Page 1

Page 2

IMPORTANT SAFETY NOTICE

Proper service and repair is important to the safe, reliable operation of all Philips

Consumer Electronics Company** Equipment. The service procedures recommended by

Philips and described in this service manual are effective methods of performing service

operations. Some of these service operations require the use of tools specially designed

for the purpose. The special tools should be used when and as recommended.

It is important to note that this manual contains various CAUTIONS and NOTICES

which should be carefully read in order to minimize the risk of personal injury to service

personnel. The possibility exists that improper service methods may damage the

equipment. It also is important to understand that these CAUTIONS and NOTICES

ARE NOT EXHAUSTIVE. Philips could not possibly know, evaluate and advise the

service trade of all conceivable ways in which service might be done, or of the possible

hazardous consequences of each way. Consequently, Philips has not undertaken any such

broad evaluation. Accordingly, a servicer who uses a service procedure or tool which is

not recommended by Philips must first satisfy himself thoroughly that neither his safety

nor the safe operation of the equipment will be jeopardized by the service method

selected.

** Hereafter throughout this manual, Philips Consumer Electronics Company will be

referred to as Philips.

WARNING

Critical components having special safety characteristics are identified with a or

"S" by the Ref. No. in the parts list and enclosed within a broken line* (where

several critical components are grouped in one area) along with the safety symbol

on the schematics or exploded views. Use of substitute replacement parts which

do not have the same specified safety characteristics may create shock, fire, or other

hazards. Under no circumstances should the original design be modified or altered

without written permission from Philips. Philips assumes no liability, express or

implied, arising out of any unauthorized modification of design. Servicer assumes all

liability.

* Broken Line ____ _ ____ _ ____ _ ____

Page 3

FIRE AND SHOCK HAZARD

1. Be sure all components are positioned in such a way as to avoid the possibility of adjacent component

shorts. This is especially important on those chassis which are transported to and from the service shop.

2. Never release a repaired unit unless all protective devices such as insulators, barriers, covers, strain

reliefs, and other hardware have been installed in accordance with the original design.

3. Soldering and wiring must be inspected to locate possible cold solder joints, solder splashes, sharp solder

points, frayed leads, pinched leads, or damaged insulation (including the ac cord). Be certain to remove

loose solder balls and all other loose foreign particles.

4. Check across-the-line components and other components for physical evidence of damage or

deterioration and replace if necessary. Follow original layout, lead length, and dress.

5. No lead or component should touch a receiving tube or a resistor rated at 1 watt or more. Lead tension

around protruding metal surfaces or edges must be avoided.

6. Critical components having special safety characteristics are identified with an 'S' by the Ref. No. in the

parts list and enclosed within a broken line* (where several critical components are grouped in one area)

along with the safety symbol on the schematic diagrams and /or exploded views.

7. When servicing any unit, always use a separate isolation transformer for the chassis. Failure to use a

separate isolation transformer may expose you to possible shock hazard, and may cause damage to

servicing instruments.

8. Many electronic products use a polarized ac line cord (one wide pin on the plug). Defeating this safety

feature may create a potential hazard to the servicer and the user. Extension cords which do not

incorporate the polarizing feature should never be used.

9. After reassembly of the unit, always perform an ac leakage test or resistance test from the line cord to all

exposed metal parts of the cabinet. Also, check all metal control shafts (with knobs removed), antenna

terminals, handles, screws, etc., to be sure the unit may be safely operated without danger of electrical

shock.

* Broken line ____ _ ____ _ ____ _ ____

Page 4

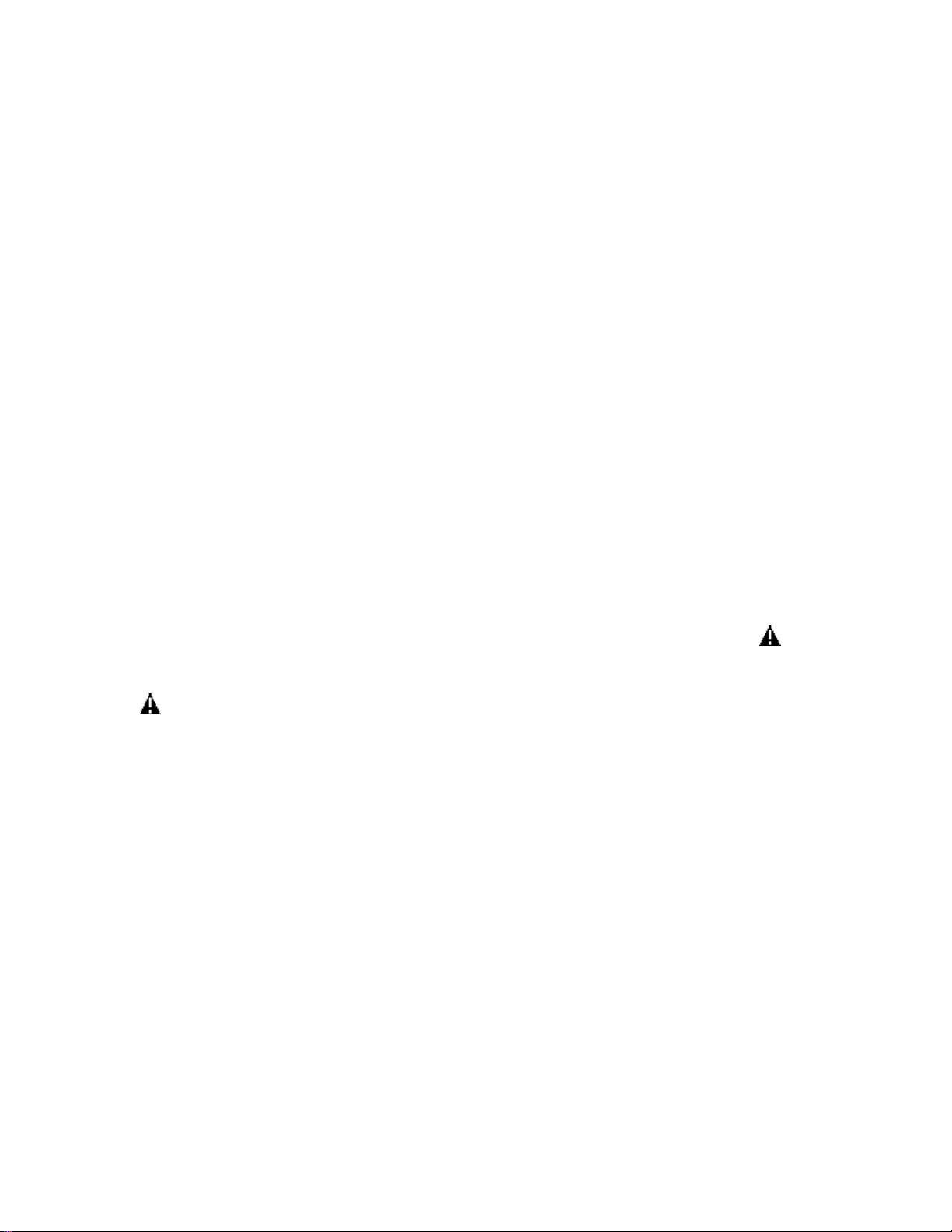

LEAKAGE CURRENT COLD CHECK

1. Unplug the ac line cord and connect a jumper between the two prongs of the plug.

2. Turn on the power switch.

3. Measure the resistance value between the jumpered ac plug and all exposed cabinet parts of the receiver,

such as screw heads, antennas, and control shafts. When the exposed metallic part has a return path to the

chassis, the reading should be between 1 megohm and 5.2 megohms. When the exposed metal does not

have a return path to the chassis, the reading must be infinity. Remove the jumper from the ac line cord.

LEAKAGE CURRENT HOT CHECK

1. Do not use an isolation transformer for this test. Plug the completely reassembled receiver directly into

the ac outlet.

2. Connect a 1.5k, 10W resistor paralleled by a 0.15uF. capacitor between each exposed metallic cabinet

part and a good earth ground such as a water pipe, as shown below.

3. Use an ac voltmeter with at least 5000 ohms/volt sensitivity to measure the potential across the resistor.

4. The potential at any point should not exceed 0.75 volts. A leakage current tester may be used to make

this test; leakage current must not exceed 0.5mA. If a measurement is outside of the specified limits,

there is a possibility of shock hazard. The receiver should be repaired and rechecked before returning it

to the customer.

5. Repeat the above procedure with the ac plug reversed. (Note: An ac adapter is necessary when a

polarized plug is used. Do not defeat the polarizing feature of the plug.)

OR

With the instrument completely reassembled, plug the ac line cord directly into a 120Vac outlet. (Do not

use an isolation transformer during this test.) Use a leakage current tester or a metering system that

complies with American National Standards Institute (ANSI) C101.1 Leakage Current for Appliances and

Underwriters Laboratories (UL) 1410, (50.7). With the instrument ac switch first in the on position and

then in the off position, measure from a known earth ground (metal water pipe, conduit, etc.) to all exposed

metal parts of the instrument (antennas, handle brackets, metal cabinet, screw heads, metallic overlays,

control shafts, etc.), especially any exposed metal parts that offer an electrical return path to the chassis.

Any current measured must not exceed 0.5mA. Reverse the instrument power cord plug in the outlet and

repeat the test. See the graphic below.

Page 5

Page 6

TV SAFETY NOTES

SAFETY CHECKS

After the original service problem has been corrected, a complete safety check should be made. Be sure to

check over the entire set, not just the areas where you have worked. Some previous servicer may have left

an unsafe condition, which could be unknowingly passed on to your customer. Be sure to check all of the

following:

Fire and Shock Hazard

Implosion

X-Radiation

Leakage Current Cold Check

Leakage Current Hot Check

Picture Tube Replacement

Parts Replacement

WARNING: Before removing the CRT anode cap, turn the unit OFF and short the HIGH VOLTAGE to

the CRT DAG ground.

SERVICE NOTE: The CRT DAG is not at chassis ground.

IMPLOSION

1. All picture tubes used in current model receivers are equipped with an integral implosion system.

Care should always be used, and safety glasses worn, whenever handling any picture tube. Avoid

scratching or otherwise damaging the picture tube during installation.

2. Use only replacement tubes specified by the manufacturer.

X-RADIATION

1. Be sure procedures and instructions to all your service personnel cover the subject of X-radiation.

Potential sources of X-rays in TV receivers are the picture tube and the high voltage circuits. The

basic precaution which must be exercised is to keep the high voltage at the factory recommended

level.

2. To avoid possible exposure to X-radiation and electrical shock, only the manufacturer's specified

anode connectors must be used.

3. It is essential that the service technician has an accurate HV meter available at all times. The

calibration of this meter should be checked periodically against a reference standard.

4. When the HV circuitry is operating properly there is no possibility of an X-radiation problem. High

voltage should always be kept at the manufacturer's rated value - no higher - for optimum

performance. Every time a color set is serviced, the brightness should be run up and down while

monitoring the HV with a meter to be certain that the HV is regulated correctly and does not exceed

the specified value. We suggest that you and your technicians review test procedures so that HV and

HV regulation are always checked as a standard servicing procedure, and the reason for this prudent

routine is clearly understood by everyone. It is important to use an accurate and reliable HV meter. It

is recommended that the HV reading be recorded on each customer's invoice, which will

demonstrate a proper concern for the customer's safety.

Page 7

5. When troubleshooting and making test measurements in a receiver with a problem of excessive high

voltage, reduce the line voltage by means of a Variac to bring the HV into acceptable limits while

troubleshooting. Do not operate the chassis longer than necessary to locate the cause of the excessive

HV.

6. New picture tubes are specifically designed to withstand higher operating voltages without creating

undesirable X-radiation. It is strongly recommended that any shop test fixture which is to be used

with the new higher voltage chassis be equipped with one of the new type tubes designed for this

service. Addition of a permanently connected HV meter to the shop test fixture is advisable. The

CRT types used in these new sets should never be replaced with any other types, as this may result in

excessive X-radiation.

7. It is essential to use the specified picture tube to avoid a possible X-radiation problem.

8. Most TV receivers contain some type of emergency "Hold Down" circuit to prevent HV from rising

to excessive levels in the presence of a failure mode. These various circuits should be understood by

all technicians servicing them, especially since many hold down circuits are inoperative as long as

the receiver performs normally.

PICTURE TUBE REPLACEMENT

The primary source of X-radiation in this television receiver is the picture tube. The picture tube

utilized in this chassis is specially constructed to limit X-radiation emissions. For continued Xradiation protection, the replacement tube must be the same type as the original, including suffix letter,

or a Philips approved type.

PARTS REPLACEMENT

Many electrical and mechanical parts in Philips television sets have special safety related

characteristics. These characteristics are often not evident from visual inspection nor can the protection

afforded by them necessarily be obtained by using replacement components rated for higher voltage,

wattage, etc. The use of a substitute part which does not have the same safety characteristics as the

Philips recommended replacement part shown in this service manual may create shock, fire, or other

hazards.

PRODUCT SAFETY GUIDELINES FOR ALL PRODUCTS

CAUTION: Do not modify any circuit. Service work should be performed only after you are thoroughly

familiar with all of the following safety checks. Risk of potential hazards and injury to the user increases if

safety checks are not adhered to.

USE A SEPARATE ISOLATION TRANSFORMER FOR THIS UNIT WHEN SERVICING.

Page 8

PREVENTION OF ELECTROSTATIC DISCHARGE (ESD)

Some semiconductor solid state devices can be damaged easily by static electricity. Such components

commonly are called Electrostatically Sensitive (ES) Devices, Examples of typical ES devices are

integrated circuits and some field-effect transistors and semiconductor "chip" components. The following

techniques should be used to help reduce the incidence of component damage caused by electrostatic

discharge (ESD).

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain

off any ESD on your body by touching a known earth ground. Alternatively, obtain and wear a

commercially available discharging ESD wrist strap, which should be removed for potential shock

reasons prior to applying power to the unit under test.

2. After removing an electrical assembly equipped with ES devices, place the assembly on a conductive

surface such as aluminum foil, to prevent electrostatic charge buildup or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES devices.

