Page 1

Micro Audio System

MCM1050B/12/58

egaPstnetnoC

1 Technical Specification and Connection Facilities

2 Laser Beam Safety Precautions......................................... 2-1

3 Important Safety Precautions .................................. 3-1 to 3-2

4 Safety Check After Servicing ............................................. 4-1

5 Safety Information General Notes & Lead Free

Requirements .................................................................... 5-1

6 Standard Notes For Servicing,Lead Free Requirements

& Handling Flat Pack IC .......................................... 6-1 to 6-4

7 Direction of Use ....................................................... 7-1 to 7-2

8 Cabinet Disassembly Instructions ........................... 8-1 to 8-2

9 Troubleshooting ................................................................. 9-1

10 Block Diagram .................................................................10-1

11 Wiring Diagram ...............................................................11-1

12 DC/MP3 Link/WPS Board

Circuit Diagram ....................................................12-1

Layout Diagram ...................................................12-1

13 Key Board

Circuit Diagram ................................................12-2

Layout Diagram ...............................................12-3

©

Copyright 2011 Philips Consumer Electronics B.V. Eindhoven, The Netherlands.

All rights reserved. No part of this publication may be reproduced, stored in a

retrieval system or transmitted, in any form or by any means, electronic,

mechanical, photocopying, or otherwise without the prior permission of Philips.

Published by Sophie-KM 122901 AVM Printed in the Netherlands

.................................................1-1 to 1-7

Contents

14 AMP Board

Circuit Diagram .................................................12-4

Layout Diagram.................................................12-5

15 MCU Board

16 Exploded View.....................................................................13-1

17 Revision List ........................................................................14-1

Circuit Diagram .................................................12-6

Layout Diagram ................................................12-7

Feature

Features

RDS

Voltage Selector

ECO Standby

DTS

Subject to modi cation EN

Different

/12

Page

/58

Version 1.0

Page 2

Technical Specification and Connection Facilities

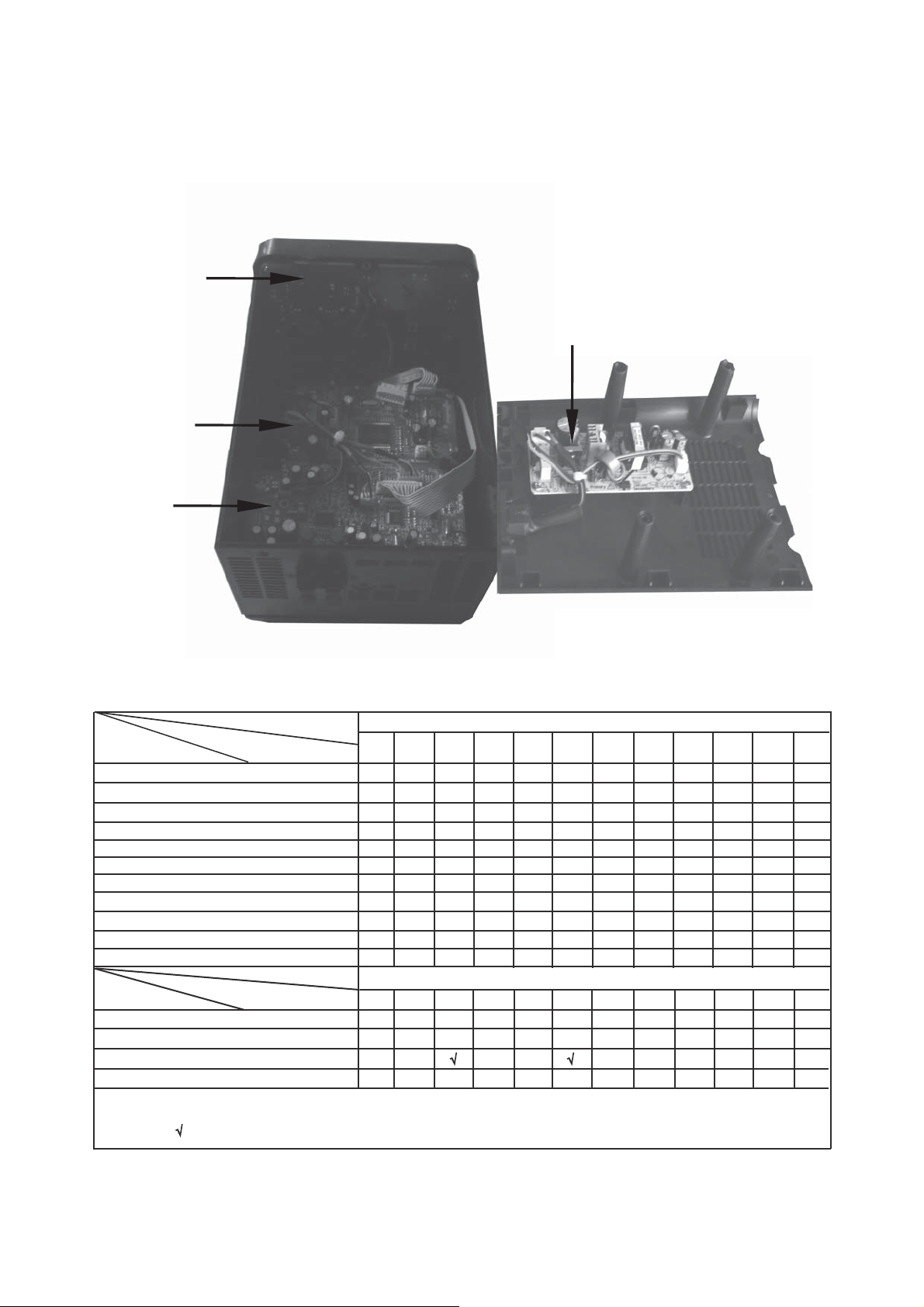

1.Location of PC Boards

Display Board

Decoder Board

AMP Board

Power Board

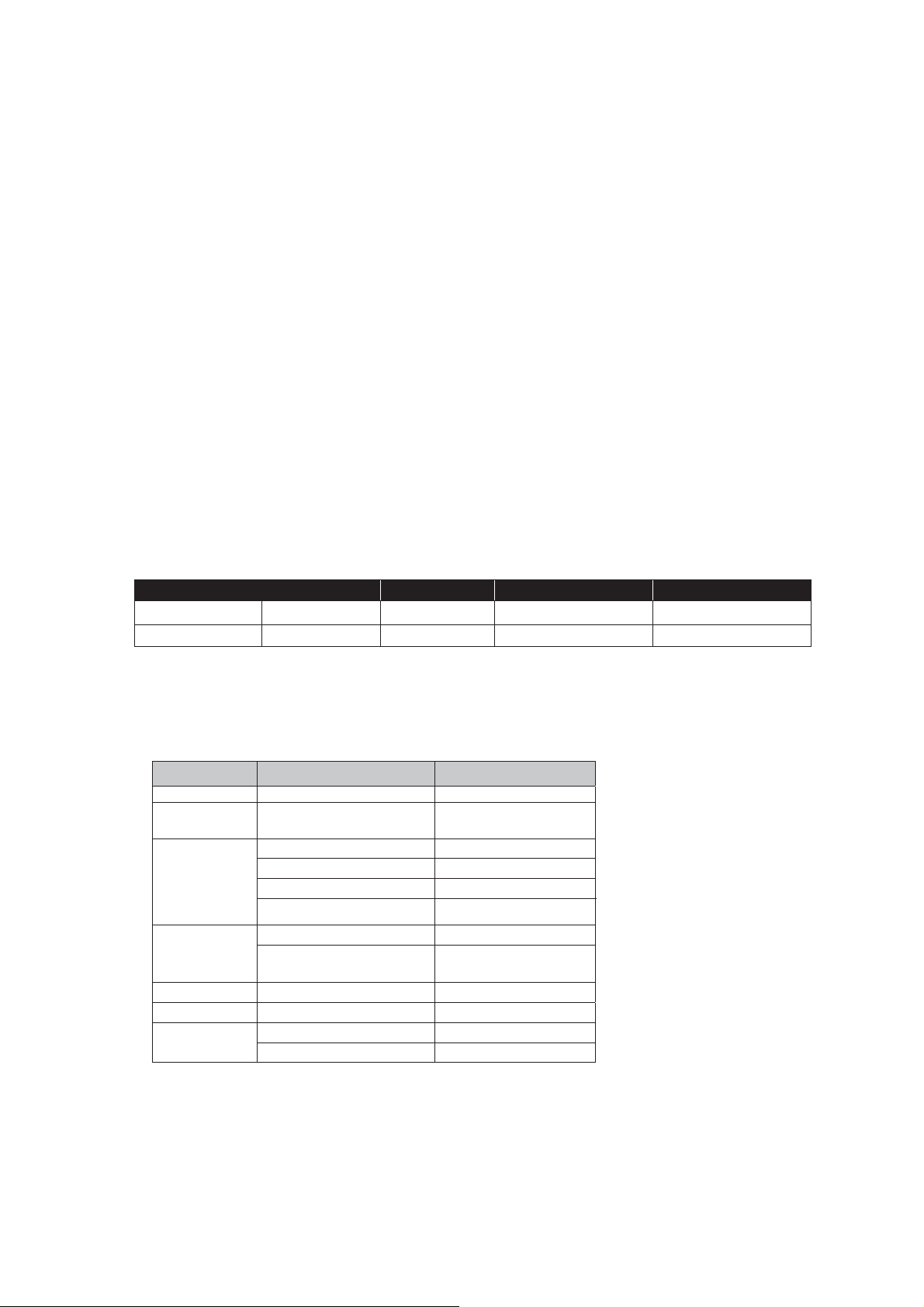

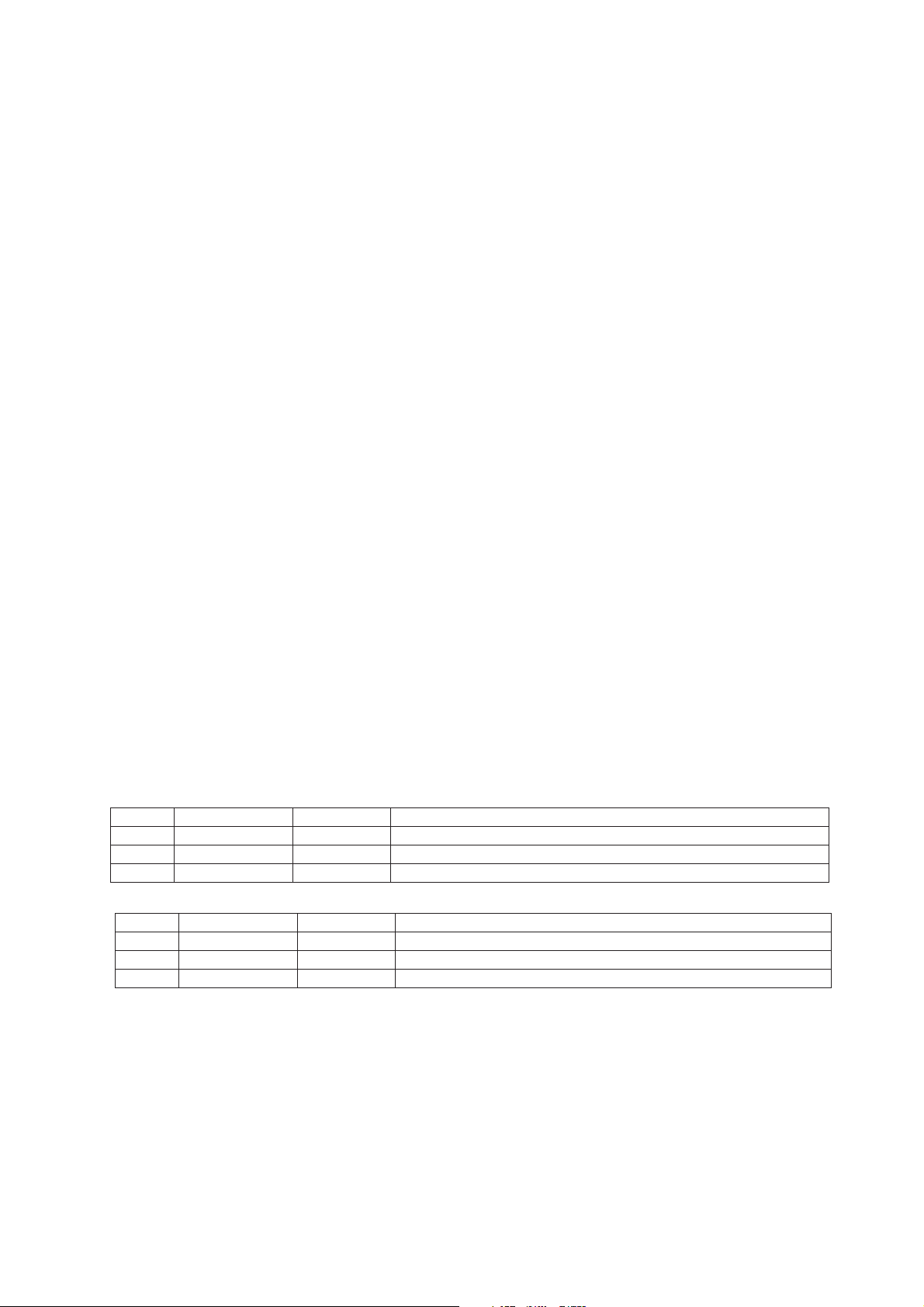

Version Variations

Type /Versions:

Board in used:

AMP Board

Decoder Board

Display Board

Power Board

Features

RDS

VOLTAGE SELECTOR

ECO STANDBY - DARK

DTS

* TIPS : C -- Component Lever Repair.

