Page 1

DVP&HTP356X(X)(K)

DVP3560K/55

DVP3568(X)/94

DVP3560KX/78

HTP3560K/93

DVP3560K/93

DVP3568K/93

DVP3560KX/77

DVP3560K/96

Service Manual

TABLE OF CONTENTS

. Technical Specifications…………....………………………..............1-2

. Safety Instruction, Warning & Notes….……………………....….....1-3

. Mechanical and Dismantling Instructions…………........................2-1

. Software Upgrades and Region Code Change.............................

. Trouble Shooting Chart………………………………………………

. Wiring Diagram………………………………………..………..….….5-1

. Electrical Diagrams and Print-layouts..….…………………....….…6-1

. Set Mechanical Exploded view & Part list.…………………..….….7-1

. Revision List..................................................................................8-1

©Copyright 2010 Philips Consumer Electronics B.V. Eindhoven, The Netherlands

All rights reserved. No part of this publication may be reproduced, stored in aretrieval system or

transmitted, in any form or by any means, electronic, mechanical, photocopying, or otherwise

without the prior permission of Philips.

Page

.

3-1

.

4-1

CLASS 1

LASER PRODUCT

Published by SL - 015 BU AVM Printed in The Netherlands Subject to modification

Version 1.6

GB

3141 785 34646

PHILIPS

Page 2

1 - 2

1. Technical Specifications, Directions for Use

Index of this chapter:

1.1 Technical Specifications

1.2 Directions for Use

Notes:

• Figures can deviate due to the different set executions.

• Specifications are indicative (subject to change).

1.1 Technical Specifications

For on-line product support please use the following website:

http://www.p4c.philips.com/cgi-bin/dcbint/cpproduct_selector.pl

Here is product information available, as well as getting started,

user manuals, frequently asked questions and software &

drivers.

1.2 Directions for Use

You can download this information from the following websites:

http://www.philips.com/support

http://www.p4c.philips.com

Page 3

1 - 3

2. Safety Instructions, Warnings, Notes, and Abbreviation List

Index of this chapter:

2.1 Safety Instructions

2.2 Warnings

2.3 Notes

2.4 Abbreviation List

2.1 Safety Instructions

Safety regulations require the following during a repair:

• Connect the set to the Mains/AC Power via an isolation

transformer (> 800 VA).

• Replace safety components, indicated by the symbol

only by components identical to the original ones. Any

other component substitution (other than original type) may

increase risk of fire or electrical shock hazard.

Safety regulations require that after a repair, the set must be

returned in its original condition. Pay in particular attention to

the following points:

• Route the wire trees correctly and fix them with the

mounted cable clamps.

• Check the insulation of the Mains/AC Power lead for

external damage.

• Check the strain relief of the Mains/AC Power cord for

proper function.

• Check the electrical DC resistance between the Mains/AC

Power plug and the secondary side (only for sets that have

a Mains/AC Power isolated power supply):

1. Unplug the Mains/AC Power cord and connect a wire

between the two pins of the Mains/AC Power plug.

2. Set the Mains/AC Power switch to the “on” position

(keep the Mains/AC Power cord unplugged!).

3. Measure the resistance value between the pins of the

Mains/AC Power plug and the metal shielding of the

tuner or the aerial connection on the set. The reading

should be between 4.5 M: and 12 M:.

4. Switch “off” the set, and remove the wire between the

two pins of the Mains/AC Power plug.

• Check the cabinet for defects, to prevent touching of any

inner parts by the customer.

2.2 Warnings

• All ICs and many other semiconductors are susceptible to

electrostatic discharges (ESD ). Careless handling

during repair can reduce life drastically. Make sure that,

during repair, you are connected with the same potential as

the mass of the set by a wristband with resistance. Keep

components and tools also at this same potential.

• Be careful during measurements in the high voltage

section.

• Never replace modules or other components while the unit

is switched “on”.

• When you align the set, use plastic rather than metal tools.

This will prevent any short circuits and the danger of a

circuit becoming unstable.

2.3 Notes

2.3.1 General

• Measure the voltages and waveforms with regard to the

chassis (= tuner) ground ( ), or hot ground ( ), depending

on the tested area of circuitry. The voltages and waveforms

shown in the diagrams are indicative. Measure them in the

Service Default Mode (see chapter 5) with a colour bar

signal and stereo sound (L: 3 kHz, R: 1 kHz unless stated

otherwise) and picture carrier at 475.25 MHz for PAL, or

61.25 MHz for NTSC (channel 3).

• Where necessary, measure the waveforms and voltages

with ( ) and without ( ) aerial signal. Measure the

voltages in the power supply section both in normal

operation ( ) and in stand-by ( ). These values are

indicated by means of the appropriate symbols.

2.3.2 Schematic Notes

• All resistor values are in ohms, and the value multiplier is

often used to indicate the decimal point location (e.g. 2K2

indicates 2.2 k:).

,

• Resistor values with no multiplier may be indicated with

either an “E” or an “R” (e.g. 220E or 220R indicates 220 :).

• All capacitor values are given in micro-farads (P u10

nano-farads (n u10

• Capacitor values may also use the value multiplier as the

decimal point indication (e.g. 2p2 indicates 2.2 pF).

• An “asterisk” (*) indicates component usage varies. Refer

to the diversity tables for the correct values.

• The correct component values are listed in the Spare Parts

List. Therefore, always check this list when there is any

doubt.

2.3.3 BGA Ball Grid Array ICs

Introduction

For more information on how to handle BGA devices, visit this

URL: www.atyourservice.ce.philips.com (needs subscription,

not available for all regions). After login, select “Magazine”,

then go to “Repair downloads”. Here you will find Information

on how to deal with BGA-ICs.

BGA Temperature Profiles

For BGA-ICs, you must use the correct temperature-profile,

which is coupled to the 12NC. For an overview of these profiles,

visit the website www.atyourservice.ce.philips.com (needs

subscription, but is not available for all regions)

You will find this and more technical information within the

“Magazine”, chapter “Repair downloads”.

For additional questions please contact your local repair help

desk.

2.3.4 Lead-free Soldering

Due to lead-free technology some rules have to be respected

by the workshop during a repair:

• Use only lead-free soldering tin Philips SAC305 with order

code 0622 149 00106. If lead-free solder paste is required,

please contact the manufacturer of your soldering

equipment. In general, use of solder paste within

workshops should be avoided because paste is not easy to

store and to handle.

• Use only adequate solder tools applicable for lead-free

soldering tin. The solder tool must be able:

– To reach a solder-tip temperature of at least 400°C.

– To stabilize the adjusted temperature at the solder-tip.

– To exchange solder-tips for different applications.

• Adjust your solder tool so that a temperature of around

360°C - 380°C is reached and stabilized at the solder joint.

Heating time of the solder-joint should not exceed ~ 4 sec.

Avoid temperatures above 400°C, otherwise wear-out of

tips will increase drastically and flux-fluid will be destroyed.

To avoid wear-out of tips, switch “off” unused equipment or

reduce heat.

• Mix of lead-free soldering tin/parts with leaded soldering

tin/parts is possible but PHILIPS recommends strongly to

avoid mixed regimes. If this cannot be avoided, carefully

clear the solder-joint from old tin and re-solder with new tin.

-9

), or pico-farads (p u10

-12

-6

),

).

Page 4

Safety Instructions, Warnings, Notes, and Abbreviation List

2.3.5 Alternative BOM identification

1 - 4

2.4 Abbreviation List

It should be noted that on the European Service website,

“Alternative BOM” is referred to as “Design variant”.

The third digit in the serial number (example:

KX2B0835000001) indicates the number of the alternative

B.O.M. (Bill Of Materials) that has been used for producing the

specific AV set. In general, it is possible that the same AV

model on the market is produced with e.g. two different types

of display, coming from two different suppliers. This

will then result in sets which have the same CTN (Commercial

Type Number; e.g. MCM394/12) but which have a different

B.O.M. number.

Also, it is possible that same model on the market is produced

with two production centers, however their partslist is the same.

In such case, no alternative B.O.M. will be created.

By looking at the third digit of the serial number, one can

identify which B.O.M. is used for the set he is working with.

If the third digit of the serial number contains the number “1”

(example: KX 1B033500001), then the set has been

manufactured according to B.O.M. number 1. If the third digit is

a “2” (example: KX 2B0335000001), then the set has been

produced according to B.O.M. no. 2. This is important for

ordering the correct spare parts!

For the third digit, the numbers 1...9 and the characters A...Z

can be used, so in total: 9 plus 26= 35 different B.O.M.s can be

indicated by the third digit of the serial number.

Identification: The bottom line of a type plate gives a 14-digit

serial number. Digits 1 and 2 refer to the production centre (e.g.

LM is Arts), digit 3 refers to the B.O.M. code, digit 4 refers

to the Service version change code, digits 5 and 6 refer to the

production year, and digits 7 and 8 refer to production week (in

example below it is 2008 week 50). The 6 last digits contain the

serial number.

Model FWM572/12

220-230 50Hz 60W

FWM572/12

LM1A0850005644

Figure 2-1 Serial number example

2.3.6 Module Level Repair MLR or Component Level Repair

CLR

If a board is defective, consult your repair procedure to decide

if the board has to be exchanged or if it should be repaired on

component level.

If your repair procedure says the board should be exchanged

completely, do not solder on the defective board. Otherwise, it

cannot be returned to the O.E.M. supplier for back charging!

2.3. Practical Service Precautions

• It makes sense to avoid exposure to electrical shock.

While some sources are expected to have a possible

dangerous impact, others of quite high potential are of

limited current and are sometimes held in less regard.

• Always respect voltages. While some may not be

dangerous in themselves, they can cause unexpected

reactions that are best avoided. Before reaching into a

powered TV set, it is best to test the high voltage insulation.

It is easy to do, and is a good service precaution.

