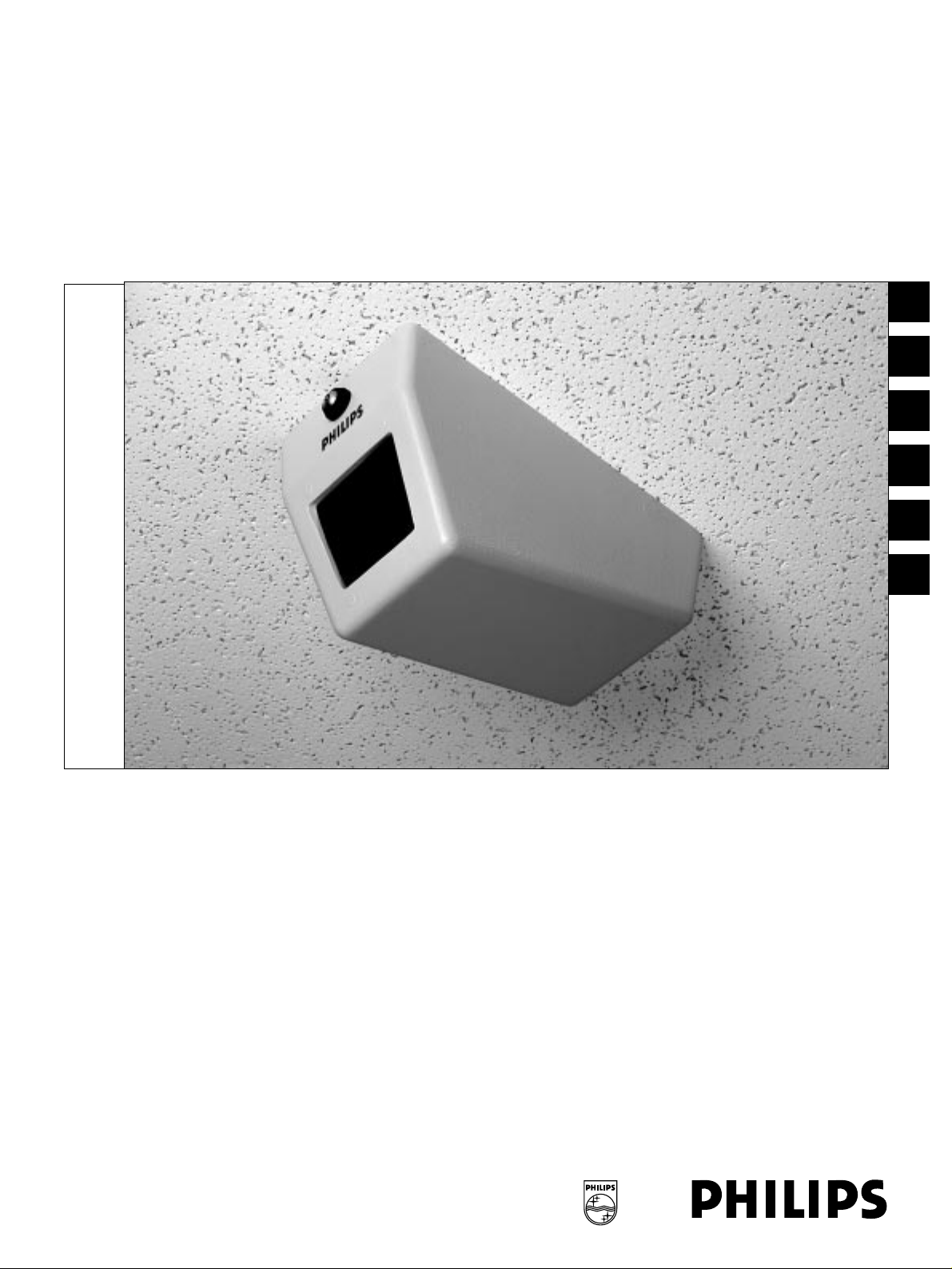

Philips LTC 9405 User Manual

LTC 9405 Series

Wall/Ceiling Security Housings

Philips

Communication &

Security Systems

Installation Instructions

Eng

F

D

E

NL

I

1.2

IMPORTANT SAFEGUARDS

1. Read Instructions - All the safety and operating instructions should be read

before the unit is operated.

2. Retain Instructions - The safety and operating instructions should be

retained for future reference.

3. Heed Warnings - All warnings on the unit and in the operating instructions

should be adhered to.

4. Follow Instructions - All operating and use instructions should be followed.

5. Cleaning - Unplug the unit from the outlet before cleaning. Do not use

liquid cleaners or aerosol cleaners. Use a damp cloth for cleaning.

6. Attachments - Do not use attachments not recommended by the product

manufacturer as they may cause hazards.

7. Water and Moisture - Do not use this unit near water - for example, near a

bath tub, wash bowl, kitchen sink, or laundry tub, in a wet basement, near

a swimming pool, in an unprotected outdoor installation, or any area which

is classified as a wet location.

8. Accessories - Do not place this unit on an unstable stand, tripod, bracket,

or mount. The unit may fall, causing serious injury to a person and serious

damage to the unit. Use only with a stand, tripod, bracket, or mount

recommended by the manufacturer, or sold with the product. Any

mounting of the unit should follow the manufacturer's instructions, and

should use a mounting accessory recommended by the manufacturer.

An appliance and cart combination should be moved with care.

Quick stops, excessive force, and uneven surfaces may cause the

appliance and cart combination to overturn.

9. Ventilation - Openings in the enclosure, if any, are provided for ventilation

and to ensure reliable operation of the unit and to protect it from

overheating. These openings must not be blocked or covered. This unit

should not be placed in a built-in installation unless proper ventilation is

provided or the manufacturer's instructions have been adhered to.

