Page 1

2. Safety Information, General Notes & Lead Free Requirements

2.1 Safety

Instructions

2.1.1 General Safety

Safety regulations require that during a repair:

• Connect the unit to the mains via an isolation transformer.

• Replace safety components, indicated by the symbol

,

only by components identical to the original ones. Any

other component substitution (other than original type)

may increase risk of fi re or electrical shock hazard.

Safety regulations require that after a repair, you must return

the unit in its original condition. Pay, in particular, attention to

the following points:

• Route the wires/cables correctly, and fi x them with the

mounted cable clamps.

• Check the insulation of the mains lead for external

damage.

• Check the electrical DC resistance between the mains

plug and the secondary side:

1. Unplug the mains cord, and connect a wire between

the two pins of the mains plug.

2. Set the mains switch to the ‘on’ position (keep the

mains cord unplugged!).

3. Measure the resistance value between the mains

plug and the front panel, controls, and chassis

bottom.

4. Repair or correct unit when the resistance

measurement is less than 1 MΩ.

5. Verify this, before you return the unit to the customer/

user (ref. UL-standard no. 1492).

6. Switch the unit ‘off’, and remove the wire between the

two pins of the mains plug.

2.1.2 Laser Safety

This unit employs a laser. Only qualifi ed service personnel

may remove the cover, or attempt to service this device (due

to possible eye injury).

2.2 Warnings

2.2.1 General

• All ICs and many other semiconductors are susceptible to

electrostatic discharges (ESD, ). Careless handling

during repair can reduce life drastically. Make sure that,

during repair, you are at the same potential as the mass

of the set by a wristband with resistance. Keep

components and tools at this same potential.

Available ESD protection equipment:

– Complete kit ESD3 (small tablemat, wristband,

connection box, extension cable and earth cable)

4822 310 10671.

– Wristband tester 4822 344 13999.

• Be careful during measurements in the live voltage

section. The primary side of the power supply, including

the heatsink, carries live mains voltage when you

connect the player to the mains (even when the

player is ‘off’!). It is possible to touch copper tracks and/

or components in this unshielded primary area, when

you service the player. Service personnel must take

precautions to prevent touching this area or components

in this area. A ‘lightning stroke’ and a stripe-marked

printing on the printed wiring board, indicate the primary

side of the power supply.

• Never replace modules, or components, while the unit is

‘on’.

2.2.2 Laser

• The use of optical instruments with this product, will

increase eye hazard.

• Only qualifi ed service personnel may remove the cover or

attempt to service this device, due to possible eye injury.

• Repair handling should take place as much as possible

with a disc loaded inside the player.

• Text below is placed inside the unit, on the laser cover

shield:

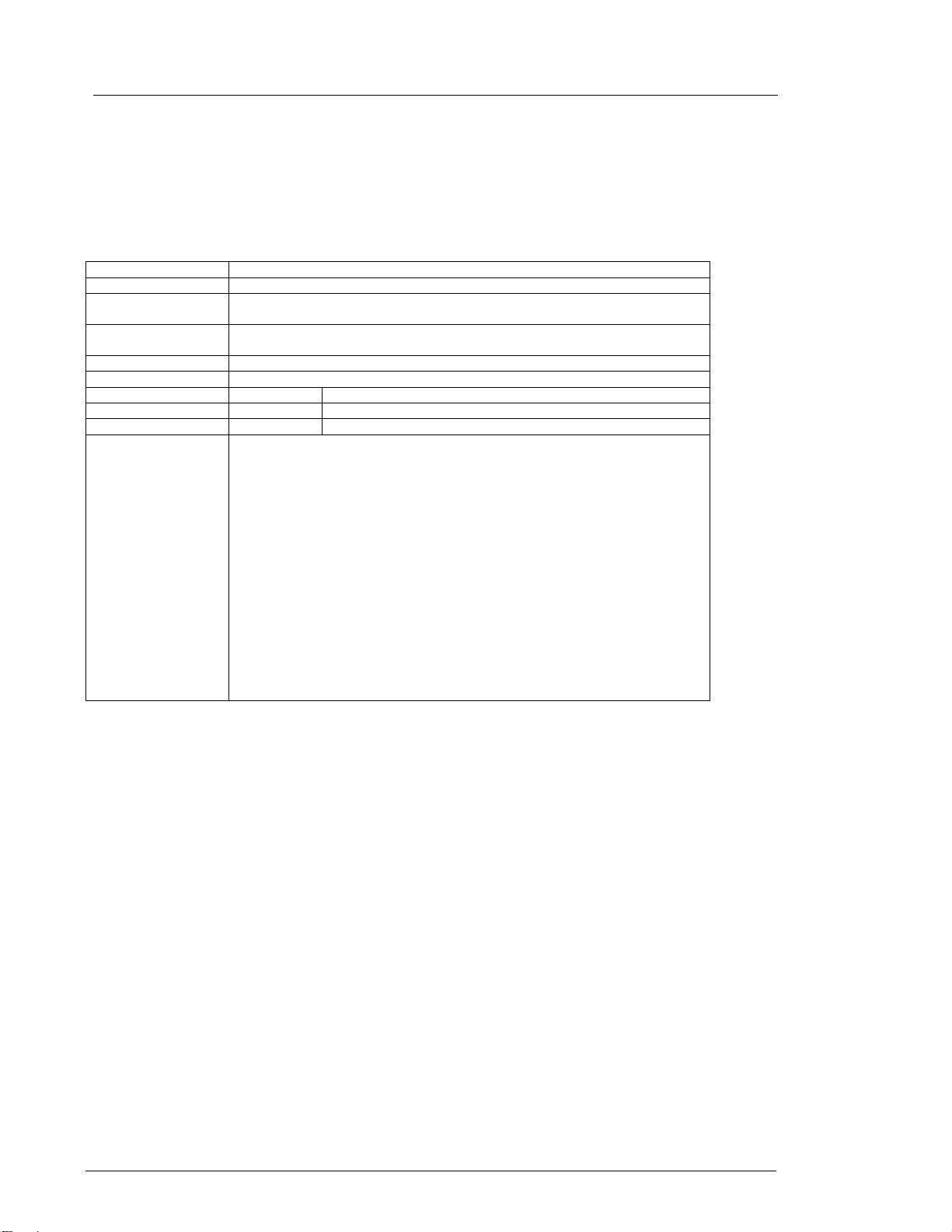

Laser Device Unit

Type : Semiconductor laser

GaAlAs

Wavelength : 650 nm (DVD)

: 780 nm (VCD/CD)

Output Power : 20 mW

(DVD+RW writing)

: 0.8 mW

(DVD reading)

: 0.3 mW

(VCD/CD reading)

Beam divergence : 60 degree

CLASS 1

LASER PRODUCT

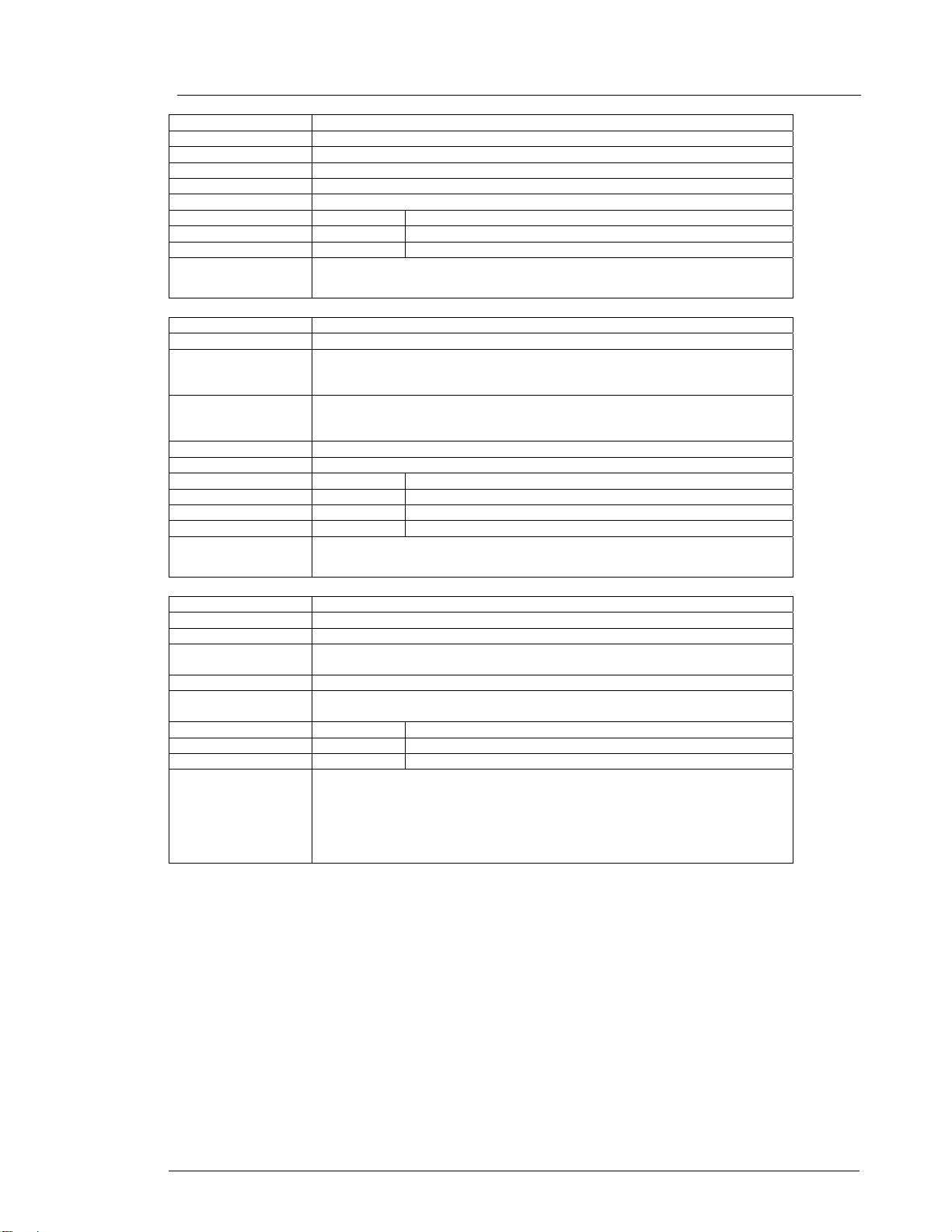

Figure 2-1

Note: Use of controls or adjustments or performance of

procedure other than those specifi ed herein, may result in

hazardous radiation exposure. Avoid direct exposure to beam.

