Philips PM2811, PM2832 User Manual

Programmable Power Supplies I

PM2811-PM2812-PM2813

PM2831-PM2832

Programmable Power Supplies

®

4822 872 00824

January 1997, Rev. 3, 5/98

© 1997 Fluke Corporation. All rights reserved. Printed in the Netherlands.

All product names are trademarks of their respective companies.

Users Manual

II Users Manual

Programmable Power Supplies III

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

LIMITED WARRANTY & LIMITATION OF LIABILITY

Each Fluke product is warranted to be free from defects in material and workmanship under

normal use and service. The warranty period is one year and be

shipment. Parts, product repairs and services are warranted for 90 days. This warranty

extends only to the ori

does not apply to fuses, disposable batteries or to any product which, in Fluke's opinion, has

been misused, altered, ne

operation or handlin

with its functional specifications for 90 days and that it has been properly recorded on nondefective media. Fluke does not warrant that software will be error free or operate without

interruption.

Fluke authorized resellers shall extend this warranty on new and unused products to enduser customers only but have no authority to extend a

of Fluke. Warranty support is available if product is purchased throu

sales outlet or Buyer has paid the applicable international price. Fluke reserves the ri

invoice Buyer for importation costs of repair/replacement parts when product purchased in

one country is submitted for repair in another country.

inal buyer or end-user customer of a Fluke authorized reseller, and

lected or damaged by accident or abnormal conditions of

. Fluke warrants that software will operate substantially in accordance

reater or different warranty on behalf

ins on the date of

h a Fluke authorized

ht to

Fluke's warranty obli

e repair, or replacement of a defective product which is returned to a Fluke

of char

authorized service center within the warranty period.

T o obtain warranty service, contact your nearest Fluke authorized service center or send the

product, with a description of the difficulty, posta

Destination), to the nearest Fluke authorized service center. Fluke assumes no risk for

e in transit. Following warranty repair, the product will be returned to Buyer,

dama

transportation prepaid (FOB Destination). If Fluke determines that the failure was caused

by misuse, alteration, accident or abnormal condition of operation or handlin

provide an estimate of repair costs and obtain authorization before commencin

Followin

Buyer will be billed for the repair and return transportation char

THIS WARRANTY IS BUYER'S SOLE AND EXCLUSIVE REMEDY AND IS IN LIEU OF

ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO

ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE. FLUKE SHALL NOT BE LIABLE FOR ANY SPECIAL, INDIRECT,

INCIDENTAL OR CONSEQUENTIAL DAMAGES OR LOSSES, INCLUDING LOSS OF

DATA, WHETHER ARISING FROM BREACH OF WARRANTY OR BASED ON

CONTRACT, TORT, RELIANCE OR ANY OTHER THEORY.

Since some countries or states do not allow limitation of the term of an implied warranty, or

exclusion or limitation of incidental or consequential dama

exclusions of this warranty may not apply to every buyer. If any provision of this W arranty is

held invalid or unenforceable by a court of competent jurisdiction, such holdin

the validity or enforceability of any other provision.

Fluke Corporation, P.O. Box 9090, Everett, WA 98206-9090 USA, or

Fluke Industrial B.V., P.O. Box 680, 7600 AR, Almelo, The Netherlands

repair, the product will be returned to the Buyer transportation prepaid and the

ation is limited, at Fluke's option, to refund of the purchase price, free

e and insurance prepaid (FOB

, Fluke will

the work.

es (FOB Shipping Point).

es, the limitations and

will not affect

IV Users Manual

g

SERVICE CENTERS

To locate an authorized service center, visit us on the World Wide Web:

http://www.fluke.com

or call Fluke usin

+1-800-443-5853 in U.S.A. and Canada

+1-425-356-5500 from other countries

any of the phone numbers listed below:

+31-402-678-200 in Europe

Programmable Power Supplies I

CONTENS

1 OPERATOR SAFETY

1.1 INTRODUCTION

1.2 SAFETY PRECAUTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.3 CAUTION AND WARNING STATEMENTS. . . . . . . . . . . . . . . . 1-1

1.4 SYMBOLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.5 IMPAIRED SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

2 INTRODUCTION

2.1 INTRODUCTION TO YOUR PROGRAMMABLE

POWER SUPPLY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.2 BASIC OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.2.1 Local operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

2.2.2 Remote operation . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

2.2.3 Sense modes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

2.3 ADVANCED OPERATION

2.3.1 Output channel interconnections . . . . . . . . . . . . . . . 2-12

2.3.2 Multiple loads. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Page

II Users Manual

gg

g

g

g

3 INSTALLATION INSTRUCTIONS

3.1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.2 INITIAL INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.3 OPERATOR SAFETY INSTRUCTIONS . . . . . . . . . . . . . . . . . . 3-1

3.4 INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3.4.1 Mechanical installation . . . . . . . . . . . . . . . . . . . . . . . 3-2

3.4.2 Electrical installation . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3.4.3 Front Connection Unit . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3.5 OUTPUT CONNECTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

3.5.1 Output channel connections . . . . . . . . . . . . . . . . . . . 3-7

3.5.2 GPIB connections . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

3.5.3 Tri

3.6 ACCEPTANCE TESTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

3.6.1 Brief check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

3.6.2 Interface check . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

3.6.3 Performance Verification. . . . . . . . . . . . . . . . . . . . . 3-12

er bus connections . . . . . . . . . . . . . . . . . . . . . . 3-8

4 GETTING FAMILIAR WITH THE POWER SUPPLY

4.1 INITIAL SETUP OF YOUR POWER SUPPLY. . . . . . . . . . . . . . 4-1

4.1.1 Power up routine . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.1.2 Instrument identification. . . . . . . . . . . . . . . . . . . . . . . 4-2

. . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

. . . . . . . . . . 4-1

4.2 FRONT PANEL LAYOUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

4.2.1 Keyboard controls . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

4.2.2 Display indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

4.3 OUTPUT CHANNEL CONNECTIONS. . . . . . . . . . . . . . . . . . . . 4-7

4.4 GETTING STARTED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

4.4.1 Selectin

4.4.2 Settin

4.4.3 Settin

an output channel . . . . . . . . . . . . . . . . . . . 4-8

an output voltage. . . . . . . . . . . . . . . . . . . . . . 4-9

an output current. . . . . . . . . . . . . . . . . . . . . 4-10

Programmable Power Supplies III

g

g

g

5 USING YOUR PROGRAMMABLE POWER SUPPLY

5.1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.2 LOCAL OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5.3 REMOTE OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

5.4 OPERATING FEATURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

5.5 HOW TO USE THE OPERATING FEATURES . . . . . . . . . . . . . 5-7

5.5.1 Output channel characteristics. . . . . . . . . . . . . . . . . . 5-7

5.5.2 Local and remote sensin

5.5.3 Constant volta

5.5.4 Store/recall function. . . . . . . . . . . . . . . . . . . . . . . . . 5-19

5.5.5 Step functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-22

5.6 ADVANCED USE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-28

5.6.1 Parallel connection of output channels . . . . . . . . . . 5-29

5.6.2 Serial connection of output channels. . . . . . . . . . . . 5-32

5.6.3 Parallel connection of loads. . . . . . . . . . . . . . . . . . . 5-35

5.6.4 Tips for Remote Sensin

e or constant current source. . . . . . 5-13

. . . . . . . . . . . . . . . . . . . . 5-10

Applications. . . . . . . . . . . 5-36

. . . . . . . . 5-1

IV Users Manual

APPENDIX A ACCESSORIES

A.1 Supplied with the instrument . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

A.2 Optional . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

APPENDIX B SCPI CONFORMANCE INFORMATION

B.1 IEEE 488.2-1987 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

B.2 SCPI Std 1993.0 Confirmed . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

