PHILIPS DVDR3350H-37, DVDR3350H-55, DVDR3360H-75, DVDR3360H-96, DVDR3360H-97 Service Manual

...

DVD-Video Recorder

CLASS 1

LASER PRODUCT

DVDR3350H/DVDR3360H/DVDR3370H

DVDR3350H/37/55, DVDR3360H/75/96/97

& DVDR3370H/75/96/97

Contents Page

1 Technical Specifications and Connection

Facilities 2

2 Safety Information, General Notes & Lead

Free Requirements 4

3 Directions for Use 6

4 Mechanical Instructions 9

5 Upgrade Software & Repair Chart 12

6 Block Diagrams,Waveforms, Wiring Diagram 23

Overall block diagram 23

Control block diagram 24

Wiring diagram 25

Waveforms of Analog Board 26

Waveforms of Digital Board 27

Test Point Overview for Analog Board 28

Test Point Overview for Digital Board 29

7 Circuit Diagram and PWB Layout 30

Analog: Frontend Video (FV) 30

Analog: Video In / Out (IOV) 31

Analog: Audio In / Out (IOA) 32

Analog: Power Supply (PS) 33

Analog: Multi Sound Processing (MSP) 34

Analog: Audio Converter (DAC_ADC) 35

Analog: Digital In / Out 1 (DIGIO 1) 36

Analog: Control Unit (CU) 37

Layout: Analog-Main Part (Top View) 38

Layout: Analog-Main Part (Bottom View) 39

Front: Front Panel - Display 40

©

Copyright 2005 Philips Consumer Electronics B.V. Eindhoven, The Netherlands.

All rights reserved. No part of this publication may be reproduced, stored in a

retrieval system or transmitted, in any form or by any means, electronic,

mechanical, photocopying, or otherwise without the prior permission of Philips.

Contents Page

Front: Front Panel - Audio/Video In 41

Layout: Front Panel (Top Copper Pattern) 42

Layout: Front Panel (Bottom Copper Pattern) 42

Front: Standby 43

Layout: Standby (Top View) 43

Layout: Standby (Bottom View) 43

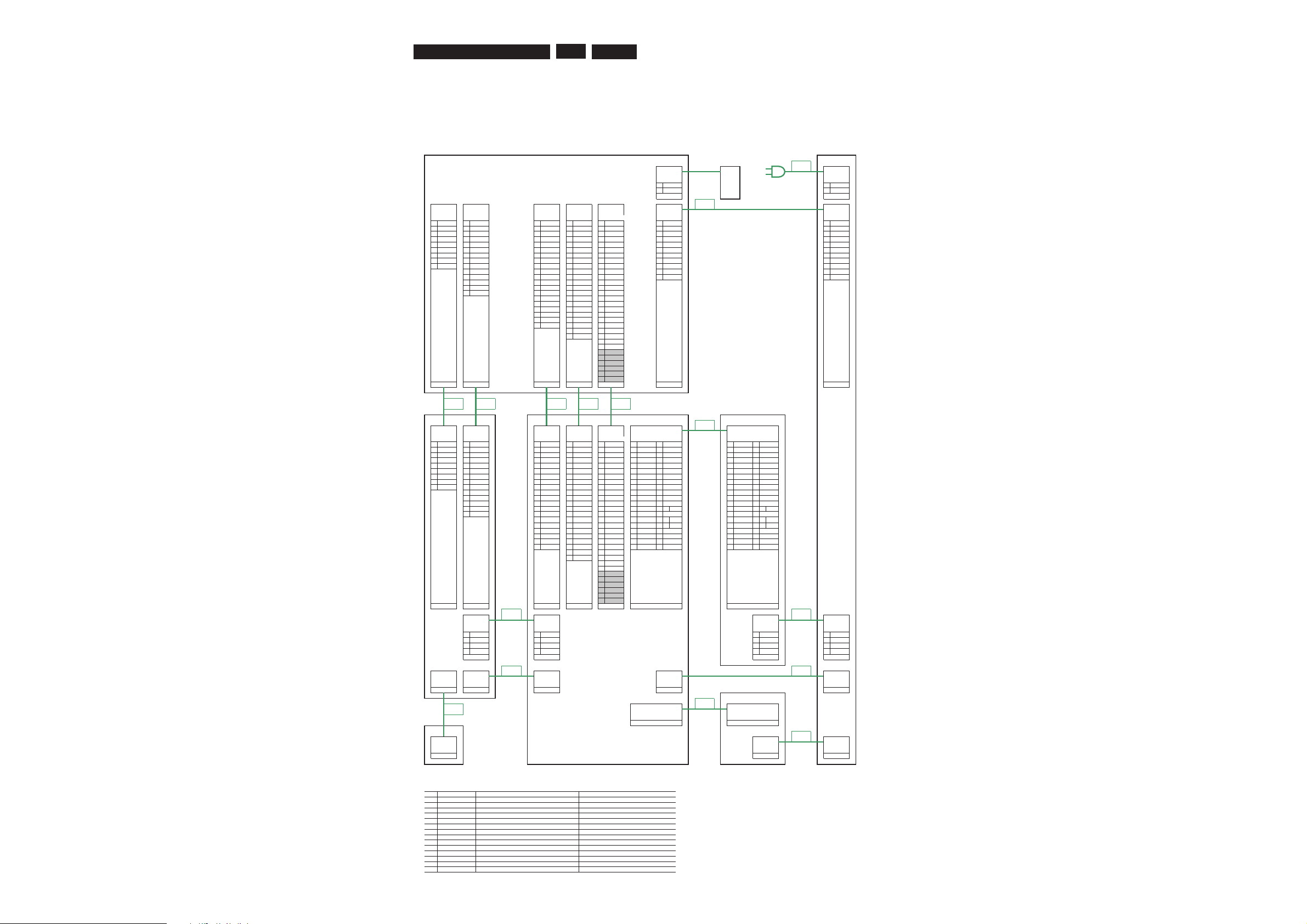

Digital: Back-end Processor 44

Digital: Memory 45

Digital: IEEE 1394 Physical Layer 46

Digital: Video Input Processor 47

Digital: Interfaces 48

Layout: Digital-Main Part (Top View) 49

Layout: Digital-Main Part (Bottom View) 50

8 Circuit- and IC Description 51

PSU Board 51

Front Board 52

Analog Board 52

Digital Board 56

Power Supply Unit 59

IC Description 59

Analog Board 59

Digital Board 64

9 Exploded View & Spare Parts List 75

Exploded View of the set 75

Spare Parts List 76

Published by KC-TE 0549 AV Systems Printed in the Netherlands Subject to modification EN 3139 785 31500

Version 1.0

EN 2

1.

3139 785 31500

Technical Specifi cations and Connection Facilities

1. Technical Specifi cations and Connection Facilities

1.1 PCB Locations

Hard-Disk

Digital Board

PSU

1.2 Diversity Matrix

DVDR3350H DVDR3360H DVDR3370H

HDD

Capacity

1.3 General:

Power Supply : 127V /37

: 110V - 240V /55

: 220V - 240V /75/97

Consumption : 25 W (typical)

Standby power consumption : < 3 W

1.4 RF Tuner

Test equipment: Fluke 54200 TV Signal generator

Test streams: Philips Standard test pattern

1.4.1 System

NTSC-M

1.4.2 RF - Loop Through:

80GB 160GB 250GB

Analog Board

1.4.4 Receiver:

PLL tuning with AFC for optimum reception

Frequency range : 55 - 805 MHz

Sensitivity at 40 dB S/N : 60dBV at 75

(video unweighted)

1.4.5 Video Performance:

Channel 25 / 503,25 MHz,

Test pattern: standard test pattern.

RF Level 74dBV

Measured on Cinch Out

Frequency response : 0.1 - 3.58 MHz -1 ± 3dB

1.4.6 Audio Performance:

Audio Performance Analogue - HiFi:

Frequency response at Cinch (L+R)

output : 100 Hz - 10 kHz / 0 ±

3dB

S/N according to DIN 45405, 7, 1967

and PHILIPS standard test pattern

video signal : 45dB

Harmonic distortion (1 kHz, ± 25

kHz deviation) : 1.5%

Basic Engine

Frequency range : 45 - 860 MHz

Gain: (ANT IN - ANT OUT) : -6dB

Radio Interference / max. input

voltage, at 75, 3 tone method (

-40dB) : no limit

1.4.3 Modulator:

Video Modulation : 80%±15%

Frequency response : 0 ± 3dB, 0...4.2MH

Audio Modulation 1kHz tone : ± 12kHz, tol. ± 4kHz

1.4.7 Tuning

Automatic Search Tuning

Scanning time without antenna : typ. 3 min.

Stop level (vision carrier) : 37dBV

Maximum tuning error during

operation : ± 100 kHz

Manual Tuning

Manual selection in “STORE” mode

Technical Specifi cations and Connection Facilities

3139 785 31500

1.

EN 3

1.5 Analogue Inputs / Outputs

1.5.1 External In (Rear)

Video - Y/C (Hosiden)

according IEC 933-5

Superimposed DC-level on pin 4 (load 100k):

< 2.4V is detected as 4:3 aspect ratio

> 3.5V is detected as 16:9 aspect ratio

Input voltage Y : 1 Vpp ± 3dB

Input impedance Y : 75

Input voltage C : burst 300 mVpp ± 3dB

Input impedance C : 75

Video Cinch

Input voltage : 1 Vpp ± 3dB

Input impedance : 75

Audio Cinch

Input voltage : 2.2 Vrms max.

Input impedance : > 10k

1.5.2 Audio/Video Front Input Connectors

Audio

Input voltage : 2 Vrms max.

Input impedance : > 10k

Video - Cinch

Input voltage : 1 Vpp ± 3dB

Input impedance : 75

Video - YC (Hosiden)

according IEC 933-5

Superimposed DC-level on pin 4 (load 100 k):

< 2.4V is detected as 4:3 aspect ratio

> 3.5V is detected as 16:9 aspect ratio

Input voltage Y : 1 Vpp ± 3dB

Input impedance Y : 75

Input voltage C : burst 300 mVpp ± 3dB

Input impedance C : 75

1.5.3 Out 1

Component Video Cinch Y/Pb/Pr / Progressive Scan

according EIO-770-1-A, EIA-770-2-A

Audio - Cinch

Output voltage : 2 Vrms max

Output impedance : < 2k

1.5.4 Out 2

Video - Y/C (Hosiden)

Output voltage Y : 1 Vpp ± 3dB

C : burst 300 mVpp ± 1dB

Output impedance Y, C : 75

Video - Cinch

Output voltage : 1 Vpp ± 1dB

Output impedance : 75

1.7 Audio Performance CD

1.7.1 Cinch Output Rear

Output voltage 2 channel mode : 2Vrms ± 1dB

Channel unbalance (1kHz) : <1dB

Crosstalk 1kHz : >100dB

Crosstalk 20Hz-20kHz : >87dB

Frequency response 20Hz-20kHz : ±0.2dB max

Signal to noise ratio (A-weighted) : >90dB

Dynamic range 1kHz : >83dB

Distortion and noise 1kHz : >83dB

Distortion and noise 20Hz-20kHz : >75dB

Intermodulation distortion : >70dB

Mute : >95dB

Outband attenuation: : >40dB above 30kHz

1.8 Digital Output

1.8.1 Coaxial

CDDA / LPCM : according IEC60958

MPEG1, MPEG2, AC3 audio : according IEC61937

DTS : according IEC61937

amendment 1

1.9 Digital Video Input (IEEE 1394)

1.9.1 Applicable Standards

Implementation according:

IEEE Std 1394-1995

IEC 61883 - Part 1

IEC 61883 - Part 2 SD-DVCR (02-01-1997)

Specifi cation of consumer use digital VCR’s using 6.3 mm

magnetic tape - dec. 1994

Mechanical connection according:

Annex A of 61883-1

1.10 Dimensions and Weight

Height of feet : 5.5mm

Apparatus tray closed : WxDxH:435x285x65mm

Apparatus tray open : WxDxH:435x422x65mm

Weight without packaging : app. 4 kg ± 0.5 kg

Weight in packaging : app. 6.0 kg

1.11 Laser Output Power & Wavelength

1.11.1 DVD

Output power during reading : 1.0mW

Output power during writing : 30mW

Wavelength : 650nm

1.11.2 CD

Output power : 1.0mW

Wavelength : 780nm

1.12 Write Speed

Audio - Cinch

Output voltage : 2 Vrms max

Output impedance : < 1k

1.6 Video Performance DVD

All outputs loaded with 75 Ohm

SNR measurements over full bandwidth without weighting.

1.6.1 All Outputs

SNR : > 48dB

Bandwidth : 4.2 MHz - 3dB

Type of Disc (Function) Disc Rotation Speed

Read Speed CD 7X CAV (25Hz)

Read Speed DVD 4X CAV (40Hz)

Write Speed DVD+RW 2.4X ZCAV

Write Speed DVD+R 2.4X ZCAV

EN 4

2.

3139 785 31500

Safety Information, General Notes & Lead Free Requirements

2. Safety Information, General Notes & Lead Free Requirements

2.1 Safety Instructions

2.1.1 General Safety

Safety regulations require that during a repair:

• Connect the unit to the mains via an isolation transformer.

• Replace safety components, indicated by the symbol ,

only by components identical to the original ones. Any

other component substitution (other than original type)

may increase risk of fi re or electrical shock hazard.

Safety regulations require that after a repair, you must return

the unit in its original condition. Pay, in particular, attention to

the following points:

• Route the wires/cables correctly, and fi x them with the

mounted cable clamps.

• Check the insulation of the mains lead for external

damage.

• Check the electrical DC resistance between the mains

plug and the secondary side:

1. Unplug the mains cord, and connect a wire between

the two pins of the mains plug.

2. Set the mains switch to the ‘on’ position (keep the

mains cord unplugged!).

3. Measure the resistance value between the mains

plug and the front panel, controls, and chassis

bottom.

4. Repair or correct unit when the resistance

measurement is less than 1 M.

5. Verify this, before you return the unit to the customer/

user (ref. UL-standard no. 1492).

6. Switch the unit ‘off’, and remove the wire between the

two pins of the mains plug.

2.1.2 Laser Safety

This unit employs a laser. Only qualifi ed service personnel

may remove the cover, or attempt to service this device (due

to possible eye injury).

2.2 Warnings

2.2.1 General

• All ICs and many other semiconductors are susceptible to

electrostatic discharges (ESD, ). Careless handling

during repair can reduce life drastically. Make sure that,

during repair, you are at the same potential as the mass

of the set by a wristband with resistance. Keep

components and tools at this same potential.

Available ESD protection equipment:

– Complete kit ESD3 (small tablemat, wristband,

connection box, extension cable and earth cable)

4822 310 10671.

