Page 1

Philips Domestic Appliances and Personal Care

Azur Mastervapor

HI 994/A

X

A

IN

M

M

MAX

Service Manual 4822 729 21714 is herewith cancelled

PRODUCT INFORMATION

Feataures : inox sole plate

variable steam

shot of steam

jet of steam

detachable water tank

control lamp : water tank empty, provided the tank is properly placed

contents water tank 0.68 l

contents boiler 0.3 l

length steam hose 1.8 m

length cordset 2.1 m

max. steam output 70 gr./min.

Voltage : 220 - 240 V

Power consumption : boiler :1370 Watts

pump : 30 Watts

iron : 800 watts

Sole plate temperature : dial at max. position : 225 ± 25 ºC

MSH coding 8820 994 00000

Product meets the requirements regarding interference

suppression on radio and television.

PublishedbyPhilipsDomesticAppliancesandPersonalCare PrintedintheNetherlands

4822 729 22052

98/10

PCS 99 731

©

Copyrightreserved Subjecttomodification

Page 2

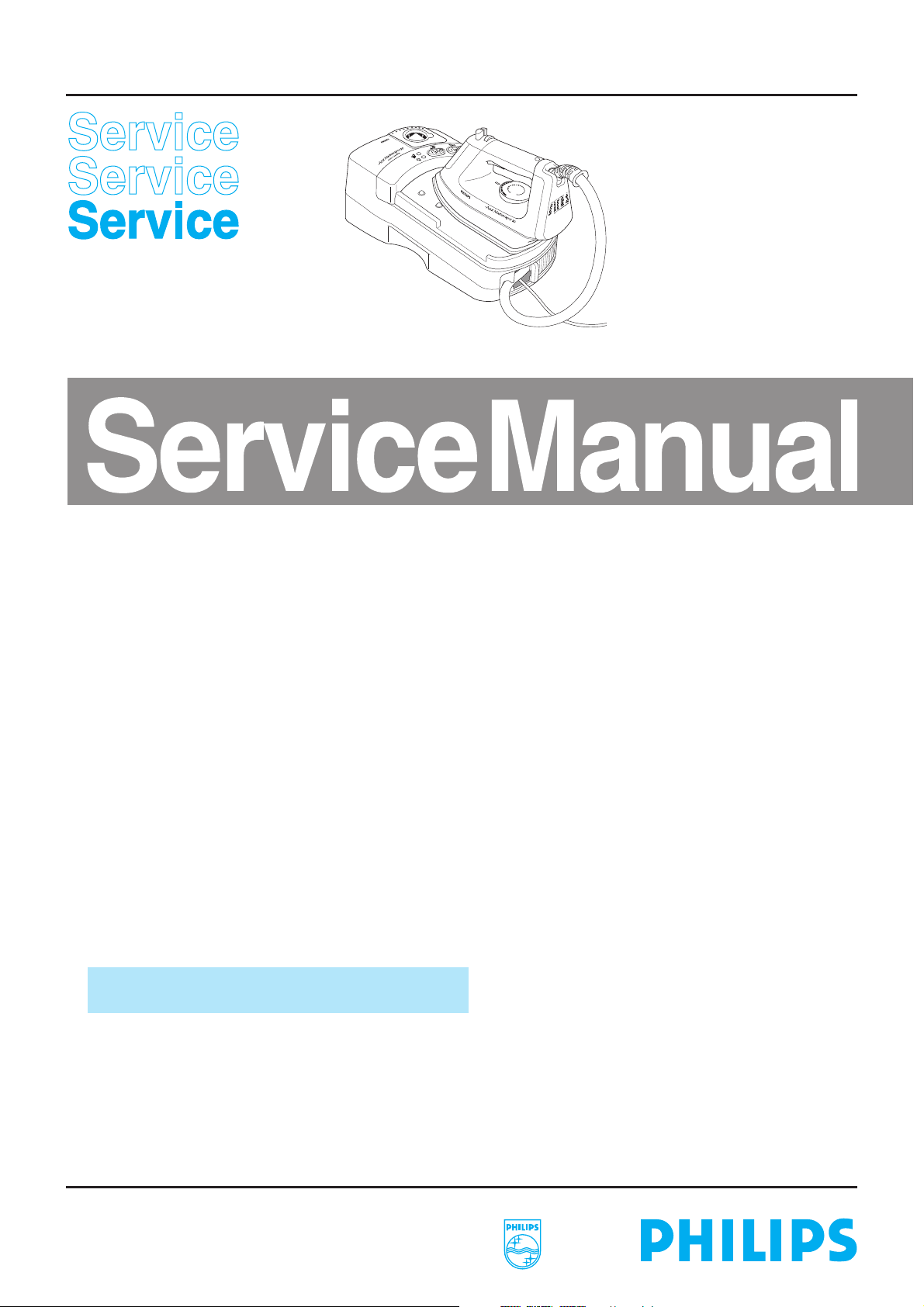

EXPLODED VIEW IRON

17

1816

19

15

25

13

14

12

11

A

20

21

9

B

22

7

26

23

24

6

10

5

C

4

C

3

2

1

D

Screws :dxlinmm

PCS 99 732

A 1x 3.0 x 12

