100 Craftway Dr.

Littlestown, Pennsylvania 17340-0128

Phone: 717-359-7131

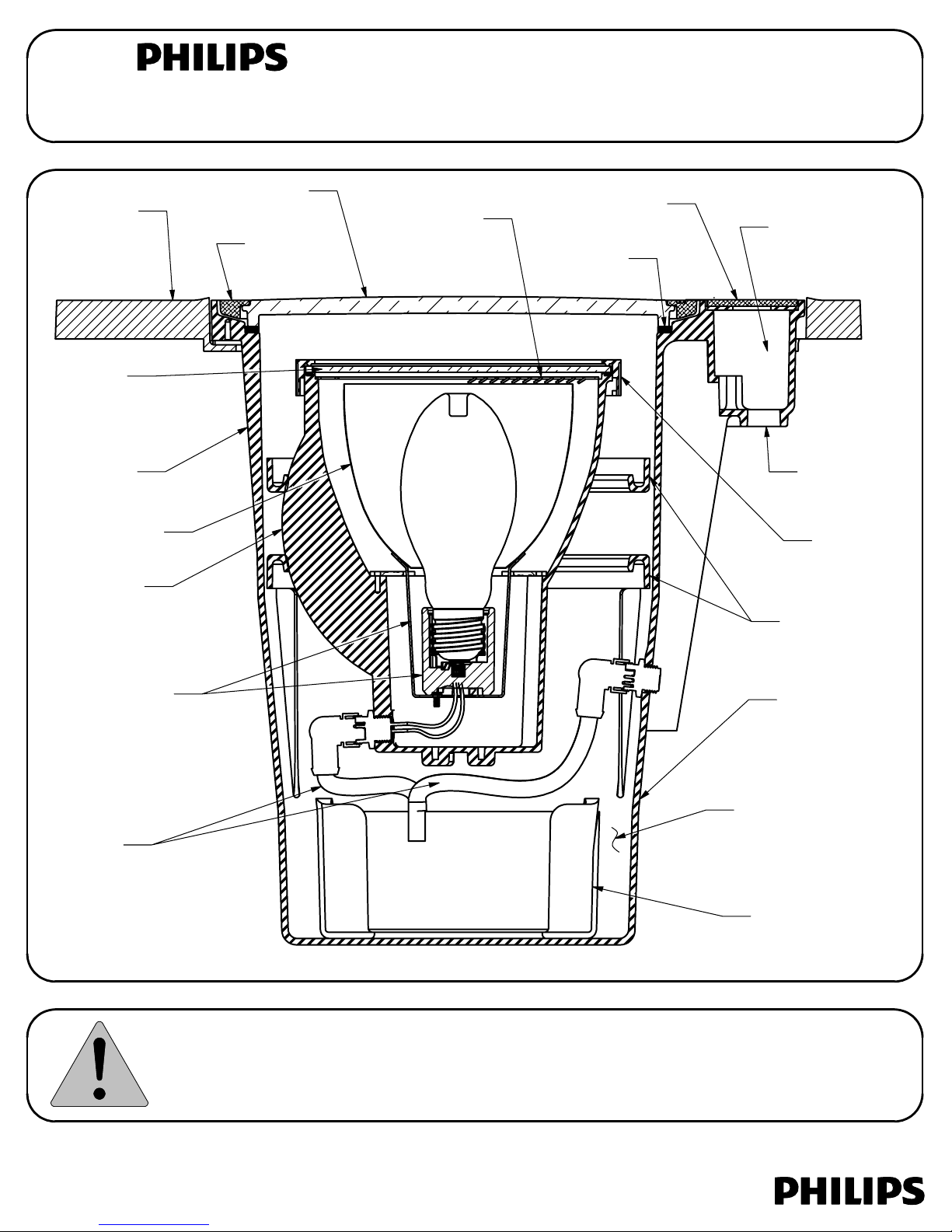

INSTALLATION INSTRUCTIONS:

DB5000 - LARGE INGROUND UPLIGHT

PAVER

ADAPTER

(OPTIONAL)

LAMPING

MODULE

LENS

HOUSING

RIBS

REFLECTOR

LAMPING

MODULE

MAIN

LENS

LENS

FRAME

INTERNAL

ACCESSORY

(OPTIONAL)

WIRING

COMPARTMENT

COVER

LENS

GASKET

WIRING

COMPARTMENT

(MUST BE SEALED

WITH SUPPLIED

RE-ENTERABLE

ENCAPSULANT)

3/4" CONDUIT

ENTRY (3X)

TWIST-LOCK

LENS FRAME

LAMPING

MODULE

GIMBAL

SOCKET &

BRACKET

LIQUIDTIGHT

CABLES

NOTE : FIXTURE STYLE, ACCESSORIES, OPTICS AND BALLAST TYPE WILL VARY WITH FIXTURE OPTIONS.

