Philips MBD-7020 Service Manual

Blue-Ray Disc Player

MBD7020/12/93

egaPstnetnoC

1 Technical Specification and Connection Facilities

2 Laser Beam Safety Precautions......................................... 2-1

3 Important Safety Precautions .................................. 3-1 to 3-2

4 Safety Check After Servicing ............................................. 4-1

5 Safety Information General Notes & Lead Free

Requirements .................................................................... 5-1

6 Standard Notes For Servicing,Lead Free Requirements

& Handling Flat Pack IC .......................................... 6-1 to 6-4

7 Direction of Use ....................................................... 7-1 to 7-6

8 Cabinet Disassembly Instructions ........................... 8-1 to 8-2

9 Troubleshooting ....................................................... 9-1 to 9-2

10 Block Diagram .................................................................10-1

11 Wiring Diagram ...............................................................11-1

12 Headphone & MP3 Link and USB、LED Board

13 AMP Board

©

Copyright 2011 Philips Consumer Electronics B.V. Eindhoven, The Netherlands.

All rights reserved. No part of this publication may be reproduced, stored in a

retrieval system or transmitted, in any form or by any means, electronic,

mechanical, photocopying, or otherwise without the prior permission of Philips.

Published by Sophie-KM 1123 AVM Printed in the Netherlands

Circuit Diagram ....................................................12-1

Layout Diagram ...................................................12-1

Circuit Diagram ....................................................12-2

Layout Diagram ...................................................12-3