B.3 SCPI approved . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-4

B.4 SCPI syntax and style . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-5

APPENDIX C ABBREVIATIONS, SYMBOLS & TERMS

C.1 Abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

C.2 Glossary of symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-5

C.3 Glossary of terms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-6

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

. . . . . . . . . . .B-1

. . . . . . . . . C-1

APPENDIX D APPLICATION FOR PM2812 AND PM2813

INDEX

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I-1

. . . . . . . D-1

Programmable Power Supplies V

g

g

g

g

g

g

g

g

gg

g

Thank you for purchasing this FLUKE power supply. It has been designed and

manufactured to the hi

free use.

hest quality standards to give you many years of trouble-

The powerful operatin

operation so that the full power of this instrument can be used every day. The

main operatin

• Multiple output, dc power supply

• Output modules with various volta

• Suitable for GPIB as well as benchtop applications

• Conforms to SCPI and IEEE 488.2 standards

• Non volatile memory for 999 settin

• Power down memory (front panel settin

• Readback of actual volta

• Manual and automatic step function

• Overvolta

• Overtemperature and sense protection

• Coupled protection of output channels

• Closed case calibration facility (protected by password)

• External tri

• Built-in self-test and dia

features are:

e and overcurrent protection

features have been combined with an easy and logical

e and current ratings

s

s)

e and current

er facilities (auto step)

nostics routines

VI Users Manual

g

g

g

g

g

g

g

INITIAL INSPECTION

Check the contents of the shipment for completeness and note whether any

e has occurred during transport. If the contents are incomplete, or if there

dama

is dama

office nearest you to facilitate the repair or replacement of the instrument or

accessories.

e to the instrument or its accessories, notify the FLUKE sales or service

The followin

•Pro

• Reference Manual En

• Operation Manual En

Operation Manual German, or

Operation Manual French

• Power Cord

• Two spare fuses

• Two mountin

For further information, refer to APPENDIX A, ‘Accessories’.

items must be included in the shipment:

rammable Power Supply

lish

lish, or

brackets (only for the 19 inch models)

Programmable Power Supplies VII

g

g

g

INSIDE THIS MANUAL

This operating manual has been aimed at the experienced user as well as the

user new to Pro

operate the power supply manually (local operation) or from a PC via the GPIB

(remote operation).

1) OPERATOR SAFETY

Gives full information about safety aspects.

2) INTRODUCTION TO YOUR PROGRAMMABLE POWER SUPPLY

Describes what your power supply is and how you can use it.

3) INSTALLATION INSTRUCTIONS

Describes the steps necessary to prepare your power supply for use.

4) GETTING STARTED WITH YOUR PROGRAMMABLE POWER SUPPLY

Describes how to

power supply. A step-by-step tutorial describes how to operate the functions

in the local (manual) mode.

5) USING YOUR PROGRAMMABLE POWER SUPPLY

Gives functional information about how to use the power supply in the local as

well as the remote mode.

rammable Power Supplies. It will help the reader to use and

et started with some commonly used functions of the

Additional information is available in the followin

A) ACCESSORIES

Gives a functional overview of the accessories that are supplied or can be

ordered.

B) SCPI CONFORMANCE INFORMATION

Gives information about versions of the confirmed and approved SCPI

commands and queries.

C) ABBREVIATIONS, SYMBOLS & TERMS

D) APPLICATION FOR PM2812 AND PM2813

Gives support information to extend maximum current of the PM2812 or

PM2813 by parallel connection of channels

appendices:

VIII Users Manual

Operator Safety 1 - 1

g

g

g

g

g

g

1 OPERATOR SAFETY

Read this page carefully before beginning to install and use the instrument.

1.1 INTRODUCTION

The instrument described in this manual is designed to be used only by qualified

personnel.

WARNING: Servicin

qualified service personnel. To avoid electrical shock, do not

service the instrument unless you are qualified to do so.

described in this manual is to be done only by

1.2 SAFETY PRECAUTIONS

For the correct and safe use of this instrument it is essential that both operating

and service personnel follow

the safety precautions specified in this manual. Specific warnin

statements, where they apply, will be found throu

necessary, the warnin

the instrument.

enerally accepted safety procedures in addition to

and caution

hout the manual. Where

and caution statements and/or symbols are marked on

1.3 CAUTION AND WARNING STATEMENTS

CAUTION: Is used to indicate correct operating or maintenance procedures in

order to prevent dama

property .

WARNING: Calls attention to a potential danger that requires correct

procedures or practices to prevent personal injury.

e to or destruction of the equipment or other

1 - 2 Users Manual

g

g

1.4 SYMBOLS

Symbol Meanin

See explanation in manual

Earth

Conformité Européenne

of symbol

1.5 IMPAIRED SAFETY

Whenever it is likely that safety has been impaired, the instrument must be turned

off and disconnected from line power. The matter should then be referred to

qualified technicians. Safety is likely to be impaired if, for example, the instrument

does not output the expected power or shows visible dama

e.

Introduction to your PPS 2 - 1

g

g

g

g

g

g

g

g

g

2 INTRODUCTION

2.1 INTRODUCTION TO YOUR PROGRAMMABLE

POWER SUPPLY

The basic function of your programmable power supply (PPS) is to supply a

predefined dc volta

Your power supply model can have one, two or three output channels. Unless

stated otherwise, the information in this manual applies to all models. For

technical and environmental performance specifications, refer to the Reference

Manual.

REMOTE OPERATION

The family of Pro

in an automatic system environment pro

reason the power supplies have been equipped with a GPIB interface and

conform to IEEE-488.2 as well as the SCPI 1993.0 standards. For remote

operation, refer to the Reference Manual (operatin

LOCAL OPERATION

The power supplies can be used as bench-top instruments (stand-alone) via

their keypads and displays. For local operation, refer to section 4.4 (

started), section 5.4 (operatin

references).

e or current in a controlled way through an output channel.

rammable Power Supplies is primarily intended to be used

rammed via a controller. For that

references).

