Page 1

Colour Television Chassis

CL 06532025_036.eps

160500

L9.1E

AB

Contents Page Contents Page

1. Technical specifications, connections and

chassis overview 2

2. Safety instructions, warnings and notes 4

3. Direction for use 6

4. Mechanical instructions 9

5. Faultfinding and repair tips 10

Block diagram

6.

Supply voltage diagram 19

Block diagram 20

Oscillogram overview 21

Testpoint overviews 21

Schematics and PWBs Diagram PWB

7.

Power supply (Diagram A1) 22 35-37

Diversity table A1-A3 23

Horizontal deflection (Diagram A2) 24 35-37

Vertical deflection (Diagram A3) 25 35-37

Synchronisation (Diagram A4) 26 35-37

Tuner + video IF (Diagram A5) 27 35-37

Video processing (Diagram A6) 28 35-37

Control (Diagram A7) 29 35-37

Front control (Diagram A8) 30 35-37

Nicam + 2CS decoder (Diagram A10) 31 35-37

Smart sound (Diagram A11) 33 35-37

Audio amplifier (Diagram A12) 32 35-37

Headphone (Diagram A13) 33 35-37

I/O Scart (Diagram A15) 34 35-37

CRT panel (Diagram B) 38 39

Side AV panel (Diagram E1) 40 40

Smart ATS (Diagram S) 41 41

Top control panel (RF) (Diagram T) 42 42

Top control panel (FSQ) (Diagram T1) 42 42

Mains harmonic panel (Diagram U) 41 41

8. Alignments 43

9. Circuit description new circuits 47

List of abbreviations 53

10. Spare parts list 55

©

Copyright 2000 Philips Consumer Electronics B.V. Eindhoven, The Netherlands.

All rights reserved. No part of this publication may be reproduced, stored in a

retrieval system or transmitted, in any form or by any means, electronic, mechanical,

photocopying, or otherwise without the prior permission of Philips.

Published by JvR 0065 Printed in the Netherlands Subject to modification 5 312278510720

Page 2

GB 2 L9.1E AB1.

Technical Specifications, connections and chassis overview

1. Technical Specifications, connections and chassis overview

1.1 Technical Specifications

Mains voltage : 90V - 276Vac; 50-

Maximum power consumption

• 25” : 75W +/- 10%

• 28” : 90W +/- 10%

• 29” : 90W +/- 10%

Standby power consumption : 6W +/- 10%

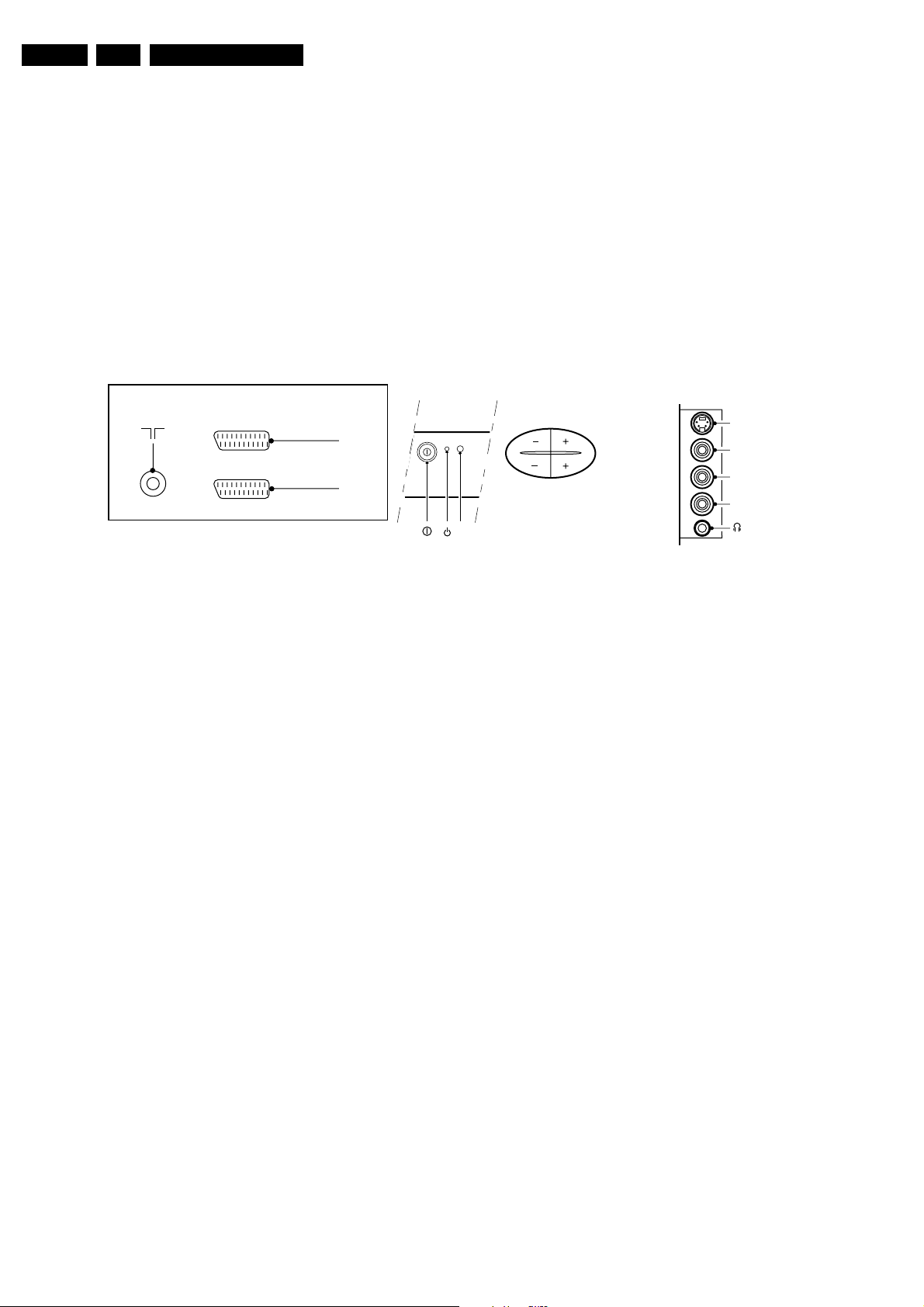

1.2 Connection facilities

60Hz

EXT1

EXT2

Colour Synchronisation :

Sub-carrier pull in range : +/- 300Hz

Horizontal Synchronisation :

Catching range : +/- 600 Hz

Holding range : +/- 1200 Hz

Vertical Locking Range : 49 Hz - 61Hz

Tuner : UV 1316/AI-2 (PAL/

FRONT + TOP CONTROL

- VOLUME +

- PROGRAM +

IR

RED

SECAM)

SIDE I/O

S-Video

Video

L

Audio

R

CL 06532025_037.eps

010200

1.2.1 Scart 1: CVBS(in/out) + RGB(in) - tuner at output

1 - Audio Out R (0.5Vrms <= 1kΩ)

2 - Audio In R (0.2-2Vrms >= 10kΩ)

3 - Audio Out L (0.5Vrms <= 1kΩ)

4 - Earth screen

5 - Earth screen

6 - Audio In L (0.2-2Vrms >= 10kΩ)

7 - Blue (0.7Vpp/75Ω)

8 - CVBS status (INT = 0-2V, EXT(16:9) = 4.5-7V,

EXT(4:3) = 9.5-12V)

9 - Earth screen

10- -

11- Green (0.7Vpp/75Ω)

12- -

13- Earth screen

14- Earth screen

15- Red (0.7Vpp/75Ω)

16- FBL (>0.9V RGB mode )

17- Earth screen

18- Earth screen

19- CVBS

20- CVBS (1Vpp/75Ω)

21- Earth screen

1.2.2 Scart 2: CVBS (in/out) + SVHS(in)

Figure 1-1

k

j

k

H

H

k

k

H

j

H

H

j

H

H

k

j

H

11- -

12- -

13- Earth screen

14- Earth screen

15- C (300mVpp/75Ω)

16- -

17- Earth screen

18- Earth screen

19- CVBS

20- CVBS/Y (1Vpp/75Ω)

21- Earth screen

1.2.3 Cinch - audio/video in

1 - CVBS

(yellow) (1Vpp 75Ω)

2 - Audio L (red) (0.2-2Vrms 10kΩ)

3 - Audio R

(white) (0.2-2Vrms 10kΩ)

1.2.4 Headphone

1 - 8-600Ω (4mW)

H

H

j

H

H

k

j

H

q

q

q

t

Input = EXT2 => output = tuner

Input = tuner/EXT1 => output = tuner/EXT1

1 - Audio Out R (0.5Vrms <= 1kΩ)

2 - Audio In R (0.2-2Vrms >= 10kΩ)

3 - Audio Out L (0.5Vrms <= 1kΩ)

4 - Earth screen

5 - Earth screen

6 - Audio In L (0.2-2Vrms >= 10kΩ)

7--

8 - CVBS status (INT = 0-2V, EXT(16:9) = 4.5-7V,

EXT(4:3) = 9.5-12V)

