...

•·

'

HFGenerator 100kHz-110MHz

PM5324

9452 053 240.l

9499 450 05411

73050l/ l/Ol

PHILIPS

Operating manual

HFGenerator 100 kHz-110MHz PM5324

9452 053 240.1

9499 450 CJS4l l

730501 /l/01

2

Important

In correspondence concerning this instrument please quote the type number and the serial number as given

on the type plate at the rear of the instrument.

© N.V. PHILIPS' GLOEILAMPENFABBIEKEN · EINDHOVEN - THE NETHERLANDS· 1973

3

Contents

1. GENERAL

4

1.1. INTRODUCTION

4

1.2. TECHNICAL

5

1.2.1. HF-Generator

5

1.2.2.

Modulation

5

1.2.3.

Calibration

6

1.2.4.

Supply

6

1.2.5.

Temperature range

7

1.2.6. Mechanical data

7

1.3. ACCESSORIES

7

1.3.1.

Included as standard

7

1.3.2.

Optional

7

1.4. DESCRIPTION OF THE BLOCK DIAGRAM

8

2.

DIRECTIONS FOR USE

10

2.1.

INSTALLATION

10

2.1.1.

Position

10

2.1.2. Connection to the mains

10

2.1.3.

Earthing

10

2.2.

OPERATION

11

2.2.1. Switching on

I

'l

2.2.2. Adjusting the frequency

11

2.2.3.

Adjusting the mode

11

2.2.4. Application

11

2.2.4.1. Unmodulated HF·signal generator

2.2.4.2. Amplitude-modulated (AM)

HF-signalgenerator

i .."'

2.2.4.3. Frequency-modulated (FM)

HF-signalgenerator

13

2.2.4.4.

Wobble generator

13

2.2.4.5.

Calibration

i

4

2.2.4.6. 1 kHz-Generator

·1.1

3.

LIST OF PARTS

15

4

1. GENERAL

1.1. Introduction

AM-FM-Generator PM 5324 produces unmodulated and modulated HF-Signals. It is very useful in radio-servicing

and in technical education.

The frequency range is from 0.1 MHz to 110 MHz in 9 sub-ranges.

Fine adjustment of the frequency is effected on a large, illuminated, easv-to-read linear scale. The range which

is in use and the scale to be read is indicated by means of LEDs. The output voltage is electronically stabilised

and is continuously adjustable.

The AM-FM-Generator may also be used in the frequency range from 150 MHz to 220 MHz, e.g. in band Ill

as a test generator for television sets, or as a generator in the frequency range for taxi-transmission.

With an internal X·tal oscillator the frequency of the generator can be checked and, if necessary, adjusted.

5

1.2. Technical data

General

- Alternative voltages are stated as r.m.s. values.

- Only values with tolerances and or numerical values are guaranteed.

- Deviations (in% or ppm) apply to the adjusted value.

- Temperature coefficients apply within temperature range.

- All specifications are met after a warming-up time of30minutes.

1.2.1. HF-GENERATOR

Frequency range

0.1 MHz up to 110 MHz

9

ranges:

0.1 ...

0.3 MHz

0.3 ...

1 MHz

1

...

3

MHz

3

...

10

MHz

10 ... 30

MHz

30

... BO

MHz

75

110 MHz

0.4

0.5

MHz

10.3 11.1MHz

Scale

Accuracy

Long-term stability

6 linear, illuminated scales

<

1.5%in the ranges 0.1 ...80MHz

<1

%

in range

75

110 MHz

<0.5

%

in range 0.4

0.5

MHz

<

0.2

%

in range 10.3 11.lMHz

<0.1

%

on calibrated points

<0.1

%

at:

~ nominal operating conditions

- mains voltage variations +10%,-15

%

- measured over7hours

Temperature coefficient

,,;;;5.2.10-4;oc

Output

HF

OUT

Frequencv-respor se

Connection : BNC connector

Output voltage:

50 mV into 75

~L,atunmodulated signal

O.lMHz ... 110 MHz

;;;;;3c1s

0.4 MHz...

0.5 MHz ( <

0_2

dB

10.3 MHz... 11

MHz

f

;;?-

60 dB,

continuous

for frequencies<

15 MHz; ;;,,

60 dB

Attenuator

1.2.2. MODULATION

Modes

unmodulated : all ranges

AM : all ranges

FM : range

75 ...

110 MHz and 10.3 ... 11.1 MHz

Wobble

: ranges

75 ...

110 MHz, 0.4 ... 0.5 MHz and

10.3 ... 11.1 MHz

Modulation frequency: 1 kHz (sine wave)

Modulation depth : 30

%

AM, internal

6

AM, external

FM, internal

FM, external

Wobble

1 kHz Output

Sweep output

1.2.3.CALIBRATION

Frequency

Error

Frequency distance of the calibration points

Zero beat indication

1.2.4. SUPPLY

Nominal mains voltage

Mains voltage deviation

Frequency

Consumption

Input· : via BNC connector LF IN

Modulation depth : > 70

%

Modulation coefficient : 0.2 V/10%AM

3 dB-Band width : 20 Hz ··- 20 kHz

Input impedance : 10 kn

Modulation frequency: 1 kHz (sine wave)

Sweep (Llf) : 25 kHz, at 10.7 MHz and 97 MHz

(dependent on freque.ncy)

Input : via BNC connector LF IN

Sweep (ll.t) : 75 kHz, at 10.7 MHz and 97 MHz

Modulation coefficient : 0.2 V/7.5 kHz at 10.7 MHz and

97 MHz (dependent on frequency)

: 20 Hz ·-· 60 kHz

: 10 kn

3

dB-Band width

Input impedance

Wobbulating sweep (2tif):

range 0.4 MHz 0.5 MHz, 0 ... 40 kHz at 450 kHz

range 10.3 MHz 11.3 MHz, 0 ... 600 kHz at rn.7 MHz

Wobble frequency: 25 Hz (sawtooth)

BNC connector; combined with sweep output

Voltage : 2 V

Frequency :1kHz (sine wave)

Impedance :1kD

BNC connector; combined with 1 kHz output

Voltage : 10 Vp-p

Frequency : 25 Hz (saw

tooth]

Impedance :1kD

10 MHz }

1 MHz

0.1 MHz

<0.02

%

spectrum with at least 10 harmonics

for every frequency

Range :

Distance

0.1 ...

0.3 MHz

0.1 MHz

0.3 ...

1

MHz

0.1

MHz

3

MHz 1

MHz

3

...

10

MHz 1

MHz

10

30 MHz 10 MHz

30

... 80

MHz 10 MHz

75

... 110

MHz

10

MHz

0.4 ....

0.5 MHz

0. 1

MHz

10.3 ...J11.1 MHz

'

0.1 MHz

By moving coil instrument, illuminated when button CAL.

is pressed

220

v

Also possible 110 V, 128 V, 202 V and 233 V

+10%,-15

%

48 ... 60 Hz

11W,13VA

1.2.5. TEMPERATURE RANGE

Reference temperature

Temperature tolerance range

Storage temperature

1.2.6. MECHANICAL DATA

Dimensions

Weight

1.3. Accessories

1.3.1. INCLUDED AS STANDARD

- Mains cable

- Directions for use

1.3.2.OPTIONAL

- Coax

cable

BNc-2

x 4 mm

PM9072

- Coax

cable

BNC-BNC,

75.nPM 9075

- Impedance transformer PM9537

7

+25

°c

+5

°c ...

+40

°c

-40

°c ...

+70

°c

Height : 192

mm

Width : 287

mm

Depth : 290 mm

5 kg

8

1.4. Description of the block diagram

The frequency of the generator is determined

by

an HF-oscillator the amplitude of which is electronically

stabilised. Frequency rs.1ges are selected with push-button MHz. With in the selected range the frequency can

be adjusted continuously by control F REOUENCY.

A frequency-modulator provides voltage-controlled frequency modulation ot the HF-oscillator· e.g. for

wobbulating purposes· in the ranges 75 MHz ...

110

MHz, 0.4 MHz ... 0.5 MHz and

10.3

MHz ...