4. Use only an anti-static solder removal device. Some solder removal devices not classified as "antistatic

(ESD protected)" can generate an electrical charge sufficient to damage ES devices.

5. Do not use Freon propelled chemicals. These can generate electrical charges sufficient to damage ES

devices.

6. Do not remove a replacement ES device from its protective package until immediately before you are

ready to install it (most replacement ES devices are packaged with leads electrically shorted together by

conductive foam, aluminum foil or comparable conductive material).

7. Immediately before removing the protective material from the leads of a replacement ES device, touch

the protective material to the chassis or circuit assembly into which the device will be installed.

CAUTION: Be sure no power is applied to the chassis or circuit and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged replacement ES devices. (Otherwise harmless

motion such as the brushing together of your clothes fabric or the lifting of your feet from a carpeted

floor can generate static electricity (ESD) sufficient to damage an ES device.)

NOTE to CATV system Installer:

This reminder is provided to call the CATV system installer's attention to article 820-22 of the NEC that

provides guidelines for proper grounding and, in particular, specifies that the cable ground shall be

connected to the grounding system of the building, as close to the point of cable entry as practical.

Page 9

PRACTICAL SERVICE PRECAUTIONS

IT MAKES SENSE TO AVOID EXPOSURE TO ELECTRICAL SHOCK. While some sources are

expected to have a possible dangerous impact, others of quite high potential are of limited current and are

sometimes held in less regard.

ALWAYS RESPECT VOLTAGES. While some may not be dangerous in themselves, they can cause

unexpected reactions – reactions that are best avoided. Before reaching into the powered color TV set, it is

best to test the high voltage insulation. It is easy to do, and is just a good service precaution.

BEFORE POWERING UP THE TV WITH THE BACK OFF (or on a test fixture), attach a clip lead to

the CRT DAG ground and to a screwdriver blade that has a well insulated handle. After the TV is powered

on and high voltage has developed, probe the anode lead with the blade, starting at the bottom of the High

Voltage Transformer (flyback – IFT). Move the blade to within two inches of the connector of the CRT. IF

THERE IS AN ARC, YOU FOUND IT THE EASY WAY, WITHOUT GETTING A SHOCK! If

there is an arc to the screwdriver blade, replace the High Voltage Transformer or the lead, (if removable)

whichever is causing the problem.

PICTURE TUBE REPLACEMENT PROCEDURE

Note: a. Two (2) people are required to handle this picture tube.

b. Safety Glasses must be worn during this procedure or whenever directly handling a picture tube.

c. Take care in each step not to damage the CRT or the cabinet.

1. Remove the Chassis and the CRT Socket Board Module from the cabinet.

2. A furniture pad or blanket should be positioned on the floor to support only the CRT Face. This pad or

blanket should be high enough to keep the CRT Face approximately 12 to 14 inches off the floor.

3. Using two people, place the cabinet in a front down position with the CRT Face on the pad or blanket.

4. Place padded blocks under each corner of the cabinet to keep it from rocking.

5. Remove the four screws, at the corners of the CRT.

6. With two people lowering the cabinet to the floor, leave the CRT elevated by the pad or blanket.

Note: Take care not to grasp the neck of the CRT during this procedure, as it is extremely fragile.

7. Two (2) people may then lift the CRT from the cabinet.

8. Remove the degaussing coil from the defective CRT and mount on the replacement. Take care to

maintain the exact shape and fit.

To install the new CRT, reverse steps 1 to 7.

Page 10

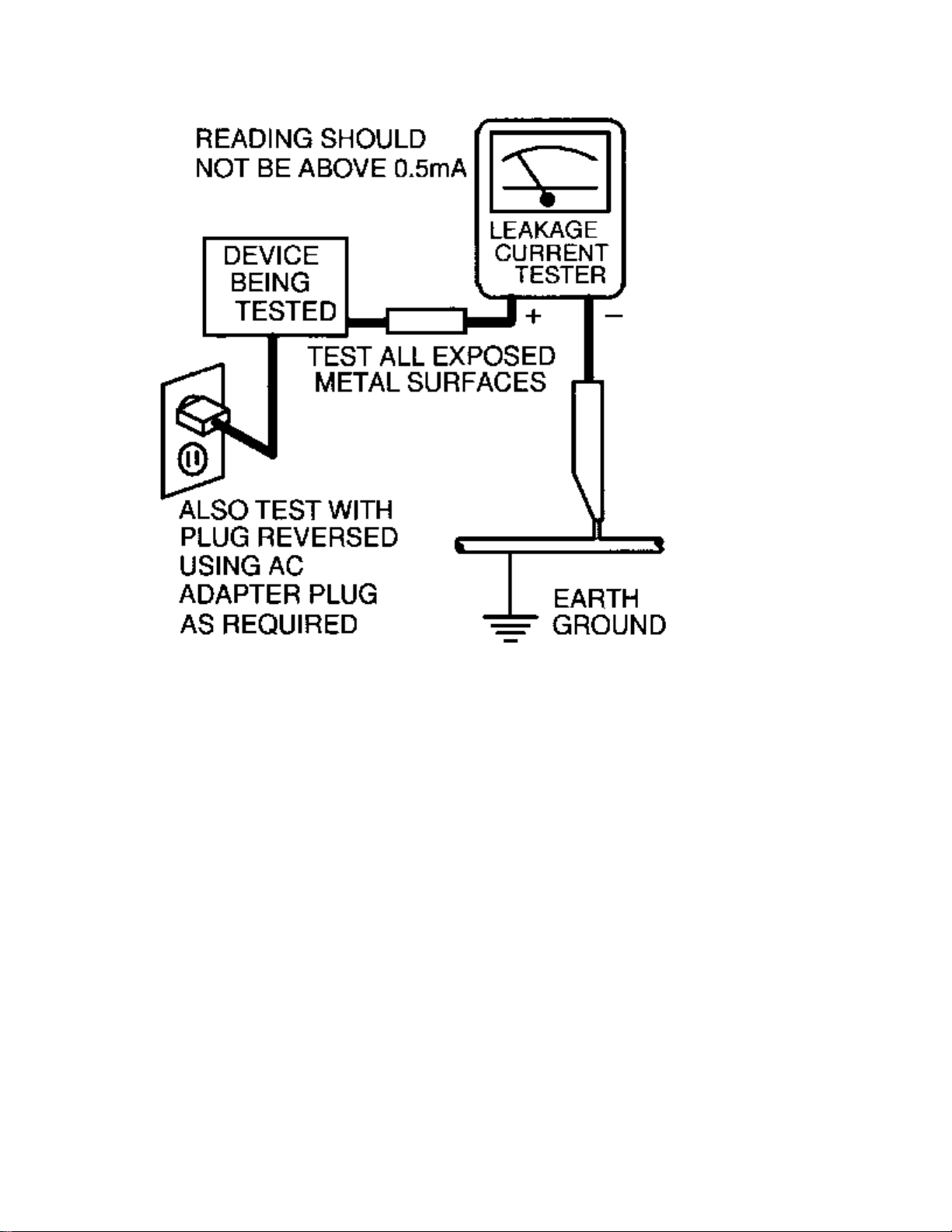

Mechanical Instructions

Index of this chapter:

1. Service Position

2. Rear Cover Removal

3. Power Supply Unit Removal

4. TV & Scaler Board Removal

5. I/O Panel Removal

6. Side I/O & Keyboard Panel and Front LED Panel Removal

7. Exchanging the LCD Panel

8. Re-assembly

Note: Figures below can deviate from the actual situation, due to different set

executions.

Note: To diagnose the set with ComPair it is not needed to open the set entirely.

1. Manually unlock and remove the cover cap (1). See figure “TV set rear view”.

2. Break away the protective plate (2) at the I/O panel bracket to get access to the

needed plugs. See figure “Protective plate”.

Figure: Protective plate

Page 11

Service Position

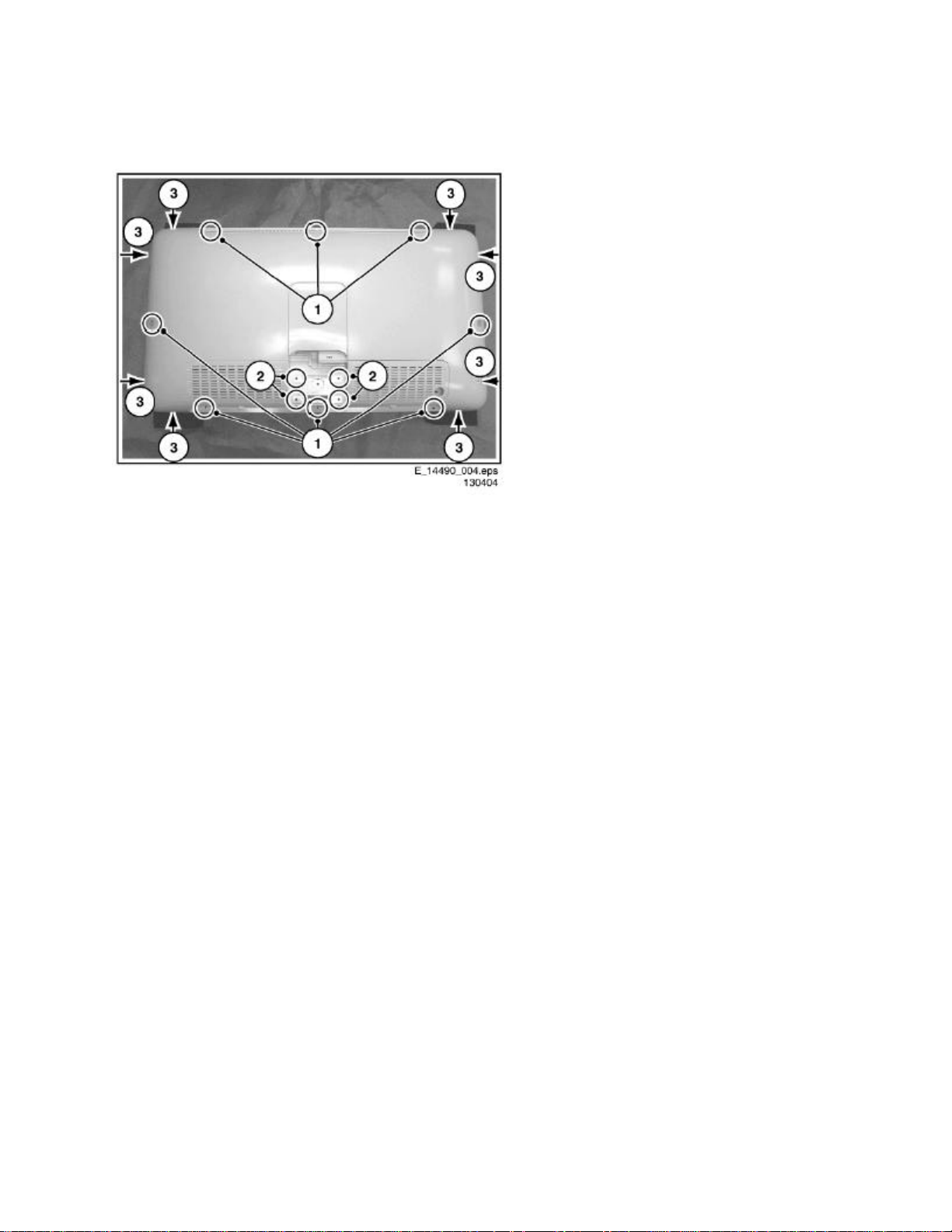

Figure: TV set rear view

Figure: TV stand removal

1. Carefully pull upwards the cover plate (2) (from its left side) to unlock it (3) and

remove the plate from the stand.

2. Unplug the AC power and the antenna cables.

3. Be sure to remove the coin slotted mounting screw (4) from the stand.

4. Carefully lift the TV from the swivel base (it uses a vertical sliding mechanism).

5. Place the TV upside down on a tabletop (use a protection sheet or foam bars). Take

care, that this is flat and free from obstacles like screws, to prevent damaging the

fragile LCD screen.

Page 12

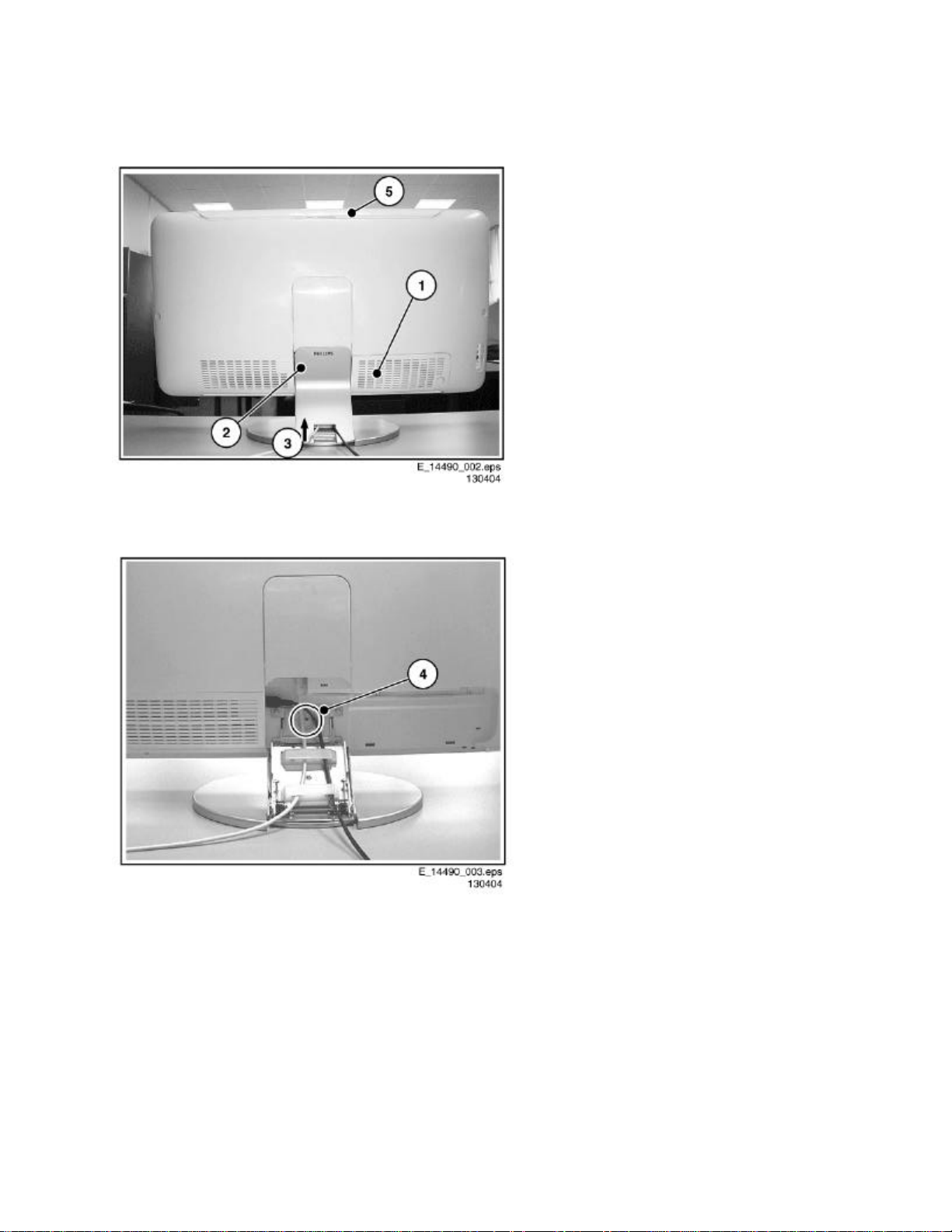

Foam Bars

Figure: Foam bars

The foam bars (order code 3122 785 90580) can be used for all types and sizes of Flat

TVs. By laying the plasma or LCD TV flat on the (ESD protective) foam bars, a stable

situation is created to perform measurements and alignments. By placing a mirror under

the TV, you can easily monitor the screen.

