Philips MC-i250 Service Manual

Service Manual

Service

Service

Micro System

Service

Service

Service

MC-i250/21M/22/37

TABLE OF CONTENTS

Page

Location of pc boards & Version variations................1-2

Technical Specifications .............................................1-3

Measurement setup ....................................................1-4

Service Aids, Safety Instruction, etc...........................1-5

Disassembly Instructions & Service positions .............. 2

Service Test Programs ...............................................3-1

Set Block diagram ......................................................4-1

Set Wiring diagram .....................................................5-1

Front Board .................................................................... 6

ECO6 Tuner Board : Systems Non-Cenelec............. 7A

Systems Cenelec..................... 7B

Mains Board................................................................... 8

Combi & Regulator Boards ............................................ 9

Universal Loader ......................................................... 10

Set Mechanical Exploded view & parts list ................. 11

Internet Audio Module - G.30WL ................................. 12

Document History ........................................................13

COMPACT

DIGITAL AUDIO

CLASS 1

©

Copyright 2003 Philips Consumer Electronics B.V. Eindhoven, The Netherlands

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system or

transmitted, in any form or by any means, electronic, mechanical, photocopying, or otherwise

without the prior permission of Philips.

Published by BB 0302 Service Audio Printed in The Netherlands Subject to modification

Version 1.1

LASER PRODUCT

GB

3139 785 30261

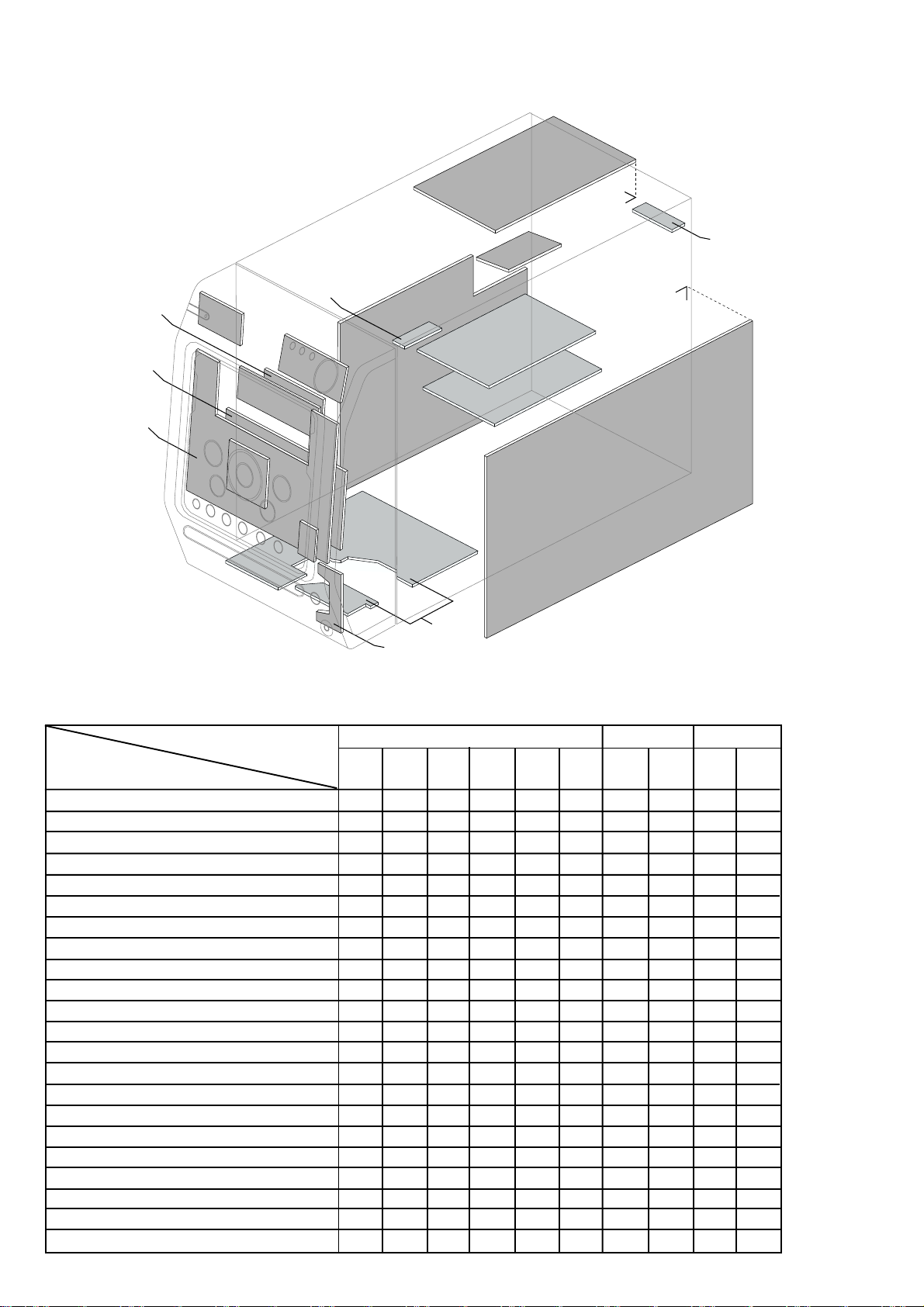

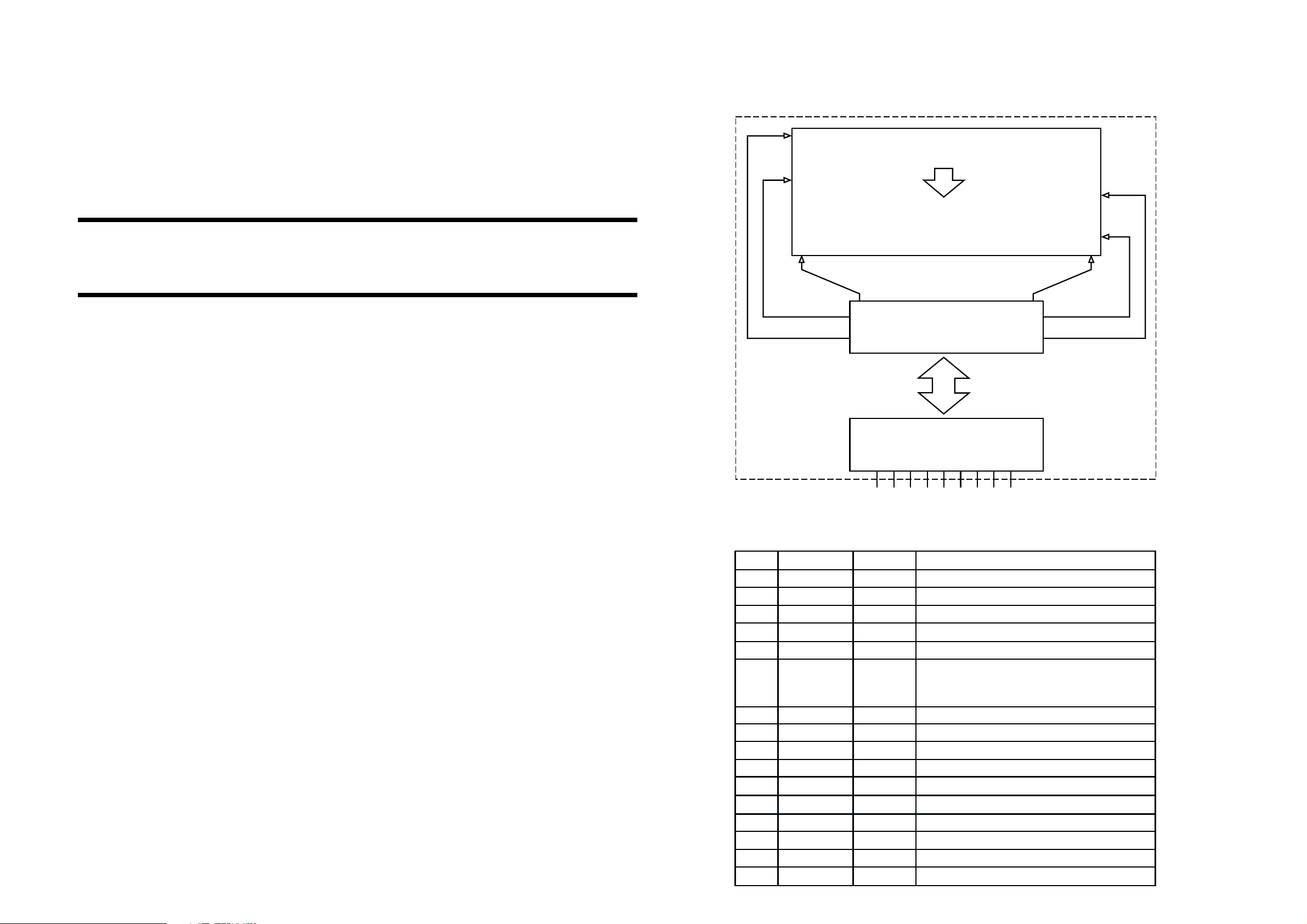

LOCATION OF PRINTED CIRCUIT BOARDS

LCD INTERCONNECT

ANTENNA BOARD

1-2

MODULE INTERNET AUDIO

MAINS SOCKET

BOARD

ANTENNA

BOARD

BOARD

CONTROL BOARD

DISPLAY BOARD

ECO STANDBY

BOARD

SHUTTLE

BOARD

VOLUME

BOARD

LCD BACK

LIGHT BOARD

IR

BOARD

MAINS BOARD

HEADPHONE

BOARD

VERSION VARIATIONS:

Type /Versions: MC-i250

Features &

/21M /22 /37

Board in used:

Aux in /CDR in x x x

Line Out x x x

Surround Out

Subwoofer Out x x x

Digital Out

Digital in

Matrix Surround

CD Text

Dolby B

RDS x

News x

Dolby Pro Logic (DPL)

Incredible Surround x x x

Karaoke Features

Voltage Selector x

ECO Power Standby (Clock Display Off) x x x

ECO6 Tuner Board - Systems Non-Cenelec x x

ECO6 Tuner Board - Systems Cenelec x

Center/Surround Channel

TUNER BOARD

CD BOARD

REGULATOR

BOARD

COMBI BOARD

SPECIFICATIONS

1-3

GENERAL:

Mains voltage : 110-127V/220-240V Switchable for /21/21M

120V for /37

220-230V for /22

Mains frequency : 50/60Hz

Power consumption : < 0.5W at ECO Power Standby

: <15W at Standby (DEMO mode off)

: 80W at Active

Clock accuracy : < 4 seconds per day

Dimension centre unit : 175 x 244 x 366mm

TUNER:

FM

Tuning range : 87.5-108MHz

Grid : 50kHz

100kHz for /37

IF frequency : 10.7MHz ± 25kHz

Aerial input : 75Ω coaxial

300Ω click fit for /37

Sensitivity at 26dB S/N : < 7µV

Selectivity at 600kHz bandwidth : > 25dB

Image rejection : > 25dB

Distortion at RF=1mV, dev. 75kHz : < 3%

-3dB Limiting point : < 8µV

Crosstalk at RF=1mV, dev. 40kHz : > 18dB

MW

Tuning range : 531-1602kHz

530-1700kHz for /21/21M/37

Grid : 9kHz

10kHz for /21/21M/37

IF frequency : 450kHz ± 1kHz

Aerial input : Frame aerial

Sensitivity at 26dB S/N : < 4.0mV/M

Selectivity at 18kHz bandwidth : > 18dB

IF rejection : > 45dB

Image rejection : > 28dB

Distortion at RF=50mV, m=80% : < 5%

AMPLIFIER:

Output power (6Ω, 1kHz, 10% THD)

L & R : 2 x 50W RMS /21M/22

Output power (6Ω, 60Hz-12.5kHz, 10% THD)

L & R : 2 x 40W FTC /37

Frequency response within -3dB : 50Hz-16kHz

Incredible Surround : ON/OFF

Treble : 12.5kHz ± 3 Steps

Bass : 55Hz ± 3 Steps

Woox : Level 1, 2, 3 & OFF

Input sensitivity

Aux in (at 1kHz) : 500mV ± 3dB at 600Ω

CDR in (at 1kHz) : 1V ± 3dB at 600Ω

Output sensitivity

Line out (Left/Right) : 500mV ± 3dB at 22kΩ

Subwoofer out (50Hz - 8kHz) : 1.5V ± 3dB at 22kΩ

Headphone output at 32Ω : 680mV ± 1dB (Vol. Max.)

COMPACT DISC:

Measurement done directly at the connector on the board.

Output resistance : < 100Ω

Output voltage (in Vrms) : 550mV ± 1dB (unloaded)

Frequency deviation : < 1%

Channel unbalance : < ±1dB

Frequency response : < ±1.5dB for 20Hz-20kHz

Signal to Noise Ratio (A-weighted) : > 80dBA

Distortion at 1kHz : < 0.02%

Crosstalk (1kHz) : >60dB

[....] Values indicated are for "ECO6 Cenelec Board" only.

LW

Tuning range : 153-279kHz /22

Grid : 3kHz

IF frequency : 450kHz ± 1kHz

Aerial input : Frame aerial

Sensitivity at 26dB S/N : [< 6.0mV/M]

Selectivity at 18kHz bandwidth : [> 24dB]

IF rejection : [> 45dB]

Image rejection : [> 30dB]

Distortion at RF=50mV, m=80% : [< 5%]

MEASUREMENT SETUP

Tuner FM

1-4

Bandpass

LF Voltmeter

e.g. PM2534

RF Generator

e.g. PM5326

DUT

250Hz-15kHz

e.g. 7122 707 48001

Ri=50Ω

S/N and distortion meter

e.g. Sound Technology ST1700B

Use a bandpass filter to eliminate hum (50Hz, 100Hz) and disturbance from the pilottone (19kHz, 38kHz).

