Philips DVDR-9000-H Service Manual

HDD & DVD Recorder

CLASS 1

LASER PRODUCT

DVDR9000H/10/75/97

Contents Page

1 Technical Specifications and Connection

Facilities 2

2 Safety Information, General Notes & Lead

Free Requirements 5

3 Directions for Use 7

4 Mechanical Instructions 10

5 Firmware Upgrading & Diagnostic Software 14

6 Block Diagrams,Waveforms, Wiring Diagram 131

Overall block diagram 131

Wiring diagram 132

Waveforms of Analog Board 133

Waveforms of Digital Board 134

Waveforms of HDMI Board 135

Test Points Overview for Analog Board 136

Test Points Overview for Front Left Board 137

Test Points Overview for Front Right Board 138

Test Points Overview for

Front AV_INPUT Board 139

Test Points Overview for Digital Board 140

Test Points Overview for HDMI Board 141

Test Points Overview for IR Blaster Board 142

©

Copyright 2005 Philips Consumer Electronics B.V. Eindhoven, The Netherlands.

All rights reserved. No part of this publication may be reproduced, stored in a

retrieval system or transmitted, in any form or by any means, electronic,

mechanical, photocopying, or otherwise without the prior permission of Philips.

Contents Page

7 Circuit Diagrams and PWB Layout 143

Analog Circuit Diagrams 143

Analog Layout Diagrams 153

PCB Front Circuit Diagrams 155

PCB Front Layout Diagrams 158

Digital Circuit Diagrams 161

Digital Layout Diagrams 172

HDMI Circuit Diagrams 174

IR Blaster Board Circuit Diagrams 178

IR Blaster Board Layout Diagrams 179

DTTM Circuit Diagrams 180

DTTM Component Diagrams 186

8 Alignments & Test Procedures 189

9 Circuit and IC description 190

Circuit Description 190

IC Description 199

10 Exploded view & Service parts list 238

Exploded View of the set 238

Service parts list 239

11 Revision List 240

Published by KC-TE 0547 AV Systems Printed in the Netherlands Subject to modification EN 3139 785 31681

Version 1.1

EN 2

1.

3139 785 31681

Technical Specifi

cations and Connection Facilities

1. Technical Specifi cations and Connection Facilities

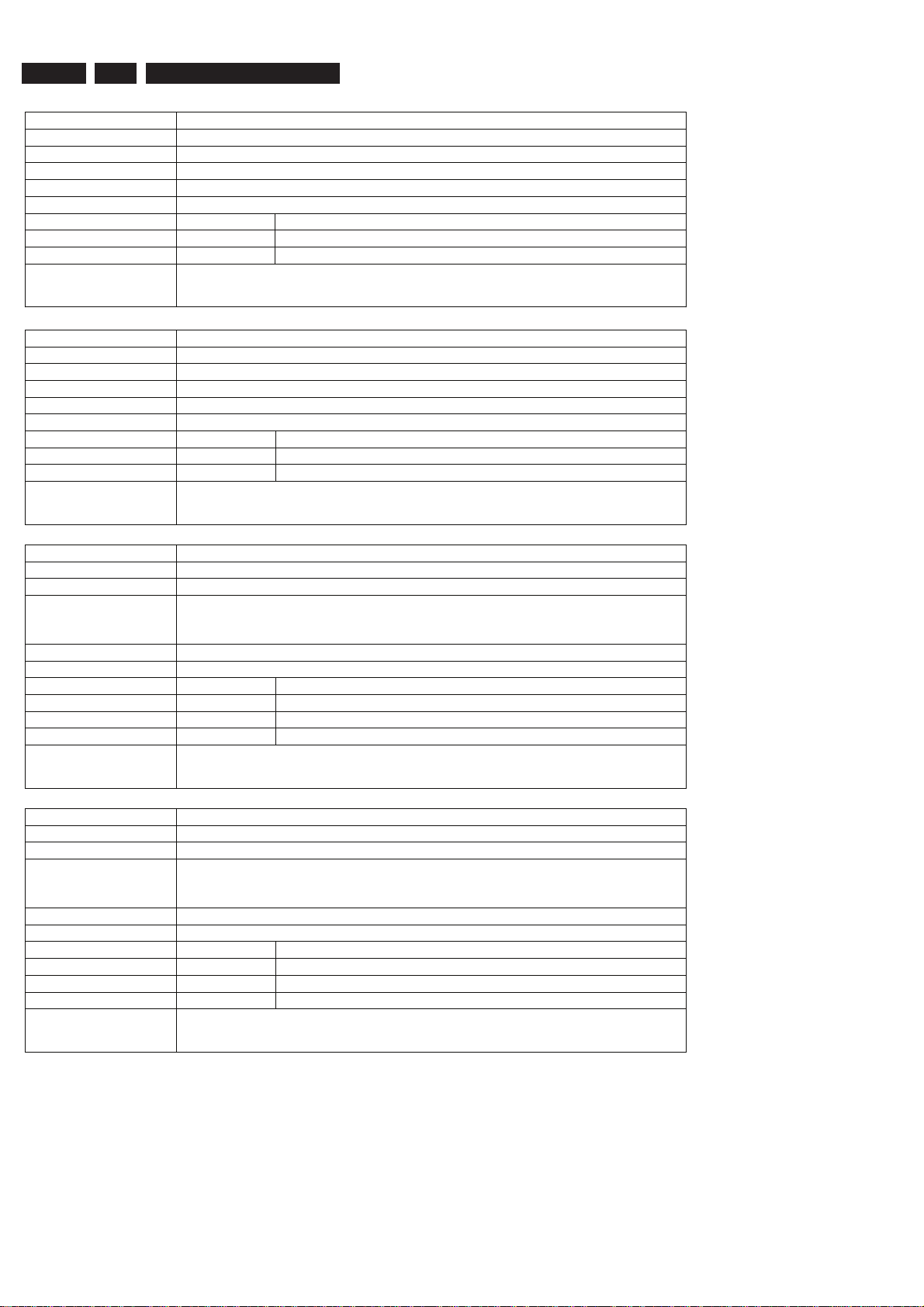

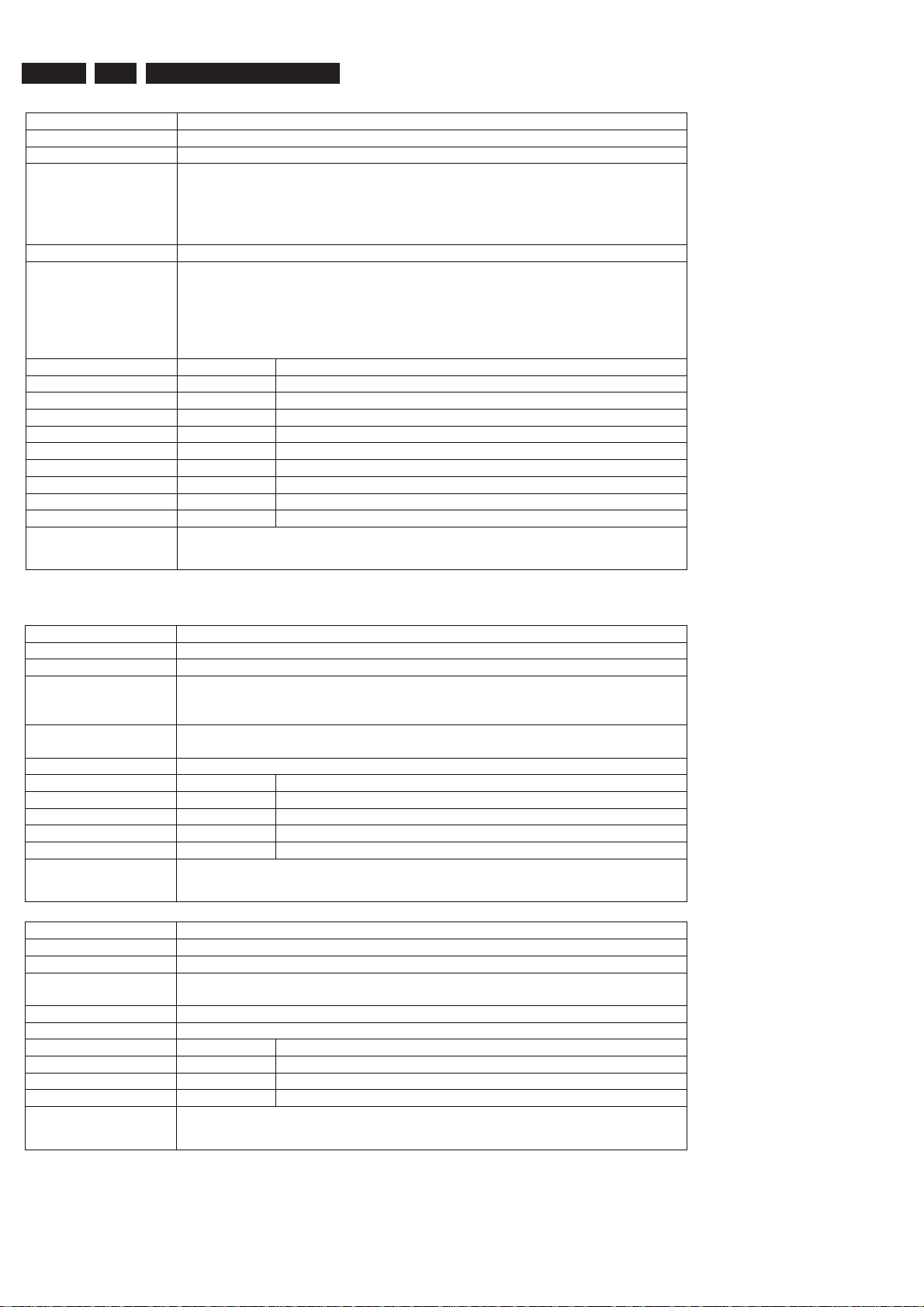

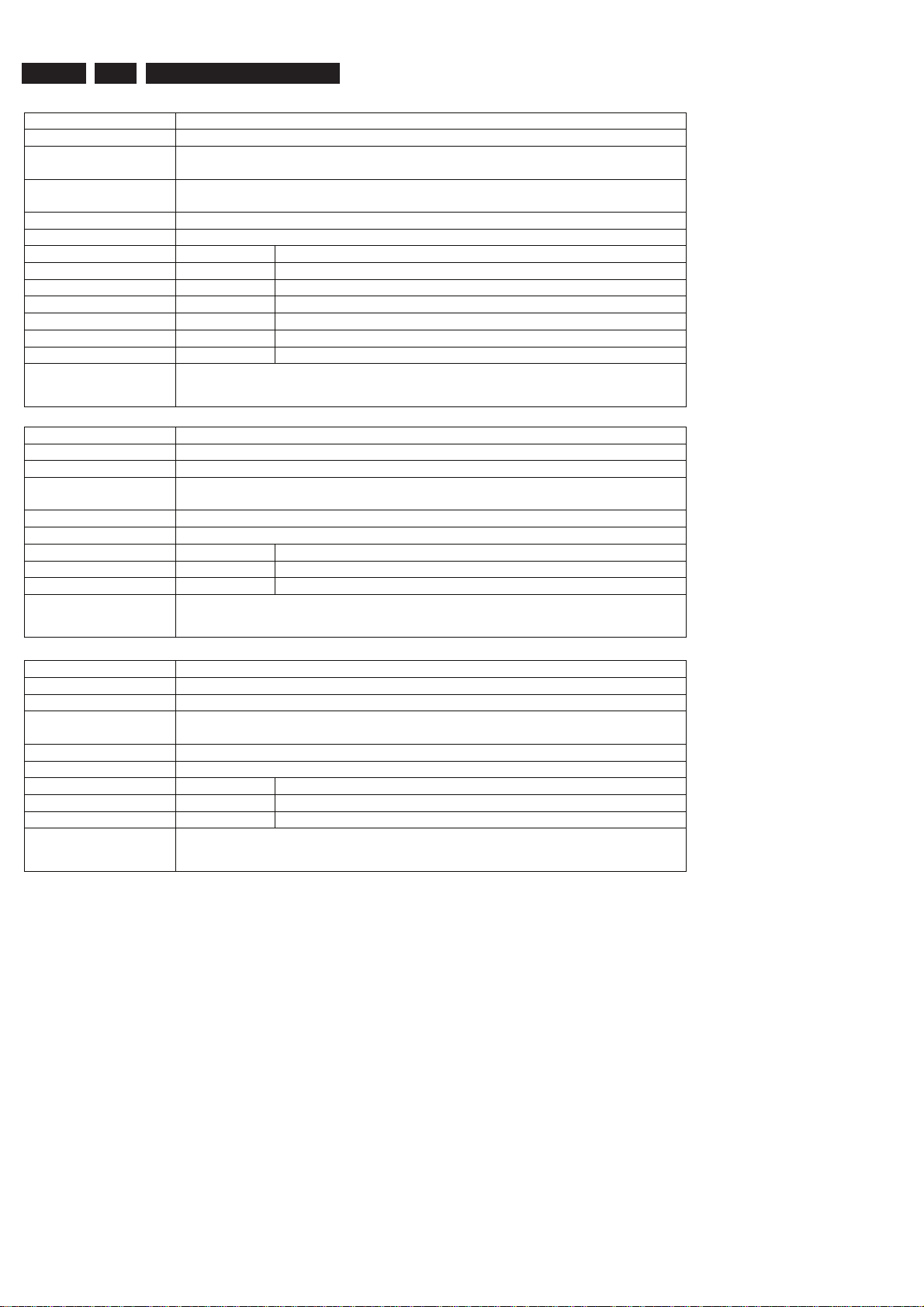

1.1 PCB Locations

Front Boards

(Behind the Front Plate)

HDD

PSU Board

(Below HDD)

