Philips CCB130AT01 Service Manual

Philips Consumer Electronics

Technical Service Data

Service and Quality

Service Publications Dept.

One Philips Drive

P.O. Box 14810

Knoxville, TN 37914

REFER TO SAFETY GUIDELINES

SAFETY NOTICE:

ANY PERSON ATTEMPTING TO SERVICE THIS CHASSIS MUST FAMILIARIZE

HIMSELF WITH THE CHASSIS AND BE AWARE OF THE NECESSARY SAFETY PRECAUTIONS

TO BE USED WHEN SERVICING ELECTRONIC EQUIPMENT CONTAINING HIGH VOLTAGES.

CAUTION: USE A SEPARATE ISOLATION TRANSFORMER FOR THIS UNIT WHEN SERVICING

© Philips Electronics North America Corporation

Visit our World Wide Web Site at http://www.forceonline.com

Manual 5871

Model no.: CCB130AT01

First Publish: 4-25-2000

Rev. Date: 9-27-2000

Print Date: 3/16/05

Pg. SCHEMATIC DIAGRAMS AND PC BOARDS

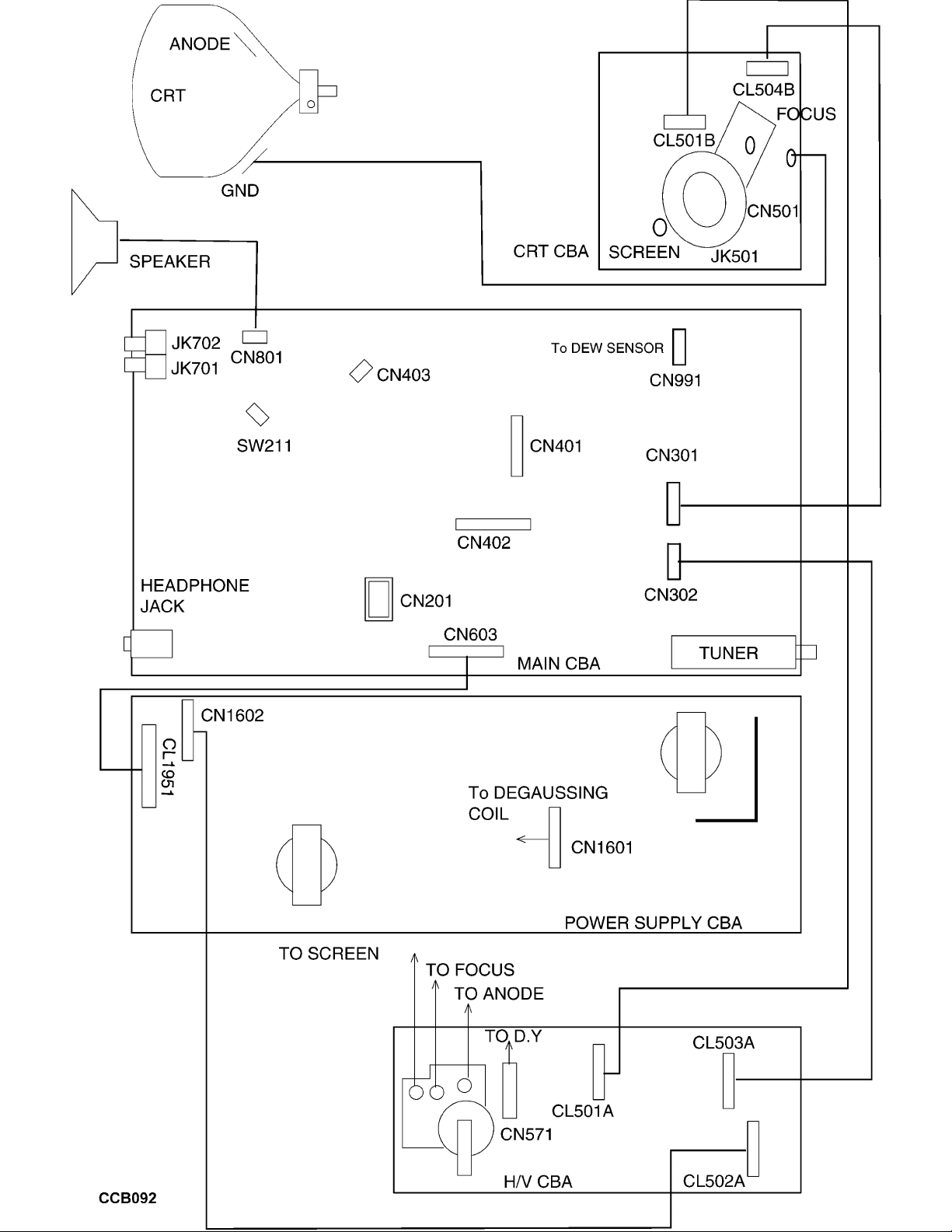

1. WIRING DIAGRAM

2. MAIN 1/4 SCHEMATIC

3. MAIN 2/4 SCHEMATIC

4. MAIN 3/4 SCHEMATIC

5. MAIN 4/4 SCHEMATIC

6. HV/CRT SCHEMATIC

7. MAIN CBA TOP VIEW

8. MAIN CBA BOTTOM VIEW

9. HV CBA TOP VIEW

10. HV CBA BOTTOM VIEW

11. CRT CBA TOP & BOTTOM VIEW

12. JUNCTION CBA TOP & BOTTOM VIEW

Philips Consumer Electronics

Technical Service Data

Service and Quality

Service Publications Dept.

One Philips Drive

P.O. Box 14810

Knoxville, TN 37914

REFER TO SAFETY GUIDELINES

SAFETY NOTICE:

ANY PERSON ATTEMPTING TO SERVICE THIS CHASSIS MUST FAMILIARIZE

HIMSELF WITH THE CHASSIS AND BE AWARE OF THE NECESSARY SAFETY PRECAUTIONS

TO BE USED WHEN SERVICING ELECTRONIC EQUIPMENT CONTAINING HIGH VOLTAGES.

CAUTION: USE A SEPARATE ISOLATION TRANSFORMER FOR THIS UNIT WHEN SERVICING

© Philips Electronics North America Corporation

Visit our World Wide Web Site at http://www.forceonline.com

Manual 5871

Model no.: CCB130AT01

First Publish: 4-25-2000

Rev. Date: 9-27-2000

Print Date: 3/16/05

Safety Notes

GENE R AL SAFETY NOT ES

I MPOR T ANT SAFETY NOT I CE

Proper service and r epai r is important to the s af e, reliable oper ati on of all Philips Consumer Electronics

Company** equipment. T he s er vi ce pr ocedur es recommended by Philips and des cr i bed i n thi s service

manual are effective methods of perfor ming s er vi ce oper at i ons . Some of these s er vi ce oper ati ons require

the us e of tool s specially des igned f or the pur pos e. T he s pecial tools should be us ed wh en and as

recommended.

I t is important to note t hat this manual contains various

CAUT I ONS

and

NOT I CES

which should be

carefully r ead i n order to mini mi ze t he r i s k of personal injury to s er vi ce per s onnel . The possibility ex is ts

that improper service met hods may damage the equi pment . I t also i s important to under s t and t h at these

CAUT I ONS

and

NOT I CES ARE NOT EXHAUSTIVE

. Philips could not possibly know, evaluate and

advise t he s er vi ce tr ade of all conceivable ways in which s er vi ce mi ght be done or of the possible

hazardous consequences of each way. Consequently, Philips has not undertaken any such broad

evaluation. Accor di n gl y , a s er vi cer who us es a s er v i ce procedur e or tool which is not recommended by

Philips must first satisfy himself thoroughly that neither his safety nor the s af e oper ati on of the equi pment

will be j eopar di z ed by the s er vi ce method s el ect ed.

** Hereafter throughout this manual, Philips Consumer Electronics Company will be r ef erred to as

Philips.

WARNING

Cr itical components having s peci al safety char acteris tics are i dent i f i ed wi t h a

or

" S"

by the R ef . No.

in the par ts list and encl os ed wi t hi n a br ok en line* (where s ever al critical components are gr ouped i n one

area) along wi th the s af et y symbol

on the s chemat i cs or exploded vi ews . Use of substitute

replacement parts which do not have the s ame s pecif i ed s afet y character is tics may cr eate s hock, fire, or

other hazards. Under no ci r cums t ances should t h e or i gi nal design be modi fi ed or altered wi t h out written

permission fr om Philips. Philips assumes no l i ability, express or implied, arising out of any unauthoriz ed

modification of design. Servicer assumes all liability.

•

Broken Li ne

____ _ ____ _ ____ _ ____

SAFETY CHECKS

After the or i gi nal service pr obl em has been corrected, a compl et e s af et y check should be made. Be s ur e

to check over the ent i r e s et, not just the ar eas where you have wor k ed. Some pr evi ous servicer may

have l eft an uns afe condit ion, which could be unknowi ngl y passed on to Your customer. Be s ur e to check

all of the f ollowing:

FIRE AND SHOCK HAZARD

IMPLOSION

X-RADIATION

LEAKAGE CURRENT COLD CHECK

LEAKAGE CURRENT HOT CHECK

PICTURE TUBE REPLACEMENT

PARTS REPLACEMENT

FI R E AND SHOCK HAZARD

1. Be s ur e all components are pos i t i oned i n s uch a way as to avoi d t he possibility of adj acent component

shorts. T his is especially important on thos e chassis which ar e t r ans por ted t o and f r om t he s er vi ce s hop.

2. Never release a r epai r ed uni t unless all protective devi ces such as insulators, barriers, covers, strain

reliefs, and other hardware have been i nstalled i n accor dan ce wi th the or i gi nal design.

3. Soldering and wi r i ng mus t be i ns pected t o l ocate possible col d s ol der joints, solder splashes, sharp

solder points, frayed l eads , pinched l eads , or damaged i ns u l at i on (incl uding the ac cor d) . Be cer t ai n to

remove loos e s ol der balls and al l other loos e f or ei gn part i cl es .

4. Check across-the-line component s and other components for physical evidence of damage or

deter ior ation and r epl ace i f necessary. Follow or iginal layout, lead l engt h, and dr es s .

5. No l ead or component should t ouch a r ecei vi ng t ube or a r es i s t or rated at 1 watt or more. Lead

tension around pr ot r udi ng met al surfaces or edges must be avoi ded.

6. Critical components having s pecial safety char acteri s tics are i denti fi ed wi th an

'S '

by the R ef . No. in

the par t s list and encl os ed wi t hi n a br ok en line* (where s ever al critical components are gr ouped i n one

area) along wi th the s af et y symbol

on the s chemat i c d i agr am s and / or exploded vi ews .

7. When s ervici ng any unit, always use a s epar ate i s ol ati on tr ansformer for the chas s i s . Failure t o us e a

separate i s olati on tr ans former may expose you to pos s i ble s hock hazar d, and may caus e damage to

servicing ins t r uments .

8. Many electronic pr odu ct s use a pol ar i z ed ac line cor d ( one wi de pi n on the pl ug) . Defeating t hi s

safety featur e may create a pot en t i al hazard t o t he s er vi cer and t he u s er . Extension cor ds which do not

incorporate t h e pol ar i z i ng f eatu r e s houl d never be us ed.

9. After reassembly of the uni t, always perform an

ac leakage test

or resistance tes t from the l i ne cor d t o

all exposed met al parts of the cabi net . Also, check all metal control shafts (with knobs removed),

antenna t er mi n al s , handles, screws, etc., to be s ur e t he uni t may be s af el y operated wi t h out danger of

electrical shock.

* Broken line ____ _ ____ _ ____ _ ____

IMPLOSION

1. All picture tubes used i n current model receivers are equi pped wi t h an i ntegral implosion s ys tem.

Care s houl d always be us ed, and s afet y glass es worn, whenever handling any picture t ube. Avoid

scratching or otherwise damagi ng t he pi ct ur e t ube dur i ng i ns tallation.

2. Use onl y r eplacement tubes specified by the manuf actur er .

X-RADIATION

1. Be s ur e pr ocedur es and ins t r ucti on s to all your service per s onnel cover the s ubj ect of X-radiation.

Potential sources of X-r ays in T V r ecei ver s are t he pi ctur e tube and t he hi gh voltage cir cui ts . T he basi c

precaution which mus t be ex er ci s ed i s to keep t he hi gh voltage at the factor y r ecommended l evel .

2. To avoi d possible expos ur e t o X- r adi ati on and elect r ical shock, only the manuf actur er ' s specified

anode connector s must be us ed.

3. It is essential that the s er vi ce technician has an accu r at e H V meter available at all times. T he

calibration of this meter should be checked per i odi cally against a r ef er ence s t andar d.

4. When the H V ci r cui t r y is operating pr oper l y ther e i s no possibility of an X-radi ation pr obl em. High

voltage s houl d al ways be k ept at the manufactur er ' s rated val ue - no hi gher - for optimum perfor mance.

Every time a col or set is serviced, the br i ght ness should be r un up and down while moni tor i ng t he H V

with a met er to be cer t ai n that the HV i s regulated correctly and does not exceed t he s peci fi ed val ue. We

sugges t that you and you r technici ans review tes t procedures so t hat HV and HV r egul ati on ar e al ways

checked as a s t andar d s er vi ci ng pr ocedur e, and the r eas on for this prudent routine i s clearly unders tood

by ever yone. It is important to us e an accu r at e and r eliable HV meter . I t is recommended t h at the HV

reading be r ecor ded on each customer's invoice, which will demonstrate a pr oper concern for the

customer's safety.

5. When tr oubleshoot i ng and mak i ng t es t measurements in a r ecei v er with a pr obl em of excessive hi gh

voltage, reduce the l i ne vol t age by means of a Var i ac t o br i ng t he HV i nt o accept abl e limits while

troubleshooti ng. Do not operate t he chassis longer than necessary to l ocate t he caus e of the excessive

HV.

6. New pictur e tubes are s peci f i cally designed to wi t hs t and hi gher operating vol tages without creating

undesirable X- r adi at i on . I t is strongly recommended that any shop t es t fixture whi ch is to be us ed wi t h

the new hi gher voltage chassis be equi pped wi t h one of the new type tubes designed f or this service.

Addi t i on of a per manent l y connected HV meter to the s hop t es t fixture i s advisable. T he CR T types used

in these n ew s ets should never be r epl aced wi t h any other types, as this may result in excessive

X-radiation.