Page 13

Rear Cover Removal

Figure: Rear cover removal

1. Manually unlock and remove the top cover cap (5). See Figure: “TV set rear view”.

2. Make sure all power-, audio-, video- and coax- cables are unplugged.

3. Remove all Torx screws (1) around the edges of the rear cover.

4. Remove the four silver coloured Torx screws (2) around the stand holder. See figure

“Rear cover removal”.

5. Carefully use a flat screwdriver to release the clamps (3). See figure “Rear cover

removal”.

6. Remove the rear cover and store it in a safe place.

Note: avoid holding the button-area during removal (it can be easily damaged).

Page 14

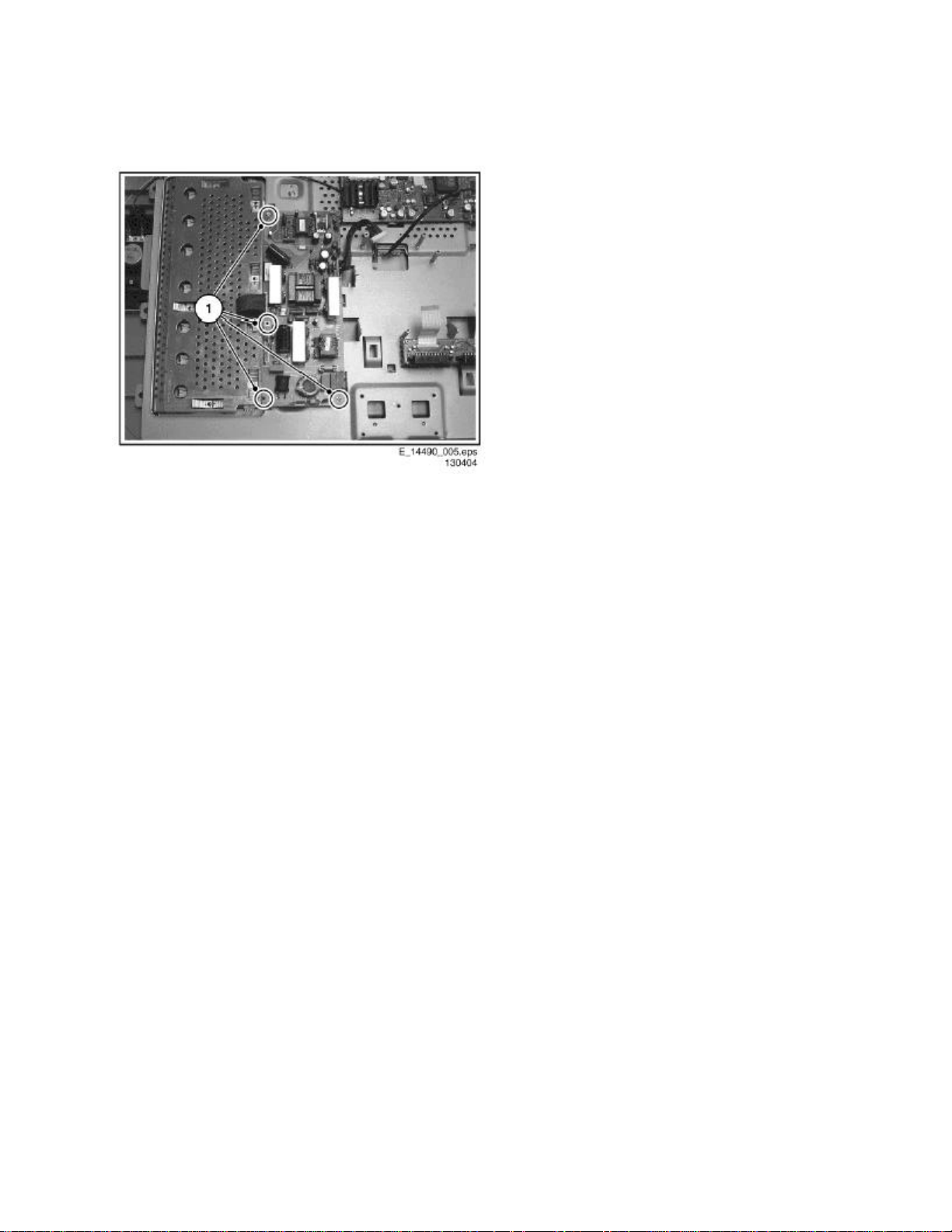

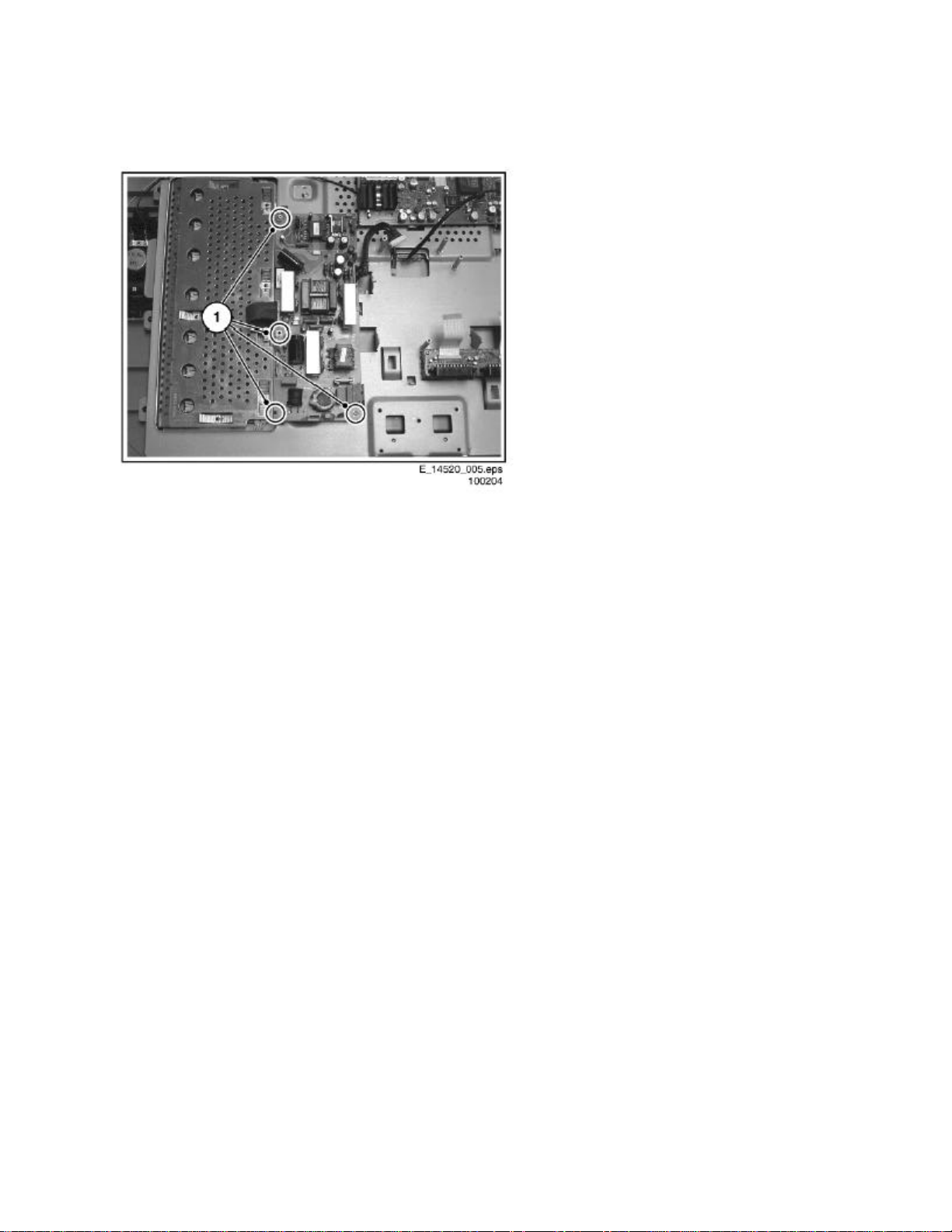

Power Supply Unit Removal

Figure: Power supply unit

1. Disconnect all cables from the Power supply unit.

2. Remove all mounting screws (1) from the Power supply unit.

3. Take out the Power supply unit.

Page 15

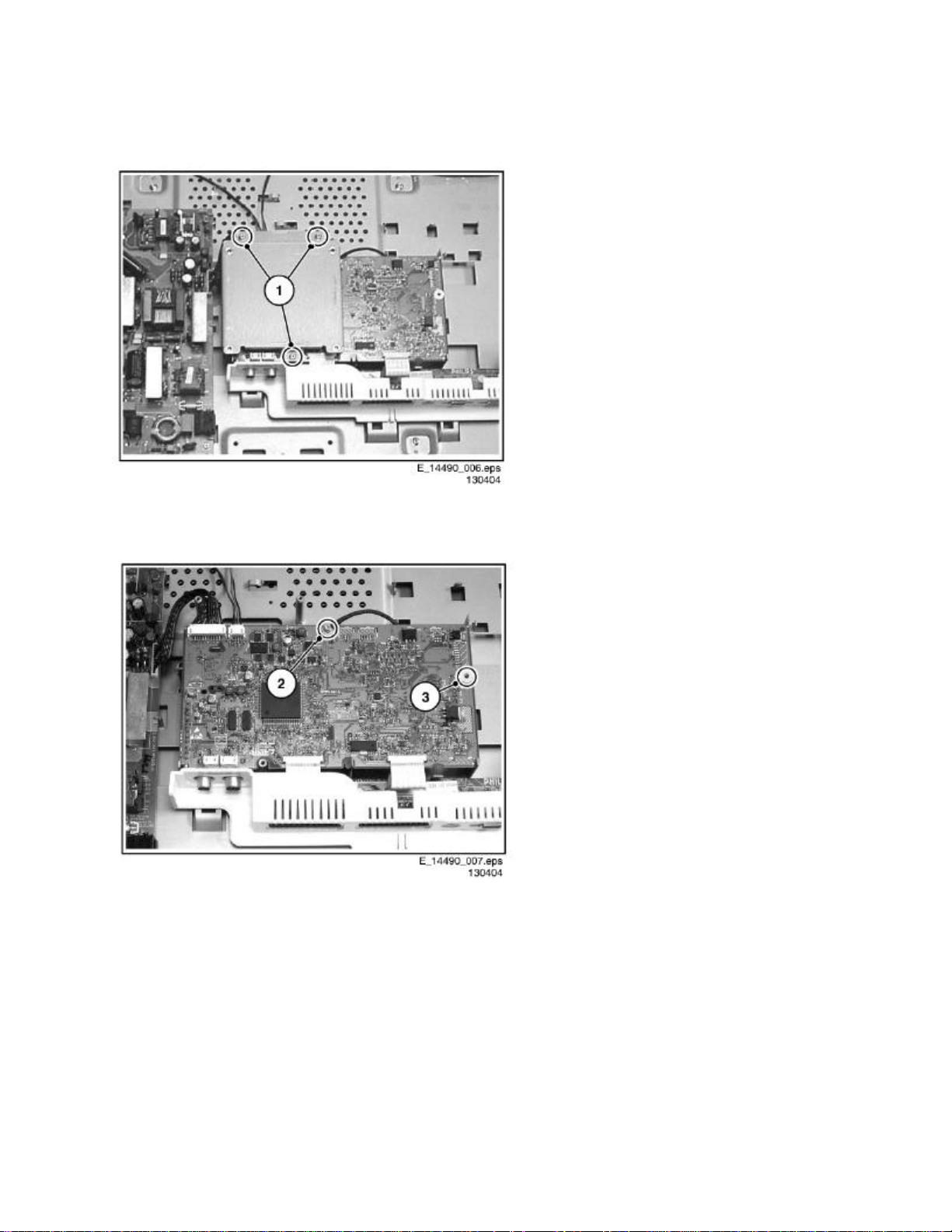

TV & Scaler Board Removal

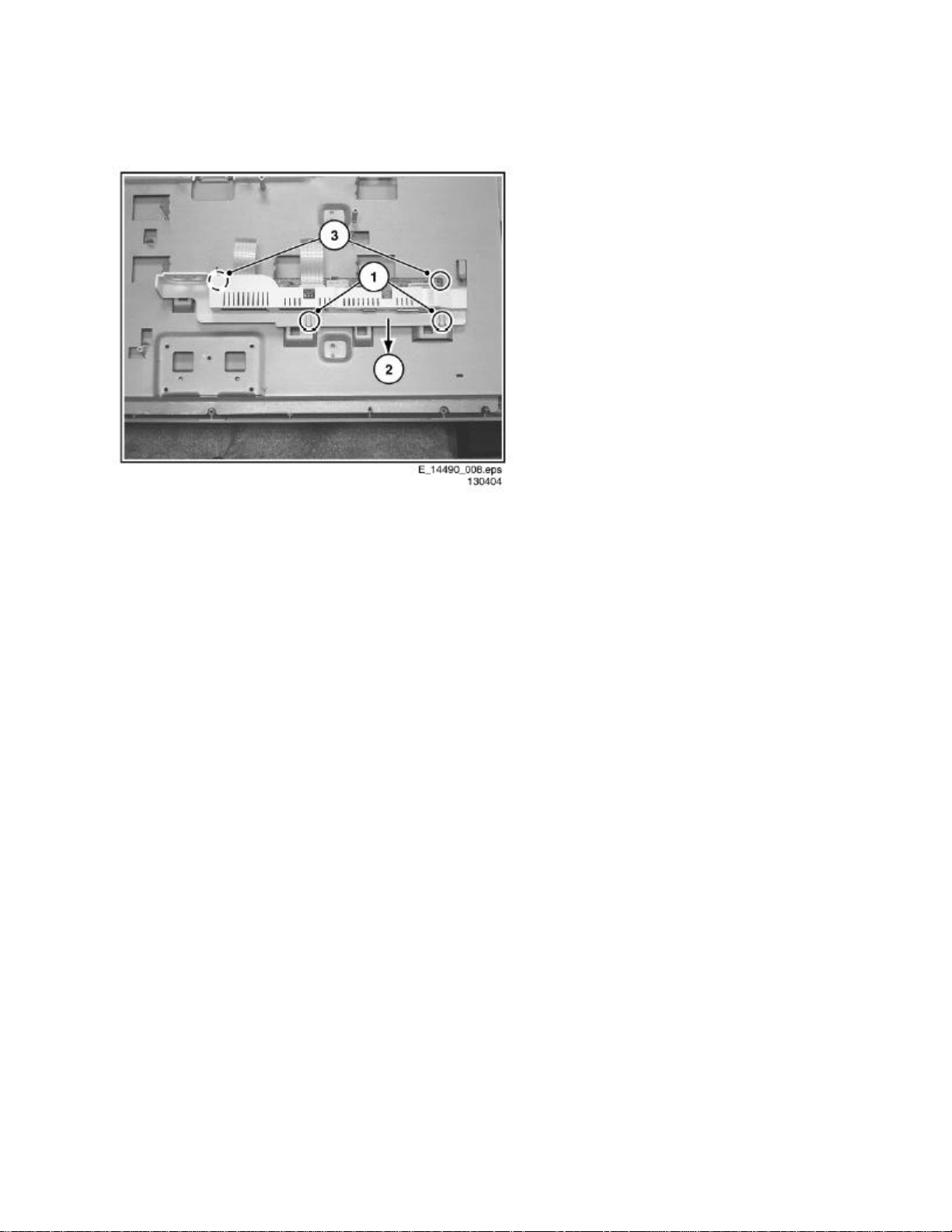

Figure: TV & Scaler board shield removal

Figure: TV & Scaler board removal

1. Disconnect all cables from the TV & Scaler board.

2. Remove all shield mounting screws (1) and remove the shield.

3. Remove the screw from the grounding cable (2).

4. Remove the mounting screw (3) and remove the board.

Page 16

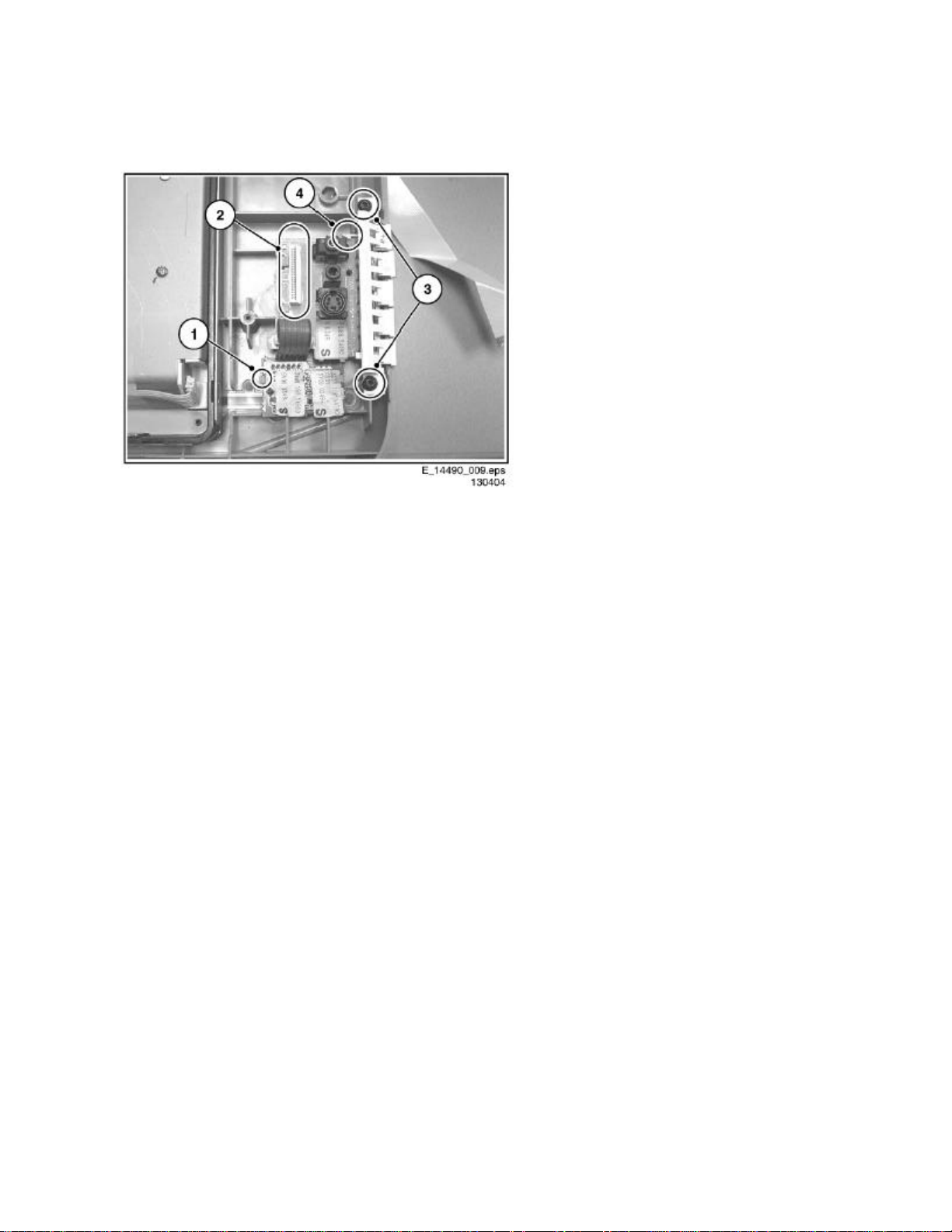

I/O Panel Removal

Figure: I/O panel removal

1. Release the two clamps (1) at the I/O panel bracket. Carefully pull the bracket in the

direction (2), as shown at the figure “I/O panel removal”, and remove it.

2. Disconnect all cables from the I/O panel.

3. Remove all mounting screws from the I/O panel (3).

4. Take out the I/O panel.

3D Comb Filter Panel Removal

1. Disconnect all cables from the 3D Comb Filter panel.

2. Remove all mounting screws from the 3D Comb filter panel.

3. Take out the 3D Comb filter panel.

Page 17

Pixel Plus Panel Removal

Figure: Power supply unit

1. Disconnect all cables from the Pixel Plus panel.

2. Remove all mounting screws from the Pixel Plus panel.

3. Take out the Pixel Plus panel.

Page 18

Side I/O & Keyboard Panel / Front LED Panel Removal

Figure: Side I/O & Keyboard panel and Front LED panel removal