etting

features) or the Reference Manual (operating

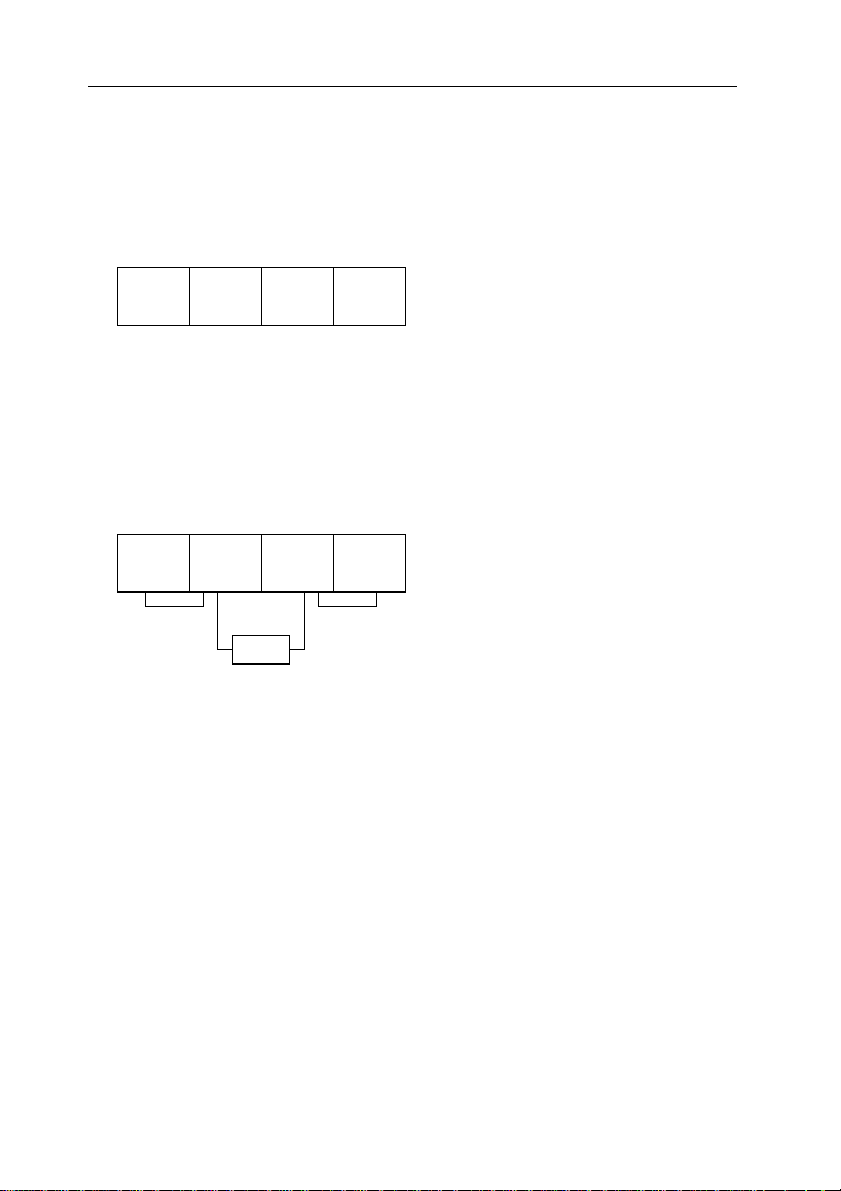

Family overview

Sin

PM2811/xyz

PM2812/xyz

PM2813/xyz

PM2831/xyz

PM2832/xyz

le Output System

Dual Output System

Triple Output System

Sin

le Output System

Dual Output System

Country Version

1 = Euro

3 = USA

4 = UK

5 = Swiss

Revision Number

1 = Standard Version

5 = Version with Front Connection Option

Number assi

(see section 3.4.3).

ned to various output ratings.

2 - 2 Users Manual

g

g

g

g

g

g

g

g

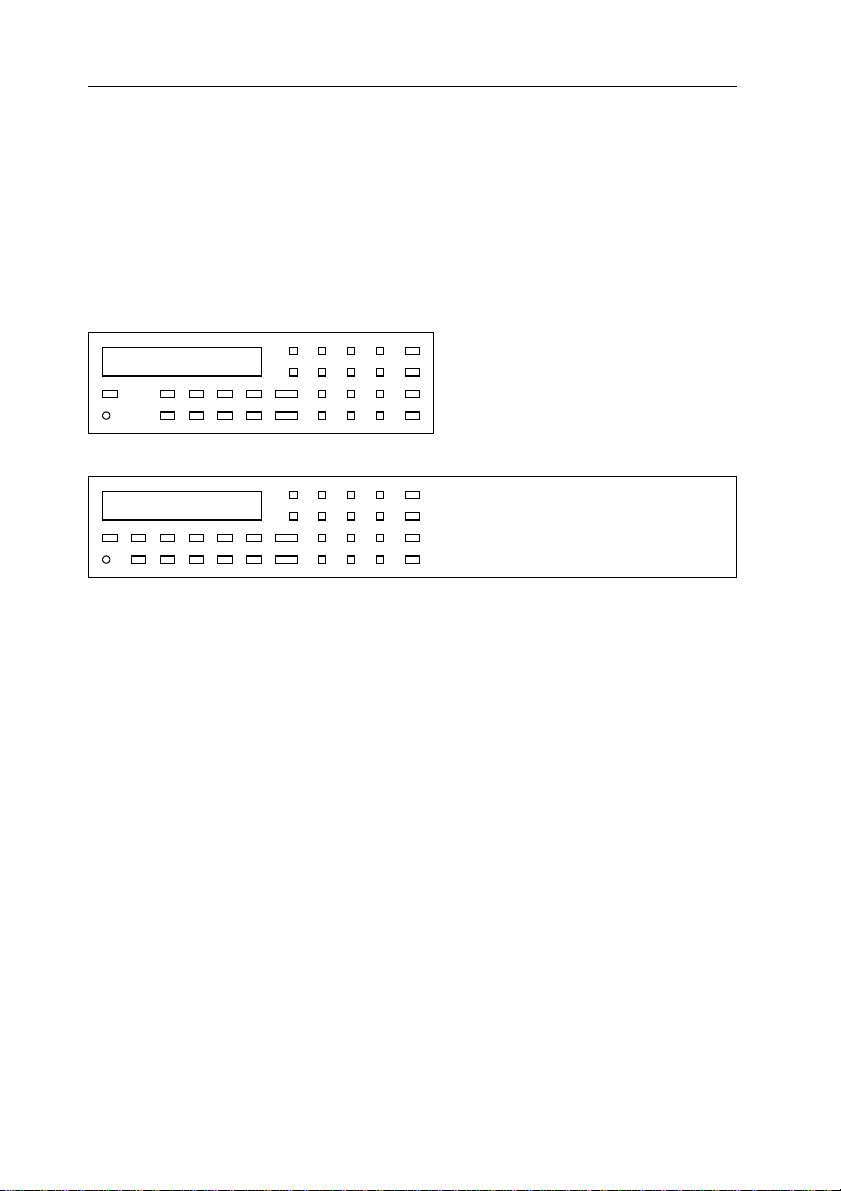

FRONT PANEL

The front panel contains a keypad and LCD for dialo

Local operation (manual) of the power supply is done via the keypad. The

display is used for passin

• response information for the operator, e.

• readback information, e.

• status information, e.

• error messa

Display

Sin

le front panel (PM2811 only)

Display

Sin

le, dual and triple output front panel

es, e.g., the OVERCURRENT message

information to the operator, such as:

., ADDRESS 12

., an output voltage and current

., display of the REM text

ue with the operator.

