Philips hudson iv 170x5, 190X5FB/20, 190X5FB/00 Service Manual

Horizontal Frequencies

30 - 82KHz

Service

Service

Service

TABLE OF CONTENTS

Published by BCU Monitors Printed in Suzhou Copyright reserved Subject to modification H Aug. 6 2004

HUDSON IV 170X5

REFER TO BACK COVER FOR IMPORTANT SAFETY GUIDELINES

CAUTION: USE A SEPARATE ISOLATION TRANSFORMER FOR THIS UNIT WHEN SERVICING.

ANY PERSON ATTEMPTING TO SERVICE THIS CHASSIS MUST FAMILIARIZE HIMSELF WITH THE CHASSIS

AND BE AWARE OF THE NECESSARY SAFETY PRECAUTIONS TO BE USED WHEN SERVICING ELECTRONIC

EQUIPMENT CONTAINING HIGH VOLTAGES.

SAFETY NOTICE

GB

3138 106 10404

17" TFT LCD Monitor

Model: 170X5FB/00

Description Page

Important Safety Notice ----------------------------------2

Technical Data ------------------------------------------3~5

On-Screen Display ----------------------------------- 9 10

Electrical Instructions ------------------------------12

Mechanical Instructions ---------------------------14~15

Factory Mode ---------------------------------------------16

Troubleshooting ------------------------------------------- 6

Installations --------------------------------------------- 7~8

~

~13

Aging Mode ----------------------------------------------- 17

Repair Flow Chart -----------------------------------18~20

Safety Test Requirement ------------------------------- 21

Repair Tips ------------------------------------------------22

Wiring Diagram -------------------------------------------23

Function Block Diagram -------------------------------- 24

Scaler Schematic Diagram ------------------------25~30

Philips Pixel Defect Policy ------------------------------11

Description Page

------------------------------------------- 44

Scaler Board C.B.A. ------------------------------- 31~32

Control Schematic Diagram & C.B.A. ---------------33

Audio Schematic Diagram ------------------------34~35

Audio Board C.B.A. --------------------------------36~37

Earphone Schematic Diagram & C.B.A. ------------38

Power Schematic Diagram------------------------39~40

Power Board C.B.A. ------------------------------- 41 ~43

Exploded View

Spare Parts List------------------------------------ 45~ 47

Recommended Parts List ----------------------------- 48

General Product Specification-------------------49~73

ISP Cable For CPU --------------------------------74~76

DDC Instructions & DDC Data -------------------77~86

Failure Mode Of Panel----------------------------------87

~90

Warning Message--------------------------------------- 91

LightFrame for Windows ------------------------ 88

Different Parts List ------------------------------------- 92

«

TM

Proper service and repair is important to the safe, reliable

operation of all Philips Consumer Electronics Company**

Equipment. The service procedures recommended by

Philips and described in this service manual are effective

methodsofperformingserviceoperations.Someofthese

service operations require the use of tools specially designed

forthepurpose.Thespecialtoolsshouldbeusedwhenand

as recommended.

Itisimportanttonotethatthismanualcontainsvarious

CAUTIONSandNOTICESwhichshouldbecarefullyreadin

order to minimize the risk of personal injury to service

personnel. The possibility exists that improper service

methods may damage the equipment. It is also important to

understand that these CAUTIONS and NOTICES ARE NOT

EXHAUSTIVE. Philips could not possibly know, evaluate and

advisetheservicetradeofallconceivablewaysinwhich

service might be done or of the possible hazardous

consequences of each way. Consequently, Philips has not

undertaken any such broad evaluation. Accordingly, a

servicer who uses a service procedure or tool which is not

recommended by Philips must first satisfy himself thoroughly

thatneitherhissafetynorthesafeoperationofthe

equipment will be jeopardized by the service method

selected.

* *Hereafter throughout this manual, Philips Consumer

Electronics Company will be referred to as Philips.

Critical components having special safety characteristics are

identifiedwitha bytheRef.No.inthepartslistand

enclosed within a broken line*

(where several critical components are grouped in one area)

along with the safety symbol on the schematics or

exploded views.

Use of substitute replacement parts which do not have the

same specified safety characteristics may create shock, fire,

or other hazards.

Under no circumstances should the original design be

modified or altered without written permission from Philips.

Philips assumes no liability, express or implied, arising out of

any unauthorized modification of design.

Servicer assumes all liability.

WARNING

* Broken Line

FOR PRODUCTS CONTAINING LASER :

Invisible laser radiation when open.

AVOIDDIRECTEXPOSURETOBEAM.

Use of controls or adjustments or

performance of procedures other than

those specified herein may result in

hazardous radiation exposure.

The use of optical instruments with this

product will increase eye hazard.

DANGER-

CAUTION-

CAUTION-

TO ENSURE THE CONTINUED RELIABILITY OF THIS

PRODUCT, USE ONLY ORIGINAL MANUFACTURER'S REPLACEMENT

PARTS, WHICH ARE LISTED WITH THEIR

PARTNUMBERSINTHEPARTSLISTSECTIONOFTHISSERVICE

MANUAL.

Take care during handling the LCD module with backlight unit

- Must mount the module using mounting holes arranged in four

corners.

-Donotpressonthepanel,edgeoftheframestronglyorelectric

shock as this will result in damage to the screen.

- Do not scratch or press on the panel with any sharp objects, such

as pencil or pen as this may result in damage to the panel.

- Protect the module from the ESD as it may damage the electronic

circuit (C-MOS).

- Make certain that treatment person s body are grounded through

wrist band.

-Donotleavethemoduleinhightemperatureandinareasofhigh

humidityforalongtime.

-Avoidcontactwithwaterasitmayashortcircuitwithinthe

module.

-Ifthesurfaceofpanelbecomedirty,pleasewipeitoffwithasoft

material. (Cleaning with a dirty or rough cloth may damage the

panel.)

Important Safety Notice

!

!

2

170X5 LCD

Go to cover page

Go to cover page

170X5 LCD

3

Technical Data

Product Features

Outstanding front of screen performance

Design that complements any interior

Great convenience

LightFrame Digital Reality maximizes multimedia experence

Zero Bright Dot eliminates LCD bright dot defects

SXGA 1280 X 1024 resolution for sharper display

Fast response time capable of handling fast moving pictures

sRGB ensures color matching between display and printouts

Exclusive, elegant, design that complements fine home decor

Ultra-modern LightTouch controls

Dual Input accepts both analog VGA and digital * DVI signals

(*available for 170X5FB/00)

Enjoy multimedia experience from built-in speakers

Play music from external audio devices even if the PC is off

Embedded power supply eliminates external power adaptors

CableGuide keeps cables in order and your space neat

Auto adjustment for perfect picture display with one touch

Easily adjust display settings with Philips SmartControl

Screen tilts for comfortable viewing from any angle

Technical Specifications*

LCD PANEL

SCANNING

VIDEO

Audio

Type TFT LCD

Screen size 17" /43.2 cm diagonal

Pixel Pitch 0.264 x 0.264 mm

1280 x 1024 pixels

R.G.B. vertical stripe

Anti-glare polarizer, hard coated

Ef fective viewing area 337.9 x270.3 mm

Display Colors 16M colors

Vertical refresh rate 56 Hz-76 Hz

Horizontal Frequency 30 kHz-82 kHz

V ideo dot rate 135 MHz

Input impedance

- Video 75 ohm

- Sync 2.2K ohm

Input signal levels 0.7 Vpp

Sync input signal

Sync polarities Positive and negative

Video interface Dial input: D-sub (analog) and

DVI-D (digital) (170X5/00)a

available and user selectable

Light Frame Brightness and sharpness

LCD Panel type

Separate sync

Composite sync

Sync on green

re

Enhancement

Loudspeaker 4W Stereo Audio (2W/channel

RMSx2, 300Hz-14kHz, 16 ohm,

THD=10%, PMPO 32 Watts)

Headphone connector 3.

5 mm mini jack

Input signal connector 3.5 mm mini jack

Resolution & Preset Modes

16 user definable modes

Maximum 1280 X 1024 at 75Hz

Recommended 1280 X 1024 at 60 Hz

16 factory preset modes:

TM

Whether there is a video display or not

as long as there is an audio input, the

audio output is always functional.

Stand-alone audio output Note: The volume adjustment can not

function under the following conditions:

1. A warning message appears on screen

2. No audio input

Contrast ratio 450:1 (typ.)

Brightness 260 cd/m (typ.)

Peak contrast angle 6 o'clock

x: 0.283y:0.297(at 9300 K)

White Chromaticity x: 0.313y:0.329 (at 6500 K)

x: 0.313y:0.329 (at sRGB)

Upper 70 (typ.)

Viewing Angle(C/R>=5) Lower 70 (typ.)

Left 80 (typ.)

Right 80 (typ.)

Response time 16 ms (typ.)

sRGB is a standard

Optical Characteristics

SRGB

for ensuring correct exchange of colors between

different devices (e.g. digital cameras, monitors, printers, scanners, etc.)

Using a standard unified color space, sRGB will help represent pictures

taken by an sRGB compatible device correctly on your sRGB enabled

Philips monitors. In that way, the colors are calibrated and you can rely

on the correctness of the colors shown on your screen.

Important with the use of sRGB is that the brightness and contrast of

your monitor is fixed to a predefined setting as well as the color gamut.

Therefore it is important to select the sRGB setting in the monitor's OSD.

To do so, open the OSD by pressing the OK button on the front of your

monitor. Use the down button to go to Adjust Color and press OK again.

Then move the down button to go to sRGB and press OK again.

After this, please do not change the brightness or contrast setting of your

monitor. If you change either of these, the monitor will exit the sRGB

mode and go to a color temperature setting of 6500K.

For more information on sRGB, please visit: www.srgb.com

2

O

O

O

O

O

O

31.5 640*350 70

31.5720*400 70

31.5 640*480 60

35.0 640*480 67

37.5 640*480 75

31.3 688*556 50

H. Freq (kHz) Resolution V. freq (Hz)

TM

4

170X5 LCD

Go to cover page

Technical Data

R

R

R

Physical Specification

Dimension (W XHXD)* 388 x 400 x181 mm (in lowest position)

Weight 5.5Kg

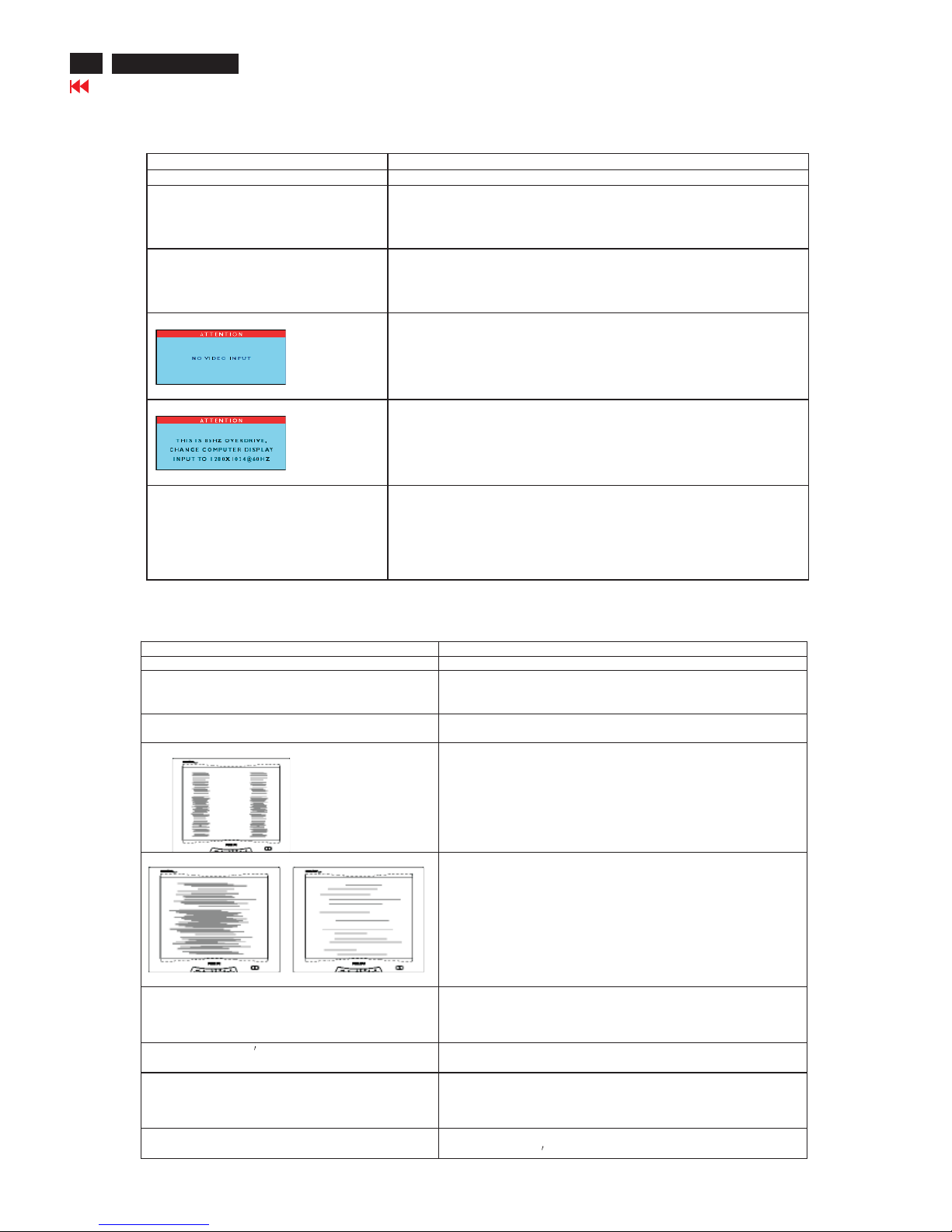

Tilt -5 --25

Power Supply 100 ---240VAC, 50/60 Hz

Power consumption 35 W* (typ.)

Temperature 5 Cto40 C (operating)

-20 Cto60 C (storage)

Relative humidity 20% to 80%

System MTBF 50K hours (excluding CCFL 40K hours)

Cabinet color Black

*This data is subject to change without notice.

