Page 1

X-RAY GENERATION

LIST OF DOCUMENTATION IN THIS BINDER:

SUBSYSTEM MANUAL OPTIMUS

UNIT MANUAL Converter R/F

UNIT MANUAL Cockpit for duo DIAGNOST

○ UNIT MANUAL Power Distribution Unit (PDU)

Note: indicates document present

LIST OF ALL BINDERS FOR X-RAY GENERA

TION:

-- SUBSYSTEM MANUAL OPTIMUS C (this binder)

4512 984 08497 REV AB

OPTIMUS_C_div 01_08497_AB

E 2003 Philips Medical Systems

ALL RIGHTS RESERVED

0.1

Page 2

SERVICE MANUAL

OPTIMUS C

742

SUBSYSTEM

INTRODUCTION AND TECHNICAL DA TA

INSTALLATION

1

2

9890 000 02191

FAULT FINDING

REPLACEMENT

PROGRAMMINGS

ADJUSTMENTS

3

4

5

6

358J92

CAN-controlled X-ray generator of the converter type

DMC Hamburg

Printed in Hamburg, Germany

E 2003 Philips Medical Systems

ALL RIGHTS RESERVED

ACCEPTANCE

SERVICE INFORMATION

PARTS LIST

SCHEMATIC DRAWINGS

7

8

P

Z1-

4512 984 08497 REV AB 1

OPTIMUS_C_reg_08497_AB

WIRING DIAGRAMS

Z2-

Page 3

SERVICE MANUAL -- SUBSYSTEM

OPTIMUS C

OPTIMUS C

Author: P. Thron

Type No: 9890 000 02191

Techn. No: Basis 4512 104 70625

Release: 1.2

In case there are any questions concerning this manual,

please send this LOPAD via fax to 49/(0)40/5078 2481

File: OPTIMUS_C_08497_AB

List of pages and drawings (LOPAD) Manual Order No: 4512 984 08497

released: 04/2003

0.1

1

3.1

3.2

_________________________________________

1--0.1 (a/02.1)

1--1 ... 11 (a/02.1)

Z--1.1 (01.0) A4 4512 982 0092.

Z--1.2 (02.0) A4 4512 982 0099.

Z--1.3 (01.0) A4 4512 982 0099.

Z--1.4 (01.0) A4 4512 982 0099.

Z--6.1 (01.0) A4 4512 982 0099.

Z--6.2 (01.0) A4 4512 982 0099.

Z--7.1 (02.0) A3 4512 982 0099.

_________________________________________

6--0.1 (a/02.1)

6--1 ... 16 (a/02.1)

_________________________________________

7--0.1 (a/02.0)

7--1 ... 4 (a/02.0)

_________________________________________

8--1 (00.0) FCO--Checklist

8--2 (00.0) FCO--Checklist

_________________________________________

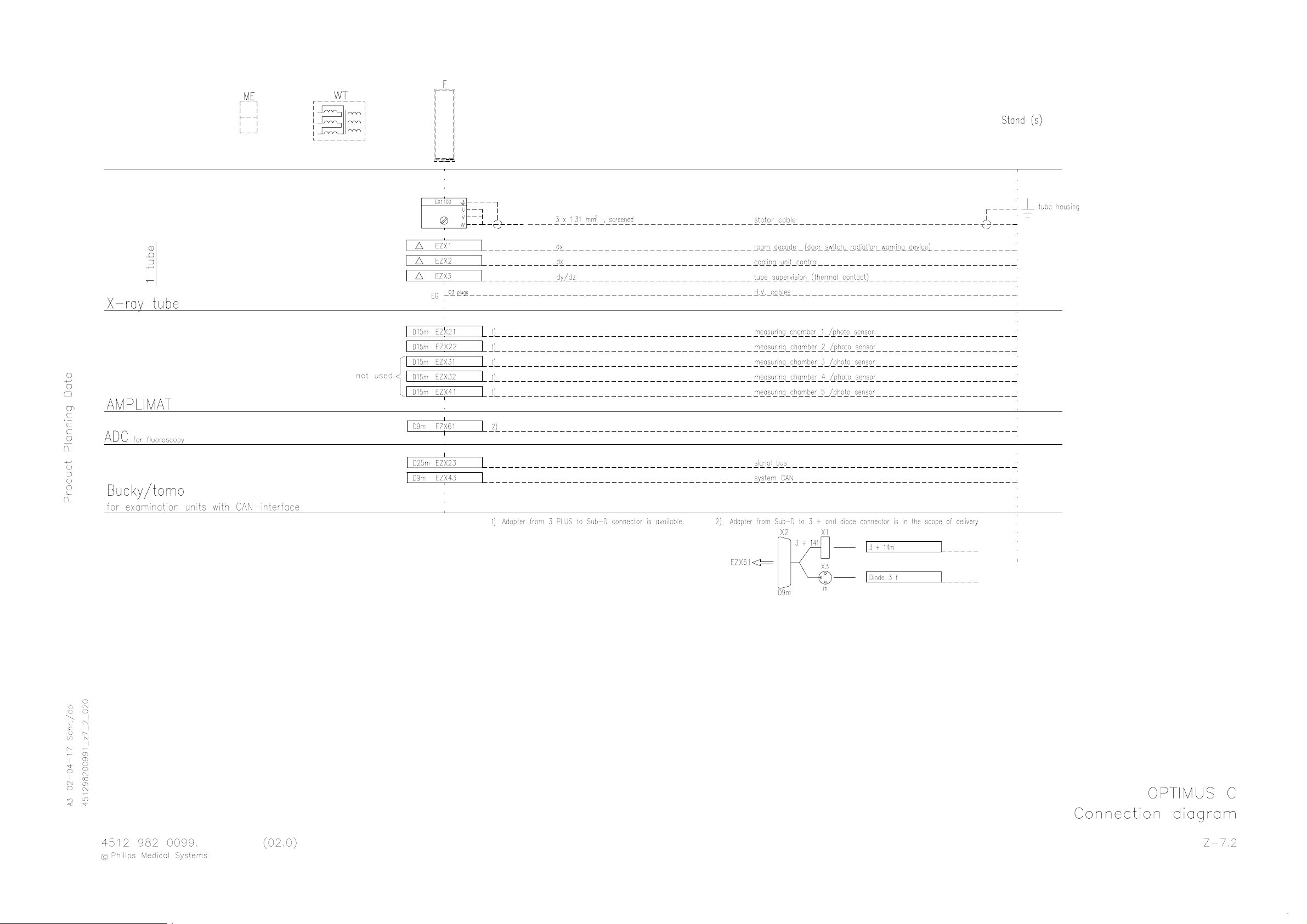

Z--7.2 (02.0) A3 4512 982 0099.

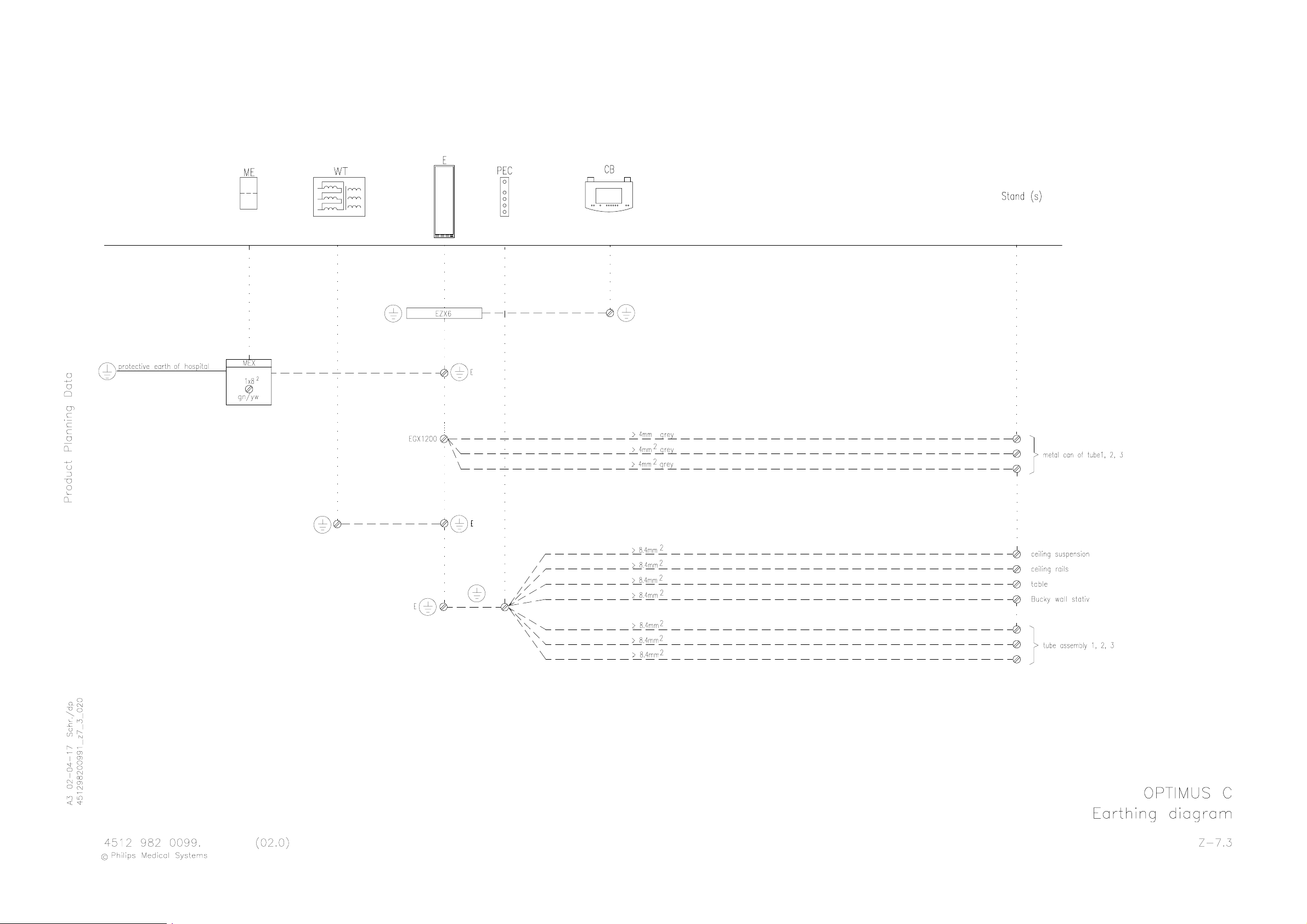

Z--7.3 (02.0) A3 4512 982 0099.

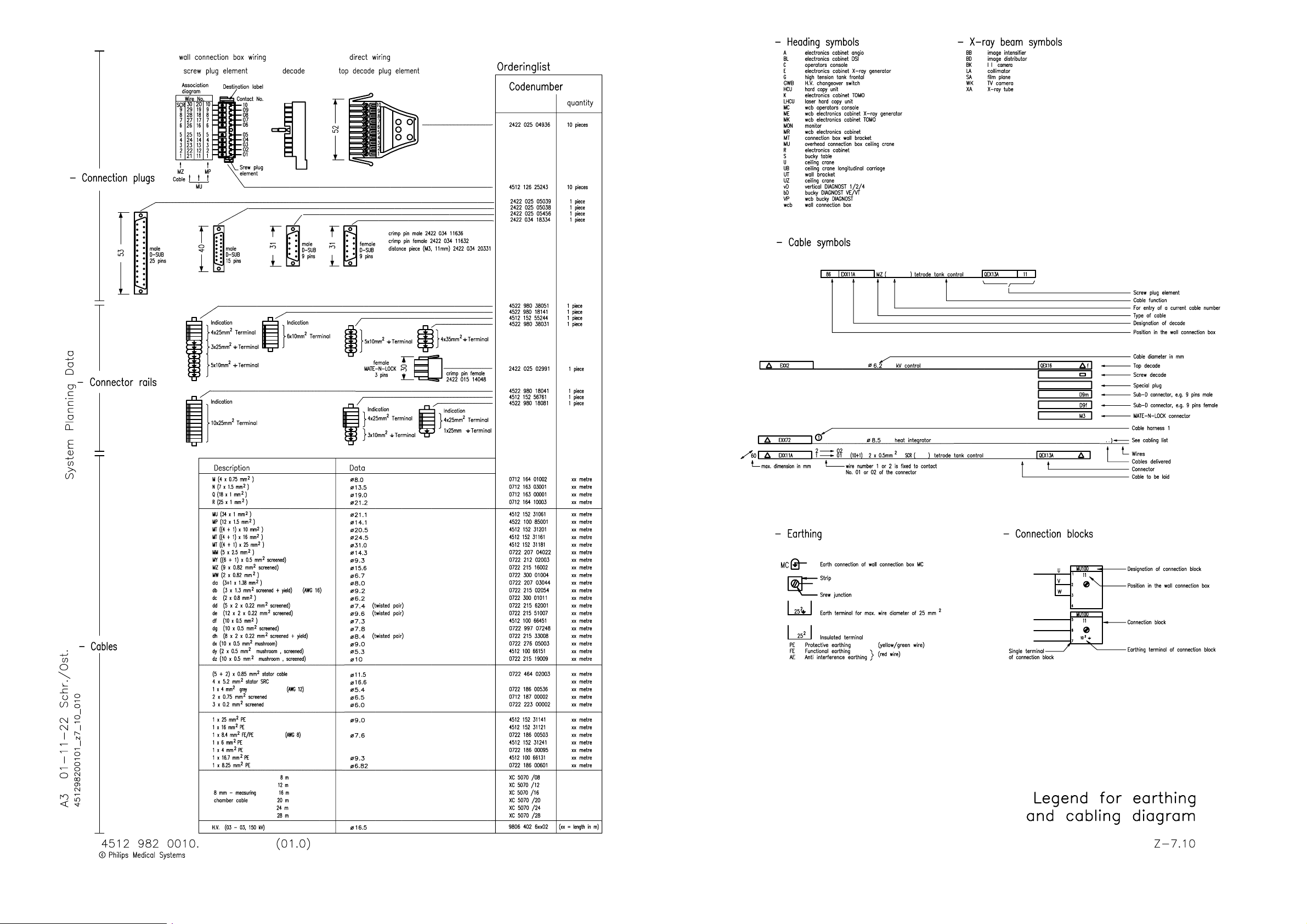

Z--7.10 (01.0) A3 4512 982 0010.

