查询PDI1394P24BD供应商

INTEGRATED CIRCUITS

PDI1394P24

2-port 400 Mbps physical layer interface

Objective data

Supersedes data of 2000 Aug 02

2001 Sep 06

Philips Semiconductors Objective data

PDI1394P242-port 400 Mbps physical layer interface

1.0 FEATURES

•Fully supports provisions of IEEE 1394–1995 Standard for high

performance serial bus and the P1394a–2000 Standard.

1

• Fully interoperable with Firewire and i.LINK implementations of

the IEEE 1394 Standard.

2

•Full P1394a support includes:

– Connection debounce

– Arbitrated short reset

– Multispeed concatenation

– Arbitration acceleration

– Fly-by concatenation

– Port disable/suspend/resume

•Provides two 1394a fully-compliant cable ports at

100/200/400 Megabits per second (Mbps)

•Fully compliant with Open HCI requirements

• Cable ports monitor line conditions for active connection to remote

node.

•Power down features to conserve energy in battery-powered

applications include:

– Automatic device power down during suspend

– Device power down terminal

– Link interface disable via LPS

– Inactive ports powered-down

•Logic performs system initialization and arbitration functions

•Encode and decode functions included for data-strobe bit level

encoding

•Incoming data resynchronized to local clock

•Single 3.3 volt supply operation

•Minimum V

of 2.7 V for end-of-wire power-consuming devices

DD

•While unpowered and connected to the bus, will not drive TPBIAS

on a connected port, even if receiving incoming bias voltage on

that port

•Supports extended bias-handshake time for enhanced

interoperability with camcorders

•Interface to link-layer controller supports both low-cost bus-holder

isolation and optional Annex J electrical isolation

•Data interface to link-layer controller through 2/4/8 parallel lines at

49.152 MHz

•Low-cost 24.576 MHz crystal provides transmit, receive data at

100/200/400 Mbps, and link-layer controller clock at 49.152 MHz

•Does not require external filter capacitors for PLL

•Interoperable with link-layer controllers using 3.3 V and 5 V

supplies

•Interoperable with other Physical Layers (PHYs) using 3.3 V and

5 V supplies

•Node power class information signaling for system power

management

•Cable power presence monitoring

•Separate cable bias (TPBIAS) for each port

•Register bits give software control of contender bit, power class

bits, link active bit, and 1394a features

•Function and pin compatible with the Lucent FW802 400 Mbps Phy

2.0 DESCRIPTION

The PDI1394P24 provides the digital and analog transceiver functions

needed to implement a two port node in a cable-based IEEE

1394–1995 and/or 1394a network. Each cable port incorporates two

differential line transceivers. The transceivers include circuitry to

monitor the line conditions as needed for determining connection

status, for initialization and arbitration, and for packet reception and

transmission. The PDI1394P24 is designed to interface with a Link

Layer Controller (LLC), such as the PDI1394L11 or PDI1394L21.

