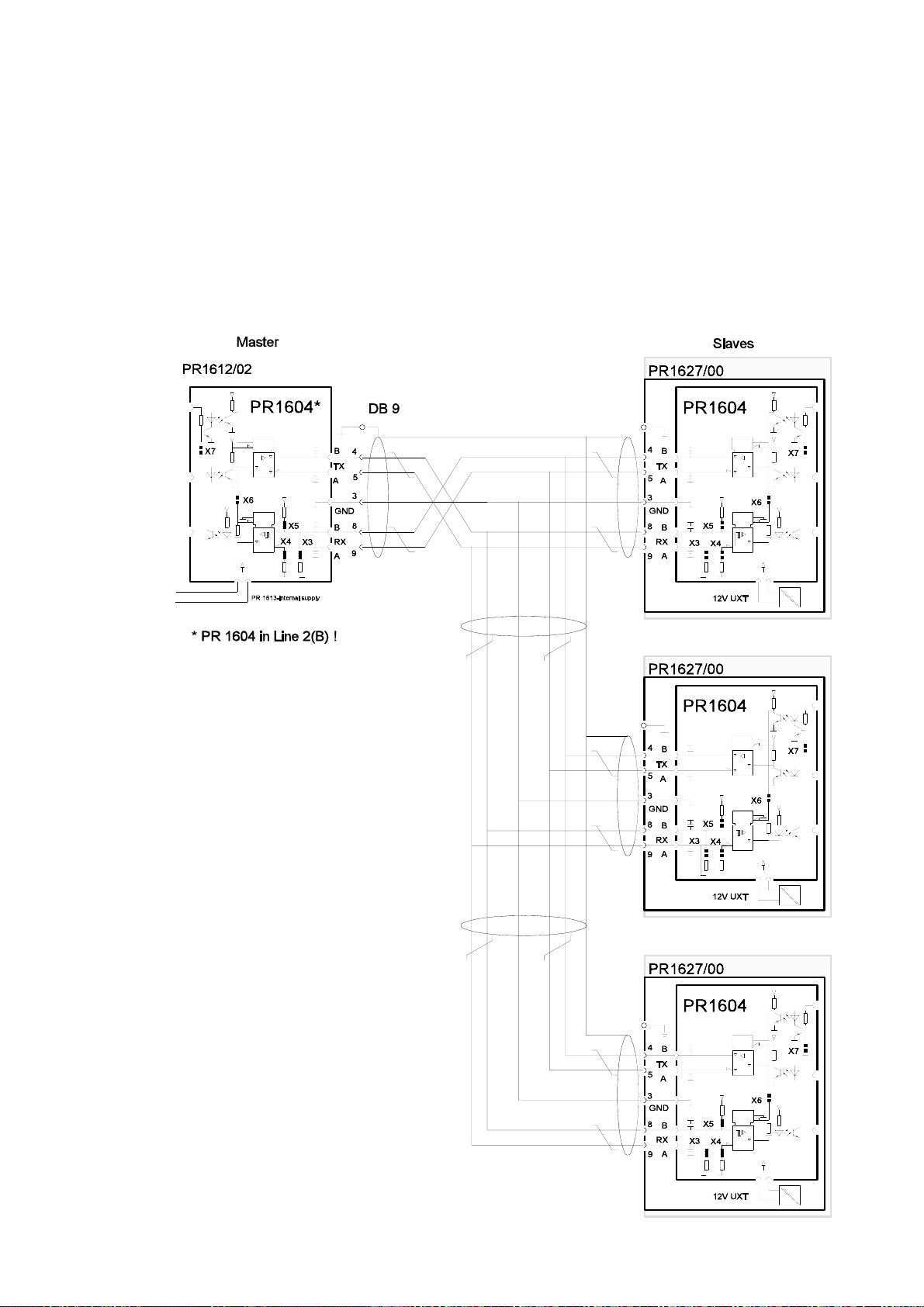

3.8.1.3 Module PR 1604

Order number 9405 316 04001

Application bidirectional, serial, opto-coupler isolated interface module for

screened cable.

balanced transmission line.

Galvanically isolated from external devices via optocoupler.

Mode either 4-wire connection in full duplex (RS 422/485),

Supply by non-regulated, internal 9..10 V DC from PR 1612/02

measured at 66

Signal level according to RS422/485 standard. Tri-state possible only with

Baud rate settable to 9600 b/s at maximum.

Cable length 1000 meters at maximum (recommended), using a pairwisely

Connecting external via 9-pole female plug of e.g. type Philips F 161,

devices or Cannon DB 9.

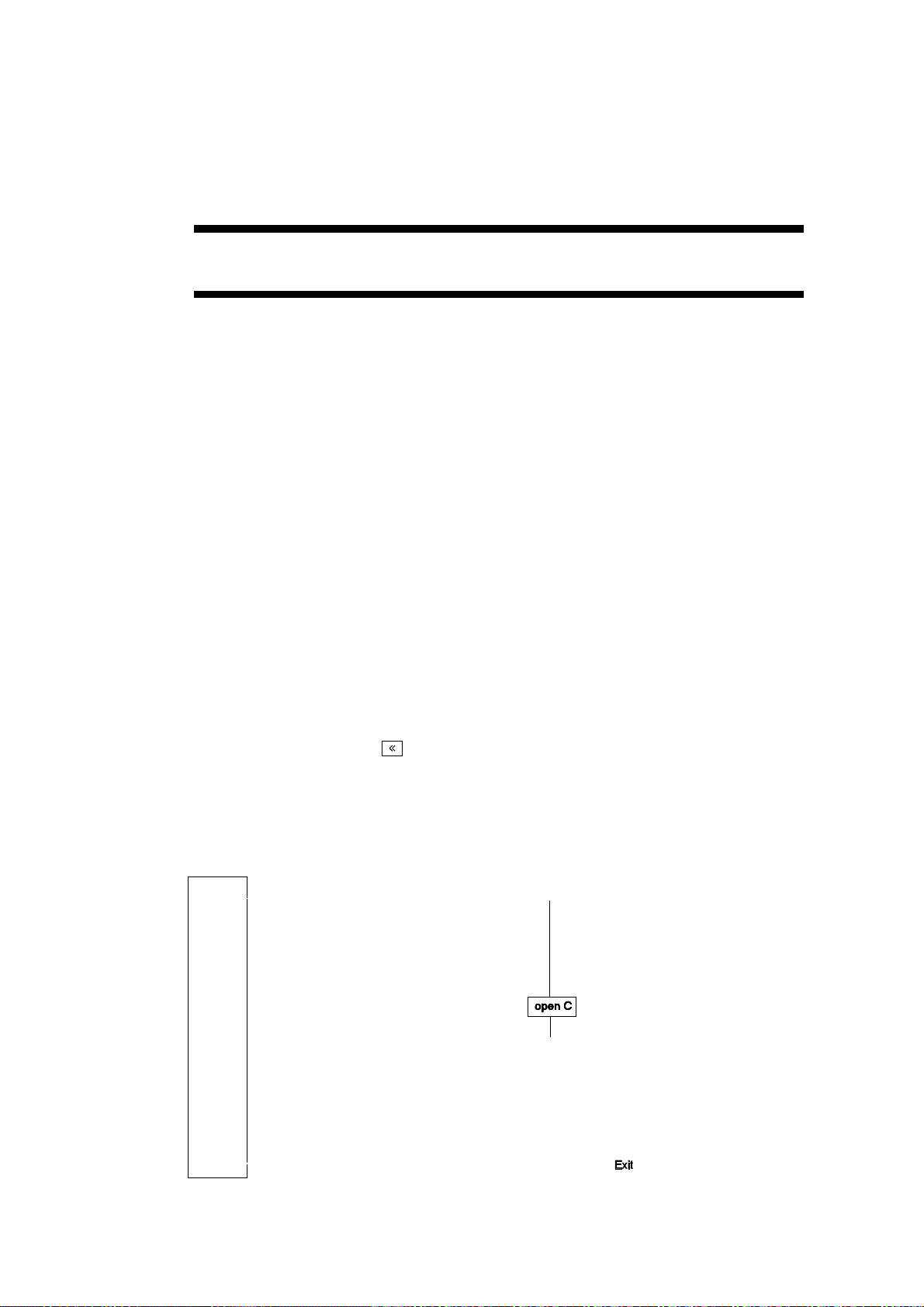

3.9 CONTROL OUTPUTS

Number Two

Features opto-isolated. No common reference potential.

or 2-wire connection in half duplex (RS 485).

Selectable by solder links on the module.

S.

RS 485.

twisted and screened cable.

Protected against wrong polarity.

Signal level/current up to max. 32 V, 75 mA.

Voltage drop I x 55 Ohm + 1V,

load

spark suppression must be provided for inductive loads as

close as possible to the load.

OPERATING MANUAL PR 1612/02, Rel. $$ 2.30 Page: 3 - 6

3.10 ANALOGUE OUTPUT MODULE PR1606 (available as option)

Order number 9405 316 06001

Application Interface module for analogue output signals of gross, or

net, or tare weight values, or values as shown at the front

display.

Selection is possible via parameter C12 of the PR 1612/02

during configuration.

Voltage output 0 .. +10 V, or }

2 .. +10 V }

RL > 5 kOhm }

} no galvanic isolation between

Current output 0 .. +20 mA, or } internal and external electronics!

4 .. +20 mA }

Burden 0.. 500 Ohm }

Resolution 4096 bit (provided f.s.d.

Accuracy approx. 1‰ (2‰ for current output)

Connection via 15 pol. female plug of e.g. Philips F161, or Cannon DB15.

Default values:

Output gross weight

Zero = 0V and 0mA, or 2V and 4mA

f.s.d. at 5000d = 10V and 20mA

3.11 BCD AND PLC OUTPUT MODULE PR 1608/00 with common supply

(available as option)

Order number 9405 316 08001

Application interface module for BCD or PLC output signals.