10. Power Sources - This unit should be operated only from the type of power

source indicated on the marking label. If you are not sure of the type of

power supply you plan to use, consult your appliance dealer or local power

company. For units intended to operate from battery power, or other

sources, refer to the operating instructions.

11. Grounding or Polarization - This unit may be equipped with a polarized

alternating-current line plug (a plug having one blade wider than the other).

This plug will fit into the power outlet only one way. This is a safety

feature. If you are unable to insert the plug fully into the outlet, try

reversing the plug. If the plug should still fail to fit, contact your electrician

to replace your obsolete outlet. Do not defeat the safety purpose of the

polarized plug.

Alternately, this unit may be equipped with a 3-wire grounding-type plug, a

plug having a third (grounding) pin. This plug will only fit into a

grounding-type power outlet. This is a safety feature. If you are unable to

insert the plug into the outlet, contact your electrician to replace your

obsolete outlet. Do not defeat the safety purpose of the grounding-type

plug.

12. Power-Cord Protection - Power-supply cords should be routed so that they

are not likely to be walked on or pinched by items placed upon or against

them, paying particular attention to cords and plugs, convenience

receptacles, and the point where they exit from the appliance.

13. Power Lines - An outdoor system should not be located in the vicinity of

overhead power lines or other electric light or power circuits, or where it

can fall into such power lines or circuits. When installing an outdoor

system, extreme care should be taken to keep from touching such power

lines or circuits as contact with them might be fatal. U.S.A. models only refer to the National Electrical Code Article 820 regarding installation of

CATV systems.

14. Overloading - Do not overload outlets and extension cords as this can result

in a risk of fire or electric shock.

15. Object and Liquid Entry - Never push objects of any kind into this unit

through openings as they may touch dangerous voltage points or short-out

parts that could result in a fire or electric shock. Never spill liquid of any

kind on the unit.

16. Servicing - Do not attempt to service this unit yourself as opening or

removing covers may expose you to dangerous voltage or other hazards.

Refer all servicing to qualified service personnel.

17. Damage Requiring Service - Unplug the unit from the outlet and refer

servicing to qualified service personnel under the following conditions:

a. When the power-supply cord or plug is damaged.

b. If liquid has been spilled, or objects have fallen into the unit.

c. If the unit has been exposed to rain or water.

d. If the unit does not operate normally by following the operating

instructions. Adjust only those controls that are covered by the

operating instructions, as an improper adjustment of other controls

may result in damage and will often require extensive work by a

qualified technician to restore the unit to its normal operation.

e. If the unit has been dropped or the cabinet has been damaged.

f. When the unit exhibits a distinct change in performance--this indicates

a need for service.

18. Replacement Parts - When replacement parts are required, be sure the

service technician has used replacement parts specified by the manufacturer

or have the same characteristics as the original part. Unauthorized

substitutions may result in fire, electric shock or other hazards.

19. Safety Check - Upon completion of any service or repairs to this unit, ask

the service technician to perform safety checks to determine that the unit is

in proper operating condition.

20. Coax Grounding - If an outside cable system is connected to the unit, be

sure the cable system is grounded. U.S.A. models only--Section 810 of the

National Electrical Code, ANSI/NFPA

No.70-1981, provides information with respect to proper grounding of the

mount and supporting structure, grounding of the coax to a discharge unit,

size of grounding conductors, location of discharge unit, connection to

grounding electrodes, and requirements for the grounding electrode.

21. Lightning - For added protection of this unit during a lightning storm, or

when it is left unattended and unused for long periods of time, unplug it

from the wall outlet and disconnect the cable system. This will prevent

damage to the unit due to lightning and power-line surges.

1.3

SAFETY PRECAUTIONS

This label may appear on the bottom of the unit due to space

limitations.

The lightning flash with an arrowhead symbol, within an

equilateral triangle, is intended to alert the user to the

presence of un-insulated "dangerous voltage" within the

product's enclosure that may be of sufficient magnitude to

constitute a risk of electric shock to persons.

The exclamation point within an equilateral triangle is

intended to alert the user to presence of important

operating and maintenance (servicing) instructions in the

literature accompanying the appliance.

CAUTION: TO REDUCE THE RISK OF ELECTRICAL

SHOCK, DO NOT OPEN COVERS. NO USER

SERVICEABLE PARTS INSIDE. REFER SERVICING TO

QUALIFIED SERVICE PERSONNEL.

WARNING

TO PREVENT FIRE OR SHOCK HAZARD, DO NOT

EXPOSE UNITS NOT SPECIFICALLY DESIGNED FOR

OUTDOOR USE TO RAIN OR MOISTURE.

1.4

1.5

CONTENTS

1 UNPACKING . . . . . . . . . . . . . . . . . . . . . . . . . .1.3

2 SERVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.3

3 CARE AND MAINTENANCE . . . . . . . . . . . . .1.3

4 DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . .1.3

5 INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . .1.4

5.1 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.4

5.2 Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.4

5.3 Mounting the Unit . . . . . . . . . . . . . . . . . . . . . . .1.5

5.4 Camera/Lens Installation . . . . . . . . . . . . . . . . . . .1.6

5.5 Final Assembly . . . . . . . . . . . . . . . . . . . . . . . . . .1.7

1 UNPACKING

Unpack carefully. This is electro-mechanical equipment and

should be handled with care.

Check for the following items:

■ Model number of unit.

■ Hardware Kit.

(1) ¼-20 Button-Head Flange Screw

(1) Tamper-resistant Tool (basic models only)

(1) Alternate Camera Bracket

(1) Key (Locking models only)

If an item appears to have been damaged in shipment, replace it

properly in its carton and notify the shipper. If any items are

missing, notify your Philips Communication & Security

Systems Sales Representative or Customer Service.

