Page 1

Provapor vario elance

HI 914

Service

Information

!

Service

Information

!

Philips Domestic Appliances and Personal Care

Service

Information

!

Service Manual

SAP coding HI 914

PRODUCT INFORMATION

Feataures : inox sole plate

boiler capacity 1 litre

length steam hose 1,9 metre

length cord set 1,9 metre

maximum steam output 70 gr/min

steam ready indicator

boiler empty indicator

Voltage : 220-240 Volt

Frequency : 50-60 Hz

Power consumptium : Boiler : 1200 Watt

Pressure : 3 bar

Iron : 800 Watt

Product meets the requirements regarding interference

suppression on radio and television.

- After the product has been repaired, it should function

properly and has to meet the safety requirements as laid

down offi cially established at this moment.

Published by Philips Domestic Appliances and Personal Care Printed in the Netherlands © Copyright reserved Subject to modification

4322 277 00123

99/10

PCS 101 316

Page 2

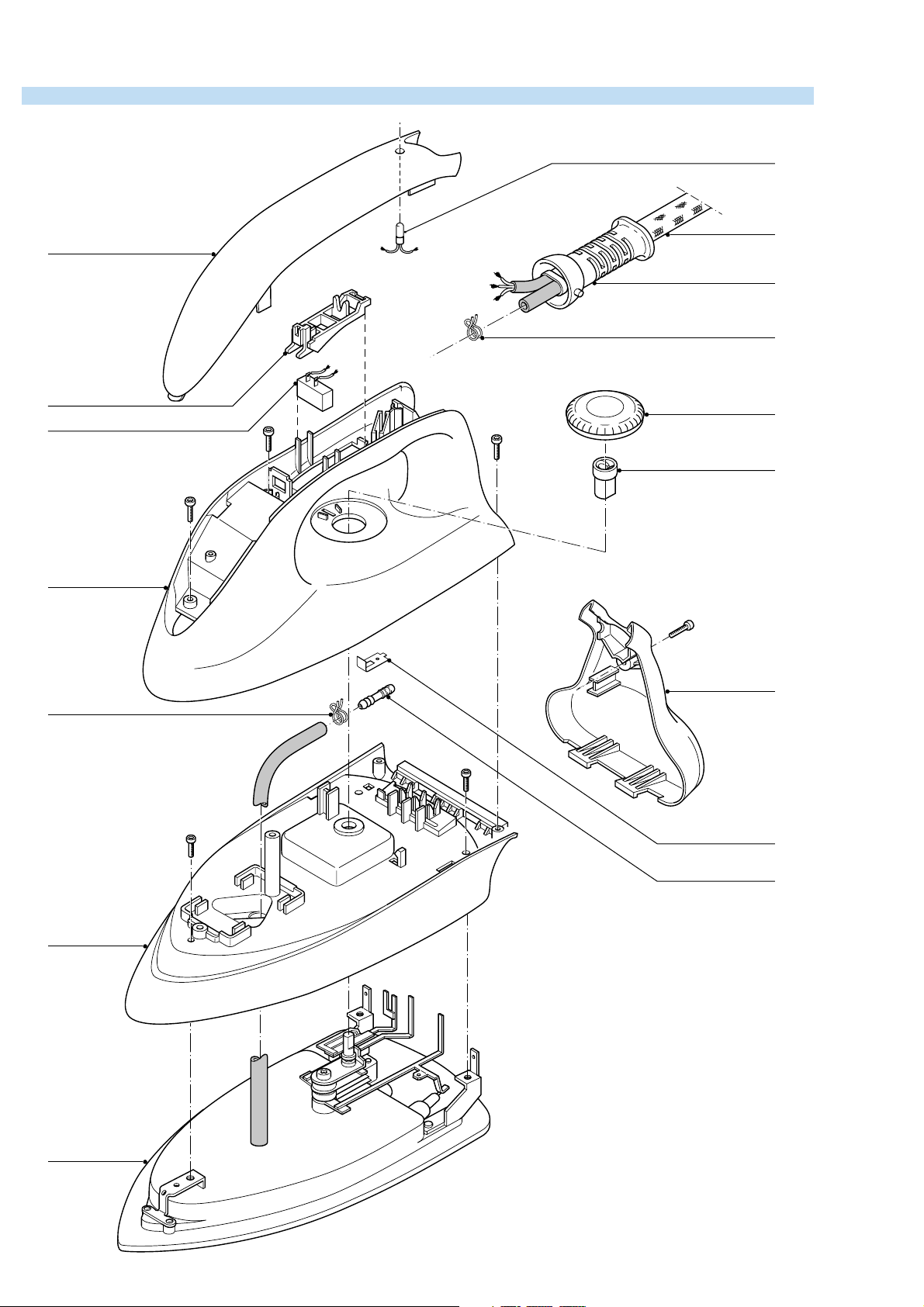

EXPLODED VIEW IRON

1

10

15

11

13

13

3

4

2

B

B

5

B

6

A

12

C

C

7

9

9

PCS 101 317

14

Screws : d x 1

A 3.5 x 12

B 3.5 x 14 (3x)