9 - Earth screen

10- -

k

j

k

H

H

j

H

Page 3

Technical Specifications, connections and chassis overview

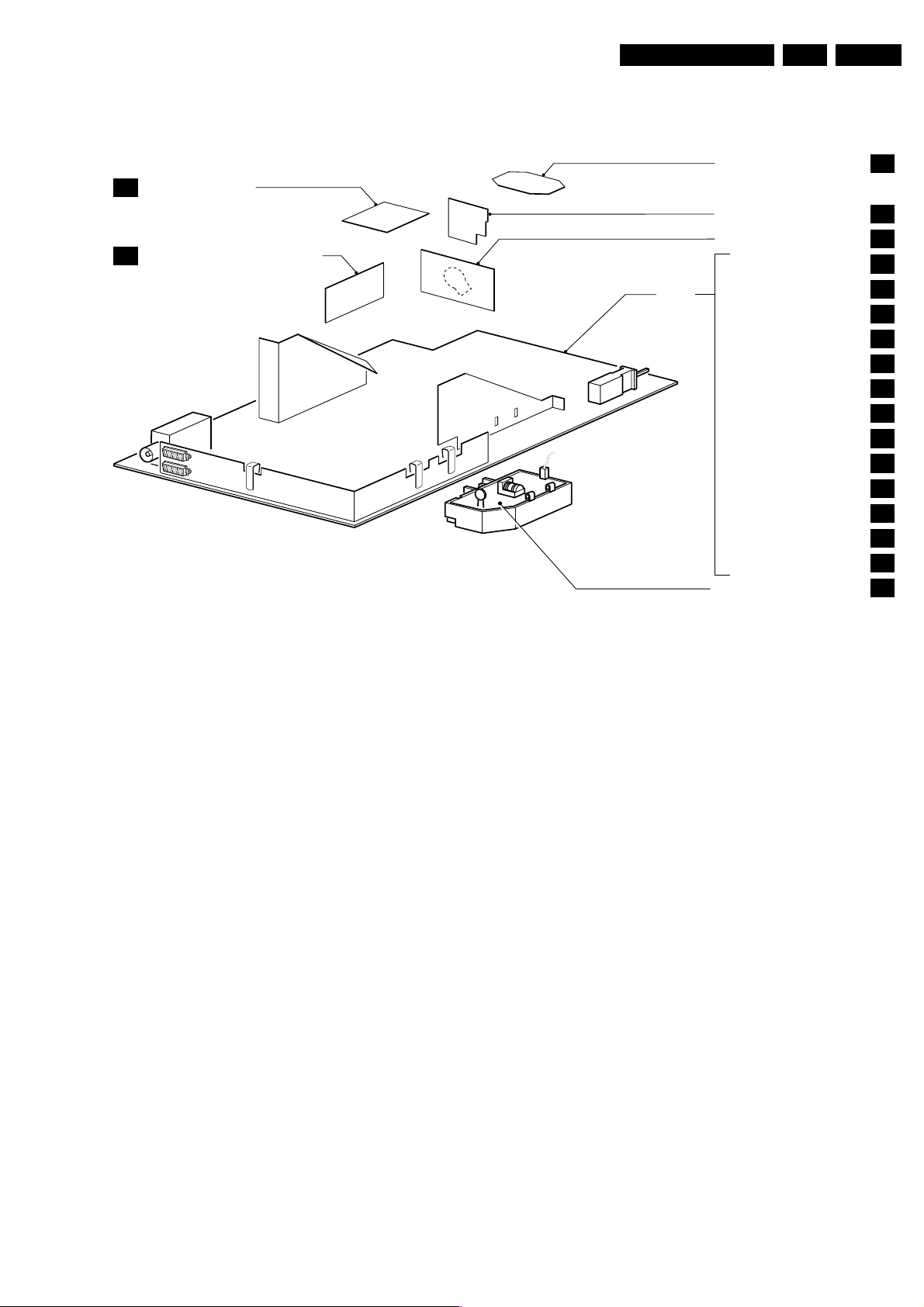

1.3 Chassis overview

GB 3L9.1E AB 1.

TOP CONTROL RF

F

SIDE AV PANEL + HEADPHONE

E1

MAIN

CHASSIS

PANEL

TOP CONTROL FSQ

SMART ATS

CRT PANEL

POWER SUPPLY

HOR.DEFLECTION

VERT. DEFLECTION

SYNCHRONISATION

TUNER + VIDEO IF

VIDEO PROCESSING

CONTROL (µC)

FRONT CONTROL

NICAM + 2CS DECODER

SMART SOUND

AUDIO AMPLIFIER

HEADPHONE

I/O SCART

MAINS HARMONIC PANEL

CL 06532025_026.eps

T1

S

B

A1

A2

A3

A4

A5

A6

A7

A8

A10

A11

A12

A13

A15

U

070600

Figure 1-2

Page 4

GB 4 L9.1E AB2.

Safety instructions, Warnings and Notes

2. Safety instructions, Warnings and Notes

2.1 Safety instructions for repairs

• Safety regulations require that during a repair:

– The set should be connected to the mains via an

isolating transformer;

– Safety components, indicated by the symbol h,

should be replaced by components identical to the

original ones;

– When replacing the CRT, safety goggles must be

worn.

• Safety regulations require that after a repair the set must

be returned in its original condition. In particular attention

should be paid to the following points.

– General repair instruction: As a strict precaution, we

advise you to resolder the solder joints through which

the horizontal deflection current is flowing, in

particular

a. All pins of the line output transformer (LOT);

b. Fly-back capacitor(s);

c. S-correction capacitor(s);

d. Line output transistor;

e. Pins of the connector with wires to the deflection

coil;

f. Other components through which the deflection

current flows.

Note: This resoldering is advised to prevent bad

connections due to metal fatigue in solder joints

and is therefore only necessary for television

sets older than 2 years.

– The wire trees and EHT cable should be routed

correctly and fixed with the mounted cable clamps.

– The insulation of the mains lead should be checked

for external damage.

– The mains lead strain relief should be checked for its

function in order to avoid touching the CRT, hot

components or heat sinks.

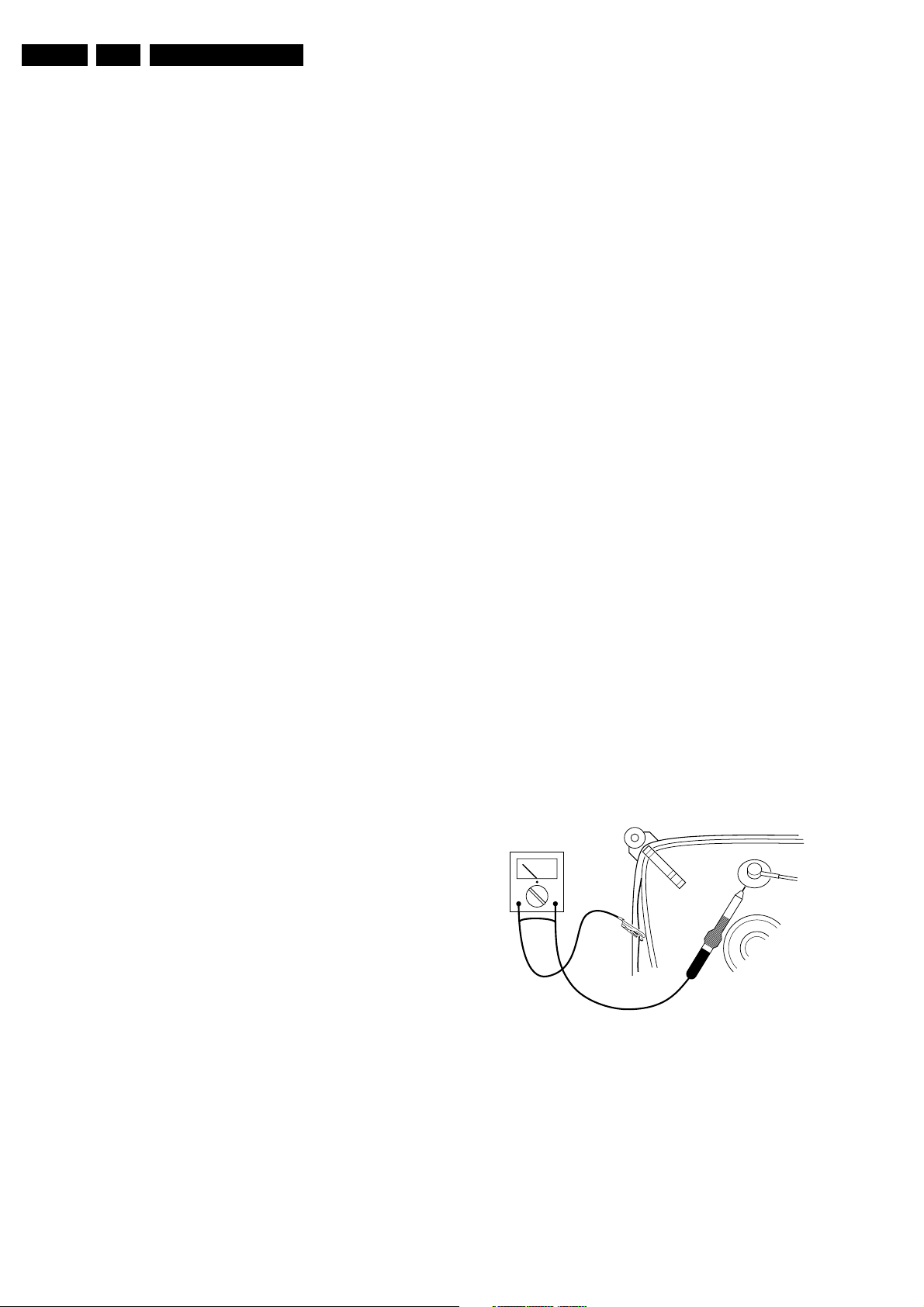

– The electrical DC resistance between the mains plug

and the secondary side should be checked (only for

sets which have a mains isolated power supply). This

check can be done as follows:

1. Unplug the mains cord and connect a wire

between the two pins of the mains plug;

2. Set the mains switch to the "on" position (keep

the mains cord unplugged!);

3. Measure the resistance value between the pins

of the mains plug and the metal shielding of the

tuner or the aerial connection on the set. The

reading should be between 4.5 MΩ and 12 M

4. Switch off the TV and remove the wire between

the two pins of the mains plug.

– The cabinet should be checked for defects to avoid

touching of any inner parts by the customer.

2.2 Maintenance instruction

It is recommended to have a maintenance inspection carried

out by a qualified service employee. The interval depends on

the usage conditions:

• When the set is used under normal circumstances, for

example in a living room, the recommended interval is 3

to 5 years.

• When the set is used in circumstances with higher dust,

grease or moisture levels, for example in a kitchen, the

recommended interval is 1 year.

• The maintenance inspection contains the following

actions:

– Execute the above mentioned 'general repair

instruction'.

– Clean the power supply and deflection circuitry on

the chassis.

– Clean the picture tube panel and the neck of the

picture tube.

2.3 Warnings

• ESD

• Available ESD protection equipment:

• In order to prevent damage to ICs and transistors, all

Ω

w

All ICs and many other semiconductors are susceptible

to electrostatic discharges (ESD). Careless handling

during repair can reduce life drastically. When repairing,

make sure that you are connected with the same

potential as the mass of the set by a wristband with

resistance. Keep components and tools also at this same

potential.

– Complete kit ESD3 (small table mat, Wristband,

Connection box, Extension cable and Earth cable)

4822 310 10671

– Wristband tester 4822 344 13999

high-voltage flashovers must be avoided. In order to

prevent damage to the picture tube, the method shown in

Fig. 2-1 should be used to discharge the picture tube.

Use a high-voltage probe and a multimeter (position DCV). Discharge until the meter reading is 0 V (after approx.

30 s).

V

CL 26532098/042

140792

Figure 2-1

• Together with the deflection unit and any multipole unit,

the flat square picture tubes used, form an integrated

unit. The deflection and the multipole units are set

optimally at the factory. Adjustment of this unit during

repair is therefore not recommended.

• Be careful during measurements in the high-voltage

section and on the picture tube.

• Never replace modules or other components while the

unit is switched on.

• When making settings, use plastic rather than metal

tools. This will prevent any short circuits and the danger

of a circuit becoming unstable.

Page 5

Safety instructions, Warnings and Notes

2.4 Notes

• The direct voltages and oscillograms should be

measured with regard to the tuner earth (H), or hot earth

(I) as this is called.

• The direct voltages and oscillograms shown in the

diagrams are indicative and should be measured in the

Service Default Mode (see chapter 5) with a colour bar

signal and stereo sound (L: 3 kHz, R: 1 kHz unless stated

otherwise) and picture carrier at 475.25 MHz.

• Where necessary, the oscillograms and direct voltages

are measured with (D) and without aerial signal (E).

Voltages in the power supply section are measured both

for normal operation (G) and in standby (F). These

values are indicated by means of the appropriate

symbols.

• The picture tube PWB has printed spark gaps. Each

spark gap is connected between an electrode of the

picture tube and the Aquadag coating.

