Philips LC260WX2, LC320W01, LC320WX2, LC420WU2, LC420WX2 Service Manual

...

Colour Television Module

LPL (LG Philips) LCD 2k7

LC260WX2

LC320W01

LC320WX2

LC420WU2

LC420WX2, LC420WX3, LC420WX5

LC470WU1, LC470WU4

Contents Page

1. Technical Specifications, Connections, and Chassis

Overview 2

2. Safety Instructions, Warnings, and Notes 3

3. Directions for Use 4

4. Mechanical Instructions 5

5. Service Modes, Error Codes, and Fault Finding 31

6. Block Diagrams, Test Point Overviews, and

Waveforms 32

7. Circuit Diagrams and PWB Layouts 32

8. Alignments 32

9. Circuit Descriptions, Abbreviation List, and IC Data

Sheets 32

10. Spare Parts List 32

11. Revision List 32

©

Copyright 2007 Philips Consumer Electronics B.V. Eindhoven, The Netherlands.

All rights reserved. No part of this publication may be reproduced, stored in a

retrieval system or transmitted, in any form or by any means, electronic,

mechanical, photocopying, or otherwise without the prior permission of Philips.

Published by MW 0767 BG CD Customer Service Printed in the Netherlands Subject to modification EN 3122 785 16890

EN 2 LCD LPL 2K71.

Technical Specifications, Connections, and Chassis Overview

1. Technical Specifications, Connections, and Chassis Overview

Index of this chapter:

1.1 Introduction

1.2 General

1.3 Specifications

Note:

• Specifications are indicative (subject to change).

1.1 Introduction

In this Service Manual you will find all necessary information to

perform the Board Level Repair (= board swap) scenario on

LCD panels. These LCD repair manuals are created per brand,

and they will contain all necessary information for the different

panels used in Philips flat LCD TVs.