M -- Module Lever Repair

Service policy

Type /Versions

Feature diffrence

-- Used

/05

/05

MCM1050B

/55

/58

/61

/37

/12/10

CC

MM

CC

MM

/79

MCM1050B

/37

/12/10

/55

/58

/61

/79

/93

/93

/94

/94

/96

/96

/98

/98

1-1

Page 3

Technical Specification and Connection Facilities

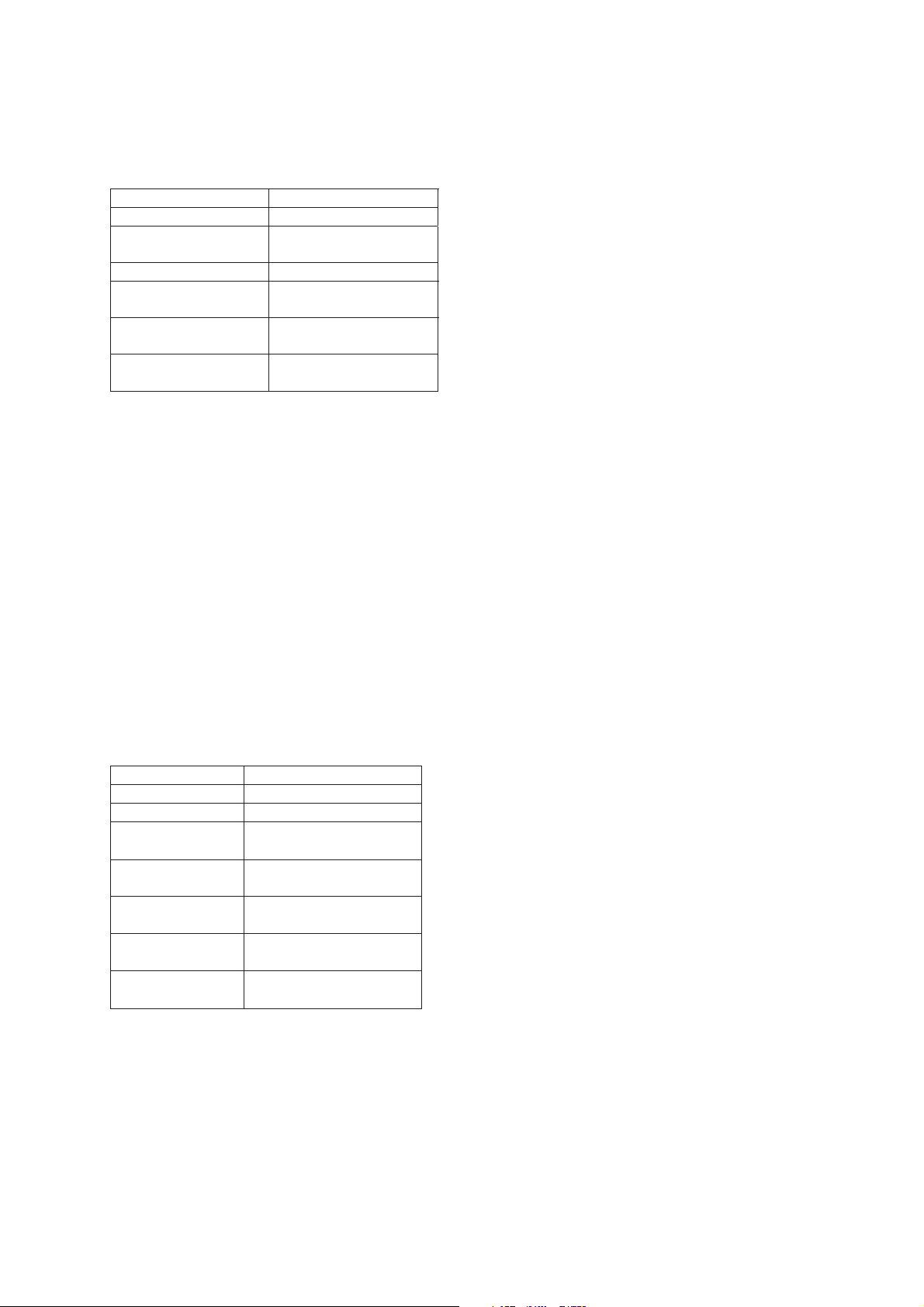

2. General Information and Requirement

2.1 Product Family Features

2.1.1 Identity and Key Features

MCM1050 series are Micro Audio System with CD/MP3 player with USB and Tuner

FM(20presets)

Elements to include as generic requirements:

1. Detachable mains cord

2. Safety certification (cUL/FCC and CB/EMC/CE)

Following is a list of key features:

1. CD /MP3 disc player (Ali-M5673)

2. USB true source

a) MSC/MTP device

b) USB 2.0HS

3. MP3 Link (via headphones jack from PC or MP3 player)

4. Headphone Out (in front of the set)

5. Tuner FM(Silicon Lab SI4705/w RDS)

6. Digital Amplifier (ST class D,TDA7491HV)

7. Rated output power @10%THD table 2

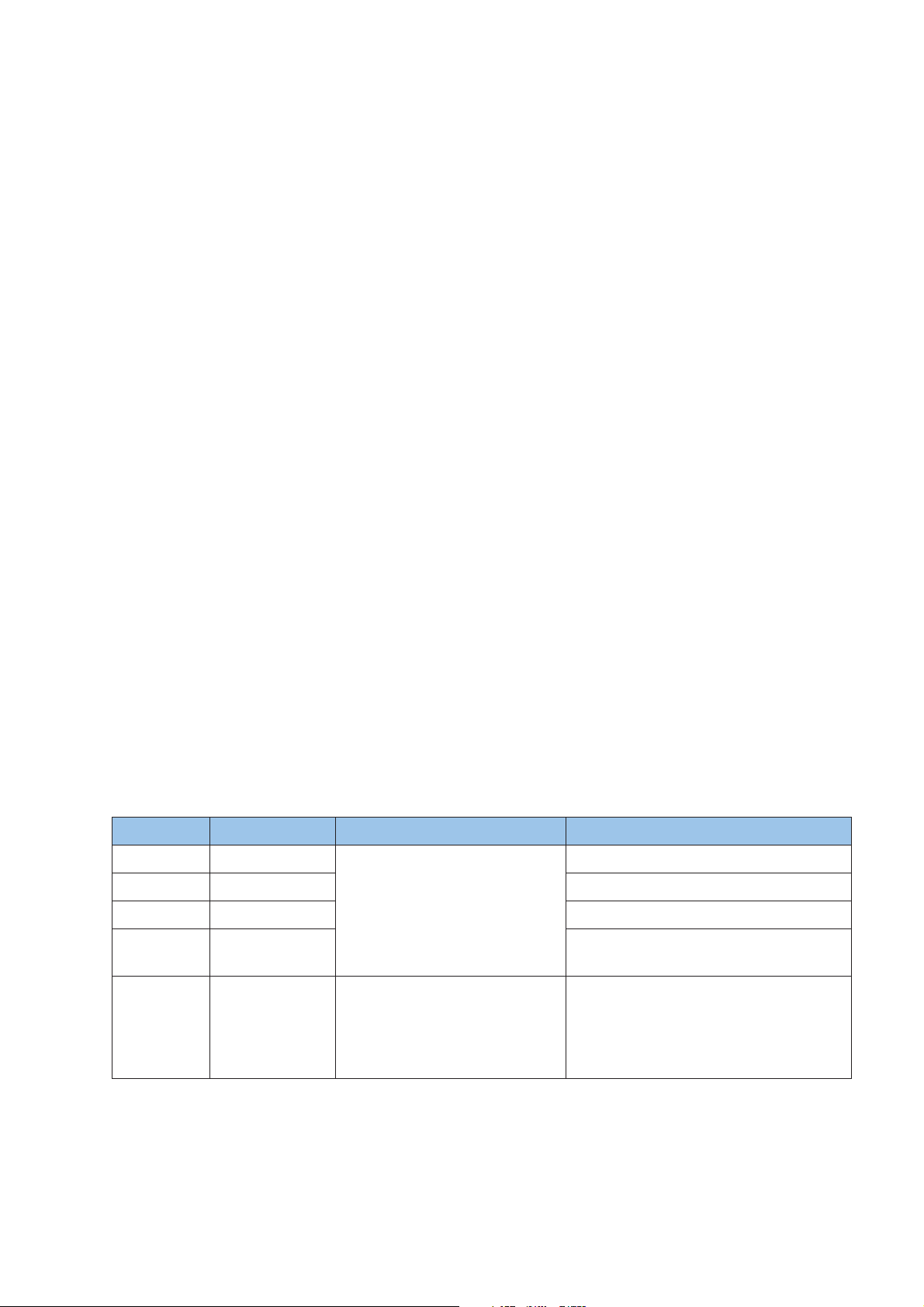

Set Type Number Stroke Versions Power(ROP) Power(Volume max) Remark

MCM1050

All version 2x5W

2x12W

2.1.2 Styling, Forms and Functions

MCM1050 appearances are defined in their respective MUS. MUS is the leading document

where product appearance is applicable..

Features Products MCM1050

Stroke versions

Design

Optical Drive Loading Tray

Front

Dimension

Weight

Cosmetics

Tray Orientation HORIZONTAL

Apparatus tray closed

W x D x H (mm)

Refer to MUS[3] for

140x143x210mm

roloC

snottuB

llA

details

elddiM noitacoL yarT

PU DCL

mm3 teef fo thgieH

gk2.1 tes niaM

gk50.1 rekaeps

Black

Black

1-2

Page 4

Technical Specification and Connection Facilities

2.1.3 External I/O Connections

Model MCM1050

Stroke Version All

iPod dock with

Authentication chip

USB √

MP3 Link

(3.5mm audio jack)

Tuner Socket

(for FM)

Headphone Out

(3.5mm audio jack)

2.1.4 Controls, Local Display and LED Indications(tbc)

Control keys on the set are:

1. Standby-On

2. Eject

3. Play/Pause

4. Next

5. Pre

6. FF

7. FB

8. Source (Disc, USB, Dock, FM, Aux, MP3)

9. Stop

10. Volume Knob

There is local display LCD(reuse). Standby LED colour: Red in Standby mode.

2.1.5 ACCESSORIES (tbc)

Model MCM1055

Stroke Version All Version

eR

Power Cord

Audio cable

(3.5mm audio)

NA

√

√

√

noig

1.5M

0.5M

Remote Control

Quickly guide

IFU

31keys

1

1

1-3

Page 5

Technical Specification and Connection Facilities

2.2 Mechanical General Information

The product appearances and functions are defined in their respective MUS. Product management

approves the MUS and it is a leading document where product appearance is applicable.

Please refer to Sh560 for mechanical information.

