Page 1

Philips Telemetry System

Service and Reference Guide

m2600-90192

Part Number M2600-90192

Printed in the U.S.A. Date May 2002

Edition 2

Page 2

Notice

Proprietary

Information

Warranty The information contained in this document is subject to change without notice.

This document contains proprietary information that is protected by copyright. All

Rights Reserved. Reproduction, adaptation, or translation without prior written

permission is prohibited, except as allowed under the copyright laws.

Philips Medical Systems

3000 Minuteman Road

Andover, MA 01810-1085

(978) 687-1501

Publication number

M2600-90192

Printed in USA

Philips Medical Systems makes no warranty of any kind with regard to this material,

including, but not limited to, the implied warranties or merchantability and fitness for

a particular purpose.

Philips Medical Systems shall not be liable for errors contained herein or for

incidental or consequential damages in connection with the furnishing, performance,

or use of this material.

Printing

History

Copyright Copyright © Philips Medical Systems, 2002

New editions of this document will incorporate all material updated since the previous

edition. Update packages may be issued between editions and contain replacement

and additional pages to be merged by a revision date at the bottom of the page. Note

that pages that are rearranged due to changes on a previous page are not considered

revised.

The documentation printing date and part number indicate its current edition. The

printing date changes when a new edition is printed. (Minor corrections and updates

that are incorporated at reprint do not cause the date to change.) The document part

number changes when extensive technical changes are incorporated.

First Edition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .June 2000

Second Edition. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .May 2002

Page 3

Table of Contents

1. Introducing the Philips Telemetry System. . . . . . . . . . . . . . . . . . . . . .1-1

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

Philips Telemetry System Compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

Philips Telemetry System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Leadsets and SpO2 Transducer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Transmitter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Antenna System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Frequency Converter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Receiver Mainframe. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Analog Output Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

TeleMon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Telemetry Configuration Tool. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Telemetry Service Tool. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

Leadsets. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

3-Wire Leadset (Standard ECG) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

5-Wire Leadset (Standard ECG) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

5-Wire Leadset (EASI ECG) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

SpO2 Transducer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

Front End Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

Case Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

Transmitter Button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Manual SpO2 Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Leads Off LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

ECG PCB. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8

Main PCB. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8

Digital Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

ECG PCB Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Lead Set Detect Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Transmitter Button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Leads Off LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Serial Infrared Port. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Power Supply Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Memory Section. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

RF Section. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

Power Supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

SpO

Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-12

2

SpO2 T ransducer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

SpO2 Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

Battery Extender. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-14

Receiver Mainframe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-15

Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-16

Antenna Distribution Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-16

Receiver Backplane . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-17

Digital Backplane . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-17

Rack Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-17

Configurable Processor Card. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-18

Utility CPU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-18

SDN Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-18

Patient Monitor/Holter Recorder Interface (Analog Output) . . . . . . . . . . . . . . . . . .1-19

Contents 1

Page 4

Receiver Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-20

RF Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-20

Frequency Synthesizer Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-20

Digital Baseband Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-21

Detector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-21

Microcontroller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-21

Peripheral Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-21

M2613/14/15A Dual-Band UHF Antenna System . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-22

406 - 480 MHz Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-22

590 - 632 MHz Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-22

Dual-Band Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-22

Antenna Strings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-23

Combining Networks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-23

Frequency Converter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-23

M2608A Active Antenna/Combiner. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-24

Line Amplifier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-25

2-Way and 4-Way Splitter/Combiners. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-25

Multiple Power Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-25

Power Tee . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-25

Power Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-25

Frequency Converter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-26

External Frequency Converter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-26

Internal Frequency Converter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-26

Attenuators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-27

Bandpass Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-27

2. Service Tools. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Controls and Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Transmitter Controls and Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Receiver Mainframe Controls and Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Front View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Rear View. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Turning the Telemetry System On/Off. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Turning on the Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Turning on the Receiver Mainframe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Turning on Antenna Components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Setting Frequencies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Matching a Transmitter Frequency to a Receiver Frequency. . . . . . . . . . . . . . . . . 2-6

Changing a Transmitter’s Frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Using the Transmitter Service Tool. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Using the Telemetry Configuration Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Using the TeleMon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Using the Wave Viewer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Changing the Receiver Frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Using the Central Station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Using the Telemetry Service Tool. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Setting a Transmitter’s Frequency After Repair . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Checking for Interference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Using the RF History Strip . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Using the RF INOP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Error Messages While Setting Frequencies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Contents 2

Page 5

Managing Frequencies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-12

Using the Frequency & Check Code Listing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-12

Frequency Registration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Frequency Management? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

Frequency Management Responsibility. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

Frequency Management Updating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

Interference from Wireless Devices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Required Information for Frequency Management . . . . . . . . . . . . . . . . . . . . 2-14

Interference Sources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Avoiding Interference. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Extended UHF Band Frequency Selection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-15

Channel 37 (608-614 MHz) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

Channels 34, 35, 36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

Available Frequency Management Tools. . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

Using the Built-in RF Tools. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-22

Turning on the RF INOP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-22

Printing RF History Strips. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-22

Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-23

Checking Receiver Mainframe Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-23

Using the Telemetry Service Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

Using the Central Station. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

Checking Transmitter Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-24

Using the Telemetry Service Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

Using the Telemetry Configuration Tool. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

Using the TeleMon. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

Using the Wave Viewer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

Changing Transmitter Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-25

Using the Telemetry Service Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-25

Using the Telemetry Configuration Tool. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-26

Using the TeleMon. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-26

Using the Wave Viewer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-26

Changing Receiver Mainframe Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-27

Performing Learn Codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-29

Checking Revision Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-30

Transmitter Revision Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-30

Using the Telemetry Service Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-30

Using the Telemetry Configuration Tool. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-30

Using the Wave Viewer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-30

Receiver Mainframe Revision Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-31

Using the Telemetry Service Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-31

Using the Central Station. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-31

Locating Serial Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-32

Upgrading Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-33

Transmitters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-33

Receiver Mainframes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-33

Rev D to Rev D Rev E to Rev E . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-33

Rev D to Rev E . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-34

Rev E to Rev D . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-35

Performing Self-Tests. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-36

Transmitter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-36

Using the Telemetry Service Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-36