Logic level selectable. No galvanic isolation between internal

and external electronics!

Connection to external via 26 pol. female plug of type DB-SUB

devices

$ 4096 divisions).

Accessories 1 x 26 pole connection cable of 3 m length equipped at one

3.13.1 BCD mode:

Outputs: 23 (switching transistor to positive external supply).

Output signals 5 decades of gross, or net, or tare values, or automatically

side with a 26 pole male plug of type AMP.

following the front display (gross, net, or tare),

minus sign, standstill, and error (in/out of range).

OPERATING MANUAL PR 1612/02, Rel. $$ 2.30 Page: 3 - 7

Sampling rate at

continuous data output according to measuring time

Supply of outputs by external +5V ... +24 V DC nominal, ( +32 V at maximum).

Voltage drop via external voltage minus 1.5 V at 25 mA, if transistor is in

transistor 'on'-state (conducting).

I 25 mA

max

Logic level of logic selectable by solder link H on the module.

output signal H = open = logic '1' = switching transistor 'on'

For the control of LS-TTL inputs of follow-up instruments

each output has to be equipped with a 1 k

S pull-down

resistor, and be supplied by external + 5 V.

For 2 4 V logic inputs each output has t o be equipped with a

2.2 k

S pull-down resistor, and to be supplied by external

+ 24 V (nominal).

(conducting)

H = closed = logic '1' = switching transistor 'off' (non conduct.)

Inputs: One

Input signal enable/hold for data outputs.

Level selectable by solder links A and B onto the module

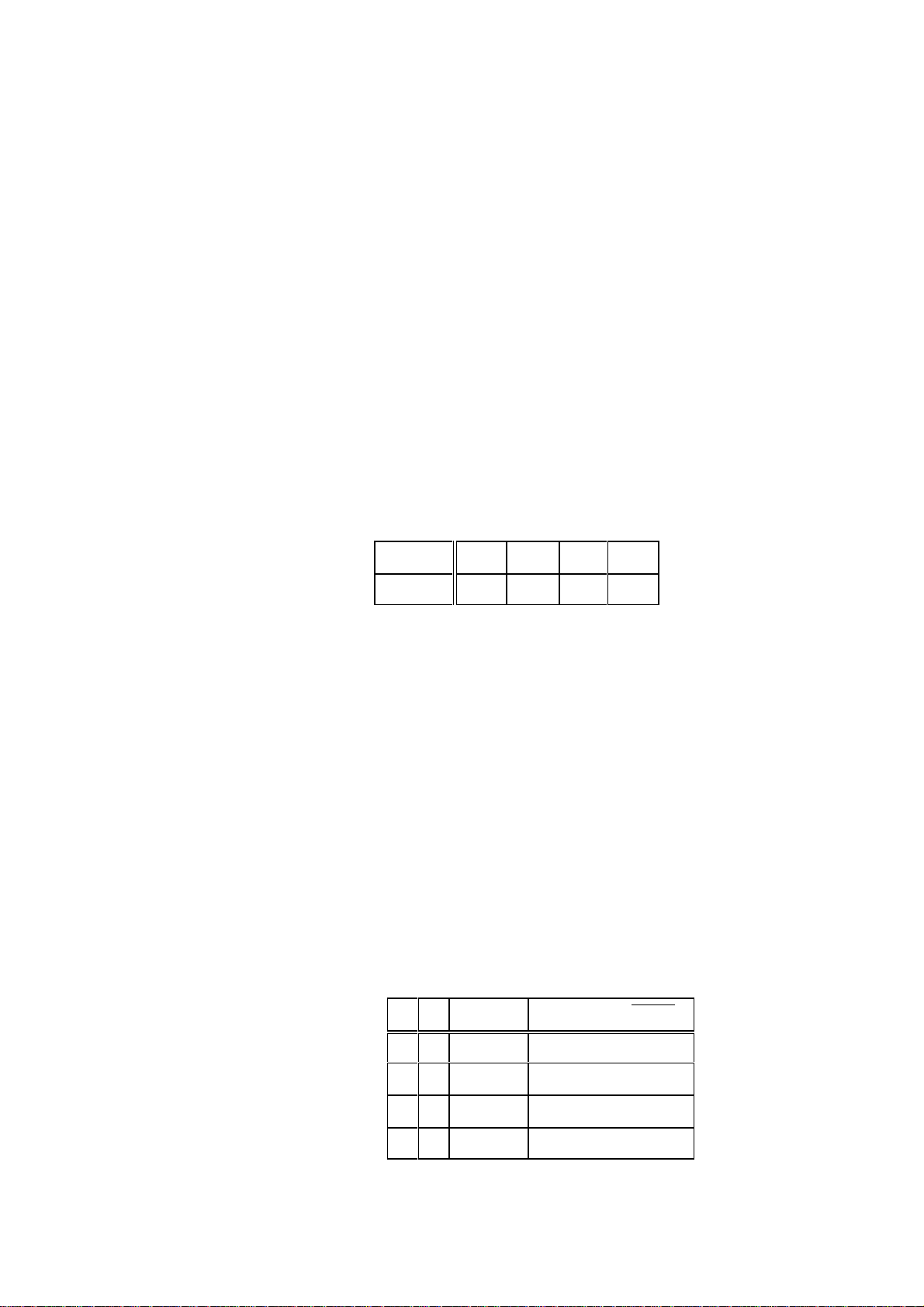

A B C mode data hold or enable

c o c 5V/TTL > 2.4 V

o c c 5V/TTL < 0.4 V

c o o 24 V > 10.0 V

o c o 24 V < 6.0 V

I 0.76 mA for 24 V mode (C = open),

input

0.17 mA for 5 V mode (C = closed)

3.12 BCD AND PLC OUTPUT MODULE PR 1608/10 with common ground

(available as option)

Order number 9405 316 08101

Application interface module for BCD or PLC output signals with common

ground. Logic level selectable.

No galvanic isolation between internal and external

electronics!

Connection to external via 26 pol. female plug of type DB-SUB

devices

OPERATING MANUAL PR 1612/02, Rel. $$ 2.30 Page: 3 - 8

Accessories 1 x 26 pole connection cable of 3 m length equipped at one

3.12.1 BCD mode

Outputs: 23 (switching transistor to GND)

Output signals 5 decades of gross, or net, or tare values, or automatically

Sampling rate at

continuous data output according to measuring time

Supply of by external voltage of nominal +5V ... +24 V DC,

external loads (+32 V at maximum).

side with a 26 pole male plug of type AMP.

following the front display (gross, net, or tare),

minus sign, standstill, and error (in/out of range).

Voltage drop via I (mA) < 10 15 25 50

transistor U (mV) 100 150 230 450

I 50 mA.

max

For the control of LS-TTL inputs of follow-up instruments

each output has to be equipped with a 1 k

S pull-up resistor.

With 24 V inputs each output has to be equipped with a

2.2 k

S pull-up resistor.

Logic level of logic selectable by solder link H onto the module.

output signal H = open = logic '1' = switching transistor 'on'

(conducting)

H = closed = logic '1' = switching transistor 'off' (non conduct.)

Inputs: 1 (with internal pull up resistor to + 5 V)

Input signal enable/hold for data outputs.

I < 0.7 mA max. (sink) at a voltage of < 0.4 V ( or when

input

connected to ground).

Level selectable by solder links A and B on the module

A B mode data hold or enable

c o 5V/TTL > 2.4 V

o c 5V/TTL < 0.4 V

c o 24 V > 10.0 V

o c 24 V < 6.0 V

OPERATING MANUAL PR 1612/02, Rel. $$ 2.30 Page: 3 - 9

3.13 ENVIRONMENTAL CONDITIONS

The given data are valid only when the instrument has been checked according to the official

test methods. Details concerning these tests and the error limits can be requested from the

local Organization of Philips Weighing.

Ambient temperature:

Reference value + 23° C

Turn-on temperature range 0° C ... + 55° C

Nominal temperature range:

For W& M applications - 10°C . . . + 40° C

For industrial applications - 10° C ... + 55° C

Limit range for storage

and transport - 40° C ... + 70° C

Relative humidity:

Reference range 45 ... 75 % }

Nominal operational range 20 ... 80 % }

Operational limits 10 ... 90 % } no condensation

Limits for storage }

and transport 5 ... 95 % }

Type of protection: housing IP 30, front plate IP 65.

Mounting: designed for panel mounting or for table top use.

Warm-up time: approx. 60 min.

Interference voltage: acc. to DEUTSCHE-POST-VERORDNUNG

VfG 243/91 and EN 55011, limit value B

3.14 ELECTROMAGNETIC COMPATIBILITY

Static discharges: acc. IEC 801-2, level 3 (8 kV with 5mJ)

Burst on line acc. IEC 801-4, level 3 (2 kV), risetime 5ns, duration 50ns.

Burst on data line acc. IEC 801-4, level 3 (1 kV), risetime 5ns

duration 50ns.

Resistance to irradiation:

electrical fields 10 kHz .. 500 MHz at 10V/m } influence less

500MHz .. 1 GHz at 2V/m } than 0.01%

magnetic fields 60 A/m at 50 Hz

mains voltage sags 100 % with > 10 ms }

50 % with > 20 ms } no failure

20 % with > 50 ms }

Rapid low-energy

transients on line: 2 kV, risetime 5 ns, duration 100 ns

OPERATING MANUAL PR 1612/02, Rel. $$ 2.30 Page: 3 - 10

Slow high-energy

transients on line: 2 kV; risetime 100 ns, duration 10 µs

3.15 DIMENSIONS AND WEIGHTS

Dimensions 96x192x229mm (HxWxD)

Weight Net approx. 2.8 kg, Shipping approx. 5.2 kg

3.16 APPROVALS

The following EC certificates of conformity are available and can be requested at:

PHILIPS Wägetechnik GmbH, Meiendorfer Str. 205, D 22145 Hamburg, Department QM

Tel.: (++49) 040-67960-300, Fax.: (++49) 040-67960-608

EC type approval No. D93-09-120 for non-automatic weighing machines,

according to directives 90/384/EEC and EN 45501.

