Philips DS63 Technical Datasheet

LUXEON Rebel

Illumination Portfolio

Optimized

solutions for

illumination applications

Technical Datasheet DS63

LUXEON® Rebel

Illumination Portfolio

ANSI Binned with Minimum CRI

Introduction

The LUXEON® Rebel Illumination Portfolio emitters in this datasheet deliver optimized

combinations of light quality and light output needed for today’s lighting applications. In

addition to delivering specified Correlated Color Temperature and Color Rendering

combinations, these parts deliver the efficacy, lifetime and reliability that all LUXEON

Rebel LEDs are renowned for. This document contains the performance data needed to

design and engineer LUXEON Rebel based applications.

LUXEON Rebel Illumination Portfolio Products

Specified CCT & CRI combinations•

ANSI compliant binning•

Exceed ENERGY STAR•

High efficacy for sustainable design•

®

lumen maintenance requirements

More light delivered at operating temperature.•

Table of Contents

Product Nomenclature ................................................................................................................................................3

Average Lumen Maintenance Characteristics ........................................................................................................3

Environmental Compliance .........................................................................................................................................3

Product Selection ..........................................................................................................................................................4

Optical Characteristics ................................................................................................................................................5

Electrical Characteristics .............................................................................................................................................6

Absolute Maximum Ratings ........................................................................................................................................7

JEDEC Moisture Sensitivity .........................................................................................................................................7

Reflow Soldering Characteristics ..............................................................................................................................8

Mechanical Dimensions ...............................................................................................................................................9

Pad Configuration ..................................................................................................................................................... 10

Solder Pad Design ...................................................................................................................................................... 10

Relative Spectral Distribution vs. Wavelength Characteristics ........................................................................ 11

Light Output Characteristics over Temperature................................................................................................. 15

Typical Forward Current Characteristics ............................................................................................................. 16

Current Derating Curves ......................................................................................................................................... 17

Typical Radiation Patterns ........................................................................................................................................ 18

Emitter Pocket Tape Packaging ................................................................................................................................ 19

Emitter Reel Packaging ............................................................................................................................................. 20

Product Binning and Labeling .................................................................................................................................. 21

LUXEON Rebel ANSI Bin Structure ..................................................................................................................... 22

LUXEON Rebel ANSI Bin Coordinates ............................................................................................................... 23

Forward Voltage Bins ................................................................................................................................................. 25

LUXEON Rebel ANSI Binned Datasheet DS63 (09/08/28) 2

Product Nomenclature

LUXEON Rebel is tested and binned at 350 mA, with current pulse duration of 20 ms. All characteristic charts where the thermal pad is kept at

constant temperature (25ºC typically) are measured with current pulse duration of 20 ms.

The part number designation is explained as follows:

L X M L - A B C D and L X M 3 - A B C D

Where:

A — designates radiation pattern (value P for Lambertian)

B — designates color (W for White)

C — designates nominal CCT

D — designates test current (value 1 for 350 mA)

Therefore products tested and binned at 350 mA follow the part numbering scheme:

L X M L - P x x 1 and L X M 3 - P x x 1

Average Lumen Maintenance Characteristics

Lumen maintenance for solid-state lighting devices (LEDs) is typically defined in terms of the percentage of initial light output remaining after a

specified period of time. Philips Lumileds projects that LUXEON Rebel products will deliver, on average, 70% lumen maintenance (L70) at 50,000

hours of operation at a forward current of up to 700 mA. This projection is based on constant current operation with junction temperature

maintained at or below 135°C. This performance is based on independent test data, Philips Lumileds historical data from tests run on similar

material systems, and internal LUXEON reliability testing. Observation of design limits included in this data sheet is required in order to achieve this

projected lumen maintenance.

Environmental Compliance

Philips Lumileds is committed to providing environmentally friendly products to the solid-state lighting market. LUXEON Rebel is compliant to the

European Union directives on the restriction of hazardous substances in electronic equipment, namely the RoHS directive. Philips Lumileds will not

intentionally add the following restricted materials to the LUXEON Rebel: lead, mercury, cadmium, hexavalent chromium, polybrominated biphenyls

(PBB) or polybrominated diphenyl ethers (PBDE).

LUXEON Rebel ANSI Binned Datasheet DS63 (09/08/28) 3

Product Selection

Product Selection for LUXEON Rebel

Thermal Pad Temperature = 25°C

Table 1.

