Page 1

M2636B TeleMon B Companion Monitor

Service Manual

Part Number M2636-90034

Printed in the U.S.A. December 2003

Third Edition

Page 2

Notice

This document contains proprietary information which is protected by copyright.

All Rights Reserved. Reproduction, adaptation, or translation without prior

written permission is prohibited, except as allowed under the copyright laws.

Copyright Philips Medical Systems, 1999-2003

All rights reserved.

Printed in U.S.A. December 2003

Part No. M2636-90034

Third Edition

Warranty The information contained in this document is subject to change without notice.

We make no warranty of any kind with regard to this material, including, but not

limited to, the implied warranties or merchantability and fitness for a particular

purpose.

We shall not be liable for errors contained herein or for incidental or

consequential damages in connection with the furnishing, performance, or use of

this material.

Copyright © 2001-2003

Page 3

Printing History

New editions of this document incorporate all material updated since the

previous edition. Update packages may be issued between editions and contain

replacement and additional pages to be merged by a revision date at the bottom

of the page. Pages that are rearranged due to changes on a previous page are not

considered revised.

The documentation printing date and part number indicate its current edition.

The printing date changes when a new edition is printed. (Minor corrections and

updates which are incorporated at reprint do not cause the date to change.) The

document part number changes when extensive technical changes are

incorporated.

All Editions and Updates of this manual and their publication dates are listed

below.

M2636-90034, First Edition....................................................... December 2001

Printing History

M2636-90034, Second Edition....................................................... January 2003

M2636-90034, Third Edition....................................................... December 2003

About this Book

This User’s Guide covers the use of TeleMon B, model M2636B, a companion

monitoring device for use with the Telemetry System Series C.

The User’s Guide contains information on performing day-to-day tasks and

troubleshooting common problems as well as detailed information about all

clinical applications. It includes lists of information messages and configuration

choices. Your purchased system may not include all the functionality

described in this document.

User information for the TeleMon Monitor is also contained in the TeleMon

Monitor On-line Info. Info focuses on how to complete basic tasks and

troubleshoot problems.

Page 4

About this Book

For operating information about the transmitter, ECG and SpO2

measurements, and the Telemetry System in general, please refer to the

Telemetry System Series C User’s Guide. See also the Information Center

User’s Guide for operating information on the Information Center.

Document

Conventions

Warnings

Warning

Warnings are information you should know to avoid injuring patients and

personnel.

Cautions

Caution

Cautions are information you should know to avoid damaging your equipment

and software.

Notes

Note—Notes contain additional information on the Telemetry System usage.

Procedures

Procedures are indicated in the text by the heading “Task Summary” followed

by the following table:

Step Action

1

2

3

Page 5

Contents

1. Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Overview and Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

System Compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

Information Messages and Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Ambulatory Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

A Quick Description of the Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Front of TeleMon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Back of TeleMon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Direct Action Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Input Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Indicators

Main Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Major Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

2. Hardware and Software Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Front Panel Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

Monitor Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Chassis Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Main Board Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

The NBP Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

The Inverter Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

The Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

The Rear Housing Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

3. Site Planning—Specific Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Environmental Considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Operating Altitude . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Radio Frequency Interference. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Antenna System Site Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

Contents-1

Page 6

Antenna Coverage Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

4. Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Placement on a Flat Surface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Mounting on a Pole . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Use of Pole Clamp with Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Use of Pole Clamp with External Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Mounting on the Wall (General) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

5. Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

6. Troubleshooting, Service and Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Purpose. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Alarms and Information Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Patient Alarms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Suspending Patient Alarms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Task Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Information Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Self-Test Error and Event Log Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

NBP Event Log Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

Power On Self-Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-11

Service Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-12

Activating Service Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-12

Restoring Standard Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-12

Entering Demo Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-13

Change Date & Time, Display Contrast . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-13

Viewing Transmitter Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-13

Performing Service Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-14

Viewing the Event Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-15

Downloading the Event Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-15

Configuring the Transmitter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-16

NBP Diagnostics, Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-17

Conducting NBP Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-18

Upgrading the Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-19

Getting Started . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-19

Setting Up the Host Computer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-20

Installing the TeleMon Support Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-22

Upgrading TeleMon’s Operating System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-22

Installing TeleMon’s Application Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-23

Contents-2

Page 7

Cloning Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-25

Changing TeleMon’s Language Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-26

Using the Battery Reconditioner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-26

Recondition a Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-27

Charging a Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-28

Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-28

Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-28

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-29

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-31

The Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-32

Removal of Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-32

Replacement of Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-32

The Front Panel Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-33

Removal of Front Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-33

Installation of Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-34

The Chassis Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-35

Removal of Chassis Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-35

Installation of Chassis Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-36

The NBP Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-38

Removal of NBP Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-38

Installation of NBP Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-38

The Inverter Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-39

Removal of Inverter Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-39

Installation of Inverter Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-40

The Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-41

Removal of Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-41

Installation of Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-41

The Main PC Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-42

Removal of Main Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-42

Installation of Main Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-43

Replacing the Main Board Fuse or Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-43

The Speaker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-44

Removal of Speaker. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-44

Installation of Speaker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-44

The Battery Compartment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-45

Removal of Battery Compartment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-45

Installation of Battery Compartment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-46

The Battery Door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-46

Removal of Battery Door. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-46

Installation of Battery Door. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-46

Contents-3

Page 8

The Transmitter Dock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-47

Removal of Transmitter Dock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-47

Installation of Transmitter Dock. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-47

The Fan Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-48

Removal of Fan Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-48

Installation of Fan Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-48

The Splash Guard. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-48

Removing the Old Splash Guard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-48

Installing the New Splash Guard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-48

7. Test and Inspection Matrix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

M2600A Telemetry System - Test and Inspection Matrix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Safety Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

M2600A Telemetry System - When to Perform Test Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

8. Maintenance and Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Date & Time. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

TeleMon Disinfection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Disinfection Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

NBP Cuff Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

NBP Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

Accessories. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

9. Safety and System Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

Safety Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

Cautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-6

Accidental Wetting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-7

Electro-magnetic Compatibility. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-8

EN 61000-4-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-8

Avoiding Electro-magnetic Interference. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-8

System Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-9

Intended Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-9

Safety Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-9

NBP Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-9

Authorized Europe/

Middle East/Africa Representative. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-10

Electrical Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-10

Environmental Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-10

NBP Measurement Specifications for TeleMon B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-11

Contents-4

Page 9

Explanation of Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-12

Contents-5

Page 10

Contents-6

Page 11

Overview and Functional Description

The M2636B TeleMon Companion Monitor is a telemetry extension device

providing non-invasive blood pressure (NBP) capability, a bedside/patient-side

monitor/display, and isolated line power or battery power to extend the M2601A

Telemetry Transmitter battery life.

As part of the Telemetry System, TeleMon with a docked transmitter provides local

display of ECG waveforms, a pleth wave, a delayed/annotated ECG wave, heart rate,

%SpO2, and NBP while simultaneously transmitting ECG, %SpO2 and NBP via a

unidirectional RF telemetry link to the Information Center. This is provided by

TeleMon within the antenna system coverage area. At the central station, a “docked

transmitter” indication will be displayed to distinguish data being sourced from a

transmitter docked with TeleMon.

1

Introduction

System Compatibility

Information Messages and Alarms

The M2636B TeleMon Monitor is designed for use with the Telemetry System

Series C, and either a conventional Series C or EASI

The communication from the transmitter to the TeleMon is via an infrared port on

the transmitter.

Patient alarms are generated and annunciated at the Information Center and at

TeleMon B when local alarms are enabled. TeleMon displays information messages;

these messages are also displayed in the patient sector at the Information Center,

along with the ECG waveforms and SpO

and NBP readings.

2

TM

transmitter.

Ambulatory Use The transition to ambulatory monitoring is seamless, given that the same transmitter

continues to source patient data and no user interaction is required to continue

monitoring. The clinician needs only to remove the transmitter from TeleMon.

