Page 1

1

Colour Television Chassis

L7.2E

AA

CL 86532008_004.ai

160298

Service Manual

Table of contents Page

1 Technical specifications 2

Location of panels

2 Connection facilities 3

3 Safety instructions, Warnings 4

and Notes

4 Mechanical instructions 6

5 Repair facilities 7

Software adjustments

and Hotel mode

6 Fault finding tree 13

Block diagram, 14

Survey of testpoints 15

Diagram supply voltages survey 15

7 Electrical Diagrams and print lay-outs

Power supply diagram A1 16 17,19

Sync, Horizontal + Vertical output diagram A2 18 17,19

Tuner, IF,Video,Chroma diagram A3 20 17,19

Control diagram A4 21 17,19

Sound processing, Sound interfacediagram A5 22 17,19

CRT panel diagram B 23 23

Sound Multi-mono panel diagram C 24 25

Sound Nicam-2CS panel diagram D 26 25

8 Electrical adjustments 27

9 Circuit diagram description (new circuits) 29

10 Directions for use 32

11 List of abbreviations 36

Published by FM 9863 TV Service DepartmentPrinted in The NetherlandsCopyright reserved 1998 Philips Consumer Electronics B.V. Eindhoven, The Netherlands. All rights reserved. No part of this publication may be reproduced, stored in a retrieval system or transmitted, in any form or by any means, electronic, mechanical, photocopying, or otherwisewithout the prior permision of Philips.Subject to modification5 4822 727 21567

12 Spareparts list 37

Diagram PWB

©

Copyright reserved 1998 Philips Consumer Electronics B.V. Eindhoven, The

Netherlands. All rights reserved. No part of this publication may be reproduced,

stored ina retrievalsystem ortransmitted, in any form or by any means, electronic, mechanical, photocopying, or otherwise without the prior permision of Philips.

Published by FM 9863 TV Service Department Printed in The Netherlands Subject to modification 5 4822 727 21567

Page 2

2 L7.2E

1 Technical specifications

Mains Voltage: : 220 - 240 V AC

1 Technical specifications

: (+/- 10%)

Power consumption : 17” 50 W

: (stand by < 7 W)

: 21” 57 W

: (stand by < 7 W)

Pull in range colour sync : +/- 300 Hz

Pull in range horizontal sync : +/- 600 Hz

Pull in range vertical sync : 45 - 64.5 Hz

Location of panels

C

OR

D

MULTIMONO

NICAM,

AUDIO PANEL

MAIN

CRT

POWER SUPPLY

SYNCHRONISATION

HOR.DEFLECTION

VERT. DEFLECTION

TUNER IF

VIDEO PROCESSING

CONTROL

AUDIO SOURCE INPUT

AUDIO PROCESSING

B

A1

A2

A3

A4

A5

CL 86532008_005.ai

260398

Page 3

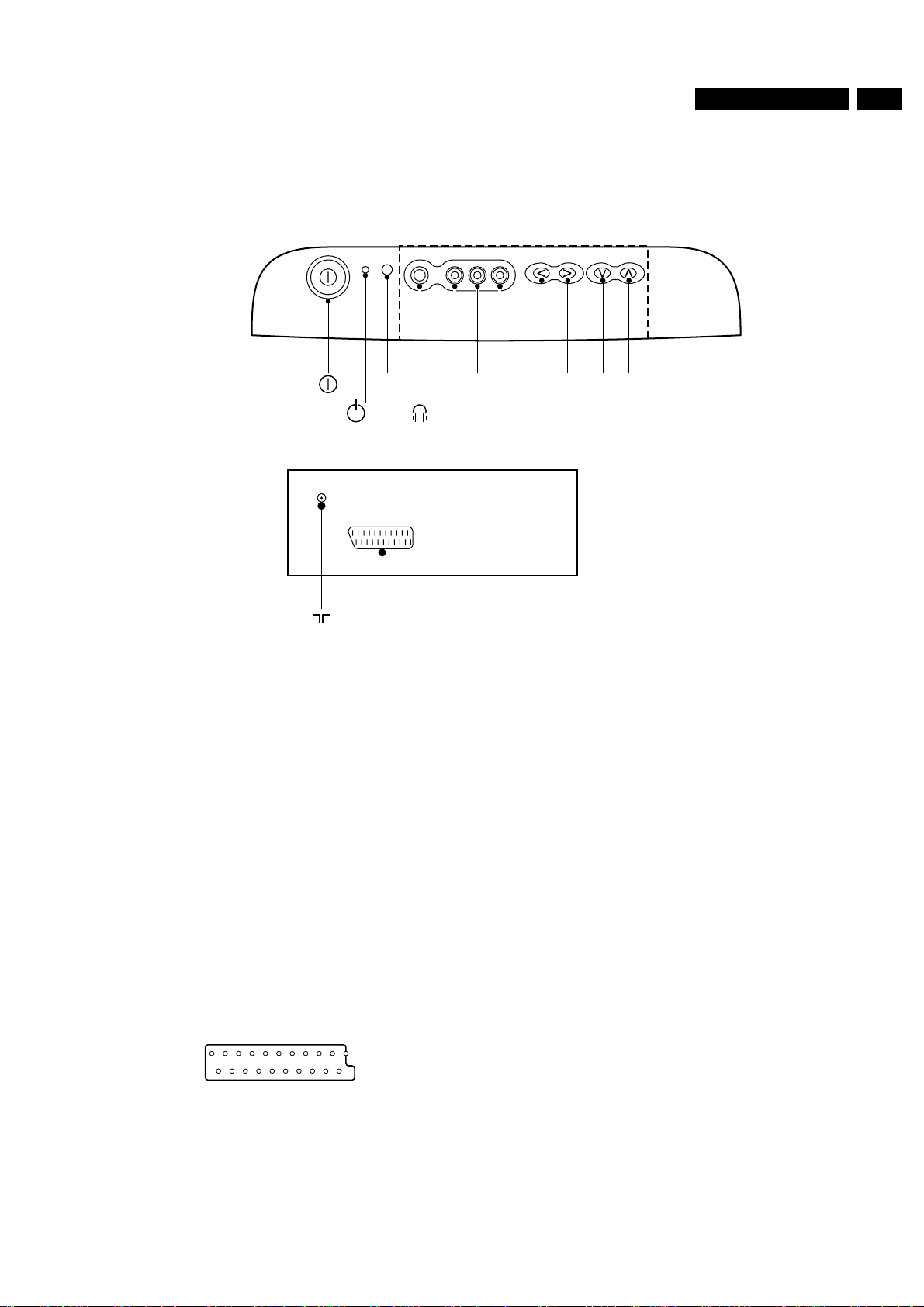

2 Connection facilities

2 Connection facilities

3L7.2E

2.1 Cinch

IR Video

Red

EXT1

(Ext2)

L R

Audio

CL86532008_008.ai

++--

ChannelVolume

170298

4.5-7V:EXT 16:9

- Video 1Vpp/75Ω q

- Audio L(0.5Vrms ≥10kΩ) q

- Audio R(0.5Vrms ≥10kΩ) q

2.2 Head phone

- (32-600Ω≥10mW) ot

2.3 Euroconnector

1- Audio R (0.5Vrms ≤1kΩ) k

2- Audio R (0.5Vrms ≥10kΩ) j

3- Audio L (0.5Vrms ≤1kΩ) k

4- Audio v

5- Blue v

6- Audio L (0.5Vrms ≥10kΩ) j

7- Blue (0.7Vpp/75Ω)

8- CVBS-

status 0-1.3V:INT

9- Green v

9.5-12V:EXT 4:3 j

1011- Green (0.7Vpp/75Ω)

1213- Red v

14- RGB-

status v

15- Red (0.7Vpp/75Ω)

16- RGB-

status (0-0.4V:INT

1-3V:EXT/75Ω)

17- CVBS v

18- CVBS v

19- CVBS (1Vpp/75Ω) k

20- CVBS (1Vpp/75Ω) j

21- Earth

socket

Page 4

4 L7.2E

3 Safety instructions, Maintenance instruction,

3 Safety instructions, Maintenance instruction, Warnings and Notes

3.1 Safety instructions for repairs

Figure 3-1

1. Safety regulations require that during a repair:

– the set should be connected to the mains via an

isolating transformer;

– safety components, indicated by the symbol (see fig.

3.1), should be replaced by components identical to

the original ones;

– when replacing the CRT, safety goggles must be worn.

2. Safety regulations require that after a repair the set must

be returned in its original condition. In particular attention

should be paid to the following points.

– As a strict precaution, we advise you to resolder the

solder joints through which the horizontal deflection

current is flowing, in particular:

• all pins of the line output transformer (LOT);

• fly-back capacitor(s);

• S-correction capacitor(s);

• line output transistor;

• pins of the connector with wires to the deflection

coil;

• other components through which the deflection

current flows.

Note: This resoldering is advised to prevent bad

connections due to metal fatigue in solder joints and is

therefore only necessary for television sets older than

2 years. The wire trees and EHT cable should be

routed correctly and fixed with the mounted cable

clamps.

– The insulation of the mains lead should be checked for

external damage.

– The mains lead strain relief should be checked for its

function in order to avoid touching the CRT, hot

components or heat sinks.

– The electrical DC resistance between the mains plug

and the secondary side should be checked (only for

sets which have a mains isolated power supply). This

check can be done as follows:

• unplugthe mains cordand connecta wirebetween

the two pins of the mains plug;

• set the mains switch to the on position (keep the

mains cord unplugged!);

• measure the resistance value between the pins of

the mains plug and the metal shielding of the tuner

or the aerial connection on the set. The reading

should be between 4.5 MW and 12 MW;

• switchoff the TV andremove the wire between the

two pins of the mains plug.

– The cabinet should be checked for defects to avoid

touching of any inner parts by the customer.

– When the set is used in circumstances with higher dust,

grease or moisture levels, for example in a kitchen, the

recommended interval is 1 year.

– The maintenance inspection contains thefollowing actions:

• Execute the above mentioned 'general repair

instruction'.

• Clean the power supply and deflection circuitry on the

chassis.

• Cleanthe picture tube panel and the neck of the picture

tube.

3.3 Warnings

1. ESD

All ICs and many other semiconductors are susceptible to

electrostatic discharges (ESD). Careless handling during

repair can reduce life drastically. When repairing, make

sure that you are connected with the same potential as the

mass of the set by a wristband with resistance. Keep

components and tools also at this same potential.