Using the Wave Viewer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-36

Receiver Mainframe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-37

Using the Telemetry Service Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-37

Contents 3

Page 6

3. Maintaining the Philips Telemetry System . . . . . . . . . . . . . . . . . . . . . 3-1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Caring for the Philips Telemetry System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Cleaning the Receiver Mainframe and Transmitters . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Cleaning the Receiver Mainframe. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Cleaning the Transmitter & Battery Extender . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Wiping the Transmitter Exterior . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Wiping the Battery Compartment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Wiping the Battery Extender. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Soaking the Transmitter & Cradle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Cross-infection Prevention for the Transmitter & Battery Extender. . . . . . . . . . . . . . . . 3-6

Cleaning the Transmitter and Battery Extender . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Cross-infection Prevention and Aeration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Equipment and Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Cross-infection Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Aeration Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

References. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Testing the Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Cleaning ECG Patient Cables and Leads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Disinfecting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Sterilizing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Cleaning SpO

Adapter Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Reusable Transducers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Adapter Cables & Transducers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

2

4. Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Troubleshooting Map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Telemetry Troubleshooting Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Subsystem Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Transmitter Non-RF/Application Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

LEADS OFF INOP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

TRANSMITTER OFF INOP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

INVALID LEADSET INOP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

NO SIGNAL INOP and an RF OUT OF LOCK INOP at Wave Viewer . . . . . . . . . . 4-8

Battery INOPs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

ECG EQUIP MALF INOP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

TRANSMITTER MALF INOP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

ARRHY REQUIRED INOP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

Transmitter SpO2 Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

EQUIP MALF INOP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

ERRATIC INOP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

INTERFERENCE INOP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

NO TRANSDUCER INOP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

NOISY SIGNAL INOP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

NON-PULSATIL INOP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

TRANS MALF INOP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

Contents 4

Page 7

Receiver Mainframe/System Faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-14

Power Does Not Come On when Receiver Mainframe is Plugged In . . . . . . . . . .4-14

NO DATA FROM BED INOP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-14

Receiver Non-RF Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-18

NO RECEIVER INOP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-18

RECEIVER MALF INOP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-19

Other Problems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-20

Pressing the Transmitter Button Does Not Give the Desired Result . . . . . . . . . . .4-20

RF Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-21

RF Problem Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-21

RF Problem INOPs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-21

CNR. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-21

Low Signal Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-22

Interference Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-22

Gathering Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-23

Methodology. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-23

Observe System Performance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-23

Question the User . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-23

Check the RF History Strips. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-24

INVALID SIGNAL E01 INOP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-24

Frequent Dropouts and NO SIGNAL, WEAK SIGNAL and TEL CANNOT

ANALYZE INOPs on a Single Channel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-25

Changing Frequencies to Troubleshoot Single-Channel Problems. . . . . . . . 4-27

Frequent Dropouts and NO SIGNAL, WEAK SIGNAL, and TEL CANNOT

ANALYZE INOPs with Multiple Channels . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-29

Frequent Dropouts and TEL CANNOT ANALYZE and INTERFERENCE INOPs .4-30

RF Troubleshooting Tools and Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-32

RF INOP Real-time Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-32

RF History Strip Historical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-33

Received Signal Strength . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-34

Invalid Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-35

Analyzing RF History Strips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-37

Expected Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-37

RF History Strip - helpful hints: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-37

Example of No Receiver Installed in a Slot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-38

Examples of Good Mean Signal Strength and Good Performance . . . . . . . . . . . .4-39

Examples of Low Signal Strength and Good Performance . . . . . . . . . . . . . . . . . .4-40

Examples of Patient Leaving Coverage Area or Sleeping in an RF Null . . . . . . . .4-41

Problems due to Low Signal Strength. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-42

Examples of RF Auto Shutoff. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-43

High Power Narrowband Interference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-44

Example: No Battery in Transmitter, No Interference Present. . . . . . . . . . . . 4-46

Example: No Battery in a Transmitter, Interference Present . . . . . . . . . . . . . 4-47

Broadband Interference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-48

Multiple Problems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-49

Distinguishing M1400X Transmitters from M2601A Transmitters . . . . . . . . . . . . .4-49

Performance Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-50

One Hour Time Period. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-52

Distinguishing RF Performance from LEADS OFF . . . . . . . . . . . . . . . . . . . . . . . .4-54

Monitoring a Channel for a Clear Frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-55

Antenna System Troubleshooting Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-56

Equipment Required. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-56

Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-58

General Faults and Symptoms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-60

Extended-Band Upgrades Faults, and Symptoms. . . . . . . . . . . . . . . . . . . . . 4-60

Analog Output Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-64

Contents 5

Page 8

5. Disassembling the Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Disassembly/Assembly of the Leadset Combiner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Disassembly of the Transmitter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Single-Use Screw Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Removing the Battery. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Removing the Battery Door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Removing the Case Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Removing the Main Cage Brace . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

Removing the SpO2 or Blank PC Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

Removing the ECG PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-13

Removing the Main PCB and Front End Assembly . . . . . . . . . . . . . . . . . . . . 5-14

Removing the Battery Contacts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

6. Reassembling the Transmitter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Single-Use Screw Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Torque Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Installing the Front End Assembly and Main PCB . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

Installing ECG PCB and SpO2 Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

Re-installing a Blank SpO2 Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-13

Installing the Main Cage Brace. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-14

Replacing/Re-installing the Case Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-17

Replacing/Re-installing the Battery Door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-21

Replacing the Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-22

Replacing/Re-installing the Battery Contacts . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-23

Post Assembly Tasks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-25

7. Disassembly/Assembly of Receiver Mainframe Components . . . . . 7-1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Disassembly/Assembly of the Receiver Mainframe . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Removing Function Cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Replacing Function Cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Removing the Front Dress Cover. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

Replacing the Front Dress Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

Removing Receiver Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

Replacing Receiver Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

Removing the Top Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

Replacing the Top Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

Removing the Rear Brace (European Version Only) . . . . . . . . . . . . . . . . . . . . 7-7

Replacing the Rear Brace . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-7

Removing the Antenna Distribution Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

Replacing the Antenna Distribution Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

Removing the Chassis Cooling Fan. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-9

Contents 6

Page 9

Replacing the Chassis Cooling Fan. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-10