– Wristband tester 4822 344 13999.

• Be careful during measurements in the live voltage

section. The primary side of the power supply, including

the heatsink, carries live mains voltage when you

connect the player to the mains (even when the

player is ‘off’!). It is possible to touch copper tracks and/

or components in this unshielded primary area, when

you service the player. Service personnel must take

precautions to prevent touching this area or components

in this area. A ‘lightning stroke’ and a stripe-marked

printing on the printed wiring board, indicate the primary

side of the power supply.

• Never replace modules, or components, while the unit is

‘on’.

2.2.2 Laser

• The use of optical instruments with this product, will

increase eye hazard.

• Only qualifi ed service personnel may remove the cover or

attempt to service this device, due to possible eye injury.

• Repair handling should take place as much as possible

with a disc loaded inside the player.

• Text below is placed inside the unit, on the laser cover

shield:

Laser Device Unit

Type : Semiconductor laser

GaAlAs

Wavelength : 650 nm (DVD)

: 780 nm (VCD/CD)

Output Power : 20 mW

(DVD+RW writing)

: 0.8 mW

(DVD reading)

: 0.3 mW

(VCD/CD reading)

Beam divergence : 60 degree

CLASS 1

LASER PRODUCT

Figure 2-1

Note: Use of controls or adjustments or performance of

procedure other than those specifi ed herein, may result in

hazardous radiation exposure. Avoid direct exposure to beam.

CAUTION VISIBLE AND INVISIBLE LASER RADIATION WHEN OPEN AVOID EXPOSURE TO BEAM

ADVARSEL SYNLIG OG USYNLIG LASERSTRÅLING VED ÅBNING UNDGÅ UDSÆTTELSE FOR STRÅLING

ADVARSEL SYNLIG OG USYNLIG LASERSTRÅLING NÅR DEKSEL ÅPNES UNNGÅ EKSPONERING FOR STRÅLEN

VARNING SYNLIG OCH OSYNLIG LASERSTRÅLNING NÄR DENNA DEL ÄR ÖPPNAD BETRAKTA EJ STRÅLEN

VARO ! AVATTAESSA OLET ALTTIINA NÄKYVÄLLE JA NÄKYMÄTTÖMÄLLE LASER SÄTEILYLLE. ÄLÄ KATSO SÄTEESEEN

VORSICHT SICHTBARE UND UNSICHTBARE LASERSTRAHLUNG WENN ABDECKUNG GEÖFFNET NICHT DEM STRAHL AUSSETSEN

DANGER VISIBLE AND INVISIBLE LASER RADIATION WHEN OPEN AVOID DIRECT EXPOSURE TO BEAM

ATTENTION RAYONNEMENT LASER VISIBLE ET INVISIBLE EN CAS D’OUVERTURE EXPOSITION DANGEREUSE AU FAISCEAU

Figure 2-2

2.2.3 Notes

Dolby

Manufactured under licence from Dolby Laboratories. “Dolby”,

“Pro Logic” and the double-D symbol are trademarks of Dolby

Laboratories. Confi dential Unpublished Works.

©1992-1997 Dolby Laboratories, Inc. All rights reserved.

Figure 2-3

Trusurround

TRUSURROUND, SRS and symbol (fi g 2-4) are trademarks

of SRS Labs, Inc. TRUSURROUND technology is

manufactured under licence frm SRS labs, Inc.

Figure 2-4

Safety Information, General Notes & Lead Free Requirements

3139 785 31500

2.

EN 5

Video Plus

“Video Plus+” and “PlusCode” are registered trademarks of

the Gemstar Development Corporation. The “Video Plus+”

system is manufactured under licence from the Gemstar

Development Corporation.

Figure 2-5

Macrovision

This product incorporates copyright protection technology that

is protected by method claims of certain U.S. patents and

other intellectual property rights owned by Macrovision

Corporation and other rights owners.

Use of this copyright protection technology must be

authorized by Macrovision Corporation, and is intended for

home and other limited viewing uses only unless otherwise

authorized by Macrovision Corporation. Reverse engineering

or disassembly is prohibited.

2.3 Lead Free Requirement

Information about Lead-free produced sets

Philips CE is starting production of lead-free sets from

1.1.2005 onwards.

INDENTIFICATION:

Regardless of special logo (not always indicated)

One must treat all sets from 1 Jan 2005 onwards, according

next rules.

Example S/N:

Due to lead-free technology some rules have to be respected by the

workshop during a repair:

• Use only lead-free solder alloy Philips SAC305 with order

code 0622 149 00106. If lead-free solder-pate is required,

please contact the manufacturer of your solder-equipment.

In general use of solder-paste within workshops should be

avoided because paste is not easy to store and to handle.

• Use only adequate solder tools applicable for lead-free

solder alloy. The solder tool must be able

o To reach at least a solder-temperature of 400°C,

o To stabilize the adjusted temperature at the solder-tip

o To exchange solder-tips for different applications.

• Adjust your solder tool so that a temperature around 360°C

– 380°C is reached and stabilized at the solder joint.

Heating-time of the solder-joint should not exceed ~ 4 sec.

Avoid temperatures above 400°C otherwise wear-out of tips

will rise drastically and fl ux-fl uid will be destroyed. To avoid

wear-out of tips switch off un-used equipment, or reduce

heat.

• Mix of lead-free solder alloy / parts with leaded solder alloy

/ parts is possible but PHILIPS recommends strongly to

avoid mixed solder alloy types (leaded and lead-free).

If one cannot avoid or does not know whether product is

lead-free, clean carefully the solder-joint from old solder

alloy and re-solder with new solder alloy (SAC305).

• Use only original spare-parts listed in the Service-Manuals.

Not listed standard-material (commodities) has to be

purchased at external companies.

• Special information for BGA-ICs:

- always use the 12nc-recognizable soldering temperature

profi le of the specifi c BGA (for de-soldering always use the

lead-free temperature profi le, in case of doubt)

- lead free BGA-ICs will be delivered in so-called ‘drypackaging’ (sealed pack including a silica gel pack) to

protect the IC against moisture. After opening, dependent

of MSL-level seen on indicator-label in the bag, the

BGA-IC possibly still has to be baked dry. (MSL=Moisture

Sensitivity Level). This will be communicated via AYSwebsite.

Do not re-use BGAs at all.

• For sets produced before 1.1.2005 (except products of

2004), containing leaded solder-alloy and components,

all needed spare-parts will be available till the end of the

service-period. For repair of such sets nothing changes.

Bottom line of typeplate gives a 14-digit S/N. Digit 5&6 is the year, digit 7&8 is

the week number, so in this case 1991 wk 18

So from 0501 onwards = from 1 Jan 2005 onwards

Important note: In fact also products of year 2004 must be treated in this way as long as you

avoid mixing solder-alloys (leaded/ lead-free). So best to always use SAC305 and the higher

temperatures belong to this.

• On our website www.atyourservice.ce.Philips.com you

BGA-de-/soldering (+ baking instructions)

Heating-profi les of BGAs and other ICs used in Philips-sets

You will fi nd this and more technical information within the

For additional questions please contact your local repair-helpdesk.

fi nd more information to:

“magazine”, chapter “workshop news”.

EN 6

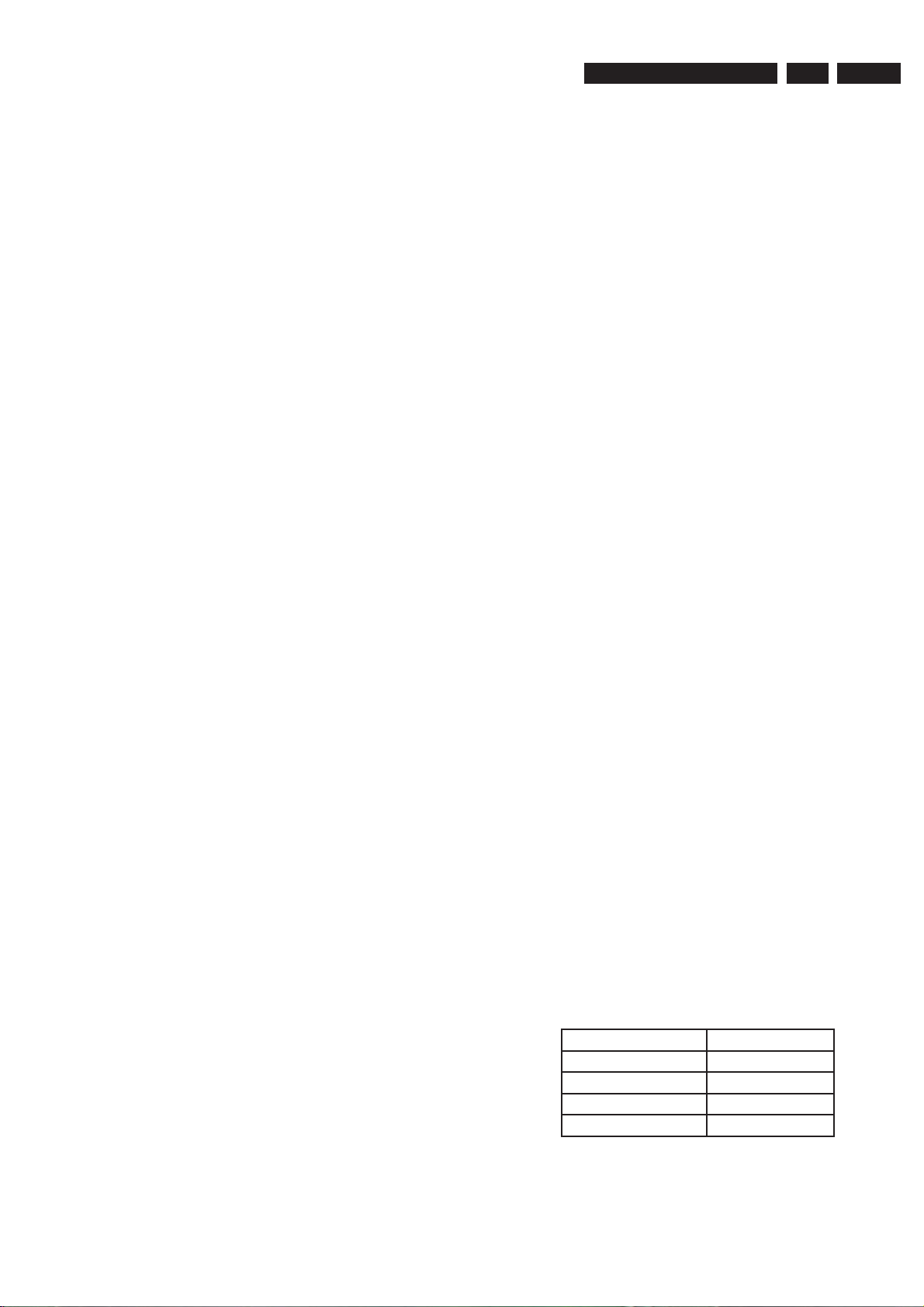

Hard Disk/ DVD Recorder DVDR 3360H

DVDR 3370H

Quick Start Guide

Connect

Set up

Enjoy

1

2

3

What’s in the box?

Hard Disk/ DVD Recorder

Quick Start Guide

RF Coaxial Cable

Remote Control

and 2 batteries

User ManualAudio/Video Cable

1

Connect

Start with the ‘Basic Connection.’

If you have a VCR, follow the instructions for ‘Connection with a VCR or similar device’.

~

MAINS

ANTENNA

TV

EXT1

VIDEO

(

CVBS

)

AUDIO

S-VIDEO

(Y/C)

AUDIO

AUDIO

R

L

P

B

OUT 2

VIDEO

(

CVBS

)

OUT 1

Y

P

R

COAXIAL

DIGITAL AUDIO OUT

L

R

S-VIDEO

(Y/C)

AUDIO

AUDIO

R

L

OUT 2

VIDEO

(

CVBS

)

OUT 1

Television (rear)

To antenna

or set-up box

Philips recorder

(rear)

A Connect the antenna cable to the

ANTENNA jack on the recorder.

B Use the supplied RF coaxial cable to connect the

TV

jack on this recorder to the Antenna In

jack on the TV.

C Use the supplied audio/video cable (yellow plug)

to connect the VIDEO (CVBS) -OUT 2 jack

on this recorder to the VIDEO IN jack on the TV.

D Use the supplied audio/video cable (red/ white

plugs) to connect the AUDIO L/R OUT 2 jack

on this recorder to the AUDIO IN jacks on the

TV.

E Connect the power cable from the recorder to

an AC power outlet.

EXT1

AUDIO IN

L

R

VIDEO IN

(

CVBS

)

~

MAINS

ANTENNA

TV

EXT1

VIDEO

(

CVBS

)

AUDIO

S-VIDEO

(Y/C)

AUDIO

R

L

OUT 2

VIDEO

(

CVBS

)

L

R

AUDIO

P

B

OUT 1

Y

P

R

COAXIAL

DIGITAL AUDIO OUT

Television (rear)

Philips recorder

(rear)

To antenna

or set-up box

VCR or similar device

(rear)

A Follow steps A to E of ‘Connecting’ under ‘Basic

Connections’ to connect the recorder before you

proceed to step B below.

B Use a yellow video cable (not supplied) to

connect the VIDEO (CVBS) EXT 1 jack on this

recorder to the yellow VIDEO OUT jack on the

VCR.

C Use another red and white audio cable (not

supplied) to connect the AUDIO L/R EXT 1

jacks on this recorder to the red and white

AUDIO OUT jacks on the VCR.

D Connect the power cable from your VCR to an

AC power outlet.

Note In this setup, the VCR cannot record TV

programs.

For additional connection diagrams, see the

accompanying User Manual.

Basic Connection

A Before Connecting

Unplug the antenna cable that is currently

connected to your TV.

B Connecting

Connection with a VCR

or similar device

A Before Connecting

Your new Philips recorder replaces the VCR for

your recording needs. First, unplug all the

connections from your VCR.