Introduction 1-1

Page 12

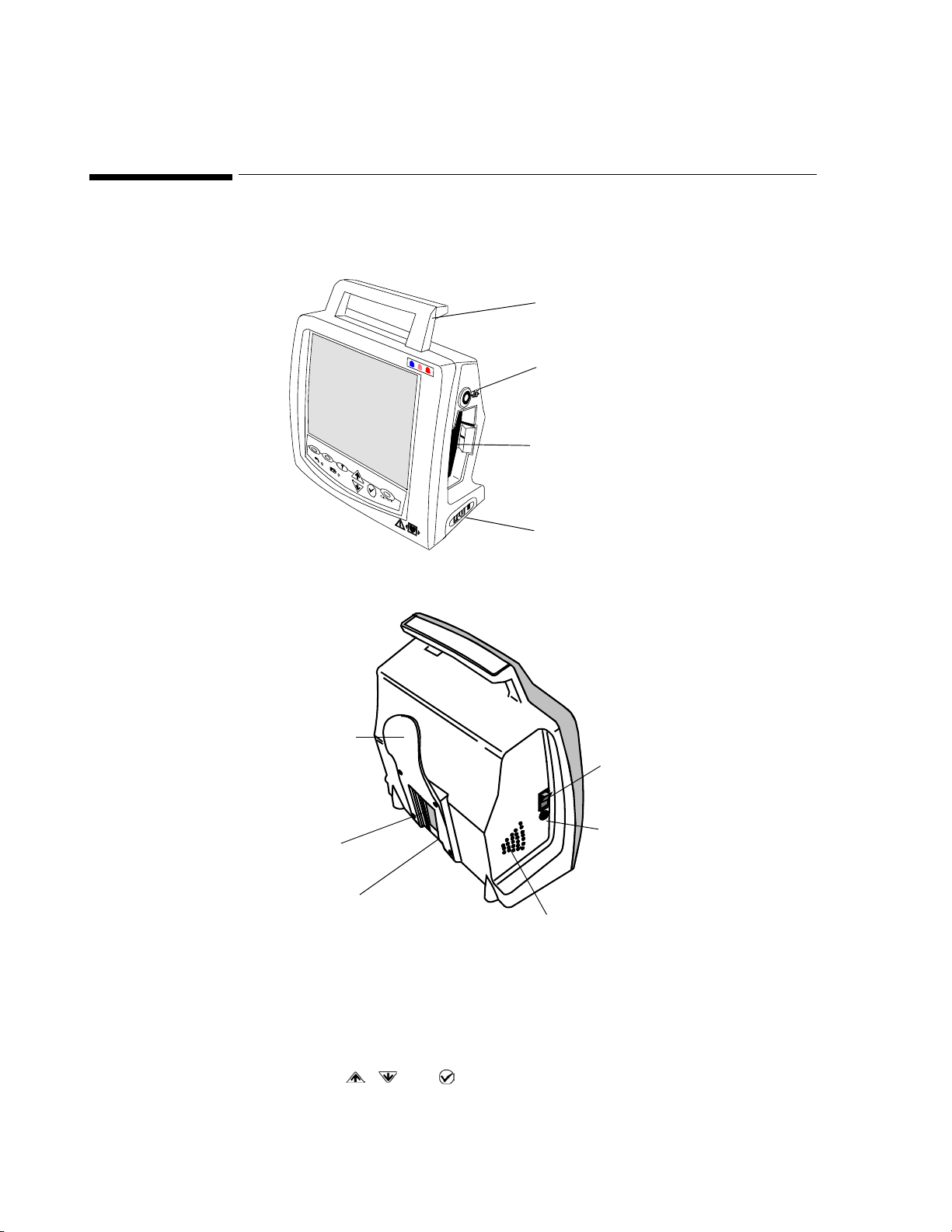

A Quick Description of the Monitor

A Quick Description of the Monitor

Front of TeleM on

Handle

NBP Connector

Transmitter

Docking Recess

Battery Compartment

Back of TeleM on

NBP Cuff Holder

Power ON/OFF

DC Power

Product Label

Upgrade Port

(underneath)

*

Use only a TeleMon-specific power supply.

Speaker

Connector*

(18V, 1.83A)

Front Panel All operational interactions except power on/off and the docking/undocking of the transmitter

are performed using the keys on the front panel. In monitoring mode, there are three kinds of

keys:

• Direct Action keys (RECORD, SUSPEND, and NBP) — enable immediate actions.

• Input keys ( , , and ) — enable you to navigate through a menu of choices.

1-2 Introduction

Page 13

A Quick Description of the Monitor

• Help key - provides access to operational information during product use.

Below the keys, two indicators provide information on the power status of the monitor.

RECORD

at Central

(Silence)

SUSPEND HELP

Input Keys

START NBP

STOP NBP

Battery Charge Status

Initiates central recording. A flashing strip above the label

indicates a recording is in progress.

Direct Action

Keys

AC Power Status

The function of each of the three Direct Action keys is displayed on the screen directly above

the key.

RECORD at Central

Silence Silences current alarm at TeleMon

SUSPEND at Central

- or -

xx:xx min to

Temporarily suspends telemetry alarms at central for 3

minutes. Indicates the number of minutes remaining.

Press again to UNSUSPEND.

UNSUSPEND

START

STOP

Starts and stops individual NBP measurement. Scheduled

measurements continue uninterrupted.

Input Keys The three Input keys enable you to select a function by moving the highlight box (cursor) and

making task choices about that function.

For general operation:

Use arrows to select a function or make a choice on a task list.

Help

For general operation:

Press check mark to open or close the task list for a selected

function.

? Displays, scrolls, and dismisses context sensitive help on the

selected function.

Introduction 1-3

Page 14

A Quick Description of the Monitor

Indicators

AC Power On/Green—AC power is connected

Off—No AC power is connected.