_________________________________________

2--0.1 ... 0.2 (a/02.1)

2--1 ... 36 (a/02.1)

2Z--4 (02.0) A4 4512 983 06161

2Z--10 (a/02.0) A3 4512 983 06171

_________________________________________

3--0.1 (a/02.1)

3--1 ... 85 (a/02.1)

3Z--1 (a/01.0) A4 OPTIMUS R/F

_________________________________________

4--0.1 (a/02.1)

4--1 ... 22 (a/02.1)

_________________________________________

5Z--1 (a/01.0) A3 OPTIMUS R/F

5Z--2 (a/01.0) A3 OPTIMUS R/F

_________________________________________

E 2003 Philips Medical Systems

ALL RIGHTS RESERVED

4512 984 08497 REV AB3.1

OPTIMUS_C_lopad_08497_AB

Page 4

OPTIMUS C

_________________________________________

Z0--1 (02.0)

Z1--1.1 (02.0) A3

Z1--2.1 (a/02.0) A3 4512 983 06181

Z1--2.2 (a/02.0) A3 4512 983 06191

Z1--2.3 (99.0) A3 OPTIMUS R/F

Z1--3.3 (a/97.2) A3 OPTIMUS R/F

Z1--4.1 (a/99.0) A3 OPTIMUS R/F

Z1--4.2 (a/99.0) A3 OPTIMUS R/F

Z1--5.1 (97.1) A3 4512 983 06551

Z1--6 (02.0) A3 4512 983 05531

Z1--13.2 (c/00.0) A3 OPTIMUS R/F

_________________________________________

Z0--2 (02.0)

Z2--1.0 (a/00.0) A4

Z2--1.1 (d/99.0) A3 4512 983 06461

Z2--1.2 (e/99.0) A3 4512 983 06471

Z2--1.3 (c/98.0) A3 4512 983 06481

Z2--2.1.1 (97.0) A3 4512 983 06491

Z2--2.1.2 (97.0) A3 4512 983 06501

Z2--2.2.1 (96.0) A3 4512 983 06511

Z2--2.2.2 (a/97.0) A3 4512 983 06521

Z2--5.1 (a/02.0) A3 OPTIMUS R/F

Z2--5.2 (b/02.0) A3 4512 983 05511

Z2--5.3 (a/02.0) A3 OPTIMUS R/F

Z2--5.4 (02.0) A3 OPTIMUS R/F

Z2--13 (d/00.0) A3 OPTIMUS R/F

Z2--14.1 (b/99.0) A3 OPTIMUS R/F

Z2--14.4 (97.0) A3 OPTIMUS R/F

Z2--17 (98.0) A3

_________________________________________

(nur für Fabrik--Auslieferung)

Service software No:

-- OMC : 4512 116 0240x

_________________________________________

4512 984 08497 REV AB

OPTIMUS_C_lopad_08497_AB

E 2003 Philips Medical Systems

ALL RIGHTS RESERVED

3.2

Page 5

OPTIMUS C

1. Product information 1--1..................................................

1.1. Applications 1--1..........................................................

1.2. Options 1--1..............................................................

1.2.1. Hardware options 1--1......................................................

1.2.2. Software options 1--1......................................................

2. Compatibility 1--1........................................................

2.1. Generator components 1--1.................................................

2.2. Tubes 1--2................................................................

2.3. System components 1--2...................................................

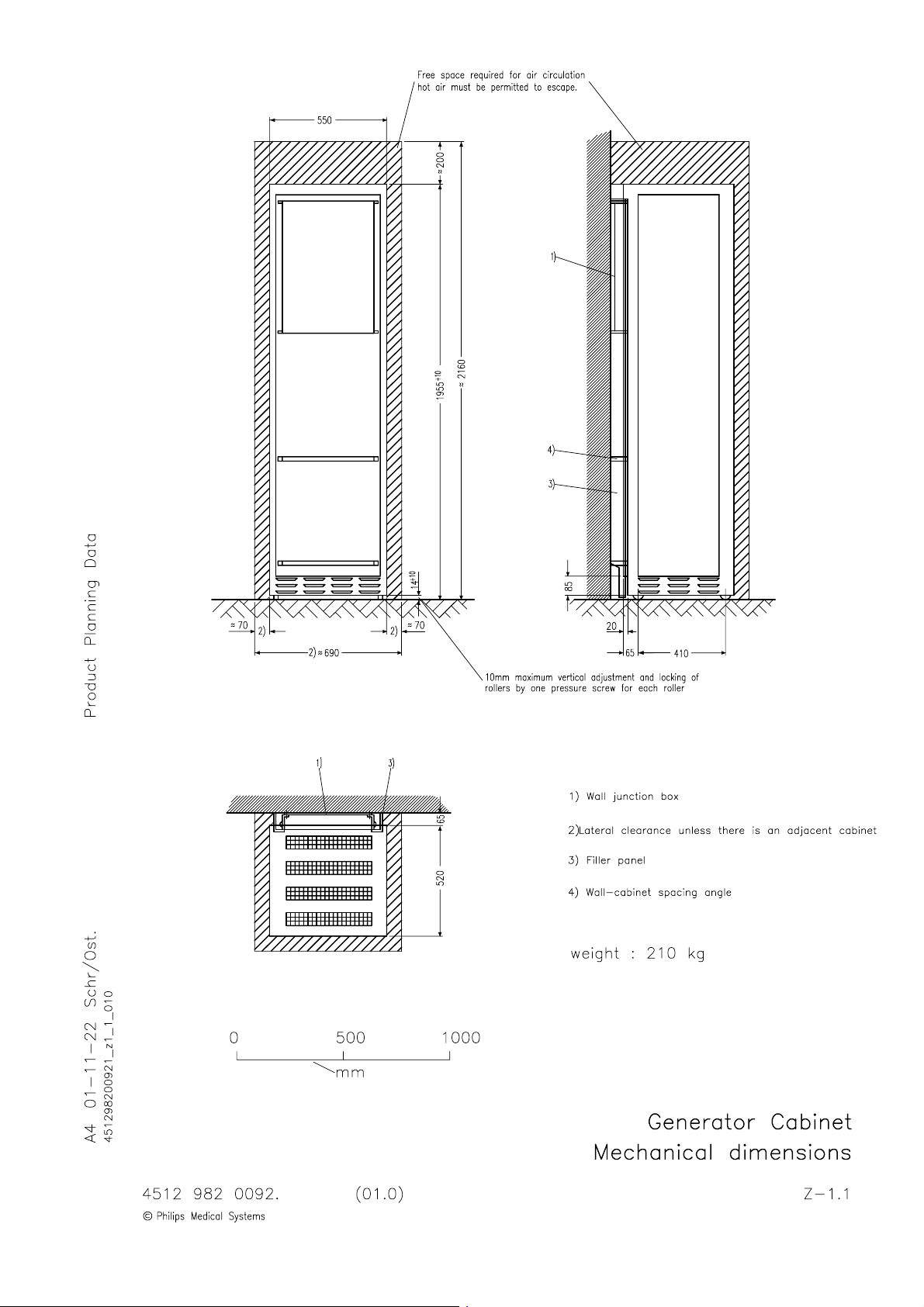

3. Mechanical data 1--2......................................................

4. Environmental data 1--3...................................................

4.1. Electrical environment 1--3..................................................

4.2. Climatic conditions 1--3.....................................................

4.3. Emission 1--3.............................................................

5. Electrical data 1--4........................................................

5.1. Power data and mains conditions 1--4........................................

5.2. Power supply for application 1--6............................................

5.3. Operating data 1--6........................................................

5.4. Power supply 1--7.........................................................

5.4.1. Type of power supply 1--7..................................................

5.4.2. Calculating the mains resistances 1--8........................................

5.4.3. Earth-leakage circuit breaker 1--9............................................

5.4.4. Emergency--OFF device 1--9................................................

6. Tools 1--9................................................................

7. Traceable items 1--9......................................................

8. Preparation 1--10..........................................................

8.1. Installation material 1--10....................................................

8.2. Cables 1--10...............................................................

8.3. Manpower 1--1 1............................................................

9. Planned maintenance 1--11.................................................

INTRODUCTION AND TECHNICAL DATA

INTRODUCTION AND TECHNICAL DATA

TEXT

Contents 1--0.1............................................................

DRAWINGS

Generator cabinet: Mechanical dimensions Z--1.1................................

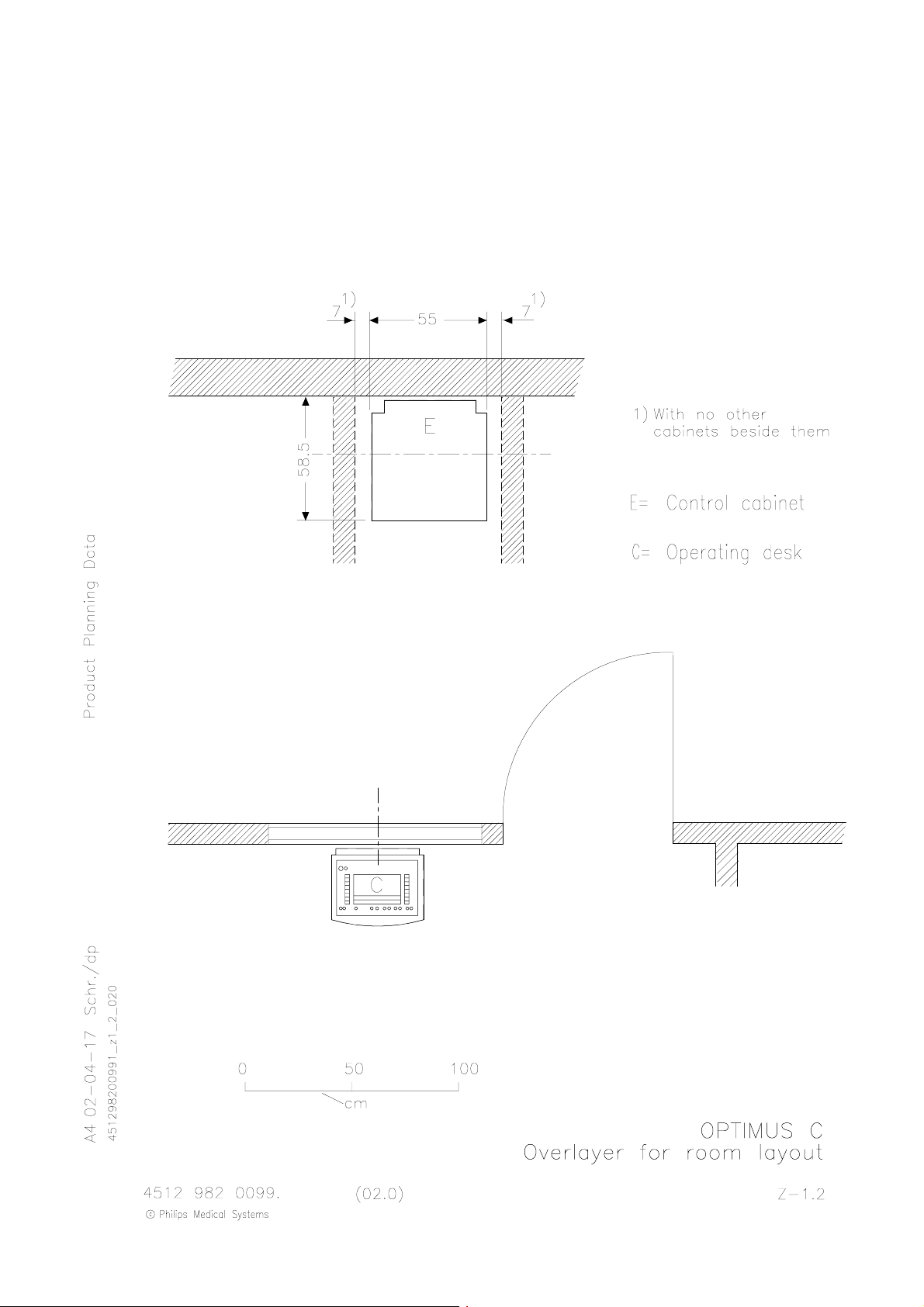

Overlayer for room layout Z--1.2..............................................

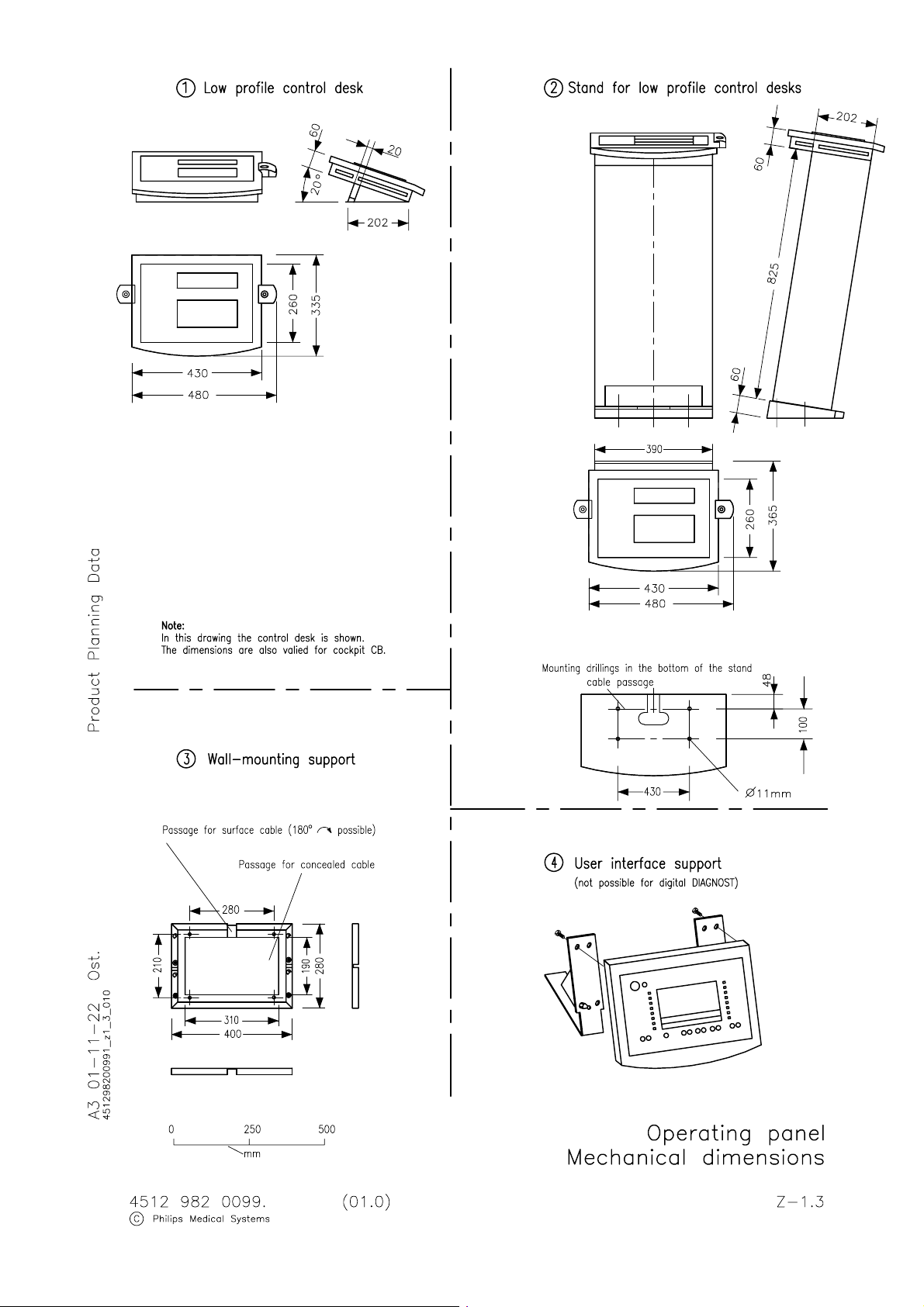

Operating panel: Mechanical dimensions Z--1.3.................................