Removing the Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-11

Replacing the Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-12

Removing the Rack Interface Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-13

Replacing the Rack Interface Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-13

Removing the Receiver Backplane . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-14

Replacing the Receiver Backplane . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-14

Removing the Digital Backplane . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-15

Replace the Digital Backplane. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-15

Removing the Antenna Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-16

Replacing the Antenna Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-16

Receiver Mainframe Post Assembly Tasks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-17

Disassembly/Assembly of a Receiver Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-18

Tools Required. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-18

Disassembly Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-19

RF Cable Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-19

Receiver Shield Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-19

Large Receiver Shield Gasket (U-shaped) . . . . . . . . . . . . . . . . . . . . . . . . . . 7-19

Small Receiver Shield Gasket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-19

Receiver Board Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-19

Receiver Board Gasket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-19

Reassembly Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-19

Receiver Board Gasket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-19

Receiver Board Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-19

Small Receiver Shield Gasket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-19

Large Receiver Shield Gasket (U-shaped) . . . . . . . . . . . . . . . . . . . . . . . . . . 7-19

Receiver Shield Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-19

RF Cable Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-19

8. Replaceable Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-1

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-1

Ordering New Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-2

Ordering Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

Philips Offices Worldwide. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-2

Unlisted Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-3

Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-4

Receiver Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-10

Receiver Mainframe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-12

Analog Output Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-16

M2613/14/15A Antenna System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-17

Frequency Converter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-19

Release C Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-20

Contents 7

Page 10

9. Standard Antenna System Design. . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

Setting Expectations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

Determining Needs and Gathering Site Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-3

Standard and Non-Standard Antenna System Design . . . . . . . . . . . . . . . . . . . . . . . . . 9-4

Standard Systems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-4

Non-Standard Systems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-4

Standard Coverage Areas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-5

Rectangular Coverage Area. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-5

Number of antennas required. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-5

Special Coverage Areas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-5

Non-rectangular coverage areas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-6

Shielded Areas. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-6

Large Open Areas and Hallways . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-6

Antenna Design Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-7

Signal Reception. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-7

Signal Preservation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-7

Designing Standard Antenna Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-8

Outlining and Marking the Coverage Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-8

Calculating Coverage Area. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-10

Determining Antennas for Contiguous Areas . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-11

Determining Antennas for Non-Contiguous Areas . . . . . . . . . . . . . . . . . . . . . . . . 9-13

Placing and Connecting Antennas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-13

Ordering Antenna System Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-15

Pre-configured Antenna Strings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-15

Pre-configured Combining Networks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-17

Site Information Checklist. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-19

Contents 8

Page 11

Appendices

A. Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Battery Life Expectancy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-4

Battery Extender. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-4

ECG Measurement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-5

SpO2 Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-6

Receiver Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-7

Receiver Mainframe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-7

Antenna System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-9

Safety Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-12

Declaration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-12

Electromagnetic Compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-13

Philips Telemetry System Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-13

EN61000-4-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-13

IEC 801-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-13

Philips Telemetry System Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-14

Avoiding EMI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-14

FCC Compliance (USA only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-14

Canadian Radio Equipment Compliance (Canada Only). . . . . . . . . . . . . . . . . . . A-15

System Symbols. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-16

Type CF Defibrillation Proof . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-19

B. Ordering Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Basic System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

System Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

Product Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

Feature Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

Frequency Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

ECG Accessory Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-4

SPO2 Accessory Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-4

Installation Materials. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-5

Receiver Mainframe Mounts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-5

Patient Monitor/Holter Recorder Interface Cables and Faceplates . . . . . . . . . B-5

Dual-band UHF Antenna System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-6

Pre-Configured Antenna Strings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-6

M2613A Dual-band UHF Non-Plenum Antenna Systems . . . . . . . . . . . . . . . . B-6

M2614A Dual-band UHF Plenum Antenna Systems . . . . . . . . . . . . . . . . . . . . B-6

Pre-configured Combining Networks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-7

M2615A Dual-band Antenna System Combining Network . . . . . . . . . . . . . . . B-7

Antenna Mounting Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-7

Antenna System Products . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-8

Attenuator (M2609A) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-8

Bandpass Filter (M2612A) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-8

External Frequency Converter (M2616A) . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-8

Antenna System Accessories (M2617A) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-9

Supplies and Accessories. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-10

ECG Leadset with Telemetry Combiner. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-10

ECG Electrodes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-10

SpO2 Transducers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-11

Transmitter Pouches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-11

Battery Products. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-11

Feature Upgrades . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-11

Contents 9

Page 12

C. M2613/14/15A Antenna System Troubleshooting -

Pass/Fail Criteria . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

M2613/14/15A Dual-Band UHF Antenna System . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-2

Frequency Option 001 406-412.5 MHz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-2

Frequency Option 002 412.5-421.5 MHz. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-3

Frequency Option 003 421.5-430 MHz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-4

Frequency Option 004 430-440 MHz. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-5

Frequency Option 005 440-450 MHz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-6

Frequency Option 006 450-460 MHz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-7

Frequency Option 007 460-470 MHz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-8

Frequency Option 008 470-480 MHz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-9

Frequency Option 034 590-596 MHz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-10

Frequency Option 035 596-602 MHz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-11

Frequency Option 036 602-608 MHz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-12

Frequency Option 037 608-614 MHz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-13

D. M1413/14/15B Antenna System Troubleshooting -

Pass/Fail Criteria . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-1

M1413/14/15B Digital UHF Antenna System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-2

Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-2

Antenna Strings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-2

Combining Networks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-2

Block Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-2

M1408A Active Antenna/Combiner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-3

Line Amplifier. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-4

2-Way and 4-Way Splitters/Combiners . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-4

Multiple Unit Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-4

Power Tee . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-4

Power Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-4

Frequency Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-5

Frequency Option 001 - 406-412.5 MHz. . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-5

Frequency Option 002 - 412.5-421.5 MHz . . . . . . . . . . . . . . . . . . . . . . . . . . . D-6

Frequency Option 003 - 421.5-430 MHz. . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-7

Frequency Option 004 - 430-440 MHz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-8

Frequency Option 005 - 440-450 MHz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-9

Frequency Option 006 - 450-460 MHz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-10

Frequency Option 007 - 460-470 MHz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-11