1.2 General

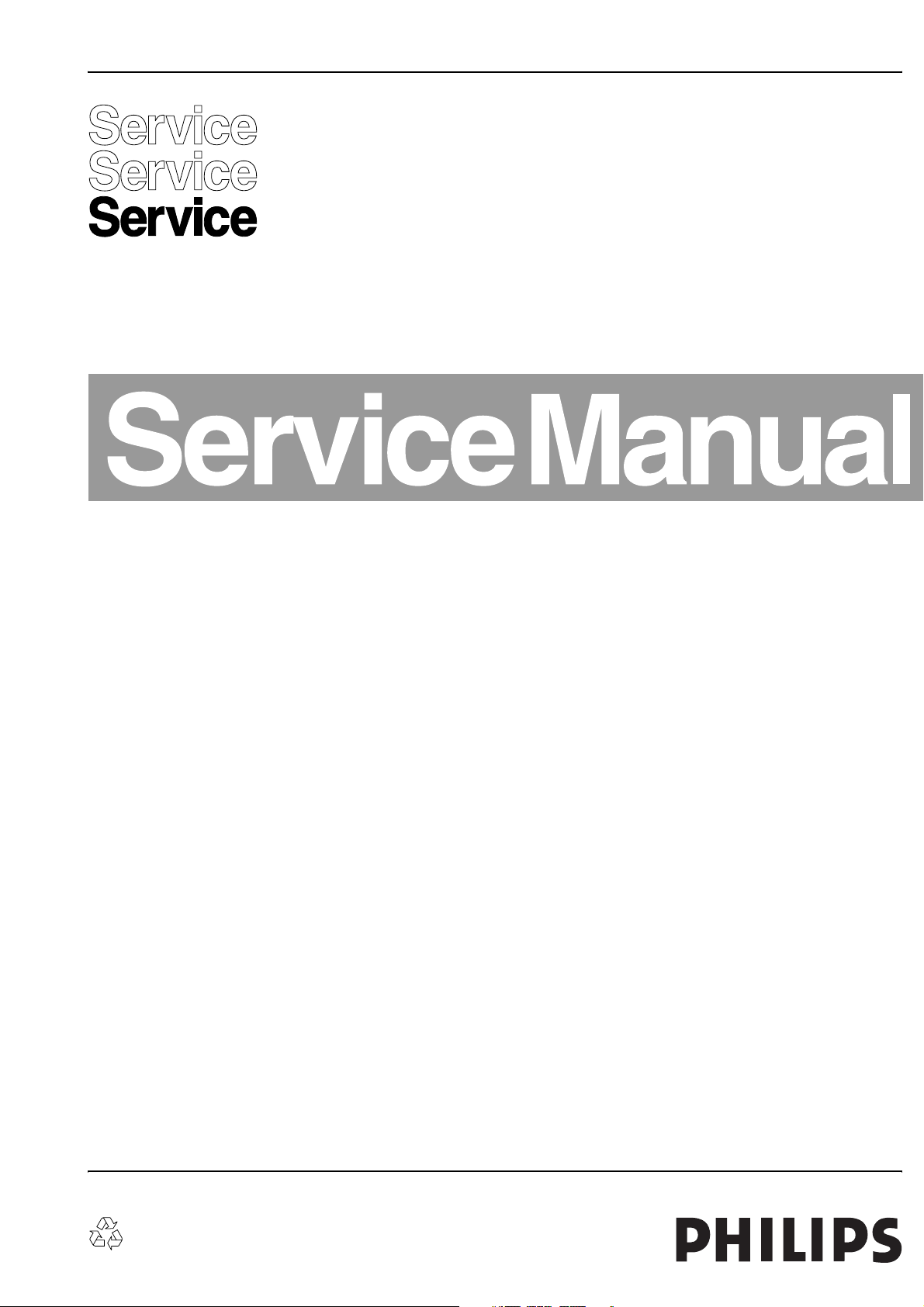

Inverter

Number of order progress.

The Marking position could be different each model of T-Con or inverter P/N.

This picture is different from origin model.

Please Use it only as a reference.

T-CON Board

Case 1

Case 2

(Master)

(Slave)

H_16890_024.eps

230507

1.3 Specifications

Below find attached the data sheets of the different LCD

panels. Click on the “model number” to open.

• Model LC260WX2

• Model LC320W01

• Model LC320WX2

• Model LC420WU2

• Model LC420WX2

• Model LC420WX3

• Model LC420WX5

• Model LC470WU1

• Model LC470WU4

Figure 1-1 LPL board labelling

Safety Instructions, Warnings, and Notes

2. Safety Instructions, Warnings, and Notes

EN 3LCD LPL 2K7 2.

Index of this chapter:

2.1 General

2.2 Safety Precautions

2.3 Servicing Precautions

2.1 General

Notes:

• Only authorised persons should perform servicing of this

module.

• When using/handling this unit, pay special attention to the

LCD Module: it should not be enforced into any other way

then next rules, warnings, and/or cautions.

• "Warning" indicates a hazard that may lead to death or

injury if the warning is ignored and the product is handled

incorrectly.

• "Caution" indicates a hazard that can lead to injury or

damage to property if the caution is ignored and the

product is handled incorrectly.

2.2 Safety Precautions

2.2.1 Warning

• Do not supply a voltage higher than specified to this

product. This may damage the product or can create

hazardous situations.

• Do not use this product in locations where the humidity is

extremely high, where it may be splashed with water, or

where flammable materials surround it.

• Do not install or use the product in a location that does no

satisfy specified environmental conditions. This may

damage the product or can create hazardous situations.

• If a foreign substance (such as water, metal, or liquid) gets

inside the product, immediately turn “OFF” the power.

Continuing to use the product may cause electric shock or

can create hazardous situations.

• If the product emits smoke and abnormal smell, or makes

an abnormal sound, immediately turn “OFF” the power.

Continuing to use the product may cause electric shock or

can create hazardous situations.

• Do not (dis)connect the connector while power to the

product is “ON”. It takes some time for the voltage to drop

to a sufficiently low level after the power has been turned

“OFF”. Confirm that the voltage has dropped to a safe level

before (dis)connecting the connector.

• Do not pull out or insert the power cable from/to an outlet

with wet hands. It may cause electric shock.

• If the power cable is damaged, or if the connector is loose,

do not use the product, otherwise, this can lead to

hazardous situations or may cause electric shock.

• The LCD Backlight Inverter unit uses a high voltage for the

lamps. Keep the cautions concerning electric shock and do

not touch the device circuitry handling the inverter unit. And

because the capacitors of the device circuitry may remain

charged at the moment of Power “OFF”, standing for 1

minute is required in order to discharge the device circuitry.

2.2.2 Caution

• Do not place this product in a location that is subject to

heavy vibration, or an unstable surface such as an inclined

surface. The product may fall off or fall over, causing

injuries.

• Before disconnecting cable from the product, be sure to

turn off the power. Be sure to hold the connector when

disconnecting cables. Pulling a cable with excessive force

may cause the core of the cable to be exposed or break the

cable, and this can lead to fire or electric shock.

