Page 1

VCR Module

HK100ED

2422 549 01124

Service

Service

Service

Service Manual

Contents

Chapter

Sec. 1: Schematic Diagrams and CBA's

Exploded Views

Mechanical and Electrical Parts Lists

Sec. 2: Standard Maintenance

Mechanism Alignment Procedures

Disassembly / Assembly of Mechanism

Deck Exploded Views

Deck Parts List

c Copyright 2006 Philips Consumer Electronics B.V. Eindhoven, The Netherlands.

All rights reserved. No part of this publication may be reproduced, stored in a retrieval

system or transmitted, in any form or by any means, electronic, mechanical, photocopying,

or otherwise without the prior permission of Philips.

Published by FU-KC 0623 Service AV Systems Printed in Netherlands Subjection to modification EN 3139 785 32220

Version 1.0

Page 2

MAIN SECTION

VCR Module

Sec. 1: Main Section

I Schematic Diagrams and CBA’s

I Exploded Views

I Mechanical and Electrical Parts List

TABLE OF CONTENTS

STANDARD NOTES FOR SERVICING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1-1

SIGNAL NAME ABBREVIATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2-1

ELECTRICAL ADJUSTMENT INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3-1

BLOCK DIAGRAMS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4-1

SCHEMATIC DIAGRAMS / CBA’S AND TEST POINTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5-1

WAVEFORMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6-1

WIRING DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7-1

IC PIN FUNCTION DESCRIPTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8-1

LEAD IDENTIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9-1

ELECTRICAL PARTS LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10-1

EXPLODED VIEWS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11-1

MECHANICAL PARTS LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12-1

Page 3

STANDARD NOTES FOR SERVICING

Circuit Board Indications

1. The output pin of the 3 pin Regulator ICs is

indicated as shown.

Top View

Out

2. For other ICs, pin 1 and every fifth pin are

indicated as shown.

Pin 1

3. The 1st pin of every male connector is indicated as

shown.

Pin 1

Input

In

Bottom View

5

10

Pb (Lead) Free Solder

When soldering, be sure to use the Pb free solder.

Information about lead-free soldering

Philips CE is producing lead-free sets from 1.1.2005

onwards.

IDENTIFICATION

Regardless of special logo (not always

indicated)

One must treat all sets from

onwards, according to the next rule:

Serial Number gives a 9-digit. Digit 2&3 shows the

WEEK, and digit 4 shows the YEAR.

So from onwards=from 1 Jan 2005 onwards

Important note: In fact also products of year 2004

must be treated in this way as long as you avoid

mixing solder-alloys (leaded/ lead- free) . So bes t to

always use SAC305 and the higher temperatures

belong to this.

Due to lead-free technology some rules have to be

respected by the workshop during a repair:

• Use only lead-free solder alloy Philips SAC305 with

order code 0622 149 00106. If lead-free solderpaste is required, please contact the manufacturer

of your solder-equipment. In general use of solderpaste within workshops should be avoided because

paste is not easy to store and to handle.

• Use only adequate solder tools applicable for leadfree solder alloy. The solder tool must be able

• To reach at least a solder-temperature of 400°C,

• To stabilize the adjusted temperature at the solder-

• To exchange solder-tips for different applications.

• Adjust your solder tool so that a temperature around

360°C

solder joint. Heating-time of the solder-joint should

not exceed ~ 4 sec. Avoid temperatures above

400°C otherwise wear-out of tips will rise drastically

and flux-fluid will be destroyed. To avoid wear-out of

tips switch off un-used equipment, or reduce heat.

• Mix of lead-free solder alloy / parts with leaded

solder alloy / parts is possible but PHILIPS

recommends strongly to avoid mixed solder alloy

types (leaded and lead-free).

If one cannot avoid or does not know whether

product is lead-free, clean carefully the solder-joint

from old solder alloy and re-solder with new solder

alloy (SAC305).

• Use only original spare-parts listed in the ServiceManuals. Not listed standard-material (commodities)

has to be purchased at external companies.

015

tip

- 380°C is reached and stabilized at the

1 Jan 2005

1-1-1 HK100_SN

Page 4

• Special information for BGA-ICs:

- always use the 12nc-recognizable soldering

temperature profile of the specific BGA (for desoldering always use the lead-free temperature

profile, in case of doubt)

- lead free BGA-ICs will be delivered in so-called

'dry-packaging' (sealed pack including a silica gel

pack) to protect the IC against moisture. After

opening, dependent of MSL-level seen on indicatorlabel in the bag, the BGA-IC possibly still has to be

baked dry. (MSL=Moisture Sensitivity Level). This

will be communicated via AYS-website.

Do not re-use BGAs at all.

• For sets produced before 1.1.2005 (except products

of 2004), containing leaded solder-alloy and

components, all needed spare-parts will be available

till the end of the service-period. For repair of such

sets nothing changes.

• On our website

www.atyourservice.ce.Philips.com

information to:

• BGA-de-/soldering (+ baking instructions)

• Heating-profiles of BGAs and other ICs used in

Philips-sets

You will find this and more technical information within

the “magazine”, chapter “workshop news”.

For additional questions please contact your local

repair-helpdesk.

you find more

How to Remove / Install Flat Pack-IC

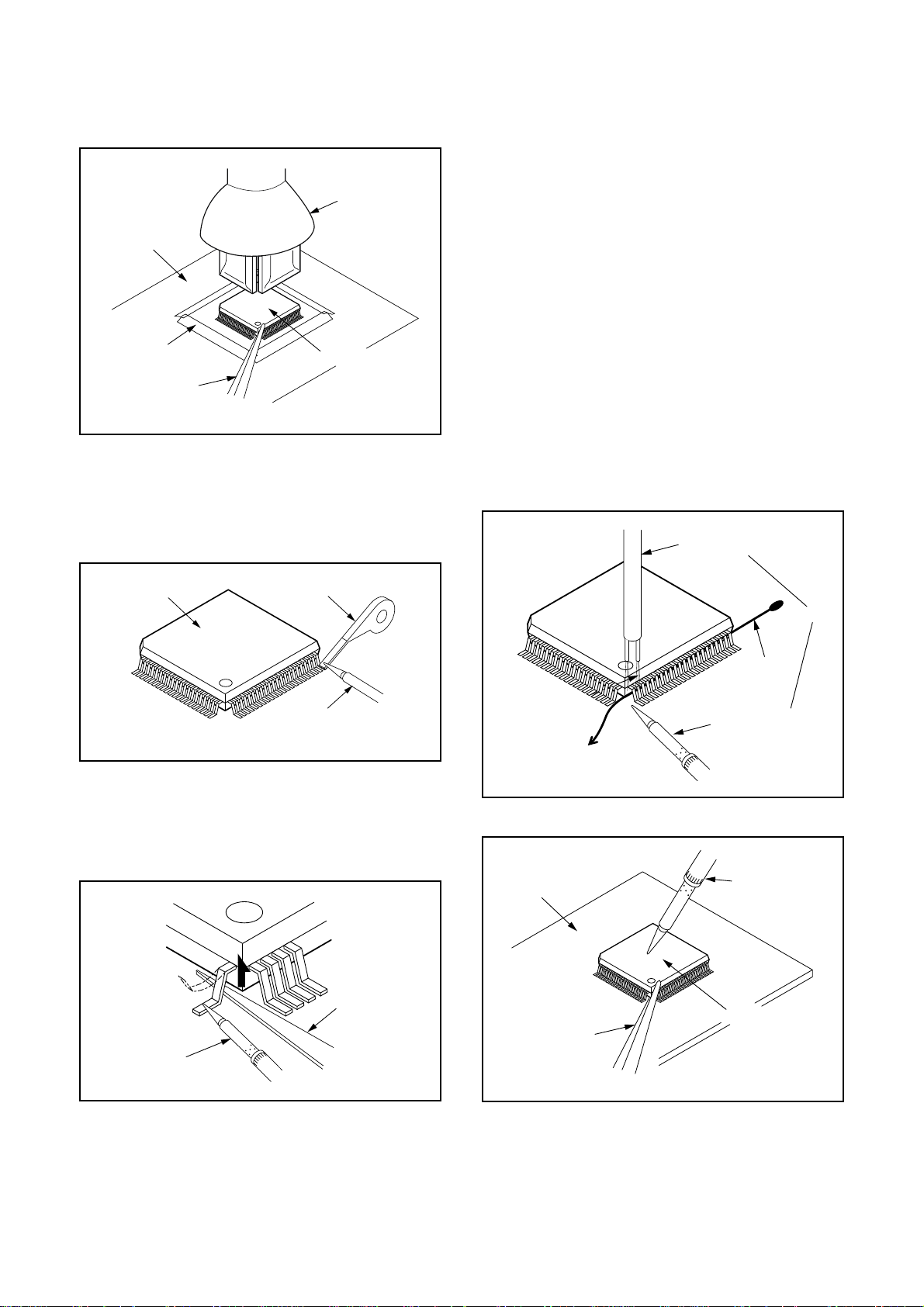

1. Removal

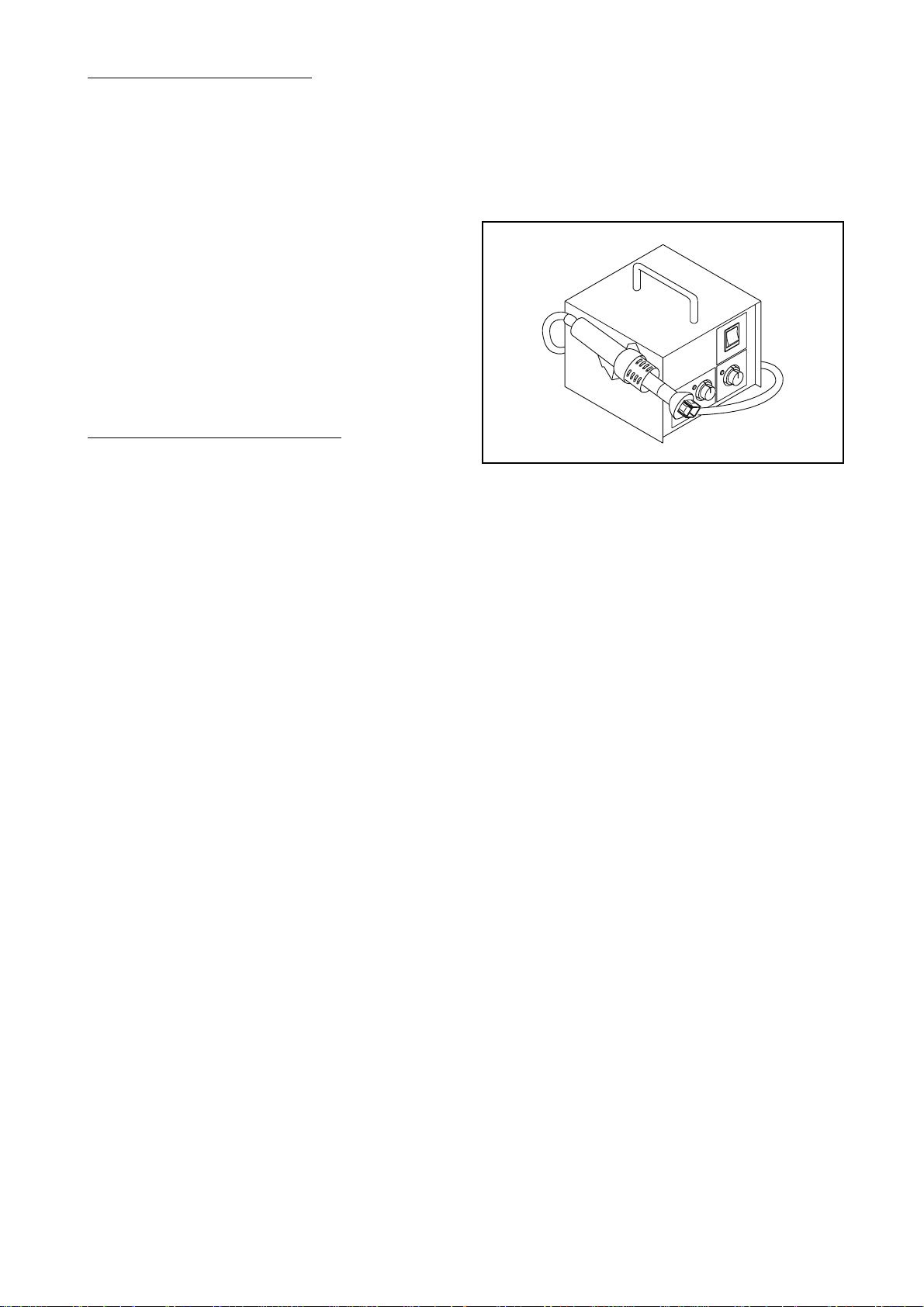

With Hot-Air Flat Pack-IC Desoldering Machine:

1. Prepare the hot-air flat pack-IC desoldering

machine, then apply hot air to the Flat Pack-IC

(about 5 to 6 seconds). (Fig. S-1-1)

Fig. S-1-1

2. Remove the flat pack-IC with tweezers while

applying the hot air.

3. Bottom of the flat pack-IC is fixed with glue to the

CBA; when removing entire flat pack-IC, first apply

soldering iron to center of the flat pack-IC and heat

up. Then remove (glue will be melted). (Fig. S-1-6)

4. Release the flat pack-IC from the CBA using

tweezers. (Fig. S-1-6)

CAUTION:

1. The Flat Pack-IC shape may differ by models. Use

an appropriate hot-air flat pack-IC desoldering

machine, whose shape matches that of the Flat

Pack-IC.

2. Do not supply hot air to the chip parts around the

flat pack-IC for over 6 seconds because damage

to the chip parts may occur. Put masking tape

around the flat pack-IC to protect other parts from

damage. (Fig. S-1-2)

1-1-2 HK100_SN

Page 5

3. The flat pack-IC on the CBA is affixed with glue, so

be careful not to break or damage the foil of each

pin or the solder lands under the IC when

removing it.

Hot-air

Flat Pack-IC

Desoldering

CBA

Masking

Tape

Machine

Flat Pack-IC

Tweezers

Fig. S-1-2

With Soldering Iron:

1. Using desoldering braid, remove the solder from

all pins of the flat pack-IC. When you use solder

flux which is applied to all pins of the flat pack-IC,

you can remove it easily. (Fig. S-1-3)

With Iron Wire:

1. Using desoldering braid, remove the solder from

all pins of the flat pack-IC. When you use solder

flux which is applied to all pins of the flat pack-IC,

you can remove it easily. (Fig. S-1-3)

2. Affix the wire to a workbench or solid mounting

point, as shown in Fig. S-1-5.

3. While heating the pins using a fine tip soldering

iron or hot air blower, pull up the wire as the solder

melts so as to lift the IC leads from the CBA

contact pads as shown in Fig. S-1-5.

4. Bottom of the flat pack-IC is fixed with glue to the

CBA; when removing entire flat pack-IC, first apply

soldering iron to center of the flat pack-IC and heat

up. Then remove (glue will be melted). (Fig. S-1-6)

5. Release the flat pack-IC from the CBA using

tweezers. (Fig. S-1-6)

Note: When using a soldering iron, care must be

taken to ensure that the flat pack-IC is not

being held by glue. When the flat pack-IC is

removed from the CBA, handle it gently

because it may be damaged if force is applied.

Hot Air Blower

Flat Pack-IC

Desoldering Braid

Soldering Iron

Fig. S-1-3

2. Lift each lead of the flat pack-IC upward one by

one, using a sharp pin or wire to which solder will

not adhere (iron wire). When heating the pins, use

a fine tip soldering iron or a hot air desoldering

machine. (Fig. S-1-4)

Sharp

Pin

Fine Tip

Soldering Iron

Fig. S-1-4

To Solid

Mounting Point

CBA

Tweezers

or

Iron Wire

Soldering Iron

Fig. S-1-5

Fine Tip

Soldering Iron

Flat Pack-IC

Fig. S-1-6

3. Bottom of the flat pack-IC is fixed with glue to the

CBA; when removing entire flat pack-IC, first apply

soldering iron to center of the flat pack-IC and heat

up. Then remove (glue will be melted). (Fig. S-1-6)

4. Release the flat pack-IC from the CBA using

tweezers. (Fig. S-1-6)

1-1-3 HK100_SN

Page 6

2. Installation

1. Using desoldering braid, remove the solder from

the foil of each pin of the flat pack-IC on the CBA

so you can install a replacement flat pack-IC more

easily.

2. The “●” mark on the flat pack-IC indicates pin 1.

(See Fig. S-1-7.) Be sure this mark matches the 1

on the PCB when positioning for installation. Then

presolder the four corners of the flat pack-IC. (See

Fig. S-1-8.)

3. Solder all pins of the flat pack-IC. Be sure that

none of the pins have solder bridges.

Example :

Pin 1 of the Flat Pack-IC

is indicated by a " " mark.

Fig. S-1-7

Instructions for Handling Semiconductors

Electrostatic breakdown of the semi-cond uc tors may

occur due to a potential difference caused by

electrostatic charge during unpacking or repair work.

1. Ground for Human Body

Be sure to wear a grounding band (1 MΩ) that is

properly grounded to remove any static electricity that

may be charged on the body.

2. Ground for Workbench

Be sure to place a conductive sheet or copper plate

with proper grounding (1 MΩ) on the workbench or

other surface, where the semi-conductors are to be

placed. Because the static electricity charge on

clothing will not escape through the body grounding

band, be careful to avoid contacting semi-conductors

with your clothing.

