Page 1

1 About This Manual

About This Manual

November 2002

M2540-92000-01 A

Copyright © 2002 by Philips Medical Systems All rights reserved

Field Service Manual

This manual provides information for troubleshooting and servicing

the Philips M2540A ultrasound system. Brief overviews for each

section in this book are listed below:

Section 1, “General Information,” presents a product overview and a

description of major features, and lists applicable safety standards.

Section 2, “Specifications,” describes the physical and electrical

specifications of the M2540A.

Section 3, “Safety,” discusses safety issues pertinent to the ultrasound

system, and describes ESD precautions to be taken when servicing the

system.

Section 4, “Theory of Operation,” includes a technical overview of

system functions. Functional descriptions are given for each system

circuit board. Functional block diagrams show the scanner and the

scan converter sections. This section also includes explanations of the

theories behind the electrical safety tests in the Performance Tests

section.

Section 5, “Installation,” explains how to unpack and assemble the

system, how to install peripheral devices, and how to configure the

system’s parameters.

Section 6, “Performance Tests,” comprises all tests and diagnostic

procedures that apply to the M2540A, including electrical safety tests.

The chapter emphasizes patient, operator, and service personnel

M2540 Ultrasound System

safety, and system safety. A procedure for verifying complete system

operation is included.

Page 2

M2540-92000-01 A M2540 Ultrasound System Field Service Manual Page 2

About This Manual: About This Manual

Section 7, “Adjustments,” contains instructions for adjusting the system monitor.

Section 8, “Preventive Maintenance,” includes procedures for periodic maintenance of the

system.

Section 9, “Troubleshooting,” contains information and procedures for finding and repairing the

causes of faults in the M2540A, including software error codes. The error-code section opens

with a key for interpreting the codes.

Section 10, “Service Procedures,” includes all service procedures, including a discussion of ESD

precautions, component removal and replacement, and peripherals installation. The chapter also

presents software procedures for backup and retrieval of customer presets, and for reloading or

upgrading system software.

Section 11, “Cabling,” includes tables listing all the standard and optional M2540A cables.

Section 12, “Configuration,” lists the jumper and switch settings for the M2540A’s disk drives.

Section 13, “Parts,” comprises parts lists and exploded diagrams of the M2540A and its

assemblies. Parts ordering methods are discussed.

Section 14, “Transducers,” lists the transducers compatible with the M2540A and their

characteristics.

Audience

Section 15, “Glossary,” is a glossary of terms used in this manual and in the ultrasound imaging

field.

This manual supports the field service maintenance and repair of the M2540A Ultrasound

System. The user of this document is a qualified ultrasound electronics technician who has

completed training classes on the system and its peripherals.

Page 3

M2540-92000-01 A M2540 Ultrasound System Field Service Manual Page 3

About This Manual: About This Manual

Format

Conventions

Service Manual Questions or Comments

This manual is in Portable Document Format (PDF), for viewing on a laptop computer using

Acrobat Reader. A list of bookmarks functions as a table of contents. Those bookmarks and

cross-references use hypertext links to provide access to the referenced information.

The following conventions are used in this manual:

• Hypertext links are blue.

• All procedures are numbered. You must complete steps in the sequence they are presented

to ensure reliable results.

• Bulleted lists indicate general information about a function or a procedure. They do not

imply a sequential procedure.

• Control names are spelled and capitalized in the manual as they are on the system.

• Menu items or titles appearing on the display are spelled and capitalized in the manual as they

are on the display.

• An English system is assumed.

If you have questions about the service manual, or if you discover an error in the manual, contact

Philips Ultrasound Technical Publications:

• atl-bothell.techpubs@philips.com

• Technical Publications, MS 964, at the first address below

Page 4

M2540-92000-01 A M2540 Ultrasound System Field Service Manual Page 4

About This Manual: About This Manual

Customer Assistance

Various support locations around the world can provide customers with technical assistance

regarding the ultrasound system. Customers should contact the sales office where they

purchased the system or the nearest Philips Ultrasound office for assistance.

• Philips Ultrasound

P.O. Box 3003

Bothell, WA 98041-3003

USA

(425) 487-7000 or (800) 426-2670

www.ultrasound.philips.com

• Philips Ultrasound

3000 Minuteman Road

Andover, Massachusetts 01810-1099

(978) 687-1501

• Authorized EU Representative:

Philips Medizin Systeme Boeblingen GmbH

Hewlett-Packard-Str. 2

71034 Boeblingen

Germany

To find your local service center phone number, go to:

www.philips.medical.com

Non-Philips Medical Systems product names may be trademarks or registered trademarks of their respective owners.

Page 5

M2540-92000-01 A M2540 Ultrasound System Field Service Manual Page 5

About This Manual: About This Manual

© 2002 Philips North America

Corporation

All Rights Reserved.

Reproduction in whole or part

is prohibited without the prior

written consent of the copyright

holder.

Publication number

M2540-98000-01

Edition 1

Published: December 2002

Printed in U.S.A.

Warra nty

The information contained in

this document is subject to

change without notice.

Philips Medical Systems makes

no warranty of any kind with

regard to this material,

including, but not limited to, the

implied warranties or

merchantability and fitness for a

particular purpose.

Philips Medical Systems shall

not be liable for errors

contained herein or for

incidental or consequential

damages in connection with the

furnishing, performance,

or use of this material.

Tra de mark s

Cannon is a registered

trademark of Cannon

Corporation.

Windows XP is a trademark of

Microsoft Corporation

WARNING

Electrical Shock Hazard

Do not remove system covers.

To avoid electrical shock, use

only supplied power cords and

connect only to properly

grounded (3-hole) wall outlets.

Explosion Hazard

Do not operate the system in the

presence of flammable

anesthetics.

Safety Information

Before you use a specialty

transducer for the first time, be

sure to read the “Description

and Use” section of the chapter

that is applicable to your

transducer. Also, for TEE and

intraoperative transducers,

review the “Electrical Safety”

sections in those chapters.

Pay special attention to the

Warnings and Cautions.

The warnings explain the

dangers of electrical shock and

explosion hazard, the safety of

ultrasound, applications,

guidelines for fetal use, and

guidelines for setting controls

that affect acoustic output and

accuracy of clinical

measurements.

Warning Symbol Used in the

Text:

WARNING

The cautions explain potential

damage to equipment.

Caution Symbol Used in the

Text:

CAUTION

Symbols on the System

Warning symbols, as well as

other symbols appearing on the

system or its probes:

This symbol on the

system advises

!

the user documentation for that

part of the system.

Monitor Radiation

The monitor used in this

system complies with the FDA

regulations that were

applicable at the date of

manufacture (21 CFR

Subcategory J).

Prescription Device

The United States Food and

Drug Administration requires

the following labeling

statement:

Caution - Federal Law restricts

this device to use by or on the

operators to consult

This symbol on the

system indicates a

potential for

electrical shock.

Important

marking is for

0123

Council Directive

93/42/EEC.

This system complies with the

Medical Device Directive.

Authorized EU

Representative:

Philips Medizinsysteme

Boeblingen GmbH

Hewlett-Packard Strasse 2

71034 Boeblingen, Germany

Page 6

M2540-92000-01 A M2540 Ultrasound System Field Service Manual Page 6

General Information: Product Overview

1 General Information

This chapter includes the following sections:

• “Product Overview” on page 6

• “System Description” on page 7

• “Optional Peripherals (VCR, Printers, and Image Devices)” on page 9

• “Preset Functions” on page 10

• “Safety Specifications” on page 12

Product Overview

The M2540A ultrasound system comprises a cart, a system control panel, and a monitor. A foot

pedal on each caster locks and unlocks the front cart wheels. All four wheels swivel. The system

control panel and the monitor adjust up and down and swivel as a unit, and the monitor tilts and

swivels on its mount.

The cart’s lower enclosure contains the M2540A’s computer, disk drives, and ultrasound

generating and processing boards.

CD-RW and floppy disk drives are standard equipment.

Optional peripheral components include a video cassette recorder, various types of printer, a

foot switch, and a magneto-optical disk (MOD) drive. The VCR is available in either NTSC or

PAL configuration. For a complete list of optional components, see “Optional Peripherals” on

page 201.

Most peripheral devices mount on top of the lower enclosure. The optional plain-paper printer

is not mounted on or powered by the system, but is connected from a remote location.

The Resident Self Test (RST) software verifies system performance and helps diagnose problems.

Page 7

M2540-92000-01 A M2540 Ultrasound System Field Service Manual Page 7

General Information: System Description

The system control panel includes four numbered option buttons whose functions are assigned

by the customer. See the online Help file for details on configuring these controls.

System Description

Cart

Major ultrasound system components are described on the following pages. These descriptions

include important features of the cart, monitor, system control panel, Physio module, e-box, and

system power supply.

References to the left and the right sides of the system are as viewed from the front of the cart.

The cart supports the system and acts as the chassis into which all system components are

installed and interconnected.

A height adjustment lets you adjust the system control panel and monitor for operator comfort.

An Input/Output (I/O) panel at the rear of the cart contains three connectors for

communication between the system and a network, and for controlling certain legacy printers.

The foot switch port, an equipotential lug, and the system ground lug are also on the I/O panel.

The panel is at the center of the lower part of the cart, and is accessible to the system operator.

See “I/O Panel” on page 45 for more information about the I/O panel.

Cart Wheels

Four wheels at the cart base provide system maneuverability and braking. All four wheels swivel,

and the front wheels can be fixed straight and locked. Foot pedals on the two front wheels lock

and unlock the front wheels to prevent the cart from rolling. Locking the wheels immobilizes the

system during patient procedures.

PC

The M2540A uses a personal computer (PC) as a central processor. The PC houses several

components as standard equipment. These include the acoustic processor input/output (APIO)

board, a video card, a CD-RW drive, and a floppy disk drive.

Page 8

M2540-92000-01 A M2540 Ultrasound System Field Service Manual Page 8

General Information: System Description

The optional Physio module installs in one of the PC’s front drive bays. An optional

magneto-optical disk (MOD) drive can also be installed in one of the drive bays. The VCR option

includes three boards that reside in the PC’s PCI slots, and a VCR that mounts on the cart.

See “Internal PC” on page 39 for more detailed information about the PC and its components.

System Monitor

e-box

System Control Panel

The monitor at the top of the cart is a 15-inch color display mounted on a “twivel” assembly.

The twivel allows tilt and swivel positioning of the display for ease of viewing.

The e-box houses the scanner circuit boards, and is accessible by opening the door at the right

rear of the cart.

There are several circuit boards in the e-box:

• Two transmit and receive (TR) boards

• A beam processor/acoustic processor (BPAP) board

• A demodulator board

• The system motherboard

• The distribution board

The system control panel at the top front of the cart is a replaceable, self-contained module. See

“Replacing the System Control Panel” on page 159. The panel interfaces with the imaging system

through a USB cable that connects to the internal PC. Power for the trackball is provided via the

USB cable. All the other control-panel functions are powered by a cable from the system power

supply.

The system control panel contains a backlit alphanumeric keyboard, slide controls, rotary

controls, hard-coded and software-driven keys, and a trackball.