Where applicable:

For /12 (EU), /05 (UK), /51 (Russia) EN/IEC 60065 7

For /37 (US, Canada) UL 60065

For /55 (LATAM), /78 (Brazil) IEC 60065 7

For /98 (AP), /69 (Singapore), /75 (Australia) IEC 60065 7

For /93 (China) GB 8898 (IEC 60065 7

For /61 (Korea) K 60065 6

For /96 (Taiwan) CNS 14408 (IEC 60065 7

Where applicable:

For /12 (EU), /05 (UK), /51 (R

For /37 (US, Canada) FCC15

For /55 (LATAM), /78 (Brazil) CISPR13

For /98 (AP), /69 (Singapore), /75 (Australia) CISPR13

For /61 (Korea) CISPR13/20

For /93 (China) GB 13837 (CISPR13)

For /96 (Taiwan) CNS 13439 (CISPR13)

Safety Standards

2.3

2.4

EMC Requirements

th

Edition

th

Edition

th

Edition

th

Edition

th

Edition)

th

Edition)

ussia) EN55013: 2001, EN55020: 2002

ESD Requirements

2.5

The product shall withstand electro static discharges on all user accessible parts of the product.

Reference: IEC61000-4-2.

For contact discharges:

Level General (kV) USA (kV) Requirement

1 0-2 0-3 No deviations allowed.

2 >2-4 >3-4 Short perceptible deviations allowed

3 >7-8 No loss of stored data allowed.

-

For air discharge:

Level General (kV) USA (kV) Requirement

1 0-4 0-6 No deviations allowed.

2 >4-8 >6-8 Short perceptible deviations allowed.

3 - >15-18 No loss of stored data allowed.

1-4

Page 6

Technical Specification and Connection Facilities

General requirement:

1. 10 arcs for positive and negative polarity for unit “on” and “off” for 1kV incremental steps.

2. Component or mechanical damage is not allowed. No loss of fixed stored data (stored in EEPROMs).

3. Hang-ups and malfunctions are allowed, as long as the customer can “recover” from the hang-up by

pressing the Standby or ON/OFF button of the set.

4. Failures that disappear only by unplugging the AC mains cord and/or power sources are not acceptable.

Environmental Condition

2.6

The environmental condition requirements and test method is according to UAN-D1590.

Ambient temperature : max. 40 ° C - all climates

Apparatus acc. to spec. : +5 to + 35 ° C

Vibration test (acc. IEC 60 068/2/6) : operational vibration test to be proceeded in operating position of the

set.

Quality

2.7

PQR-class: class 2 according to BLC A&MA PQR handbook V2.1 (2006-10-02)

Lifetime: 7 years

Tested According to: General Test Instruction UAN-D 1591

Measured According to: UAN_L 1059 unless otherwise stated

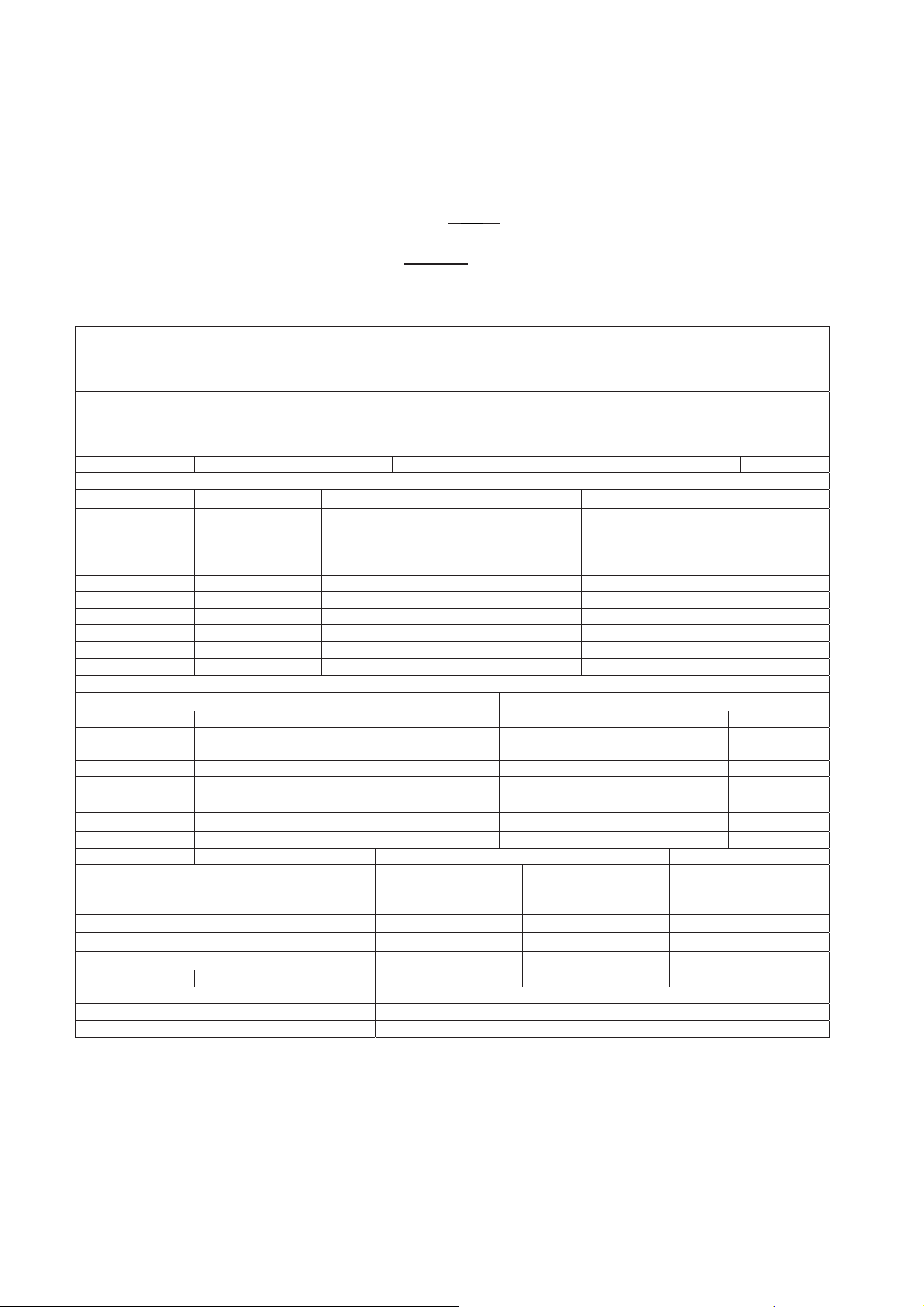

3. Technical Specifications

3.1 Power Supply

3.1.1 Type and versions

Build-inSMPS will be used for all models and stroke versions.

All using built in Power cord, will cater for all versions:

Versions Region/Country SMPS Detachable mains cords

12 / 05 EUROPE / UK

37 NAFTA

94 India

1) 100 ~240Vac nom. (wide

range from 90V~264Vac limit)

used in all versions except

India.

Frequency: 47~63Hz.

2) 100 ~310Vac limit (India

compatible with up cost) used

only for India.

Frequency: 47~63Hz.

EU (/12) round 2-pin & UK (/05) 3-pin

UL flat pin (non-polarized)

nip-2 dnuor UE CAPA 89

EU (/12) round 2-pin

nip-2 dnuor deifitrec ORTEMNI MATAL 55

All requirements per defined for each country should be met with sufficient testing.

1-5

Page 7

Technical Specification and Connection Facilities

3.1.2 Surge Immunity (Lightning Test)

The product shall withstand mains interference’s of:

Differential mode:

2kV/2 ohm criteria C for Europe.

6kV/12 ohm criteria C for NAFTA.

Parameters:

Bi-wave

Open circuit voltage: 2/50us

Short circuit current: 8/20us

From +/1kV to +/-2kV (for Europe) or +/-6kV (for Nafta) in steps of 1kV.

10 shots per combination.

One shot per minute.

Serial impedance: 2 Ohm for Europe, 12Ohm for Nafta.

Polarity and phase: Positive (phase 90º) & Negative (phase 270º)

Common mode:

6kV/2 ohm criteria C for Europe.

6kV/12 ohm criteria C for Nafta.

Parameters:

Ring-wave (100kHz)

From +/3kV to +/-6kV in steps of 1 kV.

10 shots per combination.

One shot per minute.

Serial impedance: 2 Ohm for Europe, 12Ohm for Nafta

Polarity and phase: Positive (phase 90º) & Negative (phase 270º)

Reference: IEC61000-4-5 and for USA: 3135 019 8029 Reliability evaluation.

Requirements:

Apparatus should fulfil the leakage current requirements of IEC60065 point 9.1.1 (UAN-D1631)

Defects or permanent deviations are not allowed.

3.1.3 Mains Drop-out Immunity

The product shall withstand mains failures of:

Variation 0% (=100% dip) at T-event = 50 mSec. Performance criterion B

Variation 40% (=60% dip) at T-event = 100 mSec. Performance criterion B

Variation 0% (=100% dip) at T-event = 5 Sec. Performance criterion C

Additional for USA apparatus: See 3135 019 8029 Reliability evaluation.

Variation 0% (=100% dip) at T-event = 100 mSec in standby mode. Performance criterion B

Requirement:

No misoperation and no interference of user in order to guarantee continuation of performed function.

Reference: IEC61000-4-11 For measuring method refer to UAN-D1724, as far as applicable.

Performance criterions according to IEC61000-4-4 Amendment 1

Performance Requirement

Criterion A - No any degradation of specification.

Criterion B - Temporary degradation / self recoverable.

Criterion C - No damage, resolvable hang-up.

Criterion D - Not recoverable loss of function.

1-6

Page 8

Technical Specification and Connection Facilities

x

3.1.4 Power Consumption

Power consumption at nominal AC input:

1. CD play mode at 1/8 P-rated output power

MCM1050: İ 20

W

2. Low Power Standby Mode : İ 0.5

W

3.2 Technical Description

traP larenreG

Output Stage Protection: NA Temperature : Yes Short Circuit: Yes

srotacidnI

evitcA yalpsiD kcolC :rotacidnI edoM ybdnatS

ffO snruT DEL :edoM ybdnatS rewoP

Electrical Data

DSC: Y(Flat/POP/JAZZ

/ROCK/CLASSIC)

DBB: Y(ON/OFF) Hum (Vol

Bass: NA -

Treble: NA Channel Seperation: 1kHz/10kHz 40dB/35dB

Signal to Noise Ratio(A-weighted): 77dBA 72dBA

Audio Inputputs

Audio Input Sensitivity(± 3dB) rated output power at 1kHz

Tuner FM 67.5kHz, Modulation (Limit:-6dB) Line Out(Left/Right) NA

MP3_link(front)

Output

Power(*1)

Main Operation for / all version (rms)

Tuner output power(rms)

Frequency Response(± 3dB)

Loudspeaker(Boxes): Separable speaker box Refer to package document of Speaker Box Assy

Speaker driver Impedance: Right/Left: 4Ω @ 40 Hz ~ 20kHz(-3db)

500mV ---- 1000mV; Rin ≥ 22kΩ

At THD=10%, 1kHz

sinewave

Channel Difference:

--- Vol

min

Amplification Reserve 3dB 2dB

MCM1050

(ROP,10%)

5W± 1dB

5W± 1dB

60Hz-20kHz

:refoowbuS

-20dB) 150nW -

ma

Audio Output(*1)

MCM1050

(Max Power,30%)

2X12W -1dB

NA

Normal

± 3dB

Limit

-

%0.1 %8.0 lamixaM,DHT AN :ssenduoL

Bd55 Bd06 :klatsorC

2 ± Wm51 enohpdaeH )1 kcarT ,1 csiD oiduA( kcart Bd3- 3PM/DC

dB, RL = 16Ω

)SH0.2 (evawenis zHK1 Bd3- BSU

REMARKS:

Electrical Parameters are to be measured at Speaker Terminals across rated impedance Load(4ohm) with

Rated Input Signal in CD Mode setting in DBB/Loudness Off and Pre-eq at Flat unless specified otherwise.

*--- measure max volume power with 1V MP3-link input

1-7

Page 9

Technical Specification and Connection Facilities

3.3 TUNER

FM use Silicon Lab Si4704/4705(w/RDS)

GENARAL PART

WAVE RANGE VERSION TOLERANCE TUNING GRID

FM 87.5 – 108.00 MHz /12 QUARTZ PRECISION 50kHz

FM 87.5 – 108.00 MHz /37 QUARTZ PRECISION 100kHz

AERIAL

FM : PIG TAIL ANT WIRE 75Ω

ELECTRICAL DATA

Frequency (MHz)

Units dBf DB dB mV/m dB

Susceptibility to unwanted signals(CPU,SMPS,AMP,DSP …):

Noise Limited

Sensitivity 26 dB

Search time digital tuning

system.