• This product contains glass. If shock, vibration, heat or

distortion is applied to the product, the glass may be

broken.

• If glass surface of the display breaks or is scratched, do not

touched the broken pieces or the scratched with bare

hands. You may be injured.

• LCD Module requires to be handled with special care. LCD

Module is not to be touched with metal or hard materials.

Must not be stressed by heat or mechanical impact.

• There are some particular components on the rear panel of

this product. Skin contact with these components may

cause an electric shock. So, handle with care.

• While moving the product, be sure to turn off the power,

disconnect all cables and watch your step. Dropping the

product may cause injuries from electric shock. So, while

moving the product handle with care.

• When cleaning the panel is necessary, wipe it with a soft

and moistened cloth a neural detergent. Caution on

connector area. Do not use chemicals such as thinner or

benzene.

• LCD Module emits heat from the Lamp, Backlight lamp,

and component parts. Therefore, the environmental

temperature must not exceed 50 deg. C. LCD Module

Backlight Inverter system is driven by high voltage, so it

must avoid conductive materials.

• If repairing components with a lead line, high voltage or

high temperature components must be put out from a lead

line and fix.

• Do not place an object on the surface of the display. The

glass may break or be scratched.

• This product may be damaged if it is subject to excessive

stresses (such as excessive voltage, current, or

temperature). The absolute maximum ratings specify the

limits of these stresses.

• Do not cover or wrap with any covering materials while

power is applied to the product.

• This product is made from various materials such as glass,

metal, and plastic. When discarding it, be sure to contact a

purchase place.

• If a discrepancy occurs due to any arbitrary modification or

disassembly, supplier is not responsible for function,

quality or other items.

• Within the warranty period, general faults may be charged

for depending on responsibility for the faults. You handle

with care

2.3 Servicing Precautions

A colour TFT LCD Module can easily be damaged by both

electrical and mechanical stresses. Users therefore, are

requested to follow the “Servicing precautions of colour TFT

LCD Module” on the following.

2.3.1 System Assembler

• Follow the power sequence: An abnormal power

sequence may cause critical malfunction or electrical

damage.

• Prevent physical stress.

• Prevent overheat:

– High temperatures on the surface of the screen may

cause poor quality. Please use the LCD Module on the

specified temperatures.

– Low temperatures (under 10 deg. C) makes the LCD

Module respond slowly, make the Backlight worse

operated, and will shorten very much the lifetime

accordingly.

• Keep LCD Module dust-free: The LCD Module is

sensitive against dust; it can cause visual or functional

problems.

EN 4 LCD LPL 2K73.

Directions for Use

• Do not touch TCP area: Do not touch TCP area at any

case. It can cause Driver IC cracks, film cracks, etc. The

TCP is the weakest point of the LCD Module.

• Do not pull Backlight wire: Please do not pull the

Backlight wire, as it can cause the wire to become

disconnected or damaged.

• Check the connections of the Inverter & Backlight

connectors: Incomplete connection can cause burnt in

Backlight connectors or damage the inverter.

• Handle with care:

– Please do not drop, bend, or hit the LCD Module.

– Physical stress can cause defects as broken panels.

• Keep mounting screw length and motor driver’s

torque: Strong motor driver’s torque can make a

mechanical defect on LCD Module. Please keep within the

specifications.

• Do not operate for a long time under the same pattern:

Operating the LCD Module for a long time with the same

video pattern can cause image persistence and can

eventually damage it.

• Defective panels must also be handled with care:

– To prevent making other defects, please handle the

defective LCD Module as a good one.

– Defective LCD Modules must be repaired.

• Do not stack LCD Modules: The LCD Module consists of

fragile components such as TCPs or Glasses. Stacking the

LCD Modules can cause undesired defects.

• Do not provide strong pressure at connecting: Strong

pressure can transfer the force to the TCP, which is the

weakest part of the LCD Module. It eventually can make

the TCP crack or lead to other unexpected defects.

• Let the Backlight Wire at the backside of the LCD

Module: If let the Backlight wire in front of the LCD Module,

the Backlight connector can hurt the surface of the

polariser.

• Never (dis)connect at power “ON”: The LCD Module

consists of CMOS components, which are known as weak

components against EOS. It can damage the product.

• Electrostatic discharge can make damage:

– Semi-assembled product should be handled with wrist

strap.