Page 9

M2540-92000-01 A M2540 Ultrasound System Field Service Manual Page 9

General Information: Optional Peripherals (VCR, Printers, and Image Devices)

Physio Module

Powe r Supply

Optional

The optional Physio module (see “Physio Module Option” on page 43) installs in one of the PC

drive bays. The front panel of the module bears two input connectors:

• A 3-lead ECG physio connector

• An auxiliary analog input (standard ¼-inch phone jack)

An externally generated auxiliary analog input signal using the phone jack can substitute for the

3-lead ECG physio connector at the front panel. You can also input an auxiliary ECG waveform

from an external patient monitor and display it, in all modes. The R-wave from this signal can

serve as a time reference for the system.

The power supply is an enclosed, self-contained, replaceable module that mounts under the

e-box at the right side of the cart. It accepts AC input sources from 100 V to 240 V, at 50 Hz or

60 Hz.

The power supply provides all required AC and DC voltages to the system. Three switched

120 VAC outlets for powering the monitor and two peripheral devices are at the rear of the

power supply. An unswitched outlet powers the M2540A’s internal PC. When the system is shut

down, only the 120 VAC outlet to the PC is enabled. A green LED on the left front of the power

supply lights when the power supply is energized.

The M2540A supports several types of optional peripheral devices:

Peripherals

(VCR,

Printers, and

Image

Devices)

• VCRs, including NTSC-format and PAL-format models

• Thermal color and thermal black-and-white printers

• Various biopsy kits (See “Supplies and Accessories” on page 202.)

• A magneto-optical disk (MOD) drive for data storage

“Optional Peripherals” on page 201 lists all peripherals supported by the ultrasound system.

Some peripherals mount on a shelf below the system control panel.

Page 10

M2540-92000-01 A M2540 Ultrasound System Field Service Manual Page 10

General Information: Preset Functions

Preset Functions

The ultrasound system includes programmable presets that configure the system for best imaging

results in a particular situation. Activating a preset initializes system settings to values that are

optimal for a chosen exam. The factory installed software includes several presets, tailored to

different applications. The user can define as many as 20 additional presets in each of 8 exam

types, to adjust system variables (including acoustic power) to any required configuration.

For specific information regarding the configuration and use of presets or other features of the

system, see the online Help file.

NOTE Backing up presets to a floppy disk safeguards them and preserves the operator’s

preferred configurations. If preset configurations are subsequently changed, they can be

quickly restored from the backup copy, without having to reset them manually. Keeping

a backup copy also eliminates the need to manually reconfigure the presets after a

software upgrade. See “Backing Up and Restoring Presets” on page 143 for the

procedures to back up and restore presets.

Page 11

M2540-92000-01 A M2540 Ultrasound System Field Service Manual Page 11

General Information: Keyboard Equivalencies

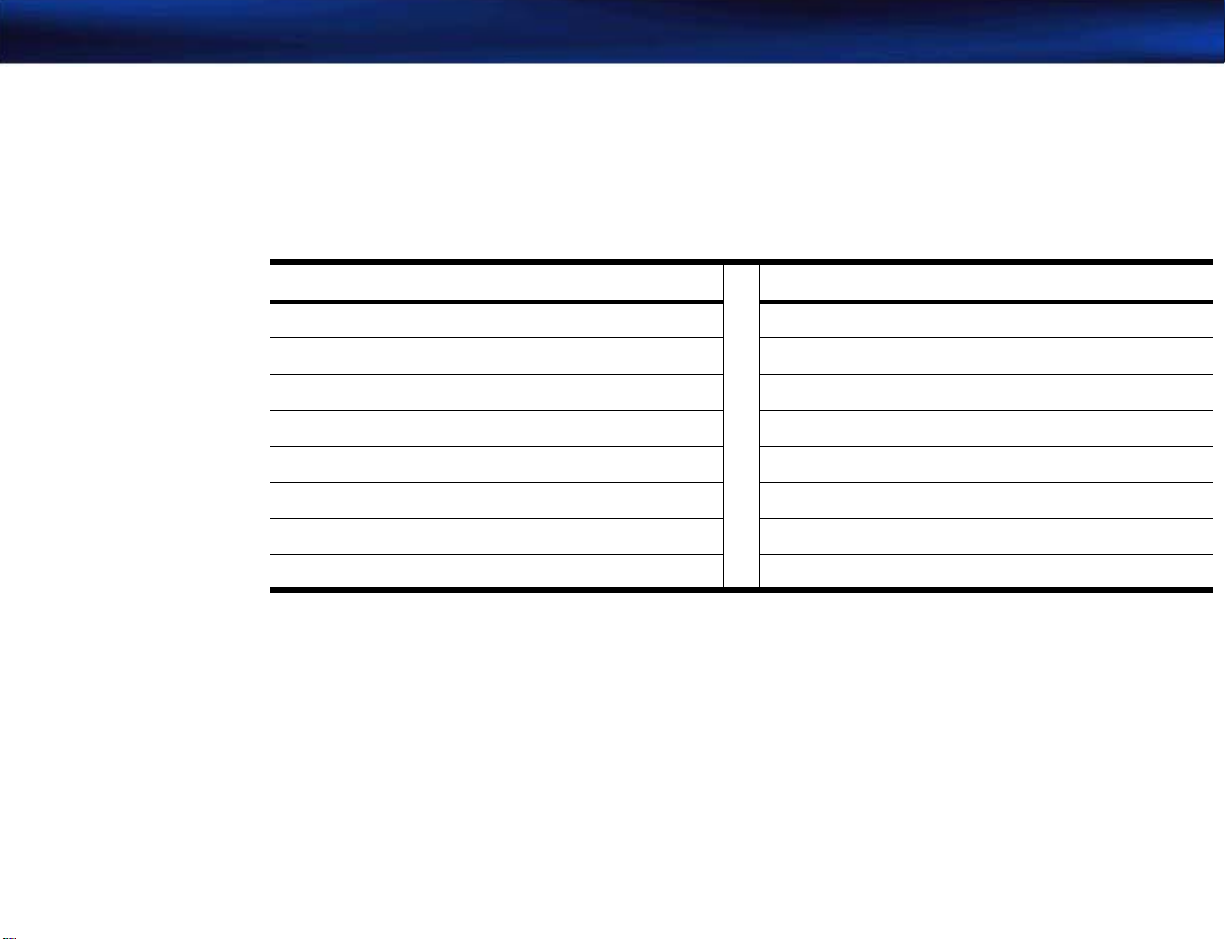

Keyboard Equivalencies

Some of the keys found on a standard PC keyboard are not present on the M2540A. Many of the

functions performed by those keys are mapped to keys that are present on the M2540A

keyboard. The M2540 keys act as PC-equivalent keys whenever the ultrasound application is not

running. The following table lists the missing PC keys and their equivalents on the M2540A:

Table 1-1 Keyboard Equivalents

PC Key M2540A Key PC Key M2540A Key

F1 Patient F9 Blank 1

F2 Preset F10 Blank 2

F3 Review F11 Blank 3

F4 Report F12 Probe

F5 Setup Esc THI

F6 Help Delete Fusion

F7 VCR Page Up Left

F8 Mic Page Down Right

Page 12

M2540-92000-01 A M2540 Ultrasound System Field Service Manual Page 12

General Information: Safety Specifications

Safety Specifications

Safety Limits

This section describes the safety specifications of the M2540A.

Table 1-2 Safety Limits

Parameter Specification

Power supply Complies with IEC60601-1

Ground wire leakage See Section 6, “Performance Tests”, and the Safety and Standards Guide

shipped with the M2540A.

System tip over Will not tip over on an incline of up to 10° under normal use.

Wheel locks With wheel locks engaged, system remains stationary on slopes of up

to 5 ° in any orientation.

System surface

temperature

Potentially hazardous

components

External sharp edges The system exterior has no sharp edges, in compliance with IEC

System surfaces do not exceed temperature limits specified in

IEC 60601-1 and EN 60601-1

The power supply and monitor comply with UL 2601-1 1997.

60601-1 and EN 60601-1

Regulatory Compliance

For information about applicable safety standards and specifications, consult the Safety and

Standards Guide shipped with the M2540A.

Page 13

M2540-92000-01 A M2540 Ultrasound System Field Service Manual Page 13

Specifications:

2Specifications

This section lists the specifications of the M2540A ultrasound system. The following specification

types are included in this section:

• “Physical Dimensions” on page 14

• “Electrical Specifications” on page 19

• “Monitor” on page 19

• “Transducer Specifications” on page 20

• “Connection and Communication Specifications” on page 21

• “Physio Port Specifications” on page 23

• “Audio/Video Specifications” on page 23

Page 14

M2540-92000-01 A M2540 Ultrasound System Field Service Manual Page 14

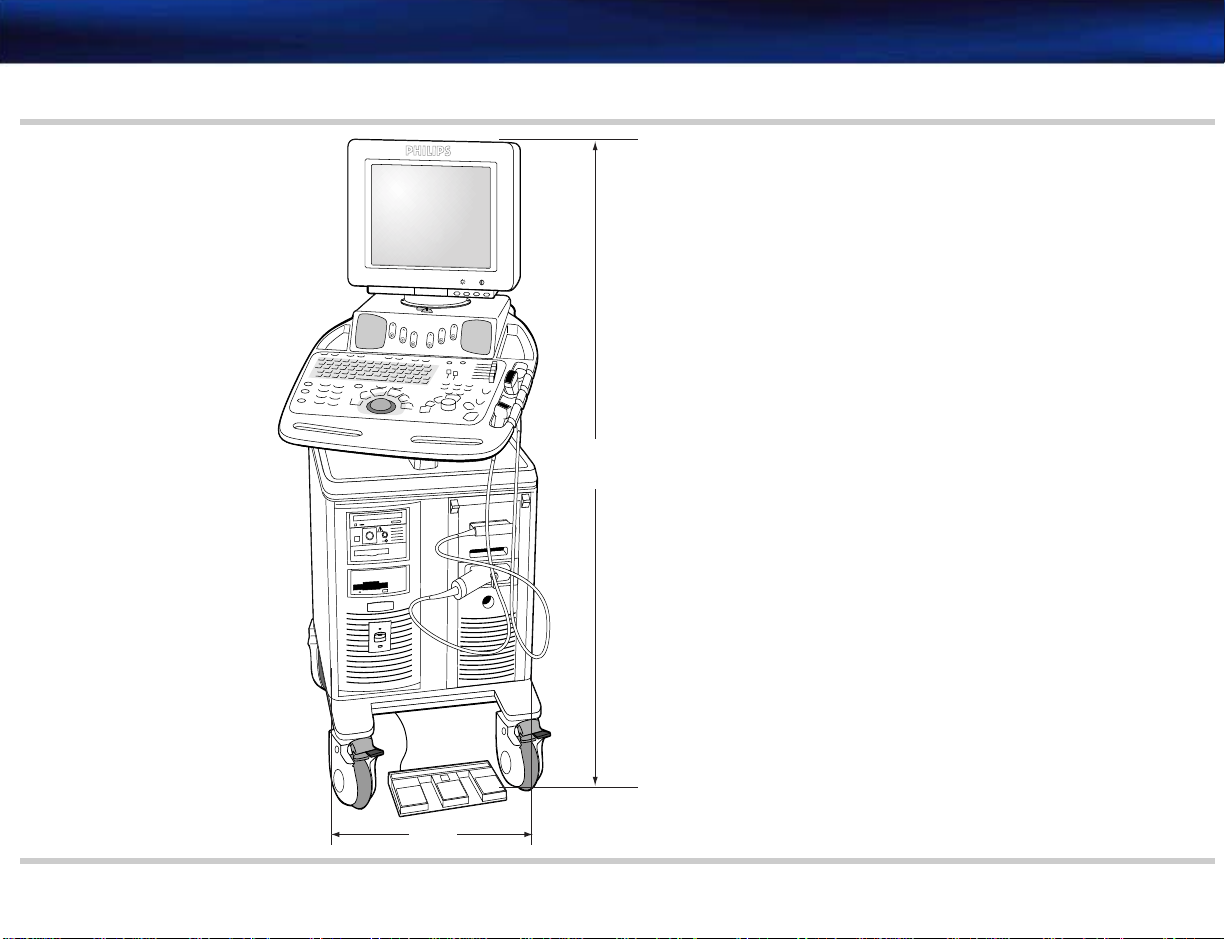

Specifications: Physical Dimensions

Physical

The tables and diagrams that follow detail the physical specifications of the M2540A.