Introduction to your PPS 2 - 3

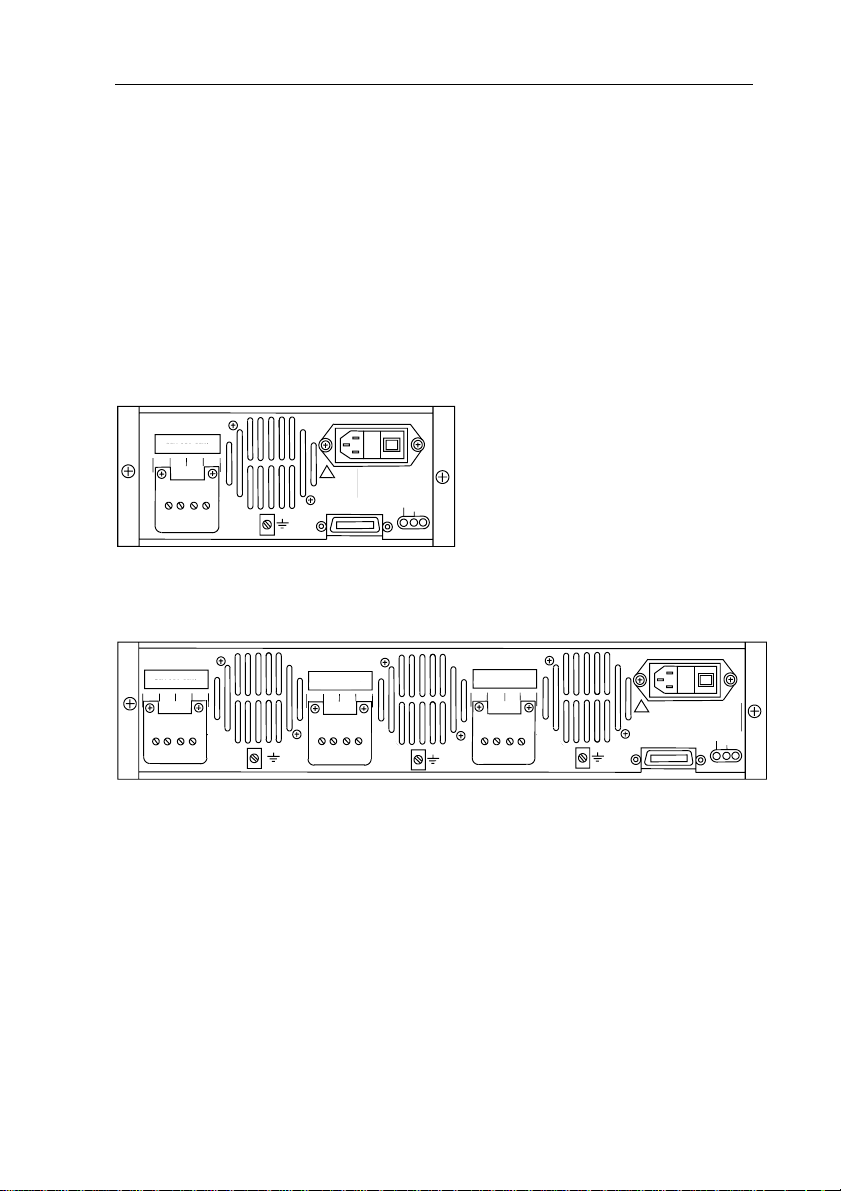

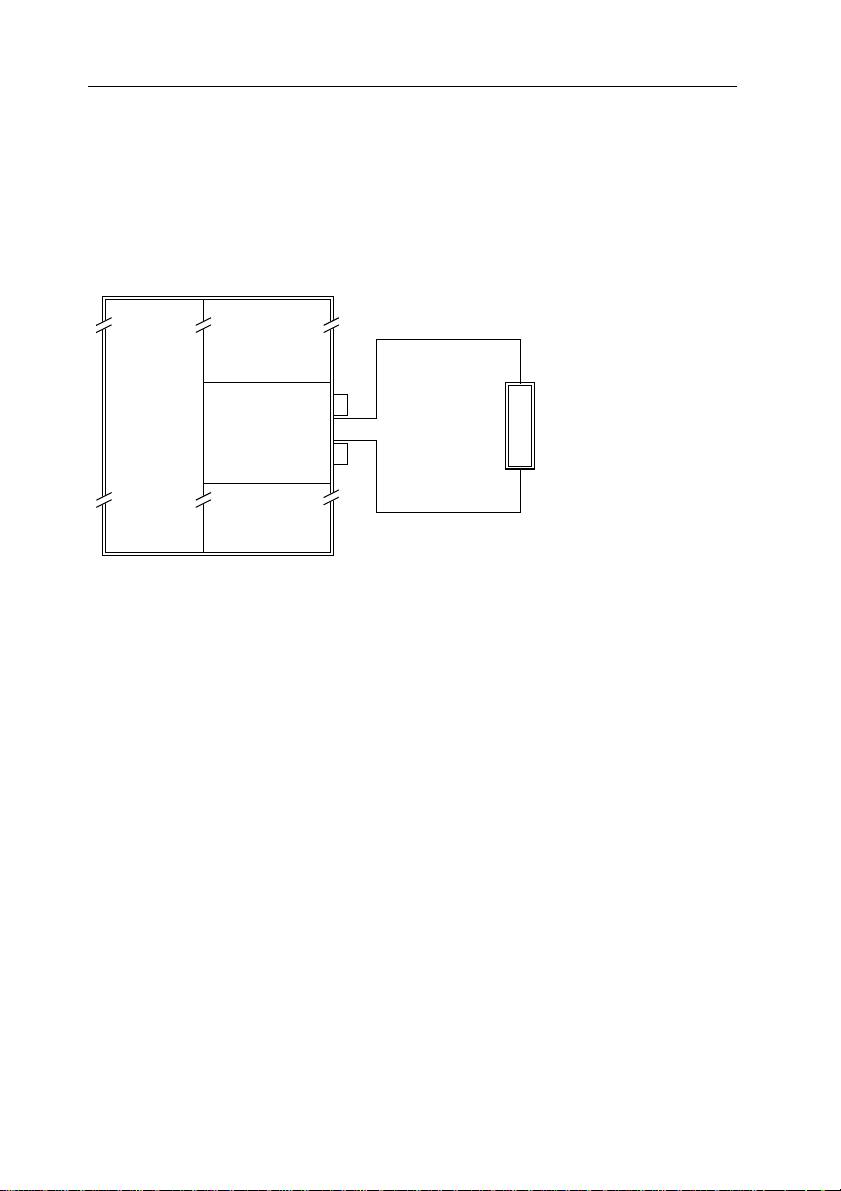

REAR PANEL

The rear panel contains connectors for the line power input, the output

channel(s), the trigger lines, and the GPIB (IEEE 488) interface. A fan

provides forced cooling of each output channel. The line power input modul e

also contains the line fuses, line filter, and the power switch.

For remote control, a GPIB (IEEE 488) connector for use with a GPIB

controller is provided.

Three SMB connectors for START, STEP, and READY are provided for

external triggering of the step mode and recalling stored instrument settings.

OUTPUT 1

30V 10A 60W

+S

-S

-V

+V

MAX

!

240V

!

FUSES

110V 2.5AT/250V

220V 1.25AT/250V

IEEE488

Single rear panel (PM2811 only)

OUTPUT 1

30V 10A 60W

-S

-V

+S

+V

MAX

!

240V

OUTPUT 2

30V 10A 60W

-S

-V

+V

Output rear panel

PM2811/111

9448 028 11011

No.DM000599

+S

MAX

240V

0

1

PHILIPS

230V

50-60Hz

155VA

READY

START

STEP

ST5825

OUTPUT 3

30V 10A 60W

+S

-S

-V

+V

MAX

!

!

240V

!

FUSES

110V 6.3AM/250V

220V 3AT/250V

IEEE488

PM2813/011

9448 028 13011

No.DM521001

0

1

PHILIPS

230V

50-60Hz

390VA

READY

START

STEP

ST5824

2 - 4 Users Manual

g

g

g

g

g

g

g

g

g

2.2 BASIC OPERATION

The programmable power supplies offer a combination of programming

capabilities and a variety of dc output power ratin

power systems applications. The +V and +S as well as the -V and -S terminals

have been connected to each other at the factory.

POWER

SUPPLY

+S

output

channel

+V

-V

-S

s that make them ideal for

+

l

o

a

d

-

Each output channel can be pro

(output function). Self-contained measurement and readback capability eliminate

the need for usin

The readback volta

monitored on the front panel display (measure function). Protective circuitry within

the power supply limits or turns off an output channel when an abnormal condition

occurs. The followin

• OVERVOLTAGE and OVERCURRENT

• UNREGULATED OUTPUT

• OVERTEMPERATURE

• OUT OF SENSE CAPABILITY

• COUPLED PROTECTION (of output channels)

Each output channel can operate as a

as a

constant current

• As a constant volta

the output current chan

• As a constant current source the output current remains constant, while

the output volta

a separate multimeter to externally meter the output channel.

e and current of the selected output channel can be

protection features have been implemented:

source or

e changes due to fluctuations of the load.

rammed to the desired dc voltage or dc current

source (

constant volta

current sink

e source the output voltage remains constant, while

es due to fluctuations of the load.