The shipping carton is the safest container in which the unit

may be transported. Save it for possible future use.

2 SERVICE

If the unit ever needs repair service, the customer should contact

the nearest Philips Communication & Security Systems Service

Center for return authorization and shipping instructions.

3 CARE AND MAINTENANCE

There are no moving parts in this unit. Regularly scheduled

maintenance will help prolong the operation life of this unit.

Clean the viewing window as needed with a mild, non-abrasive

detergent in water and a soft cloth.

4 DESCRIPTION

The LTC 9405 series are wall or ceiling mounted security

housings designed for applications such as prisons, parking

garages and hospitals. These housings are ideal for any

application requiring secure CCTV monitoring.

LTC 9405 has an overall size of 279 mm x 165 mm x 140 mm

(11 in x 6.5 in x 5.5 in). The LTC 9405 series housings accept

camera-lens combinations up to 190 L x 68 W x 68 H mm (7.5

x 2.7 x 2.7 in).

For maximum protection and durability, the light weight cast

aluminum design of the LTC 9405 series housings provide the

strength equivalent 10 gage steel with the superior strength to

weight ratio of aluminum. The standard viewing window is

constructed of 9.5 mm (0.37 in.) clear polycarbonate treated

with a scratch-resistant coating. The removable cover provides

access to the camera and is secured with a single tamperresistant and captive screw. A special tool is provided for

turning the screw to open or close the cover. During servicing

or adjustment of the camera, the cover may be completely

removed or (if mounted on a ceiling) it may be left attached to

the top panel assembly using the "hinged slots" provided.

Attractively styled these housings are designed to be mounted

on the ceiling, on the wall horizontally or on the wall vertically.

Options include a key lock on the access panel and a clear

12.7 mm (0.5 in) viewing window.

5 INSTALLATION

This installation should be made by qualified service

personel and conform to the National Electrical Code

and applicable local codes.

Tools Required.

Allenwrench - 5/32-inch.

Wrench - 10 mm.