Overall Frequency Response: 63Hz –

12.5KHz

Channel separation:400 / 1000 / 5000 Hz.

RF input: 68 dBf

Image

Rejection

Limited(d

B)

-15dB -20dB Refer to selfpollution curve

IF Rejection

Normal

(dB)

Large Signal

Handling

fBd 62 02 tnioP gnitimiL Bd 3 -

14 53 )edom oerets ta(ytivitisneS gninuT hcraeS

- 60 S

Bd 15 84 gniteiuQ Bd 64 - oeretS

54 05 muH noitaludoM

54 05 oitaR N/S

Bd 4- 0 esreveR noitacifilpmA

% 3 2 ) zHk 57.veD qrF ,Vm1 FR ( noitrotsiD

- ±3 dB

26/30/

20

S9/300 kHz

Remark

Selectivity

22 0001 46 03 81.moN MF

22 0001 46 03 81.moN MF

54 fBd 611 06 03 81.moN MF

52 fBd 801 56 52 22.miL 0.701

20/26/

18

)1*( 81 005 54 52 22.miL 0.88

)1*( 81 005 54 52 22.miL 0.89

dB

tinU timiL moN MF

zHM 7.01 FI

1-8

Page 10

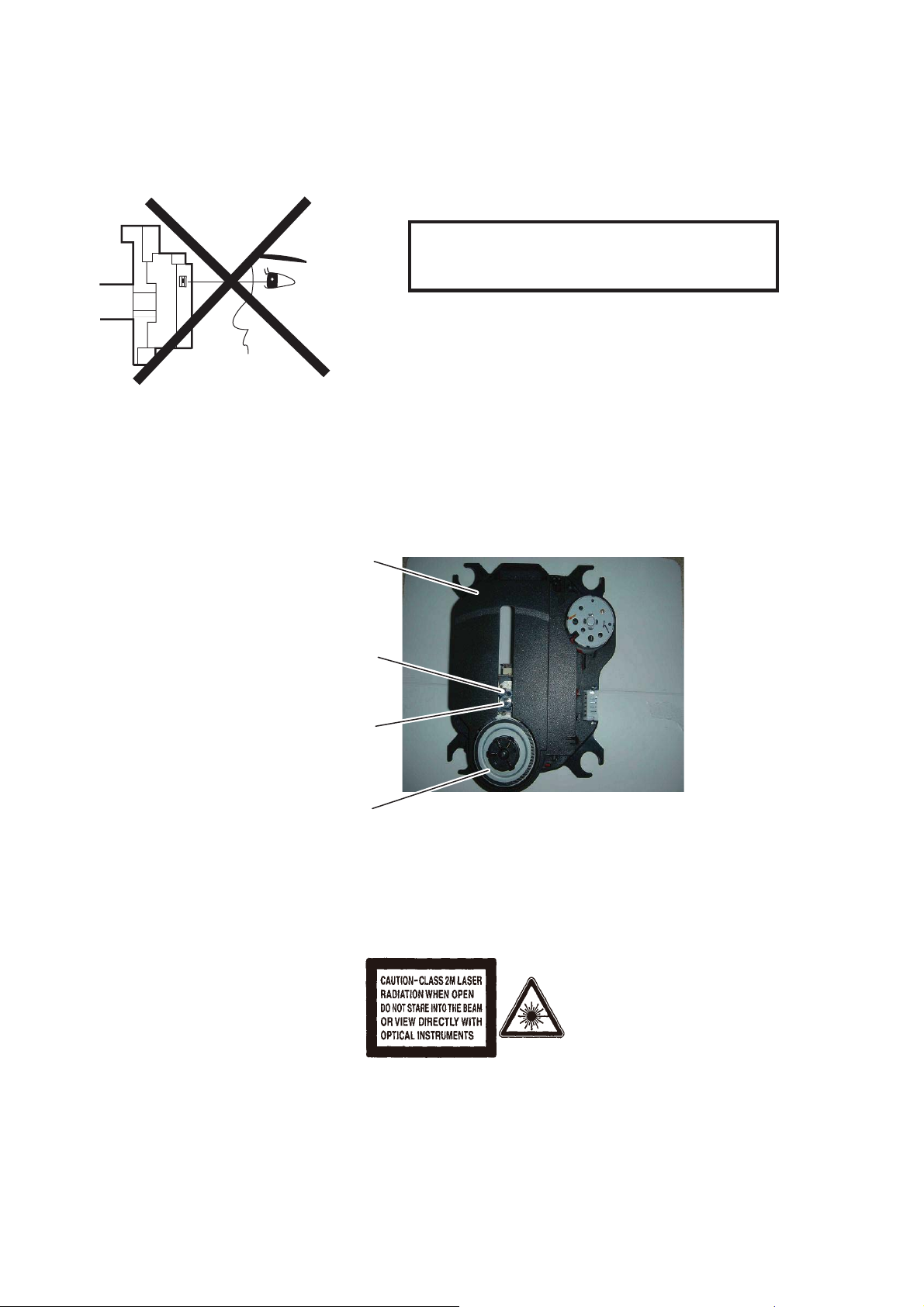

Laser Beam Safety Precautions

This Blu-Ray player uses a pickup that emits a laser beam.

Do not look directly at the laser beam coming

from the pickup or allow it to strike against your

skin.

The laser beam is emitted from the location shown in the figure. When checking the laser diode, be sure to keep

your eyes at least 30 cm away from the pickup lens when the diode is turned on. Do not look directly at the laser

beam.

CAUTION: Use of controls and adjustments, or doing procedures other than those specified herein, may result in

hazardous radiation exposure.

Drive Mechanism Assembly

Laser Beam Radiation

Laser Pickup

Turntable

Location: Inside Top of Blu-Ray mechanism.

2-1

Page 11

Important Safety Precautions

Caution: These servicing instructions are for use by qualified service personnel only.To reduce the risk

of electric shock do not perform any servicing other than that contained in the operating

instructions unless you are qualified to do so.

Important

Read and understand all instructions before you use

your home theater. If damage is caused by failure to

follow instructions, the warranty does not apply.

Safety

Riskof electricshock or fire!

Neverexposetheproductand

accessories to rain or water. Never place

liquid containers, such as vases, near the

product. If liquids are spilt on or into the

product, disconnect it from the power

outlet immediately. Contact Philips

Consumer Care to have the product

checked before use.

Never place the product and accessories

near naked

including direct sunlight.

Never insert objects into the ventilation

slots

or other openings on the product.

Where the mains plug or an appliance

coupler is used as the disconnect device,

the disconnect device shall remain readily

operable.

Disconnect the product from the power

outlet before lightning storms.

When you disconnect the power cord,

always pull the plug, never the cable.

Riskof short circuit or

Before you connect the product to the

poweroutlet,ensurethatthepower

voltage matches the value printed on the

back or bottom of the product. Never

connec

if the voltage is different.

Risk of injury or damage to the home theater!

For wall-mountable products, use only

the supplied wall mount bracket. Secure

the wall mount to a wall that can support

the combined weight of the product

and the wall mount. Koninklijke Philips

Electronics N.V. bears no responsibility

for improper wall mounting that results in

accident, injury or damage.

ames or other heat sources,

re!

ttheproducttothepoweroutlet

For speakers with stands, use only the

supplied stands. Secure the stands to

the speakers tightly. Place the assembled

stands on flat, level surfaces that can

support the combined weight of the

speaker and stand.

Never place the product or any objects

on power cords or on other electrical

equipment.

If the product is transported in

temperatures below 5°C, unpack the

product and wait u

matches room temperature before

connecting it to the power outlet.

Visible and invisible laser rad

open. Avoid exposure to beam.

Do not touch the disc optical lens inside

the disc compartment.

Risk of overheating!

Never install this product in a confined

space. Always leave a space of at least

four inches around the product for

ventilation. Ensure curtains or other

objects never cover the ventilation slots

on the product.

Risk of contamination!

Do not mix batteries (old and new or

carbon and alkaline,

Remove batteries if they are exhausted

or if the remote control is not to be used

for a long time.

Batteries contain chemical substances,

they should be disposed of properly.

ntil its temperature

iation when

etc.).

Product care

Do not insert any objects other than discs

into the disc compartment.

Do not insert warped or cracked discs

into the disc compartment.

Remove discs from the disc compartment

ifyouarenotusingtheproductforan

extended period of time.

Only use microfiber cloth to clean the

product.

3-1

Page 12

Important Safety Precautions

Disposal of your old product and

batteries

Your product is designed and manufactured

with high quality materials and components,

which can be recycled and reused.

When this crossed-out wheeled bin symbol

is attached to a product it means that the

product is covered by the European Directive

2002/96/EC.Pleaseinformyourselfaboutthe

local separate collection system for electrical

and electronic products.

Please act according to your local rules and

do not dispose of your old products with your

normal household waste.

Corr

ect disposal of your old product helps to

prevent potential negative consequences for

the environment and human hea

lth.

Your product contains batteries covered by

the European Directive 2006/66/EC, which

cannot be disposed with normal household

waste.

Please inform yourself about the local rules

on separate collection of batteries because

correct disposal helps to prevent negative

consequences for the environmental and

human health.

3-2

Page 13

Safety Check after Servicing

Examine the area surrounding the repaired location for damage or deterioration. Observe that screws, parts, and

wires have been returned to their original positions. Afterwards, do the following tests and confirm the specified

values to verify compliance with safety standards.

1. Clearance Distance

When replacing primary circuit components, confirm

specified clearance distance (d) and (d’) between

soldered terminals, and between term

surrounding metallic parts. (See Fig. 1)

Table 1: Ratings for selected area

inals and

Chassis or Secondary Conductor

Primary Circuit

AC Line Voltage Clearance Distance (d), (d

110V~220V

Note

: This table is unofficial and for reference only. Be

sure to confirm the precise values.

3.2 mm (0.126 inches)

’)

2. Leakage Current Test

Confirm the specified (or lower) leakage current

between B (earth ground, power cord plug prongs) and

externally exposed accessible parts (RF terminals,

antenna terminals, video and audio input and output

terminals, microphone jacks, earphone jacks, etc.) is

than or equal to the specified value in the table

lower

below.

Measuring Method (Power ON):

Insert load Z between B (earth ground, power cord plug

prongs) and exposed accessible parts. Use an AC

eter to measure across the terminals of load Z.

voltm

See Fig. 2 and the following table.

d' d

Fig. 1

Exposed Accessible Part

Z

AC Voltmeter

(High Impedance)

Earth Ground

B

Power Cord Plug Prongs

Table 2: Leakage current ratings for selected areas

AC Line Voltage Load Z Leakage Current (i) Earth Ground (B) to:

110V~220V

Note: This table is unofficial and for reference only. Be sure to confirm the precise values.

0.15 µF CAP. & 1.5 k

Connected in parallel

RES.

i

0.5 mA Peak Exposed accessible parts

4-1

Fig. 2

Page 14

Safety Information, General Notes & Lead Free Requirements

1 Safety Instructions

1.1 General Safety

Safety regulations require that during a repair:

Connect the unit to the mains via an isolation transformer.

Replace safety components, indicated by the symbol

only by components identical to the original ones. Any

other component substitution (other than original type)

Safety regulations require that after a repair, you must return

the unit in its original condition. Pay, in particular, attention to

the following points:

Route the wires/cables correctly

mounted cable clamps.

damage.

Check the electrical DC resistance between the mains

plug and the secondary side:

1. Unplug the mains cord, and connect a wire between

the two pins of the mains plug.

2. Set the mains switch to the ‘on’ position (keep the

mains cord unplugged!).

3. Measure the resistance value between the mains

plug and the front panel, controls, and chassis

bottom.

4. Repair or correct unit when the resistance

5. Verify this, before you return the unit to the customer/

user (ref. UL-standard no. 1492).

6. Switch the unit ‘off’, and remove the wire between the

two pins of the mains plug.

1.2 Laser Safety

This unit employs a laser

may remove the cover, or attempt to service this device (due

to possible eye injury).

2 Warnings

2.1 General

All ICs and many other semiconductors are susceptible to

,

during repair can reduce life drastically. Make sure that,

during repair, you are at the same potential as the mass

of the set by a wristband with resistance. Keep

components and tools at this same potential.

Available ESD protection equipment:

– Complete kit ESD3 (small tablemat, wristband,

4822 310 10671.

– Wristband tester 4822 344 13999.