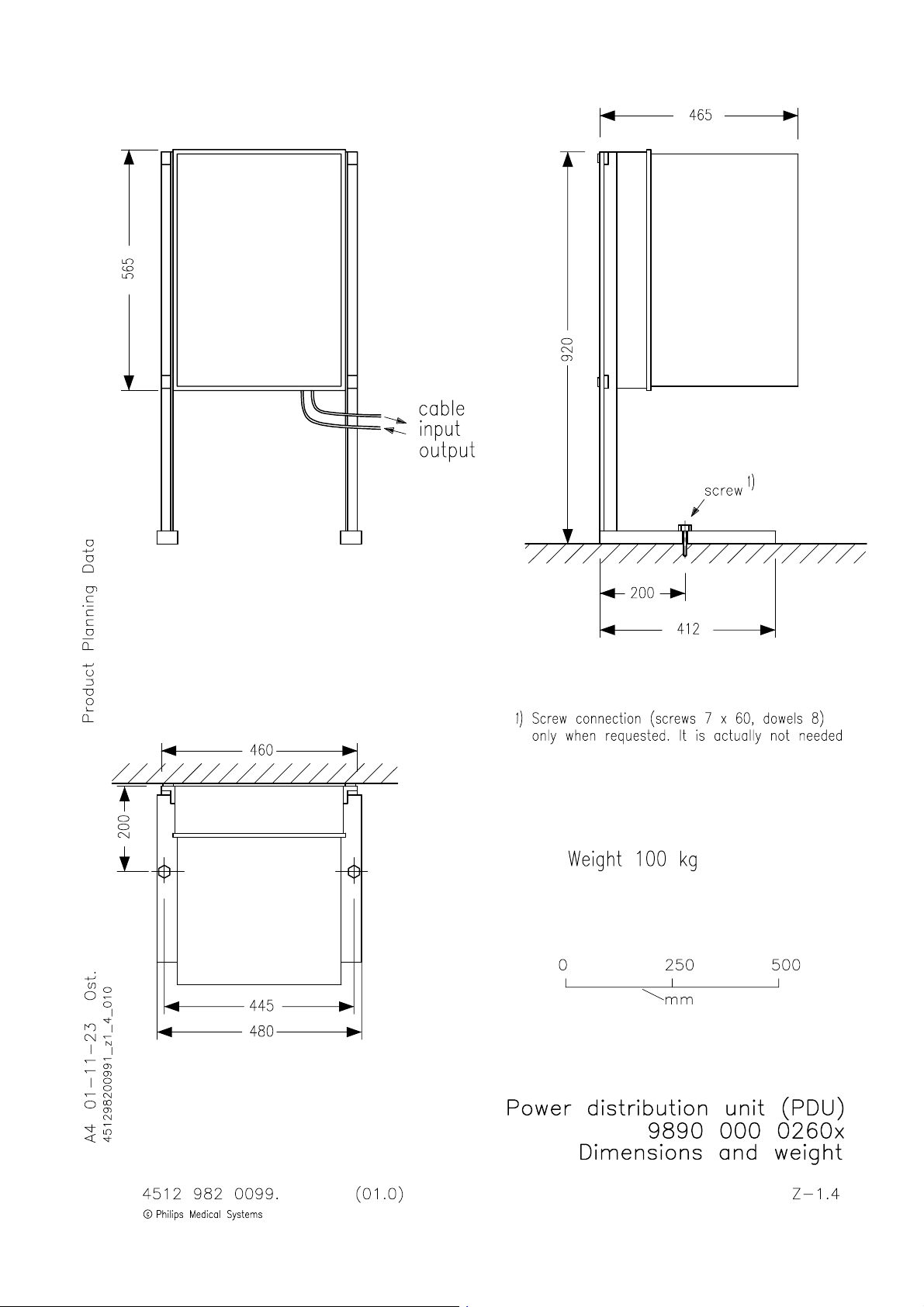

Power Distribution Unit: Dimensions and weight Z--1.4...........................

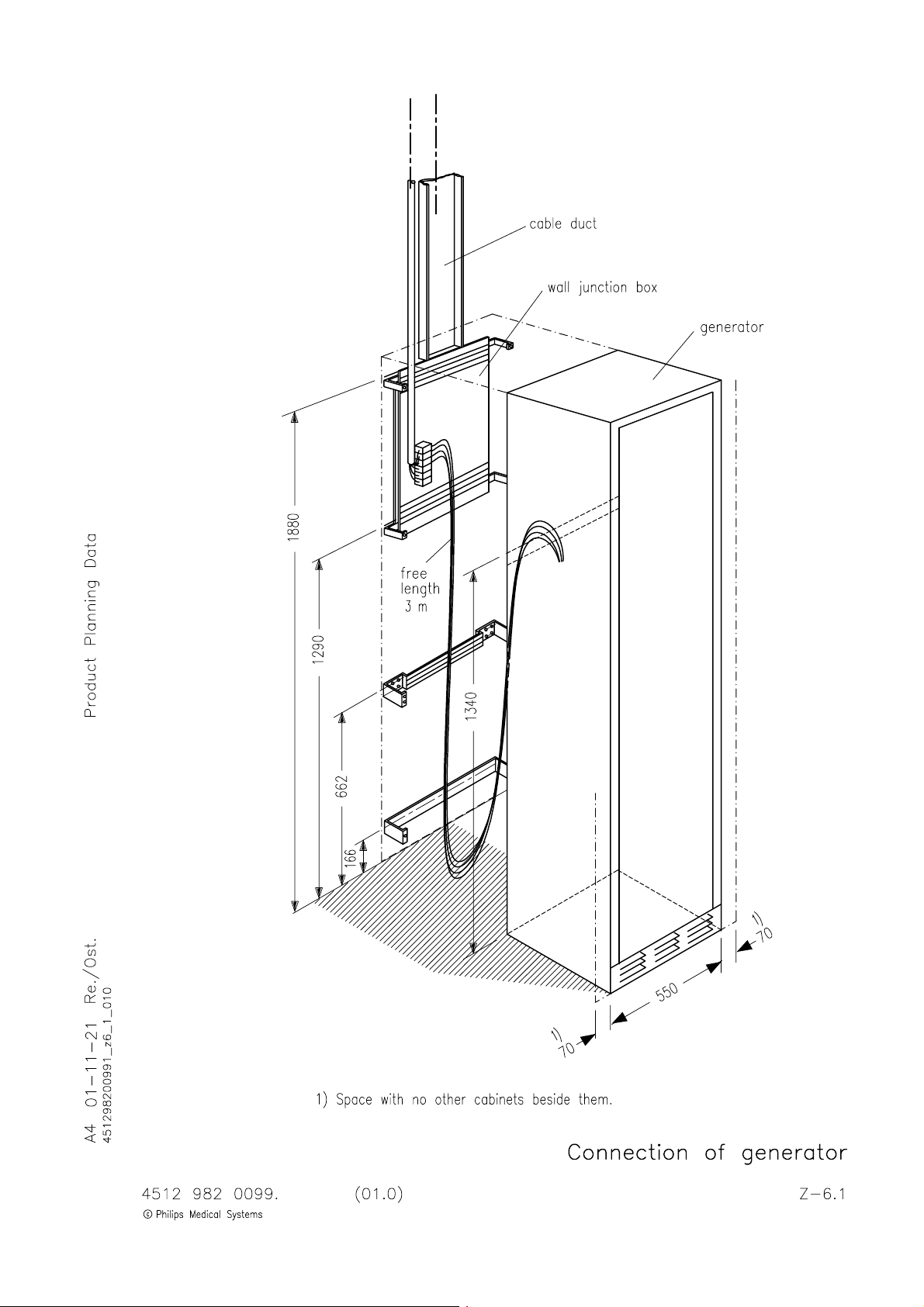

Connection of generator Z--6.1...............................................

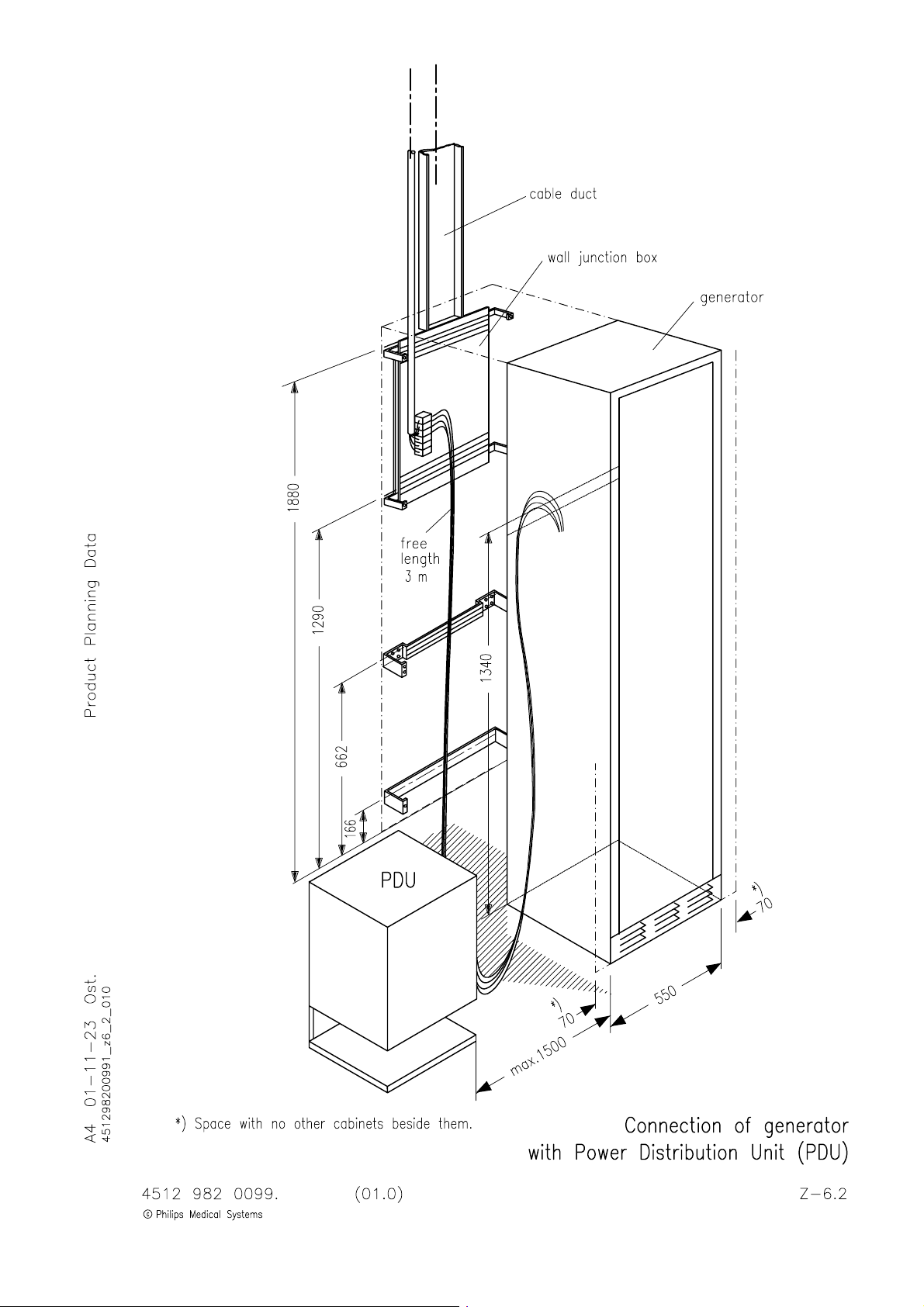

Connection of generator with PDU Z--6.2......................................

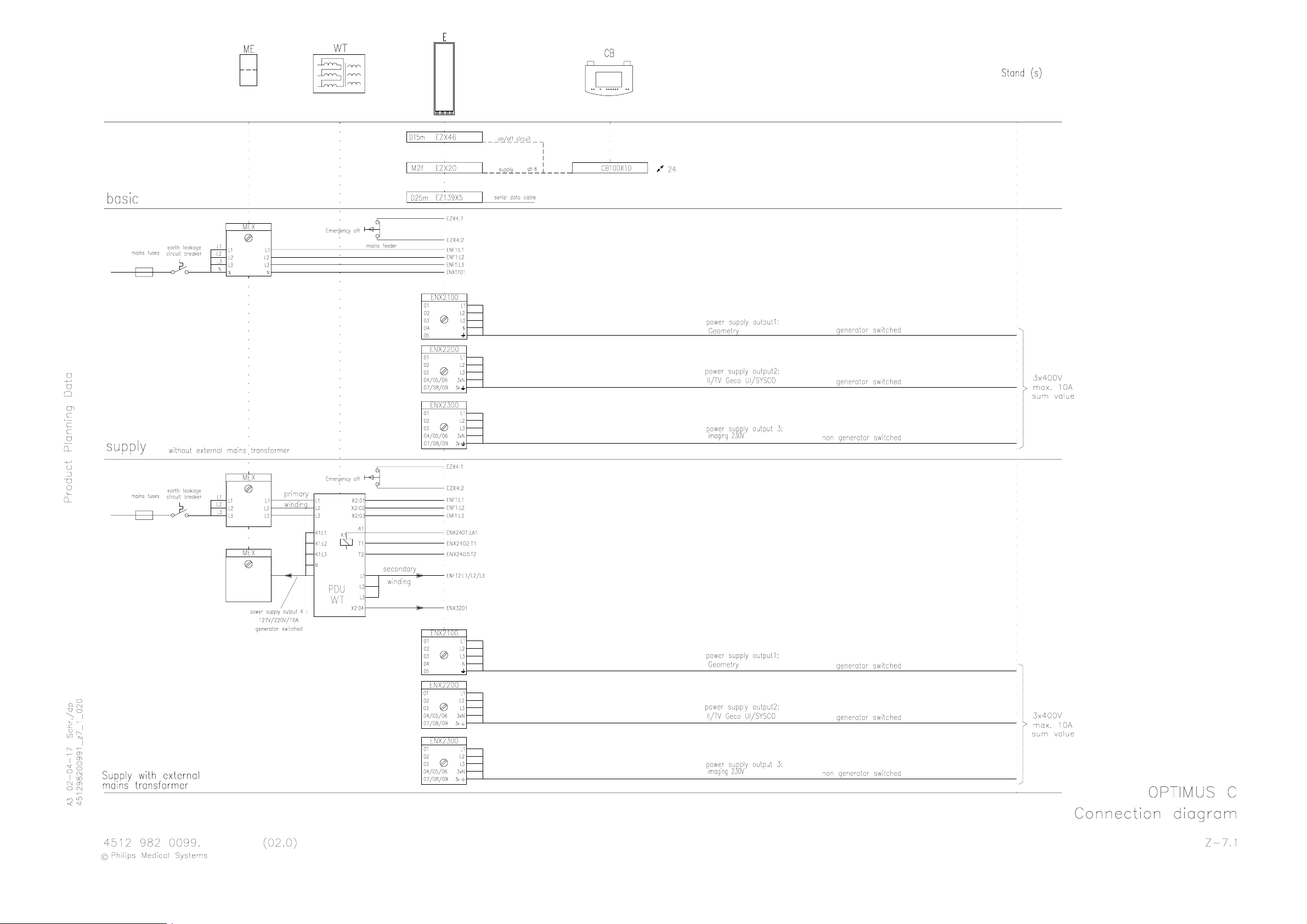

Connection diagram Z--7.1...................................................

Connection diagram Z--7.2...................................................

Earthing diagram Z--7.3.....................................................

Legend for earthing and cabling diagram Z--7.10.................................

OPTIMUS C (a/02.1)

OPTIMUS_C_1_a021_inh

E 2003 Philips Medical Systems

ALL RIGHTS RESERVED

1--0.1

Page 6

OPTIMUS C

INTRODUCTION AND TECHNICAL DATA

1. Product information

The Optimus family of generators for radiography is based on computer-controlled converter technology.

The converter operates in the non-audible frequency range.

Applicable options can be enabled by releasing software modules using customized PAL ICs depending on the

respective order.

Control between the internal Function Units (FUs) and the external online equipment takes place by a CAN bus.

Safety-relevant signals are transferred directly on the so-called “Signal bus”.

1.1. Applications

-- Radiography

-- Tomography

-- Fluoroscopy

1.2. Options

1.2.1. Hardware options

-- Mains transformer PDU: 400 -- 480V; 50 / 60Hz,

also for 400V mains supply without neutral lead N

with taps for 400 / 440 / 460 / 480V 9890 000 0260x......................................

-- Mains transformer: 190--390V; 50 / 60Hz

with taps for 190 / 200 / 207 / 220 / 230 / 240 / 250 / 343 / 380 / 390V

max. 50kW! 9803 720 8100x..........................................................

1.2.2. Software options

Software options are provided via the function key (see also 5Z--1, EZ 139 Central Unit D38).

Additional hardware components are not required.

All system options are available.

All Optimus C have the same function key configuration, there is only a difference in the power class 50/65/80kW.

2. Compatibility

2.1. Generator components

-- Base OPTIMUS C 9890 000 0219x....................................

-- H.V. transformer R/F 1 tube, 50kW 9890 000 0270x.. .................

-- H.V. transformer R/F 1 tube, 65/80kW 9890 000 0272x.. ...............

-- 50kW extension -- R/F 9890 000 0274x................................

-- 65kW extension -- R/F 9890 000 0275x................................

-- 80kW extension -- R/F 9890 000 0276x................................

-- Firmware Rel. 1.2 9890 000 0254x....................................