– Earth human body when handle the LCD Module.

– Please do not touch the interface connector pin.

2.3.2 System Assembler/End User

• Keep clean the surface:

– Please wear rubber gloves when you touch the surface

of the LCD Module screen.

– Please use soft and anti-static material with n-Hexane

as cleaner.

• Be careful not to make polariser scratch:

– Surface of polariser is soft, so it’s easily scratched.

– Please do not touch, press or rub on polariser surface

with materials over HB hardness.

• Be careful with swift temperature and humidity

changes: Swift temperature and or humidity change can

make dew condensation or ice, which can cause nonconformance such as malfunctioning.

• Keep out of water:

– Water on in the LCD Module can cause electrical short

or corrosion.

– Please wipe out or dry water carefully.

• Keep the LCD Module free from corrosive gasses:

Corrosive gas can chemically damage the polariser and

the circuitry parts and eventually will cause defects.

• Keep the suitable temperature and humidity: High

temperatures and high humidity will shorten the lifetime

3. Directions for Use

Not applicable.

4. Mechanical Instructions

Mechanical Instructions

EN 5LCD LPL 2K7 4.

Index of this chapter:

4.1 General

4.2 Model LC260WX2

4.3 Model LC320W01

4.4 Model LC320WX2

4.5 Model LC420WU2

4.6 Model LC420WX2

4.7 Model LC420WX3

4.8 Model LC420WX5

4.9 Model LC470WU1

4.10 Model LC470WU4

4.1 General

4.1.1 Warnings

• Figures can deviate due to the different module executions.

• During repair, place the set face down on a soft surface

(e.g. on foam bars as mentioned in next paragraph), in

order to prevent damaging the display.

Note: With some chassis, it is possible to measure and

replace the boards while the TV is still on its stand.

• All ICs and many other semiconductors are susceptible to

electrostatic discharges (ESD w). Careless handling

during repair can reduce life drastically. Make sure that,

during repair, you are connected with the same potential as

the mass of the set by a wristband with resistance. Keep

components and tools also at this same potential.