<Incorrect>

CBA

Presolder

Flat Pack-IC

Fig. S-1-8

<Correct>

1MΩ

CBA

Grounding Band

1MΩ

CBA

Conductive Sheet or

Copper Plate

1-1-4 HK100_SN

Page 7

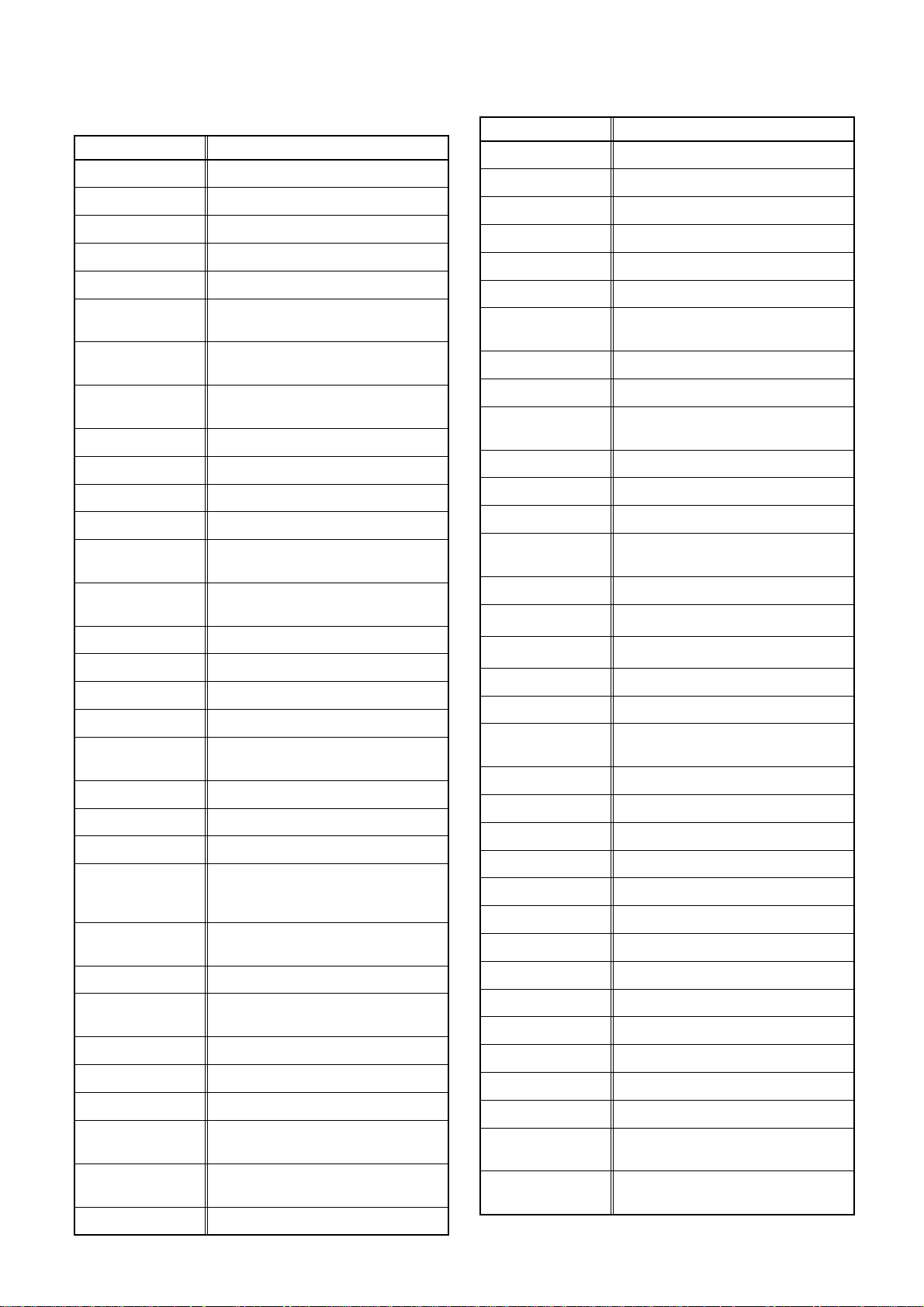

SIGNAL NAME ABBREVIATIONS

Signal Name Function

4.43MHz 4.43MHz clock

A-COM Audio Head Common

A-MODE Hi-Fi Tape Detection Signal

AE-H Audio Erase Head

AE-H/FE-H Audio Erase Head

AL+12V

AL+20V/+12V

AL+5V

AMPC CTL AMP Connected Terminal

AMPVcc AMPVcc

AMPVREF IN V-Ref for CTL AMP

AMPVREF OUT V-Ref for CTL AMP

AUDIO-MUTE-H

AUDIO-PB/REC

AUDIO(L)-IN L-ch Audio Input

AUDIO(L)-OUT L-ch Audio Output

AUDIO(R)-IN R-ch Audio Input

AUDIO(R)-OUT R-ch Audio Output

AVcc

CC Terminal

C CTL AMP Capacit or

C-CONT Capstan Motor Control Signal

C-F/R

C-FG

C-POW-SW Capstan Power Switching Pulse

C-ROTA

C-SYNC Composite Synchronized Pulse

CLKSEL Clock Select

CTL To Monitor for CTL AMP Output

CTL (+)

CTL (-)

D-CONT Drum Motor Control Signal

Always +12V with AC Plug

Connected

Always +20V/+12V with AC Plug

Connected

Always +5V with AC Plug

Connected

Audio Mute Control Signal

(Mute=“H”)

Normal Audio Play Back/Record

Signal

A/D Converter Power Input/

Standard Voltage Input

Capstan Motor FWD/REV

Control Signal (FWD=”L”/

REV=”H”)

Capstan Motor Rotation

Detection Pulse

Color Phase Rotary Changeover

SIgnal

Playback/Record Control Signal

(+)

Playback/Record Control Signal

(-)

Signal Name Function

D-PFG Drum Motor Pulse Generator

D-REC-H Delayed Record Signal

D-V-SYNC Dummy V-sync Output

END-S Tape End Position Detect Signal

FE-H Full Erase Head

FE-H-GND Ground for Full Erase Head

FSC-IN

[4.43MHz]

GND Ground

H-A-COMP Head Amp Comparator Signal

H-A-SW

Hi-Fi-AUDIO(L) Hi-Fi Audio L Head

Hi-Fi-AUDIO(R) Hi-Fi Audio R Head

Hi-Fi-COM Hi-Fi Audio Head Common

Hi-Fi-H-SW

HLF LPF Connected Terminal (Slicer)

IIC-BUS SCL

IIC-BUS SDA

KEY-1 Key Scan Input Signal 1

KEY-2 Key Scan Input Signal 2

LD-SW

LM-FWD/REV Loading Motor Control Signal

N-A-PB Normal Audio Playback

N-A-REC Normal Audio Recording

OSCin Clock Input for letter size

OSCout Clock Output for letter size

OSD-V-IN OSD Video Signal Input

OSD-V-OUT OSD Video Signal Output

OSDVcc OSDVcc

OSDVss OSD Ground

P-ON+5V +5V at Power-On Signal

P-ON+9V +9V at Power-On Signal

P-ON-L Power On Signal at Low

PB-H-OUT Playback control/Signal (PB=“H”)

PG-DELAY

POW-SAF

4.43MHz Clock Input

Video Head Amp Switching

Pulse

Hi-Fi Audio Head Switching

Pulse

2

C BUS Control Clock

I

2

I

C BUS Control Data

Deck Mode Position Detector

Signal

Video Head Switching Pulse

Signal Adjusted Voltage

P-ON Power Detection Input

Signal

1-2-1 HK100SNA

Page 8

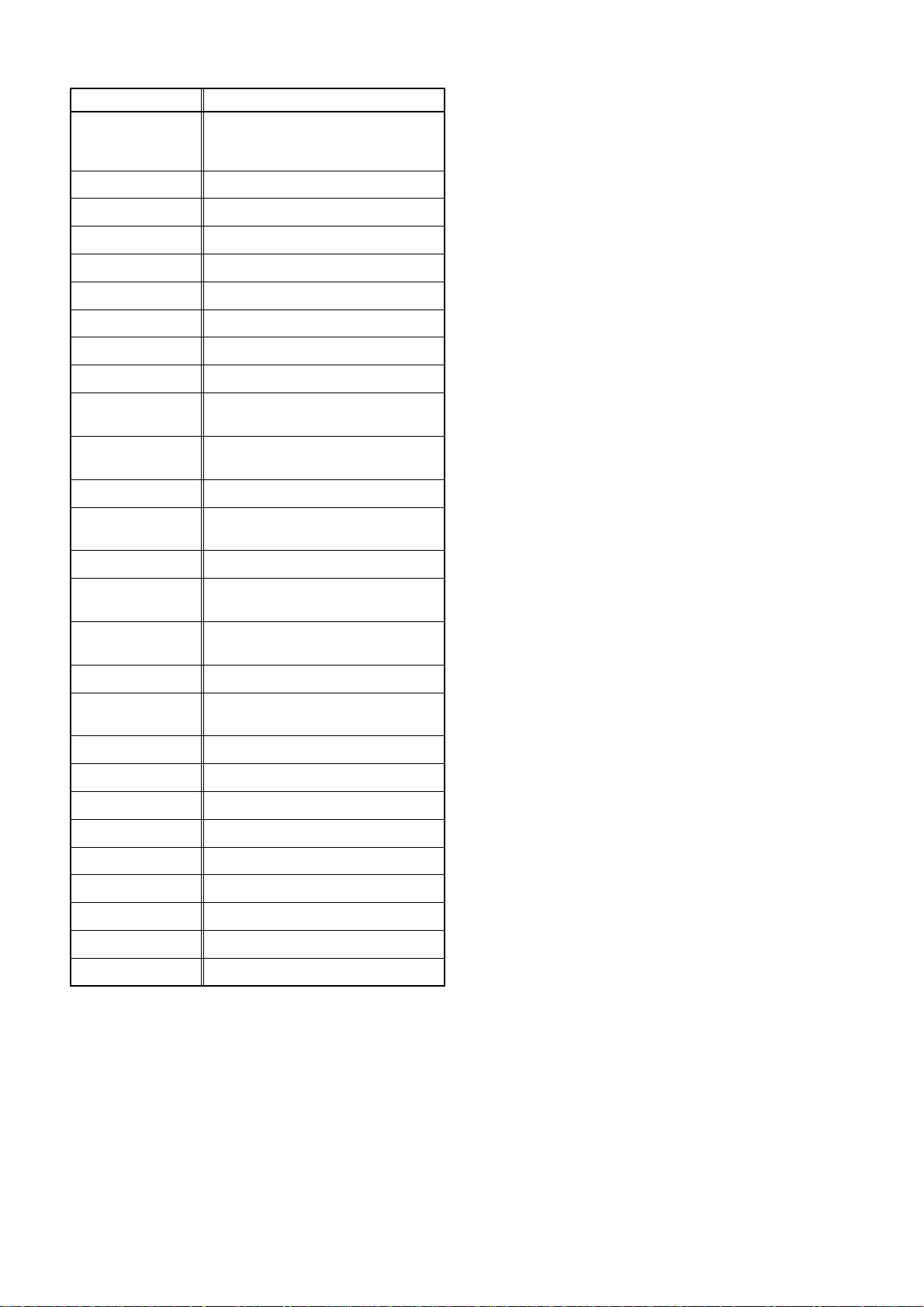

Signal Name Function

REC-SAF-SW

REMOTE Remote Control Sensor

RESET System Reset Signal (Reset=“L”)

RF-SW Video Head Switching Pulse

S-CLOCK Serial clock

S-CS Chip Select Signal

S-DATA-IN Serial Data Input

S-DATA-OUT Serial Data Output

S-REEL Supply Reel Rotation Signal

Recording Safety SW Detect

(With Record tab=“L”/With out

Record tab=“H”)

SECAM-C-IN

SECAM-FM-

OUT

SECAM-H SECAM Mode at High

ST-S

T-REEL Take Up Reel Rotation Signal

TRICK-H

V-ENV

Vcc Vcc

VG+18V

VIDEO Video Signal

VIDEO(L)-1/2 Video L Head 1/2

VIDEO(R)-1/2 Video R Head 1/2

VIDEO-COM Video Head Common

SECAM CHROMA Signal from

PAL/SECAM DETECTOR

PB video Signal to PAL/SECAM

DETECTOR

Tape Start Position Detector

Signal

Trick Play Control Signal

(Trick=“H”)

Video Envelope Comparator

Signal

Always +18V with AC Plug

Connected

VIDEO-IN Video Signal Input

VIDEO-OUT Video Signal Output

Vss Vss(GND)

X-IN Main Clock Input

X-OUT Main Clock Input

1-2-2 HK100SNA

Page 9

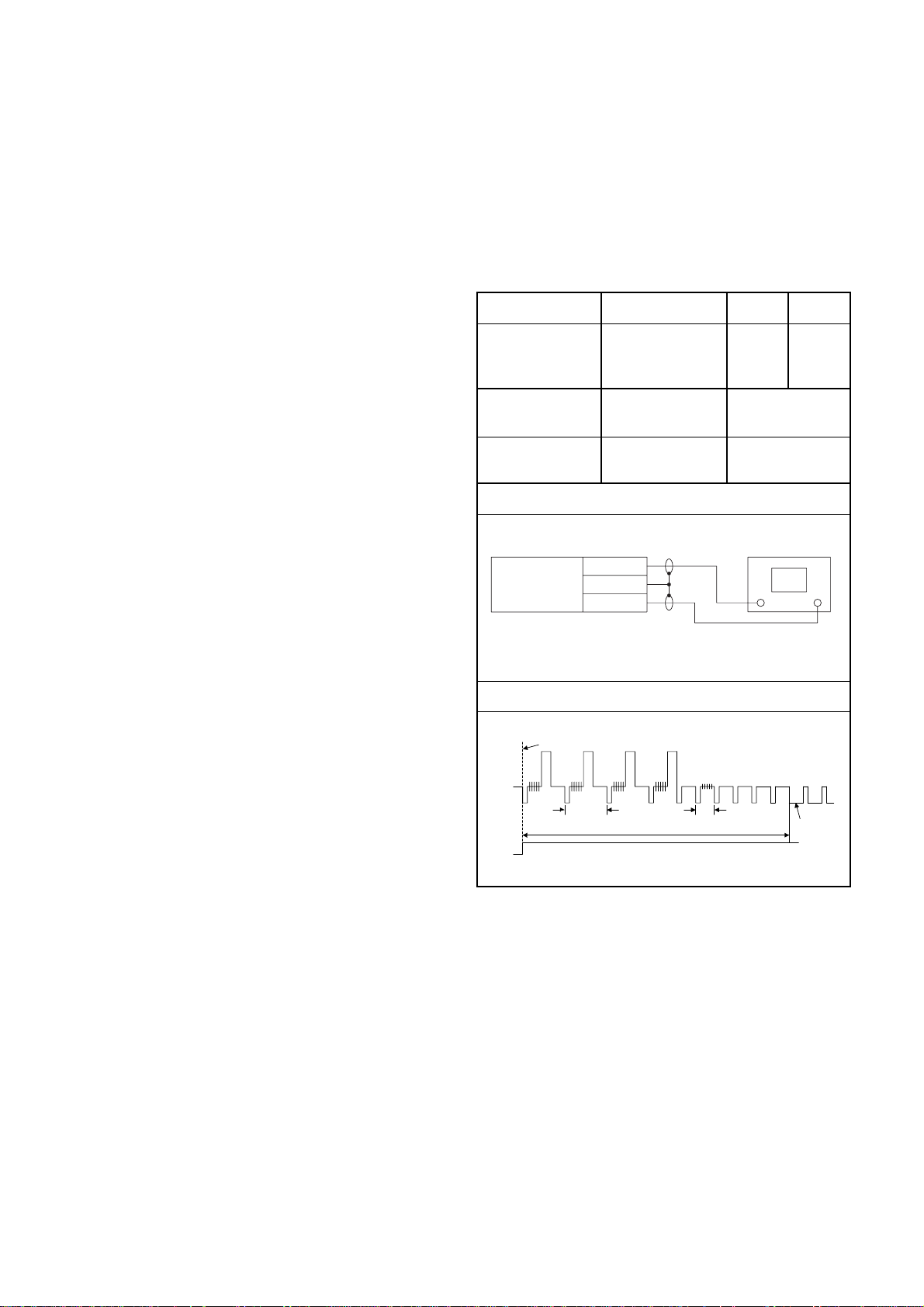

ELECTRICAL ADJUSTMENT INSTRUCTIONS

General Note: "CBA" is an abbreviation for

"Circuit Board Assembly."

NOTE:

1.Electri cal adjustm ents are re quired after re placing

circuit components and certain mechanical par ts.

It is impor tant to do these adjustments only after

all repairs and replacements have been completed. Also, do not attempt these adjustments

unless the proper equipment is available.

2.To perfor m these alignment / confirmation procedures, make sure that the tracking control is set in

the center position : Press either "PR -5??" or "PR +"

button on the remote control unit first, then the "B"

button (Front Panel only).

Te st Equipment Required

1.Oscilloscope: Dual-trace with 10:1 probe,

V-Range: 0.001~50V/Div.,

F-Range: DC~AC-20MHz

2.Alignment Tape (9965 000 14514)

Head Switching Position Adjustment

Purpose:

To determ ine the Head Switching position during

playback.

Symptom of Misadjustment:

May cause Head Switch ing noise or vertical jit ter

in the picture.

Test point Adj.Point Mode Input

J909(V-OUT)

TP504(RF-SW)

GND

Tape

9965 000 14514 Oscilloscope

Connections of Measurement Equipment

Main CBA

TP504

VR501

(Switching Point)

(MAIN CBA)

Measurement

Equipment

J909

GND

PLAY

(SP)

6.5H±1H

(416µs±64µs)

Oscilloscope

-----

Spec.

CH1 CH2

Trig. (+)

Figure 1

EXT. Syncronize Trigger Point

CH1

CH2

Reference Notes:

Playback the Alignment tape and adjust VR501 so that

the V-sync front edg e of the CH1 video out put waveform is at the 6.5H±1H (416µs±64µs) delayed position

from the rising edge o f the CH2 head switching pulse

waveform.

