Page 1

Colour

QRarrarrnrara

q)\9U

television

n

\7 U\r\g

TI

\_s,.Àr,A\tnr^íÀ

U[r\g

e)\gu

\Y

Seruice

:i,-tY:.

au94l

;jrït-eff

Chassis

MDl

.2E

AA

í;ïiri?,'

Contents

Technical

t.

Connection

2.

3.

4.

5.

6.

7.

instructions for repairs,

SaÍety

Maintenance

Wamings

Mechanical

Block diagram

Testooint

Wiring diagram

Modes,

Service

Protections,

Electrical diagrams

voltage diagram

Supply

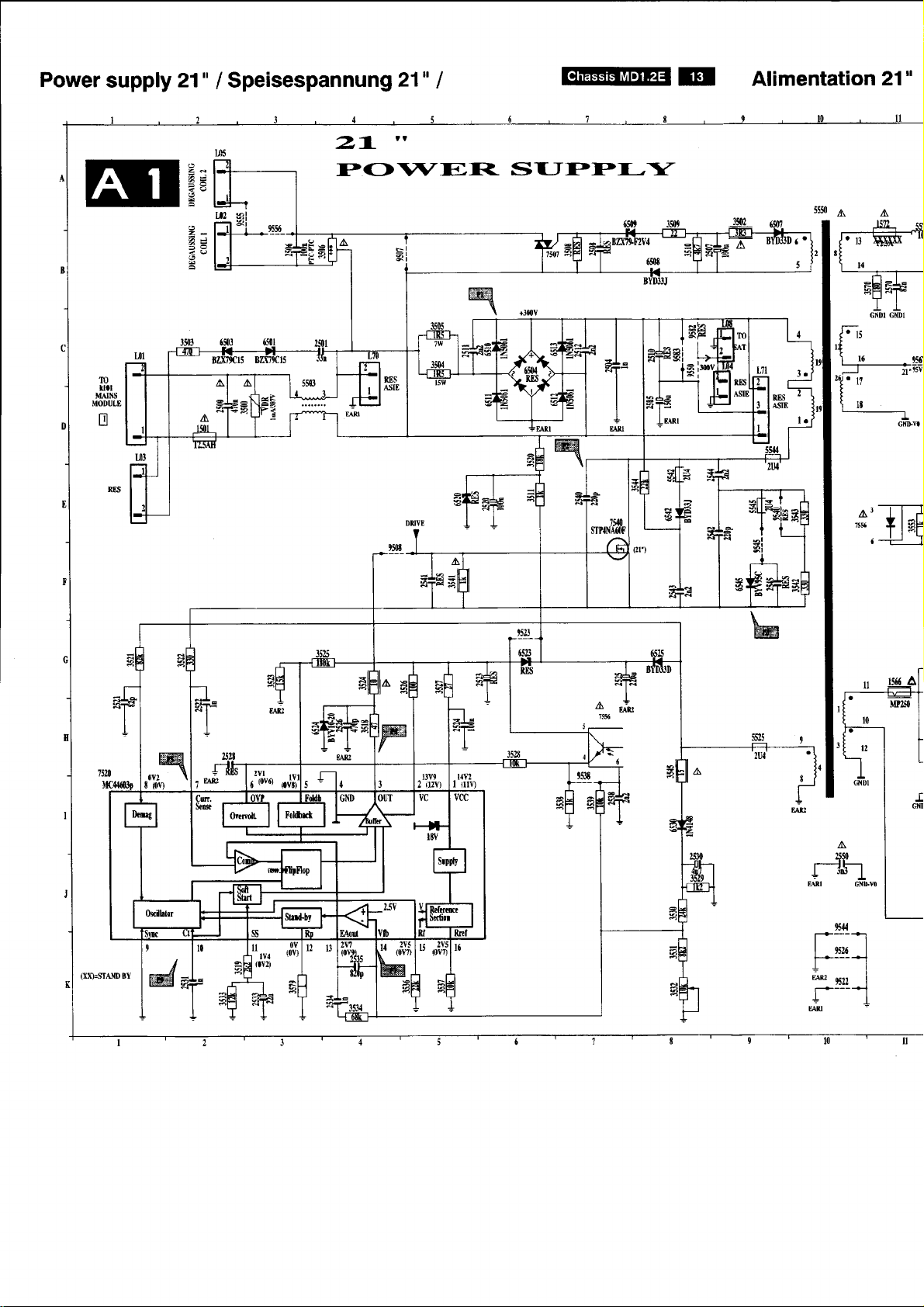

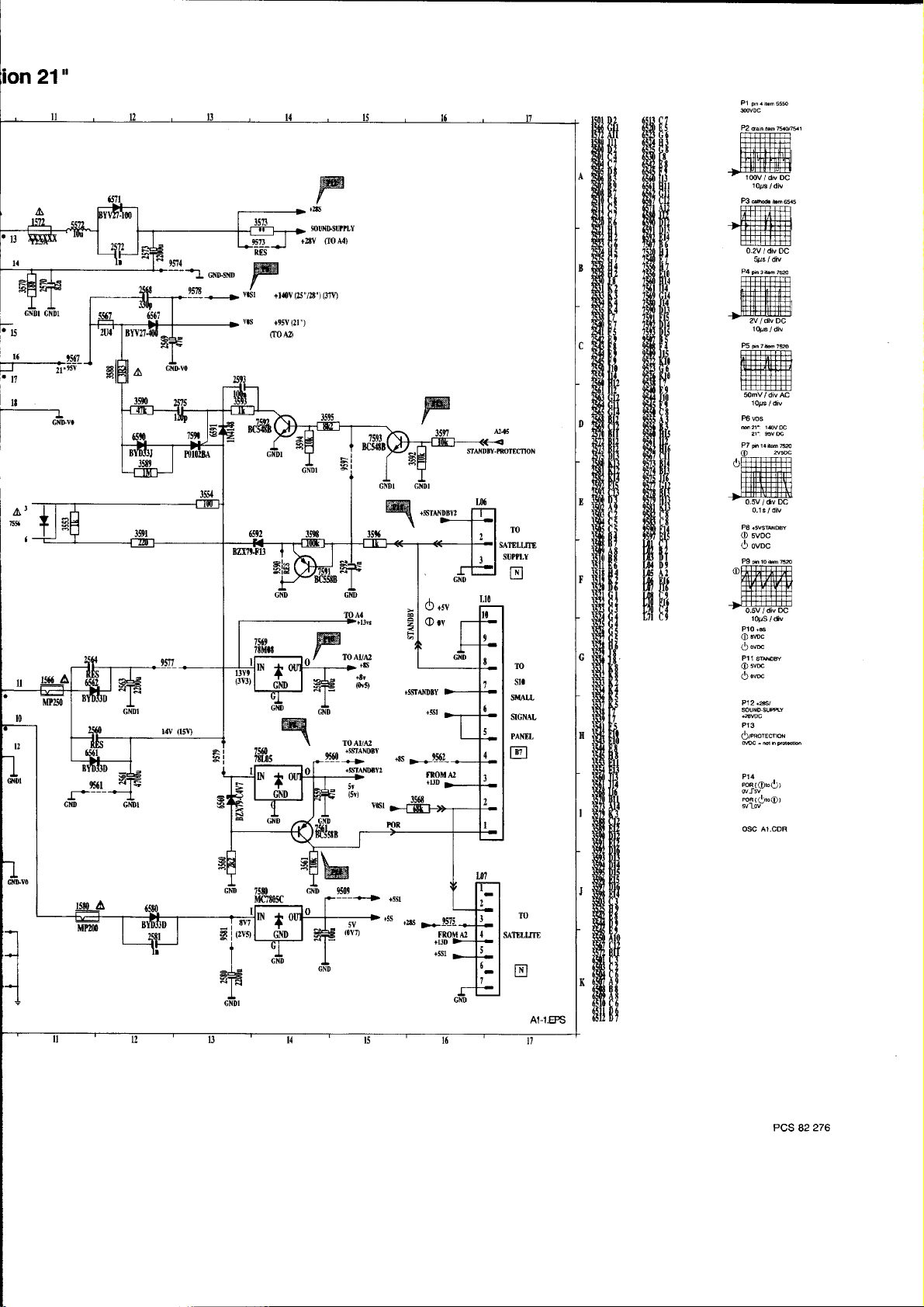

supply 21"

Power

Power supply

Horizontal

Vertical

output

Audio ampliÍier

Tuner + lF

processing

Video

speciÍications

facilities and

instructions,

Notes

and

instructions

overview

DST,

Faultfinding

and

"

>

21

output

Chassis

messages,

Error

Repair

and

PWB-layouts

(Schéma

(Schéma

(Schéma

(Schéma A3)

(Schéma

(Schéma

(Schéma

overview

tips

A1)

A1)

A2)

Aa)

81)

82)

Page

2

2

3

4

6

7

8

8

Diagram

12

13

15

16

17

17

19

20

PWB

14

14

14

14

14

18

18

Contents

Electrical diagrams

Synchronisation

lF sound

EuroconnectoÍ

Euroconneetor

Controls

Connections

module

Teletext

panel

CRT

module

Audio

Nicam L module

CTI/Black

N/S

oanel

Mains/RCS/LED

Control

Electrical

8.

Directions

10.

11. List oÍ abbreviations

12.

Spare

audio

Stretch

Inpuvoutput

and

alignments

Íor

parts

lists

1

2

panel

Panel

use

PWB-layouts

and

(Schéma

(Schéma

(Schéma

(Schéma

(Schéma

(Schema

(Schéma

(Schema

(Schéma

(Schéma

(SchémÊ

(Schema

(Schéma

(Schéma

BB)

84)

85)

86)

87)

BB)

89)

C)

01)

D2)

D

G)

l)

J)

l"g"

Diagram

21

21

22

22

23

24

24

25

26 27

27

28

29

30 30

31

32

34

37

39

PWB

18

18

18

18

18

18

18

25

27

29

29

31

Philips Consumer

means,

permission

prior

by

264 GB

82

1996

rights

All

electronic,

of Philips.

9671 TV Service

SM

Copyright

Neitíerl-ands.

reoroduced, storedjn a

ariv

thé

published

PCS

#p

reserved.

retrieval

mechanicá|,

No

systeni

Department

ElectÍonics

part

or transmitted,

photocopying,

B.V. Eindhoven,

of this

Printed in The

Publication

in any

otherwise

or

Netherlands

may be

form or

without

The

by

oCopyright

reserved

Subiect

to modification

PHILIPS

@

4822727

20979

Page 2

Technical

1.

speciÍications

voltage

Mains

Power consumption

nominal

peak

output

standby

Mains frequency

range colour synchronisation

Pull-in

Pull-in range

synchronisation

2. Connection

output

power

Watt)

horizontal

power

Watt)

(Vvatt)

facilities

90");

(t10%)

(!1O"A)

(1

130

10" SF

(1

10' SF 4:3);220

1 80

| 22O-24OV AC

(21'90");

100

:

(21"

: 160

(t10%)

: 3

: 50 Hz

+

>

:

300H2

+

>

:

600H2

and Chassis

r--------------'

t ?ooY t

--T-l--

oo

SK1

/+\

L7-\l

MENU

\:iï-

:Íffi'-''" \:.2-

\

4:3);

(1

10"

10'

SF

$F

(1

150

overview

tÍ

16:9)

16:9)

#

\? ?o

r1----------------a

o OqEo

(DGREEN

m-"-.

ileït--

ilq|-

l[o+]-

"*"

*-"

-*'

l#n

lo

*ï--'

|

lo+-

g-".-

(

*rH*

Rear connectlons

the terminal

Specification

REAR

EXTI - CVBS

RGB

tuner

Audio O R

12-

Audio € R

Audio G L

34-

Audio

Blue I

5-

Audio € L(0.2-2Vnurs>

6-

Blue o

78-

CVBS

EXT1

9-

Green

10-

-

11

Green

1213-

Red

14-

RGB status

Red o

15-

RGB status

16-

EXT1/75o)

17 - CVBS

18 - CVBS J-

19- CVBSo(1Vpp/75O)

cvBS€(1vpp/75o)

20-

-

Earth

21

of

(in/cut)

+

-

(in)

at output

(O.SVnrvrs<

(0.2-2Vnus>

(0.SVnrr,rs<

I

(0,n/pp/75o)

status(o-2V:

-1

6/9; 9.5-1 2V:EXT1

I

O

I

I

screen

INT;

(o,7vpp/75o)

I

(0,7vpp/75o)

(0-0,4V:

INT;1-3V:

sockets

lko)

10ko)

1kO)

loka)

4,5-7Vl

-4l3)

Front + Top

EXT2

-

1

-

2

-

3

-

4

56 - Audio

7-

-

8

9'10

-

-

11

1213- C I

14-

1516-

-

17

-

18

19-

-

20

21 - Earth screen

+

l/O

control

Side

-

(in/out)

CVBS

(in)

SVHS

-

Input:

=

tuneri

outPut

then

Audio

Audio

Audio

Audio

status€

CVBS

EXï2- 1 6/9

o(300mvppl75à')

c

CVBS

CVBS

CVBS0(1vpp/75o)

cvBslío

+

then

EXTz

input:

OR(o.SVnrus<lk())

O R(0.2-2Vnr'irs>10ko)

GL(o.SVnus<1ko)

I

€

;

I

I

output

other

=

inPut

L(0.2-2Vnr'rs>10ko)

(G2V:

:F-Kï 2= a

9. 5- 1 2Y

(1vppi75o)

INT; 4,s7V:

3\

|

Front + Side control

Cinch - audio

O

ctucx

(0.5Vnr',ls

O

ctNcH

(0.5Vnus

FRONT

Audiofuideo

O

crncn cvBSO

O

ctrucn

(2Vnr',rs

O

ctttcH

(2Vaus

Headphone

qn

I

SVHS

@

out

Audio L

< 1kA)

Audio R

< 1kA)

in

Audio

10kO)

>

Audio R

> 1OkO)

8-600ei

1-r

2-I

3

-

4

l/O

+ Side

(red)

I

(whire)

O

(1vpp/75o)

(red)

L

O

(white)

O

(1vppnso)

Yo

co(o,3vpp/75o)

PCS 82 265 GB

Page 3

EE-i]

EE3il

E

Topcontml Panetd#

Controld ild/oÍ InpuUOutput

Side

P28| cTu8rek srÍerch Panel

CRT Panel

E

p.zul

ElP.r6 I

Wp.n1

E

E-p.ro l

EEI

EEf-l

E-r,,t

E-p.tl

EEzg]

E

E-t

,

3. Safety

Audio Modure

Ni€m LPanet

Tuner / lF

Pirl

Vids PÍocessing

Synórcnislion

lF Sound

Euro ConnecloÍ 1

EuÍo Connsdoí

ContÍols

p.zcl

Connections

4l

Teleteí

Side ConlÍol or

Audio Module

Top ContÍol

instructions

Warnings

SaÍety

instructions Íor repairs

2

presenl

and

Íor repairs, Maintenance

Notes

y#"jt^csrueo

.Z-

<9

PoweÍ supply

HoÍizonlatoutput

VerlicalOutput E P.1il

AudioAmpliÍier

N/S Panet

instructions,

nso-]

I

Eilp.13Jd

P.16-l

E

P.t7l

E

r-l

EE

66532068_001.41

1.