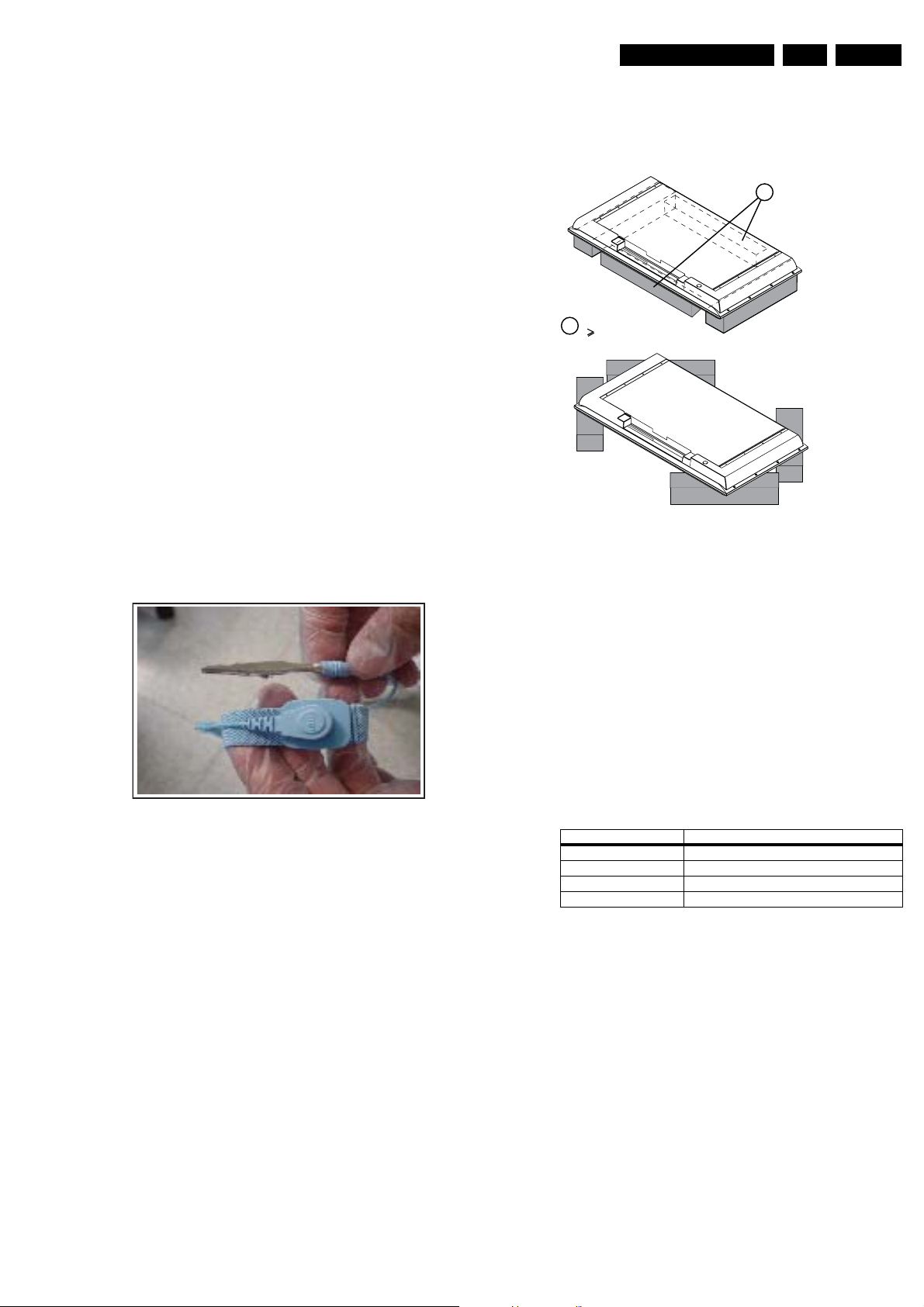

4.1.2 Foam Bars

1

Required for sets

1

42"

E_06532_018.eps

171106

Figure 4-2 Foam bars

The foam bars (order code 3122 785 90580 for two pieces) can

be used for all types and sizes of flat displays. See figure

“Foam bars” for details. Displays with a size of 42” and larger,

require four foam bars [1]. Ensure that the foam bars are

always supporting the cabinet and never only the display.

Caution: Failure to follow these guidelines can seriously

damage the display!

By laying the TV face down on the (ESD protective) foam bars,

a stable situation is created to perform measurements and

alignments. By placing a mirror under the display, you can

monitor the screen.

H_16920_001.eps

060407

Figure 4-1 ESD wristband

• Be careful during measurements in the high voltage

section. Never pull plugs out under operation conditions,

just to prevent danger caused by electrical sparks.

• Never replace modules or other components while the unit

is switched “on”.

• Connectors “to” and “from” the Inverter Boards must be

thoroughly connected to avoid any electrical sparks during

operation.

4.1.3 Torque Values

Table 4-1 Recommended Torque Values

Screw Type (cross head) Recommended Torque Value

M2 2.0 kg*F ± 0.1 kg*F

M2.5 3.0 kg*F ± 0.5 kg*F

M2.6 3.0 kg*F ± 0.5 kg*F

M3 6.0 kg*F ± 0.5 kg*F

EN 6 LCD LPL 2K74.