• The semiconductors indicated in the circuit diagram and

in the parts lists are completely interchangeable per

position with the semiconductors in the unit, irrespective

of the type indication on these semiconductors.

GB 5L9.1E AB 2.

Page 6

GB 6 L9.1E AB3.

3. Directions for use

Directions for use

Page 7

Directions for use

GB 7L9.1E AB 3.

Page 8

GB 8 L9.1E AB3.

Directions for use

Page 9

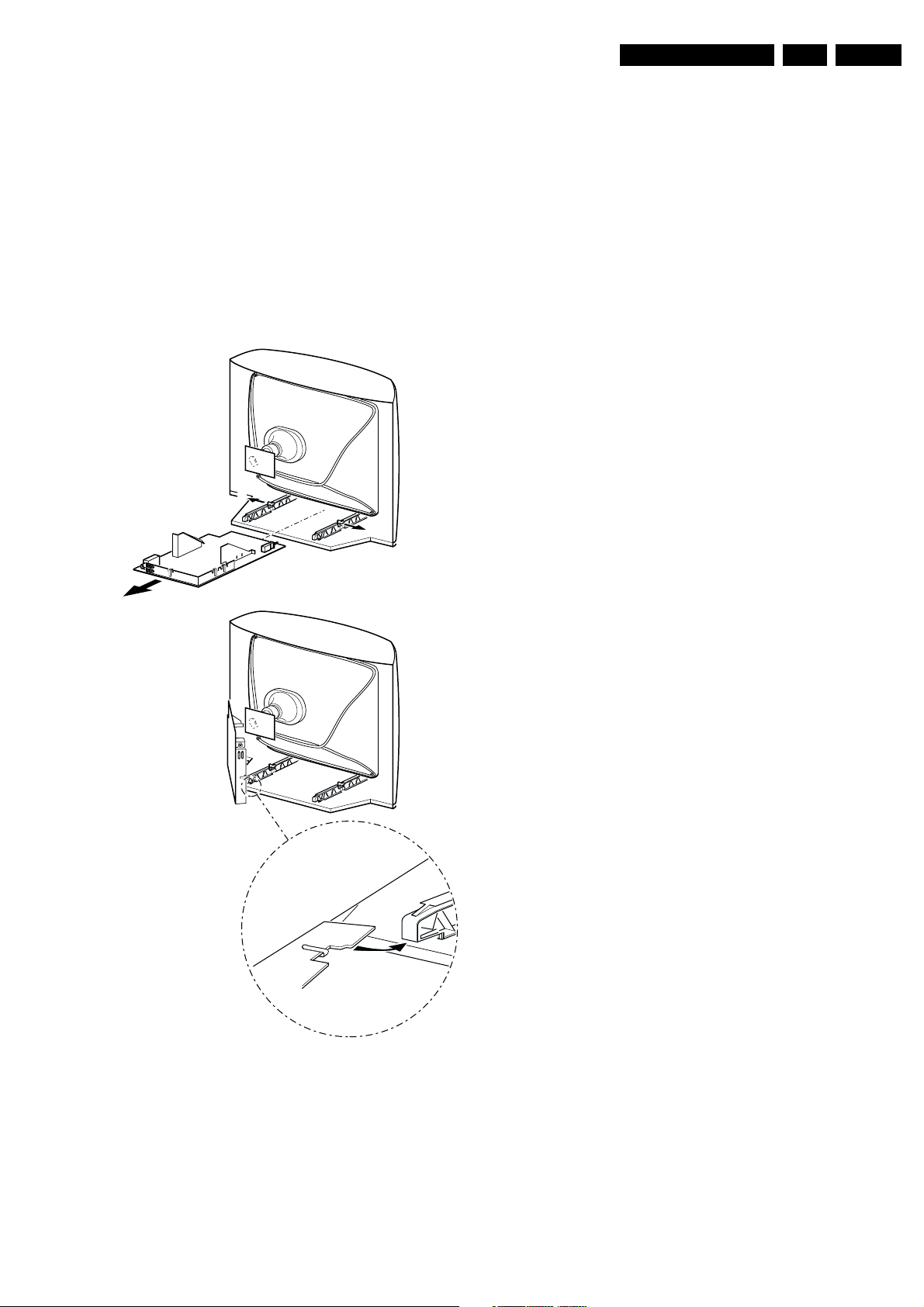

4. Mechanical instructions

4.1 Service positions

For the service position of the main carrier see figure 4.1A.

1. Disconnect the wire on the right-hand speaker and the

degaussing cable.

2. The mono-carrier can be removed by pushing the two

centre clips at both chassis brackets outwards and

pulling the panel forward.

3. Flip the mono-carrier with the component side towards

the CRT.

4. Slide the metal heatsink underneath the left chassis

bracket till the carrier is fixed. See figure 4.1B.

A

1

Mechanical instructions

GB 9L9.1E AB 4.

2

B

11

3

Figure 4-1

CL 86532104_007.ai

170299

Page 10

GB 10 L9.1E AB5.

Fault finding and repair tips

5. Fault finding and repair tips

In this chapter the following paragraphs are included:

5.1 Test points

5.2 Service Modes and Dealer Service Tool (DST)

5.3 Menus and submenus

5.4 Error code buffer and error codes

5.5 The “blinking LED” procedure

5.6 Trouble shooting tips

5.7 Customer service mode

5.8 Computer Aided Repair ( Compair )

5.9 Ordering ComPair

5.1 Test points

The L9 chassis is equipped with test points in the service

printing. These test points are referring to the functional

blocks:

• A1-A2-A3, etc.: Test points for the Nicam + 2CS decoder

/ Audio amplifier

• C1-C2-C3, etc.: Test points for the control circuit / front

control

• F1-F2-F3, etc.: Test points for the vertical deflection

circuit

• I1-I2-I3, etc.: Test points for the intermediate frequency

circuit

• L1-L2-L3, etc.: Test points for the horizontal deflection

circuit

• P1-P2-P3, etc.: Test points for the power supply

• S1-S2-S3, etc.: Test points for the synchronisation circuit

• V1-V2-V3, etc.: Test points for the video processing

circuit / CRT panel

Measurements are performed under the following conditions:

Video: colour bar signal; audio: 3KHz left, 1KHz right

5.2 Service modes and Dealer Service Tool (DST)

For easy installation and diagnosis the dealer service tool

(DST) RC7150 can be used. When there is no picture (to

access the error code buffer via the OSD), DST can enable

the functionality of displaying the contents of the entire error

code buffer via the blinking LED procedure.

5.2.1 Installation features for the dealer

The dealer can use the RC7150 for programming the TV-set

with presets. 10 Different program tables can be

programmed into the DST via a GFL TV-set (downloading

from the GFL to the DST; see GFL service manuals) or by

the DST-I. For explanation of the installation features of the

DST, the directions for use of the DST are recommended

(For the L9 chassis, download code 4 should be used).

5.2.2 Diagnose features for the servicer

– By transmitting the "DEFAULT" command with the

RC7150 Dealer Service Tool (this works both while the

set is in normal operation mode or in the SAM)

– Standard RC sequence 062596 followed by the key

“MENU”

– By shorting test-point M20 to ground on the mono-carrier

while switching on the set. After switching on the set the

short-circuit can be removed. ( Caution!! Override of 5V

protections ).

Exit the SDM:

Switch the set to Standby or press EXIT on the DST (the error

buffer is also cleared).

Note: When the mains power is switched off while the set is

in SDM, the set will switch to SDM immediately when the

mains is switched on again. ( The error buffer will be cleared

).

The SDM sets the following pre-defined conditions:

• Pal/Secam sets: tuning at 475.25 PAL (For France select

the L’-signal )

Volume level is set to 25% (of the maximum volume level).

Other picture and sound settings are set to 50%. The

following functions are “ignored” in SDM since they interfere

with diagnosing/repairing a set. “Ignoring” means that the

event that is triggered is not executed, the setting remains

unchanged.

• (Sleep)Timer

• Blue mute

• Auto switch off

• Hotel or Hospitality Mode

• Child lock or Parental lock

• Skipping, blanking of “Not favourite” present/channels

• Automatic storing of Personal Preset settings

• Automatic user menu time-out

All other controls operate normally.

5.2.4 Special functions in SDM

Access to normal user menu

Pressing the “MENU” button on the remote control will enter

the normal user menu ( TV lock, Installation, Brightness,

colour and contrast ) while “SMD” remains displayed in top

of screen). Pressing the “MENU” key again will return to the

last SDM status.

Error buffer

Pressing the “OSD” button of the remote control shows all

OSD (incl. error buffer).

Access to SAM

By pressing the “CHANNEL DOWN” and “VOLUME DOWN“

buttons on the local keyboard simultaneously the set

switches from SDM to SAM or pressing “ALIGN” on the DST

In the SDM the following information is displayed on the

screen:

L9 sets can be put in two service modes via the RC7150.

These are the Service Default Mode (SDM) and the Service

Alignment Mode (SAM).

5.2.3 Service Default Mode (SDM)

The purpose of the SDM is:

– provide a situation with predefined settings to get the

same measurements as in this manual

– override 5V protections in case of short circuiting pin 20

to ground.

– start the blinking LED procedure

– Setting of options controls

– Inspect the error buffer

Entering the SDM:

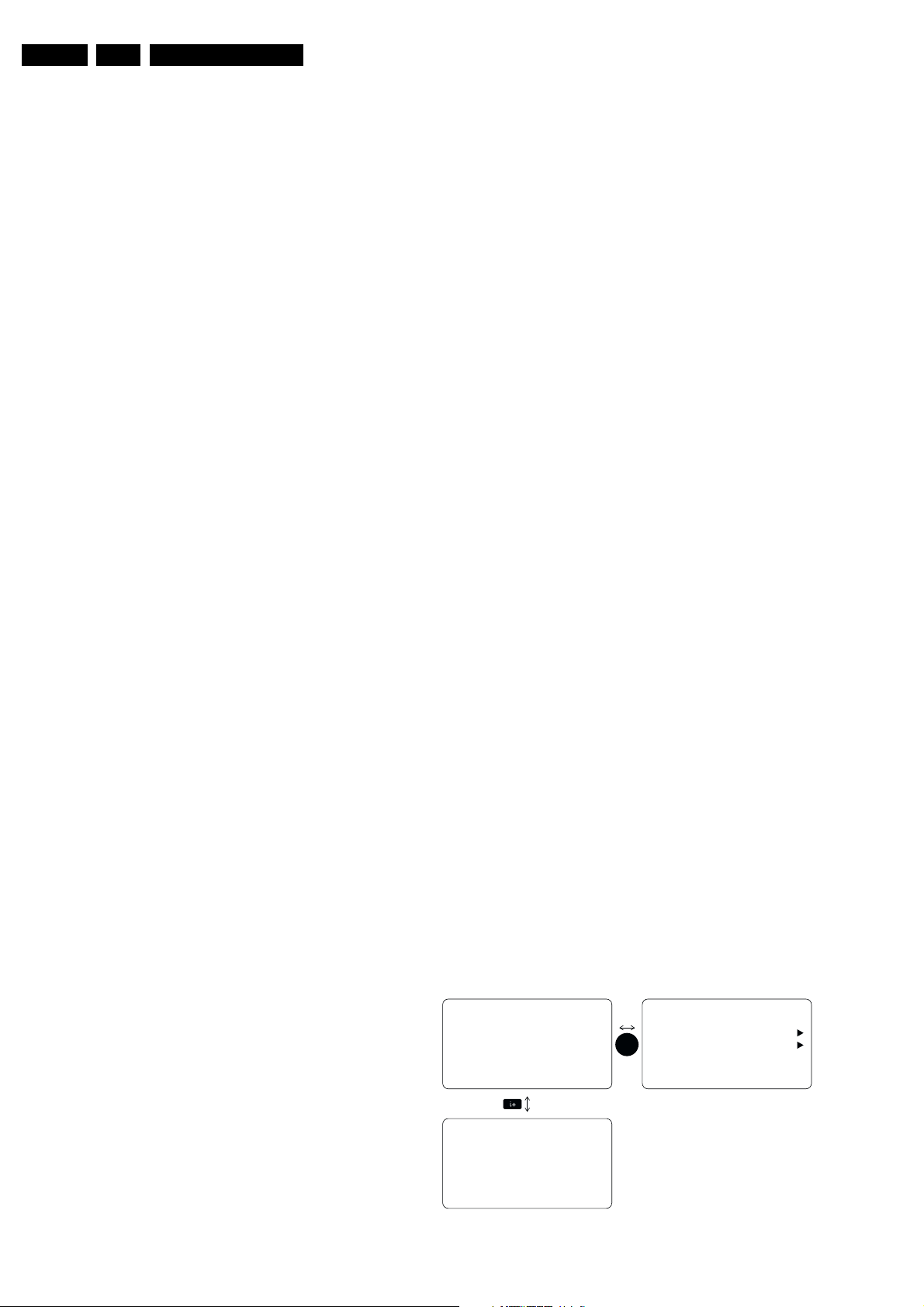

LLLL L90BBC X.Y SDM

OP VALUE

OB1 OB2 OB3 OB4 OB5 OB6 OB7

ERR xx xx xx xx xx

SDM

MENU

Figure 5-1

TV LOCK

INSTALLATION

BRIGHTNESS

COLOUR

CONTRAST

SDM

31

......

llllll

31

......

llllll

31

......

llllll

CL 86532104_015.eps

160299

Page 11

Fault finding and repair tips

Explanation notes/references:

“LLLL” Operation hours timer (hexadecimal)

(2) Software identification of the main micro controller

(L90BBC X.Y)

• L90 is the chassis name for L9.0E

• BBC is 2 letter and 1 digit combination to indicate the

software type and the supported languages:

• X = (main version number)

• Y = (subversion number) BB = (range specification )

(3) “SDM” To indicate that the TV set is in de service mode

(4) “OP” Options Code which exists of 2 characters. It is

possible to change each option code

“VALUE” The value of the selected option ( ON/OFF or a

combination of 2 letters )

“XXX” Value of the options bytes ( OB1 .. OB7)

“ERR” The last five detected errors; The left most number

indicates the most recent error detected.

The MENU UP or MENU DOWN command can be used to

select the next/previous option; The MENU LEFT and MENU

RIGHT command can be used to change the option value.

Remark: When the option-code RC = OFF, the P+ and the

P- key have the same functions as the MENU UP/DOWN

keys while the VOL+ and the VOL- key have the same

function as the MENU LEFT/RIGHT keys. It is not possible to

change the channel preset or to adjust the volume when in

SAM/SDM menu when the option RC = OFF.

Using a L9 remote control, option-code RC = ON, the P+, P, VOL- and VOL+ can be used to change the preset and/or to

adapt the volume, while the menu-cursor keys are used to

select the option and to change its value.

For an extended overview of the option codes see Chapter 8

- Options

GB 11L9.1E AB 5.

5.2.5 Service Alignment Mode (SAM)

The purpose of the SAM is to do tuning adjustments, align the

white tone, adjust the picture geometry and do sound

adjustments.

For recognition of the SAM, “SAM” is displayed at the top of

the right side of the screen

Entering SAM:

– By transmitting the "ALIGN" command with the RC7150

Dealer Service Tool

– By pressing the “CHANNEL DOWN” and “VOLUME

DOWN” key on the local keyboard simultaneously when

the set is in SDM

– Standard RC sequence 062596 followed by the key

“OSD”

Exit the SAM

Switch the set to standby or press EXIT on the DST (the error

buffer is not cleared).

Note: When the mains power is switched off while the set is

in SAM, the set will switch to SAM immediately when the

mains is switched on again. ( The error buffer will not be

cleared ).

In the SAM the following information is displayed on the

screen:

Page 12

GB 12 L9.1E AB5.

Fault finding and repair tips

TV LOCK

INSTALLATION

BRIGHTNESS

COLOUR

CONTRAST

AKB

VSD

TUNER

WHITE TONE

GEOMETRY

AUDIO

MENU

llllll

llllll

llllll

......

......

......

SAM

31

31

31

SAMAAABBC X.Y

MENU

L90 BBC X.Y

TUNER

IF-PLL

IF-PLL POS

AFA

AFB

L90 BBC X.Y

SAM

SAM

64

192

1

1

SAM

A-FM

AT

STEREO

L90 BBC X.Y

SOUND

SAM

232

15

MENU

MENU

NORMAL RED

40

SAM

L90 BBC X.Y

4

MENU

VAM

55

CL 86532104_016.eps

030399

Figure 5-2

Page 13

Fault finding and repair tips

GB 13L9.1E AB 5.

5.2.6 Access to normal user menu

Pressing the “MENU” button on the remote control will enter

the normal user menu ( TV lock, installation, brightness,

colour and contrast ) while “SAM” remains displayed in top of

screen. Pressing the “MENU” key again will return to the last

SAM status.

Pressing the “OSD” button of the remote control shows only

“SAM” in the top of screen

5.2.7 Access to SDM

By pressing the “CHANNEL DOWN” and “VOLUME DOWN”

control keys on the local keyboard simultaneously the set

switches from SAM to SDM or by pressing the “DEFAULT”

button on the DST

5.2.8 SAM menu control

Menu items (AKB, VSB, Tuner, White tone, Geometry and

Sound) can be selected with the MENU Up or MENU DOWN

key. Entry into the selected items (sub menus) is done by the

MENU LEFT or MENU RIGHT key. The selected item will be

highlighted.

With the cursor LEFT/RIGHT keys, it is possible to increase/

decease the value of the selected item.

5.3 The menus and submenus

5.3.1 Tuner sub menu

The tuner sub menu contains the following items:

– IF_PLL: PLL Alignment for all PAL/SECAM systems,

excluding SECAM-LL’

– IF_PLL POS: PLL Alignment for SECAM-LL’

– IF_PLL OFFSET: Default value = 48 ; Do not align

– AFW: AFC Window

– AGC: AGC take-over point

– YD: Default value = 12 ; Do not align

– CL: Default value = 4 ; Do not align

– AFA

– AFB

The items AFA and AFB can not be selected, they are for

monitoring purposes only.

The commands MENU UP and MENU DOWN are used to

select the next/previous item.

The commands MENU LEFT and MENU RIGHT are used to

increase/decrease the value of the selected item. The

changed values will be send directly to the related hardware.

The item values are stored in NVM if this sub menu is left.

5.3.2 White tone sub menu

The white tone sub menu contains the following items:

– NORMAL RED

– NORMAL GREEN

– NORMAL BLUE

– DELTA COOL RED

– DELTA COOL BLUE

– DELTA COOL GREEN

– DELTA WARM RED

– DELTA WARM BLUE

– DELTA WARM GREEN

OSD is kept to a minimum in this menu, in order to make

white tone alignment possible.

The commands MENU UP and MENU DOWN are used to

select the next/previous item.

The commands MENU LEFT and MENU RIGHT are used to

increase/decrease the value of the selected item. The

changed values will be send directly to the related hardware.

The item values are stored in NVM if this sub menu is left.

The Contrast Plus feature (black stretch) is set to OFF when

the white tone submenu is entered.

5.3.3 Audio sub menu

The tuner sub menu contains the following items:

– AF-M: Default value = 232 ; Do not align

– AT: Default value = 4 ; Do not align

– STEREO: Default value = 15 ; Do not align

– DUAL: Default value = 12 ; Do not align

The sound adjustments sub menu are not available in Mono

sets.

The presence of an item in the menu strongly depends on the

selected soundboard (option SB).

The commands MENU UP and MENU DOWN are used to

select the next/previous item.

The commands MENU LEFT and MENU RIGHT are used to

increase/decrease the value of the selected item. The

changed values will be send directly to the related hardware.

The item values are stored in NVM if this sub menu is left.

5.3.4 Geometry sub menu

The geometry sub menu contains the following items:

– SBL : Service blanking

– VSL : Vertical slope

– VAM : Vertical amplitude

– VSH : Vertical shift

– HSH : Horizontal shift

– VSC : Vertical S correction

– H60 : Default value = 10 ; Do not align

– V60 : Default value = 12 ; Do not align

– EWC : E-W corner

– EWT : E-W trapezium

– EWP : E-W parabola

– EWW : E-W width

5.4 Error code buffer and error codes

5.4.1 Error code buffer

The error code buffer contains all errors detected since the

last time the buffer was erased. The buffer is written from left

to right.

– when an error occurs that is not yet in the error code

buffer, the error is written at the left side and all other

errors shift one position to the right

– the error code buffer will be cleared in the following

cases:

1. exiting SDM or SAM with the “Standby" command on

the remote control

2. transmitting the commands “EXIT” with the DST

(RC7150)

3. transmitting the commands “DIAGNOSE-9-9-OK”

with the DST.

By leaving SDM or SAM with the mains switch, the error

buffer is not reset.

Examples:

ERROR: 0 0 0 0 0 : No errors detected

ERROR: 6 0 0 0 0 : Error code 6 is the last and only detected

error

ERROR: 5 6 0 0 0 : Error code 6 was first detected and error

code 5 is the last detected (newest) error

5.4.2 Error codes

In case of non-intermittent faults, clear the error buffer before

starting the repair to prevent that “old” error codes are

present. If possible check the entire content of the error

buffers. In some situations an error code is only the RESULT

of another error code (and not the actual cause).

Page 14

GB 14 L9.1E AB5.

Fault finding and repair tips

Note: a fault in the protection detection circuitry can also lead

to a protection.

Error 0 = No error

Error 1 = X-ray ( Only for USA sets )

Error 2 = High beam current protection and E/W Horizontal

protection

High beam protection active; set is switched to protection;

error code 2 is placed in the error buffer; the LED will blink 2

times ( repeatedly ).