...................................................1-1 to 1-10

Contents

14 Display Board

Circuit Diagram ................................................12-4

Layout Diagram ...............................................12-5

15 Key Board

Circuit Diagram .................................................12-6

Layout Diagram.................................................12-7

16 Power Board

17 Decoder Board

18 Exploded View....................................................................13-1

19 Revision List .......................................................................14-1

Circuit Diagram ........................................12-8 to 12-9

Layout Diagram ..............................................12-10

Circuit Diagram .................................12-11 to 12-19

Layout Diagram ..............................................12-20

Feature

Features

RDS

Voltage Selector

ECO Standby

DTS

Subject to modi cation EN

Different

/12 /93

Page

3141 785 36200

Version 1.0

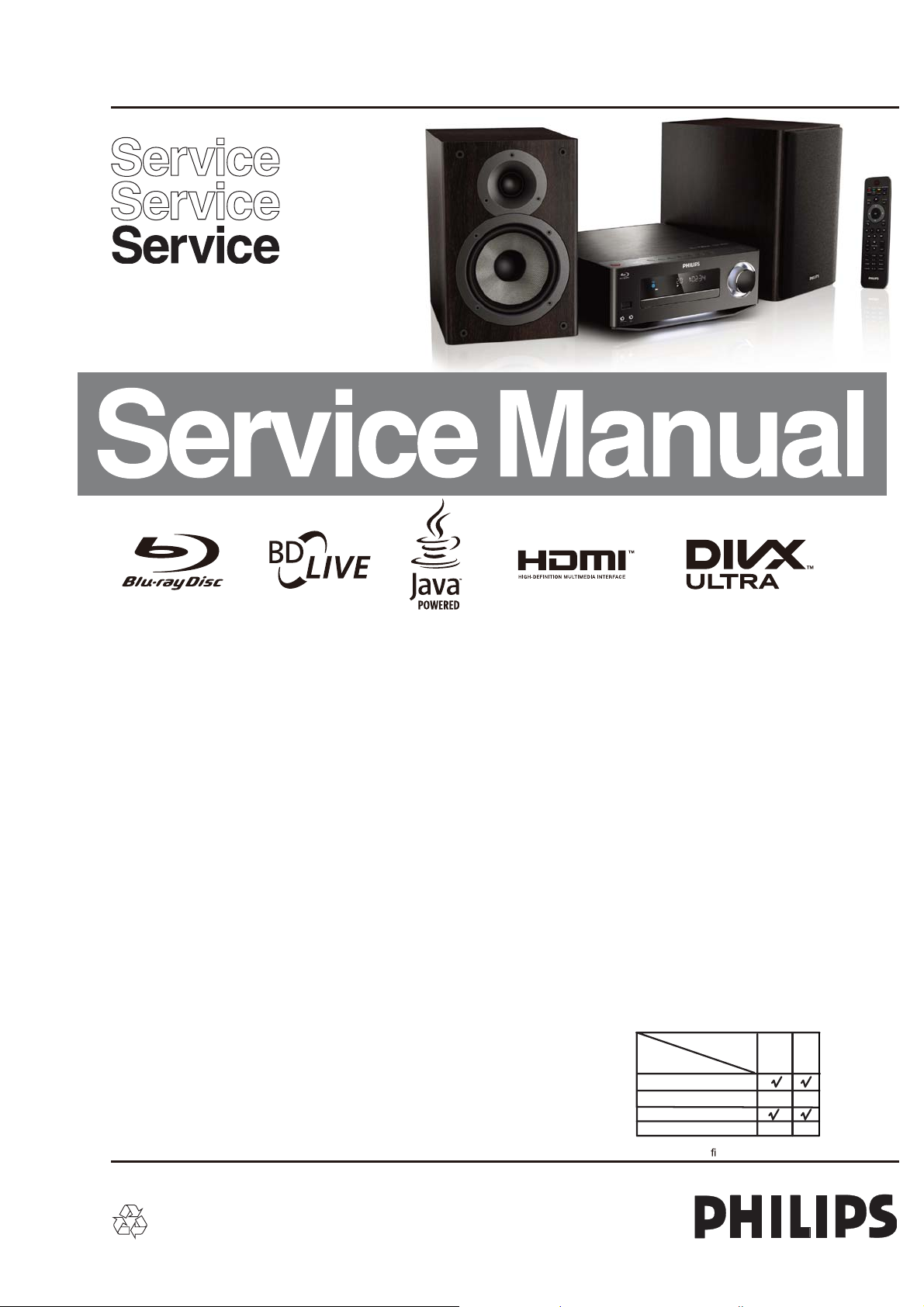

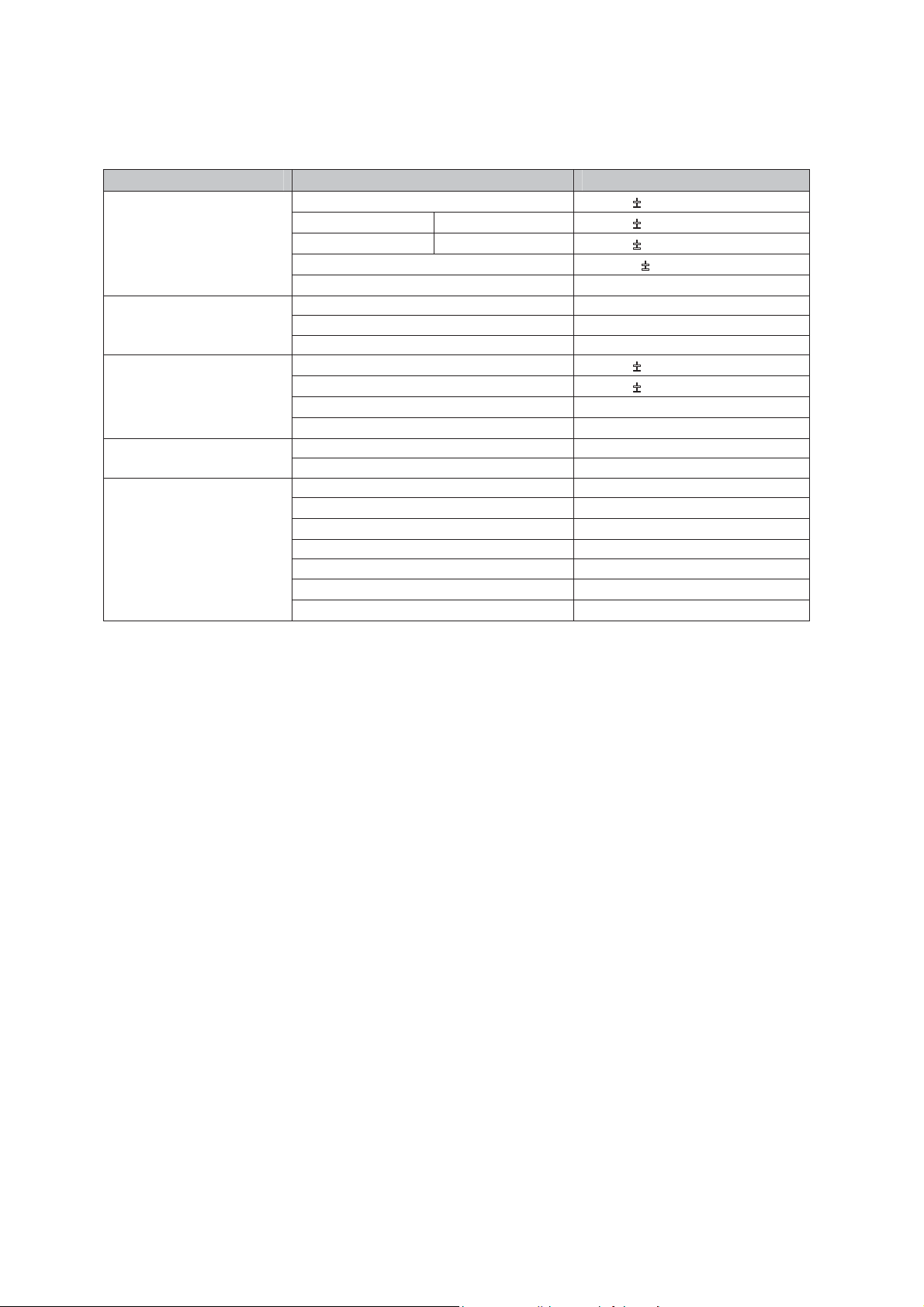

Location of PC Boards

Technical Specification and Connection Facilities

Decoder Board

AMP Board

Bl-Ray Loader

Decoder Board

Bl-Ray Loader

Key Board

Key Board

USB Board

USB Board

Headphone/MP3 Link Board

Headphone/MP3 Link Board

Display Board

Display Board

LED Board

LED Board

AMP Board

Power Board

Power Board

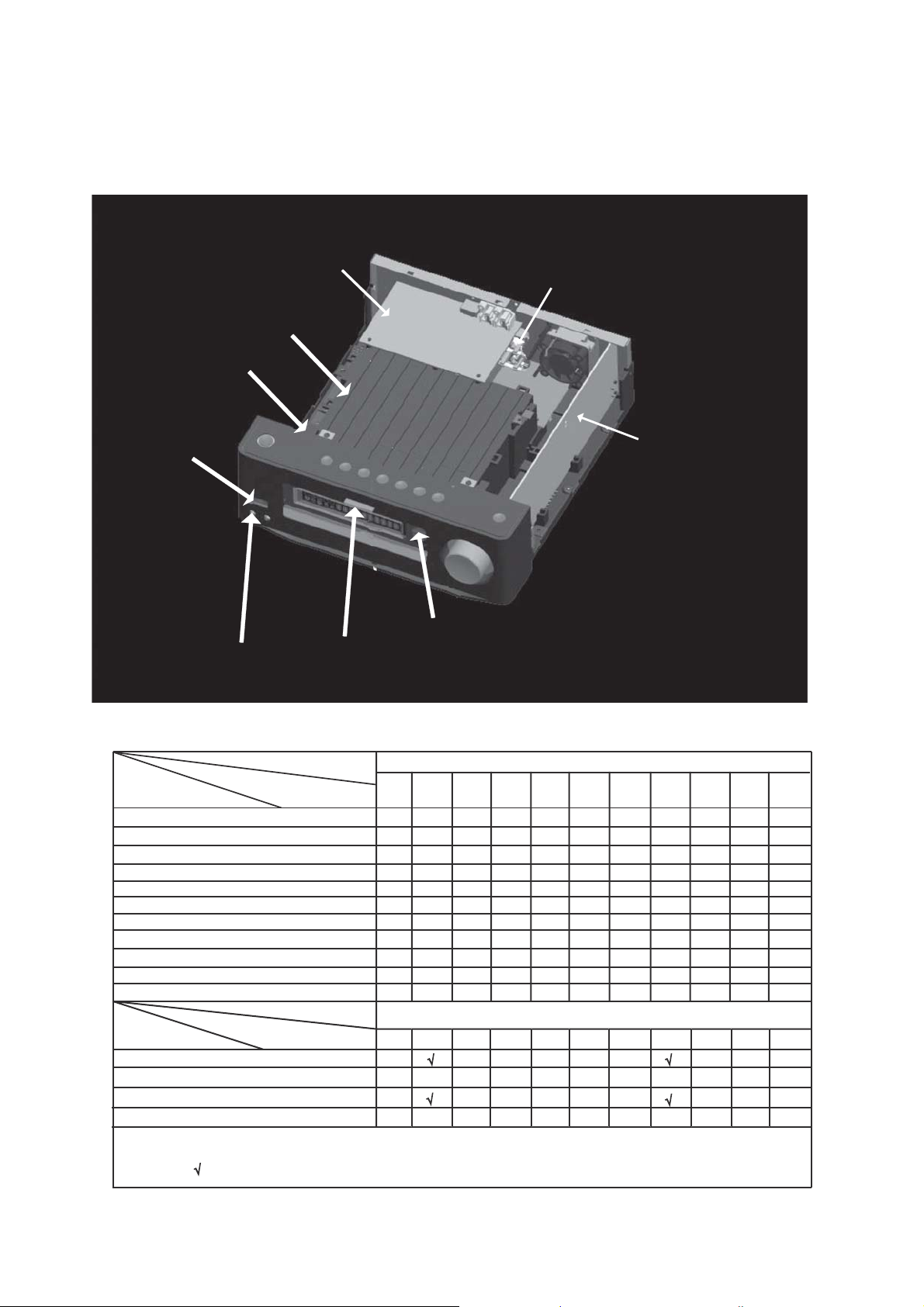

Version Variations

Board in used:

LED Board

Decoder Board

Display Board

AMP Board

Headphone & MP3 Link Board

Power Board

USB Board

Key Board

Features

RDS

VOLTAGE SELECTOR

ECO STANDBY - DARK

DTS

* TIPS : C -- Component Lever Repair.

Type /Versions:

Service policy

Type /Versions

Feature diffrence

M -- Module Lever Repair

-- Used

/05

/05

/12

C

C

C

C

C

M

C

C

/12

/51

/37

/55

/55

/58

/58

MBD7020

/61

MBD7020

/61

/79

/79

/93

C

C

C

C

C

M

C

C

/93

/94

/94

/96

/96

/98

/98

1-1

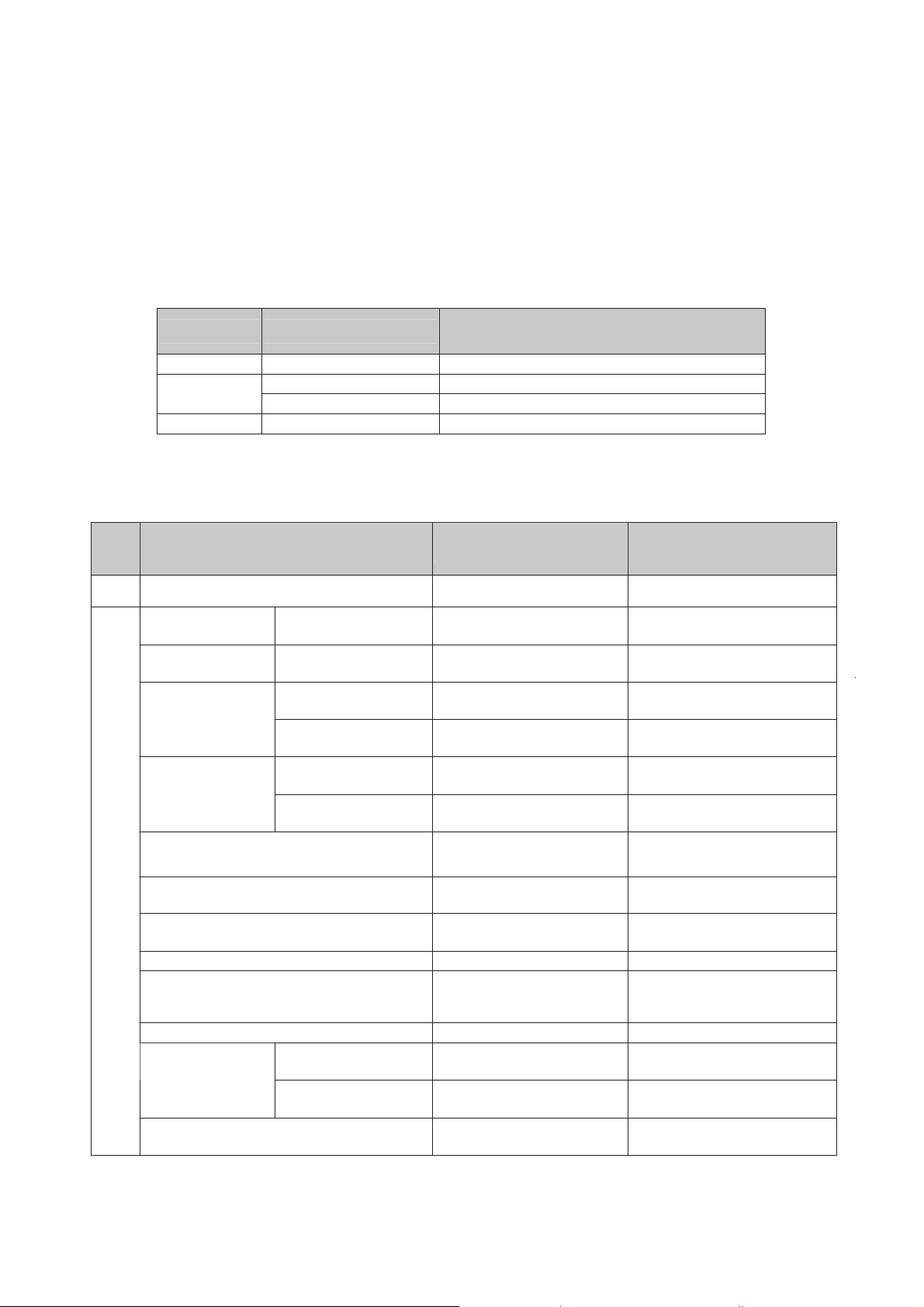

Technical Specification and Connection Facilities

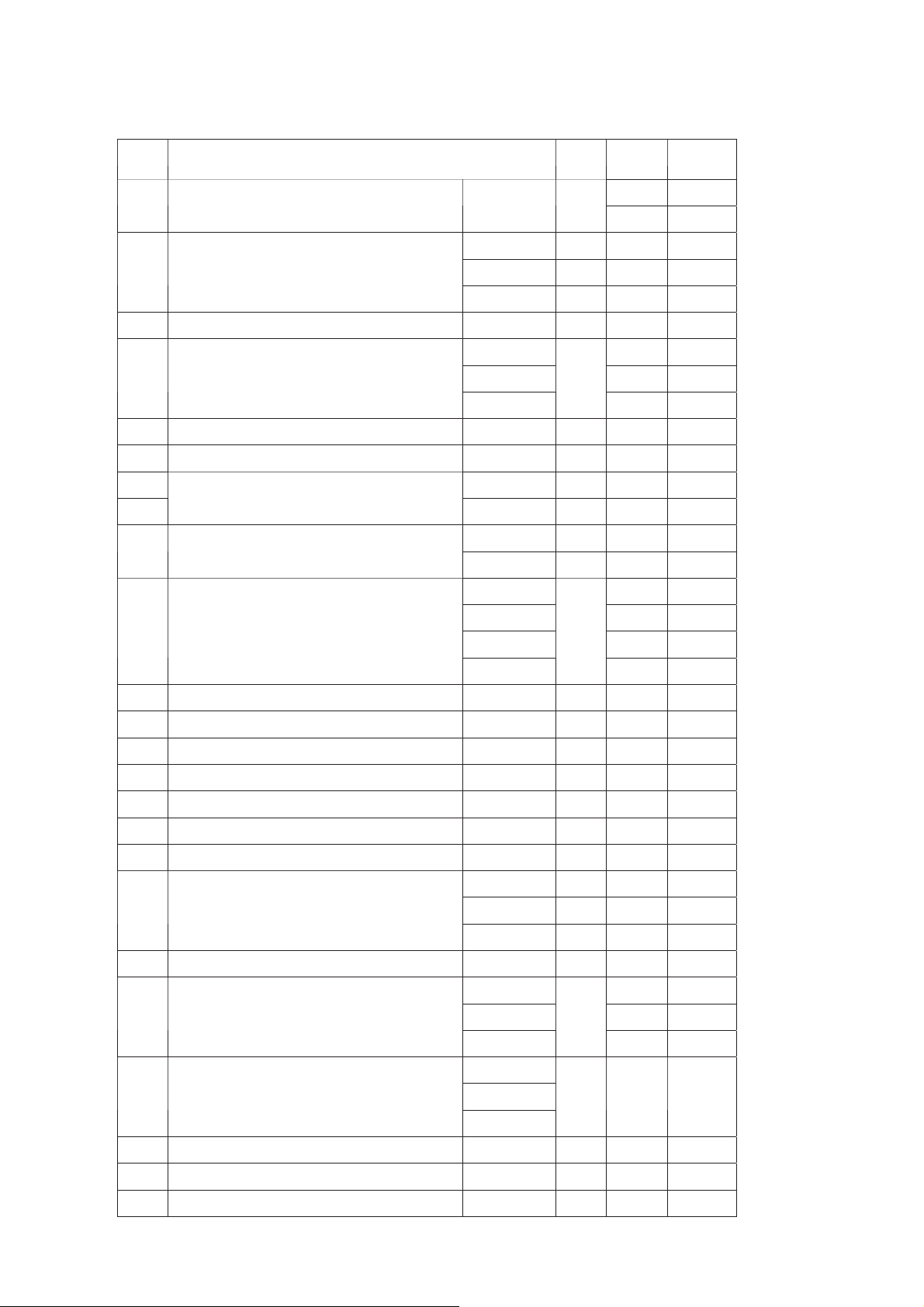

Technical Specification

2 General Specification

2.1 Product family features

2.1.1 Styling and functions

MBD7020 appearances are defined In MUS. MUS is the leading document where product appearance is

applicable.

Features Products

Dimension

Weight ][gnigakcaptuohtiW

W x D x H (mm)

teeffothgieH

[ALL Stroke Version]

Refer to Appendix A for dimensional sketch and tolerances of the set.

2.1.2 Product Interfaces

Interface Type

AC Power Input

Composite Analog

Video

Digital Audio Coaxial

Analog Audio

[Line Out]

Aux In

HDMI

CVBS

Left

Right

Left

Right

Detachable Mains cord +

Cinch

[Color : Yellow]

Cinch

[Color: Black]

Cinch

[Color : White]

Cinch

[Color : Red]

Cinch

[Color : White]

Cinch

[Color : Red]

HDMI Type A

[Receptacle]

MBD7020

sliatedrof]3[SUMotrefeRngiseD

[250x93.5 x286]mm

2.7kg

MBD7020

[ALL Storke Version]

+

+

+

+

+

+

+

Back Panel

USB

[for Wi-Fi Dongle use only]

iPhone Ready

Left

Speaker Out

Right

Upgrade Jack

USB Type A Receptacle +

Mini-Din connector to

interface 2K10 Dock

accessory

Screw-type

[ref:MCD712/MCD909]

Screw-type

[ref:MCD712/MCD909]

4 Pins FFC Jack

[Color:Red]

1-2

+54JRtenrehtE

+kcaJMM5.3yoB-M

+

+kcaJmhO57annetnAMF

+

+

+

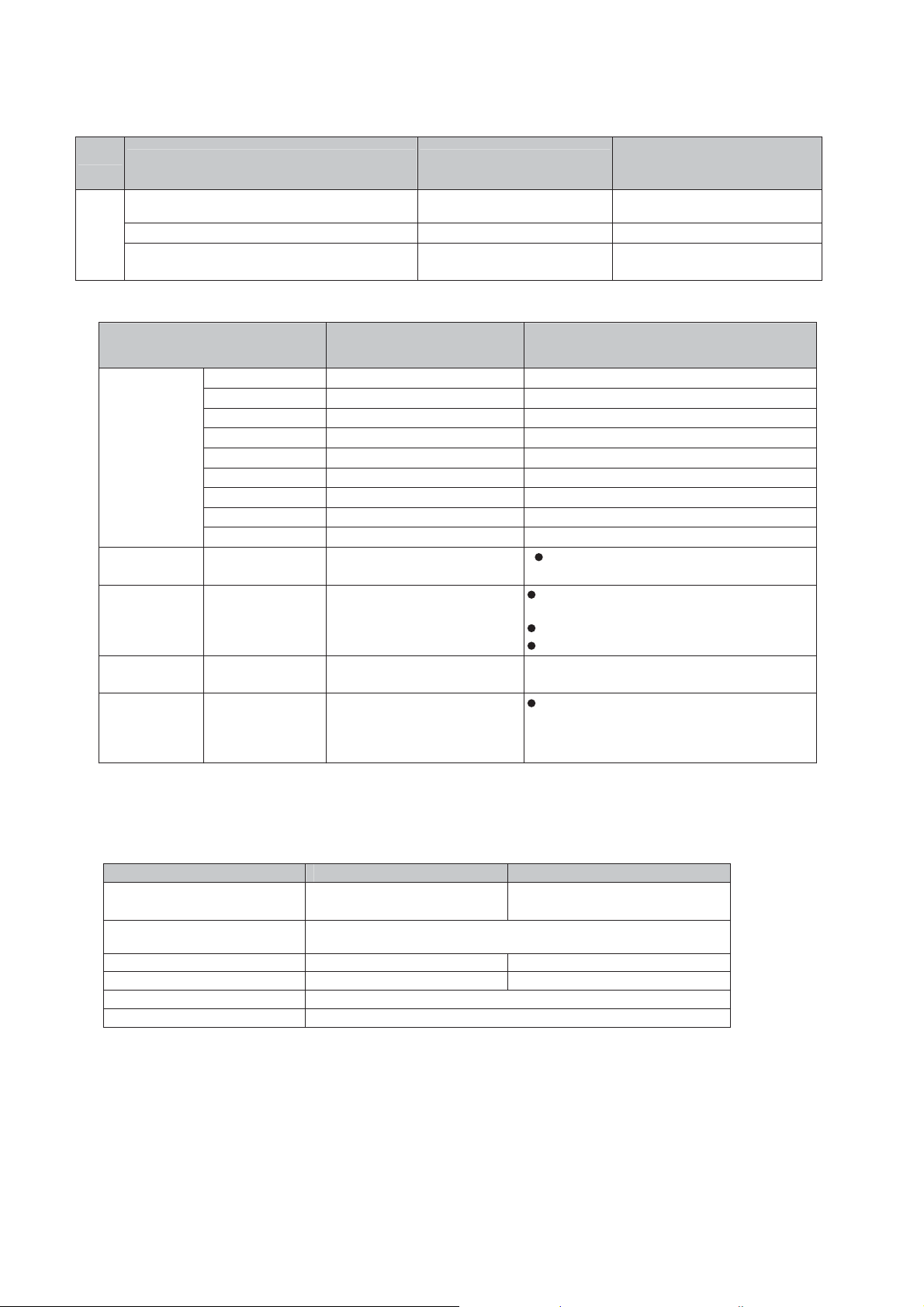

Technical Specification and Connection Facilities

Front

Panel

2.1.3 Product Controls

Controls / Indicators

Buttons

Rotary

Knob

Down Light

Indicator

VFD Display

Volume

Standby

Indicator

1-Line VFD

Display

Interface Type

USB

[ALL Stroke Version]

[with white Led]

[with white Led]

[with Red Led]

USB Type A Receptacle

[Color: Black]

MBD7020

)DELderhtiw(+NO-YBDNATS

+ecruoS

+-tesreP

++teserP

+esuaP/yalP

+drawroF

+VER

+potS

+tcejE

+

+

+

+

MBD7020

[All Stroke Version]

+kcaJMM5.3enohpdaeH

+kcaJMM5.3kniL3PM

+

Remark

Fade-on and Fade-off effect is required.