OPTIMUS C (a/02.1)

OPTIMUS_C_1_a021

E 2002 Philips Medical Systems

ALL RIGHTS RESERVED

1--1

Page 7

OPTIMUS CINTRODUCTION AND TECHNICAL DATA

C

2.2. Tubes

Recommended standard tubes:

-- RO 17 50

-- SRM 06 12

-- SRO 25 50

-- SRO 33 100

Further compatible tubes:

-- RO 12 30 -- SRO 09 51 -- SRO 20 55

-- RO 16 48 -- SRO 13 30 -- SRO 22 50

-- RO 30 50 RE -- SRO 20 50 -- SRO 32 100

Compatible tube housings:

-- ROT 350

-- ROT 351

-- ROT 504

The latest information on further tubes which are connectable is available at the service center Hamburg.

2.3. System components

-- DuoDiagnost GEOMETRY 9890 000 0290x............................

-- Stand for operating panel 9890 000 0244x.............................

-- Wall mounting of operating panel 9890 000 0245x.......................

-- User interface support 9890 000 0283x................................

-- Cable set for COCKPIT 9890 000 0279x...............................

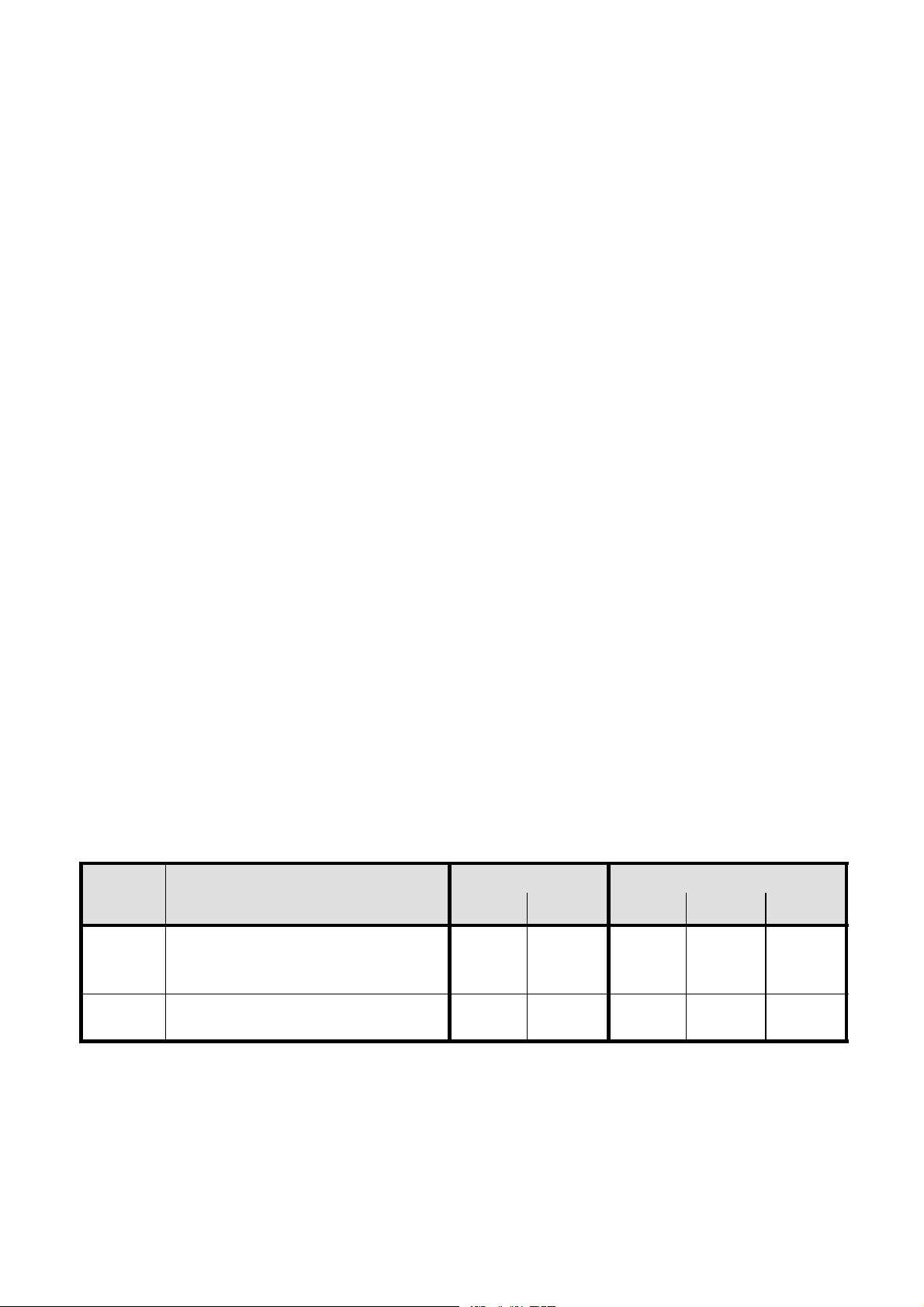

3. Mechanical data

For installation dimensions and weights see drawings Z--1.1.

Transport data:

Weights [kg] Dimensions [cm]

ase no.Contents

-- Generator cabinet

1

-- Operating panel

-- Cables

net gross length width height

178 226 210 82 84

2 -- H.V. generator; 1--tube version 73 100 77 67 80

(a/02.1)1--2

E 2002 Philips Medical Systems

ALL RIGHTS RESERVED

OPTIMUS C

OPTIMUS_C_1_a021

Page 8

OPTIMUS C

INTRODUCTION AND TECHNICAL DATA

4. Environmental data

The environmental data comply with to PMS standard UXW 13600.

4.1. Electrical environment

Class S0 -- Dedicated mains supply, 3 phases and neutral. Thus single phase voltage is also available.

A low impedance, permanently installed connection, fed in by the step down transformer of the hospital to supply

large systems like in MR, CT and X--ray departments is required.

Note

Use always a mains cable with 4 wires and concentric PE--shield, type NYCY.

4.2. Climatic conditions

Ambient temperature 10_C--40_C...................

Relative humidity 15% -- 90%; no condensation.......................

Relative atmospheric pressure 70kPa -- 110kPa...........

4.3. Emission

Heat dissipation max. 1200W; average per hour........................

Noise level, normal operation ≈ 46dBA............

Noise level, maximum power operation ≈ 55dBA....

EMC IEC 950..................................

To avoid any possible annoying noise of the implemented fans it is advisable to install the generator cabinet

outside the examination room.

OPTIMUS C (a/02.1)

OPTIMUS_C_1_a021

E 2002 Philips Medical Systems

ALL RIGHTS RESERVED

1--3

Page 9

5. Electrical data

withexternaltransformerPDU(option

)

I

3+1x1

0

2

(L1,L

2,L

3,PE)

5.1. Power data and mains conditions

Voltag e

50kW 65kW 80kW

Mains voltage 3 x 400V ±10% (415V

3 x 400 / 440 / 460V ±10% *

6%

3 x 480V

=*=

The following connection cables are recommended:

+

|

--10%

+6%

/ 380V

*

-- 5 %

OPTIMUS CINTRODUCTION AND TECHNICAL DATA

)

nput:

Output: 4 x 4mm

4+1x4mm

3 x 1,5mm

mm

2

Generator supply 3 x 400V

2

Device supply 3 x 220V (option)

2

Switch control and temperature supervision

3 x 190 ... 343V ±10% **

** = with external transformer; max. 50kW (option)

Frequency

50kW 65kW 80kW

Mains frequency 49 ... 61Hz

(a/02.1)1--4

E 2002 Philips Medical Systems

ALL RIGHTS RESERVED

OPTIMUS C

OPTIMUS_C_1_a021

Page 10

OPTIMUS C

(

)

A

INTRODUCTION AND TECHNICAL DATA

Max. mains current

Voltag e

50kW 65kW 80kW

Exposure: 400V 145A 190A 230A

440V 135A 180A 215A

460V 125A 170A 210A

480V 120A 160A 205A

190V 300A -- --

Short--time power

consumption

100kVA 132kVA 160kVA

[I x U x √3]

Fluoro: 400V -- 8A

480V -- 7A

Fuse protection

slow blow

Connected load

[I

xUx√3]

Fuse

Emergency static

power supply: (Inverter)

dynamic

(Diesel generator

with flywheel mass)

35A

100A at ≤ 240V

25kVA 35kVA

Short--time power consumption

[I x U x √3]

Connected load

[I

xUx√3]

Fuse

50

Mains resistance

Voltag e

50kW 65kW 80kW

400V ≤ 300mΩ ≤ 200mΩ

440V ≤ 350mΩ ≤ 240mΩ

460V ≤ 350mΩ ≤ 240mΩ

480V ≤ 400mΩ ≤ 300mΩ

480V valid for DOD only ≤ 300mΩ ≤ 240mΩ ≤ 180mΩ

Note

500m

Ω

is the absolute max. mains resistance.

OPTIMUS C (a/02.1)

OPTIMUS_C_1_a021

E 2002 Philips Medical Systems

ALL RIGHTS RESERVED

1--5

Page 11

5.2. Power supply for application

Generator power

Supply 50kW 65kW 80kW

OPTIMUS CINTRODUCTION AND TECHNICAL DATA

Output 1 230V / 400V; generator switched and protected ----> I

Output 2 230V / 400V; generator switched and protected ----> I

Output 3 230V / 400V; generator not switched and protected ----> I

Sum value I

max(1+2+3)

≤ 10A

Only with external

transformer PDU

Output 4 127V / 220V generator switched and protected ----> I

Output 5 double socket 127V / 15A to phase L1;

generator not switched and protected ----> I

Sum value I

max (4 +5)

≤ 16A

5.3. Operating data

Generator power

1

2

3

4

5

Data

50kW 65kW 80kW

Exposure: Tube current 1 ... 650mA 1 ... 900mA 1 ... 1100mA

Tube voltage 40 ... 150kV in kV-- or %--steps

mAs product 0,5 ... 850mAs

Exposure time 1ms ... 6s / 16s

Exposure frequency ≤ 12exp./s

Interfacing option for door contact, external radiation warning indicator

Fluoro: Tube current 0,25 ... 6mA

Tube voltage 40 ... 110kV

kV/mA curves 3

Setting time ≤ 1s

(a/02.1)1--6

E 2002 Philips Medical Systems

ALL RIGHTS RESERVED

OPTIMUS C

OPTIMUS_C_1_a021

Page 12

OPTIMUS C

5.4. Power supply

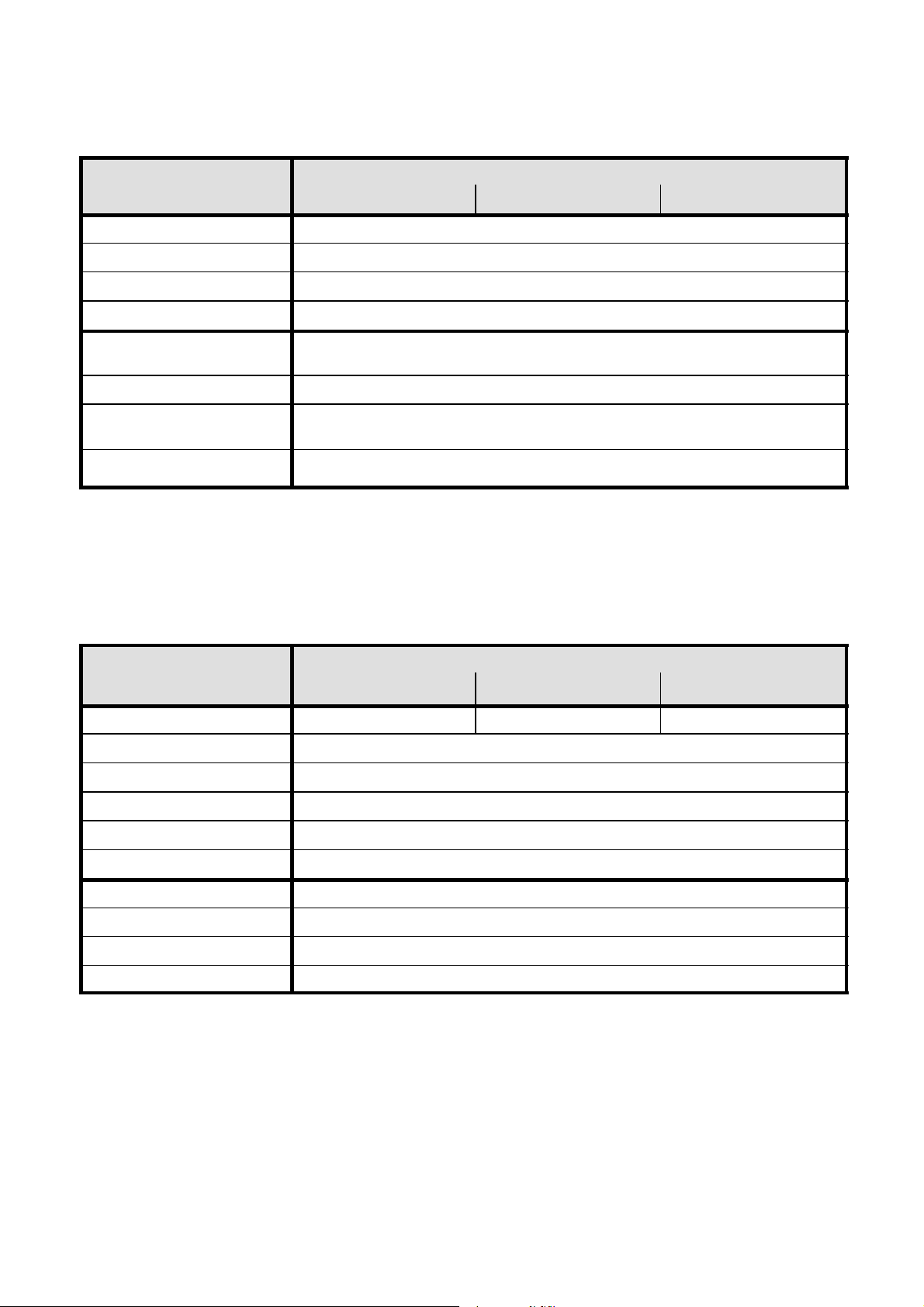

5.4.1. Type of power supply

3 phase WYE

INTRODUCTION AND TECHNICAL DATA

L1

L2

L3

(N)

3 phase DELTA,

balanced earth or floating

L1

L2

L3

X-ray

installation

X-ray

installation

-- 400V

-- 440V / 460V / 480V with

external mains transformer PDU

9890 000 0260x.

-- Neutral not required if the external

mains transformer PDU

9890 000 0260x is ordered.

-- 190V ... 343V with

external mains transformer

9803 720 8100x (max. 50kW).

-- External mains transformer PDU

9890 000 0260x is required.

-- 400V / 440V / 460V / 480V

-- 190V ... 343V with

external mains transformer

9803 720 8100x (max. 50kW).

3 phase DELTA,

grounded

L1

-- External mains transformer PDU

9890 000 0260x is required

(requires modification at the

EMC-- filter of the kV power unit).

X-ray

installation

L2

L3

Caution!

Ensure the sequence of phases in the wall junction box corresponds to designations L1, L2, L3.