1. Release the clamp (1) and take out the Front LED panel.

2. Disconnect the cable (2) from the Side I/O & Keyboard panel.

3. Remove all mounting screws (3) from the Side I/O & Keyboard panel bracket.

4. Unlock this unit by shifting it to the outside direction of the monitor.

5. Release the clamp (4) and take out the Side I/O & Keyboard panel from the bracket.

Page 19

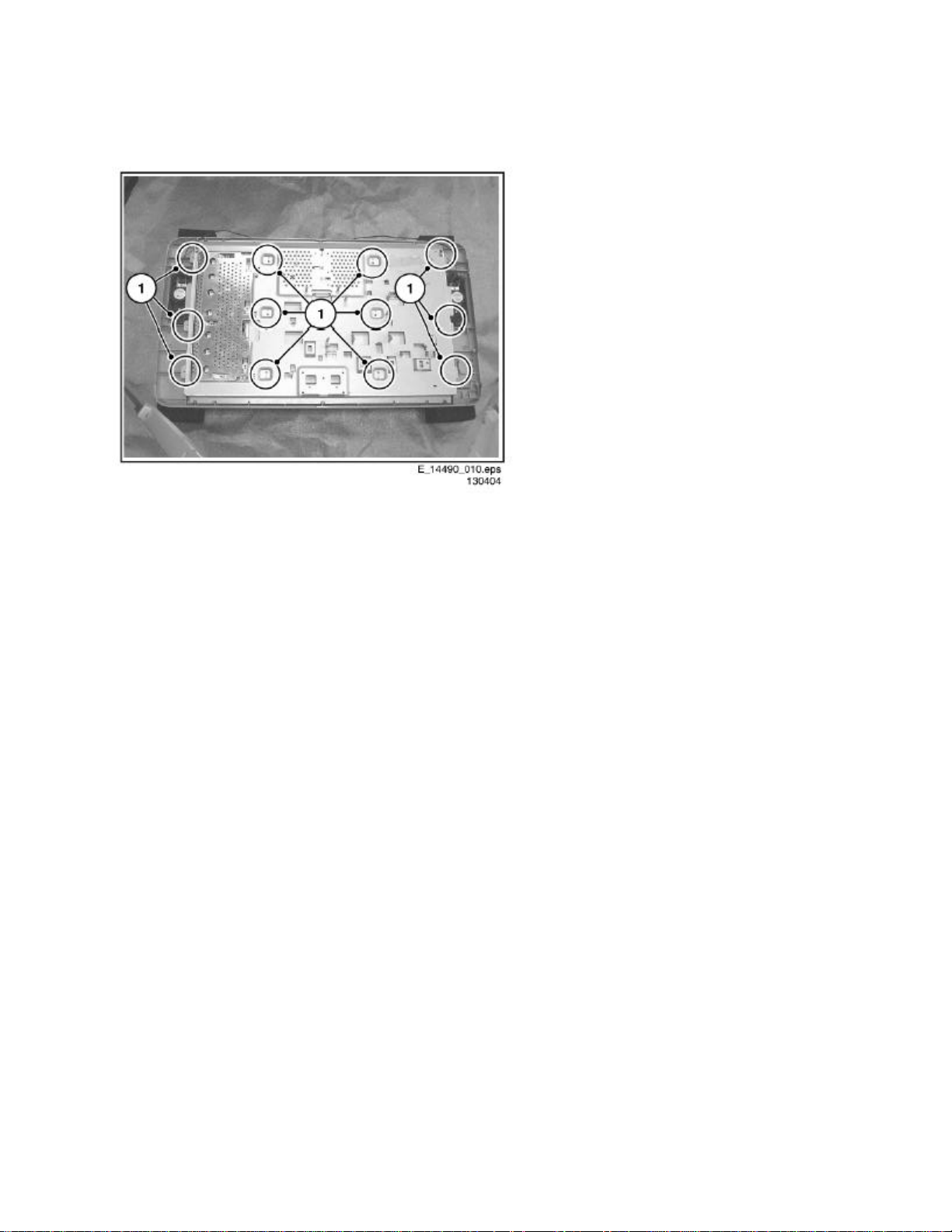

Exchanging the LCD Panel

Figure: Exchanging the LCD panel

1. Disconnect all cables from the LCD Panel.

2. Remove all mounting screws (1) from the metal cover.

3. Lift and take off the metal cover.

4. Now you can exchange the LCD panel.

Page 20

Re-Assembly

To re-assemble the whole set, do all processes in reverse order.

Notes:

l Do not forget to replace the ground cable of the TV & Scaler board, while mounting

the screw at the board topside. See figure “TV & Scaler board shield removal”.

l Make sure the ferrite ring (1) is properly tightened to the clip (this is valid only for 26

inch sets).

Figure: Ferrite ring

Page 21

Service Modes, Error Codes, and Fault Finding

Index of this chapter:

1. Test Points

2. Service Modes

3. Problems and Solving Tips (related to CSM)

4. ComPair

5. Error Codes

6. The Blinking LED Procedure

7. Fault Finding and Repair Tips

8. Power Supply

Test Points

This chassis is equipped with test points in the service printing. In the schematics test points

are identified with a rectangle box around Fxxx or Ixxx. These test points are specifically

mentioned in the service manual as “half moons” with a dot in the centre.

Perform measurements under the following conditions:

l Television set in Service Default Alignment Mode.

l Video input: Colour bar signal.

l Audio input: 3 kHz left channel, 1 kHz right channel.

Service Modes

Service Default mode (SDM) and Service Alignment Mode (SAM) offers several features for

the service technician, while the Customer Service Mode (CSM) is used for communication

between the call centre and the customer.

This chassis also offers the option of using ComPair, a hardware interface between a

computer and the TV chassis. It offers the abilities of structured troubleshooting, error code

reading, and software version readout for all chassis.

