Page 1

®

PRODUCT SPECIFICATIONS

Integrated Circuits Group

LH28F160S5T-L70A

Flash Memory

16M (2M × 8/1M × 16)

(Model No.: LHF16K55)

Spec No.: EL104104

Issue Date: April 17, 1998

Page 2

SHARP

LHF16K55

l Handle this document carefully for it contains material protected by international copyright

law. Any reproduction, full or in part, of this material is prohibited without the express

written permission of the company.

l When using the products covered herein, please observe the conditions written herein

and the precautions outlined in the following paragraphs. In no event shall the company

be liable for any damages resulting from failure to strictly adhere to these conditions and

precautions.

(1) The products covered herein are designed and manufactured for the following

application areas. When using the products covered herein for the equipment listed

in Paragraph (2), even for the following application -areas, be sure to observe the

precautions given in Paragraph (2). Never use the products for the equipment listed

in Paragraph (3).

*Office electronics

alnstrumentation and measuring equipment

*Machine tools

*Audiovisual equipment

*Home appliance

&ommunication equipment other than for trunk lines

(2) Those contemplating using the products covered herein for the following equipment

which demands high reliability, should first contact a sales representative of the

company and then accept responsibility for incorporating into the design fail-safe

operation, redundancy, and other appropriate measures for ensuring &liability and

safety of the equipment and the overall system.

*Control and safety devices for airplanes, trains, automobiles, and other

transportation equipment

*Mainframe computers

l Traff ic control systems

*Gas leak detectors and automatic cutoff devices

*Rescue and security equipment

*Other safety devices and safety equipment, etc.

(3) Do not use the products covered herein for the following equipment which demands

extremely high performance in terms of functionality, reliability, or accuracy.

*Aerospace equipment

@Communications equipment for trunk lines

*Control equipment for the nuclear power industry

*Medical equipment related to life support, etc.

(4) Please direct all queries and comments regarding the interpretation of the above

three Paragraphs to a sales representative of the company.

.

l Please direct all queries regarding the products covered herein to a sales representative

of the company.

‘.

Rev.1.8

Page 3

SHARI=

LHFl6K55

CONTENTS

PAGE PAGE

1 INTRODUCTION ......................................................

1 .l Product Overview.. .............................................. 3

2 PRINCIPLES OF OPERATION.. ..............................

2.1 Data Protection ...................................................

3 BUS OPERATION ....................................................

3.1 Read ................................................................... 7

3.2 Output Disable ....................................................

3.3 Standby ............................................................... 7

3.4 Deep Power-Down .............................................. 7

3.5 Read identifier Codes Operation..

3.6 Query Operation.. ................................................

3.7 Write ....................................................................

3 COMMAND DEFINITIONS ....................................... 8

4.1 Read Array Command.. .....................................

4.2 Read Identifier Codes Command.. .................... 11

4.3 Read Status Register Command.. ..................... 11

4.4 Clear Status Register Command.. ..................... 11

4.5 Query Command.. ............................................. 12

4.51 Block Status Register .................................. 12

4.5.2 CFI Query Identification String.. ................... 13

4.5.3 System interface Information ....................... 13

4.5.4 Device Geometry Deffnition ......................... 14

4.5.5 SCS OEM Specific Extended Query Table . . 14

4.6 Block Erase Command ......................................

4.7 Full Chip Erase Command.. .............................. 15

4.8 Word/Byte Write Command.. ............................. 16

4.9 Multi Word/Byte Write Command.. .................... 16

4.10 Block Erase Suspend Command.. ................... 17

4.11 (Multi) Word/Byte Write Suspend Command

4.12 Set Block Lock-Bit Command..

4.13 Clear Block Lock-Bits Command.. ...................

4.14 STS Configuration Command ......................... 19

....................... 8

1 1

15

... 17

........................ 18

18

5 DESIGN CONSIDERATIONS

3

5.1 Three-Line Output Control ................................ .3C

5.2 STS and Block Erase, Full Chip Erase, (Multi)

6

7

7

7

8

8

Word/Byte Write and Block Lock-Bit Configuration

Polling.. ............................................................. .3C

5.3 Power Supply Decoupling.. ................................ 3C

5.4 V,, Trace on Printed Circuit Boards..

5.5 V,,, V,,, RP# Transitions..

5.6 Power-Up/Down Protection..

5.7 Power Dissipation

6 ELECTRICAL SPECIFICATIONS.. ........................ .3i

6.1 Absolute Maximum Ratings ............................... 32

6.2 Operating Conditions ......................................... 32

6.2.1 Capacitance .................................................

6.2.2 AC Input/Output Test Conditions..

6.2.3 DC Characteristics.. ..................................... .34

6.2.4 AC Characteristics - Read-&ly Operations .36

6.2.5 AC Characteristics - Write Operations..

6.2.6 Alternative CE#-Controlled

6.2.7 Reset Operations ......................................... 43

6.2.8 Block Erase, Full Chip Erase, (Multi)

Word/Byte Write and Block Lock-Bit

Configuration Performance.. ......................... 44

7 ADDITIONAL INFORMATION ....................... . ....... .45

7.1 Ordering Information

8 PACKAGE AND PACKING SPECIFICATION;;......4 6

............................................. .31

................................ .3C

............... .3C

..............................

.............................

...............

Writes.. ............. .41

................................ .I ........ 45

.......

1

.31

.31

32

.3C

.3S

Rev. 1.8

Page 4

SHARI=

16-MBIT (2MBx8/1 MBxl6)

Smart 5 Flash MEMORY

n

Smart 5 Technology

- 5V vcc

- 5V vpp

n

Common Flash Interface (CFI)

-

Universal & Upgradable Interface

n

Scalable Command Set (SCS)

n

High Speed Write Performance

-

32 Bytes x 2 plane Page Buffer

-

2ys/Byte Write Transfer Rate

n

High Speed Read Performance

- 70ns(5V=0.25V), 80ns(5VT0.5V)

LHFl6K55

LH28F160S5T-L70A

n

Enhanced Data Protection Features

-

Absolute Protection with Vpp=GND

-

Flexible Block Locking

-

Erase/Write Lockout during Power

Transitions

n

Extended Cycling Capability

-

100,000 Block Erase Cycles

-

3.2 Million Block Erase Cycles/Chip

n

Low Power Management

-

Deep Power-Down Mode

-

Automatic Power Savings Mode

Decreases ICC in Static Mode

2

n

n

Enhanced Automated Suspend Options

-

Write Suspend to Read

-

Block Erase Suspend to Write

-

Block Erase Suspend to Read

n

High-Density Symmetrically-Blocked

Architecture

-

Thirty-two 64-Kbyte Erasable Blocks

n

SRAM-Compatible Write Interface

n

User-Configurable x8 or x16 Operation

SHARP’s LH28F160S5T-L70A Flash memory with Smart 5 technology is a high-density, low-cost, nonvolatile,

read/write storage solution for a wide range of applications. Its symmetrically-blocked architecture, flexible voltage

and extended cycling provide for highly flexible component suitable for resident flash arrays, SlMMs and memory

cards. Its enhanced suspend capabilities provide for an ideal solution for code + data storage applications. For

secure code storage applications, such as networking, where code is either directly executed out of flash or

downloaded to DRAM, the LH28F160S5T-L70A offers three levels of protection: absolute protection with V,, at

GND, selective hardware block locking, or flexible software block locking. These alternatives give designers

ultimate control of their code security needs.

The LH28F160SST-L70A is conformed to the flash Scalable Command Set (SCS) and the Common Flash Interface

(CFI) specification which enable universal and upgradable interface, enable the highest system/device data transfer

rates and minimize device and system-level implementation costs.

Automated Write and Erase

-

Command User Interface

- Status Register

n

Industry-Standard Packa;ing

- 56-Lead TSOP

n

ETOXTM’ V Nonvolatile Flash

Technology

n

Not designed or rated as radiation

hardened

The LH28F160S5T-L70A is manufactured on SHARP’s 0.4pm ETOX

standard package: the 56-Lead TSOP, ideal for

‘ETOX is a trademark of Intel Corporation.

board constrained applications.

TM* V process technology. It come in industry-

%\

Rev. 1.8

Page 5

SHARP

LHFI 6K55

1 INTRODUCTION

This

specifications. Section 1 provides a flash memory

overview. Sections 2, 3, 4, and 5 describe the

memory organization and functionality. Section 6

covers electrical specifications.

