Page 1

Colour Television

LCD1.20E

AA

Contents Page

1 Technical Specifications, Connections,

and Chassis Overview 2

2 Safety Instructions, Warnings, and Notes 3

3 Directions for Use 6

4 Mechanical Instructions 8

5 Service Modes, Error messages,

and Repair Tips 9

6 Block Diagrams

Wiring Diagram 11

Block Diagram 11

7 Electrical Diagrams and PWB lay-outs Diagram PWB

Main Board 12-16 17-18

Control, Tuner, Speaker, and MX Panel 19

8 Electrical Alignments 21

9 Circuit Descriptions 23

Abbreviation List (N.A.)

IC Data Sheets (N.A)

10 Spare Parts List 24

11 Revision List 26

©

Copyright 2003 Philips Consumer Electronics B.V. Eindhoven, The Netherlands.

All rights reserved. No part of this publication may be reproduced, stored in a

retrieval system or transmitted, in any form or by any means, electronic,

mechanical, photocopying, or otherwise without the prior permission of Philips.

Published by LM 0369 Service PaCE Printed in the Netherlands Subject to modification EN 3122 785 12521

Page 2

EN 2 LCD1.20E1.

Technical Specifications, Connections, and Chassis Overview

1. Technical Specifications, Connections, and Chassis Overview

1.1 Technical Specifications

1.1.1 Reception

Tuning system : PLL

Colour systems : PAL B/G,

: PAL D/K,

: PAL I

: SECAM B/G,

: SECAM D/K,

: SECAM L,

: SECAM L1,

: NTSC Play Back

Sound systems : 2CS B/G,

Frequency bands : VHF,

Channel selections : 100 channels

Aerial input : 75 ohm

:

: 2CS D/K,

: AV Stereo,

: NICAM B/G

: (5.5-5.85),

: NICAM D/K

: UHF,

: S-Channel,

: Hyperband

1.1.2 LCD Characteristics

Type : LCD XGA TFT

Size : 20 inch (51 cm)

Pixel format : 640x480 pixels

1.1.3 Optical Characteristics

Contrast ratio : 400:1 (typ.)

Brightness : 450 cd/m2 typ.

Viewing Angle : 140x120 deg. (HxV)

1.1.4 Audio

Speakers : Full range

1.1.5 Miscellaneous

Power consumption

Normal operation : 70 W

Standby : 3 W

Power Supply

Power Adaptor

Input : AC 95 to 264 V, 50/60

Output : DC 12 V, 3 A

: 2 x 2 W_rms

Hz

Environment

Ambient temperature : +5 to +40 deg. C

Relative humidity : 10% to 80% R.H.

Weight : 9 kg

Dimension (WxHxD) : 642x423x83 m

Page 3

Safety Instructions, Warnings, and Notes

2. Safety Instructions, Warnings, and Notes

EN 3LCD1.20E 2.

2.1 Safety Instructions

• Always connect the TV set via an Insulation transformer.

Use a transformer of adequate power to protect the

technician from injury by electrical shocks. It will also

protect the TV set and it's components from being

damaged by accidental shorts of the circuitry, which may

be occurred during the service operation.

• Replace safety components, indicated by the symbol i in

the Schematic diagram and Replacement parts list, only by

the identical components to the original ones. Any other

component substitution (other than original type) may

increase risk of fire or electrical shock hazard.

• If any fuse (or Fusible resistor) in this TV set is blown,

replace it as specified.

• While replacing a high wattage resistor (Oxide Metal Film

Resistor, over 1 W), keep the resistor 10 mm away from

PCB.

• Keep wires away from high voltage or high temperature

parts.

2.1.1 AC Leakage Current Check

Before returning the TV set to the customer, always perform an

AC leakage current check on the exposed metallic parts of

the cabinet, such as antennas, terminals, etc., to be sure the

set is safe to operate without damage by electrical shock.

Leakage Current Cold Check (Antenna Cold Check)

1. Unplug the AC cord, and connect an electrical jumper

between the two plug prongs of the AC cord.

2. Turn “on” the AC power switch (keep the AC cord

unplugged!).

3. Measure the resistance value between the plug prongs of

the AC cord and the metal shielding of the tuner or the

aerial connection of the TV set. The measured resistance

should be between 1 Mohm and 5.2 Mohm. When the

metal shielding has no return path to the chassis, the

measured resistance must be infinite.

4. Switch the TV set “off’” and remove the electrical jumper

between the two plug prongs of the AC cord.

5. Check the cabinet for defects, to prevent the possibility of

the customer touching any internal parts.

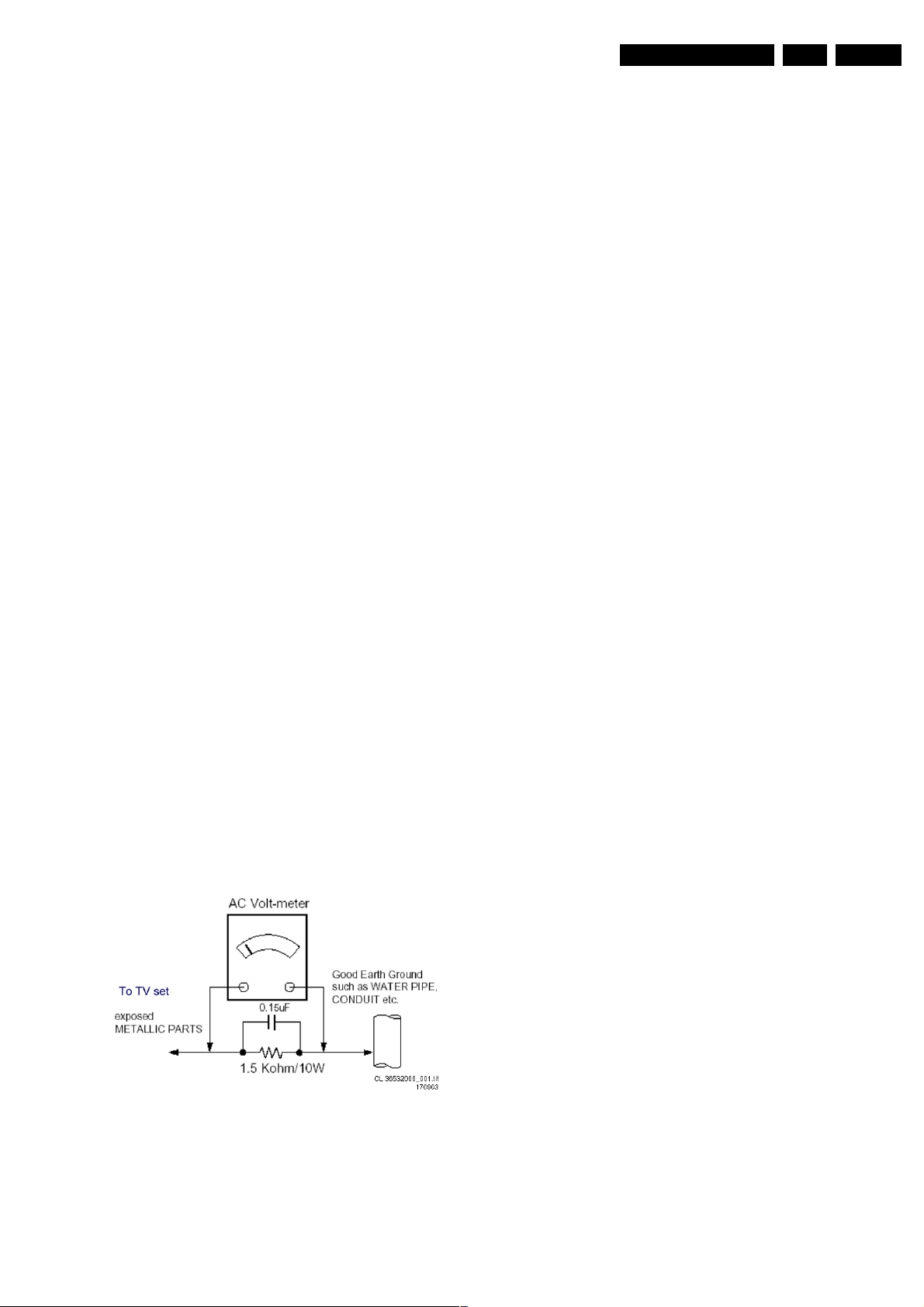

Leakage Current Hot Check

1. Plug the AC cord directly into the AC outlet.

2. Connect 1.5 kohm/10 W resistor in parallel with a 0.15 uF

capacitor between a good known earth ground (Water

Pipe, Conduit, etc.) and the exposed metallic parts.

