Philips Magnetoresistive Sensor User Manual

DISCRETE SEMICONDUCTORS

General

Magnetoresistive sensors for

magnetic field measurement

2000 Sep 06

Philips Semiconductors

Magnetoresistive sensors for

magnetic field measurement

CONTENTS

General field measurement

• Operating principles

• Philips magnetoresistive sensors

• Flipping

• Effect of temperature on behaviour

• Using magnetoresistive sensors

• Further information for advanced users

• Appendix 1: The magnetoresistive effect

• Appendix 2: Sensor flipping

• Appendix 3: Sensor layout.

General

Fig.1 Philips magnetoresistive sensors.

2000 Sep 06 2

Philips Semiconductors

Magnetoresistive sensors for

magnetic field measurement

The KMZ range of magnetoresistive sensors is

characterized by high sensitivity in the detection of

magneticfields,awideoperatingtemperaturerange,alow

and stable offset and low sensitivity to mechanical stress.

They therefore provide an excellent means of measuring

both linear and angular displacement under extreme

environmental conditions, because their very high

sensitivity means that a fairlysmall movement of actuating

components in, for example, cars or machinery (gear

wheels, metal rods, cogs, cams, etc.) can create

measurable changes in magnetic field. Other applications

for magnetoresistive sensors include rotational speed

measurement and current measurement.

Examples where their properties can be put to good effect

can be found in automotive applications, such as wheel

speed sensors for ABS and motor management systems

and position sensors for chassis position, throttle and

pedal position measurement. Other examples include

instrumentation and control equipment, which often

require position sensors capable of detecting

displacements in the region of tenths of a millimetre (or

even less), and in electronic ignition systems, which must

be able to determine the angular position of an internal

combustion engine with great accuracy.

Finally, because of their high sensitivity, magnetoresistive

sensors can measure very weak magnetic fields and are

thus ideal for application in electronic compasses, earth

field correction and traffic detection.

Ifthe KMZ sensors are to be usedtomaximum advantage,

however, it is important to have a clear understanding of

their operating principles and characteristics, and how

theirbehaviourmay be affected by external influences and

by their magnetic history.

Operating principles

Magnetoresistive (MR) sensors make use of the

magnetoresistive effect, the property of a current-carrying

magnetic material to change its resistivity in the presence

of an external magnetic field (the common units used for

magnetic fields are given in Table 1).

Table 1 Common magnetic units

1 kA/m = 1.25 mTesla (in air)