Minimum requirements for ComPair: a Pentium processor, a Windows OS, and a CD-ROM

drive (see also paragraph 'ComPair').

Page 22

Service Default Mode (SDM)

Purpose

l To create a predefined setting for measurements to be made.

l To override software protections.

l To start the blinking LED procedure.

l To inspect the error buffer.

l To check the life timer.

Specifications

l Tuning frequency: 61.25 MHz (Channel 3).

l Colour system: NTSC.

l All picture settings at 50% (brightness, colour contrast, hue).

l Bass, treble and balance at 50 %; volume at 25 %.

l All service-unfriendly modes (if present) are disabled. The service unfriendly modes are:

n Timer / Sleep timer.

n Child / parental lock.

n Blue mute.

n Hotel / hospital mode.

n Auto shut off (when no “IDENT” video signal is received for 15 minutes).

n Skipping of non-favourite presets / channels.

n Auto-storage of personal presets.

n Auto user menu time-out.

n Auto Volume Levelling (AVL).

How to enter

To enter SDM, use one of the following methods:

l Press the following key sequence on the remote control transmitter: “062596” directly

followed by the MENU button (do not allow the display to time out between entries while

keying the sequence).

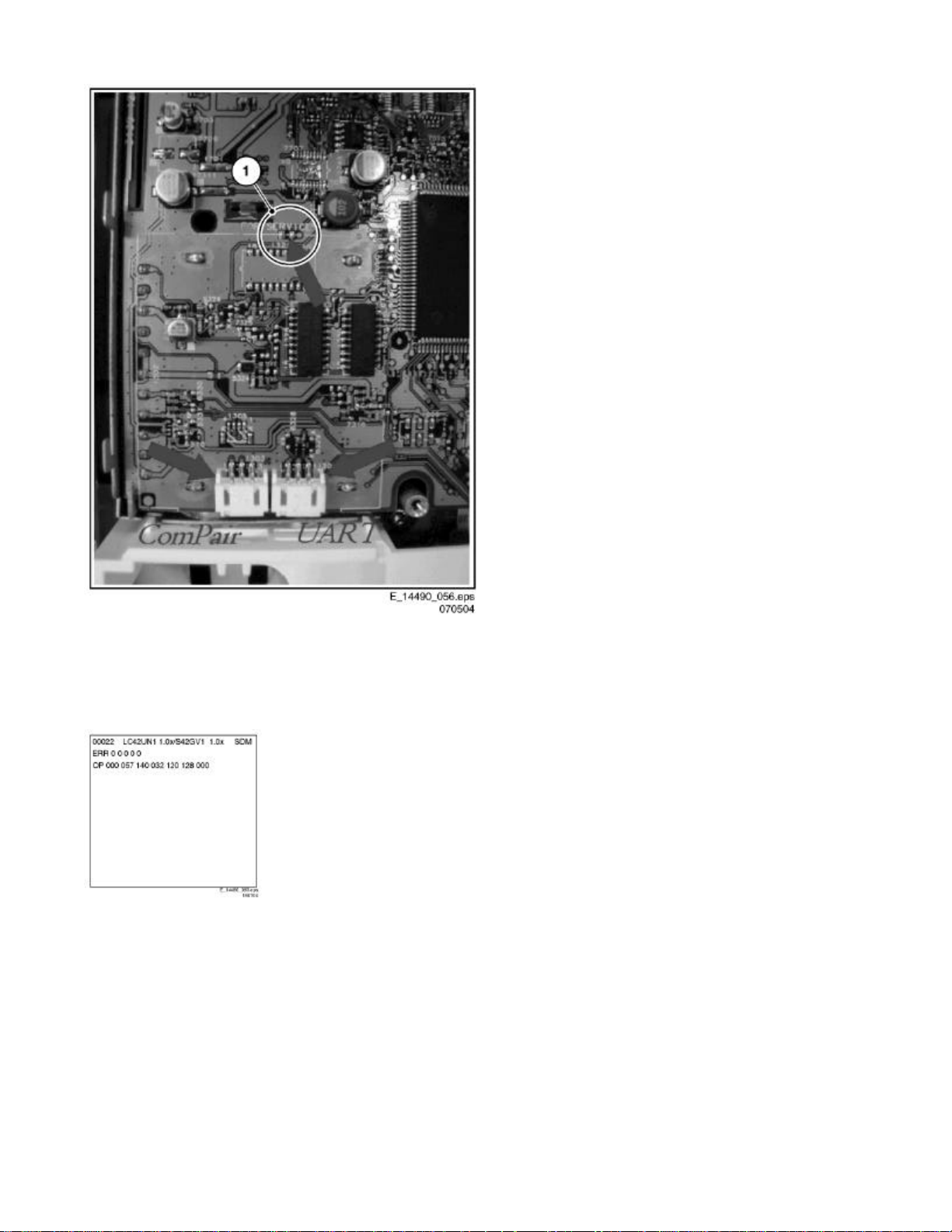

l Short 'Service' jumpers on the TV board during cold start and apply mains (see Figure

'Service jumpers'). Then press the mains button (remove the short after start-up).

Caution: Entering SDM by shorting 'Service' jumpers will override the +8V-protection.

Do this only for a short period. When doing this, the service-technician must know

exactly what he is doing, as it could damage the television set.

l Or via ComPair.

Page 23

Figure: Service jumpers

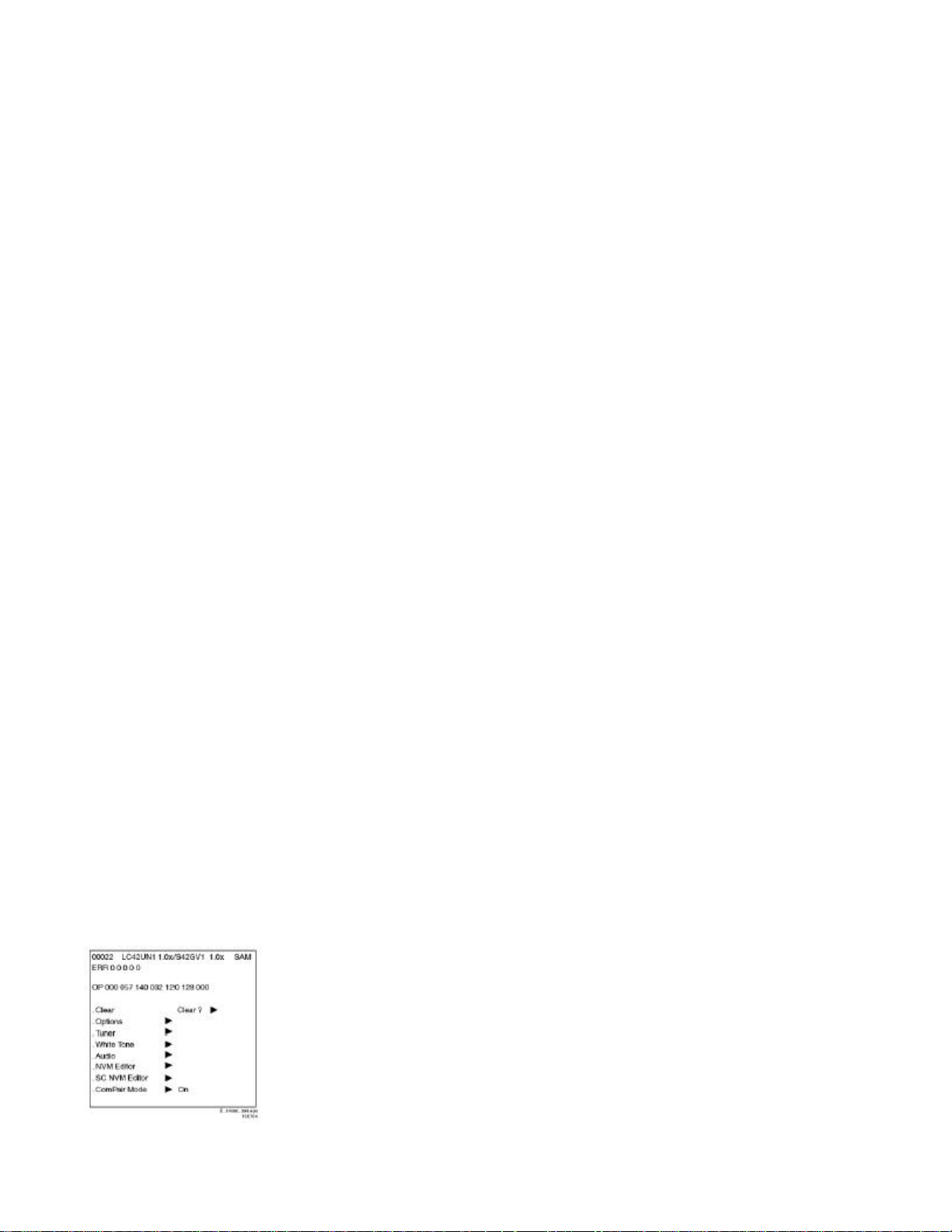

After entering SDM, the following screen is visible, with SDM in the upper right corner of the

screen to indicate that the television is in Service Default Alignment Mode.

Figure: SDM menu

Page 24

How to navigate

Use one of the following methods:

l When you press the MENU button on the remote control, the set will switch on the normal

user menu in the SDM mode.

l On the TV, press and hold the VOLUME DOWN and press the CHANNEL DOWN for a few

seconds, to switch from SDM to SAM and reverse.

How to exit

Switch the set to STANDBY by pressing the 'POWER' button on the remote control transmitter

or press the 'POWER' switch on the set.

Service Alignment Mode (SAM)

Purpose

l To change option settings.

l To display / clear the error code buffer.

l To perform alignments.

Specifications

l Operation hours counter (maximum five digits displayed).

l Software version, Error codes, and Option settings display.

l Error buffer clearing.

l Option settings.

l AKB switching.

l Software alignments (Tuner, White Tone, Geometry & Audio).

l NVM Editor.

l ComPair Mode switching.

How to enter

To enter SAM, use one of the following methods:

l Press the following key sequence on the remote control transmitter: “062596' directly

followed by the OSD/STATUS button (do not allow the display to time out between entries

while keying the sequence).

l Or via ComPair.

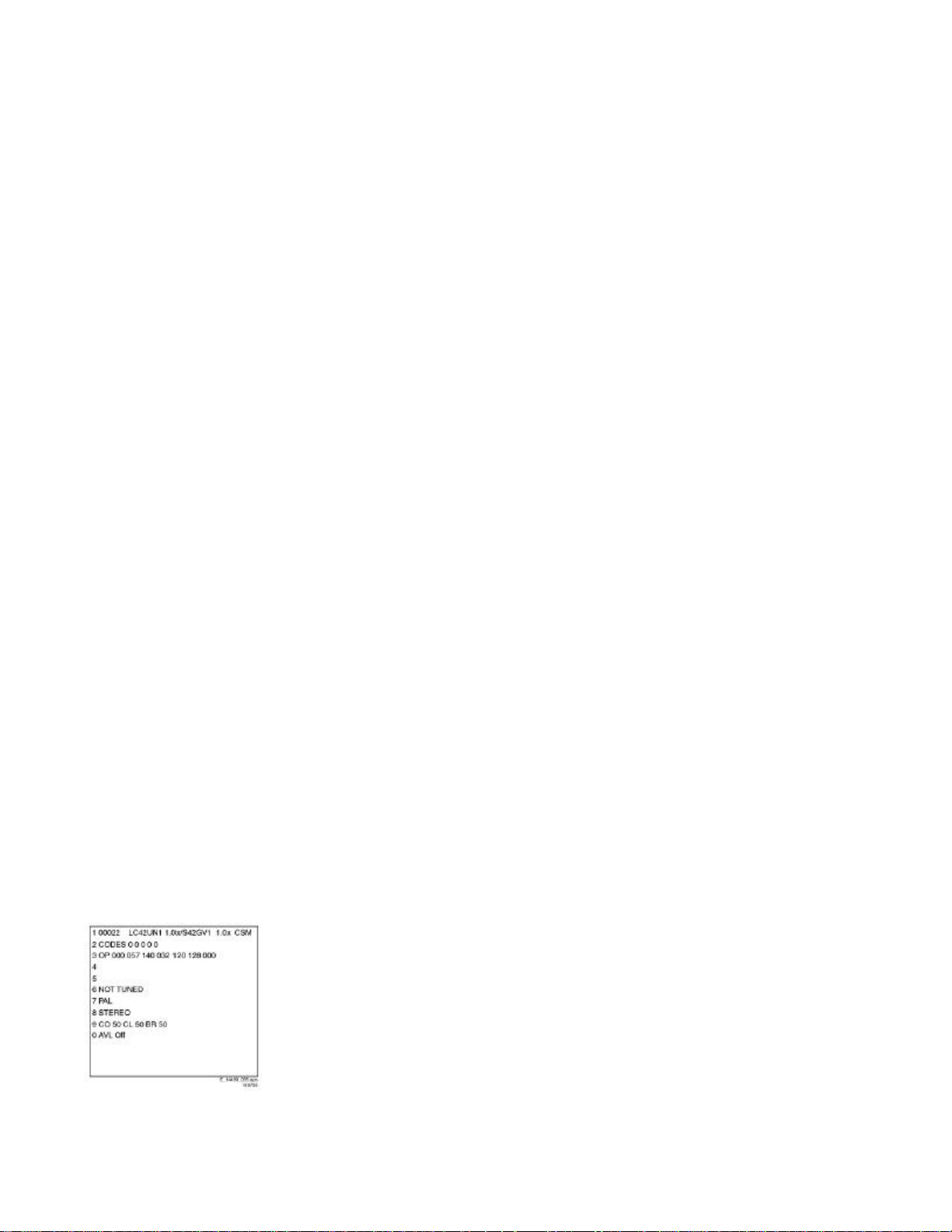

After entering SAM, the following screen is visible, with SAM in the upper right corner of the

screen to indicate that the television is in Service Alignment Mode.