CAUTION VISIBLE AND INVISIBLE LASER RADIATION WHEN OPEN AVOID EXPOSURE TO BEAM

ADVARSEL SYNLIG OG USYNLIG LASERSTRÅLING VED ÅBNING UNDGÅ UDSÆTTELSE FOR STRÅLING

ADVARSEL SYNLIG OG USYNLIG LASERSTRÅLING NÅR DEKSEL ÅPNES UNNGÅ EKSPONERING FOR STRÅLEN

VARNING SYNLIG OCH OSYNLIG LASERSTRÅLNING NÄR DENNA DEL ÄR ÖPPNAD BETRAKTA EJ STRÅLEN

VARO! AVATTAESSA OLET ALTTIINA NÄKYVÄLLE JA NÄKYMÄTTÖMÄLLE LASER SÄTEILYLLE. ÄLÄ KATSO SÄTEESEEN

VORSICHT SICHTBARE UND UNSICHTBARE LASERSTRAHLUNG WENN ABDECKUNG GEÖFFNET NICHT DEM STRAHL AUSSETSEN

DANGER VISIBLE AND INVISIBLE LASER RADIATION WHEN OPEN AVOID DIRECT EXPOSURE TO BEAM

ATTENTION RAYONNEMENT LASER VISIBLE ET INVISIBLE EN CAS D’OUVERTURE EXPOSITION DANGEREUSE AU FAISCEAU

Figure 2-2

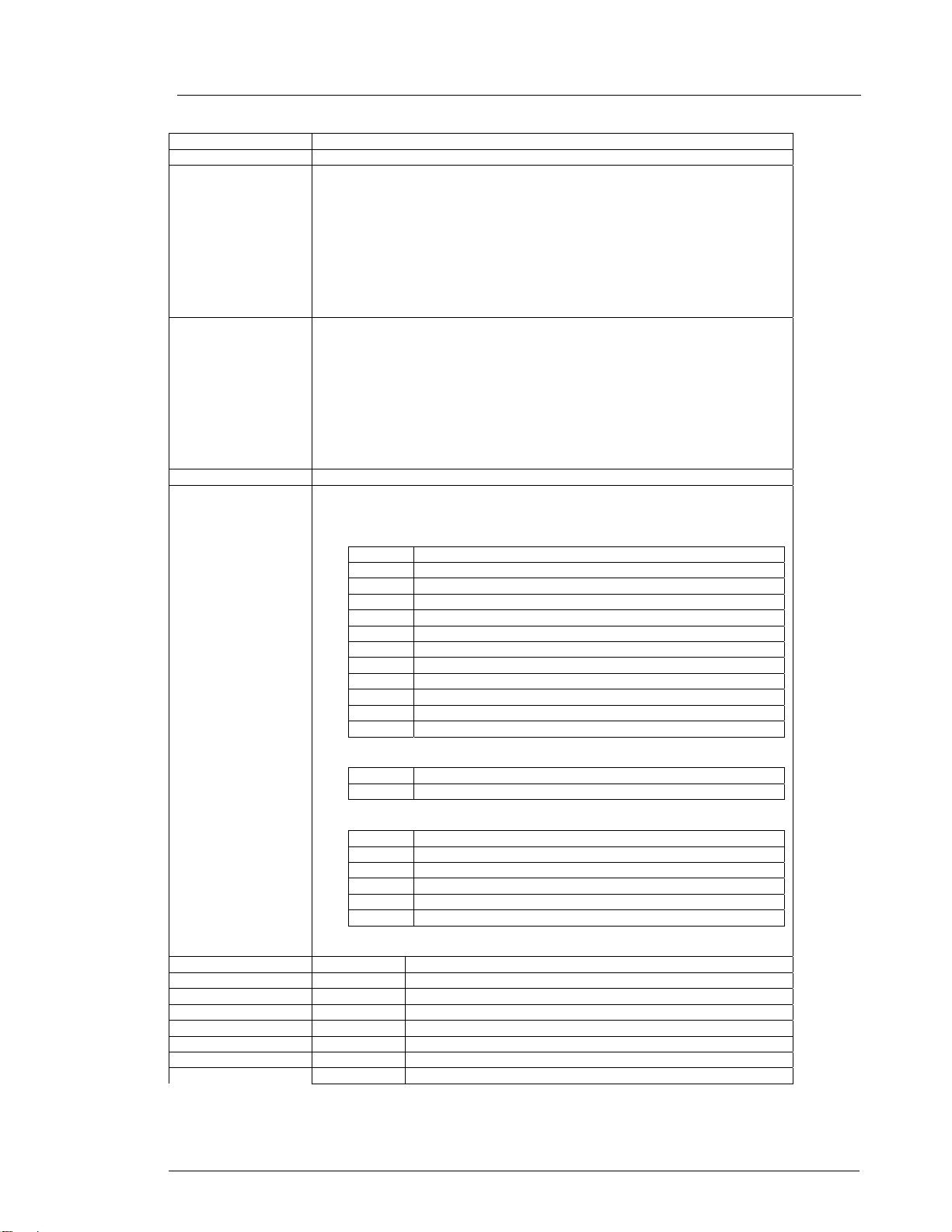

Page 2

Safety Information, General Notes & Lead Free Requirements

2.3 Lead Free Requirement

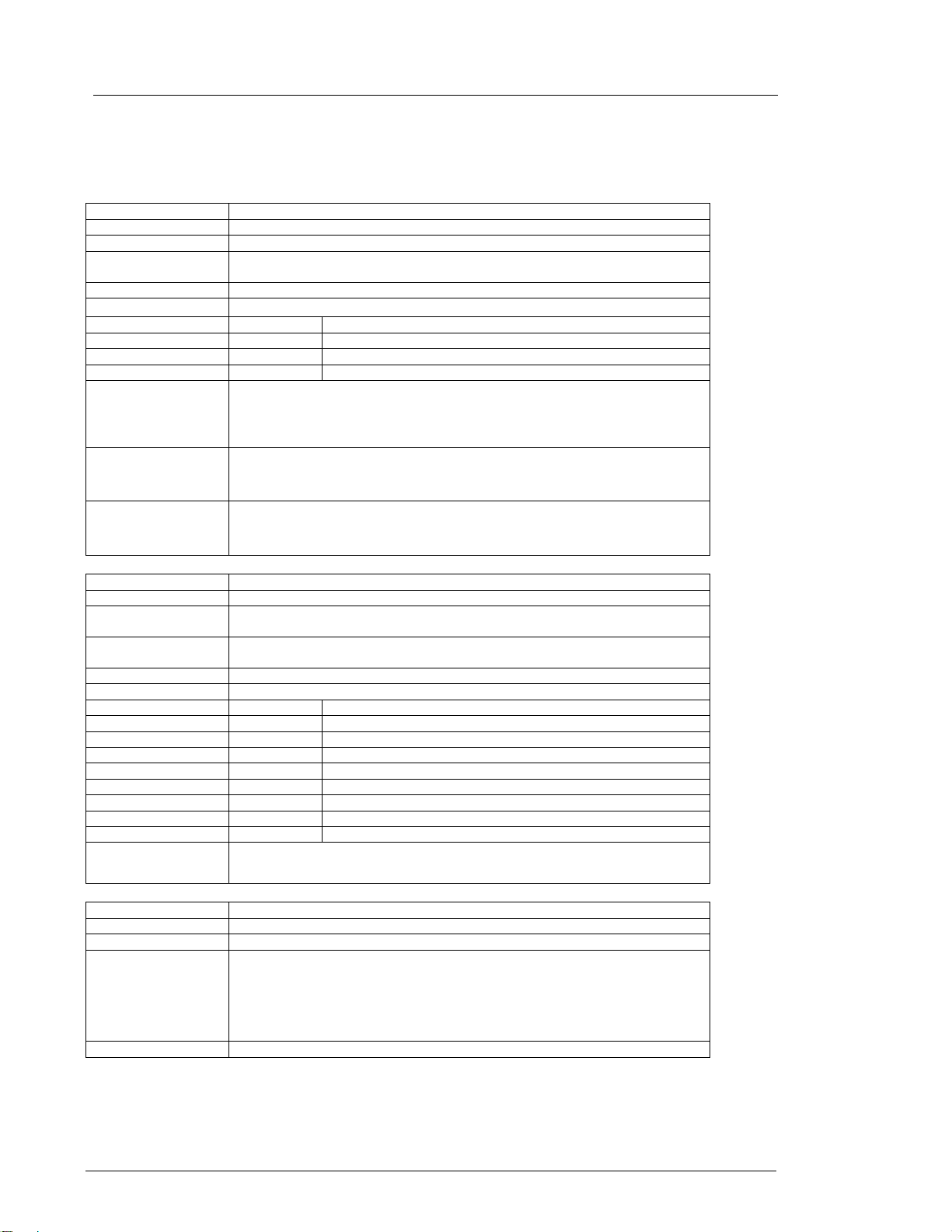

Information about Lead-free produced sets

Philips CE is starting production of lead-free sets from

1.1.2005 onwards.

INDENTIFICATION:

Regardless of special logo (not always indicated)

One must treat all sets from 1 Jan 2005 onwards, according

next rules.

Example S/N:

Bottom line of typeplate gives a 14-digit S/N. Digit 5&6 is the year, digit 7&8 is

the week number, so in this case 1991 wk 18

So from 0501 onwards = from 1 Jan 2005 onwards

• Special information for BGA-ICs:

- always use the 12nc-recognizable soldering temperature

profi le of the specifi c BGA (for de-soldering always use the

lead-free temperature profi le, in case of doubt)

- lead free BGA-ICs will be delivered in so-called ‘drypackaging’ (sealed pack including a silica gel pack) to

protect the IC against moisture. After opening, dependent

of MSL-level seen on indicator-label in the bag, the

BGA-IC possibly still has to be baked dry. (MSL=Moisture

Sensitivity Level). This will be communicated via AYSwebsite.

Do not re-use BGAs at all.

• For sets produced before 1.1.2005 (except products of

2004), containing leaded solder-alloy and components,

all needed spare-parts will be available till the end of the

service-period. For repair of such sets nothing changes.

• On our website www.atyourservice.ce.Philips.com you

fi nd more information to:

BGA-de-/soldering (+ baking instructions)

Heating-profi les of BGAs and other ICs used in Philips-sets

You will fi nd this and more technical information within the

“magazine”, chapter “workshop news”.

For additional questions please contact your local repair-helpdesk.

Important note: In fact also products of year 2004 must be treated in this way as long as you

avoid mixing solder-alloys (leaded/ lead-free). So best to always use SAC305 and the higher

temperatures belong to this.

Due to lead-free technology some rules have to be respected by the

workshop during a repair:

• Use only lead-free solder alloy Philips SAC305 with order

code 0622 149 00106. If lead-free solder-pate is required,

please contact the manufacturer of your solder-equipment.

In general use of solder-paste within workshops should be

avoided because paste is not easy to store and to handle.

• Use only adequate solder tools applicable for lead-free

solder alloy. The solder tool must be able

o To reach at least a solder-temperature of 400°C,

o To stabilize the adjusted temperature at the solder-tip

o To exchange solder-tips for different applications.

• Adjust your solder tool so that a temperature around 360°C

– 380°C is reached and stabilized at the solder joint.

Heating-time of the solder-joint should not exceed ~ 4 sec.

Avoid temperatures above 400°C otherwise wear-out of

tips will rise drastically and fl ux-fl uid will be destroyed. To

avoid wear-out of tips switch off un-used equipment, or

reduce heat.

• Mix of lead-free solder alloy / parts with leaded solder alloy

/ parts is possible but PHILIPS recommends strongly to

avoid mixed solder alloy types (leaded and lead-free).

If one cannot avoid or does not know whether product is

lead-free, clean carefully the solder-joint from old solder

alloy and re-solder with new solder alloy (SAC305).

• Use only original spare-parts listed in the Service-Manuals.

Not listed standard-material (commodities) has to be

purchased at external companies.