Tuner AM (MW,LW)

RF Generator

e.g. PM5326

Ri=50Ω

DUT

Frame aerial

e.g. 7122 707 89001

Bandpass

250Hz-15kHz

e.g. 7122 707 48001

LF Voltmeter

e.g. PM2534

S/N and distortion meter

e.g. Sound Technology ST1700B

To avoid atmospheric interference all AM-measurements have to be carried out in a Faraday´s cage.

Use a bandpass filter (or at least a high pass filter with 250Hz) to eliminate hum (50Hz, 100Hz).

CD

Use Audio Signal Disc

(replaces test disc 3)

DUT

L

R

SBC429 4822 397 30184

S/N and distortion meter

e.g. Sound Technology ST1700B

LEVEL METER

e.g. Sennheiser UPM550

with FF-filter

Recorder

Use Universal Test Cassette CrO2 SBC419 4822 397 30069

or Universal Test Cassette Fe SBC420 4822 397 30071

LF Generator

e.g. PM5110

DUT

L

R

S/N and distortion meter

e.g. Sound Technology ST1700B

LEVEL METER

e.g. Sennheiser UPM550

with FF-filter

SERVICE AIDS

1-5

Service Tools:

Universal Torx driver holder .................................. 4822 395 91019

Torx bit T10 150mm ............................................. 4822 395 50456

Torx driver set T6 - T20 ......................................... 4822 395 50145

Torx driver T10 extended ...................................... 4822 395 50423

Cassette:

SBC419 Test cassette CrO2 ................................. 4822 397 30069

SBC420 Test cassette Fe ..................................... 4822 397 30071

MTT150 Dolby level 200nWb/M ............................ 4822 397 30271

Compact Disc:

SBC426/426A Test disc 5 + 5A ............................ 4822 397 30096

SBC442 Audio Burn-in Test disc 1kHz ................. 4822 397 30155

SBC429 Audio Signals disc .................................. 4822 397 30184

Dolby Pro-logic Test Disc ...................................... 4822 395 10216

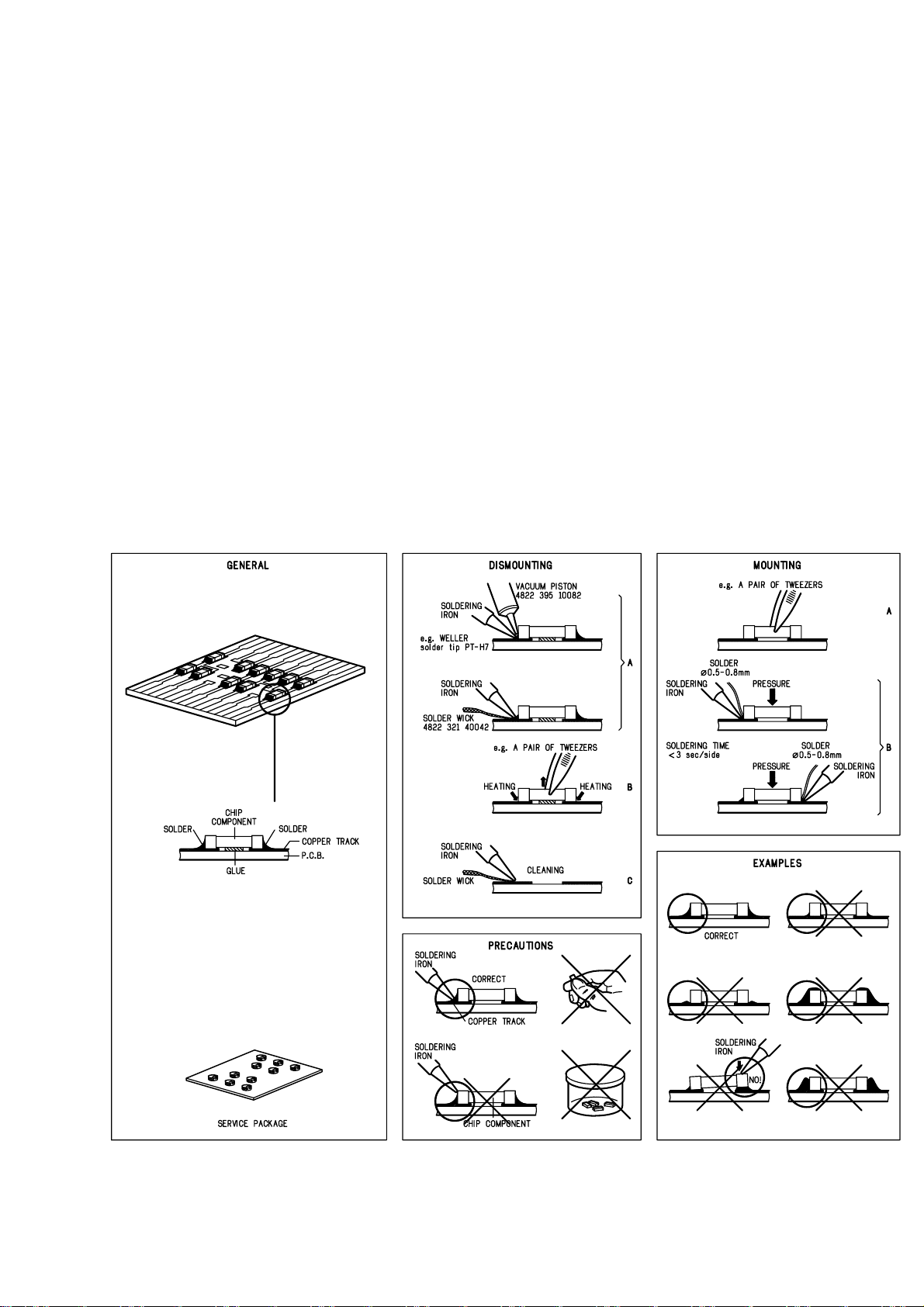

HANDLING CHIP COMPONENTS

ESD Equipment:

Anti-static table mat - large 1200x650x1.25mm ... 4822 466 10953

Anti-static table mat - small 600x650x1.25mm ..... 4822 466 10958

Anti-static wristband .............................................. 4822 395 10223

Connector box (1MΩ) ............................................ 4822 320 11307

Extension cable

(to connect wristband to conn. box) .................. 4822 320 11305

Connecting cable

(to connect table mat to conn. box) .................. 4822 320 11306

Earth cable (to connect product to mat or box) .... 4822 320 11308

Complete kit ESD3

(combining all above products) ......................... 4822 320 10671

Wristband tester .................................................... 4822 344 13999

WARNING

GB

All ICs and many other semi-conductors are

susceptible to electrostatic discharges (ESD).

Careless handling during repair can reduce life

drastically.

When repairing, make sure that you are

connected with the same potential as the mass

of the set via a wrist wrap with resistance.

Keep components and tools also at this

potential.

F

ATTENTION

Tous les IC et beaucoup d’autres

semi-conducteurs sont sensibles aux

décharges statiques (ESD).

Leur longévité pourrait être considérablement

écourtée par le fait qu’aucune précaution n’est

prise à leur manipulation.

Lors de réparations, s’assurer de bien être relié

au même potentiel que la masse de l’appareil et

enfiler le bracelet serti d’une résistance de

sécurité.

Veiller à ce que les composants ainsi que les

outils que l’on utilise soient également à ce

potentiel.

1-6

ESD

D

WARNUNG

Alle ICs und viele andere Halbleiter sind

empfindlich gegenüber elektrostatischen

Entladungen (ESD).

Unsorgfältige Behandlung im Reparaturfall kan

die Lebensdauer drastisch reduzieren.

Veranlassen Sie, dass Sie im Reparaturfall über

ein Pulsarmband mit Widerstand verbunden

sind mit dem gleichen Potential wie die Masse

des Gerätes.

Bauteile und Hilfsmittel auch auf dieses gleiche

Potential halten.

WAARSCHUWING

NL

Alle IC’s en vele andere halfgeleiders zijn

gevoelig voor electrostatische ontladingen

(ESD).

Onzorgvuldig behandelen tijdens reparatie kan

de levensduur drastisch doen verminderen.

Zorg ervoor dat u tijdens reparatie via een

polsband met weerstand verbonden bent met

hetzelfde potentiaal als de massa van het

apparaat.

Houd componenten en hulpmiddelen ook op

ditzelfde potentiaal.

I

AVVERTIMENTO

Tutti IC e parecchi semi-conduttori sono

sensibili alle scariche statiche (ESD).

La loro longevità potrebbe essere fortemente

ridatta in caso di non osservazione della più

grande cauzione alla loro manipolazione.

Durante le riparazioni occorre quindi essere

collegato allo stesso potenziale che quello della

massa dell’apparecchio tramite un braccialetto

a resistenza.

Assicurarsi che i componenti e anche gli utensili

con quali si lavora siano anche a questo

potenziale.

GB

Safety regulations require that the set be restored to its original

condition and that parts which are identical with those specified,

be used.

NL

Veiligheidsbepalingen vereisen, dat het apparaat bij reparatie in

zijn oorspronkelijke toestand wordt teruggebracht en dat onderdelen,

identiek aan de gespecificeerde, worden toegepast.

F

Les normes de sécurité exigent que l’appareil soit remis à l’état

d’origine et que soient utiliséés les piéces de rechange identiques

à celles spécifiées.

D

Bei jeder Reparatur sind die geltenden Sicherheitsvorschriften zu

beachten. Der Original zustand des Geräts darf nicht verändert werden;

für Reparaturen sind Original-Ersatzteile zu verwenden.

“Pour votre sécurité, ces documents

doivent être utilisés par des spécialistes agréés, seuls habilités à réparer

votre appareil en panne”.

CLASS 1

LASER PRODUCT

GB

Invisible laser radiation when open.

Avoid direct exposure to beam.

Osynlig laserstrålning när apparaten är öppnad och spärren

är urkopplad. Betrakta ej strålen.

Warning !

S

Varning !

3122 110 03420

I

Le norme di sicurezza esigono che l’apparecchio venga rimesso

nelle condizioni originali e che siano utilizzati i pezzi di ricambio

identici a quelli specificati.

"After servicing and before returning set to customer perform a

leakage current measurement test from all exposed metal parts to

earth ground to assure no shock hazard exist. The leakage current

must not exceed 0.5mA."

Varoitus !

SF

Avatussa laitteessa ja suojalukituksen ohitettaessa olet alttiina

näkymättömälle laserisäteilylle. Älä katso säteeseen!

DK Advarse !

Usynlig laserstråling ved åbning når sikkerhedsafbrydere er

ude af funktion. Undgå udsaettelse for stråling.

2-1

DISMANTLING INSTRUCTIONS

Opening of the Universal Loader Tray manually & Dismantling of the Cover Tray

1) Loosen 6 screws and remove the Cover Top (pos 255) by

sliding it out towards the rear before lifting up.

- 4 screws on the rear

- 1 screw each on the left & right side

2) Loosen 2 screws each to remove the Panel Left (pos 253)

and Panel Right (pos 254). The Panels are remove by

sliding it towards the rear and outwards.

- 1 screw on the side

- 1 screw on the rear

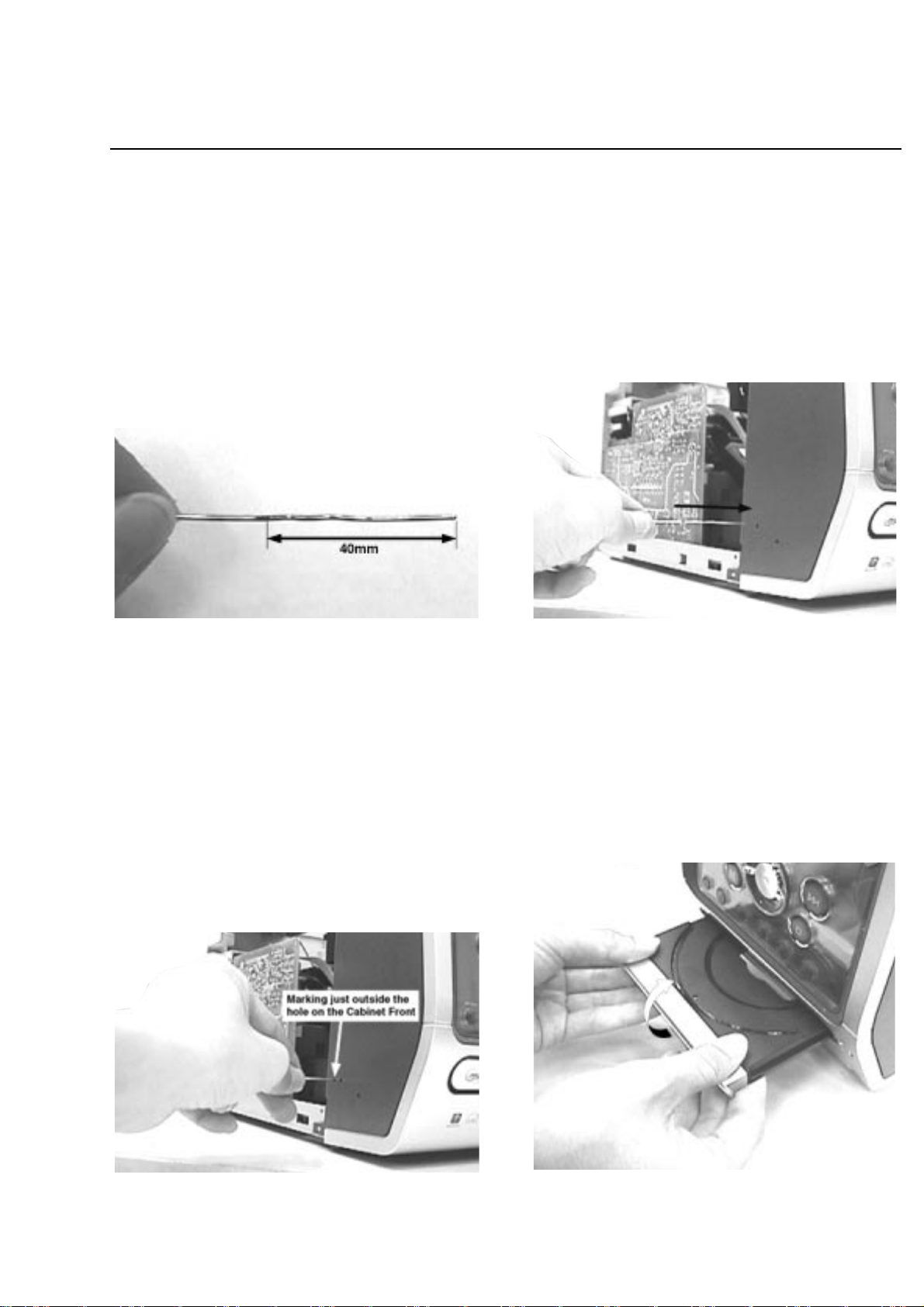

3) Take a paper clip or any stiff wire diameter of 1mm-1.5mm

and make a marking about 40mm from the tip as shown in

Figure 1.