*Resolution 1280 X 1024, standard size, brightness max., Contrast 50%,

9300 K, full white pattern, without audio.

O

O

O

O

O

O

Automatic Power Saving

If you have VESA DPMS compliance display card or software installed in

your PC, the monitor can automatically reduce its power consumption

when not in use. If an input from a keyboard, mouse or other input device

is detected, the monitor will 'wake up' automatically. The following table

shows the power consumption and signaling of this automatic power

saving feature:

VESA Mode Video H-sync V-sync Power Used LED color

ON Active Yes Yes <45W Green

OFF Blanked No No <1W Amber

This monitor is ENERGY STAR compliant. As an ENERGY STAR

Partner, PHILIPS has determined that this product meets the ENERGY

STAR guidelines for energy efficiency.

Power Management Definition

35.2 800*600 56

37.9 800*600 60

46.9 800*600 75

49.7832*62475

48.41024*768 60

60.01024*768 75

69.01152*870 75

71.81152*900 76

63.91280*102460

80.01280*102475

O

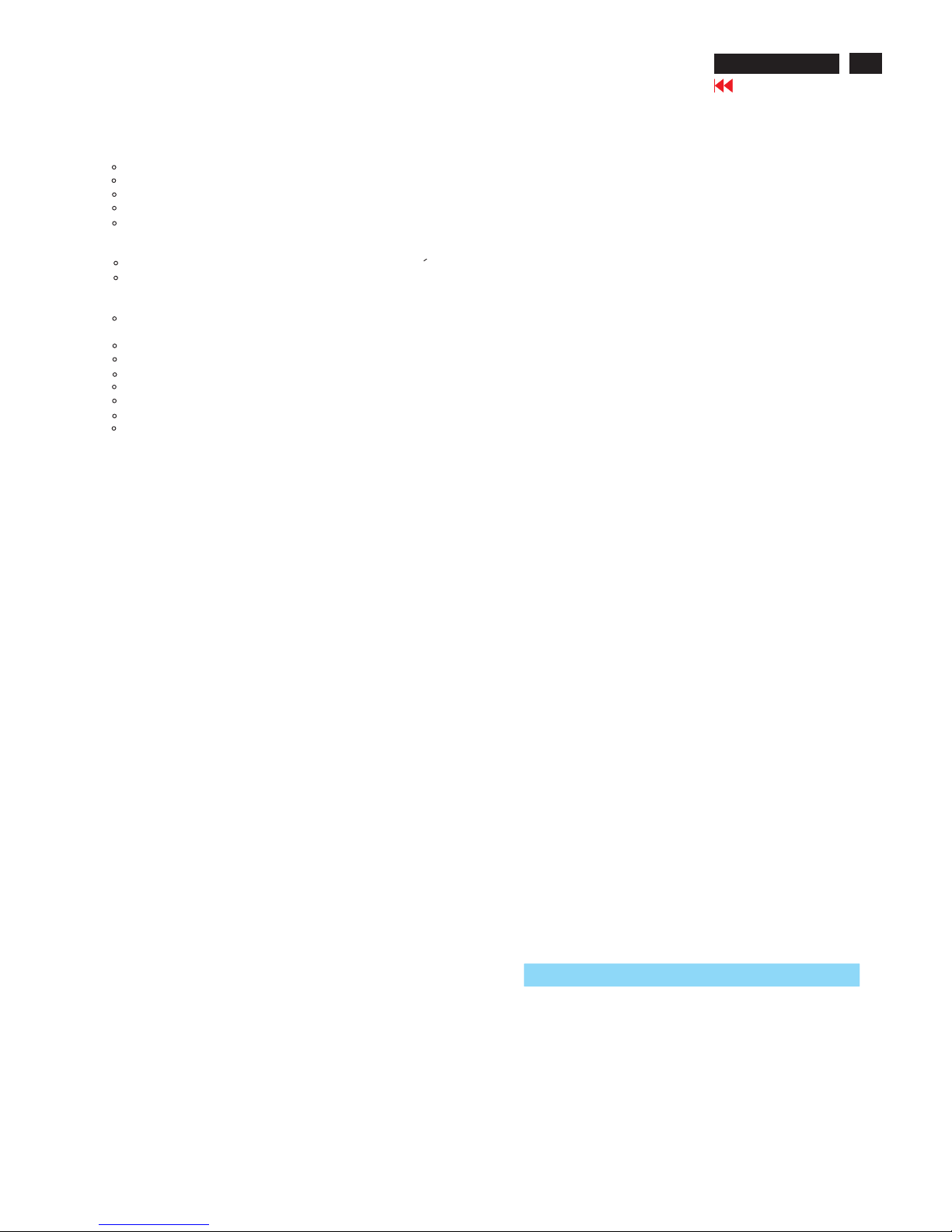

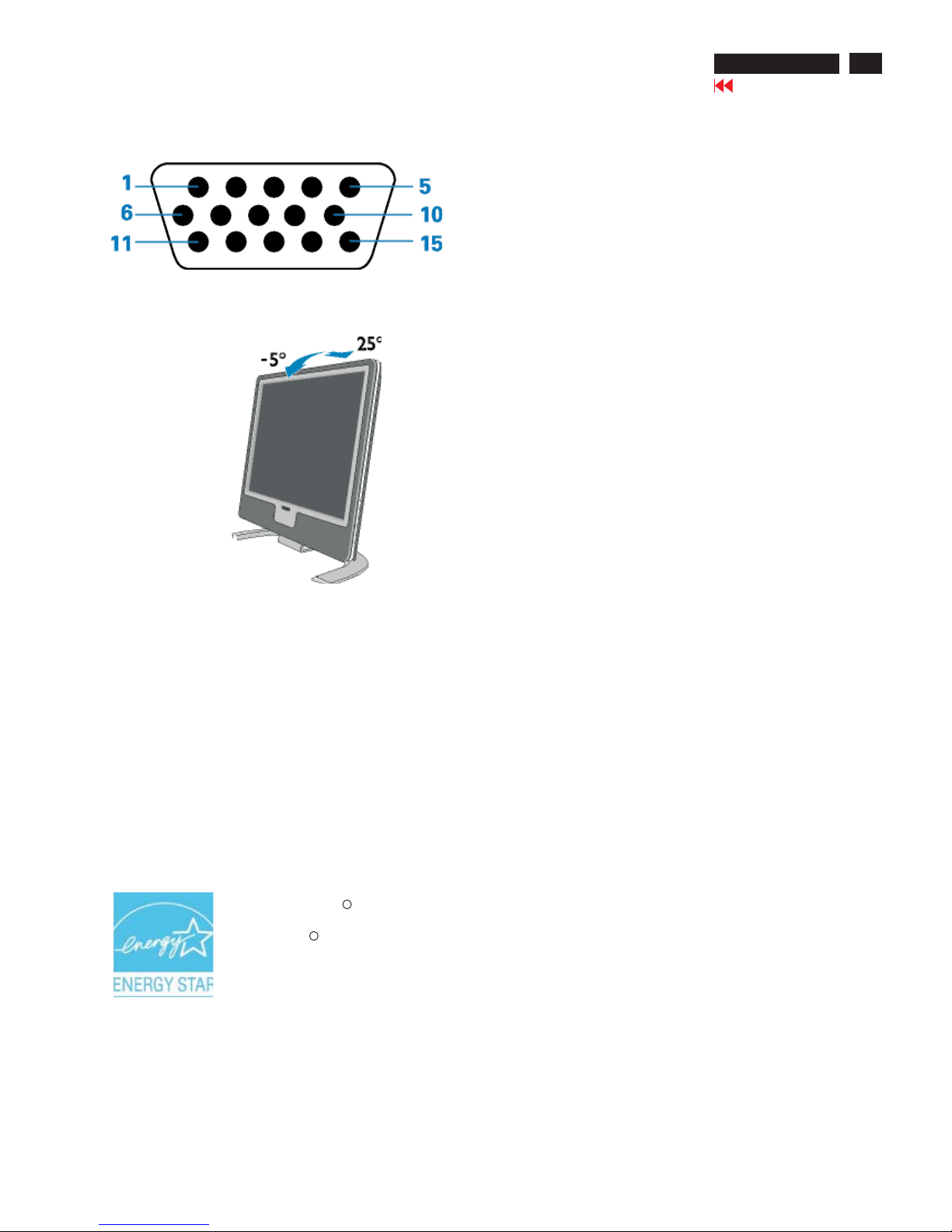

Pin Assignment

1. The digital only connector contains 24 signal conta c ts

organized in three rows of eight contacts. Signal pin

assignments are listed in the following table:

Pin

No.

Signal

Assignment

Pin

No.

Signal Assignment

Pin

No.

Signal

Assignment

1 T.M.D.S. Data2- 9 T. M.D .S . Dat a1- 17

T.M. D. S.

Data0-

2 T.M. D. S. D ata 2+ 10 T.M. D. S. D ata 1+ 18

T.M. D. S.

Data0+

3

T.M. D. S. D at a2/4

Shield

11

T.M. D. S. D at a1/3

Shield

19

T.M. D. S.

Data0/5

Shield

4 No connect 12 No connect 20 No connect

5 No connect 13 No connect 21 No connect

6 DDC Clock 14 +5V Power 22

T.M. D. S.

Clock Shield

7 DDC Data 15 Ground (for +5V) 23

T.M. D. S.

Clock+

8 No connect 16 Hot Plug Detect 24

T.M. D. S.

Clock-

2. The 15-pin D-sub connector (male) of the signal cable:

Pin

No.

Assignment

Pin

No.

Assignment

1 Red video input 9 +5V

2 Green video input/SOG 10 Logic ground

3 Blue video input 11 Ground

4 Sense (GND) 12 Serial data line (SDA)

5 Hot Plug Detect 13 H. Sync / H+V

6 Red video ground 14 V. Syn c ( VC LK for DDC)

7 Green video ground 15 Data clock line (SCL)

8 Blue video ground

Go to cover page

5

170X5 LCD

Technical Data

Physical Function

Tilt

Energy Star Declaration

PHILIPS

170X5FS

PHILIPS

This monitor is equipped with a function for saving energy which

supports the VESA Display Power Management Signaling (DPMS)

standard. This means that the monitor must be connected to a

computer which supports VESA DPMS to fulfill the requirements

in the NUTEK specification 803299/94. Time settings are

adjusted from the system unit by software.

NUTEK VESA State LED Indicator Power Consumption

Normal operation ON Green <45W

Power Saving

Alternative 2 OFF Amber <1W

One step

As an ENERGY STAR Partner, has

determined that this product meets the

ENERGY STAR guidelines for energy

efficiency.

R

R

Troubleshooting

6

Go to cover page

Common Probl ems

Having this problem? Check these items

No Picture

(power LED not lit)

· Make sure the power cord is plugged into the power outlet

and into the back of the monitor.

· First, ensure that the power button on the front of the monitor is in

the OFF position, then press it to the ON position

No Picture

(Power LED is amber or yellow)

· Make sure the computer is turned on.

· Make sure the signal cable is properly connected to your computer.

· Check to see if the monitor cable has bent pins.

· The Energy Saving feature may be activated

Screen says

· Make sure the monitor cable properly connected to your computer.

(Also refer to the Quick Set-Up Guide).

· Check to see if the monitor cable has bent pins,

· Make sure the computer is turned on.

Screen says

· Make sure the vertical sync of input signal is within the range of

56--75Hz.

· Change the refresh rate to 56--75Hz within 10 minutes.

· Re-power on monitor to start over again if you failed to change the

refresh rate within 10 minutes.

AUTO button not working properly

· The Auto Function is designed for use on standard Macintosh or

IBM-compatible PCs running Microsoft Windows.

· It may not work properly if using nonstandard PC or video card.

· The AUTO adjustment does not function when digital is used for

display.

This page deals with problems that can be corrected by the user.

170X5 LCD

Image Problems

Having this problem? Check these items

Display position is incorrect

· Press the AUTO button

· Adjust the image position using the Horizontal Position

and/or Vertical Position in OSD Main Controls.

Image vibrates on the screen

· Check that the signal cable is properly connected to the

graphics board or PC.

Vertical flicker appears

· Press the AUTO button

· Eliminate the vertical bars usin g the Clock Adjustment of

VIDEO NOISE in OSD Main Controls.

Horizontal flicker appears

· Press the AUTO button

· Eliminate the horizontal bars using the Phase

Adjustment of VIDEO NOISE in OSD Main Controls.

The screen is too bright or too dark

· Adjust the contrast and brightness on OSD Main Controls. (The

backlight of the LCD monitor has a fixed life span. When the

screen becomes dark or begins to flicker, please contact your

dealer).

LightFrame doesn twork. · Press the Auto button.

· Activate the LightFrame software again.

An after-image remains after the power has

been turned off.

· This is characteristic of liquid crystal and is not caused by a

malfunction or deterioration of the liquid crystal. The after-image

will disappear after a period of time.

Green, red, blue, and white dots remains

· The remaining dots are normal characteristic of the liquid crystal

used in today

s technology.