Certificate of conformity according to a. m. EC type approval as sample for

EC certificate of conformity according to directive 89/336/EEC including modifications

3.17 ACCESSORIES

1 operating manual

1 gasket

1 label for multirange scale

1 spring washer M4

1 oval head screw M4x8

2 screws M2.5x12

1 cable clamp

1 set of W&M labels (in this manual)

1 mains connector

1 protective rubber sleeve for mains connector

1 label for 110V

1 label for 128V

1 label for 238V

2 fuses 200mA T (delayed action) for 110/128V

2 slide clamps } already at

2 milled knobs } the indicator

manufacturer of weighing machines in languages D, GB,

and F.

(EMC).

OPERATING MANUAL PR 1612/02, Rel. $$ 2.30 Page: 4 - 0

CONTENTS OF PART 4 Page

4. MOUNTING AND INSTALLATION 4-1

4.1 MOUNTING INSTRUCTIONS 4-1

4.2 OPENING THE INSTRUMENT 4-2

4.3 SWITCHING ON THE BACK-UP BATTERY 4-2

4.4 CONNECTION POSSIBILITIES 4-2

4.5 CONNECTIONS OF MAINS AND SUPPLY VOLTAGES 4-2

4.6 REPLACING FUSES 4-3

4.7 INSTALLATION INSTRUCTIONS FOR CONNECTING DATA CABLES 4-3

4.8 CONTROL OUTPUTS 4-5

4.9 THE PARALLEL INTERFACE 4-5

4.10 THE SERIAL INTERFACE 4-5

4.10.1 Connections 4-6

4.11 CONNECTING THE LOADCELLS 4-6

4.12 EARTHING AND POTENTIAL EQUALIZATION 4-8

4.12.1 Earthing 4-8

4.12.2 Potential equalization 4-8

OPERATING MANUAL PR 1612/02, Rel. $$ 2.30 Page: 4 - 1

4. M O U N T I N G A N D I N S T A L L A T I O N

During the installation of the instruments, some presettings can already been carried out

without the mains supply switched-on.

CAUTION

Before unpacking and operating the instrument,

the safety instructions in Part 2 must be observed

4.1 MOUNTING INSTRUCTIONS

The instrument is suitable for rack and panel mounting, or for table top use.

Taking the different protection classes between front (IP 65) and housing (IP 30) into

account please take care for

- a proper isolation between both parts, and in conjunction with it

- a sufficient stability of the panel.

Mounting is to be done as follows:

- Ioosen the two clamp screws at the rear of the case until the slide clamps can be removed.

- work ing f rom the front o f the panel, insert the indicator with the gasket mounted into the

panel cut-out.

- insert slide clamps back onto the case, push them up tightly against the rear of the panel,

and fix them by means of the two clamp screws. Do not overtighten them.

- position connectors and cables as required.

OPERATING MANUAL PR 1612/02, Rel. $$ 2.30 Page: 4 - 2

4.2 OPENING THE INSTRUMENT

• disconnect the instrument from the mains and all power sources,

• carefully remove the 6 self tapping screws at the rear panel of the instrument and keep

them safely,

• pull out the inner unit from the housing carefully.

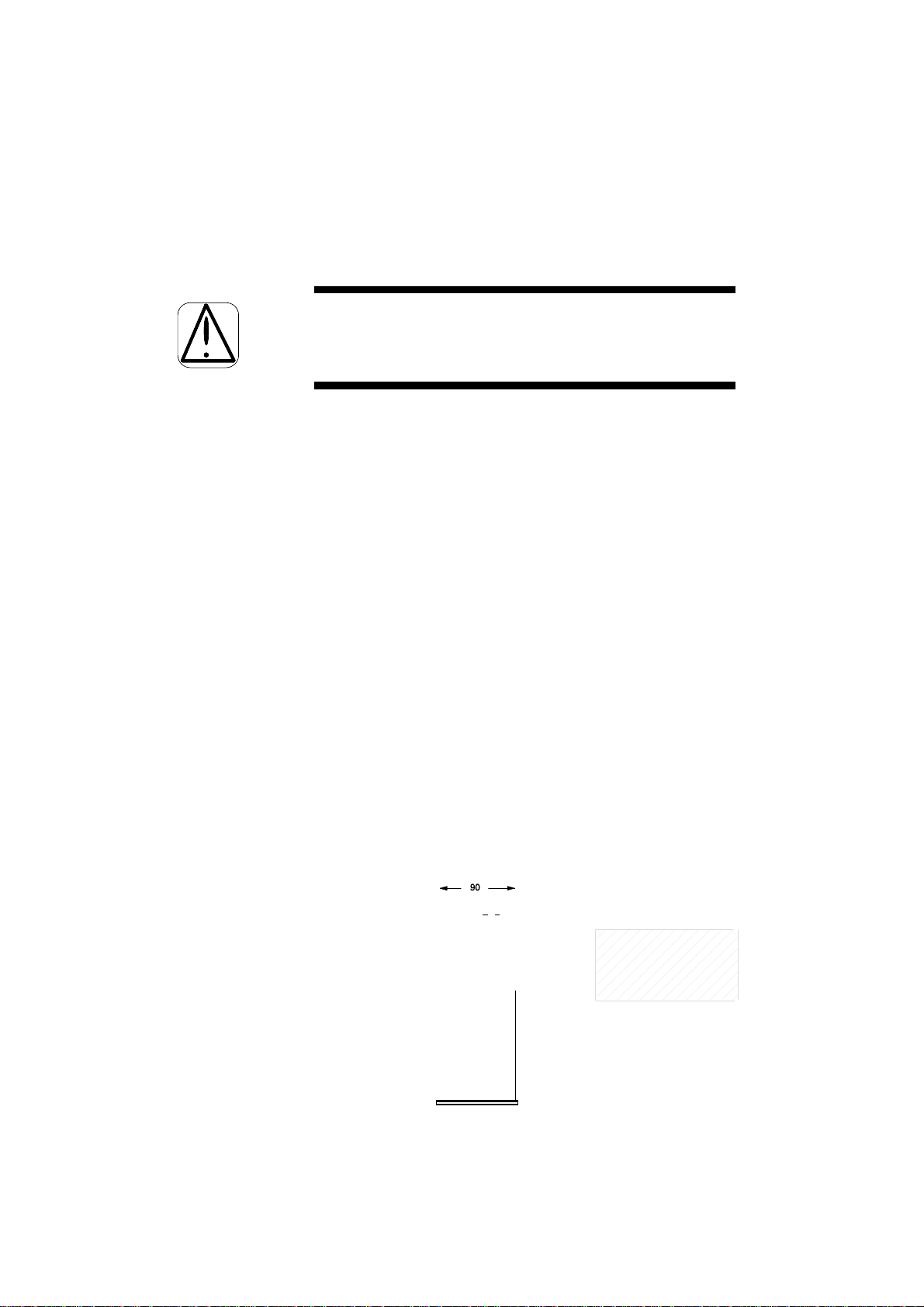

4.3 SWITCHING ON THE BACK-UP BATTERY

The PR 1612/02 is equipped with a lithium

back-up battery for its RAM. It is switched

off upon delivery.

In order to save the data of the RAM

after having put the PR 1612/02 into

operation, the battery must be switched

on by closing solder link BAT on the

main board before calibration.

Refer also to part 5.5.2.

