Philips Hudson2 200P3, 200P3G/00C Service Manual

20" TFT LCD Colour Monitor- Hudson2 200P3

Horizontal frequencies

30-82kHz

Service

Service

Service

TABLE OF CONTENTS

Published by BCU Monitor Printed in Taiwan Copyright reserved Subject to modification Oct , 03 2002

DDC/Power saving/Auto Picture Adjustment

Description Page

Important Safety Notice ---------------------------------- 2

Technical Data ------------------------------------------ 3~4

Connection to PC, Front Control------------------------ 5

Front Control,Base,Accessory Pack------------------- 6

Settings using the OSD menu---- -- -------------------- 7

OSD Attention signals-------------------------------------9

OSD menu tree - Analog---------------------------------10

OSD menu tree - Digital----------------------------------11

OSD Lock/Unlock, Aging mode------------------------ 12

Clock & Phase Adjustments-----------------------------13

DDC Hex Data---------------------------------------- 21~22

Wiring Diagram--------------------------------------------24

Mechnical

Advanced control of OSD, Factroy mode--------------8

DDC Instructions------------------------------------- 14~20

Serinal number application------------------------------23

Instructions------------------------------ 25~26

Warning and Notes----------------------------------------27

Electrical Instruction------------------ ---------------28~30

Block Diagram----------------------------------------------31

Scaler Panel(Components &Copper track)------32~33

Description Page

Scaler Diagram---------------------------------------34~42

Power Panel(C.B.A.)------------------------------------ 43

Power Diagram------------------------------------------- 44

Audio &Keypad Panel----------------------------------- 45

Audio & Mic Preamp Diagram---------------------46~47

Phone Jack Board(C.B.A.),&Diagram----------- 48~49

Inverter Panel(C.B.A.)-----------------------------------50

Inverter Diagram(AMBIT)-------------------------- 51~52

Failure Mode of LCD Panel-----------------------------53

Exploded View ------------------------------------------- 54

Recommended

Difference Parts List-------------------------------------60

Repair Flow Chart-----------------------------------61~63

Repair Tips------------------------------------------------64

CA110 Application----------------------------------65~73

Firmware upgrade for CPU------------------------74~76

General Product Specification--------------------77~99

Safety Test Requirements-----------------------------100

General troubleshooting Guide---------------------------

parts list--------------------------------55

Spare parts list-------------------------------------- 56~59

REFER TO BACK COVER FOR IMPORTANT SAFETY GUIDELINES

CAUTION: USE A SEPARATE ISOLATION TRANSFORMER FOR THIS UNIT WHEN SERVICING.

ANY PERSON ATTEMPTING TO SERVICE THIS CHASSIS MUST FAMILIARIZE HIMSELF WITH THE CHASSIS

AND BE AWARE OF THE NECESSARY SAFETY PRECAUTIONS TO BE USED WHEN SERVICING ELECTRONIC

EQUIPMENT CONTAINING HIGH VOLTAGES.

SAFETY NOTICE

GB

3138 106 10237

200P3G/00C

Important Safety Notice

2

FOR PRODUCTS CONTAINING LASER :

Invisible laser radiation when open.

AVOID DIRECT EXPOSURE TO BEAM.

Use of controls or adjustments or

performance of procedures other than

those specified herein may result in

hazardous radiation exposure.

The use of optical instruments with this

product will increase eye hazard.

DANGER-

CAUTION-

CAUTION-

TO ENSURE THE CONTINUED RELIABILITY OF THIS

PRODUCT, USE ONLY ORIGINAL MANUFACTURER'S

REPLACEMENT PARTS, WHICH ARE LISTED WITH THEIR

PART NUMBERS IN THE PARTS LIST SECTION OF THIS

SERVICE MANUAL.

Proper service and repair is important to the safe, reliable

operation of all PHILIPS Consumer Electronics Company**

Equipment. The service procedures recommended by

PHILIPS and described in this service manual are effective

methods of performing service operations. Some of these

service operations require the use of tools specially designed

for the purpose. The special tools should be used when and

as recommended.

It is important to note that this manual contains various

CAUTIONS and NOTICES which should be carefully read in

order to minimize the risk of personal injury to service

personnel. The possibility exists that improper service

methods may damage the equipment. It is also important to

understand that these CAUTIONS and NOTICES ARE NOT

EXHAUSTIVE. PHILIPS could not possibly know, evaluate

and advise the service trade of all conceivable ways in which

service might be done or of the possible hazardous

consequences of each way. Consequently, PHILIPS has not

undertaken any such broad evaluation. Accordingly, a

servicer who uses a service procedure or tool which is not

recommended by PHILIPS must first satisfy himself

thoroughly that neither his safety nor the safe operation of the

equipment will be jeopardized by the service method selected.

* * Hereafter throughout this manual, PHILIPS Consumer

Electronics Company will be referred to as PHILIPS.

Critical components having special safety characteristics are

identified with a by the Ref. No. in the parts list and

enclosed within a broken line*

(where several critical components are grouped in one area)

along with the safety symbol on the schematics or

exploded views.

Use of substitute replacement parts which do not have the

same specified safety characteristics may create shock, fire,

or other hazards.

Under no circumstances should the original design be

modified or altered without written permission from Philips.

Philips assumes no liability, express or implied, arising out of

any unauthorized modification of design.

Servicer assumes all liability.

WARNING

* Broken Line

Take care during handling the LCD module with backlight

unit

- Must mount the module using mounting holes arranged in four

corners.

- Do not press on the panel, edge of the frame strongly or electric

shock as this will result in damage to the screen.

- Do not scratch or press on the panel with any sharp objects, such

as pencil or pen as this may result in damage to the panel.

- Protect the module from the ESD as it may damage the electronic

circuit (C-MOS).

- Make certain that treatment person s body are grounded through

wrist band.

- Do not leave the module in high temperature and in areas of high

humidity for a long time.

- Avoid contact with water as it may a short circuit within the module.

- If the surface of panel become dirty, please wipe it off with a soft

material. (Cleaning with a dirty or rough cloth may damage the

panel.)

Go to cover page

Hudson2 200P3

3

Technical Data

Go to cover page

Technical Specifications

LCD PANEL

SCANNING

VIDEO

AUDIO-IN

MICROPHONE

Optical characteristics

Type :TFT LCD

Screen size :20.1" /51cm

Pixel Pitch :0.255 x0.255mm

LCD Panel type :1600 x 1200 pixels

R.G.B. vertical stripe

Anti-glare polarizer, hard coated

Effective viewing area :408 x 306mm

Display Colors :8 bits interface (16M colors)

Vertical refresh rate :56Hz-85Hz

Horizontal Frequency :30kHz-94kHz (Analog input),

:30kHz-92kHz(Digital input)

Video dot rate :202MHz

Input impedance

- Video :75 Ohm

- Sync :2K Ohm

Input signal levels :0.7 Vpp

Sync input signal :Separate sync

:Composite sync

:Sync on green

Sync polarities :Positive and negative

S-Video :Y input 1.0Vpp, C input 0.3Vpp,75ohm

input impedance

CVBS :Composite, 1.0Vpp,75ohm input

impedance

Video interface :Triple input(two connectors): D-Sub(analog)

and DVI-I(accepts both digital and analog) are

available and user selectable S-Video &CVBS

Input signal level :0.7 Vpp

Headphone out signal level :32 20+20mW

Input signal connector :3.5mm mini jack

Loudspeaker :4W Stereo Audio (2W/channel

RMSx2, 200Hz-12kHz,

4ohm,THD=10%)

Sensitivity :-45dB re 1V/ubar at 1kHz

Output impedance :2.2K max

Directivity :-5dB at 180

Frequency range :300Hz-3kHz

Contrast ratio : 300 (typ.)

Brightness :250 cd/m (typ.)

Peak contrast angle :6 o'clock

White Chromatcity: x: 0.281 y: 0.311 (at 9300 K)

x: 0.312 y: 0.338 (at 6500 K)

Viewing Angle:

(C/R>10)

Response time 30ms (typ.)

2

Upper 85 (typ.)

Lower 85 (typ.)

Left 85 (typ.)

Right 85 (typ.)

>

>

>

>

<

Physical Specifications

Dimension (WxHxD) :488 x 459 x220 mm (incl. Pedestal)

Weight :10.0 Kg

Tilt / Swivel :-5 ~ 25 /+-175

Power supply :100 240 VAC, 50/60 Hz

Power consumption :52 W (typ.)

Temperature :5 C to 35 C (operating)

:-20 C to 60 C (storage)

Relative humidity :20% to 80%

System MTBF :50K hrs (including CCFL 40K hrs)

Cabinet color :200P3M: Light Gray

200P3G: Black

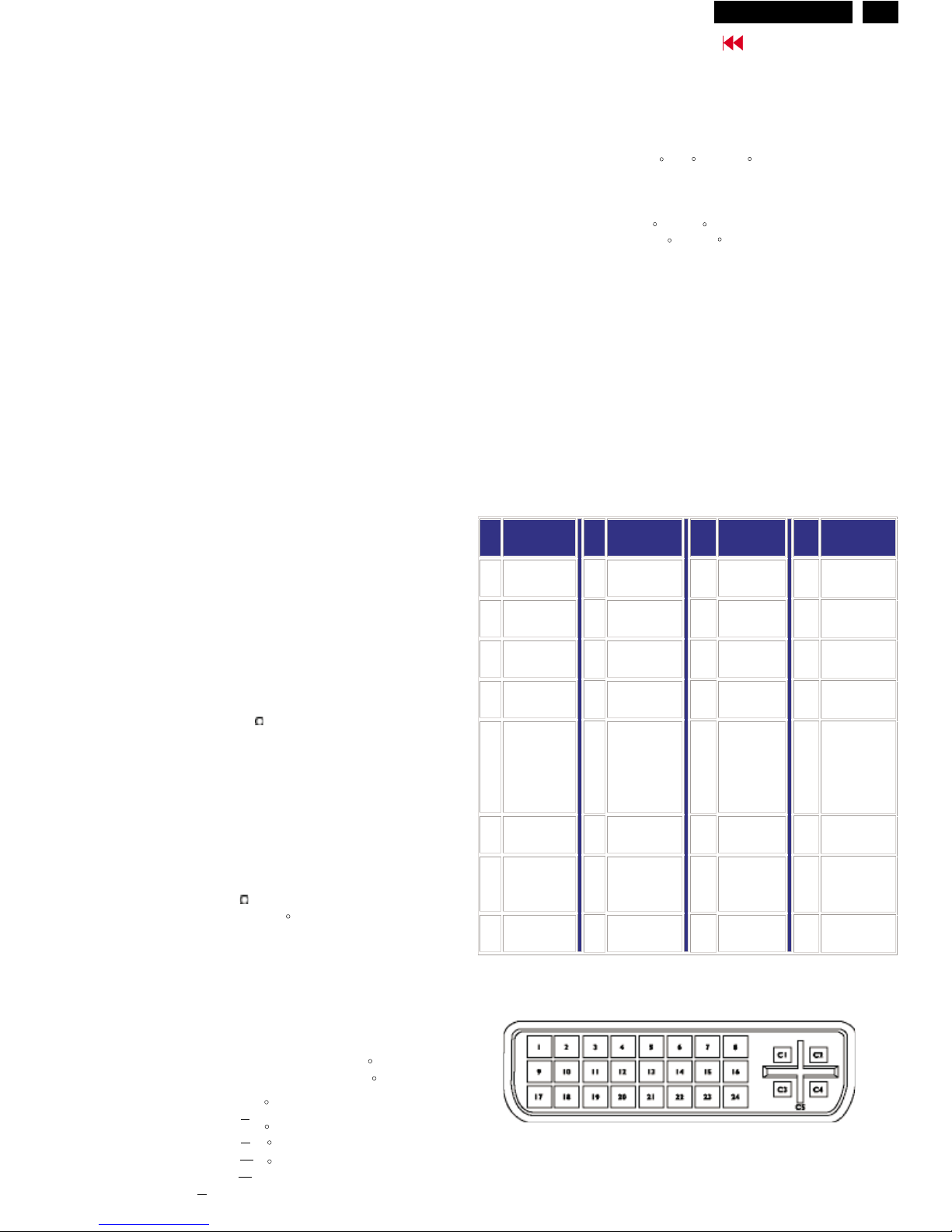

Pin

No.

Signal

Assignment

Pin

No.

Signal

Assignment

Pin

No.

Signal

Assignment

Pin

No.

Signal

Assignment

1 TMDS Data 2- 9 TMDS Data 1- 17 TMDS Data 0- C1

Analog Red

Video Out

2 TMDS Data 2+ 10 TMDS Data 1+ 18 TMDS Data 0+ C2

Analog Green

Video Out

3

TMDS Data 2/4

Shield

11

TMDS Data 1/3

Shield

19

TMDS Data

0/5 Shield

C3

Analog Blue

Video Out

4 TMDS Data 4- 12 TMDS Data 3- 20 TMDS Data 5- C4

Analog

Horizontal Sync

5 TMDS Data 4+ 13 TMDS Data 3+ 21 TMDS Data 5+ C5

Analog

Common

Ground Return

(Red, Green,

Blue Video Out)

6 DDC Clock 14 +5V Power 22

TMDS Clock

Shield

7 DDC Data 15

Ground (+5V,

Analog H/V

Sync)

23 TMDS Clock+

8

Analog Vertical

Sync

16 Hot Plug Detect 24 TMDS Clock-

Pin Assignment

1. The digital/analog DVI-I onnector contains 29

signal contacts organized in three rows of eight

contacts. Signal pin assignments are listed in the

Hudson2 200P3

Technical Data(Continued)

4

Go to cover page

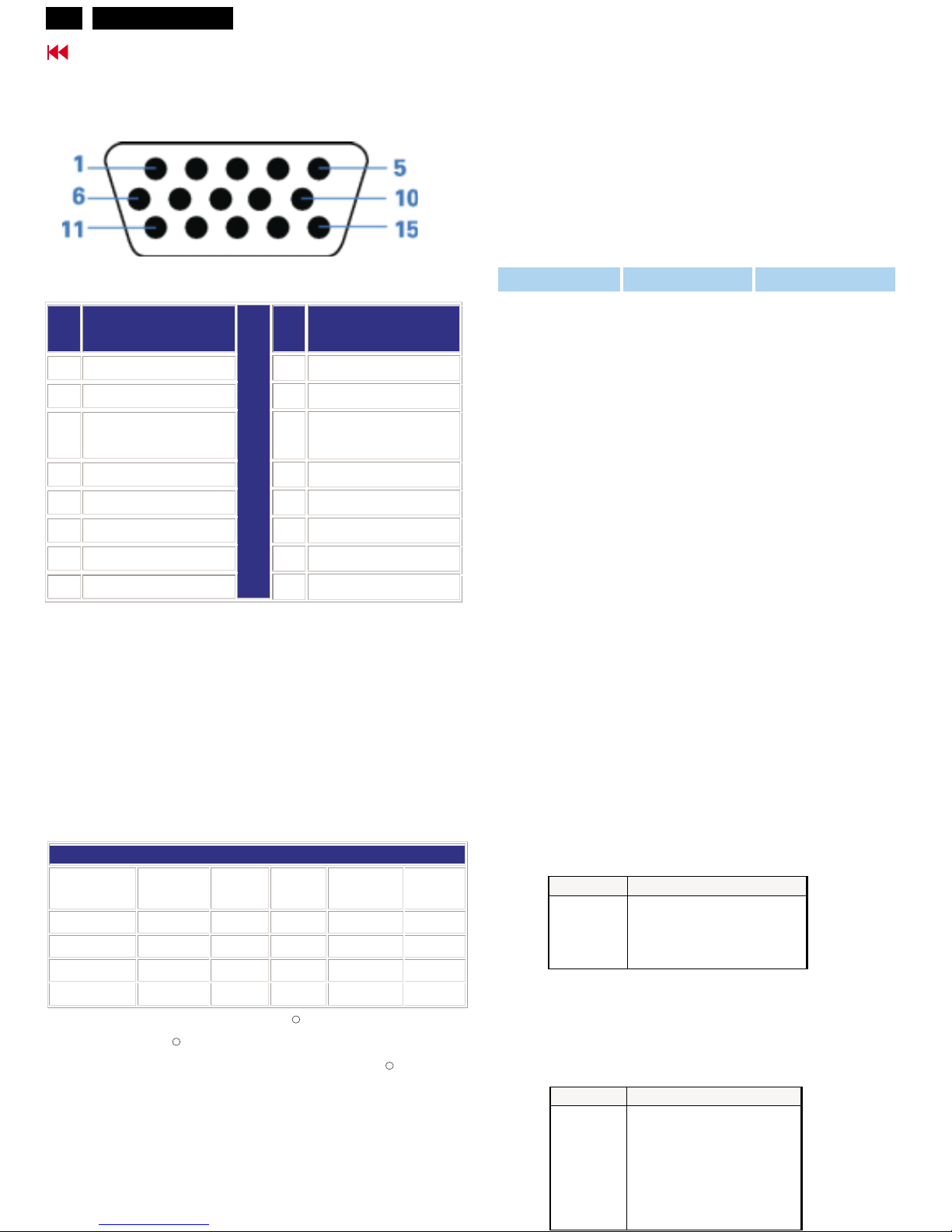

Pin

No.

Assignment

Pin

No.

Assignment

1 Red video input 9 +5V

2 Green video input/SOG 10 Logic ground

3 Blue video input 11

Identical output -

connected to pin 10

4 Sense (GND) 12 Serial data line (SDA)

5 Not connected 13 H. Sync / H+V

6 Red video ground 14 V. Sync (VCLK for DDC)

7 Green video ground 15 Data clock line (SCL)

8 Blue video ground

2. The 15-pin D-sub connector (male) of the signal cable:

Automatic Power Saving

If you have VESA's DPMS compliance display card or

software installed in your PC, the monitor can

automatically reduce its power consumption when

not in use. And if an input from a keyboard, mouse or

other input device is detected, the monitor will

automatically "wake up". The following table shows

the power consumption and signaling of this

automatic power saving features:

Power Management Definition

VESA Mode Video H-sync V-sync Power Used LED color

ON Active Ye s Yes < 60W Green

Stand-by Blanked No Ye s <3W Amber

Suspend Blanked Ye s No <3W Amber

OFF Blanked No No <3W Amber

This monitor is NERGY TAR compliant. s an

NERGY TAR artner, has determined

that this product meets the NERGY TAR

guidelines for energy efficiency.