C M4 x 124 (3x)

DAP0996

Page 3

PARTS LIST IRON

Pos

10

11

12

13

14

15

Description Service Nummer

Inlay

1

Micro switch

2

Steam command lever

3

Therm. dial

4

Extention piece

5

Handle

6

Rattle

7

Skirt

8

Soleplate

9

Lamp

Ball swivel

Back plate

Thermostat

Spring clamp

Intermediate cable

9965 000 01887

9965 000 01888

9965 000 01680

9965 000 01681

9965 000 01682

9965 000 01683

4822 492 71445

9965 000 01684

9965 000 01685

9965 000 01686

9965 000 01687

9965 002 01689

9965 000 01690

4822 492 71001

9965 000 01691

TABLE UNIT IRON

Cut out

p

Steam-

Cut

out

valve

Dry

thermostat

Steamswitch

Thermostat

Page 4

DISASSEMBLY ADVISE IRON

BACK PLATE 12

remove SCREW A

INLAY 1

remove LAMP 10

remove MICRO SWITCH 2

HANDLE 6

remove THERM. DIAL 4

remove SCREW B (4x)

unlock HANDLE carefully

SKIRT 8

remove ELECTRICAL

WIRES

remove EXTENSION

PIECE 5

remove SPRING CLAMP

FROM STEAM HOSE

remove SCREW C (3x)

Bend back the contact points

THERMOSTAT 13

ONLY

cut CONDUCTOR A

at location P

remove SCREW D

P

Q

B

A

ASSEMBLY

REQUIREMENTS

THERMOSTAT 2

Instead of metal conductor A,

the new thermostat has a wire

with AMP clamp.

After fi xing screw D, connect

the AMP clamp to tag Q.

After assembling SKIRT 8

ALWAYS turn conductor B

through 180 degrees.

D

ADJUSTMENT AND CONTROLS

Thermostat 13

Thermostat ( 13 ) supplied as a spare part or fi tted to

the sole plate ( 9 ) has already been a djusted by the

supplier and secured by glue.

To avoid disfunction of the iron , NEVER readjust the

thermostat.

NOTE :

For opening you need a Torx screwdriver 362 TR

T20 x 100.

PCS 101 318

Page 5

EXPLODED VIEW STAND

24

26

D

22

23

21

E

31

27

25

28

30

27

33

32

38

39

36

37

29

PCS 101 319

34

DAP1000

Page 6

PARTS LIST + DISASSEMBLY ADVICE STAND

Pos

21

22

23

24

25

26

27

28

29

30

31

32

33

34

36

37

38

39

DFU

Description Service Nummer

Stand rubber feet

Rubber feet above screw

Complete tray

Safety cab

Rubber ring in fi lling hole

Cover

Rubber feet boiler

Boiler complete

Locked insert

Bottom housing

Filter

Switch

Electro valve

Cordset Italian plug

Cordset Europe plug

Steam dial

Steam regulator

Boiler empty lamp

Boiler ready lamp

GBR, FRA, DEU, NLD,

9965 000 01692

9965 000 01702

9965 000 01861

9965 000 01862

9965 000 01866

9965 000 01892

4822 462 71999

9965 000 01868

9965 000 01788

9965 000 01789

9965 000 01790

9965 000 01791

4822 218 11561

9965 000 01792

9965 000 01793

9965 000 01899

9965 000 01900

9965 000 01901

9965 000 01902

4222 001 92201

ESP, PRT, ITA

OPEN THE STAND

D

Below rubber feet

remove SCREW D (1 x)

E

E

remove SCREW E (3 x)

E

ADJUSTMENT AND CONTROLS

– To avoid leakage of the sealings and damage to the

components in and on the boiler, NEVER clean

the boiler with vinegar, a descaling agent or other

chemicals.

– The boiler doesn’t contain serviceable parts.

Never disassemble the boiler body and /or components on and in the boiler.

– ALWAYS REPLACE THE BOILER ( 28 ) WHEN:

the mechanical safety valve ( 24 ) has been

*

activated.

the boiler thermostat or hand - resettable

*

safety thermostat are open, because the boiler

has been subjected to too high temperatures.

the electrovalve ( 33 ) fails or the sieve is soiled

*

with scale.

– After the product has been repaired, it should

function properly and has to meet the safety

requirements as laid down and offi cially estab-

lished at this moment.

remove LOCKED INSERT 29

NOTE:

OPEN NOW THE STAND.

DON’T WORRY IF THE SNAPS AT THE SIDE WILL BE

BROKEN.

THEY ARE ONLY FOR THE ASSEMBLY.

THE STAND REMAINS CLOSE WITHOUT THESE SNAPS.

Loading...

Loading...