TM

TM

Go to cover page

7

Installations

170X5 LCD

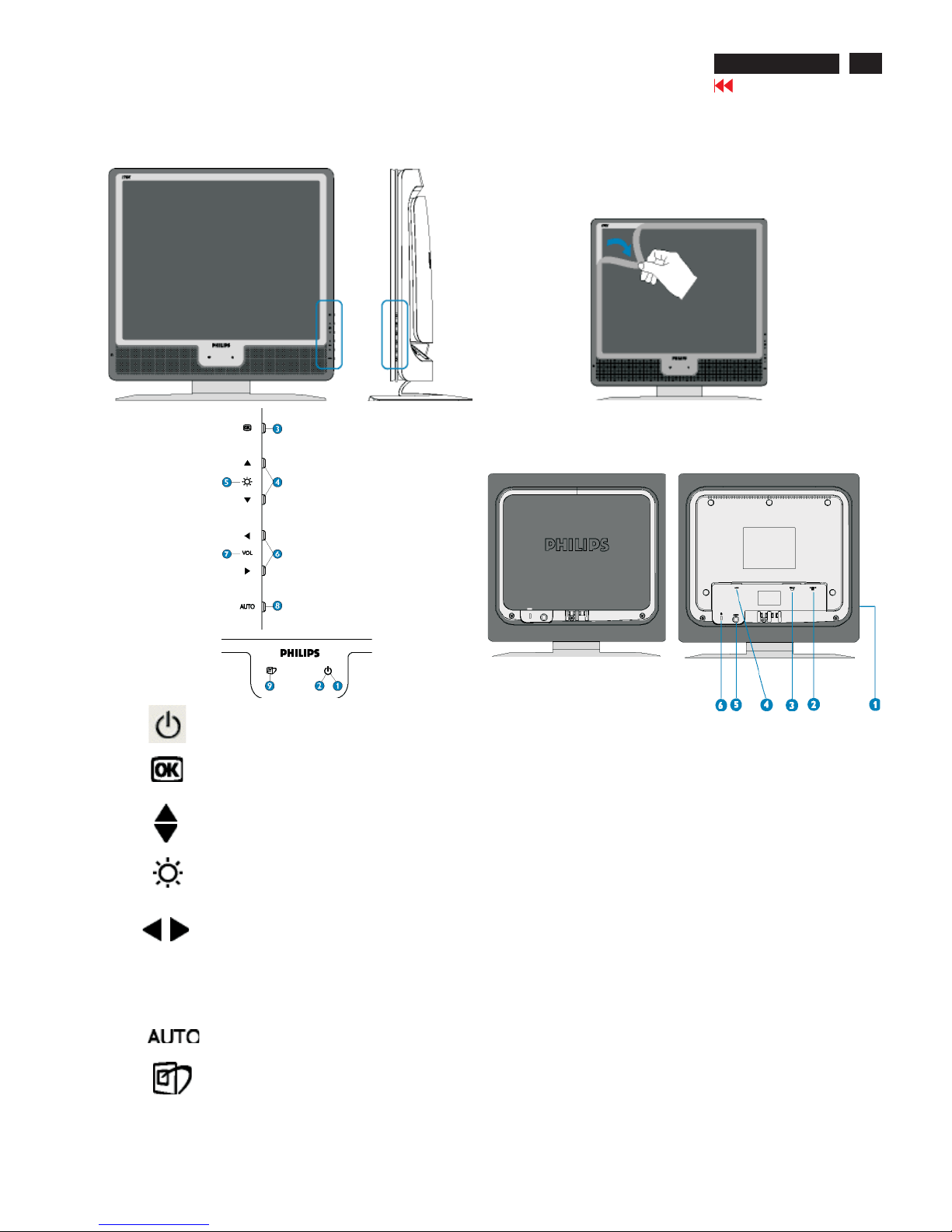

1. Power button switches your monitor on.

2. Power LED

3. OK button which when pressed will take you to the

OSD controls.

4. UP and DOWN buttons are used when adjusting the

OSD of your monitor.

BRIGHTNESS hotkey. When the UP and DOWN

arrow buttons are pressed, the adjustment controls

for the BRIGHTNESS will show up.

LEFT and RIGHT buttons, like the UP and DOWN

6. Buttons, are also used in adjusting the OSD of your

monitor.

VOLUME hotkey. When the LEFT and RIGHT arrow

7. buttons are pressed, the adjustment controls for

VOLUME will show up.

8. Automatically adjust the horizontal position, vertical

position, phase and clock setting.

9. LightFrame hotkey to select full-screen modes

among Internet, Photo and Video-TV.

VOLUME

5.

Remove protective film

A special film protects the screen frame of your new Philips monitor

during transit. Please remove the protective film from the screen before

using your monitor.

Front View Product Description

Rear View

1 Earphone jack (on side)

2 VGA input

3 DVI-D input (available for 170X5FB/00)

4 AC power input

5 PC audio input

6Kensington anti-thief lock

TM

8

Go to cover page

Installations

170X5 LCD

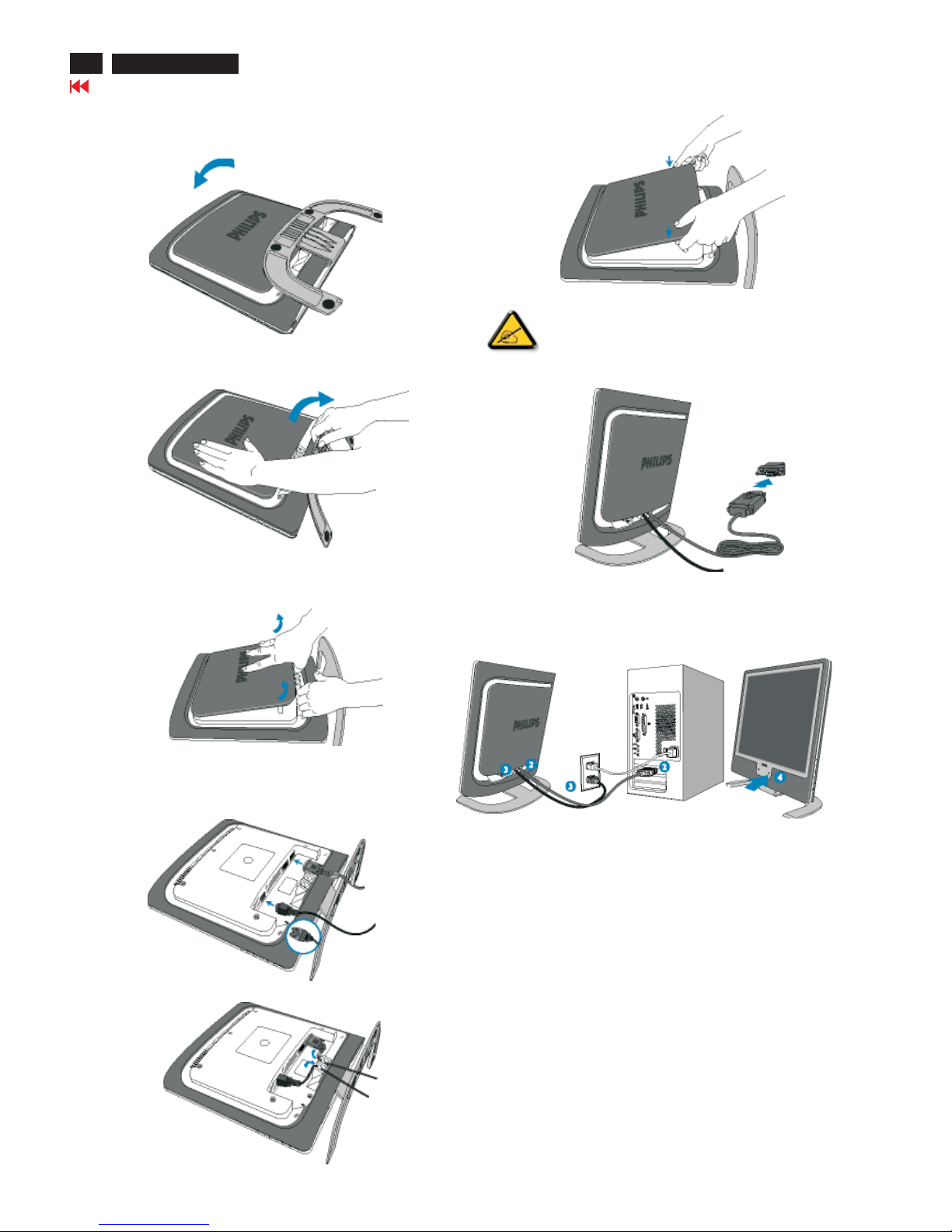

Connecting your monitor

1)

2)

3)

Cable management

4)

If you use an Apple Macintosh, you need to connect

the special Mac adapter to one end of the monitor

signal cable.

5) connect to PC

(1)

(2)

(3)

(4)

Turn off your computer and unplug its power cable.

Connect the monitor signal cable to the video connector on the

back of your computer.

Plug the power cord of your computer and your monitor into a

nearby outlet.

Turn on your computer and monitor. If the monitor displays an

image, installation is complete.

Go to cover page

9

On-Screen Display

170X5 LCD

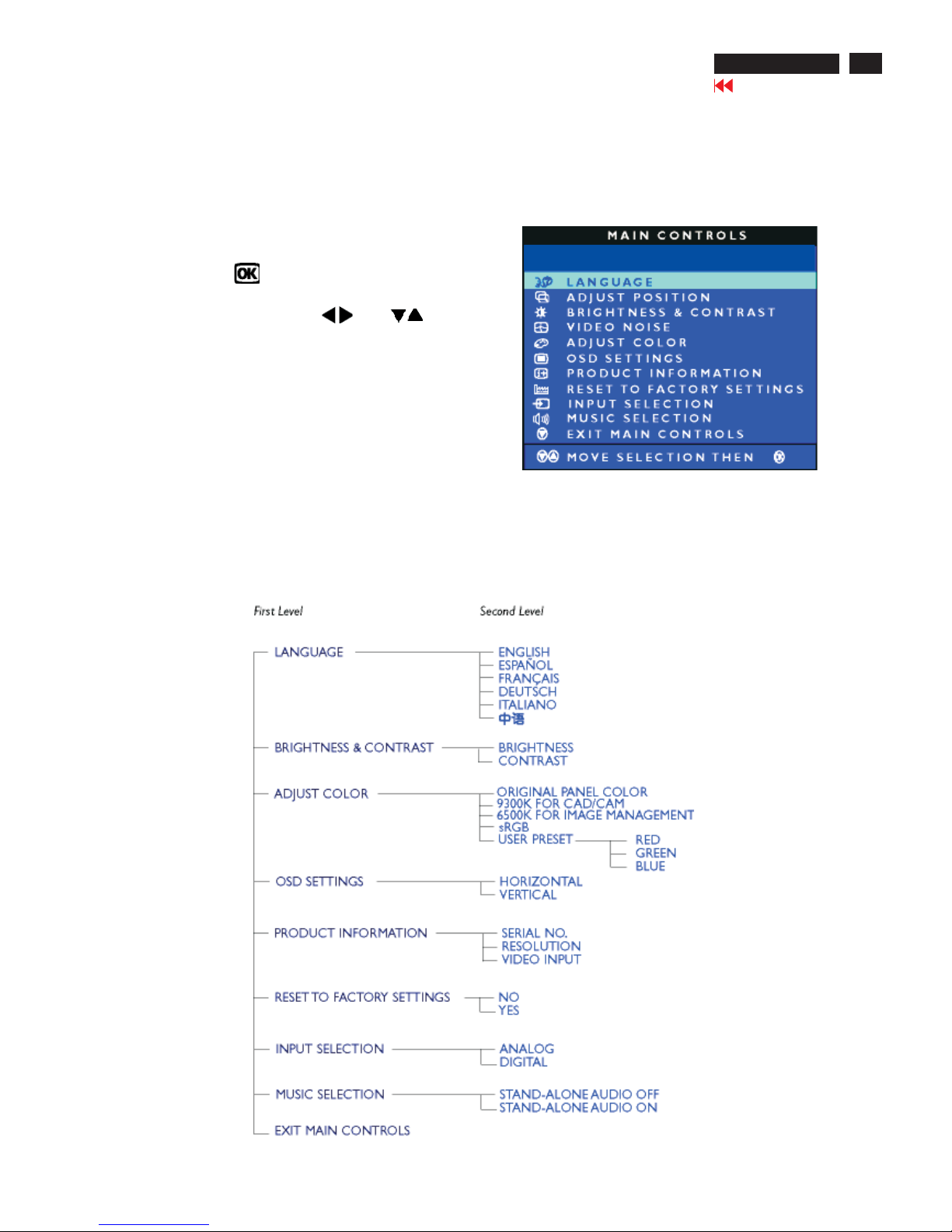

Description of the On Screen Display

What is the On-Screen Display?

This is a feature in all Philips LCD monitors. It allows an end user to adjust screen performance of

the monitors directly through an on-screen instruction window. The user interface provides userfriendliness

and ease-of-use when operating the monitor.

Basic and simple instruction on the control keys.

When you press the button on the front control of your

monitor, the On-Screen Display (OSD) Main Controls window

will pop up and you can then start making adjustments to your

monitor'svarious features. Use the or the keys to

make your adjustments.

The OSD Tree

Below is an overall view of the structure of the On-Screen Display.

You can use this as a reference when you want to work your way

around the different adjustments later on.

Digital signal input: (170X5/00)

10

Go to cover page

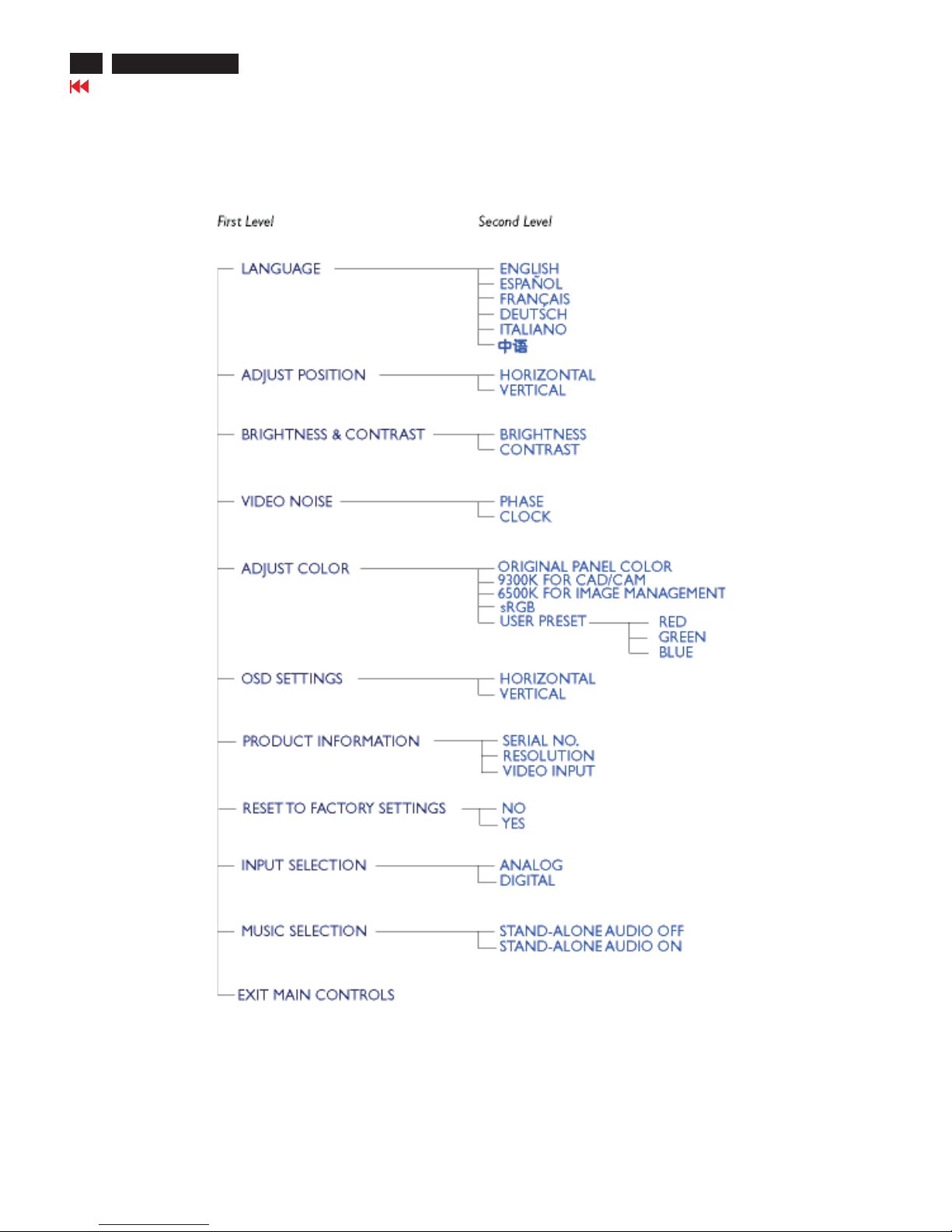

On-Screen Display

170X5 LCD

Analog signal input:

Philips' Flat Panel Monitors Pixel Defect Policy

Philips strives to deliver the highest quality products. We

use some of the industry's most advanced manufacturing

processes and practice stringent quality control. However,

pixel or sub pixel defects on the TFT LCD panels used in

flat panel monitors are sometimes unavoidable. No

manufacturer can guarantee that all panels will be free

from pixel defects, but Philips guarantees that any monitor

with an unacceptable number of defects will be repaired or

replaced under warranty. This notice explains the different

types of pixel defects and defines acceptable defect levels

for each type. In order to qualify for repair or replacement

under warranty, the number of pixel defects on a TFT LCD

panel must exceed these acceptable levels. For example,

no more than 0 .0004% of the sub pixels on a 15" XGA

monitor may be defective. Furthermore, Philips sets even

higher quality standards for certain types or combinations

of pixel defects that are more noticeable than others. This

policy is valid worldwide.

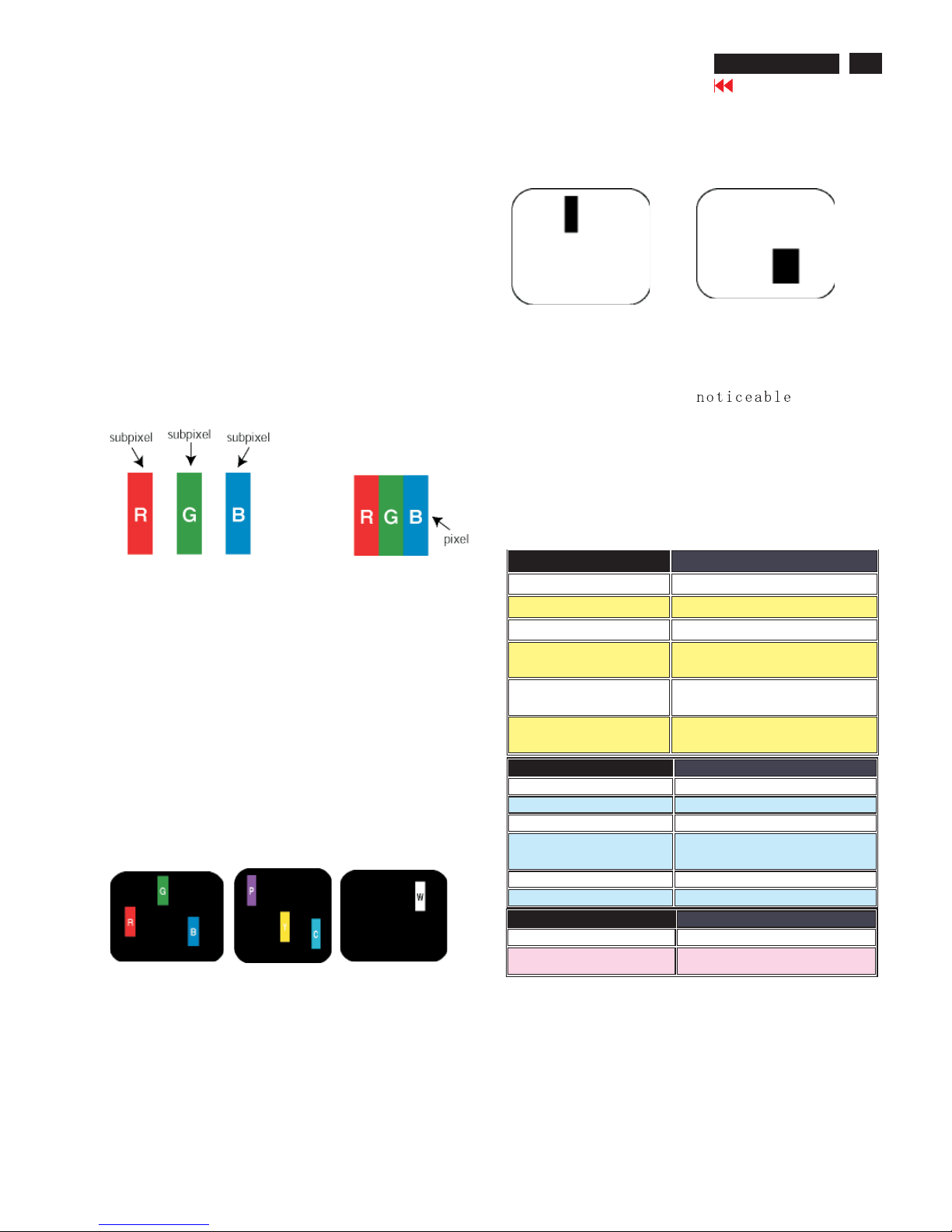

Pixels and Sub pixels

A pixel, or picture element, is composed of three sub pixels

in the primary colors of red, green and blue. Many pixels

together form an image. When all sub pixels of a pixel are lit,

the three colored sub pixels together appear as a single

white pixel. When all are dark, the three colored sub pixels

together appear as a single black pixel. Other combinations

of lit and dark sub pixels appear as single pixels of other

colors.

Types of Pixel Defects

Pixel and sub pixel defects appear on the screen in different

ways. There are two categories of pixel defects and several

types of sub pixel defects within each category. Bright dot

defects appear as pixels or sub pixels that are always lit or

'on'. These are the types of bright dot defects:

One lit red,

green or

blue sub pixel

Two adjacent lit

sub pixels:

- Red + Blue = Purple

- Red + Green = Yellow

- Green + Blue = Cyan

(Light Blue)

Three adjacent lit

sub pixels

(one white pixel)

Black Dot Defects Black dot defects appear as pixels or sub

pixels that are always dark or 'off'. These are the types of black

dot defects:

One dark sub pixel Two or three adjacent dark sub pixels

Proximity of Pixel Defects

Because pixel and sub pixels defects of the same type that are

near to one another may be more , Philips also

specifies tolerances for the proximity of pixel defects.

Pixel Defect Tolerances

In order to qualify for repair or replacement due to pixel defects

during the warranty period, a TFT LCD panel in a Philips flat panel

monitor must have pixel or sub pixel defects exceeding the

tolerances listed in the following tables.

Note:

* 1 or 2 adjacent sub pixel defects =1dot defect

All Philips monitors are ISO13406-2 Compliant

Philips Pixel Defect Policy

Go to cover page

11

170X5 LCD

BRIGHT DOT DEFECTS ACCEPTABLE LEVEL

MODEL

170X5

1 lit subpixel

0

2 adjacent lit subpixels

0

3 adjacent lit subpixels (one white

pixel)

0

Distance between two bright dot

defects*

Total bright dot defects of all types

BLACK DOT DEFECTS ACCEPTAB LE LEVEL

MODEL 170X5

1 dark subpixel 4 or fewer

2 adjacent dark subpixels 1 or fewer

3 adjacent dark subpixels 0

Distance between two black dot defects* 15 mm or more

Total black dot defect s of all types 4 or fewer

TOTAL DOT DEFECTS ACCEPTABLE LEVEL

MODEL 150C5

Total bright or black dot defects of all

types

5 or fewer

0

0

Electrical Instructions

12

170X5 LCD

Go to cover page

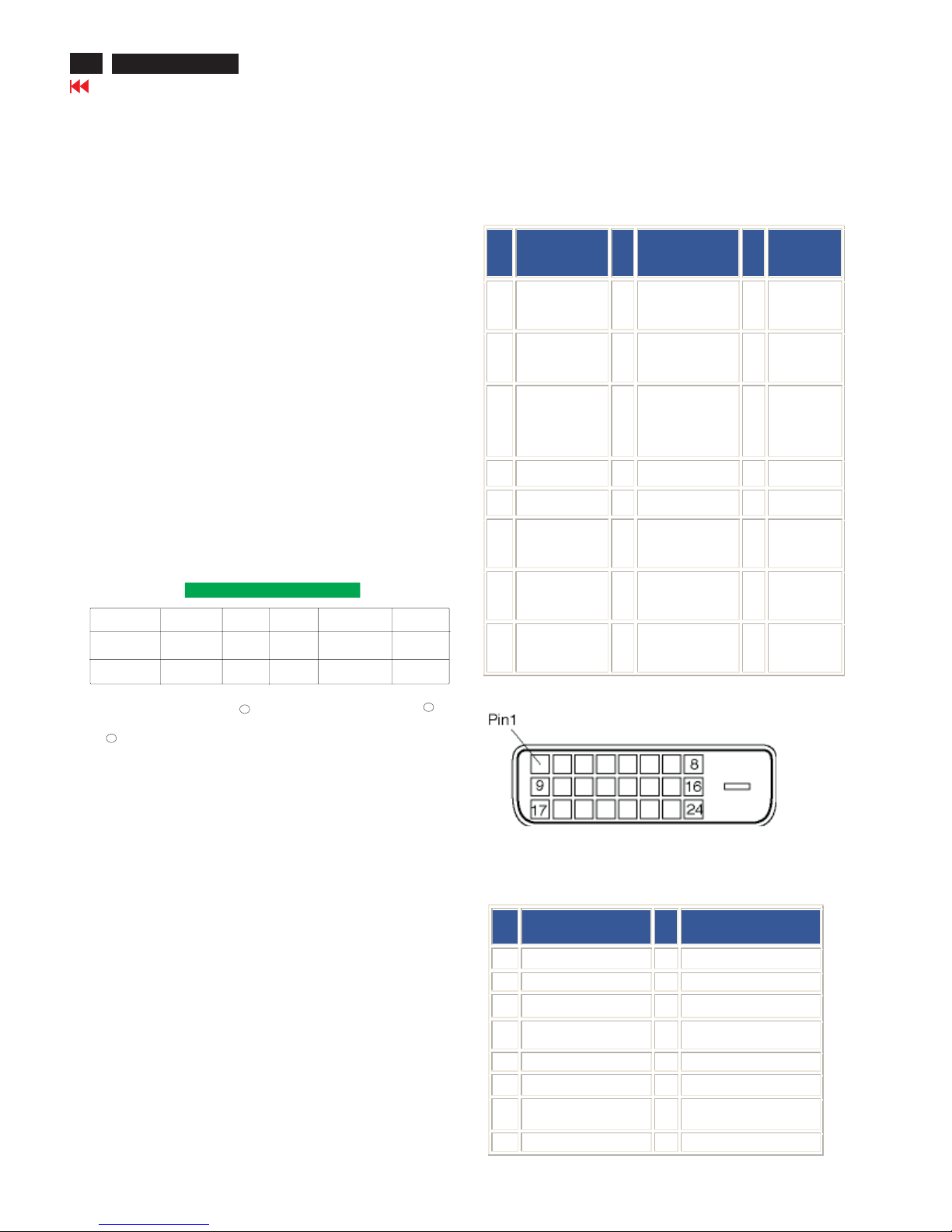

PRESET VIDEO RESOLUTION

# Resolution H-Frequency P ixel rate V-Frequency Comment

1 640X350 31.5K 25.175 70Hz IBM VGA 10h

2 720X400 31.5K 28.322 70Hz IBM VGA 3h

3640X480 31.5K 25.175 60Hz

4 640X480 35.0K 30.24 67Hz

5 640X480 37.9K 31.5 72Hz

6 640X480 37.5K 31.501 75Hz

7 640X480 43.3K 36 85Hz

8 800X600 35.2K 36 56Hz

9 800X600 37.9K 40 60Hz

10 800X600 48.1K5072Hz

11 800X600 46.9K 49.498 75Hz

12 800X600 53.7K 56.251 85Hz

13832X624 49.7K 57.28 75Hz MAC

14 1024X768 48.4K 65 60Hz

15 1024X768 56.5K 75 70Hz

16 1024X768 60.0K 78.75 75Hz

17 1024X768 61.1K 83.096 76Hz IBM XGA-2

18 1024X768 68.7K 94.5 85Hz

19 1152X864 54.0K 79.9 60Hz non-VESA

20 1152X864 67.5K 108 75Hz

21 1152X864 63.9K 94.5 70Hz non-VESA

22 1152X870 68.7K 100 75Hz MAC

23 1152X900 61.8K 92.94 66Hz SUN Mode IV

24 1152X900 71.8K 108 76Hz SUN Mode II

25 1280X960 60.0K 108 60Hz

26 1280X960 75.0K 129.895 75Hz non-VESA

27 1280X102464.0K 108 60Hz

28 1280X102471.7K 117 67Hz SUN Mode V

29 1280X102476.0K130.22372Hz DOS/V

30 1280X102480.0K 135 75Hz

311280X102481.1K 135. 008 76Hz SUN Mode I

32 688X556 31.3K 27 50Hz TV-PAL

Go to cover page

170X5 LCD

13

Electrical Instructions

9300°K 6500°K

x (center) 0.283 ± 0.020 0.313 ± 0.020

y (center) 0.297 ± 0.020 0.329 ± 0.020

sRGB

x(center) 0.313 ± 0.020

y(center) 0.329 ± 0.020

Ynits 180 ± 10

Dot rate (MHz) H. Freq (KHz) Mode Resolution V. Freq (Hz)

36.000 43. 269 VESA 640 * 480 85.008

56.250 53.674 VESA 800 * 600 85.061

94.500 68. 677 VESA 1024 * 768 84.997

3. Power Supply (S)

4. Display Adjustment

Mechanical Instructions

Front View

Back View

Step 3:

-Unscrew the four screws as shown in Fig. 5.