datasheet contains

LH28F160.%T-L70A

1 .l Product Overview

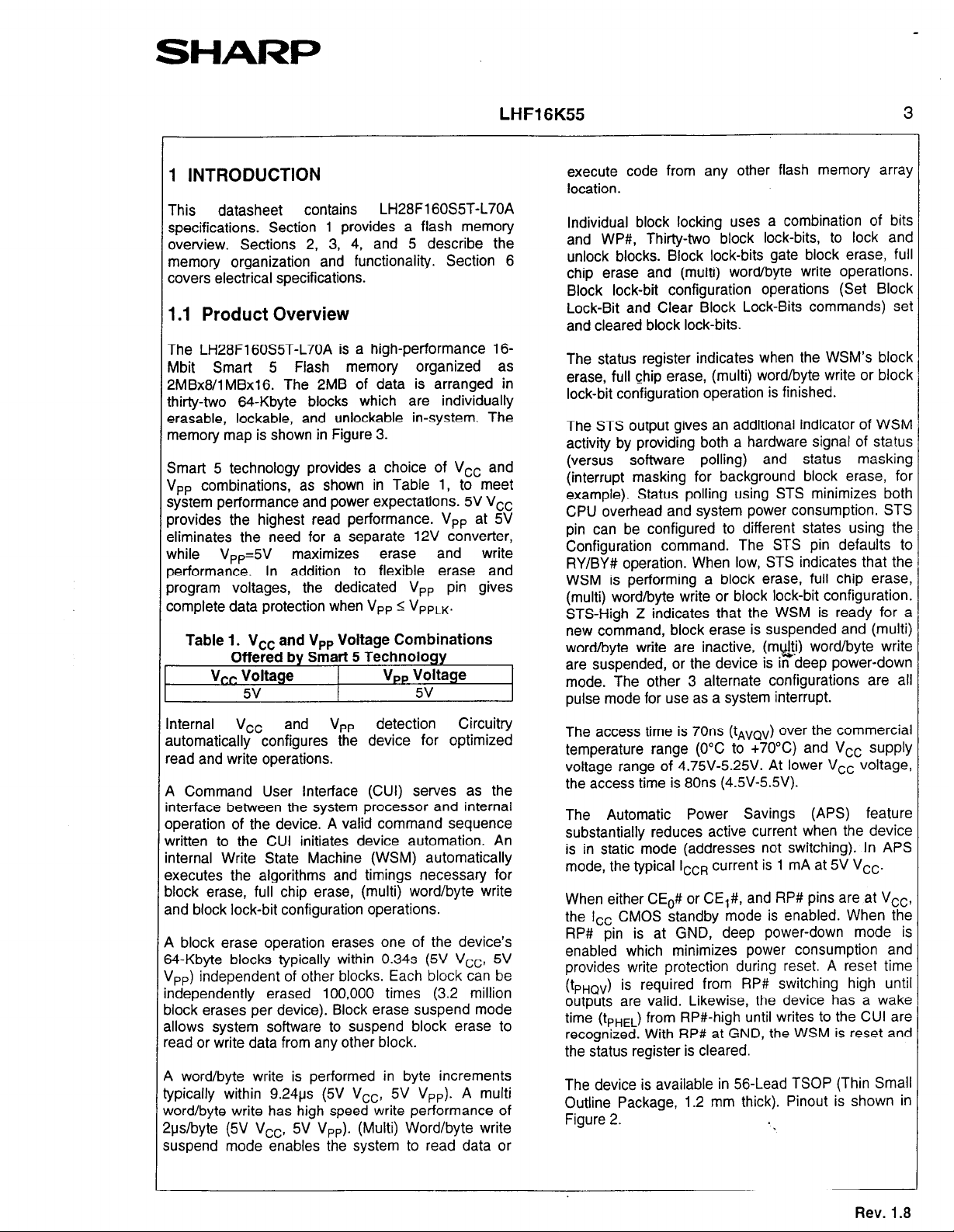

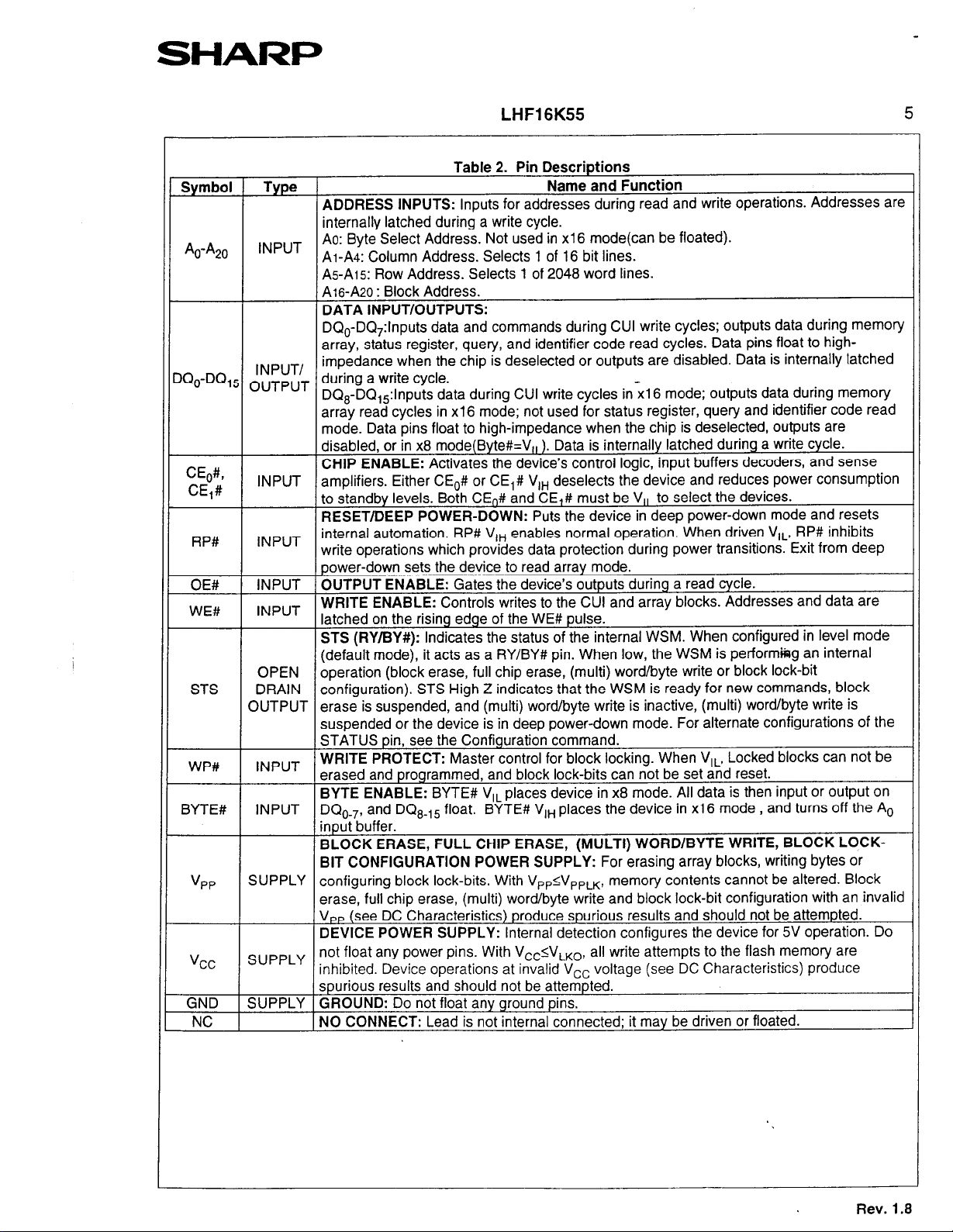

The LH28F160S5T-L70A is a high-performance 16-

Mbit Smart 5 Flash memory organized as

2MBx8/1MBxl6. The 2MB of data is arranged in

thirty-two 64-Kbyte blocks which are individually

erasable, lockable, and unlockable in-system. The

memory map is shown in Figure 3.

Smart 5 technology provides a choice of Vcc and

V,, combinations, as shown in Table 1, to meet

system performance and power expectations. 5V Voc

provides the highest read performance. V,, at 5V

eliminates the need for a separate 12V converter,

while V,,=5V maximizes erase and write

performance. In addition to flexible erase and

program voltages, the dedicated V,, pin gives

complete data protection when V,, < VppLK.

Table 1. V,, and VP, Voltage Combinations

Offered by Smart 5 Technology

Vcr: Voltage Vpp Voltage

5v 5v

Internal

automatically configures the device for optimized

read and write operations.

A Command User Interface (CUI) serves as the

interface between the system processor and internal

operation of the device. A valid command sequence

nritten to the CUI initiates device automation. An

nternal Write State Machine (WSM) automatically

executes the algorithms and timings necessary for

slack erase, full chip erase, (multi) word/byte write

and block lock-bit configuration operations.

4 block erase operation erases one of the device’s

?4-Kbyte blocks typically within 0.34s (5V Vcc, 5V

Jpp) independent of other blocks. Each block can be

ndependently erased 100,000 times (3.2 million

Ilock erases per device). Block erase suspend mode

1110~s system software to suspend block erase to

,ead or write data from any other block.

4 word/byte write is performed in byte increments

ypically within 9.241s (5V Vco, 5V VP,). A multi

vord/byte write has high speed write performance of

!us/byte (5V Voc, 5V V,,). (Multi) Word/byte write

cuspend mode enables the system to read data or

vcc

and

detection Circuitry

VW

execute code from any other flash memory array

location.

Individual block locking uses a combination of bits

and WP#, Thirty-two block lock-bits, to lock and

unlock blocks. Block lock-bits gate block erase, full

chip erase and (multi) word/byte write operations.

Block lock-bit configuration operations (Set Block

Lock-Bit and Clear Block Lock-Bits commands) se1

and cleared block lock-bits.

The status register indicates when the WSM’s block

erase, full chip erase, (multi) word/byte write or block

lock-bit configuration operation is finished.

The STS output gives an additional indicator of WSM

activity by providing both a hardware signal of status

(versus software polling) and status masking

(interrupt masking for background block erase, for

example). Status polling using STS minimizes both

CPU overhead and system power consumption. STS

pin can be configured to different states using the

Configuration command. The STS pin defaults to

RY/BY# operation. When low, STS indicates that the

WSM is performing a block erase, full chip erase,

(multi) word/byte write or block lock-bit configuration.

STS-High Z indicates that the WSM is ready for a

new command, block erase is suspended and (multi)

word/byte write are inactive, (m!&i) word/byte write

are suspended, or the device is In deep power-down

mode. The other 3 alternate configurations are all

pulse mode for use as a system interrupt.

The access time is 70ns (t,vQv) over the commercial

temperature range (0% to +70X) and Vcc supply

voltage range of 4.75V-5.25V. At lower Vcc voltage,

the access time is 80ns (4.5V-5.5V).

The Automatic Power Savings (APS) feature

substantially reduces active current when the device

is in static mode (addresses not switching). In APS

mode, the typical lCCR current is 1 mA at 5V Vcc.

When either CE,# or CE,#, and RP# pins are at Vco,

the I,, CMOS standby mode is enabled. When the

RP# pin is at GND, deep power-down mode is

enabled which minimizes power consumption and

provides write protection during reset. A reset time

(t,,o,) is required from RP# switching high until

outputs are valid. Likewise, the device has a wake

time (tPHEL) from RP#-high until writes to the CUI are

recognized. With RP# at GND, the WSM is reset and

the status register is cleared.

The device is available in 56-Lead TSOP (Thin Small

Outline Package, 1.2 mm thick). Pinout is shown in

Figure 2.

Rev. 1.8

Page 6

SHARP

LHF16K55

r

CE#

WE#

OE%

RPX

WPX

c&

NC

A20

49

Ala

A17

A16

vcc

4s

A14

A13

A12

CE,,#

VPP

RP#

41

ho

AQ

43

GND

A7

A6

A5

%

A3

A2

Al

2

3

4

5

6

7

a

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

0

Figure 1. Block Diagram

56 LEAD TSOP

STANDARD PINOUT

14mm x 20mm

TOP VIEW

WP#

WE#

OE#

STS

DQts

DQ7

DQ14

%I

DQ13

DQ5

DQ12

DQ4

vcc

GND

DQll

Ei:,

DQa

vcc

DQ9

DQI

DQs

DQo

A0

BYTE#

NC

NC

Figure 2. TSOP 56-Lead Pinout (Normal Bend)

Rev. 1.8

Page 7

SHARP

LHF16K55 5

elects 1 of 2048 word lines.

commands during CUI write cycles; outputs data during memory

ower-down mode. For alternate configurations of the

laces the device in xl 6 mode

or eraslng

NC 1 NO CONNECT: Lead is not internal connected; it may be driven or floated.

array

, and turns off the A

Rev.1.8

Page 8

SHARP

2 PRINCIPLES OF OPERATION

The LH28F160!35T-L70A Flash memory includes an

on-chip WSM to manage block erase, full chip erase,

(multi) word/byte

write and block

configuration functions. It allows for: 100% TTL-level

control inputs, fixed power supplies during block

erase, full chip erase, (multi) word/byte write and

block lock-bit configuration, and minimal processor

overhead with RAM-Like interface timings.

After initial device power-up or return from deep

power-down mode (see Bus Operations), the device

defaults to read array mode. Manipulation of external

memory control pins allow array read, standby, and

output disable operations.

Status register, query structure and identifier codes

:an be accessed through the CUI independent of the

VP, voltage. High voltage on VP, enables successful

>lock erase, full chip erase, (multi) word/byte write

lnd block lock-bit configuration. All functions

associated with altering memory contenttilock

erase, full chip erase, (multi) word/byte write and

Ilock lock-bit configuration, status, query and

dentifier codes-are accessed via the CUI and

verified through the status register.

lock-bit

LHF16K55 6

Commands are written using

standard

nicroprocessor write timings. The CUI contents serve

1s input to the WSM, which controls the block erase,

ull chip erase, (multi) word/byte write and block lock-

Iit configuration. The internal algorithms are

egulated by the WSM, including pulse repetition,

nternal verification, and margining of data.

lddresses and data are internally latch during write

:ycles. Writing the appropriate command outputs

array data, accesses the identifier codes, outputs

luery structure or outputs status register data.

nterface software that initiates and polls progress of

block erase, full chip erase, (multi) word/byte write

nd block lock-bit configuration can be stored in any

Ilock. This code is copied to and executed from

ystem RAM during flash memory updates. After

uccessful completion, reads are again possible via

ne Read Array command. Block erase suspend

illows system software to suspend a block erase to

ead or write data from any other block. Write

suspend allows system software to suspend a (multi)

vord/byte write to read data from any other flash

nemory array location.

o7oooo

OGFFFF

06ooOO

05FFFF

o5oooo

04FFFF

o4mo

OBFFFF

030000,

OZFFFF

o2owo _

OlFFFF

o1ocoo.

OOFFFF

WOO00

64-Kbyte Block 7

64-Kbyte Block

64-Kbyte Block

64-Kbyte Block

6CKbyte Block 3

64-Kbyte Block

64-Kbyte Block

64LKbyte Block

Figure 3. Memory Map

6

5

4

2

1

0

Rev. 1.8

Page 9

SHARP

LHF16K55

2.1 Data Protection

Depending on the application, the system designer

may choose to make the Vnp power supply

switchable (available only when block erase, full chip

erase, (multi) word/byte write and block lock-bit

configuration are required) or hardwired to VPPH1.

The device accommodates either design practice and

encourages optimization of the processor-memory

interface.

When Vpp~VppLK,

altered. The CUI, with multi-step block erase, full chip

erase, (multi) word/byte write and block lock-bit

configuration command sequences, provides

orotection from unwanted operations even when high

voltage is applied to V,,. All write functions are

disabled when Vcc is below the write lockout voltage

v,,, or when RP# is at V,,. The device’s block

ocking capability provides additional protection from

nadvertent code or data alteration by gating block

erase, full chip erase and (multi) word/byte write

operations.

memory contents cannot be

3 BUS OPERATION

The local CPU reads and writes flash memory insystem. All bus cycles to or from the flash memory

:onform to standard microprocessor bus cycles.

3.1 Read

nformation can be read from any block, identifier

:odes, query structure, or status register independent

)f the V,, voltage. RP# must be at V,,.

-he first task is to write the appropriate read mode

:ommand (Read Array, Read Identifier Codes, Query

jr Read Status Register) to the CUI. Upon initial

levice power-up or after exit from deep power-down

node, the device automatically resets to read array

node. Five control pins dictate the data flow in and

ut of the component: CE# (CE,#, CE,#), OE#, WE#,

IP# and WP#. CEo#, CE,# and OE# must be driven

ctive to obtain data at the outputs. CE,#, CE,# is

le device selection control, and when active enables

ie selected memory device. OE# is the data output

3Qc-DQ,,) control and when active drives the

elected memory data onto the I/O bus. WE# and

tP# must be at V,,. Figure 17, 18 illustrates a read

ycle.