1.0H

6.5H+/-1H (416µs+/-64µs)

Switching Pulse

0.5H

V-Sync

1-3-1 HK100EA

Page 10

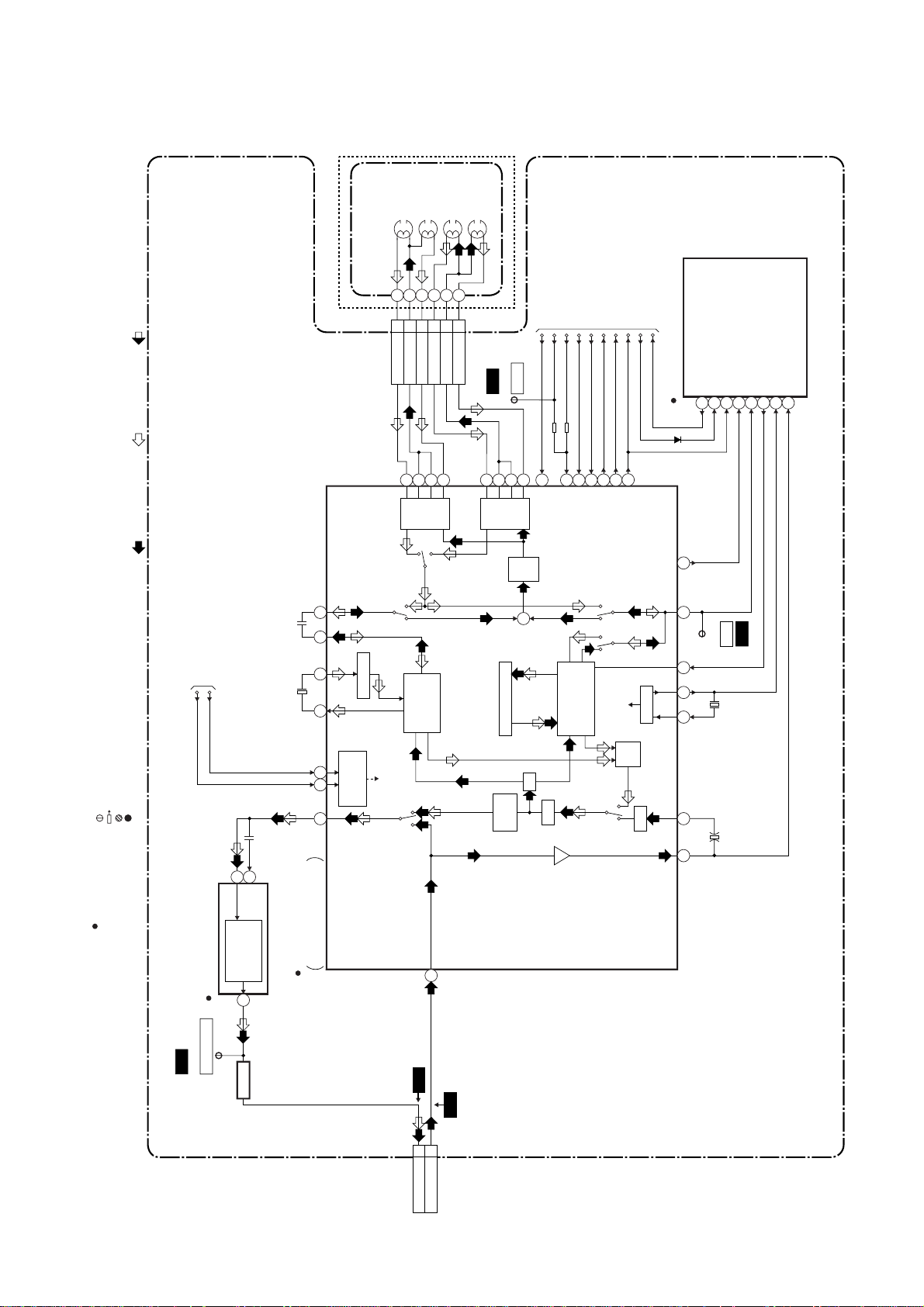

BLOCK DIAGRAMS

Servo / System Control Block Diagram

AL+20V/+12V

AL+5V

RESET

1 VG+18V

CN252

VG+18V

3

4 AL+12V

6 AL+12V

8 AL+5V

Q151

+9V REG.

AL+5V

AL+12V

P-ON+9V

AL+20V/+12V

10 C-POW-SW

Q153

P-ON+5V

CN653

TP505 SENS-INH

1 S-CLOCK

3 S-DATA-IN

7 S-CS

8 RESET

2 REMOTE

1 KEY-1

5 S-DATA-OUT

CN505

WF8WF9WF10WF11

Q515

Q152

SDA

SCL

IC502 (MEMORY)

5

6

TO AUDIO

BLOCK DIAGRAM

IIC-BUS SCL

IIC-BUS SDA

AUDIO-MUTE-H

TO Hi-Fi AUDIO

BLOCK DIAGRAM

A-MODE

Hi-Fi-H-SW

IIC-BUS SCL

IIC-BUS SDA

AUDIO-MUTE-H

RF-SW

D-REC-H

IIC-BUS SCL

IIC-BUS SDA

C-ROTA

D-V-SYNC

TO VIDEO

BLOCK DIAGRAM

V-ENV

H-A-SW

C-SYNC

TRICK-H

H-A-COMP

SECAM-H

8

7

14

KEY- 1

:INDICATES A TEST POINT WITH A JUMPER WIRE ACROSS A HOLE IN THE PCB.

:USED TO INDICATE A TEST POINT WITH A COMPONENT LEAD ON FOIL SIDE.

:USED TO INDICATE A TEST POINT WITH NO TEST PIN.

:USED TO INDICATE A TEST POINT WITH A TEST PIN.

TEST POINT INFORMATION

“ “ = SMD

NOTE FOR WIRE CONNECTORS:

1. PREFIX SYMBOL "CN" MEANS CONNECTOR.

(CAN DISCONNECT AND RECONNECT.)

2. PREFIX SYMBOL "CL" MEANS WIRE-SOLDER

HOLES OF THE PCB.

KEY- 2

REMOTE

IC501

(SERVO/SYSTEM CONTROL)

AL+5V

D555

S-LED

SW507

(WIRE IS SOLDERED DIRECTLY.)

LD-SW

MAIN CBA

CTL(+)

LD-SW

9

95

AL+5V

CN504

5 CTL(+)

67

66

S-CLOCK

S-DATA-IN

CTL(-)

94

6 CTL(-)

65

64

S-CS

S-DATA-OUT

34

RESET

END-S

ST-S

10480

60

C-POW-SW

T-REEL

S-REEL

79

END-S

TP502

PS502

Q506

S-REEL

T-REEL

75

P-ON-L

CTL

97

CTL

TP503

AL+5V

PG-DELAY

2

VR501

SW-POINT

83

AUDIO-MUTE-H

REC-SAF-SW

31

SW506

AL+5V

REC-SAFETY

CAPSTAN MOTOR

P-ON+5V

AL+20V/+12V

CN502

AL+20V/+12V

1

2 P-ON+5V

33

71

72

19

32

A-MODE

Hi-Fi-H-SW

C-FG

C-F/R

8778768177

C-F/R5C-CONT6GND7LM-FWD/REV

3 C-FG

4

IIC-BUS SCL

IIC-BUS SDA

C-CONT

LM-

MOTOR

DRIVE

CAPSTAN

D-REC-H

FWD/REV

D-CONT

D-CONT9D-PFG10GND11AL+12V

8

CIRCUIT

MOTOR

15

18

RF-SW

C-ROTA

D-PFG

90

M

17

16

13

H-A-SW

D-V-SYNC

H-A-COMP

AL+12V

VG+18V

VG+18V

12

M

6

58

V-ENV

C-SYNC

61

62

TRICK-H

SECAM-H

ACE HEAD ASSEMBLY

(DECK ASSEMBLY)

CONTROL

HEAD

Q504

ST-S

SENSOR CBA

Q503

1-4-1

END-S

SENSOR CBA

M

PG

SENSOR

DRUM

CYLINDER ASSEMBLY

MOTOR

LOADING

MOTOR

HK100BLS

Page 11

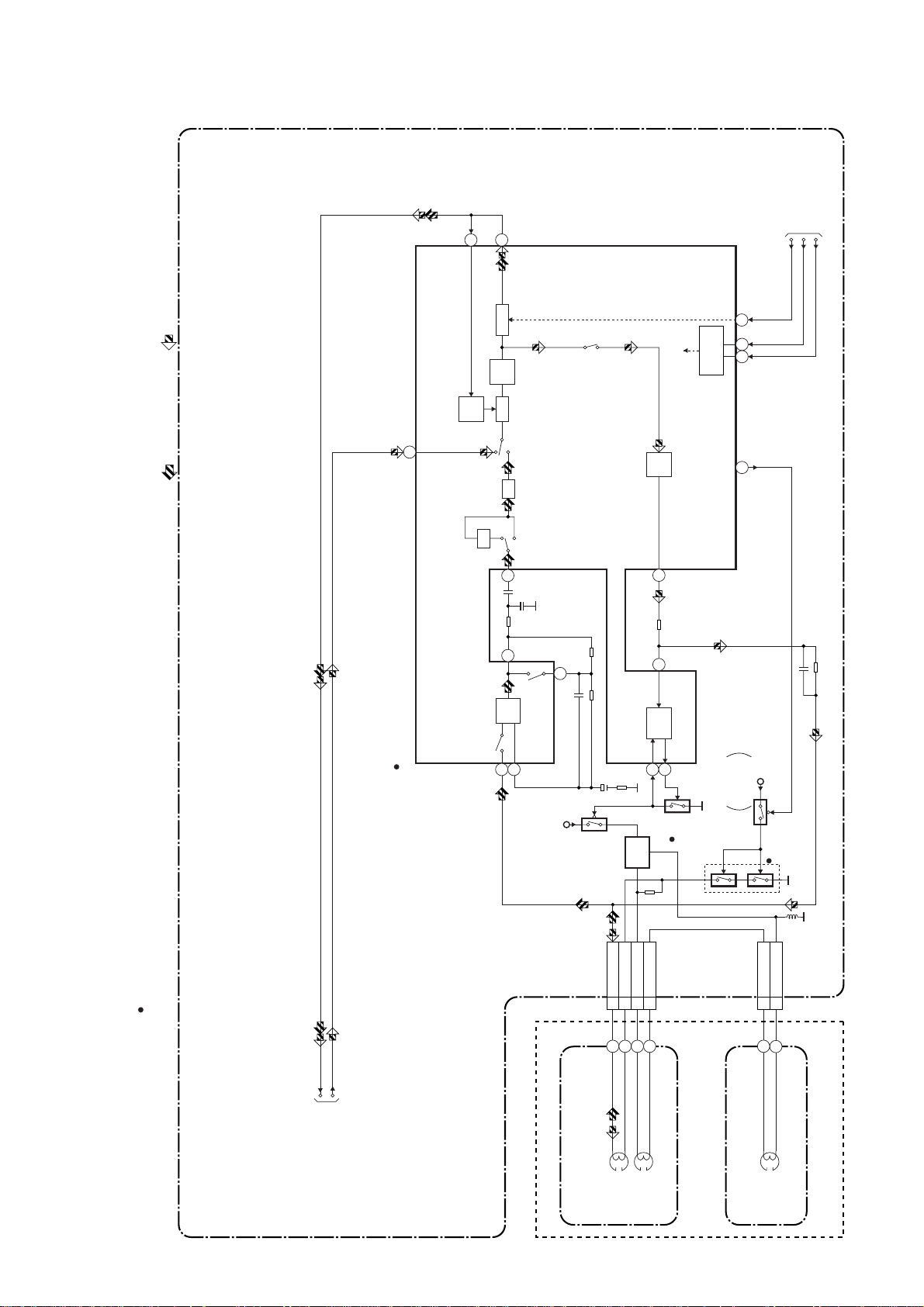

Video Block Diagram

MODE: SP/RECPB-VIDEO SIGNAL DVD VIDEO SIGNAL

VIDEO (L)-1

HEAD

VIDEO (R)-1

HEAD

VIDEO (L)-2

HEAD

CYLINDER ASSEMBLY

VIDEO (R)-2

HEAD

MAIN CBA

REC-VIDEO SIGNAL

TO SERVO/SYSTEM

CONTROL BLOCK

DIAGRAM

IIC-BUS SCL

IIC-BUS SDA

:INDICATES A TEST POINT WITH A JUMPER WIRE ACROSS A HOLE IN THE PCB.

:USED TO INDICATE A TEST POINT WITH A COMPONENT LEAD ON FOIL SIDE.

:USED TO INDICATE A TEST POINT WITH NO TEST PIN.

:USED TO INDICATE A TEST POINT WITH A TEST PIN.

TEST POINT INFORMATION

(DECK ASSEMBLY)

TO SERVO/SYSTEM

CONTROL BLOCK

456

123

CN251

VIDEO(L)-1

VIDEO(L)-2

VIDEO(R)-1

VIDEO-COM

969594

7978

46 43

6968

SERIAL

DECORDER

65

50

55

P

R

Y. DELAY

VIDEO-COM

93

SP

HEAD

AMP

SP

EP

LUMINANCE

SIGNAL

PROCESS

AGC

BYPASS

VIDEO(R)-2

908988

WF1

EP

CHARA.

RF-SW

D-REC-H

RF-SW

TP504

87

80

HEAD

AMP

D-REC-H

REC FMAGC

+

Y

C

CCD 1H DELAY

1/2

FBC

INS.

DIAGRAM

H-A-SW

C-ROTA

D-V-SYNC

H-A-COMP

83

71

62

70

H-A-SW

D-V-SYNC

H-A-COMP

RF-SW/C-ROTA

RPRP

CHROMINANCE

SIGNAL

PROCESS

V-ENV

C-SYNC

84

V-ENV

Y/C

PR

TRICK-H

SECAM-H

67

C-SYNC

VXO

MIX

AGC

PAL/SECAM

DETECTOR

IC370 (PAL/SECAM DECTECTOR)

1

171418216

29

28

44

PB-H OUT

21

WF2

C-PB

TP301

25

2928

X301

4.43MHz

58 59

“ “ = SMD

NOTE FOR WIRE CONNECTORS:

1. PREFIX SYMBOL "CN" MEANS CONNECTOR.

(CAN DISCONNECT AND RECONNECT.)

2. PREFIX SYMBOL "CL" MEANS WIRE-SOLDER

HOLES OF THE PCB.

(WIRE IS SOLDERED DIRECTLY.)

WF3

IC501 (OSD)

OSD-V-OUT

J909

COLOR

-IN

OSD

CHARACTER

MIX

52

BUFFER

Q301

VIDEO SIGNAL PROCESS

/HEAD AMP

IC301

CN253

WF7

VIDEO-OUT 9

50

VIDEO-IN 7

WF6

1-4-2

HK100BLV

Page 12

Audio Block Diagram

Mode : SP/REC

ALC

12

DET

11

MUTE

LINE

ALC

AMP

REC-ON

SERIAL

DECODER

71

68 69

TO SERVO/SYSTEM

CONTROL BLOCK

DIAGRAM

IIC-BUS SCL

IIC-BUS SDA

AUDIO-MUTE-H

PB-AUDIO SIGNAL REC-AUDIO SIGNAL

MAIN CBA

15

IC301

(AUDIO SIGNAL PROCESS)

INV

PB-ON

P

R

ATT

98

7

EQ

AMP

SP/LP-ON

5

6

P-ON+5V

Q404

Q403

BIAS

OSC

REC

AUTO

1

AMP

100

3

BIAS

2

Q406

16

AUDIO HD-SW

CONTROL

P-ON+5V

SWITCHING

D-REC-OFF

Q405

Q401

(PB=ON)

NOTE FOR WIRE CONNECTORS:

1. PREFIX SYMBOL "CN" MEANS CONNECTOR.

(CAN DISCONNECT AND RECONNECT.)

2. PREFIX SYMBOL "CL" MEANS WIRE-SOLDER

HOLES OF THE PCB.

(WIRE IS SOLDERED DIRECTLY.)

“ “ = SMD

N-A-PB

N-A-REC

TO Hi-Fi AUDIO

BLOCK DIGRAM

1-4-3

CN504

ACE HEAD ASSEMBLY

(DECK ASSEMBLY)

AUDIO-PB/REC

4

3 A-COM

1 AE-H

2 AE-H/FE-H

AUDIO

HEAD

AUDIO

ERASE

HEAD

CN501

2 FE-H

FE HEAD

FULL

ERASE

HK100BLA

1 FE-H-GND

HEAD

Page 13

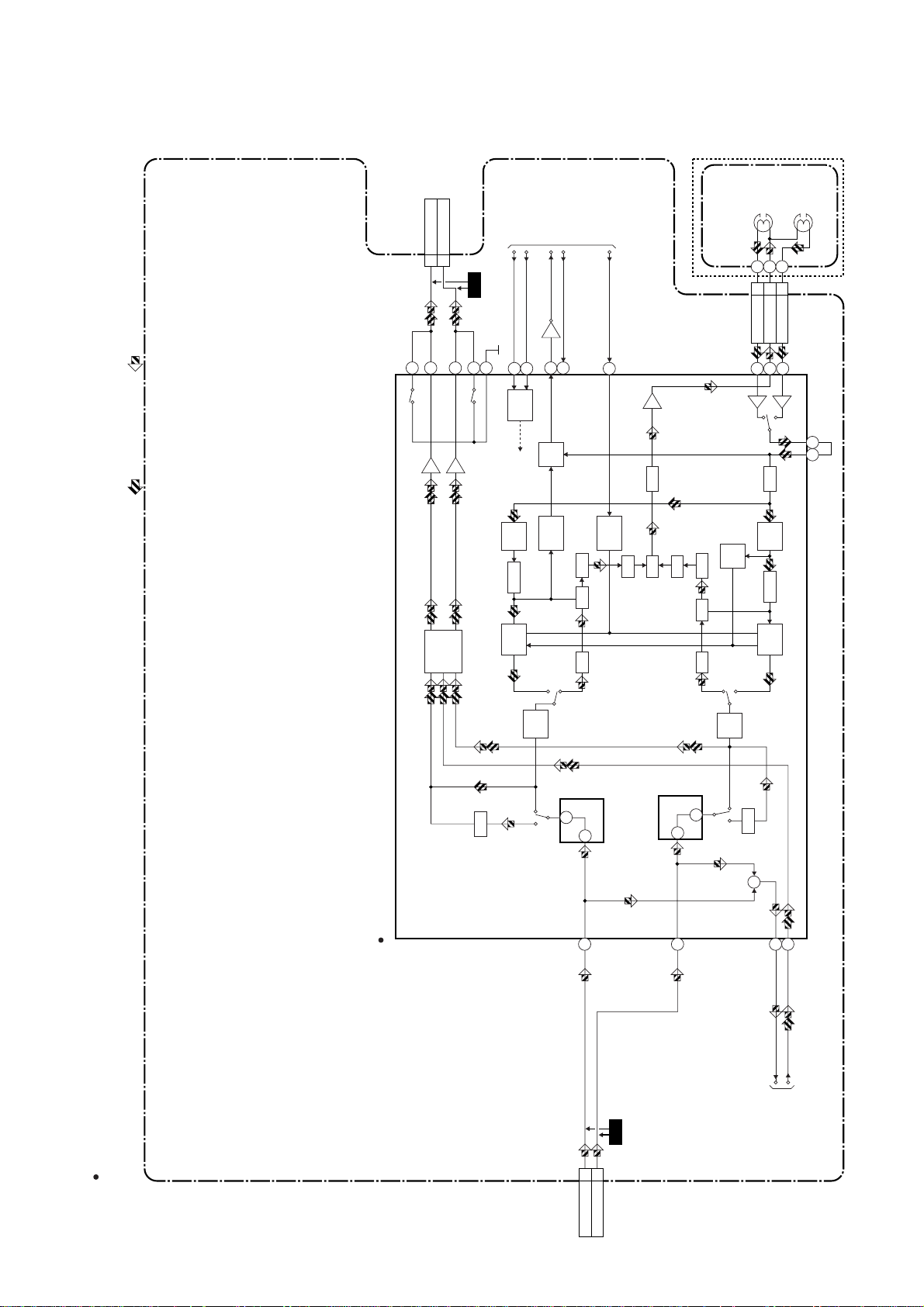

Hi-Fi Audio Block Diagram

REC-AUDIO SIGNALPB-AUDIO SIGNAL Mode : SP/REC

CN253

73

MUTE-ON

AUDIO(R)-OUT

AUDIO(L)-OUT

5

4

74

767775

WF5

MUTE-ON

A-MODE

IIC-BUS SCL

IIC-BUS SDA

Q451

37

38

LOGIC

FROM/TO

SERVO/SYSTEM

CONTROL BLOCK

AUDIO-MUTE-H

21

53

MUTE

Hi-Fi-H-SW

39

Hi-Fi

AUDIO

(R) HEAD

CYLINDER

ASSEMBLY

(DECK ASSEMBLY)

-COM 8

CN251

Hi-Fi-AUDIO(R)7Hi-Fi

242627

R

Hi-Fi

9

Hi-Fi-AUDIO(L)

L

AUDIO

(L) HEAD

MAIN CBA

R-CH

SW

OUTPUT

SELECT

ALC

(Hi-Fi AUDIO SIGNAL PROCESS)

BPF

COMP

NOISE

R-CH

ENV

NOISE

PPR

PNR

DET

DET

34 33

LIM

L-CH

DET

PNR

ALC

BPF

COMP

SW

NOISE

+

HOLD

PULSE

15

VCO

LIM DEV

DO

R

L-CH

LPF

MIX V/I

VCO

LIM DEV

47

48

LPF

14

NOTE FOR WIRE CONNECTORS:

“ “ = SMD

1. PREFIX SYMBOL "CN" MEANS CONNECTOR.

(CAN DISCONNECT AND RECONNECT.)