7. It is essential to us e t he s pecifi ed pi ctur e t ube t o avoi d a possible X- r adiati on problem.

8. Most T V r ecei ver s contain some ty pe of emer gency " Hold Down" circuit to pr event HV fr om r is i ng t o

excessive l evel s in the pr es ence of a failure mode. T hese var i ous circuits should be under s t ood by all

technicians servicing t hem, especially since many hold down cir cuits are inoper at i ve as long as the

receiver performs normally.

L EAKAGE CURRENT COLD CHECK

1. Unplug t he ac line cor d and connect a j u mper between t he t wo pr ongs of the plug.

2. Turn on the power switch.

3. Measure the r es i s t ance val u e bet ween the j umper ed ac pl ug and all exposed cabi n et parts of the

receiver, such as screw heads, antennas, and cont r ol shafts. When t he ex pos ed met allic par t has a

return path to t he chassis, the r eadi ng s houl d be bet ween 1 megohm and 5. 2 megohms. When the

exposed met al does not have a r et ur n path to t he chassis, the r eadi ng mu s t be i nfi ni ty. Remove t h e

jumper from t he ac line cor d.

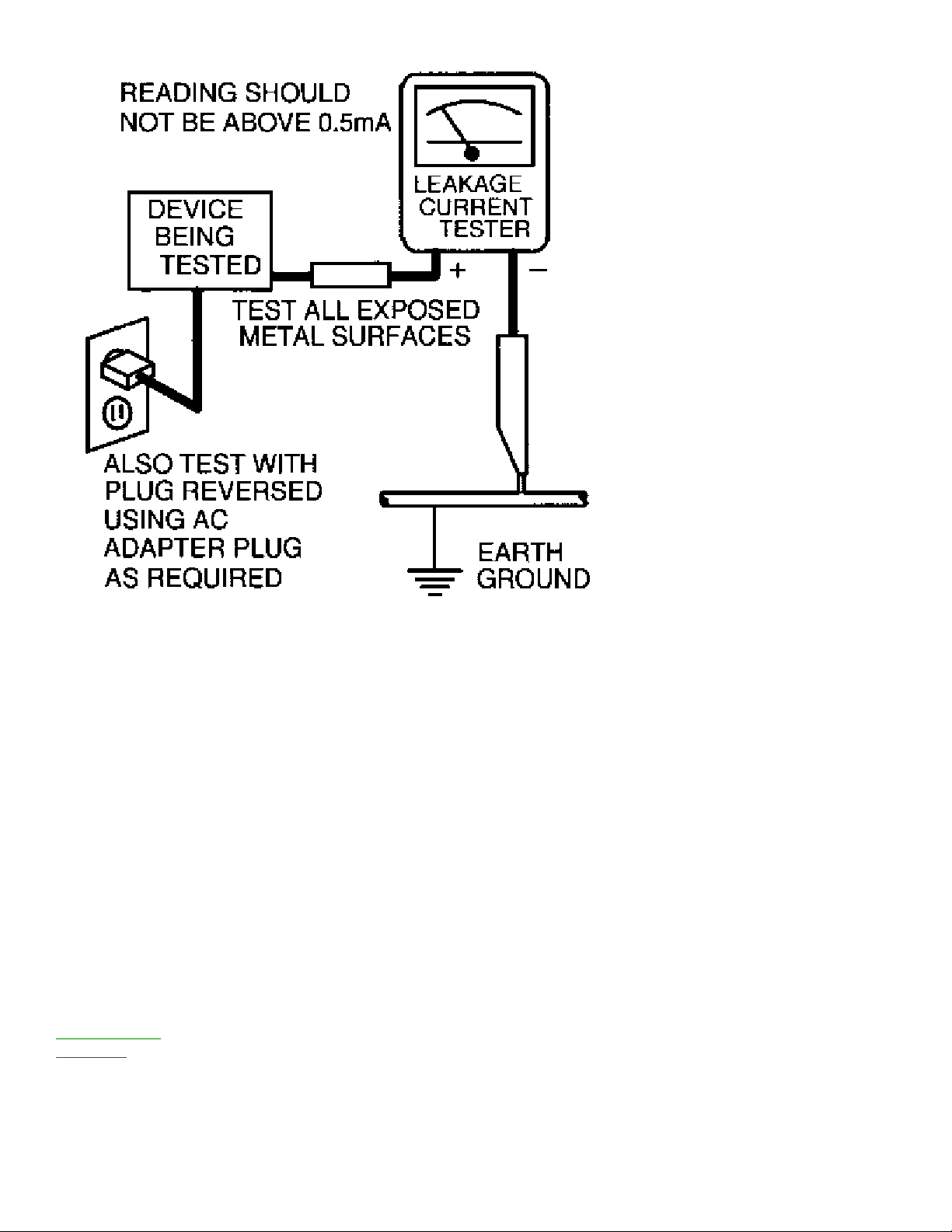

L EAKAGE CURRENT HOT CHECK

1. Do not use an is olation tr ansformer for this test. Plug the completel y reassembled r eceiver directly

into the ac ou t l et .

2. Connect a

1.5 k, 1OW resistor

paralleled by a

0.15uF. capacit or

between each exposed

metallic cabi net part and a

good ear t h ground

such as a wat er pipe, as shown bel ow.

3. Use an ac v ol t met er with at least 5000 ohms/volt sensitivity to meas ur e t he pot ent i al across the

resistor.

4.

T he potenti al at any point should not exceed 0 . 75 volts

.

A l eak age current tester may be

used t o make t h i s test; leakage current must not exceed 0 . 5 mi lliamp. I f a meas u r ement is outside of the

specified limits, there i s a possibility of shock hazard. The r ecei ver should be r epair ed and r echecked

before r etur ni ng i t to the cus t omer .

5

. Repeat the above pr ocedur e w i t h the ac pl u g r ever sed.

(Note: An ac adapt e r is

necessary when a pol ar i z ed pl ug i s used. Do not defeat the polar i z i n g f eat u r e of the pl ug. )

OR

With the i ns t r ument completely reass embled, plug the AC line cor d di r ectl y into a 120V AC ou t l et .

(Do

not use an isolation transformer during t hi s test.)

Use a l eak age current tester or a

metering s ys t em t hat complies with Amer ican Nati onal Standards Institute ( ANS I ) C101.1 Leakage

Current for Appliances and U nder wr i t er s Laboratories (UL) 1410, (50.7).

W it h the in st r umen t

AC s w i t ch first in the on position and t hen in the off position, measur e f r om a

known earth ground (met al water pipe, conduit , etc.) to all exposed met al

par t s of the in st r ument (antennas, handle br acket s, metal cabinet, screw

heads, metallic ov er l ay s , control shafts, etc.), especially any exposed met al

par t s that offer an electrical return path to t he chassis.

Any current

measur ed must not exceed 0.5 milliamp.

R everse t he i ns t r umen t power cord

plug in the out let and repeat the t est . See gr aphi c bel ow .

PICTURE TUBE REPLACEMENT

T he pr i mar y source of X-radiation in this television r eceiver is the pi ct ur e t ube. The pi ctu r e t ube ut ilized

in this chassis is specially constr ucted to l i mi t X-radiation emissions. For continued X - r adi ati on protecti on,

the r epl acement tube mus t be t he s ame t ype as the or i gi nal, including s u ffix letter, or a Philips approved

type.

PARTS REPLACEMENT

Many electrical and mechani cal parts in Philips television s ets have s peci al safety r elated char acter i s t i cs .

T hese char act er i s ti cs are oft en not evident from vis ual inspection nor can the pr otecti on afforded by them

necessarily be obt ai ned by using r epl acement components rated f or higher voltage, wattage, etc. The

use of a s u bs t i t ut e par t which does not have the s ame s afet y char acteri s tics as the Philips recommended

replacement part shown in thi s service manual may cr eate s hock, fire, or other hazards

TV SAFETY NOTES

SAFETY CHECKS

IMPLOSION

X-RADIATION

PICTURE TUBE REPLACEMENT

PARTS REPLACEMENT

W AR NI NG

Before r emovi ng t h e CRT anode cap, turn the uni t

OFF

and s hor t the

HI GH VOLT AGE

to the

CR T DAG

ground.

S E R VI CE NOT E:

T he CR T DAG

is not at chassis ground.

TV-VCR COMBI SAFETY NOTES

I MPOR T ANT SAFETY PRECAUT I ONS

Prior to s hi pment from the f actor y , our products are s t r i ctl y inspected f or recognized pr oduct safety and

electrical codes of the count r i es in which they ar e to be s ol d. However, in order to maint ain such

compliance, it is equally important to i mpl ement the f ollowing pr ecaut i ons when a s et is being s er vi ced.

SAFETY PRECAUTIONS FOR TV CIRCUITS

1. Before r et ur ni ng an i ns tr ument to t he cus tomer , always make a s af et y check of the ent i r e i ns t r ument ,

including, but not limited t o, the f ollowing i tems :

a. Be s ur e t hat no built-in protecti ve devi ces are defecti ve or have been defeated dur i n g s er vi cing. (1)

Protective s hi el ds are pr ovi ded on this chassis to pr otect both the t echni ci an and t he cus t omer .

Correctly replace al l missing pr ot ect ive s hi el ds , including any removed for servicing conveni ence. (2)

When reinstalling the chassis and/or other assembly in the cabinet , be s ur e t o put back in place all

protective devi ces , including but not limited to, nonmetallic con t r ol knobs, insulating f i s h paper s ,

adj ustment and compar tment covers/shields, and i s ol ati on r es i stor/capacitor networks. Do not

operate t hi s instrument or permit it to be oper ated wi t hout al l protective devi ces correctly installed and

functioning. Servicers who defeat safety features or fail to perf or m s afety checks may be liable f or any

resulting damage.

b. Be s ur e t hat there ar e no cabi net openings through which an adult or child mi gh t be abl e t o i ns er t

their fingers and con t act a haz ar dous voltage. Such openings include, but are not limited t o, (1)

spacing between the pi ctur e t u be and t h e cabinet mask, (2) excessively wide cabi net ventilation slots ,

and (3 ) an impr operly fitted and/or incorrectly secured cabi net back cover .

c. Do a

LEAKAGE CURRENT CHECK

ANY MEASUREMENT S NOT WITHIN T HE LI MI TS SPECIFIED HE R EI N I NDI CAT E A POT E NT I AL SHOCK

HAZARD T HAT MUST BE ELIMI NAT ED BE F OR E RETURNI NG T H E I NSTRUMENT TO T H E CUST OMER OR

BEFORE CONNE CT I NG T H E ANTENNA OR ACCE SSORIES.

d. X-R adiation and Hi gh Voltage L i mi t s

- Because the pi ctur e t ube i s the pr i mar y potential source

of X-radiation in s olid-state T V receiver s , it is specially constructed to pr ohi bit X-radiation emissions.

For continued X - r adi ati on protecti on, the r epl acement picture t u be mus t be t he s ame t ype as the

original. Also, because t he pi ctur e tube s hi el ds and mount i n g har dwar e per f or m an X-r adiati on

protection function, they must be correctly in place. High voltage mus t be meas ur ed each ti me

servicing is performed t hat involves B+, horizontal deflection or high voltage. Correct operation of the

X-radiation protecti on cir cuits also mus t be r econf i r med each time they ar e s er vi ced. (X-radiation

protection circuits also may be cal l ed " hor iz ont al disable" or "hold down. " ) Read and appl y the hi gh

voltage limits and, if the ch as s i s is so equi pped, the X- r adiat i on protecti on cir cuit specifications given

on i nstrument labels and i n the

Pr oduct Safety & X-Radiation

Warning note on the s er vi ce data

chassis schematic. High voltage is maintained wi t hi n s pecifi ed l i mi t s by close tol er ance s afet y- r el ated

components/adjustments in the hi gh- vol tage ci r cui t. I f high voltage ex ceeds specified limits, check

each component specified on the chassis schematic an d t ake corrective act i on.

2. Read and compl y with all caution and s af et y- r el at ed not es on or inside the r eceiver cabinet, on the

receiver chassis, or on the pi ctur e tube.

3. Desi gn Alteration Warning

- Do not alter or add to t he mechani cal or electrical design of this TV

receiver. Design alterati ons and addi t i on s , including, but not limited t o ci r cui t modifications and th e

addi t i on of items such as auxiliary audio and/or video out put connections, might alter the s af et y

character istics of this receiver and cr eate a haz ar d to the us er . Any desi gn alterations or additions will

void t he manuf act ur er ' s warranty and may make you, the s er vi cer , responsible f or personal injury or

property damage r es ul t i ng t her efr om.

4. Pict ur e T ube I mpl os ion Protection Warning

- The pictur e tube i n thi s receiver employs integral

implosion protecti on. For continued i mpl os i on protection, replace t he pi ctu r e tube onl y with one of the

same t y pe number . Do not remove, install, or otherwise handl e t he pictur e t ube i n any manner without

first putting on shatterproof goggles equipped wi t h side s hi el ds . People not so equi pped mus t be kept

safely away while pictur e t ubes are handl ed. Keep the pi ct ur e t ube away fr om your body. Do not handle

the pictur e t ube by its neck. Some " i n- line" picture t ubes are equi pped wi t h a per man ent l y attached

deflection yoke; because of potential hazard, do not try to r emove s uch "per manently attached" yokes

from the pi ctur e t u be.

5. Hot Chassis Warning

a. Some T V r eceiver chassis are el ectr i cally connected di r ect l y to one conductor of the ac pow e r cord

and may be s er vi ced s afel y without an is olation tr ans f or mer only if the ac po w er plug i s inserted s o

that the chass i s is connected t o t he gr ou nd s i de of the ac pow er source. T o conf i r m that the ac

power plug i s inserted correctly, with an ac vol t met er , measure bet ween the chassis and a k nown

ear th ground. I f a vol t age r eading i n excess of 1.OV i s obtained, remove and r ei ns er t the ac pow e r

plug in the oppos i t e pol ar i t y and agai n measur e t he vol t age pot ent i al between the chassis and a

known ear th ground.

b. Some T V recei ver chassis normally have 85Vac ( R MS ) between chassis and ear th ground

regardless of the ac pl ug pol ar i t y. T his chassis can be s af ety- s er vi ced onl y with an is olation

transformer inserted i n the power line between the r ecei ver and t he ac po wer source, for both

personnel and tes t equipment protection. Some T V r ecei ver chassis have a s econdar y gr ound s ys t em

in addi ti on to the mai n chassis ground. T his secondary ground s y s t em i s not isolated f r om the ac

power line. T he two gr ound s y s t ems are el ectr i cal l y separated by ins ulation materi al that must not

be def eated or altered.