3.2 Output Disable

With OE# at a logic-high level (VI,), the device

outputs are disabled. Output pins DQc-DQ,, arc

placed in a high-impedance state.

3.3 Standby

Either CE,# or CE,# at a logic-high level (V,,) place:

the device in standby mode which substantial11

reduces device power consumption. DQc-DQ,,

outputs ar_e placed in a high-impedance state

independent of OE#. If deselected during bloc1

erase, full chip erase, (multi) word/byte write ant

block lock-bit configuration, the device continue:

functioning, and consuming active power until the

operation completes.

3.4 Deep Power-Down

RP# at V,, initiates the deep power-down mode.

In read modes, RP#-low deselects the memory

places output drivers in a high-impedance state ant

turns off all internal circuits. RP# must be held low for

a minimum of 100 ns. Time tnHav is required after

return from power-down until initial memory access

outputs are valid. After this wake$p interval, norma

operation is restored. The GUI is reset to read array

mode and status register is set to 80H.

During block erase, full chip erase, (multi) word/byte

write or block lock-bit configuration modes, RP#-low

will abort the operation. STS remains low until the

reset operation is complete. Memory contents being

altered are no longer valid; the data may be partially

erased or written. Time tPHWL is required after RP#

goes to logic-high (V,,) before another command can

be written.

As with any automated device, it is important to

assert RP# during system reset. When the system

comes out of reset, it expects to read from the flash

memory. Automated flash memories provide status

information when accessed during block erase, full

chip erase, (multi) word/byte write and block lock-bit

configuration. If a CPU reset occurs with no flash

memory reset, proper CPU initialization may not

occur because the flash memory may be providing

status information instead of array data. SHARP’s

flash memories allow proper CPU initialization

following a system reset through the use of the RP#

input. In this application, RP# is controlled by the

same RESET# signal that resets the system CPU.

Rev. 1.8

Page 10

SHARI=

LHF16K55

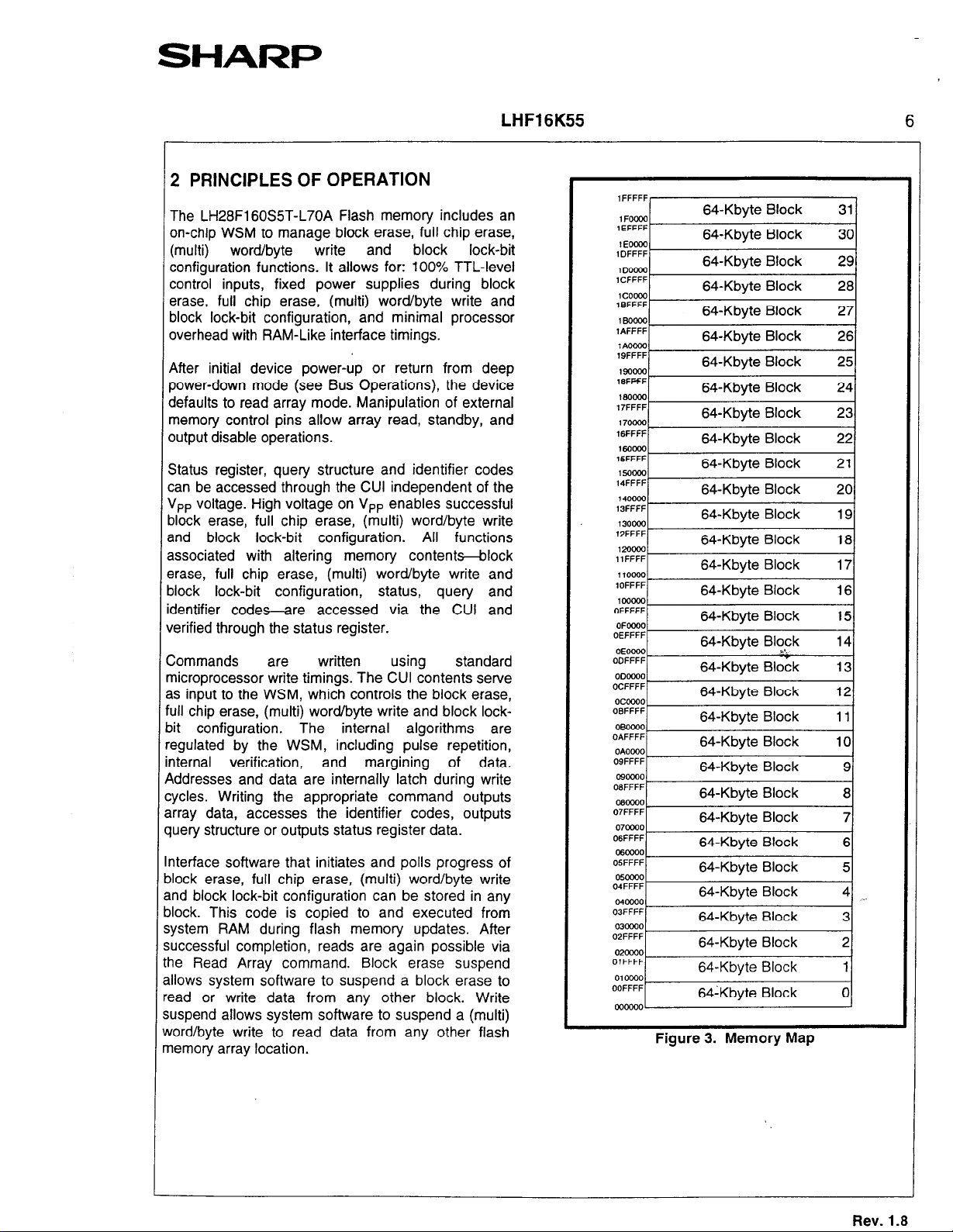

,5 Read Identifier Codes Operation

ie read identifier codes operation outputs the

anufacturer code, device code, block status codes

r each block (see Figure 4). Using the manufacturer

rd device codes, the system CPU can automatically

atch the device with its proper algorithms. The

sck status codes identify locked or unlocked block

!tiing and erase completed or erase uncompleted

ndition.

8

3.6 Query Operation

The query operation outputs the query structure.

Query database is stored in the 48Byte ROM. Query

structure allows system software to gain critica,

information for controlling the flash component.

Query structure are always presented on the lowestorder data output (DC&,-DQ,) only.

3.7 Write

Writing commands to the CUI enable reading oi

device data and identifier codes. They also control

inspection and clearing of the status register. When

Vcc=Vcc,,2 and VPP=VPPH1, the CUI additionally

controls block erase, full chip erase, (multi) word/byte

write and block lock-bit configuration.

The Block Erase command requires appropriate

command data and an address within the block to be

erased. The Word/byte Write command requires the

command and address of the location to be written.

Set Block Lock-Bit command requires the command

and block address within the device (Block Lock) to

be locked. The Clear Block Lock-Bits command

requires the command and address within the device.

‘igure 4. Device Identifier Code Memory Map

The CUI does not occupy an addressable memory

location. It is written when WE# &rd CE# are active.

The address and data needed to execute a command

are latched on the rising edge of WE# or CE#

(whichever goes high first). Standard microprocessor

write timings are used. Figures 19 and 20 illustrate

WE# and CE#-controlled write operations.

4 COMMAND DEFINITIONS

When the V,, voltage 2 V,,,,, Read operations from

the status register, identifier codes, query, or blocks

are enabled. Placing VppHl on V,, :enables

successful block erase, full chip erase, (multi)

word/byte write and block lock-bit configuration

operations.

Device operations are selected by writing specific

commands into the CUI. Table 4 defines these

commands.

.r

Rev. 1.8

Page 11

SHARf=

Mode

Read

Output Disable

LHF16K55

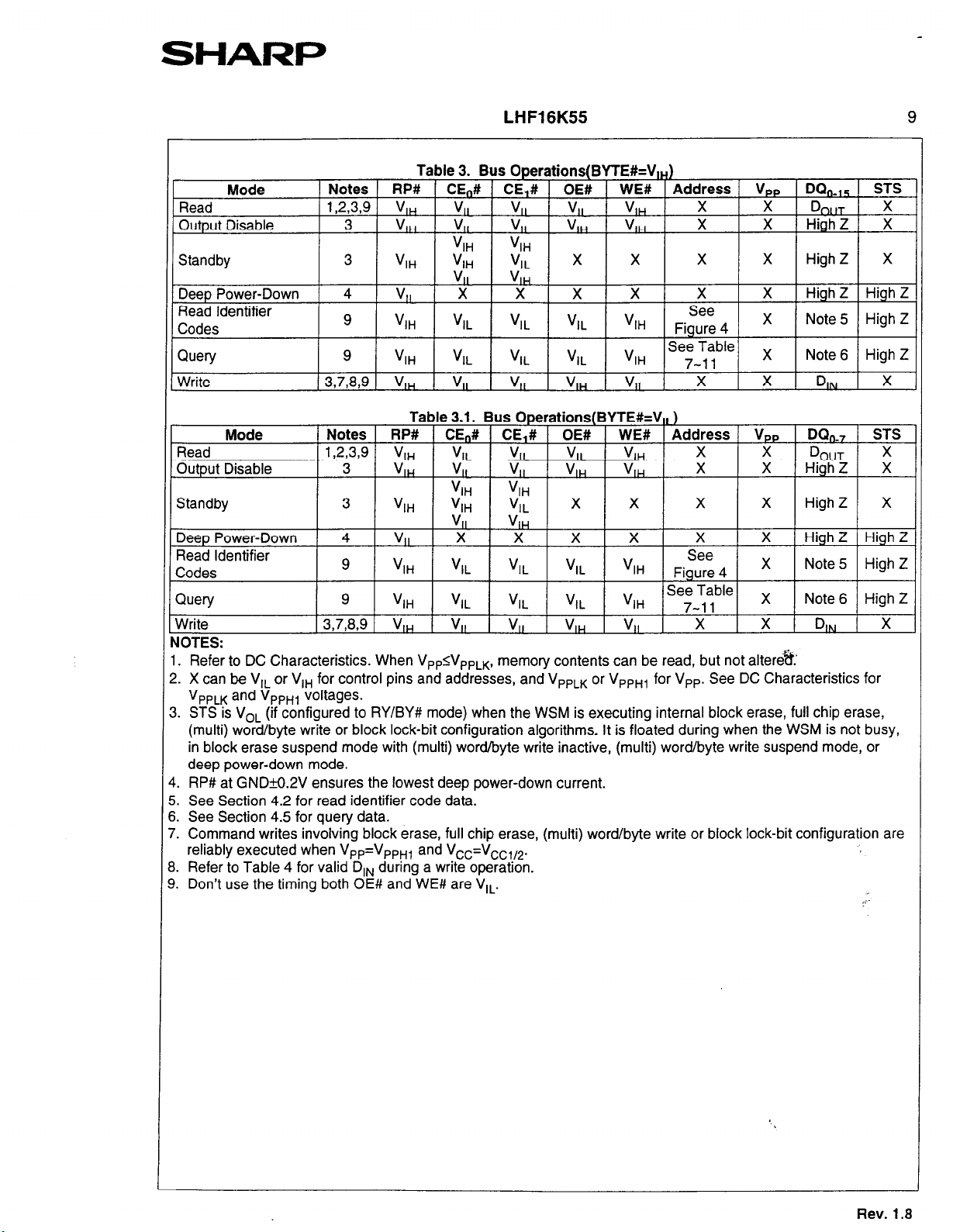

Table 3. Bus Operations(BYTE#=V,,)

Notes 1 RP# 1 CE,,# 1 CE,# OE# 1 WE# I Address

1

12733

3

3

4

9

!L

IIH-

“I,

v,,

“I,

v,,

v,,

“I,

“1,

ll!ll-

“IL

X

v,,

v,,

“I,

“IL

l!lH-

X X

“IL

V,, V,H

V,&j V,w

X

“IL

X

X

“I,

1 Vpp 1 DQn.,5 I STS ]

1 X Dn,,r

X

X High Z X

X

High Z X

X High Z High Z

X Note 5 High Z

X

9

3,mg

RB

NOTES:

1. Refer to DC Characteristics. When V,,<V,,,k,

2. X can be V,, or VrH for control pins and addresses, and V,,,, or VPPHt for V,,. See DC Characteristics for

V,nLk and V,r+n voltages.