Page 3

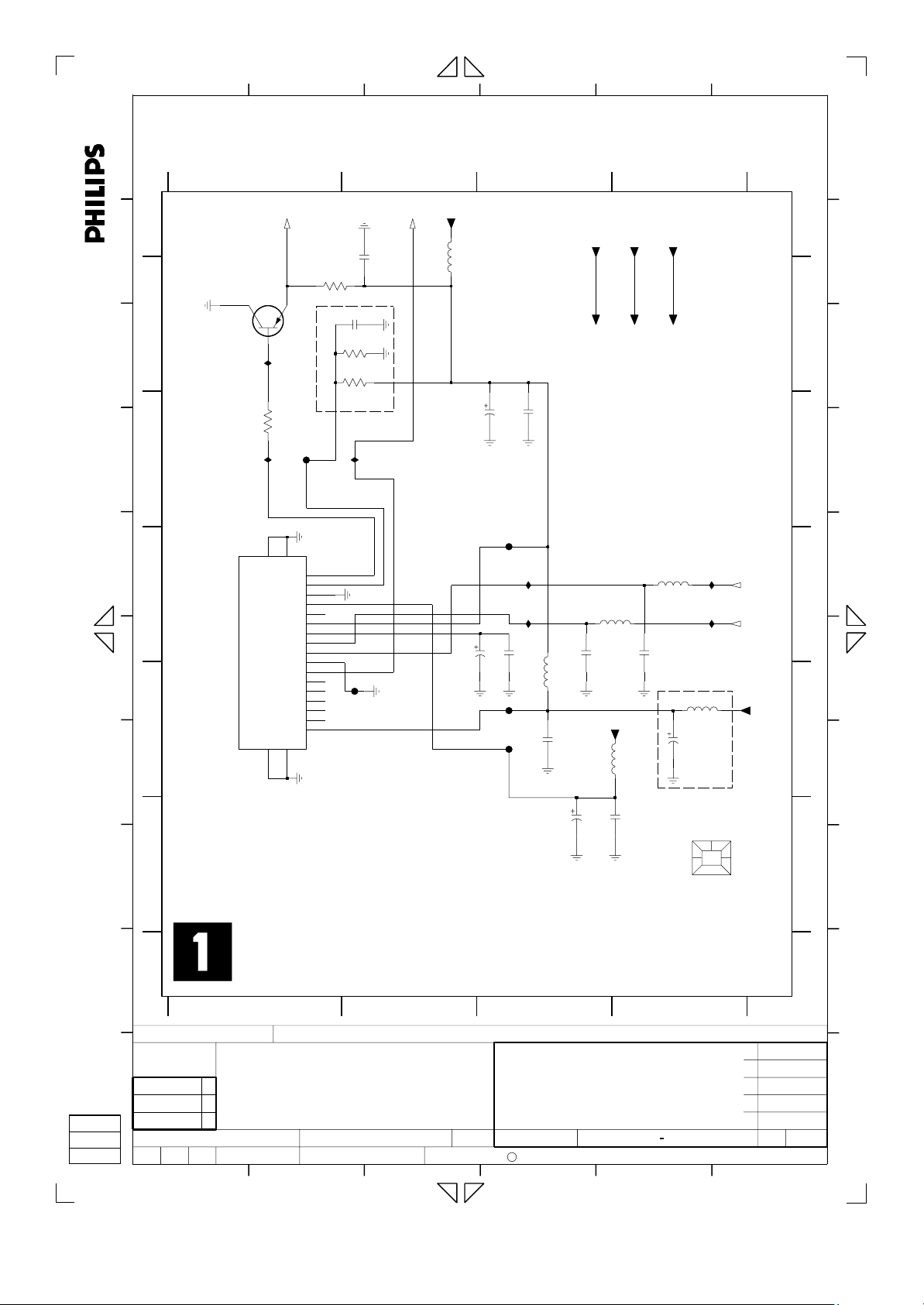

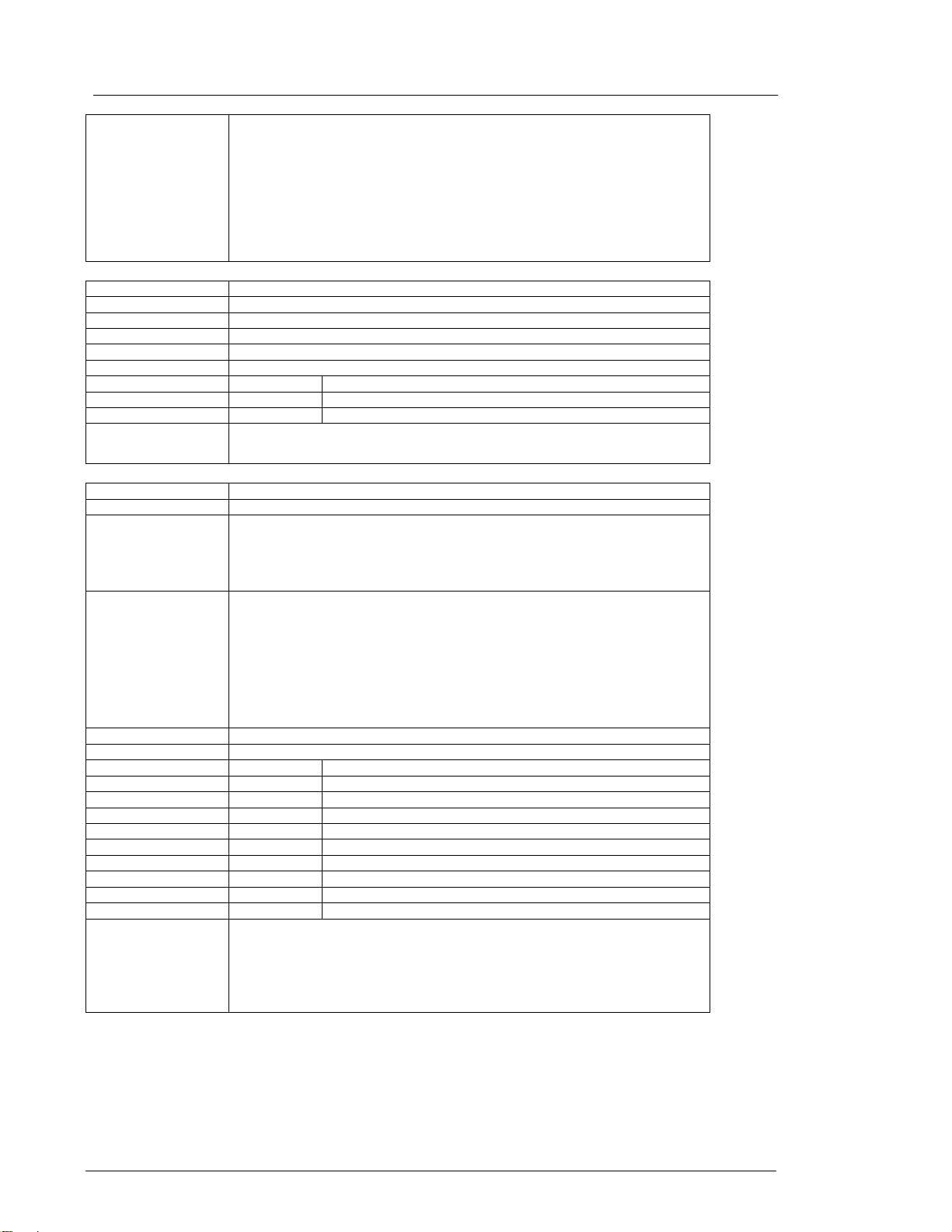

123456

0803 E4

1700 E1

2700 A2

2701 B3

2702 A2

2703 D3

A

1

B

A

C

B B

D

1700

TMQZ2

owner.

is prohibited without the written consent of the copyright

All rights reserved. Reproduction in whole or in parts

E

C

F

D

G

2705 E3

2707 C3

7701

BC857BW

I700

3704

100R

I701

1920

VIDOUT

RFAGC

TUNER

SIFOUT

VFV

to IOV,FOME

F705

18

AFT

GND2

VTU

NC5

MB

SDA

SCL

GND1

AOUT

NC4

NC3

NC2

NC1

BB

21

2708 C4

2709 B3

2710 C1

3706

2K2

17

16

15

14

13

12

10

11

9

8

7

6

5

4

3

2

1

2711 C1

2712 D4

3700 A2 5706 D4

3701 A2

3704 B1

3706 A1

5700 A22704 E3

5702 D3

5703 C4

23

5V

SIF1

to MSP

5700

22u

2711

2701

25V

22u

6.3V47u

F704

2710

F703

F702

2700

22n

3700

47K

3701

47K

I703

F701

2702

not used

100n

5704 C4

5705 D3

2709

I704

I706

10n

5705

10n

Bead

2703

7701 A1

F700 D1

F701 E3

5VSTBY

5VSTBY

2707

delete for DTTM

100n

F702 D3

F703 D3

F704 C3

from PS

5704

Bead

47p

not used

33VSTBY

5702

10u

F705 B1

I700 A1

I701 B1

I703 B2

I704 C3

I705 C4

I706 C3

I707 C4

A

4

5V

33VSTBY

B

5V

33VSTBY

A

C

D

E

C

F

D

G

2708

5703

Bead

47p

not used

2712

I705

I707

5706

10u

25V10u

for DTTM only

SCL_5V

from CU

SDA_5V

from/to CU

5VSTBY

-403A

E

H

I

CHN SETNAME dvdrw_2004

CLASS_NO

3PB120

J

2004-03-2623

NAME

1

Frontend Video FV

Friedreich

CHECK DATE

PB AB 04 E1

SUPERS.

123456

2003-01-13

50V4u7

10n

50V

2704

2705

0803

BARCODE

E

H

I

21

10

3

3103 603 3035

C

ROYAL PHILIPS ELECTRONICS N.V. 2005

130

4

2006-01-27

7

6

2005-07-07

0

2004-10-22

0

2004-05-07

0

2004-03-25

1

J

A4

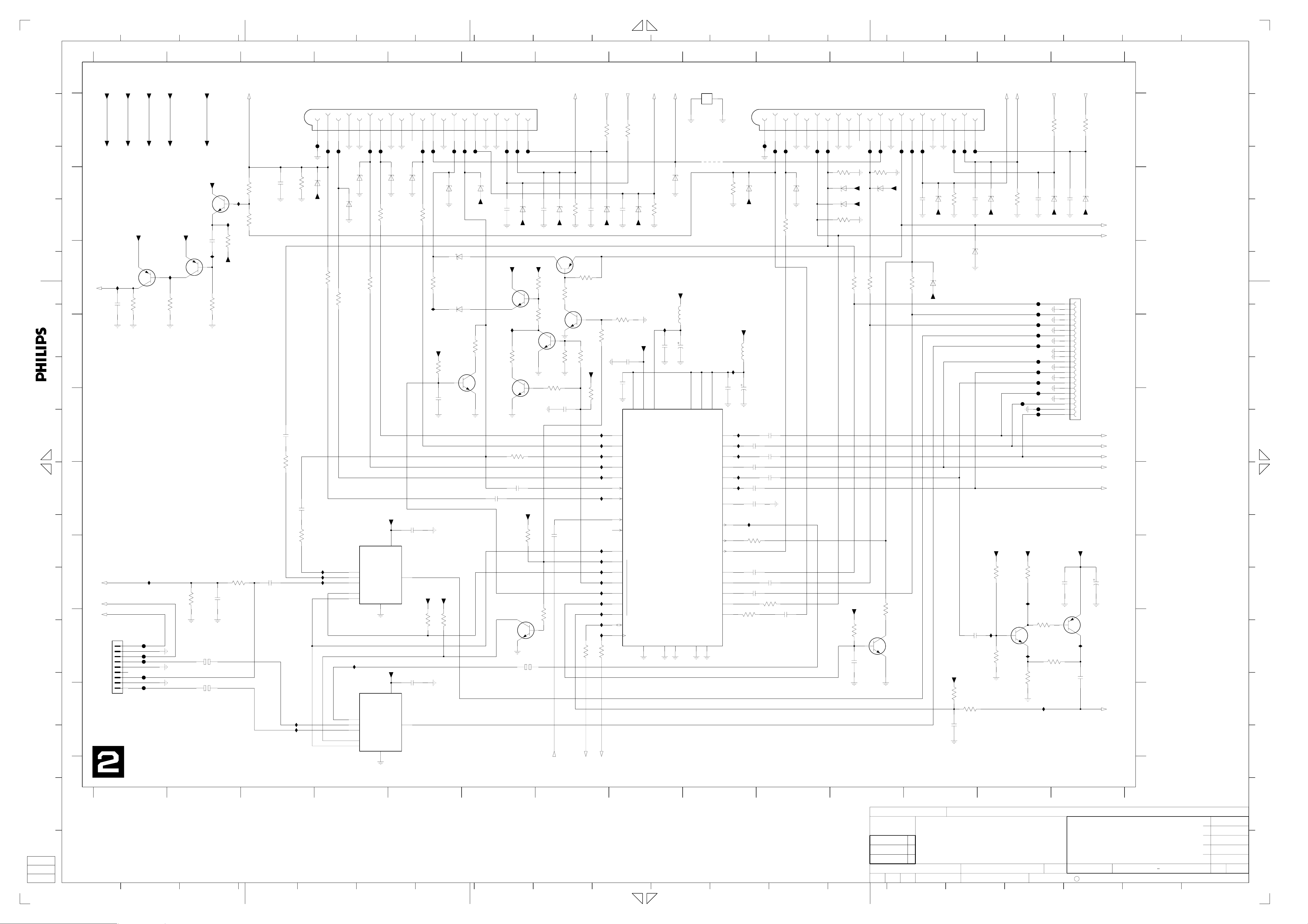

Page 4

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19

20

A

12VSTBY

5VSTBY

B

A

12VSTBY

5VSTBY

C

B

D

E

C

WU

to CU

BC857BW

I404

2402

220n

F

D

G

E

H

I

F

J

G

WSFI

to CU

K

AINFL

to IOA

AINFR

All rights reserved. Reproduction in whole or in parts

is prohibited without the written consent of the copyright

owner.