4) Place the set in the position as shown in Figure 2 and insert

the paper clip or stiff wire into the hole on the Left side of

the Cabinet Front (pos 101).

Figure 1

5) With the marking just outside the hole on the Cabinet Front

(pos 101) as shown in Figure 3, you have to feel and give

a push to unlock the tray of the Universal Loader before

sliding it out.

Figure 2

6) With the tray of the Universal Loader opened, remove the

Cover Tray (pos 158) as shown in Figure 4.

Figure 3 Figure 4

2-2

DISMANTLING INSTRUCTIONS

Detaching the Front Panel assembly from the Bottom/Rear assembly

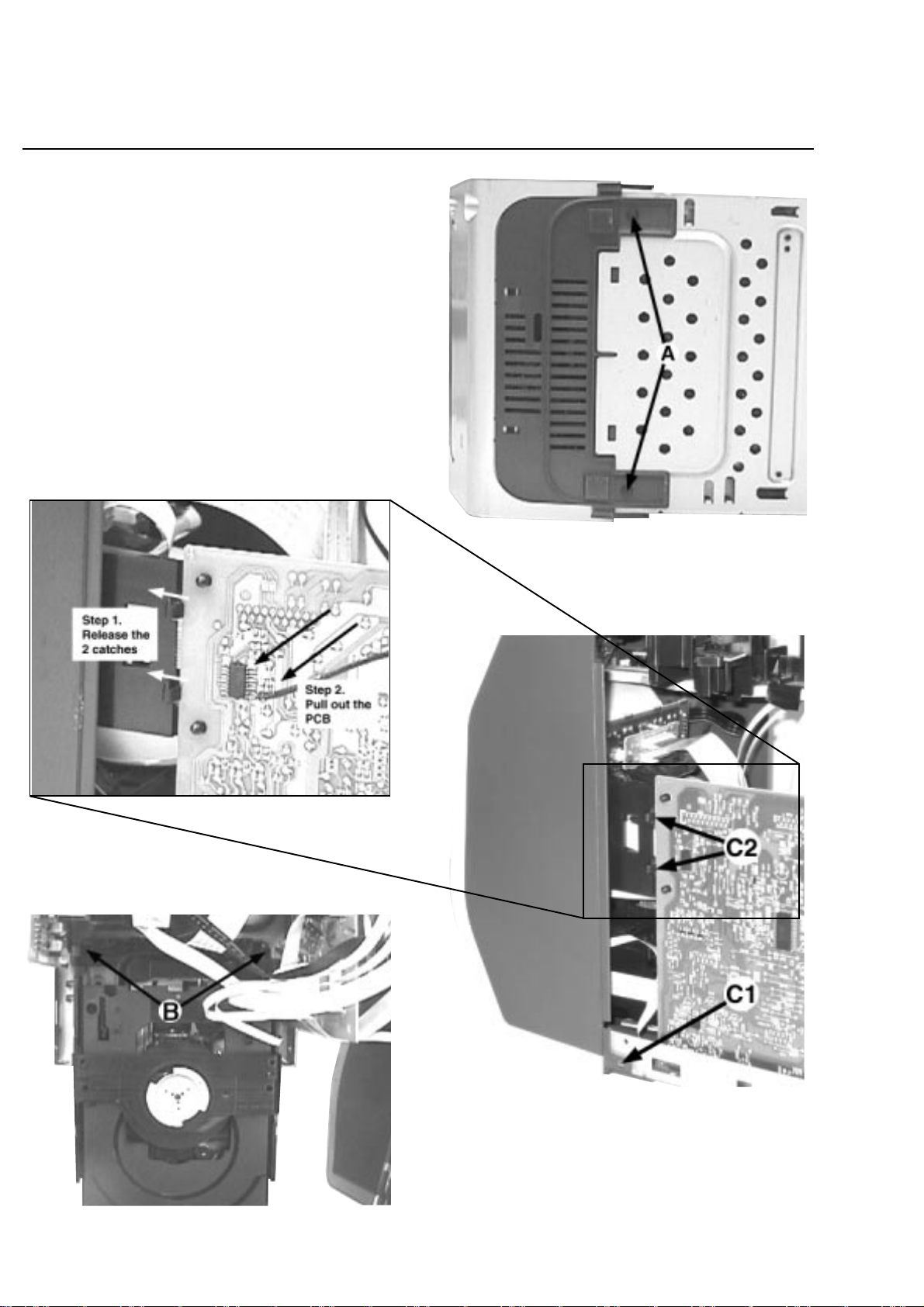

1) Remove 2 screws A (pos 226) as shown in Figure 5 from

the bottom of the Cabinet Front (pos 101).

2) Release the fixation of the Combi Board (pos 1101-1001)

to Bracket Combi (pos 252) by releasing the 2 catches C2

(see Figure 6) and pulling the board outwards as shown in

Figure 7.

3) Uncatch 2 catches C1 (see Figure 6) on the left & right

sides of the Cabinet Front (pos 101) and slides the Front

Panel assembly out towards the front.

4) Remove 2 screws B (pos 225) as shown in Figure 8 to

remove the Universal Loader (pos 1109).

Figure 7

Figure 5

Figure 8

Figure 6

DISMANTLING INSTRUCTIONS

2-3 2-3

Dismantling of the Front Panel assembly

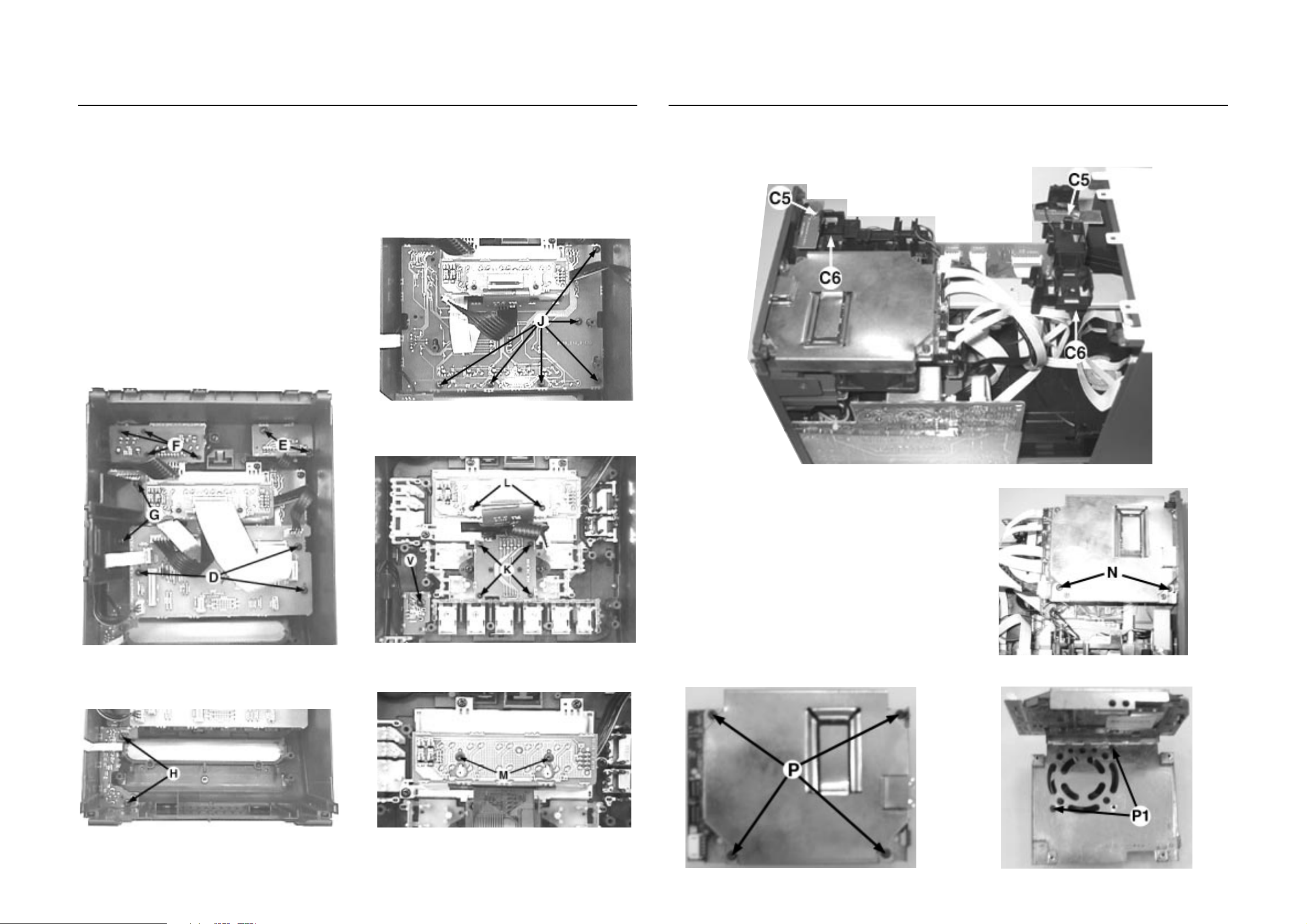

1) Loosen 3 screws D (see Figure 9) to remove the Control

Board (pos 1107-B).

2) Loosen 2 screws E (see Figure 9) to remove the ECO

Standby Board (pos 1107-D).

3) Loosen 4 screws F (see Figure 9) to remove the Volume

Board (pos 1107-H).

4) Loosen 2 screws G (see Figure 9) to remove the Bracket

Combi (pos 252).

5) Loosen 2 screws H (see Figure 10) to remove the

Headphone Board (pos 1107-F).

6) Loosen 6 screws J (see Figure 11) to remove the Display

Board (pos 1107-A).

7) Loosen 4 screws K (see Figure 12) to remove the Shuttle

Board (pos 1107-G).

8) Loosen 2 screws L (see Figure 12) to remove the LCD

Interconnect Board (pos 1107-J).

9) Loosen 1 screws V (see Figure 12) to remove the Infra

Receiver Board (pos 1107-E).

10)Loosen 2 screws M (see Figure 13) to remove the LCD

Back Light Board (pos 1107-C).

Figure 11

Dismantling of the Antenna Board, Bracket Antenna and Internet Audio Module

1) Uncatch the catches C5 (see Figure 14) to remove the

Antenna Board (pos 1106).

Figure 14

2) Uncatch the catches C6 (see Figure 14) and push

upward to remove the Bracket Antenna (pos 250).

Figure 9

Figure 12

3) Loosen 2 screws N (see Figure 14A) to remove the

Internet Audio Module assembly.

4) Loosen 4 screws P (see Figure 14B) to open the Shield

IAM (pos 262).

5) Loosen 2 screws P1 (see Figure 14C) to remove the Fan

(pos 1111).

