Philips DVDR-3440-H Service Manual

2.1 Safety Instructions

2.1.1 General Safety

Safety regulations require that during a repair:

• Connect the unit to the mains via an isolation transformer.

• Replace safety components, indicated by the symbol

,

only by components identical to the original ones. Any

other component substitution (other than original type)

may increase risk of fire or electrical shock hazard.

Safety regulations require that after a repair, you must return

the unit in its original condition. Pay, in particular, attention to

the following points:

• Route the wires/cables correctly, and fix them with the

mounted cable clamps.

• Check the insulation of the mains lead for external

damage.

• Check the electrical DC resistance between the mains

plug and the secondary side:

1. Unplug the mains cord, and connect a wire between

the two pins of the mains plug.

2. Set the mains switch to the ‘on’ position (keep the

mains cord unplugged!).

3. Measure the resistance value between the mains

plug and the front panel, controls, and chassis

bottom.

4. Repair or correct unit when the resistance

measurement is less than 1 MΩ.

5. Verify this, before you return the unit to the customer/

user (ref. UL-standard no. 1492).

6. Switch the unit ‘off’, and remove the wire between the

two pins of the mains plug.

2.1.2 Laser Safety

This unit employs a laser. Only qualified service personnel

may remove the cover, or attempt to service this device (due

to possible eye injury).

Laser Device Unit

Type : Semiconductor laser

GaAlAs

Wavelength : 650 nm (DVD)

: 780 nm (VCD/CD)

Output Power : 20 mW

(DVD+RW writing)

: 0.8 mW

(DVD reading)

: 0.3 mW

(VCD/CD reading)

Beam divergence : 60 degree

CLASS 1

LASER PRODUCT

Figure 2-1

Note: Use of controls or adjustments or performance of

procedure other than those specified herein, may result in

hazardous radiation exposure. Avoid direct exposure to beam.

2.2 Warnings

2.2.1 General

• All ICs and many other semiconductors are susceptible

to electrostatic discharges (ESD,

). Careless handling

during repair can reduce life drastically. Make sure that,

during repair, you are at the same potential as the mass

of the set by a wristband with resistance. Keep

components and tools at this same potential.

Available ESD protection equipment:

– Complete kit ESD3 (small tablemat, wristband,

connection box, extension cable and earth cable)

4822 310 10671.

– Wristband tester 4822 344 13999.

• Be careful during measurements in the live voltage

section. The primary side of the power supply, including

the heatsink, carries live mains voltage when you

connect the player to the mains (even when the

player is ‘off’!). It is possible to touch copper tracks and/

or components in this unshielded primary area, when

you service the player. Service personnel must take

precautions to prevent touching this area or components

in this area. A ‘lightning stroke’ and a stripe-marked

printing on the printed wiring board, indicate the primary

side of the power supply.

• Never replace modules, or components, while the unit is

‘on’.

2.2.2 Laser

• The use of optical instruments with this product, will

increase eye hazard.

• Only qualified service personnel may remove the cover or

attempt to service this device, due to possible eye injury.

• Repair handling should take place as much as possible

with a disc loaded inside the player.

• Text below is placed inside the unit, on the laser cover

shield:

Figure 2-2

2. Safety Information, General Notes & Lead Free Requirements

CAUTION VISIBLE AND INVISIBLE LASER RADIATION WHEN OPEN AVOID EXPOSURE TO BEAM

ADVARSEL

SYNLIG OG USYNLIG LASERSTRÅLING VED ÅBNING UNDGÅ UDSÆTTELSE FOR STRÅLING

ADVARSEL SYNLIG OG USYNLIG LASERSTRÅLING NÅR DEKSEL ÅPNES UNNGÅ EKSPONERING FOR STRÅLEN

VARNING SYNLIG OCH OSYNLIG LASERSTRÅLNING NÄR DENNA DEL ÄR ÖPPNAD BETRAKTA EJ STRÅLEN

VARO! AVATTAESSA OLET ALTTIINA NÄKYVÄLLE JA NÄKYMÄTTÖMÄLLE LASER SÄTEILYLLE. ÄLÄ KATSO SÄTEESEEN

VORSICHT SICHTBARE UND UNSICHTBARE LASERSTRAHLUNG WENN ABDECKUNG GEÖFFNET NICHT DEM STRAHL AUSSETSEN

DANGER VISIBLE AND INVISIBLE LASER RADIATION WHEN OPEN AVOID DIRECT EXPOSURE TO BEAM

ATTENTION RAYONNEMENT LASER VISIBLE ET INVISIBLE EN CAS D’OUVERTURE EXPOSITION DANGEREUSE AU FAISCEAU

2.3 Lead Free Requirement

Information about Lead-free produced sets

Philips CE is starting production of lead-free sets from

1.1.2005 onwards.