3. STS is V,, (if configured to RY/BY# mode) when the WSM is executing internal block erase, full chip erase,

(multi) word/byte write or block lock-bit configuration algorithms. It is floated during when the WSM is not busy,

in block erase suspend mode with (multi) word/byte write inactive, (multi) word/byte write suspend mode, or

deep power-down mode.

4. RP# at GNDM.2” ensures the lowest deep power-down current.

5. See Section 4.2 for read identifier code data.

6. See Section 4.5 for query data.

7. Command writes involving block erase, full chip erase, (multi) word/byte write or block lock-bit configuration are

reliably executed when VPP=VPPH1 and Vcc=Vcc,,2.

8. Refer to Table 4 for valid D,, during a write operation.

9. Don’t use the timing both OE# and WE# are VI,.

“I,

L!k.

“IL

I

“IL

V

E

memory contents can be read, but not altere%f:

“I,

v,r

X Note 6 High Z

X D,N X

.,--

Rev. 1.8

Page 12

SHARP

LHF16K55

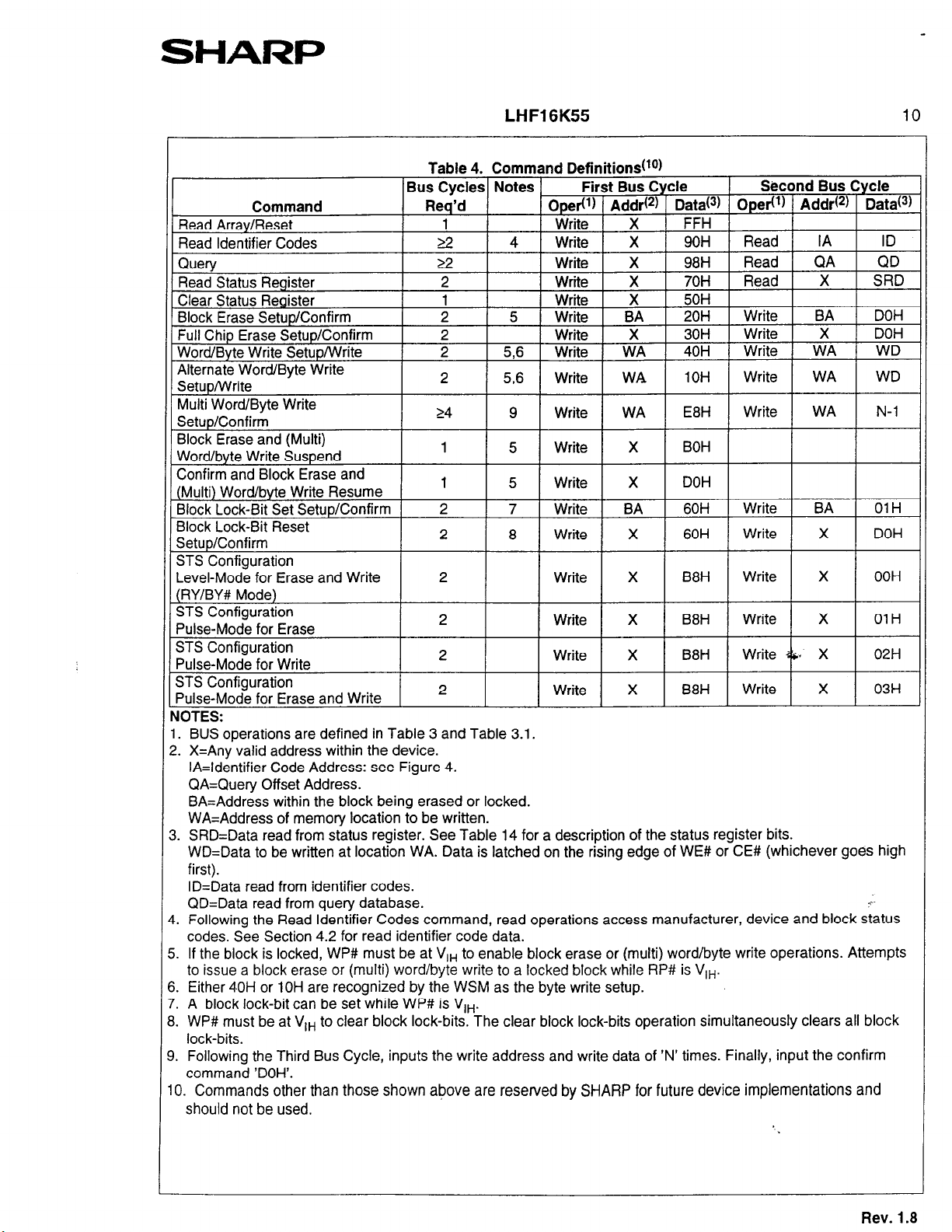

Table 4. Commanc .

Bus Cycles Notes

Command

Read Array/Reset

Read Identifier Codes

Al lternate Word/Byte Write

Setup/Write Multi Word/Byte Write

Setup/Confirm

Block Erase and (Multi)

Word/byte Write Suspend

Confirm and Block Erase and

(Multi) Word/byte Write Resume

Block Lock-Bit Set Setup/Confirm

Block Lock-Bit Reset

Setup/Confirm

STS Confiauration

Level-Mode for Erase and Write 1 2 1 I Write I X

(RY/BY# Mode)

STS Confiauration

Pulse-Mode for Erase

STS Configuration

Pulse-Mode for Write

STS Configuration

Pulse-Mode for Erase and Write

IOTES:

. BUS operations are defined in Table 3 and Table 3.1.

. X=Any valid address within the device.

IA=ldentifier Code Address: see Figure 4.

QA=Query Offset Address.

BA=Address within the block being erased or locked.

WA=Address of memory location to be written.

3

. SRD=Data read from status register. See Table 14 for a description of the status register bits.

WD=Data to be written at location WA. Data is latched on the rising edge of WE# or CE# (whichever goes high

first).

ID=Data read from identifier codes.

QD=Data read from query database.

. Following the Read Identifier Codes command, read operations access manufacturer, device and block status

codes. See Section 4.2 for read identifier code data.

. If the block is locked, WP# must be at VI, to enable block erase or (multi) word/byte write operations. Attempts

to issue a block erase or (multi) word/byte write to a locked block while RP# is V,,.

. Either 40H or 1OH are recognized by the WSM as the byte write setup.

A block lock-bit can be set while WP# is V,,.

. WP# must be at V,, to clear block lock-bits. The clear block lock-bits operation simultaneously clears all block

lock-bits.

9.

Following the Third Bus Cycle, inputs the write address and write data of ‘N’ times. Finally, input the confirm

command ‘DOH’.

II

3. Commands other than those shown above are reserved by SHARP for future device implementations and

should not be used.

Req’d

1 WI,., , ,\ , I.II ,

I

2

14

1 5 Write X BOH

2 8 Write

z vvnte A aan

2

2 Write X B8H

4 I Write I X 1 90H 1 Read 1

5,6

9

7 Write

1 Definitions(lO)

First Bus Cycle

VU) ( Ad&(*) 1 Data@) Ope#) ) AI

opt

ritn

1 Y 1 FFU I

Write

Write

Write

Write X

WA

WA

BA 2

10H

E8H

DOH 1 5 Write

I B8H I Write I X I OOH /

B8H Write b : X 02H

Second

Write WA WD

Write

Write

vvrw A Ull-l

Write X 03H

I Bus Cycle

ddr(*) Datat3)

4

4 ID

WA N-l

BA

X

7.-

Rev. 1.8

Page 13

SHARP

LHF16K55 11

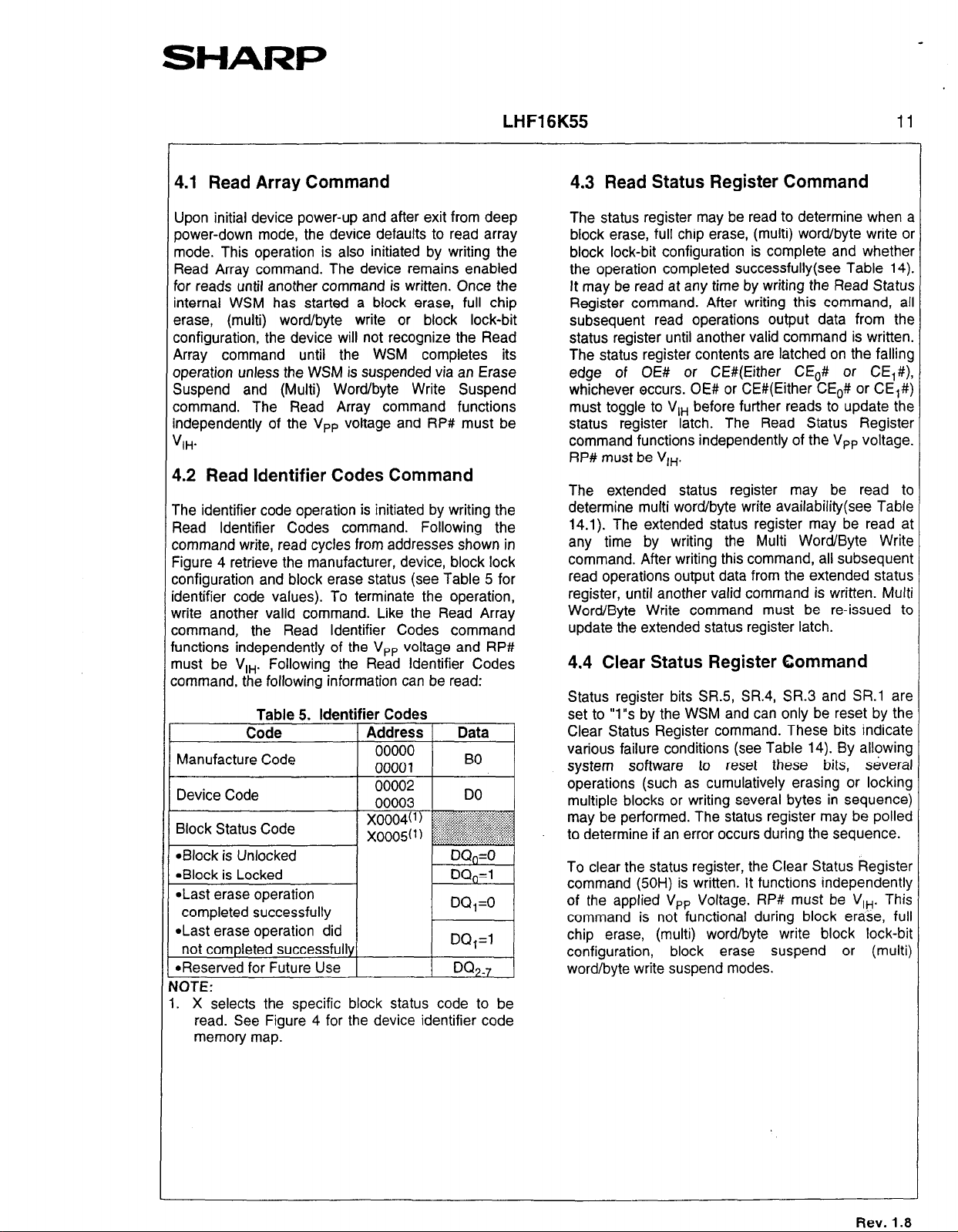

4.1 Read Array Command 4.3 Read Status Register Command

Upon initial device power-up and after exit from deep

power-down mode, the device defaults to read array

mode. This operation is also initiated by writing the

Read Array command. The device remains enabled

for reads until another command is written. Once the

internal WSM has started a block erase, full chip

erase, (multi) word/byte write or block lock-bit

configuration, the device will not recognize the Read

Array command until the WSM completes its

operation unless the WSM is suspended via an Erase

Suspend and (Multi) Word/byte Write Suspend

command. The Read Array command functions

ndependently of the Vpp

VIH-

voltage and RP# must be

1.2 Read Identifier Codes Command

The identifier code operation is initiated by writing the

qead Identifier Codes command. Following the

:ommand write, read cycles from addresses shown in

7gure 4 retrieve the manufacturer, device, block lock

:onfiguration and block erase status (see Table 5 for

dentifier code values). To terminate the operation,

Nrite another valid command. Like the Read Array

:ommand, the Read Identifier Codes command

unctions independently of the V,, voltage and RP#

nust be Vi,. Following the Read Identifier Codes

:ommand, the following information can be read:

Table 5. Identifier Codes

Code

Manufacture Code

Device Code

Block Status Code

1 Address 1 Data 1

I nr\nnn

““““”

nnnn 1

The status register may be read to determine when i

block erase, full chip erase, (multi) word/byte write OI

block lock-bit configuration is complete and whethel

the operation completed successfully(see Table 14)

It may be read at any time by writing the Read Statu$

Register command. After writing this command, al

subsequent read operations output data from the

status register until another valid command is written

The status register contents are latched on the fallin<

edge of OE# or CE#(Either CEc# or CE,#)

whichever eccurs. OE# or CE#(Either CE,# or CE,#:

must toggle to VrH before further reads to update the

status register latch. The Read Status Register

command functions independently of the V,, voltage

RP# must be V,,.