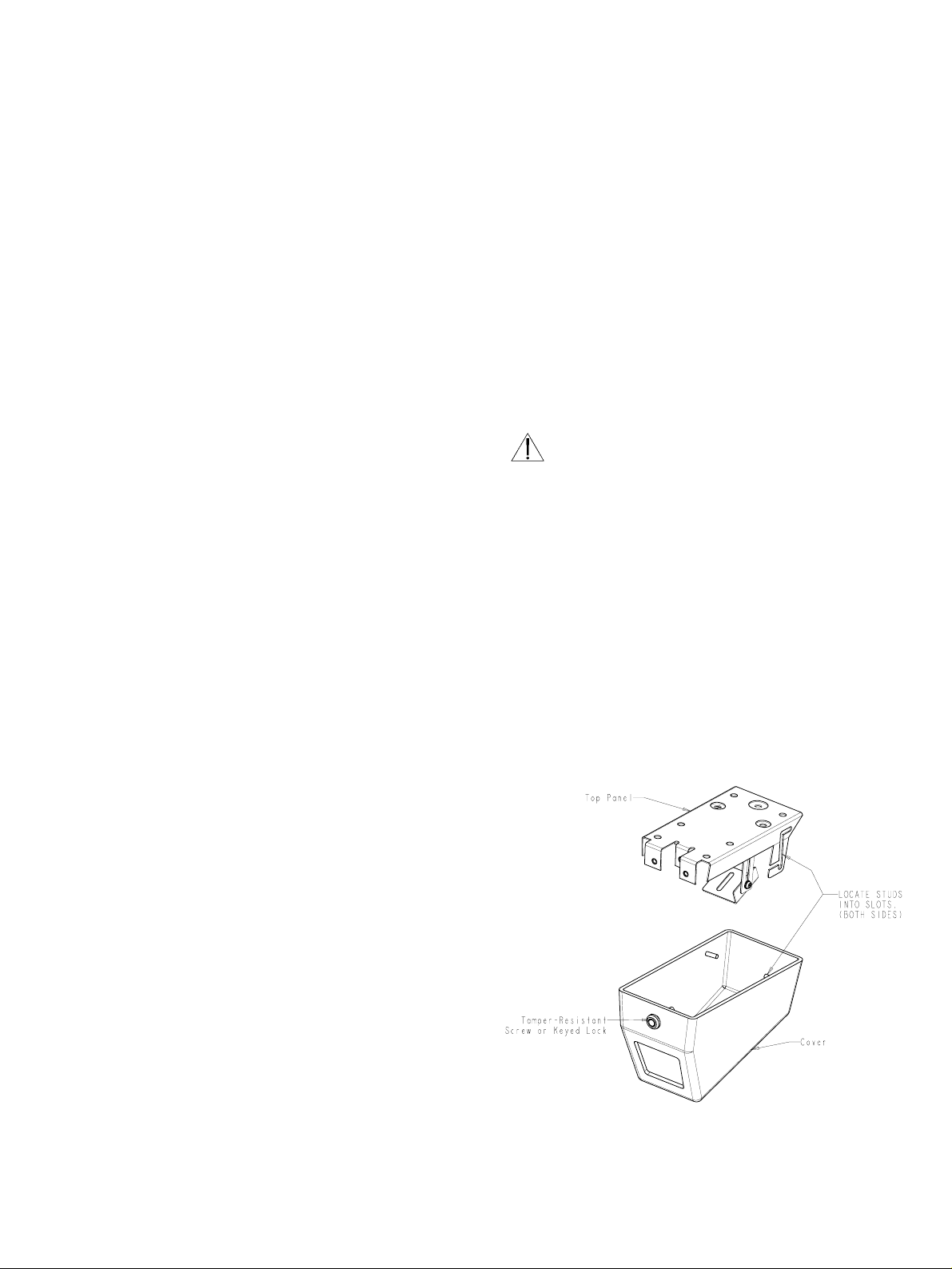

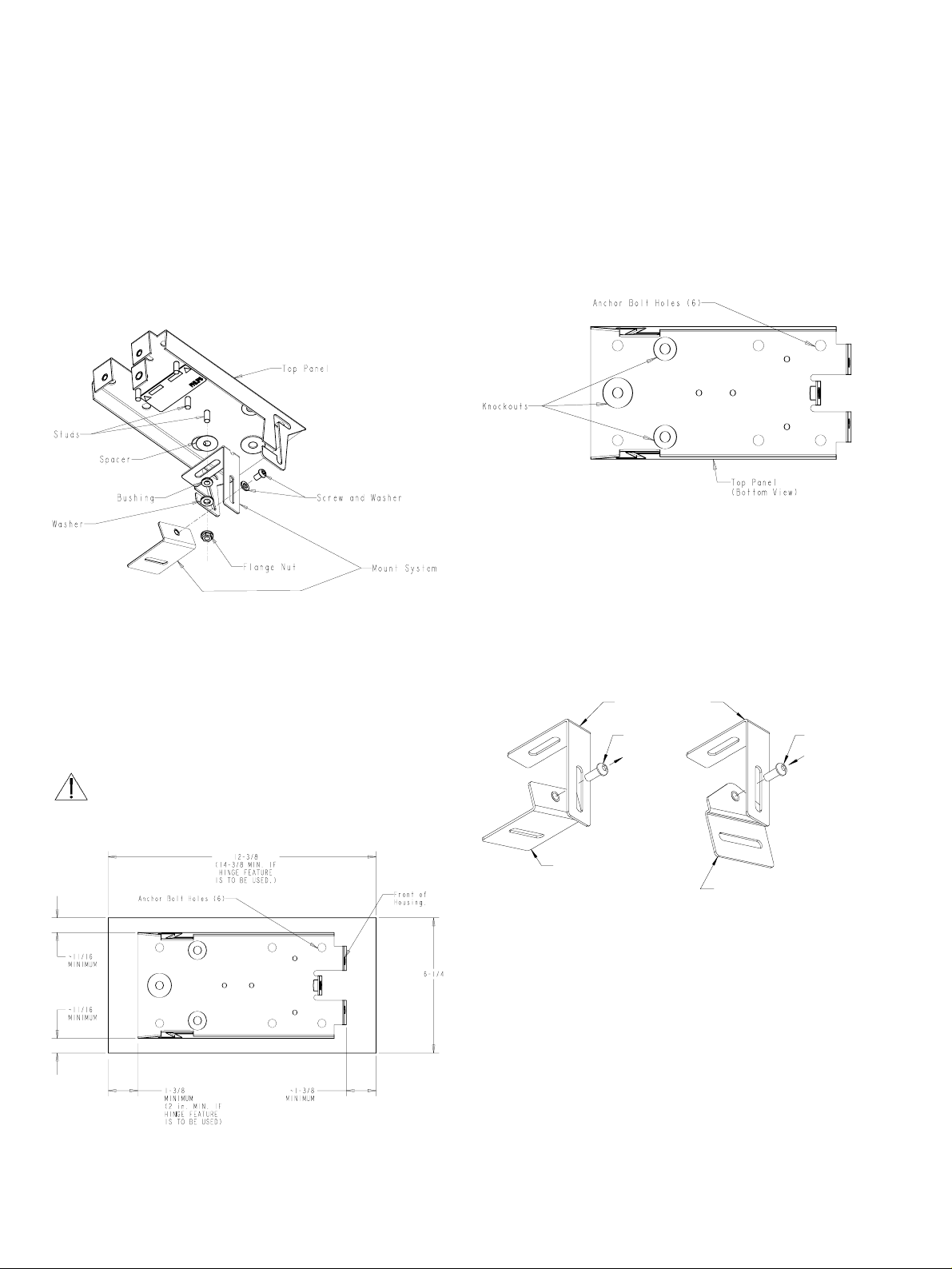

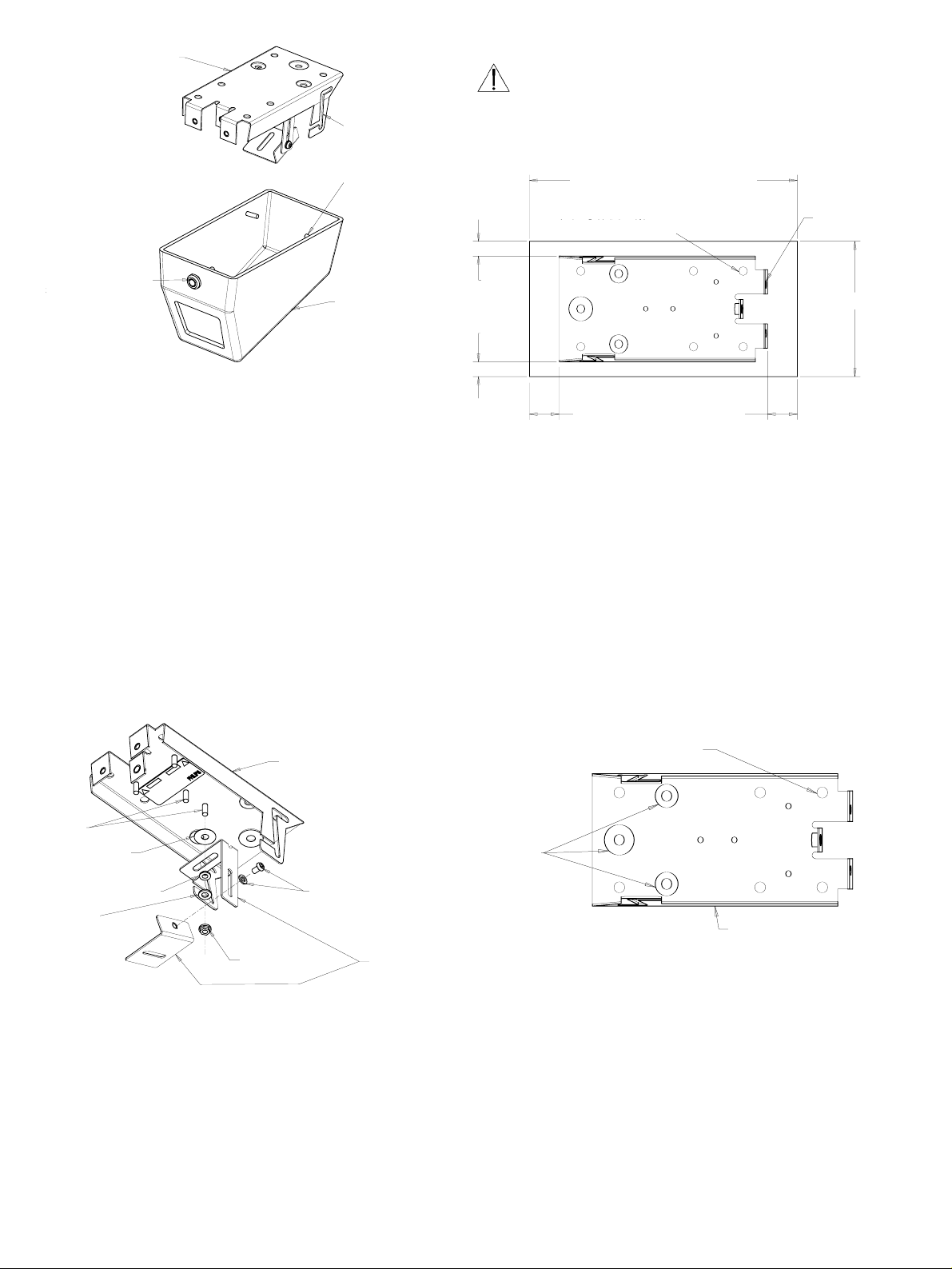

5.1 Disassembly

1. Remove the hardware kit from the shipping carton.

2. Models LTC 9405/00 and 9405/03 require the use of the

special tool to unscrew the tamper-resistant screw on the

front of the cover. See figure 1.

Models LTC 9405/01 and 9405/05 require the use of the

key to unscrew the lock on the front of the cover. See

figure 1.

Figure 1: Removing the cover

3. For all models, unscrew the screw or the lock until the front

of the cover is free from the top panel.

4. With the unit on a workbench or table, hold the cover

stationary. Remove the top panel by grasping it and pulling

it rearward, then upward for about 51 mm (2 in ), and

finally rearward again until the slots in the top panel have

cleared the studs in the cover.

5. Unscrew the flange nut and remove the camera mount

system from the top panel. See figure 2. Do not lose the

parts, they will be needed to mount the camera and

reassemble the unit.

Figure 2: Removing the Mount System

5.2 Mounting the Unit

1. Position the top panel on the ceiling or wall, horizontally or

vertically, depending on the installation requirements. See

figure 3. A smooth flat surface is ideal for proper

installation. Note the minimum space requirements shown

in figure 3.

WARNING! - Do not use the hinge feature when the

unit is mounted on a wall. The cover may fall from

the top panel.

Figure 3: Positioning the Top Panel

2. Mark the anchor bolt locations on the mounting surface

using the holes in the top panel as a template. At least four

8-mm (5/16-in.) anchor bolts will be needed. Use of six

bolts is recommended.

3. Drill holes and install anchors as required by the type of

mounting surface.

4. Decide how the wiring will be routed to the unit. Two

knockouts for ½ inch conduit and one knockout for 3/4

inch conduit are provided. See figure 4.