Minimum Typical

Luminous Luminous

Part Minimum Typical Flux (lm) Flux

Nominal CCT Number CRI CRI FV F

2700K LXM3-PW81 80 85 65 73

3000K LXM3-PW71 80 85 66 77

3000K LXML-PW71 85 90 50 66

3500K LXM3-PW61 80 85 67 80

4000K LXML-PW51 60 70 90 105

4000K LXM3-PW51 80 85 75 85

5000K LXML-PW31 65 70 90 105

5700K LXML-PW21 65 70 90 105

6500K LXML-PW11 65 70 90 105

V

Notes for Table 1:

1. Philips Lumileds maintains a tolerance of ± 6.5% on luminous flux and ± 2 on CRI measurements.

2. LUXEON Rebel products with higher performance levels will become available in the future. Please consult Philips Lumileds or Future Lighting

Solutions for more information.

3. Test current is 350 mA for all LXML-Pxx1 and LXM3-Pxx1 products.

LUXEON Rebel ANSI Binned Datasheet DS63 (09/08/28) 4

Optical Characteristics

LUXEON Rebel at Test Current

[1]

Thermal Pad Temperature = 25°C

Table 2.

Typical

Total Typical

Color Temperature

CCT Angle

Nominal (degrees) (degrees)

CCT Min. Typ. Max. u

2700K 2580K 2725K 2870K 160 120

3000K 2870K 3045K 3220K 160 120

3000K 2870K 3045K 3220K 160 120

3500K 3220K 3465K 3710K 160 120

4000K 3710K 3985K 4260K 160 120

4000K 3710K 3985K 4260K 160 120

5000K 4745K 5028K 5311K 160 120

5700K 5310K 5665K 6020K 160 120

6500K 6020K 6530K 7040K 160 120

[2]

Included Viewing

[3]

Angle

2u 1/2

0.90V

[4]

Notes for Table 2:

1. Test current is 350 mA for all LXML-Pxx1 and LXM3-Pxx1 products.

2. CCT ±5% tester tolerance.

3. Total angle at which 90% of total luminous flux is captured.

4. Viewing angle is the off axis angle from lamp centerline where the luminous intensity is ½ of the peak value.

5. All white products are built with Indium Gallium Nitride (InGaN).

LUXEON Rebel ANSI Binned Datasheet DS63 (09/08/28) 5

Electrical Characteristics

Electrical Characteristics at 350 mA for LUXEON Rebel

Thermal Pad Temperature = 25ºC

Table 3.

Typical

Temperature Typical

Coefficient of Thermal

Forward Resistance

Forward Voltage Vf

(V) (mV/°C) Thermal Pad (°C/W)

Nominal CCT Min. Typ. Max. DVf / DTJ Ru

2700K, 3000K, 3500K, 2.55 3.00 3.99 -2.0 to -4.0 10

4000K, 5000K, 5700K, 6500K

[1]

Voltage

[2]

Junction to

J-C

Notes for Table 3:

1. Philips Lumileds maintains a tolerance of ±0.06V on forward voltage measurements.

2. Measured between 25°C = TJ = 110°C at If = 350 mA.

* Dynamic resistance is the inverse of the slope in linear forward voltage model for LEDs. See Figure 13.

Typical Electrical Characteristics at 700 mA for LUXEON Rebel

Thermal Pad Temperature = 25ºC

Table 4.

Typical Forward Voltage Vf

Nominal CCT (V)

2700K, 3000K, 3500K, 4000K, 5000K, 5700K, 6500K 3.20

Notes for Table 4:

1. Philips Lumileds maintains a tolerance of ±0.06V on forward voltage measurements.

LUXEON Rebel ANSI Binned Datasheet DS63 (09/08/28) 6

Absolute Maximum Ratings

Table 5.

Parameter Maximum Performance

DC Forward Current (mA)

Peak Pulsed Forward Current (mA)

Average Forward Current (mA)

ESD Sensitivity < 8000V Human Body Model (HBM)

Class 3A JESD22-A114-E

< 400V Machine Model (MM)

Class B JESD22-A115-B

LED Junction Temperature

Operating Case Temperature at 350 mA -40°C - 135°C

Storage Temperature -40°C - 135°C

Soldering Temperature JEDEC 020c 260°C

Allowable Reflow Cycles 3

Autoclave Conditions 121°C at 2 ATM

100% Relative Humidity for 96 Hours Maximum

Reverse Voltage (Vr) See Note 2

Notes for Table 5:

1. Proper current derating must be observed to maintain junction temperature below the maximum.

2. LUXEON Rebel LEDs are not designed to be driven in reverse bias.

3. Maximum Ratings limits are specified when applied singularly and for device operation not to exceed 60 seconds.

[3]

1000

[3]

1000

[3]

1000

[1] [3]

150°C

JEDEC Moisture Sensitivity

Table 6.