B 3x 3.5 x 14

C 3x M4 x 12

D 1x M4 x 23

Page 3

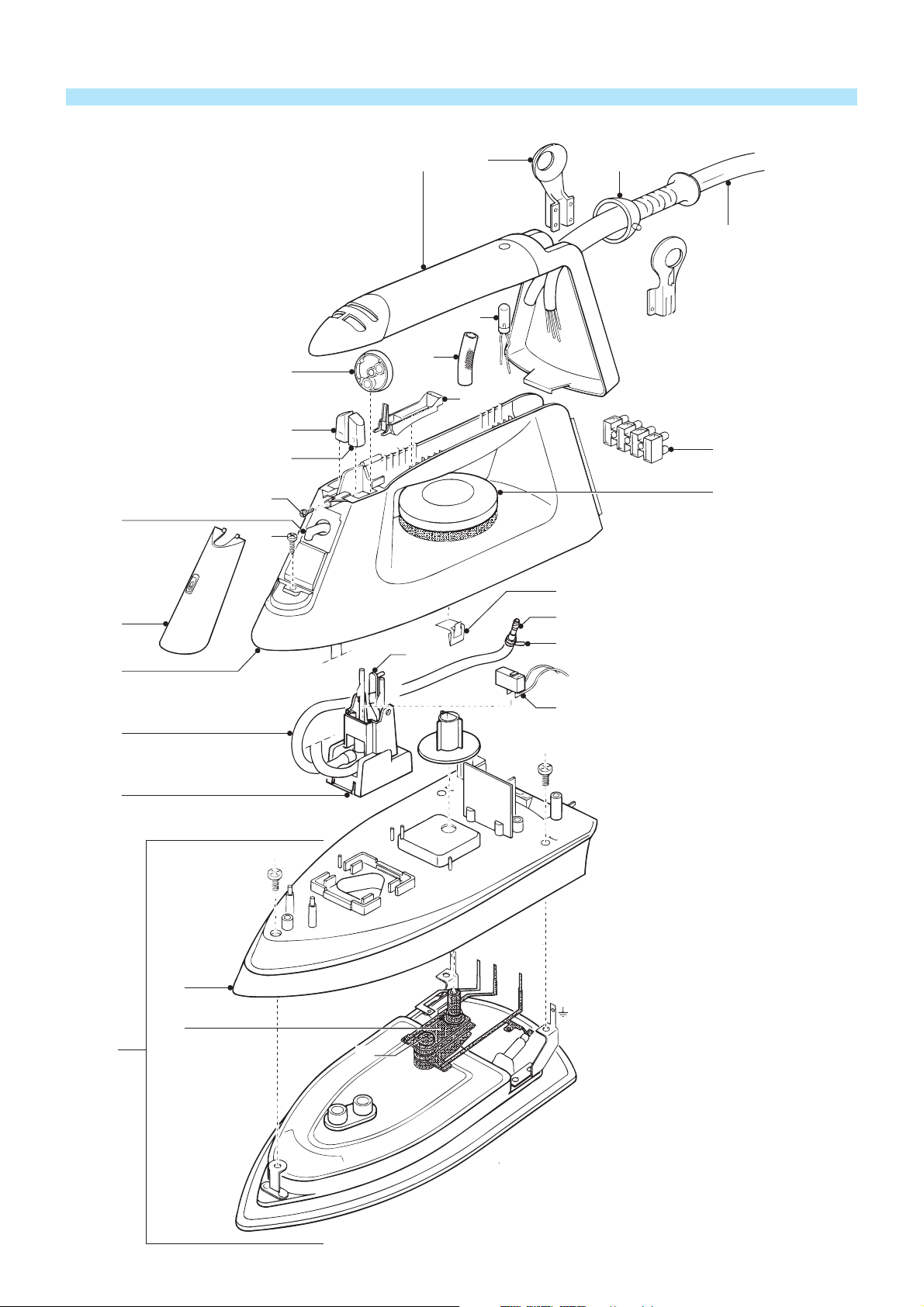

PARTS LIST + DISASSEMBLY ADVICE IRON

pos description service code

1

2

3

4

5

6

7

9

10

11+12

13

14

15

16

17

18

19

20

21

22

23

24

soleplate unit 220 - 240 V

thermostat

skirt

deviator assy

steam hose

handle printed

nose cover

jet of steam hose

microswitch

set operation knobs

steam dial

steam command lever

pilot light

inlay printed

swivel ear

ball swivel

steam hose / cable

term. block ( 4 pole )

therm. dial

rattle dial

hose joint

spring clamp

4822 259 10194

4822 282 30238

4822 442 00414

4822 360 10138

4822 690 80134

4822 498 10587

4822 441 80981

4822 690 80133

4822 282 30239

4822 410 10555

4822 410 10556

4822 410 62968

4822 134 41161

4822 442 00413

4822 325 60391

4822 325 60389

4822 530 21058

4822 290 61189

4822 410 10557

4822 492 71445

4822 530 40513

4822 492 71001

THERMOSTAT 2

SKIRT 3

remove DIAL 21

remove NOSE COVER 7

remove INLAY 16

remove STEAM DIAL 13

remove BUTTON 11

remove BUTTON 12

remove SCREWS THER-

MINAL BLOCK 20

remove STEAM HOSE 19