– Available ESD protection equipment:

– anti-static table mat (large 1200x650x1.25mm) 4822

466 10953

– anti-static table mat (small 600x650x1.25mm) 4822

466 10958

– anti-static wristband 4822 395 10223

– connection box (3 press stud connections, 1 M ohm)

4822 320 11307

– extension cable (2 m, 2 M ohm; to connect wristband

to connection box) 4822 320 11305

– connecting cable (3 m, 2 M ohm; to connect table mat

to connection box) 4822 320 11306

– earth cable (1 Mohm; to connect any product to mat or

connection box) 4822 320 11308

– complete kit ESD3 (combining all 6 prior products -

small table mat) 4822 310 10671

– wristband tester 4822 344 13999

2. In order to prevent damage to ICs and transistors, all highvoltage flashovers must be avoided. In order to prevent

damage to the picture tube, the method shown in Fig. 3.2

should be used to discharge the picture tube. Use a highvoltageprobe and a multimeter (positionDC-V). Discharge

until the meter reading is 0V (after approx. 30s).

3. Togetherwith the deflection unit and anymultipole unit, the

flat square picture tubes used from an integrated unit. The

deflection and the multipole units are set optimally at the

factory.Adjustmentofthisunit during repair is therefore not

recommended.

4. Be careful during measurements in the high-voltage

section and on the picture tube.

5. Never replace modules or other components while the unit

is switched on.

6. When making settings, use plastic rather than metal tools.

This will prevent any short circuits and the danger of a

circuit becoming unstable.

7. Wearsafety goggles during replacement ofthe picture tube

3.2 Maintenance instruction

It is recommended to have a maintenance inspection carried

out by a qualified service employee. The interval depends on

the usage conditions:

– When the set is used under normal circumstances, for

example in a living room, the recommended interval is 3 to

5 years.

3.4 Notes

1. The direct voltages and oscillograms should be measured

with regard to the tuner earth , or hot earth as this is called

(see fig. 3.3)

2. The direct voltages and oscillograms shown in the

diagrams are indicative and should be measured in the

Service Default Mode (see chapter 8) with a colour bar

signal and stereo sound (L:3 kHz, R:1 kHz unless stated

otherwise) and picture carrier at 475.25 MHz.

Page 5

3 Safety instructions, Maintenance instruction,

3. Wherenecessary, the oscillograms and directvoltages are

measured with and without aerial signal. Voltages in the

power supply section are measured both for normal

operation and in standby . These values are indicated by

means of the appropriate symbols (see fig. 3.3).

4. The picture tube PWB has printed spark gaps. Each spark

gap is connected between an electrode of the picture tube

and the Aquadag coating.

5. The semiconductors indicated in the circuit diagram and in

the parts lists are completely interchangeable per position

with the semiconductors in the unit, irrespective of the type

indication on these semiconductors.

V

CL 26532098/042

140792

Figure 3-2

5L7.2E

tuner earth

tuner aarde

la masse du tuner

Tuner-Erde

massa del tuner

tierra del sintonizador

with aerial signal

met antenne signaal

avec signal d'antenne

mit Antennensignal

con segnale d'antenna

con la señal de antena

normal condition

normaal bedrijf

fonctionnement normal

normaler Betrieb

funzionamento normale

funcionamiento normal

massa calda

zonder antenne signaal

Figure 3-3

hot earth

hete aarde

la terre directe

heißen Erde

tierra caliente

without aerial signal

sans signal d'antenne

.ohne Antennensignal

senza segnale d'antenna

sin la señal de antena

stand by

stand by

position de veille

in Bereitschaft

modo di attesa

posición de espera

Page 6

6 L7.2E

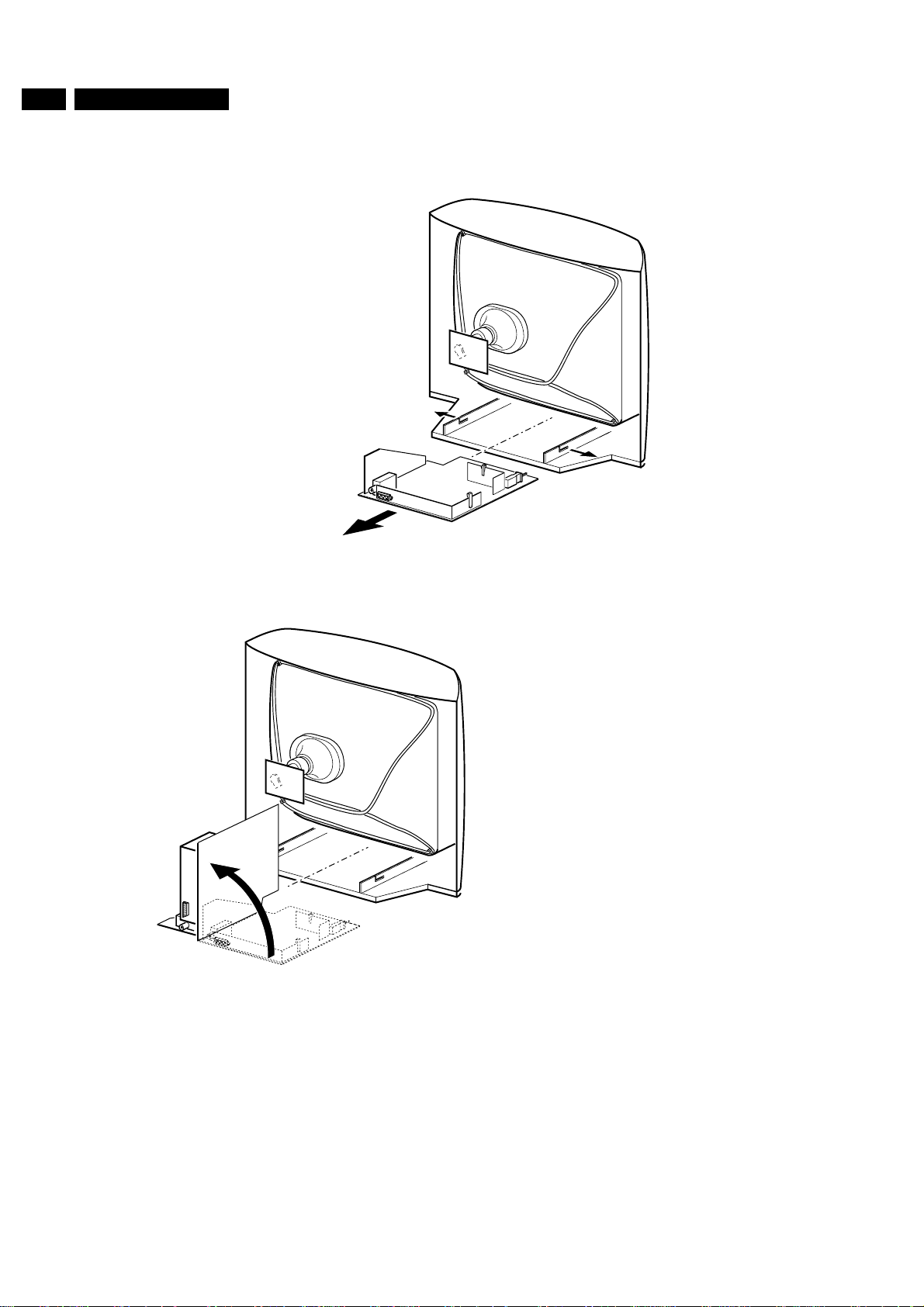

4 Mechanical instructions

For the service position of the main carrier see Fig. 4.1.

The main carrier can be removed by releasing the 2 carrier

blocking lips (1) and pulling the carrier panel backwards.

4 Mechanical instructions

1

11

B

A

CL 86532008_007.ai

160299

Figure 4-1

Page 7

5 Repair facilities

7L7.2E

5 Repair facilities

5.1 Test points

The PWB boards have service printing on both sides. In the

service printing test points are included. These test points are

referring to the electrical function as mentioned below:

Test pointElectrical function

• A1,A2, etc.: Audio

• C1,C2, etc.: Control

• F1,F2, etc.: Frame drive and frame output

• L1,L2, etc.: Line drive and line output

• P1, P2,etc.: Power supply

• S1,S2- etc.: Synchronisation

• V1,V2, etc.: Video

The numbering is done in a for diagnostics logical sequence.

Example: Checking the power supply, start with test point P1,

P2 etc.).

5.2 Service mode

The service mode is split into two parts:

– Service Default Mode (SDM).

– Service Alignment Mode (SAM).

– For Multi-Europe setsPAL-BG

– For Multi-France setsSECAM-L

Tuning:

– For sets with VST tuner: Programme number 1is selected .

Further settings:

– The automatic switch off (no IDENT) timer and the sleep

timer will be ignored.

– The child lock will be disabled.

– If the TV set was in hotel mode, this mode is disabled as

long as the TV is in SDM or SAM mode.

– Brightness, saturation, sharpness, contrast and balance

are initialised on 50% level.

– The volume is set to 25% level.

– The TV set is normally controllable.

– All displayed text in SDM and SAM menu are in English.

5.4 SDM (Service Default Mode)

5.4.1 SDM menu

Below in Fig.6.1 an example of the SDM menu is shown.

Between clamps a short explanation of each item is added.

5.2.1 Entering and leaving SDM and SAM

1. Entering SDM

• To entry the SDM , there are two possibilities:

– Via the "DEFAULT" button on the DST (Dealer

Service Tool)

– Via short circuiting the service pins 0025 and 0024

(mass), while switching on the set via the mains

switch. For 0025 and 0024 see Diagram A4 and

the PWB drawing of the main panel.

• Inthe SDM mode aS (in green) and the SDM menu(in

red) is displayed.(see Fig.6.1).

2. Entering SAM

• To entry the SAM , there are two possibilities.

– Viathe "ALIGN" button on the DST (Dealer Service

Tool)

– Via short circuiting the Service pins M28 and M29

(mass), while switching on the set via the mains

switch. For M28 and M29 see Diagram A4 and the

PWB drawing of the main panel.

• In the SAM mode a S (in green) and the SAM main

menu (in red) is displayed.(see Fig.6.2).

Remark: After the set is in the SDM or SAM mode the short

circuit can be removed.

001E 2.17.6 S

(life timer) (software

indication)

AS ON

(option abbreviation) (option status)

ERR 0 0 0 0 0

(error) (error buffer)

OPT 36C8 B805 2401

(option) (12 digit option

code)

Fig.6.1

(service mode

indication)

5.2.2 Leaving SDM or SAM

To leave the SDM or SAM mode , push the stand-by button on

the remote control

Remark:After switching off and on bythemains switch , the set

remains in the SDM or SAM mode.