1 mT = 10 Gauss

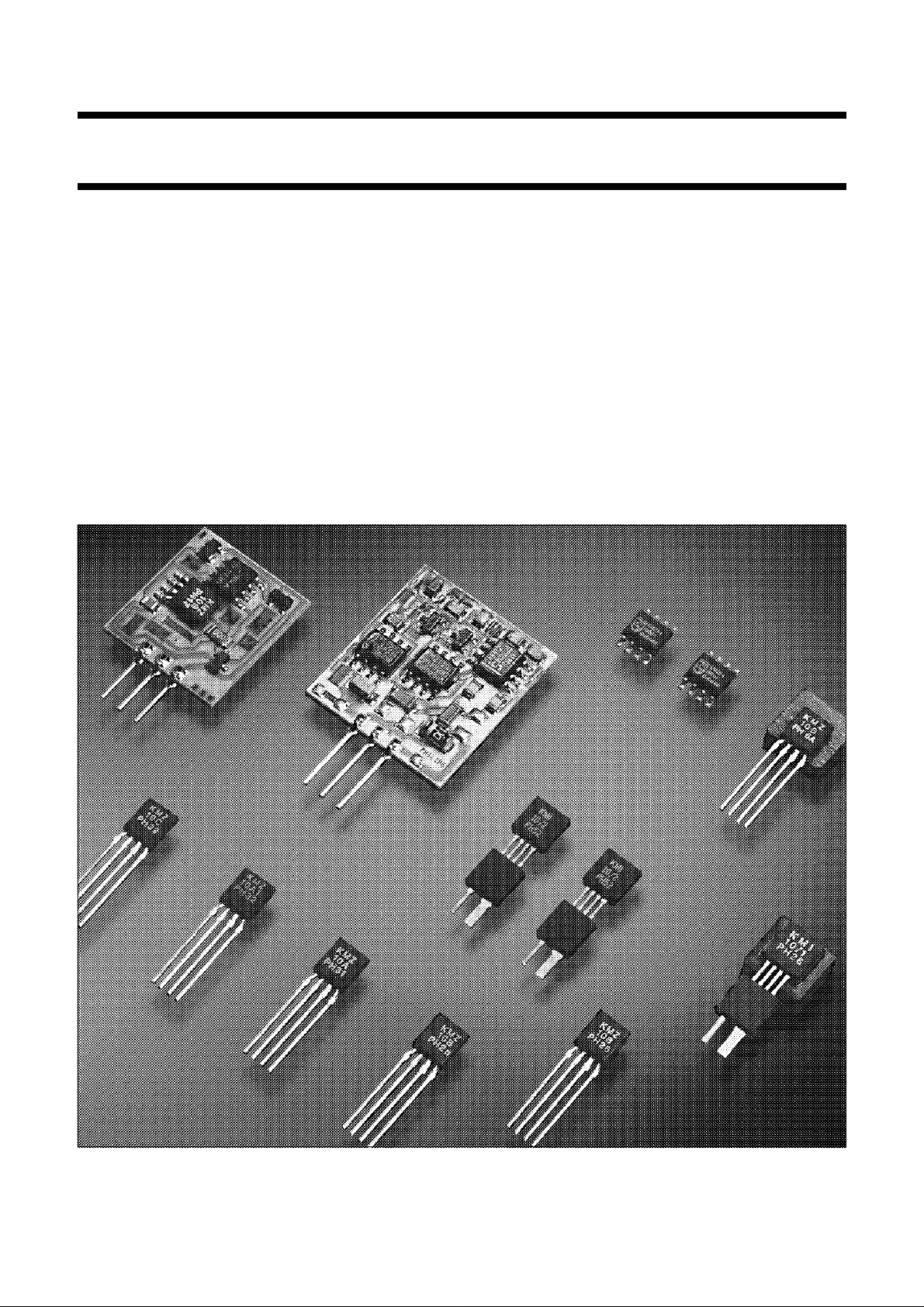

The basic operating principle of an MR sensor is shown in

Fig.2.

General

α

Current

2

I

MLC127

(1)

handbook, halfpage

H

R = R ∆ R cos α

00

Permalloy

Magnetization

Fig.2 The magnetoresistive effect in permalloy.

Figure 2 shows a strip of ferromagnetic material, called

permalloy (19%Fe, 81%Ni). Assume that, when no

external magnetic field is present, the permalloy has an

internal magnetization vector parallel to the current flow

(shown to flow through the permalloy from left to right).

If an external magnetic field H is applied, parallel to the

plane of the permalloy but perpendicular to the current

flow,the internal magnetization vector of thepermalloy will

rotate around an angle α. As a result, the resistance of R

of the permalloy will change as a function of the rotation

angle α, as given by:

RRO∆ROcos2α+=

and ∆Ro are material parameters and to achieve

R

o

optimum sensor characteristics Philips use Fe19Ni81,

which has a high Rovalue and low magnetostriction. With

this material, ∆Ro is of the order of 3%. For more

information on materials, see Appendix 1.