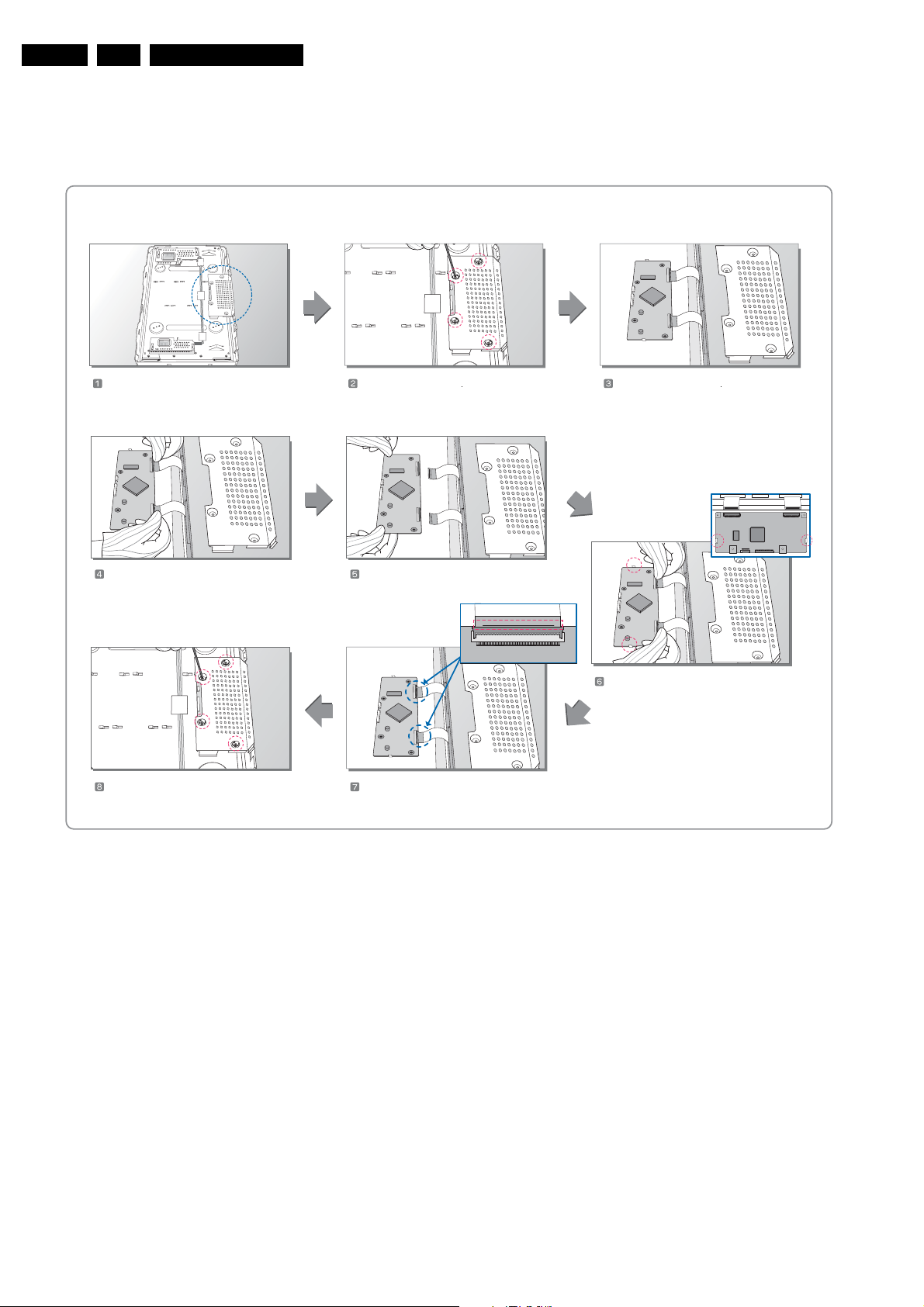

4.2 Model LC260WX2

4.2.1 Control Board (T-CON Board)

Prepare the LCM. Separate the Screw(4EA) Separate the Cover Shield

Mechanical Instructions

MODEL: LC260WX2-SLB2

Separate the FFC(60pin). Separate the T-CON Board.

Attach the Cover Shield and

Assemble the Screw(4EA).

Check the FFC(60pin).

Figure 4-3 Replacement instructions T-CON board

Replace of T-CON Board and

Assemble the FFC(60pin).

* Guide Pin station keeping check.