Battery Charge Status On/Yellow—Charging the battery

On/Blinking Yellow—Initiating communication with the

battery, or error condition

Off—No charging because either no battery or battery

charged

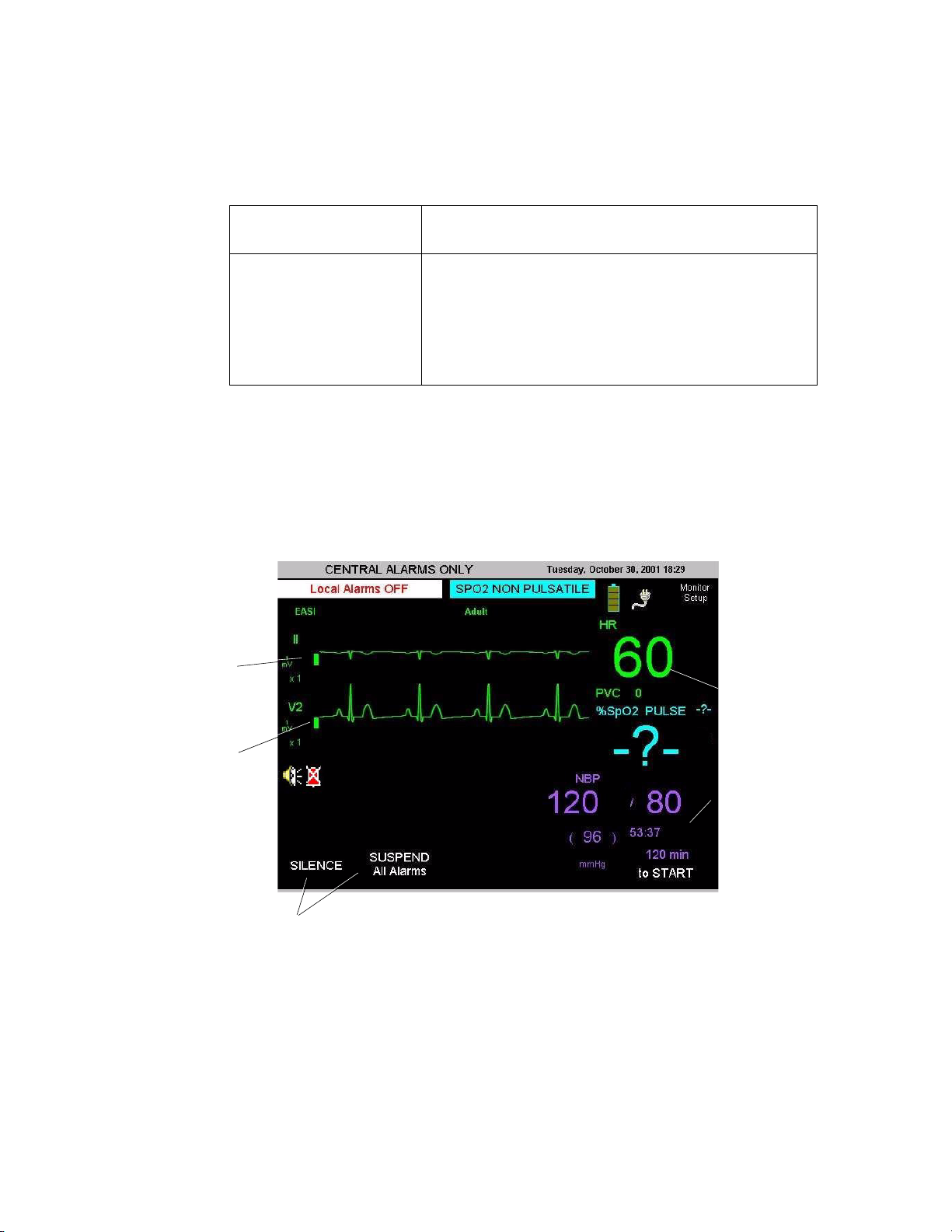

Main Screen The Main Screen presents the data in graphical and alphanumeric formats. Up to two waves

can be displayed on the screen: two ECG waves, or one ECG and the pleth wave. If an EASI

transmitter is docked, the text EASI will be displayed above the primary wave sector.

Numerics are presented on the right: HR, %SpO

, and systolic/diastolic and mean NBP.

2

Softkey labels appear across the bottom of the screen. These define the multi-purpose keys

directly below.

Waves

Size

Lead

Cal Bar

1 mV

Numerics

NBP

Measurement

Time*

Softkey labels

* Time remaining until next automatic measurement, or time of most recent manual measurement.

1-4 Introduction

Page 15

A Quick Description of the Monitor

Other information on the Main Screen includes alarm and information message status, battery

and AC power status, and access to monitor setup and service functions.

Alarm Status—

TeleMon

Alarm Status—Central

Information Message

Battery Gauge

AC Power ON

Setup &

Service

Major Assemblies

TeleMon is made up of three major assemblies:

• Front Panel Assembly

• Monitor Assembly

• Chassis Assembly

The monitor assembly has three boards, the main board, the NBP board and the Inverter

board. The distinctive functionality of each board makes this unit particularly easy to service

and troubleshoot. Additionally, the unit is designed to require little or no maintenance,

making it ideal for today’s clinical environment.

Software TeleMon software is part of the Information Center system, which contains these basic

components:

• TeleMon

• Transmitter

• TeleFrame

•SDN

• Information Center/Surveillance Center

TeleMon interfaces to the Information Center using an RF link provided by the transmitter

and an SDN interface provided by TeleFrame.

Introduction 1-5

Page 16

A Quick Description of the Monitor

Introduction 1-6

Page 17

Hardware

2

Hardware and Software Description

The following is a summary of the major TeleMon subassemblies.

Front Panel Assembly

The Front Panel Assembly (Figure 6-3 on page 6-31) contains:

• Molded plastic front housing

• Anti-glare panel bonded to the inside of the window in the front housing.

• Touch-key keyboard unit, including power status LEDs, bonded into a recess

below the window of the front housing.

• Keyboard-to-main cable.

Monitor Assembly The Monitor Assembly contains

• the Chassis Assembly, on which all the PC boards are located.

• the Rear Housing assembly, in which the transmitter dock, the battery

compartment, the cooling fan and the speaker are mounted.

Chassis Assembly The Chassis is a metal plate. To one side of it three PC boards are fastened,

containing the major electronics of the TeleMon. The LCD is fastened to the other

side.

Main Board Assembly

The Main Board (Figure 6-14 on page 6-42) contains:

• ICs required to store the software and perform the logic of measurement,

analysis, calculation and display.

• Coin battery for the Real Time (RT) clock. This clock provides time stamps

for data and times the transfer of data to and from TeleMon.

• Keyed connectors for the cables that supply power and control data to units

performing specialized functions, such as display or NBP measurement. Each

connector is uniquely keyed to prevent any misconnection. All power comes

from Main Board circuits.

• The OFF/ON Power Switch, which extends through an opening in the left side

of the rear housing when the unit is fully assembled. The switch performs the

following functions:

– When ON, applies line power to the Main Board if the External Power

Supply is connected.

– When ON, applies battery power to the Main Board if the External Power

Supply is not connected.

Hardware and Software Description 2-1

Page 18

Hardware

– When OFF, applies line power to the battery for charging if the External Power

Supply is connected. Only the various power and battery indicators are functional.

– When OFF, shuts off all power if the External Power Supply is not connected. The

coin battery on the Main Board continues to drive the Real Time (RT) clock and

some memory circuits.

• The External Power Connector, which extends through an opening in the rear housing.

Use of this connector feeds power from the External Power Supply to the Main Board,

which may also distribute it to other modules.

• Serial Port. The Serial Port Connector on the Main Board is accessed through an

opening at the bottom of the Rear Housing. The port is used for software updates. The

opening is covered by a snap-lock door.

• Optical devices. The transmitter communicates with the TeleMon, when docked,

through an infrared (IR) path. IR data is reflected onto an optical device on the Main

Board through a perforation in the IR Shield. Another device provides a control and

data path to the transmitter through a second perforation.

The NBP Board

The Inverter Board

The Non-invasive Blood Pressure (NBP) Board (Figure 6-9 on page 6-38) performs

operations relating to taking a blood pressure with the cuff. The NBP Board contains:

• IC’s for regulating the operation of the Air Pump.

• A connector for the NBP-to-Main Cable.

• The Air Pump with mounting device. The pump is specified for at least 30,000 cycles

before it needs to be replaced; 10,000 cycles before it needs to be calibrated.

• Conduit tubing for the air.

The Inverter Board (Figure 6-10 on page 6-39) applies 380 VAC at 5 mA to the LCD’s

backlight, which is fluorescent. An oscillator in the inverter circuit changes DC input current

from either the 10.8 battery or the external power supply to AC.

The Inverter Board Assembly consists of:

• A metal shield to limit radiation from the inverter circuits.

• The Inverter Board.

• Integral connectors for the Inverter-to-Main and Inverter-to-Display Cables.

The Display The Display (Figure 6-13 on page 6-41) contains:

• LCD. The LCD has a half-life of approximately two years. It should be replaced when

it loses its brightness.

• Back Light.

• Non-detachable Inverter-to-Display power cable.

2-2 Hardware and Software Description

Page 19

Hardware

• Connector for the Display-to-Main Cable, a ribbon cable conducting LCD control

signals from the Main Board.

The Rear Housing Assembly

The Rear Housing Assembly consists of:

• Molded plastic rear housing.

• Speaker Mount (Figure 6-16 on page 6-44), a formed stainless metal piece bent into

extensions for the Speaker mount and the data path reflector. Coded optical beams from

a docked transmitter are reflected onto the optical receptor of the Main Board and

beams from the emitter on the Main Board are reflected into the transmitter. Broken

beams are interpreted by software in the processing unit of the Main Board as an

undocked transmitter. On the outside of the Rear Housing, the NBP Cuff Holder is

screwed to the Speaker Mount through the housing.

• Cooling Manifold Assembly, a formed metal piece fastened to the Rear Housing above

the Transmitter Dock. A small cooling fan with integral drive motor is fastened to it.

From the fan housing extends the Fan-to-Main Cable. Cooling and venting are

facilitated by slots in the bottom and top rear surfaces of the Rear Housing, perforations

on the side of the Rear Housing, and large perforations in the Battery Housing. The fan

is powered by the OFF/ON switch at the side of the monitor.