Dimensions

Table 2-1 Physical Specifications

Parameter Specification Reference

Dimensions

Depth (front to back) 103 cm (40.5 inches) See Figure 2-2

Width 53.5 cm (21 inches) See Figure 2-1

Height (to monitor top) Lowest position: 129.5 cm (51 inches)

Highest position: 147.5 cm (58 inches)

Height of lower enclosure 76.2 cm (30 inches) See Figure 2-2

Monitor to control panel front edge 43.18 cm (17 inches) See Figure 2-2

Monitor depth

(front to back)

Weight Less than 91 kg (200 lbs) including display but no peripherals See Figure 2-2

Environmental Operational

41.71 cm (16.42 inches) See Figure 2-2

Temperature range: 0° to 40° C

Relative humidity: 20% to 80%

Atmospheric pressure: 572hPa to 1013 hPa

(VCR and printers temperature limit: 0° to 40° C at 80% RH)

See Figure 2-1

Storage

Temperature range: –40° to 55° C

Relative humidity: 20% to 90%, non-condensing

Atmospheric pressure: 572hPa to 1013 hPa

Page 15

M2540-92000-01 A M2540 Ultrasound System Field Service Manual Page 15

Specifications: Physical Dimensions

Figure 2-1 System Front Dimensions

-

+

-

+

Range:

129.5 cm (51 in) -

147.5 cm (58 in)

.

.

.

.

.

.

.

.

.

.

.

.

53.5 cm

(21 in)

Page 16

M2540-92000-01 A M2540 Ultrasound System Field Service Manual Page 16

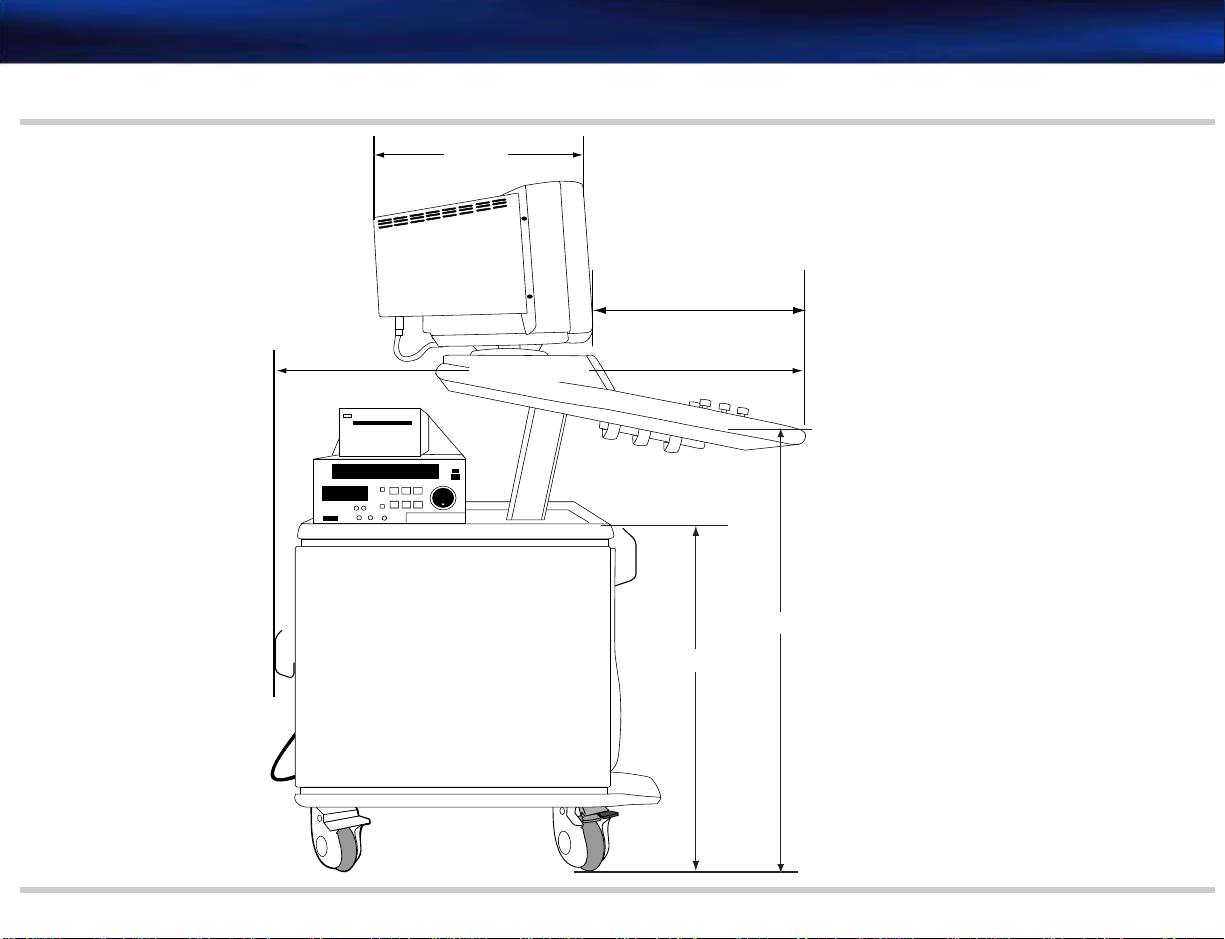

Specifications: Physical Dimensions

Figure 2-2 System Side Dimensions

41.71 cm

(16.42 in)

43.18 cm (17 in)

99 cm (39 in)

95.25 cm (37.5 in)

74.3 cm (29.25 in)

Page 17

M2540-92000-01 A M2540 Ultrasound System Field Service Manual Page 17

Specifications: Physical Dimensions

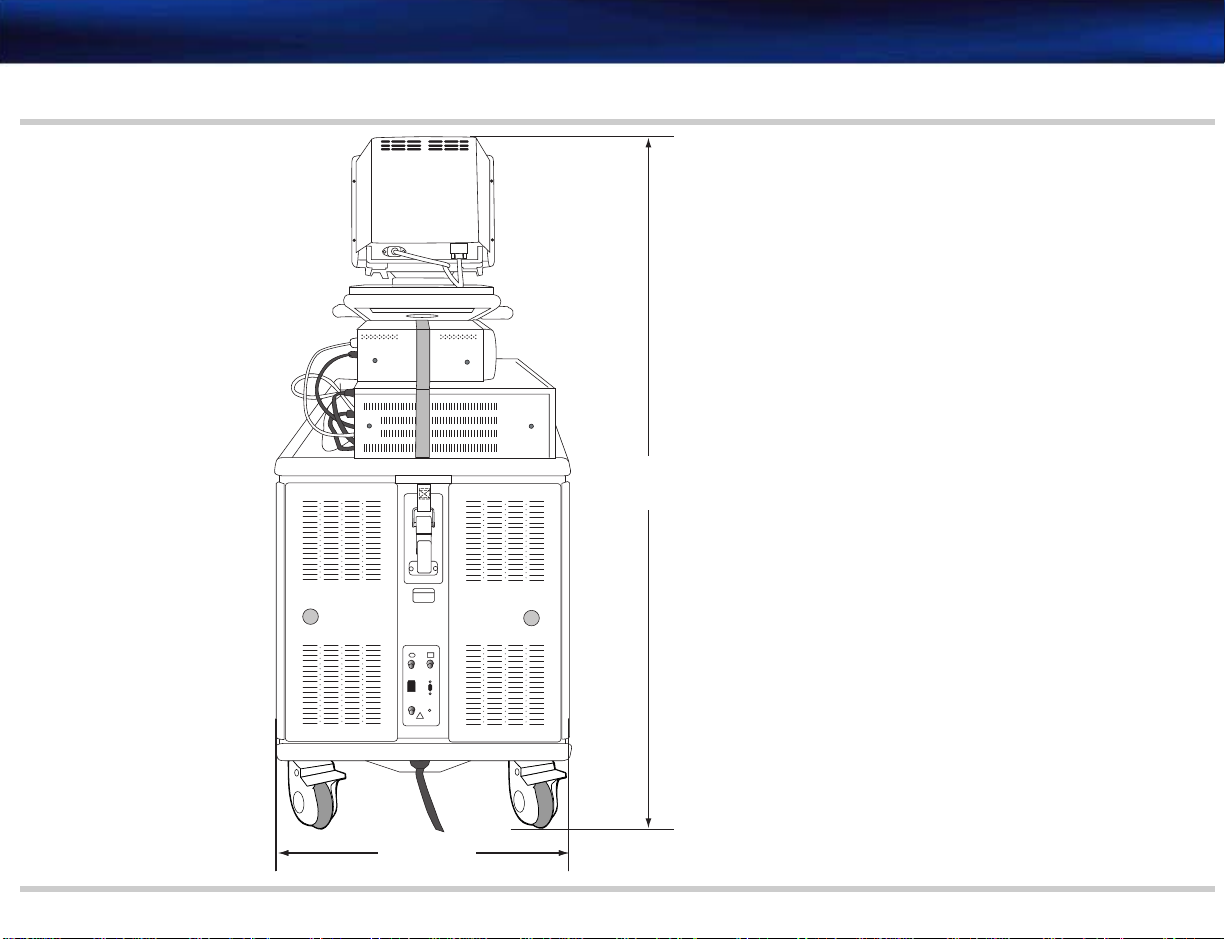

Figure 2-3 System Rear Dimensions

Range:

129.5 cm (51 in) -

147.5 cm (58 in)

53.5 cm (21 in)