(PM283x only) (

e

CV mode

CC mode

), or

):

Introduction to your PPS 2 - 5

g

g

g

g

g

g

g

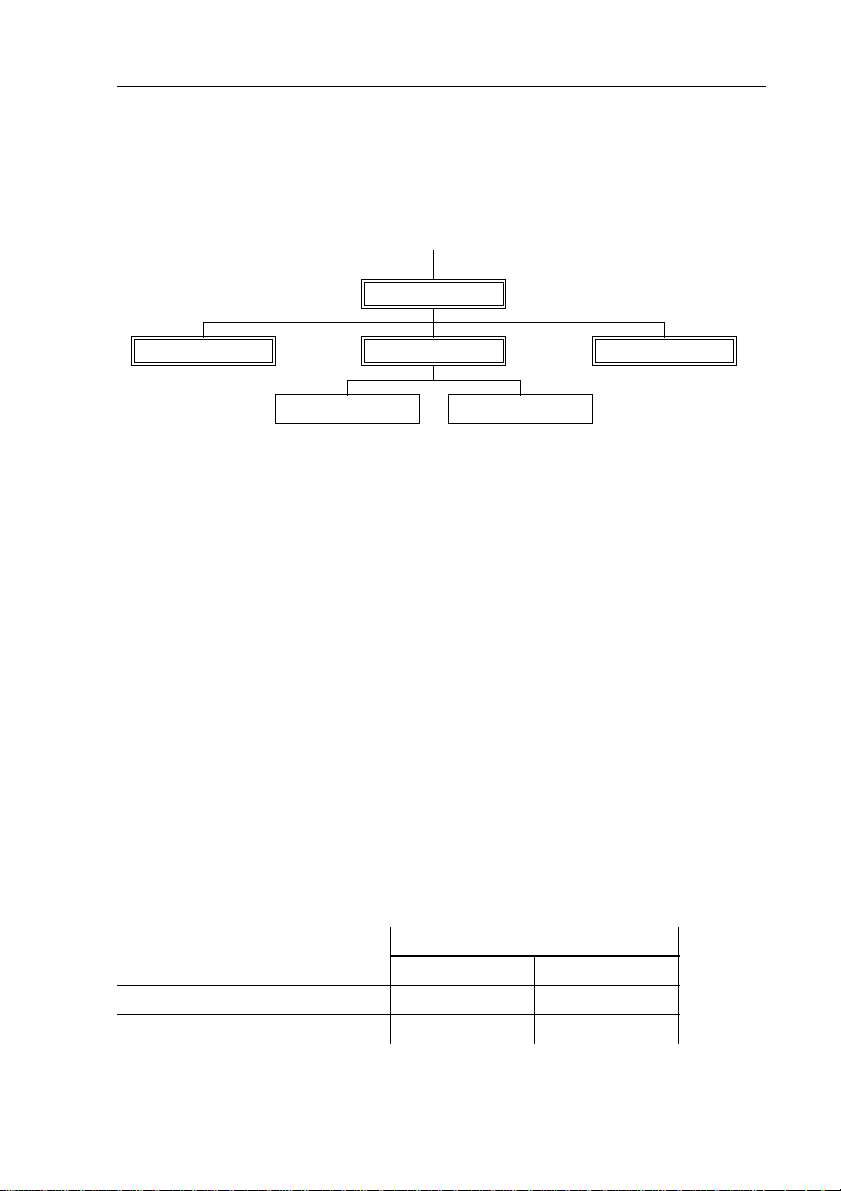

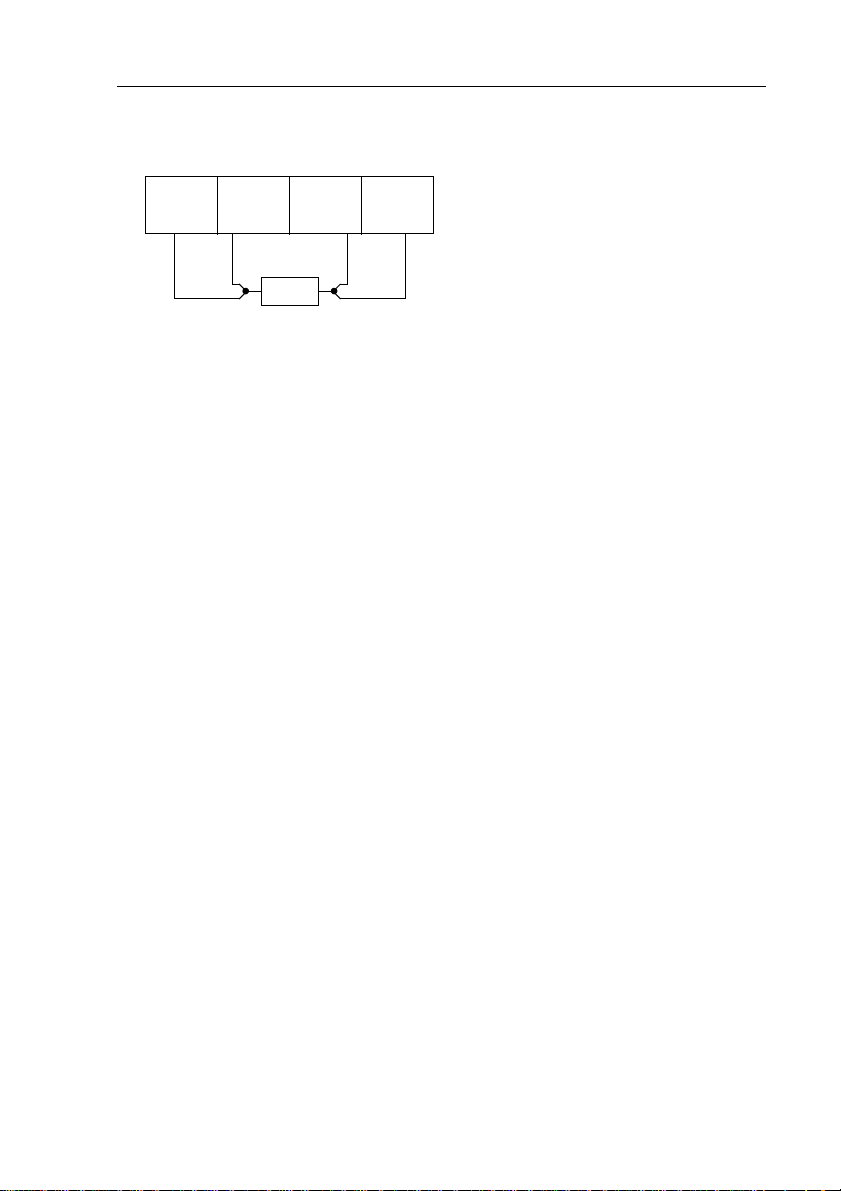

After power on, the programmable power supply performs a self-test. If the

selftest is succesful, the STANDBY, OPERATE, or CALIBRATION mode will be

entered. In the OPERATE mode, an output channel can be in the ENABLED or

DISABLED state (only multiple output models).

power on

SELF TEST

STANDBY OPERATE CALIBRATION

DISABLED ENABLED

• SELF-TEST After power on the power supply will test itself. Dependin

on

the Power ON DEFinition (PONDEF), the STANDBY or

OPERA TE mode is entered. The CALIBRATION mode can be

entered manually via the AUX key by pressin

it during power

up, or remotely via the GPIB controller.

• ST ANDBY In this mode the power supply does not output power, i.e., all

output channels have been shut off. It is possible, however, to

verify or set volta

• OPERA TE In this mode the power supply is able to output a volta

e and current settings.

e or a

current. For multiple output models each individual output

channel can be disabled (DISABLED state) or enabled

(ENABLED state). It is also possible to verify or set volta

and current settin

s.

e

• CALIBRATION In this mode the power supply can be calibrated. At the end

of the calibration, the power supply will enter STANDBY

mode.

