Page 1

About This Manual

Audience

February 2003

4730-0037-02 B

Manual Format

HDI 4000

Copyright © 2003 by Philips Ultrasound All rights reserved

Conventions in This Manual

Field Service Manual

This manual supports the field service maintenance and repair of the

HDI® 4000 Ultrasound System. The user of this document is a qualified ultrasound electronics technician who has completed training

classes on the system and its peripherals.

This manual is in Portable Document Format (PDF), for viewing on a

laptop computer with Acrobat Reader. A list of bookmarks functions

as an additional table of contents. Those bookmarks, the table of contents, and cross-references use hypertext links to provide access to

the referenced information.

The following conventions are used in this manual:

• Hypertext links are blue.

• All procedures are numbered. You must complete steps in the

sequence they are presented to ensure reliable results.

• Bulleted lists indicate general information about a function or procedure. They do not imply a sequential procedure.

• Control names and menu items or titles are spelled as they are on

the system, and they appear in bold text.

• Symbols appear as they appear on the system.

• Scanheads and pencil probes both are referred to as scanheads,

unless the distinction is important.

• An English system is assumed.

Page 2

4730-0037-02 HDI 4000 Field Service Manual Page 2

About This Manual

Service Manual Questions or Comments

Customer Assistance

If you have questions about the service manual, or you discover an error in the manual, contact

Philips Ultrasound Technical Publications:

• atl-bothell.techpubs@philips.com

• Technical Publications, MS 964, at the address below

Various support locations around the world can provide customers with technical assistance

regarding the ultrasound system. Customers should contact the sales office where they purchased the system or the neare st Philips Ultr asound offi ce. Office addresses and telephone numbers are in the system user documentation.

Philips Ultrasound

P.O. Box 3003

Bothell, WA 98041-3003

USA

(425) 487-7000 or (800) 426-2670

www.ultrasound.philips.com

“Color Power Angio”, “HDI”, and “High Q” are registered trademarks of Philips Ultrasound.

Non-Philips Ultrasound product names may be trademarks or registered trademarks of their respective owners.

Page 3

4730-0037-02 HDI 4000 Field Service Manual Page 3

Contents

Contents

About This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Manual Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Conventions in This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Service Manual Questions or Comments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Customer Assistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

System Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 1-1 HDI 4000 Ultrasound System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 1-2 HDI 4000 Ultrasound System (Philips Colors) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Figure 1-3 Control Panel and Pull-out Keyboard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Figure 1-4 Control Panel (Philips Colors) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Figure 1-5 Control Panel Labeling (English) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Scanheads Supported . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Peripherals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Physical Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Page 4

4730-0037-02 HDI 4000 Field Service Manual Page 4

Contents

Safety Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Figure 1-6 HDI 4000 System Peripherals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Supplies and Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

System Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Table 2-1 HDI 4000 System Physical Specifications and Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Table 2-2 HDI 4000 System Electrical Power Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Table 2-3 Temperature/Humidity limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Wiring Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Mechanical Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Electrical Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Safety Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

System Architecture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Operating System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Page 5

4730-0037-02 HDI 4000 Field Service Manual Page 5 Page 5

Contents

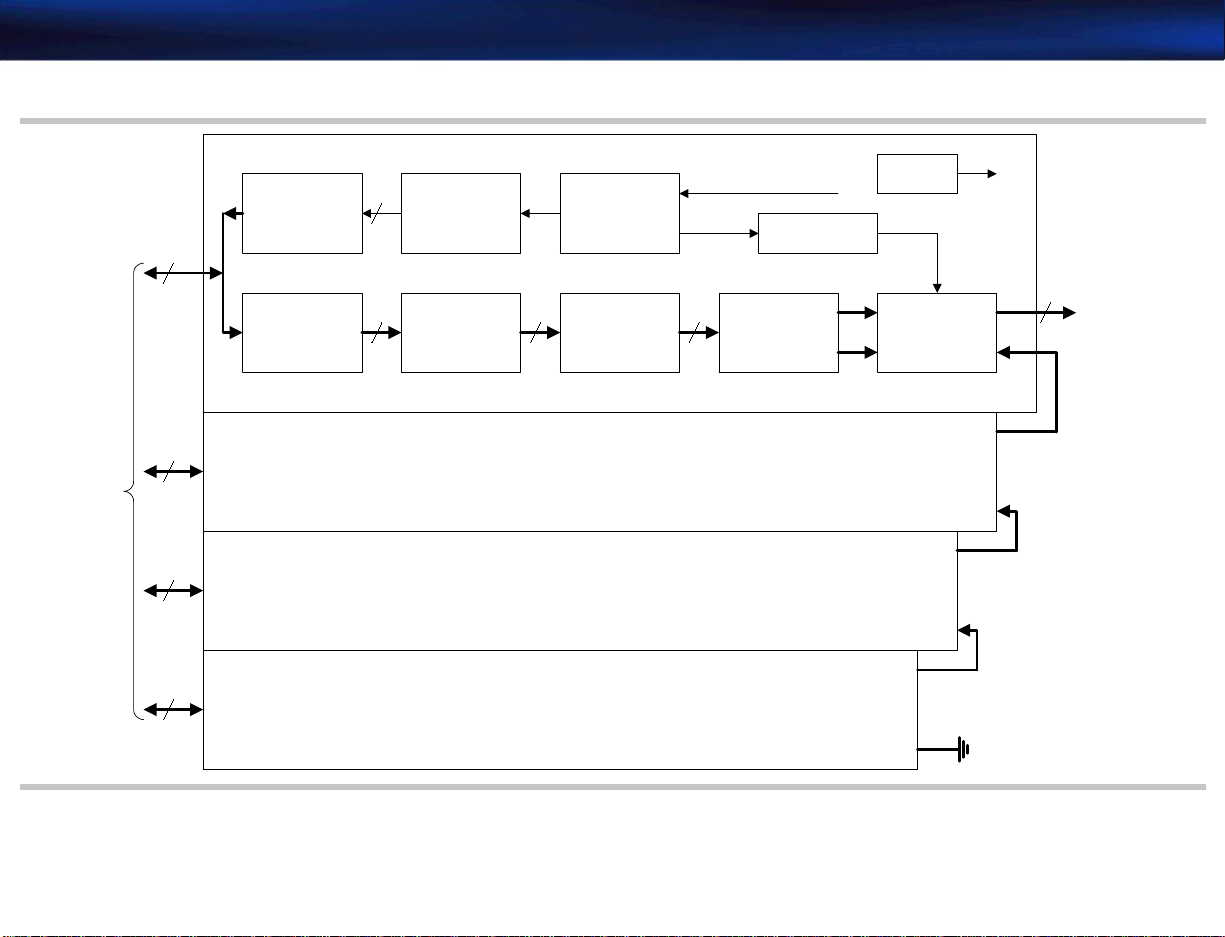

Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Figure 4-1 HDI 4000 System Functional Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Operating Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Table 4-1 Power Supply Output Voltages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Figure 4-2 Power Supply Schematic Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Probe Select Assembly (PSA) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Figure 4-3 Probe Select Assembly Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Figure 4-4 Cannon Scanhead Connector Pin Grid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Figure 4-5 Lemo Connector Pin Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Beamformer (BF0-BF3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Figure 4-6 Beamformer Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Continuous Wave Doppler Processor (CW) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Figure 4-7 CW Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Digital Signal Processors (DSP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Figure 4-8 DSP Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Digital Scan Converter (DSC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Backplane . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Figure 4-9 Digital Scan Converter Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Video Manager (VM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Figure 4-10 VM: Video Support Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Figure 4-11 VM: Audio Support Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Page 6