Page 18

M2540-92000-01 A M2540 Ultrasound System Field Service Manual Page 18

Specifications: Physical Dimensions

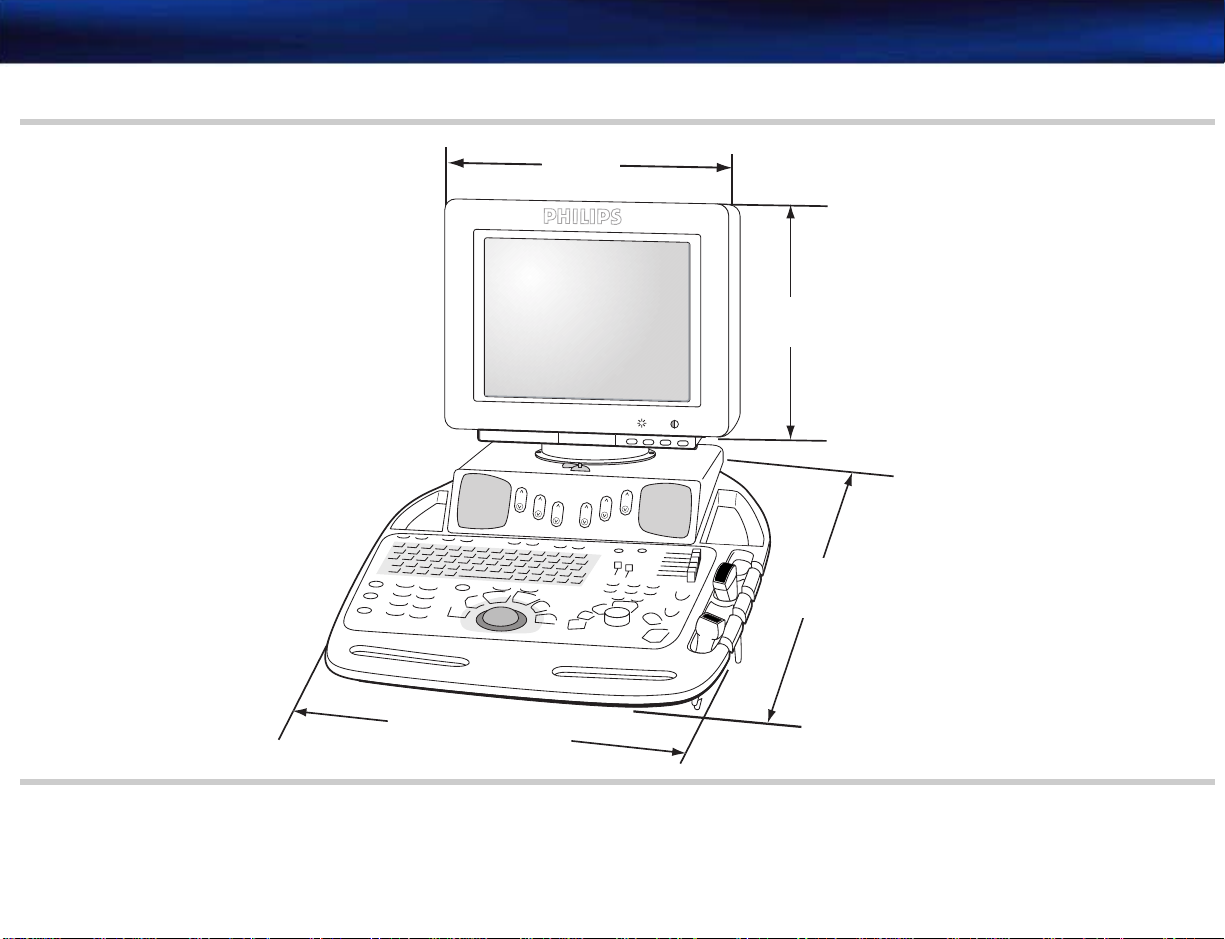

Figure 2-4 System Top Dimensions

39.4 cm

(15.5 in)

33 cm

(13 in)

-

+

-

+

72.6 cm

(28.5 in)

53.45 cm (21 in)

Page 19

M2540-92000-01 A M2540 Ultrasound System Field Service Manual Page 19

Specifications: Electrical Specifications

Electrical Specifications

Monitor

Table 2-2 Electrical Specifications

Parameter Specification

AC input 90 VAC to 264 VAC, 47 Hz to 63 Hz

Ground impedance 200 milliohm maximum

Dielectric withstand 1500 VAC mains to safety ground

2000 V mains to AC secondaries

4000 V mains to DC secondaries

Load 1150 VA maximum.

AC output 120 VAC, 60 Hz, quasi square-wave, 500 VA maximum

Table 2-3 Main Display

Parameter Specification

Screen size 15-inch diagonal

Display format VGA, 800x600

75 Hz refresh rate

RGB color display

Features Tilt ±30 degrees

Swivel ±135 degrees

Page 20

M2540-92000-01 A M2540 Ultrasound System Field Service Manual Page 20

Specifications: Transducer Specifications

Transducer Specifications

The following table lists the specifications of the transducers that the M2540A supports.

Table 2-4 Transducers

Part

Description

1

S4

Number Frequency Connector

21330A Cannon

S8 21350A Cannon

S12 21380A Cannon

c

3540 biopsy capable 1

21321A 3.5 MHz Cannon

EC6509 endocavity 21336A Cannon

L7535 linear

21359A 7.5 MHz Cannon

TEE (Omni II) 21369A 6 MHz Cannon

L1038A small parts 21376A Cannon

15-6L intraoperative 21390A Cannon

PA 4-2 biopsy capable 21422A 2 to 4 MHz Advance Vision

CA 5-2 21425A 2 to 5 MHz Advance Vision

D1914c 21221B 1.9 MHz Pencil

1. This transducer is compatible with the M2540A, but is only sold separately.

Page 21

M2540-92000-01 A M2540 Ultrasound System Field Service Manual Page 21

Specifications: Connection and Communication Specifications

Connection

and Communication

Specifications

System I/O Por ts

The following tables list the communication and connector specifications of the M2540A.

PC Ports

The following table lists the ports on the rear of the internal PC and describes their locations.

Table 2-5 PC Ports

Port Specification

Composite video output

(optional)

S-Video output (optional)

S-Video input (optional)

1

1

1

Print trigger output 3.5-mm phone jack on APIO board

VCR audio output (line out)

(optional)

VCR audio input (line in)

1

1

Female phono (RCA) on TV and video converter board

4-pin mini circular DIN on SVGA to TV video card

4-pin mini circular DIN on video capture card

Green 3.5-mm stereo phone jack on sound card

Blue 3.5-mm stereo phone jack on sound card

Microphone Pink 3.5-mm stereo phone jack

Speakers Green 3.5 mm stereo phone jack to system speaker amplifier

Monitor 15-pin D connector on graphics adapter board

Foot switch 9-pin female D-sub connector on the APIO board that carries

foot switch signals from the external I/O panel

Page 22

M2540-92000-01 A M2540 Ultrasound System Field Service Manual Page 22

Specifications: Connection and Communication Specifications

Table 2-5 PC Ports (Continued)

Port Specification

Com 1 9-pin D connector, RS-232; spare serial port used for serial

VCRs

Keyboard DIN circular connector

Mouse DIN circular connector

Token ring 50-pin connector on the APIO board

LAN RJ-45 to I/O panel for network communication

USB USB (A) for data and power to system control panel

USB For black-and-white thermal printer

USB For color printer

USB For remote plain-paper printer

PS-2 keyboard Not used

PS-2 mouse Not used

Parallel port Not used

Audio input on main board Not used

1. Only available with VCR option or external video/print option

Page 23

M2540-92000-01 A M2540 Ultrasound System Field Service Manual Page 23

Specifications: Physio Port Specifications

I/O Panel Ports

Physio Port Specifications

The following table lists the ports on the I/O panel and the signals they carry.

Table 2-6 I/O Panel Ports

Port Connector Signal

Composite video BNC Composite video signal from SVGA board

Foot switch D-sub 9 Control signal from foot switch to APIO board

Defaults are: record, freeze, and record 2

Each signal is a contact closure to ground, active low, and

TTL compatible

Print BNC Trigger signal from APIO board

LAN RJ-45 Communication with local area network

The following table lists the specifications of the M2540A’s physio ports.

Table 2-7 Physio Port Specifications

Port Specification

ECG 3 patient leads with R-wave detection

Monitoring quality only

Frequency response: 1 ±0.5 to 30 ±6 Hz

Audio/Video Specifications

Sensitivity: 3 mVpp ±2.5 mV for full scale at 100% gain

Aux 1 3-dB bandwidth: full scale DC to 100 Hz minimum

Maximum input signal: ±4 V

Sensitivity: 2.5 ±0.5 Vpp for full scale at 100% gain

The following tables list the audio and video specifications of the M2540A.

Page 24

M2540-92000-01 A M2540 Ultrasound System Field Service Manual Page 24

Specifications: Audio/Video Specifications

Audio

Table 2-8 Audio Specifications

Description Specification

Speakers Stereo—VCR, Doppler

Doppler spectrum toward transducer — left speaker

Doppler spectrum away from transducer — right speaker

Maximum power input: 4 watts

Impedance: 8 ohms

External Video

Frequency

Response

Microphone Faces front. 10 Hz to 20 KHz electret type

Table 2-9 External Video Specifications

Description Specification

Color Composite NTSC 3.58 (USA), PAL 4.43 (Europe)

Print Trigger 1 signal from the APIO board

130 Hz to 12 KHz

1.0 V p to p ±5% into 75 ohms (only with VCR option)

Active low: ON = 0.5 V max @ 1 mA; OFF = 5.25 VDC maximum

voltage

Page 25

M2540-92000-01 A M2540 Ultrasound System Field Service Manual Page 25

Specifications: Audio/Video Specifications

Video Output Specifications

Table 2-10 Video Output Specifications

Output Specification

RGBSync to system

0.7 Vpp RGB with TTL sync

monitor

S-Video Output to

VCR

1.0 Vpp luminance incorporating sync and 0.3 Vpp chrominance as

shown in Ta bl e 2 -9 . This timing is essentially RS-170 (60 Hz) or CCIR

(50Hz) video timing.

Page 26

M2540-92000-01 A M2540 Ultrasound System Field Service Manual Page 26

Safety:

3Safety

This section provides an overview of safety considerations for the ultrasound system. These

safety concerns apply to patients, operators, and service engineers. For more detailed safety

information, see the Philips Safety and Standards Guide.

The following topics are included in this section:

• “Transmit Power (Acoustical)” on page 27

• “Acoustic Exposure” on page 27

• “AIUM/NEMA Output Display Standard” on page 28

• “Explosive Hazards” on page 30

• “Electrical Warnings” on page 31

• “Peripheral Connections” on page 31

• “Glutaraldehyde Exposure” on page 32

• “Moving the System” on page 32

• “Electromagnetic Compatibility” on page 35

• “Restrictions for Use” on page 36

• “Electrosurgical Units” on page 37

Page 27

M2540-92000-01 A M2540 Ultrasound System Field Service Manual Page 27

NOTES

Safety: Transmit Power (Acoustical)

Tr a ns m i t Power (Acoustical)

Acoustic output, expressed as an index, is displayed on the screen to allow the best possible

diagnostic image with minimal power output. A display standard presents this index using one of

the following four power indices:

• Mechanical index (MI)

• Thermal index for soft tissue (TIS)

• Thermal index for bone (TIB)

• Thermal index for cranial bone (TIC)

The index setting on the System Setup menu selects the power index used. The displayed

index is based on this setting and on preset configuration and imaging mode.

