Page 1

Cucina Stand and Bowl Mixer

HR1566/AB

RI7115/AB

Philips Domestic Appliances and Personal Care

Service Manual

PRODUCT INFORMATION

- HR1566/AB - RI7115/AB :

5 speed mixer + turbo + non driven stand & bowl

- Materials used / Colours

Mixer housing PP White

Beater ejector PS Zinc Brown

Sieve ABS / Metal White / Metal

Speed selector ABS Pearl blue

Bowl (3,5 L & 1,8 L) PP White

Lids PE Zinc Brown

Stand housing PP White

Beaters / Dough hooks Chrome plated steel Metal

Sieve disc at beaters POM+Teflon White

Cord clip PP White

Spatula PP White

- After the product has been repaired, it should function

properly and has to meet the safety requirements as

officially laid down at this moment.

TECHNICAL INFORMATION

- High Voltage : 220 - 240 V, 50 - 60 Hz

- Low Voltage : 110 - 127 V, 50 - 60 Hz

- Power consumption : 300 W

- Dimensions : 340 x 240 x 370 mm

- Weight appliance

incl. Stand and bowl : 2500 gr

- Motor : Series wound, Statically and

dynamically balanced

Self lubricated

- Transmission ratio

between rotor spindle

and gearwheel : 21½ : 1

- Cordlength : 1,4 m double insulated

with molded on plug

- Speeds beaters unloaded : Switch position 1 - 650 rpm

Switch position 2 - 750 rpm

Switch position 3 - 850 rpm

Switch position 4 - 950 rpm

Switch position 5 - 1050 rpm

Turbo position - 1050 rpm

Published by Philips Domestic Appliances and Personal Care Printed in the Netherlands © Copyright reserved Subject to modification

