Page 1

Philips Semiconductors

Interconnectivity

D12 SMART

USER’S

MANUAL

Philips Semiconductors - Asia Product Innovation Centre

Visit http://www.flexiusb.com

Page 2

USER’S MANUAL D12 SMART Page 2 of 19

TABLE OF CONTENTS

D12 SMART KIT.......................................................................................... 3

1.1 Introduction.............................................................................................. 3

1.2 Description .............................................................................................. 3

1.3 Features ................................................................................................... 3

1.4 Operating Environment ............................................................................ 3

2. SETTING UP THE D12 SMART KIT..................................................... 3

2.1 Connection and System Requirement ....................................................... 3

2.1.1: The D12 Smart Evaluation System ................................................... 4

2.1.2: Block Diagram of D12 Smart Board.................................................. 4

3. INSTALLATION PROCEDURES........................................................... 5

3.1 Installing the software.............................................................................. 5

3.2 Installing the Applet................................................................................. 5

3.2.1: The icon on the desktop.................................................................... 5

3.3 Installing the device drivers...................................................................... 5

3.4 Running the applet ................................................................................... 7

4. DESCRIPTION OF D12 ENDPOINTS.................................................... 8

4.1 D12 Endpoints Configuration................................................................... 8

4.1.1 Configuration of D12 Endpoints Table ............................................... 8

4.2 Operations of D12 Endpoints................................................................... 8

4.2.1 Operations of D12 Endpoints Table .................................................... 8

5. MISCELLANEOUS................................................................................. 9

6. DESCRIPTION OF HEADERS..............................................................10

6.1 Header J1 ................................................................................................10

6.2 Header J2 ................................................................................................10

6.3 Header J3 ................................................................................................12

6.4 Header J4 (USB Upstream).....................................................................13

9. PCB PLOTS OF D12 SMART EVALUATION BOARD........................16

10. D12 SMART EVALUATION BOARD................................................18

10.1: Enlarged Picture of PDIUSBD12.......................................................18

11. BILL OF MATERIALS FOR D12 EVALUATION BOARD ...............19

_________________________________________________________________________________________________________

Philips Semiconductors - Asia Product Innovation Centre

Visit http://www.flexiusb.com

Page 3

USER’S MANUAL D12 SMART Page 3 of 19

D12 SMART KIT

1.1 Introduction

The Philips USB D12 Smart Kit is a comprehensive kit that offers you the full potential of Philips

PDIUSBD12 (or D12), in addition to the know-how on how to convert your existing legacy into

USB devices. This kit includes the D12 smart boards, test application program (or applet), USB

driver, and some sample firmware source codes.

1.2 Description

D12 is a high performance USB interface device that offers DMA transfer capability as well as

features for a cost-effective microcontroller-based system. This kit allows you to thoroughly

evaluate the capabilities and features of the device, and provide quick grounding on how to

convert your existing non-USB devices such as the digital still camera, mass storage device, and

scanner into USB devices.

1.3 Features

The simple design of this kit aims to highlight the features of a USB device. It has the D12 and

the 89C738/89C52 microcontroller interfaced to D12. Philips PDIUSBD12 implements all the

functions of the USB device, and has an 8-bit parallel data bus for microcontroller interface. The

MCU is a member of the 8051-family. The firmware implements all the USB enumeration, D12

Interrupt service, power down and resume signaling interfaces. Though the D12 has DMA

capability, for simplicity, it is not incorporated in this board. A similar evaluation board, the USBEPP, has all the DMA features built into it.

With the accompanying applet, you can operate the kit in three modes: Print, Scan, and Loop

back modes. The purpose for having the print and scan modes is to allow the evaluation board to

emulate either the printer or scanner environment. The Loop back mode is to indicate the integrity

of the data when large data packet is sent and received from the host system.

1.4 Operating Environment

Running the kit only requires a new generation PC (motherboard with USB port) with Microsoft

Windows 98 operating system. The firmware provided with the kit is written in C language (some

Assembly codes for critical timing), and so allows you to port it to any other platforms for

compiling. With this kit, you can develop your USB devices through the firmware and hardware

schematics.

2. SETTING UP THE D12 SMART KIT

2.1 Connection and System Requirement

Connect the board to the host system via the USB upstream connector. Follow the instructions on

the screen to install the device driver, and then install the software provided with the kit. Ensure

that you have the following:

_________________________________________________________________________________________________________

Philips Semiconductors - Asia Product Innovation Centre

Visit http://www.flexiusb.com

Page 4

USER’S MANUAL D12 SMART Page 4 of 19

Mouse

D12

MCU Exbus

Serial Port

D12 Exbus

USB Cable

• PC Host system with USB ports;

• Microsoft Windows 98 operating system; and

• D12 smart board, USB cable, and diskette provided with the kit.