Figure 14A

Figure 10

Figure 13

Figure 14B

Figure 14C

DISMANTLING INSTRUCTIONS

2-4

2-4

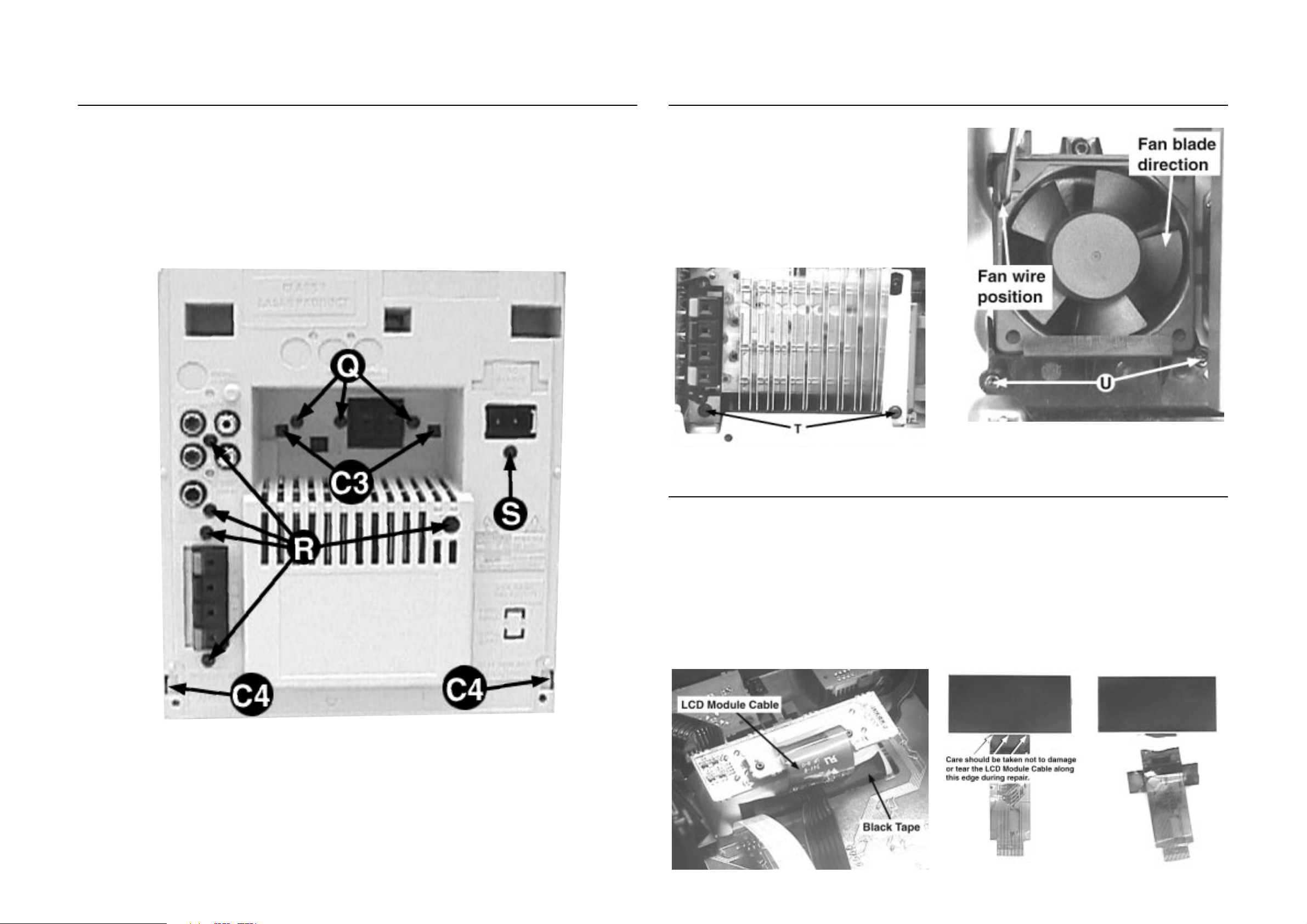

Dismantling of the Rear Panel

1) Loosen 3 screws Q and 2 catches C3 (see Figure 15) to

remove the Tuner Board assembly.

2) Loosen 1 screw S (see Figure 15) to free the Mains

Socket Board from the Panel Rear (pos 256).

3) Loosen 5 screws R and 2 catches C4 (see Figure 15) to

remove the Panel Rear (pos 256) by sliding it out towards

the rear.

Dismantling of the Bottom assembly

1) Loosen 2 screws T as shown in Figure 16 to remove the

Combi & Regulator boards assembly (pos 1101-1001 &

pos 1101-1003).

2) Loosen 2 screws U as shown in Figure 17 to remove the

Housing Fan Top (pos 267).

Note : During Fan (pos 1110) replacement, care should

be taken to ensure that the following are correct:

- fan blade direction

- fan wire position

Figure 15

Figure 16

Repair Hints

1) During repair it is possible to disconnect the ECO6 Tuner

Board completely unless the fault is suspected to be in

that area. This will not affect the performance of the rest

of the set.

2) Care should be taken not to damage or tear the LCD

Module Cable during repair (see Figure 18 & Figure 19).

The LCD Module Cable may be damage or tear as shown

in Figure 20 if too much force is applied when removing

the Black Tape during repair.

Figure 17

Note: The flex cables are very fragile, care should be taken

not to damage them during repair. After repair, be

very sure that the flex cables are inserted properly

into the flex sockets before encasing, otherwise faults

may occurs.

Figure 18 Figure 19 Figure 20

2-5 2-5

DISMANTLING INSTRUCTIONS

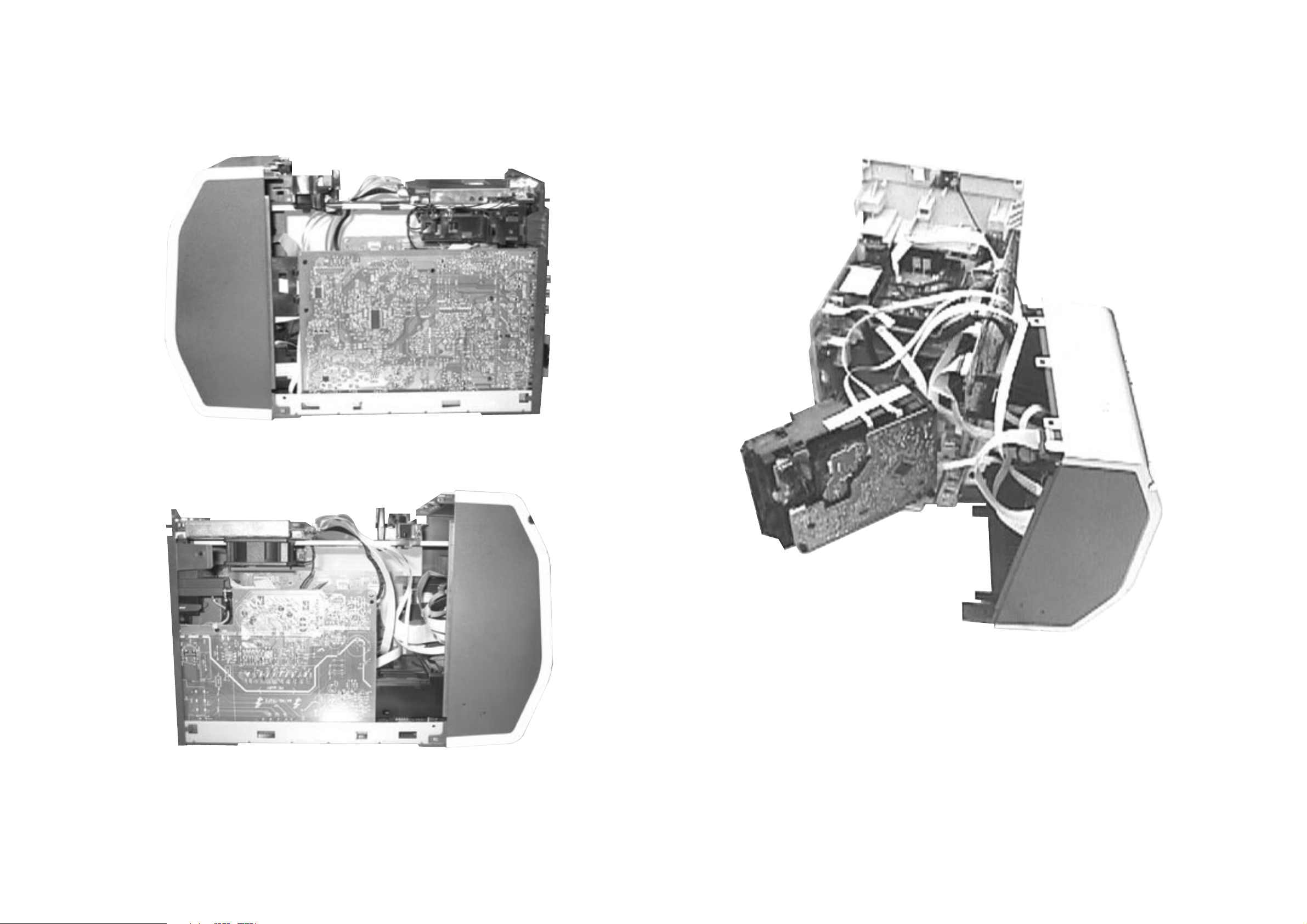

Service position A Service position B

3-1 3-1

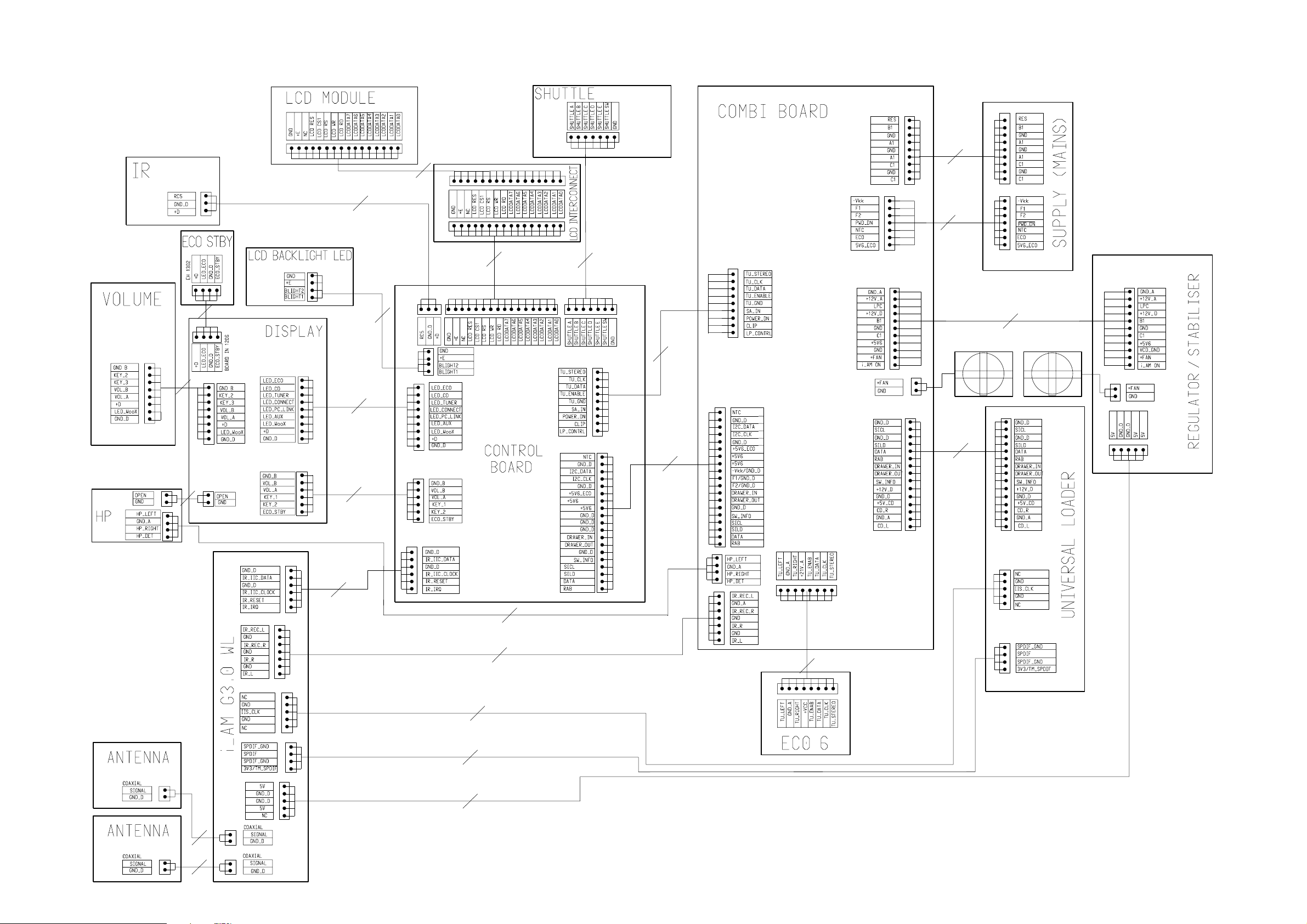

SERVICE TEST PROGRAM

TUNER

TEST

TUNER

Button pressed?

Y

Display Tuner Version

"ccc"

TUNER

Button pressed?

Service frequencies are

copied to the RAM (see Table 1)

Tuner works normally except:

PROGRAM button

Disconnect

Mains cord ?

Y

Service Mode left

N

N

N

S refers to Service Mode

V refers to Version

yy refers to Software version number

of the uProcessor

(counting up from 01 to 99)

QUARTZ

TEST

BACK ( S )

Button pressed?

Y

Display shows

32K

Output at (Front Board)

pin 11 of uP = 2048Hz

BACK ( S )

Button pressed?

Y

Display shows

12M

Output at (Front Board)

pin 11 of uP = 2,929.6875Hz

CANCEL ( 9 )

Button pressed?

Y

To start service test program

hold ENTER (

plugging in the mains cord

T

depressed while

Display shows the

ROM version

"S-Vyy"

(Main menu)

) & AUX

SERVICE

PLAY MODE

N

N

N

STANDBY-ON

Button pressed?

Y

Set is in Service PLAY Mode

CD

Button pressed?

Y

CD works as in normal operation.

In case of failures, error

codes according to Table 2

will be displayed.

The Service Play Mode is intended

to detect and identify the failures in

the CD Mode.

In this mode CD works as in normal

opeartion, at which electronics will

still be function even when an error

is detected so that repair activities

can be carried out.

N

Module Internet Audio - Software Upgrading

Press INTERNET button followed by OPTIONS button, then press the Right-Hand Soft Key ( ! )

on the set to select the "SET OPTIONS".

Use the navigation Jog Shuttle to select "ONLINE UPGRADE" from the list and press OK (

to confirm and follow the instruction given on the display.