• Transmitter Dock (Figure 6-19). Three interlocking plastic pieces forming a dock that

fits into the docking port on the side of the Rear Housing. The Dock screws to mounts

on the Rear Housing. The screws also hold the dock together. The Transmitter-to-Main

power cable interlocks to the back of the Dock and terminates in a connector for Main

Board attachment. An integral latch furnishes some resistance to docking and

undocking the transmitter, and holds the transmitter in place. An opening in the top of

the Dock passes optical data streams between the transmitter and the Main Board via a

reflector surface on the Speaker Mount. All ECG and SpO

transmitter. All RF transmission between the monitor and the Information Center

requires docking and ECG cables and leads.

data comes from the

2

• Speaker held to the Speaker Mount with a metal clip. The Speaker-to-Main Cable is

integrally attached to the speaker but features a connector on the Main Board side. The

speaker faces perforations in the Rear Housing.

• Formed metal Battery Compartment (Figure 6-17) with detachable connector for the

replaceable Battery-to-Main Cable. A flange on this compartment anchors the Chassis.

Perforations in the compartment support air cooling. The battery may get warm during

charging, especially as it approaches full charge.

• Sliding battery compartment door of molded plastic, key-locked to the Rear Housing.

• NBP tubing with collar connector on one end and external connector on the other,

fastened to the Rear Housing with a large hex nut. The tubing carries air from the Air

Pump located on the NBP Board.

• Four slip-resistant feet mounted to the bottom of the Rear Housing. They also hold the

Battery Compartment in place.

Hardware and Software Description 2-3

Page 20

Software

Software

TeleMon interfaces to the Information Center using an RF link provided by the transmitter

and an SDN interface provided by the Receiver Mainframe. However, this link is for clinical

purposes only. There is a serial port on the bottom of the rear housing of TeleMon, for use in

upgrading software.

Within TeleMon’s memory, the monitoring software and its configuration files are stored

separately from the operating system binary image, allowing the product monitoring software

to be upgraded without having to reprogram the entire operating system.

All software components necessary for upgrading a TeleMon are included on a TeleMon

Installation CD. These components include:

• TeleMon Application Software

• A compatible TeleMon OS image

• A programming tool for programming the operating system in TeleMon directory

• Microsoft® ActiveSync® Connectivity Software

Service people upgrading/programming TeleMon Monitoring Software will also need the

following components:

• TeleMon

• A host computing platform (laptop or desktop) with free serial port

• A synch cable that fits into TeleMon’s Upgrade Connector (for example an HP F122360901 cable)

• The TeleMon Installation CD

2-4 Hardware and Software Description

Page 21

3

Site Planning—Specific Requirements

This chapter provides an overview of site planning for your telemetry system. It

includes the following sections:

• Environmental Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

• Power Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

• Antenna System Site Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Site Planning—Specific Requirements 3-1

Page 22

Environmental Considerations

Environmental Considerations

The monitor should be used in an area reasonably free from vibration, dust, corrosive or

explosive gases, and extremes of temperature and humidity. The following paragraphs give

information concerning environmental considerations.

Temperature The monitor operates within specifications at ambient temperatures between 0 and 35

Celsius. Temperatures exceeding these limits could affect instrument accuracy and cause

damage.

Operating

Operate and store TeleMon at altitudes up to 3,048 meters (10,000 feet).

Altitude

Radio Frequency Interference

Management of the RF environment in your facility is important to the overall performance of

your telemetry system, including the monitor. The considerations are the same. In most cases,

use of the monitor implies that the Telemetry System is already in place and the RF

environment has already been taken into consideration. For full coverage of this topic, refer to

the Telemetry System documentation, especially Chapter 2 of the Service Guide.

WarningWarning

TeleMon units containing transmitters that are 25 kHz apart in transmitter frequency

interfere with one another at distances of 1-3 feet. This situation is aggravated by ECG

cable proximity. Symptoms include dropout (at the information center), waveform

artifact of the ECG (at central and TeleMon), and screen freeze (at TeleMon). To avoid

this situation, maintain a distance of >3 feet between TeleMon units.

o

3-2 Site Planning—Specific Requirements

Page 23

Power Requirements

The monitor is a mobile extension of the Telemetry System and can display and broadcast

information through the antenna on battery power alone for up to a five hours. However, for

bedside use it should be connected to a grounded wall outlet through its own external power

supply. The bedside wall outlet should provide input of 100 - 250 VAC at 50 - 60 Hz. The

monitor and therefore the bed need to be within 6 feet of where the external power supply is

to be mounted. The line cord between the wall outlet and the external power supply must be

grounded and routed and/or mounted to avoid accidental tripping or pulling.

The External Power Supply must be grounded during operation. If a 3-wire receptacle is not

available, then a hospital electrician must be consulted to ensure that proper grounding is

available on installation. Never attempt to use a three-wire to a two-wire adaptor with the

External Power Supply. For details, see the “Electrical Specifications” on page 9-10.

Note—The TeleMon battery may not arrive at your site fully charged due to time in transit or

storage. Make sure that the battery is fully charged before using TeleMon.

Power Requirements

Antenna System Site Information

Antenna Coverage Area

All transmitter information is available at the TeleMon, whether or not the transmitter is in the

antenna coverage area. However, if the TeleMon is outside the antenna coverage area, there is

no communication to the Information Center and no indication at the TeleMon that the RF

signal is not being received at the Information Center. Outside the coverage area, no alarms

can be generated at the Information Center.

Site Planning—Specific Requirements 3-3

Page 24

Antenna System Site Information

Site Planning—Specific Requirements 3-4

Page 25

Installation

This chapter describes the alternatives available for the installation of a TeleMon

monitor and its External Power Supply.

• Placement on a Flat Surface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

• Mounting on a Pole. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

• Mounting on the Wall (General). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

4

Installation 4-1

Page 26

Placement on a Flat Surface

Placement on a Flat Surface

The easiest and most mobile way to mount the TeleMon is simply to stand it on a flat surface.

The monitor needs to be visible and in a safe place, as free as possible from the danger of

accidental pulling, knocking over, or spilling of fluids.

The simplest placement of the External Power Supply is on the floor near the TeleMon. The

power output cable allows a distance from TeleMon of six feet. Do not place the monitor

where it can be pulled down onto the patient. The power input cord should run directly to the

wall wherever possible. It should not be strung across a passage.

WarningWarning

To avoid the risk of accidental entanglement and strangling, place or mount the AC

power cabling away from the patient. Use similar caution in temporarily storing ECG,

NBP or SpO2 cables.

WarningWarning

TeleMon units containing transmitters that are 25 kHz apart in transmitter frequency

interfere with one another at distances of 1-3 feet. This situation is aggravated by ECG

cable proximity. Symptoms include dropout (at the information center), waveform

artifact of the ECG (at central and TeleMon), and screen freeze (at TeleMon). To avoid

this situation, maintain a distance of >3 feet between TeleMon units.