11.1

MHz

(/\IVV).

In the amplitude-modulator the amplitude of the HF-signal can be modulated in all frequency ranges and the

HF-signal blanked during fly-back at mode WOB

VV).

The HF-output stage amplifies the power of the HF-signal, the amplitude of which is adjustable continuously

with attenuator HF AMPLITUDE.

The output signal is available at connector HF OUT; the output impedance amounts to 75

n.

If button CAL. is pressed an X.tal controlled calibration oscillator produces harmonics to check the

calibration of the scale. The markers are at a distance of10MHz,1MHz or

0.1

MHz, depending on the

selected frequency range.

In the mixer the signals of the HF-output stage and of the calibration oscillator are mixed. The low-frequency

signal which is obtained at approximately equal frequencies of both signals is amplified, limited, rectified and

indicated by a moving coil meter. If the HF-frequency control is set at a calibration frequency, the indicator,

at exactly equal frequencies, indicates a sharp, limited minimum between two tull scales. (Fig.

l).

A 1 k+iz-sine wave signal, produced by a 1 kHz oscillator, is used for amplitude· or frequency modulation

and selected by push-buttons AM or FM. The1kHz signal is also available at connector1kHz/SWEEP OlJT

if button WOB has not been depressed. If button AM EXT. or FM EXT. has been depressed the HF-signal can

be modulated by an external signal supplied to connector LF IN.

If button WOB has been depressed, a saw-tooth signal, produced by a saw-tooth generator, is supplied to the

frequency modulator. The sweep of the frequency can be adjusted by potentiometer SWEEP WIDTH. At the

same time the saw-tooth signal with constant amplitude is available at connector1kHz/SWEEP OUT.

A square-wave pulse derived from the saw-tooth signal blanks the output stage dur mg tlv-back.

The supply section delivers two stabilised direct voltages

(-12

V and

-18

VI and an alternating voltage for

illumination of the scale.

9

1HF<1CAL.

t

HF>fCAL.

Fig. 1. Zero beat indication

I

M~zIIF~EQUENCY \ \c~L

I

J

HF AM,F'LITUDE

I

I I I I

I I I I

~-·-··----··-:-·--~-.-.-·-..··-:-··-··-·-··-·11-:-·..--,

I

r---,----t----1-------,

r--------------,

1

1

I I I

I I I

INDICATOR

I

I

I

I

DISPLAYUNIT

I I

CALIBRATION MIXER

l I

I FOR

THE

I I

OSCILlATOR /

l ,

: I

APPLIED

I

I

DECIMAL LIMITER

I

I

I

I

SCALE

I I

DIVIDER RECTIFIER

I ,

I I I I •

: I I I I

I

I

l I I I .

AMPLITUD£- I

I

F'REOUENCV MODULATOR/ HF·OUTPUT

HF

• i.o:IJLATOR BLANKING AMPLWIER ATTENUATOR 0U1

' GATE

i

i

I

1kHzJSWEEP

....,1-==--__,3 __,

our'f]_ ' '

~--1---

--;-~----.:::r.:::--------:..

I

I

LI

J

WEEPSIGNAl,I~ - IB

v

FM EXT lkHz

1 ---

!kHz BLANKING _17

v

~OWER

1

I

GENERATOR PULSE. SUPPLV I

i=i

IN

lF

GENERATOR . OV

y

IN!l I :

~,A-M-EXT-./~1-kH~z

t-·-- - -

1

I

j

I

I .

• I

_j

L.·-··-·----··- ..

·-··-·-··---··-··-··-··-1-..

I I

I I

I l

[:@.'EEPWIDTH/

I

POWER

I

POWEP

Fig.2. Block diagram

10

2. DIRECTIONS f'OR USE

2.1. Installation

2.1.1. POSITION

The instrument may be used in any position except on its rear end. Make sure that the instrument is not

exposed to excessive heat.

2.1.2. CONNECTION TO THE MAINS

The instrument must have a.c. supply only. On delivery, it is set for a mains voltage of 220 V. Setting for a

different mains voltage is done as follows:

- Remove the left screw of the handle bar and take oft the left side-plate.

- Change the primary connections of the mains transformer according to Fig. 3, a diagram of which is in the

inside of side-plate.

- Change the mains voltage indication-plate at the rear.

- Refit the handle bar.

- Connect up the instrument.

2.1.3. EARTHING

The instrument must be earthed in accordance with the local safety regulations. The mains cable supplied is

provided with an earth core which is connected to the earth contacts of the mains plug. If the instrument is

connected to a mains socket with earth contacts, the cabinet isautomatically earthed.

The circuit earth of the instrument and the chassis-connection of the BNC-connectors are at chassis potential.

Earthing the instrument via the chassis-connection of the BNC-connectors is not permitted.

r

s

L4

i2

~i

v

.-220V-+-?

Fig. 3. Changingtheprimary connections of the mains transformer

11

2.2.

Operation

2.2.1.

SWITCHING ON

- Connect the instrument to a mains socket with earthing contacts.

- Switch on by means of switch POWER; the scale illumination lights up and a white field in the button-cap

shows that the mains switch is on.

2.2.2.

ADJUSTING THE

FREQUENCY

- Select the required frequency range with one of the range buttons MHz; the corresponding range-scale is

indicated by a LED at the left side of the scale window.

- Adjust to nominal frequency with potentiometer FREQUENCY.

2.2.3.

ADJUSTING THE

MODE

The mode isselectedbydepressing one of the6buttons in the left row of buttons.

If

no button has been pressed the generator supplies an unmodulated HF-signal with the adjusted frequency

and amplitude.

Buttons CAL., AM/EXT., AM/1 kHz, FM/EXT. and

FM/1

kHz unlock each other automatically, thus only

one button can be depressed at a time.

Button WOB. may be unlocked by pressing the button a second time, independently of the other buttons.

The mode-buttons may be combined with the frequency-range buttons according the table given below.

Range button

Mode button

(selectable)

(MHz)

CAL

AM

FM WOB

0.1 - 0.3

x

x

0.3 _ 1

x

x

3

x

x

3

- 10

x

x

10

- 30

x

x

30

- 80

x

x

75

- 110

x

x

x x

0.4 - 0.5

x

x x

10.3- , 1.,

x x

x

x

extra

WOB+AM

x

x

x

2.2.4. APPLICATION

2.2.4.1. Unmodulated

HF·signal

generator

- Depress the required range button MHz.

- The selected range scale is indicated by a LED.

- Set the pointer at the required frequency by means of potentiometer FREQUENCY.

Not marked frequency values should be interpolated between two marks.

- If necessary, calibrate the frequency at the nearest calibratlon-mark according to sub-para 2.2.4.5.

- Unlock the mode-buttons (left row of buttons).

- Apply the HF-signal, available at BNC connector HF OUT, across a cable to the object to be measured (see

accessories, chapter 1.3.).

- Adjust the required output voltage with potentiometer HF AMPLITUDE.

12

Fig. 4. Front view

Fig. 5. Rear view

13

2.2.4.2. Amplitude-modulated (AMI HF-signal generator

Internal

- Preliminary adjustment according to chap. 2.2.4. 1..

- Press button AM/1 kHz. The HF·signal is modulated in amplitude by 30%at an internal frequency of1kHz.

- For indications on checking and adjusting, see the individual checking and adjusting procedures for the

object to be measured or chapter 2.3 ..

External

- Preliminary adjustment according to chap. 2.2.4.1 ..

- Pressbutton AM/EXT.

- Supply the modulation voltage to connector LF IN; maximum 16 V peak-peak, maximum d.c. level ±12 V.

- External modulation frequency 20 Hz ... 20 kHz.

- Adjust the modulation depth by the amplitude of the modulation voltage; voltage necessary 0.2 V /10

%

ampIitude·modulation.

2.2.4.3. Frequencv-modulated (FM) HF·signal generator

Internal

- Press buttons 75 · 110 or 10.3 · 11.1 MHz.

The selected range scale is indicated by a LEO.

- Set the pointer at the required frequency by potentiometer FREOUENCY.