4.4 CONNECTION POSSIBILITIES

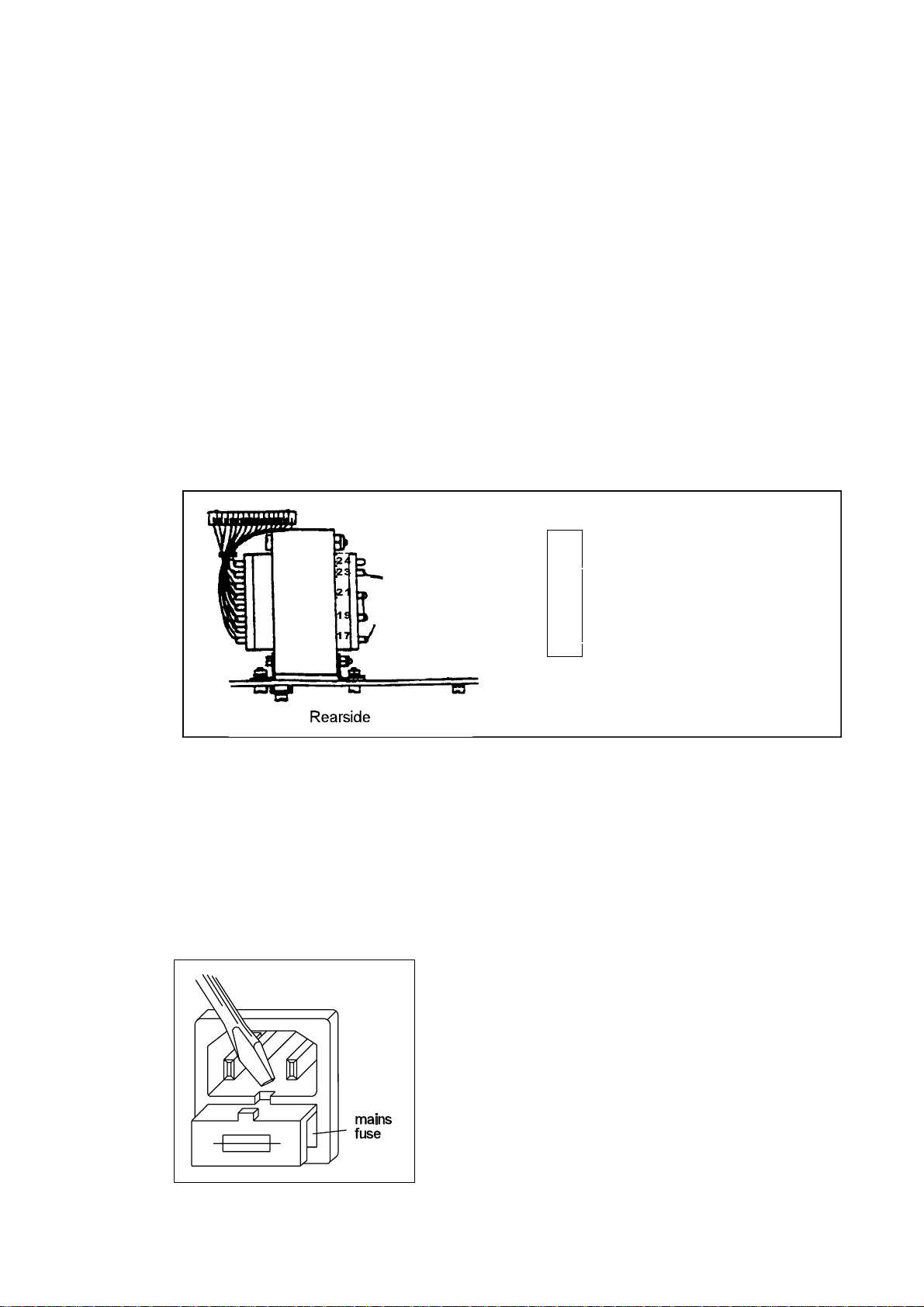

All connection facilities are located at the rear of the instrument.

OPERATING MANUAL PR 1612/02, Rel. $$ 2.30 Page: 4 - 3

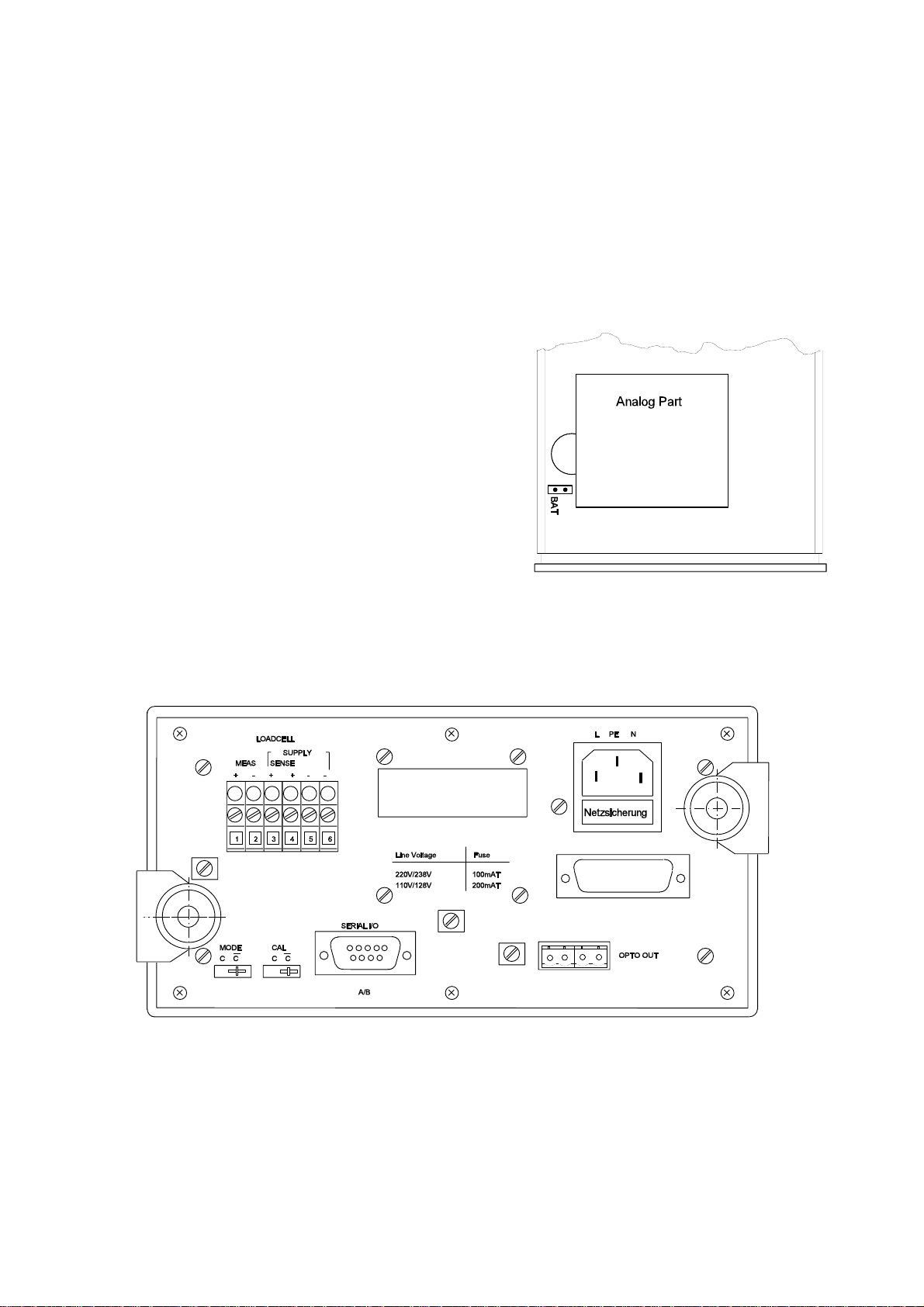

4.5 CONNECTION OF MAINS AND SUPPLY VOLTAGES

The PR 1612/02 is connected to the mains via the 3 -pole connector at the rear of the

instrument.

Please note that the instrument has no mains switch, and therefore, is ready for operation as

soon as the mains is connected.

The instrument operates at mains voltages of 110,128, 220 and 238 V AC and 50/60 Hz.

Upon delivery it is set to 220 V AC.

For changing of voltage, proceed as follows:

- disconnect the power,

- solder links on the transformer bobbin according to the following figure,

- replace the mains fuse inside the connector.

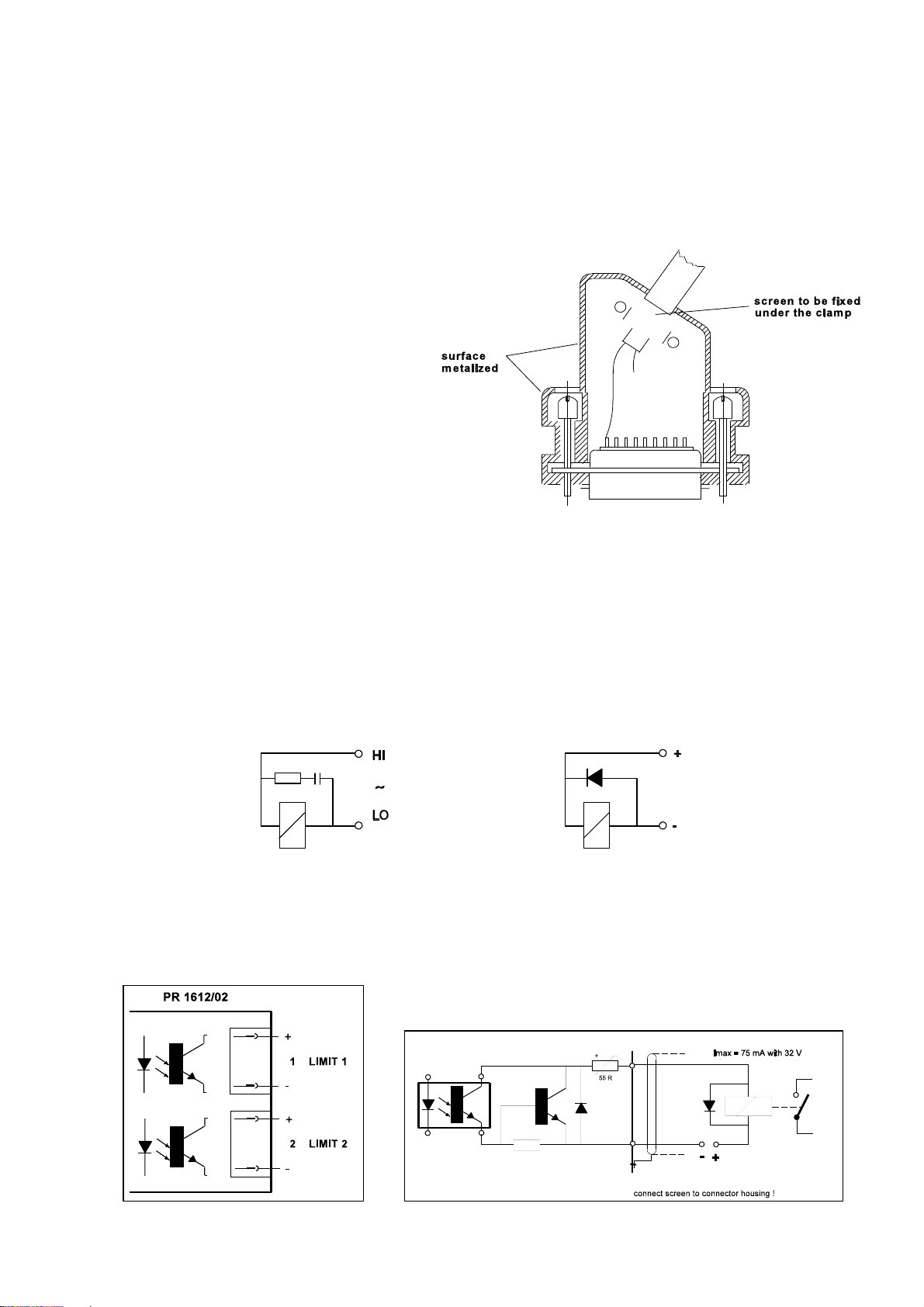

4.6 REPLACING FUSES

Before replacing fuses observe and follow the relevant safety instructions at para. 2.3 of this

manual .

