Philips OQ2545HP Datasheet

INTEGRATED CIRCUITS

DATA SH EET

OQ2545HP

SDH/SONET STM16/OC48 laser

driver

Preliminary specification

File under Integrated Circuits, IC19

1997 Nov 27

Philips Semiconductors Preliminary specification

SDH/SONET STM16/OC48 laser driver OQ2545HP

FEATURES

• Differential 50 Ω inputs for direct connection to CML

(Current-Mode Logic) outputs

• Internal retiming to minimize jitter

• Input clock phase margin of 320° at 2.5 Gbits/s

• RF output current sinking capability of 60 mA for 25 Ω

loads and 50 mA for 50 Ω loads

• Bias output current sinking capability of 100 mA

• TTL compatible control inputs

• Loop mode for system testing

• Continuous output monitoring

• Typical power dissipation: 1420 mW

• Low cost LQFP48 plastic package.

APPLICATIONS

• Digital fibre optic modulation driver in STM16/OC48

short, medium and long haul optical transmission

systems

• Optical modulation driver in high speed data networks

• High current driver for electro-optical converters

• High current electrical line driver.

GENERAL DESCRIPTION

The OQ2545HP is a driver IC intended to be used with

directly modulated laser diodes or with Electro Absorption

Modulators (EAMs) in SDH/SONET 2.5 Gbits/s optical

transmission systems.

It features differential data and clock inputs and internal

retiming for better jitter performance. Loop mode inputs

are provided for system testing, along with an output for

continuous monitoring.

The high current drive has bias and modulating current

outputs, the levels of which can be set separately. As an

additional safety measure, the active HIGH ALS

(Automatic Laser Shutdown) input can be used to switch

off the laser modulation and bias currents. Although the

circuit is intended for 2.5 Gbits/s optical transmission

systems, it can be used in any application requiring high

current drive at high frequencies.

ORDERING INFORMATION

TYPE

NUMBER

OQ2545HP LQFP48 plastic low profile quad flat package; 48 leads; body 7 × 7 × 1.4 mm SOT313-2