2.1.1: The D12 Smart Evaluation System

D12 Board

MCU

Host PC with USB host Controller

The Evaluation System based on USB D12 Kit

2.1.2: Block Diagram of D12 Smart Board

D12

MCU

Suspend & Resume

Circuitry

USB

_________________________________________________________________________________________________________

Philips Semiconductors - Asia Product Innovation Centre

Visit http://www.flexiusb.com

Page 5

USER’S MANUAL D12 SMART Page 5 of 19

3. INSTALLATION PROCEDURES

3.1 Installing the software

The software includes the firmware, the test application program (or the applet), and the device

drivers. The firmware is programmed in the 89C738/89C52 microcontroller (Flash type). If you

want to change the firmware or use your own firmware, you just need to reprogram the

89C738/89C52 microcontroller.

3.2 Installing the Applet

1. Insert the diskette into your disk drive.

2. Copy the file, D12TEST.EXE, contained in the diskette to a directory of your choice -

C:\D12 Smart.

3. Create a shortcut by dragging the file D12TEST.EXE from the directory to the desktop. An

icon similar to Figure 3.2.1 appears.

3.2.1: The icon on the desktop.

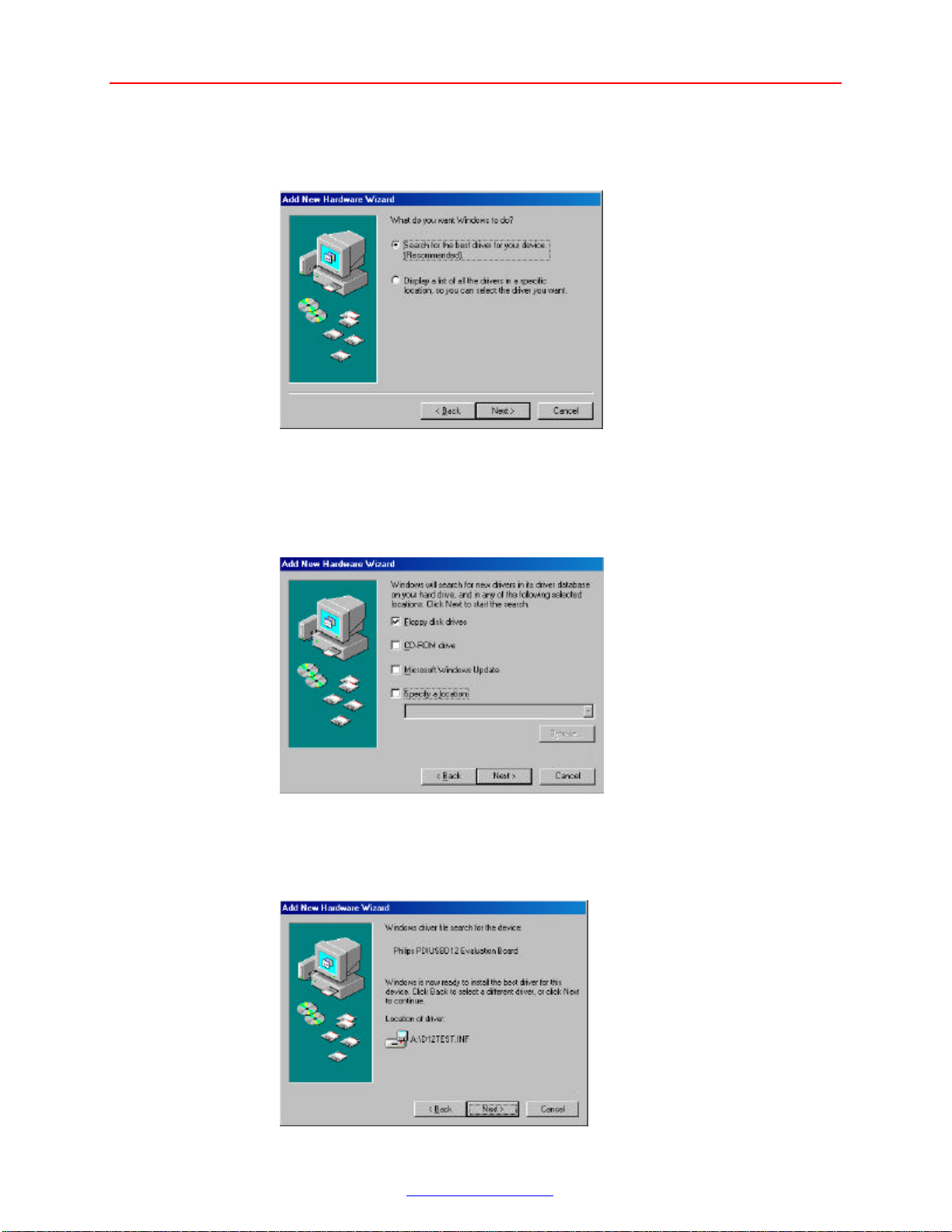

3.3 Installing the device drivers

When connecting the USB cable to your host system for the first time, a dialog box will appear

and prompt you to install the device drivers. Navigate through it and load the device drivers

provided in the floppy that comes along with the kit. To install the device drivers:

1. When you connect the USB cable to your host system for the first time, a dialog box

similar to Figure 3.3.1 appears. Click the Next button.