ES A

E S P PHILIPS

ES

R

R

R

50 user definable modes

Maximum

1600 x 1200 at 75Hz(analog input)

1600 x 1200 at 60Hz(digtal input)

Recommended 1600 x 1200 at 60Hz

18 factory preset modes:

H. freq (kHz) Resolution V. freq (Hz)

31.5 640*350 70 (IBM VGA 10h)

31.5 720*400 70

31.5 640*480 60

35.0 640*480 67

37.5 640*480 75

35.2 800*600 56

37.9 800*600 60

46.9 800*600 75

49.7 832*624 75

48.4 1024*768 60

60.0 1024*768 75

69.0 1152*870 75

71.8 1152*900 76 (SUN Mode II)

63.9 1280*1024 60

80 1280*1024 75

91.1 1280*1024 85

75.0 1600*1200 60

93.8 1600*1200 75

Resolution & Preset Modes

PIN NO. SIGNAL

1

GND

2 CVBS

3 CVBS

4 CVBS

PIN NO. SIGNAL

1

GND

2 GND

3 LUMA

4 CHROMA

5 GND

6 GND

7 GND

S-Video

The input signals are applied to display through S-Video

cable

pin assignment

CVBS

The input signals are applied to display through CVBS

cable

pin assignment

Hudson2 200P3

5

Go to cover page

Connection to PC,Front Control

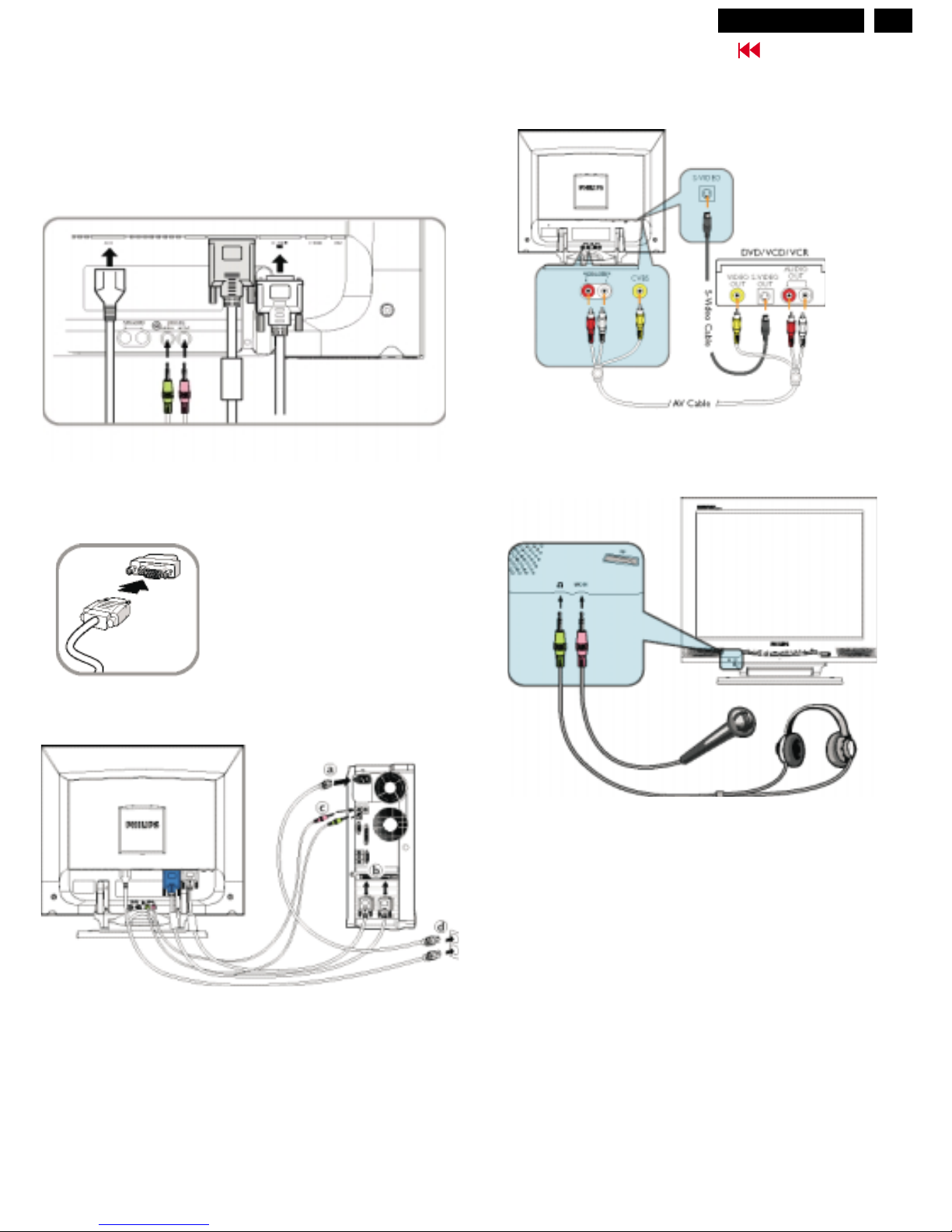

Connect to PC

Philiips has pre-connected VGA cable for the first installation.

Connect power cord, VGA, DVI, microphone and audio cables onto rear of

monitor firmly

Connect the cables to the back of your computer by following steps

(a) Turn off your computer and unplug its power cord.

(b) Connect the VGA or DVI cable to video connector.

(c) Connect the microphone and audio cables.

(d) Plug the power cord of computer and monitor into a nearby outlet.

(e) Turn on your computer and monitor. If the monitor displays an image,

installation is complete.

Connect to DVD/VCR/VCD

Connect to Microphone and Earphone

If you use an Apple MacintoshTM, you need to connect the special Mac adapter

to one end of the monitor signal cable.

Hudson2 200P3

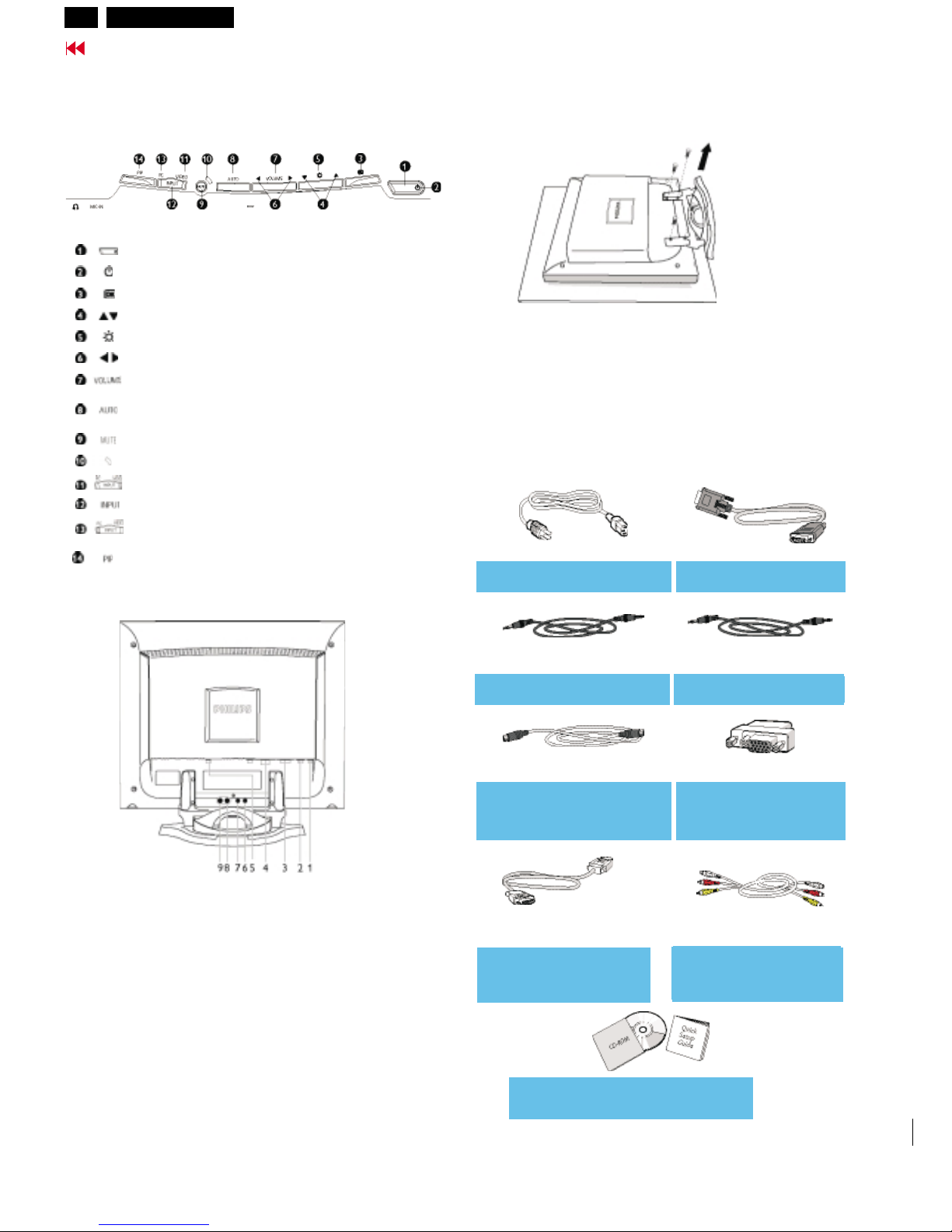

Front Control , Base

6

Go to cover page

Removing the monitor base

Front View Product Description

Rear View

To switch monitor's power On and Off

Power LED

To access OSD menu

To adjust the OSD

To adjust brightness of the display

To adjust the OSD

To adjust speakers volume

Automatically adjust the horizontal position, vertical pos

ition,

phase and

clock setting

To mute the audio sound

MUTE LED

Video input LED, lit when CVBS or S-Video activated

Signal inputs selection

PC input LED, lit when VGA or DVI activated

Activated PIP (

Picture in Picture) window

1 CVBS video input

2 S-Video video input

3 VGA input

4 DVI-I input

5 AC power in

6 Mic out

7 Audio in

8 Audio L input

9 Audio R input

The monitor surface is susceptible to scratching!

Lay the monitor on its face on a soft surface.

Remove the four screws on the rear of the monitor.

Accessory Pack

Unpack all the parts.

Power cord VGA signal cable

PC audio cable (lime) Mic cable (pink)

S-video cable

Mac adaptor

DVI to D-Sub

AV cable

(optional)

signal cable

(white/red/yellow)

EDFU pack

3138 128 74931

3138 188 72261(BLK)

3138 188 72051(white)

3138 188 75051(BLK)

3138 188 75031(white)

3138 188 74551(BLK)

3138 188 74541(white)

2422 033 00265

3138 188 74531(BLK)

3138 188 74521(white)

3138 188 75061(BLK)

3138 188 75041)white)

3138 188 72251(BLK)

3138 188 72241(white)

3138 117 04281

Hudson2 200P3

7

Go to cover page

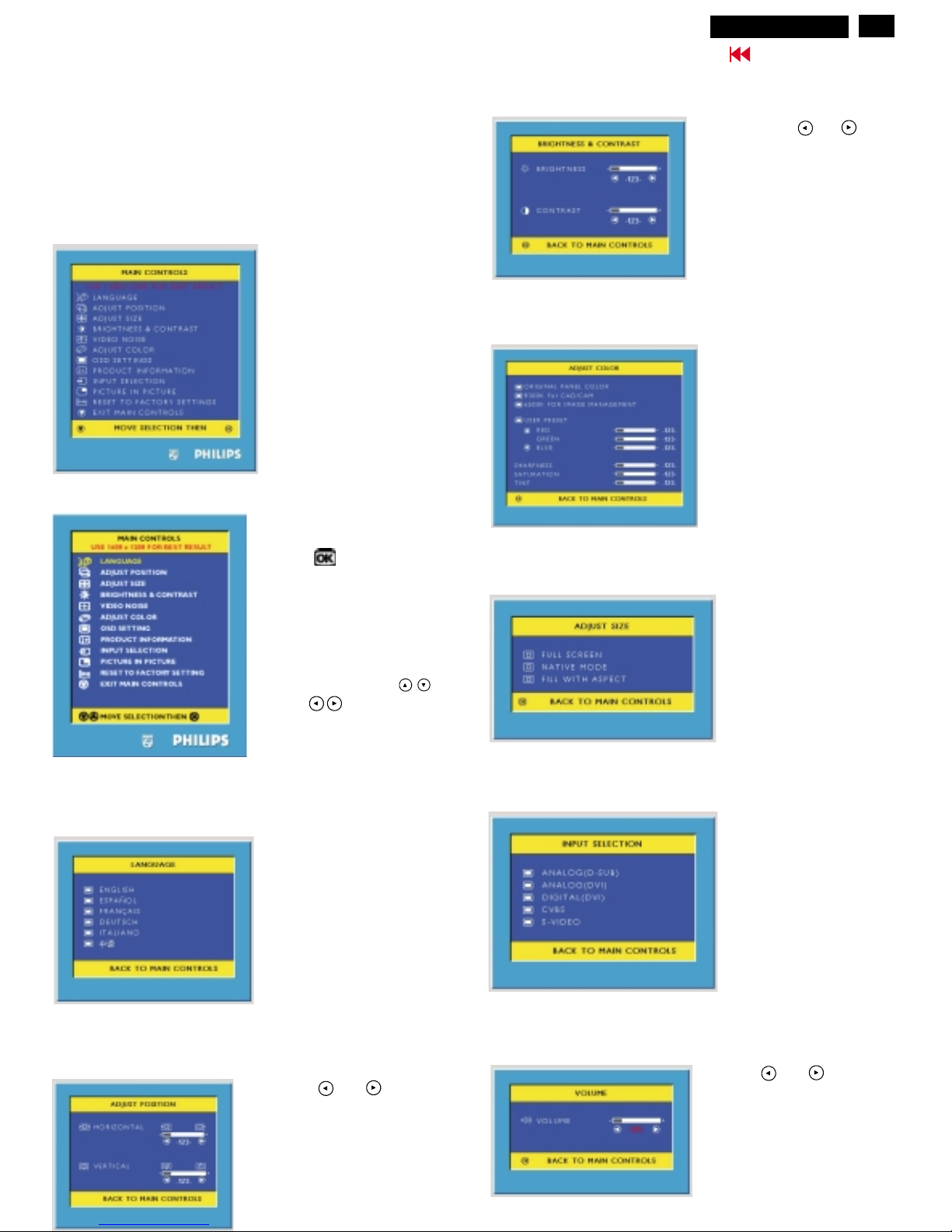

Settings using the OSD menu

Setting the colour temperature

Description of the On Screen Display

This is a feature in all Philips LCD monitors which

allows an end-user to adjust screen performance of

monitors directly through an on-screen instruction

window. The user interface provides userfriendliness and ease-of-use when operating the

monitor.

On the front controls of

your monitor, once you

press the button,

the On Screen Display

(OSD) Main Controls

window will pop up and

you can now start

making adjustments to

your monitor's various

features. Use the

or the keys to make

your adjustments within.

Press the or button to

adjust the selected function

Press the or button to

adjust the selected function

The corresponding setting window (here: )

is displayed.

ADJUST POSITION

Setting language for the OSD menu ( ).LANGUAGE

Setting Adjust Size

Selecting Input Signal

Adjusting the Brightness and Control

Adjusting the Volume

Press the key or to

mark another function or press

the MENU key to return to the

main menu.

Hudson2 200P3

8

Advanced control of OSD,

Go to cover page

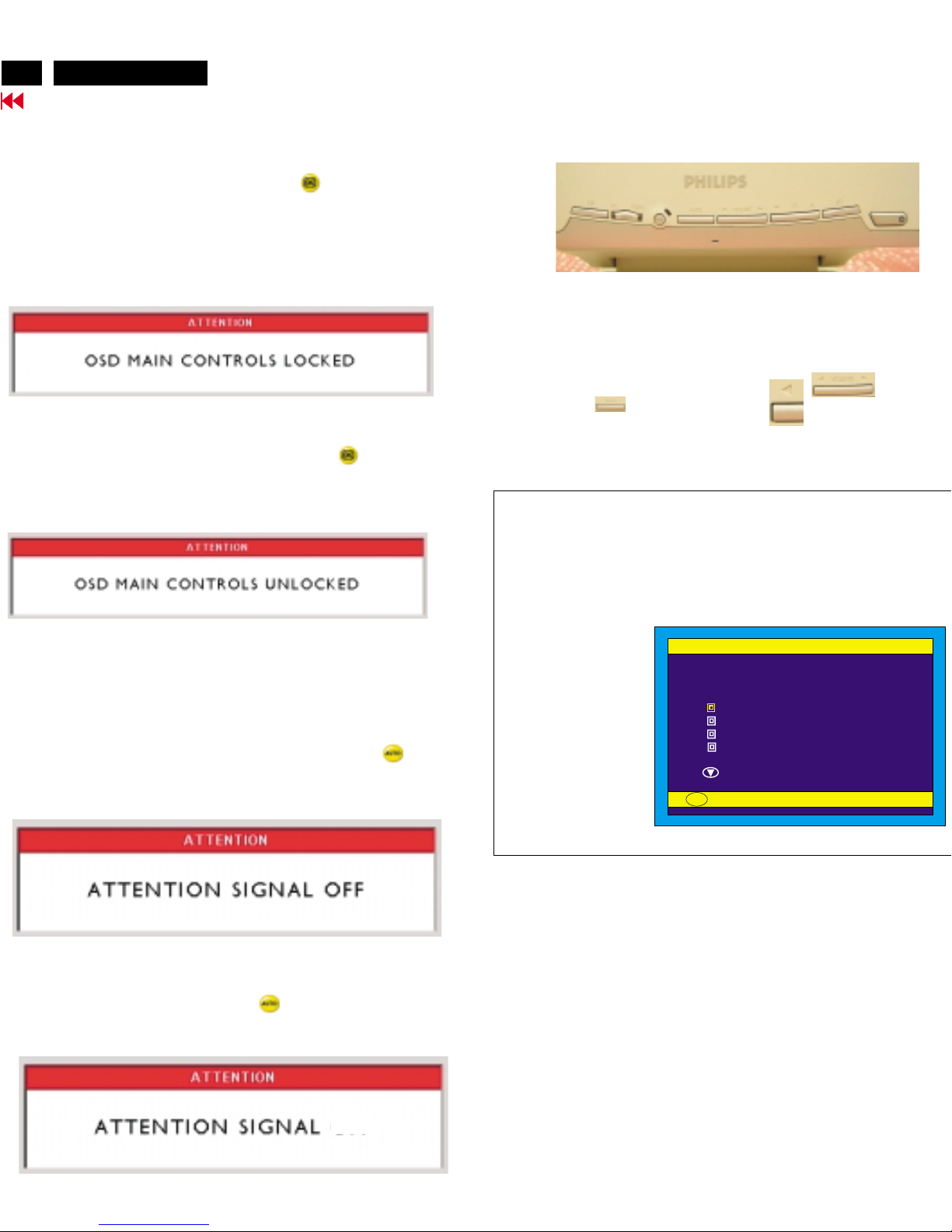

To Lock/Unlock OSD function

The OSD function can be locked by pressing button for more than

10 seconds, the screen shows following windows for 3 seconds.

Everytime when you press any button, this message appears on the

screen automatically.

Locked OSD function can be released by pressing button for

more than 10 seconds. .