The instrument is protected by means of a mains fuse which is located in the mains socket as

shown below.

nominal values service code number

------------------------------------------------------------110/128 V = 200 mA T 4822 070 32001

220/238 V = 100 mA T 4822 070 31001

OPERATING MANUAL PR 1612/02, Rel. $$ 2.30 Page: 4 - 4

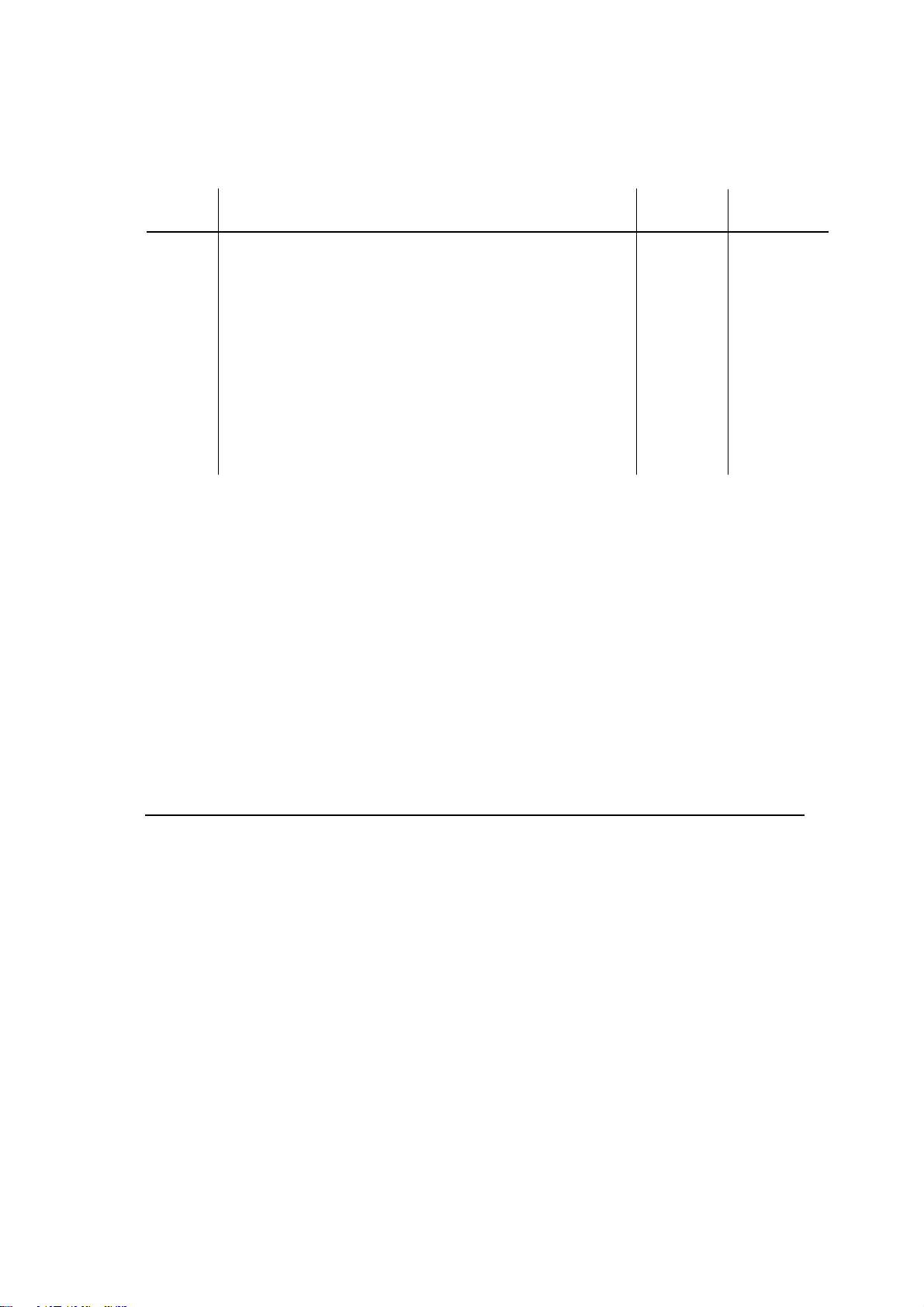

4.7 INSTALLATION INSTRUCTIONS FOR CONNECTING DATA CABLES

All cables transferring measuring

data and control signals must be

kept away from power cables and

should be screened.

The screen must be connected

to the housing of the connector

(see fig. below), or to the clamps

at the rear plate.

Relays and circuit breakers connected to the weighing system have to be spark suppressed as

follows:

- AC relays by means of an R-C combination (R = 100...300

parallel and as near as possible to the relay coil;

- DC relays by a reverse biased spark suppressing diode (e.g. BYX 10) connected in reverse

direction and in parallel and as near as possible to the relay coil.

4.9 CONTROL OUTPUTS

S, C~ 0.3 µF), connected in

OPERATING MANUAL PR 1612/02, Rel. $$ 2.30 Page: 4 - 5

4.9 THE PARALLEL INTERFACE

The PR 1612/02 Weight Indicators has a parallel interface. It can be equipped with the

interface options PR 1606, PR 1608/00 or PR 1608/10 (see also part 1.4.2) via which

corresponding subordinate or supervisory systems like remote displays, printer, recorder,

computer, or PLC's can be connected.

Mounting the interface options has to be performed as follows:

- open the indicator as described in part 4.3,

- plug in the required interface module into the socket of the parallel interface according to

the advices in part 7, and

- during configuration set up the PR 1612/02 by means of parameter C10, C12, or C17

as described in part 6.

Connections are different from module to module and have to be made as described in part

7 of this manual.

4.10 THE SERIAL INTERFACE

The PR 1612/02 Weight Indicator has one serial interface, which can only be equipped

with one of the following interface options at the same time:

- PR 1601 (20 mA current loop), o r

- PR 1602 ( RS 232), o r

- PR 1604 (RS 422/485).

Via a.m. interfaces corresponding subordinate or supervisory systems like remote displays,

printer, recorder, computer, PLC's can be connected.

Mounting the interface options has to be performed as follows:

- open the indicator as described in part 4.3,

- plug in the required interface module into the socket of line 1(A) o r line 2(B)

according to the advices in part 7, and

- during configuration set up the PR 1612/02 by means of parameter C04 .. C06, C10,

C14 .. C16, and C20 as described in part 6.

4.10.1 Connections

Connecting the serial interface and the inserted option must be performed via the 9-pol.

connector (DB9) at the rear of the respective indicator.

Application examples are shown in part 7.

Note !

The interface modules can only be connected via the pins as drawn in the following sketch.

OPERATING MANUAL PR 1612/02, Rel. $$ 2.30 Page: 4 - 6

4.11 CONNECTING THE LOAD CELLS

When selecting loadcells for connecting to the PR 1612/02, mind the criteria as given under

part 6.5.1 .

The loadcells must be connected by observing the following hints:

• Interconnecting loadcells and indicator of industrial weighing systems with cables of a

diameter up to 3mm should be done by using the PR 6130/01 junction box.

Type PR 6130/11 should be used in case of W&M approved systems.

• Before and during installation work make sure that no moisture enters the cables or

connections, especially of the loadcells and extension (measuring) cables and the

junction box (e.g. by water puddles, etc.).

• The connection of loadcells has to be preferably performed in 6-wire technique. The

cable must be connected to the instrument as shown in the diagram below.

• The screen(s) of the measuring cable has (have) to be taken to ground only at one side,

at the indicator.

• For connecting cables with different colour codes consult the respective data sheet.

• The wire strands of the cable must be twisted. They should be fixed to the terminals

without having been tinned or they should be provided with an appropriate crimp-type

cable connection.

OPERATING MANUAL PR 1612/02, Rel. $$ 2.30 Page: 4 - 7

• The permissible length of the extension (measuring) cable between loadcell and indicator

depends largely on the local conditions. According to the technical data the total length

should not exceed 300m.

4.12 EARTHING AND POTENTIAL EQUALIZATION

4.12.1 Earthing

The PR 1612/02 is protected according to class I (protective earth) of the IEC 348 and/or

VDE 0411 regulations. The connection cable must contain a protective earth conductor

which has to be connected according to the respective local safety regulations.

4.12.2 Potential equalization

If a potential equalization conductor is required, it must be connected to one of the clamps at

the rear of the instrument.

The diameter of the wire between indicator and the main equipotential bonding conductor

should be

$ 4mm².

OPERATING MANUAL PR 1612/02, Rel. $$ 2.30 Page: 5 - 0

CONTENTS OF PART 5 Page

5. OPERATING 5-1

5.1 SWITCHING ON/OFF THE INSTRUMENT 5-1

5.1.1 Switching on 5-1

5.1.2 Switching off 5-2

5.2 DESCRIPTION OF THE OPERATING CONTROLS 5-3

5.2.1 Keyboard 5-3

5.2.2 Status indicators 5-4

5.2.3 Front panel 5-4

5.2.4 Functions of the keys 5-4

5.3 ANALOG TEST 5-5

5.4 IN CASE OF AN ERROR 5-5

5.4.1 Display modes 5-5

5.4.2 Error messages 5-5

5.4.2.1 Error messages generated by wrong operation

or defective components 5-5

5.4.2.2 Error messages after power-on 5-6

5.4.2.3 Possible error messages during calibration 5-7

5.4.2.4 Possible error messages on communication 5-8

5.4.3 General error conditions 5-8

5.5 WARM START/COLD START 5-9

5.5.1 Warm start 5-10

5.5.2 Cold start (initial clear) 5-10

5.6 REPLACING FUSES 5-11

OPERATING MANUAL PR 1612/02, Rel. $$ 2.30 Page: 5 - 1

5. O P E R A T I N G

5.1 SWITCHING ON/OFF THE INSTRUMENT

5.1.1 Switching on

CAUTION !