- Remove the base.

Fig. 1

Step 4: Remove the front bezel

- Use thin "l" type screwdriver to open 4 clicks on bottom

side as shown in Fig. 6.

- Use thin "l" type screwdriver to open 3 clicks on right

and left side as shown in Fig. 7.

- Use thin "l" type screwdriver to open 4 clicks on top

side as shown in Fig. 8.

Step 1: Use "l" type screwdriver to remove the Logo Cover as shown

in Fig. 3.

Fig. 3

=============>

97

313815413521

Logo Cover

Clip

Step 2: Unscrew 3 screws as shown in Fig. 4.

Fig. 4

Fig. 5

Fig. 6

========>

========>

========>

========>

14

170X5 LCD

Go to cover page

Fig. 7

======>

======>

======>

Mechanical Instructions

Go to cover page

170X5 LCD

15

1050 823827714781 TFT-LCD MOD LM170E01-A5KE

LCD Panel

***************************************************************************

In warranty, it is not allowed to disassembly the LCD panel, even the

backlight unit defect.

Out of warranty, the replacment of backlight unit is a correct way

when the defect is cused by backlight (CCFL,Lamp).

***************************************************************************

Fig. 8

======>

=======>

======>

======>

Step 5: Remove the Back Cover Assy

-Remove the Control Board from the Back Cover Assy

-Unscrew 7 screws as shown in Fig. 9.

-Remove Audio Assy, Earphone Assy and two LSP Box

from the Back Cover Assy

-Use thin "l" type screwdriver to open clicks on left side, right

side and up side, Remove LCD Panel from Back Cover Assy

shown in Fig. 9.as

<===

1054

313815859641

CONTROL ASSY

<======

1053

313815859651

AUDIO ASSY

<======

1049

313815859631

EARPHONE ASSY

Fig. 9

Step 6: Unscrew 12 screws as shown in Fig. 10.

Remove Shielding Cover

Fig. 10

Step 7: Unscrew 9 screws as shown in Fig. 11.

Disconnect 7 connectors as shown in Fig. 11.

Fig. 11

=======>

=======>

1051

313815859731

SCALER ASSY

1052

823827716021

LIPS(T50P054.00)

Fig. 12

16

Go to cover page

170X5 LCD

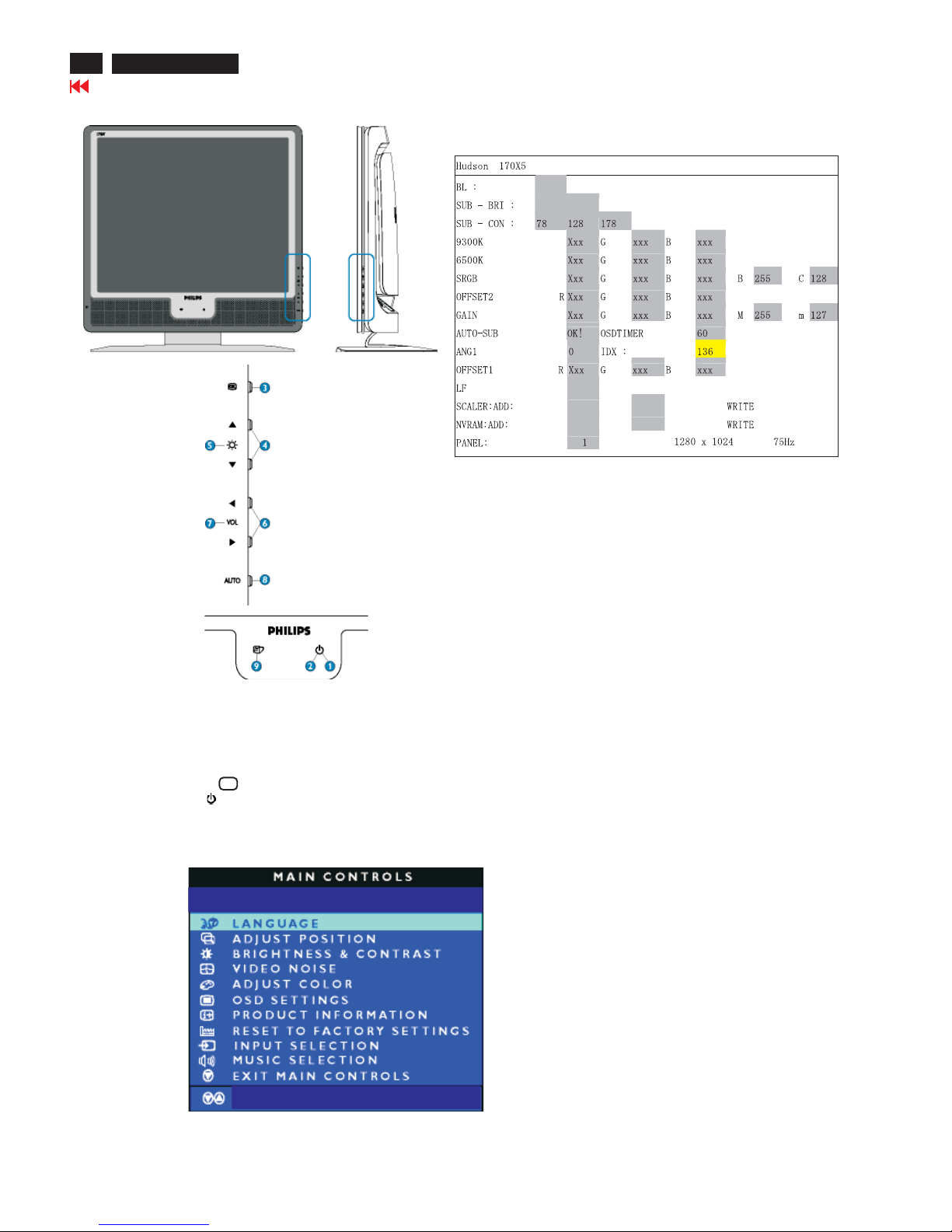

Factory Mode

How to enter Factory Mode

1. Turn off the monitor.

2. [Push "AUTO " & "OK" buttons at the same time and hold it

] + [Press power " " button until comes out "Windows screen"]

=> then release all button, then press , wait until the

OSD menu with Characters "HUDSON4 170X5 V200 20040722"

(below OSD menu) come on the Screen of the monitor

(see Fig. 2).

"OK" button

Factory Mode

Indicator

HUDSON4 170X5 V200 20040722HUDSON4 170X5 V200 20040722

----------------->

0

50

255

VAL:

READ

VAL: READ

LG 17

Factory menu

Cursor can move on gray color area

BL : Blacklevel value

SUB-BRI : Brightness value range(Min Max)

SUB-CON : Contrast value range(Min Mid Max)

SRGB-B : Brightness of sRGBv

SRGB-C : Contrast of sRGB

Gain-m : Minimum value of User Gain

Gain-M : Maximum value of User Gain

AUTO-SUB: To do Auto color function when push Menu key in white pattern

OSDTIMER : OSD time out control(sec)

ANG1:For analog only project control (0:Dual, 1:Analog only)

IDX : Limit current of inverter

SCALER : Read/Write scaler register

NVRAM : Read/Write eeprom address

Panel : LG (LG. Philips panel)

Go to cover page

17

170X5 LCD

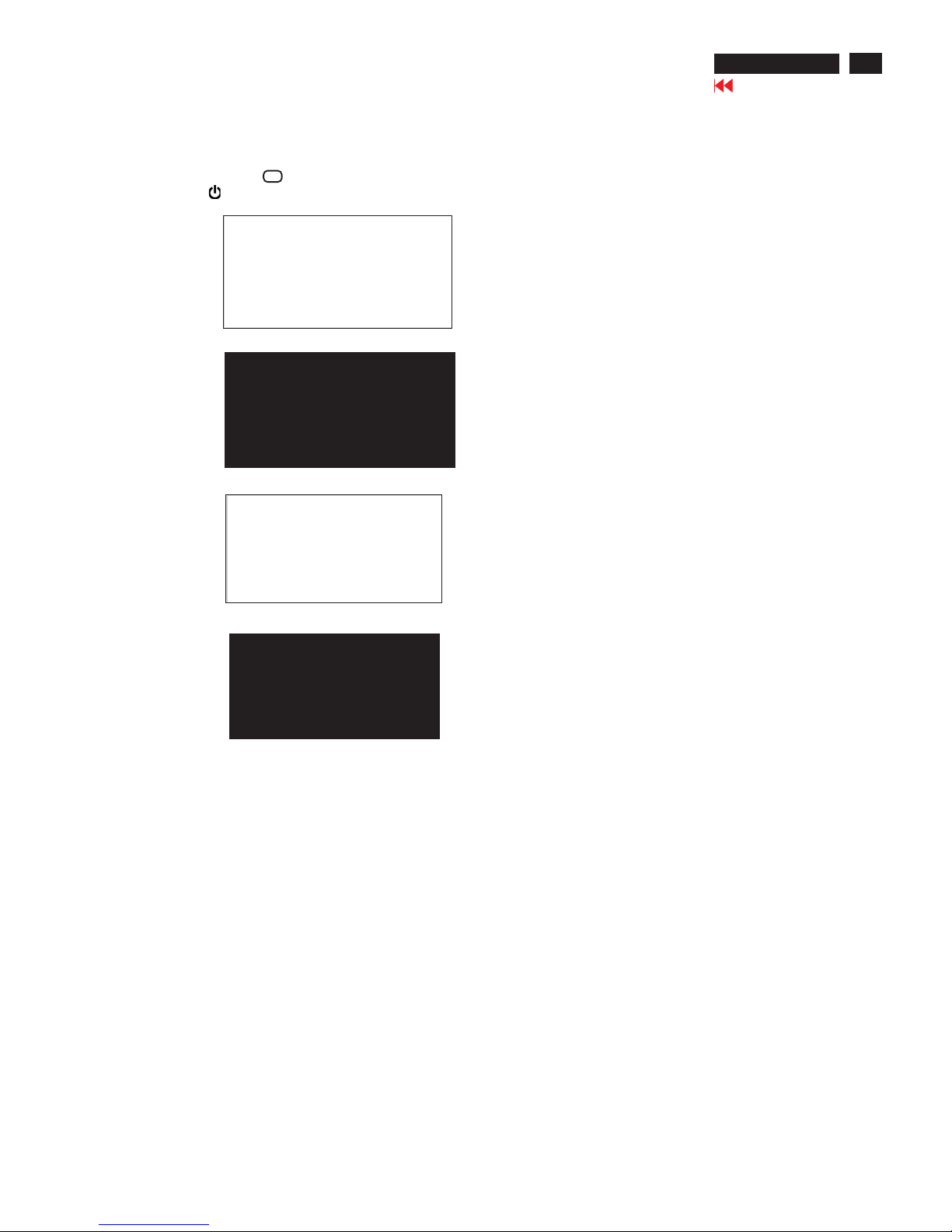

Aging Mode

AGING...

After 15 seconds,

bring up:

After 15 seconds,

bring up:

AGING...

After 15 seconds,

bring up:

----------

---------repeatly

Connect Signal cable again=> go back to normal display

How to Access Aging Mode

Step 1:Turn off LCD monitor, and disconnect Interface Cable between Monitor and PC.

Step 2:[Push "AUTO"&"OK"buttons at the same time and hold it]

+[Press power " " button untill comes out " AGING screen"] =>

then release all buttons.

Bring up:

18

Go to cover page

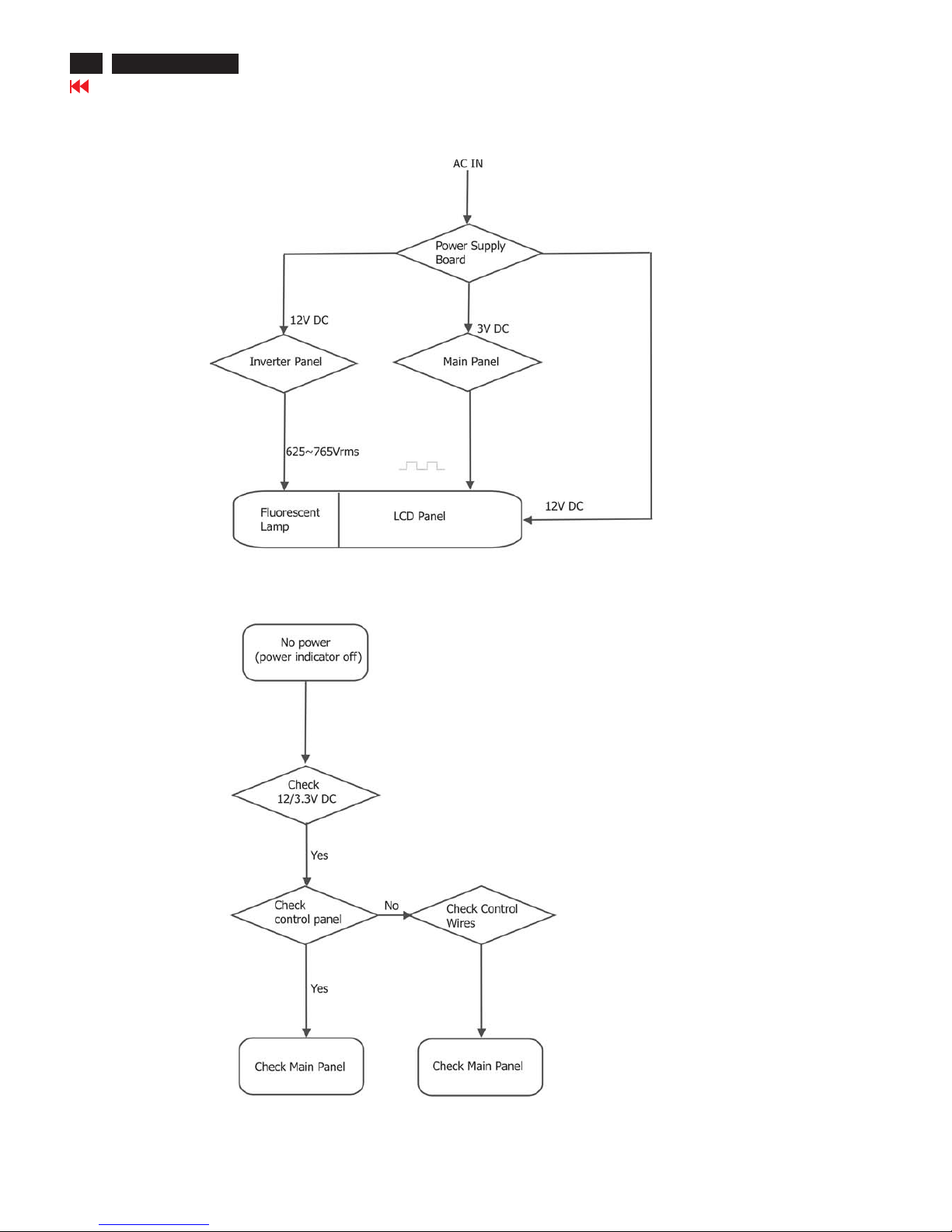

Repair Flow Chart

170X5 LCD

Go to cover page

19

No Display

Check Mains cord

& LED of Monitor

Check

Power board

12V/3.3V DC

Yes

No

Check

video signals input

interface

Video source

Yes

No

No

OK

Check

Inverter panel

625~765Vrms with load

Check fluorescent

lamp

Check inverter

panel

Check main panel

Front control key

does not work

Check

Front control panel

(Key & SW)