Refer to UIS for LED detailed behavior

Light cast downward ,bright at the centre

and fades towards the sides

Fade-on and Fade-off effect is required

Refer to UIS[2] for detail light behavior

IIIumination must vanish within 5 seconds

after AC mains switch off

Design must be able to cater for VFD

display on/off during standby mode.

Refer to UIS for VFD dimming and

standby mode behavior

3 Environmental Condition

3.1 Set Operating Condition

Description Full Specification Full Function

Ambient Temperature 10°C to 35°C 5°C to 40°C

Maximum Temperature

change

Absolute Humidity [g/m3] 3..20 1½..25

Relative Humidity [%]

Condensation

Air pressure 55..110 kPa (55kPa equals an altitude of some 3,800 m)

11°C per hour

10..80 5..90

Not allowed

1-3

Technical Specification and Connection Facilities

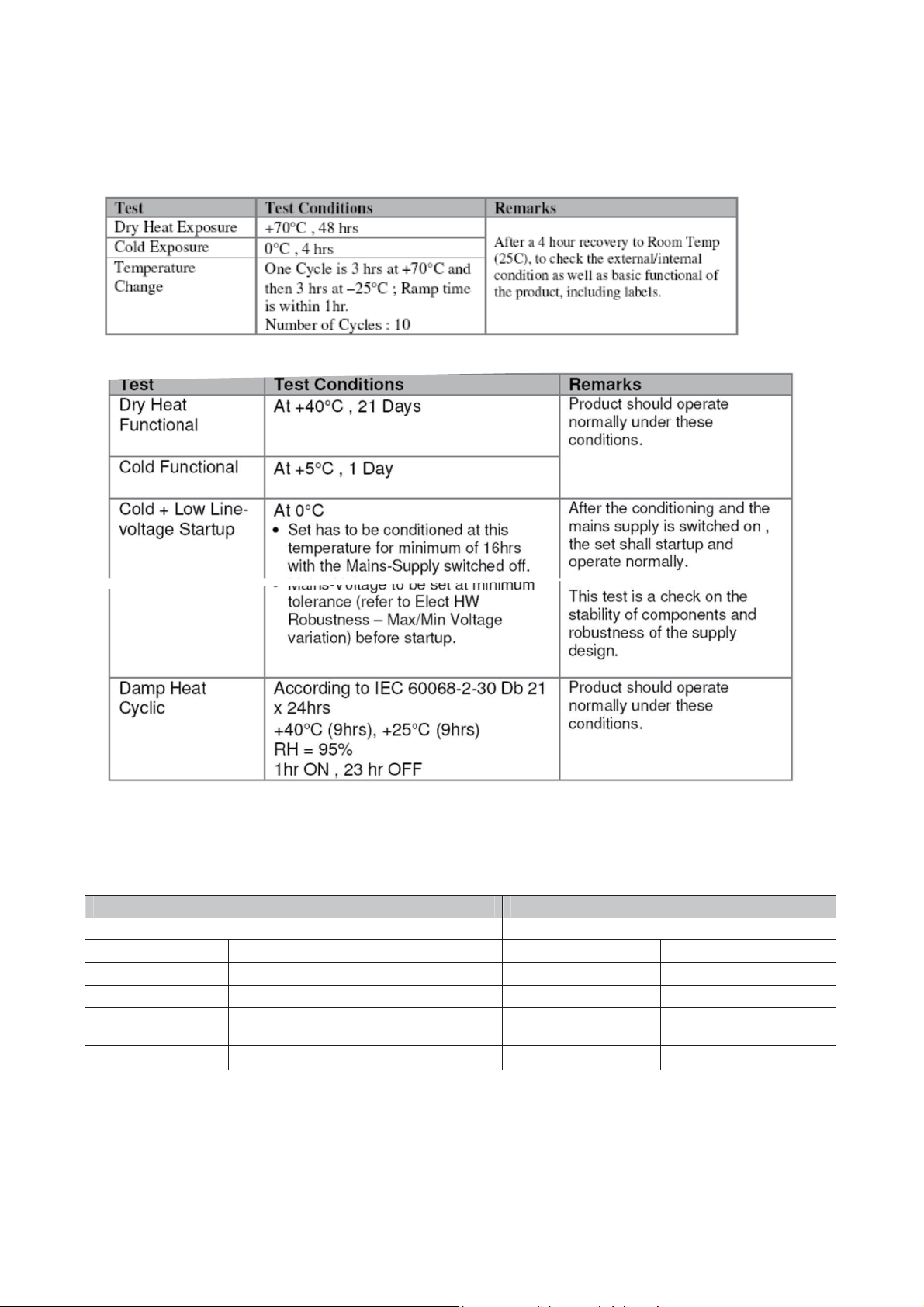

3.2 Climatic Tests

3.2.1 Exposure Test (Non-Operating)

3.2.2 Functional Test (Operating)

4 Performance Specifications

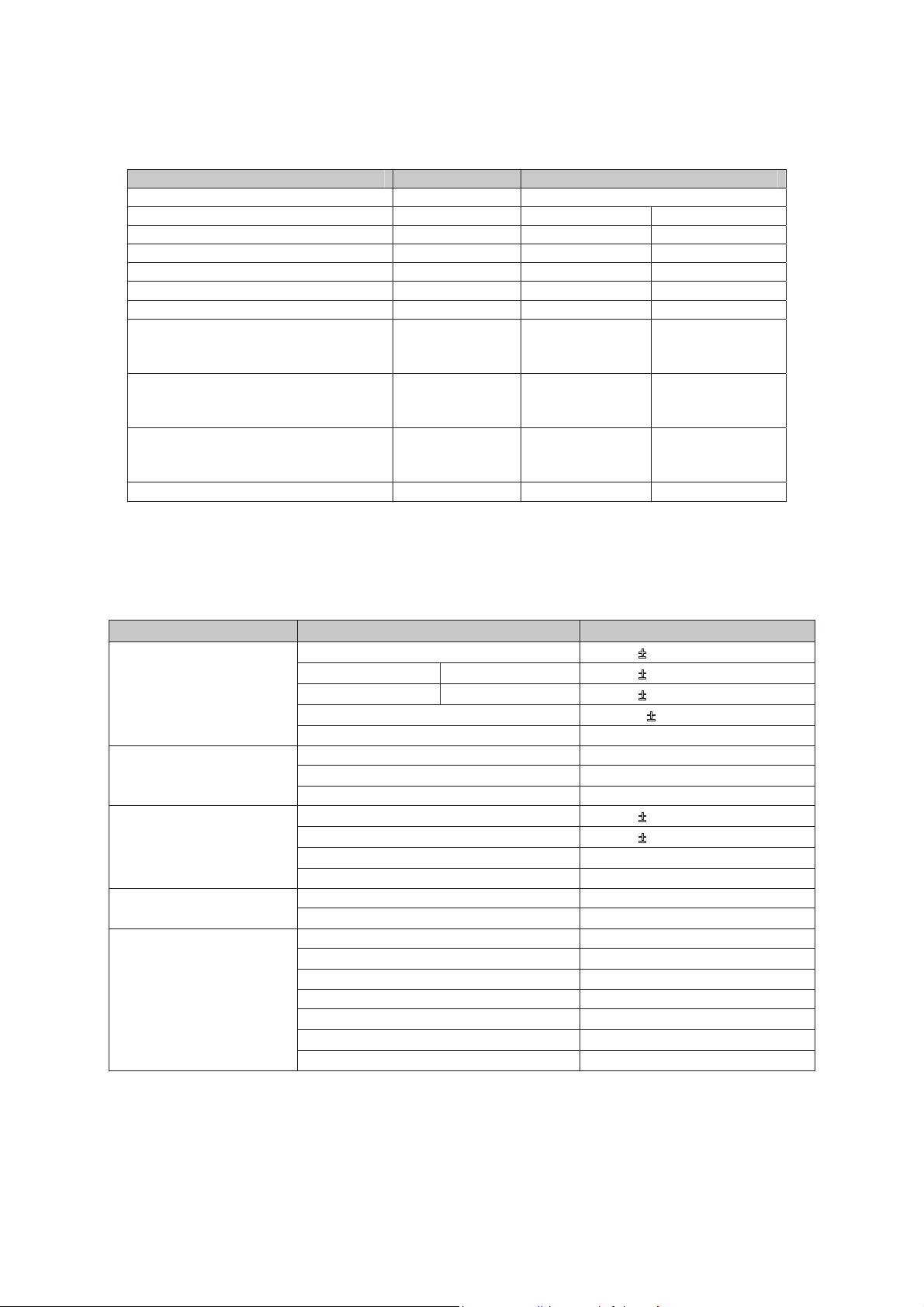

4.1 Audio Performance

4.1.1 Reference levels

Audio inputs Audio Outputs

Audio Input Sensitivity (±3dB) rated output power at 1KHz Audio Output(*1)

Tuner FM 67.5KHz,Modulation (Limit:-6dB) Line Out (Left/Right)

CD / MP3 0dB track (Audio Disc 1 ,Track 1) Headphone

USB 0dB 1KHz sine wave (2.0HS) Line Out S/N 80dB

Aux1(Back)

MP3_Link(Front)

1V;Rin 16Kȍ

0.5V; Rin 16Kȍ

Amplifier

1-4

2Vrms ± 2dB

500mV± 2dB,RL=32ȍ

2 x 50W(10%THD)

± 0.5dB,6 ȍ

Technical Specification and Connection Facilities

4.1.2 Amplifier Output

Measurements are done with rated speaker impedance.

Description Specification

Rated Output Power @ 10%THD

Channel Unbalance(1KHz) |2.0|dB

Crosstalk (20Hz – 20KHz) |50|dB

Frequency Response (30Hz – 16KHz )

Frequency Response with De-emphasis

( 20Hz – 20KHz )

THD+N before clipping (1KHz,5KHz) -0.05%

Hum(Vol min ---Vol max -20db) 150nW

Residual Noise (Volume Minimum) 40nW

Acoustical 26dB

4.1.3 Analogue Audio Headphone Output

CD-DA(PCM)

Description Specification

Output Power 30mW

Output Level

Load impedance

Channel Unbalance(1KHz) |0.3|dB

Crosstalk

Frequency Response 20Hz – 20KHz

Signal –to-Noise Ratio A-weighted -80dB

Dynamic Range

THD+N

1KHz |65|dB

16Hz – 20KHz |60|dB

1KHz |65|dB

20Hz – 20KHz |65|dB

1KHz -65dB

16Hz – 20KHz -65dB

50W± 0.5dB

± 3dB

+0.5 / -2.0dB

500mV ± 2dB ,RL=32ȍ

8ȍ to 2Kȍ

± 3.0dB

4.1.4 Analogue Audio Line Output

4.1.4.1 CD-DA (PCM) / Video CD (MPEG-1)

CD-DA(PCM) /Video CD (MPEG-1)

Description Specification

Output Voltage

Channel Unbalance(1KHz) |0.3|dB

Crosstalk 16Hz – 20KHz |55|dB

Frequency Response 20Hz – 20KHz +0.5/ -2.0dB

Frequency Response with De-emphasis

20Hz – 20KHz

A-weighted

Dynamic Range

THD+N 16Hz – 20KHz

Phase Difference Between Channels

Phase Non-Linearity

Level Non-Linearity

Outband Attenuation 35dB(Above 40KHz)

20Hz – 20KHz |65|dB

-60dB to -90dB

2.0V ± 0.5dB

+0.5/ -2.0dB

-80dBSignal –to-Noise Rati o unweighted

-80dB

1KHz |65|dB

-65dB

-65dB

±1°

tuptuotaesluPevitisoP)H(FFF7ytiraloPtuptuO

8000(H)Negative Pulse at output

1-5

Technical Specification and Connection Facilities

4.1.5 Digital Audio Outputs

Standard Reference

IEC 60958

IEC 61937

4.1.5.1 Coaxial & Optical Output

Required to support up to bitrate of up to 96KHz SPDIF input.

Description Specification Test Condition

Output signal amplitude 0.5 Vpp ± 20%

Output impedance 75 ± 20%

DC output voltage < 0.05 V

Clock accuracy < 100 ppm (typical)

T

and T

rise

Intrinsic jitter < 0.05 UI Weighted High Pass Filter used

For specific TOSLINK requirements, refer to Jeita CP-1212 standard.

fall

75ȍ termination

75ȍ termination

< 1000 ppm (maximum)

IU4.0<

(-3dB at 700Hz,-20dB at 70Hz)

4.2 Standard Definition Analog Video Performance

4.2.1 CVBS

Description Test Signal Specification

Amplitude output 100% White 1000mVpp ± 10% 1000mVpp ± 10%

Sync. Amplitude 100% White 286mV ± 10% 300mV ± 10%

Burst Amplitude

Burst /chroma ratio 100% Color bar ± 5% ± 5%

S/N luminance

S/N chroma

AM

PM

Video Bandwidth

0.5MHz – 4MHz

4.8MHz

5.8MHz

Chroma Subcarrier Frequency 75% Color bar 3.579545 MHz ±

Chroma / luminance delay 2T pulse

Subcarrier locked/unlocked 75% Color bar locked locked

All figures are to be measured with 75ȍ output termination.

75% Color bar 286mV, +1dB / -

100% White

100% Red

Multi-burst

kcalB%0leveLCD

NTSC PAL

4dB

60 dB 60 dB

57 dB

57 dB

-1.5dB

-5dB

25ppm

20ns 20ns

1V 1V

300mV, +1dB / -4dB

60 dB

57 dB

+1dB/-1dB

-2dB

-5dB

4.433618MHz ±

30ppm

%01±Vm007%01±Vm417etihW%001rabetihW

1-7

Technical Specification and Connection Facilities

4.2.2 Component Video (Y/Pb/Pr)

Description Test Signal Specification

PbPr peak to peak 75% Color bar 525mV ± 10% 535mV ± 10%

PbPr Output unbalance

S/N on outputs

Video Bandwidth

Video Bandwidth (Progressive)

Pb / Pr

4.2MHz

5.8MHz

8.4MHz

9.6MHz

75% Color bar

Y

100% White

75% Color bar

Multi-burst -1.5dB

Multi-burst -1.5dB

kcalB%0leveLCD

Interlace/Progressive

NTSC PAL

3% 3%

60 dB 60 dB

-1.5dB

-5dB

-5dB

1V 1V

-5dB

-1.5dB

-5dB

%01±Vm0001%01±Vm0001etihW%001tuptuoedutilpmA

%01±Vm007%01±Vm417etihW%001rabetihW

%01±Vm003Vm04±Vm682etihW%001edutilpmA.cnyS

All figures are to be measured with 75ȍ output termination.

4.3 High Definition Analog Video Performance

4.3.1 720P Component Video (Y/Pb/Pr)

Test Picture Parameter Specification

Y White Level

Sync Amplitude Positive Part

100% White

0% Black

75% Color Bar

100% Red

Multi-burst

Sync Amplitude Negative Part

Y Amplitude O/P

S/N Y 60dB

DC Level Y(Blanking Level) 1V

DC Level P b(Blanking Level) 1V

DC Level P

Pb Amplitude O/P

Pr Amplitude O/P

PbPr Unbalance 3%

Component Vector Within 5% box

S/N Pb 60dB

S/N Pr 60dB

Video Amplitude

5MHz -1.5dB

10MHz -1.5dB

15MHz -1.5dB

20MHz -1.5dB

25MHz -1.5dB

30MHz -5dB

r(Blanking Level) 1V

700mV±

300mV±

300mV±

1000mV±

525mV±

525mV±

10%

10%

10%

10%

10%

10%

1-7

Technical Specification and Connection Facilities

4.3.2 1080i Component Video (Y/Pb/Pr)

Test Picture Parameter Specification

Y White Level

Sync Amplitude Positive Pary

100% White

0% Black

75% Color Bar

100% Red

Multi-burst

Sync Amplitude Negative Part

Y Amplitude O/P

S/N Y 60dB

DC Level Y(Blanking Level) 1V

DC Level P b(Blanking Level) 1V

DC Level P

Pb Amplitude O/P

Pr Amplitude O/P

PbPr Unbalance 3%

Component Vector Within 5% box

S/N Pb 60dB

S/N Pr 60dB

Video Amplitude

5MHz -1.5dB

10MHz -1.5dB

15MHz -1.5dB

20MHz -1.5dB

25MHz -1.5dB

30MHz -5dB

700mV±

300mV±

300mV±

1000mV±

r(Blanking Level) 1V

525mV±

525mV±

10%

10%

10%

10%

10%

10%

4.4 FNAC Requirement

MBD7020 is to attain 4 starts fnac rating.

4.5 Sound Requirement

Reference

MBD7020 Sound Requirement Specification [8]

4.6 FM Tuner

Test conditions:

Power Supply: AC According to Ver

Ref Output :6ȍ 1W, sound effect off

FM MONO:22.5KHz Dev, 1KHz Modulation , 75ȍ Impedance , 60dBu

FM Stereo: Main+Sub =50KHz,Pilot:10Khz, Composite :40.0KHz

IF: FM IF:10.7MHz

1-8

Technical Specification and Connection Facilities

NO TEST ITEMS UNIT NOM. LIMIT

1 Frequency Range MHz

90MHz dBf 24~30 19~35

13 TUNING SENS

3 -3dB LIMITING POINT dBf 17 23

2 26dB QUENTING SENSITIVITY

4 FM IF REJEDION 98MHZ S/N=26dB dB 65 60

5 IMAGE REJECT 98MHZ S/N=26dB dB 30 25

SELECTIVITYS

6

14 TUNING ACCURAY

7 S/N AWIGHTED

98MHz dBf 24~30 19~35

106MHz dBf 24~30 19~35

90 18 22

98 18 22

106

300kHz 30 25

>500KHz dB 55 48

˘91 dBf 0

˚91 dBf ±1

MONO 193 55 50

ST 193 55 50

MONO 65 60

dBf

18 22

dB

87.5

108

ST

10 FREQUENCY RSEPOUSE

8 OVERALL DISTERTION % 2 3

17 THD 10% POWER W 50 45

9 MODULATION HUM dB 55 45

15 STEREO TURNON dBf 17.5 23.5

16 STEREO CHANNEL SEPARATION

14 AUTO TUNING SENG ALL dBf 24~30 19~35

19 RDS SENSITIVITY

20 RDS 乥أ SENSITIVITY

63Hz

12.5KHz ±3

400Hz dB 26 20

1KHz dB 30 26

5KHz dB 20 18

90Hz 30 36

98Hz 30 36

106Hz

90Hz

98Hz

dB

dB

KHz 0.4 0.6

65 60

±3

30 36

106Hz

11 AM SUPPRESSION I/B 48--82dBf dB 35 30

12 8/9/10 HARMONICS WHISTLE dB 40 35

18 IF MHz 10.7 ±0.2

1-9

4.7 HDMI

Standard Reference

High-Definition Multimedia Interface Specification version 1.3a

High-Definition Multimedia Interface Compliance Test Specification version 1.4

4.7.1 USB

Standard Reference:

USB specification Revision 2.0,dated 27 April 2000

USB-IF USB 2.0 Electrical Test Specification Version1.03, dated January 2005

USB-IF Embedded Host Compliance Plan , Revision 1.0, dated August 2006

USB 1A requirement

4.8 Ethernet

Standard Reference: IEEE802.3-2005

Physical Layer:10/100Base-T

Data rate: 10/100Mbps

With Auto MDI/MDIX

4.9 WiFi

Standard Reference

IEEE 802..11b Sept 1999

IEEE802.11g June 2003

IEEE802.11n Draft 2.0

WiFi-N module is interfaced via USB

Technical Specification and Connection Facilities

4.10 iPod / iPhone Support

Standard Reference :

iPod/iPhone Hardware Specification , Release R9

iPod/iPhone Accessory Testing and Certification Specification ,Release R1

iPod/iPhone Accessor

y Protocol Interface Specification , Release R39

1-10

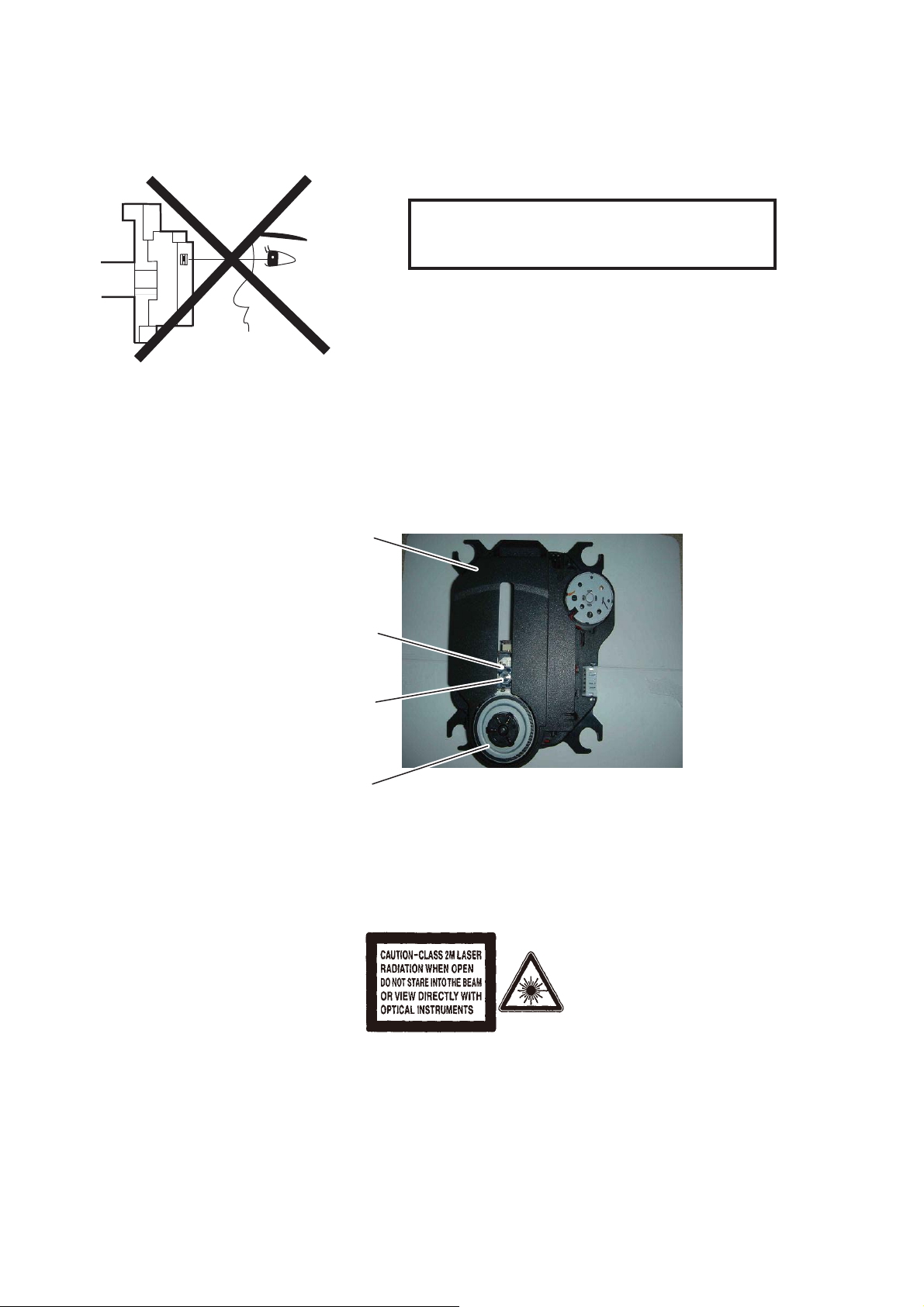

Laser Beam Safety Precautions

This Blu-Ray player uses a pickup that emits a laser beam.

Do not look directly at the laser beam coming

from the pickup or allow it to strike against your

skin.

The laser beam is emitted from the location shown in the figure. When checking the laser diode, be sure to keep

your eyes at least 30 cm away from the pickup lens when the diode is turned on. Do not look directly at the laser

beam.

CAUTION: Use of controls and adjustments, or doing procedures other than those specified herein, may result in

hazardous radiation exposure.

Drive Mechanism Assembly

Laser Beam Radiation

Laser Pickup

Turntable

Location: Inside Top of Blu-Ray mechanism.

2-1

Important Safety Precautions

Caution: These servicing instructions are for use by qualified service personnel only.To reduce the risk

of electric shock do not perform any servicing other than that contained in the operating

instructions unless you are qualified to do so.

Important

Read and understand all instructions before you use

your home theater. If damage is caused by failure to

follow instructions, the warranty does not apply.

Safety

Riskof electricshock or fire!

Never expose the product and

accessories to rain or water. Never place

liquid containers, such as vases, near the

product. If liquids are spilt on or into the

product, disconnect it from the power

outlet immediately. Contact Philips

Consumer Care to have the product

checked before use.

Never place the product and accessories

near naked

including direct sunlight.

Never insert objects into the ventilation

slots

or other openings on the product.

Where the mains plug or an appliance

coupler is used as the disconnect device,

the disconnect device shall remain readily

operable.

Disconnect the product from the power

outlet before lightning storms.

When you disconnect the power cord,

always pull the plug, never the cable.

Riskof short circuit or

Before you connect the product to the

poweroutlet,ensurethatthepower

voltage matches the value printed on the

back or bottom of the product. Never

connec

if the voltage is different.

Risk of injury or damage to the home theater!

For wall-mountable products, use only

the supplied wall mount bracket. Secure

the wall mount to a wall that can support

the combined weight of the product

and the wall mount. Koninklijke Philips

Electronics N.V. bears no responsibility

for improper wall mounting that results in

accident, injury or damage.

ames or other heat sources,

re!

ttheproducttothepoweroutlet

For speakers with stands, use only the

supplied stands. Secure the stands to

the speakers tightly. Place the assembled

stands on flat, level surfaces that can

support the combined weight of the

speaker and stand.

Never place the product or any objects

on power cords or on other electrical

equipment.

If the product is transported in

temperatures below 5°C, unpack the

product and wait u

matches room temperature before

connecting it to the power outlet.

Visible and invisible laser rad

open. Avoid exposure to beam.

Do not touch the disc optical lens inside

the disc compartment.

Risk of overheating!

Never install this product in a confined

space. Always leave a space of at least

four inches around the product for

ventilation. Ensure curtains or other

objects never cover the ventilation slots

on the product.

Risk of contamination!

Do not mix batteries (old and new or

carbon and alkaline,

Remove batteries if they are exhausted

or if the remote control is not to be used

for a long time.

Batteries contain chemical substances,

they should be disposed of properly.

ntil its temperature

iation when

etc.).

Product care

Do not insert any objects other than discs

into the disc compartment.

Do not insert warped or cracked discs

into the disc compartment.

Remove discs from the disc compartment

ifyouarenotusingtheproductforan

extended period of time.

Only use microfiber cloth to clean the

product.

3-1

Important Safety Precautions

Disposal of your old product and

batteries

Your product is designed and manufactured

with high quality materials and components,

which can be recycled and reused.

When this crossed-out wheeled bin symbol

is attached to a product it means that the

product is covered by the European Directive

2002/96/EC.Pleaseinformyourselfaboutthe

local separate collection system for electrical

and electronic products.

Please act according to your local rules and

do not dispose of your old products with your

normal household waste.

Corr

ect disposal of your old product helps to

prevent potential negative consequences for

the environment and human hea

lth.

Your product contains batteries covered by

the European Directive 2006/66/EC, which

cannot be disposed with normal household

waste.

Please inform yourself about the local rules

on separate collection of batteries because

correct disposal helps to prevent negative

consequences for the environmental and

human health.

3-2

Safety Check after Servicing

Examine the area surrounding the repaired location for damage or deterioration. Observe that screws, parts, and

wires have been returned to their original positions. Afterwards, do the following tests and confirm the specified

values to verify compliance with safety standards.

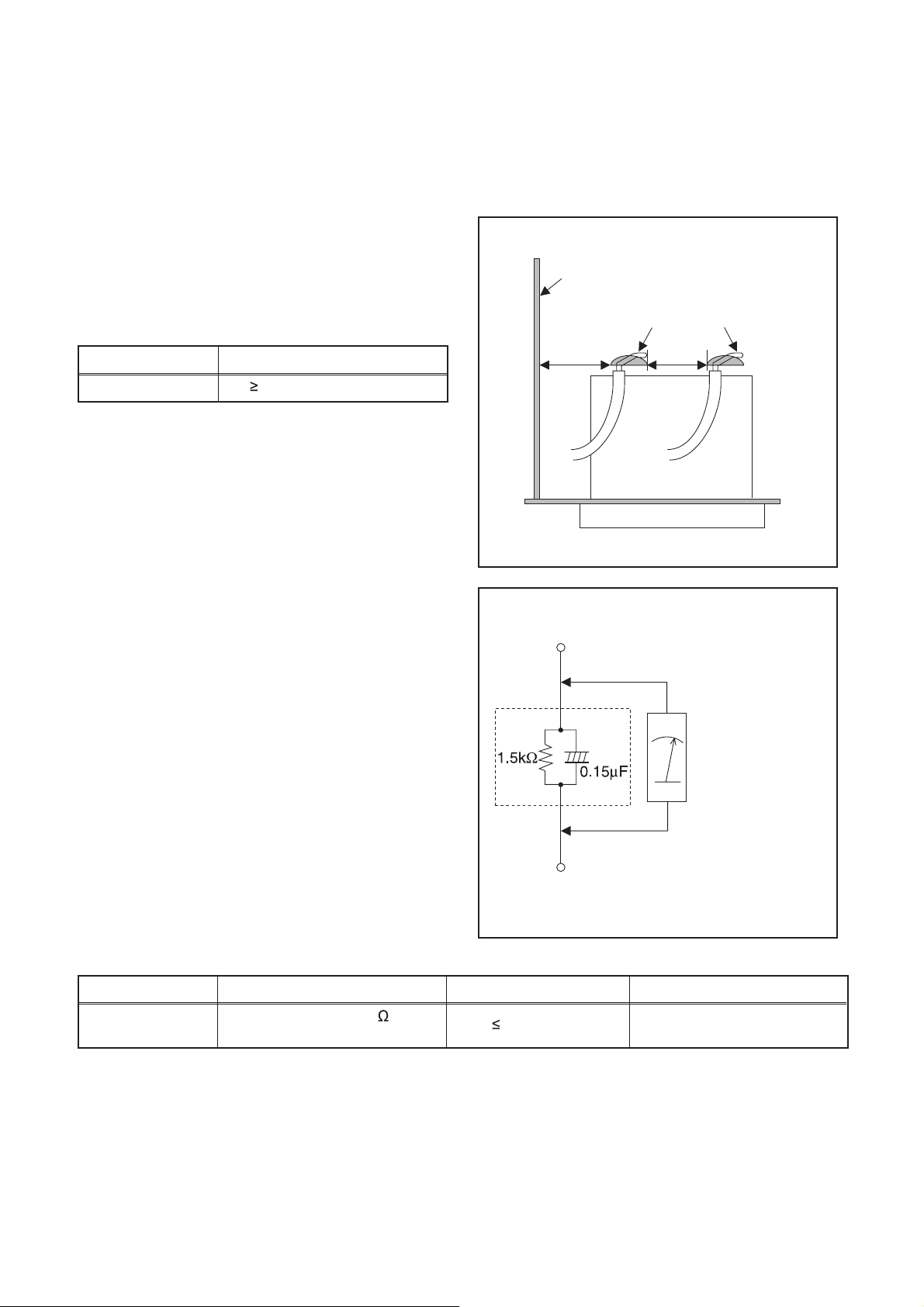

1. Clearance Distance

When replacing primary circuit components, confirm

specified clearance distance (d) and (d’) between

soldered terminals, and between term

surrounding metallic parts. (See Fig. 1)

Table 1: Ratings for selected area

inals and

Chassis or Secondary Conductor

Primary Circuit

AC Line Voltage Clearance Distance (d), (d

110V~220V

Note

: This table is unofficial and for reference only. Be

sure to confirm the precise values.

3.2 mm (0.126 inches)

’)

2. Leakage Current Test

Confirm the specified (or lower) leakage current

between B (earth ground, power cord plug prongs) and

externally exposed accessible parts (RF terminals,

antenna terminals, video and audio input and output

terminals, microphone jacks, earphone jacks, etc.) is

than or equal to the specified value in the table

lower

below.

Measuring Method (Power ON):

Insert load Z between B (earth ground, power cord plug

prongs) and exposed accessible parts. Use an AC

eter to measure across the terminals of load Z.

voltm

See Fig. 2 and the following table.

d' d

Fig. 1

Exposed Accessible Part

Z

AC Voltmeter

(High Impedance)

Earth Ground

B

Power Cord Plug Prongs

Table 2: Leakage current ratings for selected areas

AC Line Voltage Load Z Leakage Current (i) Earth Ground (B) to:

110V~220V

Note: This table is unofficial and for reference only. Be sure to confirm the precise values.

0.15 μF CAP. & 1.5 k

Connected in parallel

RES.

i

0.5 mA Peak Exposed accessible parts

4-1

Fig. 2

Safety Information, General Notes & Lead Free Requirements

1 Safety Instructions

1.1 General Safety

Safety regulations require that during a repair:

Connect the unit to the mains via an isolation transformer.

Replace safety components, indicated by the symbol

only by components identical to the original ones. Any

other component substitution (other than original type)

Safety regulations require that after a repair, you must return

the unit in its original condition. Pay, in particular, attention to

the following points:

Route the wires/cables correctly

mounted cable clamps.

damage.

Check the electrical DC resistance between the mains

plug and the secondary side:

1. Unplug the mains cord, and connect a wire between

the two pins of the mains plug.

2. Set the mains switch to the ‘on’ position (keep the

mains cord unplugged!).

3. Measure the resistance value between the mains

plug and the front panel, controls, and chassis

bottom.

4. Repair or correct unit when the resistance

5. Verify this, before you return the unit to the customer/

user (ref. UL-standard no. 1492).

6. Switch the unit ‘off’, and remove the wire between the

two pins of the mains plug.

1.2 Laser Safety

This unit employs a laser

may remove the cover, or attempt to service this device (due

to possible eye injury).

2 Warnings

2.1 General

All ICs and many other semiconductors are susceptible to

,

during repair can reduce life drastically. Make sure that,

during repair, you are at the same potential as the mass

of the set by a wristband with resistance. Keep

components and tools at this same potential.

Available ESD protection equipment:

– Complete kit ESD3 (small tablemat, wristband,

4822 310 10671.

– Wristband tester 4822 344 13999.

Be careful during measurements in the live voltage

section. The primary side of the power supply, including

the heatsink, carries live mains voltage when you

connect the player to the mains (even when the

player is ‘off’!). It is possible to touch copper tracks and/

or components in this unshielded primary area, when

you service the player. Service personnel must take

precautions to prevent touching this area or components

in this area. A ‘lightning stroke’ and a stripe-marked

printing on the printed wiring board, indicate the primary

side of the power supply.

Never replace modules, or components, while the unit is

‘on’.

2.2 Laser

The use of optical instruments with this product, will

Only quali ed service personnel may remove the cover or

attempt to service this device, due to possible eye injury.

Repair handling should take place as much as possible

with a disc loaded inside the player.

T

shield:

electrostatic discharges (ESD,

). Careless handling

Laser Device Unit

epyT

:AIGalnN(BD)

:AIGalnP(DVD)

: AIGalnP(CD)

Wavelength : 650 nm (DVD)

)DC/DCV(mn087:

405nm(BD):

Output Power : 20 mW

)gnitirwWR+DVD(

Wm8.0:

)gnidaerDVD(

Wm3.0:

)gnidaerDC/DCV(

Beam divergence : 60 degree

CLASS 1

LASER PRODUCT

1-2erugiF

Note: Use of controls or adjustments or performance of

procedure other than those speci

ed herein, may result in

A

CAUTION VISIBLE AND INVISIBLE LASER RADIATION WHEN OPENAVOID EXPOSURE TO BEAM

ADVARSEL SYNLIG OG USYNLIG LASERSTRÅLING VED ÅBNING UNDGÅ UDSÆTTELSE FOR STRÅLING

ADVARSEL SYNLIG OG USYNLIG LASERSTRÅLING NÅR DEKSEL ÅPNES UNNGÅ EKSPONERING FOR STRÅLEN

VARNING SYNLIG OCH OSYNLIG LASERSTRÅLNING NÄR DENNA DEL ÄR ÖPPNAD BETRAKTA EJ STRÅLEN

VARO!AVATTAESSA OLET ALTTIINA NÄKYVÄLLE JA NÄKYMÄTTÖMÄLLE LASER SÄTEILYLLE. ÄLÄ KATSO SÄTEESEEN

VORSICHT SICHTBARE UND UNSICHTBARE LASERSTRAHLUNG WENNABDECKUNG GEÖFFNET NICHT DEM STRAHL AUSSETSEN

DANGER VISIBLE AND INVISIBLE LASER RADIATION WHEN OPENAVOID DIRECT EXPOSURE TO BEAM

ATTENTION RAYONNEMENT LASER VISIBLE ET INVISIBLE EN CAS D’OUVERTURE EXPOSITION DANGEREUSE AU FAISCEAU

Figure 2-2

5-1

Standard Notes for Servicing, Lead Free Requirements & Handling Flat Pack IC

Circuit Board Indications

1. The output pin of the 3 pin Regulator ICs is

indicated as shown.

Top View

Out

2. For other ICs, pin 1 and every fifth pin are

indicated as shown.

Pin 1

3. The 1st pin of every male connector is indicated as

shown.

Pin 1

Input

In

Bottom View

5

10

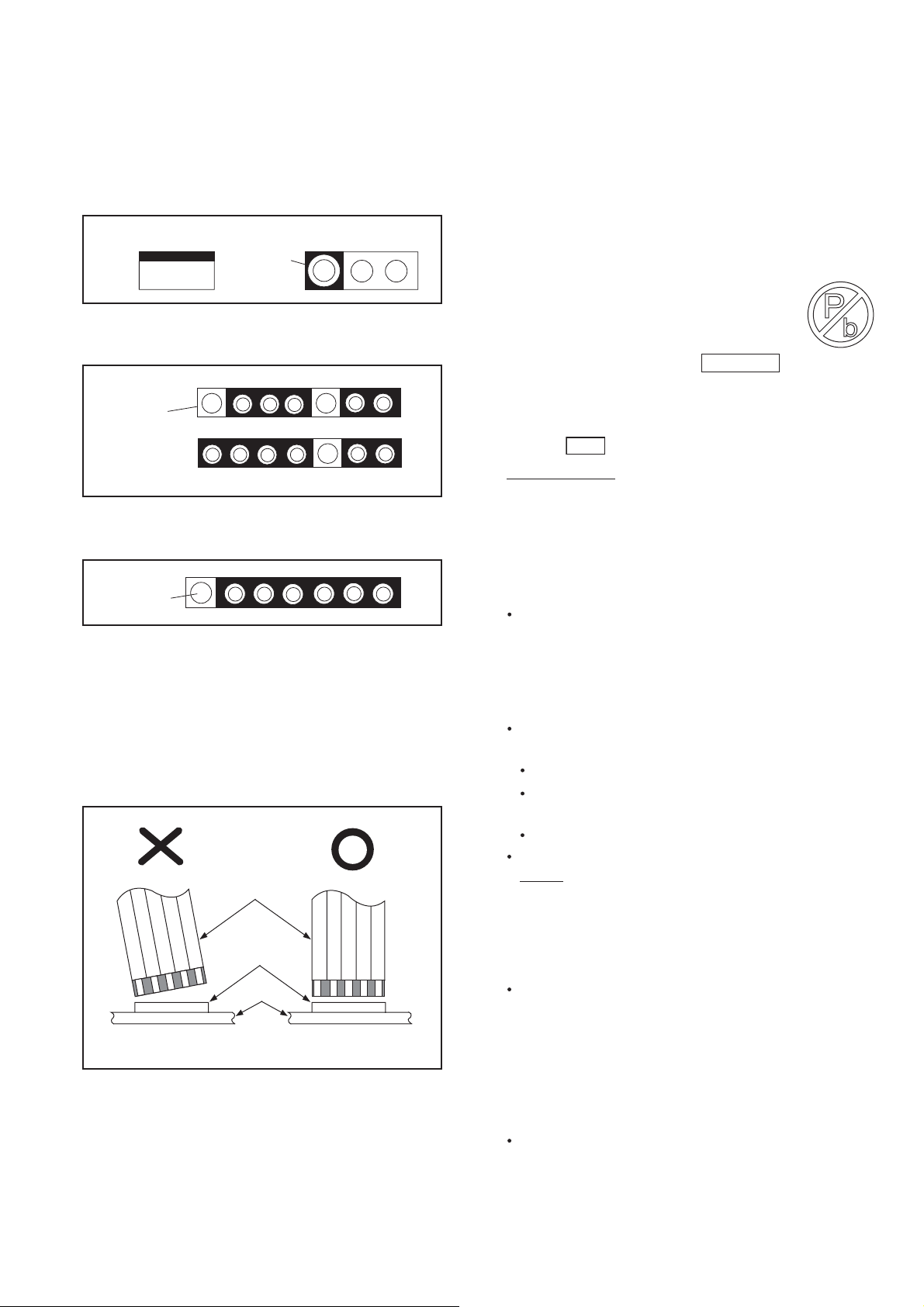

Instructions for Connectors

1. When you connect or disconnect the FFC (Flexible

Foil Connector) cable, be sure to first disconnect

the AC cord.

2. FFC (Flexible Foil Connector) cable should be

inserted parallel into the connector, not at an

angle.

FFC Cable

Connector

CBA

* Be careful to avoid a short circuit.

Pb (Lead) Free Solder

When soldering, be sure to use the Pb free solder.

Information about lead-free soldering

Philips CE is producing lead-free sets from 1.1.2005

onwards.

IDENTIFICATION

Regardless of special logo (not always

indicated)

One must treat all sets from

onwards, according to the next rule:

Serial Number gives a 14-digit. Digit 5&6 shows the

YEAR, and digit 7&8 shows the WEEK.

So from onwards=from 1 Jan 2005 onwards

0501

Important note : In fact also products of year 2004

must be treated in this way as long as you avoid

mixing solder-alloys (leaded/ lead-free). So best to

always use SAC305 and the higher temperatures

belong to this.

Due to lead-free technology some rules have to be

respected by the workshop during a repair:

Use only lead-free solder alloy Philips SAC305 with

order code 0622 149 00106. If lead-free solderpaste is required, please contact the manufacturer

of your sol

paste within workshops should be avoided because

paste is not easy to store and to handle.

Use only adequate solder tools applicable for leadfree solder alloy. The solder tool must be able

To reach at least a solder-temperature of 400°C,

To stabilize the adjusted temperature at the solder-

tip

To exchange solder-tips for different applications.

Adjust your solder tool so that a temperature around

360°C

solder joint. Heating-time of the solder-joint should

not exceed ~ 4 sec. Avoid temperatures above

400°C otherwise wear-out of tips will rise drastically

and flux-fluid will be destroyed. To avoid wear-out of

tips switch off un-used equipment, or reduce heat.

Mix of lead-free solder alloy / parts with leaded

solder alloy / parts is possible but PHILIPS

recommends strongly to avoid mixed solder alloy

types (leaded

If one cannot avoid or does not know whether

product is lead-free, clean carefully the solder-joint

from old solder alloy and re-solder with new solder

alloy (SAC305).

Use only original spare-parts listed in the ServiceManuals. Not listed standard-material (commodities)

has to be purchased at external companies.

der-equipment. In general use of solder-

- 380°C is reached and stabilized at the

and lead-free).

1 Jan 2005

6-1

Standard Notes for Servicing, Lead Free Requirements & Handling Flat Pack IC

Special information for BGA-ICs:

- always use the 12nc-recognizable soldering

temperature profile of the specific BGA (for desoldering always use the lead-free temperature

profile, in case of doubt)

- lead free BGA-ICs will be delivered in so-called

'dry-packaging' (sealed pack including a silica gel

pack) to protect the IC against moisture. After

opening, dependent of MSL-level seen on indicatorlabel in the bag, the BGA-IC possibly still has to be

baked dry. (MSL=Moisture Sensit

will be communicated via AYS-website.

Donotre-useBGAsatall.

For sets produced before 1.1.2005 (except products

of 2004), containing leaded solder-alloy and

components, all needed spare-parts will be available

till the end of the service-period. For repair of such

sets nothing changes.

On our website

www.atyourservice.ce.Philips.com

information to:

BGA-de-/soldering (+ baking instructions)

Heating-profiles of BGAs and other ICs used in

Philips-sets

You will find this and more technical information within

the “magazine”, chapter “workshop news”.

For additional questions please contact your local

repair-helpdesk.

ivity Level). This

you find more

How to Remove / Install Flat Pack-IC

1. Removal

With Hot-Air Flat Pack-IC Desoldering Machine:

1. Prepare the hot-air flat pack-IC desoldering

machine, then apply hot air to the Flat Pack-IC

(about 5 to 6 seconds). (Fig. S-1-1)

Fig. S-1-1

2. Remove the flat pack-IC with tweezers while

applying the hot air.

3. Bottom of the flat pack-IC is fixed with glue to the

CBA; when removing entire flat pack-IC, first

soldering iron to center of the flat pack-IC and heat

up. Then remove (glue will be melted). (Fig. S-1-6)

4. Release the flat pack-IC from the CBA using

tweezers. (Fig. S-1-6)

apply

CAUTION:

1. The Flat Pack-IC shape may differ by models. Use

an appr

machine, whose shape matches that of the Flat

Pack-IC.

2. Do not supply hot air to the chip parts around the

flat pack-IC for over 6 seconds because damage

to the chip parts may occur. Put masking tape

around the flat pack-IC to protect other parts from

damage. (Fig. S-1-2)

opriate hot-air flat pack-IC desoldering

6-2

Loading...

Loading...