Switch ON/OFF attention signals

All attention signals can be switched off by keep pressing button

for more than 10 seconds if there is no video signal supplied.

Recover attention signals by pressing button for more than 10

seconds without video signal input.

ON

Factory mode

Access Factory Mode

Factory Mode:

How to Get into Factory Mode Menu

Turn on LCD monitor.

Push AUTO " " & Left-VOLUME" " buttons

simultaneously 3 seconds around.

Bring up Factory mode indication as shown in Fig 6.

Fig. 5

---------->

AUTO

---------->

VOLUME

HUDSON 150P V1.56D 01-03-09

Fig. 6

Factory Mode

CODE VERSION. 2.02 2002-08-07

CONFIG VERSION. 2.02 2002-08-07

OSD VERSION. 2.02 2002-08-07

ORIGINAL PANEL COLOR

9300K For CAD/CAM

6500K FOR IMAGE MANAGEMENT

AUTO COLOR ADJUST

EXIT MAIN CONTROLS

TO PROCESS ADJUSTING

OK

Factory Mode

indication===========>

Check Firmware version : example as below.

CODE VERSION. 2.02 2002-08-07

CONFIG VERSION. 2.02 2002-08-07

OSD VERSION. 2.02 2002-08-07

Hudson2 200P3

9

Go to cover page

OSD Attention signals

NO VIDEO INPUT

CANNOT DISPLAY THIS VIDEO MODE..

This screen appears if there is no video signal input. Please check

that the signal cable is properly connected to the video card of PC

and make sure PC is on.

This screen warns when the input frequency from the computer is not

a standard video mode or out of the monitor's scanning range.

Please change the display mode of the operating software in the

computer(i.e. Windows) to 1600 x1200 @ 60Hz for best display

results.

The monitor will detect various display situation automatically. When

the monitor detects the problems, the screen will show the different

warning signals to remind you what is happen to your monitor.

WAIT FOR AUTOMATIC ADJUSTMENT

This screen appears when you touch the button. It will

disappear when the monitor is properly adjusted.

ENTERING SLEEP MODE

This screen appears when the monitor is about to enter the sleep

mode. Please press any key on the keyboard or click the mouse to

wake up the monitor and computer.

Hudson2 200P3

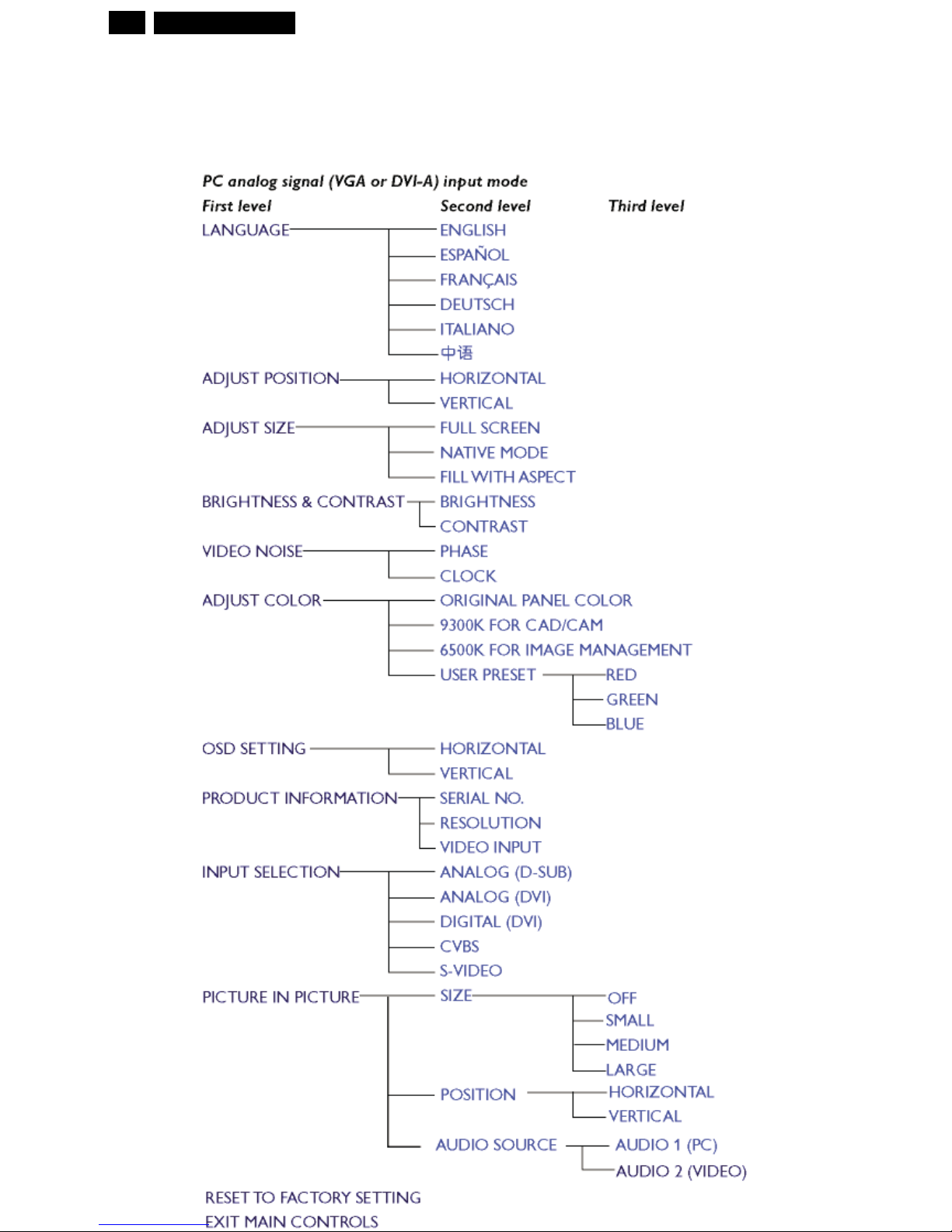

OSD menu tree -Analog

10

The OSD Tree

Below is an overall view of the structure of the On-Screen Display. You can use this as reference

when you want to later on work your way around the different adjustments.

9

Go to cover page

Hudson2 200P3

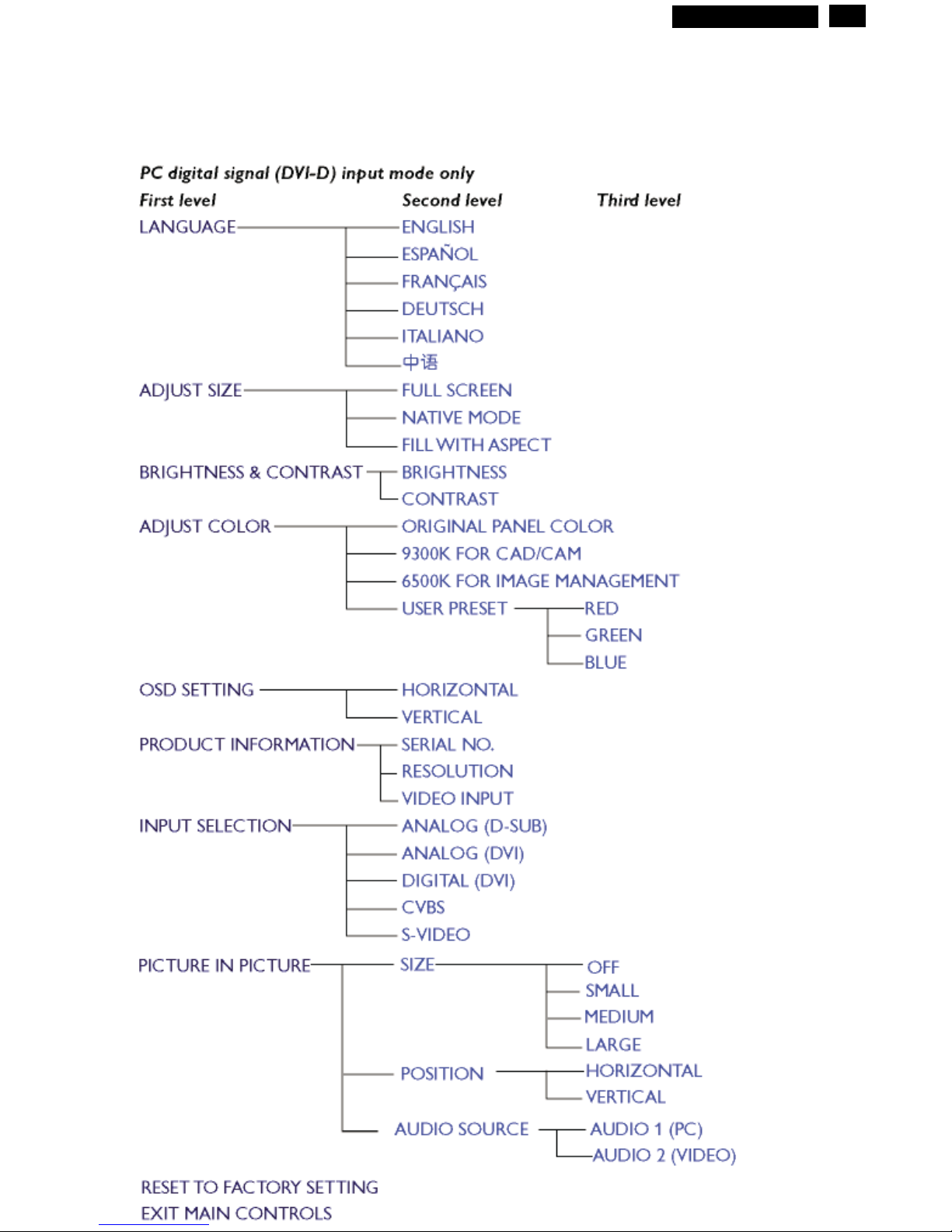

OSD menu tree - Digital

11

The OSD Tree

Below is an overall view of the structure of the On-Screen Display. You can use this as reference

when you want to later on work your way around the different adjustments.

9

Go to cover page

Hudson2 200P3

12

OSD Lock/Unlock, Aging Mode

Go to cover page

ATTENTION

OSD MAIN CONTROLS LOCKED

ATTENTION

OSD MAIN CONTROLS UNLOCKED

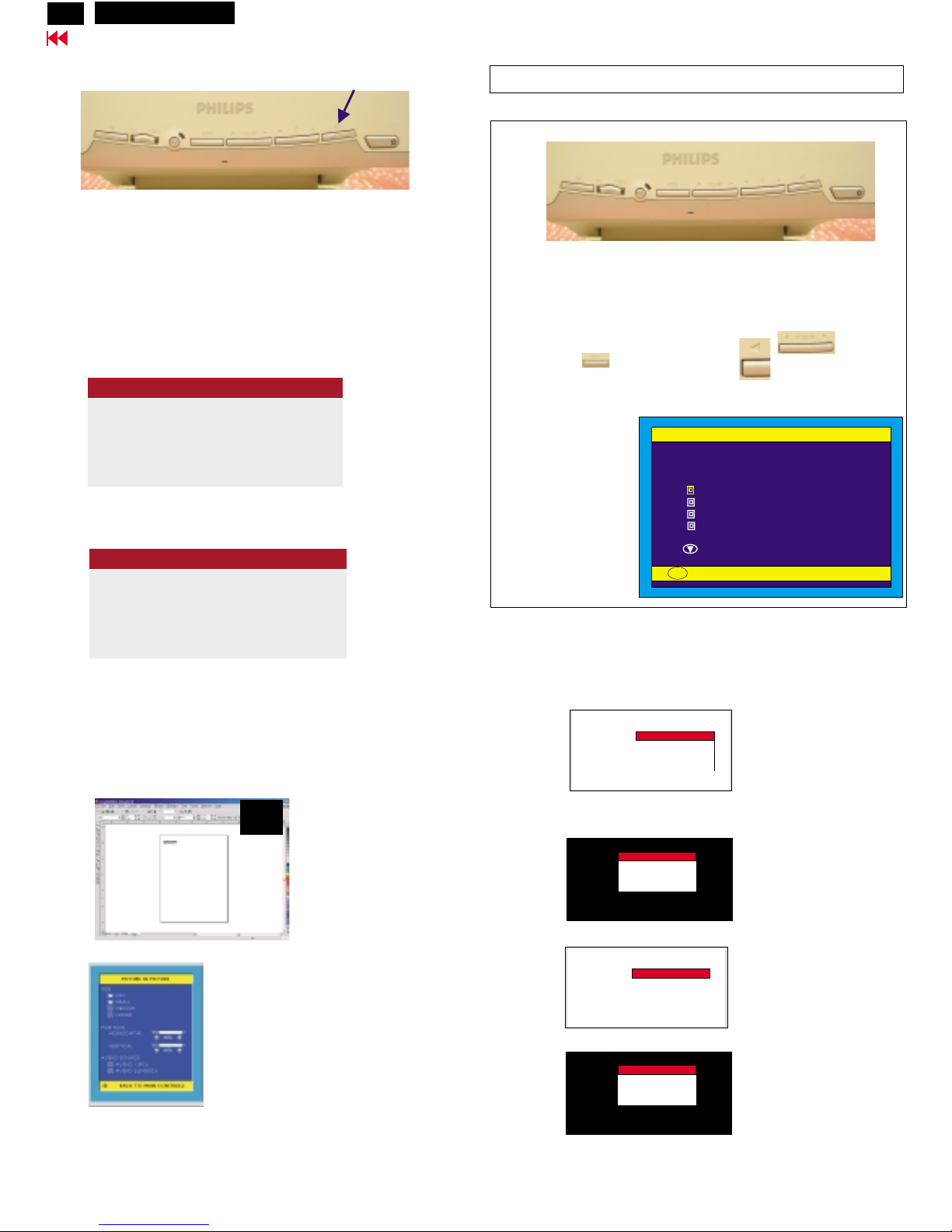

To Lock/Unlock OSD function (User Mode)

The OSD function can be locked by pressing "OK" button(1) for more

than 10 seconds, the screen shows following windows for 3 seconds.

Everytime when you press "AUTO" or "OK" button, this message

appears on the screen automatically.

Unlock OSD function:

Locked OSD function can be released by pressing"OK" button for

more than 10 seconds again.

PICTURE IN PICTURE (PIP):

Press the PIP hotkey on front control, will bring up PIP screen as

shown in Fig. 1.

Monitor (embeded software) will detect CVBS and S-Video input

for PIP function automatically at this moment.

Step 1:

Step 2:

When Factory mode comes on monitor screen, disconnect the

Signal Cable at this moment.

Access Factory Mode

Factory Mode:

How to Get into Factory Mode Menu

Turn on LCD monitor.

Push AUTO " " & Left-VOLUME" " buttons

simultaneously 3 seconds around.

Bring up Factory mode indication as shown in Fig 2.

Fig. 2

Fig. 1

---------->

AUTO

---------->

VOLUME

Factory Mode

CODE VERSION. 2.02 2002-08-07

CONFIG VERSION. 2.02 2002-08-07

OSD VERSION. 2.02 2002-08-07

ORIGINAL PANEL COLOR

9300K For CAD/CAM

6500K FOR IMAGE MANAGEMENT

AUTO COLOR ADJUST

EXIT MAIN CONTROLS

TO PROCESS ADJUSTING

OK

Factory Mode

indication===========>

Front control panel

1 = Buttons for the OSD menu (On-Screen-Display)

2 = Power indicator (PC)

3 = Power button

(OK button for OSD lock/unlock)

Fig. 1

Fig. 2

Fig. 3

Fig. 1

---------->

-------------->

---------->

------------>

---------->

AUTO

PIP

(OK)

1

2

3

Bring up

After 5 seconds, bring up :

After 5 seconds, bring up :

:

After 5 seconds, bring up :

----------

---------repeatly

Connect signal cable again => go back to normal display.

Access Aging.. Mode

A GI N G MODE.......AGI N G MODE.......

FACTORY MODE

A GI N G MODE.......AGI N G MODE.......

FACTORY MODE

A GI N G MODE.......AGI N G MODE.......

FACTORY MODE

A GI N G MODE.......AGI N G MODE.......

FACTORY MODE

<---------- PIP

Hudson2 200P3

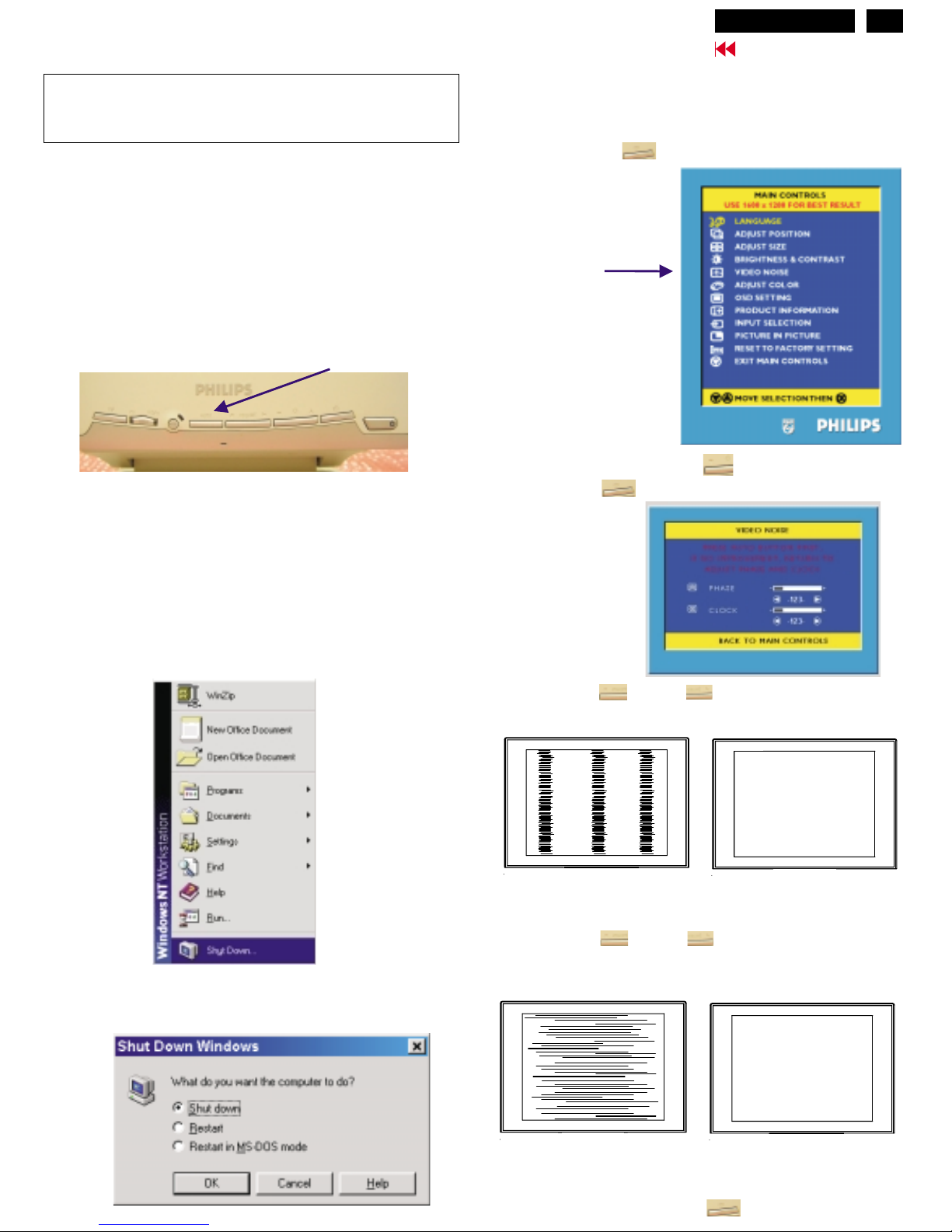

CLOCK & PHASE Adjustments

13

Go to cover page

Step 1 : Click on the Start button (Win95, Win98 or Win NT)

and choose " Shut Down...". as shown in Fig. 2.