2. PREFIX SYMBOL "CL" MEANS WIRE-SOLDER

HOLES OF THE PCB.

(WIRE IS SOLDERED DIRECTLY.)

IC451

1-4-4

52

2AUDIO(R)-IN

CN253

WF4

1AUDIO(L)-IN

6

78

80

N-A-REC

N-A-PB

TO AUDIO BLOCK

HK100BLH

Page 14

SCHEMATIC DIAG RAMS / CBA'S AND TEST POINTS

Standard Notes

WARNING

Many electrical and mechanical parts in this chassis

have special characteristics. These characteristics

often pass unnoticed and the protection afforded by

them cannot necessarily be obtained by using

replacement components rated for higher voltage,

wattage, etc. Replacement parts that have these special safety character istics are id entified in th is manual

and its supplements; electrical components having

such features are identified by the mark " ! " in the

schematic diagram and the par ts list. Before replacing

any of these components, read the parts list in this

manual carefully. The use of substitute replacement

parts that do not have the same safety characterist ics

as specified in the pa r ts list may create sh ock, fire, or

other hazards.

Capacitor Temperature Markings

Mark

(B)

(F)

(SR)

(Y)

Capacity

change rate

±10%

±30 - 80%

±15%

±22.5%

Capacitors and transistor s are represente d by the following symbols.

Standard

Temperature

temperature

20°C -25~+85°C

20°C –25~+85°C

20°C –25~+85°C

20°C –25~+85°C

range

Notes:

1. Do not use the part number shown on th ese drawings for ordering. The correct part number is

shown in the parts list, and may be slightly different

or amended since these drawings were prepared.

2. To maintain original function and reliability of

repaired units, use only orig inal replacement par ts

which are listed with their part numbers in the parts

list section of the service manual.

3. How to read converged lines.

1-D3

Distinction Area

Line Number

(1 to 3 digits)

Examples:

1. "1-D3" means that line number "1" goes to the line number

"1" of the area "D3".

2. "1-B1" means that line number "1" goes to the line number

"1" of the area "B1".

4. All resistance values are indicated in ohms

3

(K=10

, M=106).

5. Resistor wattages ar e 1/4W or 1/6 W unless otherwise specified.

6. All capacitance values are indicated in µF

-6

(P=10

µF).

7. All voltages are DC voltages unless otherwise

specified.

8. Voltage indications for PLAY and REC modes on

the schematics are as shown below.

3

AREA D3

2

1

AREA B1

1-D3

ABCD

1-B1

< PCB Symbols >

(Top View) (Bottom View)

+

(Bottom View)

Transistor or Digital Transistor

E C B

(Top View)

NPN Transistor

E C B

(Top View)

NPN Digital Transistor

E C B

Electrolytic Capacitor

(Top View)

E C B

(Top View)

E C B

Unit: Volts

The same voltage for

both PLAY & REC modes

PNP Transistor

PNP Digital

Transistor

PLAY mode

REC mode

5.0

231

5.0

(2.5)

Indicates that the voltage

is not consistent here.