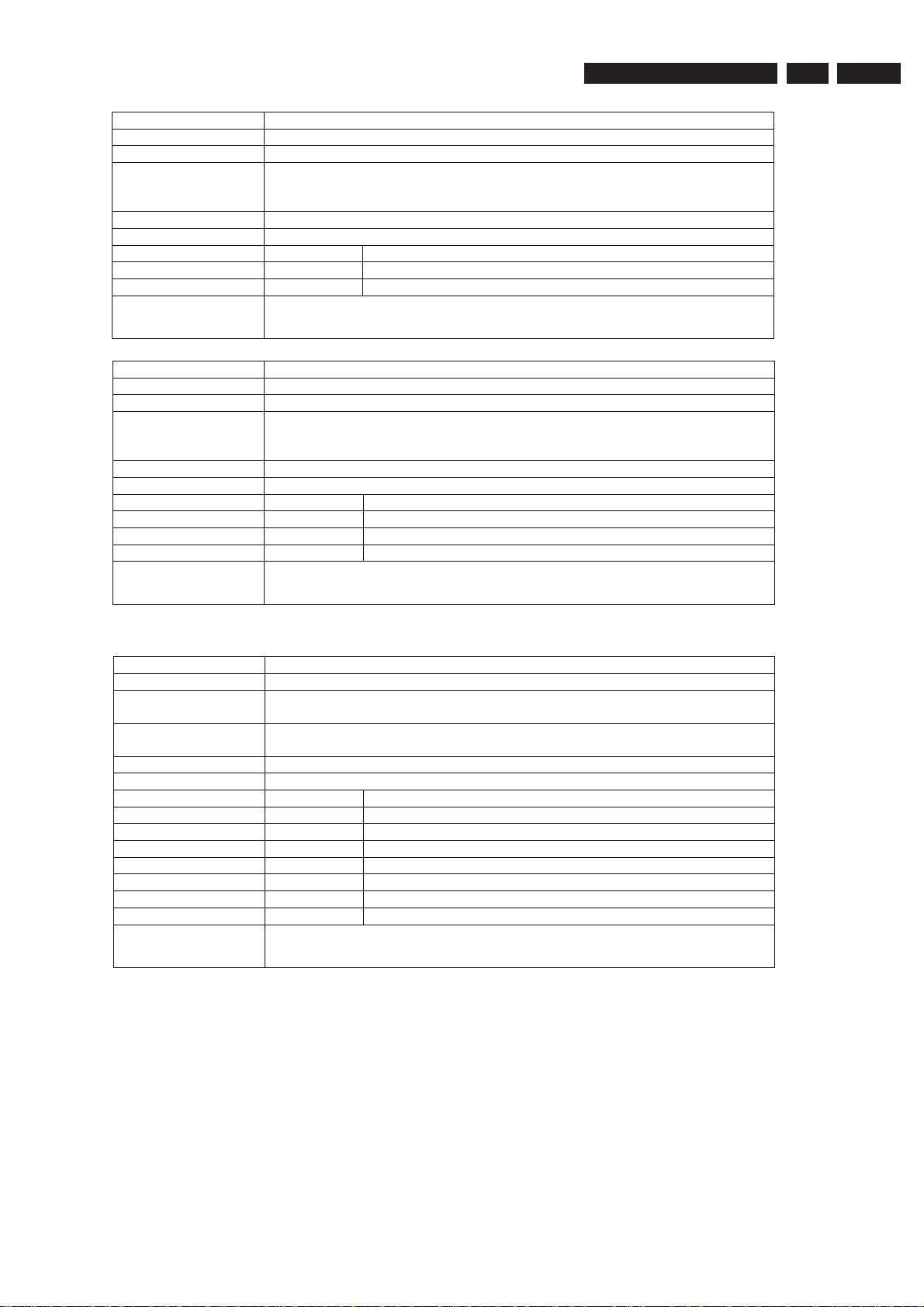

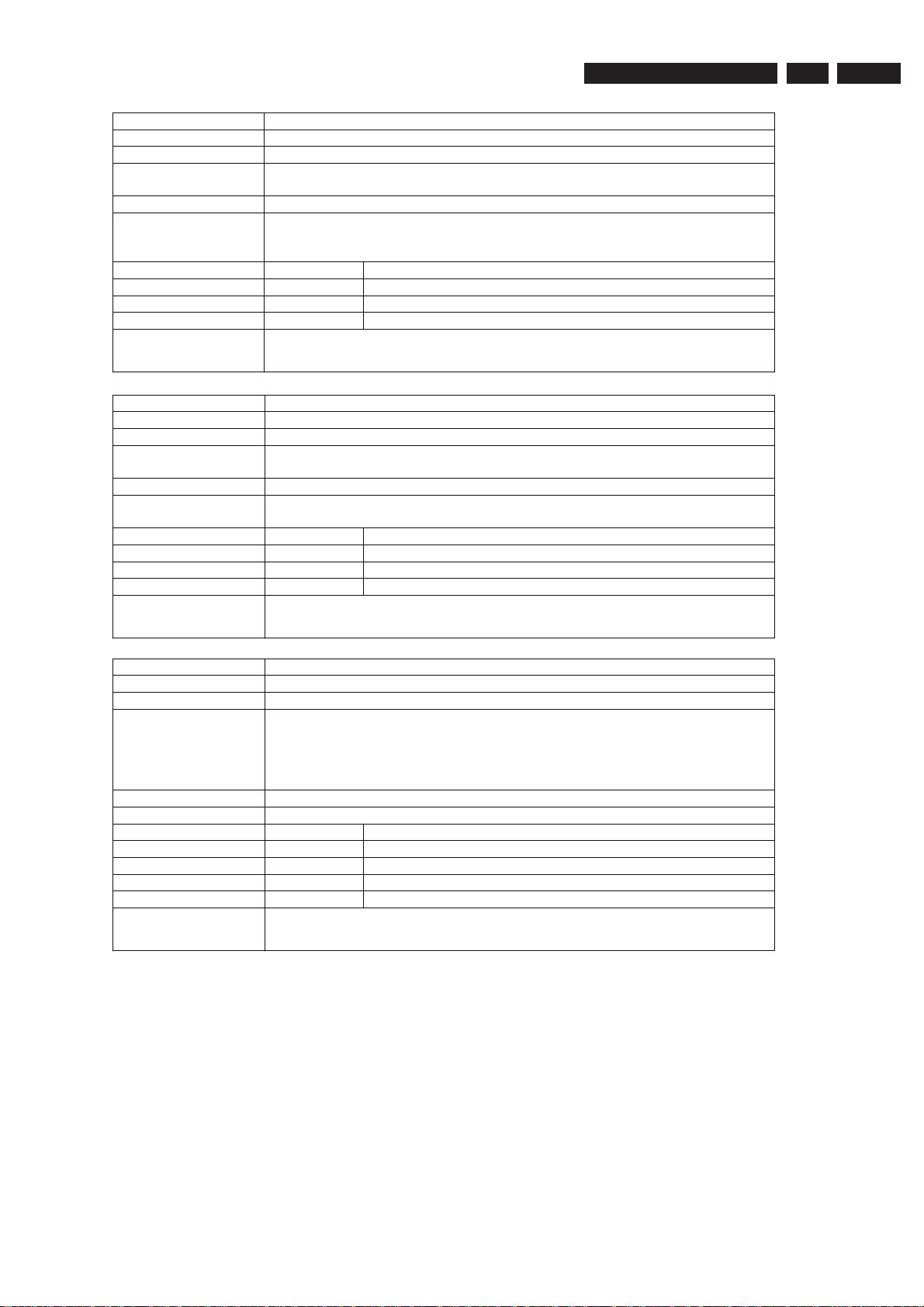

1.2 Read / Write Speed

Type of Disc (Function) Disc Rotation Speed

Read Speed CD 7X CAV

Read Speed DVD 4X CAV

Write Speed DVD+R/+RW 2.4X ZCAV

Write Speed DVD-R/-RW 2X

1.3 General:

Mains voltage : 200V – 240V

Mains frequency : 50 Hz

Power consumption (record) : 51 W

Standby Power Consumption : < 5 W

Eco standby : < 3 W

DTTM

Digital

Board

Analog Board

(Below DTTM)

HDMI

Board

IR Blaster Board

(Below HDMI Board)

1.4.1.4 Video Performance:

Channel 25 / 503,25 MHz,

Test pattern: PAL BG PHILIPS standard test pattern,

RF Level 74dBV, Measured on SCART 1

Frequency response : 0.1 MHz – 4 MHz ± 3dB

Group delay (0.1 MHz - 4.4 MHz) : 0 nsec ± 150 nsec

1.4.1.5 Audio Performance:

Audio Performance Analogue - HiFi:

Frequency response at SCART 1

(L+R) output : 100 Hz – 12 kHz / 0 ±

3dB

S/N Ratio (20Hz – 20kHz)

unweighted : 50dB

Harmonic distortion (1 kHz, ± 25

kHz deviation) : 1.5%

1.4 RF Tuner

1.4.1 RF Tuner (Analogue)

1.4.1.1 System

PAL B/G, PAL D/K, SECAM L/L’, PAL I

1.4.1.2 RF - Loop Through:

Frequency range : 45 MHz – 860 MHz

Gain: (ANT IN - ANT OUT) : -6dB to 0dB

1.4.1.3 Receiver:

PLL tuning with AFC for optimum reception

Frequency range : 45.25 MHz – 857 MHz

Sensitivity at 40dB S/N

(video unweighted) : 60dBV at 75

Audio Performance NICAM:

Frequency response at SCART 1

(L+R) output : 40 Hz – 15 kHz / 0 ±

3dB

S/N Ratio (20Hz – 20kHz)

unweighted : 60dB

Harmonic distortion (1kHz, ± 25

kHz deviation) : 0.5%

1.4.1.6 Tuning

Automatic Search Tuning

Scanning time without RF signal : 3min. typical

Stop level (vision carrier) : 37dB/V

Maximum tuning error of a recalled

program : ± 100 kHz

Maximum tuning error (drift) during

operation : ± 100 kHz

Tuning Principle:

Automatic B, G, I, DK and L/L’ detection

Manual selection in “STORE” mode

Technical Specifi

cations and Connection Facilities

3139 785 31681

1.

EN 3

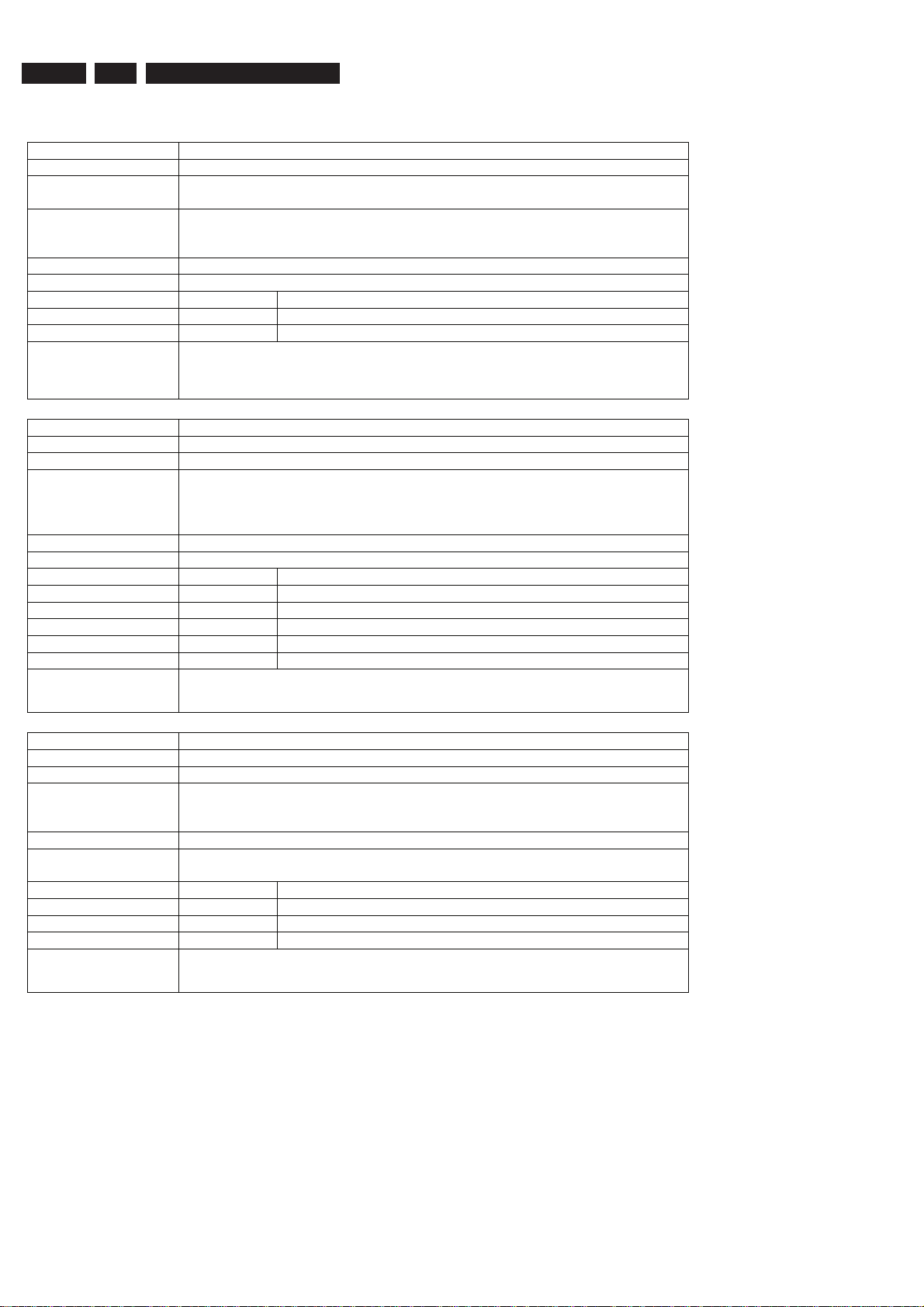

1.4.2 RF Tuner (Digtal Terrestial)

1.4.2.1 DVB - T - Tuner

Frequency range : 49-861MHz

Gain (ANT IN – ANT OUT) : -1 dB to 3 dB

Auto Search scanning time

(without Antenna input signal) : 40 sec typical

1.4.2.2 DVB-T- Video Performance

DVB-T – RF antenna signal IN ; Video performance measured

at Rear Cinch Audio Out:

- S/N(Unweighted,5MHz-BW limitation,

SC trap ON) : 52dB

- Frequency response 0.1

to 4.8 MHz : +1/-5dB

- Y/Chroma delay : 55ns

1.4.2.3 DVB-T- Audio Performance

DVB-T – RF antenna signal IN ; Audio performance measured

at Rear Cinch Audio Out:

- S/N(A-weighted,

22kHz-BW limited) : 88dB

- Frequency response 20Hz

to 20kHz : ± 1dB

- THD + Noise (at 1 kHz) : 85dB

- THD + noise (ratio) for 16Hz

to 20kHz : 65dB

- Channel Separation (at 1kHz) : 100dB

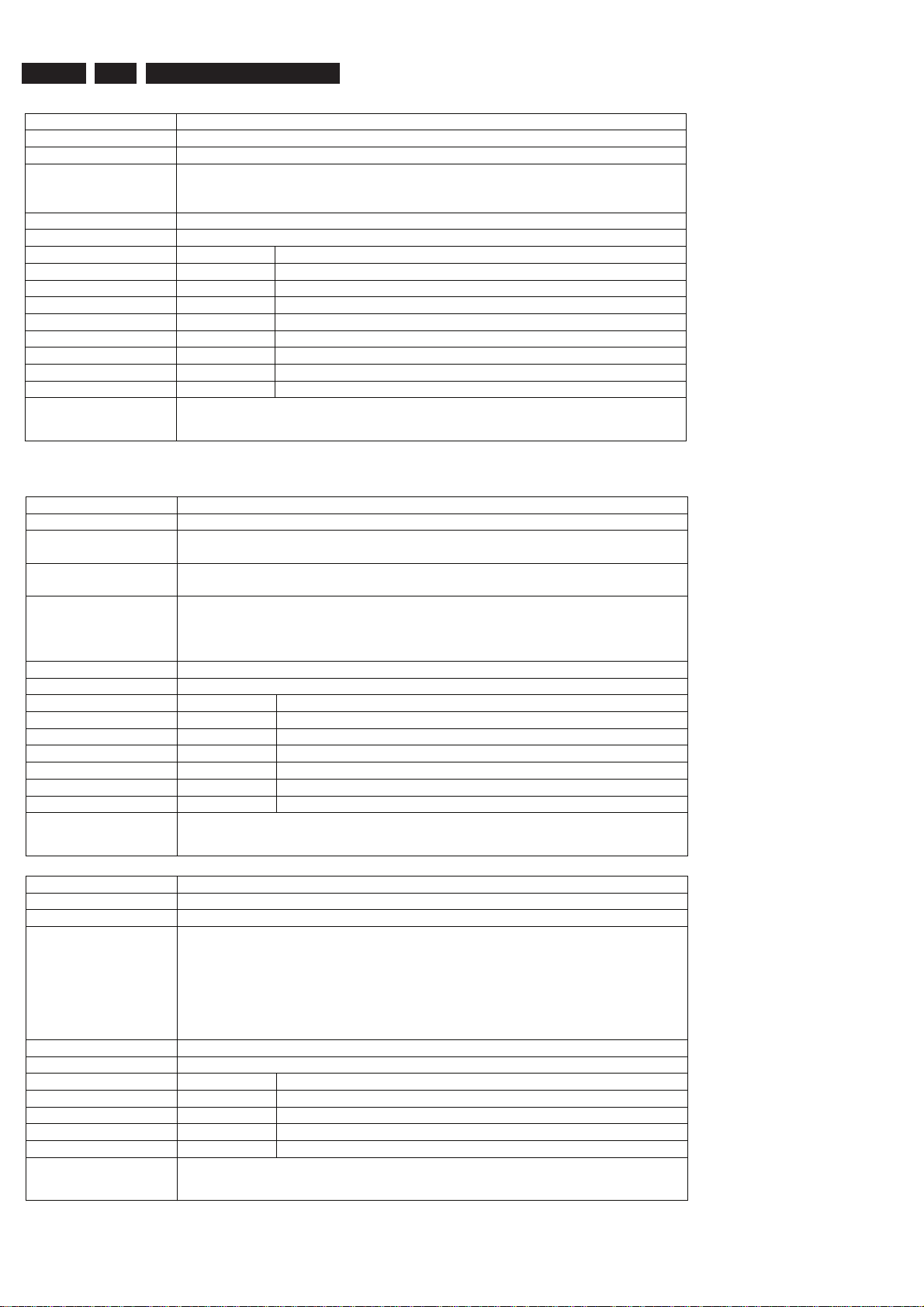

1.5 Analog Inputs / Outputs

1.5.1 SCART 1 (Connected to TV)

Pin Signals:

1 Audio-out R 1.8V RMS

2 Audio-in R

3 Audio-out L 1.8V RMS

4 Audio GND

5 Blue / Chroma GND

6 Audio-in L

7 Blue-out 0.7Vpp ± 0.1V into 75

8 Function switch < 2V = TV

> 4.5V / < 7V = asp. Ratio 16:9 DVD

> 9.5V / < 12V = asp. Ratio 4:3 DVD

9 Green GND

10 P50 control not use

11 Green out 0.7Vpp ± 0.1V into 75

12 NC

13 Red / Chroma GND

14 Fast switch GND

15 Red-out / 0.7Vpp ± 0.1V into 75

Chroma-out 300mVpp ± 3dB

16 Fast switch

RGB / CVBS

or Y out < 0.4V into 75 = CVBS

>1V / < 3V into 75 = RGB

17 Y/CVBS-out GND

18 CVBS-in GND

19 CVBS-out / Y-out 1Vpp ± 0.1V into 75

20 CVBS-in

21 Shield

1.5.2 SCART 2 (Connected to AUX)

Pin Signals:

1 Audio-out R 1.8V RMS

2 Audio-in R

3 Audio-out L 1.8V RMS

4 Audio GND

5 Blue / Chroma GND

6 Audio-in L

7 Blue-in

8 Function switch

9 Green GND

10 NC

11 Green-in

12 NC

13 Red / Chroma GND

14 Fast switch GND

15 Red-in /

Chroma-in

16 Fast switch

RGB / CVBS or Y in

17 CVBS-out GND

18 Y / CVBS-in GND

19 CVBS-out 1Vpp ± 0.1V into 75

20 CVBS-in / Y-in

21 Shield

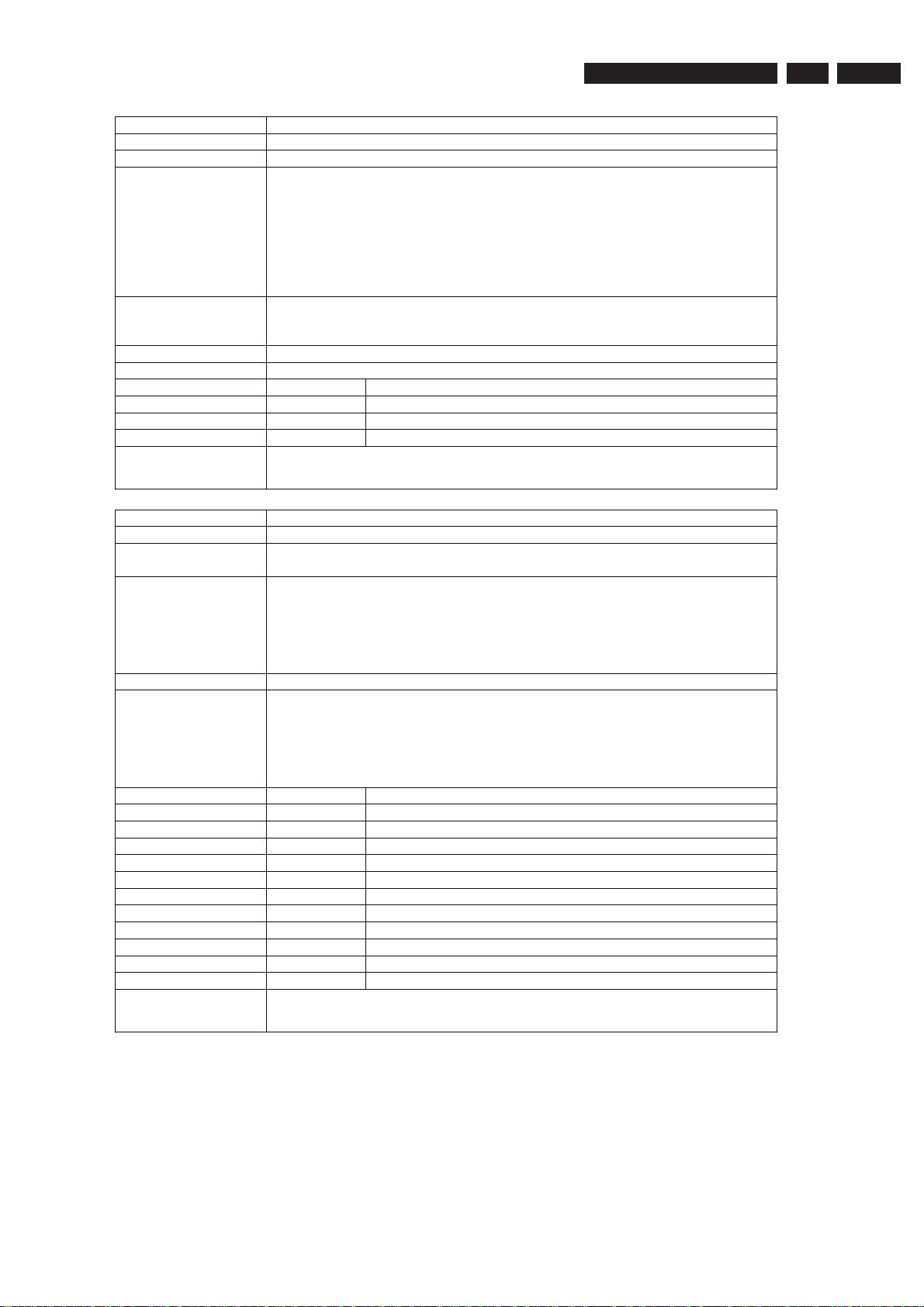

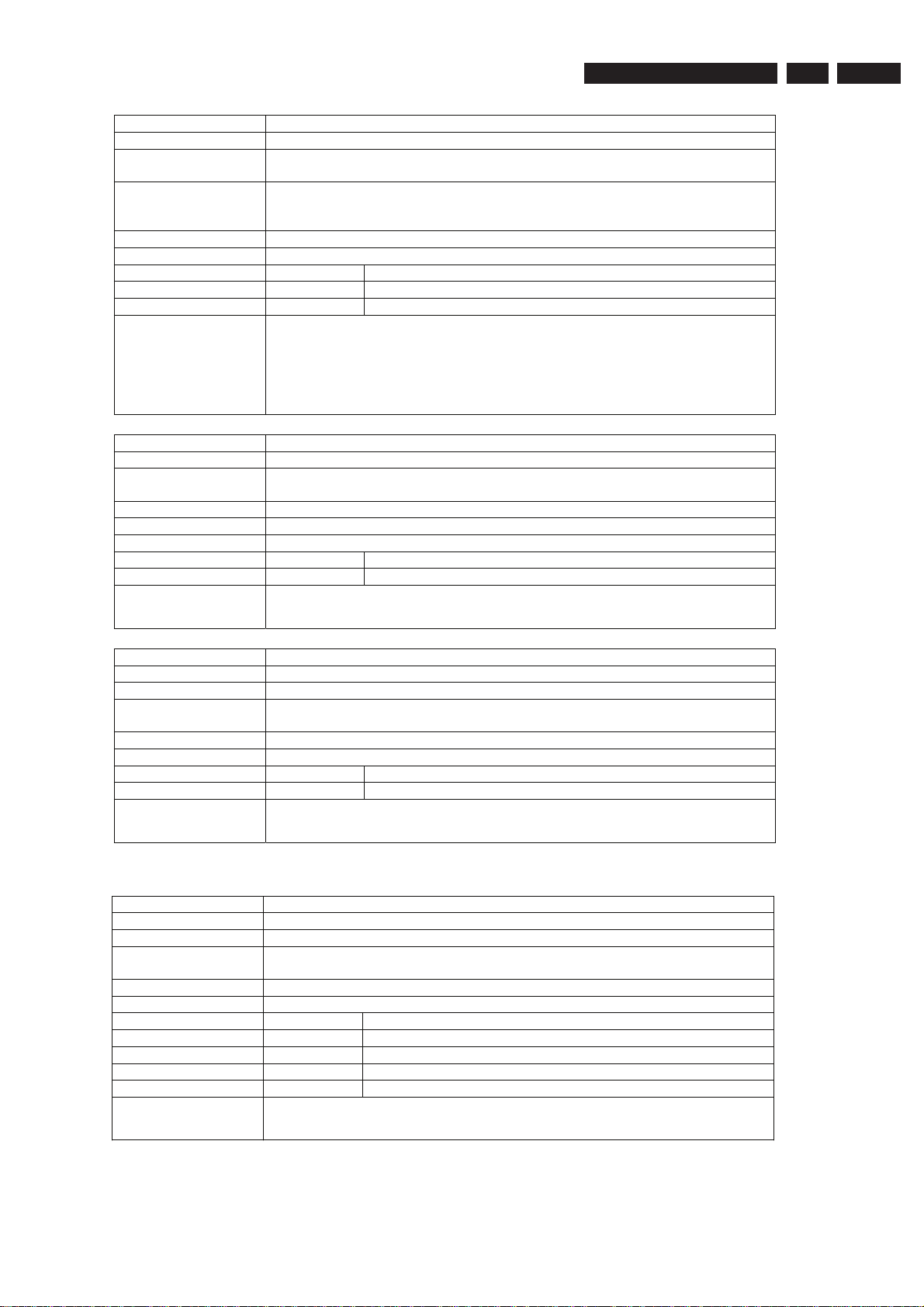

1.5.3 Audio/Video Front Input Connectors

Audio - Cinch

Input voltage : 2.2Vrms

Input impedance : > 10k

Video - Cinch

Input voltage : 1Vpp ± 3dB

Input impedance : 75

Video - YC (Hosiden)

According to IEC 933-5

Superimposed DC-level on pin 4 (load = 100k)

< 2.4V is detected as 4:3 aspect ratio

> 3.5V is detected as 16:9 aspect ratio

Input voltage Y : 1Vpp ± 3dB

Input impedance Y : 75

Input voltage C : 300mVpp ± 3dB

Input impedance C : 75

1.5.4 Out 1

Component Video Cinch Y/Pb/Pr

according EIO-770-I-A, EIA-770-2

Audio - Cinch

Output voltage : 2.2Vrms max.

Output impedance : > 10k

1.5.5 Out 2

Audio - Cinch

Output voltage : 2Vrms max.

Output impedance : > 10k

Video - Cinch

Output voltage : 1Vpp ± 3dB

Output impedance : 75

Video - YC (Hosiden)

According to IEC 933-5

Superimposed DC-level on pin 4 (load > 100k)

< 2.4V is detected as 4:3 aspect ratio

> 3.5V is detected as 16:9 aspect ratio

Output voltage Y : 1Vpp ± 3dB

Input impedance : 75

Output voltage C : 300mVpp ± 3dB

Input impedance : 75

EN 4

1.

3139 785 31681

Technical Specifi

cations and Connection Facilities

1.6 Digital Inputs / Outputs

1.6.1 Digital Output

Digital Audio – Coaxial / Optical

LCM : according IEC 60958

MPEG 1, MPEG 2, AC3 : according IEC 61937

DTS : according IEC 61937 +

addendum

1.6.2 HDMI Output

Type A connector (19 pins)

1.6.3 Digital Video Input (IEEE 1394)

Implementation Standard according:

IEEE Std 1394-1995

IEC61883 - Part1

IEC61883 - Part 2 SD-DVCR (02-01-1997)

Specifi cation of consumer use digital VCR’s using 6.3mm

magnetic tape – dec.1994

Mechanical connection according to Annex of IEC 61883-1

1.6.4 G-Link (for IR-remote transmitting device)

Output voltage : 5 ± 0.5V (high level)

0.4 ± 0.3V (low level)

Output impedance : 150

1.9 Dimensions and Weight

Height of feet : 5.5mm

Apparatus tray closed : WxDxH:435x390x89mm

Apparatus tray open : WxDxH:435x525x89mm

Weight without packaging : approx. 7.1 ± 0.5kg

Weight with packaging : approx. 8.5kg

1.10 Laser Output Power & Wavelength

1.10.1 DVD

Output power during reading : 0.8mW

Output power during writing : 20mW

Wavelength : 650nm

1.10.2 CD

Output power : 0.3mW

Wavelength : 780nm

1.7 Video Performance

All outputs loaded with 75

SNR measurements over full bandwidth without weighting.

1.7.1 SCART (RGB)

SNR : 55dB on all output

Bandwidth : 4.8MHz -3dB

1.8 Audio Performance

1.8.1 Cinch Output Rear

Output voltage 2 channel mode : 2Vrms ± 2dB

Channel unbalance (1kHz) : < 0.22dB

Crosstalk 1kHz : > 100dB

Crosstalk 16Hz-20kHz : > 87dB

Frequency response 20Hz-20kHz : ± 0.5dB

Signal to noise ratio (unweighted) : > 85dB

Dynamic range 1kHz : > 83dB

Distortion and noise 1kHz : > 83dB

Distortion and noise 16Hz-20kHz : > 75dB

Intermodulation distortion : > 70dB

Mute : > 95dB

1.8.2 Scart Audio

Output voltage 2 channel mode : 1.6Vrms ± 2dB

Channel unbalance (1kHz) : < 1dB

Crosstalk 1kHz : > 85dB

Crosstalk 16Hz-20kHz : > 70dB

Frequency response 20Hz-20kHz : ± 0.5dB

Signal to noise ratio (unweighted) : > 80dB

Dynamic range 1kHz : > 75dB

Distortion and noise 1kHz : > 75dB

Distortion and noise 16Hz-20kHz : > 50dB

Intermodulation distortion : > 70dB

Mute : > 80dB

Safety Information, General Notes & Lead Free Requirements

3139 785 31681

2.

2. Safety Information, General Notes & Lead Free Requirements

EN 5

2.1 Safety

Instructions

2.1.1 General Safety

Safety regulations require that during a repair:

• Connect the unit to the mains via an isolation transformer.

• Replace safety components, indicated by the symbol ,

only by components identical to the original ones. Any

other component substitution (other than original type)

may increase risk of fi re or electrical shock hazard.

Safety regulations require that after a repair, you must return

the unit in its original condition. Pay, in particular, attention to

the following points:

• Route the wires/cables correctly, and fi x them with the

mounted cable clamps.

• Check the insulation of the mains lead for external

damage.

• Check the electrical DC resistance between the mains

plug and the secondary side:

1. Unplug the mains cord, and connect a wire between

the two pins of the mains plug.

2. Set the mains switch to the ‘on’ position (keep the

mains cord unplugged!).

3. Measure the resistance value between the mains

plug and the front panel, controls, and chassis

bottom.

4. Repair or correct unit when the resistance

measurement is less than 1 M.

5. Verify this, before you return the unit to the customer/

user (ref. UL-standard no. 1492).

6. Switch the unit ‘off’, and remove the wire between the

two pins of the mains plug.

2.1.2 Laser Safety

This unit employs a laser. Only qualifi ed service personnel

may remove the cover, or attempt to service this device (due

to possible eye injury).

2.2 Warnings

2.2.1 General

• All ICs and many other semiconductors are susceptible to

electrostatic discharges (ESD, ). Careless handling

during repair can reduce life drastically. Make sure that,

during repair, you are at the same potential as the mass

of the set by a wristband with resistance. Keep

components and tools at this same potential.

Available ESD protection equipment:

– Complete kit ESD3 (small tablemat, wristband,

connection box, extension cable and earth cable)

4822 310 10671.

– Wristband tester 4822 344 13999.

• Be careful during measurements in the live voltage

section. The primary side of the power supply, including

the heatsink, carries live mains voltage when you

connect the player to the mains (even when the

player is ‘off’!). It is possible to touch copper tracks and/

or components in this unshielded primary area, when

you service the player. Service personnel must take

precautions to prevent touching this area or components

in this area. A ‘lightning stroke’ and a stripe-marked

printing on the printed wiring board, indicate the primary

side of the power supply.

• Never replace modules, or components, while the unit is

‘on’.

2.2.2 Laser

• The use of optical instruments with this product, will

increase eye hazard.

• Only qualifi ed service personnel may remove the cover or

attempt to service this device, due to possible eye injury.

• Repair handling should take place as much as possible

with a disc loaded inside the player.