OPTIMUS C (a/02.1)

OPTIMUS_C_1_a021

E 2002 Philips Medical Systems

ALL RIGHTS RESERVED

-- 400V / 440V / 460V / 480V

1--7

Page 13

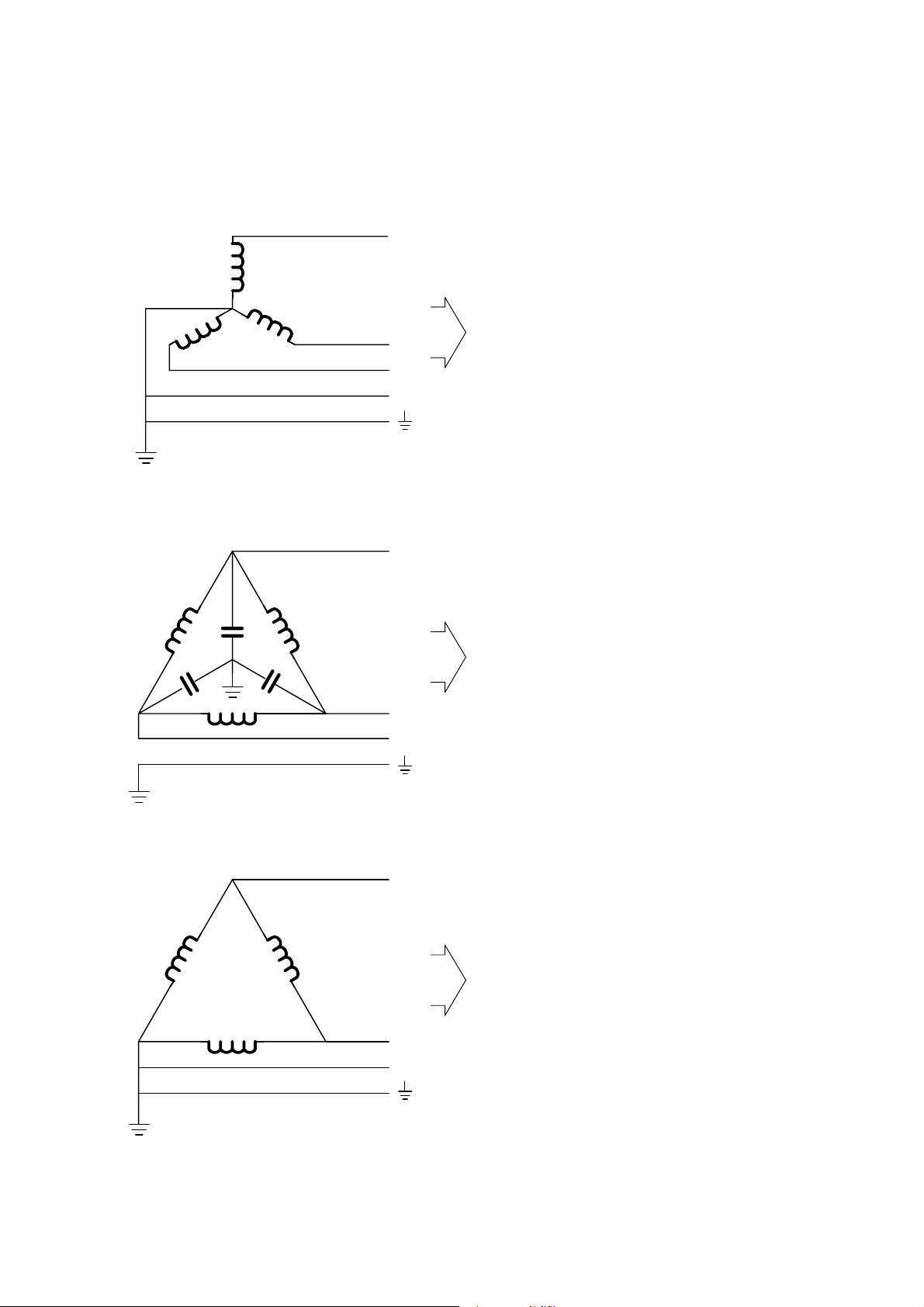

5.4.2. Calculating the mains resistances

Note

The cross section of lead l

must not exceed 25mm2. (See figure below).

3

OPTIMUS CINTRODUCTION AND TECHNICAL DATA

If possible the sum of R

smaller than the R

requires.

XG

0,R1,R2

and R3should be

R

+R1+R2+R3<R

0

With higher internal mains resistances the generator

output is reduced correspondingly.

R

designates the mains resistance of the distributor transformer

0

R

depends on the length of lead l1between distributor transformer and mains distributor

1

L1

L2

L3

l

1

and on the selected cross section as well:

==> R

R

consists of upstream elements such as:

2

1=l1

× R

Cu

RCufrom table below

-- Emergency-OFF switch 4.0mΩ.................

-- Earth-leakage circuit breaker 5.5mΩ............

l

3

XG

MEX 100

L1

L2

L3

357J94

-- Fuse 5.5mΩ.................................

-- Surge arrester WN 23.0mΩ...................

R

depends on the length of lead l3between mains distributor and wall junction box

3

and on the selected cross section as well:

==> R

3=l3

× R

Cu

RCufrom table below

The resistances consider the go and return lines so that the calculation can be based on simple cable lengths.

Copper cross section

[mm

2

]

Resistance R

[mΩ/m]

Cu

16 2.19

25 1.4

35 1.0

50 0.7

70 0.5

95 0.38

120 0.30

150 0.24

Note

500m

Ω

is the absolute max. mains resistance.

(a/02.1)1--8

E 2002 Philips Medical Systems

ALL RIGHTS RESERVED

OPTIMUS C

OPTIMUS_C_1_a021

Page 14

OPTIMUS C

INTRODUCTION AND TECHNICAL DATA

5.4.3. Earth-leakage circuit breaker

To be provided between mains fuse and X-ray installation depending on local regulations.

Siemens earth-leakage circuit breaker:

-- Order No.: 5SZ3 466 OKG00

-- Rated fault current 30mA

-- Rated current 63A

-- Connection terminals for wire cross sections of up to 25mm

2

5.4.4. Emergency--OFF device

To be provided depending on local regulations.

There are 2 possibilities:

1. All the emergency--OFF buttons are connected in series and looped into the switch--ON circuit (12VDC) of the

generator.

2. The emergency--OFF circuit acts on an external mains contactor which switches OFF the power before it is

fed into the generator.

6. Tools

-- Service engineer standard tool kit

-- Service-PC:

IBM-compatible, 640kB RAM, 3.5” floppy disk drive, ≥ 1 serial port

-- Installation and service software OMC: 4512 116 024xx.

Supplied on a floppy disk within this generator service manual.

-- PC-hardkey (DIAGGEN):

Necessary to carry out the installation and to run the service software (special programmings, fault finding).

-- 0-modem cable:

Minimum length is distance between generator cabinet and operating desk.

Male 25-pole D-Sub connector at the generator side.

A 5m data cable of bucky controller can be used: 4512 130 5693x

-- Mains resistance measuring instrument

-- Dose measuring instrument

-- mAs--meter

-- Multimeter

-- Digital oscilloscope with 2-beam memory

-- Recommended PLCC extraction tool (AMP 822154--1): 2422 487 89772

7. Traceable items

The following items have serial numbers of the following format when delivered ex factory:

1. Generator cabinet 6 digit serial number........

2. H.V. tank 7 digit serial number................

OPTIMUS C (a/02.1)

OPTIMUS_C_1_a021

E 2002 Philips Medical Systems

ALL RIGHTS RESERVED

1--9

Page 15

8. Preparation

Connection of the generator: see drawing Z--6.1................

Connection of the generator with PDU: see drawing Z--6.2.......

Operating panel: see drawing Z--1.3..........................

Connection diagram: see drawing Z--7.1/.2.......................

Earthing diagram: see drawing Z--7.3.........................

Legend for earthing and cabeling: see drawing Z--7.10...........

8.1. Installation material

To be ordered from the service department of PMS Hamburg:

-- Wall junction box 4512 103 7538x.............................

2

inclusive connection block (25mm

-- Relay for radiation warning indicator 4512 100 4523x............

1 interface relay with a floating contact (230V/1A) is included in the scope of delivery of the generator.

8.2. Cables

) for mains supply and connection block (10mm2) for unit supply.

OPTIMUS CINTRODUCTION AND TECHNICAL DATA

H.V . cables

with O3 / O3 plugs: 9806 402 6xx02................................

length: 6m -- 30m in steps of 2m...........................................

capacity: 155pF/m.........................................

diameter: 16.5mm........................................

The cable length is indicated by the 9th and 10th digit of the numeric code.

Thermal contact cable

-- 2-wire screened for 1 excess temperature switch 4512 100 66151..................

-- 10-wire screened for additional supervision like

temperature alarm switch, buzzer, selection indicator 0722 215 19005..............

Stator cable

-- Tube SRM--0612 : 3x 1,31 mm

2

, screened with uMNL--connector 3322 405 14191....

-- all other tubes :

2

3×1.31mm

, screened 0722 215 02054........................................

AMPLIMAT cable

with D-Sub and 3--Plus plug:

12m 9890 000 01721......................

16m 9890 000 01731......................

20m 9890 000 01741......................

24m 9890 000 01751......................

Note

The above described cables are part of the pre--assembled systems.

(a/02.1)1--10

E 2002 Philips Medical Systems

ALL RIGHTS RESERVED

OPTIMUS C

OPTIMUS_C_1_a021

Page 16

OPTIMUS C

INTRODUCTION AND TECHNICAL DATA

8.3. Manpower

At least two persons are necessary to insert the H.V. tank in the generator cabinet.

The weight is about 73kg.

9. Planned maintenance

The technical documentation for carrying out maintenance work in compliance with the applicable regulations are

available at the responsible authority of Philips Medical Systems.

The importance of having maintenance implemented is pointed out to the operator in the operating instructions.

It must be guaranteed that the person carrying out maintenance work knows about the respective national

regulations and that this person observes these regulations throughout all steps of maintenance work.

OPTIMUS C (a/02.1)

OPTIMUS_C_1_a021

E 2002 Philips Medical Systems

ALL RIGHTS RESERVED

1--11

Page 17

Page 18

Page 19

Page 20

Page 21

Page 22

Page 23

Page 24

Page 25

Page 26

Page 27

OPTIMUS C

1. Installing the wall junction box 2--1........................................

2. Mounting the H.V. generator in the cabinet 2--2.............................

2.1. Mounting of the H.V. generator in the cabinet 2--2..............................

2.2. Electrical connection of the H.V. generator 2--3................................

3. Installing the operating panel 2--4.........................................

4. Electrical connection 2--5.................................................

4.1. Earthing 2--5..............................................................

4.2. Mains connection 2--5......................................................

4.2.1. Mains connection of the generator 2--5.......................................

4.2.2. Mains connection of the PDU 2--6...........................................

4.3. Stator connection 2--7......................................................

4.3.1. Shielding 2--7.............................................................

4.3.2. Connection 2--8...........................................................

4.4. Signal cables 2--9.........................................................

4.4.1. Room decade cable 2--9....................................................

4.4.2. Tube supervision 2--10......................................................

4.4.3. CAN interface 2--10.........................................................

4.4.4. Dose input 2--10............................................................

4.4.5. Dose rate input 2--10........................................................

4.5. H.V . cables generator side 2--11..............................................

4.6. Emergency--OFF circuit 2--1 1................................................

5. Hardware programming 2--12...............................................

6. Switch--ON of the generator 2--13...........................................

7. Installation software XRGSCOPE 2--13......................................

7.1. PC and generator settings to avoid problems during up/downloading of

7.2. Installation procedure 2--14..................................................

8. Setting-to-work overview 2--17.............................................

8.1. Configuration 2--17.........................................................

8.1.1. Date and time 2--17.........................................................

8.1.2. Mains data 2--17...........................................................

8.1.3. Tube data set 2--18.........................................................

8.1.4. Tube speed selection 2--18..................................................

8.1.5. Tube limits 2--18............................................................

8.1.6. Capacitance of tube connection 2--19.........................................

8.1.7. Tube operating modes 2--20.................................................

8.1.8. Disable tube 2--20..........................................................

8.2. Tube adjustment 2--21......................................................

8.2.1. Tube conditioning 2--21......................................................

8.2.2. Tube adaptation 2--25.......................................................

8.3. Dose rate control 2--28......................................................

8.3.1. AMPLIMAT sensitivity 2--28..................................................

8.3.2. Screen/film combinations 2--28...............................................

8.3.2.1. Automatic DRC processing 2--29.............................................

8.3.2.2. Manual DRC processing 2--30................................................

8.3.2.3. Density correction for AEC technique (option) 2--31.............................

INSTALLATION

INSTALLATION

TEXT

Contents 2--0.1............................................................

CU complete files 2--13......................................................

OPTIMUS C (a/02.1)

OPTIMUS_C_2_a021_inh

E 2002 Philips Medical Systems

ALL RIGHTS RESERVED

2--0.1

Page 28

OPTIMUS CINSTALLATION

8.3.3. Image intensifier (II) 2--32....................................................

8.3.4. Fault exposure detection 2--32...............................................

8.3.5. Continuous fluoroscopy 2--32................................................

8.4. Application limits 2--34......................................................

8.4.1. X--mode limits 2--34.........................................................

8.4.2. Thoravison limits 2--34......................................................

8.4.3. Overload-dependent limits 2--34..............................................

8.5. Area exposure product calculatio(option) 2--35..................................

8.6. Acceptance test 2--35.......................................................

8.7. Backup of all configuration data 2--35.........................................

9. Labels 2--36...............................................................

10. Final installation work 2--36................................................

DRAWINGS

Data sets of chambers 2Z--4.........................................................

Labelling 2Z--10.....................................................................

E 2002 Philips Medical Systems

ALL RIGHTS RESERVED

OPTIMUS C(a/02.1)2--0.2

OPTIMUS_C_2_a021_inh

Page 29

OPTIMUS C

INSTALLATION

1. Installing the wall junction box

S Mount the wall junction box at the place where the generator is intended to be installed.

(See drawing “Connection of generator” in section 1 and manual UNIT 4512 103 75380 for wall junction boxes).

S If necessary, install the optional surge arrester WN inside the wall junction box.

(See surge arrester documentation.)

S If applicable, mount the filler panels of the generator to the wall junction box.

S Have the mains cable present at the clinic connected to mains terminal MEX by a person who is authorized for

this job.

S Check the phase sequence of L1, L2 and L3.

Warning!

Switch OFF the mains supply present at the clinic and make sure that it cannot be switched

ON again accidentally

.

OPTIMUS C (a/02.0)

OPTIMUS_C_2_a021

E 2002 Philips Medical Systems

ALL RIGHTS RESERVED

2--1

Page 30

OPTIMUS CINSTALLATION

2. Mounting the H.V. generator in the cabinet

2.1. Mounting of the H.V. generator in the cabinet

Caution!

Do not tilt the H.V. generator while transporting it.

In case of a tilting angle larger than 45_, the setting-to-work of the generator can be started not before a

waiting time of about 8 hours has passed. Otherwise the H.V. generator may be destroyed by electrical

sparkover.

S Unpack generator cabinet E.

S In case the packing material is strongly soiled with

oil check the oil level. Repair it if necessary.