Frequency Option 008 - 470-480 MHz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-12

Replaceable Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-13

Contents 10

Page 13

E. INOP Logs, Status Logs, and Error Codes . . . . . . . . . . . . . . . . . . . . E-1

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-1

INOP Logs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-1

Status Logs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-1

Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-2

Device Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-2

Heart Module Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-4

Rack Manager Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-5

Alarm Manager Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-9

SDN Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-12

INOP Module Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-13

Service Module Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-15

User Interface Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-17

3-Channel ST Module Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-23

F. Wave Viewer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-1

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-1

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-2

Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-2

Wave Viewer Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-3

Wave Viewer Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-4

ECG Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-4

SpO2 Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-4

System Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-5

Starting the Wave Viewer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-6

Exiting the Wave Viewer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-8

Using the Wave Viewer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-9

To Check Wave Viewer Revision Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-9

To Check Transmitter Revision Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-9

To Check Transmitter Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-9

To Change Transmitter Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-10

To Copy Configuration Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-10

To Configure Specific Items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-11

To Change a Transmitter’s Frequency. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-12

To Test the Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-12

Troubleshooting the Wave Viewer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-14

Wave Viewer Hangs-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-14

Wave Viewer will not Communicate with the Transmitter . . . . . . . . . . . . . . . . . . F-14

Wave Viewer Beeps and Shuts Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-14

Cleaning the Palmtop Computer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-15

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-15

Replaceable Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-16

Contents 11

Page 14

Contents 12

Page 15

Overview

1

Introducing the Philips Telemetry

System

Chapter 1 provides a functional description of the Philips Telemetry System.

It describes how the system works as a whole and explains the various

assemblies that make up the telemetry system.

Following are the topics in this chapter.

• Philips Telemetry System . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

• Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

• Receiver Mainframe . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15

• Receiver Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-20

• M2613/14/15A Dual-Band UHF Antenna System. . . . . . 1-22

Philips Telemetry System Compatibility

Warning Philips Medical Systems has done extensive validation of the systems

Software and hardware compatibility information provided in this document is

valid at the time of publication. New revisions are likely.

Compatibility revision changes are updated regularly in Service Notes.

Information in this document reflects information provided in Service Note

M2600A-007G Compatibility Char ts and M2600A -008G Softwar e Hist ory. As

updates occur, the last character in the service note number increments (for

example, M2600A-007G, H, I). The latest Service Note is available from a

Philips Medical Systems Response Center.

specified as compatible in the compatibility charts. Failure to adhere

to these compatibility charts could result in a malfunction or in

unspecified behavior.