5.3 Initial states

The initial state after switching on in the SDM or SAM mode is:

System:

Below a more detailed information of each item is given

5.4.2 Life timer

The indication is in hexadecimal notation. Each hour the set is

switched on (not standby) the number is incremented by 1.

Also each time the set is switched on the number is

incremented by 1.

Page 8

8 L7.2E

5 Repair facilities

5.4.3 Software indication number.

For each software change this number will be changed.

5.4.4 Service mode indication.

The S indicates that the set is in SDM or SAM mode.

5.4.5 ERROR and ERROR buffer

(ERR refers to the "ERROR BUFFER")

00000 represent the contents of the so called "ERROR

BUFFER". This buffer consist of 5 digits. In each digit an

ERROR code can be displayed. The last five errors, are stored

in the EEPROM, and are shown in this buffer. An error will be

added to the buffer if this error differs from the last error in the

buffer. The last detected error is displayed on the most left

digit.

Example: Suppose the display shows: 3 4 1 3 1. This means

the last found error is error code 3; the last found error but one

is error code 4, etc.

Remark: The ERROR BUFFER is erased when the set is

switched from SDM or SAM in stand by , or via code 99 via

DST.(Dealer service Tool).

5.4.7 Option abbreviation and Option status.

To select another option abbreviation use the MENU UP/

DOWN buttons and to change the status use the MENU LEFT/

RIGHT buttons.

Elucidation:

With above items the option statuses stored in the EEPROM

can be changed.

This is necessary if the EEPROM is replaced by a fresh

EEPROM, because a fresh EEPROM is initial loaded with

default options and statuses by the microcomputer. The

options stored in the factory can differ per type and stroke

number. Therefore it is necessary to load the EEPROM with

the correct statuses These options with statuses are indicated

on a sticker glued on the CRT. For an example of the sticker

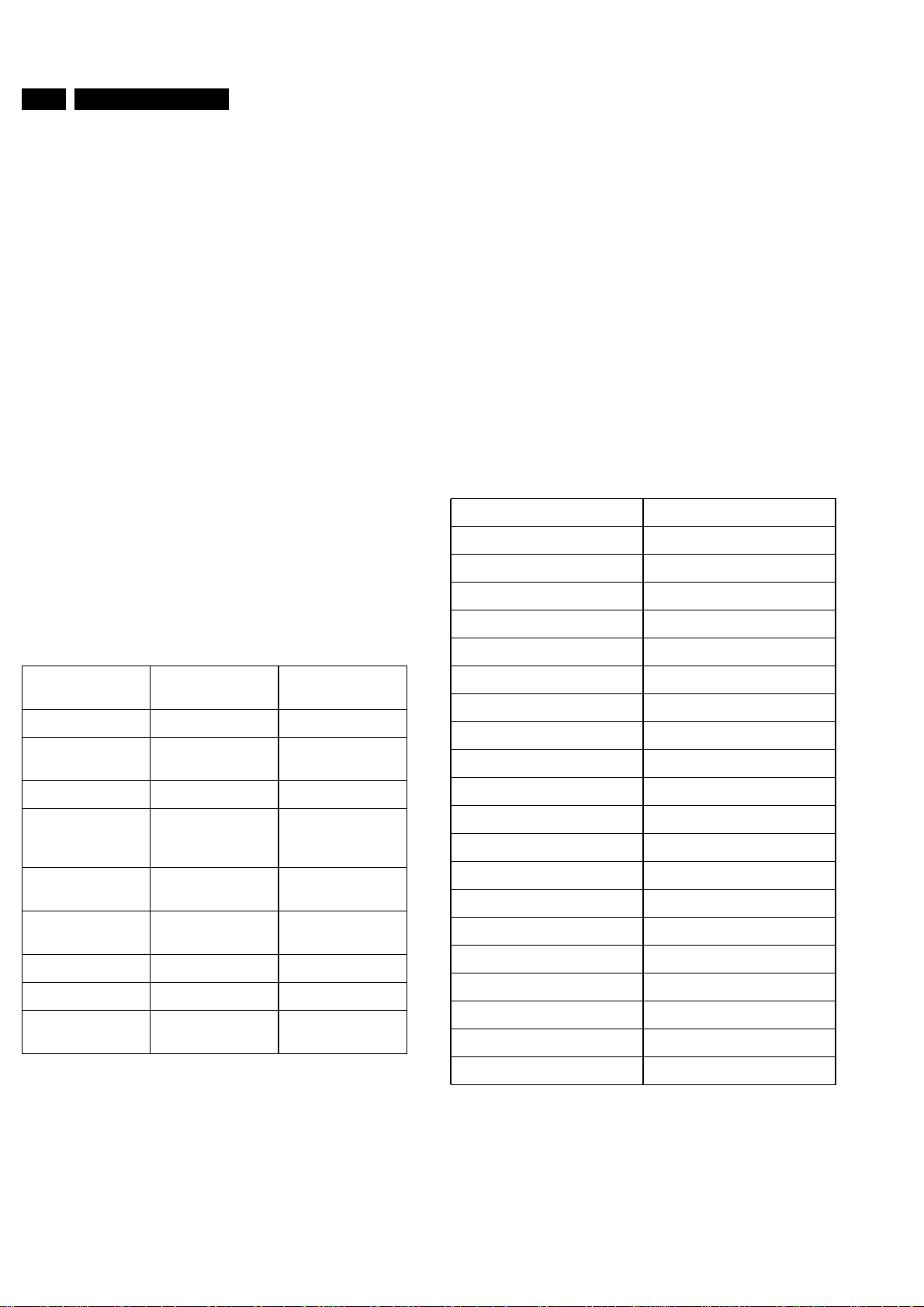

see table 6.1 (this table is valid for 21PT1663/00).

Table 6.1

Option abbreviation Status

AT ON

AV ON

The following error codes have been defined:

Error code Error description Possible defective

0 No error

1 Internal RAM error

of æC

2 General I2C error

3 EEPROM

Configuration error

(Checksum error)

4 I2C error audio

processor

5 I2C error TV

processor

6 EEPROM error ST24C04

7 I2C error PLL tuner PLL tuner

8 POR bit high (43-

IC7600)

omponent

IC7600

Set not correct

configured

MSP3410 on

NICAM panel

TDA8373/74

BA ON

BL ON

CO OFF

GM ON

HO ON

MT PH

PG ON

PR 99

SA ON

SB IN

SP ON

SS ON

SU ON

SY EW

TR ON

UH OFF

VI OFF

5.4.6 ERROR code indication via blinking stand by LED

The ERROR codes 2, 5 and 8 are also indicated via blinking of

the stand by LED. This is important if no OSD function or

picture is available.

The method is to show LED blinks as many as the error code.

Example: Error code 5 will result in five blinks ( 0.25 seconds

ON and 0.25 seconds OFF).

After this sequence the LED will be OFF for 3 seconds.

XT ON

(Table only valid for 21PT1663/00)

Loading a fresh EEPROM

– Switch on the TV via the power switch.

– Audio mute the TV (to get no big noise).

– Change the option statuses as indicated on the sticker on

theCRT.

– Put TV in stand by via the remote control.

– Switch on the TV again via the remote control.

Page 9

5 Repair facilities

9L7.2E

– Switch OFF the TV via the power switch

– Switch on the TV again via the power switch.

In table 2 all the possible option abbreviation with full option

name and possible statuses for "Europe" sets are listed. The

status can be "ON", "OFF" or can have another indication.

Table 2 : Options

Option abbr Option full name Status possibilities

AT Auto tuning system ON/OFF

AV AVL ON/OFF

BA Bass ON/OFF

BL Balance ON/OFF

CO Clock In Menu ON/OFF

GM Game mode ON/OFF

HO Hotel mode ON/OFF

MT Menu type PH = Philips

5.4.8 OPTION code

OPT is the abbreviation of OPTION, this abbreviation refers to

the following 12 digit hexadecimal option codes (36C8 B805

2401)

The option code can not be selected. It only give a quick

indication in hexadecimal form of the options settings of the

relevant set.

5.5 SAM (Service Alignment Mode)

Via the SAM, service software alignments can be executed.

When entering SAM a main menu is displayed Via the main

menu sub menus can be selected.

5.5.1 SAM main menu (see Fig. 6.2)

In the main menu the items of the basic software alignments

are indicated.

Theitems can be selected withthe UP(+)/DOWN(-) arrow keys

on the remote control. Entry into the sub menus is executed

with the VOL.(+)/VOL.(-) arrow keys.

SAM MAIN MENU

NB = National brand

MV = Magnavox

PG Program guide ON/OFF

PR Presets 99

59

79

SA Spatial ON/OFF

SB Sound Board IN = ITT NICAM

IT = ITT 2CS

MA = MONO ALL

MM = Multi Mono

SP Smart picture ON/OFF

SS Smart Sound Full ON/OFF

SU Surf ON/OFF

SY System Cluster EW = Europe West

EE = Europe East

EM = Europe

Manual

SS = Single System

TR Treble ON/OFF

UH UHF only ON/OFF

VI Virgin Mode ON/OFF

XT EXT 2 Available ON/OFF

S

AKB ON

TUN.FOA ON

TUN.FOB ON

EXT.FOA ON

EXT.FOB OFF

TUNER >

WHITE TONE >

GEOMETRY >

Fig.6.2

Below each item is explained.

5.5.2 AKB (Auto Kine Biasing)

With the option AKB the "black current loop" can be enabled

or disabled

ON =enabled, OFF = disabled.

5.5.3 TUNER Speed setting.

With the items TUN.FAO and TUN.FOB the speed ( time

constant) for internal signals is set. The speed can be set to

normal, slow or fast.

Table 3: Options for Tuner Speed settings

Page 10

10 L7.2E

5 Repair facilities

5.5.6 White tone

TUN.FOA TUN.FOB Speed

OFF OFF Normal

OFF ON Slow

ON X Fast

5.5.4 EXTERNAL A/V Speed setting

With the items EXT.FAO and EXT.FOB the speed ( time

constant) for external signals is set. The speed can be set

normal, slow and fast.

Table 4: Options for External AV Speed settings

EXT.FOA EXT.FOB Speed

OFF OFF Normal

OFF ON Slow

ON X Fast

5.5.5 Tuner

Below an example of the sub menu Tuner is shown.

Below an example of the white tone sub menu and the derived

"WARM", "COOL" and "NORMAL" sub menus are given. With

these menus the WARM, COOL and NORMAL colour

temperatures can be changed.