Be careful during measurements in the live voltage

section. The primary side of the power supply, including

the heatsink, carries live mains voltage when you

connect the player to the mains (even when the

player is ‘off’!). It is possible to touch copper tracks and/

or components in this unshielded primary area, when

you service the player. Service personnel must take

precautions to prevent touching this area or components

in this area. A ‘lightning stroke’ and a stripe-marked

printing on the printed wiring board, indicate the primary

side of the power supply.

Never replace modules, or components, while the unit is

‘on’.

2.2 Laser

The use of optical instruments with this product, will

Only quali ed service personnel may remove the cover or

attempt to service this device, due to possible eye injury.

Repair handling should take place as much as possible

with a disc loaded inside the player.

T

shield:

electrostatic discharges (ESD,

). Careless handling

Laser Device Unit

epyT

:AIGalnN(BD)

:AIGalnP(DVD)

: AIGalnP(CD)

Wavelength : 650 nm (DVD)

)DC/DCV(mn087:

405nm(BD):

Output Power : 20 mW

)gnitirwWR+DVD(

Wm8.0:

)gnidaerDVD(

Wm3.0:

)gnidaerDC/DCV(

Beam divergence : 60 degree

CLASS 1

LASER PRODUCT

1-2erugiF

Note: Use of controls or adjustments or performance of

procedure other than those speci

ed herein, may result in

A

CAUTION VISIBLE AND INVISIBLE LASER RADIATION WHEN OPENAVOID EXPOSURE TO BEAM

ADVARSEL SYNLIG OG USYNLIG LASERSTRÅLING VED ÅBNING UNDGÅ UDSÆTTELSE FOR STRÅLING

ADVARSEL SYNLIG OG USYNLIG LASERSTRÅLING NÅR DEKSEL ÅPNES UNNGÅ EKSPONERING FOR STRÅLEN

VARNING SYNLIG OCH OSYNLIG LASERSTRÅLNING NÄR DENNA DEL ÄR ÖPPNAD BETRAKTA EJ STRÅLEN

VARO!AVATTAESSA OLET ALTTIINA NÄKYVÄLLE JA NÄKYMÄTTÖMÄLLE LASER SÄTEILYLLE. ÄLÄ KATSO SÄTEESEEN

VORSICHT SICHTBARE UND UNSICHTBARE LASERSTRAHLUNG WENNABDECKUNG GEÖFFNET NICHT DEM STRAHL AUSSETSEN

DANGER VISIBLE AND INVISIBLE LASER RADIATION WHEN OPENAVOID DIRECT EXPOSURE TO BEAM

ATTENTION RAYONNEMENT LASER VISIBLE ET INVISIBLE EN CAS D’OUVERTURE EXPOSITION DANGEREUSE AU FAISCEAU

Figure 2-2

5-1

Page 15

Standard Notes for Servicing, Lead Free Requirements & Handling Flat Pack IC

Circuit Board Indications

1. The output pin of the 3 pin Regulator ICs is

indicated as shown.

Top View

Out

2. For other ICs, pin 1 and every fifth pin are

indicated as shown.

Pin 1

3. The 1st pin of every male connector is indicated as

shown.

Pin 1

Input

In

Bottom View

5

10

Instructions for Connectors

1. When you connect or disconnect the FFC (Flexible

Foil Connector) cable, be sure to first disconnect

the AC cord.

2. FFC (Flexible Foil Connector) cable should be

inserted parallel into the connector, not at an

angle.

FFC Cable

Connector

CBA

* Be careful to avoid a short circuit.

Pb (Lead) Free Solder

When soldering, be sure to use the Pb free solder.

Information about lead-free soldering

Philips CE is producing lead-free sets from 1.1.2005

onwards.

IDENTIFICATION

Regardless of special logo (not always

indicated)

One must treat all sets from

onwards, according to the next rule:

Serial Number gives a 14-digit. Digit 5&6 shows the

YEAR, and digit 7&8 shows the WEEK.

So from onwards=from 1 Jan 2005 onwards

0501

Important note : In fact also products of year 2004

must be treated in this way as long as you avoid

mixing solder-alloys (leaded/ lead-free). So best to

always use SAC305 and the higher temperatures

belong to this.

Due to lead-free technology some rules have to be

respected by the workshop during a repair:

Use only lead-free solder alloy Philips SAC305 with

order code 0622 149 00106. If lead-free solderpaste is required, please contact the manufacturer

of your sol

paste within workshops should be avoided because

paste is not easy to store and to handle.

Use only adequate solder tools applicable for lead-

free solder alloy. The solder tool must be able

To reach at least a solder-temperature of 400°C,

To stabilize the adjusted temperature at the solder-

tip

To exchange solder-tips for different applications.

Adjust your solder tool so that a temperature around

360°C

solder joint. Heating-time of the solder-joint should

not exceed ~ 4 sec. Avoid temperatures above

400°C otherwise wear-out of tips will rise drastically

and flux-fluid will be destroyed. To avoid wear-out of

tips switch off un-used equipment, or reduce heat.

Mix of lead-free solder alloy / parts with leaded

solder alloy / parts is possible but PHILIPS

recommends strongly to avoid mixed solder alloy

types (leaded

If one cannot avoid or does not know whether

product is lead-free, clean carefully the solder-joint

from old solder alloy and re-solder with new solder

alloy (SAC305).

Use only original spare-parts listed in the ServiceManuals. Not listed standard-material (commodities)

has to be purchased at external companies.

der-equipment. In general use of solder-

- 380°C is reached and stabilized at the

and lead-free).

1 Jan 2005

6-1

Page 16

Standard Notes for Servicing, Lead Free Requirements & Handling Flat Pack IC

Special information for BGA-ICs:

- always use the 12nc-recognizable soldering

temperature profile of the specific BGA (for desoldering always use the lead-free temperature

profile, in case of doubt)

- lead free BGA-ICs will be delivered in so-called

'dry-packaging' (sealed pack including a silica gel

pack) to protect the IC against moisture. After

opening, dependent of MSL-level seen on indicatorlabel in the bag, the BGA-IC possibly still has to be

baked dry. (MSL=Moisture Sensit

will be communicated via AYS-website.

Donotre-useBGAsatall.

For sets produced before 1.1.2005 (except products

of 2004), containing leaded solder-alloy and

components, all needed spare-parts will be available

till the end of the service-period. For repair of such

sets nothing changes.

On our website

www.atyourservice.ce.Philips.com

information to:

BGA-de-/soldering (+ baking instructions)

Heating-profiles of BGAs and other ICs used in

Philips-sets

You will find this and more technical information within

the “magazine”, chapter “workshop news”.

For additional questions please contact your local

repair-helpdesk.

ivity Level). This

you find more

How to Remove / Install Flat Pack-IC

1. Removal

With Hot-Air Flat Pack-IC Desoldering Machine:

1. Prepare the hot-air flat pack-IC desoldering

machine, then apply hot air to the Flat Pack-IC

(about 5 to 6 seconds). (Fig. S-1-1)

Fig. S-1-1

2. Remove the flat pack-IC with tweezers while

applying the hot air.

3. Bottom of the flat pack-IC is fixed with glue to the

CBA; when removing entire flat pack-IC, first

soldering iron to center of the flat pack-IC and heat

up. Then remove (glue will be melted). (Fig. S-1-6)

4. Release the flat pack-IC from the CBA using

tweezers. (Fig. S-1-6)

apply

CAUTION:

1. The Flat Pack-IC shape may differ by models. Use

an appr

machine, whose shape matches that of the Flat

Pack-IC.

2. Do not supply hot air to the chip parts around the

flat pack-IC for over 6 seconds because damage

to the chip parts may occur. Put masking tape

around the flat pack-IC to protect other parts from

damage. (Fig. S-1-2)

opriate hot-air flat pack-IC desoldering

6-2

Page 17

Standard Notes for Servicing, Lead Free Requirements & Handling Flat Pack IC

3. The flat pack-IC on the CBA is affixed with glue, so

be careful not to break or damage the foil of each

pin or the solder lands under the IC when

removing it.

Hot-air

Flat Pack-IC

Desoldering

CBA

Masking

Tape

Machine

Flat Pack-IC

Tweezers

Fig. S-1-2

With Soldering Iron:

1. Using desoldering braid, remove the solder from

all pins of the flat pack-IC. When you use solder

flux which is applied to all pins of the flat pack-IC,

you can remove it easily. (Fig. S-1-3)

Flat Pack-IC

Desoldering Braid

4. Release the flat pack-IC from the CBA using

tweezers. (Fig. S-1-6)

With Iron Wire:

1. Using desoldering braid, remove

all pins of the flat pack-IC. When you use solder

flux which is applied to all pins of the flat pack-IC,

you can remove it easily. (Fig. S-1-3)

2. Affix the wire to a workbench or solid mounting

point, as shown in Fig. S-1-5.

3. While heating the pins using a fi

iron or hot air blower, pull up the wire as the solder

melts so as to lift the IC leads from the CBA

contact pads as shown in Fig. S-1-5.

4. Bottom of the

CBA; when removing entire flat pack-IC, first apply

soldering iron to center of the flat pack-IC and heat

up. Then remove (glue will be melted). (Fig. S-1-6)

5. Release the flat pack-IC from the CBA using

tweezers. (Fig. S-1-6)

Note: When using a soldering iron, care must be

taken to

being held by glue. When the flat pack-IC is

removed from the CBA, handle it

because it may be dama

flat pack-IC is fixed with glue to the

ensure that the flat pack-IC is not

the solder from

ne tip soldering

gently

ged if force is applied.

Hot Air Blower

Soldering Iron

Fig. S-1-3

2. Lift each lead of the flat pack-IC upward one by

one, using a sharp pin or wire to whic

not adhere (iron wire). When heating the pins, use

a fine tip soldering iron or a hot air de

machine. (Fig. S-1-4)

h solder will

soldering

Sharp

Pin

Fine Tip

Soldering Iron

3. Bottom of the flat pa

CBA; when removing entire flat pack-IC, first apply

soldering iron to center of the flat pack-IC and heat

up. Then remove (glue will be melted). (Fig. S-1-6)

ck-IC is fixed with glue to the

Fig. S-1-4

6-3

To Solid

Mounting Point

CBA

Tweezers

or

Iron Wire

Soldering Iron

Fig. S-1-5

Fine Tip

Soldering Iron

Flat Pack-IC

Fig. S-1-6

Page 18

Standard Notes for Servicing, Lead Free Requirements & Handling Flat Pack IC

2. Installation

1. Using desoldering braid, remove the solder from

the foil of each pin of the flat pack-IC on the CBA

so you can install a replacement flat pack-IC more

easily.

2. The “

(See Fig. S-1-7.) Be sure this mark matches the 1

on the PCB when positioning for installation. Then

presolder the four corners of the flat pack-IC. (See

Fig. S-1-8.)

3. Solder all pins of the flat pack-IC. Be sure that

none of the pins have solder bridges.

” mark on the flat pack-IC indicates pin 1.

Example :

Pin 1 of the Flat Pack-IC

is indicated by a " " mark.

Fig. S-1-7

Instructions for Handling Semiconductors

Electrostatic breakdown of the semi-conductors may

occur due to a potential difference caused by

electrostatic charge during unpacking or repair work.

1. Ground for Human Body

Be sure to wear a grounding band (1 M ) that is

properly grounded to remove any static electricity that

may be charged on the body.