NAME DESCRIPTION VERSION

PACKAGE

1997 Nov 27 2

Philips Semiconductors Preliminary specification

SDH/SONET STM16/OC48 laser driver OQ2545HP

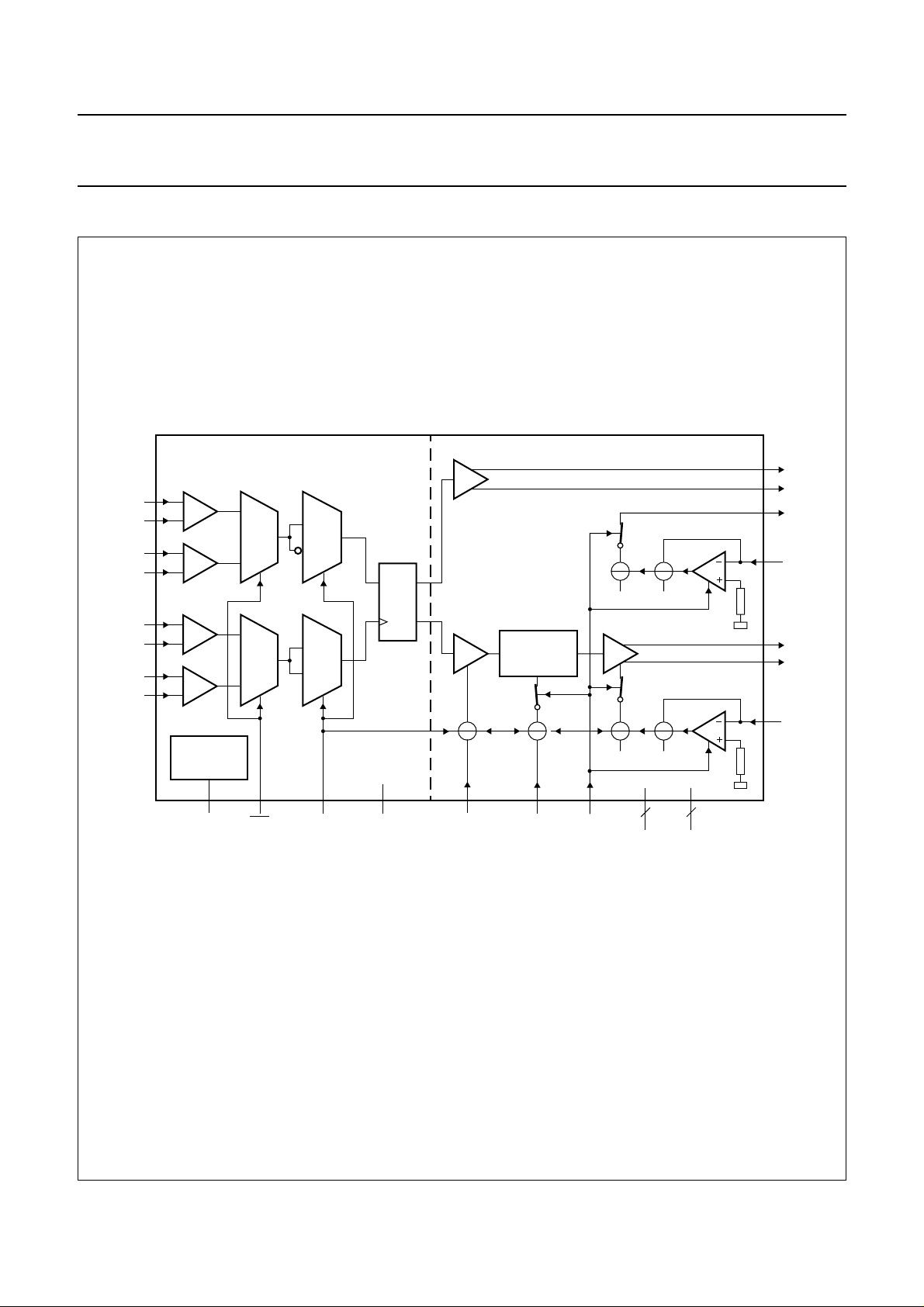

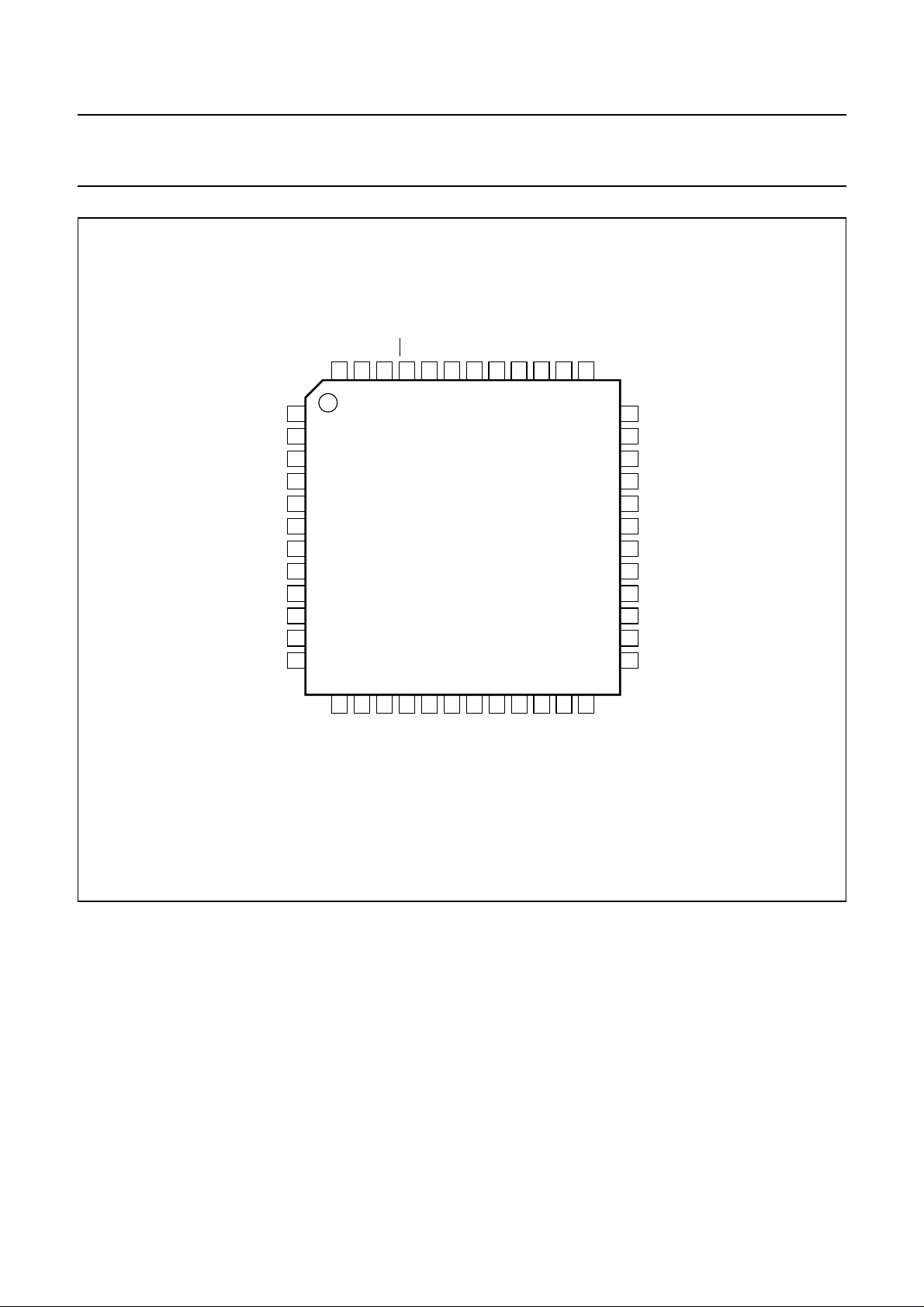

BLOCK DIAGRAM

handbook, full pagewidth

33

DIN

CIN

34

22

21

30

31

28

27

DINQ

DLOOP

DLOOPQ

CINQ

CLOOP

CLOOPQ

BAND GAP

REFERENCE

BGCAP

DIGITAL SECTION

4543 17

ENL SMOD V

ANALOG SECTION

MONITOR

BUFFER

OQ2545HP

FF

42 16 15 44

EE1

PRE-

AMPLIFIER

2×

EMITTER

FOLLOWERS

AMPADJ EFADJ ALS

MODULATION

DRIVER

(1)

8

V

EE2

GND

40

MON

39

MONQ

10

IBIAS

19

SIBIAS

5, 6

7, 8

(2)

MGK368

14

LA

LAQ

18

SIMOD

(1) Pins 1, 12, 13, 24, 25, 36, 37 and 48

(2) Pins 2, 4, 9, 11, 14, 20, 23, 26, 29, 32, 35, 38, 41 and 47.

Fig.1 Block diagram.

1997 Nov 27 3

Philips Semiconductors Preliminary specification

SDH/SONET STM16/OC48 laser driver OQ2545HP

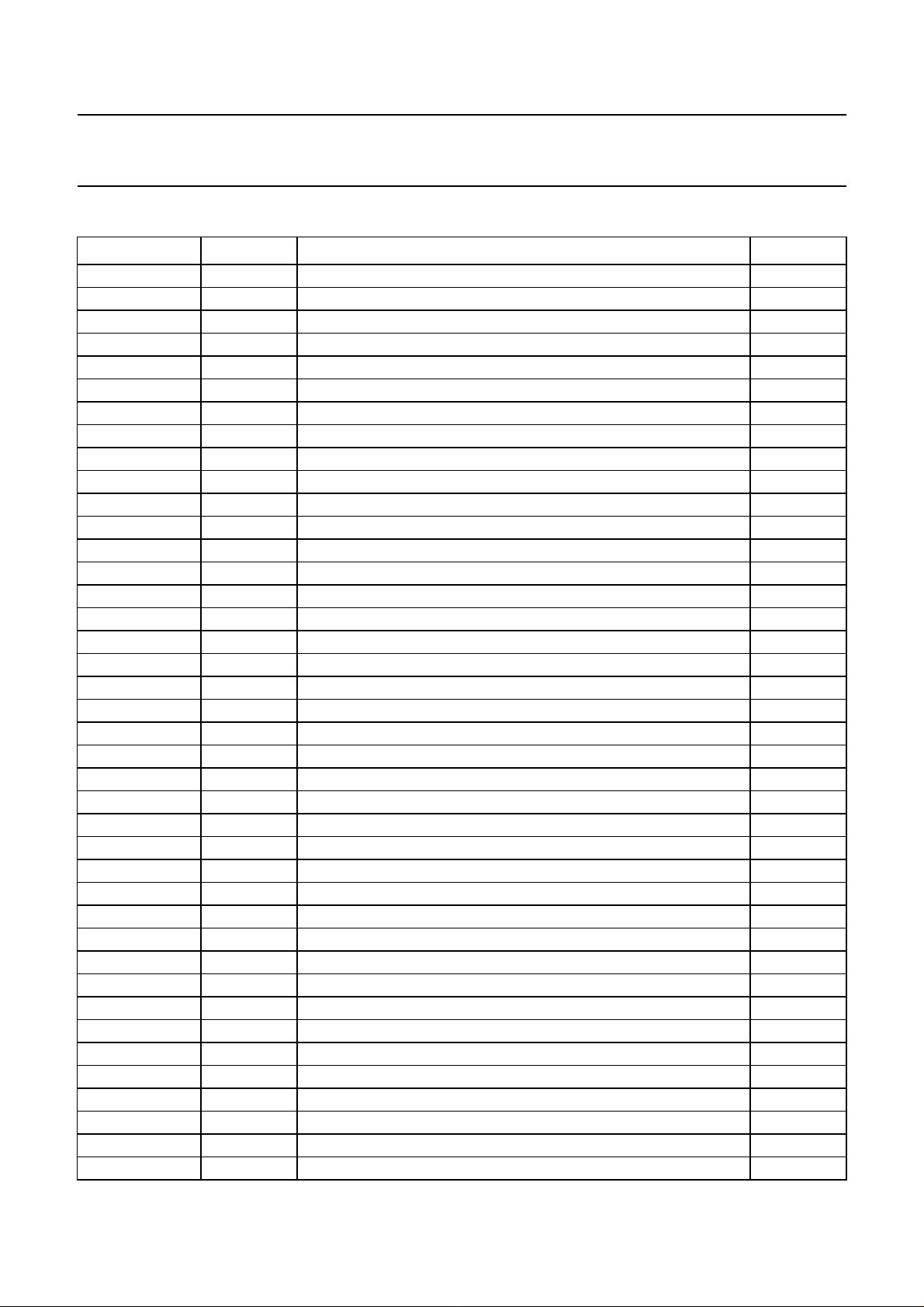

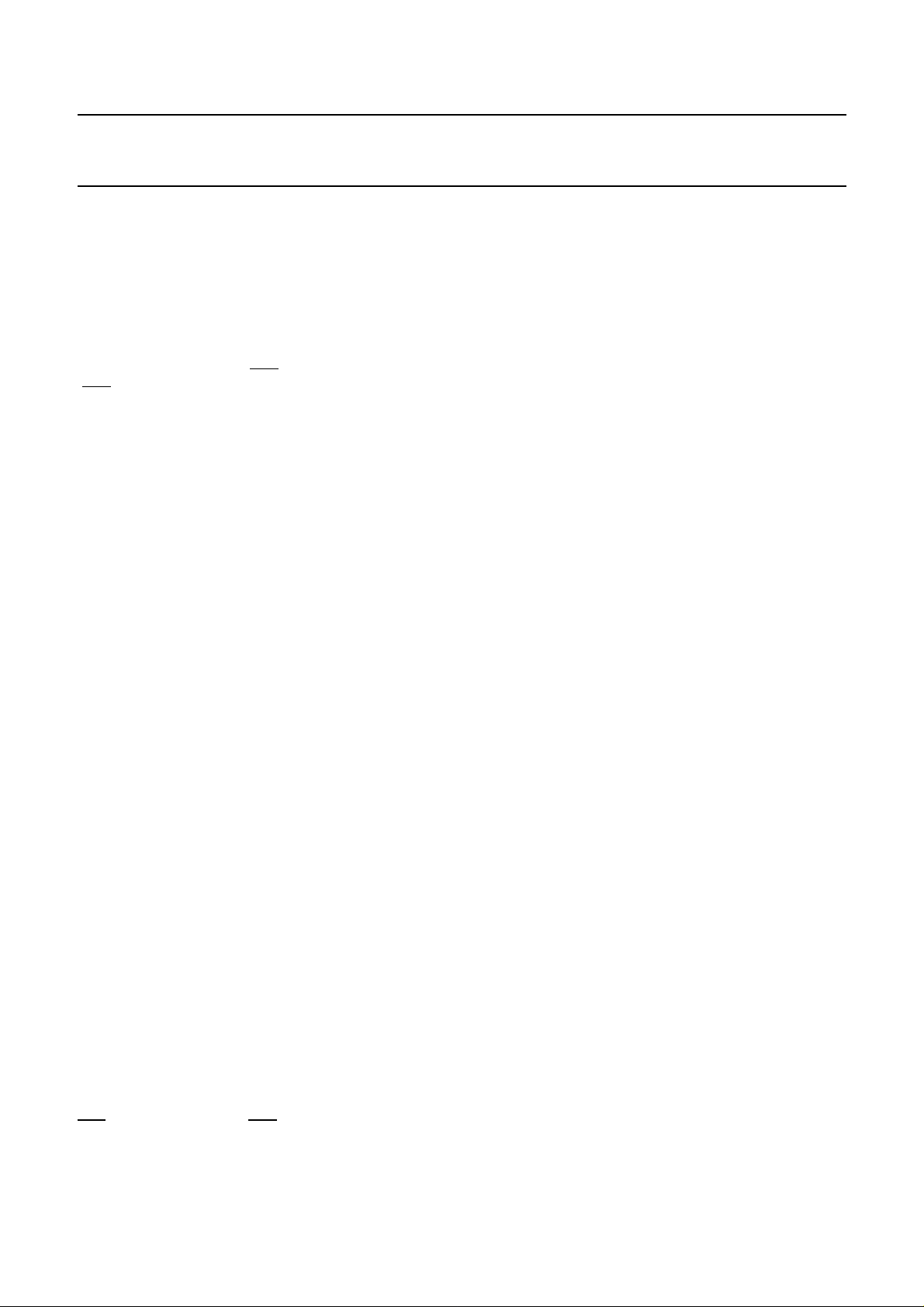

PINNING

SYMBOL PIN DESCRIPTION TYPE

V

EE2

1 supply voltage for analog section S

GND 2 ground S

DIOA 3 anode of temperature sensing diode array A

GND 4 ground S

LA 5 modulation current output O

LA 6 modulation current output O

LAQ 7 modulation current output inverted O

LAQ 8 modulation current output inverted O

GND 9 ground S

IBIAS 10 bias current output O

GND 11 ground S

V

EE2

V

EE2

12 supply voltage for analog section S

13 supply voltage for analog section S

GND 14 ground S

EFADJ 15 input for emitter follower current adjustment AI

AMPADJ 16 input for preamplifier current adjustment AI

SMOD 17 data polarity switch I

SIMOD 18 RF modulated output current adjustment I

SIBIAS 19 DC output current adjustment I

GND 20 ground S

DLOOPQ 21 loop mode data input inverted I

DLOOP 22 loop mode data input I

GND 23 ground S

V

EE2

V

EE2

24 supply voltage for analog section S

25 supply voltage for analog section S

GND 26 ground S

CLOOPQ 27 loop mode clock input inverted I

CLOOP 28 loop mode clock input I

GND 29 ground S

CIN 30 clock input I

CINQ 31 clock input inverted I

GND 32 ground S

DIN 33 data input I

DINQ 34 data input inverted I

GND 35 ground S

V

EE2

V

EE2

36 supply voltage for analog section S

37 supply voltage for analog section S

GND 38 ground S

MONQ 39 data monitor output inverted O

MON 40 data monitor output O

(1)

1997 Nov 27 4

Philips Semiconductors Preliminary specification

SDH/SONET STM16/OC48 laser driver OQ2545HP

SYMBOL PIN DESCRIPTION TYPE

GND 41 ground S

V

EE1

42 supply voltage for digital section S

BGCAP 43 pin for connecting band gap reference decoupling capacitor A

ALS 44 automatic laser shut down control (active HIGH) I

ENL 45 loop mode enable (active LOW) I

V

CC

46 supply voltage for TTL interface S

GND 47 ground S

V

EE2

48 supply voltage for analog section S

Note

1. Pin type abbreviations: O = Output, I = Input, S = power Supply, A = Analog function.

(1)

1997 Nov 27 5

Philips Semiconductors Preliminary specification

SDH/SONET STM16/OC48 laser driver OQ2545HP

handbook, full pagewidth

V

48

EE2

GND

47

CC

V

ENL

ALS

46

45

44

V

BGCAP

43

42

EE1

GND

41

MON

40

MONQ

39

GND

38

EE2

V

V

EE2

GND

DIOA

GND

LA

LA

LAQ

LAQ

GND

IBIAS

GND

V

EE2

24 37

EE2

V

36

35

34

33

32

31

30

29

28

27

26

25

MGK367

V

EE2

GND

DINQ

DIN

GND

CINQ

CIN

GND

CLOOP

CLOOPQ

GND

V

EE2

1

2

3

4

5

6

7

8

9

10

11

12

13

14

EE2

GND

V

15

EFADJ

OQ2545HP

16

17

SMOD

AMPADJ

18

19

SIBIAS

SIMOD

20

GND

21

22

DLOOP

DLOOPQ

23

GND

Fig.2 Pin configuration.

1997 Nov 27 6

Philips Semiconductors Preliminary specification

SDH/SONET STM16/OC48 laser driver OQ2545HP

FUNCTIONAL DESCRIPTION

The OQ2545HP can be divided into two functional blocks:

• A digital section on the input side

• An analog section on the output side.

The input buffers present an impedance of 50 Ω to the

data stream on the DIN, DINQ, DLOOP and DLOOPQ

differential inputs. The input data is then fed to a

multiplexer where normal (ENL = HIGH) or loop mode

(ENL = LOW) inputs are selected. A second multiplexer

inverts the input signals when SMOD is connected to

(this is necessary when driving an EAM). An external

V

EE1

clock connected to a master-slave flip-flop is then used to

retime the data. This reduces jitter on the data signal to a

minimum.

The preamplifier following the flip-flop boosts the signal to

a suitable level for the modulation driver. Two emitter

followers provide the necessary signal isolation between

the preamplifier and the high current modulation driver.

The bias currents for the preamplifier and the emitter

followers contains an output level dependent component,

along with an independent component. The independent

component is adjusted by means of the AMPADJ

(preamplifier) and EFADJ (emitter followers) inputs.

The output level dependent component is controlled by the

SIMOD input and the op-amp circuit, which also sets the

modulation driver level. The AMPADJ input also controls

the shape of the output signal at LA and LAQ.

An independently adjustable on-chip bias current source is

provided for when the OQ2545HP is driving directly

modulated laser diodes. The SIBIAS input is used to set

the bias current level. The output current at IBIAS will be

about 106 times greater than the input current at SIBIAS.

A similar arrangement is used to control the modulation

current at LA and LAQ. The output current at LA and LAQ

is approximately 70 times the input current at SIMOD.

The active HIGH TTL compatible ALS input can be used to

switch off all current sources. This function makes it

possible to implement safety measures that will shut down

the circuit in the event of an optical system malfunction.

The buffered differential 50 Ω outputs MON and MONQ

can be used to monitor the optically modulated data (at the

flip-flop outputs).

Automatic laser shutdown

A HIGH level (TTL) on ALS switches off the laser

modulation and bias currents. This function allows the

circuit to be shut down in the event of an optical system

malfunction or for system maintenance. If not connected,

ALS is pulled LOW (TTL) by an internal pull-down resistor.

Data monitoring

Pins MON and MONQ can be used as data monitor

outputs. They need to be AC-coupled (for example, to a

50 Ω matched RF amplifier with sufficient bandwidth).

Output polarity selection

The SMOD input is used to set the correct logic

assignment between data inputs DIN and DINQ (or

DLOOP and DLOOPQ) and outputs LA, LAQ, MON and

MONQ. This is necessary because directly modulated

laser diodes and EAMs have different output voltage

requirements. When a laser diode is used, a low voltage

on the LA output (and thus a high current because the

diode is connected between ground and the LA output)

corresponds to a logic HIGH, while a high voltage on the

LA output (low current) corresponds to a logic LOW.

The opposite is the case with an EAM, so an inversion is

needed between input and output. This happens in the

second multiplexer (see Fig.1) when SMOD is connected

to V

which is the laser diode setting.

Modulation current setting

The SIMOD input is used to adjust the modulation current

at outputs LA and LAQ. This is achieved by regulating the

internal current mirror, which serves as a reference current

for the modulation driver. The reference port of the control

op-amp is connected to ground through an internal 4 kΩ

resistor, thus establishing a ‘virtual earth’ on the SIMOD

pin (0 V DC). An external 3 to 4 kΩ resistor connected to

an adjustable voltage source is needed to regulate the

internal current mirror. This adjustable voltage source

could be a part of the laser current control box (see Fig.8).

The maximum output current of 60 mA is achieved with a

4 V input. The input current at SIMOD would be about

1 mA in this case.

(LOW). If left open SMOD is pulled up to GND,

EE1

Loop mode

Loop mode is provided for system testing. A LOW level on

ENL selects loop mode. If ENL is left open, it is pulled

HIGH (TTL) by an internal pull-up resistor.

1997 Nov 27 7

Bias current setting

An independently adjustable on-chip bias current source is

provided for when the OQ2545HP is driving directly

modulated laser diodes. The SIBIAS input is used to adjust

the bias current at output IBIAS, in a similar arrangement

Philips Semiconductors Preliminary specification

SDH/SONET STM16/OC48 laser driver OQ2545HP

to that used for adjusting the modulation current.

The reference port of the control op-amp is again

connected to ground through an internal 4 kΩ resistor,

thus establishing a ‘virtual earth’ on the SIBIAS pin (0 V

DC). An adjustable voltage source connected to SIBIAS

through a 3 to 4 kΩ resistor is used to regulate the internal

current mirror. The maximum output current of 100 mA

would be achieved with a 4 V input. The input current at

SIBIAS would be about 1 mA in this case.

Band gap decoupling capacitor

The band gap voltage should be decoupled to V

EE1

with an

external 10 nF capacitor to minimize noise. It cannot be

used as an external reference voltage for other circuits.

Preamplifier bias current adjustment

The bias current for the preamplifier contains a modulation

dependent component and a modulation independent

component. The modulation dependent current is adjusted

via SIMOD (see Section “Modulation current setting”

above). The modulation independent current will be

adequate under normal circumstances. However, in some

applications it may be necessary to customize the shape

of the modulation current. This can be done by adjusting

the preamplifier bias current by means of the AMPADJ pin.

With this pin left floating, the bias current is 0.6 mA. If this

pin is connected to ground, the maximum bias current will

be about 3 mA. A resistor can be connected between

AMPADJ and ground to adjust the current level within this

range. The bias current can be decreased by connecting a

resistor between AMPADJ and V

(however care should

EE2

be taken as the preamplifier will not be able to drive the

modulation driver if the bias current is too low).

Emitter follower bias current adjustment

The bias currents for the emitter followers connected

between the preamplifier and the modulation driver

contain two components: a modulation dependent

component (controlled via SIMOD; see Section

“Modulation current setting” above) and a modulation

independent component. The modulation independent

currents, 8.2 and 16.4 mA, are sufficient to ensure the

emitter followers operate correctly under normal

circumstances. In some applications, however, the output

currents at LA and LAQ may need to be optimized. This is

achieved by connecting an external resistor between the

EFADJ pin and ground. If EFADJ is connected directly to

ground without using a resistor, the maximum currents for

the two emitter followers will be approximately

25 and 50 mA, respectively. Because the emitter followers

buffer the signal from the preamplifier, the range over

which the current can be adjusted through EFADJ is

dependent on the AMPADJ setting.

Grounding and power supply decoupling

The ground connection on the PCB needs to be a large

copper area fill connected to a common ground plane with

as low inductance as possible. The large area fill will

improve heat transfer to the PCB and thus aid IC cooling.

The power supply pins need to be decoupled using chip

capacitors mounted as close as possible to the IC.

To avoid high frequency resonance, multiple bypass

capacitors should not be mounted at the same location.

To minimise low frequency switching noise in the vicinity of

the OQ2545HP, the power supply line should ideally be

filtered once using an LC-circuit with a low cut-off

frequency.

1997 Nov 27 8

Loading...

Loading...