MAIN WHITE TONE MENU

S

WARM <

COOL <

NORMAL <

WARM TEMPERATURE SUB MENU

WARM S

RED 39

Tuner S

AGC 23

F-PLL 3

IF PLL L' 0

AFW 240 KHz

AFA 0

AFB 1

Item AGC:

For the setting of the item AGC see RF AGC adjustment

paragraph 8.1.4 of chapter 8.

Item IF-PLL, IF-PLL L ACCENT, AFW, AFA and AFB,

When the main signal processor IC TDA8373/74 is changed,

the IF-PLL and IF-PLL L ACCENT need to be realigned

GREEN 39

BLUE 25

COOL TEMPERATURE SUB MENU

COOL S

RED 39

GREEN 39

BLUE 25

NORMAL TEMPERATURE SUB MENU

NORMAL S

RED 39

GREEN 39

BLUE 25

Forthe settings of IF-PLL, IF-PLL L ACCENTandAFW see the

picture demodulator adjustments paragraph 8.1.5 of chapter 8.

Remark: AFA and AFB are adjusting indicators and therefore

not selectable.

Remark:

Only one of the 3 items (RED, GREEN or BLUE) will be

displayedonthescreen.Via"scrollingwiththeUP/DOWN keys

the items can be changed.

The item's red, green or blue can be changed by first pressing

the control left/right keys to highlight the desired setting. With

the desired setting high lighted, the user can increment or

decrement the setting by using the control up/down key. All

Page 11

5 Repair facilities

11L7.2E

changed data are stored into the EEPROM after returning to

the SAM main menu via the OK key.

The initial default value for all setting is 37.

The factory settings of the colour temperatures are:

WARM; R = 45, G = 32, B = 26

NORMAL; R = 37, G = X, B = Y

COOL; R = 37, G = 32, B = 31

Remark: In NORMAL position the values X (G) and Y (B) are

adjusted for 8500K colour temperature.

5.5.7 GEOMETRY

The geometry menu contains the following information:

S

HSH 25

VSL 32

VAM 23

– All software is suspended till the DST mode is left.

– The dealer mode status is left if the stand-by command is

received

5.7 Hotel-mode

Entering the hotel-mode :

– Select channel 38

– Push the menu button on the local keyboard (vol. + & vol.

- ) and the OSD-button of the RC simultaneously for 3

seconds.

– The screen shows the "HOTEL MODE SUB MENU "ON".

Via this menu the wanted blanked channels can be

selected.

Leaving the hotel mode :

– Same as entering the hotel mode.

– The screen shows the "HOTEL MODE SUB MENU "OFF".

Remarks:

– In the HOTEL mode the Installation menu cannot be

entered.

– When entering the hotel mode the maximum volume will

be the current value.

– The set will always switch to a selectable channel when

set is switched on.

SC 13

VSH 27

Uponenter into the picture geometry menu, thefirstitem will be

highlighted.

The value can be incremented or decremented by pressing the

control right or left key.

Therestof the parameters can be scrolled through by usingthe

control up/down keys.

All changed data will be stored into the EEPROM after

returning to the service main menu via the OK key.

Abbreviation explanation

– HSH - Horizontal shift

– VSL - Vertical linearity

– VAM - Vertical amplitude

– SC - S-correction

– VSH - Vertical shift

5.6 Use of Dealer Service Tool (DST)

With the SDM, under mentioned extra service features can be

executed

HOTEL MODE SUB MENU "ON"

38 HOTEL ON

EXIT >

HOTEL CHANNEL 38

HOTEL MODE SUB MENU " OFF "

38 HOTEL OFF

– Direct entering SDM via the "DEFAULT" button on the

DST.

– Direct entering SAM via the "ALIGN" button on the DST.

– Incase of no (OSD)picture theerror buffercan be readout

using the "BLINKING LED"procedure (see also paragraph

6.7) by pressing the "DIAGNOSE" button on the DST.

Remark:

– Entry of the SDM and SAM via the DST is possible in all

states, except from stand-by.

Remark: The Hotel mode can only be activated if the Hotel

mode option status (HO=ON), see table 2.

Page 12

12 L7.2E

5 Repair facilities

Page 13

Check:

- R3451 [A2]

- R3449 [A2]

No

Reference

[A1] Diagram

13L7.2E

THE TV. SET

SWITCH - ON

No picture

Sound OK

No Sound

No picture

Reaction on RC

Over voltage protection

Yes

>2v5?

Peak voltage

at pin 6 IC7520 [A1]

LED

No

No

ON ?

Continuously

is OK ?

Voltage

+13V, -13V (Lot)

<2v5?

Voltage

at pin 14 IC7520 [A1]

Check:

D6540, L5540 [A1]

"Take-over circuit"

No

No

Yes

Check:

LED Blinking?

(not error codes)

Yes

Check:

"Primary circuit sensing

"Feedback loop"

D6537, R3541 [A1]

Yes

No

LED reaction on RC

Check:

Heater voltage [A2]

Check:

+8V supply

FM / CVBS

Check:

Horz. cicuit

No

Check:

D6445 [A2]

TS7445 [A2]

mode?

Set in Hick-up

Check:

IC7401 [A2]

Vertical defl. problem

FET7518 [A1]

No

No

present?

Voltag on C2508 [A1]

Yes

Check:

R3500 [A1]

TS7518 [A1]

FUSE Item 1500 [A1]

Check:

+5V (supply control)

FUSE Item 1560 [A1]

Check:

No

IC7520? [A1]

Voltage at pin 1

R3510 [A1]

D6510 [A1]

Yes

Yes

IC7520? [A1]

Pulses at pin3

Check:

R3525 [A1]

R3517 [A1]

No

Replace IC7520 [A1]

FET7518 [A1]

No Sound

No picture

Reaction on RC

Yes

Check:

"Protection mode".

Set in "Stand-by" or

Stand-by circuit

+8V, VFL, Flyback

+13V (LOT), IC7541

Yes

Check:

D6445 [A2]

FET7518 [A1]

TS7445 on Shortcircuit [A2]

whiteSnowB/W

+160V

Check:

Tuner

Check:

Check:

Vertical

Check:

Horzontal

Check:

C 2205 [A3]

R3470 [A2]

+9V

Voltage

Pin 6 [A3]

Defl.circuit

IC 7401 [A2]

Defl.circuit

D 6441 [A2]

D 6445 [A2]

TS 7445 [A2]

R 3234 [A3]

R 3254 [A3]

D 6560 [A1]

IC 7541 [A1]

6 Fault finding, Block diagram

6 Fault finding, Block diagram

86532008_001.AI

120298

Page 14

PANELS

SYSTEM

-

AUDIO

DIFFERENT

C

MONO

-

MULTI

C

MONO

MULTI

A5

A5

0033

M 11

0130

7501-2B

7505‚7507

1501 7501-2A

A5

0030

0030

D

0130

0088

NICAM

0022

0033

0022

A5

A5

A5

M 9

AM

M 9

M 11

8

DET.

7511,7514

0030

0130

6

AUDIO OUTPUT

7402

TDA7056B (3WATT)

3

BASS

TRBLE

7508‚7510

12345

12345

+ R

8

AMPLIFIER

PROC.

˜˜˜

+8V

19

N C

MOD_L_IN1

+13V/+9V

123456789

0022

123456789

M 9

INT/EXT

+10V/14V

(A4- 48)

A3

3141

55

FM

AUDIO

7225_6F

7225 - 5E

1

A5

1101

14L7.2E

123456789

0033

1236789

4

M 11

SCL

LEFT_OUT

RIGHT_OUT

(A4 - 40)

(A4 - 38)

(A4 - 37)

CVBS EXT1 (A3-18)

2018161412

2119171513

SCART

CVBS - OUT(A3-29)

5

SDA

(A4 - 39)

BL TXT1 OSD(A3-27)

+8V

R TXT OSD(A3-26)

10

11

101112131415161718

CVBS_SOUND

MOD_L_IN2

MOD_R_IN2

(A3 - 34)

(A4-80)

864

10

97531

11

G TXT OSD(A3-25)

13141516171819

L - EXT 1

AV1/AV2/AVL

MONO/STROB/BG-L

(A3 - 31) IF

(A4 - 45)

(A4 - 43)

CHROM2-STATUS

MOD_L_IN1

2

B TXT OSD(A3-24)

LEFT OUT(A5-37)

SIF/FM

MOD_R_IN1

MOD_R_IN1

RIGHT OUT(A5-38)

SOUND-PROCESSING VIDEO-INTERFACE SOUND-INTERFACE

A 5

(A1 - 2)

(A3 - 21)

SDA

V-TUNE

(A3 - 33)

(A3 - 34)

VOLUME

(A5 - 51)

(A3 - 13)

SCL

0025

7620

BG-L

/

STOBE

/

MONO

(A5 - 43)

(A3 - 22)

SERVICE

DK

/

BG

-

or

-

L

/

BG

(A5 - 36)

(A3 - 40)

SDM

MODE

0024

EEPROM

SW

-

STR

-

BLACK

(A5 - 23)

(A3 - 80)

1670

RESET

7603

REMOTE

RECEIVER

CHROMA-2 / STATUS

RC5

+5 VD

C6

101112

101112

AVL

LL

2/

/

AV

EXT

STA

/

/

1 -

SID

AV

TREBLE

INT

(A5 - 52)

(A5 - 48)

(A5 - 45)

(A5 - 49)

X - TAL

7601

(NONTXT)

BASS

(A5 - 50)

HZ

12M

30

48K

13

13

(A3 - 12)

C3

+5 VD

C2

C1

525150494847464544434241394038

42414039383736353433323129

123456789

123456789

CONTROL

A4

6 Fault finding, Block diagram

(A4 - 54)

STANDBY

7681

28

151416

OCAL

L

(A2 - 9)

(A2 - 10)

VFL

FLYBACK

36

37

27

1718192021 32

1718192021

KEYBOARD

BS 1(A3 - 43)

(A3 - 35) CVBS - SOUND

(A3 - 27)

(A3 - 26)

OSD

OSD

_

_

TXT

TXT

_

_

R

BL

BS 2

STANDBY

(A3 - 43)

(A1 - 3)

Ω/3W

16

4

CONN

HEAD PHONE

- L

- R

+ L

EARTH

5

TREBLE

BASS

MONO_OUT

VOLUME

(A4- 49)

(A4- 50)

(A4- 51)

15

2

DET

˜˜˜

(A4 - 36) BG/L - D - BG/DK

(A3 - 25)

(A3 - 24)

OSD

OSD

_

_

TXT

TXT

_

_

B

G

333435

31

2223242526

LED

0028

SERVICE

(A4 - 54)

Ω/3W

16

123

6

SID/STA/LL'

(A4- 52)

5128

NC

302928

7600 (TXT)

23

24

0029

SAM

MODE

2130

SAA5297

252622

27

64K

TXT

-

CVBS

(A3 - 28)

MODULE

CRT

B

IF

/

UNER

T

A 3

V 3

7225 - 5B

(A5- 17)

(A5 - 18)

(A5 - 32)

(A5- 35)

(A5 - 34)

I F (A5 - 31)

+5.5V+9V

CHROMA

/

VIDEO

V15a V16a

7255

( Y )

28

Y

TDA8373/74

13

CVBS -OUT

+8Vb

40039011

CRT

G

0177

077

V 14V 13

27

7225 - 5C

TDA8373/74

V 11

11

TDA4665

V 4

(B - Y) _ OUT

17

-INT

CVBS - EXT2

CVBS -EXT1

CVBS -SOUND

7215

5260

R

G

V16b

R

7302/7307/7306

GRB

12354

12354

212219

20

GRB

DOS

Blank

R G B

G- Y

C

2

MATRIX

I

8

32

31

12

V 12

-(R-Y)

-(B-Y)

64uS

64uS

V 5

(R - Y) _ OUT

V6

293033

PAL/NTSC

DECODER

38 35 34

SY

10

11

CVBS

+8Vb

7200

+8Vb

3216

6

I 1

34

DET

VIDEO

7225 - 5A

TDA8373/74

48

49

˜˜˜

1015

11

10

I 2

6

3010

!