Introducing the Philips Telemetry System 1-1

Page 16

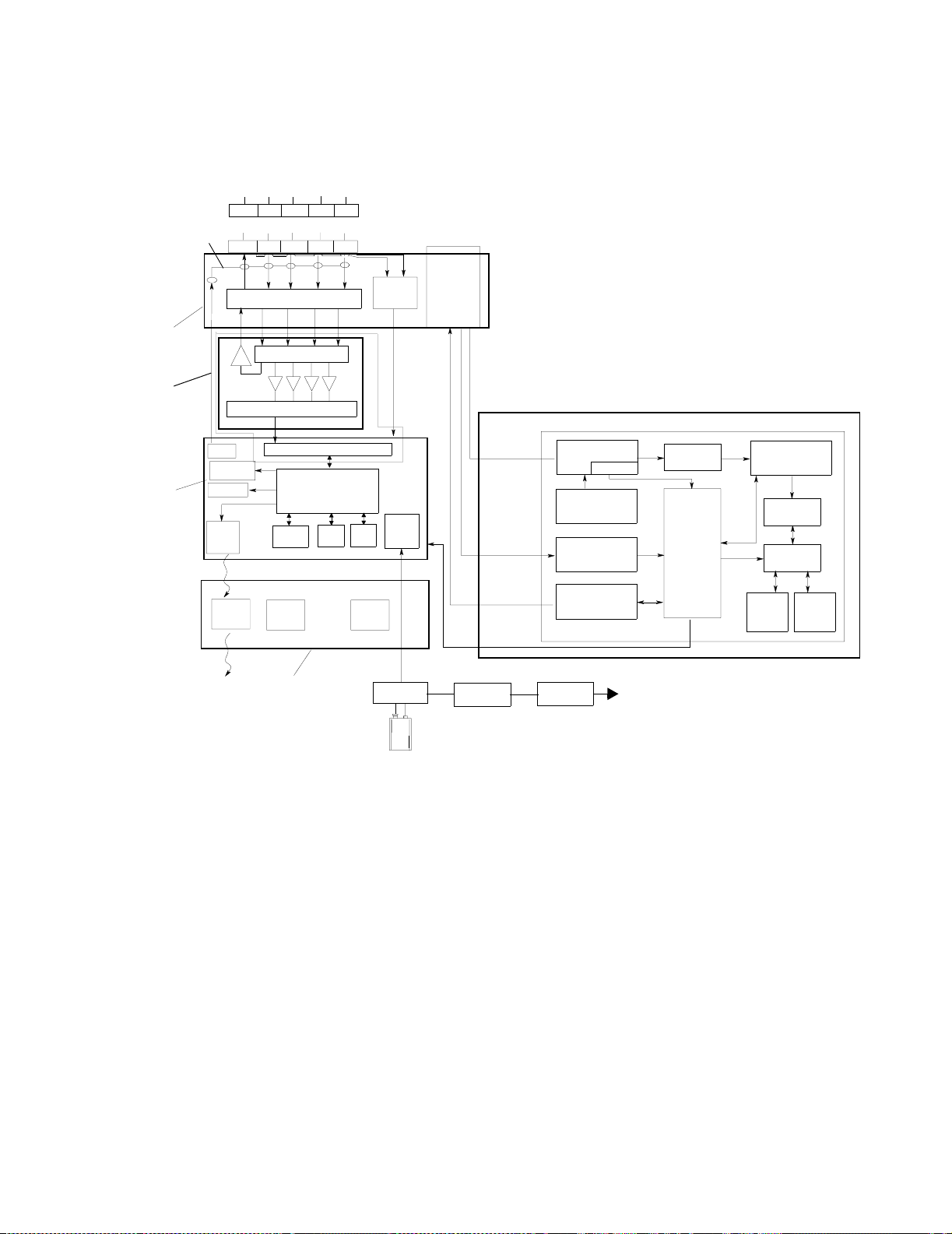

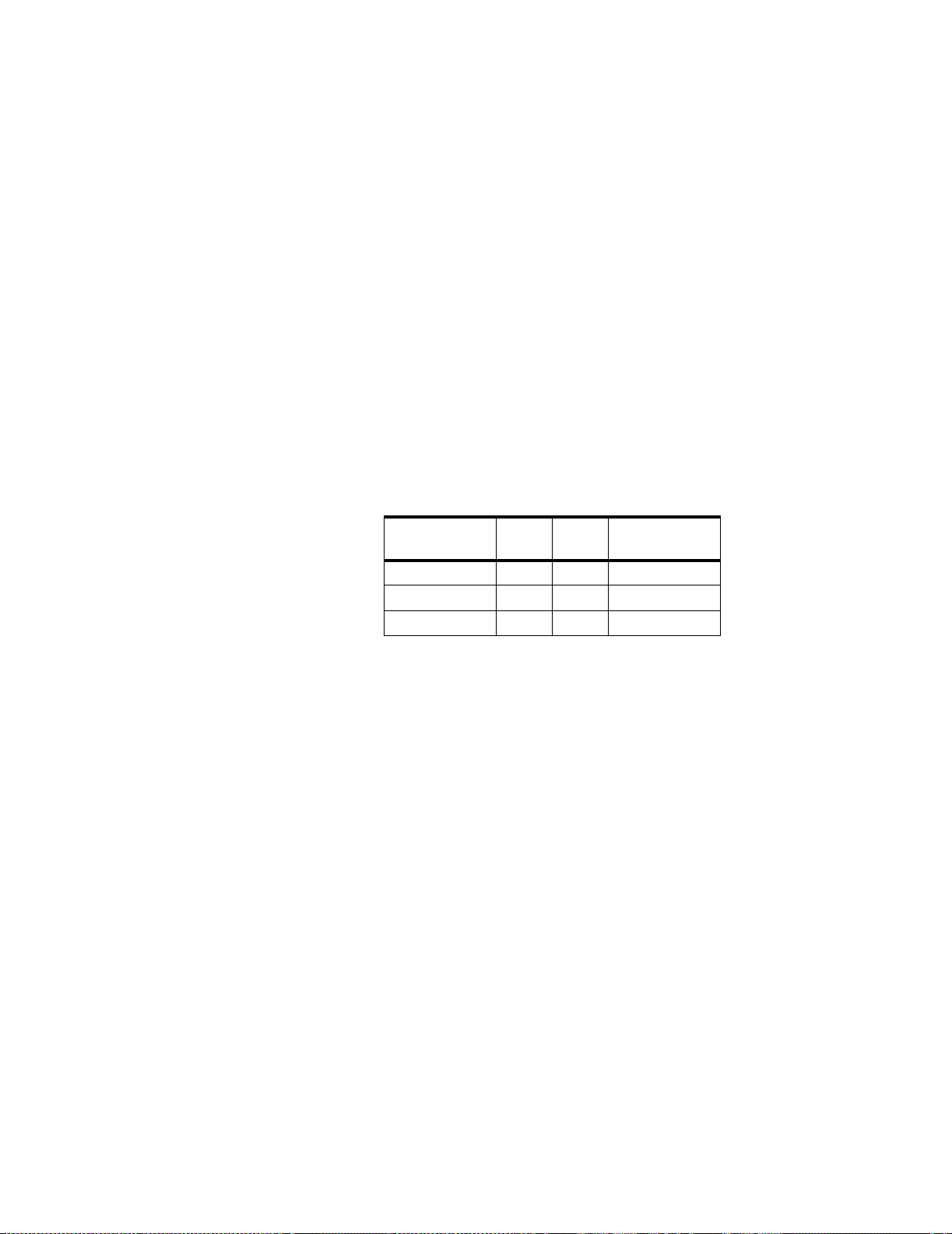

Philips Telemetry System

Philips Telemetry System

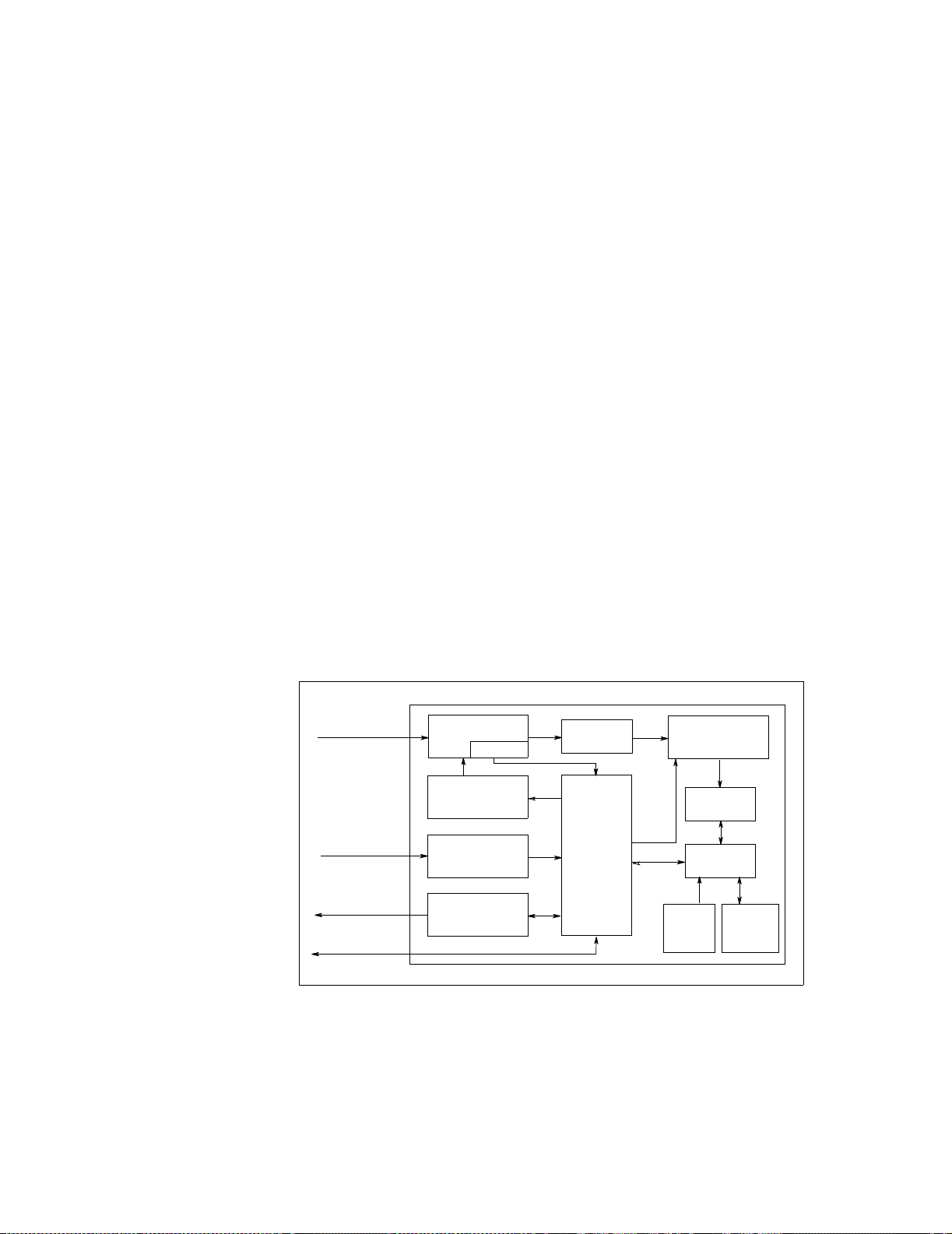

The Philips Telemetry System consists of the following components. See

Figure 1-1.

1. pocket sized Transmitters with removable Leadsets and SpO

Transducers

2. Philips Receiver Mainframe

3. Philips Receiver Modules (up to 8), housed in the Receiver Mainframe

4. active and passive Antenna Components

5. TeleMon (M2636B)

6. Telemetry Configuration Tool

7. Telemetry Service Tool

Patient

Electrode

Lead Set

Transmitter

9-V

Battery

SpO

2

Transducer

Digital UHF

Signal

Antenna System

2

Receiver Mainframe

IR Link

TeleMon

Configuration

Tool

Service

Tool

RCVR

Module

Processing &

Distributing CPUs

(up to 8

Receiver Modules

per Mainframe)

FE

Link

SDN

System

Communications

Controller

Figure 1-1 Philips Telemetry System Block Diagram

Leadsets and SpO

Transducer

The telemetry system provides ECG and SpO2 monitoring of ambulatory and

2

non-ambulatory patients. ECG and SpO

from the patient via Patient Electrode Leadsets and an SpO

data are acquired by the Transmitter

2

Transducer.

2

Transmitter The Transmitter processes the signals and broadcasts them via Radio

Frequency (RF) to the Receiver and via infrared signals to the TeleMon.

Antenna System The Antenna System is designed to create coverage areas where radio

signals can be picked up. Standard band transmitters broadcast signals at

characteristic frequencies between 406 and 480 MHz. These signals are

received by the antenna system, which distributes them to the receiver

Central

Station

1-2 Introducing the Philips Telemetry System

Page 17

Philips Telemetry System

mainframe. Inside the mainframe, they are distributed further to the receiver

modules, each of which is tuned to receive from one transmitter.

For operation at extended UHF frequencies, transmitters broadcast signals in

the range 590-632 MHz. These signals are received by the antenna system and

sent to the Frequency Converter.

Frequency Converter A Frequency Converter shifts or “converts” the signal from the antenna

system to a lower frequency. The “converted” signal is then fed into the receiver

mainframe, which distributes it further to the installed receivers. The receivers

are tuned to the transmitter frequency less the Frequency Converter frequency.