4-2 Installation

Page 27

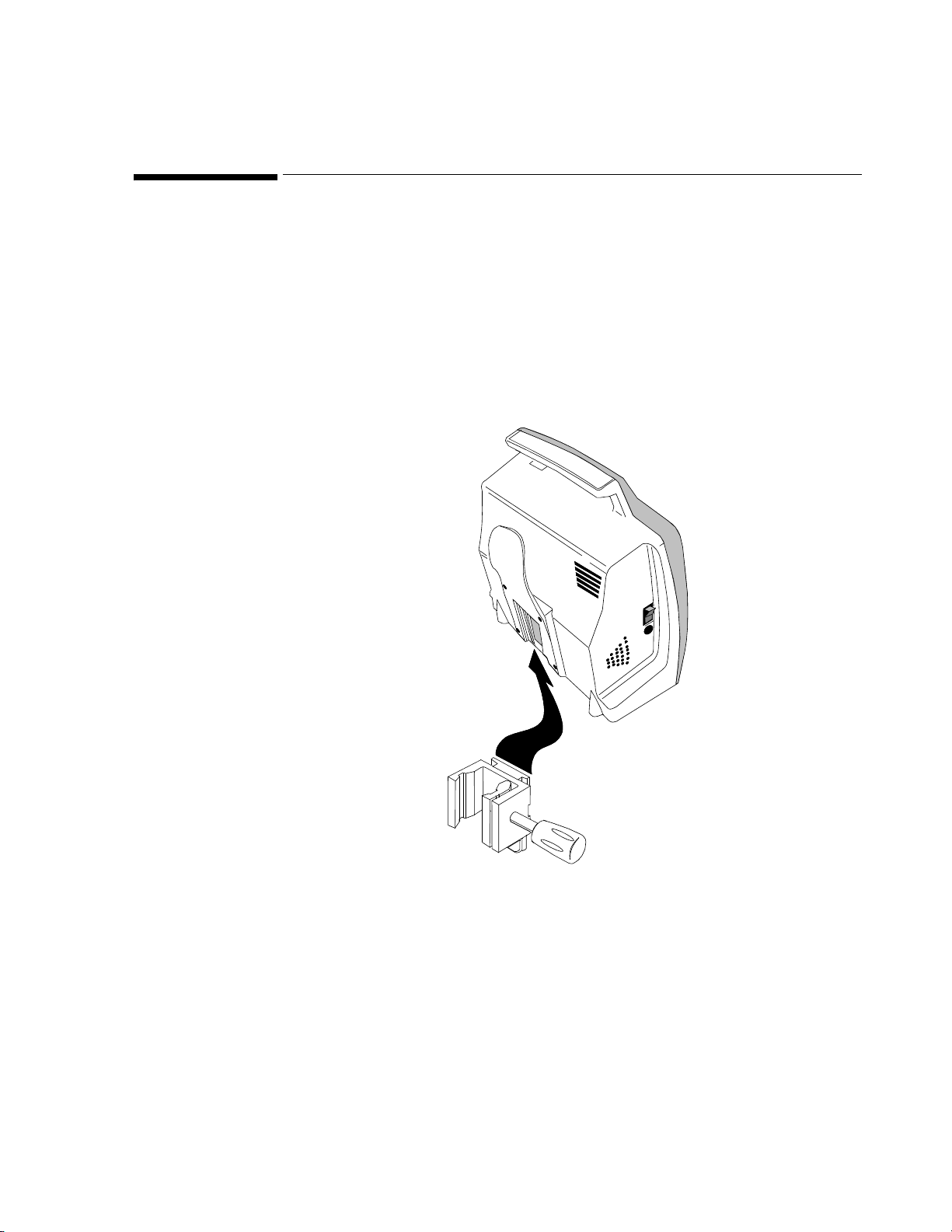

Mounting on a Pole

Mounting on an IV pole combines mobility with stability. The External Power Supply can be

mounted apart or near the TeleMon on the same pole. For example, mount the power supply

at the bottom of the IV pole.

Note—The power input cord must run from the TOP of the power supply to the monitor, to

avoid seepage of spills into the plug on the other side (Figure 4-2).

For pole mounting, use the Pole Clamp, Part Number 5061-8363, which can support a

maximum load of 14 pounds (6.5 kg).

Mounting on a Pole

Use of Pole Clamp with Monitor

Figure 4-1 Mounting TeleMon with Pole Clamp

Step 1. Screw the Dovetail to the rear surface of the Pole Clamp, using the screws provided

with the Dovetail. Two alignments are available, horizontal and vertical.

Step 2. Fasten the Pole Clamp to the supporting rail or pole. Use your judgement to

determine the most stable and solid method of mounting.

Step 3. Slide the NBP Cuff Holder on the back of the TeleMon down over the Dovetail

until the latch snaps.

Note—To remove the monitor, slide your finger under the TeleMon and push the latch

at the back, which is on the Dovetail.

Installation 4-3

Page 28

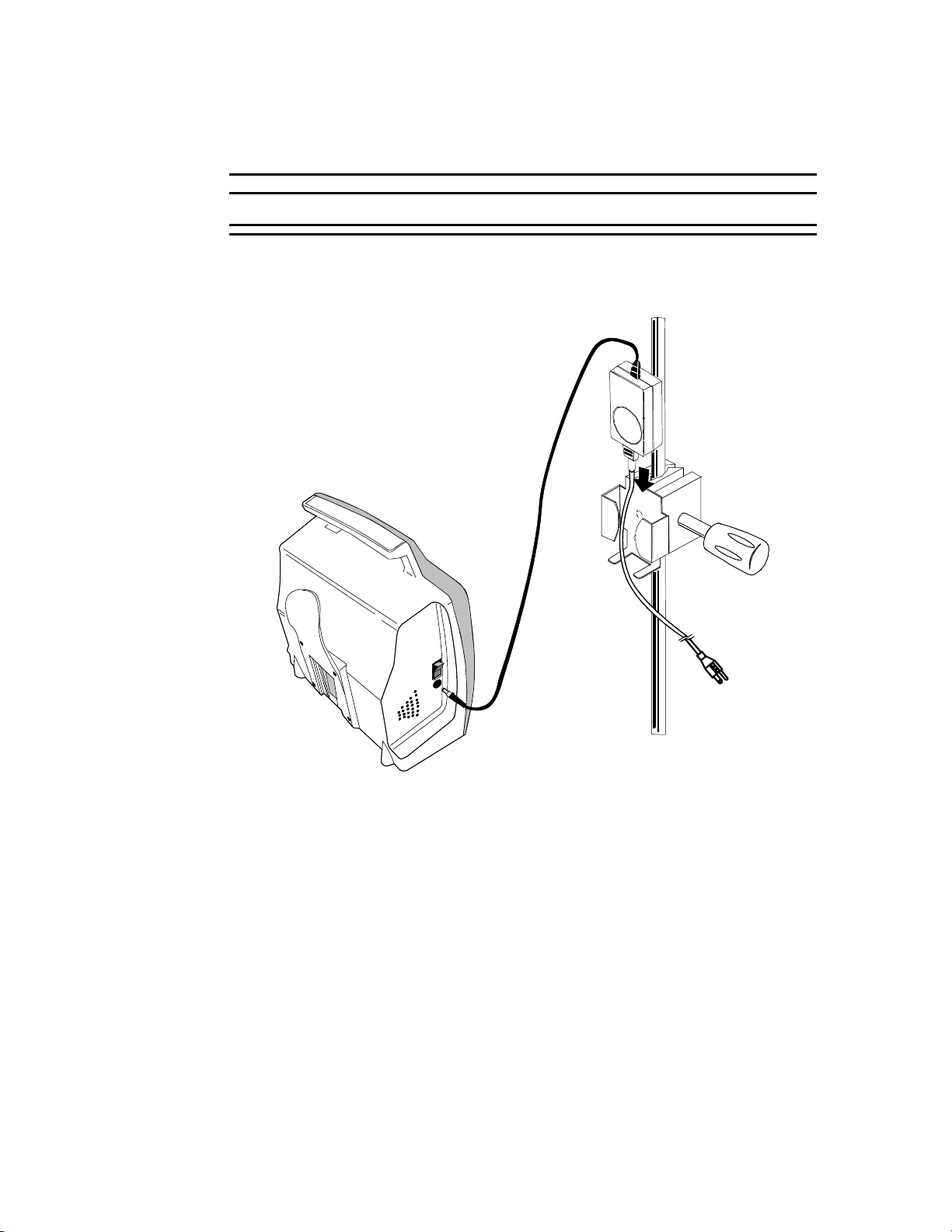

Mounting on a Pole

Use of Pole Clamp with External Power Supply

WarningWarning

Do not mount the TeleMon below fluids, which may drip or leak onto it.

4-4 Installation

Figure 4-2 Mounting Power Supply with Pole Clamp

Step 1. Screw the External Power Supply Bracket to a Pole Clamp with the screws

provided.

Step 2. Fasten the Pole Clamp to the supporting rail or pole.

Step 3. Slide the External Power Supply into its bracket.

Page 29

Mounting on the Wall (General)

Wall mounting requires the most preparation and is the most stable, but least mobile,

configuration.