This fixture is intended for installation in accordance with the National Electrical Code and local code

specifications. Failure to adhere to these codes and instructions may result in serious injury and/or damage

to the ballast and void the warranty. These instructions do not purport to cover all details or variations in

equipment, nor to provide for every possible contingency related to installation, operation, maintenance,

or mounting situation. Should specific problems occur that are not addressed by these instructions, contact

your Sales Representative or distributor for assistance. Retain these instructions for future reference.

MAIN

HOUSING

BALLAST

COMPARTMENT

BALLAST MODULE

(HID ONLY)

32001316, revision J

page 1 of 4

SAFETY WARNING:

ALWAYS TURN FIXTURE OFF/DISCONNECT POWER AND ALLOW TO COOL BEFORE

PERFORMING ANY MAINTENANCE, INCLUDING RELAMPING AND CLEANING!

This fixture can become very HOT! The fixture housing and lens, especially if it is glass, can become hot enough

to blister hands. Attention should be paid to where the fixture is mounted, particularly if it can be touched by

children or pets. To help prevent premature failure, decreased performance, overheating and risk of fire, keep

fixture and lens clean and free of leaves, mulch, debris and mineral deposits from water. The fixture and lens

can be cleaned using a soft cloth and a solution of mild liquid soap and warm water. Wipe clean and dry with a

soft, lint-free dry cloth. Avoid polishing fixture or lens.

INSTRUCTIONS PERTAINING TO A RISK OF FIRE OR INJURY TO PERSONS

IMPORTANT SAFETY INSTRUCTIONS - SAVE THESE INSTRUCTIONS!

WARNING - Lamp gets HOT quickly! To reduce the risk of FIRE OR INJURY TO PERSONS:

Do not operate fixture with a missing or damaged lens/lens assembly.

Contact only switch or plug when turning fixture on or off. Do NOT touch hot lens or housing.

Turn off or unplug fixture and allow to cool before relamping. Keep lamp away from combustibles.

Do NOT touch lamp with bare hands at any time, use a soft cloth as oil from skin may damage lamp.