• The power index setting on the System Setup menu selects any of the four power indices

for display at any time.

• The Powe r rotary control at the right side of the system control panel is the only control

that affects transmit power level.

For additional information on acoustical power settings and power index, see the Philips Safety

and Standards Guide.

Acoustic Exposure

Although no harmful effects have been demonstrated for any of the ultrasound frequencies,

intensities, and exposure times used in examinations with Philips ultrasound systems, Philips

recommends that you consider the following, and use the lowest ultrasound exposure that

produces diagnostically acceptable information:

• Use diagnostic ultrasound only when there is a good medical reason.

• Reset the controls at the start of every examination.

Page 28

M2540-92000-01 A M2540 Ultrasound System Field Service Manual Page 28

Safety: AIUM/NEMA Output Display Standard

• Reduce exposure time, independent of acoustic index value.

• Use techniques that let you collect clinical data quickly and end the examination promptly.

• Select a transducer that provides good resolution and focal depth for the region of interest.

Then use the imaging controls to fine-tune image resolution.

For more detailed information on acoustic exposure, see the Output Display Standards and ODS

Acoustic Tables booklet.

AIUM/NEMA Output Display Standard

In compliance with the Output Display Standard (ODS) jointly proposed by the American

Institute of Ultrasound in Medicine and the National Electrical Manufacturers Association, the

Philips ultrasound system displays power output indices related to the potential for bioeffects.

Real-time information related to the power output is displayed on the monitor, indicating the

type of index displayed and the value of that index for the acoustic output currently being used.

For example, if the output corresponds to a mechanical index of 0.8, the following is displayed:

MI: 0.8

The displayed index is one of four types: MI, TIS, TIB, or TIC. These ultrasound abbreviations

conform to the AIUM/NEMA Output Display Standard.

Soft tissue thermal index (TIS) is used in cardiac, fetal, and abdominal scanning.

The thermal index for bone (TIB) is used in applications such as second or third trimester fetal

scanning and neonatal cephalic (through the fontanelle) scanning.

The cranial bone thermal index (TIC) is used for transcranial imaging.

Page 29

M2540-92000-01 A M2540 Ultrasound System Field Service Manual Page 29

Safety: AIUM/NEMA Output Display Standard

NOTE The power index displayed on the screen depends on the preset type, the active

transducer type, the imaging mode, and the selected power index. Any of the four

power indices is selectable for display at any time, using the power index setting in the

System Setup menu.

Automatic Index Selection

For automatic selection of a power index based on system mode, the user selects the power

index setting of Normal from the System Setup menu. This directs the system to choose an

index based on the active preset and imaging mode.

When MI is Displayed With the Normal Setting

MI is displayed if any of the following conditions exist:

• 2D Only is the active imaging mode.

• Black-and White MMode Preview is the active imaging mode.

• Black-and White Doppler Preview is the active imaging mode.

• Black-and White Doppler 2D Live is the active imaging mode.

When TIS is Displayed With Normal Setting

If none of the conditions in “When MI is Displayed With the Normal Setting” on page 29 exist, if

no transcranial preset is active, and any of the following conditions exist, TIS displays:

• Color is turned on.

• Angio is turned on.

• MMode Trace is the active imaging mode.

• Doppler Spectral is the active imaging mode (with 2D Live off).

Page 30

M2540-92000-01 A M2540 Ultrasound System Field Service Manual Page 30

Safety: Explosive Hazards

When TIC is Displayed With Normal Setting

If none of the conditions in “When MI is Displayed With the Normal Setting” on page 29 exist, a

transcranial preset is active, and any of the following conditions exist, TIS displays:

• Color is turned on.

• Angio is turned on.

• MMode Trace is the active imaging mode.

• Doppler Spectral is the active imaging mode (with 2D Live off).

If the user selects an ODS setting other than Normal, the selected index type is used as the

preferred acoustic power display format, regardless of the mode, the transducer, or the preset

that is selected.

The displayed index value does not provide an exact value of the potential for adverse bioeffects

in the patient. However, for any patient, the higher the value, the higher the potential for adverse

bioeffects. The user can minimize the potential for bioeffects by keeping the index value as low as

possible, by choosing the right transducer and making adjustments. Minimizing examination time

also minimizes bioeffects.

WAR NING

Explosive Hazards

The ODS power index formulas were defined for reasonable worst case patient conditions. It is

likely that a particular patient's actual conditions are better than indicated by the index. The

operator should be aware of patient conditions that mitigate the actual exposure.

Observe the following practices to avoid explosive hazards:

• Do not operate the system in the presence of flammable anesthetics.

Page 31

M2540-92000-01 A M2540 Ultrasound System Field Service Manual Page 31

Safety: Electrical Warnings

• When using the imaging system in the operating room, do not switch system power on or

off. Be sure system power is on before the operation starts, and leave it on for the duration

of the procedure.

WAR NING

Electrical Warnings

WAR NINGS

Peripheral Connections

Do not use the foot switch in the operating room.

Observe the following precautions to prevent electric shock:

• Only qualified service personnel should remove system covers (trim and service panels).

Accidental contact with electrical circuits inside the system could cause serious injury.

• Use only the power cords supplied with the system, and connect them only to properly

grounded electrical outlets.

• Failure to follow these warnings can affect both patient and operator safety.

• Do not connect the ultrasound system to the same circuit used for life support devices.

Peripherals (such as a VCR or a printer) typically meet general electrical safety usage

requirements, but do not meet medical device standards. Therefore, do not use system

peripherals within six feet of a patient unless the peripherals receive power from an isolated

power outlet on the imaging system, or from an isolation transformer that meets medical safety

standards. The 120 VAC outlets on the power supply are isolated. The specific peripherals listed

in “Optional Peripherals” on page 201 meet medical device standards when installed in the

system as recommended.

Page 32

M2540-92000-01 A M2540 Ultrasound System Field Service Manual Page 32

Safety: Glutaraldehyde Exposure

Glutaraldehyde

Exposure

Moving the System

The United States Occupational Safety and Health Administration (OSHA) has issued a

regulation dealing with levels of acceptable glutaraldehyde exposure in the working environment.

Philips does not sell glutaraldehyde-based disinfectants with its products. However, this type of

disinfectant is recommended for disinfection of transesophageal (TEE) or endocavity

transducers.

To minimize exposure to glutaraldehyde fumes, make sure the area is well ventilated and use

appropriate eye and skin protection.

Although the system is designed to be mobile, remember that it is very heavy, and that you

must take precautions when moving the system.

The ultrasound system has been designed to be as lightweight and mobile as possible. However,

the system weight—including the weight of the monitor, a printer, and a +VCR—is

approximately 100 kg (220 pounds). Because of this weight, you must use caution when moving

the system, since the ability to move any ultrasound machine is directly related to an individual’s

size and strength.

Some sonographers, particularly those weighing less than 100 pounds, have stated that they

injured their backs moving similar systems. These complaints could not be directly tied to one

particular incident. They do, however, point out the need to be careful in transporting medical

equipment such as an ultrasound system.

Before Moving the System

To move the system, take the precautions listed in the following sections, and

• Before moving the system, be sure to remove any loose equipment from the top of the system, disconnect the system power cord, and disconnect all external devices.

• Before transporting the system in a vehicle, remove the monitor and all transducers from the

system and put them in a packing box.

Page 33

M2540-92000-01 A M2540 Ultrasound System Field Service Manual Page 33

Safety: Moving the System

When Moving the System

WAR NING

Moving on Ramps or Uneven Surfaces

This system is equipped with a front handle and brakes on the front wheels.

Always use the handle at the front of the cart to move the system from place to place.

Never strap or secure the system at any point above the peripheral tray.

NOTE Use caution and follow these steps when moving the system from patient to patient.

1. Unlock the wheel locks before moving the system.

2. Make sure the control top is locked, to prevent its pivoting during transport.

3. Engage the track locks on the front wheels to ease straight-line travel.

4. Push with the handle at the front of the cart.

5. After the system is in position, engage the wheel locks to immobilize the system, and unlock

the control top to allow it to pivot.

Do not move the system over uneven elevator entrances by lifting the machine or any part of the

machine.

Always use two people when moving the ultrasound system up and down ramps longer than 20

feet or steeper than 5 degrees. (Wheelchair ramps are usually less than 5 degrees.) Avoid ramps

that are steeper than 10 degrees, to eliminate the danger of the system tipping over.

System Tilting

The system has been tested for stability using the IEC 60601-1 test protocol. Following this

protocol, the system will not tip over on an incline of up to 10 degrees in any direction. When

this amount of incline is exceeded, there is a potential for the system to tip over.

Page 34

M2540-92000-01 A M2540 Ultrasound System Field Service Manual Page 34

Safety: Moving the System

WAR NING

Transporting the System in a Vehi cle

WAR NING

Use care when tilting the system for an incline. The amount of incline allowable to prevent

tip-over is 10 degrees. Moving the system over a roadside curb or other small but steep incline

can cause the system to exceed 10 degrees of incline.

Always engage the wheel locks while transporting the system in a vehicle, and use restraining

straps to secure the system in place. Do not rely on the wheel locks to hold the system on

inclines greater than 5 degrees.

Be sure that the transporting vehicle can handle the weight of the system (or systems) plus the

passengers.

Be sure the load capacity of the loading lift can accommodate the weight of the ultrasound

system. A minimum capacity of 550 pounds is recommended.

Always secure the ultrasound system while it is on the loading lift so that it cannot roll. Make

sure the control top is locked, to prevent its pivoting. Engage the wheel locks and use wood

chocks, restraining straps, or other similar types of constraints as an added safety measure. Do

not attempt to hold the system in place manually.

Never strap or secure the system at any point on the control top or monitor.

Load and unload the ultrasound system while the transporting vehicle is parked on a level

surface. The system’s weight can easily cause it to roll on any incline.

The system’s weight on an extended loading lift may cause the transporting vehicle to tilt, which

could cause personal injury or system damage.

Page 35

M2540-92000-01 A M2540 Ultrasound System Field Service Manual Page 35

Safety: Electromagnetic Compatibility

WAR NING

Electromagnetic

Compatibility

Avoiding

Electromagnetic

Interference

Never ride on a loading lift with the system. Your weight combined with the system's weight can

exceed the lift's load capacity.

Be sure the ultrasound system is firmly secured while inside the transporting vehicle. Any

movement, combined with the system’s weight, could cause the system to break loose.

NOTE If you use the ultrasound system in a mobile van, follow the same fundamental

transporting precautions listed in the sections above.

This system has been tested for electromagnetic compatibility (EMC) according to the

international standard for EMC with medical devices, as determined by the International

Electrotechnical Commission (IEC 60601-1-2). This IEC standard has been adopted in Europe as

the European Norm EN 60601-1-2.

Medical devices can generate or receive electromagnetic interference (EMI). The EMC standards

describe tests for both emitted and received interference. Emission tests deal with interference

generated by the device being tested. The Philips ultrasound system does not generate

interference based on the tests described in the standards.

Ultrasound systems are designed to receive radio frequency (RF) energy and are therefore

susceptible to EMI generated by other RF energy sources. Examples of other sources of EMI are

medical devices, information technology products, and radio and television transmission towers.