B Connecting

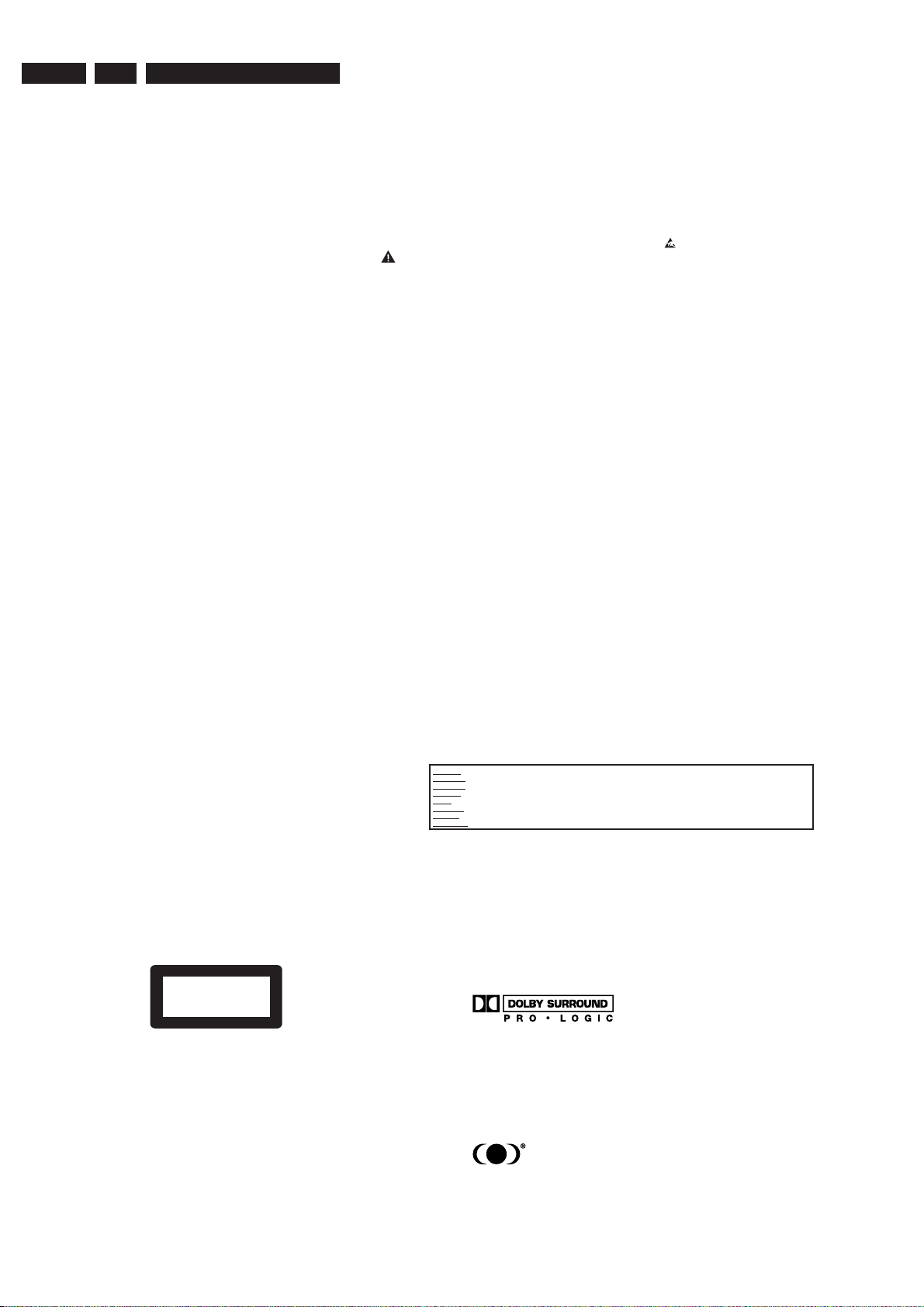

3.

3139 785 31500 Directions For Use

3. Directions For Use

The following except of the Quick Use Guide serves as an introduction to the set.

The Complete Direction for the Use can be downloaded in different languages from the internet site of Philips Customer care Center:

www.p4c.philips.com

Record Quality

Auto Program

Manual Program

SP

Search

Edit

Sort

OK

Auto Chapter Marker

5min.

SETUP MENU - GENERAL

.

Hours of Recording that can be stored

Record Quality

34

68

85

102

136

204

HQ High Quality

SP Standard Play

SP+ Standard Play Plus

LP Long Play

EP Extended Play

SLP Super Long Play

DVDR3360H

160GB HDD

DVDR3370H

250GB HDD

Values are estimates only. Parts of the HDD storage will be reserved for the

operations of this recorder and time shifting.

53

106

132

159

212.5

318

to jump back 10 seconds upon every

Start Recording

Instant Replay

While watching a live TV program, you can press

LEFT

single press for instant replay.

RIGHT

To return to live broadcast, press and hold

A Before recording to hard disk

CH003/P03

Shows TV channel or

video input source

Directions For Use

.

to con rm.

repeatedly until you highlight

mode of recording quality and press OK

You can preset the recording quality for content

recorded to the time shift buffer.

{ Record Quality } and press RIGHT

Press DOWN

Press SETUP on the remote control.

Highlight and press RIGHT .

B

10:15:36 AM

08:30:45 AM

Use UP / DOWN to select the preferred

C

A

time

Current

Time of current

screen playback

TSB

status icon

in playback

or or if you

B Record to hard disk

channel you wish to record.

Press TUNER to switch to tuner mode.

Press CH or to go to the TV program

A

B

,

.

3139 785 31500

10:15:36 AM

LIVE

to display the time shift video bar.

07:15:36 AM

device, press SOURCE repeatedly to cycle

C Press

through video input sources from:

Note To record from a connected external

{ CAM 1 } : VIDEO jack on the front

to continue.

while watching any live TV

3.

EN 7

.

repeatedly to extend 30

to start recording.

to record from a DV camcorder

connected via the DV IN jack on the recorder.

{ CAM 2 } : S-VIDEO jack on the front

{ EXT 1 } : EXT 1 jack on the back

or Press DV

minutes increments per single press.

D Press REC

Note Press REC

E To stop recording, press STOP

Enjoy

3

Set up

Start time

of program

About the Time Shift

Buffer (TSB)

Once you switch on this recorder, the currently

selected TV program will be stored in a temporary

C Initial installation

A Press SETUP on the remote control.

Remote control

(back)

(The TSB in playback mode)

storage called the ‘TSB’ (Time Shift Buffer). The TSB

can store up to 3 hours of recordings temporarily.

Press once to display the Time Shift video bar.

Philips recorder (front panel)

Program stored

07:15:36 AM

.

in TSB

and press OK to proceed.

repeatedly until you highlight

OK

OK

Î A warning message will appear.

DOWN

{ Auto Program - Search } and press OK

Highlight and press RIGHT . Press

Setup and install TV channels.

B

z

Select

z

and press OK to start automatic

OK

CONTINUE

ÎThe automatic TV channel search will start. This

process may take several minutes. Once complete, the

total number of channels found will appear on the TV.

Select

z

.

, DVD REC

Pause ‘live’ TV

switch to another mode: SOURCE

The contents on the time shift buffer will be erased

once you press CH

DV

– select the System Language

– select the Audio Language for DVD disc playback.

antenna connection and start the channel search

again.

TV channel search.

Note If no channels were found, check the

SP

5min.

Record Quality

Auto Chapter Marker

SETUP MENU - GENERAL

– select the Subtitle Language for DVD disc playback.

Highlight and press RIGHT .

Select the language.

C

z

OK

Search

Edit

Auto Program

Manual Program

Sort

To exit, press [SETUP].

At times, you may be interrupted while

– select the Disc Menu Language for DVD disc

playback.

Set the date and time

D

program to suspend it.

watching your favourite program. Now you

can PAUSE it, as if you were in control of the

broadcast.

A Press PAUSE

then press OK to con rm

Highlight and press RIGHT . zUse the numeric keypad 0 - 9 to input the date/time,

Press SETUP to nish installation.

z

E

RIGHT .To jump forward playback, press RIGHT once for every 30 seconds.

B Press PLAY

C To return to live broadcast, press and hold

Your Philips recorder is now ready for use!

2

A Inserting Batteries

* Note where the positive and negative ends go.

STANDBY-ON

B Finding the viewing channel

switched off or in standby mode before

A Press STANDBY-ON on the recorder

proceeding.

B Switch on the TV.

Note If connected to your VCR, make sure it is

then press the Channel Down button

repeatedly until you see the { SETUP

MENU - GENERAL } page. This is the

correct viewing channel for the recorder.

D Press ‘0’ on the TV’s remote control,

C Press SETUP

on the TV’s remote control (if available) to select

the correct viewing channel. See your TV’s user

manual.

Note You may press the AV or SELECT button

EN 8

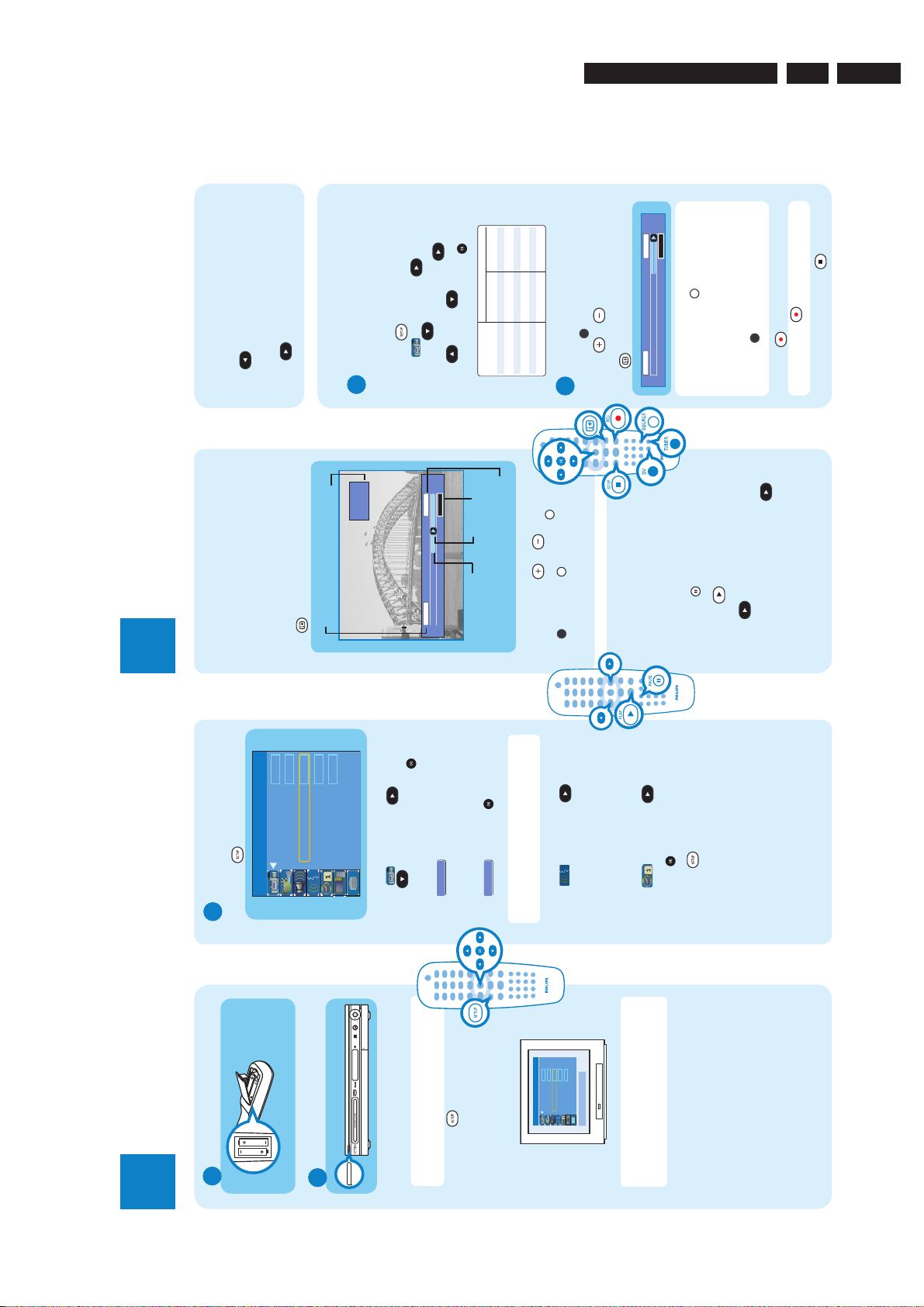

3. My movie

05 / 08 / 2005

09 : 31 : 53 AM

SP 00 : 06 : 45

2. Nature

09 / 07 / 2005

15 : 30 : 45 PM

SP+ 00 : 05 : 59

1. Sports

11 / 05 / 2005

12 : 31 : 53 PM

SP 00 : 03 : 00

Empty

DVDR3360H_QSG_eng-final.indd 1 2005-10-17 4:18:16 PM

3.

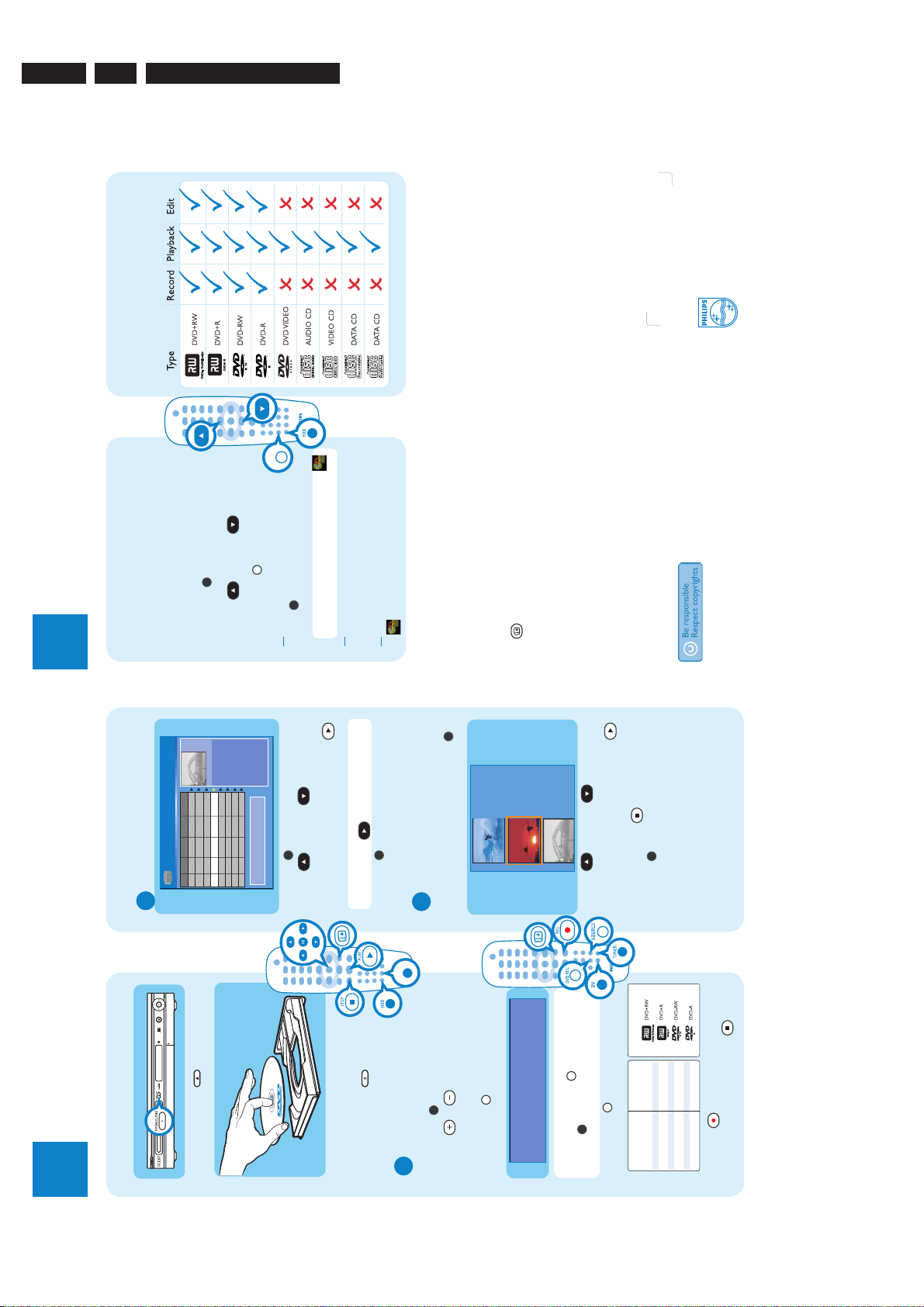

Types of discs used on

3139 785 31500

this recorder

Directions For Use

2005 © Koninklijke Philips N.V.