The Frequency Converter can be external to the Receiver Mainframe (Option

#C07) or on a PC board internal to the Receiver Mainframe (Option #C08)

Receiver Mainframe The Receiver Mainframe houses the Receiver Modules and converts the

received signal into a format that can be sent over the network and routes the

signal to the central station for display and analysis. The Receiver Mainframe

can accommodate up to 8 Receiver Modules.

Analog Output Option An Analog Output Option converts the SDN formatted signal back into an

analog value in the mainframe and is routed to a bedside or a Holter interface.

TeleMon The M2636B TeleMonB is a portable monitor display that can be docked to a

transmitter via an IR link. It provides local display of 2 waves -- ECG waveforms,

pleth wave or a delayed/annotated arrhythmia wave -- and numerics for heart

rate, % SpO

, and NBP. The TeleMon also transmits NBP, recording, suspend

2

requests, and INOPs through the transmitter to a Philips Information Center

simultaneously with the transmission of the Transmitter’s ECG and SpO

signals.

2

Note Use of the TeleMon is not described in detail in this Guide. For information on

the TeleMon Monitor, consult the

(PN M2636-90035), which includes the following

TeleMonB Customer Documentation CD ROM

M2636B TeleMonB Monitor

documents:

• Instructions for Use

• Service Manual

• Quick Guide

Telemetry

Configuration Tool

The Telemetry Configuration Tool is a software application that runs on a

computer that operates DOS and links to the transmitter via an IR link. It can be

used to set several transmitter parameters -- operating frequency, %SpO

sample

2

rate, auto shut off. For a description of the Telemetry Configuration Tool, see

Philips Telemetry System Configuration Tool Guide on the Philips Telemetry

the

System Service and User Documentation CD ROM

(PN M2600-90187).

Telemetry

Service Tool

The Telemetry Service Tool is a software application that runs on a computer

that operates Windows 98 or Windows NT. It links to transmitters via an IR link

and to the Receiver Mainframe via an RS232 PC board that must be mounted in

in the rear of the Mainframe. The Service Tool can be used for a variety of

configuration, service, and firmware upgrading tasks. For a description of the

Telemetry Configuration Tool, see the

Guide

on the Philips Telemetry System Service and User Documentation CD

ROM

(PN M2600-90187).

