Page 1

Philips Lighting North America Corporation

200 Franklin Square Drive

Somerset, NJ 08873, USA

Phone: 855-486-2216

www.philips.com/luminaires

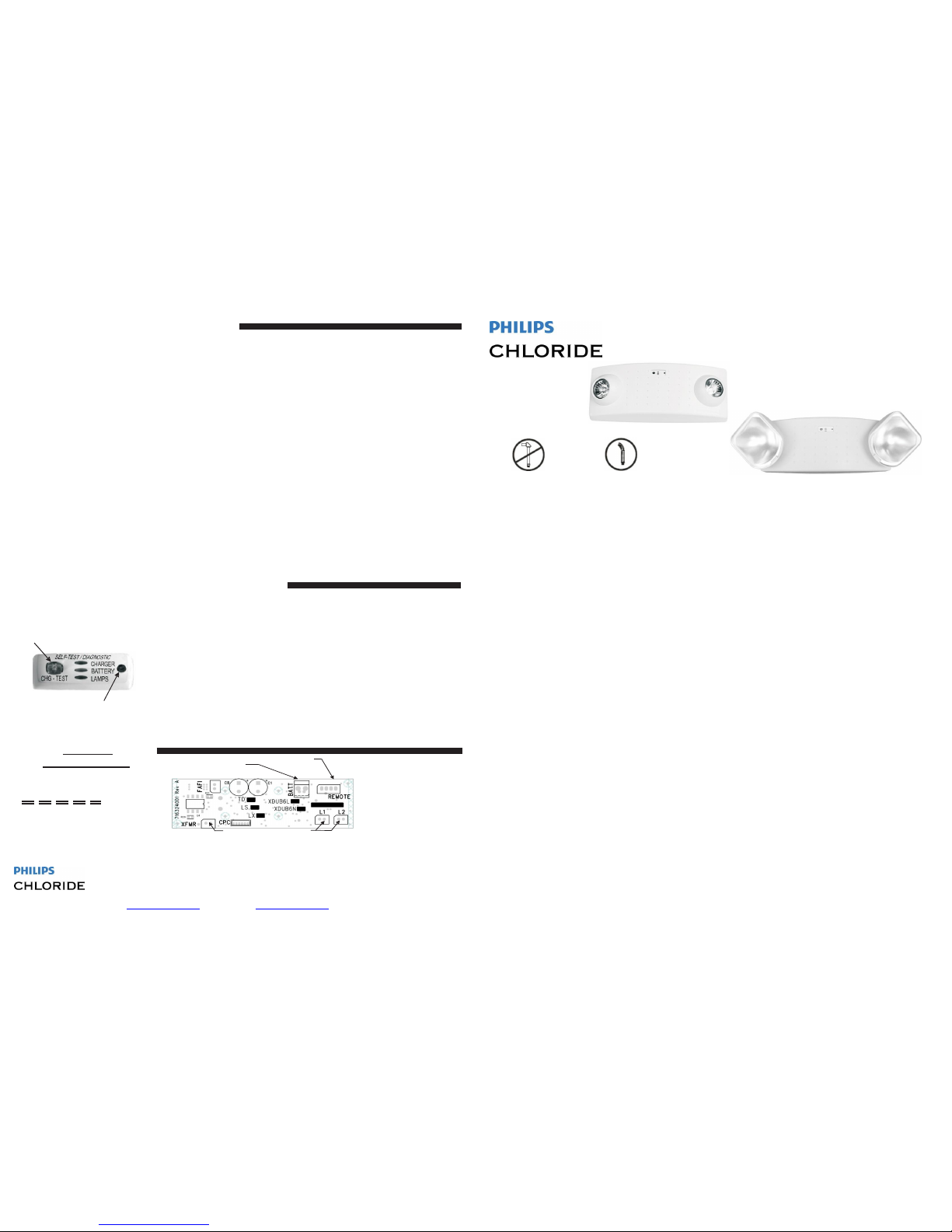

NORMAL OPERATION/MANUAL TEST

OP-PANEL INDICATORS/OPERATION:

GREEN - Status: Solid indicates system normal and AC power is on.