Tracing the source of radiated interference can be a difficult task.

See “Electromagnetic Interference” on page 137 to identify sources of EMI.

Only a physician can determine if an artifact caused by radiated interference has a negative

impact on image quality and the subsequent diagnosis.

Page 36

M2540-92000-01 A M2540 Ultrasound System Field Service Manual Page 36

Safety: Restrictions for Use

Restrictions for Use

Immunity Level Test Results

The M2540A ultrasound system is subject to certain restrictions that are described in the

following sections.

The EMC standards require that manufacturers of patient-coupled equipment specify

electrostatic discharge immunity levels for their systems. This type of device is designed to

receive and amplify low-level signals in the same bandwidth as the interference to which it is

susceptible.

Immunity is defined in the standard as the ability of a system to perform without degradation in

the presence of an electromagnetic disturbance. Degradation in image quality is a qualitative

assessment that can be subjective. The simplest way to assess degradation is to note when the

first sign of an artifact is seen. This method has two advantages: It removes the issue of subjective

decision-making and provides the most stringent test results.

Caution should therefore be taken in comparing immunity levels of different ultrasound systems.

The criteria used for measuring degradation are not specified by the standard, and can vary with

the manufacturer.

Philips has tested each class of transducer for every operating mode over a wide range of

frequencies. This testing showed PW Doppler to be the most susceptible to radio-frequency

interference.

Electrostatic Discharge

Please see the Philips Safety and Standards Guide shipped with your system for additional

information about compliance with EMC standards.

Electrostatic discharges can cause the ECG heart rate display to increase by 10 to 15% for a few

seconds after the discharge. However, the ECG heart rate display returns to normal within four

seconds.

Page 37

M2540-92000-01 A M2540 Ultrasound System Field Service Manual Page 37

Safety: Electrosurgical Units

Electrosurgical Units

Electrosurgical units (ESUs) and other devices intentionally introduce radio frequency

electromagnetic fields or currents into patients. Because imaging ultrasound frequencies are also

in the radio frequency range, ultrasound transducer circuits are susceptible to radio frequency

interference. While an ESU is in use, the noise generated severely interferes with the

black-and-white image and completely obliterates the color image.

Page 38

M2540-92000-01 A M2540 Ultrasound System Field Service Manual Page 38

Theory of Operation: Overview

4 Theory of Operation

Overview

This section provides a technical overview of system functions. The discussion focuses on the

main functions and features of the system’s PC, circuit boards, and power distribution. Main

system functions are also shown in the functional block diagrams at the end of this section.

The M2540A’s internal PC replaces the back-end electronics used in earlier ultrasound systems

to handle display processing. The beam processor/acoustic processor (BPAP) board handles the

acoustic and beam processing front-end functions.

This section covers the following areas of the system:

• “Internal PC” on page 39

• “TR Boards” on page 40

• “BPAP Board” on page 42

• “Demodulator Board” on page 43

• “APIO Board” on page 43

• “Physio Module Option” on page 43

• “System Motherboard” on page 44

• “Distribution Board and Connector Modules” on page 44

• “I/O Panel” on page 45

• “System Control Panel” on page 45

• “Power Supply” on page 46

• “Functional Block Diagrams” on page 47

• “Transducer Safety Testing: Test Setup and Theory” on page 52

Page 39

M2540-92000-01 A M2540 Ultrasound System Field Service Manual Page 39

Theory of Operation: Internal PC

Internal PC

Standard PC Components

The M2540A uses an internal PC to coordinate and perform many of the functions that required

dedicated circuit boards in earlier ultrasound systems. The power button on the front of the PC

is the system power switch. Turning on the PC starts the ultrasound system.

The M2540A’s internal PC contains the following standard components:

• A motherboard

• A hard drive

• A graphics card in the AGP slot

• The Acoustic Processor I/O (APIO) board, in a PCI slot (See “APIO Board” on page 43)

• A 3

1

-inch floppy disk drive

/

2

• A CD-RW drive

PC Ports

The PC motherboard’s ports are used as follows:

• A USB port communicates with the system control panel.

• A USB port communicates with an optional black-and-white thermal printer.

• A USB port communicates with an optional color printer.

• A USB port communicates with an optional plain-paper printer.

• A USB port communicates with the optional physio module.

• A LAN port connects the PC to a network.

• A 3.5 mm phono jack receives audio signals from a microphone.

• A 3.5 mm phono jack supplies the signal that drives the system’s speakers.

• An RS-232 port (Com1) controls an optional VCR.

Page 40

M2540-92000-01 A M2540 Ultrasound System Field Service Manual Page 40

Theory of Operation: TR Boards

VCR-Option Components in the PC

The VCR option includes several cards inside the PC and an adapter that connects to the SVGA

output of the PC’s graphics adapter board. See Figure 4-1 on page 48 for a detailed

representation of how the VCR option’s components function in the ultrasound system.

The following cards are part of the VCR option, and reside in the PC’s PCI slots:

• A sound card that receives audio from the VCR, and supplies sound to the VCR

• A video capture board that receives S-Video signals from the VCR

• An SVGA-to-S-Video card that converts the SVGA signal from the graphics adapter board (in

the AGP slot) to S-Video for the VCR

• An SVGA adapter that connects the graphics adapter board to the SVGA-to-TV video card

and to the monitor

See “VCR Option Parts” on page 198 for a list of all the components of the VCR option.

Optional Drive-Bay Components

The PC’s drive bays accept the following components:

TR Boards

• The Physio module that provides ECG monitoring capability. The drive bay’s power connec-

tor powers the module, but the module does not use the drive bay’s data port. The module

communicates with the ultrasound system through a USB cable to the PC motherboard. See

“Physio Module Option” on page 43, and Figure 4-3 on page 51 for detailed information on

the Physio module.

• A magneto-optical disk (MOD) drive that allows archiving of images, studies, and reports on

removable disks. The MOD uses the drive bay’s data and power ports.

The M2540A’s e-box contains two transmit-and-receive (TR) boards. Each has a connector that

plugs into the motherboard and another connector that passes through the motherboard and

Page 41

M2540-92000-01 A M2540 Ultrasound System Field Service Manual Page 41

Theory of Operation: TR Boards

plugs into the distribution board. The two boards form electronic beams of the transmit and

receive signals. Each TR board contains 64 transmitters and 32 preamps multiplexed into 64

receive channels. This allows multiplexing the system’s 64 active channels into 128 element

arrays. Each receive channel consists of time gain compensation (TGC) amplifiers, low pass

filters, 10-bit A/D converters, and one eighth of a digital beam-forming circuit. Each TR board

sends on its output bus a value that is the sum of the data from its 32 channels plus its 18-bit

input bus. The last TR board in this chain outputs the final summed radio-frequency (RF) data to

the demodulator board.

The transmit and receive beam-forming coefficients for acoustic lines are downloaded on the

coefficient bus from the BPAP board.

The BPAP board generates the timing to start and stop each firing line, and sends the transmit

signal to the TR board, through the distribution board and the connector modules to the

transducer. Analog drivers generate the transmitted RF data. A digital timing generator delays

and times each of the analog drivers. The delay generators receive the appropriate delay values

from the BPAP for each channel. The system power supply controls the amplitude of the

transmitted waveform.

The received signal is preamplified, TGC amplified, low-pass filtered, and digitized (in all modes

except CW). The BPAP board generates TGC control signals through the demodulator board.

After being digitized, the signal on each line is delayed appropriately. The outputs of all channels

are daisy-chained together to sum the outputs. The RF data output of one TR board is the input

to the next TR board, and the outputs of the TR boards are summed to form the received beam.

The summed output signal (RF DATA) goes to the demodulator board.

The CW Doppler signal is mixed to an analog intermediate frequency (IF) signal. The CW

Doppler output is a single differential signal routed to the demodulator board.

Page 42

M2540-92000-01 A M2540 Ultrasound System Field Service Manual Page 42

Theory of Operation: BPAP Board

BPAP Board

Omni TEE Circuitry

The beam processor/acoustic processor (BPAP) board contains two processors. One of them

controls beam-forming, line-to-line operation. The other handles the processing of scan

conversion, color flow, and Doppler signals.

The BPAP board does the following:

• Provides the interface between the PC and the TR boards

• Provides the interface between the PC and the demodulator board

• Receives control data sets from the PC, processes them for specific register values, and

sends them to the TR boards

• Houses the transesophageal echo cardiography (TEE) transducer interface circuitry (TEE

motor control and temperature monitoring)

• Houses the transducer ID circuitry

• Detects the presence of standalone transducers

• Houses electronic switching that allows selection of a single active transducer from the four

that can be connected

• Controls the high-voltage output from the system power supply

The Omni Probe control circuitry on the BPAP board supplies power to the TEE transducer's

motor. It also measures the position of the angle-position sensor. The signal is digitized and sent

to the APIO board for monitoring by the PC.

The beam processor circuitry monitors thermistors in the transducer and insures that high

voltage is not applied to the transmitter unless the thermistor values are within limits.

Page 43

M2540-92000-01 A M2540 Ultrasound System Field Service Manual Page 43

Theory of Operation: Demodulator Board

Demodulator Board

APIO Board

The demodulator board performs image and Doppler demodulation for BMode, MMode, PW

and CW phased and non-imaging Doppler modes, and color flow mode. It sends a baseband data

stream to the BPAP board.

The demodulator board contains the following:

• Digital filters and mixers for demodulating 2D, color flow, and PW RF data

• The independent transducer CW Doppler electronics and steerable CW detector functions

• The 120 MHz system clock. The clock signal is distributed to the TR and BPAP boards.

• Circuitry that generates TGC signals

The acoustic processor I/O (APIO) board is the token ring interface between the system’s PC

and the e-box. The APIO board also handles input from the foot switch’s three control buttons

(via the I/O panel) and forwards them to the PC. The board also generates trigger signals for

legacy printers.

The board handles these signals from the PC:

• The R-wave pulse from the physio module that it sends to the BPAP board

• The DC on-off bit that it sends to the power supply

• Commands that program the BPAP board at startup

Physio Module Option

• Acoustic data from the BPAP board for the acoustic imaging display

The self-contained Physio module resides in one of the PC’s drive bays. The module receives

power from the drive bay’s power connector, but it communicates with the system through a

USB cable to the PC’s motherboard. A shielded and grounded enclosure prevents

electromagnetic interference. See Figure 4-3 on page 51 for a detailed representation of the

module’s functions and connections.

Page 44

M2540-92000-01 A M2540 Ultrasound System Field Service Manual Page 44

Theory of Operation: System Motherboard

Primary Functions

Connectors

System Motherboard

Distribution Board and Connector Modules

The module’s primary functions are as follows:

• Process electrocardiogram (ECG) signals from patient electrodes and deliver the data to the

M2540A’s PC

• Send a detected R-wave trigger to the APIO board for frame triggering in various scanning

modes

• Provide gain control for ECG waveforms

The Physio module has two connectors on its front panel:

• The ECG-input connector is a round, 12-pin connector that is isolated from chassis ground.

• A ¼-inch phone plug jack accepts auxiliary input and has both signal and shield grounds.

