Page 1

DVD Player

DVP3136/94

DVP3136/94

Service

Service Manual

©Copyright 2007 Philips Consumer Electronics B.V. Eindhoven, The Netherlands

All rights reserved. No part of this publication may be reproduced, stored in aretrieval system or

transmitted, in any form or by any means, electronic, mechanical, photocopying, or otherwise

without the prior permission of Philips.

Published by TCL-HY 0707 Service Audio Printed in The Netherlands Subject to modification

Version 1.0

TABLE OF CONTENTS

Page

. Technical Specifications……………………………………...................1-2

. Safety Instruction, Warning & Notes….……………………….....….....1-3

. Mechanical and Dismantling Instructions………….............................2-1

. Region Code, Software Version& Upgrades……………....................

. Trouble Shooting Chart………………………………………….………

. Wiring Diagram………………………………………..…....….…..….….5-1

. Electrical Diagrams and Print-layouts..….……………..…….......….…6-1

. Set Mechanical Exploded View & Electrical Part list.……….....….….7-1

. Revision List……………………...........……………………....….....…...8-1

.3-1

.4-1

CLASS 1

LASER PRODUCT

GB

3139 785 32840

PHILIPS

Page 2

Technical Specifications

TV standard (PAL/50Hz) (NTSC/60Hz)

Number of lines 625 525

Playback Multi standard (PAL/NTSC)

Video performance

Video DAC 14 bit

YPbPr 0.7Vpp ---- 75 ohm

Video output 1Vpp ----- 75 ohm

Video format

Digital Compression MPEG 2 for DVD,SVCD

MPEG 1 for VCD

DVD 50Hz 60Hz

Horiz resolution 720 pixels 720 pixels

Vertical resolution 576lines 480 lines

1-2

Spearker Output

Signal-Noise(1KHz) >70dB

Dynamic range(1KHz) >60dB

Crosstalk (1KHz) >60dB

Distortlon/noise(1KHz) >-62dB

Speaker Power Output

@10%THD 6¡ <=10W rms/ch

(2 channels)

Frequency Response 20Hz-20kHz

MPEG MP3 MPEG Audio L3

Connections

YPbPr output Cinch 3x

Video output Cinch( yellow)

Audio output (L+R ) Cinch (white/red)

Digital output 1 coaxial

IEC60958 for CDDA/ LPCM

IEC61937 for MPEG1/2

VCD 50Hz 60Hz

Horiz. resolution 352 pixels 352 pixels

Vertical resolution 288lines 240 lines

Audio format

Digital MPEG/AC-3/ Compressed

PCM Digital

16, 20, 24bits

fs, 44.1, 48, 96kHz

MP3(ISO 9660) 96,112,128,256kbps

& variable bit rate fs,32,

44.1,48 kHz

Analogue Sound Stereo

Dolby surround compatible downmix from Dolby Digital multi-channel

sound

Audio performance

DA converter 24bits, 192KHz

DVD fs 96kHz 4Hz----44kHz

fs 48kHz 4Hz----22kHz

SVCD fs 48kHz 4Hz----22kHz

fs 44.1kHz 4Hz----20kHz

CD/ VCD fs 44.1kHz 4Hz----20kHz

Line Output

Signal-Noise (1kHz) >70dB

Dynamic Range (1kHz) >60dB

Cross talk (1kHz) >70dB

Distortion/Noise (1kHz) >65dB

6 channal analog output

Audio Front L/R Clinch (white/red)

Audio Rear L/R Clinch (white/red)

Audio Center Clinch (blue)

Audio Subwoofer Clinch (black)

2 channel speaker output

Audio+RCH-Clip (red/black)

Audio+LCH-Clip (red/black)

Cabinet

Dimensions (w X h X d) 360 x 37 x 237mm

Weight Approximately 2kg

Power consumption

Power supply Rating 110V -240V;

50/60HZ

Power consumption <12W

Power consumption in standby mode <2W

Standby mode

Specifications subject to change without prior notice.

Page 3

1-3

Safety instruction, Warning & Notes

Safety instruction

1. General safety

Safety regulations require that during a repair:

. Connect the unit to the mains via an isolation transformer.

. Replace safety components indicated by the symbol

only by components identical to the original ones. Any

other component substitution (other than original type)

may increase risk of fire or electrical shock hazard.

Safety regulations require that after a repair, you must

return the unit in its original condition. Pay, in particular,

attention to the following points:

. Route the wires/cables correctly, and fix them with the

mounted cable clamps.

. Check the insulation of the mains lead for external

damage.

. Check the electrical DC resistance between the mains

plug and the secondary side:

1) Unplug the mains cord, and connect a wi re b etween

the two pins of the mains plug.

2) Set the mains switch the “on” position (keep the

mains cord unplug).

3) Measure the resistance value between the mains

plug and the front panel, controls, and chassis

bottom.

4) Repair or correct unit when the resistance

measurement is less than 1M¡.

5) Verify this, before you return the unit to the

customer/user (ref. UL-standard no. 1492).

6) Switch the unit “off”, and remove the wire between

the two pins of the mains plug.

2.Laser safety

This unit employs a laser. Only qualified service personnel

may remove the cover, or attempt to service this device

,

(due to possible eye injury).

Laser device unit

Type : Semiconductor laser GaAlAs

Wavelength : 650nm (DVD)

: 780nm (VCD/CD)

Output power : 7mW (DVD)

: 10mW (DVD /CD)

Beam divergence: 60 degree

Note: Use of controls or adjustments or performance of

procedure other than those specified herein, may result in

hazardous radiation exposure. Avoid direct exposure to

beam.

Page 4

Warning

1.General

. All ICs and many other semiconductors are susceptible to

electrostatic discharges (ESD). Careless handing during

repair can reduce life drastically. Make sure that, during

repair, you are at the same potential as the mass of the

set by a wristband with resistance. Keep components and

tools at this same potential. Available ESD protection

equipment:

1) Complete kit ESD3 (small tablemat, wristband,

connection box, extension cable and earth cable)

4822 310 10671.

2) Wristband tester 4822 344 13999.

. Be careful during measurements in the live voltage

section. The primary side of the power supply , including

the heat sink, carries live mains voltage when you

connect the player to the mains (even when the player is

“off”!). It is possible to touch copper tracks and/or

components in this unshielded primary area, when you

service the player. Service personnel must take

precautions to prevent touching this area or components

in this area. A “lighting stroke” and a stripe-marked

printing on the printed wiring board, indicate the primary

side of the power supply.

. Never replace modules, or components, while the unit is

“on”.

1-4

2. Laser

. The use of optical instruments with this product, will

increase eye hazard.

. Only qualified service personnel may remove the cover

or attempt to service this device, due to possible eye

injury.

. Repair handing should take place as much as possible

with a disc loaded inside the player.

. Text below is placed inside the unit, on the laser cover

shield:

CAUTION: VISIBLE AND INVISIBLE LASER

RADIATION WHEN OPEN, AVOID EXPOSURE

TO BEAM.

Notes: Manufactured under licence from Dolby

Laboratories. The double-D symbol is trademarks of Dolby

Laboratories, Inc. All rights reserved.

Page 5

Notes

Lead-Free requirement for service

1-5

INDENTIFICATION:

Regardless of special logo (not always indicated)

One must treat all sets from 1.1.2005 onwards, according

next rules.

Important note

be treated in this way as long as you avoid mixing

solder-alloys (leaded/ lead-free). So best to always use

SAC305 and the higher temperatures belong to this.

Due to lead-free technology some rules have to be

respected by the workshop during a repair:

x Use only lead-free solder alloy Philips SAC305 with

order code 0622 149 00106. If lead-free solder-paste is

required, please contact the manufacturer of your

solder-equipment. In general use of solder-paste within

workshops should be avoided because paste is not easy

to store and to handle.

x Use only adequate solder tools applicable for lead-free

solder alloy. The solder tool must be able

o To reach at least a solder-temperature of 400°C,

o To stabilize the adjusted temperature at the

o To exchange solder-tips for different applications.

x Adjust your solder tool so that a temperature around

360°C

joint. Heating-time of the solder-joint should not exceed

~ 4 sec. Avoid temperatures above 400°C otherwise

wear-out of tips will rise drastically and flux-fluid will be

destroyed. To avoid wear-out of tips switch off un-used

equipment, or reduce heat.

x Mix of lead-free solder alloy / parts with leaded solder

alloy / parts is possible but PHILIPS recommends

strongly to avoid mixed

solder alloy types (leaded and lead-free). If one cannot

avoid, clean carefully the

solder-joint from old solder alloy and re-solder with new

solder alloy (SAC305).

: In fact also products a little older can also

solder-tip

– 380°C is reached and stabilized at the sol der

x Use only original spare-parts listed in the

Service-Manuals. Not listed standard-material

(commodities) has to be purchased at external

companies.

x Special information for BGA-ICs:

- always use the 12nc-recognizable soldering

temperature profile of the specific BGA (for

de-soldering always use highest lead-free

temperature profile, in case of doubt)

- lead free BGA-ICs will be delivered in so-called

‘dry-packaging’ (sealed pack including a silica gel

pack) to protect the IC against moisture. After

opening, dependent of MSL-level seen on

indicator-label in the bag, the BGA-IC possibly

still has to be baked dry. This will be

communicated via AYS-website.

Do not re-use BGAs at all.

x For sets produced before 1.1.2005, containing

leaded soldering-tin and components, all needed

spare-parts will be available till the end of the

service-period. For repair of such sets nothing

changes.

x On our website:

www.atyourservice.ce.Philips.com

You find more information to:

BGA-de-/soldering (+ baking instructions)

Heating-profiles of BGAs and other ICs used in

Philips-sets

You will find this and more technical i nformation

within the “magazine”, chapter “workshop news”.

For additional questions please contact your local

repair-helpdesk.

Page 6

2-1

Mechanical and Dismantling Instructions

Dismantling Instruction

The following guideline is a general instruction for how to dismantle the player, Detailed operation done according the set unit.

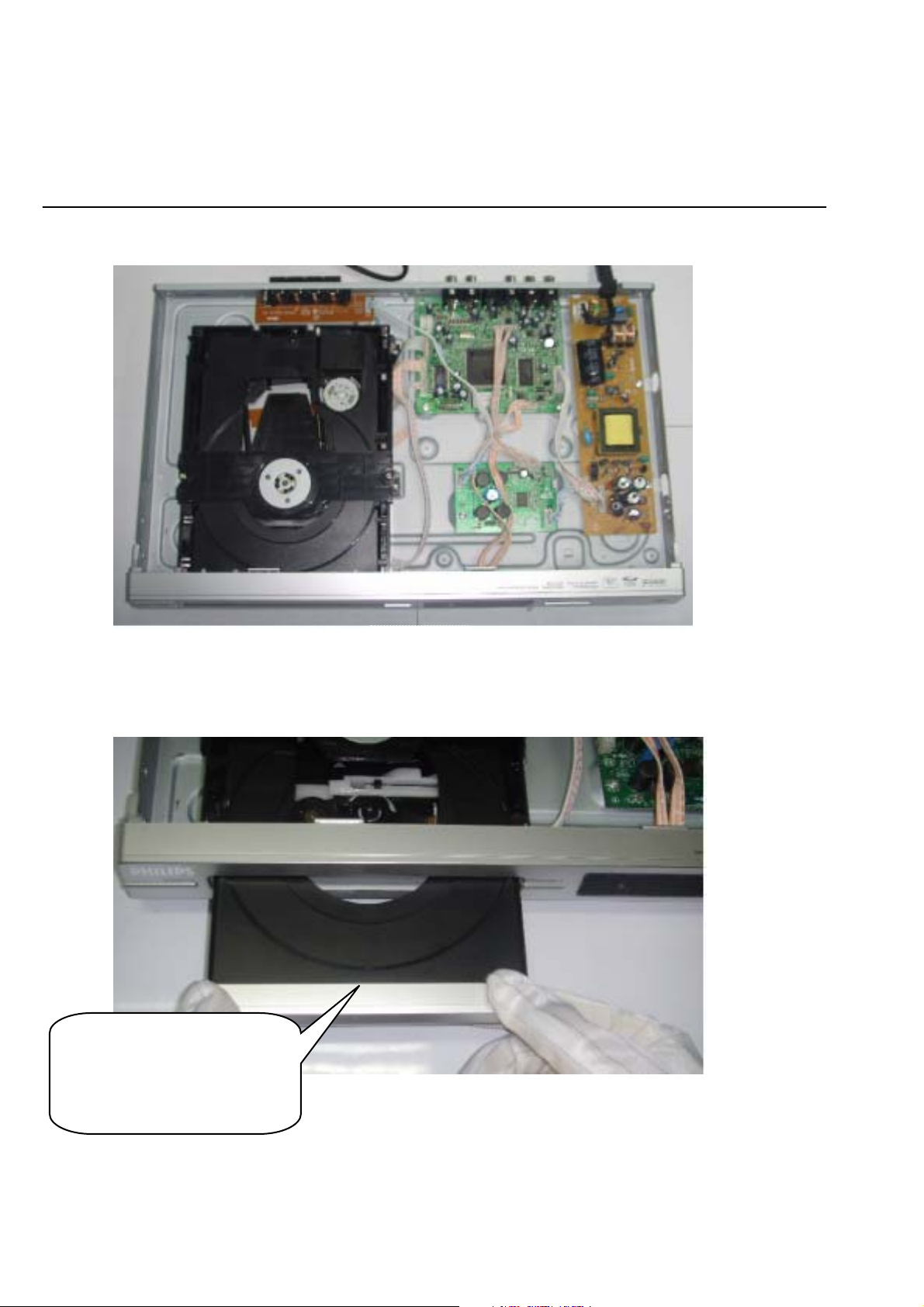

Step1: Remove 5 screws around the Top Cover, then remove the Top Cover (Figure 1).

Step2: If it is necessary to dismantle Loader or Front Panel, It should be remove the Front door assembly first. (Figure 2)

Note: Make sure to operate gently otherwise the guider would be damaged.

Please kindly note that dismantle

the front door assembly carefully

to avoid damage tray and the front

door assembly.

Figure 1

Figure 2

Page 7

2-2

Mechanical and Dismantling Instructions

Dismantling Instruction

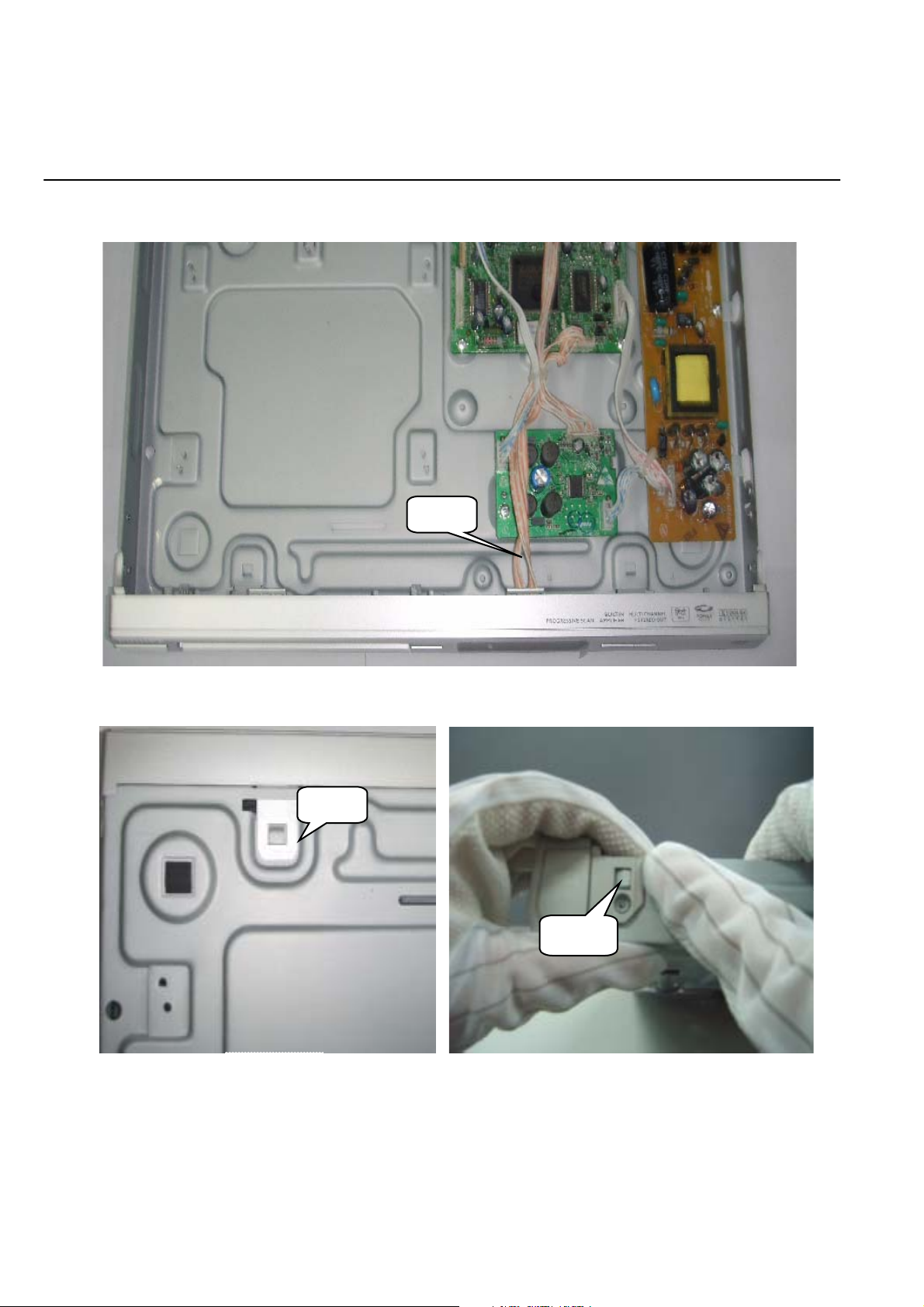

Step3: If the tray can’t open in normal way, you can make it through the instruction as below (Figure 3).

Note: Make sure to operate gently otherwise the guider would be damaged.

Push the guider until the tray out.

Make sure to operate gently to

avoid damage happening.

Figure 3

Step4: Dismantling Loader, disconnect the 3 connectors aiming in the below figure, and remove screw around the

Loader. (Figure 4)

CON1

CON2

CON3

Figure 4

Page 8

2-3

Mechanical and Dismantling Instructions

Dismantling Instruction

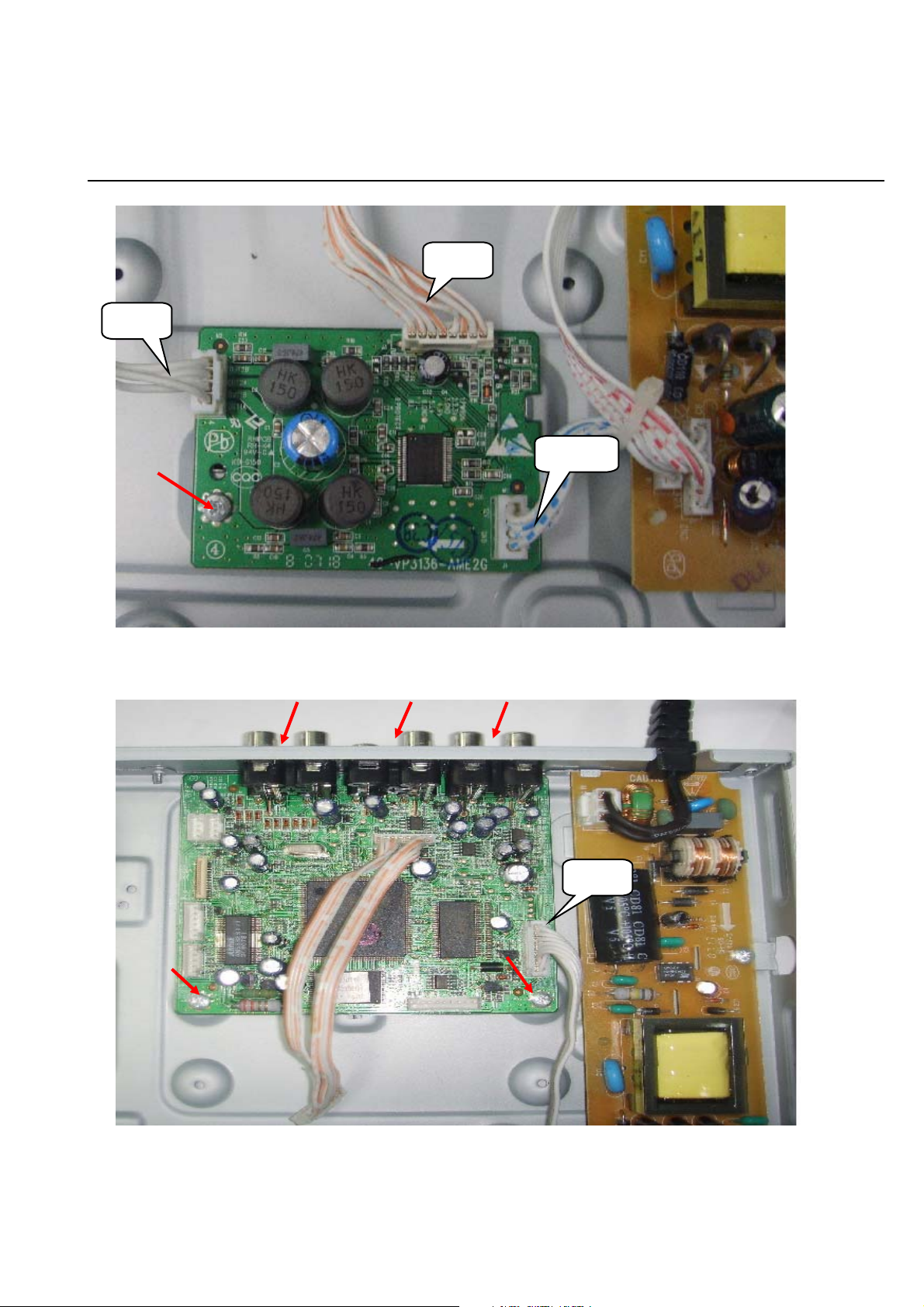

Step5: Dismantling Front Panel, disconnect the 1 connector, then release the snaps on the both sides of Front Panel and bottom

cabinet , then gently pull the Panel out from the set. (Figure 5 & 6 & 7)

CON4

Figure 6

Figure 5

Snap1

Snap 2

Figure 7

Page 9

2-4

Mechanical and Dismantling Instructions

Dismantling Instruction

Step6: Dismantling Amplifier Board, first disconnect the 3 connector, then remove 1 screw. (Figure 8)

CON5

CON6

CON7

Step7: Dismantling Main Board, first disconnect the 1 connector, then remove 5 screws to remove the Main board. (Figure 9)

Figure 8

Figure 8

CON8

Figure 9

Page 10

2-5

Mechanical and Dismantling Instructions

Dismantling Instruction

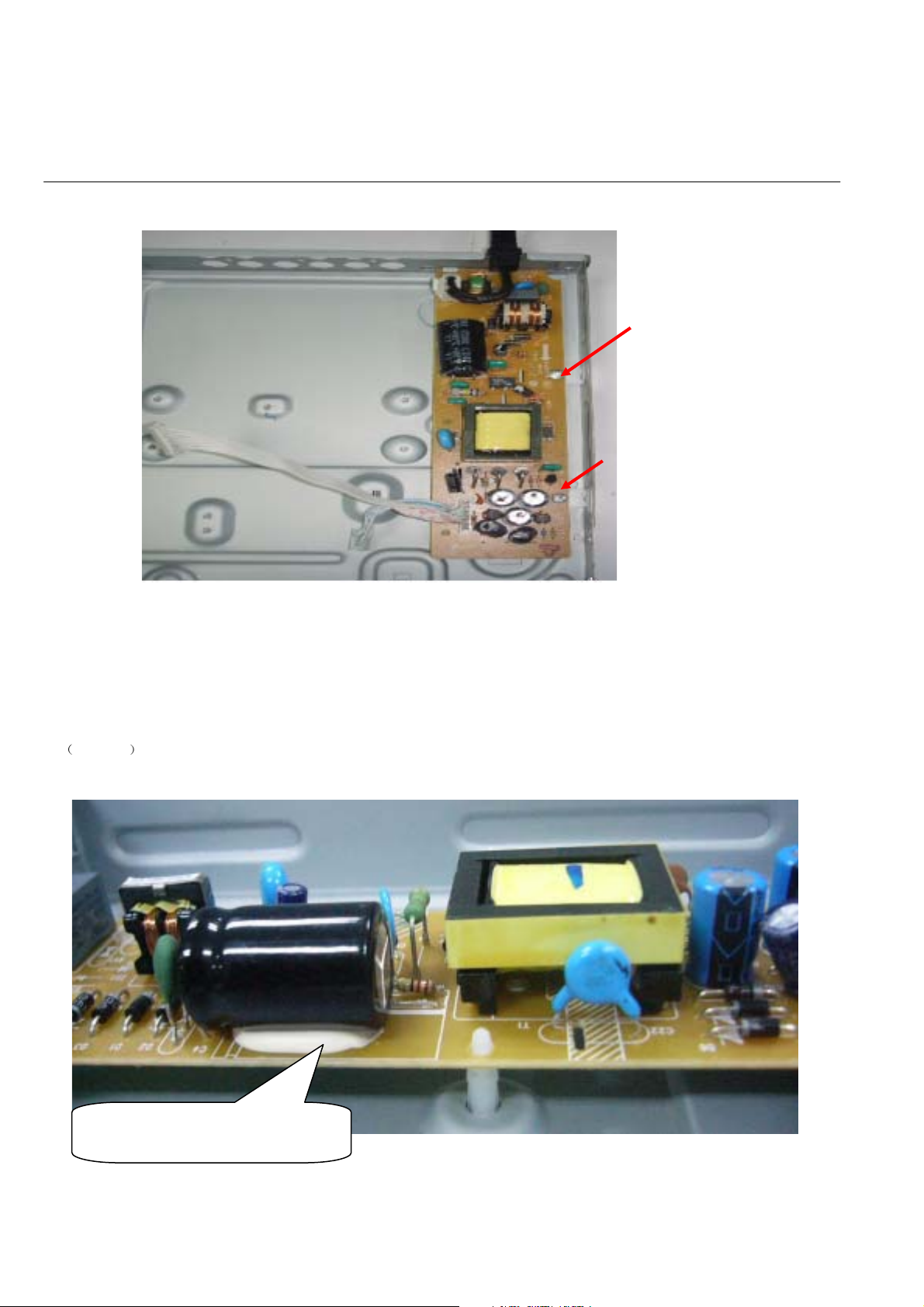

Step8: Remove the 2 screws on Power Board to dismantle the Power Board. (Figure 10)

Figure 10

ATTENTION OF REPAIRING

Make sure adding silicon glue to fix the capacitor C4 after repairing, ( Avoid the hazard of C4 touching the Top Cover.)

嗻

Figure11

嗼

Add Silicon glue or Heat glue to fix

C4 to keep this status

Figure 11

Page 11

2-6

Mechanical and Dismantling Instructions

Dismantling Instruction

Step9: Remove the 2 screws on Input/Output Board to dismantle the Input/Out Board. (Figure 12)

Figure12

Page 12

Software upgrade

3-1

Preparation to upgrade software

1) Start the CD Burning software and create a new CD

project (Data Disc) with the following setting:

Label: DVP3XXX (No need the label name)

Note: It is required capital letter for the File System

name, and it no need have the File name during

start the CD burning software for Zoran project.

2) Burn the data onto a blank CDR

A. Procedure for software upgrade:

1) Power on the set and insert the prepared Upgrade

CDR.

2) The set will starts reading disc & response with the

following display TV screen:

Loading

Firmware Upgrade Erase and program.

Start Cancel

Select Start to start upgrade.

3) Press <OK> button to confirm, then screen will display :

Firmware Upgrade Programming, Please Wait...

Do not Switch the Player Off !

4) The upgraded disc will automatically out when files

coping complete, then take out the disc.

5) About 1 minute later, the tray will automatically close

when upgrading complete.

B. Read out the software versions to confirm upgrading

1) Power on e set and Open the tray door.

2) Press <9><6><6>button to check the software

information.

The software version and other information are display

on the TV screen as follows:

BE Version: DVP3XXXXX_XX.XX

FE Version: DCX.XXXXXX.XX.XX

DSP Version: DSP.XX

Region Code: X

Caution: The set must not be power off during

upgrading, Otherwise the Main board will be

damaged entirely.

Page 13

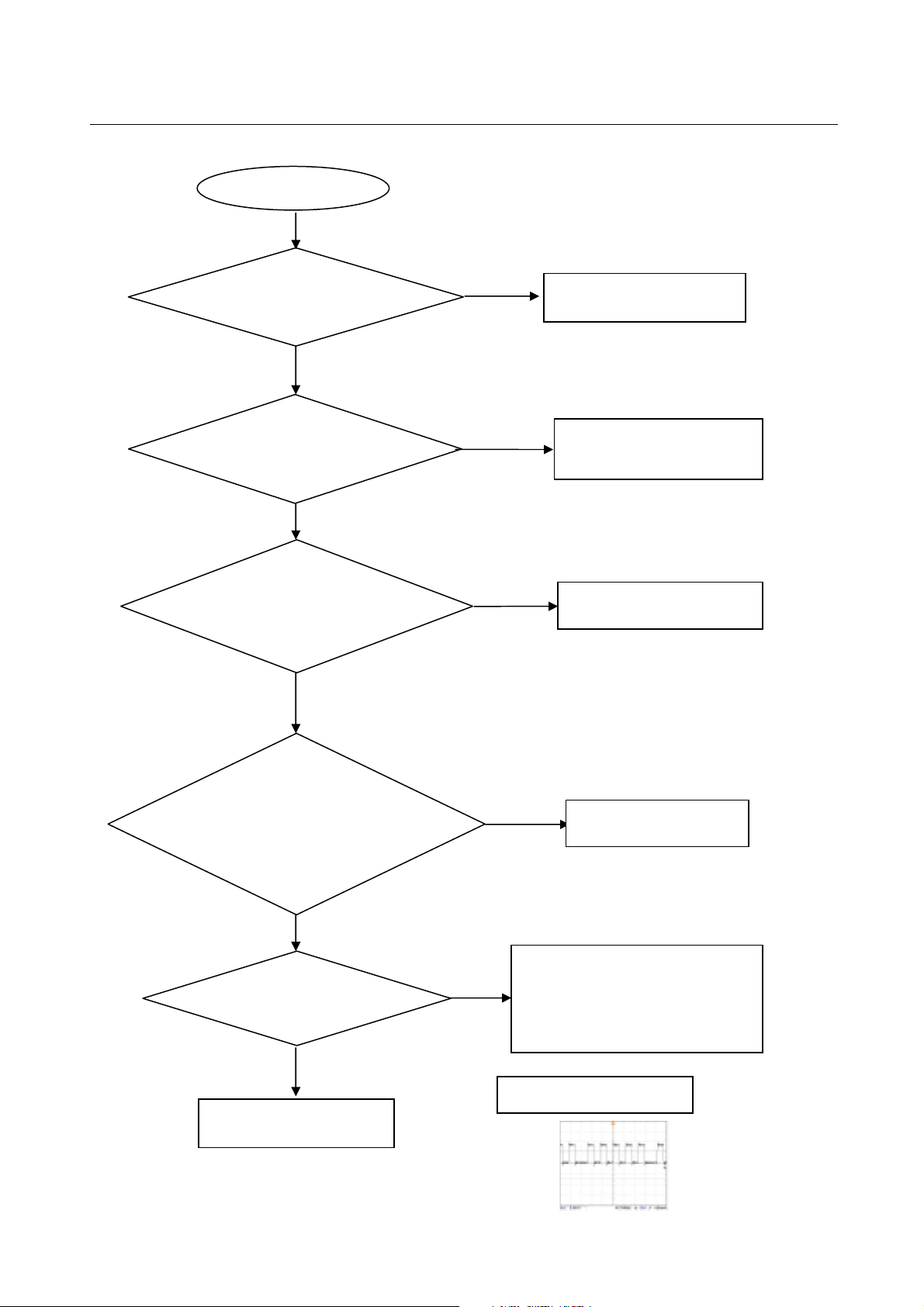

Spindle motor does not move

Motor no move

Go

4-1

Trouble shooting chart

Check the FFC connection

between 24P and the loader.

Yes

Check whether “RFA5V”

(+5V) voltage is normal.

Yes

Check whether laser voltage

(2.3V for DVD & 1.9V for CD)

on Collector of Q2 and Q3

Yes

No

No

No

Correct connection

Check the RFA5V power

supply

Check/Replace Q2ǃQ3.

1.Whether voltage on pin 129 of U1

varies between 0 and 3.3V (3.3V for

CD and 0V for DVD),

2.Whether peripheral components

are eroded or badly soldered.

Yes

Have no focus

Yes

Check/Replace the loader

No

1. Check U1 182pin

No

FOCUS_PWM signals

2.If there are F+, F-, T+ and Tsignals output from U7.

FOCUS_PWN waveform

Check/ Replace U1.

Page 14

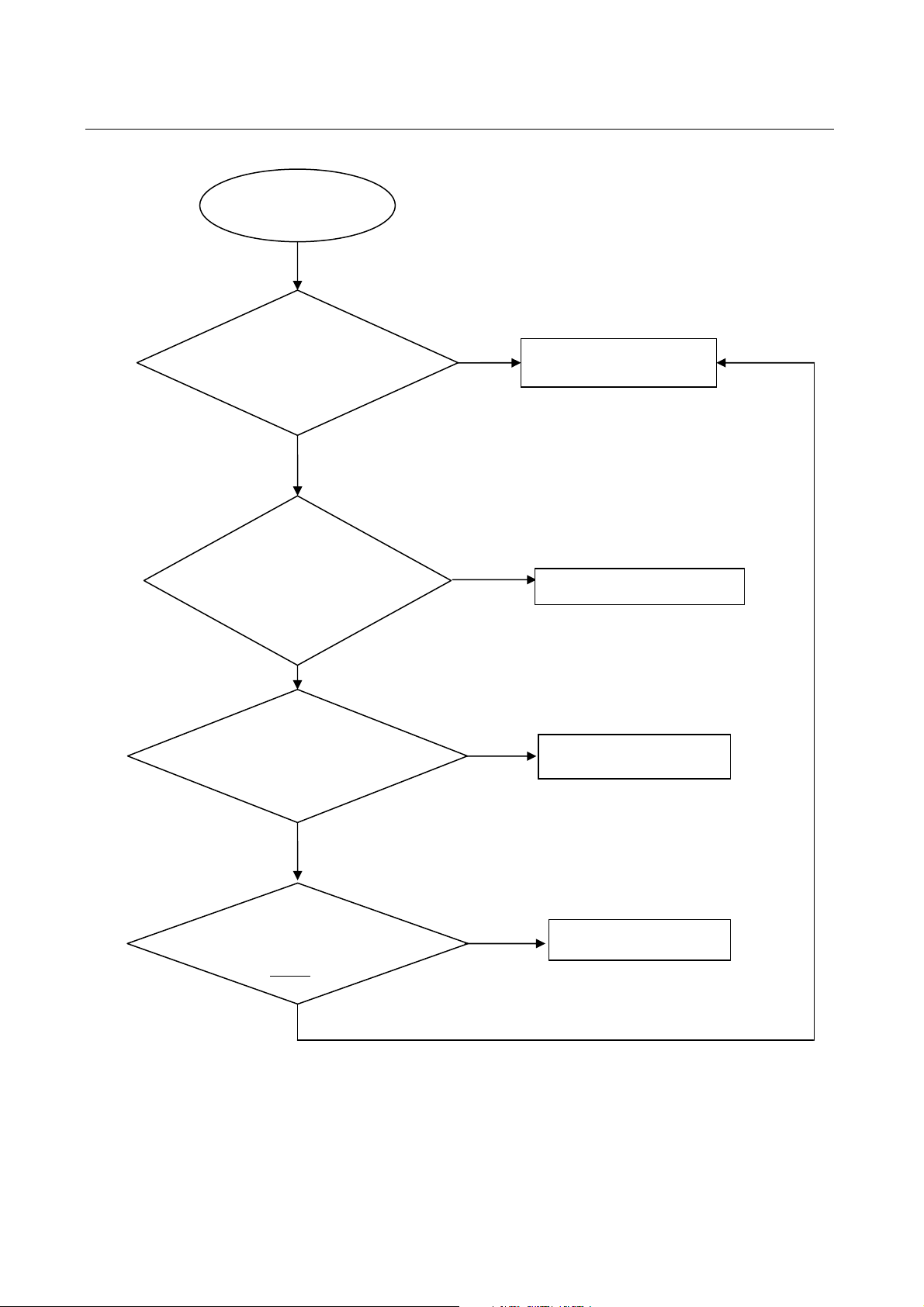

The power can not be on or off

The power can’t be

on or off

Go

4-2

Trouble shooting chart

Check the power supply

on the power board is

normal.

Yes

Check if the CON301 on

the front board to CN5 on

the decoder board is in

good contact.

Yes

Whether the connection

to K301 is broken.

Ye s

No

No

No

Repair the power board

Check/Correct connection

Correct the connection

Yes

Whether there is 0V and

3.3V voltage difference on

Pin 94 PCON

of U1.

Yes

No

Replace U1.

Page 15

4-3

All output voltages on the power board is 0V or deviated.

All output voltages on

the power board is 0V or

deviated

Yes

Trouble shooting chart

Check whether

F1 is blown

No

Check whether there is

300V on C1 or C2.

Yes

Check whether 100KHz

oscillating signal on

Pin6 of U1

Yes

Yes

No

No

Replace F1

Replace C1&C2 if D1, D2, D3, D4 are

normal.

Check/ replace U1.

U1(PIN 3 - RC waveform)

U1(PIN 8 - Drain waveform)

Check if +5V, , +12V and -12V

are short.

Yes

Check whether the components in the

short-circuit voltage are defected or eroded.

No

Check whether U1 are eroded.

Page 16

Disc cannot be read.

Disc cannot be read.

Yes

4-4

Trouble shooting chart

Check the FFC connection

between 24P and the loader.

Yes

Check whether there is laser

voltage (2.3V for DVD and 1.9V

for CD) on Collector of Q2 &Q3

Yes

Check U1, U7, and

peripheral components are

eroded or badly soldered.

No

No

No

Check the loaded circuit

1.Check voltage on pin 100 of U1 varies

between 0 and 3.3V:

Æ3.3V for CD

Æ0V for DVD

2.Check whether peripheral components

are eroded or defect

Re-solder or replace the defective parts

Yes

Check if there is RFO signal on

pin10 of CN2. (The normal RFO

signal is a clear reticulated wave)

Yes

Check the connection

between U1

Yes

Replace U1 or loader.

No

No

Check U1 and peripheral components

Correct connection

Page 17

4-5

p

p

Only DVD disc or only disc except DVD can be played

Only DVD disc, or only disc

exce

t DVD can be Played.

Go

Trouble shooting chart

Check the FFC

connection between

24pin and the loader.

Yes

Check laser voltage (2.3V) output

on Collector of Q2, if pin181 of

U1is at low level.

Yes

Check whether there

is voltage variance on

in 182 of U1.

No

No

No

Check the loaded circuit

Check the solder status on U1 and

peripheral components

check if bad solder exist on U1 and

peripheral components

Yes

Check whether pins of U1 and

peripheral components are

badly soldered, defected

Yes

Check Q2 whether

in good condition

Yes

Change U1 or the loader.

No

Replace the bad spare parts

No

Correct connection

Page 18

4-6

No display on LED, and buttons do not work

No display on LED, and

buttons do not work

Yes

Trouble shooting chart

Check whether there is

correct contact between

CON301 and CN5

Yes

Check VCC(+5v) voltage

on the power and front

board

Yes

Check there are CS, DATA

and CLK signals on CON301

on the front board.

No

Correct connection

No

No

CN5 (PIN 2 CLK) CN5 (PIN4 DOUT)

Fix power supply board top

a power supply for should

electric circuit

Check the U1’s pin 131,132,133

arrive the CN5 connect condition

Yes

1.Check whether bad solder exists on

U301 and pins of LED,

2.Check whether the circui t connected to

K302, K303, K304 and K301 is broken,

3.Check whether R300, R301 and R302

are open-circuit.

Yes

Replace U301 or LED

No

Correct connection

Page 19

Distorted audio and loud noise(Line out)

Distorted audio and

loud noise(line out0

Yes

Check the power supply voltages

+12V to the operation amplifying

Q27 and -12V are normal.

Yes

No

4-7

Check Q27

Trouble shooting chart

Check whether the

muting transistor R176

andR175 are normal

Yes

Check whether the

muting transistor

Q17~Q18ˈQ40~Q43ˈ

Yes

Checking the U1 leads the

feet has no to break to

open

Yes

Replace U1

No

No

Replace R176 and R175

Replace Q17~Q18 ,Q40~Q43

No

Correct connection

Page 20

Distorted audio and loud noise(Speaker)

Correct connection

Distorted audio and

loud noise(speaker)

Yes

Check the power supply voltages

+12V to the operation amplifying

Q27 and -12V are normal.

Yes

No

4-8

CheckQ27

Trouble shooting chart

Check whether the

muting transistor FB1

are normal

Yes

Check whether the

muting transistor

Q3~Q5ˈ,D1 are normal

Yes

Checking the U1 leads the

feet has no to break to

open

Yes

Replace U1

No

No

Replace FB1

Replace Q3~Q5ˈ,D1

No

Page 21

Abnormal color of video picture

p

p

Abnormal color of

video

icture

Yes

4-9

Trouble shooting chart

Check whether the

27MHz out

Yes

Check whether the 3.3V

and 1.8V power supply

voltages on the decoder

board are normal.

Check whether the

video filter network

circuit is normal.

ut signal

Yes

No

Check Y1, R13, C38 and C39

No

Check other of power supply electric

circuit

No

Correct the connection

Yes

Check if the video signals on Pin

147,149,151,152,154 of U1 are normal

No

change U1

Page 22

Remote reception is insensitive or fails.

prop

Remote reception is

insensitive or fails.

Go

4-10

Trouble shooting chart

Check if the remote

control works

erly.

Yes

Check if the power supply

voltage to the remote censor

is normal

Yes

Use an oscilloscope to check if there is

output waveform from the first pin IR of the

remote censor after pressing button on the

remote control.

Yes

No

No

Check battery

Check R315ǃC315

No

REM301(PIN1 - RC waveform)

Check if there is IR

signal on pin 134 of U1

No

Correct connection

Yes

Change U1

IR waveform

Page 23

No video picture, no sound.

y

g

No video picture,

no sound.

4-11

Trouble shooting chart

Check whether all the voltages

from the power board to the

decoder board are normal.

Yes

Check if the reset circuit consisting

ofEC9, D1 and Q1 is normal (at a

high level for tens of milliseconds,

then constantl

at 0V).

Yes

Check whether there is

27MHz si

nal output.

Yes

Check if there is 135MHz

signal output on R2.

No

No

No

Check the loaded circuit

Change EC9, D1and Q1.

Crystal oscillator Y1 and

peripheral components

are defected or eroded.

No

CVBS(R21 point) waveform

27Mhz waveform

Check whether

short-circuit or bad

solder on U2,U4

Yes

Check if short-circuit and

bad solder exist on Pin

151

Yes

Reconnect the component in

SDRAM(R2 PCLK) waveform

No

No

Check U1.

Yes

Page 24

5-1 5-1

A

4 4

B

C

D

E

DVP3136 WIRING DIAGRAM

CN8

SR

SL

AUDIO AMP&LPF

AM5888S

MOTER DRIVER

1

SW

CN

24

3 3

CN2

24PIN*0.5

DVD LOADER

(TCL)TDM+KHM313AAM

SP-

SP+

LIMIT

GND

SLSL+

1

1

CN4

6PIN*2.0

6

LOAD+

LOAD-

2 2

TROUT

GND

TRIN

1

CN3

5PIN*2.0

5

R

L

8M

FLASH

CN5

9PIN*2.0

CLK

POWER-K

DATACS+5V

CN7

ZORAN962

IR

DV33

GND

COAX

GND

Pr

Pb

CN6

VIDEO LPF&DRIVE

/94 CVBS

䳔ࡴ䱨Ⳉ⬉ᆍ

Y

CVBS

⠜ᴀ ϔ䏃

POWER

SUPPLY

CN202

KARAOKE A/D

CS5340

EEPROM

1

+5V

7PIN*2.5

CN1

16M SDRAM

7

+5V

GND

GND

+12V

AGND

-12V

1

7PIN*2.5

7

MAIN BOARD

9

18

114

12V

12V

GND

R+

L+

R-

DV33

GND

ML

2

SWITCH

BOARD

1 1

A

CN303

2PIN*2.0

GND

POWER-K

1

1

CN302

2PIN*2.0

2

B

9

9PIN*2.0CN301

LED-DISPLAY+ET6202/KEY

front BOARD

1

C

18

STA533W

AMP BOARD

L-

GND

D

GND

4

OUT1A

OUT1B

OUT2A

OUT2B

AMP OUT

BOARD

E

Page 25

6-1 6-1

1

A A

2

3

4

5

Input/Output Electric Diagram for DVP3136/94

B B

C1

B

2

C2

B

2

C3

B

2

C4

B

2

J4

B

1

J5

B

2

X4

E

C1

J4

CON4 PTH 2.5

4

3

2

1

OUT2A

OUT2B

OUT1A

OUT1BOUT1B

C2

102

102

C3

C4

102

102

J5

1

1

2

2

3

3

4

4

5

6

SPEAK1

C C

4

D D

E E

1

2

3

4

5

Page 26

6-2 6-2

1

A A

2

3

4

5

Switch Board Electric Diagram for DVP3136/94

B B

2

B

1

4

C C

K301 POWER

1

2

3

LED1

4

CN301

C319

47p

SWITCH BOARD

C318

C317

47p

47p

CN301

2

B

C317

2

B

C318

2

B

C319

2

B

K301

2

B

LED1

4

E

X1

D D

E E

1

2

3

4

5

Page 27

1

6-3 6-3

Amplifier Board Electric Diagram for DVP3136/94

2

3

4

5

A A

PWRDN

J1

CON4 PTH2.5

1

12V

2

3

GND

4

J3

1

2

3

4

5

6

7

8

9

PITCH2.0*9

C1

2

B

C2

2

B

C3

1

B

C4

1

C

C5

1

C

C6

2

C

C7

1

C

C8

1

C

C9

3

C

C10

1

C

C11

2

C

C13

1

C

C14

2

C

C15

1

C

C16

2

C

C17

1

C

C18

2

C

C19

2

C

C20

2

C

C21

1

C

C22

1

C

C23

1

C

C24

2

C

C27

1

C

C28

2

C

C29

2

C

C30

1

C

C32

3

B

D1

3

B

FB1

3

C

FB2

3

C

FB3

3

C

FB4

3

C

FB5

3

C

J1

4

B

J2

1

C

J3

4

C

L1

2

B

L2

2

C

L3

2

C

L4

2

C

Q3

3

B

Q4

3

B

Q5

3

B

R5

1

C

R7

3

C

R8

1

C

R9

2

C

R10

2

B

R11

2

C

R12

2

C

R13

2

C

R14

1

C

R16

1

C

R17

2

C

R19

3

B

R20

3

B

R21

3

B

R22

3

B

R23

3

C

R24

3

B

U1

2

C

X4

4

E

B B

C2

C1

+

1000uF/16V

104

L1 22uH

OUT1A

C3

104

C4

R5

104

C8

C7

103

103

J2

CON4 PTH 2.5

4

4

OUT1B OUT1B

3

3

OUT2A OUT2A

2

2

1

1

C C

OUT2B

C17

C21

103

103

0.47uF

OUT2B

C5

C22

0.47uF

6

R8

C10

6

104

C13

104

C15

104

C23

R14

104

6

R16

C27

6

104

C30

104

C6

330PF

R9

C11

20

L2

L3

22uH

L4

1uF

22uH

C14

104

22uH

C16

104

R17

20

C24

330PF

U1

2915

IN1AVCC1A

OUT1A

OUT1A

GND1A

VCC1B

OUT1B

OUT1B

GND1B

VCC2A

OUT2A

OUT2A

GND2A

VCC2B

OUT2B

OUT2B

GND2B

STA533

CONFIG

PWRDN

FAULT

TRI-STAE

TH-WAR

VCCsing

VCC sing

GND-reg

GND-SUB

23

VL

24

25

27

26

28

30

IN1b

21

Vdd

22

Vdd

33

Vss

34

Vss

35

36

31

IN2A

20

19

GND

32

IN2B

1

R11

10K

R13

NC

C20

C19

C18

104

104

104

C29

NC

17

16

14

12

11

10

13

7

8

9

6

4

3

2

5

C28

1uF

R10

10K

DC 3.3V

R12

10K

R21

4.7k

Q5

3904

Q4 2N3906

+

12

R20

330

3.3V

GND

R+

1N4148

C32

100UF/16V

D1

Q3

3904

C9

NC

INDUCTOR

FB1

FB2500Z

L+

RL-

R22

3.3K

R19

3.3K

R24

4.7K

R7

4.7K

R23

NC

FB3500Z

FB4500Z

FB5500Z

protect

D D

E E

1

2

3

4

5

Page 28

6-4 6-4

1

2

3

4

5

A A

Front Board Electric Diagram for DVP3136/94

B B

FROM MAIN BOARD

CON301

GND

1

5V

2

IR

3

DV33

4

GND

5

DATA

6

CS

7

CLK

8

POWER_K

9

CON9(2.0)

C314

47p

CLK

CS

REM301

REM

3

VCC

2

GND

1

IR

R300 100

R301 100

R302 100

IR

C315

47p

5V

4K7

C C

DV33

R315

100 ohm

+

CE301

C306

47uF

0.1u

R303

R304

R305

5VL

4K7

4K7

R307 10K

C300

C301

C302

100P

100P

100P

R308 10K

CE300

+

C303

0.1u

47uF

CON302

CON2(2.0)

GND

1

POWER_K

2

C316

47p

R306

51K

U301

ET6202

1

OSC

2

DI/O

3

CLK

4

10

11

12

13

14

SEG[1:6]

5

6

7

8

9

STB

KEY1

KEY2

VDD

SEG1/KS1

SEG2/KS2

SEG3/KS3

SEG4/KS4

SEG5/KS5

SEG6/KS6

SEG7/KS7

D3011N4148

D3021N4148

R312 1K

R311 1K

R309 1K

R310 1K

SEG1

SEG2

SEG3

SEG4

SEG5

SEG6

KEY1

KEY2

GRID1

GRID2

GRID3

GRID4

SEG14/GRID5

SEG13/GRID6

SEG12/GRID7

SEG10/KS10

SEG9/KS9

SEG8/KS8

28

GND

27

26

25

GND

24

23

22

GND

5VL

21

VDD

20

19

18

17

16

15

KS1

KS2

GRID[1:7]

GRID1DATA

GRID2

GRID3

GRID4

GRID7

GRID6

GRID5

K304

open/close

GRID1

GRID2

GRID3

GRID4

GRID5

GRID6

GRID7

SEG1

SEG2

SEG3

SEG4

SEG5

SEG6

K302 stop

LED1

1

GRID1

2

GRID2

3

GRID3

4

GRID4

5

GRID5

6

GRID6

7

GRID7

8

SEG1

9

SEG2

10

SEG3

11

SEG4

12

SEG5

13

SEG6

JDD350501AG

K303

play/pause

CE300

CE301

CON301

CON302

C300

C301

C302

C303

C306

C314

C315

C316

D301

D302

K302

K303

K304

LED1

REM301

R300

R301

R302

R303

R304

R305

R306

R307

R308

R309

R310

R311

R312

R315

U301

X1

C

2

B

2

B

1

B

2

C

2

C

2

C

2

C

2

B

2

B

1

B

2

B

2

C

3

C

3

C

3

C

3

C

3

B

3

B

2

C

2

C

2

C

2

B

2

B

2

B

2

B

2

C

2

C

2

C

2

C

2

C

3

C

3

B

2

B

3

E

4

D D

E E

1

2

3

4

5

Page 29

6-5 6-5

1

2

3

4

5

A A

Power Board Electric Diagram for DVP3136/94

TR1

5D210

LF1

1mH

12

RV1

NL

B B

CN1

AC INPUT

T2AL/250Vac

14K471

F1

815647

SM

C C

R1

1/6W 1M

R2

1/6W 1M

CX1

0.1uF/275Vac

U1

D

NC

TOP246P

CSS

S

3

2

R4

6.8 1/6w

C5

0.1uF

+

C6

47uF/25V

D1

RL207

LF2

30mH

D2

+

C1

RL207

100uF/400V

D3

RL207

D4

RL207

C3

R3

103/400V

2W 100K

D5

HER108

+

ZD1

33V 1/2W

12

43

U2

PC123X92

1uF/50V

103/400V

D6

1N4007

C4

C2

CY1

222/400Vac

T1

EPC27

6

5

4

1

3 11

2

R8

1/6W 2.2k

3

1

U3

AMC431

2

8

9

12

7

13

14

10

0.1uF/50V

C8

102

R5

22 1/4W

C14

SR3100

D8

R7

1/6W 220

D10

1N5822

SR3100

D7

FR104

D9

R11

1/6W 2.2k

+

C9

1000uF/16V

+

C7

47uF/25V

+

1000uF/16V

CN1

B

1

CN2

B

3

CN3

B

3

CX1

B

1

CY1

B

2

C1

B

L1

6.8uH

+

L2

6.8uH

C12

C10

1000uF/16V

+

+

C11

470uF/16V

C13

470uF/16V

R6

1/4W10k

R9

1/6W 5.1K 1%

R10

1/6W 5.1k 1%

4X2.5mm

1

2

3

4

7

6

5

4

3

2

1

CN2

+12V

+12V

GND

GND

-12V

GND

+12V

GND

GND

+5V

+5V

CN3

7X2.5mm

2

C2

B

2

C3

B

2

C4

C

2

C5

C

1

C6

C

1

C7

B

2

C8

B

2

C9

B

2

C10

B

2

C11

B

3

C12

C

2

C13

C

3

C14

C

2

D1

B

2

D2

B

2

D3

B

2

D4

B

2

D5

B

2

D6

B

2

D7

B

2

D8

B

2

D9

B

2

D10

C

2

F1

B

1

LF1

B

1

LF2

B

1

L1

B

2

L2

C

2

RV1

B

1

R1

B

1

R2

B

1

B

2

R3

C

1

R4

B

2

R5

B

3

R6

C

2

R7

C

2

R8

C

3

R9

C

3

R10

C

2

R11

B

1

TR1

B

2

T1

C

1

U1

C

2

U2

C

2

U3

E

4

X13

C

2

ZD1

* CAUTION :

THE PARTS MARKED WITH ARE IMPORTANT PARTS ON THE SAFETY.

D D

PLEASE USE THE PARTS HAVING THE DESIGNATED PARTS NUMBER WITHOUT FAIL.

E E

1

2

3

4

5

Page 30

6-6 6-6

1

2

3

4

5

Main Board Electric Diagram for DVP3136/94: Vaddis_SDRAM_Flash

RF

R10

392 Ohm 1%

VDDDAC

VDDDAC

VDDPLL

C202 1000pF

FB7 75Z

FB8

FB9 75Z

C15

10nF

OSCIN

OSCOUT

RESET#

DUPRD1

DUPTD1

DUPRD0

DUPTD0

75Z

Important power supply!

VDDPWM

VDD1AFE

VDDAFE

C27

10nF

VDDDAC

VDDPLL

Close to

Vaddis

R19 75R 1%

R20 75R 1%

R21 75R 1%

IRRCV

IRRCV

FPC_DOUT

FPC_DOUT

FPC_CLK

FPC_CLK

FPC_STB

FPC_STB

INSW

INSW

CD_DVD

CD_DVD

DRVSB

DRVSB

IN_OUT_SW

IN_OUT_SW

CLOSE

CLOSE

OPEN

OPEN

HOMESW

HOMESW

AIN

AIN

S/PDIF_OUT

S/PDIF_OUT

ABCLK

ABCLK

ALRCLK

ALRCLK

AMCLK

AMCLK

APWM_L-

APWM_L-

APWM_L+

APWM_L+

APWM_R-

APWM_R-

APWM_R+

APWM_R+

APWM_SL-

APWM_SL-

APWM_SL+

APWM_SL+

APWM_SR-

APWM_SR-

APWM_SR+

APWM_SR+

APWM_CEN-

APWM_CEN-

APWM_CEN+

APWM_CEN+

R56 4.7R

+

EC20

NM

[470uF/6.3V]

DSPVCC33

R226

10K

[NM]

V1 V2

R227

10K

[NM]

500Z

C26

10nF

C29

10nF

R22 75R 1%

DSPVCC33

A A

Flash speed <= 70 nS.

If plan to use 90ns

Flash, it needs to be

verified by s/w.

U4

MEMADD15

1

MEMADD14

MEMADD13

MEMADD12

MEMADD11

MEMADD10

MEMADD9

MEMADD8

MEMADD19

R39 0R

MEMWR#

DSPVCC33

R40 NM

MEMADD18

MEMADD17

MEMADD7

MEMADD6

MEMADD5

MEMADD4

MEMADD3

MEMADD2

MEMADD1

B B

A15

2

BYTE#

A14

3

A13

4

A12

5

A11

6

A10

7

A9

8

A8

9

A19

NC

10

A20

11

WE#

12

RP#

13

NC

VPP

14

NC

WP#

15

RY/BY#

A19

16

A18

17

A17

18

A7

19

A6

20

A5

21

A4

22

A3

23

A2

24

A1

SST39VF800

[39VF400/800/160]

R39 R40Flash select

Intel NM 0R

AMD/SST 0R NM

MEMADD16

48

A16

47

VCCQ

46

GND

MEMDAT15

45

DQ15

MEMDAT7

44

DQ7

MEMDAT14

43

DQ14

MEMDAT6

42

DQ6

MEMDAT13

41

DQ13

MEMDAT5

40

DQ5

MEMDAT12

39

DQ12

MEMDAT4

38

DQ4

DSPVCC33

37

VCC

MEMDAT11

36

DQ11

MEMDAT3

35

DQ3

MEMDAT10

34

DQ10

MEMDAT2

33

DQ2

MEMDAT9

32

DQ9

MEMDAT1

31

DQ1

MEMDAT8

30

DQ8

MEMDAT0

29

DQ0

MEMRD#

28

OE#

27

GND

MEMCS0#

26

CE#

MEMADD0

25

A0

DSPVCC33

C48

10nF

Close to Pin37 of U4

FOCUS_S

TRACK_S

SPDL_S

SLED_S

C C

MEMADD2

MEMADD1

Play OPEN OPEN

Download

SW debug

JP2

BOOTSEL1[NM]

JP3 JP2BOOTSEL

OPEN CLOSE

CLOSE OPEN

R41

1K

[NM]

JP3

BOOTSEL1[NM]

DSPVCC33

R42

1K

[NM]

Close to Vaddis!

FOCUS_S

TRACK_S

SPDL_S

SLED_S

DSPVCC18

DSPVCC33

MEMDAT2

MEMDAT10

MEMDAT3

MEMDAT11

MEMDAT4

MEMDAT12

MEMDAT5

MEMDAT13

MEMDAT6

MEMDAT14

MEMDAT7

MEMDAT15

MEMADD16

MEMADD15

MEMADD14

MEMADD13

MEMADD12

MEMADD11

MEMADD10

MEMADD9

MEMADD8

MEMWR#

MEMADD18

MEMADD17

MEMADD7

MEMADD6

MEMADD5

MEMADD4

MEMADD3

MEMADD2

MEMADD1

MEMADD19

RAMADD4

RAMADD3

RAMADD5

RAMADD2

RAMADD6

RAMADD1

RAMADD7

C31

1000pF

C32

1000pF

C33

27nF

214

U1A

215

G

216

G

217

G

218

G

219

G

220

G

1

MEMDAT[2]

2

MEMDAT[10]/GPIO[0]

3

MEMDAT[3]

4

MEMDAT[11]/GPIO[1]

5

MEMDAT[4]

6

MEMDAT[12]/GPIO[2]

7

MEMDAT[5]

8

MEMDAT[13]/GPIO[3]

9

MEMDAT[6]

10

MEMDAT[14]/GPIO[4]

11

GNDC

12

MEMDAT[7]

13

MEMDAT[15]

14

VDDC

15

VDDP

16

MEMADD[16]

17

MEMCS1#/GPIO[5]

18

MEMADD[15]

19

MEMADD[14]

20

MEMADD[13]

21

MEMADD[12]

22

MEMADD[11]

23

MEMADD[10]

24

MEMADD[9]

25

MEMADD[8]

26

MEMWR#

27

MEMADD[18]/GPIO[6]

28

MEMADD[17]

29

MEMADD[7]

30

MEMADD[6]

31

GNDC

32

MEMADD[5]

33

MEMADD[4]

34

MEMADD[3]

35

VDDP

36

MEMADD[2]

37

MEMADD[1]

38

MEMADD[19]/IGPIO[7]

39

USBVDD

40

USBDP/GPO[67]

41

USBDN/GPO[68]

42

USBGND

43

RAMADD[4]

44

RAMADD[3]

45

RAMADD[5]

46

VDDIP

47

GNDC

48

RAMADD[2]

49

RAMADD[6]

50

RAMADD[1]

51

RAMADD[7]

VDDC

221

G

222

G

223

G

224

G

225

G

226

G

227

R3 51K

R4 51K

R5 22K

R6 51K

C34

1000pF

213

G

GGGGG

228

D D

C11

C12

10nF

10nF

C22

C23

10nF

10nF

FB1

DSPVCC33

500Z

EC1

47uF/16V

+

E E

Place de-coupling capacitors close to power pins.

C8

C9

C10

10nF

C21

10nF

10nF

10nF

10nF

DSPVCC18

C19

C20

10nF

10nF

SDRAM3.3V

C3

C4

C2

10nF

10nF

C6

C5

10nF

10nF

10nF

DSPVCC33

C7

DSPVCC33

U2

OPU: 313A HD65

R5: 22K 11K

R6: 33K 18K

WPCON

STBY_KEY

I2C_CLK

TRACK_PWM

I2C_DAT

SPDL_PWM

SLED_PWM

C51

0.1uF

MEMDAT8

MEMDAT9

MEMDAT0

MEMDAT1

MEMCS0#

MEMRD#

MEMADD0

208

207

206

205

204

203

202

201

200

209

210

211

212

GGGGG

199

VDDP

MEMRD#

MEMCS0#

MEMDAT[1]

MEMDAT[0]

MEMADD[0]

GPIO[63]/MEMCS2#

GPIO[9]/MEMDAT[9]

GPIO[8]/MEMDAT[8]

GPIO[62]/FCU_IORD#

R9 100R

R8 100R

198

197

196

195

194

193

192

191

190

189

188

187

186

185

184

VDDC

GNDC

GNDPWM

GPIO[56]/FCU_RST

IGPIO[55]/FCU_IRQ

GPIO[53]/PWMCO[4]

GPIO[52]/PWMCO[3]

GPIO[51]/PWMCO[2]

GPIO[59]/FCU_CS2#

GPIO[58]/FCU_CS3#

GPIO[60]/FCU_SCLK

IGPIO[54]/PWMCO[5]

GPIO[57]/FCU_WAIT#

GPIO[61]/FCU_IOWR#

Vaddis 9

ZR36966/36962

RAMADD[0]

RAMADD[8]

RAMADD[10]

GNDC

VDDP

RAMADD[9]

RAMADD[11]/GPO[64]

RAMBA

RAMCS0#

RAMCS1#/GPO[65]

RAMRAS#

VDDP

RAMCAS#

GNDC

RAMWE#

GNDPCLK

PCLK

VDDPCLK

RAMDAT[8]

RAMDQM

RAMDAT[7]

RAMDAT[9]

VDDP

RAMWE-

RAMDQM

Close to

Vaddis

RAMDAT11

RAMDAT10

DQ11

DQ10

VSSQ

VDDQ

VDDQ

DQ4

DQ5

VSSQ

RAMDAT4

RAMDAT5

RAMDAT[6]

RAMDAT7

IPCLK

RAMDAT9

RAMDAT6

RAMDAT8

R2

75R

C201

0.1uF

PCLK

C37

10pF

[NM]

RAMDAT12

RAMDAT13

RAMDAT14

RAMDAT15

50494847464544434241403938373635343332313029282726

VSS

DQ15

DQ14

DQ13

DQ12

VSSQ

VDD

DQ0

DQ1

VSSQ

DQ2

DQ3

12345678910111213141516171819202122232425

RAMDAT0

RAMDAT1

RAMDAT2

RAMDAT3

G

535254555756585961606263656466676970717268737476757778807981828483858689879091

229

230

231

232

RAMCS1-

RAMADD9

RAMADD8

RAMADD0

RAMCS0-

RAMADD11

RAMBA

RAMCAS-

RAMADD10

RAMRAS-

C45

22pF

RAMCKE

[NM]

R1 4.7K

RAMDAT8

RAMDAT9

RAMDQM

RAMADD6

RAMADD5

PCLK

RAMADD7

RAMADD9

RAMADD4

RAMADD8

A9A8A7A6A5

A4

NC

NC

CLK

VSS

16Mbit: K4S161622C-TC/L70

VDD

RAMADD3

RAMADD1

RAMADD0

RAMADD2

DQ9

DQ8

CKE

VDDQ

UDQM

DQ6

DQ7

VDDQ

LDQM

WE

CAS

RASCSBA

A10/APA0A1A2A3

RAMCS0-

RAMDAT7

RAMDQM

RAMDAT6

RAMBA

RAMRAS-

RAMCAS-

RAMWE-

RAMADD10

VDDPWM

183

VDDPWM

GPIO[50]/PWMCO[1]

GNDC

RAMDAT[10]

RAMDAT10

SDRAM3.3V

LD_DVD

LD_CD

LD_DVD

FOCUS_PWM

182

180

181

DVD_LD

GPIO[49]/PWMCO[0]

RAMDAT[11]

RAMDAT[5]

RAMDAT11

RAMDAT5

RAMDAT4

FB30500Z

U3

SDRAM3.3V

LD_CD

CD_LD

RAMDAT[4]

MD_DVD

MD_CD

MD_DVD

MD_CD

VDDAFE

178

179

177

CD_MD

DVD_MD

VDDSAFE

RAMDAT[12]

VDDP

RAMDAT[3]

RAMDAT12

RAMDAT3

DSPVCC33

RF_E

RF_A

RF_F

RF_B

RF_D

RF_C

C194 33pF

C193 33pF

C192 33pF FB6

C191 33pF

C190 33pF

C189 33pF

VC

SPDL_SENS-

MIC_VOCAL

SPDL_SENS+

R7 15.4K 1%

C49 0.1uF

RF_E

RF_F

MIC_VOCAL

VC

RESOUT

VREF

SPDL_SENS+

176

174

175

173

172

170

171

167

168

166

169

F

K

E

H

G

VC

VREF

GNDAFE

RESOUT

GNDREF

GND1AFE

GNDC

RAMDAT[13]

RAMDAT[14]

RAMDAT[2]

RAMDAT[1]

RAMDAT[15]

RAMDAT[0]

VDDC

VDDP

RAMDQM2/RAMCKE/GPO[66]

GNDC

92

8893949596979899100

RAMDAT14

RAMDAT13

RAMDAT15

RAMDAT1

RAMDAT2

RAMDAT0

LED/PCON

RAMDAT15

RAMDAT11

RAMDAT10

RAMDAT13RAMDAT2

RAMDAT12

RAMDAT14

RAMDAT9

54

VSS

DQ9

DQ10

DQ11

DQ12

DQ13

DQ14

DQ15

VSSQ

VSSQ

VDDQ

NM

[64Mbit:K4S641632H-UC70]

VDD

DQ0

VDDQ

DQ1

DQ2

VSSQ

DQ3

DQ4

VDDQ

DQ5

DQ6

123456789101112131415161718192021222324252627 28

RAMDAT5

RAMDAT4

RAMDAT0

RAMDAT1

RAMDAT3

RAMDAT6

RF_A

RF_B

RF_C

RF_D

SPDL_SENS-

VDD1AFE

VDDAFE

161

163

165

162

159

160

164

J

B

A

C

D

VDDAFE

GPIO[45]/PWMCO[5]/DUPTD0

GPIO[34]/RAMCKE/SPDIFIN

GPIO[28]/AOUT[0]/APWM0GPIO[26]/AOUT[1]/APWM1GPIO[24]/AOUT[2]/APWM2-

GPIO[22]/AOUT[3]/APWM3-

GPIO[19]/PWMCO[5]/APWM4+

RAMCKE/SDI_PSC/GPIO[10]

GPAIO/IGPIO[11]

APWM7+/GPIO[12]

APWM7-/GPIO[13]

APWM6+/GPIO[14]

APWM6-/GPIO[15]

101

102

RAMCKE

APWM_LFE+

DAC_RST#

VOCAL_DET

V1

V2

ML

DAC_RST#

VOCAL_DET

RAMCKE

PCLK

RAMDQM

RAMDAT8

NC

CLK

VSS

DQ8

VDDQ

DQMH

VSSQ

DQ7

VDD

DQML

WE#

CAS#

RAMDQM

RAMDAT7

RAMCAS-

RAMWE-

RAMRAS-

C35 1000pF

C36 1000pF

RFN

RFP

Close to Vaddis!

158

157

254

255

256

257

RFP

RFN

VDD1AFE

GNDDACBS2

VDDDAC

VDDDAC

GNDDAC_D

VDDPLL

GNDPLL

RESET#

GPIO[48]/DUPRD1

GPIO[47]/DUPTD1

GPIO[46]/DUPRD0

IGPIO[44]

GPIO[43]/TDO

GPIO[42]/TCK

GPIO[41]/TDI/NMI

GPIO[40]

GPIO[39]

GPIO[38]

IGPIO[37]/TMS/NMI

GPIO[36]

GPIO[35]

GPIO[33]/AIN/SPDIFIN

GPIO[32]/SPDIFO

GPIO[31]/ABCLK

GPIO[30]/ALRCLK

GPIO[29]/AMCLK

GPIO[27]/APWM0+

GPIO[25]/APWM1+

IGPIO[23]/APWM2+

GNDAPWM

GPIO[21]/APWM3+

GPIO[20]/APWM4-

VDDAPWM

APWM5+/GPIO[16]

APWM5-/GPIO[17]

AIN/SPDIFIN/IO[18]

GGGGG

103

104

233

234

235

236

APWM_LFE-

APWM_LFE-

APWM_LFE+

RAMADD8

RAMADD7

RAMADD9

RAMADD5

RAMADD6

RAMADD11

A9

NC

A11

CKE

RAS#

CS#

BA0

BA1

A10A0A1A2A3

RAMCS1-

RAMADD0

RAMADD1

RAMADD2

RAMCS0-

RAMADD10

RAMBA

RF

C50

33pF

251

252

253

GGGGGGG

250

G

249

G

248

G

247

G

246

G

245

G

156

155

RSET

154

DAC1

153

152

DAC2

151

DAC3

150

149

DAC4

148

147

DAC5

146

XIN

145

XO

144

143

142

141

GNDC

140

VDDC

139

138

137

136

135

VDDP

134

133

132

131

130

129

128

127

126

125

124

123

122

121

120

119

VDDP

118

117

GNDC

116

115

114

113

112

111

110

109

108

107

106

105

244

G

243

G

242

G

241

G

240

G

239

G

G

237

238

RAMADD4

29303132333435363738394041424344454647484950515253

A4A5A6A7A8

SDRAM configuration:

1X16Mbit: CS0# = Low;

1X64Mbit: CS1# = Low; CS0#=BA1

SDRAM speed <=7ns

Tras <=44.4ns

Trp <=22.2ns

VDD VSS

RAMADD3

Imax 0.5mA

R235 4.7R

+

EC4

C24

100uF/16V

10nF

Imax 120mA

500Z

FB3

C25

100nF

Imax 165mA

FB4500Z

C28

100nF

Imax 9mA

R238 4.7R

C30

100nF

C_B_U

C_B_U

Y_R_V

Y_R_V

CVBS_C

CVBS_C

CVBS_G_Y

CVBS_G_Y

DUPRD1 MUTE_CTL

R24 0R

C205

1000pF

STBY_KEY

STBY_KEY

LED/PCON

LED/PCON

DAC_RST#

DAC_RST#

R228

10K

[NM]

R229

10K

[NM]

SERVO33

DSPVCC33

DSPVCC33

DSPVCC18

DSPVCC33

MUTE_CTL

Crystal

Use it to connect the shell of the crystal with ground.

OSCOUT

R14

220K

OSCIN

C206

R13 75R

NM

[20p]

IRRCV

R30

15K

RESET

DSPVCC33

EC9

10uF/16V

R34 10K

D1

LL4148

CN12

ML

FB35500Z

APWM_R+

APWM_L+

APWM_RAPWM_L-

EEPROM

DSPVCC33

I2C_CLK

I2C_DAT

WPCON

1

2

3

4

5

6

7

8

PITCH2.0*8

R225 0R[NM]

R38

2K

UART

DSPVCC33

DUPTD0

DUPRD0

1

2

3

4

DOWN_LOAD_I/F

R35

10K

CN109

C39 22pF

R15

75R

Y1

27.000MHz

Third overtone

C38 22pF

CN10

D

4

C202

3

CN12

CN109

C2

C3

C4

C5

C6

C7

C8

C9

C10

C11

C12

C15

C19

C20

C21

C22

C23

C24

C25

C26

330R

R33

R36 100R

RESET#

Q1

BT3904

C43

0.22uF

DSPVCC33

R224

4.7K

[NM]

R223 NM [0R]

U5

1

8

A0

VCC

2

7

A1

WP

3

6

A2

SCL

4

5

GND

SDA

C44

R37

NM

2K

[0.1uF]

DSPVCC33

DUPTD1

DUPRD1

NM

[24LC02 ]

CN10

1

2

3

4

HYPER_TERMINAL I/F

C27

C28

C29

C30

C31

C32

C33

C34

C35

C36

C37

C38

C39

C43

C44

C45

C48

C49

C50

C51

C189

C190

C191

C192

C193

C194

C201

B

C

4

C205

3

B

D

4

C206

4

A

D

1

D1

4

B

D

1

EC1

1

D

D

1

EC4

3

A

D

1

EC9

4

B

D

1

EC20

3

C

D

1

FB1

1

D

D

1

FB3

3

A

D

1

FB4

3

A

D

1

FB6

3

A

D

1

FB7

3

B

D

1

FB8

3

B

C

3

FB9

3

C

D

1

FB30

2

C

D

1

FB35

4

C

D

1

JP2

1

C

D

1

JP3

1

C

D

1

Q1

4

B

A

3

R1

2

D

A

3

R2

2

C

A

3

R3

2

A

A

3

R4

2

A

A

3

R5

2

A

A

3

R6

2

A

A

3

R7

2

A

A

2

R8

2

A

A

2

R9

2

A

A

2

R10

3

B

A

2

R13

4

A

A

3

R14

4

A

A

3

R15

4

A

C

2

R19

3

B

A

4

R20

3

B

A

4

R21

3

B

B

4

R22

3

B

C

4

R24

3

B

D

2

R30

4

B

A

1

R33

4

B

A

2

R34

4

B

A

3

R35

4

B

A

2

R36

4

B

A

3

R37

4

C

A

3

R38

4

C

A

3

R39

1

A

A

3

R40

1

A

A

3

R41

1

C

A

3

R42

1

C

C

2

R56

3

C

R223

4

C

R224

4

C

R225

4

C

R226

3

C

R227

3

D

R228

3

C

R229

3

D

R235

3

A

R238

3

A

U1A

2

B

U2

2

D

U3

2

D

U4

1

A

U5

4

C

X11

4

E

Y1

4

A

1

2

3

4

5

Page 31

6-7 6-7

1

2

3

4

5

A A

B B

C C

Main Board Electric Diagram for DVP3136/94: Front End

EMC

DVDLD

C52

NM

1uF

CN2 is used for Sanyo/So n y O P Us

1

GND-LD

2

LD-DVD

3

NC

4

HFM

5

MD

6

LD-CD

7

VR-DVD

8

VR-CD

9

NC

10

E

OPU5V

11

VCC

VC1

12

VC

13

GND-PD

14

F

15

B

16

A

17

RF

18

CD/DVD

19

D

20

C

TACT-

21

T-

TACT+

22

T+

FACT+

23

F+

FACT-

24

F-

25

GND

26

GND

27

GND

28

GND

CN2

SF-HD6B/0.5mm,24P TOP

CN4

6

SLED+

5

SLED-

4

GND

3

HOMESW

2

SP+

1

SP-

NM(SLED & SPINDLE)

CDLD

Close to CN2

C54

1000pF

C57

0.1uF

SP_MOT+

SP_MOT-

C196

1000pF

C53

NM

1uF

C55

1000pF

DVDLD

OPU_HFM

CDLD

VR_DVD

VR_CD

L2 10uH

R48 33R

C58

0.1uF

SL_MOT+

SL_MOT-

DSPVCC33

R43

+

EC10

4.7R

47uF/16V

Q2

R44 220R

EC11

47uF/16V

R46 220R

R47 [0R]

C56

[1000pF]

RF_E

VC

RF_F

RF_B

RF_A

RF

RF_D

RF_C

FOCUS_S

SLED_S

TRACK_S

SPDL_S

DRVSB

VC2

SP_MOT+

SP_MSL_MOT+

SL_MOTFACTFACT+

TACTTACT+

LOADLOAD+

CD_DVD

LD_DVD

LD_CD

C195

1000pF

+

EC12

100uF/16V

RFA5V

RFA5V

R52

3.3K

CD_DVD

CD/DVD Control :

DVD=LOW

CD=HIGH

EC14

220uF/16V

FOCUS_S

0.1uF

C62

TR_B1

REGO2

SLED_S

REGO1

CLOSE

9012

DSPVCC33

R45

+

4.7R

Q3

9012

2.1V

+

EC13

47uF/16V

FOCUS_S

SLED_S

TRACK_S

SPDL_S

DRVSB

U7 AM5888S(HSOP-28)

R61 0R

1

2

3

4

5

6

OPEN

7

29 30

8

LOAD-

9

LOAD+

10

SL_MOT-

11

SL_MOT+

12

FACT-

13

FACT+

14

OPU 313A HD65 502W

R49: 100R 0R 91R

R50: 100R 0R 91R

R49

100R

VR_CD

VR_DVD

R50

100R

28

MUTE

VINFC

TR_B1

REGO2

VINSL

REGO1

FWD

REV

GND GND

VCC1

VOTRVOTR+

VOSL+

VOSLVOFCVOFC+

TR_B2

VOLD+

VOTK+

27

BIAS

26

VINTK

25

24

NC

23

VINLD

22

GND

21

VCTL

20

NC

19

VCC2

18

VOLD-

17

16

VOTK-

15

VC2

R62 0R

SP_MSP_MOT+

TACTTACT+

TR_B2

SPDL_S

M5VM5V

MD_DVD

MD_CD

TRACK_S

R74

2K

SP_M-

OPU: 313A HD65

R76: 2.2R 1R

SP_MOT-

R76

1R

R75

2K

Close to motor driver.

R84

1K 1%

VC2

R85

C67

1K 1%

0.1uF

Imax=600mA

M5V

DRVSB

R66

C63

100pF

1K

RR2

2.2 OHM 2W

TR_B1 TR_B2

Q4

SS8550D

REGO1 REGO2

R70

20k

1%

R71

12k

1%

Imax=250mA

RR1

6.8 OHM 1W

SS8550D

Q5

DSPVCC33

b

SPDL_SENS-

SPDL_SENS-

D19

DSPVCC18DSPVCC33

R72

4.7k

R73

10k

3

SPDL_SENS+

1%

1%

DSPVCC33

SPDL_SENS+

Close to Q4

R219 0R

+

EC38

220uF/16V

Close to Q5

+

EC39

C125

220uF/16V

220pF

CN2

B

1

CN3

D

1

CN4

C

1

C42

D

1

C52

A

1

C53

A

1

C54

B

1

C55

B

1

C56

B

1

C57

B

1

C58

B

1

C62

C

2

C63

C

3

C64

D

1

C65

D

1

C66

D

1

C67

B

3

C68

B

3

C123

C

4

C124

C

4

C125

C

4

C126

C

4

C127

C

4

C195

B

1

C196

B

1

D19

A

3

EC10

A

1

EC11

B

1

EC12

B

1

EC13

B

1

EC14

C

2

EC38

C

4

EC39

C

4

L2

B

1

Q2

A

1

Q3

B

1

Q4

C

3

Q5

C

3

RR1

C

3

RR2

C

3

R43

A

1

R44

A

1

R45

B

1

R46

B

1

R47

B

1

R48

B

1

R49

B

2

R50

B

2

R52

B

2

R61

C

2

R62

C

2

R66

C

3

R70

C

3

R71

C

3

R72

C

3

R73

C

SERVO33

DSPVCC33

C124

C123

1000pF

220pF

DSPVCC18

C126

C127

1000pF

0.1uF

3

R74

A

3

R75

B

3

R76

B

3

R84

B

3

R85

B

3

R86

B

3

R87

D

1

R88

D

1

R90

D

1

R91

D

1

R92

D

1

R219

C

4

U7

C

2

X12

E

4

2

1

BAT54C

R86

33K

C68

0.1uF

ec

GND GND

HOMESW

R92

4.7K

C64

NM

[1nF]

DSPVCC33

R90

R91

4.7K

4.7K

HOMESW

IN_OUT_SW

IN_OUT_SW

INSW

INSW

C66

C65

NM

NM

[1nF]

[1nF]

D D

CN3

LOADLOAD+

OUTSW

GND

INSW

NM(TRAY_CNN)

1

2

3

4

5

C42

LOAD-

LOAD+

R87 NM [0R]

R88 0R

[NM]

0.1uF

E E

1

2

3

4

5

Page 32

6-8 6-8

1

Main Board Electric Diagram for DVP3136/94: Audio Input_Output

2

3

4

5

A A

Max. amplitude of Mic_Audio signal is 4Vrms

MIC_IN

R105

NM

R106

150

NM

[NM]

EC30

R57 NM

MIC_VOCAL

VA

R51 NM

Value in [] is for external ADC.

ADC circuit for Karaoke

B B

LRIN

DAC_RST#

DAC_RST#

C86

NM

[0.1uF]

+

NM

[0R]

[10uF/16V]

R58

NM

[3.3K]

C88

NM

[2200pF]

[4.7K]

LRIN

Mic vocal detected by ADP software

Mic signal mute/mix/echo process by ADP

ADP: Audio Digital Process

VA

DSPVCC33

C85

R101 NM

NM

R100

[0.1uF]

NM

16

M1

15

FILT+

14

REF_GND

13

VA

12

AINR

11

VQ

10

AINL

NM

[CS5340]

C89

C90

NM

NM

[1uF]

[0.1uF]

Full scale input: 0.65Vrms (when VA=3.3V)

M0=1, M1=1: clock slave;

Package: TSSOP16.

SDOUT

DSPVCC33

R102

[4.7R]

NM

[4.7K]

U13

1

M0

2

MCLK

3

VL

R104 NM

4

5

GND

6

VD

ABCLK

7

SCLK

LRCK/RST

ALRCLK

89

C84

NM

[0.1uF]

FB10 500Z

EC31

+

C83

NM

NM

[10uF/16V]

[0.1uF]

R103

NM

[10K]

AMCLK

AMCLK

AIN

ABCLK

ALRCLK

AIN

[33R]

[3.3K]

C87

NM

[1uF]

MIC_IN

-12V

D5V

DSPVCC33

NM

External MicroPhone detection

D5V

R117

R114

NM

[2K]

R113

NM

NM

[1M]

EC34

R112

NM

C C

MIC_IN

NM

[10uF/16V]

[15K]

+

Q21

NM

[BT3094]

+

D16

NM

[1N4148]

EC32

[10uF/16V]

NM

D15

[1N4148]

+

EC33

NM

[22uF/16V]

M5V

D D

DSPVCC33

MUTE_CTL

MUTE_CTL

Low:

Mute.

M5V

D4

LL4148

R116

NM

[2K]

R115

NM

[10K]

LL4148

R127 10K

MUTE_CTL

R126 100R

R125

47K

NM

[4.7K]

VOCAL_DET

R124

220R

EC36

47uF/25V

R130

NM

[6.8K]

Q15

9012H

EC35

470uF/16V

D3 LL4148

VOCAL_DET

Q13

9012H

R120

100K

R123

100K

Q22

NM

[BT3094]

D2

R129 33R

R128 10K

Q14 9012H

C132

1000pF

CN9

1

2

3

4

C133

4PIN*2.0

1000pF

MUTE

-12VA

APWM_L-

APWM_L+

APWM_R-

APWM_R+

APWM_SL-

APWM_SL+

APWM_SR-

APWM_SR+

APWM_CEN-

APWM_CEN+

APWM_LFE-

APWM_LFE+

4.7K 1%

R133

R136

4.7K 1%

R139

4.7K 1%

R142

4.7K 1%

R353

4.7K 1%

R354

4.7K 1%

R350

4.7K 1%

R351

4.7K 1%

R356

4.7K 1%

R357

4.7K 1%

R359

4.7K 1%

R360

4.7K 1%

R134

R135

4.7K 1%

4.7K 1%

C93

C91

180pF

200pF

R137

R140

R143

C310

200pF

C312

200pF

R138

4.7K 1%

4.7K 1%

4.7K 1%

C94

C92

180pF

200pF

4.7K 1%

R320

4.7K 1%

C220

C314

180pF

200pF

R321

4.7K 1%

R330

4.7K 1%

C316

200pF

R331

4.7K 1%

R300

4.7K 1%

C210

180pF

R301

4.7K 1%

R310

R313

4.7K 1%

4.7K 1%

C215

180pF

R311

R355

4.7K 1%

4.7K 1%

R141

4.7K 1%

R144

4.7K 1%

R323

4.7K 1%

R358

4.7K 1%

C225

180pF

R352

4.7K 1%

C95

33pF

C96

33pF

R303

4.7K 1%

R333

4.7K 1%

R361

4.7K 1%

R149

120K 1%

R160

120K 1%

C315

R324

33pF

120K 1%

C317

33pF

C311

R304

33pF

120K 1%

C313

R314

33pF

120K 1%

R150

120K 1%

R161

120K 1%

R334

120K 1%

R397

120K 1%

R393

120K 1%

R383

120K 1%

R151

120K 1%

R162

120K 1%

R387

120K 1%

R398

120K 1%

R152 120K 1%

R154 120K 1%

R155 120K 1%

C97 33pF

R153 120K 1%

R157 120K 1%

R158 120K 1%

C98 33pF

R381 120K 1%

R382 120K 1%

C221 33pF

R384

120K 1%

R385 120K 1%

R386 120K 1%

R388

120K 1%

R391 120K 1%

R392 120K 1%

C211 33pF

R394

120K 1%

U14B

-

6

7

+

5

NJM4560 OPA

8 4

U14A

-

2

1

+

3

NJM4560 OPA

8 4

R322 120K 1%

U17B

-

6

+

5

8 4

R332 120K 1%

C226 33pF

U17A

-

2

+

3

NJM4560 OPA

8 4

R302 120K 1%

U16B

-

6

+

5

8 4

R395 120K 1%

R396 120K 1%

R312 120K 1%

C216 33pF

-

2

+

3

NJM4560 OPA

8 4

7

NJM4560 OPA

1

7

NJM4560 OPA

U16A

1

-12VA

C100

0.1uF

EC27

CEN_OUT

LFE_OUT

SL_OUT

SR_OUT

22uF

EC28

22uF

+12VA

C99

0.1uF

-12VA

C222

0.1uF

EC42

+12VA

C223

0.1uF

+12VA

C213

0.1uF

22uF

EC43

+

22uF

-12VA

C212

0.1uF

EC40

+

22uF

EC41

+

22uF

R325

+

6.8K

MUTE

R326

5.6K

R335

6.8K

R337

MUTE

R336

470R

5.6K

R305

6.8K

R307

MUTE

R306

470R

5.6K

R315

6.8K

R317

MUTE

R316

470R

5.6K

SL_OUT

R327

Q42

BT3904

470R

SR_OUT

Q43

BT3904

CEN_OUT

Q40

BT3904

LFE_OUT

Q41

BT3904

R169

+

6.8k

[1K]

MUTE

R171

5.6k

[NM]

R170

+

6.8k

[1K]

MUTE

R172

5.6k

[NM]

-12VA

R176 100R

EC26

+

47uF/25V

+12VA

R175 100R

+

EC25

47uF/25V

S/PDIF_OUT

NM

LMAIN_OUT

RMAIN_OUT

COAX_SPDIF

C227

100pF

Q31

R194

39R

C129

100pF

C214

100pF

S/PDIF_OUT

100pF

C224

BT3904

R195

56R

R196

C217

100pF

LMAIN_OUT

R173

Q17

BT3904

470R

1

R128

D

4

CN7

C

2

CN9

A

4

CN11

D

1

C83

A

1

C84

B

1

C85

A

1

C86

B

1

C87

RMAIN_OUT

R174

Q18

BT3904

470R

-12V

+12V

D5V

C120

0.1uF

Close to Q31

C121

R197

62R

C130

100pF

0.1uF

CN11

1

2

3

4

5

6

AUDIO OUT

C122

22pF

CN7

1

2

3

4

5

6

AUDIO OUT

COAX_SPDIF

B

1

C88

B

1

C89

B

1

C90

B

2

C91

A

2

C92

B

2

C93

A

2

C94

A

3

C95

A

3

C96

B

3

C97

A

3

C98

A

3

C99

A

3

C100

A

4

C120

C

4

C121

C

4

C122

C

4

C129

C

4

C130

C

2

C132

A

2

C133

A

2

C210

C

3

C211

C

3

C212

C

3

C213

D

4

C214

D

2

C215

D

3

C216

D

4

C217

D

2

C220

B

3

C221

B

3

B

C222

3

B

C223

4

D

C224

2

C

C225

3

C

C226

4

D

C227

2

C

C310

3

C

C311

2

D

C312

2

D

C313

2

B

C314

3

B

C315

2

C

C316

3

C

C317

1

C

D2

1

D

D3

1

D

D4

1

B

D15

1

B

D16

4

B

EC25

4

B

EC26

4

A

EC27

4

B

EC28

1

EC30

A

1

EC31

A

1

EC32

B

1

EC33

B

1

EC34

B

1

EC35

C

1

EC36

D

3

EC40

C

3

EC41

D

3

EC42

B

3

EC43

C

2

FB10

A

1

Q13

C

1

Q14

D

1

Q15

D

4

Q17

A

4

Q18

B

1

B

Q21

1

B

Q22

4

C

Q31

4

C

Q40

4

D

Q41

4

B

Q42

4

C

Q43

1

A

R51

1

A

R57

1

A

R58

1

A

R100

1

A

R101

1

A