NOTE: To start the Manual test, simply press the Green Indicator (button) as indicated below. To Reset/Cancel a test press the Green Indicator

(button) once during any test. When Unit is in test mode the Green Indicator LED is flashing.

1 Press: perform a 5-sec brief lamp test, all Lamps operating from battery only.

2 Presses: perform a 1-min diagnostic test, all Lamps operating from battery only.

3 Presses: perform a 90-min diagnostic test, all Lamps operating from battery only.

6-sec Continuous

Press: perform a RESET operation.

CONTINUOUS MONITORING: The system monitors the following continuously:

Battery, 2) Lamps, 3) Charger, 4) Transfer function.

The battery requires at least 72 hours of charge time to perform any extended diagnostic test. If the battery ha s not charged for 72 hours after

installation and a diagnostic test is requested, the charger light will come on and stay on for one m inute indicating that the battery is not fully charged

for attempted test. (The 5-sec brief lamp test is always allowed.)

Emergency Lighting

COMPAC Thermoplastic Unit Equipment

No Rigid Conduit Flexible Conduit Only

CAX/CTX

Series

INSTRUCTION SHEET

OPTIONAL FACTORY EQUIPPED ITEMS:

REMOTE: Unit will be supplied with pigtail connector cable required to contr ol and operate a remote of up to rated MAX. wattage.

TIME DELAY (TD): After a power failure and power is restored, the lamps will remain lit for a 15-min pe riod (provided battery capacity remains).

Note: The Green power indicator LED will flash slowly during the 15-min. period.

LASER TEST (LX): To operate using a laser pen: use laser pen and point the laser beam over the remote sensor (see below), thereby duplicating

the manual button (1,2,3) pushes. The laser must impact the remote sensor for at least 0.2 seconds to be reco gnized.

LESS SELF-TEST (LS): Monthly automatic self-tests will not be performed. (Lamps will not energize on an automatic monthly schedule.)

TROUBLE INDICATORS/TROUBLESHOOTING

IMPORTANT SAFEGUARDS

READ AND FOLLOW ALL SAFETY INSTRUCTIONS

WARNING: Electrical Shock Potential!! Do not attempt to install, maintain or relamp without disconnecting

all power. Failure to disconnect power can result in electrocution, shock, or severe burns.

CAUTION: This fixture is designed for permanent installation in ordinary (NON-HAZARDOUS) locations in

accordance with the National Electrical Code and all applicable local codes. Do not use in areas of limited

ventilation or in high ambient enclosures. The lamp and fixture operate at high temperatures; contact with

combustible material can cause fire and personal contact can cause severe burns. When using electrical

TEST

Button

REMOTE SENSOR

(IF EQUIPPED)

Xtest DISPLAY PANEL INDICAT

OR:

GREEN - Status: solid indicates system normal and AC power is on and flashes during any

manual/auto test cycle.

RED – CHARGER FLASHING: a charger failure requires the diagnostic charger board to be

replaced.

RED – BATTERY FLASHING: battery is disconnected or if it is connected, a replacement is

needed. RED - LAMP FLASHING: Lamp(s) is disconnected or if it is connected, a replacement is

needed. (If

4-pin remote pigtail is connected to diagnostic charger board and no remote lamp is attached, the

LAMPS indicator will flash. Connect a remote lamp or disconnect remote pigtail.)

ALL 3 RED FLASHING: bad transfer; battery and lamps are disconnected or if they are

connected a replacement diagnostic charger board is needed.

equipment, basic safety precautions should always be followed; including the following:

READ AND FOLLOW ALL SAFETY INSTRUCTIONS.

Do not use outdoors.

Do not let power supply cords touch hot surfaces.

Do not mount near gas or electric heaters.

Use caution when servicing batteries. Battery acid can cause burns to skin and eyes. If

acid is spilled on skin or in eyes, flush acid with fresh water and contact a physician

immediately.

Equipment should be mounted in locations and at heights where it will not readily be

WIRING

INFORMATION

Transformer Inputs

BLACK - 120V

WHITE - Common or Neutral

RED - 277V

Battery Connector

Transformer Connector

Remote Connector

(Optional)

Lamp

Connectors

subjected to tampering by unauthorized personnel.

The use of accessory equipment not recommended by the manufacturer may cause an

unsafe condition.

CAUTION: Halogen cycle lamp(s) are used in this equipment. To avoid shattering: Do not

operate lamp in excess of rated voltage, protect lamp against abrasion and scratches and

against liquids when lamp is operating, dispose of lamp with care.

Halogen cycle lamps operate at high temperatures. Do not store or place flammable

materials near lamp.

Do not use this equipment for other than intended use.

Servicing of this equipment should be performed by qualified personnel only.

SAVE THESE

INSTRUCTIONS

Diagnostic Charger

Board

Philips Lighting Canada Ltd.

281 Markham Road,

Markham, ON, Canada L6C 2S3

Phone: 800-668-9008

www.philips.com/luminaires

717054102

CMANU0552A

February 2016

Page 2

Philips Lighting North America Corporation

200 Franklin Square Drive

Somerset, NJ 08873, USA

Phone: 855-486-2216

www.philips.com/luminaires

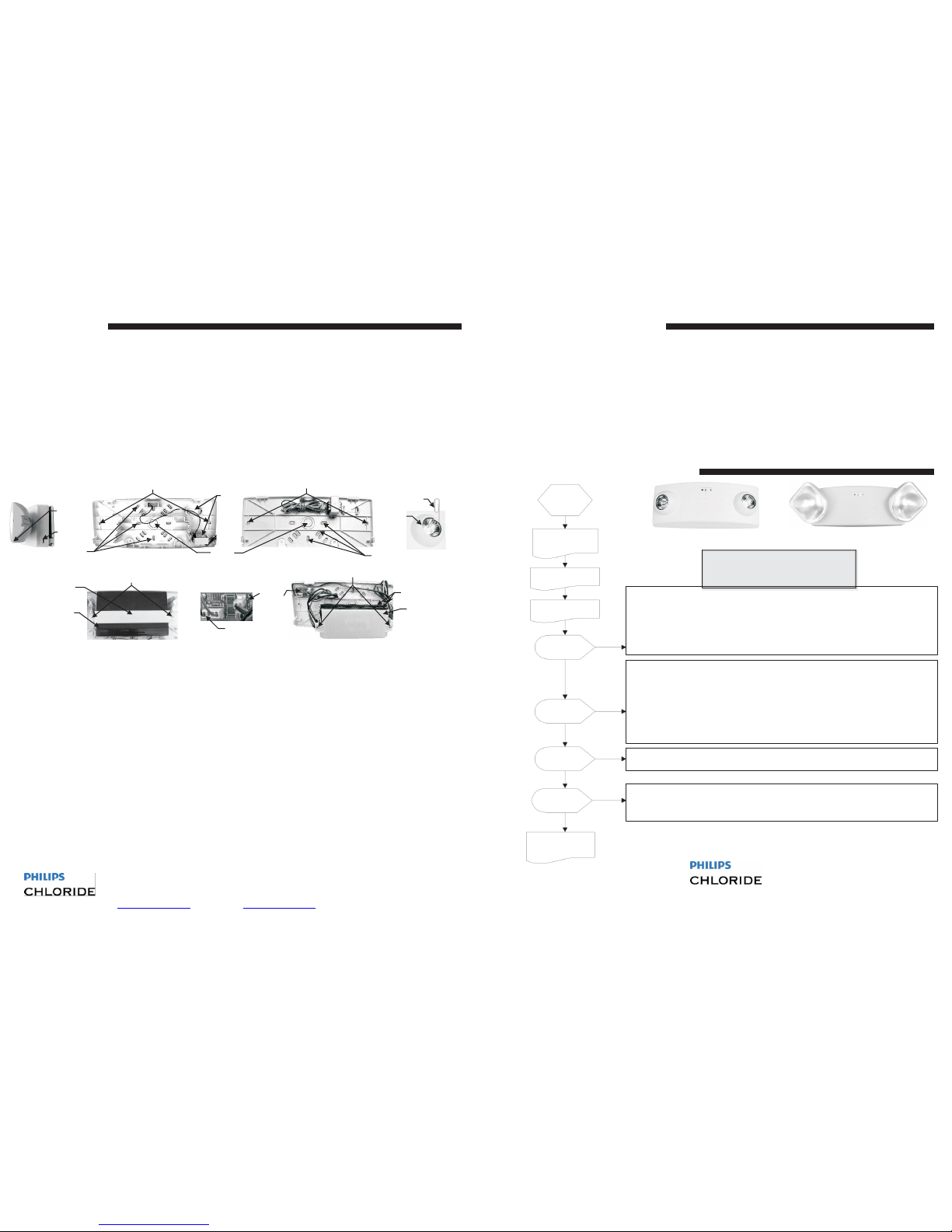

INST

ALLATION

INSTRUCTIONS WALL (BACK) MOUNT

Open front cover using a flat-head screwdriver by pressing the tab on the side of the unit in to release; see Fig. 1.

Remove main knockout hole in back housing and appropriate outlet box pattern knockout; see Fig. 2 - if needed, loosen screws holding battery in place (see Fig. 3) and

remove battery.

Route AC service wires through main knockout hole in back housing. Mount back housing to outlet box using screws. See Fig. 2.

Make AC service connection at this time. See OPERATING INSTRUCTIONS below.

Replace the cover and snap tabs into place; see Fig. 1.

INSTRUCTIONS CEILING MOUNT

Open front cover using a flat-head screwdriver by pressing the tab on the side of the unit in to release; see Fig. 1.

Remove main knockout hole in back housing and appropriate ceiling mounting knockouts; see Fig. 2 - if needed, loosen screws holding battery in place (see Fig. 3) and

remove battery..

Route AC service wires through main knockout hole in back housing. Mount back housing to ceiling/surface box using screws. See Fig. 2.

CAUTION: (2) Screws must be used to mount the back-plate to the ceiling surface with suitable hardware to prevent sag

and/or

the unit

falling.

Make AC service connection at this time. See OPERATING INSTRUCTIONS below.

Replace the cover and snap tabs into place; see Fig. 1.

INSTALLATION CONTINUED

INSTRUCTIONS LAMP REPLACEMENT -

Disconnect

power before

re-lamping.

CTX -Open lens using a small flat-head screwdriver by gently releasing the tab on the corner of the lamp head; see Fig. 1. Replace lamp,

snap cover back into place.

CAX-Open front cover (see instructions above), disconnect la mp from the diagnostic charger board. Using an opened paper clip,

release the lamp retaining ring; see Fig. 4. Replace with new lamp. Reinstall retaining ring and connect new lamp to diagnostic charger

board. Snap cover back into place.

REMOTE LAMP HEAD HOOKUP INSTRUCTIONS (If remote

capability

is

available)

NOTE: Observe output rating and do not exceed maximum load

combining

all lamp

connections.

1. The Maximum total watts on L1 or L2 must not exceed replacement lamp wattage listed on Nameplate for all CAX/CTX units.

2. The remote lamp connection (REMOTE) may not exceed the output rated maximum minus the output on L1 & L2.

3. Do not short the lamp leads to ground.

Failure to

properly

follow

conditions

stated above may result in damage to the unit and void the unit's

warranty

.

NORMAL POWER-UP SEQUENCE

CTX

Lens

Release

Tab

(push in)

Outlet Box

Ceiling Mounting holes

Transformer

Locations

Main

Ceiling Mounting holes

Paperclip

CAX

Retaining

Ring

APPLY

ALL INDICATOR

LEDs FLASH 6

TIMES

CAX CTX

SELF-TESTING / SELF-DIAGNOSTIC

Fig. 1

CTX

Knockouts

Lead Acid

CTX

Battery Screws

Knockout

Fig. 2

CAX

Battery Screws

Outlet Box

Knockouts

Fig. 4

CAX

EMERGENCY LAMPS

BRIEFLY ON

The unit willself-test approximately

every 30 days for a minimum of 30

minutes.

Battery Strap

Lead Acid

Battery

Fig. 3a

Wire harness

Fig. 3

Battery

Integration

Board

Fig. 3b

Ni-Cad

Battery

Ni-Cad

Battery Strap

GREEN STATUS - ON

Battery Charging

BATTERY INDICATOR

FLASHING

Y

BATTERY DIAGNOSTIC INDICATOR FLASHING AFTER POWER-UP:

1) Most likely the Batter y is not connected. Verify that the Battery is connected to the diagnostic charger

board.

2) If the Battery is connected, wait for 72 ho urs to charge the Battery. After 72 hours, if the Battery

indicator LED is flashing, the Battery is faulty and needs to be replaced.

3) After Battery replacement, t he Battery indicator LED will stop flashing within approximately 10 to 20sec.

OPERATING INSTRUCTIONS

1. Connect AC supply wires to transformer leads and push through knockout into outlet or ceiling/surface box. Observe the wire colors.

BLACK wire 120 volt AC input.

WHITE wire common or neutral for 120 or 277 volts AC input. RED wire

277 volt AC input.

CAUTION: CAP ALL UNUSED BLACK OR RED WIRES TO PREVENT SHORTING OR ELECTRICAL SHOCK.

Note: when all wiring connections are made, push wires thru knockout into outlet box.

2. Battery Connections:

Lead Acid

a. If needed, Place battery into back housing, secure using strap and (2) screws; See Fig. 3a.

b. Connect the red and black wire with the 2-pin connector from battery to the BATT location on the diagnostic charger board inside front cover. (See WIRING

INFORMATION on back page)

Ni-Ca d

a. If needed, Place battery into back housing, secure using strap and (2) screws; See Fig. 3b.

Note: If there is only one Ni-Cad battery pack, connect the red and black wire with the 2-pin connector from battery to the BATT location on the diagnostic charger

board inside front cover. Continue to step 3.

b. Connect the red and black wires with the 2-pin connectors from batteries into the battery integration board 2-pin connectors.

c. Connect the red and black wire harness from battery integration board to the BATT location on the diagnostic charger board inside front cover.

3. Connect the red and white wire with the 2-pin connector from transformer to XFMR connector on the diagnostic charger board on inside of front cover.

4. Energize AC power to equipment and check the unit using the POWER-UP SEQUENCE (see next page). Leave AC connected for a minimum of 72 hours to

charge battery before performing normal operation/manual tests.

N

LAMP

INDICATOR

FLASHING

N

CHARGE

INDICATOR

FLASHING

N

ALL 3

RED

N

TO NORMAL

OPERATION

LAMP DIAGNOSTIC INDICATOR FLASHING AFTER POWER-UP:

1) Verify that the lamps are connected to the diagnostic charger board. Check the remote lamp if unit is

equipped with remote option.

2) Push the green test switch once t o test. All emergency lamps should turn on briefly, if not, replace the

faulty lamp(s).

Y

NOTE: If unit is equipped with remote option, and the remote pigtail (4- pin connector with 2 wires) is

connected to the diagnostic charger board but is not connected to a remote load, the Lamp Indicator

LED will flash. Either connect a load to the remote pigtail or disconnect it from the diagnostic charger

board.

Y

CHARGER DIAGNOSTIC INDICATOR FLASHING AFTER POWER-UP:

1) Indicates a faulty diagnostic char ger board that must be replaced.

ALL 3 DIAGNOSTIC INDICATORS FLASHING AFTER POWER-UP:

Y

1) Verify that the lamps and the Battery are connected to t he diagnostic charger board.

2) If everything is connected then th e Transfer function is faulty and the diagnostic charger board must be

replaced.

Philips Lighting Canada Ltd.

281 Markham Road,

Markham, ON, Canada L6C 2S3

Phone: 800-668-9008

www.philips.com/luminaires

717054102

CMANU0552A

February 2016

Loading...

Loading...