Safety regulations requiÍe that during a

-

the set should

be connected

transformer:

-

saÍety components, indicated by

should be replaced

original ones;

2.

-

Safety

be Íeturned in

should be

-

replacing

when

regulations require

paid

As

a strict

joints

solder

current

o

pins

all

o

fly-backcapacitor(s);

.

S-@rrectioncapacitor(s);

o

line

. pins

o

other components through

the CRT, safety

'rts

original condition.

to the Íollowing

precaution,

through which the

is flowing,

oÍ the line output transformer

output transistor;

of the

connector

current Ílows.

components

by

that after a

points:

we advise

particulaÍ:

in

with

repair:

mains via

to the

the symbol

identical to the

goggles

Íepair the

particular

In

you

to resolder the

horizontal

wires to the

which the

an isolating

a

must be worn.

set must

attention

deÍlection

(LOT);

deÍlection coil;

deÍlection

Note:

This resoldering

metal Íatigue

Íor television sets

-

The

and

-

The

external

-

The

tunction

components

-

The electrical DC

the secondary

which

This

o

e

.

o

-

The cabinet

touching

is

in solder

older than 2

wire

trees and

Íixed with the mounted cable clamps.

insulation oÍ the mains lead

damage.

lead

mains

in

order

or heat sinks.

have a mains isolated

can be done as

check

the mains cord and

unplug

pins

the two

mains

set the

mains cord unplugged

measuÍe

mains

aerial connection on the set.

between

switch off the

two

the

plug

4.5 MO and 12 MO;

pins

oÍ the

should

oÍ any

advised

joints

and is thereÍore only

EHT

cable should be

relieÍ

strain

to avoid

touching the GRT,

resistance

side should be checked

oÍ the mains

switch to the on

resistance

the metal

and

TV

and

mains

checked Íor defects

be

paÍts

inner

bad connections

years.

should

be checked

should

between the

power

supply).

Íollows:

connect

plug;

position (keep

!);

value between

shielding

The reading should be

remove the wire between

plug.

by the customer.

prevent

to

due to

necessary

routed correctly

be checked

for its

hot

plug

mains

(only

for

sets

wire

a

between

the

pins

the

oÍ the tuner oÍ

to avoid

lor

oÍ

the

and

the

the

Page 4

Maintenance instructions

Notes

recommended to have a maintenance inspection

It is

carried out by a

depends on the usage conditions:

r

r

The maintenance inspection contains the Íollowing

.

.

.

qualiÍied

when the set is used under

Íor

example

interval is 3 to 5

when the

grease

dust,

kitchen, the

execute the above mentioned

instruction";

clean the

the chassis;

the

clean

pictuÍe

tube.

seÍvice employee.

in a living room, the recommended

years;

is used in circurnstances with higher

set

or moisture

recommended interval

power

picture

supply

panel

tube

levels,

and

Warnings

1. In order to

high-voltage flashovers must

prevent

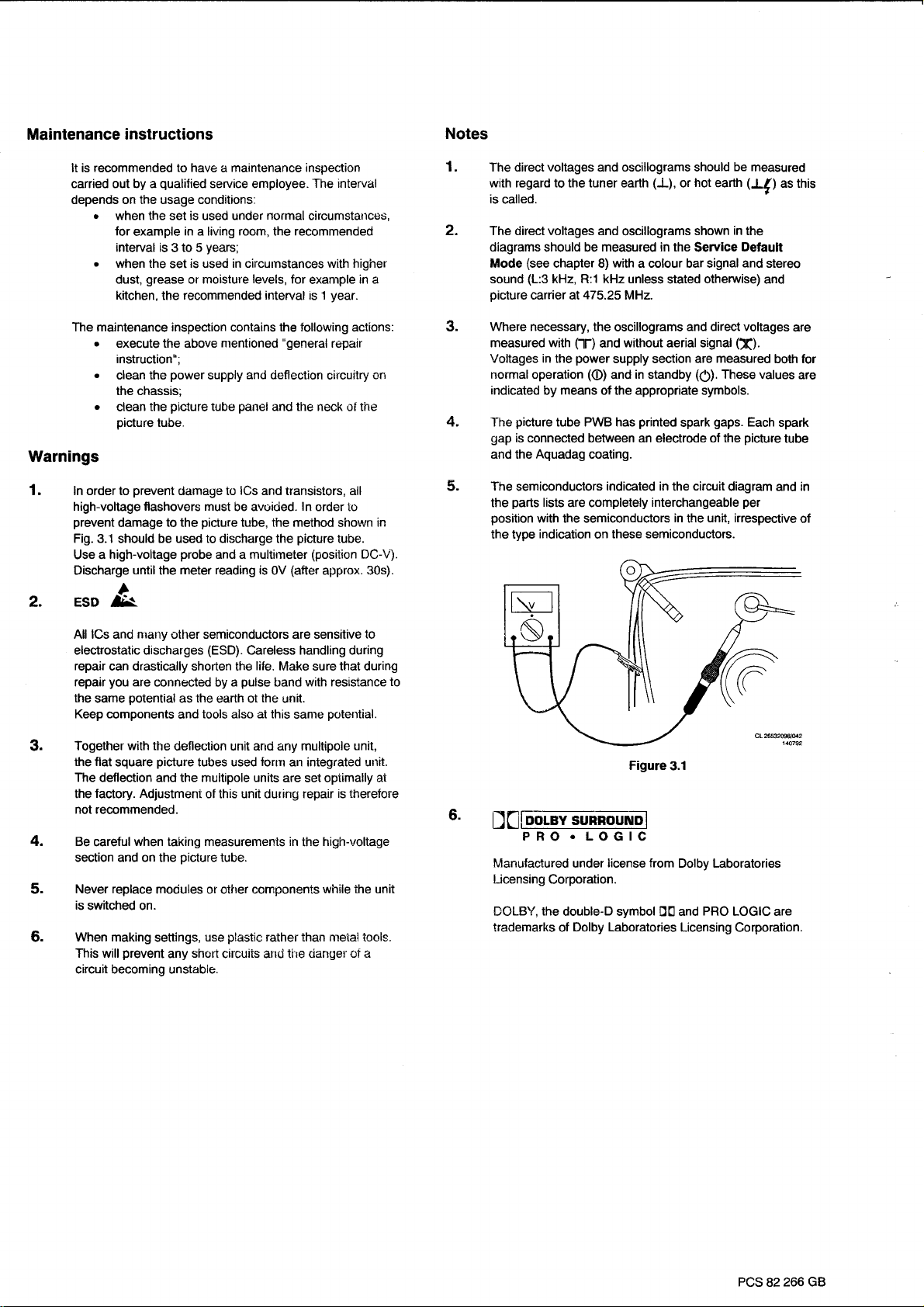

Fig. 3.1

Use a

Discharge

ESD IÈs.

2.

prevent

damage

should

high-voltage

until

l

damage to

to the

be used to discharge the

probe

meteÍ reading is

the

lcs

be ave,ided.

picture

tube, the method

and a multimeter

The interval

normal

circumstances,

for

exanrple

year.

1

is

"general

deflection circuitry

and the neck

and transistors, all

0V

In

order 1o

picture

(position

(afier

repair

oÍ

shon'n

tube.

approx. 30s).

in a

actions:

on

the

in

DC-V)

The diÍect voltages and oscillograms should

1.

with regard to the tuner earth

is

called.

The direct voltages and

2.

diagrams

(see

Mode

(L:3

sound

picture

carrier at

WheÍe necessary, the

3.

measured with

Voltages in the

normal operation

indicated

picture

The

4.

gap

is

connected between an electrode oÍ the

and the Aquadag coating.

The

5.

semiconductors

parts

the

position

the type

should be

chapter 8)

kHz, R:1 kHz unless

means

by

tube PWB has

lists

are completely

with the semiconductors

indication

oscillograms

measured in the

with

475.25

MHz.

oscillograms

(''ll-)

power

without aerial signal

and

supply section

(@)

in standby

and

of the appropriate symbols.

indicated in

these semiconductors.

on

(J),

hot

or

earth

shown

Service

a colour bar signal

otherwise)

stated

and direct voltages

are measured

(O).

These values

printed

interchangeable

gaps.

spark

circuit

the

in

unit, inespective

the

diagram and in

be

measured

(I{)

in

the

DeÍault

and

([).

Each

picture

per

as tnis

stereo

and

are

both Íor

are

spark

tube

oÍ

All lCs and

electrostatic discharges

repair

repair

the

Keep components

Together with the

3.

the flat

The deÍlection and the multipole units

the

not recommended.

Be

4.

section and on the

Never replace

5.

is

switched on.

When making

6.

This will

circuit becoming unstable.

nrarry

other semiconductors are sensitive to

can drastically shorten the

you

are

connected by a

potential

same

square

Íactory. Adiustmeni

careful

prevent

as the earth ot

and

deÍlection unit ancj any multipoie

picture

when

taking

picture

mocjules or otheÍ components

settings,

any

(ESD).

Careless handling during

liÍe.

Make sure that during

pulse

band

the

unit.

tools

tubes used

of this unit during repair

measurements in

use

short

at this

also

tube.

plastic

circuiis and tire ciangei

same

forrn

an integrated unit.

aíe set opiimally

ratheÍ than metal tools.

with resistance

potential

unil,

ai

is thereÍore

high-voltage

the

while the unit

oÍ a

to

Figure

3.1

6.

DCtpoLBY

PRO o LOGIC

ManuÍactured

l-icensing

DOLB'/,

trademarks oÍ

sunnounol

license from

under

Corporation.

the

double-D symbol

Dolby Laboratories

Dolbv Laboratories

PRO

and

D!

Licensing Corporation.

LOGIC are

PCS

82

266 GB

Page 5

4.

Mechanical

The

MD1 .2E

executions.

4.1

Styling

(also

Removing

1.

2. The

3. The

with top

applicable Íor

the

First

all screws on the rear

.

4

Screws are located

.

2 Screws

corners oÍ

.

4

Screws are

with the Euroconnectors

rear cover is

between

2

clicks

loosening

driver),

the rear cover

cover

connectoÍs

following

the

click connection

plate.

Process position

chassis has

controland

Íear

cover

located

are

rear

the

Íixed

now held

the

cabinet and the

at the left, 2 at

all clicks

plate

way:

on

and

aerial input

remove

(by

the

at the bottom

instructions

two

different

MD1.1E

at each

at the left

cover.

at the 4

the right

releasing

can

l/O

the

mechanical

side

inpuVoutput

Widescreen)

cover have

and aerial input.

position

in

rear

be removed.

panel

can be removed

screw in

to be

corner of the

and right bottom

corners

oÍ the l/O

by 6 clicks

cover. There

and 2

at the top. After

them with

with

the Euro-

the middle, release

and lift

removed.

cabinet.

are

a screw-

in the

the cover

panel

Service

Small

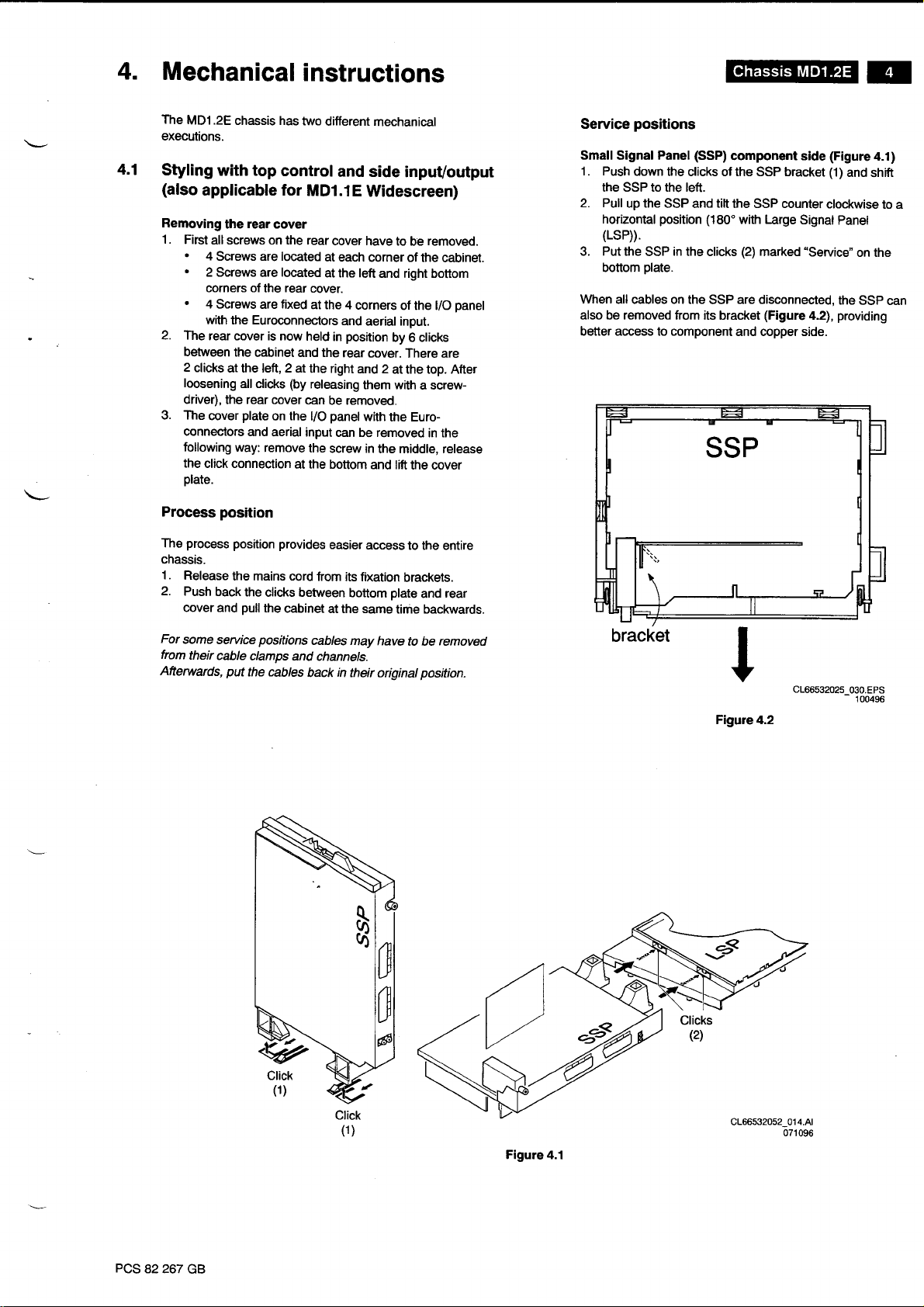

1 . Push

2. Pull

positions

(SSP)

Panel

Signal

down the

the SSP to the lefi.

up the

horizontal

clicks oÍ the SSP bracket (1)

SSP and

position (180'with

tilt

(LsP)).

3. Put the

bottom

When

all cables on the

also be removed from

better access to component

SSP

plate.

in

the clicks

its bracket

SSP

component side

the SSP counter

Large

Signal

marked

(Figure

"Sewice"

4.2),

(2)

are disconnected,

and copper side.

(Figure

4.1)

and

shift

clockwise

Panel

on the

the

SSP can

providing

to a

process

The

chassis.

1.

Release

2.

Push

cover and

For

some

from

AÍterwards, put

their

back

service

cable

the mains cord

position provides

the

clicks between

pull

the

cabinet

positions

clamps and

the cables

easier

Írom

at the same

cables

channets.

in

back

access

its Íixation

plate

bottom

time backwards.

may have

their original

to the entire

brackets.

rear

and

removed

to be

position.

bracket

PCS

82 267

GB

Click

(1)

Figure 4.1

_014.41

071096

Page 6

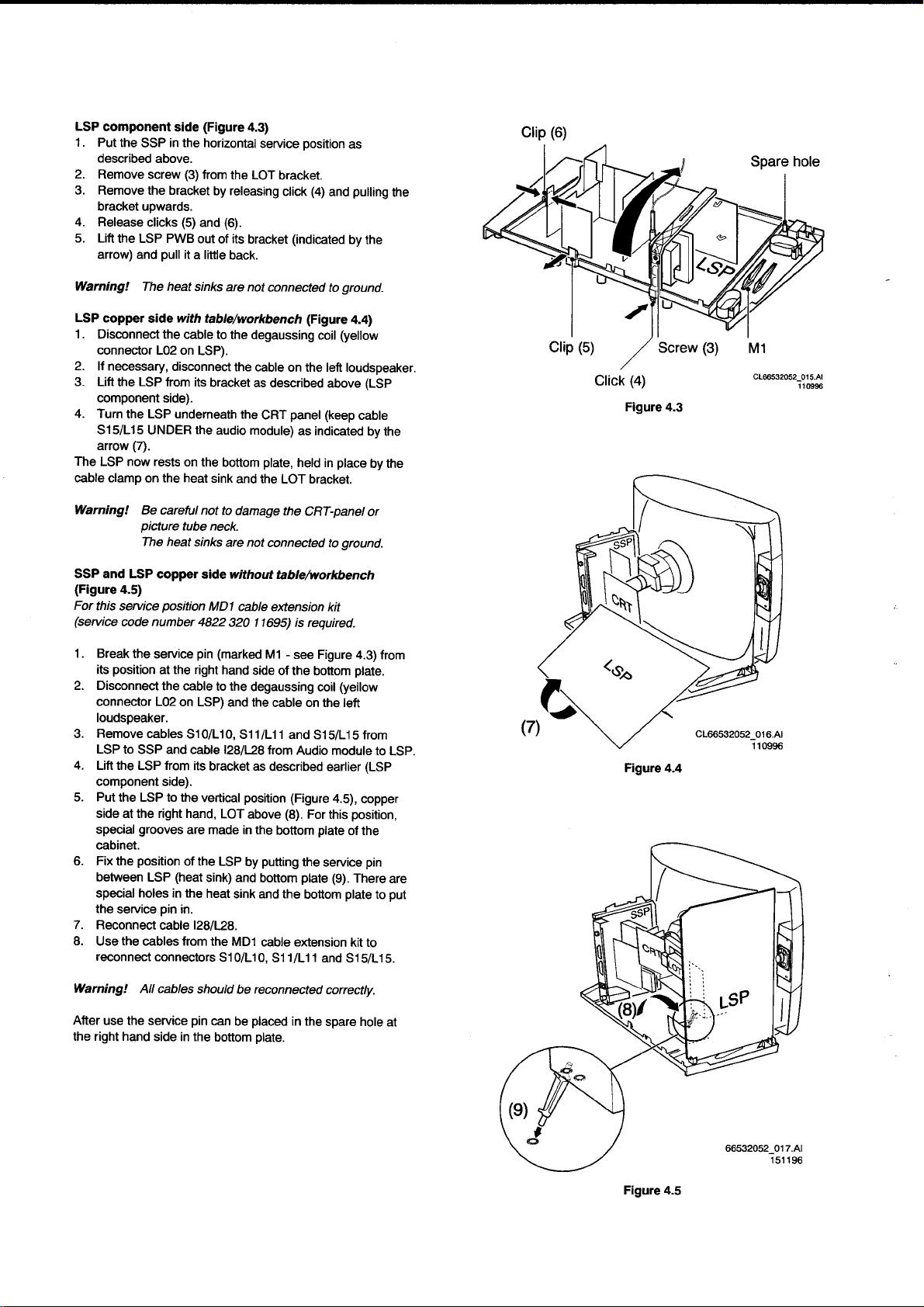

LSP

component

1.

Put the

described

2.

Remove screw

SSP

above.

(Figure

side

in

the horizontal

(3)

from

3. Remove the bracket

bracket upwards.

4. Release

5. Lift

the LSP PWB

arrow) and

clicks

pull

(5)

it

a little

and

out

the LOT

releasing

by

(6).

its

of

back.

4.3)

service

bracket.

bracket

position

(4)

click

(indicated

and

as

pulling

by the

the

Clip

(6)

Warning!

LSP

1.

The heat

copper

side

Disconnect the

connector L02 on

2.

lÍ necessary,

3. Lift

component

4. Turn

515/L15

arrow

the

disconnect

LSP

Írom its

side).

the LSP undemeath

UNDER

(7).

The LSP now rests

cable clamp

Warning!

the heat

on

Be careful

picture

The heat

SSP and LSP

(Figure

For

this seruice

(service

1.

Break the

its

2. Disconneqt

copper si]de without

4.5)

position

code number 4822

service

position

the right

at

the cable

connector L02

loudspeaker.

Remove

3.

LSP

4.

Lift the

component

Put

5.

cables

to SSP and cable l28lL28

lrom

LSP

side).

the LSP to the

side at the right hand,

grooves

special

cabinet.

position

Fix

6.

the

between LSP

special holes in the

the

7.

Reconnectcable

8.

Use

reconnect

pin

service

the

cables Írom the

connectors

sinks arc not

x/ith

table/workbencá (Figure

cable to

connected

the degaussing

LSP).

the cable

bracket

as described

the

the

on the

sink

not to

CRT

audio module)

plate,

bottom

and the LOT bracket.

damage the

tube neck.

sinks

are not

connected to

MDl

cable

extension kit

320 11695)

pin (marked

to the

on LSP)

51 0/L10,

hand

side

degaussing

and the

51 1/L1 1

M't

cable on the left

Írom

its

bracket as

vertical

LOT

described

position

above

are made in the

oÍ the LSP

(heat

sink) and

heat

putting

by

bottom

sink and the

in.

128/128.

MD1

cable extension

S1 0/L1 0,

S1

ground.

to

4.4)

(yellow

coil

on the left loudspeaker.

(LSp

above

panel (keep

as indicated

held in

CRT-panel

cable

place

by the

by the

or

ground.

tabte/workbench

is required.

-

see Figure 4.3)

oÍ the bottom

coil

and 51

5/L1 5

Audio module

earlier

(Figure

(8).

bottom

4.5),

For this

plate

the service

ptate

(9).

bottom

ptate.

(yellow

Írom

(LSP

copper

position,

of the

pin

There

plate

from

to

to

kit to

1

1

and 51

/L1

S/Li S.

LSp.

are

put

Click

(4)

Figure 4.3

Figure 4.4

c166532052_01

5.Al

1 10996

Warning! All cables

After

use the service

the right hand

side in the

should

pin

can

bottom

be reconnected

placed

be

in the

plate.

correctly.

spare hole

at

665320s2 017.41

Figure 4.5

Page 7

Mechanical

instructions

Accessing the module with mains switch,

receiver

1. Cut

2.

3. To

4.

Afterwards

(10).

4.2

Styling

control)

Removing

1.

Fot

írom their cable clamps and channels.

cables back

(Fig.4.6)

the tie rap

bottom side

bottom corner

space to handle the mains

Remove

pulling

and

get

be

can

The mains

with

First

all screws on the

.

6 Screws are located at the

.

2 Screws

the rear cover.

.

3 Screws

cover

some service

of the degaussing

(10).

Remove the

Írom

Íixation bracket

its

red mains

the

it backwards

more

movement

pushed

panel

the

degaussing coil should

side control and

ttre rear

aÍe

are located

plate

positions

in

their original

pànel

space, the

pulled

or

can now be

cover

rear

located at the

of the

UO

cables

LED

coil at the left hand

degaussing coil in the left

(1

1)

module.

bracket by

(12).

upwards

removed.

side

cover

just

above,

connections.

may

position.

lifting

left top of the cabinet

(13).

retied at

be

inpuVoutput

have

to

comers oÍ the cabinet.

right

left and

under and left oÍ the

haveto be removed

Aftenttards,

RC5

and

get

to

more

the end

position

(no

be removed.

bottom oÍ

put

the

top

(10)

(1

1)

(12)

Figure 4.6

66532052_01 8.Al

071096

Process

The

chassis

1.

2. When the clicks

Service

SSP copper and component side,

(Figure

'1

. Release the

2. Lift the SSP a little and turn

Service

1.

2.

3.

position

process position provides

during the

The chassis

fixed in the bottom

pushed

pulled

positions

4.7)

LSP.

(16)

180"

provides

This

SSP and also allows

position

Disconnect the cable

connector L02 on the

the

Lifi

backwards

Turn the entire chassis around the CRT

The

chassis rests

LSP backwards.

service

can be

between

back, the chassis and

backwards.

click construction

Írom the LSP.

better access

with table/workbench

from

chassis

(17).

easier

posltions.

pulled

lifted,

plate.

bottom

it to an angle oÍ

to the

for the removal

the

degaussing

to

LSP).

the bottom

the SSP

on

access to the entire

(t

Íorward

plate

the bottom

module servicing

(14)

clmponent

plate

with the

Scm) and

rear cover are

plate

between the SSP and

135'

oÍ modules.

(Fig.

4.8)

(yellow

coil

pull

and

panel (18).

copper side of

can be

(15)

or

side oÍ the

it

the

(14)

Figure

4.7

66532052_01 9.Al

250996

Warnlng!

careful

tube

not

neck.

Be

picture

The heat sinks

to damage

not

are

connected to

the CRT-panel

ground.

or

FiguÍe 4.8

Page 8

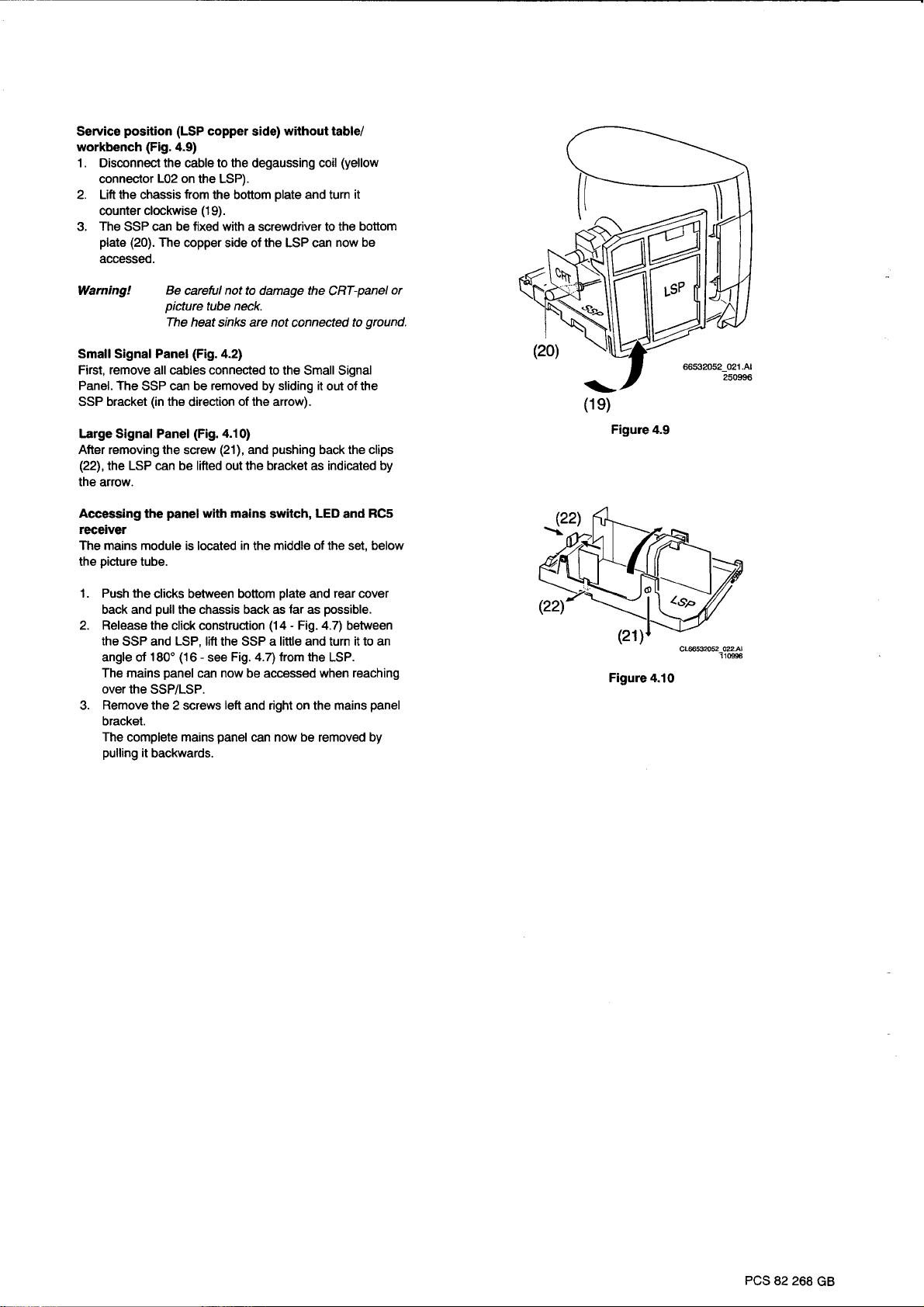

position

Service

workbench

1.

Disconnect

connector

2. Lift the chassis

counter

(LSP

(Fig.4.9)

the

cable

L02

on the LSP).

Írom

clockwise

copper

to the

the bottom

(1

9).

3. The SSP can be Íixed with a

plate (20).

The

copper side ofthe LSP can

accessed.

without table/

side)

degaussing

plate

and turn

screwdriver

(yellow

coil

it

to the bottom

now be

Waming!

Be

picture

The

Small Signal Panel

First, remove

Panel. The

bracket

SSP

cables connected

all

SSP can be

(in

the

Large Signal Panel

After removing the

(22),

the LSP can be lifted out the bracket as indicated by

the

arrow.

Accessing

the

panel

notto

careful

tube

damage the

neck.

heat sinks are not

(Fig.4.2)

removed

direction

by sliding

of the arrow).

(Fig.4.10)

(21),

with

and

mains

screw

cannected

to the Small Signal

it

pushing

back the clips

LED

switch,

ÍeceiveÍ

The mains module

picture

the

1. Push the

back and

2. Release the

the

SSP and LSP, lift the SSP a little and turn it to an

angle oÍ

The mains

over

the SSP/LSP.

Remove

3.

is located

tube.

clicks between bottom

pull

the chassis back as

click constÍuction

(16

180'

panel

the 2 screws

in

-

Fig. 4.7)lrom the

see

now

can

be accessed when

left

and right on the mains

middle oÍ the set. below

the

plate

and

Íar

as

-

(14

Fig.4.7)

bracket.

The complete mains

pulling

it

backwards.

panel

can now be removed by

CRT-panel

ground.

to

out of the

RCS

and

rear

cover

possible.

between

LSP.

reaching

panel

or

Figure 4.9

cffi262 02.A1

-i1ffi

Figure 4.10

PCS

82 268

cB

Page 9

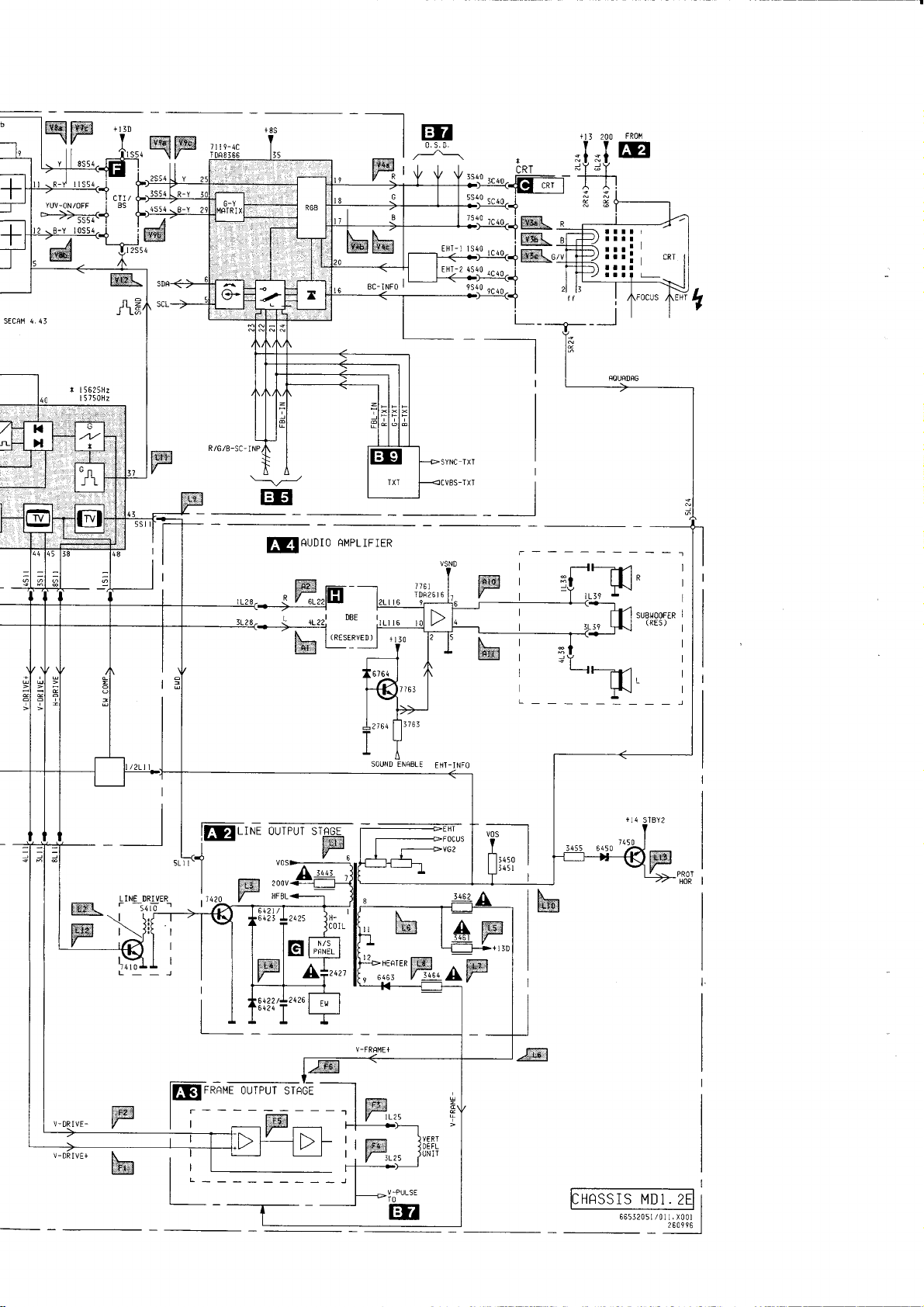

5.B|ockdiagram/B|ockscha|tbi|d/Schéma.bloc@r

7l I 9-4ê

PANEL

I

Titr

SÍEREO

SND(L /R

)-SC2-OUTP

FBL-PRESENI

STATUS

(FOR

IF

STEREO OSS

NICêM

,

I

*rry

)

i* .,r*ro

x

L

os, o'*

t1'rttfïr%,htit

cv8s-sc

cvBs-sc

| - INP

2-0uT

PÊL/NTSC

*Tt

PHASE-COMP

OR SECAM

ryF

4. {3

t

i

l_

SOUND(L/R) HEADP-OUÏP

t

1392/1394

!

mr-lmalrcto

puDro

(r

/R)

uoourE]

!l

: I

tl

6504

3ND(L/R )

/R

-SC

I'I NP

-5C2lÊR-t

)

hm,/qt?&]

-

v

m

v

73so/r3sr

f--;1

A

::i;i:?\,'" F

,6|$ffii!$i,

s

I

PROT

t@

tr

,Ó

È

Ift-ltl

SND(L/R)-scr-ouTp

/R)-SC2-0UÍP

SELECT

2

SND(L/R

)-CL OUTP

ut

rrtoe*

ffi

E

Y

PCS

L-

82

269

Page 10

--l

rytr+

ffii{r

Íts

t I 5525H2

I 5750H2

,ryffi

ffi

EEI

EEAUDIO

I

ÍEA .

|

V-*

AMPLIFIER

EHT-2

4540

iiiiicRT

I

I

I

I

I

I

I

DBE

(RESERVED

)

ïï:'"&aP

v-DRIvÊ+

WT

IÍGIrnnur

r::ï | -----

lËr I l----rar---l

f

t\

lr.r-

I tlP-

--r\rt

OUïPUÏ

STAGE

|:H

|

V'PULSE

TO

EA

HÊSSIS

MD

66532051 /01

1

]

.

X00

t

Page 11

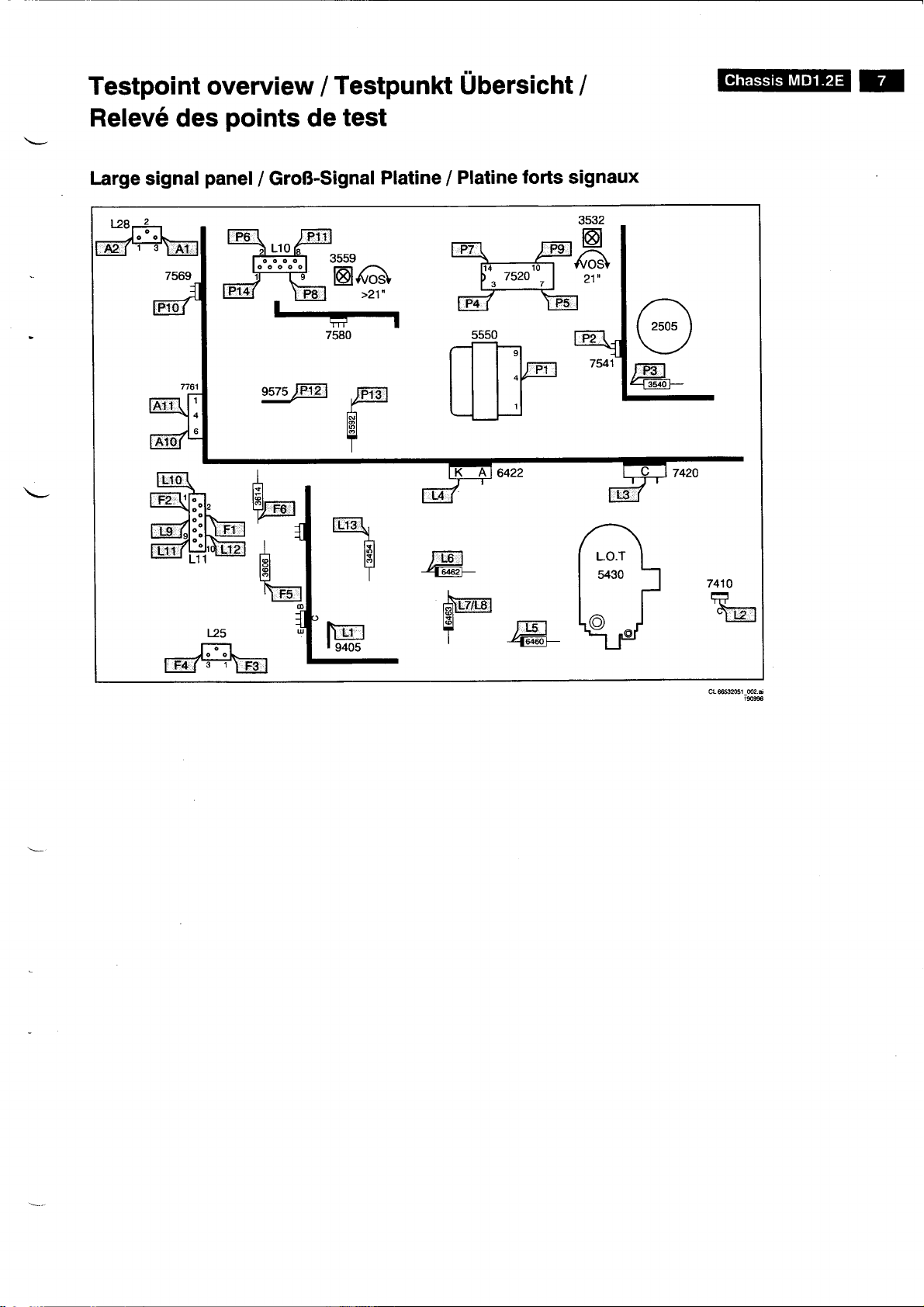

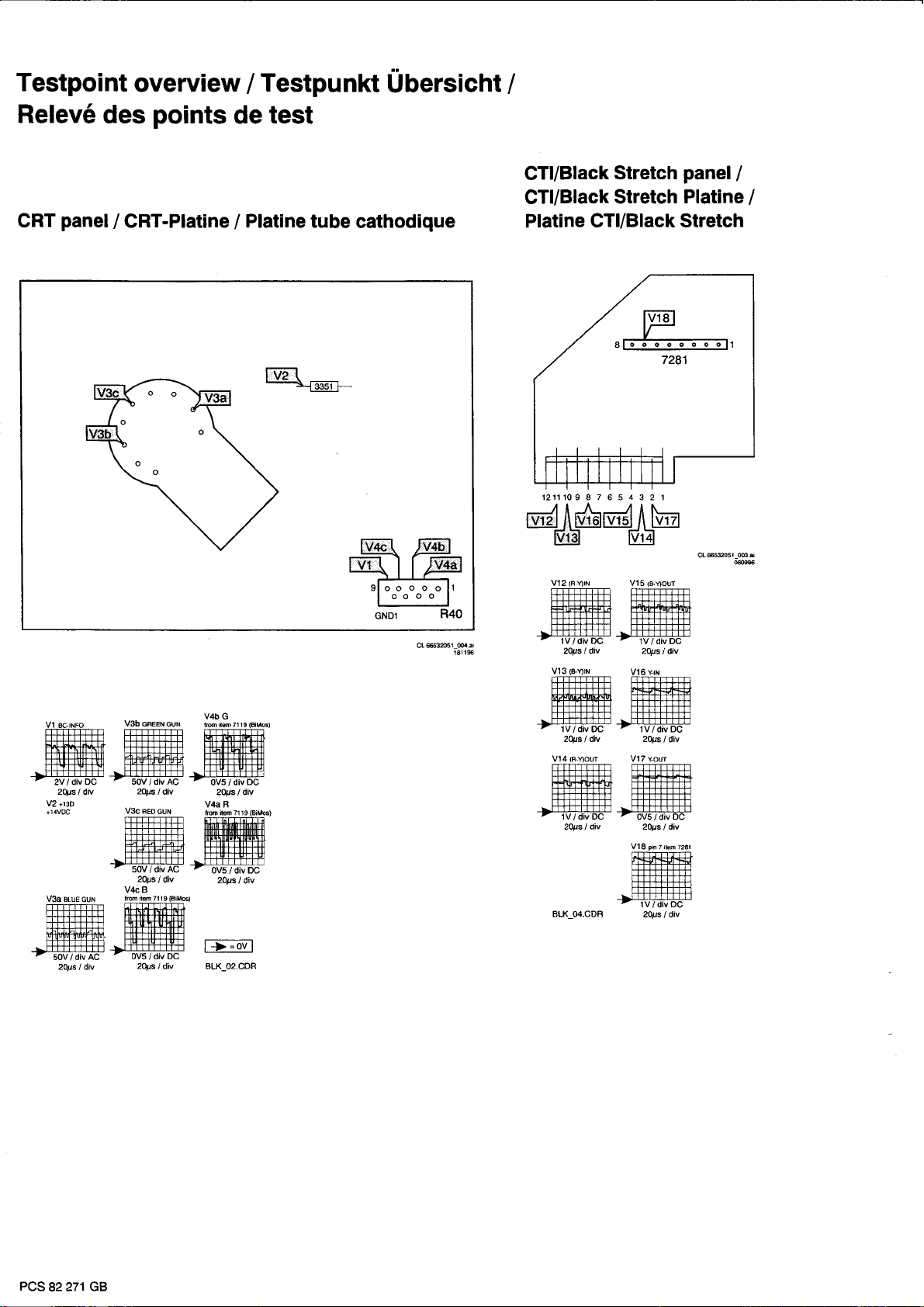

Testpoint overview

/

Testpunkt

Ubersicht

/

@z

Relevé

l-arge

des

signal

points

panel

/

test

de

GroB-Signal

Platine

Platine

/

Íorts

signaux

c1ffi261-@.d

1$S

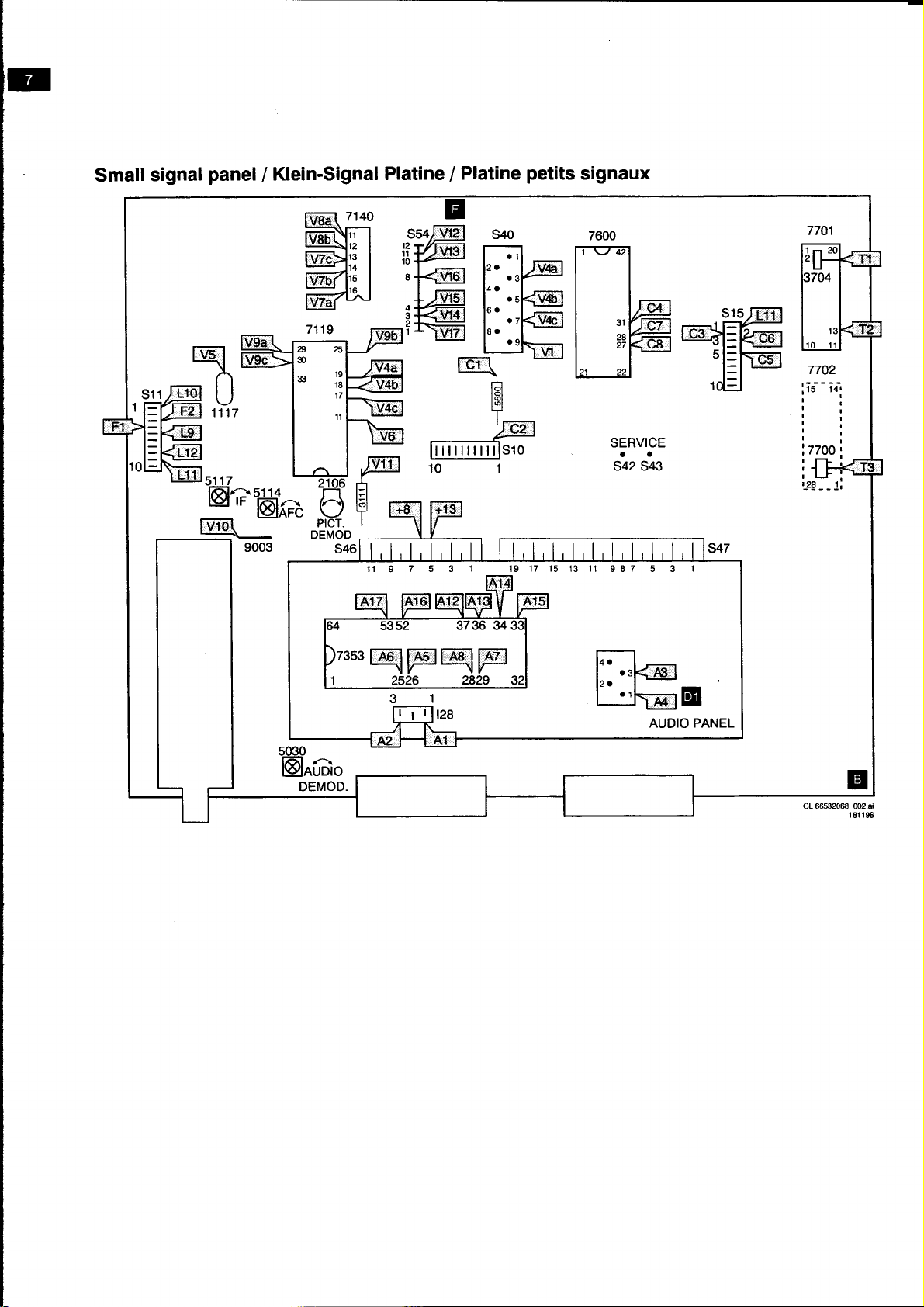

Page 12

z

Small

s11

signal

panel

Klein-Signal

/

a6

O

to

33

;;

17

11

Platine

Platine

/

petits

signaux

7600

\Jt

42

1

31

2A

27

:C8

SERVICE

aa

s42 s43

c4

7701

7702

ï4-'

:ïi

It

It

It

It

ll

y

i77oo

ifii

V9--1.

qtr

2526

E

CL 66532068_002.ai

181196

Page 13

Testp

Relev

A1 ND6-L,3KHZ Al0 Adb ilp. od C'l

(wrlmkrinsed)

FTffi

TFFEFFEL*LI 'ítrtt'f.'r'r

mnÍrirrÍf,Il|sr

m '' w

ffil.++w

F#r#tfH ffiMl-*td/i

TrrrTrT-trTn TrtrrrrrT-rfl

div

50mV

/

O.sns /

A2ruDo-B-iffiz

(wilm€MiEs6€O 3ft2r4(id.wrlm)

IKH:igh(iffi.dm€)

ffi

r-rT\1-TÍT1\TT1

0V2

AC

div

div

AC

/

O.l ms / div

All ^dbilp.od F3vERTrcaL

+5$NDBY

(Ên.2itm7&o) F2voRvE- L5+13D

Mc

czrclreogr

-$ï:i:]-ffi

CjvpuLSÊ OEFLECTToN(LV-)

ffi f;fffiffi Tffïffi

ffi

H#++H#

í)mv/divAc

O.Sms/div

A3 sNoL-HmPH-ouT A1 2

Hp rÉ.wrom,

{3G2,

"hïïiffi

ffi-ffi-ffi ffi

H+ËH+W HSH++ffi

ov2/dvAc

o.zms/div

pin

37 n€m

(S'-OUT-1,

3KHz)

ïfiïïPft

ovs/divDc SV/divDC!

sms/div sms/div sms/div

73$ F4 vEtrrsl V6

g

-

(8MHzffiiltu4

+ffi ffifii ffi

ffi

ffi

ffi

H{++fi+#

OEÈECTTON

, HrJ#tt+r

-ryii"tê-

(Lvr)

14wm

'*ïJ:**.

P4pingirmuszo

ffi

ffi

;;-**

LgEwo

ffi

L10 S-COMP P6 vOS

ffi

P5íh7íêm7m

ffi

ffififrffi

Fffffl-l-Frï1

'ád**vroiurc

1oírs/div

*"Íl:,119"?" rllrrr|T

Pl2*28

souNo-suPPLy

Íi:::,,.,."

*fr:Ïn'"':*.rmffi

P14

tri:,?":'

!""ïÁ.ó"o'-ffiffi.ffi

pin

its zO1

T1

2

V4c B

hmilma1g(aik)

ilr6qrilfin

ffi-ffi ffi

Vsaa3MH2qFd

.

ffi

ffiffi

2omvfd'dDc ï5viáil#

62-5gs/div 2q[s/div

CWS-TEFR$T

(Pd]

-T];ff

ffiffiHfivtrfrn-ffi'ffi ffiffi-ffiffi

ffi)trffiffiffiffi

O.2ms/div

A4sNDR-HmpH,oUT

(rffi,HPiEdumê,

rE.woFRn]

r-rJ-+-r-r+r-r.r-1 ++4r-+-r-r-r-r

ffi

ffiffi>'ïuF,Jï'"''

O.2ms/div

A5

Írn6Mre$

(tiP-L

oW - 3KHz) (gz-óur-r.

ffiffiffi::* ffi8:Y3:

ffi-ffi-ffffi,$

o.2rc/div

m.'Jtïr':ïá1ï

ffi ffi

ffi ffi''$Frrrflrrl

lVrH-+\,í-H +t++rffi.j

Hffiffi

o.2ms/div

pn

A7

ê nsm

(LNOSffiËF-1,

liïi'fifi,ï,]

ffi

ryfrWW

ffi

o.2ms/div

A8Íhanem73s

(LOUSffiRA,

,,(u*"*6)iarzat..irlt-ETrr

ffiffi

ffi

O.2ms / div

o.zmsidiv 62.5ns/div sms/div

A13Írn$bm73s

(sc1-oUT-R,1KHz)

trrtrrFrrrrr'l

CssoA L F5b$oídm76o2

ll. Il li't

[]ju_lH

ffi-ffirffiffiffiffififfi-ffiffi

1V

div

/

Z)ms/div

o.2ms/div

pn3ail€m73s

414

sxnr)

o.2ms/div

êHS,},ïï[,fi"

20ms / div

ScL F6 VFMME*

C6

2oms/div

:"t;l;:g'Sg

ryiïiffi ffi

lffit Hi*tN1f6

uffi)ffi

73s

o.2ms/div

lq/s/div

C8pin2zils7ru

ffi

ffi ffi H+trilffi"Tliffïfrf ffiflfiffi-ffi ffi

Hffi

êl?.ïÍ.li?"*e,ffiïg

Ar;;;;;r"*

lscr-ir-a,rxx.,

È6. $ud ON)

sms/div

Fl vDRG*m L4

.Tf[mfi

Fïïffi

%ffi+ffi>Hm

0-2ms / div sms

-tftfEttr]::m

+H-Ftttï ttutffi-rh

DC

ffi)tr#)ffiffi

1oms/div

*ï.r';9tr-ffi

L26róíM74,0 Lr3Bc.pBm

H+Hd

lQt/s/div

L3ar@rilem74a P2ddní€m7Ím1

ffi

Fu1l+tffi

+ffi

lq/s/div

ffi

W-ffiÉ,*r-"

div

/

5ms /

div

sms/div

Lít SAND

Í-TTr-rfrrl-T-l t.|-trrTT'arÍTr [-fffl_Í-T_ff|l roI-rn-fr ro

1ops/div

L12 H-oR

2orjs/div

w2rc

plpnilms$o

ËErl|T-ili,;FrilTtT]Tl

ffi ffitilïn

-qffi

tqss/div

P3 dhde ím 6í5

fi:ffi

q:í##

gls

P7pin14rem73o

(D ry5rc

"tthhbftf++r

o.1s/div 0.59s/div

_

vE

+rySÍaNoW (r=oN)

PB

pspinloibmTs

offi

ffiffi +ffifififfirffi ffi

H-r-rfr1.j

+ffi'ffi

lqgs/div

Pgphlon*7ffi

)ffi

o.1s/div 2qss/div

Pto+Es V4bG

(O

SW

[ou*

ó*

/ div

,q|ffiffiffiffi

2qgs/div

T2pin1orm77o1

frurel

H-H # H+#+#

T3 sYNC-w

sq/s/div

v1

Es.]rrc

ffffi ffi

t1ïïfr*l

2qgs/div

V,fa R

Miêm7119(sM6)

ffi

1q6/div

V6cvBs-TERffiaT

(s*m)

ffi

1ops/div sqis/div

Xlli",J,?i;,

ft'.-ïhï

ffiffi

lqps/div

V7c Y ouT

(Ítnr3im714o) V1z(Ê-Y)LL

ffi--I-Í-Tifr-rr

r-l$ifl11u1l

ffi

tom

7119

ísm

ffi rffi ffi

ffiffi ffi

+riv,,o-"o'#

2q!s / div

ffi

lqgs/div

VgaF-Y

(pin

(BMc)

r 1 n6m 7l{)

-dEffi)"ffi

2Ws I div

V8b 8-Y

(pin12

ilm714)

FEfn"TfFFtr

!!!(B-\4oW

-T[rrnTr

ffifu

V9a(B-Y)OUT

trffi

ïïFïFïl-l -

vgb YOUT

rrr--Ttm Ftr;r-ifrn

2qgs/div 2qgs/div

Vgc(R-Y)oW V17Y-ouÍ

-",->ffi

vll NEsNprys

E'rrïrrtr

fï'Íïfi-rll-

-

2qgs/div

ffi

2qss/div

(8-ïlN

v13

20t1s / div

Vl5€'\4OUr

ffi

ffi

H1+H++H

+-fV;a;Oe-

2qts/div

yrN

V16

-TTrfrFÏ

+r#

f+=ovl

BLK Oí.CDR

CRT

V1 Bc-rNF(

ffi

Hl-tsHtl

Ffitfl-1-ttl

rffï1-t't

)=ffi

V2 +13o

+1.Vrc

pa

2OUs

I

PCS

82 270

PCS

82

27

Page 14

Testpoint

overview

Testpunkt

/

Ubersicht

/

Relevé

CRT

Vl rc-rNFo

ffi+Fffi

HÁHS,{+rh,l.H

ffi1-fffttfiitiÍl

ilqIqTTF]

>qffi

V2 +t3D

4vrc

+1

ffim'

IflFi'FFffiS+

des

panel/

2qgs / div

'>}#+'ffi

2qls / div

points

de

test

CRT-Platine / Platine tube

V3b

GREflGUN

frfftfrl+ï

l..]...]..]...]...l..]'."1+

titrfft+r

FliJ+FUfft{

n-TTn-TT--l-1

)-Siftr'ïd

2ots

V3c RED

ffi

-ï-t-TTn-ï-TF

uïtrEEtmf

Í..]...l:::]l..]...|::]].]...m

n-Í-rft-n-n

''.'ofrbi;ïd'

2ogs / div

V4c B

IlHÏfi1Uï1

2qgs

ffiffiffim'

ffi

TtT|TgtTgl

+5ffi

div

/

GUN

/ div BLK-o2.CDR

2qgs / div

V4a R

MM71r9(Bft)

W

ffifmEt

+ffi

20us

l>=ovl

div

/

cathodique

cLffiru1_@.ai

1811S

CTUBlaek

CTI/Black

Platine

1211109 8 7 6 5 4 3 2 1

Stretch

Stretch

CTI/Black Stretch

dAtrd/\b

Ed Éa

V12

G-Y)|N

ffiEffi

ffi$ïïFtrï1

ffiffi

>'iiititb"

2ogs/div 2qps/div

(B.Y)|N

V13

ifift[T-m

ffiffi

tfft-ft-l-f-t1

>'ïiii*tb"

20ps / div 2qgs

V'14

íR-souÍ

lTfrfl_Tff|r

r.|M

ffiirHrffiH rir-ffi

ET]ffiTI]]] EIT]IIE]T

L|!n -a*_l

>'ï#i*ib" >-btÈïàibÉ

2qps / div 2Ws I div

BLK_O4.CDR

(B.tour

V15

Frtrtlriltf

+'5v#JÈ#

yrN

V16

rrnTTTFm

Ffl-Fffn-ff1

-'!l

+'ïii#iË

V17 Y-our

gErrrrT-n

LIJ+.qJaJJ

div

/

panel

/

Platine

cLwost_m.d

ffi

/

PCS

82

271 GB

Page 15

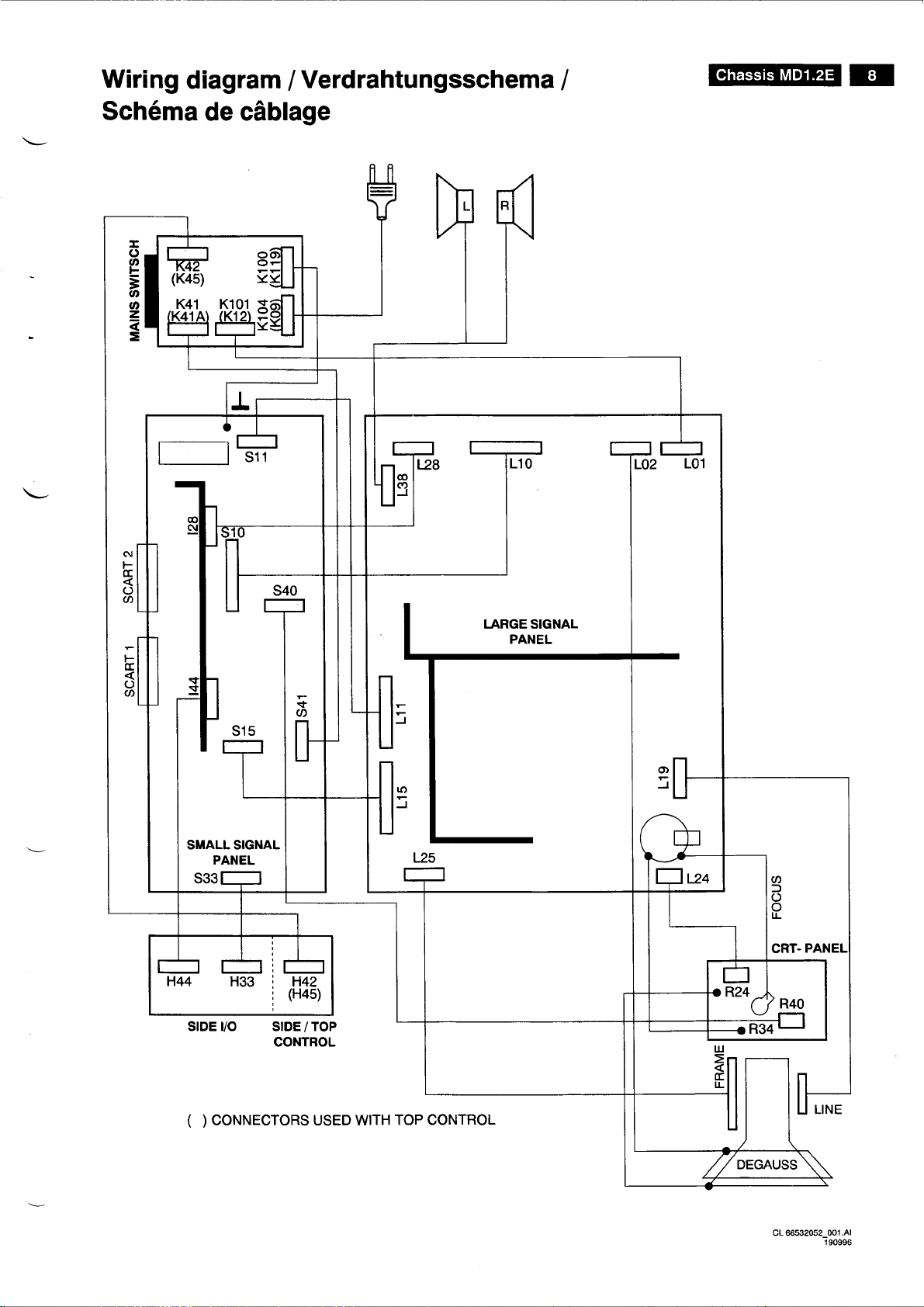

Wiring

diagram

Verdrahtungsschema

/

/

@r

Schéma

de

riiiSl

í11^, lÍ.1.E

T--__lï"

càblage

v

I

SMALL SIGNAL

PANEL

SIDE I/O SIDE / TOP

CONTROL

(

CoNNECïORS USED WrrH

)

TOP CONTROL

U)

l

O

lL

CRT.

cL 66532052_001.41

190996

Page 16

6.

Service

Modes,

DST, Error

messages,

Protections,

Faultfinding and

following

In this chapter

6.1

6.2

6.3

6.4 Protections

6.5

6.1 Test

The MD1 chassis

printing.

blocks:

A1-42-43, etc.: Test

*

* C1-C2-C3,

* F1-F2-F3, etc.:

L1-L2-L3, etc.:

*

P1-P2-P3, etc.: Test

*

* T1-T2-T3, etc.: Test

V'l-V2-V3, etc.:

*

6.2 Service

For

easy

RC7150

TV

sets,

also called

number of

Installation Íeatures Íor the dealer

6.2.1

The dealer

presets,

with

the

points

Test

Service Modes and Dealer

codes

Error

finding

Fault

points

is

These test

etc.: Test

modes

installation

is introduced. The

including

all set of

Dealer Service Tool

the DST

can use the RC7150 for

Tv-settings,

Repair tips

paragraphs

"blinking

and

repair

and

equipped

points

with

are reÍerring to the

points

circuitry

points

points

Test

frame output circuitry

Test

ooints

output circuitry

points

point

points

Test

circuitry

and Dealer Service

and diagnosis

RC7150 can be used

the MD1 chassis. The RC7150 is

(RC7150)

is

Dish

are included:

Tool

Service

procedure

LED"

tips

points

test

for the audio

for

control circuitry

the

frame drive and

for the

Íor the line drive and line

power

for the

for the teletelc circuitry

Íor

video

the

the

dealer

DST. The ordering

or

4€,22 218 21232.

programming

settings.

(DST)

in the service

functional

processing

supply

processing

(DST)

Tool

remote

control

for

new

all

Tv-set

the

Exiting the SDM:

-

Switch

cleared).

Note: When

The

SDM

microprocessor controlled

-

For recognition of the SDM

the screen.

oÍ

-

Tuning

Nicam L), PAL on other

-

Volume level

level).

-

Auto switch off

switched off

for 15 minutes).

-

Sleep

-

All other controls

-

When

procedure (See

error buífer,

to the value of

This function

plcture.

or

Alignment Mode

Seruice

6.2.2.2

Entering

-

By transmitting

Dealer Service

normal operation

-

pressing

By

keyboard simultaneously

the

to stand-by

set

the set

immediately

again'

Íollowing

has the

475.25 MHz

at

is

set

picture

Other

timer is disabled.

the microprocessor supports the

SAM:

disabled

when no

operate

6.3) and an error code is

the LED

the last error code.

will

the

Tool

mode or

"MENU"

the

(the

error buffer

the mains

is in SDM,

to

also

"ALIGN'

power

the

set

the mains is switched on

when

pre-deÍined

tuning and linear functions:

"SER"

is displayed at the top

(Secam

on

Multi-France sets

sets).

(oÍ

25olo

the

maximum

sound settings are set to 5096.

and

(normally

video

will

blink

work when there is

(SAM)

(this

and':"

the set

(IDENT)

signal

normally.

the number of times, equai

command with the

works both while the set

in

the SDM).

key

when the set

is also

is

switched off

will enter to SDM

conditions

on

Íor

volume

is

automatically

was received

"blinking

present

no

the local

is in

SDM.

RC7150

while

all

(with

LED"

in the

soud

is in

10

Differenl

via a GFL or

to

the

DST-I

For

directions

program

tables can be

MD2 TV-set

(downloading

DST; see GFL or MD2 service manuals) or by the

(DST/PC

explanation

interf

ace; orderin g code 4822

of the installation

for use of

the

DST

chassis, download code 4 should be used).

Diagnose

6.2.2

The MD'|

DST RC7150.

and the Service

entered by

6.2.2.1 Service

Entering the SDM:

-

-

features

.2

sets can be

These

Default

short circuiting the

Defauft Mode

transmitting the

By

RC7150

By temporarily

Signal

Dealer

Panel.

for the servicer

put

are the Service Alignment

Mode

(SDM)

"DEFAULT'

Service

shorting

programmed

from the

into the DST

GFL

21 8 21 27

Íeatures

recommended

are

of the

DST, the

(For

in the two service modes

Mode

(SDM).

"seÍvice".pins

Tool.

pins

S42 and

can also

SDM

on the SSP.

command

S43 on the Small

with

the

or MD2

n.

the MD1

via the

(SAM)

be

Êxiting SAM:

-

Switch the set

Note: When the

ln the

SAM

screen:

-

Software

microprocessor

version identiÍication

versions in the Software Survey

Product Survey.

-

Error code buffer

-

Options

-

Alignment and

8.2.1, 8.3.1

to stand-bv.

mains

is in

Íhe sef

immediately when the

again.

the following

version

(see

and 8.3.2).

information is displayed on the

(the

software

in the

set

corresponds

(see

paragÍaph

geometry

power

is switched off while

the set will entet SDM

SAM,

is displayed. This software

paragraph

8.4).

information

mains is

version oÍ the

with

the software

published

as

6.3).

paragraph

(see

switched

on

in the

Page 17

Service Modes,

(1)

SoÍtware version

(21

Error

(3)

(4)

buffer

Options

Alignments

and

DST, Error

geometry

messages,

Example:

Errorcodeposition

Errorbuffer

c

afterenteing SDM

(2x) - pause

blink

.

after transmlfÍ,íng

(4x) - pause

blink

o

blink-pause-blink

.

nothing happens

transmrftlng

after

after transmltÍrÍng

-

blink

-

blink

1 2

2 4 1

(2x)

"DIAGNOSE

(4x)

"DIAGNOSE

"DIAGNOSE

3 4 5 6 7

0 0

2 OK

with the

with

3 OK'

4

with

OK'

0 0

DST

the DST

the DST

6.3

Figure

6.1

Error

codes

Ïhe

error code

last

time

the buffer

to right.

-

-

The last

The

error detected

error buffer will

1. exiting

remote

2. transmitting

the DST

-

By leaving

buffer is not reset.

Examples:

ERROR:

ERROR:

ERROR:

The

contents

through the

useful when

1. When

"blinking

there is

the SDM is

oÍ times,

The

LED will

times,

equal

2.

With the DST

made visible.

"DIAGNOSEx

The

LED will

now Íor

the error

Screen

Mode

and

buÍÍer

the

control

the SAM with

oÍ

the

Service

Alignment

(SAM)

"blinking

LED"

contains all errors detected

was

SAM with the

the

The

erased.

(actual)

reset in the Íollowing

be

commands

buffer is written Írom

is the error at the

"standby"

"DIAGNOSE

mains

the

switch,

command

procedure

since the

left side

cases:

on the

9 9 OK with

the error

000000: Noerrorcodedetected

3 0 0 0 0

0:

Error

code 3 is the last

and

only detected error

530000: ErrorcodeSfirstanderror

last

code 5

of the

erÍor bufier

equal to

stay

LED:

no

entered,

the value oÍ

off briefly and blink again the

can also be made visible

procedure.

picture.

There

the

the

to the value to the /ast

a// error

codes

in

While in SDM. transmit the

Ol( wherex is the

error

x ranges Írom 1,

(actual)

detected

This is

especially

two

are

methods:

LED will

blink the number

/asÍ error

code.

error code

the error buffer

command:

position

to

buffer

be made visible

(the

error) to 7

number

can be

in the

last

(the

Íirst

error)

operate in the

code

on

same

position

way

x.

as in

point

1,

but

left

Note!

lmportant!

Enor

code

Note

the set respons

lnterruption

lead to incorrect

Not

chassis support

and the DIAGNOSE

versions

procedure

it

that

all software

NOT

are MlZBAx-x.x

EÍor desoiption

may

take up

to a DIAGNOSE

of

the blinking

results.

versions

the blínking

99 command.

supporting

Bfinking

l€D,

to 7 seconds

contmand.

sequence may

of the MDl.2E

procedure

LED

Software

the

blinking LED

and Ml2COx-3.x.

Pgssble

deÍectve-

before

.

,

coÍnpgnents:

No error

0

BIMOS

(ID48366)

2 MSP3400/3410

erÍor

lzc

3

4 Wrong EEPROM 4x

5 EEPROM

defective

b Tuner errol

oÍ

7 TXT

Histogram Proc.

8

eÍror

9

error

10 WSSB module

error

11 Dolby

erÍor

detected

error

bus error

error 7x

processor

16:9

processor

1x

1c7119

(SSP)

2x

1c7353

(ssP)

3x All lzC-related

components

(SSP)

rc7685

5x 1c7685

6x

8x 1c7210

9x 1c7440

10x

11x

(SSP)

(ssP)

u1000

(ssP)

rc7702

(Íeserved)

(16x9

module)

tc7540

(WSSB

module)

rc7600

(Audio

module)

Table

6.1 Error

code

list

Page 18

Protections,

FaultÍinding

and

Repair

tips

Protections

6.4

In

6.4.1

the MD 1.2E

the

possible:

Protections

o

o

o

.

DeÍlection:

o

o

r

Soítware

o

.

o

Power

6.4.2

The

mode

r

r

o

o

ln hick-up

Pin 1

approximately

protection

hick-up

squeak is

6.4.3 Horizontahprotection

When

the voltage

conducting

is 0V7,

Via

the

switching

is

still

mode)

6.4.4

Ew-protectaon

generated

Overload

Undedoad

Over voltage

Under voltage

Horizontal

EW-Protection

Vertical

BIMOS

Set

there is no

SDA

Set is

restart.

No +SDb

standby via

power

Overload

Under load

Over voltage

Under voltage

the hold-circuitry

protection

protection

Protection

Protection

protection

lC71 19

can be

switched between

picture,

or SCL

switched

or +8Sc

supply

supply will

in

following

the

protection

mode

of 1C7520

2 seconds, immediately

is astivated.

mode.

When the

audible

the beam

across

and as soon

TS7450

will

mode

the set

present,

the set will

again.

deÍective

shorted

to

standby

protections

starts up

every 2

current

C2450 will

conduct, making PROT

of

(standby)

off and

(not

standby via

atgC

go

situations:

Íollowing

the

by

no OSD,

protections

power

--+

+

+

-+

-+

-+

-+

-+

standby

sound is

-+

standby line,

-+

line,

set tries to restart.

to a very

from

This

good

the

start circuit Íor

cycle is constantly

set is in hick-up

seconds.

becomes too

drop. D&50 will

as the voltage

power

the

on

Íor 21"

supply, the, set will stay

and

can only be reset by

via

the mains

switch

to standby

sets)

are

supply:

Hick

up mode

Hick up mode

Hick up mode

Hick

up mode

Supply

to standby

Supply

to standby

BIMOS

standby

(ErroÍ

code 1)

and ON, but

noise.

only

(Error

code 3)

tries

set

is

Set

switched to

audible hick-up

after that the

repeated in

mode

a short

high Íor a long

staÍt

drop across R34S6

high.

switch. lÍ the Íault

(protection

mode

to

period

in

The

EasVWest

the Easvwest

Note:

The current through

the LSP via

In

case oÍ a line

too high

rises.

to

and the voltage

When

conduct and

becomes HIGH.

high

(e.9.

when

switched

conduct

The

a

on with the mains

and EW-PROTECTION

East/West

cases:

1.

Bad contacts

.

bad contacts

r

bad contacts

.

bad contacts oÍ

2.

Bad

contacts

3. Shorted flyback

4.

Shorted S-correction

5. Bad solder

When

EW-protection

transistor

6.4.5

Vertical-protection

7420 may

The vertical

VERTICAL-PROTECïON

when

it is

the

interrupted,

mode.

functioning

BIMOS lC71

the BIMOS

In the BIMOS

oÍf the VDRIVE+

6.4.6

blanked.

line output

switch to

Software

The

It

Circuit breaker

stage will not work

hick-up

protection

software

continuously verifies

supply voltages

When

switch the

pÍotection

the

power

STANDBY line.

a squeaking sound.

protection

power

A cunent

is too high

part

precision

2

problem,

detects when

output

stage

through the

can be

in the line-deflectíon

the

EastArVest

resistors (R3483

the

easvwesÈcurrent

across resistors

the

voltage level

exceeds

STANDBY-SUPPLY

When the voltage

problem

line

ís

already

switch), D6zl81

protection

becomes

oÍ horizontal

deÍlection

of horizontal

oÍ linearity

S-correction

oÍflyback capacrtor

diode D6421

capacttoí C2427.

contacts in

output

has

also be

stage creates

line

the

been active, the line

defective.

pulses

correctly. These

19-4D

pin

on

37. When the

will

switch to BIMOS

STANDBY mode,

and VDRIVE-

'l463

may

and the

(under

mode

protection

pin

on

becomes

supply on

In

this situation

voltage

is

managed

presence

the

34 and the

active, the

and off continuously via

the current

with

TS7480

Easwest

caused by

is too

stage

a defective

circuitrv!

stage is measured

and

R3484).

becomes

R3483

and

0.6V, D6480

PROTECTION

across

C2480

is very

present

when

and D6,f82

is

activated very

active in the

Íast.

Íollowing

circuit:

deflection

corrector

coil

coil L542i

capacitoÍ

C2427

C2425.

D6423.

or

output stage.

output

at every flyback

pulses

are sensed

pulse

STANDBY

the BTMOS

while the

RGB outputs

be open. Probably,

power

supply will

protection).

by the microprocessor.

of the +5

activity oÍ

and

the l2C bus.

soÍtware will

the

power

supply

produces

through

high.

that

on

R3484

stans

the

set is

pulse

by

train is

switches

are

the

+8

the

The

EasVWest

standby

PROTECTION.

the

set will stay in

only

be

switch. lf

standby

protection

via the

signal line

Via

reset

by switching the

the Íault is

(protection

switches the

STANDBY-SUPPLY

the hold-circuitry

protection

the

still

mode)

set

present,

again.

mode

oÍf and on via the mains

the

power

power

of the

(standby)

will

set

supply

suppty,

and can

switch to

to

PCS

82 272GB

Page 19

Service

-

-

Modes,

protection

l'C

The

l2C

ThereÍore

condition.

repeatedly

and the

l2C-protection

.

SDA

.

SCL

.

SDA

When

and

the

.

SDÁ/SCL

the

LED

RED,

GREEN,

.

SDIy'SCL

LED

GREEN,

+SDb

+SDb

entire

microprocêssor

+SSDb

present.

míssing,

bus

is controlled

every

When

incorrect,

set

switches

is

shorted to

shoÍted

and

SCL shorted

SCL

or

SDA

LED lights

shorted when

mains

switch:

is

8 seconds RED,

8

seconds

flashes

shorted

is

I seconds

Ílashes

and +8Sc

and +8Sc

small

signal

senses whether

+8Sc

or

coming

When

one or

the

set switches

DST,

l2C

the defined

generated

protection

are the

at each l2O-command.

command

error

to software protection.

earth

to

earth

is

shorted,

in

a clearly recognisable

GREEN,

RED,

during

GREEN, flashes

RED,

procêssing

both the

has

start/stop

placed

3 is

in

the Íollowing

the

the

8 seconds

flashes

etcetera.

operation

ercetera,

of

the microprocessor

main

supply voltages

oÍ the

fÍom

the

supply

to soítware

Error

a defined

set tries to restart

set is

set.

the

supply voltages

power

starístop

condítion is

in

the enor buffer

situations:

pattern.

switched

GREEN, flashes

RED, 8 seconds

g

RED,

of the

pin

At

supply

voltages

protection.

messages,

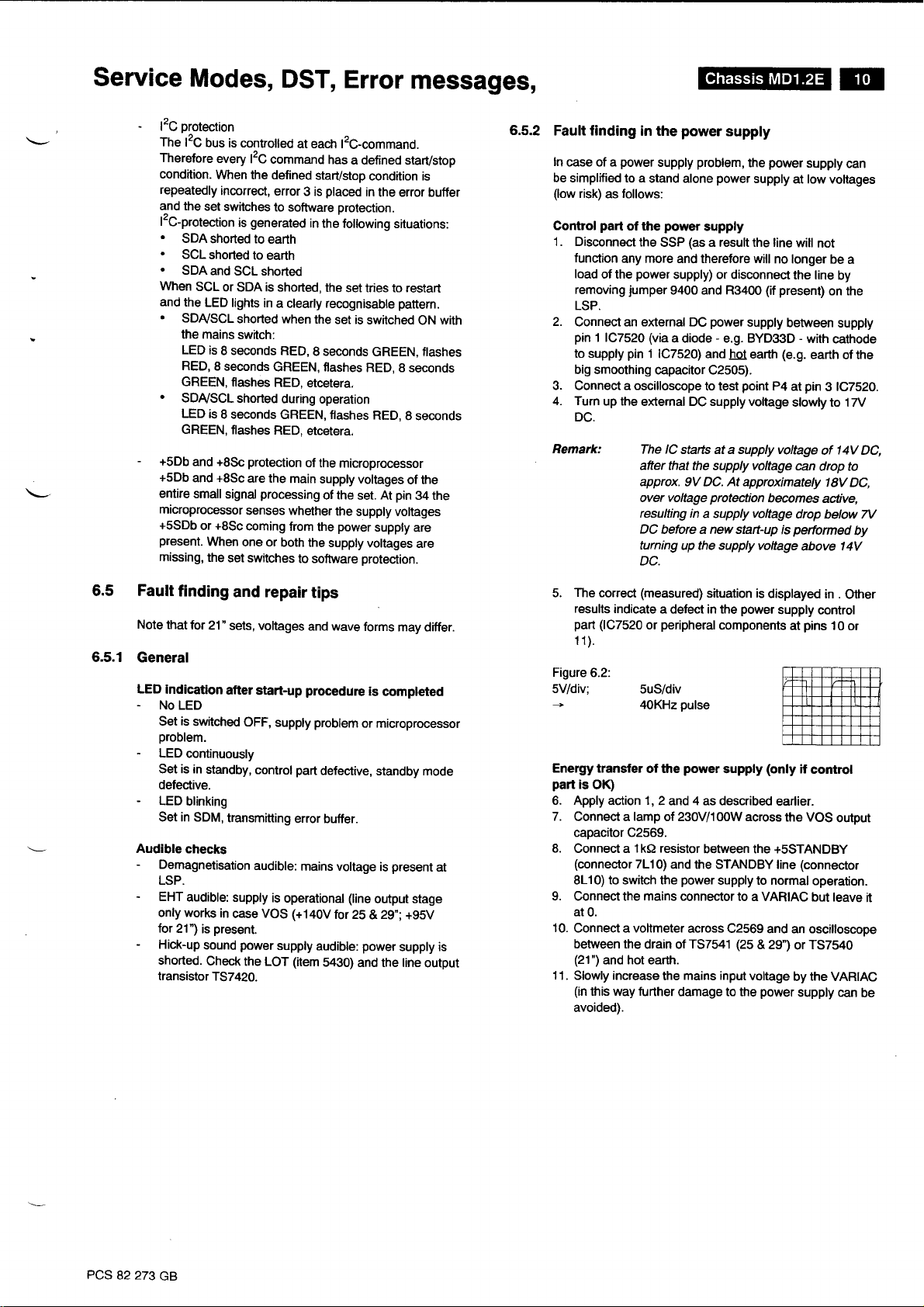

6.5.2

with

ON

seconds

34 the

are

are

Fault Íinding

In

case of a

power

be simpliÍied to a

(low

risk)

Íollows:

as

part

Control

oÍ the

1. Disconnect

function

load

removing

any more and therefore will

oÍ the

jumper

power

in the

problem,

supply

stand alone

power

supply

the

power

(as

SSP

supply) or disconnect

9400 and R3400

LSP.

2.

Connect an external DC

pin

1 1C7520

to supply

big smoothing

3. Connect a oscilloscope

4. Turn

(via

a diode - e.g. BYDSÉID

pin

1 1C7520) and hot

capacitor C2505).

to test

up the

exteÍnal DC supply voltage

DC.

Remark:

The lC

statts at a supply voltage

after that the supply voftage

approx. 9V DC. At approximately

voftage

over

resulting in

DC

turning

a supply voftage

before a new staft-up

up the supply voftage

DC.

supply

power

the

power

supply

a result the line

no longer

(if present)

power

supply

between

(e.9.

earth

point

P4

at

protection

becomes

is

supply

can

at low voltages

will

not

be

the line

a

by

on the

supply

-

with

cathode

earth

oÍ the

g

pin

ICZSZO.

slowly to 17V

14V

of

DC,

can

drop to

18V DC,

adive,

drop

below 7V

performed

above

by

14V

6.5 Fault

Note

that

6.5.1

General

LED

andication

-

No

Set

problem.

-

LED

Set is in

defective.

-

LED

Set in SDM,

Audible

-

Demagnetisation

LSP.

-

EHT

only works

lor 21")

-

Hick-up

shorted.

transistor

finding

Íor

21'

sets, voltages

LED

after

is

switched

continuously

standby,

blinking

transmitting

checks

audible:

in

present.

is

sound

Check

TS7420.

and repair

start-up

OFF,

supply

part

control

error bufÍer.

audible:

supply

case

power

the LOT

mains voltage

is

operational

VOS (+140V

supply

(item

tips

and wave

procedure

problem

forms

or microprocessor

deÍective,

(line

for 25 & 29';

power

audible:

5430)

and the line

is

may differ.

completed

standby mode

present

is

output stage

at

+95V

supply is

output

The

5.

results

part (1C7520

correct

indicate

(measured)

a deÍect in the

peripheral

or

1 1).

Figure

6.2:

SV/div;

+

Energy tÍansÍer

part

is

OK)

6. Apply action 1

7.

Connect a

SuS/div

zlOKHz

pulse

power

oÍ the

2 and 4 as described

,

lamp

of 230V/100W across

capacitor C2569.

8.

Connect a

(connector

8L10) to switch the

Connect the mains connector

9.

at

0.

10.

Connect a voltmeter

between the

(21")

11.

Slowly increase

(in

avoided).

1kQ resistor

7L10)

drain of

and hot earth.

this way

further damage to the

and the STANDBY line

power

mains input

the

situation is

components

power

supply

displayed

supply

pins

at

(only

iÍ

earlier.

the VOS

between the +SSTANDBY

supply to normal

to a VARIAC

across C2569

TS7541

(25

voltage

(connector

and an oscilloscope

& 29)

or

by

power

supply can

in .

Other

control

10

or

control

output

operation.

but leave

TS7540

the

VARIAC

it

be

PCS

82 273

GB

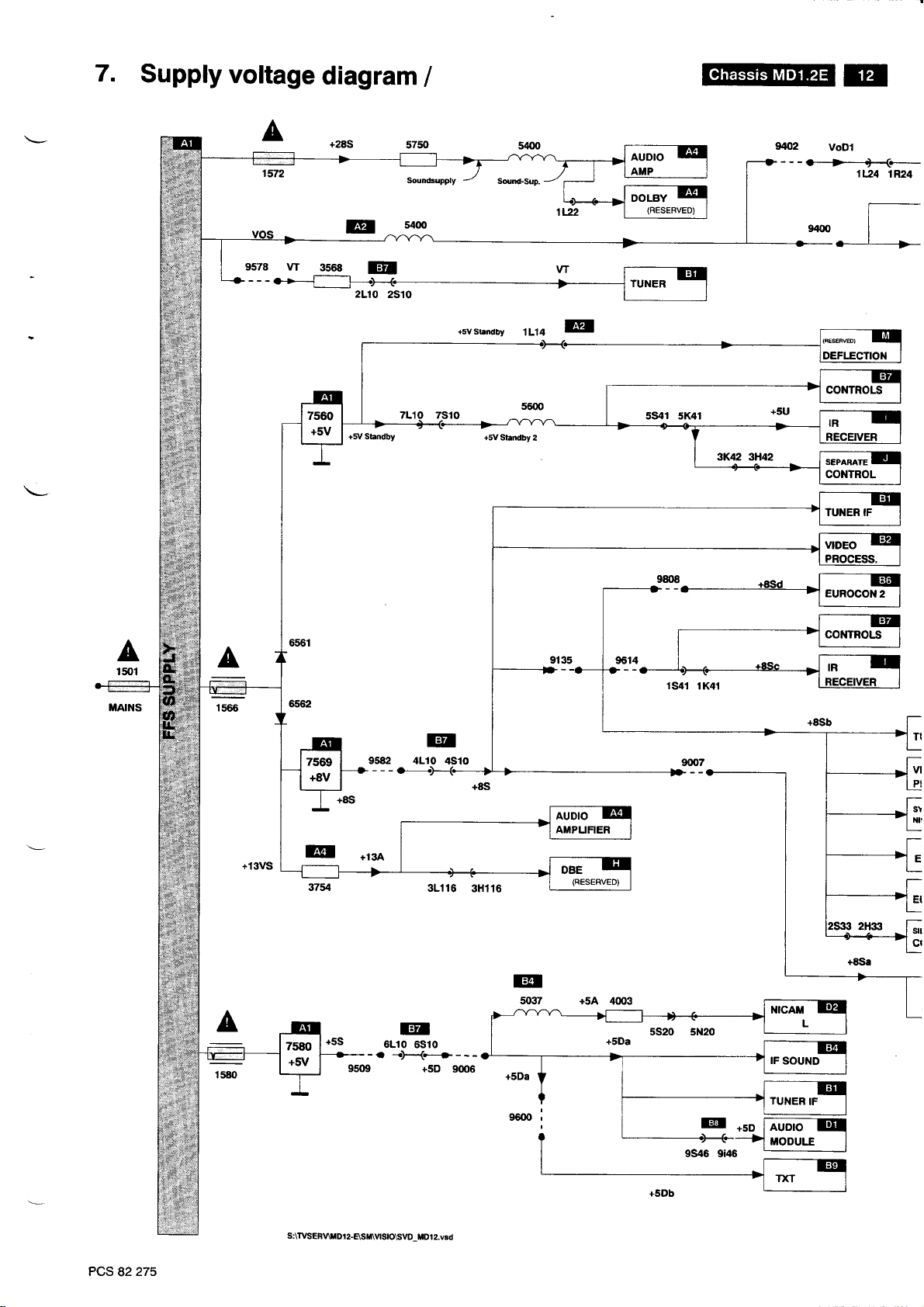

Page 20

----------------

l

Protections,

The wave forms Íor

Mains

lOVAC:

2OV AC:

4OV AC:

65V AC:

>

In case

or the voltage will

1. Figure

2. Figure

3.

4. Figure 6.6:

Fault

6.5.3

When the horizontal

simplified to a stand alone'switched

voltages

1. Disconnect

2.

3. Conneot

4. Replace

5.

voltage

in

65V AC:

of a

6.3:

Mains in 10V

10v/div;

6.4:

Mains in 20V AC

20vldiv;

+ zlokHz

+

Figure

6.5:

Mains in 40V

S0V/div;

+

Mains in

S0V/div; SuS/div

+

+

finding oÍ the horizontal

(low

Discoínect the

current

(between

level

pulse

at the base

PCB).

Connect

FaultÍinding

the Íollowing

20kHz and VOS

40kHz

ztOkHz

zlOkHz

Stable situation,

feedback

exceed 140V

AC

1Ous/div

SuS/div

VOS3OV

AC

SuS/div

ulokHz

VOS8OV

65V AC

40kHz

VOS

circuitry itselÍ

risk)

as Íollows:

the

set

SSP

an eldemal

measurement

the HDRIVE

0 and

a oscilloscope

output transisto r 7

Possibilities:

1. Figure

6.7:

point

L3; test

transistor

S0V/div;

at collector

(7420)

lOps/div

Currertt Írom external

approx. 100m4

Obseruation: normal

and VOS

and

VOS

and VOS

problem,

pulse

pulse

pulse

14OV

Írom

mains.

removing

by

50V DC

possibility

by an

5V); duty cycle

oÍ TS7410

to test

42Q\.

line

DC

supply

pulses

l6kHz

mains

voltage

7V5

30V

80V

1,10V

40kHz

so

the

situation

(95V

with

circuitry

is

defective, h

mode

all cables to

(or

40V DC)

across

eliternal LF

(near

LOT

point

L1

output

and 100mA

and

aÍe

given:

Repair

and 140V

will not stabilise

21')

ffiffi

l+-t-t-L.trl-t-1-l-lJ

H*#fll-HrflH

fffiffiHtÏf\ffi

rfiiïftj-tH

n--|-rï-rrn-t

ffiffi

Ht+++-llt+i-t_1

Íïï]ïflï-ïïÏ]

F+#+fl-I-rt-fi

frrï--rm-n

ffiffiF

ffiffiffi

l-t--]----l-ff-1

ffiffi

ffi

n-n*-T-|-Ít

can be

supply"

C2400.

generator

50olo) with a t6

at the side

(collector

low

at

the SSp.

supply with

[fTL

of the

oÍ line

suppty

kHz

current

tips

Correct hóÍizontal

Note

that ihè amplitude

Írequency

2.

Figure

L3; test

transiBtor

S0V/div; lossidiv

Line

Current from e)dernal

appÍoximately

Obseruatlon:

Causes: horizontal

3. Figure

L3;

test

transistor

SoV/diq 1ops/div

Current

approx

Obseruatlon:

Cause: horizontal

When the line

only a number

does not

e)Íernal DC

4.

Figure 6.10:

L3;

test

transietor

1O0V/div;

Current ftom

approximately 150mA

Obseruatlon: flyback

Cause: flybackcapacitor

5. Figure

L3; test

transiÉtor

1OOV/div;

Curretlt from

Obseruatlón:

Cause:

generator.

of the

6.8:

point

at collector line output

(7420)

deflection open'.

small

supply current

linearity

S-conection C2427

6.9:

point

at collector line

(7420)

from

external DG

500m4 !!

fast oscillations

deflection coil shofted)

show the oscillation

supply

point

at collector line outpui

(7420)

1OpS/div

e)dernal DC

between, 150mA

6.11:

point

at clllector line

(7420)

1OrrS/div

external DC supply > 1A

2

from

short-circuit in

(e.9.

circuitry

oÍ the signal strongly

DC supply is

100m4.

pulse

followed

deflection

L5421

coil

supply

and 500mA suppty

deflection

deflection

of windings

is

not completely

are shorted, the wave Íorm

is

approximately

supply

time is shofter,

pulses per

cycle extra and

morethan 1A

picture

EHT

to Aquadag)

depends on the

by wide

coil open

open

open

pulse

and

output

cunent

(e.9.

shorted

and the curront of the

200fnA.

line

shorted but

is

one exta

supply

cunent

pulse

C2425 open

output

suppty current

tube

100mA

in

Page 21

Service

Modes,

DST,

Error

messages,

6.5.4 Fault

the video

When

that there is

ïDA8366,

For

measuring,

the aeriAl input

oscilloscope

triggered

Normal

1 . First

16, | 7,

are

Figure

Red

CRT

1O0V/div

100us/div

The total

16 TDA8366

The TDA8366

TDA8366

<

> 4.5V :

2.

Secónd

measured

Red, line

measured.

-

-

Figure

Red

R43

(upper

SOV/divAC;

100!s/div

finding

"no

controller

there is

no

problem

a

the RGB

connect a video

with a white

field

with VDRIVE+

start up

phase

oÍ start up; 4 white

1 8)

and the main

better visible ff

6.12:

(pin

8 oÍ connector R43

panel)

and

DC:

beam

during

4.5V :

set remains

set continues

phase

and the main

16 is

differences

compensated

when

the

phase

with

6.13:

(lower

line)

on the

CRr

line)

sun

picture,

lC

picture

and

with

ampliÍiers or the

ftequent. A

at

procedure

the

green gun

current is measured and fed

19)

0C71

checks the voltage

these lines

of

start up; each beam is

Green

and

between

diffeÍences

3, otheruise it remains

(pin

8 of connector

panel)

(pin

6)

protection"

no

part

TDA8366-4C)

protection,

no

the BC_INFO caused

pattern

pin

picture

and

picture

generator (e.9.

to the tuner.

picture

stable

4

511.

measuring lines

picture

is muted

tube is

on the

(pin

6)

pin

at

phase

in this

up

start

with

picture

is

still muted.

line 17

is Blue. BC_INFO

the lines

are minimal the

(guns)

sreen

cold);

(problem

it is

most likely

by the

tube.

PM5518)

Trigger

is

obtained

(wave

1

6 of the

phase

separately

are

set continues

phase

in

[HfIFIl

'

f+JJq+t+{4q4

if

(lines

forms

back

to

2

Line 15 is

2

the

pin

is

l-TT-TH-tTf

.FlTTfmmm

H-i-lt_t-t-l

at

15,

in

start up

bright

picture

hangs in

phase

white hórizontal

is darlt

first

picture

6.12.

(1C71

The

1. A

the

(set

Oscilloscope

like figure

TDA8366

OK

There should be 4.5V

Possible

problem:

TD48366, there is

components)

2.

Small

rest

the

(set

hangs in second

In

horizontal rcd,

oÍ the

TDA8366 is OK

Possible

picture

Measure at

problem:

tube are bad

pin

R or G or B liÍle) is/are

ampliÍier(s) or

gun(s)

3. No lines visible

pin

Measure

-

0V:

-

5V:

-

Pulses

16

:

oÍ the set

19),

can be identiÍied:

line

phase

oÍ start up

oÍ the voltage

picture

tube

pin

at

16

iÍ there is

a defect

(in

at the top; the

procedure)

over

and RGB amplifrers

TDA8366.

present

no 4.5V

one

or more

the BC_INFO Íeedback

green

and

pictuÍe

is

phase

one or more

'16

TDA8366

smaller; the

is/are