Step 2 : The menu of " Shut Down Windows " is as shown in Fig. 3

Step 3 : Retain Shut Down Window on the screen , follow

the CLOCK and PHASE adjustment instructions for the

optimal video display.

PHASE phenomenon

Due to the different quality of video signal generated from graphics

cards. By press AUTO button for

t is necessary to adjust

CLOCK and PHASE functions for the optimal video display of LCD

monitor by manual. Following steps will guide you to make correct

adjustment of CLOCK and PHASE.

However, CLOCK and PHASE functions are only available while analog

video signal is supplied. Operating unit under digital signal state, the

video clock information can be obtained from graphics cards directly.

Therefor, it is unnecessary to adjust these functions.

CLOCK and PHASE adjustment

automatically. Sometimes, the deviation of video signal which generated

from graphics cards is out of control, then i

Manual adjustment

If the quility of display still poor or flicker, you may also improve it by

manual adjust CLOCK and PHASE functions to eliminate the flicker.

Step 4 : Press the OK button to bring up MAIN CONTROLS

(OSD menu).

Step 8 : Press Left or Right to adjust PHASE.

The picture will be adjusted as following figure, adjust PHASE

and check the picture, stop at the point that without any vertical

jitter bar remaining on the screen.

button

Step 5 : Select Video Noise by press button.

Step 6 : Press OK to bring up it s submenu.button

Step 7 : Press Left or Right to adjust CLOCK. The

picture will be adjusted as following figure, adjust CLOCK to

fine-tune the video until optimal display is obtained.

button

Step 9 : Quit OSD menu by press OK button to save the settings.

CLOCK Phenomenon

Video Noise

Using UP or DOWN

button to select it.

(Auto adjustment hotkey)

Front control panel

1 = OK button for the OSD menu (On-Screen-Display)

2 = Power indicator (PC)

3 = Power button

AUTO button

The monitor has build-in a auto adjustment hotkey on the front panel,

you may obtained a optimal video display by simply press the

button and save the settings. CLOCK, PHASE, Vertical position, and

Horizontal position are adjusted automatically.

AUTO

Fig. 1

Fig. 4

Fig. 5

Fig. 2

(Before)

(Before)

(After)

(After)

Fig. 3 (Win 98)

---------->

---------->

------------>

---------->

AUTO

OK

1

2

3

Hudson2 200P3

14

Go to cover page

DDC Instructions

General

Pin assignment

1

10

6

11

15

5

Assignment

Assignment

Pin No.

Pin No.

Ground

No Connected

Ground

Blue video input

2

7

6

8

4

5

3

1

9

12

11

14

13

15

10

Red video ground

Blue video ground

Green video ground

+5V

Ground

Data clock line(SCL)

V.Sync(VCLK for DDC)

H.Sync

Serial data line(SDA)

Green video input

Red video input

A. 15-pin D-Sub Connector

DDC Data Re-programming

Analog DDC IC, Digital DDC IC & EEPROM

Additional information

In case the DDC data memory IC or main EEPROM which storage all

factory settings were replaced due to a defect, the serial numbers have

to be re-programmed" ".

It is advised to re-soldered DDC IC and main EEPROM from the old

board onto the new board if circuit board have been replaced, in this

case the DDC data does not need to be re-programmed.

Additional information about DDC (Display Data Channel) may be

obtained from Video Electronics Standards Association (VESA).

Extended Display Identification Data(EDID) information may be also

obtained from VESA.

DDC EDID structure

For Analog interface: Standard Version 3.0

Structure Version 1.2

For Digital inferface: Standard Version 3.0

Structure Version 1.3

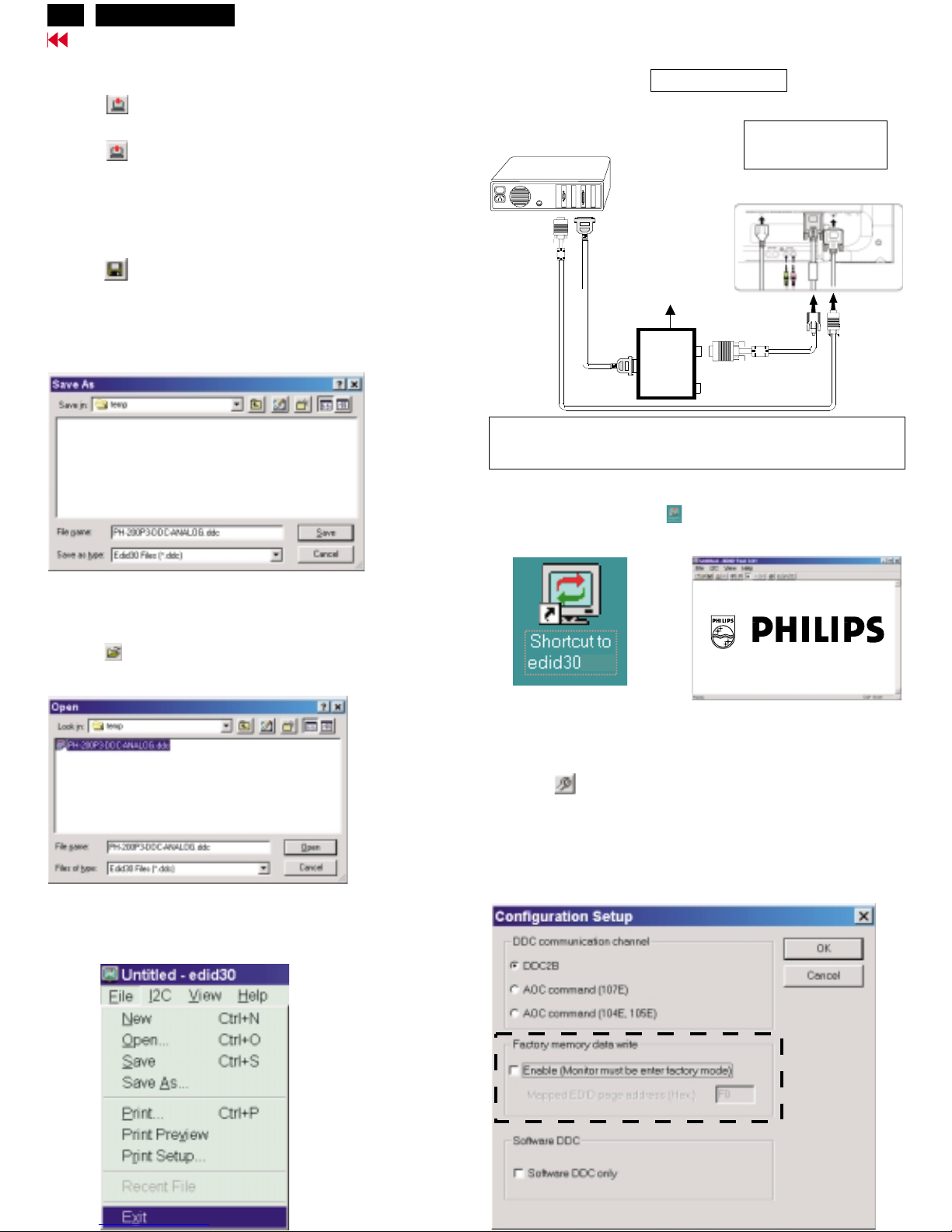

1. An i486 (or above) personal computer or compatible.

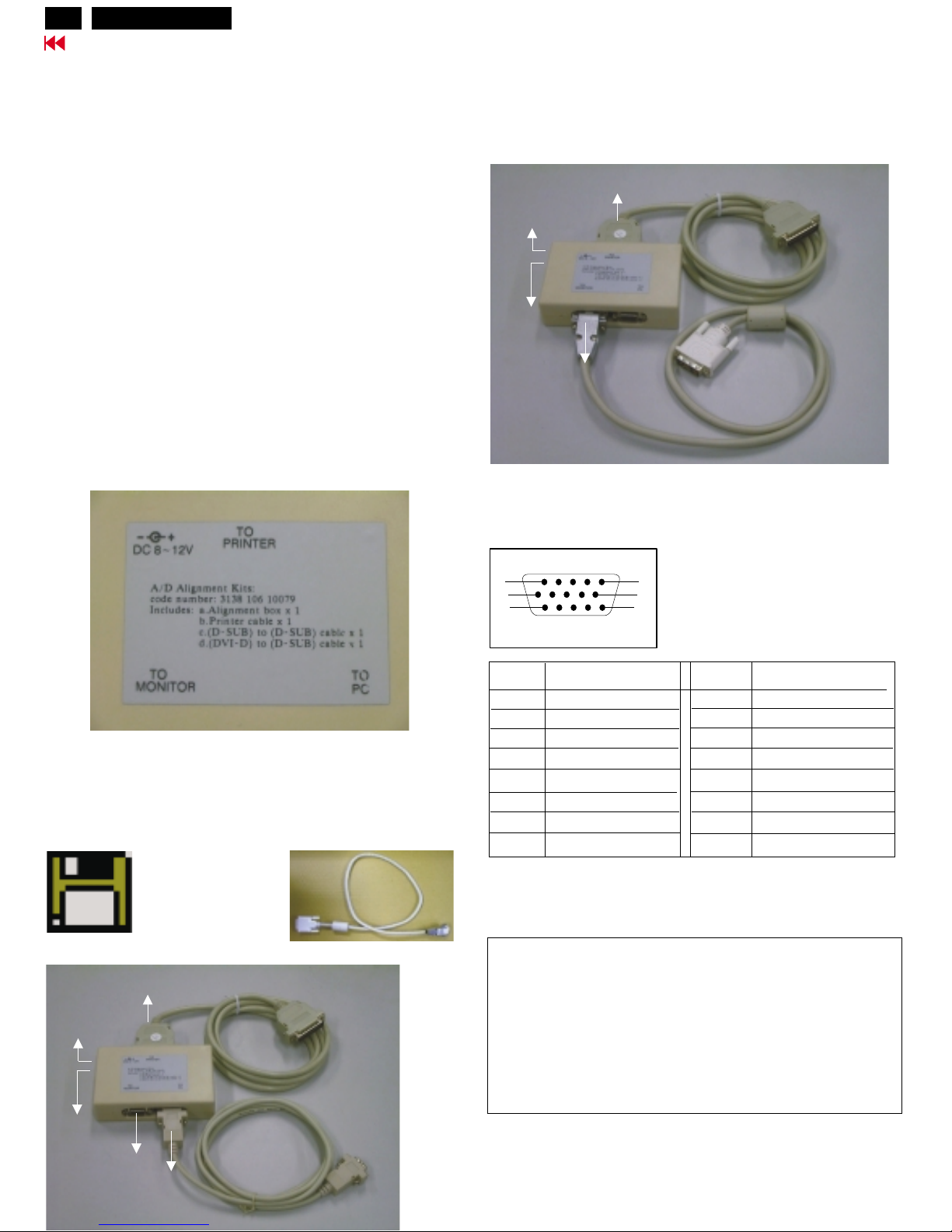

2. Microsoft operation system Windows 95/98.

4. A/D Alignment kits (3138 106 10079):

inclusion : a. Alignment box x1 (as Fig. 2)

b. Printer cable x1

c. (D-Sub) to (D-Sub) cable x1

d. (DVI-D) to (D-Sub) cable x1 (as Fig. 3)

Note: The EDID301.EXE (Release Version 1.58 20000818)is a

windows-based program, which cannot be run in MS-DOS.

System and equipment requirements

3. EDID301.EXE program (3138 106 10103) as shown in Fig. 1

**********************************************************************************

(pos. 7601, 128 bytes data) with :

=> updated by DDC Alignment kit.

(pos. 7463, OSD data, Factory data)

(pos. 7201, 128 bytes data) with :

=> updated by DDC Alignment kit.

with :

=> updated by another tool and application software.

**********************************************************************************

Analog DDC IC serial number

EEPROM

Digital DDC IC serial number

serial number

Diskette with EDID301.EXE

EDID301.EXE

Ver:1.58

(DVI-D) to (D-Sub) cable

Note: The alignment box has already build-in a batteries socket for

using as power source. Pull out the socket by

remove four screws at the rear of box. Please do not forget that

remove batteries after programming. The energy of batteries can

only drive circuits for a short period of time.

batteries (9V)

To Monitor

DC 8V~12V

Video Card

Video Card

To Printer

Power

indicator

A/D Alignment Kits - Analog connectionA/D Alignment Kits - Analog connection

A/D Alignment Kits - Digital connectionA/D Alignment Kits - Digital connection

Fig. 2Fig. 2

Fig. 1Fig. 1

Fig. 3Fig. 3

To Monitor

(Digital port)

DC 8V~12V

To Printer

Power

indicator

Hudson2 200P3

Go to cover page

15

DDC Instructions (Continued)

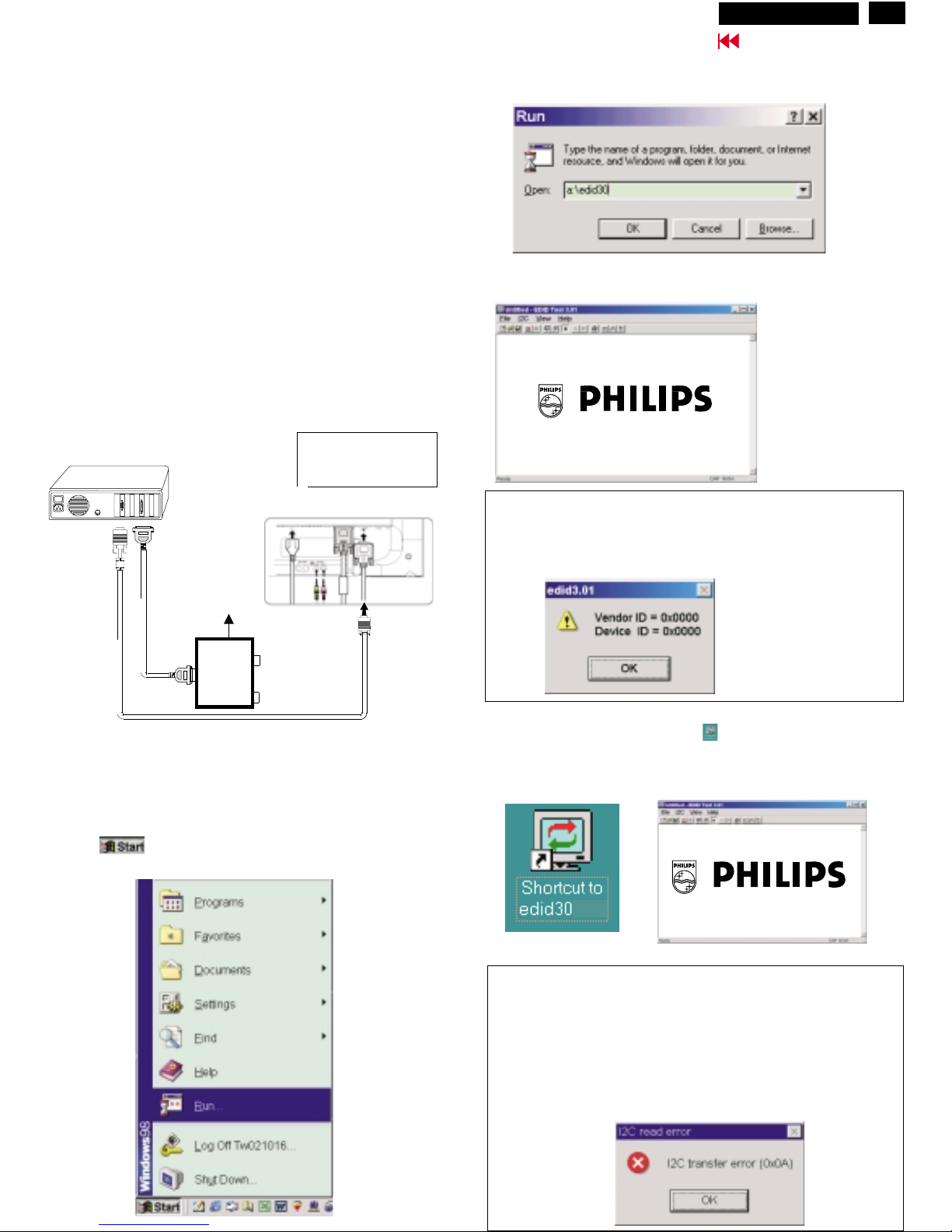

Step 3: Installation of EDID301.EXE

Method 1: Start on DDC program

Start Microsoft Windows.

1. Insert the disk containing EDID301.EXE program into floppy disk

drive.

2. Click , choose Run at start menu of Windows 95/98 as

shown in Fig. 4.

Fig. 4

4. Click button. The main menu appears (as shown in Fig. 6).OK

This is for initialize alignment box.

Fig. 6

Fig. 5

Fig. 7

Note 1: If the connection is improper, you will see the following error

message (as shown in Fig. 7) before entering the main menu.

Meanwhile, the (read EDID) function will be disable. At this time,

please make sure all cables are connected correctly and fixedly,

and the procedure has been performed properly.

3. At the submenu, type the letter of your computer's floppy disk drive

followed by :EDID301 (for example, A:\EDID301, as shown in Fig. 5).

Method 2: After create a shortcut of EDID301.EXE

This is for initialize alignment box.

: Double click EDID301 icon (as shown in Fig. 8) which is

on the screen of Windows Wallpaper.

Bring up main menu of EDID301 as shown in Fig. 9.

Fig. 9

Note 2: During the loading, EDID301 will verify the EDID data which just

loaded from monitor before proceed any further function, once

the data structure of EDID can not be recognized, the following

error message will appear on the screen as below. Please

confirm following steps to avoid this message.

1. The data structure of EDID was incorrect.

2. DDC IC that you are trying to load data is empty.

3. Wrong communication channel has set at configuration setup

windows.

4. Cables loosed or poor contact of connection.

Fig. 8

1

Configuration and procedure

There are 2 chips contained OSD string, serial number..etc

on the circuit board,

main EEPROM which storage all factory settings,OSD string.

