Philips Grind & Brew HD7762 Service Manual

Coffeemaker Grind & Brew

HD7762

Philips Consumer Lifestyle

Service Manual

PRODUCT INFORMATION

Safety

• This product meets the requirements regarding

interference suppression on radio and TV.

• After the product has been repaired, it should function

properly and has to meet the safety requirements as

officially laid down at this moment.

TECHNICAL INFORMATION

• Voltage : 220-240V

• Frequency : 50 Hz

• Power consumption : 1000W

• Color setting : Black / Metal

• Dimensions

Appliance H x W x D : 440 x 210 x 310 mm

F-Box L x W x H : 320 x 280 x 505 mm

• Cord length : 0,8 m

• Filter size : 1x4

• Contents

Jug (max.) : 1320 mL

Water container (min.) : 264 mL (2 cups)

Water container (max.) : 1320 mL (10 cups)

Avg. water loss during brew process : 10%

• Materials

Appliance : PP

Metal wrap : Stainless steel

Jug : Glass

Hoses : Silicon

• Brew time (max.) : 10 min

• Temperature (full jug) : > 80 °C

• Keep warm time : 120 minutes

Published by Philips Consumer Lifestyle Printed in the Netherlands © Copyright reserved Subject to modification

13/04

TECHNICAL INFORMATION

De-scaling

When the appliance indicates it needs to be descaled,

operate the coffeemaker a few times with vinegar or with

a 10-15% solution of either vinegar (acetic acid), citric acid

or tartar acid, into cold tap water.

Use a paper lter to catch any particles coming out.

Do not use other de-scaling agents as these may harm the

appliance.

If this procedure does not restore the function, then switch

off the coffeemaker when the acid is passing through. Keep

the appliance in this condition overnight and continue/

repeat the cleaning operation.

After the de-scaling procedure, operate the coffeemaker

twice with tap water in order to rinse any residual

substances.