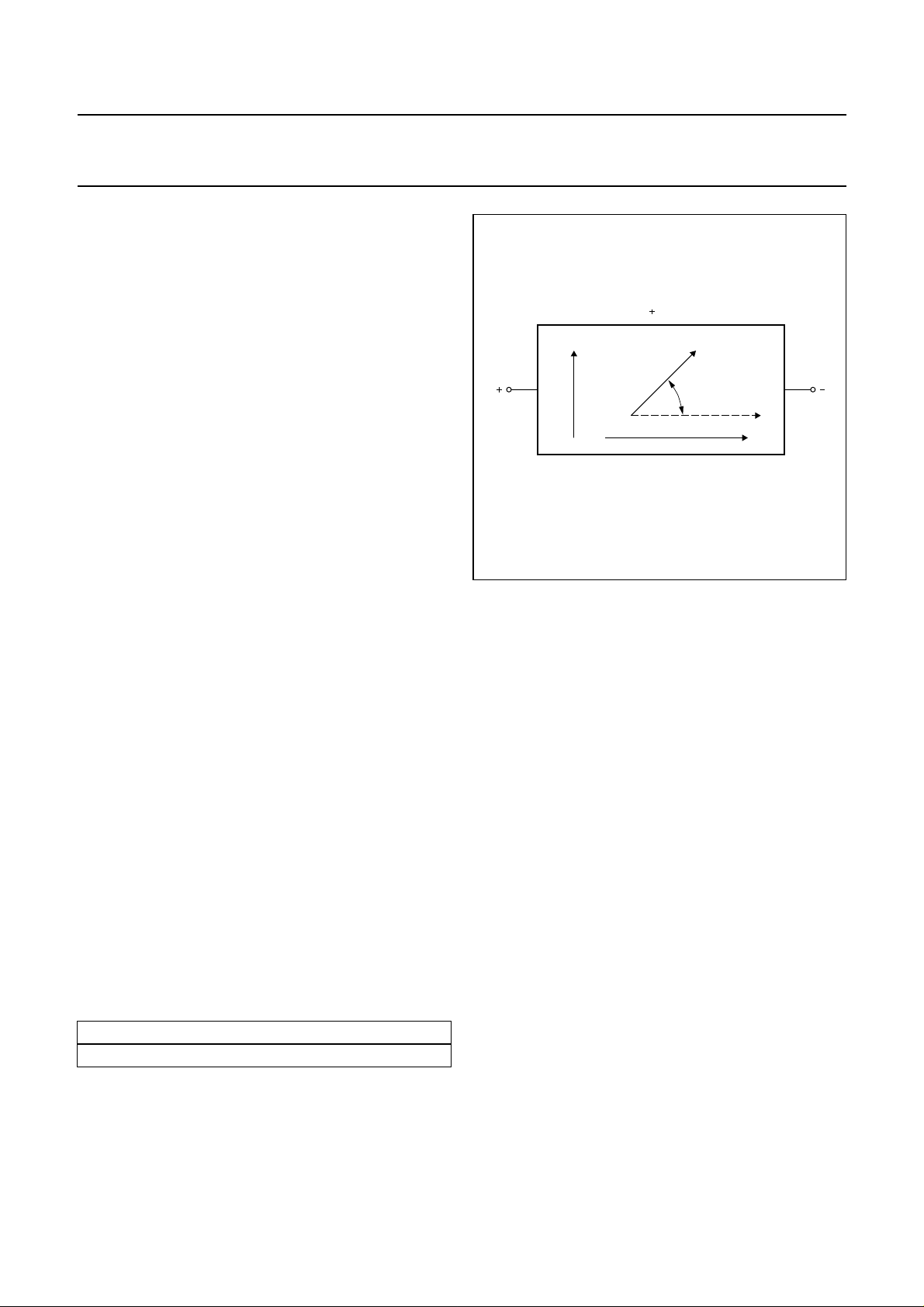

It is obvious from this quadratic equation, that the

resistance/magneticfieldcharacteristicisnon-linearandin

addition, each value of R is not necessarily associated

with a unique value of H (see Fig.3). For more details on

the essentials of the magnetoresistive effect, please refer

to the Section “Further information for advanced users”

laterin this chapter or Appendix 1, which examines the MR

effect in detail.