L

H

M

to IOA

1942

AINFR

GND

AINFL

CVBSFIN

GND

NC

CFIN

GND

from/to FRONT A/V

YFIN

1

2

3

4

5

6

7

8

9

B9B-PH-K

I

N

1

from PS

5V

5V

5VSTBY

7403

3K9

3408

I405

F4201

F4203

F4204

F4207

F4209

5NSTBY

5NSTBY

BC857BW

I406

3405

5VSTBY

7401

22K

from PROG

BC847BW

82K

3489

10u 16V

5NESD

5NESD

5VSTBY

7402

2450

I407

3406

not used

2428

2421

10u16V

100n

470K

2412

I409

3407

5NSTBY

10n

I408

3K3

3429

47K

CVBSIN

3446

3447

to FOME

47K

47K

2459

100n

2401

2410

3490

SCART 1

3404

100p

not used

100n

150R

2404

3435

I422

I423

F4021

1%

75R

6401

5NESD

100n

150R

I419

I420

CVBSIN1

GND

20A

21A

F4020

BZX384-C12

3445

I418

YCVBSOUT1

19A

F4019

6420

150R

1%

75R

3414

7412

NJM2234M

43

GND

GND

17A

18A

F4016

6414

BZX384-C6V8

BZX384-C6V8

3412

3-INPUT

VIDEO SW

1

VIN1

3

VIN2

5

VIN3

2

SW1

4

SW2

I421

NJM2235M

3-INPUT

VIDEO SW

1

VIN1

3

VIN2

5

VIN3

2

SW1

4

SW2

FBOUT

16A

F4015

3409

75R

Φ

GND

7413

Φ

GND

RCOUT

15A

6402

1%

75R

5V

V+

VOUT

8

5V

6

V+

VOUT

8

GND

GND

13A

14A

6403

BZX384-C6V8

2406

1u0

6

7

2407

1u0

5

NC

12A

F4011

BZX384-C6V8

3413

7

GOUT

11A

F4010

1%

75R

3422

I402

5VSTBY

5V

3437

P50

10A

3430

2403

10K

GND

9A

6423

BAT54 COL

820R

4K7

100n

5V

3438

8SC1

BOUT/CIN

8A

F4008

F4007

BZX384-C12

6421

6410

BAS316

7404

BC817-25W

10K

7A

F4006

5NESD

3403

AIN1L

6A

6404

1%

75R

62

GND

GND

4A

5A

F4003

BZX384-C12

2424

12VSTBY

7405

BC847BW

7407

BC847BW

2419

1u0

7416

BC847BW

AOUT1L

3A

F4002

470p

5NESD

I467

BC847BW

33K

3424

3410

75R

2413

1u0

AOUT1R

AIN1R

2A

F4001

6405

BZX384-C12

12VSTBY

7409

1%

5VSTBY

3451

2417

16V 10u

1A

10K

1940-1

2425

3421

3423

3450

ROW_A

27K

390R

BC847BW

3428

100K

7

AIN1R

MRC-021V-10 PC

6406

3443

3426

2447

10n

not used

1u0

from FV

VFV

3472

BZX384-C12

7414

BC857BW

47K

33K

3442

470p

5NESD

7415

2446

100K

to IOA,MSP

2426

100K

3441

470K

150K

5VSTBY

3439

F444

3433

100R

from/to CU

SDA_5V

3475

6407

470p

5NESD

3448

10K

I461

I462

I463

I464

I465

I466

I415

I416

I417

I468

I401

I403

I469

I470

3432

SCL_5V

from IOA

AOUT1R

100R

2429

BZX384-C12

3444

18K

100K

2411

34

33

40

41

1

43

28

42

44

2

14

16

18

38

37

100R

from/to CU

8

from IOA

AOUT1L

3476

100R

470p

6408

BZX384-C12

5NESD

5VSTBY

2414

100n

100n

20

36

VDD

VCCB-REC

R|PR|COUT-TV

G|YOUT-TV

B|PBOUT-TV

FBOUT-TV

Y|CVBSOUT-TV

CIN-TV

Y|CVBSIN-TV

Y|CVBSIN-TUN

CIN-TUN

C-GATE

1

VS

CS

2

3

DIGOUT

4

5

6

SDA

SCL

GNDB-REC

22

AIN1L

3471

8

VCC

to IOA,MSP

100K

I456

2435

7408

STV6618D

P50

from/to CU

6409

BZX384-C6V8

5VSTBY

5406

2434

100n

Φ

MRC-021V-10 PC

10u

6.3V47u

VIDEO SWITCH

MATRIX

Y|CVBSOUT-REC

Y|CVBSOUT-AUX

GND1

GND2

3

12

9

MT2

1940-3

MT1MT2

4401

not used

24

30

32

VCCB3

VCCB2

VCCB1

R|PR|CIN-ENC

G|YIN-ENC

B|PBIN-ENC

CVBSIN-ENC

CIN-ENC

YIN-ENC

DECV

COUT-AUX

R|PR|CIN-AUX

G|YIN-AUX

B|PBIN-AUX

FBIN-AUX

Y|CVBSIN-AUX

GNDB

GNDD

39

26

I414

2409

1029

1127

21

23

25

17

15

13

35

19

3427

5VSTBY

100n

931

4

6

7

5

SCART 2

1%

75R

6424

5NESD

10u

5402

2405

47u 6.3V

I483

2441

I482

1u0

I481

2437

1u0

I479

2438

I478

1u0

2433

47n

I476

3449

75R

2418

1u0

2427

1u0

3452

150R

GND

21B

F4121

F4120

BZX384-C12

2440

1u0

2436

1u0

2439

1u0

2423

1u0

3494

150R

10

YCVBSIN2

CVBSOUT2

20B

19B

F4119

3411

2416

1u0

GND

18B

6419

BZX384-C6V8

75R

GND

17B

FBIN

16B

F4116

GND

RCIN

15B

F4115

3401

75R

6415

BZX384-C12

6422

BZX384-C6V8

3417

75R

GND

14B

1%

5VSTBY

2408

11 12 13

13B

3491

3436

NC

12B

F4211

5NESD

5NESD

3492

150R

4K7

100n

GIN

P50

10B

11B

F4110

3402

1%

75R

6416

BZX384-C12

150R

3425

7406

BC817-25W

GND

9B

75R

F4108

5NESD

1%

8SC2

8B

F4107

3493

BIN/COUT

AIN2L

6B

7B

F4106

2431

150R

5NESD

GND

470p

6425

5NESD

6417

5B

GND

AOUT2L

3B

4B

F4103

3470

BZX384-C12

BZX384-C12

5VSTBY

3431

2422

AIN2R

F4102

100K

4K7

3434

4K7

10n

2B

F4101

2443

6418

100n

2415

AOUT2R

1940-2

1B

470p

6412

5NESD

BZX384-C12

I411

ROW_B

5V

3416

3418

to IOA

to IOA

AIN2L

AIN2R

MRC-021V-10 PC

3469

100K

BZX384-C12

F4720

5V

27K

22K

3415

I410

I412

3420

2442

F4701

F4703

F4705

F4707

F4709

F4712

F4714

F4716

F4718

F4721

F4722

1K0

3440

100R

7411

BC847BW

100R

I451

3478

6411

470p

5NESD

3419

100R

AOUT2L

14

from MSP

2444

1947

100n

I413

3477

470p

6413

5NESD

A_VR

GND

A_UB

GND

A_YG

GND

A_C

GND

A_YCVBS

GND

GND

D_CVBS

GND

D_Y

GND

D_C

GND

D_VR

GND

D_YG

GND

D_UB

5V

7410

BC857BW

2420

100R

BZX384-C12

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

22FMN-BTRK-A

2430

from MSP

AOUT2R

100R

BZX384-C12

2432

100n

1940-1 A7

1940-2 A13

1940-3 A9

1942 H1

1947 C14

2401 B3

2402 C1

2403 E5

2404 F3

2405 E9

2406 F5

2407 H5

2408 H11

2409 E9

A

2410 E3

2411 D8

2412 G2

2413 F6

2414 D8

2415 H12

2416 H10

2417 H6

2418 G9

2419 F6

2420 I14

2421 I2

2422 I12

B

2423 G10

2424 B6

2425 B7

8SC2

to CU

FB

to CU

2426 B7

2427 G9

2428 H2

2429 B8

2430 G14

2431 B12

2432 G14

2433 F9

2434 D8

C

2435 D8

2436 E10

2437 F9

2438 F9

2439 F10

2440 E10

2441 E9

2442 B13

2443 B12

2444 B14

2446 G7

2447 E7

2450 C2

D

2459 G3

3401 B11

3402 B11

3403 D6

3404 B3

3405 C1

3406 C2

3407 C2

from/to DIGTAL BOARD

3408 C1

3409 B4

3410 E6

3411 B10

3412 C4

E

D_VR

to PROG

D_YG

to PROG

D_UB

to PROG

D_CVBS

to PROG

3413 B5

3414 C4

3415 G13

3416 G13

3417 B11

3418 H13

3419 H14

3420 I13

3421 C6

3422 C5

3423 D6

D_Y

to PROG

F

3424 D6

3425 H11

3426 D7

3427 B9

3428 D7

3429 G2

3430 D5

3431 I12

3432 H7

3433 H7

3434 I13

3435 G3

3436 H11

3437 H5

G

3438 H5

3439 E7

3440 H13

22u 16V

3441 C7

3442 D7

3443 C7

3444 D8

3445 C4

3446 B3

3447 B3

3448 D7

3449 G9

3450 H7

H

3451 G6

3452 H9

3469 B13

3470 B12

3471 B8

3472 B7

3475 A7

3476 A8

3477 A14

3478 A13

3489 G2

CRout

to PROG

I

3490 F3

3491 C11

3492 C11

3493 C12

3494 G10

4401 A9

5402 D9

5406 D8

6401 B3

6402 B4

6403 B5

6404 B6

6405 B6

6406 B7

6407 B7

6408 B8

6409 B8

6410 C5

6411 B13

6412 B13

6413 B14

6414 B4

6415 B11

6416 B11

6417 C12

6418 C12

6419 B10

6420 B4

6421 C5

6422 B11

6423 B5

6424 B9

6425 B12

7401 C2

7402 B2

7403 C1

7404 D5

7405 C6

7406 H11

7407 D6

7408 E8

7409 D7

7410 H14

7411 H13

7412 G4

7413 I4

7414 C7

7415 D7

7416 H6

F4001 A6

F4002 A6

F4003 A6

F4006 A6

F4007 A5

F4008 A5

F4010 A5

F4011 A5

F4015 A4

F4016 A4

F4019 A4

F4020 A4

F4021 A3

F4101 A12

F4102 A12

F4103 A12

F4106 A12

F4107 A12

F4108 A11

F4110 A11

F4115 A10

F4116 A10

F4119 A10

F4120 A10

F4121 A10

F4201 H1

F4203 H1

F4204 H1

F4207 H1

F4209 I1

F4211 A11

F444 G7

F4701 C13

F4703 C13

F4705 D13

F4707 D13

F4709 D13

F4712 D13

F4714 D13

F4716 D13

F4718 E13

F4720 E13

F4721 E13

F4722 E13

I401 G7

I402 C5

I403 H7

I404 C1

I405 G1

I406 C2

I407 C2

I408 B2

I409 B2

I410 H13

I411 H13

I412 H13

I413 H14

I414 D9

I415 G7

I416 G7

I417 G7

I418 G4

I419 G4

I420 G4

I421 H4

I422 I3

I423 I3

I451 I13

I456 D8

I461 E7

I462 E7

I463 E7

I464 F7

I465 F7

I466 F7

I467 D6

I468 G7

I469 H7

I470 H7

I476 F9

I478 F9

I479 F9

I481 E9

I482 E9

I483 E9

A

B

C

D

E

F

G

H

I

J

K

L

M

N

O

P

1

2

3

4

65

7

8

9

654321 201918171615

10 11 12

CHN SETNAME dvdrw_2004

CLASS_NO

3PB120

1

2

2004-03-26

NAME

Neubauer

3

CHECK

1413121110987

13 14

PB AB 04 E1

Video In/Out IOV

SUPERS.

DATE

2003-01-13

10

O

7

2006-01-27

6

2005-07-07

0

2004-10-22

3103 603 3035

0

2004-05-27

0

2004-05-07

2

130

C

ROYAL PHILIPS ELECTRONICS N.V. 2005

A2

P

Page 5

1234 56

A

A

B

RSA2

RSA1

from MSP

C

D

All rights reserved. Reproduction in whole or in parts

is prohibited without the written consent of the copyright

owner.

E

B

C

D

AINFR

from IOV

AINFL

from IOV

AIN2L

from IOV

AIN2R

from IOV

AIN1L

from IOV

AIN1R

from IOV

IMUTE

from CU

ASC1

from CU

AFER

from MSP

AFEL

from MSP

ALDAC

from DAC_ADC

F

ARDAC

from DAC_ADC

ALDAC

G

E

H

GND

ARDAC

GND

AIN1R

GND

AIN1L

GND

AIN2L

to AUX AV

GND

AIN2R

for RECEIVER only

1

F510

F509

F508

F507

F505

F506

F503

2508

1u0

2507

1u0

2

2501

1u0

2506

1u0

2504

1u0

2505

1u0

2525

1u0

2524

1u0

2513

1u0

X5R

2515

1u0

X5R

I514

I516

I502

I504

3507

3534

100K

100K

3510

100K

3

3516

100K

3514

100K

3504

3511

100K

100K

7

45

5VSTBY

7501

3503

100K

3506

100K

I527

I521

F502

I515

F501

I513

3505

100K

HEF4052B

10

9

6

12

14

15

11

1

5

2

4

7504

HEF4052B

10

9

6

12

14

15

11

1

5

2

4

0

1

G4

0

1

2

3

0

1

2

3

5NSTBY

0

1

G4

0

1

2

3

0

1

2

3

5NSTBY

16

VDD

0

4X

3

MDX

VEE VSS

7

8

5VSTBY

16

VDD

0

4X

3

MDX

VEE VSS

7

8

13

3

13

3

I518

I517

6

3509

1K0

3502

1K0

3523

1K0

3515

1K0

8 9 10 11 12 13

1950 E1

7

8

from PS

5VSTBY

6.3V

2510

47u

5VSTBY

2521

100n

7509-2

5

6

3

2

5VSTBY

7505-2

5

6

3

2

84

MC33078D

5NSTBY

5VSTBY

7505-1

84

MC33078D

5NSTBY

84

5NSTBY

5VSTBY

84

5NSTBY

2531

100n

7

2532

100n

1

MC33078D

7

2530

100n

7509-1

MC33078D

1

2526

100u 16V

2522

100u

16V

I540

I535

3525

220R

2527

3522

220R

2523

5VSTBY

1n0

3527

1n0

3524

5NSTBY

5NSTBY

I528

I505

7506

BC817-25W

820R

7508

BC817-25W

820R

2519

I506

I507

9

6.3V

47u

3517

4K7

3519

4K7

ARADC

to DAC_ADC

ALADC

to DAC_ADC

AOUT1L

to IOV

AKILL

from DAC_ADC

AOUT1R

to IOV

A

B

C

D

E

2501 C2

2504 C2

2505 C2

2506 C2

2507 B2

2508 B2

2510 A8

2513 D2

2515 D2

2519 A9

2521 A7

2522 E7

2523 E8

2524 D2

2525 D2

2526 D7

2527 D8

2530 B7

2531 C7

2532 D7

3502 C6

3503 C4

3504 C3

3505 C5

3506 C4

3507 E4

3509 B6

3510 E3

3511 E3

3514 E3

3515 E6

3516 E3

3517 D9

3519 E9

3522 E8

3523 D6

3524 E8

3525 D8

3527 D8

3534 E2

7501 A5

7504 C5

7505-1 D7

7505-2 E7

7506 D9

7508 E9

7509-1 B7

7509-2 C7

F501 D5

F502 D5

F503 F1

F505 E1

F506 E1

F507 E1

F508 E1

F509 E1

F510 F1

I502 D2

I504 D2

I505 C9

I506 D9

I507 E9

I513 D5

I514 B2

I515 D5

I516 B2

I517 B6

I518 B6

I521 D5

I527 C5

I528 B9

I535 E8

I540 D8

A

B

C

D

E

F

G

H

J

F

F

I

I

1

2

3

45

6

CHN SETNAME dvdrw_2004

CLASS_NO

3PB120

7

PB AB 04 E1

1

89

7

6

0

2006-01-27

2005-07-07

2004-10-22

J

3103 603 3035

2

Audio In/Out IOA

0

2004-05-07

2004-03-26

NAME

1 89

234 56

7

Fischer

3

CHECK DATE

SUPERS.