remove THERMINAL

BLOCK 20

remove CLAMP 24

remove SCREW B (3x)

remove SCREW C (3x)

remove HANDLE 6

THERMOSTAT 2 ONLY

cut CONDUCTOR A

at location P

remove SCREW D

ASSEMBLY

REQUIREMENTS

THERMOSTAT 2

Instead of metal conductor A,

the new thermostat has a wire

with AMP clamp.

After fixing screw D, connect

the AMP clamp to tag Q.

After assembling SKIRT 3

ALWAYS turn conductor B

through 180 degrees.

NOSE COVER 7

LAMP 15

MICROSWITCH 10

STEAM DIAL 13

JET OF STEAM

BUTTON 11

SHOT OF STEAM

BUTTON 12

remove NOSE COVER 7

remove SCREW A

DIAL 21

HANDLE 6

SOLEPLATE 1

MICROSWITCH 10

DEVIATOR 5

THERMINAL BLOCK20

JET OF STEAM

HOSE 11

remove DIAL 21

remove NOSE COVER 7

remove INLAY 16

remove STEAM DIAL 13

remove BUTTON 11

remove BUTTON 12

remove SCREWS THER-

MINAL BLOCK 20

remove STEAM HOSE 19

remove CLAMP 24

remove SCREW B (3x)

ADJUSTMENT AND CONTROLS

Thermostat 2

Thermostat(2)supplied as a spare part or fitted to the sole plate

( 1 ) has already been adjusted by the supplier and secured by glue.

To avoid disfunction of the iron , NEVER readjust the

thermostat.