0/6/12 SCART switch control signal on A/V

board. 0 = loop through (AUX to TV),

6 = play 16 : 9 format, 12 = play 4 : 3

format

2DNR Spatial (2D) Noise Reduction

3DNR Temporal (3D) Noise Reduction

AARA Automatic Aspect Ratio Adaptation:

algorithm that adapts aspect ratio to

remove horizontal black bars; keeps

the original aspect ratio

ACI Automatic Channel Installation:

algorithm that installs TV channels

directly from a cable network by

means of a predefined TXT page

ADC Analogue to Digital Converter

AFC Automatic Frequency Control: control

signal used to tune to the correct

frequency

AGC Automatic Gain Control: algorithm that

controls the video input of the feature

box

AM Amplitude Modulation

ANR Automatic Noise Reduction: one of the

algorithms of Auto TV

AP Asia Pacific

AR Aspect Ratio: 4 by 3 or 16 by 9

ASF Auto Screen Fit: algorithm that adapts

aspect ratio to remove horizontal black

bars without discarding video

information

ATSC Advanced Television Systems

Committee, the digital TV standard in

the USA

ATV See Auto TV

Auto TV A hardware and software control

system that measures picture content,

and adapts image parameters in a

dynamic way

AV External Audio Video

AVC Audio Video Controller

AVIP Audio Video Input Processor

B/G Monochrome TV system. Sound

carrier distance is 5.5 MHz

BLR Board-Level Repair

BTSC Broadcast Television Standard

Committee. Multiplex FM stereo sound

system, originating from the USA and

used e.g. in LATAM and AP-NTSC

countries

B-TXT Blue TeleteXT

C Centre channel (audio)

CEC Consumer Electronics Control bus:

remote control bus on HDMI

connections

CL Constant Level: audio output to

connect with an external amplifier

CLR Component Level Repair

COLUMBUS COlor LUMinance Baseband

Universal Sub-system

ComPair Computer aided rePair

CP Connected Planet / Copy Protection

CSM Customer Service Mode

CTI Color Transient Improvement:

manipulates steepness of chroma

transients

CVBS Composite Video Blanking and

Synchronization

DAC Digital to Analogue Converter

DBE Dynamic Bass Enhancement: extra

low frequency amplification

DDC See “E-DDC”

Page 5

1 - 5

Safety Instructions, Warnings, Notes, and Abbreviation List

D/K Monochrome TV system. Sound

carrier distance is 6.5 MHz

DFI Dynamic Frame Insertion

DFU Directions For Use: owner's manual

DMR Digital Media Reader: card reader

DMSD Digital Multi Standard Decoding

DNM Digital Natural Motion

DNR Digital Noise Reduction: noise

reduction feature of the set

DRAM Dynamic RAM

DRM Digital Rights Management

DSP Digital Signal Processing

DST Dealer Service Tool: special remote

control designed for service

technicians

DTCP Digital Transmission Content

Protection; A protocol for protecting

digital audio/video content that is

traversing a high speed serial bus,

such as IEEE-1394

DVB-C Digital Video Broadcast - Cable

DVB-T Digital Video Broadcast - Terrestrial

DVD Digital Versatile Disc

DVI(-d) Digital Visual Interface (d= digital only)

E-DDC Enhanced Display Data Channel

(VESA standard for communication

channel and display). Using E-DDC,

the video source can read the EDID

information form the display.

EDID Extended Display Identification Data

(VESA standard)

EEPROM Electrically Erasable and

Programmable Read Only Memory

EMI Electro Magnetic Interference

EPLD Erasable Programmable Logic Device

EU Europe

EXT EXTernal (source), entering the set by

SCART or by cinches (jacks)

FBL Fast BLanking: DC signal

accompanying RGB signals

FDS Full Dual Screen (same as FDW)

FDW Full Dual Window (same as FDS)

FLASH FLASH memory

FM Field Memory or Frequency

Modulation

FPGA Field-Programmable Gate Array

FTV Flat TeleVision

Gb/s Giga bits per second

G-TXT Green TeleteXT

H H_sync to the module

HD High Definition

HDD Hard Disk Drive

HDCP High-bandwidth Digital Content

Protection: A “key” encoded into the

HDMI/DVI signal that prevents video

data piracy. If a source is HDCP coded

and connected via HDMI/DVI without

the proper HDCP decoding, the

picture is put into a “snow vision” mode

or changed to a low resolution. For

normal content distribution the source

and the display device must be

enabled for HDCP “software key”

decoding.

HDMI High Definition Multimedia Interface

HP HeadPhone

dnuoS.metsysVTemorhconoMI

2

I

C Inter IC bus

2

I

D Inter IC Data bus

2

I

S Inter IC Sound bus

carrier distance is 6.0 MHz

IF Intermediate Frequency

Interlaced Scan mode where two fields are used

to form one frame. Each field contains

half the number of the total amount of

lines. The fields are written in “pairs”,

causing line flicker.

IR Infra Red

IRQ Interrupt Request

ITU-656 The ITU Radio communication Sector

(ITU-R) is a standards body

subcommittee of the International

Telecommunication Union relating to

radio communication. ITU-656 (a.k.a.

SDI), is a digitized video format used

for broadcast grade video.

Uncompressed digital component or

digital composite signals can be used.

The SDI signal is self-synchronizing,

uses 8 bit or 10 bit data words, and has

a maximum data rate of 270 Mbit/s,

with a minimum bandwidth of 135

MHz.

ITV Institutional TeleVision; TV sets for

hotels, hospitals etc.

JOP Jaguar Output Processor

LS Last Status; The settings last chosen

by the customer and read and stored

in RAM or in the NVM. They are called

at start-up of the set to configure it

according to the customer's

preferences

LATAM Latin America

LCD Liquid Crystal Display

LED Light Emitting Diode

L/L' Monochrome TV system. Sound

carrier distance is 6.5 MHz. L' is Band

I, L is all bands except for Band I

LORE LOcal REgression approximation

noise reduction

LPL LG.Philips LCD (supplier)

LS Loudspeaker

LVDS Low Voltage Differential Signalling

Mbps Mega bits per second

M/N Monochrome TV system. Sound

carrier distance is 4.5 MHz

MIPS Microprocessor without Interlocked

Pipeline-Stages; A RISC-based

microprocessor

MOP Matrix Output Processor

MOSFET Metal Oxide Silicon Field Effect

Transistor, switching device

MPEG Motion Pictures Experts Group

MPIF Multi Platform InterFace

MUTE MUTE Line

NC Not Connected

NICAM Near Instantaneous Compounded

Audio Multiplexing. This is a digital

sound system, mainly used in Europe.

NTC Negative Temperature Coefficient,

non-linear resistor

NTSC National Television Standard

Committee. Color system mainly used

in North America and Japan. Color

carrier NTSC M/N= 3.579545 MHz,

NTSC 4.43= 4.433619 MHz (this is a

VCR norm, it is not transmitted off-air)

NVM Non-Volatile Memory: IC containing

TV related data such as alignments

O/C Open Circuit

OSD On Screen Display

OTC On screen display Teletext and

Control; also called Artistic (SAA5800)

P50 Project 50: communication protocol

between TV and peripherals

PAL Phase Alternating Line. Color system

mainly used in West Europe (color

carrier= 4.433619 MHz) and South

America (color carrier PAL M=

Page 6

1 - 6

Safety Instructions, Warnings, Notes, and Abbreviation List

3.575612 MHz and PAL N= 3.582056

MHz)

PCB Printed Circuit Board (same as “PWB”)

PCM Pulse Code Modulation

PDP Plasma Display Panel

PFC Power Factor Corrector (or Pre-

conditioner)

PIP Picture In Picture

PLL Phase Locked Loop. Used for e.g.

FST tuning systems. The customer

can give directly the desired frequency

POR Power On Reset, signal to reset the uP

Progressive Scan Scan mode where all scan lines are

displayed in one frame at the same

time, creating a double vertical

resolution.

PTC Positive Temperature Coefficient,

non-linear resistor

PWB Printed Wiring Board (same as “PCB”)

PWM Pulse Width Modulation

QRC Quasi Resonant Converter

QTNR Quality Temporal Noise Reduction

QVCP Quality Video Composition Processor

RAM Random Access Memory

RGB Red, Green, and Blue. The primary

color signals for TV. By mixing levels

of R, G, and B, all colors (Y/C) are

reproduced.

RC Remote Control

RC5 / RC6 Signal protocol from the remote

control receiver

RESET RESET signal

ROM Read Only Memory

R-TXT Red TeleteXT

SAM Service Alignment Mode

S/C Short Circuit

SCART Syndicat des Constructeurs

d'Appareils Radiorécepteurs et

SCL Serial Clock I

Téléviseurs

SCL-F CLock Signal on Fast I

SD Standard Definition

SDA Serial Data I

SDA-F DAta Signal on Fast I

2

C

2

C bus

2

C

2

C bus

SDI Serial Digital Interface, see “ITU-656”

SDRAM Synchronous DRAM

SECAM SEequence Couleur Avec Mémoire.

Color system mainly used in France

and East Europe. Color carriers=

4.406250 MHz and 4.250000 MHz

SIF Sound Intermediate Frequency

SMPS Switched Mode Power Supply

SoC System on Chip

SOG Sync On Green

SOPS Self Oscillating Power Supply

S/PDIF Sony Philips Digital InterFace

SRAM Static RAM

SRP Service Reference Protocol

SSB Small Signal Board

STBY STand-BY

SVGA 800x600 (4:3)

SVHS Super Video Home System

SW Software

SWAN Spatial temporal Weighted Averaging

Noise reduction

SXGA 1280x1024

TFT Thin Film Transistor

THD Total Harmonic Distortion

TMDS Transmission Minimized Differential

Signalling

TXT TeleteXT

TXT-DW Dual Window with TeleteXT

UI User Interface

uP Microprocessor

UXGA 1600x1200 (4:3)

V V-sync to the module

VCR Video Cassette Recorder

VESA Video Electronics Standards

Association

VGA 640x480 (4:3)

VL Variable Level out: processed audio

output toward external amplifier

VSB Vestigial Side Band; modulation

method

WYSIWYR What You See Is What You Record:

record selection that follows main

picture and sound

WXGA 1280x768 (15:9)

XTAL Quartz crystal

XGA 1024x768 (4:3)

Y Luminance signal

Y/C Luminance (Y) and Chrominance (C)

signal

YPbPr Component video. Luminance and

scaled color difference signals (B-Y

and R-Y)

YUV Component video

Page 7

2-1

Mechanical and Dismantling Instructions

Dismantling Instruction

The following guidelines show how to dismantle the player.

Step1: Remove 5 screws around the Top Cover, and then remove the Top Cover (Figure 1).

Sample model is DVP3560K/55.

Detailed information please refer to the model set.

Figure 1

Step2: If it is necessary to dismantle Loader or Front Panel, the Front door should be removed first. (Figure 2)

Note: Make sure to operate gently otherwise the guider would be damaged.

Please kindly note that dismantle the front door

assembly carefully to avoid damage tray and the front door.