UV 1300

B

V16c

7301/7304/7305

V15b

V 15

18

23

25

38

7

9

-(R-Y)

ADD FOR SECAM

REF

7241

TDA8395

+8Va

4.43MHz

1275

I6

3202

6MHz

1207

5.5MHz

1206

7214

54

RF-AGC

1

92

354

25kV

B

V15c

7265

BLACK CURRENT

26

24

10

-(B-Y)

INDENT

CHROMA

1

16

7204

V2

or

6MHz

1208

6.5MHz

3217

˜

I 3

I 5

TUNE

V -

SCL

SDA

ONLY FST

(A4 - 13)

(A4 - 12)

3341

7303/7308/7309

BCI

BL-TXT-OSD

R-TXT_OSD

G

TXT_OSD

-

B

TXT_OSD

-

BLACK

STR-SW

-

SCL

SDA

SAND-CASTLE

3

3208

-1

SWITCH

AND

B

BS 1

ONLY VST

(A4 - 15)

+160V

CVBS-TXT

CVBS-OUT

BS 2

(A4 - 14)

15

FOCUS

EHT

V

VG2

0166

FF

FF

!

(A2 - 11)

(A4 - 27)

(A4 - 26)

(A4 - 25)

(A4 - 24)

(A4 - 23)

(A4 - 22)

(A4 - 21)

(A2 - 30)

(A4 - 28)

(A5 - 29)

(A5 - 33)

321

321

E H T

OCUS

F

VG2FOCUS

VG2

V

E H T

25K

!

54457445

2470

1

6470

+160V

L 1

(A5 - 18)

(A2- 1)

DISCHARGE

6420

!

!

P1

!!!

!

6445

BUT11AX

3447

L 2

3444

1571

5570

5545

6502/05

5500

SK 1

3442

7440

FLYBACK

+8V

2420

10

7

2508

AC

1500

3470

0055

7441

SANDCASTLE

!

SYNC

P11

T 1.6 A

5572

11

4

T 4 AL

220V˜

2

3443

L 3

3430 3440

3405

+10V / 14V

6570

DC

FF

FF

M 6

HORIZONTAL

+14V+95V

(A2 - 8)

DEFLECTION

SYNC - HORZ. & VERTICAL

A 2

7420/7421

MAINS SUPPLY

A1

7

1

BCI

(A2 - 6)

+13V

3450

2460

8

DEFECTION

HORZ.

3461 2469

2571

7518

STP6N60FI

(A2 - 6)

BCI

2

2450

37

42

7225 - 5D

TDA8374

P10

12

P3

D

G

7520

MC44603AP

(A2 - 7)

+95V

6550

(A3 - 11)

2462

G

SYNC

BAT

V

5573

S

P4

40

43

+95V

+5,5V

+9V

+13V

L 12

L 10

L 11

2452

6454

!

3450

9

10

VERTICAL

L 4

47

44

16kHz

41

S 1

SANDCASTLE

(A2 - 8)

(A3 -38)

+95A

5551

P13

6480

7480

2480

6481

!

3480

4

L 6

2443

L 7

6443

6449

!

!

3451

5

3449

6

3

M 4

263

TDA9302H

BCI

(A2 - 7)

7541

TDA8139

2

5

+

7

3415

DISCHARGE

(A1 - 1)

+8V

0V6 STB

2563

9

8

2

Op.Amp

1

3417

3

VERT.

1

F 3

-

P14

2562

4

DEFECTION

4

F 2

(A4 - 2)

RESET

P12

!

F 4

6468 2463

+13V

7401

F 1

46

50

HZ

G

50

3435

52

51

+5V

+14V

P15

120198

-13V

86532008_002.ai

2453

(A5 - 9)

VFL

3411

(A4 - 3)

STANDBY

2551

2561

6560

14

16

13

15

1

2

3518

!

3525

P8

3

UFFER

B

SC

O

!

6540

3541

2540

2537

3538 6537

3528

P9

2

7

8

14

3540

BAT

+95V

Adjust

V

4

Page 15

C

µ

µ

µ

µ

µ

µ

µ

D

AUDIO PANELS

2M9

P11

+10V / 14V

6570

!

1571

5570

10

!

5545

7

P1

6502/05

!!

0011

A1 MAINS SUPPLY

+10V / 14V

+8V

T 1.6 A

2508

AC

1500

6M11

5572

T 4 AL

2571

Mains

A4

CONTROL

11

4

+33V

Tuning voltage

3617

50-7225-5D

(for protection)

CIRCUIT

DISCHARGE

7420.7421

6420

DC

6610

!

7518

A3

!

IF & VIDEO

P10

12

P3

D

G

STP61160FI

P4

7520

+8VB

+8VA

3234

5203

5201

+95V

BAT

V

6550

5550

14

S

!

7520

MC44603AP

A2

6451

2 - 5445 (LOT)

LINE OUTPUT STAGE

+95A

5551

2551

16

3518

3525

3

BUFFER

Control

+8VC

P13

6560

IC

+8V

!

3447

3430

+14V

6540

A5

SOUND PROCESSING

+5V

P15

13

!

6537

3528

2

7541

14

4

+8V

2563

TDA8139

2561

15

A4

D

+5V

33 - 7600

19 - 7600

5601

CONTROL

P14

9

2

1

3541

P9

3540

STANDBY

RESET 1

2562

+8V

P12

8

6

4

2

+95V

Adjust

BAT

V

B

+160Va

Anode CRT

!

3341

FOCUS GRID

1-0166

+160V

6470

FOCUS

E H T (25kV)

2470

2

BAT

V

+95V

VG2 GRID

VG 2

+14V+95V

CRT PANEL

L 8

3470

!

5445

A2 SYNC - HORZ & VERTICAL DEFL

Filement CRT

0003

2-0166

3-0166

FF

FF

+13V

VG2FOCUS

3460

2460

9

BUT11AX

3442

L 2

7440

G

7441

40

10

DEFECTION

HORZ.

3443

L 3

16kHz

HOR

DRIVE

8

1

7

L 1

7445

3447

3444

L 4

3430

+8V

37

!

7225-5D

TDA8373/74

A3

3010

4003

TUNER

+5,5V

L 11

2452

6454

!

3450

3

BCI

Discharge (from A1)

50

42

{

INPUTS

Protection

+VB

!

9011

+9V

L 10

7480

6481

!

3480

4

2480

A2

200298

2 - 7401

4 - 7401

-13V

2453

(from 3-7401

vertical output,

see diagram A2)

86532008_003.AI

FRAME OUTPUT

+13V

L 12

6480

2443

L 7

6443

6449

!

!

3451

6

+13V

16

Protection

3449

VFL

37

{

INPUTS

5

7600 (µp)

A4

15L7.2E

6505

7600

0.5V / div DC

0.5V / div DC

5V / div AC

2508

P3

2

7541

P13

µC

5ms / div

5µs / div

1ms / div

7520

D

7518

SG

8

9

P14

P15

AUDIO

PANEL

(5- 7401)

F3

(3 - 7520)

P4

(52 - 7600)

C1

5V DC

P9

14

3

1

P4

V9

16

1

7255

5ms / div

(7- 7401)

F1

(7 - 5545)

P1

(1 - 7225 - 5E)

A1

(1 - 7401)

0.5V / div DC

F2

(S - 7518)

5ms / div

100V / div DC

P3

(55 - 7225 - 5E)

0.1ms / div

0.1V / div AC

A2

sk1

1500

P1

0024

SDM

0025

7620

6600

EEPROM

C1

Main panel (component side)

C6

C3

C5

C2

50

49

27

42

41

152

0028

SAM

26

0029

6 Fault finding, Block diagram

7241

V10

5ms / div

(3 - 7401)

20V / div DC

F4

5ms / div

(C - 7445)

10V / div DC

L1

(3445 / 3442)

20µs / div

100V / div DC

L2

(E- 7440)

20µs / div

2V / div DC

L3

(40 - 7225 - 5D)

20µs / div

2V / div DC

L4

(2M7)

20µs / div

2V / div DC

V14

(3 - 7520)

5µs / div

2V / div DC

P4

(50 - 7600)

C2

3445

L2

B

E

P6

10

7

P8

P11

6570

2571

2561

V7

161

V6

14

12

C

7445

7441

3540

L3

6444

2551

2448

2562

6550

6550

P10

2452

V14

V13

8

L7

V3

28113

7225

29

30

V4

V2

V5

6481

2480

A3

V1

15

405641

38

L4

S1

0077

1

5

V15

V11

V12

11

8

5

V8

5µs / div

(10 - 7520)

2V / div DC

P6

(49 - 7600)

5ms / div

1V / div DC

C3

B

E

C

L1

LOT

6454

2453

L6

I1

A1

6

F2

L11

6443

1

F4

2443

6449

357

L12

F3

F1

TUNER

7401

5µs / div

(7 - 7520)

1V / div DC

P8

(42 - 7600)

5ms / div

1V / div DC

C6

(13 - 7225 - 5B)

V1

0166

0004

V16a

B

R

G

V16c

V16b

CRT panel (track side)

5µs / div

(14 - 7520)

0.5V / div DC

P9

(30 - 7225 - 5B)