Soak Requirements

Level Floor Life Standard

Time Conditions Time Conditions

1 unlimited [ 30°C / 168h 85°C / 85%

85% RH + 5 / -0 RH

LUXEON Rebel ANSI Binned Datasheet DS63 (09/08/28) 7

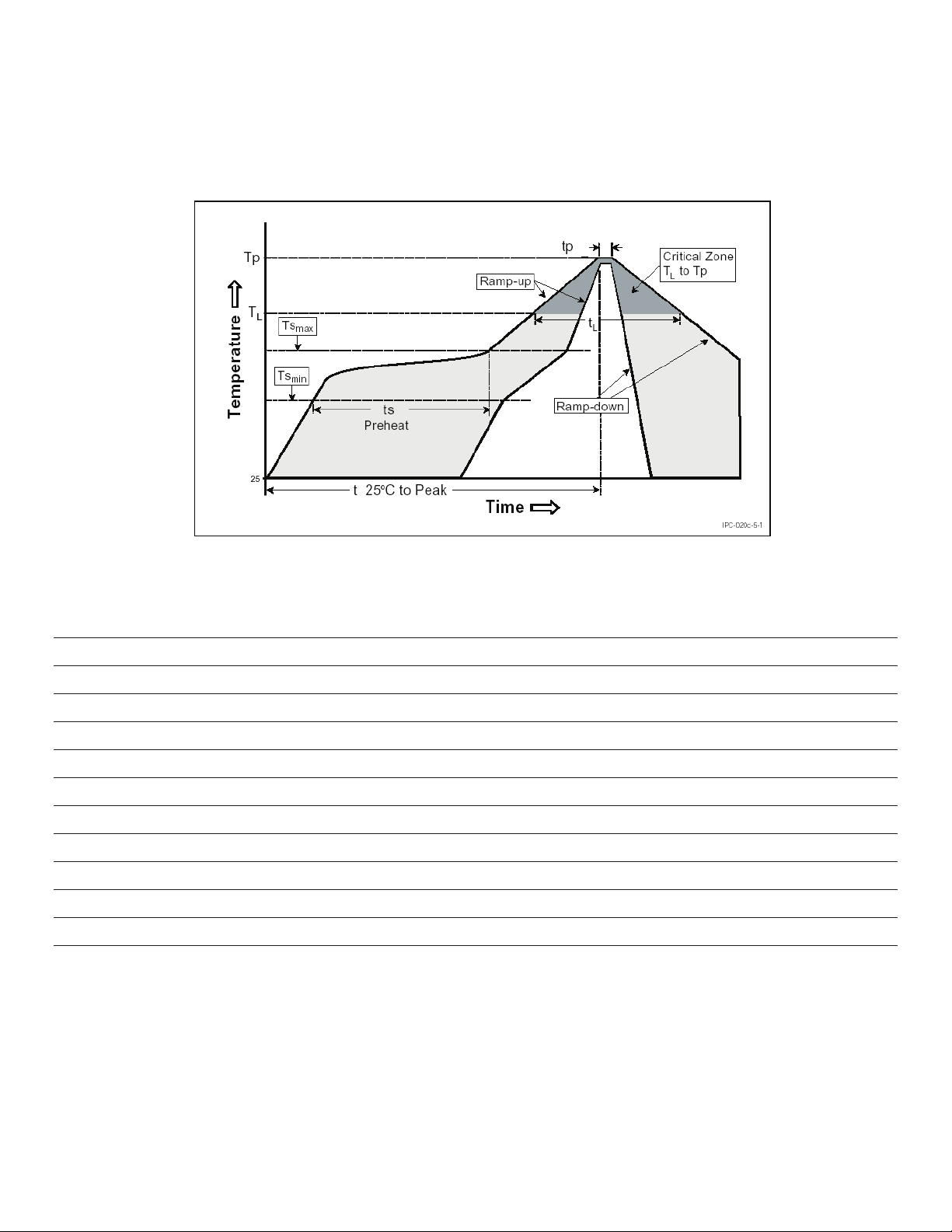

Reflow Soldering Characteristics

JEDEC 020c

Temperature Profile for Table 7.

Table 7.

Profile Feature Lead Free Assembly

Average Ramp-Up Rate (Ts

Preheat Temperature Min (Ts

Preheat Temperature Max (Ts

Preheat Time (ts

min

Time Maintained Above Temperature (TL) 217°C

Time Maintained Above Time (tL) 60 - 150 seconds

Peak / Classification Temperature (TP) 260°C

Time Within 5°C of Actual Peak Temperature (tP) 20 - 40 seconds

Ramp - Down Rate 6°C / second max

Time 25°C to Peak Temperature 8 minutes max

Notes for Table 7:

1. All temperatures refer to the application Printed Circuit Board (PCB), measured on the surface adjacent to the package body.

to Tp) 3°C / second max

max

) 150°C

min

) 200°C

max

to ts

) 60 - 180 seconds

max

LUXEON Rebel ANSI Binned Datasheet DS63 (09/08/28) 8

Loading...

Loading...