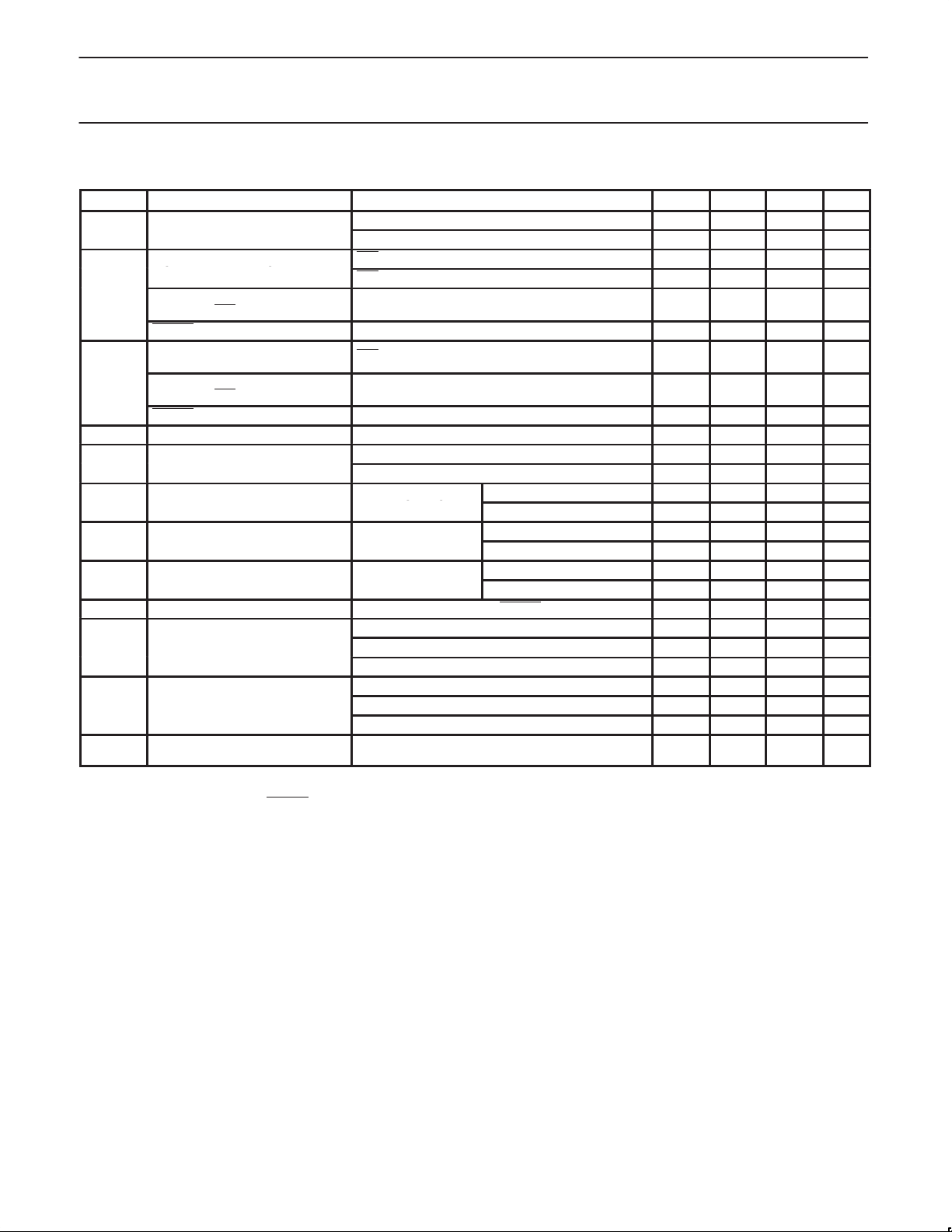

3.0 ORDERING INFORMATION

PACKAGE TEMPERATURE RANGE ORDER CODE PKG. DWG. #

64-pin plastic LQFP 0 to +70°C PDI1394P24BD SOT314-2

1. Implements technology covered by one or more patents of Apple Computer, Incorporated and SGS Thompson, Limited.

2. Firewire is a trademark of Apple Computer Inc. i.LINK is a trademark of Sony.

2001 Sep 06

2

Philips Semiconductors Objective data

PDI1394P242-port 400 Mbps physical layer interface

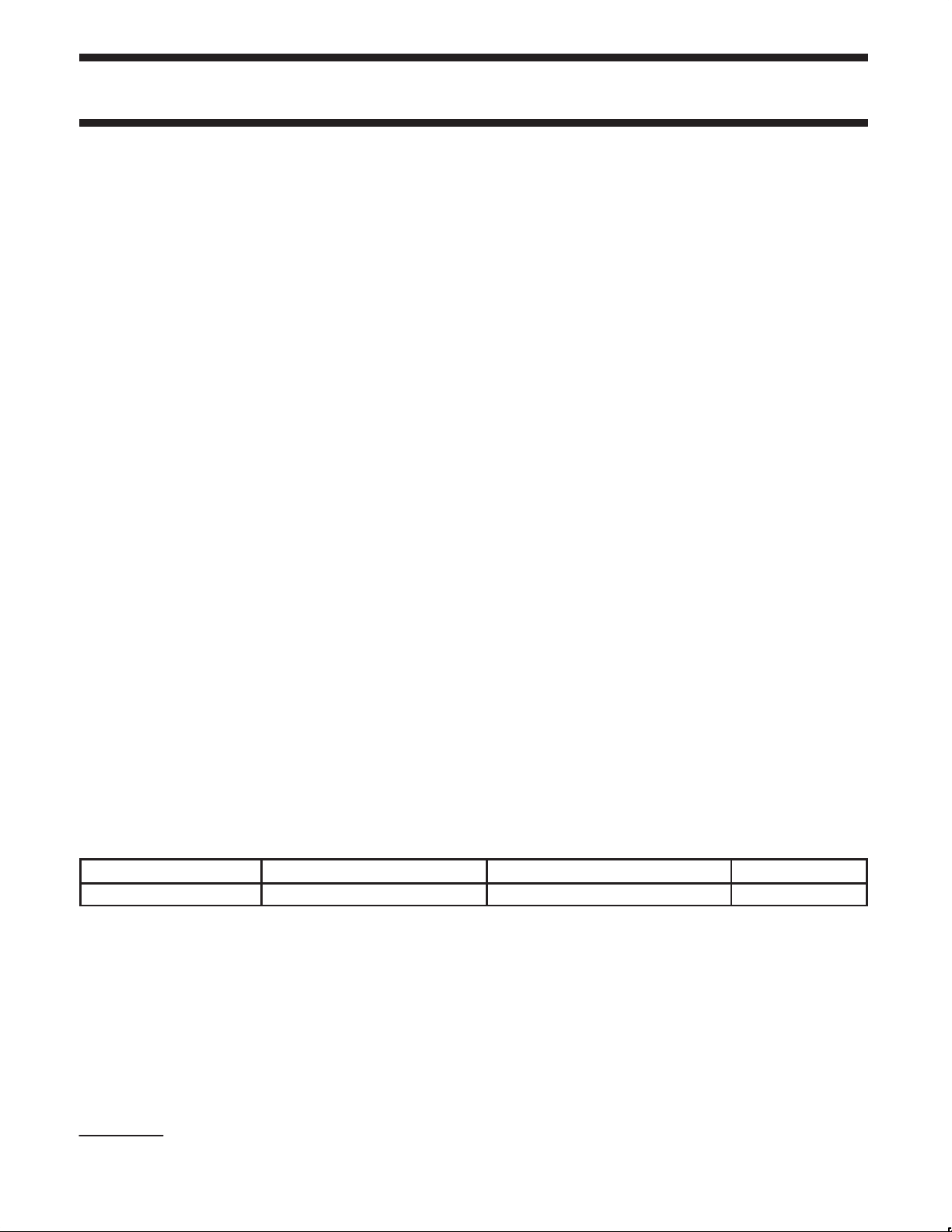

4.0 PIN CONFIGURATION

LREQ

DGND

CTL0

CTL1

DVDD

DGND

CNA

LPS

DGND

SYSCLK

62 61 60 59 58 57 56 55 5464 63 53 52 51 50 49

1

2

3

4

5

D0

6

D1

7

8

D2

9

D3

10

D4

11

D5

12

D6

13

D7

14

15

16

19 20 21 22 23 24 25

DVDD

C/LKON

DVDD

PD

/RESET

PC0

XOXIPLLGND

PLLVDD

PDI1394P24

PC1

PC2

/ISO

CPS

DGND

26 2717 18

DGND

R1

R0

AGND

28 29 30 31 32

DVDD

DVDD

TEST1

AGND

TEST0

AVDD

AVDD

AVDD

AVDD

AGND

AGND

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

NC

NC

NC

NC

NC

AVDD

TPBIAS1

TPA1+

TPA1–

TPB1+

TPB1–

TPBIAS0

TPA0+

TPA0–

TPB0+

TPB0–

2001 Sep 06

SV001823

3

Philips Semiconductors Objective data

PDI1394P242-port 400 Mbps physical layer interface

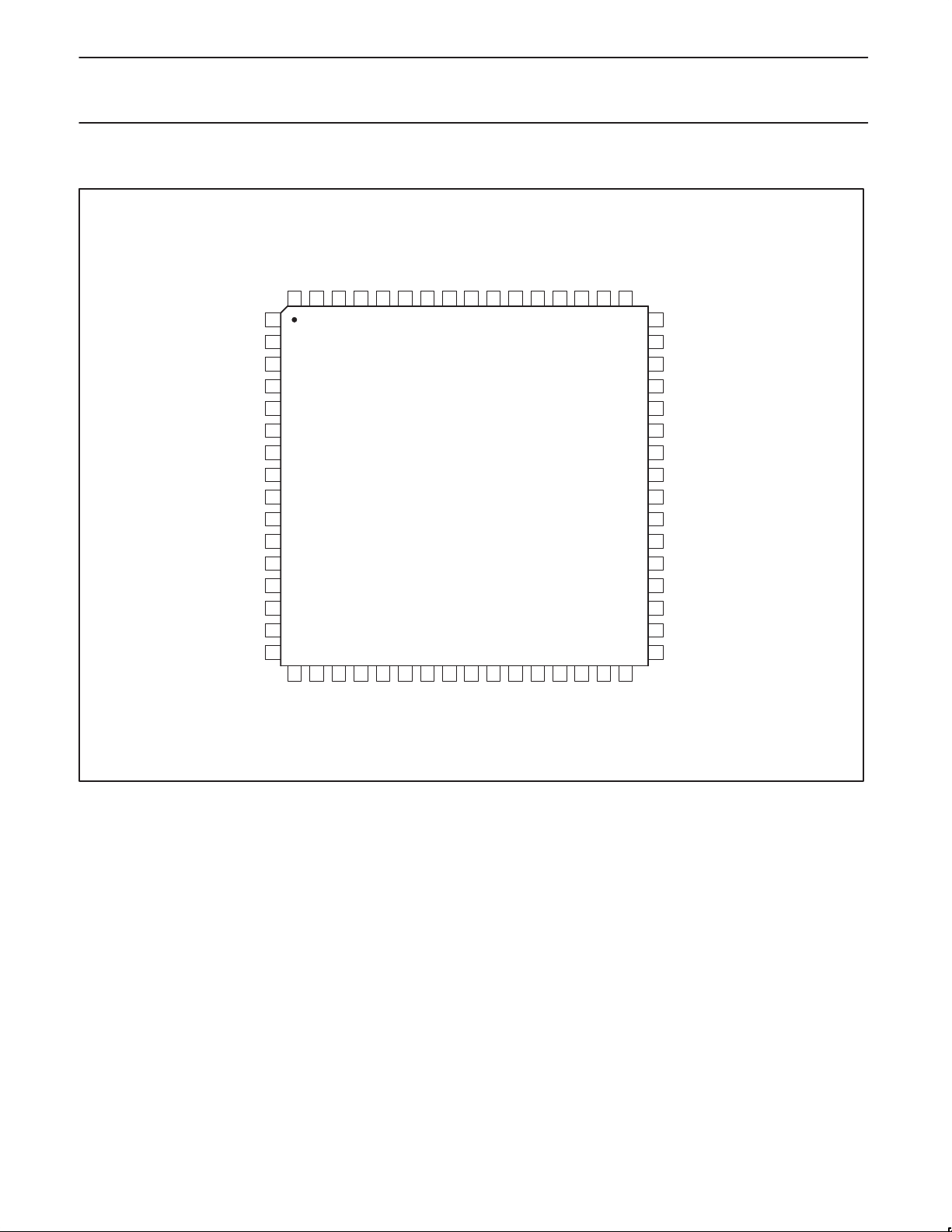

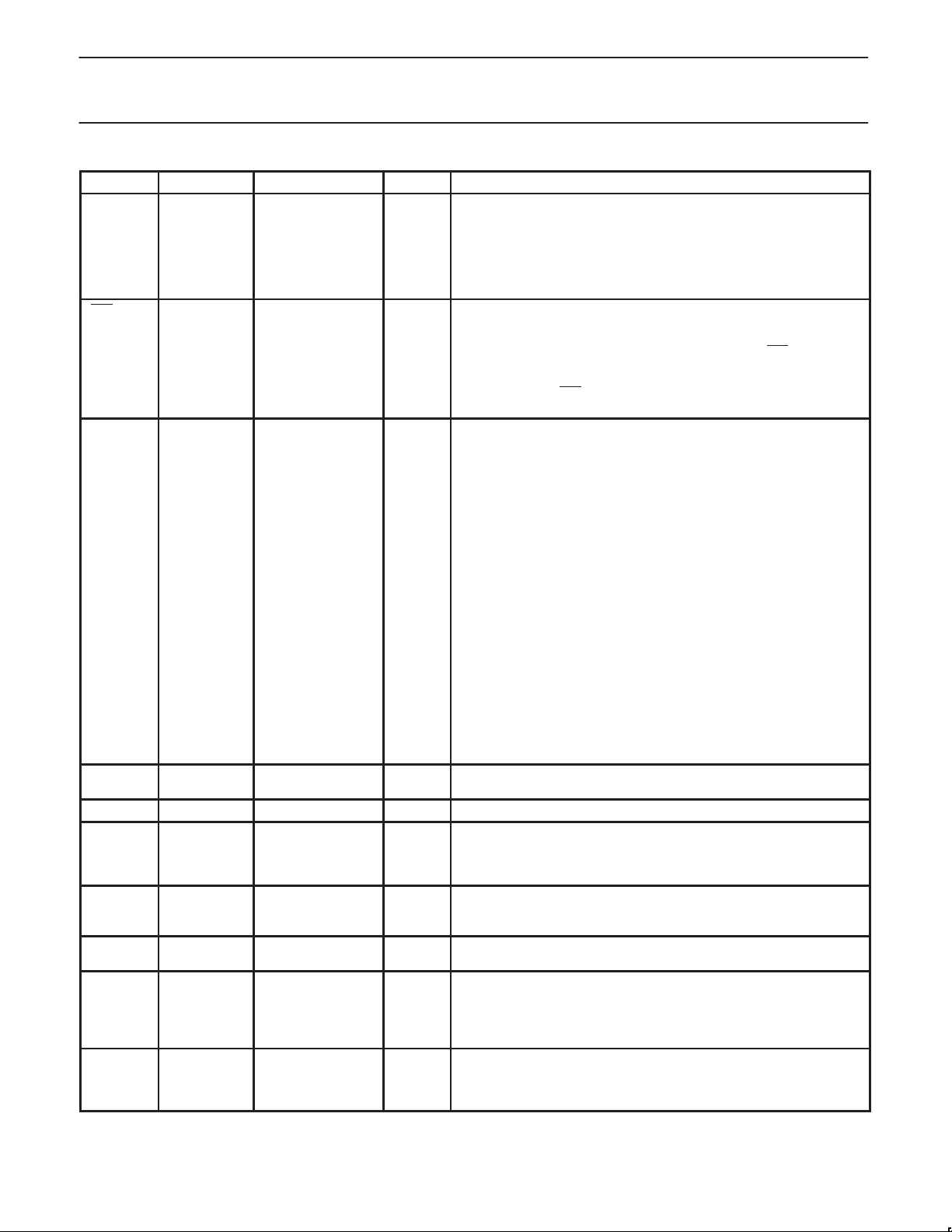

5.0 PIN DESCRIPTION

Name Pin Type Pin Numbers I/O Description

AGND Supply 32, 49, 52, 53 — Analog circuit ground terminals. These terminals should be tied together

AV

DD

C/LKON CMOS 5V tol 18 I/O Bus Manager Contender programming input and link-on output. On

CNA CMOS 15 O Cable Not Active output. This terminal is asserted high when there are

CPS CMOS 24 I Cable Power Status input. This terminal is normally connected to cable

CTL0,

CTL1

D0–D7 CMOS 5V tol 5, 6, 8, 9, 10, 1 1,

DGND Supply 2, 14, 25, 56, 64 — Digital circuit ground terminals. These terminals should be tied together

Supply 30, 31, 43, 50, 51 — Analog circuit power terminals. A combination of high frequency

CMOS 5V tol 3, 4 I/O Control I/Os. These bi-directional signals control communication

I/O Data I/Os. These are bi-directional data signals between the

12, 13

to the low impedance circuit board ground plane.

decoupling capacitors on each side are suggested, such as paralleled

0.1 µF and 0.001 µF. Lower frequency 10 µF filtering capacitors are also

recommended. These supply terminals are separated from PLLV

internal to the device to provide noise isolation. They should be

DV

DD

tied at a low impedance point on the circuit board.

hardware reset, this terminal is used to set the default value of the

contender status indicated during self-ID. Programming is done by tying

the terminal through a 10-kΩ resistor to a high (contender) or low (not

contender). The resistor allows the link-on output to override the input.

If this pin is connected to a LLC driver pin for setting Bus Manager/IRM

contender status, then a 10-kΩ series resistor should be placed on this

line between the PHY and the LLC to prevent possible contention. In this

case. the pull-high or pull-low resistors mentioned in the previous

paragraph should not be used. Refer to Figure 9.

Following hardware reset, this terminal is the link-on output, which is

used to notify the LLC to power-up and become active. The link-on

output is a square-wave signal with a period of approximately 163 ns (8

SYSCLK cycles) when active. The link-on output is otherwise driven low,

except during hardware reset when it is high impedance.

The link-on output is activated if the LLC is inactive (LPS inactive or the

LCtrl bit cleared) and when:

a) the PHY receives a link-on PHY packet addressed to this node,

b) the PEI (port-event interrupt) register bit is 1, or

c) any of the CTOI (configuration-timeout interrupt), CPSI

(cable-power-status interrupt), or STOI (state-timeout interrupt)

register bits are 1 and the RPIE (resuming-port interrupt enable)

register bit is also 1.

Once activated, the link-on output will continue active until the LLC

becomes active (both LPS active and the LCtrl bit set). The PHY also

deasserts the link-on output when a bus-reset occurs unless the link-on

output would otherwise be active because one of the interrupt bits is set

(i.e., the link-on output is active due solely to the reception of a link-on

PHY packet).

NOTE: If an interrupt condition exists which would otherwise cause the

link-on output to be activated if the LLC were inactive, the link-on output

will be activated when the LLC subsequently becomes inactive.

no ports receiving incoming bias voltage.

power through a 390 kΩ resistor. This circuit drives an internal

comparator that is used to detect the presence of cable power.

between the PDI1394P24 and the LLC. Bus holders are built into

these terminals.

PDI1394P24 and the LLC. Bus holders are built into these terminals.

Unused Dn pins should be pulled to ground through 10 kΩ resistors.

to the low impedance circuit board ground plane.

DD

and

2001 Sep 06

4

Philips Semiconductors Objective data

PDI1394P242-port 400 Mbps physical layer interface

Name DescriptionI/OPin NumbersPin Type

DV

DD

ISO CMOS 23 I Link interface isolation control input. This terminal controls the operation

LPS CMOS 5V tol 16 I Link Power Status input. This terminal is used to monitor the

LREQ CMOS 5V tol 1 I LLC Request input. The LLC uses this input to initiate a service request

NC No connect 44, 45, 46, 47, 48 — No connect.

PC0, PC1,

PC2

PD CMOS 5V tol 19 I Power Down input. A logic high on this terminal turns off all internal

PLLGND Supply 58 — PLL circuit ground terminals. These terminals should be tied together to

PLLV

DD

R0, R1 Bias 54, 55 — Current setting resistor terminals. These terminals are connected to

Supply 7, 17, 26, 27, 62 — Digital circuit power terminals. A combination of high frequency

CMOS 5V tol 20, 21, 22 I Power Class programming inputs. On hardware reset, these inputs set

Supply 57 — PLL circuit power terminals. A combination of high frequency decoupling

decoupling capacitors near each side of the IC package are suggested,

such as paralleled 0.1 µF and 0.001 µF. Lower frequency 10 µF filtering

capacitors are also recommended. These supply terminals are

separated from PLLV

isolation. They should be tied at a low impedance point on the circuit

board.

of output differentiation logic on the CTL and D terminals. If an optional

isolation barrier of the type described in Annex J of IEEE Std 1394–1995

is implemented between the PDI1394P24 and LLC, the ISO terminal

should be tied low to enable the differentiation logic. If no isolation barrier

is implemented (direct connection), or bus holder isolation is

implemented, the ISO

differentiation logic.

active/power status of the link layer controller and to control the state of

the PHY -LLC interface. This terminal should be connected to either the

VDD supplying the LLC through a 10 kΩ resistor, or to a pulsed output

which is active when the LLC is powered. A pulsed signal should be

used when an isolation barrier exists between the LLC and PHY. (See

Figure 8)

The LPS input is considered inactive if it is sampled low by the PHY for

more than 2.6 µs (128 SYSCLK cycles), and is considered active

otherwise (i.e., asserted steady high or an oscillating signal with a low

time less than 2.6 µs). The LPS input must be high for at least 21 ns in

order to be guaranteed to be observed as high by the PHY.

When the PDI1394P24 detects that LPS is inactive, it will place the

PHY -LLC interface into a low-power reset state. In the reset state, the

CTL and D outputs are held in the logic zero state and the LREQ input is

ignored; however, the SYSCLK output remains active. If the LPS input

remains low for more than 26 µs (1280 SYSCLK cycles), the PHY-LLC

interface is put into a low-power disabled state in which the SYSCLK

output is also held inactive. The PHY -LLC interface is placed into the

disabled state upon hardware reset.

The LLC is considered active only if both the LPS input is active and the

LCtrl register bit is set to 1, and is considered inactive if either the LPS

input is inactive or the LCtrl register bit is cleared to 0.

to the PDI1394P24. Bus holder is built into this terminal.

the default value of the power class indicated during self-ID.