HD7762

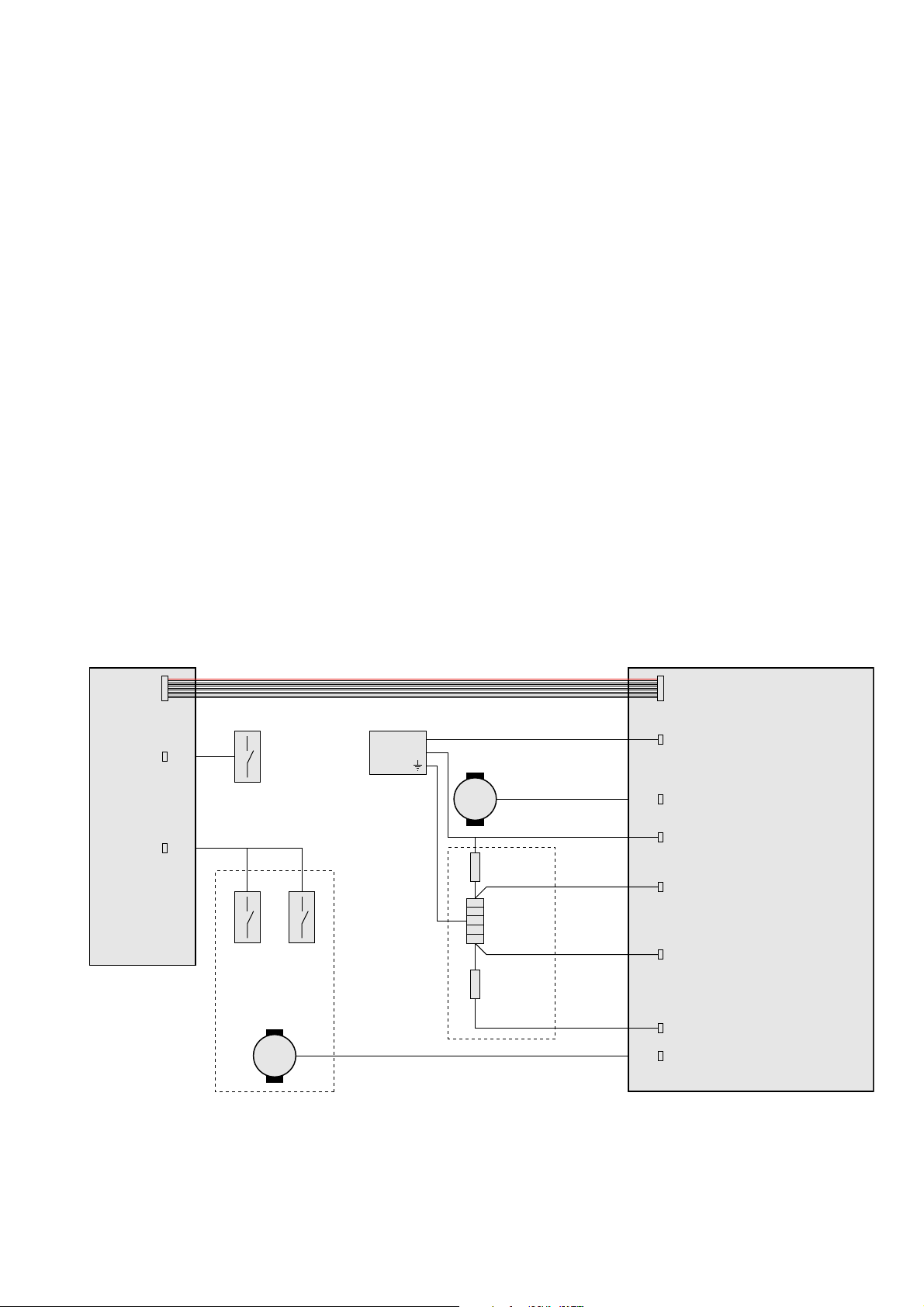

Schematics

UI PCBA

Micro switch

inspection

cover

Micro

switch

M

Micro

switch

Valve

motor

Powe r

cord

CN2CN1

Main PCBA

L

N

M

Grinder

Thermostat

Heater

Fuse

L

Grind motor

N

Warm 1

Warm 2

Heat

Gate motor

2-15

TECHNICAL INFORMATION

HD7762

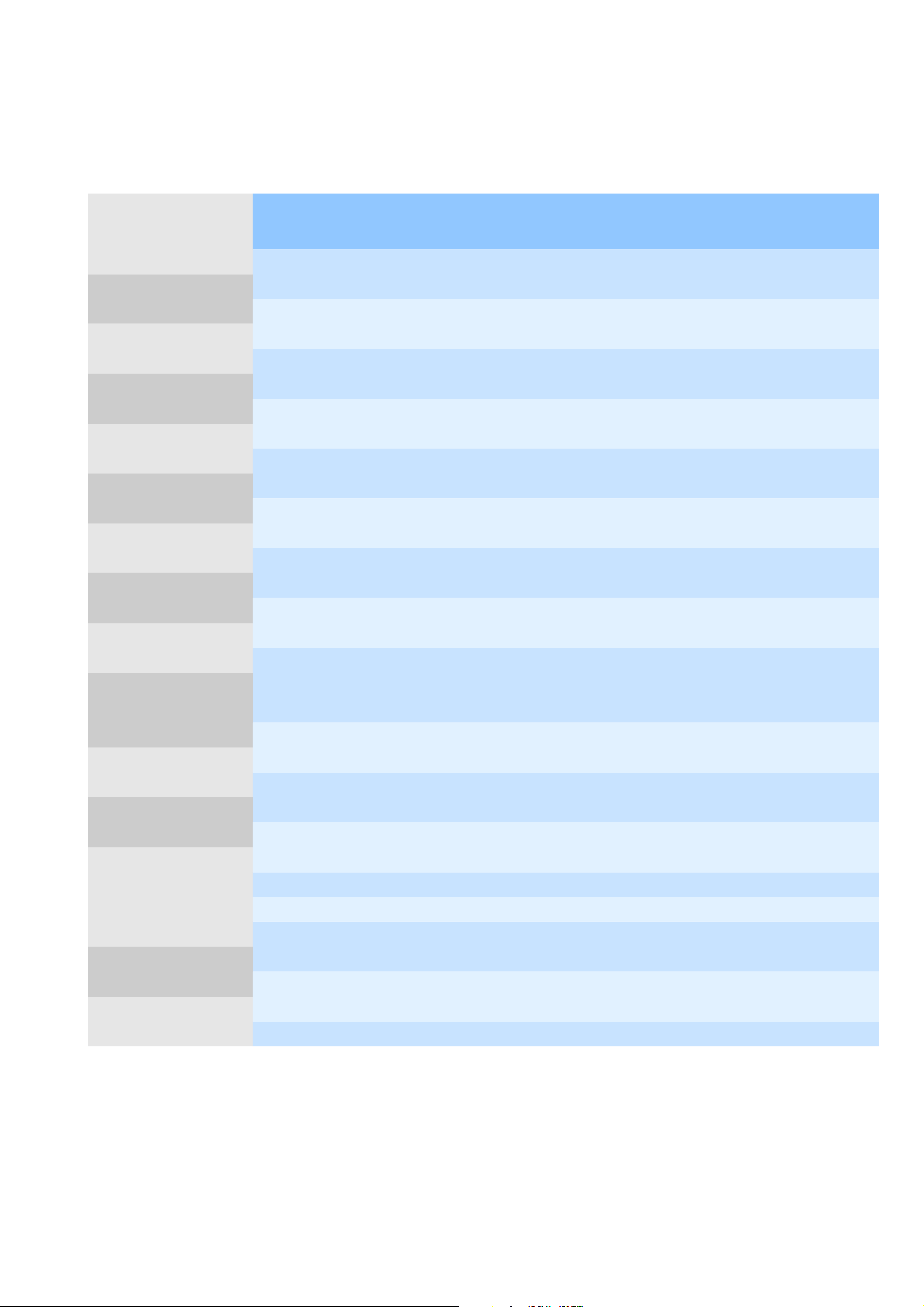

Self-Check mode

The appliance is equipped with a self-check mode, this enables you to quickly check the function of the main components of