3. Measure the AC voltage across the resistor, using the AC

voltmeter with 1000 ohm/V or higher sensitivity.

4. Plug again the AC cord into the AC outlet and repeat AC

voltage measurements for each exposed metallic part. Any

voltage measured must not exceed 0.75 V_rms, which

corresponds to 0.5 mA.

5. If any measurement is out of the specified limits, there is a

possibility of a shock hazard, and the set must be checked

and repaired before returning to the customer.

2.2 Warnings:

Before servicing TV sets, covered by this service manual and

its supplements and addenda, read and follow the Safety

Instructions of this manual.

Note: If unforeseen circumstances create conflict between the

following Servicing Precautions and any of the Safety

Instructions of this manual, always follow the Safety

Instructions. Remember: Safety First.

2.2.1 General Servicing Precautions

1. Always unplug the TV set AC power cord from the AC

power source before:

1. Removing or reinstalling any component, circuit board

module, or any other receiver assembly;

2. Disconnecting or reconnecting any TV set electrical

plug or other electrical connection;

3. Connecting a test substitute in parallel with an

electrolytic capacitor in the receiver.

Caution: A wrong part substitution or incorrect polarity

installation of electrolytic capacitors may result to an

explosion hazard.

2. Test high voltage only by measuring it with an appropriate

high voltage meter or other voltage measuring device

(DVM, FETVOM, etc), equipped with a suitable high

voltage probe. Do not test high voltage by "drawing an arc".

3. Do not spray chemicals on or near this TV set or any of its

assemblies.

4. Unless specified otherwise in this service manual, clean

electrical contacts only by applying the following mixture to

the contacts with a pipe cleaner, cotton-tipped stick or

comparable nonabrasive applicator; 10% (by volume)

Acetone and 90% (by volume) Isopropyl alcohol (90%-99%

strength).

Caution: This is a flammable mixture.

5. Unless specified otherwise in this service manual,

lubrication of contacts in not required.

6. Do not defeat any plug/socket B+ voltage interlocks, with

which the TV sets might be equipped.

7. Do not apply AC power to this TV set and/or any of its

electrical assemblies, unless all solid-state device heat

sinks are correctly installed.

8. Always connect the test TV set ground lead to the TV set

chassis ground before connecting the test TV set positive

lead.

9. Always remove the test TV set ground lead last.

10. Use with this TV set only the test fixtures, specified in this

service manual.

Figure 2-1 Leakage current hot check circuit

Note: Do not use a line Insulation transformer during this

check.

Caution: Do not connect the test fixture ground strap to any

heat sink in this TV set.

Page 4

EN 4 LCD1.20E2.

Safety Instructions, Warnings, and Notes

2.2.2 Electrostatically Sensitive (ES) Devices

Some semiconductor (solid state) devices can be damaged

easily by static electricity. Such components commonly are

called Electrostatically Sensitive (ES) Devices. Examples of

typical ES devices are integrated circuits and some field-effect

transistors and semiconductor "chip" components. The

following techniques should be used to help to reduce the

incidence of component damage, caused by static electricity.

1. Immediately before handling any semiconductor

component or semiconductor-equipped assembly, drain off

any electrostatic charge on your body by touching a known

earth ground. Alternatively, obtain and wear a

commercially available discharging wrist strap device,

which should be removed to prevent potential shock

reasons prior to applying power to the unit under test.

2. After removing an electrical assembly, equipped with ES

devices, place the assembly on a conductive surface, such

as aluminium foil, to prevent electrostatic charge build-up

or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder

ES devices.

4. Use only an anti-static type solder removal device. Some

solder removal devices, not classified as "anti-static", can

generate electrical charges, sufficient to damage ES

devices.

5. Do not use freon-propelled chemicals. These can generate

electrical charges, sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective

package, until immediately before you are ready to install

it. (Most replacement ES devices are packed r with leads

electrically shorted together by conductive foam,

aluminium foil or comparable conductive material).

7. Immediately before removing the protective material from

the leads of a replacement ES device, touch the protective

material to the chassis or circuit assembly, into which the

device will be installed.

Caution: Be sure no power is applied to the chassis or

circuit, and observe all other safety precautions.

8. Minimize bodily motions, when handling unpackaged

replacement ES devices. (Otherwise harmless motion,

such as the brunching together of your clothes fabric or the

lifting of your foot from a carpeted floor, can generate static

electricity, sufficient to damage an ES device).

2.2.3 General Soldering Guidelines

1. Use a grounded-tip, low-wattage soldering iron and

appropriate tip size and shape, that will maintain tip

temperature within the range of 500 deg. F to 600 deg. F.

2. Use an appropriate gauge of RMA resin-core solder

composed of 60 parts tin/40 parts lead.

3. Keep the soldering iron tip clean and well tinned.

4. Thoroughly clean the surfaces to be soldered. Use a small

wire-bristle brush (0.5 inch or 1.25cm) with a metal handle.

Do not use freon-propelled spray-on cleaners.

5. Use the following unsoldering technique:

1. Allow the soldering iron tip to reach normal

temperature (500 deg. F to 600 deg. F).

2. Heat the component lead until the solder melts.

3. Quickly draw the melted solder with an anti-static,

suction-type solder removal device or with solder braid.

Caution: Work quickly to avoid overheating the circuit

board printed foil.

6. Use the following soldering technique:

1. Allow the soldering iron tip to reach the normal

temperature (500 deg. F to 600 deg. F).

2. First, hold the soldering iron tip and solder the strand

against the component lead until the solder melts.

3. Quickly move the soldering iron tip to the junction of the

component lead and the printed circuit foil, and hold

there only until the solder flows onto and around of the

both of the component lead and the printed circuit foil.

Caution: Work quickly to avoid overheating the circuit

board printed foil.

4. Closely inspect the solder area and remove any

excess or splashed solder with a small wire-bristle

brush.

2.3 Maintenance Instructions

2.3.1 IC Remove/Replacement

Some chassis circuit boards have slotted holes (oblong),

through which the IC leads are inserted and then bent flat

against the circuit foil. When holes are the slotted type, the

following technique should be used to remove and replace the

IC.

Removal

1. Desolder and straighten each IC lead in one operation, by

gently prying up the lead with the soldering iron tip, as the

solder melts.

2. Draw away the melted solder with an anti-static suction

type solder removal device (or with solder braid) before

removing the IC.

Replacement

1. Carefully insert the replacement IC in the circuit board.

2. Carefully bend each IC lead against the circuit foil pad and

solder it.

3. Clean the soldered areas with a small wire-bristle brush. It

is not necessary to reapply acrylic coating to the areas.

2.3.2 "Small-Signal" Discrete Transistor Removal/ Replacement

1. Remove the defective transistor by clipping its leads as

close as possible to the component body.

2. Bend into a "U" shape the end of each of three leads,

remaining on the circuit board.

3. Bend into a "U" shape the replacement transistor leads.

4. Connect the replacement transistor leads to the

corresponding leads, extending from the circuit board, and

crimp the "U" with long nose pliers to insure metal to metal

contact. Then solder each connection.

2.3.3 Power Output, Transistor Device Removal/ Replacement

1. Heat and remove all solder all around from the transistor

leads.

2. Remove the heat sink mounting screw (if so equipped).

3. Carefully remove the transistor from the heat sink of the

circuit board.

4. Insert a new transistor in the circuit board.

5. Solder each transistor lead, and clip off excess lead.

6. Replace the heat sink.

2.3.4 Diode Removal/ Replacement

1. Remove defective diode by clipping its leads as close as

possible to diode body.