Programming is done by tying the terminals high or low. Refer to

Table 21 for encoding.

circuitry except the cable-active monitor circuits which control the CNA

output. For more information, refer to Section 17.2

the low impedance circuit board ground plane.

capacitors near each terminal are suggested, such as paralleled 0.1 µF

and 0.001 µF. These supply terminals are separated from DVDD and

AVDD internal to the device to provide noise isolation. They should be

tied at a low impedance point on the circuit board.

an external resistance to set the internal operating currents and

cable driver output currents. A resistance of 2.49 kΩ ±1% is required to

meet the IEEE Std 1394–1995 output voltage limits.

and AVDD internal to the device to provide noise

DD

terminal should be tied high to disable the

2001 Sep 06

5

Philips Semiconductors Objective data

matched and as short as possible to the external load resistors and to

matched and as short as possible to the external load resistors and to

PDI1394P242-port 400 Mbps physical layer interface

Name DescriptionI/OPin NumbersPin Type

RESET CMOS 5V tol 61 I Logic reset input. Asserting this terminal low resets the internal logic. An

SYSCLK CMOS 63 O System clock output. Provides a 49.152 MHz clock signal, synchronized

TEST0 CMOS 29 I Test control input. This input is used in manufacturing tests of the

TEST1 CMOS 28 I Test control input. This input is used in manufacturing tests of the

TPA0+,

TPA1+

TPA0–,

TPA1–

TPB0+,

TPB1+

TPB0–,

TPB1–

TPBIAS0,

TPBIAS1

XO, XI Crystal 60, 59 — Crystal oscillator inputs. These terminals connect to a 24.576 MHz

Cable 36, 41 I/O

Cable 35, 40 I/O

Cable 34, 39 I/O

Cable 33, 38 I/O

Cable 37, 42 I/O Twisted-pair bias output. This provides the 1.86V nominal bias voltage

internal pull-up resistor to VDD is provided so only an external

delay capacitor is required for proper power-up operation. For more

information, refer to Section 17.2. This input is otherwise a standard

Schmitt logic input, and can also be driven by an open-drain type driver.

with data transfers, to the LLC.

PDI1394P24. For normal use, this terminal should be tied to GND.

PDI1394P24. For normal use, this terminal should be tied to GND.

Twisted-pair cable A differential signal terminals. Board traces from each

pair of positive and negative differential signal terminals should be kept

p

the cable connector. TPA+ and TPA– can be left unconnected on an

unused port.

Twisted-pair cable B differential signal terminals. Board traces from each

pair of positive and negative differential signal terminals should be kept

p

the cable connector. TPB+ and TPB– should be tied together and pulled

to ground on an unused port.

needed for proper operation of the twisted-pair cable drivers and

receivers, and for signaling to the remote nodes that there is an active

cable connection. Each of these terminals must be decoupled with a

0.3 µF–1 µF capacitor to ground. TPBIAS can be left unconnected on an

unused port.

parallel resonant fundamental mode crystal. The optimum values for the

external shunt capacitors are dependent on the specifications of the

crystal used. Can also be driven by an external clock generator (leave

XO unconnected in this case and start supplying the external clock

before resetting the PDI1394P24). For more information, refer to

Section 17.5.

2001 Sep 06

6

Philips Semiconductors Objective data

PDI1394P242-port 400 Mbps physical layer interface

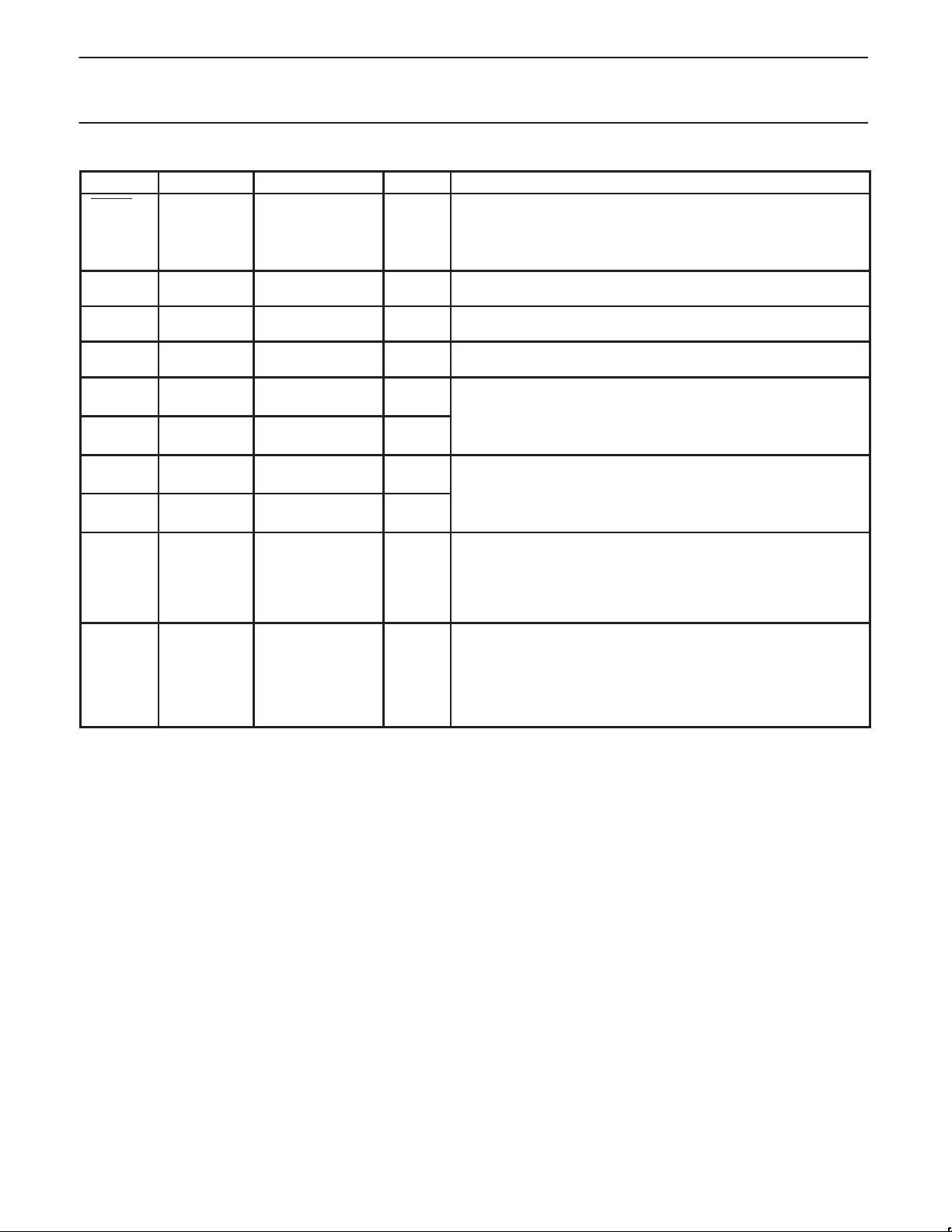

6.0 BLOCK DIAGRAM

LPS

/ISO

C/LKON

SYSCLK

LREQ

CTL0

CTL1

PC0

PC1

PC2

CNA

TPBIAS0

TPBIAS1

PD

/RESET

RECEIVED DATA

DECODER/

RETIMER

LINK

D0

D1

D2

D3

D4

D5

D6

D7

R0

R1

INTERFACE

I/O

ARBITRATION

AND CONTROL

STATE MACHINE

LOGIC

BIAS VOLTAGE

AND

CURRENT

GENERATOR

TRANSMIT

DATA

ENCODER

CABLE POWER

DETECTOR

CABLE PORT 0

CABLE PORT 1

CRYSTAL

OSCILLATOR,

PLL SYSTEM,

AND CLOCK

GENERATOR

CPS

TPA0+

TPA0–

TPB0+

TPB0–

TPA1+

TPA1–

TPB1+

TPB1–

XI

XO

SV01824

2001 Sep 06

7

Philips Semiconductors Objective data

PDI1394P242-port 400 Mbps physical layer interface

7.0 FUNCTIONAL SPECIFICA TION

The PDI1394P24 requires only an external 24.576 MHz crystal as a

reference. An external clock can be connected to XI instead of a

crystal. An internal oscillator drives an internal phase-locked loop

(PLL), which generates the required 393.216 MHz reference signal.

This reference signal is internally divided to provide the clock signals

used to control transmission of the outbound encoded Strobe and

Data information. A 49.152 MHz clock signal, supplied to the

associated LLC for synchronization of the two chips, is used for

resynchronization of the received data. The Power Down (PD)

function, when enabled by asserting the PD terminal high, stops

operation of the PLL and disables all circuits except the cable bias

detectors at the TPB terminals. The port transmitter circuitry and the

receiver circuitry are also disabled when the port is disabled,

suspended, or disconnected.

The PDI1394P24 supports an optional isolation barrier between

itself and its LLC. When the ISO

LLC interface outputs behave normally. When the ISO

tied low, internal differentiating logic is enabled, and the outputs are

driven such that they can be coupled through a capacitive or

transformer galvanic isolation barrier as described in

section 5.9.4

the ISO

using single capacitor isolation, please refer to the Philips Isolation

Application Note AN2452.

Data bits to be transmitted through the cable ports are received from

the LLC on two, four or eight parallel paths (depending on the

requested transmission speed). They are latched internally in the

PDI1394P24 in synchronization with the 49.152 MHz system clock.

These bits are combined serially, encoded, and transmitted at

98.304/196.608/393.216 Mbps (referred to as S100, S200, and

S400 speed, respectively) as the outbound data-strobe information

stream. During transmission, the encoded data information is

transmitted differentially on the TPB cable pair(s), and the encoded

strobe information is transmitted differentially on the TP A cable

pair(s).

During packet reception the TPA and TPB transmitters of the

receiving cable port are disabled, and the receivers for that port are

enabled. The encoded data information is received on the TPA cable

pair, and the encoded strobe information is received on the TPB

cable pair. The received data-strobe information is decoded to

recover the receive clock signal and the serial data bits. The serial

data bits are split into two-, four- or eight-bit parallel streams

(depending upon the indicated receive speed), resynchronized to

the local 49.152 MHz system clock and sent to the associated LLC.

The received data is also transmitted (repeated) on the other active

(connected) cable ports.

Both the TPA and TPB cable interfaces incorporate dif ferential

comparators to monitor the line states during initialization and

arbitration. The outputs of these comparators are used by the

internal logic to determine the arbitration status. The TPA channel

monitors the incoming cable common-mode voltage. The value of

this common-mode voltage is used during arbitration to set the

speed of the next packet transmission (speed signaling). In addition,

the TPB channel monitors the incoming cable common-mode

voltage on the TPB pair for the presence of the remotely supplied

twisted-pair bias voltage (cable bias detection).

The PDI1394P24 provides a 1.86 V nominal bias voltage at the

TPBIAS terminal for port termination. The PHY contains two

independent TPBIAS circuits. This bias voltage, when seen through

a cable by a remote receiver, indicates the presence of an active

. To operate with single capacitor (bus holder) isolation,

on the PHY terminal must be tied high. For more details on

input terminal is tied high, the

terminal is

IEEE 1394a

connection. This bias voltage source must be stabilized by an

external filter capacitor of 0.3 µF–1 µF.

The line drivers in the PDI1394P24 operate in a high-impedance

current mode, and are designed to work with external 112 Ω

line-termination resistor networks in order to match the 110 Ω cable

impedance. One network is provided at each end of all twisted-pair

cable connections. Each network is composed of a pair of

series-connected 56 Ω resistors. The midpoint of the pair of resistors

that is directly connected to the twisted-pair A terminals is connected

to its corresponding TPBIAS voltage terminal. The midpoint of the pair

of resistors that is directly connected to the twisted-pair B terminals is

coupled to ground through a parallel R-C network with recommended

values of 5 kΩ and 220 pF. The values of the external line termination

resistors are designed to meet the standard specifications when

connected in parallel with the internal receiver circuits. An external

resistor connected between the R0 and R1 terminals sets the driver

output current, along with other internal operating currents. This

current setting resistor has a value of 2.49 kΩ ±1%.

When the power supply of the PDI1394P24 is removed while the

twisted-pair cables are connected, the PDI1394P24 transmitter and

receiver circuitry presents a high impedance to the cable in order to

not load the TPBIAS voltage on the other end of the cable.

When the PDI1394P24 is used with one or more of the ports not

brought out to a connector, the twisted-pair terminals of the unused

ports must be terminated for reliable operation. For each unused

port, the TPB+ and TPB– terminals can be tied together and then

pulled to ground, or the TPB+ and TPB– terminals can be connected

to the suggested termination network. The TPA+ and TPA– and

TPBIAS terminals of an unused port can be left unconnected.