2000 Sep 06 3

Philips Semiconductors

Magnetoresistive sensors for

magnetic field measurement

handbook, halfpage

Fig.3 The resistance of the permalloy as a

function of the external field.

R

H

MLC128

General

In this basic form, the MR effect can be used effectively for

angular measurement and some rotational speed

measurements, which do not require linearization of the

sensor characteristic.

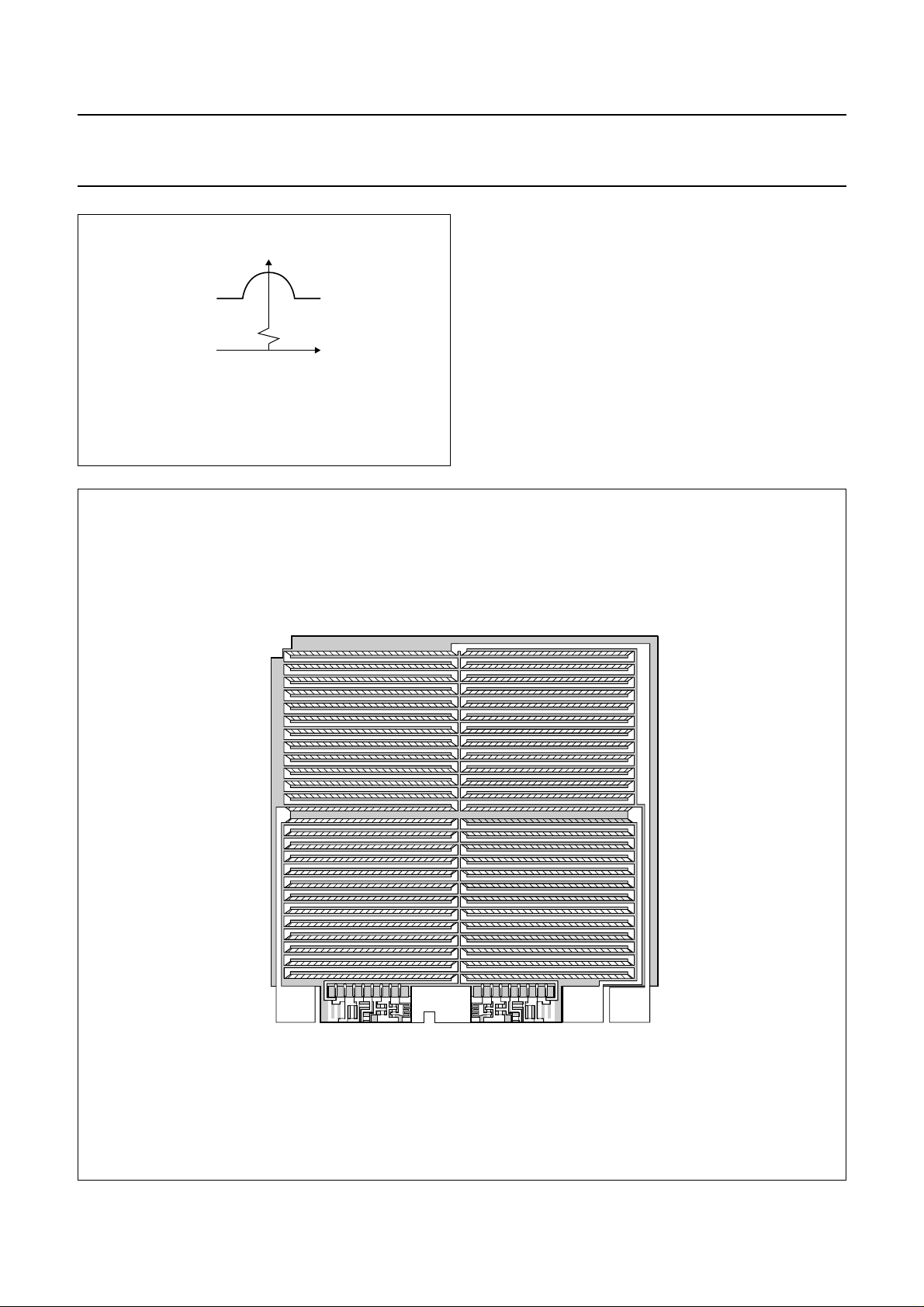

In the KMZ series of sensors, four permalloy strips are

arranged in a meander fashion on the silicon (Fig.4 shows

one example, of the pattern on a KMZ10). They are

connected in a Wheatstone bridge configuration, which

has a number of advantages:

• Reduction of temperature drift

• Doubling of the signal output

• The sensor can be aligned at the factory.

handbook, full pagewidth

MBC930

Fig.4 KMZ10 chip structure.