03/02

Page 2

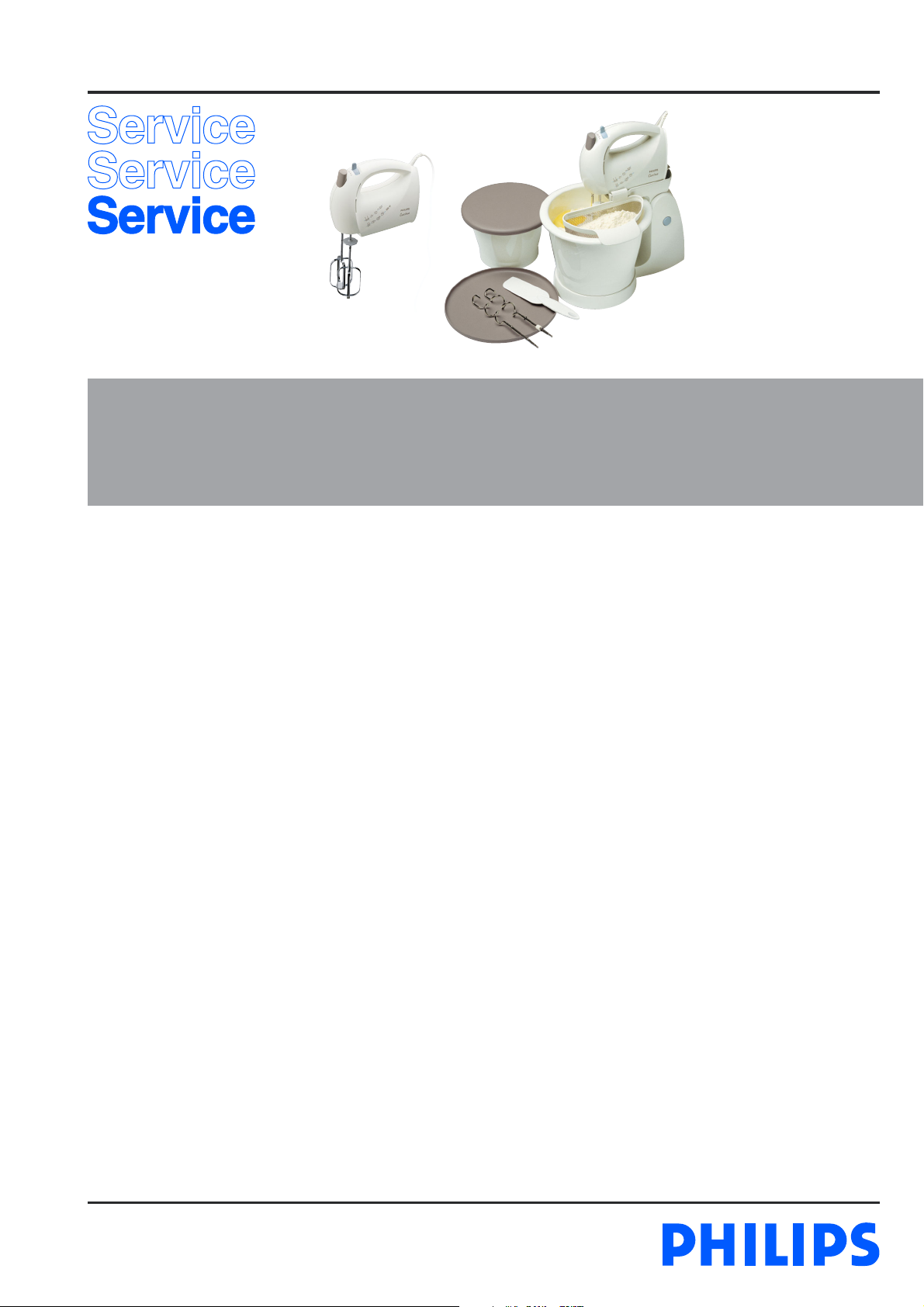

DISASSEMBLY- AND RE-ASSEMBLY ADVISE

- Use the blade of a knife to remove the hinged arm from the

stand. Insert the blade between the arm and the lower part

of the stand in such a way that the hinge located at triangle

(1) can be pushed inwards and the arm (2) can be pulled

upwards and out of the lower part of the stand.

- Reassemble the arm by placing it horizontally back into the

lower part of the stand, making sure the V-shaped groove

of the hinge fits round the guide rib in the lower part of the

stand.