• Text below is placed inside the unit, on the laser cover

shield:

Laser Device Unit

Type : Semiconductor laser

GaAlAs

Wavelength : 650 nm (DVD)

: 780 nm (VCD/CD)

Output Power : 20 mW

(DVD+RW writing)

: 0.8 mW

(DVD reading)

: 0.3 mW

(VCD/CD reading)

Beam divergence : 60 degree

CLASS 1

LASER PRODUCT

Figure 2-1

Note: Use of controls or adjustments or performance of

procedure other than those specifi ed herein, may result in

hazardous radiation exposure. Avoid direct exposure to beam.

CAUTION VISIBLE AND INVISIBLE LASER RADIATION WHEN OPEN AVOID EXPOSURE TO BEAM

ADVARSEL SYNLIG OG USYNLIG LASERSTRÅLING VED ÅBNING UNDGÅ UDSÆTTELSE FOR STRÅLING

ADVARSEL SYNLIG OG USYNLIG LASERSTRÅLING NÅR DEKSEL ÅPNES UNNGÅ EKSPONERING FOR STRÅLEN

VARNING SYNLIG OCH OSYNLIG LASERSTRÅLNING NÄR DENNA DEL ÄR ÖPPNAD BETRAKTA EJ STRÅLEN

VARO ! AVATTAESSA OLET ALTTIINA NÄKYVÄLLE JA NÄKYMÄTTÖMÄLLE LASER SÄTEILYLLE. ÄLÄ KATSO SÄTEESEEN

VORSICHT SICHTBARE UND UNSICHTBARE LASERSTRAHLUNG WENN ABDECKUNG GEÖFFNET NICHT DEM STRAHL AUSSETSEN

DANGER VISIBLE AND INVISIBLE LASER RADIATION WHEN OPEN AVOID DIRECT EXPOSURE TO BEAM

ATTENTION RAYONNEMENT LASER VISIBLE ET INVISIBLE EN CAS D’OUVERTURE EXPOSITION DANGEREUSE AU FAISCEAU

Figure 2-2

EN 6

2.

3139 785 31681

Safety Information, General Notes & Lead Free Requirements

2.3 Lead Free Requirement

Information about Lead-free produced sets

Philips CE is starting production of lead-free sets from

1.1.2005 onwards.

INDENTIFICATION:

Regardless of special logo (not always indicated)

One must treat all sets from 1 Jan 2005 onwards, according

next rules.

Example S/N:

Bottom line of typeplate gives a 14-digit S/N. Digit 5&6 is the year, digit 7&8 is

the week number, so in this case 1991 wk 18

So from 0501 onwards = from 1 Jan 2005 onwards

• Special information for BGA-ICs:

Do not re-use BGAs at all.

• For sets produced before 1.1.2005 (except products of

• On our website www.atyourservice.ce.Philips.com you

BGA-de-/soldering (+ baking instructions)

Heating-profi les of BGAs and other ICs used in Philips-sets

You will fi nd this and more technical information within the

For additional questions please contact your local repair-helpdesk.

- always use the 12nc-recognizable soldering temperature

profi le of the specifi c BGA (for de-soldering always use the

lead-free temperature profi le, in case of doubt)

- lead free BGA-ICs will be delivered in so-called ‘dry-

packaging’ (sealed pack including a silica gel pack) to

protect the IC against moisture. After opening, dependent

of MSL-level seen on indicator-label in the bag, the

BGA-IC possibly still has to be baked dry. (MSL=Moisture

Sensitivity Level). This will be communicated via AYS-

website.

2004), containing leaded solder-alloy and components,

all needed spare-parts will be available till the end of the

service-period. For repair of such sets nothing changes.

fi nd more information to:

“magazine”, chapter “workshop news”.

Important note: In fact also products of year 2004 must be treated in this way as long as you

avoid mixing solder-alloys (leaded/ lead-free). So best to always use SAC305 and the higher

temperatures belong to this.

Due to lead-free technology some rules have to be respected by the

workshop during a repair:

• Use only lead-free solder alloy Philips SAC305 with order

• Use only adequate solder tools applicable for lead-free

o To reach at least a solder-temperature of 400°C,

o To stabilize the adjusted temperature at the solder-tip

o To exchange solder-tips for different applications.

• Adjust your solder tool so that a temperature around 360°C

• Mix of lead-free solder alloy / parts with leaded solder alloy

• Use only original spare-parts listed in the Service-Manuals.

code 0622 149 00106. If lead-free solder-pate is required,

please contact the manufacturer of your solder-equipment.

In general use of solder-paste within workshops should be

avoided because paste is not easy to store and to handle.

solder alloy. The solder tool must be able

– 380°C is reached and stabilized at the solder joint.

Heating-time of the solder-joint should not exceed ~ 4 sec.

Avoid temperatures above 400°C otherwise wear-out of

tips will rise drastically and fl ux-fl uid will be destroyed. To

avoid wear-out of tips switch off un-used equipment, or

reduce heat.

/ parts is possible but PHILIPS recommends strongly to

avoid mixed solder alloy types (leaded and lead-free).

If one cannot avoid or does not know whether product is

lead-free, clean carefully the solder-joint from old solder

alloy and re-solder with new solder alloy (SAC305).

Not listed standard-material (commodities) has to be

purchased at external companies.

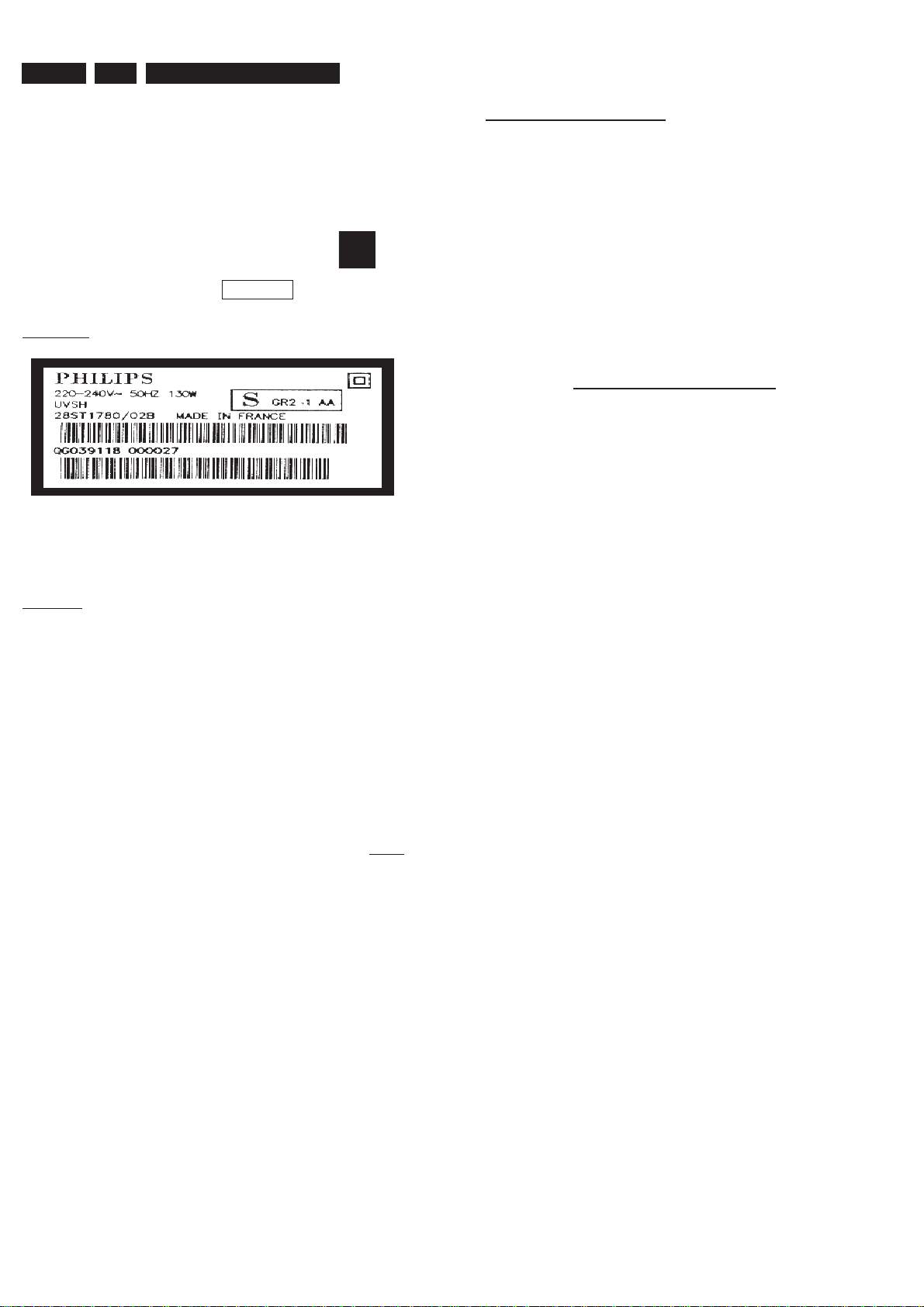

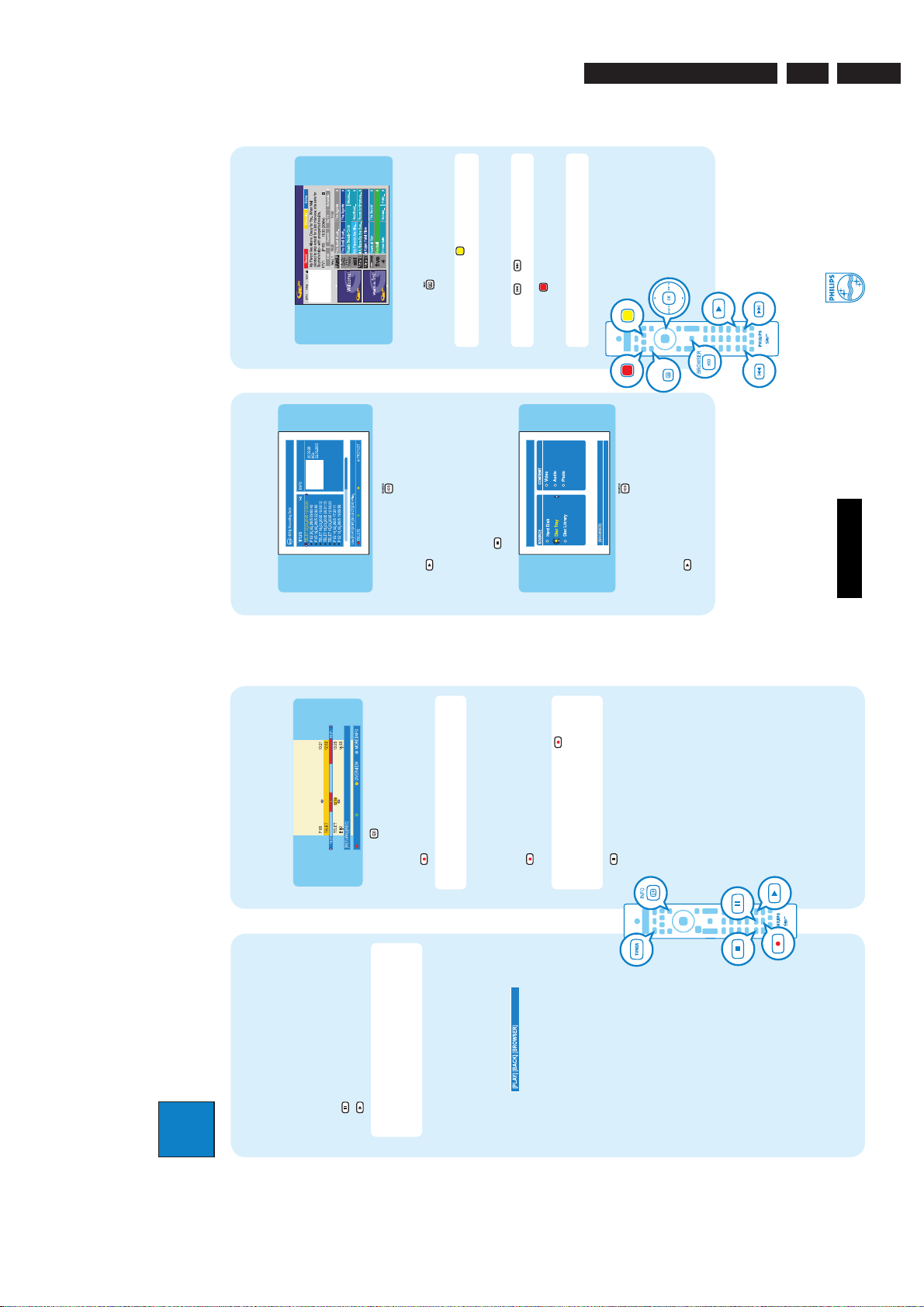

)%%%7%1MBZFS3FDPSEFS %7%3)

2VJDL4UBSU(VJEF

$POOFDU

4FUVQ

&OKPZ

8IBUTJOUIFCPY

)%%%7%1MBZFS3FDPSEFS

3'DPBYJBMDBCMF

3FNPUF$POUSPM

BOECBUUFSJFT

6TFS.BOVBM4DBSUDBCMF

5VOFSJOUFSMJOLDBCMF

2VJDL4UBSU(VJEF

1PXFSDBCMF (-*/,DBCMF

USBOTNJUUFS

Directions For Use

$POOFDU

4UBSUXJUIUIFA#BTJDDPOOFDUJPO

*GZPVIBWFB7$3GPMMPXUIFJOTUSVDUJPOTGPSA$POOFDUJPOXJUI7$3PSTJNJMBSEFWJDF

*GZPVIBWFBTFUUPQCPYGPMMPXUIFJOTUSVDUJPOTGPSA$POOFDUJPOXJUITFUUPQCPY

#BTJD$POOFDUJPO

"

#FGPSF$POOFDUJOH

6OQMVHUIFBOUFOOBDBCMFUIBUJTDVSSFOUMZDPOOFDUFEUP

ZPVS57

*GZPVIBWFPOMZBTJOHMFPGGBJSBOUFOOBGPMMPXA#

DPOOFDUJPO

*GZPVIBWFCPUIUIFPGGBJSBOUFOOBBOEEJHJUBMUFSSFTUSJBM

BOUFOOBGPMMPXA#DPOOFDUJPO

$POOFDUJOH

( %JTDPOOFDUUIFBOUFOOBDBCMFGSPNZPVS57BOE

DPOOFDUJUUPUIF"/5&//" TPDLFUPOUIJT

SFDPSEFS

2 6TFUIFTVQQMJFE3'DPBYJBMDBCMFUPDPOOFDUUIF57

TPDLFUPOUIJTSFDPSEFSUPUIF"OUFOOB*OTPDLFU

POUIF57

1 6TFUIFTVQQMJFE5VOFSJOUFSMJOLDBCMFUPDPOOFDU

UIFUXPA"TPDLFUTPOUIJTSFDPSEFS

* 6TFUIFTVQQMJFETDBSUDBCMFUPDPOOFDUUIF

&955057*0TDBSUTPDLFUPOUIJTSFDPSEFSUP

UIF4$"35*/TPDLFUPOZPVS57

" 1MVHJOUIFQPXFSDBCMFGSPNUIFSFDPSEFSUPBO"$

QPXFSPVUMFU

( %JTDPOOFDUUIFBOUFOOBDBCMFGSPNZPVS57BOE

DPOOFDUJUUPUIF

TPDLFUPOUIJTSFDPSEFS

2 $POOFDUUIFJOEPPS%7#5BOUFOOBDBCMFUPUIF

"/5&//" TPDLFUPOUIJTSFDPSEFS

2 6TFUIFTVQQMJFE3'DPBYJBMDBCMFUPDPOOFDUUIF

57

TPDLFUPOUIJTSFDPSEFSUPUIF"OUFOOB*O

TPDLFUPOUIF57

* 6TFUIFTVQQMJFETDBSUDBCMFUPDPOOFDUUIF

&955057*0TDBSUTPDLFUPOUIJTSFDPSEFSUP

UIF4$"35*/TPDLFUPOZPVS57

" 1MVHJOUIFQPXFSDBCMFGSPNUIFSFDPSEFSUPBO"$

QPXFSPVUMFU

#

$POOFDUJOHXJUIEJHJUBMUFSSFTUSJBM

BOUFOOB

#

'SPNBOPGGBJS

BOUFOOBPSDBCMFCPY

5FMFWJTJPOSFBS

5FMFWJTJPOSFBS

'SPNBOPGGBJS

BOUFOOBPSDBCMFCPY

1IJMJQT3FDPSEFSSFBS

1IJMJQT3FDPSEFSSFBS

'SPNEJHJUBM

UFSSFTUSJBM

BOUFOOB

/PUF4FFUIFBDDPNQBOZJOHVTFSNBOVBMGPSPUIFSQPTTJCMFDPOOFDUJPOTFH)%.*$PNQPOFOU7JEFP

3139 785 31681

3.

3. Directions For Use

The following except of the Quick Use Guide serves as an introduction to the set.

The Complete Direction for the Use can be downloaded in different languages from the internet site of Philips Customer care Center:

www.p4c.philips.com

EN 7

EN 8

6HWXS([WHUQDO5HFHLYHU

+DVWKH([WHUQDO5HFHLYHUFKDQJHGWR

3URJUDPPH1XPEHU"

*8,'(

3.

3139 785 31681

UPHPUPUIFOFYUTDSFFO4FMFDU

Directions For Use

UPUSZB

*OTUBMMUIFTFUUPQCPY

%

4FUVQ

'JOEJOHUIFWJFXJOHDIBOOFM

"

/PUF1SFTT

QSFTT

*GZPVEPOPUIBWFBTFUUPQCPYTLJQA%BOEHPUPA&

( 1SFTTTEPXOUPTFMFDUA&YUFSOBM3FDFJWFSBOE

2 1SFTT BHBJOUPDPOUJOVF

5IFSFDPSEFSXJMMEJTQMBZA*4570/

:PVTIPVMETFFUIF\&"4:4&561^NFOV

( 1SFTTT45"/%#:0/POUIFSFDPSEFS

2 4XJUDIPOUIF57

\/POF^JGOPOFPGUIFFOUSJFTBSFBQQMJDBCMF

CSBOEOBNFPGUIFDPOOFDUFETFUUPQCPY

1 4FMFDUUIFUZQFPGSFDFQUJPOTFSWJDFQSPWJEFSBOE

/PUF*GDPOOFDUFEUPZPVS7$3NBLFTVSFJUJT

UVSOFEPGGCFGPSFQSPDFFEJOH

UPQCPYJTDPOOFDUFEFHA&95GPS&95"69*0

TPDLFUBOEQSFTT

* 4FMFDUUIFSFDPSEFSTPDLFUUISPVHIXIJDIZPVSTFU

OVNCFSPOUIFTFUUPQCPY

" 5VSOPOZPVSTFUUPQCPYBOETFMFDUDIBOOFM

+ 3FBEUIFJOTUSVDUJPOTPOUIF57BOEQSFTT

SFNPUFDPOUSPMSFQFBUFEMZPS"74&-&$5CVUUPO

1 *GOPUQSFTTUIF$IBOOFM%PXOCVUUPOPOUIF57T

4UBSUCBTJDTFUVQ

VOUJMZPVTFFUIFNFOV5IJTJTUIFDPSSFDUWJFXJOH

DIBOOFMGPSUIFSFDPSEFS

#

6TFUIFSFDPSEFSTSFNPUFDPOUSPMBOEGPMMPXUIFPO

TDSFFOJOTUSVDUJPOTUPDPNQMFUFUIFJOTUBMMBUJPO

QSPHSBNNFOVNCFSBTEJTQMBZFEPOUIF57TFMFDU

\:FT^JOUIFNFOVBOEQSFTT

, *GUIFTFUUPQCPYIBTTXJUDIFEUPUIFTBNF

UPHP

UPUIFOFYUTDSFFO

/PUF4FMFDU\%POF^JOUIFNFOVBOEQSFTT

UIF57TIBQF

( 4FMFDUUIFEFTJSFENFOVMBOHVBHFZPVSDPVOUSZBOE

CVUUPOUPFYJU

/PUF*GOPUTFMFDU\/P^BOEQSFTT

EJHJUBMUVOFSSBEJP

2 "DUJWBUFBVUPNBUJDDIBOOFMTFBSDIGPSBOBMPHVFBOE

/PUF5PTXJUDIUIF(6*%&1MVTTZTUFNTIPTU

EJGGFSFOUDPEF

- :PVSTFUUPQCPYJTOPXJOTUBMMFE1SFTTUIFHSFFO

TFMFDU\$POUJOVF^BOEQSFTT

1 $IFDLUIFEBUFBOEUJNFBOEQSFTT

* 5PDPOUJOVFXJUIUIF(6*%&1MVTJOTUBMMBUJPO

-PBEUIF57MJTUJOHEBUB

DIBOOFMNBOVBMMZHPUP\)PTU$IBOOFM4FUVQ^

&

( 1SFTT(6*%& UPFYJU(6*%&1MVTTZTUFN

8BJUVOUJMUIFSFDPSEFSIBTGJOJTIFEJOJUJBMJTJOH

0UIFSXJTFTFMFDU\%POPUJOTUBMMOPX^BOEQSFTT

*OTUBMMUIF(6*%&1MVTTZTUFN

UIFTZTUFNUIFOQSFTT BHBJO

/PUF*GZPVUVOFUPZPVS)PTU$IBOOFMCFGPSFHPJOH

-FBWFUIFSFDPSEFSJOATUBOECZNPEFBOEUVSOAPO

UIFTFUUPQCPYPWFSOJHIUUPDPMMFDUUIF57MJTUJOH

EBUBUIJTNBZUBLFVQUPIPVST

$

UPATUBOECZNPEFUIJTSFDPSEFSXJMMTUBSUEPXOMPBEJOH

UIF57MJTUJOHTEBUBJNNFEJBUFMZ

UIFTPVSDFBOEQSPHSBNNFOVNCFSTBSFNBUDIJOH

GPSBMMDIBOOFMT

2 $IFDLUIF\&EJUPS^TDSFFOUIFOFYUEBZUPFOTVSF

/PUF*GOPPSXSPOHQPTUBMDPEFJTFOUFSFEJUXJMM

DBVTFOP(6*%&1MVT&1(TFSWJDFJOGPSNBUJPO

MBOHVBHFDPVOUSZBOEFOUFSUIFQPTUBMDPEFPGZPVS

BSFB

( 'PMMPXUIFPOTDSFFOJOTUSVDUJPOTUPTFMFDUZPVS

5FMFWJTJPOSFBS

$POOFDUJPOXJUITFUUPQCPY

:PVSOFX1IJMJQT3FDPSEFSQSPWJEFTB(-*/,

USBOTNJUUFSXIJDIBMMPXTZPVUPDPOUSPMUIFUVOFSPGUIF

TFUUPQCPYTBUFMMJUFSFDFJWFSDBCMF57CPYUISPVHI

UIF(6*%&1MVTTZTUFN:PVDBOSFDPSEUIF57

QSPHSBNNFTUIBUBSFSFDFJWFEUISPVHIUIFTFUUPQCPY

#FGPSF$POOFDUJOH

$POOFDUJPOXJUI7$3PS

TJNJMBSEFWJDF

"

:PVSOFX1IJMJQT3FDPSEFSSFQMBDFTUIF7$3GPSZPVS

$POOFDUJOH

5FMFWJTJPOSFBS

$POOFDUJOH

'SPNBOPGGBJS

SFDPSEJOHOFFET'JSTUVOQMVHBMMUIFDPOOFDUJPOTGSPN

ZPVS7$3

#

BOUFOOBPSDBCMFCPY

4FU5PQ#PYSFBS

5PTPVSDF

1IJMJQT3FDPSEFS

SFBS

4FUUPQCPY

1PTJUJPOJOHPG(-*/,

USBOTNJUUFS

7$3PSTJNJMBS

EFWJDFSFBS

(-*/,USBOTNJUUFS

UIJTSFDPSEFSCFGPSFZPVQSPDFFEUPTUFQCFMPX

"CPWFJMMVTUSBUJPOTIPXOUIFDPOOFDUJPOXJUIPVU

UIFEJHJUBMUFSSFTUSJBMBOUFOOB

TPDLFUPOUIJTSFDPSEFS

UPQCPYJOTVDIBXBZUIBUJUDBOBDRVJSFUIFTJHOBM

( 'PMMPXTUFQUPPGA#BTJDDPOOFDUJPOUPDPOOFDU

( 'PMMPXTUFQUPPGA#BTJDDPOOFDUJPOUPDPOOFDU

2 $POOFDUUIFTVQQMJFE(-*/,DBCMFUPUIF(-*/,

UIJTSFDPSEFSCFGPSFZPVQSPDFFEUPTUFQCFMPX

"CPWFJMMVTUSBUJPOTIPXOUIFDPOOFDUJPOXJUIPVU

UIFEJHJUBMUFSSFTUSJBMBOUFOOB

2 6TFBOPUIFSTDBSUDBCMFOPUTVQQMJFEUPDPOOFDU

CSPBEDBTUFECZUIFUSBOTNJUUFS

1 1MBDFUIF(-*/,USBOTNJUUFSJOGSPOUPGZPVSTFU

* $POOFDUUIFQPXFSDBCMFGSPNUIFTFUUPQCPYUP

UIF&95"69*0TDBSUTPDLFUPOUIJTSFDPSEFSUP

/PUF*OUIJTTFUVQUIF7$3DBOOPUSFDPSE57

UIF4$"35065TPDLFUPOZPVS7$3

QPXFSPVUMFU

1 $POOFDUUIFQPXFSDBCMFGSPNUIF7$3UPBO"$

BO"$QPXFSDBCMF

QSPHSBNNFT

6TJOHUIF(6*%&1MVTTZTUFN

.BLFTVSFUIBUUIFBOBMBHVFUVOFSJOTUBMMBUJPOBOE57

MJTUJOHEBUBEPXOMPBEJTDPNQMFUFE

3FDPSE57QSPHSBNNFT

( 1SFTT(6*%&

Directions For Use

PGBMMUIFBWBJMBCMFDIBOOFMTBOEDIPPTFGSPNUIFSF

/PUF1SFTTUIFZFMMPX CVUUPOUPTFFBOPWFSWJFX

2 1SFTTTEPXOUPTFMFDUB57DIBOOFM

/PUF1SFTT PS UPHPEJSFDUMZUPBEBZCFGPSF

PSUIFOFYUEBZ57MJTUJOHT

QSPHSBNNF

1 1SFTTW3&1-":PS/&95XUPTFMFDUB57

* 1SFTTUIFSFE CVUUPOUPTFUUIFIJHIMJHIUFE

/PUF:PVDBOTUPSFVQUPQSPHSBNNFTGPS

QSPHSBNNFGPSSFDPSEJOH

3139 785 31681

SFDPSEJOH

*8,'(

3.

EN 9

¥,POJOLMJKLF1IJMJQT/7

"MMSJHIUTSFTFSWFE

/$

XXXQIJMJQTDPDN

'SPNUIFIBSEEJTL

4UBSUQMBZCBDL

"

TUPSBHF

$POUFOUTJOUIFUFNQPSBSZ)%%

3FDPSEUPIBSEEJTL

"

( 1SFTT)%%#3084&3 UIFOQSFTT/&95X

UIFIBSEEJTLTUPSBHF

( 1SFTT*/'0 UPTFFXIBUJTUFNQPSBSJMZTUPSFEJO

'SPNBEJTD

VOUJMZPVTFFUIF\5*5-&4^BOE\*/'0^NFOVT

2 1SFTTSVQPSTEPXOUPTFMFDUBUJUMF

1 1SFTT 1-":UPTUBSUQMBZCBDL

/PUF5IFUJUMFXJMMCFNBSLFEJOSFEBOEUIF

SFDPSEJOHXJMMPOMZUBLFFGGFDUXIFOZPVUVSOPGGUIF

XBOUUPSFDPSE

2 1SFTTSVQPSTEPXOUPDIPPTFUIFUJUMFZPV

SFDPSEFS

1 1SFTT 3&$03%UPSFDPSEUIFUJUMF

-PBEBEJTDBOEDMPTFUIFEJTDUSBZ

#

( )PMEEPXO 4501VOUJMUIFEJTDUSBZPQFOT

$VSSFOU57QSPHSBNNF

/PUF5PTFUUIFSFDPSEJOHUJNFQSFTT SFQFBUFEMZ

SFDPSEVQUPIPVST

#

( 1SFTT 3&$03%UPTUBSUSFDPSEJOH*UDBO

NFOV4FMFDU\%JTD5SBZ^BOEQSFTT/&95XVOUJM

ZPVTFFUIF\5*5-&4^\53"$,4^PS\1)050

30--4^NFOVEFQFOEJOHPOUIFEJTDUZQF

2 1SFTT)%%#3084&3 UPHPUPUIFEJTD

UPFYUFOEUIFSFDPSEJOHUJNFJONJOVUFJODSFNFOUT

VQUPIPVST*G(6*%&1MVTTZTUFNJTBWBJMBCMF

A3FDPSEQSPHSBNJTEJTQMBZFEBOEUIFDVSSFOU

QSPHSBNNFXJMMCFSFDPSEFE

2 1SFTT 4501UPTUPQUIFSFDPSEJOHJNNFEJBUFMZ

1 1SFTTSVQPSTEPXOUPTFMFDUBUJUMF

* 1SFTT 1-":UPTUBSUQMBZCBDL

/FFEIFMQ

(6*%&1MVTTZTUFN

(PUPXXXFVSPQFHVJEFQMVTDPN

6TFS.BOVBM

4FFUIFVTFSNBOVBMUIBUDBNFXJUIZPVS1IJMJQT3FDPSEFS

0OMJOF

(PUPXXXQIJMJQTDPNTVQQPSU

&OKPZ

/PUF8IFOUIFSFDPSEFSJTUVSOFEPOUIF

QSPHSBNNFZPVBSFXBUDIJOHXJMMCFTUPSFEJOUIF

UFNQPSBSZIBSEEJTLTUPSBHF8IFOZPVTXJUDIUIF

SFDPSEFSUPBOPUIFSJOQVUTJHOBMFH$".PSUP

CFUXFFOBOBMPHVFBOEEJHJUBMUVOFSUIFOQSFTT

8BUDI57m1BVTFMJWF57

:PVS1IJMJQT3FDPSEFSBMMPXTZPVUPDPOUSPMUIF57

QSPHSBNNF:PVDBO1"64&JUBTJGZPVXFSFJODPOUSPM

$)UPTFMFDUB57QSPHSBNNF

PGUIFMJWFCSPBEDBTU

( 5VSOPOZPVSSFDPSEFSBOEQSFTT56/&3UPTXJUDI

2 1SFTT 1"64&UPTVTQFOEJU

1 1SFTT 1-":UPDPOUJOVF

TUBOECZNPEFUIFQSPHSBNNFXJMMCFFSBTFE

* 1SFTT56/&3UPSFUVSOUPUIFMJWFCSPBEDBTU

)FMQUFYUJOGPSNBUJPOCBS

5IFIFMQUFYUCBSMPDBUFEBUUIFCPUUPNPGUIFTDSFFOJT

TUBUF

QSPWJEJOHUIFJOGPSNBUJPOPO

l SFNPUFDPOUSPMLFZTUIBUDBOCFVTFEBUUIFDVSSFOU

l CSJFGJOGPSNBUJPOPGUIFTFMFDUFEJUFN

EN 10

4.

3139 785 31681

Mechanical Instructions

4. Mechanical Instructions

Note: The position numbers given here refers to the

Exploded view on chapter 10.

4.1 Dismantling of the DVD Tray cover manually

1) Insert a screw-driver into the slot provided at the bottom

of the set and push in the direction as shown in

picture 4-1 to unlock before sliding the Tray cover

assembly 910 out.

Figure 4-1

2) Remove the Tray cover assembly 910 as shown in

Figure 4-2.

3) Remove 2 screws to loosen the Bracket Loader 191 and

uncatch the Dust cover assembly 902.

4) Remove 4 screws to loosen the Cover of the Basic

Engine to reach Service position Figure 4-4.

Figure 4-4: Basic Engine Service position

4.3 Dismantling of the HDD / PSU Board

1) Remove 4 screws to loosen the HDD assembly

1009+192+222 as shown in Figure 4-5.

Figure 4-2

4.2 Dismantling of the Basic Engine (Drive D4.3)

1) Remove 9 screws to loosen Top cover 210.

2) Remove 4 screws to loosen the Basic Engine assembly

1008+191+902 as shown in Figure 4-3.

Figure 4-3

Figure 4-5: Digital Board

Mechanical Instructions

3139 785 31681

4.

EN 11

2) Remove 4 screws 285 to separate the Bracket HDD

192 and Bracket HDD suspension 222 from the HDD as

shown in Figure 4-6.

Note: Screws 285 are special type of screws that must be

replaced only with those specifi ed in the Service Parts list on

Chapter 10.

Figure 4-6

4) Service position for PSU Board is given in Figure 4-8.

Insulation Sheet

Figure 4-8: PSU Board Service Position

4.4 Dismantling of the Digital Board

1) Remove 4 screws to loosen the Digital Board 1004 as

shown in Figure 4-9.

3) Remove 4 screws to loosen the PSU Board 1007 as

shown in Figure 4-7.

Figure 4-7

Figure 4-9

EN 12

4.

3139 785 31681

Mechanical Instructions

2) Service position for Digital Board is given in Figure

4-10.

Insulation Sheet

Figure 4-10: Digital Board Service Position

4.5 Dismantling of the DTTM, HDMI, IR Blaster

and Analog Boards

1) Remove 4 screws and 3 catches the HDMI board (1x)

and DTTM board (2x) as shown in Figure 4-11.

2) Remove 8 screws to loosen the Analog Board (3x) and

IR Blaster board (2x) + bracket 193 assembly (3x) as

shown in Figure 4.12.

Figure 4-12

3) Remove 9 screws on the Rear Panel to remove the

Analog Board as shown in Figure 4.13.

Note: It may be necessary to loosen the Digital Board

because the cable from the Front Panel is sandwiched

between the Digital and Analog Boards.

Figure 4-11

Figure 4-13

Mechanical Instructions

4) Service Position is achieved by placing the Analog Board

in the vertical position as shown in Figure 4-14.

Insulation Sheet

Insulation Sheet

Figure 4-14: HDMI and Analog Boards Service Position

4.6 Dismantling of the Front Panel assembly

3139 785 31681

4.

EN 13

1) Remove the DVD Tray cover assembly 910 as given in

step 4-1.

2) Loosen the Digital Board 1004 as given in step 4-4.

There are 2 cables below the Digital Board that are

tapped to the Bottom plate 182 that must be released in

order to dismantle the Front Panel assembly.

3) Loosen the DTTM and IR Blaster Boards (see step 4.5) to

disconnect the 2 cables

4) Loosen 4 screws + 4 catches (top) and 4 screws + 2

catches (bottom) to pull the Front Panel assembly

towards the front away from the Bottom chassis 178.

5) Service position is achieved by placing the Front Panel

assembly by the side & reconnecting the 3 cables.

Figure 4-15: Front Board Service position

EN 14

5.

3139 785 31681

Firmware Upgrading & Diagnostic Software

5. Firmware Upgrading & Diagnostic Software

5.1 Firmware Upgrading

A. Preparation to upgrade fi rmware:

1. Unzip the zip-archive fi le

2. Start the CD Burning software and create a new CD project (data disc) with the following settings:

File system: Joliet

Format: MODE 2: CDROM XA

Recording mode: SINGLE SESSION (TRACK-AT-ONCE), FINALIZED CD

Note: Long fi le name is necessary for the preparation of the upgrade disc

3. Place the content of the zip-archive into the root directory of the new CD project.

4. Burn the data onto a blank CDR or CD-RW

B. Procedure to apply the fi rmware upgrade:

1. Hold the <Record> + <Open/Close> buttons down and Power up the set.

2. The tray opens and set will display:

FORCE DL −>…. PUT DSC

3. Insert the prepared Upgrade CDROM and close the tray.

4. The set will display:

INIT DSC −> ………. DOWNLOAD −>……….

The whole process takes less than 15 minutes

Note: Do not press any buttons or interrupt the mains supply during the upgrading process, otherwise the set may becomes

defective.

5. When the upgrade is completed the tray will open automatically and the set will display:

REMOVE

6. Close the tray and the set will display:

DONE

C. How to read out the fi rmware version to confi rm set has been upgraded:

1. Power up the set.

2. Press <System> button on the Remote control and select {Setup} option

3. Press <Right> button to select {System}

4. The set will prompt you about clearing the Time Shift Buffer

5. Select {Yes} and press <OK> button

6. Press <Down> button several times to select {Version info}

7. Press <OK> button

8. The TV connected to the set will display:

DIF05_3/493AN SV11205

BE 43.2.13 ASP3,9,1,10FP

DTTM HW:01020102 DTTM

SW:00040200

SIT9000-FF3F-S3_F540

20051020-1815 pro sxcplusint

EPG:3.04 DPMS:P_DPM

9. Press <System> button to exit

Firmware Upgrading & Diagnostic Software

Diagnostic Software

3139 785 31681

5.

EN 15

Due to the complexity of the DVD recorder, the time to find a

defect in the recorder can become long. To reduce this time,

the recorder has been equipped with Diagnostic and Service

software (DS). The DS offers functionality to diagnose the

DVDR hardware and tests the following:

• Interconnections between components

• Accessibility of components

• Functionality of the audio and video paths

This functionality can be accessed via several interfaces:

1. End user/Dealer script interface

2. Command Interface

5.2 End User/Dealer Script Interface

5.2.1 Description

The End user/Dealer script interface gives a diagnosis on a

stand alone DVD recorder. During this mode, a number of

hardware tests (nuclei) are automatically executed to check if

the recorder is faulty. The diagnosis is simply a "fail" or "pass"

message. If the message "FAIL" appears on the display, there

is apparently a failure in the recorder. If the message "PASS"

appears, the nuclei in this mode have been executed

successfully. There can be still a failure in the recorder

because the nuclei in this mode don't cover the complete

functionality of the recorder.

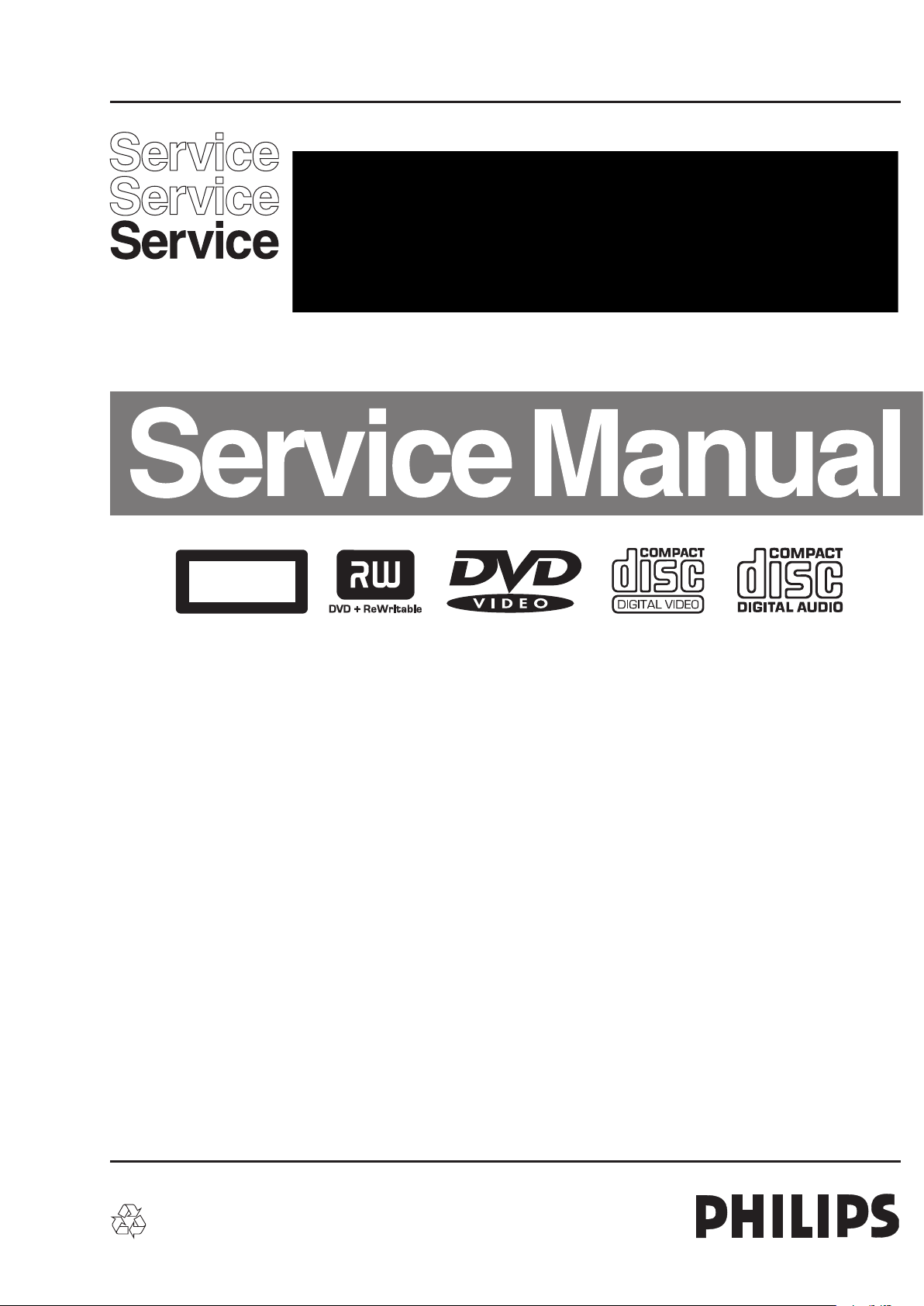

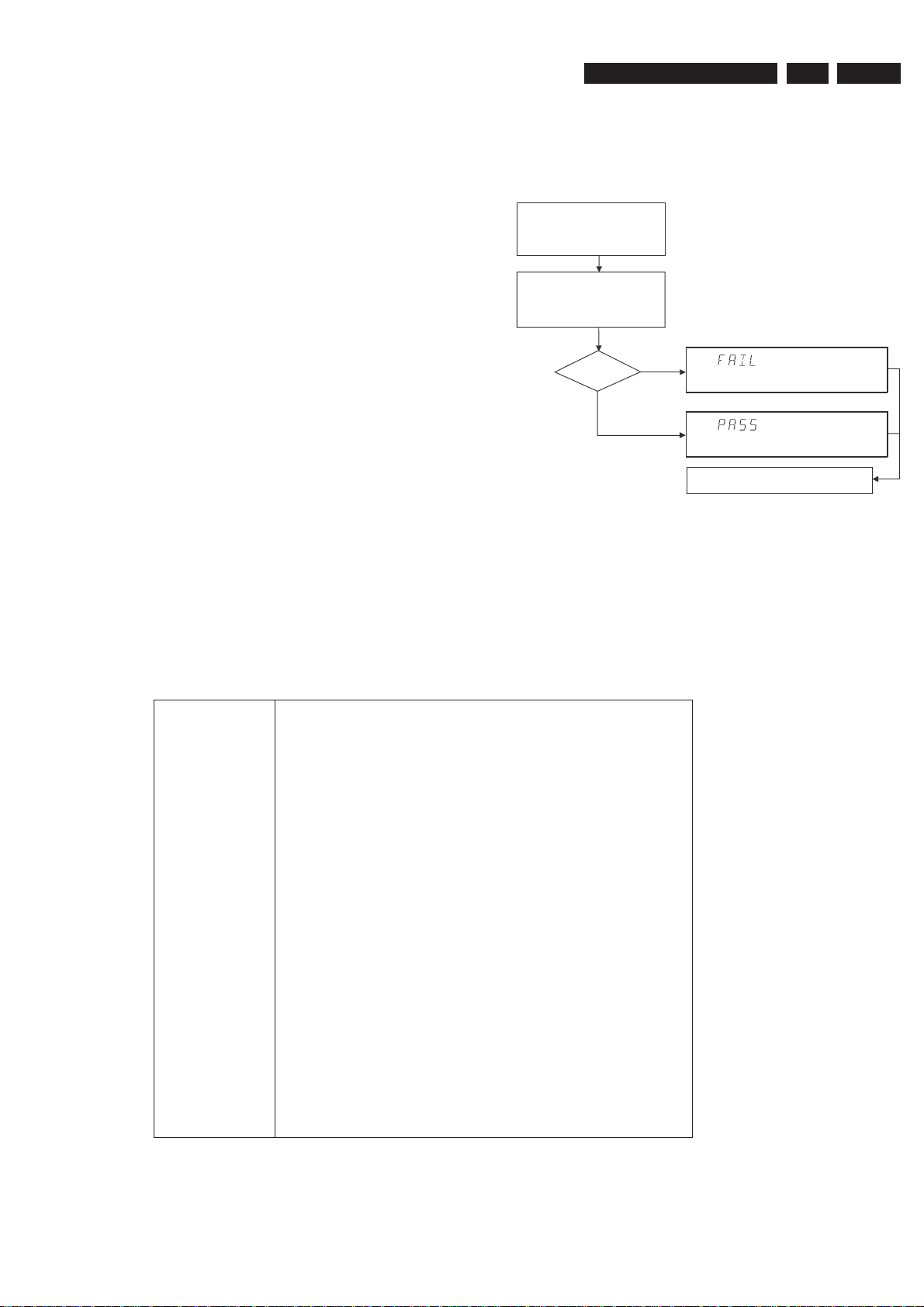

5.2.2 Structure

Unplug the power cord

Hold key <PLAY> pressed

while you plug the recorder

During the test, the display will show

the a sequence of nuclei under test

SET O.K.?

NO

YES

To exit DEALER SCRIPT, unplug the power cord

Figure 5-1

The End use/Dealer script executes all diagnostic nuclei that

do not need any user interaction and are meaningful on a

standalone DVD recorder.

TR 18029_001

120304

5.2.3 Contents

Included tests: 1.DS_ANAB_COM MUN ICATIONECHO_NU C

2.DS_DCB_COMMUNICATIONECHO_NUC

3. DS_BROM_COMMUNICATION_NUC

4. DS_SYS_SETTINGSDISPLAY_NUC

5. DS_CHR_DEVTYPEGET_NUC

6. DS_CHR_INT_PIC_NUC

7. DS_CHR_DMA_NUC

8. DS_BROM_WRITEREAD_NUC

9. DS_NVRAM_COMMUNICATION_NUC

10. DS_NVRAM_WRITEREAD_NUC

11. DS_SDRAM_WRITEREADFAST_NUC

12. DS_FLASH_WRITEREAD_NUC

13.DS_FLASH_CHECKSUMPROGRAM_NUC

14.DS_SYS_HARDWAREVERSIONGET_NUC

15. DS_VIP_DEVTYPEGET_NUC

16. DS_VIP_COMMUNICATION_NUC

17. DS_DVIO_LINKDEVTYPEGET_NUC

18. DS_DVIO_PHYDEVTYPEGET_NUC

19. DS_DVIO_LINKCOMMUNICATION_NUC

20. DS_DVIO_PHYCOMMUNICATION_NUC

21.DS_PSCAN_COMMUNICATIONDENC_NUC

22.DS_PSCAN_COMMUNICATIONDEINTERLACER_NUC

23. DS_BE_COMMUNICATIONECHO_NUC

24.DS_ANAB_COMMUNICATIONIICNVRAM_NUC

25.DS_ANAB_COMMUNICATIONIICTUNER_NUC

26.DS_ANAB_COMMUNICATIONIICSOUNDPROCESSOR_NUC

27.DS_ANAB_COMMUNICATIONIICAVSELECTOR_NUC

28. DS_ANAB_CHECKSUMPROGRAM_NUC

EN 16

5.

3139 785 31681

5.3 Player Script Interface

Virgin mode

5.3.1

Firmware Upgrading & Diagnostic Software

5.4.2 Error Handling

If you want that the recorder starts up in Virgin mode, follow this

procedure:

• Unplug the recorder

• plug the recorder again while you keep the STAND BY/ON

key pressed

• the set starts up in Virgin mode.

5.4 Menu and Command Mode Interface

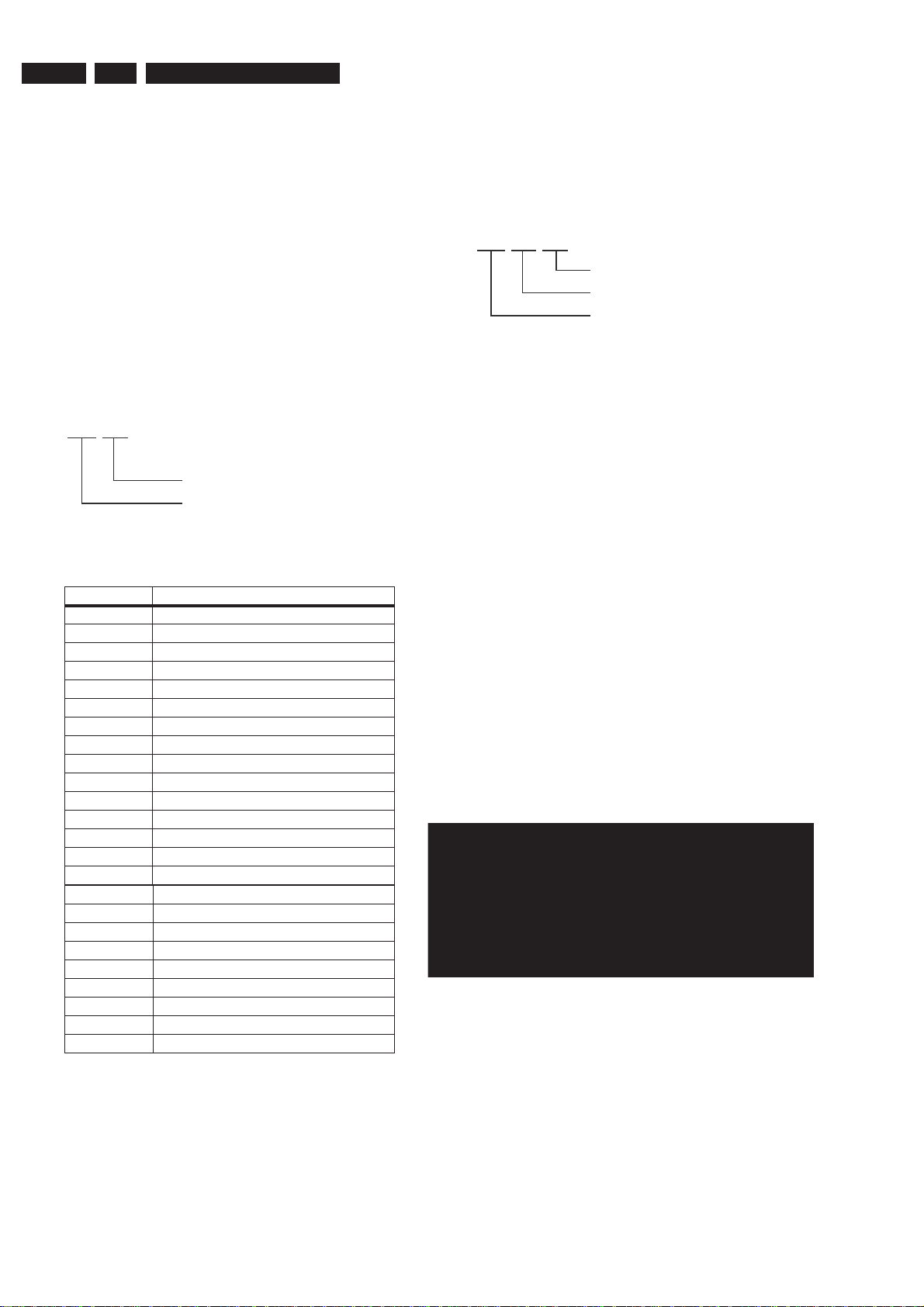

5.4.1 Nuclei Numeration

Each nucleus has a unique number of four digits. This number

is the input of the command mode.

[ XX YY ]

Nucleus number

Nucleus group number

Figure 5-3

Group number Group name

0 Scripts

1 Codec (e.g. Chrysalis, Leco)

2 Boot EEPROM

3NVRAM

4 SDRAM

5 Flash

6 Video Input Processor

7DVIO

8 Progressive Scan

9 Basic Engine

10* Display and Control Board

11* Analogue Board

12 System

13 Electronic Program Guide Board

14* PCMCIA

15 HDMI

16 Analogue Slave Processor

17 Analogue Board EEPROM

18 Video Matrix

19 Audio Matrix

20 Front End

21 Hard Disk

22 Di

23* USB

* Not applicable for DVDR9000H Range

gital Terrestrial Tuner Module

CL 06532152_012.eps

051200

Each nucleus returns an error code. This code contains six

numerals, which means:

[ XX YY ZZ ]

Error code

Nucleus number

Nucleus group number

Figure 5-4

The nucleus group numbers and nucleus numbers are the

same as above.

5.4.3 Command Mode Interface

Set-Up Physical Interface Components

Hardware required:

• Service PC

• one free COM port on the Service PC

• special cable to connect DVD recorder to Service PC

The service PC must have a terminal emulation program (e.g.

Hyperterminal) installed and must have a free COM port (e.g.

COM1). Activate the terminal emulation program and check

that the port settings for the free COM port are: 19200 bps, 8

data bits, no parity, 1 stop bit and no flow control. The free COM

port must be connected via a special cable to the RS232 port

of the DVD recorder. This special cable will also connect the

test pin, which is available on the connector, to ground (i.e.

activate test pin).

Code number of PC interface cable: 3122 785 90017

Activation of Diagnostic Software

1. Pull the mains cord from the recorder and reconnect it

again (reboot).

2. The next welcome message will appear on the PC:

Welcome screen D&S program

Figure 5-5

Now, the prompt 'DS:>' will appear. The diagnostic software is

now ready to receive commands. The commands that can be

given are the numbers of the nuclei. If you see above shown

screen, continue with paragraph 'Nuclei Codes'.

CL 06532152_013.eps

051200

Firmware Upgrading & Diagnostic Software

3139 785 31681

5.

EN 17

3. It is possible that the next messages will appear when

starting the DVD+RW for the first time

Error messages D&S program

Figure 5-6a

Error messages D&S program

Enter "Y" to program a safe string. With this automatically

generated string the board will work in principle but it has to be

checked if all board settings were detected correctly.

Diversity String Input

4. Execute nucleus 1226 to enter the string. Please see

chapter 8 for details

Nucleus 1226 execution with string

Figure 5-7

5. To check if the hardware info is filled correctly, you can

execute nucleus 1228.

Nucleus 1228 info example

Figure 5-6b

In these cases, the boot EEPROM of the Digital Board does not

contain the required string with the hardware information. To

update the Digital Board with the correct string, nucleus 1226

must be executed.

See next section 'Diversity String Input'.

There can also be the next error message.

Figure 5-8

6. Exit the 'Terminal' program.

Figure 5-6c

7. Reboot the DVD recorder to allow the software to start.

EN 18

Command overview Digital Board

Below you will find an overview of the nuclei, their numbers,

and their error codes. This overview is preliminary and subject

to modifications.

Note: AV3 in the overview includes also the AV3.5 drive.

Codec Host Controller (CHR)

5.

3139 785 31681

Firmware Upgrading & Diagnostic Software

Nucleus Name

DS_CHR_DevTypeGet

Nucleus Number 100

Description Retrieves the device id, the module ids and revisions of the Codec and returns

them to the stdout port.

Technical - Determine the codec id by means of comparing version ids of the modules.

- Read the module-id register of every module and display it to the user.

Execution Time Less than 1 second.

User Input None

Error Number Description

10000 Getting the information succeeded

10001 Wrong codec id detected

Example

DS:> 100

010000:

Device ID 7100

Codec ID PNX7100_C

F-BCU (0x0102) 1.0 INTC (0x011d) 1.0 PCI-XIO(0x0113) 1.0

SIF (0x013b) 1.0 EJTAG (0x0104) 0.1 S-BCU (0x0102) 1.0

BOOT (0x010a) 1.0 CONFIG (0x013f) 1.1 RESET (0x0123) 1.0

DEBUG (0x0116) 0.0 UART0 (0x0107) 0.1 UART1 (0x0107) 0.1

UART2 (0x0107) 0.1 UART3 (0x0107) 0.1 I2C0 (0x0105) 0.1

I2C1 (0x0105) 0.1 GPIO (0x013c) 1.0 SYNC (0x013a) 1.0

DISP0 (0xa015) 1.12 DISP1 (0xa00f) 1.1 OSD (0x0136) 0.1

SPU (0xa00e) 0.0 MIXER (0x0137) 1.0 DENC (0x0138) 1.0

CCIR (0x0139) 1.0 VDEC (0x0133) 0.2 PARSER (0xa00d) 0.0

DV (0xa00c) 0.0 BEI (0xa00a) 0.1 IDE (0xa009) 0.1

SGDX (0xa008) 1.0 BYTE (0xa00b) 0.1 OUTPUT (0xa003) 1.0

ACOMP (0xa000) 1.0 VFE (0xa001) 0.1 VCOMP (0xa002) 1.0

SCR (0x0000) 0.0 SIFF (0xa011) 0.1 WMD (0xa010) 0.0

AUDIO0 (0xa015) 1.12 AUDIO1 (0xa00f) 1.1 PSCAN (0xa018) 0.1

Test OK @

Nucleus Name

DS_CHR_TestImageOn

Nucleus Number 101

Description Generates a test-image of a selected video standard on selected video output

on the digital board. When no input is given, the default values will be used (see

user input description below). Make sure to use the proper nuclei to route the

video signal on the analogue board to get the video signal to the proper output.

Note: Although a DTT has a Chrysalis C3, the codec IC may never use the

YUV functionality of the internal DENC. This is specified by the hardware. The

digital boards for DTT do have a YUV-matrix. The signals from this YUV-matrix

are not routed to the regular video output connector but to the progressive scan

output connector.

Technical - Validate the user input.

- Initialise the SYNC module.

- Initialise the DISPLAY module.

- Initialise the MIXER module.

- Initialise the DENC module.

- Set the selected video standard.

- Generate the selected test image in memory.

- Start the DISPLAY module.

- Start the MIXER module.

- Start the DENC module according to the selected test image id.

Execution Time 6 seconds.

Firmware Upgrading & Diagnostic Software

3139 785 31681

User Input The user has to decide which test image, video standard and video output must

be used: < Test image id > < Video standard > < Video output >

Test image id:

0 VERTICAL_COLOURBAR (default)

1 HORIZONTAL_COLOURBAR

2WHITE

3 YELLOW

4 CYAN

5 GREEN

6 MAGENTA

7 RED

8 BLUE

9 BLACK

10 GRAY

11 TEST_IMAGE_FOR_PROGRESSIVE_SCAN

Video standard:

PAL Standard PAL 50 Hz (default)

NTSC Standard NTSC 60 Hz

Video output:

ALL CVBS and YC and RGB DACs are enabled (default)

CVBS CVBS DAC is enabled

YC Y and C DAC is enabled

RGB CVBS, R, G, and B DACs are enabled

YUV Y, U, and V DACs are enabled

PSCAN Progressive scan is enabled.

5.

EN 19

Error Number Description

10100 Generating the test image succeeded.

10101 Invalid input was provided.

10102 The Codec SYNC-module cannot be initialised.

10103 The Codec MIXER-module cannot be initialised.

10104 The Codec VPP-module cannot be initialised.

10105 The Codec DENC-module cannot be initialised.

10106 The digital board hardware information is corrupt

Example

Nucleus Name

DS:> 101

010100:

Test OK @

DS:> 101 0 pal cvbs

010100:

Test OK @

DS:> 101 4 ntsc yc

010100:

Test OK @

DS_CHR_TestImageOff

Nucleus Number 102

Description Switches the test-image off.

Technical - Stop the DENC module.

Execution Time Less than 1 second.

User Input None

Error Number Description

10200 Stopping the test image generation succeeded

10201 The Codec DENC-module failed.

Example

DS:> 102

010200:

Test OK @

EN 20

5.

3139 785 31681

Firmware Upgrading & Diagnostic Software

Nucleus Name

DS_CHR_SineOn

Nucleus Number 103

Description Generate an audio sine signal on the audio output of the digital board.

Note: Left channel 6kHz, right channel 12 kHz sine. Make sure to route the

signal first.

Technical - De-mute the analogue board

- Set fifo parameters for audio

- Set the volume

- Set the I2S outputs and configuration paths

- Set the decoder mode

- Configure the audio decoder

- Put the AC3 audio in the fifo

- Send ‘prepare’ command to the audio decoder

- Send ‘play’ command to the audio decoder

Execution Time Less than 1 second

User Input None

Error Number Description

10300 The sine signal was successfully generated

10301 The analogue board could no t be de-muted

10302 The audio decoder did not initialise

10303 The dsp2 (DUET) of the audio decoder did not configure

10304 The dsp1 (PALM) of the audio decoder did not configure

10305 There was a delay-error before starting

10306 Wrong input was given to the decoder function

10307 Wrong input was given to the decoder function @@@@@

10308 The audio decoder did not get into the ‘prepared’ state

Example

DS:> 103

010300:

Test OK @

Nucleus Name

DS_CHR_SineOff

Nucleus Number 104

Description Stop generating the audio sine signal

Technical - Reset the audio block of the Codec

Execution Time Less than 1 second.

User Input None

Error Number Description

10400 Switching off the audio sine signal succeeded

10401 Failed to reset the audio decoder

Example

Nucleus Name

DS:> 104

010400:

Test OK @

DS_CHR_SineBurst

Nucleus Number 105

Description Generate an audio sine signal on the audio output of the digital board for 4

seconds.

Note: Left channel 6kHz, right channel 12 kHz sine with some known hick-ups

Technical - Call the DS_CHR_SineOn nucleus

- Delay for 4 seconds

- Call the DS_CHR_SineOff nucleus

Execution Time 4 seconds

User Input None

Error Number Description

10500 The sine signal burst was successfully generated

10501 The delay did not succeed during the burst

10502 The audio sine could not be generated

Example

DS:> 105

010500:

Test OK @

Firmware Upgrading & Diagnostic Software

3139 785 31681

5.

EN 21

Nucleus Name

DS_CHR_MuteOn

Nucleus Number 106

Description Mute the audio outputs of the digital bo ard

Technical - Send the ‘Mute’ command to the audio decoder

- Activate the ‘audio mute’ PIO pin

Execution Time Less than 1 second.

User Input “PIO” to just use the PIO pin mute. When muting using this, also de-mute using

this as this works ‘paired’.

Error Number Description

10600 Muting the audio succeeded

10601 Muting the audio through the PIO-pin failed

Example

Nucleus Name

DS:> 106

010600:

Test OK @

DS:> 106 PIO

010600:

Test OK @

DS_CHR_MuteOff

Nucleus Number 107

Description De-mute the audio outputs of the digital board

Technical - Send the ‘DeMute’ command to the audio decoder

- Deactivate the ‘audio mute’ PIO pin

Execution Time “PIO” to just use the PIO pin de-mute. Only de-mute using this when you muted

using the PIO parameter, as this works ‘’paired.

User Input None

Error Number Description

10700 De-muting the audio succeeded

10701 De-muting the audio through the PIO-pin failed

Example

DS:> 107

010700:

Test OK @

DS:> 107 PIO

010700:

Test OK @

Nucleus Name

DS_CHR_DvLedOn

Nucleus Number 108

Description Check the connection to the DV-LED on the digital board by switching it on

Technical - Write to the PIO pin to light the DV LED

Execution Time Less than 1 second.

User Input None

Error Number Description

10800 Switching the DV-LED on succeeded

10801 Switching the DV-LED on failed

Example

Nucleus Name

DS:> 108

010800:

Test OK @

DS_CHR_DvLedOff

Nucleus Number 109

Description Switch off the DV-LED on the digital board

Technical - Write to the PIO pin to switch off the DV LED

Execution Time Less than 1 second.

User Input None

Error Number Description

10900 Switching the DV-LED off succeeded

10901 Switching the DV-LED off failed

Example

DS:> 109

010900:

Test OK @

EN 22

5.

3139 785 31681

Firmware Upgrading & Diagnostic Software

Nucleus Name

DS_CHR_MacroVisionOn

Nucleus Number 110

Description Turn on MacroVision.

Technical - Set some registers of the DENC module in the Codec.

Execution Time Less than 1 second.

User Input None

Error Number Description

11000 Turning on MacroVision succeeded

11001 Turning on MacroVision failed

Example

Nucleus Name

DS:> 110

011000:

Test OK @

DS_CHR_MacroVisionOff

Nucleus Number 111

Description Turn off MacroVision.

Technical - Set some registers of the DENC module in the Codec.

Execution Time Less than 1 second.

User Input None

Error Number Description

11100 Turning off MacroVision succeeded

11101 Turning off MacroVision failed

Example

Nucleus Name

DS:> 111

011100:

Test OK @

DS_CHR_Peek

Nucleus Number 112

Description Peek a value on a specified address

Technical - Check the user input

- Read out the address specified

- Check whether the address to be read is aligned on 4 bytes

Execution Time Less than 1 second.

User Input The address to peek on

Error Number Description

11200 Peeking on the specified address succeeded

11201 Peeking on the specified address failed, wrong user input

11202 Peeking on the specified address failed due to misalignment

Example

DS:> 112 0xa0700000

011200: Value read = 0x000001BD

Test OK @

Nucleus Name

DS_CHR_Poke

Nucleus Number 113

Description Poke a value on a specified address

Technical - Check the user input

- Change the value on the address specified

- Check whether the address to be modified is aligned on 4 bytes

Execution Time Less than 1 second.

User Input The address to poke and the value: <address><value>

Error Number Description

11300 Poking the specified address succeeded

11301 Poking the specified address failed, wrong user input

11302 Poking the specified address failed due to misalignment

Example

DS:> 113 0xa0700000 0xaabbccdd

011300:

Test OK @

Firmware Upgrading & Diagnostic Software

3139 785 31681

5.

EN 23

Nucleus Name

DS_CHR_INT_PICInterrupts

Nucleus Number 114

Description Test all interrupts of the priority interrupt controller

Technical - Install interrupt handlers

- Generate interrupts

- Test whether all interrupts were received

Execution Time Less than 1 second.

User Input Error Number Description

11400 Testing all the PIC interrupts succeeded

11401 Testing all the PIC interrupts failed

Example

Nucleus Name

DS:> 114

011400:

Test OK @

DS_CHR_DMA_TestDMA

Nucleus Number 115

Description Test the memory to memory DMA transfer

Technical - Create a block with known data in memory

- Copy this block to the consecutive area using 3 different DMAs

- Check whether all DMAs transferred the data properly

Execution Time Less than 2 seconds.

User Input Error Number Description

11500 The testing of the DMAs succeeded

11501 The initialisation of the DMAs failed for one or more DMA

11502 One or more DMAs failed the test

Example

DS:> 115

011500:

Test OK @

Boot EEPROM (BROM)

Nucleus Name

DS_BROM_Communication

Nucleus Number 200

Description Check the communication between the IIC controller of the Codec and the boot

EEPROM

Technical - Initialise IIC

- Read something from the EEPROM

Execution Time Less than 1 second.

User Input None

Error Number Description

20000 The data is properly read so the commu nication is OK

20001 The IIC bus was not accessible

20002 There was a timeout reading the device

20003 The IIC acknowledge was not received

20004 An IIC-bus error occurred

20005 The IIC bus initialisation failed

20006 An unexpected IIC error occurred

Example

DS:> 200

020000:

Test OK @

EN 24

5.

3139 785 31681

Firmware Upgrading & Diagnostic Software

Nucleus Name

DS_BROM_WriteRead

Nucleus Number 201

Description Check whether the Boot EEPROM can be written to and read from

Technical - Initialise IIC

- Write something to the EEPROM

- Read from the same location and check whether it is the same as written

Execution Time Less than 1 second.

User Input None

Error Number Description

20100 The write-read test succeeded

20101 The write-read test failed

20102 An IIC-bus error occurred

20103 There was a timeout reading the device

20104 The IIC bus was not accessible

20105 The IIC acknowledge was not received

20106 Got unknown IIC bus error

20107 The IIC bus initialisation failed

Example

Non Volatile RAM (NVRAM)

Nucleus Name

DS:> 201

020100:

Test OK @

DS_NVRAM_Communication

Nucleus Number 300

Description Check the communication between the IIC controller of the Codec and the

NVRAM EEPROM

Technical - Initialise IIC

- Read from a location in the NVRAM EEPROM device

Important note:

This nucleus only checks the physical connection between the Codec and IIC

EEPROM. If no EEPROM is mounted this test will fail. However other NVRAM

nuclei might still work because the software will store NVM data into flash

memory

Execution Time Less than 1 second.

User Input None

Error Number Description

30000 Something is properly read so the communication is OK

30001 The IIC bus was not accessible

30002 There was a timeout reading the device

30003 The IIC acknowledge was not received

30004 The communication with the device failed

30005 The IIC bus initialisation failed

Example

DS:> 300

030000:

Test OK @

Nucleus Name

DS_NVRAM_WriteRead

Nucleus Number 301

Description Check whether the EEPROM can be written to and read from

Technical - Initialise IIC

- If no IIC EEPROM was found then initialise flash memory to use NVM

pages

- Backup data from location to modify

- Write to location and read it back again

- Write back the backed up data to the location to leave the NVRAM as

found

Execution Time Less than 1 second

User Input None

Error Number Description

30100 The write-read test succeeded

30101 The IIC bus could not be initia lised

30102 There was an NVRAM IO error

30103 The value could not be read back from the NVRAM

Example

DS:> 301

030100:

Test OK @

Firmware Upgrading & Diagnostic Software

3139 785 31681

5.

EN 25

Nucleus Name

DS_NVRAM_Clear

Nucleus Number 302

Description Make the EEPROM empty, containing all zeroes.

Technical - Initialise IIC

- If no IIC EEPROM was found then initialise flash memory to use NVM

pages

- Read the DVID and diversity string from NVM (either EEPROM or Flash)

- Create a memory block filled with zeroes

- Write this block to the NVRAM (either EEPROM or Flash)

- Write back the Read the DVID and diversity string to NVM (either

EEPROM or Flash)

Important note:

The Hardware Diversity Information and unique identification number

(IEE1394-specific) of the Digital Video proc essing part is NOT cleared by this

nucleus!

Execution Time 16 seconds

User Input None

Error Number Description

30200 The clearing of the NVRAM succeeded

30201 There was an IIC error

30202 Clearing the NVRAM failed

Example

Nucleus Name

DS:> 302

030200:

Test OK @

DS_NVRAM_Modify

Nucleus Number 303

Description Modifies one or more locations in NVRAM and updates the checksum of the

section modified

Technical - Initialise IIC

- If no IIC EEPROM was found then initialise flash memory to use NVM

pages

- Decode user input

- Modify the NVRAM as indicated

- Validate the NVRAM by calculating the checksum and storing it

Execution Time Less than 1 second

User Input 1. The location that must be modified

i.e. "ALL" "BOOT" "DIAGNOSTICS" "DOWNLOAD" "CONFIG"

"RECORDER" or no string if an offset from the base address of the

NVRAM is required

2. The offset and data which to put on the selected loc ation

<offset> <length> <data>

Error Number Description

30300 Modifying the NVRAM contents succeeded

30301 Unable to initialise NVM

30302 Modifying the NVRAM contents failed

30303 length out of range

30304 unable to decode length

30305 offset out of range

30306 unable to decode offset

30307 unknown location specifie d

30308 no location is specified

30309 number of values incorrect

30310 There was an IIC error

Example

DS:> 303 DIAGNOSTICS 5 1 0x5a

030300: Section is modified successfully

Test OK @

EN 26

5.

3139 785 31681

Firmware Upgrading & Diagnostic Software

Nucleus Name

DS_NVRAM_Read

Nucleus Number 304

Description Read out one or more locations in the NVRAM

Technical - Initialise IIC

- If no IIC EEPROM was found then initialise flash memory to use NVM

pages

- Decode user input

- Read from the NVRAM and return this info to the user

Execution Time Less than 1 second

User Input 1. The location which must be read

i.e. "ALL" "BOOT" "DIAGNOSTICS" "DOWNLOAD" "CONFIG"

"RECORDER" or no string if an offset from the base address of the

NVRAM is required

2. The offset and number of bytes to read

<offset> <length>

Error Number Description

30400 Value read

30401 Unable to initialise NVM

30402 Reading the NVRAM contents failed

30403 Length out of range

30404 Unable to decode length

30405 Offset out of range

30406 Unable to decode offset

30407 Unknown location specified

30408 No location is specified

Example

304 DIAGNOSTICS 0 6

030400: Value read = 0x00 0x00 0x00 0x00 0x00 0x5A

Test OK @

SDRAM (SDRAM)

Nucleus Name

DS_SDRAM_WriteRead

Nucleus Number 400

Description Check all data lines, address lines and memory locations of the SDRAM

Technical - Test the data b us

- Test the address bus

- Test the integrity of the device itself (memory locations)

Execution Time 11 seconds for 32 Mb

23 seconds for 64 Mb

User Input None

Error Number Description

40000 The write-read test succeeded

40001 The data bus contains an error

40002 The address bus contains an error

40003 The SDRAM itself contains an error

Example

Nucleus Name

DS:> 400

040000:

Test OK @

DS_SDRAM_WriteReadFast

Nucleus Number 401

Description Check all data lines and address lines of the SDRAM

Technical - Test the data b us

- Test the address bus

Execution Time Less than 1 second

User Input None

Error Number Description

40100 The write-read test succeeded

40101 The data bus contains an error

40102 The address bus contains an error

Example

DS:> 401

040100:

Test OK @

Firmware Upgrading & Diagnostic Software

3139 785 31681

5.

EN 27

Nucleus Name

DS_SDRAM_Write

Nucleus Number 402

Description Write to a specific un-cached memory address

Technical - Decode the us er input and check its ranges and alignment on 4 bytes

- Write the data to the SDRAM

Execution Time Less than 1 second

User Input 1. The location that must be modified

(SDRAM starts at address 0xA0000000)

2. The value to put on the selected location

Error Number Description

40200 Writing to the SDRAM succeeded

40201 Writing to the SDRAM failed; Wrong user input

40202 Address is not dividable by 4

Example

Nucleus Name

DS:> 402 0xa1000010 0xad112222

040200:

Test OK @

DS_SDRAM_Read

Nucleus Number 403

Description Read from a specific un-cached memory address

Technical - Decode the us er input and check the ranges

- Read from the SDRAM and return this info to the user

Execution Time Less than 1 second

User Input The location from which the data must be read

(SDRAM starts at address 0xA0000000)

Error Number Description

40300 Reading from the SDRAM succeeded

40301 Reading from the SDRAM failed; Wrong user input

40302 Address is not dividable by 4

Example

DS:> 403 0xa1000010

040300: Value read = 0xAD112222

Test OK @

Nucleus Name

DS_SDRAM_DmaWriteRead

Nucleus Number 404

Description Write a pattern to the entire SDRAM using DMA and check the data

Technical - Check if the Stack pointer is not in the write range

- Clear a 64kb block and then fill it with a pattern

- Initialise the DMA controller and write the data to the SDRAM

- Then check if all the data was written correctly (except descriptor tables)

- Repeat the process 4 times with 4 different patterns

Execution Time 24 seconds

User Input None.

Error Number Description

40400 Writing to the SDRAM succeeded

40401 Stack area definition ERROR!

40402 DMA controller could not be initialised.

40403 Not all data was transferred correctly

Example

DS:> 404

040400:

Test OK @

EN 28

FLASH (FLASH)

5.

3139 785 31681

Firmware Upgrading & Diagnostic Software

Nucleus Name

DS_FLASH_DevTypeGet

Nucleus Number 500

Description Get the device (revision) type information of the FLASH ICs. (type,

manufacturer, device ID and size)

Technical - Set the timing for the flash writing

- Write a command sequence to determine device type information

- Return the information to the user

Execution Time Less than 1 second

User Input None

Error Number Description

50000 Getting the information from the FLASH succeeded

50001 Getting the information from the FLASH failed

Example

Nucleus Name

DS:> 500

050000: Found FLASH memory:

NOR AMD 29DL640G 8MB,NOR AMD 29DL640G 8MB

Test OK @

DS_FLASH_WriteRead

Nucleus Number 501

Description Check whether the FLASH can be written to and read from

Technical - Find the test segment in flash

- Read the data into SDRAM

- Modify the data

- Write this data from SDRAM to FLASH and verify it by reading back again

Execution Time Less than 1 second.

User Input None

Error Number Description

50100 The FLASH write-read test succeed ed

50101 The test segment could not be found

50102 All bits in the TEST region are filled with 0 (region exhausted)

50103 The Write Read test failed

50104 The Write Failed

Example

DS:> 501

050100:

Test OK @

Nucleus Name

DS_FLASH_Read

Nucleus Number 502

Description Read from a specific memory address in FLASH

Technical - Decode the user input and check the ranges and whether the address is

aligned on 4 bytes

- Read the data and return this to the user

Execution Time Less than 1 second.

User Input The location from which data must be read

(FLASH starts at address 0xB8000000)

Error Number Description

50200 Reading the FLASH succeeded

50201 Reading the FLASH failed; Wrong user input

50202 Address is not dividable by 4

Example

DS:> 502 0xb8000000

050200: Value read = 0x3C08A000

Test OK @

Firmware Upgrading & Diagnostic Software

3139 785 31681

5.

EN 29

Nucleus Name

DS_FLASH_ChecksumProgram

Nucleus Number 503

Description Check the checksum of the application partitions by recalculating and

comparing partition checksums

Technical - Determine the number of segments

- Find the application in each segment and determine its checksum

- Check whether the checksums stored match the newly calculated

Execution Time 6 seconds

User Input None

Error Number Description

50300 The checksum is valid, the test succeeded

50301 The checksum is invalid

Example

Nucleus Name

DS:> 503

050300:

BootCode checksum is: 0xBABE5B6F, which is correct

Diagnostics checksum is: 0xBABEBAFF, which is correct

Download checksum is: 0xBABEEDBF, which is correct

Application checksum is: 0xBABE8EEC, which is correct

Test OK @

DS_FLASH_CalculateChecksum

Nucleus Number 504

Description Calculate the checksum over all memory addresses. Used to check entire

FLASH contents

Technical - Run the check sum calculation algorithm on all flash memory addresses

Execution Time 6 seconds

User Input None

Error Number Description

50400 Calculating the checksum over all addresses succeeded

Example

DS:> 504

050400: The Checksum = 0xBABE30A4

Test OK @

Nucleus Name

DS_FLASH_CalculateChecksumFast

Nucleus Number 505

Description Calculate a checksum over a selected number of address locations

Technical - Run the check sum calculation algorithm on a selected number of flash

memory addresses

Execution Time 6 seconds

User Input None

Error Number Description

50500 Calculating the checksum over selected addresses succeeded

Example

Video Input Processor (VIP)

Nucleus Name

DS:> 505

050500: The Checksum = 0xBABEB064

Test OK @

DS_VIP_DevTypeGet

Nucleus Number 600

Description Get the device (revision) type information of the VIP IC

Technical - Initialise IIC

- Read out the device (revision) type information of the VIP IC

Execution Time Less than 1 second

User Input None

Error Number Description

60000 Getting the information from the VIP succeeded

60001 The IIC bus initialisation failed

60002 The was an error getting the information from the VIP

60003 Type not according to t ype stored in HW diversity string

Example

DS:> 600

060000: Found SAA7118

Test OK @

EN 30

5.

3139 785 31681

Firmware Upgrading & Diagnostic Software

Nucleus Name

DS_VIP_Communication

Nucleus Number 601

Description Check the communication between the IIC controller of the Codec and the VIP

IC

Technical - Initialise IIC

- Read data from a location in the VIP

Execution Time Less than 1 second

User Input None

Error Number Description

60100 Communicating with the VIP succeeded

60101 The IIC bus was not accessible

60102 There was a timeout reading the device

60103 The IIC acknowledge was not received

60104 The communication with the device failed

60105 The IIC bus initialisation failed

Example

Nucleus Name

DS:> 601

060100:

Test OK @

DS_VIP_ClockOutputOn

Nucleus Number 602

Description Switch the clock output on

Technical - Initialise IIC

- Set the clock output through IIC

Execution Time Less than 1 second

User Input None

Error Number Description

60200 Switching the clock output on succeeded

60201 Switching the clock output on faile d

Example

DS:> 602

060200:

Test OK @

Nucleus Name

DS_VIP_ClockOutputOff

Nucleus Number 603

Description Switch the clock output off

Technical - Initialise IIC

- Reset the clock output through IIC

Execution Time Less than 1 second

User Input None

Error Number Description

60300 Switching the clock output off succeeded

60301 Switching the clock output off failed

Example

DS:> 603

060300:

Test OK @

Loading...

Loading...