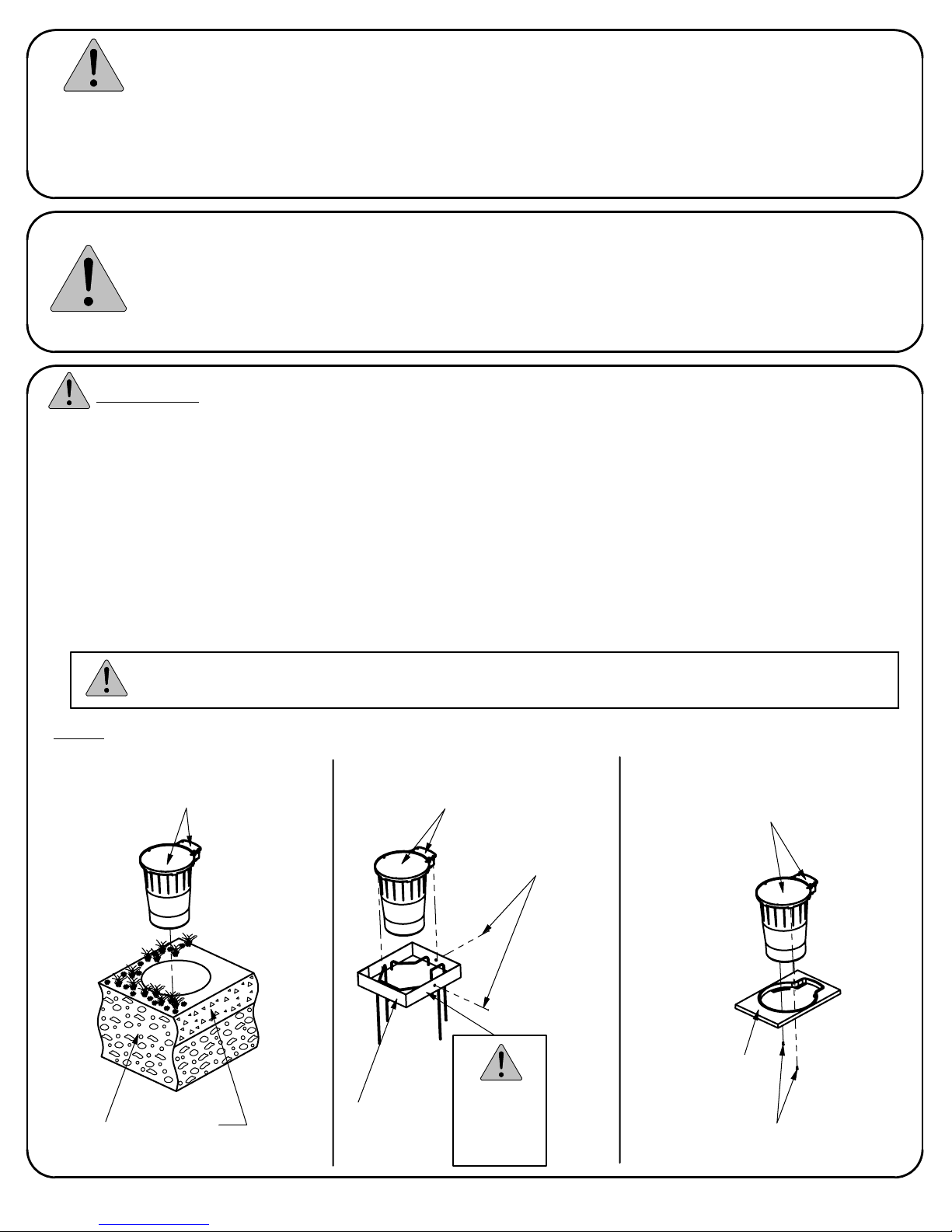

CAUTION:

WARNING: TURN POWER OFF BEFORE INSTALLING OR PERFORMING ANY MAINTENANCE ON THIS FIXTURE.

1.

Failure to do so may result in severe injury or death.

The housing should not be installed in insulating materials such as bark, vermiculite, etc. for the full depth

2.

of the housing. Surface use of these materials around BUT NOT ON TOP of the fixture is acceptable.

IMPORTANT: To prevent overheating, regularly check lens and keep it clean and free of debris such as

3.

dirt, sand, leaves, mulch, etc.

Conduit entry ways should be properly sealed around threads and duct seal should be used in the

4.

conduit around the wires to prevent water entry through the conduit. Unused conduit entry ways

should be properly plugged and sealed.

The fixture should not be installed in low lying areas or where water may accumulate and stand for long

5.

periods of time.

Soil should be mounded up around the fixture to promote drainage.

6.

Do not install fixture within 10 feet (3 meters) of a pool, spa or fountain

7.

Failure to do so will void warranty and could cause a fire.

Failure to do so will void warranty.

.

INSTALLATION

IF A MOUNTING ACCESSORY IS USED, IT MUST BE ATTACHED TO THE HOUSING BEFORE

CONTINUING! KEEP DIRT COVERS IN PLACE ACCORDING TO DIRECTIONS.

Step 1:

Excavate soil for fixture, or fixture with mounting accessory, as well as conduits.

NO ACCESSORY

Dirt Covers

DB5CMF

Dirt Covers

Mounting

Screws

DB5PA

Dirt Covers

Paver

Adapter

(DB5PA)

Soil

or cement

removed for fixture

and conduits

32001316, revision J

Concrete

mounting

frame

(DB5CMF)

Back fill

between

housing &

DB5CMF.

Mounting

Screws

page 2 of 4

Step 2:

Connect conduit using

thread sealant.

Unused conduit entry

ways should be properly

plugged and sealed.

Supply wires

pulled through

conduit

Junction Box

Step 3:

Set aside junction box dirt

cover (retain for future use). Pull

wires through conduit into junction

box. The contractor must pull a

ground wire or make a ground

connection to a metal conduit

system. Place duct seal in the

conduits around the wires.

Step 4:

Duct

Seal

Conduit

(By others)

Backfill around housing and mounting accessory (if used) with dirt, cement or decorative stone as

Failure to properly seal

conduit may allow water

into junction box and

will void the warranty.

required for finishing the particular installation. DO NOT back fill with bark or vermiculite.