Not marked frequency values should be interpolated between two marks.

- It necessary, calibrate the frequency at the nearest calibratlon-rnark according to sub-para 2.2.4.5 ..

- Press button FM/1 kHz; the HF-signalismodulated in frequency by1kHz and a frequency sweep of about

25 kHz.

- Apply the signal, available at BNC connector HF OUT, across a cable to the object to be measured.

Isse accessories, chapter 1.3.).

- Adjust the required output voltage by means of potentiometer

HF

AMPLITUDE.

Note

When using harmonics the frequency sweep is multiplied by ~he order-number of the harmonics.

External

- Preliminary adjustment according to chap. 2.2.4.3 ..

- Press button FM/EXT.

- Supply the modulation voltage to

BNC

connector LF

IN;

maximum input voltage

70 V peakpeak.

- Adjust the external modulation frequency; 20 Hz ... 60 kHz.

- Adjust the modulation sweep with the external voltage; necessary voltage 0.2 V/7.5 kHz sweep (maximum

sweep75kHz).

- If

necessary, supply a multiplex-signal to

BNC

connector LF IN

2.2.4.4. Wobble generator

- Pressrange·button 75 ... 110 or 10.3 ... 11.1 MHz.

The selected range-scale is indicated by a LED.

- Set the pointer to the required frequency by potentiometer FREQUENCY.

Not marked frequency values should be interpolated.

- Press button WOB.

- Connect BNC-connector 1 kHz/SWEEP OUT to the X·input of an oscilloscope.

- Adjust the X-amplitude of the oscilloscope.

- Apply the wobbulated signal across a cable to the object to be tested.

14

- Set the band-pass curve at the middle of the picture with potentiometer FREQUENCY.

- Adjust the height of the band-pass curve with potentiometer HF AMPLITUDE.

- Adjust the width of the band-pass curve with potentiometer SWEEP WIDTH.

- Check the band-pass curve; if necessary, correct it. The effect of an adjustment can be determined

immediately on the band-pass curve.

Note

When using harmonics the frequency sweep is multiplied by the order number of the harmonics.

Determining the band width

By defined shifting in the horizontal direction the band width (at 70%of the height of the picture) can be

determined as follows:

- Position the point of intersection, e.g. of the right edge of the band-pass curve and a fictitions horizontal

line at 70%of the height of the curve on a prominent point on the graticule by means of potentiometer

FREQUENCY.

- Read the frequency at the scale and note the value.

- Shift the band-pass curve horizontally with potentiometer FREQUENCY so that the second edge is

positioned at the same flctitions point of intersection (at 70%of the height of the picture) asinthe first

adjustment.

- Read the frequency; the difference between the two frequencies is the band width.

Note

Use a d.c. indicator (oscilloscope or meter) so that the base line is horizontal and undistorted at a large

wobbu Iating-sweep.

2.2.4.5. Calibration

The calibration points are indicated on the scale by the symbolYor

A .

A moving coil meter, which is

illuminated at calibration mode, serves as indicator.

Checking

If a very accurate HF-signal, e.g. of 21.5 MHz is needed, this can be checked as follows:

- Switch on the instrument and wait at least 30 minutes for it to warm up.

- Depress range-button 10 - 30 MHz; the diode alongside the top scale will light up.

- Depress button CAL.; the indicator will light up. If necessary, unlock button WOB..

- Set the scale pointer to that calibration mark ( V at mark .2) which is nearest to the nominal value of 21.5 MHz.

- Set the scale pointer exactly on the minimum which lies between two full-scale deflections of the indicator.

- Check, that the line of the scale pointer corresponds to the calibration mark.

Calibration

If the line of the scale pointer is not exactly over the calibration mark calibrate as follows:

- Set the scale pointer exactly on the calibration mark.

- Hold the largest knob of control FREQUENCY with one hand.

- Adjust the smaller knob - against the resistance of the slipping clutch - to obtain the required minimum

(zero beat) between two maxima.

- Release the large button.

- Adjust for exact zero beat.

- Check that the line of the scale pointer corresponds to tHe calibration mark. Repeat the calibration procedure,

if necessary.

2.2.4.6. 1 kHz-Generator

- Release all push-buttons, especially button WOB.

- The 1 kHz-signal, with an amplitude of 2

Vr.m.s .•

is available at BNC-connector 1 kHz/SWEEP OUT.

15

List of parts

MECHANICAL

Item Fig.