Figure 2

Page 8

2-2

Mechanical and Dismantling Instructions

Dismantling Instruction

Step3: If the tray can’t open in normal way, you can make it through the instruction as below (Figure 3).

Note: Make sure to operate gently otherwise the guider would be damaged.

Detailed information please refer to the model set.

Step4: Dismantling Front Panel, disconnect the connectors (XP

of bottom cabinet , then gently pull the Panel out from the set. (Figure 4 - Figure 6)

XP2

XP4

XP3

Figure 3

XP7

XP5

5 , XP6, XP7,XP8), need release 3 snaps of Front Panel & 2 snaps

XP8

XP1

XP6

Figure 4

Page 9

2-3

Mechanical and Dismantling Instructions

Dismantling Instruction

Step5: Dismantling Loader, disconnect the 3 connectors (XP2, XP3, XP4) aiming in the below figure, and remove 1 screw that

connects the loader and the bottom cabinet. (Figure 5)

Detailed information please refer to the model set.

Figure 5

Step6: Dismantling Main Board, first disconnect the connector (XP1), and then rem

Step7: Remove the 4 screws on Power Board to dismantle the Power Board. (Figure 6)

ove 5 screws. (Figure 6)

Figure 6

Page 10

3-1

Softeware upgrade and region code change

Preparation to upgrade software

1) Power on the set and open the tray, then press "5""5"

on remote control to check the SW File Name.

2) Start the CD Burning software and create a new CD

project (Data Disc) with the following setting:

Label: DVP(HTP)3XXX(K)

SW File Name:

Note: It is required to keep the SW file name accord.

3) Burn the data onto a blank CDR

A. Procedure for software upgrade:

A) Upgrade software via CDR:

1) Power on the set and insert the prepared Upgrade CDR.

2) The set will starts reading disc & response with the

following display TV screen:

Upgrade file detected

Upgrade ?

Press PLAY to start

3) Press "PLAY" button to confirm, then screen will display:

Upgrade file detected

Do not power off

File Copying

4) The upgraded tray will automatically open when file

copying completed, then take out the disc.

5) About 1 minute later, the trace will automatically close

when upgrading completed.

(No need the label name)

DVPXXXX(K)_XX.bin

Upgrade file detected

Do not power off

Upgrading

B. Read out the software versions to confirm upgrading

1) Power on the set and press "Setup" button on the

remote control.

2) Press "1""3""7""9" button or press down cursor

on remote control to select "Preferences" and press

right & down cursor to select "Version Info".

The software version and other informations will be

displayed on the TV screen as follows:

Version XX.XX.XX.XX (Main version)

Sub-Ver XX.XX.XX.XX (version of applicaton software)

8032 XX.XX.XX.XX

Servo XX.XX.XX.XX (software version of

RISC XX.XX.XX.XX

DSP XX.XX.XX.XX

Region Code X

Servo)

Caution: The set must not be power off during

upgrading, Otherwise the Main board will be

damaged entirely.

B) Upgrade software via USB Flash Drive:

1) Create the correct software file onto the USB flash drive.

2) Power on the set and keep no disc, then insert it to the

USB jack of the front panel.

3) When the DVD player switchs to the USB state automatically,

pls follow the instructions on the TV screen to confrim the

upgrade operation.

Region Code Change

1) Power on the set and open the tray door;

2) Press the "Setup" button on the remote control, then the

setup interface will be displayed on the TV screen;

3) Move the down cursor on remote control to select "Preferences"

and press "1""3""8""9""3""1" on the remote control;

4) Then move the up or down cursor to select the region code.

Note: Restart after above steps.

Page 11

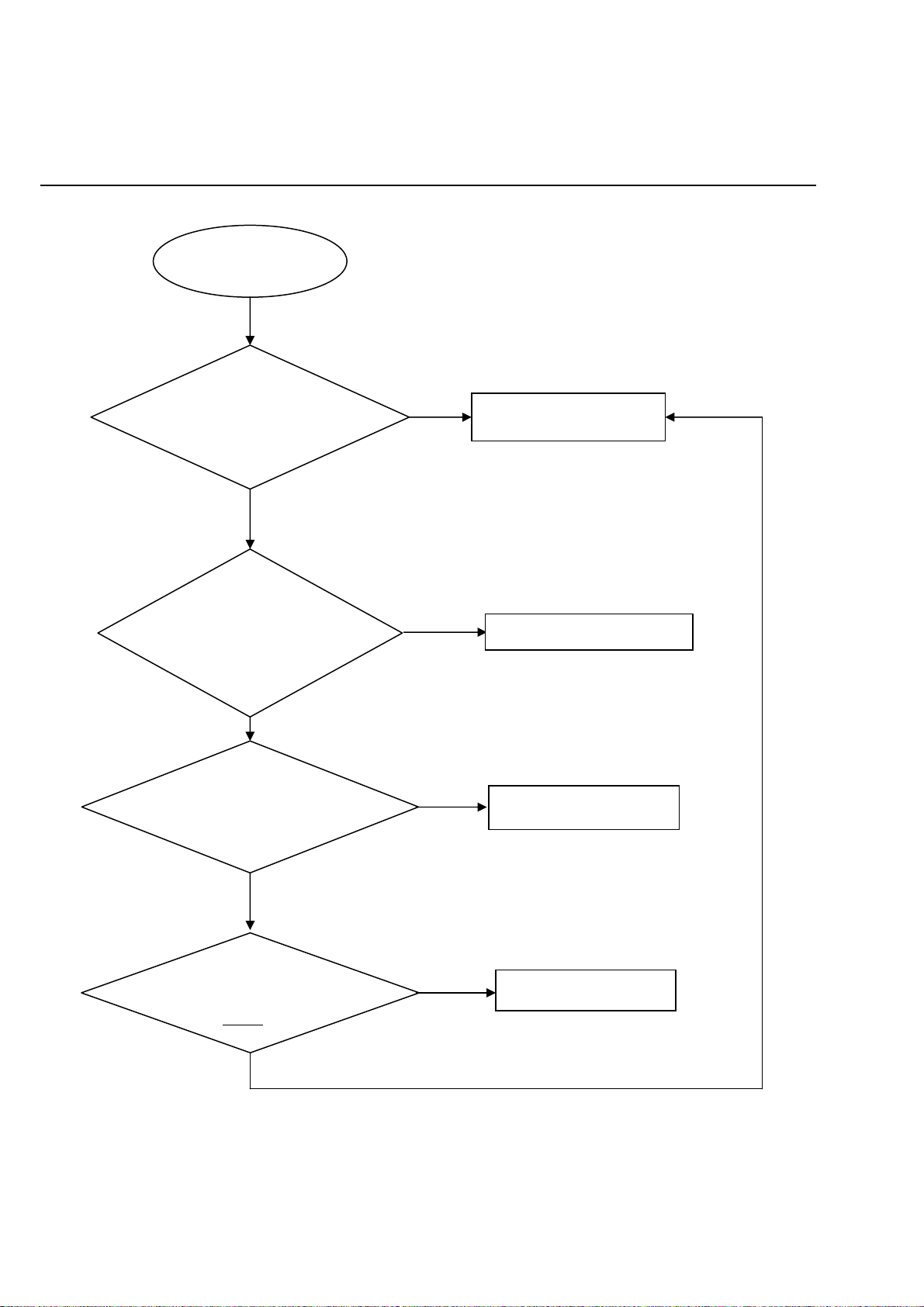

Spindle motor does not move

Motor no move

Go

4-1

Trouble shooting chart

Check the FFC connection

between 24P and the loader.

Yes

Check whether “MO_VCC”

voltage is normal.

(+5V)

Yes

Check whether laser voltage

(1.9V for CD & 2.4V for DVD)

on L9 and L10

Yes

No

No

No

Correct connection

Check the MO_VCC power

supply

Check/Replace Q5,Q6,Q7,Q8.

1.Whether voltage on pin 15of U20

varies between 0 and 3.3V (3.3V for

CD and 0V for DVD),

2.Whether peripheral components

are eroded or badly soldered.

Yes

Check opu focus

Yes

Check/Replace the loader

No

No

Check/ Replace U20.

1. Check U20 pin17 FOCUS_PWM signals

2.If there are F+, F-, T+ and T- signals output

from U2.

FOCUS_PWN waveform

Page 12

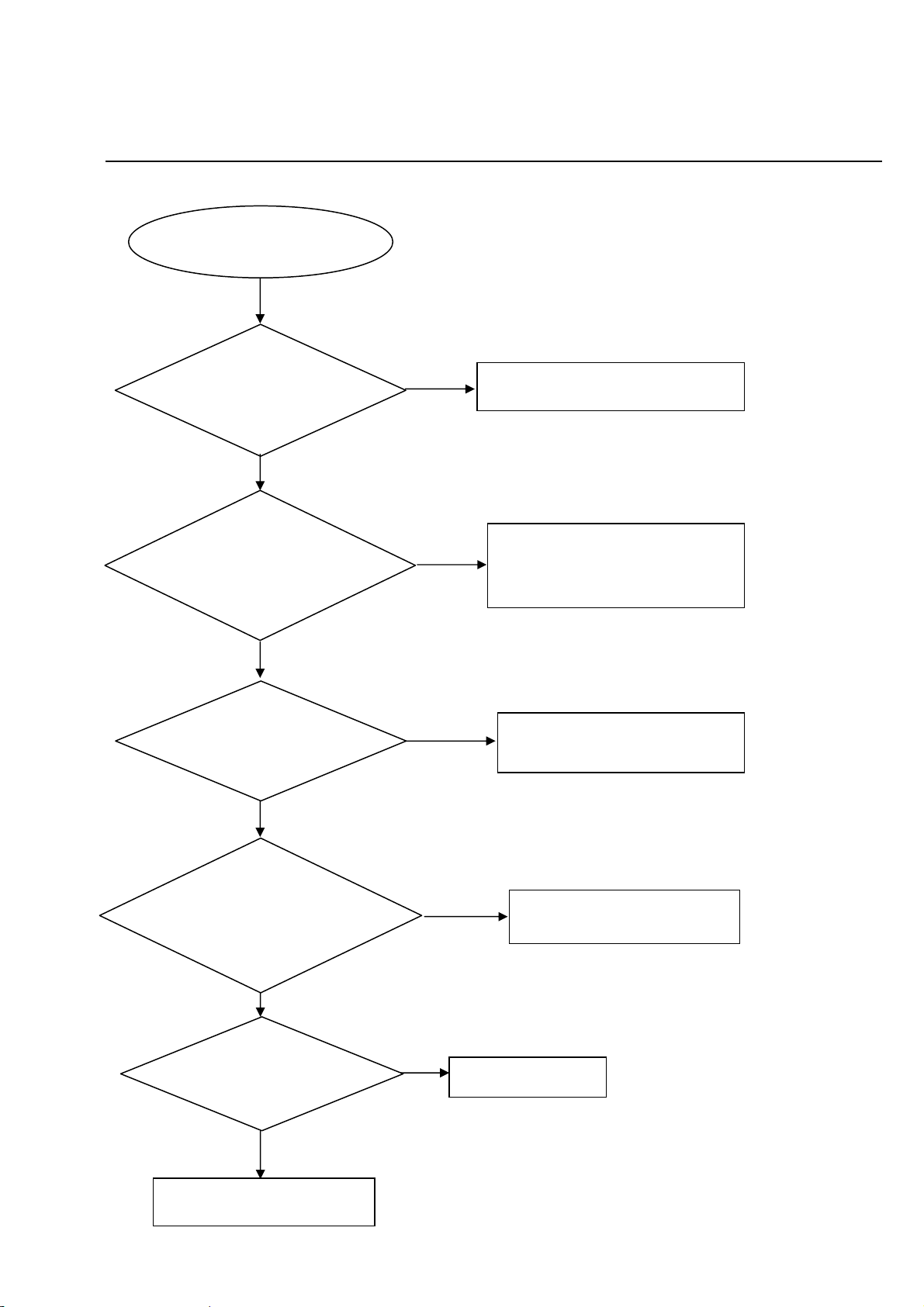

The power can not be on or off

r

The power can’t be

on or off

Go

4-2

Trouble shooting chart

Check the power supply

on the power board is

no

mal.

Yes

Check if the XS301 on the

front board to XP5 on the

decoder board is in good

contact.

Yes

Whether the connection

to K303 is broken.

Ye s

No

No

No

Repair the power board

Check/Correct connection

Correct the connection

Yes

Whether there is 0V and

3.3V voltage difference on

Pin 39 PCON

of U20.

Yes

No

Replace U20.

Page 13

4-3

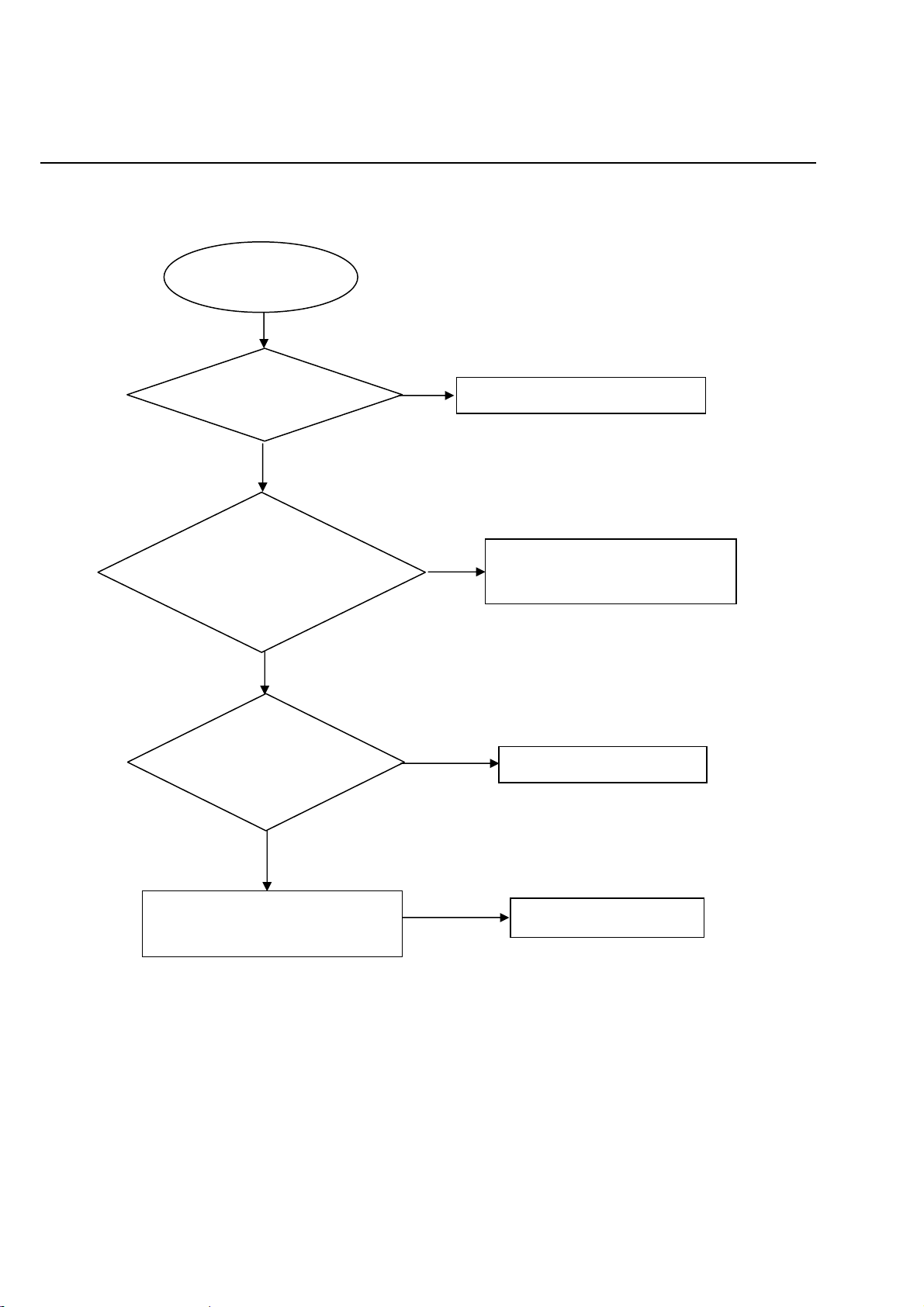

All output voltages on the power board is 0V or deviated.

All output voltages on

the power board is 0V or

deviated

Yes

Trouble shooting chart

Check whether

F1 is blown

No

Check whether there is

300V on C1 or C2.

Yes

Check whether 100KHz

oscillating signal on

Pin6 of U20

Yes

Yes

No

No

Replace F1

Replace C1&C2 if D1, D2, D3, D4 are

normal.

Check/ replace U20.

U1(PIN 3 - RC waveform)

U1(PIN 8 - Drain waveform)

Check if +5V and +12V are

short.

Yes

Check whether the components in the

short-circuit voltage are defected or eroded.

No

Check whether U20 are eroded.

Page 14

4-4

Trouble shooting chart

Disc cannot be read

Disc cannot be read.

Check the FFC connection

between 24P and the loader.

Check whether there is laser

voltage (1.9V for CD and 2.4V for

DVD) on L9 and L10.

.

Yes

Yes

No

No

Check the loaded circuit

1.Check voltage on pin 15 of U20 varies

between 0 and 3.3V:

Æ3.3V for CD

Æ0V for DVD

2.Check whether peripheral components

are eroded or defect

Yes

Check U20, U2, and

peripheral components are

eroded or badly soldered.

Yes

Check if there is RFO signal on

pin17 of XP2. (The normal RFO

signal is a clear reticulated wave)

Yes

Check the connection

between U20

No

No

No

Re-solder or replace the defective parts

Check U20 and peripheral components

Correct connection

Yes

Replace U20 or loader.

Page 15

4-5

p

p

Only DVD disc or only disc except DVD can be played

Only DVD disc, or only disc

exce

t DVD can be Played.

Go

Trouble shooting chart

Check the FFC

connection between

24pin and the loader.

Yes

Check laser voltage (2.4V)

output on L10, if pin10 of U20 is

at low level.

Yes

Check whether there

is voltage variance on

in 17 of U20.

Yes

No

No

No

Check the loaded circuit

Check the solder status on U20 and

peripheral components

check if bad solder exist on U20 and

peripheral components

Check whether pins of U20

and peripheral components

are badly soldered, defected

No

Replace the bad spare parts

Yes

Check Q5, Q7 whether

in good condition

No

Correct connection

Yes

Change U20 or the loader.

Page 16

No display on LED, and buttons do not work

No display on LED, and

buttons do not work

Yes

4-6

Trouble shooting chart

Check whether there is

correct contact between

XS301 and XP5

Yes

Check VCC(+5v) voltage

on the power and front

board

Yes

Check there are STB, SDA

and SCK signals on XS301

on the front board.

No

No

Correct connection

Fix power supply board top a

power supply for should

electric circuit

No

Check the U20’s pin 36,37,38

arrive the XP5 connect condition

XP5 (PIN 1 CLK) XP5 (PIN3 DOUT)

Yes

1.Check whether bad solder exists on

U301 and pins of LED,

2.Check whether the circuit connected to

K302, K303 and K301 is broken,

3.Check whether R300, R301 and R302

are open-circuit.

Yes

Replace U301 or LED

No

Correct connection

Page 17

Distorted audio and loud noise

Distorted audio and

loud noise

Yes

4-7

Trouble shooting chart

Check the power supply

voltages +12V to the

operation amplifying Q3 is

normal.

Yes

Check whether the muting

transistor R167ˈ R152 are

normal

Yes

Check whether the muting

transistor Q48,Q50, are

normal

Yes

No

Check Q3

No

Replace R167ˈR152

No

Replace Q48,Q50,

Checking the U12 leads

the feet has no to break to

open

Yes

Check the voltage on

pin3 or pin5 of U12 is OK

(Should be 2.5~3.1V)

Yes

Check whether the U1 or

U12 powersupply normal

Yes

Replace U20

No

Correct connection

No

Replace R76, CE38, C152

No

Check U12

Page 18

Abnormal color of video picture

p

p

Abnormal color of

video

icture

Yes

4-8

Trouble shooting chart

Check whether the

27MHz out

Yes

Check whether the 3.3V

and 1.8V power supply

voltages on the decoder

board are normal.

Check whether the

video filter network

circuit is normal.

ut signal

Yes

No

Check Y2, R20,R27,C22 and C23

No

Check other of power supply electric

circuit

No

Correct the connection

Yes

Check if the video signals on Pin

98,100,101,102, of U1 are normal

No

Change U20

Page 19

Remote reception is insensitive or fails.

prop

Remote reception is

insensitive or fails.

Go

4-9

Trouble shooting chart

Check if the remote

control works

erly.

Yes

Check if the power supply

voltage to the remote censor

is normal

Yes

Use an oscilloscope to check if there

is output waveform from the first pin

IR of the remote censor after pressing

button on the remote control.

No

Check battery

No

Check R315ǃC315

No

REM301(PIN1 - RC waveform)

Yes

Check if there is IR

signal on pin 33 of U20

No

Correct connection

Yes

Change U20

IR waveform

Page 20

No video picture, no sound.

y

No video picture,

no sound.

4-10

Trouble shooting chart

Check whether all the voltages

from the power board to the

decoder board are normal.

Yes

Check if the reset circuit consisting

ofCE7, D2 is normal (at a low level

for tens of milliseconds, then

constantl

at 3.3V).

Yes

Check whether there is

27MHz signal output.

Yes

Check if there is 128MHz

signal output on R67.

No

No

No

Check the loaded circuit

Change CE7, D2.

Crystal oscillator Y2 and

peripheral components

are defected or eroded.

No

CVBS(R21 point) waveform

27Mhz waveform

Check whether

short-circuit or bad

solder on U4,U5ˈU8ˈ

U7

SDRAM(R67 DCLK) waveform

No

Yes

Check if short-circuit and

bad solder exist on Pin

98

No

Check U20.

Yes

Yes

Reconnect the component in

Page 21

5-1

5-1

A

E E

D D

DVD LOADER

SPS+

LIMIT

GND

SL-

ASA F8829 + SANYO DV38

SL+

LOAD+

LOADTROUT

GND

TRIN

C C

SWITCH

BOARD

XS303

4PIN*2.0

4

GND

POWER-K

LED+

LED-

1

B B

B

C

HTP&DVP3560K WIRING DIAGRAM

HDMI

P5

24

XP2

24PIN*0.5

1

1

U10

XP4

6PIN*2.0

MOTER

6

1

5PIN*2.0

DRIVER

XP3

5

MAIN BOARD

MP-1

1

XS302

2PIN*2.0

4

Pr

Pb

CVBS

P1 P2

VIDEO LPF&DRIVE

U20

MT1389G

AM5888S

16M

FLASH

XP5

10PIN*2.0

1

5V

GND

GND

VSCK

VSTB

VSDA

POWER_K

STANDBY_LED

10

XS301

10PIN*2.0

LED/KEY&LEDˇET6202

COAX

Y

U176

4PIN*2.0

10

1

IR

DV33

1

XP7

R

L

AUDIO

AMP&LPF

U186

64M

SDRAM

XP6

3PIN*2.0

1

4

USB_DM

USB_DP

GND

VCC_USB

3

1

XP1

5PIN*2.5

5

+12VA

GND

MIC

+5V

+5V

GND

+12V

GND

5

7PIN*2.0XS601

71

USB+OK BOARD

1

XS201

5PIN*2.5

POWER

SUPPLY

D

E

MT1389G 128 PIN GPIO LIST

NAME PIN FEATURES

TRAY_OPEN

TRAY_CLOSE

FG / GPIO2

UP1_6

UP1_7

GPIO3

GPIO4

GPO5 7

GPIO6

GPIO7

GPIO8

GPIO9

GPIO10 81 HPD

GPIO11

GPIO12

GPIO13

GPO14 96

GPIO19

GPIO20

GPIO21

ARF

ARS

ALS

ALF

GPIO34

GPIO35

RFIN / OPOUT

VIDEO/YUV

AR

AL

34

14

15

18

28

29

35

31

39

38

37

30

80

36

103

104

105

109

110

114

115

107

108

120

98

102

101

100

111

113 AL

VR_CD

VR_DVD

TRIN

HDM_SCL

HDMI_SDA

U_CEC

VSCK

TRCLOSE

TxD

PCON

POWER_K

VSDA

RxD

SPDIF

VSTB

AUDIO_MUTE

AVCM

AKIN1

TROPEN

STBY

LIMIT

AR

STANDBY_LED

AUDIO_ARF

AUDIO_ARS

AUDIO_ALS

AUDIO_ALF

LDSW

TROUT

V_CVBS

V_R/V

V_B/U

V_G/Y

A A

A

B

C

D

E

Page 22

5-1

5-1

A

B

C

D

E

MT1389G 128 PIN GPIO LIST

NAME PIN FEATURES

DVP3568(X)(K) 6CH WIRING DIAGRAM

D D

AR

AL

AUDIO

AMP&LPF

U4

64M

SDRAM

XP6

3PIN*2.0

1

4

USB_DM

USB_DP

GND

VCC_USB

ARS ACENT

ALS ASUB

P4

XP1

5PIN*2.5

3

+12VA

GND

MIC

USB+OK BOARD

POWER

CON5.3

5PIN*2.5

SUPPLY

1

+5V

+5V

GND

+12V

GND

5

7PIN*2.0XS601

1

5

71

COAX

Y

Pr

HDMI

Pb

CVBS

P3

24

XP5

1

1

6

1

5

24PIN*0.5

XP4

6PIN*2.0

XP3

5PIN*2.0

U10

MOTER

DRIVER

XP5

10PIN*2.0

1

C C

DVD LOADER

SPS+

LIMIT

GND

SL-

ASA F8829 + SANYO DV38

SL+

LOAD+

LOADTROUT

GND

TRIN

VIDEO LPF&DRIVE

AM5888S

16M

FLASH

P1 P2

U20

MT1389G

U5

XP7

4PIN*2.0

10

1

MAIN BOARD

MP-1

5V

IR

GND

GND

VSCK

VSTB

VSDA

POWER_K

STANDBY_LED

B B

SWITCH

BOARD

XS303

4PIN*2.0

4

GND

POWER-K

LED+

LED-

1

1

4

XS302

2PIN*2.0

10

XS301

10PIN*2.0

LED/KEY&LEDˇET6202

DV33

1

TRAY_OPEN

TRAY_CLOSE

FG / GPIO2

UP1_6

UP1_7

GPIO3

GPIO4

GPO5 7

GPIO6

GPIO7

GPIO8

GPIO9

GPIO10 81 HPD

GPIO11

GPIO12

GPIO13

GPO14 96

GPIO19

GPIO20

GPIO21

ARF

ARS

ALS

ALF

GPIO34

GPIO35

RFIN / OPOUT

VIDEO/YUV

AR

AL

34

14

15

18

28

29

35

31

39

38

37

30

80

36

103

104

105

109

110

114

115

107

108

120

98

102

101

100

111

113 AL

VR_CD

VR_DVD

TRIN

HDM_SCL

HDMI_SDA

U_CEC

VSCK

TRCLOSE

TxD

PCON

POWER_K

VSDA

RxD

SPDIF

VSTB

AUDIO_MUTE

AVCM

AKIN1

TROPEN

STBY

LIMIT

AR

STANDBY_LED

AUDIO_ARF

AUDIO_ARS

AUDIO_ALS

AUDIO_ALF

LDSW

TROUT

V_CVBS

V_R/V

V_B/U

V_G/Y

A A

Remark: DVP3568(X) has not karaoke output.

A

B

C

D

E

Page 23

6-1 6-1

5

Front Board Circuit Diagram:

REM301

REM301

5

)5200$,1%2$5'

D D

for dvp352x

C C

XS301

XS301

IR

VCC

GND

DATA

CS

CLK

CON10(2.0)

CON10(2.0)

U5V

1

2

VCC

3

4

DATA

5

CS

6

CLK

7

8

POWER_K

9

STB_LED

10

DATA

CLK

CS

R320 0RR320 0R

5

4

4

REM

REM

IR

3

VCC

2

GND

1

IR

R300 100R300 100

R301 100R301 100

R302 100R302 100

C315

C315

47p

47p

5VL

4

VCC

R318

R318

100R/NC

100R/NC

U5V

C303

C303

0.1u

0.1u

R319

R319

0 ohm

0 ohm

CE300

CE300

+

+

47uF

47uF

R307 10KR307 10K

R308 10KR308 10K

R315

R315

100 ohm

100 ohm

IR

4K7

4K7

R303

R303

C306

C306

0.1u

0.1u

C300

C300

100P

100P

4K7

4K7

R304

R304

+

+

CE301

CE301

47uF

47uF

C301

C301

100P

100P

R305

R305

4K7

4K7

C302

C302

100P

100P

VCC

3

10

11

12

13

14

SEG[1:6]

U5VLED+

1

2

3

4

5

6

7

8

9

D3011N4148 D3011N4148

C307

C307

100p

100p

U301

U301

ET6202

ET6202

OSC

DI/O

CLK

STB

KEY1

KEY2

VDD

SEG1/KS1

SEG2/KS2

SEG3/KS3

SEG4/KS4

SEG5/KS5

SEG6/KS6

SEG7/KS7

R312 1KR312 1K

5VL

1

2

3

4

XS302

XS302

CON4(2.0)

CON4(2.0)

R309 1KR309 1K

R310 1KR310 1K

SEG1

SEG3

SEG4

SEG5

SEG6

LED- STB_LED

POWER_K1

POWER_K

C316

C316

100p

100p

R306

R306

51K

51K

2

C308

C308

100p

100p

GND

GRID1

GRID2

GND

GRID3

GRID4

GND

VDD

SEG14/GRID5

SEG13/GRID6

SEG12/GRID7

SEG10/KS10

SEG9/KS9

SEG8/KS8

1

LED-

R317 33RR317 33R

LED1

K302

K302

LED1

1

2

3

4

5

6

7

8

9

10

11

12

13

JDD350501AG

JDD350501AG

play/pause

play/pause

GRID1

GRID2

GRID3

GRID4

GRID5

GRID6

GRID7

SEG1

SEG2

SEG3

SEG4

SEG5

SEG6

28

27

26

25

24

23

22

21

20

19

18

17

16

15

GRID1

GRID2

GRID3

GRID4

GRID7SEG2

GRID6

GRID5

K301

K301

R316 33RR316 33R

open/close

open/close

GRID[1:7]

LED+

GRID1

GRID2

GRID3

GRID4

GRID5

GRID6

GRID7

SEG1VCC

SEG2

SEG3

SEG4

SEG5

SEG6

KEY1

KEY2

B B

A A

C304

C304

100p

100p

D3021N4148 D3021N4148

C305

C305

100p

100p

R311 1KR311 1K

KS2 POWER_K

R311 R313 R314

0.3W

1W

R313 0RR313 0R

NNY

YYN

POWER_K1

R314

R314

0R/NC

0R/NC

5

4

3

2

1

Page 24

6-2

6-2

A

B

C

D

E

Switch Board Circuit Diagram:

1 1

K303

K303

POWER

POWER

XP1

XP1

CON4(2.0)

CON4(2.0)

1

2

3

4

C319

C319

47p

47p

LED3LED3

C317

C317

47p

47p

C318

C318

47p

47p

2 2

SWITCH BOARD

3 3

4 4

A

B

C

D

E

Page 25

6-3

6-3

1

2

3

4

5

OK Board & USB Board Electric Diagram

A A

P601

KARAOKE INPUT

47-EAR024-XX0

B B

KARAOKE

1

2

3

12V 12VA

ĭ3.5mm

C C

P600

USB

47-USB003-XX2

1

USB

D D

MGND AGND

MGND SGND

2

3

4

5

6

L200

500Z

L201

500Z

L202

500Z

MGND

MGND

VCC

SGND

AGNDMGND

R210

150

R200

10K

USB_DN

USB_DP

R201

5.6K

CE201

22uF

C210

2.2uF

C201

0.1u

C203

1000p

C205 47p

R205 180K

2

3

REF

R208

1K

R209

680

-

+

NJM4558

8 4

12VA

U200A

1

12V

VCC

SGND

USB_DN

USB_DP

C211

2.2uF

MICMIC_OUT

12VA

8PIN/2.0mm

XP601

R202

22K

1

2

3

4

5

6

7

R203

22K

REF

R211

100K

C204

100p

C208

100p

R206

20K

CE200

22uF

84

5

+

6

-

R207 100K

C206 47p

C209

2.2uF

NJM4558

7

U200B

MIC_OUT

E E

1

2

3

4

5

Page 26

6-

4

6-4

A

B

C

D

E

Power Board Circuit Diagram:

1 1

* CAUTION :

THE PARTS MARKED WITH ARE IMPORTANT PARTS ON THE SAFETY.

PLEASE USE THE PARTS HAVING THE DESIGNATED PARTS NUMBER WITHOUT FAIL.

TR501

F501

F501

T2AL/250ac

2

CON502

CON502

+

+

1

AC INPUT

AC INPUT

4

TNY177PNU1TNY177PN

T2AL/250ac

3

NC

Drain

U1

S5S

P501P501

1

AC INPUT

2

CN501

CN501

+

+

AC INPUT

AC INPUT

1

1

2 2

P502P502

3 3

TR501

NTC 10

NTC 10

L503

L503

CX501

CX501

20mH

20mH

RV501

RV501

0.1uF/275Vac

0.1uF/275Vac

10K471

10K471

R15

R15

1/6W 10K

1/6W 10K

C509

C509

+

+

10uF/16V

10uF/16V

2

1

BP/M

EN/UV

S

S

8

6

7

C512

C512

+

+

10uF/50V

10uF/50V

R5061/6W 680R5061/6W 680

R513

R513

1/6W100k

1/6W100k

D501

D501

1N4007

1N4007

D503

D503

1N4007

1N4007

C504

C504

152/1KV

152/1KV

D508

D508

FR102

FR102

D502

D502

1N4007

1N4007

D504

D504

1N4007

1N4007

1/4W120K

1/4W120K

C501

C501

+

+

(10uF)22uF/400V(250V)

(10uF)22uF/400V(250V)

R502

R502

1/4W120K

1/4W120K

D507

D507

IN4007

IN4007

L501

L501

680uH

680uH

FB501FBFB501

R503

R503

FB

43

C502

C502

+

+

(10uF)22uF/400V(250V)

(10uF)22uF/400V(250V)

12

U502

U502

PC123X92

PC123X92

7

T501T501

6

D506

R516

R516

1/6W10k

1/6W10k

C511

C511

0.1uF/63V

0.1uF/63V

D506

FR102

FR102

+

+

C507

C507

2200uF/10V

2200uF/10V

L502

L502

6.8uH

6.8uH

R504

+

+

C508

C508

470uF/16V

470uF/16V

R504

1/6W10k

1/6W10k

R505

R505

1/6W12K 1%

1/6W12K 1%

R507

R507

1/6W11.3k 1%

1/6W11.3k 1%

C505

C505

+

+

47uF/25V

47uF/25V

5

4

3

2

1

AZ431

AZ431

U503

U503

3

2

8

10

11

9

R508

R508

1/6W1k

1/6W1k

1

C513

C513

0.1uF/63V

0.1uF/63V

R510

R510

1/6W10k

1/6W10k

R509

R509

1/6W100

1/6W100

D509 SR360D509 SR360

CON503

CON503

5

GND

4

+12V

3

GND

2

+5V

1

+5V

5X2.5 HEADER

5X2.5 HEADER

CY501

CY501

102/400Vac

102/400Vac

4 4

* No use the Class 1 environment management materials of SS-00259

* All of moulding resinous, ink, paint and coating electric wire must be ordered from designated GP supplier of

A

B

Philips.

C

D

E

Page 27

6-5

6-5

A

TO POWER BOARD

XP1

XP1

5pin/2.5mm

5pin/2.5mm

+5VD

1

+5VP

2

GND

3

+P12V

4

5

+12V: +12V(+-10%)

1 1

2 2

+5V: +5V(+-2.5%)

R8

0/FB500R80/FB500

4.7/0603R64.7/0603

+

+

FB1

FB1

500

500

+

+

FB6

FB6

500

500

R6

3 3

CE23

CE23

47uF/6.3V

47uF/6.3V

CE24

CE24

47uF/6.3V

47uF/6.3V

AADVDD

C4

0.1uFC40.1uF

C76

C76

0.1uF

0.1uF

DV33

C75

C75

0.1uF

0.1uF

960mA

R22

R22

4.7K

4.7K

PCON

R33

R33

4.7K

4.7K

RFV33

C73

C73

0.1uF

0.1uF

CE6

CE6

+

+

100uF/16V

100uF/16V

+

+

C12

C12

0.1uF

0.1uF

89M_3V3

AADVDD

CE5

CE5

47uF/16V

47uF/16V

C1

0.1uFC10.1uF

RFV33DV33

SD33

AUDIO ADC

L1 FB AXIALL1 FB AXIAL

R291KR29

1K

Main Board Circuit Diagram: POWER SUPPLY

C112

C112

0.1uF

0.1uF

Q3

SS8550Q3SS8550

R12

R12

4.7K

R14

R14

1.3K

1.3K

Q2

BT3904Q2BT3904

4.7K

USBPC

R13

R13

22K

22K

MO_VCC

+12V

100mA

+12V

B

R10 NC/0R10 NC/0

Q10

Q10

SS8550

SS8550

C77

C77

1uF

1uF

R58

R58

2.2K

2.2K

MO_VCC

810mA 370mA

D30

D30

RL207

RL207

TR_B13

REGO13

440mA

C109

C109

0.1uF

0.1uF

R48

R48

1R/1W

1R/1W

Q16

Q16

SS8550

SS8550

R95

R95

20K 1%

20K 1%

R96

R96

12K 1%

12K 1%

VCC

C111

C111

0.1uF

0.1uF

R40

R40

4.3R/2W

4.3R/2W

+

+

IR

VSCK

POWER_K

STANDBY_LED

PCON STANDBY_LED

DV33

CE3

CE3

220uF/16V

220uF/16V

VSDA

VSTB

TR_B23

C107

C107

0.1uF

0.1uF

C

R50 100R50 100

R51 100R51 100

R52 100R52 100

R53 100R53 100

R99 1KR99 1K

R109 1KR109 1K

Q17

Q17

SS8550

SS8550

R97

R97

0R/5.1K 1%

0R/5.1K 1%

R98

R98

NC/10K 1%

NC/10K 1%

DV33

R113

R113

4.7K

4.7K

C44

C44

NC(47pF)

NC(47pF)

REGO2 3

R120

R120

4.7K/NC

4.7K/NC

NC(47pF)

NC(47pF)

+

+

C45

C45

CE4

CE4

220uF/16V

220uF/16V

R115

R115

4.7K/NC

4.7K/NC

C42

C42

NC(47pF)

NC(47pF)

V12

R118

R118

4.7K/NC

4.7K/NC

C108

C108

0.1uF

0.1uF

C43

C43

100pF

100pF

100pF

100pF

D

VCC

DV33

TO FRONT PANEL

XP510PIN/2.0mm XP510PIN/2.0mm

10

9

8

7

6

5

4

3

2

C81

C81

C82

C82

100pF

100pF

C46

C46

NC(100pF)

NC(100pF)

C25

C25

NC(0.1UF)

NC(0.1UF)

1

E

OFF-PAGE CONNECTION

URST#

URST# (3,4)

MO_VCC

MO_VCC (2,3,6)

SD33

SD33 4

VCC

VCC (2,3,6,7)

DV33

DV33 (2,3,4,7)

RFV33

RFV33 3

89M_3V3

89M_3V3 3

V12

V12 (3)

VSCK

VSDA

VSTB

IR

PCON

AADVDD

POWER_K

USBPC

VSCK 3

VSDA 3

VSTB 3

IR 3

PCON 3

AADVDD 3

POWER_K 3

USBPC 3

DV33

R19

R19

R15

R15

15K

15K

R17

R17

3.3K

3.3K

R16

R16

4.7K

4.7K

2N3904

2N3904

R18

R18

3.3K

3.3K

Q21

Q21

2N3904

2N3904

1N4148/NCD21N4148/NC

22K

22K

D2

Q22

Q22

+

+

CE7

CE7

22uF/16V

22uF/16V

CEL5-5

CEL5-5

URST#

R261KR26

URST#

1K

C21

C21

1uF

1uF

4 4

RESET Circuit

A

B

C

D

E

Page 28

6-5

6-5

A

TO POWER BOARD

XP1

XP1

5pin/2.5mm

5pin/2.5mm

+12V: +12V(+-10%)

1 1

+5V: +5V(+-2.5%)

2 2

+5VD

1

+5VP

2

GND

3

+P12V

4

GND

5

R8

0/FB500R80/FB500

+

+

FB1

FB1

500

500

+

+

Main Board Circuit Diagram for DVP3568(X)(K): POWER SUPPLY

Q3

SS8550Q3SS8550

R14

R14

1.3K

1.3K

Q2

BT3904Q2BT3904

MO_VCC

USBPC

R12

R12

NC/4.7K

NC/4.7K

CE23

CE23

47uF/6.3V

47uF/6.3V

CE24

CE24

47uF/6.3V

47uF/6.3V

DV33

C75

C75

0.1uF

0.1uF

960mA

R22

R22

4.7K

4.7K

PCON

RFV33

C73

C73

0.1uF

0.1uF

0.1uF

0.1uF

C12

C12

89M_3V3

0.1uFC10.1uF

RFV33DV33

C1

L1 FB AXIALL1 FB AXIAL

R291KR29

1K

R13

R13

22K

22K

100mA

+12V

B

R10 NC/0R10 NC/0

VCC

+12V

Q10

Q10

SS8550

SS8550

C77

C77

1uF

1uF

R58

R58

2.2K

2.2K

C

IR

R50 33R50 33

VSDA

R51 100R51 100

VSTB

VSCK

POWER_K

STANDBY_LED

PCON STANDBY_LED

R52 100R52 100

R53 100R53 100

R113 1KR113 1K

R116 1KR116 1K

R111

R111

4.7K

4.7K

C112

C112

NC(47pF)

NC(47pF)

DV33

R122

R122

4.7K/NC

4.7K/NC

NC(47pF)

NC(47pF)

D

DV33

R121

R121

R117

R117

4.7K/NC

4.7K/NC

4.7K/NC

4.7K/NC

C109

C109

C43

C88

C88

NC(47pF)

NC(47pF)

C43

100pF

100pF

100pF

100pF

C82

C82

C111

C111

100pF

100pF

VCC

C110

C110

NC(100pF)

NC(100pF)

TO FRONT PANEL

XP510PIN/2.0mm XP510PIN/2.0mm

10

9

8

7

6

5

4

3

2

1

E

OFF-PAGE CONNECTION

URST#

URST#

MO_VCC

MO_VCC

SD33

SD33

VCC

VCC

DV33

DV33

RFV33

RFV33

89M_3V3

89M_3V3

V18

V18

VSTB

VSCK

VSDA

POWER_K

IR

PCON

AADVDD

USBPC

VSTB

VSCK

VSDA

POWER_K

IR

PCON

AADVDD

USBPC

FB6

FB6

500

500

C76

C76

0.1uF

0.1uF

R6

4.7/0603R64.7/0603

3 3

DV33

R15

R15

15K

15K

R17

R17

Q21

Q21

3.3K

3.3K

2N3904

2N3904

R16

R16

4.7K

4.7K

AADVDD

C4

0.1uFC40.1uF

R19

R19

22K

2N3904

2N3904

22K

Q22

Q22

R18

R18

3.3K

3.3K

SD33

CE6

CE6

+

+

100uF/16V

100uF/16V

AADVDD

AUDIO ADC

+

CE5

+

CE5

47uF/16V

47uF/16V

RESET Circuit

1N4148/NCD21N4148/NC

D2

CE7

CE7

+

+

22uF/16V

22uF/16V

CEL5-5

CEL5-5

URST#

R261KR26

URST#

1K

C21

C21

1uF

1uF

C21 must closer to PIN43 of 1389L/K.

MO_VCC

810mA 370mA

D30

D30

RL207

RL207

TR_B1

REGO1

308mA

R48

R48

1R/1W

1R/1W

Q16

Q16

SS8550

SS8550

R95

R95

20K 1%

20K 1%

R96

R96

12K 1%

12K 1%

R40

R40

4.3R/2W

4.3R/2W

+

+

CE3

CE3

220uF/16V

220uF/16V

DV33

C107

C107

0.1uF

0.1uF

TR_B2

Q17

Q17

SS8550

SS8550

R97

R97

0R/5.1K 1%

0R/5.1K 1%

R98

R98

NV/10K 1%

NV/10K 1%

REGO2

+

+

CE4

CE4

220uF/16V

220uF/16V

V12

C108

C108

0.1uF

0.1uF

4 4

A

B

C

D

E

Page 29

6-6

6-6

A

Main Board Circuit Diagram: MT1389G

C27

C27

0.1uF

0.1uF

1

D3

BAT54CD3BAT54C

2

OP-SP-

DV33

3

V12

R126 0R126 0

R127 0R127 0

RFV12-2

RFV12-1

0.1uF

0.1uF

R24 10KR24 10K

C24

C24

R251R25

0.1uF

0.1uF

1

SP-A OPO

R28 10KR28 10K

SERVO RF DeCAP.

XP4

XP4

6PIN/2.0mm

1 1

2 2

3 3

4 4

DV33

G

2

2SK3018

SC-70

SONY 313

25

26

TOP

TOP

27

28

TP12TP12

TP14TP14

MO_VCC

R23 10KR23 10K

SLSL+

D

3

S

1

XP2

XP2

SMD0.5 TOP

SMD0.5 TOP

1

LD-DVD

2

3

4

MDI1

5

LD-CD

6

7

8

9

E

10

AVCC1

11

V20

12

13

F

14

B

15

A

16

RFO

17

IOA

18

D

19

C

20

T-

21

T+

22

F+

23

F-

24

FF+

TP8TP8

SL+

SL-

C95

C95

0.1uF

0.1uF

LIMIT

VR_DVD

R38

R38

100

100

C94 0.1uFC94 0.1uF

NC/0.1uF

NC/0.1uF

TT+

R54 10KR54 10K

R55 10KR55 10K

FMSO

TR_B2

TRSO

V1P4

STBY

R61

R61

10K

10K

VR_CD

C37NCC37

NC

R39

R39

100

100

NC/0R

NC/0R

C79

C79

C20

C20

0.1uF

0.1uF

R60

R60

C96

C96

0.1uF

0.1uF

SP-A

SP+

R128 1KR128 1K

L9

10uHL910uH

TP9TP9

U2

15

VOTK+

16

VOTK-

17

VOLD+

18

VOLD-

19

VCC2

20

NC

21

VCTL

30

G2

22

GND

23

VINLD

24

NC

25

TRB2

26

VINTK

27

BIAS

28

MUTE

AM5888U2AM5888

6PIN/2.0mm

1

2

3

4

5

6

C32

C32

0.1uF

0.1uF

Very Important to

reduce Noise

L10

L10

10uH

10uH

Q7

9012Q79012

R45 4.7R45 4.7

R46 4.7R46 4.7

Q8

9012Q89012

TP10TP10

VOFC+

VOFC-

VOSLVOSL+

VOTR+

VOTR-

VCC

REV

FWD

REGO1

VINSL+

REGO2

TRB1

VINFC

G1

L6FBL6

FB

+

CE10

+

CE10

100uF/16V

100uF/16V

C78

C78

NC/0.1uF

NC/0.1uF

14

13

12

11

10

9

8

29

7

6

5

4

3

2

1

VCC

CE11

CE11

+

+

47uF/6.3V

47uF/6.3V

CE12

CE12

+

+

47uF/6.3V

47uF/6.3V

LOAD+

LOAD-

TROPEN

TRCLOSE

R56 10KR56 10K

FOSO

TP11TP11

C71

C71

+

+

0.1uF

0.1uF

RF Reference

Q23

Q23

9012

9012

Q24

Q24

9012

9012

SPSP+

TP16TP16

TP17TP17

CE15

CE15

+

+

220uF/16V

220uF/16V

V20 V1P4

C72

C72

CE8

CE8

47uF/6.3V

47uF/6.3V

0.1uF

0.1uF

LIMIT TROUTGPI36

LDO2

R49 10KR49 10K

RFV33

R32 10KR32 10K

LDO1

TP13TP13

TP15TP15

MO_VCC

REGO1

DMSO

REGO2

TR_B1

MotorDriver

B

C33

C33

0.1uF

0.1uF

C84

C84

C83

C83

0.1uF

VR_CDPIN_14

89M_CECGPIO3

TRCLOSEGPO5

TROPENGPIO34 IOA

STBYGPIO35

DV33

0.1uF

+

+

VR_DVDPIN_15

+

+

CE9

CE9

47uF/6.3V

47uF/6.3V

89M_3V3

V12

FB4 0RFB4 0R

1N4148D41N4148

D4

R57 33KR57 33K

CE33

CE33

100uF/10V

100uF/10V

89M_3V3

C85

C85

0.1uF

0.1uF

Chip Decap.

R62 10KR62 10K

R63 10KR63 10K

89M_3V3

10uF/10VC910uF/10V

C49 0.1uFC49 0.1uF

FB3 0RFB3 0R

C9

C86

C86

0.1uF

0.1uF

TROUT

TRIN

0.1uF

0.1uF

RFV33

C18

C18

RFV33

XI

R200 51R200 51

R1 15K/NCR1 15K/NC

C5

4.7uFC54.7uF

C3

0.1uFC30.1uF

R3 5.1K 1%R3 5.1K 1%

C8

0.1uFC80.1uF

FOSO

TRSO

FMSO

DMSO

C87

C87

0.1uF

0.1uF

R11 1KR11 1K

C19

C19

0.1uF

0.1uF

RFV33

C35

C35

0.01uF

0.01uF

RFV12-2

RFVDD3 DACVDD3

XO

V20

V1P4

GPO5

MDI1

LDO1

LDO2

AVDD33

DMO

FMO

C6

PIN_14

0.1uFC60.1uF

PIN_15

TRO

FOO

TRIN

USB_DP

C7

USB_DM

10uF/10VC710uF/10V

USB_V33

USB_V12

SF_CS

SF_DO

SF_DI

SF_CK

UP1_6

UP1_7

GPIO11

GPIO6

URST#

C39

C39

C40

C40

C38

C38

330pF

330pF

0.1uF

0.1uF

330pF

330pF

V12

C90

C90

0.1uF

0.1uF

5PIN/2.0mm

5PIN/2.0mm

LOADLOAD+

R9 1KR9 1K

C36

C36

2200pF

2200pF

U20

U20

1

AVDD12_2

2

AVDD33_1

3

XTALI

4

XTALO

5

V20

6

V14

7

REXT / GPO5

8

MDI1

9

LDO1

10

LDO2

11

AVDD33_2

12

DMO

13

FMO

14

TRAY_OPEN

15

TRAY_CLOSE

16

TRO

17

FOO

18

FG / GPIO2

19

USB_DP

20

USB_DM

21

VDD33_USB

22

PAD_VRT / GPIO37

23

VDD12_USB

24

SF_CS_

25

SF_DO

26

SF_DI

27

SF_CK

28

UP1_6 / SCL

29

UP1_7 / SDA

30

GPIO11

31

GPIO6

32

PRST#

R41 27kR41 27k

R42 27kR42 27k

R43 15kR43 15k

R44 10kR44 10k

C41

C41

0.015uF

0.015uF

C91

C91

C92

C92

0.1uF

0.1uF

0.1uF

0.1uF

XP3

XP3

1

2

3

4

5

RFVDD3

129

V1P4

F

E

128

127

RFF

RFE

E-PAD/GND

GPIO3 / INT#

IR

GPIO4

34

33

35

VSCK

GPIO3

IR

D

A

126

RFD

GPIO1336GPIO937DVDD33

VSDA

VSTB

FOO

TRO

FMO

DMO

C

ADACVDD

OPO

OP-

B

C

121

124

123

125

122

RFB

RFA

RFC

RFG / OPINP

RFH / OPINN

RD041RD142RD243RD344RD445RD546RD647RD748DQM049RD1550RD1451DVDD1252RD1353RD1254RD1155RD1056RD957RD858DQM159RCLK60RA1161RA962RA8

GPIO838GPIO7 / CKE

40

39

DQ0

POWER_K

PCON

89M_3V3

R30 0R30 0

DACVDD3

CE110uF/6.3V+CE110uF/6.3V

C34

C34

+

0.1uF

0.1uF

+

C28 4.7uFC28 4.7uF

C9310uF/10V C9310uF/10V

CE2 470uF/10V+CE2 470uF/10V

RFO

C29220pF C29220pF

C30 1uFC30 1uF

AL

AR

ADACVDD

RFV12-1

GPI36

114

112

117

116

115

113

118

119

120

RFIP

AVCM

AVDD12

AL / GPIO

ALS / GPIO

ADACVDD2

ADACVDD1

CENTER / GPIO

RFIN / OPOUT / GPI36

MT1389G

MT1389G

LQFP 128

LQFP 128

V1.0

V1.0

DQ4

DQ5

DQ1

DQ2

DQ6

DQ7

DQ3

DQM0

DQ15

DQ14

F1

F1

[FUSE(500MA)]

[FUSE(500MA)]

USB_DM

USB_DP

U3

U3

2

1

PRTR5V0U2X

PRTR5V0U2X

C48

C48

0.1uF

0.1uF

GPIO35

108

109

110

111

AR / GPIO

LFE / GPIO

ARS / GPIO

PAD_APLLCAP / GPIO35

DQ13

DQ12

V12

MO_VCC

PBSS5320T

PBSS5320T

R210R21

0

C15 0.1uFC15 0.1uF

C17 10uF/10VC17 10uF/10V

V_G

V_B

V_R

AKIN1

GPIO34

ADVCM

AADVDD

DACVDD3

105

103

101

107

102

104

106

99

100

B

R

G

AADVDD

AKIN1 / GPIO21

AKIN2 / GPIO19

ADVCM / GPIO20

APLLVDD_GPIO / GPIO34

63

DQ11

DQ10

DQ9

DQ8

DQM1

DCLK

MA11

MA9

MA8

R31 180R31 180

R59 180R59 180

Q9

Q9

0.1uF

0.1uF

3

VCC_USB

4

89M_3V3

CVBS_OUT

98

97

FS

CVBS

DACVDDB

VREF / GPO14

DACVDDC

AVDD12_D

AVSS12

AVDD12_C

AVDD33_12

EXT_RES

GPIO10 / HPLG

SPDIF / GPIO12

DVDD12

DVDD33

RA7

MT1389G

MT1389G

64

MT1389M

MT1389M

MA7

USBPC

VCC_USB

4PIN/2.0mm

4PIN/2.0mm

C74

C74

R108

R108

560

560

TX2P

TX2N

TX1P

TX1N

TX0P

TX0N

TXCP

TXCN

RA10

RAS#

CAS#

RWE#

D

E

OFF-PAGE CONNECTION

DQ[0..15]

MA[0..11]

DQM[0..1]

Crystal

XI

FB10

FB10

0R/FB500R

0R/FB500R

R20 100KR20 100K

Y2

C22

C22

27MHzY227MHz

33pF

33pF

Put these circuits as

closer as possible to

MT1389

C23

C23

33pF

33pF

R27 51R27 51

XO

C31

C31

NC/15pF

NC/15pF

BA[0..1]

DCLK

RAS#

CAS#

WE#

DRAM I/F

SF_CK

SF_CS

SF_DI

SF_DO

S-FLASH

CVBS_OUT

V_R

V_B

V_G

VIDEO I/F

AR

AL

GPO14 AUDIO_MUTE AUDIO_MUTE

GPO14

96

95

94

93

92

91

90

89

88

87

86

85

84

83

82

81

80

79

78

RA3

77

RA2

76

RA1

75

RA0

74

73

BA1

72

BA0

71

70

69

68

67

RA4

66

RA5

65

RA6

C14 0.1uF/NCC14 0.1uF/NC

TX2+

TX2-

TX1+

TX1-

TX0+

TX0-

TXC+

TXC-

R4 2.5K 1%R4 2.5K 1%

HPLG

ASPDIF

V12

MA3

MA2

MA1

MA0

MA10

BA1

BA0

89M_3V3

RAS#

CAS#

WE#

MA4

MA5

MA6

RS-232

NC(100pF)

NC(100pF)

C16

C16

R101

R101

NC/4.7K

NC/4.7K

C13

C13

0.1uF

0.1uF

C11

C11

0.1uF

0.1uF

R102

R102

NC/4.7K

NC/4.7K

C10

C10

NC(100pF)

NC(100pF)

FB2 0RFB2 0R

R5 2.2RR5 2.2R

C80

C80

4.7uF

4.7uF

DV33

3V3

C2

NC(100pF)C2NC(100pF)

V12

Q1

Q1

NC(CES2302)

NC(CES2302)

23

1

RXD

TxD

GND

4pin/2.0mm

4pin/2.0mm

R114 1K R114 1K

89M_3V3

C133

C133

10uF/10V

10uF/10V

MO_VCC

XP8

XP8

1

2

3

4

Default

RXDGPIO11

TXDGPIO6

XP7

XP7

1

2

3

4

ASPDIF

AKIN1

AUDIO I/F

TXC+

TXC-

TX0+

TX0-

TX1+

TX1-

TX2+

TX2-

HPLG

UP1_[6..7]

89M_CEC

TMDS I/F

URST#

DV33

AADVDD

89M_3V3

V12

RFV33

MO_VCC

VCC

Power

IR

Front

TR_B1

REGO1

TR_B2

REGO2

PCON

VSCK

VSDA

VSTB

USBPC

POWER_K

DQ[0..15] 4

MA[0..11] 4

DQM[0..1] 4

BA[0..1] 4

DCLK 4

RAS# 4

CAS# 4

WE# 4

SF_CK 4

SF_CS 4

SF_DI 4

SF_DO 4

CVBS_OUT 5

V_R 5

V_B 5

V_G 5

AR 6

AL 6

AUDIO_MUTE 6

ASPDIF 6

AKIN1 6

TXC+ 7

TXC- 7

TX0+ 7

TX0- 7

TX1+ 7

TX1- 7

TX2+ 7

TX2- 7

HPLG 7

URST# (2,4)

DV33 (2,3,4,7)

AADVDD 2

89M_3V3 1

V12 (2)

RFV33 1

MO_VCC 2

VCC (2,3,7)

IR 2

TR_B1 2

REGO1 2

TR_B2 2

REGO2 2

PCON 2

USBPC 2

POWER_K 2

UP1_[6..7] 7

89M_CEC 7

VSCK 2

VSDA 2

VSTB 2

A

B

C

D

E

Page 30

6-6

6-6

A

C27

C27

0.1uF

0.1uF

6PIN/2.0mm

6PIN/2.0mm

C32

C32

0.1uF

0.1uF

OP-

1

D3

3

BAT54CD3BAT54C

2

OPO

XP4

XP4

1

2

3

4

5

6

+

+

Very Important to

reduce Noise

L10

L10

10uH

10uH

Q7

9012Q79012

R45 4.7R45 4.7

R46 4.7R46 4.7

Q8

9012Q89012

TP10TP10

VOFC+

VOFC-

VOSLVOSL+

VOTR+

VOTR-

VCC

G1

REV

FWD

REGO1

VINSL+

REGO2

TRB1

VINFC

DV33

L6FBL6

FB

CE10

CE10

100uF/16V

100uF/16V

C78

C78

NC/0.1uF

NC/0.1uF

14

13

12

11

10

9

8

29

7

6

5

4

3

2

1

VCC

CE11

CE11

+

+

47uF/6.3V

47uF/6.3V

CE12

CE12

+

+

47uF/6.3V

47uF/6.3V

LOAD+

LOAD-

TROPEN

TRCLOSE

R56 10KR56 10K

FOSO

TP11TP11

V12

R126 0R126 0

R127 0R127 0

C71

C71

0.1uF

0.1uF

RF Reference

Q23

Q23

9012

9012

Q24

Q24

9012

9012

SPSP+

TP16TP16

TP17TP17

RFV12-2

SERVO RF DeCAP.

V20

+

+

CE8

CE8

47uF/6.3V

47uF/6.3V

LIMIT TROUTGPI36

LDO2

R49 10KR49 10K

RFV33

R32 10KR32 10K

LDO1

TP13TP13

TP15TP15

REGO1

REGO2

TR_B1

CE15

CE15

+

+

220uF/16V

220uF/16V

R24 10KR24 10K

C24

C24

R251R25

0.1uF

0.1uF

1

SP-A

1 1

2 2

3 3

DV33

G

2

2SK3018

SC-70

SONY 313

25

26

TOP

TOP

27

28

TP12TP12

TP14TP14

MO_VCC

R23 10KR23 10K

D

3

S

1

XP2

XP2

SMD0.5 TOP

SMD0.5 TOP

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

SL+

SL-

4 4

R28 10KR28 10K

SP-A

SP+

LIMIT

SLSL+

LD-DVD

MDI1

LD-CD

E

AVCC1

V20

F

B

A

RFO

IOA

D

C

TT+

F+

F-

FF+

TP8TP8

R54 10KR54 10K

R55 10KR55 10K

C95

C95

0.1uF

0.1uF

R38

R38

C94 0.1uFC94 0.1uF

R61

R61

10K

10K