DISPLAY

TEST

N

OK (2)

Button pressed?

Y

Display shows Figure 1

and switch all LEDs on

OK (2)

Button pressed?

Y

Display shows Figure 2

and switch alternate LEDs on

(see Table 3)

CANCEL ( 9 )

Button pressed?

Y

N

N

N

É

Module Internet Audio - Clear Email Address and Presets memory

By holding the INTERNET and ENTER ( T ) buttons depressed while switching on the Mains

supply (without the need to be in either Service or Factory mode), all Email address and presets

)

stored in the memory will be cleared.

The display will shows "STARTING UP" for a few seconds. When the stored information in the memory

has been cleared, the display will shows "FACTORY RESET". Subsequently, the software is upgraded

(if necessary) when the set is first connected to the internet.

Alternatively, press INTERNET button followed by OPTIONS button, then press the Right-Hand Soft

Key (

!

) on the set to select the "SET OPTIONS".

Use the navigation Jog Shuttle to select "RESET SETTINGS" from the list and press OK (

É

) to

confirm and follow the instruction given on the display.

Figure 1

PRESET

* Depending on the selected grid frequency

Note: By holding the TUNER and ENTER (

Europe

"EUR"

1

87.5MHz

2

108MHz

3

531kHz

4

1602kHz

5

558kHz

6

1494kHz

7

153kHz

8

279kHz

9

198kHz

10

98MHz

11

87.5MHz

(9 or 10kHz).

buttons depressed while switching on the

Mains supply, the tuning grid frequency is

toggled between 9kHz and 10kHz for the

Oversea (/21) version.

USA

"USA"

87.5MHz

108MHz

530kHz

1700kHz

560kHz

1500kHz

98MHz

87.5MHz

87.5MHz

87.5MHz

87.5MHz

Table 1

Oversea

"OSE"

87.5MHz

108MHz

531/530kHz*

1602/1700kHz*

558/560kHz*

1494/1500kHz*

87.5/98MHz*

87.5MHz

87.5MHz

87.5MHz

98/87.5MHz*

T

Service Play Mode Error Codes

Error code

E1000

E1001

E1002

E1003

E1005

E1006

E1007

E1008

E1020

)

E1030

E1079

Error Description

Focus Error

Triggered when the focus cannot be found within a certain time when starting up the CD, or if

the focus is lost for more than a certain time during playing of CD.

Radial Error

Triggered when the radial servo is off-track for a certain time during playing the CD.

Sledge In Error

The sledge did not reach its inner position (inner-switch is close) before approximately 6 sec.

have passed by - Inner-switch or sledge motor problem.

Sledge Out Error

The sledge did not come out of its inner position (inner-switch is open) before approximately

250ms have passed by - Inner-switch or sledge motor problem.

Jump Error

Triggered in normal play when the jump destination could not be found within a certain time.

Subcode Error

Triggered when a new subcode was missing for a certain time during playing CD.

PLL Error

The Phase-Lock-Loop could not lock within a certain time.

Turntable Motor Error

Generated when the CD could not reached 75% of speed during startup within a certain time.

Disc motor problem.

Focus Search Error

The focus point has not been found within a certain time.

EBU Connection Error

Generated when IM module could not receive any data from EBU interface within a certain

time.

The drawer could not enter the inside position and is opening again. This can happen if the

drawer is blocked such that it cannot go fully inside, or if the drawer switch is defective and

does not close.

Table 2

LEDs

ECO POWER

PC LINK

TUNER

wOOx

LCD Back Light 2

Table 3

MC-i250

On

On

On

On

On

Figure 2

TEST

EEPROM TEST A test pattern will be sent to the EEPROM.

TEST

ROTARY

ENCODER TEST

DEMO TOGGLE

LEAVE SERVICE

TEST PROGRAM

Activated with

ENTER ( T )

CANCEL ( 9 )

Rotary Volume Knob

to Exit

OPTIONSEEPROM FORMAT

Jog Shuttle Display shows "LEVEL -1" or "LEVEL +1" when the Jog Shuttle turn in

TREBLE

Disconnect

mains cord

ACTION

"PASS" is displayed if the uProcessor read back the test pattern correctly,

otherwise "FAIL" will be displayed.

Load default data. Display shows "NEW" for 1 second.

Caution! All presets from the customer will be lost!!

Display shows value for 2 seconds.

Values increases or decreases until Min. (-87dB) or Max. (0dB) is reached.

anti-clockwise or clockwise for the first step.

Display shows "LEVEL -2" or "LEVEL +2" when the Jog Shuttle turn in

anti-clockwise or clockwise for the second step.

Pressing this button will toggle between DEMO ON and DEMO OFF.

The DEMO status will be displayed.

Micro 2003 MC-i250 Service Test Program (dd wk0248)