Qty

Ordering number

Description

2 5322 460 60017

Ornamental strip

2

2

5322 460 60014

Ornamental surround

3

1 5322 414 74024

Knob, 0 18.7

4

1

5322 414 74025 Knob, 0 24

5

1

5322 414 74022

Knob cover

6

1 5322 447 94107

Securety cover

7

2

l

Washer handle-bracket

8

2

5322 310 10044

Handle-bracket screw

9

2

j

Handle bar

10

2 Screw for handle bar

11

1

5322 276 84034

Push-button switch

12

3

5322 267 10004

BNC-connector 851-853

13

2 5322 414 74021

Knob cover

14

2

5322414 74023 Knob, 0 18.7

15

1 5322 455 74022

Textplate

16

1

53?2 276 14128

Mains switch 801

17

1 5322 276 64009

Push-button switch 803

18

1

5322 450 84015

Pointer

19

1 5322 450 64041 Plexiglass window

20

4

5322 462 50101 Foot

21

4

5322 462 40157 Rubber stud

22

1

5322 492 6434 7 Spring

23

1

5322 265 30066 Mains input connector 854

24

1

5322 255 44064 Heat sink

25

1 5322 256 44065

Mica washer

26

1

4822 390 20023 Silicon grease

--~

27

1

5322 450 34022 Scale

28 1

5322 628 24057

Drive

29

1

5322 502 14083

Grub screw

30

1

5322 358 54039 Ball-cord

31 2

5322 522 34452 Return sheave

32 1 5322 321 10071 Mains cable

16

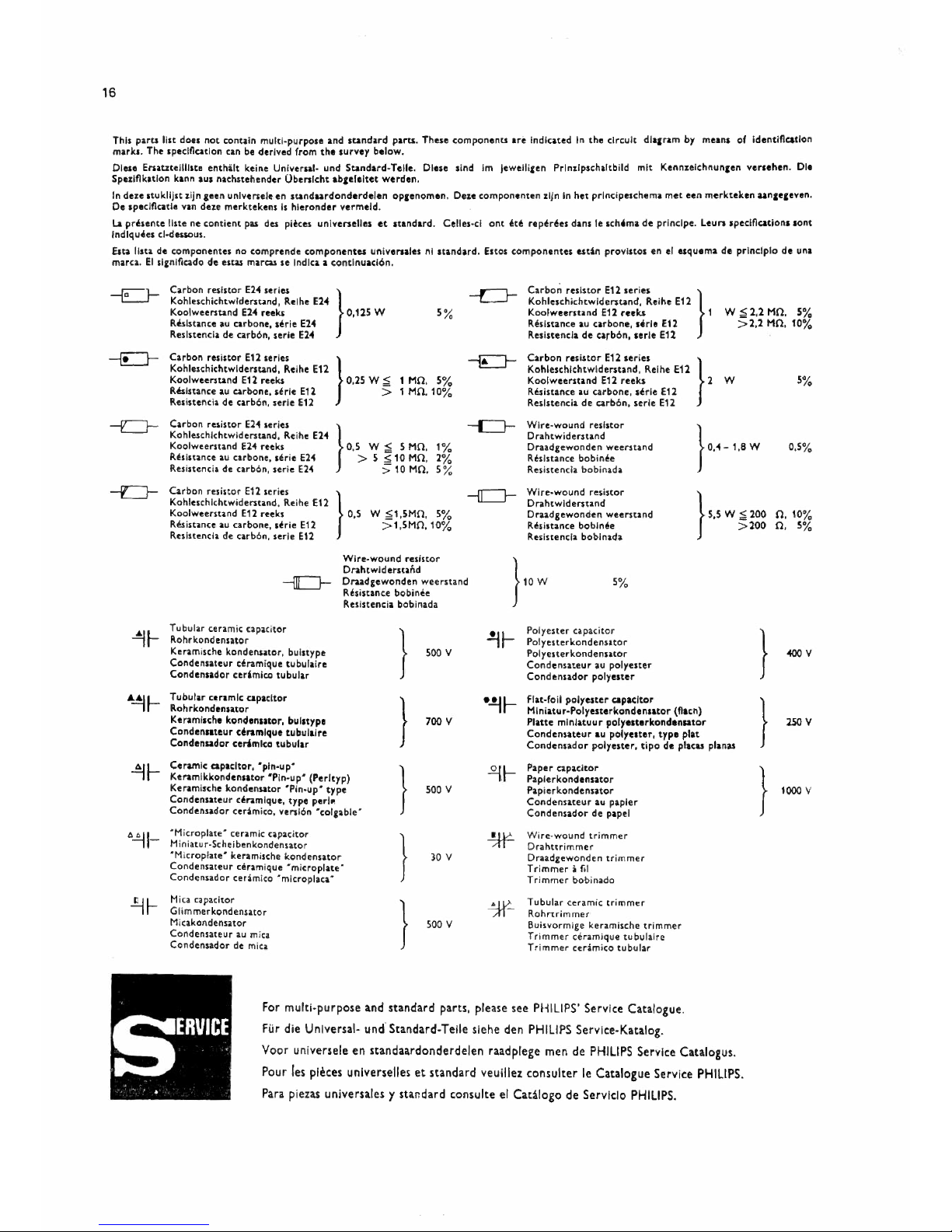

This parts list does not contain multi-purpose and standard parts. These components are Indicated In the circuit dla1rambymeans of ldentlflcitlon

marks. The specification can be derived from the survey below.

Dlese ErnuteJlllste enthalt keine Universal- und Standard-Telle. Dlese slnd Im jewell!gen Prlnilpschaltbild mlt Kenn:i:eichnuncen versehen, Die

Spe:i:lflkatlon kann aus nachstehnder Oberslcht ab1eleltet werden.

In deze stuklljst 1ijn geen unlversele en standurdonderdelen opgenomen. Deze componenten zljn In het prlnclpeschema met een merkteken aan1e1even.

De speclflcatla van

deze

merktekens Is hleronder vermeld.

La preHnte line ne contient pas des pieces unlverselles et standard. Celles-cl ont ete reperees dans le sch•ma de prlnclpe. Leurs speclncatlons sont

lndlquees cl-desseus.

Esta lista de componentes no comprende componentes unJversales nl standard. Estos componentes esttn provlstos en el esquema de princlplo de una

marca. El slgnlficado de estas marcas se lndica a conrtnuactcn.

-E}-

Carbon reslstcr El<H•lu }

-LJ-

C•• boO ~"00' E\l series }

Kohle"hichtwldersund, Reihe E2'4 Kohleschichtwlderstand, Reihe E12

Koolweerstand E2'4reeks 0,125 W

5%

Koolweersnnd E12 reeks 1

W ;:i:i2,2MO.

5%

Resistance au carbone, sl!rie E24 Resistance au carbone, sirie E12

>2,2 MO. 10%

Reslstenda de carbon, serle E2'4

fl.esistencia de carbon, serle E1l

--le}-

Carbon ml•~• E12 serles }

~

c••

boo mb•o' "'"''" }

Kohleschichtwiderstand, Reihe

E12

Kohleschichtwlderstand, Reihe E12

Koolweerstand E1l reeks

0,25 W;;;;:

1 Mn, 5% Koolweerstand E12 reeks

2

w

5%

Reslsnnce au carbone, drie E12 > 1MO.10%

Resistance au carbone, serle E12

Resistencia de carb6n, serte E12

Reslstencia de carb6n, serie E12

-C}--

Carbon reslstor El< "''" }

-ro-

Wire-wound resistor

}'·'- i.e

w

Kohleschichtwlderstand, Reihe EH

Drahtwiderstand

Koolweerstand EH reeks 0,5 W ;;;;: 5 MO, 1%

Draadgewonden weerstand

0,5%

Resistance au carbone, serie El-4 > 5 ~ 10 Mn, 2%

Resistance bobini!e

Resistencia de carbon, serie E24

>

10 MO. 5

%

Resistenda bobinada

~

Carbon resistor "'"''" }

--{C}-

Wire-wound resistor

Kohleschlchtwiderstand, Reihe E12

Drahtwlderstand

Koolweerstand E12reeks 0,S

W ~1,5MO,

5%

Draadgewonden weerstand

l

w '""

n, 10%

Resistance au carbone, st!rie E12

>1,SMn.10% Resistance boblnee

>200

n,

5%

Resistencla de carb6n, serle E12

Resistencla bobinada

Wire-wound resistor

Drahtwidersund

Draadgewonden weerstand

Rbistance boblnee

Resistencia bobinada

5%

~a-

Tubular ceramic capacitor

}

fl.ohrkondenntor

Keramische kondenntor, buistype

Condensateur ct!ramique tubulalre

Condensador cerimlco tubular

"'..!Jl--

Tubular ceramic capacitor

}

Rohrkondensator

Keramlsche konden11tor, buluype

Condensateur ceramlque tubulalre

Condensador cerimlco tubular

~l--

Ceramic capacitor, "pin-up·

}

Keramikkondenntot •Pin-up• (Perltyp)

Keramische kondensator "Pin-up• type

Condensateur ceramique, type perl~

Condensador cerimico, versl6n ·colgabie"

6-11-

'Micropiate" ceramic capacitor

}

Hin

iatu

r-Schei benkondensator

'Hlcrop!ate• keramische kondensator

Condensateur ceramique "mlcroplate "

Condensador ceramico "rnlcroplaca"

.!JI-

Hica capaclter

}

Gfimmerkondensator

Micakondensator

Condensateur au mica

Condensador de mica

500

v

Polyester capacitor

Poiyesterkondensator

Polyesterkondenntor

Condensateur au polyester

Condenudor polyester

"°°

v

}

700

v

flat-foil polyester capacitor

Mlniatur-Polyesterkondenutor (fiach)

Platte mlnlatuur polyesterkondensator

Condensateur au polyester, type plat

Condensador polyester, tipo de placas planas

250V

}

500

v

Paper capacitor

Paplerkendensatcr

Papierkondenntor

Condensateur au papier

Condensadot de papel

1000

v

}

30

v

Wire-wound trimmer

Drahttrimmer

Draadgewonden trimmer

TrimmeriIii

Trimmer bobinado

500

v

Tubular ceramic trimmer

R.ohrtrimmer

Buisvormige keramische trimmer

Trimmer ceramique tubulaire

Trimmer eerarntce tubular

For multi-purpose and standard parts, please see PHILIPS' Service Catalogue.

Fi.ir die Universal-

und

Standard-Telle slehe den PHILIPS

Servtce-Katalog.

Voor universele en standaardonderdelen raadplege men de PHILIPS Service Catalogus.

Pour !es pieces unlverselles et standard veulllez consulter le Catalogue Service PHILIPS.

Para piezas universalesystandard consulte el Catalogo de Servlclo PHILIPS.