4730-0037-02 HDI 4000 Field Service Manual Page 6 Page 6

Contents

Industrial PC Motherboard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Table 4-2 System Computer Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Table 4-3 STANDARD CMOS SETUP Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Table 4-4 BIOS FEATURES SETUP Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Table 4-5 CHIP FEATURES SETUP Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Table 4-6 POWER MANAGEMENT SETUP Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Table 4-7 PNP/PCI CONFIGURATION Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Table 4-8 INTEGRATED PERIPHERALS Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Table 4-9 I/O Device Port Address Map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Table 4-10 Interrupt Controller NMI Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Input/Output Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Figure 4-12 Rear I/O Connector Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

User Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Data Paths . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Figure 4-13 Data Path . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .81

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Pre-Installation Evaluation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Checking Physical Access for Delivery, Installation, and Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

➤ To check that the site is prepared for system installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Checking the Operating Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Page 7

4730-0037-02 HDI 4000 Field Service Manual Page 7 Page 7

Contents

Wiring Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Checking the Electrical Power Source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

➤ To verify a dedicated AC line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Checking for Electrostatic Discharge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

System Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Preliminary Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

➤ To inspect the shipping crate for signs of damage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Unpacking the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

➤ To unpack the system shipping crate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

➤ To remove the system from the crate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Figure 5-1 Shipping Crate Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Figure 5-2 Unpacking the Shipping Crate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

General Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

➤ Inspection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Installing the Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

➤ To install the system monitor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Figure 5-3 Monitor Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Installing the Hard Disk Drive (HDD) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Figure 5-4 Hard Disk Drive Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Installing the Footswitch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Figure 5-5 Footswitch Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Page 8

4730-0037-02 HDI 4000 Field Service Manual Page 8 Page 8

Contents

Installing the Probe Cable Hangers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

➤ To install the probe cable hangers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Figure 5-6 Probe Cable Hangers Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Setting Up the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

➤ To set up the system. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Figure 5-7 AC Power Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

➤ To configure the HDI 4000 system for DICOM operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Figure 5-8 DICOM Settings Screen - No Services (see also Figure 5-9) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Figure 5-9 DICOM Settings Screen With Server Entries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Figure 5-10 Network and Dial-up Connection Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Figure 5-11 Local Area Connection and TCP/IP Properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

➤ To add a storage server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Figure 5-12 Storage Server Settings Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

➤ To add a printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Figure 5-13 Printer Settings Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

➤ To add a modality worklist server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Figure 5-14 Modality Worklist Server Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

➤ To edit or delete a server. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Installing a Network Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

➤ To install a Codonics NP-1660 Network Printer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Figure 5-15 Codonics NP-1660 Printer LAN Connection Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Page 9

4730-0037-02 HDI 4000 Field Service Manual Page 9 Page 9

Contents

Figure 5-16 Codonics NP-1660 Printer Ethernet Wall Jack Connection Diagram . . . . . . . . . . . . . . . . . . . . . . . . 114

Figure 5-17 Codonics NP-1660 Printer Point-to-Point Connection Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Language Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

➤ To verify that the operating system language setting and the control panel language setting match. . . . . . . . . . . 116

Presenting the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Performance Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .119

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Preparations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Warnings and Cautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Initial Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Initialization and Monitor Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Figure 6-1 Power Switch Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Figure 6-2 System Startup display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Functional Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

General System Confidence Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

User Interface Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

2D Image Test - Curved Array Scanheads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

2D Image Test - Phased Array Scanheads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

2D Image Test - Linear Array Scanheads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Freehand 3D Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Volume 3D Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Page 10

4730-0037-02 HDI 4000 Field Service Manual Page 10 Page 10

Contents

Live 3D Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

CW Static Probe Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

ECG Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Image Save Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Peripheral Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Safety Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

End of Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Performance Test Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .137

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Warnings and Cautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Totoku Monitor Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

➤ To check or adjust the monitor contrast and brightness settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

➤ To check or adjust the advanced monitor settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Figure 7-1 CONTRAST On-Screen Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Figure 7-2 BRIGHTNESS On-Screen Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Figure 7-3 MAIN MENU On-Screen Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Preventive Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .141

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Equipment and Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Page 11

4730-0037-02 HDI 4000 Field Service Manual Page 11 Page 11

Contents

General System Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

OEM Peripherals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

Alignment, Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

Other Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .144

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Start Here . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Warnings and Cautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

Failure Symptoms and Solutions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

Table 9-1 Symptoms and Recommended Action . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

Table 9-2 System Boot Errors and Likely Cause . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

Checking Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Table 9-3 Fuse Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Figure 9-1 Protect Circuit Location & Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

Running the System On-Board Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Figure 9-2 System Diagnostics Access Point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

Figure 9-3 On-System or Remote Diagnostics Selection Point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

Figure 9-4 System Diagnostics Run-Confirm Dialog Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

Figure 9-5 System Diagnostics Access-Authorization Dialog Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

Figure 9-6 Diagnostics Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

Figure 9-7 System Environments Results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

Page 12

4730-0037-02 HDI 4000 Field Service Manual Page 12 Page 12

Contents

Figure 9-8 Software Options Results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

Figure 9-9 Version Check Results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

Figure 9-10 System Test Results (1 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

Figure 9-11 System Test Results (2 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

Figure 9-12 Save Results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

Checking the Power Supply Voltages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

Table 9-4 Power Supply Voltages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

Figure 9-13 Power Supply Voltage LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

Figure 9-14 System Power Supply Connector Voltage Map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

Figure 9-15 Power Supply Connector Voltages (Right Side View) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

Figure 9-16 Power Supply Connector Voltages (Rear View) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

Checking for EMI and RFI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

DICOM Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

➤ To troubleshoot a DICOM problem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

➤ To test the system IP configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

Figure 9-17 Opening a Command Prompt Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

Figure 9-18 Command Prompt Window - IP Configuration and Ping Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

Backing Up the Ultrasound Images . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

Equipment Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

Backup Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

➤ To back up the ultrasound images . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

Page 13

4730-0037-02 HDI 4000 Field Service Manual Page 13 Page 13

Contents

Restoring the Ultrasound Images from a Backup Disk . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

Equipment Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

Restore Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

➤ To restore the ultrasound images to the system hard drive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

Making the Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

Disassembly and Re-Assembly Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .181

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

Warnings and Cautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

Disassembly for Shipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

Preparing the Sony UP-21 for Transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

➤ To secure the Sony UP-21 print head for transport:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

System Panel Removal and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

Front End/PSA Removal and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

Figure 10-1 Beamformer Guide Install Orientation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

Primary Card Cage PCBs Removal and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

Figure 10-2 I/O Panel PCB Assembly Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

Control Panel Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

ECG/Power Switch Assembly Removal and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

Power Supply Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

Figure 10-3 ECG/Power Switch Assembly Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