PCS 99 733

Page 4

EXPLODED VIEW BOILER

30

51

48

33

E

34

35

G

110

109

105

47

46

44

45

54

41

F

101

42

38

39

37

111

107

36

106

49

108

52

40

PCS 99 734

50

Screws :dxlinmm

E 4x T10 x 16

F 2x 3.5 x 17

Page 5

PARTS LIST + DISASSEMBLY ADVICE BOILER

pos description service code

detach. tank + filler cap 31

30

tray

33

cover + rubber display

34

rubber display

35

boiler complete

36

black cold water hose

37

red steam hose

38

one way valve + buffers + sieve

39

pump + buffers + fuse

40

red hose

41

control / steering unit / pcb

42

cordset Euro

43

cordset Italy

cordset UK

holder detach. tank

44

connecting tube

45

reed contact

46

microswitch

47

switch

48

rubber buffer

49

bottom housing

50

pilot lamp

51

sliding door

52

rubber foot

53

4822 418 10221

4822 418 10222

4822 441 11847

4822 442 00678

4822 218 11551

4822 530 10315

4822 530 10316

4822 360 10245

4822 360 10246

4822 530 10317

4822 214 11983

4822 321 11031

4822 321 11029

4822 321 11028

4822 256 10322

4822 530 10318

4822 277 11662

4822 277 11662

4822 276 13822

4822 466 11398

4822 441 11848

4822 277 11662

4822 443 10502

4822 462 10837

54 Clamping ring 4822 532 12742

GENERAL

OPEN THE STAND

remove DETACH. TANK 30

remove TRAY 33

remove TORQUE

SCREW E (4x)

with screwdriver unlock the

HOOKS

remove COVER 34

COVER 34

DISPLAY RUBBER 35

STEAM HOSE /

CABLE 19

CORDSET 43

SWITCHES 48

DOOR 52

BLACK COLD WATER

TUBE 37

RED STEAM TUBE 38

RUBBER BUFFERS 49

BOILER COMPLETE 36

open the STAND

PUMP 40

CONNECTING

TUBE 45

open the STAND

lift CONNECTING

BLOCK 101

remove SCREW F (2x)

lift HOLDER DETACH.

TANK 44

remove TUBES 41 and 45

remove connect. wires PUMP

PCB 42

open the STAND

lift CONNECT.

BLOCK 101

remove purper wire PCB

remove SCREW F (2x)

lift HOLDER DETACH.

TANK 44

lift PUMP 40

remove connect. wires

ADJUSTMENT AND CONTROLS

– To avoid leakage of the sealings and damage to the

components in and on the boiler, NEVER clean the boiler

with vinegar, a descaling agent or other chemicals.

– The boiler doesn’t contain serviceable parts

Never disassemble the boiler body and /or components on

and in the boiler.

– ALWAYS REPLACE THE BOILER ( 36) WHEN:

*

the mechanical safety valve ( 105 ) has been activated.

*

the pressostat ( 106 ) doesn’t function properly.

*

the thermo fuse ( 107 ), boiler thermostat ( 108 ) or

hand - resettable safety thermostat ( 109 ) are open,

because the boiler has been subjected to too high

temperatures.

*

the sensor ( 110 ) doesn’t function properly

*

the electrovalve ( 111 ) fails or the sieve is soiled with

scale.

–

After the product has been repaired, it should function

properly and has to meet the safety requirements as laid

down and officially established at this moment.

ONE-WAY VALVE 39

open the STAND

lift CONNECT.

BLOCK 101

remove TUBES 37 and 41

REED CONTACT 46

MICROSWITCH 47

open the STAND

remove SCREW F

lift CONNECT.

BLOCK 101

lift PUMP 40

remove SCREW F (2x)

lift HOLDER DETACH.

TANK 44

N.B. Components pos. 46, 47 and 51 are supplied in one set

Components with numbers from 100 and higher cannot

be ordered separately

PCS 99 735

Page 6

FUNCTIONAL DESCRIPTION OF THE HI 994 MASTER VAPOR

Description of the water supply.

Apin(1)inthebottom of the housing activates the valve in

•

the watertank.

The microswitch(2)makes sure that the electric circuit is

•

closed, provided the tank has been fit properly.

The reed contact(3)makes sure that the system switches

•

off when there is no sufficient water in the tank.

The floater in the tank(4)drops when water is

pumped to the boiler.

Once the floater is at the bottom, the magnet in the

floater activates the reed contact, so the reed contact

is openend and the circuit is interupted.

The light goes on.

Sensor(5)intheboiler activates the pump, when the

•

water level reaches the lowest specified water level.

The sensor detects the resistance between the sensor

and the water level.

When the water level is low, the resistance will be

rather high and the pump is activated.

When the water level is high, the resistance is low and

the pump stops.

The HI994 consists of an iron and a stand.

Cold water is pumped from the detachable tank to the boiler,

where steam is generated.

After operating the steam valve, steam flows into the iron.

The stand consists of:

I ) A detachable tank :

There is a floater in the tank, which activates the reed

contact.

II ) A pump :

The pump is protected against overheating by an

automatically resettable cut-out.