< Schematic Diagram Symbols >

Digital Transistor

1-5-1 SC_08

Page 15

Main 1/4 Schematic Diagram Parts Location Guide

Ref No. Position Ref No. Position Ref No. Position

CAPACITORS

C502 A-4 C562 C-4 R539 C-4

C505 E-1 R540 C-4

C506 B-1

C508 C-1

C509 A-2

C510 A-2 CN505 F-2 R545 C-1

C511 B-3 CN653 A-1 R546 C-1

C512 A-2

C514 A-2 D510 D-4 R560 D-4

C515 B-3 D555 E-3 R567 E-4

C516 B-2 R568 E-4

C517 B-2 IC501 C-3 R569 E-4

C518 B-3 IC502 B-4 R570 D-1

C519 B-2 R572 D-4

C521 B-2 L501 E-3 R574 E-3

C522 B-1 L502 D-4 R577 E-3

C524 B-4 L503 E-3 R578 E-3

C527 C-1 R582 E-2

C531 E-4 Q506 E-1 R583 E-2

C533 E-4 Q515 E-2 R585 E-2

C534 D-4 R586 E-2

C535 D-4

C536 D-4 R511 A-1 R595 B-3

C538 D-4 R512 E-1 R596 B-3

C539 E-3 R513 E-1 R597 B-3

C540

C541 E-3 R516 A-1

C542 E-2 R517 E-3 SW506 D-1

C545 E-3 R519 A-1 SW507 A-1

C546 E-3

C547 E-3 R525 A-3 VR501 B-1

C548 E-2 R526 A-3

C549 E-2 R528 B-1 X501 E-2

C550E-2R530C-4

C553 E-2 R531 C-4 PS502 E-1

C555E-4R532C-4

C557 A-2 R533 C-4 TP502 A-4

C559 C-4 R536 B-2 TP503 A-2

C560 C-4 R537 B-2 TP504 C-1

C561 C-4 R538 B-4 TP505 C-1

E-3 R514 A-1 R598 C-1

CONNECTORS

CN501 A-2

CN502 F-4

CN504 A-3

DIODES

ICS

COILS

TRANSISTORS

RESISTORS

R509

R523

E-1

A-1

RESISTORSCAPACITORS

R541 B-1

R542 B-1

R543 B-1

R559

R588

SWITCHES

VARIABLE RESISTOR

CRYSTAL OSCILLATOR

MISCELLANEOUS

TEST POINTS

E-3

F-3

1-5-2

Page 16

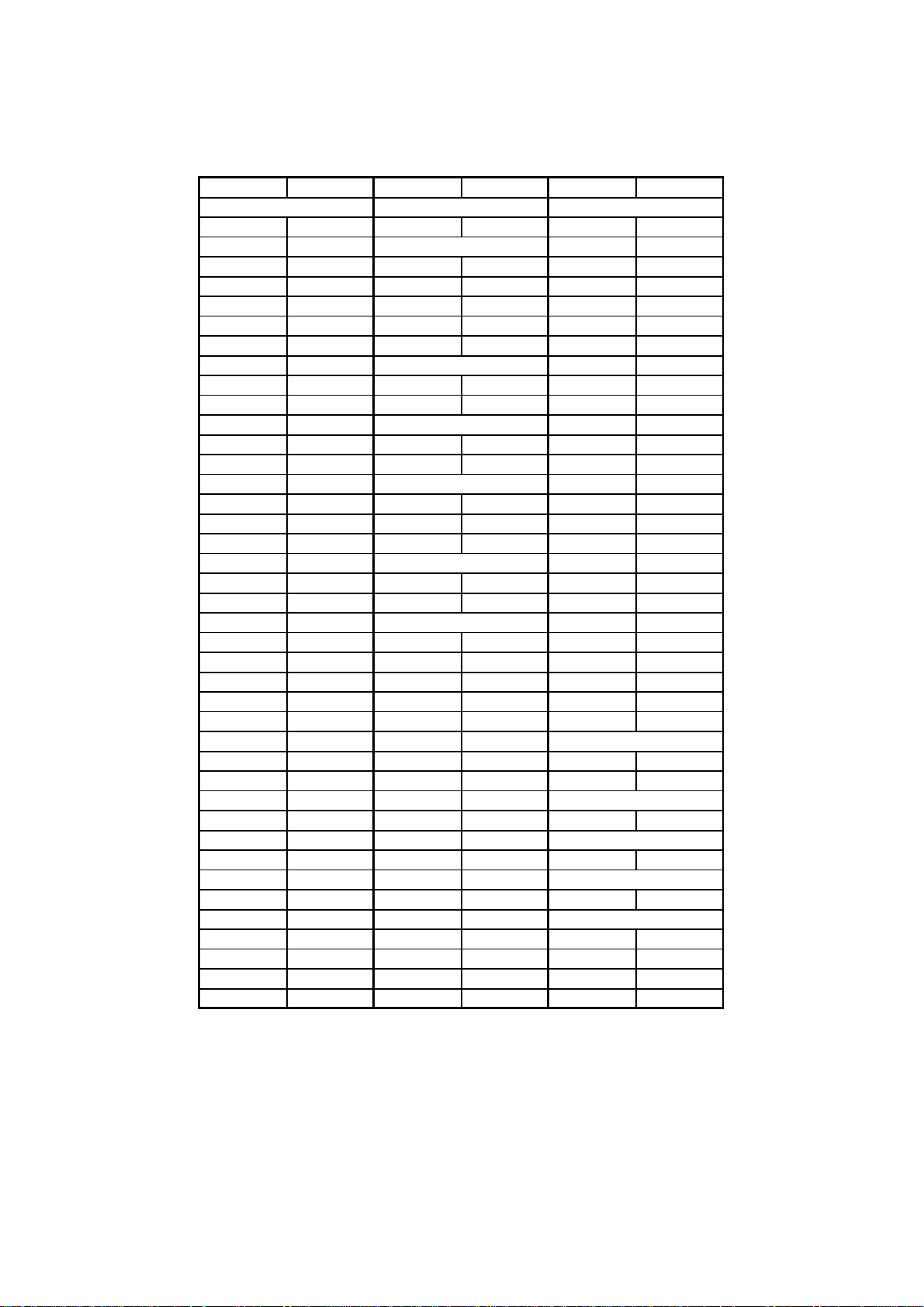

Main 1/4 & Sensor Schematic Diagram

“ “ = SMD

1-5-3

HK100SCM1

Page 17

Main 2/4 Schematic Diagram

“ “ = SMD

1-5-4

HK100SCM2

Page 18

Main 2/4 Schematic Diagram Parts Location Guide

Ref No. Position Ref No. Position Ref No. Position Ref No. Position

CAPACITORS

C151 K-1 C344 J-4 L251 H-3 R328 I-4

C152 K-1 C345 J-4 L302 I-4

C251 H-3 C348 K-4 L401 G-2

C252 H-3 C349 J-4 L402 H-1

C253 H-3 C350 H-4

C254 H-3 C402 G-2 Q151 K-2

C301 J-1 C403 G-2 Q152 K-1

C302 J-2 C404 H-2 Q153 K-1

C303 J-1 C405 H-2 Q301 K-4 R401 G-2

C305 J-1 C407 I-1 Q302 H-3 R402 G-2

C306 J-2 C408 I-2 Q401 G-1

C307 J-1 C409 I-1 Q403 H-1 R405 H-2

C308 J-1 C410 I-1 Q404 G-2

C311 K-3 C411 I-1 Q405

C312 K-3 C412 I-2 Q406 H-1

C313 K-3 C413 I-2 R409 H-2

C314 K-3 C414 I-1 R151 K-1 R410 H-2

C315 K-2 C415 I-1 R152 K-1 R411 I-2

C316 K-3 C416 I-1 R153 K-2 R412 I-1

C317 K-3 C417 I-2 R251 H-3 R413 I-2

C318 K-2 C418 I-1 R252 H-3 R414 I-1

C321 L-3 C419 J-1 R301 J-1 R415 I-1

C322 K-3 C420 J-2 R303 J-1 R416 I-1

C324 K-3 C421 J-1 R305 K-2 R417 I-1

C325 K-2 C422 L-4 R308 K-2 R418 I-1

C328 K-3 C423 L-4 R309 J-4 R419 I-1

C329 K-2 C426 L-3 R310 K-3 R420 I-1

C330 L-4 C427 L-3 R312 K-2 R421 J-1

C331 K-4 R314 K-2

C333 I-4 CN251 G-3 R316 G-4 X301 J-2

C334 I-4 CN252 L-2 R317 J-4

C335 I-4 CN253 L-4 R318 K-4 TP301 G-3

C336 I-4 R319 H-3

C337 I-4 D151 K-1 R320 H-3

C339 I-4 D301 Q-4 R321 K-4

C340 I-4 R322 H-4

C341 I-4 IC301 Q-2 R325 I-4

C342 I-4 R326 I-4

C343 J-4 L151 L-1 R327 I-4

CAPACITORS

CONNECTORS

DIODES

IC

COILS

COILS

TRANSISTORS

H-1 R407

RESISTORS

RESISTORS

R330

R331

R332

R333

R334

R336

R337

R404

R406

R408

CRYSTAL OSCILLATOR

TEST POINT

I-4

H-4

H-4

I-4

I-4

J-4

J-4

H-1

H-2

H-2

H-2

1-5-5

Page 19

Main 3/4 Schematic Diagram Parts Location Guide

Ref No. Position Ref No. Position Ref No. Position

CAPACITORS

C452O-2C475O-4R462Q-2

C4 53 O-2 C47 6 O-4 R46 3 P-2

C454 O-2 C478 N-3 R464 P-3

C455O-2C479N-3R466O-4

C456O-2C482N-3R467N-4

C457O-2C483N-3R470N-4

C458 P-2 C484 N-2

C461 Q-2 C485 N-2

C462 P-2 C486 N-2

C463 P-2 C487 N-1

C464 P-2 C489 N-1

C465 P-3 R484 M-2

C466 P-3 IC451 N-2

C467 P-3

C468 P-3 L451 P-3

C469 P-4 L452 Q-2

C470 P-4

C4 71 O-4 Q451 Q-2

C472 O-4

C473 O-4 R453 N-1

C474 O-4 R454 N-1

IC

COILS

TRANSISTOR

RESISTORS

RESISTORSCAPACITORS

R479

R480

R481

R482

R483

M-3

M-3

M-2

M-2

M-2

1-5-6

Page 20

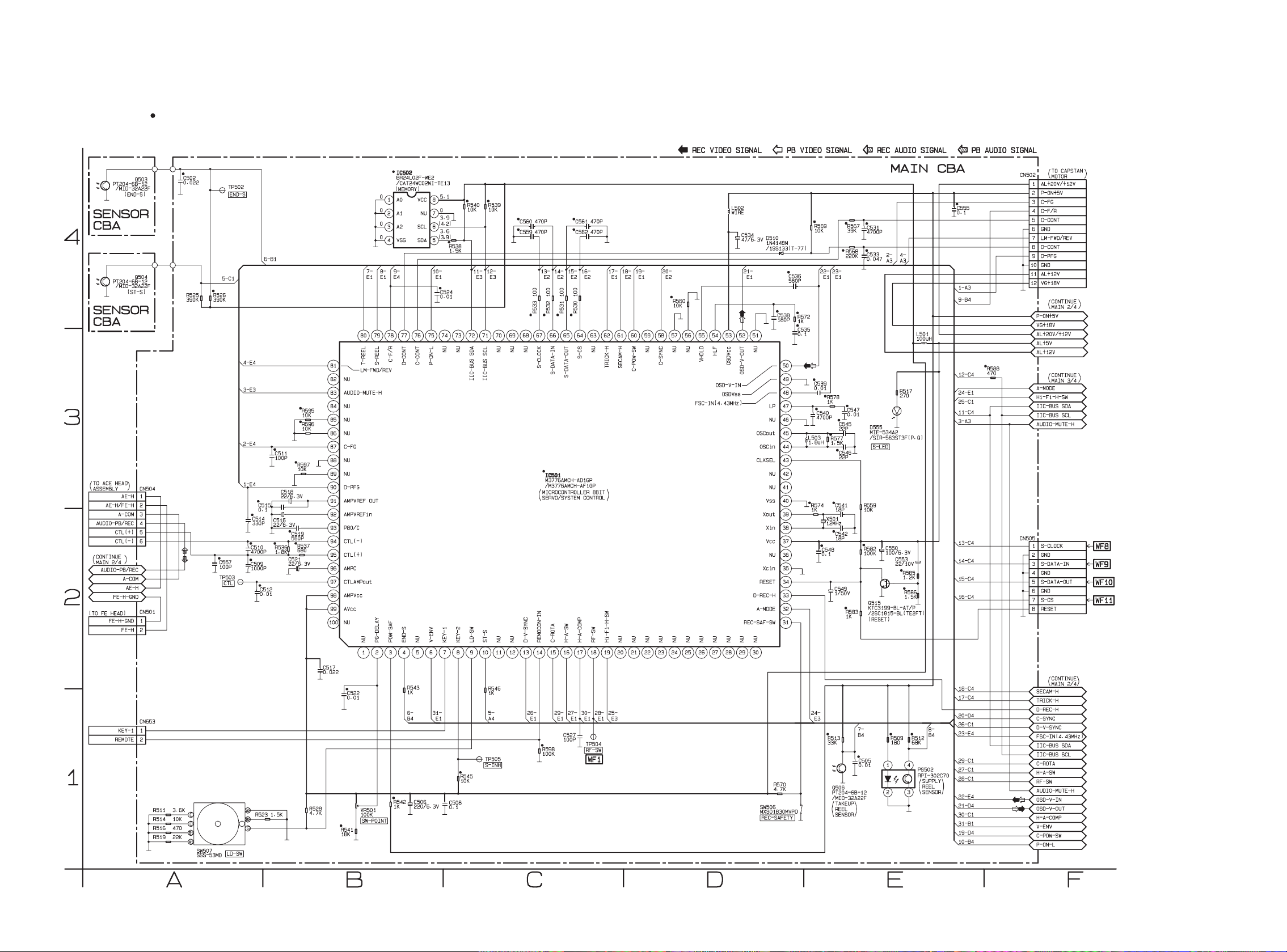

Main 3/4 Schematic Diagram

“ “ = SMD

1-5-7

HK100SCM3

Page 21

Main 4/4 Schematic Diagram

“ “ = SMD

MAIN 4/4 Schematic Diagram

Parts Location Guide

Ref No. Position

CAPACITORS

C370 S-2

C371 S-2

C372 S-2

C373 S-2

C374 T-1

C375 T-1

C376 T-1

C377 T-2

C378 T-2

C379 S-2

C381 T-2

C382 S-2

C383 S-2

C384 R-2

DIODE

D370 R-1

IC

IC37 0 R-2

COIL

L370 T-2

RESISTORS

R370

R371

R372 R-2

S-2

S-2

1-5-8

HK100SCM4

Page 22

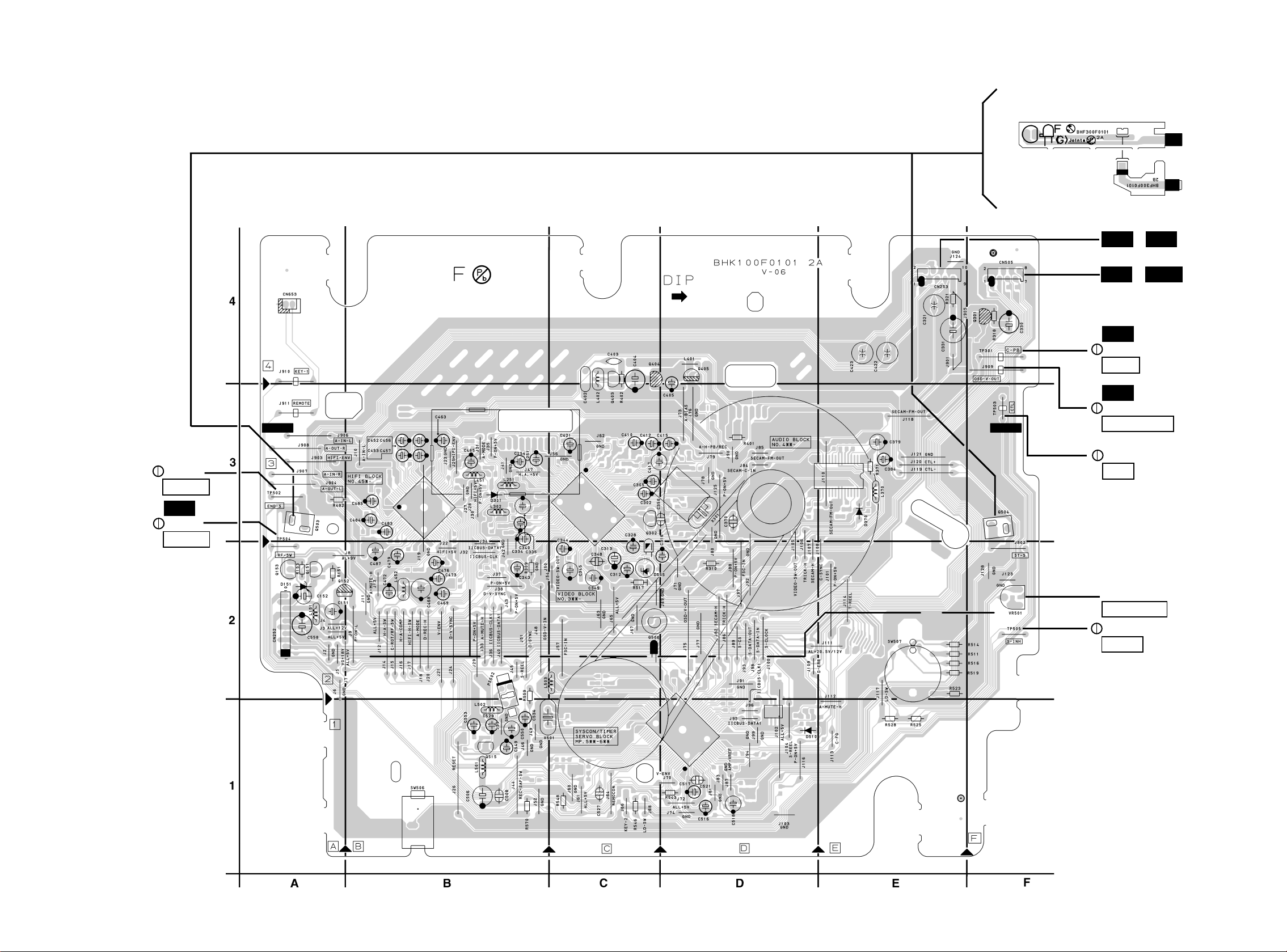

Main CBA Top View

Sensor CBA Top View

BHF300F01012A

BHF300F01012B

WF4 WF7

~

CN253

WF8 WF11

~

CN505

WF2

TP301

C-PB

WF3

J909

OSD-V-OUT

TP502

END-S

WF1

TP504

RF-SW

TP503

CTL

VR501

SW-POINT

TP505

S-INH

1-5-9

BHK100F01012A

Page 23

Main CBA Bottom View

1-5-10

BHK100F01012A

Page 24

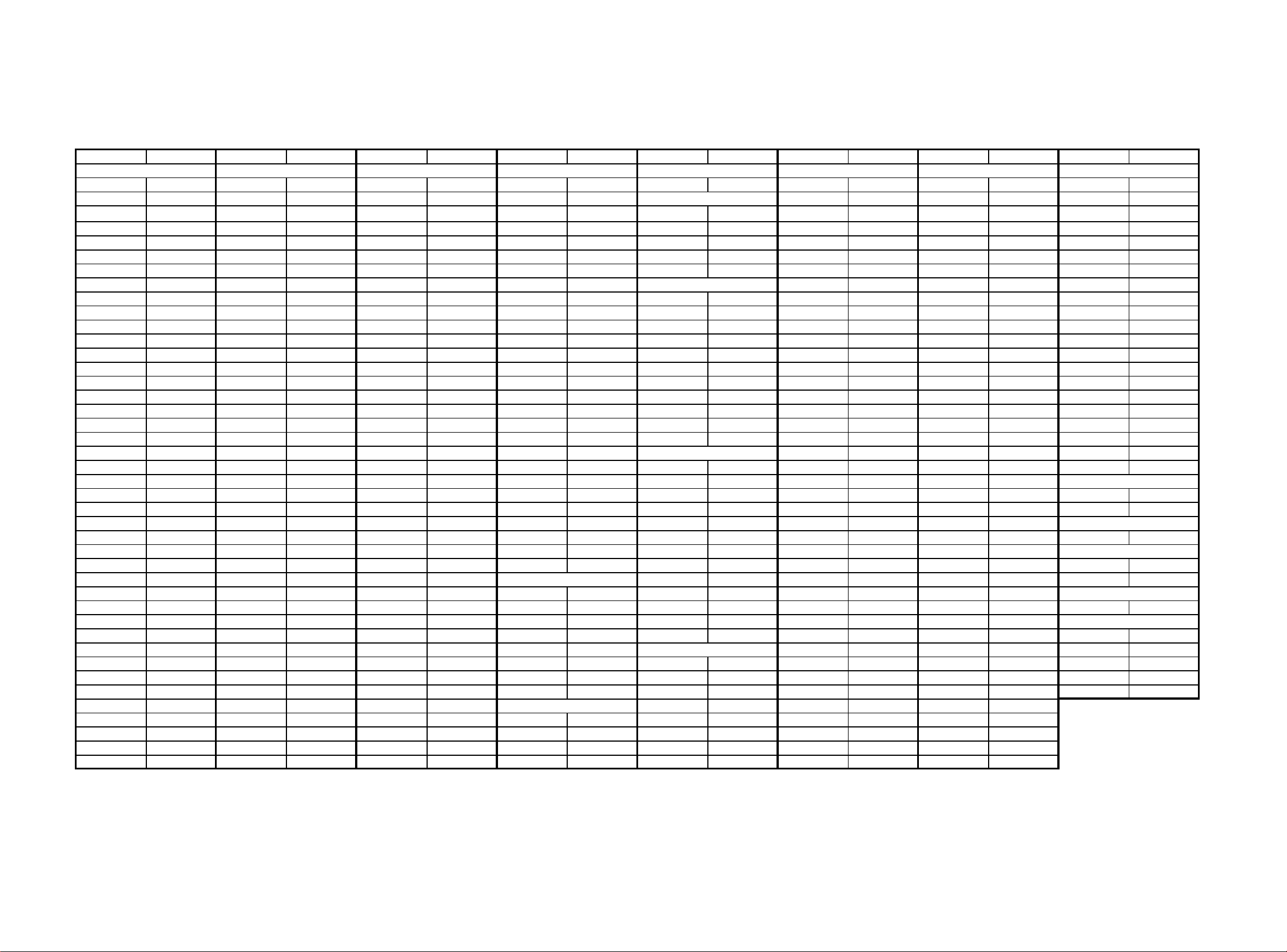

Main CBA Parts Location Guide

Ref No. Position Ref No. Position Ref No. Position Ref No. Position

D555 C-2 R308 D-3 R418 C-3 R545 C-1

R309 B-2 R419 D-3 R546 C-1

IC301 C-3 R310 D-2 R420 D-3

R559

B-2

IC370 D-3 R312 D-3 R421 D-3 R560 D-2

IC451 B-3 R314 D-2 R453 B-3 R567 D-2

IC501 D-1 R316 D-3 R454 B-3 R568 D-2

IC502 D-2 R317 F-4 R462 B-3 R569 E-1

R318 F-4 R463 B-3 R570 B-1

L151 A-2 R319 D-3 R464 B-3 R572 D-2

L251 B-3 R320 B-3 R466 B-2 R574 C-1

L302 B-3 R321 E-4 R467 B-2 R577 C-1

L370 E-3 R322 B-3 R470 B-2 R578 C-2

L401 D-4 R325 B-3 R479 B-3 R582 B-1

L402 C-3 R326 B-3 R480 B-3 R583 B-1

L451 B-3 R327 B-3 R481 B-3 R585 B-1

L452 B-2 R328 B-3 R482 A-3 R586 B-1

L501 B-1 R330 B-3 R483 B-3 R588 B-2

L502 B-1 R331 B-2 R484 B-3 R595 D-1

L503 B-2 R332 B-2 R509 B-2 R596 D-1

R333 C-1 R511 F-2 R597 D-1

Q151 A-2 R334 B-1 R512 B-1 R598 C-1

Q152 A-2 R336 B-2 R513 E-1

Q153 A-2 R337 B-2 R514 F-2 SW506 B-1

Q301 F-4 R370 E-3 R516 F-2 SW507 E-2

Q302 C-3 R371 E-3 R517 C-2

Q401 D-3 R372 E-3 R519 F-2 VR501 F-2

Q403 C-3 R401 D-3 R523 E-2

Q404 C-4 R402 C-3 R525 E-1 X301 D-3

Q405 D-4 R404 C-3 R526 C-1 X501 B-1

Q406 B-3 R405 C-3 R528 E-1

Q451 B-3 R406 D-4 R530 D-2 PS502 B-2

Q506 C-2 R407 B-3 R531 D-2

Q515 B-1 R408 C-3 R532 D-1 TP301 F-4

R409 C-3 R533 D-1 TP502 A-3

R151 A-2 R410 C-3 R536 D-1 TP503 F-3

R152 A-2 R411 C-3 R537 D-1 TP504 A-3

R153 A-2 R412 C-3 R538 D-1 TP505 F-2

R251 B-3 R413 C-3 R539 D-2

R252 B-3 R414 C-3 R540 D-2

R301 D-3 R415 C-3 R541 F-2

R303 D-3 R416 C-3 R542 D-1

R305 D-2 R417 D-3 R543 D-1

RESISTORS

TEST POINTS

RESISTORS

SWITCHES

RESISTORS RESISTORS

VARIABLE RESISTORS

DIODES

CRYSTAL OSCILLATORS

MISCELLANEOUS

ICS

TRANSISTORS

COILS

Ref No. Position Ref No. Position Ref No. Position Ref No. Position

CAPACITORSCAPACITORS CAPACITORS

C151 A-2 C349 C-2 C455 B-3 C519 D-1

C152 A-2 C350 C-3 C456 B-3 C521 D-1

C251 B-3 C370 D-3 C457 B-3 C522 D-1

C252 B-3 C371 E-3 C458 B-3 C524 E-1

C253 B-3 C372 E-3 C461 B-3 C527 C-1

C254 B-3 C373 E-3 C462 B-3 C531 D-1

C301 D-3 C374 D-3 C463 B-3 C533 E-1

C302 C-3 C375 D-3 C464 B-3 C534 B-1

C303 C-3 C376 D-3 C465 B-3 C535 D-2

C305 C-3 C377 E-3 C466 B-3 C536 D-2

C306 D-3 C378 E-3 C467 B-3 C538 D-2

C307 D-3 C379 E-3 C468 B-2 C539 C-2

C308 D-3 C381 E-3 C469 B-2 C540 C-2

C311 C-2 C382 E-3 C470 B-2 C541 C-1

C312 C-2 C383 E-3 C471 B-2 C542 C-1

C313 C-2 C384 E-3 C472 B-2 C545 C-2

C314 D-2 C402 C-3 C473 B-2 C546 C-1

C315 D-3 C403 C-4 C474 B-2 C547 C-2

C316 D-3 C404 C-4 C475 B-3 C548 C-1

C317 D-2 C405 D-3 C476 B-2 C549 B-1

C318 D-3 C407 C-3 C478 B-2 C550 B-1

C321 E-4 C408 C-3 C479 B-2 C553 B-1

C322 D-2 C409 C-3 C482 B-2 C555 E-2

C324 C-2 C410 C-3 C483 B-3 C557 D-1

C325 D-3 C411 C-3 C484 B-3 C559 F-4

C328 C-3 C412 C-3 C485 B-3 C560 F-4

C329 D-2 C413 C-3 C486 B-3 C561 F-4

C330 F-4 C414 C-3 C487 B-2 C562 F-4

C331 E-4 C415 C-3 C489 B-2

C333 B-3 C416 D-3 C502 A-3 CN251 B-3

C334 B-2 C417 C-3 C505 D-2 CN252 A-2

C335 B-2 C418 D-3 C506 B-1 CN253 E-4

C336 B-3 C419 D-3 C508 B-1 CN501 B-3

C337 B-3 C420 B-3 C509 D-1 CN502 E-2

C339 B-3 C421 C-3 C510 D-1 CN504 D-3

C340 B-2 C422 E-4 C511 D-1 CN505 F-4

C341 B-3 C423 E-4 C512 D-1 CN653 A-4

C342 D-2 C426 E-4 C514 D-1

C343 B-2 C427 E-4 C515 D-1 D151 A-2

C344 C-3 C452 B-3 C516 D-1 D301 B-3

C345 C-2 C453 B-3 C517 D-1 D370 E-3

C348 C-2 C454 B-3 C518 D-1 D510 D-1

CAPACITORS

CONNECTORS

DIODES

1-5-11

Page 25

WAVEFORMS

NOTE:

Input

VCR: COLOR BAR SIGNAL (WITH 1KHz AUDIO SIGNAL)

(WF1~WF11)

WF2

UPPER

TP301

WF1

LOWER

TP504

C-PB 10mV x 10

RF-SW 0.5V x 10

5ms

WF3

UPPER

J909

WF1

LOWER

TP504

V-OUT 0.1V x 10

RF-SW 0.5V x 10

50µs

WF4

Pin 1, 2 of CN253

AUDIO( L,R )-IN 1V

WF5

Pin 4, 5 of CN253

AUDIO( L,R )-OUT 1V

2.5ms

WF8

Pin 1 of CN505

S-CLK 1V0.5ms 1ms

WF9

Pin 3 of CN505

S-DATA-IN 1V 1ms

MAIN

CBA

WF3

J909

V-OUT E-E

10µs 50mV x 10

WF6

Pin 7 of CN253

VIDEO-IN 0.2V

WF7

Pin 9 of CN253

VIDEO-OUT 0.2V

20µs

20µs

WF10

Pin 5 of CN505

S-DATA-OUT 1V 1ms

WF11

Pin 7 of CN505

S-CS 1V 20ms

CN252 CN253 CN505

Pin No. Voltage WF No. Pin No. Voltage WF No. Pin No. Voltage WF No.