Wheel Cap Removal and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

Page 14

4730-0037-02 HDI 4000 Field Service Manual Page 14 Page 14

Contents

➤ To remove a wheel cap: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

➤ To install a wheel cap:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

Cabling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .190

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

System Interconnection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

Cable Part Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

Figure 11-1 System Signal Cable Interconnect Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

Figure 11-2 System Power Cable Distribution Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

Connectors and Cabling Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

Figure 11-3 Probe (Scanhead) Connection Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

Figure 11-4 AC Power Connection Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

Figure 11-5 Rear I/O Connection Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

Figure 11-6 Power Supply Connection Panel (Back Side) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

Figure 11-7 Power Supply Connection Panel (Right Side) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

Figure 11-8 Motherboard Backplane (Front View) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

Figure 11-9 Motherboard Backplane (Back View) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

Figure 11-10 UP-21MD Color Printer Cabling Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

Figure 11-11 CP800E/UM Color Printer Cabling Diagram (External Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

Figure 11-12 UP-895MD Black and White Printer Cabling Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 202

Figure 11-13 AG-MD835E/P VCR Cabling Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

Figure 11-14 Ground Cable Location (2275-0516-01) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

Page 15

4730-0037-02 HDI 4000 Field Service Manual Page 15 Page 15

Contents

Part Number Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 205

Table 11-1 HDI 4000 Signal Interconnect Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 205

Table 11-2 HDI 4000 Power Distribution Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

Table 11-3 Peripheral Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

OEM Peripheral Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

Table 11-4 UP-895 Printer Switch Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

Table 11-5 UP-21MD Printer Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

Table 11-6 CP800 Main Menu Control Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 214

Table 11-7 CP800 Printer Service Menu Parameter Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 216

Table 11-8 AG-MD835 VCR Switch Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 218

Table 11-9 AG-MD835 VCR Configuration Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

Change History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .222

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 222

Initial System Release (v1.00.01.030) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 222

System Baseline Software Release (v1.00.02.035) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 222

Features Supported . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 222

Changes and Problems Corrected . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 223

Hardware Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 223

System Software Release (v1.00.04.049) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 223

Features Supported . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 223

Changes and Problems Corrected . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 223

Page 16

4730-0037-02 HDI 4000 Field Service Manual Page 16 Page 16

Contents

Hardware Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 224

System Baseline Software Release (v1.00.05.053) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 224

Features Supported . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 224

Changes and Problems Corrected . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

Hardware Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

System Software Release (v1.01.00.063) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 226

Features Supported . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 226

Table 12-1 Diagnostics Tests to Ignore . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 228

Hardware Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

System Release (No New Software ) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

Features Supported . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

Hardware Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230

Table 12-2 Parts with the Philips Colors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230

Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .233

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 233

Compatibility Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 233

System Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 233

Table 13-1 System Software CD Part Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 233

PCB Reference Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 234

Locating and Identifying Primary PCBs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 234

Figure 13-1 Scanhead Select Module (Probe Select Assembly) Detail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 235

Page 17

4730-0037-02 HDI 4000 Field Service Manual Page 17 Page 17

Contents

Figure 13-2 Primary System PCB Names and Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 236

Figure 13-3 Front Card Cage PCB Detail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 237

Figure 13-4 Rear I/O Connector Panel PCB Detail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 238

Figure 13-5 Motherboard (Backplane) PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 239

Figure 13-6 CW PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 240

Figure 13-7 Beamformer PCB (BF0, 1, 2, 3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 241

Figure 13-8 Digital Signal Processor (DSP) PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 242

Figure 13-9 Digital Scan Converter (DSC) PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 243

Figure 13-10 Video Manager (VM) PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 244

Figure 13-11 PC Mother Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 245

Figure 13-12 Motor Controller PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 246

Figure 13-13 Rear Connector Panel PCBs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 247

Figure 13-14 ECG PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 248

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .249

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 249

Ordering Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 249

How to Find a Part Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 250

➤ How to use the parts figures and tables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 250

Illustrations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 253

Figure 14-1 HDI 4000 System Parts Locator Map (Front and Rear Ends) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 253

Figure 14-2 HDI 4000 System Parts Locator Map (Left and Right Sides) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 254

Page 18

4730-0037-02 HDI 4000 Field Service Manual Page 18 Page 18

Contents

Figure 14-3 Video Monitor Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 255

Figure 14-4 Upper Cart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 256

Figure 14-5 Monitor Support Arm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 257

Figure 14-6 Top Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 258

Figure 14-7 Speakers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 259

Figure 14-8 Disk Drive Assemblies (CD and MO) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 260

Figure 14-9 ECG Connector and System Power Switch Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 261

Figure 14-10 Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 262

Figure 14-11 Control Panel Top . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 263

Figure 14-12 Control Panel Bottom . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 264

Figure 14-13 Keyboard (Control Panel) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 265

Figure 14-14 OEM Bays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 266

Figure 14-15 Printer OEM Bay Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 267

Figure 14-16 VCR OEM Bay Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 268

Figure 14-17 Enclosure Covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 269

Figure 14-18 Rear Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 270

Figure 14-19 Fender Covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 271

Figure 14-20 Card Cage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 272

Figure 14-21 Probe Select Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 273

Figure 14-22 Card Cage (Front) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 274

Figure 14-23 Rear Cart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 275

Page 19

4730-0037-02 HDI 4000 Field Service Manual Page 19 Page 19

Contents

Figure 14-24 Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 276

Figure 14-25 Rear Connector Panel Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 277

Figure 14-26 Disk Drive Assembly (Hard Drive) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 278

Figure 14-27 Lower Cart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 279

Figure 14-28 Footswitch Housing Connector Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 280

Figure 14-29 Lower Fan Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 281

Figure 14-30 Air Filter Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 282

Figure 14-31 Front Caster Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 283

Figure 14-32 Rear Wheel Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 284

Figure 14-33 Wheel Assembly (Exploded) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 285

Figure 14-34 Hard Disk Drive Assembly (Shipping Container) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 286

Figure 14-35 HDI 4000 Accessory Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 287

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 288

Table 14-1 HDI 4000 System Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 288

Table 14-2 Peripheral Part Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 302

Scanheads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .303

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 303

Scanhead Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 303

Table 15-1 Scanhead Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 303

Table 15-2 Scanhead Types, Capabilities, and Advantages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 304

Table 15-3 Scanhead Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 307

Page 20

4730-0037-02 HDI 4000 Field Service Manual Page 20 Page 20

Contents

Table 15-4 Scanhead Doppler Frequencies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 308

Table 15-5 Scanhead Part Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 312

Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .315

Acronyms and Abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 315

Terms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 317

Page 21

4730-0037-02 HDI 4000 Field Service Manual Page 21

General Information: Introduction

1 General Information

Introduction

System Overview

This section contains a general overview and physical description of the HDI® 4000 Ultrasound

System. System application, feature, and regulatory information are summarized.

The HDI 4000 system (Figure 1-1 through Figure 1-4) is a general-purpose, mobile, software-controlled, diagnostic ultrasound system.

The HDI 4000 system uses a personal computer (PC) platform with a Windows 2000 Professional operating system and digital broadband bea mforming to provide high-resolution, high-penetration ultrasound imaging.