Figure 4: Bolt Holes and Knockouts

5. Mount the top panel using the bolts and rout the wiring.

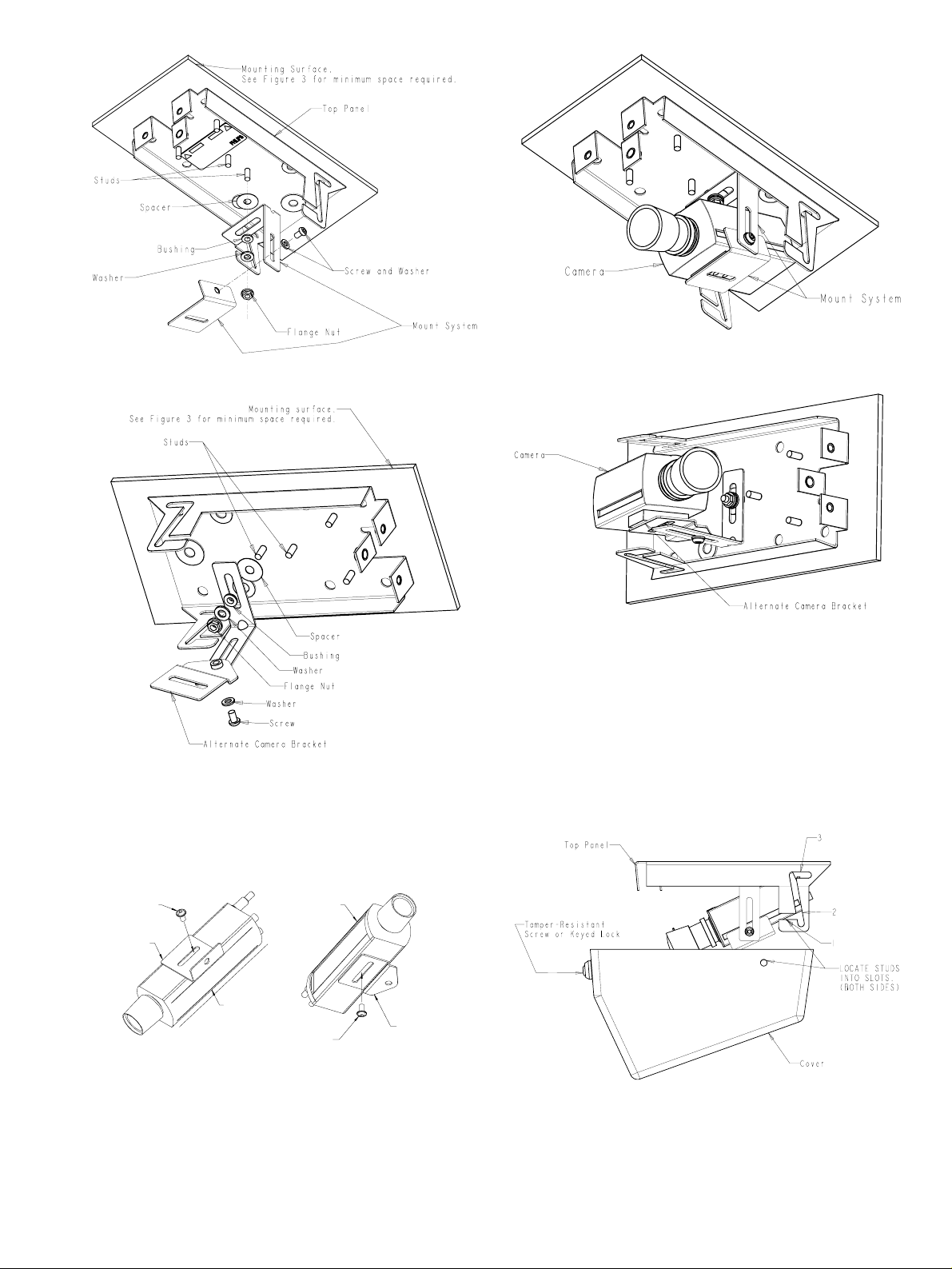

5.3 Camera/Lens Installation

1. If the installation requires that the camera be mounted

horizontally to a wall, remove the camera bracket from the

mounting system and install the alternate camera bracket

provided in the hardware kit. See figure 5.

Figure 5: Alternate Camera Mount

2. Reattach the camera mounting system to the top panel using

the same hardware that was removed in step 5 of section

5.1. Use either of the two studs near the center of the

panel, depending on the camera / lens size. See figures 6

and 7.

1.6

Mounting Bracket

Screw

Screw

Camera Bracket

Alternate

Camera Bracket

W9404408AE

Figure 6: Installing the Mount System

Figure 7: Securing the Mount System with Alternate Bracket

3. Secure the camera to the mount using the ¼-20 x ½ inch

button-head flange screw provided in the hardware kit. See

figures 8, 9 and 10.