Since the PR 1612/02 indicator has got no mains switch it can be operated and set-up as

soon as the mains voltage is applied.

The instrument is protected by a mains fuse which is located in the housing of the mains

connector (see page 4-3).

Before the PR 1612/02/00 is switched on for the first time, mains voltage adaptation and

installation must be finished (see part 4).

Therefore, check

• if the mains voltage adjustment is correct (see part 4.5),

• if all connections are correct (see parts 4.4 and following),

• if the back-up battery is switched on (see part 4.3)

After switching on, the indicator performs an internal test at first.

In case of a defect or a malfunction the PR 1612/02 generates a corresponding error

message.

An explanation of the particular messages can be found in part 5.4.

As part of the test the PR 1612/02 switches on all segments at its weight display module

during approx. two seconds.

If the internal test is completed successfully, the display shows for some seconds the type of

indicator.

For example:

PR 1612

Then, for a couple of seconds, it shows the type of software inserted.

For example:

00-2=30

If enabled by means of a licence number, the corresponding 'SW-option' will be displayed

now.

For example:

13=05

OPERATING MANUAL PR 1612/02, Rel. $$ 2.30 Page: 5 - 2

Thereafter, the program changes the weight value display over to the

NORMAL WEIGHING MODE.

For example:

Symbol appears as soon as the weight does not change any more (standstill display).

After about 60 minutes warm-up time, set-up and/or calibration work may begin.

5.1.2 Switching off

With obvious defects of the instrument, or with repairs/changes, the mains supply voltage

must be disconnected by removing the mains connector.

In case of trouble, e.g. with the communication to superordinate or subordinate system

components interrupted or blocked, we recommend interrupting the mains (supply) voltage

in order to carry out a "warm" or "cold" start (refer to part 5.5).

00654kg

OPERATING MANUAL PR 1612/02, Rel. $$ 2.30 Page: 5 - 3

5.2 DESCRIPTION OF THE OPERATING CONTROLS

5.2.1 Keyboard

KEY REMARK

TEST

Pressing causes an analog self-check, dependent of selected check mode

either a

- display of an analog test figure, or

- display of the difference between F.S.D. and analog test number, or

- the checksum of the EEPROM.

GROSS MODE

Switches display to gross weight as long as key is pressed.

The gross weight display will be confirmed additionally by status indicator B.

TARE MODE

Switches display to tare as long as key pressed and provided it has

previously been tared. This will be confirmed by a lit status indicator T.

When releasing the key again, the actual net weight will be displayed,

confirmed by lit status indicator NET.

SET TARE

Pressing moves the actual gross weight into the tare memory (taring),

provided that:

- the weight is in 'standstill', and the weight value is 'in range', i.e.

< f.s.d. and > 0,

- the instrument is not in failure mode, and

- a test has not been activated.

Consequently, the weight display changes automatically to NET mode,

indicated by lit status indicators NET .

RESET TARE

Pressing clears the tare memory and switches the display to gross weight

display.

ZERO

Pressing sets the gross weight to zero with an accuracy of ±1/4d, provided

the weight is in standstill mode,

- the gross weight is in the ZERO SET RANGE (selectable up to +/- 255d),

i. e. the centre-of-zero status indicator is lit.

PRINT

Print weighing document (configurable via parameter C10, C15 and C22).

OPERATING MANUAL PR 1612/02, Rel. $$ 2.30 Page: 5 - 4

5.2.2 Status indicators

for centre of zero indication, (within ± 1/4 d)

standstill

B gross on display

NET net on display

T tare on display

5.2.3 Fron t panel

5.2.4 Functions of the keys

The 7 keys below the weight value display have set-up function in addition to the operating

function.

Please note:

A page with adhesive strips on which the additional functions of the keys are marked in

various languages is included in this Instruction Manual.

If required, cut a strip in the required language, fit it below the keys and remove it after

adjustment (configuration).

OPERATING MANUAL PR 1612/02, Rel. $$ 2.30 Page: 5 - 5

5.3. ANALOG TEST

During CALIBRATION of the indicator, an analog test value will be automatically determined

and stored in the EEPROM (C46. .C49) . This value should also be written down (see also

C58) in order to be able to compare it with the current test value.

When the analog test is activated, the measuring signal of the load cells will be

disconnected from the input of the instrument.

If the test is performed by pressing key the display will show the following values,

depending on the initiated type of test:

a. either the current test value (which is to be compared with the original value),

or

b. the difference between the originally stored test value and the current test value,

or

c. a checksum of the EEPROM (required inter alia for Switzerland ).

If the test is automatically activated, it will be repeated after a period of 1 to 24 hours that

can be preselected during calibration.

In case of an error, the test will be continuously repeated. If the deviation will still be too

great, the instrument must be switched off and the Customer Support of the local

Organization of Philips Weighing must be informed.

5.4 IN CASE OF AN ERROR

5.4.1 Display modes

5.4.2 Error messages

5.4.2.1 Error messages generated by wrong operation or defective components.

They will automatically be indicated, or when selecting parameter C29.

Display via parameter C29 e.g.

K02 ,A=0

OPERATING MANUAL PR 1612/02, Rel. $$ 2.30 Page: 5 - 6

Error code standard RAM EPROM EEPROM

H= 00

H= 01 X

H= 02 X

H= 03 X X

H= 04 X

H= 05 X X

H= 06 X X

H= 07 X X X X = faulty

Error code cause / meaning

A = 1 (Err 1) Internal number domain overflow, e.g. by wrong calibration, by the input

voltage being too high, or because of a checksum error in a total weight

buffer.

A = 2 (Err 2) Measuring value higher than f.s.d. + overload.

A = 3 (Err 3) Hardware error in the ADC (e.g. open measuring input or analog circuit

disconnected from digital circuit, or analog circuit without voltage supply).

A = 4 (Err 4) Checksum error during A/D conversion.

A = 5 (Err 5) Internal number domain underflow, e.g. by wrong calibration, or by the in-

put voltage being too low.

A = 6 (Err 6) Overload of the ADC (measuring voltage too high or wrong SPAN adjust-

ment).

A = 7 (Err 7) Negative input voltage at ADC (wrong polarity of the measuring voltage).

A display of

indicates that the actual board number in parameter C82 has been reset.

Please contact the Customer Support of your local Philips Weighing Organization.

5.4.2.2 Error messages after power-on

A display of

indicates lost RAM data, because:

- battery not switched on via link BAT, or

- battery low voltage (should be > 3V), or

- battery defective, or

- of a program(EPROM) change, or

- of external disturbances.

Refer to hints in part 5.5.

no Dat

(OLD !!

OPERATING MANUAL PR 1612/02, Rel. $$ 2.30 Page: 5 - 7

A display of bat

for approx. 6 seconds after power-on

indicates that the back-up battery has either not been switched-on, or that its voltage is too

low, i.e. there is a risk of data loss.

The battery voltage has to be checked from time to time, or has to be checked by the

Customer Support of the local Organization of Philips Weighing in connection with a system

test.

If necessary, the battery must be replaced and to be disposed of acc. to the official

regulations.

A display of

indicates an interrupted access to the board number.

Please contact the Customer Support of your local Organization of Philips Weighing

immediately, as the possibly activated SW option PR 1613/05 can not be used any more.

A display of

indicates a malfunctioning or a physical defect of

the inserted EEPROM. Please contact the Customer Support of your local Organization of

Philips Weighing.

5.4.2.3 Possible error messages during calibration

A display of

indicates one of the following possible calibration errors:

Display Remark with: in step:

CErr 1 step: C35 }

error: entered CAL weight > f.s.d. }

e.g. f.s.d. = 1500 kg }

cal. weight = 2000 kg }

CErr 2 error: meas. signal too low for calibration }

(< 0.2mV). }

CErr 3 step: C35 } NEXT weighing

error: meas. signal too high. Sum of deadload } STEP mode

signal and determined meas. signal are }

out of scale, or }

step: C37 }

error: zero point correction too far in pos. }

direction. With maximum meas. input }

the scale range will be exceeded. }

board !!

EEPROA!!

(Err

proceed instrument

}

}

OPERATING MANUAL PR 1612/02, Rel. $$ 2.30 Page: 5 - 8

proceed instrument

Display Remark with: in step:

CErr 4 stop: C35 }

error: too less measuring voltage per scale }

step, i.e. desired resolution too high. }

} NEXT weighing

CErr 5 error: no standstill during calibration } STEP mode

}

CErr 8 step: C35 }

error: resolution too high (see also 6.5.2) }

CErr 9 step: C83

error: wrong license number.

Only valid for SW-option PR 1613/05.

A display of

appears when a calibration with

a negative measuring signal will be started.

5.4.2.4 Possible error messages on communication

Refer to part 8.3.7.1

5.4.3 General error conditions

condition possible fault how to solve

Display totally dark • mains interruption check,

• mains fuse defective } mind hints in

• instrument defective } part 2

Display confused • RAM - error check battery,

• processor disturbed perform WARM-start,

• bad contacts contact Service

No communication to • wrong interface module }

supervisory or slave • wrong interface setting }

system(s) • no supply of the interfaces } check

• incorrect connection }

• bad contacts }

neg-adu

• protocols not properly see part 8.

• bad contacts check connectors/

terminals.

OPERATING MANUAL PR 1612/02, Rel. $$ 2.30 Page: 5 - 9

condition possible fault how to solve

Communication to • C04..C14 not properly set check

supervisory • hang-up due to external

or disturbances. perform WARM-start.

slave system(s) • protocols not properly see part 8.

disturbed • interface modules defective contact Service

Weight display • mechanical problems } check at pipes,

unstable at the } bellows, hoses and

weighing device } constrainers for dirt.