This board connects all data paths between the TR boards, the BPAP board, and the distribution

board. It is also the distribution point for DC power and ground to all boards (the BPAP board

and distribution board also receive power directly from the system power supply.). It also sends

filtered high voltage to the TR boards.

The distribution board passes transducer signal inputs to the imaging system. The system power

supply provides high voltage directly to the distribution board to fire transducers.

Signals that pass through this board include

• Transducer identification signals from the BPAP board to and from the transducer

• Transmit and receive signals from the TR boards to the active transducer

• TEE motor-control and temperature-sense signals from the BPAP to and from the TEE trans-

ducer

Page 45

M2540-92000-01 A M2540 Ultrasound System Field Service Manual Page 45

Theory of Operation: I/O Panel

Tr a ns d u ce r Connector Module Types

I/O Panel

System Control Panel

The four transducer module bays accept the following types of modules in any combination:

• Cannon connector

• Advance Vision connector

• Pencil-type transducer connector

• Blank module

See Table 13-2 on page 179 for a list of the modules and their part numbers.

The I/O panel bears four connectors and two ground points. The main system ground used for

safety testing, and an equipotential post are the two ground points on the panel.

The I/O panel’s connectors are

• An RJ-45 (CAT 5) connector for connection to a LAN

• A BNC connector that carries composite video signals for a legacy printer

• A BNC connector that carries trigger signals for a legacy printer

• A 9-pin D connector for the optional foot switch

The system control panel contains the circuitry to process control inputs, the system keyboard,

rotary and slide controls, and the trackball. A USB cable carries control inputs from the control

panel to the PC. An auxiliary cable carries power from the system power supply. The system

control panel circuit board also carries the amplifiers for the system’s stereo speakers.

All control inputs and LEDs are controlled by the system’s PC, and their functions are

determined by resident control-panel and system software.

Circuit boards inside the system control panel are not field serviceable or replaceable. The

entire assembly, including circuit boards, bezel assembly, and labels, is available as a replaceable

Page 46

M2540-92000-01 A M2540 Ultrasound System Field Service Manual Page 46

Theory of Operation: Power Supply

part. Rotary and sliding knobs, rotary encoders for the knobs, the trackball assembly, and the

trackball cable are all available as separate parts.

Power Supply

The M2540A power supply is a self-contained unit that accepts AC input from 90 to 264 V, at 50

or 60 Hz, and supplies 120 VAC at 60 Hz to the system’s PC, monitor, and two peripherals. It

also provides all DC power required by system components. No switch settings are required to

configure the power supply for different AC mains; the power supply automatically adjusts to use

the power connected to it. Except for the 120 VAC to the PC, all power output is activated by a

signal from the PC. The system cooling fan is the only serviceable part on the power supply. See

Figure 4-1 on page 48 for details of the power supply’s outputs. The power supply activates when

it receives an “AWAKE_N” signal, which is generated by the PC, and then sent through the BPAP

board to the power supply.

The system power supply does the following:

• Provides DC power to all system electronics through the system motherboard and the BPAP

board

• Provides DC power directly to the system cooling fan

• Provides high voltage to the distribution board for multiplexing transducers

• Isolates AC mains from secondary AC and DC circuitry

• Transforms primary voltages to secondary voltages

• Filters line AC

• Provides an isolated 120 VAC unswitched outlet to power the internal PC

• Provides three isolated 120 VAC switched outlets to power the monitor and two peripherals

Page 47

M2540-92000-01 A M2540 Ultrasound System Field Service Manual Page 47

Theory of Operation: Functional Block Diagrams

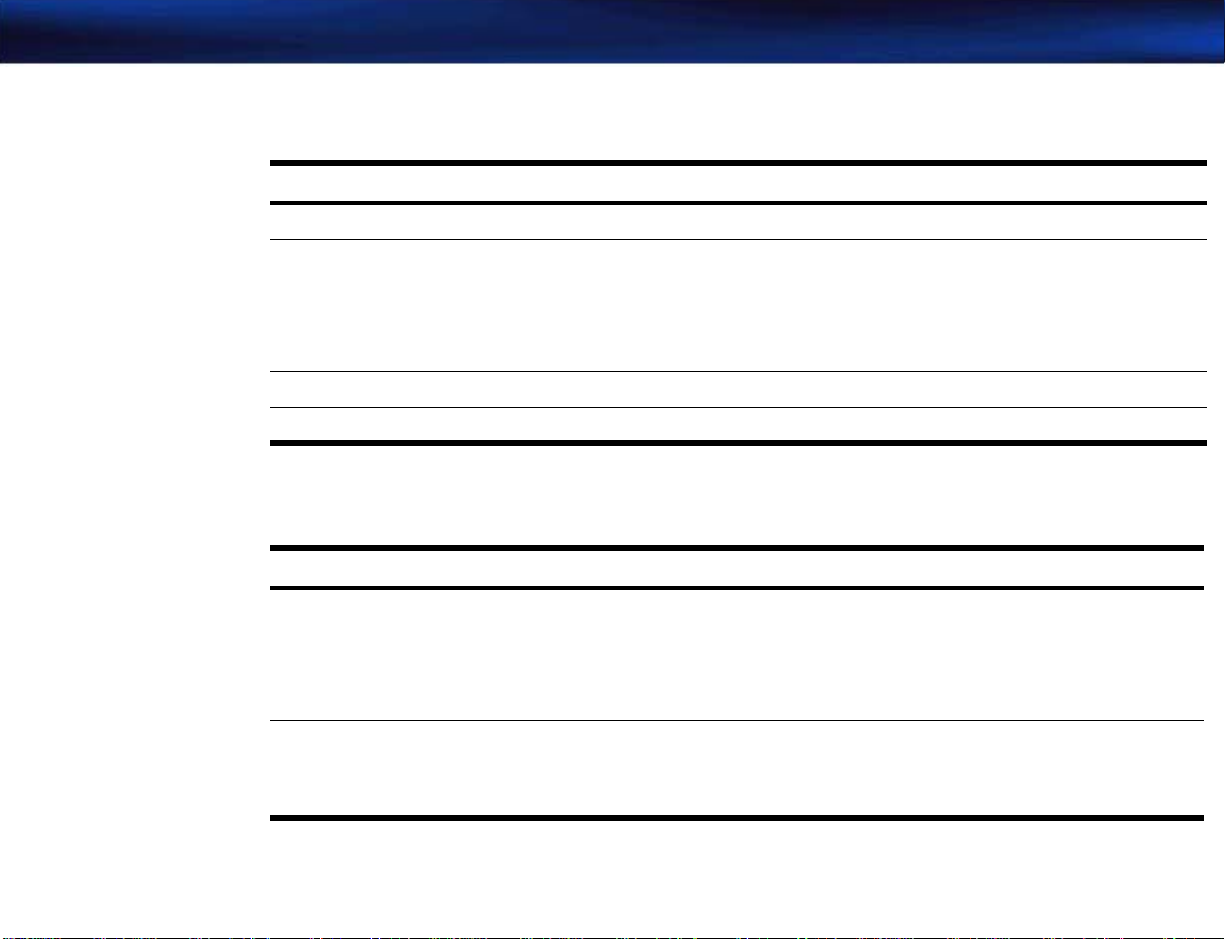

Functional Block Diagrams

System Functional Block Diagram

This section contains block diagrams of the system’s components and their connections.

The section includes the following block diagrams:

• Figure 4-1 on page 48 shows the ultrasound system with the VCR option installed. This dia-

gram does not include the e-box or the system’s power supply. Those components are

shown in Figure 4-2 on page 49.

• Figure 4-2 shows the e-box and the system power supply and their connections to other

components of the ultrasound system.

• Figure 4-3 on page 51 shows the optional Physio module and its internal connections.

Figure 4-1 shows the M2540A system with the VCR option installed.

Page 48

M2540-92000-01 A M2540 Ultrasound System Field Service Manual Page 48

Theory of Operation: Functional Block Diagrams

Figure 4-1 System Block Diagram with VCR Option

Speaker Speaker

Floppy disk

drive

Optional

MO drive

CD-RW drive

Optional

Physio module

USB

Internal PC

R-wav

Hard disk drive

PC

motherboar

VCR option

sound board

VCR option

capture board

VCR option

converter

board

Graphics

adapter board

APIO board

PC power

Com

S-video

SVGA

adapter

Audio

USB

USB

USB

Audio

LAN

RS-232

Audio

S-video

Composite video

SVGA video

Trigger

Foot switch

To k e n r i ng

To e-box (see Figure 4-2)

System control panel

Microphone

Audio

I/O

panel

AC power

DC power

Optional printers

(up to 2)

Optional

VCR

Monitor

AC power

System power

supply

(see Figure 4-2

for detail)

To remote

USB printer

AC power

AC power

Page 49

M2540-92000-01 A M2540 Ultrasound System Field Service Manual Page 49

C

Theory of Operation: Functional Block Diagrams

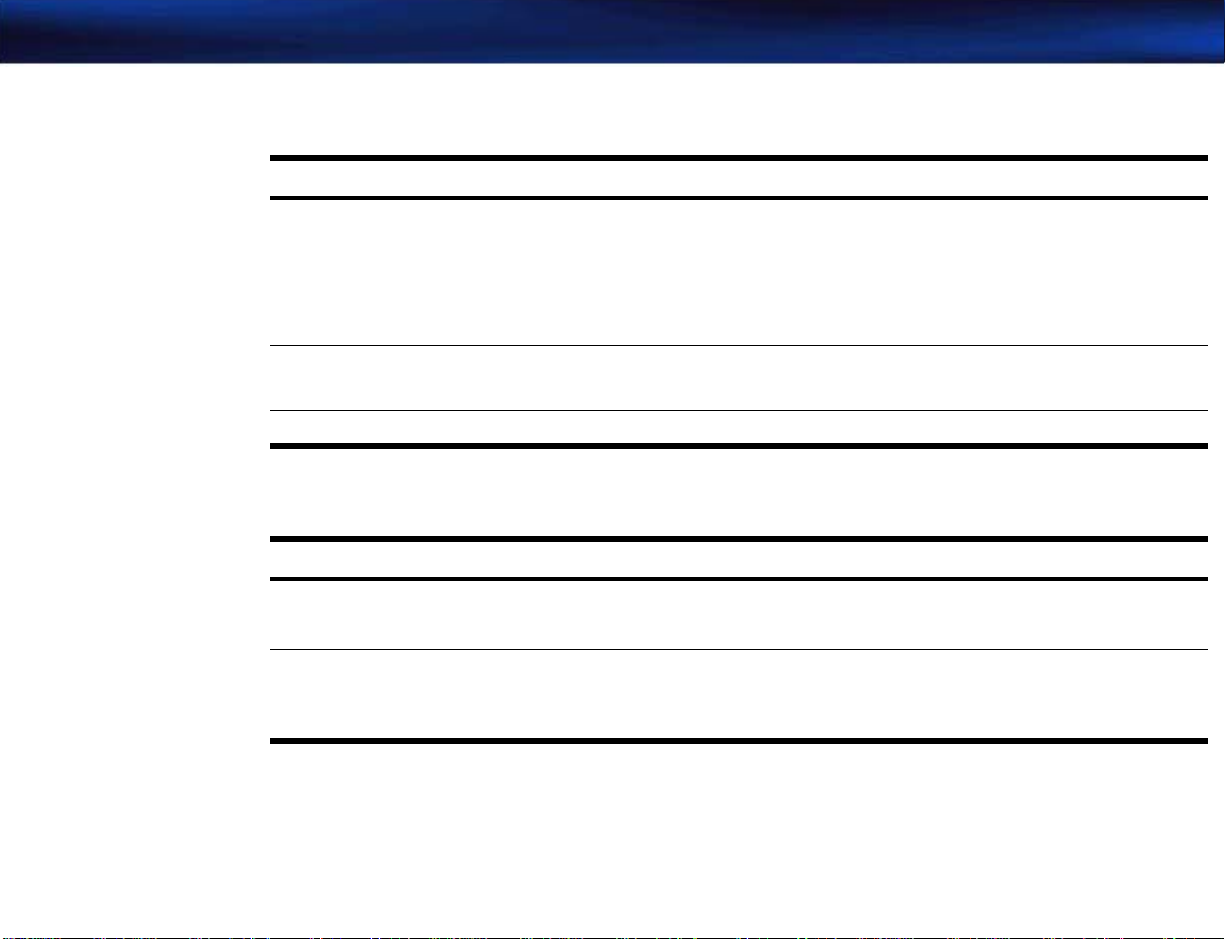

e-box and Power

Supply

Figure 4-2 shows the system’s power supply and the e-box and their connections to each other

and other components.