DDC IC which storage 128byte EDID data(serial number ..etc.).

Following descirptions are the connection and procedure for Analog

and Digital DDC application, the main EEPROM can be

re-programmed along with Analog/Digital IC by enable factory memory

data write function on the DDC program (EDID301.EXE).

Initialize alignment box

In order to avoid that monitor entering power saving mode due to

sync will cut off by alignment box, it is necessary to initialize

alignment box before running programming software

(EDID301.EXE). Following steps show you the procedures and

connection.

Step 1: Supply 8~12V DC power source to the Alignment box by

plugging a DC power cord or using batteries.

Step 2: Connecting printer cable and video cable of monitor as Fig. 3

1=Power connector

2=DVI-I connector

3=D-SUB connector

Fig. 3

PC

Rear view of 200P3

~

~

To printer port (LTP1)

DC Power

8~12 V

Printer

Port

To video card

To

Monitor

To P C

1

2

3

Hudson2 200P3

16

Go to cover page

DDC Instructions (Continued)

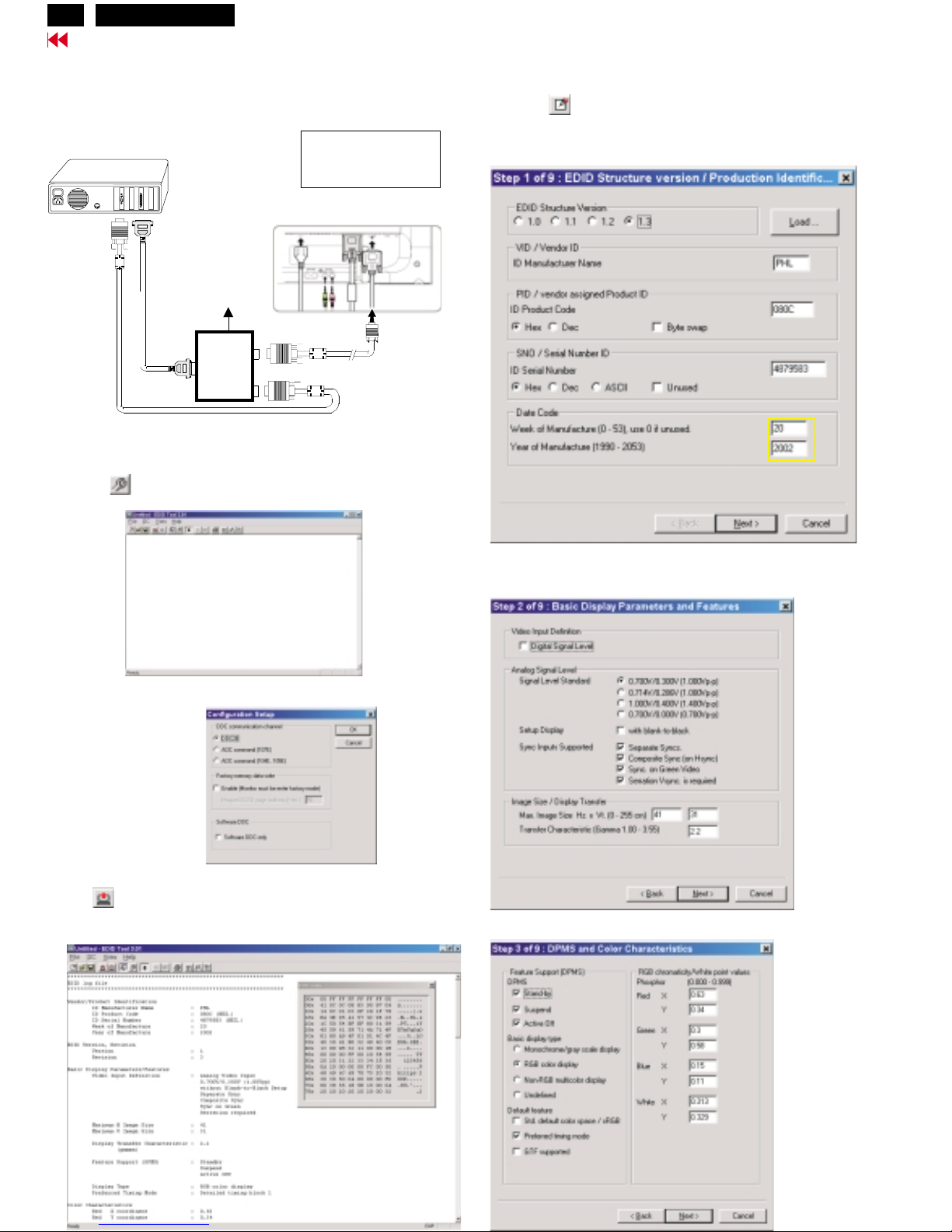

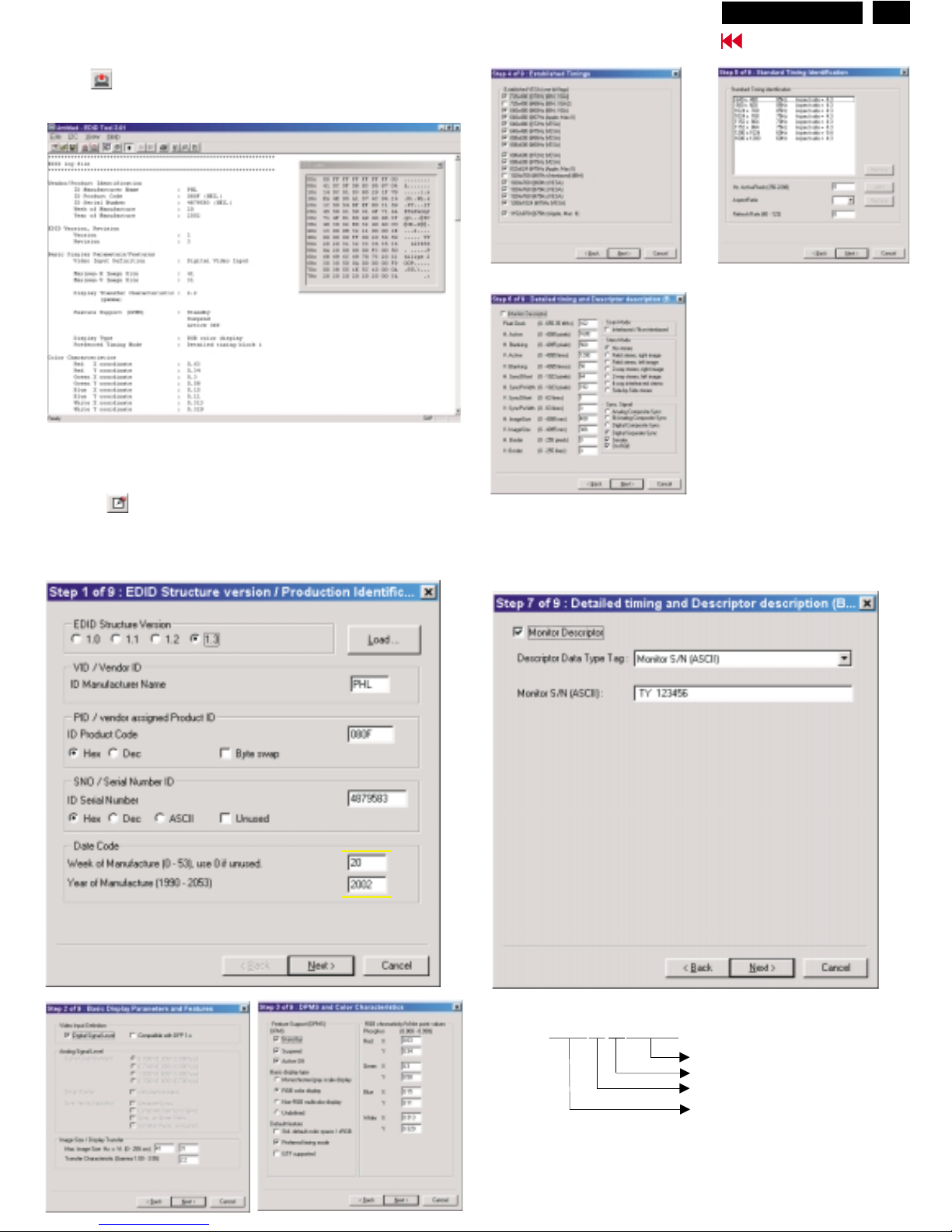

Re-programming Analog DDC IC

Step 1: After initialize alignment box, connecting all cables and

box as shown in Fig. 10

Fig. 11

Step 2: Read DDC data from monitor

1. Click icon as shown in Fig. 11 from the tool bar to bring up

the Channels "Configuration Setup" windows as shown in Fig. 12.

Step 3: Modify DDC data (verify EDID version, week, year)

1. Click (new function) icon from the tool bar, bring up

Step 1 of 9 as shown in Fig. 14 .

EDID301 DDC application provides the function selection and

text change (select & fill out) from Step 1 to Step 9.

Step 4: Modify DDC data (Monitor Serial No.)

Next1. Click , bring up Fig. 15.

2. Click , bring up Fig. 16.Next

3. Click OK button to confirm your selection.

4. Click icon (Read EDID function) to read DDC EDID data from

monitor. The EDID codes will display on screen as shown in Fig. 13.

Fig. 15

Fig. 16

Fig. 12

2. Select the DDC2B as the communication channel.

(Disable "Factory memory data write")

as shown in Fig. 12.

Fig. 13

Fig. 14

Fig. 10

~

~

PC

To video card

To printer port (LTP1)

DC Power

8~12 V

Printer

Port

To

Monitor

To P C

Rear view of 200P3

1

2

3

1=Power connector

2=DVI-I connector

3=D-SUB connector

Don't close this screen. --->

<---<

-

- -

For AnalogFor Analog

select and fill out,

if necessary.

select and fill out,

if

necessary.

Hudson2 200P3

Go to cover page

17

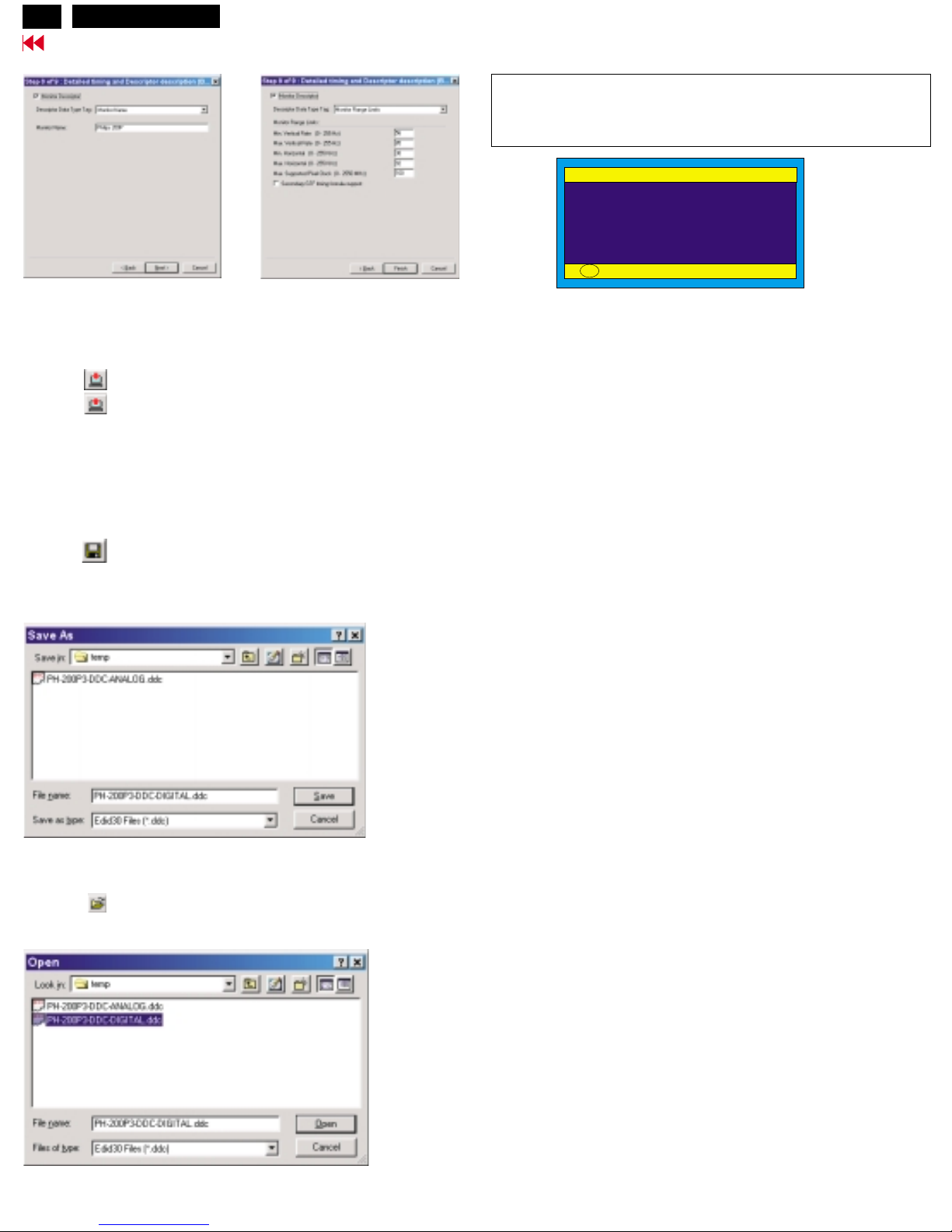

DDC Instructions (Continued)

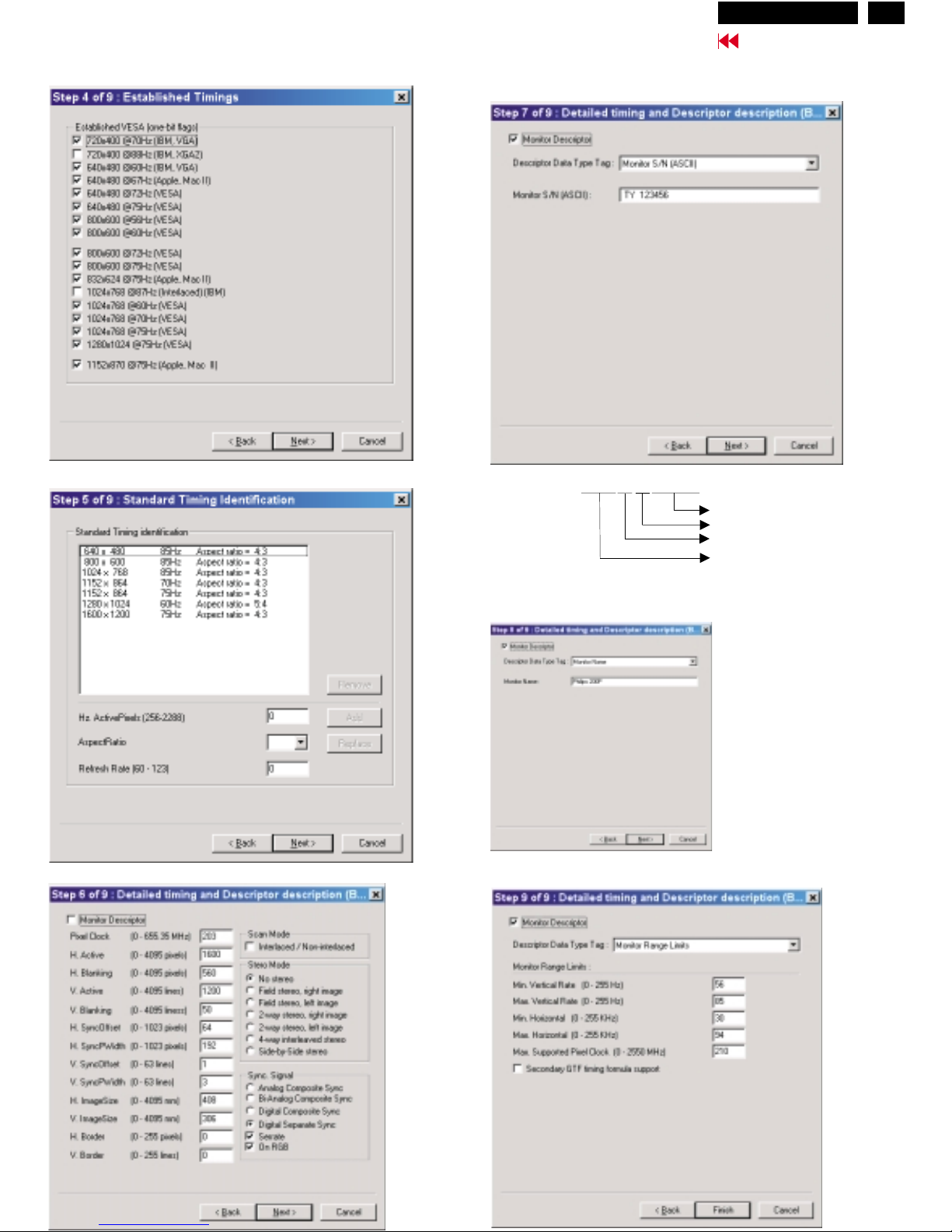

Fig. 17

Fig. 20

Fig. 21

Fig. 18

Fig. 19

3. Click , bring up Fig. 17.Next

6. Click , bring up Fig. 20.

(Serial number can be filled up or be changed at this moment.

Next

7. Click , bring up Fig. 21.Next

4. Click , bring up Fig. 18.Next

5. Click , bring up Fig. 19.Next

Fig. 22

8. Click , bring up Fig. 22.

- Click to exit the Step window.

Next

Finish

Definition of Serial Number (barcode format)

TY000028000001

Serial Number (U.S.A: 8 digit)

Week

Year

TY Code

TY----Chungli

CX----Dong Guan

HD----Hungary

BZ----Suzhou

(Others regions: 6 digit)

two space

(for example: change it from TY 503960

to TY 123456)

------>

Hudson2 200P3

18

Go to cover page

DDC Instructions (Continued)

Fig. 23

Fig. 24

Fig. 25

Step 7: Save DDC data

Sometimes, you may need to save DDC data as a text file for using

in other IC chip. To save DDC data, follow the steps below:

1. Click (Save) icon (or click "file"-> "save as") from the tool bar

and give a file name as shown in Fig. 23.

The file type is EDID301 file (*.ddc) which can be open in WordPad.

By using WordPad, the texts of DDC data & table (128 bytes,

hex code) can be modified. If DDC TEXTS & HEX Table are completely

correct, it can be saved as .ddc flie to re-load it into DDC IC

for DDC Data application.

Step 8: Load DDC data

Open

1. Click from the tool bar.

2. Select the file you want to open as shown in Fig. 24.

3. Click .

2. Click .Save

Step 8: Exit DDC program

Pull down the File menu and select Exit as shown in Fig. 25.

Step 6: Write DDC data

Bring up "BLACK screen" for a few seconds.