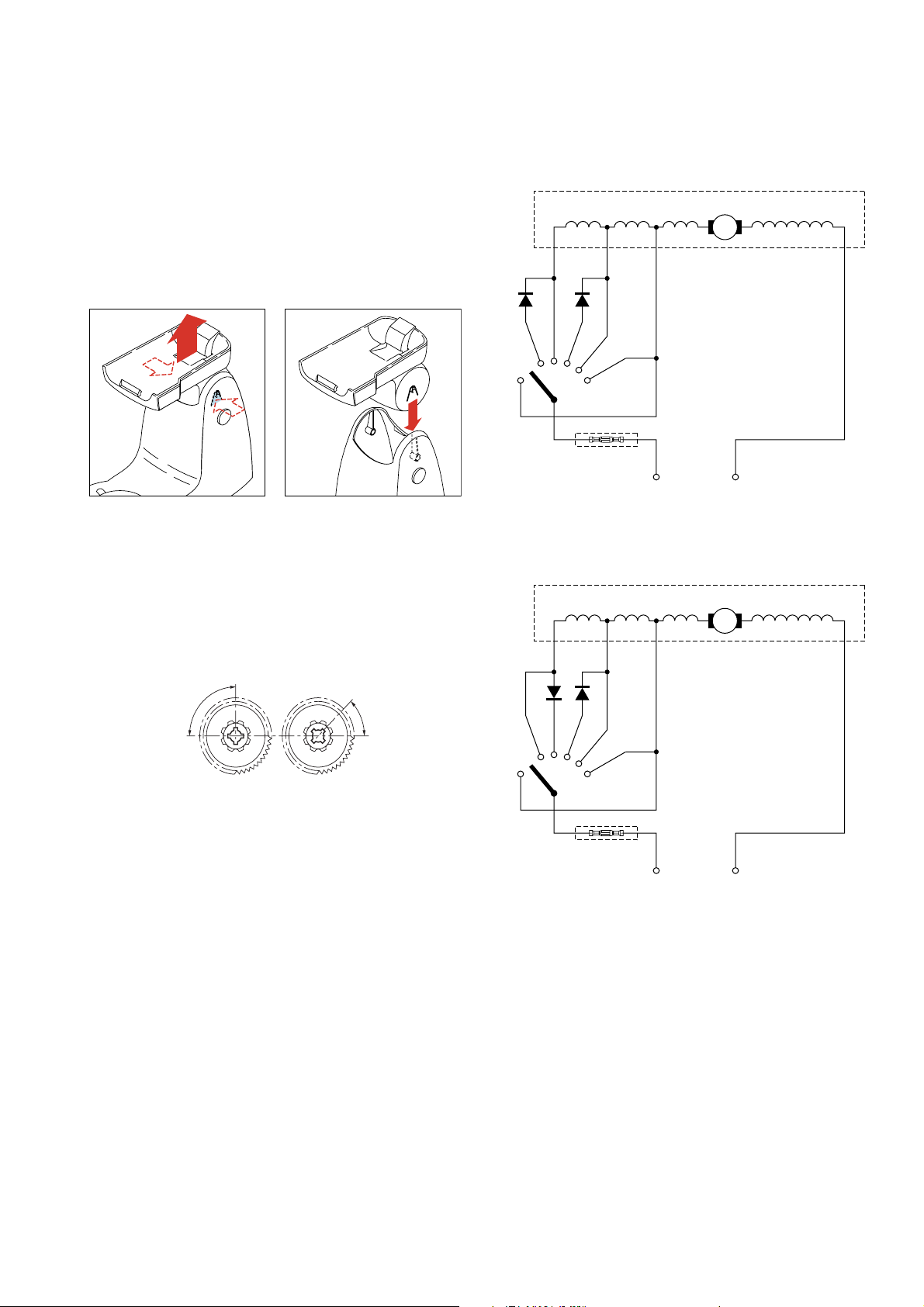

Circuit diagram 115 - 127 V

Motor assy

HR1566/AB

RI7115/AB

Rotor

Red GrayBlackGreen

2

1

1

REPAIR INSTRUCTION

Mounting gearwheels

When mounting the gearwheels make sure that the cams of

the gearwheels are situated at the front of the beaters.

The angle between the beaters must be 45°.

So when carrying out a repair be sure that the gearwheels are

mounted correctly (see Fig. 1).

90

˚

Fig. 1

45

˚

0

T

0

T

2

1

3

4

5

Circuit diagram 220 - 240 V

Motor assy

2

1

3

4

5

MAINS

Rotor

Red GrayBlackYellow

Lubrication

Use graphite grease code no. 4822 390 20004 to grease the

appliance on the following points:

1. Spaces between the teeth of the wormwheels.

2. Both sides of the wormwheel shaft.

Motor

The motor cannot operate properly, when, due to

contamination, carbon brush is unable to move freely in

guide bush and consequently cannot be pressed against the

commutator.

OPTIONAL (accessories)

- No specific issues.

MAINS

2-4

Page 3

PARTS LIST & EXPLODED VIEW

HR1566/AB

RI7115/AB

12

A

A

3

4

2 6

1

5

7

8

Pos Description Service code

1

Housing set - HR1566/AB

Housing set - RI7115/AB

2

Switch assy ( 220 V )

Switch assy ( 110 V )

3

Ejector

4

Ejector spring

5

Cord set – Mexico

Cord set – EU

Cord set – ARG

Cord set – Brazil

6

Cord clip

7

Cord grommet

8

Bearing plate

9

Strip beaters in pair

10

Dough hooks in pair

11

Motor buffer

12

Driven gearwheel

A

Screw 2,9 x 13

4206 136 54240

4206 136 54270

4206 136 55200

4206 136 53770

4206 133 94630

4206 132 07960

4206 100 02240

4206 100 02230

4206 100 02220

4206 100 02210

4206 133 86150

4206 133 53720

4206 133 94650

4206 136 54210

4206 136 54180

4206 133 53120

4206 133 82320

11

109

3-4

Page 4

PARTS LIST & EXPLODED VIEW

18

HR1566/AB

RI7115/AB

20

17

16

19

21

13

Pos Description Service code

13

Arm with sieve assy

14

Stand assy

15

Rubber stud

16

Sieve

17

Bowl 3,5 L

18

Big lid

19

Bowl 1,8 L

20

Small lid

21

Spatula

4206 136 55280

4206 136 54630

4206 133 53300

4206 136 53880

4206 133 94740

4206 133 94800

4206 133 94750

4206 133 94810

4206 133 89830

14

15

4-4

Loading...

Loading...