Caution

These mounting instructions are neither applicable in California nor sanctioned by the

California OSHPD for installation in the State of California, U.S.A., in conformance to

that state’s requirements for seismic protection.

The following instructions describe surface wall mount base installation to a wall.

Before instruments have been installed, the hospital or other facility, its consultants, or its

contractors shall be responsible for meeting the following conditions:

• That the wall is adequate to safely mount monitoring instruments, including the

selection of fasteners and their proper installation.

Mounting on the Wall (General)

• That the installation has been completed in accordance with accepted standards of good

workmanship.

• Anchorage or support in a metal stud or wood stud wall must be verified by a registered

professional engineer before installing the mounting system.

Installation 4-5

Page 30

Mounting on the Wall (General)

WarningWarning

Existing wall construction and reinforcement:

The wall mounts must be capable of supporting four times the specified weight capacity

after they have been properly installed. To provide this support in plaster, plasterboard,

or gypsum board walls, the wall covering must be removed in the area of work and a

reinforcement must be provided within the wall structure.

Do not install a wall mount onto solid brick or brick veneer walls, or onto crumbly wall

material such as cinder blocks or deteriorated concrete or concrete block.

Ensure that no electrical wiring, piping, or other utilities within the wall interfere with or

can be damaged by the installation process.

Fastenings:

Lead expansion bolts or plastic expansion anchors specifically are not adequate or safe.

Use the anchors specified for solid concrete construction.

Never mount heavy instrumentation to plain gypsum board using expansion anchors.

The wall covering (plasterboard or plaster) must be removed and the wall must be

reinforced internally, in new or existing construction.

In Installation:

No portion of the mount or mainframe may extend over a patient’s bed.

Never exceed the maximum rated load specified on the label(s) attached to the wall

mount in use.

Never exceed any maximum instrument stacking height specified on the label(s) attached

to the wall mount in use.

Do not attempt to remove any wall mount while instruments are attached.

The wall mount is mounted directly to the wall. All mountings and anchorages must conform

to local building codes and regulations. A variety of mounts are available and can be

purchased, or the user can devise his own, provided it conforms to the warnings and

regulations stated in this manual.

Installation consists of building a mount to which the Dovetail or External Power Supply

Bracket are fastened. The monitor then slides and snaps onto the Dovetail and the External

Power Supply slips into its bracket. The bracket can also be mounted directly on the wall.

In general, wall mounts must be installed securely to the wall’s internal structure with number

10 sheet metal screws, 1/4-20 or 10-32 pan head machine screws, or bolts with nuts or toggle

wings. The type of fastening and method depends on the wall construction.

Note—Machine screws have built-in lock washers or other means of securing threads. All

sheet-metal screws have type-A threads.

4-6 Installation

You can install the mount base in three ways:

1. On Hollow Block or Hollow Tile Walls.

2. On Solid Concrete or Solid Block Walls.

3. On Drywall.

Page 31

Mounting on the Wall (General)

WarningWarning

Do not install wall mount onto solid brick walls or tile veneer walls, or onto weak or

crumbly wall material such as cinder blocks, brick, brick veneer, clay or rubble

construction.

Installation 4-7

Page 32

Mounting on the Wall (General)

Installation 4-8

Page 33

This chapter includes an orderable parts list for the M2636B TeleMon Monitor.

Number Description Part

0950-3769 Transformer between the wall outlet and the TeleMon

monitor.

External Power Supply

5

Parts List

0950-3919 A PC board mounting the electronics for the inverter.

1420-0864 3 V Lithium battery pressed into a holder mounted on the

main board. It powers the internal RT clock.

2090-0392 A 19.6 cm. color DSTN Liquid Crystal Display (LCD) with

integral backlight, used as the front display screen.

8121-0109 Runs between the Battery Compartment and the Main

Board. Integral connectors on each end.

M1204-61025 Circular speaker with integral input cable.

M1275-01026 Wire clip holding speaker to mount.

M2626-40001 Pre-formed plastic case for mounting the other parts of the

Rear Housing Assembly.

M2636-01007 Formed metal exhaust conduit to which the cooling fan with

integral cable have been bonded.

M2636-01008 The bracket holding the External Power Supply to its

mount.

M2636-11302 Contains the operating system, application software and PC

Connectivity Tool.

Inverter Board

Coin Cell Battery

Display

Battery-to-Main Cable

Speaker and Cable

Speaker Clip

Rear Housing

Cooling Manifold Assembly

External Power Supply Bracket

Software CD ROM Kit

M2636-20010 Fastens battery cable connector to the Battery Compartment. Alignment Pin for battery

connector

M2636-40002 Pre-formed plastic part.

M2636-40003 Pre-formed plastic part, one-half of the Transmitter Dock.

M2636-40004 The other half of the Transmitter Dock.

M2636-40005 Pre-formed plastic part, fastened to rear of Rear Housing. It

hold the external cables and cuff attaching to the monitor.

M2636-40006 Plastic foot attached to bottom of monitor.

M2636-40007 Pre-formed plastic part, which screws to a wall or pole

mount. It then slides into the NBP Cuff Holder and is held

by a snap latch.

Battery Door

Transmitter Bay

Transmitter Latch

NBP Cuff Holder

Monitor Foot (4)

Dovetail

Parts List 5-1

Page 34

Number Description Part

M2636-40008 Pre-formed plastic part. The door covering the serial

upgrade port, visible through an opening in the bottom of

Serial Upgrade Door

the Rear Housing.

M2636-60100 Assembly consisting of pre-formed plastic case, display,

antiglare panel, keyboard and keyboard overlay.

M2636-60101 Splash guard kit consisting of plastic film with adhesive.

M2636-60102 Kit of extra screws required for reassembly. Consists of:

Screw used for monitor assembly.

Screw used for monitor assembly.

Screw used for monitor assembly.

Screw used for monitor assembly.

Screw used for monitor assembly.

Screw used for monitor assembly.

M2636-60110 Ribbon cable between the LCD and the Main Board. Splits

at one end. Three integral connectors.

M2636-60120 Runs between the Inverter Board and the LCD. Integral

connectors on each end.

M2636-60130 Runs between the NBP Board and the Main Board. Integral

connectors on each end.

Front Panel Assembly

Splash Guard Kit

Screw Kit

M3.0x8mm Torx T-10

M2.0x4mm Torx T6

M3.0x14mm Torx T-10

M3.0x6mm Torx T-10

M3.0x4mm Torx T-10

M3.0x16mm Torx T-10

LCD Data Cable

Inverter-to-LCD Cable

NBP-to-Main Cable

M2636-60140 Power cable running between the transmitter and the Main

Board. Integral connector on each end.

M2636-60302 A PC board mounting the electronics and the cuff pump for

non-invasive blood pressure (NBP) measurements.

Note—The new NBP module is compatible with older

versions of the TeleMon software and hardware.

M2636-60301 The air conduit tubing, mount, and collar connector.

M2636-60412 Device for reconditioning the battery.

M2636-60500 10.8-volt, rechargeable NiMH.

M2636-68200 A PC board mounting ICs and other electrical components,

containing the TeleMon’s major electronics (exchange

assembly).

M2636-90035 TeleMon Release B User and Service Documentation (CD-

ROM).

5-2 Parts List

Transmitter-to-Main Cable

NBP Board Assembly

NBP Connector Assembly

Battery Conditioner

Internal Battery

Main Board

User and Service Documentation

CD

Page 35

6

Troubleshooting, Service and Repair

This chapter describes maintenance, troubleshooting and service. It includes the

following sections:

• Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

– Purpose. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

– Alarms and Information Messages. . . . . . . . . . . . . . . . . . . . . . . . 6-2

— Patient Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

— Suspending Patient Alarms . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

— Task Summary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

— Information Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

– Self-Test Error and Event Log Messages. . . . . . . . . . . . . . . . . . . 6-8

— NBP Event Log Error Codes . . . . . . . . . . . . . . . . . . . . . . . . 6-9

– Power On Self-Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-11

• Service Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-12

– Activating Service Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-12

– Performing Service Functions . . . . . . . . . . . . . . . . . . . . . . . . . . 6-14

– Configuring the Transmitter. . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-16

– Upgrading the Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-19

– Cloning Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-25

– Changing TeleMon’s Language Display . . . . . . . . . . . . . . . . . . 6-26

• Using the Battery Reconditioner . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-26

• Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-28

– Tools. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-28

– Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-29

– Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-31

– The Battery. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-32

– The Front Panel Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-33

– The Chassis Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-35

– The NBP Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-38

– The Inverter Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-39

– The Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-41

– The Main PC Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-42

– The Speaker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-44

– The Battery Compartment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-45

– The Battery Door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-46

– The Transmitter Dock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-47

– The Fan Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-48

– The Splash Guard. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-48

Troubleshooting, Service and Repair 6-1

Page 36

Troubleshooting

Troubleshooting

Purpose This section provides troubleshooting instructions for TeleMon. To properly troubleshoot

TeleMon, a clear understanding of the Telemetry system is required.