The TEST0 and TEST1 terminals are used to set up various

manufacturing test conditions. For normal operation, the TEST0 and

TEST1 terminals should be connected to ground. TEST1 can also

be tied through a 1 kW resistor to ground.

Four package terminals, used as inputs to set the default value for

four configuration status bits in the self-ID packet, should be

hard-wired high or low as a function of the equipment design. The

PC0–PC2 terminals are used to indicate the default power-class

status for the node (the need for power from the cable or the ability

to supply power to the cable). See Table 21 for power class

encoding. The C/LKON terminal is used as an input to indicate that

the node is a contender for bus manager.

The PHY supports suspend/resume as defined in the IEEE 1394a

specification. The suspend mechanism allows pairs of directly

connected ports to be placed into a low power state while

maintaining a port-to-port connection between 1394 bus segments.

While in a low power state, a port is unable to transmit or receive

data transaction packets. However, a port in a low power state is

capable of detecting connection status changes and detecting

incoming TPBIAS. When all two ports of the PDI1394P24 are

suspended, all circuits except the bias-detection circuits are

powered down, resulting in significant power savings. The TPBIAS

circuit monitors the value of incoming TPA pair common-mode

voltage when local TPBIAS is inactive. Because this circuit has an

internal current source and the connected node has a current sink,

the monitored value indicates the cable connection status. This

monitor is called connect-detect.

2001 Sep 06

8

Philips Semiconductors Objective data

SYMBOL

PARAMETER

CONDITION

UNIT

Electrostatic discharge

PDI1394P242-port 400 Mbps physical layer interface

Both the cable bias-detect monitor and TPBIAS connect-detect

monitor are used in suspend/resume signaling and cable connection

detection. For additional details of suspend/resume operation, refer

to the 1394a specification. The use of suspend/resume is

recommended for new designs.

The port transmitter and receiver circuitry is disabled during power

down (when the PD input terminal is asserted high), during reset

(when the RESET

cable is connected to the port, or when controlled by the internal

arbitration logic. The port twisted-pair bias voltage circuitry is

disabled during power down, during reset, or when the port is

disabled as commanded by the LLC.

The CNA (cable-not-active) terminal provides a high when there are

no twisted-pair cable ports receiving incoming bias (i.e., they are

either disconnected or suspended), and can be used along with LPS

to determine when to power-down the PDI1394P24. The CNA

output is not debounced. When the PD terminal is asserted high, the

CNA detection circuitry is enabled (regardless of the previous state

of the ports) and a pull-down is activated on the RESET

as to force a reset of the PDI1394P24 internal logic.

The LPS (link power status) terminal works with the C/LKON

terminal to manage the power usage in the node. The LPS signal

from the LLC is used in conjunction with the LCtrl bit (see Table 1

and Table 2) to indicate the active/power status of the LLC. The LPS

signal is also used to reset, disable, and initialize the PHY -LLC

interface (the state of the PHY -LCC interface is controlled solely by

the LPS input regardless of the state of the LCtrl bit).

input terminal is asserted low), when no active

terminal so

The LPS input is considered inactive if it remains low for more than

2.6

µs and is considered active otherwise. When the PDI1394P24

detects that LPS is inactive, it will place the PHY -LLC interface into a

low-power reset state in which the CTL and D outputs are held in the

logic zero state and the LREQ input is ignored; however, the

SYSCLK output remains active. If the LPS input remains low for

more than 26 µs, the PHY-LLC interface is put into a low-power

disabled state in which the SYSCLK output is also held inactive. The

PHY -LLC interface is also held in the disabled state during hardware

reset. The PDI1394P24 will continue the necessary repeater

functions required for normal network operation regardless of the

state of the PHY -LLC interface. When the interface is in the reset or

disabled state and LPS is again observed active, the PHY will

initialize the interface and return it to normal operation.

The PHY uses the C/LKON terminal to notify the LLC to power up

and become active. When activated, the C/LKON signal is a square

wave of approximately 163 ns period. The PHY activates the

C/LKON output when the LLC is inactive and a wake-up event

occurs. The LLC is considered inactive when either the LPS input is

inactive, as described above, or the LCtrI bit is cleared to 0. A

wake-up event occurs when a link-on PHY packet addressed to this

node is received, or conditionally when a PHY interrupt occurs. The

PHY deasserts the C/LKON output when the LLC becomes active

(both LPS active and the LCtrl bit set to 1). The PHY also deasserts

the C/LKON output when a bus-reset occurs unless a PHY interrupt

condition exists which would otherwise cause C/LKON to be active.

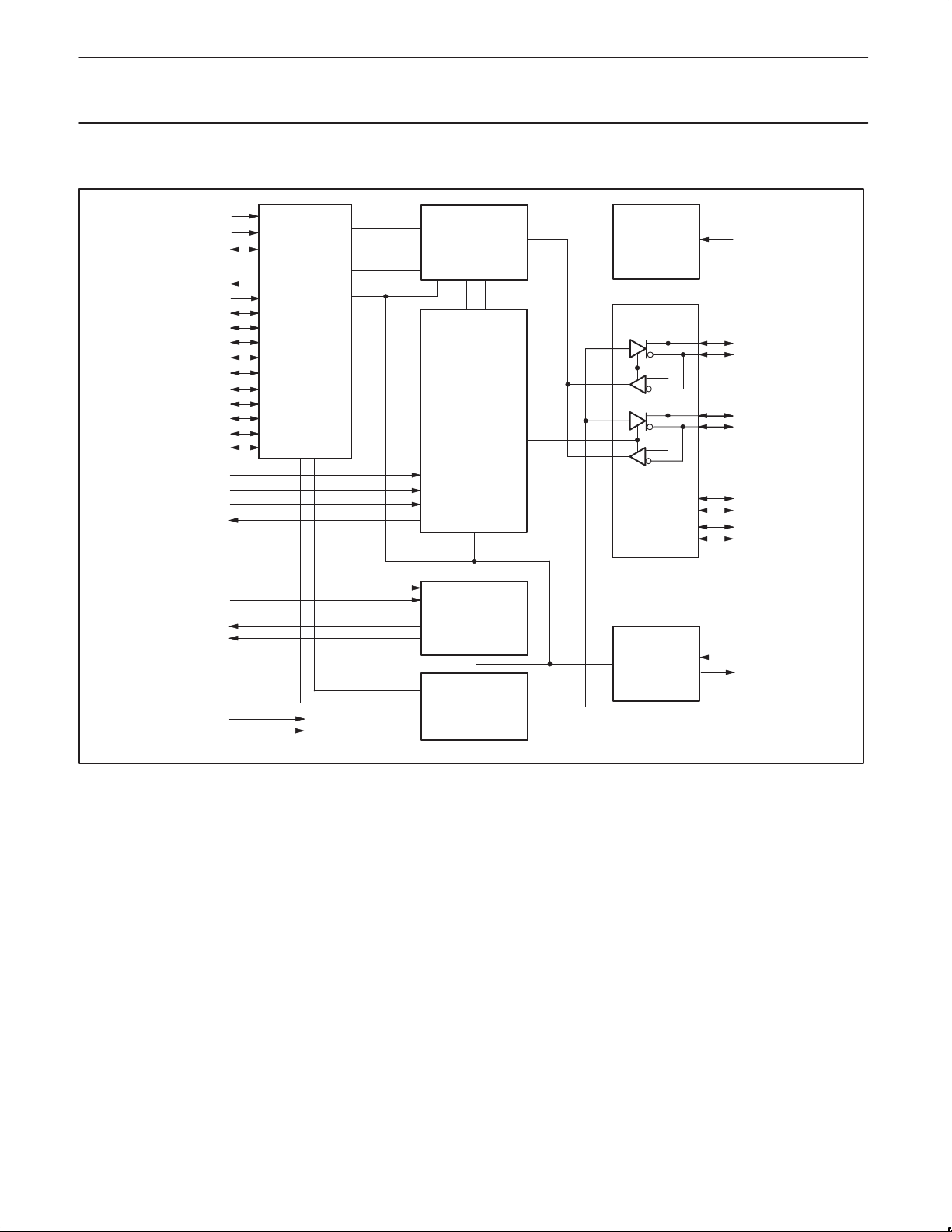

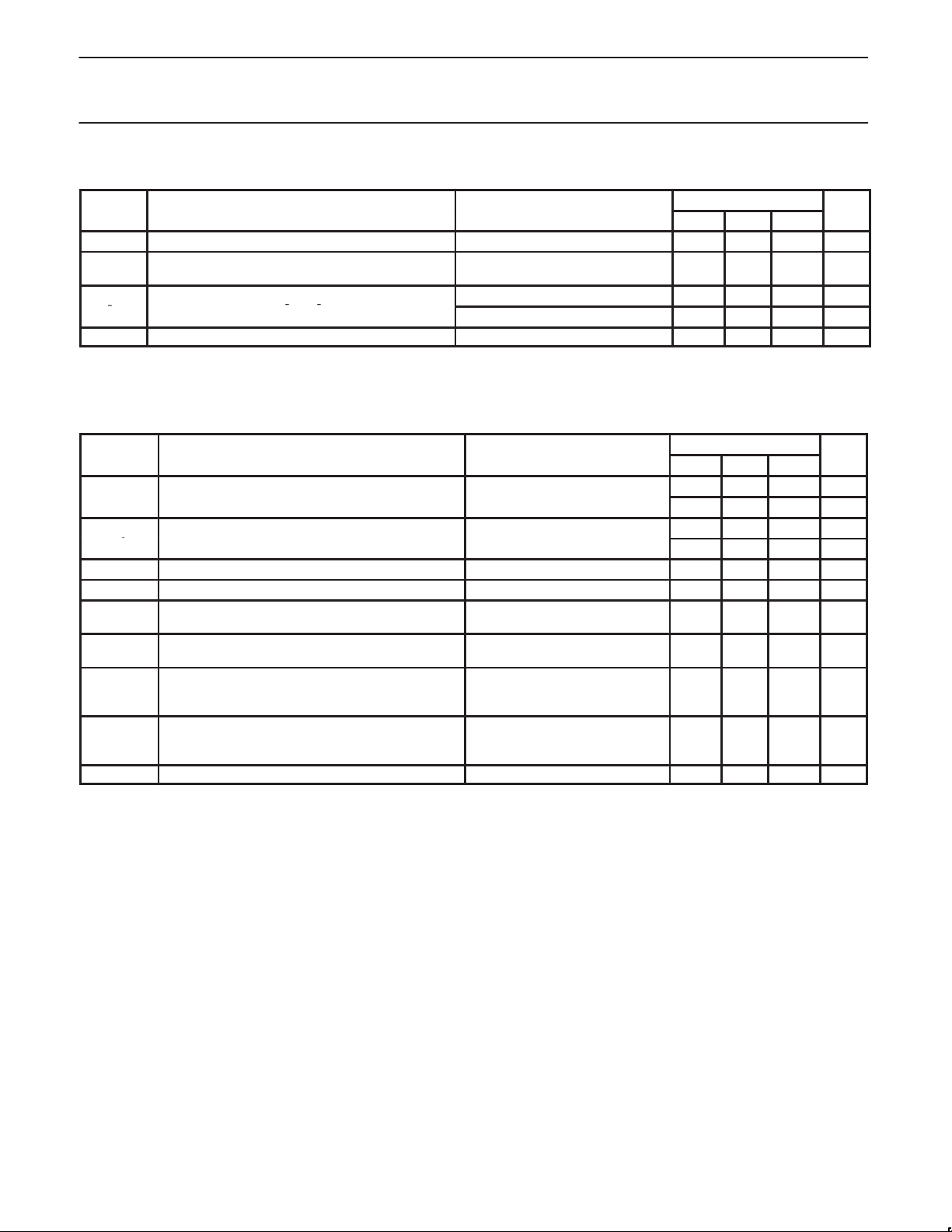

8.0 ABSOLUTE MAXIMUM RATINGS

In accordance with the Absolute Maximum Rating System (IEC 134). Voltages are referenced to GND (ground = 0 V).

V

VI–5V 5 volt tolerant input voltage range –0.5 5.5 V

V

T

amb

T

NOTE:

1. Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings

only, and functional operation of the device at these or any other conditions beyond those indicated under “Recommended Operating

Conditions” is not implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability .

DC supply voltage –0.5 4.0 V

DD

V

DC input voltage –0.5 VDD+0.5 V

I

DC output voltage range at any output –0.5 VDD+0.5 V

O

Operating free-air temperature range 0 +70 °C

Storage temperature range –65 +150 °C

stg

1

LIMITS

MIN MAX

Human Body Model — 2 kV

Machine Model — 200 V

2001 Sep 06

9

Philips Semiconductors Objective data

SYMBOL

PARAMETER

CONDITION

MIN

TYP

MAX

UNIT

VDDSu ly voltage

gg

VIDDifferential in ut voltage am litude

V

TPB common-mode in ut voltage

gg

V

TPB common-mode in ut voltage

S200 s eed signal

V

TPB common-mode in ut voltage

S400 s eed signal

PDI1394P242-port 400 Mbps physical layer interface

9.0 RECOMMENDED OPERATING CONDITIONS

pp

High-level input voltage, LREQ,

CTL0, CTL1, D0-D7

V

IH

High-level input voltage, C/LKON2,

Source power node 3.0 3.3 3.6 V

Non-source power node 2.7

ISO = VDD, VDD >= 2.7 V 2.3 — — V

ISO = VDD, VDD >= 3.0 V 2.6 — 5.5 V

PC0–PC2, ISO, PD

RESET 0.6 V

Low-level input voltage, LREQ,

CTL0, CTL1, D0–D7

V

Low-level input voltage, C/LKON2,

IL

PC0–PC2, ISO, PD,

ISO = V

DD

RESET — — 0.3 V

I

Output current TPBIAS outputs –6 — 2.5 mA

O

TPA, TPB cable inputs, during data reception 118 — 260 mV

TPA, TPB cable inputs, during data arbitration 168 — 265 mV

Speed signaling off

or S100 speed signal

p

p

Source power node 1.165 — 2.515 V

Non-source power node 1.165 — 2.015

Source power node 0.935 — 2.515 V

Non-source power node 0.935 — 2.015

Source power node 0.523 — 2.515 V

Non-source power node 0.523 — 2.015

IC-100

IC-200

IC-400

t

PU

p

p

p

p

p

Power–up reset time Set by capacitor between RESET pin and GND 2 — — ms

TPA, TPB cable inputs, S100 operation — — 1.08 ns

Receive input jitter

TPA, TPB cable inputs, S200 operation — — 0.5 ns

TPA, TPB cable inputs, S400 operation — — 0.315 ns

Between TPA and TPB cable inputs, S100 operation — — 0.8 ns

Receive input skew

Between TPA and TPB cable inputs, S200 operation — — 0.55 ns

Between TPA and TPB cable inputs, S400 operation — — 0.5 ns

f

XTAL

Crystal or external clock frequency

Crystal connected according to Figure 10 or external

clock input at pin XI

NOTES:

1. For a node that does not source power to the bus (see Section 4.2.2.2 in the IEEE 1394-1995 standard).

2. C/LKON is only an input when RESET

= 0.

1

3.0 3.6 V

0.7 V

— — V

DD

— —

DD

— — 0.7 V

— — 0.2 V

DD

DD

V

—

1

V

1

V

1

V

24.5735 24.576 24.5785 MHz

2001 Sep 06

10

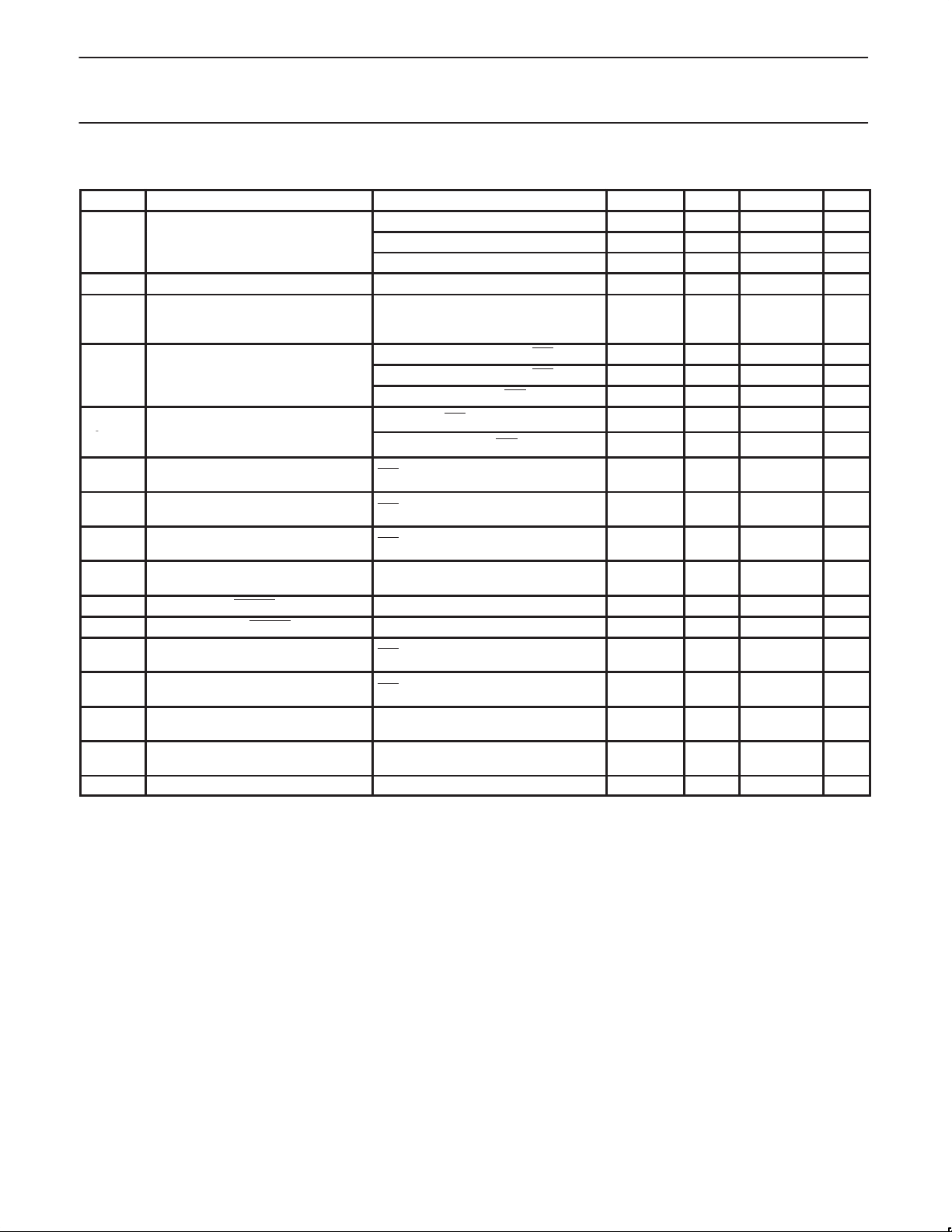

Philips Semiconductors Objective data

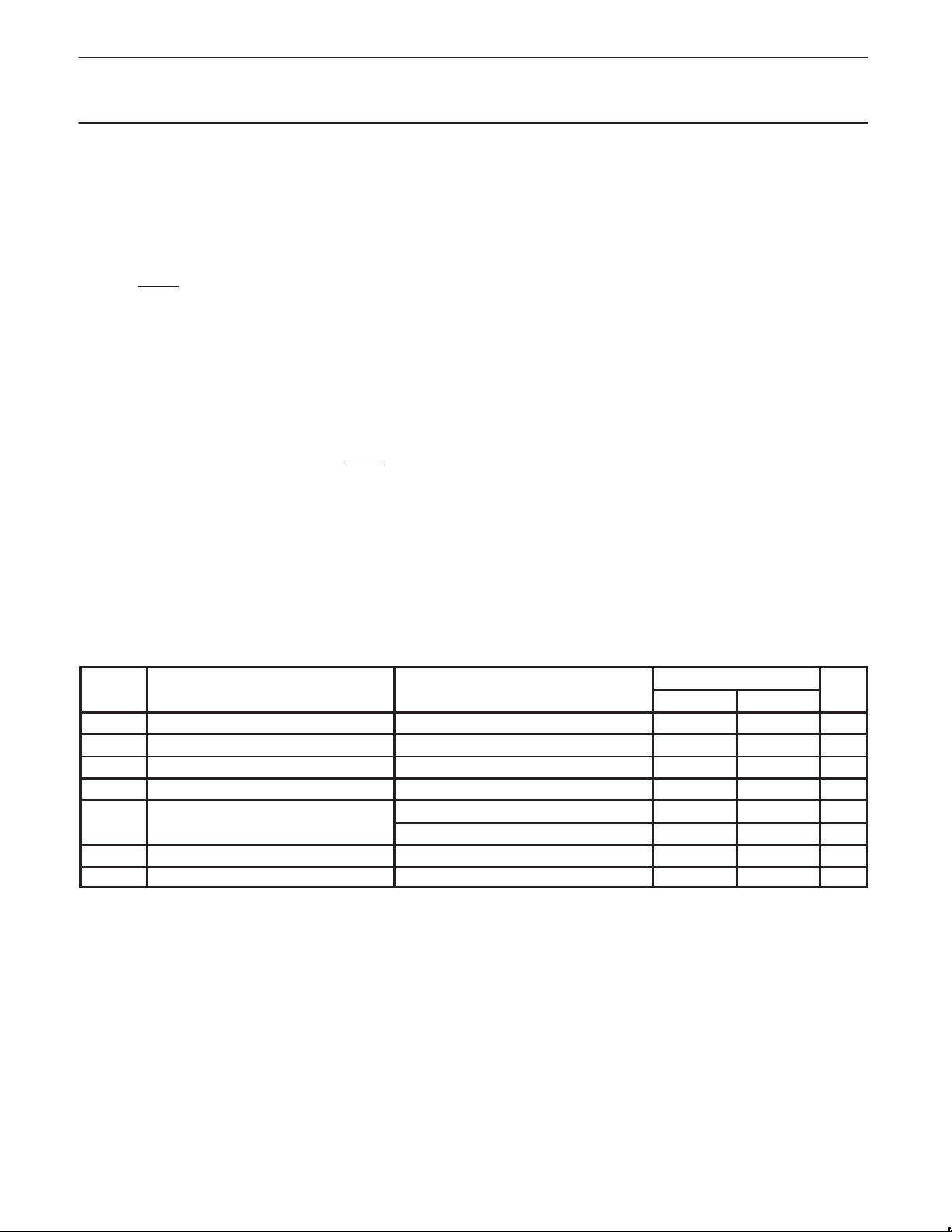

SYMBOL

PARAMETER

TEST CONDITION

UNIT

I

gg , ,

SYMBOL

PARAMETER

TEST CONDITION

UNIT

ZIDDifferential input impedance

Drivers disabled

ZICCommon mode input impedance

Drivers disabled

PDI1394P242-port 400 Mbps physical layer interface

10.0 CABLE DRIVER

LIMITS

MIN TYP MAX

V

I

O(diff)

V

OFF

NOTES:

1. Limits defined as algebraic sum of TPA+ and TPA– driver currents. Limits also apply to TPB+ and TPB– algebraic sum of driver currents.

2. Limits defined as one half of the algebraic sum of currents flowing out of TPB+ and TPB–.

11.0 CABLE RECEIVER

V

V

V

V

V

TH–SP200

V

TH–SP400

Differential output voltage 56 Ω load 172 — 265 mV

OD

Drivers enabled,

Driver Difference current, TP A+, TPA–, TPB+, TPB–

Common mode speed signaling output current, TPB+,

TPB–

2

SP

1

speed signaling OFF

–0.88 — 0.88 mA

200 Mbps speed signaling enabled –4.84 — –2.53 mA

400 Mbps speed signaling enabled –12.4 — –8.10 mA

OFF state differential voltage Drivers disabled — — 20 mV

LIMITS

MIN TYP MAX

10 14 —

— — 4 pF

20 — — kΩ

— — 24 pF

TH-R

TH-CB

TH+

TH–

p

p

p

p

Receiver input threshold voltage Drivers disabled –30 — 30 mV

Cable bias detect threshold, TPBn cable inputs Drivers disabled 0.6 — 1.0 V

Positive arbitration comparator input threshold

voltage

Negative arbitration comparator input threshold

voltage

Drivers disabled 89 — 168 mV

Drivers disabled –168 — –89 mV

TPBIAS–TPA common mode

Speed signal input threshold

voltage, drivers disabled 200

49 — 131 mV

Mbps

TPBIAS–TPA common mode

Speed signal input threshold

voltage, drivers disabled 400

314 — 396 mV

Mbps

I

CD

Connect detect output at TPBIAS pins Drivers disabled — — –76 µA

kΩ

2001 Sep 06

11

Philips Semiconductors Objective data

High level out ut voltage. ins CTL0

C/LKON

V

CTL1, D0–D7, CNA, C/LKON

PDI1394P242-port 400 Mbps physical layer interface

12.0 OTHER DEVICE I/O

SYMBOL PARAMETER TEST CONDITION MIN TYP MAX UNIT

See Note 1 — TBD — mA

I

DD

I

DD–PD

V

TH

V

OH

Supply current

Supply current in power down mode PD = VDD in power down mode — TBD — µA

Cable power status threshold voltage

-

p

p

CTL1, D0–D7, SYSCLK, CNA,

Low-level output voltage, pins CTL0,

OL

I

BH+

I

BH–

I

I

I

OZ

I

RST-UP

I

RST-DN

V

IT+

V

IT–

V

LIT+

V

LIT–

V

O

SYSCLK

Positive peak bus holder current, pins

CTL0, CTL1, D0–D7, LREQ

Negative peak bus holder current, pins

CTL0, CTL1, D0–D7, LREQ

Input current, pins LREQ, LPS, PD,

TEST0, TEST1, PC0–PC2

Off-state current, pins CTL0, CTL1,

D0–D7, C/LKON

Pullup current, RESET input VI = 1.5 V or 0 V –90 — –20 µA

Pulldown current, RESET input VI = VDD, PD = V

Positive going threshold voltage, LREQ,

CTL0, CTL1, D0–D7, C/LKON inputs

Negative going threshold voltage, LREQ,

CTL0, CTL1, D0–D7, C/LKON inputs

Positive going threshold voltage, LPS

inputs

Negative going threshold voltage, LPS

inputs

TPBIAS output voltage At rated IO current 1.665 — 2.015 V

,

NOTES:

1. Transmit Max Packet (2 ports transmitting max size isochronous packet (4096 bytes), sent on every isochronous interval, S400, data value

of 0xCCCCCCCCh), V

2. Repeat typical packet (1 port receiving DV packets on every isochronous interval, 1 port repeating the packet, S100), V

= 3.3 V, TA = 25°C

DD

TA = 25°C

3. Idle (receive cycle start on one port, transmit cycle start on other port) V

See Note 2 — TBD — mA

See Note 3 — TBD — mA

390 kΩ resistor between cable power

and CPS pin: Measured at cable power

4.7 — 7.5 V

side of resistor

VDD >= 2.7 V, IOH = –4 mA, ISO = V

,

VDD >= 3.0 V, IOH = –4 mA, ISO = V

DD

DD

2.4 — — V

2.8 — — V

Annex J: IOH = –9 mA, ISO = 0 VDD–0.4 — — V

IOL = 4 mA, ISO = V

DD

— — 0.4 V

Annex J: IOL = 9 mA, ISO = 0 — — 0.4 V

ISO = VDD, VI = 0 V to V

ISO = VDD, VI = 0 V to V

DD

DD

0.05 — 1.0 mA

–1.0 — –0.05 mA

ISO = 0 V; VDD = 3.6 V — — 5 µA

VO = VDD or 0 V –5 — 5 µA

DD

.4 1.6 2.8 mA

ISO = 0 V VDD/2 + 0.3 — VDD/2 + 0.9 V

ISO = 0 V VDD/2 – 0.9 — VDD/2 – 0.3 V

V

V

LREF

LREF

= 0.24 × V

= 0.24 × V

DD

DD

= 3.3 V, TA = 25°C

DD

— — V

V

+0.2 — — V

LREF

LREF

= 3.3 V,

DD

+1 V

2001 Sep 06

12

Philips Semiconductors Objective data

SYMBOL

PARAMETER

TEST CONDITION

UNIT

PDI1394P242-port 400 Mbps physical layer interface

13.0 THERMAL CHARACTERISTICS

LIMITS

MIN TYP MAX

RΘjA Junction-to-free-air thermal resistance Board mounted, no air flow — 68 — °C/W

14.0 AC CHARACTERISTICS

SYMBOL PARAMETER CONDITION MIN TYP MAX UNIT

Transmit jitter TPA, TPB — — 0.15 ns

Transmit skew Between TPA and TPB — — 0.10 ns

t

TPA, TPB differential output voltage rise time 10% to 90%; At 1394 connector 0.5 — 1.2 ns

r

t

TPA, TPB differential output voltage fall time 90% to 10%; At 1394 connector 0.5 — 1.2 ns

f

t

C

Setup time, CTL0, CTL1, D0–D7, LREQ to SYSCLK 50% to 50%; See Figure 2 5 — — ns

SU

t

Hold time, CTL0, CTL1, D0–D7, LREQ after SYSCLK 50% to 50%; See Figure 2 0 — — ns

H

t

Delay time SYSCLK to CTL0, CTL1, D0–D7 50% to 50%; See Figure 3 0.5 — 11 ns

D

Capacitance load value CTL0, CTL1, D0–D7, SYSCLK — 10 — pF

L

C

Input capacitance CTL0, CTL1, D0–D7, LREQ — 3.3 — pF

i

15.0 TIMING WAVEFORMS

TPAn+

TPBn+

56 Ω

TPAn–

TPBn–

SV01098

Figure 1. Test load diagram

SYSCLK

t

SU

Dn, CTLn, LREQ

Figure 2. Dn, CTLn, LREQ input setup and hold times

t

H

SV01099

SYSCLK

t

D

Dn, CTLn

SV01803

Figure 3. Dn, CTLn, output delay relative to SYSCLK

2001 Sep 06

13

Philips Semiconductors Objective data

ADDRESS

PDI1394P242-port 400 Mbps physical layer interface

16.0 INTERNAL REGISTER CONFIGURATION

There are 16 accessible internal registers in the PDI1394P24. The

configuration of the registers at addresses 0 through 7 (the base

registers) is fixed, while the configuration of the registers at

addresses 8h through Fh (the paged registers) is dependent upon

which one of eight pages, numbered 0h through 7h, is currently

selected. The selected page is set in base register 7h.

Table 1. Base Register Configuration

0 1 2 3 4 5 6 7

0000 Physical ID R CPS

0001 RHB IBR Gap_Count

0010 Extended (11 1b) Rsvd Num_Ports (0010b)

0011 PHY_Speed (010b) Rsvd Delay (0000b)

0100 LCtrl C Jitter (000) Pwr_Class

0101 RPIE ISBR CTOI CPSI STOI PEI EAA EMC

0110 Reserved

0111 Page_Select Rsvd Port Select

The configuration of the base registers is shown in Table 1, and

corresponding field descriptions are given in Table 2. The base

register field definitions are unaffected by the selected page number.

A reserved register or register field (marked as Reserved or Rsvd in

the following register configuration tables) is read as 0, but is subject

to future usage. All registers in address pages 2 through 6 are

reserved.

BIT POSITION

Table 2. Base Register Field Descriptions

FIELD SIZE TYPE DESCRIPTION

Physical ID 6 Rd This field contains the physical address ID of this node determined during self-ID. The physical-ID is

R 1 Rd Root. This bit indicates that this node is the root node. The R bit is reset to 0 by bus reset, and is set to

CPS 1 Rd Cable-power-status. This bit indicates the state of the CPS input terminal. The CPS terminal is normally

RHB 1 Rd/Wr Root-holdoff bit. This bit instructs the PHY to attempt to become root after the next bus reset. The RHB

IBR 1 Rd/Wr Initiate bus reset. This bit instructs the PHY to initiate a long (166 µs) bus reset at the next opportunity.

Gap_Count 6 Rd/Wr Arbitration gap count. This value is used to set the subaction (fair) gap, arb-reset gap, and arb-delay

Extended 3 Rd Extended register definition. For the PDI1394P24, this field is 111b, indicating that the extended register

Num_Ports 4 Rd Number of ports. This field indicates the number of ports implemented in the PHY. For the PDI1394P24

PHY_Speed 3 Rd PHY speed capability. For the PDI1394P24, this field is 010b, indicating S400 speed capability.

Delay 4 Rd PHY repeater data delay. This field indicates the worst case repeater data delay for this PHY,

invalid after a bus reset until self-ID has completed as indicated by an unsolicited register-0 status

transfer.

1 during tree-ID if this node becomes root.

tied to serial bus cable power through a 390 kΩ resistor. A 0 in this bit indicates that the cable power

voltage has dropped below its threshold for ensured reliable operation.

bit is reset to 0 by a hardware reset, and is unaffected by a bus reset.

Any receive or transmit operation in progress when this bit is set will complete before the bus reset is

initiated. The IBR bit is reset to 0 after a hardware reset or a bus reset.

times. The gap count can be set either by a write to the register, or by reception or transmission of a

PHY_CONFIG packet. The gap count is reset to 3Fh by hardware reset or after two consecutive bus

resets without an intervening write to the gap count register (either by a write to the PHY register or by

a PHY_CONFIG packet).

set is implemented.

this field is 2.

expressed as 144+(delay × 20) ns. For the PDI1394P24, this field is 1.

2001 Sep 06

14

Philips Semiconductors Objective data

PDI1394P242-port 400 Mbps physical layer interface

FIELD DESCRIPTIONTYPESIZE

LCtrl 1 Rd/Wr Link-active status control. This bit is used to control the active status of the LLC as indicated during

C 1 Rd/Wr Contender status. This bit indicates that this node is a contender for the bus or isochronous resource

Jitter 3 Rd PHY repeater jitter. This field indicates the worst case difference between the fastest and slowest

Pwr_Class 3 Rd/Wr Node power class. This field indicates this node’s power consumption and source characteristics and is

RPIE 1 Rd/Wr Resuming port interrupt enable. This bit, if set to 1, enables the port event interrupt (PEI) bit to be set

ISBR 1 Rd/Wr Initiate short arbitrated bus reset. This bit, if set to 1, instructs the PHY to initiate a short (1.3 µs)

CTOI 1 Rd/Wr Configuration time-out interrupt. This bit is set to 1 when the arbitration controller times-out during

CPSI 1 Rd/Wr Cable-power-status interrupt. This bit is set to 1 whenever the CPS input transitions from high to low

STOI 1 Rd/Wr State time-out interrupt. This bit indicates that a state time-out has occurred. This bit is reset to 0 by

PEI 1 Rd/Wr Port event interrupt. This bit is set to 1 on any change in the connected, bias, disabled, or fault bits for

EAA 1 Rd/Wr Enable arbitration acceleration. This bit enables the PHY to perform the various arbitration acceleration

EMC 1 Rd/Wr Enable multispeed concatenated packets. This bit enables the PHY to transmit concatenated packets of

Page_Select 3 Rd/Wr Page_Select. This field selects the register page to use when accessing register addresses 8 through

Port_Select 4 Rd/Wr Port_Select. This field selects the port when accessing per-port status or control (e.g., when one of the

self-ID. The logical AND of this bit and the LPS active status is replicated in the L field (bit 9) of the

self-ID packet. The LLC is considered active only if both the LPS input is active the and LCtrl bit is set.

The LCtrl bit provides a software controllable means to indicate the LLC active status in lieu of using the

LPS input.

The LCtrl bit is set to 1 by hardware reset and is unaffected by bus-reset.

NOTE: The state of the PHY-LLC interface is controlled solely by the LPS input, regardless of the state

of the LCtrl bit. If the PHY -LLC interface is operational as determined by the LPS input being active,

then received packets and status information will continue to be presented on the interface, and any

requests indicated on the LREQ input will be processed, even if the LCtrl bit is cleared to 0.

manager. This bit is replicated in the “c” field (bit 20) of the self-ID packet. This bit is set to the state

specified by the C/LKON input terminal by a hardware reset and is unaffected by a bus reset.

repeater data delay, expressed as (Jitter + 1) × 20 ns. For the PDI1394P24, this field is 0.

replicated in the pwr field (bits 21–23) of the self-ID packet. This field is reset to the state specified by

the PC0–PC2 input terminals upon hardware reset, and is unaffected by a bus reset. See Table 21.

whenever resume operations begin on any port. This bit is reset to 0 by hardware reset and is

unaffected by bus reset.

arbitrated bus reset at the next opportunity. This bit is reset to 0 by a bus reset.

NOTE: Legacy IEEE Std 1394–1995 compliant PHYs are not capable of performing short bus resets.

Therefore, initiation of a short bus reset in a network that contains such a legacy device results in a long

bus reset being performed.

tree-ID start, and may indicate that the bus is configured in a loop. This bit is reset to 0 by hardware

reset, or by writing a 1 to this register bit.

NOTE: If the network is configured in a loop, only those nodes which are part of the loop should

generate a configuration time out interrupt. All other nodes should instead time out waiting for the

tree-ID and/or self-ID process to complete and then generate a state time-out interrupt and bus-reset.

indicating that cable power may be too low for reliable operation. This bit is set to 1 by hardware reset,

and set to 0 by writing a 1 to this register bit.

hardware reset, or by writing a 1 to this register bit.

any port for which the port interrupt enable (PIE) bit is set. Additionally, if the resuming port interrupt

enable (RPIE) bit is set, the PEI bit is set to 1 at the start of resume operations on any port. This bit is

reset to 0 by hardware reset, or by writing a 1 to this register bit.

enhancements defined in P1394a (ACK-accelerated arbitration, asynchronous fly-by concatenation,

and isochronous fly-by concatenation). This bit is reset to 0 by hardware reset and is unaffected by bus

reset.