III) A boiler :

On the boiler the following controls are fitted

-

hand-resettable safety thermostat

-

boiler thermostat

-

fuse

-

pressostat

-

mechanical safety valve

-

sensor

-

electro valve + sieve

IV) An electronic control / steering unt, which consists of :

a PCB, located below the pump

a sensor, located in the boiler

Functioning of the system

– The water tank is filled with water and fitted on the stand.

– Switch is operated, light goes on, indicating that water

is being heated.

– Water is pumped from the tank to the boiler. This can be

clearly heared.

– Once enough water is in the boiler, the pump stops.

– When the pressure is within the limites 2 ± 0.3 bar, there is

sufficient steam to start ironing and the the pressostat comes

into operation and switches off the element.

–

Switch can be operated to start ironing.

Pilot light switch goes on.

–

Once the water level reaches the lowest specified level, the

sensor activates the pump.

–

The whole process starts again.

The pump is a vibration pump which makes noise during pumping.

This is normal. The pump doesn’t pump water continuously.

It pumps at the start and during ironing after finishing steaming.

STAND

Safety

therm.

Boiler

therm.

N

S

Waterlevel

control unit

Steam-

valve

IRON

Steamswitch

PCS 99 736

p

Prestostat

Pump

Thermostat

Page 7

POSSIBLE FAILURE CAUSES

COMPLAINT : WATER RUNS OUT OF THE SOLEPLATE

Check if temperature dial ( 21 ) is set to the highest position.

•

If steam dial ( 13 ) is set to the highest pos. and the temp. dial to medium or low position the

soleplate doesn’t become hot enough and the steam condenses.

Steam from former use condensed in the hose.

•

This is normal.

The water disappears when the iron heats up.

COMPLAINT : IT DOESN’T STEAM

operate the steam command lever ( 14 )

•

no click is heared

<

the electrovalve ( 111 ) is broken.

→

replace the complete boiler ( 36 ).

*

the microswitch of the steam activator is broken.

→

replace the component.

*

a “click” is heared clearly

<

the water supply is OK

<

GENERAL TEST :

connect the system to the mains, switch the boiler and iron on, set the temp. dial to the

•

highest pos.

when measuring : 800 Watts

<

when measuring : 1400 Watts

<

when measuring : 2200 Watts

<

pump makes noise continuously

<

pump doesn’t make noise

<

CHECK WATER SUPPLY

the electrovalve ( 111 ) functions properly.

→

check the water supply. ( see further on )

*

the sieve of the electrovalve has been soiled with scale.

→

replace the boiler ( 36 ).

*

boiler defective

→

replace boiler

*

iron defective

→

check sole plate / thermostat.

*

possible problem in the water supply

→

check water supply

*

check water supply

*

A

switch on the boiler and lift the stand about 7 cm ( see picture A )

•

the pump doesn’t make noise

<

the pump makes noise and

<

the water level in the tank drops

the pump makes noise and

<

the water level DOESN’T drop

check PCB control unit. ( see further on )

*

the water supply is OK.

→

check the boiler

*

check water supply. ( see further on )