1 18.1 1 WF4 1 WF8

20 2 WF4 2 0

3 12.7 3 0 3 WF9

4 12.1 4 WF5 4 0

50 5 WF5 5 WF10

6 12.0 6 0 6 0

70 7 WF6 7 WF11

85.3 8 0 8 4.8

90 9 WF7

10 0 10 0

1-6-1

U31MWF

Page 26

1

KEY-1

CN653

2

REMOTE

WIRING DIAGRAM

1

2

3

4

5

6

7

8

9

10

GND

GND

GND

GND

CN252

VG+18V

AL+12V

AL+20V/+12V

AL+12V

AL+5V

CN253

C-POW-SW

MAIN CBA

1AUDIO(L)-IN

2AUDIO(R)-IN

3

GND

4AUDIO(L)-OUT

5AUDIO(R)-OUT

6

7VIDEO-IN

GND

8

9VIDEO-OUT

GND

10GND

1S-CLOCK

CN505

2GND

3

S-DATA-IN

4GND

5S-DATA-OUT

6

GND

7S-CS

8

RESET

NOTE FOR WIRE CONNECTORS:

1. PREFIX SYMBOL "CN" MEANS CONNECTOR.

(CAN DISCONNECT AND RECONNECT.)

SENSOR CBA

2. PREFIX SYMBOL "CL" MEANS WIRE-SOLDER

HOLES OF THE PCB.

(WIRE IS SOLDERED DIRECTLY.)

SENSOR CBA

CN504

AE-H2AE-H/FE-H

A-COM4AUDIO-PB/REC

1

AUDIO

ACE HEAD ASSEMBLY

CTL(+)6CTL(-)1FE-H-GND

3

5

AUDIO HEAD

ERASE HEAD

CONTROL HEAD

CN501

FE-H

2

FULL

ERASE HEAD

FE HEAD

CAPSTAN

MOTOR

CN502

AL+20V/+12V

P-ON+5V3C-FG4C-F/R5C-CONT6GND7LM-FWD/REV

1

2

M

M

LOADING

CYLINDER ASSEMBLY

MOTOR

MOTOR

PG

DRIVE

CIRCUIT

SENSOR

D-CONT9D-PFG

GND11AL+12V12VG+18V

8

10

M

DRUM

MOTOR

VIDEO

(R)1

CAPSTAN

VIDEO

HEAD

CN251

VIDEO(R)-1

1

MOTOR

(L)1

HEAD

VIDEO-COM

VIDEO(L)-1

VIDEO(L)-2

2

3

4

VIDEO

VIDEO

(L)2

HEAD

VIDEO-COM

VIDEO(R)-2

Hi-Fi-AUDIO(R)

Hi-Fi-COM9Hi-Fi-AUDIO(L)

5

6

7

8

(R)2

HEAD

Hi-Fi AUDIO

(R) HEAD

Hi-Fi AUDIO

(L) HEAD

(DECK ASSEMBLY)

1-7-1

HK100WI

Page 27

IC PIN FUNCTION DESCRIPTIONS

IC501( SERVO / SYSTEM CONTROL IC )

“H” ≥ 4.5V, “L” ≤ 1.0V

Pin

IN/

Signal

No.

OUT

1 - NU Not Used -

2IN

3INPOW-SAF

4 IN END-S

5 - NU Not Used 6INV-ENV

7INKEY-1

8INKEY-2

9INLD-SW

10 IN ST-S

11 - NU Not Used -

12 - NU Not Used 13 OUT

14 IN

15 OUT C-ROTA

16 OUT H-A-SW

17 IN

18 OUT RF-SW

19 OUT

20 - NU Not Used -

21 - NU Not Used 22 - NU Not Used 23 - NU Not Used 24 - NU Not Used 25 - NU Not Used -

Name

PGDELAY

D-VSYNC

REMOCON

-IN

H-ACOMP

Hi-Fi-H-SWHi-Fi Audio Head

Function

Video Head Switching

Pulse Signal Adjusted

Voltage

P-ON Power

Detection Input Signal

Tape End Position

Detect Signal

Video Envelope

Comparator Signal

Key Scan Input Signal

1

Key Scan Input Signal

2

Deck Mode Position

Detector Signal

Tape Start Position

Detector Signal

Dummy V-sync

Output

Remote Control

Sensor

Color Phase Rotary

Changeover SIgnal

Video Head Amp

Switching Pulse

Head Amp

Comparator Signal

Video Head Switching

Pulse

Switching Pulse

Active

Level

A/D

A/D

A/D

A/D

A/D

A/D

A/D

A/D

H/Hi-z

H/L

H/L

H/L

H/L

H/L

Pin

IN/

Signal

No.

OUT

26 - NU Not Used 27 - NU Not Used 28 - NU Not Used 29 - NU Not Used 30 - NU Not Used -

31 IN

32 IN A-MODE

33 OUT D-REC-H

34 IN RESET

35 IN Xcin Sub Clock (GND) -

36 - NU Not Used 37 - Vcc Vcc 38 IN Xin Main Clock Input 39 OUT Xout Main Clock Input 40 - Vss Vss(GND) 41 - NU Not Used 42 - NU Not Used -

43 IN CLKSEL

L

44 IN OSCin

45 OUT OSCout

46 - NU Not Used -

47 - LP LP 48 IN

49 - OSDVss OSDVss 50 IN OSD-V-IN

51 - NU Not Used 52 OUT

53 - OSDVcc OSDVcc 54 - HLF

Name

RECSAF-SW

FSC-IN

[4.43MHz]

OSD-VOUT

Function

Recording Safety SW

Detect (With Record

tab="L"/With out

Record tab="H")

Hi-Fi Tape Detecti on

Signal

Delayed Record

Signal

System Reset Signal

(Reset=”L”)

Clock Select (VCC

Pull UP)

Clock Input for letter

size

Clock Output for letter

size

4.43MHz Clock Input -

OSD Video Signal

Input

OSD Video Signal

Output

LPF Connected

Terminal (Slicer)

Active

Level

H

L

H

L

-

-

-

-

-

-

1-8-1 HK100PIN

Page 28

Pin

No.

IN/

OUT

Signal

Name

Function

Active

Level

Pin

No.

IN/

OUT

Signal

Name

Function

Active

Level

55 - VHOLD COLOR-IN 56 - NU Not Used 57 - NU Not Used -

58 IN C-SYNC

Composite

Synchronized Pulse

PULSE

59 - NU Not Used 60 OUT

61 IN

62 OUT

C-POW-SWCapstan Power

Switching Signal

SECAM-HSECAM Video Signal

Input

TRICK-H

Special playback =

“H” in SECAM Mode

H/L

63 - NU Not Used 64 IN S-CS

65 OUT

66 IN

S-DATAOUT

S-DATA-INDVD (MCU) SIO

DVD (MCU) SIO

Interface CS

DVD (MCU) SIO

Interface Clock Out

Interface Data In

H/L

H/L

83 OUT

A-MUTE-HAudio Mute Control

Signal

H

84 - NU Not Used 85 - NU Not Used 86 - NU Not Used -

Capstan Motor

87 IN C-FG

Rotation Detection

PULSE

Pulse

88 - NU Not Used (GND) -

H

H

L

89 - NU Not Used 90 IN D-PFG

91 -

92 -

AMPVRE

F OUT

AMPVRE

Fin

Drum Motor Pulse

Generator

PULSE

V-Ref for CTL AMP -

V-Ref for CTL AMP 93 - P80/C P80/C Terminal 94

IN/

OUT

CTL (-)

Playback/Record

Control Signal (-)

H/L

67 OUT S-CLOCK

DVD (MCU) SIO

Interface Clock

H/L

68 - NU Not Used 69 - NU Not Used 70 - NU Not Used -

71 OUT

IN/

72

OUT

IIC-BUS

SCL

IIC-BUS

SDA

2

I

C BUS Control

Clock

2

I

C BUS Control Data

H/L

H/L

73 - NU Not Used 74 - NU Not Used -

75 OUT P-ON-L

76 OUT C-CONT

77 OUT D-CONT

Power On Signal at

Low

Capstan Motor

Control Signal

Drum Motor Control

Signal

PWM

PWM

Capstan Motor FWD/

78 OUT C-F/R

REV Control Signal

H/L

(FWD=”L”/REV=”H”)

IN/

95

OUT

CTL (+)

96 - AMPC

97 -

CTLAMP

out

Playback/Record

Control Signal (+)

CTL AMP Connected

Terminal

To Monitor for CTL

AMP Output

H/L

-

PULSE

98 - AMPVcc AMPVcc -

A/D Converter Power

99 - AVcc

Input/ Standard

-

Voltage Input

100 - NU Not Used -

Notes:

L

Abbreviation for Active Level:

PWM -----Pulse Wide Modulation

A/D--------Analog - Digital Converter

79 IN S-REEL

80 IN T-REEL

81 OUT

LM-FWD/

REV

Supply Reel Rotation

Signal

Take Up Reel

Rotation Signal

Loading Motor Control

Signal

PULSE

PULSE

H/L/

Hi-z

82 - NU Not Used -

1-8-2 HK100PIN

Page 29

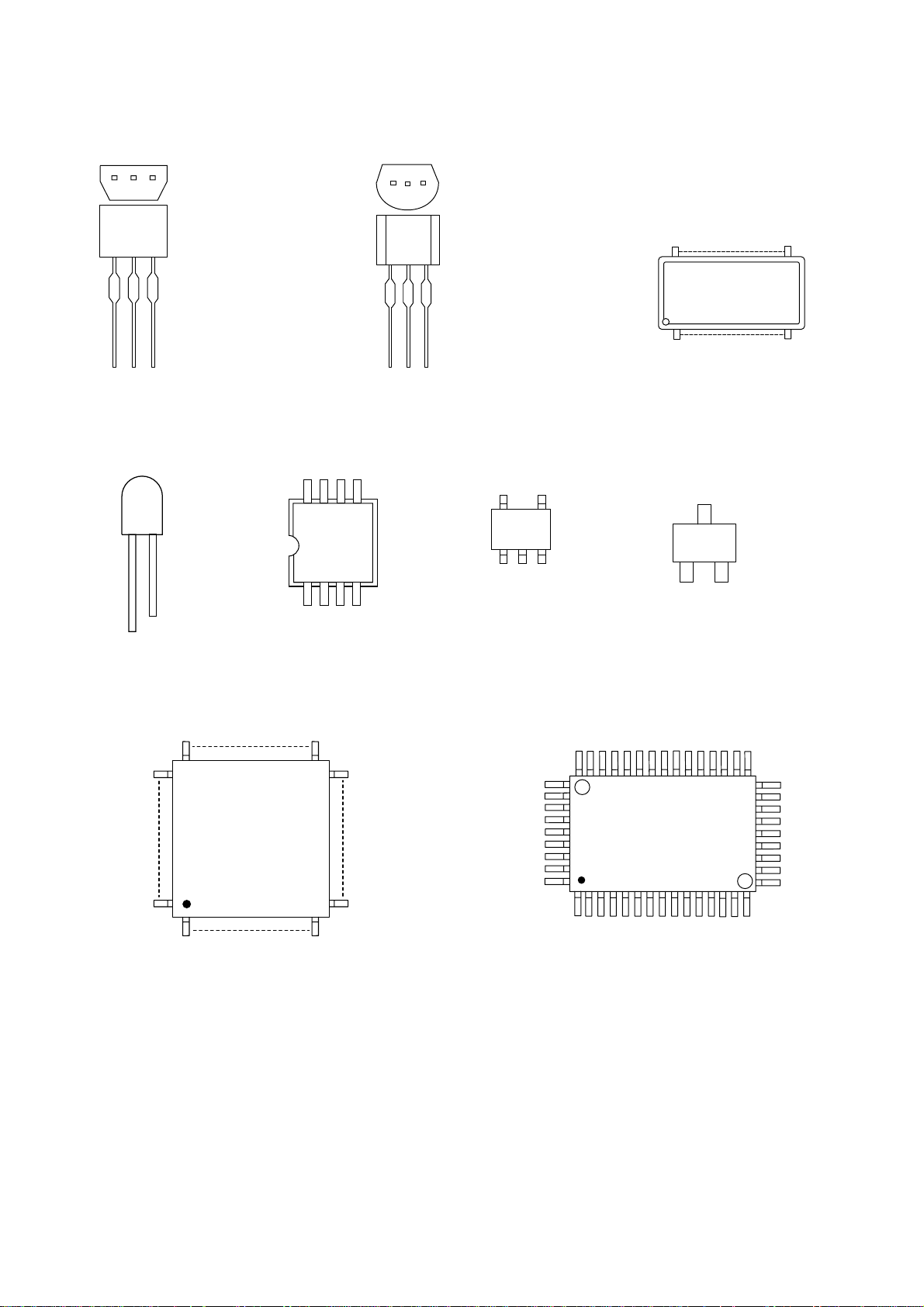

LEAD IDENTIFICATIONS

E C B

MID-32A22F

PT204-6B-12

C

E

KRA103M-AT/P

KRC103M-AT/P

KTA-1266-GR-AT/P

KTC3199-(BL,GR,Y)-AT/P

BR24L02F-WE2

CAT24WC02WI-TE13

8

1

2SA1015-GR(TE2 F T)

2SC1815-(BL,GR,Y)(TE2 F T)

2SC2120-Y(TE2 F T)

2SC3266-Y(TPE2 F)

KTC3203-Y-AT/P

KTC3205-Y-AT/P

KTC3198-(GR,Y)-AT/P

E C B

RN1511(TE85R.F)

C1 C2

5

4

B1 E B2

LA70100M-TRM-E

30

1

KRC103S-RTK/P

KTC3875S-Y-RTK/P

C

16

15

BE

61

80

LA72648M-MPB-E

60

1

41

20

40

21

81

100

LA71750EM-MPB-E

M3776AMCH-AD1GP

M3776AMCH-AF1GP

80

1

51

50

31

30

Note:

A: Anode

K: Cathode

E: Emitter

C: Collector

B: Base

R: Reference

S: Source

G: Gate

D: Drain

1-9-1 HK100LE

Page 30

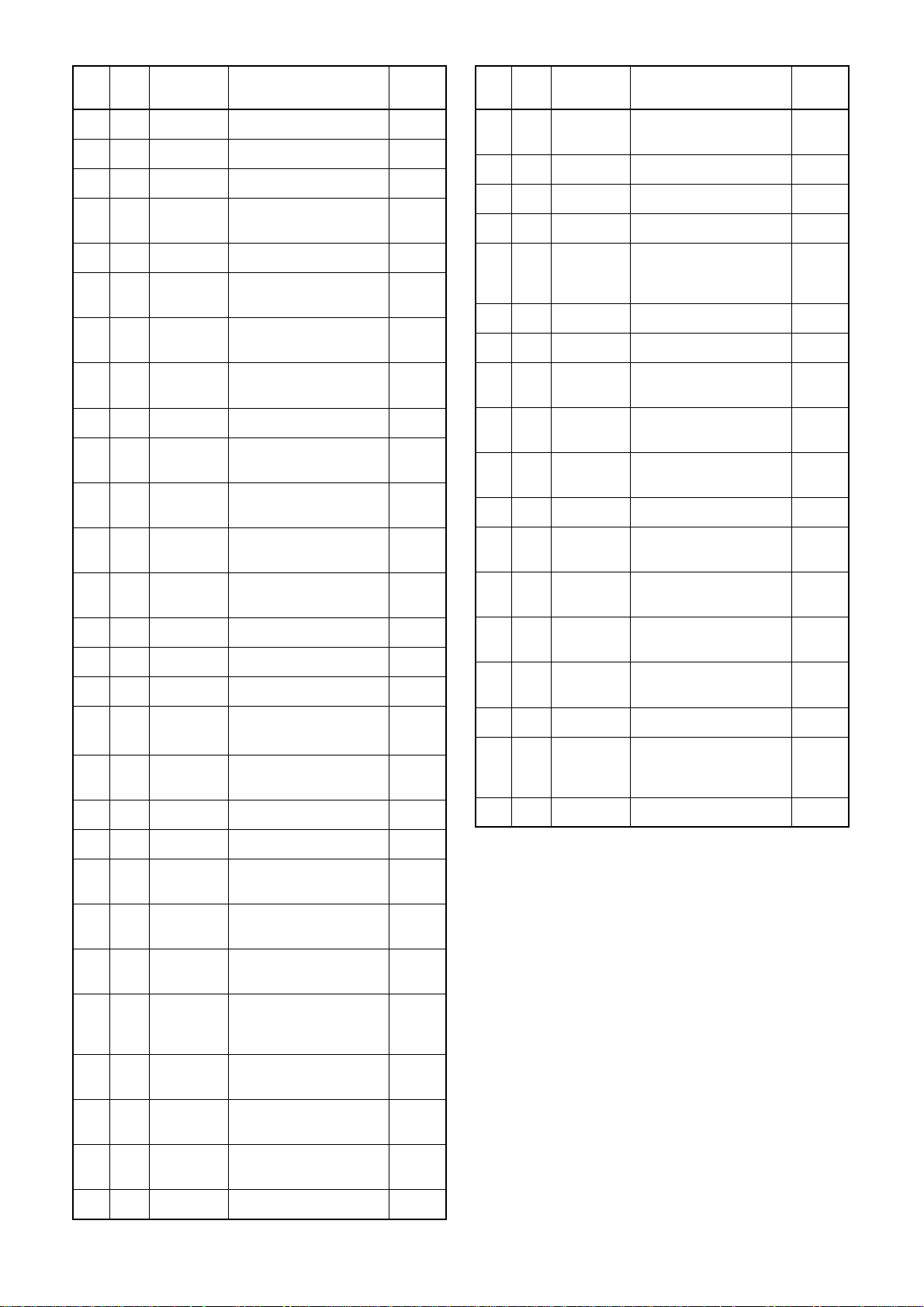

ELECTRICAL PARTS LIST

PRODUCT SAFETY NOTE: Products marked with a

! have special characteristics important to safety.

Before replacing any of these components, read

carefully the product safety notice in this service

manual. Don't degrade the safety of the product through

improper servicing.

NOTES:

Parts that are not assigned par t numbers (---------) ar e

not available.

Tolerance of Capacitors and Resistors are noted with

the following symbols.