Figure: SAM menu

Page 25

Menu explanation

1. LLLLL. This represents the run timer. The run timer counts normal operation hours, but

does not count standby hours.

2. AAABCD-X.Y/EEEEEE F.GG This is the software identification of the main

microprocessor:

n A = the project name (LC42).

n B = the region: E= Europe, A= Asia Pacific, U= NAFTA, L= LATAM.

n C = the software diversity:

n Europe: T= 1 page TXT, F= Full TXT, V= Voice control.

n LATAM and NAFTA: N= Stereo non-dBx, S= Stereo dBx.

n Asian Pacific: T= TXT, N= non-TXT, C= NTSC.

n ALL regions: M= mono, D= DVD, Q= Mk2.

n D = the language cluster number.

n X = the main software version number (updated with a major change that is incompatible

with previous versions).

n Y = the sub software version number (updated with a minor change that is compatible

with previous versions).

n EEEEEE = the scaler sw cluster

n F = the main sw version no.

n GG = the sub-version no.

3. SAM. Indication of the Service Alignment Mode.

4. Error Buffer. Shows all errors detected since the last time the buffer was erased. Five

errors possible.

5. Option Bytes. Used to set the option bytes. See “Options” in the Alignments section for a

detailed description. Seven codes are possible.

6. Clear. Erases the contents of the error buffer. Select the CLEAR menu item and press the

MENU RIGHT key. The content of the error buffer is cleared.

7. Options. Used to set the option bits. See “Options” in the Alignments section for a detailed

description.

8. AKB. Used to disable (Off) or enable (On) the “black current loop” (AKB= Auto Kine Bias).

9. Tuner. Used to align the tuner. See “Tuner” in the Alignments section for a detailed

description.

10. White Tone. Used to align the white tone. See “White Tone” in the Alignments section for a

detailed description.

11. Geometry. Used to align the geometry settings of the television. See “Geometry” in the

Alignments section for a detailed description.

12. Audio. No audio alignment is necessary for this television set.

13. NVM Editor. Can be used to change the NVM data in the television set. See table “NVM

data” further on.

14. SC NVM Editor. Can be used to edit Scaler NVM.

15. ComPaIr. Can be used to switch on the television to In System Programming (ISP) mode,

for software uploading via ComPair. Caution: When this mode is selected without ComPair

connected, the TV will be blocked. Remove the AC power to reset the TV.

Page 26

How to navigate

l In SAM, select menu items with the MENU UP/DOWN keys on the remote control

transmitter. The selected item will be highlighted. When not all menu items fit on the screen,

use the MENU UP/DOWN keys to display the next / previous menu items.

l With the MENU LEFT/RIGHT keys, it is possible to:

n Activate the selected menu item.

n Change the value of the selected menu item.

n Activate the selected submenu.

l In SAM, when you press the MENU button twice, the set will switch to the normal user

menus (with the SAM mode still active in the background). To return to the SAM menu press

the MENU or STATUS/EXIT button.

l When you press the MENU key in while in a submenu, you will return to the previous menu.

How to store SAM settings

To store the settings changed in SAM mode, leave the top level SAM menu by using the

POWER button on the remote control transmitter or the television set.

How to exit

Switch the set to STANDBY by pressing the power button on the remote control transmitter or

press the 'POWER' switch on the set.

Customer Service Mode (CSM)

Purpose

The Customer Service Mode shows error codes and information on the TV's operation

settings. The call centre can instruct the customer (by telephone) to enter CSM in order to

identify the status of the set. This helps the call centre to diagnose problems and failures in the

TV set before making a service call.

The CSM is a read-only mode; therefore, modifications are not possible in this mode.

How to enter

To enter CSM, press the following key sequence on the remote control transmitter: “123654”

(do not allow the display to time out between entries while keying the sequence).

Upon entering the Customer Service Mode, the following screen will appear:

Figure: CSM menu

Page 27

Menu explanation

1. Indication of the decimal value of the operation hours counter, Software identification of the

main microprocessor (see 'Service Default or Alignment Mode' for an explanation), and the

service mode (CSM= Customer Service Mode).

2. Displays the last five errors detected in the error code buffer.

3. Displays the option bytes.

4. Displays the type number version of the set.

5. Reserved item for P3C call centres (AKBS stands for Advanced Knowledge Base System).

6. Indicates the television is receiving an 'IDENT' signal on the selected source. If no 'IDENT'

signal is detected, the display will read 'NOT TUNED'

7. Displays the detected Colour system (e.g. PAL/NTSC).

8. Displays the detected Audio (e.g. stereo/mono).

9. Displays the picture setting information.

10. Displays the sound setting information.

How to exit

To exit CSM, use one of the following methods:

l Press the MENU, STATUS/EXIT, or POWER button on the remote control transmitter.

l Press the POWER button on the television set.

Page 28

Problems and Solving Tips Related to CSM

Picture Problems

Note: The problems described below are all related to the TV settings. The procedures used to

change the value (or status) of the different settings are described.

Picture too dark or too bright

If:

l The picture improves when you press the AUTO PICTURE button on the remote control

transmitter, or

l The picture improves when you enter the Customer Service Mode,

Then:

1. Press the AUTO PICTURE button on the remote control transmitter repeatedly (if

necessary) to choose PERSONAL picture mode.

2. Press the MENU button on the remote control transmitter. This brings up the normal user

menu.

3. In the normal user menu, use the MENU UP/DOWN keys to highlight the PICTURE sub

menu.

4. Press the MENU LEFT/RIGHT keys to enter the PICTURE sub menu.

5. Use the MENU UP/DOWN keys (if necessary) to select BRIGHTNESS.

6. Press the MENU LEFT/RIGHT keys to increase or decrease the BRIGHTNESS value.

7. Use the MENU UP/DOWN keys to select PICTURE.

8. Press the MENU LEFT/RIGHT keys to increase or decrease the PICTURE value.

9. Press the MENU button on the remote control transmitter twice to exit the user menu.

10. The new PERSONAL preference values are automatically stored.

White line around picture elements and text

If:

The picture improves after you have pressed the AUTO PICTURE button on the remote control

transmitter,

Then:

1. Press the AUTO PICTURE button on the remote control transmitter repeatedly (if

necessary) to choose PERSONAL picture mode.

2. Press the MENU button on the remote control transmitter. This brings up the normal user

menu.

3. In the normal user menu, use the MENU UP/DOWN keys to highlight the PICTURE sub

menu.

4. Press the MENU LEFT/RIGHT keys to enter the PICTURE sub menu.

5. Use the MENU UP/DOWN keys to select SHARPNESS.

6. Press the MENU LEFT key to decrease the SHARPNESS value.

7. Press the MENU button on the remote control transmitter twice to exit the user menu.

8. The new PERSONAL preference value is automatically stored.

Page 29

Snowy picture

Check CSM line 6. If this line reads “Not Tuned”, check the following:

l Antenna not connected. Connect the antenna.

l No antenna signal or bad antenna signal. Connect a proper antenna signal.

l The tuner is faulty (in this case line 2, the Error Buffer line, will contain error number 10).

Check the tuner and replace/repair the tuner if necessary.

Black and white picture

If:

The picture improves after you have pressed the AUTO PICTURE button on the remote control

transmitter,

Then:

1. Press the AUTO PICTURE button on the remote control transmitter repeatedly (if

necessary) to choose PERSONAL picture mode.

2. Press the MENU button on the remote control transmitter. This brings up the normal user

menu.

3. In the normal user menu, use the MENU UP/DOWN keys to highlight the PICTURE sub

menu.

4. Press the MENU LEFT/RIGHT keys to enter the PICTURE sub menu.

5. Use the MENU UP/DOWN keys to select COLOUR.

6. Press the MENU RIGHT key to increase the COLOUR value.

7. Press the MENU button on the remote control transmitter twice to exit the user menu.

8. The new PERSONAL preference value is automatically stored.

Menu text not sharp enough

If:

The picture improves after you have pressed the AUTO PICTURE button on the remote control

transmitter,

Then:

1. Press the AUTO PICTURE button on the remote control transmitter repeatedly (if

necessary) to choose PERSONAL picture mode.

2. Press the MENU button on the remote control transmitter. This brings up the normal user

menu.

3. In the normal user menu, use the MENU UP/DOWN keys to highlight the PICTURE sub

menu.

4. Press the MENU LEFT/RIGHT keys to enter the PICTURE sub menu.

5. Use the MENU UP/DOWN keys to select PICTURE.

6. Press the MENU LEFT key to decrease the PICTURE value.

7. Press the MENU button on the remote control transmitter twice to exit the user menu.

8. The new PERSONAL preference value is automatically stored.

Page 30

ComPair

Introduction

ComPair (Computer Aided Repair) is a service tool for Philips Consumer Electronics products.

ComPair is a further development on the European DST (service remote control), which allows

faster and more accurate diagnostics. ComPair has three big advantages:

ComPair helps you to quickly get an understanding on how to repair the chassis in a short

time by guiding you systematically through the repair procedures.

ComPair allows very detailed diagnostics (on I2C level) and is therefore capable of

accurately indicating problem areas. You do not have to know anything about I2C

commands yourself because ComPair takes care of this.

ComPair speeds up the repair time since it can automatically communicate with the chassis

(when the microprocessor is working) and all repair information is directly available. When

ComPair is installed together with the Force electronic manual of the defective chassis,

schematics and PWBs are only a mouse click away.

Specifications

ComPair consists of a Windows based faultfinding program and an interface box between PC

and the (defective) product. The ComPair interface box is connected to the PC via a serial or

RS232 cable.

In this chassis, the ComPair interface box and the TV communicate via a bi-directional service

cable via the service connector.

The ComPair faultfinding program is able to determine the problem of the defective television.

ComPair can gather diagnostic information in two ways:

l Automatic (by communication with the television): ComPair can automatically read out the

contents of the entire error buffer. Diagnosis is done on I2C level. ComPair can access the

I2C bus of the television. ComPair can send and receive I2C commands to the micro

controller of the television. In this way, it is possible for ComPair to communicate (read and

write) to devices on the I2C busses of the TV-set.

l Manually (by asking questions to you): Automatic diagnosis is only possible if the micro

controller of the television is working correctly and only to a certain extend. When this is not

the case, ComPair will guide you through the faultfinding tree by asking you questions (e.g.

Does the screen give a picture? Click on the correct answer: YES / NO) and showing you

examples (e.g. Measure test-point I7 and click on the correct waveform you see on the

oscilloscope). You can answer by clicking on a link (e.g., text or a waveform picture) that will

bring you to the next step in the faultfinding process.

By a combination of automatic diagnostics and an interactive question / answer procedure,

ComPair will enable you to find most problems in a fast and effective way.

Page 31

How To Connect

1. First, install the ComPair Browser software (see the Quick Reference Card for installation

instructions).

2. Connect the RS232 interface cable between a free serial (COM) port of your PC and the

PC connector (marked with 'PC') of the ComPair interface.

3. Connect the mains adapter to the supply connector (marked with 'POWER 9V DC') of the

ComPair interface.

4. Switch the ComPair interface “off”.

5. Switch the television set OFF (remove AC power).

6. Connect the ComPair interface cable with the connector on the rear side of the compare

interface (marked with 'I2C') and the additional ComPair interface cable. Connect the other

side of the additional ComPair interface cable with the ComPair (or Service) connector at

the rear side of the TV.

7. Plug the mains adapter in a mains outlet, and switch the interface “on”. The green and red

LEDs light up together. The red LED extinguishes after approx. 1 second while the green

LED remains lit.

8. Start the ComPair program and read the 'Introduction' chapter.

Figure: E06532-008 ComPair Interface connection

Page 32

Error Codes

The error code buffer contains all errors detected since the last time the buffer was erased.

The buffer is written from left to right. When an error occurs that is not yet in the error code

buffer, it is displayed at the left side and all other errors shift one position to the right.

How To Read The Error Buffer

You can read the error buffer in 3 ways:

l On screen via the SAM (if you have a picture).

Examples:

n ERROR: 0 0 0 0 0 : No errors detected

n ERROR: 6 0 0 0 0 : Error code 6 is the last and only detected error

n ERROR: 9 6 0 0 0 : Error code 6 was detected first and error code 9 is the last detected

(newest) error

l Via the blinking LED procedure (when you have no picture). See “The Blinking LED

Procedure”.

l Via ComPair.

How To Clear The Error Buffer

The error code buffer is cleared in the following cases:

l By using the CLEAR command in the SAM menu:

n To enter SAM, press the following key sequence on the remote control transmitter: “062596”

directly followed by the OSD/STATUS button (do not allow the display to time out between

entries while keying the sequence).

n Make sure the menu item CLEAR is highlighted. Use the MENU UP/DOWN buttons, if

necessary.

n Press the MENU RIGHT button to clear the error buffer. The text on the right side of the

“CLEAR” line will change from “CLEAR?” to “CLEARED”

l If the contents of the error buffer have not changed for 50 hours, the error buffer resets

automatically.

Note: If you exit SAM by disconnecting the mains from the television set, the error buffer is not

reset.

Page 33

Error Codes

In case of non-intermittent faults, write down the errors present in the error buffer and clear the

error buffer before you begin the repair. This ensures that old error codes are no longer

present.

If possible, check the entire contents of the error buffer. In some situations, an error code is

only the result of another error and not the actual cause of the problem (for example, a fault in

the protection detection circuitry can also lead to a protection).

Table: Error code overview

Page 34

The Blinking LED Procedure

Using this procedure, you can make the contents of the error buffer visible via the front LED.

This is especially useful when there is no picture.

When the SDM is entered, the front LED will blink the contents of the error-buffer:

l The Led blinks with as many pulses as the error code number, followed by a time period of

1.5 seconds, in which the LED is off.

l Then this sequence is repeated.

Any RC5 command terminates this sequence.

Example of error buffer: 12 9 6 0 0

After entering SDM, the following occurs:

l 1 long blink of 5 seconds to start the sequence,

l 12 short blinks followed by a pause of 1.5 seconds,

l 9 short blinks followed by a pause of 1.5 seconds,

l 6 short blinks followed by a pause of 1.5 seconds,

l 1 long blink of 1.5 seconds to finish the sequence,

l The sequence starts again at 12 short blinks.