Check

Signal connectors

Yes

Yes

Check main panel

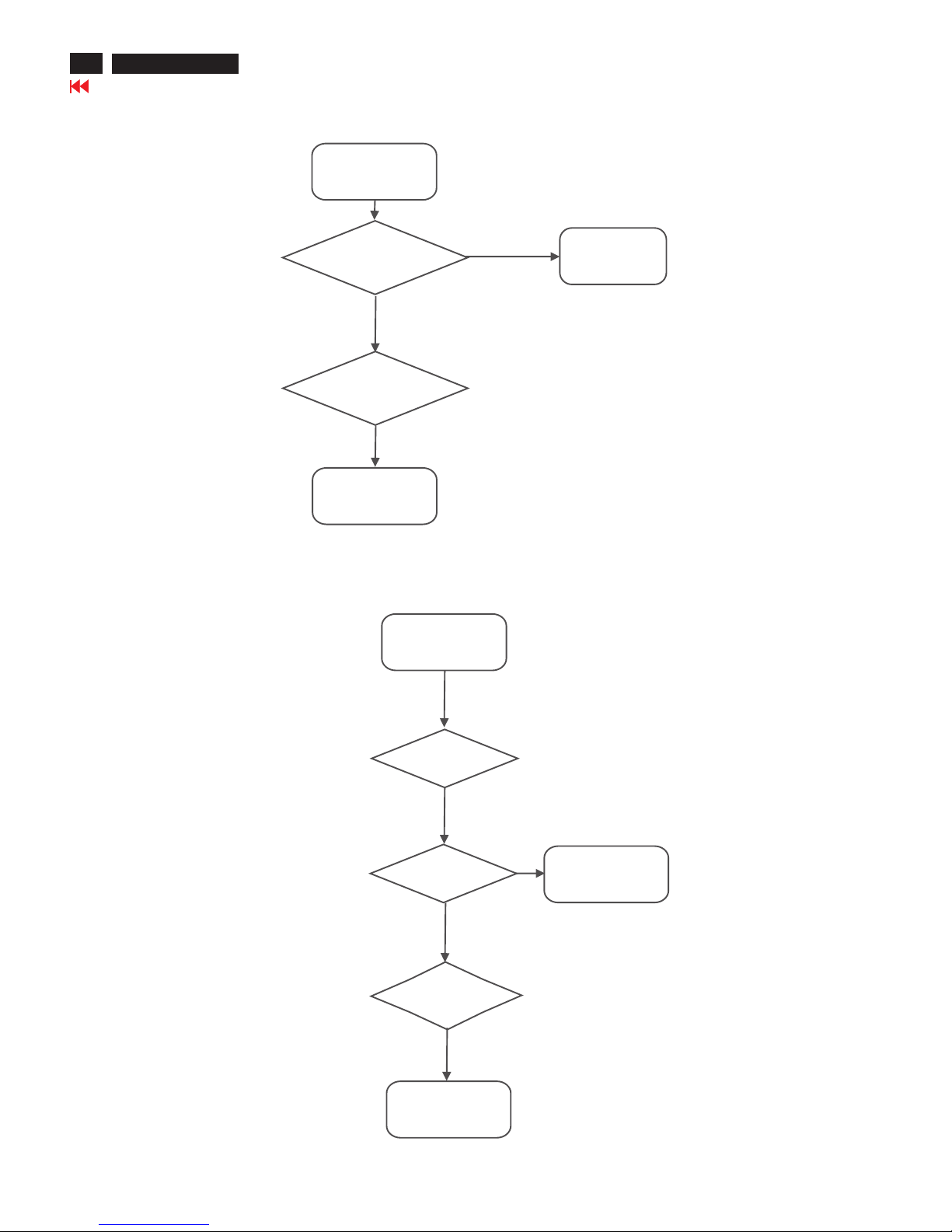

Repair Flow Chart-2

170X5 LCD

20

Go to cover page

Bad brightness

No

Check

Inverter panel output

625~765Vrms

Bad Inverter

panel

Yes

Check fluorescent

lamp

No

Check LCD panel

Bad image

Check

Video, fh/fv

signals

Yes

Check main panel

Yes

Check components

cold soldering

No

Check

all connectors &

LVDS cable

No

Check LCD panel

Repair Flow Chart-3

170X5 LCD

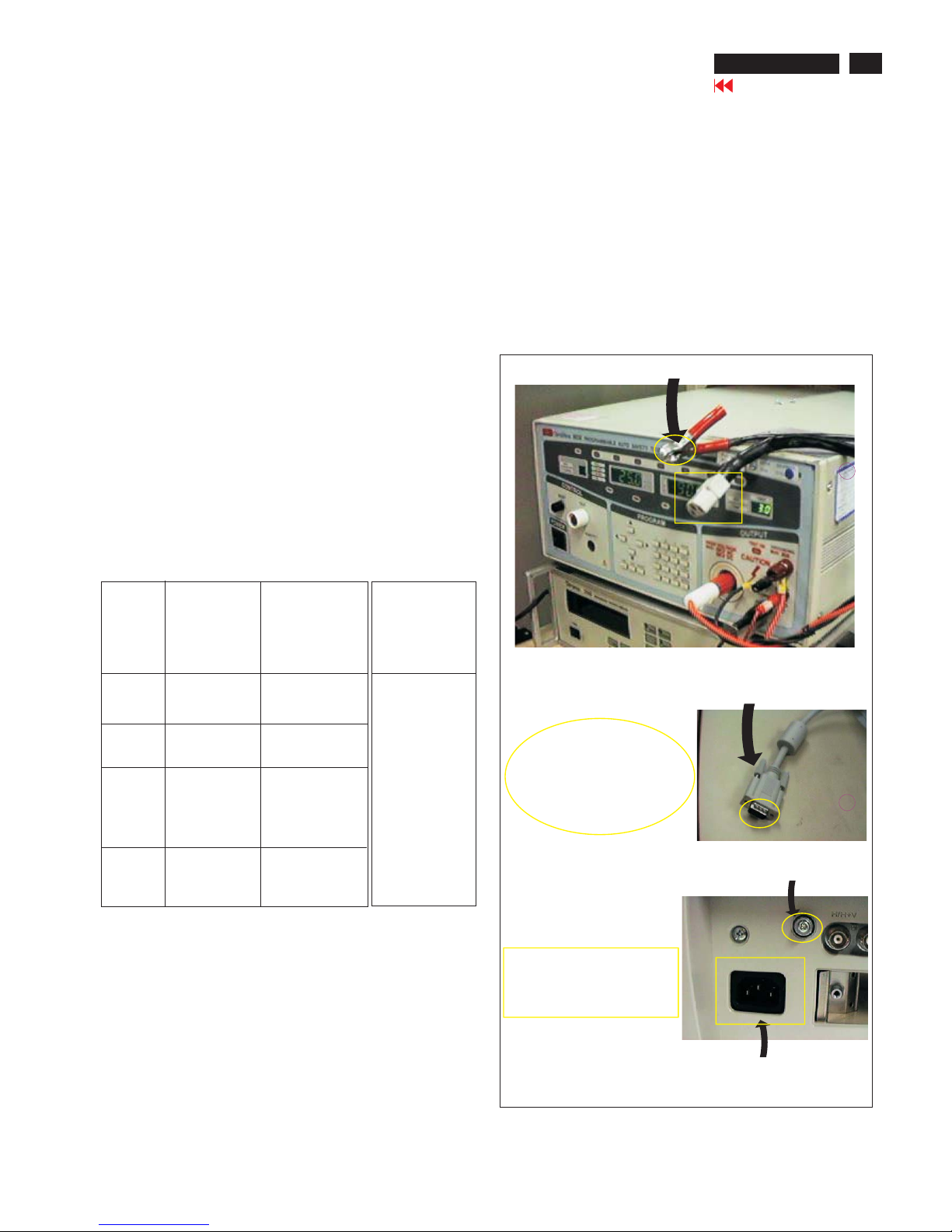

All units that are returned for service or repair must pass the

original manufactures safety tests. Safety testing requires both

and testing.Hipot Ground Continuity

HI-POT TEST INSTRUCTION

1.Application requirements

Test method

1.1 All mains operated products must pass the Hi-Pot test as

described in this instruction.

1.2 This test must be performed again after the covers have

been refitted following the repair, inspection or modification

of the product.

2.1 Connecting conditions

2.1.1 The test specified must be applied between the parallel-

blade plug of the mainscord and all accessible metal

parts of the product.

2.1.2 Before carrying out the test, reliable conductive

connections must be ensured and thereafter be

maintained throughout the test period.

2.1.3 The mains switch(es) must be in the "ON" position.

2.2 Test Requirements

All products should be HiPot and Ground Continuity tested as

follows:

Test 2820VDC 1700VDC Test current:

voltage (2000VAC) (1200VAC) 25A,AC

Test time:

Test time 3 seconds 1 second 3 seconds(min.)

(min.) Resistance

required:

Trip set at 100 uA 5 mA <=0.09+Rohm,

current for Max. R is the

(Tester) limitation; set resistance of

at 0.1 uA for the mains cord.

Min. Limitation

Ramp set at 2

time seconds

(Tester)

2.

Condition HiPot Test for HiPot Test for Ground Continuity

products where products where Test requirement

the mains input the mains input is

range is Full 110V AC(USA

range(or 220V type)

AC)

2.2.1 The minimum test duration for Quality Control Inspector

must be 1 minute.

2.2.2 The test voltage must be maintained within the specified

voltage + 5%.

2.2.3 There must be no breakdown during the test.

2.2.4 The grounding blade or pin of mains plug must be

conducted with accessible metal parts.

3. Equipments and Connection

3.1. Equipments

For example :

- ChenHwa 9032 PROGRAMMABLE AUTO SAFETY

TESTER

- ChenHwa 510B Digital Grounding Continuity Tester

- ChenHwa 901 (AC Hi-pot test), 902 (AC, DC Hi-pot test)

Withstanding Tester

3.2. Connection

4. Recording

Hipot and Ground Continuity testing records have to be kept

for a period of 10 years.

* Turn on the power switch of monitor before Hipot and

Ground Continuity testing.

Connect the "video cable"

or "grounding screw"

to the CLIP on your tester.

Video cable

(Rear view of monitor)

Connect the power cord

to the monitor.

Grounding screw

Power outlet

(ChenHwa 9032 tester)

Clip

Clip

Safety Test Requirement

Go to cover page

21

170X5 LCD

0. Warning

All ICs and many other semi-conductors are susceptible to

electrostatic discharges (ESD). Careless handling during

repair can reduce life drastically. When repairing, make sure

that you are connected with the same potential as the mass

of the unit via a wrist wrap with resistance. Keep components

and tools also at the same potential !

1. Servicing of SMDs (Surface Mounted Devices)

1.1 General cautions on handling and storage

- Oxidation on the terminals of SMDs results in poor soldering.

Do not handle SMDs with bare hands.

- Avoid using storage places that are sensitive to oxidation

such as places with sulphur or chlorine gas, direct sunlight,

high temperatures or a high degree of humidity. The

capacitance or resistance value of the SMDs may be

affected by this.

- Rough handling of circuit boards containing SMDs may

cause damage to the components as well as the circuit

boards. Circuit boards containing SMDs should never be

bent or flexed. Different circuit board materials expand and

contract at different rates when heated or cooled and the

components and/or solder connections may be damaged

due to the stress. Never rub or scrape chip components as

this may cause the value of the component to change.

Similarly, do not slide the circuit board across any surface.