Figure 8: Camera Mounts

Figure 9: Camera and Mount System

Figure 10: Camera Mounted with Alternate Bracket to a

Wall

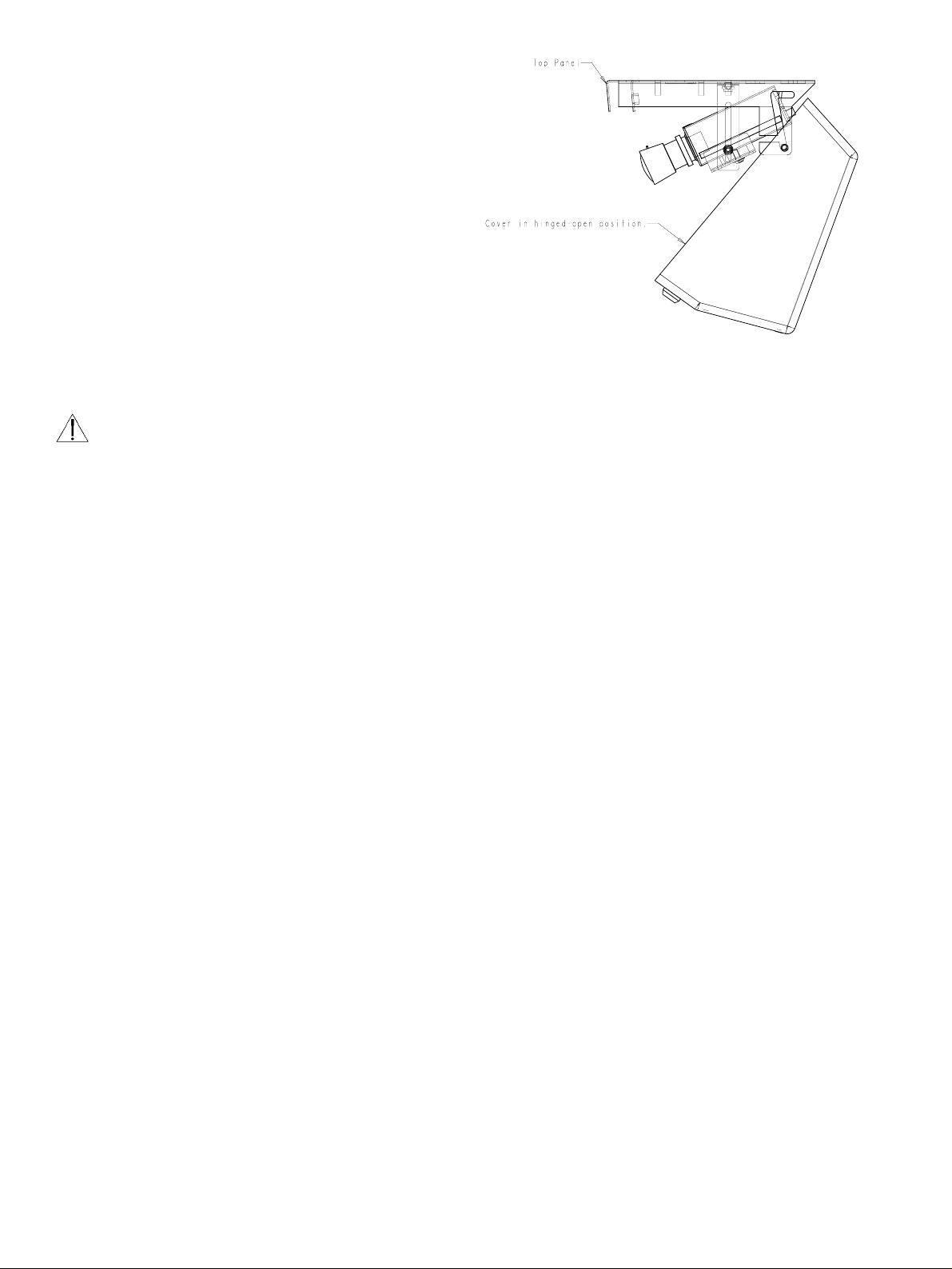

5.4 Final Assembly

1. Mount the cover by aligning the two studs near the rear of

the cover with the openings of the z-shaped slots in the top

panel. Slide the cover to the rear, then upward and finally

to the rear again. Tighten tamper-resistant screw or lock

with key. See figure 11.

Figure 11: Installing the Cover

1.7

Button Head

Flange Screw

Camera

Camera

Button Head

Flange Screw

Alternate

Camera Bracket

W9404411AE

Camera

Bracket

2. Inspect the alignment of the camera / lens in the unit. The

camera / lens should be placed as close to the viewing

window as possible. Remove the cover and make

adjustments as needed and then replace the cover.

3. Secure the cover by turning either the tamper-resistant screw

(using the drive tool supplied) or the keyed lock (using the

key supplied) clockwise until the cover is in tight contact

with the top panel.

Note: Save the drive tool or the key for future use.

4. For installations where the unit is mounted to the ceiling,

the top cover may be hinged open for servicing or adjusting

the camera / lens. Simply allow the two studs in the rear of

the cover to rest in the bottom of the z-slots in the top

panel.

WARNING! - Do not use the hinge feature when the

unit is mounted to a wall, the cover may fall from the

top panel.

Figure 12: Cover Hinged Open

1.8

2.1

SECURITE

En raison de limitation de place, cette étiquette peut être placée sur le

dessous de l'appareil.

L'éclair fléché dans un triangle équilatéral, avertit

l'utilisateur de la présence d'une "tension dangereuse" non

isolée à l'intérieur de l'appareil et d'une valeur suffisante

pour constituer un risque d'électrocution.

Le point d'exclamation contenu dans un triangle

équilatéral, avertit l'utilisateur de la présence, dans la

documentation qui accompagne l'appareil, de consignes

d'utilisation et de maintenance importantes.

RISQUE DE CHOC ELECTRIQUE.

NE PAS OUVRIR.

ATTENTION

DANGER: POUR ÉVITER TOUT RISQUE

D'ÉLECTROCUTION, NE PAS OUVRIR LE BOÎTIER. IL

N'Y A PAS DE PIÈCES REMPLAÇABLES À

L'INTÉRIEUR. POUR TOUTE RÉVISION, S'ADRESSER

À UN TECHNICIEN SPÉCIALISÉ.

ATTENTION

POUR ÉVITER LE RISQUE D'ÉLECTROCUTION OU

D'INCENDIE, NE PAS EXPOSER À LA PLUIE OU À

L'HUMIDITÉ UN APPAREIL NON CONÇU POUR

UNE UTILISATION EXTÉRIEURE.

2.2

2.3

TABLE DES MATIERES

1 DEBALLAGE . . . . . . . . . . . . . . . . . . . . . . . . . . .2.3

2 MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . .2.3

3 ENTRETIEN ET MAINTENANCE . . . . . . . . .2.3

4 DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . .2.3

5 INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . .2.3

5.1 Démontage . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.3

5.2 Montage de l'unité . . . . . . . . . . . . . . . . . . . . . . .2.4

5.3 Installation du bloc caméra/objectif . . . . . . . . . . .2.5

5.4 Montage final . . . . . . . . . . . . . . . . . . . . . . . . . . .2.6

1 DEBALLAGE

Déballez soigneusement le contenu de l'emballage. Il contient

un équipement électromécanique qui doit être manipulé avec

précaution.

Vérifiez que vous disposez des éléments suivants :

■ Le numéro de référence de l'unité.

■ Un kit matériel.

(1) Vis à tête demi-ronde ¼-20

(1) Outil de protection contre les effractions (modèles

de base uniquement)

(1) Applique de fixation amovible de la caméra

(1) Clé (modèles avec verrouillage uniquement)

Si l'un des éléments semble avoir été endommagé lors du

transport, remettez-le dans son carton d'emballage et avertissez

le transporteur. Si l'un des éléments manque, contactez votre

représentant ou votre service clientèle Philips Communication

& Security Systems.

Aucun container n'est mieux adapté que le carton d'emballage

pour transporter l'unité. Nous vous conseillons donc de le

conserver. Vous pourriez en avoir besoin ultérieurement.

2 MAINTENANCE

Veuillez contacter le service de maintenance Philips

Communication & Security Systems le plus proche de votre

domicile pour assurer la maintenance ou la réparation de l'unité.

Vous obtiendrez une autorisation et toutes les informations

utiles sur le renvoi du produit.