All rights reserved.

12 NC 3139 246 18191

www.philips.com

Enjoy

3

disk.

1. Press [SELECT] to

mark or unmark

Travel

News

08.30

03.30

30/04/05

28/03/05

CH008

CH002

004

005

recordings.

Title 3

11.00

12/04/05

CH008

006

or DOWN to select the

title.

C Press UP

copy selected

recordings to DVD.

2. Press [HDD] to

News

Discover

09.30

22.30

07/04/05

23/07/05

CH002

CH011

007

008

to mark the titles you

D Press SELECT

Press [SHUFFLE] to

sort by title.

For other options, press [DVD], [DV],

[TUNER] keys. Press [RIGHT] to edit menu.

to view the titles on the hard

Copying to a DVD

Start playback

Insert a recordable DVD disc.

recordable disc

You can copy the contents in your hard disk to a

DVD recordable disc.

A

B Press HDD

00:20:20

SP NTSC

Drama

News

Nature

Title

16.30

14.00

14.00

Date Time

14/05/05

20/05/05

25/04/05

HDD

CH003

CH009

Ch.

001 CH001

002

003

No

A Playback from hard disk

SELECT

wish to copy.

DVD disc.

will be shown on the screen.

HDD to start copying to the recordable

Once you nish your selection, press

E

programs in tuner mode or select another HDD

During copying, you can continue watching TV

Note When copying is in progress, the icon

F

or DOWN to select the

to start playback.

title.

A Press HDD to view the titles on the hard disk.

B Press UP

Note To access the edit menu, highlight the title

C Highlight the title you want and press PLAY

will no longer be shown.

title for playback.

Once the copying process completes, the icon

G

Need help?

Onscreen Helptext

.

to go back to the disc menu

B Playback from a disc

anytime.

and press RIGHT

D Press HDD

If the disc menu does not show, press DVD to

view the list of titles on the disc.

A Insert a CD or DVD disc.

when using your Philips recorder.

Press on the remote control for onscreen helptext

User Manual

See the user manual that came with your Philips recorder.

Online

Go to www.philips.com/support.

the list of options and/or titles.

to start playback.

C Highlight the title you want and press PLAY

B Press UP or DOWN to scroll through

.

the accompanying User Manual.

anytime.

For more recording and playback options, see

E Press DVD to go back to the disc menu

D To stop, press STOP

Enjoy

3

Inserting discs

Philips recorder (front panel)

recorder.

A Press OPEN CLOSE on the front of the

DVD

again to close

the tray.

facing up.

B Place a DVD disc in the tray with the label

C Record to a DVD

C Press OPEN CLOSE

channel you wish to record.

recordable disc

Insert a recordable DVD disc.

Press CH or to go to the TV program

B

C

A Press TUNER to switch to tuner mode.

repeatedly OR

to switch to direct record

Elapsed Time: 00:00:00 Remaining Time: 02:25:25

System State: Stop

Record to Optical Disc As Standard Play

Press DVD REC

mode and display the information bar.

press DV to record from a DV camcorder

connected via the DV IN jack on the recorder.

device, press SOURCE

Note To record from a connected external

Types of discs for recording

1

2

346

2.5

4.7 GB

repeatedly to select the

DVD±R/±RW disc

that can be stored

Hours of Recording

Record Quality

High Quality HQ

Standard Play SP

Standard Play Plus SP+

Long Play LP

Extended Play EP

preferred mode of recording quality.

D Press SELECT

Super Long Play SLP

E Press REC to start recording.

.

F To stop the recording, press STOP

4. Mechanical Instructions

Mechanical Instructions

3139 785 31500

4.

EN 9

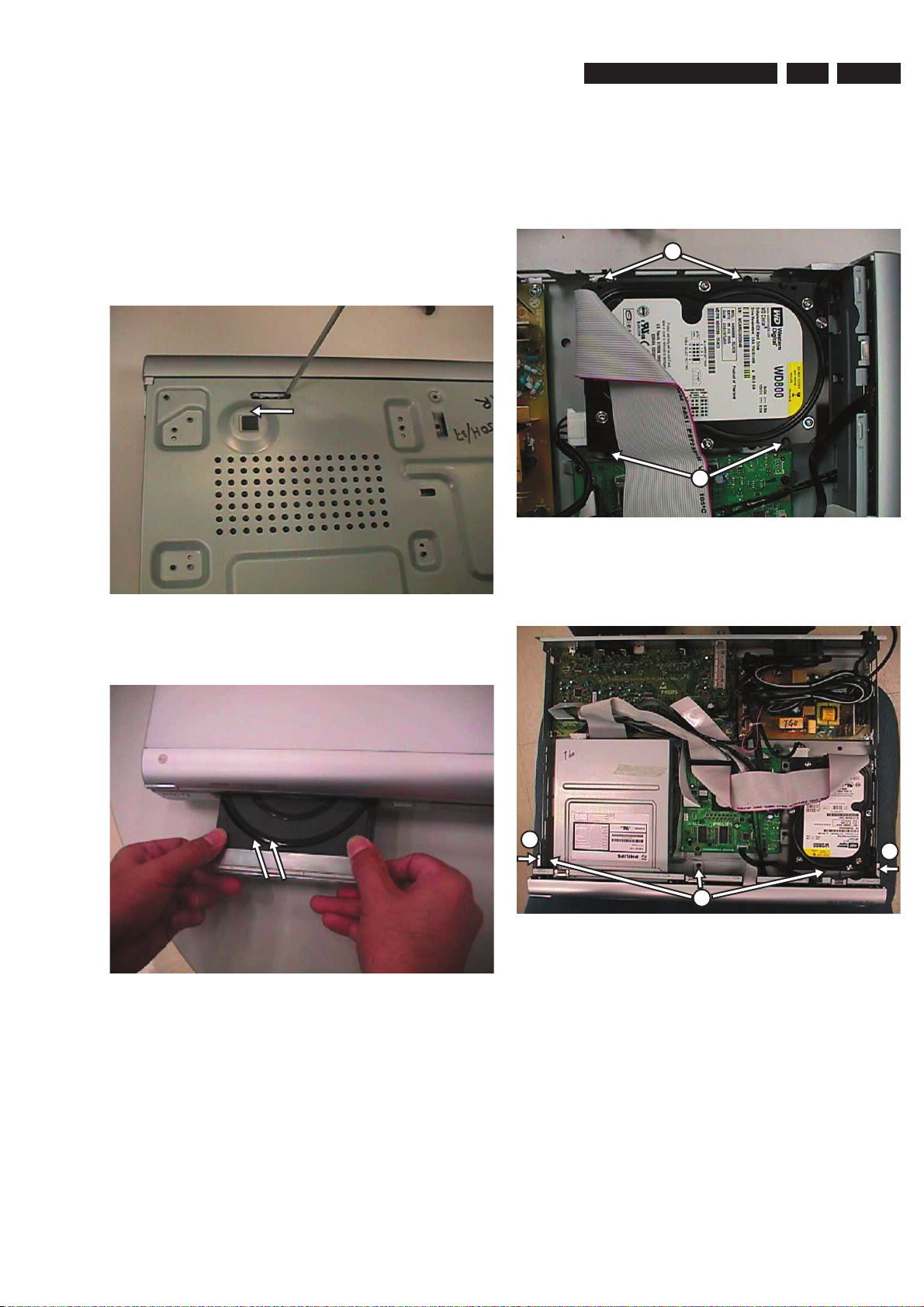

4.1 Dismantling and Assembly of the Set

For item numbers please see the exploded view in Chapter 9.

4.1.1 Dismantling of the DVD Loader Tray Cover

1) Inserting a minus screw driver and push the lever in the

direction as shown in Figure 4-1 to unlock the tray before

sliding it out.

Figure 4-1

4.1.2 Dismantling of the Hard-Disk Drive & Front Panel

Assembly

1) Remove the 4 screws from the Hard-Disk Drive.

1

1

Figure 4-3

2) Remove the 3 screws and release the 2 snap hooks on

the side before removing the front assembly.

2) Remove the Tray Cover as shown in Figure 4-2.

Figure 4-2

2

2

Figure 4-4

2

EN 10

4.

3139 785 31500 Mechanical Instructions

3) Remove the 6 screws to remove the front plate 184

as shown in Figure 4-5.

3

Figure 4-5

4.1.3 Dismantling of the Basic Engine

1) Remove the Cover Tray (See 4.1.1).

2) Remove the 4 screws to free the Basic Engine.

3) Place the Basic Engine in the service position by fl ipping

the basic engine to the vertical position.

3

Figure 4-7

4.1.4 Dismantling of the Digital Board

1) Remove the 4 screws to loose the Digital Board as shown

in Figure 4-8.

4

Figure 4-6

5

5

Figure 4-8

Mechanical Instructions

3139 785 31500

4.

EN 11

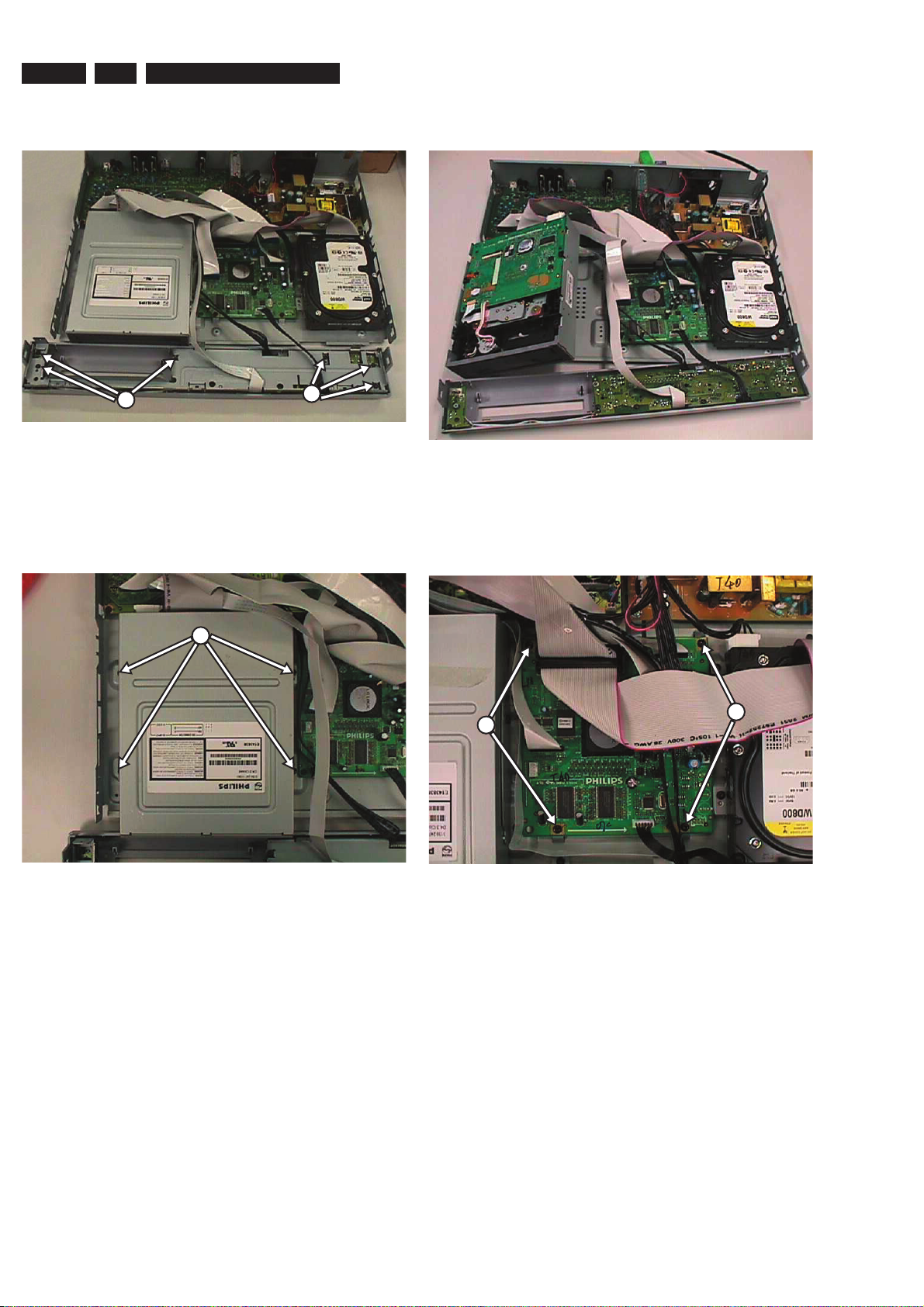

2) Service Position can be achieved by fl ipping the Digital

board to the Vertical Position as shown in Figure 4-9.

Figure 4-9

Note: The cable (just to transfer the service connection to the

MOBO board) from socket 1101 can be removed and use for

hyper terminal connection.

4.1.5 Dismantling of the Analog Board

3) Service Position can be achieved by fl ipping the Analog

board to the Vertical Position as shown in Figure 4-10.

Figure 4-12

1) Remove 5 screws 246 and 4 screws 254 and screw 230.

6

7

Figure 4-10

2) Remove 3 screws 270 and release 2 catches on the

board.

8

9

Figure 4-11

EN 12

5.