The HDI 4000 system uses linear array, convex arra y, phased array, static and, volume scanheads

to perform all major clinical applications. The standard operating modes are 2D/gray scale,

M-mode, color M-mode, color Doppler , Color P ow er Angio® (CPA) imaging, pulsed-wave (PW)

Doppler, steered continuous-wave (CW) Doppler, static CW Doppler , Tissue Harmonic Imaging,

Pulse Inversion Harmonic Imaging and tri-plex mode simultaneous. Volume 3D imaging mode is

optional.

The system can store up to 40,000 images (depending on har d disk dri v e installed and imag e file

size) and recall them. Data can be exported to a removable disk and transferred to the PC environment in either JPEG or BMP formats. High-density removable media capability is standard,

and the system supports compatible ink-jet printers.

The HDI 4000 system has an online Help feature. Help displays instructions for use of the HDI

4000 system on-screen, by pressing the ? button on the control panel.

Page 22

4730-0037-02 HDI 4000 Field Service Manual Page 22

General Information: System Overview

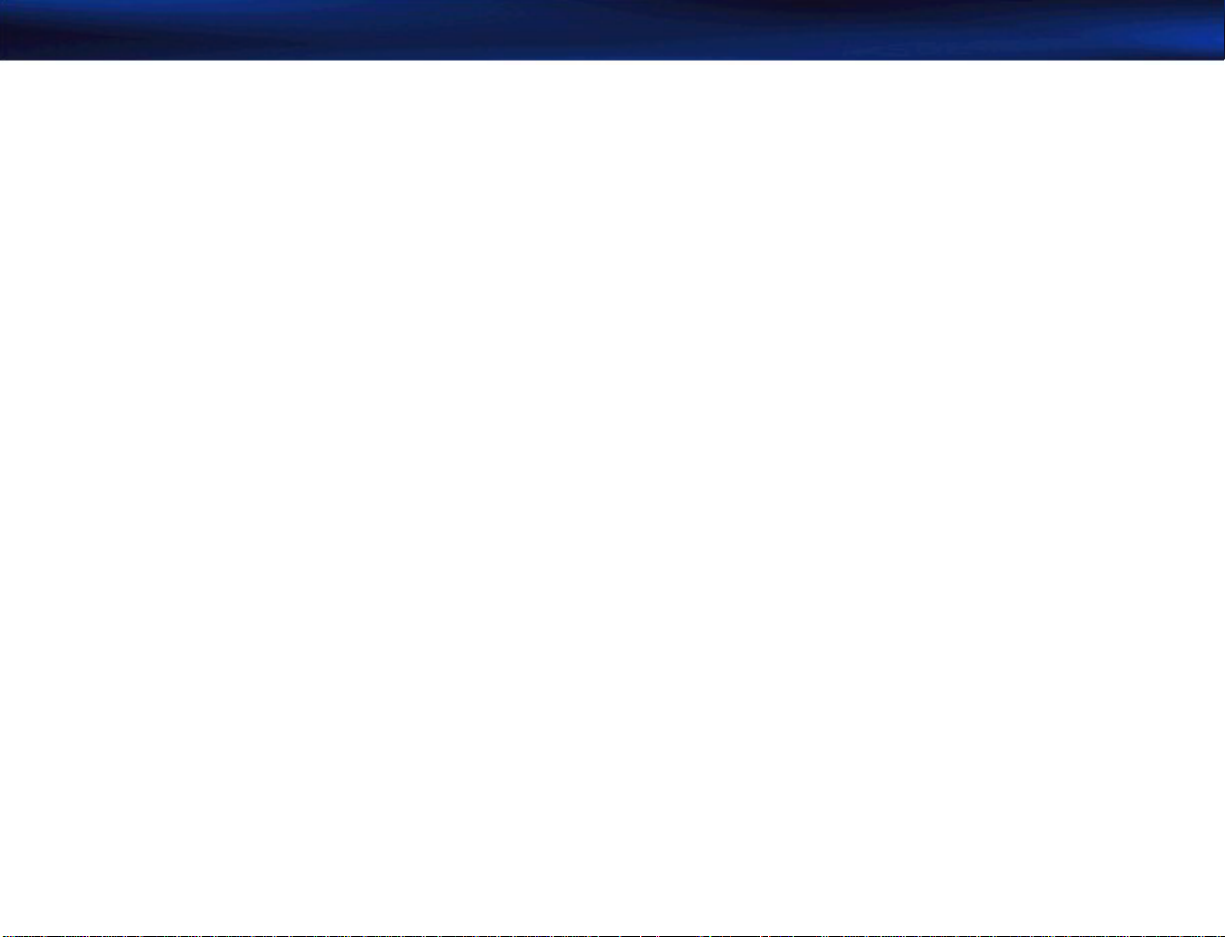

Figure 1-1 HDI 4000 Ultrasound System

Pull-out keyboard

See Figure 1-3

Page 23

4730-0037-02 HDI 4000 Field Service Manual Page 23

General Information: System Overview

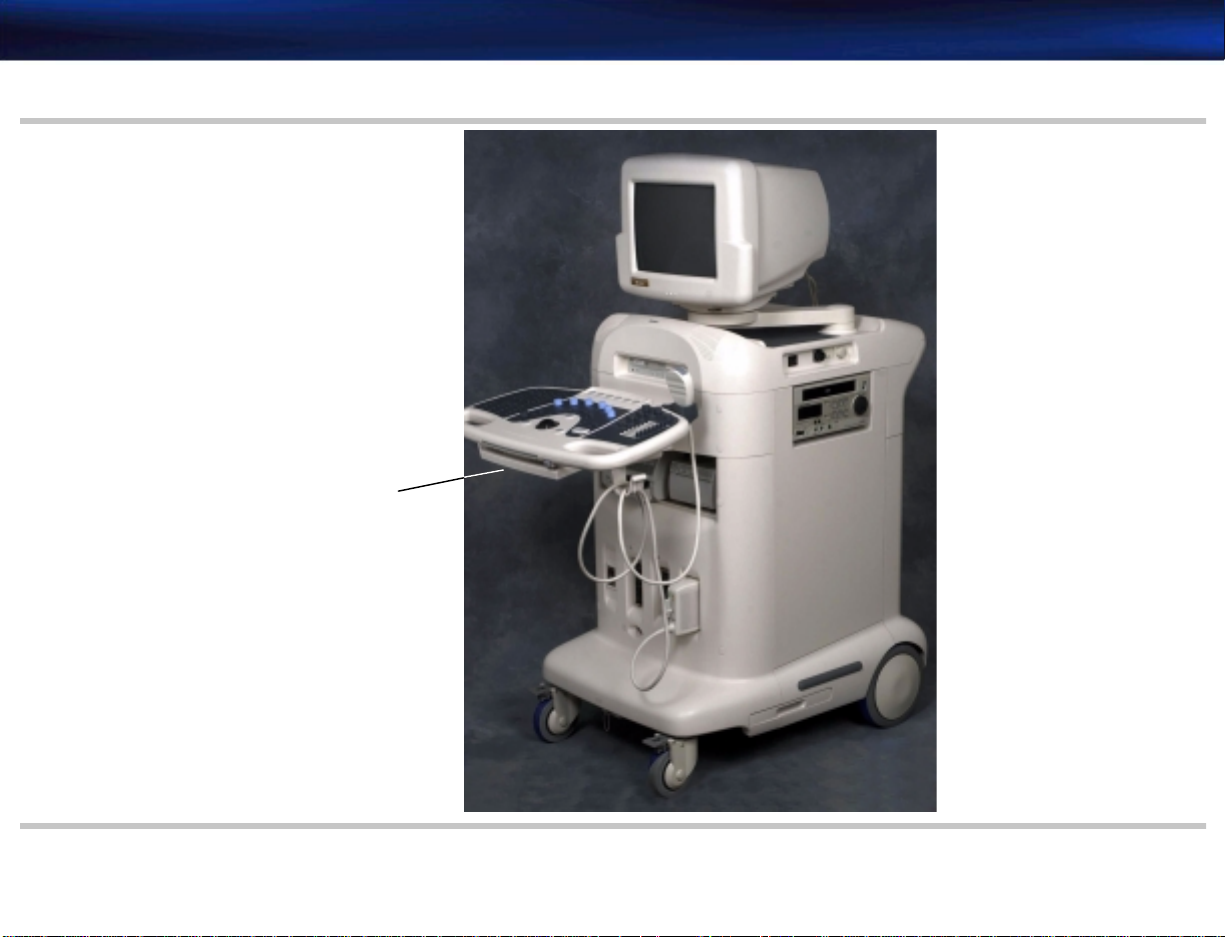

Figure 1-2 HDI 4000 Ultrasound System (Philips Colors)