H_16890_028.eps

230507

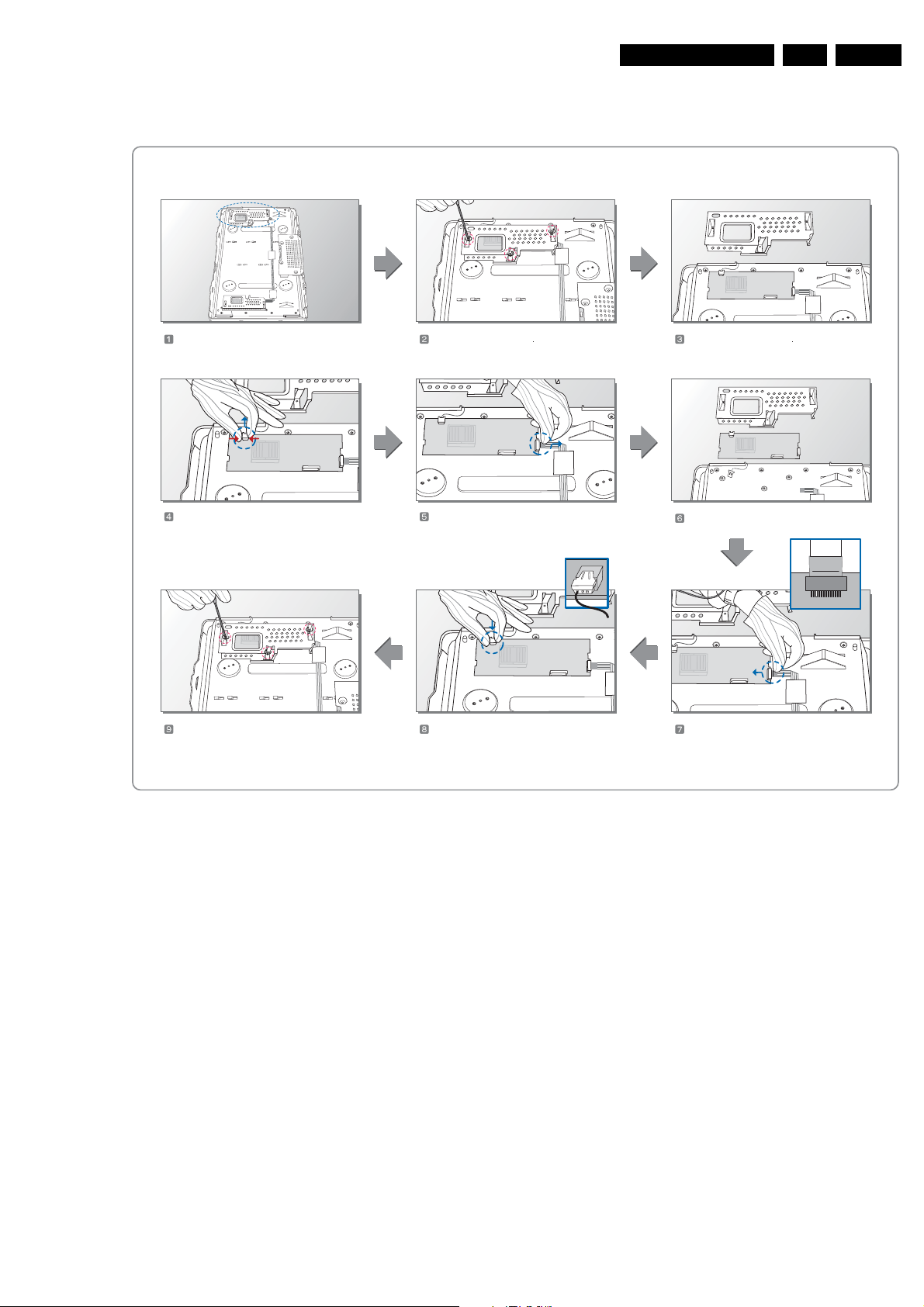

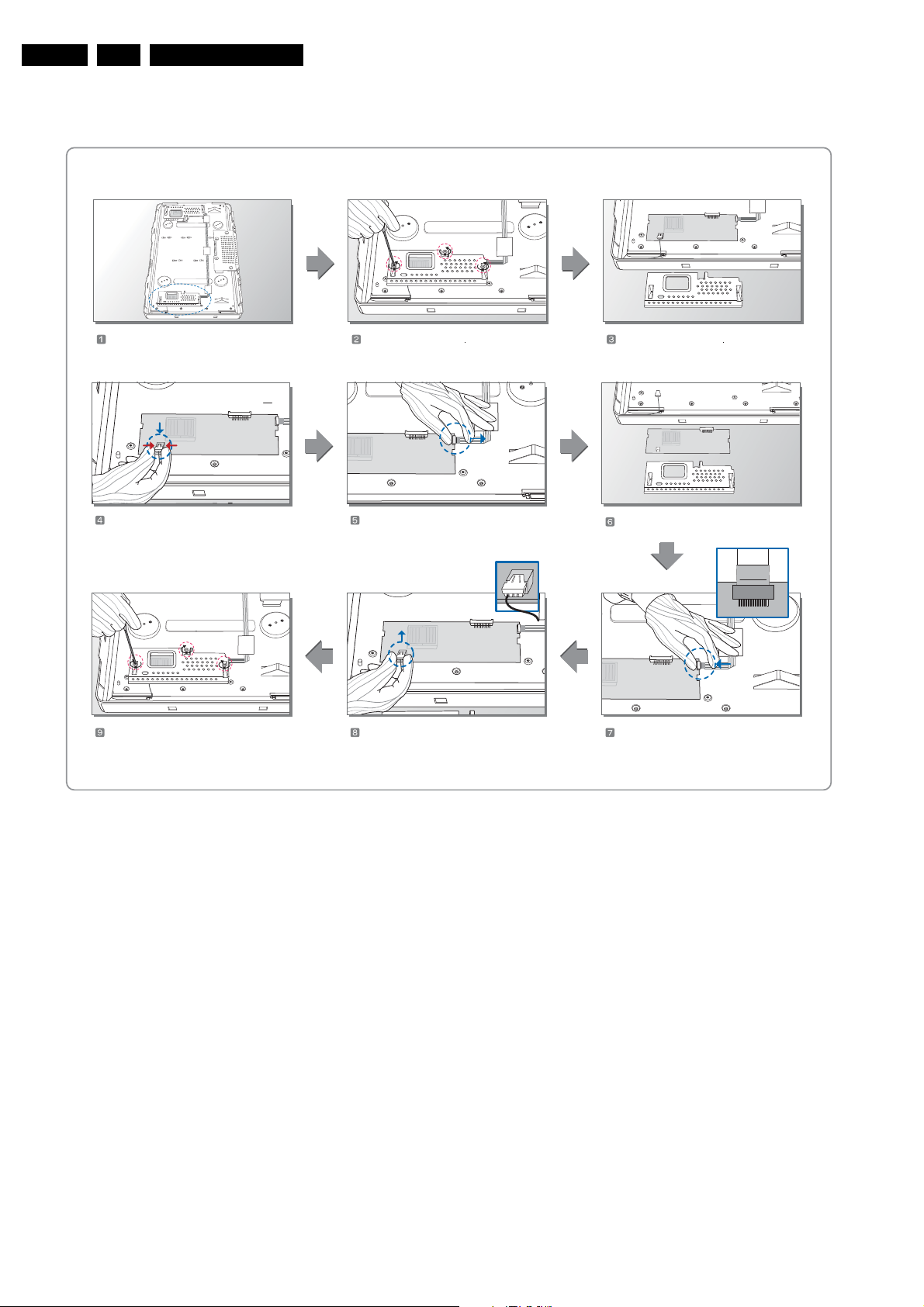

4.2.2 Inverter (Master) Board

Mechanical Instructions

MODEL: LC260WX2-SLB2

EN 7LCD LPL 2K7 4.

Prepare the LCM. Separate the Screw(3EA)

Unlock of Connector and

sperate the Wire Connector(2pin).

Attach the Cover Shield and

Assemble the Screw(3EA).

Separate the FFC(11pin).

Assemble the Wire Connector(2pin).

Separate the Cover Shield

Separate the Inverter.

Replace of Inverter and

Assemble the FFC(11pin).

H_16890_029.eps

230507

Figure 4-4 Replacement instructions Inverter (master) board

EN 8 LCD LPL 2K74.

4.2.3 Inverter (Slave) Board

Prepare the LCM. Separate the Screw(3EA) Separate the Cover Shield

Mechanical Instructions

MODEL: LC260WX2-SLB2

Unlock of Connector and

sperate the Wire Connector(2pin).

Attach the Cover Shield and

Assemble the Screw(3EA).

Separate the FFC(11pin) .

Assemble the Wire Connector(2pin).

Figure 4-5 Replacement instructions Inverter (slave) board

Separate the Inverter.

Replace of Inverter and