3139 785 31500

Upgrade Software & Repair Chart

5. Firmware upgrading and HDD Formatting

Important Instructions

• Each of the 3 Upgrade procedures has to be recorded into 3 separate discs.

• The FLASH fi rmware and HDD fi rmware must be matched (i.e. Same version no.)

• FLASH fi rmware upgrading must be done before HDD fi rmware upgrading.

5.1 Firmware Upgrading

A. Preparation to upgrade fi rmware:

1. Unzip the zip-archive fi le

2. Start the CD Burning software and create a new CD project (data disc) with the following settings:

File system: Joliet

Format: MODE 1: CDROM

Recording mode: SINGLE SESSION (TRACK-AT-ONCE), FINALIZED CD

Note: Long fi le name is necessary for the preparation of the upgrade disc

3. Place the content of the zip-archive into the root directory of the new CD project.

4. Burn the data onto a blank CDR or CD-RW

B. Procedure to apply the FLASH fi rmware upgrade:

1. Power up the set and open tray.

2. Insert the prepared Upgrade CDROM and close the tray,

3. The TV connected to the set will display:

Software Upgrade Disc detected

Select OK to start or CANCEL to exit

4. Press <OK> button to confi rm upgrading (use left/right button for selection)

5. The TV connected to the set will display:

Upgrading Software, Please wait

Do not switch off the power

The whole process takes less than 5 minutes.

Note: Do not press any button or interrupt the mains supply during the upgrading process, otherwise the set may becomes defective

6. When the upgrading process is successful the tray will open and the TV connected to the set will display:

System is successfully upgraded.

Remove disc from tray & reset system

7. Remove the Upgrade Disc and press <OK> button to confi rm

8. The TV screen goes blank, tray close and after a while the Philips Logo screen appear again.

C. Procedure to apply the HDD fi rmware upgrade:

1. Power up the set and open tray.

2. Insert the prepared Upgrade CDROM and close the tray,

3. The TV connected to the set will display:

Software Upgrade Disc detected

Select OK to start or CANCEL to exit

4. Press <OK> button to confi rm upgrading (use left/right button for selection)

5. The TV connected to the set will display:

Upgrading Software, Please wait

Do not switch off the power

The whole process takes less than 5 minutes.

Note: Do not press any button or interrupt the mains supply during the upgrading process, otherwise the set may becomes defective

6. When the upgrading process is successful the tray will open and the TV connected to the set will display:

System is successfully upgraded.

Remove disc from tray & reset system

5.

Upgrade Software & Repair Chart

7. Remove the Upgrade Disc and press <OK> button to confi rm.

8. The TV screen goes blank, tray close and after a while the Philips Logo screen appear again.

9. Press <Tuner> and <Setup>.

10. In “SETUP MENU – HDD”, select “Delete HDD” and press <OK>

11. The TV connected to the set will display:

All video programs on the HDD will be deleted

Press OK to continue.

12. Press <OK> button to confi rm deleting. (Use the left/right button for selection)

The whole process takes less than 15 minutes.

Note: Do not press any button or interrupt the mains supply during the upgrading process, otherwise the set may becomes defective.

13. When the upgrading process is successful, the set will go into Standby Mode.

Note: All existing channels will be lost.

3139 785 31500

EN 13

D. Procedure to apply the SERVO fi rmware upgrade:

1. Power up the set and open tray.

2. Insert the prepared Upgrade CDROM and close the tray,

3. The TV connected to the set will display:

Software Upgrade Disc detected

Select OK to start or CANCEL to exit

4. Press <OK> button to confi rm upgrading (use left/right button for selection)

5. The TV connected to the set will display:

Upgrading Software, Please wait

Do not switch off the power

The whole process takes less than 15 minutes.

Note: Do not press any button or interrupt the mains supply during the upgrading process, otherwise the set may becomes defective

6. When the upgrading process is successful the tray will open and the TV connected to the set will display:

Loader upgrade process has completed successfully.

Press OK to reboot the system.

7. Remove the Upgrade Disc and press <OK> button to confi rm

8. The TV screen goes blank, tray close and after a while the Philips Logo screen appear again.

E. How to read out the fi rmware version to confi rm upgrading.

1. Power up the set and press <SETUP>.

2. Press <321> and <SELECT> buttons on the remote control.

3. Press <OK> to exit.

5.2 Procedure for replacing a new HDD:

1. Replace the faulty HDD with a new HDD.

2. Power up the set and open tray.

3. Insert HDD fi rmware upgrade disc and follow “Procedure to apply the HDD fi rmware upgrade” (See 5.1 C).

The whole process takes less than 15 minutes.

Note: Do not press any button or interrupt the mains supply during the upgrading process, otherwise the set may becomes defective.

4. When the HDD upgrading process is successful, the set will go into Standby Mode.

5. To upgrade the set, follow Firmware Upgrading. (See 5.1)

EN 14

5.

3139 785 31500

Upgrade Software & Repair Chart

NOTES:

1. For references to voltage levels, NOK represents voltage measurements that are outside the range of +-10% of specifi ed

values

2. For references to soldering touch ups and replacing components, OK means the set no longer shows the problem and is

working fi ne. NOK means the problem still exists.

3. For references to square pulses,

OK – signal shape resembles a square, with peak to peak voltage level of 3.3V +-10%

NOK – means if the measurement is out the specifi cation stated in the OK condition above

4. For references to sine waves,

OK – signal shape resembles a sine wave, with peak to peak voltage level of 5.6V +-10% (note that this voltage level is

obtained by using a 0dB test signal.

NOK – means if the measurement is out the specifi cation stated in the OK condition above

5. For references to video waveforms,

OK – the measured waveforms resembles (shape and voltage level +-10%) their respective waveforms under the

WAVEFORM section.

NOK – if the waveforms do not match (shape and voltage level +-10%) the waveforms in the WAVEFORM section OR if

there are no waveforms at all.

REMINDER: For points 3 – 5, please refer to the WAVEFORM section as a guideline.