*

Page 8

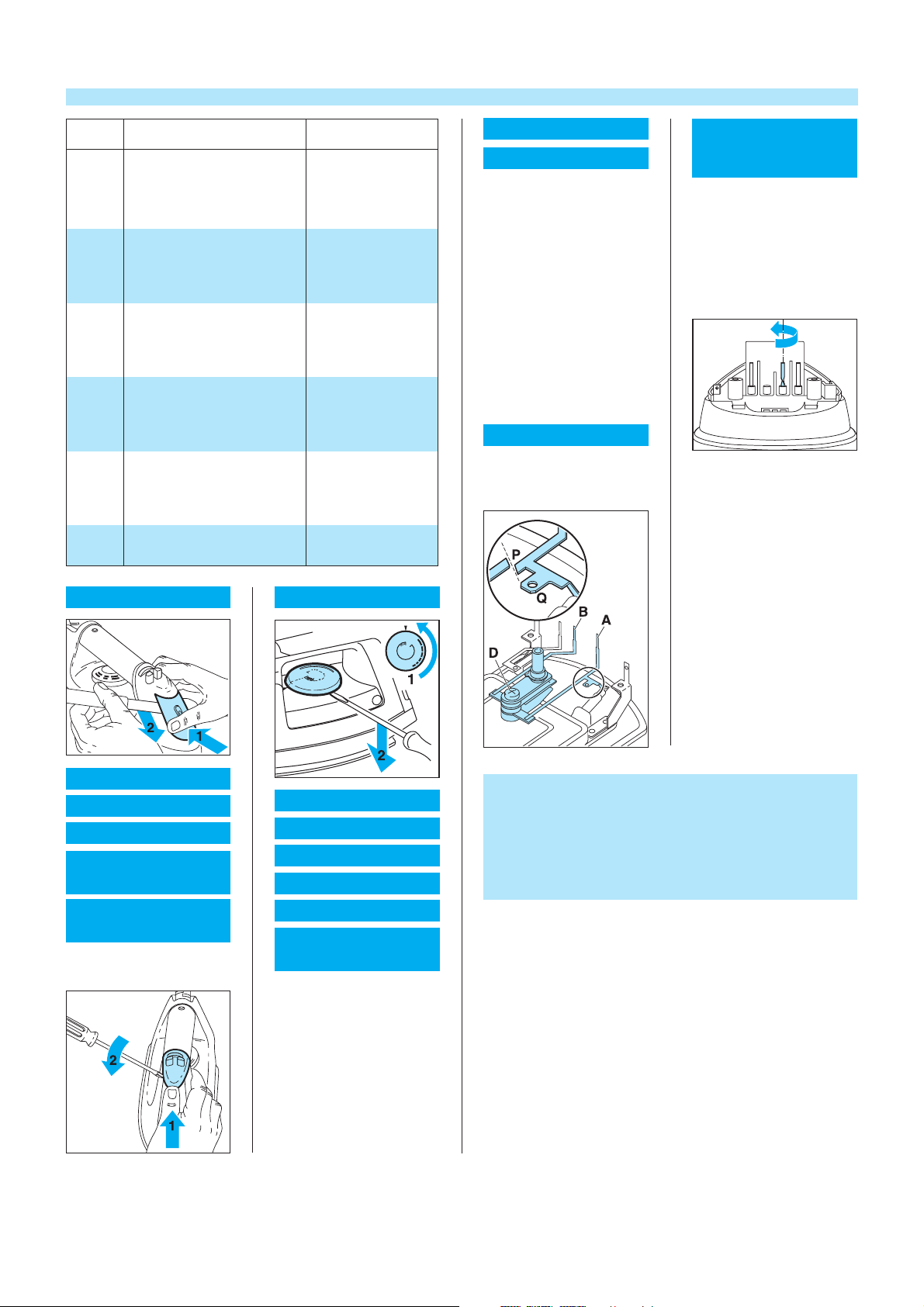

B

Check PCB control unit

remove screw(G)andswitch the product on ( see picture B )

•

pump starts

<

pump doesn’t start

<

when measuring : 180 volts AC

<

when measuring : 220 volts AC

<

too much water in the boiler.

→

check voltage over connecting points. ( see picture C )

→

the PCB is OK

→

check the pump for possible defect.

*

the diode is defective

→

C

when measuring : 0 volts AC

<

Check water supply

check if water tank has been filled with water.

•

check if filled water tank has been fitted properly. If not, pilot light goes on.

•

check if operation lever bottomplate has not been broken. If so, replace bottom housing.

•

check if connecting tube tank - pump ( 45 ) has been fitted properly.

•

check if reed contact functions properly :

•

the reed contact will be opened.

<

The pump stops and the electrovalve

cannot be opened while operating the

steam activator.

check if the total water supply has been clogged by scale.

•

D

when water flows out of the tube,

<

the water inlet has been soiled

by scale or the like.

replace the PCB + diode

*

the PCB is broken

→

replace the PCB

*

push floater downwards with a plastic spoon.

*

remove tube ( 37 ) and switch the product on.

*

( see picture D )

take a little drill, diam. 2.5 mm and remove the scale by

*

turning the little drill carefully by hand. ( see picture E )

no water flows out of the tube

<

E

“NUISANCE CALL” :

The pump has been provided with an automatical cut-out.

This cut out is activated when the pump becomes to hot.

This is caused by a not properly functioning of the water supply ( clogged with scale or dirt ) or

internal failure in the pump.

This happens after a relative long period of use.

After a cooling-down period the cut-out is reset automatically so it may function properly at the

repair shop.

When such a situation arises, check the water supply and/or pump as described before.

one-way valve is soiled

→

replace the valve.

*

PCS 99 737

Loading...

Loading...