the unit.

Keep the On/Off button pressed while

plugging the mains cord into the socket.

Hardware version CH 201

Press any other button

Software version CH 0004

Press any other button

Heating element enabled CH 1

Press any other button

Heating element disabled CH 2

Press any other button

Grinder motor enabled CH 3

Press any other button

Grinder motor disabled + 6 Beeps CH 4

Press any other button

Microcontroller check CH 5 = ok E1 = Nok

Press any other button

Zero-cross detection CH 6 = ok E2 = Nok

Press any other button

Valve micro switches CH CLO = valve is closed

Press any other button CH ---- = valve is working

Inspection window micro switch L- = Closed 8

Press any other button H- = Open 8

Thermostat CH 1111 = Thermostat closed

Press any other button CH 0000 = Thermostat open

Rotary knob 2 9

Press any other button

Rotary knob rotate clockwise Increasing 9

Rotary knob rotate anti-clockwise Decreasing 9

LED check All digits on All digits on

Press any other button

LED check All digits off All digits off

Press On/Off button

Stand-by

Left side

display

CH OPE = valve is open

Right side display

3-15

REPAIR INSTRUCTION

Repair of this appliance should be carried out on part and or assembly level, most repairs can be allocated to a couple of main

components:

• Bean container and duo-bean mechanics

Disassembly instructions until Step 1.

• User interface assy

Disassembly instructions until Step 4.

When in the UI panel itself has been disassembled, please make sure the wire and flat cable seal is properly installed.

Upon reinstallation of the complete panel, please make sure the seal underneath the UI panel is put back.

• Main PCBA

Disassembly instructions until Step 4.

When only the PCBA needs replacement, skip steps 1 - 3. Upon reinstallation of the PCBA, please make sure the PCBA

holder slides back into its guiding recesses. Please note the position of the Grinder (DC-motor), and Synchro-motor

(AC-motor) leads, when reversed the appliance will not start up.

• Grinder

Disassembly instructions until Step 6, skip step 3 and 5.

It is not advisable to disassemble the grinder, as this will disrupt the grinders’ calibration. In production special tools are

used to adjust the grind-fineness to the optimal level.

HD7762

• Synchro motor + valve and seal

Disassembly instructions until Step 6, skip step 3 and 5.

When the valve and or seal have been removed, please make sure that the seal does not get damaged, and that the seal gets

reinstalled correctly. The seal is critical to seal the grinder from steam coming from the coffee filter.

• Heater, bottom water supply

Disassembly instructions Step 4 and 5.

It is not advisable to disassemble the heater from the keep-warm plate. Heat-conductive paste should be applied to ensure

optimal heat transfer from the element to the plate, jug and coffee.

• Top water supply

Disassembly instructions Step 1 and 2.

The Silicon hose between the elbow joint and the showerhead does not need to be removed to uninstall this component,

when the hose does need replacement, make sure the hose clamps are put back properly, this is to prevent leakage.

When the showerhead has been removed it should be cleaned from any residual liquid gasket and new liquid gasket

(supplied in tubes of 45 g.) should be applied to ensure a proper seal.

• Complete Base, incl. metal wrap

Disassembly instructions Step 4 and 5.

The main PCBA and Heater assy need to be taken out completely, the base is screwed to the top by means of 6 screws.