2000 Sep 06 4

Philips Semiconductors

Magnetoresistive sensors for

magnetic field measurement

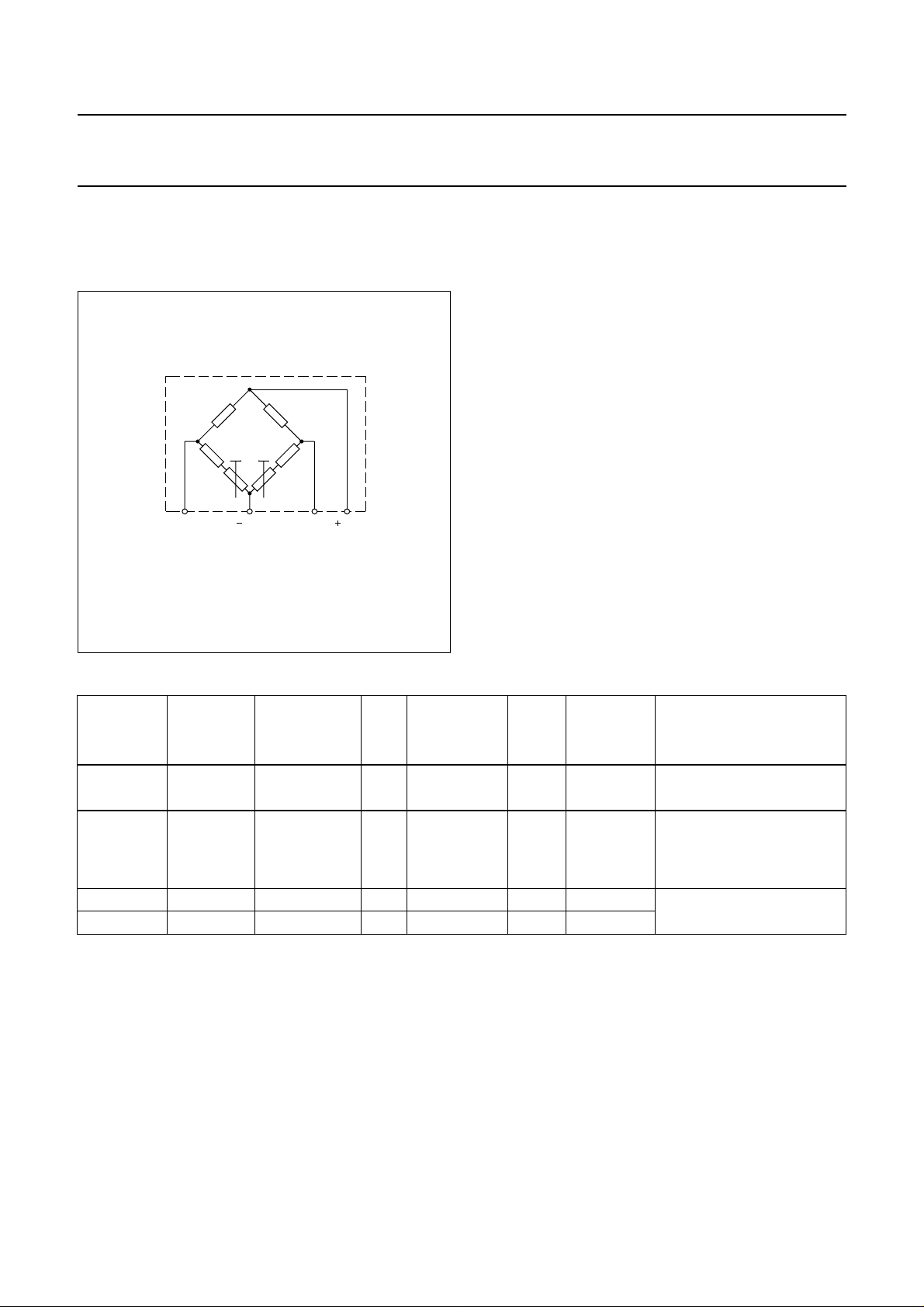

Two further resistors, RT, are included, as shown in Fig.5.

Theseare for trimming sensor offset down to (almost)zero

during the production process.

MLC129

handbook, halfpage

R

T

V

CC

R

T

GND

2 1

V

O

34

V

O

General

Forsome applications however, the MR effect can be used

to its best advantage when the sensor output

characteristic has been linearized. These applications

include:

• Weak field measurements, such as compass

applications and traffic detection;

• Current measurement; and

• Rotational speed measurement.

For an explanation of how the characteristic is linearized,

please refer to the Section “Further information for

advanced users” later in this chapter.

Philips magnetoresistive sensors

Based on the principles described, Philips has a family of

basic magnetoresistive sensors. The main characteristics

of the KMZ sensors are given in Table 2.

Fig.5 Bridge configuration with offset trimmed to

zero, by resistors RT.

Table 2 Main characteristics of Philips sensors

SENSOR

TYPE

PACKAGE

FIELD

RANGE

(kA/m)

(1)

V

(V)

CC

SENSITIVITY