2. Ground for Workbench

Be sure to place a conductive sheet or copper plate

with proper grounding (1 M

other surface, where the semi-conductors are to be

placed. Because the static electricity charge on

clothing will not escape through the body grounding

band, be

with your clothing.

careful to avoid contacting semi-conductors

<Incorrect>

) on the workbench or

CBA

Presolder

Flat Pack-IC

Fig. S-1-8

<Correct>

1M

CBA

Grounding Band

1M

CBA

Conductive Sheet or

Copper Plate

6-4

Page 19

FLOW CHART NO.1

No sound from whole unit

Troubleshooting

check if speaker is ok

check and change speaker and output wire

Yes

No

check if public circuit of whole unit

AMP circuit is ok

No

check radio tube and periphery circuit

Yes

check if power supply circuit of whole

unit is ok

No

check and change transormer of power supply and

power commutate circuit

Yes

check staic noisy circuit CPU circuit and change components

FLOW CHART NO.2

no sound from radio

check if output of radio is normal

No

check public circuit and circuit of power supply

Yes

No

check radio controlled circuit

check and change the related components of radio controlled circuit

Yes

check if power supply of radio is

normal

Yes

check if radio circuit an components

of around it is normal

FLOW CHART NO.3

no sound from CD

check if CD output is normal

No

Yes

check if CD controlled circuit is ok

Yes

check if the related components of CD

signal channel

tie wires socket is normal

No

check and change related components of power supply circuit

No

check and change components of around it

check public circuit

components

No

check and change the related components of CD

controlled circuit

check and change the related components of CD

No

tie wires

power supply circuit and change related

socket

Yes

change decoding board

9-1

Page 20

no search from CD

check if supply +12V of decoding board is normal

Yes

Troubleshooting

No

check steady circuit

check if laser head ass'y can light normally

No

check if tie wires of laser head ass'y

is loosen and broken

No

laser head ass'y broken

Yes

Yes

decoding board is broken

check and change good laser head ass'y

9-2

Page 21

MP3_Link

HP_OUT

MP3_LR_IN

5.6V

HEADSET DRIVER

PT2309

FL_OUT

TDA7491P

AMPLIFIER

STB/MUTE

FR_OUT

8OHM_5W*2

A3.3V

OPEN/CLOSEDRIVER

FM_LR_IN

DVD/CD_RL

D-/D+

IIC

MCU3.3V

9V

M3.3V

EEPROM

MCU

LCD BUS

Stb,clk data

BD3490FS

M3.3V

M24C02

CP2.0B

Apple Ceriticiate

R5F21266

IR

AD_KEY

STB/MUTE

TX/RX/CTL/DET

MCU3.3V

9V_BD3491/3490

VUSB_ON

DVD_ON

CD_5.6V

AMP JDA7491HV

9435

AP1501

DC/DC

12V/18V

CD/DVD_ON

GND

M3.3V

1117

5.6V

ECO

IGND

7333

LDO

I5V/3.3V

IPOD/IPHONE_5V

9.1V

ECO

10-1 10-1

M3.3V

si4705

FM(RDS)

A3.3V

FLASH

MX25L1605D

A3.3V

ALi5673

MAIN CHIPSET

CD_5.6V

RF

CD_5.6V

LOADER MOTOR DRIVER

AM5766

CD_5.6V

M3.3V

IR

Block Diagram

AS6622Q

LCD Controller

DA11

USB

WXD-8210D

(host 2.0)

LCD DISPLAY SCREEN

TRANSFORMER

AC220V

PSU BOARD

Page 22

CON4

AC220V

CON2

CON1

Power Board

PJ2

CON3

CON3

Decoder Board

J1

J3

CN1

J1

CON1

JP4

CON2

CON1

Display Board

Wiring Diagram

J7

PJ3

J6

AMP Board

J4

J2

CD Loader driver(machanism)

11-1 11-1

Page 23

Q1

8050

LED1

10K

470

22uF/10V

R20

3.3V

47R

R18

C8

100P

EC1

VCC

1

47uF/6.3V

GND

2

IR

REM

3

R14

10R

IR

SEG10

SEG09

SEG08

SEG07

SEG06

SEG05

SEG04

33

1

COM1

2

COM2

3

COM3

4

COM4

5

COM5

6

COM6

7

COM7

8

COM8

9

SEG1

10

SEG2

11

SEG3

12

SEG4

13

SEG5

14

SEG6

15

SEG7

16

SEG8

17

SEG9

LCD1

18

SEG10

19

SEG11

20

SEG12

21

SEG13

22

SEG14

23

SEG15

24

SEG16

25

SEG17

26

SEG18

27

SEG19

28

SEG20

29

SEG21

30

SEG22

31

SEG23

32

SEG24

COM00

COM01

COM02

COM03

COM04

COM05

COM06

COM07

COM[00:07]

SEG00

SEG01

SEG02

SEG03

SEG04

SEG05

SEG06

SEG07

SEG23

SEG22

SEG21

SEG20

SEG19

SEG18

SEG17

SEG16

SEG15

SEG14

SEG13

SEG12

SEG11

SEG10

SEG09

SEG08

SEG03

SEG02

SEG01

SEG00

SEG[00:23]