4-15

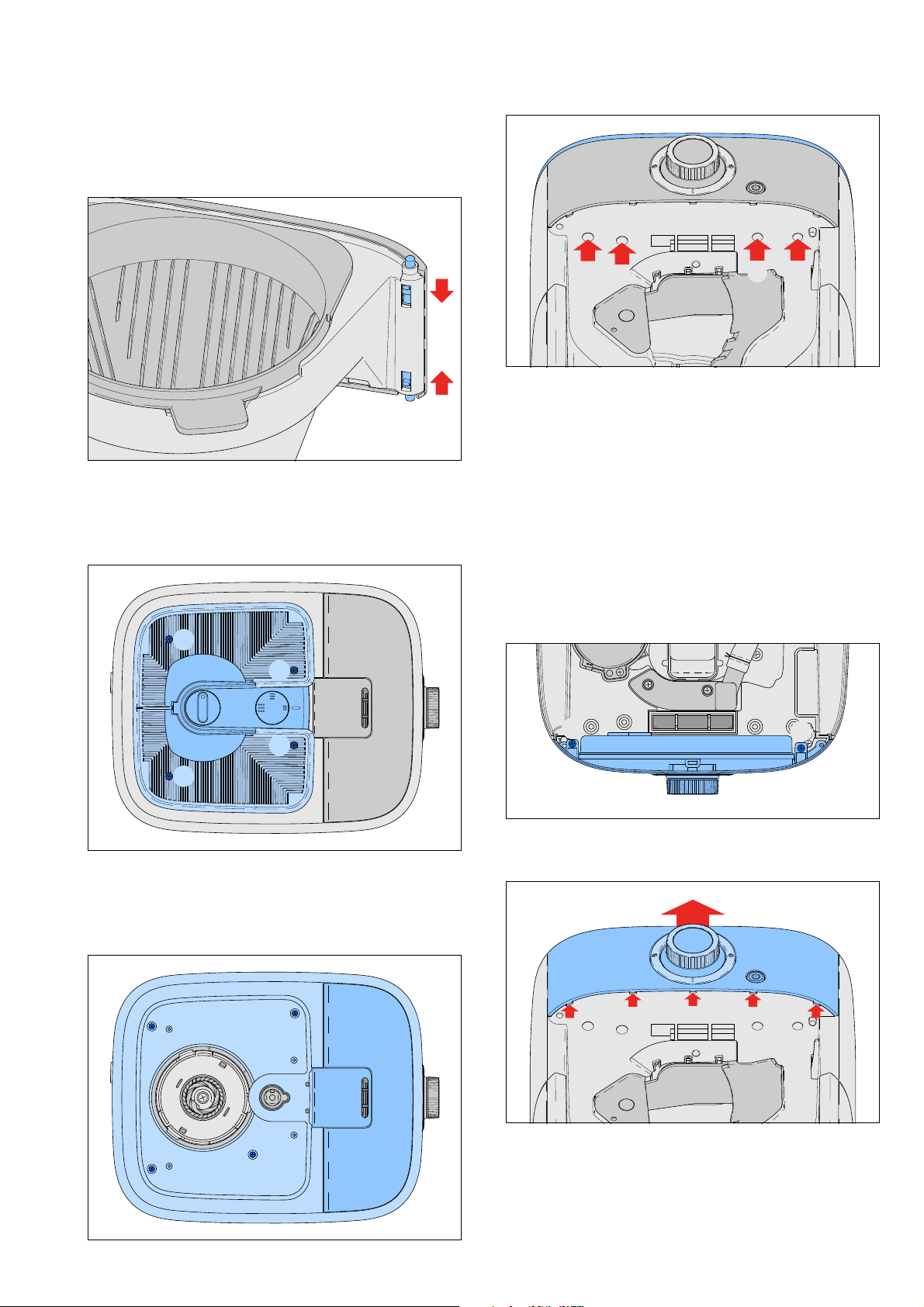

DISASSEMBLY INSTRUCTIONS

Remove all removable and detachable items like the Bean

container lid, jug, lter holder and brush. The lter door

can be removed for convenience by undoing both latches

on the top and bottom side of the hinge.

HD7762

Step 1: Bean container removal

To remove the complete bean container, including DuoBean feature, remove the 4 screws (C) inside the bean

container.

C

C

G

G

Please note the cable connecting to the Inspection window

detection switch. The Water Level Indicator (WLI) cannot

be removed without damaging the Top cover. When the

top cover needs to be replaced the WLI can be reused,

when the WLI needs to be replaced a new top cover needs

to be ordered as well.

Step 3: UI panel removal

To be able to remove the UI panel, you need to disconnect

the leads to the Synchro motor, and the atcable to the

main PCBA. The UI panel is held in place by two screws

accessible from the top side of the appliance, and 5 clicks

accessible from the bottom side of the UI panel. Unscrew

both screws (J).

G G

C

C

Step 2: Top cover removal

The top cover can be opened by removing the four screws

(F) located underneath the Bean container and the four

screws (G) accessible from the underside of the UI panel.

F

F

F

F

J

Undo the snaps by tracing the curve of the UI panel with a

at-head screwdriver, while pulling the UI panel upwards.

The UI panel can be disassembled, the rotary knob can

simply be pulled off, the rotary encoder is secured by a

single nut, remove the nut. The PCBA cover is held in place

by six screws (L), once unscrewed the PCBA can be taken

out. Please mind the rubber seal, preventing steam from

reaching the UI PCBA.

J

5-15

Loading...

Loading...