As the name implies, the cause of this protection is a too high

beam current (bright screen with flyback lines). Check

whether the +200V supply to the CRT panel is present. If the

voltage is present, the most likely cause is the CRT panel or

the picture tube. Disconnect the CRT panel to determine the

cause. If the +200V voltage is not present, check R3340 (

CRT panel - B ), R3485 and D6485 ( Horizontal Deflection A2 )

EW protection:

If this protection is active, the causes could be one of the

following;

– horizontal deflection coil 5445

– linearity coil 5457

– S-correction capacitor 2466/2468

– flyback capacitor 2465

– line output stage

– short circuit of:

– flyback diode 6460

– EW transformer (bridge coil) 5465/5470 or 5463/5471

(version dependent)

– S-correction capacitor 2457

– EW power-transistor 7460 or driver-transistor 7461

Error 3 = Vertical / Frame protection

There are no pulses detected at pin 47 of the main

microprocessor 7600 ( panel A7 ).

If this protection is active, the causes could be one of the

following items;

– IC 7401 is faulty

– Open circuit of vertical deflection coil

– Vlotaux +11V not present and/or Vlotaux -11V not

present

– Resistor 3409

Error 4 = Sound processor I

2

C error ( MSP3415D )

Sound processor does not respond to the micro controller

Error 5 = Bimos start-up error ( POR bit )

Bimos start-up register is corrupted or the I

2

C line to the

Bimos is always low or no supply at pin 12 of the Bimos). This

error is usually detected during start-up and hence will

prevent the set from starting up.

Error 6 = Bimos (TDA8844) I

2

C error

Note that this error may also be reported as a result of error

codes 4 (in that case the Bimos might not be the actual

problem)

Error 7 = General I

2

C error. This will occur in the following

cases:

• SCL or SDA is shorted to ground

• SCL is shorted to SDA

• SDA or SCL connection at the micro controller is open

circuit.

Error 8 = Microprocessor internal RAM error

The micro controller internal RAM test indicated an error of

the micro controller internal memory (tested during start-up);

Error 9 = EEPROM Configuration error ( Checksum error );

EEPROM is corrupted.

Error 10 = I

does not respond to the micro controller

Error 11 = I

2

C error EEPROM error. NV memory (EEPROM)

2

C error PLL tuner. Tuner is corrupted or the I2C

line to the Tuner is low or no supply voltage present at pin 9,

pin 6 or pin 7 of the tuner.

Error 12 = Black current loop instability protection. The black

current could not be stabilised. The possible cause could be

a defect in one or more of the RGB amplifiers, RGB guns or

RGB driving signals.

5.5 The “blinking LED” procedure

The contents of the error buffer can also be made visible

through the “blinking LED” procedure. This is especially

useful when there is no picture. There are two methods:

1. When the SDM is entered, the LED will blink the number

of times, equal to the value of the last (newest) error code

(repeatedly).

2. With the DST all error codes in the error buffer can be

made visible. Transmit the command: “DIAGNOSE x

OK” where x is the position in the error buffer to be made

visible x ranges from 1, (the last (actual) error) to 6 (the

first error). The LED will operate in the same way as in

point 1, but now for the error code on position x.

Example:

Error code position1 2 3 4 5

Error buffer:8 9 5 0 0

• after entering SDM: blink (8x) - pause - blink (8x) - etc.

• after transmitting “DIAGNOSE- 2- OK” with the DST blink

(9x) - pause - blink (9x) - etc.

• after transmitting “DIAGNOSE- 3- OK” with the DST

blink(5x) - pause - blink(5x) - etc.

• after transmitting “DIAGNOSE- 4- OK” with the DST

nothing happens

5.6 TROUBLE SHOOTING TIPS

In this paragraph some trouble shooting tips for the deflection

and power supply circuitry are described. For detailed

diagnostics, check the fault finding tree or use COMPAIR.

5.6.1 THE DEFLECTION CIRCUIT:

1. Measure the +VBATT ( 140V) is present across 2551 (

A1 POWER SUPPLY ). If the voltage is not present,

disconnect coil 5551 ( A1 Power Supply) (Horizontal

deflection stage is disconnected). If the voltage is

present then the problem might be caused by the

deflection circuit. Possibilities:

– Transistor 7460 is faulty

– The driver circuit around transistor 7461 is faulty

– No horizontal drive signal coming from the BIMOS

7250-D pin 40 ( A4 - Synchronisation )

1. Note: If the Collector of 7460 is shorted to the Emitter,

hick-up noise can be heard from the power supply circuit.

1. To determine whether the fault is present in the

horizontal deflection circuit or in the E/W circuit ( A2 Horizontal Deflection ), de-solder jumper 9465 and insert

jumper into position number 9461. In this case the E/W

protection is disabled. If the basic deflection is correctly

working ( a parabolic picture ) then the fault is present in

the E/W circuit. If there is no horizontal deflection, the

fault is present in the basic deflection circuitry.

The 25V-version ( 26” tube ) and the 27V-version (29” tube)

do not have an E/W correction circuit.

1. Also take note of protection circuits in the line output

stage. If any of these circuits are activated, the set will

shut down. Depending on the protection, the led will blink

according to the fault defined. In order to determine

which protection circuit is active, isolation of each

separate circuit is necessary. These protection circuits

are:

– High beam current protection ( LED blinks

repetitively 2 times ) - CRT panel ( B )

– E/W Horizontal protection ( LED blinks repetitively 2

times ) - Horizontal deflection ( A2 )

Page 15

– Vertical protection ( LED blinks repetitively 3 times )

1 HHHH L90BBC-X.Y CSM

2 CODES xx xx xx xx xx

3 OP xxx xxx xxx xxx xxx xxx xxx

4 SYS: xxxxxxxxxxx

5 NOT TUNED

6 TIMER

7 LOCKED

8 (HOSPITAL) (HOTEL)

9 VOL LIM <value>

CL 86532104_014.eps

080299

- Vertical deflection ( A3 )

5.6.2 THE POWER SUPPLY

To trouble shoot the L9 SMPS, first check the Vaux voltage

on C2561. If this voltage is not present, check fuse F1572

and D6560. If F1572 or D6560 is not open circuit, the

problem might be caused on the primary side of the switching

supply. Check the output of the bridge rectifier on the C2508

for approximately 300V DC. If this voltage is missing, check

the bridge rectifier 6505 and the fuse 1500. If fuse F1500 is

found open, check MOSFET 7518 to make sure that there is

no short circuit present and check R3518. If the 300V DC is

present on C2508, check for a start-up voltage of approx.

13V on pin 1 of IC7520. If no start-up voltage is present,

check if R3510 is open; zener 6510 is a short-circuit. It is

necessary to have a feedback signal from the hot primary

side of switch mode transformer T5545 at pin 8 and pin 9 for

the power supply to oscillate. If this start-up voltage is

present on pin 1 of IC7520 and the supply is not oscillating,

check R3529 and D6540.

Check for a drive signal at the gate of MOSFET 7518, square

wave signal - P2. Check pin 3 of IC7520, R3525 and D6514

To determined whether OVP is active, check whether Vaux

is present at C2561.

5.7 Customer Service Mode (CSM)

All L9.1 sets are equipped with the “Customer Service Mode”

(CSM). CSM is a special service mode that can be activated

and deactivated by the customer, upon request of the service

technician/dealer during a telephone conversation in order to

identify the status of the set. This CSM is a 'read only' mode,

therefore modifications in this mode are not possible.

Entering the Customer Service Mode. The Customer Service

Mode can be switched on by pressing simultaneously the

button (MUTE) on the remote control and any key on the

control buttons (P+, P-, VOL +, VOL -) on the TV for at least

4 seconds.

When the CSM is activated:

• picture and sound settings are set to nominal levels

•“Service unfriendly modes” are ignored

Exit the Customer Service Mode.

The Customer Service Mode will switch off after:

– pressing any key on the remote control handset (except

“P+” or “P-”)

– switching off the TV set with the mains switch.

All settings that were changed at activation of CSM are set

back to the initial values

5.7.1 The Customer Service Mode information screen

The following information is displayed on screen:

Text “CSM” on the first line

• Line number for every line (to make CSM language

independent)

• Operating hours

• Software version L90BBC X.Y)

• Text “CSM” on the first line

• Error buffer contents

• Option code information

• Configuration information

• Service unfriendly modes

Fault finding and repair tips

SYS: xxxxxx = xxxxxx is the SYSTEM THAT IS SET FOR

THIS PRESET

NOT TUNED = no ident signal present

TIMER = (SLEEP) TIMER is actived

LOCKED = Channel/preset locked via parental lock, child

lock

HOTEL = HOTEL mode activated; HOSPITAL = HOSPITAL

mode activated

VOL LIM = Volume limiter activated and set to

5.7.2 Exit

Any key (RC or local keyboard) except “channel up” /

“channel down” (standby switched to standby, mains OFF

switches set off, other keys switch to normal operation)

5.8 Compair

5.8.1 Introduction

Compair (Computer Aided Repair) is a service tool for Philips

Consumer Electronics products. Compair is a further

development on the DST service remote control allowing

faster and more accurate diagnostics. Compair has three big

advantages:

• Compair helps you to quickly get an understanding how

to repair the L9.1E in short time by guiding you step by

step through the repair procedures.

• Compair allows very detailed diagnostics (on I

and is therefore capable of accurately indicating problem

areas. You do not have to know anything about I

commands yourself; Compair takes care of this.

• Compair speeds up the repair time since it can

automatically communicate with the L9.1E (when the

micro processor is working) and all repair information is

directly available. When Compair is installed together

with the SearchMan L9.1E electronic manual,

schematics and PCBs are only a mouse-click away.

Compair consists of a Windows based fault finding program

and an interface box between PC and the (defective)

product. The Compair interface box is connected to the PC

via a serial or RS232 cable. In case of the L9.1E chassis, the

Compair interface box and the L9 communicate via an I

cable (bi-directional) and via infra red communication (unidirectional; from Compair interface box to L9.1E)

The Compair fault finding program is able to determine the

problem of the defective television. Compair can gather

diagnostic information in 2 ways:

1. Communication to the television (automatic)

2. Asking questions to you (manually)

Figure 5-3

GB 15L9.1E AB 5.

2

C level)

2

C

2

C

Page 16

GB 16 L9.1E AB5.

Fault finding and repair tips

Compair combines this information with the repair

information in its database to find out how to repair the L9.xE.

5.8.2 Automatic information gathering

Reading out the error buffer, Compair can automatically read

out the contents of the entire error buffer.

Diagnosis on I

2

C level. Compair can access the I2C bus of

the television. Compair can send and receive I

to the micro controller of the television. In this way it is

possible for Compair to communicate (read and write) to

devices on the I

2

C busses of the L9.xE.

5.8.3 Manual information gathering

Automatic diagnosis is only possible if the micro controller of

the television is working correctly and only to a certain

extend. When this is not the case, Compair will guide you

through the fault finding tree by asking you questions and

showing you examples. You can answer by clicking on a link

(e.g. text or an waveform pictures) that will bring you to the

next step in the faultfinding process.

A question could be: Do you see snow? (Click on the correct

answer)

YES / NO

An example can be: Measure testpoint I7 and click on the

correct oscillogram you see on the oscilloscope

I7 B7502

2

C commands

4. Switch the Compair interface OFF

5. Switch the television set OFF with the mains switch

6. Remove the rear cover of the television set

7. Connect the interface cable (4822 727 21641) to the

connector on the rear side of the Compair interface that

is marked “I

2

C” (See Figure 5-5)

8. Connect the other end of the interface cable to the

Compair connector on the monocarrier (see figure 5-6)

9. Plug the mains adapter in the mains outlet and switch ON

the interface. The green and red LEDs light up together.