INDENTIFICATION:

Regardless of special logo (not always indicated)

One must treat all sets from

1 Jan 2005 onwards, according

next rules.

Example S/N:

Bottom line of typeplate gives a 14-digit S/N. Digit 5&6 is the year, digit 7&8 is

the week number, so in this case 1991 wk 18

So from 0501 onwards = from 1 Jan 2005 onwards

Important note: In fact also products of year 2004 must be treated in this way as long as you

avoid mixing solder-alloys (leaded/ lead-free). So best to always use SAC305 and the higher

temperatures belong to this.

Due to lead-free technology some rules have to be respected by the

workshop during a repair:

• Use only lead-free solder alloy Philips SAC305 with order

code 0622 149 00106. If lead-free solder-pate is required,

please contact the manufacturer of your solder-equipment.

In general use of solder-paste within workshops should be

avoided because paste is not easy to store and to handle.

•

Use only adequate solder tools applicable for lead-free

solder alloy. The solder tool must be able

o To reach at least a solder-temperature of 400°C,

o To stabilize the adjusted temperature at the solder-tip

o To exchange solder-tips for different applications.

• Adjust your solder tool so that a temperature around 360°C

– 380°C is reached and stabilized at the solder joint.

Heating-time of the solder-joint should not exceed ~ 4 sec.

Avoid temperatures above 400°C otherwise wear-out of

tips will rise drastically and flux-fluid will be destroyed. To

avoid wear-out of tips switch off un-used equipment, or

reduce heat.

• Mix of lead-free solder alloy / parts with leaded solder alloy

/ parts is possible but PHILIPS recommends strongly to

avoid mixed solder alloy types (leaded and lead-free).

If one cannot avoid or does not know whether product is

lead-free, clean carefully the solder-joint from old solder

alloy and re-solder with new solder alloy (SAC305).

• Use only original spare-parts listed in the Service-Manuals.

Not listed standard-material (commodities) has to be

purchased at external companies.

• Special information for BGA-ICs:

- always use the 12nc-recognizable soldering temperature

profile of the specific BGA (for de-soldering always use the

lead-free temperature profile, in case of doubt)

- lead free BGA-ICs will be delivered in so-called ‘drypackaging’ (sealed pack including a silica gel pack) to

protect the IC against moisture. After opening, dependent

of MSL-level seen on indicator-label in the bag, the

BGA-IC possibly still has to be baked dry. (MSL=Moisture

Sensitivity Level). This will be communicated via AYSwebsite.

Do not re-use BGAs at all.

•

For sets produced before 1.1.2005 (except products of

2004), containing leaded solder-alloy and components,

all needed spare-parts will be available till the end of the

service-period. For repair of such sets nothing changes.

•

On our website www.atyourservice.ce.Philips.com you

find more information to:

BGA-de-/soldering (+ baking instructions)

Heating-profiles of BGAs and other ICs used in Philips-sets

You will find this and more technical information within the

“magazine”, chapter “workshop news”.

For additional questions please contact your local repair-helpdesk.