mV V⁄()

--------------------kA m⁄()

R

bridge

(kΩ)

LINEARIZE

MR

EFFECT

APPLICATION

EXAMPLES

KMZ10A SOT195 −0.5 to +0.5 ≤9 16.0 1.2 Yes compass, navigation, metal

KMZ10A1

(2)

SOT195 −0.05 to +0.05 ≤9 22.0 1.3 Yes

detection, traffic control

KMZ10B SOT195 −2.0 to +2.0 ≤12 4.0 2.1 Yes current measurement,

KMZ10C SOT195 −7.5 to +7.5 ≤10 1.5 1.4 Yes

angular and linear position,

reference mark detection,

wheel speed

KMZ51 SO8 −0.2 to +0.2 ≤8 16.0 2.0 Yes compass, navigation, metal

KMZ52 SO16 −0.2 to +0.2 ≤8 16.0 2.0 Yes

detection, traffic control

Notes

1. In air, 1 kA/m corresponds to 1.25 mT.

2. Data given for operation with switched auxiliary field.

2000 Sep 06 5

Philips Semiconductors

Magnetoresistive sensors for

magnetic field measurement

Flipping

The internal magnetization of the sensor strips has two

stable positions. So, if for any reason the sensor is

influenced by a powerful magnetic field opposing the

internal aligning field, the magnetization may flip from one

position to the other, and the strips become magnetized in

the opposite direction (from, for example, the ‘+x’ to the

‘−x’ direction). As demonstrated in Fig.6, this can lead to

drastic changes in sensor characteristics.