Figure 3.3.1

_________________________________________________________________________________________________________

Philips Semiconductors - Asia Product Innovation Centre

Visit http://www.flexiusb.com

Page 6

USER’S MANUAL D12 SMART Page 6 of 19

2. When a dialog box similar to Figure 3.3.2 appears, select the first item and click the Next

button.

Figure 3.3.2

3. When a dialog box similar to Figure 3.3.3 appears, select Floppy disk drives and click the

Next button.

Figure 3.3.3

4. When a dialog box similar to Figure 3.3.4 appears, click the Next button.

Figure 3.3.4

_________________________________________________________________________________________________________

Philips Semiconductors - Asia Product Innovation Centre

Visit http://www.flexiusb.com

Page 7

USER’S MANUAL D12 SMART Page 7 of 19

5. When a dialog box similar to Figure 3.3.5 appears, click the Finish button to end the

installation.

Figure 3.3.5

3.4 Running the applet

The applet supports three test modes: Print, Scan, and Loop back modes. The print and scan

modes allow the evaluation board to emulate either the printer or scanner environment. The Loop

back mode shows the integrity of the data when a large data packet is sent and received by the

host system.

To run the applet, click the D12Test.exe icon on your desktop and an interface similar to Figure

3.4.1 appears.

Figure 3.4.1

_________________________________________________________________________________________________________

Philips Semiconductors - Asia Product Innovation Centre

Visit http://www.flexiusb.com

Page 8

USER’S MANUAL D12 SMART Page 8 of 19

This pipe is defined as Interrupt pipe. The D12-Smart

evaluation board sends specific data packet to the host system

This pipe is defined as Bulk Out pipe. Data packet received

from the host system is interpreted as LED control, and the

These pipes are defined as Bulk In/Out endpoints. The Applet

and the evaluation board support 3 test modes: loop back,

4. DESCRIPTION OF D12 ENDPOINTS

4.1 D12 Endpoints Configuration

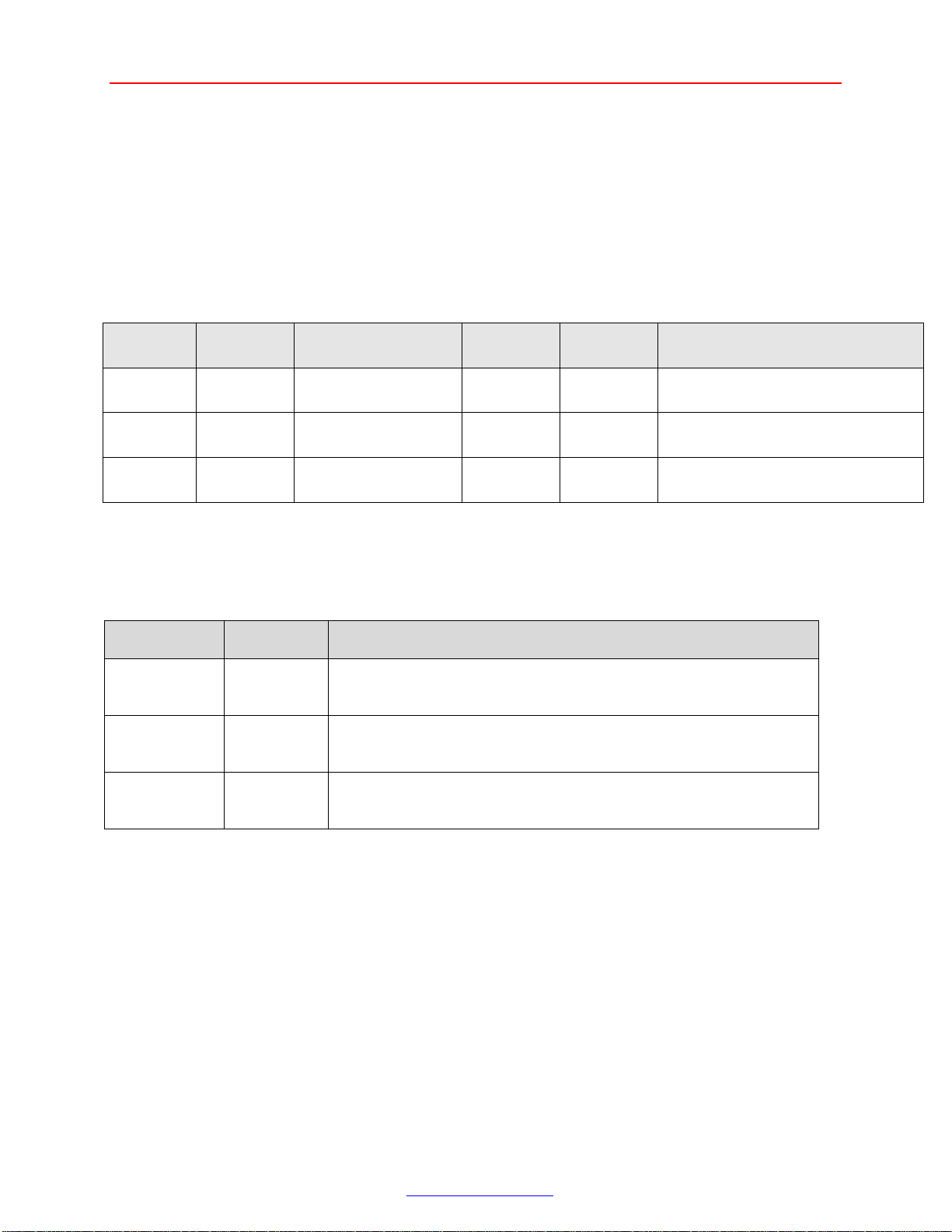

Table 4.1.1 describes the PDIUSBD12 Endpoints configuration Mode 0, i.e., it is Non-Iso mode.

The reset 3 mode (Isochronous mode ) can be found on the D12 specification.

4.1.1 Configuration of D12 Endpoints Table

Endpoint

Number

0 0

1 2

2 4

Endpoint

Index

1

3

5

Transfer

Type

Control Out

Control In

Generic Out

Generic In

Generic(Main) Out

Generic(Main) In

Endpoint

Direction Max Packet Size(Bytes)

Type

Default Out

In

Generic

Generic

Generic

Generic

Out

In

Out

In

16

16

16

16

64(another 64 for double buffer)

64(another 64 for double buffer)

4.2 Operations of D12 Endpoints

The table below describes in detail the operations of the endpoints.

4.2.1 Operations of D12 Endpoints Table

Endpoint

Number

Endpoint

Type

Operations

1 Generic In

when the test key is pressed or released.

1 Generic

Out

firmware will light up the corresponding LED.

2 Main In

Main Out

print, and scan modes.