The extended status register may be read tc

determine multi word/byte write availability(see Table

14.1). The extended status register may be read ai

any time by writing the Multi Word/Byte Writs

command. After writing this command, all subsequeni

read operations output data from the extended status

register, until another valid command is written. Mutt1

Word/Byte Write command must be re-issued tc

update the extended status register latch.

4.4 Clear Status Register Command

Status register bits SR.5, SR.4, SR.3 and SR.l are

set to “1”s by the WSM and can only be reset by the

Clear Status Register command. These bits indicate

various failure conditions (see Table 14). By allowing

system software to reset these bits, several

operations (such as cumulatively erasing or locking

multiple blocks or writing several bytes in sequence)

may be performed. The status register may be polled

to determine if an error occurs during the sequence.

*Last erase operation did

not completed successfully

*Reserved for Future Use

IOTE:

X selects the specific block status code to be

read. See Figure 4 for the device identifier code

memory map.

DC!,=1

DQ?-,

To clear the status register, the Clear Status Register

command (50H) is written. It functions independently

of the applied V,, Voltage. RP# must be V,,. This

command is not functional during block erase, full

chip erase, (multi) word/byte write block lock-bii

configuration, block erase suspend or (multi)

word/byte write suspend modes.

Rev. 1.8

Page 14

SHARP

LHF16K55 12

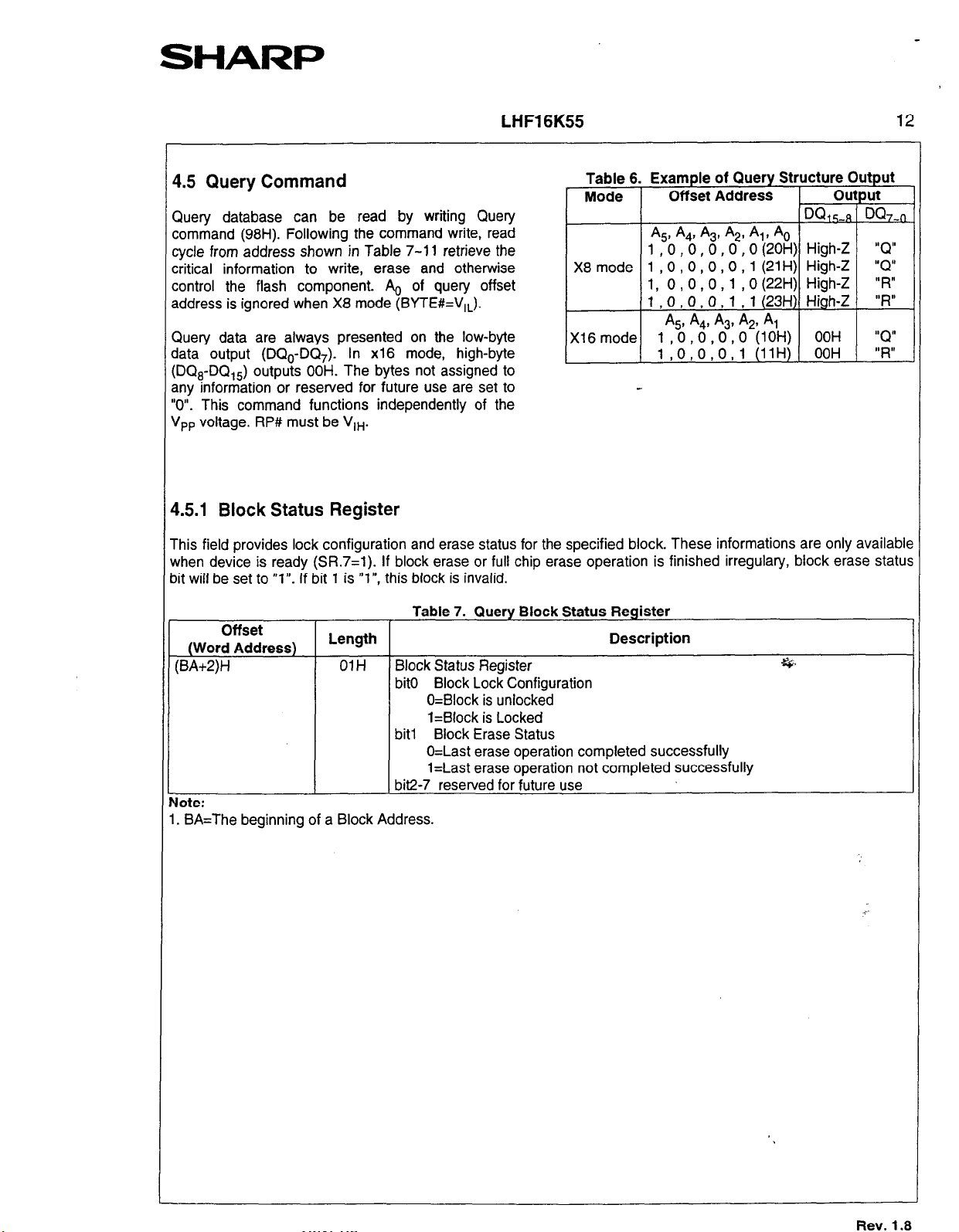

1.5 Query Command

Juery database can be read by writing Query

:ommand (98H). Following the command write, read

ycle from address shown in Table 7-11 retrieve the

xitical information to write, erase and otherwise

:ontrol the flash component. A, of query offset

tddress is ignored when X8 mode (BYTE#=V,L).

Juery data are always presented on the low-byte

fata output (D&JDQ,). In x16 mode, high-byte

DQs-DQ,,) outputs OOH. The bytes not assigned to

iny information or reserved for future use are set to

0”. This command functions independently of the

Ipp voltage. RP# must be V,,.

Table 6. Example of Query Structure Output

Mode Off set Address

A,, A,, A,, A2, A, t A,

1 , 0 , 0 , 0 , 0 , 0 (20H) High-Z

X8mode 1 ,O,O,O,O,l (21H) High-Z

1, O,O,O,l ,0(22H) High-Z

1 , 0 , 0 , 0 , 1 , 1 (23H) High-Z “R”

Xl6 mode 1 , 0 , 0 , 0 , 0 (10H) OOH “0”

A,, A,, A,, A,,

l,O,O,O,l (11H) OOH “R”

A,

output

DQ, q-~ DQ7-c

“Q”

“Q”

“R”

1.5.1 Block Status Register

-his field provides lock configuration and erase status for the specified block. These informations are only availabk

vhen device is ready (SR.7=1). If block erase or full chip erase operation is finished irregulary, block erase statu.

bit will be set to “1”. If bit 1 is “l”, this block is invalid.

Table 7. Query Block Status Register

Off set

(Word Address)

(BA+2)H OlH Block Status Register

lote:

. BA=The beginning of a Block Address.

Length

bit0 Block Lock Configuration

O=Block is unlocked

l=Block is Locked

bit1 Block Erase Status

O=Last erase operation completed successfully

l=Last erase operation not completed successfully

bit2-7 reserved for future use

Description

%g.

Rev. 1.8

Page 15

SHARP

LHF16K55

13

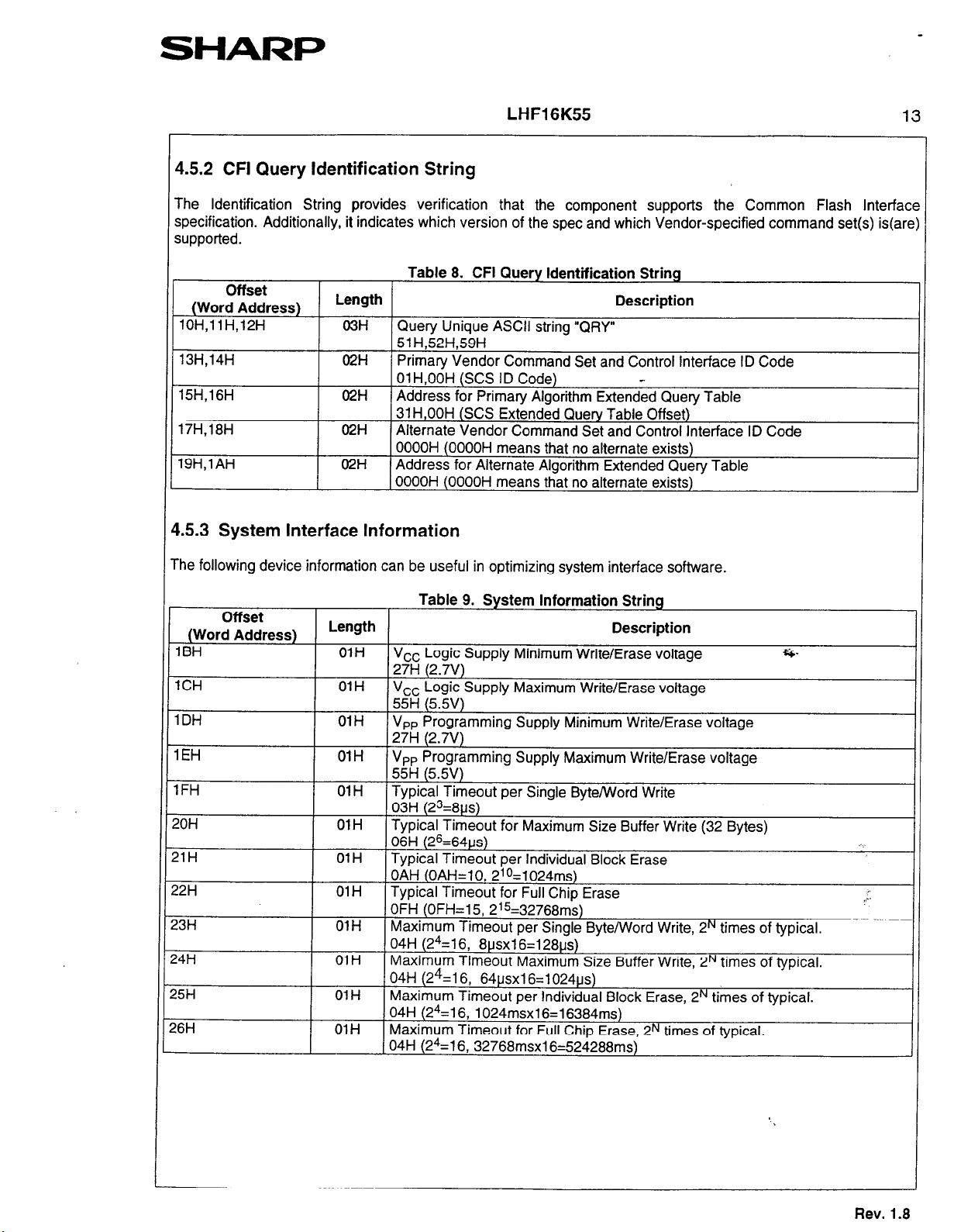

4.52 CFI Query Identification String

The Identification String provides verification that the component supports the Common Flash Interface

specification. Additionally, it indicates which version of the spec and which Vendor-specified command set(s) is(are)

supported.

Table 8. CFI Query Identification String

Offset

(Word Address)

lOH,l lH,l2H

13H,l4H

15H,l6H

17H,l8H

lSH,lAH

Length

WH Query Unique ASCII strinq “QRY”

51 H,52H,59H

02H Primary Vendor Command Set and Control Interface ID Code

01 H,OOH (SCS ID Code)

02H Address for Primary Algorithm Extended Query Table

31 H,OOH (SCS Extended Query Table Offset)

02H Alternate Vendor Command Set and Control Interface ID Code

OOOOH (OOOOH means that no alternate exists)

02H Address for Alternate Algorithm Extended Query Table

OOOOH (OOOOH means that no alternate exists)

Description

4.5.3 System Interface Information

The following device information can be useful in optimizing system interface software.