17

Resistors

Item Orderingnumber

Vafue (fl)

%

Type

Description

601 5322 105 40007

75

25 0.1

w

HF-voltagedivider

602

5322 101 24012 22 k

Potentiometer

Unit 1

606 5322 116 50253 324

k

1

MR30

Metal film

607 5322 100 10088 220

k

20 0.1

w

Potentiometer

608

4822 100 10107 470 k

20

0.1

w

Potentiometer

609 5322 100 10088

220 k

20

0.1

w

Potentiometer

610 5322 116 54328

51

k 2

CR25

Carbon

612 5322 100 10036

4.7 k

20

0.1

w

Potentiometer

614 5322 116 50524

3 k 2

CR25 Carbon

616 5322 116 54328

51 k

2

CR25 Carbon

623 5322 116 54202

7.5 k 2

CR25 Carbon

626 5322 116 50095 510 k 2

CR25 Carbon

628 5322 116 54207 1 k 2

CR25 Carbon

630 5322 116 50752 1.5 k

2

CR25 Carbon

631

5322 100 10036

4.7 k 20

0.1

w

Potentiometer

663

5322 116 54188

1

M 1

MR30

Metal film

665 5322 116 54327 10 k

1 MR25

Metal film

666 5322 116 50726

36.5 k

1

MR25 Metal film

667 5322 116 50897 18.2 k

1 MR25 Metal film

668 5322 116 50666 73.2 k

1 MR25 Metal film

669 5322 116 50446 66.5 k 1

MR25 Metal film

Unit 2

601 5322 116 50524

3

k 2

CR25

Carbon

602

5322 116 54148 9.1 k

2

CR25

Carbon

603 5322 116 50859 91

k

2

CR25

Carbon

604 5322 116 54293 4.7 k

2

CR25 Carbon

605 5322 116 64147

3.9 k

2 CR25 Carbon

606 5322 116 54079 36 k 2

CR25

Carbon

607

5322 116 50872

62

k

2

CR25 Carbon

611 5322 11650747

l

k 2

CR25

Carbon

612 5322 116 50603

360 k

2

CR25

Carbon

614 5322 116 54405

750 k

2 CR25 Carbon

615

5322 116 54343

5.1 k

2

CR25 Carbon

616 5322 116 50747 1

k

2 CR25

Carbon

617 5322 116 50603

360

k

2

CR25

Carbon

621 5322 116 50309

24

k

2

CR25 Carbon

623

5322 116 54191

30

k

2

CR25

Carbon

624

5322 116 54171

2.2 k

2

CR25

Carbon

625 5322 116 54089

6.2 k 2

CR25

Carbon

629 5322 116 54343 5.1 k

2

CR25

Carbon

632

4822 100 10035 10 k 20 0.1

w

Potentiometer

635

5322 116 54001 15

k

1

MR25 Metal film

636

5322 116 54202 7.5 k 1

MR25

Metal film

638 4822 100 10029

2.2 k 20 0.1

w

Potentiometer

18

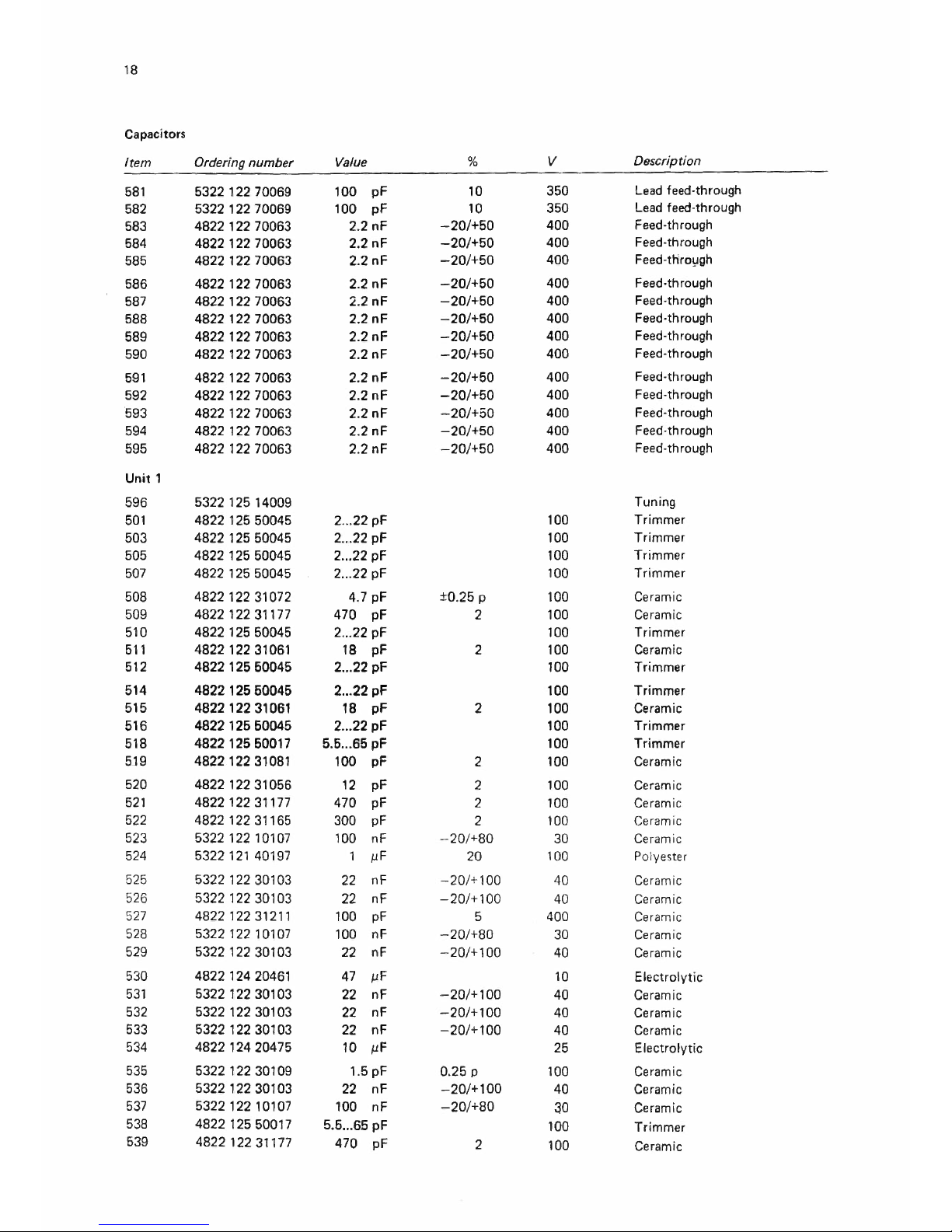

Capacitors

Item

Orderingnumber

Value

%

v

Description

581

5322 122 70069

100

pF

10

350

Lead feed-through

582

5322 122 70069 100

pF

10

350

Lead feed-through

583

4822 , 22 70063 2.2

nF

-20/+50

400

Feed-through

584 4822 122 70063 2.2

nF

-20/+50

400

Feed-through

585

4822 122 70063 2.2

nF

-20/+50

400

Feed-through

586

4822 , 22 70063 2.2

nF

-20/+50 400

Feed-through

587 4822 122 70063 2.2

nF

-20/+50

400

Feed· through

588

4822 122 70063 2.2

nF

-20/+50

400

Feed-through

589 4822 122 70063

2.2

nF

-20/+50

400

Feed-through

590

4822 122 70063