NOTE: The EAA bit should be set only if the attached LLC is P1394a compliant. If the LLC is not

P1394a compliant, use of the arbitration acceleration enhancements can interfere with isochronous

traffic by excessively delaying the transmission of cycle-start packets.

differing speeds in accordance with the protocols defined in P1394a. This bit is reset to 0 by hardware

reset and is unaffected by bus reset.

NOTE: The use of multispeed concatenation is completely compatible with networks containing legacy

IEEE Std 1394–1995 PHYs. However, use of multispeed concatenation requires that the attached LLC

be P1394a compliant.

15. This field is reset to 0 by a hardware reset and is unaffected by bus-reset.

port status/control registers is accessed in page 0). Ports are numbered starting at 0. This field is reset

to 0 by hardware reset and is unaffected by bus reset.

2001 Sep 06

15

Philips Semiconductors Objective data

ADDRESS

PDI1394P242-port 400 Mbps physical layer interface

The Port Status page provides access to configuration and status information for each of the ports. The port is selected by writing 0 to the

Page_Select field and the desired port number to the Port_Select field in base register 7. The configuration of the port status page registers is

shown in Table 3 and corresponding field descriptions given in T able 4. If the selected port is unimplemented, all registers in the port status page

are read as 0.

Table 3. Page 0 (Port Status) Register Configuration

BIT POSITION

0 1 2 3 4 5 6 7

1000 AStat BStat Ch Con Bias Dis

1001 Peer_Speed PIE Fault Reserved

1010 Reserved

1011 Reserved

1100 Reserved

1101 Reserved

1110 Reserved

1111 Reserved

Table 4. Page 0 (Port Status) Register Field Descriptions

FIELD SIZE TYPE DESCRIPTION

AStat 2 Rd TPA line state. This field indicates the TPA line state of the selected port, encoded as follows:

Code Arb Value

11 Z

01 1

10 0

00 invalid

BStat 2 Rd TPB line state. This field indicates the TPB line state of the selected port. This field has the same

Ch 1 Rd Child/parent status. A 1 indicates that the selected port is a child port. A 0 indicates that the selected

Con 1 Rd Debounced port connection status. This bit indicates that the selected port is connected. The

Bias 1 Rd Debounced incoming cable bias status. A 1 indicates that the selected port is detecting incoming cable

Dis 1 Rd/Wr Port disabled control. If 1, the selected port is disabled. The Dis bit is reset to 0 by hardware reset (all

Peer_Speed 3 Rd Port peer speed. This field indicates the highest speed capability of the peer PHY connected to the

PIE 1 Rd/Wr Port event interrupt enable. When set to 1, a port event on the selected port will set the port event

Fault 1 Rd/Wr Fault. This bit indicates that a resume-fault or suspend-fault has occurred on the selected port, and that

encoding as the ASTAT field.

port is the parent port. A disconnected, disabled, or suspended port is reported as a child port. The Ch

bit is invalid after a bus-reset until tree-ID has completed.

connection must be stable for the debounce time of 330ms–350ms for the Con bit to be set to 1. The

Con bit is reset to 0 by hardware reset and is unaffected by bus reset.

NOTE: The Con bit indicates that the port is physically connected to a peer PHY, but the port is not

necessarily active.

bias. The incoming cable bias must be stable for the debounce time of 41.6µs–52µs for the Bias bit to

be set to 1.

ports are enabled for normal operation following hardware reset). The Dis bit is not affected by bus

reset.

selected port, encoded as follows:

Code Peer Speed

000 S100

001 S200

010 S400

011–11 1 invalid

The Peer_Speed field is invalid after a bus reset until self-ID has completed.

NOTE: Peer speed codes higher than 010b (S400) are defined in P1394a. However, the PDI1394P24

is only capable of detecting peer speeds up to S400.

interrupt (PEI) bit and notify the link. this bit is reset to 0 by a hardware reset, and is unaffected by

bus-reset.

the port is in the suspended state. A resume-fault occurs when a resuming port fails to detect incoming

cable bias from its attached peer. A suspend-fault occurs when a suspending port continues to detect

incoming cable bias from its attached peer. Writing 1 to this bit clears the fault bit to 0. This bit is reset to

0 by hardware reset and is unaffected by bus reset.

2001 Sep 06

16

Philips Semiconductors Objective data

ADDRESS

ADDRESS

PDI1394P242-port 400 Mbps physical layer interface

The Vendor Identification page is used to identify the vendor/manufacturer and compliance level. The page is selected by writing 1 to the

Page_Select field in base register 7. The configuration of the Vendor Identification page is shown in Table 5, and corresponding field

descriptions are given in Table 6.

Table 5. Page 1 (Vendor ID) Register Configuration

BIT POSITION

0 1 2 3 4 5 6 7

1000 Compliance

1001 Reserved

1010 Vendor_ID[0]

1011 Vendor_ID[1]

1100 Vendor_ID[2]

1101 Product_ID[0]

1110 Product_ID[1]

1111 Product_ID[2]

Table 6. Page 1 (Vendor ID) Register Field Descriptions

FIELD SIZE TYPE DESCRIPTION

Compliance 8 Rd Compliance level. For the PDI1394P24, this field is 01h, indicating compliance with the P1394a

Vendor_ID 24 Rd Manufacturer’s organizationally unique identifier (OUI). For the PDI1394P24, this field is 00_60_37h

Product_ID 24 Rd Product identifier. For the PDI1394P24, this field is 42_39_x0h (the MSB is at register address 1101b).

specification.

(Philips Semiconductors) (the MSB is at register address 1010b).

The Vendor-Dependent page provides access to the special control features of the PDI1394P24, as well as configuration and status information

used in manufacturing test and debug. This page is selected by writing 7 to the Page Select field in base register 7. The configuration of the

Vendor-Dependent page is shown in Table 7 and corresponding field descriptions given in Table 8.

Table 7. Page 7 (Vendor-Dependent) Register Field Descriptions

BIT POSITION

0 1 2 3 4 5 6 7

1000 Reserved Link_Speed

1001 Reserved for test

1010 Reserved for test

1011 Reserved for test

1100 Reserved for test

1101 Reserved for test

1110 Reserved for test

1111 Reserved for test

Table 8. Page 7 (Vendor-Dependent) Register Field Descriptions

FIELD SIZE TYPE DESCRIPTION

Link_Speed 2 Rd/Wr Link speed. This field indicates the top speed capability of the attached LLC. Encoding is as follows:

Code Speed

00 S100

01 S200

10 S400

11 illegal

This field is replicated in the “sp” field of the self-ID packet to indicate the speed capability of the node

(PHY and LLC in combination). However, this field does not affect the PHY speed capability indicated to

peer PHYs during self-ID; the PDI1394P24 PHY identifies itself as S400 capable to its peers regardless

of the value in this field. This field is set to 10b (S400) by hardware reset and is unaffected by bus-reset.

An 11b can be written into this field, however, a 10b will be sent in the self-ID packet.

2001 Sep 06

17

Philips Semiconductors Objective data

PDI1394P242-port 400 Mbps physical layer interface

17.0 APPLICATION INFORMATION

PDI1394P24

CABLE PORT

CPS

TPBIAS

TPAn+

TPAn–

TPBn+

TPBn–

220pF

390KΩ

0.3–1.0 µF

56Ω56Ω

56Ω56Ω

5 kΩ

VP

VG

CABLE

POWER PAIR

CABLE

PAIR A

CABLE

PAIR B

OUTER SHIELD

TERMINATION

SV01825

The IEEE Std 1394–1995 calls for a 250 pF capacitor, which is a non-standard component value. A 220 pF capacitor is recommended.

Figure 4. Twisted pair cable interface connections

COMPLIANT DC-ISOLATED

OUTER SHIELD TERMINATION

OUTER CABLE SHIELD

0.1 µF0.01 µF1 MΩ

NON-ISOLATED

OUTER SHIELD TERMINATION

OUTER CABLE SHIELD

CHASSIS GROUND

Figure 5. Typical outer shield termination

3

DGND (AGND)

0.001 µF

0.1 µF

V

DD

6

(AVDD)

DV

DD

SV01805

Use one of these networks per side for all digital power and ground

pins and one per side for all analog power and ground pins. Place

the network as close to the PHY as possible.

Figure 6. Power supply decoupling network

CHASSIS GROUND

10 kΩ

LINK POWER

SQUARE WAVE INPUT

SV01748

LPS

LPS

10 kΩ

SV01806

Figure 7. Non-isolated connection variations for LPS

2001 Sep 06

18

Philips Semiconductors Objective data

PDI1394P242-port 400 Mbps physical layer interface

PHY V

DD

24 kΩ

PHY CHIP

C/LKON

SQUARE WAVE SIGNAL

3.3nF

7.5 kΩ

LPS

LINK LAYER CHIP

CONTENDER/

LINKON

10 K

SV01819

Figure 8. Isolated circuit connection for LPS

10 K

LINK LAYER CHIP

LINKON

TIE TO LLCVDD (CONTENDER)

OR GND (NOT CONTENDER)

PHY CHIP

C/LKON

SV01873

Figure 9. Three configurations for C/LKON signal in a

non-isolated system

2001 Sep 06

19

Philips Semiconductors Objective data

PDI1394P242-port 400 Mbps physical layer interface

17.1 External Component Connections

REFER TO SECTION 17.5

CONNECT RESET

AS THE LINK IC OR THROUGH

OPTOCOUPLER FOR GALVANIC ISOLATION.

USE 0.1 µF CAPACITOR TO GND ONLY IN

NON-LINK DESIGNS.

LINK PULSE

OR LINK V

AND FIGURE 8

TO THE SAME SOURCE

CNA OUT

DD

OR V

DD

REFER TO

FIGURE 7

DGND

1

LREQ

2

DGND

3

CTL0

4

CTL1

5

D0

6

D1

7

DVDD

8

D2

9

D3

10

D4

11

D5

12

D6

13

D7

14

DGND

15

CNA

16

LPS

DVDD

V

DD

12 pF12 pF

2.49 kΩ

PLLVDD

PLLGND

±1%

DGND

R1

R0

AGND

AGND

AVDD

24.576 MHz

62 61 60 59 58 57 56 55 5464 63 53 52 51 50 49

DVDD

RESET

SYSCLK

XO

0.1 µF

0.001 µF

XI

PDI1394P24

C/LKONPDPC0

19 20 21 22 23 24 25

PC1

PC2

ISO

ISO

CPS

DGND

26 2717 18

DVDD

DVDD

TEST1

28 29 30 31 32

TEST0

AVDD

AVDD

AVDD

AGND

TPBIAS1

TPBIAS0

AGND

NC

NC

NC

NC

NC

AVDD

TPA1+

TPA1–

TPB1+

TPB1–

TPA0+

TPA0–

TPB0+

TPB0–

48

47

46

45

44

43

42

41

TP CABLES INTERFACE

40

CONNECTION (REFER TO

FIGURES 4 AND 5)

39

38

37

36

35

TP CABLES INTERFACE

CONNECTION (REFER TO

34

FIGURES 4 AND 5)

33

0.3–1.0 µF

TPBIAS

0.3–1.0 µF

TPBIAS

POWER DOWN

(SEE FIGURE 9)

370–

410 kΩ

POWER CLASS

PROGRAMMING

See Figure 6 for recommended power and ground connections.

Figure 10. External Component Connections

2001 Sep 06

SV001826

CABLE POWER

20

Philips Semiconductors Objective data

PDI1394P242-port 400 Mbps physical layer interface

17.2 RESET and Power Down

Forcing the RESET pin low resets the internal logic to the Reset

Start state and deactivates SYSCLK. Returning the RESET

causes a Bus Reset condition on the active cable ports. For

power-up (and after Power Down is asserted) RESET

asserted low for a minimum of 2 ms from the time that the PHY

power reaches the minimum required supply voltage. This is

required to assure proper PLL operation before the PHY begins

using the clock.

The PHY must come out of RESET

Link comes out of RESET

properly. To assure that this happens, it is recommended that the

same signal source originate LLC and PHY reset signals. If galvanic

isolation is used, an optocoupler should be used to drive the RESET

pin of the PHY. (See Philips AN2452 “IEEE 1394 bus node galvanic

isolation and power supply design”.) If galvanic isolation is not used,

the LCC and PHY reset pins should be connected directly together.

A single capacitor on the RESET

is recommended only in designs without an LLC device (i.e. repeater

designs).

An internal pull-up resistor is connected to V

delay capacitor is required. When using a passive capacitor on the

RESET

terminal to generate a power-on reset signal, the minimum

reset time will be assured if the capacitor has a minimum value of

0.1 µF and also satisfies the following equation:

C

= 0.0077 × T + 0.085

min

where C

µF, and T is the V

An alternative to the passive reset is to actively drive RESET low for

the minimum reset time following power on. This input is a standard

logic Schmitt buffer and may also be driven by an open drain logic

output buffer.