Page 24

4730-0037-02 HDI 4000 Field Service Manual Page 24

General Information: System Overview

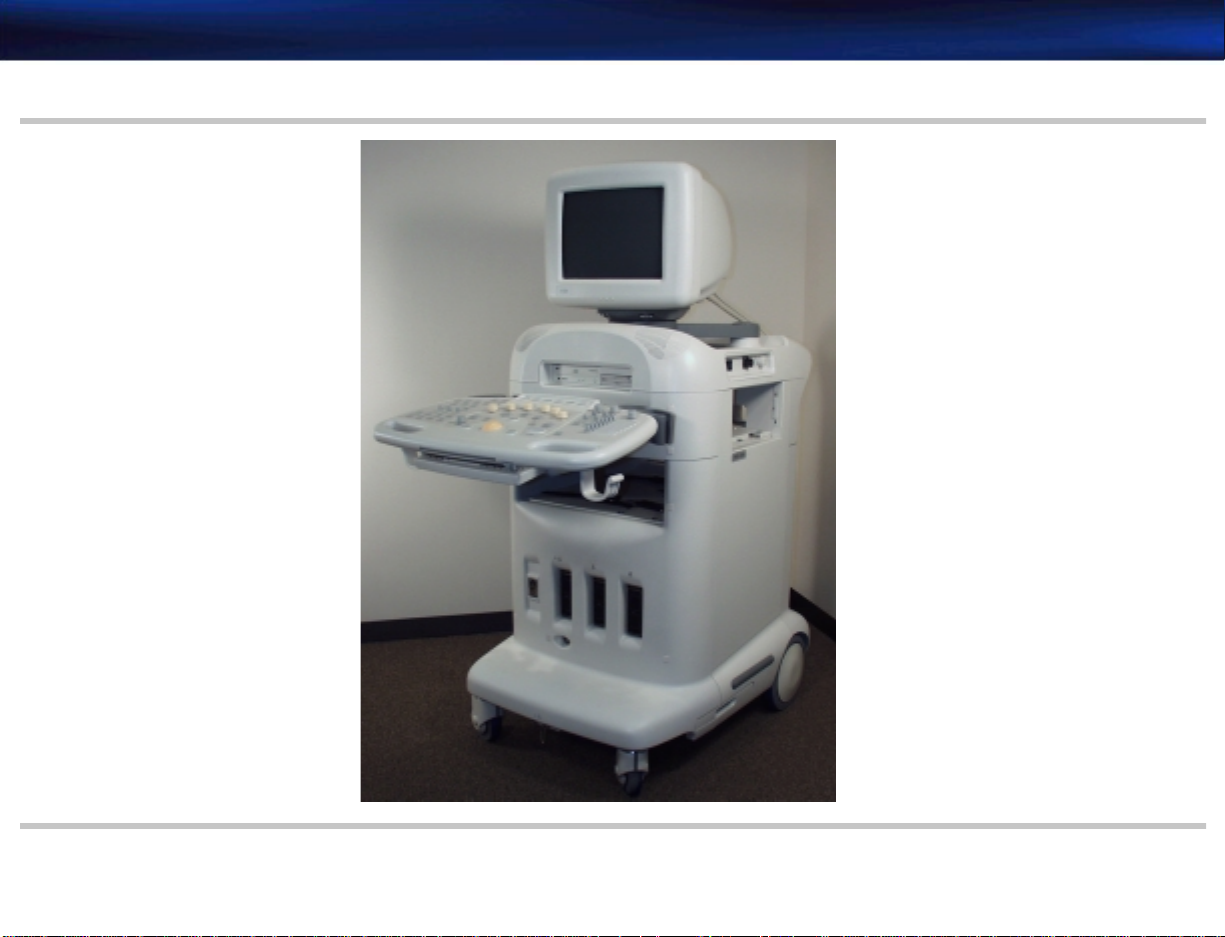

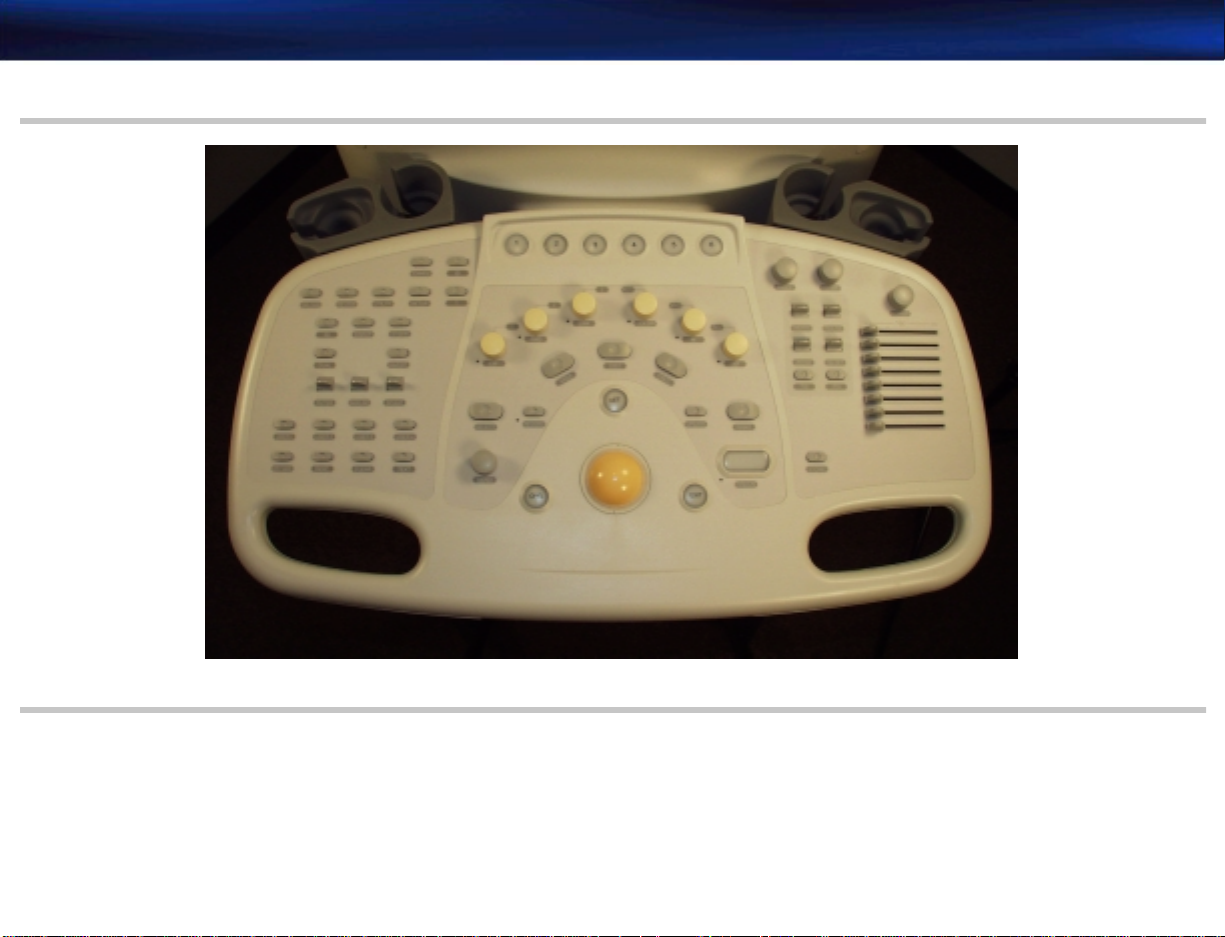

Figure 1-3 Control Panel and Pull-out Keyboard

Overla y

See Figure 1-5

Page 25

4730-0037-02 HDI 4000 Field Service Manual Page 25

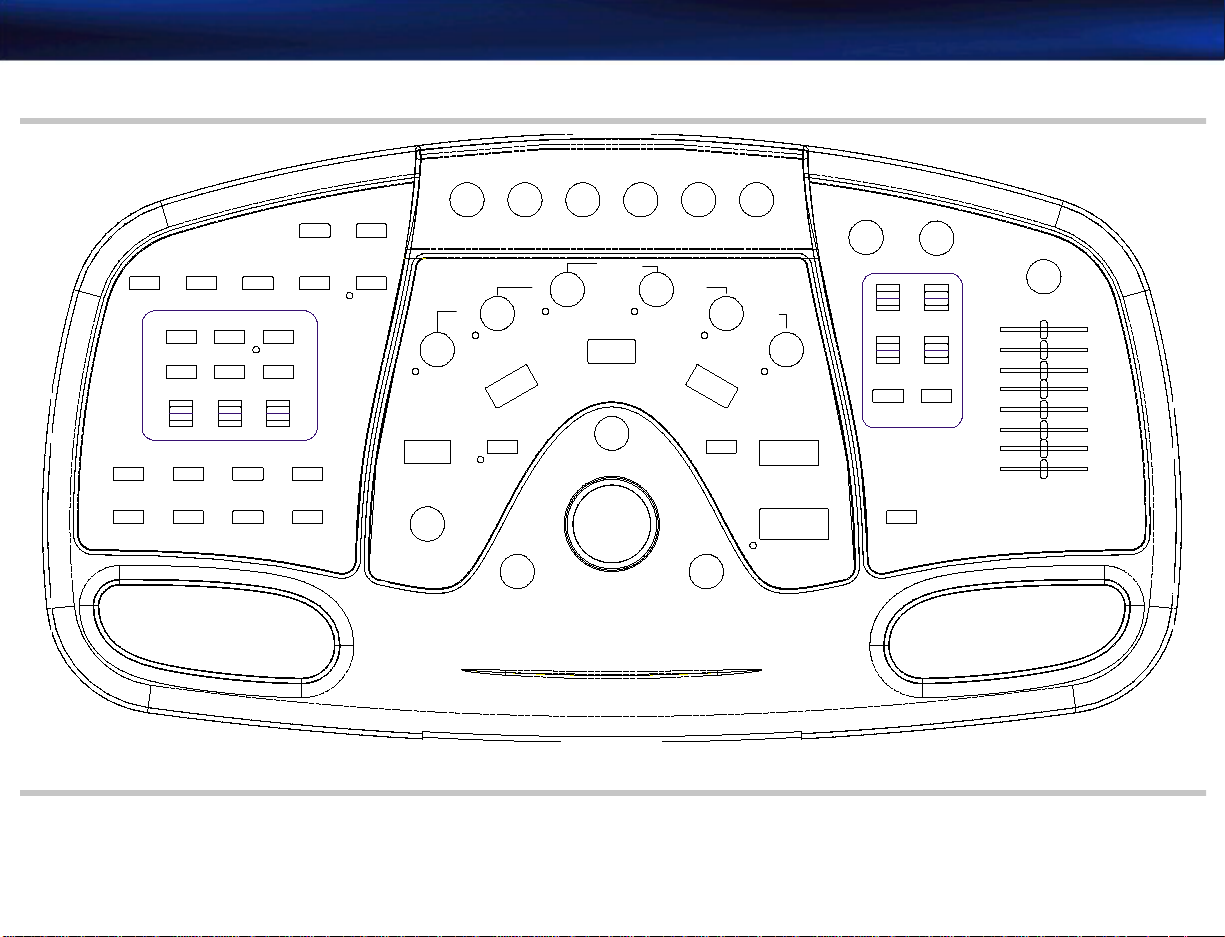

General Information: System Overview

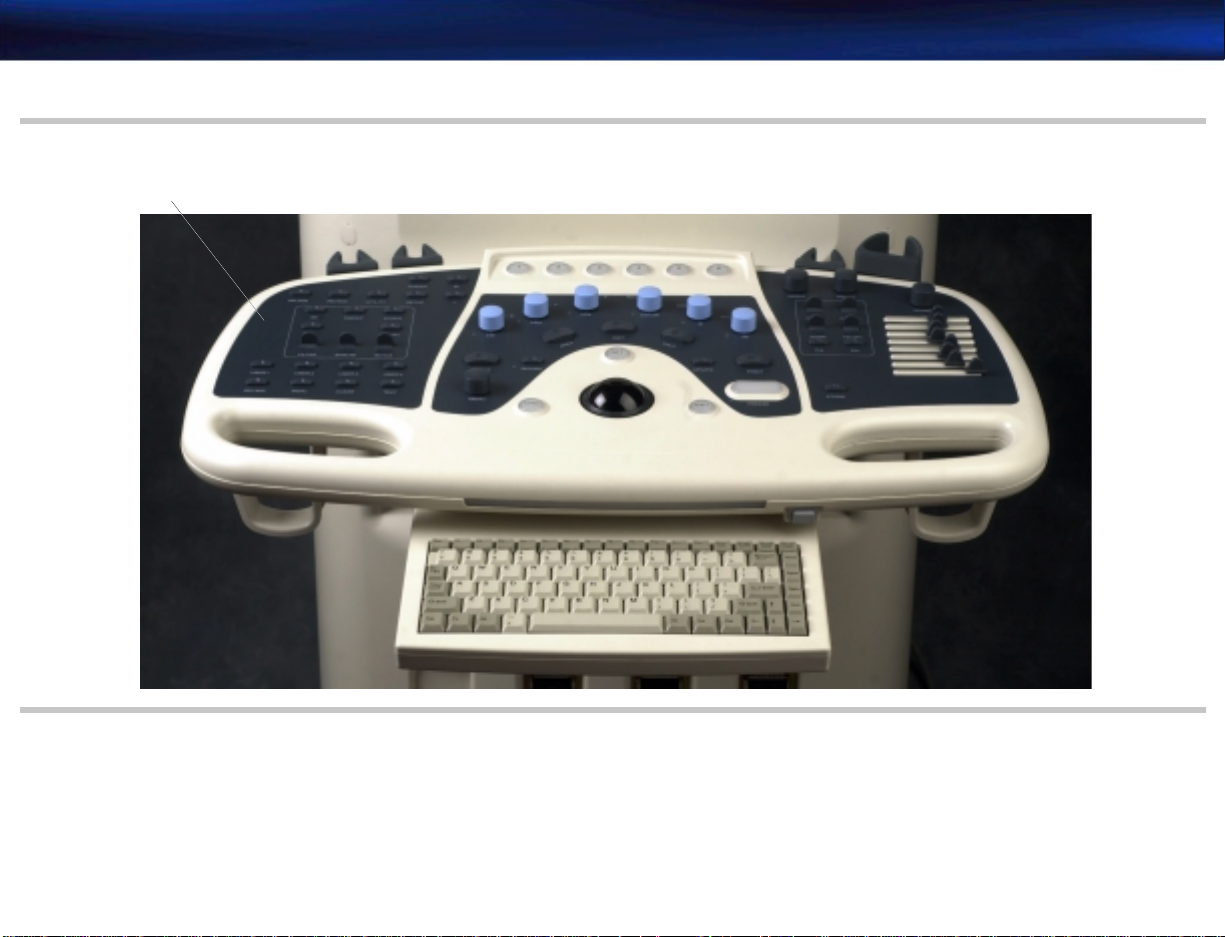

Figure 1-4 Control Panel (Philips Colors)

Page 26

4730-0037-02 HDI 4000 Field Service Manual Page 26

General Information: System Overview

Figure 1-5 Control Panel Labeling (English)

END EXAM

REVIEW SETUP

3D

DUAL

FILTER

USER2USER1

BODY MARK

INDIC.

See Figure 14-10

SWEEP

BASELINE

USER3

UTILITY

SCANHEAD ID

STEER

INVERT

SCALE

USER4

TEXTCLEAR

3

2

1

?

SELECT

MENU

X

X

CW

Y

CPA

PWD

AREA

RECORD

CHG.

4

Z

RECT.L

MAG

Y

COLOR

DIST.

CALC.

SET

5

UPDATE

EXIT

6

DEPTH

ZOOM

THI

VOLUME

POWER

FOCAL POS

TSI OPT.

PIH

STORE

ANGLE

TH.L

M

2D

PRINT

FREEZE

Page 27

4730-0037-02 HDI 4000 Field Service Manual Page 27

General Information: A pplications

Applications

• Abdominal

• Breast

• Cardiac

• Cardiac TEE

• Carotid

• Fetal Echo

• General

• GYN

• Intra-Operative

• Musculoskeletal

• Neo-natal Head

• OB

• Pediatric

• Pediatric Abdomen

• Pediatric Cardiology

• Prostate

• Renal

• Small Parts

• Trans-Cranial Doppler (TCD)

• Vascular

• Venous