Various

other Tests

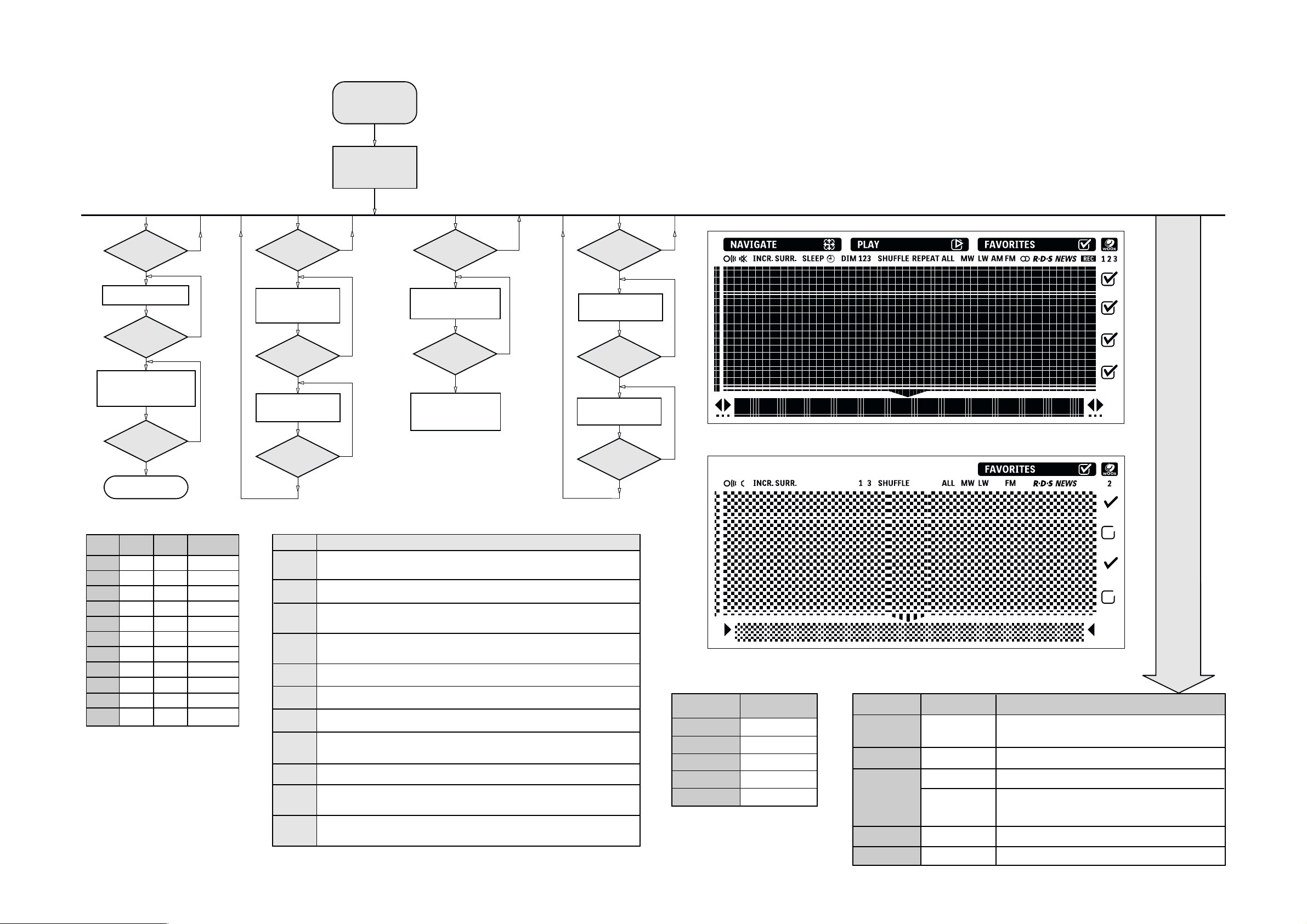

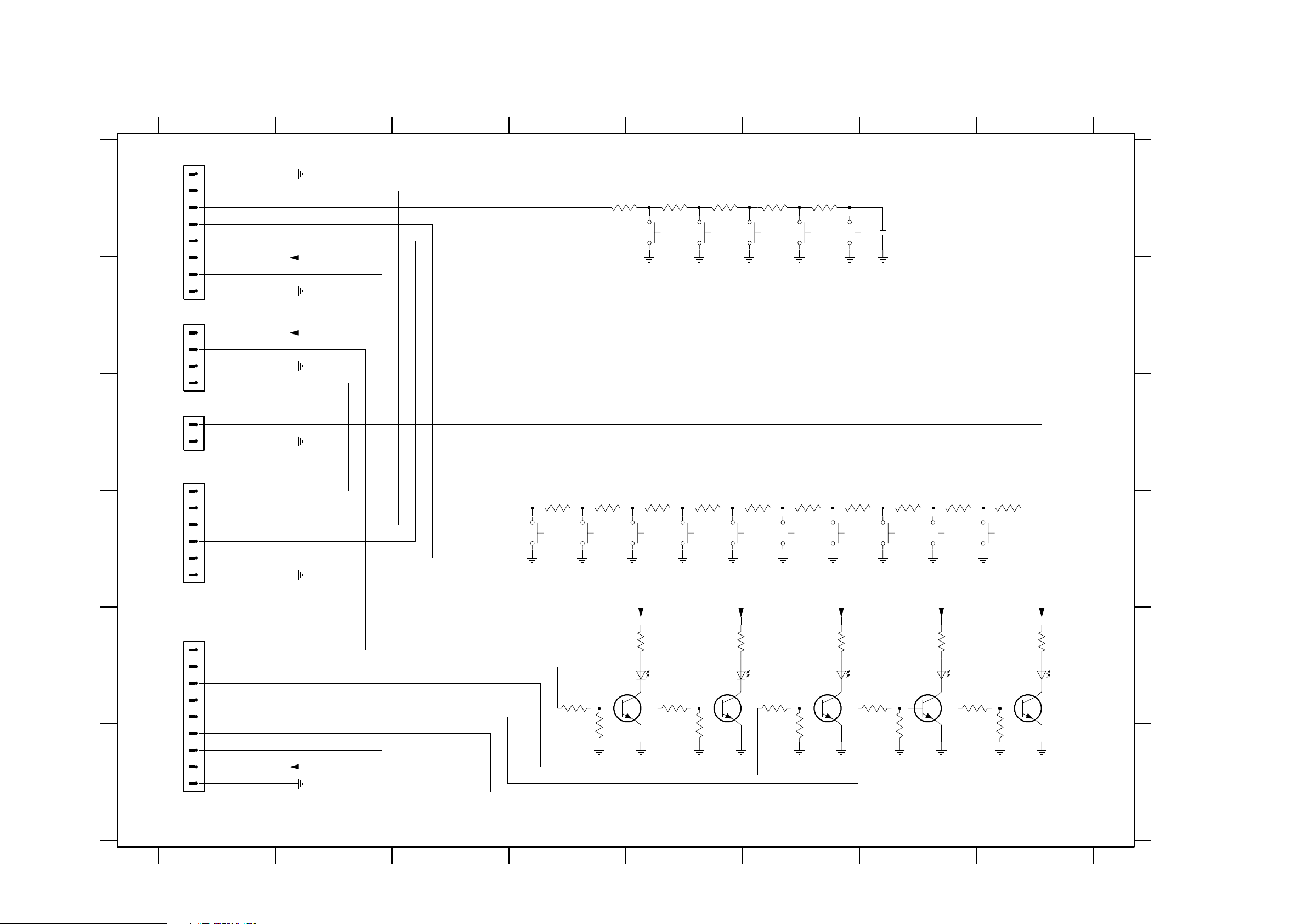

SET BLOCK DIAGRAM

4-1 4-1

Block Diagram_3139 119 34740 dd wk0217

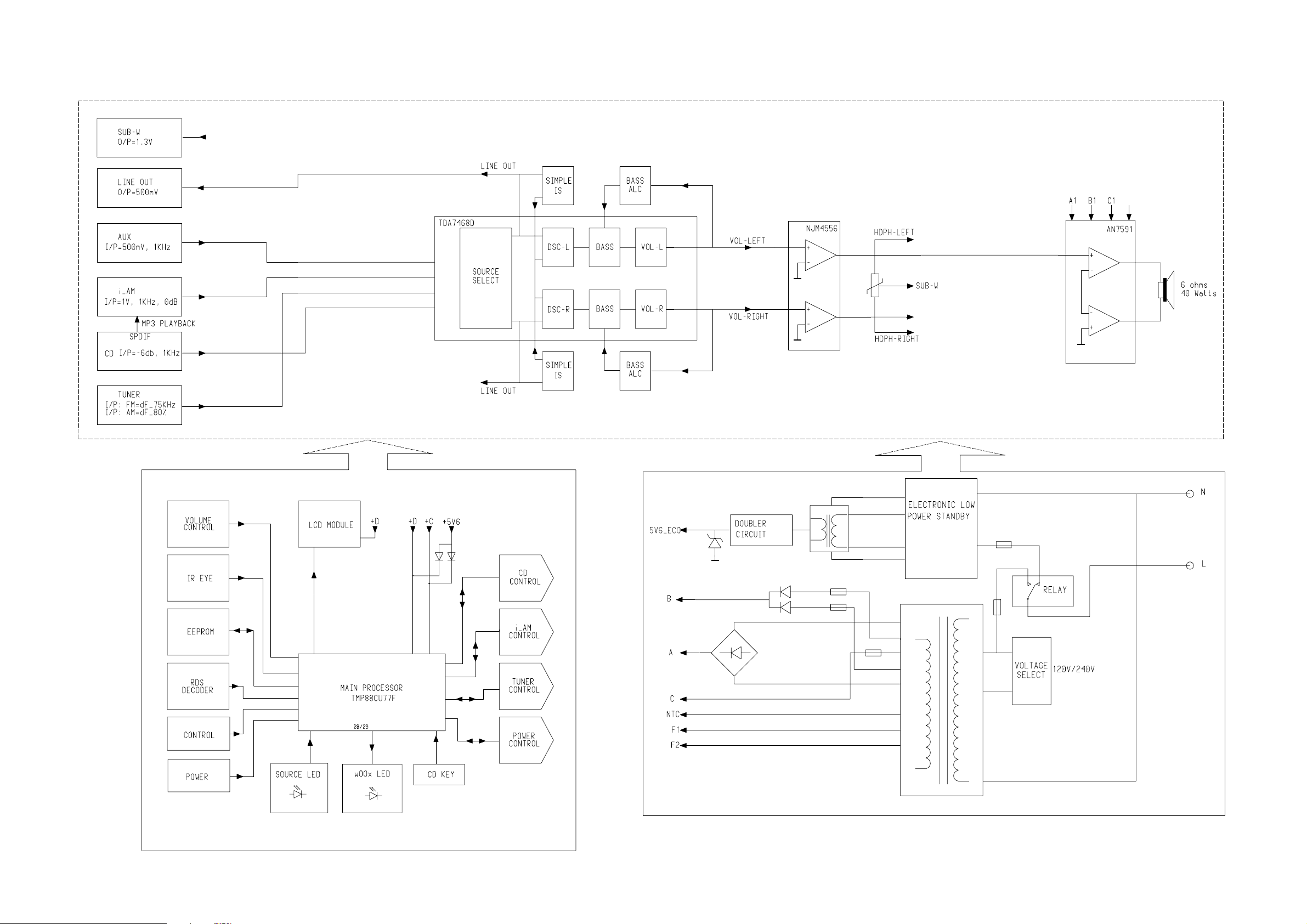

SET WIRING DIAGRAM

5-1

5-1

EH-S 1301

Board-In 1320

1

8124

8P/140mm

1

1

1

EH 1203

FE 1209

8200

11P/120mm

FE 1805

FAN

1

EH 1401

1

EH 1400

1

EH 1020

FE 1030

1

8201

9P/220mm

8010

7P/220mm/AD

1

FAN

1

1

EH 1302

1

1

1

EH 1211

1

FE 12121

1

FE 1700

1

FE 1701

FE 1200

1

8123

16P/180mm/AD

1

FE 1203

1615

7P/140mm

1

1320

3P/180mm

10 DIPMATE

1

1206

4P/80mm

1

EH-S 1208

1

FE 1224 1

1

1134

4P/140mm

8122

9P/140mm/BD

EH 1210

Board-In 1615

FE 1304

1

FE 1025

EH 1314

EH 1207

1

8002

9P/340mm/AD

FE 10261

EH 1303

FE 1304

2P/80mm

1

1

1500

1209

1

BOARD IN 1209

FE 1223

FE 1103

FE 1102

FE 1106

FE 1104

PH 1101 1

FE 1201

1

1

8121

6P/140mm/BD

1

8009

6P/280mm/AD

1

1

1

1

FE 1213

FE 1204

1

8005

4P/180mm/AD

8004

7P/280mm/AD

8007

5P/340mm/AD (1mm pitch)

8008

4P/340mm/AD (1mm pitch)

1160

5P/220mm

8006

19P/180mm/AD

1

FE 1014

FE 10231

FE 1013

1

8P/280mm/AD Fold

8003

1

FE 1120

8001

15P/280mm/AD

FE 1802

1

FE 1804

1

DIPMATE 0003

1

1500

8013

1P/280mm

8014

1P/280mm

Wiring Diagram_3139 119 35960 dd wk0247

6-1

FRONT BOARD

LCD MODULE (WD-G1306K-7BNN)

BLOCK DIAGRAM

COM1

VIEW DIRECTION

COM32

LCD PANEL

132 * 64 DOTS

SEG1

SEG1 SEG132

6-1

COM33

COM64

SEG132

TABLE OF CONTENTS

LCD Module - Block diagram .......................................... 6-1

LCD Module - Interface Pin Function .............................. 6-1

Control Part - Component & Chip layout ......................... 6-2

Control Part - Circuit diagram .......................................... 6-3

Display Part - Component & Chip layout ........................ 6-4

Display Part - Circuit diagram ......................................... 6-5

ECO Standby Part - Layout & Circuit diagram ................ 6-6

Infra Receiver Part - Layout & Circuit diagram ............... 6-6

Headphone Part - Layout & Circuit diagram ................... 6-7

Shuttle Part - Layout & Circuit diagram........................... 6-7

LCD Interconnect Part - Layout & Circuit diagram.......... 6-8

LCD Back Light Part - Layout & Circuit diagram............. 6-9

Volume Part - Layout & Circuit diagram ........................ 6-10

Electrical parts list.......................................................... 6-11

COM32

COM64

LCD DRIVER IC

COM1

VSS

VDD

V0

/RES

/CS1

RS

/WR

COM33

/RD

D0-D7

INTERFACE PIN FUNCTION

NO SYMBOL LEVEL FUNCTION

1. VSS - GND

2. VDD - Power for Logic Circuit

LCD

3. V0 - V

4. /RES - Reset

5. /CS1 H/L Chip Select

6. RS H/L H : D0 to D7 Display Data

7. /WR H/L L : Writes Data to Internal Register

8. /RD H/L L : Read Data from Register

9. D7 H/L Data Bus

10. D6 H/L Data Bus

11. D5 H/L Data Bus

12. D4 H/L Data Bus

13. D3 H/L Data Bus

14. D2 H/L Data Bus

15. D1 H/L Data Bus

16. D0 H/L Data Bus

Output

Instruction & Data Register Select

L : D0 to D7 are Display Control Data

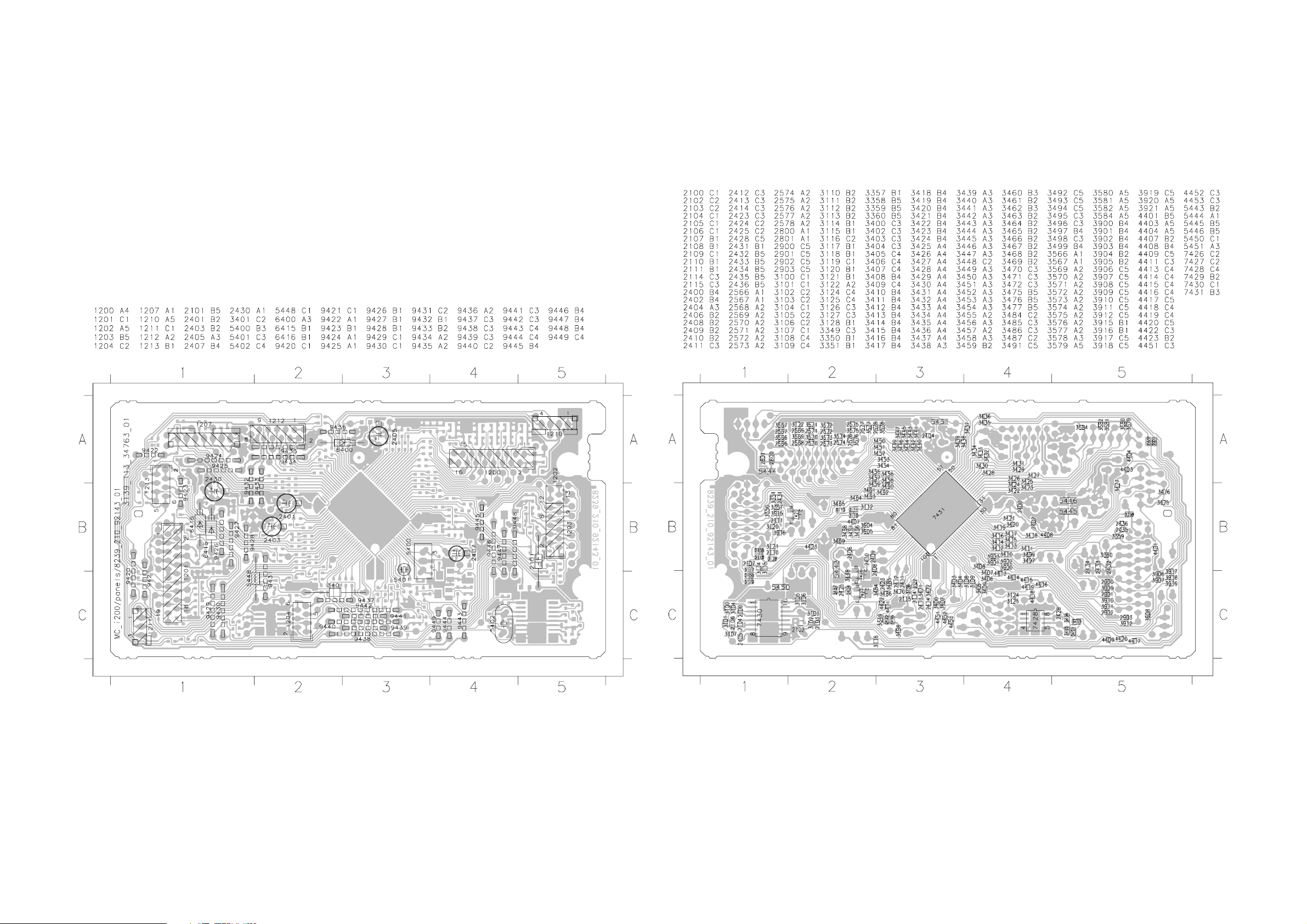

CONTROL BOARD - COMPONENT LAYOUT CONTROL BOARD - CHIP LAYOUT

6-26-2

This assembly drawing shows a summary of all possible versions. For components used in a specific version see schematic diagram and respective parts list.

3139 113 3476 pt3 dd wk0248

This assembly drawing shows a summary of all possible versions. For components used in a specific version see schematic diagram and respective parts list.

3139 113 3476 pt3 dd wk0248

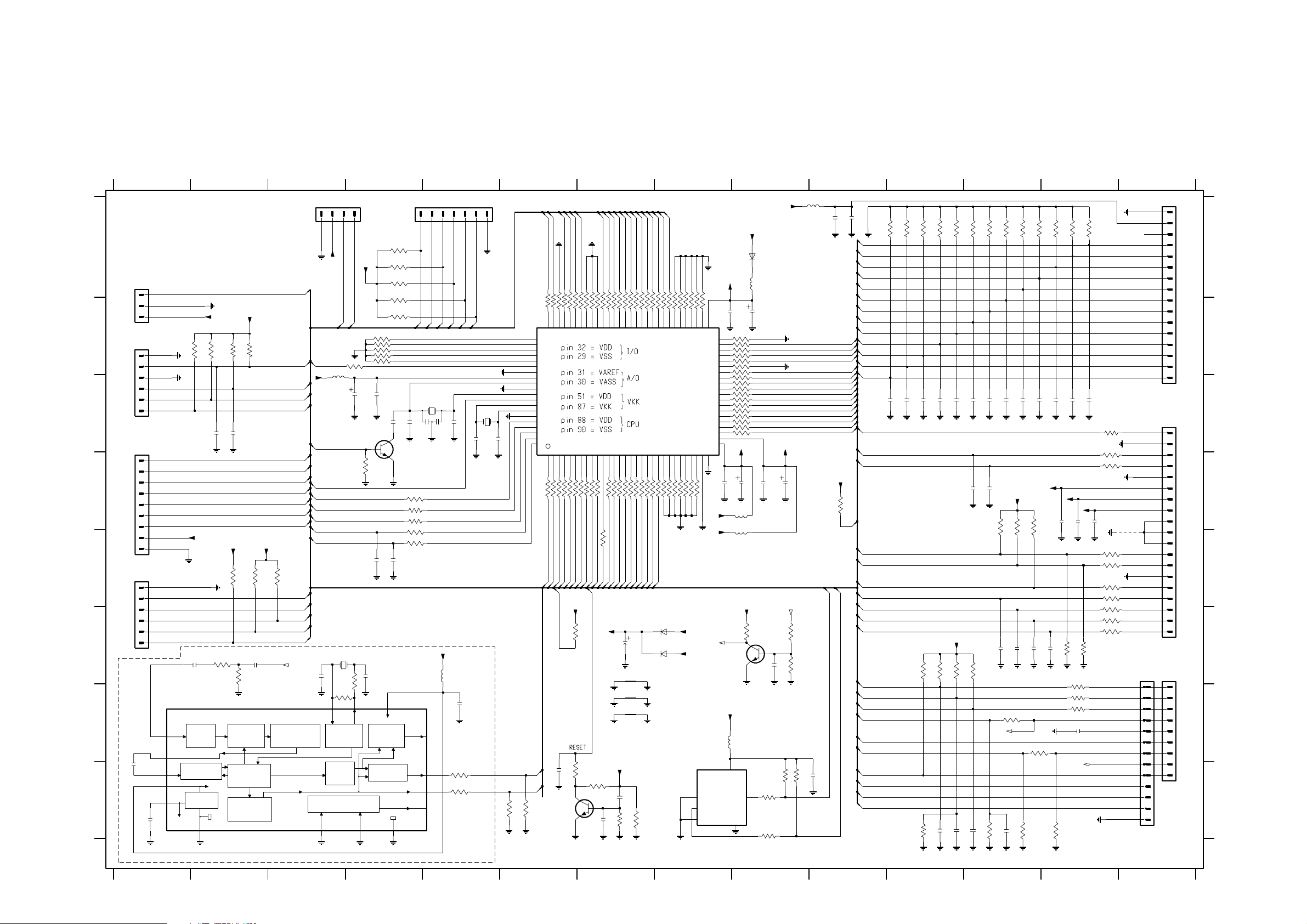

CONTROL BOARD - CIRCUIT DIAGRAM

6-3 6-3

1200 A14

1201 C14

1202 F14

1203 F14

1204 B1

1207 A4

1210 A3

1211 A1

1212 D1

1213 E1

2100 F2

2101 F2

2102 F3

2103 F4

2104 G5

2105 H1

2106 H1

2107 H11

2108 H11

2109 H12

2110 H12

2111 G13

2114 C2

2115 C2

2400 D8

2401 D9

2402 D9

2403 D9

2404 B8

2405 B9

2406 C4

2407 C4

1 2 3 4 5 6 7 8 9 10 11 12 13 14

Control PCB

Note : Some values may varies, see respective

parts list for correct value.