2. Bend the two remaining leads perpendicular to the circuit

board.

3. Observing diode polarity, wrap each lead of the new diode

around the corresponding lead on the circuit board.

4. Securely crimp each connection and solder it.

5. Inspect (on the circuit board copper side) the solder joints

of the two "original" leads. If they are not shiny, reheat them

and, if necessary, apply additional solder.

2.3.5 Fuse and Conventional Resistor Removal/ Replacement

1. Clip each fuse or resistor lead at the top of the circuit board

hollow stake.

Page 5

Safety Instructions, Warnings, and Notes

EN 5LCD1.20E 2.

2. Securely crimp the leads of replacement component

around notch at stake top.

3. Solder the connections.

Caution: Maintain original spacing between the replaced

component and adjacent components and the circuit board to

prevent excessive component temperatures.

2.3.6 Circuit Board Foil Repair

Excessive heat applied to the copper foil of any printed circuit

board will weaken the adhesive that bonds the foil to the circuit

board, causing the foil to separate from or "lift-off" the board.

The following guidelines and procedures should be followed

whenever this condition is encountered.

At IC Connections

To repair a defective copper pattern at IC connections, use the

following procedure to install a jumper wire on the copper

pattern side of the circuit board. (Use this technique only on IC

connections).

1. Carefully remove the damaged copper pattern with a sharp

knife. (Remove only as much copper as absolutely

necessary).

2. Carefully scratch away the solder resist and acrylic coating

(if used) from the end of the remaining copper pattern.

3. Bend a small "U" in one end of a small gauge jumper wire

and carefully crimp it around the IC pin. Solder the IC

connection.

4. Route the jumper wire along the path of the out-away

copper pattern and let it overlap the previously scraped end

of the good copper pattern. Solder the overlapped area and

clip off any excess jumper wire.

2.4 Notes

2.4.1 Schematic Notes

• All resistor values are in ohms and the value multiplier is

often used to indicate the decimal point location (e.g. 2K2

indicates 2.2 kohm).

• Resistor values with no multiplier may be indicated with

either an "E" or an "R" (e.g. 220E or 220R indicates 220

ohm).

• All capacitor values are expressed in micro-farads (µ= x

10^-6), nano-farads (n= x 10^-9), or pico-farads (p= x 10^-

12).

• Capacitor values may also use the value multiplier as the

decimal point indication (e.g. 2p2 indicates 2.2 pF).

• An "asterisk" (*) indicates component usage varies. Refer

to the diversity tables for the correct values.

• The correct component values are listed in the Electrical

Replacement Parts List. Therefore, always check this list

when there is any doubt.

At Other Connections

Use the following technique to repair the defective copper

pattern at connections, other than IC Pins. This technique

involves the installation of a jumper wire on the component side

of the circuit board.

1. Remove the defective copper pattern with a sharp knife.

Remove at least 1/4 inch of copper, to ensure that a

hazardous condition will not exist if the jumper wire opens.

2. Trace along the copper pattern from both sides of the

pattern break and locate the nearest component that is

directly connected to the affected copper pattern.

3. Connect insulated 20-gauge jumper wire from the lead of

the nearest component on one side of the pattern break to

the lead of the nearest component on the other side.

4. Carefully crimp and solder the connections.

Caution: Be sure the insulated jumper wire is dressed so it

does not touch components or sharp edges.

Page 6

EN 6 LCD1.20E3.

B

M

a

AUTO

AUTO

w

Y-Z

C

h

fg

c

b

e

k

Ò

‡

π

®

†

U

D

1

2

9

3

6

5

7

4

8

0

0

LIST

MENU

OK

P

¬

V

V Volum e

Press + or - to adjust the

vo lum e.

¬ Mute

Tem porarily interrupt the

sound or restore it.

P Programme selection

•to brow se through the TV

channels which are no t

skipped

•to sw itch the TV on fro m

standb y.

®Ò‡π† Video

reco rd er keys

U Time disp lay

The time,downloaded fro m the

TV channel (with teletext

broadcast) stored on

programme num ber 1 or the

low est not sk ipped programme

num ber,is displayed on the

screen.

0/9Digit keys

To select a TV channel.

0 Previous programme

To disp lay the previously

selectedTV channel.

LIST

Programme list

To disp lay the programme list.

b Teletext on/off

Teletext functions

hUfgcek

D

Sleep timer

With this key you can set a

time period after which the

TV sho uld sw itch itself to

standb y.

Press the key rep e atedly to

select the num ber of minutes.

The counter runs fro m B 0,

10,20,30...to 240 minutes.

The timer begins to count

dow n fro m the num ber of

minutes selected.

Note:To view the rem aining time,

pre ss the

D

key once.To can cel

the sleep time,repeatedly press

the

D

key until B 0 appears.

MENU

Press rep e a tedly to

display each menu.

O K Press this key to activate

yo ur cho ice,w hen in the menus.

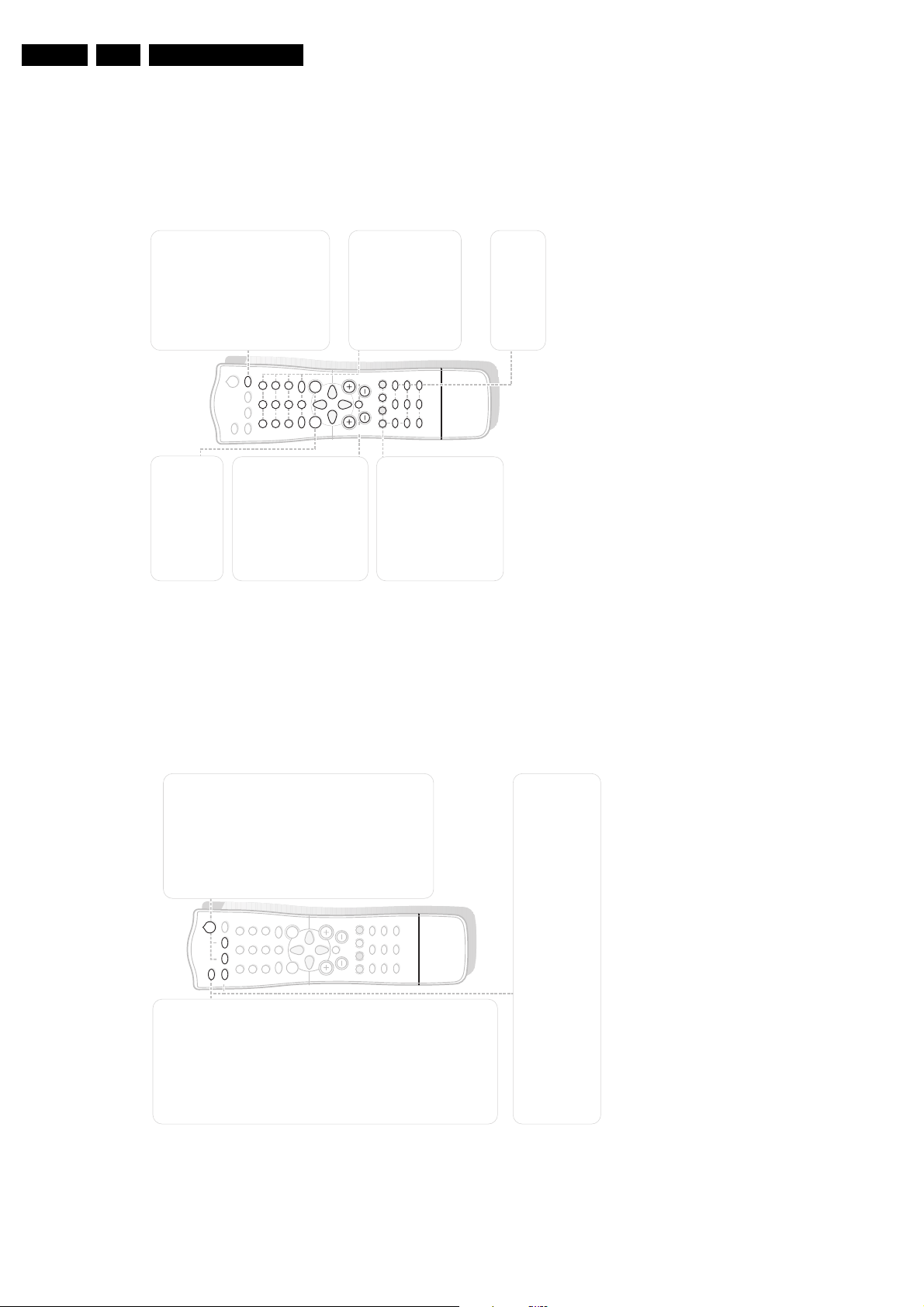

3. Directions for Use

Directions for Use

picture

keys

AUTO

a

and sound se ttings.