6. Observe or i gi nal lead dr ess. T ake ext r a car e to assure correct lead dr ess in the f oll owi ng ar eas :

a.

near sharp edges ,

b. near thermally hot parts - be s ur e t hat leads and compon ent s do not touch

thermally hot parts,

c. the ac s uppl y ,

d. high voltage, and

e. antenna wi r i ng. Always inspect in all areas

for pinched, out of place, or frayed wi r i ng. Check ac pow e r cord for damage.

7. Components, parts, and/or wiring t hat appear to have over heated or are ot h er wi s e damaged s houl d be

replaced wi t h components , parts, or wiring t h at meet original specifications. Additionally, determine th e

cause of overheating and/or damage and, if necessary, take corrective act i on to r emove any potential

safety hazard.

PRECAUTIONS DURING SERVICE

A. Parts identified by the

symbol are cr i t i cal for safety. Replace onl y with par t number specified.

B. I n addi tion to s af et y, other parts and assemblies are s peci f i ed f or conformance wi t h regulations

appl y i ng t o s pur i ous radiation. These mus t also be r epl aced onl y with s pecifi ed r epl acement s .

Examples:

RF converters, RF cables, noise bl ocki ng capaci tor s , and noi s e bl ocki ng f ilters, etc.

C. Use s peci f i ed i nt er nal wiring. Note es peci al l y:

1) Wires covered wi t h PVC t u bi ng

2) Double i ns u l ated wi r es

3) High voltage leads

D. Use s pecif i ed i n s ul ati ng mat er i al s for hazardous

live par ts . Note es pecially:

1) Insulation T ape

2) PVC t u bi ng

3) Spacers

4) Insulators for transistors

E. When r epl acing ac pr i m ar y side component s (transformers, power cord, etc.), wrap ends of wires

securely about the ter mi nals before s ol der i ng.

F. Observe that the wi r es do not contact heat producing par t s (heatsinks, oxide met al film r es i s tor s ,

fusible r es i s t or s , etc.)

G. Check that replaced wi r es do not contact sharp edged or pointed par t s .

H. When a power cord has been r eplaced, check that 10-15 kg of force i n any dir ecti on will not

loos en it.

I . Also check areas surrounding r epai r ed l ocat i ons .

J. Use care t hat foreign obj ects (screws, solder droplets, etc.) do n ot remain ins i de the s et .

K. Crimp t ype w ir e connector

When replaci ng the power transformer in s ets where the connecti ons between the power cord and power

transformer primary lead wi r es are per f or med us ing cr imp t y pe connectors , in order to pr event shock

hazards, perform car efully and pr eci s el y the following s t eps .

R eplacement procedure

1) Remove the ol d connector by cutting the wi r es at a poi n t clos e t o the connector.

I mport ant :

Do

not re-use a connect or (discard i t ) .

2) Strip about 15 mm of the ins ul ati on fr om the ends of the wi r es . I f the wi r es are s t r anded, twist

the st r ands to avoi d f r ayed conductor s .

3) Align the l engt hs of the wi r es to be connected. Insert the wi r es fully into t he connector .

4) Use t he cr i mpi ng t ool to cr i mp t he met al sleeve at the cent er position. Be s ur e t o cr i mp f u lly to

the compl ete clos ur e of the tool .

L. When connecti ng or disconnecti ng the VCR connectors , first, disconnect the ac pl u g f r om the ac s u ppl y

socket.

SAFETY CHECK AFTER SERVICING

Examine the ar ea s urrounding t he r epai r ed l ocati on for damage or deterioration. Observe t h at screws,

parts and wi r es have been r eturned to or i gi nal positions. Afterwards, perform t he f ollowing t es ts and

confirm the s peci fi ed val ues in or der to ver i fy compliance wi t h safety standar ds.

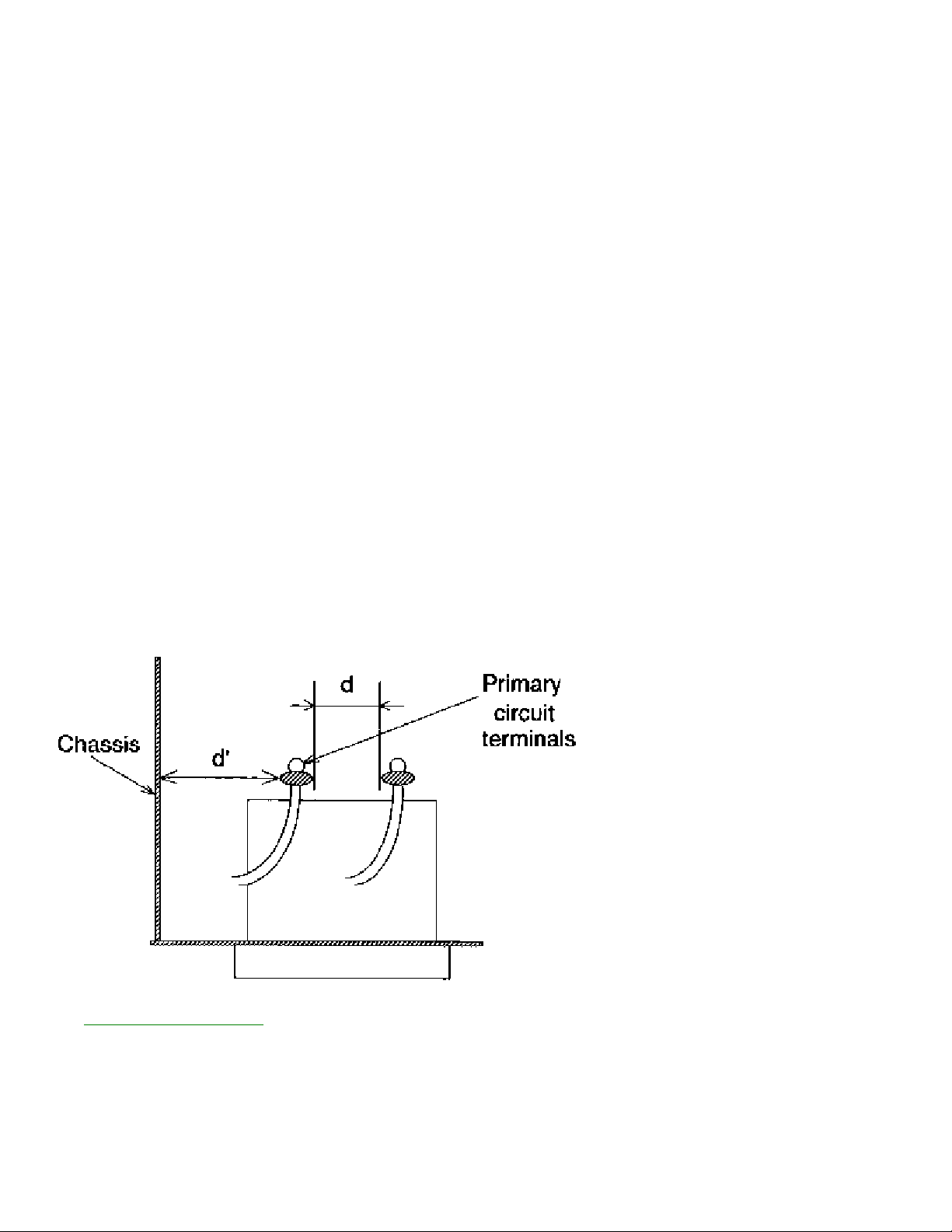

1. Clearance D i st ance

When replaci ng pr i mar y circuit components, confirm s peci fi ed cl ear ance di s t ance ( d) and ( d' ) between

solder ed t er mi n al s , and between terminals and s urrounding met al lic par t s . (See gr aphi c bllow)

T able 1 : Ratings for selected ar ea

AC L i n e Volt age R egion Clear ance Distance

(d) (d')

USA or > 3.2 mm

110 to 130 V CANADA (0.126 inches)

Note

: This table is unofficial and f or reference onl y. Be s ur e t o conf i r m the pr eci s e v al ues .

2.

LEAKAGE CURRENT CHECKS

VCR SAFETY NOTES

FIRE & SHOCK HAZARD (VCR)

1. Be s ur e that all components are pos i ti oned i n such a way to avoi d possibility of shorts to adj acent

components. T his is especially i mportant on those chassis which are t r ans por ted t o and f r om the r epai r

shop.

2. Always replace all protective devi ces such as insulators and barriers after working on a s et .

3. Check for damaged i ns u l at i on on wir es including t he ac cor d.

4. Check across-the-line component s for damage and r epl ace if necessar y.

5. After re-assembly of the uni t , always perform an ac l eak age t es t on t he ex pos ed met allic par t s of the

cabinet such as the k nobs , antenna t er mi nal s , etc. to be s ur e t he s et is safe to oper ate wi thout danger of

electrical shock.

Do n ot use a line i s ol at i on transf ormer during this test.

Use an ac v ol t met er

having 5000 ohms per volt or more s ens i t i v i t y in the f ollowing manner: Connect a 1500 ohm 10 wan

resistor, paralleled by 0. 15 MFD ac t y pe capaci tor , between a k now n good ear t h ground ( wat er pipe,

conduit, etc.) and the ex pos ed met allic par t s , one at a ti me. Measure t he ac v ol t age acr oss the

combination 1500 ohm r es i s t or and 0 . 15 MFD capacitor . Reverse t he ac pl ug on the s et and r epeat ac

voltage meas ur ement s again for each expos ed met allic par t . Voltage meas ur ed mu s t not exceed O.6 volts

R.M.S. T his corresponds to 0. 4 milliamp ac. Any value ex ceedi ng t hi s limit cons titutes a pot ent i al shock

hazard and mus t be corrected i mmedi atel y.

GENE R AL

Power Supply-This receiver is designed f or operation on 120 Volts , 6OHz alternating current (ac) only.

Never connect to a s uppl y having a di fferent frequency or voltage.

IMPORTANT NOTICE

T his device empl oys many ci r cuits , components, and mechani cal parts designed f or protection agai ns t

fire, shock and R F interference. For continued s afet y any servici ng s h oul d be per f or med by qualified

personnel and exact replacement parts should be us ed. Under no cir cums t ances should t he or i gi nal

design be al ter ed.

PRODUCT SAFETY GUIDELINES FOR ALL PRODUCTS

CAUT I ON

: Do not modify any ci rcuit. Service wor k should be per f or med on l y after you ar e t hor oughl y

familiar with all of the following s afet y checks . Risk of potential hazards and i nj u r y to the us er increases if

safety checks are not adhered to.

US E A S E P AR AT E I SOLATI ON T RANSFORMER FOR THIS UNI T WHEN SER VI CI NG.

PREVENTION OF ELECTROSTATIC DISCHARGE (ESD)

Some s emi conductor solid s tat e devi ces can be damaged eas i l y by static el ect r i ci t y . Such components

commonl y ar e called E l ectr os t at i cally Sensitive ( E S ) Devices, Examples of typical ES devices are

integrated ci r cui t s and s ome f i el d-ef f ect transis tors and s emi conductor "chip" components. T he following

techniques should be us ed t o hel p r educe the i nci dence of component damage caus ed by electrostatic

dis charge (E S D) .

1. Immediatel y before handl i ng any semiconductor component or semiconductor-equipped assembly,

drain off any ESD on your body by touching a k nown ear th ground. Alternatively, obtain and wear a

commer ci all y available di s char gi ng E S D wr is t strap, which should be r emoved f or potential shock reas ons

prior to appl yi ng power to the uni t under test.

2. After removing an electr ical assembly equipped wi t h E S devices, place the assembly on a con duct i ve

surface s uch as aluminum foil, to pr event electrostatic ch ar ge bui l dup or exposure of the assembly.

3. Use onl y a gr oun ded- t i p s ol der i ng i r on to s ol der or unsolder ES devices.

4. Use onl y an anti -s tatic s ol der removal device. Some s ol der removal devices not classified as "antistatic

(ESD protected)" can generate an electr ical charge s ufficient to damage E S devices.

5. Do not use f r eon· pr opel l ed chemi cal s . T hese can gener ate el ect r i cal charges sufficient to damage ES

devices.

6. Do not remove a r epl acement ES device f r om i t s protective pack age un t il immediatel y before you ar e

ready to ins t all it (Most replacement ES devices are pack aged wi th l eads electrically shorted toget h er by

conductive f oam, aluminum f oil or comparable conducti ve mat er i al) .

7. Immediatel y before r emovi ng t he pr otecti ve mater i al from the l eads of a r epl acemen t ES device, touch

the prot ect i ve mat er i al to the chassis or circuit assembly into whi ch the devi ce will be i ns t alled.

CAUT I ON

: Be s ur e no power is applied to t he chassis or circuit and obs er ve all other safety pr ecautions.

8. Minimize bodily motions when handli ng u n pack aged r epl acement ES devices. (Otherwise har ml ess

motion such as the br us h i ng t ogether of your clothes fabric or the l i f t i ng of your feet fr om a car pet ed

floor can generate s tat i c el ect r i ci t y (ESD) sufficient to damage an ES device.)

NOT E to CAT V s yst em I nst aller:

T his reminder is provided to cal l the CAT V sys tem i ns taller's attention to ar ti cl e 820-22 of the NE C t h at

provides guidelines for proper grounding and, in par ticular , specifies that the cable gr ound s h all be

connected t o t he gr oundi ng s ys t em of the building, as close to t h e poi nt of cable ent r y as practical.

Philips Consumer Electronics

Technical Service Data

Service and Quality

Service Publications Dept.

One Philips Drive

P.O. Box 14810

Knoxville, TN 37914

REFER TO SAFETY GUIDELINES

SAFETY NOTICE:

ANY PERSON ATTEMPTING TO SERVICE THIS CHASSIS MUST FAMILIARIZE

HIMSELF WITH THE CHASSIS AND BE AWARE OF THE NECESSARY SAFETY PRECAUTIONS

TO BE USED WHEN SERVICING ELECTRONIC EQUIPMENT CONTAINING HIGH VOLTAGES.