J8

R19

R31

47K

3.3V

SEG11

SEG12

SEG16

SEG13

SEG15

SEG14

13

12

SG11

SG16

SG15

SG14

SG13

SG12

11

SG10

10

SG9

9

SG8

8

SG7

7

SG6

6

SG5

5

SG4

4

SG3

3

SG2

2

SG1

1

DI

100R

R21

J3

J2

DATA

SG17

U1

OSC

VDDCECLK

VSS

R27

560R

100R

100R

102

R4

R3

J4

R29

J5

100P

100P

J1

CS

WR

EC4

10R

100uF/10V

R28

A5V

SEG19

SEG17

SEG18

SEG20

21

19

1817161514

20

SG21

SG19

SG18

SG20

I-PT6533

COM1

VLCD

COM2

COM3

COM01

COM02

COM00

C6

68K

C7

C11

EC5

22uF/10V

Q4

8050

R32

10K

82K

R33

5V

SEG21

22

SG22

SEG22

23

SG24

24

SEG23

SG25

25

SG26

26

SG27

27

SG28

28

SG29

29

COM8

COM07

30

COM7

31

COM06

COM6

COM05

32

COM5

COM04

33

COM4

3435363738394041424344

COM03

R7

240K

WR

R6

240K

A5V

J9

CS

R5

240K

LED2

150R

R22

A5V

C5

100P DATA

100P

C9

100P

C10

EC3

0

R24

8050

Q2

R25

100K

10K

R23

AD1

EC2

47K

2.2u/10V

R26

J7

J6

LED_PWM

R12

33K

SW5

ON/OFF

R11

20K

SW4

ON/OFF

R9

5.1K

SW2

ON/OFF

R8

470R

SW1

ON/OFF

R10

10K

SW3

J11

AD2

ON/OFF

R17

33K

SW9

ON/OFF

R16

10K

SW8

ON/OFF

R15

4.7K

SW7

ON/OFF

234

1

R13

470R

SW6

ON/OFF

SM4

SMARK

SM3

SMARK

SM2

SMARK

R30

120K

A5V

SM1

SMARK

Display Board -- Circuit Diagram

MP3_R

AUTO-OFF

AGND

1

321

CON1

2.0-3P

AGND

MP3_L

103

C2

47K

R2

103

C1

R1

47K

FB1

MP3_R

MP3_L

2

345

LRH

P

G

JP1

TE-03575

DDGND

DDGND

USB

DGND

GND

D+D-VBUS

D+

D-

ESD

Q3

2.0*5

CON2

12345

UVCC

121110

AUTO-OFF

GND

IR

AD1

WR

GND

CS

LED_PWM

DATA

987654321

5V

A5V

3.3V

AD2

D1

5819

DD

TP1

1

PJ4

CON12-2.0-AW

P5

P1

P2

P3

P4

DD

TP2

1

12-1 12-1

Page 24

Display Board -- Layout Diagram

12-2 12-2

Page 25

NC

C15

GND

NC

C14

9V

CON2

GND

9V

GND

9V

4

2

3

XH2.54-3PIN

1

R22

NC

R21

NC

C7

1000uF,10V

GND

GND

NC

3.3V

Q3

NC

Q2

C16

NC

NC

R23

NC

C18

IC3

NC

NC

R24

SOT23

NC

GND

GND

GND

D12

NC

HV

LT1

VIN

RT1

9V

UU9.8-30MH

D1

D2

2M,1206

JUMPER

1

2

1N4007

1N4007

2M,1206

C17

C19

R3

R2

104,275V

MOV1

103P,1KV

C1

47uF,400V

103/1KV

CX1

NC

2200uF,10V

GND

1nF,50V,0805

R26 22R,1206

2

L2

0R,0805

1 2

200K,1206

R1

200K,1206

R9

103P,630V

NC

L3

D11

7

4

NC

SW2

D7

C8

6

8

FR107

SW1

VCC

NC

R14

5.1R,0805

D6

FR107

GND GND

HGND

9VA

C4

221P,2KV

Q1

4N60

DRV2

R13

68R,0805

DRV1

R25

330R,0805

FB

R11

D5

NC

R29

9V

IC1

PC817

C11

HGND

10K,0805

NC

IC4

R20

R16

3.3K,0805

470pF,0805

CS1

CS2

4

CS

SOT23-6

KB8235

OUT

6

R18

5.1K,1%,0805

R17

NC

C13

10K,0805

C12

0.1uF,0805

HGND

R10

1.2R,1206

R8

NC

NC

R7

1.2R,1206

R6

R12

1K,0805

C9

470pF,0805

FB

R15

100K,1%,0805

3

2

1

FB

RT

GND

VCC

5

C10

12K

R19

2.32K,1%,0805

IC2

TL431A-0.5%

SOT23

HGND

HGND HGND HGND

HGND

HGNDHGND

NC

GND

GND

GND

HGND

GND

2200P,400V

CY1

HGND

12-3 12-3

L1

2.2uH,3*15mm

C6

9VA

HGND

9V 4A

D9

SB3100

HV

D8

T1

SB3100

EE22

C21

R35 22R,1206

10

1

C3

R28

GND

4

3

D4

1N4007

D3

1N4007

R5

2M,1206

R4

2M,1206

F1

T2AL250V

2PIN

CON1A

3

2

1

Power Board -- Circuit Diagram

22uF,50V

HV

R33

1M,1206

R27

1M,1206

C2

HGND

Page 26

Power Board -- Layout Diagram

12-4 12-4

Page 27

P1

WP4-3

324

1

L0603B

R_OUT

220uF/35V

CD11X/220UF16V/D6.3H7

CD11X/10UF16V/D4H7

0.1uF

+

CE2 10UF/16V

CB10 33PF

U2

1A12A23B14B25C16C27D18D29

33PF

33PF

33PF

33PF

L1 FB/1K

C9 4.7uF

R5

22K

C4

680pF

R4

22K

C3

680pF

1uF

C7

L_FM

R_FM

R47

20NC19

18

17

16

15

14

13

DFS

LOUT

DOUT

GPIO1

IRQ/GPIO2

GND

DCLK/GPIO3

FMI3RFGND4TXO5RST6SEN7SCLK8SDIO9RCLK10VIO

1NC2

FMRST

10K

100pF

R6

C33

100pF

100R

C22

R87

100R

FM_RST

R63

MSCL

L_OUT

C-0603

R25 3K

2.2UFC-0603

+

L7 FB/1K

C19 4.7uF

22K

680pF

22K

C17

FM_IN_R

R16 0R

R15 1K

23

OUT1

L9 FB/1K

C20 4.7uF

680pF

4700pF

C26

R18 NC

R20 0R

21SR22

20

SB2

SB1

SEL210SEL111VOL112VOL213TC214TC1

C25 2.2uF

L11 FB/1K

CB11 33PF

C24 4.7uF

R19 1K

FM_IN_L

C21

R28

22pF

C11

C23

DETECT

GND

GND

AUTO-OFF

1234567891011

R29 3K

2.2UF

CE4

+

33pF

0.22uF

0.22uF

0.22uF

0.22uF

L12 FB/1K

CB13

CB16

CB17

CB19

CB18

15

BCB216BCA217BCA118BCB119OUT2

BD3490

BD3490FV

BD3490FV

3300pF

C32

C27 2.2uF

C31

3300pF

CB15 33PF

CB14 33PF

CB12 33PF

C-0603

470pF

C36

470pF

C29

47K

R33

470pF

C35

47K

R23

C28

470pF

R32

47K

R31 1K

R30 1K

47K

R22

R21 1K

AL

AR

FM_IN_R

C30

0.1uF

1u

0R

C12

1uF

C8

104

GND

A

Y1

32.768KHz

22pF

4.7R

R34

D_5V

TP1.5-TOP

LCD_5V

LCD_5V

AD1

LCD_DATA

LCD_WR

LED_PWM

REMOTE

LCD_CS

AD2

MCU3_3V

GND

LO

RO

HP_MUTE

LCD_5V

LED_PWM

GND

LCD_DATA

LCD_CS

AD2

MCU3_3V

LCD_WR

AD1

REMOTE

12

J4

CON12

L15

U4

10K

R158

AD1

AD2

IPOD_ACCDET

IPOD_AUDIO_DET

AUTO-OFF

STBY

IPOD_CHARGE

100R

TP-CTC

330R

47K

R161

MCU3_3V

10K

R37 10K

MCU3_3V

C39

LO

1000pF

220uF/16V

+

CE7

220uF/16V

47uF/16V

47uF/16V

+

+

CE9

CE6

C37 0.1uF

5

6

7

8

IN2

VDD

BIAS

OUT2

OUT12MUTE3IN14GND

1

R35 10K

+

CE8

47uF/16V

R36 100k

HP_MUTE

12

+

220uF/16V

CE5

D2 1N4148

R41 47k

1000pF

C38

RO

MUTE1

R_OUT

CE3

MSCL

MSDA

R11 1K

R8 1K

L8 FB/1K

24

VCC26SDA27GND28FIL25SCL

L4 FB/1K

L5 FB/1K

L3 FB/1K

L2 FB/1K

C13 4.7uF

C10 4.7uF

C15 4.7uF

C16 4.7uF

R13

C18

R12

R7 4.7K

R10 4.7K

IPOD_L

IPOD_R

FM_IN_L

1uF

C14

M3_3V

10R

R26

4.7R

12

11

VDD

GND

ROUT

R65

U1

SI4702

GND

A

100R

R27

MSDA

MP3_R

MP3_L

123

J3

CON1

R-0805

R1

10R

8V

A

CE1

+

CB9

CB8

CB4

33PF

CB7

CB3

33PF

CB6

CB2

33PF

CB5

CB1

33PF

R3 1K

R2 1K

C1

4.7uF

C-0603

C2 4.7uF

MP3_L

MP3_R

A

GND

R9

0R

A

GND

PJ3

AV2-8.4-9

231

11223

3

J6

TP37

TP38

TP39

PJ2-A

JP-CK3511

1

3

11

2

10

GND

CD_5V

123

J1

CON1

TP14

CD_5V

J2

CON5

M3_3V

GND

100p

100p

C5

C6

FB4

FB/100R

FB3

FB/100R

PJ2-B

ALARGND

CD/DVD_MUTE

SSCL

SSDA

12345

6

AL

AR

TP33

SSCL

SSDA

CD/DVD_MUTE

21

GND

10K

R83

104

C40

270nH

FMRST

FB6

TP1.5-TOP

GND1

RO

LO

HP_MUTE

HP_MUTE

FLO-

FRO-

FLO+

FRO+

FLO+

FLO-

FRO-

FRO+TP1.5-TOP

0.1UF

C46

C45

100pF

C44

8.2R

0.22uF

R56

C50

15UH

L14

R57

20R

C43

100pF

1uF

100R/6A/100M

GND

SUB_GND22INPA23INNA27SGND26VDDS28DIAG19VDDPW18PGND25SYNCLK24ROSC30GAIN031GAIN135SVCC

1

GND

C41 4.7uF

5.6k

R55

R_OUT

R53 100

R52 100

R51 1K

R50 100R

R49 100R

R24

R160

R40 10K

R39 10K

IPOD_RX

R38 10K

R17

R46 10K

R45 10K

REM

R44 10K

MSCL

R43 68K

MSDA

R42 4.7K

L_OUT

R48 47k

+

CE10

U3

PT2309 SO8

+

CE11

47uF/16V

Q1

2N3904

13

2

R58

R54 4.7K

HP_LINE_MUTE

C54

C53

C52

C51

R59

68K

R149

IPOD_CHARGE

MUTE_PH_LINE

LED_PWM

IPOD_TX

47K

C57

C56

C55

GND

0.47UF

C48

C49 0.1uF

0.1UF

100pF

0.22uF

C58

330P

C62

100pF

L20

VDDS

DIAG

L18

FB/1K

FB-0603

C-0603

C61

0.1uF

1000pF

1uF

1000pF

1500PF

2.2k

C60 104

C59 104

MCU3_3V

8.2R

R60

R71 8.2R

15UH

15UH

L13

L10

GND

C67

100pF

L24

100R/6A/100M

100R/6A/100M

2

OUTPB

C66

0.1uF

22R

100k

R61

R64

L21

FB/1K

FB-0603

VDDS

SSDA

R68 100R

L23FB/0603/2.2K

24

SSDA

AD_KEY

25

FM_RST

26

CLOSE_M

27

RTC_IN

28

OPEN_M

29

CLOSE_SW

30

OPEN_SW

31

TRIN

32

SSCL2DVD_ON3RESET4P4_75AVSS6P4_67VCC8MODE

1

L22

FB/0603/2.2K

R69 1K

R66 100R

SSCL

CD/DVD_ON

R62

4.7K

MUTE1

4.7K

R67

D4

1N4148

D3

1N4148

CD/DVD_MUTE

LCD_WR

R70 100R

L26FB/0603/2.2K

+

0.1UF

C70

C69

100pF

C68

0.22uF

R73

20R

R75 0R

LCD_CS

R74 100R

L27FB/0603/2.2K

22

VFD_STB23VFD_CLK

J7

4P_1.0UP

1u/50V

CE12

R72

68K

D6

D5

MCU_MUTE

C76

R76 100R

L29FB/0603/2.2K

123

1N4148

1N4148

C75

C74

C73

LCD_DATA

21

U5

L30 DCR33R

M3V3

TP1.5-TOP

GND

0.47UF

1uF

0.1uF

R78 0R

0.1uF

R77

VFD_DATA

R5F21266

GND2

TP1.5-TOP

C82

0.22uF

C79

C80

GND

L31 FB/1K

C78

0.1uF

39K

C77

1500PF

2.2k

R80

MCU3_3V

R79 33R

R81 100R

20

VREF

R5F21266-LQFP32

4

MODE

RESET

TP1.5-TOP

TP1.5-TOP

HP_LINE_MUTE

MUTE_PH_LINE

0.1UF

C81

100pF

R82 8.2R

15UH

L6

330P

C87

L35

100R/6A/100M

8

9

OUTNB4PGNDB5PGNDB6PVCCB7PVCCB3OUTPB11OUTNA10OUTNA13PVCCA12PVCCA14PGNDA17OUTPA16OUTPA15PGNDA

OUTNB

VSS32INPB33INNB21MUTE20STBY

36

L33 FB/1K

C85 4.7uF

5.6k

R85

L_OUT

IPOD_TX

REMOTE

R84 100

REM

17TX18

19

REMOTE

ECO_POWER

L32 DCR33R

D7

1N4148

GND

100pF

C92

34

29

SVR

VREF

R89 30k

C91

1000pF

C90

1uF

C89

1000pF

MCU3_3V

IPOD_DET

R88 10K

R86 4.7K

RX

16

STANDBY

15

MSCL

14

MSDA

13

MUTE

12

LED_CTRL

11

ROTB

10

ROTA

9

X1

32.768kHz

R90

MCU3_3V

10u/10V

GND

D8

10K

+

CE13

C94

10u/10V

37

TDA7491P

TDA7491HV

C98

C97

R91

30K

C96

C95

REST

1N4148

12

C93

0.1uF

220uF/16V

3.3R

R106

0.01UF

C103

0.1uF

C102

GND

8V_IN

EC3

1000U/35V

GND

2.2UF

2.2u

BS3904

Q2

32

1

C101

0.1uF

R107 100

22k

R105

R95 10k

R93 10k

MCU3_3V

L37 FB/0603/2.2K

L36 FB/0603/2.2K

15PF

15PF

D9

C99

STBY

R104 3.3k

MUTE1

IPOD_RX

R94 100

ECO_POWER

R103 100

MSCL

R102 100R

MSDA

R101 100R

MCU_MUTE

R100 100R

FM_RST

R99 100R

LED_PWM

R98 100R

MUTE_PH_LINE

R92 100

SSDA

C109 100pF

SSCL

C108 100pF

LCD_CS

C107 100pF

LCD_DATA

C106 10pF

MSDA

C105 100pF

MSCL

C104 100pF

ESD

0.01UF

1A02A13A24

GND

24C02

SDA6SCL7TEST8VDD

5

0.1uF

C100

R97 330R

R96 330R

L39 FB

MSDA

MSCL

M3_3V

MUTE1

BAS316

D20

R159

1K

Q9

8550

CE15

+

M3_3V

C110

47uF/16V

CAP-4X7MM

0.1uF

2.2uF

C111

100K

R110

MP3_L

D1

BAS316

R115

NC

NC

R114

NC16

16

NC17

17

NC18

18

NC19

19

NC20

20

VSS1

21

AUTO-OFF

D10

C113 1uF

R111

100K

R113

C112 2.2uF

100K

R112

MP3_R

C34

10UF

1

MSDA

MSCL

R123 NC/330R

R120 NC/330R

R119 NC/10K

14

15

NC15

MODE0

iPod_CP_2.0

NC/KITMFI341S2164 QFN20

NC12MODE13NC34NRESET5VCC

1

NC/0R

R118 10K

R122

FM_RST

M3_3V

+

CE16

47uF/16V

R117

100K

BAS316

BAS316

D11

R116

100K

R121

VCC11

8

7

7

6

6

5

5

47K

CF4558

2

11

12

VSS

NC10

10

I2C_SCL13I2C_SDA

NC9

9

NC8

8

NC7

7

NC6

6

CB21 0.1uF

CB20

0.1uF

+

CE17

47uF/16V

R124 NC/0/0805

M3_3V

IPOD_AUDIO_DET

+

CE18

47uF/16V/NC

R134

D12

BAS316

100K/NC

D13

BAS316

R131

R125 47K/NC

100K/NC

10K/NC

C116 1uF/NC

2

2

3

3

VSS

4

100K/NC

R130

C114 2.2uF/NC

C115 2.2uF/NC

100K/NC

100K/NC

R127

R129

R_IPOD_BT

L_IPOD_BT

C118 33PF/NC

IPOD_R

IPOD_L

C117

33PF/NC

10K/NC

R133

TP22

10K/NC

R132

IPOD_RX

IPOD_DET

IPOD_TX

IPOD_L

L42 0/NC

R126 FB1K/NC

IPOD_R

R128 FB1K/NC

TP1.5-TOP

TP26

IPOD_ACCDET

IPOD_TX

IPOD_RX

IPOD_ACCDET

A

L_IPOD_BT

R_IPOD_BT

1

L43 0R/NC

IPOD_DET

8765432

CON1

CON8-FFC-90

12-5 12-5

8V_IN

8V_IN

R109

10K

R108

AMP Board -- Circuit Diagram 1

Page 28

U9

SOP8-P

IP5V

100R/5A

L46

IPOD_5V

22UH

L45

AP1534/SOP-8

VCC

4

100R/5A

L44

CD/DVD_ON

CE22

+

FB

OCSET

C128

0.1uF

10u/10V

VSS

VSS

EN

DRBOM

+

R144

220u/10V

R143

8

7

2

0.1uF

CE23

1K

1.2K

D15

SK34

0

R145

ECO_POWER

220u/25V

8V_IN

TP30

C129

MCU3_3

10K

R146

1

Q4

0.1uF

R147

32

BS3904

R148

22R

22K

NC

R14

MCU3_3V/IP5V

U11

LCD_5V

100R/5A

FB2

SOT89

NC/HT7333

MCU3_3 V

3

2

100R/5A

L51

OUT1

IN

D_5V

100R/5A

FB5

ECO_POWER

CE26

100u/10V

+

M3_3V

C131

0.1uF

Q5

8550

47K

R150

0.1uF

C130

+

CE25

100u/10V

GND

1

+

CE24

100u/16V/NC

10K

R152

22K

R153

1

32

R151

1K

Q6

BS3904

A8V

R155

1K

32

BS3904

8550

100R/5A

L52

Q7

Q8

1

47K

R154

220u/25V

CE27

+

R157

10K

R156

ECO_POWER

22K

12-6 12-6

CE21

100u/10V

D_5V

+

C

SOT-23-A

Q3

1

LPM9017

23

47K

U10

SOP8-P

8V_IN

100R/5A

FB1

5V

22UH

L49

AP1534/SOP-8

VCC

4

100R/5A

L48

R142

C127

C126

R141

6.8K

C125

NS/100nF

1

5

O/P6O/P

3

NS/100nF

C124

R140

4.7K

IGND

J8

3

11223

A

GND

100R/5A

TP-CTC

L16

0.1uF

C121

+

R136

6.8K

C120

153

1

5

FB

O/P6O/P

VSS

VSS

EN

OCSET

3

NS/100nF

C119

4.7K

R135

C122

+

CE19

0.1uF

220u/10V

R137

8

7

2

DRBOM

CE20

1.2K

D14

SK34

0

R138

IPOD_CHARGE

GNDGND

220u/25V

A

GND

R139

22R

A

GND

A

A

GND GND

GND

A

C123

0.1uF

A

A

AMP Board -- Circuit Diagram 2

GND

8V_IN

11223

MCU3_3V/IP5V

3

CON3

Page 29

AMP Board -- Layout Diagram

12-7 12-7

Page 30

VREF_16

CD_TRIN

R73 33

1

CON1

CON2.0-6

SPIN+1SPIN-

SLED-4LIMIT1

LIMIT2

SLED+

2

5

6

LRCK

73

70

74

72

71

75

XGPIOD7/SPDIF

XGPIOD6/I2S_WCLK

XGPIOE3/SD_MS_WP

XGPIOE1/DOCD_DATI(I)