The RESET

activated by the Power Down pin. For a reset during normal

operation, a 10 µs low pulse on this pin will accomplish a full PHY

reset. This pulse, as well as the 2 ms power up reset pulse, could be

microprocessor controlled, in which case the external delay

capacitor would not be needed. For more details on using single

capacitor isolation with this pin, please refer to the Philips Isolation

Application Note AN2452

The Power Down input powers down all device functions with the

exception of the CNA circuit to conserve power in portable or

battery-powered applications. It must be held high for at least 2 ms

to assure a successful reset after power down.

is the minimum capacitance on the RESET terminal in

min

pin also has an internal n-channel pull-down transistor

so that the LLC/PHY handshake occurs

ramp time, 10%–90%, in ms.

DD

simultaneously or just after the

pin of the PHY as described below

, so only an external

DD

pin high

must be

17.3 Using the PDI1394P24 with a non-P1394a

link layer

The PDI1394P24 implements the PHY-LLC interface specified in the

P1394a Supplement. This interface is based upon the interface

described in informative Annex J of IEEE Std 1394-1995, which is the

interface used in older PHY devices. The PHY-LLC interface specified

in P1394a is completely compatible with the older Annex J interface.

The P1394a Supplement includes enhancements to the Annex J

interface that must be comprehended when using the PDI1394P24

with a non-P1394a LLC device.

•A new LLC service request was added which allows the LLC to

temporarily enable and disable asynchronous arbitration

accelerations. If the LLC does not implement this new service

request, the arbitration enhancements should not be enabled (see

the EAA bit in PHY register 5).

•The capability to perform multispeed concatenation (the

concatenation of packets of differing speeds) was added in order

to improve bus efficiency (primarily during isochronous

transmission). If the LLC does not support multispeed

concatenation, multispeed concatenation should not be enabled

in the PHY (see the EMC bit in PHY register 5).

•In order to accommodate the higher transmission speeds expected

in future revisions of the standard, P1394a extended the speed

code in bus requests from 2 bits to 3 bits, increasing the length of

the bus request from 7 bits to 8 bits. The new speed codes were

carefully selected so that new P1394a PHY and LLC devices

would be compatible, for speeds from S100 to S400, with legacy

PHY and LLC devices that use the 2-bit speed codes. The

PDI1394P24 correctly interprets both 7-bit bus requests (with 2-bit

speed code) and 8-bit bus requests (with 3-bit speed codes).

Moreover, if a 7-bit bus request is immediately followed by another

request (e.g., a register read or write request), the PDI1394P24

correctly interprets both requests. Although the PDI1394P24

correctly interprets 8-bit bus requests, a request with a speed code

exceeding S400 results in the PDI1394P24 transmitting a null

packet (data-prefix followed by data-end, with no data in the

packet).

17.4 Using the PDI1394P24 with a lower-speed

link layer

Although the PDI1394P24 is an S400 capable PHY, it may be used

with lower speed LLCs. In such a case, the LLC has fewer data

terminals than the PHY, and some Dn terminals on the PDI1394P24

will be unused. Unused Dn terminals should be pulled to ground

through 10 kΩ resistors.

The PDI1394P24 transfers all received packet data to the LLC,

even if the speed of the packet exceeds the capability of the LLC to

accept it. Some lower speed LLC designs do not properly ignore

packet data in such cases. On the rare occasions that the first 16

bits of partial data accepted by such a LLC match a node’s bus and

node ID, spurious header CRC or tcode errors may result.

In discussing this topic, the reader should be aware that the

IEEE1394a-2000 standard (paragraph 8.3.2.4.2) made the speed

maps defined in IEEE1394-1995 obsolete and defined a new field

(

link_spd

) in the Configuration ROM Bus_Info_Block where the

maximum speed of the node’s link layer is available. The

PDI1394P24 PHY’s default maximum speed is reported in the

self-ID packet. The IEEE1394a-2000 standard notes that bus

managers that implement the SPEED_MAP registers as specified

by IEEE Std 1394-1995 are compliant with the IEEE1394a-2000

standard but users are cautioned that the addresses utilized by

these registers may be redefined in future IEEE standards. Without

a bus manager-created and maintained speed map, in order to

transmit at the highest speed along a path, a transmitting node must

determine the

speed) for a target node and each of the PHY speed capabilities

along the path between the source and target nodes. That is, each

node would have to create a network speed map. Some designers

may choose to implement a speed map in bus manager-capable

nodes to maximize transmission speed when a slower-than-PHY

link chip exists in a node along the transmission path. The following

paragraphs are presented for use with products that utilize speed

maps.

node

speed capability (lesser of link speed or PHY

2001 Sep 06

21

Philips Semiconductors Objective data

PDI1394P242-port 400 Mbps physical layer interface

During bus initialization following a bus-reset, each PHY transmits a

self-ID packet that indicates, among other information, the speed

capability of the PHY. The bus manager (if one exists) may build a

speed-map from the collected self-ID packets. This speed-map

gives the highest possible speed that can be used on the

node-to-node communication path between every pair of nodes in

the network. However, as explained below, the speed reported in the

self-ID packet of a PDI1394P24 PHY may be adjusted to account for

a slow link chip.

In the case of a node consisting of a higher-speed PHY and a

lower-speed LLC, the speed capability of the node (lesser of the

PHY and LLC speed) is that of the lower-speed LLC. A

sophisticated bus manager can determine the LLC speed capability

by reading the configuration ROM Bus_Info_Block, or by sending

asynchronous request packets at different speeds to the node and

checking for an acknowledge; the speed-map may then be adjusted

accordingly. The speed-map should reflect that communication to

such a node must be done at the lower speed of the LLC, instead of

the higher speed of the PHY. However, speed-map entries for paths

that merely pass through the node’s PHY, but do not terminate at

that node, should not be restricted by the lower speed of the LLC.

To assist in building an accurate speed-map, the PDI1394P24 has

the capability of indicating a speed other than S400 in its transmitted

self-ID packet. This is controlled by the Link_Speed field in

register 8 of the Vendor-Dependent page (page 7). Setting the

Link_Speed field affects only the speed indicated in the self-ID

packet; it has no effect on the speed signaled to peer (adjacent

directly connected) PHYs during self-ID. The PDI1394P24 identifies

itself as S400 capable to its peers regardless of the value in the

Link_Speed field.

Generally , the Link_Speed field in register 8 of the

Vendor-Dependent page should not be changed from its power-on

default value of S400 unless it is determined that the speed-map (if

one exists) is incorrect for path entries terminating in the local node

(i.e. the node has a slower link layer chip). If the speed-map is

incorrect, it can be assumed that the bus manager has used only

the self-ID packet information to build the speed-map. In this case,

the node may update the Link_Speed field in register 8 to reflect the

lower speed capability of the LLC and then initiate another bus-reset

to cause the speed-map to be rebuilt. Note that in this scenario any

speed-map entries for node-to-node communication paths that pass

through the local node’s PHY will be restricted by the lower speed.

In the case of a leaf node (which has only one active port) the

Link_Speed field in register 8 may be set to indicate the speed of the

LLC without first checking the speed-map. Changing the

Link_Speed field in a leaf node can only affect those paths that

terminate at that node, since no other paths can pass through a leaf

node. It can have no effect on other paths in the speed-map. For

hardware configurations which can only be a leaf node (all ports but

one are unimplemented), it is recommended that the Link_Speed

field be updated immediately after power-on or hardware reset.

2001 Sep 06

22

Philips Semiconductors Objective data

PDI1394P242-port 400 Mbps physical layer interface

17.5 Crystal selection

The PDI1394P24 is designed to use an external 24.576 MHz crystal

connected between the XI and XO terminals to provide the

reference for an internal oscillator circuit. This oscillator in turn

drives a PLL circuit that generates the various clocks required for

transmission and resynchronization of data at the S100 through

S400 media data rates.

A variation of less than ±100 ppm from nominal for the media data

rates is required by IEEE Std 1394. Adjacent PHYs may therefore

have a difference of up to 200 ppm from each other in their internal

clocks, and PHYs must be able to compensate for this difference

over the maximum packet length. Larger clock variations may cause

resynchronization overflows or underflows, resulting in corrupted

packet data.

For the PDI1394P24, the SYSCLK output may be used to measure

the frequency accuracy and stability of the internal oscillator and

PLL from which it is derived. The frequency of the SYSCLK output

must be within ±100 ppm of the nominal frequency of 49.152 MHz.

The following are some typical specifications for crystals used with

the PDI1394P24 in order to achieve the required frequency

accuracy and stability:

•Crystal mode of operation: Fundamental

•Frequency tolerance at 25°C: Total frequency variation for the

complete circuit is +100 ppm. A crystal with +30 ppm frequency

tolerance is recommended for adequate margin.

•Frequency stability (over temperature and age): A crystal with

+30 ppm frequency stability is recommended for adequate

margin.

itself (C

). The value of C

BD

is typically about 1 pF, and CBD is

PHY

typically 0.8 pF per centimeter of board etch; a typical board can

have 3 pF to 6 pF or more. The load capacitors C9 and C10

combine as capacitors in series so that the total load capacitance is:

C

= [(C9 * C10) / (C9+C10)] + C

L

C9

24.576 MHz

ls

C10

+ CBD.

PHY

X1 C

PHY

+ C

XI

BD

XO

SV01808

Figure 11. Load Capacitance for the PDI1394P24 PHY

NOTE: The layout of the crystal portion of the PHY circuit is

important for obtaining the correct frequency, minimizing noise

introduced into the PHY’s Phase Lock Loop, and minimizing any

emissions from the circuit. The crystal and two load capacitors

should be considered as a unit during layout. The crystal and load

capacitors should be placed as close as possible to one another

while minimizing the loop area created by the combination of the

three components. V arying the size of the capacitors may help in

this. Minimizing the loop area minimizes the effect of the resonant

current (Is) that flows in this resonant circuit. This layout unit (crystal

and load capacitors) should then be placed as close as possible to

the PHY XI and XO terminals to minimize trace lengths.

NOTE: The total frequency variation must be kept below ±100 ppm

from nominal with some allowance for error introduced by board and

device variations. Trade–offs between frequency tolerance and

stability may be made as long as the total frequency variation is less

than ±100 ppm. For example, the frequency tolerance of the crystal

may be specified at 50 ppm and the temperature tolerance may be

specified at 30 ppm to give a total of 80 ppm possible variation due

to the crystal alone. Crystal aging also contributes to the frequency

variation.

•Load capacitance: For parallel resonant mode crystal circuits, the

frequency of oscillation is dependent upon the load capacitance

specified for the crystal. Total load capacitance (C

of not only the discrete load capacitors, but also board layout and

circuit. It may be necessary to iteratively select discrete load

capacitors until the SYSCLK output is within specification. It is

recommended that load capacitors with a maximum of "5%

tolerance be used.

As an example, for a board which uses a crystal specified for 12 pF

loading, load capacitors (C9 and C10 in Figure 11) of 16 pF each

are appropriate for the layout of that particular board. The load

specified for the crystal includes the load capacitors (C9, C10), the

loading of the PHY terminals (C

), and the loading of the board

PHY

) is a function

L

C9 C10

X1

SV01809

Figure 12. Recommended Crystal and Capacitor Layout

It is strongly recommended that part of the verification process for

the design be to measure the frequency of the SYSCLK output of

the PHY. This should be done with a frequency counter with an

accuracy of 6 digits or better. If the SYSCLK frequency is more than

the crystal’s tolerance from 49.152 MHz, the load capacitance of the

crystal may be varied to improve frequency accuracy. If the

frequency is too high add more load capacitance; if the frequency is

too low decrease load capacitance. Typically, changes should be

done to both load capacitors (C9 and C10 above) at the same time,

and both should be of the same value. Additional design details and

requirements may be provided by the crystal vendor.

2001 Sep 06

23

Philips Semiconductors Objective data

PDI1394P242-port 400 Mbps physical layer interface

18.0 PRINCIPLES OF OPERATION

The PDI1394P24 is designed to operate with an LLC such as the

Philips Semiconductors PDI1394L1 1 or PDI1394L21. The following

paragraphs describe the operation of the PHY -LLC interface.

The interface to the LLC consists of the SYSCLK, CTL0–CTL1,

D0–D7, LREQ, LPS, C/LKON, and ISO

terminals on the

PDI1394P24 as shown in Figure 13.

PDI1394P24

SYSCLK

LINK LAYER

CONTROLLER

CTL0–CTL1

D0–D7

LREQ

LPS

C/LKON

/ISO/ISO/ISO

SV01827

Figure 13. PHY-LLC interface

The SYSCLK terminal provides a 49.152 MHz interface clock. all

control and data signals are synchronized to, and sampled on, the

rising edge of SYSCLK.

The CTL0 and CTL1 terminals form a bidirectional control bus,

which controls the flow of information and data between the

PDI1394P24 and LLC.

The D0–D7 terminals form a bidirectional data bus, which is used to

transfer status information, control information, or packet data