Philips DVDR-985 Schematic

Color Television Chassis

Service

Service

2022

Service

ServiceManual

Contents Contents

1. Technical Specifications 00

2. Safety & Maintenance Instructions, Warnings and Notes 00

4. Mechanical Instructions 00

5. Service Modes, Error Codes and Faultfinding 00

6. Block Diagrams and Testpoints 00

7. Electrical Diagrams and PWB's Diagram PWB

Set Wiring Diagram 1

Set Block Diagram 2

Basic Engine Block Diagram 3

Power Supply (Page 1) Schematic 4 35

Power Supply (Page 2) Schematic 5 35

Display Panel Schematic 6 37

Front AV Panel Schematic 7 39

IR and Standby Panel Schematic 8

Analog Board: All in One 1 Schematic 9 41

Analog Board: All in One 2 Schematic 10 41

Analog Board: Tuner / Dem odulator Schemati c 11 41

Analog Board: In / Out 1 Schematic 12 41

Analog Board: In / Out 2 Schematic 13 41

Analog Board: In / Out 3 Schematic 14 41

Analog Board: Sound Processing Schematic 15 41

Analog Board: Power Supply Schematic 16 41

Analog Board: Converter Schematic 17 41

Analog Board: RGB-YUV Converter Schematic 18 41

Analog Board: Digital In / Out Schem atic 19 41

Analog Board: Fan Control Schem atic 20 41

DVIO Front Board Schematic 21 43

DVIO Board: 1394 Interface Schematic 22 44

DVIO Board: Microprocessor Schematic 23 44

DVIO Board: Fifo & Control Schematic 24 44

DVIO Board: DVCODEC Schematic 25 44

DVIO Board: Audio & Video Output Schematic 26 44

Digital Board: VSM, Buffer Mem & Bit Engine Interface Schematic 27 46

Digital Board: AV Decoder STI5508 Schematic 28 46

Digital Board: AV Decoder Memory 29 46

Digital Board: Video Encoder, Empress 30 46

Digital Board: VIP CVBS Y/C Video Input 31 46

Digital Board: Analog Board Cons. Video In / Output 32 46

Digital Board: Progressive Scan - 1 33 46

Digital Board: Progressive Scan - 2 34 46

Digital Board: Power, Clock, and Reset Audio Clock 35 46

Servo Board 43015: Pre- Processor Schem atic 36 58

Servo Board 43015: MACE3 Schematic 37 58

Servo Board 43015: Driver Schematic 38 58

Servo Board 43015: Decoder / Encoder Schematic 39 58

Servo Board 43015: Power Schematic 40 58

Servo Board 43353: Pre- Processor Schem atic 41 60

Servo Board 43353: MACE3 Schematic 42 60

Servo Board 43353: Driver Schematic 43 60

Servo Board 43353: Decoder / Encoder Schematic 44 60

Servo Board 43353: Power Schematic 45 60

Power Supply CBA (Top View) 46

Power Supply CBA (Bottom View) 47

Display Panel CBA (Top View) 48

Display Panel CBA (Bottom View) 49

Front AV Panel CBA (Top) 50

Front AV Panel CBA (Bottom) 51

Analog Board CBA (Top View) 52

©

Copyrig ht 2001 Philips Consumer Electronics B.V. Eindhoven, The Netherlands.

All rights reser ved. No p art of this p ublication may be reproduced, stored in a

retrieval system or transmitted, in any form or by means, electronic, m echanical,

photographic, or otherwise w ithout the prior permission of Philips.

Published by Philips Consumer Electronics Subject to modification 2005 Nov 03

Analog Board CBA (Bottom View) 53

DVIO Front Board CBA (Top View) 54

DVIO Board CBA (Top View) 55

DVIO Board CBA (Bottom View) 56

Digital Board CBA (T op View) 57

Digital Board CBA (Bottom View) 58

Layout Servo Board 43015: (Top Side) 59

Layout Servo Board 43015: (Bottom Side) 60

Layout Servo Board 43353: (Top Side) 61

Layout Servo Board 43353: (Bottom Side) 62

Layout Analog Board (Testlands Top View) 63

Layout Analog Board (Testlands Bottom View) 64

Layout DVIO Board (Testlands Bottom View) 65

Layout Digital Board (Testlands Bottom View) 66

Test Point Overview Servo Board 43015 67

Test Point Overview Servo Board 43353 68

8. Adjustments 00

9. Circuit Description 00

10. Spare Parts List 00

Diagram PWB

Safety Instructions, Warnings, Notes, and

Service Hints

Safety Instructions

General Safety

Safety regulations require that during a repair:

Connect the unit to the mains via an isolation transformer.

z

Replace safety components, indicated by the symbol h , only by components identical to

z

to the original ones. Any other component substitution (other than original type) may

increase risk of fire or electrical shock hazard.

Safety regulations require that after a repair, you must return the unit in its original condition.

Pay, in particular, attention to the following points:

z Route thewires/cables correctly, and fix them with the mounted cable clamps.

z Check the insulation of the mains lead for external damage.

z Check the electrical DC resistance between themains plug and the secondary side:

1. Unplug themains cord, and connect a wire between the two pins of the mains plug.

2. Set the mains switch to the "on" position(keep the mains cord unplugged!).

3. Measure the resistance value between the mainsplug and the front panel, controls,

and chassis bottom.

4. Repair or correct unit when the resistance measurementis less than 1 MΩ.

5. Verify this, before you return the unit to the customer/user (ref. UL-standard no.

1492).

6. Switch the unit ‘off’, and remove the wire between the two pins of the mains plug.

Laser Safety

This unit employs a laser. Only qualified service personnel may remove the cover, or attempt

to service this device(due to possible eye injury).

Laser Device Unit

Feature Data

z

Type

Semiconductor laser GaAlAs

:

z Wavelength

z Output Power

Beam divergence

z

650 nm (DVD)

:

780 nm (VCD/CD)

:

20 mW(DVD+RW writing)

:

0.8 mW(DVD reading)

:

0.3 mW(VCD/CD reading)

:

60 degree

:

Figure:

Note: Use ofcontrols or adjustments or performance of procedure other than those specified

herein, may result in hazardous radiation exposure. Avoid direct exposure to beam.

Warnings

General

z AllICs and many other semiconductors are susceptible to electrostatic discharges (ESD,

).Careless handling during repair can reduce life drastically. Make sure that, during

w

repair, you are at the same potential as the mass of the set by a wrist band with

resistance. Keep components and tools at this same potential. Available ESD protection

equipment:

Complete kit ESD3 (small tablemat, wristband, connection box, extension cable

and earth cable) 4822 310 10671.

Wrist band tester 4822 344 13999.

z Be careful during measurements in the live voltage section. The primary side of the

power supply (pos. 1005), including the heatsink, carries live mains voltage when you

connect the player to the mains (even when the player is "off"!). It is possible to touch

copper tracks and/or components in this unshielded primary area, when you service the

player. Service personnel must take precautions to prevent touching this area or

components in this area. A "lightning stroke" and a stripe-marked printing on the printed

wiring board, indicate the primary side of the power supply.

z Never replace modules, or components, while the unit is ‘on’.

Laser

z Theuse of optical instruments with this product, will increase eye hazard.

z Only qualified service personnel may removethe cover or attempt to service this device,

due to possible eye injury.

z Repair handling should take place as much aspossible with a disc loaded inside the

player.

z Text below is placed inside the unit, on the laser cover shield:

Figure:

Notes

Dolby

Manufactered under licence from Dolby Laboratories. “Dolby”, “ProLogic” and the double-D

symbol are trademarks of Dolby Laboratories. Confidential Unpublished Works.©1992-1997

Dolby Laboratories, Inc. All rights reserved.

Figure:

Trusurround

TRUSURROUND, SRS and symbol (fig 2-4) are trademarks of SRS Labs, Inc.

TRUSURROUND technology is manufactured under licence frm SRS labs, Inc.

Figure:

Video Plus

“Video Plus+” and “PlusCode” are registered trademarks of the Gemstar Development

Corporation. The “VideoPlus+” system is manufactored under licence from the Gemstar

Development Corporation.

Figure:

Macrovision

This product incorporates copyright protection technology that is protected by method claims of

certain U.S. patents and other intellectual property rights owned by Macrovision Corporation

and other rights owners.

Use of this copyright protection technology must be autorized by Macrovision Corporation, and

is intended for home and other limited viewing uses only unless otherwise authorized by

Macrovision Corporation. Reverse engineering or disassembly is prohibited.

TechnicalSpecifications and Connection

Facilities

General:

Feature Data

Mains voltage

z

120V (90 -140VAC)

:

z Mains frequency

z Power consumption mains

z Power consumption standby

Power consumption low power

z

stand-by

50 Hz - 60Hz

:

32 W (typical, record)

:

< 7 W

:

< 3 W

:

RF Tuner

Test equipment : Fluke 54200 TV Signal generator

Test streams : PAL BG Philips Standard test pattern

System:

NTSC-M (USA/BTSC-Stereo+SAP)

Rf - Loop Through:

Feature Data

z Frequency range

z Gain: (ANT IN - ANT OUT)

45 MHz - 860 MHz

:

-4 dB /±2 dB

:

Radio Interference:

Feature Data

input voltage /3tone method

z

(+40 dB min)

typ. 80 dBμV at 75 Ω

:

Receiver:

PLL tuning with AFC for optimum reception

Feature Data

z Frequency range:

z Sensitivity at 40 dB S/N

45.25 MHz - 860 MHz

:

≥ 60dBμV at 75 Ω (video unweighted)

:

Video Performance:

Channel 25 / 503,25 MHz

Test pattern: PAL BG PHILIPS standard test pattern

Modulation 54 %

RF Level 74 dBV

Measured on YUV-EXT1

Feature Data

z Frequency response:

z Group delay ( 0.1 MHz - 3.3

MHz )

0.5 MHz - 4,00 MHz ± 2 dB

:

0 nsec ± 30 nsec

:

Audio Performance:

Audio-BTSC:

Feature Data

z Frequency responseat audio

cinch output:

z S/N according to DIN 45405,

7,1967

z and PHILIPS standard test

pattern videosignal:

z Harmonic distortion ( 1 kHz, ±

25 kHzdeviation ):

40 Hz - 15 kHz / ± 1,5 dB

:

:

≥ -50 dB unweighted

:

≤ 0.5 %

:

Audio-SAP:

Feature Data

z Frequency responseat audio

cinch output:

40 Hz - 15 kHz ± 1,5 dB

:

z S/N according to DIN 45405,

7,1967

:

and PHILIPS standard test

z

pattern videosignal

≥ -60 dB unweighted

:

z Harmonic distortion (1 kHz):

≤ 0.5 %

:

Tuning

Automatic Search Tuning

Feature Data

scanning time withoutantenna

z

z stop level (vision carrier)

z Maximum tuning error of a

recalled program

z Maximum tuning error during

operation

Tuning Principle

≤ 2,5 min

:

≥ 65dBμV, 75 Ω

:

± 62,5 kHz

:

± 100 kHz

:

Automatic detection

Manual channel activation

Analogue inputs

Audio/video Front Input Connectors

Audio

Feature Data

z Input voltage

z Input impedance

Video - Cinch

Feature Data

2 Vrms

:

>10k Ω

:

z Input voltage

1 Vpp ± 0.1V

:

Input impedance

z

75 Ω

:

Video - YC (Hosiden)

Feature Data

z Input voltage Y

Input impedance Y

z

z Input voltage C

z Input impedance C

1Vpp ± 0.1V (with sync)

:

75 Ω

:

burst 286 mVpp ± {x} dB

:

75 Ω

:

Cinch Audio/video Line Input Rear

Audio (EXT1/2 and EXT3)

Feature Data

z Input voltage

Input impedance

z

Video (EXT2-USA)

2 Vrms

:

>10k Ω

:

Feature Data

z Input voltage

Input impedance

z

1 Vpp ± 0.1V (with sync)

:

75 Ω

:

Yc Input Rear (Hosiden; Ext1-usa)

Connector Kind Value Symbol

1

2

3

4

GND

GND

Input voltage Y 1Vpp ± 0.1V/ 75 Ω (with sync)

Input voltage C Burst 286mVpp ± {x} dB/ 75 Ω

v

v

j

Ypbpr Cinch Input Rear (Ext3)

Feature Data

Input voltage Y

z

1Vpp ± 0.1 (with sync)

:

z Input voltage Pr

z Input voltage Pb

z Input impedance

0.7 Vpp

:

0.7 Vpp

:

75 Ω

:

Video Performance

All outputs loaded with 75 Ohm

SNR measurements over full bandwidth without weighting.

Cvbs Output Rear (Ext2)

Feature Data

z SNR Luminance

z SNR Chrominance AM

SNR Chrominance PM

z

> -65 dB

:

> -65 dB

:

> -65 dB

:

z Bandwidth Luminance

5 MHz ± 1dB

:

Yc Output Rear (Hosiden ; Ext1)

Feature Data

z SNR

z SNR Chrominance AM

z

z Bandwidth Luminance

SNR Chrominance PM

> -65 dB

:

> -65 dB

:

> -65 dB

:

5 MHz ± 1dB

:

Ypbpr Out (Ext3)

Feature Data

z SNR

z

Bandwidth

> -65 dB

:

5 MHz ± 1dB

:

Ypbpr Out (Progressive Scan)

Progressive scan is off during stand-by mode

Feature Data

z Progressive scan resolution

z Output impedance

Output amplitude Y

z

z Output amplitude PrPb

z SNR

z Bandwidth Y

z

z YprPb crosstalk

Bandwidth PrPb

525 lines x 60 frames/second

:

75 Ω

:

700mV (100% white, without sync)

:

700mV (100% level)

:

> 60dB (all channels)

:

> 12 MHz ± 3dB

:

> 6 MHz ± 3dB

:

< -50dB (bandwidth < 10 MHz)

:

Audio Performance

Cinch Output Rear (Ext1/2)

Feature Data

Output voltage 2channel mode

z

z Output voltage 5.1 channel

Dolby

z Channel unbalance (1kHz)

Crosstalk 1kHz

z

z Crosstalk 20Hz-20kHz

z Frequency response 20Hz-

20kHz

z

z Dynamic range 1kHz

z Dynamic range 20Hz-20kHz

z Distortion and noise 1kHz

z

20kHz

Signal to noise ratio

Distortion and noise 20Hz-

2Vrms ± 1.5dB

:

1.41Vrms ± 1.5dB

:

<0.85dB

:

>105dB

:

> 95dB

:

± 0.1dB max

:

>100 dB

:

>90dB

:

>88dB

:

>90dB

:

>80dB

:

z Intermodulation distortion

z Phase non linearity

>87dB

:

± 1( max.

:

Level non linearity

z

± 0.5dB max.

:

z Mute (spin-up, pause, access)

z Outband attenuation:

>100dB

:

> 50dB above 25kHz

:

Cinch Output Rear (Ext3)

Feature Data

z Output voltage 2channel mode

z Output voltage 5.1 channel

Dolby

z Channel unbalance (1kHz)

Crosstalk 1kHz

z

z Crosstalk 20Hz-20kHz

z Frequency response 20Hz-

20kHz

z

Signal to noise ratio

2Vrms ± 1.5dB

:

1.41Vrms ± 1.5dB

:

<0.85dB

:

>105dB

:

> 95dB

:

± 0.1dB max

:

>100 dB

:

z Dynamic range 1kHz

z Dynamic range 20Hz-20kHz

z Distortion and noise 1kHz

Distortion and noise 20Hz-

z

20kHz

z Intermodulation distortion

z Phase non linearity

z

z Mute (spin-up, pause, access)

z Outband attenuation:

Level non linearity

Digital Output

>90dB

:

>88dB

:

>90dB

:

>80dB

:

>87dB

:

± 1( max

:

± 0.5dB max

:

>100dB

:

> 50dB above 25kHz

:

Coaxial Output

Feature Data

CDDA/LPCM(incl. MPEG1)

z

According IEC958

:

z MPEG2, AC3 audio

z DTS

According IEC1937

:

According IEC1937

:

Optical output

Identical to coaxial

Digital Video Input/output (Iee1394)

Applicable Standards

Implementation according:

IEEE Std 1394-1995

IEC 61883 - Part 1

IEC 61883 - Part 2 SD-DVCR (02-01-1997)

Specification of consumer use digital VCR’s using6.3 mm magnetic tape - dec.1994

Mechanical connection according:

Annex A of 61883-1

Audio Quality

Feature Data

Output voltage 2channel mode

z

z Channel unbalance (1kHz)

z Crosstalk 1kHz

z Crosstalk 20Hz-20kHz

Frequency response 20Hz-

z

12kHz

z Signal to noise ratio

z Dynamic range 1kHz

z

z Distortion and noise 1kHz

z Distortion and noise 20Hz-

20kHz

Dynamic range 20Hz-20kHz

2Vrms +/- 1.5dB

:

Tbd

:

> 95 dB

:

> 85 dB

:

+/- 1dB max

:

>95 dB

:

Tbd

:

Tbd

:

>65dB

:

>65dB

:

Intermodulation distortion

z

>80dB

:

z Phase non linearity

z Level non linearity

z Mute (spin-up, pause, access)