MLC130

handbook, halfpage

V

O

(mV)

10

0

2424

H (kA/m)

y

General

The field (e.g. ‘−Hx’) needed to flip the sensor

magnetization, and hence the characteristic, depends on

the magnitude of the transverse field ‘Hy’: the greater the

field ‘Hy’, the smaller the field ‘−Hx’. This follows naturally,

since the greater the field ‘Hy’, the closer the

magnetization's rotation approaches 90°, and hence the

easier it will be to flip it into a corresponding stable position

in the ‘−x’ direction.

Looking at the curve in Fig.7 where Hy= 0.5 kA/m, for

such a low transverse field the sensor characteristic is

stable for all positive values of Hx and a reverse field of

≈1 kA/m is required before flipping occurs. At Hy= 2 kA/m

however, the sensor will flip even at smaller values of ‘Hx’

(at approximately 0.5 kA/m).

Fig.6 Sensor characteristics.

handbook, full pagewidth

10

reversal

of sensor

characteristics

MLC131

V

O

(mV)

100

50

0

3

2

50

100

1231

H =

y

2 kA/m

0.5 kA/m

H (kA/m)

x

Fig.7 Sensor output ‘Vo’ as a function of the auxiliary field ‘Hx’ for several values of transverse field ‘Hy’.

2000 Sep 06 6

Philips Semiconductors

Magnetoresistive sensors for

magnetic field measurement

Figure 7 also shows that the flipping itself is not

instantaneous, because not all the permalloy strips flip at

thesamerate.Inaddition, it illustrates the hysteresis effect

exhibited by the sensor. For more information on sensor

flipping, see Appendix 2 of this chapter.

Effect of temperature on behaviour

Figure 8 shows that the bridge resistance increases

linearly with temperature, due to the bridge resistors’

temperature dependency (i.e. the permalloy) for a typical

KMZ10B sensor. The data sheets show also the spread in

this variation due to manufacturing tolerances and this

should be taken into account when incorporating the

sensors into practical circuits.

In addition to the bridge resistance, the sensitivity also

varies with temperature. This can be seen from Fig.9,

which plots output voltage against transverse field ‘Hy’ for

various temperatures. Figure 9 shows that sensitivity falls

with increasing temperature (actual values for given for

every sensor in the datasheets). The reason for this is

rather complex and is related to theenergy-band structure

of the permalloy strips.

General

handbook, halfpage

3

R

bridge

(kΩ)

2

1

40 160

0 40 80 120

Fig.8 Bridge resistance of a KMZ10B sensor as

a function of ambient temperature.

MBB897

T ( C)

amb

o

2000 Sep 06 7

Philips Semiconductors

Magnetoresistive sensors for

magnetic field measurement

V

O

(mV/V)

15

10

5

handbook, full pagewidth

T = 25 C

amb

o

MLC134

o

25 C

o

75 C

o

125 C

General

0

5

10

operating range

15

32

1

0

1

2

H (kA/m)

3

y

Fig.9 Output voltage ‘Vo’ as a fraction of the supply voltage of a KMZ10B sensor as a function of transversefield

‘Hy’ for several temperatures.

2000 Sep 06 8

Philips Semiconductors

Magnetoresistive sensors for

magnetic field measurement

Figure 10 is similar to Fig.9, but with the sensor powered

by a constant current supply. Figure 10 shows that, in this

case, the temperature dependency of sensitivity is

significantly reduced. This is a direct result of the increase

in bridge resistance with temperature (see Fig.8), which

V

O

(mV/V)

75

50

handbook, full pagewidth

General

partly compensates the fall in sensitivity by increasing the

voltage across the bridge and hence the output voltage.

Figure 8 demonstrates therefore the advantage of

operating with constant current.

MLC135

T = 25 C

amb

o

o

25 C

o

75 C

o

125 C

25

0

25

50

75

42

operating range

0

2

H (kA/m)

y

4

Fig.10 Output voltage ‘Vo’ of a KMZ10B sensor as a function of transverse field ‘Hy’ for several temperatures.

2000 Sep 06 9

Loading...

Loading...