To select predefined picture

AUTO

standb y or off to standb y.

Sw itche s the TV on fro m

B Standby

D

B

M

AUTO

a

AUTO

w

Y-Z

selected,corresponding with

different picture se tting is

Each time it is pre ssed,a

9

3

6

LIST

2

8

5

0

0

7

4

1

sound

AUTO

Contrast,Brigh tne ss,C o lour

and Sharpness.

M

spe c ific factory settings of

OK

MENU

different sound se tting is

Each time it is pre ssed,a

P

¬

V

refers to the personal

in the picture and sound menu.

and sound se lected an d stored

preference se ttings of picture

treb le an d bass.

selected,corresponding with

spe c ific factory settings of

Perso nal

π

k

b

‡

e

fg

C

h

Ò

c

U

†

®

DESCRIPTION OF CONTROLS

AV1,AV2,S-VIDEO

,

TV

Source

peripherals:p re ss rep e atedly to

select

Select you r com puter or other

w

monitor mode.

PC

or

X Bilingual cho ice an d

to

Nicam

Stereo

to

sound in case of

Mono

Nicam Stereo

stereo tran sm ission,or fro m

• to sw itch fro m

Press this key

sound mode selection

,in case of digital

Mono

tran sm ission

lY,

Dua

Z or

Nicam Dual

• to sw itch fro m

X in case

X in case of

Dual

Z or

Nicam Dual

Y to

Nicam Dual

Y se nd s the primary

of bilingual tran sm ission:

Dual

Dual

Nicam Dual tran sm ission

broadcast language to the

• to choose betw een

Z se nd s the seco n d ar y

loudspeakers;

Dual

loudspeakers;

broadcast language to the

X se nd s a se p ara te

Dual

lan guage to each loudspeaker.

Nica m stereo transm ission,select

sound sign als,w ith stereo or

Note:in case of weak stereo

fro m the aud io R input to the righ t loudspeaker

•R+R:the audio sign al fro m the au d io R input is se nt to the left and right loudspeakers.

•L+L:the audio sign al fro m the au d io L input is sent to the left an d righ t loudspeakers

•L+R:the audio signal fro m the au d io L input is sent to the left loudspeaker,the au dio signal

Press the X ke y rep e atedly to select:

Sound output se lection in AV mode

mono reception.

In AV mode,you can select the output sound for the left and right loudspeakers.

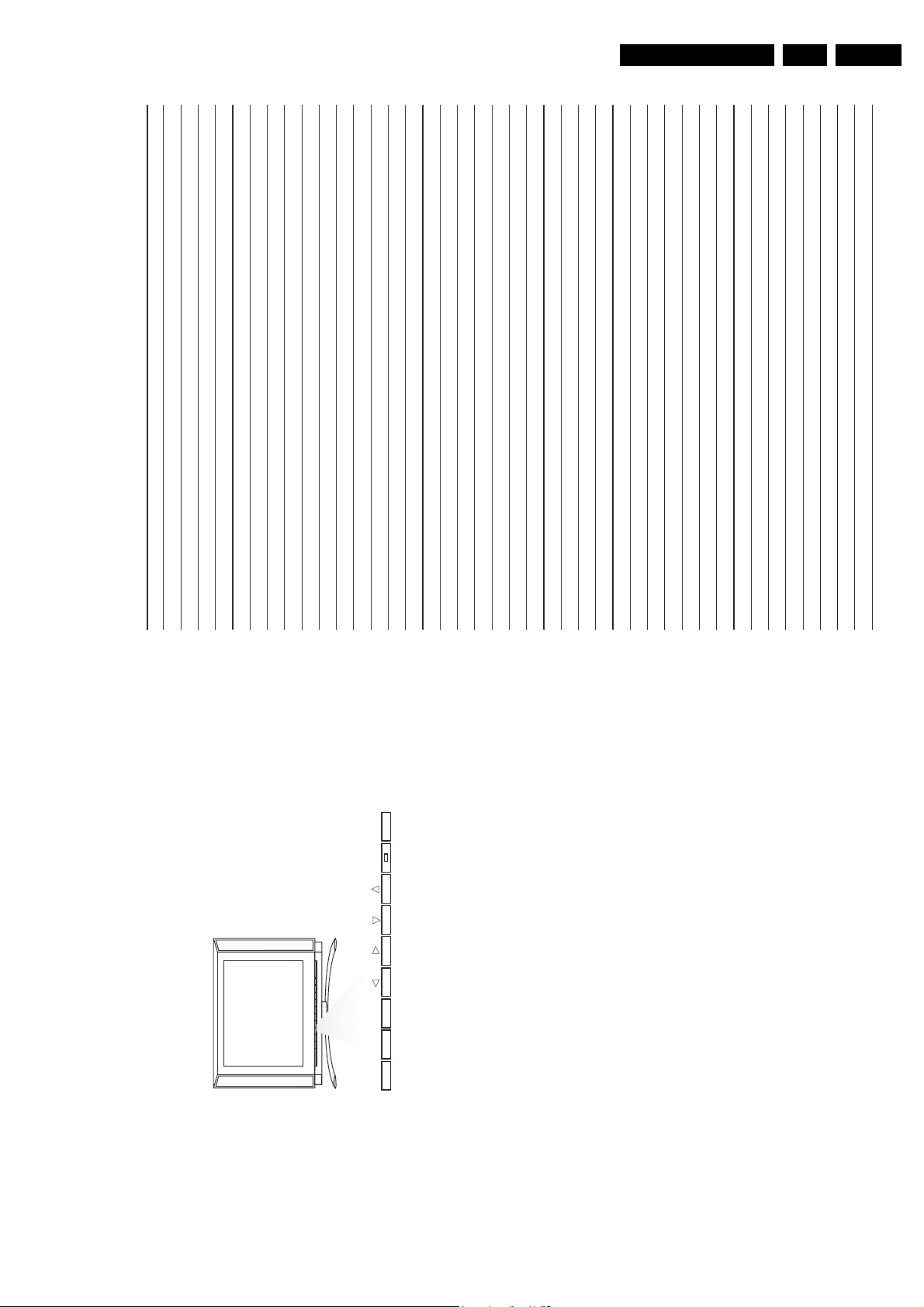

Page 7

Directions for Use

EN 7LCD1.20E 3.

Personal Notes:

ON/OFF

B

+

CH/PR

_

+

VOL

_

OK

TV/VIDEO MENU

monitor mode

PC

or

AV

,

TV

key to sw itch the TV on or off

ON/OFF

:P ress the power

in fro nt of the TV.

Sho uld your rem o te co n trol be lost or bro ken yo u can still operate yourTV with the keys

ON/OFF

:Keep the OK key p re ssed for abo u t 10 sec o n d s.

:P ress rep e atedly to select

Auto dem onstration

All the menus are being disp layed autom atically one after the other.

To stop Auto dem o nstratio n ,p re ss any key on the fro n t panel.

-

:P ress rep e atedly to display each menu

TV/VIDEO

MENU

OK: - P re ss this key to activate yo ur cho ice when in the menu

:- P ress - or + to brow se through the TV channels which are not sk ipped;

- Pre ss - or + to adjust the menu settings.

- Pre ss - or + to adjust the vo lum e;

:- P ress - or + to select a menu item ;

-V O L +

- CH /PR +

sw itch ed on.