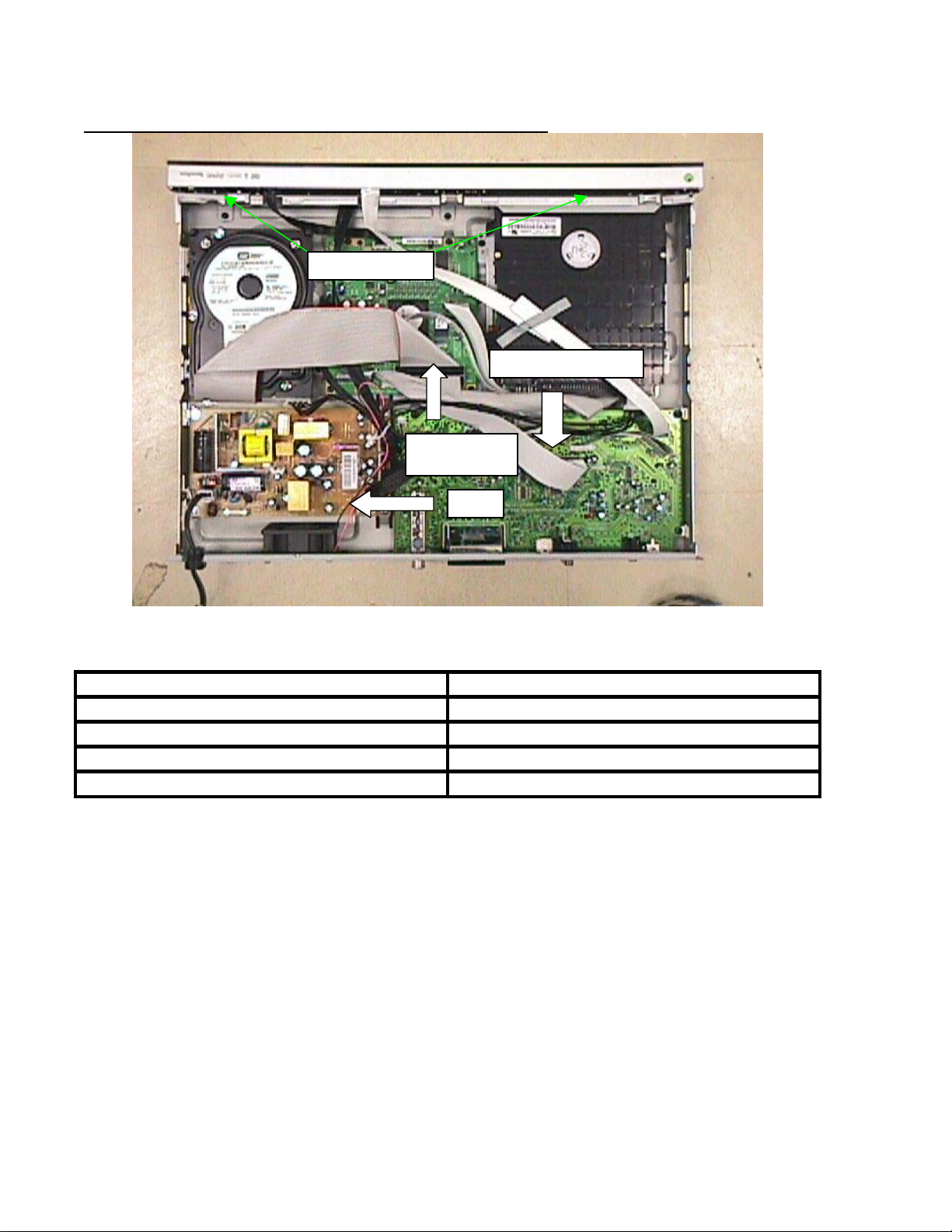

1.Technical Specifications and Connection Facilities

A

Front Board

nalogue Board

Digital Board

PSU

1.1 Read / Write Speed

Type of Disc(Function) Disc Rotation Speed

Read Speed CD 7X CAV

Read Speed DVD 4X CAV

Write Speed DVD+R/RW 2.4X ZCAV

Write Speed DVD-R/RW 2X

1.3 General:

Mains voltage : 220V-240V

Mains frequency : 50Hz

Standby Power consumption : <3W

1.4 RF Tuner

Test Equipment :Fluke 54200 TV Signal generator

Test Stream:PAL BG Philips Standard test pattern

1.4.1.1 System:

PAL B/G, PAL D/K, SECAM L/L’, PAL I

1.4.1.2 RF – Loop Through

Frequency range : 43MHz-860MHz

Gain: (ANT IN-ANT OUT) : -4dB ± 2dB

1.4.1.3 Receiver:

PLL tuning with AFC for optimum reception

Frequency range : 45.25MHz - 857MHz

Sensitivity at 40dB S/N

(video unweighted) : ≤ 40dBµV at 75Ω

(high end)