Page 28

4730-0037-02 HDI 4000 Field Service Manual Page 28

General Informa t ion: Fe at ur e s

Features

Electrical Standard

• 120 Vac, 60 Hz

• 240 Vac, 50 and 60 Hz

Languages

• English

• French

• German

• Italian

• Spanish

Scanhead Selection

• Four scanhead receptacles

• Electronic switching between scanheads

Imaging Modes

• Real-time 2D gray-scale imaging

• Motion mode (M-mode)

• Color Doppler Imaging

• Color Power Angio Imaging

• Pulsed-wave (PW) Doppler

• Continuous-wave (CW) Doppler (steered and static)

Page 29

4730-0037-02 HDI 4000 Field Service Manual Page 29

General Informa t ion: Fe at ur e s

• Tissue Harmonic Imaging (Cardiac and General applications only for P4-2, P5-3, and MPT7-4

prior to v1.01.00.063 software and L7-4, C5-2, C7-4, 3D5-3, 3D7-4, CL15-7, P4-2, P5-3,

P7-4, and MPT7-4 for v1.01.00.063 and higher software)

• Pulse Inversion Harmonic Imaging 2D real-time and 3D (P7-4 Pediatrics and General; P5-3

Cardiac and General; P4-2 Cardiac, General, and Contrast (Contrast is v1.01.00.063 and

higher software); MPTEE all applications; and for v1.01.00.063 and higher software, C5-2

General, Abdominal, Renal, Abdomen, and Contrast; 3D5-3 all applications; and 3D7-4 all

applications)

• 1.01.00.063 and higher software, Contrast Specific Imaging (CSI) application is available for

the C5-2 and P4-2

Image Presentation

• Top/Bottom

• Left/Right

• Dual side-by-side

Image Processing