When troubleshooting TeleMon consider that problems can occur because of:

• Equipment malfunctions: hardware failures, etc.

• Application faults: usually leads off, battery problems, ECG equipment malfunction,

transmitter malfunction, %SpO

• RF problems: as a result of RF environmental conditions, or problems like not receiving

a signal, receiving a weak signal, etc. (Solutions to this type of problem are described in

the Telemetry System Service and Reference Guide.)

This section presents symptoms that show up when failures occur, and provides a corrective

action to fix those failures. In this section you will find:

• Alarms and Information Messages

• Self-test Error and Event Log Messages

• NBP Event Log Error Codes

• Additional Troubleshooting Tips

•Power O2

•n Self-test

malfunction.

2

Alarms and Information Messages

Patient Alarms When a transmitter is docked in TeleMon, all patient alarms are generated, displayed,

Two types of signals can be generated during monitoring:

• Patient alarms indicate a life-threatening situation or less urgent situation, such as heart

rate alarm.

• Information messages indicate that the monitor cannot measure or detect alarm

conditions reliably.

recorded, and silenced either at TeleMon locally, or at the Information Center and

Surveillance Center.

WarningWarning

No patient alarms are annunciated at the TeleMon when local alarms are off. When

local alarms are off, telemetry alarms are presented at the central monitor only, and all

alarm adjustments must be made at central.

All central alarms can be temporarily suspended for 3 minutes from TeleMon. When alarms

are suspended at TeleMon, any active alarm will be silenced. When alarms are unsuspended,

the arrhythmia time outs will be reset.

NBP alarm settings (limits and on/off) are adjusted at central.

Visual Indicators on TeleMon for Patient Alarms:

• Message CENTRAL ALARMS ONLY displayed in black on top banner

• Message Local Alarms OFF displayed in alarm message area.

6-2 Troubleshooting, Service and Repair

Page 37

Troubleshooting

Suspending

Patient Alarms

You can suspend central telemetry alarms from TeleMon for 3 minutes to prevent false alarms

from occurring during a change of electrodes or other activity that could cause motion artifact

alarms.

Visual Indicators on TeleMon for Suspended Alarms:

• Message CENTRAL ALARMS SUSPENDED displayed in red on top banner

opposite the date.

• Number of minutes remaining in the suspension period displayed above the Suspend

Alarms key.

• The SUSPEND at Central key label changed to xx:xx min to UN SUSPEND.

Note—When the transmitter is undocked, the suspend capability reverts to standard telemetry

operation; that is, suspend is enabled at central.

Task Summary To suspend alarms at central from TeleMon, use the following procedure.

Step 1. Press the key below SUSPEND at Central to suspend all telemetry alarms at

central for 3 minutes.

Step 2. To restart suspended alarms, press xx:xx min to UNSUSPEND.

Information

Messages

The following table lists all the information messages that TeleMon can display. These

messages are text only; no sound is generated at TeleMon when any of these conditions is

active.

WarningWarning

When local alarms are off, information messages at TeleMon are silent.

If multiple information messages are active, an up arrow (↑) will be displayed to the right of

the information message area. Messages will cycle through the sector at a rate of one every

two seconds. There is no audible indicator for any information signal.

All information messages are non-latching, that is, the information message resets

automatically when the condition is corrected, and the information message is erased from the

display. NBP information messages will remain on the display until the situation is corrected.

Visual Indicators on TeleMon for Information Message Conditions:

• Message displayed in information message area

Troubleshooting, Service and Repair 6-3

Page 38

Troubleshooting

The following table lists all of the information signals (in alphabetic order) that could appear

in the information message area at the top center of the TeleMon display.

Table 6-1. TeleMon Information Messages

Information Message Problem Corrective Action

CHARGE MON BAT

TeleMon battery is <= 25%.

If TeleMon battery level is <=

Note—Will not be

displayed at central if

Xmtr BATTERY WEAK

message is also in effect,

but both information

messages will be

displayed at TeleMon.

15%, TeleMon will start a 5minute shutdown counter, and if

no action is taken to clear the

condition, TeleMon will

shutdown the device and latch the

power supply until it is connected

to AC power.

CUFF NOT DEFLATED Cuff pressure is greater than a

specified safety limit for a period

of time.

ECG EQUIP MALF ECG PC board in the transmitter

is malfunctioning

Connect to AC power and

charge battery, or insert battery

with >25% charge.

Remove cuff from patient and

disconnect from tubing. Gently

expel any air. [If water in cuff,

replace cuff.] Reconnect and

reapply cuff to patient.

Note—If the alarms are

suspended at the Information

Center, this information message

unsuspends them. To clear the

information message, initiate a

new NBP measurement.

Replace transmitter.

For details, see the Telemetry

System Service Training and

Reference Guide.

INVALID LEADSET EASI transmitter has a 3-wire

LEADS OFF Lead(s) not connected, or 3-wire

CHECK LEADS Selectable lead unavailable due to

6-4 Troubleshooting, Service and Repair

leadset, or no leadset attached to

it.

leadset is connected to a 5-lead

transmitter trunk cable.

leads off condition.

Undock transmitter and attach a

5-wire leadset.

Reconnect lead(s).

Attach 3-lead trunk cable.

Reconnect lead(s).

Page 39

Troubleshooting

Table 6-1. TeleMon Information Messages

Information Message Problem Corrective Action

NBP CUFF

OVERPRESS

Cuff pressure increased above

overpressure safety limits

NBP EQUIP MALF The tube in the cuff may be

kinked or disconnected, or there is

a malfunction in the NBP

hardware.

Remove cuff from patient and

disconnect from tubing. Gently

expel any air. [If water in cuff,

use new cuff.] Reconnect and

reapply cuff to patient.

Note—If the alarms are

suspended at the Information

Center, this information message

unsuspends them. To clear the

information message, initiate a

new NBP measurement.

Unkink and/or connect tubing.

Reconnect the transmitter by

redocking.

Take another measurement. If

problem persists, contact your

service provider.

Replace the cuff.

Conduct an NPB calibration,

(see “NBP Diagnostics,

Calibration” on page 6-17 ).

NBP INTERRUPTED The preset maximum time for

total measurement has been

exceeded because of motion

artifact or arrhythmia activity or,

the user pressed STOP during the

measurement.

NBP MEASURE

FAILED

No measurement values can be

derived because no pulse or

inconstant pulse is sensed.

Troubleshooting, Service and Repair 6-5

If necessary, replace the NBP

Board (see “The NBP Board” on

page 6-38 ).

Reapply cuff. Ask patient to

refrain from moving during

measurement.

Reapply cuff, or choose a new

location.

Reconnect the transmitter by

redocking.

Obtain a manual measurement.

If problem persists, use a

different transmitter.

Page 40

Troubleshooting

Table 6-1. TeleMon Information Messages

Information Message Problem Corrective Action

XMTR FAIL Error writing TeleMon data to

transmitter eeprom.

SPO2 EQUIP MALF Malfunction in the %SpO

2

hardware, or transducer/adapter

cable damaged

SPO2 ERRATIC Erratic %SpO

measurements,

2

often due to a faulty transducer or

incorrect positioning of the

transducer

May also be caused by optical

shunting if sensor too big or too

small.