Philips Telemetry System Service Tool

Introducing the Philips Telemetry System

1-3

Page 18

Transmitter

Transmitter

The Philips Transmitter is a battery powered (9-volt) Transmitter worn by

the patient. It acquires ECG and SpO

and SpO

Transducer, amplifies and digitizes the data, and broadcasts them at

2

data from the patient via a ECG Leadset

2

ultra high frequency (UHF) to a Receiver Module in the Receiver Mainframe.

processing occurs in the Transmitter. ECG processing takes place in the

SpO

2

Receiver Mainframe, Central Station, or at the bedside (analog output).

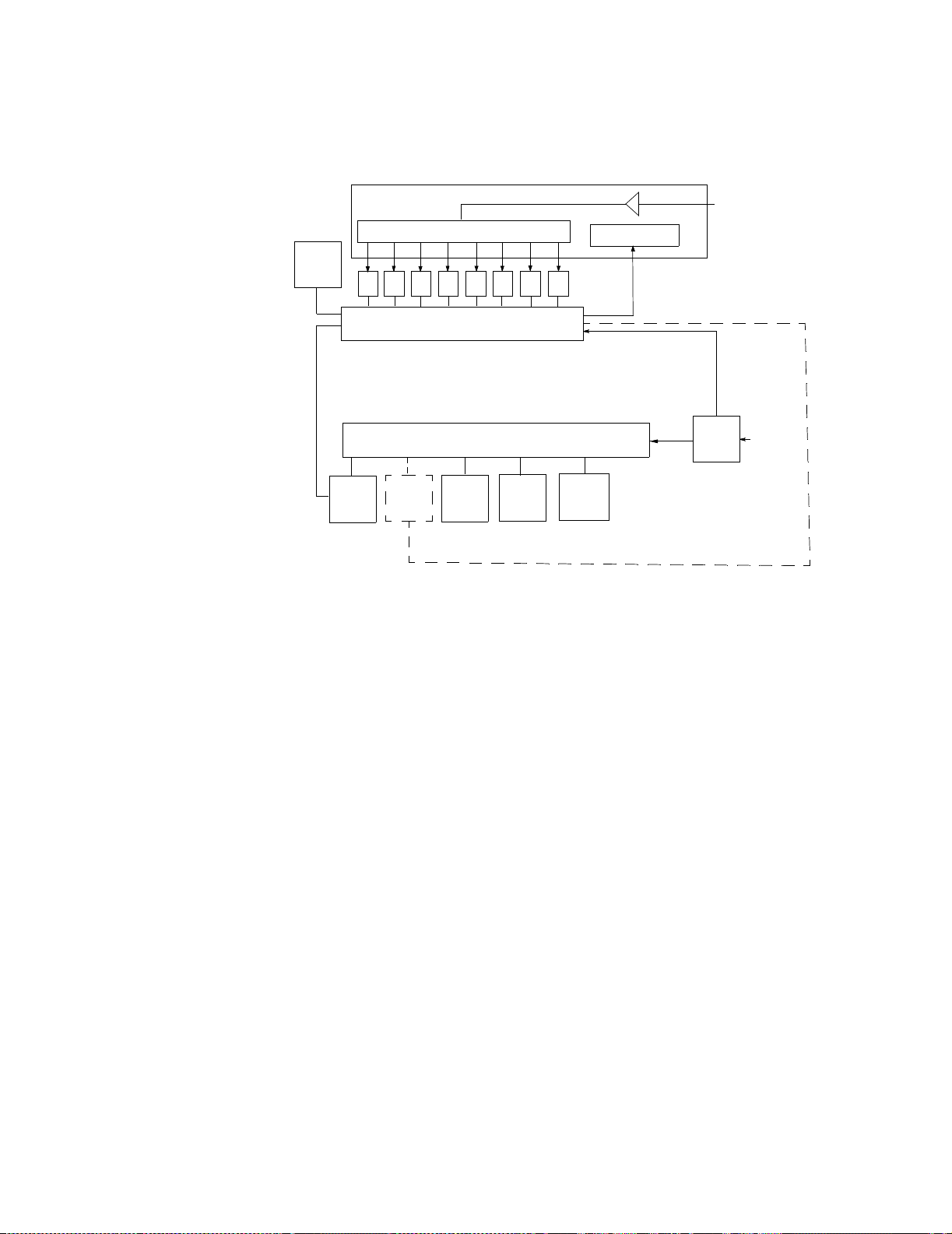

The Transmitter consists of the following assemblies. See Figure 1-1.

•ECG Leadset

• SpO

Transducer

2

• Front-end Assembly

• Case Assembly

• ECG Printed Circuit Board (PCB)

• Main Digital PCB, which contains the following subsections:

a. digital section

b. RF section, including the synthesizer

c. power supply

• SpO

• SpO

PCB

2

Transducer

2

•Battery

• Battery extender

1-4 Introducing the Philips Telemetry System

Page 19

Transmitter

RF Connected to

Leadset Shield

Front

End

Assembly

RF

Cable

Main

PCB

Ref.

S

RL

LA

Defibrillator Protection

Lead Sel.& Calibration

A to D Converter (Analog Portion)

RF Out

Frequency

Synthesizer

Modulator

SIR

Interface

Window

A to D Converter (Digital Portion)

EEPROM

Lead Off

IR

LEDS

I

RA

ECG PCB

Digital

ASIC

RAM

EASI Leadset

E

ECG Leadset

V

Leadset

Detect

Switch

DSP

Patient

Button

Power

Supply

SpO

2

Connector

and

Gasket

SpO2 Transducer

Photo Current

Rtype/Rlambda

LED Current

Photo Amplifier

Clip Output

Selftest Signal

Generator

RCode

Measurement

LED Driver

Bandpass

MAIN - CPU

SpO2 PCB

Variable Gain

ADC

ASIC

Pierce

Osc.

Digital

Signal

Processor

A

LL

Case

Assembly

Battery

Contacts

Cradle

PWR

Module

Wall

Receptacle

Figure 1-2 Block Diagram of Philips Transmitter

Leadsets The standard ECG system supports two leadset configurations: 3-wire and 5-

wire. With a 3-wire leadset, only 1 lead is transmitted (lead II is the default),

and leads I, II, or III can be selected if the transmitter is configured for 3-wire

leadset selection. For EASI, a 5-wire leadset is required.