The red LED extinguishes after approx. 1 second (the

green LED remains lit).

10. Start-up Compair and select “File” menu, “Open...:;

select “L9.1 Fault finding” and click “OK”

11. Click on the icon to switch ON the communication mode

(the red LED on the Compair interface wil light up)

12. Switch on the television set with the mains switch

13. When the set is in standby. Click on “Start-up in Compair

mode from standby” in the Compair L9.x fault finding

tree, otherwise continue.

PC VCR I2CPower

9V DC

86532027_003.EPS

050898

1V / div DC

10µs / div

Figure 5-4

By a combination of automatic diagnostics and an interactive

question/answer procedure, Compair will enable you to find

most problems in a fast and effective way.

5.8.4 Additional features

Beside fault finding, Compair provides some additional

features like:

• Uploading/downloading of presets

• Managing of preset lists

• Emulation of the Dealer Service Tool

5.8.5 Connecting the Compair interface

The Compair Browser software should be installed and setup

before connecting Compair to the L9.xE. (See the Compair

Browser Quick Reference Card for installation instructions.)

1. Connect the RS232 interface cable to a free serial

(COMM) port on the PC and the Compair interface PC

connector (connector marked with "PC").

2. Place the Compair interface box straight in front of the

television with the infrared window (marked "IR") directed

to the television LED. The distance between Compair

interface and television should be between 0.3 and 0.6

meter. (Note: make sure that (also) in the service

position, the Compair interface infra red window is

pointed to the standby LED of the television set (no

objects should block the infra red beam)

3. Connect the mains adapter to the connector marked

"POWER 9V DC" on the Compair interface

Figure 5-5

The set has now started up in Compair mode. Follow the

instruction in the L9.1 fault finding tree to diagnose the set.

Note that the OSD works but that the actual user control is

disabled

COMPAIR

0267

1

3

TUNER

CL 96532017_001.EPS

190299

Figure 5-6

Page 17

5.8.6 Preset installation

Presets can be installed in 2 ways with the L9.1E.

• Via infra red

• only sending TO the television

• the rearcover does NOT have to be removed

Click on “File” “Open” and select “TV - use Compair as DST”

to use infra red

• Via cable

• sending TO the television and reading FROM the

television

• the rearcover has to be removed

Click on “File” “Open” and select “L9.1 fault finding” to use the

cable

Presets can be installed via menu “Tools”, “Installation”,

“Presets”.

5.8.7 Ordering Compair

Compair order codes:

• Starterkit Compair+SearchMan software + Compair

interface (excluding transformer): 4822 727 21629

• Compair interface (excluding transformer): 4822 727

21631

• Compair transformer (continental) Europe: 4822 727

21632

• Compair transformer United Kingdom: 4822 727 21633

• Starterkit Compair software: 4822 727 21634

• Starterkit SearchMan software: 4822 727 21635

• Starterkit Compair+SearchMan software: 4822 727

21636

• Compair CD (update): 4822 727 21637

• SearchMan CD (update): 4822 727 21638

• Compair interface cable (for L9): 4822 727 21641

Fault finding and repair tips

GB 17L9.1E AB 5.

Page 18

GB 18 L9.1E AB5.

Personal notes:

Fault finding and repair tips

Page 19

8. Alignments

Alignments

GB 43L9.1E AB 8.

General: the Service Default Mode (SDM) and Service

Alignment Mode (SAM) are described in chapter 5.

8.1 Alignment conditions

All electrical adjustments should be performed under the

following conditions:

• Supply voltage : 220V - 240V ( 10% )

• Warm-up time: 10 minutes

• The voltages and oscillograms are measured in relation

to the tuner earth.

• Test probe: Ri > 10MΩ Ci < 2,5 pF.

8.1.1 Selection of the SDM-menu

– By transmitting the "DEFAULT" command with the

RC7150 Dealer Service Tool (this works both while the

set is in normal operation mode or in the SAM)

– Standard RC sequence 062596 ( within OSD time-out )

MENU

– By shorting test-point M20 to ground on the mono-carrier

while switching on the set. After switching on the set the

short-circuit can be removed. ( Caution!! Override of 5V

protections ).

8.1.2 Selection of the SAM-menu

– By transmitting the "ALIGN" command with the RC7150

Dealer Service Tool

– By pressing the “CHANNEL DOWN” and “VOLUME

DOWN” key on the local keyboard simultaneously when

the set is in SDM

– Standard RC sequence 062596 ( within OSD time-out )

OSD

8.2 Electrical Alignments

8.2.1 VG2

• Use a pattern generator to display a normal black picture.

• Program the pattern generator with a frequency of

475.25 MHz for PAL/SECAM and select L’ for France

• Switch on the TV set.

• Select the SDM-MENU. The tuner is set to a frequency

of 475.25 MHz.

• Select the” SAM-MENU”. This can be done by pressing

the “ALIGN” key on the DST or typing the RC sequence

“0-6-2-5-9-6” and finishing with the “OSD” key. Press the

“MENU” key on the RC to leave the SAM-MENU and go

to the normal user menu ( “SAM” remains displayed at

the top of the screen). Select with the MENU UP/DOWN

command the sub-menu BRIGHTNESS. Change the

default value from 31 to 50 with the MENU LEFT/RIGHT

keys. Select the CONTRAST sub-menu and change the

value from 31 to 0.

• Leave the normal user menu to return to the SAMMENU, by pressing the MENU key on the RC.

• Select sub-menu VSB and change the value from 0 to 1

by pressing the MENU LEFT key. CAUTION!! Depending

on the position of the VG2 potentio-meter, the screen will

turn completely black because the Vertical Scan has

been disabled.

• Adjust with VG2 potentiometer (positioned at LOT 5445)

the blue line at the middle of the screen till this line is just

not visible.

• The alignment of the VG2 has been completed; Switch

the set to Standby. The values adapted at the

BRIGHTNESS- and the CONTRAST-menu during the

alignment, will change back again to their default values.

8.2.2 Focusing

Set pattern generator (e.g. PM5418) with Circle and Small

Squares pattern and connect to aerial input with RF signal

amplitude - 10mv. Adjusted with focusing potentiometer

(positioned at LOT 5445 ) for maximum sharpness of the

picture.

8.3 SOFTWARE ADJUSTMENT

8.3.1 Geometry adjustments

• Set pattern generator (e.g. PM5418) with Circle and

Small Squares pattern on 475.25 MHz for PAL/SECAM

and connect to aerial input with RF signal amplitude 10mV, France select L’-signal.

• First enter the SDM mode to set the tuner at 475.25 MHz.

• Enter the SAM mode and then select GEOMETRY with

the up/down keys buttons on the RC the respective items

can be selected. Use the left/right buttons to adjust the

selected items to correct the picture geometry as stated

below.

Vertical Amplitude and Position

• Select Vertical Slope “VSL” and shift the test pattern to

the top. The text VSL and its value should be above the

upper half of the screen

• Select Service Blanking “SBL” and set it to 1. The lower

half of the picture will be blanked.

• Press the up button once to select Vertical Slope “VSL”.

Now align “VSL” to start the blanking exactly at the

horizontal white line at the centre of the test circle. “VSL”

has the correct value now and should not be changed

anymore.

• Press the down button once to select “SBL” and set it

back to 0. The full picture reappears.

• Now select Vertical Amplitude “VAM” and align the

picture height to the top of the screen, so that the top

horizontal line just disappears. This corresponds with an

over scan of approx. 6%.

• Select Vertical Shift “VSH” and align for vertical centring

of the picture on the screen.

• Repeat the last two steps if necessary.

Select Vertical S-correction “VSC” to align the top/bottom

squares till they have the same size as the squares in the

middle of the screen.

Horizontal Amplitude and Phase

• Select Horizontal Shift “HSH” to horizontally centre the

picture on the screen

For sets with E/W correction follow the instructions below:

• Select East-West Width “EWW” and align the picture

with a substantial over scan.

• Select East-West Trapezium “EWT” and align for a

rectangle if necessary

• Select East-West Parabola “EWP” and align for straight

vertical lines.

• Select East-West Corner “EWC” and align the corners.

• Repeat if necessary.

• Option code “H60” and “V60” do not need any alignment.

Default value H60 and V60 = 10.

To go back to the main SAM-menu , press the MENU key on

the RC.

To leave the SAM-menu and store the alignments in the

NVN, press the STANDBY-key on the RC.

8.3.2 AGC

Set pattern generator (e.g. PM5418) with colour bar pattern

and connect to aerial input with RF signal amplitude - 10mV

Page 20

GB 44 L9.1E AB8.

Alignments

and set frequency for PAL/SECAM to 475.25 MHz. For

France select the L’-signal.

• Select the” SAM-MENU”. This can be done by pressing

the “ALIGN” key on the DST or typing the RC sequence

“0-6-2-5-9-6” and finishing with the “OSD” key.

• Select at the TUNER sub-menu the option AFW and

select the value of 80kHz.

• Select the AGC subsub-menu

• Connect a DC multi-meter at pin 1 of the tuner IC 1000.

• Adjusting the AGC until the voltage at pin 1 of the tuner

is 1.0V +/- 0.1V.

• The value can be incremented or decremented by

pressing the right/left MENU-button on the RC.

• Switch the set to standby.

8.3.3 IF-PLL / IF-PLL POS

Set pattern generator (e.g. PM5418) with colour bar pattern

and connect to aerial input with RF signal amplitude - 10mV

and set frequency for PAL/SECAM to 475.25 MHz.

• Select the ” SAM-MENU”.

• Select at the TUNER sub-menu the option AFW and

select the value of 80kHz.

Within the TUNER-menu we now have two options : IF-PLL

and IF-PLL POS.

The IF-PLL option is used for all PAL/SECAM signal

excluding SECAM L’,

The IF-PLL POS option is used for only the SECAM L’ signal

For the IF-PLL option the following should be done:

• Select at the TUNER menu the IF-PLL subsubmenu

• Adjust the IF-PLL value until the AFA becomes “1” and

AFB alternates between “0” and “1”

• Switch the set to Standby or go to the IF-PLL POS menu.

For the IF-PLL POS option the following should be done:

• Change the signal at the pattern generator from PAL to

SECAM and select the L’-signal.

• Select at the TUNER menu the IF-PLL POS

subsubmenu.

• Adjust the IF-PLL POS value until the AFA becomes “1”

and AFB alternates between “0” and “1”

• Switch the set to Standby or go to the IF-PLL menu.

8.3.6 Audio

NO ADJUSTMENTS NEEDED FOR SOUND.

The default values for the audio alignments as displayed in

the table below:

AUDIO Alignment Options

A-FM 232

AT 4

STEREO 15

DUAL 15

8.4 Options

Options are used to control the presence / absence of certain

features and hardware. There are two ways to change the

option settings. The various option configurations and the

descriptions of the two character-codes are explained below.

Changing a single option: A single option can be selected

with the MENU UP/DOWN keys and its setting can be

changed with the MENU LEFT/RIGHT keys.