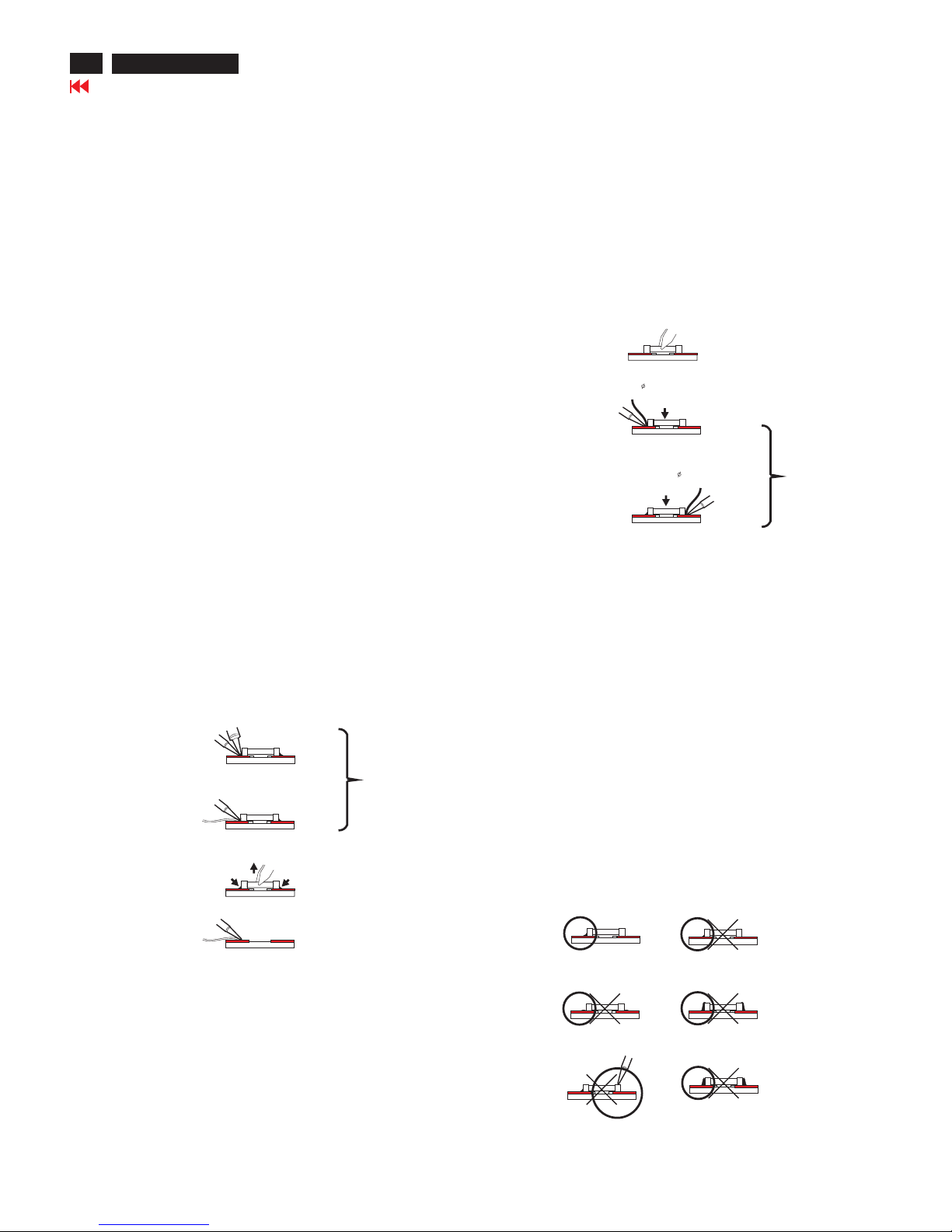

1.2 Removal of SMDs

- Heat the solder (for 2-3 seconds) at each terminal of the

chip. By means of litz wire and a slight horizontal force,

small components can be removed with the soldering iron.

They can also be removed with a solder sucker (see Fig.

1A)

- While holding the SMD with a pair of tweezers, take it off

gently using the soldering iron's heat applied to each

terminal (see Fig. 1 B).

- Remove the excess solder on the solder lands by means of

litz wire or a solder sucker (see Fig. 1C).

1.3 Caution on removal

- When handling the soldering.iron. use suit able pressure and

be careful.

- When removing the chip, do not use undue force with the

pair of tweez ers.

-Thesolderingirontobeused(approx.30W)should

Fig. 1 DISMOUNTING

SOLDERING

IRON

E.g. WELLER

SOLDER TIP PT-H7

VACUUM PISTON

4822 395 10159

SOLDER WICK

4822 321 40042

E.g. A PAIR OF TWEEZERS

HEATING

SOLDERING

IRON

SOLDER WICK

C

B

A

SOLDERING

IRON

HEATING

Fig. 2 MONUTING

E.g. A PAIR OF TWEEZERS

SOLDER

0.5-0.8 mm

PRESURE

SOLDERING

IRON

SOLDERING TIME

< 3 sec/side

B

A

SOLDER

0.5-0.8 mm

PRESURE

SOLDERING

IRON

Fig. 3 Examples

RIGHT

SOLDERING

IRON

Preferably be equipped with a thermal control

(soldering temperature:225 degree V to 250 degree C.

-The chip, once removed, must never be reused.

-Locate the SMD on the solder lands by means of tweezers

and solder the component on one side. Ensure that the

component is positioned correctly on the solder lands (see Fig. 2A)

-Next complete the soldering of the terminals of the component.

(See Fig. 2B)

1.4 Attachment of SMDs

2. Caution when attaching SMDs

- When soldering the SMDs terminals, do not touch them

directly with the soldering iron. The soldering should be

directly with the soldering iron. The soldering should be

done as quickly as possible, care must be taken to avoid

damage to the terminals of the SMDs themselves.

- Keep the SMD's body in contact with the printed board

when soldering.

- The soldering iron to be used (approx. 30W) should

preferably be equipped with a thermal control (soldering

temperature:225 degree C to 250 degree C).

- Soldering should not be done outside the solder land.

- Soldering flux (of rosin) may be used, but should not

be acidic.

- After soldering, let the SMDs cool down gradually at room

temperature.

- The quantity of solder must be proportional to the size of

the solder land. If the quantity is too great, the SMD might

crack or the solder lands might be torn loose from the

printed board (See Fig. 3).

Repair Tips

22

Go to cover page

170X5 LCD

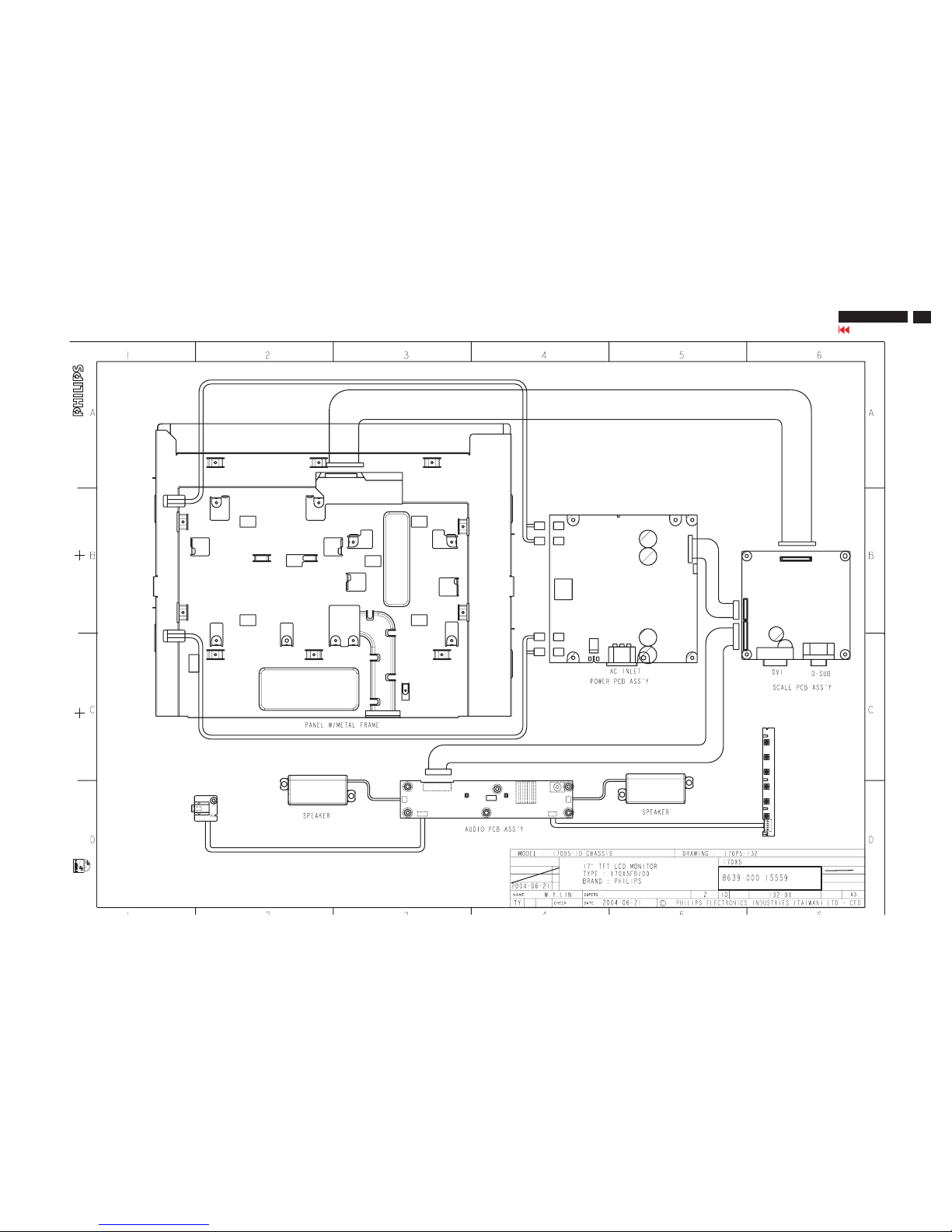

23

170X5 LCD

Go to cover page

Wiring Diagram

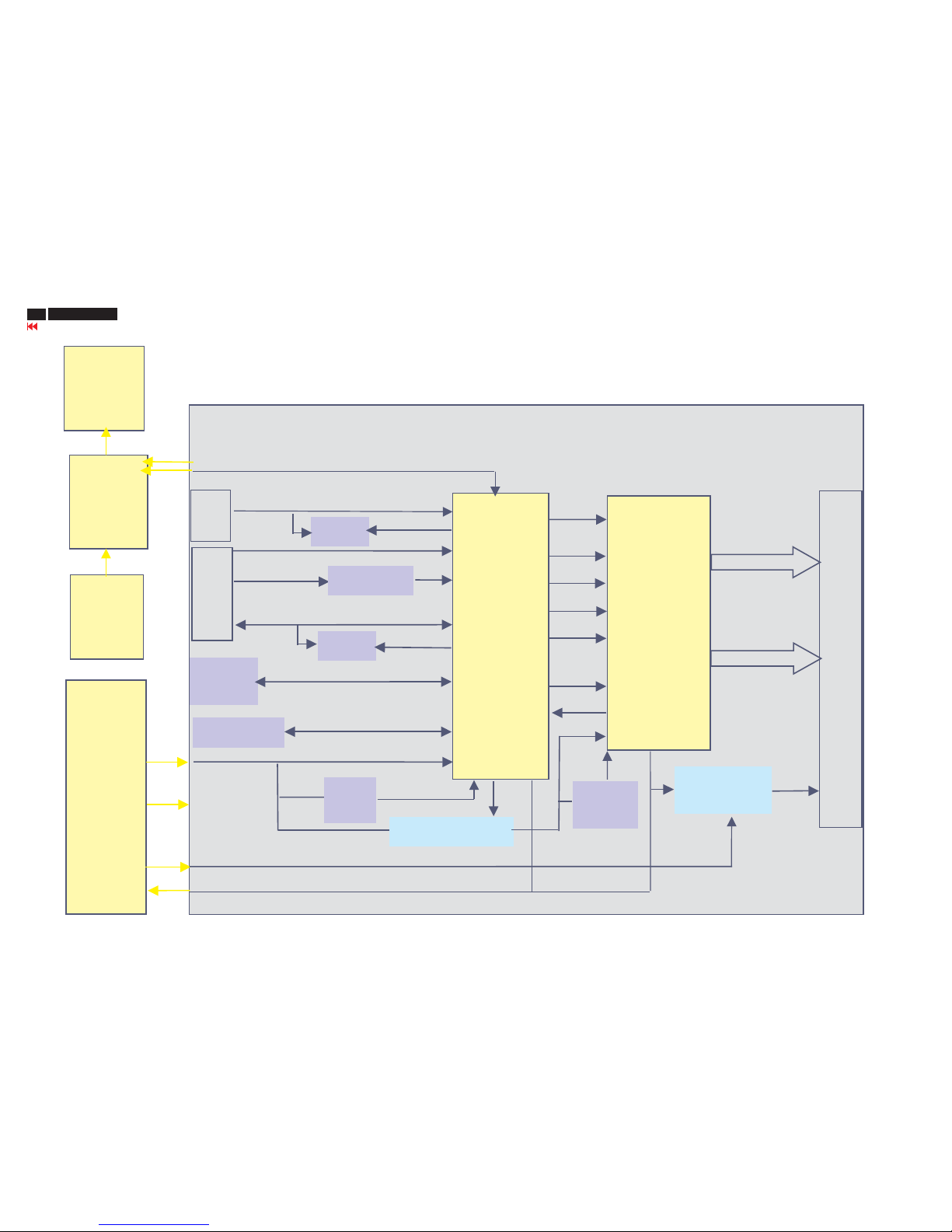

24

170X5 LCD

Go to cover page

Function Block Diagram

Scaler

gm5321BC

R/G/B

ADDR0/17, Data0/7

Bank, OM_OE/WE/CSN

Flash

ROM

D-SUB

Schmitt

HS/VS

DDC

EEPROM

IIC

AC to DC

Inverter

Board

BL_EN / Brightness

Panel PWR

MOS

5V

Audio

Control

Board

3.3V

5V

1.8V

Reg.

TXE/0/1/2/3/C

30 pin connector

TXO/0/1/2/3/C

ISPSCL,SDA

OSD Key

LEDR,G/LF_LED/Volume/PWR/OSD Key

DVI

R+-/G+-/B+-/CLK+-

LF IC

Pacific

1SB

2.5V/1.5V

Reg.