≤ 60dBµV at 75Ω

(low end)

1.4.1.5 Video Performance:

Channel 25 / 503,25MHz,

Test pattern: PAL BG PHILIPS standard test pattern,

RF Level 74dBV

Measured on SCART 1

Frequency response : 0.1MHz - 4.00MHz ± 3dB

Group delay (0.1MHz-4.4MHz) : 0 nsec ± 150 nsec

1.4.1.6 Audio Performance:

Audio Performance Analogue – HiFi:

Frequency response at SCART 1

(L + R) output : 100Hz -12kHz / 0 ± 3dB

S/N Ratio (20Hz- 20KHz)

unweighted

Harmonic distortion

(1kHz, ± 25kHz deviation) :≤ 1.5%

Audio Performance NICAM:

Frequency response at SCART 1

(L + R) output : 40 Hz – 15 kHz / 0 ± 3dB

S/N according to DIN 45405,7,1967

and PHILIPS standard test pattern

video signal : ≥ 40dB

Harmonic distortion (1kHz) : ≤ 1.5%

1.4.1.7 Tuning

Automatic Search Tuning

scanning time without antenna : 3min. typical

stop level (vision carrier) : ≥ 37dBµV

Maximum tuning error(drift) during

operation : ± 100kHz

Tuning Principle

Automatic B, G, I, DK and L/L’ detection .Manual selection in “STORE” mode

1.5 Analogue Inputs / Outputs

1.5.1 SCART 1(Connected to TV)

Pin Signals:

1 - Audio-out R 1.8V RMS

2 - Audio-out R

3 - Audio-out L 1.8V RMS

4 - Audio GND

5 - Blue / Chroma GND

6 - Audio- in L

7 - Blue-out 0.7Vpp ± 0.1V into 75 W

8 - Function switch < 2V = TV

> 4.5V / < 7V = asp. Ratio 16:9 DVD

> 9.5V / < 12V = asp. Ratio 4:3 DVD

9 - Green GND

10 – P50 control not use

11 – Green out 0.7Vpp ± 0.1V into 75W (*)

12 - NC

13 - Red / Chroma GND

14 - Fast switch GND

15 - Red-out / Chroma-out 0.7Vpp ± 0.1V into 75W (*)

16 - Fast switch

RGB / CVBS or Y out < 0.4V into 75W = CVBS

>1V / < 3V into 75W = RGB

17 - Y/CVBS GND OUT

18 - CVBS GND IN

19 - CVBS-out 1Vpp ± 0.1V into 75W(*)

20 - CVBS-in

21 - Shield

1.5.2 SCART 2 (Connected to AUX)

Pin Signals:

1 - Audio-out R 1.8V RMS

2 - Audio-in R

3 - Audio-out L 1.8V RMS

4 - Audio GND

5 - Blue / Chroma GND

6 - Audio-in L

7 - Blue-in

8 - Function switch

9 - Green GND

10 - NC

11 - Green-in

12 - NC

13 - Red / Chroma GND

14 - Fast switch GND

15 - Red-in/Chroma-in

16 - Fast switch

RGB / CVBS or Y in

17 - CVBS-OUT GND

18 – Y/CVBS in GND

19 - CVBS out sync 1Vpp ± 0.1V into 75Ω

20 – CVBS in / Y-in

21 – Shield

1.5.3 Audio/Video Front Input Connectors

Audio – Cinch

Input voltage : 2.2Vrms

Input impedance : > 10kΩ

Video – Cinch

Input voltage : 1Vpp ± 3dB

Input impedance : 75Ω

Video – YC (Hosiden)

According to IEC 933-5

Superimposed DC-level on pin 4(load >100kΩ)

<2.4V is detected as 4:3 aspect ratio

>3.5V is detected as 16:9 aspect ratio

Input voltage Y : 1Vpp ± 3dB

Input impedance Y : 75Ω

Input voltage C : 300 mVpp ± 3dB

Input impedance C : 75Ω

1.6 Digital Inputs / Outputs

1.6.1 Digital Output

Digital Audio – Coaxial

LCM : according IEC 60958

MPEG 1,MPEG2,AC3 : according IEC 61937

DTS : according IEC 61937+addendum

1.7.3 Digital Video Input(IEEE 1394)

Implementation Standard according:

IEEE Std 1394-1995

IEC61883 - Part1

IEC61883 - Part2 SD-DVCR (02-01-1997)

Specification of consumer use digital VCR’s using 6.3mm magnetic tape – dec.