Changing multiple options by changing option byte values:

Option bytes make it possible to set very fast all options. An

option byte represents a number of different options. All

options of the L9 are controlled via 7 option bytes. Select the

option byte (OB1, OB2, OB3, OB4, OB5, OB6 or OB7) and

key in the new value.

Changes in the options and option bytes settings are saved

when the set is switched to standby. Some changes will only

take affect after the set has been switched OFF and ON with

the mains switch (cold start).

The following options in SDM can be identified:

8.3.4 Tuner options CL, YD and IF-PLL OFFSET

NO ADJUSTMENTS NEEDED FOR THESE ALIGNMENTS.

The tuner option code IF-PLL-OFFSET is only used in

combination with sets with the TDA8845 BiMOS (IC7250).

(Typically this is for Secam LL’). The default values for these

option codes are:

• CL : 4

• YD : 12

• IF-PLL-OFFSET : 48

8.3.5 White tone

• Connect a pattern generator (e.g. PM5418) and set it to

colour bar and circle pattern.

• Set frequency for PAL 475.25MHz with RF signal

amplitude - 10mv and connect to tuner (aerial) input

• Enter the SAM -MENU.

• Enter into WHITE TONE menu, select item NORMAL,

DELTAWARM, or DELTACOOL depending on the item

which has to be aligned. Only one of the three items (R,

G or B) will be displayed on the screen.

The default values for the colour temperature as displayed in

the table below:

10500KR = 40G = 40B =

NORMAL

(DELTA)COOL 14000KR = -2G = 0 B = 6

40

(DELTA)WARM 8200K R = 2G = 0 B = -

7

Page 21

Alignments

OP OPTION (ON=enabled / present) Explanation / Remark

AC Alternate Channel Alternate channel function (SWAP between last presets) enabled

AM Animated menu

2X External 2

AO Audio out Default value is OFF

AS Auto startup/Micro controller startup Default value is ON (ON = start-up via micro controller, OFF = auto

AT Automatic Tuning System (ATS)

BM Blue Mute (ON = enabled) Enabled: blue mute background in case of no video ident /poor signal

BS BiMOS standby mode Default value = ON

BT Bass/Treble Control Menu controls for BASS and TREBLE available when enabled

C8 Maximum Program ( ON = 80 programmes ) C8 is OFF : Maximum of 100 programs

CD Auto Cable Detect Default value = OFF (Not applicable for European sets)

CI Automatic Channel Installation (ACI)

CK Clock (Volatile) Clock function available when enabled

CL Child Lock Menu item Child lock/Parental control when enabled

CP Contrast Plus Menu item Contrast Plus available when enabled

CT Colour Temperature Menu item Colour Temperature available when enabled

CX 16:9 Compress Menu item 16:9 compress when enabled

DM Demo Mode Demonstration of TV functions on screen when enabled

DP Slider Bar Value Display Slider bar value displayed when enabled

DU Dual I/II Possibility of language selection when enabled

DV Delta Volume (Delta) Volume is stored separately for channel 0..40 and external

EW East-West Control East-West Alignment in SAM GEOMETRY menu available when

EX 4:3 Expand 4:3 expand mode available when enabled

FV Favourite page Favourite TXT-page feature present when enabled

FQ Frequency display Frequency displayed when enabled

GM Games Mode Optimisation of setting for games possible when enabled

HS Hospital Mode Possibility to block the local keyboard when enabled

HT Hotel Mode Possibility to pre-select the channel numbers when enabled

IS Incredible Surround Incredible surround function available when enabled

LV Automatic Volume Leveller (AVL) Menu item AVL available when enabled

NI No Ident Auto Standby Set switches to standby after 10min. when NI enabled

NR Noise Reduction Menu item Noise Reduction available when enabled

RC

(*)

SB Sound Board (Set the sound hardware

SP Smart Picture Smart picture command is processed when enabled

SS Smart Sound Smart sound command is processed when enabled

ST Sound systems supported SS = BG, I, DK, M

SY Systems supported SS

TN Tuner (OFF: Philips tuner; ON: Alps tuner) Default value = OFF

Separate preset/volume control on remote control

(ON = separate control (A8 RC); OFF = combined

control (L7 RC))

configuration)

start-up BiMOS)

conditions

sources when enabled; OFF = not available

enabled

See note below table. Default value is OFF

MA = Mono ALL

ND = Stereo/2CS/Nicam

IT = German 2CS

AD = BG/I, BG/DK, I/DK

SP = Single system with NTSC Playback

AD = Dual Mono

ED = Europe Tri Mono

EF = Europe Full Multi

EL = Europe Full Multi with LL’

GB 45L9.1E AB 8.

Page 22

GB 46 L9.1E AB8.

OP OPTION (ON=enabled / present) Explanation / Remark

TW Channel Select Time Window (OFF: 2 seconds;

ON: 5 seconds)

UB Ultra Bass Ultra bass function available when enabled

VI Virgin Mode OSD at very first installation when enabled

VL Volume Limiter Menu item Volume Limiter available when enabled

VM Video Mute Screen blanking during channel switching when enabled

WE Europe West (ON: Western Europe; OFF: other)

XS External Source Colour Select External source colour selection available when enabled

XT External 1 External 1 source input available when enabled

OB1 Option Byte 1 See option bits

OB2 Option Byte 2 See option bits

OB3 Option Byte 3 See option bits

OB4 Option Byte 4 See option bits

OB5 Option Byte 5 See option bits

OB6 Option Byte 6 See option bits

OB7 Option Byte 7 See option bits

(*) Remark: When option RC = OFF, the P+ and the P- key

on the remote control have the same functions as the MENU

UP/DOWN keys while the VOL+ and the VOL- key have the

same function as the MENU LEFT/RIGHT keys. When

RC=OFF, it is not possible to change the channel preset or

to adjust the volume in SAM/SDM with the remote control.

RC = OFF for use with L7-based remote control (only cursor

keys). RC = ON for use with A8-based remote control (cursor

keys, P+/P- and Volume+/Volume-).

Alignments

Time interval for entering a second digit for channel selection

8.5 Option bits/bytes

Option bytes

OB1 bits 8, 7, ..., 1: DP, FQ, AM, HS, HT, DM, GM, VI

OB2 bits 8, 7, ..., 1: CK, CL, AT, CI, (res), (res), SS, SP

OB3 bits 8, 7, ..., 1: RC, WE, (res), (res), TW, AC, C8, VM

OB4 bits 8, 7, ..., 1: TN, FV,XT,2X, XS, CD, BM, NI

OB5 bits 8, 7, ..., 1: EX, CX, NR, CP, CT, EW, BS, AS

OB6 bits 8, 7, ..., 1: BT, IS, VL, DV, UB, LV, DU, AO

OB7 bits 8, 7, ..., 1: ST, ST, SB, SB, SB, SY, SY, SY

An option byte value is calculated in the following way:

value “option bit 1” x 1 =

value “option bit 2” x 2 =

value “option bit 3” x 4 =

value “option bit 4” x 8 =

value “option bit 5” x 16 =

value “option bit 6” x 32 =

value “option bit 7” x 64 =

value “option bit 8” x 128 =

Total : value “option byte” =

Page 23

Circuit description new circuits

9. Circuit description new circuits

GB 47L9.1E AB 9.

Power supply (diagram A1)

9.1 Introduction

9.1.1 General

The switch mode power supply (SMPS) is mains isolated.

The control IC7520 (MC44603A) produces pulses for driving

FET 7518. Power supply regulation is achieved by using duty

cycle control at a fixed frequency of nominal 40 kHz in normal

operation. In stand-by, slow-start and overload situations the

SMPS runs at frequencies other than 40 kHz.

Basic characteristics of this SMPS :

– Mains Isolated flyback Converter type

– Input range : 90 - 276 Volts AC

– Secondary Sensing by Opto-coupler

– IC7520 is Featured with Slow-Start circuitry

– Protection Circuits

– Degaussing circuit

9.1.2 Output voltages

• Audio Supply ( +16.5V ) for the AUDIO AMPLIFIER (

Diagram A12 )

• Mains Supply ( +140V ) for the HORIZONTAL

DEFLECTION stage (A2) and the CRT discharge circuit

(A3)

• Vaux ( +11.3V ) for the Video IF (A5), Video processing

(A6) and Control circuit (A7)

9.1.3 The switching periods of TS7518

The power supply duty cycle is dependent on the T-on of FET

7518. The FET is driven by pin 3 of IC7520. This IC controls

the secondary voltage (VBATT via opto-coupler 7581 and

regulator 7570. The switching period of TS7518 can be

divided into three main phases: Duty cycle T-on, T-off and Tdead.

• During T-on, FET 7518 conducts.

• Energy is stored in the primary winding (2-5) of

transformer T5545 by using a linear increasing primary

current. The slope depends on the rectified mainsvoltage present across C2508. The T-on period is varied

to provide regulation of the drive waveform at pin 3 of

IC7520. By controlling the duty cycle of the SMPS in this

way the (VBATT is controlled.

• During T-off, FET 7518 is switched off and therefore

does not conduct. The energy is now transferred to the

secondary side of the transformer and then supplied to

the load via the secondary diodes (D6550, D6560 and

D6570,D6590). The current through the secondary side

of the transformer decreases until it reaches zero.

• During T-dead FET 7518 does not conduct .The voltage

at the drain of the FET decays and eventually reaches

the input voltage of approximately 300V.

9.2 Primary side

9.2.1 Mains input and degaussing

high current involved and becomes high-ohmic which

reduces the degaussing-current. During normal

operation, the degaussing current is zero, because relay

1580 is open due to the absence of the (P - Reset signal.

9.2.2 Start up and take over

– Start-up : The start-up circuitry consisting of 3510, 3530

and 3529 use the voltage coming from the 230V AC

mains to start-up IC7520 via the supply pin 1. The output

drive waveform (pin 3) is blocked by using the ICs

internal logic until the voltage on pin 1 reaches 14.5 Volts

however with less than 14.5 volts on Pin 1 the IC only

consumes 0.3mA. Once pin 1 reaches the 14.5 Volts

threshold, IC7520 will start up (FET 7518 will conduct)

and pin 1 sinks a typical supply current of about 17 mA.

This supply current cannot be delivered by the start-up

circuitry, so a take-over circuit must be present. If takeover does not occur then the voltage on pin 1 will

decrease below 9V and IC7520 will switch off. The

supply begins a new Start-up cycle, see top of this

paragraph. This cycle will repeat itself and can be noticed

by an audible hick-up sounding noise.

– Take for IC7520: During start-up a voltage across

winding 8 - 9 is gradually built up. At the moment the

voltage across winding 8 - 9 reaches approx. (14.5 Volts,

D6540 start conducting and takes over the supply

voltage Vpin 1 of IC7520 (take over current is approx.

17mA).

Note: This power supply is a SMPS (= Switched Mode Power

Supply) and not a SOPS (= Self Oscillating Power Supply).