CAUTION: USE A SEPARATE ISOLATION TRANSFORMER FOR THIS UNIT WHEN SERVICING

© Philips Electronics North America Corporation

Visit our World Wide Web Site at http://www.forceonline.com

Manual 5871

Model no.: CCB130AT01

First Publish: 4-25-2000

Rev. Date: 9-27-2000

Print Date: 3/16/05

Mechanical Adjustments

DISASSEMBLY INSTRUCTIONS

Cabinet and Main Assemblies

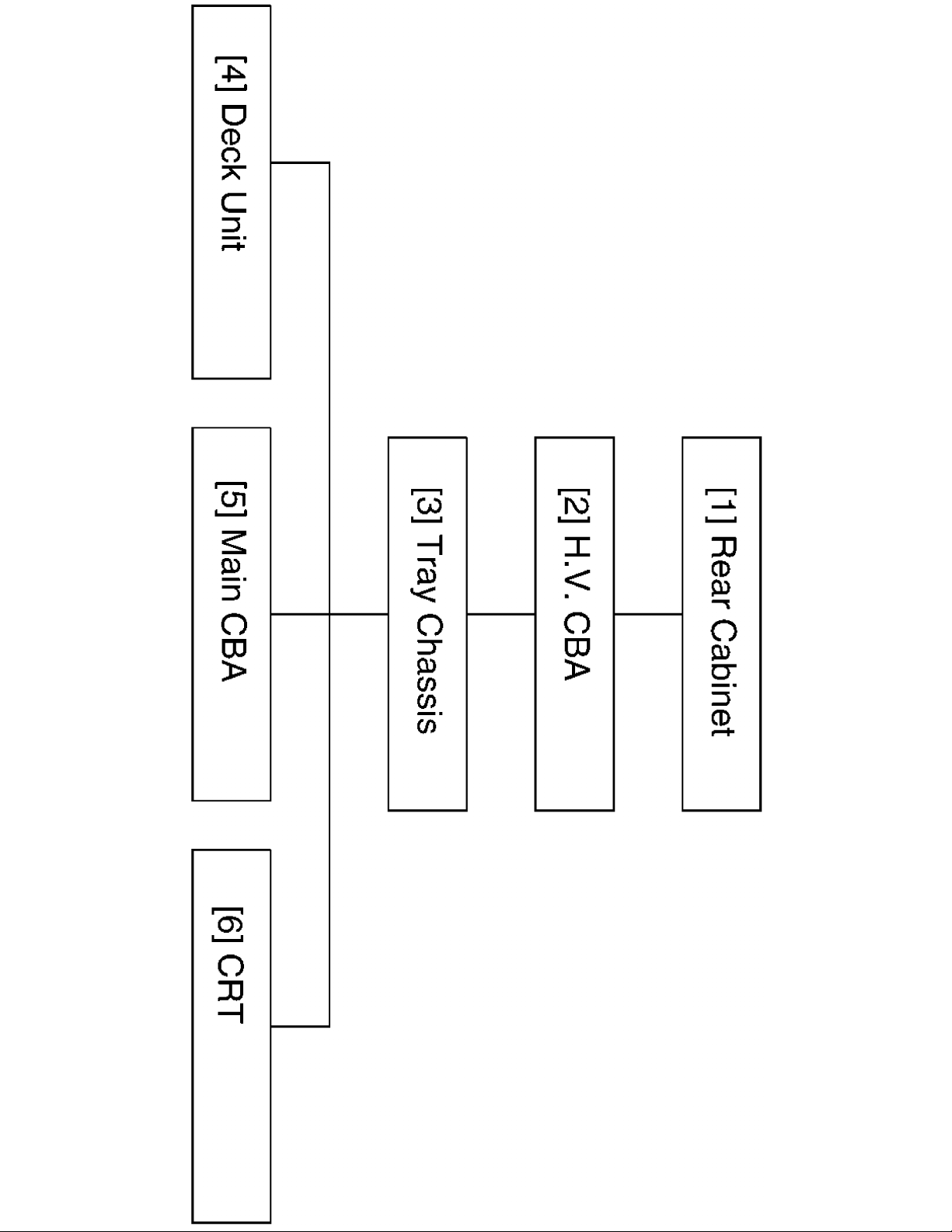

Disassembly Flowchart

This flowchart indicates the disassembly steps for the cabinet parts, and the CBA in

order to gain access to item(s) to be serviced. When reassembling, follow the steps

in reverse order. Bend, route and dress the cables as they were.

Click here for Disassembly Flowchart

Caution !

When removing the CRT, be sure to discharge the Anode Lead of the CRT with the

CRT Ground Wire before removing the Anode Cap.

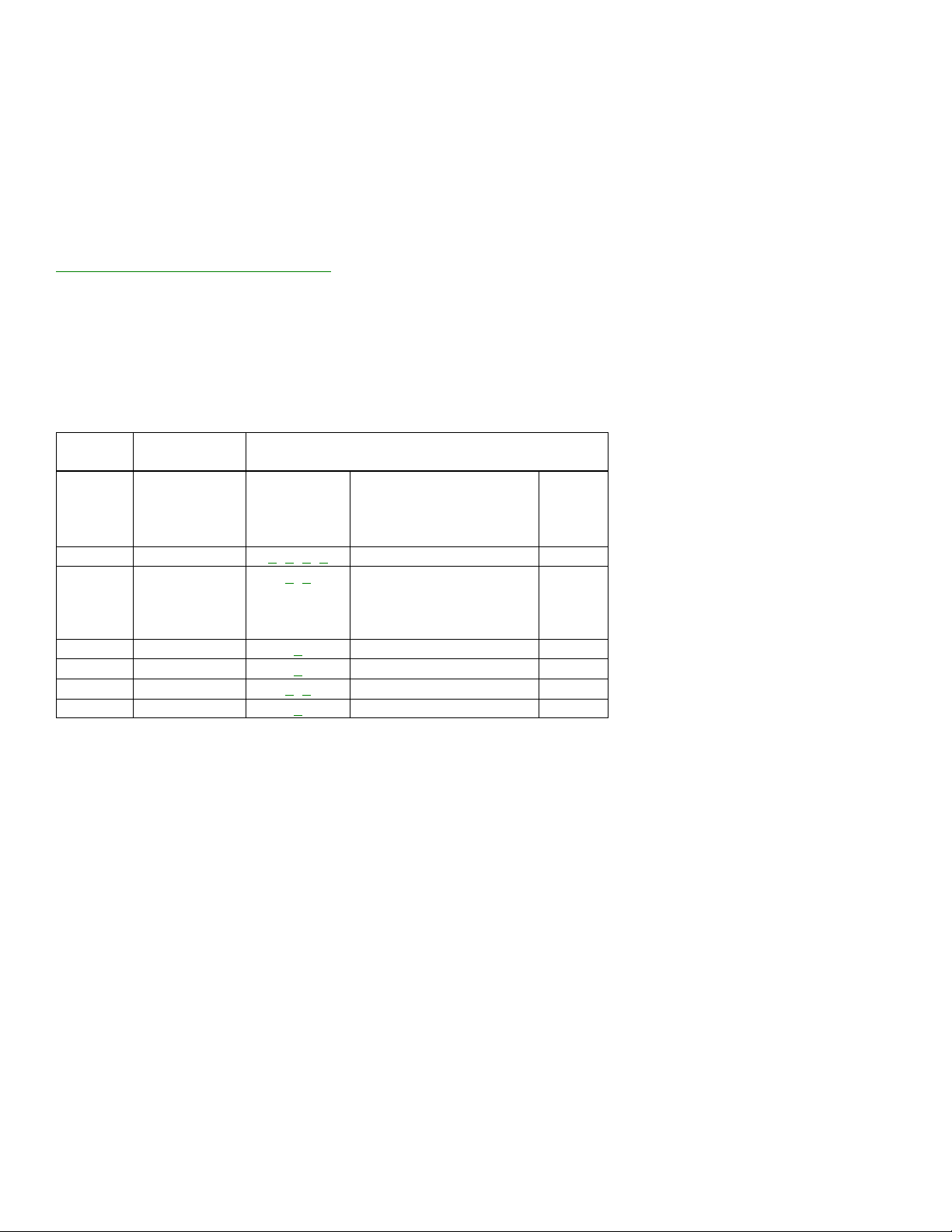

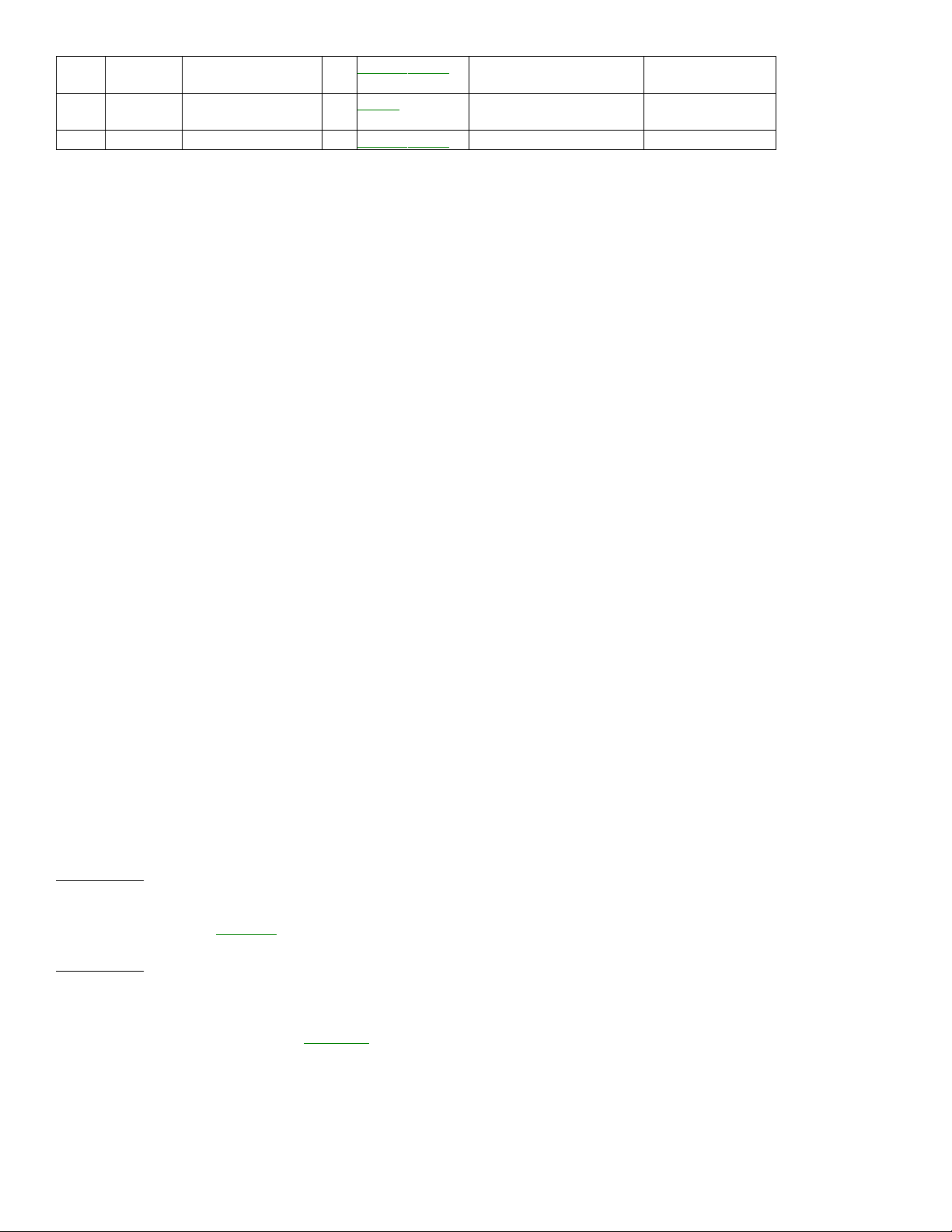

Disassembly Method (CCB132)

STEP/

LOC. NO.

PART

REMOVAL

FIG. NO.