R/G/B

DHS

DVS

DEN

DCLK

LF_PWR MOS

DDC

12V

12V

LF_RSTN

MINTN

DDC_WP

DDC_WP

BL_EN

Brightness

OSD

Key

Board

Headphone

Board

25

Go to cover page

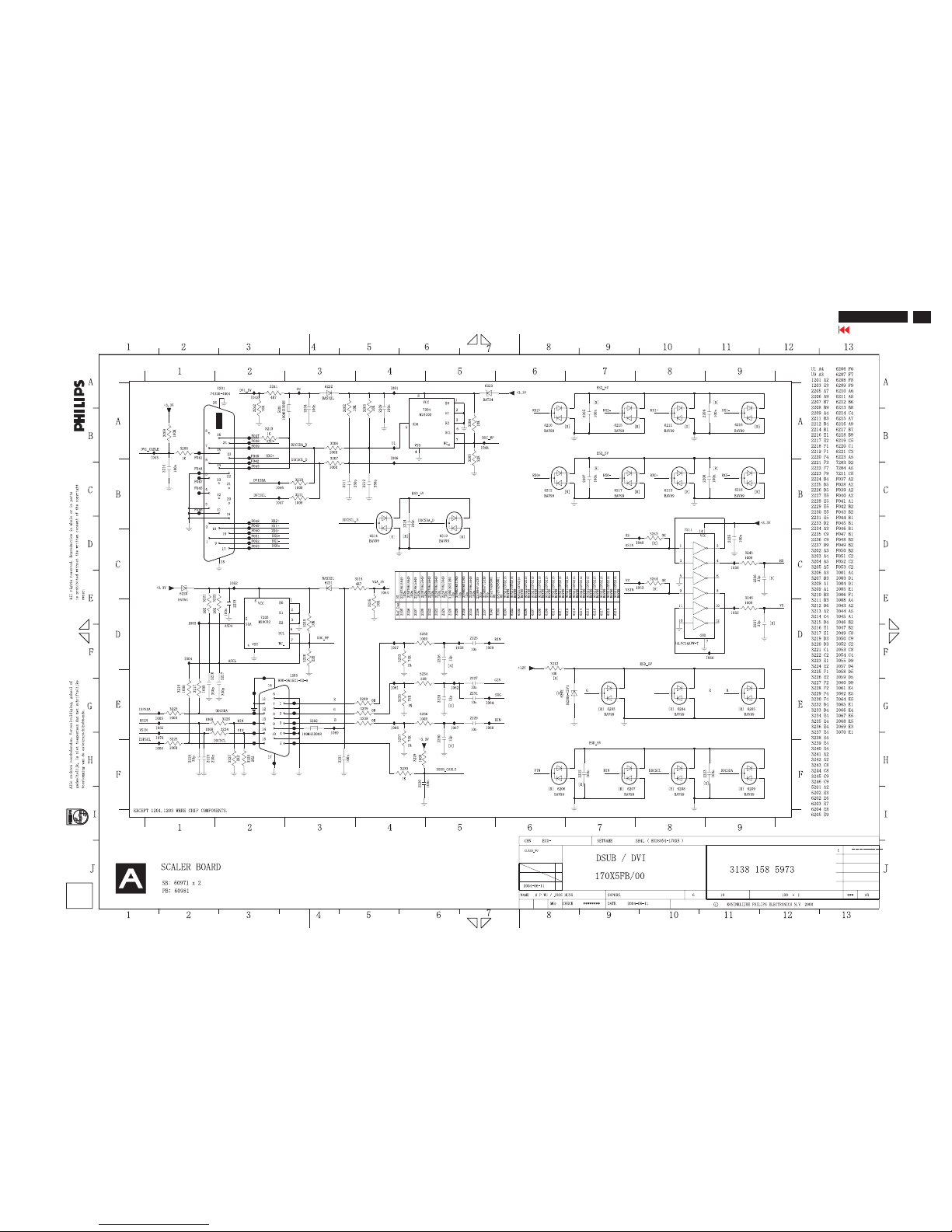

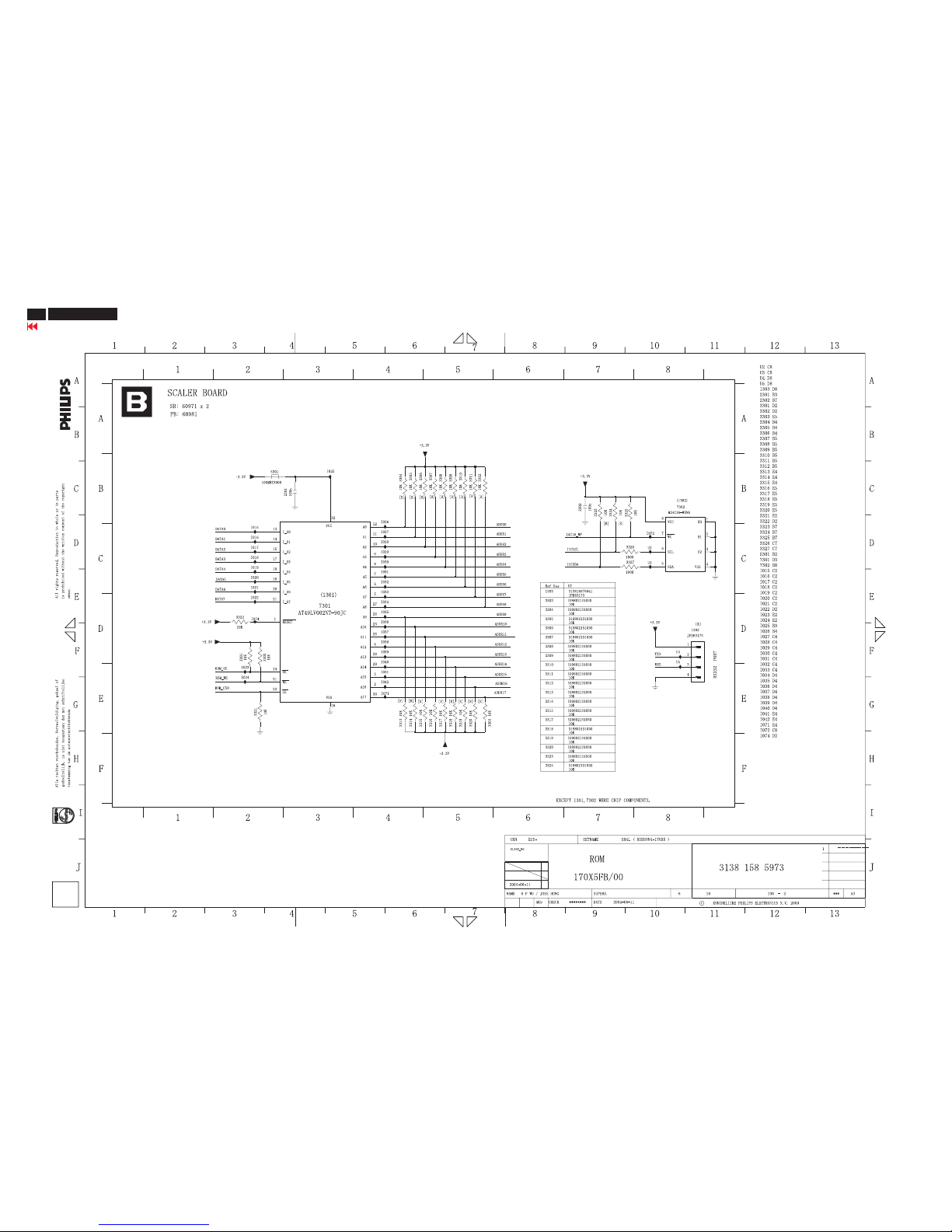

Scaler Schematic Diagram-1

170X5 LCD

26

Go to cover page

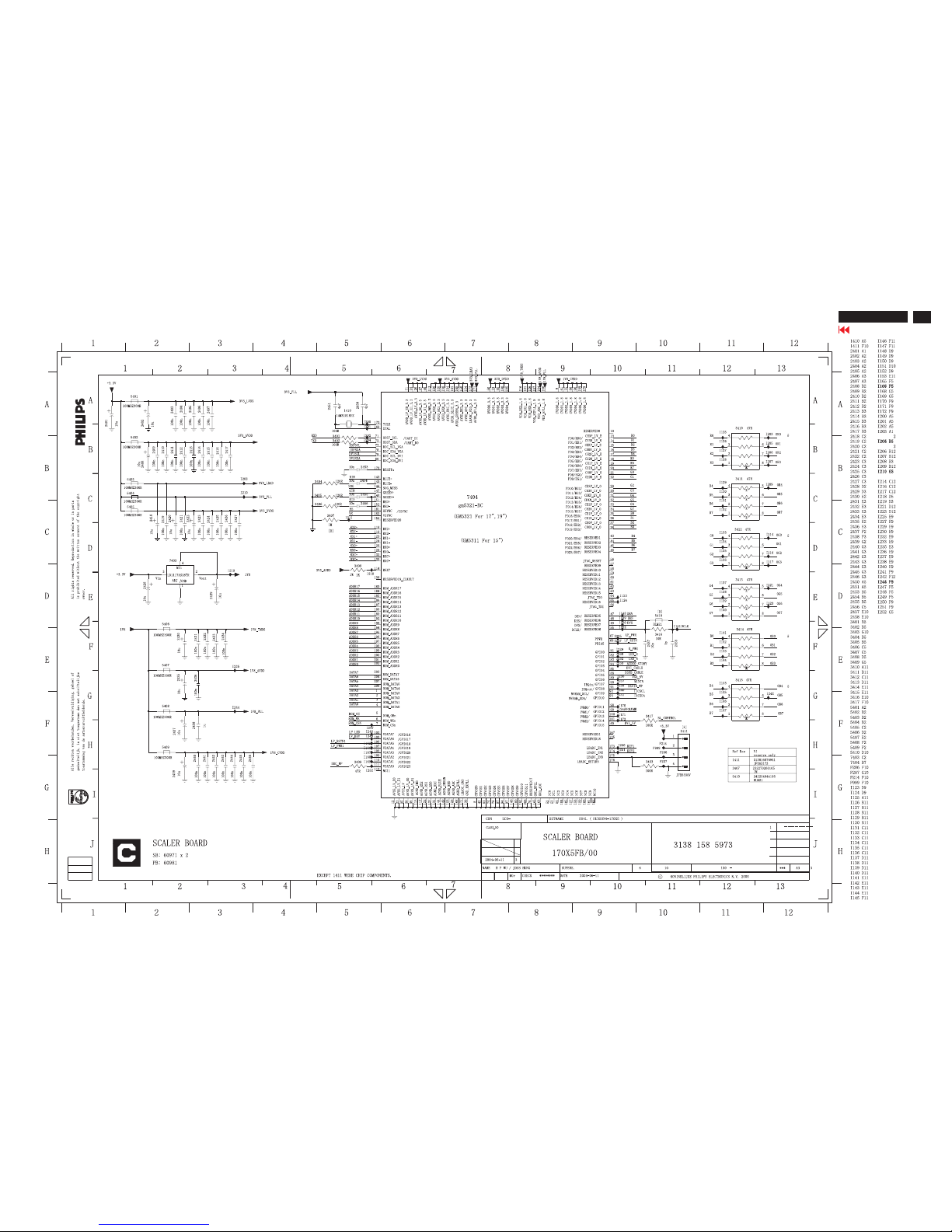

Scaler Schematic Diagram-2

170X5 LCD

27

Go to cover page

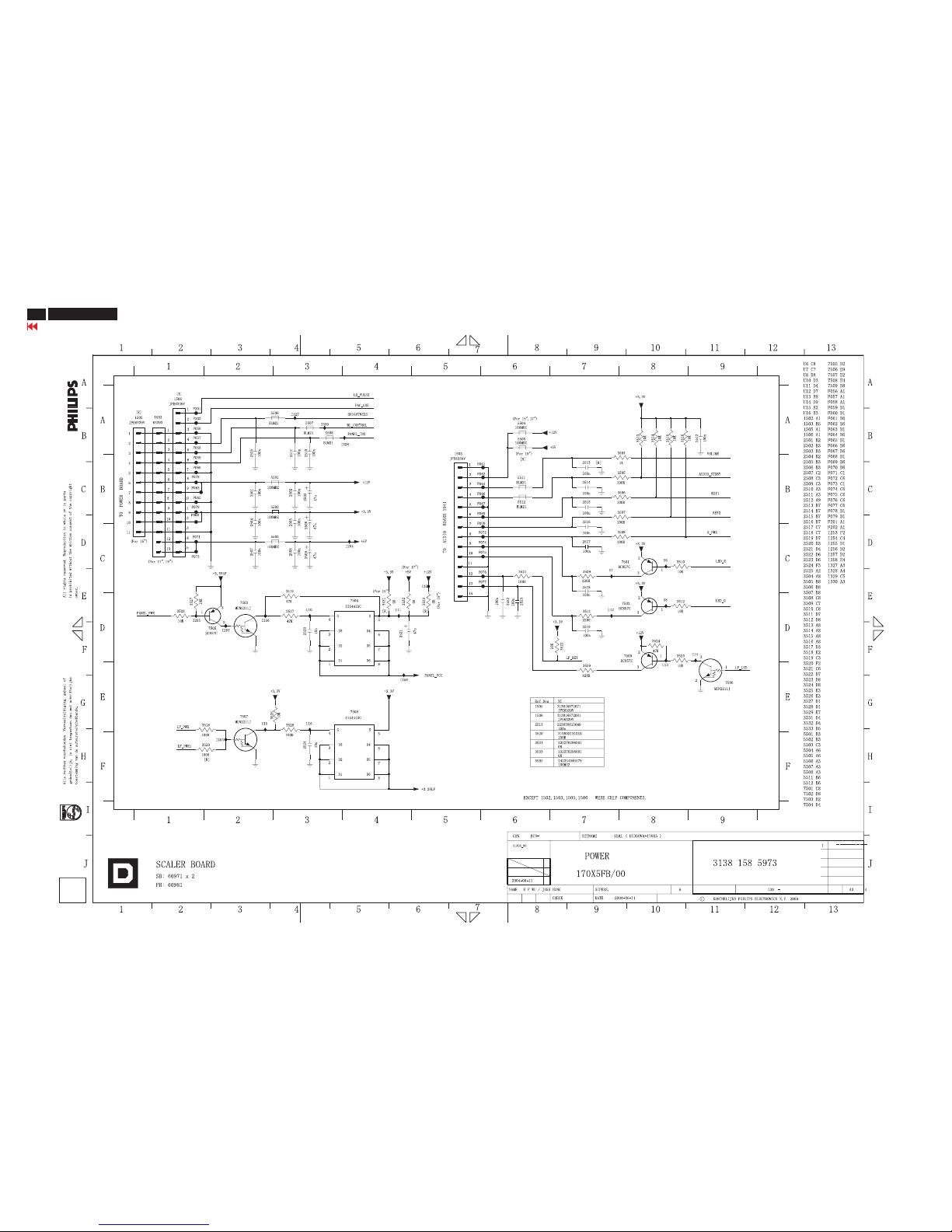

Scaler Schematic Diagram-3

170X5 LCD

28

Go to cover page

Scaler Schematic Diagram-4

170X5 LCD

Loading...

Loading...