Offset

(Word Address)

1BH

1CH

1DH

1EH

1FH

20H

21H

22H

23H

24H

25H

26H

Table 9. System Information String

Length Description

01H Vcc Logic Supply Minimum Write/Erase voltage

27H (2.7V)

OlH Vcc Logic Supply Maximum Write/Erase voltage

55H (5.5V)

OlH V,, Programming Supply Minimum Write/Erase voltage

27H (2.7V)

OlH V,, Programming Supply Maximum Write/Erase voltage

55H (5.5V)

OlH Typical Timeout per Single Byte/Word Write

03H (23=8us)

01H Typical Timeout for Maximum Size Buffer Write (32 Bytes)

06H (26=64us)

OlH Typical Timeout per Individual Block Erase

OAH (OAH=lO, 210=1024ms)

OlH

01H Maximum Timeout per Single Byte/Word Write, 2N times of typical.

OlH Maximum Timeout Maximum Size Buffer Write, 2N times of typical.

01H

01H Maximum Timeout for Full Chip Erase, 2N times of typical.

Typical Timeout for Full Chip Erase

OFH (OFH=15, 215=32768ms)

04H (24=1 6, 8usxl6=128us)

04H (24=1 6, 64usxl6=1024us)

Maximum Timeout per Individual Block Erase, 2N times of typical.

04H (24=1 6, 1024msx16=16384ms)

04H (24=1 6,32768msxl6=524288ms)

+i;.

,i-

Rev. 1.8

Page 16

SHARP

LHF16K55

14

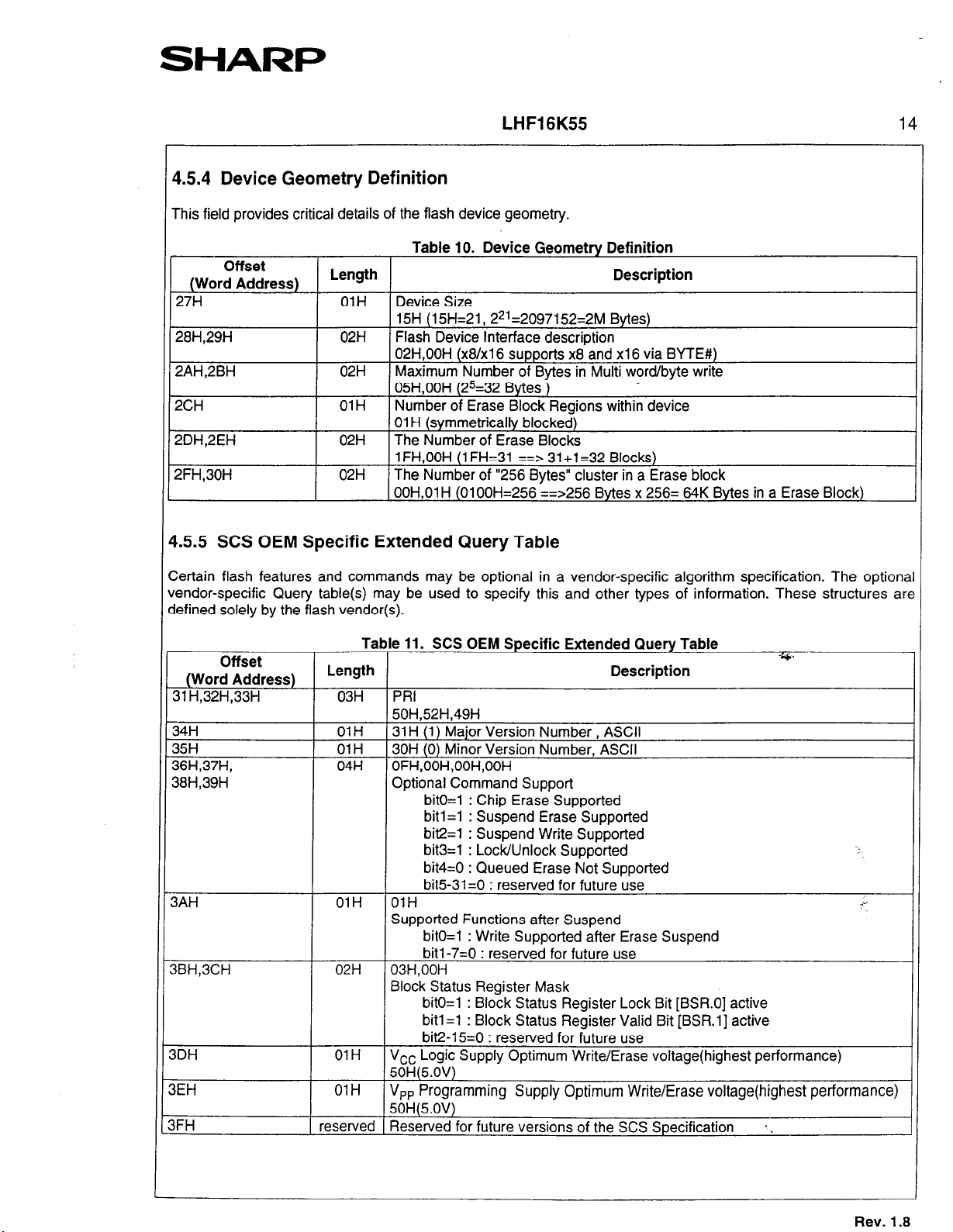

4.5.4 Device Geometry Definition

This field provides critical details of the flash device geometry.

Table 10. Device Geometry Definition

Offset

(Word Address)

27H 01H Device Size

28H,29H 02H Flash Device Interface description

2AH,2BH 02H Maximum Number of Bytes in Multi word/byte write

2CH

2DH,2EH 1 02H 1 The Number of Erase Blocks

2FH,30H

Length

15H (15H=21, 22i=2097152=2M Bytes)

02H,OOH (x8/x1 6 supports x8 and xl 6 via BYTE#)

05H,OOH (2s=32 Bytes )

OlH Number of Erase Block Regions within device

1 01 H (symmetrically blocked)

1 FH,OOH (1 FH=31 ==> 31 +1=32 Blocks)

02H The Number of “256 Bytes” cluster in a Erase block

OOH,Ol H (01 OOH=256 ==>256 Bytes x 256~ 64K Bytes in a Erase Block)

Description

1.5.5 SCS OEM Specific Extended Query Table

Zertain flash features and commands may be optional in a vendor-specific algorithm specification. The optional

rendor-specific Query table(s) may be used to specify this and other types of information. These structures are

defined solely by the flash vendor(s).

Offset

(Word Address)

31 H,32H,33H

34H

35H

36H,37H,

38H,39H

3AH

3BH,3CH

3DH

IEH

3FH

Table 11. SCS OEM Specific Extended Query Table

Length

03H PRI

50H,52H,49H

OlH

OlH 30H (0) Minor Version Number, ASCII

04H OFH,OOH,OOH,OOH

OlH OlH

02H 03H,OOH

OlH Vco Logic Supply Optimum Write/Erase voltage(highest performance)

OlH V,, Programming Supply Optimum Write/Erase voltage(highest performance)

reserved Reserved for future versions of the SCS Specification

31H (1) Major Version Number, ASCII

Optional Command Support

bitO=l : Chip Erase Supported

bit1 =l : Suspend Erase Supported

bit2=1 : Suspend Write Supported

bit3=1 : LocWUnlock Supported

bit4=0 : Queued Erase Not Supported

bit531 =O : reserved for future use

Supported Functions after Suspend

bitO=l : Write Suooorted after Erase Susoend

bit1 -7=O : reserved for future use

Block Status Register Mask

bitO=l : Block Status Register Lock Bit [BSR.O] active

bitl=l : Block Status Register Valid Bit [BSR.l] active

bit2-15=0 : reserved for future use

50H(5.OV)

50H(5.OV)

Description

’

‘I

*.

!i-

Rev. 1.8

Page 17

SHARP

LHF16K55

4.6 Block Erase Command

Block erase is executed one block at a time and

initiated by a two-cycle command. A block erase

setup is first written, followed by an block erase

confirm. This command

appropriate sequencing and an address within the

block to be erased (erase changes all block data to

FFH). Block preconditioning, erase and verify are

handled internally by the WSM (invisible to the

system). After the two-cycle block erase sequence is

written, the device automatically outputs status

register data when read (see Figure 5). The CPU can

detect block erase completion by analyzing the

output data of the STS pin or status register bit SR.7.

When the block erase is complete, status register bit

SR.5 should be checked. If a block erase error is

detected, the status register should be cleared before

system software attempts corrective actions. The CUI

?emains in read status register mode until a new

:ommand is issued.

This two-step command sequence of set-up followed

)y execution ensures that block contents are not

lccidentally erased. An invalid Block Erase command

sequence will result in both status register bits SR.4

lnd SR.5 being set to “1 I’. Also, reliable block erasure

:an only occur when Vcc=Vcc1,2 and VPP=VPPH1. In

he absence of this high voltage, block contents are

lrotected against erasure. If block erase is attempted

vhile V,+V,,,,, SR.3 and SR.5 will be set to “1”.

successful

:orresponding block lock-bit be cleared or if set, that

rVP#=V,,. If block erase is attempted when the

:orresponding block lock-bit is set and WP#=V,,,

jR.1 and SR.5 will be set to “I”.

block erase requires that the

sequence requires

I.7 Full Chip Erase Command

erase setup is first written, followed by a full chi

erase confirm. After a confirm command is writter

device erases the all unlocked blocks from block 0 t

Block 31 block by block. This command sequenc#

requires appropriate

preconditioning, erase and verify are handle1

internally by the WSM (invisible to the system). Afte

the two-cycle full chip erase sequence is written, thl

device automatically outputs status register dat;

when read (see Figure 6). The CPU can detect fu

chip erase completion by analyzing the output data c

the STS pin or status register bit SR.7.

When the full chip erase is complete, status registe

bit SR.5 should be checked. If erase error i:

detected, the status register should be cleared befort

system software attempts corrective actions. The CU

remains in read status register mode until a nev

command is issued. If error is detected on a bloc1

during full chip erase operation, WSM stops erasing

Reading the block valid status by issuing Read II:

Codes command or Query command informs which

blocks failed to its erase.

This two-step command sequence of set-up follower

by execution ensures that block contents are no

accidentally erased. An invalid Full Chip Erase

command sequence will result in both status registe

bits SR.4 and SR.5 being set to “&‘!. Also, reliable ful

chip erasure can only occur when Vcc=Vcc1,2 ant

VPP=VPPHi-

contents are protected against erasure. If full chir

erase is attempted while Vpp~Vpp,,, SR.3 and SR.!

will be set to “1”. When WP#=V,,, all blocks arc

erased independent of block lock-bits status. Wher

WP#=V,,, only unlocked blocks are erased. In thi:

case, SR.l and SR.4 will not be set to “1“. Full chir

erase can not be suspended.

In the absence of this high voltage, bloc1

sequencing.

Bloc

‘his command followed by a confirm command

30H) erases all of the unlocked blocks. A full chip

Rev. 1.8

Page 18

SHARP

LHF16K55

4.8 Word/Byte Write Command

Word/byte write is executed by a two-cycle command

sequence. Word/Byte Write setup (standard 40H or

alternate 10H) is written, followed by a second write

that specifies the address and data (latched on the

rising edge of WE#). The WSM then takes over,

controlling the word/byte write and write verify

algorithms internally. After the word/byte write

sequence is written, the device automatically outputs

status register data when read (see Figure 7). The

CPU can detect the completion of the word/byte write

event by analyzing the STS pin or status register bit

SR.7.

When word/byte write is complete, status register bit

SR.4 should be checked. If word/byte write error is

detected, the status register should be cleared. The

Internal WSM verify only detects errors for “1”s that

do not successfully write to “0%. The CUI remains in

,ead status register mode until it receives another

zommand.

qeliable word/byte writes can only occur when

Jcc=Vcc1,2 and VPP=VPPH1. In the absence of this

iigh voltage, memory contents are protected against

Nerd/byte writes. If word/byte write is attempted while

J,,IV,,,,, status register bits SR.3 and SR.4 will be

set to “1”.

he corresponding block lock-bit be cleared or, if set,

hat WP#=V,,. If word/byte write is attempted when

he corresponding block lock-bit is set and WP#=V,,,

jR.1 and SR.4 will be set to “1”. Word/byte write

operations with V,,<WP#<V,, produce spurious

esults and should not be attempted.