C.....±0.25% D .....±0.5% F .....±1%

G.....±2% J......±5% K.....±10%

M.....±20% N.....±30% Z.....+80/-20%

ELECTRICAL PARTS LIST

Pos.No. ! 12 NC Description

MCV CBA 1

Consists of the following:

MAIN CBA 1

SENSOR CBA 1

MAIN CBA

2B7 SHIELD ASSEMBL Y H9500 ED 1

2B8 BUSH LED(F) H3700UD 1

2B46 ROHM HOLDER H7770JD 1

PS502 PHOT O INTE RR UPTE R RPI- 302C70 1

TP301 PCB JUMPER D0.6-P14.0 1

TP502 PCB JUMPER D0.6-P10.0 1

TP503 PCB JUMPER D0.6-P6.0 1

TP504 PCB JUMPER D0.6-P8.0 1

TP505 PCB JUMPER D0.6-P7.5 1

VR501 CARBON P.O. T. VZ067TL1 B104 PB(F) 1

X301 XT AL 4.433619MHZ 1

X301 QUARTZ CR YSTAL 4.433619MHZ 1

X301 XT AL 1K*044334EE 1

X501 QUARTS CR YSTAL 12.000000MHZ 1

X501 XT AL 12MHZ 12.000MHZ 1

CAPACITORS

C151 ELECTR OLYTIC CAP. 47UF/1 6V M H7 1

C151

C152 ELECTR OLYTIC CAP. 10UF/1 6V M H7 1

C152 ELECTR OLYTIC CAP. 10UF/1 6V M H7 1

C251 ELECTR OLYTIC CAP. 10UF/1 6V M H7 1

C251

C252

C252

C253

C254 ELEC TROLYTIC CAP. 1UF/ 50V M H7 1

C254

C301

C301

C302 ELEC TROLYTIC CAP. 1UF/ 50V M H7 1

C302

C303 CHIP CERAMIC CAP. F Z 0.22UF/ 16V 1

C305 ELEC TROLYTIC CAP. 1UF/ 50V M H7 1

ALUMINUM ELECTROL YTIC CAP

47UF/16V H7

ALUMINUM ELECTROL YTIC CAP

10UF/16V H7

CHIP CERAMIC CAP.(1608) F Z 0.1UF/

50V

CHIP CERAMIC CAP.(1608) F Z 0.1UF/

25V

CHIP CERAMIC CAP.(1608) B K

1000PF/50V

ALUMINUM ELECTROL YTIC CAP 1UF/

50V H7

CHIP CERAMIC CAP.(1608) B K

0.022UF/50V

CHIP CERAMIC CAP.(1608) B K

0.022UF/25V

ALUMINUM ELECTROL YTIC CAP 1UF/

50V H7

1

1

1

1

1

1

1

1

1

ELECTRICAL PARTS LIST

Pos.No. ! 12 NC Description

C305

C306

C306

C307

C307

C308

C308

C311

C311

C312 ELECTROL YTIC CAP. 10UF/16V M H7 1

C312

C313 ELECTROL YTIC CAP. 1UF/50V M H7 1

VCR Module

C313 ELECTROL YTIC CAP. 1UF/50V M H7 1

C314

C315

C315

C316 ELECTROL YTIC CAP. 1UF/50V M H7 1

C316

C317

C317

C318

C318

C321

C322

C322

C324

C325 CHIP CERAMIC CAP. B K 8200PF/50V 1

C328 ELECTROL YTIC CAP. 47UF/6.3V M H7 1

C328

C329

C329

C330 ELECTROLYTIC CAP. 100UF/16V M 1

C330 ELECTROLYTIC CAP. 100UF/16V M 1

C331 ELECTROLYTIC CAP. 470UF/6.3V M 1

C331 ELECTROLYTIC CAP. 470UF/6.3V M 1

C333

C333

C334 ELECTROL YTIC CAP. 1UF/50V M H7 1

C334

C335 ELECTROLYTIC CAP. 100UF/6.3V H7 1

C335

C336 CHIP CERAMIC CAP. CH J 220PF/50V 1

ALUMINUM ELECTROL YTIC CAP 1UF/

50V H7

CHIP CERAMIC CAP.(1608) B K

0.047UF/50V

CHIP CERAMIC CAP.(1608) B K

0.047UF/25V

CHIP CERAMIC CAP.(1608) B K

0.022UF/50V

CHIP CERAMIC CAP.(1608) B K

0.022UF/25V

CHIP CERAMIC CAP.(1608) F Z 0.1UF/

50V

CHIP CERAMIC CAP.(1608) F Z 0.1UF/

25V

CHIP CERAMIC CAP.(1608) F Z 0.1UF/

50V

CHIP CERAMIC CAP.(1608) F Z 0.1UF/

25V

ALUMINUM ELECTROL YTIC CAP

10UF/16V H7

CHIP CERAMIC CAP.(1608) B K 0.01UF/

50V

CHIP CERAMIC CAP.(1608) B K

0.047UF/50V

CHIP CERAMIC CAP.(1608) B K

0.047UF/25V

ALUMINUM ELECTROL YTIC CAP 1UF/

50V H7

CHIP CERAMIC CAP.(1608) F Z 0.1UF/

50V

CHIP CERAMIC CAP.(1608) F Z 0.1UF/

25V

CHIP CERAMIC CAP.(1608) B K

0.022UF/50V

CHIP CERAMIC CAP.(1608) B K

0.022UF/25V

ELECTROL YTIC CAP. 47UF/6.3V M NP

H7

CHIP CERAMIC CAP.(1608) F Z 0.1UF/

50V

CHIP CERAMIC CAP.(1608) F Z 0.1UF/

25V

CHIP CERAMIC CAP.(1608) B K 0.01UF/

50V

ALUMINUM ELECTROL YTIC CAP

47UF/6.3V H7

CHIP CERAMIC CAP.(1608) F Z 0.1UF/

50V

CHIP CERAMIC CAP.(1608) F Z 0.1UF/

25V

CHIP CERAMIC CAP.(1608) F Z 0.1UF/

50V

CHIP CERAMIC CAP.(1608) F Z 0.1UF/

25V

ALUMINUM ELECTROL YTIC CAP 1UF/

50V H7

ALUMINUM ELECTROL YTIC CAP

100UF/6.3V H7

VCR Module

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

20060508 1-10-1 HK100EL

Page 31

ELECTRICAL PARTS LIST

ELECTRICAL PARTS LIST

Pos.No. ! 12 NC Description

C337

C337

C339 CHIP CERAMIC CAP. CH J 120PF/5 0V 1

C340 ELEC TROLYTIC CAP. 1UF/ 50V M H7 1

C340

C341

C342

C342 CHIP CERAMIC CAP. CH J 10 00PF/25V 1

C343 ELECTR OLYTIC CAP. 10UF/1 6V M H7 1

C343

C344

C345 ELECTR OLYTIC CA P. 0.47UF /50V M H7 1

C345

C348 CERAMIC CAP.(AX) F Z 0.1UF/50 V 1

C349 ELECTR OLYTIC CA P. 0.47UF /50V M H7 1

C349

C350 CERAMIC CAP.(AX) F Z 0.1UF/50 V 1

C370 CERAMIC CAP.(AX) Y M 0.01UF /16V 1

C371

C371

C372

C372

C373

C373

C374

C374

C375

C376

C376

C377

C378

C379 ELECTR OLYTIC CA P. 0.47UF /50V M H7 1

C379

C381

C381

C382 CHIP CERAMIC CAP. B K 2 200PF/50V 1

C383 CHIP CERAMIC CAP. B K 2 200PF/50V 1

C384 ELECTROLYTIC CAP. 2.2UF/50 V M H7 1

C384

C402 FILM CAP.(P) 0.018UF/50V J 1

C402 FILM CAP.(P) 0.018UF/50V J 1

C403 CERAMIC CAP. B K 470PF/100V 1

C404 ELECTROLYTIC CAP. 220UF/6.3V M H7 1

C404 ELECTROLYTIC CAP. 220UF/6.3V M H7 1

C405 ELECTR OLYTIC CAP. 47 UF/6 .3V M H7 1

C405

C407 CHIP CERAMIC CAP. B K 8 20PF/50V 1

CHIP CERAMIC CAP.(1608) F Z 0.1UF/

50V

CHIP CERAMIC CAP.(1608) F Z 0.1UF/

25V

ALUMINUM ELECTROL YTIC CAP 1UF/

50V H7

CHIP CERAMIC CAP.(1608) CH D 10PF/

50V

CHIP CERAMIC CAP.(1608) CH J

1000PF/50V

ALUMINUM ELECTROL YTIC CAP

10UF/16V H7

ELECTROLYTIC CAP. 4.7UF/25V M NP

H7

ALUMINUM ELECTROL YTIC CAP

0.47UF/50V H7

ALUMINUM ELECTROL YTIC CAP

0.47UF/50V H7

CHIP CERAMIC CAP.(1608) B K

0.022UF/50V

CHIP CERAMIC CAP.(1608) B K

0.022UF/25V

CHIP CERAMIC CAP.(1608) F Z 0.1UF/

50V

CHIP CERAMIC CAP.(1608) F Z 0.1UF/

25V

CHIP CERAMIC CAP.(1608) F Z 0.1UF/

50V

CHIP CERAMIC CAP.(1608) F Z 0.1UF/

25V

CHIP CERAMIC CAP.(1608) F Z 0.1UF/

50V

CHIP CERAMIC CAP.(1608) F Z 0.1UF/

25V

CHIP CERAMIC CAP.(1608) B K 0.01UF/

50V

CHIP CERAMIC CAP.(1608) B K

0.022UF/50V

CHIP CERAMIC CAP.(1608) B K

0.022UF/25V

CHIP CERAMIC CAP.(1608) B K 0.01UF/

50V

CHIP CERAMIC CAP.(1608) B K 0.01UF/

50V

ALUMINUM ELECTROL YTIC CAP

0.47UF/50V H7

CHIP CERAMIC CAP.(1608) F Z 0.1UF/

50V

CHIP CERAMIC CAP.(1608) F Z 0.1UF/

25V

ALUMINUM ELECTROL YTIC CAP

2.2UF/50V H7

ALUMINUM ELECTROL YTIC CAP

47UF/6.3V H7

Pos.No. ! 12 NC Description

VCR Module

C408 CHIP CERAMIC CAP. B K 1800PF/50V 1

1

C409

1

C410 ELECTROL YTIC CAP. 10UF/16V M H7 1

C410

C411

1

C412 ELECTROL YTIC CAP. 33UF/6.3V M H7 1

1

C412

1

C413

C413

1

C414

1

C415 ELECTROL YTIC CAP. 4.7UF/25V M H7 1

C415

1

C416

C417 ELECTROL YTIC CAP. 22UF/6.3V M H7 1

C417

1

C418

C418

1

C419 CHIP CERAMIC CAP. CH J 220PF/50V 1

1

C420

1

C421 ELECTROL YTIC CAP. 47UF/6.3V M H7 1

C421

1

C422

1

C423

1

C426

1

C427

1

C452 ELECTROL YTIC CAP. 10UF/16V M H7 1

1

C452

1

C453 ELECTROL YTIC CAP. 22UF/10V M H7 1

C453

1

C454

1

C454

1

C455

1

C455

1

C456 ELECTROL YTIC CAP. 10UF/16V M H7 1

C456

1

C457 ELECTROL YTIC CAP. 4.7UF/25V M H7 1

C457

C458

1

C461

C462

C463 ELECTROL YTIC CAP. 22UF/10V M H7 1

C463

1

C464

C465 ELECTROL YTIC CAP. 10UF/16V M H7 1

CHIP CERAMIC CAP.(1608) CH J 33PF/

50V

ALUMINUM ELECTROL YTIC CAP

10UF/16V H7

CHIP CERAMIC CAP.(1608) B K 0.01UF/

50V

ALUMINUM ELECTROL YTIC CAP

33UF/6.3V H7

CHIP CERAMIC CAP.(1608) F Z 0.1UF/

50V

CHIP CERAMIC CAP.(1608) F Z 0.1UF/

25V

CHIP CERAMIC CAP.(1608) B K 0.01UF/

50V

ALUMINUM ELECTROL YTIC CAP

4.7UF/25V H7

CHIP CERAMIC CAP.(1608) B K

4700PF/50V

ALUMINUM ELECTROL YTIC CAP

22UF/6.3V H7

CHIP CERAMIC CAP.(1608) F Z 0.1UF/

50V

CHIP CERAMIC CAP.(1608) F Z 0.1UF/

25V

CHIP CERAMIC CAP.(1608) B K 0.01UF/

50V

ALUMINUM ELECTROL YTIC CAP

47UF/6.3V H7

ELECTROL YTIC CAP. 47UF/6.3V M NP

H7

ELECTROL YTIC CAP. 47UF/6.3V M NP

H7

CHIP CERAMIC CAP.(1608) CH J

470PF/50V

CHIP CERAMIC CAP.(1608) CH J

470PF/50V

ALUMINUM ELECTROL YTIC CAP

10UF/16V H7

ALUMINUM ELECTROL YTIC CAP

22UF/10V H7

CHIP CERAMIC CAP.(1608) F Z 0.1UF/

50V

CHIP CERAMIC CAP.(1608) F Z 0.1UF/

25V

CHIP CERAMIC CAP.(1608) F Z 0.1UF/

50V

CHIP CERAMIC CAP.(1608) F Z 0.1UF/

25V

ALUMINUM ELECTROL YTIC CAP

10UF/16V H7

ALUMINUM ELECTROL YTIC CAP

4.7UF/25V H7

CHIP CERAMIC CAP.(1608) B K 0.01UF/

50V

CHIP CERAMIC CAP.(1608) B K 0.01UF/

50V

CHIP CERAMIC CAP.(1608) B K

4700PF/50V

ALUMINUM ELECTROL YTIC CAP

22UF/10V H7

CHIP CERAMIC CAP.(1608) B K 0.01UF/

50V

VCR Module

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

20060508 1-10-2 HK100EL

Page 32

ELECTRICAL PARTS LIST

ELECTRICAL PARTS LIST

Pos.No. ! 12 NC Description

C465

C466

C466

C467

C467

C468 ELECTROLYTIC CAP. 220UF/6.3V M H7 1

C468

C469 ELECTR OLYTIC CAP. 22UF/1 0V M H7 1

C469

C470

C471

C472 ELECTROLYTIC CAP. 4.7UF/25 V M H7 1

C472

C473 ELECTR OLYTIC CAP. 10UF/1 6V M H7 1

C473

C474

C474

C475

C475

C476 ELECTR OLYTIC CAP. 22 UF/6 .3V M H7 1

C476

C478

C478

C479 ELECTR OLYTIC CAP. 10UF/1 6V M H7 1

C479

C482

C482

C483 ELECTROLYTIC CAP. 4.7UF/25 V M H7 1

C483

C484 ELECTROLYTIC CAP. 4.7UF/25 V M H7 1

C484

C485 ELECTR OLYTIC CAP. 10UF/1 6V M H7 1

C485

C486

C486

C487 ELECTR OLYTIC CAP. 47UF/1 6V M H7 1

C487

C489 CHIP CERAMIC CAP. B K 2 200PF/50V 1

C502

C502

C505

C506 ELECTROLYTIC CAP. 220UF/6.3V M 1

C506 ELECTROLYTIC CAP. 220UF/6.3V M 1

C508 CERAMIC CAP.(AX) F Z 0.1UF/50 V 1

ALUMINUM ELECTROL YTIC CAP

10UF/16V H7

CHIP CERAMIC CAP.(1608) F Z 0.1UF/

50V

CHIP CERAMIC CAP.(1608) F Z 0.1UF/

25V

CHIP CERAMIC CAP.(1608) F Z 0.1UF/

50V

CHIP CERAMIC CAP.(1608) F Z 0.1UF/

25V

ALUMINUM ELECTROL YTIC CAP

220UF/6.3V H7

ALUMINUM ELECTROL YTIC CAP

22UF/10V H7

CHIP CERAMIC CAP.(1608) B K

4700PF/50V

CHIP CERAMIC CAP.(1608) B K 0.01UF/

50V

ALUMINUM ELECTROL YTIC CAP

4.7UF/25V H7

ALUMINUM ELECTROL YTIC CAP

10UF/16V H7

CHIP CERAMIC CAP.(1608) F Z 0.1UF/

50V

CHIP CERAMIC CAP.(1608) F Z 0.1UF/

25V

CHIP CERAMIC CAP.(1608) F Z 0.1UF/

50V

CHIP CERAMIC CAP.(1608) F Z 0.1UF/

25V

ALUMINUM ELECTROL YTIC CAP

22UF/6.3V H7

CHIP CERAMIC CAP.(1608) F Z 0.1UF/

50V

CHIP CERAMIC CAP.(1608) F Z 0.1UF/

25V

ALUMINUM ELECTROL YTIC CAP

10UF/16V H7

CHIP CERAMIC CAP.(1608) F Z 0.1UF/

50V

CHIP CERAMIC CAP.(1608) F Z 0.1UF/

25V

ALUMINUM ELECTROL YTIC CAP

4.7UF/25V H7

ALUMINUM ELECTROL YTIC CAP

4.7UF/25V H7

ALUMINUM ELECTROL YTIC CAP

10UF/16V H7

CHIP CERAMIC CAP.(1608) F Z 0.1UF/

50V

CHIP CERAMIC CAP.(1608) F Z 0.1UF/

25V

ALUMINUM ELECTROL YTIC CAP

47UF/16V H7

CHIP CERAMIC CAP.(1608) B K

0.022UF/50V

CHIP CERAMIC CAP.(1608) B K

0.022UF/25V

CHIP CERAMIC CAP.(1608) B K 0.01UF/

50V

Pos.No. ! 12 NC Description

VCR Module

1

C509

C510

1

C511

1

C512

1

C512

1

C514 CHIP CERAMIC CAP. CH J 330PF/50V 1

1

C515

C515

1

C516 ELECTROL YTIC CAP. 22UF/6.3V M H7 1

1

C516

C517 CERAMIC CAP.(AX ) F Z 0.022UF/ 25V 1

1

C518 ELECTROL YTIC CAP. 22UF/6.3V M H7 1

C518

1

C519 CHIP CERAMIC CAP. CH J 560PF/50V 1

C521 ELECTROL YTIC CAP. 22UF/6.3V M H7 1

1

C521

1

C522

1

C524

C527 CERAMIC CAP.(AX) B K 100PF/50V 1

1

C531

1

C533

1

C533