-To sw itch the TV on fro m standb y.

- Pre ss - or + to select a menu item ;

TheB indicator ligh ts up brigh tly when the TV is in standby,dims when the TV is

B:Switches the TV on fro m stan db y or off to standb y.

Page 8

EN 8 LCD1.20E4.

Mechanical Instructions OLD!!!!

4. Mechanical Instructions OLD!!!!

Notes:

• To gain access to the boards of the TV set, after removing

the cover cup, unstick carefully supportive stickers.

• Place the stickers aside, adhesive side upwards.

• When you re-assemble the TV set, don’t forget to put the

stickers back.

• If the stickers are not adhesive anymore, you can order

them by ordering number 3104 301 24501

Page 9

Service Modes, Error Codes, and Fault Finding

5. Service Modes, Error Codes, and Fault Finding

5.1 General Features

Table 5-1 General Features

No. Symptom Cause Check Point

1 No screen Input error of inverter connector 1) Bend the pin legs of P801 connector -> recheck them

2) Check and repair the IC806, 807 SI4925, IC801 SI786, IC803 SI4808.

P502 and Pin 21 connector being

slipped out

Cracked components and soldering at tuner board

2 Dark screen 1) Defective LCD lamp

2) Defective inverter

3) Input error of inverter connector

3 Defective OSD display Defective the IC508 Check and replace the IC508

5.2 TV and External Input

Table 5-2 TV and External Input

1) Check and fix P503B connector

2) Check and fix the components at P502 LCD module and at main board.

3) Check Pin50.

1) Check and repair tuner board and main board

2) Solder Q101

1) Replace the LCD lamp 2) Replace the inverter

2) Check the connector input

EN 9LCD1.20E 5.

No. Symptom Cause Check Point

4 No sound

- Speaker

- Earphone

5 Video colour beat

noise

6 Video Jitter Defective P501B Pin20 connec-

Defective Reset IC of

IC902Defective MSP3410D of

IC901Defective B+ (8 V, 5 V) of

ICC903, 904.

Soldering IC201 and IC502,

IC501 or masking is short

tor

1) Check volume and speaker- Sound comes out only when being inputted

into Audio L/R

2) Check after replacing IC902

3) Replace IC901

4) Check and replace B+ of IC903, 904

Check and re-solder

Check the P501B Pin20 connector and repair

Page 10

EN 10 LCD1.20E5.

Personal Notes:

Service Modes, Error Codes, and Fault Finding

Page 11

Block Diagrams, Testpoint Overview, and Waveforms

11LCD1.20E 6.

6. Block Diagrams, Testpoint Overview, and Waveforms

Wiring Diagram

RE/RL - 20LA40 Wiring Diagram (20.1 ” )

To Panel

9965 000 20604

9965 000 16580

P803B

P501B

SC801

9965 000 16581

P503B

P501A

9965 000 20582

Tuner

9965 000 20605

P802B

P602

To Speaker

To Lamp

To Lamp

CL 36532069_002.eps

240903

LCD PANNEL

L

C

2

0

1

V

1

A

3

3.3V

VIDEO RAM

2M

R / G / B

8 /8 /8bit

15V

Dual Audio AMP

LA4282

Block Diagram

3.3V 5V(FOR RESET IC 3,3V)

SCALER(Format Converter)

MX88L-284FC-V

14.318MHz

8.0V

5.0V

Audio Processor

MSP-34XX

RF : 2, SCART : 4

MONO : 1

I2S : 2

------18.432MHz--L-SPK/WOOFER

H/P, I2S

SCART OUT : 2

R/G/B

24

RESET 4.2V

SCL/SDA

3.3V

AD Converter

AD9884AKS

9V

Multi-Component

Processor(BBVSP)

CXA 2101AQ

YCrCb : 2 / 4

RGB : 4 / 2

OUT RGB :1, TUV : 1

Y/U/V

(480P)

3.3V 3.3V

SCAN Converter

SDA-9410

27.0MHz

SCL/SDA

Analog

R/G/B/H/V

Y/U/V

(480P)

0.5-0.7

IC302

SCART(R/G/B/FB)

DVD-Y in(SCART-Vin)

SCL/SDA

Y/U/V

SCL/SDA

DVD-U/V in

4:2:2

(DRP Processor)

S-VHS(VIN1 : Y/C))

H/V

(2H)

R/G/B/FB

TEXT

SCL/SDA

IC301

H- FILTER

LGTV-1001

SWITCHING

CXA2040AQ

IC3

H-sync

CLK

Y/U/V

4:2:2

V-OUT

RF-IN

M/O(CVBS)

EEP

EEP

ROM

ROM

3.3V

SCL1/SDA1

IC1

MICOM / TXT

6.0MHz

480I/P

Detect

H-Sync.

SEP

5V 3.3V

IC201

Color Decoder/

A/D Converter

VPC-3230D

. COMB/FIL : 4H

INPUT . 4 CVBS . 1 S-VHS

. 2 RGB/YCrCb

. 1 F/B

. 1 CVBS OUTPUT

. Y/Cr/Cb OUTPUT

RF(VIN3 : CVBS)

M/O(CVBS)

TV/OUT(CVBS)

SCL/SDA

5V

3.3V

33V

BRI-ADJ TO MICOM

POWER-ON/OFF TO MICOM

20.25MHz

POWER

DC to DC Converter

(SI786,SI4808DY,T801)

DC to AC

INVEERTER

30V

5V

SCL

SDA

CVBS

15V

15V

R-SPK

L-SPK

DC OUT

(12V)

12V

REG.

AV2 in(CVBS)

R/G/B/FB L/ Rin TV/L/R out

Y/U/V in

. .

..

Y PB PR L R V L R V L R

SCART JACK

DVD/DTV

(480I/480P)

H/P S-VIDEO A/V IN

A/V OUT

DC IN

(15V)

SIF

IF AGC

TUNER

TUNER

ANT (RF)

CL 36532069_003.eps

240903

Page 12

Circuit Diagrams and PWB Layouts

7. Circuit Diagrams and PWB Layouts

Main Board (Overview)

Part 1

CL36532069_04a

12LCD1.20E 7.

Part 2

CL36532069_04b

Part 3

CL36532069_04c

Part 4

CL36532069_04d

CL 36532069_004.eps

240903

Page 13

Main Board (Part 1)

Circuit Diagrams and PWB Layouts

13LCD1.20E 7.

Part 1

CL 36532069_04a.eps

240903

Page 14

Main Board (Part 2)

of MF-004A

Circuit Diagrams and PWB Layouts

14LCD1.20E 7.

P/N : 3854VA0077A-S

DATE : 2000.10.02

Part 2

CL 36532066_04b.eps

170903

Page 15

Main Board (Part 3)

Circuit Diagrams and PWB Layouts

15LCD1.20E 7.

Part 3

CL 36532069_04c.eps

240903

Page 16

Main Board (Part 4)

Part 4

Circuit Diagrams and PWB Layouts

16LCD1.20E 7.

CL 36532069_04d.eps

240903

Page 17

Main Board (Top Side)

Circuit Diagrams and PWB Layouts

17LCD1.20E 7.

CL 36532069_005.eps

240903

Page 18

Circuit Diagrams and PWB Layouts

Main Board (Bottom Side)

18LCD1.20E 7.

CL 36532069_006.eps

240903

Page 19

Circuit Diagrams and PWB Layouts

19LCD1.20E 7.

Control, Tuner, and Speaker Panel

Control Panel (Top Side) Tuner Panel (Top Side)

TunerPanel (Bottom Side)

Control Panel (Bottom Side)

Top Panel (Top Side)

MX Panel

Top Side Bottom Side

CL 36532069_007.eps

240903

CL 36532069_008.eps

240903

Page 20

Personal Notes:

Circuit Diagrams and PWB Layouts

20LCD1.20E 7.

Page 21

8. Electrical Alignments

8.1 General Alignment Conditions

Note: This set uses an adapter, so connect the adapter and the

set correctly before adjustment.