The Generic In and Generic Out endpoints have a maximal packet size of 16 bytes. This

capacity makes them suitable for devices that require small size data transfer such as the

keyboard, mouse and logic controls. The main endpoints have a maximal packet size of 64

bytes for Bulk/Isochronous mode or 128 bytes for Isochronous mode with double buffering

capacity. Hence, they are suitable for high data rate and large size data transfer.

Three test modes are supported at the main endpoints. They are:

• Scan mode: The evaluation board emulates the scanner environment. This mode is used

to evaluate the maximal Bulk In transfer rate.

• Print mode: The evaluation board emulates the printer environment. This mode is used

to evaluate the maximal Bulk Out transfer rate.

• Loop back mode: The evaluation board receives data packets from the Main Out

endpoint (Endpoint Index 4) and sends them back to the host system from the Main In

endpoint (Endpoint Index 5). This mode helps test the firmware’s ability to control the

_________________________________________________________________________________________________________

Philips Semiconductors - Asia Product Innovation Centre

Visit http://www.flexiusb.com

Page 9

USER’S MANUAL D12 SMART Page 9 of 19

data flow and the integrity of data transfers.

Since the firmware is protocol-based, the host system can inform the firmware to set any

possible modes. There is, therefore, no longer any need to manually set the scan test mode

before running the scan test on the firmware.

The “buffer size” of the applet is the size of the data buffer, which the applet transmits to the

USB system drivers for receiving or transmitting. Hence, it is the responsibility of the USB

system drivers to divide them into smaller data packets, e.g., 64 bytes for bulk transfer. The

maximal buffer size is limited by the USB system drivers. The best transfer rate over the USB

can be achieved by optimizing the buffer size.

5. MISCELLANEOUS

• Press-Button S1—Reset or Resume the system

• Press-Button S2—PIPE testing

• Press-Button S3—PIPE testing

• LED D1—USB interface GoodLink indicator. When it is on, it means that the link between

the USB host and the USB device has been set up and the enumeration done. If it is blinking,

it means that data is being transmitted or received

• LED D2—PIPE testing

• LED D3—PIPE testing

• Header pin J5 —Connected to Ground leads

• HCT123 with D12 and MCU firmware support the Power down and RESUME operations,

i.e., when D12 comes out from suspend state, the suspend pin state changes from high to low.

When this happens, the HCT123 monostate generates a positive pulse to reset/wakeup

89C52/89C738.

_________________________________________________________________________________________________________

Philips Semiconductors - Asia Product Innovation Centre

Visit http://www.flexiusb.com

Page 10

USER’S MANUAL D12 SMART Page 10 of 19

6. DESCRIPTION OF HEADERS

6.1 Header J1

The J1 test header is for D12’s signals as illustrated in the following table:

Pin No. Signal Name Signal Type Description

1

2

D∅

D12A∅

I/O

I

D12 Data ∅

D12 Address A∅

3 D1 I/O D12 Data 1

4 /D12RST I D12 Reset

5 D2 I/O D12 Data 2

6 /D12 EOT I D12 End of Transfer

7 D3 I/O D12 Data 3

8 /D12DACK I D12 DMA ACK

9 D4 I/O D12 Data 4

10 D12REQ O D12 DMA Request

11 D5 I/O D12 Data 5

12 /D12WR I D12 Write

13 D6 I/O D12 Data 6

14 /D12RD I D12 Read

15 D7 I/O D12 Data 7

16 /D12CS I D12 Chip Select

17 5V Power 5 Volts Power

18 D12ALE I D12 Address Catch

19 5V Power 5 volts Power

20 D12SUSPD I/O D12 Suspend

21 Not Connected

22 /D12INT O D12 Interrupt

23 GND Power Ground

24 Not Connected

25 GND Power Ground

26 CLK12M O D12 Clock Out

6.2 Header J2

The expansion connector J2 is connected from Pin1 to Pin 40 of the MCU. These connectors

allow the use of MCUs from other makes through a pin converter. It will also allow you to debug

signal lines of MPU.

_________________________________________________________________________________________________________

Philips Semiconductors - Asia Product Innovation Centre

Visit http://www.flexiusb.com

Page 11

USER’S MANUAL D12 SMART Page 11 of 19

Header J2

Pin No. Signal Name Signal Type Description

1 GND Power Ground

2 SWM0 I

Press Button ∅

3 GND Power Ground

4 SWM1 I Press Button 1

5 GND Power Ground

6 RLED0 O