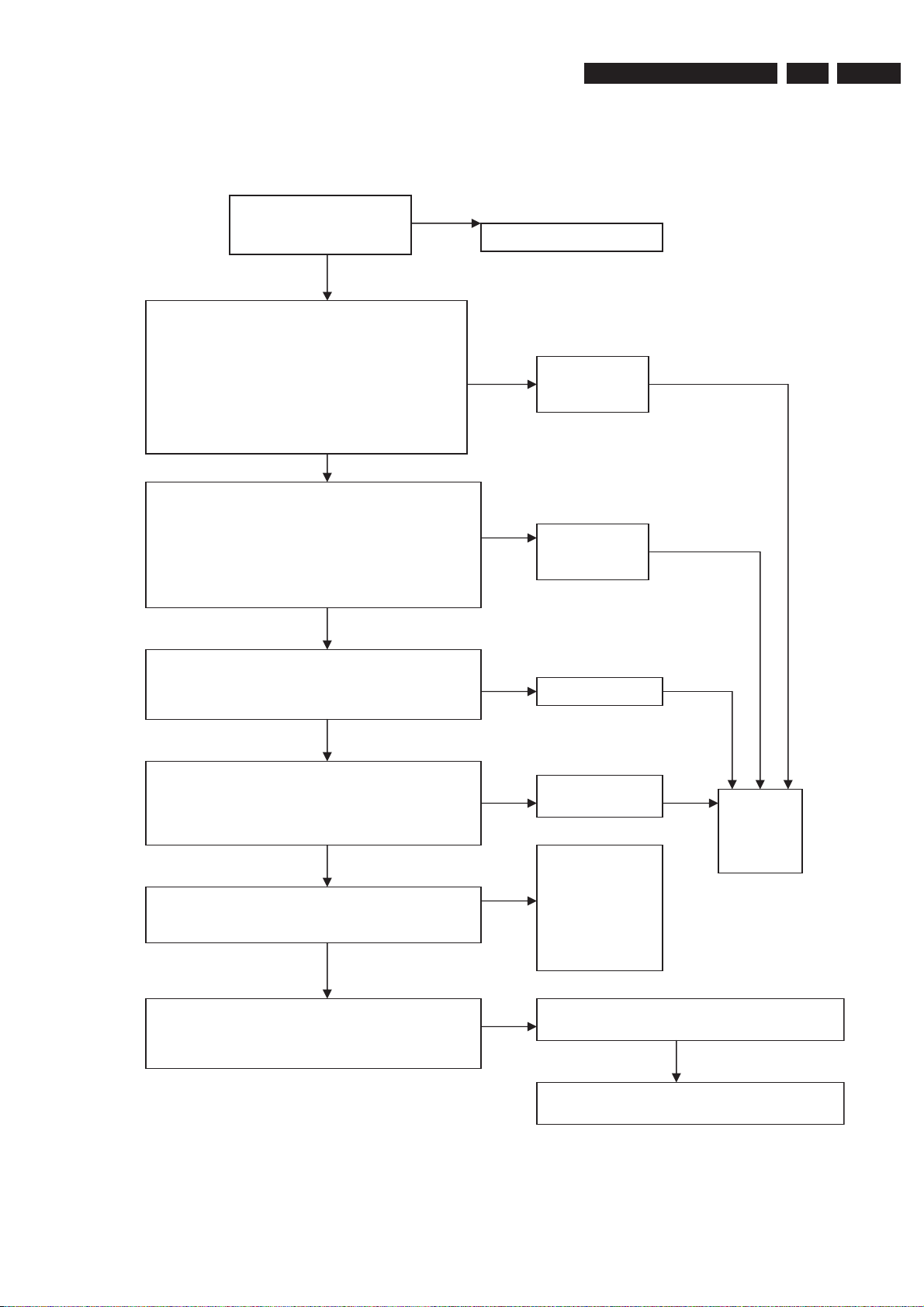

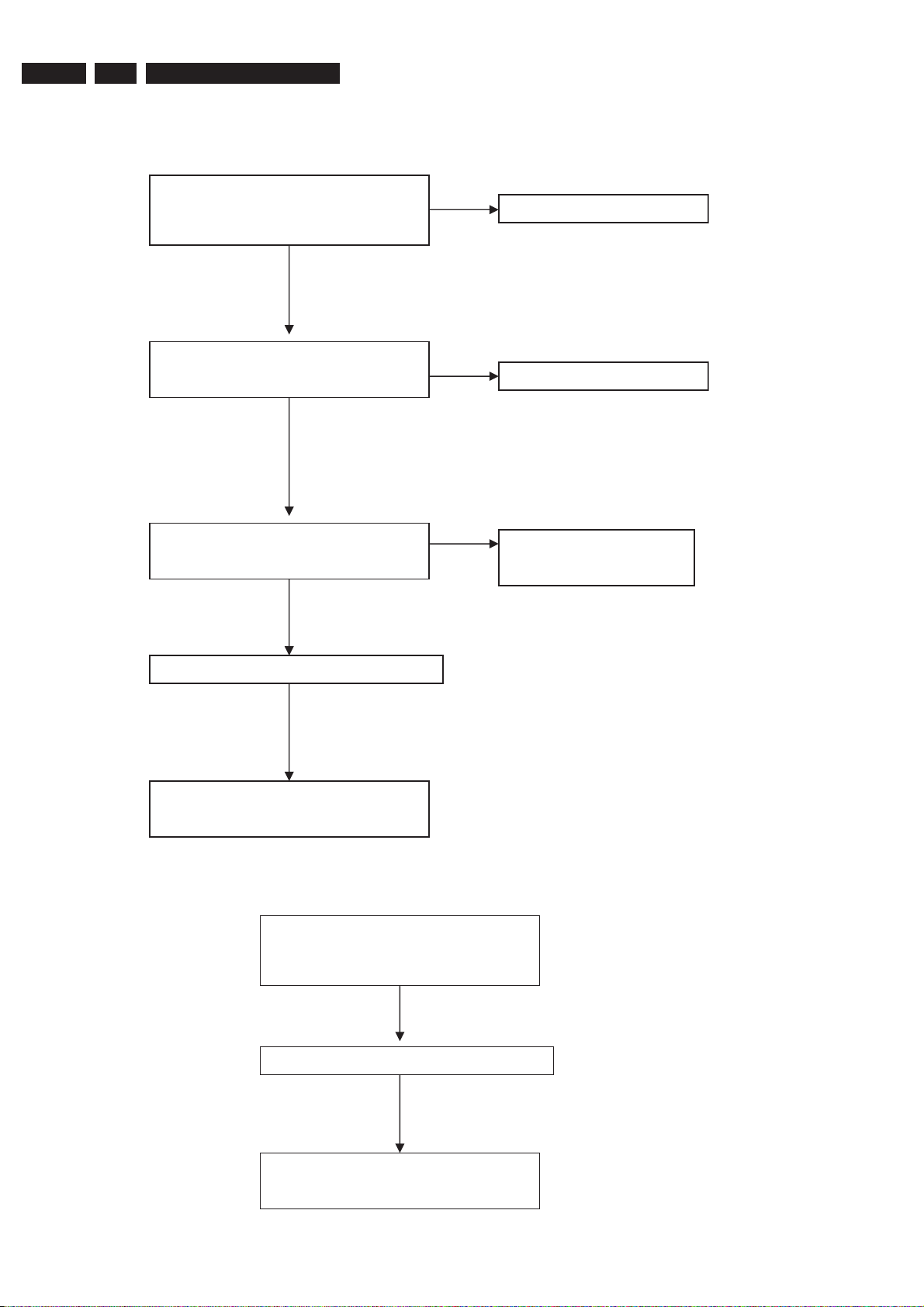

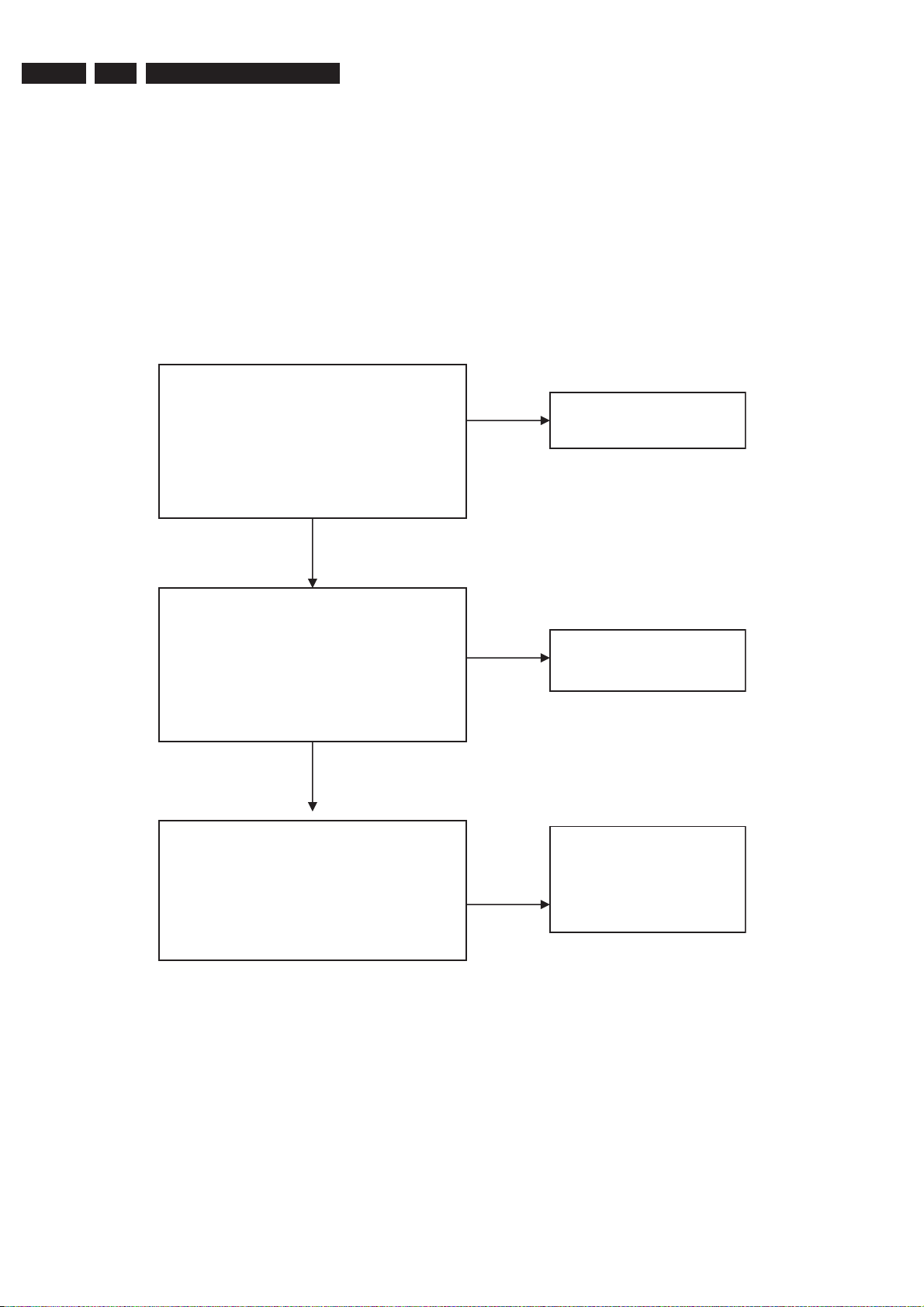

5.3 Repair Chart

f

)

)

K

K

K

N

NOK

NOK

NOK

NOK

NOK

NOK

NOK

NOK

K

NOK

NOK

5.3.1 Completely Dead Set

Check all cable connections

for visible disconnections

or loose connections

Check Voltage at Digital Board Connector 1501

Check Voltage at Analog Board Connector 1400

Pin 7 = -5.00v

Upgrade Software & Repair Chart

o visible problems with

Pin 1=3.30v

Pin 2 =3.30v

Pin 3 =3.30v

Pin 4 =3.30v

Pin 6 =12.00v

Pin 9 =5.00v

Pin 12 =-5.00v

O

Pin 1 = 12.00v

Pin 3 = 5.00 v

Pin 5 = 3.30v

Pin 9 = 32.00v

Pin 11 = -26.00v

Visible problems with

connections

Fix the cable connections

3139 785 31500

Replace Digital

Board

Replace

Analog Board

5.

EN 15

O

Check Voltage at PSU Connector J5

Pin 1 = 12.00v

Pin 4 = 5.00v

O

Check voltage at Analog Board Connector 1803

Pin 10 = 5.00v

Pin 13 = -26.00v

Pin 14 = 12.00v

OK

Check Voltage at PSU Connector J6

Pin 1 = 12.00v

Pin 4 = 5 00v

O

Touch up soldering on SDRAM (item 7211 & 7231 on

Digital Board)

Replace Drive

Replace Front

Panel

Replace

Power

Supply

Replace Hard

Unit

Disk (After

replacing Hard

Disk, reinstall the

Software for the

Hard Disk

portion)

Replace SDRAM (item 7211 & 7231 on Digital

Board

Replace Hard Disk (After replacing Hard Disk,

reinstall the So

tware for the Hard Disk portion

EN 16

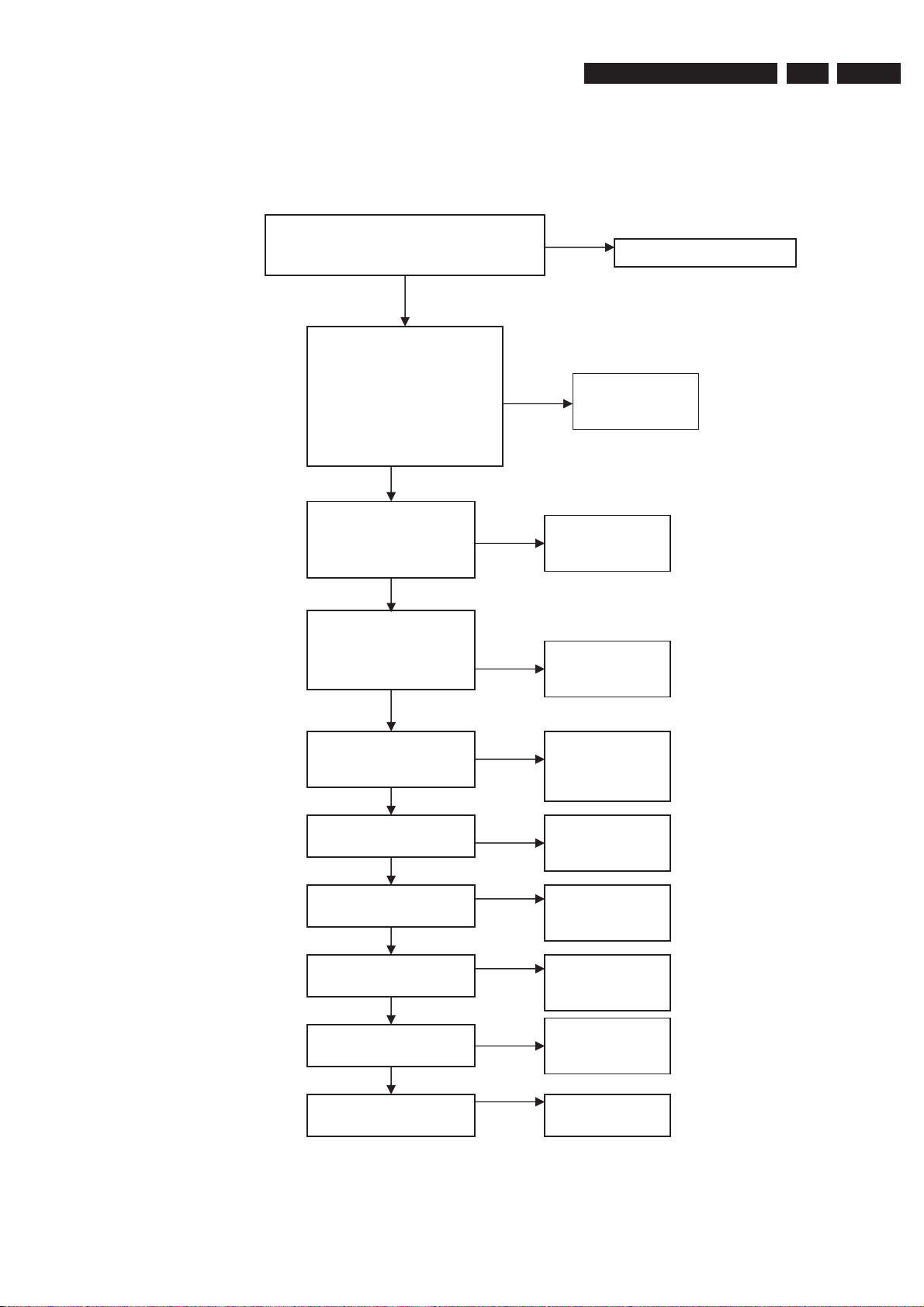

5.3.2 Cannot Read Disk

5.

3139 785 31500

Upgrade Software & Repair Chart

Check supply cable from PSU Connector J5

to Drive 4 pin connector for visible

disconnections or loose connections

No visible problems with

connections

Check cable connection from Digital board

connector 1571 to Drive 40 pin connector for

visible disconnections or loose connections

No visible problems

with connections

Visible problems with

connections

Fix the cable connection

Visible problems with

connections

Fix the cable connection

5.3.3 Disk Unknown

Check Voltage at PSU Connector D

Pin 1 = 12.00v

Pin 4 = 5 00v

OK

Replace Power Supply cable from PSU to Drive

NOK

Replace Loader

Check cable connection:

Supply cable from PSU Connector D to

Drive 4 pin connector

NOK

Replace PSU

OK

Replace Power Supply cable from PSU to Drive

OK

Replace Loader

5.

KOKOKOK

NOK

KOKOK

5.3.4 Audio No Sound (Playback)

Upgrade Software & Repair Chart

3139 785 31500

NOTE1: To start debugging this section, playback in repeat mode a 1kHz 0dB sine wave from a test CD

NOTE2: All references are to Analog Board unless otherwise specified

Visible problems with

Check cables on connector 1600 and 1400

on analog board for visible disconnections or

loose connections

No visible problems

with connections

Check Voltage at Connector

1400 (Analog Board)

Pin 1 = 12.00v

Pin 3 = 5.00 v

Pin 5 = 3.30v

Pin 7 = -5.00v

Pin 9 = 32.00v

Pin 11 = -26.00v

OK

connections

Fix the cable connections

Replace Analog

Board

NOK

EN 17

Check Test Point

I613 = 11.2V –12V

I624 = 3.3V

I615 = high

O

Check Test Points on

Analog Board

I603, I604, I605, I609 =

square pulse

Monitor Test Point

I618 & I620 = 1KHz

2Vrms Sine Wave

Monitor Test Point

I616 & I617 = 3.3V

Monitor Test Point

I600 = -5V

(high)

O

Replace Analog

Board

NOK

Replace Digital

Board

Change Audio

DAC, item 7603

on Analog Board

Change Audio

DAC, item 7603

on Analog Board

Change transistor

item 7600

Monitor Test Point

F603 = <0.6V

(low)

Monitor Test Point

I601 = 5V

(high)

Monitor Test Point

F408 = 5V

(high)

Change Digital

Board

Change transistor

item 7602

Change PSU

EN 18

K

K

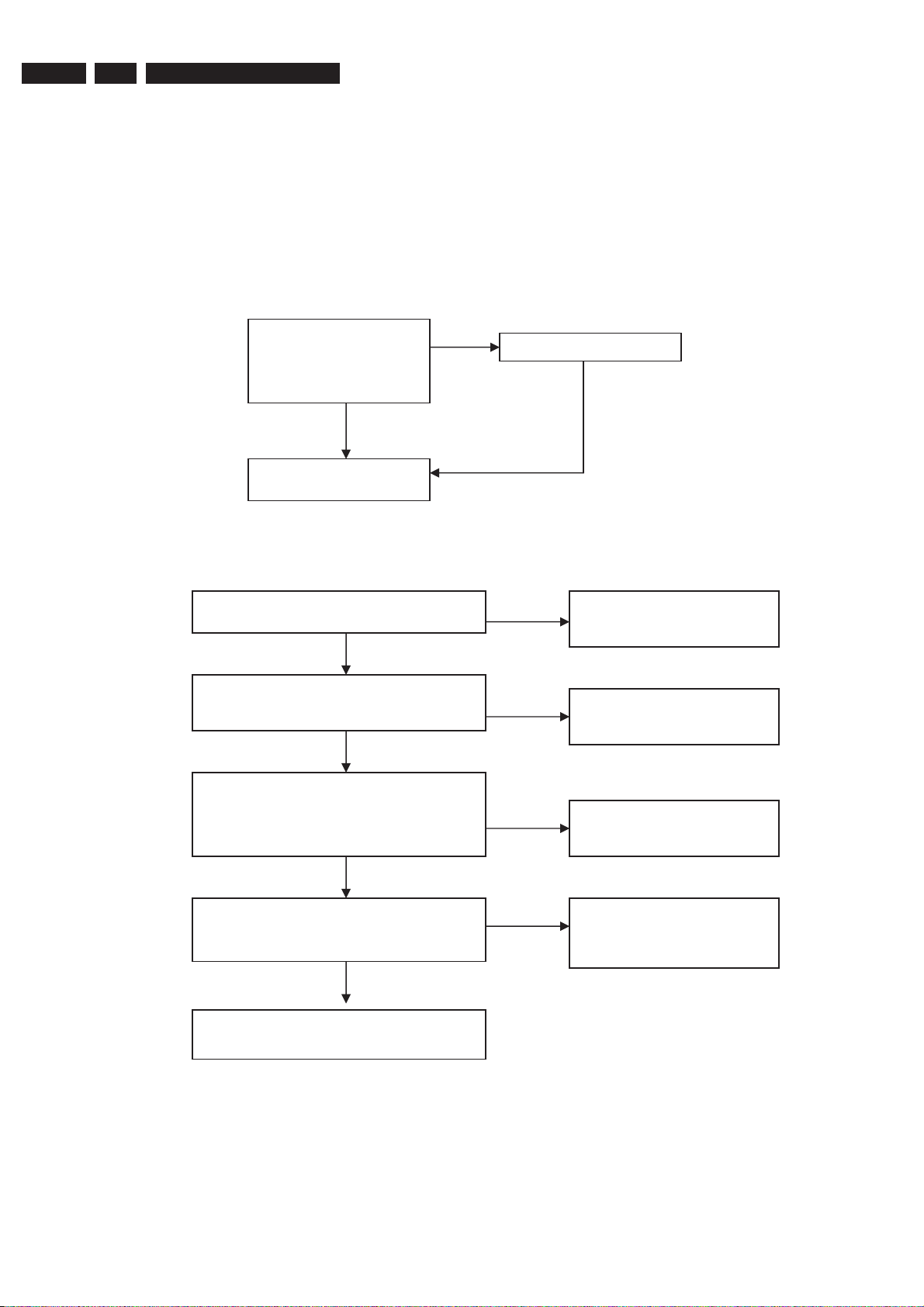

5.3.5 Audio No Sound (TV & External Source)

5.

3139 785 31500

Upgrade Software & Repair Chart

NOTE1: To start debugging this section, playback a 0dB 1kHz sine wave from a test

disc on the external source which exhibits the problem.