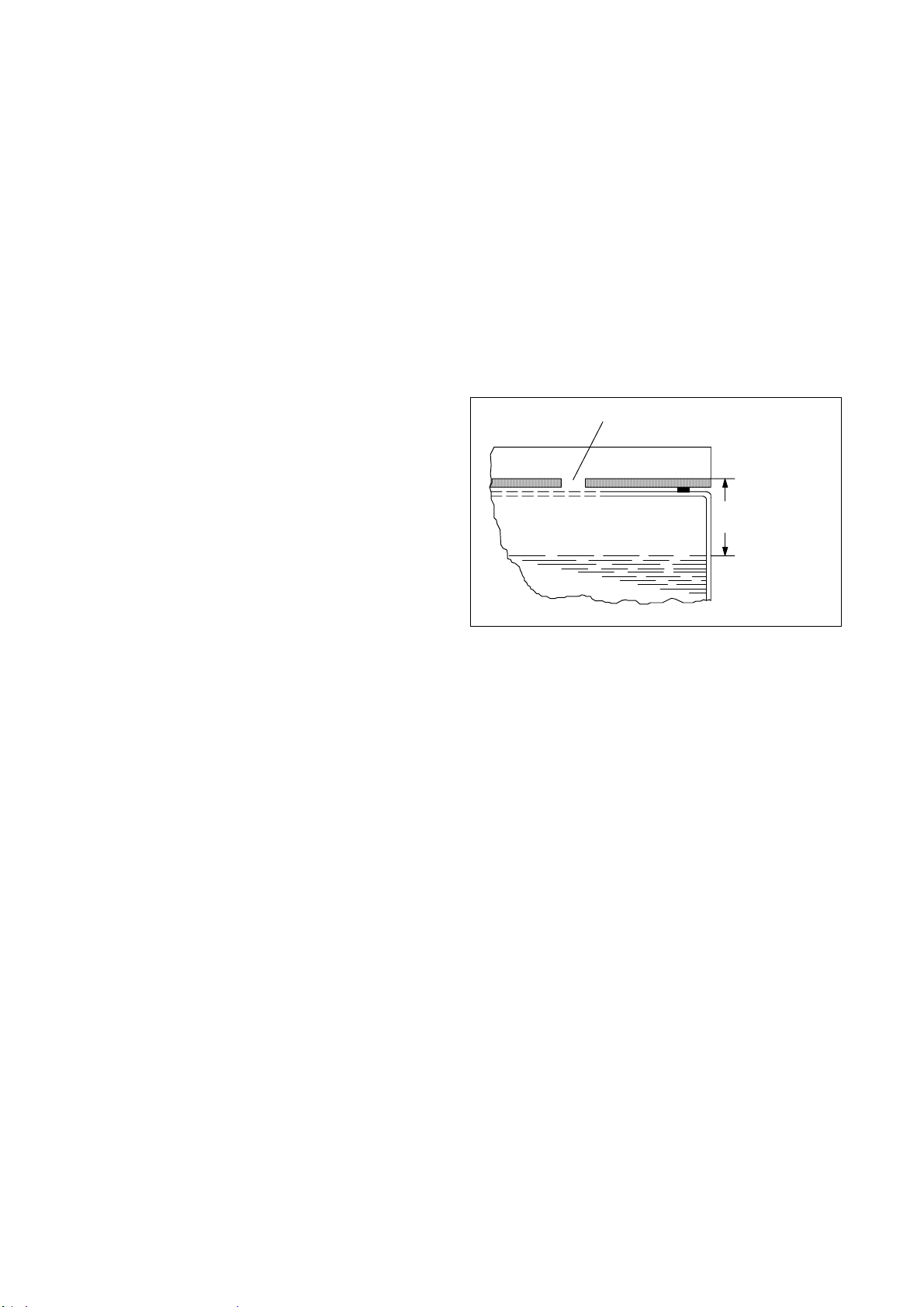

deaerating hole

Tolerance: 2mm

Oil: Shell Diala G in 2.5l container

4512 148 43172

24mm at 20 - 30_C

22mm at 30 - 36_C

329H97

S Remove the deaerating screw completely from the cover of the H.V. generator. Only this way the precision of

the high voltage measuring divider corresponds to the specification.

In case of return shipment of the H.V. generator this screw must be fixed again. Therefore, keep the screw laying

on top of the cover.

Caution!

Make sure that no foreign matter falls into the oil. Otherwise the transformer must be exchanged.

S Take the two transport bars from the rear side of the cabinet.

S Lift the H.V. generator into the generator cabinet with the transport bars.

The 4 connecting bolts GX1001 to 1004 must point at the front of the generator cabinet.

E 2002 Philips Medical Systems

ALL RIGHTS RESERVED

OPTIMUS C(a/02.0)2--2

OPTIMUS_C_2_a021

Page 31

OPTIMUS C

Generator

R

k

Routethecablesalongthefrontandlef

t

Seedrawingp

age2--4

thereasonofkVsymmetry

Not

e

k

W

Seedrawingp

age2--4

2.2. Electrical connection of the H.V. generator

S Connect the H.V. generator electrically:

INSTALLATION

Generator

version

50/65/80kW

50kW

Connection

emar

from <------> to

E1 (GND) <------> GX1100 (GND) Ground

ZX12 <------> G100X15

ZX35 <------> G100X14

Route the cables alongthe front and left-hand edge of the H.V. generator. Fix them.

Twist the cables!

QC13:1 <------> GX1003

Note

The sequence of the connecting bolts is not

in numerical order.

Push the screening cap forward over the

QC03:1 <------> GX1002

connecting bolts and tighten it. Attach the

converter cables including the screening to

the screening cap with cable ties.

The 50kW version might have direct links

GX1001 <------> GX1003

on each side or a link on one side and a

choke of 1 ... 6 loops on the other side for

.

.

65/80

GX1004 <------> GX1002

QC13:1 <------> GX1001

QC03:1 <------> GX1002

2QC13:1 <------> GX1003

2QC03:1 <------> GX1004

Note

Do not change these links or chokes.

Twist the cables!

The sequence of the connecting bolts is not

in numerical order.

.

Push the screening cap forward over the

connecting bolts and tighten it.Attach the

converter cables including the screening to

the screening cap with cable ties.

OPTIMUS C (a/02.0)

OPTIMUS_C_2_a021

E 2002 Philips Medical Systems

ALL RIGHTS RESERVED

2--3

Page 32

OPTIMUS CINSTALLATION

S Turn the two earthing angles of the H.V . generator outward and screw them on to the members of the cabinet.

converter cables (twisted)

fixed at the screening cap

earthing angles

Connection of

50kW version

screening cap

terminal for the screen

of the filament cable

fixing signal cable

199H96

Connection of

65/80kW version

QC13:1

Twist the cable

Link or choke

X1001

QC 03:1

Link or choke

X1002X1003 X1004

3. Installing the operating panel

See Unit Manual COCKPIT for DuoDiagnost.

Twist the cables

QC13:1

QC03:1

X1001 X1003

X1002

2QC13:1

2QC03:1

X1004

E 2002 Philips Medical Systems

ALL RIGHTS RESERVED

OPTIMUS C(a/02.0)2--4

OPTIMUS_C_2_a021

Page 33

OPTIMUS C

Mai

INSTALLATION

4. Electrical connection

4.1. Earthing

See ”Earthing diagram” in section 1.

4.2. Mains con n ectio n

4.2.1. Mains connection of the generator

Warning!

Switch OFF the mains supply present at the clinic and make sure that it cannot be switched

ON again accidentally

See ”Connection diagram” in section 1.

S Measure the internal mains resistance at the terminal MEX with a suitable measuring instrument.

.

L1 - L2: R

L1 - L3: R

L2 - L3: R

= ............... mΩ

i

= ............... mΩ

i

= ............... mΩ

i

Required max. mains resistance at generator input:

ns voltage

30kW 50kW 65/80kW

190V * -- 40mΩ --

220V * 130mΩ 60mΩ --

240V * 160mΩ 80mΩ --

380V 500mΩ 300mΩ 200mΩ

400V 500mΩ 300mΩ 200mΩ

440V 500mΩ 350mΩ 240mΩ

460V 500mΩ 350mΩ 240mΩ

480V 500mΩ 400mΩ 300mΩ

Mains resistance

* with external mains transformer (max 50kW)

Maximum permissible internal mains resistance: 500mΩ

Internal resistance of Power Distribution Unit PDU: 20mΩ at 50Hz

23mΩ at 60Hz

OPTIMUS C (a/02.0)

OPTIMUS_C_2_a021

E 2002 Philips Medical Systems

ALL RIGHTS RESERVED

2--5

Page 34

OPTIMUS CINSTALLATION

Caution!

Connect phase wires in correct phase sequence.

S Connect the mains cable of the generator to terminal MEX: L1 / L2 / L3 within the wall connection box.

If the optional Power Distribution Unit PDU WT is fitted, connect the cables at that point to terminal WTX2.

S Connect the examination unit supply (max. 10A) to (230V / 400V):

Output 1 Geometry power ENX2101/...5

Output 2 I.I. / TV; GECO; UI; SYSCO ENX2201/...9

Output 3 Imaging ENX2301/...9

(Output 3not switched by generator)

4.2.2. Mains connection of the PDU

See delivered Unit Manual “Power Distribution Unit”.

E 2002 Philips Medical Systems

ALL RIGHTS RESERVED

OPTIMUS C(a/02.0)2--6

OPTIMUS_C_2_a021

Page 35

OPTIMUS C

INSTALLATION

4.3. Stator connection

4.3.1. Shielding

Caution!

To suppress interferences of the high-speed rotor control, the stator connections must be provided with

a 360_ screen at the tube and generator end.

General remarks:

-- SRM--0612 : 3322 405 14191..................

-- all othes tubes :

S Always use screened cables: 0722 215 02054.....

S Shorten the stator cable to the required length. Do not accommodate excess lengths at the generator.

S Keep stator cable separate from all the other signal cables to avoid interference.

S Earth the screen at both cable ends.

Screening procedure:

S Remove any enamel or dirt from the clamp

providing drag relief in the tube housing to make

sure the clamp is conductive.

S Remove the plastic covering around the clamp,

about 1cm (0.5”).

S Wrap copper foil around the visible screen of the

cable until the original diameter of the cable is

obtained.

S Remove the present red wire going from the

screen end to the earthing point of the tube

housing.

S Fix the screen of the stator cable with the clamp.

Ensure that the clamp is secured and the ground

contact works!

Wire must be discarded

Copper foil layers up to

the insulation diameter

ROT 350 fixing clamp

Screening of the stator cable.

327H97

OPTIMUS C (a/02.0)

OPTIMUS_C_2_a021

E 2002 Philips Medical Systems

ALL RIGHTS RESERVED

2--7

Page 36

4.3.2. Connection

Caution!

Do not mix up the phases, otherwise components of the rotor control may be destroyed.

OPTIMUS CINSTALLATION

At the tube end - only

SRM--0612

Note

The following steps are valid for SRM 0612 tubes only.

S Connect the stator cable with the MATE-N-LOCK

connector.

S Connect protective earth and earth of tube CAN as

shown in figure beside.

S Earth the screening of the stator cable at the tube

housing with the metallic clamp.

At the tube end - all other

tubes

S Place the jumpers across terminals 100 and 200

according to the figure.

Central connection

pointofprotective

earth

Connection

earth of

tube CAN

W

V

U Stator supply

U

101 202

XA

Connection to the

cap of the housing

100

123

V

W

109 210

S Connect the stator cable:

wire 1 ------> phase U

wire 2 ------> phase V

wire 3 ------> phase W

S Earth the screening of the stator cable at the tube housing with the metallic clamp.

SRO/RO

148H94

E 2002 Philips Medical Systems

ALL RIGHTS RESERVED

OPTIMUS C(a/02.0)2--8

OPTIMUS_C_2_a021

Page 37

OPTIMUS C

INSTALLATION

At the generator

end

See ”Connection diagram” in section 1.

S Connect the stator cable to the terminal EX1100

(U--V--W).

S Check the stator connection by measuring the

resistances:

U -- V = wire 1 -- 2 ≈ 11Ω

U -- W = wire 1 -- 3 ≈ 20Ω

V -- W = wire 2 -- 3 ≈ 9Ω

S If an inductance meter is available, measure the

following inductance values:

U -- V = wire 1 -- 2 = 57mH ±10%

V -- W = wire 2 -- 3 = 34mH ±10%

S Fix the screen below the screening clamp.

S Relieve the tension of the stator cable by a cable

tie.

4.4. Signal cables

E

rotor control

U

1

X1100

VW

2

3

cable tie

screening

clamp

tube

191H96

See: -- ”Connection diagram” in section 1.

-- Z1--6 ”Basic interface” in section “Schematic drawings”

4.4.1. Room decade cable

S Connect the door switches at the generator:

EZX1: 8 <------> switch <------> 10

or

E W B X 2 2 : 8 < -- -- -- > s w i t c h < -- -- -- > 1 0

In case no switch is present

l i n k : p i n 8 < -- -- -- > p i n 1 0

EZ150 K1:

max. switching and loading current = 1A

max. Load = 60VA AC

= 30W DC

Caution!

Make sure the polarity of the relay is correct.

EZX1

10

4

5

6

8

9

--

+

SW UN EX

PO26V

CMSW

RM DR CT

RM DR 0V

Door switch connection

wall junction box

ME

door switches

screen

U

= 230V

max

I

=1A

max

radiation

indication

(not required for

DuoDiagnost

systems)

OPTIMUS C (a/02.0)

OPTIMUS_C_2_a021

E 2002 Philips Medical Systems

ALL RIGHTS RESERVED

2--9

Page 38

4.4.2. Tube supervision

S Connect the thermal switch or the thermal sensor

of the tube housing assembly.

For U.S.A. and U.K. only:

S Connect the HHS-lamp to indicate the selected

tube housing assembly.

OPTIMUS CINSTALLATION

EZX3

6

7

PO 26V

9

10

Tube supervision connection

4.4.3. CAN interface

S For examination units which are provided with a CAN system interface connect:

-- EZX 23 -- signalbus

-- EZX 43 -- system CAN

TH OL SW

CM TH SW

HHS lamp

24V/ max. 5W

screen

4.4.4. Dose input

S Connect the measuring chambers to the D-Sub connectors EZX21/22.

EZX31/32/41 are not used.

Note

There are restrictions on assignment because the measuring chambers are assigned to certain auxiliaries in SW

programming of COCKPIT.

4.4.5. Dose rate input

S Connect the dose rate output of TV chain for fluoroscopy at EZX61.

Use the I.I./TV adapter on EZX61.

SeealsodrawingZ1--5.1”Centralunit”.

OPTIMUS C(a/02.0)2--10

E 2002 Philips Medical Systems

ALL RIGHTS RESERVED

OPTIMUS_C_2_a021

Page 39

OPTIMUS C

INSTALLATION

4.5. H.V. cables generator side

See ”Connection diagram” in section 1.

S Mark the H.V. cables at the generator and the tube end with the correct polarity.

S Fix the H.V. cables on the left-hand side of the wall junction box on the middle rail to provide drag relief for the

cables. The short ends of the H.V . cables which are going to the H.V. generator must be routed in downward

direction in this area.

The free cable lengths including plugs have to be about 1.5m.

S Twist the H.V. cables counter-clockwise by one turn and connect them to the H.V. generator.

The twisting of the cables allows that the H.V. cables can be put into a loop when the cabinet is placed against

the wall.

S Check whether the H.V. sockets are filled with some oil. At least the lower half of the plugs must be wet with oil.

Caution!

Do not use a silicone washer.

Do not grease the plugs with silicone.

The union nuts of the high-voltageconnectors must be tightened up to ensure good electrical contact for

screening.

Only high-voltage connectors which have threaded flange halves may be used.

Older high-voltage cables still have connectors where the flange halves are kept together with a spring

washer.

In such cases the modification kit 4512 103 8085x is required.

4.6. Emergency--OFF circuit

S Connect the emergency--OFF buttons to EZX4:1/2.

If not necessary, link pins 1 -- 2.

See Z1--2.1 ”Power supply” in “Schematic drawings” section and Z2--5.2 “Backpanel Basic rack--2Z” in the

“Wiring diagrams” section.

OPTIMUS C (a/02.0)

OPTIMUS_C_2_a021

E 2002 Philips Medical Systems

ALL RIGHTS RESERVED

2--11

Page 40

5. Hardware programming

V

Programmings on PCB EZ150 basic interface:

Note

Never change jumper W1.

S Voltage supply for the amplifiers of connected

measuring chambers:

OPTIMUS CINSTALLATION

EZ 150

Basic interface

oltage

15V default OFF ON

Soldering link

EZ 150 W2 EZ 150 W3

Working voltage range for ALC measuring

chambers: 15

... 45V

S Set the gain factor for AEC techniques with jumper

EZ150:W4:

-- Factor 1 ==> W4 in position 3 = default

For screen/film combination with at least one

system speed ≤ 200.

-- Factor 4 ==> W4 in position 1

For screen/film combinations with all system

speeds > 200.

S The software programming has to be set accordingly.

W1 do not change!

PCB layout print different from figure.

195H96

The rest of the generator hardware has been properly programmed at the factory.

If required, refer to section 5: PROGRAMMINGS.

E 2002 Philips Medical Systems

ALL RIGHTS RESERVED

OPTIMUS C(a/02.0)2--12

OPTIMUS_C_2_a021

Page 41

OPTIMUS C

INSTALLATION

6. Switch--ON of the generator

S Switch ON the fuses present at the clinic.

S Switch ON automatic circuit-breakers ENF1, ENF2 and ENF3.

The yellow LED on EN100 power ON circuit must be illuminated.

7. Installation software XRGSCOPE

7.1. PC and generator settings to avoid problems during up/downloading of CU complete files

Any kind of interruption can cause the loading process to fail.