Red LED ∅

7 GND Power Ground

8 RLED1 O Red LED 1

9 GND Power Ground

10 P1x4 I/O MCU Port 1 bit 4 (Not in use)

11 GND Power Ground

12 P1x5 I/O MCU Port 1 bit 5 (Not in use)

13 GND Power Ground

14 /D12CS I D12 Chip Select

15 GND Power Ground

16 /D12RST O D12 Reset

17 GND Power Ground

18 MCURST I MCU Reset

19 GND Power Ground

20 S232RXD I Receive Data Line

21 GND Power Ground

22 S232TXD O Transmit Data Line

23 GND Power Ground

24 /D12INT I D12 Interrupt

25 GND Power Ground

26 D12 SUSPD I/O D12 Suspend

27 GND Power Ground

28 P3x4 I/O MCU Port 3 bit 4 (Not in use)

29 GND Power Ground

30 P3x5 I/O MCU Port 3 bit 5 (Not in use)

31 GND Power Ground

32 /D12WR O D12 Write

33 GND Power Ground

34 /D12RD O D12 Read

35 GND Power Ground

36 MCUXTAL2 O Crystal Output

37 GND Power Ground

38 MCUXTAL1 I Crystal Input

39 GND Power Ground

40 VCC Power +5V

_________________________________________________________________________________________________________

Philips Semiconductors - Asia Product Innovation Centre

Visit http://www.flexiusb.com

Page 12

USER’S MANUAL D12 SMART Page 12 of 19

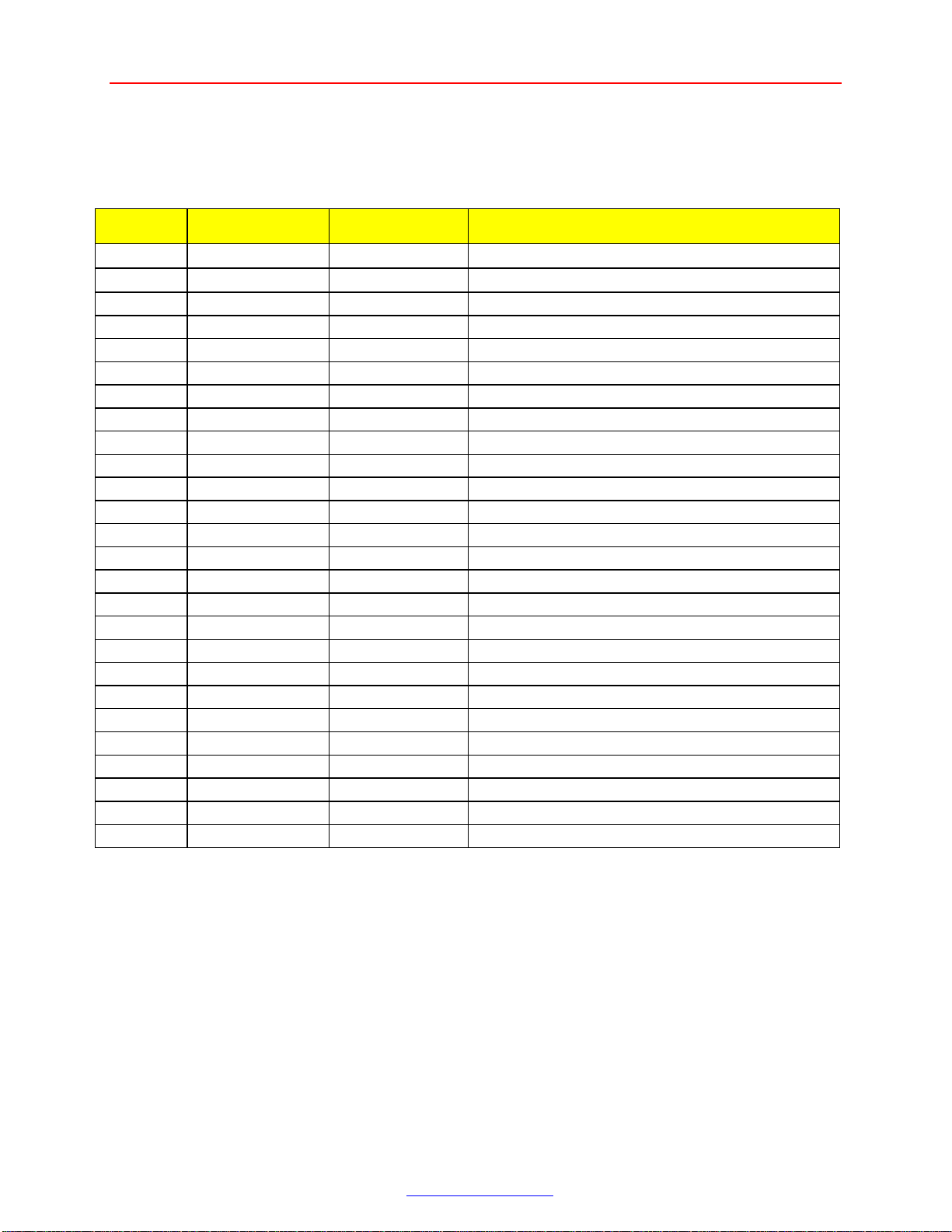

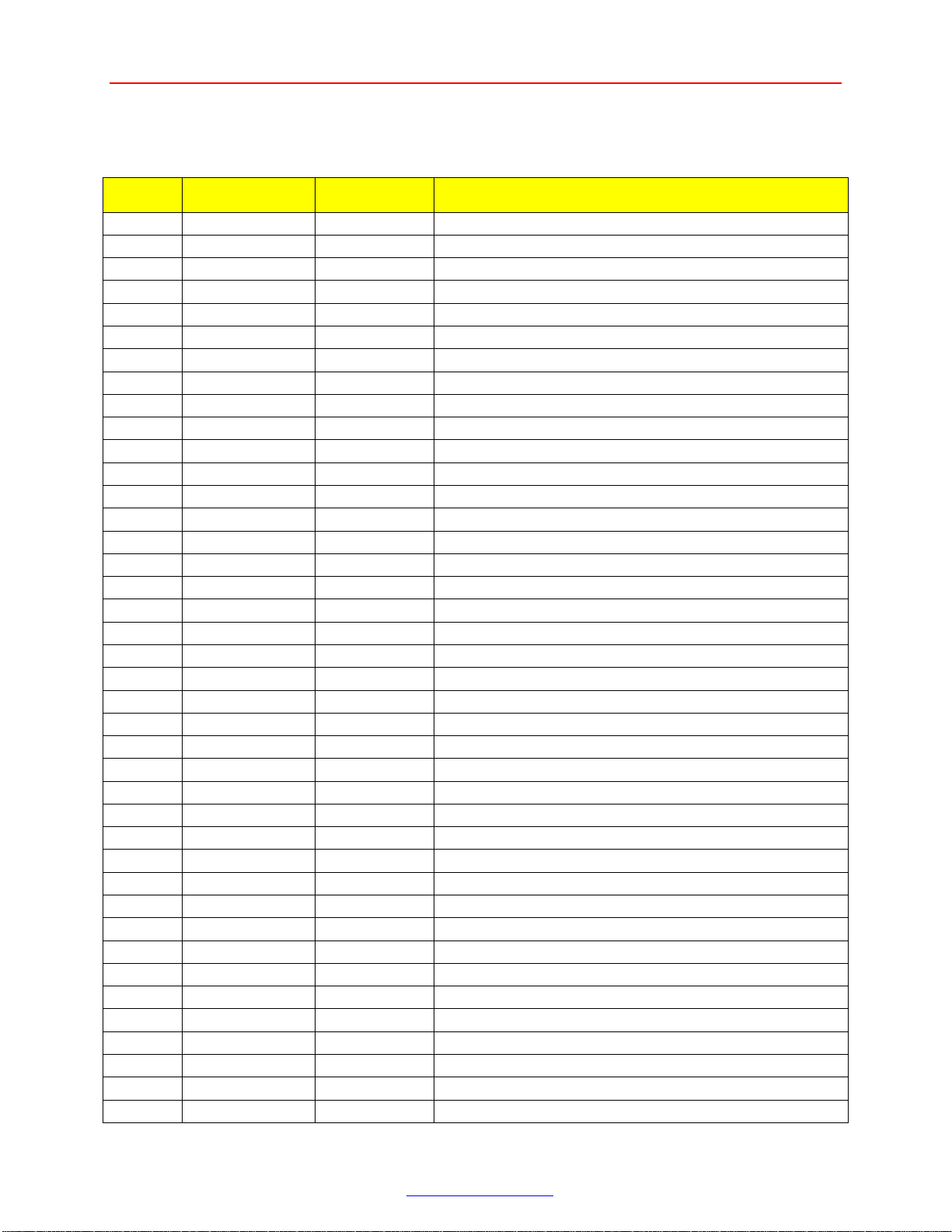

6.3 Header J3

Pin No. Signal Name Signal Type Description

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

23.