NOTE2: All references are to Analog Board unless otherwise specified

Visible problems with

connections

Part 1

Check connections on

connector 1600 and 1204

for visible disconnections

or loose connections

No visible problems with

connections

Go to Part1 and then Part2

Check supply voltage

I614 = 3.3V

OK

Check Test Point

SYSCLK I608 = square pulse 12.28MHz

F609, F610, F611 = square Pulse

OK

Fix the cable connections

NOK

NOK

NOK

Change ADC

Replace Digital Board

Check control line

I612 = 0V (low)

I611 = 1.7 V

I610 = 1.6V

O

Check I316 & I319 = sine wave

&

Check I606 & I607= sine wave

O

Replace Analog Board

NOK

NOK

Change ADC

Replace the component in

between these 2 test point (Op

Amp 7300)

Part 2

d

Upgrade Software & Repair Chart

Check I310 & I311

Verify against Truth Table below

OK

IF MDX 7301 pin 3 & 13 = no sine wave

Verify Input of MDX 7301

I300, I301, I312, I313

I314, I315, I303, I305

NOK

3139 785 31500

Check MSP (7500) Xtal at I509 =

18.432MHz

Check Supply voltage at

F420 = 8V

I508 = 5V

I515 = 5V

OK

I503 = 4.5MHz 300~500mVpp Sine wave

5.

EN 19

OK

Change Analog Boar

Pin9 Pin10 Source

0 0 RF tuner audio

0 1 Front Audio in

1 0 Rear audio in

1 1 Rear audio in 2

OK

Touch up joint

OR

Replace IC MSP (7500)

Truth Table

(provision)

EN 20

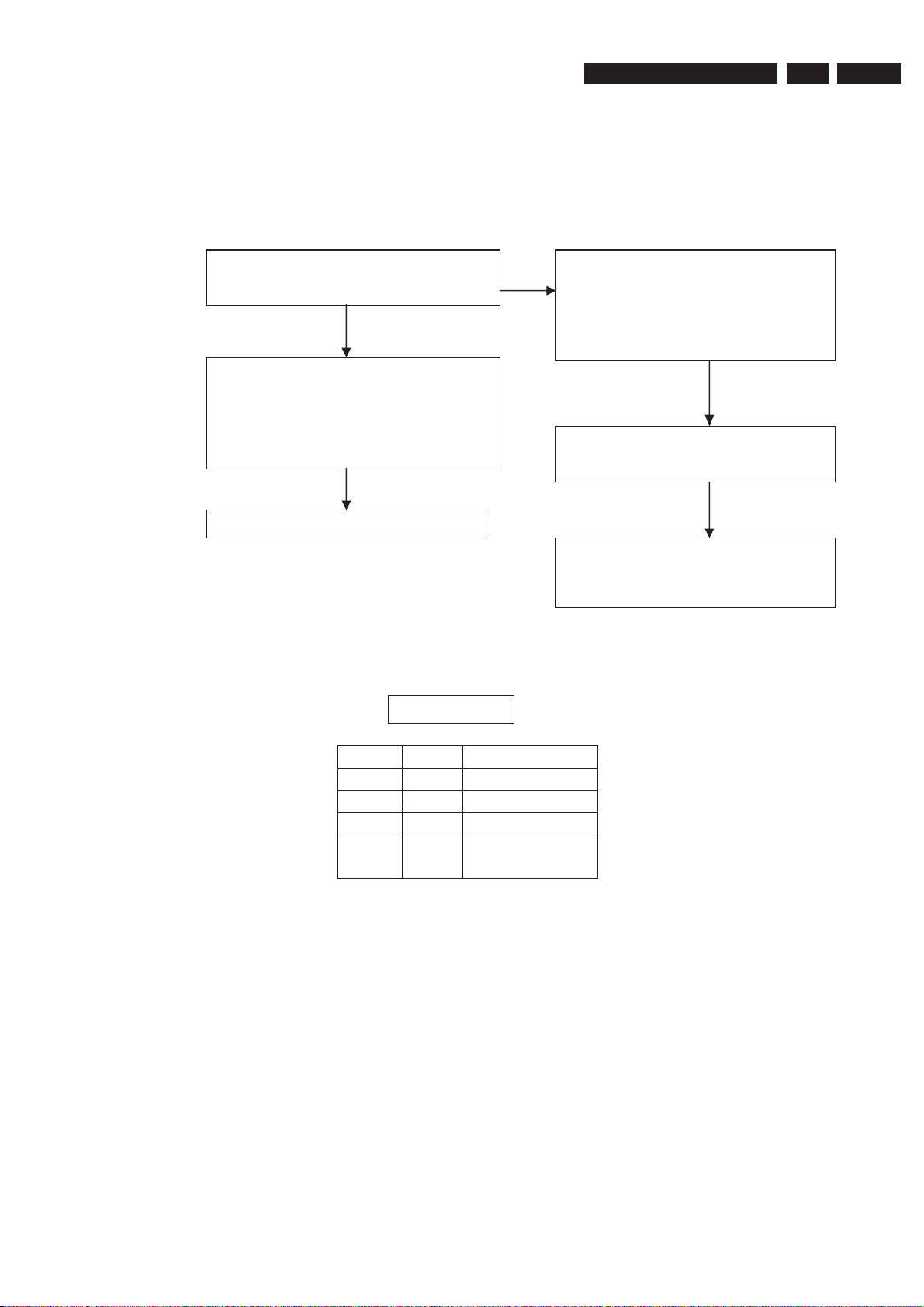

5.3.6 No Video Out Upon Power ON (Assume set is not dead)

5.

3139 785 31500

Upgrade Software & Repair Chart

NOTE: To verify that the set is not dead, you should be able to do the following.

1. See on the Front Display the words “Ch001” after the required boot up time has

elapsed

2. Eject the tray and Close the tray

NOTE2: To debug this section, playback a 75% Color Bar title

Check Digital Board Waveform at testpoints

CVBS T524

Y T522

C T523

GY T520

BPb T518

RPr T521

OK

Check Analog Board waveform at testpoints

CVBS F235

C F236

Y F237

D-VR F238

D_YG F239

D_UB F240

OK

NOK

Replace Digital Board

NOK

Replace FFC cable on

connector 1205 (analog board)

Check Analog Board waveform at test points

D_YG F213

D_UB F214

D_VR F215

Y F219

C F220

CVBS F222

NOK

Replace corresponding

transistors (7200, 7201, 7202,

7203, 7204, 7205)

5.3.7 No Video In Only

NOK

oard

N

N

d

N

NOK

NOK

NOTE1: All references are to Digital Board unless otherwise specified

NOTE2: For problem with Rear Video Input, refer to Section1. For problem with

Front Video Input, go to Section2.

Upgrade Software & Repair Chart

Section2Section1

3139 785 31500

5.

EN 21

D

Visible loose

Check FFC cable on

connector 1521 for loose

connection

o visible loose

connections

Check for cracks on the

Analog Board PCB (near

cinch connector 1207

o visible cracks

on PCB

Go to D Go to D

connections

Fix the loose

connection

Visible cracks on

PCB

Replace Analog

Boar

Check Clock At

T461 & T462 = 14.318MHz

Check FFC cable on

connector 1204 on Analog

Board for loose connections

o visible loose

connections

Replace Front Panel

NOK

Visible loose

connections

Fix the loose

connection

Replace Crystal 1461

Check respective i/p

test point

of video in at analog

board

NOK

Replace Analog

B

OK

OK

Check Video Input for waveform

T525, T526, T527, T528, T529, T530, T531,

T532 T533 T535

OK

Replace VIP (7401) IC

NOK

Replace Digital Board

EN 22

r

5.3.8 Tuner Not Functioning

5.

NOTE: All references are to Analog Board

3139 785 31500

Upgrade Software & Repair Chart

Check for visible cracks on PCB at the areas near

to the Tune

OK

Check Voltage at testpoints

I119 = 33V

F101 = 5V

OK

Check I100 & I102 On I2C

OK

Direct access tuner to any channel.

If there are video and no audio then check MSP

Xtal (item 1500) for Clock at 18.432MHz

NOK

NOK

NOK

NOK

Replace Analog Board

Replace PSU

Replace Tuner

Replace MSP Xtal (item 1500)

OK

Replace Tuner

EN 23

3139 785 31500

6.

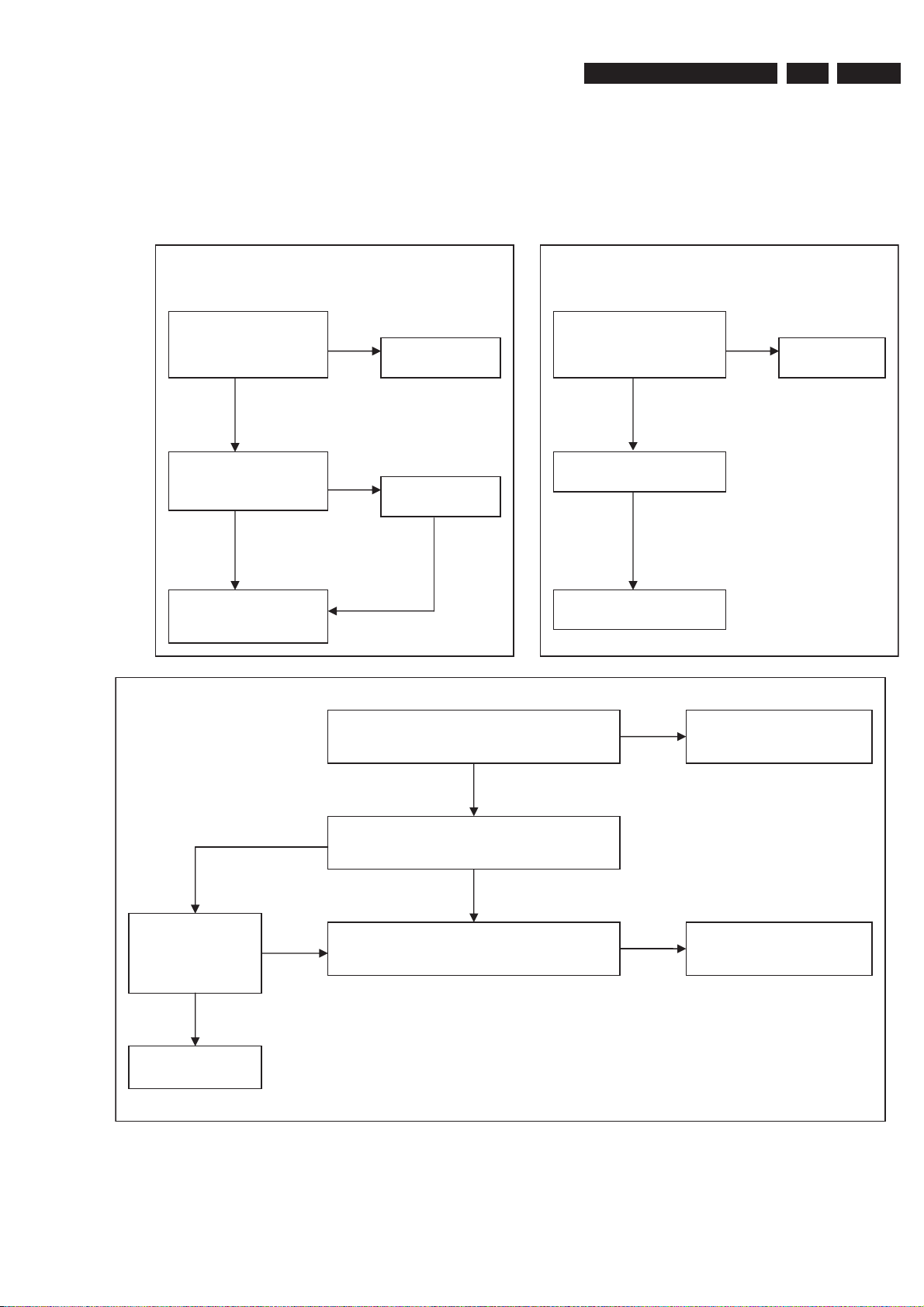

6. Block Diagrams, Waveforms, Wiring Diagram

Block Diagrams, Waveforms, Wiring Diagram.

Overall Block Diagram of the Set

Front Keyboards

Digital Video

Input IEEE1394

CVBS-YUV-Y/C

AUDIO PCM I2S

A_BCLK

A_WCLK

A_DATA

SPDIF_OUT

D_KILL

AUDIO ENCODER I2S

YUV-YC-CVBS

ANALOG AUDIO / VIDEO

D_CVBS

D_C

D_Y

D_V

D_Y1

D_U

A_V

A_U

A_Y

A_C

TUNER

INPUT/OUTPUT

PROCESSING &

SOURCE

SELECTION

ANALOG BOARD

F439

F440

F441

F442

F443

F444

2

1

AFCRI

AFCLI

CVBSFIN

CFIN

YFIN

3

4

5

7

9

1922

1201

1512

1204

1205

1600

1536

S-VIDEO

CVBS

AUDIO R

AUDIO L

AINFR

AINFL

CVBSFIN

CFIN

YFIN

ADC

7

9

11

12

13

14

15

12

14

16

18

20

22

DDRAM

FLASH

VIDEO INPUT

PROCESSING

DIGITAL AUDIO

RS2321671

SERVICE

1111

1522

1551

DIG.VIDEO

21

20

18

2

16

7

1

3

5

7

9

S-VIDEO

CVBS

RF IN - ANTENNA

RF OUT - TV

PHY

F438

DIGITAL AUDIO OUT

DOMINO DMN-8652

MPEG 2, AC3 CODEC

EEPROM

DIGITAL AUDIO

I2C

A_PCMCLK

A_xCLK

BUFFER

A_YCVBS

DA C

D_DATA0

D_WCLK

D_BCLK

9

11

12

14

D_PCMCLK

D_xCLK

ANALOG VIDEO

1800

CONTROL LINES

CONTR

OL LINES SCK,D_FM,D_HOST,RDY_FM,ATN_FM,HOST_RESET

IDE BUS

FAN

1804

6

IDE BUS

IN-EXT

OUT2

OUT1

DVD+RW ENGINE D4.3

TRAY CONTROL

SERVO

READ

WRITE

DISC

HARD DISK

POWER SUPPLY UNIT

40

40

LASER

1600-1

1571

AUDIO L/R

Y

Pb

Pr

AUDIO L/R

CVBS

AUDIO L/R

CONTROL LINES, AND SUPPLY LINES

1803

(LOOP THROUGH)

CONTROL UNIT SLAVE

MICROPROCESSOR

UPD 16316GB-006

For Digital Video version only

(OPTION)

DIGITAL BOARD

IDE BUS

+12V

GND

GND

+5V

+12V

GND

GND

+5V

IDE BUS

12VSTBY

STBY

5VSTBY

DD_ON

3V3STBY

IPFAIL

5NSTBY

GND

33VSTBY

GND

VGNSTBY

1

11

1400

12VSTBY

STBY

5VSTBY

DD_ON

3V3STBY

IPFAIL

5NSTBY

GND

33VSTBY

GND

VGNSTBY

1

11

CON A

3V3

3V3

3V3

3V3

GND

12V

GND

GND5VHDDSW

GND

NC

1

12

1501

3V3

3V3

3V3

3V3

GND

12V

GND

GND

5V

HDDSW

GND

NC

1

12

CON B

+12V

GND

GND

+5V

CON G

+12V

GND

GND

+5V

CON D

EN 24

3139 785 31500

6.Block Diagrams, Waveforms, Wiring Diagram.