1. Click (Write EDID) icon from the tool bar to write DDC data.

2. Click (Read EDID) to re-confirm (check contents) it.

Re-programming Digital DDC IC

Connecting all cables and alignment box as shown in

Fig. 26.

Step 1:

After connection for Digital DDC application, if it is still in Analog DDC

application of EDID301.

Exit EDID301 program before Digital DDC application.

Fig. 27

Fig. 28

Step 2: Initialize alignment box

(Shortcut of EDID301.EXE on

Double click EDID301 icon (as shown in Fig. 27) which is

on the screen of Windows Wallpaper.

Bring up main menu of EDID301 as shown in Fig. 28.

Windows Wallpaper already.)

Step 3: Read DDC data from monitor

1. Click icon from the tool bar to bring up the Channels

Configuration Setup windows as shown in Fig. 28.

2. Select the DDC2B as the communication channel.

as shown in Fig. 29.

Disable "Factory memory data write" for Digital DDC

application

3. Click OK button to confirm your selection.

Fig. 29

1

1

Fig. 26

DVI

D-SUB

~

~

PC

To video card

To printer port (LTP1)

DC Power

8~12 V

To

Monitor

To P C

Printer

Port

D-Sub connector

Rear view of 200P3

1

2

3

1=Power connector

2=DVI-I connector

3=D-SUB connector

Hudson2 200P3

19

Go to cover page

DDC Instructions (Continued)

4. Click icon (Read EDID function) to read DDC EDID data from

monitor. The EDID codes will display on screen as shown in Fig. 30.

Fig. 30

Step 4: Modify DDC data (verify EDID version, week, year)

1. Click (new function) icon from the tool bar, bring up

Step 1 of 9 (Digital) as shown in Fig. 31 .

EDID301 DDC application provides the function selection and

text change (select & fill out) from Step 1 to Step 9.

Fig. 32

Fig. 33

Fig. 31

<--< - -

For DigitalFor Digital

select and fill out,

if necessary.

select and fill out,

if

necessary.

Step 5: Modify DDC data (Monitor Serial No.)

Monitor S

as shown in Fig. 37.

erial No. can be filled up or be changed (for example,

TY 123456)

Fig. 34

Fig. 35

Fig. 36

Fig. 37

Definition of Serial Number (barcode format)

TY000028000001

Serial Number (U.S.A: 8 digit)

Week

Year

TY Code

TY----Chungli

CX----Dong Guan

HD----Hungary

BZ----Suzhou

(Others regions: 6 digit)

two space

(for example: change it from TY 503960

to TY 123456)

------>

Hudson2 200P3

20

Go to cover page

DDC Instructions (Continued)

Step 6: Write DDC data

1. Click (Write EDID) icon from the tool bar to write DDC data.

2. Click (Read EDID) to re-confirm (check contents) it.

The 128bytes DDC data which had been written into DDC IC of

Digital Mode.

Fig. 40

Fig. 41

2. Click .Save

Step 9: Exit DDC program

Pull down the File menu and select Exit as shown in Fig. 25.

Step 7: Save DDC data

Sometimes, you may need to save DDC data as a text file for using

in other IC chip. To save DDC data, follow the steps below:

1. Click (Save) icon (or click "file"-> "save as") from the tool bar

and give a file name as shown in Fig. 40.

Step 8: Load DDC data

Open

1. Click from the tool bar.

2. Select the file you want to open as shown in Fig 41.

3. Click .

The display of SERIAL NO. by OSD can be change/update by

Analog Mode only.

It means "Analog Mode and Digital Mode are using same EEPROM

for display of SERIAL NO. by OSD" as shown in Fig. 42.

Fig. 42

************************************************************************

************************************************************************

Change/update the serial number which should be proceed

by another application software.

------->

----------------------------------

Click to exit the Step window as shown in Fig. 39.Finish

Fig. 38

Fig. 39

PRODUCT INFORMATION

SERIAL NO: TY 123456

RESOLUTION: 1024 X 768 / 75Hz

VIDEO INPUT: ANALOG(D-SUB)

BACK TO MAIN CONTROLS

OK

Hudson2 200P3

21

DDC Data of Digital

Go to cover page

**********************************************************************

EDID log file

**********************************************************************

Vendor/Product Identification

ID Manufacturer Name : PHL

ID Product Code : 080F (HEX.)

ID Serial Number : 4879583 (HEX.)

Week of Manufacture : 20

Year of Manufacture : 2002

EDID Version, Revision

Version : 1

Revision : 3

Basic Display Parameters/Features

Video Input Definition : Digital Video Input

Maximum H Image Size : 41

Maximum V Image Size : 31

Display Transfer Characteristic : 2.2

(gamma)

Feature Support (DPMS) : Standby

Suspend

Active Off

Display Type : RGB color display

Preferred Timing Mode : Detailed timing block 1

Color Characteristics

Red X coordinate : 0.63

Red Y coordinate : 0.34

Green X coordinate : 0.3

Green Y coordinate : 0.58

Blue X coordinate : 0.15

Blue Y coordinate : 0.11

White X coordinate : 0.313

White Y coordinate : 0.329

Established Timings

Established TimingsI:720x400@70Hz (IBM,VGA)

640 x 480 @60Hz (IBM,VGA)

640 x 480 @67Hz (Apple,Mac II)

640 x 480 @72Hz (VESA)

640 x 480 @75Hz (VESA)

800 x 600 @56Hz (VESA)

800 x 600 @60Hz (VESA)

Established Timings II : 800 x 600 @72Hz (VESA)

800 x 600 @75Hz (VESA)

832 x 624 @75Hz (Apple,Mac II)

1024 x 768 @60Hz (VESA)

1024 x 768 @70Hz (VESA)

1024 x 768 @75Hz (VESA)

1280 x 1024 @75Hz (VESA)

Manufacturer's timings : 1152 x 870 @75Hz (Apple,Mac II)

Standard Timing Identification #1

Horizontal active pixels : 640

Aspect Ratio : 4:3

Refresh Rate : 85

Standard Timing Identification #2

Horizontal active pixels : 800

Aspect Ratio : 4:3

Refresh Rate : 85

Standard Timing Identification #3

Horizontal active pixels : 1024

Aspect Ratio : 4:3

Refresh Rate : 85

Standard Timing Identification #4

Horizontal active pixels : 1024

Aspect Ratio : 4:3

Refresh Rate : 75

Standard Timing Identification #5

Horizontal active pixels : 1152

Aspect Ratio : 4:3

Refresh Rate : 70

Standard Timing Identification #6

Horizontal active pixels : 1152

Aspect Ratio : 4:3

Refresh Rate : 75

Standard Timing Identification #7

Horizontal active pixels : 1280

Aspect Ratio : 5:4

Refresh Rate : 60

Standard Timing Identification #8

Horizontal active pixels : 1600

Aspect Ratio : 4:3

Refresh Rate : 60

Detailed Timing #1

Pixel Clock (MHz) : 162

H Active (pixels) : 1600

H Blanking (pixels) : 560

V Active (lines) : 1200

V Blanking (lines) : 50

H Sync Offset (F Porch) (pixels) : 64

H Sync Pulse Width (pixels) : 192

V Sync Offset (F Porch) (lines) : 1

V Sync Pulse Width (lines) : 3

H Image Size (mm) : 408

V Image Size (mm) : 306

H Border (pixels) : 0

V Border (lines) : 0

Flags : Non_interlaced

: Normal Display, No stereo

: Digital Separate sync.

: Positive Vertical Sync.

: Positive Horizontal Sync.

Monitor Descriptor #2

Serial Number : TY 123456

Monitor Descriptor #3

Monitor Name : Philips 200P

Monitor Descriptor #4

Monitor Range Limits

Min. Vt rate Hz : 56

Max. Vt rate Hz : 85

Min. Horiz. rate kHz : 30

Max. Horiz. rate kHz : 92

Max. Supported Pixel : 160

No secondary GTF timing formula supported.

Extension Flag : 0

Check sum : 3A (HEX.)

**********************************************************************

EDID data (128 bytes)

**********************************************************************

0: 00 1: ff 2: ff 3: ff 4: ff 5: ff 6: ff 7: 00

8: 41 9: 0c 10: 0f 11: 08 12: 83 13: 95 14: 87 15: 04

16: 14 17: 0c 18: 01 19: 03 20: 80 21: 29 22: 1f 23: 78

24: ea 25: 4e 26: 95 27: a1 28: 57 29: 4c 30: 94 31: 26

32: 1c 33: 50 34: 54 35: bf 36: ef 37: 80 38: 31 39: 59

40: 45 41: 59 42: 61 43: 59 44: 61 45: 4f 46: 71 47: 4a

48: 71 49: 4f 50: 81 51: 80 52: a9 53: 40 54: 48 55: 3f

56: 40 57: 30 58: 62 59: b0 60: 32 61: 40 62: 40 63: c0

64: 13 65: 00 66: 98 67: 32 68: 11 69: 00 70: 00 71: 1e

72: 00 73: 00 74: 00 75: ff 76: 00 77: 20 78: 54 79: 59

80: 20 81: 20 82: 31 83: 32 84: 33 85: 34 86: 35 87: 36

88: 0a 89: 20 90: 00 91: 00 92: 00 93: fc 94: 00 95: 50

96: 68 97: 69 98: 6c 99: 69 100: 70 101: 73 102: 20 103: 32

104: 30 105: 30 106: 50 107: 0a 108: 00 109: 00 110: 00 111: fd

112: 00 113: 38 114: 55 115: 1e 116: 5c 117: 10 118: 00 119: 0a

120: 20 121: 20 122: 20 123: 20 124: 20 125: 20 126: 00 127: 3a

Hudson2 200P3

DDC Data of Analog

22

Go to cover page

**********************************************************************

EDID log file

**********************************************************************

Vendor/Product Identification

ID Manufacturer Name : PHL

ID Product Code : 080C (HEX.)

ID Serial Number : 4879583 (HEX.)

Week of Manufacture : 20

Year of Manufacture : 2002

EDID Version, Revision

Version : 1

Revision : 3

Basic Display Parameters/Features

Video Input Definition : Analog Video Input

0.700V/0.300V (1.00Vpp)

without Blank_to_Black Setup

Separate Sync

Composite Sync

Sync on Green

Serration required

Maximum H Image Size : 41

Maximum V Image Size : 31

Display Transfer Characteristic : 2.2

(gamma)

Feature Support (DPMS) : Standby

Suspend

Active Off

Display Type : RGB color display

Preferred Timing Mode : Detailed timing block 1

Color Characteristics

Red X coordinate : 0.63

Red Y coordinate : 0.34

Green X coordinate : 0.3

Green Y coordinate : 0.58

Blue X coordinate : 0.15

Blue Y coordinate : 0.11

White X coordinate : 0.313

White Y coordinate : 0.329

Established Timings

Established Timings I : 720 x 400 @70Hz (IBM,VGA)

640 x 480 @60Hz (IBM,VGA)

640 x 480 @67Hz (Apple,Mac II)

640 x 480 @72Hz (VESA)

640 x 480 @75Hz (VESA)

800 x 600 @56Hz (VESA)

800 x 600 @60Hz (VESA)

Established Timings II : 800 x 600 @72Hz (VESA)

800 x 600 @75Hz (VESA)

832 x 624 @75Hz (Apple,Mac II)

1024 x 768 @60Hz (VESA)

1024 x 768 @70Hz (VESA)

1024 x 768 @75Hz (VESA)

1280 x 1024 @75Hz (VESA)

Manufacturer's timings :1152 x 870 @75Hz (Apple,Mac II)

Standard Timing Identification #1

Horizontal active pixels : 640

Aspect Ratio : 4:3

Refresh Rate : 85

Standard Timing Identification #2

Horizontal active pixels : 800

Aspect Ratio : 4:3

Refresh Rate : 85

Standard Timing Identification #3

Horizontal active pixels : 1024

Aspect Ratio : 4:3

Refresh Rate : 85

Standard Timing Identification #4

Horizontal active pixels : 1152

Aspect Ratio : 4:3

Refresh Rate : 70

Standard Timing Identification #5

Horizontal active pixels : 1152

Aspect Ratio : 4:3

Refresh Rate : 75

Standard Timing Identification #6

Horizontal active pixels : 1280

Aspect Ratio : 5:4

Refresh Rate : 60

Standard Timing Identification #7

Horizontal active pixels : 1600

Aspect Ratio : 4:3

Refresh Rate : 75

Detailed Timing #1

Pixel Clock (MHz) : 203

H Active (pixels) : 1600

H Blanking (pixels) : 560

V Active (lines) : 1200

V Blanking (lines) : 50

H Sync Offset (F Porch) (pixels) : 64

H Sync Pulse Width (pixels) : 192

V Sync Offset (F Porch) (lines) : 1

V Sync Pulse Width (lines) : 3

H Image Size (mm) : 408

V Image Size (mm) : 306

H Border (pixels) : 0

V Border (lines) : 0

Flags : Non_interlaced

: Normal Display, No stereo

: Digital Separate sync.

: Positive Vertical Sync.

: Positive Horizontal Sync.

Monitor Descriptor #2

Serial Number : TY 123456

Monitor Descriptor #3

Monitor Name : Philips 200P

Monitor Descriptor #4

Monitor Range Limits

Min. Vt rate Hz : 56

Max. Vt rate Hz : 85

Min. Horiz. rate kHz : 30

Max. Horiz. rate kHz : 94

Max. Supported Pixel : 210

No secondary GTF timing formula supported.

Extension Flag : 0

Check sum : 32 (HEX.)

**********************************************************************

EDID data (128 bytes)

**********************************************************************

0: 00 1: ff 2: ff 3: ff 4: ff 5: ff 6: ff 7: 00

8: 41 9: 0c 10: 0c 11: 08 12: 83 13: 95 14: 87 15: 04

16: 14 17: 0c 18: 01 19: 03 20: 0f 21: 29 22: 1f 23: 78

24: ea 25: 4e 26: 95 27: a1 28: 57 29: 4c 30: 94 31: 26

32: 1c 33: 50 34: 54 35: bf 36: ef 37: 80 38: 31 39: 59

40: 45 41: 59 42: 61 43: 59 44: 71 45: 4a 46: 71 47: 4f

48: 81 49: 80 50: a9 51: 4f 52: 01 53: 01 54: 4c 55: 4f

56: 40 57: 30 58: 62 59: b0 60: 32 61: 40 62: 40 63: c0

64: 13 65: 00 66: 98 67: 32 68: 11 69: 00 70: 00 71: 1e

72: 00 73: 00 74: 00 75: ff 76: 00 77: 20 78: 54 79: 59

80: 20 81: 20 82: 31 83: 32 84: 33 85: 34 86: 35 87: 36

88: 0a 89: 20 90: 00 91: 00 92: 00 93: fc 94: 00 95: 50

96: 68 97: 69 98: 6c 99: 69 100: 70 101: 73 102: 20 103: 32

104: 30 105: 30 106: 50 107: 0a 108: 00 109: 00 110: 00 111: fd

112: 00 113: 38 114: 55 115: 1e 116: 5e 117: 15 118: 00 119: 0a

120: 20 121: 20 122: 20 123: 20 124: 20 125: 20 126: 00 127: 32

Hudson2 200P3

23

Go to cover page

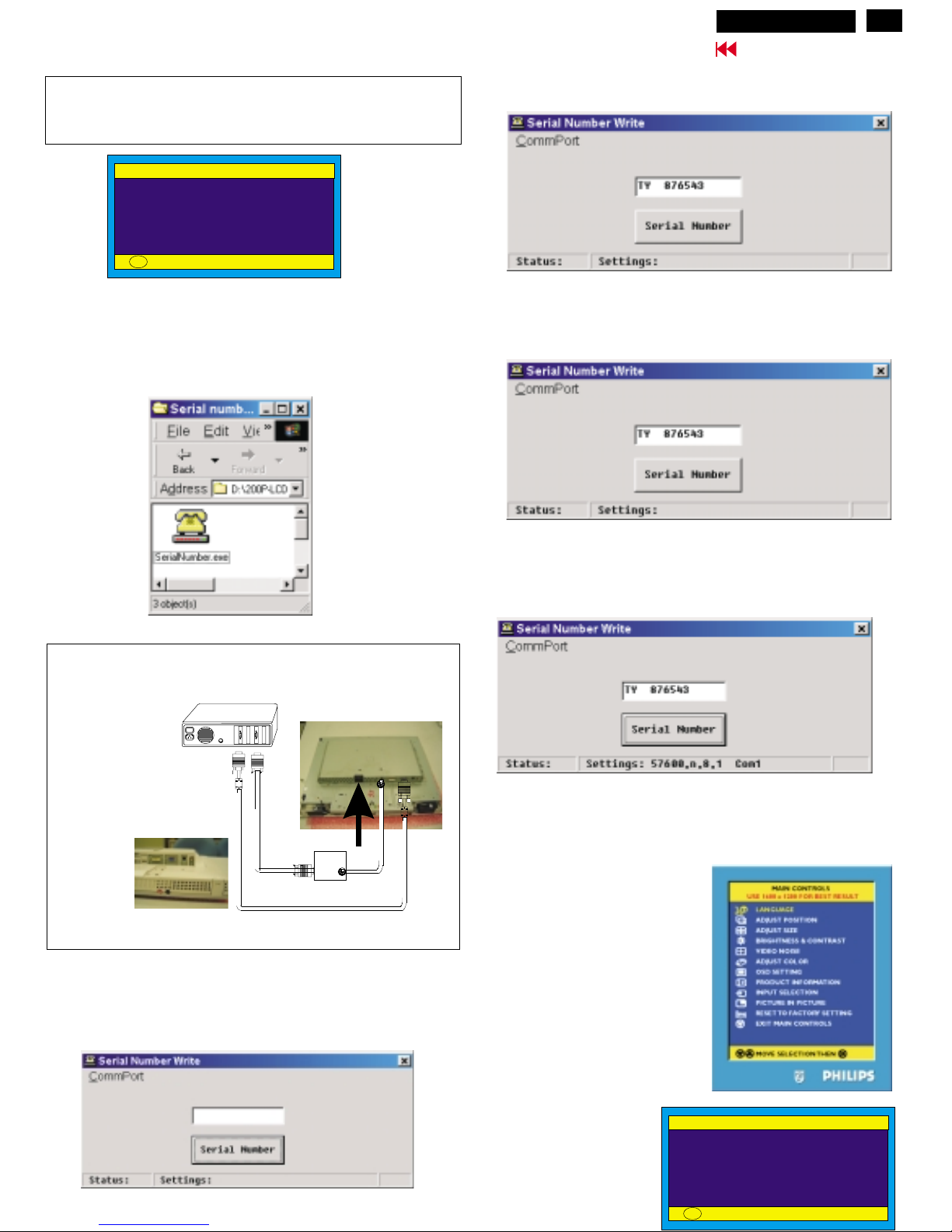

Serial number application

The display of SERIAL NO. by OSD can be change/update by

another application software only.