1994

Mechanical connection according to Annex of IEC 61883-1

1.8 Video Performance

All outputs loaded with 75 Ω

SNR measurements over full bandwidth without weighting.

1.8.1 SCART (RGB)

SNR : > -65dB on all output

Bandwidth : 4.8MHz ± 2dB

1.9 Audio Performance CD

1.9.1 Cinch Output Rear

Output voltage 2 channel mode : 2Vrms ± 2dB

Channel unbalance (1kHz) : < 0.22dB

Crosstalk 1kHz : > 100dB

Crosstalk 16Hz-20kHz : > 87dB

Frequency response 20Hz-20kHz : ± 0.5dB max

Signal to noise ratio : < 85dB

Dynamic range 1kHz : <83dB

Distortion and noise 1kHz : < 83dB

Distortion and noise 16Hz-20kHz : < 75dB

Intermodulation distortion : < 70dB

Mute : < 95dB

1.9.2 Scart Audio

Output voltage 2 channel mode : 1.6Vrms ± 2dB

Channel unbalance (1kHz) : < 1dB

Crosstalk 1kHz : > 85dB

Crosstalk 16Hz-20kHz : > 70dB

Frequency response 20Hz-20kHz : ± 0.5dB max

Signal to noise ratio : > 80dB

Dynamic range 1kHz : > 75dB

Distortion and noise 1kHz : > 75dB

Distortion and noise 16Hz-20kHz : > 50dB

Intermodulation distortion : > 70dB

Mute : > 80dB

Height of feet : 5.5mm

Apparatus(WxDxH) : 435 x 65 x 340 mm

Weight without packaging : 4.3 kg

Weight with packaging : 6.0kg

1.10 Laser Output Power & Wavelength

1.10.1 DVD

Output power during reading : 0.8mW

Output power during writing : 20mW

Wavelength 650nm

1.10.2 CD

Output power :0.3mW

Wavelength :780nm

1.11 Supported disc type and media speed

Disc Media Speeds

DVD+R 1x - 16x

DVD+RW 2.4x - 4x

DVD -R 1x - 16x

DVD -RW 2.4x - 4x

DVD+R DL 2.4x

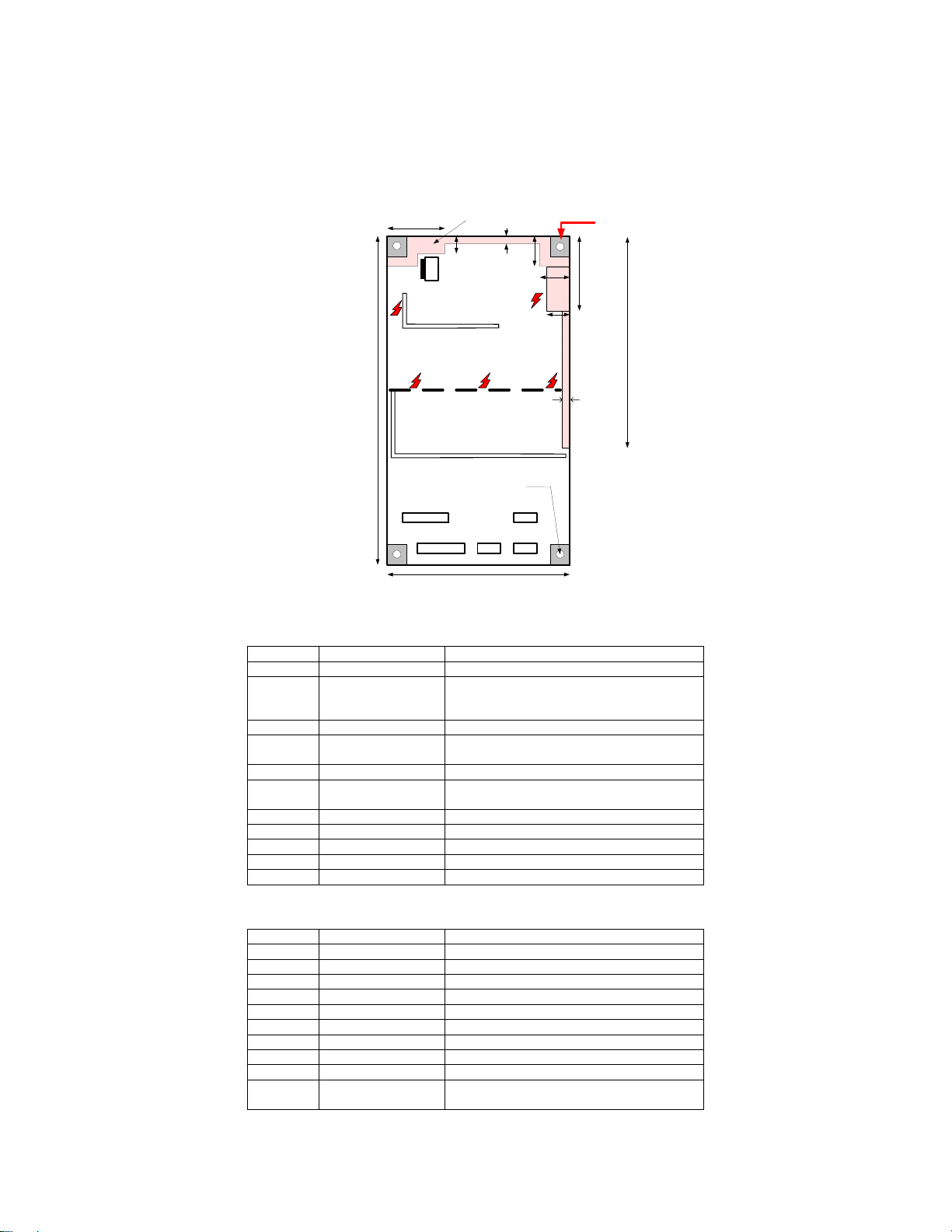

1.1. PSU Board

1.1.1. General

No component, No copper

30.5+/-0.15

170+/-0.2

Keep 10x10 area as base of

track area

9+/-0.1

Y

R