9.3 Control circuitry

9.3.1 IC7520 control mechanisms

IC7520 controls the T-on time of FET 7518 in four different

ways:

•“Secondary-output-sensing” controls the secondary

output voltages via the feedback voltage pin 14

•“Primary current sensing” control due to the mains

voltage via the current sense voltage pin 7

•“Demagnetization control” prevents the transformer

T5545 from going into saturation via the so-called

“DEMAG” function at pin 8

• Mains voltage control via R3514 and R3516

9.3.2 Secondary voltage sensing (pin 14 of IC7520)

When the output voltage +VBATT increases (due to a

reduction in the load ) the current through the led in the optocoupler 7581 will increase due to the fact that the seriesresistor in regulator 7570 decreases. An increase in optocoupler led-current (7581) results in a decrease in the Vce of

transistor 7581, therefore the voltage across capacitor 2576

increases. This will reduce the on-time of FET 7518 due to

an increase of the voltage present on pin 14.

In the event of an increase of the load (decrease of output

voltage +VBATT ), the control circuit will work in the opposite

way to the explanation above.

– Mains voltage: this voltage is filtered by L5500 and

L5502, rectified by a diode bridge rectifier 6505 and then

smoothed by C2508 which provides a DC input voltage

of 300V DC for an ac input voltage of 230V.

– Degaussing : R3503 is a PTC. When switching “on” the

set, the PTC is cold and has a low-ohmic value. Relay

1580 is activated while the Reset signal, coming from the

(P is present. This allows a very high degaussing current

at initial power on. The PTC will then heat up due to the

9.3.3 Primary sensing (pin 7 of IC7520)

The current sense voltage at pin 7 is used to measure the

primary current through FET7518. The primary current is

converted into a voltage by R3518. R3514. 3516. couples a

part of the main voltage to the same pin 7 of IC 7520 by

dividing this sample of the voltage.

Page 24

GB 48 L9.1E AB9.

Circuit description new circuits

Hence the higher the input voltage the more the primary

current is limited. In this way the maximum output power of

the power-supply is limited.

9.3.4 Demagnetization control (pin 8 of IC7520)

Winding 8 - 9 has the same polarity as the secondary winding

that supply the load. When FET 7518 is turned off the voltage

at winding 9 becomes positive. The power supply transfers

the stored energy at the secondary side. Until the transformer

is demagnetized the voltage on the winding remains positive.

At the moment that the energy is fully transferred to the load,

the voltage at pin 9 of the transformer becomes negative.

Additionally with a certain dead time the voltage at control pin

8 of IC 7520 also drops below zero which releases the output

buffer (pin 3) and a new cycle starts.

9.3.5 Peak current limiting

An internal clamp at pin 7 allows peak current limiting to be

achieved . This pin can never exceed 1V DC and so the

maximum primary current through FET 7518, and also the

maximum output power is determined. In case of an output

being short-circuited or loaded excessively, the I-prim

becomes too high which is detected by pin 7. As a result the

primary current is limited to its maximum value and the

secondary voltages will drop. The voltage at pin 1, which is

coupled with the output voltage, will also drop. When the

voltage at pin 1 drops below the 9V, IC7520 will stop

functioning and the output voltage will rapidly drop to zero.

Via start-up circuitry 3510, 3530 and 3529 the voltage

originating from the 230V AC mains is used to start-up

IC7520 via the supply pin 1. As soon as this voltage reaches

the 14.5V, IC7520 starts functioning. If the load is still too

much or the output is short-circuited the same cycle will

happen again. This fault condition can be clearly identified as

the power supply will be loudly tripping.

9.3.9 Thermal Protection

The thermal shutdown circuit triggers the latch circuit when

the internal temperature of IC7520 exceeds 155(C ( max.

Value ).

9.3.10 Protections

Over voltage protection of the secondary voltages.

After start-up the supply voltage pin 1 will be “taken over” by

winding 8 - 9. Pin 1 of IC 7520 is used to detect an over

voltage situation on the secondary side of the transformer. If

this voltage exceeds 17V (typically the output buffer is

disabled, and IC 7520 goes into over voltage protection and

a complete restart sequence is required. Check in this case

IC7520, IC7581 and the secondary voltage +VBATT ( +140V

).

REMARK: In the event of the over voltage situation

remaining present, the SMPS will go in protection, start up

cycle, protection, etc. The standby led on the front of the set

starts flashing.

Under voltage protection of the secondary voltages

If the supply voltage at pin 1 of IC 7520 drops below 9V

because of a short-circuit or excessive load, the drive pulse

present at pin 3 will be disabled and IC7520 will switch off the

complete SMPS. Capacitor C2450 is charged up via start-up

resistors 3510, 3530 and 3529, however once the voltage

exceeds 14.5V start up threshold, the SMPS will once again

commence a re start cycle.

In the event of the under voltage situation remaining, the

SMPS will again go in protection mode, start up cycle,

protection, etc. and so the cycle repeats. This effect is highly

audible.

9.4 Audio processing

9.3.6 Cycle-by-cycle control

The T-on control is regulated on a cycle-by-cycle basis. By

using this method the secondary voltages control, peak

current limitation and all protections are extremely accurate

and fast.

9.3.7 Slow-start

As soon as Vpin 1 > 14.5V the SMPS will start-up. During the

slow-start procedure both the frequency and the duty cycle

will be built up slowly. The duty cycle will initially slowly

increase commencing with the absolute lowest possible duty

cycle. The maximum duty cycle is determined by C2530 at

pin 11 of IC7520, as C2530 is uncharged at start-up.

9.3.8 Standby mode

In standby mode the SMPS switches to the so-called

“reduced frequency mode” and runs at about 20 kHz. During

standby the SMPS only has to deliver a minimal level of

output power. The minimal load threshold level is determined

by R3532 at pin 12. In the L9 chassis the SMPS does not

have a burst mode in standby but only a reduced frequency

mode of about 20 kHz as stated above. In normal operation

mode the internal oscillator is around 40 kHz. This frequency

is controlled by C2531 at pin 10 of IC7520 and by R3537 at

pin 16 of IC7520. In standby mode the frequency of operation

is determined by R3536 at pin 15 of IC7520.

The following systems are available:

• BASIC : FM MONO ( M,BG, I and DK : single or dual

system )

• NICAM : FM STEREO / NICAM L/L’, NICAM I, NICAM B/

G, NICAM DK

• 2CS : FM STEREO / FM MONO ( all standards 4.5, 5.5,

6.5 MHz )

BASIC models incorporating 2CS (two carrier stereo) use a

TDA8844/43 BIMOS device (built-in Mono FM Demodulator

circuit)

NICAM LL’, /BG, /I versions use a TDA8845 BIMOS (AM

sound demodulator & QSS-IF circuit ; built-in)

The Audio Module incorporates the MSP3415 multi digital

sound processor. This IC incorporates digital audio

processing for volume, bass. Treble, balance, mute, spatial

sound, incredible sound, smart sound and source selection

(SIF-signal, EXT1 or EXT2).

9.4.1 Mono sets

The basic set does not have the digital sound processor

MSP3415 IC7833. Instead it is equipped with a SMART

SOUND system. This circuit controls the bass and the treble

via discrete components and two control signals (BASS and

TREBLE) coming from the microprocessor.

Page 25

Circuit description new circuits

2CS

TDA 8844

R

+

L

+

R

-

L

-

8

13

10

11

7952/7951

7833

EXT. 1

AUDIO

EXT. 2

AUDIO

CL 86532104_009.eps

050299

48

49

7250-A

(CVBS+SIF)

6

5

3

MSP3415

52 53 49 50

58

28

29

36

37

IF

LEFT OUT

RIGHT OUT

15

SCART

GB 49L9.1E AB 9.

MONO

TREBLE

BASS

P3 DUAL

MONO

1001

1002

SIF

EXT. AUDIO

1

MONO

7250

SMART

15

55

2

REAR I/O

AUDIO

L/MONO

SOUND

7250-A

48

IF

49

TDA 8844

6

CVBS+SIF

Figure 9-1

The video IF output is present at pin 11 of the tuner 1000.

7952

5

3

CL 86532104_008.eps

+

L

6

-

8

L

050299

amplifier IC 7950 or IC7951. Signal P10MuteVolume enables

the output of the sound amplifier.

9.4.3 2CS

This analogue F.M stereo audio standard is predominately

used in Germany and The Netherlands. It is used on some

cable television networks.

The diagram below indicates the AUDIO path for 2CS.

The CVBS + SIF signals present at pin 6 from BIMOS, TDA8844-, are passed through a high pass filter and are then

fed back into pin 58 of IC 7833 (MSP3415D) for further

demodulation. All variants of 2CS are demodulated in this IC.

This signal goes through a sound SAW filter and is fed to the

BIMOS via pins 48 and 49, where the signal is demodulated.

At pin 6 of BIMOS IC 7250-A, the CVBS + SIF signal is fed

to another SAW filter. Signal P3Duall/Mono selects either

SAW filter 1001 or SAW filter 1002.

The system hardware configuration, option code SY, is set at

AD - Dual Mono for a Dual configuration, while option code

SY is set at SS for the Mono configuration ( BG,I, DK, M ). Via

P3Duall/Mono, a signal coming from the Micro-processor

IC7600, it possible to switch between two Mono

configurations (BG/DK or BG/I or DK/I).

The audio output of the MSP3415 is fed to the power

This signal goes back to pin 1 of the BIMOS , for further

Figure 9-3

demodulation. The demodulated FM signal or the REAR I/O

audio signal, ExtAudioMono, is switched by the BIMOS and

is present at pin 15 and pin 55. Pin 55 goes directly to the I/

O SCART - AudioOutL/Mono.

The signal at pin 15 is fed to panel A11 - SMART SOUND.

After adjustments of the bass and treble, the signal goes to

sound amplifier 7953 ( 2W - Mono ).

Audio signals coming from the rear I/O panel are connected

to pin 49/50 of IC7833 for the Ext1Audio signals, while pin 52/

53 of IC 7833 are used for the Ext2Audio signals. IC 7833

performs source selection as well as audio processing such

as volume, balance, tone control, mute, spatial stereo,

incredible surround sound and SMART sound. The audio

output from IC 7833, pin 28 and pin 29, is fed to the power

9.4.2 Nicam

amplifier IC 7950 or IC7951. Signal P10MuteVolume enables

the output of the sound amplifier.

This high quality digital audio format is used in Eastern

Europe, France, and UK, while NICAM LL’ is being used in

France. The figure below shows the AUDIO path for NICAM.

P2LLP/MTRAP

1000

11

7701 7702

1

1003

2

124

1204

NICAM

7250-A

4548

VIF

49

3

5

3

258

TDA 8845

55 56

SELECTION

15

FILTER

REAR

EXT 1

AUDIO

52

MSP 3415

53

36 37

EXT 2

AUDIO

7833

49

50

28

29

7950

R-OUT

L-OUT

TDA 7057

7951

TDA 7053

CL 86532104_010.eps

080299

-

L+/L

-

R+/R

9.5 Tuner and Video IF (see circuit diagram A5)

9.5.1 Introduction:

In Figure 9-4 a simplified block diagram of the video path is

shown. The main item in the block diagram shown in Fig.9-5

is the video processor item 7250. The IC performs the

following functions, video IF demodulation, chroma