Analog Mode and Digital Mode are using same EEPROM(pos. 7463)

for display of SERIAL NO. by OSD" as shown in Fig. 1.

Fig. 1 (example, SERIAL NUMBER by OSD)

Step 1: Double click "SerialNumber.exe"

Bring up: Fig. 4

Step 2: Click "Serial Number" as shown in Fig. 6.

Step 3: Verify "Serial Number" by OSD as shown in Fig. 8,9.

Press OK button

=>select "PRODUCT INFORMATION"

=>press OK button

Bring up :

Fig. 9 for verification.

Fig. 2

Fig. 4

*****************************************************************************

*****************************************************************************

Change/update the serial number which should be proceed

by application software "SerialNumber.exe" as shown in Fig. 2..

------->

----------------------------------

PRODUCT INFORMATION

SERIAL NO: TY 123456

RESOLUTION: 1024 X 768 / 75Hz

VIDEO INPUT: ANALOG(D-SUB)

BACK TO MAIN CONTROLS

OK

PRODUCT INFORMATION

SERIAL NO: TY 876543

RESOLUTION: 1024 X 768 / 75Hz

VIDEO INPUT: ANALOG(D-SUB)

BACK TO MAIN CONTROLS

OK

Fill out serial number of monitor.

For example "TY 876543" as shown in Fig. 5.

Fig. 5

Fig. 6

Fig. 7

Fig. 8

Fig. 9

---------->

(two space)

(click "Serial Number")

(Com port for application)

Bring up Fig. 7 with "57600,n,8,1 Com1"

-------------------->

---------------->

---->

Fig. 3

Connection: for Serial Number application

Rear view of 200P3

PC

To Com1 or Com2 (PC)

To video card

Video cable

Com1 or

Com2

25 pins

9 pins

9 pins

Monitor

D-Sub

Connect to

Mains cord

Remove

plastic cover-->

Hudson2 200P3

24

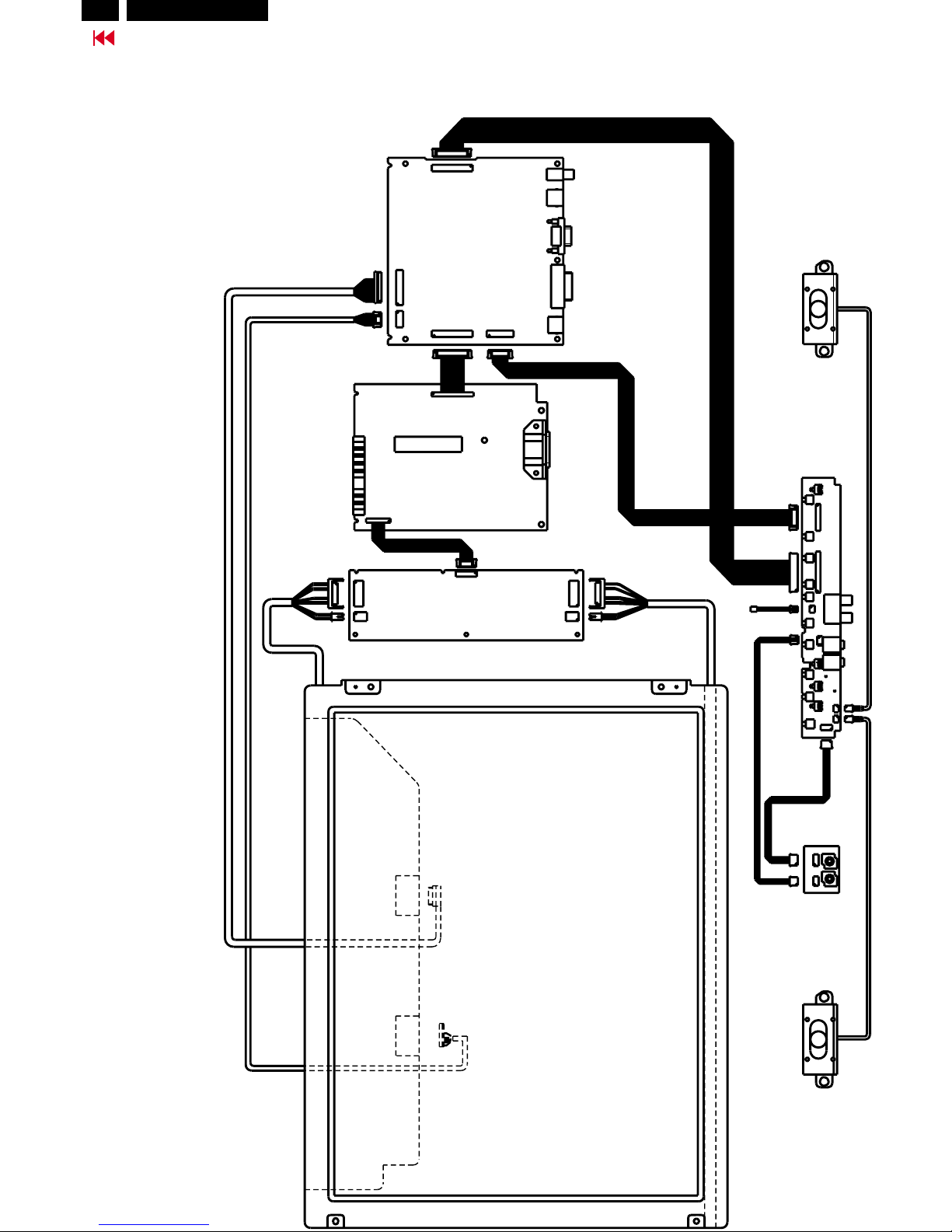

Wiring Diagram

Go to cover page

Hudson2 200P3

Model : 200P3G/00C

SCALER PCB

POWER PCB

INERTER

PCB

SPEAKER-L

SPEAKER-R

AUDIO PCB

LCD PANEL

CONTROL - AUDIO PCB

1701

8052

1711

8051

1704

1311

DVI-1

AC IN

1902

1912

1307

MIC

1903

1904

1931

1933

1905

1908

CN5

CN1

CN2

CN4

CVBS

D-SUB

S-VIDEO

1705

CN2

CN3

25

Go to cover page

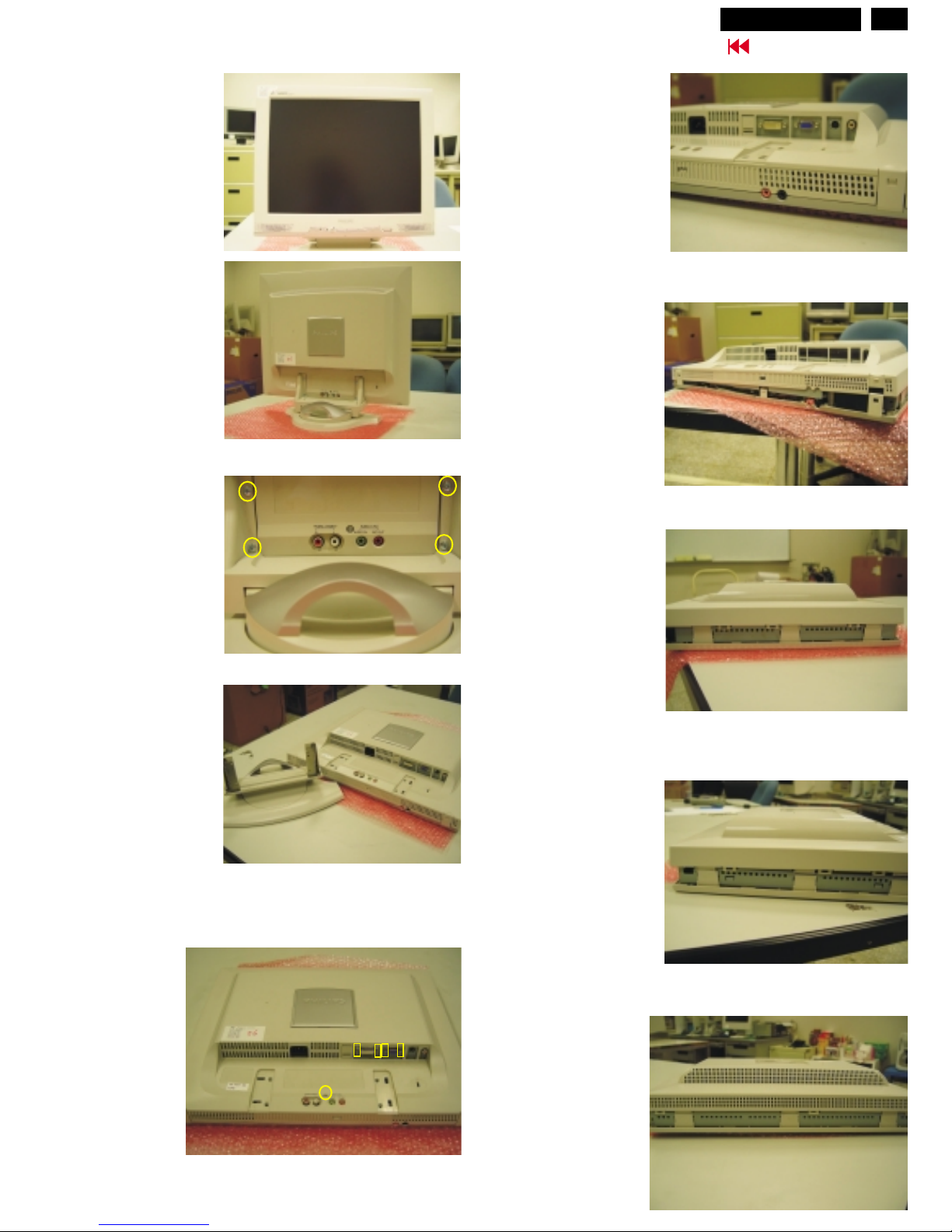

Mechanical Instructions

Front view as shown

in Fig. 1.

Rear view as shown

in Fig. 2.

Fig. 1

Fig. 2

Step 1 :

Disconnect and remove the

signal and power cables from

the back of the monitor as

shown in Fig. 2.

Fig. 3 (Before)

Step 2 :

1.

on a soft area to

prevent it from getting

scratched, defaced, or

broken.

2.Remove the 4 screws

as shown in Fig. 3.

3.Remove the monitor

base from the monitor

as shown in Fig. 4.

Lay the front bezel

down

Fig. 4 (After)

base assembly-------->

4 SCREWs

SCREW

Fig. 5

Step 3 :

1.

on a soft area

to prevent it from

getting scratched,

defaced, or broken.

2.Remove 5 screws

as shown in Fig. 5.

Lay the front bezel

down

Fig. 9 (Right side view)

Fig. 10 (Top side view)

Fig. 8 (Left side view)

Fig. 7 (Bottom side view)

Fig. 6 (Bottom side view)

Step 4 :

Turn the set over

and release all the

plastic clips (12 claws)

by plastic scew

and hands

as shown in

Fig. 6,7,8,9 & 10.

Step 5 :

Remove rear cover.

Rear cover==>

Rear cover==>

===>

===>

===>

===>

===>

===>

===>

===>

===>

===>

===>

===>

===>

===>

Plastic clips

Plastic clips

Plastic clips

Plastic clips

Plastic clips

Hudson2 200P3

26

Go to cover page

Mechanical Instructions (Continued)

Hudson2 200P3

Step 8 :

Remove 5 screws and

disconnect the connectors,

then Scaler board can be

taken out as shown

in Fig. 13.

Step 10 :

Remove 3 screws and

disconnect the connectors,

then Power board can be

taken out as shown

in Fig. 15.

Fig. 12

Fig. 13

1703

CN3

CN5

CN2

CN4

1201

1601

1632

1633

5 SCREWs

1701

1311

1705

1711

1704

10 SCREWs

metal shield

<==

<==

<=

<==

<=

Fig. 14

Fig. 15

CN1 ===========>

Step 9 :

Disconnect CN1~CN5

on inverter board and

remove 3 screws, inverter

board can be taken out

as shown in Fig. 14.

SCREWs

SCREW

*************************************************************************

In warranty, it is not allowed to disassembly the LCD panel,

even the "Backlight unit" defect.

************************************************************************

Step 14 :

Remove 4 screws

as shown in Fig. 18.

Fig. 11 (metal shield)

Fig. 12

inverter

power

scaler

Step 6 :

Remove 10 screws

as shown in Fig. 11.

Step 7 :

After removing metal shield,

inverter, power & scaler

board are as shown in

Fig. 12.

===>

===>

Step 11 :

Inverter,power & scaler

board are as shown in Fig. 16.

Step 12 :

Remove a screw

as shown in Fig. 16.

Step 13 :

Turn the "Panel with metal shield",

then remove the Front Bezel

(plastic clip)

as shown in Fig. 17.

Fig. 16

Fig. 17

Front bezel ----->

Front control board

------------->

scaler board ===>

SCREW

1912

1906

Fig. 18

Step 15 :

remove metal frame of

LCD panel as shown in

Fig. 19.

Turn the panel again,

PCB assembly of

LCD panel as shown in

Fig. 20.

Step 16 :

Remove 2 screws

as shown in

Fig. 19.

Fig. 20

Fig. 19

metal frame

LCD panel

screw

PCB assembly ----------->

27

Go to cover page

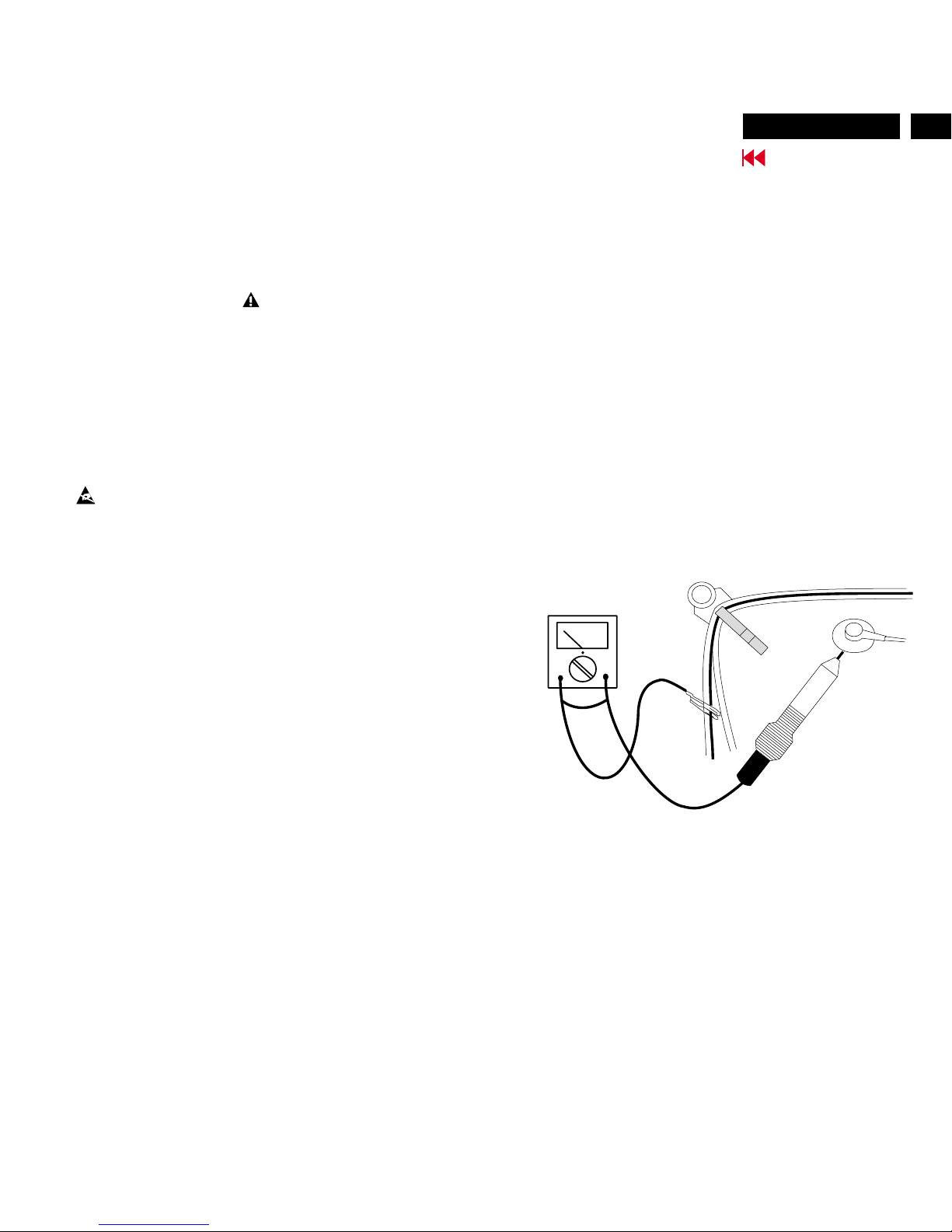

Warning and Notes

Fig.1

V

Warnings

1

2

0V

3 ESD

4

5

6

7

8

9

10.

11.

. Safety regulations require that the unit should be returned

in its original condition and that components identical to

the original components are used. The safety components

are indicated by the symbol .

. In order to prevent damage to ICs and transistors, all

high-voltage flash-overs must be avoided. In order to

prevent damage to the picture tube, the method shown

in Fig. 1 should be used to discharge the picture tube.

Use a high-voltage probe and a multimeter (position DC-V).

Discharge until the meter reading is (after approximately

30 seconds).

.

All ICs and many other semiconductors are sensitive to

electrostatic discharges (ESD). Careless handling during

repair can drastically shorten their life. Make sure that

during repair you are connected by a pulse band with

resistance to the same potential as the ground of the unit.

Keep components and tools also at this same potential.

. When repairing a unit, always connect it to the AC Power

voltage via an isolating transformer.

. Be careful when taking measurements in the high-voltage

section and on the picture tube panel.

. It is recommended that saferty goggles be worn when

replacing the picture tube.

. When making adjustments,use plastic rather than metal tools.

This will prevent any short-circuit or the danger of a

circuit becoming unstable.

. Never replace modules or other components while the

unit is switched on.

. Together with the defleciton unit, the picture tube is used

as an integrated unit. Adjustment of this unit during repair

is not recommended.

After repair, the wiring should be fastened in place with

the cable clamps.

All units that are returned for service or repair must pass

the original manufactures safety tests.

Notes

The direct voltages and waveforms are average voltages.

They have been measured using the Service test software

and under the following conditions :

- Mode : 640 * 480 (31.5kHz / 60Hz)

- Signal pattern : grey scale

- Adjust brightness and contrast control for the

mechanical mid-position (click position)

The picture tube panel has printed spark gaps.

Each spark gap is connected between an electrode of the

picture tube and the Aquadag coating.

The semiconductors indicated in the circuit diagram(s)

and in the parts lists are completely interchangeable per

position with the semiconductors in the unit, irrespective

of the type indication on these semiconductors.

1.

2.

3.