2003-01-13

10 11 12 13

10

0

130

C

ROYAL PHILIPS ELECTRONICS N.V. 2005

3

2004-03-25

A3

Page 6

A

123

1351 A3

1352 A3

1353 B3

1932 A1

2352 D3

2353 E1

3358 D4

3361 C3

3362 D3

3363 C1

3364 C1

3365 D1

3366 D3

3367 D1

3368 D1

3369 E3

4701 A33360 C1 F362 B4

5351 A3

5352 B3

5353 B3

6352 D1

6353 E1 F367 A1

7351 E3

7352 D3

7353 D2

7354 D2

7355 E4

9702 B3

9703 B3

9704 C3 F375 B3

F351 A4

F352 A4

F353 A3

F354 A3

456

F355 A1

F356 A2

F357 A2

F358 A1

F359 A2

F360 A1

F361 A2

F363 A1

F364 A1

F365 A1

F366 A2

F368 A1

F369 A1

F370 D3

F371 E2

F372 E4

F373 A1

F374 B3

I351 D3

I352 D1

I353 D1

A

1932

12VSTBY

B

A A

C

B

D

owner.

is prohibited without the written consent of the copyright

All rights reserved. Reproduction in whole or in parts

E

STBY

5VSTBY

DD_ON

3V3STBY

IPFAIL

5NSTBY

GND

33VSTBY

GND

from POWER SUPPLY

VGNSTBY

B11B-PH-K

C

12VSTBY

F

4K7

3365

D

G

6352

BZX384-C8V2

100n

2353

6353

BAS316

E

H

1

3368

100R

F352

5VSTBY

F362

3V3STBY

7355

BC847BW

4

12VSTBY

STBY

from CU

5VSTBY2

to CU

5VSTBY

to IOV,IOA,DAC_ADC,CU

DD_ON

from CU

3V3STBY

IPFAIL

to DAC_ADC

5NSTBY

to IOA,IOV,PROG,CU,

DAC_ADC

33VSTBY

to FV

VGNSTBY

to CU

to IOV,FOME,FV,MSP,

DAC_ADC,DIGIO,PROG,CU

10K

3358

F372

to IOV,CU

to CU

5V

3V3SW

to DAC_ADC

8VSTBY

to MSP

B

C

D

E

B

C

D

E

F

G

H

2

F357

F373

1

F368

2

F358

3

4

5

6

7

8

9

10

11

I353

F369

F360

F367

F363

F365

F355

F364

F359

F361

F366

F356

12VSTBY

3360

3363

3364

3367

I352

7354

BC847BW

47R

47R

33R

33R

F371

7353

PDTC124EU

3V3STBY

3361

I351

3366

1352

800mA

9702

1353

125mA

not used

2M2

2352

100n50V

2M2

3369

3

4701

1351

500mA

not used

F353

F374

5VSTBY

100K

7351

BC857BW

F354

F375

5353

10u

9704

not used

7352

SI2306DS

5351

22u

5352

10u

9703

not used

F370

3362

3K3

F351

12VSTBY

I

1

CHN SETNAME dvdrw_2004

CLASS_NO

3PB120

J

2004-03-2623

NAME

1

Power Supply PS

Folzberger

CHECK DATE

PB AB 04 E1

SUPERS.

123456

2003-01-13

I

2

10

34

3103 603 3035

4

130

C

ROYAL PHILIPS ELECTRONICS N.V. 2005

7

6

0

0

0

2006-01-27

2005-07-07

2004-10-22

2004-05-07

2004-03-25

A4

J

Page 7

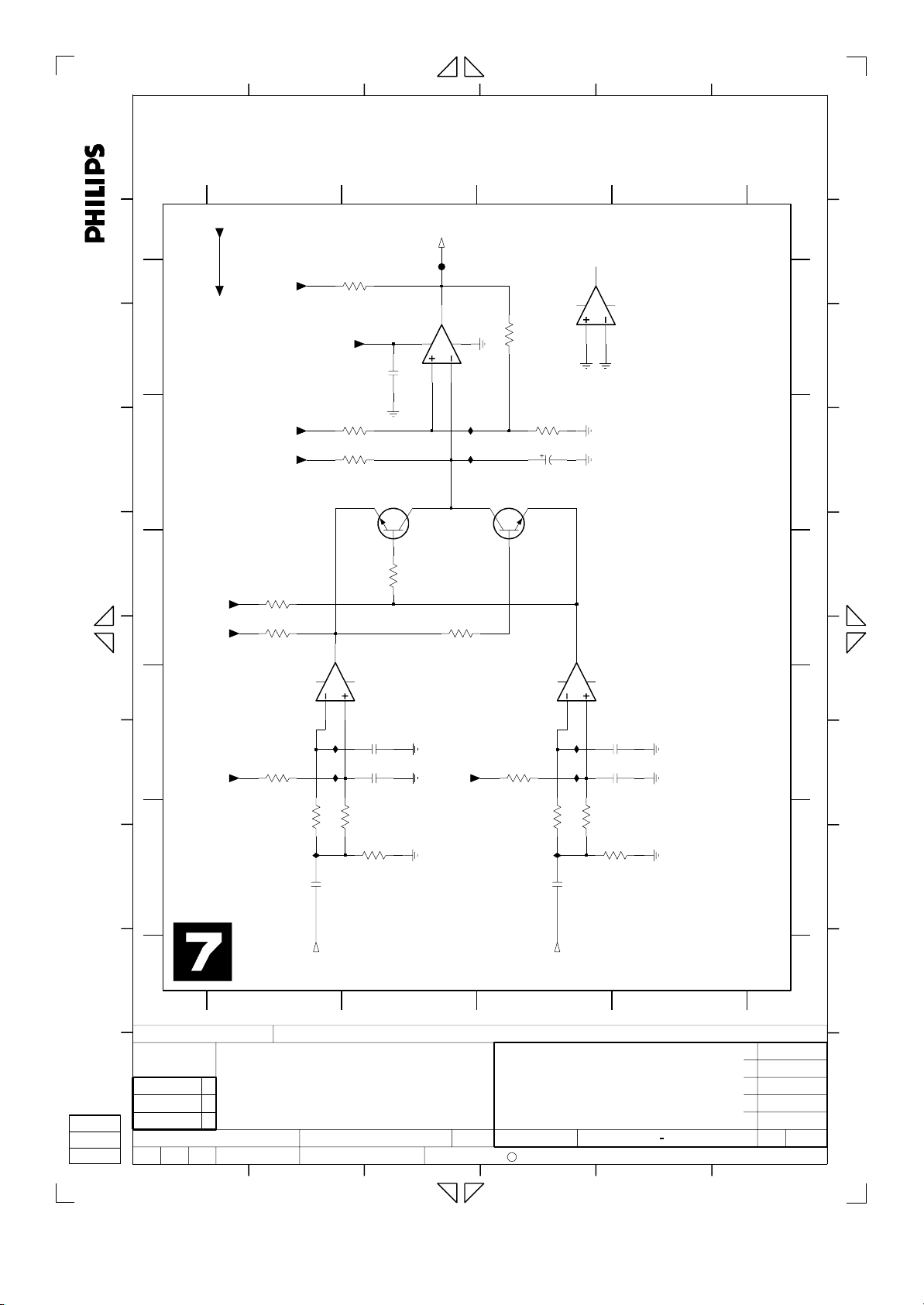

1234 56

7

8 9 10 11

12 13

A

A

B

SCL_5V

from/to CU

SDA_5V

from/to CU

C

B

D

SIF1

C

All rights reserved. Reproduction in whole or in parts

is prohibited without the written consent of the copyright

owner.

E

from FV

D

AIN1R

from IOV

F

AIN1L AOUT2R

from IOV

ARDAC

from DAC_ADC

from DAC_ADC

ALDAC

E

G

H

F

I

3616

2K2

3617

2K2

1

8VSTBY

2624

2625

2u2 50V

from PS

3603

100R

50V2u2

5V8VSTBY

5V

3619

12K

3601

100R

I607

3618

2605

2626

12K

10u 25V

2607

56p

2609

56p

3614

1K0

3615

1K0

1u0

1u0 50V

2630

2627

1u0

2631

50V1u0

I615

I616

I606

I608

7600

MSP3415G

12

I2C_CL

13

I2C_DA

14

I2S_CL

15

I2S_WS

16

I2S_DA_OUT

17

I2S_DA_IN1

21

I2S_DA_IN2

3 ANA_IN-

2 ANA_IN+

43 MONO_IN

41 SC1_IN_R

40 SC1_IN_L

38 SC2_IN_R

37 SC2_IN_L

3

DEMODULATOR

VREF2

25

VREF1

29

AHVSS

35

18

ADR_CL

IDENT

A/D

A/D

ASG

39

I602

10

ADR_SEL

4

AVSS

44

RSA1

3611

I624

8

D_CTR_IO1

S1...4

FM1

FM2

NICAM A

NICAM B

IDENT

SCART-L

SCART-R

SCART

DVSS

20

to IOA

10K

3612

I625

52

RSA2

to IOA

10K

4

9

TESTEN

D_CTR_IO0

I2SL/R

DFP

Switching Facilities

NC

23

24

I2SL/R

LOUDSPEAKER R

LOUDSPEAKER L

HEADPHONE R

HEADPHONE L

28

5V

SCART-R

SCART-L

32

5602

10u

2600

AVSUP

1

I613

2623

25V10u

D/A

D/A

100n

10n

2601

42

VREFTOP

D/A

D/A

TP

7

6

8VSTBY

2602

33

AHVSUP

LOUDSPEAKER

XTAL_IN6XTAL_OUT

5

I610

2620

1600

18M432

3p3

10u 25V

34

CAPL_M

STBYQ

DVSUP

RESETQ

AGNDC

2603

2621

100n

2611

11

19

22

26DACM_R

27DACM_L

36

30SC1_OUT_R

31SC1_OUT_L

I611

3p3

7

16V47u

I614

I605

I617

I618

I619

2618

2612

I620

I623

2628

3604

12K

1n0

50V4u7

1n0

2610

2629

3605

2619

10n

1n0

22K

1n0

2613

2614

6600

25V10u

25V10u

5V

3602

BAS316

2608

I621

I622

8

PDTC124EU

4K7

10u

3606

220R

3607

220R

7601

2622

5V

5600

2606

2615

1n0

not used

10u

100n

I612

1n0

not used

I634

9

7602

BC817-25W

7603

BC817-25W

3609

3610

4K7

4K7

STBY

from CU

AFER

to IOA

AFEL

to IOA

to IOV

AKILL

from DAC_ADC

AOUT2L

to IOV

A

B

C

D

E

F

1600 F6

2600 A6

2601 A6

2602 A6

2603 A7

2605 A2

2606 B8

2607 C2

2608 C8

2609 C2

2610 D7

2611 A7

2612 D7

2613 D8

2614 E8

2615 E8

2618 C7

2619 C7

2620 F6

2621 F7

2622 F8

2623 F5

2624 D1

2625 D1

2626 E2

2627 E2

2628 E7

2629 E7

3601 B2

3602 B8

3603 B2

3604 A7

3605 A7

3606 D8

3607 E8

3608 E8

3609 E9

3610 E9

3611 A4

3612 A5

3613 F8

3614 D2

3615 D2

3616 E1

3617 E1

3618 E1

3619 E1

5600 B8

5602 F5

6600 B8

7600 A3

7601 A8

7602 E9

7603 F9

I602 A4

I603 A6

I604 A6

I605 B7

I606 C2

I607 C2

I608 C2

I609 D7

I610 F6

I611 F7

I612 D8

I613 F5

I614 B7

I615 B2

I616 B2

I617 B7

I618 C7

I619 C7

I620 D7

I621 D8

I622 E8

I623 E7

I624 A4

I625 A4

I626 D2

I627 D2

I628 D2

I629 D2

I630 E1

I631 E2

I632 E1

I633 E2

I634 F8

A

B

C

D

E

F

G

H

I

J

1

2

34

5

6

CHN SETNAME dvdrw_2004

CLASS_NO

3PB120

1

7

PB AB 04 E1

8

9

7

6

0

2006-01-27

2005-07-07

2004-10-22

3103 603 3035

2

Multi Sound Processing MSP

2004-03-26

NAME

1 8 9 10 11 12 13

234 56

7

Posch K.H.

3

CHECK DATE

SUPERS.