Perform all electrical adjustments under the following

conditions:

• Temperature and humidity conditions: 25 ± 5 deg.C / 65 ±

10% RH

• Mains voltage and frequency: 220 to 240 V / 50 Hz.

• Allow the set to warm up for approximately 30 minutes.

• Test probe: Ri > 10 M ohm; Ci < 2.5 pF.

Notes:

The “Heat Run” must be performed with the full white signal or

the TV noise signal in the internal part of the set.

The time for the “Heat Run” can be changed, owing to

production plan.

8.2 Hardware Alignments

There are no hardware alignments foreseen for the LCD1.20E.

8.3 Software Alignments

8.3.1 Auto RGB Adjustment

Electrical Alignments

8.3.4 Default Option Adjustment

Note: This alignment is also implemented in ComPair.

1. Press the SVC key.

2. Use the SWAP/ADJUST key to find needed options or use

the OP1, OP2, OP3 keys.

3. Use the PR+/- key to select the option.

4. Use the VOL+/- key to change the value.

5. Press the OK key to store settings.

EN 21LCD1.20E 8.

Figure 8-1 Brightness adjustment

Required Equipment

A service remote control (9965 000 20079) or ComPair.

Preparation for Adjustment

Receive the Digital Pattern.

Adjustment

1. Select AUTO RGB ADJ by pressing SVC key.

2. Select “A RGB” item.

3. Press the VOL+/- key to appear “OK” on the screen.

8.3.2 RGB Level Adjustment

Required Equipment

• Pattern Generator (408NPS-READER), with possible 10

STEPs.

• A service remote control (9965 000 20079) or ComPair.

Adjustment

1. Select RGB Level by pressing SVC key.

2. Adjust than until 9th and 10th STEPs are undistinguished

by using VOL+/- key in R-LVL item.

3. Adjust G-LVL and B-LVL at the same way.

4. When adjustment is finished, store it by pressing the OK

key. Escape it by pressing the TV/AV key.

8.3.3 Brightness Adjustment

Use it in a case when brightness adjustment is needed.

Table 8-1 Default option settings

Option Code Function Remark Default

value

S-B 23

FP 21

NP 89

S1VOL 105

S2VOL 105

Table 8-2 Option 1

Option Code Function Remark Default

value

200PR

TEXT

I II SA

TOP

SCART

A2 ST

SYS

0 100 PROGRAM SAVE 0

1 200 PROGRAM SAVE

0 Without TXT 1

1With TXT

0No Save DUAL

SOUND Condition

1 Save DUAL SOUND

Condition

0 FLOF TEXT 1

1 TOP TEXT

0DVD JACK 1

1 SCART JACK

0 NICAM CHECK 1

1 NICAM and FM Stereo

0 B/G, I, D/K 0 (EU),

1 B/G, L/L

2 B/G, I, D/K, M

3 Reserved

0

1 (Fr)

Page 22

EN 22 LCD1.20E8.

Electrical Alignments

Table 8-3 Option 2

Option Code Function Remark Default

value

0 Without ACMS func-

ACMS

VOL

BBACK

LANG

(1) English, German, French, Italian, Spanish.

(2) English, Dutch, Swedish, Norwegian, Danish, Swiss,

Portuguese, Romanian, Polish, Hungarian, Czech, Russian.

(3) English, French, Arab, Urdu.

tion

1 With ACMS function

0Normal Volume Curve 0

1 Rushed Volume Curve

0 Without Blue Back 0

1 With Blue Back

0 English only English 6

1 English + EU4 (1)

2 English + other EU (2)

3 Farsi English,

4 Arab + Urdu (3)

5 English + China English,

6 Reserved

7 Reserved

Australia 1

Farsi

China

Option Code Function Remark Default

0 West Europe Teletext

Lan-

guage

1East Europe

2Turkey

3 Czech/Hungary

4 Cyrillic 1

5 Cyrillic 2

6 Cyrillic 3

T-LANG

7 Turkey/Greek 1

8 Turkey/Greek 2

9 Turkey/Greek 3

10 Arab/France

11 Arab/English

12 Arab/Hebrew 1

13 Arab/Hebrew 2

14 Farsi/English

15 Farsi/France

16 Farsi all

value

0

Table 8-4 Option 2

Option Code Function Remark Default

value

0 LOCAL KEY (20A20

KEY

TSS

PANEL

IICT

INVT

MD SA

MONO

CH+AU

MODEL)

1 LOCAL KEY (20LA30

MODEL)

0 Without TURBO

SEARCH function

1 With TURBO SEARCH

function

0 LCD Panel option 0

1 Reserved

0 Tuning with AFT Volt-

age

1 Tuning with ADC of IF

IC

0 INVERTER option 0

1 Reserved

0 Without LAST MODE

SAVE

1 With LAST MODE

SAVE

0 Without Forced MONO

sound system

1 With Forced MONO

sound system

0 Without D/K CHINA or

BB system

1 With D/K CHINA or BB

system

0

0

0

0

0

Page 23

Circuit Descriptions, List of Abbreviations, and IC Data Sheets

EN 23LCD1.20E 9.

9. Circuit Descriptions, List of Abbreviations, and IC Data Sheets

Not Applicable

Page 24

EN 24 LCD1.20E10.

10. Spare Parts List

Spare Parts List

LC1.20E

Various

00A1 9965 000 14322 DFU

00A2 9965 000 14330 RC25109/01

00A3 9965 000 14329 Adapter RF CAM-1550

00A4 9965 000 14331 Audio cable 2m

0112 9965 000 16522 LC201V1-A1

0120 9965 000 16523 Loudspeaker

0121 9965 000 16524 Tweeter C050D10K1452

0174 9965 000 14327 Mains cord for M2511A-

0174 9965 000 16412 Mains cord MP5004

0300 9965 000 16525 Cabinet

0310 9965 000 16526 Push buttons (7x)

0320 9965 000 16527 Coil

0330 9965 000 16528 Mains knob

0400 9965 000 16529 Rear cover

0401 9965 000 16591 Cover A/V

0410 9965 000 14325 Stand 20"