C534 ELECTROL YTIC CAP. 47UF/6.3V M H7 1

1

C534

1

C535

1

C535

C536 CHIP CERAMIC CAP. CH J 560PF/50V 1

1

C538 CHIP CERAMIC CAP. CH J 180PF/50V 1

1

C539

C540

1

C541 CHIP CERAMIC CAP. CH J 18PF/50V 1

C542 CHIP CERAMIC CAP. CH J 18PF/50V 1

1

C545

C546

1

C547

1

C548

1

C548

C549 ELECTROL YTIC CAP. 1UF/50V M H7 1

1

C549

C550 ELECTROLYTIC CAP. 100UF/6.3V H7 1

1

C550

1

C553 ELECTROL YTIC CAP. 22UF/10V M H7 1

1

C553

C555

CHIP CERAMIC CAP.(1608) B K

1000PF/50V

CHIP CERAMIC CAP.(1608) B K

4700PF/50V

CHIP CERAMIC CAP.(1608) CH J

100PF/50V

CHIP CERAMIC CAP.(1608) F Z 0.1UF/

50V

CHIP CERAMIC CAP.(1608) F Z 0.1UF/

25V

CHIP CERAMIC CAP.(1608) F Z 0.1UF/

50V

CHIP CERAMIC CAP.(1608) F Z 0.1UF/

25V

ALUMINUM ELECTROL YTIC CAP

22UF/6.3V H7

ALUMINUM ELECTROL YTIC CAP

22UF/6.3V H7

ALUMINUM ELECTROL YTIC CAP

22UF/6.3V H7

CHIP CERAMIC CAP.(1608) B K 0.01UF/

50V

CHIP CERAMIC CAP.(1608) B K 0.01UF/

50V

CHIP CERAMIC CAP.(1608) B K

4700PF/50V

CHIP CERAMIC CAP.(1608) B K

0.047UF/50V

CHIP CERAMIC CAP.(1608) B K

0.047UF/25V

ALUMINUM ELECTROL YTIC CAP

47UF/6.3V H7

CHIP CERAMIC CAP.(1608) F Z 0.1UF/

50V

CHIP CERAMIC CAP.(1608) F Z 0.1UF/

25V

CHIP CERAMIC CAP.(1608) B K 0.01UF/

50V

CHIP CERAMIC CAP.(1608) B K

4700PF/50V

CHIP CERAMIC CAP.(1608) CH J 22PF/

50V

CHIP CERAMIC CAP.(1608) CH J 22PF/

50V

CHIP CERAMIC CAP.(1608) B K 0.01UF/

50V

CHIP CERAMIC CAP.(1608) F Z 0.1UF/

50V

CHIP CERAMIC CAP.(1608) F Z 0.1UF/

25V

ALUMINUM ELECTROL YTIC CAP 1UF/

50V H7

ALUMINUM ELECTROL YTIC CAP

100UF/6.3V H7

ALUMINUM ELECTROL YTIC CAP

22UF/10V H7

CHIP CERAMIC CAP.(1608) F Z 0.1UF/

50V

VCR Module

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

20060508 1-10-3 HK100EL

Page 33

ELECTRICAL PARTS LIST

ELECTRICAL PARTS LIST

Pos.No. ! 12 NC Description

C555

C557

C559

C560

C561

C562

CONNECTORS

CN252

CN253

CN505

CN653

DIODES

D151 ZENER DIODE DZ-10BSBT265 1

D151 ZENER DIODE MTZ JT-7710B 1

D301 SWITCHING DIODE 1N4148M 1

D301 SWITCHING DIODE 1SS133(T -77) 1

D370 SWITCHING DIODE 1N4148M 1

D370 SWITCHING DIODE 1SS133(T -77) 1

D510 SWITCHING DIODE 1N4148M 1

D510 SWITCHING DIODE 1SS133(T -77) 1

D555 LED MIE-534A2 1

D555 LED SIR-563ST3F P 1

D555 LED SIR-563ST3F Q 1

ICS

IC301 IC Y/C/A LA71750EM-MPB-E 1

IC370 IC SECAM LA70100M-TRM-E 1

IC451 IC HIFI LA72648M-MPB-E 1

IC501 SYSCONIC M3776AMCH-AD1GP 1

IC502 IC BR24L02F-WE2 1

IC502 IC CAT24WC02WI-TE13 1

COILS

L151 INDUCTOR 100UH-J-5FT 1

L251 INDUCTOR 5.6UH-K-26T 1

L302 INDUCTOR(100UH K) LAP02TA101K 1

L370 PCB JUMPER D0 .6-P5.0 1

L401 PCB JUMPER D0 .6-P5.0 1

L402 IN DUCT OR 47UH-K-5FT 1

L451 IN DUCT OR 47UH-K-5FT 1

L452 IN DUCT OR 27UH-K-5FT 1

L501 INDUCTOR(100UH K) LAP02TA101K 1

L502 PCB JUMPER D0 .6-P5.0 1

L503 INDUCTOR 1.8UH-K-26T 1

TRANSISTORS

Q151 TRANSISTOR KTC3198-Y-A T/P 1

Q151 TRANSISTOR KTC3198-GR-AT/P 1

Q152 NPN TRANSISTOR K RC103M-AT/P 1

Q153 TRANSISTOR KTC3205-Y -AT/P 1

Q153 TRANSISTOR 2SC3266-Y(TPE2 F) 1

Q301 TRANSISTOR KTA-1 266-GR-AT/P 1

Q301 TRANSISTOR 2SA1015-GR(TE2 F T) 1

Q302 TRANSISTOR KTC3199-Y -AT/P 1

Q302 TRANSISTOR KTC3199-GR-A T/P 1

Q302 TRANSISTOR 2SC1815-Y(TE2 F T) 1

Q302 TRANSISTOR 2SC1815-GR(TE2 F T) 1

Q401 CHIP TRANSISTOR RN1 511(TE85R. F) 1

Q403 TRANSISTOR KTC3203-Y -AT/P 1

Q403 TRANSISTOR 2SC2120-Y(TE2 F T) 1

Q404 TRANSISTOR KTA-1 266-GR-AT/P 1

Q404 TRANSISTOR 2SA1015-GR(TE2 F T) 1

CHIP CERAMIC CAP.(1608) F Z 0.1UF/

25V

CHIP CERAMIC CAP.(1608) CH J

100PF/50V

CHIP CERAMIC CAP.(1608) CH J

470PF/50V

CHIP CERAMIC CAP.(1608) CH J

470PF/50V

CHIP CERAMIC CAP.(1608) CH J

470PF/50V

CHIP CERAMIC CAP.(1608) CH J

470PF/50V

PH CONNEC T OR (W HITE ) T OP 10 P

B10B-PH-K-S(LF)

FE CONNECTOR TOP 10P 10FE-BTVK-N

FE CONNECTOR T O P 8P 08FE-BT-VKN

PH CONNEC T OR (W HITE ) T OP 2P

B2B-PH-K-S(LF)

Pos.No. ! 12 NC Description

VCR Module

1

Q405

Q406

1

Q451 TRANSISTOR KRC103S-RTK/P 1

1

Q506 PHOTO TRANSIST OR PT204-6B-12 1

Q506 PHOTO TRANSISTOR MID-32A22F 1

1

Q515 TRANSISTOR KTC3199-BL-AT/P 1

Q515 TRANSISTOR 2SC1815-BL(TE2 F T) 1

1

RESISTORS

1

R151 CARBON RES. 1/4W J 10K OHM 1

R152 CHIP RES. 1/10W J 1K OHM 1

R152 RES CHIP 1608 1/10W J 1.0K OHM 1

1

R153 CARBON RES. 1/4W J 150 OHM 1

R251 CHIP RES. 1/10W J 39K OHM 1

1

R251 RES CHIP 1608 1/10W J 39K OHM 1

R252 CHIP RES. 1/10W J 2.2K OHM 1

1

R252 RES CHIP 1608 1/10W J 2.2K OHM 1

R301 CHIP RES. 1/10W J 1.2K OHM 1

1

R301 RES CHIP 1608 1/10W J 1.2K OHM 1

R303 CHIP RES. 1/10W J 8.2K OHM 1

R303 RES CHIP 1608 1/10W J 8.2K OHM 1

R305 CHIP RES. 1/10W J 10K OHM 1

R305 RES CHIP 1608 1/10W J 10K OHM 1

R308 CHIP RES. 1/10W J 3.9K OHM 1

R308 RES CHIP 1608 1/10W J 3.9K OHM 1

R309 CARBON RES. 1/6W J 100 OHM 1

R309 CARBON RES. 1/4W J 100 OHM 1

R310 PCB JUMPER D0.6-P5.0 1

R312 CHIP RES. 1/10W J 5.6K OHM 1

R312 RES CHIP 1608 1/10W J 5.6K OHM 1

R314 CHIP RES. 1/10W J 3.9K OHM 1

R314 RES CHIP 1608 1/10W J 3.9K OHM 1

R316 CHIP RES. 1/10W J 1.8K OHM 1

R316 RES CHIP 1608 1/10W J 1.8K OHM 1

R317 CHIP RES. 1/10W J 220 OHM 1

R317 RES CHIP 1608 1/10W J 220 OHM 1

R318 CARBON RES. 1/4W J 680 OHM 1

R319 CHIP RES. 1/10W J 1K OHM 1

R319 RES CHIP 1608 1/10W J 1.0K OHM 1

R320 CHIP RES. 1/10W J 47K OHM 1

R320 RES CHIP 1608 1/10W J 47K OHM 1

R321 CARBON RES. 1/6W J 82 OHM 1

R321 CARBON RES. 1/4W J 82 OHM 1

R322 CHIP RES. 1/10W J 10K OHM 1

R322 RES CHIP 1608 1/10W J 10K OHM 1

R325 CHIP RES. 1/10W J 1.2K OHM 1

R325 RES CHIP 1608 1/10W J 1.2K OHM 1

R326 CHIP RES. 1/10W J 4.7K OHM 1

R326 RES CHIP 1608 1/10W J 4.7K OHM 1

R327 CHIP RES. 1/10W J 6.8K OHM 1

R327 RES CHIP 1608 1/10W J 6.8K OHM 1

R328 CHIP RES. 1/10W J 1K OHM 1

R328 RES CHIP 1608 1/10W J 1.0K OHM 1

R330 CHIP RES. 1/10W J 2.2K OHM 1

R330 RES CHIP 1608 1/10W J 2.2K OHM 1

R331 CHIP RES. 1/10W J 18K OHM 1

R331 RES CHIP 1608 1/10W J 18K OHM 1

R332 CHIP RES. 1/10W J 10K OHM 1

R332 RES CHIP 1608 1/10W J 10K OHM 1

R333 CHIP RES. 1/10W J 18K OHM 1

R333 RES CHIP 1608 1/10W J 18K OHM 1

R334 CHIP RES. 1/10W J 10K OHM 1

R334 RES CHIP 1608 1/10W J 10K OHM 1

R336 CHIP RES. 1/10W J 4.7K OHM 1

R336 RES CHIP 1608 1/10W J 4.7K OHM 1

R337 CHIP RES. 1/10W J 6.8K OHM 1

R337 RES CHIP 1608 1/10W J 6.8K OHM 1

R370 CHIP RES. 1/10W J 2.7K OHM 1

RES. BUIL T-IN TRANSISTOR

KRA103M-A T/P

CHIP TRANSISTOR KTC3875S-Y - RTK/

P

VCR Module

1

1

20060508 1-10-4 HK100EL

Page 34

ELECTRICAL PARTS LIST

ELECTRICAL PARTS LIST

Pos.No. ! 12 NC Description

R370 RES CHIP 1608 1/10W J 2.7K OHM 1

R371 CARBON RES. 1/6W J 5.6K OHM 1

R371 CARBON RES. 1/4W J 5.6K OHM 1

R372 CHIP RES. 1/10W J 3.9 K OHM 1

R372 RES CHIP 1608 1/10W J 3.9K OHM 1

R401 CARBON RES. 1/6W J 820 OHM 1

R401 CARBON RES. 1/4W J 820 OHM 1

R402 CARBON RES. 1/6W J 100 OHM 1

R402 CARBON RES. 1/4W J 100 OHM 1

R404 CHIP RES.(1608) 1/10W 0 OHM 1

R404 RES CHIP 1608 1/10W J 0 OHM 1

R405 CHIP RES. 1/10W J 47K OHM 1

R405 RES CHIP 1608 1/10W J 47K OHM 1

R406 CHIP RES. 1/10W J 22K OHM 1

R406 RES CHIP 1608 1/10W J 22K OHM 1

R407 CHIP RES. 1/10W J 5.6 K OHM 1

R407 RES CHIP 1608 1/10W J 5.6K OHM 1

R408 CHIP RES. 1/10W J 12K OHM 1

R408 RES CHIP 1608 1/10W J 12K OHM 1

R409 CHIP RES. 1/10W J 5.6 K OHM 1

R409 RES CHIP 1608 1/10W J 5.6K OHM 1

R410 CHIP RES. 1/10W J 1K OHM 1

R410 RES CHIP 1608 1/10W J 1.0K OHM 1

R411 CHIP RES. 1/10W J 27K OHM 1

R411 RES CHIP 1608 1/10W J 27K OHM 1

R412 CHIP RES. 1/10W J 120 OHM 1

R412 RES CHIP 1608 1/10W J 120 OHM 1

R413 CHIP RES. 1/10W J 330K OHM 1

R413 RES CHIP 1608 1/10W J 330K OHM 1

R414 CHIP RES. 1/10W J 12K OHM 1

R414 RES CHIP 1608 1/10W J 12K OHM 1

R415 CHIP RES. 1/10W J 1.8 K OHM 1

R415 RES CHIP 1608 1/10W J 1.8K OHM 1

R416 CHIP RES. 1/10W J 1.2 K OHM 1

R416 RES CHIP 1608 1/10W J 1.2K OHM 1

R417 CHIP RES. 1/10W J 2.2 K OHM 1

R417 RES CHIP 1608 1/10W J 2.2K OHM 1

R418 CHIP RES. 1/10W J 12K OHM 1

R418 RES CHIP 1608 1/10W J 12K OHM 1

R419 CHIP RES. 1/10W J 10K OHM 1

R419 RES CHIP 1608 1/10W J 10K OHM 1

R420 CHIP RES. 1/10W J 5.6 K OHM 1

R420 RES CHIP 1608 1/10W J 5.6K OHM 1

R421 CHIP RES. 1/10W J 4.7 K OHM 1

R421 RES CHIP 1608 1/10W J 4.7K OHM 1

R453 CHIP RES. 1/10W J 5.6 K OHM 1

R453 RES CHIP 1608 1/10W J 5.6K OHM 1

R454 CHIP RES. 1/10W J 39K OHM 1

R454 RES CHIP 1608 1/10W J 39K OHM 1

R462 CHIP RES. 1/10W J 10K OHM 1

R462 RES CHIP 1608 1/10W J 10K OHM 1

R463 CHIP RES. 1/10W J 470 OHM 1

R463 RES CHIP 1608 1/10W J 470 OHM 1

R464 CHIP RES. 1/10W J 3.3 K OHM 1

R464 RES CHIP 1608 1/10W J 3.3K OHM 1

R466 CHIP RES. 1/10W J 8.2 K OHM 1

R466 RES CHIP 1608 1/10W J 8.2K OHM 1

R467 CHIP RES. 1/10W J 5.6 K OHM 1

R467 RES CHIP 1608 1/10W J 5.6K OHM 1

R470 CHIP RES. 1/10W J 39K OHM 1

R470 RES CHIP 1608 1/10W J 39K OHM 1

R479 CHIP RES. 1/10W J 33 OHM 1

R479 RES CHIP 1608 1/10W J 33 OHM 1

R480 CHIP RES. 1/10W J 100 OHM 1

R480 RES CHIP 1608 1/10W J 100 OHM 1

R481 CHIP RES. 1/10W J 33 OHM 1

R481 RES CHIP 1608 1/10W J 33 OHM 1

R482 CARBON RES. 1/6W J 100 OHM 1

Pos.No. ! 12 NC Description

VCR Module

R482 CARBON RES. 1/4W J 100 OHM 1

R483 CHIP RES. 1/10W J 22K OHM 1

R483 RES CHIP 1608 1/10W J 22K OHM 1

R484 CHIP RES. 1/10W J 6.8K OHM 1

R484 RES CHIP 1608 1/10W J 6.8K OHM 1

R509 CHIP RES. 1/10W J 180 OHM 1

R509 RES CHIP 1608 1/10W J 180 OHM 1

R511 CARBON RES. 1/6W G 3.6K OHM 1

R511 CARBON RES. 1/4W G 3.6K OHM 1

R512 CHIP RES. 1/10W J 68K OHM 1

R512 RES CHIP 1608 1/10W J 68K OHM 1

R513 CHIP RES. 1/10W J 33K OHM 1

R513 RES CHIP 1608 1/10W J 33K OHM 1

R514 CARBON RES. 1/6W G 10K OHM 1

R514 CARBON RES. 1/4W G 10K OHM 1

R516 CARBON RES. 1/6W G 470 OHM 1

R516 CARBON RES. 1/4W G 470 OHM 1

R517 CARBON RES. 1/4W J 270 OHM 1

R519 CARBON RES. 1/6W G 22K OHM 1

R519 CARBON RES. 1/4W G 22K OHM 1

R523 CARBON RES. 1/6W G 1.5K OHM 1

R523 CARBON RES. 1/4W G 1.5K OHM 1

R525 CARBON RES. 1/6W J 390K OHM 1

R525 CARBON RES. 1/4W J 390K OHM 1

R526 CHIP RES. 1/10W J 390K OHM 1

R526 RES CHIP 1608 1/10W J 390K OHM 1

R528 CARBON RES. 1/6W G 4.7K OHM 1

R528 CARBON RES. 1/4W G 4.7K OHM 1

R530 CHIP RES. 1/10W J 100 OHM 1

R530 RES CHIP 1608 1/10W J 100 OHM 1

R531 CHIP RES. 1/10W J 100 OHM 1

R531 RES CHIP 1608 1/10W J 100 OHM 1

R532 CHIP RES. 1/10W J 100 OHM 1

R532 RES CHIP 1608 1/10W J 100 OHM 1

R533 CHIP RES. 1/10W J 100 OHM 1

R533 RES CHIP 1608 1/10W J 100 OHM 1

R536 CHIP RES. 1/10W J 1.8K OHM 1

R536 RES CHIP 1608 1/10W J 1.8K OHM 1

R537 CHIP RES. 1/10W J 680 OHM 1

R537 RES CHIP 1608 1/10W J 680 OHM 1

R538 CHIP RES. 1/10W J 1.5K OHM 1

R538 RES CHIP 1608 1/10W J 1.5K OHM 1

R539 CHIP RES. 1/10W J 10K OHM 1

R539 RES CHIP 1608 1/10W J 10K OHM 1