(CRT ONLY)

Hudson2 200P3

28

Go to cover page

Electrical Instructions

0. General

With normal VGA card:

AC/DC Measurement:

When carry-out the electrical settings in many cases a video signal

must be applied to the monitor. A computer with :

- ATI VGA 1024 V6-1.04/PH BETA4 interface card

- PGA 1024 (4822 212 30916), Mach 8.

- PGA 1280 (4822 212 30917), Mach 32.

- ATI GPT-1600 (4822 397 10065), Mach 64 (up to 107kHz)

are used as the video signal source. The signal patterns are

selected from the "service test software" package, see user

guide 4822 727 19896 (ATI1024),

or 4822 727 20273 (PGA 1280), or

4822 727 21046 (GPT-1600).

0.1

If not using the ATI card during repair or alignment, The service

engineer also can use this service test software adapting with

normal standard VGA adaptor and using standard VGA mode

640 x 480, 31.5 kHz/60 Hz (only) as signal source.

0.2

The measurements for AC waveform and DC figure is based on

640 x 480 31.5 kHz/60 Hz resolution mode with test pattern

"16 gray scale".

Power input: 110V AC

General points

1.1 During the test and measuring, supply a distortion free AC mains

voltage to the apparatus via an isolated transformer with low

internal resistance.

1.2 All measurements mentioned hereafter are carried out at a normal

mains voltage (90 - 132 VAC for USA version, 195 -264 VAC for

EUROPEAN version, or 90 - 264 VAC for the model with full range

power supply, unless otherwise stated.)

1.3 All voltages are to be measured or applied with respect to ground,

unless otherwise stated.

Note: don't use heat-sink as ground.

1.4 The test has to be done on a complete set including LCD panel

in a room with temperature of 25 +/- 5 degree C.

1.5 All values mentioned in these test instruction are only applicable

of a well aligned apparatus, with correct signal.

1.6 The letters symbols (B) and (S) placed behind the test instruction

denotes

(B): carried out 100% inspection at assembly line

(S): carried out test by sampling

1.7 The white balance (color temperature), has to be tested in subdued

lighted room.

1.8 Repetitive power on/off cycle are allowed.

(1) Factory Preset Modes (19 modes)

2.2 Input signal mode

2.

Signal type

2.1.1 Analog Video : 0.7 Vp-p linear, positive polarity

Sync. : TTL level, separate, positive or negative polarity

Signal source: pattern generator format as attachment.

(table 1 to 47) Reference generator : QuantumData 802G

2.1.2 Digital Video :600mVp-p TMDS Signal

2.1.3 CVBS Video :1Vp-p,75 Ohm

2.1.4 S-Video :Y-1Vp-p,75 Ohm

C-0.3Vp-p,75 Ohm

2.1.5 Audio Signal : For S-terminal L/R audio input

PC line in

Microphone in

Input signal

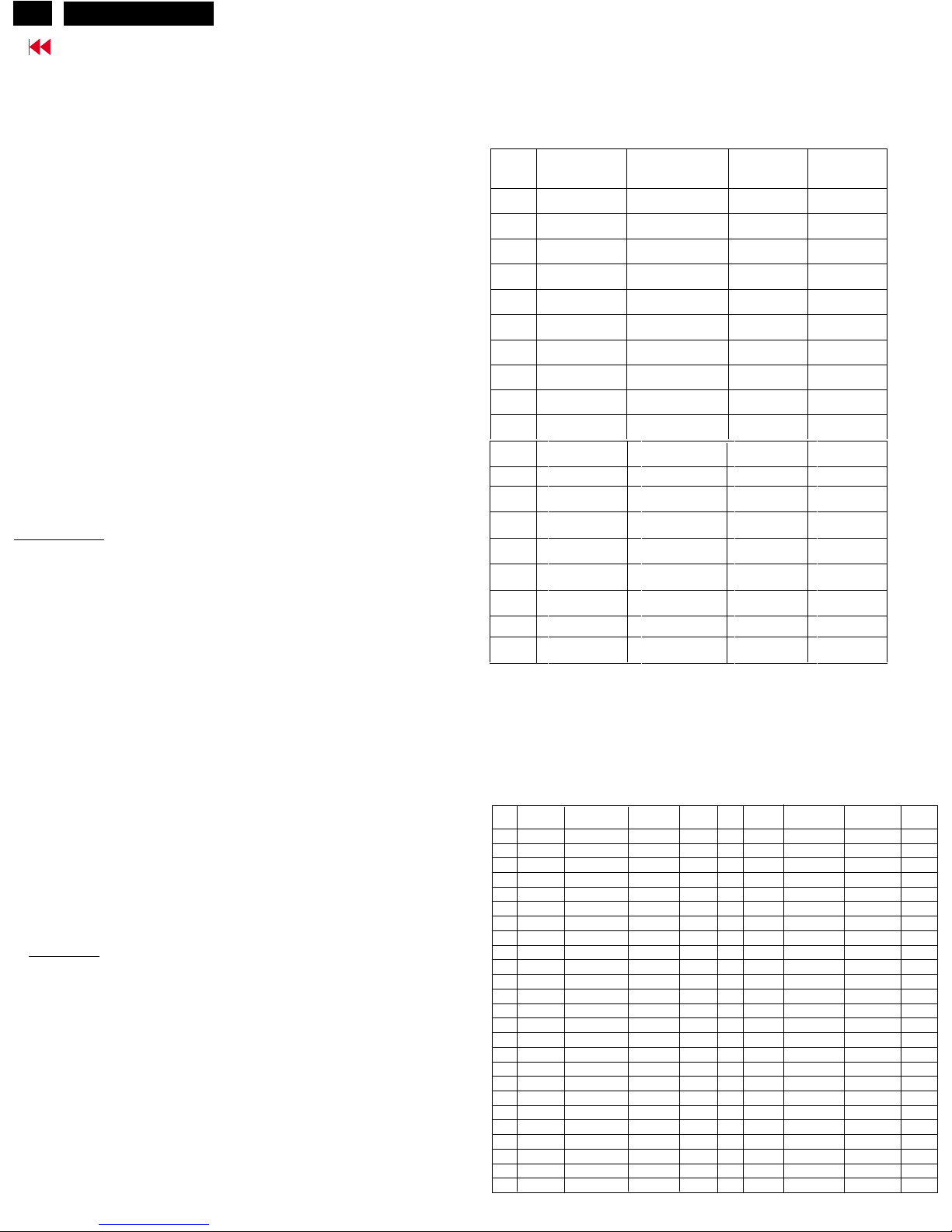

Item H.Freq.

(KHz)

Mode Resolution V.Freq.

(Hz)

1 31.469 IBM VGA 10H 640x350 70.086

2 31.469 IBM VGA 3H 720x400 70.087

3 31.469 IBM VGA 12H 640x480 59.940

4 35.000 MACINTOSH 640x480 67.000

5 37.500 VESA 640x480 75.000

6 35.156 VESA 800x600 56.250

7 37.879 VESA 800x600 60.317

8 46.875 VESA 800x600 75.000

9 49.700 MACINTOSH 832x624 75.000

10 48.363 VESA 1024x768 60.004

11

60.023 VESA

1024x768

75.029

12

68.700 MACINTOS

H

1152x870

75.000

13

71.810 SUN WS

1152x900

76.150

14

63.981 VESA

1280x1024

60.020

15

79.976 VESA

1280x1024

75.025

16

91.1 VESA

1280x1024

85

17

75.0 VESA

1600x1200

60

18

93.8 VESA

1600x1200

75

19

31.250 TV-PAL

688x556

50.

(2) Preset Modes (47 modes)

Item

H.Freq.

(KHz)

Mode

Resolution

V.Freq.

(Hz)

Item

H.Freq.

(KHz)

Mode Resolution

V.Freq.

(Hz)

1

31.469 IBM VGA 10H

640x350 70.086 26

71.810

SUN WS

1152x900

76.150

2

31.469 IBM

VGA 3H

720x400 70.087 27

59.673

SUN WS

1280x768

72.000

3

31.469 IBM VGA 12H

640x480 59.940 28

60.000

VESA 1280x960

60.000

4

35.000

MACINTOSH

640x480 67.000 29

75.000

VESA

1280x960

75.000

5

37.861

VESA

640x480 72.809 30

85.939

VESA 1280x960

85.002

6

37.

500

VESA

640x480 75.000 31

63.981

VESA

1280x1024

60.020

7

43.269 VESA

640x480 85.008 32

71.691

SUN WS

1280x1024

67.189

8

35.156

VESA

800x600 56.250 33

76.000 DOS/V 1280x1024

72.000

9

37.879 VESA

800x600 60.317 34

79.976

VESA

1280x1024

75.025

10

48.077

VESA

800x600 72.188 35

81.130 SUN WS

1280x1024

76.110

11

46.875

VESA

800x600 75.000 36

91.1

VESA

1280x1024

85

12

53.674 VESA

800x600 85.061 37

80.000

MACINTOSH

1360x1024

75.000

13

49.700

MACINTOSH

832x624 75.000 38

70.794

SUN WS

1440x900

76.000

14

81.1

SUN WS

960x680 112.000 39

78.66

SUN WS

1600x1000

76.000

15

48.363

VESA

1024x768 60.004 40

68.31 SUN WS

1600x1000

66.000

16

56.476

VESA

1024x768 70.069 41

84.000

MACINTOSH

1600x1200

69.000

17

60.023 VESA

1024x768 75.029 42

80.000 DOS/V 1600x1200

60.000

18

61.080 IBM XGA-2

1024x768 75.781 43

75.0

VESA 1600x1200

60

19

68.677

VESA

1024x768 84.997 44

81.3

VESA

1600x1200

65

20

68.820 SUN WS

1024x768 87.000 45

87.5

VESA

1600x1200

70

21

54.1

1152x864 60 46

93.8

VESA 1600x1200

75

22

63.851

VESA

1152x864 70.012 47

31.250

TV-PAL

688x556

50

23

67.500 VESA

1152x864 75.000

24

68.700

MACINTOSH

1152x870 75.000

25

61.845 SUN WS

1152x900 66.004

Hudson2 200P3

29

Go to cover page

Electrical Instructions (Continued)

Hudson2 200P3

3. AC, DC Adaptor

3.1 Setup the AC I/P at 90VAC, and Output DC loading at 3.33Amp,

The DC output voltage is 18.0 0.9 V DC, Adjusting is no need.

3.2 DC setting

3.01 Detach 8052 to the scaler board before testing the function.

3.02 Apply 1.2Amp 18V DC voltage to 1105. (B)

3.03 Connect inverter board to 8051 (B)

3.04 Check voltage at C2067 should be within the range 5V +/- 0.2V

(B)

3.05 Check voltage at C2077 should be within the range 3.3V +/- 0.15V

(B)

4. Display Adjustment

4.1Input signals check

In factory mode, use 64 gray level and set the R,G,B gain to 100%.

4.2 Display quality test

Use timing mode as describe in 2.2, and use the pixel on / off

pattern to adjust the clock until no stripe and adjust the phase

until clear picture.

Check all pre-setting 19 modes.

4.2.1 SOG mode test : Use following timing for SOG test

64 KHz/60Hz, 1280 X 1024, pixel=108 MHz

Horizontal

Vertical

Frame border= 0 Frame border= 0

Total size = 15.620ms Total size = 16.670 ms

Display size = 11.852ms Display size = 16.000 ms

Rear porch = 2.000ms Rear porch = 0.580 ms

Sync width = 1.000ms Sync width = 0.080 ms

Sync polarity = - Sync polarity = -

Sync on green

4.3 Check of WHITE-D (B)

Apply a 1280*1024 / 60Hz signal with gray 64 pattern, set brightness

control at 100%, and contrast control at 50%. Adjust the R,G,B sub_gain,

for the screen center,

the 1931 CIE chromaticity (X, Y) co-ordinates shall be;

Use Minolta CA-110 for color coordinates and luminance check.

Luminance : 200 Nits in the center of the screen when brightness at

100% and contrast set to 100%.

4.4 Check the digital interface

Check the 64 gray level color poor & noise condition.

Please refer to General Product Specification for timing table 1~47.

TIMING FOR HUDSON 200P 20" TFT UXGA COLOR LCD MONITOR

(VESA monitor timing standard Version 1.0 Release 0.7)

REFERENCE PATTERN GENERATOR : QuantumData 802G

9300 K 6500 K

x (center) 0. 281 0.015

0.015

0.015

0.312

y (center) 0.311 0.015 0.338

5.

5.1.1 PIN ASSIGNMENT OF INVERTER & WAFER 8051

PIN No. SIGNAL (INVERTER BOARD)

1 backlight power (18V)

2 backlight power (18V)

3 backlight power (18V)

4 backlight GND

5 backlight GND

6 backlight GND

7 backlight brightness ; 3.3V :8.0mA 0.5mA

0V :3.0mA 0.4mA

8 backlight ;ON/OFF control :ON>2V,OFF<1V

PIN No. SIGNAL (WAFER 8051)

1 backlight power (18V)

2 backlight power (18V)

3 backlight power (18V)

4 backlight GND

5 backlight GND

6 backlight GND

7 backlight brightness ; 3.3V :8.0mA 0.5mA

0V :3.0mA 0.4mA

8 backlight ;ON/OFF control :ON>2V,OFF<1V

5.1.2 PIN ASSIGNMENT OF WAFER 8052

PIN No. SIGNAL (WAFER 8052)

1 LIGHT_BRI_CTL

2 LIGHT_PWR_CTL

3 GND

4 DC_SW

5 +3.3V

6 GND

7 +3.3V

8 GND

9 +5V

10 +5V

11 GND

12 GND

13 +18V

14 +18V

15 GND

16 GND

PIN ASSIGNMENT OF VARIOUS WAFERS

30

Go to cover page

Electrical Instructions (Continued)

5.1.3 PIN ASSIGNMENT OF WAFER TO CONTROL BOARD

PIN No. SIGNAL (WAFER 1701)

1 OSD

2UP

3 DOWN

4 RIGHT

5 LEFT

6 AUTO

7 PIP

8 SOURCE

9 DCSW1

10 MUTEIN

11 GND

12 POWER LED

13 SLEEP LED

14 PC LED

15 VIDEO LED

16 GND

5.1.4 PIN ASSIGNMENT OF WAFER TO CONTROL BOARD

PIN No. SIGNAL (WAFER 1704)

1 +18V

2 +18V

3 GND

4 GND

5 AUDIOMUX

6 AUDIOPW

7 VOLUME

8 MUTEOUT

9 DCSW2

10 GND

5.1.5 PIN ASSIGNMENT OF WAFER TO PANE

PIN No. SIGNAL (WAFER 1705)

1 GND

2 GND

3 LCM18V

4 LCM18V

5 GND

6 GND

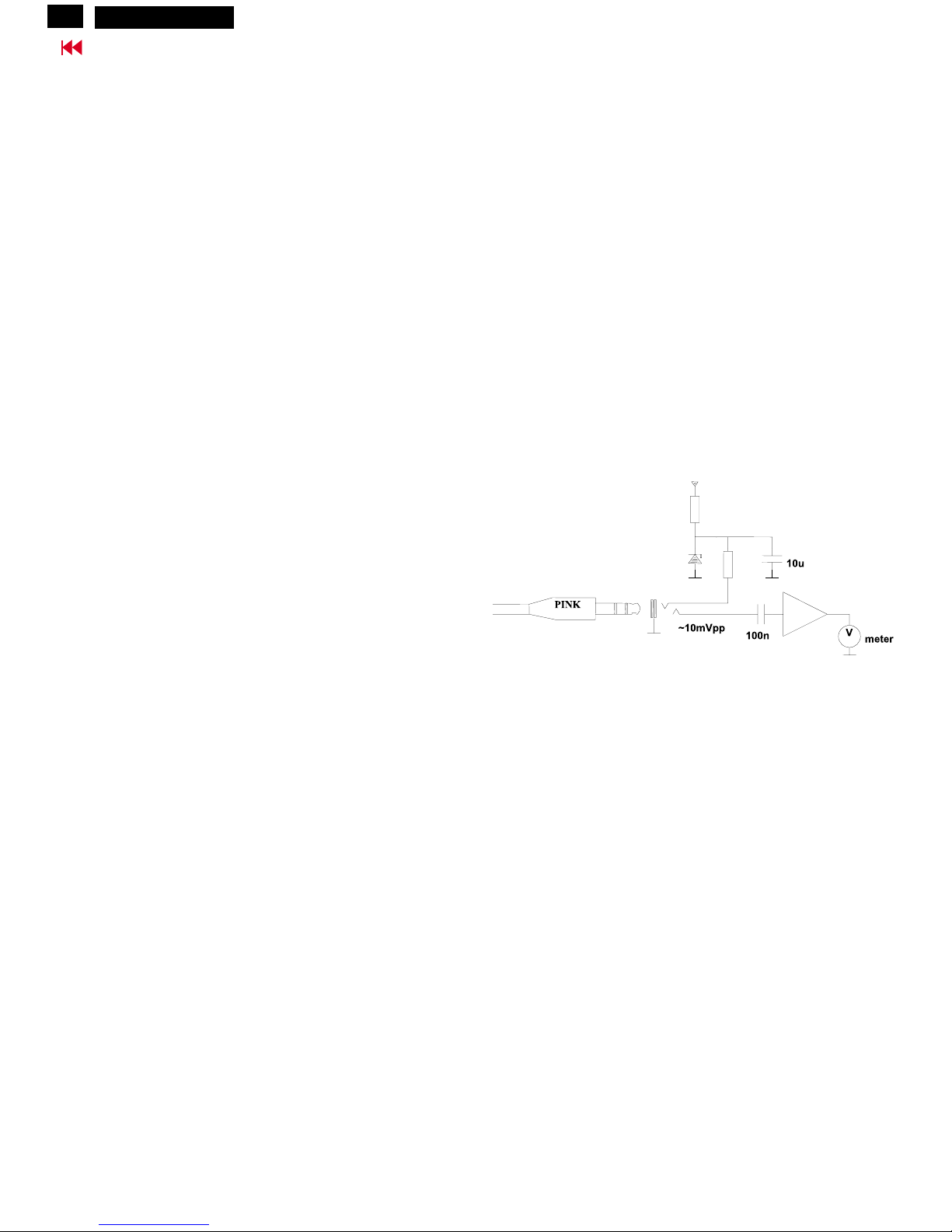

6. Microphone test (B)

The aim of the set-up below is to test whether the microphone is

operating correctly.

Connect the microphone pink plug to a signal measuring equipment

with incorporate DC bias according circuit below:

Place a reference sine wave sound source close to the microphone

openings and check the microphone output for correct output signal.

Please note that the microphone has two openings: One at front and

one at the bottom. The reference sound source should be positioned

in such a way that the sound reaches both openings.

The actual quality of microphone can only be checked by recording and

listening tests, using PC software like Microsoft Sound Recorder

(available in Windows'98/95 Multimedia menu )

+5V

220

Microphone

Test Circuit

2V4

1K

Hudson2 200P3

Loading...

Loading...