3 ENTRETIEN ET MAINTENANCE

Cette unité n'intègre aucune pièce détachée. Une maintenance

régulière permet d'en prolonger la durée de vie. Nettoyez la

fenêtre au moyen d'un chiffon doux et d'un produit d'entretien

non abrasif dilué dans de l'eau.

4 DESCRIPTION

Les boîtiers de protection LTC 9405 pour montage mural ou

sur plafond ont été notamment conçus pour assurer la

surveillance des prisons, des parkings ou des garages et des

hôpitaux. Cependant, ils s'adaptent parfaitement à toutes les

applications nécessitant la mise en place d'un système de

vidéosurveillance en circuit fermé.

D'un encombrement réduit de 279 x 165 x 140 mm, les

LTC 9405 prennent en charge des blocs caméra/objectif aux

dimensions maximales suivantes : 190 (l) x 68 (d) x 68 (h) mm.

Grâce à leur conception ultra-légère en aluminium fondu, les

boîtiers LTC 9405 sont d'une résistance équivalente à un acier

de calibre 10 supérieure au ratio pondéré de l'aluminium et

bénéficient ainsi d'une protection et d'une solidité optimales. La

fenêtre de visualisation standard est conçue en polycarbonate

transparent de 9,5 mm et recouvert d'une couche anti-abrasive.

Le capot amovible, fixé au moyen d'une seule vis captive antieffraction, permet d'accéder à la caméra. Un outil spécial

(fourni) permet de l'ouvrir ou de le fermer en vissant ou

dévissant la vis. Lors de l'entretien ou du réglage de la caméra, il

est nécessaire de retirer complètement le capot. Dans le cadre

d'un montage sur plafond, cependant, il doit rester attaché au

panneau de montage supérieur au moyen des pitons de fixation.

Ces boîtiers attrayants sont conçus pour un montage mural, à

l'horizontale ou à la verticale, et sur plafond. Vous disposez en

option d'un verrou situé sur le panneau d'accès et d'une fenêtre

de visualisation transparente de 12,7 mm.

5 INSTALLATION

Seul un technicien qualifié est habilité à installer cette

unité, conformément aux normes électriques en vigueur

dans votre pays.

Outils requis :

Clé à vis 5/32".

Clé à vis 10 mm.

5.1 Démontage

1. Retirez le kit matériel du carton d'emballage.

2. Pour retirer la vis anti-effraction située sur le panneau avant

du capot des modèles LTC 9405/00 et 9405/03, vous devez

utiliser l'outil spécial correspondant. Veuillez vous référer à

la figure 1.

Pour ouvrir le verrou situé sur le panneau avant du capot des

modèles LTC 9405/01 et 9405/05, vous devez utiliser la clé

correspondante. Veuillez vous référer à la figure 1.

2.4

Figure 1 : Retrait du capot

3. Quel que soit le modèle, retirez la vis ou ouvrez le verrou

afin de dégager le panneau avant du capot du panneau

supérieur.

4. Placez l'unité sur un plan de travail ou une table et

immobilisez le capot. Retirez le panneau supérieur en le

tenant fermement et en le tirant vers l'arrière, en le soulevant

vers le haut sur environ 51 mm, puis en le tirant de nouveau

vers l'arrière jusqu'à ce que les supports de fixation soient

totalement dégagés des pitons correspondant situés sur le

capot.

5. Dévissez l'écrou, puis retirez le support de montage de la

caméra du panneau supérieur. Veuillez vous référer à la

figure 2. Ne perdez aucun éléments, vous en aurez besoin

pour remettre la caméra en place et remonter l'unité.

Figure 2 : Retrait du système de montage

5.2 Montage de l'unité

1. Placez le panneau supérieur sur le plafond ou le mur, à

l'horizontale ou à la verticale, en fonction des exigences

requises par votre installation (figure 3). Pour que celle-ci

soit correcte, choisissez de préférence une surface plane et

lisse. Veuillez noter l'espace minimum requis en vous

référant à la figure 3.

AVERTISSEMENT - N'utilisez pas le système de

supports de fixation en forme de Z/pitons lorsque

vous montez l'unité sur un mur. En effet, le capot

pourrait se détacher du panneau supérieur.

Figure 3 : Installation du panneau supérieur

2. Marquez l'emplacement des boulons sur la surface de

montage au moyen des orifices situés sur le panneau

supérieur. Vous devez utiliser au moins quatre boulons de 8

mm. Nous vous recommandons cependant d'en utiliser six.

3. Percez les trous et installez les chevilles appropriées à la

surface de montage.

4. Déterminez l'acheminement des câbles jusqu'à l'unité. Cette

dernière intègre deux parois amovibles permettant le passage

d'un câble d'1/2" et une paroi amovible de 3/4". Veuillez

vous référer à la figure 4.

Figure 4 : Orifices pour boulons et parois amovibles

5. Fixez le panneau supérieur au moyen des boulons et

acheminez les câbles.

Panneau supérieur

Insérez les pitons

(situés de chaque côté)

dans les supports de

fixation en forme de Z

Vis anti-effraction ou

verrou

Capot

Panneau supérieur

Boulons

Bague

d'insertion

Bague de réduction

Rondelle

Vis et rondelle

Ecrou

Support de

montage

12-3/8 (14-3/8 min)

Si le système de supports de fixation en

forme de Z/pitons est utilisé

Panneau

avant du

boîtier

Orifices de fixation des boulons avec cheville (6)

Panneau supérieur (vue de

dessous)

Parois

amovibles

Orifices de fixation des boulons

avec cheville (6)

1-3/8 minimum

(2 in min. Si le

système de supports

de fixation en forme

de Z/pitons est

utilisé

-11/16

minimum

-11/16

minimum

-1-3/8

minimum

6-1/4

Loading...

Loading...