Mains connector

A

M

I

R

P

Dia=3.2+/-0.05 (4x)

metal plate for screws

4+/-0.1

16+/-0.1

A

D

B

95+/-0.15

The PSU board provides the following connection to the rest of the set:

• Connector A: Supply/Signal to Analog Board

Pin no. Supply / Signal Remarks

1 12VSTBY

2 STBY control >2.5V = supply for conn. B is off (Standby

mode)

<0.5V = supply for conn. B is on (On mode)

3 5VSTBY

4 DD_ON >2.5V = supply for conn. D is on

<0.5V = supply for conn. D is off

5 3V3STBY

6 IPFAIL >4.0V = power is good

<0.5V = power fail

7 5NSTBY

8 GND

9 33VSTBY

10 GND

11 VGNSTBY

• Connector B: Supply to Digital Board

Pin no. Supply / Signal Remarks

1 3V3D

2 3V3D

3 3V3D

4 3V3D

5 GND

6 12VD

7 GND

8 GND

9 5VD

10 HD_ON >2.5V = supply for conn. C & G is on

<0.5V = supply for conn. C & G is off

16+/-0.1

12+/-0.1

C

This screw can

be used as EMC

Y-capacitor

connection

39+/-0.1

110+/-0.1

3.5+/-0.1

G

11 GND

• Connector C: not in use

• Connector D: Supply to Basic Engine

• Connector E: Supply to HDD

! The Mains must be disconnected from the Set before attempting the procedure mentioned below:

The PSU is designed with short-circuit protection that will shutdown the power supply. When this happen, the

voltage stored in capacitor C1 and C2 will prevent the Power Supply to turn-on, therefore they must be

discharged with a screwdriver with high electrical isolation handle before the PSU can function normally again.

Note :During the process of discharging the capacitors ,spark can be observed which is typical of the high

voltage stored in Capacitor C1 and C2.

12 5ND

Pin no. Supply

1 12VE

2 GND

3 GND

4 5VE

Pin no. Supply

1 12VH

2 GND

3 GND

4 5VH

Loading...

Loading...