2003-01-13

10

130

C

ROYAL PHILIPS ELECTRONICS N.V. 2005

5

0

0

2004-05-07

2004-03-25

J

A3

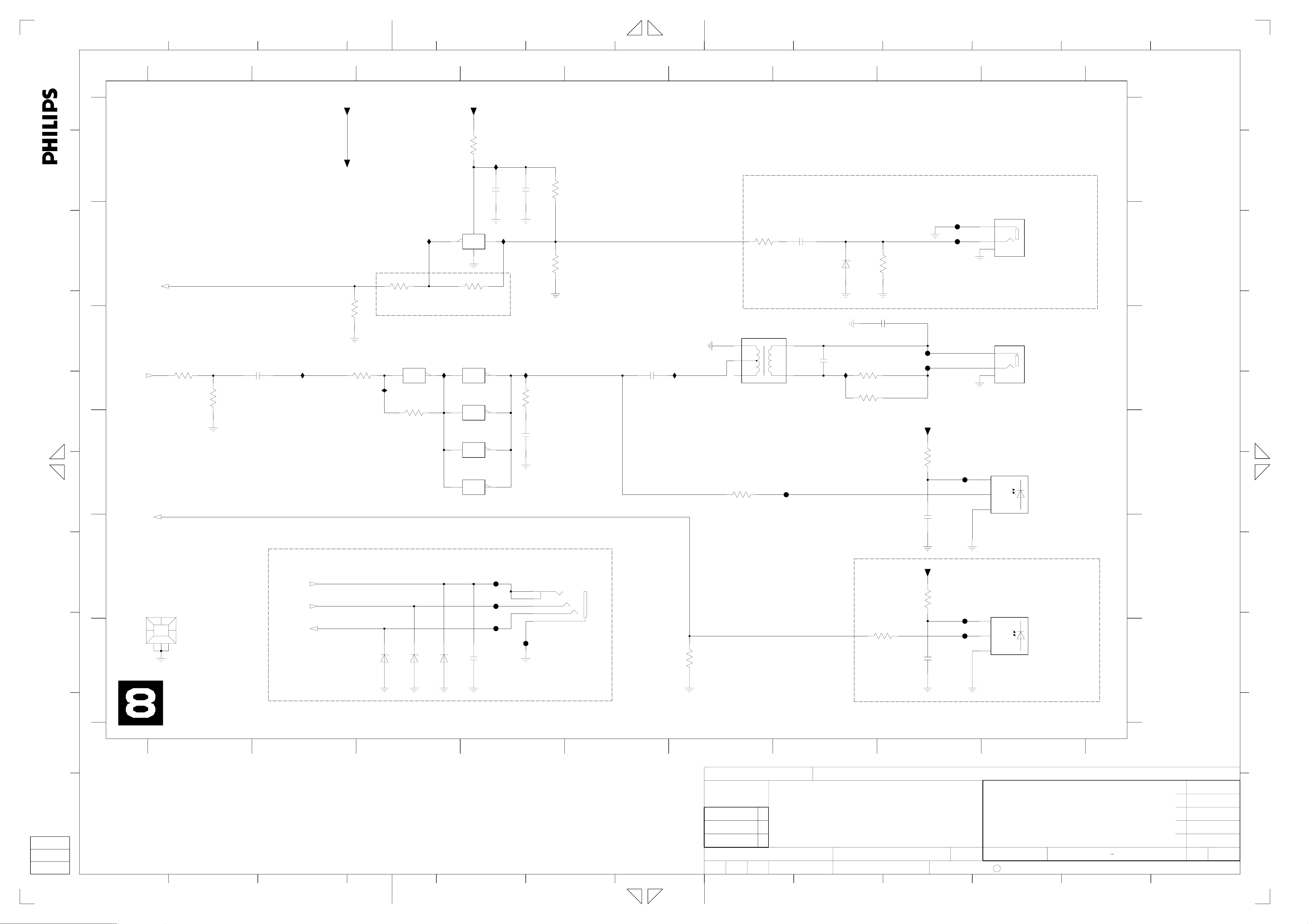

Page 8

1234 56

7

8 9 10 11 12 13

A

B

C

D

A

B

1920 A1 2216 B7

1921 C10 2217 C1

1922-A C5

1922-B A10

1922-C B5

1923 E5

2201 A8

2202 A4

2204 A7

2205 A3

2206 B2

2207 B5

2208 B7

1

1920

GND

Pr

GND

Pb

GND

Y

GND

from Digital Board

07FMN-BTRK-A

D_VR

from IOV

D_UB

from IOV

D_YG

from IOV

1

2

3

4

5

6

7

F203

F204

F205

2206

2210

22u 16V

2214

1u0

2209 B3

2210 B2

2211 B5

2212 B7

2213 B3

2214 B2

2215 B5

2 910

16V22u

2218 D2

2219 D3

2220 D7

2221 D8

2222 E72200 A5

2205

22u16V

2209

16V22u

2213

1u0

4601

I203

I207

I211

2223 E10

2224 E7

2225 E1

2226 E7

2227 E10

2228 E2

2229 E3

IPRO

from CU

3215

3216

3219

3

NJM2584M

I201

150R

150R

150R

2230 E7

2231 A9

2232 A9

2233 A9

2234 A9

2235 A10

2236 A10

7200

12

16

1

11

14

8

9

2237 A6

2239 A5

3200 A8

3201 B8

3202 B8

3203 B8

3204 C8

5V

5200

134

V+

Φ

3-CIRCUIT

VIDEO SW

CTL

IN1A

IN1B

IN2A

IN2B

IN3A

IN3B

GND

15

3205 D8

3206 C2

3208 D1

3209 D2

3210 E6

3211 E2

3213 E7

3214 E1

3215 C1

3216 C1

3217 E2

3218 E7

3219 C2

5200 A4

5201 D8

5202 C3

5203 E3

6200 B8

6201 B8

6202 B9

6203 D9

45

10u

F201

6.3V100u

2200

100n

I204

I208

I212

NC

OUT1

OUT2

OUT3

10

2

7

3

5

6

2202

100n

2239

2207

16V22u

2211

22u16V

2215

1u0

6204 D9

6205 D3

6206 D4

6207 E3

7200 A3

7201 A6

7202 D3

678

7201

NJM2580M

7

1

3

5

7203 D8

7204 E3

F201 A6

F202 A9

F203 A1

F204 A1

F205 A1

100n

2237

14

12

10

V+

Φ

3-CHANNEL

VIDEO AMP

PWR_SAVE

VIN1

VIN2

VIN3

GND

2

4

VSAG

VOUT1

VOUT2

VOUT3

6

13

11

F206 B9

F207 B9

F208 B9

F209 B9

F210 C8

F211 C8

F212 D9

F213 C4

F214 D4

F215 D8

F216 D4

I201 A3

I202 A7

I203 A3

I204 A6

I205 A7

I206 A8

I207 B3

I208 B6

I209 B7

I210 B8

I211 B3

I212 B6

I213 B7

I214 B8

I215 C7

I216 C1

I217 C2

I218 D2

I219 D7

I220 D8

I221 E9

I222 E8

I223 E1

I224 E2

I225 E8

I226 E9

I227 E8

I228 E2

A

from PS

5V

5NSTBY

B

3200

1K0

F202

2201

25V10u

2231

100n

2232

2233

100n

100n

2234

2235

100n

100n

2236

5NESD

to IOV

100n

A

5V

5NESD

I202

8

I205

I209

I213

9

2208

2212

2216

100u

6.3V470u

6.3V470u

6.3V

2204

47u 6.3V

I206

I210

I214

3201

75R

3202

75R

3203

75R

1%

1%

1%

F206

9

F207

10

F208

11

F209

1922-B

T-331520-10-10

V

U

Y

REAR OUT

B

8

C

D

All rights reserved. Reproduction in whole or in parts

is prohibited without the written consent of the copyright

owner.

E

C

F

ARDAC

from DAC_ADC

D

BKILL

G

H

E

from DAC_ADC

from DAC_ADC

2217

10u 16V

2225

16V10u

BKILL

from DAC_ADC

I216

3208

I223

3214

100K

100K

3206

270R

3209

470R

3211

270R

3217

470R

2218

I224

2228

I217

470p

I218

470p

I228

5202

Bead

7202

BC817-25W

5203

Bead

7204

BC817-25W

6205

5NESD

6207

5NESD

2219

470p

BZX384-C15

2229

470p

BZX384-C15

6206

5NESD

F213

F214

F216

BZX384-C12

REAR OUT

1922-C

T-331520-10-10

6

7

5

1922-A

T-331520-10-10

2

3

4

1

1923

1

2

3

4

LPR6520-G020G

Aud R

Aud L

CVBS

Aud R

Aud L

Aud R

Aud L

CVBS

for PROGRESSIVE only

I215

3210

75R

1%

I219

3213

100K

3218

2222

100u

6.3V

2224

6.3V100u

2226

100u 6.3V

2230

100u 6.3V

100K

3204

75R

2220

I220

I222

I225

I227

1%

F215

100n

2221

6200

5NESD

6201

BZX384-C12

5NESD

6202

BZX384-C12

5NESD

BZX384-C12

E

1921

TCS7927-24-401

1

5V

F210

F211

3

REAR OUT

4

S-VIDEO

F212

2

7

2223

4u7 50V

2227

50V4u7

5

6

CRout

from IOV

D_CVBSALDAC

from IOV

D_Y

from IOV

1%

6.3V47u

5201

V+

10u

7203

NJM2267M

7

Φ

3205

68R

6203

5NESD

6204

BZX384-C12

5NESD

BZX384-C12

DUAL 6dB

VIDEO AMP

4

3

5

6

VOUT1

VSAG1

VOUT2

VSAG2

GND

I221

VIN1

VIN2

2

1

I226

8

C

D

E

F

G

H

J

delete for PROGRESSIVE

I

I

12

3

4

5

6

CLASS_NO

3PB120

7

8

dvdrw_2004SETNAMECHN

9

PB AB 04 E1

1

10

7

6

0

2006-01-27

2005-07-07

2004-10-22

J

3103 603 3035

2004-03-26

NAME

Norbert Fischer

2

3

Progressive PROG

SUPERS.

DATECHECK

2003-01-13

10

130

C

ROYAL PHILIPS ELECTRONICS N.V. 2005

6

0

0

2004-05-07

2004-03-25

A3

1 8 9 10 11 12 13

234 56

7

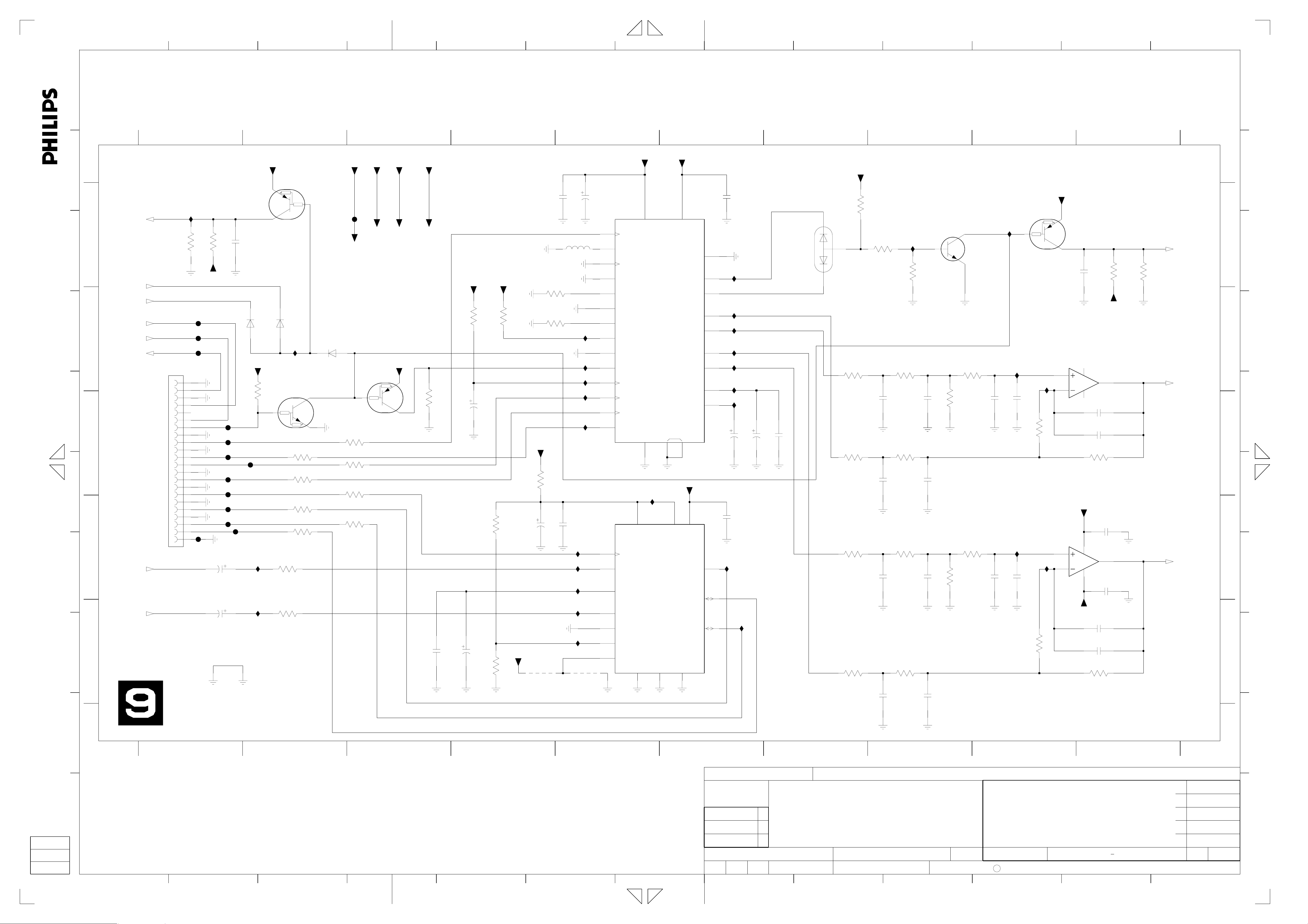

Page 9

123456

2944 D4

2945 D2

2946 E1 3952 B3

2947 E3 7934-1 D1

from PS

5V

A

2941 B3

2942 D2

2943 D4

B

5V

A

C

B

D

owner.

is prohibited without the written consent of the copyright

All rights reserved. Reproduction in whole or in parts

E

C

5V

5V

F

2

7932

4K7

100n

7934-3

3

3945 E3

3946 E2

3948 A2

F950

2

LM339D5

to CU

FOME

4

3939

4K7

3950 A3

3953 B2

3950

12

I951

I952

100K

7933

BC847BW

3937 C1 7934-2 D3

3938 C1

3939 C2

3940 D1

3941 D3

3942 E1

3943 E1

1

7934-1

LM339D

14

3948

4K7

3951

22K

3953

4K7

5V

2940

BC847BW

3954

3937

2K2

3938

2K2

5V

5V

5V

3

3952

15K

2941

10u 25V

LM339D

7934-2

3954 C2

7932 B2

7933 B33947 E4

LM339D

7934-4

7

13

7934-3 A2

7934-4 A3

F950 A2

I951 B22940 A2

I952 B23951 B2

I956 D1

I957 D1

I958 D3

I959 D3

I960 E1

I961 E33944 E3

A

4

1

6

B

A

C

D

B

E

C

F

11

9

8

D

3940

G

E E

H

I

5V

10M

3942

I960

2946

CVBSIN

1

CHN SETNAME dvdrw_2004

CLASS_NO

3PB120

J

2004-03-2623

NAME

1

Follow Me FOME

Neubauer

CHECK DATE

PB AB 04 E1

SUPERS.