REMOVE/

UNLOCK/RELEASE/

UNPLUG/

UNCLAMP/DESOLDER

NOTE

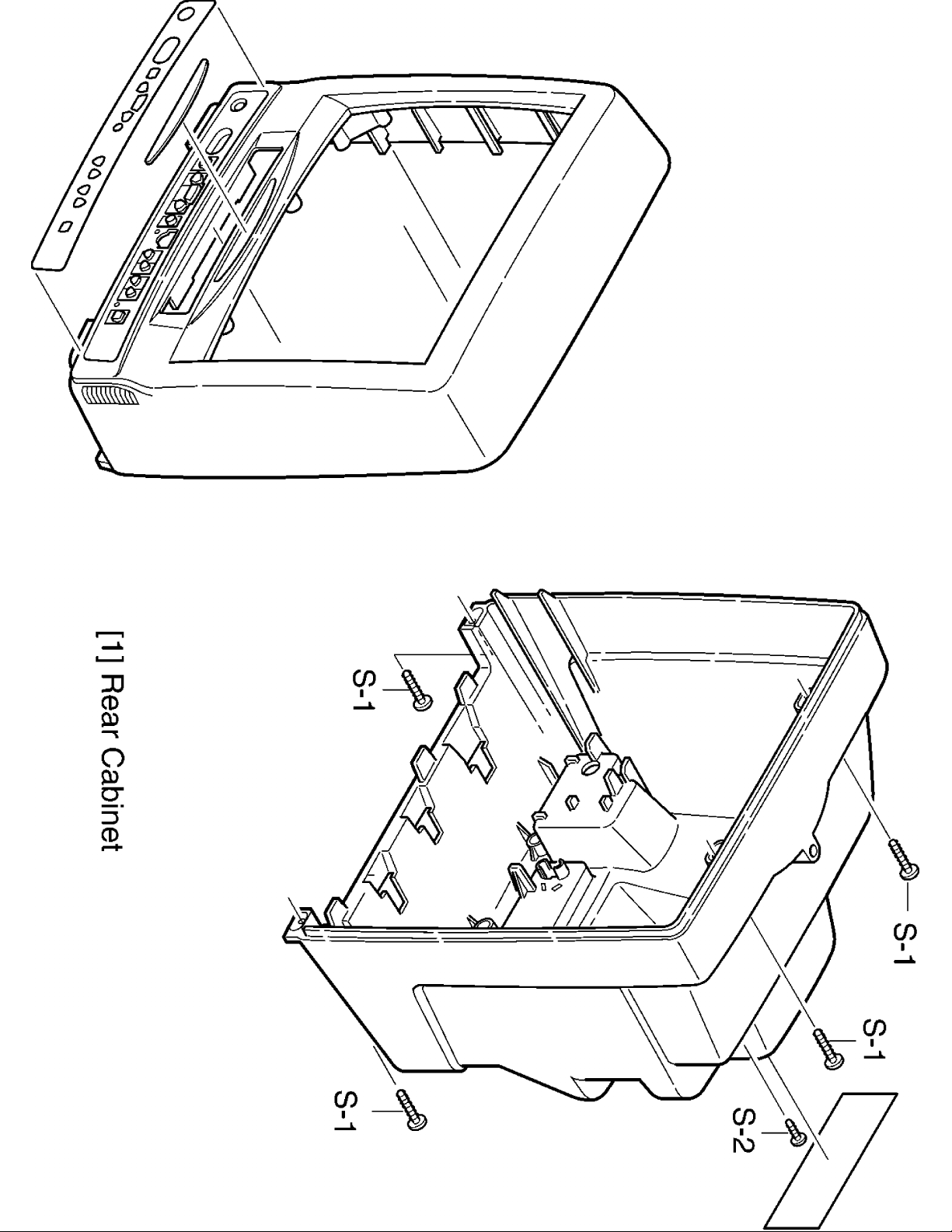

[1]

Rear Cabinet

1

,

2,

3,

4

4(S-1), (S-2)

1

[2]

H/V CBA(With

Holder)

5

,

7

Anode Cap, CRT CBA,

CL501A, CN503, CN571,

CN575, CN602 2(S-3),

2(L-1)

2

[3]

TrayChassis

5

CN601, CN801

3

[4]

Deck Unit

5

7( S-4), 1( S-5)

4

[5]

Main CBA

5

,

7

6(S-6)

5

[6]

CRT

6

4(S-7)

6

[1] [2] [3] [4] [5]

[1]

Order of steps in procedure. When reassembling, follow the steps in reverse

order. These numbers are also used as the identification (location) No. of parts

in figures.

[2]

Parts to be removed or installed.

[3]

Fig No. showing procedure of part location

[4]

Identification of part to be removed, unhooked, unlocked, released, unplugged,

unclamped, or desoldered.

S=Screw, P=Spring, L=Locking Tab, CN=Connector, *=Unhook, Unlock,

Release, Unplug, or Desloder

2(S-2) = two Screws (S-2)

[5]

Refer to the following ”Reference Notes in the Table“

Reference Notes in the Table

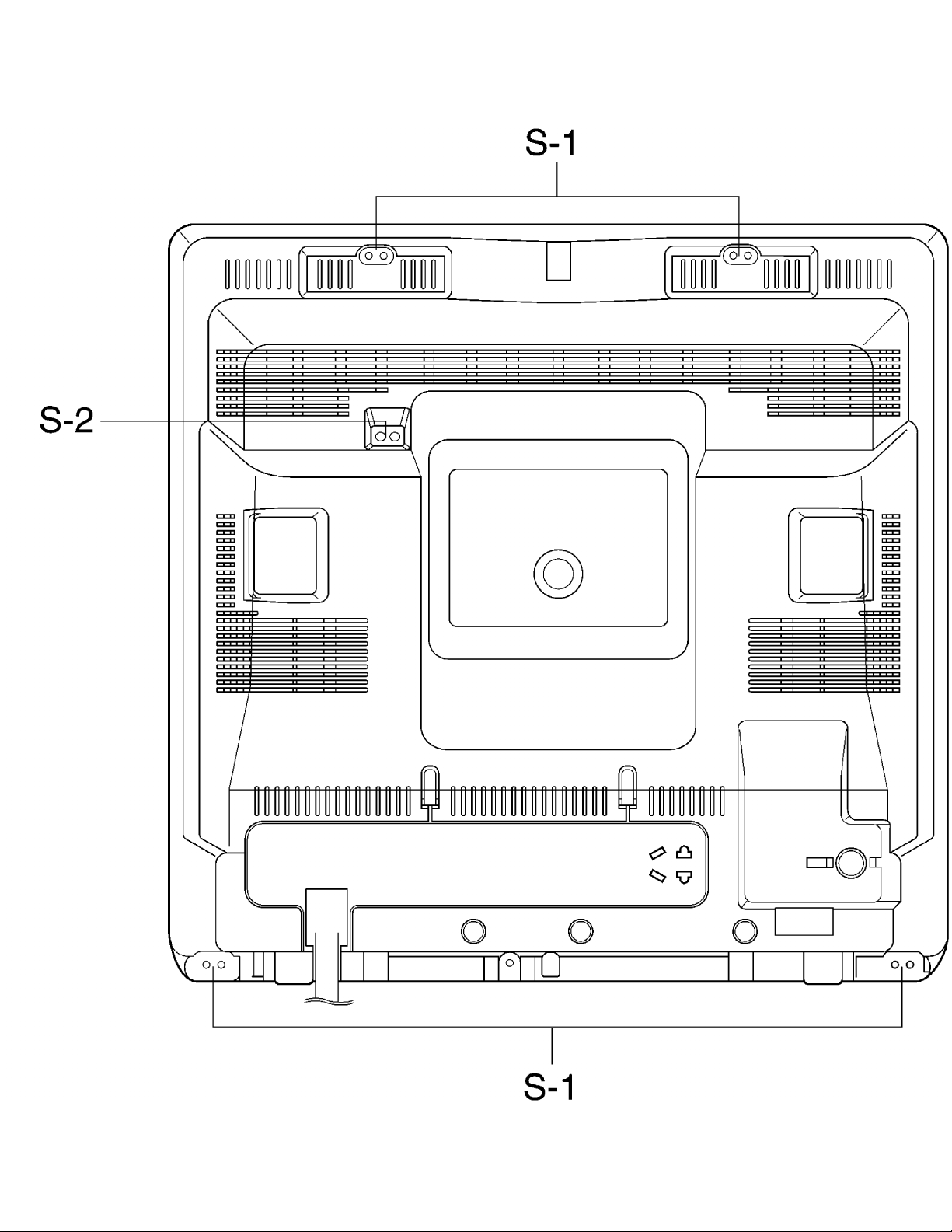

1. Removal of the Rear Cabinet.

Remove Screws 4(S-1) and 1(S-2)

Caution!

Discharge the Anode Lead of the CRT with the CRT Ground

Wire before removing the Anode Cap.

2. Removal of the H/V CBA with Holder. Discharge the Anode lead of the CRT with

the CRT Ground Wire before removing the Anode Cap.

Disconnect the following: Anode Cap, CRT CBA, CL501A, CN503, CN571,

CN575, and CN602.

Remove 2(S-3). Unlock 2(L-1). Pull the H/V CBA backward.

3. Removal of the Tray Chassis. Disconnect CN601 and CN801. Pull the Tray

Chassis backward.

4. Removal of the Deck Unit. Remove 7(S-4) and 1(S-5). Lift up the Deck Unit.

5. Removal of the Main CBA. Remove 6(S-6). Lift up the Main CBA.

6. Removal of the CRT. Remove 4(S-7) and pull the CRT backward.

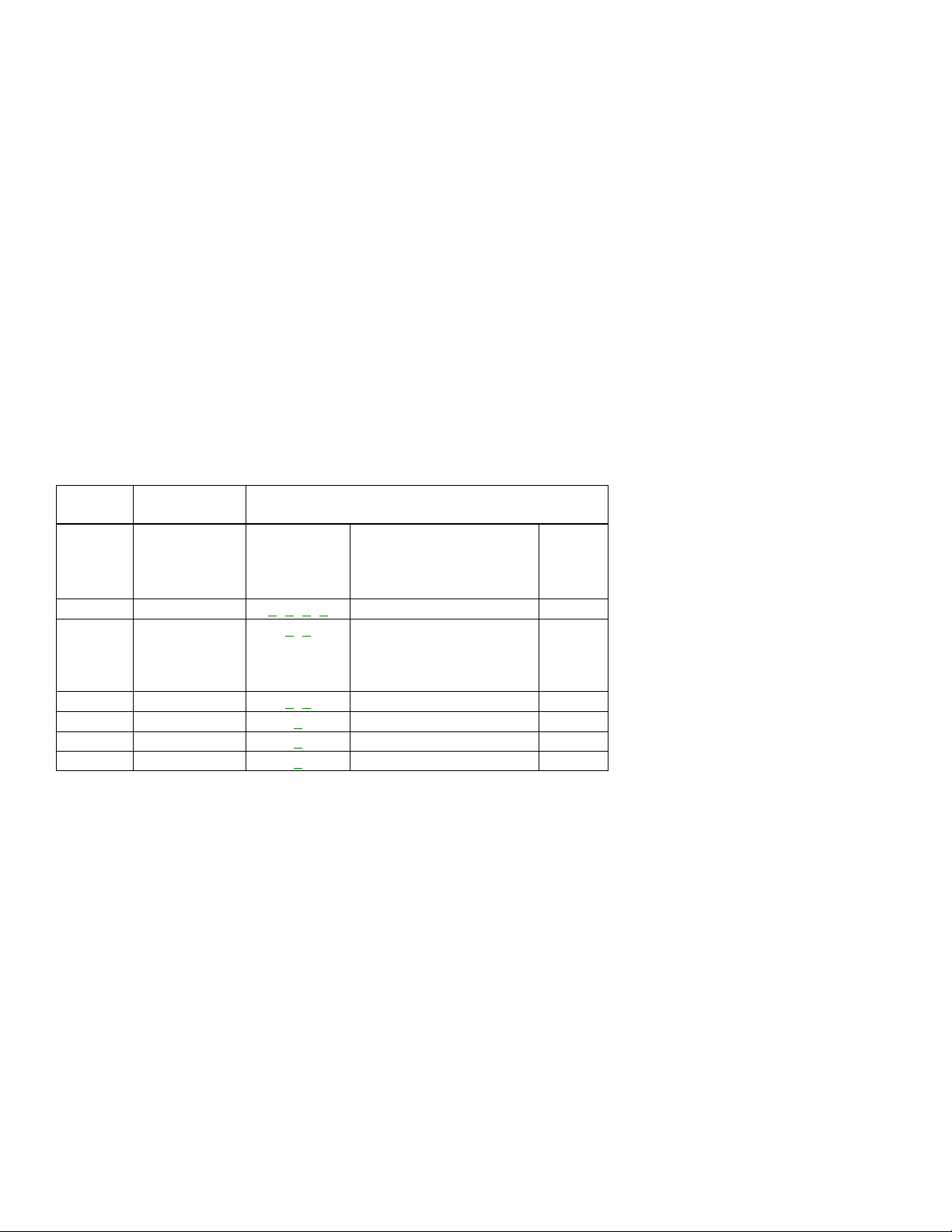

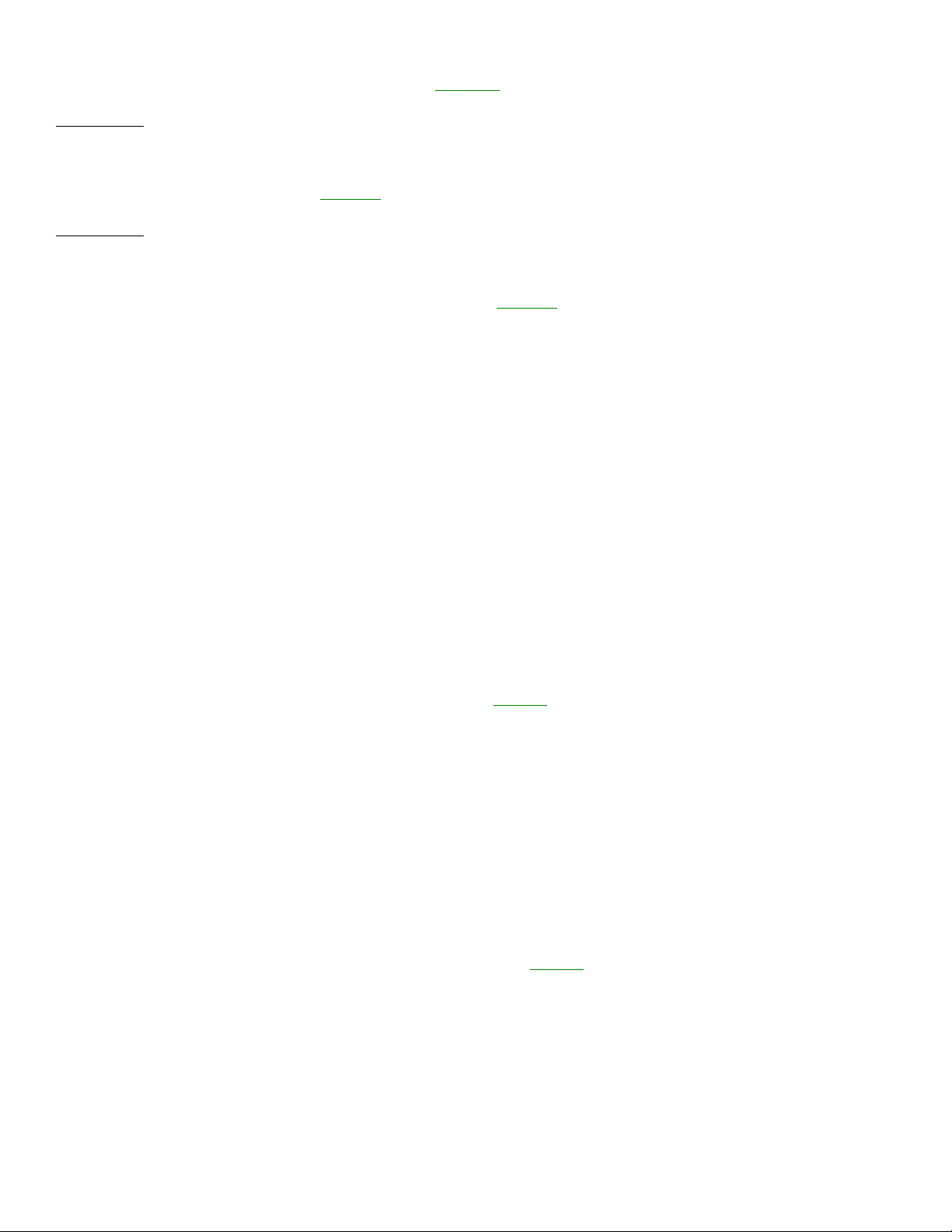

Disassembly Method (CCB255)

STEP/

LOC.