A

B

C

D

E

F

G

H

: Provision

*

EH-B

1211

1

2

3

To IR PCB

1204

1

2

3

4

5

6

To iAM Module

FE-BT-VK-N

1212

1

2

3

4

5

6

7

To Display PCB

8

9

D

+D

1K

10K

3124

3125

D

*

D

+D

D

FE-BT-VK-N

1213

1

2

3

4

5

6

To Display PCB

2100

3100

560p

1K5

7430

SAA6581T

ANTI-

4

MUX

ALIASING

FILTER

8

SCOUT

2105

560p

2106

2u2

D

7

CIN

5

VDDA

3

VREF

CLOCKED

COMPARATOR

VP1

REFERENCE

VOLTAGE

VSSA VSSD

6

D

123456789101112

2408 C5

2409 C4

2410 C4

2411 C5

2412 C5

2413 E4

2414 E4

2423 H6

47K

3496

10p

10p

2114

2115

D

D

+5V

10K

3475

B

10K

D

57 Khz

BANDPASS

(8th ORDER)

COSTAS LOOP

VARIABLE AND

FIXED DIVIDER

CLOCK

REGENERATION

AND SYNC

+D

47K

3495

LED_CONNECT

LED_PCLINK

3476

2101

1n

3101

2424 H7

2425 H7

2428 H9

2430 F7

2431 F9

2432 D13

2433 D13

2434 D13

IR_I2C_DATA

IR_I2C_CLK

IR_Reset

IR_IRQ

LED_ECO

LED_CD

LED_TUNER

LED_AUX

LED_wOOx

+C

2K7

2K7

3477

VOL_B

VOL_A

KEY_1

KEY_2

ECO_STDBY

TuRDS

RECONSTRUCTION

FILTER

2435 D12

2436 D12

2566 C13

2567 C13

2568 C13

2569 C12

2570 C12

2571 C12

EH-B

1210

1

2

E

+E

RC5

MPOscShift

5443

+5V

2u2

MPOscShift

RESET

PWDN

IR_I2C_DATA

IR_I2C_CLK

I2C_DATA

I2C_CLK

AT-51

5402

82p

2102

D

3103

220K

13

OSCI

OSCILLATOR

AND

DIVIDER

BIPHASE

SYMBOL

DECODER

TEST LOGIC AND OUTPUT

SELECTOR SWITCH

MODE

9

D

2572 C12

2573 C12

2574 C11

2575 C11

2576 C11

2577 C11

2578 C11

2800 A10

3

4

BLIGHT_1

BLIGHT_2

E

1K

3469

2407

3102

OSCO

D

C

14

TEST

+D

47u

3448

C

2K2

10

D

2801 A10

2900 F12

2901 F12

2902 F12

2903 F13

3100 F2

3101 F2

3102 F4

3579

10K

3580

10K

3581

10K

3582

10K

3584

10K

3904 1K

3905 1K

3466 1K

3468 1K

2406

100n

C

22p

2410

BC847B

10K

C

1K

220R

220R

220

220R

10p

2414

2413

D

D

47p

2103

12

VDDD

QUALITY

BIT

GENERATOR

DIFFERENTIAL

DECODER

11

D

7426

R

10p

3103 G3

3104 H5

3105 H5

3106 H6

3107 H6

3108 D6

3109 D7

3110 A6

1207

EH-B

1K3467

2409

C

QUAL

RDDA

RDCL

123

SHUTTLE_A

15p

T57

3111 A6

3112 A6

3113 A6

3114 F11

3115 F11

3116 F12

3117 G13

3118 G13

To Shuttle PCB

456

SHUTTLE_B

SHUTTLE_D

SHUTTLE_C

SHUTTLE_E

5400

22p

2408

CC

3470

3126

3127

3471

3472

+D

2u2

5450

100n

2104

D

1

3104

2

1K

3105

16

1K

15

(For /22 only)