Functional Block

Diagram

Figure 4-2 e-box and Power Supply Block Diagram

Distribution board

Motherboard

Connector

module

Connector

module

Connector

module

Connector

module

Fan

+11, +5

+60, -140

mux V

+12 VDC variable

±12, -5,

±HV

TR board

TR board

Demodulator board

BPAP board

+3, +5

VDC

+2 VDC

Power supply

Control

To APIO board in PC

Token ring

To PC

Unswitched

120 VAC

Switched 120 VAC

Switched 120 VAC

Switched 120 VAC

+5, +12, -12 VDC

To peripherals

To monitor

To system

control panel

90 - 264 VA

Page 50

M2540-92000-01 A M2540 Ultrasound System Field Service Manual Page 50

Theory of Operation: Functional Block Diagrams

Token Ring Cable

The token ring cable carries the following signals between the BPAP board and the APIO board:

• R-wave communication

• On and off signal that switches on the outputs from the power supply (the 120 VAC output

for the PC is always on)

• Program enable and program done (on separate circuits)

• Ring in and ring out (on separate circuits)

Page 51

M2540-92000-01 A M2540 Ultrasound System Field Service Manual Page 51

Theory of Operation: Functional Block Diagrams

Physio

Functional Block

Figure 4-3 shows how the Physio module functions, its internal connections, and connections to

other components.

Diagram

Figure 4-3 Physio Module Block Diagram

Isolated front end

Bandpass

0.35 to 30Hz

AUX In

clk24

ECG leads

Differential

amp

and

driver

Signal

isolation

Power

isolation

islout

Clock

divider

X216

filter

M

U

X

auxsel

Phy1 offset

gain adjust

Phy2 offset

gain adjust

nlddac2

EZ-USB

controller

and

and

dacdata

phy1

phy1

phy2

spi-do

spi-di

spi-ck

nadccs

R-wave

detector

A/D

converter

r-raw

dacdata

nlddac1

To APIO

R-wave trig

To PC motherboard

USB

Page 52

M2540-92000-01 A M2540 Ultrasound System Field Service Manual Page 52

Theory of Operation: Transducer Safety Testing: Test Setup and Theory

Transducer Safety Testing: Test Setup and Theory

This section provides background and supporting information for the transducer leakage tests in

Section 6, “Performance Tests”; this information is not required to perform the tests.

In transducer safety tests, a container filled with saline solution functions as a conductive

medium (see Figure 4-4 on page 53). The solution penetrates any faults in the transducer

insulation and provides an electrical path between the submerged lead wire and the grounded

inner transducer shield.

The test for transthoracic and endocavity transducers differs from the test for TEE transducers

only by the extent that the transducers are submerged in the test solution.

Page 53

M2540-92000-01 A M2540 Ultrasound System Field Service Manual Page 53

Theory of Operation: Transducer Safety Testing: Test Setup and Theory

Figure 4-4 Transducer Leakage Current Test Setup and Theory Diagram

See Key for

Figure 4-4

I

Hot

Neutral

Ground

Neutral condition:

Mode selector on safety analyzer:

Open Neutral button

Open Ground button

SAFETY ANALYZER

system

I

measured

A

Closed for normal condition

Closed for 1st single fault condition

Open for 2nd single fault condition

Ultrasound

metal chassis

C

I

chassis

2

S

1

Ground condition:

ECG for transducer leakage test

Case Leakage, Ground Conductor for ground wire leakage test

Transducer Cable

Outer

plastic

skin

Grounded

shielding

jacket

Insertion

depth

Saline

Closed for normal condition

Open for 1st single fault condition

Closed for 2nd single fault condition

Z

I

transducer

ECG

lead wire

Internal

circuitry

7ASW030-1

Page 54

M2540-92000-01 A M2540 Ultrasound System Field Service Manual Page 54

Theory of Operation: Transducer Safety Testing: Test Setup and Theory

Table 4-1 Key for Figure 4-4

A = Microammeter in the safety analyzer

I

measured

= Leakage current

S = Switch that connects the ammeter either directly to the chassis or

through the ECG lead wire. (This is the mode selector on the Safety

Analyzer. Select ECG for transducer leakage and Case Leakage, or select

Ground Conductor for chassis leakage.)

C = Stray capacitance from the system's power wiring to the chassis.

Z= Impedance between the transducer’s metal parts and the test electrode:

≈ 800 KΩ if the outer insulating layer is intact

< 500 Ω if the outer layer is compromised

Insertion depth:

• For transthoracic and endocavity transducers, submerge the head and 5 cm of the cable,

being careful to not submerge the connector.

• For TEE transducers, submerge all of the flexible shaft that would normally enter the body of

the patient: 100 cm for adult TEE, 60 cm for pediatric TEE.

Theory of the Transducer Leakage Current Test

Leakage current I

, driven by the line supply, flows through the stray capacitance C between

chassis

the primary wiring and the system’s metal chassis.

Page 55

M2540-92000-01 A M2540 Ultrasound System Field Service Manual Page 55

Theory of Operation: Transducer Safety Testing: Test Setup and Theory

Figure 4-5 Transducer Leakage Current Test Diagram for the Normal Condition

I

S

system

C

I

chassis

Z

I

transducer

7ASW030-2

Hot

Neutral

Ground

I

measured

A

The leakage current normally flows from the chassis safely out through the ground wire. If there

is a fault in the transducer insulation, some of the current follows this path and is measured by

the safety analyzer. This I

transducer

is still fairly low, unless the chassis is not properly grounded.

Page 56

M2540-92000-01 A M2540 Ultrasound System Field Service Manual Page 56

Theory of Operation: Transducer Safety Testing: Test Setup and Theory

Figure 4-6 Transducer Leakage Current Test Diagram for 1st Single Fault Condition

I

S

system

C

I

chassis

Z

I

transducer

7ASW030-3

Hot

Neutral

Ground

I

measured

A

When an open ground condition is imposed, all I

I

transducer

is still fairly low unless its sheath is compromised.

is forced through the transducer. This

chassis

Figure 4-7 Transducer Leakage Current Test Diagram for 2nd Single Fault Condition

I

S

system

C

I

chassis

Z

I

transducer

7ASW030-4

Hot

Neutral

Ground

I

measured

A

Page 57

M2540-92000-01 A M2540 Ultrasound System Field Service Manual Page 57

Theory of Operation: Transducer Safety Testing: Test Setup and Theory

Imposing an open neutral condition prevents all system current from flowing. This creates a

higher potential for leakage current I

flows through the transducer. This I

transducer

. Most flows safely through the ground wire; some

chassis

is still fairly low, unless the chassis is not properly

grounded.

Figure 4-8 Ground Wire Leakage Test Diagram (for Comparison with 1st Single Fault

Condition)

I

S

system

C

I

chassis

Z

I

transducer

7ASW030-5

Hot

Neutral

Ground

I

measured

A

With the transducer circuit disconnected, all of the leakage current I

flows through the

chassis

analyzer by way of the ground wire.

In the 1st single fault condition transducer leakage test (Figure 4-6 on page 56), all the leakage

current I

flows through the analyzer by way of the transducer. In that condition, only the

chassis

resistance or impedance of the respective paths varies.

• If the transducer sheath is intact, its resistance is high, and I

test is low when compared with I

measured

in the ground wire leakage test.

measured

in the transducer leakage

Page 58

M2540-92000-01 A M2540 Ultrasound System Field Service Manual Page 58

Theory of Operation: Transducer Safety Testing: Test Setup and Theory

• If the transducer sheath is compromised, its resistance is close to that of the ground wire.

Transducer leakage current equaling 80% or more of ground wire leakage current indicates a

fault or break in the transducer insulation.

Sheath integrity is tested this way because there could be a break in the transducer sheath

causing significant I

transducer

, and yet that leakage current could still be within acceptable limits.

Comparison to the ground wire leakage current is the only way to ensure sheath integrity.

Page 59

M2540-92000-01 A M2540 Ultrasound System Field Service Manual Page 59

Installation: Overview

5 Installation

Overview

Assemble the System

Powe r Cord a nd Monitor Installation

This chapter includes procedures for installing and setting up the M2540A.

The following sections are in this chapter:

• “Assemble the System” on page 59

• “System Startup” on page 62

• “System Configuration” on page 64

• “Customer Training” on page 88

Complete the following steps to assemble the M2540A ultrasound system:

➤ Installing the Power Cord and Monitor

1. Attach the system power cord to the receptacle at the bottom rear of the system.

2. Loosen the screw that secures the cord retainer, rotate the retainer 180 degrees, and

tighten the screw.

3. Rotate the twivel base to its proper position. (The monitor cables pass through the rear of

the twivel base.)

4. Install the monitor on the twivel.

Peripherals Installation

5. Connect the VGA cable the and monitor power cable to the monitor.

When installing peripherals, keep the following points in mind:

• No more than two peripherals can be mounted on the cart.

• When two peripherals are installed, the smaller one must be on top of the larger one.

Page 60

M2540-92000-01 A M2540 Ultrasound System Field Service Manual Page 60

Installation: Assemble the System

• Peripherals should mount toward the rear of the system, with about one centimeter

between the lower peripheral and the inside edge of cart top.

➤ Installing a VCR

1. Loosen the peripheral strap, and slide the VCR under it.

2. Connect the power cable, audio input cable, audio output cable, and S-video cable

to the VCR.

3. Connect the serial cable to the VCR, and screw it in place.

4. If another peripheral is part of the installation, place the VCR peripheral tray on the top of

the VCR.

5. Tighten the peripheral strap on top of the peripherals.

6. Turn on the VCR power switch.

7. Set the VCR switches to the following settings: