Philips DVDR-985 Service manual

Philips DVDR985

Technical Training Manual

Philips Service and Quality/Training

One Philips Drive

Knoxville, TN 37914-1810

P. O. Box 14810

PH: 865-521-4397

FAX: 865-521-4818

EMAIL: TECHNICAL.TRAINING@PHILIPS.COM

Introduction

This Manual is intended for use by the Service

Technician. The first portion of this manual contains a basic description of disc based data playback and recording technologies. Self

Diagnostics are included to aid in troubleshooting. Technical Descriptions of the circuitry is followed by a Troubleshooting Section.

The DVDR985 is the forth in a line of DVD

recorders. The DVDR1500 was the first.

Recordings can be made from broadcast transmissions, and from other analog or digital

sources. The DVDRW format allows the user to

record and erase a disc many times. The recorded discs will play on most existing and future

DVD players. The DVDR985 has a connection

for DV or Digital camcorders via an I-Link or

Firewire connection. This connection technically

is called an IEEE 1394 connection. This machine

records on 4.7Gbyte DVD+R and DVD+RW

discs. This machine uses a real-time MPEG2

Variable Bit Rate, VBR, Video encoder. The

DVDR985 plays back DVD Video, Video CD,

Audio CD, CD-R, and CD-RW discs.

Its many features include: Favorite Scene

Selection for easy editing, Index Picture Screen

for instant overview of contents, Digital Time

Base Correcter, Digital Audio output (DTS, AC3, MPEG, PCM), TruSurround for 3D sound,

Zoom + Perfect Still. It is Widescreen, 16:9

compatible, and has a Universal Remote

Control, 20 disc resume, Disc Lock, and One

Touch Recording.

Virgin Mode

The DVDR985, when first hooked up, needs to

get information from the user about what language and what local broadcast system the

unit is going to operate with. Use the remote to

make those selections. The unit will not operate

until this process is completed. If you want the

recorder to start up in Virgin mode, unplug the

recorder. Plug the recorder in again while holding the STANDBY-ON button.

DVD Basics

Philips with nine other manufacturers chose a

format specification for DVDR and RW on March

16, 2001. This new format uses Real Time

recording. Its recording is compatible with DVDVideo, and DVD ROM. The data blocks use lossless linking. The physical layout matches very

closely that of DVD ROM. See Figure 1. It also

uses Direct Overwrite when a RW disc is used.

Laser Technology

CDs use a red laser created by a diode and lens

system often called a Light Pen. Refer to Figure

2. The narrow beam of light is focused onto the

reflective layer of a disc. At the instant that focus

is achieved, the disc is spun. The laser starts on

the innermost tracks of the CD and reads outward. At the beginning of the disc is the Table of

Contents. At the bottom of the Light Pen are

Monitoring Diodes. The Monitoring Diodes provide information about focus and tracking. Data

is retrieved from the disc in the form of pulses of

Figure 1 – DVD ROM Disc

1

light reflecting from the disc. The pulses are

created by Pits in the Reflective Layer of the

disc. The Pits reflect less light than the intact

surface of the Reflective Layer, called Lands.

Disc Mechanical Layout

The DVD and CD share much of their technology. We will start with CDs and work our

way to the DVD. The CD is a plastic disc

120mm in diameter, with a thickness of

1.2mm. Refer to Figure 3. It has a silver col-

ored Reflective Layer. The maximum playing

time for a music recording on a Compact

Disc, CD, is 74 Min.

The CD is less vulnerable to damage than an

analog record. That does not mean it does

not have to be treated with care. Dirt and

heavy scratches can interfere with playability.

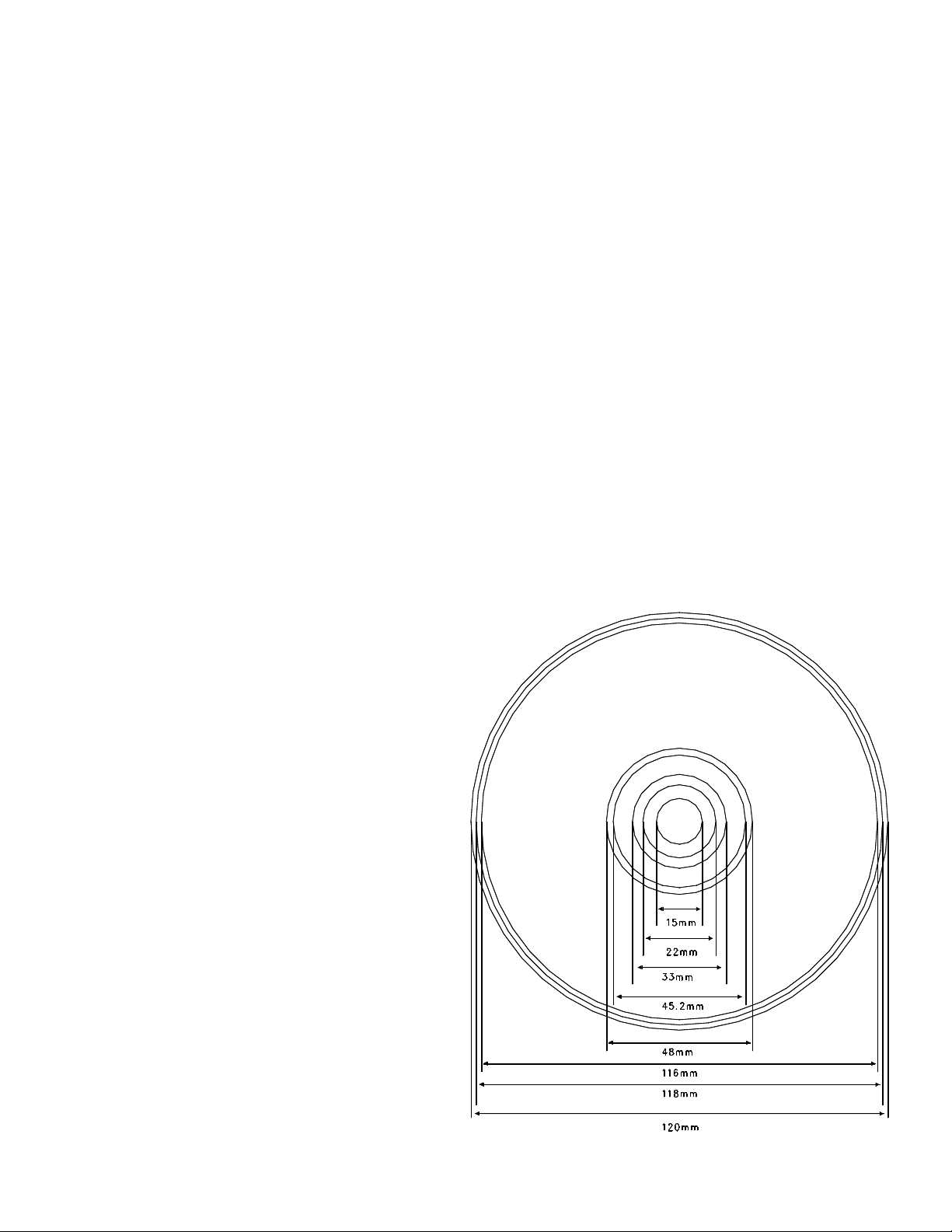

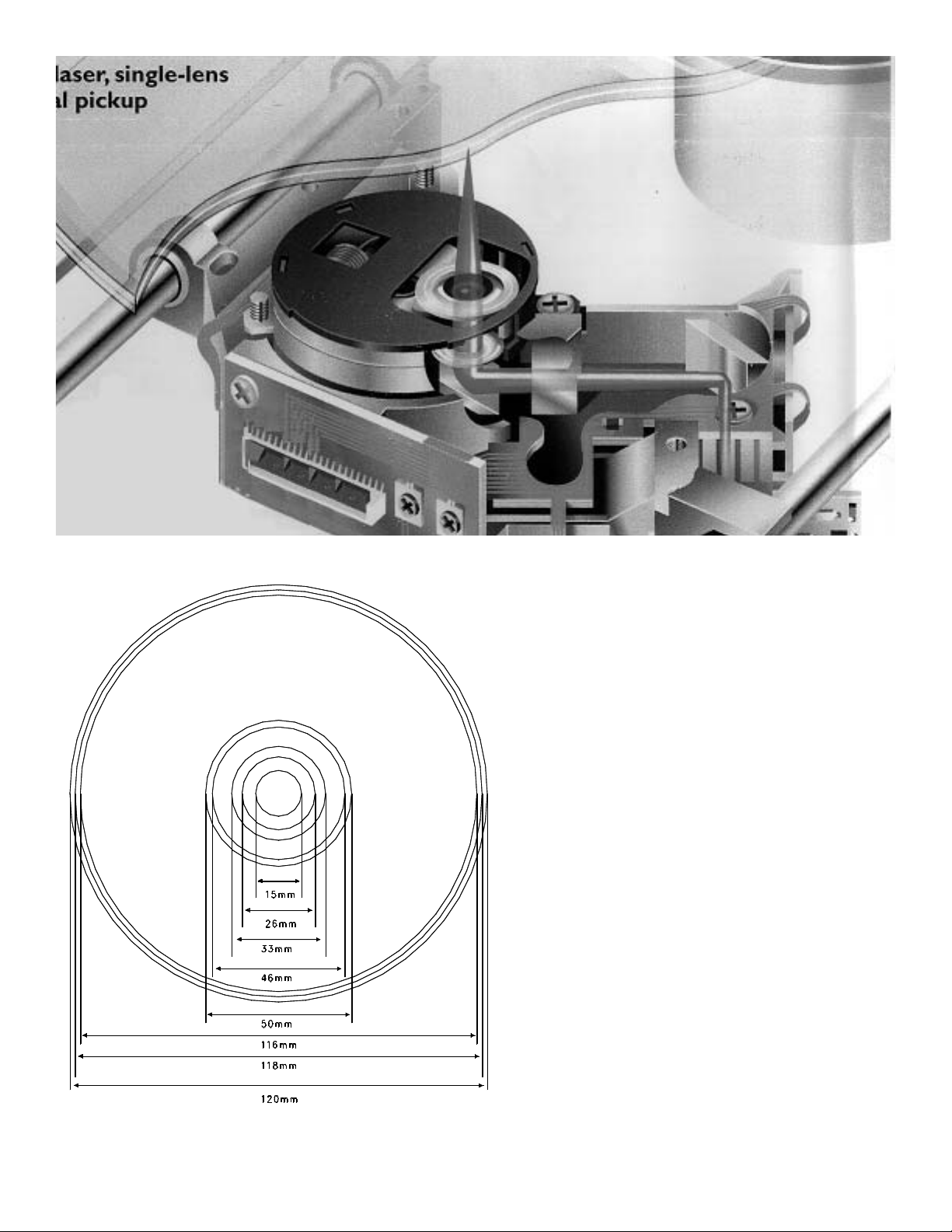

Figure 2 – CD Laser Operation

Figure 3 – Mechanical Layout of a CD.

2

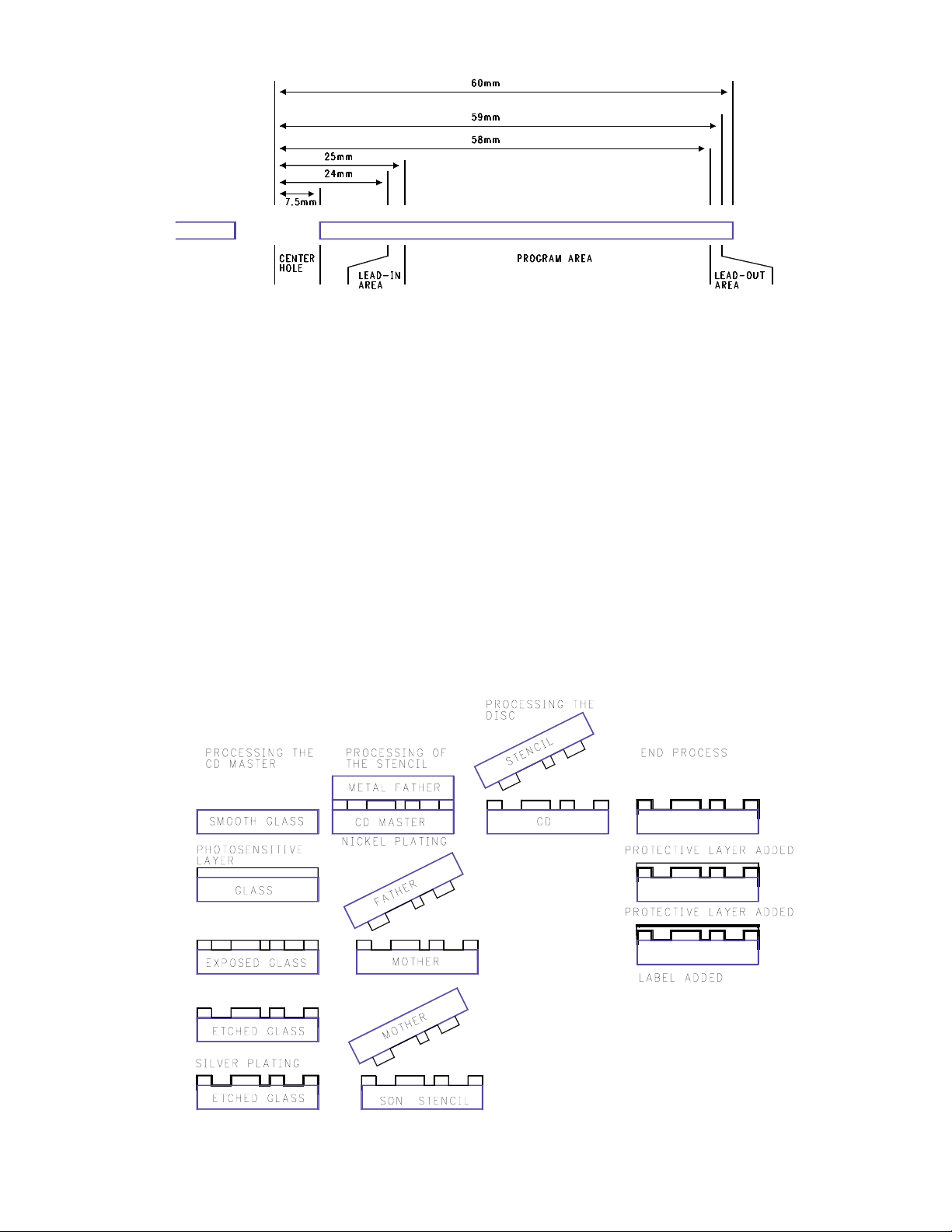

As shown in Figure 4, the CD is subdivided into

three parts: the Lead In Track, the Program

Area, and the Lead Out Area. These three sections together are considered the Information

Area. There is a hole in the center for holding

the disc. The disc is held between two equally

sized concentric rings. The rings have an inner

diameter of 29mm and an outer diameter of

31mm.

The Data on the disc is recorded on a spiral

shaped track with pits and lands. The reflective

side of the disc contains the tracks.

The production of a disc is a high tech process

explained in Figure 5. The process starts with

glass that is photo etched. The glass is silver

plated and is used as a form for a metal cast.

The metal cast is used to stamp a nickel Mother

Stencil. The Mother Stencil is used to stamp the

Son Stencil. Son Stencils are used to stamp the

foil of the discs. A protective layer and label are

added.

Read Process

The Servo circuit is responsible for focusing the

laser and moving the Light Pen to follow the spiraling tracks on the rotating disc. The digital High

Figure 4 - The Disc

Figure 5 - Creating a CD

3

Frequency information, HF, is demodulated and

stored in RAM. When the RAM is half full, the

data is fed out to the Digital to Analog

Converters. The speed of the rotating disc is

servo controlled to keep the RAM half full. The

analog signals are amplified and sent to the output connectors.

Record Once Technology

Disc Mechanical Layout

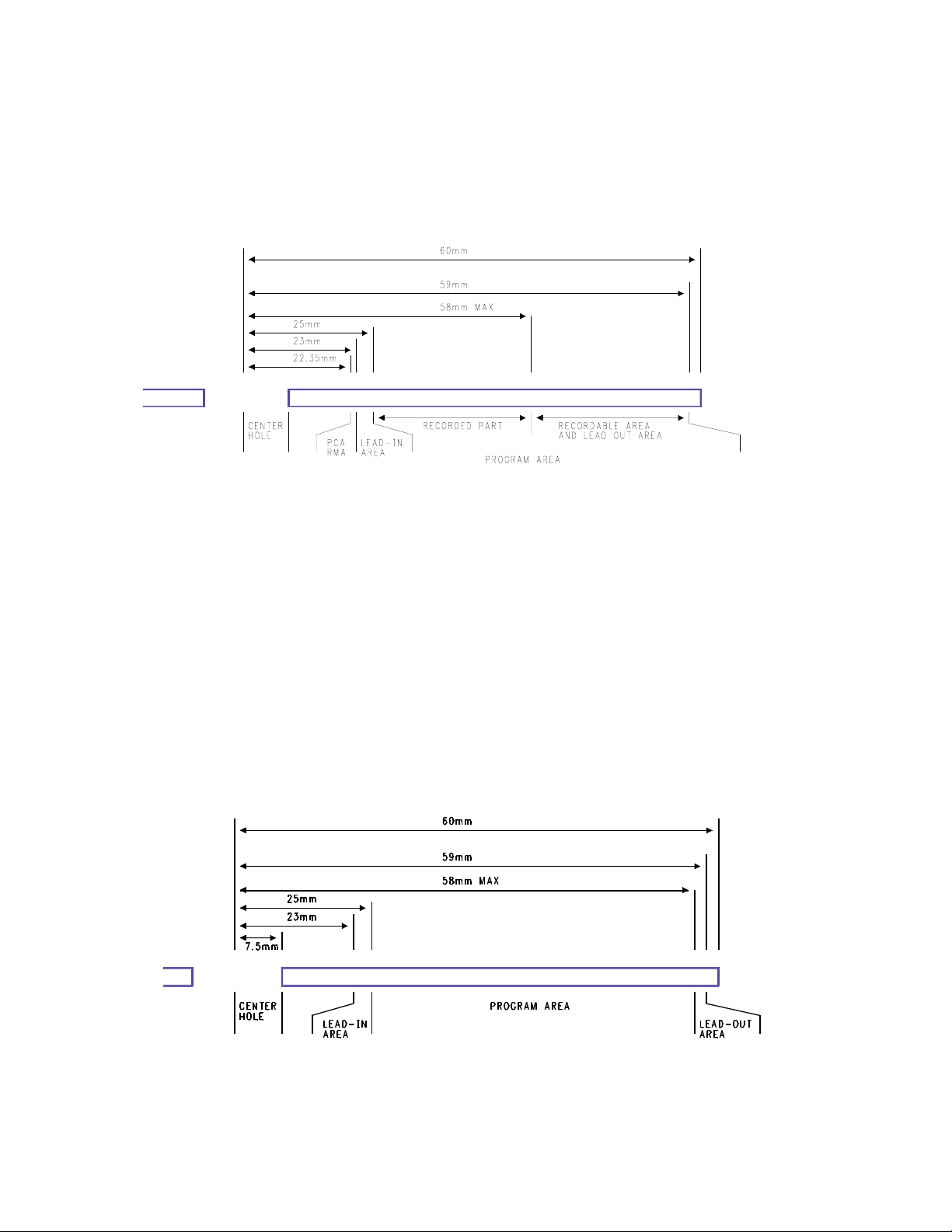

From an external point of view, a DVD is the

same as the CD. Recordable media creates the

need for three physical layouts. There are three

possible states of a disc: a blank disc, a partially

recorded disc, and a full or finalized disc. The

difference is in the way the Information Area is

divided. The Information Area of a blank disc

extends from 22.35 mm centered on the disc to

59 mm centered on the disc. Refer to Figure 6.

A partially recorded disc’s Information Area has

four sections: a PCA/RMA area, a Lead In Area,

a Recorded Program Area, and a Recordable

Program Area. See Figure 6 for the dimensions.

The PCA Area is the Power Calibration Area,

PCA. The RMAArea is the Recording

Management Area.

A fully recorded or finalized disc’s Information

Area has three sections: A lead in Area, the

Program Area, and the Lead Out Area. See

Figure 7 for the dimensions.

The disc’s recordable layer contains major differences from that of a stamped disc. The blank

disc has a Pre-groove stamped into the recordable layer of the disc. This is polycarbonant for

DVD+Rs and organic dye material for

DVD+RWs. This spiral Pre-groove is for the

Servo circuit to provide a mechanical reference

Figure 6 – A Partially Recorded Disc.

Figure 7 – Fully Recorded or Finalized Disc

4

during recording. The dye based RW recordable

layer provides a reflectivity of 40% light return

and 70% light return. 40 percent reflectivity represents Pits and the 70% represent the Lands.

Record Process

The record process shares most of its mechanical operation with that of the play process. The

main difference is how the Servo is locked to the

disc. The Servo follows the Pre-groove for Radial

Tracking and disc speed. The speed of the disc

is locked to a wobble signal that is part of the

spiral grove stamped into the disc.

The intensity of the laser beam is modulated

from playback intensity to write intensity. As the

disc reads the Pre-groove, the laser arrives at a

position where a Pit is to be formed. The laser

power increases from 4mW to 11mW. This raises

the temperature of the disc to 250 degrees

Celsius. The recordable layer melts, reducing its

volume. The polycarbonate flows into the space

vacated by the dye. The modulation from read

laser power to write laser power forms a pit and

land pattern effectively the same as a prerecorded disc.

Re-recordable Technology

Disc Mechanical Layout

Disc usage mechanically is identical to the

recordable media. The only difference is the

chemical make up of the recordable layer. The

recordable layer is made up of an alloy of silver,

indium, antimony and tellurium.

Re-Recording Process

The Re-Record process shares much of its operation with that of a CDR. The blank disc’s

Information Area is in a polycrystalline state.

During recording, the laser power is modulated

from 8mW to 14mW. 8mW is the playback laser

power and 14mW is the record laser power. The

polycrystalline state of the recordable surface

changes, or melts at 500-700 degrees C into an

amorphous state. The melted, amorphous areas

reflect light less than the crystalline areas, creating a pattern similar to the stamped CD. A major

difference of CDRWs from CDRs is the ability to

erase.

The Erase Process

To Erase a CDRW disc, the recordable layer

must be returned to its polycrystalline state. This

is done by heating up the temperature of the

recorded surface to 200 degrees C. This is less

than the melting point. This is done at X2 recording speed. The slower speed allows time for the

alloy to return to its proper state. This takes

approximately 37 min. Some software erases the

just the TOC on the disc and allows the disc to

be rewritten. This method is not as reliable

Over Writing Process

Overwriting combines the processes of erasing

and writing. When the disc and Light Pen are in

position to start writing the new data, the laser

power starts modulating in the same manner as

it does for normal recording with one difference.

During the time there is to be a land, the laser

power goes to the erase level rather than the

playback level.

Figure 8 – Mechanical Layout of a DVD

5

DVDs

All of the previously discussed technologies

apply to the DVD. Like CDs, DVDs are also

stamped into play only discs. In this discussion,

we will point out the differences between DVDs

and CDs. If you are new to disc based technology, you will want to start with the information preceding this discussion.

DVD Disc Mechanical Differences

Most DVDs are single sided, however, the DVD

specification allows for two readable layers, and

the disc can be double sided. We will start our

discussion with single sided, single layered

discs. A Digital Versatile Disc, DVD, looks very

similar to a CD. Refer to Figure 8. The Clamping

Area is larger, starting at 11 mm centered to 16.5

mm centered. The Lead In Area is smaller,

measuring 22.7 mm centered to 24 mm centered. The Information Area is limited to 116mm

centered.

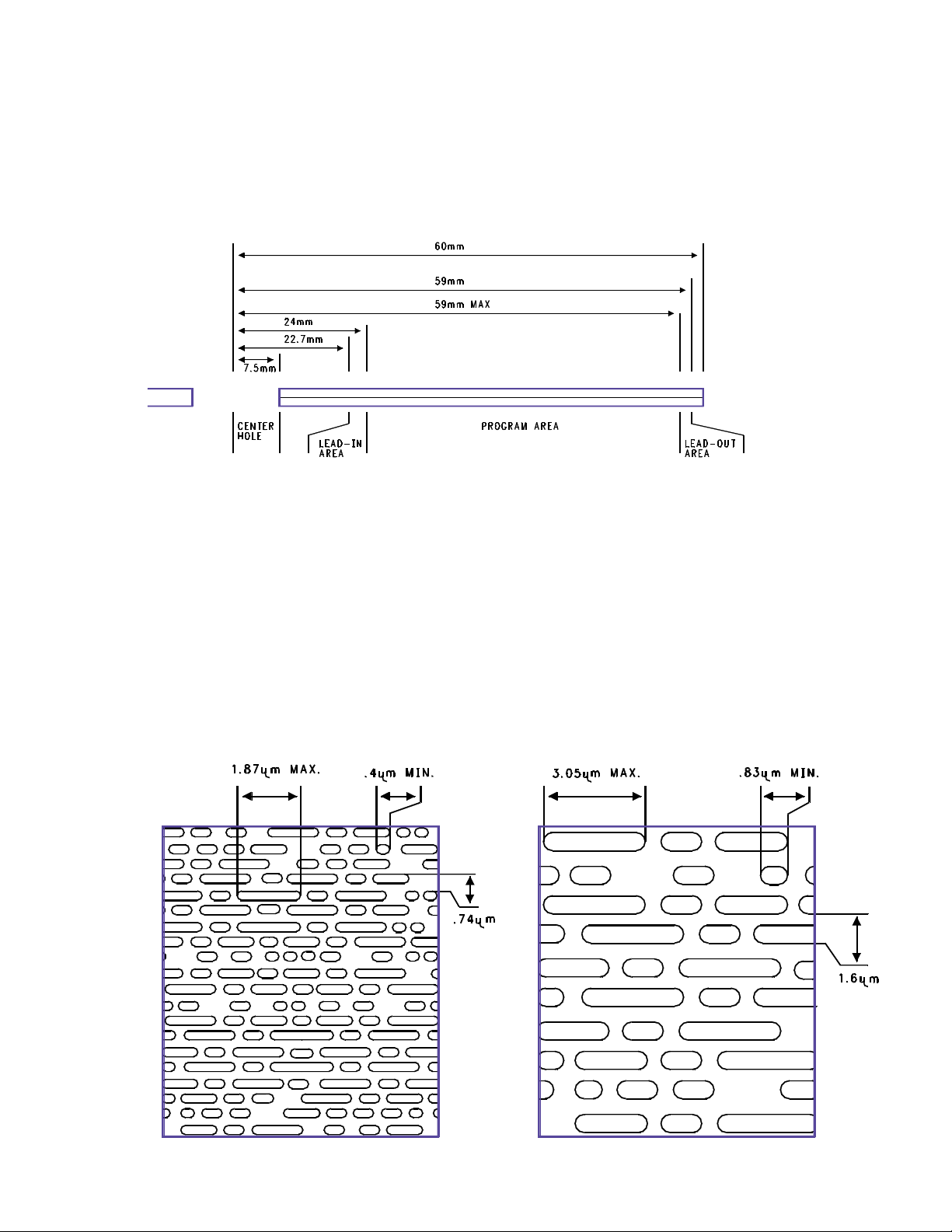

Two of the big differences between DVDs and

CDs are the Pit and Land sizes, and the track

widths. Refer to Figure 9.

The Manufacturing process of a DVD is comparable to that of a CD. The main difference is the

thickness. The DVD can be a double sided product. Each side is .6mm. The two sides are glued

back to back, producing 1.2mm total thickness.

Figure 8 - DVD Mechanical Layout

Figure 9 – DVD and CD Pit Structure.

CD

DVD

6

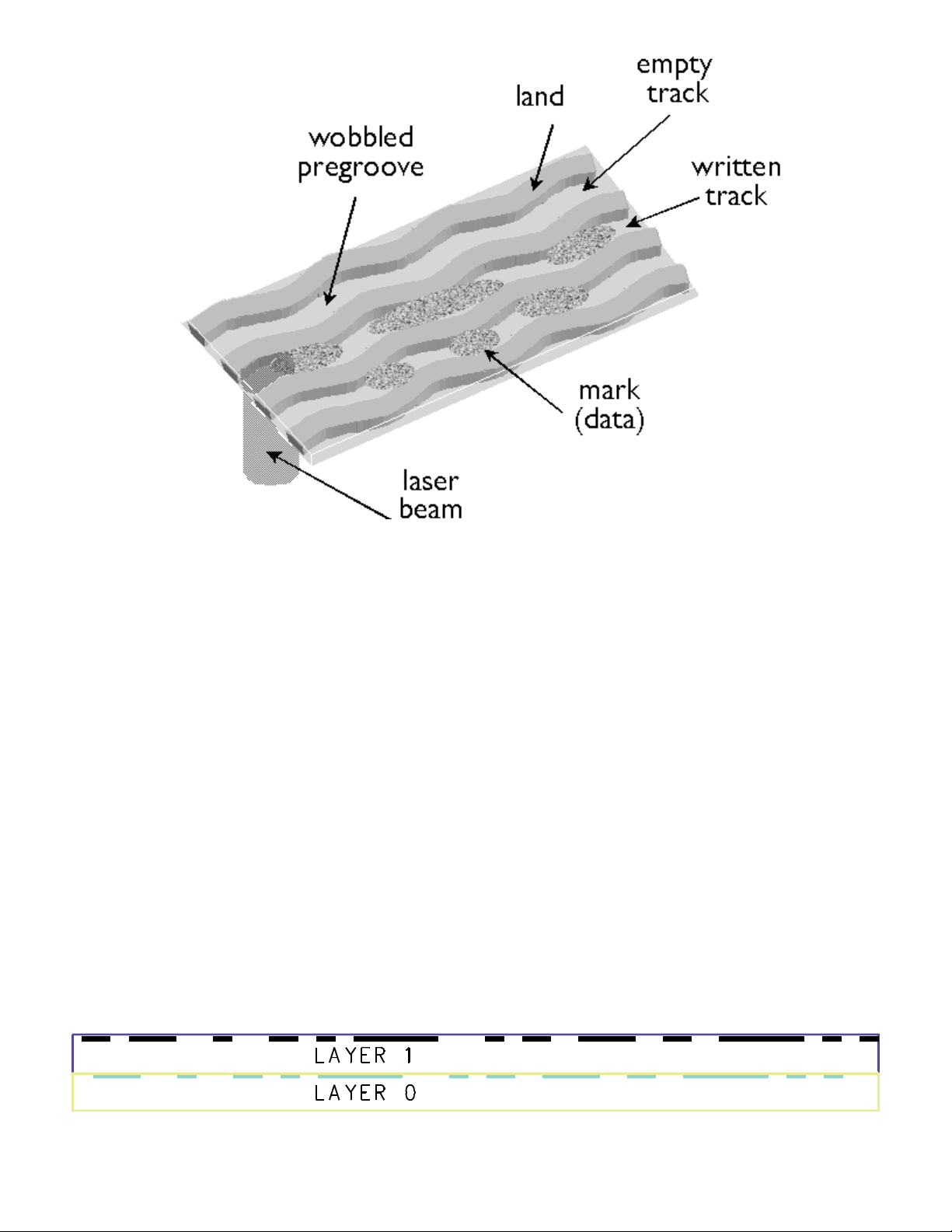

Wobble

A Pre-groove is stamped on writable discs.

All recordable DVD media types feature a microscopic wobble groove embedded in the plastic

substrate. This wobble provides the recorder

with the timing information needed to place the

data accurately on the disc. During recording,

the drive's laser follows this groove, to ensure

consistent spacing of data in a spiral track. The

walls of the groove are modulated in a consistent

sinusoidal pattern, so that a drive can read and

compare it to an oscillator for precise rotation of

the disc. This modulated pattern is called a wobble groove, because the walls of the groove

appear to wobble from side to side. This signal is

only used during recording, and therefore has no

effect on the playback process. Among the DVD

family of formats, only recordable media use

wobble grooves.

Dual Layer Discs

Two information layers are separated by a thin

transparent layer. Refer to Figure 11. The first

layer is partially transparent. This allows the second layer to be read through the first layer. Both

layers are read by controlling the focus. There

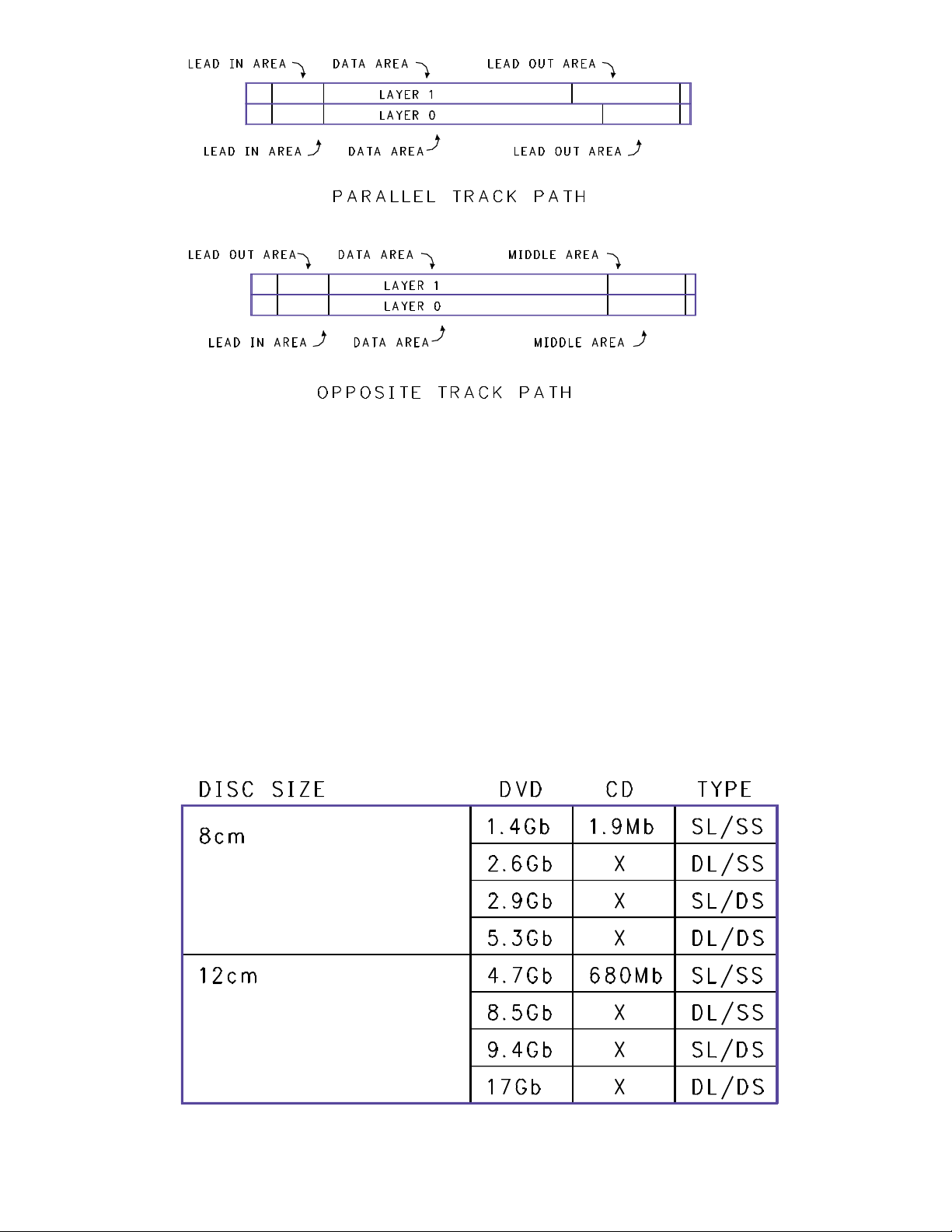

are two methods for reading the data of a Dual

Layer disc, PTP and OTP. Refer to Figure 12.

PTP is Parallel Track Path. That means the Lead

In and Out Areas of the two layers correspond to

each other. Each Lead In Area is on the inner

portion of the disc, and the Lead Out Area is on

the outer portion of the disc. This is useful to link

data between the layers.

Figure 11 – Dual Layer DVD

7

Figure 10 - Wobble Pregroove

This allows instant access to the additional data

or scene. OTP is Opposite Track Path. This

method links the end of one layer to the beginning of the other. The Lead In Area is still on the

inner portion of the disc. There is a Middle Track

Area on both of the layers located on the outer

portion of the layers. The Middle Track Area links

the data on the two layers together. The Lead

Out Area is on the second layer on the inner portion of the disc.

Capacity

Because a stamped DVD can be Dual Layered

and Double Sided, there are four different capacities. Refer to Figure 13. These capacities strictly pertain to raw data. The time available for

Video and Audio has many extra factors that

determine the length of time on each side or

layer. The picture complexity and the amount of

movement in the picture affect compression and

time on a disc. The number of languages affect

the time on a disc. The type and quality of the

Audio has an affect on the time also. It can be

mono, stereo, or AC-3. Therefore, the media

itself determines the capacity in time on the disc.

Figure 13 – DVD Multi-Layered Capacities

8

Figure 12 – PTP and OTP Layout

Description

The End User/Dealer Self Diagnostics work without the need for other equipment. A number of

hardware tests are automatically executed to

check for faults in the recorder. The diagnosis

ends with a “FAIL” or “PASS” message. If the

message “FAIL” appears on the display, an Error

Code is displayed. If the message “PASS”

appears, the tests have been executed successfully. There can still be a failure in the recorder.

The tests do not cover the complete unit. The

following list describes the tests being preformed

while the test number is being displayed on the

Front Panel. To place the unit in the Self Test

Mode, hold the Play pushbutton on the Front

Panel while suppling AC power to the unit. The

display counts down numerically the test it is

performing.

The following is a list of the test displayed as:

“Test Number” is displayed on the Front Panel

“Name”of the test

Description of the test

22

SdramWrR

Checks all memory locations of the 4Mbyte

SDRAM

21

HostdDramWrR

Checks all the DRAM connected to the microcomputer on the Digital Board

20

HostdI2cNvram

Checks the data line (SDA) and the clock line

(SCL) of the I2C bus between the host decoder

and NVRAM

19

SAA7118I2c

Checks the interface between the Host I2C controller and the SAA7118 Video Input Processor

18

VideoEncI2c

Checks the interface between the host I2C controller and Empress

17

AudioEncI2c

Checks the I2C connection between the host

decoder and Empress

16

AudioEncAccess

Tests the HIO8 interface lines between the host

decoder and the audio encoder

15

AudioEncSramAccess

Checks the access of the SRAM by the audio

encoder (address and data lines).

14

AudioEncSramWrR

Tests the SRAM connected to the audio encoder

13

AudioEncInterrupt

Tests the interrupt line between the host decoder

and the audio encoder

12

VsmAccess

Checks whether the VSM interrupt controllers

and DRAM are accessible

11

VsmInterrupt

Checks both interrupt lines between the VSM

and the host decoder

10

VsmSdramWrR

Tests the entire SDRAM of the VSM

9

Automatic Self Diagnostic Modes

(End User/Dealer Script Interface)

9

Clock11.289MHz

Switches the A_CLK of the micro clock to

11.2896 MHz

8

Clock12.288MHz

Switches the A_CLK of the micro clock to 12.288

MHz

7

BeS2Bengine

Checks the S2B interface with the Basic Engine

by sending an echo command

6

DisplayEcho

Checks the interface between the host processor

and the slave processor on the display board

5

AnalogEcho

Checks the interface between the host processor

and the microprocessor on the Analog Board

4

AnalogNvram

Checks the NVRAM on the Analog Board

3

Tuner

Checks whether the Tuner on the Analog Board

is accessible

2

LoopAudioUserDealer

Tests the components in the audio signal path:

The host decoder on the Analog Board, the

audio encoder, the VSM. The Audio is internally

looped back thru the Digital Board

1

LoopVideoUserDealer

Tests the components on the Video signal system path: - The VIP- The Video encoder- The

VSM- The host decoder. The Analog Board On

Video signal is internally routed back to the

Digital Board.

Color bars appears on the output. It is a PAL colorbar pattern which means you may see a

greyscale bar pattern. The pull in range of the

monitor, will affect what is seen. An NTSC color

bar signal can be output from the Host Decoder

using ComPair.

10

Description

The Manual Diagnostics provide the opportunity

to perform tests and exercise the unit in a way

that helps determine which of the DVD

recorder’s circuit boards are faulty. If no Errors

are found, it performs an endurance loop test. To

successfully perform the tests, the DVD recorder

must be connected to a TV set. The Servicer

must respond to what is seen and heard on the

monitor. (i.e. to approve a test picture or a test

sound). Some tests require that a DVD+RW disc

be inserted.

Structure of the Player Script

The player script (Manual Diagnostics) tests the

circuit boards in the DVD recorder: the Display

PCB, the Digital PCB, the Analog In/Out PCB

and the Basic Engine.

The Player tests are done in two phases, interactive tests and a burn in test. The interactive

tests depend strongly on user interaction and

input to determine the results and to progress

through the full test. The Burn-in Loop test will

perform the same set of tests as the dealer test,

but it will loop through the list indefinitely. Is is

especially usful if you reset the Error Log. You

can do this using ComPair. You can then read

the error codes using ComPair.

Step by Step Description

1

Press OPEN/CLOSE and PLAY buttons at the

same time and provide AC to the recorder to

start the player script. Press Play to perform the

test described on the display. Press Stop to skip

the test and go to the next test. Press Record to

indicate to the Microcomputer the desired result

malfunctioned.

2

The display shows FP SEGM. Press PLAY to

start the test. First the starburst pattern is lit,

then the horizontal segments are lit, followed by

the vertical segments and the last test lights all

the segments. After each of the four tests, the

user has to confirm that the correct pattern was

lit. Press PLAY to confirm that the correct pattern

was lit (four times if the FPSEGMENTS test was

successful). Press RECORD to indicate that the

correct pattern was not successfully lit. Press

STOP to skip this test.

3

The display shows FPLABELS. All labels should

be lit

4

The display shows FPLIGHT ALL. Everything

should be lit.

5

The display shows FPLED. The LED changes

color.

6

The display shows FP LED. The red Record light

comes on. Press play to confirm it lit.Press

STOP to skip this test.

7

The display shows FPKEYBRD. All keys have to

be pressed to get a positive result! This includes

the Power button. Press PLAY for more than two

seconds to confirm that all the keys were

pressed and that it was shown on the display.

Press STOP for more than one second to skip

this test.

8

The display shows FP REMCTL. Press PLAY to

confirm that a key on the remote control was

pressed and shown on the local display. Only

one key has to be pressed to get a successful

result.

11

Manual Service Diagnostics

(Player Script)

9

The display shows FPDIMMER. Press PLAY to

activate the dimming feature. Press Play to confirm that the text on the local display was

dimmed.

10

The display shows ROUTE VID. Press Play to

advance.

11

The display shows ROUTE AUD. Press Play to

advance.

12

The display shows COLORBAR ON.Press Play

to advance. An NTSC Colorbar Pattern should

apear at the output. Press play to advance.

13

The display shows PINKNOISE ON. The monitor

should produce Pink noise.

14

The display shows PINKNOISE OFF. Press Play

to advance.

15

The display shows BE RESET. Press PLAY to

Reset the Basic Engine (Mechanism/Servo

PCB).

16

The display shows BE TRAY OPEN. Press

PLAY to open the tray. Place a RW disc in the

tray.

17

The display shows BE TRAY CLOS. Press PLAY

to close the tray.

18

The display shows BE WRITE READ. This

requires a RW disc to be in the machine. The BE

resets and a small write is preformed, and then a

read. this will take 20 seconds or so.

19

The display shows BE TRAY OPEN. This opens

the tray.

20

The display shows BE TRAY CLOS. This closes

the tray.

21

The display shows ERRORLOG READ. If there

was an error a code will be displayed. If you

press PLAY, the User/Dealer script will start an

endless loop. If the unit fails a test, the local display will display FAIL and the error code

In case of failure, the display shows “ FAIL

XXXXXX “The description of the shown error

code should be found in the list to follow. Once

an error occurs, press the STOP key to jump

over the failure and to continue the diagnostics.

There is a Error Code Table in Force Manual

2064

10000 - Checksum is OK

10001 -Segment name Checksum doesn’t match

or segment name segment not found

10101 - FLASH 1 Write access test failed

10201 - FLASH 2 Write access test failed

10301 - FLASH write test failed

10302 - FLASH write command failed

10303 - FLASH write test done max. number of

times

10401 - HostDec SDRAM Memory data bus test

fails.

10402 - HostDec SDRAM Memory address bus

test fails.

10403 - HostDec SDRAM Physical memory

device test fails.

10501 - HostDec SDRAM Memory data bus test

fails.

10502

HostDec SDRAM Memory address bus test

12

fails.

10503

HostDec SDRAM Physical memory device test

fails.

10601 - HostDec DRAM Memory data bus test

fails.

10602 - HostDec DRAM Memory address bus

test fails.

10603 - HostDec DRAM Physical memory

device test fails.

10701 - HostDec DRAM Memory data bus test

fails.

10702 - HostDec DRAM Memory address bus

test fails.

10703 - HostDec DRAM Physical memory

device test fails.

10800 - Host Decoder version (cut) number: version number Digital hardware version

10801 - Can not find version in FLASH.

10901 - Error muting Audio

11001 - Error un-muting

11501 - Init of I2C failed

11502 - The selection of the clock source failed

11504 - The un-mute of the Audio failed

11601 - Init of I2C failed

11602 - The mute of the Audio failed

11701 - Init of I2C failed

11702 - The muting of the Audio failed

11703 - The un-mute of the Audio failed

11704 - The selection of the clock source failed

11707 - Setup of Front panel failed

11708 - Sine on Front panel keyboard failed

11801 - Init of I2C failed

11802 - The muting of the Audio failed

11803 - The un-mute of the Audio failed

11804 - The selection of the clock source failed

11805 - Error cannot start VSM audio in port

11901 - Init of I2C failed

11902 - The muting of the Audio failed

11903 - The un-mute of the Audio failed

11904 - The selection of the clock source failed

11905 - Error cannot start VSM Audio in port

12001 - Invalid input

12201 - I2C bus busy before start

12202 - NVRAM access time-out

12203 - No NVRAM acknowledgement

12204 - NVRAM time-out

12205 - NVRAM Write/Read back failed

12301 - I2C bus busy before start

12302 - NVRAM read access time-out

12303 - No NVRAM read acknowledgement

12304 - NVRAM read failed

13000 - Bootcode application version boot version

13001 - Can not find version in FLASH.

13100 - Recorder application version: recorder

version

13

13101 - Can not find version in FLASH.

13200 - Diagnostics application version: diagversion

13201 - Can not find version in FLASH.

13300 - Download application version: download

version

13301 - Can not find version in FLASH.

13701 - Turning off Macrovision failed

20001 - I2C bus busy before start

20002 - Video Encoder access time-out

20003 - No acknowledgement from Video

Encoder

20004 - No data send/received to or from Video

Encoder

20005 - SAA7118 VIP can not be initialized

20201 - I2C bus busy before start

20202 - SAA7118 VIP access time-out

20203 - No acknowledgement from SAA7118

VIP

20204 - No data received from SAA7118 VIP

20301 - Error audio encoder SRAM access cannot initialize I2C

20302 - Error audio encoder SRAM access cannot reset DSP through I2C

20303 - Error audio encoder SRAM access cannot download boot

20304 - Error audio encoder cannot download

test code

20305 - Error audio encoder cannot obtain result

of test

20306 - Error audio encoder SRAM access

stuck-at-zero data line

20307 - Error audio encoder SRAM access

stuck-at-one data line

20308 - Error audio encoder SRAM access

stuck-at-one address line

20309 - Error audio encoder SRAM access

address line. Address line x is connected to data

line y

20310 - Error audio encoder SRAM access

address lines address line x and address line y

are connected

20311 - Error audio encoder SRAM access data

lines data line x and data line y are connected

20312 - Error audio encoder SRAM access illegal data received

20401 - Error audio encoder access cannot initialize I2C

20402 - Error audio encoder access cannot reset

DSP through I2C

20403 - Error audio encoder accessing ICR register

20404 - Error audio encoder access stuck-atzero of data line

20405 - Error audio encoder access stuck-at-one

of data line

20406 - Audio encoder access data lines data

line x and data line y are interconnected

20501 - Error audio encoder SRAM WRR cannot

initialize I2C

20502 - Error audio encoder SRAM WRR cannot

reset DSP through I2C

20503 - Error audio encoder WRR cannot down-

14

load boot

20504 - Error audio encoder cannot download

test code

20505 - Error audio encoder SRAM WRR cannot

obtain result of test

20506 - Error audio encoder WRR SRAM stuckat-zero data bit

20507 - Error audio encoder WRR SRAM stuckat-one data bit

20508 - Error audio encoder WRR SRAM data

lines data line x and data line y are connected

20509 - Error audio encoder WRR SRAM illegal

data received

20601 - Error audio encoder interrupt cannot initialize I2C

20602 - Error audio encoder interrupt cannot

reset DSP through I2C

20603 - Error audio encoder cannot download

test code

20604 - Error occurred accessing VSM

20605 - Audio encoder interrupt not received

20606 - Error occurred while activating the

encoder

20607 - Error audio encoder interrupt cannot initialize empress

20608 - Error occurred while getting interrupt

reason

20701 - Error audio encoder I2C cannot reset

DSP through I2C

20702 - Error audio encoder cannot download

boot

20703 - Error audio encoder cannot download

TEST code

20704 - Error audio encoder I2C bus busy

20705 - Error audio encoder I2C cannot write

slave address

20706 - Error audio encoder I2C no acknowledgement received

20707 - Error audio encoder I2C cannot

send/receive data

20708 - Error audio encoder received data

through I2C was invalid

20801 - I2C access failed.

20802 - SAA7118 VIP can not be initialized.

20803 - Invalid input

20900 - B1. B2. B3. B4. B5. B6. B7. B8. B9.

B10. B11. B12.

20901 - Firmware download of EMPRESS failed

20902 - I2C bus busy before start

20903 - EMPRESS access time-out

20904 - No acknowledgement from the

EMPRESS

20905 - No data send to the EMPRESS

20906 - No data received from the EMPRESS

30001 - VSM SDRAM Bank1 Memory data bus

test fails.

30002 - VSM SDRAM Bank1 Memory address

bus test fails.

30003 - VSM SDRAM Bank1 Physical memory

device test fails.

30004 - VSM SDRAM Bank2 Memory data bus

test fails.

30005 - VSM SDRAM Bank2 Memory address

bus test fails.

15

30006 - VSM SDRAM Bank2 Physical memory

device test fails.

30007 - VSM SDRAM Bank1 VSM interrupt register A has a-stuck at- error for value:

30008 - VSM SDRAM Bank2 VSM interrupt register A has a-stuck at- error for value:

30101 - VSM SDRAM Bank1 Memory data bus

test fails.

30102 - VSM SDRAM Bank1 Memory address

bus test fails.

30103 - VSM SDRAM Bank1 Physical memory

device test fails.

30104 - VSM SDRAM Bank2 Memory data bus

test fails.

30105 - VSM SDRAM Bank2 Memory address

bus test fails.

30106 - VSM SDRAM Bank2 Physical memory

device test fails.

30201 - VSM SDRAM Bank1 Memory data bus

test fails.

30202 - VSM SDRAM Bank1 Memory address

bus test fails.

30203 - VSM SDRAM Bank1 Physical memory

device test fails.

30204 - VSM SDRAM Bank2 Memory bus test

wrong.

30205 - VSM SDRAM Bank2 Memory address

bus test fails.

30206 - VSM SDRAM Bank2 Physical memory

device test fails.

30301 - VSM interrupt register A has a -stuck aterror for value:

30302 - VSM interrupt register B has a -stuck aterror for value:

30303 - Interrupt A wasn’t raised.

30304 - Interrupt B wasn’t raised.

30305 - Interrupts A and B were raised.

30401 - VSM SDRAM Bank1 Memory data bus

test fails.

30402 - VSM SDRAM Bank1 Memory address

bus test fails.

30403 - VSM SDRAM Bank1 Physical memory

device test fails.

30404 - VSM SDRAM Bank2 Memory data bus

test fails.

30405 - VSM SDRAM Bank2 Memory address

bus test fails.

30406 - VSM SDRAM Bank2 Physical memory

device test fails.

30501 - Communication with the Analog Board

fails.

30502 - Echo test to Analog Board returned

wrong string.

40001 - NVRAM Reset; I2C failed

40100 - NVRAM address = 0xaddress ->

Bytevalue = 0xvalue

40101 - NVRAM Read; I2C failed

40102 - NVRAM Read; Invalid input

40201 - NVRAM Modify; I2C failed

40202 - NVRAM Modify; Invalid input

40300 - DV Unique ID = id

40301 - NVRAM Read DV Unique ID; I2C failed

40400 - \r\n Error log: \r\n error String \r\n Ö

40401 - NVRAM error log; I2C failed

16

40402 - NVRAM error log is invalid

40403 - Front panel failed

40701 - NVRAM error log reset; I2C failed

40900 - Region code Change counter is reset

40901 - NVRAM region code reset; I2C failed

41001 - NVRAM Store DV Unique ID; I2C failed

41002 - NVRAM Store DV Unique ID; Invalid

input

50007 - Execution of the command on the

Analog Board failed.

50008 - The front panel could not be accessed

by the Analog Board.

50009 - The echo from the front panel processor

was not correct.

50100 - Front panel version: FP version

50102 - Execution of the command on the

Analog Board failed.

50103 - The front panel could not be accessed

by the Analog Board.

50204 - Execution of the command on the

Analog Board failed.

50205 - The front panel could not be accessed

by the Analog Board.

50206 - The front panel did not show a starburst.

50207 - The user skipped the FP-which pattern

test.

50208 - The user returned an unknown confirmation: confirmation

50209 - The front panel did not show horizontal

segments.

50210 - The front panel did not show vertical

segments.

50304 - Execution of the command on the

Analog Board failed.

50305 - The front panel could not be accessed

by the Analog Board.

50306 - The front panel did not light all labels.

50307 - The user skipped the rest of the FPlabel test.

50308 - The user returned an unknown confirmation: confirmation

50404 - Execution of the command on the

Analog Board failed.

50405 - The front panel could not be accessed

by the Analog Board.

50406 - The LED’s could not be turned on.

50407 - The user skipped the rest of the FP-LED

test.

50408 - The user returned an unknown confirmation: confirmation

50502 - Front panel Keyboard; test failed

50503 - Front panel Keyboard; test aborted

50504 - Front panel Keyboard; not all keys were

pressed

50505 - Front panel keyboard I2C connection

failed

50506 - Unable to get slash version

50602 - Front panel Remote control; test failed

50603 - Front panel Remote control; test aborted

50604 - Front panel remote control; can not

access FP

17

50605 - Front panel remote control; no user

input received

50701 - Execution of the command on the

Analog Board failed.

50702 - The front panel could not be accessed

by the Analog Board.

50703 - The front panel did not show a starburst.

50704 - The user skipped the FP-starburst test.

50705 - The user returned an unknown confirmation: confirmation

50801 - Execution of the command on the

Analog Board failed.

50802 - The front panel could not be accessed

by the Analog Board.

50803 - The front panel did not show vertical

segments.

50804 - The user skipped the FP-vertical segments test.

50805 - The user returned an unknown confirmation: confirmation

50901 - Execution of the command on the

Analog Board failed.

50902 - The front panel could not be accessed

by the Analog Board.

50903 - The front panel did not show horizontal

segments.

50904 - The user skipped the FP-horizontal segments test.

50905 - The user returned an unknown confirmation: confirmation

51401 - Execution of the command on the

Analog Board failed.

51402 - The front panel could not be accessed

by the Analog Board.

51403 - The beeper did not sound.

51404 - The user skipped the FP-Beep test.

51405 - The user returned an unknown confirmation: confirmation

51501 - Execution of the command on the

Analog Board failed.

51502 - The front panel could not be accessed

by the Analog Board.

51503 - The disc bar did not display properly.

51504 - The user skipped the disc bar test.

51505 - The user returned an unknown confirmation: confirmation

51601 - Execution of the command on the

Analog Board failed.

51602 - The front panel could not be accessed

by the Analog Board.

51603 - The disc bar dots did not display properly.

51604 - The user skipped the disc bar dots test.

51605 - The user returned an unknown confirmation: confirmation

51701 - Execution of the command on the

Analog Board failed.

51702 - The front panel could not be accessed

by the Analog Board.

51703 - The VU grid did not display properly.

51704 - The user skipped the VU grid test.

51705 - The user returned an unknown confirmation: confirmation

51801 - Execution of the command on the

Analog Board failed.

18

51802 - The front panel could not be accessed

by the Analog Board.

51803 - The front panel could not be dimmed.

51804 - The user skipped the FP-Dim test.

51805 - The user returned an unknown confirmation: confirmation

51901 - Execution of the command on the

Analog Board failed.

51902 - The front panel could not be accessed

by the Analog Board.

51903 - The front panel did not show segments

blinking.

51904 - The user skipped the FP-blinking test.

51905 - The user returned an unknown confirmation: confirmation

52001 - Execution of the command on the

Analog Board failed.

52002 - The front panel could not be accessed

by the Analog Board.

52003 - The front panel did not show all segments lit.

52004 - The user skipped the FP-light all segments test.

52005 - The user returned an unknown confirmation: confirmation

52201 - Communication with Analog Board fails.

52202 - front panel can not be accessed by the

Analog Board.

52301 - Communication with Analog Board fails.

52302 - front panel can not be accessed by the

Analog Board.

60101 - Basic Engine returned error number 0x

error number

60102 - Parity error from Basic Engine to Serial

60103 - Communication time-out error

60104 - Unexpected response from Basic

Engine

60105 - Echo loop could not be closed

60106 - Wrong echo pattern received

60200 - Version: nr1.nr2.nr3

60201 - Basic Engine returned error number

0xerrornumber

60202 - Parity error from Basic Engine to Serial

60203 - Communication time-out error

60204 - Unexpected response from Basic

Engine

60205 - Front Panel failed.

60301 - Basic-Engine time-out error

60401 - Basic Engine returned error number

0xerrornumber

60402 - Parity error from Basic Engine to Serial

60403 - Communication time-out error

60404 - Unexpected response from Basic

Engine

60405 - Focus loop could not be closed

60501 - Basic Engine returned error number

0xerrornumber

60502 - Parity error from Basic Engine to Serial

60503 - Communication time-out error

19

60504 - Unexpected response from Basic

Engine

60601 - Basic Engine returned error number

0xerrornumber

60602 - Parity error from Basic Engine to Serial

60603 - Communication time-out error

60604 - Unexpected response from Basic

Engine

60701 - Basic Engine returned error number

0xerrornumber

60702 - Parity error from Basic Engine to Serial

60703 - Communication time-out error

60704 - Unexpected response from Basic

Engine

60801 - Basic Engine returned error number

0xerrornumber

60802 - Parity error from Basic Engine to Serial

60803 - Communication time-out error

60804 - Unexpected response from Basic

Engine

60805 - Radial loop could not be closed

60901 - Basic Engine returned error number

0xerrornumber

60902 - Parity error from Basic Engine to Serial

60903 - Communication time-out error

60904 - Unexpected response from Basic

Engine

61501 - Basic Engine returned error number

0xerrornumber

61502 - Parity error from Basic Engine to Serial

61503 - Communication time-out error

61504 - Unexpected response from Basic

Engine

61601 - Basic Engine returned error number

0xerrornumber

61602 - Parity error from Basic Engine to Serial

61603 - Communication time-out error

61604 - Unexpected response from Basic

Engine

61701 - BE tray-in command failed

61702 - BE read-TOC command failed

61703 - BE VSM interrupt initialization failed

61704 - BE set IRQ command failed

61705 - BE no disc or wrong disc inserted

61706 - BE rec-pause command failed

61707 - BE VSM BE out DMA initialization failed

61708 - BE VSM BE out initialization failed

61709 - BE VSM BE out DMA start failed

61710 - BE VSM BE out start failed

61711 - BE rec command failed

61712 - BE VSM out under run error occurred

61713 - BE record complete interrupt not raised

61714 - BE get IRQ command failed

61715 - BE no interrupt was raised by BE

61716 - BE VSM DMA out not finished

61717 - BE stop command after writing failed

20

61718 - BE VSM Sector processor initialization

failed

61719 - BE VSM sector processor DMA initialization failed

61720 - BE VSM sector processor DMA start

failed

61721 - BE VSM sector processor start failed

61722 - BE seek command failed

61723 - BE VSM sector processor error occurred

61724 - BE read timeout occurred

61725 - BE stop command after reading failed

61726 - BE difference found in data at disc sector 0xdiscsector

61727 - This nucleus cannot be executed

because the Self-Test failed

61801 - BE I2C initialization failed

61802 - This nucleus cannot be executed

because the Self-Test failed

61901 - The Self Test failed with result: 0xnr1

0xnr20xnr3

61902 - Basic Engine returned error number

0xerrornumber

61903 - Parity error from Basic Engine to Serial

61904 - Communication time-out error

61905 - Unexpected response from Basic

Engine

62001 - Self-Test: errorstring1 Laser-Test:

errorstring2 Spindle M-Test: errorstring3 Sledge

M-Test: error string4 Focus-Test: errorstring5

62100 - The forward sense level is 0xlevel

62101 - Basic Engine returned error number

0xerrornumber

62102 - Parity error from Basic Engine to Serial

62103 - Communication time-out error

62104 - Unexpected response from Basic

Engine

62201 - The BE-self-diagnostic-spindle-motortest failed

62202 - Basic Engine returned error number

0xerrornumber

62203 - Parity error from Basic Engine to Serial

62204 - Communication time-out error

62205 - Unexpected response from Basic

Engine

62301 - The BE-focus-test failed

62302 - Basic Engine returned error number

0xerrornumber

62303 - Parity error from Basic Engine to Serial

62304 - Communication time-out error

62305 - Unexpected response from Basic

Engine

62401 - The BE-self-diagnostic-sledge-motor-test

failed

62402 - Basic Engine returned error number

0xerrornumber

62403 - Parity error from Basic Engine to Serial

62404 - Communication time-out error

62405 - Unexpected response from Basic

Engine

62700 - BE EEPROM address = address -> Byte

value = 0xvalue

62701 - Basic Engine returned error number

21

0xerrornumber

62702 - Parity error from Basic Engine to Serial

62703 - Communication time-out error

62704 - Unexpected response from Basic

Engine

62705 - BE read EEPROM; invalid input

62801 - Basic Engine returned error number

0xerrornumber

62802 - Parity error from Basic Engine to Serial

62803 - Communication time-out error

62804 - Unexpected response from Basic

Engine

62805 - BE write EEPROM; invalid input

62901 - Basic Engine returned error number

0xerrornumber

62902 - Parity error from Basic Engine to Serial

62903 - Communication time-out error

62904 - Unexpected response from Basic

Engine

62905 - Radial loop could not be closed

63001 - Basic Engine returned error number

0xerrornumber

63002 - Parity error from Basic Engine to Serial

63003 - Communication time-out error

63004 - Unexpected response from Basic

Engine

63100 - Number of times Tray went

Open/Closed: nr1 Total hours the CD laser was

on: nr2 Total hours the DVD laser was on: nr3

Total hours the write laser was on: nr4

63101 - Basic Engine returned error number

0xerrornumber

63102 - Parity error from Basic Engine to Serial

63103 - Communication time-out error

63104 - Unexpected response from Basic

Engine

63201 - Basic Engine returned error number

0xerrornumber

63202 - Parity error from Basic Engine to Serial

63203 - Communication time-out error

63204 - Unexpected response from Basic

Engine

63300 - Momentary errors (Byte 1 - Byte 7):

0xb1 0xb2 0xb30xb4 0xb5 0xb6 0xb7

Cumulative errors (Byte 1 - Byte 7): 0xb10xb2

0xb3 0xb4 0xb5 0xb6 0xb7 Fatal errors (Oldest Youngest): 0xb1 0xb2 0xb3 0xb4 0xb5

63301 - Basic Engine returned error number

0xerrornumber

63302 - Parity error from Basic Engine to Serial

63303 - Communication time-out error

63304 - Unexpected response from Basic

Engine

63401 - Basic Engine returned error number

0xerrornumber

63402 - Parity error from Basic Engine to Serial

63403 - Communication time-out error

63404 - Unexpected response from Basic

Engine

63501 - Basic Engine returned error number

0xerrornumber

22

63502 - Parity error from Basic Engine to Serial

63503 - Communication time-out error

63504 - Unexpected response from Basic

Engine

63505 - Error string Ö The basic engine will

reject all player commands

63901 - Basic Engine returned error number

0xerrornumber

63902 - Parity error from Basic Engine to Serial

63903 - Communication time-out error

63904 - Unexpected response from Basic

Engine

64000 - BE OPU number = opu number

64001 - Basic Engine returned error number

0xerrornumber

64002 - Parity error from Basic Engine to Serial

64003 - Communication time-out error

64004 - Unexpected response from Basic

Engine

64100 - The data was successfully written on

and read from a DVD disc

64101 - The tray-in command failed

64102 - The read-TOC command failed

64103 - The VSM interrupt initialization failed

64104 - The set IRQ command failed

64105 - No disc or wrong disc inserted

64106 - The rec-pause command failed

64107 - The VSM BE out DMA initialization failed

64108 - The VSM BE out initialization failed

64109 - The VSM BE out DMA start failed

64110 - The VSM BE out start failed

64111 - The rec command failed

64112 - The VSM out under run error occurred

64113 - The record complete interrupt was not

raised

64114 - The get IRQ command failed

64115 - There was no interrupt raised by BE

64116 - The VSM DMA did not finished

64117 - The stop command after writing failed

64118 - The VSM Sector processor initialization

failed

64119 - The VSM sector processor DMA initialization failed

64120 - The VSM sector processor DMA start

failed

64121 - The VSM sector processor start failed

64122 The seek command failed

64123 - The VSM sector processor error

occurred

64124 - The read timeout occurred

64125 - The stop command after reading failed

64126 - There was a difference found in data at

a specific disc sector

64127 - The result of the self test contains errors

64128 - An error interrupt was raised by BE

23

64129 - The calibrate-record command failed

64130 - To many retries

64131 - BE update RAI command after writing

failed

64132 - BE find first recordable address command failed

64133 - DVD+R disc is full

64201 - BE i2c initialization failed

64202 - This nucleus cannot be executed

because the Self-Test failed

70000 - Echo test OK

70001 - Echo test returned wrong string.

70002 - Communication with Analog Board fails

70300 - Software Version

70301 - Can not find segment in FLASH ROM

on the Analog Board

70302 - Communication with Analog Board fails

70400 - Hardware Version

70401 - Can not find segment in FLASH ROM

on the Analog Board

70402 - Communication with Analog Board fails

70500 - Clock adjusted OK

70501 - Can not adjust the clock on the Analog

Board.

70502 - Wrong date/time text size.

70503 - Communication with Analog Board fails

70600 - Tuner accessibility test OK

70601 - Can not access Tuner on the Analog

Board.

70602 - Communication with Analog Board fails

70700 - Frequency download OK

70701 - Wrong frequency table size.

70702 - Can not download the frequency table

into the Analog NVRAM.

70703 - Can not download the frequency table

into the Analog NVRAM.

70704 - Communication with Analog Board fails

70800 - Data Slicer test OK

70801 - Test of the Data Slicer on the Analog

Board fails.

70802 - Communication with Analog Board fails

70900 - Sound Processor test OK

70901 - Test of the Sound Processor on the

Analog Board fails.

70902 - Communication with Analog Board fails

71000 - AV Selector test OK

71001 - Test of the AV Selector on the Analog

Board fails.

71002 - Communication with Analog Board fails

71100 - NVRAM test OK

71101 - Test of the NVRAM on the Analog Board

fails.

71102 - Communication with Analog Board fails

71200 - Video routing on the Analog Board OK

71201 - Routing the Video on the Analog Board

fails.

71202 - Invalid input.

24

71203 - Communication with Analog Board fails

71300 - Audio routing on the Analog Board OK

71301 - Routing the Audio on the Analog Board

fails.

71302 - Invalid input.

71303 - Communication with Analog Board fails

71501 - Invalid slash version, default slash version is set.

71502 - Setting the slash version on the Analog

Board fails.

71503 - Communication with Analog Board fails

71600 - Application Version

71601 - Can not find segment in FLASH ROM

on the Analog Board

71602 - Communication with Analog Board fails

71700 - Diagnostics Version

71701 - Can not find segment in FLASH ROM

on the Analog Board

71702 - Communication with Analog Board fails

71800 - Download Version

71801 - Can not find segment in FLASH ROM

on the Analog Board

71802 - Communication with Analog Board fails

72001 - Adjusting BarGraph Level failed

72002 - Communication with Analog Board fails

72101 - Storing clock correction failed

72102 - Value out of range: default value stored

72103 - Invalid input.

72104 - Communication with Analog Board fails

72201 - Initializing the 1Hz signal on the Clock

IC failed

72202 - Communication with Analog Board fails

72301 - Clearing the NVRAM on the Analog

Board fails

72302 - Communication with Analog Board fails

72400 - Segment checksum is: checksum which

is correct for every segment

72401 - Segment could not be found or segment

checksum is: checksum C, however it should be:

checksum E for every segment

72402 - Communication with Analog Board fails

72900 - Date received

72901 - Data returned

72902 - Communication on I2C-bus failed on the

Analog Board fails.

72903 - Communication with Analog Board fails

73001 - Storing the external presets on the

Analog Board fails

73002 - Communication with Analog Board fails

73100 - 0xslash version where slash version is

the slash version read from the Analog Board

73101 - Error while reading out slash version.

73102 - I2C Write error.

73103 - I2C Read error.

73104 - Communication with Analog Board fails

73201 - Storing the Reference Voltage for the

Tuner failed

25

73202 - Invalid input.

73203 - Communication with Analog Board fails

80000 - The DVIO module is present in the system.

80001 - The DVIO module is not present in the

system.

80100 - The DVIO module has been reset OK.

80101 - The DVIO module is not present in the

system.

80102 - The DVIO module could not be reset.

80103 - Could not initialize I2C before Reset.

80200 - The accessibility of the DVIO module is

OK.

80201 - The DVIO Board is not present in this

DVDR.

80202 - Could not initialize I2C.

80203 - Unable to reset the DVIO module.

80204 - Unable to receive the reset indication

from the DVIO module.

80205 - Unable to send the configuration to the

DVIO module.

80206 - Unable to download the chip ID to the

DVIO module.

80207 - Unable to set the mode of the DVIO

module to IDLE.

80208 - Software Error in function Handle State

Awaiting Reply!!

80209 - Maximal number of retries reached by

Handle State Sending!!

80210 - Maximal number of retries (NACKs)

reached (Handle State Sending)

80211 - We tried to receive a reply for

DVIO_MAX_RETRIES_ACKREPLY times !!

80212 - We tried to receive a reply for

DVIO_MAX_RETRIES_REPLY times !!

80213 - We tried to receive an Ack for

DVIO_MAX_RETRIES_ACK times!!

80214 - VSM UART error timeout transmitting

command

80215 - VSM UART error timeout receiving reply

80216 - VSM UART frame error occurred receiving from DVIO Board

80217 - VSM UART parity error occurred receiving from DVIO Board

80218 - The confirmation/indication from the

DVIO module is invalid.

80300 - The accessibility of the DVIO module is

OK.

80301 - The DVIO Board is not present in this

DVDR.

80302 - Could not initialize I2C.

80303 - Unable to reset the DVIO module.

80304 - Unable to receive the reset indication

from the DVIO module.

80305 - Unable to send the configuration to the

DVIO module.

80306 - Unable to download the chip ID to the

DVIO module.

80307 - Unable to set the mode of the DVIO

module to IDLE.

80308 - Software Error in function Handle State

Awaiting Reply!!

26

80309 - Maximal number of retries reached by

Handle State Sending!!

80310 - Maximal number of retries (NACKs)

reached (Handle State Sending)

80311 - We tried to receive a reply for

DVIO_MAX_RETRIES_ACKREPLY times !!

80312 - We tried to receive a reply for

DVIO_MAX_RETRIES_REPLY times !!

80313 - We tried to receive an Ack for

DVIO_MAX_RETRIES_ACK times!!

80314 - VSM UART error timeout transmitting

command

80315 - VSM UART error timeout receiving reply

80316 - VSM UART frame error occurred receiving from DVIO Board

80317 - VSM UART parity error occurred receiving from DVIO Board

80318 - The confirmation/indication from the

DVIO module is invalid.

80400 - The accessibility of the DVIO module is

OK.

80401 - The DVIO Board is not present in this

DVDR.

80402 - Could not initialize I2C.

80403 - Unable to reset the DVIO module.

80404 - Unable to receive the reset indication

from the DVIO module.

80405 - Unable to send the configuration to the

DVIO module.

80406 - Unable to download the chip ID to the

DVIO module.

80407 - Unable to set the mode of the DVIO

module to IDLE.

80408 - Software Error in function Handle State

Awaiting Reply!!

80409 - Maximal number of retries reached by

Handle State Sending!!

80410 - Maximal number of retries (NACKs)

reached (Handle State Sending)

80411 - We tried to receive a reply for

DVIO_MAX_RETRIES_ACKREPLY times !!

80412 - We tried to receive a reply for

DVIO_MAX_RETRIES_REPLY times !!

80413 - We tried to receive an Ack for

DVIO_MAX_RETRIES_ACK times!!

80414 - VSM UART error timeout transmitting

command

80415 - VSM UART error timeout receiving reply

80416 - VSM UART frame error occurred receiving from DVIO Board

80417 - VSM UART parity error occurred receiving from DVIO Board

80418 - The confirmation/indication from the

DVIO module is invalid.

80501 - The DVIO Board is not present in this

DVDR.

80502 - The I2C could not be initialized.

80503 - The DVIO module could not be reset.

80504 - Unable to receive the reset indication

from the DVIO module.

80505 - Unable to send the configuration to the

DVIO module.

80506 - Unable to download the chip ID to the

DVIO module.

80507 - Unable to set the mode of the DVIO

module to IDLE.

27

80508 - Software Error in Handle State Awaiting

Reply function!

80509 - Maximal number of retries reached by

Handle State Sending!

80510 - Maximal number of retries (NACKs)

reached (Handle State Sending)

80511 - We tried to receive a reply for

DVIO_MAX_RETRIES_ACKREPLY times!

80512 - We tried to receive a reply for

DVIO_MAX_RETRIES_REPLY times!

80513 - We tried to receive an

Acknowledgement for

DVIO_MAX_RETRIES_ACK times

80514 - VSM UART error timeout transmitting

command

80515 - VSM UART error timeout receiving reply

80516 - VSM UART frame error occurred receiving from DVIO Board

80517 - VSM UART parity error occurred receiving from DVIO Board

80518 - The confirmation/indication from the

DVIO module is invalid.

80519 - Setting the DVIO module in/out diagnostics mode failed

80520 - Invalid input

80521 - Getting the errors of the self-test failed

80522 - Self-test failed

80601 - The DVIO Board is not present in this

DVDR.

80602 - The I2C could not be initialized.

80603 - The DVIO module could not be reset.

80604 - Unable to receive the reset indication

from the DVIO module.

80605 - Unable to send the configuration to the

DVIO module.

80606 - Unable to download the chip ID to the

DVIO module.

80607 - Unable to set the mode of the DVIO

module to IDLE.

80608 - Software Error in Handle State Awaiting

Reply function!

80609 - Maximal number of retries reached by

Handle State Sending!

80610 - Maximal number of retries (NACKs)

reached (Handle State Sending)

80611 - We tried to receive a reply for

DVIO_MAX_RETRIES_ACKREPLY times!

80612 - We tried to receive a reply for

DVIO_MAX_RETRIES_REPLY times!

80613 - We tried to receive an

Acknowledgement for

DVIO_MAX_RETRIES_ACK times!

80614 - VSM UART error timeout transmitting

command

80615 - VSM UART error timeout receiving reply

80616 - VSM UART frame error occurred receiving from DVIO Board

80617 - VSM UART parity error occurred receiving from DVIO Board

80618 - The confirmation/indication from the

DVIO module is invalid.

80619 - Setting the DVIO module in/out diagnostics mode failed

80701 - The DVIO Board is not present in this

DVDR.

28

80702 - The I2C could not be initialized.

80703 - The DVIO module could not be reset.

80704 - Unable to receive the reset indication

from the DVIO module.

80705 - Unable to send the configuration to the

DVIO module.

80706 - Unable to download the chip ID to the

DVIO module.

80707 - Unable to set the mode of the DVIO

module to IDLE.

80708 - Software Error in Handle State Awaiting

Reply function!

80709 - Maximal number of retries reached by

Handle State Sending!

80710 - Maximal number of retries (NACKs)

reached (Handle State Sending)

80711 - We tried to receive a reply for

DVIO_MAX_RETRIES_ACKREPLY times!

80712 - We tried to receive a reply for

DVIO_MAX_RETRIES_REPLY times!

80713 - We tried to receive an

Acknowledgement for

DVIO_MAX_RETRIES_ACK times!

80714 - VSM UART error timeout transmitting

command

80715 - VSM UART error timeout receiving reply

80716 - VSM UART frame error occurred receiving from DVIO Board

80717 - VSM UART parity error occurred receiving from DVIO Board

80718 - The confirmation/indication from the

DVIO module is invalid.

80719 - Setting the DVIO module in/out diagnos-

tics mode failed

90121 - Error: Audio data in host memory contains wrong frequency: frequency Hz

90122 - Error: Audio data in host memory contains silence!

90123 - There is no correct audio frame in the

buffer

90124 - The audio frame has an illegal version

bit

90125 - The audio frame has an illegal bitrateindex

90126 - The audio frame has an illegal sampling

rate

90127 - The CRC of the audio frame is wrong

90128 - The audio frame is not MPEG-I layer II !

90129 - Error cannot de-mute DAC on Analog

Board

90201 - Initialization of I2C failed

90202 - Initialization of VIP and EMPIRE failed

90203 - Initialization of PLL / Link failed.

90204 - Next descriptor address set wrong.

90205 - Turning on the colorbar failed

90206 - No I2C communication possible to start

video encoder.

90207 - Starting the video encoder failed.

90208 - Transfer of data from video encoder to

VSM failed.

90209 - Stopping the encoder failed.

90210 - Turning off the colorbar failed.

90211 - Cannot initialize hostdecoder parallel

29

Loading...

Loading...