NO.

PART

REMOVAL

FIG.

NO.

REMOVE/*UNLOCK/

RELEASE/UNPLUG/

UNCLAMP/DESOLDER

NOTE

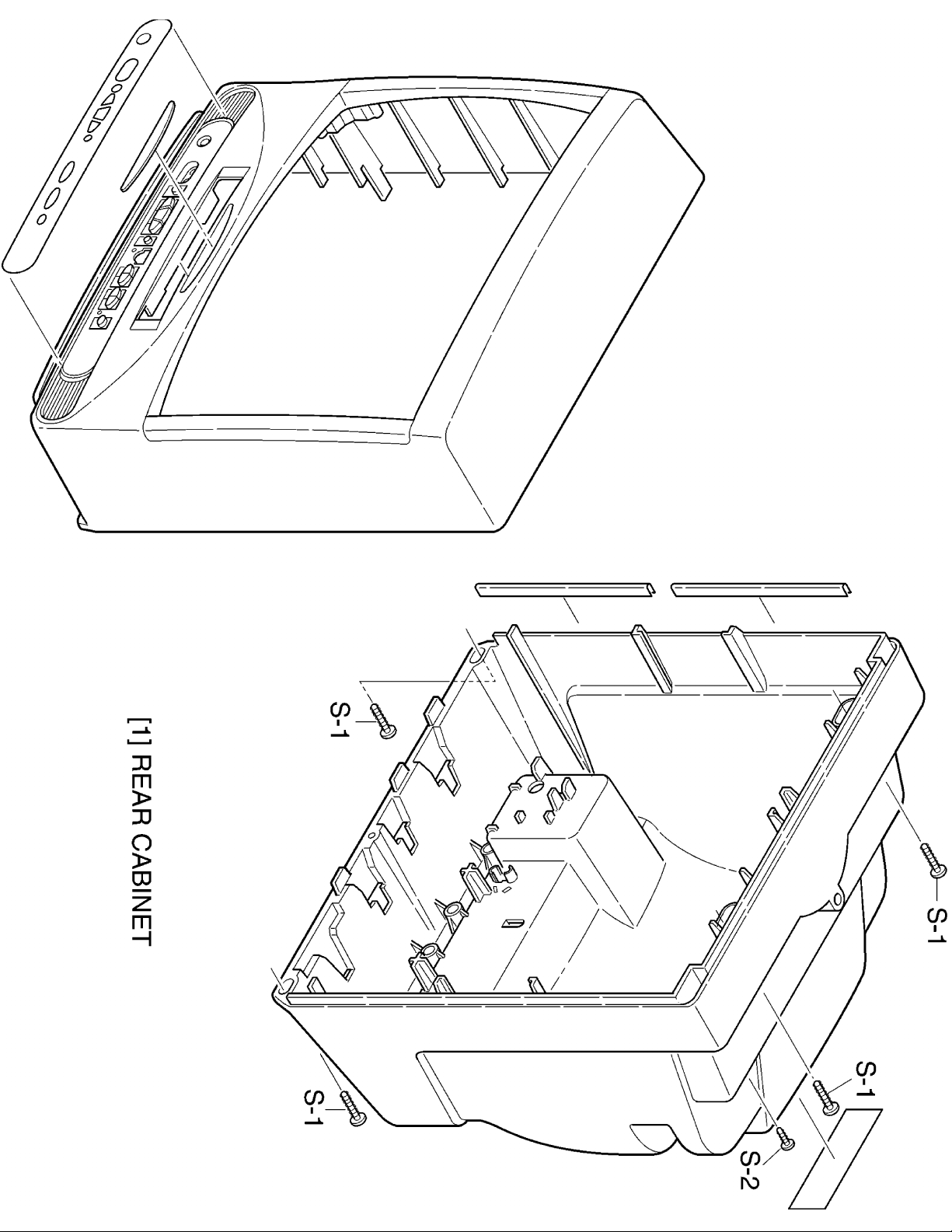

[1]

Rear Cabinet

1

,

2

6(S-1), 1(S-2)

1

[2]

Power Supply

CBA

3

,

5

1(S-3) Anode Cap, CRT CBA, CN301,

CN302, CN571, CN603

2

[3]

Tray Chassis

3

CN801

3

[4]

Deck Unit

3

7(S-4)

4

[5]

Main CBA

3

,

5

3(S-5), 1(S-6)

5

[6]

CRT

4

4(S-7)

6

[1] [2] [3] [4] [5]

[1]

Order of steps in procedure. When reassembling, follow the steps in reverse

order. These numbers are also used as the identification (location) No. of

parts in figures.

[2]

Parts to be removed or installed.

[3]

Fig No. showing procedure of part location

[4]

Identification of part to be removed, unhooked, unlocked, released,

unplugged, unclamped, or desoldered.

S=Screw, P=Spring, L=Locking Tab, CN=Connector, *=Unhook, Unlock,

Release, Unplug, or Desloder

e.g., 2(S-2) = two Screws (S-2)

[5]

Refer to the following ”Reference Notes in the Table“

Reference Notes in the Table

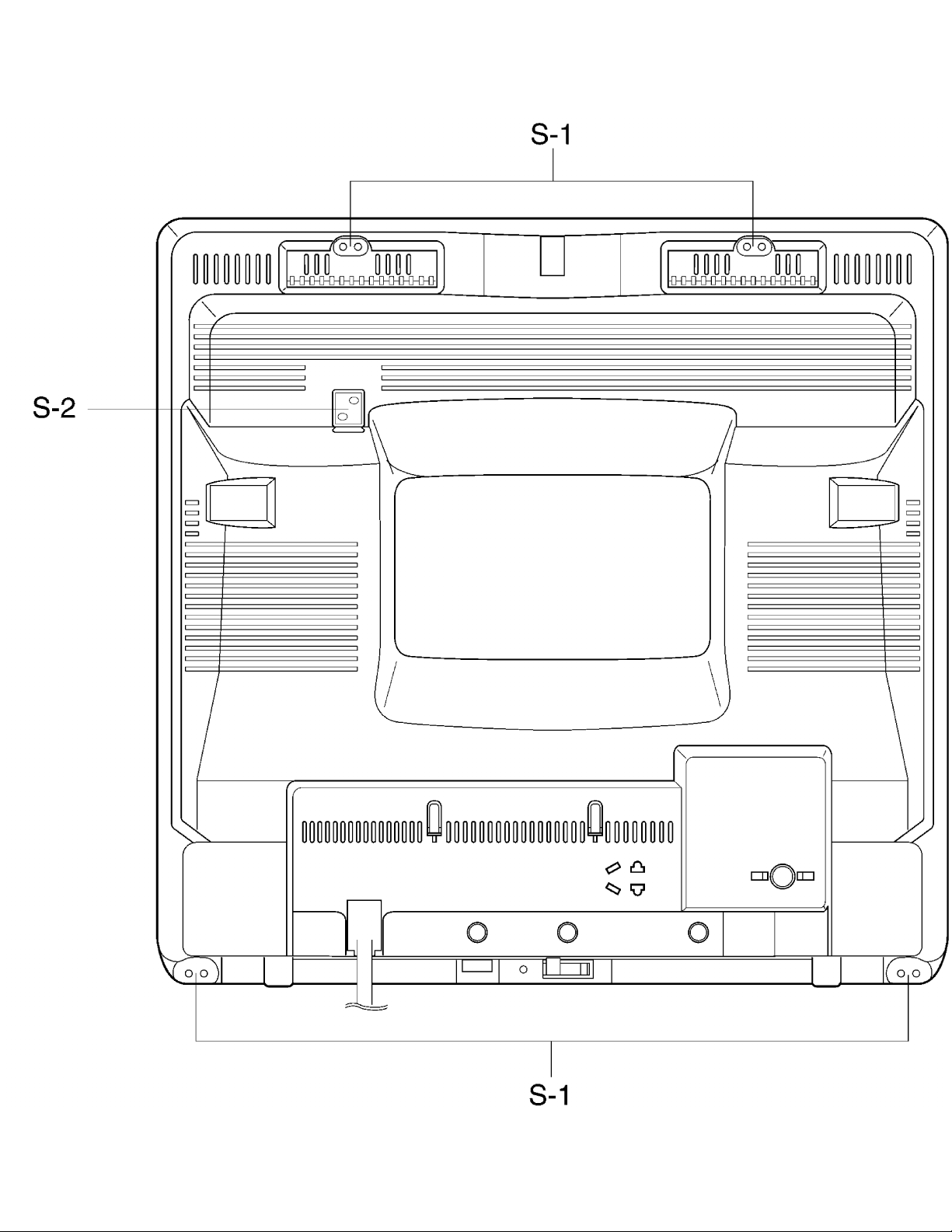

1. Removal of the Rear Cabinet. Remove screws 6(S-1) and 1(S-2).

Caution!

Discharge the Anode Lead of the CRT with the cRT Ground Wire before removing the

Anode Cap.

2. Removal of the Power Supply CBA. Discharge the Anode Lead of the CRT with the

CRT ground wire before removing the Anode Cap.

Disconnect the following: Anode Cap, CRT CBA, CN301, CN302,

CN571, CN603.

Remove 1(S-3).

4. Removal of the Tray chassis. Disconnect CN801, then slide Tray chassis

backward.