0.5µs / div

1V / div DC

V5

(38 - 7225 - 5B)

20µs / div

1V / div DC

V2

1

3

0322

8

0003

1

0177

5

170298

CL86532008_009.ai

V15bV15a

V15c

(12 - 7225)

5µs / div

0.5V / div DC

V12

(11 - 7225 - 5B)

20µs / div

0.5V / div DC

V6

(28 - 7225 - 5B)

20µs / div

1V / div DC

V3

(41 - 7225 - 5D)

S1

(Green)

V16b

(4M7)

V15a,b,c

(PAL)

3.5V DC

(3M7)

20µs / div

0.5V / div DC

V13

(11 - 7255)

V11

(29 - 7225 - 5B)

20µs / div

1V / div DC

V4

20µs / div

(6 - 7225 - 5A)

1V / div DC

I1

(Red)

20µs / div

20V / div DC

V16c

(Blue)

20µs / div

1V / div DC

V16a

s / div

20

1V / div DC

s / div

20

1V / div DC

s / div

20

0.5V / div DC

s / div

20

0.5V / div DC

s / div

20

1V / div DC

s / div

20

20V / div DC

s / div

20

20V / div DC

Page 16

(7 - 7520)

P8

5µs / div

(14 - 7520)

0.5V / div DC

P9

(C - 6550)

5µs / div

0.5V / div DC

P10

95V DC

(C - 6550)

P10

104V DC

(C - 6570)

16V DC

P11

(C - 6570)

P11

14.4V DC

(6 - 7541)

P12

2.1V DC

(6 - 7541)

P12

2V DC

(2 - 7541)

14.5V DC

P13

(2 - 7541)

P13

13.6V DC

(8 - 7541)

8V DC

P14

(8 - 7541)

P14

0.6V DC

(9 - 7541)

5V DC

P15

(9 - 7541)

P15

5V DC

(7 - 5545)

P1

(C - 6510)

5ms / div

100V / div DC

P2

(S - 7518)

5ms / div

5V / div DC

P3

(3 - 7520)

5µs / div

0.5V / div DC

P4

(3 - 7520)

5µs / div

2V / div DC

P4

5µs / div

2V / div DC

(1 - 7520)

P5

14V DC

(10 - 7520)

P6

5µs / div

(6 - 7520)