24.

25.

26.

27.

28.

29.

30.

31.

32.

33.

34.

35.

36.

37.

38.

39.

40.

VCC Power

GND Power Ground

D0 I/O

GND Power Ground

D1 I/O Data 1

GND Power Ground

D2 I/O Data 2

GND Power Ground

D3 I/O Data 3

GND Power Ground

D4 I/O Data 4

GND Power Ground

D5 I/O Data 5

GND Power Ground

D6 I/O Data 6

GND Power Ground

D7 I/O Data 7

GND Power Ground

/MCUEA O MCU External Excess

GND Power Ground

D12ALE O D12 Address Catch Enable

GND Power Ground

/PSEN O Program Strobe Enable

GND Power Ground

P2x7 I/O MCU Port 2 bit 7 (Not in use)

GND Power Ground

P2x6 I/O MCU Port 2 bit 6 (Not in use)

GND Power

P2x5 I/O MCU Port 2 bit 5 (Not in use)

GND Power Ground

P2x4 I/O MCU Port 2 bit 4 (Not in use)

GND Power Ground

P2x3 I/O MCU Port 2 bit 3 (Not in use)

GND Power Ground

P2x2 I/O MCU Port 2 bit 2 (Not in use)

GND Power Ground

P2x1 I/O MCU Port 2 bit 1 (Not in use)

GND Power Ground

P2x0 I/O MCU Port 2 bit 0 (Not in use)