Assemble the FFC(11pin).

H_16890_030.eps

230507

4.3 Model LC320W01

4.3.1 Control Board (T-CON Board)

Mechanical Instructions

MODEL: LC320W01-B6K1

EN 9LCD LPL 2K7 4.

Prepare the LCM. Separate the Screw(4EA)

Separate the FFC(50pin).

Attach the Cover Shield and

Assemble the Screw(4EA).

Separate the T-CON Board.

Check the FFC(50pin).

Separate the Cover Shield

Replace of T-CON Board and

Assemble the FFC(50pin).

* Guide Pin station keeping check.

H_16890_025.eps

230507

Figure 4-6 Replacement instructions T-CON board

EN 10 LCD LPL 2K74.

4.3.2 Inverter (Master) Board

Mechanical Instructions

MODEL: LC320W01-B6K1

Prepare the LCM. Separate the Screw(3EA)

Unlock of Connector and

sperate the Wire Connector(2pin).

Attach the Cover Shield and

Assemble the Screw(3EA).

Separate the FFC(8pin).

Assemble the Wire Connector(2pin).

Separate the Cover Shield

Separate the Inverter.

Replace of Inverter and

Assemble the FFC(8pin).

H_16890_026.eps

230507

Figure 4-7 Replacement instructions Inverter (master) board

Loading...

Loading...