1V / div DC

P7

015_008.EPS

5µs / div

0.5V / div DC

16L7.2E

7 Diagrams and print lay-outs

7 Diagrams and print lay-outs

Page 17

9615C2

9616C3

9620C1

9628D3

9637C1

9643D2

9644D3

9647D2

9649C2

9650C3

9651C4

9658C1

9660C2

9663D2

9667D2

9677C2

9690D2

9691C3

9692C3

9693C3

9900B5

9901B5

9902D5

9903C5

9904D5

9905D5

9906D5

9907C5

M0 B3

M11 E4

M9 E3

*=chip

component

9103E4

9104E4

9107D4

9108E5

9109E4

9110E3

9111 E2

9112D5

9113C4

9115E4

9116E3

9118C3

9122E4

9123E4

9124E4

9125E4

9126D4

9131D5

9132B1

9133E3

9134E3

9135E3

9137E5

9138E5

9139D2

9141D3

9145D5

9147D5

9148D5

9202D4

9203C4

9206C3

9207C3

9208D3

9209C3

9210E4

9211D3

9212D3

9220D3

9221C3

9225C3

9229D2

9233D1

9235D3

9236D3

9237C3

9238D3

9240C4

9245D3

9246D3

9247C3

9248C3

9250D3

9251D3

9252D1

9261D3

9270C3

9313E1

9317D1

9334E2

9337E1

9341E2

9347E2

9370E1

9372E1

9377E1

9403B4

9404C5

9405C3

9406B5

9408C5

9410C4

9411B5

9413C5

9416C4

9417C2

9418D3

9419C4

9423C4

9424C4

9425C4

9426D3

9443D5

9448B4

9450A4

9454A5

9461B4

9462B4

9469C5

9500A2

9501A1

9505B2

9515A3

9518C3

9519C3

9520C2

9590C3

9601D3

9602C1

9603B1

9604D3

9605D2

9606E4

9607C2

9611D2

9613D1

9614D2

6455A5

6456A5

6461B4

6464B4

6468C5

6470B5

6480C4

6481C4

6502B2

6503B2

6504B2

6505B2

6507B3

6508A3

6510A2

6524A3

6537A3

6540A3

6550C3

6560B3

6570B3

6581C2

6583B4

6585C2

6586C2

6600C1

6610D1

6653C1

6661D2

6663A1

6690D2

6691C3

6692C3

6693C3

7001E3*

7002E3*

7003E3*

7100C3*

7101C3*

7115D5 *

7118E5 *

7200C4*

7204D3*

7214C4*

7215C4*

7220D3*

7225D4

7241D3

7255E3

7265C3*

7301E2

7302E2

7303E1

7304E2

7305E2

7306E2

7307E2

7308E1

7309E1

7401C5

7420D5*

7421C4*

7440C3*

7441A4

7445A4

7518B3

7520A3

7541C3

7581A4

7583B3*

7584B4*

7585C2*

7586C2*

7587C2*

7600C2

7601C2

7603C2*

7608D1*

7610D1*

7620C1

7644D3*

7655C1*

7681C2*

7682C2*

7683C2*

7684C2*

9001E4

9003E5

9006E4

9007D4

9008D2

9009E3

9010E3

9011E3

9013E4

9016D5

9018D5

9019D4

9020D3

9021D3

9023C3

9024E4

9025D4

9040E4

9100C4

9101C4

9102E3

4003E3*

4004D4*

4007D5*

4008D4*

4011E5*

4013E5*

4014E5*

4026E4*

4052D4*

4100B1*

4101E3*

4102B1*

4107B1*

4113C5 *

4116C4 *

4121D5*

4177E2*

4178E5*

4180C5*

4200E3*

4201E3*

4202D4*

4211D4*

4212D4*

4213D4*

4214C4*

4216C4*

4217B1*

4219D2*

4235C4*

4236C5*

4251E3*

4421C4*

4555C2*

4600C1*

4601C2*

4603C2*

4605C2*

4609C2*

4613D2*

4621D2*

4647C2*

4677E1*

4682C2*

4684C2*

4694C2*

4695C2*

4696C2*

5010E4

5128D4

5201C3

5202D4

5203E3

5206C3

5260D4

5370E1

5441A5

5442A4

5443A5

5445B4

5451A4

5456B4

5457B4

5458B4

5500B2

5515A3

5516B3

5540A3

5545B3

5550B3

5551C4

5553C3

5570B3

5571E3

5572B3

5573B3

5600D1

5601C1

5602C2

5603C2

5605C2

5620C1

6001E3

6002E3

6003E4

6016D5

6100C4

6101C4

6109D5

6110D5

6111 C3

6254E3

6265C4

6311E2

6321D2

6331D2

6332E1

6341E2

6347E2

6420C3

6440A4

6441A4

6443C5

6444B4

6445A4

6449C4

6454B4

3505B1

3506B2

3507B2

3510B2

3512A3 *

3513A3 *

3517A3 *

3518A3

3520A3 *

3521A3

3524A3 *

3525A3

3528A3

3529A3

3530A3

3532A3 *

3534A3 *

3536A3 *

3537A3 *

3538A3

3539A3

3540A3

3541A3

3542A2

3545B2

3546B3

3552C3*

3553C3*

3554C3*

3565C2*

3570B3*

3580C2*

3581C2*

3582C2*

3585B4

3586B4*

3587B3*

3588B4*

3589B3*

3590C2*

3591C2*

3593C2*

3601C1

3602D2

3603D1

3604C2*

3605C2*

3606C2*

3607C2*

3608D1

3610D1*

3612D1*

3613D1

3614D1*

3615E4

3616D1*

3617C3

3618C3

3621C1*

3622C1*

3623C1*

3624C1*

3625C1*

3628E3*

3629C1*

3630D1*

3632D2*

3633D2

3634D2

3636E3

3637E2

3640E2*

3641E2*

3644D2

3653D1*

3654D2*

3655D2

3656C1*

3657D2

3660D2*

3661D2*

3662D2*

3663C1*

3664D3*

3665D2*

3666D2*

3667C1*

3670C2

3671C1*

3674C2

3675C2

3676C2*

3681C2

3684C2*

3685C2

3686C2*

3688C2*

3689C2*

3690C2

3693C2*

3694C2*

3695C2*

3696C2*

3698C2*

3699D2*

4000E5*

4002E4*

3216C4*

3217C4*

3218C4*

3220C4

3221C4

3223D3

3224D3*

3225D3*

3227D4*

3229D4*

3234D3

3248E3*

3249D3*

3250D3*

3251D3

3252E3*

3253E3*

3254E3*

3265C3*

3266C3

3267C4

3273D4*

3280D3*

3311E2

3312E2*

3313E2*

3314D2

3315E2

3316D2

3317E2

3321E2*

3322E2*

3323E2*

3324E2

3325E2

3326E2

3327E2

3331E1*

3332E1*

3333E1*

3334E1

3335E2

3336E1

3337D1

3341E1

3342D1

3347E2

3371E1

3372E1

3374E2

3400E4

3401C5

3402C5

3403D4*

3404C5

3405E4*

3406C5

3407C5

3408E4*

3410D4*

3411C5

3412B5*

3413C5

3415C5*

3417C5*

3418B5

3420C4*

3421D4*

3422D4*

3423D4*

3430E4

3431A5

3432A5

3433D4

3434D4*

3435D4

3436C5

3437C4

3440C3*

3441C3*

3442A4

3443B4*

3444A4

3445A4

3446A4

3447B4

3448B4

3449B5

3450B4

3451B4

3456A5

3457A5

3458A5

3459A4

3460B5

3461C3*

3462B4

3470B5

3471A5

3480C4

3481C4

3490D4*

3491D4*

3500A2

3501A1

3503B2

3504B2

2607D2*

2608D2*

2610D1

2611D1

2613D1*

2615E4

2621C1*

2622C1*

2623C1*

2630D1

2639D2*

2644D2

2650D1*

2652D1*

2655C1

2660D2*

2661D2*

2663D3*

2664D2*

2666D2*

2670C1*

2671A1

2674C2*

2680C2*

2682C2*

2683C2*

2684C2*

2685C2*

2690C2*

2691C2*

2692C2*

2693C2*

2694C2*

2695C2*

3000E4*

3001E4

3002E4

3004E4*

3005E3*

3006E3*

3007E3

3008E3*

3009E3*

3010E3

3013E3

3015E3

3016D5

3020E5*

3022E5*

3040E4*

3100B1

3104C3

3105C3*

3106C3*

3107C3*

3108C4*

3114C1

3115C1

3121C5

3122C5

3123D5

3124D5*

3125D5

3126C3*

3127D5

3128D5

3129C3*

3130C3*

3141D3

3144D4*

3160D5

3161C5

3162D5

3163D5

3164D5

3165D5*

3166D5*

3167D5*

3168D5*

3169C4*

3170E5*

3178E5*

3179E5*

3180E5*

3181E5*

3185C1

3186C1

3187C1

3188C1

3191B1

3192B1

3193B1

3194E5

3195D5

3201D4*

3202D4*

3203D4

3204D5*

3205D4

3206C4*

3207C4

3208D3*

3209D4*

3210C4*

3211C4*

3214C4*

3215C4*

2222E3*

2224D4

2226D3

2240D3*

2241D3*

2242D3*

2248E3*

2249D3*

2251E3*

2252E3*

2254E3*

2260D3

2261C3*

2272D4*

2273D3*

2275D4*

2277D4*

2283C3*

2284C3*

2285C3*

2313E2*

2321E2*

2323E2*

2333E1*

2341E1

2342D1

2373E1

2401C5

2403D4

2406D4*

2409D4*

2410D4

2414C5

2420C3

2421D4

2422B2

2430D4

2434D4*

2436D4*

2437D4*

2440C3

2442A4 *

2443C4

2444A4

2445A4

2448B4

2450A5

2451A4

2452C4

2453C4

2456A5

2460B5

2461D3

2462A4

2463C5

2464B5*

2465B5*

2466C5*

2467C5*

2468C5*

2469A4

2470A5

2471A4

2476C5*

2480C4

2485B5*

2487C5*

2500A1

2502B2

2504B2

2505B2

2508A2

2509B3

2510B3

2517A3 *

2518B2

2520A3 *

2521A3 *

2522A3 *

2524A3 *

2529A3 *

2530A3

2531A3

2532A3 *

2533A3 *

2534A3 *

2537A3

2540A3

2541A3

2545B3

2550B4

2551B4

2553C2*

2554C2*

2560B3*

2561C3

2562B4

2563C2

2570B3*

2571C3

2572B3*

2580C2*

2582B4*

2583C2

2584C2

2601C1*

2602C1

0003E2

0004D1

0010C2

0011A2

0015D3

0020B1

0022B1

0024C1

0025C1

0026D1

0028D2

0029D2

0030B1

0044C5

0055A4

0066B5

0077D3

0088B1

0139A1

0166E1

0177E2

0231C5

0232B1

0233D1

0321E1

0322E1

1000E5

1015D4

1060C1

1061D1

1062D1

1063D1

1064A1

1100B1 *

1102D4

1103B1 *

1104D4

1105C1 *

1106B1 *

1107B1 *

1108C5 *

1109C5 *

1110D5*

1111 C5 *

1112D5*

1120B1 *

1121B1 *

1122B1 *

1123B1 *

1206C3

1207C4

1208C4

1209E4

1275D4

1277D4

1500A2

1560C3

1571B3

1670B1

1681C2

2008E5*

2010D4

2011E4*

2016D5

2042E4*

2043E4*

2104E5

2105D5

2108D4

2110D5

2115B1

2116B1

2117C4 *

2120D5

2121D5

2124C1*

2125C1*

2128D4*

2130D4*

2144D4

2145D5*

2161D5

2163C1

2164C1

2166C5*

2167D5

2168C5*

2169C5*

2170E5

2171E5

2180C5*

2198B1

2199B1

2200D5*

2201D4*

2202D4

2203D4*

2205E3

2209D4*

2211D4

2212D4*

2213D4*

2214C1*

2215D4*

2217C4

2218D4*

A

B

C

D

E

2221E3*

170398

015_006.EPS

5

17L7.2E

4

3

2

1

7 Diagrams and print lay-outs

Page 18

9615C2

9616C3

9620C1

9628D3

9637C1

9643D2

9644D3

9647D2

9649C2

9650C3

9651C4

9658C1

9660C2

9663D2

9667D2

9677C2

9690D2

9691C3

9692C3

9693C3

9900B5

9901B5

9902D5

9903C5

9904D5

9905D5

9906D5

9907C5

M0 B3

M11 E4

M9 E3

*=chip

component

9103E4

9104E4

9107D4

9108E5

9109E4

9110E3

9111 E2

9112D5

9113C4

9115E4

9116E3

9118C3

9122E4

9123E4

9124E4

9125E4

9126D4

9131D5

9132B1

9133E3

9134E3

9135E3

9137E5

9138E5

9139D2

9141D3

9145D5

9147D5

9148D5

9202D4

9203C4

9206C3

9207C3

9208D3

9209C3

9210E4

9211D3

9212D3

9220D3

9221C3

9225C3

9229D2

9233D1

9235D3

9236D3

9237C3

9238D3

9240C4

9245D3

9246D3

9247C3

9248C3

9250D3

9251D3

9252D1

9261D3

9270C3

9313E1

9317D1

9334E2

9337E1

9341E2

9347E2

9370E1

9372E1

9377E1

9403B4

9404C5

9405C3

9406B5

9408C5

9410C4

9411B5

9413C5

9416C4

9417C2

9418D3

9419C4

9423C4

9424C4

9425C4

9426D3

9443D5

9448B4

9450A4

9454A5

9461B4

9462B4

9469C5

9500A2

9501A1

9505B2

9515A3

9518C3

9519C3

9520C2

9590C3

9601D3

9602C1

9603B1

9604D3

9605D2

9606E4

9607C2

9611D2

9613D1

9614D2

6455A5

6456A5

6461B4

6464B4

6468C5

6470B5

6480C4

6481C4

6502B2

6503B2

6504B2

6505B2

6507B3

6508A3

6510A2

6524A3

6537A3

6540A3

6550C3

6560B3

6570B3

6581C2

6583B4

6585C2

6586C2

6600C1

6610D1

6653C1

6661D2

6663A1

6690D2

6691C3

6692C3

6693C3

7001E3*

7002E3*

7003E3*

7100C3*

7101C3*

7115D5 *

7118E5 *

7200C4*

7204D3*

7214C4*

7215C4*

7220D3*

7225D4

7241D3

7255E3

7265C3*

7301E2

7302E2

7303E1

7304E2

7305E2

7306E2

7307E2