• Depth control

• View Area control

• Direction (Left & Right) control

• Apex (Up & Down) control

• Zoom control

• Focus (positio n & number ) control

• Reject Level selection

Page 30

4730-0037-02 HDI 4000 Field Service Manual Page 30

General Informa t ion: Fe at ur e s

• Gain control

• Dynamic Range control

• TGC Value adjustment

• Power control

• Persistence control

• Capture control

• Tag control

• Histogram utility

• 3D controls

Image Storage and Retrieval

• 256-frame Cine review memory

• Save images to and retrieve and view images from the system hard disk (in proprietary for-

mat)

• Copy images to the MO disk (in BMP or JPEG format) or to the CD-R/W disk (in BMP or

DICOM format, depending on the operation). Images can be backed up in a DICOM or 3D

format or exported in JPEG, TIF, or BMP format).

Backup and Export to CD-RW and CD-R

With v1.01.00.063 and higher software, you can reuse CD-RW (rewritable) and CD-R (recordable) disks for backup and export operations if the disk has sufficient disk space left. This allows

you to continue to add images and studies to a CD-RW or CD-R without reformatting and

deleting information from the disk.

Page 31

4730-0037-02 HDI 4000 Field Service Manual Page 31

General Informa t ion: Fe at ur e s

Measurements

• 2D mode: Distance, Angle, Area, Ellipse, Circumference, Volume.

• Doppler: Velocity, Pressure, Acceleration.

• M-mode: Time, Slope, Distance .