Problems occur mainly during the download to the PC.

A download file which is not complete cannot be used as a safety backup file.

Start XRGSCOPE always from DOS if possible.

When using any WINDOWS version:

S Switch OFF all screensavers.

S Do not run other programs.

S Do not insert any CD in the drive.

Any kind of power management of the PC hardware (BIOS) as well as the windows power management should

be switched OFF.

If connected to mains power some of these might be automatically OFF.

OPTIMUS C (a/02.0)

OPTIMUS_C_2_a021

E 2002 Philips Medical Systems

ALL RIGHTS RESERVED

2--13

Page 42

OPTIMUS CINSTALLATION

7.2. Installation procedure

S Provide the service PC with the hardware key and switch it ON.

The hardware key provides access to special program settings and to menu ”Faultfind”.

Standard programming is possible without a hardware key .

S Connect the PC to X5 on EZ139 CENTRAL UNIT CU via a serial data cable.

A 5m long data cable can be ordered via 12NC: 4512 130 5693x.

Data cable Optimus C Rel. 1.x for DuoDiagnost with handshake can also be used for Optimus RAD and R/F Rel.

3.x.

PC: COM1

(9-pole, female) (25-pole, female)

Generator: EZ139X5

120

6

2

3

4

2

3

6

8

5

7

8

7

5

4

S Insert the floppy disks containing the self-unpacking exe-files of the firmware in the disk drive of the PC:

OMC: 4512 116 024xx

For unpacking on the harddisk of the PC about 5MB are needed.

S Generate a directory e.g. [C:\OPT_C] on the PC by entering <md C:\OPT_C> or use WIN commands.

S Copy the firmware from both floppy disks to the PC into the same directory C:\OPT_C by entering

<copy A:\*.* C:\OPT_C> or use WIN commands.

S Start unpacking the programs by entering <OMCxxxxx.exe> or doubleclick on <*.exe> --file.

The programs unpack all files needed for the update of the firmware and the newest service tools.

S After unpacking [OMCxxxxx.exe] can be deleted on the harddisk by entering <del OMCxxxxx.exe>.

S For the current contents of [OMCxxxxx.exe] read [OMCxxxxx.txt] on the floppy disk.

S For a new installation of the generator firmware see section 4 REPLACEMENT, chapter 4

”Exchange or update of firmware ...”.

S Call the installation program by entering <xrgscope> or <xrgscope lcd> for PCs with LCD screen.

OPTIMUS C(a/02.0)2--14

E 2002 Philips Medical Systems

ALL RIGHTS RESERVED

OPTIMUS_C_2_a021

Page 43

OPTIMUS C

INSTALLATION

S Start with an XRGSCOPE--screen CUSTOMER.tdl with data which are actually stored in CUSTOMER.tdl.

Enter “XRGSCOPE customer”.

Whenever data screens like ’error log index’ are saved to an xxx.tdl file (function save <F3> appears in the

bottom line), ‘Customer Data’ being saved in the CUSTOMER.tdl file are attached to the saved data screen. It

helps to separate saved screen files of different sites, customers or rooms in the same hospital.

Site data must be stored in CUSTOMER.tdl file, only data of this file are attached to the saved screens. One

can save site specific customer data in self-made files using <F3>. To recall site data use the load <F4> function.

Procedure:

Either the CUSTOMER.tdl screen is open or open the ‘Customer Data’ screen. Push <F4> and select a site data

file. The old data screen comes up. Now save this screen with <F3> entering in CUSTOMER as file name.

-- Customer

-- City /

Country:

--

-- Generator

-- Generator Serial

-- Generator 12

Memo1:

--

Memo2:

--

Memo3:

--

Name:

State:

Location:

Number:

NC:

After <ESC> the following menu line appears:

File OPTIMUS C Select Unit Options Help

S Select ”OPTIMUS C”.

The following menu line appears:

Program Adjust Accept Faultfind Quit

OPTIMUS C (a/02.0)

OPTIMUS_C_2_a021

E 2002 Philips Medical Systems

ALL RIGHTS RESERVED

2--15

Page 44

OPTIMUS CINSTALLATION

General information:

-- Button <F1> <help> Call help / cancel help.

-- Button <F2> <transmit> Store screen contents / data set in the generator ==> transmit to generator.

-- Button <F3> <save> Store data screen on disk.

For an open data screen the path desired can be selected.

-- Button <F4> <load> Load data set from disk.The desired path can be selected.

-- Button <ESC> Commands one step back. Can be used repeatedly.

-- Fields with ↓ Select the possible range of values by pushing <RETURN>.

The data are specified by the generator as fixed values.

-- Fields with [...] Input of data via the keyboard.

Error numbers which appear at the beginning of the programming procedure must be erased from the screen

by pushing the <RETURN> key.

Current data files, for instance, for online help, tube types, APR programming are available in the PHILIPS--Intranet.

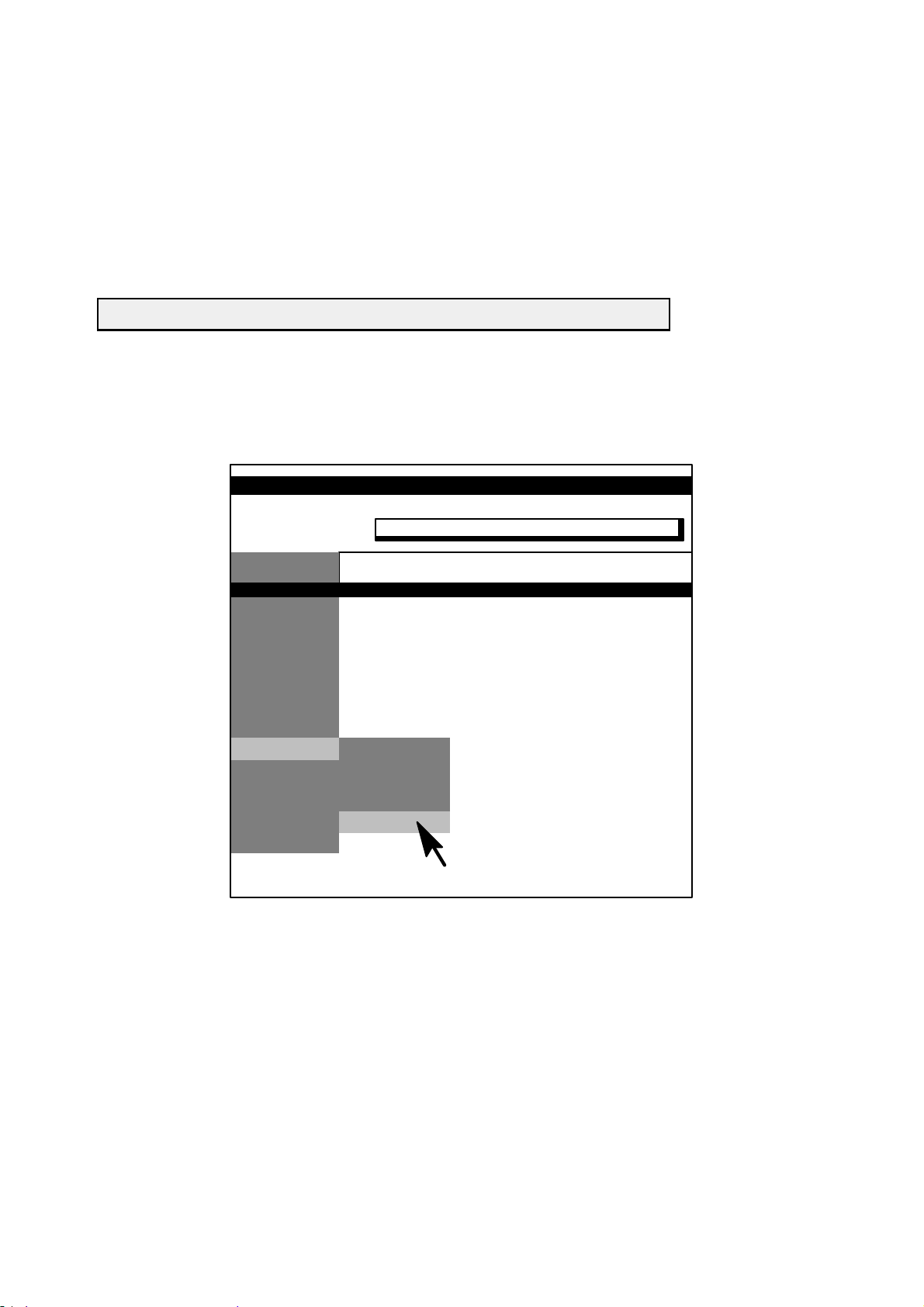

Use path: http://technet.best.ms.philips.com/ and pull down menu as shown below.

PMS TechNet

http://technet.best.ms.philips.com/

PHILIPS

Insight Medical Systems

...

...

...

...

...

...

XRAY GENERATORS ...

...

...

...

...

...

DOWNLOAD

412H01

If the installation program is called with <xrgscope ?> the possible starting parameters for the service program

are listed.

OPTIMUS C(a/02.0)2--16

E 2002 Philips Medical Systems

ALL RIGHTS RESERVED

OPTIMUS_C_2_a021

Page 45

OPTIMUS C

8. Setting-to-work overview

Note

The programming of a generator must take place in the sequence specified below.

S Switch the generator ON.

8.1. Configuration

8.2. Tube adjustment

S RESET the generator

8.3. Dose rate control

S RESET the generator

8.4. Application limits

S RESET the generator

8.5. Area exposure product calculation (option). Function not applicable for DuoDiagnost.

INSTALLATION

8.6. Acceptance test

8.7. Backup of all configuration data

8.1. Configuration

S Switch the generator ON.

8.1.1. Date and time

S Select menu:

PROGRAM/ DATE AND TIME

S Enter the respective local data.

8.1.2. Mains data

S Select menu:

PROGRAM/ MAINS DATA

S Select the nominal value of the mains voltage U.

Range: 380V , 400V, 440V, 480V

Default: 400V

If 460V is present program 480V.

If 415V is present program 400V.

S Enter the maximum internal mains resistance R

.

i

Range: 0 ... 500mΩ

Depending on the internal mains resistance and the mains voltage the generator calculates the maximum possible

output.

OPTIMUS C (a/02.0)

OPTIMUS_C_2_a021

E 2002 Philips Medical Systems

ALL RIGHTS RESERVED

2--17

Page 46

OPTIMUS CINSTALLATION

R

8.1.3. Tube data set

S Select menu:

PROGRAM/ TUBES/TUBE 1 ... 3/ TUBE 1

S Start the displayed file TUBExxx.tdl with <RETURN>.

All the permitted combinations of tube type and housing type are listed in a window.

S Select the respective combination of tube type and housing type from the list and push <RETURN>.

S RESET the generator.

The data which have been configured up to now are read by the processor when the system is started.

8.1.4. Tube speed selection

Depending on the type of tube loaded the anode speed is automatically programmed.

Caution!

Wrong programming can cause tube problems.

S Select menu:

PROGRAM/ TUBES/TUBE 1 ... 3/ TUBE 1

RPM \ tube type

otation

RO SRO

Exposure rotation [RPM] 3000 9000

Fast exposure rotation [RPM] n/a n/a

Fluoroscopy rotation [RPM] 3000 3000

8.1.5. Tube limits

S Select menu:

PROGRAM/ TUBES/ TUBE LIMITS

S Program the maximum working voltage which is indicated on the data label:

Max. tube voltage limit

Range: 40 ... 150kV

Default: 150kV

Adaptation of the tube takes place only up to this limit.

After adaptation of a tube the upper kV limit is displayed for each focus of each tube under:

Adapted to [kV]: e.g. 125kV

All the other limit programmings are performed by the generator automatically and do not usually have to be

observed.

OPTIMUS C(a/02.0)2--18

E 2002 Philips Medical Systems

ALL RIGHTS RESERVED

OPTIMUS_C_2_a021

Page 47

OPTIMUS C

S

inglel

h

[m]

8.1.6. Capacitance of tube connection

S Select menu:

PROGRAM/ TUBES/ CAPACITANCE TUBE CONNECTOR

Range: 2.000 ... 10.000nF

The total capacitance for each tube connected is indicated:

INSTALLATION

C=

½ (C

H.V. generator+CH.V. cable

)

= 4.550nF Default for H.V. generator + 20m H.V. cable (155pF/m)

xL Cc= specific cable capacitance in [pF/m]

C

c

C [nF] = 3 + -- ---- -- -- -- -- -- L = single cable length in [m]

2000

Capacitance tube connection [nF]

engt

For 155pF/m cable For 200pF/m cable

14 4.085 4.400

16 4.240 4.600

18 4.395 4.800

20 4.550 5.000

22 4.705 5.200

24 4.860 --

26 5.015 --

28 5.170 --

30 5.325 --

The high-voltage cables type 9806 402 6xx02 currently being supplied have a capacitance of 155pF/m.

OPTIMUS C (a/02.0)

OPTIMUS_C_2_a021

E 2002 Philips Medical Systems

ALL RIGHTS RESERVED

2--19

Page 48

8.1.7. Tube operating modes

S Select menu:

PROGRAM/ TUBES/ TUBE OPERATING MODE

-- Intermediate boost:

Select ... Disable = During preparation the rated filament current is applied (default).

Enable = During preparation a reduced filament current is applied.

After the release of exposure boosting takes place for a short time before the

exposure is released. Effective with tube currents > 80% of max. value.

-- Rotation prolongation after PREP:

Select ... Disable = The tube is braked as soon as preparation has been cancelled.

Enable = After cancellation of preparation the tube is only braked after 30s. Within this

time preparation can be repeated as often as necessary.

Recommended for paediatrics and casualty rooms.

8.1.8. Disable tube

OPTIMUS CINSTALLATION

For correction of the configuration.

S Select menu:

PROGRAM/ TUBES/ DISABLE TUBE

When the tube is disabled the above stored data set of the tube is erased. To enable the tube the data set has to

be loaded again.

E 2002 Philips Medical Systems

ALL RIGHTS RESERVED

OPTIMUS C(a/02.0)2--20

OPTIMUS_C_2_a021

Page 49

OPTIMUS C

INSTALLATION

8.2. Tube adjustment

8.2.1. Tube conditioning

Warning!

Radiation is released during the conditioning procedure!

S RESET the generator. It must be in READY state.

S Select free cassette auxiliary.

S Select large focus only.

S Run reconditioning procedure for an adapted tube, refer to following table, left column TUBE ADAPTED.

or

S Run conditioning procedure for a new or non--adapted tube, refer to following table right column TUBE NOT

ADAPTED.

S It is recommended that the high tension be monitored during conditioning.

Connect the scope:

Channel1: kV A V HT at EZ130 X3 (1V/div), scale: 20kV/V

Trigger external: CTRL_X_C/ at backpanel EZ X74, negative slope

Time base: 2ms/div

S In case of problems like tube arcing see the following flowchart EXPOSURE SEQUENCE as an example.

The flowchart applies for applicable kV range only, e. g.:

109kV is the max. kV value for normal application, perform just up to next higher kV step = 117kV.

Note

Refer to flowchart EXPOSURE SEQUENCE.

If the tube arcs at a certain kV value, switch another 3 exposures with same parameters and 10s pause

between subsequent exposures. In case of success (no arcing anymore) continue with next kV step of the

following table.

If the last exposure still arcs go one kV step back and follow normal procedure. If this routine has been

performed three times without improvement: ==>

Replace the tube!