7308E1

7309E1

7401C5

7420D5*

7421C4*

7440C3*

7441A4

7445A4

7518B3

7520A3

7541C3

7581A4

7583B3*

7584B4*

7585C2*

7586C2*

7587C2*

7600C2

7601C2

7603C2*

7608D1*

7610D1*

7620C1

7644D3*

7655C1*

7681C2*

7682C2*

7683C2*

7684C2*

9001E4

9003E5

9006E4

9007D4

9008D2

9009E3

9010E3

9011E3

9013E4

9016D5

9018D5

9019D4

9020D3

9021D3

9023C3

9024E4

9025D4

9040E4

9100C4

9101C4

9102E3

4003E3*

4004D4*

4007D5*

4008D4*

4011E5*

4013E5*

4014E5*

4026E4*

4052D4*

4100B1*

4101E3*

4102B1*

4107B1*

4113C5 *

4116C4 *

4121D5*

4177E2*

4178E5*

4180C5*

4200E3*

4201E3*

4202D4*

4211D4 *

4212D4*

4213D4*

4214C4*

4216C4*

4217B1*

4219D2*

4235C4*

4236C5*

4251E3*

4421C4*

4555C2*

4600C1*

4601C2*

4603C2*

4605C2*

4609C2*

4613D2*

4621D2*

4647C2*

4677E1*

4682C2*

4684C2*

4694C2*

4695C2*

4696C2*

5010E4

5128D4

5201C3

5202D4

5203E3

5206C3

5260D4

5370E1

5441A5

5442A4

5443A5

5445B4

5451A4

5456B4

5457B4

5458B4

5500B2

5515A3

5516B3

5540A3

5545B3

5550B3

5551C4

5553C3

5570B3

5571E3

5572B3

5573B3

5600D1

5601C1

5602C2

5603C2

5605C2

5620C1

6001E3

6002E3

6003E4

6016D5

6100C4

6101C4

6109D5

6110D5

6111 C3

6254E3

6265C4

6311E2

6321D2

6331D2

6332E1

6341E2

6347E2

6420C3

6440A4

6441A4

6443C5

6444B4

6445A4

6449C4

6454B4

3505B1

3506B2

3507B2

3510B2

3512A3 *

3513A3 *

3517A3 *

3518A3

3520A3 *

3521A3

3524A3 *

3525A3

3528A3

3529A3

3530A3

3532A3 *

3534A3 *

3536A3 *

3537A3 *

3538A3

3539A3

3540A3

3541A3

3542A2

3545B2

3546B3

3552C3*

3553C3*

3554C3*

3565C2*

3570B3*

3580C2*

3581C2*

3582C2*

3585B4

3586B4*

3587B3*

3588B4*

3589B3*

3590C2*

3591C2*

3593C2*

3601C1

3602D2

3603D1

3604C2*

3605C2*

3606C2*

3607C2*

3608D1

3610D1*

3612D1*

3613D1

3614D1*

3615E4

3616D1*

3617C3

3618C3

3621C1*

3622C1*

3623C1*

3624C1*

3625C1*

3628E3*

3629C1*

3630D1*

3632D2*

3633D2

3634D2

3636E3

3637E2

3640E2*

3641E2*

3644D2

3653D1*

3654D2*

3655D2

3656C1*

3657D2

3660D2*

3661D2*

3662D2*

3663C1*

3664D3*

3665D2*

3666D2*

3667C1*

3670C2

3671C1*

3674C2

3675C2

3676C2*

3681C2

3684C2*

3685C2

3686C2*

3688C2*

3689C2*

3690C2

3693C2*

3694C2*

3695C2*

3696C2*

3698C2*

3699D2*

4000E5*

4002E4*

3216C4*

3217C4*

3218C4*

3220C4

3221C4

3223D3

3224D3*

3225D3*

3227D4*

3229D4*

3234D3

3248E3*

3249D3*

3250D3*

3251D3

3252E3*

3253E3*

3254E3*

3265C3*

3266C3

3267C4

3273D4*

3280D3*

3311E2

3312E2*

3313E2*

3314D2

3315E2

3316D2

3317E2

3321E2*

3322E2*

3323E2*

3324E2

3325E2

3326E2

3327E2

3331E1*

3332E1*

3333E1*

3334E1

3335E2

3336E1

3337D1

3341E1

3342D1

3347E2

3371E1

3372E1

3374E2

3400E4

3401C5

3402C5

3403D4*

3404C5

3405E4*

3406C5

3407C5

3408E4*

3410D4*

3411C5

3412B5*

3413C5

3415C5*

3417C5*

3418B5

3420C4*

3421D4*

3422D4*

3423D4*

3430E4

3431A5

3432A5

3433D4

3434D4*

3435D4

3436C5

3437C4

3440C3*

3441C3*

3442A4

3443B4*

3444A4

3445A4

3446A4

3447B4

3448B4

3449B5

3450B4

3451B4

3456A5

3457A5

3458A5

3459A4

3460B5

3461C3*

3462B4

3470B5

3471A5

3480C4

3481C4

3490D4*

3491D4*

3500A2

3501A1

3503B2

3504B2

2607D2*

2608D2*

2610D1

2611D1

2613D1*

2615E4

2621C1*

2622C1*

2623C1*

2630D1

2639D2*

2644D2

2650D1*

2652D1*

2655C1

2660D2*

2661D2*

2663D3*

2664D2*

2666D2*

2670C1*

2671A1

2674C2*

2680C2*

2682C2*

2683C2*

2684C2*

2685C2*

2690C2*

2691C2*

2692C2*

2693C2*

2694C2*

2695C2*

3000E4*

3001E4

3002E4

3004E4*

3005E3*

3006E3*

3007E3

3008E3*

3009E3*

3010E3

3013E3

3015E3

3016D5

3020E5*

3022E5*

3040E4*

3100B1

3104C3

3105C3*

3106C3*

3107C3*

3108C4*

3114C1

3115C1

3121C5

3122C5

3123D5

3124D5*

3125D5

3126C3*

3127D5

3128D5

3129C3*

3130C3*

3141D3

3144D4*

3160D5

3161C5

3162D5

3163D5

3164D5

3165D5*

3166D5*

3167D5*

3168D5*

3169C4*

3170E5*

3178E5*

3179E5*

3180E5*

3181E5*

3185C1

3186C1

3187C1

3188C1

3191B1

3192B1

3193B1

3194E5

3195D5

3201D4*

3202D4*

3203D4

3204D5*

3205D4

3206C4*

3207C4

3208D3*

3209D4*

3210C4*

3211C4*

3214C4*

3215C4*

2222E3*

2224D4

2226D3

2240D3*

2241D3*

2242D3*

2248E3*

2249D3*

2251E3*

2252E3*

2254E3*

2260D3

2261C3*

2272D4*

2273D3*

2275D4*

2277D4*

2283C3*

2284C3*

2285C3*

2313E2*

2321E2*

2323E2*

2333E1*

2341E1

2342D1

2373E1

2401C5

2403D4

2406D4*

2409D4*

2410D4

2414C5

2420C3

2421D4

2422B2

2430D4

2434D4*

2436D4*

2437D4*

2440C3

2442A4 *

2443C4

2444A4

2445A4

2448B4

2450A5

2451A4

2452C4

2453C4

2456A5

2460B5

2461D3

2462A4

2463C5

2464B5*

2465B5*

2466C5*

2467C5*

2468C5*

2469A4

2470A5

2471A4

2476C5*

2480C4

2485B5*

2487C5*

2500A1

2502B2

2504B2

2505B2

2508A2

2509B3

2510B3

2517A3 *

2518B2

2520A3 *

2521A3 *

2522A3 *

2524A3 *

2529A3 *

2530A3

2531A3

2532A3 *

2533A3 *

2534A3 *

2537A3

2540A3

2541A3

2545B3

2550B4

2551B4

2553C2*

2554C2*

2560B3*

2561C3

2562B4

2563C2

2570B3*

2571C3

2572B3*

2580C2*

2582B4*

2583C2

2584C2

2601C1*

2602C1

0003E2

0004D1

0010C2

0011A2

0015D3

0020B1

0022B1

0024C1

0025C1

0026D1

0028D2

0029D2

0030B1

0044C5

0055A4

0066B5

0077D3

0088B1

0139A1

0166E1

0177E2

0231C5

0232B1

0233D1

0321E1

0322E1

1000E5

1015D4

1060C1

1061D1

1062D1

1063D1

1064A1

1100B1 *

1102D4

1103B1 *

1104D4

1105C1 *

1106B1 *

1107B1 *

1108C5 *

1109C5 *

1110D5*

1111 C5 *

1112D5*

1120B1 *

1121B1 *

1122B1 *

1123B1 *

1206C3

1207C4

1208C4

1209E4

1275D4

1277D4

1500A2

1560C3

1571B3

1670B1

1681C2

2008E5*

2010D4

2011E4*

2016D5

2042E4*

2043E4*

2104E5

2105D5

2108D4

2110D5

2115B1

2116B1

2117C4 *

2120D5

2121D5

2124C1*

2125C1*

2128D4*

2130D4*

2144D4

2145D5*

2161D5

2163C1

2164C1

2166C5*

2167D5

2168C5*

2169C5*

2170E5

2171E5

2180C5*

2198B1

2199B1

2200D5*

2201D4*

2202D4

2203D4*

2205E3

2209D4*

2211D4

2212D4*

2213D4*

2214C1*

2215D4*

2217C4

2218D4*

2221E3*

110398

015_007.EPS

1

18L7.2E

2

34

5

7 Diagrams and print lay-outs

A

B

C

D

E

Page 19

015_009.EPS

19L7.2E

(3 - 7401)

F4

(5- 7401)

F3

(1 - 7401)

F2

(7- 7401)

F1

(C - 6443)

(C - 6454)

L11

5V DC

L12

(40 - 7225 - 5D)

L4

13V DC

5ms / div

10V / div DC

5ms / div

20V / div DC

5ms / div

0.5V / div DC

5ms / div

0.5V / div DC

20µs / div

2V / div DC

7 Diagrams and print lay-outs

(E- 7440)

L3

(3445 / 3442)

L2

(C - 7445)

L1

(41 - 7225 - 5D)

S1

20µs / div

2V / div DC

20µs / div

2V / div DC

20µs / div

100V / div DC

20µs / div

1V / div DC

Page 20

(12 - 7225)

V12

(3M7)

20µs / div

0.5V / div DC

V13

(2M7)

20µs / div

1V / div DC

V14

(4M7)

20µs / div

1V / div DC

V15

20µs / div

1V / div DC

(6 - 7225 - 5A)

I1

20µs / div

(IF - Tuner)

1V / div DC

I2

20µs / div

(1 - Tuner)

0.2V / div AC

I3

20µs / div

(1 - Tuner)

0.5V / div DC

I4

(2 - Tuner)

only FST tuner

I5

2V DC

015_010.EPS

(16 - 7241)

V7

(PAL)

(11 - 7225 - 5B)

V6

3.5V DC

(30 - 7225 - 5B)

V5

(29 - 7225 - 5B)

V4

(28 - 7225 - 5B)

V3

(38 - 7225 - 5B)

V2

20µs / div

0.5V / div DC

20µs / div

0.5V / div DC

(11 - 7255)

20µs / div

0.5V / div DC

V11

(14 - 7255)

20µs / div

1V / div DC

V10

(16 - 7255)

20µs / div

1V / div DC

V9

20µs / div

0.5V / div DC

20µs / div

0.5V / div DC

20µs / div

0.5V / div DC

20L7.2E

(13 - 7225 - 5B)

V1

(5 - 7255)

20µs / div

1V / div DC

V8

20µs / div

1V / div DC

7 Diagrams and print lay-outs

Page 21

21L7.2E

C1 (52 - 7600)

5V DC

(50 - 7600)

C2

5ms / div

1V / div DC

C3 (49 - 7600)

5ms / div

1V / div DC

(with RC5 signal)

C4 (1 - 1670)

(41 - 7600)

5ms / div

1V / div DC

C5

(42 - 7600)

0.5µs / div

1V / div DC

C6

0.5µs / div

1V / div DC

7 Diagrams and print lay-outs

Page 22

015_012.EPS

22L7.2E

A7, A8, A9, A10

(Video out)

A6

(Audio out)

A5

(Audio out)

A4

(15 - 7225 - 5E)

A3

(55 - 7225 - 5E)

A2

1ms / div

0.1V / div DC

20µs / div

1V / div DC

0.5ms / div

1V / div DC

0.5ms / div

1V / div DC

0.5ms / div

1V / div DC

1ms / div

5V / div AC

7 Diagrams and print lay-outs

(1 - 7225 - 5E)

A1

0.1ms / div

0.1V / div AC

Page 23

A

100398

015_004.EPS

9347A2

9370B1

9372B1

9377B2

3

2

3

2

*=chipcomponent

1

7308B1

7309A1

9313B1

9317A1

9334A3

9337B1

9341B3

9347A2

6347B3

7301B3

7302B3

7303A1

7304B3

7305B2

7306B3

7307B3

3374B2

4677B1*

5370B1

6311A2

6321A3

6331A3

6332A1

6341B3

2

3335B3

3336A1

3337A1

3341A1

3342A1

3347B3

3371B1

3372B1

3324A3

3325B3

3326A3

3327A3

3331B1*

3332B1*

3333B1*

3334A1

3313B3*

3314A3

3315A3

3316A2

3317A2

3321B3*

3322B3*

1

1

2321B3*

3323B3*

3

2323B3*

2333A1 *

2341B1

2342A1

2373B2

3311B3

3312B3*

3313B3*

B

100398

015_005.EPS

9347A2

9370B1

9372B1

9377B2

*=chipcomponent

1

7308B1

7309A1

9313B1

9317A1

9334A3

9337B1

9341B3

9347A2

6347B3

7301B3

7302B3

7303A1

7304B3

7305B2

7306B3

7307B3

3374B2

4677B1*

5370B1

6311A2

6321A3

6331A3

6332A1

6341B3

2

3335B3

3336A1

3337A1

3341A1

3342A1

3347B3

3371B1

3372B1

3324A3

3325B3

3326A3

3327A3

3331B1*

3332B1*

3333B1*

3334A1

3313B3*

3314A3

3315A3

3316A2

3317A2

3321B3*

3322B3*

3323B3*

3

2321B3*

2323B3*

2333A1 *

2341B1

2342A1

2373B2

3311B3

3312B3*

3313B3*

23L7.2E

A A

B B

A

A428 A 2

A399 A 5

A390 A 4

A382 F 4

A381 B 3

A380 E 5

A379 C 1

A378 G 2

A377 F 3

A376 E 4

A375 D 2