• Pre-measurement calibration of VCR images from HDI 4000 system.

• The images stored to Revie w can be r ecalled and measur ed for both dis tance and ar ea. These

measurements cannot be transferred to any of the analysis packages, but the measurements

can be recorded to hard copy.

Calculations

• Automatic measurement of various parameters

• Obstetrical analysis in 2D

• GYN

• Cardiology

• Vascular

• Standard Gestational Age tables

• Standard OB tables

• User-defined OB tables

DICOM

• Modality worklist

• Simultaneous network print and store

Page 32

4730-0037-02 HDI 4000 Field Service Manual Page 32

General Information: Scanheads Supported

Open Line Transfer

Open line serial data transfers of OB patient r eport to off-line printers, computers, and w orkstations (the data is sent to and appears on a computer monitor or prints on a serial printer).

On-System User Instructions (Online Help)

An online Help feature provides instructions for use of the HDI 4000 system, on-screen, by

pressing the ? button on the control panel.

Scanheads Supported

• Linear array

- L7-4

- L12-5 38 mm/50 mm

- CL15-7

• Curved array

- C5-2

- C7-4

- C8-4v

- C9-5

- C8-5

• Phased array

- P4-2

- P7-4

- P5-3

- MPT7-4

Page 33

4730-0037-02 HDI 4000 Field Service Manual Page 33

General Information: Peripherals

• Dual Element Pencil Scanhead

- D2 CW

- D5 CW

• Volume Scanhead

- 3D5-3

- 3D7-4

- 3D8-5v

Peripherals

CAUTION To av oid damaging the Son y UP-21 Printer, if the need arises, be sure to secure the thermal print-

Physical Description

• Panasonic AG-MD835 Video Cassette Recorder (purchase option - Figure 1-6)

• Sony UP-895MD Black and White Video Page Printer (purchase option - Figure 1-6)

• Mitsubishi CP800 Color Video Page Printer (purchase option - Figure 1-6)

• Sony UP-21MD Color Video Page Printer (purchase option - Figure 1-6)

ing head before shipping as described in “To secur e the Son y UP-21 print head f or transport:” on

page 182.

System Components

• Primary printed circuit boards (PCBs):

- Probe Select Assembly (PSA)

- Beamformer (BF)

- Continuous Wave Doppler Processor (CW)

- Digital Scan Converter (DSC)

Page 34

4730-0037-02 HDI 4000 Field Service Manual Page 34

General Information: Safety Requirements

- Digital Signal Processor (DSP)

- Video Manager (VM)

- Backplane (ultrasound motherboard)

- PC Motherboard

-ECG

• System operating software

• Mobile cart/system housing

- Color VGA monitor with tilt/swivel base

- Main chassis (supports the monitor, control panel, disk drives, scanhead connectors,

cable management system, and storage areas)

- Control panel and pull-out keyboard

- I/O connection panel

Safety Requirements

HDI 4000 complies with the requirements for the International Electrotechnical Commission

(IEC), Canadian Standard Association (CSA), and Underwriters Laboratories (UL).

• IEC 60601-1

• CSA22.2 No. 601.1

• UL 2601-1

Page 35

4730-0037-02 HDI 4000 Field Service Manual Page 35

General Information: Safety Requirements

Figure 1-6 HDI 4000 System Peripherals

- UP-895MD Sony Video Graphic Printer -

- UP-21MD Sony Color Video Printer -

(Black and White)

- CP800 Mitsubishi Color Printer -

- AG-MD835 Video Cassette Recorder -

Page 36

4730-0037-02 HDI 4000 Field Service Manual Page 36

General Information: Supp lies and Accesso ries

Supplies and Accessories

Philips product-specific and general purpose supplies and accessories, including scanhead biopsy

guides, are a va ilable fr om CIVCO Medica l Instruments at the ad dr esses a nd numbers belo w. Supplies and accessories are no longer available from Philips.

CIVCO Medical Instruments

102 First St. South

Kalona, IA 52247-9589

Phone: (800) 445-6741, Ex. 1 for Customer Service (USA)

(319) 656-4447 (International)

Fax: (877) 329-2482 (USA)

(319) 656-4451 (International)

E-mail: info@civcomedical.com

Internet: www.ultrasoundsupplies.com

Page 37

4730-0037-02 HDI 4000 Field Service Manual Page 37

Specifications: Introduction

2 Specifications

Introduction

System Specifications

Table 2-1 HDI 4000 System Physical Specifications and Limits

Parameter Value

Height 1492 mm (58.7 in)

Width 692 mm (27.2 in)

Depth 1115 mm (43.9 in)

This section summarizes the system specifications for the HDI 4000 Ultrasound System. Scanhead specifications are provided in Section 15, “Scanheads”.

The configuration of the computer platform is as follows:

• PC with Intel processor

• 512 MB main memory

• 40 GB HDD (may be a 20-GB HDD in earlier systems)

• MO drive

• CD-R/W drive

• Sound/LAN/VGA capa bilities

• PC Interface for ultrasound module interface

Weight without peripherals approximately 166 kg (365 lbs)

Ambient Operational Temperature 10°C to 40°C (50°F to 104°F)

Operational Relative Humidity 15% to 95% RH (non-condensing)

Page 38

4730-0037-02 HDI 4000 Field Service Manual Page 38

Specifications: System Specifications

Table 2-1 HDI 4000 System Physical Specifications and Limits (Continued)

Parameter Value

Storage and Shipping Temperature -25°C to 65°C (-13°F to 149°F)

Storage Relative Humidity 20%-95%

1. Atmospheric pressure (Storage) at 1,060 hPa to 500 hPa (375–795 mmHg).

2. Atmospheric pressu re (Operating) at 1,060 hPa to 700 hPa (525

–795 mmHg).

Table 2-2 HDI 4000 System Electrical Power Specifications

Parameter Value

Hot/Neutral 90-132 Vac (RMS) at 50 or 60 Hz + 3 Hz

180-264 Vac (RMS) at 50 or 60 Hz + 3 Hz

Current Draw (rated)

1

10 A (at 100–120 Vac)

5 A (at 200–240 Va c)

Current Draw (measured) 6.79 A (at 120 Vac)

3.50 A (at 240 Vac)

Power Draw (measured) 811 VA (at 120 Vac)

840 VA (at 240 Vac)

Source < 48 A

Thermal Load

1

Approximately 2,550 BTU

Power Dissipation1, maximum 763 W (at 120 Vac)

775 W (at 240 Vac)

Chassis leakage current 100-240V systems 500µA max

Page 39

4730-0037-02 HDI 4000 Field Service Manual Page 39

Specifications: Wiring Sp ecification

Table 2-2 HDI 4000 System Electrical Power Specifications (Continued)

Parameter Value

Dielectric withstand voltage (DWV) between

isolation transformer primary and secondary

DWV between AC mains and exposed conductive

parts (chassis)

DWV between patient applied parts and AC mains 4000V

1. Includes the effect of peripherals operating at their maximum normal condition (for example, recording or printing).

Table 2-3 Temperature/Humidity limit

Storage/Shipping Operating Environment

High Temperature 65°C40°C

Low Temperature -25°C10°C