Control Block Diagram Analog Board

Frontend

Tuner

I2C Bus

Level Shifter

NEC uPD-16316GBT

Audio Switches

HEF4052B

Fan

>=1

Reset

Multi Sound

Processor

MSP34x5

ADC / DAC

>=1

KILL

Supply

VFT

Display

Power

Supply

RC

Front

Keys

DIGITAL BOARD

DVDR

I2S

D_KILL_N

IDE0

Hard Disk

IDE1

HOST_Reset

I2C

5V

INT

I2C

3V3

Reset

5VSTBY

AFC

2

2

2

1

1

35

STBY

IPFAIL

AKILL

MUTE

RSA1,RSA2

FRONT Board

FAN_CTRL

Front Panel Processor

Control Block Diagram

EN 25

3139 785 31500

6.

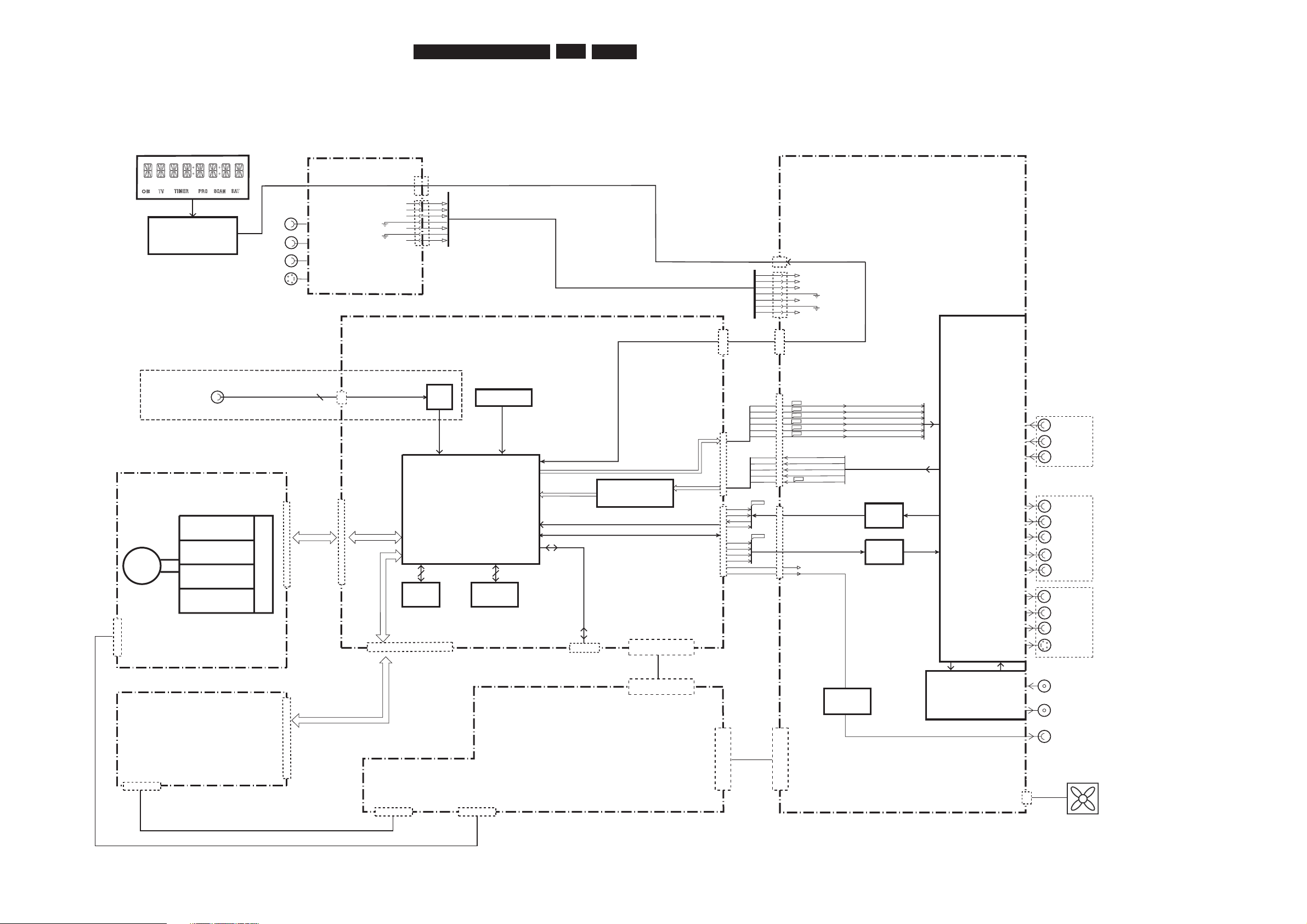

Block Diagrams, Waveforms, Wiring Diagram.

Wiring Diagram

Analog board PSU

8000

FAN1 Fan1 Mains

EH 2.5mm VH 7.6mm

ItemNr: 1804 Item Nr: J3

1 FAN1P 1 MAINS_L

2 FAN1N 2 MAINS_N

2p 2p

8006

FAV FCOM COM AIO VIO1 / VIO2 ANA_PS 120mm ANA_PS

PH 2mm FFC 1mm FFC 1mm FFC 1mm FFC 1mm PH 2mm PH 2mm

Item Nr: 1204 Item Nr: 1803 Item Nr: 1800 Item Nr: 1600 Item Nr: 1205 / 1206 Item Nr: 1400 Item Nr: J2

1 FYIN 1 GND 1 GND 1 GND 1 DB_PB 1 12VSTBY 1 12VSTBY

2 GND 2 FPSCK 2 SCL0 2 ABCK 2 GND 2 PWRCTL 2 PWRCTL

3 FCIN 3 D_FM 3 SDA0 3 AWCK 3 DG_Y 3 5VSTBY 3 5VSTBY

4 GND 4 D_HOST 4 RDY_FM 4 GND 4 GND 4 ODD_ON 4 HDD_ON

5 FCVBSIN 5 GND 5 D_FM 5 ADA0 5 DR_PR 5 3V3STBY 5 3V3STBY

6 GND 6 RDY_FM 6 D_HOST 6 GND 6 GND 6 IPFAIL 6 IPFAIL

7 FAULIN 7 ATN_FM 7 GND 7 AMCK 7 DY 7 5NSTBY 7 5NSTBY

8 GND 8 HOSTRST 8 FPSCK 8 GND 8 GND 8 GND 8GND

9 FAURIN 9 RC 9 ATN_FM 9 DBCK 9 DC 9 33VSTBY 9 33VSTBY

10 5V 10 HOSTRST 10 GND 10 GND 10 GND 10 GND

11 PWRCTL 11 TUNDET0 11 DWCK 11 DCVBS 11 VGNSTBY 11 VGNSTBY

12 PWRFAIL 12 TUNDET1 12 DDA0 12 GND

13 VKKN 13 AINSW0 13 GND 13 TUCVBS

14 12V 14 AINSW1 14 DMCK 14 GND

15 FANCTL 15 GND 15 RCVBSIN

16 FBSCRT 16 AMUTE 16 GND

17 SBSCRT0 17 AINCOAX 17 RYIN

18 SBSCRT1 18 NC 18 GND

19 GND 19 AINOPT 19 RCIN

20 ODD_ON 20 GND 20 GND

21 SPDIFO 21 FCVBSIN

22 GND 22 FCIN

23 GND

24 FYIN

25 GND

26 AR_PR

27 GND

28 AB_PB

29 GND

30 AG_Y

9p 14p 20p 22p 24p / 30p 11p 11p

8001 8002 8003 8004 8005

340mm 480mm 340mm 280mm 180mm

Front board

Digital board

HDD

8021

FAV FCOM COM AIO VIO1 / VIO2 HDD_IDE 280mm HDD_IDE

PH 2mm FFC 1mm FFC 1mm FFC 1mm FFC 1mm IDE 2.54mm IDE 2.54mm

Item Nr: 1300 Item Nr: 1201 Item Nr: 1551 Item Nr: 1536 Item Nr: 1522 / 1521 Item Nr: 1671 Item Nr: NA

1 FYIN 1 GND 1 GND 1 GND 1 DB_PB 1 RSTN 21 DMARQ 1 RSTN 21 DMARQ

2GND 2SCK 2SCL0 2ABCK 2GND 2GND 22GND 2GND 22GND

3 FCIN 3 D_FM 3 SDA0 3 AWCK 3 DG_Y 3 DD[7] 23 DIOWN 3 DD[7] 23 DIOWN

4 GND 4 D_HOST 4 RDY_FM 4 GND 4 GND 4 DD[8] 24 GND 4 DD[8] 24 GND

5 FCVBSIN 5 GND 5 D_FM 5 ADA0 5 DR_PR 5 DD[6] 25 DIORN 5 DD[6] 25 DIORN

6 GND 6 RDY_FM 6 D_HOST 6 GND 6 GND 6 DD[9] 26 GND 6 DD[9] 26 GND

7 FAULIN 7 ATN_FM 7 GND 7 AMCK 7 DY 7 DD[5] 27 IORDY 7 DD[5] 27 IORDY

8 GND 8 HOSTRST 8 FPSCK 8 GND 8 GND 8 DD[10] 28 CSEL 8 DD[10] 28 CSEL

9 FAURIN 9 RC 9 ATN_FM 9 DBCK 9 DC 9 DD[4] 29 DMACKN 9 DD[4] 29 DMACKN

10 5V 10 HOSTRST 10 GND 10 GND 10 DD[11] 30 GND 10 DD[11] 30 GND

11 PWRCTL 11 TUNDET0 11 DWCK 11 DCVBS 11 DD[3] 31 INTRQ 11 DD[3] 31 INTRQ

12 PWRFAIL 12 TUNDET1 12 DDA0 12 GND 12 DD[12] 32 IOCS16 12 DD[12] 32 IOCS16

13 VKKN 13 AINSW0 13 GND 13 TUCVBS 13 DD[2] 33 DA1 13 DD[2] 33 DA1

14 12V 14 AINSW1 14 DMCK 14 GND 14 DD[13] 34 PDIAGN 14 DD[13] 34 PDIAGN

15 FANCTL 15 GND 15 RCVBSIN 15 DD[1] 35 DA0 15 DD[1] 35 DA0

16 FBSCRT 16 AMUTE 16 GND 16 DD[14] 36 DA2 16 DD[14] 36 DA2

17 SBSCRT0 17 AINCOAX 17 RYIN 17 DD[0] 37 CS0N 17 DD[0] 37 CS0N

18 SBSCRT1 18 NC 18 GND 18 DD[15] 38 CS1N 18 DD[15] 38 CS1N

19 GND 19 AINOPT 19 RCIN 19 GND 39 DASPN 19 GND 39 DASPN

20 ODD_ON 20 GND 20 GND 20 Keypin 40 GND 20 Keypin 40 GND

21 SPDIFO 21 FCVBSIN

22 GND 22 FCIN

23 GND

24 FYIN

25 GND

26 AR_PR

27 GND

28 AB_PB

29 GND

30 AG_Y

9p 14p 20p 22p 24p / 30p 40p 40p

8011 8031

USB (option) Not used USB (option) HDD_PS 180mm HDD_PS

PH 2mm PH 2mm IDE_PSU EH 2.5mm

Item Nr: 1401 Item Nr: 1502 Item Nr: NA Item Nr: J6

1 USB5V 1 USB5V 1 12VH 1 12VH

2 USBP 2 USBP 2GND 2GND

3 USBM 3 USBM 3GND 3GND

4GND 4GND 45VH 45VH

4p 4p 4p 4p

8012 8033

STBY IEEE1394 180mm IEEE1394 DIG_PS 220mm DIG_PS

DIPMATE PH 2mm PH 2mm PH 2mm PH 2mm

Item Nr: 0100 Item Nr: 1219 Item Nr: 1511 Item Nr: 1501 2Item Nr: J1

2p 6p 6p 12p 12p

ODD

8022

8013 ODD_IDE 280mm ODD_IDE

220mm IDE 2.54mm IDE 2.54mm

Item Nr: 1571 Item Nr: NA

40p 40p

Standby board

8032

STBY ODD_PS 340mm ODD_PS

DIPMATE IDE_PSU EH 2.5mm

Item Nr: 0013 Item Nr: NA Item Nr: J5

2p 4p 4p

Wire list

Item 12NC Description Remark

8000 2422 070 98202 MAINSCORD UL 6A 2M3 VH BK

B

Mains cord (NAFTA)

8001 3104 157 02021 CBLE PH 9P/340/9P PH 26ST BK Front board AV input

8002 3139 241 01371 FFC FOIL 14P/480/14P BD 1MMP Front board communication IO

8003 3139 241 01361 FFC FOIL 20P/340/20P BD 1MMP Digital board communication IO

8004 3139 111 03991 FFC FOIL 22P/280/22P BD 1MMP Audio IO

8005 3139 110 35851 FFC FOIL 24P/180/24P BD 1MMP Video IO

8006 3139 110 28181 CWAS 11PH/11PH 120 6+5 BK 26S Analog board power supply

8012 3139 110 27881 CBLE PH 06P/180/06P PH 26ST BK Front board IEEE1394

8013 3139 110 37171 CBLE HR 02P/220/02P OE26 OS BK Front board to Standby board

8021 3139 241 00921 CBLE IDE 40P/280/40P IDE UL Hard disk drive IDE

8022 3139 241 00921 CBLE IDE 40P/280/40P IDE UL Optical disk drive IDE

8031 3103 601 00472 CBLE HR 4P/180/4P LC UL Hard disk drive power supply

8032 3139 241 01211 CBLE HR 04P/340/04P LC UL Optical disk drive power supply

8033 3139 110 28301 CBLE PH 12P/220/12P PH 26ST BK Digital board power supply

Note: To see the pin assignments, open the corresponding group by clicking the [+] / [-] icon(s) next to the left margin.

Hide all groups to see block diagram and interconnections in one screen.

Wire list is located at the bottom.

DVDR3350H, DVDR3360H and DVDR3370H

Loading...

Loading...