Page 35

Fault Finding and Repair Tips

Notes:

l It is assumed that the components are mounted correctly with correct values and no bad

solder joints.

l Before any fault finding actions, check if the correct options are set.

NVM Editor

In some cases, parts of the NVM contents need to be changed. This can be done with the

“NVM Editor” option in SAM mode. With this option single bytes can be changed.

Load default NVM values

In case a blank NVM is placed or when the NVM content is corrupted, default values can be

downloaded into the NVM. After the default values are downloaded it will be possible to start

up and to start aligning the TV set. This is no longer initiated automatically; to initiate the

download the following action has to be performed:

1. Switch off the TV set via the mains switch

2. Short circuit the SDM jumpers (keep short circuited)

3. Press P+ or Ch+ on the local keyboard (and keep it pressed)

4. Switch on the TV set via the mains switch

5. When the set has started up the P+/Ch+ button can be released and the short circuit of the

SDM jumpers can be removed.

6. The red LED will be on continuously to indicate that the download is initiated (normally

when SDM is activated the red LED will start with the Blinking LED sequence).

7. Wait +/- 30 Seconds (time needed to download default values to the NVM)

Result: The set is in SDM, the NVM is loaded with default values and the blinking LED is not

activated (The blinking LED is not activated in this case to show that the download has been

performed), the LED will be on.

Page 36

Tuner and IF

No Picture in RF mode

1. Check if picture is present in AV. If not, go to Video processing troubleshooting section.

2. If present, check that the Option settings are correct.

3. Check that all supply voltages are present.

4. Check if I2C lines are working correctly (3.3V).

5. Manually store a known channel and check if there is IF output at Tuner pin 11.

6. Feed in 105 dBuV at Tuner pin 11 and check whether there is RGB output from Video

Processing IC. If yes, Tuner may be defected. Change Tuner.

Sound in picture problem for L' system (rolling horizontal lines)

1. Check whether AGC L' in Sam mode is set to 0.

2. If yes, align the set to correct value.

Required system is not selected correctly

1. Check whether the Service jumper (#4022, 08 05 size) is present. If yes, remove it.

2. Check whether SEL_IF pin is according to what is specified.

Video Processing

No power

1. Check +12 V and 3V3 at position 1910.

2. If no supply, check the connector 1910.

3. If it is correct, check the power supply board.

Power supply is correct but no green light

1. Check the two connectors 1005 and 1601, if they are properly inserted.

2. If they are inserted correctly, check if the 3V3 is present.

No picture display

1. Check the RGB signal.

2. If it is present, check 3-IC7016 (NE555).

3. If it has output, the problem is in SCALER part.

4. Otherwise, check H-out on pin 2 of NE555. If the input signal of pin2 is present, but no

output, the IC is failed.

Note:

l If the H-out (pin 67) doesn't have signal or the level is low, check the output of NE555 (pin 3)

during start up.

l If the H-out (pin 67) has a signal (or has a signal for a very short time), change IC7016

(NE555).

Page 37

No TV but PC is present

1. Check if HSYNC and VSYNC are present at PIN 3 of 7071 and 7015.

2. If they are present, check RGB output.

3. If there is no RGB output, the IC TDA120xx can be failed.

Comb Filter not working

1. Check the option bit 5 in SAM.

2. Check NVM setting. Address 1229 is 0000.

Power Supply

Check fuses

This power supply contains three fuses. One is near the mains inlet (marked on the board as

1102) and two other are near the output connectors (marked 1610 and 1660).

1. Check with power supply in off state by means of ohmic measurement.

2. Fuse 1102 may open in case of severe lightning strikes and/or failures in the power supply.

Despite the fact, that this fuse is mounted in a fuse holder and the marking text on the

board, it is not meant to be field replaceable.

3. Fuses 1610 and 1660 may open in case a severe overload of the 12 V outputs.

Replacement of the power supply is needed, but not before the cause of the overload

conditions is resolved.

Standby mode

1. Apply a 12 ohm load resistor of sufficient power rating to all outputs (+3 V3, +12 VAL, +12

VL and +24 V). Connect the STBY pin to GND.

2. Over an input voltage range of 90 V_ac to 264 V_ac only the +3 V3 output shall be up and

within regulation (±5%). The voltage on the POWER DOWN pin shall be < 0.3 V at an input

voltage below 160 V_ac, and 3.3 V ±10% at an input voltage higher than 240 V_ac.

Normal mode:

1. Apply a 12 ohm load resistor of sufficient power rating to all outputs (+3 V3, +12 VAL, +12

VL and +24 V). Connect the STBY pin to the +3 V3 output.

2. Over an input voltage range of 90 V _ac to 264 V_ac all outputs shall be up and within

regulation (±5%). The voltage on the POWER DOWN pin shall be 3.3 V ±10% over the

entire input voltage range. Additionally, the voltage on the big capacitor mounted flat on the

PCB shall be 400 V ±10%.

Page 38

Alignments

General: The Service Default Mode (SDM) and Service Alignment Mode (SAM) are

described in chapter 5. Menu navigation is done with the cursor Up, Down, Left or Right

keys of the remote control transmitter.

General Alignment Conditions

Perform all electrical adjustments under the following conditions:

Mains voltage and frequency: 100-240 V / 50/60 Hz.

Allow the set to warm up for approximately 10 minutes.

Test probe: Ri > 10 M ohm; Ci < 2.5 pF.

Hardware Alignments

There are no hardware alignments foreseen for the LCD-TV.

Software Alignments

With the software alignments of the Service Alignment Mode (SAM) the geometry, white

tone and tuner (IF) can be aligned.

To store the data: Use the RC button Menu to switch to the main menu and next, switch

to 'Stand-by' mode.

Page 39

SAM Menu

Figure: E14490-054 SAM Menu (nieuw nummer)

Page 40

White Tone

In the White Tone sub menu the colour values for the colour temperature values can be

changed.

The colour temperature mode (Normal, Delta Cool, Delta Warm) or the colour (R, G, B)

can be selected with the Right/Left cursor keys. The mode or value can be changed

with the Up/Down cursor keys.

First the values for the Normal colour temperature should be selected. Range: 0-255,

128 represent the middle of the value (no offset difference). Then the offset values for

the Delta Cool and Delta Warm mode can be selected. Note that the alignment values

are non-linear. The range is: -50 to +50, 0 represents the middle value, (no offset

difference).

Input signal strength: >=10 mV rms (80 dBµV) terminal voltage.

Input injection point: Aerial input.

Alignment Method

Initial Set-up

l 12 minutes soaking time before carrying out Colour Temp alignment.

l Incredible Picture/Contrast+ and Active Control & Light Sensor must be switched Off

for proper tracking.

l Set all colour temperature settings to their initial values, i.e. Red=135; Green=128;

Blue=133.

l The offset values for Cool & Warm should be preloaded into NVM.

l The alignment is done for Normal only.

Method of alignments

1. Place the colour sensor of the meter at the centre of the screen with standard

orientation (at 0 degree orientation).

2. Set the meter in (T, delta UV, Y) mode.

3. Set Brightness and Colour to nominal (Factory mode, Brightness 60).

4. Set Colour temp to normal.

5. Set Contrast to make the light output Y on the meter 250 nit +/-10%.

6. Set Green=128.

7. Adjust Red and Blue to bring delta UV and T to the value as in the table.

8. Repeat the procedure if necessary to obtain the values as in the table.

Expected Results

l Measured parameters: Refer to table,

l Specifications: Refer to table,

l Units of measurement: Kelvin.

Table: Colour temperatures

Page 41

Tuner Adjustment

AGC (RF AGC Take Over Point)

Set pattern generator (e.g. PM5580) with colour bar pattern and connect to aerial input

with RF signal amplitude - 10mV and set frequency for NTSC to 61.25 MHz.

l Activate the SAM-menu. Go to the sub-menu Tuner, select the sub-menu option AFC

Window and adjust the value to 100kHz.

l Select the AGC sub-menu.

l Connect a DC multi-meter to F306 pin1 of the tuner.

l Adjust the AGC until the voltage at pin 1 of the tuner is 3.3 Volts +0.5 / -1.0.

l The value can be incremented or decremented by pressing the right/left Menu-button

on the RC.

l Switch the set to standby to store the data.

Grey Scale Adjustment

SDTV Grey Scale Adjustment

Alignment Method

l Switch to TV mode,

l Press the Mute button on RC,

l Set Smart Picture to soft mode,

l Activate the auto colour function by pressing key-sequence: “Info+”, “Mute”, “Mute”,

“Mute”, “Info+”, “Menu”, “Info+”

Expected Results

Visual:

l Check for 8 Grey levels.

Analogue PC Grey Scale Adjustment

Input Requirements

Input Signal Type:

l PC input signal, with 64 levels Grey scale pattern,

l 1024x768 @ 60Hz (format=81:DMT1060, pattern=123:Grey 64). Input Injection Point:

l PC input at Dsub connector.

Alignment Method

l Switch to PC mode,

l Press the Mute button on RC,

l Set Brightness & Contrast to nominal 50,

l Activate PC Auto Colour function by pressing key-sequence: “Info+”, “Mute”, “Mute”,

“Mute”, “Info+”, “Menu”, “Info+”

Expected Results

Visual:

l Check for 64 Grey levels.

Page 42

HD Grey Scale Adjustment

Input Requirements

Input Signal Type:

l HD input signal, Top half 100% colour bar and bottom half Grey scale pattern,

l 1920x1080i@60Hz YPrPb (Format=1080i30, Image=HDBar100).

Input Injection Point :

l HD input at Dsub connector

Alignment Method

l Switch to HD mode,

l Press the Mute button on RC,

l Activate HD Auto Colour function by pressing key-sequence: “Info+”, “Mute”, “Mute”,

“Mute”, “Info+”, “Menu”, “Info+”

Expected Results

Visual:

l Check that Colour bar tint and Grey scale are correct.

Sound

No adjustments needed for sound.

The default values for the audio alignments are:

l QSS: On

l FMI: Off

l NICAM Alignment: 63

l Lip Sync: Off

l DBE: Off

Page 43

Options

Options are used to control the presence/absence of certain features and hardware.

How to change an Option Byte

An Option Byte represents a number of different options. Changing these bytes directly

makes it possible to set all options very fast. All options are controlled via seven option

bytes. Select the option byte (OP1.. OP7) with the Menu Up/ Down keys, and enter the

new value.

Leaving the OPTION submenu saves the changes in the Option Byte settings. Some

changes will only take effect after the set has been switched “off” and “on” with the AC

power switch (cold start).

Table: Option values per model

Page 44

LC4.2U AA(7670)

F302 F303 F306

I344 F701 F702

I341

F705

F706 F707 F708

F452 F613 F615

I904

F617

F624 F625

F626

Page 45

All Models (7670) - Chassis Overview

Page 46

All Models (7670) - Power Supply [A1]

Page 47

All Models (7670) - Hercules [A2]

Page 48

All Models (7670) - Histogram [A3]

Page 49

All Models (7670) - Audio Amplifier [A5]

Page 50

All Models (7670) - TV-Supply [A6]

Page 51

All Models (7670) - Scaler [A7]

Page 52

All Models (7670) - Scaler Interface [A9]

Page 53

All Models (7670) - SDRAM [A10]

Page 54

All Models (7670) - Flash / Control [A11]

Page 55

All Models (7670) - HDMI [A12]

Page 56

All Models (7670) - PCHD-MUX [A13]

Page 57

All Models (7670) - Supply [A14]

Page 58

All Models (7670) - 3D Comb Filter [CB]

Page 59

All Models (7670) - Side IO and LKB Panel [D]

Page 60

All Models (7670) - Cinch (17?) [H1]

Page 61

All Models (7670) - PCHD-IO (17?) [H2]

Page 62

All Models (7670) - Rear IO Cinch (23"/26?) [H1]

Page 63

All Models (7670) - PCHD-IO (23"/26?) [H2]

Page 64

All Models (7670) - Front IR / LED Panel [J]

Page 65

All Models (7670) - EPLD Control [PP1]

Page 66

All Models (7670) - LVDS In [PP2]

Page 67

All Models (7670) - EPLD I/O [PP3]

Page 68

All Models (7670) - Power Supply [PP4]

Page 69

All Models (7670) - Layout Tv & Scaler Board: (Overview Top Side)

Page 70

All Models (7670) - Layout Tv & Scaler Board: (Overview Bottom Side)

Page 71

All Models (7670) - Layout 3D Comb Filter (Top Side)

Page 72

All Models (7670) - Layout 3D Comb Filter (Bottom Side)

Page 73

All Models (7670) - Layout Side IO and LKB Panel (Top Side)

Page 74

All Models (7670) - Layout Side IO and LKB Panel (Bottom Side)

Page 75

All Models (7670) - Layout Rear IO Panel (17?) (Top Side)

Page 76

All Models (7670) - Layout Rear IO Panel (17?) (Bottom Side)

Page 77

All Models (7670) - Layout Rear IO Panel (23?/26?) (Top Side)

Page 78

All Models (7670) - Layout Rear IO Panel (23?/26?) (Bottom Side)

Page 79

All Models (7670) - Layout Front IR / LED Panel (Top Side)

Page 80

All Models (7670) - Layout Front IR / LED Panel (Bottom Side)

Page 81

All Models (7670) - Layout Pixel Plus Panel (Top Side)

Page 82

All Models (7670) - Layout Pixel Plus Panel (Bottom Side)

Page 83

All Models (7670) - Testpoint Overview TV & Scaler Board (Bottom Side)

Page 84

All Models (7670) - Testpoint Overview TV & Scaler Board (Top Side)

Page 85

All Models (7670) - Wiring Diagram

Page 86

All Models (7670) - Block Diagram Tuner and IF Video

Page 87

All Models (7670) - Block Diagram Scaler

Page 88

All Models (7670) - I2C IC Overview

Page 89

All Models (7670) - Supply Voltage Overview

Page 90

Circuit Descriptions, Abbreviation List,

and IC Data Sheets

Index of this chapter

1. Introduction

2. Block Diagram

3. Power Supply

4. Input/Output

5. Tuner and IF

6. Video: TV Part

7. Video: Scaler Part

8. Video: Pixel Plus Part

9. Audio Processing

10. Control

11. LCD Display

12. Abbreviation List

13. IC Data Sheets

Introduction

The LC4.2 LCD TV is a global LCD TV for the year 2004. It is the successor of the LC03

LCD TV and covers screens sizes 17, 23 and 26 inch (all in 16:9 ratio) and has a new

styling, called Disc.