Successful word/byte write requires that

16

continue monitoring XSR.7 by writing multi word/byte

write setup with write address until XSR.7 transitions

to 1. When XSR.7 transitions to 1, the device is reac

for loading the data to the buffer. A word/byte COUI

(N)-1 is written with write address. After writing

word/byte count(N)-1, the device automatically turn

back to output status register data. The word/byl

count (N)-1 must be less than or equal to IFH in x

mode (OFH in x16 mode). On the next write, devic

start address is written with buffer data. Subsequer

writes provide additional device address and datz

depending on the count. All subsequent addres

must lie within the start address plus the count. Aftc

the final buffer data is written, write confirm (Dot-

must be written. This initiates WSM to begin copyin

the buffer data to the Flash Array. An invalid Mul

Word/Byte Write command sequence will result i

both status register bits SR.4 and SR.5 being set t

“1”. For additional multi word/byte write, write anoths

multi word/byte write setup and check XSR.7. Th

Multi Word/Byte Write command can be queue

while WSM is busy as long as XSR.7 indicates “1’

because LH28F160S5T-L70A has two buffers. If a

error occurs while writing, the device will stop writin

and flush next multi word/byte write command loadeN

in multi word/byte write command. Status register b

SR.4 will be set to “1”. No multi word/byte writ1

command is available if either SR.4 or SR.5 are SE

to “1”. SR.4 and SR.5 should %e cleared befort

issuing multi word/byte write command. If a mul

word/byte write command is attempted past an eras

block boundary, the device will write the data to Flasl

Array up to an erase block boundary and then stol

writing. Status register bits SR.4 and SR.5 will be SE

to “1 I’.

IY

It

a

IS

:e

8

e

1t

1,

S

1;

9

ti

n

0

?r

:

8,

I;

:

it

e

?t

e

ti

;

P

!t

I.9 Multi Word/Byte Write Command

Aulti word/byte write is executed by at least four:ycle or up to 35cycle command sequence. Up to

12 bytes in x8 mode (16 words in xl 6 mode) can be

laded into the buffer and written to the Flash Array.

Yrst, multi word/byte write setup (E8H) is written with

ie write address. At this point, the device

utomatically outputs extended status register data

KSR) when read (see Figure 8, 9). If extended

‘atus register bit XSR.7 is 0, no Multi Word/Byte

/rite command is available and multi word/byte write

?tup which just has been written is ignored. To retry,

Reliable multi byte writes can only occur wher

Vcc=Vc-.,,2 and VPP=VPPH1. In the absence of thi:

high voltage, memory contents are protected agains

multi word/byte writes. If multi word/byte write i:

attempted while V,,<V,,,,, status register bits SR.:

and SR.4 will be set to “1”. Successful mull

word/byte write requires that the corresponding bloc1

lock-bit be cleared or, if set, that WP#=V,,. If mull

byte write is attempted when the corresponding bloc1

lock-bit is set and WP#=V,,, SR.l and SR.4 will bc

set to “1 ‘I.

Rev. 1.8

n

S

it

S

3

ti

k

ti

I,

Page 19

SHARP

LHF16K55

4.10 Block Erase Suspend Command

The Block Erase Suspend command allows block-

erase interruption to read or (multi) word/byte-write

data in another block of memory. Once the blockerase process starts,

Suspend command requests that the WSM suspend

the block erase sequence at a predetermined point in

the algorithm. The device outputs status register data

when read after the Block Erase Suspend command

is written. Polling status register bits SR.7 and 33.6

can determine when the block erase operation has

been suspended (both will be set to “1”). STS will

also transition to High-Z. Specification twHRH2

defines the block erase suspend latency.

At this point, a Read Array command can be written

to read data from blocks other than that which is

suspended. A (Multi) WordByte Write command

sequence can also be issued during erase suspend

to program data in other blocks. Using the (Multi)

Word/Byte Write Suspend command (see Section

4.1 l), a (multi) word/byte write operation can also be

suspended. During a (multi) word/byte write operation

with block erase suspended, status register bit SR.7

will return to “0” and the STS (if set to RY/BY#)

output will transition to V,. However, SR.6 will

remain “1” to indicate block erase suspend status.

The only other valid commands while block erase is

suspended are Read Status Register and Block

Erase Resume. After a Block Erase Resume

command is written to the fiash memory, the WSM

will continue the block erase process. Status register

Sits SR.6 and SR.7 will automatically clear and STS

will return to VOL. After the Erase Resume command

IS written, the device automatically outputs status

register data when read (see Figure IO). V,, must

remain at V,,,, (the same V,, level used for block

arase) while block erase is suspended. RP# must

also remain at V,,. Block erase cannot resume until

writing the Block Erase

17

(multi) word/byte write operations initiated during

block erase suspend have completed.

4.11 (Multi) Word/Byte Write Suspend

Command

The (Multi) Word/Byte Write Suspend command

allows (multi) word/byte write interruption to read data

in other flash memory locations. Once the (multi)

word/byte write process starts, writing the (Multi)

Word/Byte Write Suspend command requests that

the WSM suspend the (multi) word/byte write

sequence ‘at a predetermined point in the algorithm.

The device continues to output status register data

when read after the (Multi) Word/Byte Write Suspend

command is written. Polling status register bits SR.7

and SR.2 can determine when the (multi) word/byte

write operation has been suspended (both will be set

to “1”). STS will also transition to High-Z.

Specification twHRH, defines the (multi) word/byte

write suspend latency.

At this point, a Read Array command can be written

to read data from locations other than that which is

suspended. The only other valid commands while

(multi) word/byte write is suspended are Read Status

Register and (Multi) Word/Byte Write Resume. After

(Multi) Word/Byte Write Resumecommand is written

to the flash memory, the WSM’will continue the

(multi) word/byte write process. Status register bits

SR.2 and SR.7 will automatically clear and STS will

return to VOL. After the (Multi) Word/Byte Write

command is written, the device automatically outputs

status register data when read (see Figure 11). V,,

must remain at V,,,, (the same V,, level used for

(multi) word/byte write) while in (multi) word/byte

write suspend mode. WP# must also remain at V,, or

VI,.

Rev. 1.8

Page 20

SHARP

LHF16K55

4.12 Set Block Lock-Bit Command

A flexible block locking and unlocking scheme is

enabled via block lock-bits. The block lock-bits gate

program and erase operations With WP#=V,,,

individual block lock-bits can be set using the Set

Block Lock-Bit command. See Table 13 for a

summary of hardware and software write protection

options.

Set block lock-bit is executed by a two-cycle

command sequence. The set block lock-bit setup

along with appropriate block or device address is

Nritten followed by either the set block lock-bit

:onfirm (and an address within the block to be

ocked). The WSM then controls the set block lock-bit

algorithm. After the sequence is written, the device

automatically outputs status register data when read

:see Figure 12). The CPU can detect the completion

If the set block lock-bit event by analyzing the STS

)in output or status register bit SR.7.

Nhen the set block lock-bit operation is complete,

status register bit SR.4 should be checked. If an error

s detected, the status register should be cleared.

The CUI will remain in read status register mode until

1 new command is issued.

‘his two-step sequence of set-up followed by

execution ensures that block lock-bits are not

tccidentalfy set. An invalid Set Block Lock-Bit

:ommand will result in status register bits SR.4 and

sR.5 being set to “1”. Also, reliable operations occur

only when Vcc=Vcc,,2 and VPP=VPPH1. In the

absence of this high voltage, block lock-bit contents

Ire protected against alteration.

18

block lock-bits can be cleared using only the Clea

Block Lock-Bits command. See Table 13 for ;

summary of hardware and sofhvare write protectiol

options.

Clear block lock-bits operation is executed by a two

cycle command sequence. A clear block lock-bit!

setup is first written. After the command is written, the

device automatically outputs status register dat:

when read (see Figure 13). The CPU can detec

completion of the clear block lock-bits event bl

analyzing the STS Pin output or status register bi

SR.7. -

When the operation is complete, status register bi

SR.5 should be checked. If a clear block lock-bit erro

is detected, the status register should be cleared

The CUI will remain in read status register mode unti

another command is issued.

This two-step sequence of set-up followed b\

execution ensures that block lock-bits are no

accidentally cleared. An invalid Clear Block Lock-Bit:

command sequence will result in status register bit:

SR.4 and SR.5 being set to “1”. Also, a reliable cleai

block lock-bits operation can only occur wher

Vcc=Vcc1,2 and VPP=VPPH1. If a clear block lock-bit2

operation is attempted while VpplVppLK, SR.3 ant

SR.5 will be set to “1”. In the a&ence of this higt

voltage, the block lock-bits content are protectec

against alteration. A successful clear block lock-bit:

operation requires WP#=V,,. If it is attempted witt-

WP#=V,,, SR.l and SR.5 will be set to “1” and the

operation will fail. Clear block lock-bits operations

with V,,cRP# produce spurious results and shoulc

not be attempted.

I successful set block lock-bit operation requires

VP#=V,,. If it is attempted with WP#=V,,, SRI and

iR.4 will be set to “1” and the operation will fail. Set

‘lock lock-bit operations with WP#cV,, produce

purious results and should not be attempted.

#.I3 Clear Block Lock-Bits Command

/II set block lock-bits are cleared in parallel via the

:lear Block Lock-Bits command. With WP#=V,,,

If a clear block lock-bits operation is aborted due tc

V,, or V,, transitioning out of valid range or RP#

active transition, block lock-bit values are left in an

undetermined state. A repeat of clear block lock-bits

is required to initialize block lock-bit contents tc

known values.

Rev. 1.8

Page 21

SHARP

LHF16K55

4.14 STS Configuration Command

The Status (STS) pin can be configured to different

states using the STS Configuration command. Once

the STS pin has been configured, it remains in that

configuration until another configuration command is

issued, the device is powered down or RP# is set to

V,,. Upon initial device power-up and after exit from

deep power-down mode, the STS pin defaults to

RY/BY# operation where STS low indicates that the

WSM is busy. STS High Z indicates that the WSM is

ready for a new operation.

To reconfigure the STS pin to other modes, the STS

Sonfiguration is issued followed by the appropriate

zonfiguration code. The three alternate configurations

are all pulse mode for use as a system interrupt. The

STS Configuration command functions independently

3f the V,, voltage and RP# must be VI,.

Table 12. STS Configuration Coding Description

Configuration

Bits

OOH

OlH

02H

03H

L

Set STS pin to default level mode

(RY/BY#). RY/BY# in the default

level-mode of operation will indicate

WSM status condition.

Set STS pin to pulsed output signal

for specific erase operation. In this

mode, STS provides low pulse at

the completion of BLock Erase,

Full Chip Erase and Clear Block

Lock-bits operations.

Set STS pin to pulsed output signal

for a specific write operation. In this

mode, STS provides low pulse at

the completion of (Multi) Byte Write

and Set Block Lock-bit operation.

Set STS pin to pulsed output signal

for specific write and erase

operation. STS provides low pulse

at the completion of Block Erase,

Full Chip Erase, (Multi) Word/Byte

Write and Block Lock-bit

Configuration operations.

Effects

19

Operation

Block Erase, 0

(Multi) Word/Byte

Write

Full Chip Erase

Set Block Lock-Bit X

Clear Block Lock-Bits

Block

Lock-Bit

071

X V,w All blocks are erased

X

Table 13. Write Protection Alternatives

WP# Effect

V,, or VI,, Block Erase and (Multi) Word/Byte Write Enabled

1

VI,

VI,

V,, All unlocked blocks are erased, locked blocks are not erased

V,, Set Block Lock-Bit Disabled

V,# , Set Block Lock-Bit Enabled

V,,

V,, Clear Block Lock-Bits Enabled

Block is Locked. Block Erase and (Multi) Word/Byte Write

Disabled

Block Lock-Bit Override. Block Erase and (Multi) Word/Byte

Write Enabled

Clear Block Lock-Bits Disabled

4.

.,--

Rev. 1.8

Page 22

SHARI=

1

LHF16K55

Table 14. Status Register Definition

WSMS )

7

SR.7 = WRITE STATE MACHINE STATUS

1 = Ready

0 = Busy

SR.6 = BLOCK ERASE SUSPEND STATUS

1 = Block Erase Suspended

0 = Block Erase in Progress/Completed

SR.5

= ERASE AND CLEAR BLOCK LOCK-BITS

STATUS

1 = Error in Erase or Clear Bloc1 Lock-Bits

0 = Successful Erase or Clear Block Lock-Bits

SR.4 = WRITE AND SET BLOCK LOCK-BIT STATUS

1 = Error in Write or Set Block Lock-Bit

0 = Successful Write or Set Block Lock-Bit

SR.3

= V,p STATUS

1 = V,, Low Detect, Operation Abort

O=V,,OK

SR.2 = WRITE SUSPEND STATUS

1 = Write Suspended

0 = Write in Progress/Completed

SR.l = DEVICE PROTECT STATUS

1 = Block Lock-Bit and/or WP# Lock Detected,

Operation Abort

0 = Unlock

SR.0 = RESERVED FOR FUTURE ENHANCEMENTS

BESS

6 5

( ECBLBS 1 WSBLBS [ VPPS 1 wss

4

20

DPS R

3

NOTES:

Check STS or SR.7 to determine block erase, full chip

erase, (multi) word/byte write or block lock-bit

configuration completion.