Outband attenuation

z

+/- 1 degree

:

Tbd

:

Tbd

:

Tbd

:

Dimensions And Weight

Feature Data

z Height of feet

z Apparatus tray closed

z Apparatus tray open

Weight without packaging

z

z Weight

12 mm

:

WxDxH :435 x 325 x 107

:

WxDxH :435 x 465 x 107

:

5.670 g

:

1.675 g

:

Laser Output Power & Wavelength

DVD

Feature Data

Output power duringreading

z

z Output power during writing

z Wavelength

CD

Feature Data

z Output power

Wavelength

z

0.8mW

:

20mW

:

660nm

:

0,3mW

:

780nm

:

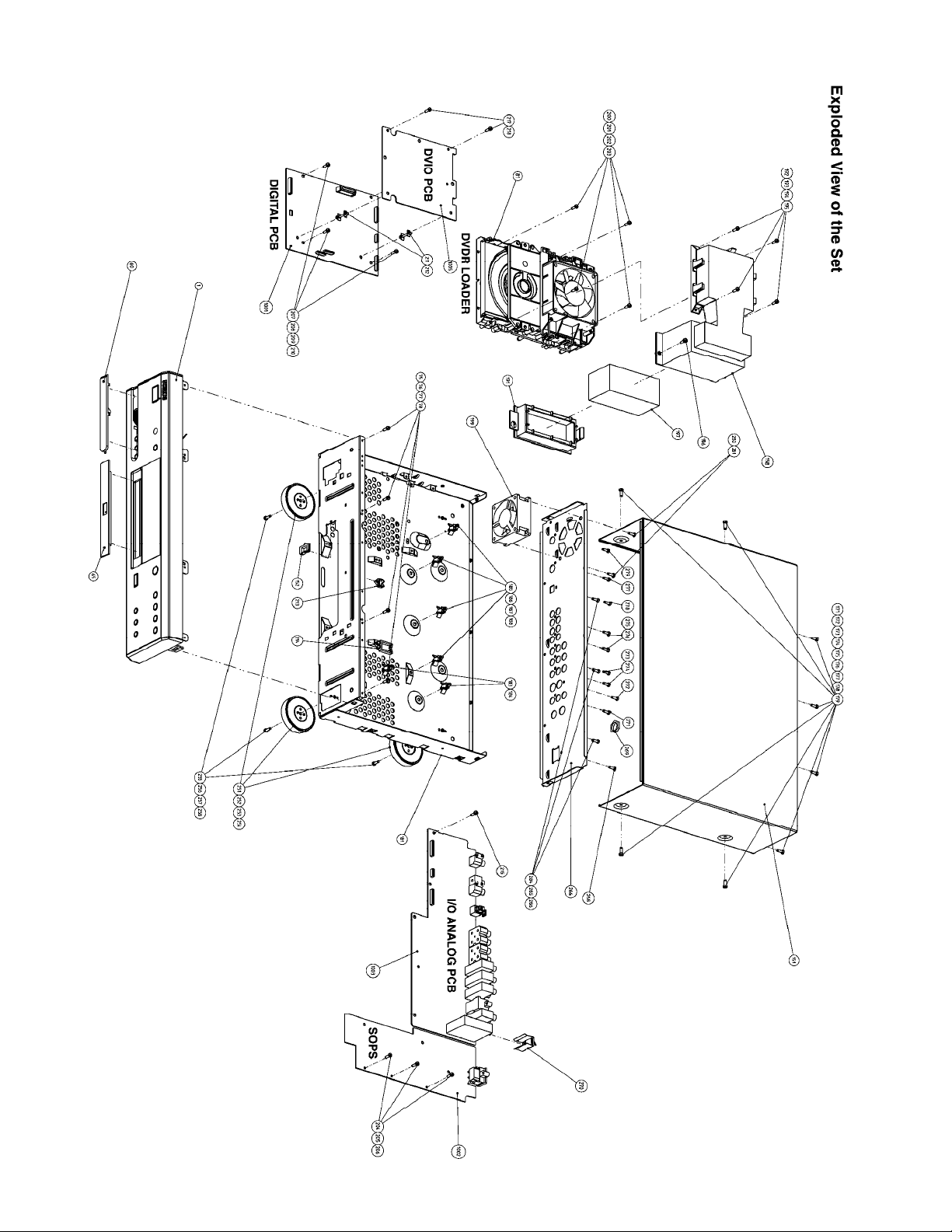

Complete Set Exploded View

Front Assembly ExplodedView

Basic Engine Exploded View

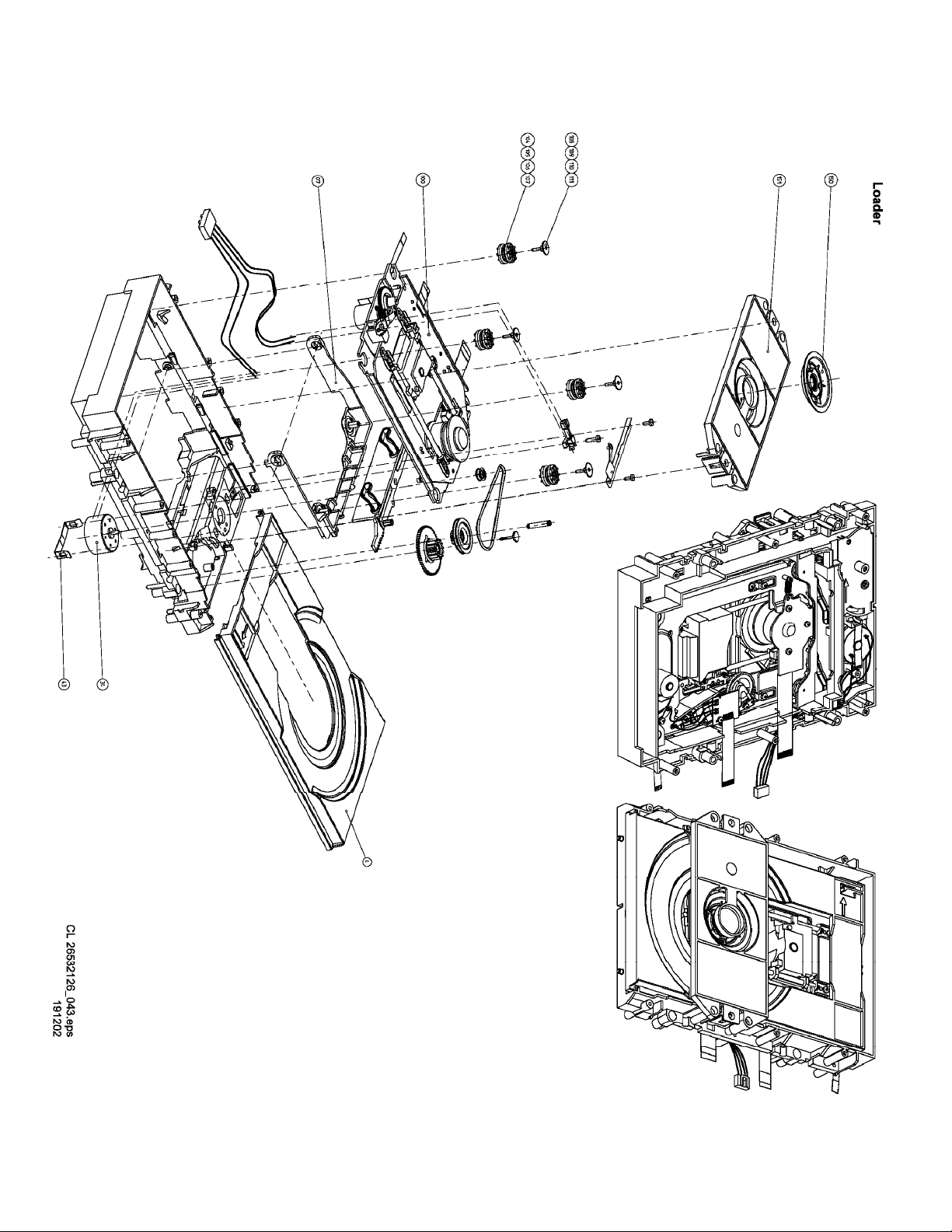

Loader Exploded View

DVM Exploded View

(2022)