2.2

nF

-20/+50

400

Feed-through

591 4822 122 70063

2.2

nF

-20/+50

400

Feed· through

592

4822 122 70063

2.2

nF

-20/+50

400

Feed-through

593

4822 122 70063

2.2

nF

-20/+50

400

Feed-through

594 4822 122 70063

2.2

nF

-20/+50

400

Feed-through

595 4822 122 70063

2.2

nF

-20/+50

400

Feed-through

Unit 1

596

5322 125 14009

Tuning

501 4822 125 50045 2...22

pF

100

Trimmer

503

4822 125 50045 2...22

pF

100

Trimmer

505

4822 125 50045 2...22

pF

100

Trimmer

507

4822 ,25 50045

2...22

pF

100

Trimmer

508 4822 122 31072 4.7

pF

±0.25

p

100

Ceramic

509 4822 122 31177

470

pF

2

100

Ceramic

510

4822 125 50045 2...22

pF

100

Trimmer

511 4822 122 31061 18

pF

2 100

Ceramic

512 4822 125 60045

2...22

pF

100

Trimmer

514 4822 125 60045 2...22

pF

100

Trimmer

515 4822 122 31061

18

pF

2 100

Ceramic

516

4822 125 60045

2...22

pF

100

Trimmer

518 4822 125 50017 5.5...65

pF

100

Trimmer

5-19

4822 122 31081 100

pF

2

100

Ceramic

520

4822 12231056 12

pF

2 100

Ceramic

521 4822 122 31177

470

pF

2 100

Ceramic

522

4822122 31165 300

pF

2

100

Ceramic

523 5322 122 10107

100

nF

-20/+80

30

Ceramic

524 5322 121 40197

1

µF

20

100

Polyester

525

5322 122 30103

22

nF

-20/+100 40

Ceramic

526

5322 122 30103

22

nF

-20/+100

40

Ceramic

527

4822 122 31211

100

pF

5 400

Ceramic

528 5322 122 10107

100

nF

-20/+80 30

Ceramic

529

5322 12230103

22

nF

-20/+100

40

Ceramic

530

4822 124 20461

47

µF

10

Electrolytic

531 5322 122 30103

22

nF

-20/+100

40

Ceramic

532

5322 122 30103

22

nF

-20/+100 40

Ceramic

533

5322 122 30103 22

nF

-20/+100 40

Ceramic

534 4822 124 20475

10

µF

25

Electrolytic

535

5322 122 30109 1.5

pF

0.25 p

100

Ceramic

536 5322 122 30103

22

nF

-20/+100 40

Ceramic

537 5322 122 10107

100

nF

-20/+80

~o

Ceramic

538 4822 125 50017

5.5...65

pF

100

Trimmer

539

4822 122 31177

470

pF

2

100

Ceramic

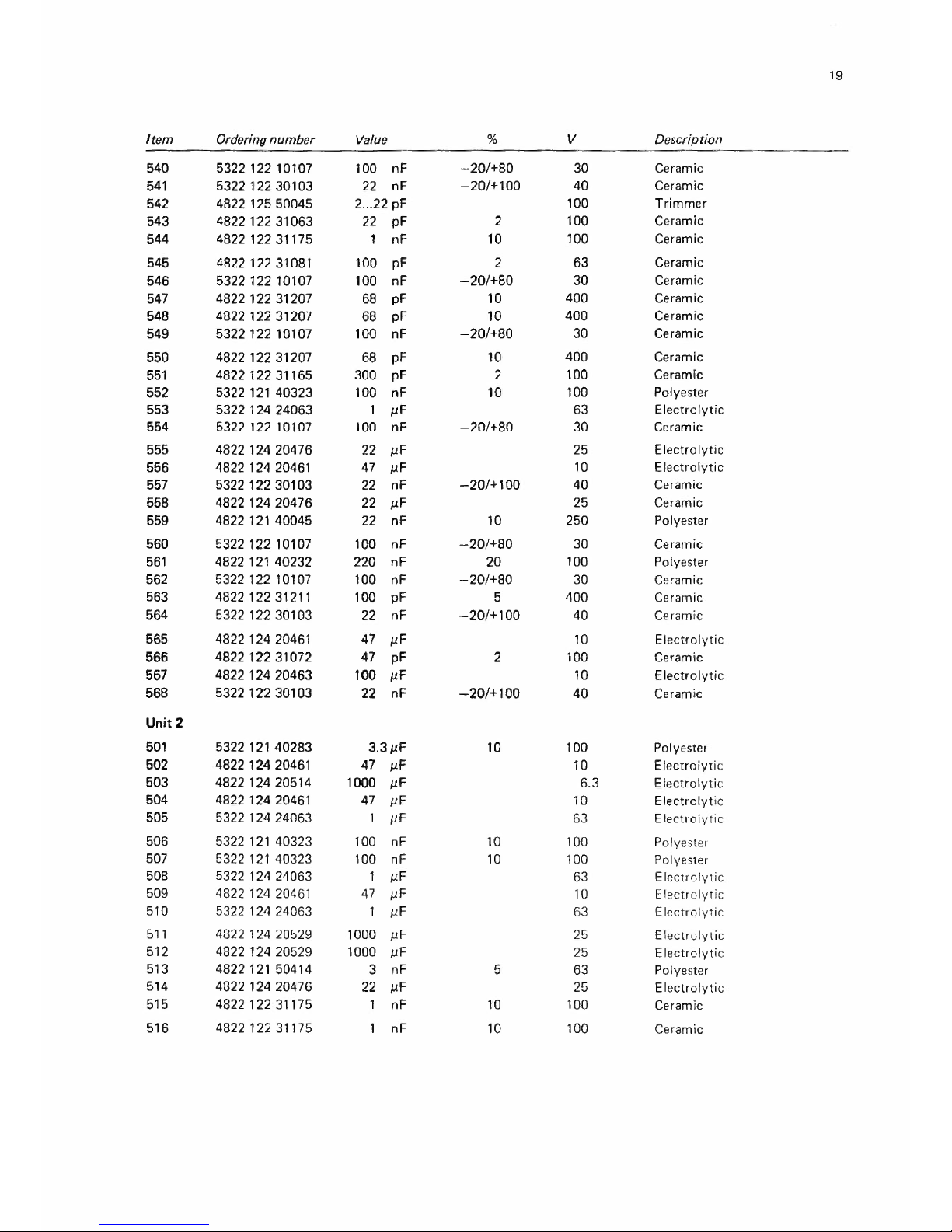

19

Item

Orderingnumber Value

%

v Description

540

5322 122 10107 100

nF -20/+80 30 Ceramic

541 5322 122 30103

22 nF

-20/+100

40

Ceramic

542

4822 125 50045 2...22 pF

100 Trimmer

543

4822 122 31063 22

pF

2

100

Ceramic

544 4822 122 31175 1 nF 10

100 Ceramic

545 4822 122 31081

100 pF

2 63

Ceramic

546 5322 122 10107

100

nF

-20/+80 30

Ceramic

547

4822 122 31207

68

pF

10

400 Ceramic

548 4822 122 31207

68

pF

10

400 Ceramic

549 5322 122 10107 100 nF

-20/+80

30 Ceramic

550 4822 122 31207 68

pF

10

400 Ceramic

551 4822 12231165

300

pF

2

100 Ceramic

552

5322 121 40323 100 nF 10

100 Polyester