2942

I956 I958

2n2

2945

I957

33K

3943

1u0

from IOV

180p

33K

3946

33K

3941

5V

10M

2

10

2003-01-13

C

10

2944

2n2

2943

I959

180p

33K

33K

3945

3944

I961

2947

VFV

3

3947

33K

1u0

from FV

4

3103 603 3035

7

130

ROYAL PHILIPS ELECTRONICS N.V. 2005

123456

7

6

0

0

0

2006-01-27

2005-07-07

2004-10-22

2004-05-07

2004-03-25

A4

D

G

H

I

J

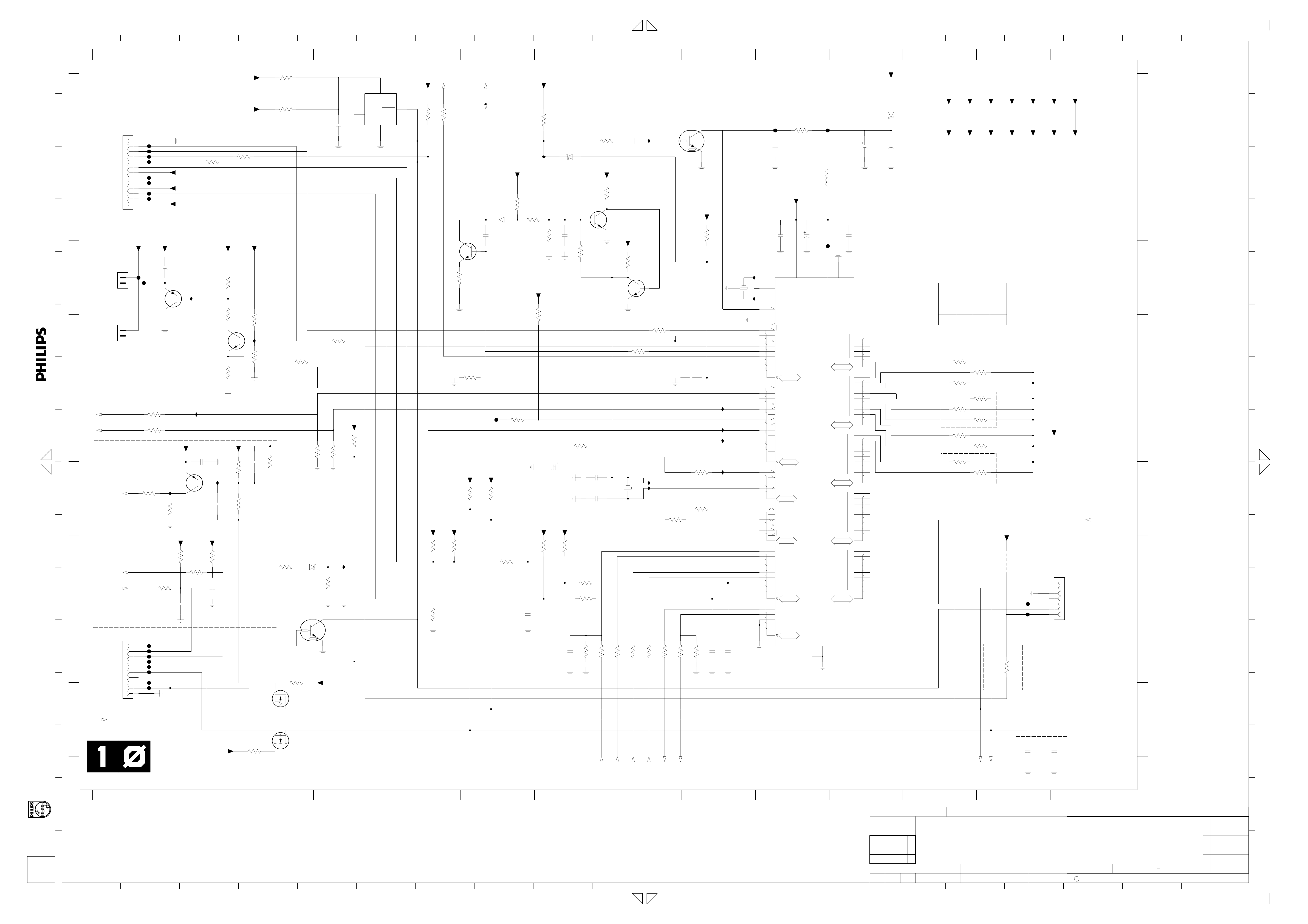

Page 10

1

A

A

B

C

B

DAINCOAX

to DAC_ADC

D

C

DAOUT

from DAC_ADC

All rights reserved. Reproduction in whole or in parts

is prohibited without the written consent of the copyright

owner.

E

D

F

DAINOPT

to DAC_ADC

E

G

0005

H

F

1

3253

750R

1%

BRACKET

234 56

I252

452

10n

10V1u0

2250

I254

3262

560R

1n0

2257

1924

HSJ1637-010510

5

4

3

2

1

F2401

3257

100K

3255

100K

G-Link

OUT

2255

100n

3254

100R

2256

100n

I258

IROUT

from CU

GLINK_TXD

from CU

GLINK_RXD

to CU

from PS

5V

5V

3266

3261

470R

560R

not used

3

7250-6

SN74HCU04D

I251

3265

100R

for DIGITAL COAX IN only

7250-1

SN74HCU04D

12

I256

3260

2K2

6251

6252

BZX384-C6V8

BZX384-C6V8

12

3258

10K

7250-3

SN74HCU04D

I253

56

7250-2

SN74HCU04D

34

7250-5

SN74HCU04D

11

7250-4

SN74HCU04D

98

for EPG only

6253

BZX384-C6V8

5V

3250

1

11

1

1

1

2267

470R

I250

2265

13

714

10

F2405

F2403

F2402

1n0

7

I255

3267

1K8

6

8 9 10 11 12 13

0001 E1

78

for DIGITAL COAX IN only

F251

2251

100n

6

2254

6250

150p

I257

3252

100R

5250

34

2

1

6RG

3264

100R

not used

3256

BZX384-C6V8

2266

100n

3259

75R

3251

82R

3269

180R

75R

F2503

F2502

5V

3263

2259

5V

3268

2262

47R

25V100n

47R

100n

F2603

F2602

F266

3

2

1

3

2

1

2

1

3

1926

YKC21-3416

1925

YKC21-3416

6255

VS

IN

GND

JFJ1000

for DIGITAL OPT IN only

F267

F250

1

3

2

6269

VS

OUT

GND

JFJ2000

9

DIGITAL

IN

CINCH

DIGITAL

OUT

CHINCH

DIGITAL

OUT

OPTICAL

DIGITAL

IN

OPTICAL

A

B

C

D

E

F

1924 E4

1925 C8

1926 B8

1927 A1

2250 A4

2251 B7

2252 B2

2254 C7

2255 C5

2256 C2

2257 D4

2259 E8

2262 F8

2265 A4

2266 C8

2267 F4

3250 A4

3251 C7

3252 B6

3253 C1

3254 C1

3255 B4

3256 B8

3257 A4

3258 B4

3259 C7

3260 C3

3261 C3

3262 C4

3263 D8

3264 D6

3265 B3

3266 C2

3267 F6

3268 E8

3269 F8

5250 C6

6250 B7

6251 F3

6252 F3

6253 F3

6255 D9

6269 E9

7250-1 C3

7250-2 C4

7250-3 C4

7250-4 D4

7250-5 D4

7250-6 B3

F2401 F4

F2402 F4

F2403 E4

F2405 E4

F250 F8

F2502 C8

F2503 C8

F251 D7

F2602 B8

F2603 B8

F266 D8

F267 E8

F2701 A1

F2702 A1

F2704 A1

F2706 A1

F2708 B2

I250 A4

I251 B3

I252 B4

I253 C3

I254 C4

I255 C6

I256 C3

I257 C7

I258 C2

A

B

C

D

E

F

G

H

J

I

I

1

2

3

4

5

6

CHN SETNAME dvdrw_2004

CLASS_NO

3PB120

78

PB AB 04 E1

**-**-**

1

9

7

6

0

2006-01-27

2005-07-07

2004-10-22

J

3103 603 3035

**-**-**

2004-03-26

NAME

1 8 9 10 11 12 13

234 56

7

Fischer

2

3

CHECK DATE

Digital In/Out DIGIO

SUPERS.

**** *** *****

2003-01-13

10

0

0

130

C

ROYAL PHILIPS ELECTRONICS N.V. 2005

8

2004-05-07

2004-03-25

A3

Page 11

1234 56

7

8 9 10 11 12 13

A

1900 B1

2002 A5

2003 A5

2004 A6

2005 A1

2006 C8

2007 C9

2008 C8

2009 C9

2010 C10

2011 D10

2012 D10

2013 D9

2014 E10

B

AKILL

to IOA,MSP

A

C

IMUTE

from CU

IPFAIL

from PS

DAINOPT

from DIGIO

D

B

All rights reserved. Reproduction in whole or in parts

is prohibited without the written consent of the copyright

owner.

E

C

F

D

G

E

H

DAINCOAX

from DIGIO

DAOUT

to DIGIO

DAINCOAX

D_PCMCLK

D_DATA0

A_PCMCLK

from/to Digital Board

ARADC

from IOA

ALADC

from IOA

1900

GND

DAOUT

GND

DAINOPT

N.C.

D_KILL

GND

GND

D_WCLK

GND

D_BCLK

GND

GND

A_DAT

GND

A_WCLK

A_BCLK

GND

22FMN-BTRK-A

2015 A10

2017 C10

2018 C4

2019 C6

2020 C6

2021 C7

2023 C8

2025 C8

2030 D8

2032 D8

2033 D9

2035 D6

2037 D5

2038 D4

2041 E10

2042 E3

2043 E4

2045 E8

2047 E8

2048 E1

2050 D1

3001 B7

3003 D4

3004 C8 7003-1 B10

3005 B5

3006 B5

3007 E4

3008 B8

3009 C7

3010 B9

3011 A1

3012 C3

3013 C9

3014 D7

3015 A1

3016 C8

3017 C10

3018 E7

3019 C2

3020 B4

3021 B4

3022 C3

3023 C2

3024 C3

3025 A10

3026 D2

3027 D8

3028 D3

3029 A10

3030 D8

3031 B2

3032 D9

3033 D2

3034 C4

3036 E9

3037 A8

3039 E8

3040 E10

3046 A7

3047 E2

3050 A8

3053 D2

3054 C3

4001 E4

4002 E5

5000 A5

6003 B2

6004 B2

6005 B2

6006 A7

7001 B3

7002 A2

7003-2 D10

7004 A5

7005 A9

7006 C2

7007 D5

7010 A8

F001 B1

F002 B1

F003 B1

F004 C1

F005 C1

F006 A3

F007 C1

F008 C1

F009 D1

F010 C1

F012 D1

F013 D1

F014 D1

F015 C2

I001 B2

I002 C5

I004 C5

I005 B5

I006 B5

I007 B5

I009 A1

I010 A6

I011 A9

I012 A8

I013 D5

I014 D5

I015 D5

I017 B6

I018 D5

I019 B6

I020 B6

I020 B6

I021 E2

I022 E5

I023 C6

I024 B6

I025 B6

I026 B9

I027 B9

I028 D9

I030 D2

I031 E6

I032 E5

I033 D9

I034 D6

c001 E1

12345678910

I009

3011

GND

F001

F002

F003

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

F014

3015

100K

5NSTBY

GND

GND

GND

GND

GND

GND

GND

GND

2050

2048

47u 6.3V

GND

PDTA124EU

22K

2005

GND

F010

F004

F005

F007

F008

F009

F012

F013

GND

6.3V47u

c001

7002

22n

6005

5VSTBY

3031

F015

I030

I021

A

5VSTBY

6004

BAS316

4K7

I001

3053

10K

3047

10K

BAS316

3019

3023

22R

3026

22R

22R

6003

BAS316

7006

PDTC124EU

GND

22R

3033

3V3SW

F006

3V3SW

3054

22R

22R

3024

22R

3028

22R

from PS

5VSTBY

5V

5VSTBY

5V

PDTA124EU

7001

3022

5V

5NSTBY

5NSTBY

3012

GND

2042

10K

A

100n

5V

3020

2018

GND

2043

A

4K7

25V10u

47u 6.3V

5V

3021

3003

3007

A

10K

47K

3V3SW

47K

GND

GND

GND

3V3SW

3034

2038

A

4001

not used

GND

3005

4K7

3006

4K7

1R0

100u 6.3V

2003

2037

A

GND

100n

GND

5000

Bead

GND

I005

GND

I006

I007

I002

I004

100n

I015

I014

I018

I032

I022

4002

2002

GND

GND

6.3V

7004

100u

AD1852JRS

2

3

4

5

7

9

10

21

20

23

24

25

26

27

7007

UDA1361TS

8

3

2

1

6

7

14

GND

MCLK

CLATCH

CCLK

CDATA

192-48_

DEEMP

96-48_

IDPM0

IDPM1

MUTE

PD_-RST

LRCLK

BCLK

SDATA

SYSCLK

VINR

VREF

VINL

SFOR

PWON

MSSEL

5V

28

Φ

DVDD

DAC

DGND

1

GND

I013

16

VDDA VRP

24-BIT AUDIO

VSSA VSSD

15

A

Φ

ADC

VRN

4

A

AGND

11

A

5

GND

5V

AVDD

ZEROL

ZEROP

OUTL-

OUTL+

OUTR-

OUTR+

FILTR

FILTB

15 18

3V3SW

9

VDDD

DATAO

BCK

10

NC

WS

22

16

17

13

12

14

19

13

11

12

6

8

GND

2004

A

I010

I017

I019

I020

I024

I025

I023

2019

2035

100n

A

100n

I034

I031

GND

2020

10u 25V

5VSTBY

5VSTBY

22K

3046

I011

BAW56W

6006

3001

5K6

1%

25V10u

100n

2021

3009

A

A

5K6

1%

3014

5K6

1%

3018

5K6

1%

3037

100K

2006

A

2023

A

2030

A

2045

I012

7010

BC847BW

33K

3050

GND GND

3008

27K

1%

1n0

NP0 2%

3016

27K

1%

1n0

NP0 2%

3030

27K

1%

1n0

NP0 2%

3039

27K

1%

1n0

NP0 2%

2008

A

2025

A

2032

A

2047

NP0 2%

1n0

1n0

NP0 2%

1n0

1n0

GND

not used

not used

A

I026

2009

A

I028

2033

A

3010

6K8

1%

1%

33K

3004

AA

NP0 2%

3032

6K8

1%

1%

33K

3027

A

NP0 2%

2007

2013

2%

100p

2%

100p

I027

3013

I033

3036

6K8

6K8

7005

PDTA124EU

3

2

1%

5

6

1%

2015

7003-1

MC33078D

5VSTBY

8

4

5NSTBY

22n

3025

5NSTBY

1

2017

2%

100p

2010

not used

27p

3017

33K

1%

2011

100n

7003-2

MC33078D

7

2012

100n

2041

27p

33K

1%

2%

not used

100p

2014

3040

22K

A

A

3029

GND

BKILL

to PROG,CU

100K

ALDAC

to IOA,MSP,PROG

ARDAC

to IOA,MSP,PROG

A

B

C

D

E

A

B

C

D

E

F

G

H

J

A

A

I

I

1 456789

23

CHN SETNAME dvdrw_2004

CLASS_NO

3PB120

PB AB 04 E1

1

10

7

6

0

2006-01-27

2005-07-07

2004-12-07

J

3103 603 3035

2004-03-26

NAME

Fischer

2

3

Audio Converter DAC_ADC

CHECK DATE

SUPERS.