Vdrain(stby) Vdrain.tif Vgate(stby). Vgate.tif

Vsource(stby Vsource.tif

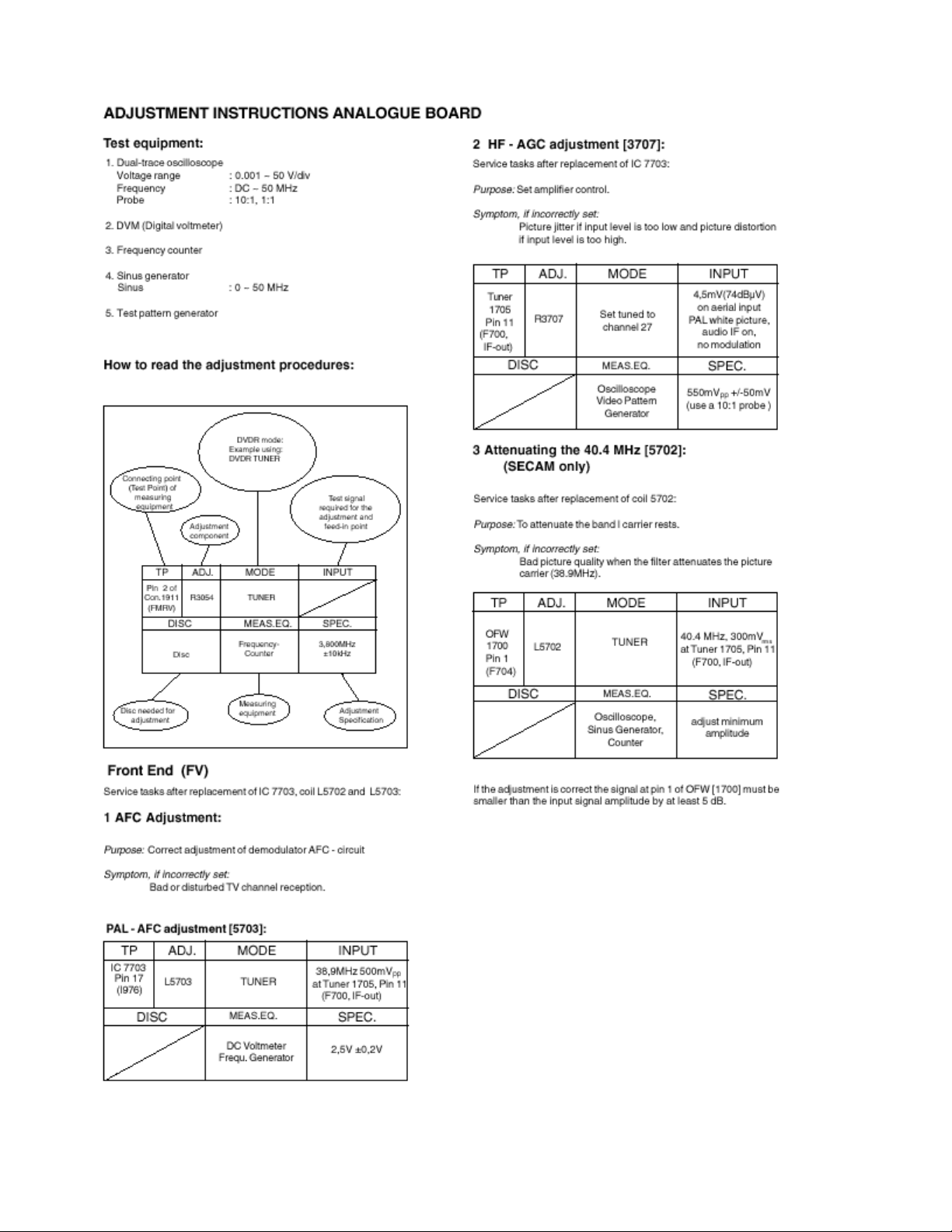

Alignments

Alignment Instructions analog Board

Figure: Alignments Analog PCB Eur

Reprogramming Procedure of NVM on the analog PCB

The NVM, item 7815, on the analog board contains the following factory settings:

1. Bargraph 0dB correction factor

2. Clock correction factor

3. AFC reference value

4. Slash version

The settings 1,2 and 3 are stored in the NVM during the production of the analog board.

The slash version is stored at the end of the production line of the set.

In case of failure, the NVM must be replaced by an empty device. By way of commands via the

Diagnostic Software or via ComPair, the factory settings must be restored in the NVM.

Bargraph 0db Alignment

For an exact functionality of the bar graph in the display, a correction factor for the left and the

right channel is stored in the NVM.