5. Removal of the Deck Unit. Remove 7(S-4). Lift up the Deck Unit.

6. Removal of the Main CBA. Remove 3(S-5) and 1(S-6). Pull the Main CBA.

7. Removal of the CRT. Remove 4(S-7) and pull the CRT backward.

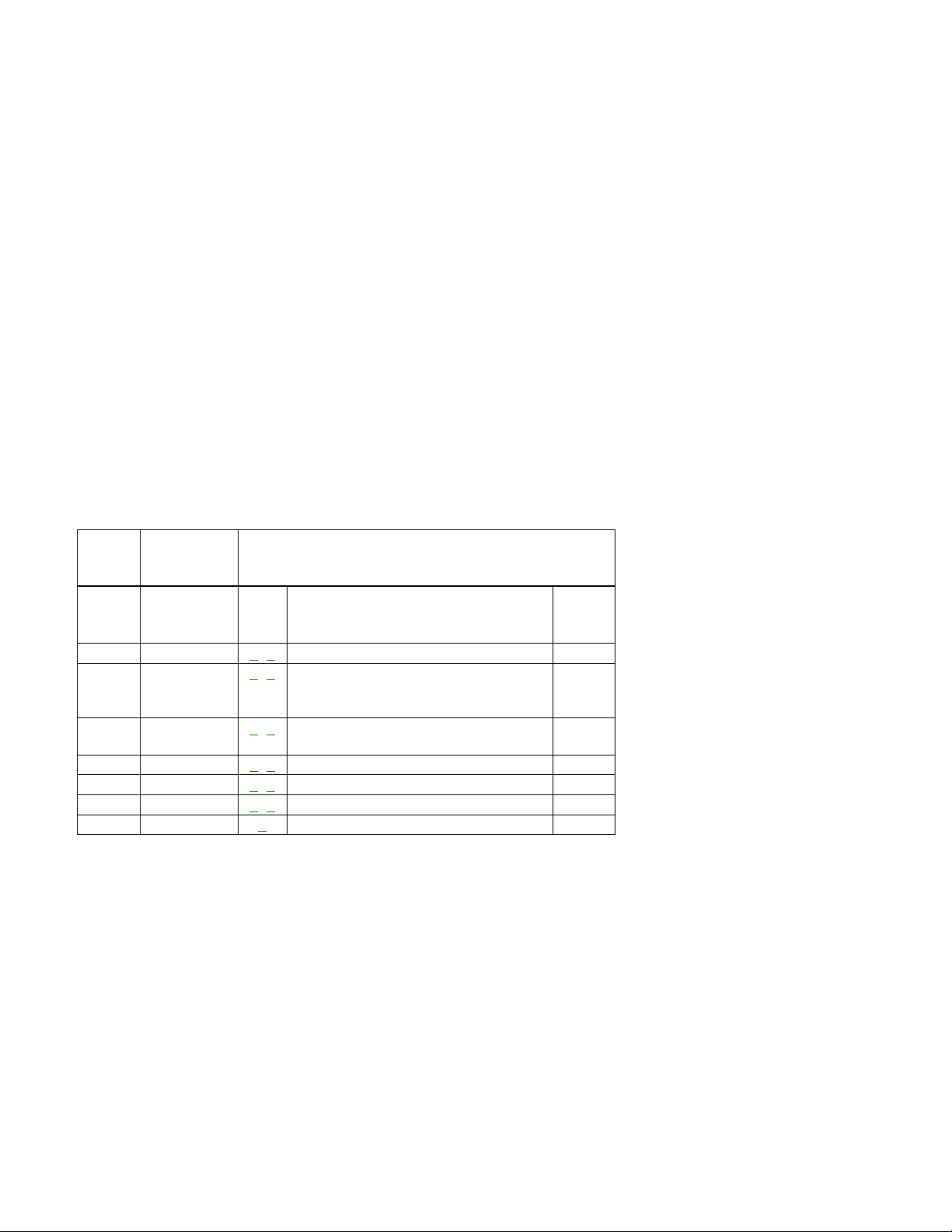

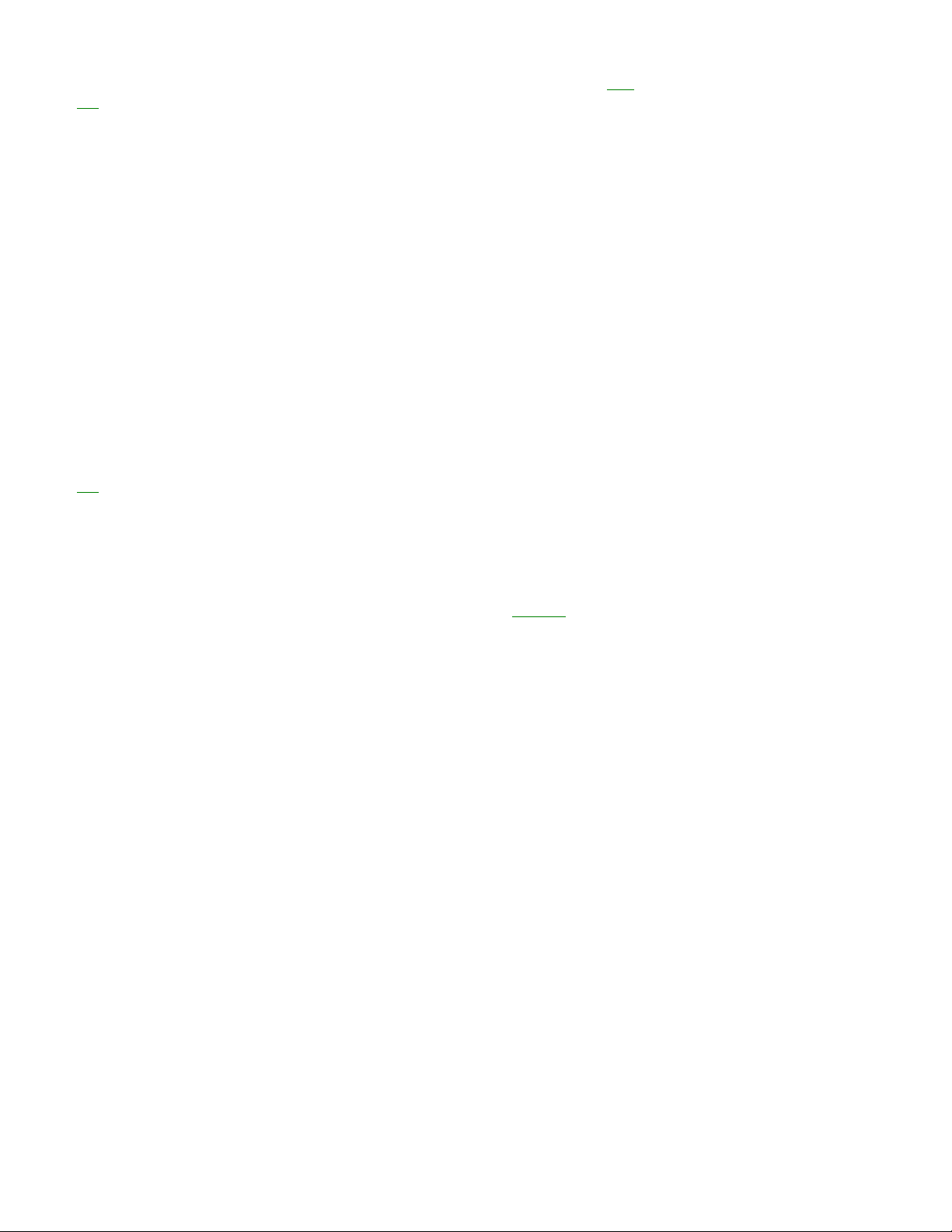

Disassembly Method (VRB130, 190)

STEP/

LOC. NO.

PART

REMOVAL

FIG. NO.

REMOVE/

UNLOCK/RELEASE/

UNPLUG/

UNCLAMP/DESOLDER

NOTE

[1]

Rear Cabinet

1

,

2,

3,

4

4(S-1), (S-2)

1

[2]

H/V CBA(With

Holder)

5

,

7

Anode Cap, CRT CBA,

CL501A, CN503, CN571,

CN575, CN602 2(S-3),

2(L-1)

2

[3]

TrayChassis

3

,

5

CN601, CN801

3

[4]

Deck Unit

3

7( S-4), 1( S-5)

4

[5]

Main CBA

3

6(S-6)

5

[6]

CRT

4

4(S-7)

6

[1] [2] [3] [4] [5]

[1]

Order of steps in procedure. When reassembling, follow the steps in reverse

order. These numbers are also used as the identification (location) No. of

parts in figures.

[2]

Parts to be removed or installed.

[3]

Fig No. showing procedure of part location

[4]

Identification of part to be removed, unhooked, unlocked, released,

unplugged, unclamped, or desoldered.

S=Screw, P=Spring, L=Locking Tab, CN=Connector, *=Unhook, Unlock,

Release, Unplug, or Desloder

2(S-2) = two Screws (S-2)

[5]

Refer to the following ”Reference Notes in the Table“

Reference Notes in the Table

1. Removal of the Rear Cabinet.

Remove Screws 4(S-1) and 1(S-2)

Caution!

Discharge the Anode Lead of the CRT with the CRT Ground

Wire before removing the Anode Cap.

2. Removal of the H/V CBA with Holder. Discharge the Anode lead of the CRT with

the CRT Ground Wire before removing the Anode Cap.

Disconnect the following: Anode Cap, CRT CBA, CL501A, CN503, CN571,

CN575, and CN602.

Remove 2(S-3). Unlock 2(L-1). Pull the H/V CBA backward.

3. Removal of the Tray Chassis. Disconnect CN601 and CN801. Pull the Tray

Chassis backward.

4. Removal of the Deck Unit. Remove 7(S-4) and 1(S-5). Lift up the Deck Unit.

5. Removal of the Main CBA. Remove 6(S-6). Lift up the Main CBA.

6. Removal of the CRT. Remove 4(S-7) and pull the CRT backward.

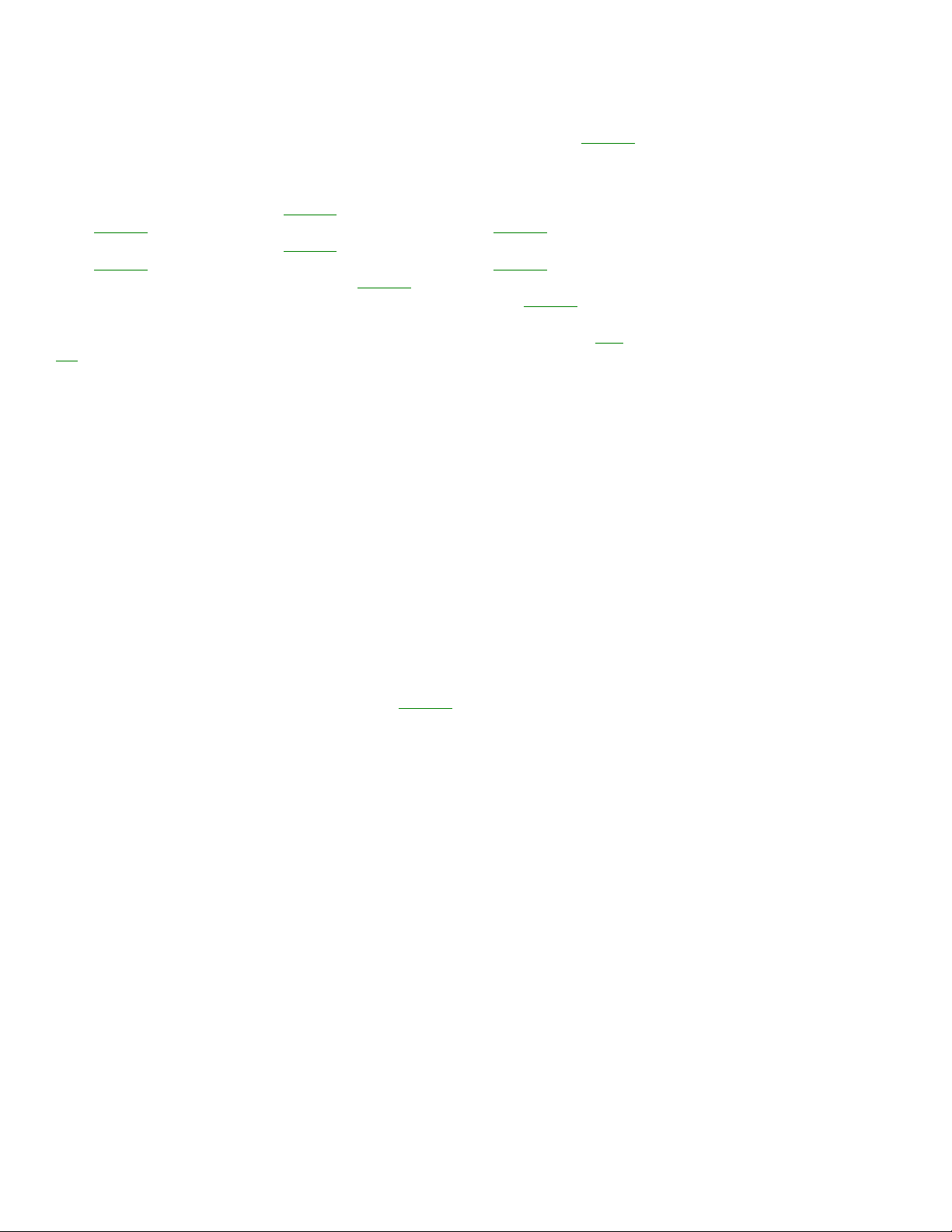

Disassembly Method (VRB092)

STEP/

LOC.

NO.

PART

REMOVAL

FIG.

NO.

REMOVE/*UNLOCK/

RELEASE/UNPLUG/

UNCLAMP/DESOLDER

NOTE

[1]

Rear Cabinet

1

,

2

4(S-1), 1(S-2), 2(S-3), (S-4)

1

[2]

H/V CBA

3

,

5

Anode Cap, CRT CBA, CL501A,

CN503,CN571,CN575,CN602,

Unclamp H/V CBA

2

[3]

Power Supply

CBA

3

,

5

CN1601,CN603,3(S-6),2(L-1), 4(S-7)

3

[4]

Tray Chassis

3

,

5

CN802

54

[5]

Deck Unit

3

,

5

6(S-8)

5

[6]

Main CBA

3

,

5

4(S-9)

6

[7]

CRT

4

4(S-10)

7

[1] [2] [3] [4] [5]

[1]

Order of steps in procedure. When reassembling, follow the steps in reverse

order. These numbers are also used as the identification (location) No. of

parts in figures.

[2]

Parts to be removed or installed.

[3]

Fig No. showing procedure of part location

[4]

Identification of part to be removed, unhooked, unlocked, released,

unplugged, unclamped, or desoldered.

S=Screw, P=Spring, L=Locking Tab, CN=Connector, *=Unhook, Unlock,

Release, Unplug, or Desloder

2(S-2) = two Screws (S-2)

[5]

Refer to the following ”Reference Notes in the Table“

Reference Notes in the Table

1. Removal of the Rear Cabinet. Remove screws 4(S-1), 1(S-2) and 2(S-3) and

2(S-4).

2. Removal of the H/V CBA. Discharge the Anode Lead of the CRT with the CRT

ground wire before removing the Anode Cap.

Disconnect the following: Anode Cap, CRT CBA, CL501A,

CN503, CN571, CN575, CN602 and unclamp the H/V CBA.

3. Removal of the Power Supply CBA. Disconnect CN1601 and CN603. Slide Power

Supply CBA holder backward. Remove screws 2(S-6). Slide the Power Supply

CBA Holder backward. Remove screws 4(S-7) and release 2(L-1). Pull the Power

Supply CBA backward.

4. Removal of the Tray chassis. Disconnect CN802, then slide Tray chassis

backward.

5. Removal of the Deck Unit. Remove screws 7(S-8). Lift up the Deck Unit.

6. Removal of the Main CBA. Remove screws 4(S-9).

7. Removal of the CRT. Remove screws 4(S10) and pull the CRT backward.

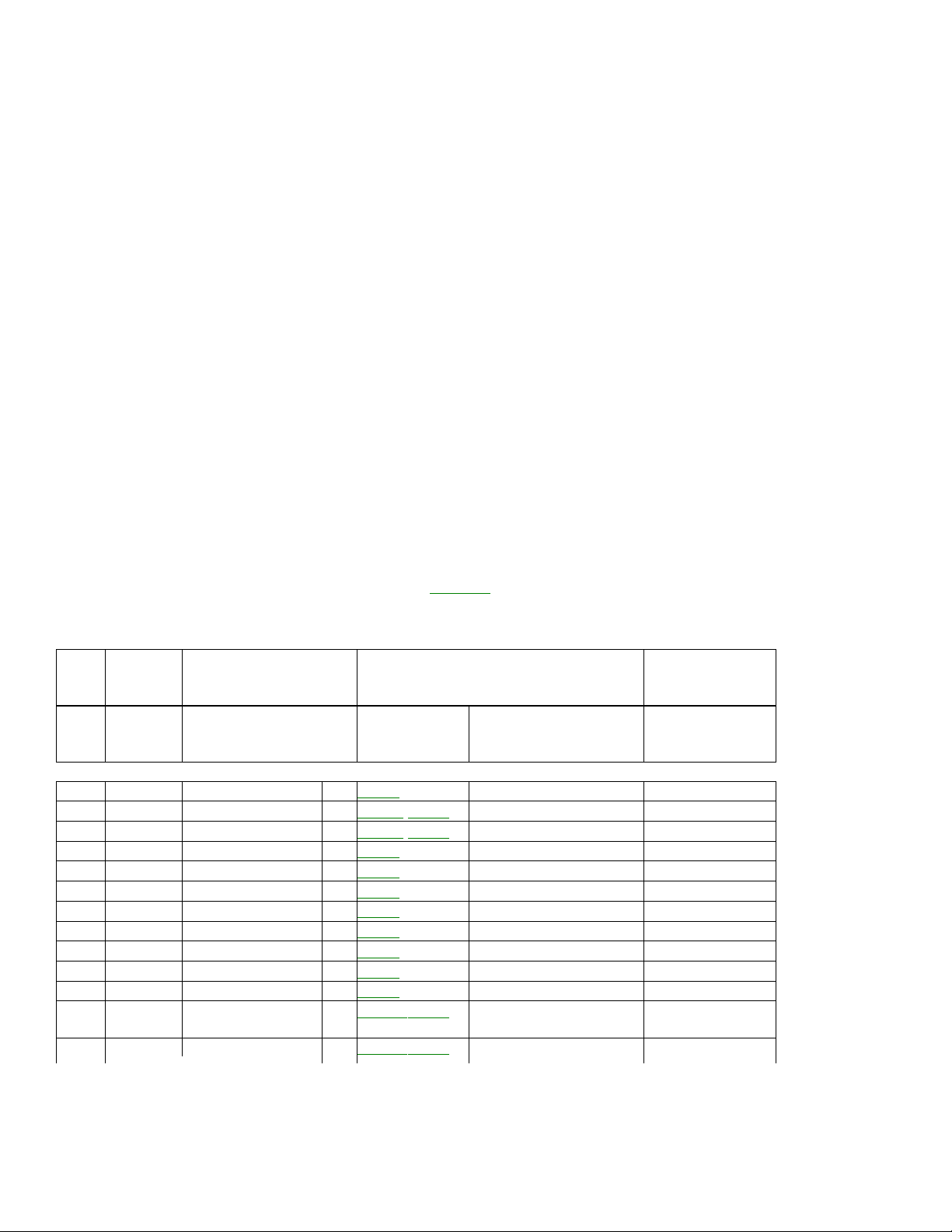

Front Loading Assembly

Before following the procedures described below, be sure to remove Front Loading Assembly

from the main mechanism of the deck assembly. (See

Fig DM3

.) When reassembling, start

with the unit in Cassette-in mode and follow the steps in reverse order.