2003-01-13

10

0

0

130

C

ROYAL PHILIPS ELECTRONICS N.V. 2005

9

2004-10-22

2004-05-07

A3

1 8 9 10 11

234

56

7

12 13

Page 12

1

2

3

4

5

6

7

8

9

10 19

11

12

13

14

15

16

17

18

20

1

A

B

A

1911

GND

SDA_F

SCL_F

CSN_F

IPOR1

RC

C

B

5VSTBY

TEMP_SENSE

KEY1

12VSTBY

KEY2

F_IROUT

VGNSTBY

from/to FRONT PANEL

13FMN-BTRK-A

D

12VSTBY

1913

E

F

C

D

FAN_P

FAN_N

to FAN 1

B2B-EH-A

FAN_P

FAN_N

B2B-EH-A

to FAN 2

1

2

1916

1

2

not used

G

STBY

to PS,MSP

E

DD_ON

H

to PS

for EPG only

I

F

IROUT

to DIGIO

J

G

K

All rights reserved. Reproduction in whole or in parts

owner.

is prohibited without the written consent of the copyright

L

H

M

I

GLINK_TXD

to DIGIO

GLINK_RXD

from DIGIO

1914

RESET

RXD

TXD

INT

SDA0

SCL0

SCL0

N.C.

D_IROUT

FB

GND

10FMN-BTK-A

from/to DIGITAL BOARD

FB

from IOV

N

gedeeltelijk, is niet toegestaan dan met schriftelijke

toestemming van de auteursrechthebbende.

Alle rechten voorbehouden. Verveelvuldiging, geheel of

1

2

3

4

5

6

7

8

9

10

11

12

13

1

2

3

4

5

6

7

8

9

10

F1301

F1302

BC327-25

3123

100R

3124

1K0

3129

150R

F1102

F1103

F1104

F1105

F1108

F1109

F1111

F1112

12VSTBY

2110

7104

3145

1K0

F1401

F1402

F1403

F1404

F1405

F1406

F1407

F1408

5VSTBY

12VSTBY

VGNSTBY

25V10u

7109

BC857BW

I123

1K0

3132

3V3SW

3138

2116

5V

23

3108

I107

I120

100K

3142

1K0

100p

2121

100n

BC847BW

I114

2123

3V3SW

3139

2115

3106

100R

12VSTBY

3112

3116

7105

3161

100p

100K

100p

3V3SW

5VSTBY

12VSTBY

1%

3K3

1%1%

680R

1K0

5V

10K

3127

4K7

3128

3105

100R

5V

3113

3122

2124

3168

1K0

4K7

I108

1% 1%

4K7

100p

7114

BSN20

3162

4K7

910R

3107

47K

3141

1K0

1%

1%

3115

3158

1K0

7115

BSN20

4K7

3126

6106

BAT54 COL

2104

3118

100R

10K

3K3

3166

I118

3143

2114

100K

7111

PDTC124EU

3V3SW

4

7100

NCP301LSN

4

5

100n

3V3STBY

10K

3135

100n

2

45

VCC

NC RESET

GND

3

not used

56

7

8 9 10 11 12 13 14

1100 C9

1101 F8

1911 A1

5VSTBY

5VSTBY

IPRO

to PROG

1

10K

3159

1K0

3160

P50

from/to IOV

5VSTBY

5VSTBY

3100

I102

10K

BAT54 COL

6101

3102

470R

5VSTBY

2100

220n

I101

7101

PDTC124EU

F126

2101

10n

3101

10K

F124

5100

Bead

2102

220m 5.5V

6100

2103

BAT760

47u 6.3V

12VSTBY

12VSTBY

from PS

5V

5VSTBY

5VSTBY

5V

5NSTBY

5NSTBY

3V3STBY

3V3STBY

VGNSTBY

VGNSTBY

5VSTBY2

A

5VSTBY2

1913 C1

1914 H1

1915 G14

1916 D1

2100 A8

2101 A10

2102 A11

2103 A11

2104 A4

2105 B6

2106 B11

2107 B10

2108 B7

2109 H9

2110 C1

2111 H9

2112 F7

2113 F7

2114 G4

2115 G2

2116 G2

2117 H7

2118 D9

2119 I14

2120 I13

2121 E2

6102

BAS316

3103

27K

3183

220K

7112

BC847BW

3182

47K

5VSTBY

B

5VSTBY

2122 H6

2123 F2

2124 F3

2125 B10

2126 F7

3100 A7

3101 A10

3102 A7

3103 B6

3104 B9

3105 A3

3106 B2

3109 C6

3111 H13

3112 C2

3113 D3

3115 D3

3116 D2

3117 D8

3118 D4

3121 D8

3122 D3

3123 E1

3124 E1

3125 E7

3126 E4

3127 F2

3128 F2

3129 F1

3130 F6

3131 F6

3132 F2

3133 F9

3134 F8

3135 E4

3136 F9

3137 G5

3138 G2

3139 G2

3140 G6

3141 G3

3142 G2

3143 G4

3144 G7

3145 G1

3146 G7

3147 G7

3148 G7

3149 H7

3150 H7

3151 H8

3152 H8

3153 H8

3154 H8

3155 H8

3156 H9

3158 H3

3159 A5

3160 A5

3161 E2

3162 F3

3163 D6

3164 G5

3165 H5

3166 E4

3168 I3

3170 D12

3171 D12

5VSTBY

3164

3165

5VSTBY

1M0

not used

1M0

not used

3137

BC847BW

220R

1%

10K

3109

3163

33K

5V

3130

7102

3K9

2105

F100

220p

TPClock

5V

3131

3K9

3140

3180

1K0

10K

2122

5VSTBY

3181

5VSTBY

3147

10n

3184

47K

2126

6p0

not used

2K2

82K

2108

3125

-50p

5VSTBY

3148

2K2

2117

220p

3185

1K0

100R

3146

100R

10n

3144

3149

2M2

2112

18p

2113

18p

4K7

3150

6K8

5VSTBY

3151

3186

3121

1101

1K0

4K7

7113

BC847BW

32K768

1K0

3152

33K

I115

I117

3153

3117

100R

10K

3154

3134

100R

10K

3155

2118

100n

1K0

3136

100R

3133

100R

3156

3104

4K7

2109

10K

I110

I119

I112

I113

100n

8M01100

Version Detect

for MOBO

100n

2111

I103

I104

8

10

13

79

80

1

2

3

4

5

6

15

16

17

18

19

20

21

22

14

12

11

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

100n

2125

9

1

XTAL

2

RESET

TEST

SCK1

SI1

SO1

P0<0:7>

INT0

INT1

TC2

PPG

DVO

TC4

PDO

PWM

INT3

TC1

INT2

INT4

TC3

P1<0:7>

INT5

STOP

XTIN

XTOUT

P2<0:2>

SCL

SI0

SDA

SO0

SCK0

P3<0:2>

0

1

2

3

AIN

4

5

6

7

P4<0:7>

10

11

AIN

12

13

39

VAREF

2107

47u 6.3V

F125

40

Φ

MC

78

VDD

PD<0:4>

P6<0:7>

P7<0:7>

P8<0:7>

P9<0:7>

2106

100n

7108

TMP87CH74F

VKK

2

3

4

V3

5

6

0

1

2

3

V

4

5

6

7

8

9

10

11

V

12

13

14

15

16

17

18

19

V

20

21

22

23

24

25

26

27

V

28

29

30

31

73

74

75

76

77

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

*

VERSIONS

E1

E2

E3/5300H

not used

not used

3170

2k2

3170

2K2

3172

2K2

3174

2K2

3176

2K2

3178

2K2

3171

---

2k2

---

--- ---

*

3171

2K2

*

3173

2K2

3175

2K2

3177

2K2

3179

2K2

*

3172

2k2

5VSTBY2

4101

for DTTM only

F1209

F1208

5VSTBY

1915

1

2

3

4

5

6

7

07FMN-BTRK-A

SCL_5V

SDA_5V

GND

INT1

BKILL

IPOR_R

IRES_S

BKILL

from DAC_ADC

N.C.

SDA_5V

GND

INT1

BKILL

IPOR_R

5VSTBY2

from/to AUX AV Board

or DTTM Board

C

D

E

F

G

for RECEIVER or DTTM only

P5<0:3>

VSS

VASS

7

38

H

6106 G3

7100 A4

7101 A8

7102 C6

7104 D1

7105 D2

7108 C11

7109 F2

7111 H4

7112 B7

7113 C8

7114 I3

7115 I3

F100 E6

F1102 A1

F1103 A1

F1104 A1

F1105 B1

F1108 B1

F1109 B1

F1111 B1

F1112 B1

F1208 H13

F1209 G13

F124 A10

F125 C10

F126 A10

F1301 C1

F1302 C1

F1401 H1

F1402 H1

F1403 H1

F1404 H1

F1405 H1

F1406 H1

F1407 H1

F1408 I1

I101 A8

I102 A7

I103 C9

I104 C9

I107 D2

I108 D3

I110 E9

I112 E9

I113 F9

I114 F2

I115 F8

I117 F8

I118 G4

I119 E9

I120 E2

I123 F2

A

B

C

D

E

F

G

H

I

J

K

L

3172 D12

4102

3111

100R

for RECEIVER only

3173 E12

3174 E12

3175 E12

3176 E12

3177 E12

3178 E12

3179 F12

M

3180 E6

3181 D7

I

3182 B7

3183 B6

3184 B7

3185 C7

3186 C8

2120

22p

2119

22p

4101 G13

N

4102 H13

8SC2

from IOV

from IOV

WSFI

FOME

from FOME

WU

from IOV

to IOA

ASC1

IMUTE

to DAC_ADC

to FV,IOV,MSP

to FV,IOV,MSP

SCL_5V

SDA_5V

delete for RECEIVER

5100 B10

6100 A11

6101 A7

6102 B6

O

P

1

1

2

2

3

4

3

4

6

5

7

678

8

9

10

11

9

12

10

13

11 12

AV003415

CLASS_NO

3PB120

1

2

3

15

14

2004-03-26

NAME

Neubauer

13 14

dvdrw_2004SETNAMECHN

PB AB 04 E1

Control Unit CU

SUPERS.

DATECHECK

165

2003-01-13

17

10

3103 603 3035

130

C

KONINKLIJKE PHILIPS ELECTRONICS N.V. 2000

18

19

10

7

6

0

0

0

20

2006-01-27

2005-07-07

2004-06-09

2004-05-27

2004-05-07

A2

O

P

Page 13

Page 14

Page 15

Page 16

Philips Consumer Electronics

BLC Audio Video Systems

620A, Lorong 1 Toa Payoh, Singapore 319762

ATLAS_DSW

User Manual

Diagnostic Software

Document

Author : ATLAS_DSW team Date : 2005-09-02

Reference :

Version : 3.4 Archive : Atlas_dsw

Status : Draft Classification : COMPANY RESTRICTED

©

Philips E l e ct r o n i c s N. V . 2005

Project Documentation.dot, version 1.0

This information is furnished for guidance, and with no guarantee as to its accuracy or completeness; its publication con veys no

license under any patent or other right, nor does the publisher assume liability, for any consequence of its use; specifications and

availability of goods mentioned in it are subject to change without notice; it is not to be reprod uced, in whole or i n part, without

the written consent of the publisher.

SGP_AVS_SW_ATLAS-05-04

Filename : atlas_user_manual_DS_ver

3.4.doc

Page 1 of 168

Page 17

Reference : SGP_AVS_SW_ATLAS-05-04 Classification : COMPANY RESTRICTED

Version : 3.4 Project : ATLAS_DSW

Status : Draft Chapter : User Manual

Date : 2005-09-02 Section : Diagnostic Software

TABLE OF CONTENTS

DOCUMENT CHANGE HISTORY 4

1 INTRODUCTION 5

1.1 R

1.2 G

1.3 P

1.4 N

EFERENCES