• bad connections } check connectors/

} terminals.

• not properly controlled air }

pressure conditions in } check valves

container and pipes }

• Ioadcell(s) defective contact Service

Changed zero point • mechanical modification } check and if so correct

at the weighing device } by means of C37

• Ioadcell(s) defective/overloaded contact Service

Weight display wrong • calibration data lost check position of switch

• not properly controlled air check valves, bellows,

pressure conditions in and

container pipes .

• calibration changed perform new calibration

• Ioadcell(s) defective contact Service

Set-up not possible • switch CAL not in position C check and correct

• code word in C21 enter correct one

5.5 WARM START / COLD START

A "WARM" or "COLD" start is always carried out when switching on the mains voltage.

Whether "WARM" or "COLD" start, depends on the position of switches CAL and MODE on

the instrument rear or bottom respectively.

CAL and the battery,

compare settings

by means of previous

print-out (C58).

During normal operation, switches MODE and CAL are normally in position

¯c.

OPERATING MANUAL PR 1612/02, Rel. $$ 2.30 Page: 5 - 10

5.5.1 Warm start

A "WARM START" is purposeful e.g. with the instrument processor stopped due to external

disturbances (display of Err..), or with the communication sequence to other system

components interrupted.

- MODE position:

- CAL position:

5.5.2 Cold start (initial clear)

- MODE position: C 1. INITIAL CLEAR, all data in RAM will be

- CAL position: C the instrument uses the default

For instance, a "COLD START" must be carried out with message

¯c instrument uses the configuration

¯c instrument uses the calibration

(old !!

displayed after instrument switch-on.

parameters entered last.

parameters stored last.

reset, and therefore

2. the instrument uses the default

configuration settings.

calibration settings.

This message indicates that RAM data are lost and that the instrument must be re-initialized

by means of a cold start.

Possible causes are e.g.:

- jumper BAT on the main board not fitted, i.e. the back-up battery for the RAM is not

connected (see following figure), and

the RAM data are therefore not protected.

- back-up battery is empty or back-up battery voltage too low (see part 5.4.2.2).

- software was changed (e.g. by EPROM replacement), or

- RAM data lost due to external influences.

A 'cold start' has to be performed as follows:

1. Open the instrument

2. Close jumper BAT

3. Select supply voltage for load cells (see chapter 6.5.1)

4. Close instrument

5. Switch MODE to position: C } default configuration parameters and

6. Switch CAL to position: C } default calibration parameters will be activated

7. Switch power-on

8. Switch MODE to position: ¯c

OPERATING MANUAL PR 1612/02, Rel. $$ 2.30 Page: 5 - 11

9. Perform calibration after 60 minutes warm-up time (see next pages).

10. Store the entered parameter, see chapter 6.6

11. Switch CAL to position: ¯c

12. Enter configuration parameter

Please note:

Very often malfunctions of the indicator can simply be removed by resetting the RAM.

For this

- move switch MODE to position C,

- keep switch CAL in position ¯c, and

- switch off/on the mains supply.

All data in the RAM will be reset to its initial state.

Performing this kind of cold start the calibration data in the EEPROM will not be influenced,

and consequently re-calibration will not be necessary.

5.6 REPLACING FUSES

Before replacing fuses follow the relevant instructions in parts 2.3 and 4.7 of this manual.

OPERATING MANUAL PR 1612/02, Rel. $$ 2.30 Page: 6 - 0

CONTENTS OF PART 6 Page

6. SETTING THE INDICATOR 6-1

6.1 PROCEDURE 6-1

6.1.1 Selecting the set-up level 6-1

6.1.2 Changing the parameter code 6-2

6.1.3 Changing the parameter-value 6-2

6.1.4 Display of the next parameter-code 6-2

6.1.5 Leaving the set-up level 6-2

6.1.6 Leaving the set-up level and storing the calibration data 6-2

6.2 SHORT SURVEY OF THE CONFIGURATION PARAMETERS 6-3

6.3 CONFIGURATION 6-3

6.3.1 Sequence 6-4

6.4 SHORT SURVEY OF THE CALIBRATION PARAMETER 6-10

6.5 CALIBRATION 6-10

6.5.1 Input signal range (loadcell rating) 6-10

6.5.1.1 How to determine the deadload signal 6-11

6.5.1.2 How to determine the measuring signal 6-11

6.5.1.3 How to set the loadcell supply voltage 6-11

6.5.2 Important advices for calibration 6-12

6.5.3 Calibration procedure 6-13

6.5.4 Calibration by means of calibration weights 6-16

6.5.5 Incremental calibration with make-up weights 6-18

6.5.6 Checking the linearity (accuracy) of the scale 6-20

6.5.7 Setting, modifying, or re-entering zero point, scale end, and

span value without calibration weights 6-20

6.5.7.1 Modific. of the zero point setting at an empty scale 6-21

6.5.7.2 Re-entering the last valid zero point setting at a

loaded scale 6-22

6.5.7.3 Re-entering the last valid scale end and span value

at a loaded scale 6-23

6.5.7.4 Setting zero point, scale end, and span value

without calibration weights 6-24

6.5.8 Continuation of the calibration procedure 6-26

6.6 PROTECTING/STORAGE OF ENTERED CALIBRATION DATA 6-33

6.7 SET-UP LIST (including of default values) 6-34

6.7.1 Print-out example of the default values 6-36

OPERATING MANUAL PR 1612/02, Rel. $$ 2.30 Page: 6 - 1

6. S E T T I N G T H E I N D I C A T O R

The indicator must be allowed to warm up during approx. 60 minutes

before any settings are carried out

Setting the PR 1612/02 indicator will be performed by means of:

- CONFIGURATION - parameters, and

- CALIBRATION - parameters.

CONFIGURATION parameters contain non-system-specific data stored in RAM.

The y a r e protected against mains failure by a back-up battery, the voltage of which must be

checked from time to time.

Configuration parameters can also be protected against operator error (write-protected) by a

code number in parameter C21. Data in parameter C01 (Year, date, and time) are not

protected.

CALIBRATION parameters contain system-specific data, which can be stored in an EEPROM

and thus be protected against mains failure.

Moreover they can be write protected when switch CAL at the instrument rear or bottom is in

position

¯c .

6.1 PROCEDURE

6.1.1 Selecting the set-up level

- move switch CAL and MODE to position C

- press keys EXIT and (B+T) simultaneously

- display of:

•

(01

OPERATING MANUAL PR 1612/02, Rel. $$ 2.30 Page: 6 - 2

6.1.2 Changing the parameter code

•

- display of e.g.

- change to the next parameter by pressing key NEXT STEP , or

- move directly to the next desired parameter by:

- position the cursor (indicated by flashing digit • ) by means of keys and

to the desired decade. If the cipher does not flash, parameter is possibly write- protected

(CAL on ¯c , or C21 coded).

- change parameter code by means of key or

- accept parameter code by pressing key NEXT STEP

6.1.3 Changing the parameter value

- display of e.g.

- position the cursor (indicated by flashing digit • ) by means of keys and

to the desired decade. If the digit does not flash, parameter is possibly write-protected

(CAL on ¯c , or C21 coded).

- select value by means of key or .

Repeat that for each digit position (decade).

(01

•

( 12,00

- accept parameter value by pressing key NEXT STEP .

6.1.4 Display of the next parameter code

- display of e.g.:

- start again at point 2 (6.1.2)

6.1.5 Leaving the set-up level

- press key EXIT in order to leave the set-up level

Note:

If switch CAL in pos.

if switch CAL in pos. C, follow hints at part 6.1.6.

6.1.6 Leaving the set-up level and

- after pressing key EXIT

¯c , the display changes immediately to the actual weight value,

storing the calibration data

•

(02

- during approx. 3 seconds display of:

Store ?

OPERATING MANUAL PR 1612/02, Rel. $$ 2.30 Page: 6 - 3

•

- then change to :

•

- using key modify into:

remaining on no means 'no storage of entered data' !

- press key EXIT

- display changes to:

- set switch CAL to position ¯c

6.2 SHORT SURVEY OF THE CONFIGURATION PARAMETER

C00 without function

C01 year, date, and time

C02 without function

C03 without function

C04° line 1/A Baudrate

C05° linie 1/A XON/XOFF

C06° line 1 7/8 databit and parity

C07 without function

C08 without function

C09 without function

C10° configuration of l/O data

C11 not used

C12° configuration of PR 1606 and

PR 1608

C13° provided for PR 1613/05 only

C14° remote display on/off

C15° configuration of print out

C16° setting number of weight ticket

C17° analog output of PR 1606,

C18 without function

C19 without function

C20° controlling a W&M approved printer

C21 write-protection code number

C22° instrument address A .. Z

C24° disable key functions

C25° limit 1, on value

C26° limit 1, off value

C27° limit 2, on value

C28° limit 2, off value

C29 error display

( no

( Yes

AlldAt

0/20mA (0/10V), or 4/20mA (2/10V)

° can be write-protected by a code number in parameter C21.

6.3 CONFIGURATION

In order to configure the instrument, no settings by means of switches must be carried out.

If it should not be possible to modify parameter values, they perhaps are write-protected by a

code number in parameter C21 (see also part. 6.3.1, C21).

By pressing keys B and T simultaneously, the program jumps from the normal weighing

mode to the set- up level and displays the first parameter C00 (see also parts. 6.1.1 to

6.1.6).

Select the required parameter and enter the desired values/data by pressing the keys as

specified below.

OPERATING MANUAL PR 1612/02, Rel. $$ 2.30 Page: 6 - 4

Selecting a specific parameter can also be done directly, i.e. independently of the order listed

below. For this, change the displayed parameter digit into the required one and press key

NEXT STEP ( ) .