The followin

diagram shows the possible output channel states:

OUTPUT CHANNEL

DISABLED ENABLED

Power supply STANDBY no power no power

Power supply OPERATE no power power output

2 - 6 Users Manual

g

g

g

g

g

g

g

g

g

g

g

g

g

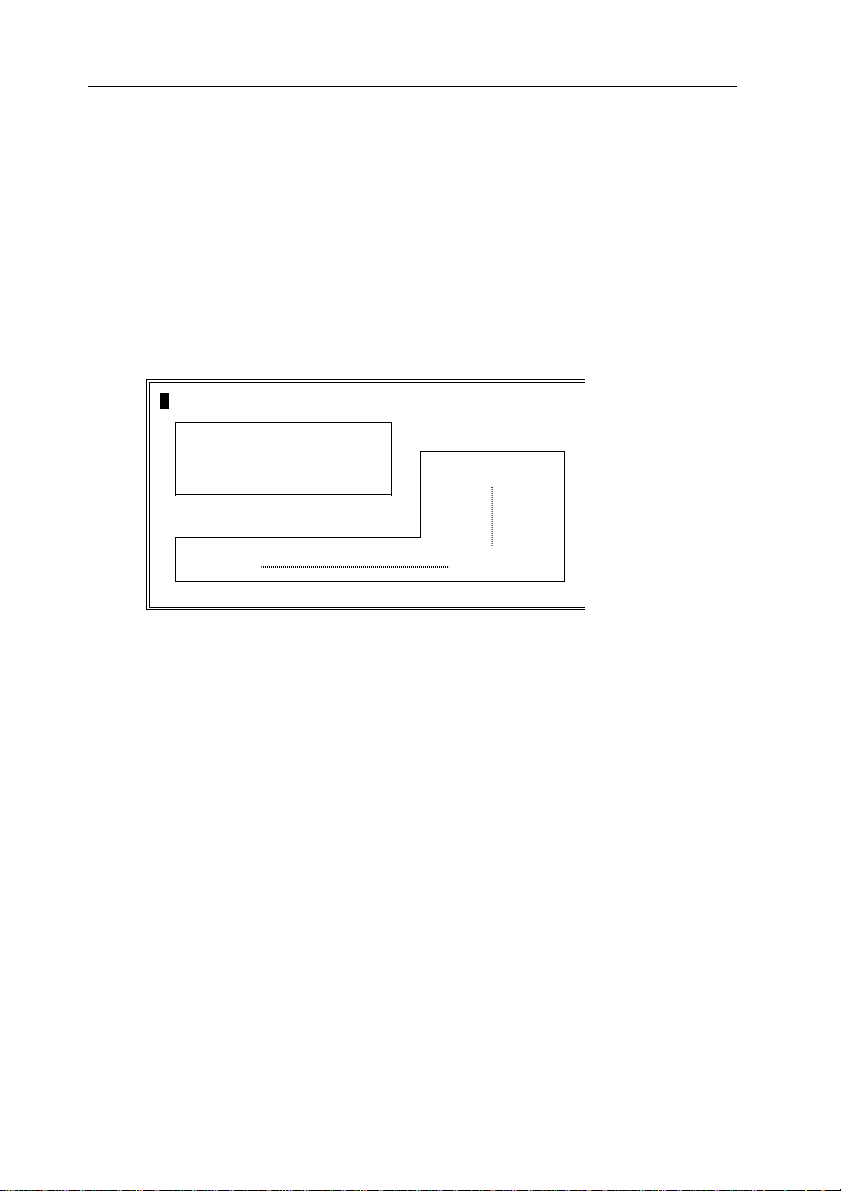

2.2.1 Local operation

the front panel keys, you can program an output channel voltage or current.

Usin

On the front panel display you can read back the actual volta

selected output channel. Operatin

information about the instrument and the

selected output channel, as well as output-specific error messa

the display in the followin

ways (see the following figure):

e and current of the

es, are shown on

• text

• annunciators, pointin

at abbreviations on the front panel right below the

display.

PM28xx programmable power supply xxV/yyA/zzW

• • •

LCD display

text annunciators text

keypad

abbreviations

keypad

keypad

You can use the keypad as follows to control your power supply:

• control interface and

eneral functions via a menu

• switch between the operate and standby mode

• set the supply to local control (if not remotely locked)

• reset the power supply, i.e., return to the ’power on’ state

• store/recall/step volta

e and current settings (1 to 999) in the instrument’s

battery backed-up memory (recall memory)

You can use the keypad as follows to control one of the output channels:

• select an output channel (only for multiple output models)

• enable or disable an output channel (only for multiple output models)

• unmask, delay, or display the settin

• reset the overvolta

e and overcurrent protection

of bits in the fault register

You can use the keypad as follows to perform an output channel settin

• set or chan

• set the overvolta

e the output voltage or current

e trip level

• enable or disable the overcurrent protection

:

Introduction to your PPS 2 - 7

g

g

g

g

g

g

g

2.2.2 Remote operation

Via the General Purpose Interface Bus (GPIB), you can pro

rammable power supply to receive input data and to send output data. An

pro

example of input data (listener) is that a volta

directly to the selected output channel. An example of output data (talker) is the

readback volta

e and current of the selected output channel.

e and current can be programmed

ram your

IEEE 488.2 compatibility

IEEE 488.2 is a standard that is additional and complementary to the IEEE 488.1

standard. Your pro

standard. For more information refer to the Reference Manual.

rammable power supply conforms to the IEEE 488.2

SCPI compatibility

SCPI (Standard Commands for Programmable Instruments) is a command

definition standard for pro

rammable power supply conforms to the SCPI standard. For more

pro

information, refer to the Reference Manual.