XGPIOE2/DOCD_CLK(O)

XGPIOE0/DOCD_DATO(O)

XPAD_BICAFL

XPAD_LINEOUTL

XAVSS33_CKG

XAVDD18_1

XPAD_BOCAPL

XAVSS18_1

32

30

31

33

28

29

C26

0.1UF/NC

C26

0.1UF/NC

104

CD_L

C25

RF_1V8

Y1

16.9344MHz

30pF

R24

100k

C27

TP5

SCLK

MCLK

SDATA

68

67

69

66

XGPIOD5/I2S_DI

XGPIOD4/I2S_DO

XGPIOD2/I2S_SCLK

XGPIOD3/I2S_REFCLK

XPAD_LINEOUTR

XPAD_BICAPR

XAVSS33_AUD

XPAD_BOCAPR

35

36

34

37

C28

0.1UF/NC

C28

0.1UF/NC

CD_R

TP6

TP4

3

SL+

SPIN+

SPIN-

LIMIT

SL-

TP7

TP8

TP9

TP12

TP10

TP11

SPIN-

104

C31

SPIN+

SSDA

3V3SD

R25 330RR25 330R

65

XGPIOD1/I2CM_DAT(B)

XAVDD33_AUD

38

C32

104

EC11

10uF/16V

AUD_3V3

C30

102

102

C29

CN1

R26 4.7KR26 4.7K

SF-P200Z(FPC)

1

3.3Ω

L2

2

HAVC

1

2

VC

RX

TX

XGPIOD0/I2CM_CLK(O)

XGPIOC3/URRX

XGPIOC2/URTX

XGPIOC1/SFSCK

XGPIOC0/SFCSB

XGPIOB7/SFDI

XGPIOB6/SFDO

VDD_PAD

GND_PAD

GND_CORE

VDD_CORE

XDP

XDM

XPAD_SFGN

XPAD_SFGP

XPAD_XVREF

XPAD_V15R

XPAD_V08R

XPAD_V15L

XPAD_V08L

XPAD_MICBIAS

XPAD_LINEINL

FMINL

XPAD_MICIN

XPAD_LINEINR

FMINR

3V3SD

EC12

C33

MAPUH

MDPUH

TNI

R27 33K

3

4

E

D

VCC

R28 4.7KR28 4.7K

64

63

62

61

60

59

58

57

56

55

54

53

52

51

50

49

48

47

46

45

44

43

42

41

40

39

220uF/16V

104

MBPUH

6

A5B

V18

GNDM-OPEN_SW

CLOSE_SW

TP16

TP15

3V3SD

SSCL

330R

R31

TPI

MCPUH

R29 33K

8

7

F

C

RF_1V8

L3 DCR33

M+

TP18

TP17

10K

R30

R32 10K

RX

TX

LD

10

9

LD

GND

SEV_3V3

1

2

CON3

CON2.0-4

C35

104

EC18

100uF/16V

USB5V

F1

2

D4

1N5819

1

+5.6V

AUD_3V3

DCR33

L7

D6

NC

D5

NC

SPIN-

22K

R45

10K

SMD0805P100TF 1A 6V

R42

R44 1.5K

EC19

10uF/16V

104

C36

R41 NC/0R

AUD_3V3

3V3SD_IC

DCR33

L8

SPIN+

10K

R47

1

234

TX

M33V

V18_CORE

C34

104

DCR33

DCR33

L6

L4

M33V

CON2

CON2.0-5

12345

TP19

4

3

D+

L5 DCR33

Ferrite Bead 500mA

TP22

F_CS

F_DI

F_DO

F_CLK

TP21

TP20

33R

33R

R37

R38

R35

15k

M33V_PAD

R34

15k

V18_CORE

EC14

10uF/16V

EC17

10uF/16V

EC16

10uF/16V

EC13

10uF/16V

FOCUS-

TRACK+

MDI

FOCUS+

TRACK-

14

13

11

15

16

12

T-

F-

F+

T+

VR

MD

M33V_PAD

C42

CD_MUTE

LIMIT

CD_TRIN

C41

DCR33

L9

R51 4.7K(NC)

R54 4.7K(NC)

R53 10K

M33V

3V3SD

CD_R1

CD_L1

474

474

C133

C143

CD_L

CD_R

R49 27K

1.5K

R48

R56

100K

3V3SD

C40

104

8

VCC

CS#1DO

R55

100K

F_CS

2

3

2

3

HOLE/GND

H2

9

8

9

8

2

3

2

3

HOLE/GND

CON4

CON2.0-4

H1

8

9

8

9

104

C38

104

104

+5V

F_DO

F_CLK

6

5

7

CLK

HOLD#

WP#3GND

4

2

WP

GND

F_DI HOLD#

5

445

6

7

6

7

5

4

5

4

7

6

7

6

M33V_CKG

C43

104

DCR33

L10

R57 220R

+3.3V

C44

+5V

D7

1 2

+5.6V

DI

U3

SFLASH EON25P20(1M bit)

1

1

1

1

M33V_LDO

3V3SD

C46

104

DCR33

DCR33

L11

L12

CDR 2

CDL 2

A

C51

2200P

CDR

CDL

R67

10K

D8

3.3V/SMD

1uF/50V

2R2

R58

IN4001

U4

+3.3V

HOLE/GND

H4

2200P

C50

10K

R66

R64 10K

R63 10K

+

+

22UF/6.3V/4*7

CE2

CD_R1

CD_L1

C52

2.2uF

C49

2.2uF

A

A

2

C45 2.2uF

11

10

13

14

9

8

12

L13 DCR33

1

VA

GND

FLYP

FLYN

-VFILT

AOUTB

AOUTA

CS4354

CE4354

VL

MCLK3LRCK

GND6FILT+

SDIN

SCLK/DEM

5

1

4

7

2

2.2uF

C48

C47

0.1uF

R65

10K

R60 22R

R61 22R

R59 22R

R62 22R

LRCK

MCLK

SDATA

SCLK

CD_MUTE

220uF/10V

EC15

+5.6V

CD_5V

SSDA

C53

104

SSCL

R72 33R

1

2

5

3

4

J2

CON5

2

4

5

5

2

334

1

1

8

9

776

8

9

6

MK1MK1

MK2MK2

12-8 12-8

VREF_16

XSLEGP

EC1

VREF_16

10uF/16V

C1

104

TRACK

R1 51k

2

J3

CON3

MUTE34

C4

V18_CORE

3V3SD_IC

C3

SEV_3V3

C2

TRACK+

SPIN-

XSPINDLE

XTRACK

SPIN+

TRACK-

VREF_16

0R

474

C8

R2

R5 1K

C5 103

15

SPINDLE

+5.6V1

16

17

3.9K

18

19

R9 560K/0

R4

20

21

R8

82K/39K

22

23

24

25

26

27

28

C6

104

MUTE34

C7

104

+5.6V1

EC2

1000uF/10V

R3 2.2R

+5.6V

R11

3V3SD

CD_MUTE

LIMIT

CD_TRIN

R7

4.7K

R6

10K/NC

103

104

105

106

107

108

109

110

111

M33V_PAD

112

VREF_16

XSLEGP

XSPINDLE

XFOCUS

XTRACK

113

114

115

116

117

118

119

120

FMO

121

122

DMO

123

124

125

FOO

126

TRO

127

MDI

128

MDI

3V3SD

2

DCR33

L1

1

EC5

R10

15R

104

104

104

VOTKVOLD+

VOLDVCC2

OPIN

VCTL

GND29GND

GND

VINLD

OPOUT

TRB_2

VINTK

BIAS

MUTE

U2

AM5766FM

EC4

10uF/16V

2

4.7K

3

Q2

102

XGPIOI2/IRC

XGPIOI3

XGPIOI4

XGPIOI5

XGPIOI6

XGPIOI7

XGPIOJ0

XGPIOJ1

XGPIOJ2

GND_PAD

VDD_PAD

GND_CORE

VDD_CORE

XAVDD_D33

BTN_ADIN1

BTN_ADIN2

BTN_ADIN3

VREF16

XAVD33_1

XAVSS33_1

GPWM

1

LDO

47uF/16V

2

13

Q1

D1

12

VOFC+14VOTK+

VOFC-

13

VOSL-

12

VOSL+

11

VOTR+

10

VOTR-

9

VCC1

8

30

REV

7

FWD

6

REGO1

5

VINSL+

4

REGO2

3

TRB_1

2

VINFC

1

+5.6V

R13

47K

1 2

D2

1N4148

1

2N3904

1K

R12

RESETJ

96

97

99

100

101

98

XPRSTB

XGPIOH5/LCDA0(O)

XGPIOI1/PWM0_0(O)

XGPIOI0/LCDWRJ(O)

XGPIOH6/LCDCSJ(O)

XGPIOH7/LCDRDJ(O)

MB

LDO

TP2

MC

MD

5

2

3

4

6

MCPUH

TNI

TPIRXMAPUH

MBPUH

MDPUH

SEV_3V3

8550,DIP

1N4148

LD

FOCUS+

FOCUS-

SL+

SL-

+5.6V1

R14

10R/0.5W

D3

ESD

C10

105

94

91

93

95

92

XGPIOH1/DATA4(B)

XGPIOH3/DATA6(B)

XGPIOH2/DATA5(B)

XGPIOH4/DATA7(B)

XGPIOH0/DATA3(B)

XGPIOG7/DATA2(B)

V12

XAVDD33_2

XAVSS33_2

MA7TP1

TELP

HAVC

8

9

10

12

11

C12 104

104

C9

C13

EC6

C11

104

EC7

HAVC

10uF/10V

2

1

Q3

8550,DIP

3V3SD

R15 10K

87

86

88

89

90

XGPIOG3/USI_DI

XGPIOG2/USI_DO

XGPIOG4/USI_CLK

XGPIOG5/DATA0(B)

XGPIOG6/DATA1(B)

MPXOUT2

COSP

MPXOUT1

COSN

MPXOUT3

15

14

16

13

17

SBLPFO

C14 105

TELPFO

FELPFO

SB

TE

SEV_3V3

FE

104

10uF/10V

473

C18

R19 0R

3.3K

R18

R17 15K

SLEGP

20K

R16

3

M33V

M33V_PAD

104

C17

82

83

85

84

VDD_PAD

GND_PAD

XGPIOF3/SD_MS_DET

U1

U1

VTB

VTP20XTALI

XAVDD33_3

18

21

19

104

C15

EC8

C16 104

XGPIOF2/SD_MS_PWR

XAVSS33_3

M33V_LDO

R20

12K

C19

EC9

470uF/10V

C22

104

81

80

XGPIOF1/SD/MS_CLK(O)

XGPIOF0/SDCMD(B)/MSBS(O)

XAVSS33_LDO

XAVDD33_LDO

23

22

V18

C20 104

10uF/10V

VREF_16

XFOCUS

0R

103

R23

C24

R22 43k

FOCUS

104

77

76

79

78

XGPIOE5/SDD1(B)

XGPIOE4/SDD0(B)

XGPIOE7/SDD3(B)

XGPIOE6/SDD2(B)

ALi M5673

ALi M5673

XAVDD33_CKG

XAVDD18_LDO

XTALO

26

24

25

27

M33V_CKG

EC10

1000uF/10V

0R

R21

104

C21

C23 30pF

Decoder Board -- Circuit Diagram

Page 31

Decoder Board -- Layout Diagram

12-9 12-9

Page 32

PCB1

S007

S012

S003

S006

SCREW

CD Door Gear

Gear Bracket

CDM

Screw

PCB4

PCB2

S010

Screw

Screw

PCB3

Screw

S001