Procedure:

z Put the setin DSW command mode

z route Audio path from Audio front connectors to digital with the following command: DD:>

713 01

z apply a sine wave of 1 kHz, 1.65 Vrms (0 dB)to the front connectors, audio left and right

z store 0 dB bar graph level with command 720DD:>720

Clock Correction Adjustment

To guarantee an exact function of the real time clock, an adjustment of the clock frequency is

possibe and stored in the NVM.

Procedure:

Connect a pull up resistor of 10k between pin 7 an 8 of the clock IC PCF8593T,item

z

7811, on the analog PCB

put the set in service command mode

z

execute command 722 to initiate that a 1 Hz signal is available on pin 7 of the clock

z

ICDD:>722

z measure the frequency of the Clock Crystal with an accuracy of ±1(s. Normally the

measured frequency must be between 999902 (s and 1000097 (s. If the frequency is

outside this range, the clock IC must be replaced.

z Execute command 721 with the measured frequency as an input parameter

example:DD:>721 1000023

AFC Reference Voltage Tuner

This function stores the reference voltage for the tuner in the NVM. Before this value can be

stored, the AFC adjustment, described in the adjustment instructions of the analog board, must

be carried out.

Procedure:

z Adjust AFC circuit

z Calculate the reference value

z Execute command 732 and use the calculated reference value as parameter

example:DD:>732 128

Slash Version

The slash version is stored with command 715 followed by the slash version as parameter.

The slash versions used in DVDR1000 and DVDR1500 are the following:

DVDR980/17X: 103

z

DVDR985/17X: 104

z

Example:

DD:>715 1

Reset of Slash Version

Use command 729 to reset the analog board to the default setting.

Procedure:

z Put the setin DSW command mode

z Execute command 729 with the following parameters: DD:> 729w 0xA0 3 0x07 0xD0

0x00

z Leave the DSW command mode and start up the set in application mode No background

is visible on the TV screen. The analog board is ready to accept the appropriate slash

version.

Rework ProcedureIEEE Unique Number

Scope:

The procedure describes how to upgrade sets with a unique number after repair. This unique

number is stored in the NVRAM (item 7201) of the digital board at the end of the production

line.

This procedure is only valid or necessary when:

z The digital board is replaced

z NVRAM on the digital board is replaced

z NVRAM is cleared

In all other cases the repaired set retains its unique number.

The procedure defines several means to re-assure the unique number, depending on the

possibilities of repair or the state the faulty set is in.

Handling:

State of Original (Defective) Board:

1. The digital board starts up in Diagnostics Mode: follow procedure A to retrieve the valid

unique number

2. The digital board does NOT start up in Diagnostics Mode: follow procedure B.

Procedure A

1. Connect defective digital board to PC via serial cable (3122 785 90017)

2. start up hyper terminal or any other serial terminal via the correct settings (DSW

command mode interface)

3. read out existing unique number via nucleus 403 example:DD:> 40340300: DV Unique

ID = 00D7A1FC6CTest OK @

4. note read out

5. program new digital board via nucleus 410 example: DD:> 410 00D7A1FC6C41000:Test

OK @

The set has now the original unique number

Procedure B

1. Notethe serial number of the set example: AH050136130156

AH = production center Hasselt. According to UAW-500: A=1 and H=8

05 = change code (this is not used for this calculation)

01 = YEAR

36 = Production WEEK

130156 = Lot and SERIAL number

2. Calculate the unique number: this number always exists out of 10 hexadecimal numbers.

3. First 5 numbers: First we calculate a decimal number according to the formula below:

35828*YEAR + 676* WEEK + 26*A + H + 8788The figures are fixed, YEAR + WEEK +

factory code( A + H) are variable Example: 35828*01+676*36+26*1+8+8788 = 68986

(decimal)Then we translate the decimal number to a hexadecimal number.example:

68986 (decimal)= 10D7A (hex)

4. Last 5 numbers: The last 5 numbers exist out of the Lot and SERIAL number. We have

to translate the decimal number to the next 5 hexadecimal numbers: Example: 130156

(decimal) = 1FC6C (hex)

5. Program new digital board via nucleus 410 Therefore we use the 10 hexadecimal

numbers we calculated above: example:DD:> 410 10D7A1FC6C41000:Test OK @

The set has now its original unique number

Mechanical, and Dismantling Instructions,and

Exploded Views

Service Positions

Front

Figure: Front

DVIO Board

To put the DVIO board in a service position,an extender board must be used. This extender

board can be orderedwith codenumber 3104 128 07770.

Figure: DVIO Extender

Figure: DVIO 1

Loading...

Loading...