rammable test and measurement instruments. Your

2 - 8 Users Manual

g

g

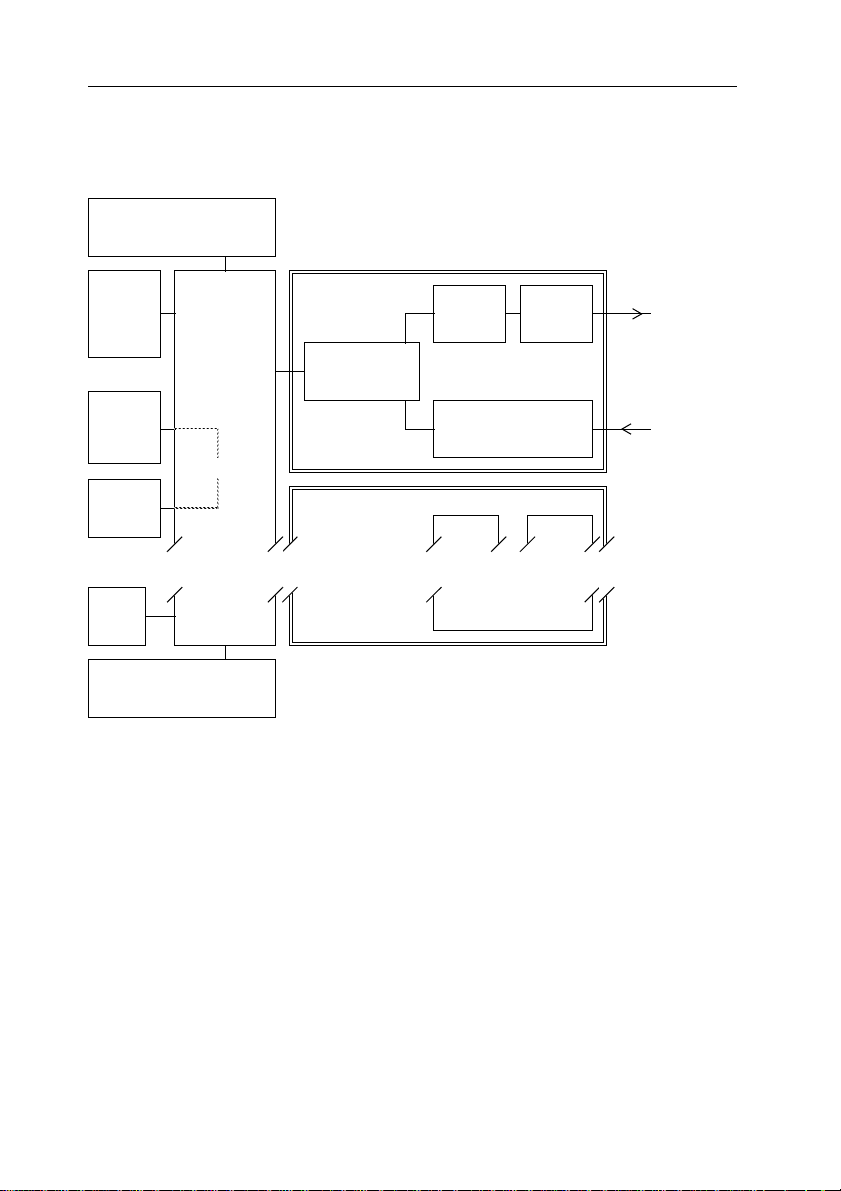

The programmable functions have been implemented via the GPIB by means of

the followin

SYSTem

SCPI subsystems:

DISPlay

SOURce OUTPut

volta

e

output

channel 1

ABORt

INITiate

TEST

INSTrument

•

•

STATus

step

•••

•

CALibration

•

•

MEASure

• • •••

•

sense

input

channel 1

input/output

channel n

Introduction to your PPS 2 - 9

g

g

g

g

g

g

g

g

g

• ABORt

This subsystem is used for stoppin

the step function of the power supply.

• CALibration

This subsystem is used for calibration of the instrument. Your power supply

can be calibrated without removin

the cover or removing the power supply

from your rack measurement setup. This feature allows you to calibrate the

power supply at its normal operatin

temperature. The recommended

calibration interval is one year. Refer to the Reference Manual for complete

calibration details.

• DISPlay

This subsystem is used to control the front panel display.

• INITiate

This subsytem is used to start up (initiate) the step function of the power

supply.

• INSTrument

This subsystem is used to control the instrument functions.

• MEASure

This subsystem is used to measure (readback) output volta

e and output

current.

• OUTPut

This subsystem is used to control an output channel.

• SOURce

This subsystem is used for source and settin

functions of an output channel,

such as : - source definitions

- volta

- current (protection) settin

e (protection) settings

s

- automatic steppin

• STATus

This subsystem is used for handlin

the device-dependent operational and

questionable status information.

• SYSTem

This subsystem is used to handle system and control functions, such as:

- lockout front panel control

- define the ’power on clear’ behavior

- request for status information

• TEST

This subsystem is used to test the instrument.

2 - 10 Users Manual

g

g

g

g

g

glig

2.2.3 Sense modes

Each output channel has been provided with a set of four terminals. The inner

terminals have been marked as - V(olta

e) and + V(oltage), while the outer

terminals have been marked as - S(ense) and + S(ense).

- S- V+ V+ S

Each output channel can be connected to a load in two different ways:

• throu

h the +V and -V terminals, causing the power supply to operate in

its local sense mode.

• throu

h the +V and -V and +S and -S terminals, causing the power supply

to operate in its remote sense mode.

Local sensin

- S- V+ V+ S

load

At delivery the sense terminals are interconnected with the voltage terminals. This

is called local sensin

ible, the voltage at the load will equal the programmed value.

ne

. If the voltage drop across both of the wires to the load is

Introduction to your PPS 2 - 11

g

g

g

g

g

g

Remote sensin

- S- V+ V+ S

load

If the voltage drop across the +V and -V wires to the load is substantial, the

e at the load will be less than the programmed value. T o prevent the voltage

volta

at the load from bein

be connected to the load (remote sensin

supply to compensate for volta

and the load. The sense wires must be connected directly to the load poles.

less than the programmed value, the sense wires must also

). This way of sensing allows the power

e drops in the wires between the power supply

Note: Long sense wires are susceptible to noise pickup. To minimize noise

pickup, twist each pair of sense wires to

ether. Shielding around the

sense wires may be necessary in more extreme cases.

2 - 12 Users Manual

g

g

g

g

2.3 ADVANCED OPERATION

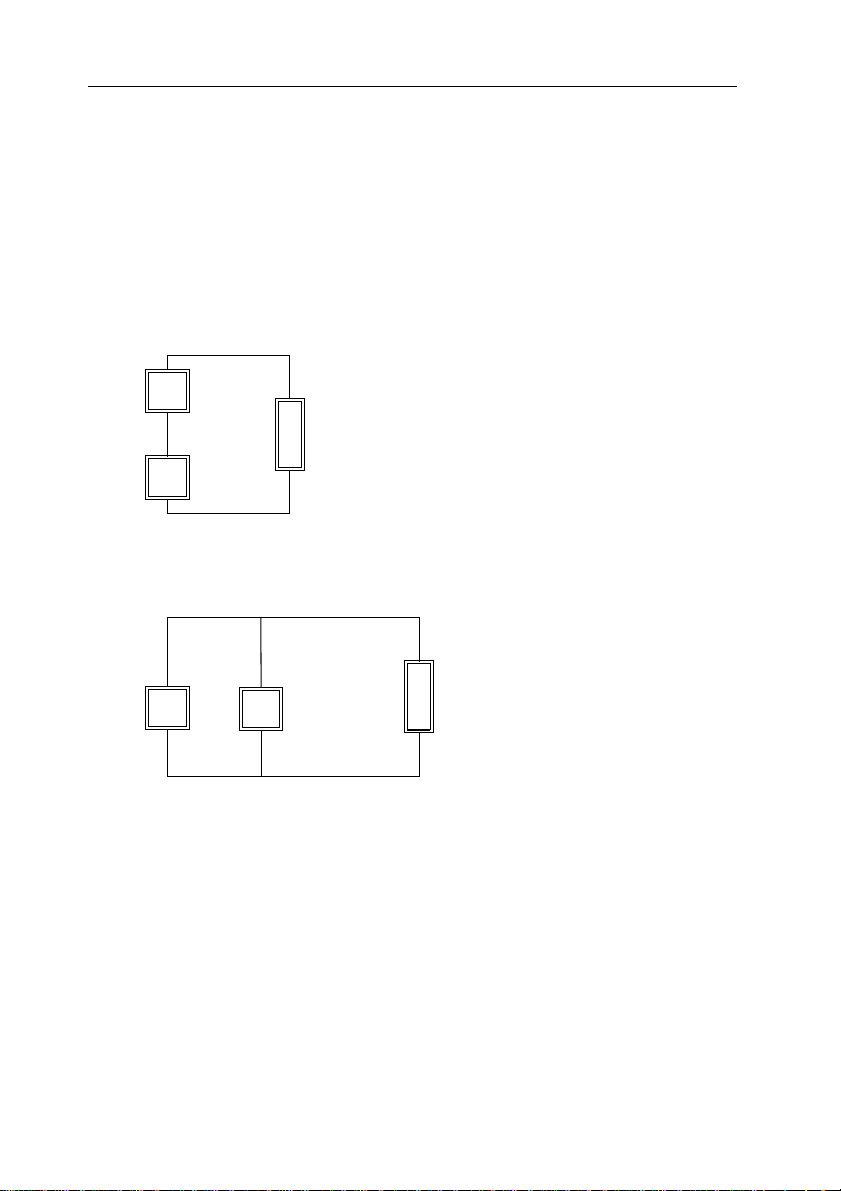

2.3.1 Output channel interconnections

Identical output channels can be connected in the followin

ways to increase the

total output capability:

•In

series

to increase the output volta

e capability. Refer to section 5.6.2

"Serial connection of output channels" for more information.