STEP

/LOC.

No.

START-

ING

No.

PART

REMOVAL

INSTALLATION

Fig. No.

REMOVE/*UNHOOK/

UNLOCK/RELEASE/

UNPLUG/DESOLDER

ADJUSTMENT

CONDITION

[1]

[1]

Guide Holder

T

DM17

2(S-1)

[2]

[1]

Slider Gear

L,R

DM16

,

DM17

*4(L-2)

Eject Position

*[3]

[2]

Slider Shaft

T

DM16

,

DM17

Eject Position

[4]

[4]

Cassette Plate

T

DM17

2(S-2)

[5]

[4]

Slider L

T

DM17

[6]

[4]

Slider R

T

DM17

(S-3)

[7]

[6]

Door Opener A

DM17

[8]

[8]

Lock Lever

DM17

(S-4), *(P-1)

[9]

[3]

Cassette Guide R

DM17

[10]

[3]

Cassette Guide L

R

DM17

[11]

[11]

Joint Holder A

L

DM17

(S-5), *(P-2)

[12]

[11]

Cassette Drive Sub

Gear

R

DM17

, DM18

Eject Position

[13]

[11]

Cassette Drive

R

DM17

, DM18

Eject Position

[13]

[11]

Cassette Drive

Gear

R

DM17

, DM18

Eject Position

[14]

[13]

Cassette Drive

Lever

R

DM17

Cassette Drive Spring

Eject Position

[15]

[14]

Front Door Opener

DM17

, DM18

¯ ¯ ¯ ¯ ¯ ¯ ¯

(1) (2) (3) (4) (5) (6) (7)

(1)

Follow steps in sequence. When reassembling, follow the steps in reverse

order. These numbers are also used as Identification (location) No. of parts

in the figures.

(2)

Indicates the part to start disassembling with in order to disassemble the part in

column (1).

(3)

Name of the part

(4)

Location of the part: T=Top B=Bottom R=Right L=Left

(5)

Figure Number

(6)

Identification of parts to be removed, unhooked, unlocked, released, unplugged,

unclamped, or desoldered.P=Spring, W=Washer, C=Cut Washer, S=Screw,

*=Unhook, Unlock, Release, Unplug, or Desolder e.g., 2(L-2) = two Locking

Tabs (L-2).

(7)

Adjustment Information for Installation(+): Refer to Deck Exploded Views for

lubrication.

*[3]: T

hey are divided into two steps because, before reassembling Slider Shaft, one

Slider Gear must be preinstalled at either end of Slider Shaft.

ALIGNMENT PROCEDURES OF MECHANISM

The following procedures describe how to align the individual gears and levers that

make up the tape loading/unloading mechanism. Since information about the state of

the mechanism is provided to the System Control Circuit only through the Mode

Switch, it is essential that the correct relationship between individual gears and levers

be maintained.

All alignments are to be performed with the mechanism in Eject mode

, in the

sequence given. Each procedure assumes that all previous procedures have been

completed.

IMPORTANT:

If any one of these alignments is not performed properly, even if off by only one tooth,

the unit will unload or stop and it may result in damage to the mechanical or electrical

parts.

Alignment points in Eject Position

Alignment 1

Loading Arm, S and T Assembly

1. Install Loading Arm S and T Assembly so that their triangle marks point to each

other as shown in

Fig. AL2

.

Alignment 2

Mode Gear

1. Keeping the two triangles pointing at each other, install the Loading Arm T

Assembly so that the last tooth of the gear meets the most inside teeth of the

Loading Lever Assembly. See

Fig. AL2.

Tape Guide Arm Assembly

1. Measurement of the screw must be as specified in

Fig. AL3

.

Alignment 3

Cassette Drive Gear, Cassette Drive Sub Gear

Install the Cassette Drive Gear and Cassette Drive Sub Gear so that their triangle

marks point to each other as shown in

Fig. AL4

.

Alignment 4

Cam Gear (A), Cassette Drive Sub Gear

Install the Front Loading Assembly so that the triangle mark of Cassette Drive Sub

Gear is aligned with the indent of the Cam Gear (A) as shown in

Fig. AL4

.

MECHANICAL ALIGNMENT PROCEDURES

Explanation of alignment for the tape to correctly run starts on the next page. Refer

to the information below on this page if a tape gets stuck, for example, in the

mechanism due to some electrical trouble of the unit.

Service Information

A. Method for Manual Tape Loading/Unloading

To load a cassette tape manually

:

1. Disconnect the AC plug.

2. Remove the Rear Cabinet (Refer to CABINET DISASSEMBLY

INSTRUCTIONS).

3. Insert a cassette tape. Though the tape will not be automatically loaded, make

sure that the cassette tape is all the way in at the inlet of the Cassette Holder.

To confirm this, lightly push the cassette tape further in and see if the tape

comes back out, by a spring motion, just as much as you have pushed in.

4. Turn the LDG Belt (B) in the appropriate direction shown in

Fig. M1

until the First

Gear starts turning. Stop turning the LDG Belt (B). Then, turn the First Gear in

the appropriate direction continuously. However, movement of the Cam Gear

will be very slow. Allow a minute or two to complete this task.

To unload a cassette tape manually

:

1. Disconnect the AC plug.

2. Remove the Rear Cabinet. (Refer to CABINET DISASSEMBLY

INSTRUCTIONS .)

3. Make sure that the Moving guide assemblies are in the Eject Position. When

the Moving guide assemblies are in the Loading Position, go to step 4. When

the Moving guide assemblies are in the Eject Position, go to step 6.

4. First, turn the LDG Belt (B) in the appropriate direction shown in

Fig. M1

until

the First Gear starts turning.

5. Stop turning the LDG Belt (B) immediately after the First Gear starts turning.

6. Turn the First Gear in the appropriate direction until Moving guide assemblies

come to the Eject Position. Stop turning when the assemblies begin clicking or

can not be moved further. However, the tape will be left wound around the

cylinder.

7. Turn the LDG Belt (B) in the appropriate direction continuously, and the cassette

tape will be ejected. As stated, movement of the Cam Gear will be very slow.

Allow a minute or two to complete this task.

Method to place the Cassette Holder in the tape-loaded

position without a cassette tape

1. Disconnect the AC Plug.

2. Remove the Rear Cabinet. (Refer to CABINET DISASSEMBLY

INSTRUCTIONS.)

3. Turn the LDG Belt (B) in the appropriate direction shown in

Fig. M1

. Release

the locking tabs shown in

Fig. M1

and continue turning the LDG Belt (B) until

the Cassette Holder comes to the tape-loaded position. Allow a minute or two

to complete this task.

Tape Interchangeability Alignment

Click here for Flowchart of Alignment for tape traveling

Note:

To do these alignment procedures, make sure that the Tracking Control Circuit is

set to the center position every time a tape is loaded or unloaded. (Refer to

procedure 1-C, step 2.)

Equipment required:

Dual Trace OscilloscopeVHS Alignment Tape (VFMS0001H6)Guide Roller Adj.

ScrewdriverX-Value Adj. Screwdriver

Note:

Before starting this Mechanical Alignment, do all Electrical Adjustment procedures.

Preliminary/Final Checking and Alignment of Tape Path

Purpose:

To make sure that the tape path is well stabilized.

Symptom of Misalignment:

If the tape path is unstable, the tape will be damaged.

Note:

Do not use an Alignment Tape for this procedure. If the unit is not correctly

aligned, the tape may be damaged.

1. Play back a blank cassette tape and check to see that the tape runs without

creasing at Guide Rollers [2] and [3], and at points A and B on the lead surface.

(Refer to Fig

M3 and

M4.)

2. If creasing is apparent, align the height of the guide rollers by turning the top of

Guide Rollers [2] and [3] with a Guide Roller Adj. Screwdriver. (Refer to Fig.

M3

and

M5.)

Note:

Beneath each Guide Roller, there is a small screw. (Refer to Fig.

M5.) This

screw works to apply adequate torque to the shaft of each Guide Roller so that the

Guide Roller turns properly. Even when adjusting the height of the Guide

Roller(s), do not touch these two small screws.

3. Check to see that the tape runs without creasing at Take-up Guide Post [4] or

without snaking between Guide Roller [3] and AC Head.(Fig.

M3 and

M5)

4. If creasing or snaking is apparent, adjust the Tilt Adj. Screw of the AC Head. (

Fig.

M6

)

1-B. X Value Alignment

Purpose:

To align the Horizontal Position of the Audio/Control/Erase Head.

Symptom of Misalignment:

If the Horizontal Position of the Audio/Control/Erase Head is not properly aligned,

maximum envelope cannot be obtained at the Neutral position of the Tracking Control

Circuit.

1. Connect the oscilloscope to J149 [Models CCB130, 190] or TP004 [Model

CCB092] (C-PB) and J152 [Models CCB130, 190] or TP008 [Model CCB092]

(CTL) on the Main CBA. Use J96 [Models CCB130, 190] or TP005 [Model

CCB092] (RF-SW) as a trigger.

2. Play back the Gray Scale of the Alignment Tape (VFMS0001H6) and confirm that

the PB FM signal is present.

3. Set the Tracking Control Circuit to the center position by pressing the CH UP

button then the PLAY button on the TVCR.

Note:

Upon completion of the adjustment of Guide Rollers [2] and [3] (Refer to Fig.

M3

), check the X Value by pushing the CH UP or DOWN buttons alternately, to

check the symmetry of the envelope. Check the number of pushes to ensure

center position. The number of pushes UP to achieve 1/2 level of envelope should

match the number of pushes DOWN from center. If required, redo the "X Value

Alignment.“

4. Use the X-Value Adj. Screwdriver so that the PB FM signal at J149 [Models

CCB130, 190] or TP004 [Model CCB092] (C-PB) is maximum. (

Fig. M6

)

5. Press CH UP button on the TVCR until the CTL waveform has shifted by approx.

+2msec. Make sure that the envelope is simply attenuated (shrinks in height)

during this process so that you will know the envelope has been at its peak.

6. Press CH DOWN button on the TVCR until the CTL waveform has shifted from its

original position (not the position achieved in step 5, but the position of CTL

waveform in step 4) by approximately -2msec. Make sure that the envelope is

simply attenuated (shrinks in height) once CTL waveform passes its original

position and is further brought in the minus direction.

7. Set the Tracking Control Circuit to the center position by pressing the CH UP

button and then the PLAY button on the TVCR.

Checking/Adjustment of Envelope Waveform

Purpose:

To achieve a satisfactory picture and precise tracking.

Symptom of Misalignment:

If the envelope output is poor, noise will appear in the picture. The tracking will then

lose precision and the playback picture will be distorted by any slight variation of the

Tracking Control Circuit.

1. Connect the oscilloscope to J149 [Models CCB130, 190] or TP004 [Model

CCB092] (C-PB) on the Main CBA. Use J96 [Models CCB130, 190] or TP005

[Model CCB092] (RF-SW) as a trigger.

2. Play back the Gray Scale on the Alignment Tape (VFMS0001H6). Set the

Tracking Control Circuit to the center position by pressing the CH UP and then the

PLAY button on the TVCR. Adjust the height of Guide Rollers [2] and [3] (

Fig. M3

)

watching the oscilloscope display so that the envelope becomes as flat as

possible. To do this adjustment, turn the top of the Guide Roller with the Guide

Roller Adj. Screwdriver.

3. If the envelope is as shown in

Fig. M7

, adjust the height of Guide Roller [2] (Refer

to

Fig. M3

) so that the waveform looks like the one shown in

Fig. M9

.

4. If the envelope is as shown in

Fig. M8

, adjust the height of Guide Roller [3] (Refer

to

Fig. M3

) so that the waveform looks like the one shown in

Fig. M9

.

4. When Guide Rollers [2] and [3] (Refer to

Fig. M3

) are aligned properly, there is no

envelope drop either at the beginning or end of track as shown in

Fig. M9

.

Note:

Upon completion of the adjustment of Guide Rollers [2] and [3] (Refer to

Fig.

M3

), check the X Value by pushing the CH UP or DOWN buttons alternately, to check

the symmetry of the envelope. Check the number of pushes to ensure center

position. The number of pushes UP to achieve 1/2 level of envelope should match

the number of pushes DOWN from center. If required, redo the "X Value Alignment.“

Azimuth Alignment of Audio/Control/Erase Head

Purpose:

To correct the Azimuth alignment so that the Audio/Control/Erase Head meets tape

tracks properly.

Symptom of Misalignment:

If the position of the Audio/Control/Erase Head is not properly aligned, the Audio S/N

Ratio or Frequency Response will be poor.

1. Connect the oscilloscope to the audio output jack on the rear side of the deck.

2. Play back the alignment tape (VFMS0001H6) and confirm that the audio signal

output level is 6 kHz.

3. Adjust Azimuth Adj. Screw so that the output level on the AC Voltmeter or the

waveform on the oscilloscope is at maximum. (

Fig. M6

)

Click here for Disassembly Flowchart

12345

Loading...

Loading...