OPTIMUS C (a/02.0)

OPTIMUS_C_2_a021

E 2002 Philips Medical Systems

ALL RIGHTS RESERVED

2--21

Page 50

OPTIMUS CINSTALLATION

Exposure parameters for conditioning

Tube adapted # exposures Tube not adapted

kV mA ms kV mAs

80 10 50 <1> 80 0.5

80 10 500 <1> 80 5

80 200 250 <1> 80 50

10 seconds pause 10 seconds pause

80 max. mA 100 <1> 80 100

1 minute pause 1 minute pause

90 10 50 <1> 90 0.5

90 10 500 <1> 90 5

90 200 250 <1> 90 50

10 seconds pause 10 seconds pause

90 max. mA 100 <1> 90 100

1 minute pause 1 minute pause

100 10 50 <1> 100 0.5

100 10 500 <1> 100 5

100 200 250 <1> 100 50

10 seconds pause 10 seconds pause

100 max. mA 100 <1> 100 100

1 minute pause 1 minute pause

110 10 50 <1> 11 0 0.5

110 10 500 <1> 11 0 5

110 200 250 <1> 110 50

10 seconds pause 10 seconds pause

110 max. mA 100 <1> 110 100

1 minute pause 1 minute pause

120 10 50 <1> 120 0.5

120 10 500 <1> 120 5

120 200 250 <1> 120 50

10 seconds pause 10 seconds pause

120 max. mA 100 <1> 120 100

1 minute pause 1 minute pause

130 10 50 <1> 130 0.5

130 10 500 <1> 130 5

130 200 250 <1> 130 50

10 seconds pause 10 seconds pause

130 max. mA 100 <1> 130 100

1 minute pause 1 minute pause

E 2002 Philips Medical Systems

ALL RIGHTS RESERVED

OPTIMUS C(a/02.0)2--22

OPTIMUS_C_2_a021

Page 51

OPTIMUS C

INSTALLATION

Exposure parameters for conditioning

Tube adapted # exposures

Tube not adapted

kV mA ms kV mAs

140 10 50 <1> 140 0.5

140 10 500 <1> 140 5

140 200 250 <1> 140 50

10 seconds pause 10 seconds pause

140 max. mA 100 <1> 140 100

1 minute pause 1 minute pause

145 10 50 <1> 145 0.5

145 10 500 <1> 145 5

145 200 250 <1> 145 50

10 seconds pause 10 seconds pause

145 max. mA 100 <1> 145 100

1 minute pause 1 minute pause

148 10 50 <1> 148 0.5

148 10 500 <1> 148 5

148 200 250 <1> 148 50

10 seconds pause 10 seconds pause

148 max. mA 100 <1> 148 100

1 minute pause 1 minute pause

150 10 50 <1> 150 0.5

150 10 500 <1> 150 5

150 200 250 <1> 150 50

10 seconds pause 10 seconds pause

150 max. mA 100 <1> 150 100

1 minute pause 1 minute pause

OPTIMUS C (a/02.0)

OPTIMUS_C_2_a021

E 2002 Philips Medical Systems

ALL RIGHTS RESERVED

2--23

Page 52

kV step 1

80kV

kV step n

OPTIMUS CINSTALLATION

Exposure sequence

kV step n+1

kV step n+2

= kV limit

no

exposure

with arcing

3 exposures

with same

parameters.

Wait 10s

after each

exposure!

stillarcing?

yes

max. 3 loops

END

394H00

Note

If the tube arcs at any kV value which is not required for application the max. kV (e.g.117kV) program this new limit

value by XRGSCOPE:

PROGRAM/ TUBES/ TUBE LIMITS/ MAX. TUBE VOLTAGE LIMIT [kV]/ [117]

As the limit value decreases for this reason, a following re--adaptation procedure sets the field

ADAPTED TO [kV] to this value as well.

S Set RGDV programming to original status if no adaptation procedure has to be executed.

S RESET the generator.

E 2002 Philips Medical Systems

ALL RIGHTS RESERVED

OPTIMUS C(a/02.0)2--24

OPTIMUS_C_2_a021

Page 53

OPTIMUS C

8.2.2. Tube adaptation

Warning!

Radiation is released during the adaptation procedure!

Note

The tube must be properly conditioned before the adaptation procedure is started.

For break--in procedure see previous chapter 8.2.1. ”Tube conditioning”.

Tube adaptation is an automatic process which includes:

1. The measurement of the mA offset of

-- the kV measuring circuit.

-- the emission current voltage / frequency converter.

2. The measurement of the individual standby filament current.

INSTALLATION

3. The kV dependent filament / emission current behavior.

4. The boost adaptation to calculate the positive and negative boost in one procedure.

For more information refer to section 3: FAUL T FINDING.

Note

In case of problems check the symptom / solution list at the end of this chapter.

Repeat the adaptation for this particular focus.

S Press <RETURN>.

An opening screen asks to wait 20 seconds after the screen comes up.

S Press <F2> to transmit the data.

Tube:

1stTube

nd

Tube not applicable

2

rd

3

Tube not applicable

Focus:

small

medium a tube with a (third) medium filament does not exist yet, it is not

large

OPTIMUS C (a/02.0)

OPTIMUS_C_2_a021

E 2002 Philips Medical Systems

ALL RIGHTS RESERVED

VARIOFOCUS

2--25

Page 54

OPTIMUS CINSTALLATION

After data transmission COCKPIT displays [Adaptation X--Ray tube] (locally programmed language).

READY returns (waiting time is about 15 seconds).

S Push <PREP> and <EXP> button at the control desk or use footswitch.

The generator switches about 125 exposures for each focus.

The radiation sign at the desk indicates exposures and a beep is audible at the end of every exposure.

There is no display of the actual kV parameters during adaptation.

The termination of the adaptation procedure is indicated at the PC screen and a beep from the PC is audible.

S RESET the generator.

S Adapt both small and large focus to use VARIOFOCUS.

APRs using VARIOFOCUS cannot be selected as long as both, small and large are not adapted.

The COCKPIT screen indicates a non--adapted focus.

E 2002 Philips Medical Systems

ALL RIGHTS RESERVED

OPTIMUS C(a/02.0)2--26

OPTIMUS_C_2_a021

Page 55

OPTIMUS C

INSTALLATION

Problems during adaptation -- Symptoms and

solutions

1. A warning cannot be displayed on the control desk, the [WAITING] screen on the PC is flickering instead during

this event and logged in the error log index.

2. If the tube has already been at a high temperature level (but the tube load indication still indicates green or

green--yellow for 100% power) it might happen that the load indication changes straight to red and the adaptation

is on hold.

[WAITING] is flickering on the PC.

Solution:

Keep the handswitch pushed, once the temperature is down adaptation continues automatically.

Note

An increment of one of the temperature levels inhibits the 100% power condition. This event is always logged

as warning 00BV in the error log index.

3. An error message just flashes for a very short moment and is instantly covered by [ADAP] on the desk

afterwards.

[WAITING] is flickering on the PC.

4. All buttons at the control desk including the RESET button are inactive during adaptation.

The only way to RESET an error is to release the PREP switch which causes an interrupt similar to the RESET

command.

5. After letting go of the PREP switch wait until the desk indicates [READY].If[READY] does not appear at least

after 20 seconds run a warmstart of the generator by pushing the RESET button on CU EZ139.

6. If adaptation seems to do nothing for more than 30 seconds let go of the PREP switch. Wait until the desk

indicates READY. If [READY] does not appear at least after 20 seconds run a warmstart of the generator by

pushing the RESET button on CU EZ139.

7. If a constant [READY] indication appears for more than 2 seconds while PREP and EXP is activated by the

handswitch during adaptation let go of the handswitch.

Wait until the desk indicates [READY].If[READY] does not appear at least after 20 seconds run a warmstart

of the generator by pushing the RESET button on CU EZ139.

8. If adaptation does not carry on with or without [READY] indication check whether one of the function units

indicates a FATAL error by turning on the red LED. Let go of the handswitch and run a warmstart of the generator

by pushing the RESET button on CU EZ139.

9. If adaptation has been interrupted by a generator warmstart check the error log index before restarting

adaptation: kV errors 02WG and/or 02WH indicate tube arcing.

In this case run conditioning of the tube as described in chapter 8.2.1 and/or reduce the max. kV value to the

required application value.

OPTIMUS C (a/02.0)

OPTIMUS_C_2_a021

E 2002 Philips Medical Systems

ALL RIGHTS RESERVED

2--27

Page 56

8.3. Dose rate control

8.3.1. AMPLIMAT sensitivity

S Select menu:

PROGRAM/ DOSE RATE CONTROL AMPLIMAT/ SENSITIVITY

S Depending on HW programming of jumper EZ150:W4. W4 programs sensitivity accordingly:

high = × 4 = EZ150:W4 in position 1

===> All screen/film combinations with a system speed > 200.

low = × 1 = EZ150:W4 in position 3

===> At least one screen/film combination with a system speed ≤ 200.

8.3.2. Screen/film combinations

5 screen/film combinations can be programmed for each of the 5 measuring chambers:

S Select menu:

PROGRAM/ DOSE RATE CONTROL/ AMPLIMAT CHAMBER 1 + 2/ DATA SET 1 ... 5

OPTIMUS CINSTALLATION

The number of the chamber corresponds to the specified unit number of the dose measuring unit.

The choice between automatic and manual DRC processing is possible when an authorized hardware key is

inserted in the PC.

Automatic is selected as default and must be used for the initial programming.

Data sets of adjacent rooms can be copied but have to be aligned afterwards.

Access manual DRC processing by pushing the <ESC> key.

The manual mode is suitable for:

-- Copying complete programming to other measuring chambers.

-- Setting the basic density.

-- Changing the desk-displayed names of the programmed screen/film combinations.

-- Creating backups of the DRC programmings.

E 2002 Philips Medical Systems

ALL RIGHTS RESERVED

OPTIMUS C(a/02.0)2--28

OPTIMUS_C_2_a021

Page 57

OPTIMUS C

INSTALLATION

8.3.2.1. Automatic DRC processing

S Select the desired data from the files offered for the following programming steps.

The files are part of the installation software.

-- Select the programming field with the cursor and enter <RETURN>.

-- Enter the desired file from the list offered.

-- Select the desired data as required.

FILM: File FILM.TDL Film types according to description of the

manufacturer.

File FILM_BL/ _GR/ _UV.TDL General classification of the film according

to color, sensitivity S and

RLF compensation.

SCREEN: File SCREEN.TDL Screen types according to description of

the manufacturer.

File LUMAT_LG.TDL -- Screen types according to luminous

matter.

-- Imaging plates.

CHAMBER: File CHAMBER.TDL Different types of measuring chambers.

CASSETTE: File CASSETTE.TDL Different types of cassettes.

SYSTEM CORRECTION: File SYSCOR.TDL Select no corr. (ISO 9236-1)

CORRECTION FACTOR: Default 1.00 Correction factor for switch--OFF dose.

Based on the combination of the components entered, the processor calculates the switch--OFF dose, kV

correction and RLF compensation. The name for the screen/film combination, e.g. ”B400”, is taken from the

“screen” default data set.

Dose Rate Control setting Optimus for Computed Radiography (PCR or other imaging

plates)

The following example is for a 400 speed system, determined by the selection of the LG06 400 speed type from

file LUMAT_LG.TDL (luminous groups).

Ignore the violet screen colour of LG06, the data set just requires its kV characteristic.

FILM: File FILM.TDL X --CONSTANT RLF=1

SCREEN: File LUMAT_LG.TDL LG06 S400 vi

CHAMBER: File CHAMBER.TDL the installed chamber type

CASSETTE: File CASSETTE.TDL normal cassette (def)

SYSTEM CORRECTION: File SYSCOR.TDL no corr. (ISO9236--1)

CORRECTION FACTOR: 1.00

Note

Film, screen, etc. data selected are not directly stored in the generator.

It is recommended that they be entered in the table ”Data sets of chambers” 2Z --4 at the end of this section.

S RESET the generator.

Color and sensitivity class of the screen/film combination are displayed on the desk, e.g.: “B400”.

Other screen/film combinations (data set 1 ... 5) for the chamber can be selected by the buttons.

OPTIMUS C (a/02.0)

OPTIMUS_C_2_a021

E 2002 Philips Medical Systems

ALL RIGHTS RESERVED

2--29

Page 58

8.3.2.2. Manual DRC processing

The current data set of the screen/film combination is displayed.

* Abbreviation: Abbreviation for the screen/film combination.

Example: B400 = blue, speedclass 400.

Dose Request Chamber: Sensitivity of the measuring chamber type in [mGy/V].

* Dose of FSC: Switch--OFF dose of the screen/film combination in [mGy].

Linear ratio with respect to the film density.

kV70-Char. U_0 ... 9: Checkpoints for kV-dependent density correction.

kV70-Char. Drel_0 ... 9: Relative correction value for the dose.

RLF t_0 ... 9: Checkpoints for time-dependent density correction.

(RLF = Reciprocity Law Failure).

RLF Drel_0 ... 9: Relative correction value for the dose.

* = Only these fields may be changed according to the system requirements.

All other fields must not be changed.

OPTIMUS CINSTALLATION

S If required, change the data and the abbreviation name.

Usually no value except the basic density ”Dose of FSC” must be changed (see next page).

S Transmit the data set with <F2>.

S RESET the generator.

The SAVE <F3> and LOAD <F4> functions of XRGSCOPE permit straightforward copying of the measuring

chamber programmings.

E 2002 Philips Medical Systems

ALL RIGHTS RESERVED

OPTIMUS C(a/02.0)2--30

OPTIMUS_C_2_a021

Page 59

OPTIMUS C

8.3.2.3. Density correction for AEC technique (option)

Basic density per screen/film combination:

A hardware key is required at the PC for direct access to the switch--OFF dose.

S Make a test exposure for each screen/film combination.

To do so, set the density correction = 0.

S Determine the density of the test exposures.

S Select menu:

PROGRAM/ DOSE RATE CONTROL/ AMPLIMAT/ CHAMBER 1 + 2/ DATA SET 1 ... 5

S Select manual DRC programming by pushing the <ESC> key.

S Correct the switch--OFF dose = “Dose of FSC” according to formular below:

INSTALLATION

N e w s w i t c h -- O F F d o s e = -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- x O l d s w i t c h -- O F F d o s e

Desired density

Measured density

S Transmit the data set by pushing the <F2> key.

S Repeat the procedure for each screen/film combination at each chamber.

S RESET the generator.

The switch--OFF dose can be set on the PC even without a hardware key .

To do so, call up the automatic DRC programming, repeat all the selections and change the correction factor for

switch--OFF dose accordingly. Each time this programming is called up all the selections must be repeated.

OPTIMUS C (a/02.0)

OPTIMUS_C_2_a021

E 2002 Philips Medical Systems

ALL RIGHTS RESERVED

2--31

Page 60

OPTIMUS CINSTALLATION

8.3.3. Image intensifier (II)

-- II lead time

-- Density voltage correction: Default = 1V

-- Dynamic factors

8.3.4. Fault exposure detection

Fault exposure detection is switched ON as a default for AEC and TDC. If in the initial phase of an exposure too

little dose is measured, the exposure is aborted to protect the patient.

-- Time of control measurement: 10% of backup time,

min. 250ms at TDC

-- Dose minimum: 4% of set density voltage at AEC,

4 ... 10% at TDC

-- Backup time AEC: Calculated time from 9.5 times mAs of the respective 2-factor technique,

max. 4s

-- Backup time TDC: Exposure time set 0.3 ... 6s

This additional precaution can be switched OFF for both techniques individually in the menu:

PROGRAM/ DOSE RATE CONTROL/ FAULT EXPOSURE DETECTION/ AECORTDC

For details see section 4 FAULT FINDING, chapter “Optimus AEC switch--OFF philosophy”.

This monitoring does not take effect in the following cases, irrespective of programming:

-- Using screen/film combinations with high speed in AEC technique.

-- Exposure time in TDC technique is shorter than 1s.

8.3.5. Continuous fluoroscopy

Factors for continuous fluoroscopy can be modified:

(see also section 4 FAULT FINDING, ”Explanation of programming”)

-- scantime TV [ms] : = 20.00ms (default) for scantime of the TV system ≤ 20ms (50Hz and 60Hz)

= Scantime of the TV system for scantime > 20ms

-- scantime TV valid : = YES default

= NO no function yet

-- P_max_EDL [W] : = 250W (default) (EDL = Entrance Dose Limiter)

(range = 0 ... 9000W) The maximum output of the tube during continuous fluoroscopy and with the SID

signal prevailing is limited to the programmed wattage.