0520 9965 000 16531 Main board -/12S

0520 9965 000 16592 Main board -/19S

0530 9965 000 16532 MX panel

0540 9965 000 16533 Control panel

0570 9965 000 16534 Inverter 15V

0580 9965 000 16535 Tuner MF-002A EU

0580 9965 000 16593 Tuner MF-002A FR

FB801 9965 000 16454 Filter HH-1M3216-501

FB802 9965 000 16454 Filter HH-1M3216-501

P1001 9965 000 16580 Cable 12P 450mm

P1002 9965 000 16581 Cable 4P 450mm

P501 9965 000 20582 Cable P501A-P501B

P502 9965 000 20604 Cable P503B

P503 9965 000 20604 Cable P503B

P802 9965 000 20605 Cable P802B

PA1001 9965 000 16493 TSOP2238MQ1

PJ801 9965 000 16582 4P Power jack

S001 9965 000 16530 20" VESA PLATE

S002 9965 000 14332 VGA cable 7M

S030 9965 000 20079 Service RC

S031 3104 301 24501 Conductive sticker 50X35

SJ201 9965 000 16479 Socket scart

SW1001 9965 000 16502 SDKLA11100

SW1002 9965 000 16503 Tact switch

SW1003 9965 000 16503 Tact switch

SW1004 9965 000 16503 Tact switch

SW1005 9965 000 16503 Tact switch

SW1006 9965 000 16503 Tact switch

SW1007 9965 000 16503 Tact switch

SW1008 9965 000 16503 Tact switch

SY302 9965 000 16587 Filter TH355LSK-K5214

SY525 9965 000 16489 Filter 3216 4S600

SY526 9965 000 16489 Filter 3216 4S600

SY527 9965 000 16489 Filter 3216 4S600

SY532 9965 000 16489 Filter 3216 4S600

TU301 9965 000 16507 Tuner TAFC-M130D

TU301 9965 000 16521 Tuner TAFC-S120D

X1 9965 000 16508 Crystal 6 MHz HC49U

X301 9965 000 16588 Filter 27 MHz HC49U

X302 9965 000 16509 Crystal 20.250 MHz

X501 9965 000 16510 Crystal 14.318MHz

X601 9965 000 16510 Crystal 14.318MHz

X90 9965 000 16511 Crystal 500kHz

X901 9965 000 16512 Crystal 18.432 MHz

Z101 9965 000 16505 Filter MKT40.4MA110P-

Z101 9965 000 16520 Filter MKT41.4MA110P-

Z102 9965 000 16504 Filter MKT40.4MA110P-

ZD101 9965 000 16589 HZT33

C080L30K145X 5W/7W

001 EUR

1206

1206

SKHV17910B

SKHV17910B

SKHV17910B

SKHV17910B

SKHV17910B

SKHV17910B

SKHV17910B

HC49U

CSB500F9

HC49U

TF01

TF01

TF0

g

C1001 9965 000 16429 100µF 10V

C1002 9965 000 16430 0.01µF 80% 50V

C101 9965 000 16536 47µF 25V

C104 9965 000 16537 1000µF 10V

C107 9965 000 16434 10µF 50V

C111 9965 000 16432 100µF 16V

C112 9965 000 16435 4.7µF 50V

C112 9965 000 16441 22µF 16V

C205 9965 000 16432 100µF 16V

C206 9965 000 16438 220µF 16V

C211 9965 000 16441 22µF 16V

C217 9965 000 16441 22µF 16V

C240 9965 000 16439 220000pF 16V 0805

C241 9965 000 16439 220000pF 16V 0805

C243 9965 000 16435 4.7µF 50V

C248 9965 000 16439 220000pF 16V 0805

C249 9965 000 16439 220000pF 16V 0805

C250 9965 000 16439 220000pF 16V 0805

C251 9965 000 16439 220000pF 16V 0805

C252 9965 000 16435 4.7µF 50V

C253 9965 000 16439 220000pF 16V 0805

C255 9965 000 16439 220000pF 16V 0805

C257 9965 000 16439 220000pF 16V 0805

C262 9965 000 16538 0.47µF 50V SMD

C263 9965 000 16539 220µF 25V

C274 9965 000 16538 0.47µF 50V SMD

C275 9965 000 16435 4.7µF 50V

C276 9965 000 16540 330µF 16V

C278 9965 000 16432 100µF 16V

C280 9965 000 16435 4.7µF 50V

C281 9965 000 16435 4.7µF 50V

C284 9965 000 16541 33µF 16V

C289 9965 000 16542 1µF 50V

C343 9965 000 16433 47µF 16V

C349 9965 000 16431 10µF 16V

C402 9965 000 16433 47µF 16V

C408 9965 000 16543 0.47µF 50V

C417 9965 000 16433 47µF 16V

C418 9965 000 16431 10µF 16V

C418 9965 000 16544 10µF 16V

C419 9965 000 16542 1µF 50V

C422 9965 000 16543 0.47µF 50V

C423 9965 000 16431 10µF 16V

C423 9965 000 16544 10µF 16V

C431 9965 000 16545 47µF 50V

C435 9965 000 16546 100µF 16V

C438 9965 000 16547 1µF 50V

C439 9965 000 16548 470µF16V

C443 9965 000 16547 1µF 50V

C445 9965 000 16547 1µF 50V

C5 9965 000 16546 100µF 16V

C604 9965 000 16549 100µF 16V SMD

C606 9965 000 16549 100µF 16V SMD

C607 9965 000 16550 10µF 25V SMD

C627 9965 000 16549 100µF 16V SMD

C631 9965 000 16549 100µF 16V SMD

C640 9965 000 16551 220µF 6.3V SMD

C641 9965 000 16551 220µF 6.3V SMD

C7 9965 000 16432 100µF 16V

C7 9965 000 16546 100µF 16V

C801 9965 000 16545 47µF 50V

C802 9965 000 16432 100µF 16V

C802 9965 000 16546 100µF 16V

C803 9965 000 16548 470µF16V

C804 9965 000 16548 470µF16V

C805 9965 000 16548 470µF16V

C806 9965 000 16548 470µF16V

C807 9965 000 16552 220µF 25V

C812 9965 000 16552 220µF 25V

C814 9965 000 16435 4.7µF 50V

C816 9965 000 16448 100µF 25V

C819 9965 000 16431 10µF 16V

C820 9965 000 16539 220µF 25V

C826 9965 000 16553 330µF 25V

C827 9965 000 16548 470µF16V

C828 9965 000 16548 470µF16V

C871 9965 000 16444 470µF 16V

C872 9965 000 16553 330µF 25V

C880 9965 000 16548 470µF16V

C881 9965 000 16432 100µF 16V

C881 9965 000 16546 100µF 16V

C882 9965 000 16539 220µF 25V

C882 9965 000 16552 220µF 25V

C904 9965 000 16545 47µF 50V

C908 9965 000 16546 100µF 16V

C909 9965 000 16554 2.2µF 50V

C910 9965 000 16555 0.022µF 100V

C914 9965 000 16556 100µF 25V

C916 9965 000 16432 100µF 16V

C92 9965 000 16542 1µF 50V

C922 9965 000 16431 10µF 16V

C926 9965 000 16432 100µF 16V

C927 9965 000 16546 100µF 16V

C928 9965 000 16554 2.2µF 50V

C930 9965 000 16546 100µF 16V

C932 9965 000 16439 220000pF 16V 0805

C933 9965 000 16439 220000pF 16V 0805

C935 9965 000 16431 10µF 16V

C936 9965 000 16439 220000pF 16V 0805

C937 9965 000 16439 220000pF 16V 0805

C938 9965 000 16439 220000pF 16V 0805

C94 9965 000 16433 47µF 16V

C940 9965 000 16439 220000pF 16V 0805

C943 9965 000 16445 3.3µF 50V

C944 9965 000 16431 10µF 16V

C945 9965 000 16444 470µF 16V

C95 9965 000 16547 1µF 50V

C951 9965 000 16555 0.022µF 100V

C954 9965 000 16557 470µF 25V

C955 9965 000 16545 47µF 50V

C959 9965 000 16557 470µF 25V

C960 9965 000 16557 470µF 25V

f

R1001 9965 000 16498 4.7k 5% 1/6W

R1003 9965 000 16499 1.2k 5% 1/6W

R1004 9965 000 16500 330Ω 5% 1/6W

R1006 9965 000 16498 4.7k 5% 1/6W

R1007 9965 000 16498 4.7k 5% 1/6W

R1008 9965 000 16498 4.7k 5% 1/6W

R1009 9965 000 16498 4.7k 5% 1/6W

R1010 9965 000 16498 4.7k 5% 1/6W

R1011 9965 000 16498 4.7k 5% 1/6W

R250 9965 000 16501 120Ω 5% 1/2W

R253 9965 000 16501 120Ω 5% 1/2W

R321 9965 000 16583 22k 1% 1/6W

R322 9965 000 16584 56k 1% 1/6W

R932 9965 000 16585 5.6Ω 5% 2W

RA501 9965 000 16586 100Ω 5%

RA502 9965 000 16586 100Ω 5%

RA503 9965 000 16586 100Ω 5%

RA504 9965 000 16586 100Ω 5%

RA505 9965 000 16586 100Ω 5%

RA506 9965 000 16586 100Ω 5%

RA507 9965 000 16489 Filter 3216 4S600

b

L1 9965 000 16497 2N7000TA

L1001 9965 000 16482 22µH 2.3 X 3.4

L101 9965 000 16454 Filter HH-1M3216-501

L102 9965 000 16454 Filter HH-1M3216-501

L103 9965 000 16577 27µH 4.0 X 10.5

L2 9965 000 16497 2N7000TA

L201 9965 000 16485 12µH 2.3 X 3.4

L202 9965 000 16483 Filter HB-1M2012-800JT

L203 9965 000 16483 Filter HB-1M2012-800JT

L204 9965 000 16483 Filter HB-1M2012-800JT

L205 9965 000 16483 Filter HB-1M2012-800JT

L207 9965 000 16484 Filter HB-1S2012-080JT

L209 9965 000 16484 Filter HB-1S2012-080JT

L210 9965 000 16454 Filter HH-1M3216-501

L211 9965 000 16484 Filter HB-1S2012-080JT

L212 9965 000 16484 Filter HB-1S2012-080JT

L213 9965 000 16454 Filter HH-1M3216-501

L214 9965 000 16578 3.3µH 2.3 X 3.4

L215 9965 000 16484 Filter HB-1S2012-080JT

L216 9965 000 16484 Filter HB-1S2012-080JT

1206

1206

0805

0805

0805

0805

0805

0805

1206

0805

0805

1206

0805

0805

Page 25

Spare Parts List

EN 25LCD1.20E 10.