GND Power Ground

+5V

Data ∅

Ground

_________________________________________________________________________________________________________

Philips Semiconductors - Asia Product Innovation Centre

Visit http://www.flexiusb.com

Page 13

USER’S MANUAL D12 SMART Page 13 of 19

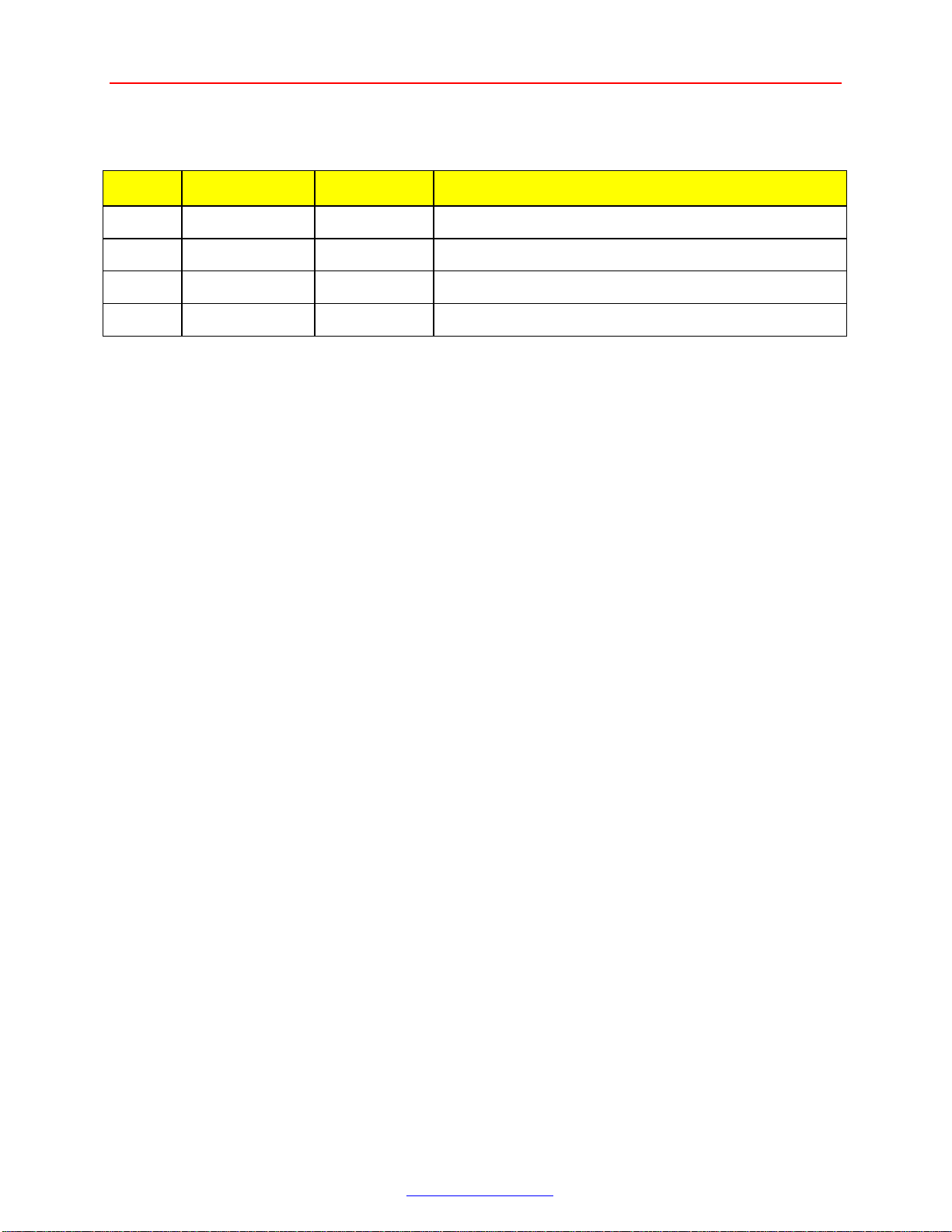

6.4 Header J4 (USB Upstream)

Pin No. Signal Name Signal Type Description

1 V_BUS Power +5V

2 D- I/O Data Minus Line,

3 D+ I/O Data plus Line

4 GND Power Ground

_________________________________________________________________________________________________________

Philips Semiconductors - Asia Product Innovation Centre

Visit http://www.flexiusb.com

Page 14

USER’S MANUAL D12 SMART Page 14 of 19

7. SCHEMATIC OF D12 SMART EVALUATION BOARD

_________________________________________________________________________________________________________

Philips Semiconductors - Asia Product Innovation Centre

Visit http://www.flexiusb.com

Page 15

USER’S MANUAL D12 SMART Page 15 of 19

8. ENLARGED SCHEMATIC OF D12 EXPANSION BUS

_________________________________________________________________________________________________________

Philips Semiconductors - Asia Product Innovation Centre

Visit http://www.flexiusb.com

Page 16

USER’S MANUAL D12 SMART Page 16 of 19

9. PCB PLOTS OF D12 SMART EVALUATION BOARD

Top Layer

Bottom Layer

_________________________________________________________________________________________________________

Philips Semiconductors - Asia Product Innovation Centre

Visit http://www.flexiusb.com

Page 17

USER’S MANUAL D12 SMART Page 17 of 19

..........con’t from pg 18

Top Overlay

_________________________________________________________________________________________________________

Philips Semiconductors - Asia Product Innovation Centre

Visit http://www.flexiusb.com

Page 18

USER’S MANUAL D12 SMART Page 18 of 19

10. D12 SMART EVALUATION BOARD

10.1: Enlarged Picture of PDIUSBD12

_________________________________________________________________________________________________________

Philips Semiconductors - Asia Product Innovation Centre

Visit http://www.flexiusb.com

Page 19

USER’S MANUAL D12 SMART Page 19 of 19

11. BILL OF MATERIALS FOR D12 EVALUATION BOARD

Item Description Reference Value Quantity

1. Capacitor C1, C11, C26, C27, C28 1.0uF16V 5

2. Capacitor

C3, C2

20pF 2

3. Capacitor C4 10uF16V 1

4. Capacitor C5, C17, C18, C19, C20, C21, C22,

0.01uF2KV 11

C23, C31, C32, C33

5. Capacitor C6, C13, C14 4.7uF16V 3

6. Capacitor C7 470pF 1

7. Capacitor C8, C12, C15, C16, C30 0.1uF 5

8. Capacitor C9 68pF 1

9. Capacitor C10 22pF 1

10. Capacitor C24, C25 100pF 2

11. Light Emitting Diode D1 LED_GREEN 1

12. Light Emitting Diode D3, D2 LED_RED 2

13. Jumper J1

HEADER 13×2

1

14. Jumper J2 LEFT Exbus 1

15. Jumper J3 RIGHT Exbus 1

16. Jumper J4 UP_CONN 1

17. Jumper J5 CON1 1

18. Jumper J6 RS232 1

19. Ferrite Bead L1, L2, L3 FERRITE BEAD 3

20. Transistor Q1 2N3906 1

21. Resistor Array RP1 4.7K 1

22. Resistor R2 8.2K 1

23. Resistor R3, R4, R11, R12, R15, R18, R21,

10K 10

R22, R28, R29

24. Resistor R5 1.5K 1

25. Resistor R6, R13, R14 470R 3

26. Resistor R8, R7

18R±1%

2

27. Resistor R9, R10, R16 1M 3

28. Resistor R17, R25 1K 2

29. Resistor R19, R20, R23 0R 3

30. Resistor R24, R26, R27 100K 3

31. Switches S1, S2, S3 PUSHBUTTON 3

32. Integrated Circuit U1 PDIUSBD12_SOP 1

33. Integrated Circuit U2 PDIUSBD12TSSOP 1

34. Integrated Circuit U3 89C738ABP 1

35. Integrated Circuit U4 SN75240 1

36. Integrated Circuit U5 74HCT123 1

37. Crystal X1 6MHz 1

38. Crystal X2 33MHz 1

_________________________________________________________________________________________________________

Philips Semiconductors - Asia Product Innovation Centre

Visit http://www.flexiusb.com

Loading...

Loading...