After set-up, store the data according to the instruction in part 6.6 and protect them against

accidental alteration and mains failure by setting switch CAL into position

6.3.1 Sequence

Switch on back-up battery (refer to part 4.3)

press keys EXIT and (B+T) simultaneously, in order to change from weighing mode to

set-up level.

¯c.

•

display of e.g. parameter

(• means flashing digit)

press key NEXT STEP

YEAR, DATE, and TIME

press key NEXT STEP

display of :

enter actual year, e.g:

press key NEXT STEP

display of :

enter actual date in DD,MM, e.g.:

(00

•

(01

•

(y ====

•

(y 1996

•

(d ==.==

•

(d 28,05

press key NEXT STEP

display of :

enter actual time between 00,00 .. 23,59, e.g.:

press key NEXT STEP

unrealistic data will not be accepted!

•

(t ==,==

•

(t 19,15

OPERATING MANUAL PR 1612/02, Rel. $$ 2.30 Page: 6 - 5

•

LINE 1: BAUD RATE

press key NEXT STEP

Note:

If this parameter and the following ones are write-protected by means of a code number in

parameter C21, digit 4 does not flash. If so, select parameter C21 directly and enter the

correct code number.

In this case

display of parameter

press key NEXT STEP

enter correct code number

if correct, for some seconds display of: Good

if faulty, for some seconds display of: FAIL

Note !

If the correct number was lost or is not available

any more, contact your local Philips Weighing Customer Support.

(04

(21

When performing a 'cold start' (switch MODE in position C and power off/on), the code

number in C21 can be cleared, but

all previously entered data protecte by C21 are also reset to the default data.

For setting parameter C21, refer to the following procedure.

press key NEXT STEP

display of parameter

by means of keys and go back to parameter C04 and continue with the

configuration as follows:

Note:

Parameter marked with sign ° , will be write-protected if C21 is set accordingly.

(22

OPERATING MANUAL PR 1612/02, Rel. $$ 2.30 Page: 6 - 6

Parameter Function Data Default value

C04° line 1: baud rate 300 .. 9600 4800bd

C05° line 1: XON/XOFF 0=off, 1=on 0

C06° line 1: 7/8 bit and parity 0 = 7 / even 0

1 = 8 / even

2 = 7 / odd

3 = 8 / odd

4 = 7 / none

5 = 8 / none

C10° serial output functions 1 = printer via line 1(A) 1

(witout hand shake mode),

or

remote display via line 2(B)

2 = printer via line 2(B)

(with hand shake mode)

3 = Communication mode via line 1(A)

Note !

mode C10 C14 C15 C20 C53

---------------------------------------------------------------------------------------------printer without hand shake 1 off on on/off off

via line 1(A)

or

remote display via line 2(B) 1 on off off off

---------------------------------------------------------------------------------------------printer with hand shake 2 off on on/off off

via line 2(B)

---------------------------------------------------------------------------------------------communication 3 off off off on

via linie 1(A)

Parameter Function Data Default Value

C12° analog output 0 = output of gross value 0

of PR 1606, or 1 = output of net value

BCD output 2 = output of tare value

of PR 1608 3 = value as shown at front

display (G or N or T)

4 = absolute net values with sign

on SPM address 1.7.

5 = like 3, but with absolute

net value like 4.

Note !

When using the PR 1606:

- only an output signal of positive weight values will be generated,

- if the gross weight will be > f.s.d + Amax, or at the indication of ERR1, 2, 3,

or 6, the last valid output signal will be kept, until the value falls below a.m.

limits again.

OPERATING MANUAL PR 1612/02, Rel. $$ 2.30 Page: 6 - 7

- if the gross weight is < ±¼ d, or with the indication of ERR4, 5, or 7, the

output signal remains on 'zero' level signal as selected by C17, until < ±¼ d

will be exceeded again.

- after taring in output mode 1 and 3 (weight display and output signal = net)

the output signal will be kept at 'zero' level, if the net weight becomes

negative.

Parameter Function Data Default value

C13° not provided for standard PR 1612/02 software, only

for SW option PR 1613/05. Please refer to corresponding manual.

C14° type of remote display 0 = off 0

protocol 1 = PR 1577/..- protocol on

2 = PR 1627/PR 1628 protocol on

Note:

The remote display protocol runs only via an interface in

line 2 (B).

C15° configuration of the 0 = print out (00000) 41000

weighing ticket. 1 = print out of gross weight

The sequence of the 2 = print out of net weight

weight data can be 3 = print out of tare weight

defined and combined 4 = print out of date and time

as mentioned. 5 = print out of current ticket number

6 = CR/LF

7 = address of device 'A...B'

(observe C22)

Note:

- In order to print net and tare values, the PR 1612/02 must be tared

previously.

Examples of print out sequences (in W&M mode):

Configuration: 41000

26.03.1996 20:08 <01000 kg>N

Configuration: 41200

26.03.1996 20:10 <01000 kg>B <00600 kg>N

Configuration: 41230

26.03.1996 20:12 <01000 kg>B <00600 kg>N <01000 kg>T

Configuration: 41235

26.03.1996 20:08 <01000 kg>B <00600 kg>N <01000 kg>T #00001

OPERATING MANUAL PR 1612/02, Rel. $$ 2.30 Page: 6 - 8

Parameter Function Data Default value

C16 ° current number of 0 .. 65536 000000

weigt ticket, or

configuration parameter

for PR 1613/10.

The first print-out starts with the adjusted digit + 1.

C17° span of the analog 0..20 mA, 0..10 V = 0 0

output module PR 1606 4..20 mA, 2..10 V = 1

C18 without function

C19 without function

C20° W&M-approved 0 = off, 1 = on 0

printer on/off

C21 write-protection code 0001 .. 9999 0000

number 0000 = no write protection

Note:

- the write-protection will be activated after exit from the configuration level.

- if write-protected the parameter values will be displayed, but

cannot be modified.

- in case of need follow hints as mentioned before parameter C04.

C22° address of the A .. Z A

PR 1612/02 to a

printer or remote

display unit.

C23 not used

C24° disable key functions 0000 = all keys enabled 0000

0001 = analog test }

0002 = gross weight }

0004 = tare weight }

0008 = tare set }

0016 = tare reset } disabled

0032 = zero setting }

0064 = print }

0128 = B+T }

0256 = without function }

e.g. 0097 = (1+32+64) = functions 'analog test + zero setting + print' will be

disabled.

Note:

Disabled key functions can be released by a 'cold start'.

C25 .. 28° Limit values "LIM1/LIM2"

(For connections refer to part 4.11.2)

OPERATING MANUAL PR 1612/02, Rel. $$ 2.30 Page: 6 - 9

Note:

If the on value is set equal to off value, the following switching conditions

are valid:

• LIMIT 1 output is active if weight > set value

• LIMIT 1 output is switched off if weight

• LIMIT 2 output is active if weight < set value

• LIMIT 2 output is switched off if weight

# set value

$ set value

Parameter Function Data Default value

C25° Alarm switch-on 00000 (off) .. scale end value 00000

threshold for

limit value 1 (LIM 1)

C26° Alarm switch-off 00000 (off) .. scale end value 00000

threshold for

limit value 1 (LIM 1)

C27° Alarm switch-on 00000 (off).. scale end value 00000

threshold for limit

value 2 (LIM 2)

C28° Alarm switch-off 00000 (off) .. scale end value 00000

threshold for limit

value 2 (LIM 2)

C29 Error messages (see Part 5.4.2.1) H00, A=0

Should the set-up level have to be left after having finished the configuration, press key

B (EXIT) instead of key (NEXT STEP).

The display moves automatically to the normal weighing mode.

Switch MODE (and CAL) must be set to position

¯c after having left the set-up level !

OPERATING MANUAL PR 1612/02, Rel. $$ 2.30 Page: 6 - 10

6.4 SHORT SURVEY OF THE CALIBRATION PARAMETERS

C30° Decimal point C51° Min. weight limit for print-out

C31° Dimension kg/t/g/lb C52° Switch-over point of a multi-range scale

C32° Step width C53° Communication protocol

C33° Overload value C54° Slave address for communication mode

C34° Measuring time C55° Weights & measures operation

C35° Measuring range C56° without function

C36° Display multiplied by 10, magnifier C57° Analog filter

C37° Deadload suppression without C58 Configuration and calibration parameter

re-calibration print-out

C38° Deadload suppression by mV/V- C59° Multi-range scale in gross/net mode

setting

C39° Calibration by mV/V-setting C80 Display of the already used part of

C40° Standstill range the 'zero setting range' C42.

C41° Standstill time C82 Display of the 'board number'.

C42° Zero setting range C83 Entry of PR 1613/05 licence number

C43° Automatic zero tracking range C84 Reset of Licence number(s)

C44° Automatic zero tracking step width C85 without function

C45° Autom. zero tracking interval time C86 without function

C46° TEST-mode of analog-test, C90..95 without function

C47° TEST-key function C96 Test number for factory-internal use

C48° Tolerance of test value C99 Display of all enabled SW versions

C49° Repetition time for an autom. test

C50° Generation of test value for an

automatic test

° will be write-protected by setting switch CAL to position ¯c , and by a code number in C21

6.5 CALIBRATION

6.5.1 Input signal range (loadcell rating)

When selecting the loadcell(s) mind the following rating criteria:

• the PR 1612/02 can be set for 12 V or 20 V loadcell supply voltage (refer to 6.5.1.3),

• the signal from the loadcells (dead load signal plus measuring signal) may be 36mV at

maximum,

• for OIML class C3 (Ill) the minimum measuring signal must be

2.4 mV with 12V loadcell supply voltage, or

6.0 mV with 20V loadcell supply voltage.

With PHILIPS load cells which are not installed in a hazardous area it is recommended to

use a 20 V loadcell supply, provided the 36 mV input signal will not be exceeded.

CAUTION !