Step 5:

Connect supply leads to the fixture wiring (see below) using the supplied liquid tight wire nuts. Be sure

colored fixture supply wire, per table below, matches supply voltage. Replace junction box dirt cover.

WARNING: 3 UNUSED VOLTAGE WIRES MUST BE INDIVIDUALLY CAPPED OFF USING LIQUID TIGHT

WIRE NUTS (BY OTHERS). FAILURE TO DO SO WILL VOID WARRANTY, DAMAGE FIXTURE, AND

COULD RESULT IN INJURY.

3 Liquid Tight Wire Nuts

(Supplied)

voltage taps -

COLOR

WHITE

BLACK

ORANGE

RED

BLUE

GREEN

VOLTAGE

Quad-tap

Tri-tap

50Hz

120/277V

127/220V

NEUTRAL NEUTRAL NEUTRAL NEUTRAL NEUTRAL

120V 120V 120V 120V 127V

208V 220V 220V

240V 240V

277V 277V 277V

GROUND GROUND GROUND GROUND

None

347V

None

None

None None

None

GROUND

WHITE

to supply

neutral

GREEN

to supply

ground

Supply hot

Unused

individually

capped

(3 places)

ENSURE GASKET SEATING

SURFACES ARE CLEAN AND

FREE OF DEBRIS BEFORE SEALING.

Wiring Compartment Cover

(Stainless steel or brass)

HID Lamping Module

Ensure ballast

wattage matches

lamp module

Ballast Module

(Core & Coil

HID Only)

Step 7:

Remove round dirt cover. Attach ballast

module (HID only) and lamping module using

the cordsets. Aim lamping module in direction

desired.

Take care not to

pinch any wires.

3

2

If debris in screw holes prevents proper

gasket seating, holes must be blown

clear or cleared with a 1/4-20 tap.

Step 6:

Remove junction box dirt cover.

Screw the wiring compartment cover

to housing with 70 in-lb of torque in an

1

alternating pattern as shown below.

4

Incandescent,

Fluorescent &

Electronic HID

Lamping Module

(INC/FL/eHID only)

32001316, revision J

page 3 of 4

Step 8: NOTE: To help decrease moisture

, energize fixture for 20

minutes prior to attaching main lens. Place main lens assembly

on the housing. (Do not remove protective tape on edge of

lens). Screw lens frame to housing with 70 in-lb of torque in an

alternating star pattern as shown.

DO NOT

torque in a radial

pattern (1 to 3 to 5 etc).

1

Torque sequence

6

3

4

5

2

Main Lens Assembly

(Main Lens, Lens Gasket & Lens Frame)

RELAMPING

All fixtures ship pre-lamped unless otherwise specified. Fixtures may be relamped in the field or in a

controlled indoor environment. It may be desirable to keep spare lamping modules to field swap. MAKE SURE

POWER IS OFF BEFORE RELAMPING. Remove lens frame, main lens and lens gasket. Inspect gasket for damage

and replace, if necessary.

Relamping indoors: Remove lamping module from main housing and disconnect cordset. Replace lamping

module with a pre-lamped one. Re-seal fixture per Step 8 above - ensure gasket seating surfaces are clean and

free of debris. Take lamping module to work area and relamp per below. Keep this pre-lamped module for

future use.

Relamping in the field: Twist the lens frame on the lamping module and lift up to remove. Remove lamp module

lens and any internal accessory. Replace lamp with a new one of identical electrical characteristics. [NOTE: For

metal halide T6 (G12 base) lamps, Bronzelite recommends using only Philips MasterColor™ lamps or

GE ConstantColor CMH™ lamps. If using a lamp from another manufacturer, ensure it is electrically compatible

with supplied ballast.] For T6 optics, if it is necessary to remove the optics assembly, position the bottom band of

the optics assembly around the four pins indicated in the "T6 Optics - Seating Illustration" below and simply

press-fit into place.

Pins

Bottom

Band

T6 Optics - Seating Illustration

Replace internal accessory (if applicable) and lamp module lens, re-seat lamp module lens

frame and twist to secure. Re-seal the fixture per Step 8 above - ensure gasket seating surfaces are clean and

free of debris.

32001316, revision J

page 4 of 4

Loading...

Loading...