3119 G13

3120 G12

3121 H12

3122 A13

3124 B2

3125 B2

3126 D5

3127 D5

7

D

SHUTTLE_SW

5401

22p

2411

2412

C

32K768

DT-38

3128 H11

3349 F9

3350 F9

3351 F9

3357 G12

3358 C13

3359 D13

3360 D13

E

C

C

22p

C

TuRDSDATA

# 3106

# - not for /22

TuRDSCLK

47K

# 3107

3400 D6

3401 D6

3402 D6

3403 D6

3404 D6

3405 D7

3406 D7

3407 D7

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

47K

DD

3408 D7

3409 D7

3410 D7

3411 D7

3412 D7

3413 D7

3414 D8

3415 D8

TU_CE

TU_CLK

HP_DET

MIC_DET

E

1K3112

470R3113

3465 1K

5

4

34041K3109

34031K3402

1K

1K

IR_IRQ

TuRDSCLK

LPC

OPTIONS

10n

C

7427

FREQ_Class_D

1K3464

1K3463

1K3462

7

31081K

3405

470R

TuRDSDATA

VOL_A

TU_DATA

+C

10K

3499

1K

3485

E

1K

3461

9

3406

1K

ECO_STDBY

3486

*

680K

TU_STEREO

470R

3110 470R

3111

110

3400

34011K

1K

CLIPPING

RC5

2423

BC847B

C

LCD_RES

1K3459

1K3460

70717273747576777879880

3416 D8

3417 D8

3418 D8

3419 D8

3420 D8

3421 D8

3422 C9

3423 C9

LCD_RS

LCD_CS1

1K3458

3457 1K

LCD_RD

LCD_WR

3455 1K

3456 1K

3424 C9

3425 C9

3426 C9

3427 C9

3428 C9

3429 C9

3430 C9

3431 C9

LCD_DATA_7

LCD_DATA_6

LCD_DATA_5

LCD_DATA_4

1K

1K

1K

3453

3451 1K

3454

3452

LCD_DATA_3

LCD_DATA_2

1K

1K

3449

3450

TMP88CU77F

11

12 13 14 15 16 17 18 192 2 0212223242526

39011K

39001K

34111K

3410

34131K

39021K

39031K

34091K

34071K

3414

1K

1K 3412

1K

3408

1K

SW_INFO

IR_Reset

+5V

D

B

47u

OPTIONS

2430

D

NTC

VOL_B

KEY_1

6415

1N4003

6416

1N4003

E

D

KEY_2

SILD

DATA

SICL

RAB

LED_ECO

CD

+D

2424

470n

10n

3484

3487

100K

680K

2425

C

C

C

3432 C9

3433 B9

3434 B9

3435 B9

3436 B9

3437 B9

3438 B9

3439 B9

LCD_DATA_1

LCD_DATA_0

1K3447

1K3444

1K3445

1K3446

7431

3418

34151K

3417

34161K

1K

1K

1K3442

1K3443

5556575859660616263646566676869

27 28 293 30

3419

1K

1K 3420

B

+5V6

CLIPPING

+5V6_ECO

1

2

3

6

7

D

1K3440

3441 1K

51525354

34211K

D

7428

M24C08

E0

E1

E2

SCL

WC_

3440 A8

3441 A8

3442 A8

3443 A8

3444 A8

3445 A8

3446 A8

3447 A8

E

50

49

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32

31

B

+5V

+5V

+E

2404

2400

B

BC847B

+5V6

5448

VCC

D

E

100n

8

VSS

100n

+C

2u2

5446

2u2

5445

7429

2u2

SDA

2401

4

3448 D4

3449 A8

3450 A7

3451 A7

3452 A7

3453 A7

3454 A7

3455 A7

+5V6

6400

5451

2405

47u

B

+D

3349

D

5

1N4148

2u2

47u

E

3439 1K

3437 1K

3436

3435 1K

3434 1K

3433

3431 1K

3430

3428 1K

3426 1K

3425 1K

3423 1K

3422

2402

D

10K

3491

470R

3492

470R

1K3438

1K

1K

1K3432

1K

1K3429

1K3427

1K3424

1K

100n

2431

3456 A7

3457 A7

3458 A7

3459 A7

3460 A7

3461 A7

3462 A7

3463 A7

+E

+D

2403

D

10n

D

6K8

3493

E

E

CLIP

3350

3351

47u

3464 A6

3465 A6

3466 B4

3467 B4

3468 B4

3469 B4

3470 D5

3471 E5

3472 E5

3475 E2

3476 E2

3477 E3

3484 H7

3485 H6

3486 H7

3487 H7

3491 H9

3492 H9

3493 H9

3494 H9

3495 B2

3496 B2

3497 D10

3498 F11

3499 F7

3566 A13

3567 A13

3569 A13

3570 A12

3571 A12

3572 A12

3573 A12

3574 A11

3575 A11

3576 A11

3577 A11

3578 A11

3579 A4

3580 A4

3581 A4

3582 B4

3584 B4

3900 D7

3901 D7

3902 D7

3903 D7

3904 B4

3905 B4

5444

2u2

4u7

2801

100n

2800

E

E

BLIGHT_2

BLIGHT_1

Drawer_OUT

Drawer_IN

LED_CD

LED_TUNER

LED_CONNECT

LED_PCLINK

LED_AUX

LED_wOOX

SHUTTLE_SW

SHUTTLE_E

SHUTTLE_D

SHUTTLE_C

SHUTTLE_B

SHUTTLE_A

E

LCD_RES

LCD_CS1

LCD_RS

LCD_WR

LCD_RD

LCD_DATA_7

LCD_DATA_6

LCD_DATA_5

LCD_DATA_4

LCD_DATA_3

LCD_DATA_2

LCD_DATA_1

LCD_DATA_0

NTC

I2C_DATA

I2C_CLK

6K8

2578

3578

22p

6K8

2577

6K8

6K8

6K8

6K8

2576

3575

3576

22p

E

2575

3574

3573

22p

22p

22p

2574

2573

E

E

3577

22p

EE

+D

10p 2435

D

+D

10K

3115

3116

2108

100p

2109

DD

D

10K

100p

680R

NTC

3497

DRAWER_IN

Drawer_OUT

SW_INFO

SICL

SILD

DATA

I2C_CLK

RAB

TU_STEREO

TU_CLK

TU_DATA

TU_CE

SA_IN

PWDN

LPC

HP_DET

MIC_DET

FREQ_Class_D

3498

3128

D

10K

10K

3114

2107

D

10K

**

22p

47K

I2C_DATA

10K

D

6K8

2428

100n

D

3494

3906 E13

3907 E13

3908 E13

3909 E13

3910 F13

3911 F13

3912 F13

3915 H13

6K8

6K8

3571

3572

22p

22p

2571

2572

E

EE

+D

10p 2436

10K

3918

3917

***

10p

2901

2900

D

22K

3120

TuRDS

22p

3121

2110

100K

D

D

D

6K8

3570

22p

2570

E

+5V6_ECO

10K

3919

10p

2902

D

3357

680K

1M

3916

6K8

2569

E

10K

10p

3916 H12

3917 D12

3918 D12

3919 D12

3920 F13

3921 F13

4401 E14

5400 C5

6K8

3122

22p

2568

D

10p

2903

DD

D

3915

D

E

2432

3569

22p

3920

3117

3118

3119

1M

6K8

2567

4u7

D

D

2111

100p

E

2433

5K6

5401 C5

5402 F3

5443 B3

5444 A10

5445 E9

5446 D9

5448 G8

5450 F5

6K8

3567

22p

2566

+5V6

4u7

D

3921

100R

100R

100R

CLIP

3906

3907

5K6

D

E

2434

3908

3909

3910

3911

3912

D

3566

22p

3358

3359

3360

+5V6

4u7

5451 A9

6400 A9

6415 F8

6416 F8

7426 D4

7427 H6

7428 H8

7429 F9

1R

D

220R

220R

D

D

1K

1K

D

1K

220R

220R

220R

220R

4401

7430 G1

7431 C8

FE-BT-VK-N

1200

1

E

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

1201

FE-BT-VK-N

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

A

To LCD Interconnect PCB

B

C

D

To Combi PCB

E

F

1203

1202

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

10

11

12

13

G

To Combi PCB

H

3139 118 55850...8239 210 92143...for 3476 pt3 dd wk0248

13 14

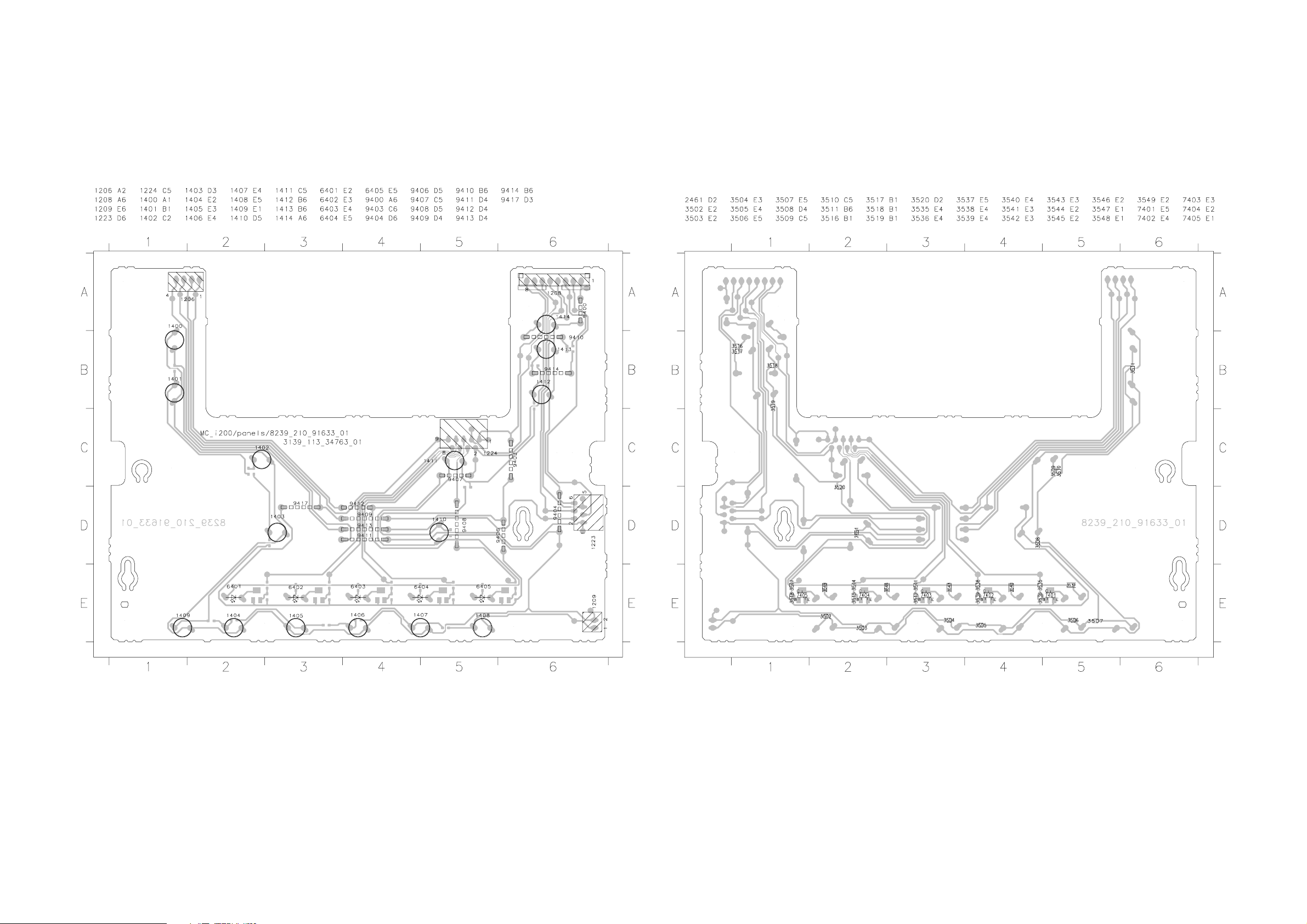

DISPLAY BOARD - COMPONENT LAYOUT DISPLAY BOARD - CHIP LAYOUT

6-46-4

This assembly drawing shows a summary of all possible versions. For components used in a specific version see schematic diagram and respective parts list.

This assembly drawing shows a summary of all possible versions. For components used in a specific version see schematic diagram and respective parts list.

3139 113 3476 pt3 dd wk0248

3139 113 3476 pt3 dd wk0248

DISPLAY BOARD - CIRCUIT DIAGRAM

6-5 6-5

A

B

C

D

E

F

12345678

1208

1

2

3

4

5

VOLUME PCB

ECO STANDBY PCB

HP PCB

CONTROL PCB

CONTROL PCB

6

7

8

EH-B

1206

1

2

3

4

35022

1209

1

2

35022

1223

1

2

3

4

5

6

FE-ST-VK-N

1224

9

8

7

6

5

4

3

2

1

FE-ST-VK-N

KEY_2

KEY_3

VOL_B

VOL_A

LED_WOOX

LED_ECO

ECO_STDBY

KEY_4

ECO_STDBY

KEY_1

KEY_2

VOL_A

VOL_B

LED_ECO

LED_CD

LED_TUNER

LED_CONNECT

LED_PCLINK

LED_AUX

LED_WOOX

1206 B1

1208 A1

1209 C1

Display PCB

1223 C1

1224 E1

1400 D4

B

+D

KEY_3

3516

270R

3517

390R

1414

B

FAV

1413

B

MARKER

3518

560R

1412

B

S_RIGHT

3519

820R

1411

B

ENTER

3520

1K2

1410

B

STOP

100p

B

A

2461

1401 D4

1402 D4

1403 D5

1404 D6

1405 D6

1406 D7

1407 D7

1408 D7

1409 D5

1410 A6

1411 A6

1412 A5

D

B

+D

1413 A5

1414 A5

2461 A7

3502 D8

3503 D7

3504 D7

3505 D6

3506 D6

D

3507 D6

3508 D5

3509 D5

3510 D4

3511 D4

3516 A4

C

B

3517 A5

3518 A5

3519 A6

3520 A6

3535 E4

3536 F4

3537 E5

3538 E5

3539 F5

3540 E6

3541 E6

3542 F6

3543 E6

3544 E7

3545 F7

1401

B

S_LEFT

3510

220R

3509

270R

1402

BB

BACK

3511

150R

1400

B

B

VIEW

1403

B

PAUSE

3508

390R

1409

OPTION

3507

560R

1404

B

CONNECT

3506

820R

1405

B

PC_LINK

3505

1K2

1406

B

CD

3504

1K8

1407

B

TUNER

3503

2K7

1408

B

AUX

3502

4K7

D

3546 E7

3547 E7

+D

+D

+D

+D

+D

3548 F8

3549 E8

6401 E5

6402 E5

6403 E6

6404 E7

6405 E8

7401 E4

7402 E5

7403 E6

7404 E7

7405 E8

3535

4K7

LED_CD

7401

BC847B

10K

3536

D

270R

6401

D

3537

3538

4K7

LED_TUNER

7402

BC847B

10K

3539

D

3540

270R

LED_CONNECT

6402

7403

3541

4K7

10K

3542

D D

D

270R

6403

D

3543

3544

4K7

LED_PCLINK

7404

BC847BBC847B

10K

3545

D

3546

270R

LED_AUX

6404

7405

BC847B

3547

4K7

10K

3548

DD

270R

6405

3549

E

+D

D

F

Note : Some values may varies, see respective parts list for correct value.

12345678

3139 118 55850...8239 210 91633 for...3476 pt3 dd wk0248

*

*

*

B

C

1320 A1 2440 B2 2441 B3 2442 B2 2443 B2 3585 A3

To Control PCB

*

123

123

A

B

C

A

2443

4u7

3586 B3 3587 B3 4450 B3 6460 B2

D

GND

+D

RC5

2442

4u7

35022

1320

1

2

3

3587

1K

4u7

2440

100R

3585

2441

DD

2n2

GND4MT

1OUT

2

VSUP

10K

3586

D

4450

6460

TSOP2236ZC1

3

+D

Infra Receiver PCB

3139 118 55850...8239 210 92093...for 3476 pt3 dd wk0248

Note : Some values may varies, see respective

parts list for correct value.

: Provision

6-6

6-6

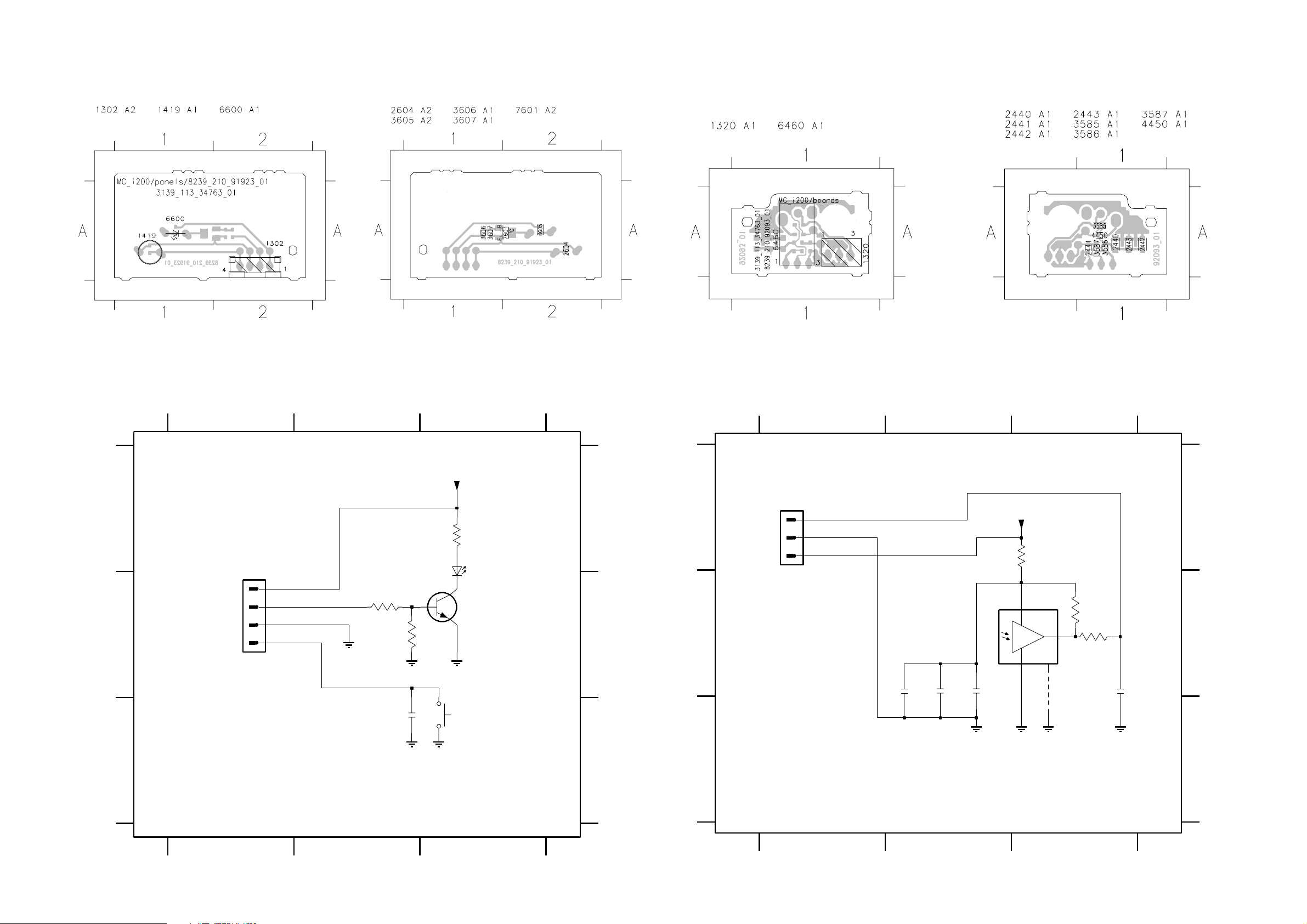

ECO STANDBY BOARD - COMPONENT LAYOUT

This assembly drawing shows a summary of all possible versions. For components

used in a specific version see schematic diagram and respective parts list.

3139 113 3476 pt3 dd wk0248

ECO STANDBY BOARD - CIRCUIT DIAGRAM

ECO STANDBY BOARD - CHIP LAYOUT

This assembly drawing shows a summary of all possible versions. For components

used in a specific version see schematic diagram and respective parts list.

3139 113 3476 pt3 dd wk0248

INFRA RECEIVER BOARD - COMPONENT LAYOUT

This assembly drawing shows a summary of all possible

versions. For components used in a specific version see

schematic diagram and respective parts list.

3139 113 3476 pt3 dd wk0248

INFRA RECEIVER BOARD - CIRCUIT DIAGRAM

INFRA RECEIVER BOARD - CHIP LAYOUT

This assembly drawing shows a summary of all possible

versions. For components used in a specific version see

schematic diagram and respective parts list.

3139 113 3476 pt3 dd wk0248

1302 B1 1419 C3 2604 C2 3605 A3 3606 B2 3607 B2 6600 B3 7601 B2

123

ECO Standby PCB

A

B

LED_ECO

ECO_STDBY

EH-B

1302

To Display PCB

1

2

3

4

+D

1K

D

3606

4K7

7601

BC847B

10K

D

2604

D

3607

10n

6600

D

1419

D

A

3605

B

C

Note : Some values may varies, see respective

parts list for correct value.

123

3139 118 55850...8239 210 91923...for 3476 pt3 dd wk0248

STANDBY

C

Loading...

Loading...