+

V

•

1

–

+

V

2

–

Parallel

to increase the output current capability. Refer to section 5.6.1

L

O

V

= V1 + V

load

A

D

2

"Parallel connection of output channels" for more information.

I

1

+

V

1

–

I

2

+

V

2

–

L

O

I

= I1 + I

load

A

D

2

CAUTION: Only output channels with equivalent voltage and current ratings

may be connected in series or parallel to prevent dama

e to one of

the channels. For maximum output capacity, refer to section 5.5.1

"Output channel ratin

s and characteristics". For more information

about connections, refer to section 5.6 "Advanced use".

Introduction to your PPS 2 - 13

g

g

g

g

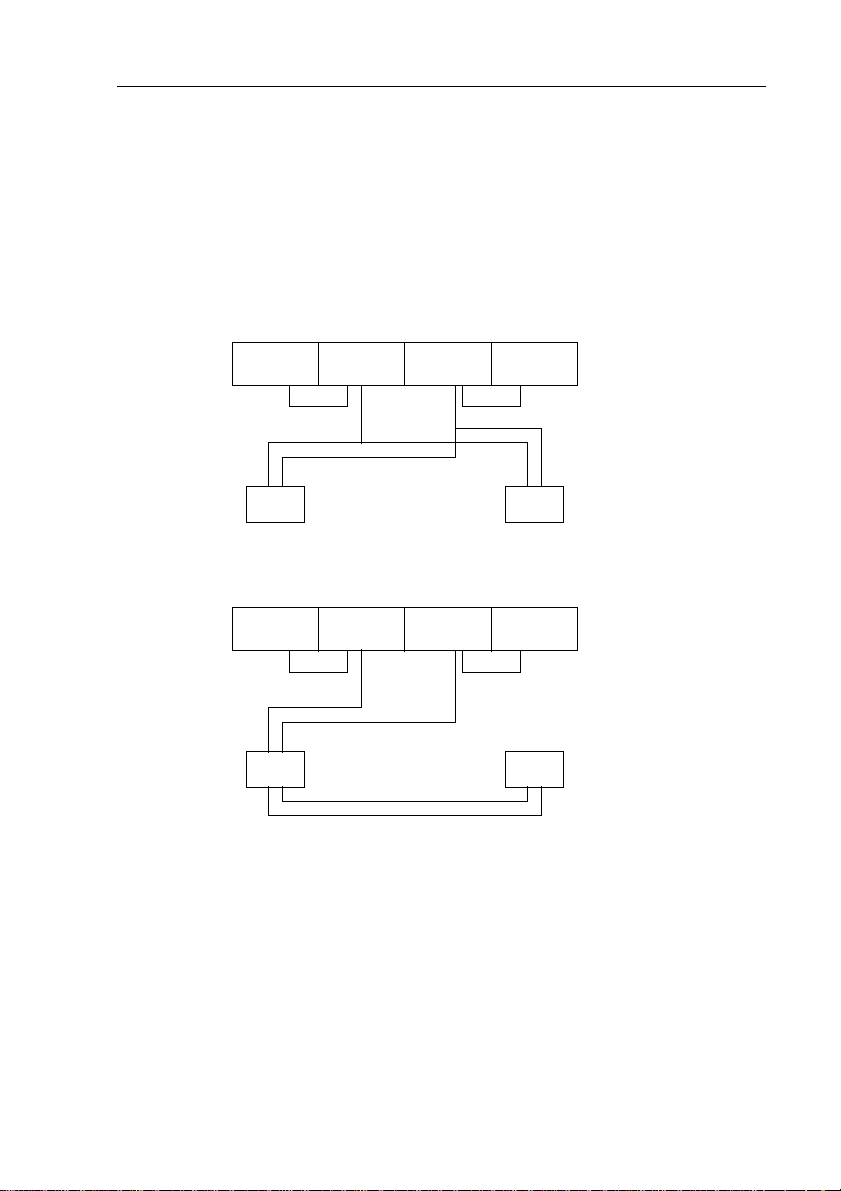

2.3.2 Multiple loads

If more than one load is connected to an output channel, use separate wires to

connect each load. This minimizes mutual couplin

advanta

e of the power supply’s low output impedance. Each pair of wires should

effects and takes full

be as short as possible to reduce wire inductance and noise pickup to prevent the

loads from mutually influencin

each other, due to load fluctuations. The loads

must be connected in parallel, not in series.

- S - V + V + S

–+ –+

load 1 load 2

CORRECT: Parallel connection of loads

- S - V + V + S

–+

load 1 load 2

–+

–+

WRONG: Series connection of loads

Note: To prevent noise pickup, you are advised to twist the sense wires and

shield them from each other.

In principle there is no restriction about the number of loads that can be

connected. Remote volta

e sensing is recommended if one load is more sensitive

than the other(s); therefore, sense directly at the most sensitive load.

Installation Instructions 3 - 1

g

g

g

g

g

g

g

g

g

g

g

3 INSTALLATION INSTRUCTIONS

3.1 INTRODUCTION

This section contains instructions for the following:

• inspectin

durin

• ensurin

• installin

•makin

• performin

the contents of the shipment for completeness and/or damage

transport (initial inspection)

the safety of the operator

the power supply

the input and output connections

the installation acceptance checks

3.2 INITIAL INSPECTION

Inspect the contents of the shipment for completeness and note whether any

e has occurred during transport. If the contents are not complete, or if there

dama

is dama

replacement of the instrument can be arran

Pay special attention to the followin

The shipment must contain one power supply plus the accessories supplied. For

a complete list of accessories supplied, refer to the INITIAL INSPECTION pa

in the front of this manual.

e, inform your FLUKE Sales and Service Center so that repair or

ed.

parts :

• accessories to be supplied (refer to Appendix A).

• front panel keys and display.

• rear panel connectors and terminal blocks.

• cabinet surfaces.

e

3.3 OPERATOR SAFETY INSTRUCTIONS

The instrument has been designed and tested in accordance with IEC Publication

1010 for Class 1 instruments and has been supplied in a safe condition. This

Operation Manual contains WARNING and CAUTION statements, that must be

followed by the user to ensure safe operation and to keep the instrument in a safe

condition.

3 - 2 Users Manual

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

The instrument described in this manual is to be used by properly trained

personnel.

Do not remove the cover or perform any adjustment, maintenance, or repair

unless you are qualified to do so and are aware of the hazards involved.

Symbol Before connectin

power

is made, the instrument must be connected to the earth (

conductor via the three-conductor power cord. The power plu

must be inserted into a socket outlet provided with

The

extension cord without a

WARNING : Any interruption of the protective conductor inside or outside

the instrument or disconnection of the protective

terminal is likely to make the instrument dan

Intentional interruption is prohibited.

The instrument is shipped from the factory with a power cord that has a plu

appropriate for the country in which it is sold. If a different power plu

cord is required, contact your Fluke Sales and Service Center.

round is functioning correctly . Before any other connection

rounding protection must not be defeated by use of an

the instrument to line power, ensure that the

round)

round contact.

round conductor.

round

erous.

or power

CAUTION: When an instrument is brought from a cold into a warm environment,

condensation may cause a hazardous condition; therefore, make

sure that the

rounding requirements are strictly adhered to.

3.4 INSTALLATION

3.4.1 Mechanical installation

The instrument is fan cooled and must be installed in a location that allows

sufficient space at the three important sides: rear, left, and ri

have a space of at least 1 inch (25 mm). The fan, located at the rear, cools the

instrument by drawin

s on the sides. Each instrument output channel has its own fan.

openin

air into the openings at the rear and exhausting it through

ht. Each side must

Loading...

Loading...