553 5322 124 24063 1

µF

63

Electrolytic

554

5322 122 10107 100

nF

-20/+80 30

Ceramic

555 4822 124 20476

22

µF

25

Electrolytic

556 4822 124 20461

47 µF

10 Electrolytic

557

5322 122 30103 22

nF

-20/+100

40

Ceramic

558

4822 124 20476 22

µF 25 Ceramic

559 4822 121 40045 22

nF

10

250

Polyester

560

5322 122 10107 100

nF -20/+80 30 Ceramic

561 4822 121 40232 220 nF 20 100

Polyester

562

5322 122 10107

100 nF -20/+80

30

Ceramic

563

4822 122 31211 100 pF

5

400

Ceramic

564 5322 122 30103

22

nF -20/+100

40

Ceramic

565 4822 124 20461 47 µF

10

Electrolytic

566

4822 122 31072 47 pF

2

100 Ceramic

567

4822 124 20463

100

µF

10

Electrolytic

568

5322 122 30103

22

nF -20/+100 40 Ceramic

Unit 2

501 5322 121 40283

3.3µF

10 100 Polyester

502 4822 124 20461 47 µF

10 Electrolytic

503

4822 124 20514

1000

µF

6.3 Electrolytic

504

4822 124 20461

47

µF

10

Electrolytic

505 5322 124 24063 1

µF

63 Electrolytic

506

5322 121 40323

100

nF

10 100

Polyester

507

5322 121 40323

100 nF

10

100 Polyester

508 5322 124 24063

1

µF

63 Electrolytic

509 4822 124 20461

47

µF

10 Electrolytic

510 5322 124 24063

1

µF

63 Electrolytic

511 4822 124 20529

1000

µF

25

Electrolytic

512

4822 124 20529 1000

µF

25

Electrolytic

513

4822 121 50414

3

nF

5 63 Polyester

514 4822 124 20476

22

µ.F

25

Electrolytic

515 4822 122 31175 1

nF 10

100

Ceramic

516 4822 122 31175

1 nF 10 100

Ceramic

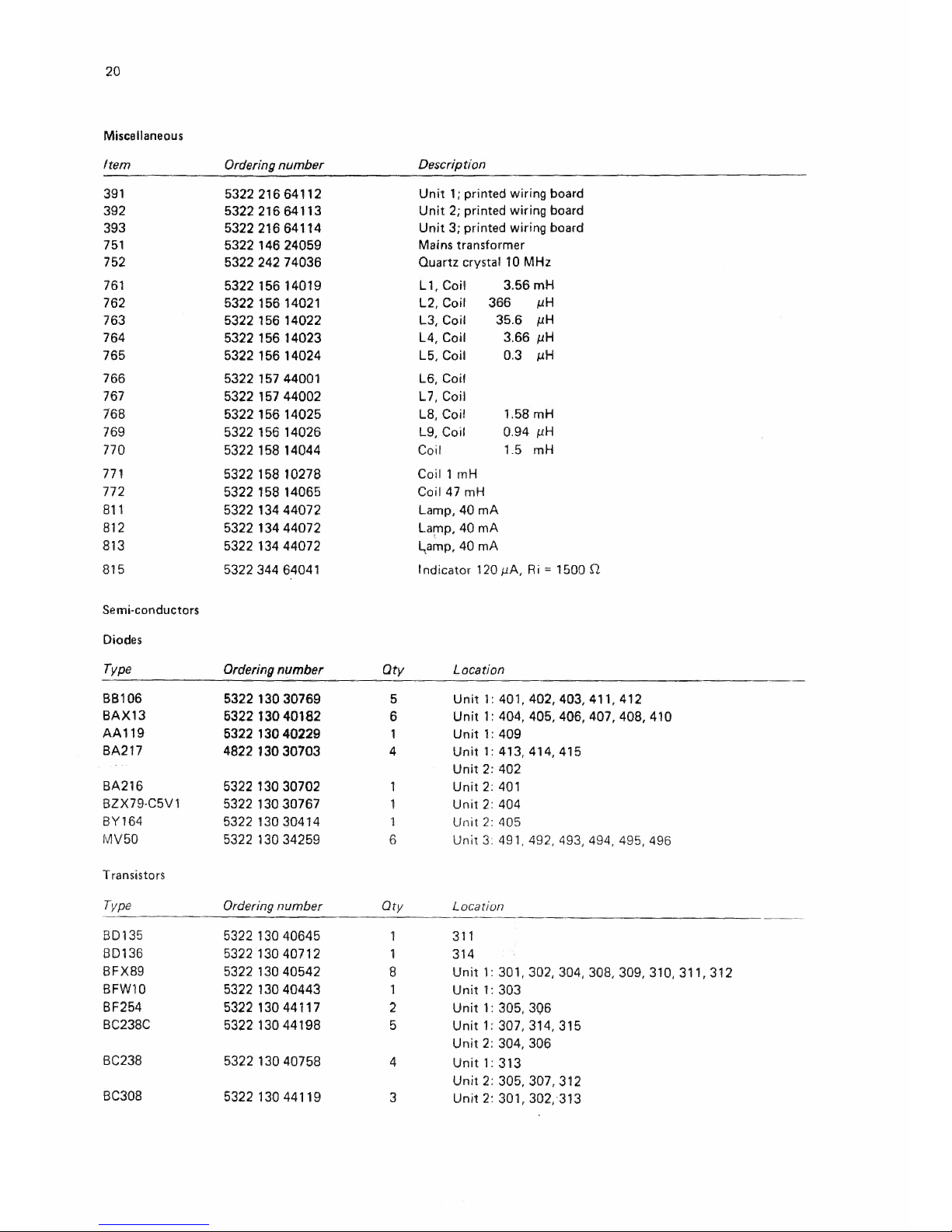

20

Miscellaneous

Item

Orderingnumber

Description

391

532221664112

Unit l; printed wiring board

392

5322 216 64113

Unit 2; printed wiring board

393

5322 216 64114

Unit 3; printed wiring board

751

5322 146 24059

Mainstransformer

752

5322 242 74036

Quartz crystal 10 MHz

761

5322 156 14019

Ll, Coil

3.56 rnH

762

5322 156 14021

L2, Coil 366

µH

763 5322 156 14022

L3, Coil

35.6

µH

764

5322 156 14023

L4, Coit

3.66 µH

765

5322 156 14024

L5, Coil 0.3

µH

766

5322 157 44001 L6, Coit

767

5322 15744002 L7, Coil

168

5322 156 14025 LS, Coil

1.58 mH

769

5322 156 14026

L9, Coil

0.94 µH

770

5322 158 14044

Coil

1.5 mH

771

5322 158 10278

Coil 1 mH

772

5322 158 14065

Coil 47 mH

811

5322 13444072 Lamp, 40 rnA

812

5322 134 44072

La[11p,40 mA

813

5322 134 44072 L.amp,40 mA

815 5322 344 6404, Indicator 120µA, Ri=1500

i1

Semi-conductors

Diodes

Type

Orderingnumber

Qty

Location

88106

5322 130 30769 5 Unit 1: 401, 402, 403, 411, 412

BAX13

632213040182

6

Unit 1: 404, 405, 406, 407, 408, 410

AA119

6322 ,30 40229

1 Unit 1: 409

BA217

4822 130 30703 4 Unit 1:413, 414, 415

Unit 2: 402:

BA216

5322 130 30702

1

Unit 2: 401

BZX79-C5V1

5322 130 30767

1

Unit 2: 404

BY164

5322 130 30414 1

Unit 2: 405

fV1V50

5322 13034259

6

Unit 3. 491, 492, 493, 494, 495, 496

Transistors

Type

Orderingnumber Oty

Location

BD135

5322 130 40645

1

311

80136

5322 130 40712

1 314

BFX89 5322 130 40542

8 Unit 1: 301, 302, 304, 308, 309, 310, 311, 312

BFW10

5322 130 40443

1

Unit 1: 303

BF254

5322 130 44117

2

Unit 1: 305, 306

BC238C

5322 13044198

5 Unit 1: 307, 314, 315

Unit 2: 304, 306

BC238

5322 13040758

4

Unit 1: 313

Unit 2: 305, 307, 312

BC308

5322 130 44119

3

Unit 2: 301, 302, 313

21

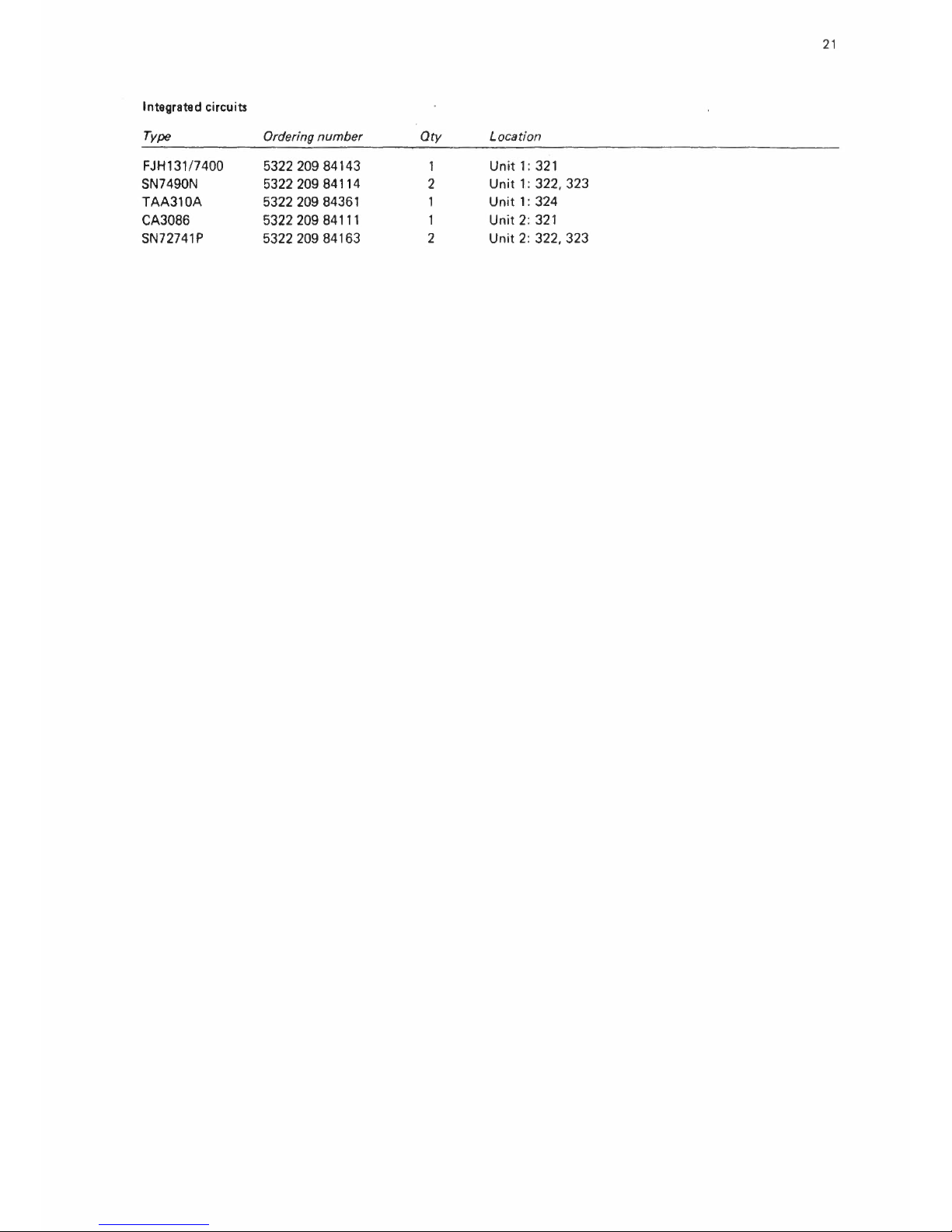

Integrated circuits

Type

Orderingnumber

Oty Location

FJH131/7400

5322 209 84 143 1

Unit 1: 321

SN7490N 5322 209 84114

2

Unit 1: 322, 323

TAA310A 5322 209 84361

1

Unit1:324

CA3086 5322 209 84111

1 Unit 2: 321

SN72741P

5322 209 84 163

2

Unit 2: 322, 323

22

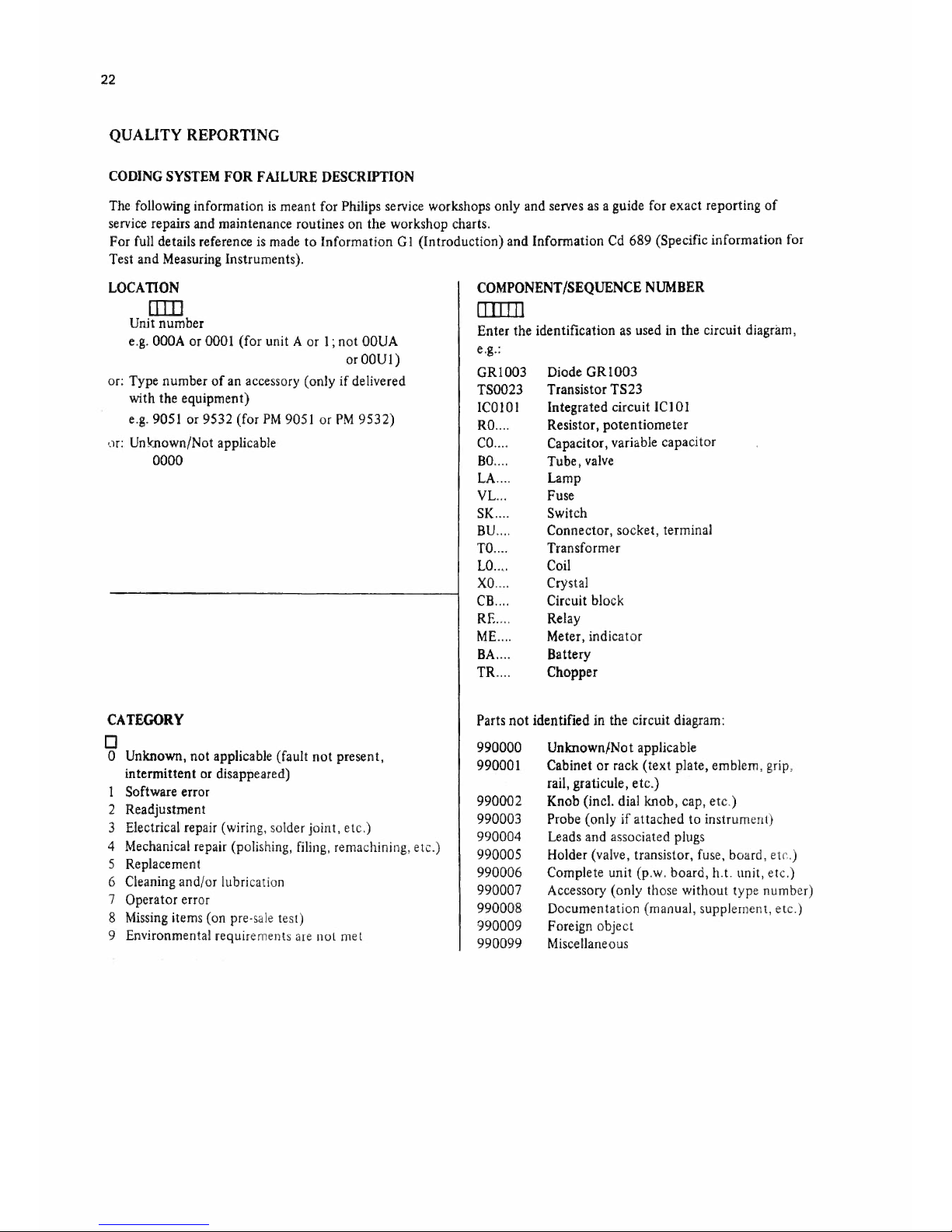

QUALITY REPORTING

CODING SYSTEM FOR FAILURE DESCRIPTION

The following information ismeant for Philips service workshops only and serves as a guide for exact reporting of

service repairs and maintenance routines on the workshop charts.

For full details reference is made to Information Gl (Introduction) and Information Cd 689 (Specific information for

Test and Measuring Instruments).

LOCATION

ITID

Unit number

e.g. OOOAor 0001 (for unit A or 1; not OOUA

orOOUl)

or: Type number of an accessory (only if delivered

with the equipment)

e.g.

9051or9532 (forPM9051 orPM9532)

or: Unknown/Not applicable

0000

CATEGORY

0

0 Unknown, not applicable (fault not present,

intermittent or disappeared)

Software error

2 Readjustment

3 Electrical repair (wiring, solder joint, etc.)

4 Mechanical repair (polishing, filing, rernachining, etc.)

S

Replacement

6 Cleaning and/ or lubrication

7 Operator error

8 Missing items (on pre-sale test)

9 Environmental requirements are not met

COMPONENT /SEQUENCE NUMBER

1111111

Enter the identification as used in the circuit diagram,

e.g.:

GR1003 Diode GRI003

TS0023 Transistor TS23

ICOIOI

RO .

co .

BO .

LA .

VL. ..

SK .

BU .

TO .

LO .

XO .

CB .

RE .

ME .

BA .

TR .

Integrated circuit

ICIO!

Resistor, potentiometer

Capacitor, variable capacitor

Tube, valve

Lamp

Fuse

Switch

Connector, socket, terminal

Transformer

Coil

Crystal

Circuit block

Relay

Meter, indicator

Battery

Chopper

Parts not identified in the circuit diagram:

990000

990001

990002

990003

990004

990005

990006

990007

990008

990009

990099

Unknown,lNot applicable

Cabinet or rack (text plate, emblem, grip,

rail, graticule, etc.)

Knob (incl. dial knob, cap, etc.)

Probe (only if attached to instrument)

Leads and associated plugs

Holder (valve, transistor, fuse, board, etc.)

Complete unit (p.w. board, h.t. unit, etc.)

Accessory (only those without type number)

Documentation (manual, supplement, etc.)

Foreign object

Miscellaneous

Loading...

Loading...