This chassis has the following (new) features:

l Audio: The sound processor is part of the UOC processor (called “Hercules”). The

chassis has a FM Radio with 40 preset channels.

l Video: Pixel Plus, Enhanced video features, video drivers, Active Control and multiple

PIP.

The architecture consists of a TV and Scaler panel, I/O panel, Side I/O and Local

Keyboard panel, Power Supply panel and for 23 and 26 inch models only a 3D Comb

filter panel and Pixel Plus panel.

The functions for video/audio processing, microprocessor (P), and CC/Teletext (TXT)

decoder are all combined in one IC (TDA120xx, item 7011), the so-called third

generation Ultimate One Chip (UOC-III) or “Hercules”. This chip has the following

features:

l Control, small signal, mono/stereo, and extensive Audio/Video switching in one IC.

l Upgrade with digital sound & video processing.

l Alignment free IF, including SECAM-L/L1 and AM.

l FM sound 4.5/5.5/6.0/6.5, no traps/bandpass filters.

l Full multi-standard color decoder.

l One crystal reference for all functions (microprocessor, RCP, TXT/CC, RDS, color

decoder, and stereo sound processor).

Page 91

Block Diagram

Figure: Block Diagram LC4.2

The PLL tuner UR1336 (with FM radio) delivers the IF-signal, via audio & video SAWfilters, to the Video Signal Processor and FLASH embedded TEXT/Control/Graphics

Micro Controller TDA120x1 (item 7011, also called Hercules). This IC has the following

functions:

l Analogue Video Processing

l Sound Demodulation

l Audio Interfaces and switching

l Volume and tone control for loudspeakers

l Reflection and delay for loudspeaker channels

l Micro Controller

l Data Capture

l Display

The Hercules has one input for the internal CVBS signal and a video switch with 3

external CVBS inputs and a CVBS output. All CVBS inputs can be used as Y-input for

Y/C signals.

However, only 2 Y/C sources can be selected because the circuit has 2 chroma inputs.

It is possible to add an additional CVBS (Y)/C input (CVBS/YX and CX) when the YUV

interface and the RGB/YPRPB input are not needed. The I/O is divided over two parts:

Rear I/O and Side I/O. The rear has two AV inputs with CVBS, Y/C and YUV, a PC

(VGA) input, and an HDMI input. The side has a CVBS and Y/C (SVHS) input. The

video part delivers the RGB signals to the Scaler IC.

Page 92

The Genesis GM1501 Malibu Scaler IC can receive two video input signals: SDTV (from

Hercules), DVI (from external DVI source), or PC (from external computer).

After the video processing, the digital data is send via a Low Voltage Differential

Signaling bus to the LCD panel. LVDS is used to improve data speed and to reduce

EMI significantly.

There are two I2C lines and two interrupt and communication lines (TV_IRQ and

TV_SC_COM) for the Scaler control. The Scaler communicates with the Hercules as a

slave device. To avoid buffer overflow at the Scaler side, the TV_SC_COM line provides

the necessary hardware flow control. To allow bi-directional communication, the Scaler

can initiate a service interrupt-request to the Hercules via the TV_IRQ line.

The Hercules, and EEPROM are supplied with 3.3 V, which is also present during

STANDBY.

The EEPROM, or NVM (Non Volatile Memory) is used to store the settings.

The sound part is built up around the Hercules. The Source Selection, Decoding and

Processing is all done by the Hercules.

Power supply input are several DC voltages coming from a supply panel.

Power Supply

For Service, this supply panel is a black box. When defect (this can be traced via the

faultfinding tips, or by strange phenomena), a new panel must be ordered (see table

below for ordering codes), and after receipt, the defective panel must be send for repair.

Screen Size (inches) Ordering Code

17 3122 137 23040

23 3122 137 23070

26 3122 137 23080

Table: Ordering Codes Power Supply

Input/Output

The I/O is divided over two parts: Rear I/O and Side I/O. The rear has two AV inputs

with CVBS, Y/C and YUV, a PC (VGA) input, and an HDMI input. The side has a CVBS

and Y/C (SVHS) input.

AV1: The input of AV1 is CVBS + YUV + L/R.

AV2: The input of AV2 is Y/C + CVBS + L/R.

AV2: The input of AV2 is Y/C + CVBS + L/R.

The selection of the external I/O's is controlled by the Hercules.

PC (VGA) in: This input is directly going to the Scaler IC. See paragraph “Video: Scaler

Part”.

HDMI in: This input is directly going to the Scaler IC. See paragraph “Video: Scaler

Part”.

Page 93

Tuner and IF

A Philips UR13xx Tuner with second input (for FM Radio) is used in the TV board. The

SIF and FM signals are decoded by the Hercules. Tuning is done via I2C.

Video IF Amplifier

The IF-filter is integrated in a SAW (Surface Acoustic Wave) filter. One for filtering IFvideo (1328) and one for IF-audio (1330). The type of these filters is depending of the

standard(s) that has to be received.

The output of the tuner is controlled via an IF-amplifier with AGC-control. This is a

voltage feedback from pin 31 of the Hercules to pin 1 of the tuner. The AGC-detector

operates on top sync and top white level. AGC take-over point is adjusted via the

service alignment mode 'Tuner' - 'AGC'. If there is too much noise in the picture, then it

could be that the AGC setting is wrong. The AGC-setting could also be mis-aligned if

the picture deforms with perfect signal; the IF-amplifier amplifies too much.

Video: TV Part (diagrams A1, A2, and A3)

Figure: Block diagram video processing

Page 94

The video processing is completely handled by the Hercules:

l IF demodulator.

l Chrominance decoder.

l Sync separator.

l Horizontal & vertical drive.

l RGB processing.

l CVBS and SVHS source select.

It has also build in features like:

l CTI.

l Black stretch.

l Blue stretch.

l White stretch.

l Slow start up.

l Dynamic skin tone correction etc.

Further, it also incorporates sound IF traps and filters, and requires only one crystal for

all systems.

Histogram (YUV picture improvement) IC

The demodulated video-signal can be checked on pins 74, 75, and 76 of IC7011 and is

fed to pins 70, 71, and 72. In this path, the Histogram IC TDA9171 is inserted.

This TDA9178 can control various picture improvements:

l Histogram processing.

l Colour transient improvement.

l Luminance transient improvement.

l Black and white stretch.

l Skin tone correction.

l Green enhancement.

l Blue stretch.

l Smart peaking.

l Video dependent coring.

l Colour dependent stretching.

Since the TDA9171 is connected to the Hercules, picture improvement works only for

signals that are routed trough the Hercules and not for signals directly connected to the

Scaler.

Page 95

Video: Scaler Part (diagram A7 and A13)

The Genesis gm1501 Scaler is a dual channel graphics and video processing IC for

LCD monitors and televisions incorporating Picture in Picture, up to SXGA output

resolutions. The Scaler controls the display processing in an LCD TV, e.g. like the

deflection circuit in a CRT-based TV. It controls all the view modes (e.g. like 'zooming'

and 'shifting'). Features like PC (VGA) or HD inputs, are also handled by this part.

Figure: Block diagram Scaler Part

Page 96

Features

The Scaler provides several key IC functions:

l Scaling.

l Auto-configuration/ Auto-Detection.

l Various Input Ports:

n Analog RGB.

n DVI Compliant.

n Video Graphics.

l Integrated LVDS Transmitter.

l On-chip Micro-controller

Inputs

PC (VGA) input

The VGA input is processed by the VGA block of the Scaler. The Scaler supports pixel

frequencies up to 165MHz. YpbPr format is also supported via the VGA interface and

covers a resolution of 480p/560p/720p/1080i.

HDMI input

HDMI input signals are fed to the HDMI Panellink Receiver (item 7808 on diagram A12).

This IC consists of a flexible audio and video interface. The video part delivers

RGB/YPbPr output that directly is fed to the Scaler. The audio part delivers a 2-channel

I2S digital audio signal that is fed to the audio DAC (item 7809). After DA conversion,

the signals are fed to the Hercules.

Note: For more information about the HDMI signals refer to the A02U AA Service

Manual.

Output

The Display Output Port provides data and control signals that permit the Scaler to

connect to a variety of display devices using a TTL or LVDS interface. The output

interface is configurable for single or dual wide TTL/LVDS in 18, 24 or 30-bit RGB pixels

format. All display data and timing signals are synchronous with the DCLK output clock.

The integrated LVDS transmitter is programmable to allow the data and control signals

to be mapped into any sequence depending on the specified receiver format.

Page 97

Video: Pixel Plus Part (diagram PP1 to PP4)

The Pixel Plus functionality is completely handled by an Electronic Programmable Logic

Device, EPLD (item 7101 on diagram PP1, PP3). The LVDS output from the TV &

Scaler Board is fed trough a LVDS receiver (item 7201 on diagram PP2) and then

delivered to the EPLD. The EPLD processes the signal and it is fed to the LCD panel

via a LVDS transmitter (item 7403 on diagram PP3).

The EPLD takes care of all picture improvement processing, like:

l Colour improvement

n Blue stretch

n Green enhancement

n Saturation control

l Sharpness enhancement

n Non-linear horizontal peaking

n Non-linear vertical peaking

n Coring, clipping

n Sharpness meter

l Contrast improvement

l Gamma Look-Up Table

All other picture improvement processing is done in the Scaler.

Audio Processing

Figure: Block diagram audio processing

Page 98

The audio decoding is done entirely via the Hercules. The IF output from the Tuner is

fed directly to either the Video-IF or the Sound-IF input, depending on the type of

concept chosen.

There are mainly two types of decoder in the Hercules, an analogue decoder that

decodes only Mono, regardless of any standards, and a digital decoder (or DEMDEC)

that can decode both Mono as well as Stereo, again regardless of any standards.

In this chassis, the analogue decoder is used in two cases:

l It is used for AM Sound demodulation in the Europe SECAM LL' transmission.

l It is used for all FM demodulation in AV-Stereo sets.

Diversity

The diversity for the Audio decoding can be broken up into two main concepts:

l The Quasi Split Sound concept used in Europe and some AP sets.

l The Inter Carrier concept, used in NAFTA and LATAM.

The UOC-III family makes no difference anymore between QSS- and Intercarrier IF,

nearly all types are software-switchable between the two SAW-filter constructions.

Simple data settings are required for the set to determine whether it is using the Inter

Carrier or the QSS concept. These settings are done via the “QSS” and “FMI” bit found

in SAM mode.

Due to the diversity involved, the data for the 2 bits are being placed in the NVM

location and it is required to write once during startup.

On top of that, it can be further broken down into various systems depending on the

region. The systems or region chosen, will in turn affect the type of sound standard that

is/are allowed to be decoded.

l For the case of Europe, the standard consists of BG/DK/I/LL' for a Multi-System set.

There are also versions of Eastern Europe and Western Europe set and the

standard for decoding will be BG/DK and I/DK respectively. FM Radio is a feature

diversity for the Europe sets. The same version can have either FM Radio or not,

independent of the system (e.g. sets with BG/DK/I/LL' can have or not have FM

radio).

l For the case of NAFTA and LATAM, there is only one transmission standard, which

is the M standard. The diversity then will be based on whether it has a dBx noise

reduction or a Non-dBx (no dBx noise reduction).

l For the case of AP, the standard consists of BG/DK/I/M for a Multi-System set. The

diversity here will then depends on the region. AP China can have a Multi-System

and I/DK version. For India, it might only be BG standard.

Page 99

Functionality

The features available in the Hercules are as follows:

l Treble and Bass Control.

l Surround Sound Effect that includes:

n Incredible Stereo.

n Incredible Mono.

n 3D Sound (not for AV Stereo).

n TruSurround (not for AV Stereo).

n Virtual Dolby Surround, VDS422 (not for AV Stereo).

n Virtual Dolby Surround, VDS423 (not for AV Stereo).

n Dolby Pro-Logic (not for AV Stereo).

l Bass Feature that includes:

n Dynamic Ultra-Bass.

n Dynamic Bass Enhancement.

n BBE (not for AV Stereo).

l Auto-Volume Leveler.

l 5 Band Equalizer.

l Loudness Control.

All the features stated are available for the Full Stereo versions and limited features for

the AV Stereo.

Audio Amplifier

The audio amplifier part is very straightforward. It uses the integrated power amplifier

TDA7297D, and delivers a maximum output of 2 x 15 W_rms.

The maximum operating condition for this amplifier is 20 V unloaded. Normal operating

supply is from 6.5 V to 18 V.

Muting is done via the SOUND_ENABLE line connected to pin 13 of the amplifier-IC

and coming from the Hercules.

Audio: Lip Sync

The LC4.2E is not equipped with Lip Sync. This is not needed.

Page 100

Control

Hercules

The System Board has two main micro-controllers on board. These are:

l On-chip x86 micro-controller (OCM) from Genesis LCD TV/Monitor Controller.

l On-chip 80C51 micro-controller from Philips Semiconductor UOCIII (Hercules)

series.

Each micro-controller has it own I2C bus which host its own internal devices.

The Hercules is integrated with the Video and Audio Processor. For dynamic data

storage, such as SMART PICTURE and SMART SOUND settings, an external NVM IC

is being used.

Another feature includes an optional Teletext/Closed Caption decoder with the

possibility of different page storage depending on the Hercules type number.

The Micro Controller ranges in ROM from 128 kB with no TXT-decoder to 128 kB with a

10 page Teletext or with Closed Caption.

Block Diagram

The block diagram of the Micro Controller application is shown below.

Figure: Micro Controller block diagram

Loading...

Loading...