L217 9965 000 16454 Filter HH-1M3216-501

L218 9965 000 16454 Filter HH-1M3216-501

L219 9965 000 16454 Filter HH-1M3216-501

L220 9965 000 16454 Filter HH-1M3216-501

L221 9965 000 16454 Filter HH-1M3216-501

L305 9965 000 16454 Filter HH-1M3216-501

L306 9965 000 16454 Filter HH-1M3216-501

L307 9965 000 16454 Filter HH-1M3216-501

L308 9965 000 16454 Filter HH-1M3216-501

L309 9965 000 16454 Filter HH-1M3216-501

L310 9965 000 16454 Filter HH-1M3216-501

L311 9965 000 16454 Filter HH-1M3216-501

L312 9965 000 16484 Filter HB-1S2012-080JT

L401 9965 000 16454 Filter HH-1M3216-501

L402 9965 000 16454 Filter HH-1M3216-501

L403 9965 000 16454 Filter HH-1M3216-501

L511 9965 000 16484 Filter HB-1S2012-080JT

L512 9965 000 16484 Filter HB-1S2012-080JT

L519 9965 000 16483 Filter HB-1M2012-800JT

L601 9965 000 16454 Filter HH-1M3216-501

L602 9965 000 16454 Filter HH-1M3216-501

L603 9965 000 16454 Filter HH-1M3216-501

L801 9965 000 16488 26µH

L802 9965 000 16488 26µH

L803 9965 000 16454 Filter HH-1M3216-501

L804 9965 000 16487 9.5µH

L805 9965 000 16454 Filter HH-1M3216-501

L806 9965 000 16454 Filter HH-1M3216-501

L807 9965 000 16454 Filter HH-1M3216-501

L90 9965 000 16454 Filter HH-1M3216-501

L901 9965 000 16454 Filter HH-1M3216-501

L902 9965 000 16454 Filter HH-1M3216-501

L903 9965 000 16454 Filter HH-1M3216-501

L910 9965 000 16454 Filter HH-1M3216-501

LA801 9965 000 16489 Filter 3216 4S600

LA802 9965 000 16489 Filter 3216 4S600

LA803 9965 000 16489 Filter 3216 4S600

LA804 9965 000 16489 Filter 3216 4S600

LA805 9965 000 16489 Filter 3216 4S600

LA806 9965 000 16489 Filter 3216 4S600

LA811 9965 000 16489 Filter 3216 4S600

LA812 9965 000 16489 Filter 3216 4S600

LA813 9965 000 16489 Filter 3216 4S600

LA814 9965 000 16489 Filter 3216 4S600

LA815 9965 000 16489 Filter 3216 4S600

LD1001 9965 000 16490 LED assy

T801 9965 000 16506 Transformer 13-Z320UH

1206

1206

1206

1206

1206

1206

1206

1206

1206

1206

1206

1206

0805

1206

1206

1206

0805

0805

0805

1206

1206

1206

1206

1206

1206

1206

1206

1206

1206

1206

1206

DC-DC

d

D1 9965 000 16452 KDS181

D801 9965 000 16558 SM3411 (DL-11S2GN1)

D802 9965 000 16559 SR3411 (DL-11S2RN1)

D804 9965 000 16451 EU1ZV(1)

D804 9965 000 16452 KDS181

D805 9965 000 16452 KDS181

D806 9965 000 16452 KDS181

D807 9965 000 16452 KDS181

D901 9965 000 16452 KDS181

Y-Green

Red

D902 9965 000 16452 KDS181

ce

IC1 9965 000 16560 SDA555XF

IC10 9965 000 16459 LA7217M

IC2 9965 000 16456 AT24C16-10PC-2.7

IC201 9965 000 16561 VPC3230D QA

IC204 9965 000 16562 KIA7809API

IC3 9965 000 16563 CXA2040AQ

IC301 9965 000 16564 LGTV1001

IC302 9965 000 16565 SDA9410

IC303 9965 000 16566 Filter SMD H354LAI-

IC305 9965 000 16566 Filter SMD H354LAI-

IC4 9965 000 16458 KA75270Z

IC401 9965 000 16567 CXA2101AQ

IC402 9965 000 16568 PQ09RD21

IC501 9965 000 16569 THS8083

IC502 9965 000 16570 MX88L284-V

IC505 9965 000 16468 K4S161622D-TC80

IC506 9965 000 16474 SI4925DY

IC507 9965 000 16571 KIA7027AF

IC508 9965 000 16469 SC786107DWR2

IC509 9965 000 16572 KIA7033AF

IC801 9965 000 16475 SI786

IC802 9965 000 16573 SI4808DY

IC803 9965 000 16573 SI4808DY

IC806 9965 000 16474 SI4925DY

IC807 9965 000 16474 SI4925DY

IC808 9965 000 16474 SI4925DY

IC809 9965 000 16574 KIA7812API

IC850 9965 000 16568 PQ09RD21

IC851 9965 000 16457 PQ3RF23

IC852 9965 000 16575 KIA78L05BP

IC854 9965 000 16576 PQ12RF21

IC854 9965 000 16594 PQ12RD21

IC901 9965 000 16472 MSP3410D-QA-C5

IC902 9965 000 16572 KIA7033AF

IC903 9965 000 16461 KIA7808API

IC904 4822 209 16128 KIA7805PI

IC905 4822 209 31855 LA4282

Q1001 9965 000 16494 KTA-1266

Q101 9965 000 16495 2SC3875S

Q103 9965 000 16495 2SC3875S

Q104 9965 000 16495 2SC3875S

Q105 9965 000 16496 2SA1504S

Q106 9965 000 16495 2SC3875S

Q107 9965 000 16496 2SA1504S

Q201 9965 000 16495 2SC3875S

Q202 9965 000 16495 2SC3875S

Q203 9965 000 16495 2SC3875S

Q204 9965 000 16495 2SC3875S

Q205 9965 000 16495 2SC3875S

Q206 9965 000 16495 2SC3875S

Q207 9965 000 16495 2SC3875S

Q208 9965 000 16495 2SC3875S

Q209 9965 000 16495 2SC3875S

Q210 9965 000 16495 2SC3875S

Q211 9965 000 16496 2SA1504S

Q301 9965 000 16496 2SA1504S

Q302 9965 000 16496 2SA1504S

Q303 9965 000 16496 2SA1504S

Q304 9965 000 16496 2SA1504S

Q305 9965 000 16496 2SA1504S

Q306 9965 000 16496 2SA1504S

Q401 9965 000 16496 2SA1504S

Q402 9965 000 16496 2SA1504S

Q403 9965 000 16496 2SA1504S

Q404 9965 000 16495 2SC3875S

Q460 9965 000 16495 2SC3875S

Q50 9965 000 16495 2SC3875S

Q501 9965 000 16495 2SC3875S

Q801 9965 000 16495 2SC3875S

Q90 9965 000 16495 2SC3875S

Q901 9965 000 16496 2SA1504S

Q902 9965 000 16496 2SA1504S

Q903 9965 000 16496 2SA1504S

Q904 9965 000 16496 2SA1504S

Q905 9965 000 16496 2SA1504S

EJ201 9965 000 16480 Socket SHVS

MJ201 9965 000 16579 PJ6054P

K5206

K5206

Page 26

EN 26 LCD1.20E11.

11. Revision list

11.1 Manual 3122 785 12521

1. Wiring diagram is added.

2. Adjustment instruction is corrected.

3. Parts list is corrected

Revision list

Loading...

Loading...