SPO2 INTERFERENCE Level of ambient light is so high

that the %SpO

measure %SpO

transducer cannot

2

or pulse rate.

2

Transducer or adapter cable is

damaged.

May also be due to electrical

interference.

May also be generated by a

defective transmitter.

Replace transmitter and contact

service.

Change transducer or adapter

cable.

If message persists, replace

transmitter.

Line up light source and

photodetector - they must be

opposite each other and light

must pass through the arteriolar

bed.

Reposition transducer to site

with higher perfusion.

Replace transducer or adapter

cable.

Use different sensor with correct

fit.

Cover sensor with non-white

opaque material (for example,

pulse oximeter probe wraps Posey wrap or equivalent) to

reduce ambient light.

If message persists, inspect and

replace transducer or adapter

cable as needed.

Reduce sources of electrical

interference.

6-6 Troubleshooting, Service and Repair

If the above corrective actions

are ineffective, use a different

transmitter, and replace the

defective one.

Page 41

Troubleshooting

Table 6-1. TeleMon Information Messages

Information Message Problem Corrective Action

SPO2 NOISY SIGNAL Excessive patient movement or

electrical or optical interference is

causing irregular pulse patterns

SPO2 NON PULSATILE Pulse too weak or not detectable

May also be generated by a

defective transmitter.

NPB measurement being made on

the same extremity as %SpO

SPO2 TRANS MALF The %SpO

transducer is

2

2

malfunctioning.

%SpO

connector on the

2

transducer or transmitter is dirty

or corroded.

Locate sensor at site with less

movement.

Reduce sources of electrical or

optical interference.

If the above corrective actions

are ineffective, consult the

Telemetry System Service

Training and Reference Guide.

Relocate sensor to site with

improved circulation.

Warm area to improve

circulation.

Try another sensor type.

If the above corrective actions

are ineffective, use a different

transmitter.

Replace the transducer or

adapter cable.

Change the transmitter.

Xmtr BATTERY DEAD If it communicates, transmitter

was docked with a dead 9-volt

Undock transmitter and replace

transmitter battery.

battery.

Transmitter EPROM may be

damaged; ECG monitoring may

stop.

Xmtr BATTERY WEAK

Note—Overrides

Transmitter was docked with a

weak 9-volt battery.

Undock transmitter and replace

transmitter battery.

CHARGE MON BAT

message at central, but

both messages will be

displayed at TeleMon.

XMTR MALF Transmitter malfunctioning Replace transmitter.

Troubleshooting, Service and Repair 6-7

Page 42

Troubleshooting

Self-Test Error and Event Log Messages

The following table describes TeleMon Self-Test Error Messages, and Event Log Messages

(available in Service Mode). Additionally, this table provides corrective action to remedy

these failures.

There are differences in the severity of event log messages and error messages:

• Error messages can prevent TeleMon from getting into monitoring mode, and require

immediate attention.

• Screen messages and event log messages, on the other hand require attention, but don’t

prevent TeleMon from getting into monitoring mode.

For details on displaying the Event Log, see “Viewing the Event Log” on page 6-15 .

Table 6-2. TeleMon Information Messages

Message Problem Message

Battery dead. System

will shut down.

Restart with AC

cable attached.

Battery needs

reconditioning

Battery Error No Recharge battery.

Battery Message No Recondition

Type

Log

Entry

Corrective

Action

battery. If problem

persists, replace

battery.

Button “xxx” is not

functioning

Calibration

EXPIRED

Calibration

INVALID

NBP communication

failure

Calibration date

UNKNOWN

Keyboard Error No Reboot. If problem

persists, replace

keyboard.

NBP Message No Conduct NBP

calibration.

NBP Error No NBP Calibration

process has failed.

Recalibrate NBP

module.

NBP Error Yes

“NBP test

err

XXXXX”

NBP Message No Caused by

Reboot TeleMon.

If problem persists,

replace NBP

board.

TeleMon software

upgrades where

the NBP module

has been used

more than 100

measurements.

Conduct NBP

calibration.

6-8 Troubleshooting, Service and Repair

Page 43

Table 6-2. TeleMon Information Messages

Troubleshooting

Message Problem Message

Type

No/FFX1/Startup.ini

OS Err 2

Cannot find ‘selftest,’ (or one of its

components).

Make sure the path

and filename are

correct and that all

required libraries are

available.

None Time Error No Set clock correctly.

OS Error No TeleMon

OS Error No Irreversible

Log

Entry

Corrective

Action

automatically tries

to connect to host

PC for service.

Reload the

TeleMon

application

software.

damage to the

main processor

board caused by

disconnecting

adapter cable

during application

software upgrade.

Replace main

processor board.

If problem persists,

replace coin cell

battery.

NBP Event Log

Error Codes

None Time (Reboot

with no

corresponding

error log)

None Time (Time

stamp on NBP

measurement is

incorrect)

Every NBP measurement is captured in the event log in the following format:

INFO <time> <date> Nbp.cpp(349) NBP SunTech Err=XX data=SYS/DIA/MEAN

where,

• XX = the error code (see table below)

• SYS = returned systolic value

• DIA = returned diastolic value

• MEAN = returned mean value

Error No Replace coin cell

battery.

Error No Replace coin cell

battery.

Troubleshooting, Service and Repair 6-9

Page 44

Troubleshooting

The following table lists NBP error codes and their appropriate TeleMon message. For details

on troubleshooting NBP messages, see “TeleMon Information Messages” on page 6-4 .

Table 6-3. NBP Event Log Error Codes

NBP

Error

Code

TeleMon Message Probable Cause

Additional

Information

0 N/A No error Valid NBP

measurement

1 NBP MEASURE FAILED Weak or no oscillometric signal

2 N/A Artifact/erratic oscillometric

signal

Questionable

NBP

measurement

3 NBP MEASURE FAILED Exceeded retry count

4 NBP INTERRUPTED Exceeded measurement time

limit

85 NBP MEASURE FAILED Blocked valves of pneumatics

86 NBP INTERRUPTED User aborted measurement

87 NBP INTERRUPTED Inflation time-out, or air leak

88 NBP INTERRUPTED Safety time-out

89 NBP CUFF OVERPRESS Cuff overpressure

90 NBP EQUIP MALF Power supply out of range, or

other hardware problem

91 NBP EQUIP MALF Safety override fitted or

autozero out of range

97 NBP EQUIP MALF Transducer out of range

98 NBP EQUIP MALF A/D out of range

99 NBP EQUIP MALF EEPROM calibration data CRC

failure

NBP MEASURE FAILED Any communication failures

CUFF NOT DEFLATED Cuff has pressure > 15 mmHg

after 3 minutes of measurement

Table 6-4. Additional Troubleshooting Tips

Issue Probable Cause

Parameters transmitted

to Information Center

Antenna coverage area It is important to keep the patient within the antenna covering

6-10 Troubleshooting, Service and Repair

TeleMon displays ECG waveforms, a pleth wave, a delayed/

annotated ECG wave, heart rate, %SpO2, and NBP, and transmits

to the IC ECG, %SpO2 and NBP. ECG, %SpO2 and NBP are

calculated by TeleMon, the remainder parameters are calculated

by the transmitter.

area because TeleMon does not indicate when and if the

transmitter is outside the covering area.

Page 45

Troubleshooting

Table 6-4. Additional Troubleshooting Tips

Issue Probable Cause

Display looks dark If the display looks dark even after adjusting the brightness, it’s

possible the display needs to be replaced. The display’s estimated

half-life is approximately two years. (For details, see “The

Display” on page 6-41 .)

NBP measurement

difficulties

Diminishing battery life If the battery life seems to be diminishing after a number of

If you experience difficulties conducting NPB measurements,

(for example a new patient has higher HR than the previous one),

reboot TeleMon to reset internal settings.

charge/discharge cycles, the battery may need reconditioning. For

details on how to recondition the battery, see “Using the Battery

Reconditioner” on page 6-26 .

Power On Self-Test

The self-test function checks the following components:

• Circuit boards operation (including processor board)