SR.6-0 are invalid while SR.7=“0”.

If both SR.5 and SR.4 are “1% after a block erase, full

chip erase, (multi) word/byte write, block lock-bit

configuration or STS configuration attempt, an improper

command sequence was entered.

SR.3 does not provide a continuous indication of V,,

level. The WSM interrogates and indicates the V,, level

only after block erase, full chip erase, (multi) word/byte

write or block lock-bit configuration command

sequences. SR.3 is not guaranteed to reports accurate

feedback only when V,,+V,,,,.

SRI does not provide a continuous indication of block

lock-bit values. The WSM interrogates block lock-bit,

and WP# only after block erase, full chip erase, (multi)

word/byte write or block lock-bit configuration command

sequences. It informs the system, depending on the

attempted operation, if the block lock-bit is set and/or

WP# is not V,,. Reading the block lock configuration

codes after writing the Read Identifier Codes command

indicates block lock-bit status.

SR.0 is reserved for future use and should be masked

out when polling the status register.

2

1

0

1

Table 14.1. Extended Status Register Definition

SMS

7 6

GR.7 = STATE MACHINE STATUS

1 = Multi Word/Byte Write available

0 = Multi Word/Byte Write not available

(SRG-O=RESERVED FOR FUTURE ENHANCEMENT,

R

R R R

5 4

R

3

NOTES:

After issue a Multi Word/Byte Write command: XSR.7

indicates that a next Multi Word/Byte Write command is

available.

XSR.G-0 is reserved for future use and should be

masked out when polling the extended status register.

2 1

R R

0

.-.

Rev. 1.8

II

Page 23

SHARP

LHF16K55

]

Block Address

Check if Desired

FULLSTANSCHECKPROCEDURE

Read

Erase Setup

Wnte

Read / 1 Status Register Data

Repeat for subsequent block etasures.

Full otatus check can be done after each block emse or after a sequence of

block erasures.

Write FFH after the

Ease

confirm

last

operation to place device in read army mode.

Status Regrster Data

Data+UH

Add,=Within Block to be Erased

Data..DOH

Ad-z&Within Block to be Erased

Standby

Standby

ck-diie Protect Error

Standby

Standby

SR.S.SR.4.SR.J and SR. 1 are only cleared by the Clear Status

Register Command in cases where multiple blocks are erased

Sbck Erase Error

before full status is checked.

f arror is detected. clear the Status Register before attempting

retry or other error recovery.

Figure 5. Automated Block Erase Flowchart

Comments

Check SR.3

lnVpp Error Detect

Check SR. 1

l=Device Protect Detect

WP#=V,,.Block Lock-Sit is Set *’

Only required for systems

implementing lock-bit confgurabon

Check SR.4.5

Both l=Command Sequence Error

Check SR.5

l=Blcck Erase Error

.+.

r

Rev. 1.8

Page 24

SHARP

starI

f

Write 70H

+

Read stalw

Wile DOH

f

Read status

LHF16K55

Full status dreck can be done alter each full chip arase.

Write FFH after the last operation to place device in read away mode.

Full Status

Check if Desired

+

Block Erase

Ccmplete

FULL STATUS CHECK PROCEDURE

Read Status Regtster

Data(See Above) Command Comments

Check SR.3

trVpp Error Detect

Check SR.4,5

Both l=CommandSquence Error

Check SR.5

l=Bbck Erase Error

Block Erase Error

Standby

Standby

SR.S.SR.4.SR.3 and SR.l are only dewed by the Clear Status

Register Command in cases where multiple blocks are erased

before full stahlr IS checked.

If error is detected. clear the Status Regrster before attempting

retry or olher error r*co”ery.

.Eg,

Block Erase Successful

Figure 6. Automated Full Chip Erase Flowchart

Rev. 1.8

Page 25

SHARI=

Stall

c-

el

LHF16K55

23

1

--I

Read Status

Flsglster Add,=X

Write WordByte write

Read

standby

I I

bpeat for subsequent wordlbyte writes.

jR fulf status check can be done after each w&byte write, or after P sequence of

word4lyta wlites.

Write FFH after me last word~%y?e write operation to place device in

read army mode.

Data-70H

DataData to Be Written

Addr=Localton to Be Written

Status Register Data

Check SR.7

,=WSM Ready

O=WShl Busy

FULL STATUS CHECK PROCEDURE

Read Status Register

Data(See Above)

standty

m

Device Pmtect Error

Standby

jR.4.SR.3 and SR.1 are only cleared by the Clear Stahn Register

command in cases where multiple locations are written before

full status is checked.

I error is detected. clear the St&s Register before attempting

retry or other *rrOr recovery.

Figure 7. Automated Word/byte Write Flowchart

Command

Check SR.3

t=Vpp Error Detect

implementing lock-bit configuration

/

Check SR.4

t=Data Write Error

n--

Rev. 1.8

Page 26

SHARP

‘I

Write EBH.

Start Address

+

Reed stetus

Rsglster

Wnte Buffer Data,

Start Address

A

wnta Another

Block Address.

LHF16K55

Bus

opaelion

Write

Reed

stemby

Write

wote2.3)

Read Status Register Data

Command

SUP

~ufti WordlByte Write Ad&Start Address

Data=EBH

Extended Status Register Data

Check XSR.7

tMul6 WordByte Wdte Ready

O=Mulb woldmyte write Busy

Data=Word or Byte Count (N)-1

Add,-Start Address

Dala=Suffer Data

Add&tart Address

DatazBuffer Data

Add,=Dsvne Address

Data=DOH

Addr=X

Comments

24

Write Buffer Data.

Dew% Address

Check if Dewed

Standby

1. Syta or word count values on DClo., are loaded into the count register.

2. Write Suffer contents will be programmed at the start address.

3. Align the start address on a Write Buffer boundary for maximum

pmgramming parfonance.

4.The device aborts the Multi Word/Byte Write command if the current address is

outs!& of the original block address.

5% Status Register indicates an ‘improper command sequence’ if the Multi

WorrVeyte command is aborted. Follow this mm a Clear Stahls Register command.

SR full statis check can be done after each multi worclbyte write.

or after a sequence of multi worcubyte writes.

Write FFH after the Iat muili word/byte write cfzeratnon to place device m

reed may mode.

Check SR.7

1.WSM Ready

c=WSM BUSY &$*

Figure 8. Automated Multi Word/Byte Write Flowchart

Rev. 1.8

Page 27

SHARI=

FULL STATUS CHECK PROCEWRE FOR

MLfLTt WORD/BYTE WRITE OPERATlON

Road status Reglrter

Dwce Protect Enor

LHF16K55 25

Elm

Opmrtion

Stan&y

standby

Command

Check SR.3

,=Vpp Error Detect

Check SR.1

I=Dome Pmtect Detect

WPX-VIL.Blcck Lock-Bit IS Set

Only required for oyttems

implementing lock-bit configuration

Check SR.4.5

Boti l-Command Sequence Error

Commcnb

standby

SR.S.SR.4.SFt.3 and SR.1 are only deamd by the Clear S&IS Register

command in cases where multiple locations are wlitten before

lull status is checked.

If ~rmr ia detected, clear the Stahts Register before attemptmg

retry or other elmr recwefy.

Check SR.4

tdlata Write Error

Figure 9. Full Status Check Procedure for Automated Multi Word/Byte Write

L

Rev. 1.8

Page 28

SHARP

LHF16K55

Check SR.7

l=WSM Ready

O=WSM Busy

Read Array Data

4 (Multi) WcdByte write LOOP I

Figure 10. Block Erase Suspend/Resume Flowchart

smldby

Write

Check SIT.6

l=Slock Erase Suspended

O-Block Erase Completed

EtXe DaQDOH

Resume

Add-X

Rev. 1.8

Page 29

SHARP

LHF16K55 27

Comments

Wnta BOH

(Ml&l) wofveyte write

Completed

Data&OH

Addr=X

Status Register Data

Add-X

Check SR.7

Standby

I-

standby

Write Read Amy

l--L

Read

Write

E

(Multi) word/Byte wmt

Resume

l=WSM Ready

O-WSM Busy

Chedc SR.2

b(Mulb) Word/Byte Write

suspwldsd

OS(MUlti) wotdmyte write

Compkdd

Data=FFH

Addr-X

Road Array locations other

than tiat being written.

Datad30k-l

AddbX

Figure 11. (Multi) Word/Byte Write Suspend/Resume Flowchart

Rev. 1.8

Page 30

SHARP

LHF16K55

Write OlH.

Block Address

I

g +

NLL STATUS CHECK PROCEDURE

I

Read

Status Register

SR.7= SR.7=

1 1

Check If Desired

Read Status Register

Data&See Above)

0 0

Bus

OprMfOll

write

Read

Standby

Repeat for subsequent Mock lock-bit set operations.

%II status chedc can b-a done after each block lock-bit set operation

or after a sequence of block lock-bit set operations.

Write FFH after the last block bck-bit set operation to place device in

read amay mode.

BUS

opsrrtfon

I

Standby

commnd Comments

Set Bock

Lock-Bit Confirm

Command Commentr

I

Data-01 H.

Add&lock Address

Stabs Register Data

Check SR.7

l=WSM Ready

o=WSM Busy

Check SR.3

tsVpp Error Detect

*-

Set Black Lock-EN

successful

Device Protect Error

Figure 12. Set Block Lock-Bit Flowchart

Standby

SR.S.SR.4.SR.3 and SR.1 are onfy deared by the Clear Status

Register command in cases where multiple block lock-bits are set before

full status is checked.

If error is detected, dear the St&s Register before attempting

retry or omer em, recovaly.

Check SR.4

l=Set Block Lock-Sit Error

Rev. 1.8

Page 31

SHARI=

LHF16K55

Write 60H

Write DOH

Full Status

Check 11 Dewed

Clear Block Lock-Bit

Complete

FULL STATUS CHECK PROCEDURE

Read Status Regiriter

Data(See Above)

Bus

OpNrtiOll

Write

Write

Read

Standby

Write FFH after the Clear Block Lock-Bib operahon to

place device in read array mode.

BUS

OpadiOll

Standby

Command

Clear Block

Lock-Bits Setup

Clear Blcck

Lock-Bits Confin

Command

Data&OH

Addr=X

Da&ZWH

Add,=X

St&s Register Data

Check SR.7

1PwsM Ready

O-WSM Busy

Check SR.3

lz.Vpp Error Detect

Commmb

Comments

a$<

Device Protect Enor

Figure 13. Clear Block Lock-Bits Flowchart

Check SR.l

smdby

Standby

standby

SR.S.SR.4.SR.3 and SR.l are only cleared by the Clear Status

Regster command.

If ermr is detected. clear the Status Register before attempbng

retry 0, omer mm, recovely.

t-Device Pmtect Detect

WP#‘V,L

Check SR.4.5

Both t=Command

Sequence Ermr

Check SR.5

t&tear Block Lock-Bits Error

Rev. 1.8

Page 32

SHARP

LHFl6K55

5 DESIGN CONSIDERATIONS

5.1 Three-Line Output Control

The device will often be used in large memory arrays.

SHARP provides three control inputs to

accommodate multiple memory connections. ThreeLine control provides for:

a. Lowest possible memory power dissipation.

b. Complete assurance that data bus contention will

not occur.

To use these control inputs efficiently, an address

decoder should enable CE# while OE# should be

connected to all memory devices and the system’s

READ# control line. This assures that only selected

memory devices have active outputs while

deselected memory devices are in standby mode.

RP# should be connected to the system

DOWERGOOD signal to prevent unintended writes

during system power transitions. POWERGOOD

should also toggle during system reset.

5.2 STS and Block Erase, Full Chip

Erase, (Multi) Word/Byte Write and

Block Lock-Bit Configuration Polling

STS is an open drain output that should be

:onnected to Vcc y b a pullup resistor to provide a

iardware method of detecting block erase, full chip

erase, (multi) word/byte write and block lock-bit

:onfiguration completion. In default mode, it

ransitions low after block erase, full chip erase,

multi) word/byte write or block lock-bit configuration

:ommands and returns to VOH when the WSM has

inished executing the internal algorithm. For

Ilternate

;onfiguration command.

STS pin

configurations,

see the

STS, in default mode, is also High-Z when the device

is in block erase suspend (with (multi) word/byte write

inactive), (multi) word/byte write suspend or deer

power-down modes.

5.3 Power Supply Decoupling

Flash memory power switching characteristics require

careful device decoupling. System designers are

interested in three supply current issues; standby