The ECG leadset provides connection from the inputs of the transmitter to the

electrodes on the patient. Each lead has its own front end circuitry in the

transmitter that routes the signal from each lead to the transmitter’s

processing circuits. The transmitter sources an active lead for each

connection. Each signal is then combined to generate the transmitted leads.

3-Wire Leadset

(Standard ECG)

The 3-wire leadset broadcasts one lead (lead II is the default) of ECG for

display at the Central Station. The selection of leads for display using the 3wire leadset are determined by whether the lead selection function is

enabled (

Yes) or disabled (No - factory default) in the transmitter

configuration.

Introducing the Philips Telemetry System

1-5

Page 20

Transmitter

Lead Selection Enabled - With lead selection enabled, the cardiotach

lead, which is broadcast, can be selected using the Telemetry Service

Tool or Wave Viewer. In this mode, the broadcast lead can be selected

from Leads I, II, or III. The lead label is automatically changed at the

Central Station when the lead is changed.

Lead Selection Disabled (Factory Default) - When lead selection is

disabled, the broadcast lead is set at Lead II. The only way the lead can

be changed is by changing the electrode placement on the patient to a

non-standard configuration. When doing this, place the leads that

normally monitor lead II over the limb lead to be monitored. This means

that Leads I, II, III, or MCL can be monitored; however, the central

station will still display Lead II. The lead label must also be changed at

the Central Station to the lead being broadcast.

5-Wire Leadset

(Standard ECG)

With the 5-wire leadset, 3 leads are broadcast: II, III, and MCL. From these 3

leads, the software in the receiver mainframe can reconstruct the remaining 5

leads: I, aVR, aVL, aVF, and a true V lead. The leads to view can be selected at

the Central Station.

5-Wire Leadset

(EASI ECG)

When the transmitter is configured for monitoring the 12-lead EASI ECG, a 5wire leadset must be used. The 3 directly acquired or “raw” EASI leads (AI,

AS, ES) are broadcast by the transmitter. Software in the Philips Information

1

2

3

4

5

Center mathematically reconstructs the following leads: I, II, III, aVR, aVL,

aVF, V1, V2, V3, V4, V5, V6, and will perform arrhythmia analysis on 2 of the

leads and ST analysis on all 12.

EASI

If monitoring is attempted with a 3-wire leadset attached to an EASI ECG

transmitter, the system will report an

message (INOP) at the central station.

SpO2 Transducer When SpO

processed by a dedicated SpO

parameter values are sent as part of the broadcast.

Front End Assembly

The Front End Assembly the Transmitter is where the ECG Leadset and the

Transducer plug in. It contains the following features:

SpO

2

1. Leadset detect switches that identify which leadset (3- or 5-lead) is

connected to the transmitter and sends the information to the digital

ASIC on the Main PCB. The leadset detect switches are positioned next

to the RL and V lead wires in the standard ECG configuration, or next to

the Reference and E lead wires in the EASI configuration (the two

connector cutouts are rectangular not square).

2. High impedance resistors that provide defibrillator protection to the

signal acquisition circuits on the ECG PCB.

3. Radio Frequency (RF) cable connection to the leadset shield that

allows the RF signal to be transmitted through the leadset, which acts as

an antenna.

INVALID LEADSET inoperative

is monitored, the data are received via a SpO2 Transducer,

2

circuit within the transmitter, and the

2

1-6 Introducing the Philips Telemetry System

Page 21

Transmitter

Case Assembly The Case Assembly provides protection to the internal electronics of the

transmitter. It also contains the nurse-call button and the leads-off Light

Emitting Diodes (LEDs).

Transmitter Button The Transmitter Button is a membrane switch that toggles a bit in the

transmitted message to ON when the switch is pressed. Electrically, the

transmitter button has two positions:

OFF (not pressed)

ON (pressed)

The Transmitter Button can be configured in the receiver mainframe to

perform the following actions when it is pressed:

1. generate a yellow-level nurse call alarm at the central station

2. generate a recording at the central station

3. generate both a nurse call alarm and a recording at the central station

4. do nothing

Once the alarm or recording has been started, it can only be stopped at the

central station. Pressing the button on the transmitter again does not affect

the alarm or the recording.

Manual SpO

Measurements

Even if the transmitter button is configured for DISABLED or if the button is

2

turned

OFF at the central station, Manual SpO

Transmitter button are still possible.

If a transmitter is set for intermittent SpO

measurements (manual mode, 1

2

minute and 5 minutes), manual measurements from the transmitter can be

initiated at any time using the transmitter button or Wave Viewer. SpO

be turned on at the central station for alarms and for display and trending.

Note If the transmitter is in manual mode, the SpO

will turn on automatically when a measurement is initiated. If the transmitter

is in the 1-minute or 5-minute sample mode, SpO

central station by the user.

To initiate a Manual SpO2 Measurement at the transmitter, do the following:

• Plug the transducer cable into the transmitter.

• Attach the transducer to the patient.

• Press and hold the transmitter button (approximately 6 seconds) until

the LA light for standard ECG (S light for EASI ECG) begins flashing.

When the transducer light turns off, the measurement is complete.

• Remove the transducer from the patient after the transducer light goes

out. The measurements value and time stamp will be displayed at the

Central Station for up to 1 hour or until the next measurement is made,

whichever comes first.

Measurements using the

2

must

2

parameter at the central station

2

must be turned on at the

2

Leads Off LEDs A Leads Off Light Emitting Diode (LED) turns on whenever one of the

leads falls off the patient, or if the circuitry for that lead is defective. There is

one LED for each electrode, and they are shown in the electrode placement

diagram on the transmitter in the standard lead placement.

Introducing the Philips Telemetry System

1-7

Page 22

Transmitter

ECG PCB The ECG Printed Circuit Board (PCB) contains the ECG Front-end

Circuitry, which acquires the ECG signal from the leadset. This circuitry

provides basic preamplification of the signals, filters the signals, then

performs the first stage of analog-to-digital conversion.